Coupling adhesive for ultrasonic real-time broken rail monitoring system and preparation method and use method thereof

A monitoring system and ultrasonic technology, applied in the field of coupling glue, can solve problems such as affecting detection accuracy, lack of usability, and ultrasonic energy reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

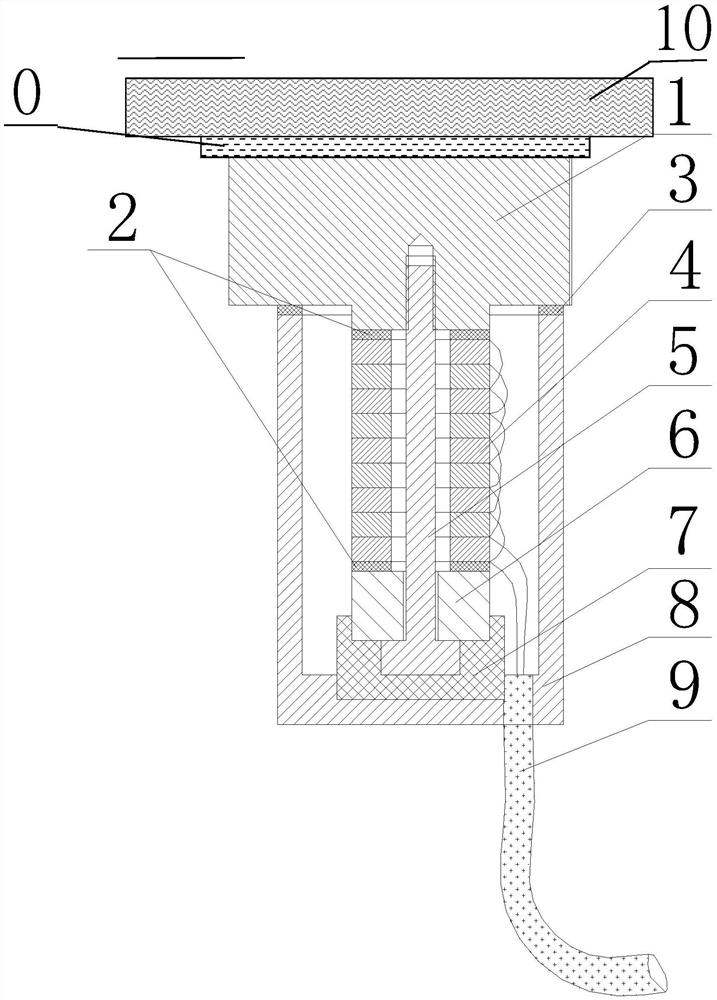

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing coupling glue used in the ultrasonic real-time rail broken monitoring system, which includes the following steps:

[0065] (1) Mix vinyl silicone resin and hydrogen-containing silicone resin to obtain a premix;

[0066] (2) The premix obtained in the step (1) is ground with the acetylenic alcohol reaction inhibitor to obtain the main agent;

[0067] (3) Mixing the main agent obtained in the step (2) with the catalyst, and then degassing, to obtain the coupling glue for the ultrasonic real-time rail breaking monitoring system.

[0068] The invention mixes vinyl silicone resin and hydrogen-containing silicone resin to obtain a premix. The present invention does not specifically limit the mixing manner of the vinyl silicone resin and the hydrogen-containing silicone resin, and a mixing manner well known to those skilled in the art can be used to achieve uniform mixing of the vinyl silicone resin and the hydrogen-containing...

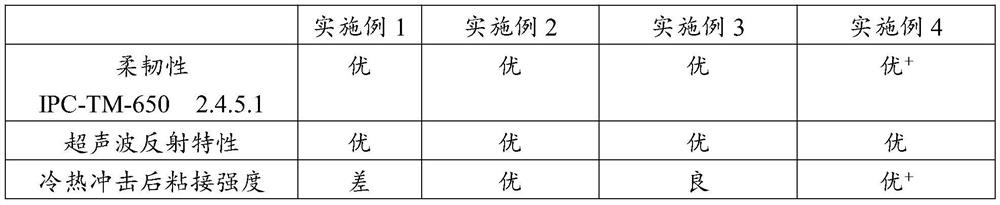

Embodiment 1

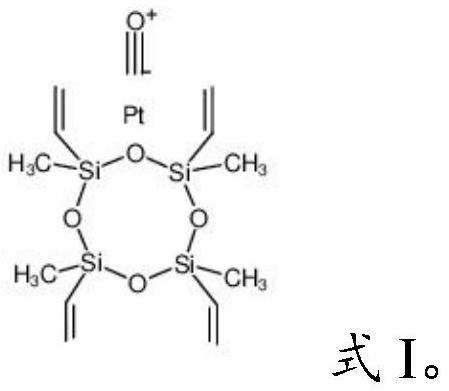

[0096] Material: vinyl-terminated silicone resin: [R 1 R 2 R 3 SiO 1 / 2 ] 2 [R 1 R 2 R 4 SiO 1 / 2 ] 3 [R 1 R 5 SiO 2 / 2 ] 4 [R 1 SiO 3 / 2 ] 5 , Where R 1 , R 2 , R 3 , R 4 And R 5 Respectively linear C5 alkane groups; (Formula I)

[0097] Hydrogen-containing silicone resin: [R 1 R 2 R 8 SiO 1 / 2 ] e [R 1 R 9 SiO 2 / 2 ] f [R 1 SiO 3 / 2 ] g , Where R 1 , R 2 They are linear C5 alkane groups, R 8 , R 9 They are linear C10 alkane groups, e=0.62, f=0.19, g=0.19; (Formula II)

[0098] Alkynol reaction inhibitor: 3-phenyl-1-buten-3-ol;

[0099] Catalyst: chloroplatinic acid.

[0100] Preparation method: In parts by weight, 80 parts of the vinyl-terminated silicone resin of formula I in the raw material and 30 parts of the hydrogen-containing silicone resin of formula II in the raw material are stirred in a dual planetary power mixer to obtain a premix, wherein the stirring temperature is 25℃, stirring time is 40min, stirring speed is 300r / min. The obtained premix and 1 part of the acetylenic alco...

Embodiment 2

[0102] In parts by weight, 90 parts of the vinyl-terminated silicone resin of formula I in the raw material of Example 1 and 30 parts of the hydrogen-containing silicone resin of formula II in the raw material of Example 1 are stirred in a dual planetary power mixer to obtain a premix, wherein The temperature is 25℃, the stirring time is 40min, and the stirring rate is 300r / min. The obtained premix and 1 part of the acetylenic alcohol reaction inhibitor (3-phenyl-1-buten-3-ol) are ground to a particle size of less than 6 μm using three rolls to obtain the main agent. The obtained main agent and 3 parts of the catalyst (chloroplatinic acid) are mixed using a double planetary power mixer, the mixing time is 20 minutes, after the mixing is completed, the present invention puts the mixed system on stand for 30 minutes for degassing to obtain ultrasonic Coupling glue for real-time broken rail monitoring system. Coating the obtained coupling glue for the ultrasonic real-time rail br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com