Patents

Literature

108results about How to "Play the role of dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

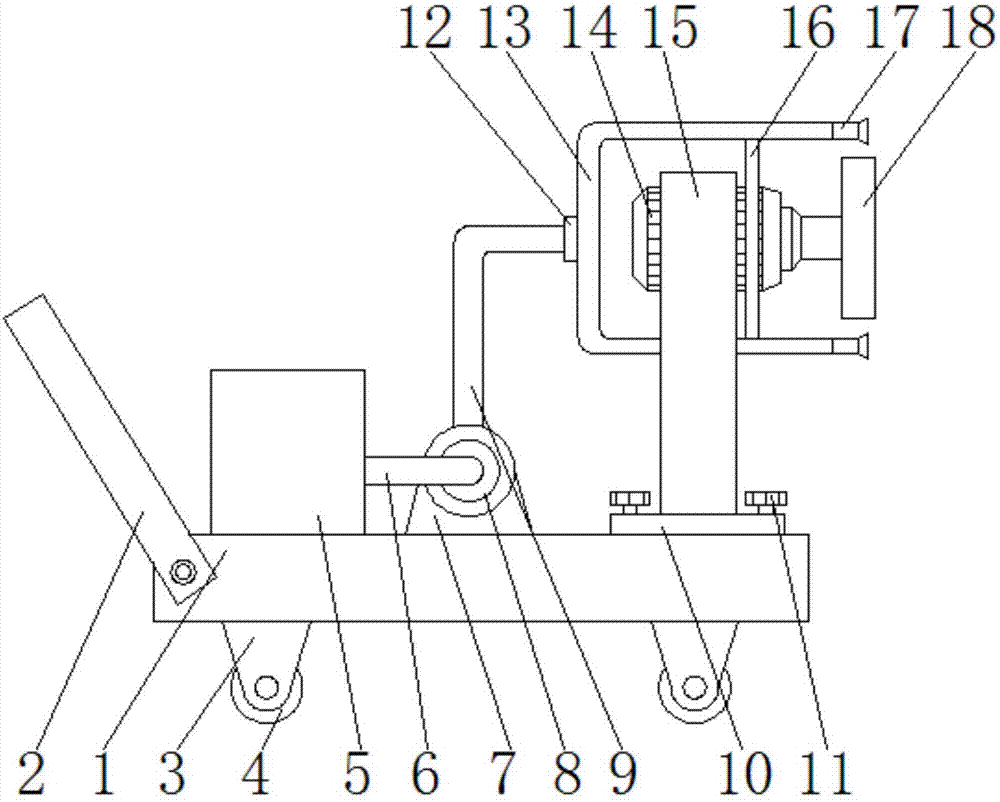

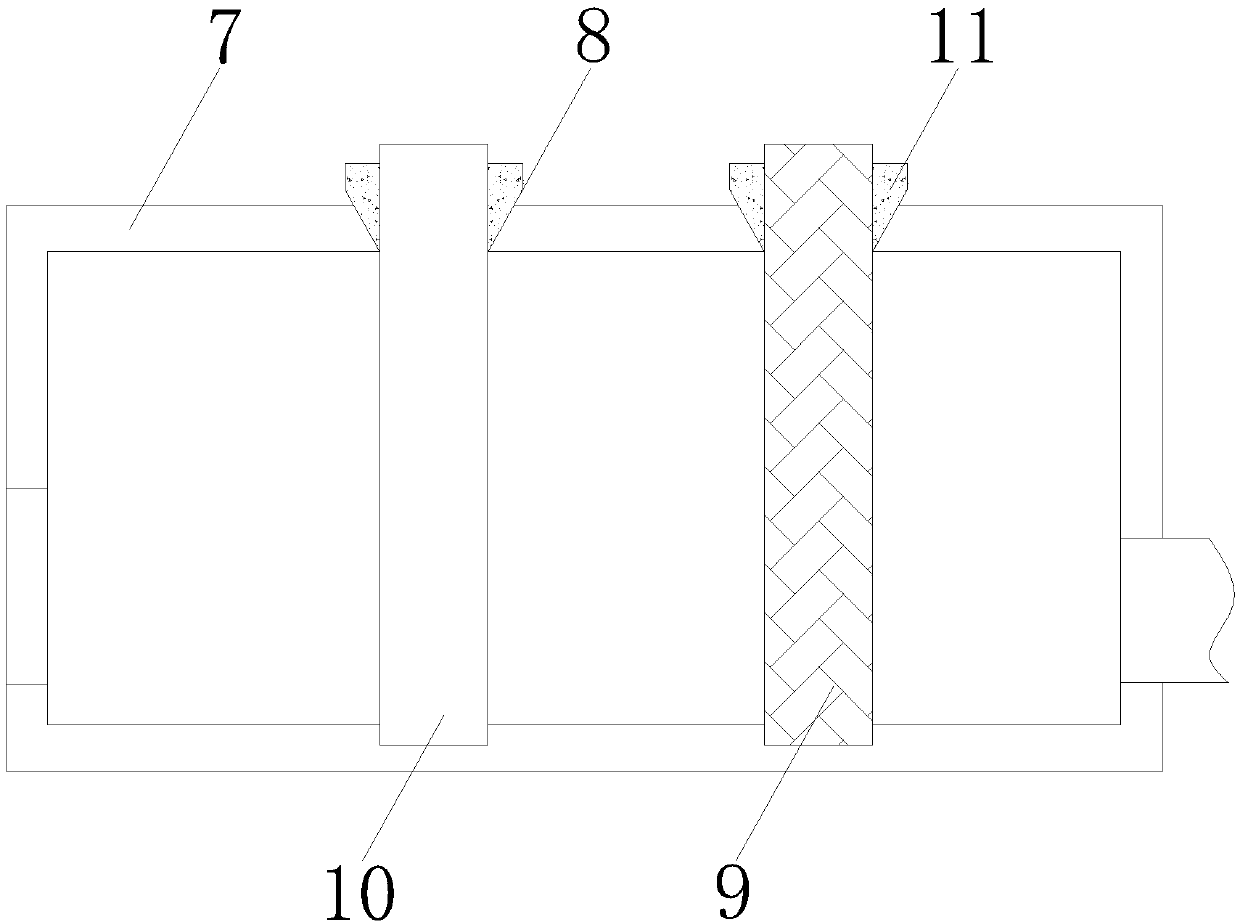

Hot-pressing compound device and method for producing membrane filter material

ActiveCN103273717AImprove breathabilityPlay the role of dust removalLaminationLamination apparatusCompound aGlass fiber

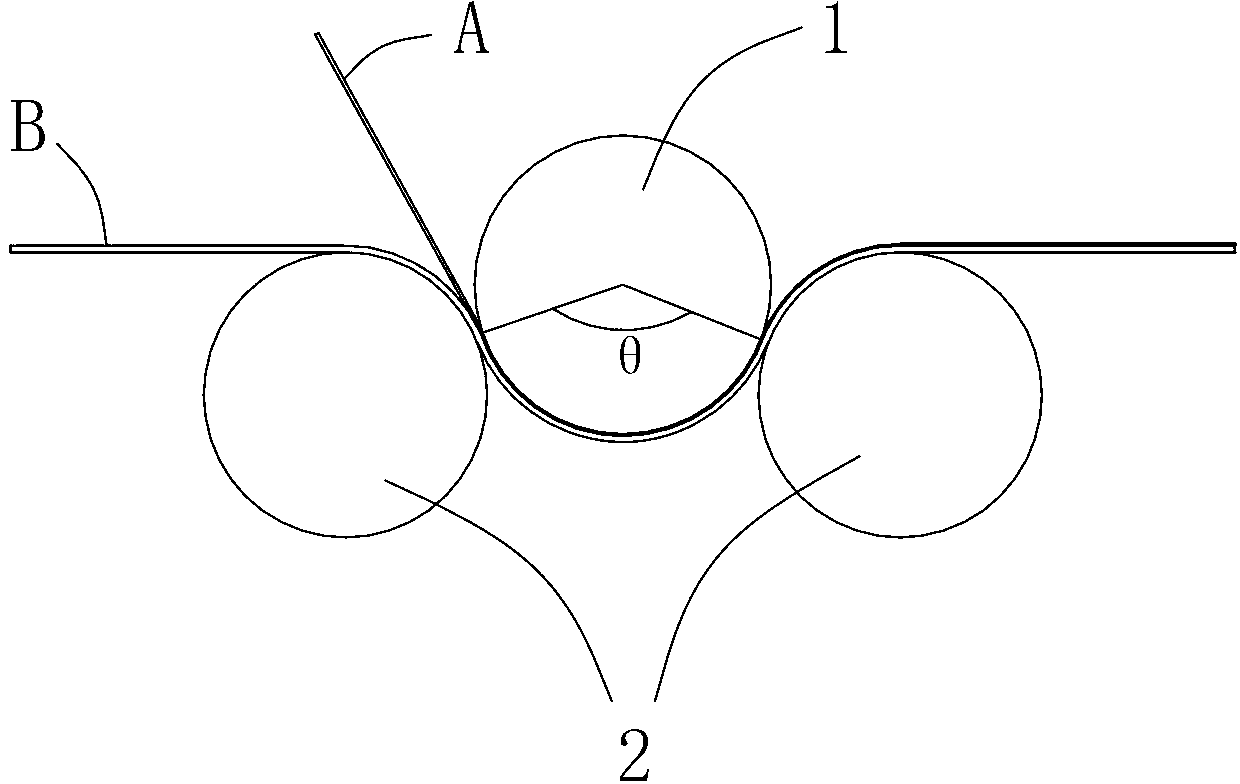

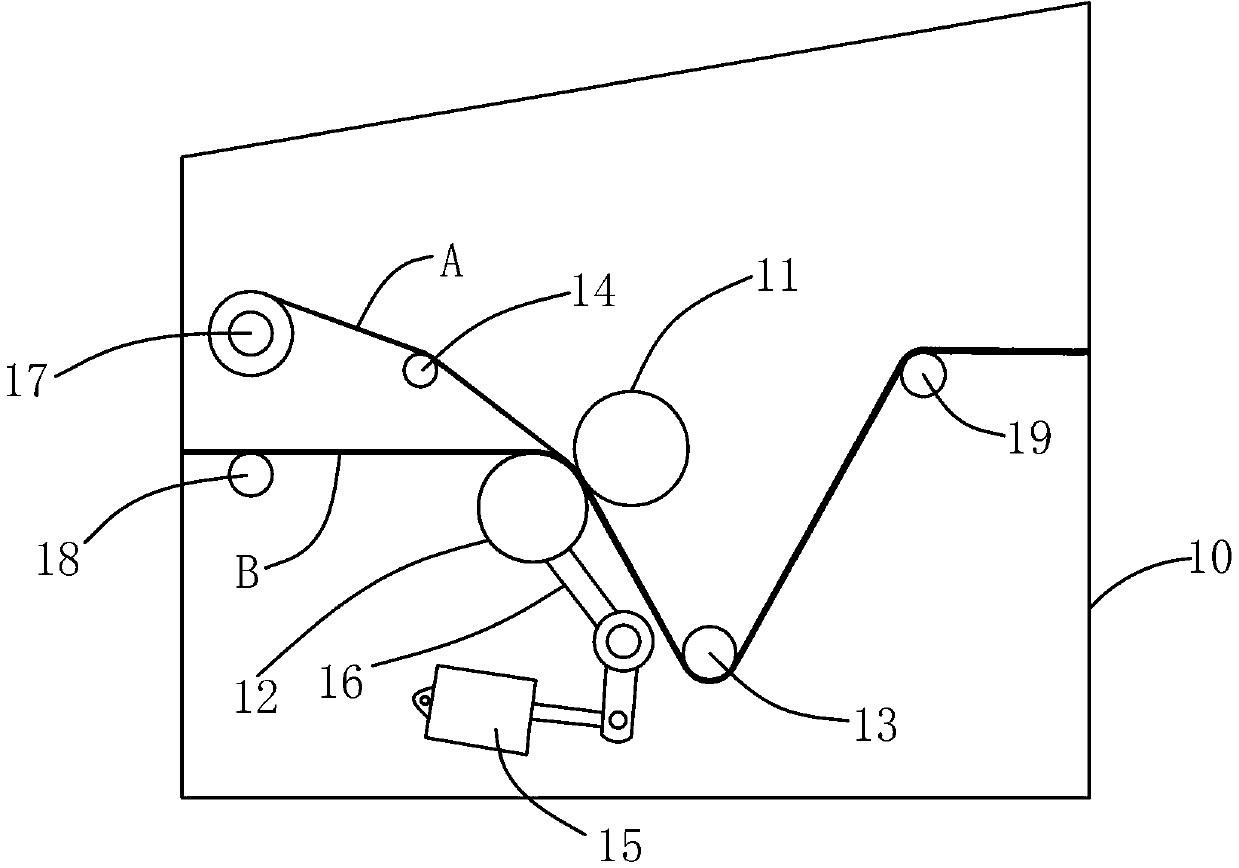

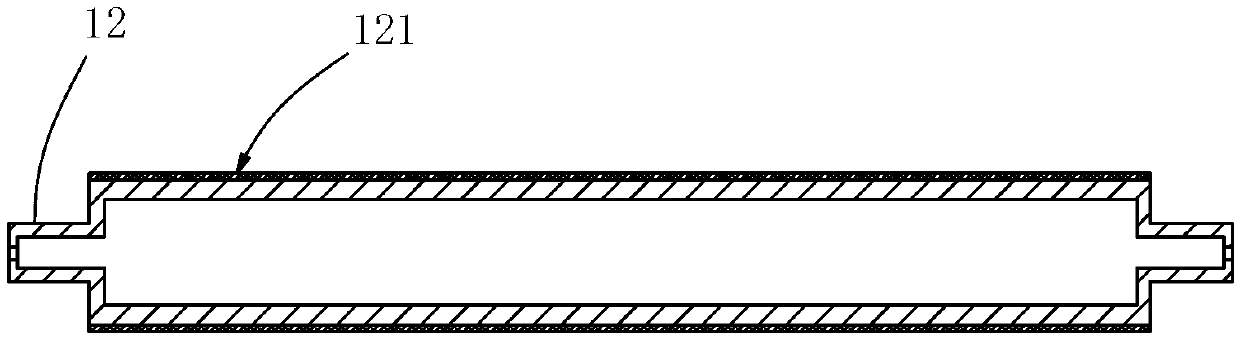

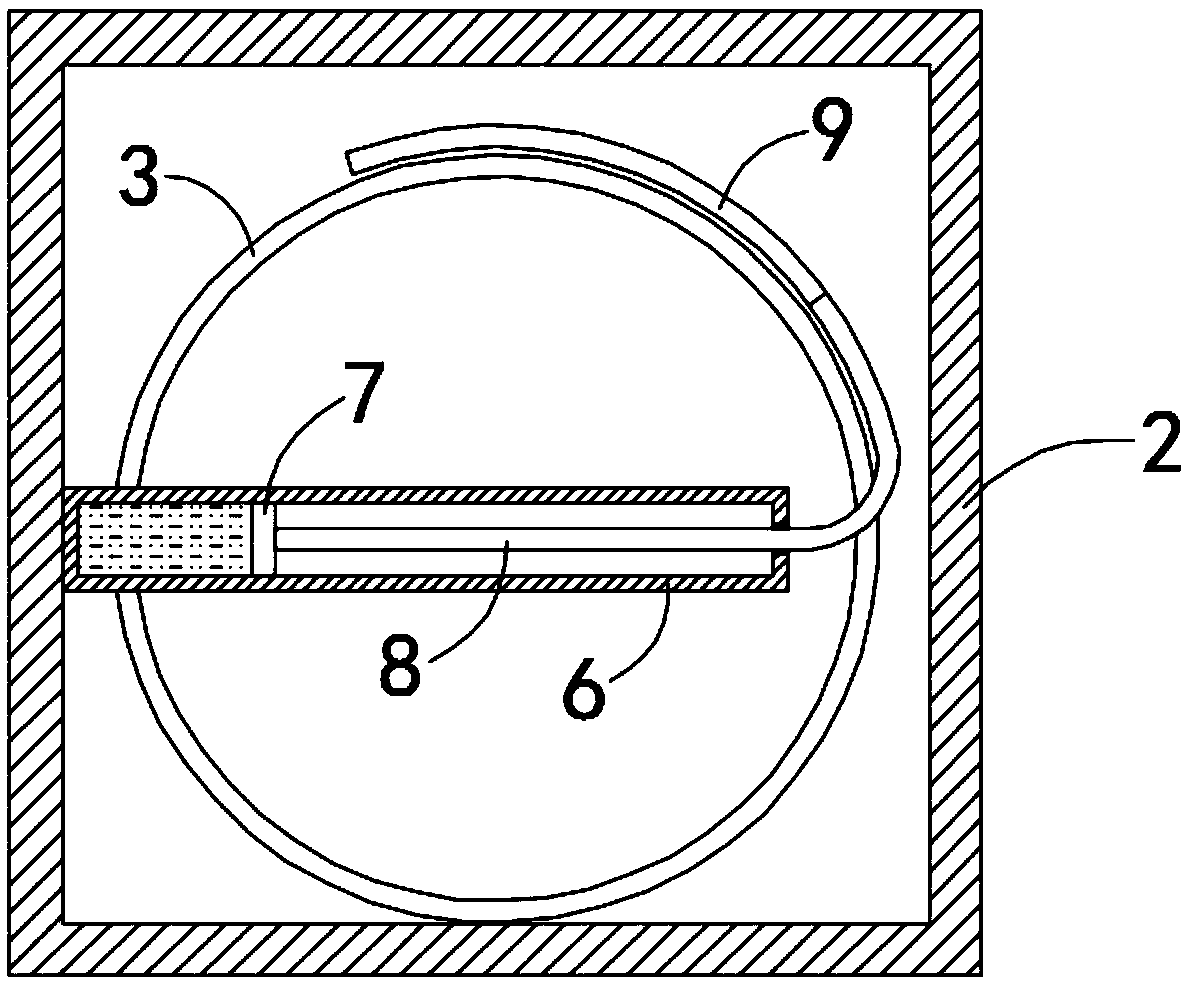

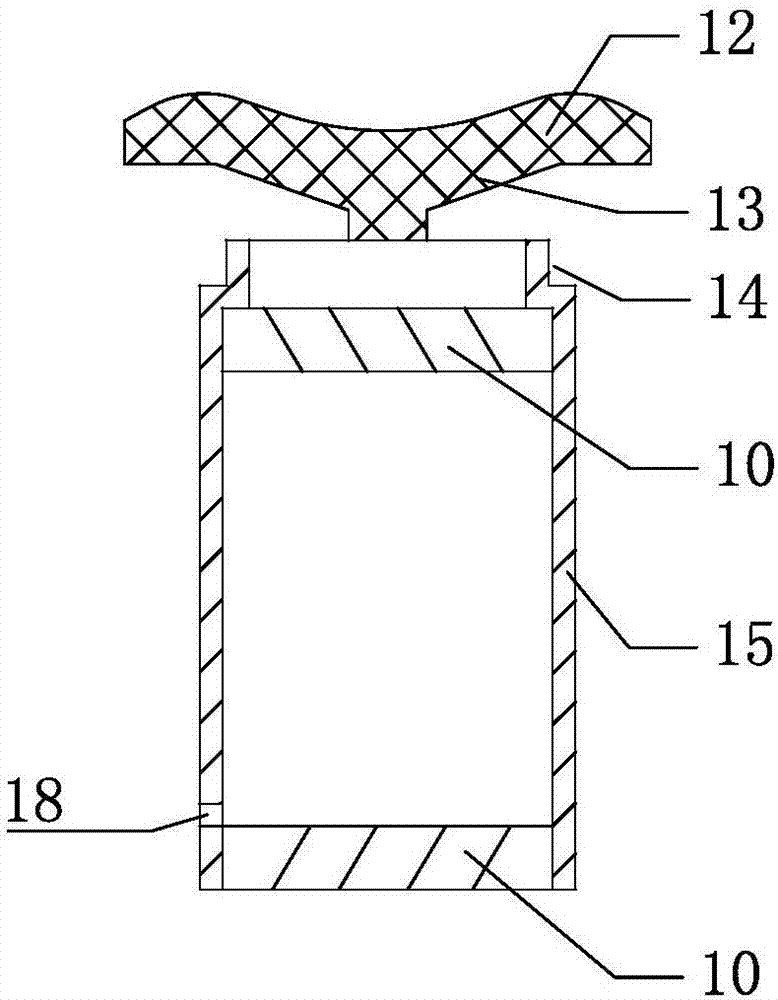

The invention discloses a hot-pressing compound device which comprises a rack and a hot pressing mechanism arranged on the rack and used for hot-pressing and compounding a PTFE (Poly Tetra Fluoro Ethylene) film and a piece of glass fiber cloth, wherein the hot-pressing mechanism comprises a heating roll and a pressing roll which are arranged in parallel correspondingly, a feeding mechanism used for feeding the PTFE film to the hot pressing mechanism and a guide roll used for outputting a membrane filter material formed by the hot pressing and the compounding are respectively arranged at the upper side and the lower side of the hot pressing mechanism, and the PTEF film positioned between the guide roll and the feeding mechanism is in line contact hot-pressing compounding with the roll surface of the heating roll. The PTFE film between the guide roll and the supply mechanism is in line contact with the roll surface of the heating roll in the hot pressing and compounding manner, and therefore, the PTFE film is subjected to rapid hot pressing compounding with base layer fiber cloth, and the microporosity and the high air permeability of the PTFE film can be kept, and further the prepared membrane filter material is high in air permeability and good in dust removal effect.

Owner:黄山无极雪食品有限公司

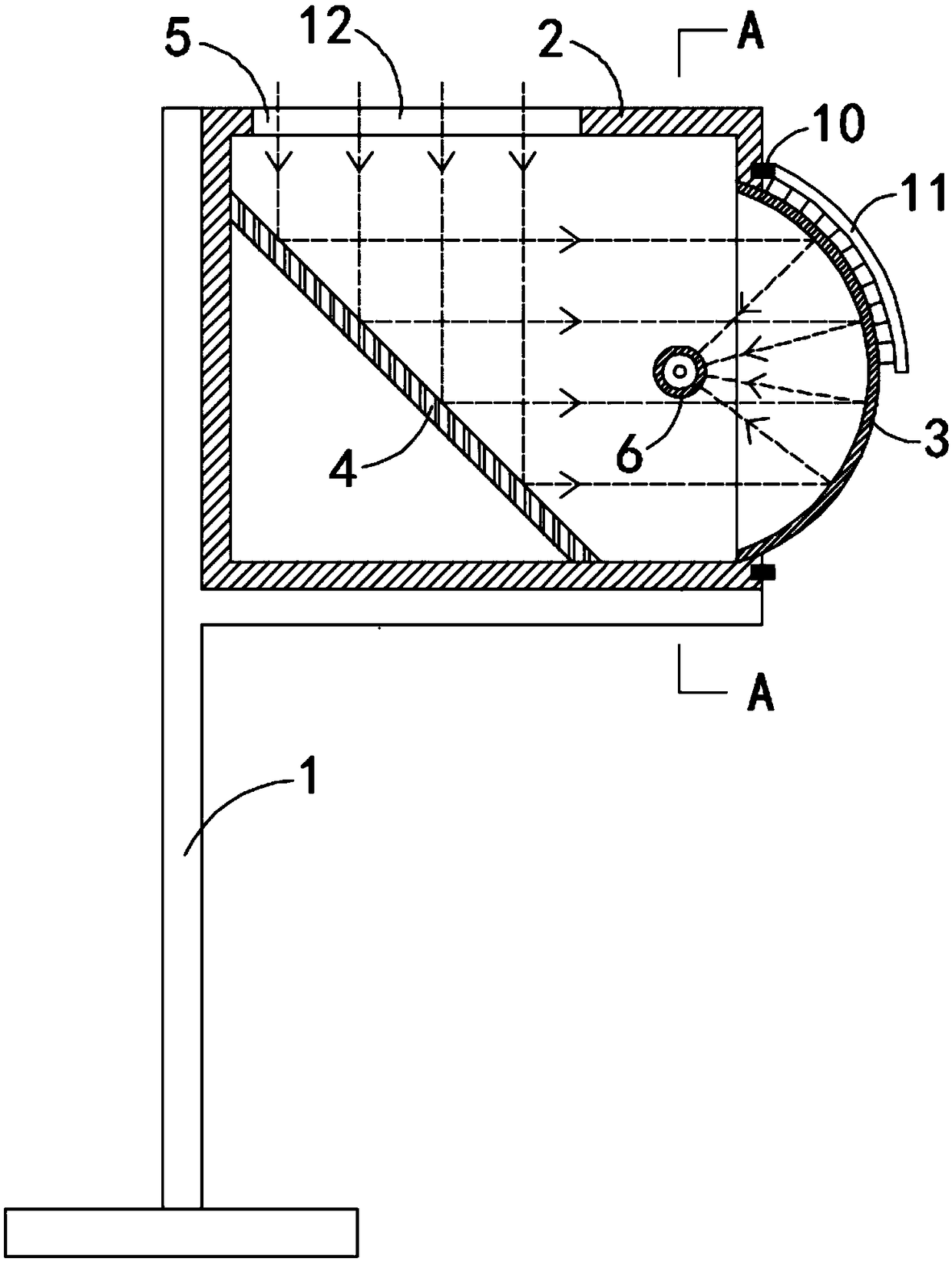

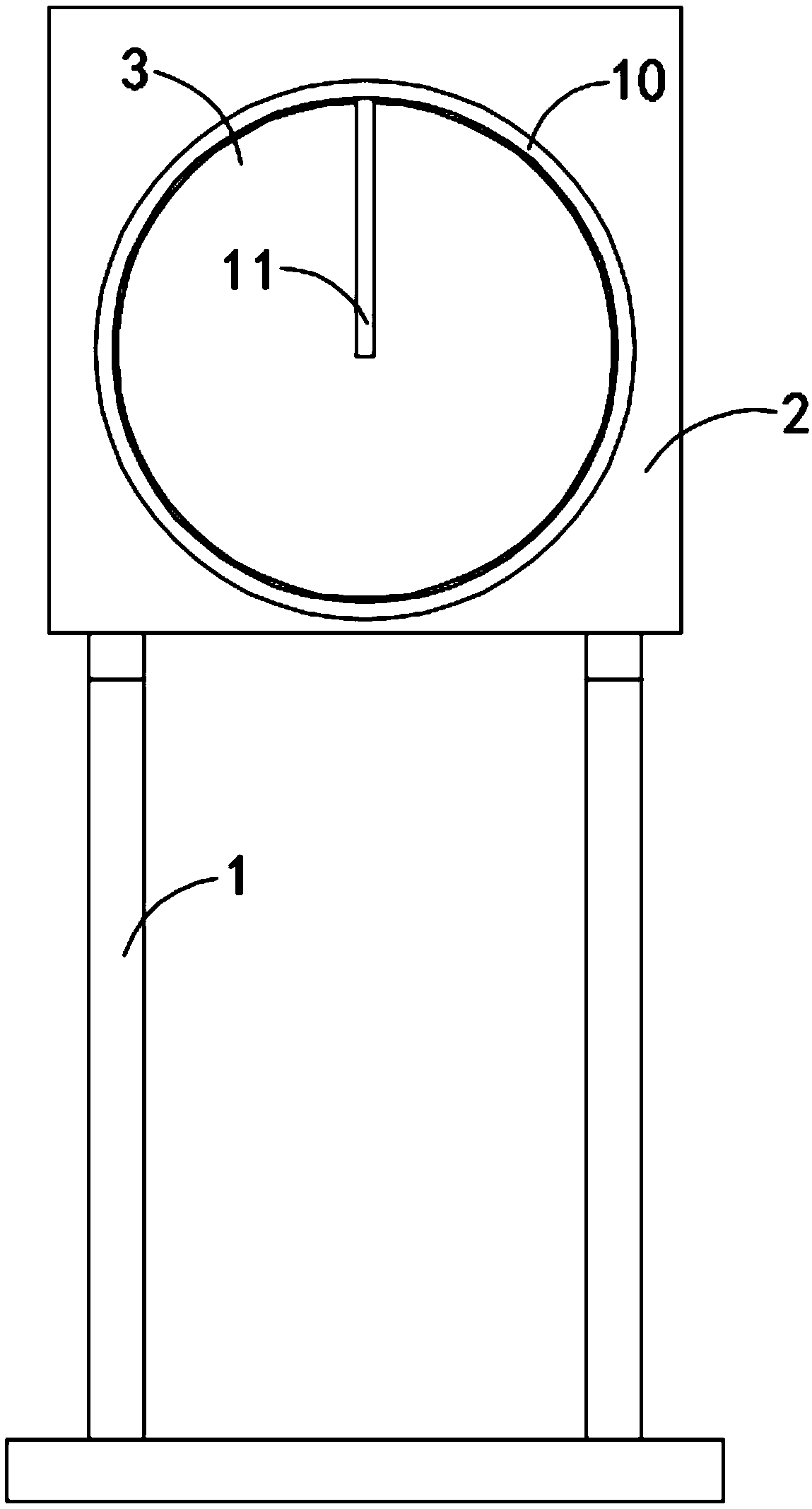

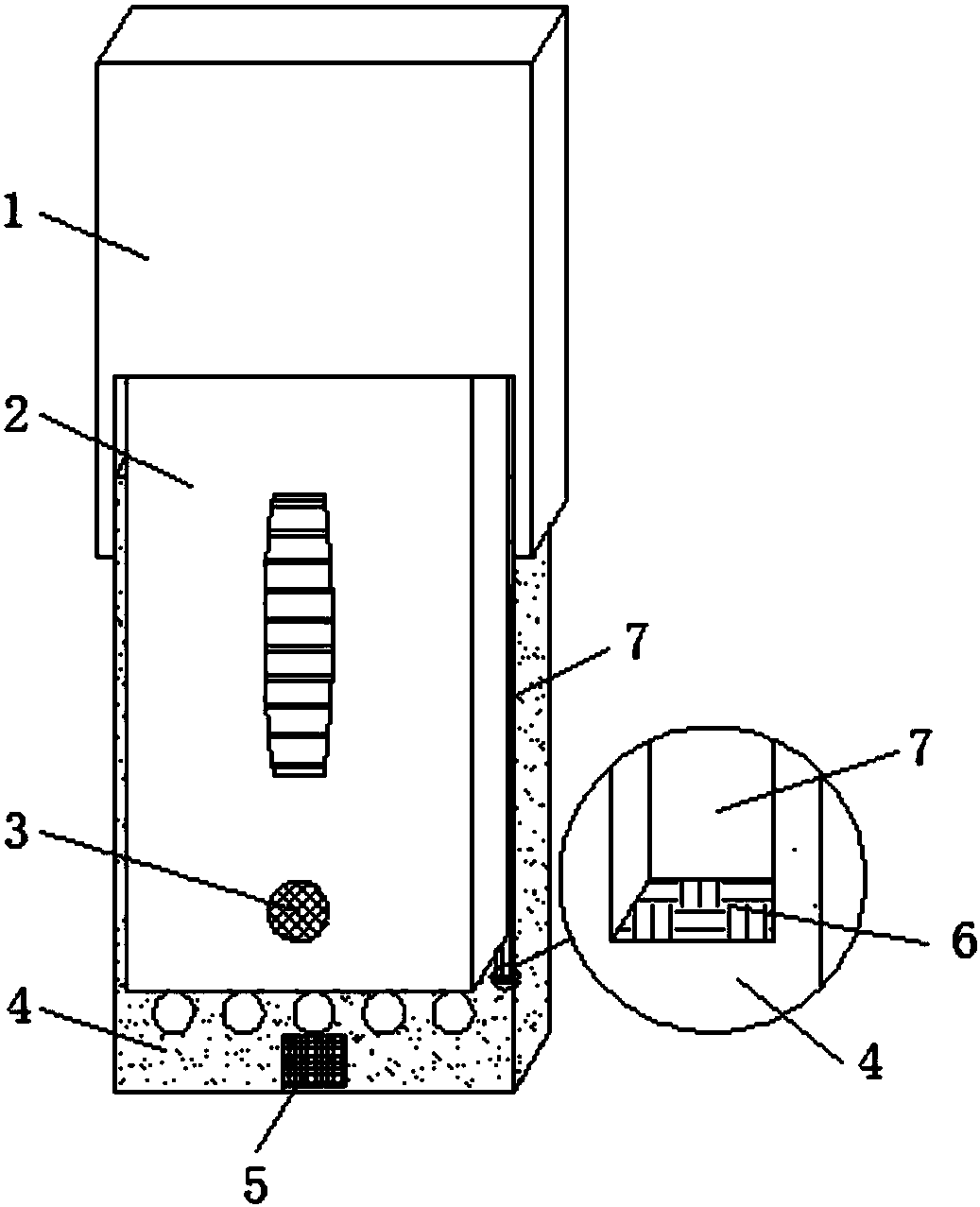

Light-condensing-type self-cleaning road reflecting mirror

ActiveCN109468973APlay the role of dust removalAvoid enteringTraffic signalsRoad signsElectric powerPiston

The invention belongs to the field of municipal transportation, and particularly relates to a light-condensing-type self-cleaning road reflecting mirror. The light-condensing-type self-cleaning road reflecting mirror comprises a bracket, a shell is fixedly connected to the upper end of the bracket, the side wall of the shell is provided with an opening, a convex-surface reflecting mirror body is fixedly connected into the opening, an inclined planar reflecting mirror body is fixedly connected into the shell, and the included angle between the planar reflecting mirror body and the inner bottomsurface of the shell is 45 degrees; the upper side wall of the shell is provided with a light inlet, a reflecting layer is arranged at the concave surface of the convex-surface reflecting mirror body,a horizontal liquid storage cylinder is fixedly connected into the shell, the axis of the liquid storage cylinder penetrates through a focal point of the concave surface of the convex-surface reflecting mirror body, a piston block is sealedly and slidingly connected into the liquid storage cylinder, a closed space formed by the piston block and the liquid storage cylinder is filled with evaporating liquid, a transmission strip is fixedly connected to the other side wall of the piston block, and the inner side wall of the shell is provided with an arc sliding groove matched with the transmission strip. The light-condensing-type self-cleaning road reflecting mirror does not need to be driven with power, solar energy is fully utilized for cleaning the reflecting mirror, the energy is saved,and the environment is protected.

Owner:HANGZHOU ZHUILIE TECH

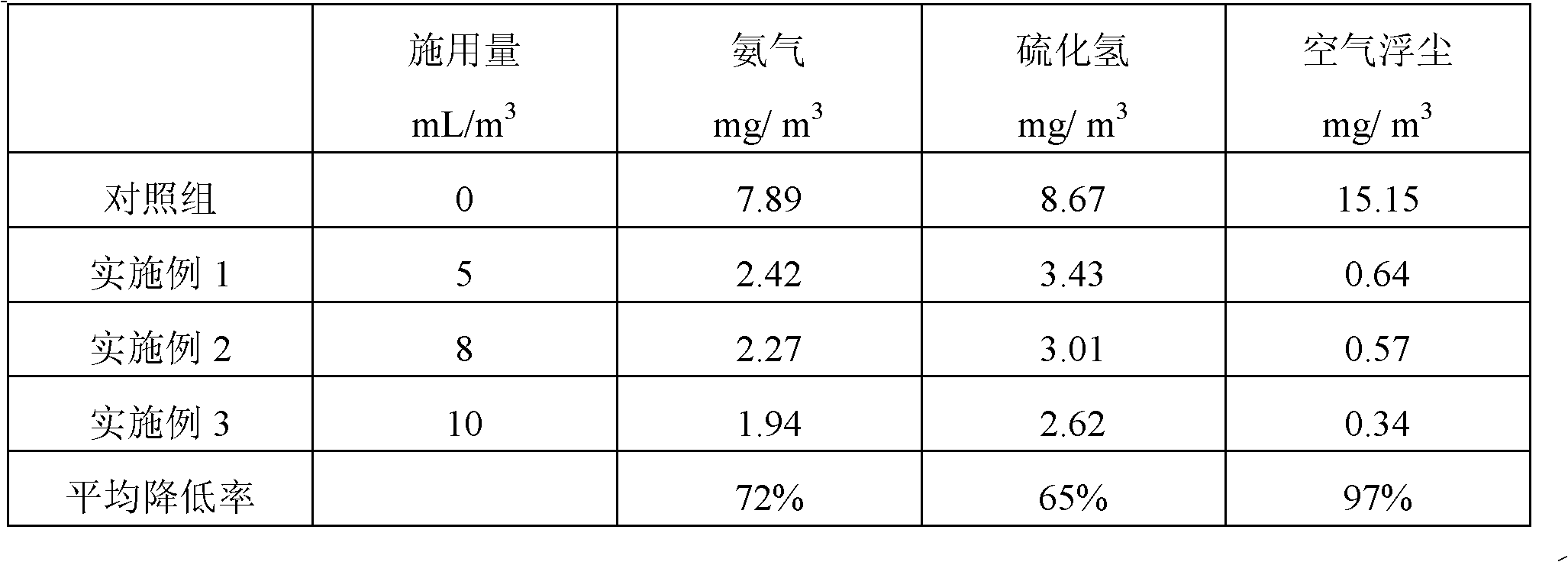

Deodorizing and dedusting agent for chicken farm and preparation method thereof

InactiveCN102688516AImprove smellPlay the role of dust removalBacteriaDispersed particle separationToxicityEssence oil

The invention discloses a deodorizing and dedusting agent for a chicken farm, comprising the following components in parts by weight: 30-50 parts of bacillus subtilis fermentation liquor, 5-10 parts of soya bean lecithin and 1-2 parts of plant essential oil; and the mixed fermentation liquor is formed by fermenting bacillus subtilis liquor with the viable bacterium amount over 108 / mL and enterococcus faecalis liquor which are in the weight ratio of 1:(1-5). The deodorizing and dedusting agent for the chicken farm, provided by the invention, is made of pure natural preparations so as to have no toxicity or harm to working staffs and the chicken crowd and have a health care function. The deodorizing and dedusting agent has the application amount of 5-10mL / m<3> when being used.

Owner:HENAN UNIV OF SCI & TECH

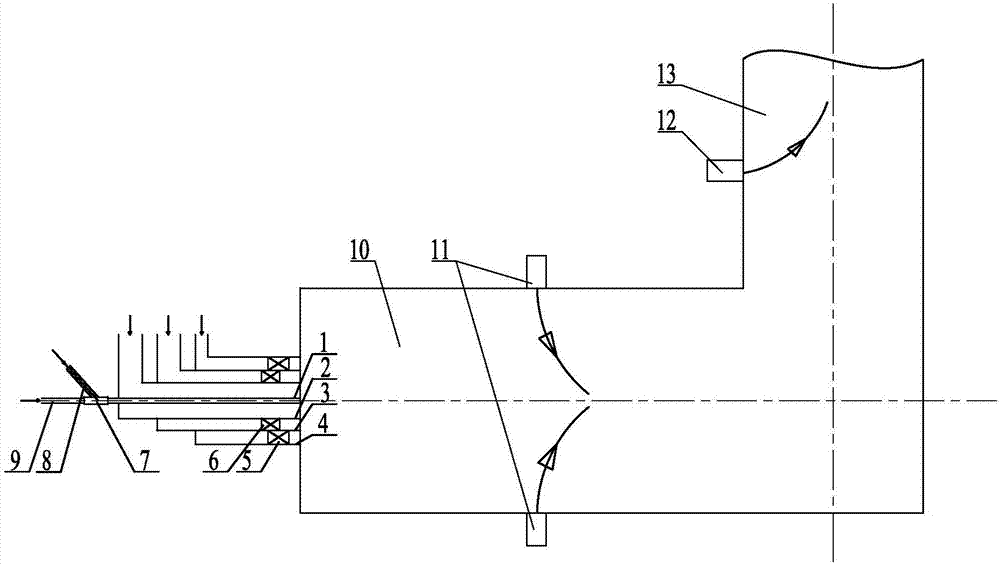

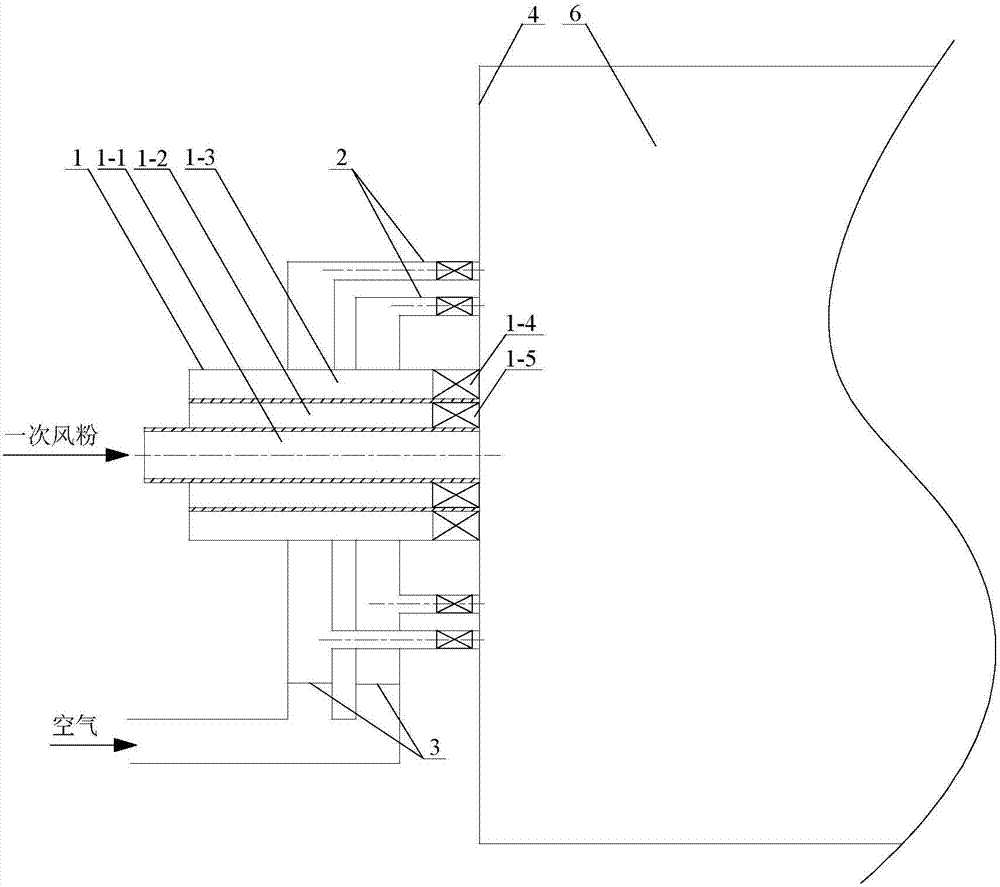

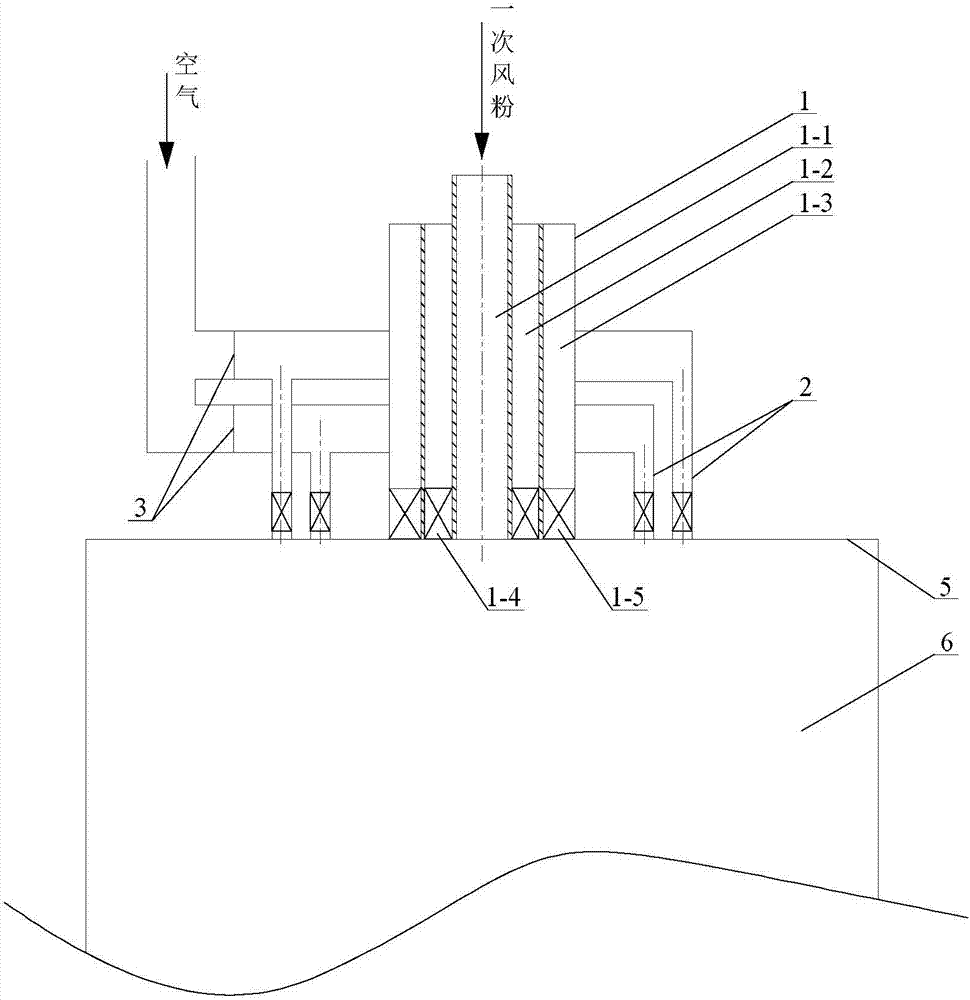

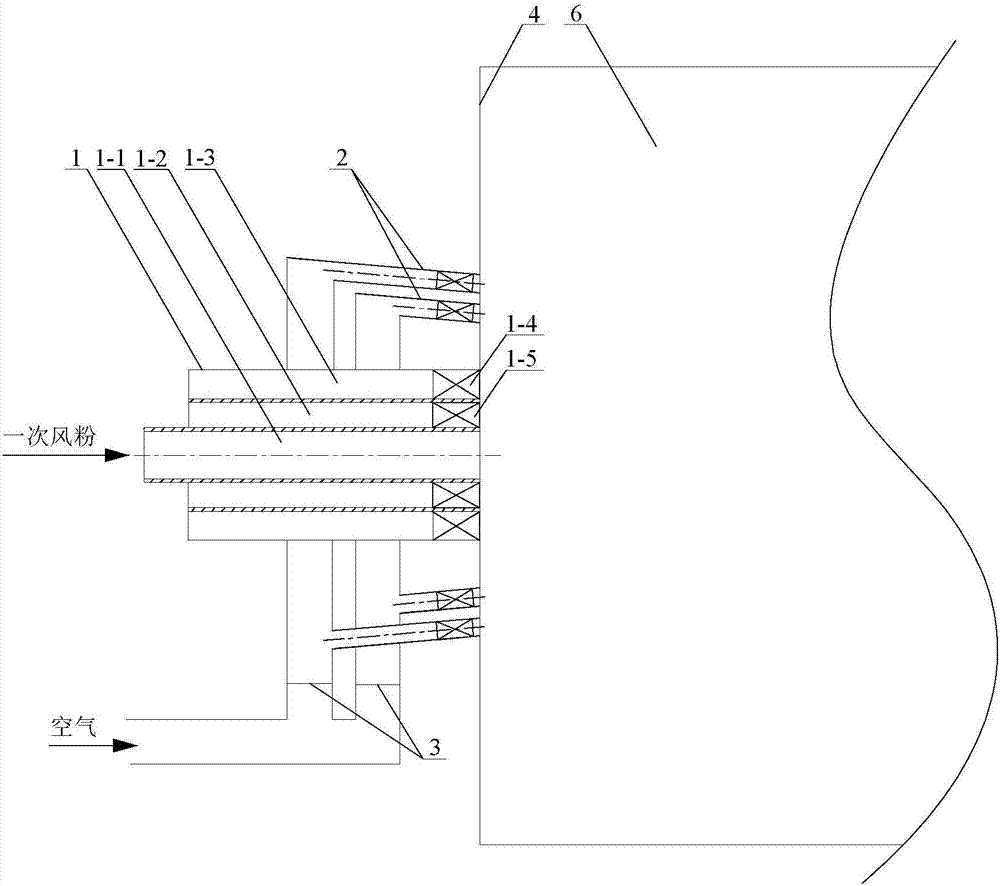

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

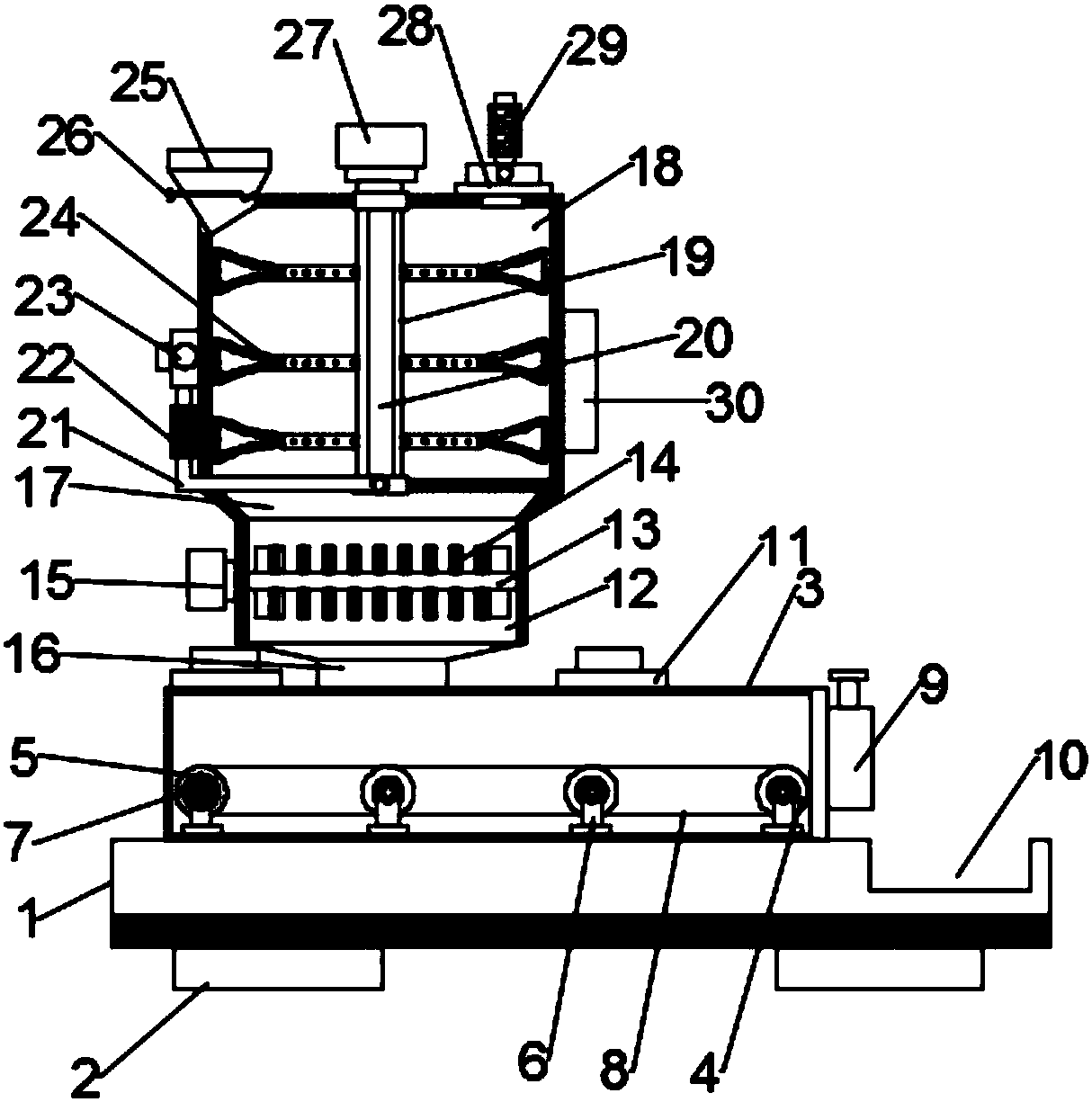

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

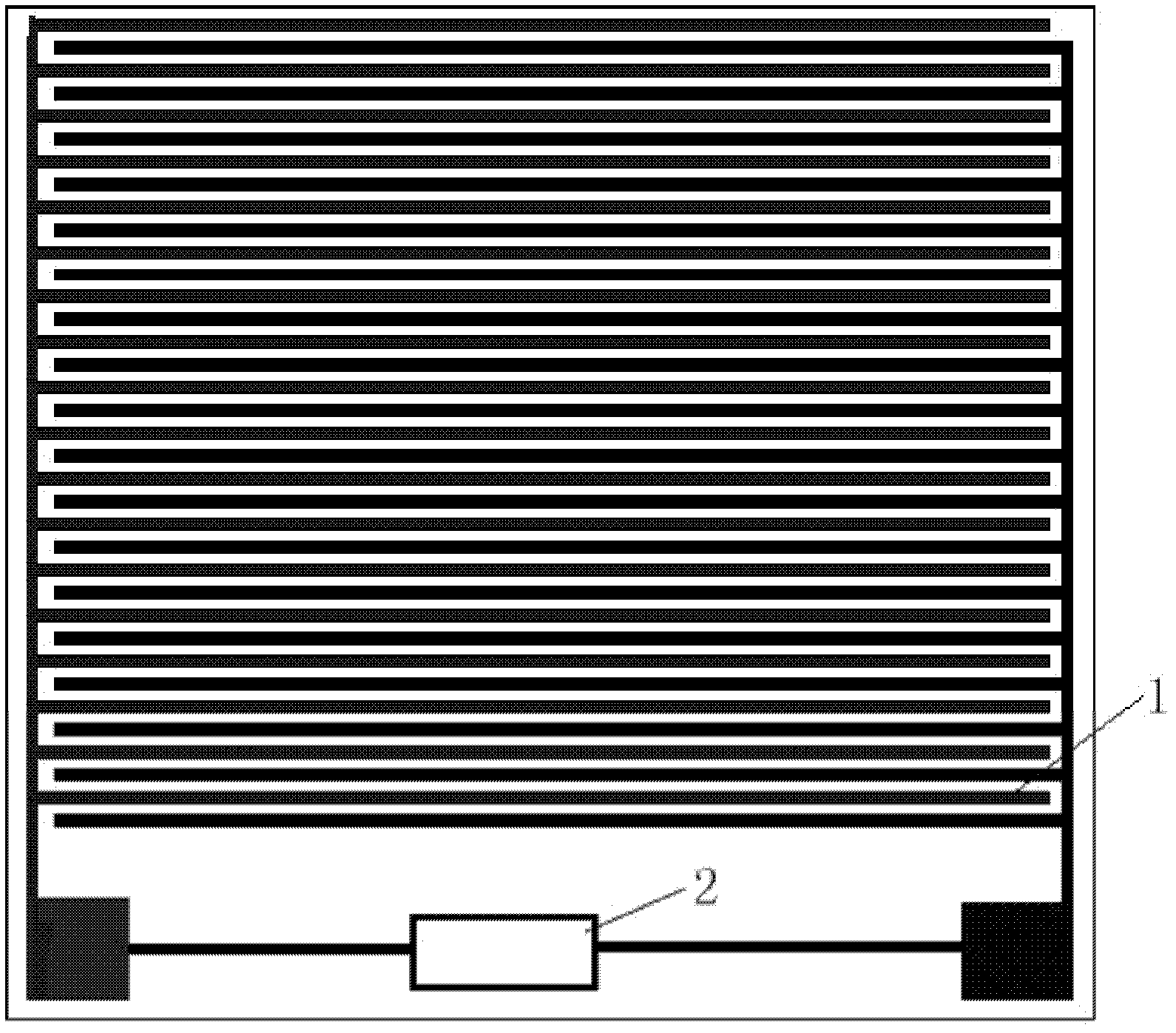

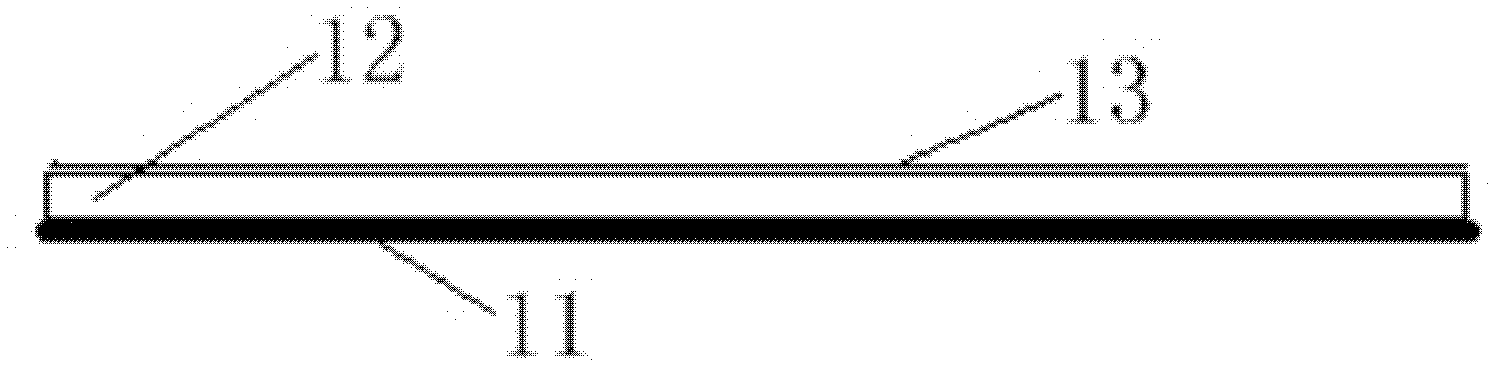

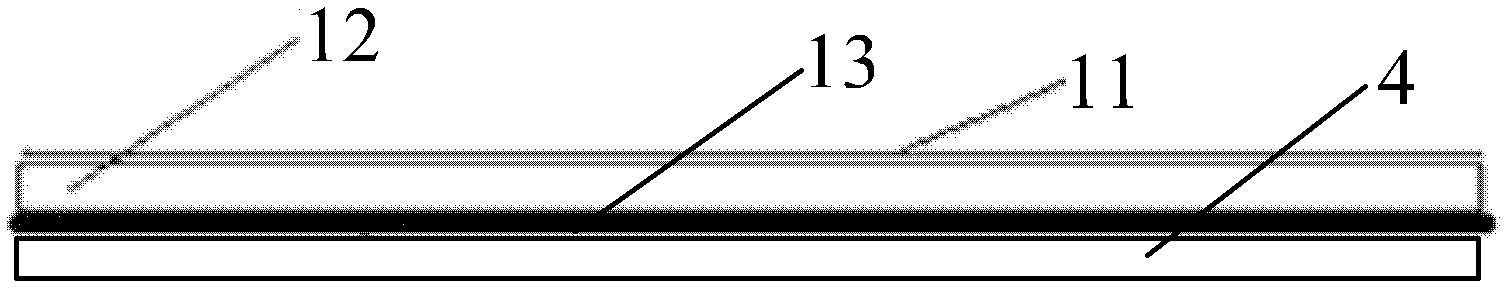

Dedusting device and dedusting structure

The invention discloses a dedusting device and a dedusting structure, belonging to the field of dedusting. The device comprises a transparent dedusting electrode and a power supply, wherein the transparent dedusting electrode is of a three-layer structure, a supporting substrate made of a transparent insulating solid material serves as the bottom layer, an interdigital electrode formed by etching a transparent film conductive material arranged on the supporting substrate serves as the intermediate layer, and a transparent self-cleaning insulating film covering the interdigital electrode serves as the upper layer; the two electrodes of the interdigital electrode are electrically connected with the electrodes of the power supply, respectively; the output voltage of the power supply is 1000-1500 V and the frequency is 10-50 Hz. The dedusting device has the advantages of transparency and simple structure, and no movable element is arranged thereon, furthermore, the dedusting device can be arranged on the surface of an object needing dedusting, and the transparent dedusting electrode of the dedusting device is periodically supplied with power to dedust; besides, the transparent self-cleaning insulating film can degrade organic pollutants to improve the transparency on thickness, and the film is a self-cleaning coating. The dedusting device disclosed by the invention has the advantages of good dedusting effect and low cost.

Owner:吴召干

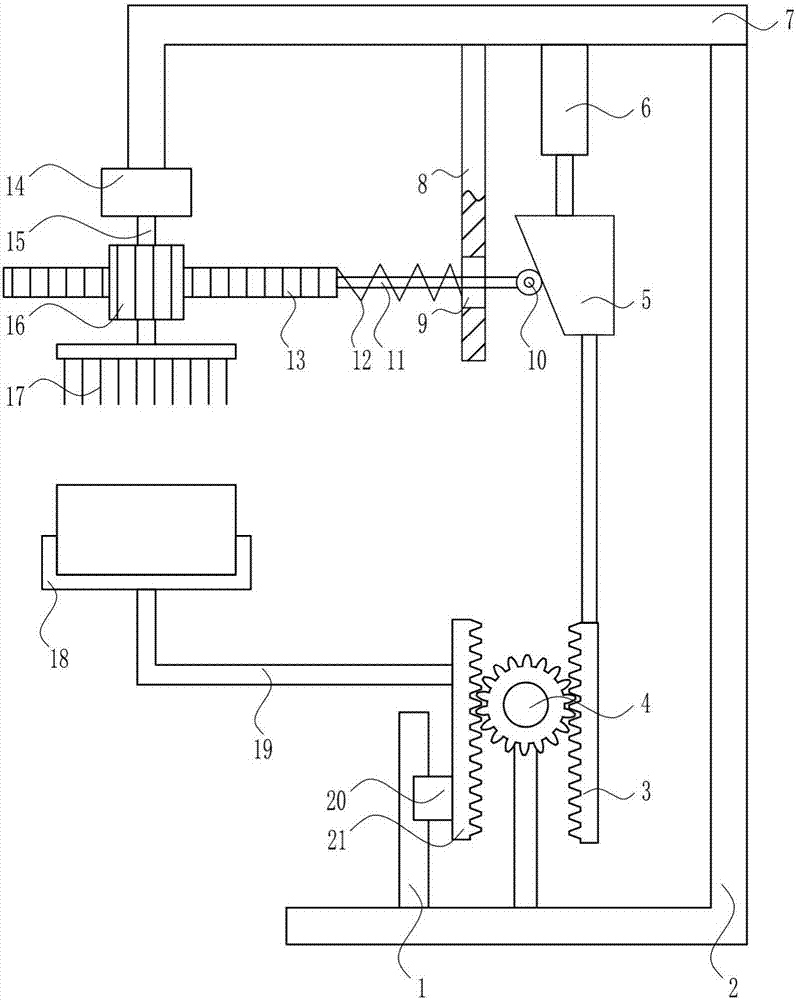

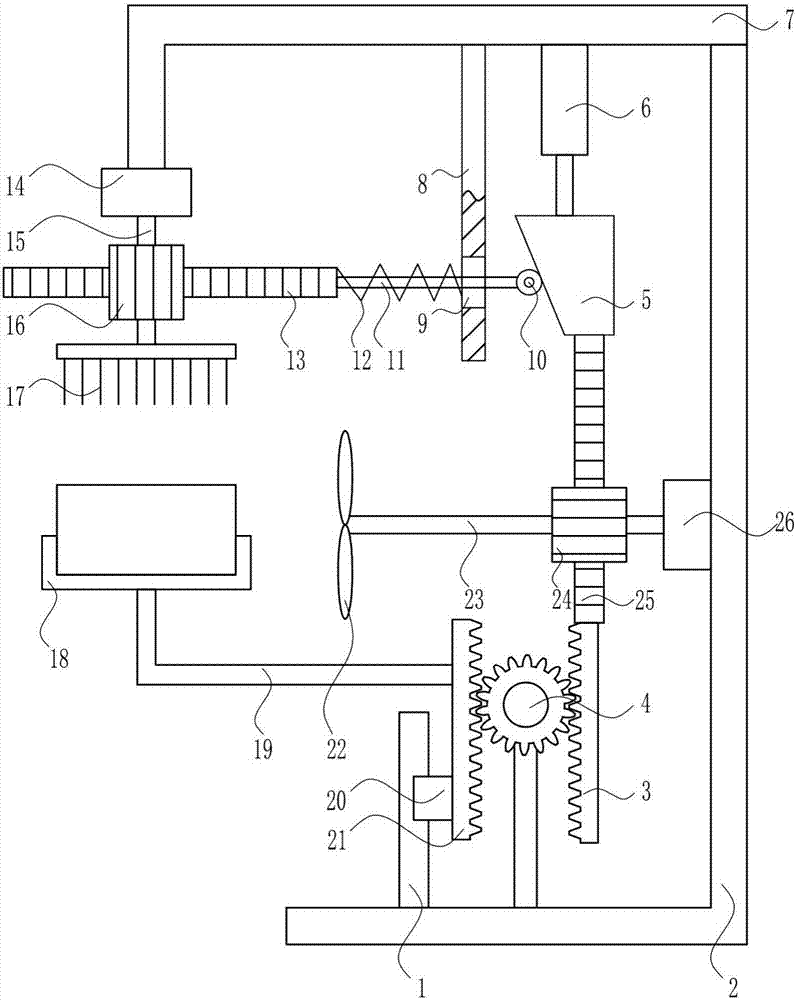

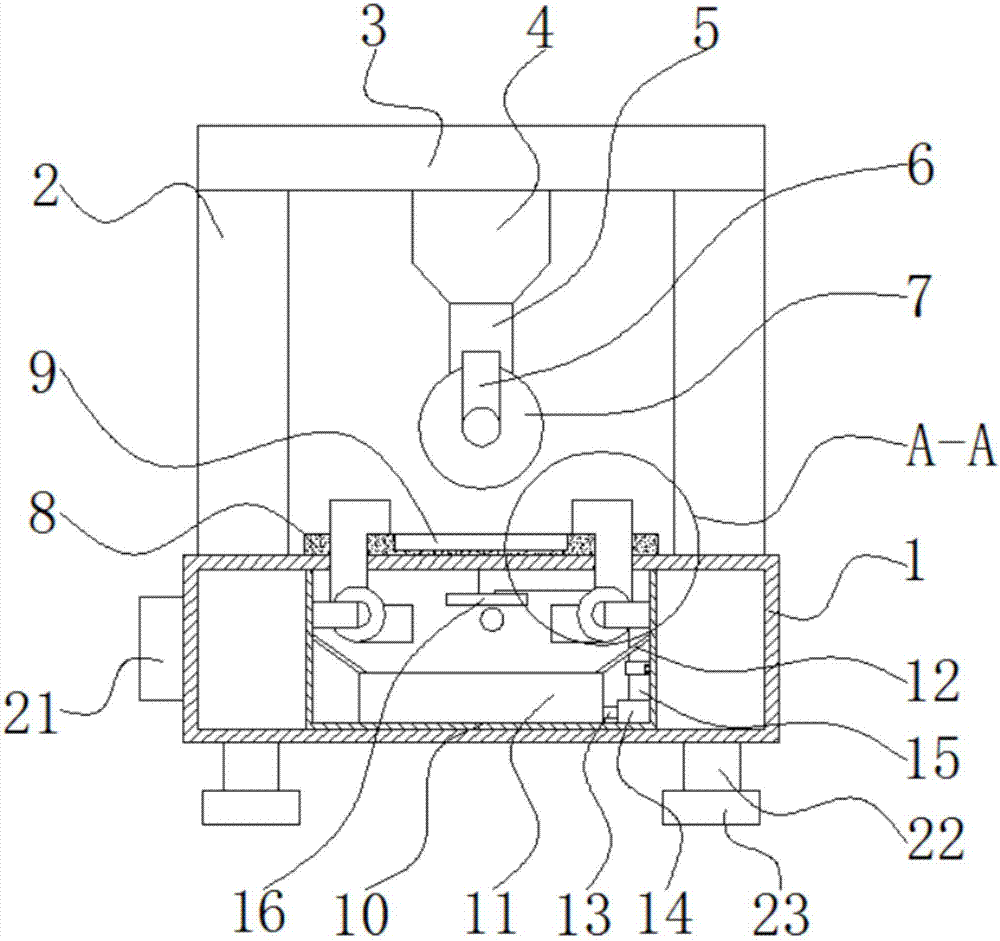

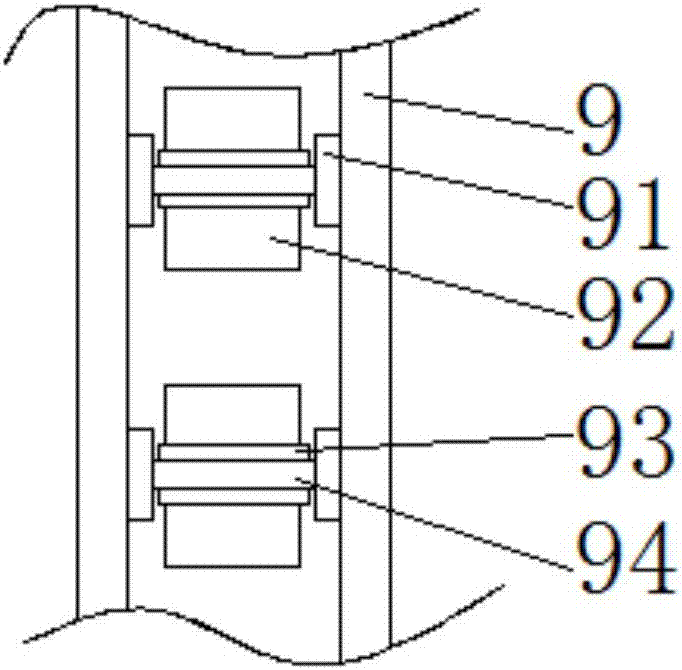

Rapid radiating and dust removing device for power filter

ActiveCN106391525APlay the role of dust removalThoroughly dust and cleanDomestic cooling apparatusLighting and heating apparatusFunctional diversityEngineering

The invention relates to a radiating and dust removing device, in particular to a rapid radiating and dust removing device for a power filter. The technical effect that the rapid radiating and dust removing device for the power filter which is complete in radiating, diversified in function and easy and convenient to operate is provided is achieved. In order to achieved the technical effect, the provided rapid radiating and dust removing device for the power filter comprises an L-shaped frame, a first wedge block, a second wedge block, a first sliding block, a first sliding rail, a bottom plate, a movable rod, a sliding shaft, a movable block, a second sliding rail, a second sliding block and the like. The L-shaped frame and the first sliding rail are arranged at the top of the bottom plate. The L-shaped frame is located on the left side of the first sliding rail. A cylinder block is arranged on the left side of the L-shaped frame. A piston is arranged in the cylinder block. The second wedge block is arranged at the bottom of the piston. The effects of complete radiating, diversified functions and easy and convenient operation are achieved, the functions of radiating, cooling, dust removing and the like can be started simultaneously, and the functional diversity of the device is achieved.

Owner:安力德工程技术有限公司

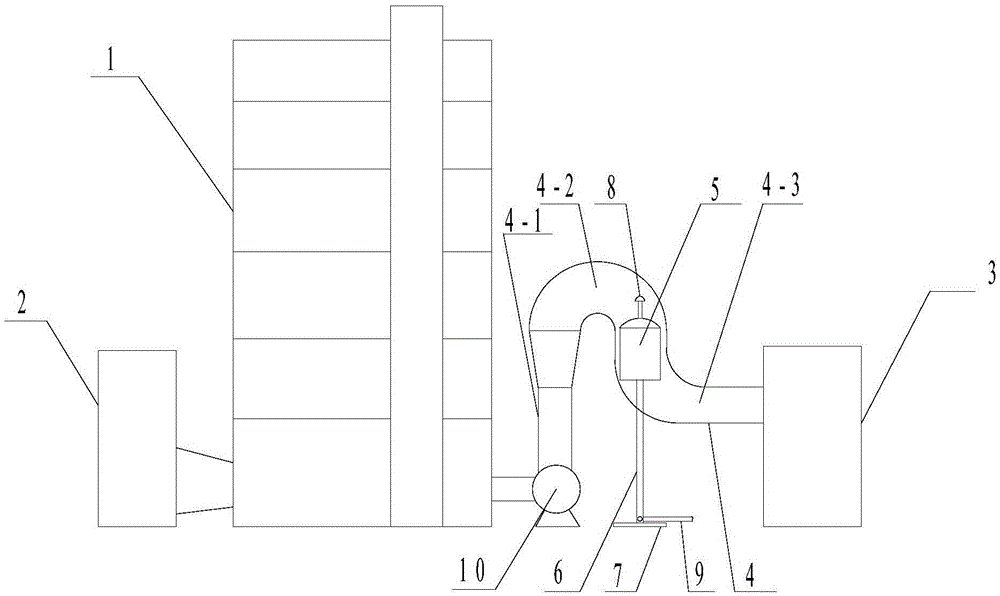

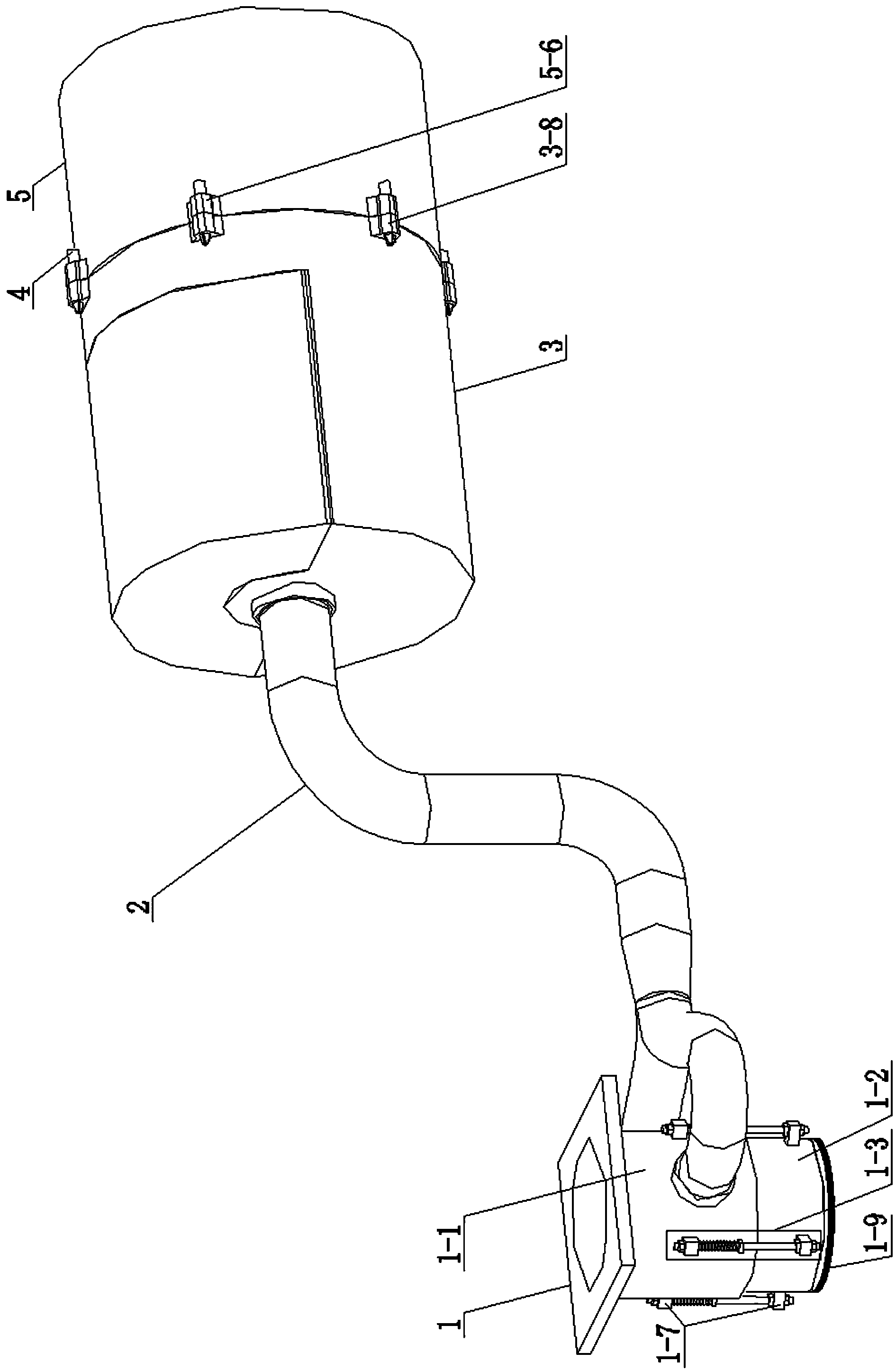

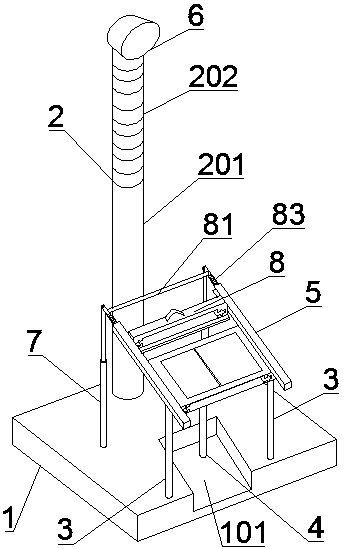

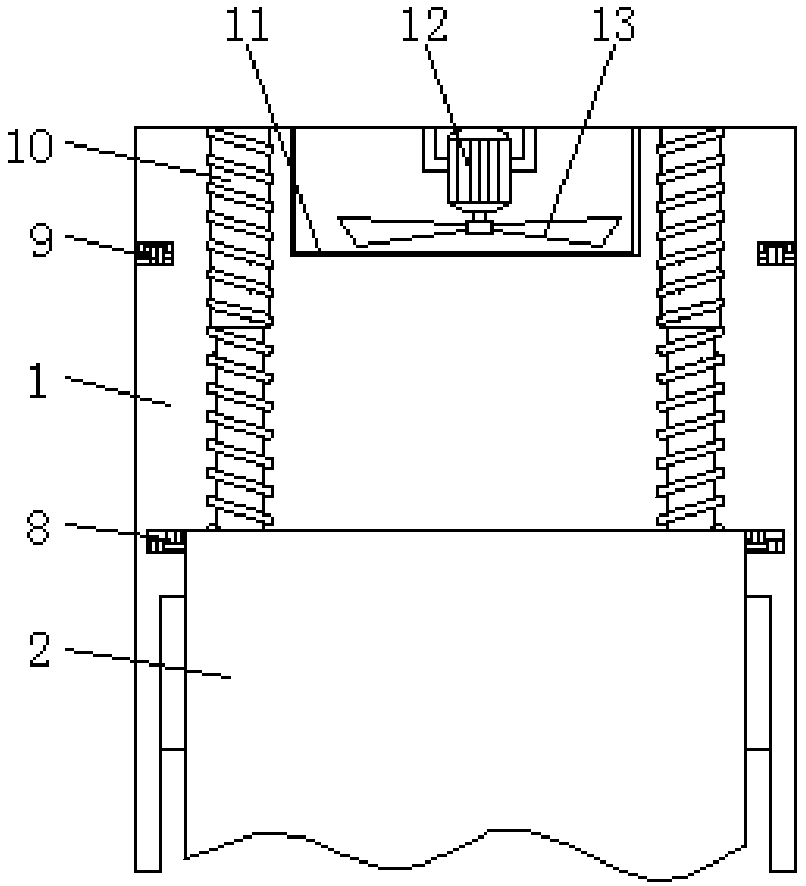

Grain drying device

ActiveCN105486074AReduce volumeImprove efficiencyFood processingClimate change adaptationEngineeringTower

The invention discloses a grain drying device. The grain drying device comprises a drying tower (1); one side of the drying tower (1) is communicated with a heat pump (2) for supplying hot wind; a dust collecting chamber (3) for collecting grain dust is arranged on the other side of the drying tower (1), and is communicated with the drying tower (1) through a dust removing pipe (4); and an evaporator (5) of the heat pump (2) is arranged in the dust removing pipe (4). The grain drying device is provided with the evaporator of the heat pump in the dust removing pipe, can improve the efficiency of the evaporator by using heat of dust-contained gas, and is energy-saved and environment-friendly.

Owner:苏州市农业机械有限公司

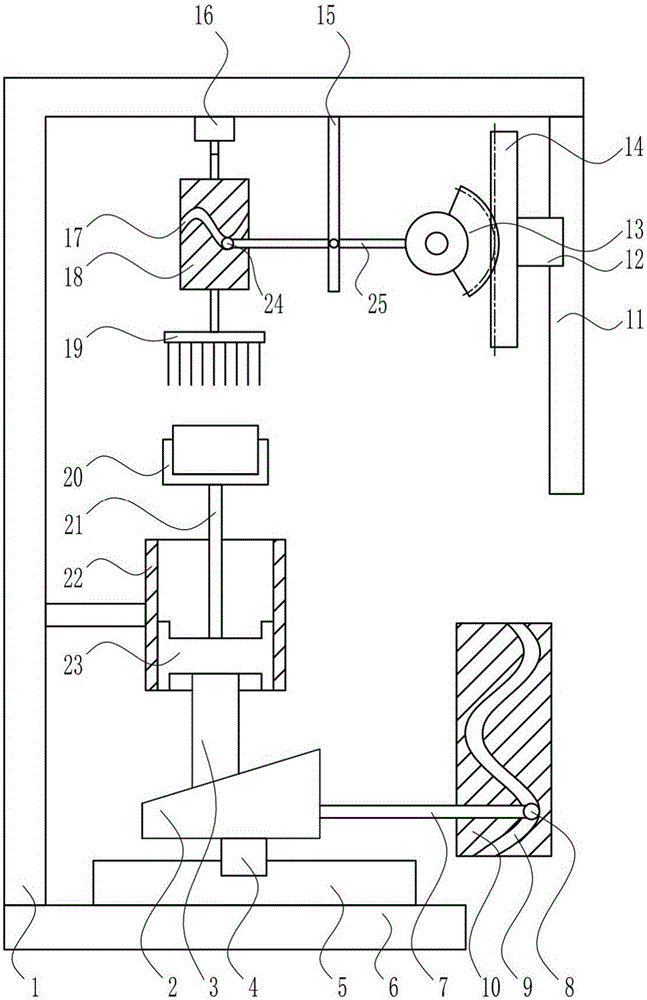

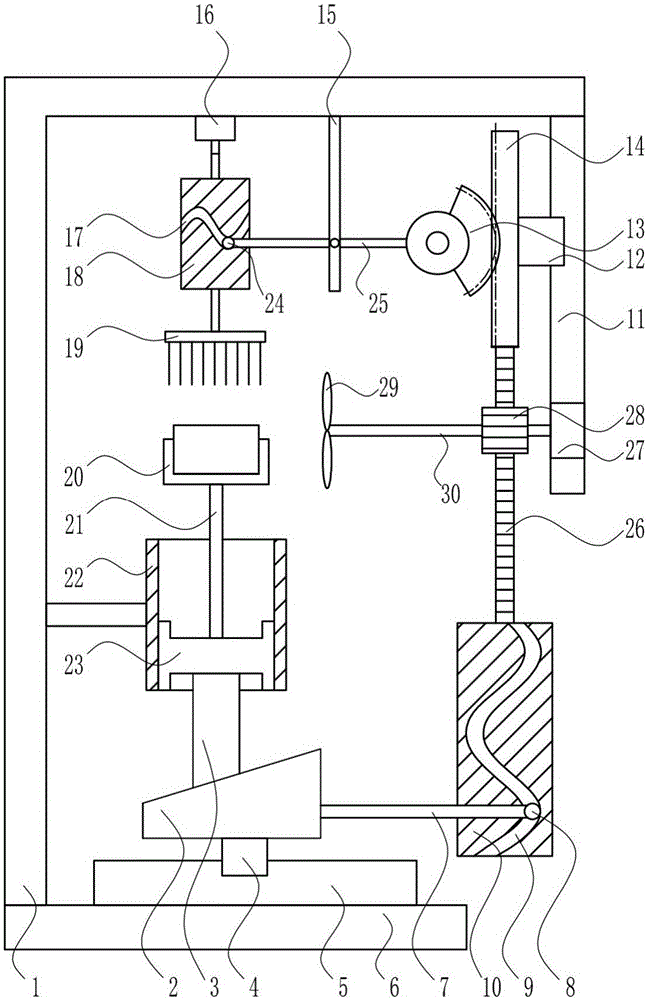

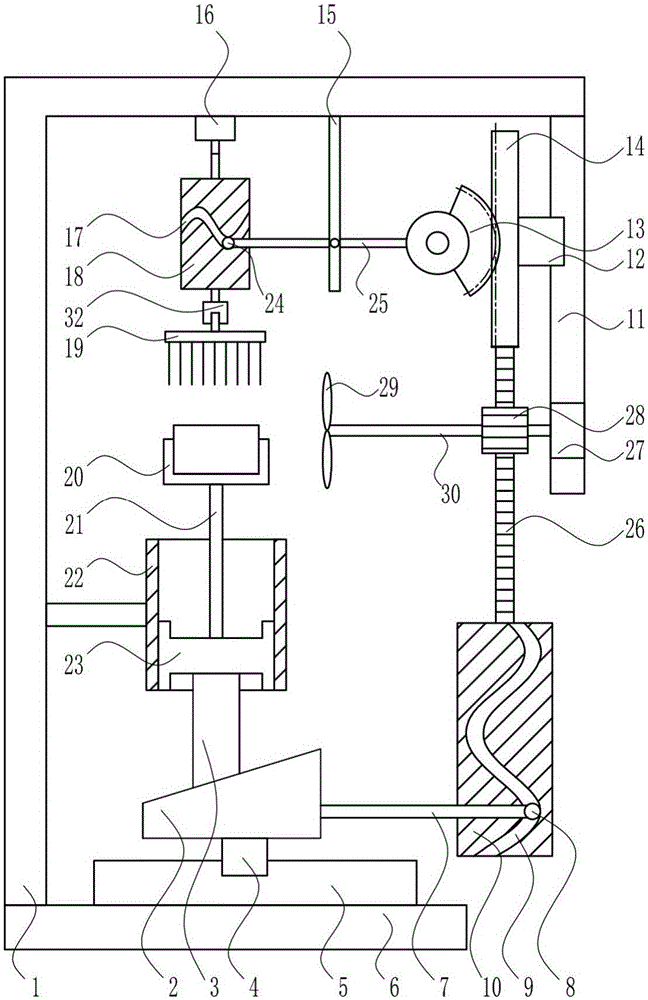

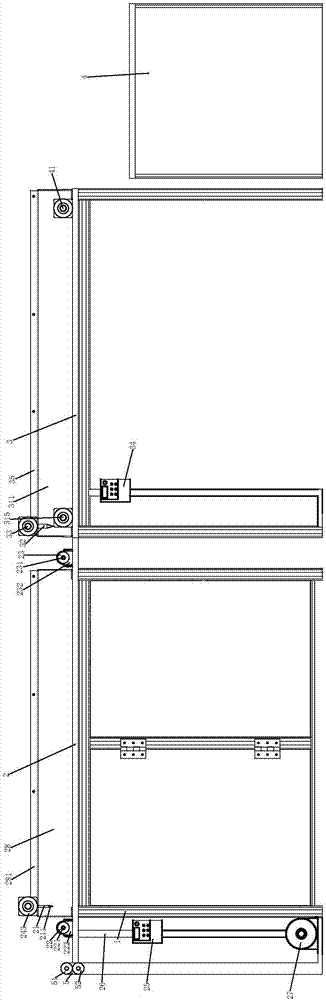

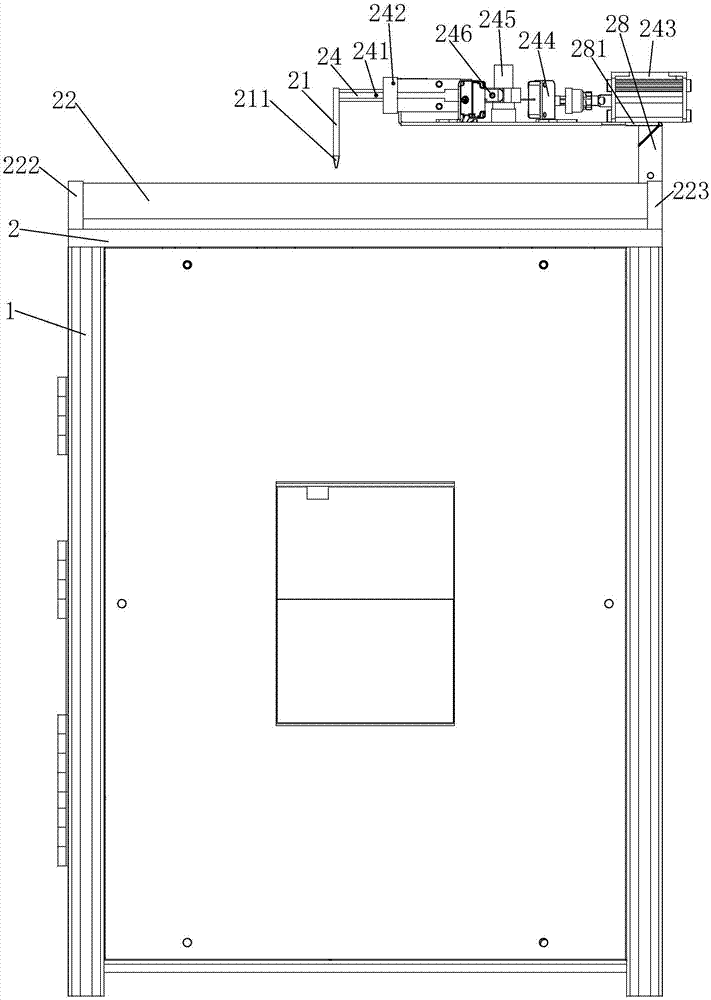

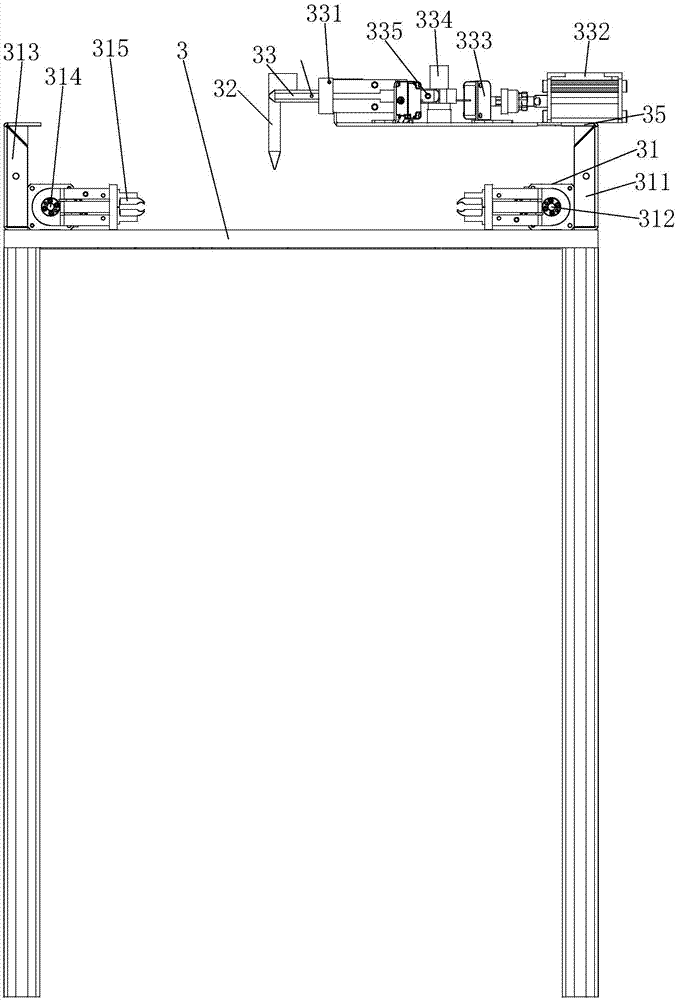

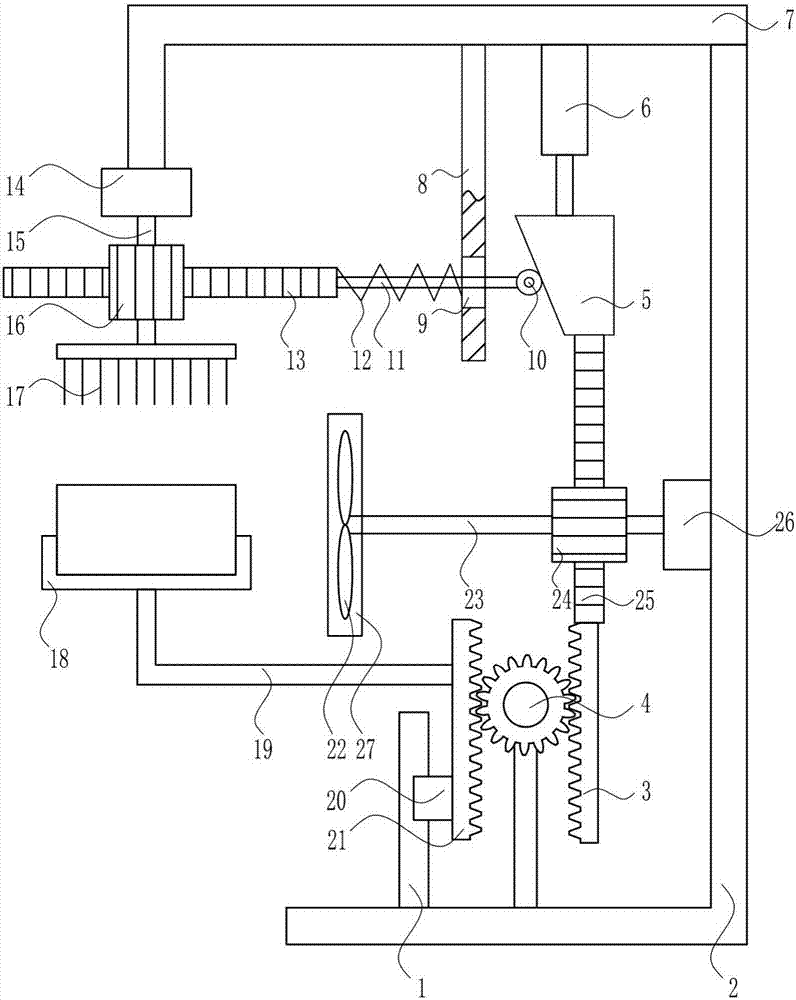

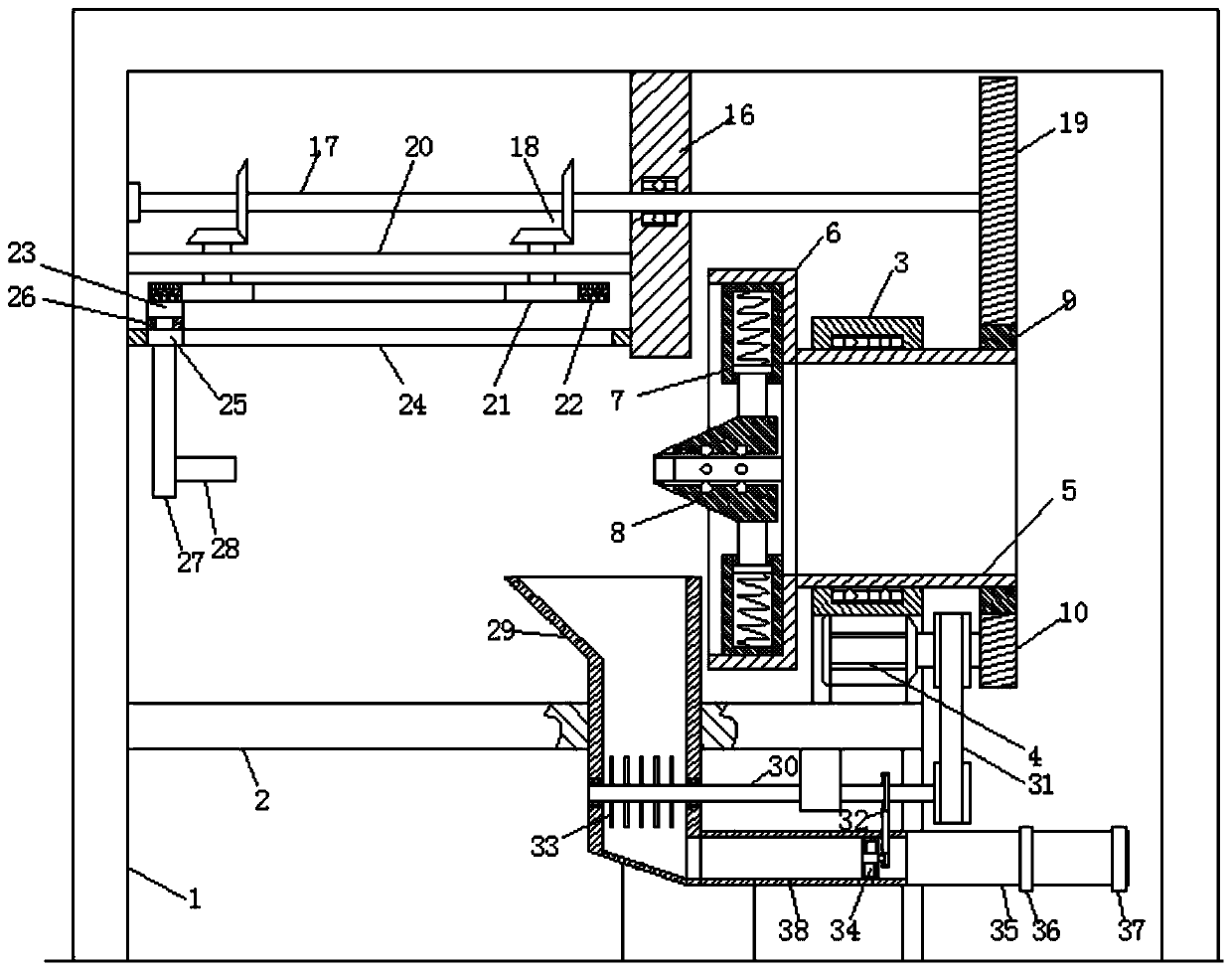

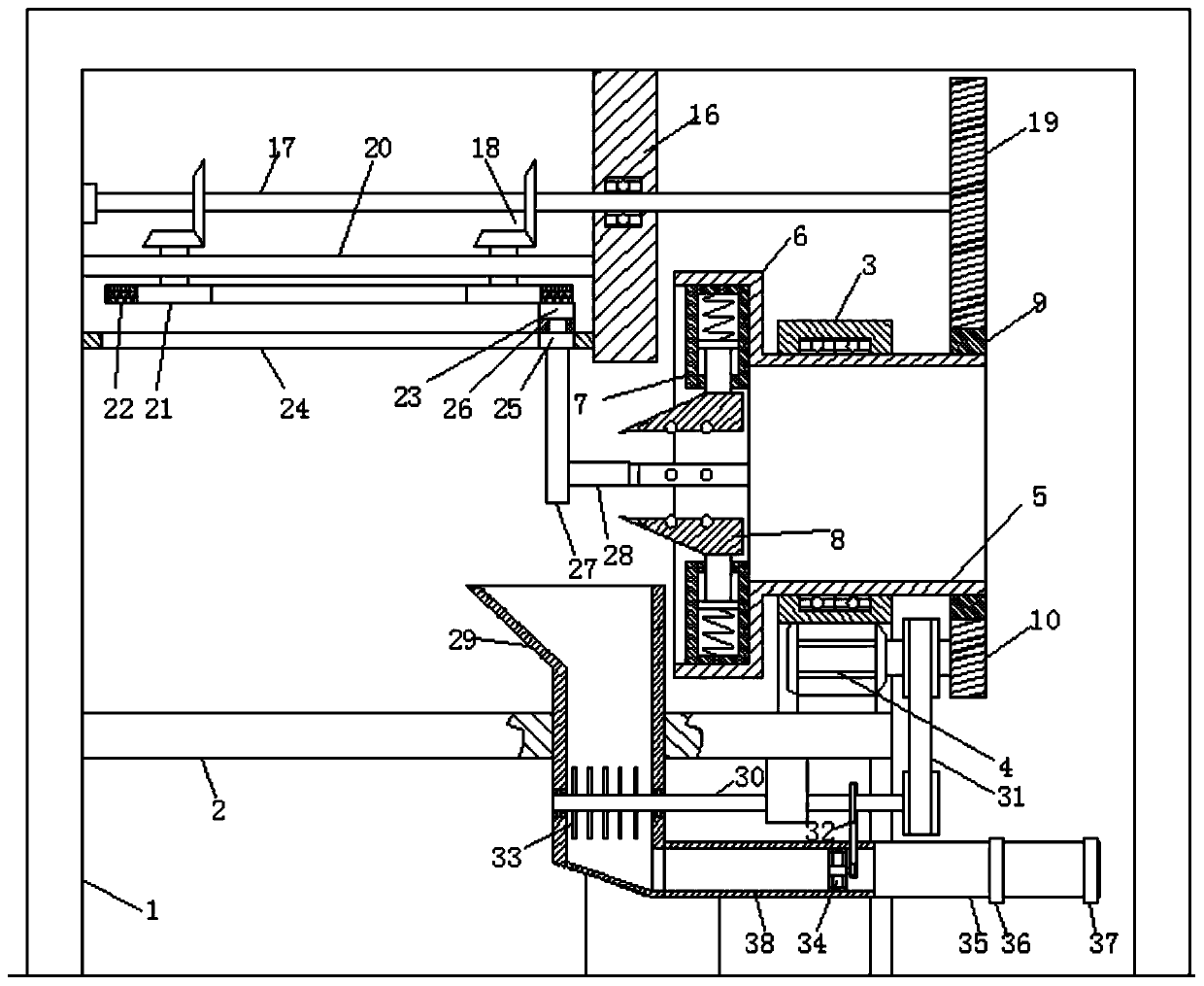

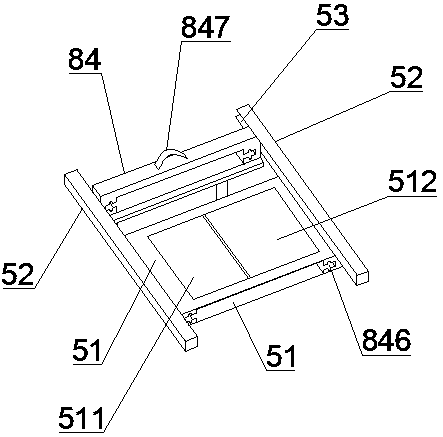

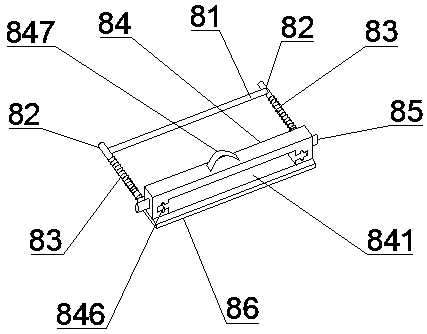

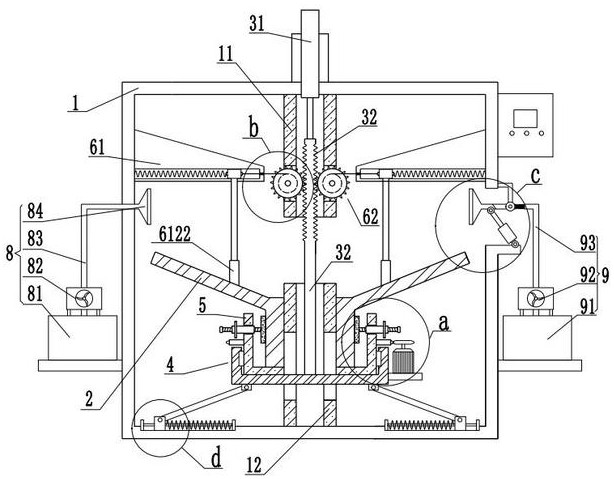

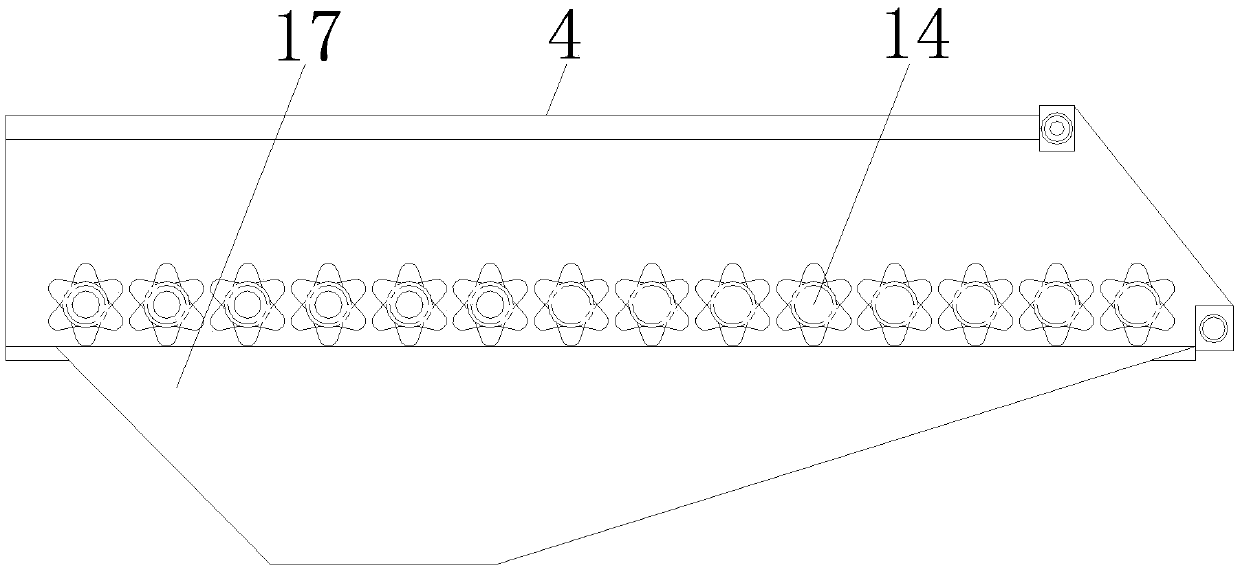

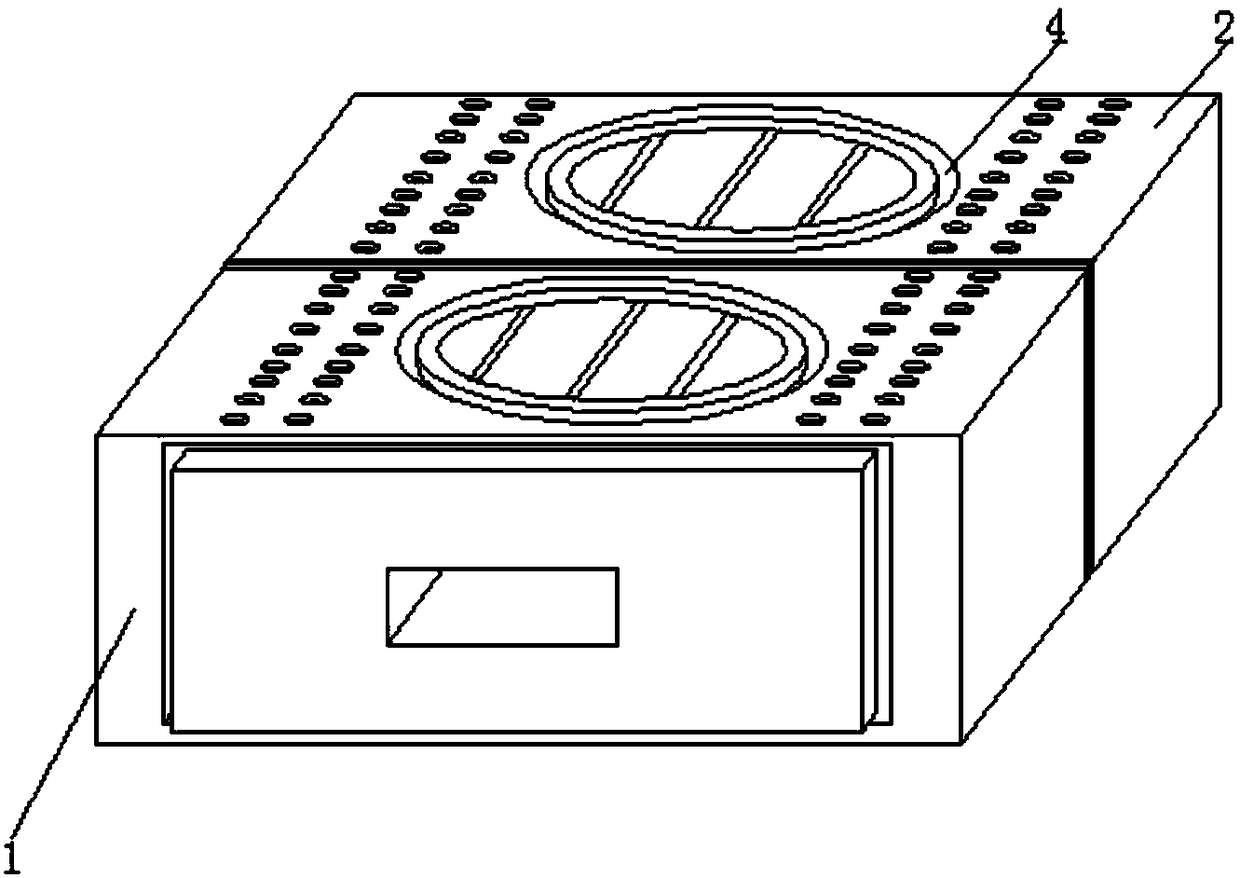

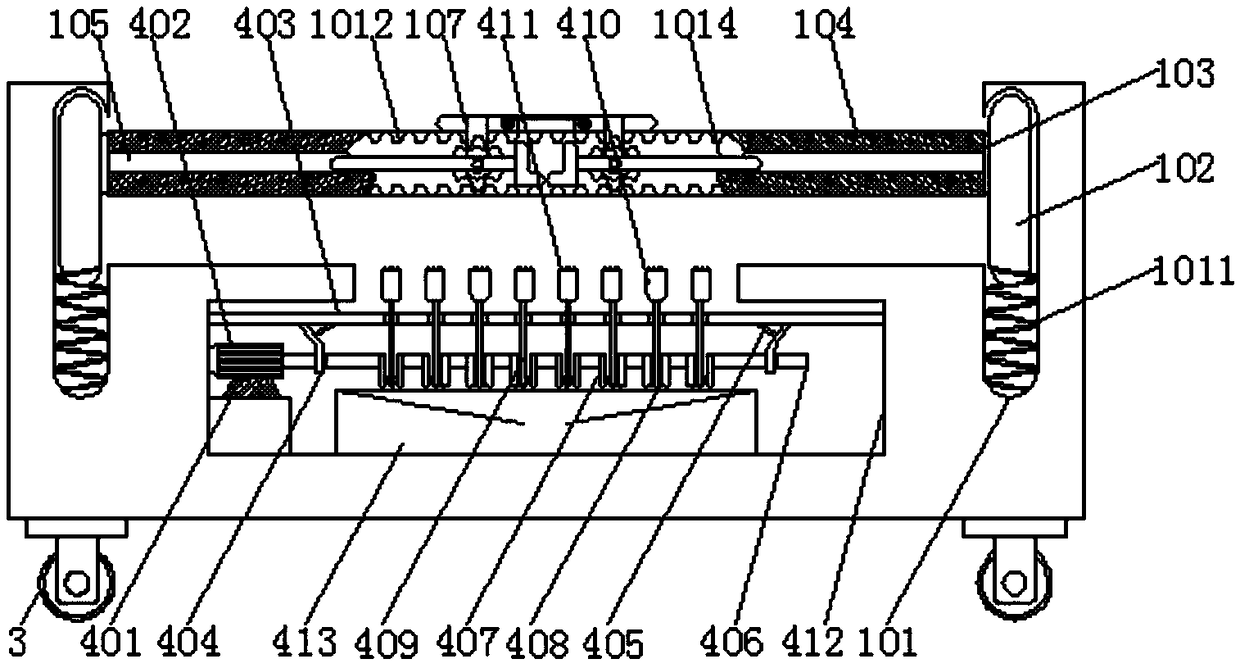

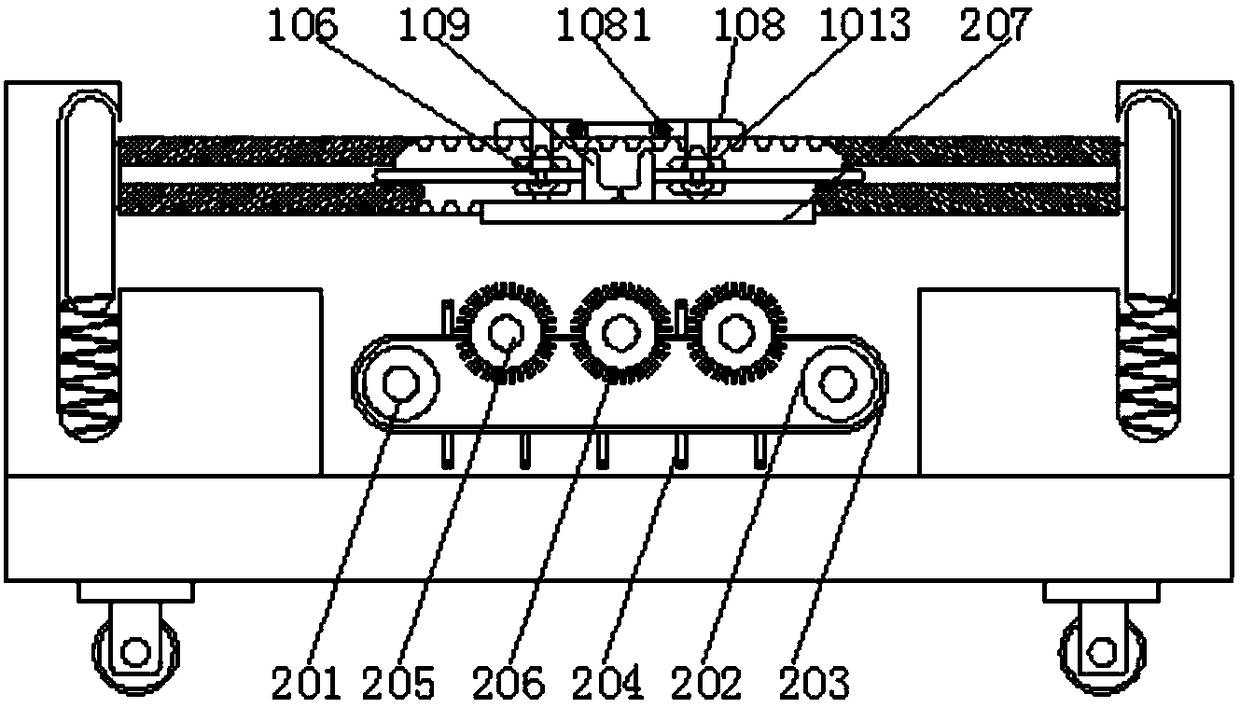

Automobile seat cover tailoring and sewing integral machine having dust removing device

InactiveCN107419439AImplement automatic croppingPlay the role of dust removalProgramme-controlled sewing machinesWorkpiece carriersDyeingMachining process

The invention provides an automobile seat cover tailoring and sewing integral machine having a dust removing device, and belongs to the technical field of weaving and dyeing, which can solve the problem that automobile seat covers are polluted by dust in the conventional processing stage. The automobile seat cover tailoring and sewing integral machine having the dust removing device includes a rack; a dust removing device for removing dust on an automobile seat cover fabric, a tailoring device for tailoring the automobile seat cover fabric, and a sewing device for sewing the tailored automobile seat cover fabric are arranged on the rack; the dust removing device, the tailoring device and the sewing device are successively arranged along the rack; the dust removing device includes an upper dust removing roller and a lower dust removing roller; and a first channel for allowing the automobile seat cover fabric to pass is formed between the upper dust removing roller and the lower dust removing roller. The automobile seat cover tailoring and sewing integral machine can remove dust on the automobile seat cover before processing.

Owner:海宁市现代汽车座套有限公司

Gradient adjusting type self-cleaning infrared monitor

ActiveCN110519569AImprove adaptabilityImprove imaging effectClosed circuit television systemsCleaning using toolsEngineeringMonitor equipment

The invention belongs to the technical field of monitoring equipment, in particular to a gradient adjusting type self-cleaning infrared monitor. The monitor comprises a cylindrical shell and a monitoring head, the monitoring head is arranged at the lower half part of the shell; a rotary drum is coaxially and rotationally connected to the center of the shell. The side wall of the front end of the drum is fixedly connected with a light filter plate; the light filtering plate is formed by splicing a plurality of fan-shaped plates of which the light filtering intensity is sequentially increased; an arc-shaped cavity is formed in the side wall of the shell; one end of the arc-shaped cavity is closed, the other end of the arc-shaped cavity is communicated with a pressure stabilizing channel, anarc-shaped friction strip is slidably and hermetically connected into the arc-shaped cavity, expansion liquid is filled between the arc-shaped friction strip and the closed end of the arc-shaped cavity, a friction wheel is rotatably connected into the shell, the lower end of the friction wheel contacts with the side wall of the drum, and the upper end extends into the arc-shaped friction strip. According to the invention, the light filter plate is formed by splicing the plurality of fan-shaped plates of which the filtering intensities are sequentially increased, and the light filter plate canbe adjusted according to different illumination intensities, so that a better imaging effect is achieved.

Heat dissipation and dust removal device for electric filter

InactiveCN106938261APlay the role of dust removalConvenience to workDomestic cooling apparatusLighting and heating apparatusFunctional diversityEngineering

Owner:钟苡苇

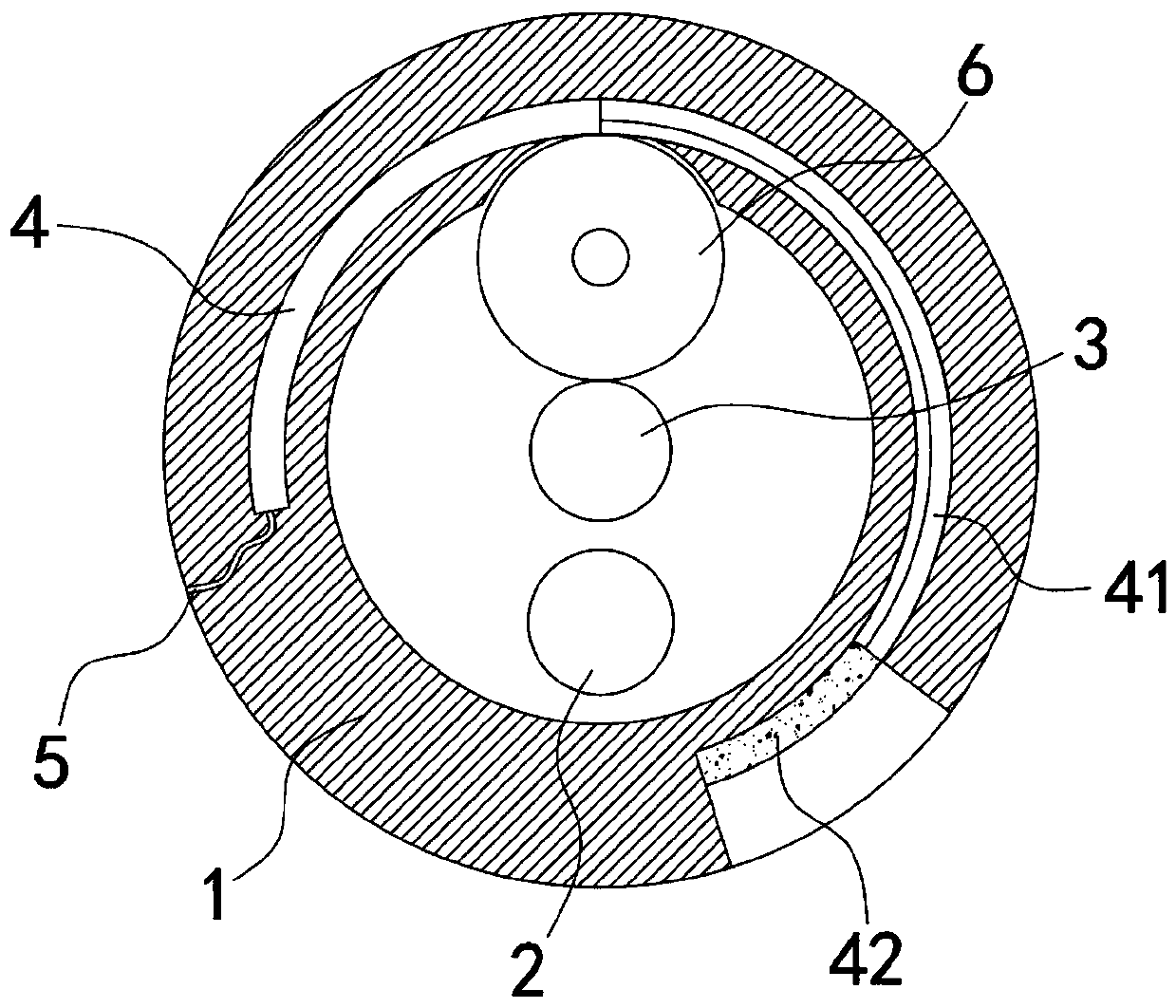

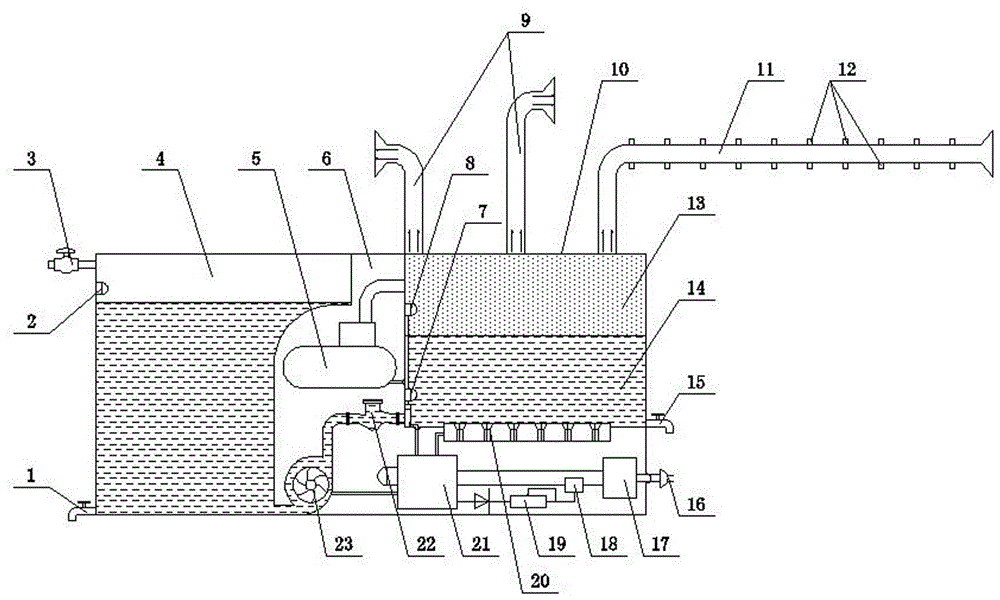

Piezoelectric driving type ultrasonic water-mist humidifying-cooling dust remover

InactiveCN106731348AAchieve replacementSimple and quick maintenanceMechanical apparatusSpace heating and ventilation safety systemsWater storage tankAir pump

The invention discloses a piezoelectric driving type ultrasonic water-mist humidifying-cooling dust remover. The dust remover is characterized by comprising a body, wherein a water storage tank is arranged at a left part in the body, a sealed atomizing chamber is arranged at a right upper part in the body, and a cavity chamber for mounting parts is arranged between the water storage tank and the atomizing chamber; the bottom of the water storage tank is communicated with the bottom of the atomizing chamber through a pipeline, an electromagnetic water valve and a water pump are mounted on the pipeline, an atomizing driving device is mounted at the bottom in the atomizing chamber, a mist outlet is formed in the top of the atomizing chamber, an air pump and a control circuit are mounted in the cavity chamber, and an air outlet pipeline of the air pump is communicated with the upper half part of the atomizing chamber; and the air pump, the electromagnetic water valve, the water pump and the atomizing driving device are connected with an inlet end of the control circuit, and an adjusting knob for regulating the vibration strength of the atomizing driving device is electrically connected to an output end of the control circuit. The piezoelectric driving type ultrasonic water-mist humidifying-cooling dust remover is of a compact structure and high in humidifying-cooling dust removal efficiency and can be used in different working regions.

Owner:河南感联智能科技有限公司

Removed material collecting and dust removing system during drilling process of carbon fiber composite material

InactiveCN104385353AAvoid contactAvoid damaging effectsDispersed particle filtrationDirt cleaningDust controlMachine tool

The invention discloses a removed material collecting and dust removing system during a drilling process of a carbon fiber composite material, belongs to the technical field of machining an engineering composite material and aims to solve the problem of a frustrating effect which is generated on workpiece quality, environment, machine tool equipment and operators due to powder generated by drilling of the carbon fiber composite material. The removed material collecting and dust removing system is characterized in that an air inlet of an air inlet manifold is fixedly connected with the side wall of a main shaft connecting sleeve of a telescopic dust removing device in the feeding direction and is communicated with an inner cavity of the main shaft connecting sleeve, and an air outlet of the air inlet manifold is fixedly connected with the closed end of a collecting and dust removing shell of a removed material collecting and dust removing device and is communicated with an inner cavity of the collecting and dust removing shell of the removed material collecting and dust removing device; the collecting and dust removing shell of the removed material collecting and dust removing device is connected with a draught fan shell of a turbofan draught fan device through multiple self-locking opening pins. The removed material collecting and dust removing system disclosed by the invention is used for carrying out collecting and dust removing during the drilling process of the carbon fiber composite material, and the frustrating effect which is generated on the workpiece quality, the environment, the machine tool equipment and the operators can be effectively avoided.

Owner:HARBIN UNIV OF SCI & TECH

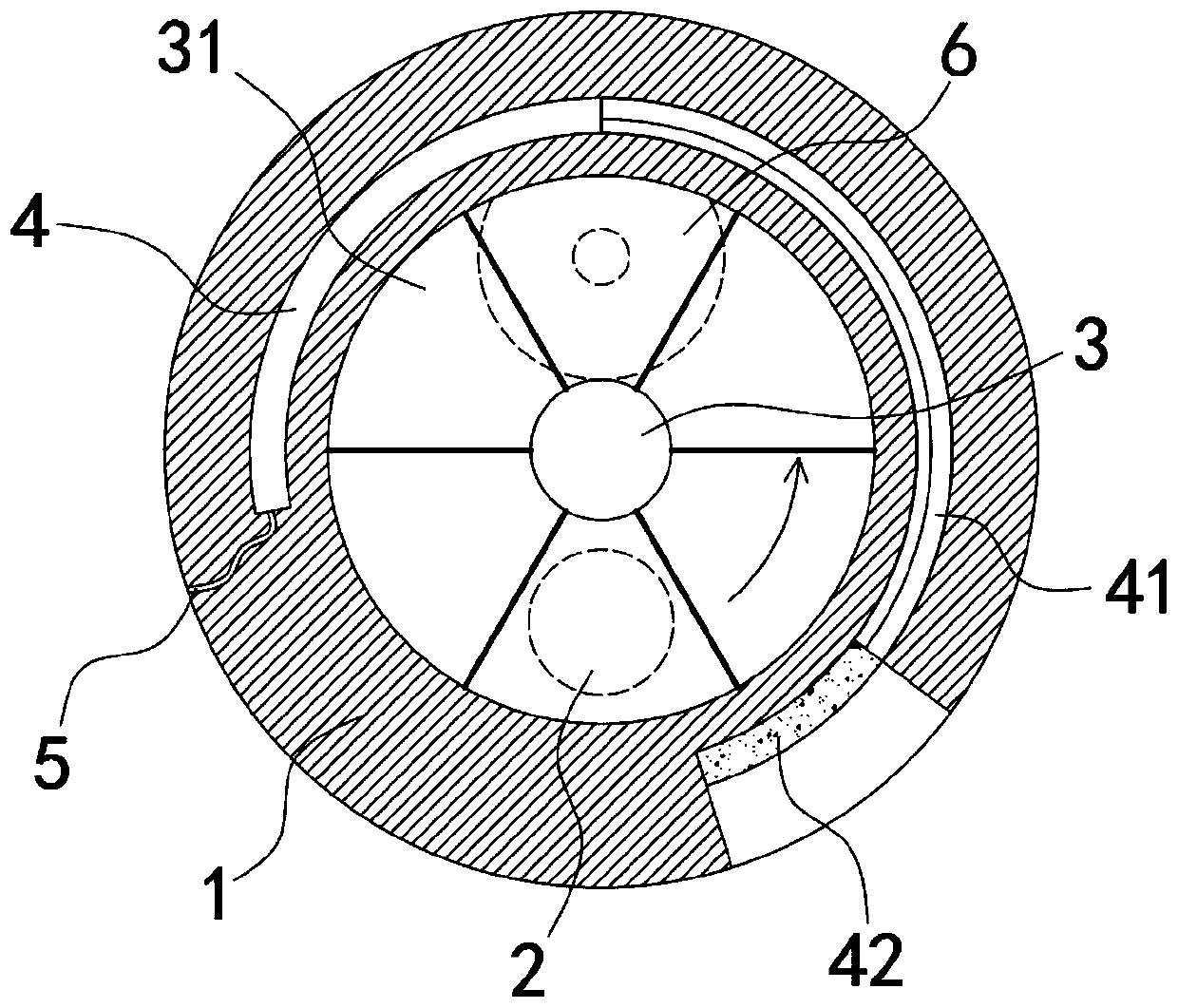

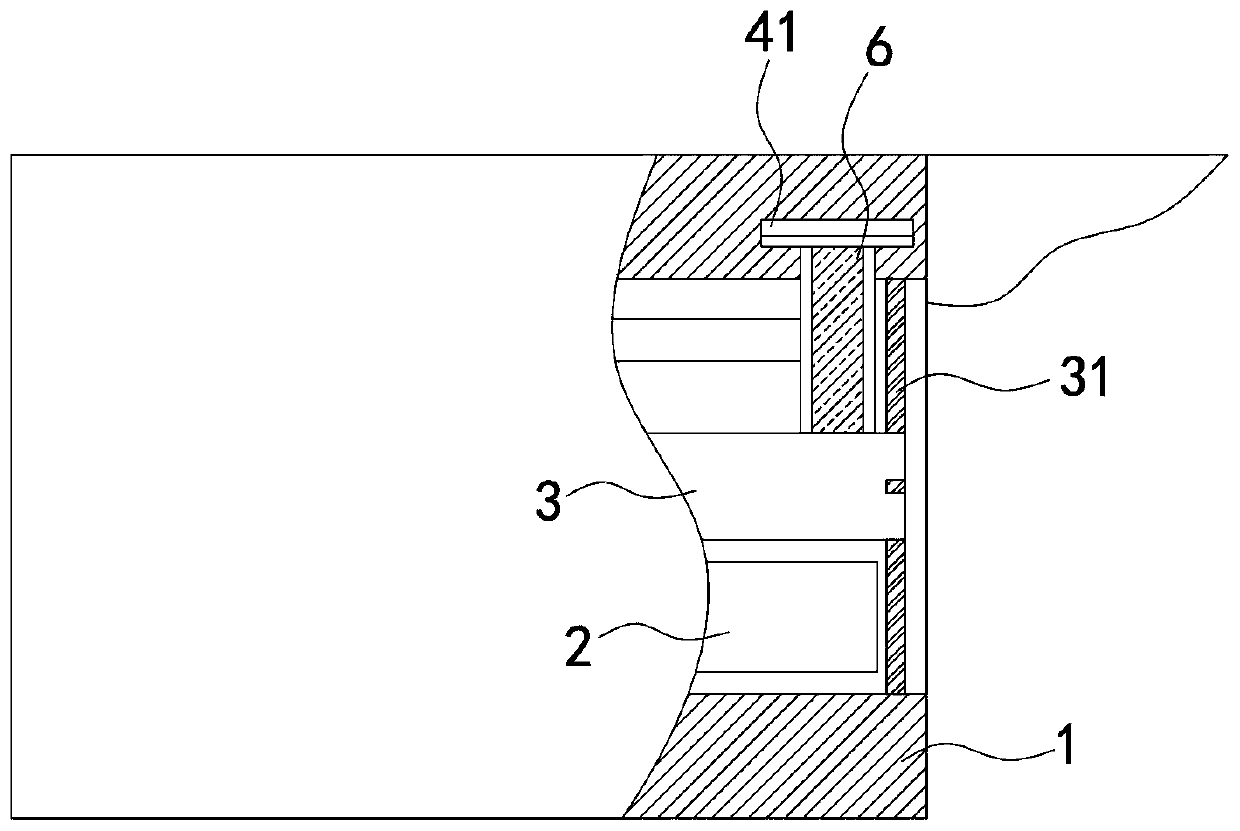

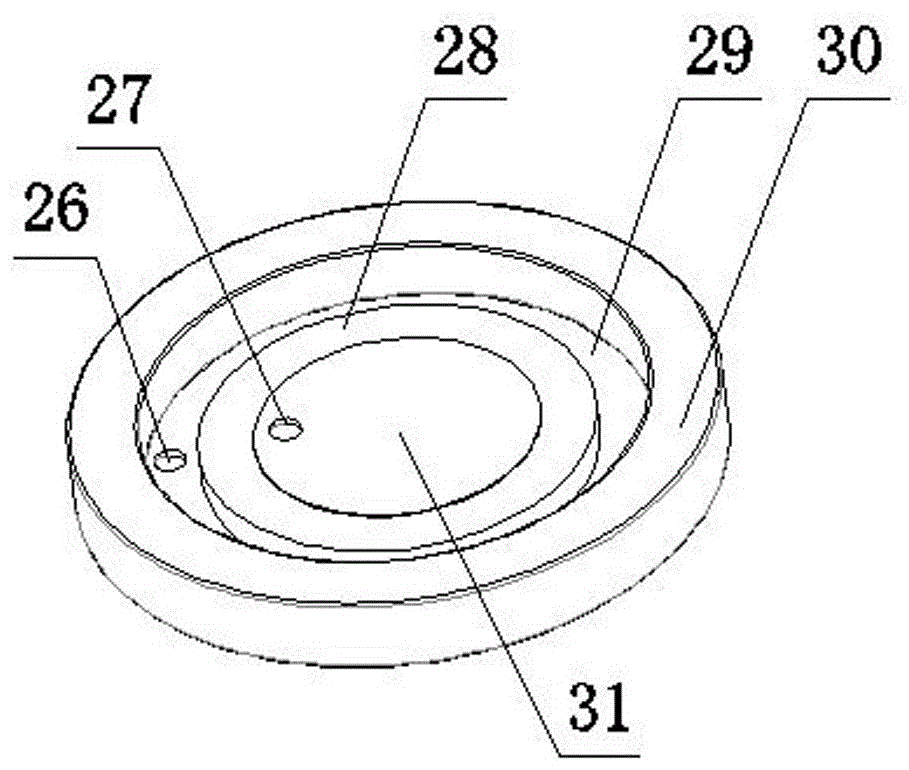

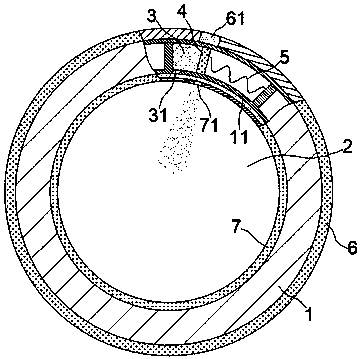

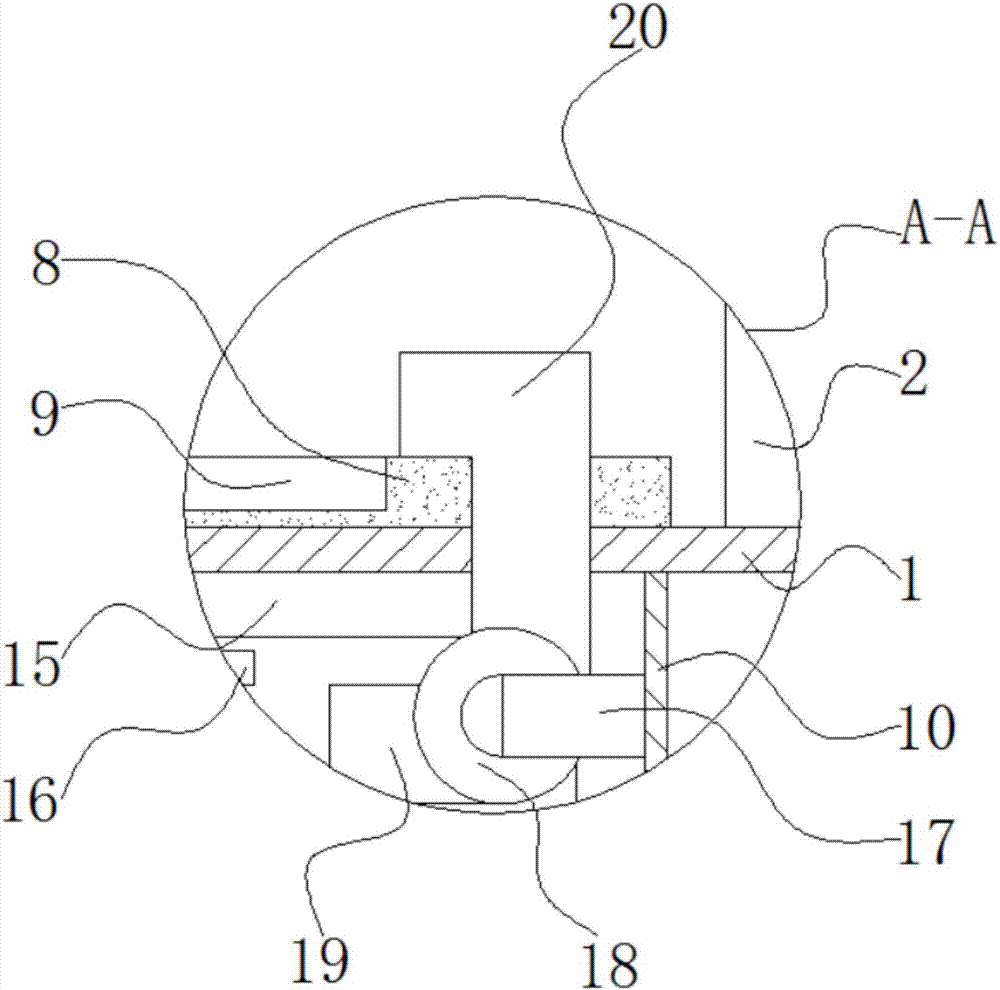

Camera easy to remove dust

ActiveCN110266925APlay the role of dust removalEasy to cleanTelevision system detailsColor television detailsPistonInjection air

The invention relates to a camera easy to remove dust. The camera easy to remove dust comprises a machine body and a camera, the device further comprises a dust removal part. The dust removal component comprises a dust removal ring made of a hollow material; the lens is fixedly mounted on the inner ring wall of the dust removal ring; dust removal cavities are rotationally and symmetrically formed in the hollow area of the dust removal ring, and a piston plate is arranged in each dust removal cavity in a sliding mode. A reset spring is arranged between the piston plate and the side wall of the dust removal cavity, and an air injection hole is formed in the dust removal cavity; an operation ring is coaxially arranged on the outer ring wall of the dust removal ring in a sleeving manner; operation blocks which are matched with the piston plates one by one and directly face the piston plates are arranged on the operation ring, and the operation blocks and the piston plates are made of magnetic materials which attract each other; the camera is novel in structure and unique in principle, dust can be easily removed without an external tool, the cleaning difficulty is effectively reduced, and the working efficiency is improved.

Owner:李峥炜

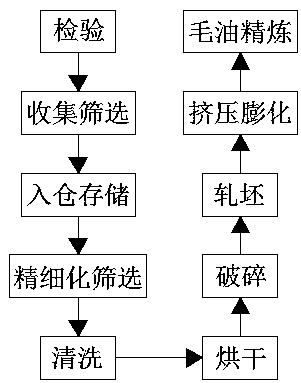

Soybean oil processing method

InactiveCN109135913AQuality improvementImprove dust removal effectFatty-oils/fats refiningFatty-oils/fats productionOil processingHardness

The invention discloses a soybean oil processing method. The soybean oil processing method comprises the following steps of an inspection process including that, before soybeans are put in storage, inspection personnel randomly sample three points from soybeans to be stored for spot inspection, then equally divide samples of every point into three and detect the humidity, saturation fullness and hardness of the soybeans through detecting instruments, and a collecting and screening process including that the inspection personnel purchase the soybeans inspected to be qualified. Through interaction of inspection, collection, screening, bin storage, fine screening, cleaning, drying, crushing, rolling, extruding and crude oil refining, the soybean oil processing method has the advantages of high soybean dust cleaning effects and high yield of crude oil, solves the problem that existing soybean oil processing methods are poor of soybean dust cleaning effects and low crude oil yield, and during oil processing, can avoid low crude oil quality due to impurities inside crude oil and improve the quality of soybean oil.

Owner:许昌泰禾农业科技发展有限公司

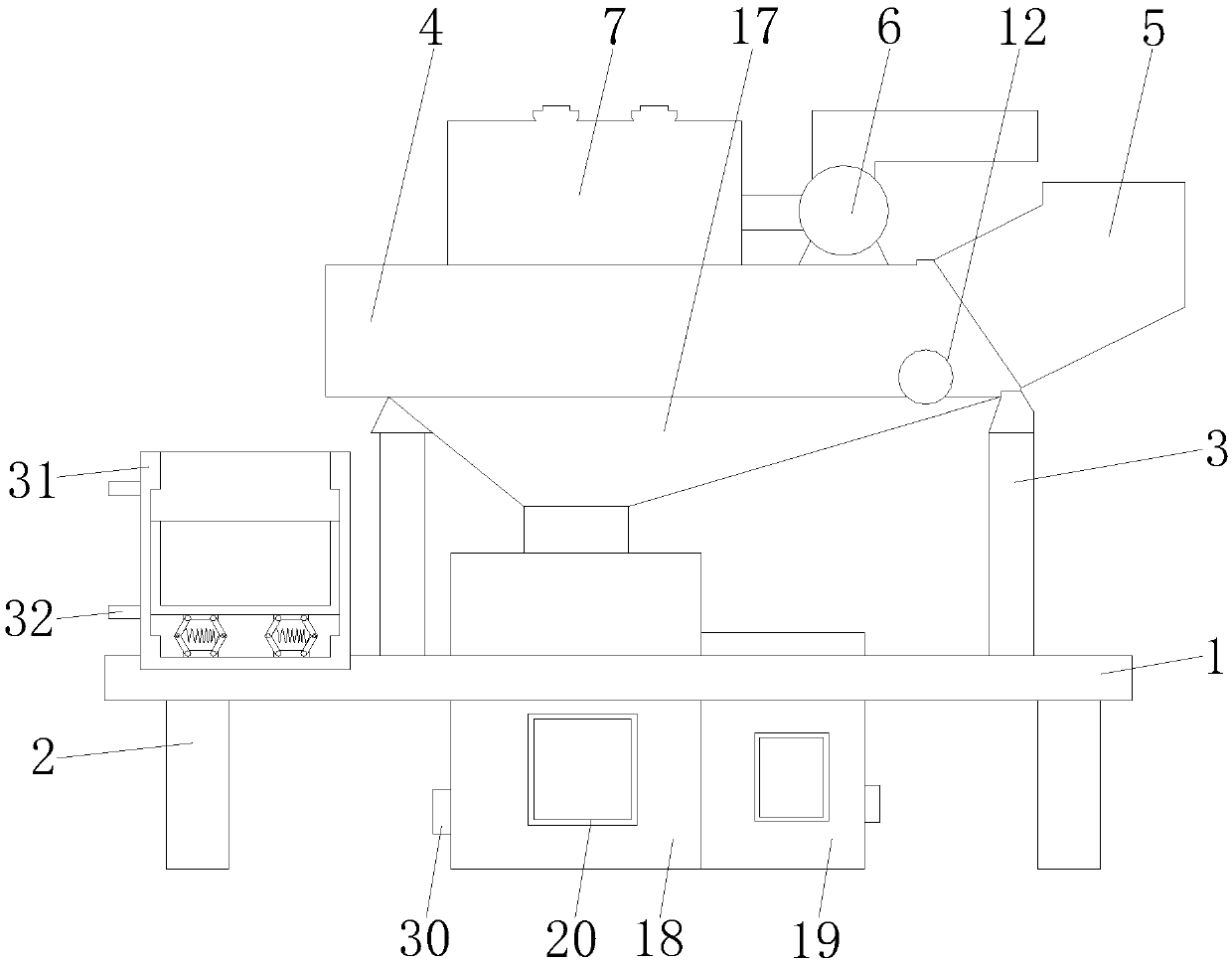

Pretreatment all-in-one machine for bamboo processing

InactiveCN111283834APlay the role of dust removalWon't hurtTree debarkingCane mechanical workingPulp and paper industryMechanical engineering

The invention belongs to the field of bamboo processing equipment, and particularly relates to a pretreatment all-in-one machine for bamboo processing. The pretreatment all-in-one machine includes a portal frame, a supporting table is fixed on the inner side of the portal frame, a cutting mechanism for cutting branches and leaves of bamboo tubes is arranged on the supporting table, a material pushing mechanism for pushing the bamboo tubes is arranged on the upper part of the portal frame, and the cutting mechanism is in drive connection with the material pushing mechanism; and a crushing mechanism for crushing the branches and leaves removed by the cutting mechanism is arranged on the lower part of the supporting table, and the cutting mechanism and the crushing mechanism are in driving connection. According to the pretreatment all-in-one machine for bamboo processing, the removal of the branches and leaves from the bamboo tubes is realized, the production efficiency is improved, safety is achieved, people are prevented from being stabbed by generated sharp spikes, the branches and leaves removed by the cutting mechanism do not need to be transported to other crushing equipment forcrushing treatment, the production process is simplified, the production cost is reduced, meanwhile, the crushing mechanism further plays a role of dust removal, and the generation of dust during theremoval of the branches and leaves on the bamboo tubes is avoided, so that the environment and the body of an operator are protected.

Owner:张肇圣

Human body biological characteristic collecting device

InactiveCN109973771AEasy to assemble and disassembleEasy to replaceFouling preventionCharacter and pattern recognitionHydraulic cylinderHuman body

The invention belongs to the technical field of biological characteristic identification, and relates to a human body biological characteristic collecting device. The human body biological characteristic collecting device structurally comprises a base, a first supporting column, third supporting columns, a hydraulic cylinder, a fingerprint collecting devices and a camera, wherein the first supporting column is arranged at one side of the base; the camera is arranged at the upper end of the first supporting column; the hydraulic cylinder and the third supporting columns are sequentially arranged on the base and are located at one side of the first supporting column; the fingerprint collecting device is arranged above the third supporting columns and the hydraulic cylinder; the third supporting columns are pairwise arranged and are respectively located at the two sides under the front end of the fingerprint collecting device; the hydraulic cylinder is located under the central position of the fingerprint collecting device; the fingerprint collecting device comprises an operating platform and slideways fixedly arranged at the two sides of the operating platform; the operating platformis in hinge joint with the two third supporting columns through the slideways at the two sides; and a fingerprint collection faceplate and a control panel are arranged on the upper surface of the operating platform. The human body biological characteristic collecting device facilitates the wiping of a fingerprint collection platform to prevent dust deposit from affecting information collection, and is convenient and quick to use.

Owner:韩薏菲

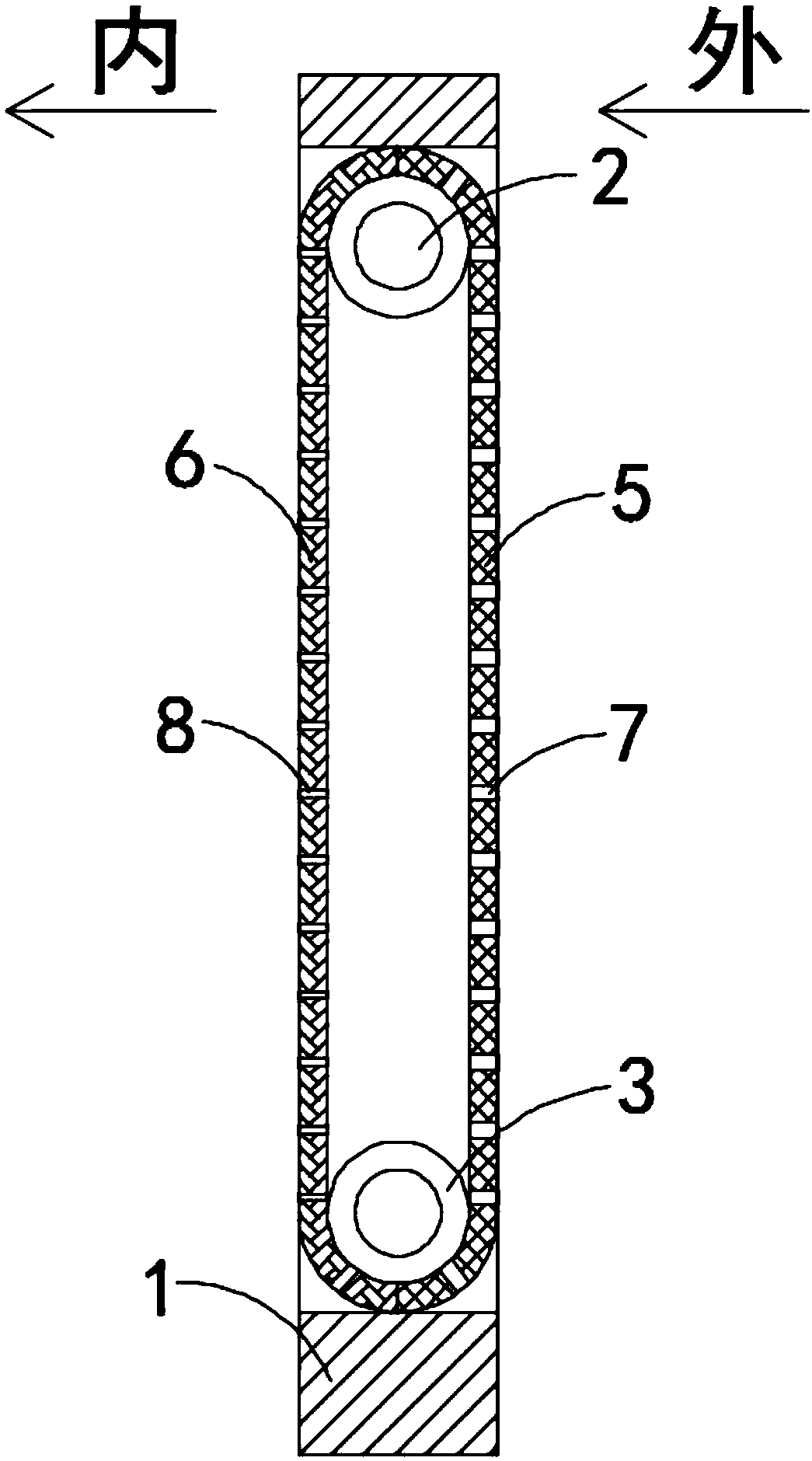

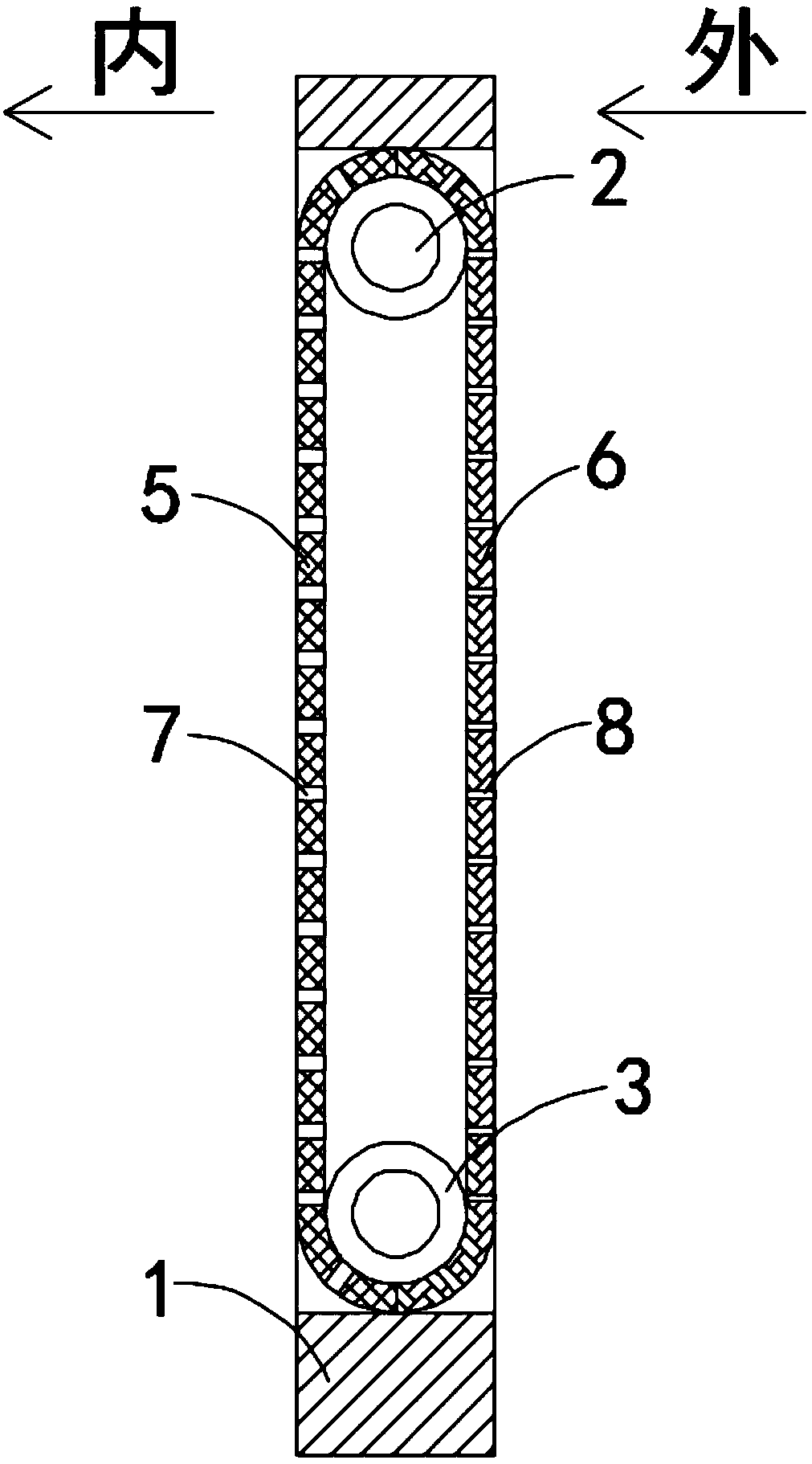

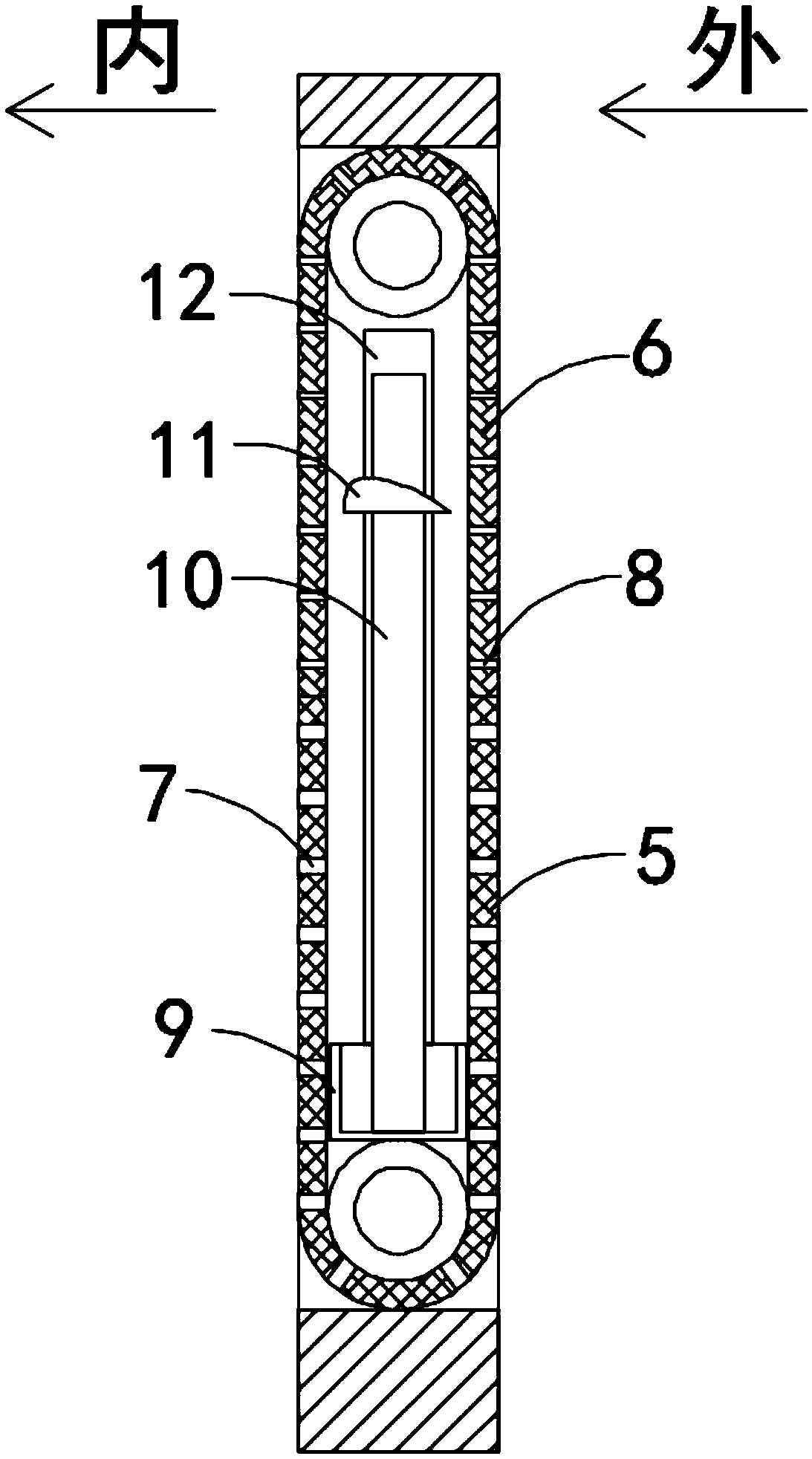

Dedusting screen window with temperature adjusting function

ActiveCN109577846AIncrease relative movement rangeImprove adsorption capacityElectrostatic separationInsect protectionElectrical and Electronics engineeringSecond screen

The invention belongs to the field of doors / windows and particularly relates to a dedusting screen window with a temperature adjusting function, comprising a window frame. Two rotary shafts horizontally arranged with one above the other are fixedly connected inside the window frame; the two rotary shafts are positioned in a same vertical plane; a drum is rotationally connected to each rotary shaft; a screen tape is wound around the two drums and is composed of first and second screen strips equal in length; the first screen strip is evenly provided with a plurality of first air holes; the second screen strip is evenly provided with a plurality of second air holes; the first air holes are greater than the second air holes in diameter; a dedusting mechanism is arranged between the two rotaryshafts. The screen tape herein can be rotated to adjusting flow speed of air, so that certain temperature adjusting effect is achieved; an electrostatic vertical plate can attract dust in air, thereby removing dust and providing purifying.

Owner:江西玉祥智能装备制造有限公司

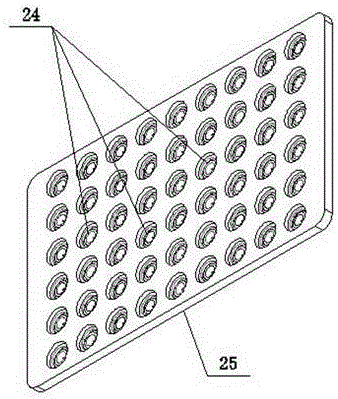

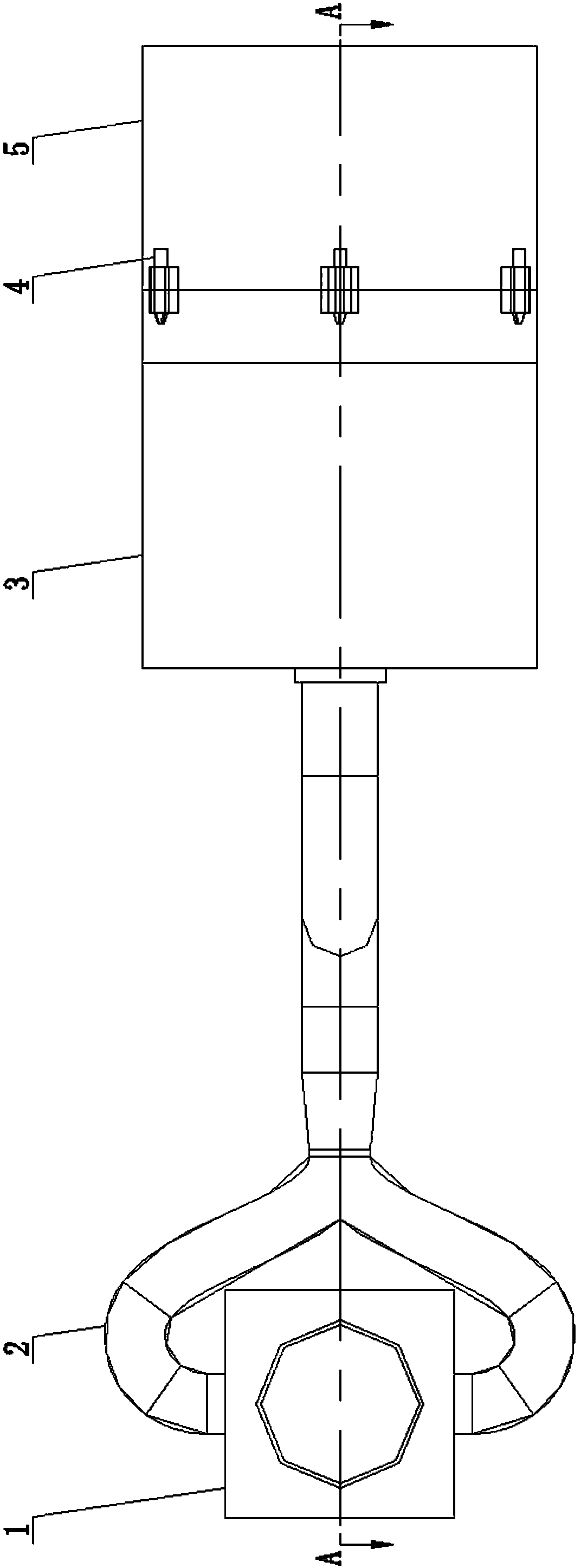

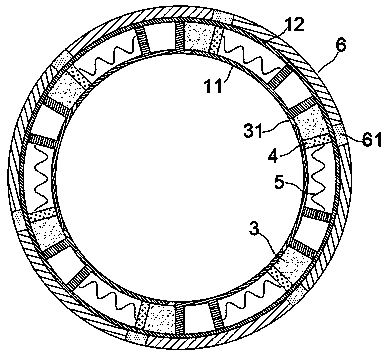

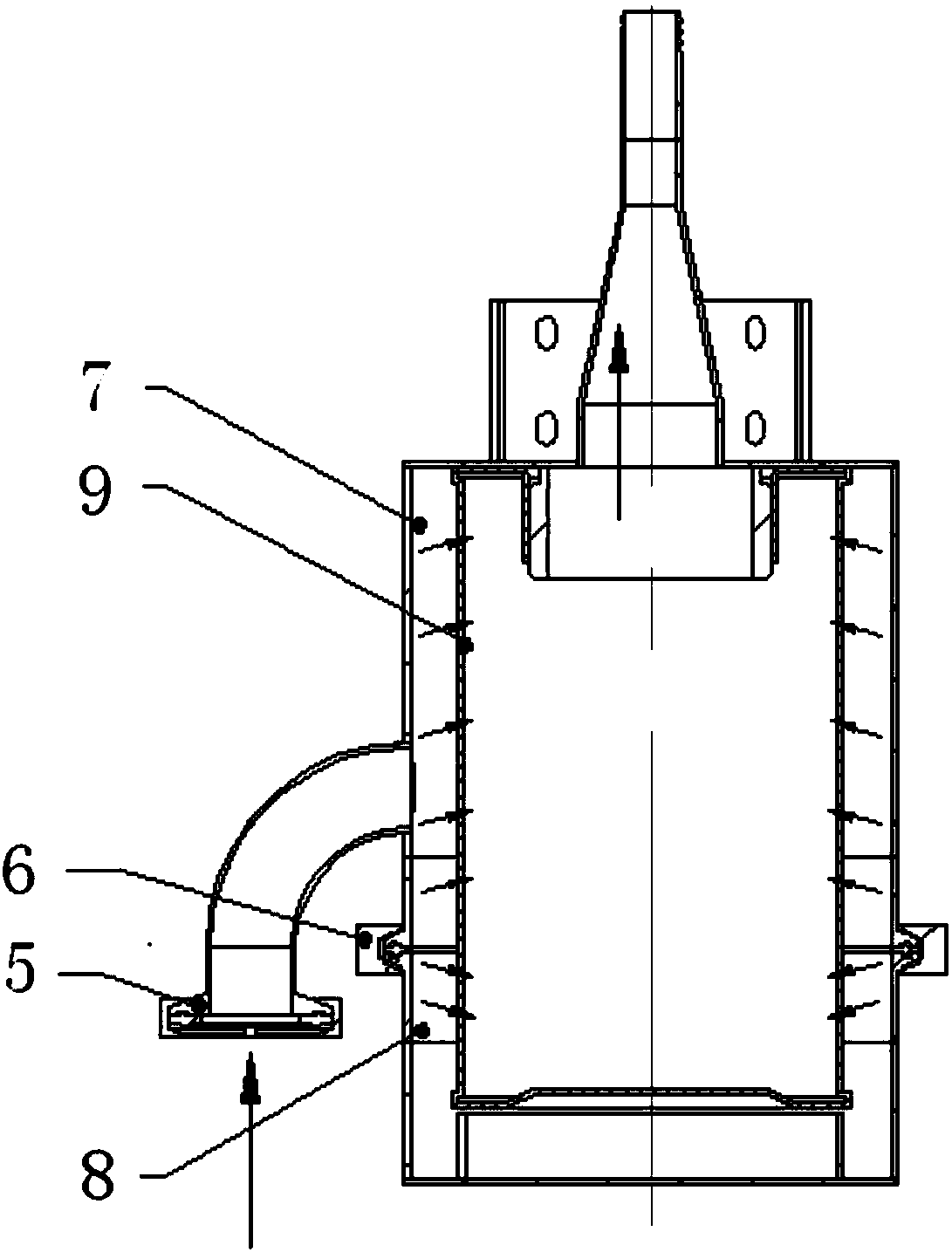

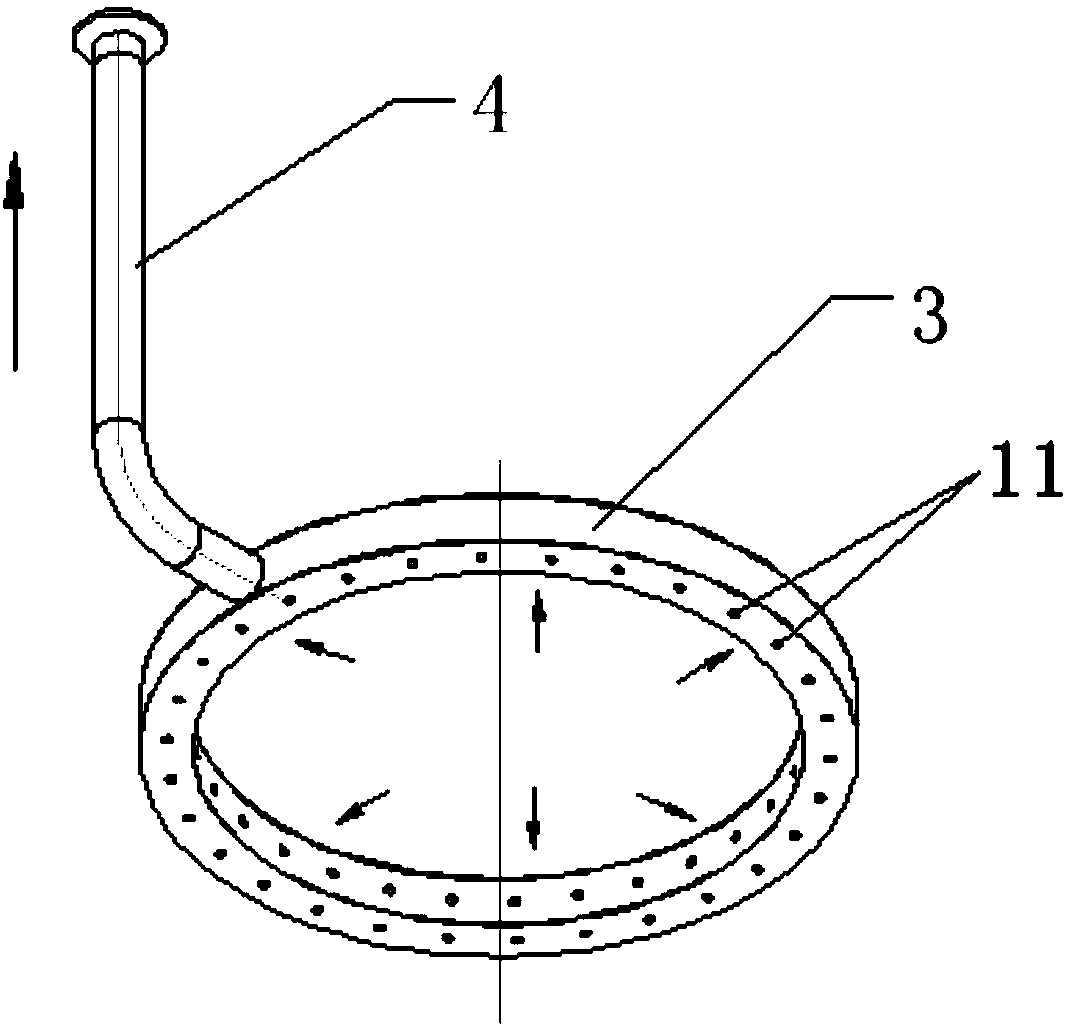

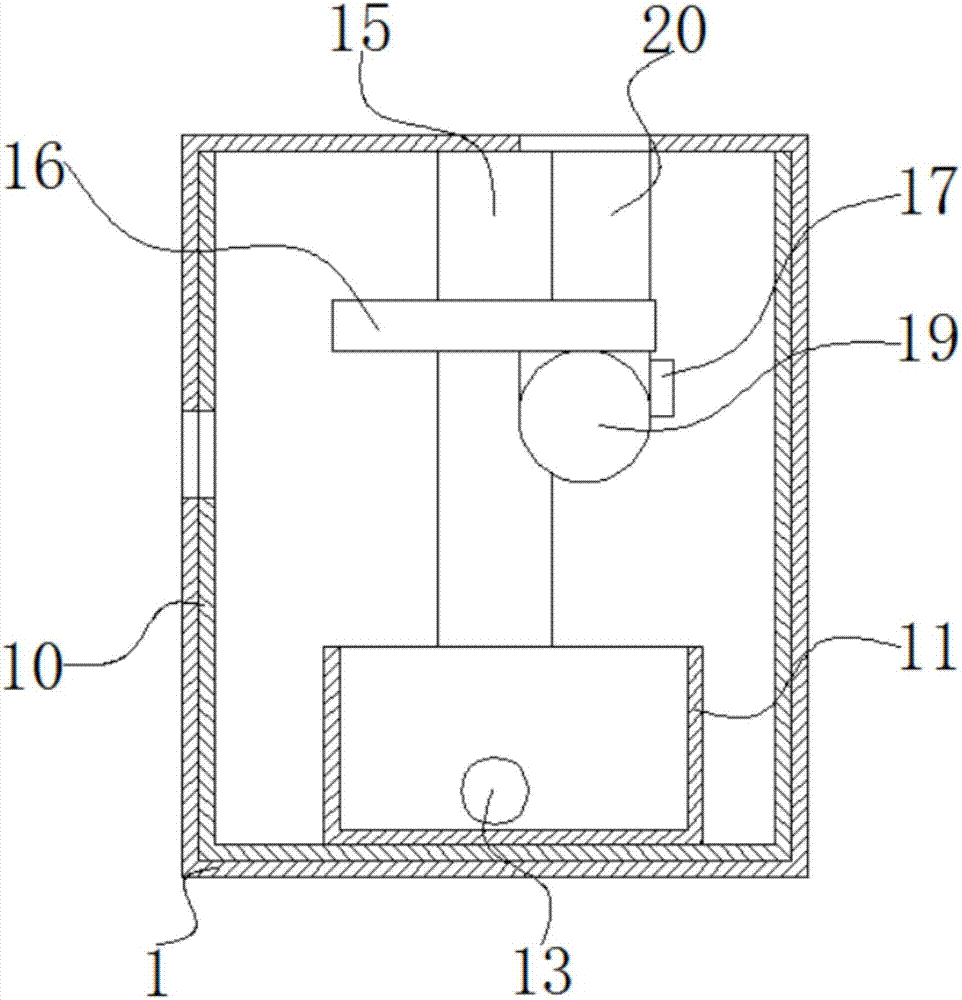

Powder-feeding head dust-collecting device for coaxial powder-feeding equipment

PendingCN107626163ADoes not affect normal operationPlay the role of dust removalAdditive manufacturing apparatusDispersed particle filtrationFilter elementWaste management

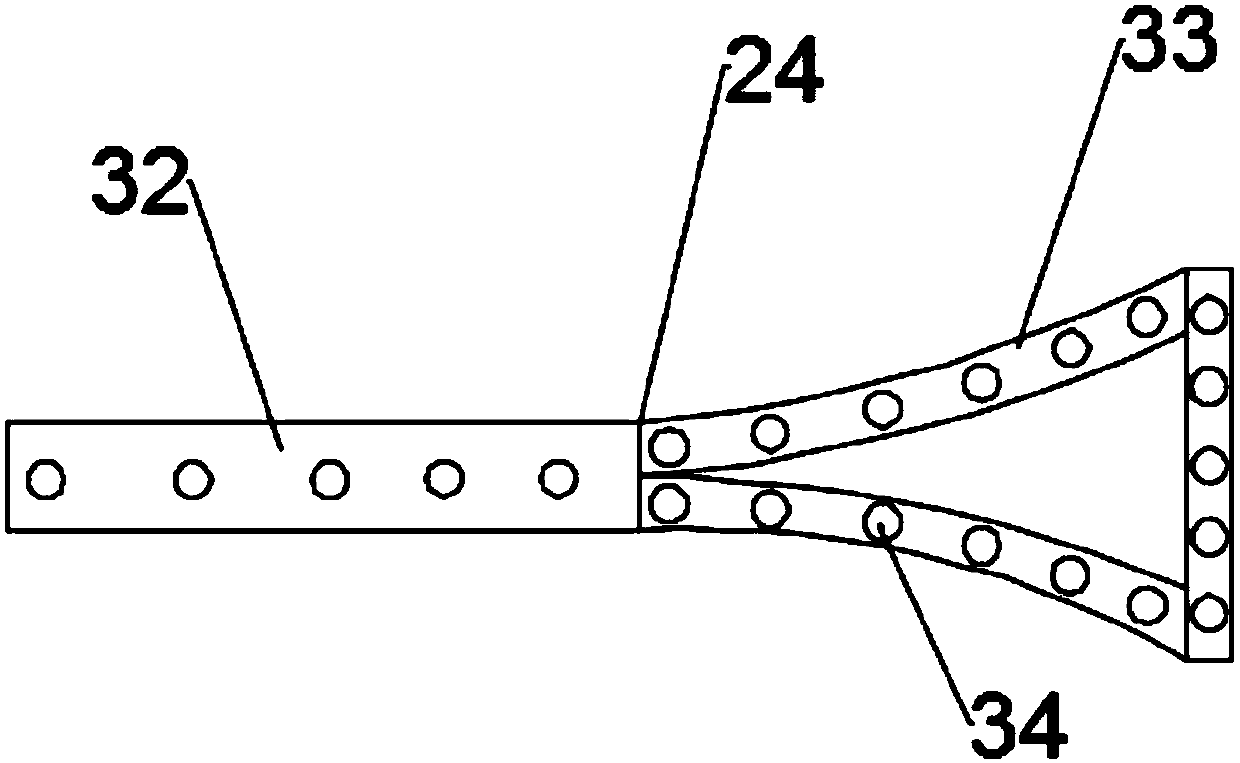

The invention discloses a powder-feeding head dust-collecting device for coaxial powder-feeding equipment. The coaxial powder-feeding equipment comprises a sealed cavity, a powder-feeding head is arranged into the sealed cavity. The dust-collecting device comprises a dust-collecting mechanism, a filtering mechanism and a power mechanism, the dust-collecting mechanism is arranged above a powder-feeding nozzle of the powder-feeding head and is connected with the filtering mechanism through a dust-collecting pipeline; the filtering mechanism comprises a filtering shell and a filtering element arranged in the filtering mechanism; the power mechanism is used for intaking the air around the powder-feeding nozzle into the dust-collecting mechanism, enabling the air to enter the filtering mechanism along the dust-collecting pipeline and discharging into the sealed cavity after filtering by the filtering element, the dust-collecting mechanism is an annular dust-collecting pipeline arranged around the powder-feeding nozzle, the filtering shell comprises an upper shell and a lower shell, the filtering element is connected to the top inside of the upper shell in a detachable manner, the dust-collecting pipeline is connected with the side wall of the upper shell, the lower shell is connected with the upper shell in the detachable manner. According to the invention, the design is simple, thedevice is convenient to dismount and mount and clean, and the dust-collecting effect is good.

Owner:TSC LASER TECH DEV BEIJING CO LTD

Internal heat dry distillation furnace

InactiveCN105802654AEasy to importShorten speedLiquid hydrocarbon mixture productionSpecial form destructive distillationMetallurgyMaterials science

An oil shale internal heat dry distillation furnace with the advantages of strong treatment ability, high oil yield and less supplanted saturated steam comprises a furnace body, the middle in the furnace body is provided with an arc table, the inner wall of the furnace body corresponding to the arc table is provided with an annular upper mixing chamber and an annular lower mixing chamber, the lower mixing chamber is provided with generation gas inlets connected with a gasification segment, gas spray holes connected with a dry distillation segment are arranged surrounding the upper mixing chamber, the upper mixing chamber is provided with a heat cycle gas inlet, and the arc table is provided with annular distribution holes used for connecting the dry distillation segment with the lower portion gasification segment; the upper portion of the dry distillation segment in the furnace body is provided with an umbrella with a downward open end; and an ash discharge device is composed of an ash discharger, a wind head, a water basin, a transmission device and a spade, the water basin is arranged on a furnace bottom furnace plate, a water seal is arranged below the water basin, the transmission device is arranged outside the furnace body and is connected with the water basin, the ash discharger is arranged on the water basin, the spade is arranged on the furnace body with an angle between the spade and the furnace bottom of 45DEG, and the lower end of the spade is positioned in the upper surface of the water basin and corresponds to the outside of the fin of the ash discharger.

Owner:BEIPIAO BEITA OIL SHALE INTEGRATED DEV UTILIZATION CO LTD

Mechanical part production polishing equipment for improving glossiness

The invention relates to the technical field of polishing equipment, and provides mechanical part production polishing equipment for improving the glossiness, the mechanical part production polishing equipment comprises a bearing mechanism, a lifting assembly, a supporting shell, a rotating shell and a traction assembly, the bottom of the bearing mechanism is fixedly connected with a second fixing pipe, and the second fixing pipe is sleeved with a workpiece; one end of the lifting assembly is fixedly connected to the upper portion of the bearing mechanism, the other end of the lifting assembly is fixedly connected with the supporting shell, the second fixing pipe is movably sleeved with the supporting shell and the rotating shell, the rotating shell is rotationally connected into the supporting shell, the workpiece is sleeved with the rotating shell, and a clamping part is arranged on the rotating shell; a first transmission gear is further fixedly connected to the outer side of the rotating shell, a driving part in meshed connection with the first transmission gear is installed on the supporting shell, and the traction assembly comprises a winding part in meshed connection with the lifting assembly; and the horizontal adjusting part is connected with the winding part, and a polishing block connected with the surface of the workpiece in an attached mode is arranged in the horizontal adjusting part.

Owner:南通同贵模具科技有限公司

Efficient desulfurizing tower

The invention relates to the technical field of environmental protection equipment, and in particular to an efficient desulfurizing tower. The efficient desulfurizing tower comprises a tower body, wherein a smoke outlet is formed in the top part of the tower body; the tower body is internally provided with multiple stages of spraying systems; multiple demisting and dedusting devices are arranged at the lower part of each stage of spraying system; the multiple demisting and dedusting devices are arranged in parallel or in series; the tower body is also internally provided with a row of smoke outlet demisting and dedusting devices; the smoke outlet demisting and dedusting devices are arranged near the smoke outlet; each of the demisting and dedusting devices and the smoke outlet demisting and dedusting devices comprises a shell, rotational flow plates are respectively arranged on the upper end and the bottom end of the shell, the rotational flow plates comprise rotational flow blades, and rotation directions of the rotational flow blades of the two rotational flow plates are opposite; the smoke outlet is connected with a smoke and dust purifier. The efficient desulfurizing tower disclosed by the invention is simple in structure and high in water mist removing rate.

Owner:山东恒科环保设备有限公司

Multifunctional machining mechanical equipment for plastic particle production

The invention discloses multifunctional machining mechanical equipment for plastic particle production. The multifunctional machining mechanical equipment comprises a supporting underframe, a fixed base and a conveying box. A conveying device is arranged in the conveying box, a driving wheel is arranged at the left end of the conveying device, and a driven wheel is arranged at the right end of theconveying device. Conveying frames are arranged at the lower end of the driving wheel and the lower end of the driven wheel, the driving wheel is connected with a conveying motor, and a conveying belt is arranged between the driving wheel and the driven wheel. An impurity removal box is arranged at the upper end of the conveying box, a discharging pipeline passes between the conveying box and theimpurity removal box, and a stirring box is arranged at the upper end of the impurity removal box. The multifunctional machining mechanical equipment is simple and reasonable in structural design andconvenient and fast to operate when used, and is used for the machining work of plastic particles. The equipment is easy and convenient to operate and high in automation degree, and has multiple functions of drying, impurity removal and conveying, the machining equipment of the plastic particles can be improved, and great convenience is brought to workers.

Owner:颍上县皖佳保木业有限责任公司

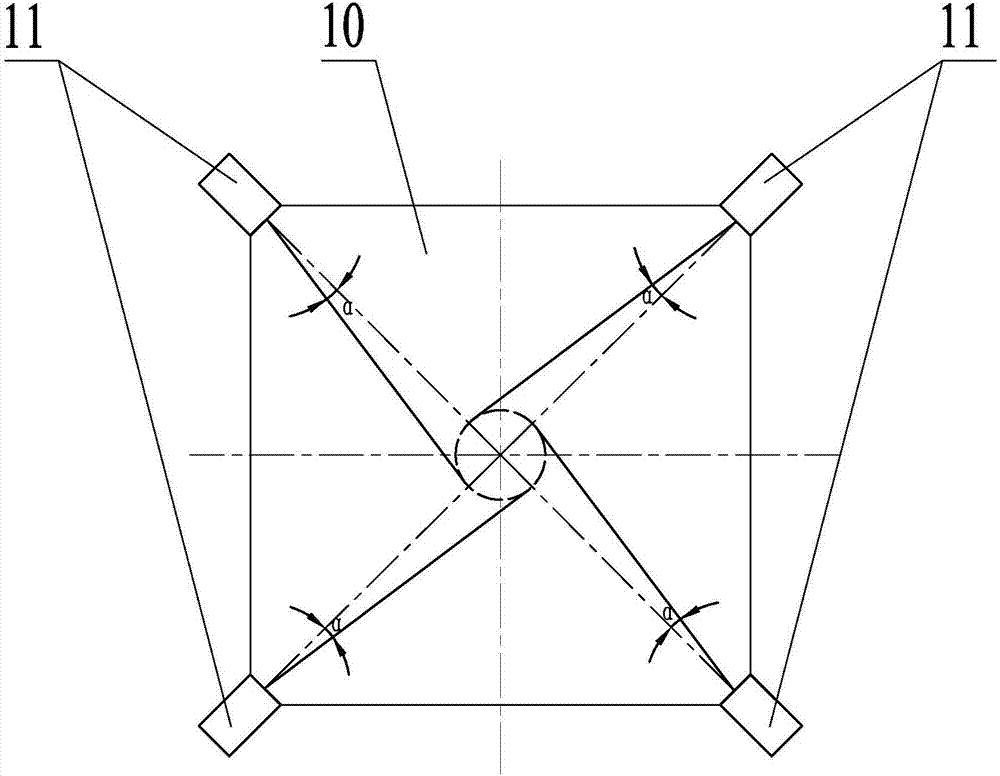

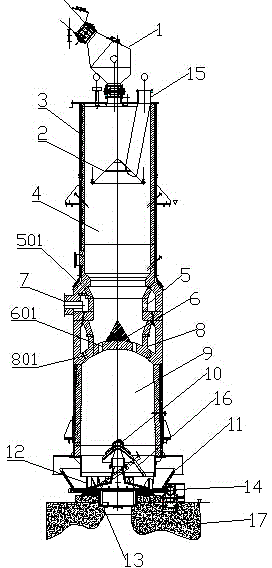

Centrally-feeding swirl pulverized coal combustion device adopting double-layer jet flow of separated secondary air

InactiveCN107477572AReduce generationDegree of strong classificationPulverulent fuel combustion burnersHigh concentrationCombustor

The invention discloses a centrally-feeding swirl pulverized coal combustion device adopting the double-layer jet flow of separated secondary air, and relates to a pulverized coal combustion device. The invention solves the problem that an existing pulverized coal combustion device is poor in NOx emission reduction effect under the conditions of a variable coal type and a variable load, so that slag formation in a hearth is easily caused. A first axial swirl blade is installed in an inner swirl secondary air pipe, a second axial swirl blade is installed in an outer swirl secondary air pipe, and the nozzle of each air pipe of a swirl pulverized coal combustor is level with the inner wall of a hearth; high-concentration pulverized coal airflow is conveyed in a primary air pipe; a plurality of separated secondary air pipes are annularly arranged around the swirl pulverized coal combustor and on double layers, the circle where the centers of the outlets of the separated secondary air pipes on each layer are located and the swirl combustor are coaxially arranged, the separated secondary air pipes on the two layers are mutually uniformly arranged in a staggered manner, and the pipe diameters of the separated secondary air pipes are configured to be the same and the outlet ends of the separated secondary air pipes are level with the inner wall of the hearth; and a separated secondary air duct baffle is arranged in an air inlet of each separated secondary air pipe. The pulverized coal combustion device disclosed by the invention is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

Cutting machine dust removal device for refractory matter

InactiveCN106965334APlay the role of dust removalAvoid it happening againWorking accessoriesStone-like material working toolsArchitectural engineeringRefractory

The invention discloses a dust removal device for a cutting machine for refractory materials, which comprises a workbench. Columns are fixedly connected to both sides of the top of the workbench. The top of the column is fixedly connected to a cantilever beam. The center of the bottom of the cantilever beam is A cylinder is fixedly connected at the bottom of the cylinder, and a telescopic column is movably connected to the bottom of the cylinder, and a connection block is fixedly connected to the front of the telescopic column, and a cutting piece is movably connected to the bottom of the connection block through a movable shaft. The present invention achieves the effect of dedusting by arranging water tank, baffle plate, second water pipe, water pump, first water pipe, spray head, bracket, blower, air outlet pipe, air inlet pipe and controller to cooperate with each other, and can be used in fire-resistant When the material cutting machine is in use, it can remove dust from the refractory material cutting machine, avoiding a large amount of dust generated when the refractory material cutting machine is in use, thereby reducing the long-term inhalation of dust by workers and protecting the health of workers. It is suitable for promotion use.

Owner:长兴鼎峰铸材科技股份有限公司

Wall polishing device for building

InactiveCN107471015APlay the role of dust removalWorks well when sandingPlane surface grinding machinesGrinding/polishing safety devicesEngineeringWater pipe

The invention discloses a building wall polishing device, which comprises a workbench, a water tank is arranged on the left side of the top of the workbench, a water pump is arranged on the right side of the water tank, and a water suction pipe is arranged at the input end of the water pump. The end of the water suction pipe away from the water pump is fixedly connected to the water tank, and the inner cavity of the water suction pipe communicates with the water tank. The output end of the water pump is provided with a water outlet pipe. The corresponding side of the movable base is movably connected with a rotating rod, the top and bottom of the rotating rod are provided with wind flow plates, and the right side of the top of the workbench is provided with a bracket. The invention cooperates with the water tank, water suction pipe, water pump, water outlet pipe, movable base, air flow plate, rotating rod, connecting pipe and spray head, and can play the role of dust removal on the polishing device when the wall is polished by the polishing device. Sanding units work better when sanding walls.

Owner:FOSHAN LIANZHI XINCHUANG TECH CO LTD

Sliding intelligent door lock protection cover

InactiveCN108442816AThere will be no ash seepageRealize full anti-dust functionBuilding locksEngineeringMagnet

The invention discloses a sliding intelligent door lock protection cover. The sliding intelligent door lock protection cover comprises a sliding protection cover body and an intelligent door lock. Oneside of the intelligent door lock is slidably connected with the sliding protection cover body through a sliding groove. A first magnet is fixed to an inner bottom plate of the sliding groove. A PLCis arranged on one side of the sliding protection cover body. An air inlet is formed in the top of the sliding protection cover. A sensor is arranged on one side of the intelligent door lock. A fixedprotection cover body is welded to the top of the intelligent door lock. According to the sliding intelligent door lock protection cover, the fixed protection cover body is welded to the top of the intelligent door lock, the sliding protection cover body is slidably connected with one side of the intelligent door lock, the top of the sliding protection cover body is located in the fixed protectioncover body, when the sliding protection cover body is pushed upwards for unlocking, due to the full-surrounded arrangement of the fixed protection cover body, the ash seepage phenomenon of the top ofthe intelligent door lock is avoided, and the thorough dust prevention function of the intelligent door lock is achieved.

Owner:郑州仟嘉安环保科技有限公司

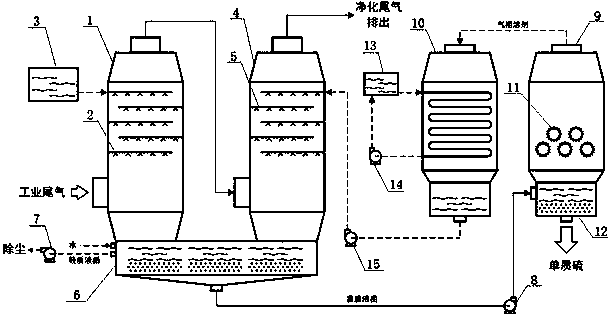

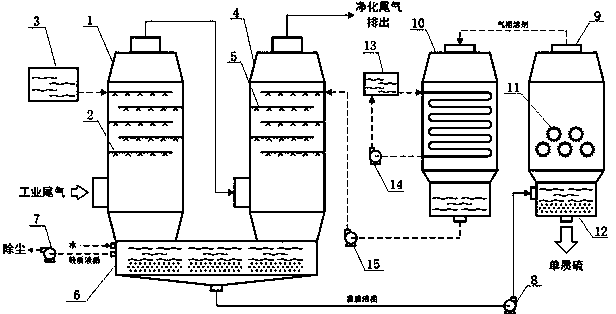

Gas-solid separating method and system for simple substance sulphur in sulphur-containing exhaust

ActiveCN109911862AAvoid pollution accidentsReduce desulfurization costGas treatmentUsing liquid separation agentSulfurGas phase

The invention discloses a gas-solid separating method and a gas-solid separating system for simple substance sulphur in sulphur-containing exhaust. The gas-solid separating method for simple substancesulphur in sulphur-containing exhaust comprises the following steps: first, cooling sulphur-containing exhaust at an extremely high speed; then, separating dust; finally, recycling a heavy liquid phase solvent and simple substance sulphur; according to the method disclosed by the invention, the separating efficiency of the simple substance sulphur is up to 90 percent or above; moreover, the exhaust is further purified, and an environment pollution accident is avoided; in a separating process of the simple substance sulphur, the heavy liquid phase solvent of the simple substance sulphur evaporates to form a gas phase solvent which can be recycled as the liquid phase solvent for reusing through cooling, so that the sulphur removing cost is reduced. The system comprises a quick cooling system, a low-temperature washing purifying system, a light liquid phase and heavy liquid phase separating system, a washing liquid recycling system and a simple substance sulphur recycling system. The system disclosed by the invention has the advantages of stability and high efficiency in high sulphur-containing exhaust treatment, high simple substance sulphur separating efficiency, energy conservation and environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

Screening device after crushing and grinding waste roasting sagger for lithium battery anode materials

InactiveCN109675672APlay the role of crushing againAvoid pollutionDispersed particle filtrationDirt cleaningActivated carbonEngineering

The invention discloses a screening device after crushing and grinding waste roasting sagger for lithium battery anode materials. The screening device comprises a workbench, wherein support posts arefixedly connected to the bottom of the workbench, support rods are fixedly connected to the top of the workbench, a material conveying channel is fixedly connected to the tops of the support rods, a feed hopper is fixedly connected to one side of the material conveying channel, a suction fan and a dedusting box are fixedly connected to the top of the material conveying channel respectively, a non-woven filter screen and an activated carbon filter screen are respectively inserted into the dedusting box, and a motor is fixedly connected to the front surface of the material conveying channel. According to the screening device, a screening box, a piece of elastic cloth, a sieve plate, a vibrator, a telescopic sleeve rod, a first spring, a fixed block, a material conveying port and a sponge matare arranged, so that crushed materials can be screened, the crushed materials of small particle size fall in a collecting case, the crushed materials of large particle size enters a collecting box from the material conveying port, and the buffering and damping effects can be achieved by virtue of the telescopic sleeve rod and the first spring during screening.

Owner:广东山摩新材料科技有限公司

Indoor door entering shoe sole cleaning device for avoiding white pollution

ActiveCN108742465APrecise positioningPrecise positioning, precise dust removalFootwear cleanersParticulatesEngineering

The invention discloses an indoor door entering shoe sole cleaning device for avoiding white pollution, and relates to the technical field of indoor cleaning. The cleaning device comprises a dust removal box, a drying box is arranged on the back of the dust removal box through a hinge joint device, rollers arranged on the fronts and the backs of two sides of the bottoms of the dust removal box andthe drying box, and containing grooves are formed in the middles of the tops of the dust removal box and the drying box. According to the indoor door entering shoe sole cleaning device for avoiding the white pollution, a spring mechanism of the dust removal box is mainly used for folding placing plates and controls the distance between the two placing plates to remove dust on shoes with differentsizes, a crushing block is mainly used for vertically moving to impact a shoe sole to remove particulate matters adhered on the shoe sole through vibration, the shoe sole is continually impacted, a certain pressure is transferred and applied to a foot sole, a foot can be massaged when the dust on the shoe sole is removed, and fatigue is relieved.

Owner:中枢物联网科技(嘉兴)有限公司

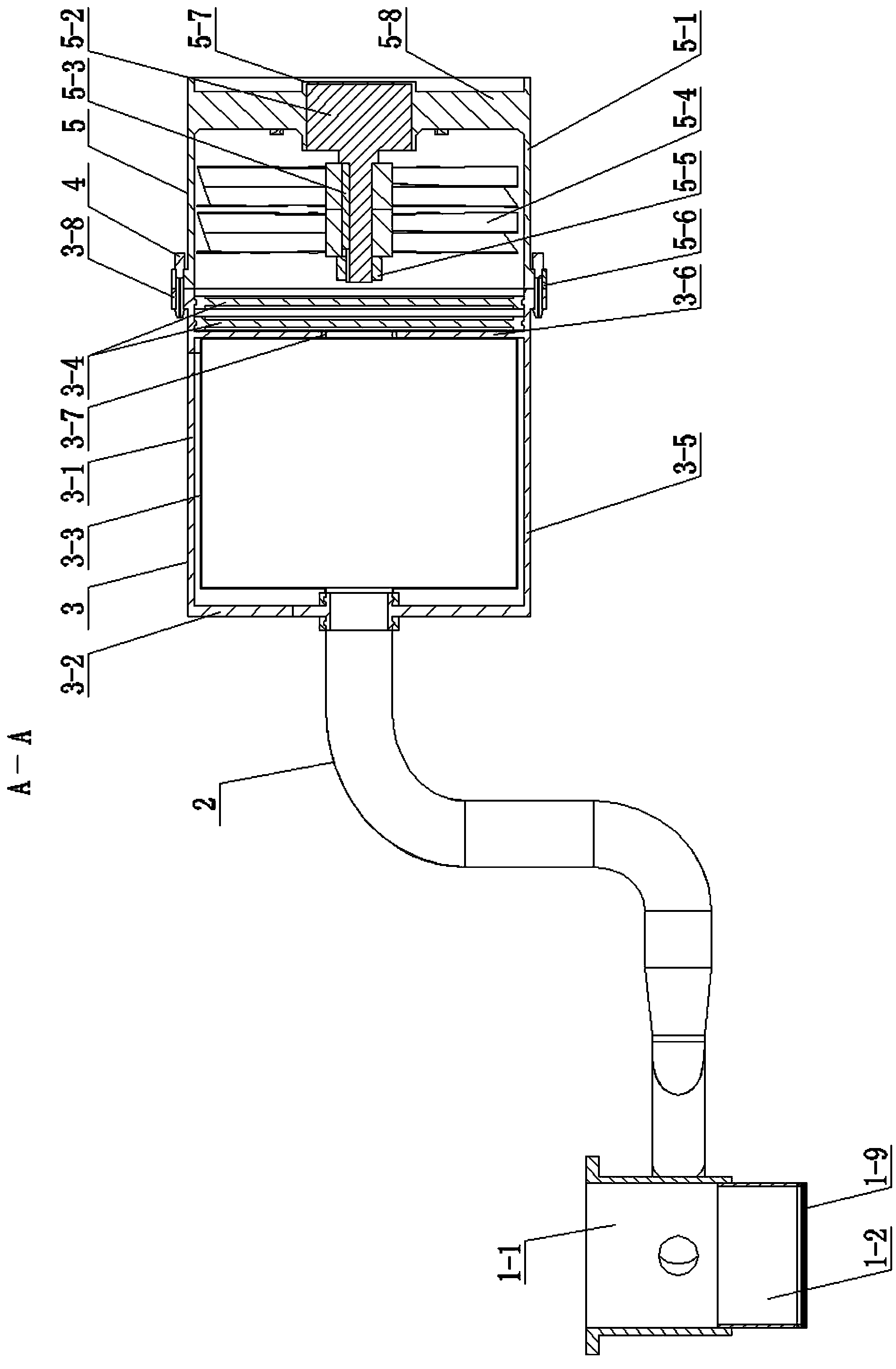

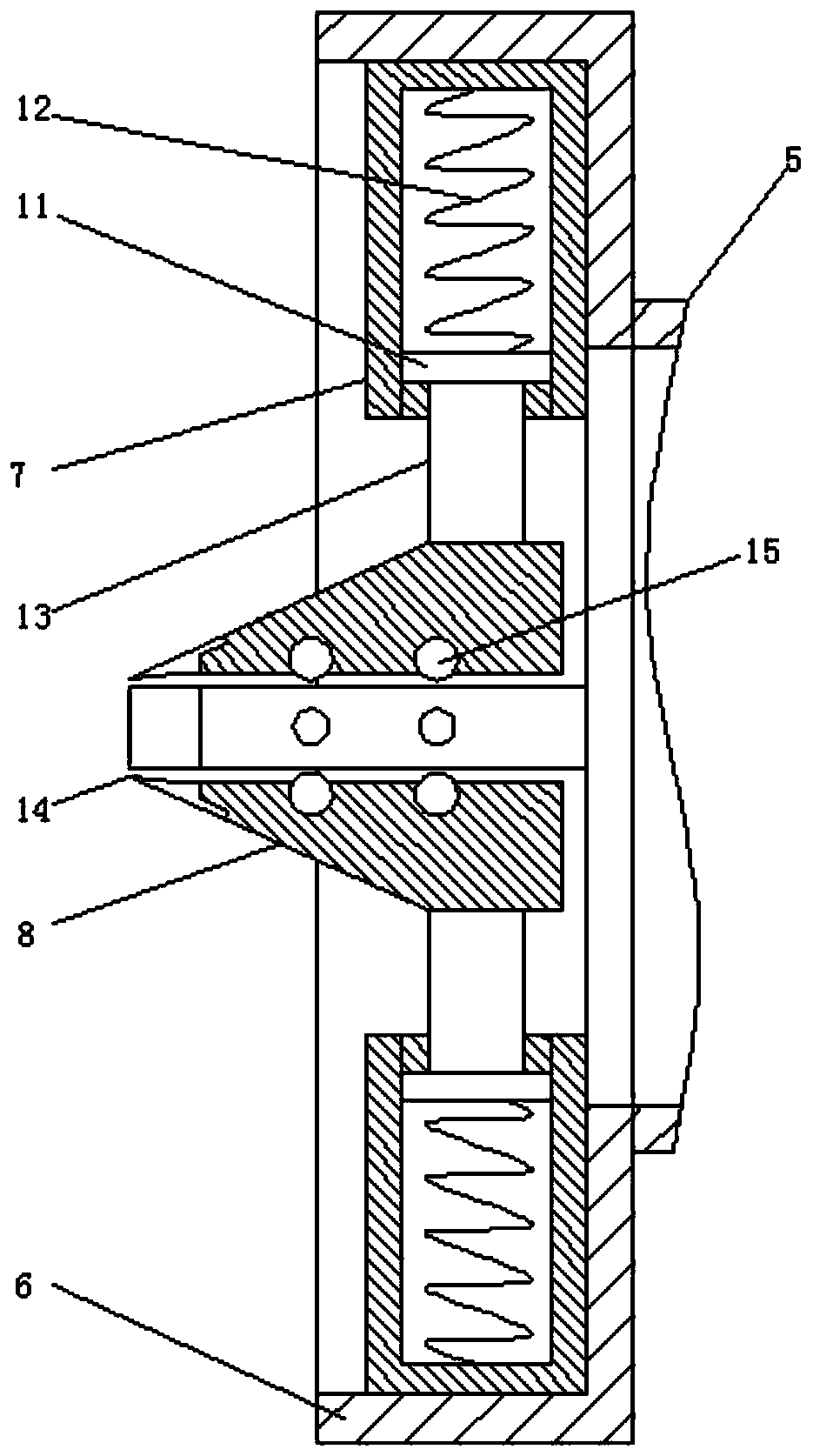

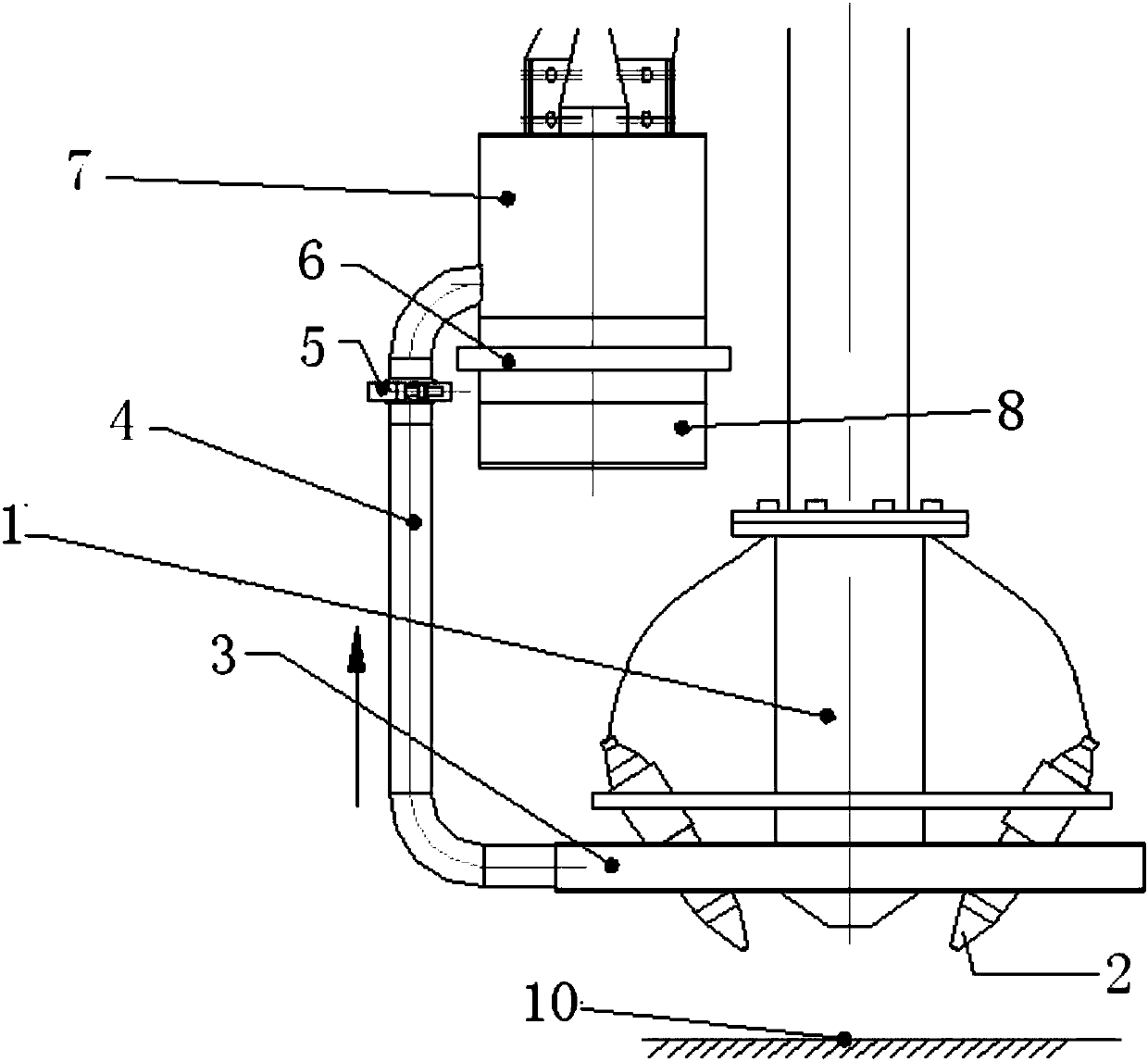

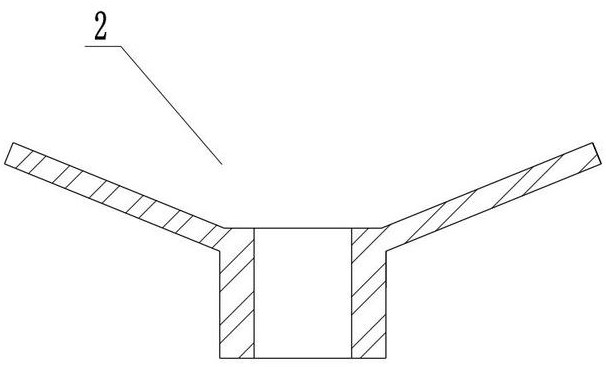

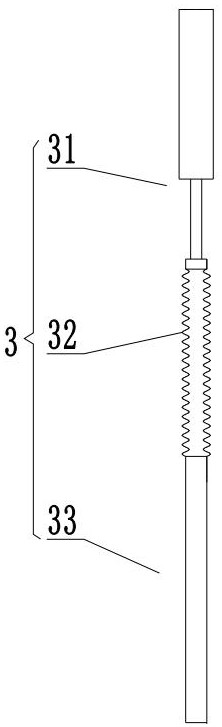

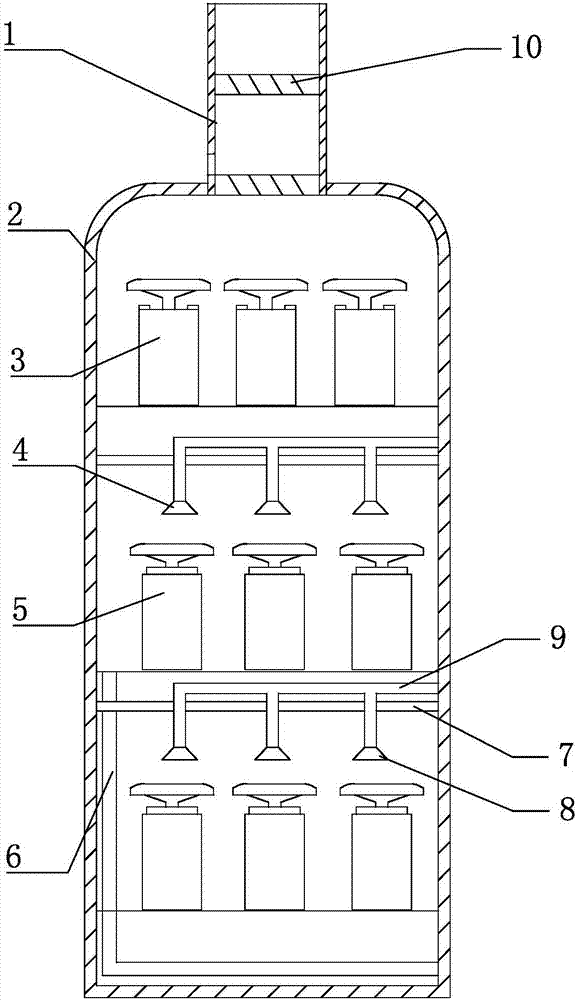

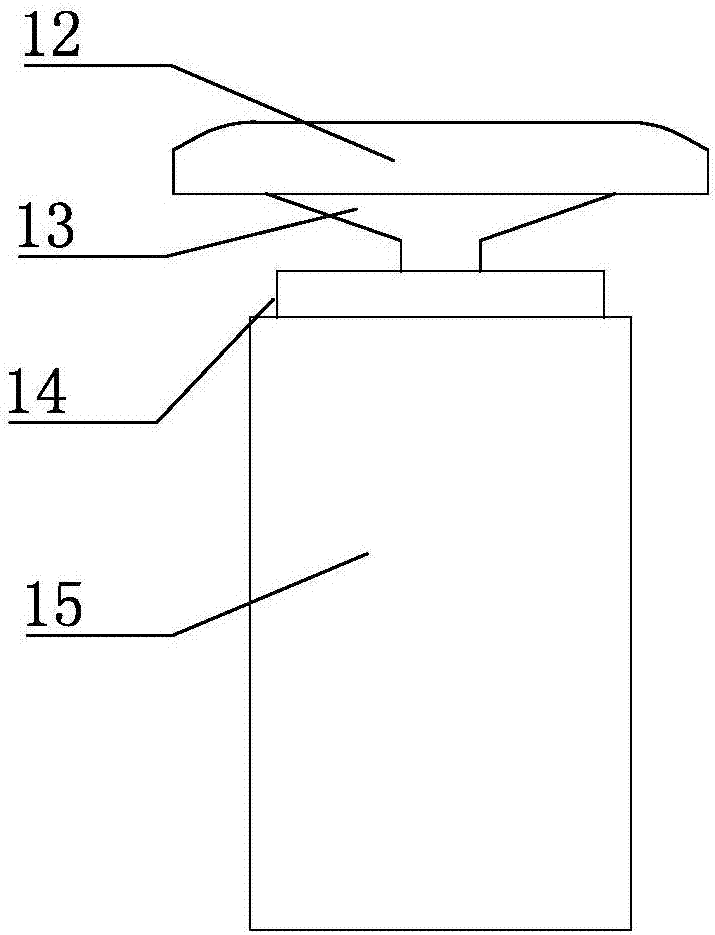

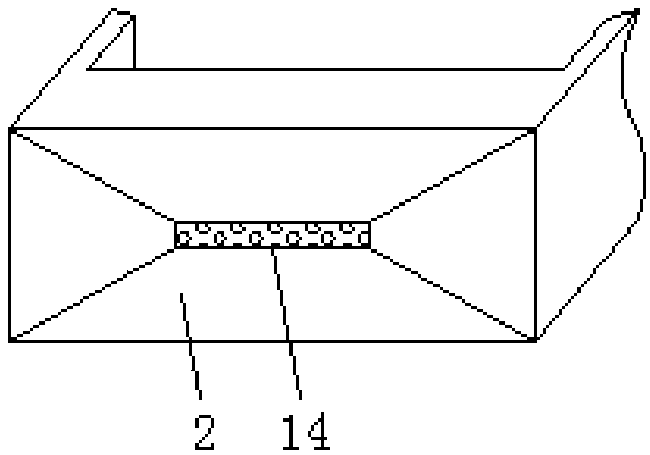

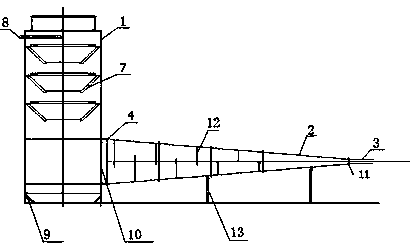

Pressure-reduction, anti-explosion and dust-removal device for aerodynamic reservoir reform of coal-bed gas well

ActiveCN103821551AAvoid generatingPrevent deflagrationDust removalFire preventionGas passingEngineering

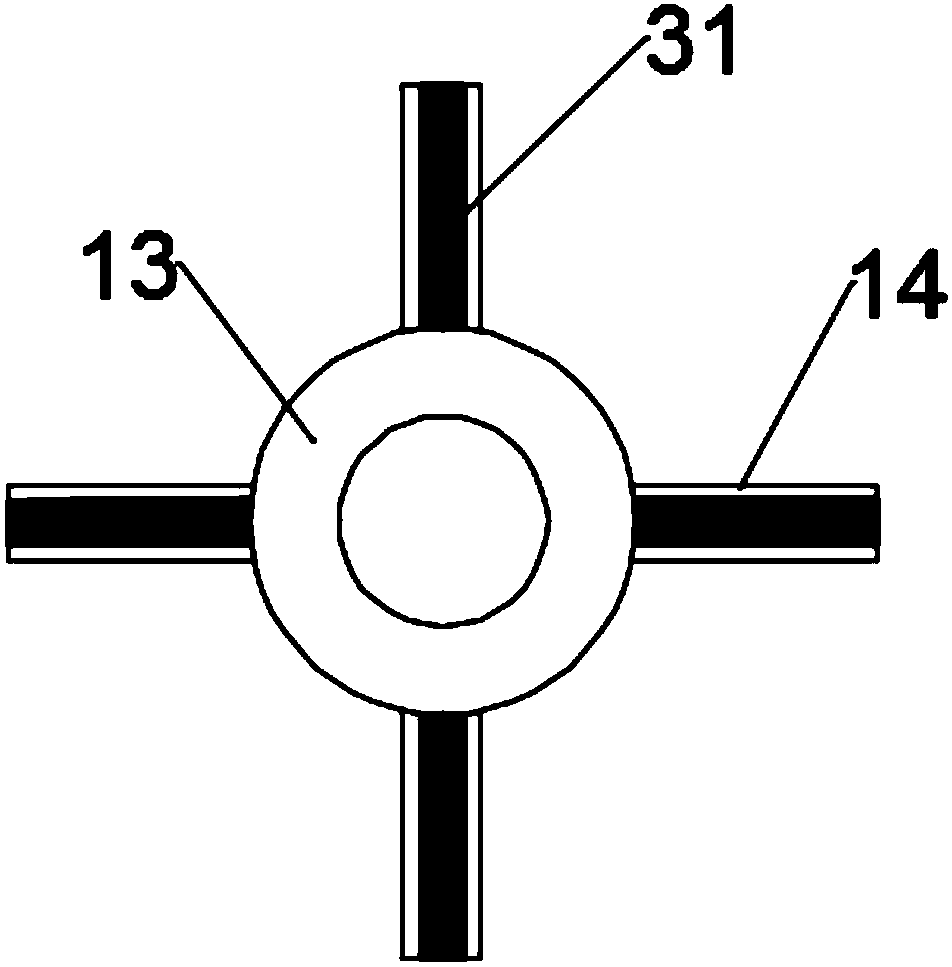

The invention provides a pressure-reduction, anti-explosion and dust-removal device for aerodynamic reservoir reform of a coal-bed gas well, and is applicable to the technical field of gas power operation of the coal-bed gas well. The pressure-reduction, anti-explosion and dust-removal device mainly comprises a dust remover (1), a diffusion tube (2) and a gas feeding tube (3). During technical construction of a gas power reform coal storage reservoir, high-flow-speed gas is not directly released in air in a pressure releasing stage, is guided by the gas feeding tube (1) to enter the diffusion tube (2), and is subjected to eight pressure reduction effects under the action of eight wind shields (12) in the diffusion tube (2). Gas flows to the dust remover (1) through auxiliary round ventilating holes (5) in the wind shields (12), and coal (rock) powders or particles in the gas are stopped by the wind shields (12), drop, are blown by the gas, enter the dust remover through a coal passing hole (6) and then are removed. A four-stage blade type vortex plate tower tray (7) is arranged in the dust remover (1), the gas is forced to spirally rise by using the four-stage blade type vortex plate tower tray (7), and liquid flow is formed by water flow injected through a water injection tube, is distributed on blades of the vortex plate tower tray (7), is thrown to a wall of a tower by centrifugal force, and then flows in a water draining hole (9).

Owner:河南省资源环境调查二院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com