Deodorizing and dedusting agent for chicken farm and preparation method thereof

A deodorizing and dust-removing agent, chicken farm technology, applied in biochemical equipment and methods, deodorization, separation methods, etc., can solve problems such as endangering the respiratory system of workers and chickens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

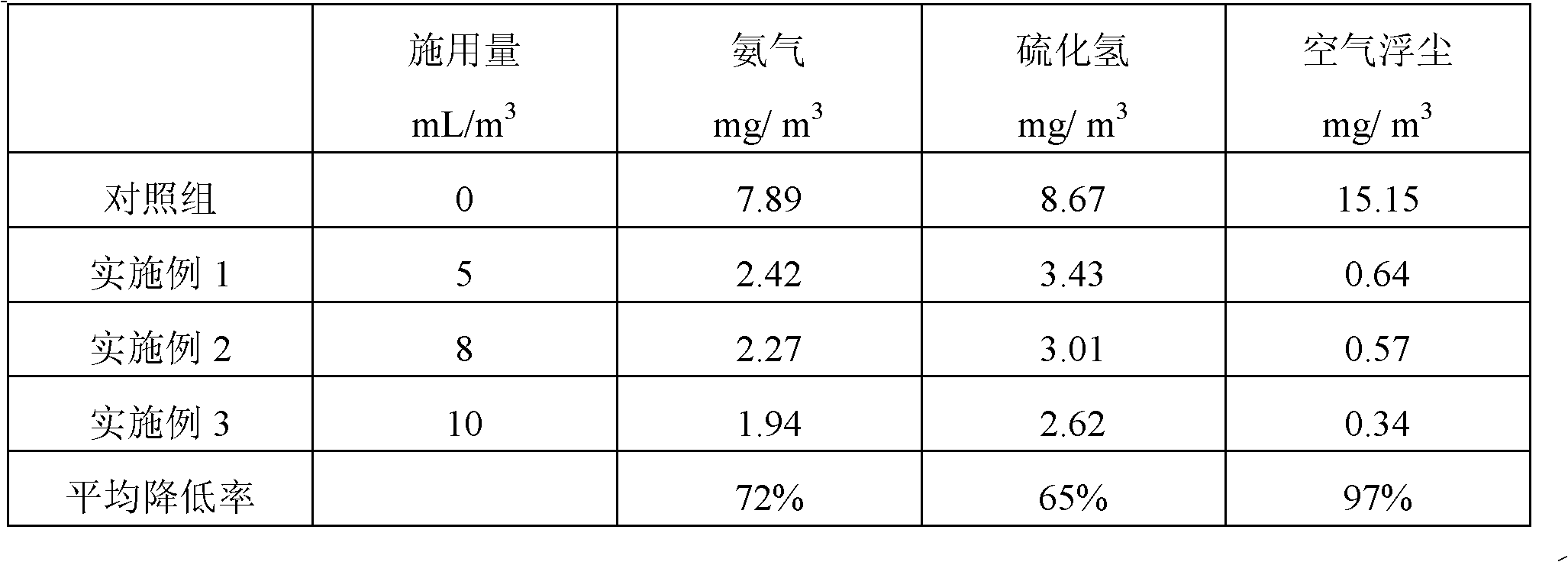

Examples

Embodiment 1

[0016] The deodorizing and dust-removing agent for chicken farms of the present embodiment is composed of the following components by weight: 30 parts of mixed fermented liquid, 5 parts of soybean lecithin, and 1 part of plant essential oil; 8 The Bacillus subtilis liquid and the Enterococcus faecalis liquid above / ml are fermented, and the weight ratio of the Bacillus subtilis liquid and the Enterococcus faecalis liquid is 1:1.

[0017] The deodorizing and dust-removing agent for chicken farms of the present embodiment is prepared by the following method:

[0018] 1) Preparation of Bacillus subtilis liquid: the first culture medium consists of 30 g of glucose, 18 g of peptone, 8 g of sodium chloride, 1 g of beef extract, 20 g of agar, 1 L of distilled water, pH 7.2, and autoclaved at 121° C. for 20 min; by weight percentage Take 5% Bacillus subtilis and 95% Bacillus subtilis culture medium, inoculate Bacillus subtilis in the culture medium under aseptic conditions, and cultiv...

Embodiment 2

[0023] The deodorizing and dust-removing agent for chicken farms of the present embodiment is composed of the following components in parts by weight: 40 parts of mixed fermented liquid, 7 parts of soybean lecithin, and 1.5 parts of plant essential oil; 8 The Bacillus subtilis liquid and the Enterococcus faecalis liquid above / ml are fermented, and the weight ratio of the Bacillus subtilis liquid and the Enterococcus faecalis liquid is 1:3.

[0024] The deodorizing and dust-removing agent for chicken farms of the present embodiment is prepared by the following method:

[0025] 1) Preparation of Bacillus subtilis liquid: the first culture medium consists of 30 g of glucose, 18 g of peptone, 8 g of sodium chloride, 1 g of beef extract, 20 g of agar, 1 L of distilled water, pH 7.2, and autoclaved at 121° C. for 20 min; by weight percentage Take 5% Bacillus subtilis and 95% Bacillus subtilis culture medium, inoculate Bacillus subtilis in the culture medium under aseptic conditions...

Embodiment 3

[0030] The deodorizing and dust-removing agent for chicken farms of the present embodiment is composed of the following components by weight: 50 parts of mixed fermented liquid, 10 parts of soybean lecithin, and 2 parts of plant essential oil; 8 The Bacillus subtilis liquid and the Enterococcus faecalis liquid of more than 1 / ml are fermented, and the weight ratio of the Bacillus subtilis liquid and the Enterococcus faecalis liquid is 1:5.

[0031] The deodorizing and dust-removing agent for chicken farms of the present embodiment is prepared by the following method:

[0032] 1) Preparation of Bacillus subtilis liquid: the first culture medium consists of 30 g of glucose, 18 g of peptone, 8 g of sodium chloride, 1 g of beef extract, 20 g of agar, 1 L of distilled water, pH 7.2, and autoclaved at 121° C. for 20 min; by weight percentage Take 5% Bacillus subtilis and 95% Bacillus subtilis culture medium, inoculate Bacillus subtilis in the culture medium under aseptic conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com