Submicron powder bazheng powder normal temperature preparation method and special bidirectional airflow sieving machine thereof

A technology of Bazheng powder and ultrafine powder is applied in the field of veterinary medicine preparations, which can solve the problems of restricting the large-scale production of veterinary traditional Chinese medicine ultrafine powder, low bioavailability, and reduced pulverization efficiency, and is suitable for large-scale industrial production and improves cell efficiency. Wall breakage rate, odor and taste improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

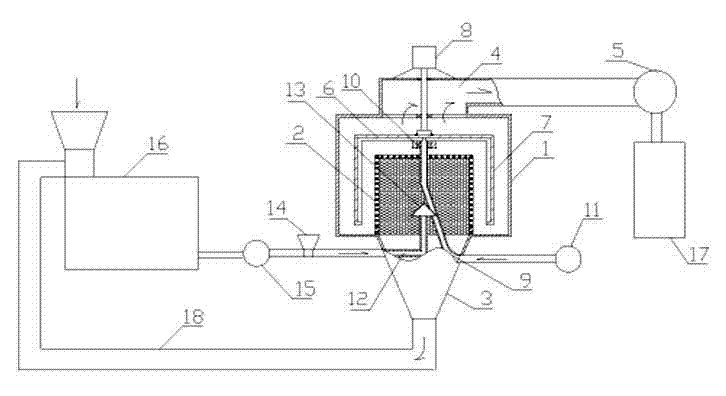

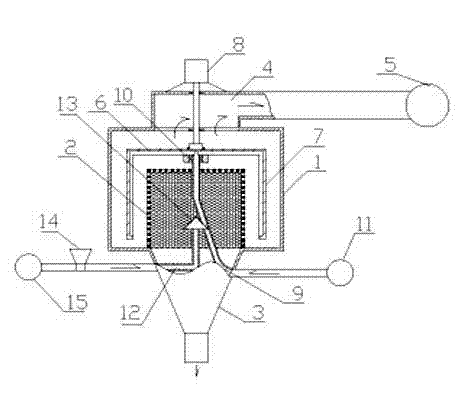

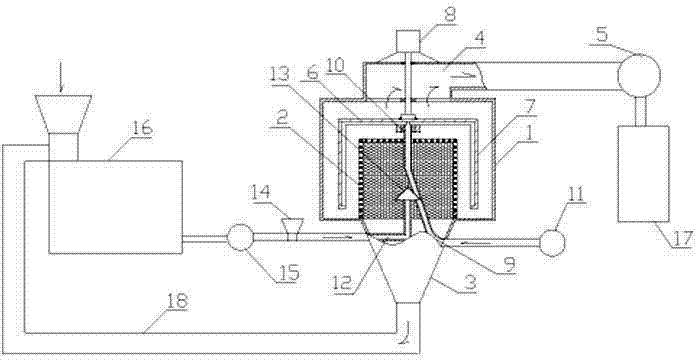

[0054] Such as figure 1 , 2 Shown, the normal temperature preparation method of superfine powder Bazheng powder of the present invention, comprises the following steps:

[0055] The first step, according to the ratio of parts by weight of 6:6:6:5:6:6:3:12:6, select the decoction pieces of raw materials Akebia, Qumai, Liquor, Licorice, fried gardenia, wine rhubarb, rush And talc, psyllium raw materials, through natural drying or drying to moisture content ≤ 10%;

[0056] In the second step, the above-mentioned raw materials are pulverized respectively at a temperature of 20° C. to 25° C. to obtain coarse powder of traditional Chinese medicine with a particle size of 60 to 80 meshes; the oil in the coarse powder of Semen Plantaginis is extracted, and Semen Plantaginis oil and dregs are used for subsequent use;

[0057] Step 3: Mix Akebia, Qumai, Liquor, Licorice, Stir-fried Gardenia, Wine Rhubarb, Rush, Talc Coarse Powder and Plantago Seed Dregs;

[0058] In the fourth step,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com