Special silica gel base material 3D structure decorating part and preparation process thereof

A technology of decorative parts and silica gel, which is applied in the field of special silica gel base material 3D structural decorative parts and its preparation process, which can solve the problems of poor printing quality and printing peeling on the surface of simple silica gel, so as to avoid poor printing adhesion effect and ensure flexibility The effect of sex and touch, good elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

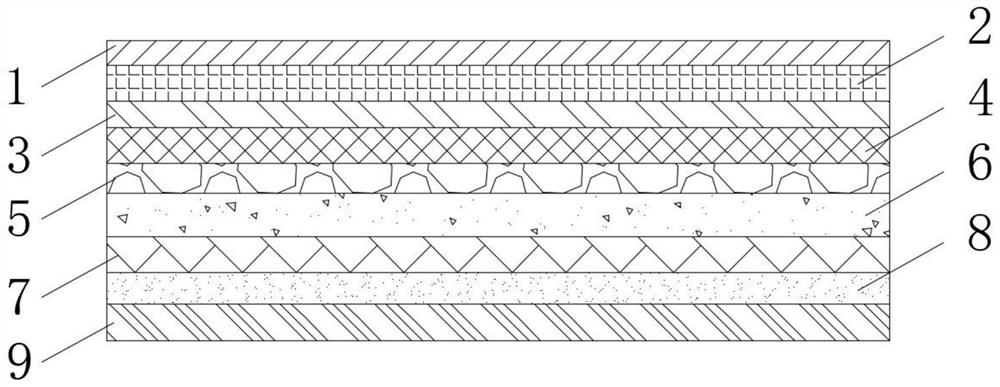

[0024] Such as figure 1 As shown, the embodiment of the present invention provides a special silicone substrate 3D structure decoration, including a PET film 1, the PET film 1 is made of a high melting point film, the bottom surface of the PET film 1 is attached with a TPU protective film 2, and the TPU protection The bottom surface of the film 2 is attached with a TPU sheet 3, the thickness of the TPU sheet 3 is 0.025-0.25mm, the bottom surface of the TPU sheet 3 is attached with a UV transfer layer 4, and the bottom surface of the UV transfer layer 4 is attached with a vacuum The coating layer 5, the bottom surface of the vacuum coating layer 5 is bonded with an elastic ink layer 6, the bottom surface of the elastic ink layer 6 is bonded with a treatment agent layer 7, the bottom surface of the treatment agent layer 7 is bonded with a silicone ink layer 8, and the silicone ink layer 8 Halogen-free high-temperature silicone ink is used, and the maximum temperature resistance ...

Embodiment 2

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a preparation process of a special silicone substrate 3D structure decoration, including the following steps:

[0027] Sp1, preparing a decorative layer, the decorative layer includes a PET film 1, a TPU protective film 2, a TPU sheet 3, a UV transfer layer 4 and a vacuum coating layer 5;

[0028] Sp1-1, use 0.025-0.25mm TPU sheet 3 as the base material for lamination, and set TPU protective film 2 and PET diaphragm 1 in turn on the top;

[0029] Sp1-2, a UV transfer layer 4 is photocured at the bottom of the TPU sheet 3, and a vacuum coating layer 5 is processed on the bottom surface of the UV transfer layer 4;

[0030] Sp2, placing the decorative layer prepared by Sp1 and the silica gel to be processed in the forming mold;

[0031] Sp3, the components in Sp2 are molded and vulcanized in the equipment;

[0032] Sp4. Attach a release protective film 9 on the bottom surface of the molded produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com