High-elastic, high-toughness and environment-friendly rubber sole material and preparing method thereof

An environmentally friendly rubber and sole material technology, applied in the field of sole materials, can solve the problems of insufficient environmental protection, poor elasticity and flexibility, and achieve the effects of improving degradability and environmental protection, improving lipophilicity, and excellent flexibility and elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

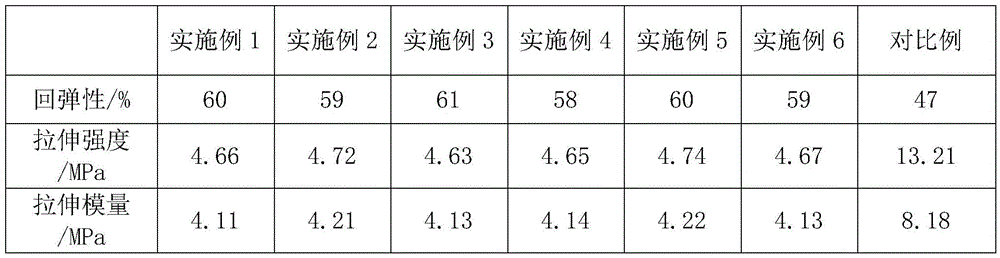

Examples

Embodiment 1

[0028] High-elasticity, high-toughness, environment-friendly rubber sole material, by weight, includes the following components:

[0029] 48 parts of nitrile rubber, 16 parts of PVC, 0.5 parts of paraffin, 1.1 parts of antioxidant MB, 0.6 parts of silane coupling agent, 2.5 parts of sulfur, 1.7 parts of accelerator DM, 12.5 parts of ATBC, 3.5 parts of foaming agent OB , 0.6 parts of TAIC, 5 parts of zinc oxide powder, 3 parts of stearic acid, 18 parts of composite carbon powder.

[0030] The preparation method of this high-elasticity, high-toughness, environment-friendly rubber sole material is:

[0031] (1) Wash the discarded broccoli stems and discarded cauliflower stems with a weight ratio of 1:1, then air-dry them naturally, crush them with a pulverizer, pass through a 50-mesh sieve, and dry them with a blast dryer to constant weight to obtain mixed stem powder , the mixed stem powder is added to the phosphoric acid solution with a weight concentration of 70%, and the mix...

Embodiment 2

[0036] High-elasticity, high-toughness, environment-friendly rubber sole material, by weight, includes the following components:

[0037] 50 parts of nitrile rubber, 20 parts of PVC, 0.7 parts of paraffin, 1.3 parts of anti-aging agent RD, 0.8 parts of silane coupling agent, 2.4 parts of sulfur, 1.5 parts of accelerator DM, 11 parts of ATBC, 4.5 parts of foaming agent OB, TAIC0 .8 parts, 5 parts of zinc oxide powder, 3 parts of stearic acid, 24 parts of composite carbon powder.

[0038] The preparation method of this high-elasticity, high-toughness, environment-friendly rubber sole material is:

[0039] (1) Wash the discarded broccoli stems and discarded cauliflower stems with a weight ratio of 1:1, then air-dry them naturally, crush them with a pulverizer, pass through a 50-mesh sieve, and dry them with a blast dryer to constant weight to obtain mixed stem powder , the mixed stem powder is added to the phosphoric acid solution with a weight concentration of 70%, and the mixed ...

Embodiment 3

[0044] High-elasticity, high-toughness, environment-friendly rubber sole material, by weight, includes the following components:

[0045] 52 parts of nitrile rubber, 18 parts of PVC, 0.9 parts of paraffin, 1.5 parts of antioxidant MB, 0.7 parts of silane coupling agent, 2 parts of sulfur, 1.9 parts of accelerator DM, 10 parts of ATBC, 3 parts of foaming agent OB, 1 part of TAIC, 5 parts of zinc oxide powder, 3 parts of stearic acid, 24 parts of composite carbon powder.

[0046] The preparation method of this high-elasticity, high-toughness, environment-friendly rubber sole material is:

[0047] (1) Wash the discarded broccoli stems and discarded cauliflower stems with a weight ratio of 1:1, then air-dry them naturally, crush them with a pulverizer, pass through a 50-mesh sieve, and dry them with a blast dryer to constant weight to obtain mixed stem powder , the mixed stem powder is added to the phosphoric acid solution with a weight concentration of 70%, and the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com