High-weather-resistance high-stain-resistance white paint for outdoor woodware and preparation method of paint

A white topcoat, high weather resistance technology, applied in the direction of coating, etc., can solve the problems of low strength, anti-contamination and poor weather resistance, etc., to achieve the effect of improving product hardness, low odor and VOC, and excellent safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned high weather resistance and stain resistance outdoor wood white finish paint with simple process and low cost. This preparation method comprises the steps:

[0065] S01. Weigh each component according to the composition of the high weather resistance and stain resistance outdoor wood white finish: obtain each component according to the ingredients and content of the above-mentioned high weather resistance and stain resistance outdoor wood white finish;

[0066] S02. Prepare a mixture of titanium white paste, water-based pure acrylic emulsion and water-based self-crosslinking acrylic emulsion: add the titanium white paste obtained in step S01 to the mixture of water-based pure acrylic emulsion and water-based self-crosslinking acrylic emulsion for mixing Processing to form the first mixed solution;

[0067] S03. Prepare a mixed solution containing defoamer ...

Embodiment 1

[0079] A highly weather-resistant and stain-resistant outdoor wood white finish paint and its preparation method:

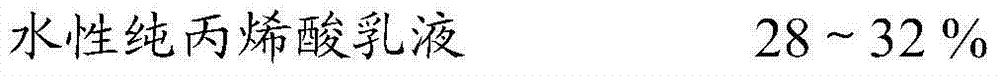

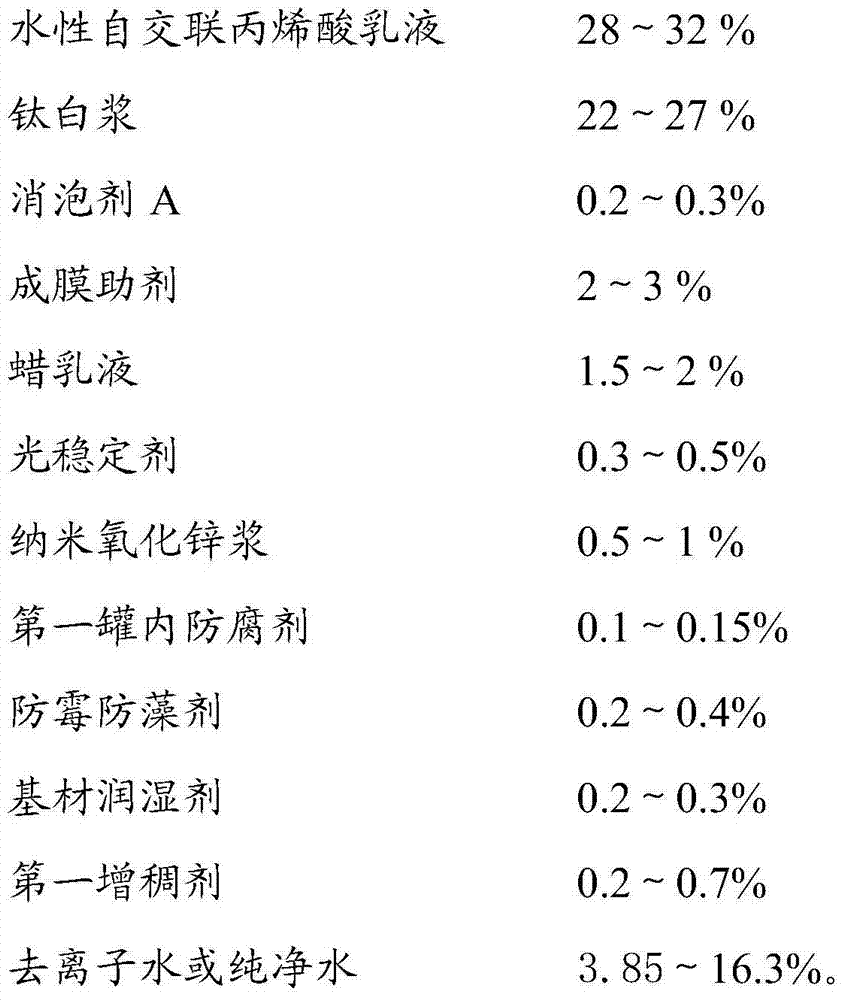

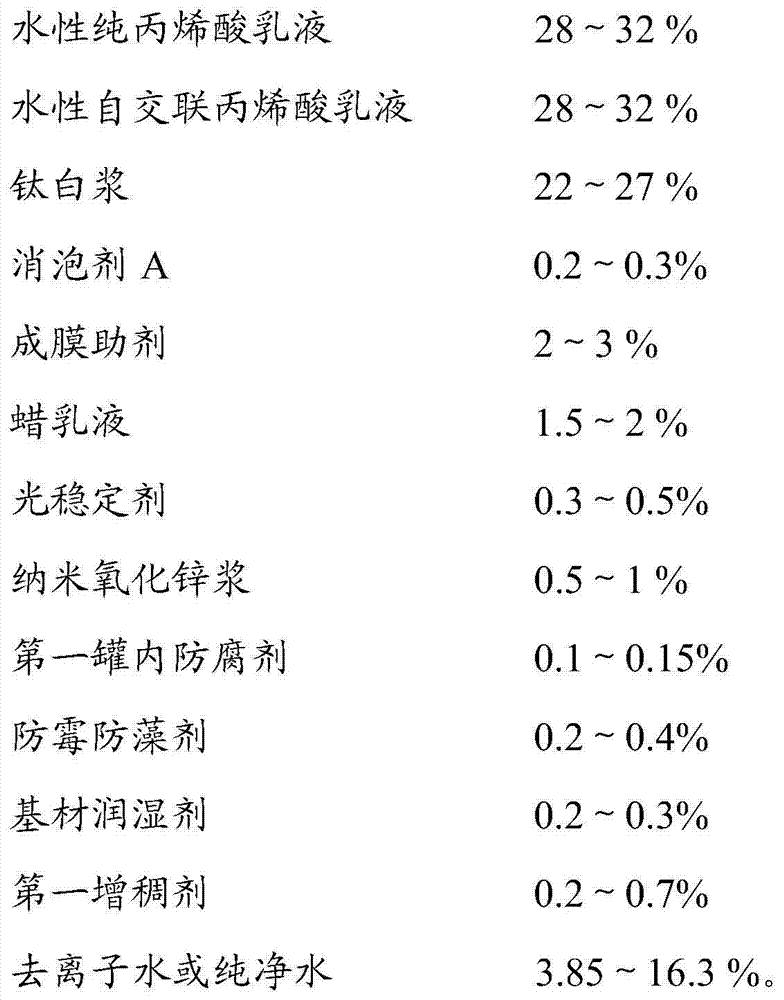

[0080] S11. Weigh each component according to the formula of high weather resistance and stain resistance outdoor wood white finish paint in the following table 1; wherein, the water-based pure acrylic emulsion is 28 parts by mass, the water-based self-crosslinking acrylic emulsion is 28 parts by mass, titanium dioxide The mass part of slurry is 22, the gas chemical Surfynol MD20 of 0.2 mass part as defoamer, the DPNB of 2 mass parts of film-forming aid, the MICHELMAN43040 of 1.5 mass parts of wax emulsion, the Clariant Hostavin3225- of 0.3 mass part of light stabilizer 2XP, the nano zinc oxide slurry is 0.5 parts by mass of Buhler Oxylink3101, the preservative in the tank is THOR ACTICIDE RS of 0.1 parts by mass,

[0081] The anti-mildew and anti-algae agent is 0.2 parts by mass of THOR ACTICIDE CF, the substrate wetting agent is 0.2 parts by mass of BYK349, and...

Embodiment 2

[0090] A highly weather-resistant and stain-resistant outdoor wood white finish paint and its preparation method:

[0091] S21. Weigh each component according to the formula of high weather resistance and stain resistance outdoor wood white finish paint in the following table 1; wherein, the water-based pure acrylic emulsion is 30 parts by mass, the water-based self-crosslinking acrylic emulsion is 30 parts by mass, titanium dioxide The mass part of slurry is 25, the defoamer is 0.3 mass parts of gas chemical Surfynol MD20, the film-forming aid is 2 mass parts of DPNB, the wax emulsion is 2 mass parts of MICHELMAN43040, and the light stabilizer is 0.4 mass parts of Clariant Hostavin3225- 2XP, the nano zinc oxide slurry is 0.5 parts by mass of Buhler Oxylink3101, the preservative in the tank is THOR ACTICIDE RS of 0.1 parts by mass,

[0092] The anti-mildew and anti-algae agent is 0.3 parts by mass of THOR ACTICIDE CF, the substrate wetting agent is 0.3 parts by mass of BYK349,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com