Patents

Literature

1443results about How to "Guaranteed mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

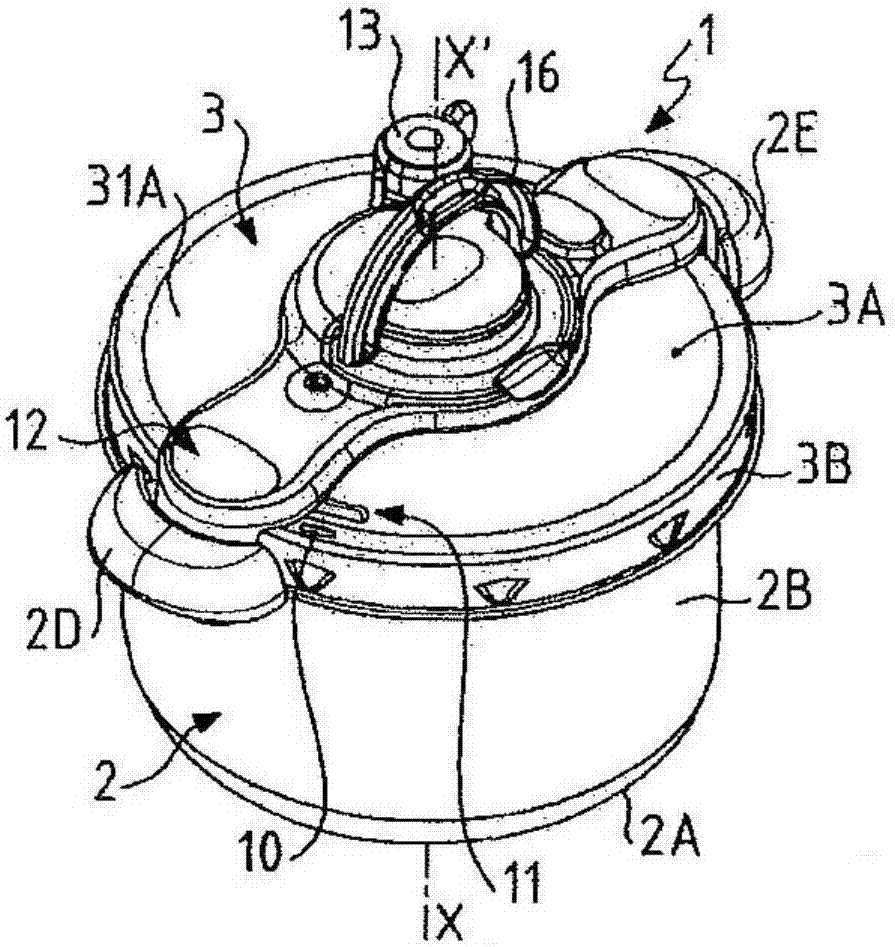

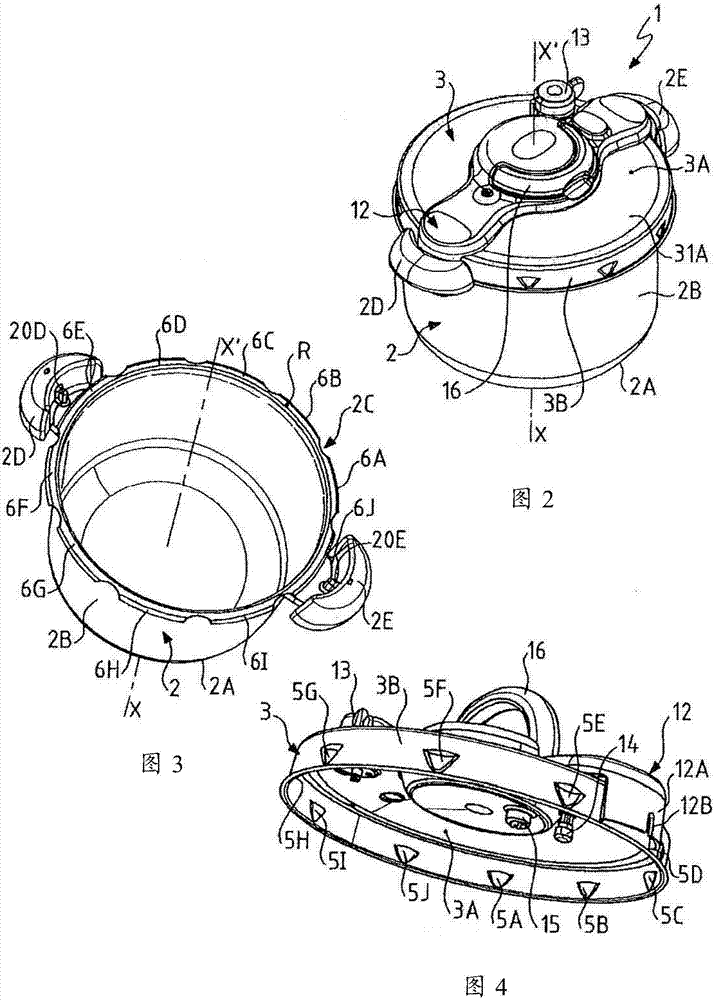

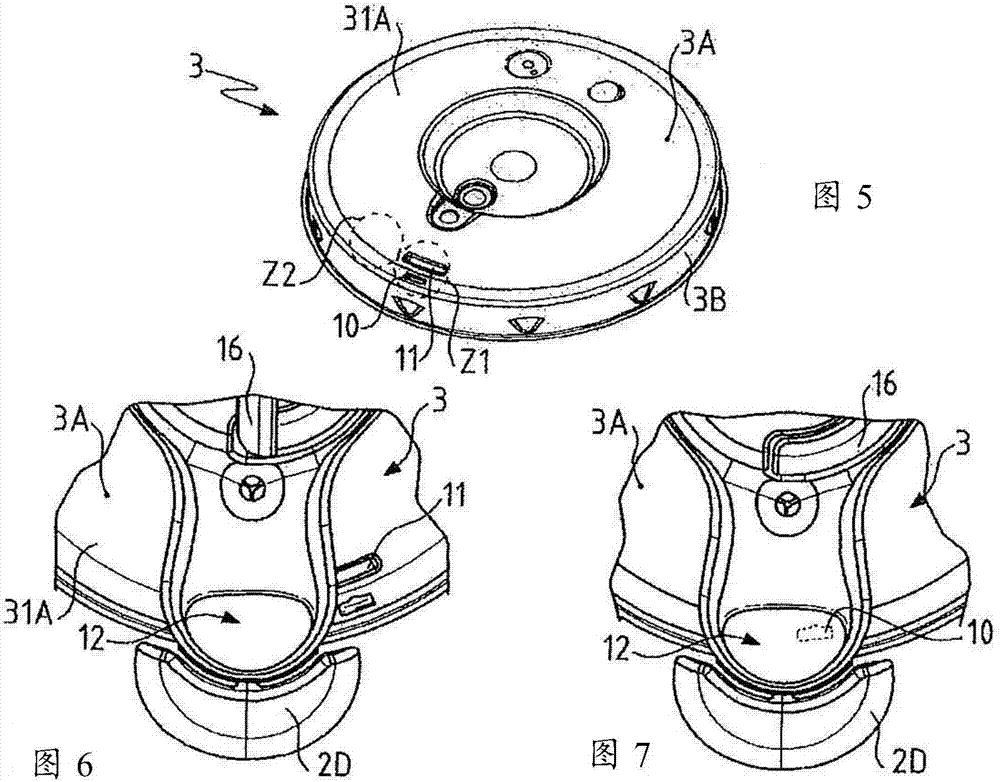

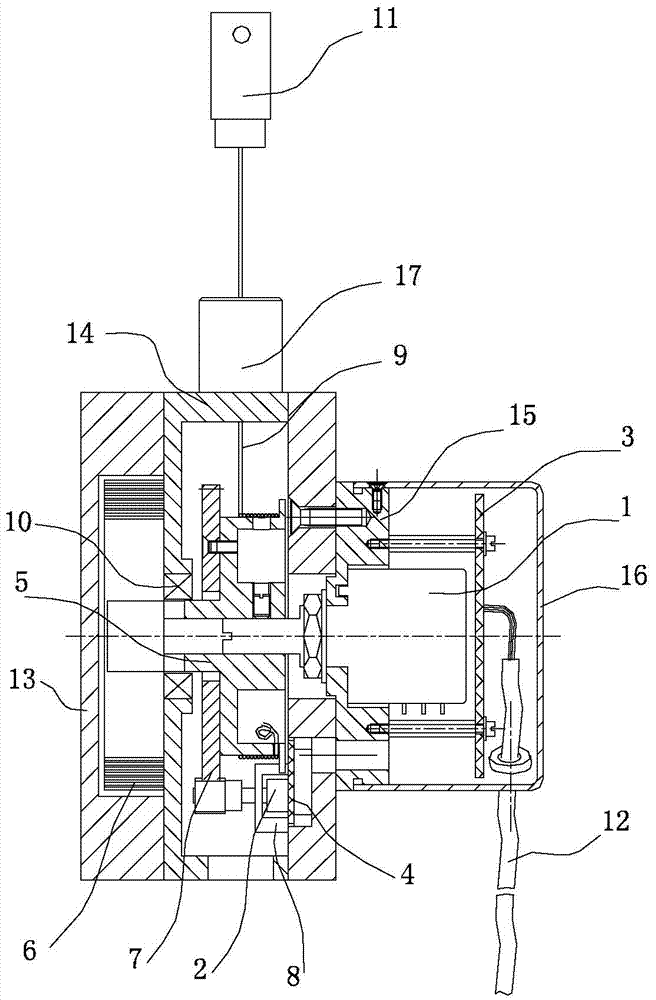

Pressure Cooker Provided With Lid Opening

ActiveCN107259978AVerify operating statusLimit any risk of sprayingPressure-cookersEngineeringCooker

The present invention relates to a cooking device 1 for cooking food under pressure. The cooking device 1 comprises a container 2 and a cover 3 used for cooperating with the container 2 to form a cooking shell; a sealing gasket 4 inserted between the cover 3 and the container 2 to rise the pressure in the cooking container; and an opening 10 formed by aligning the cover 3 at the sealing gasket 4. The device is characterized by also comprising a covering element 12, wherein the cover 3 and the covering element 12 are arranged to move relative to each other, thereby executing between the first configuration that the covering element covers the opening 10 and the second configuration that the covering element 12 exposes the opening 10.

Owner:SEB SA

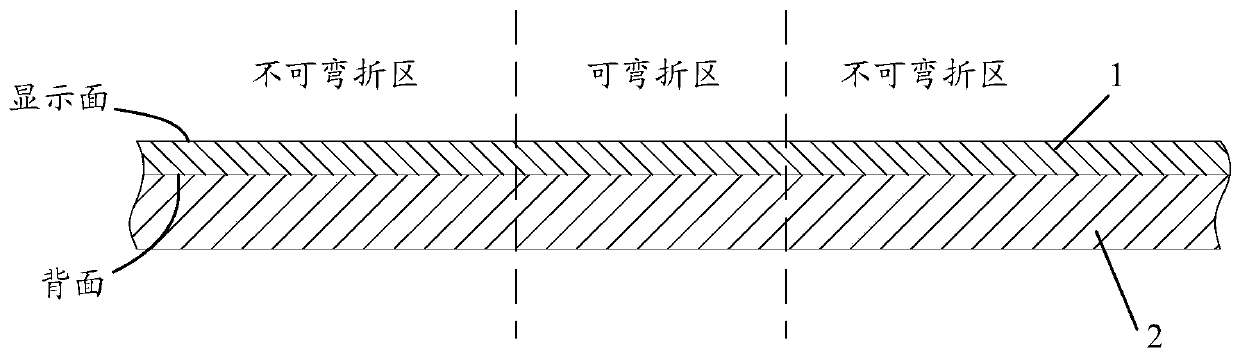

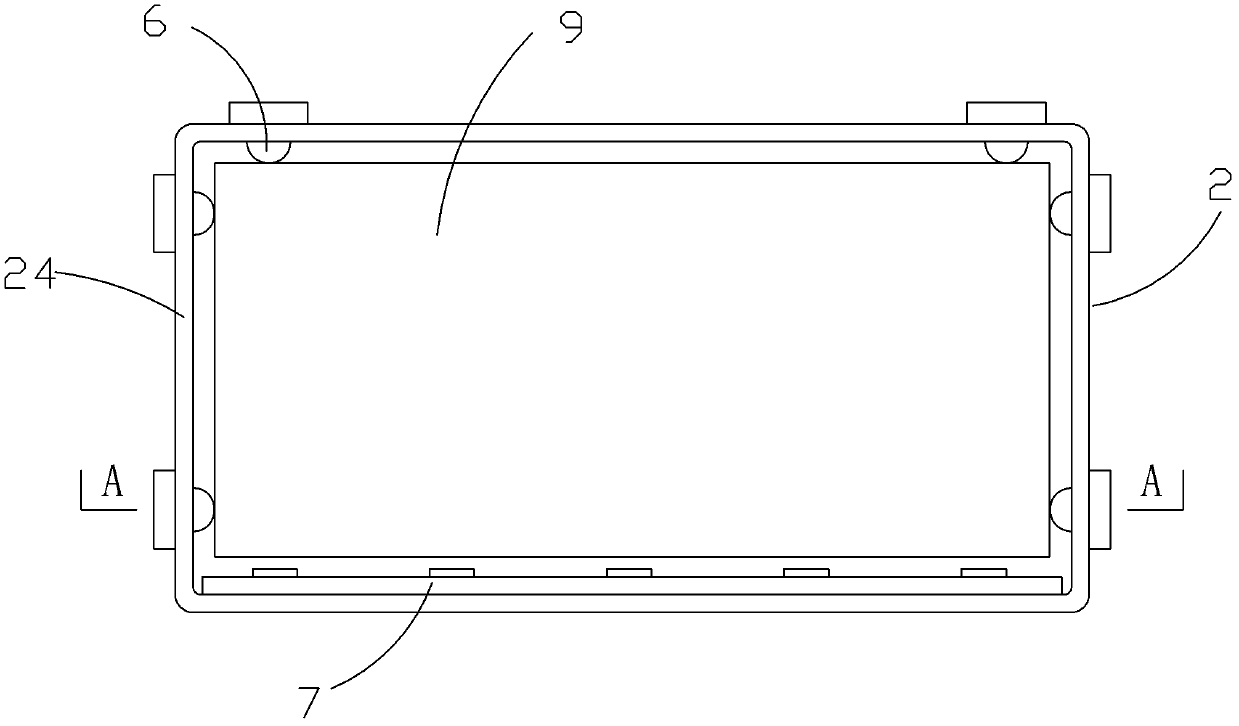

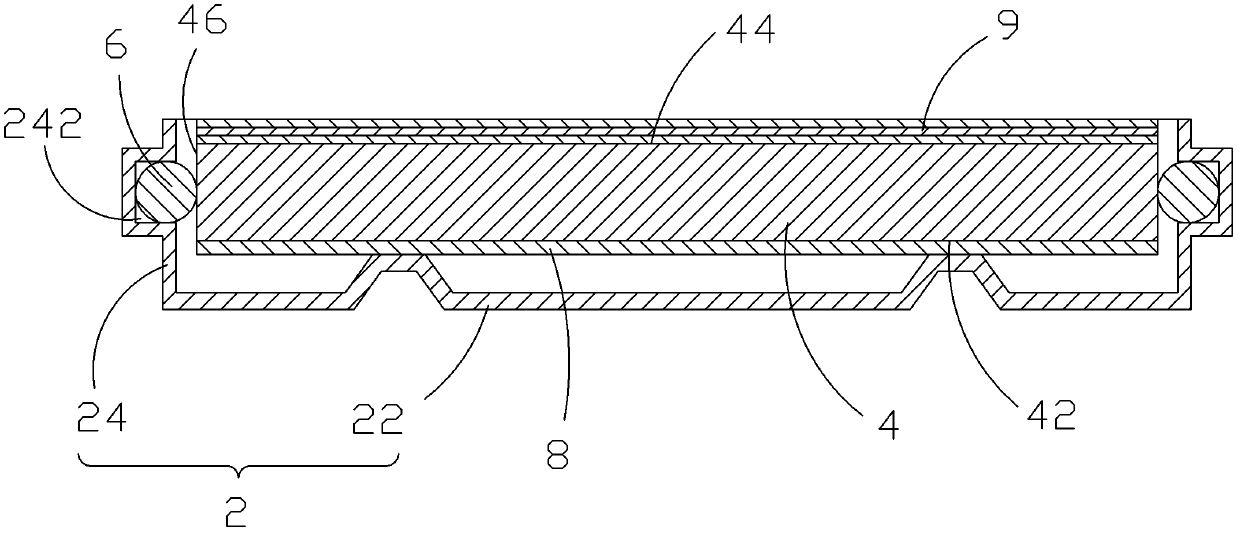

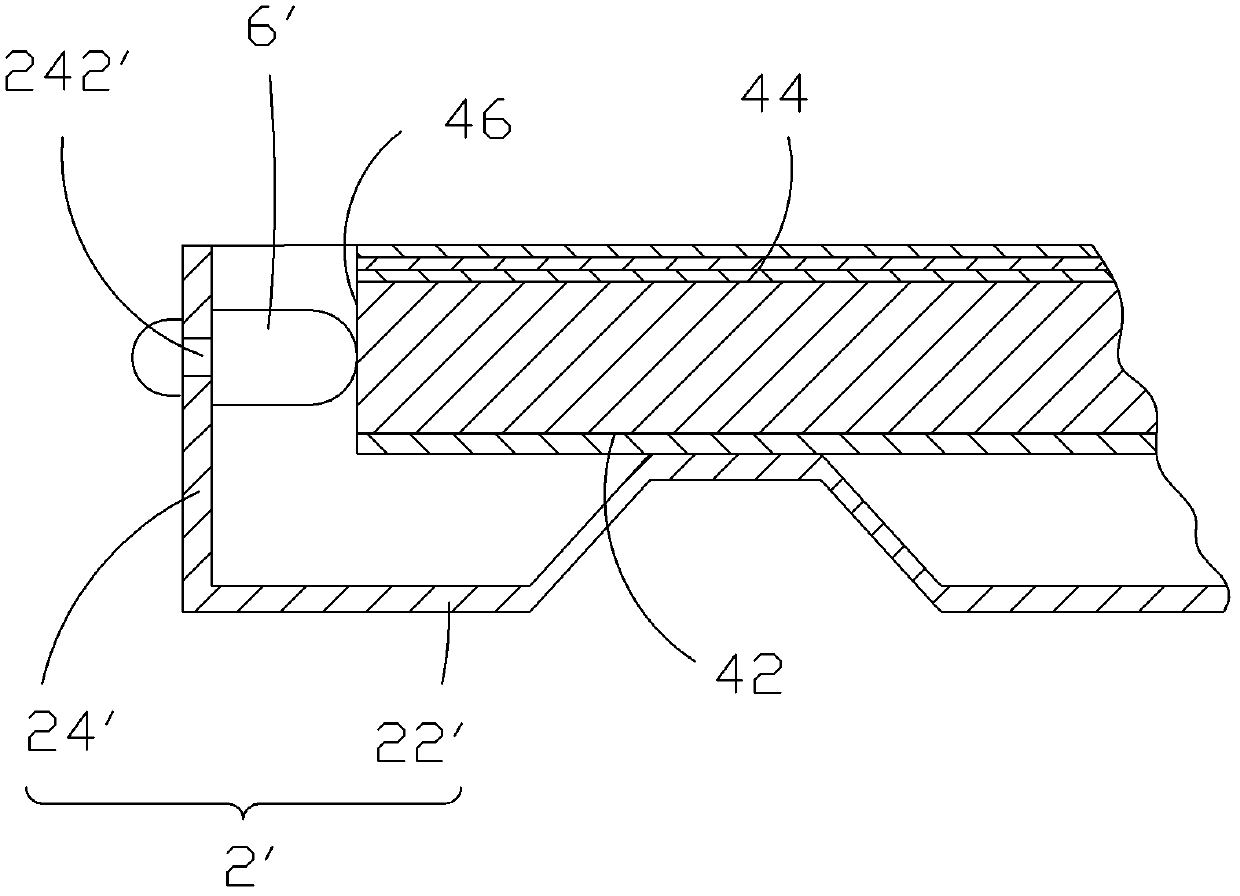

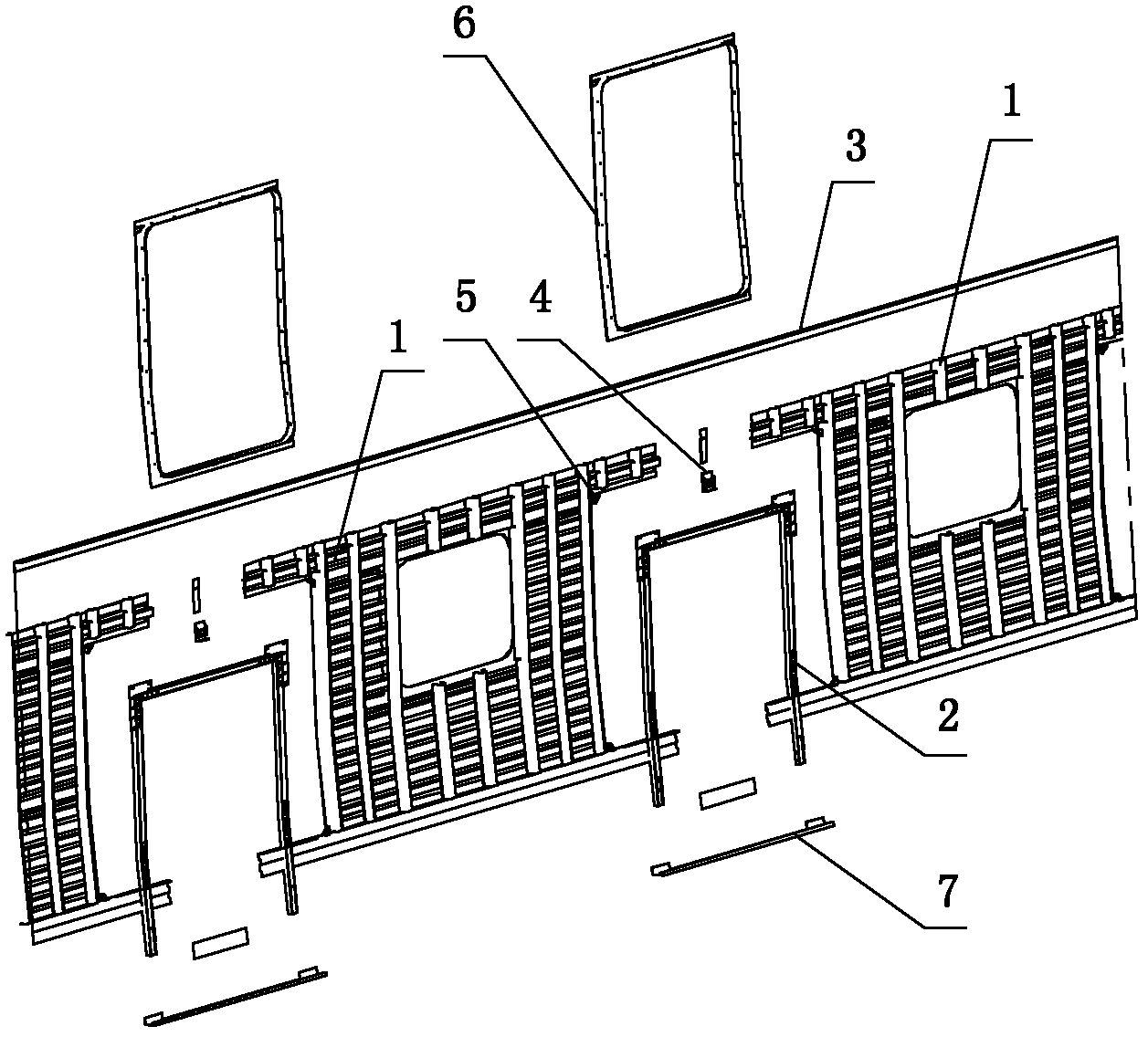

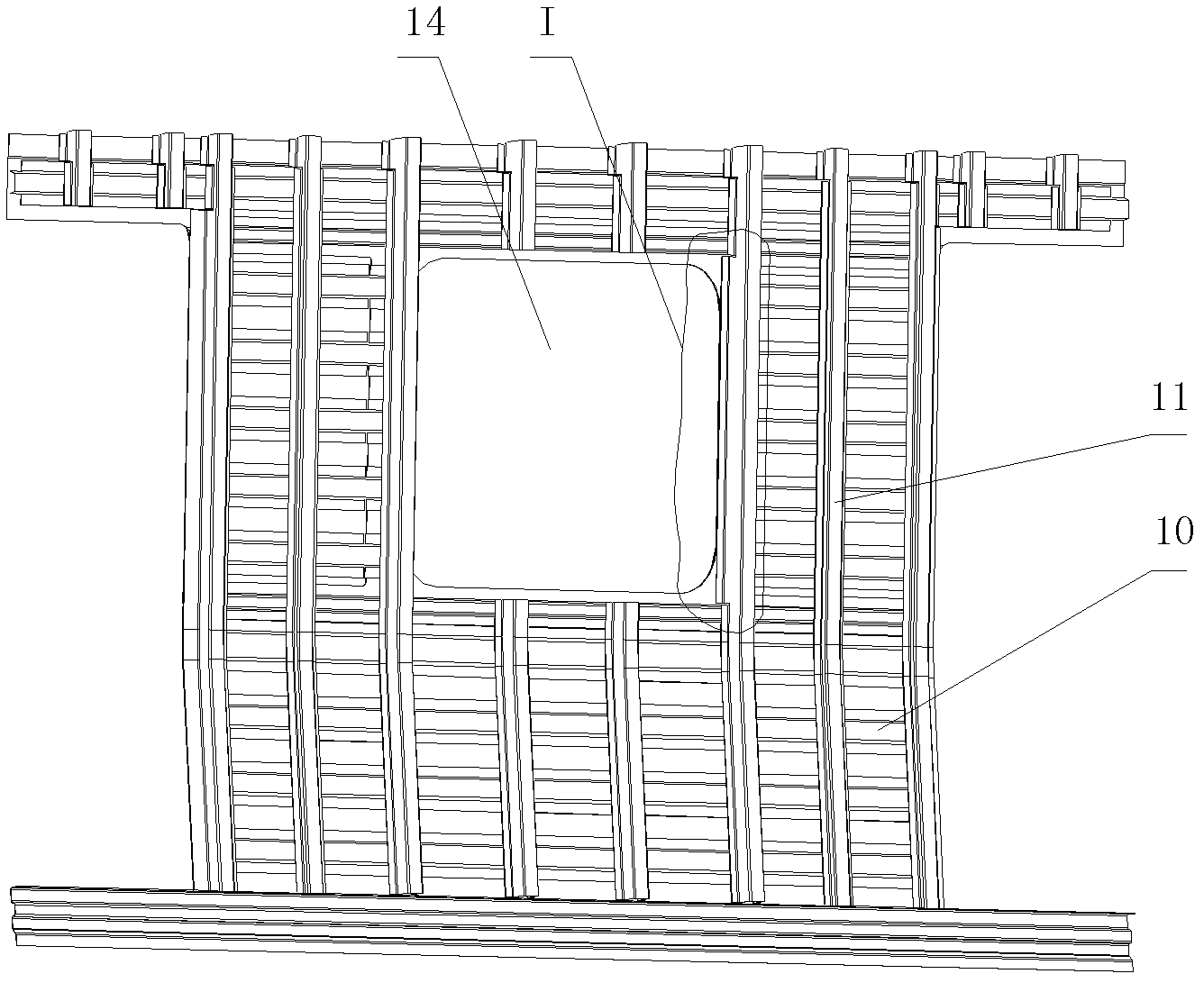

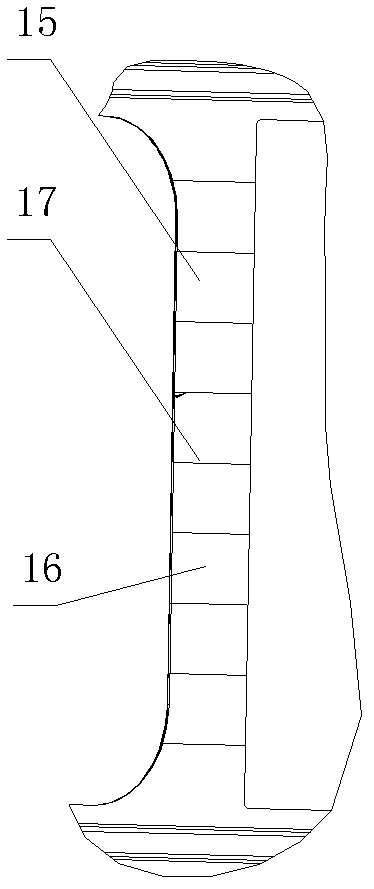

Supporting piece for foldable terminal device and foldable terminal device

InactiveCN110062077AGuaranteed mechanical strengthStable supportDigital data processing detailsTelephone set constructionsTerminal equipmentEngineering

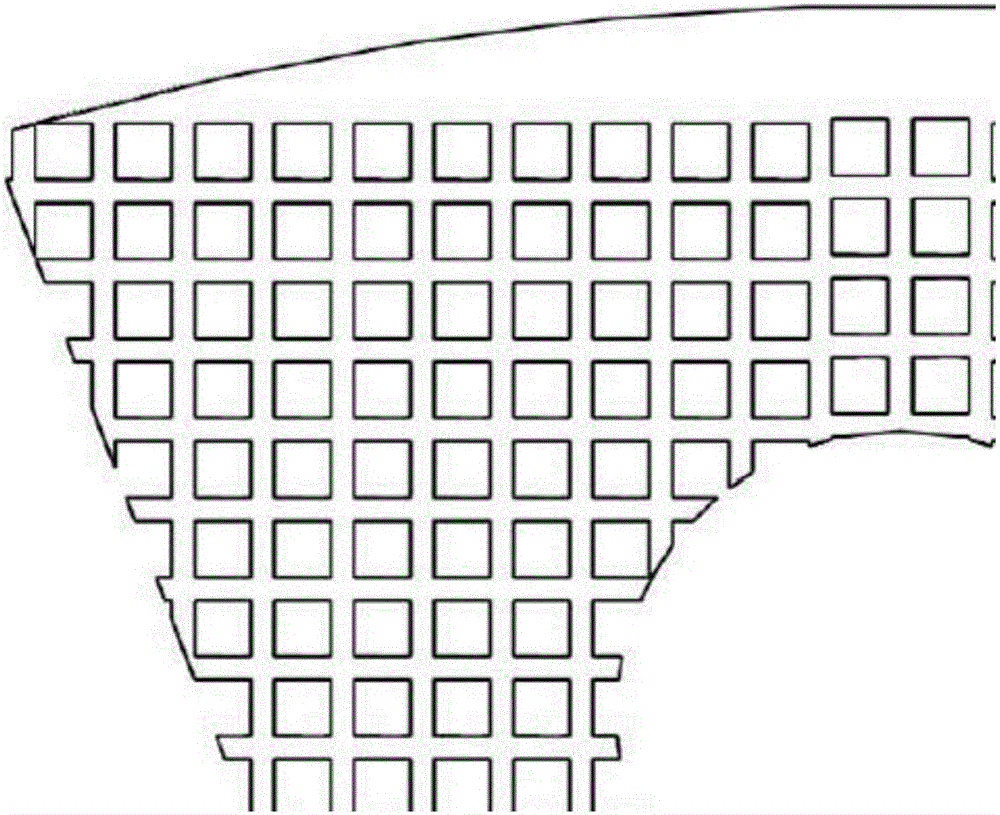

The invention provides a supporting piece for foldable terminal device and the foldable terminal device, relates to the technical field of terminal device. The supporting piece and the device and canimprove the surface flatness of the terminal device on the premise that the bending activity of the terminal device is not limited. The terminal device comprises a flexible display screen and a supporting piece arranged on one side of the flexible display screen. The supporting piece comprises at least one bendable area, a plurality of gaps are formed in at least one bendable area. Each gap is provided with at least one opening, and the orientation of at least one opening in each gap is the same as the bending direction of the bendable area where the gap is located. When the bendable area of the supporting piece is bent, the gap can absorb stress generated in the bending process, the bending movement of the terminal device cannot be limited, the supporting piece can provide a supporting effect for the flexible display screen, and the surface flatness of the terminal device is improved. The terminal device provided by the invention can be folded, and has the functions of providing large-size display, being convenient to carry and the like.

Owner:HUAWEI DEVICE CO LTD

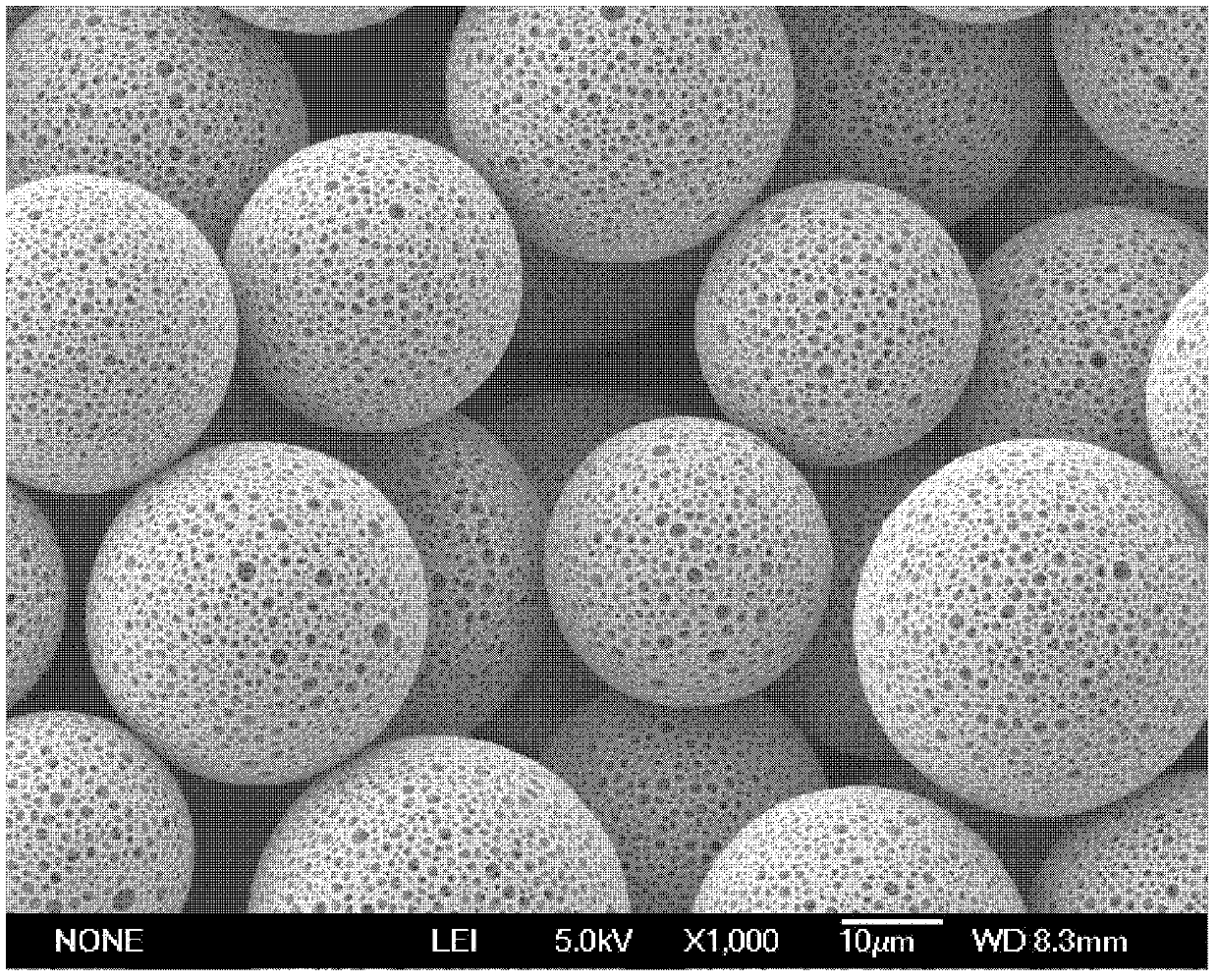

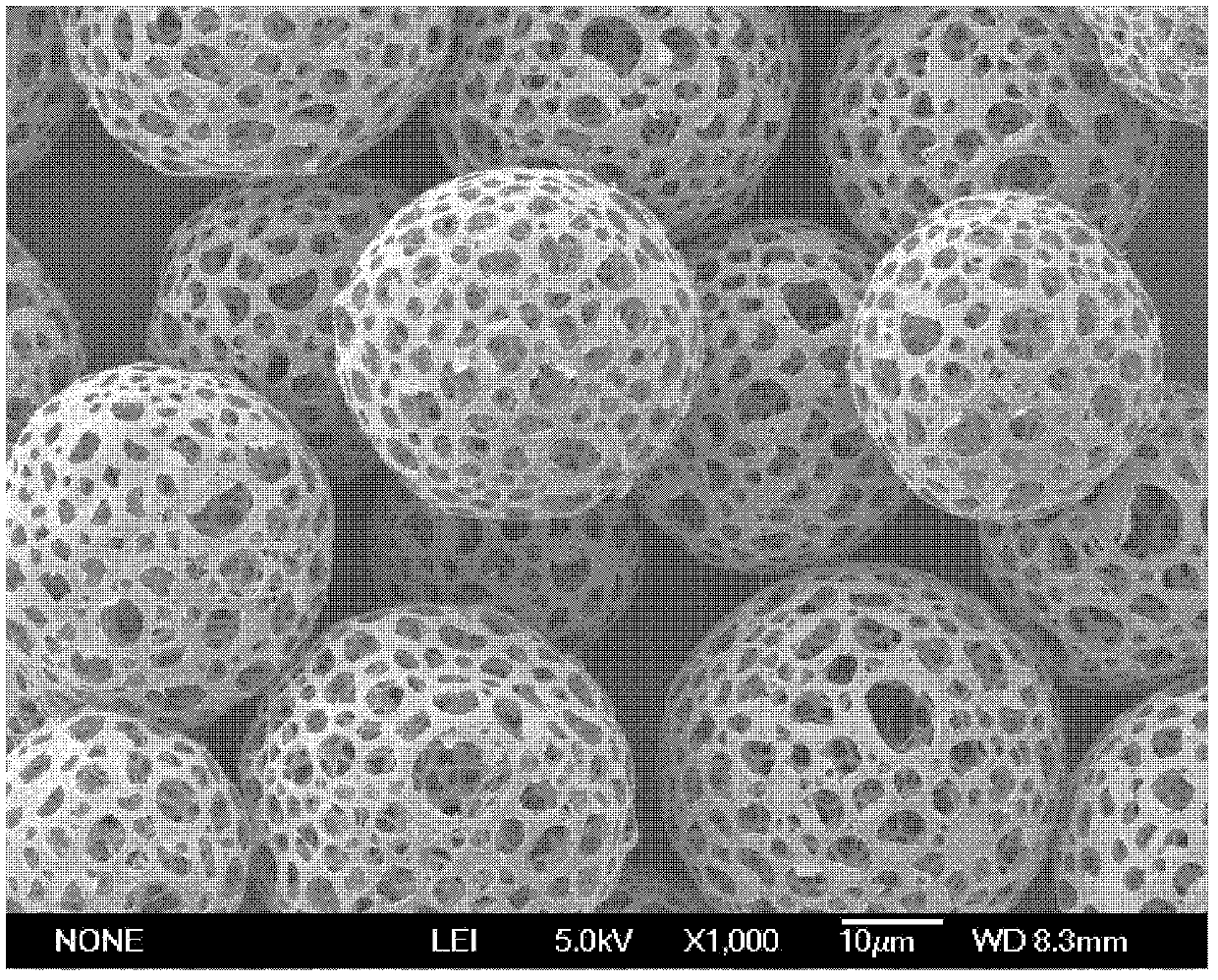

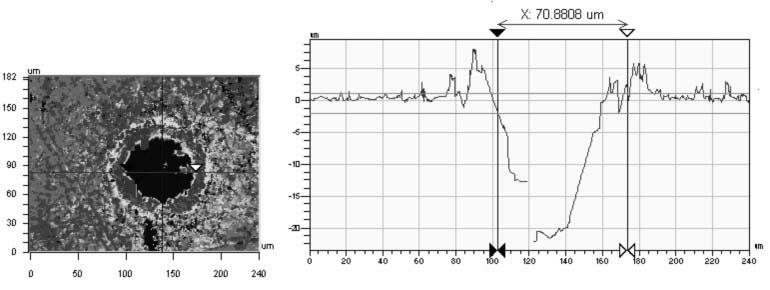

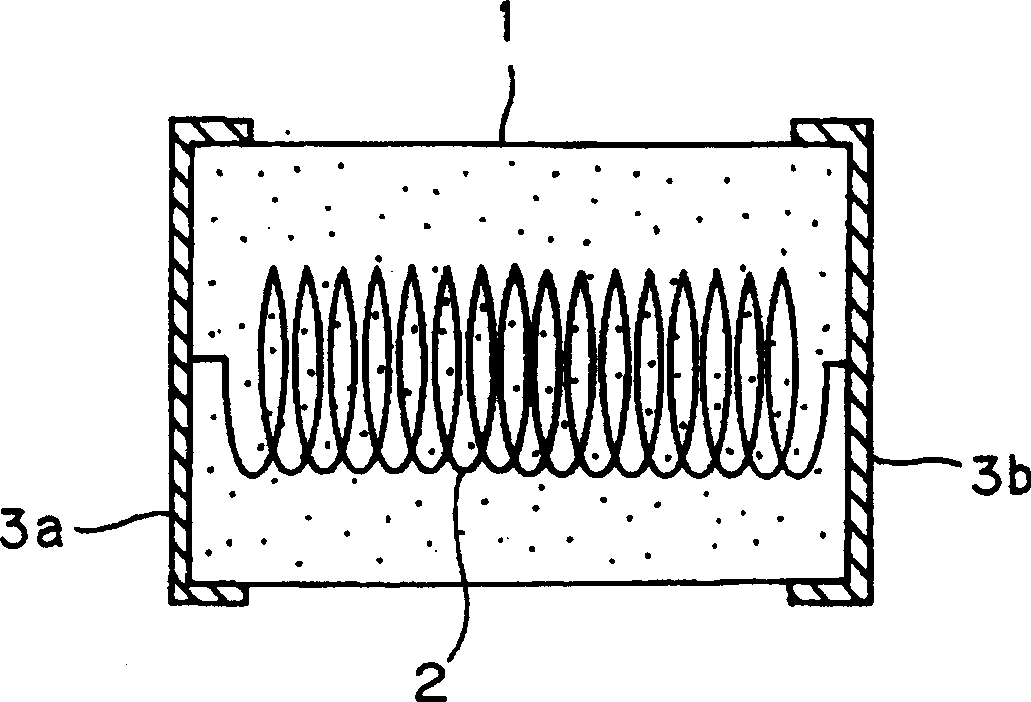

Super macroporous polymer microspheres and preparation method thereof

ActiveCN103374143AControl areaEasy to controlOther chemical processesTissue culturePorosityChromatographic separation

The invention provides super macroporous polymer microspheres and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing an oil-in-water in-water composite emulsion as a template for super macroporous microspheres through a two-step emulsion process; then, solidifying an oil phase by using a solvent removal method to form super macroporous microspheres provided with inner-outer through pore passages; and finally, after molding the microspheres, further crosslinking microsphere skeleton molecules to obtain microspheres with rigid resin structures. The microspheres prepared by the method have a through pore passage structure, the controllable particle size range is 0.1-300 microns, the controllable pore size range is 0.09-90 microns, and the controllable porosity range is 10-90%. Super macroporous structures are beneficial for biological macromolecules to penetrate through and enter the microspheres, the mass transfer by convection in the microspheres can be realized, and the rigid structure can tolerate higher pressure and higher flow velocity. The super macroporous polymer microspheres can be used as stationary phase fillers for chromatographic separation, immobilized carriers of enzymes, cell culture micro-carriers, tissue engineering micro scaffold materials, adsorbing materials and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Prepn. method and application of high-dispersion loading type nickel-based catalyst

InactiveCN1751789AImprove activity and stabilityStrong effectHydrogenCatalyst activation/preparationIonAcetylacetone

A high-dispersity carried Ni-base catalyst for reforming, oxidizing, or oxidizing-reforming methane in fluidized bed is prepared by direct dipping to make the Ni ions be carried by microspherical silica gel or alumina. Its advantages are high activity and high stability.

Owner:ZHEJIANG UNIV

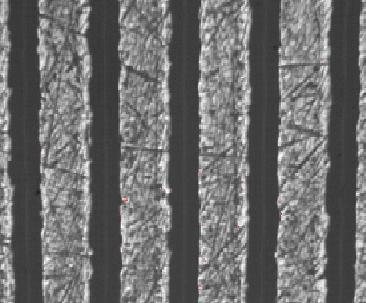

Etching process for aluminum foil for electrolytic capacitor

InactiveCN101275269AGuaranteed mechanical strengthReduce concentration polarizationCapacitor electrodesPre treatmentConcentration polarization

The invention relates to a corrosion process of aluminum foil used in an electrolytic capacitor, which includes six steps: pre-treatment, exchange of pre-corrosion, intermediate processing, post-level AC corrosion, DC corrosion, and after treatment, is characterized in that ultrasound-assisted corrosion is used in the post-level AC corrosion; at the same time, the invention divides the post-level AC corrosion into a plurality of levels, the temperatures are gradually reduced from the first level to the end, but the current densities are increased gradually. The craft of the invention keeps that the etching solution is transferred smoothly in a tank, effectively prevents concentration polarization at the interface of aluminum foil-etching solution, promotes the removing of the corrosion sediments, and greatly enhances the corrosion efficiency.

Owner:日丰(清远)电子有限公司 +1

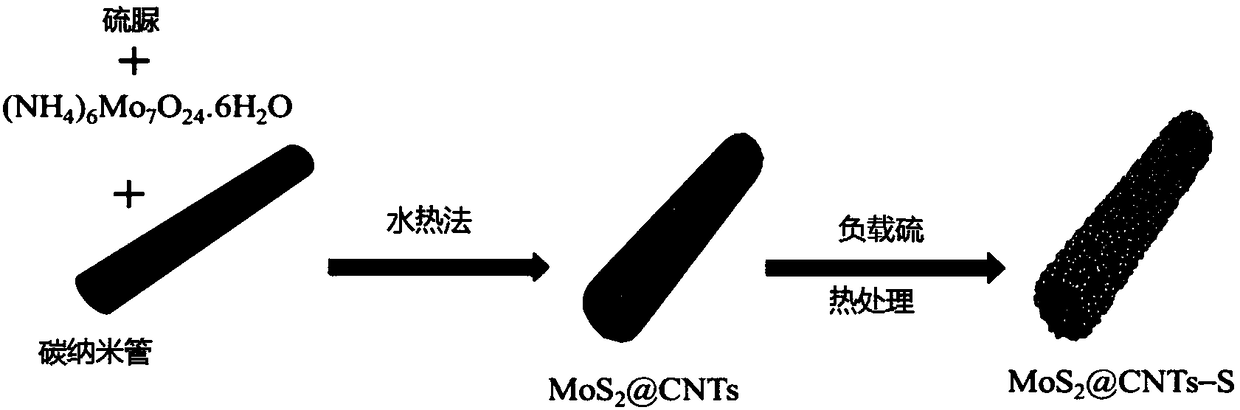

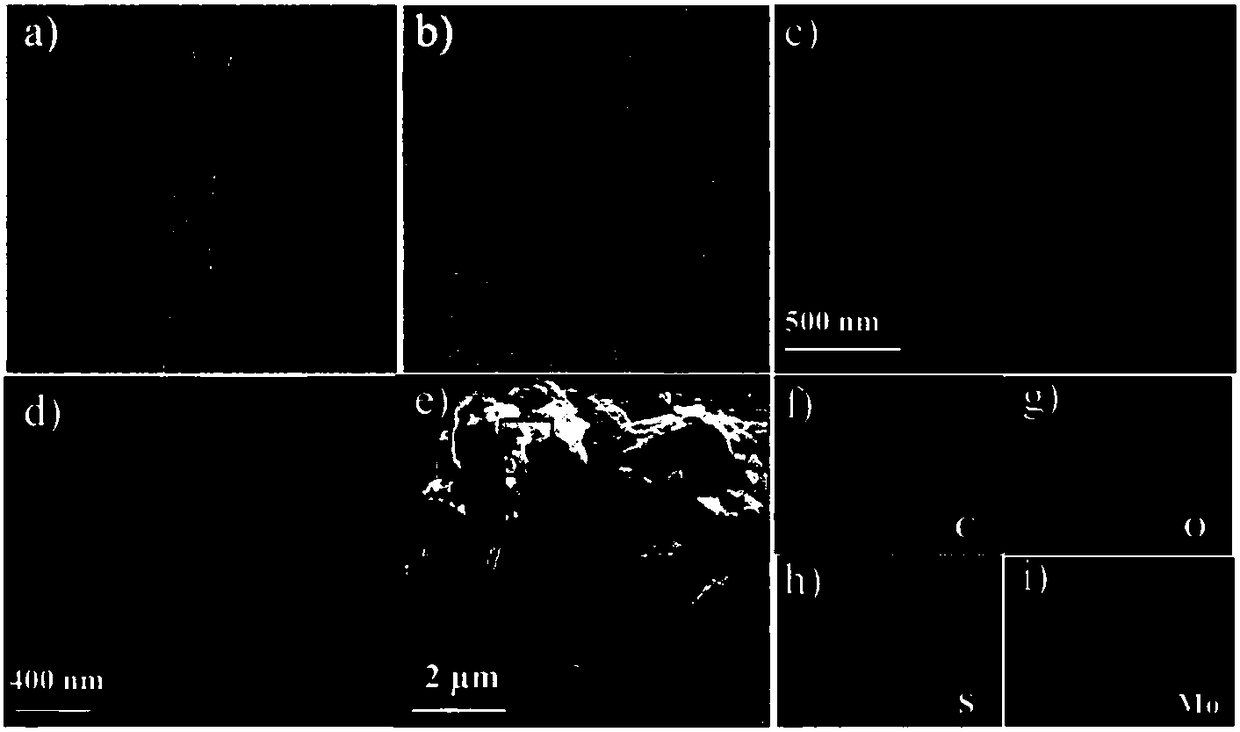

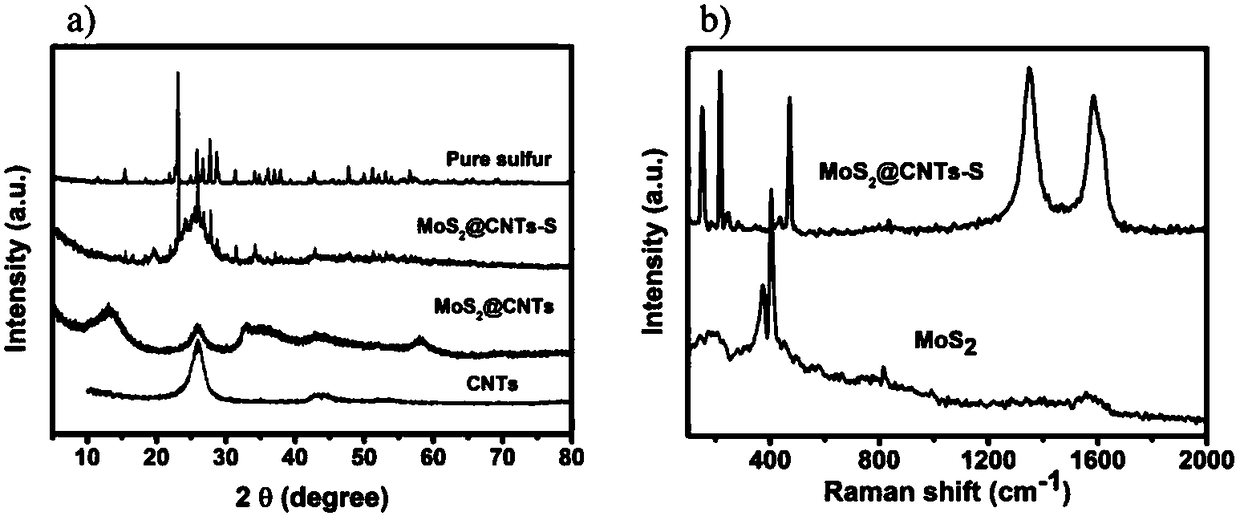

Lithium sulfur battery positive electrode material and preparation method thereof

InactiveCN108232164AFacilitate the transfer of electronsImprove charge and discharge propertiesPositive electrodesLi-accumulatorsChemistryHigh rate

The invention belongs to the field of lithium sulfur battery material, and in particular, relates to a lithium sulfur battery positive electrode material including a host material and elemental sulfurloaded on the host material; the host material includes carbon nanotubes and a transition metal sulfide compounded on the carbon nanotubes. The invention also discloses a preparation method and an application of the positive electrode material. According to the lithium sulfur battery positive electrode material, a strategy of adding the transition metal sulfide is adopted for reducing a back-and-forth shuttling effect; secondly, the carbon nanotubes are added to prevent the collapse of an electrode structure; the positive electrode material has excellent electrochemical performance, and is applied to a lithium sulfur battery to show high initial discharge capacity, high coulombic efficiency and high rate performance.

Owner:CENT SOUTH UNIV

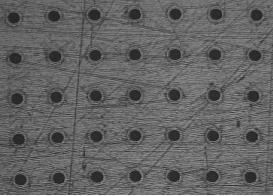

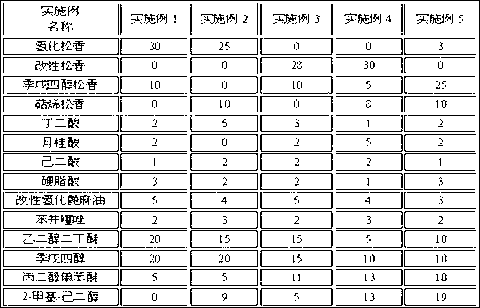

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

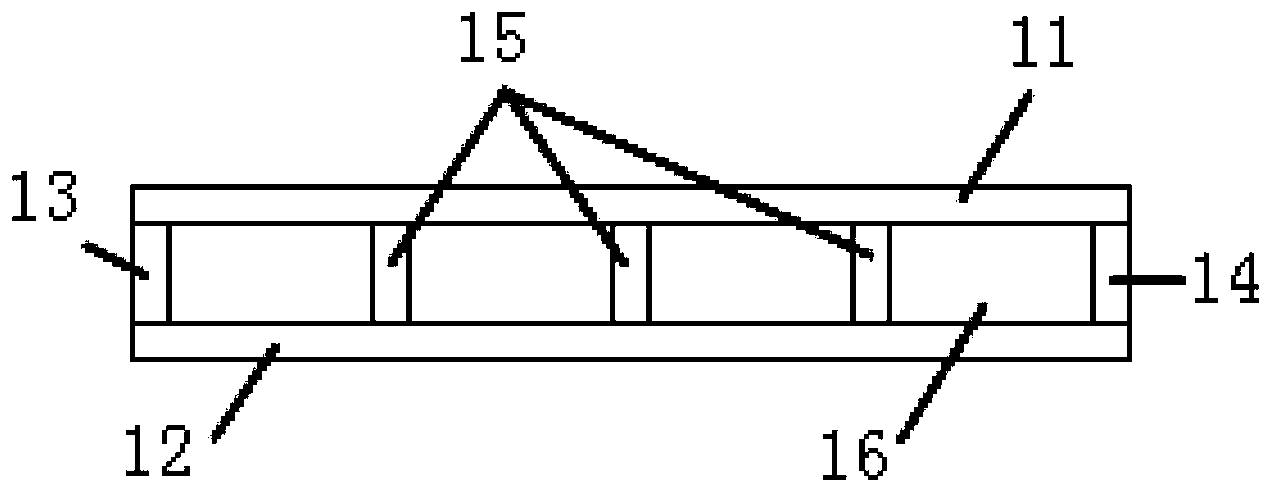

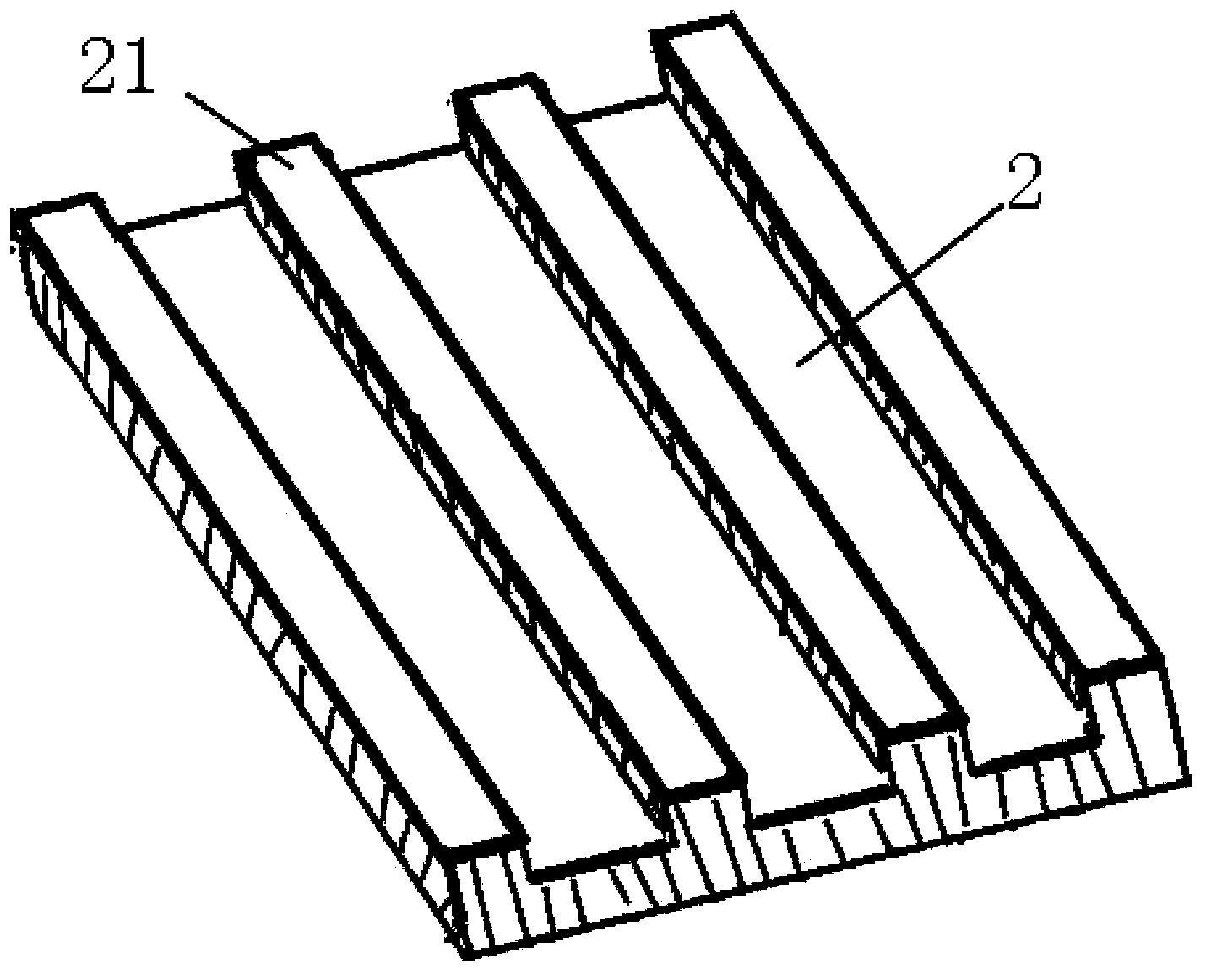

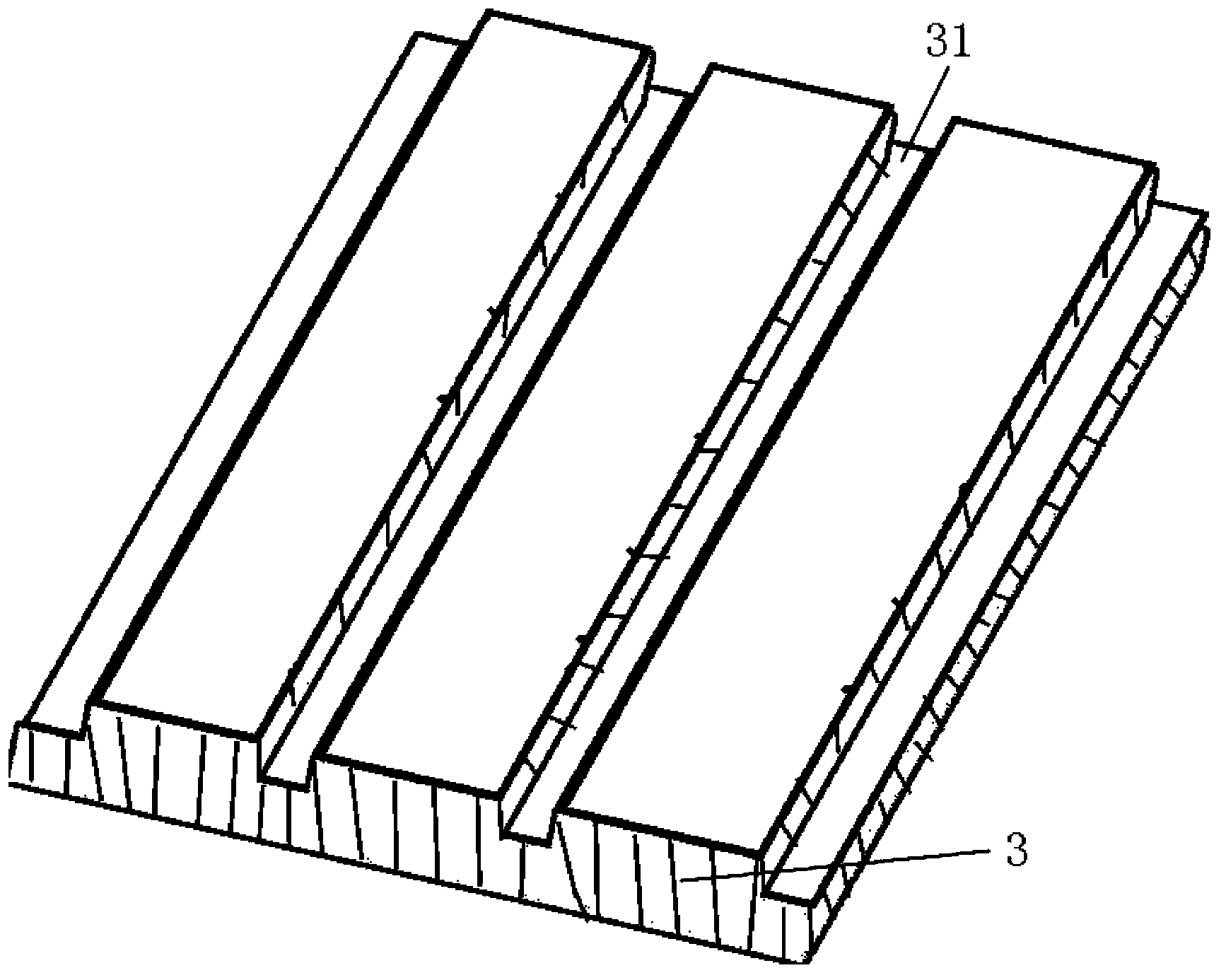

Ceramic flat membrane supporting body and production method thereof

ActiveCN103381338AImprove filtration efficiencyGuaranteed mechanical strengthSemi-permeable membranesSurface layerSlurry

The invention discloses a ceramic flat membrane supporting body and a production method thereof. The ceramic flat membrane supporting body is formed by two layers of flat membranes, the left lateral wall, the right lateral wall and at least a supporting column; the two layers of flat membranes, the left lateral wall and the right lateral wall form into a flat-pipe-shaped structure; the supporting column is arranged between the two layers of flat membranes; the flat membranes which are in asymmetric structures comprise surface layers of sponge hole structures and internal layers of finger-shaped hole structures; separation selectivity, permeation flux and mechanical strength of the flat membranes are high. The production method of the ceramic flat membrane supporting body comprises preparing slurry, producing dies through a phase inversion method, forming through a die pressing method and sintering. The production technology is easy and flexible, the costs are low, the dies are cheap, the replacing is convenient, a plurality of assemblies in different sizes can be formed at one time, and the production efficiency is high.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

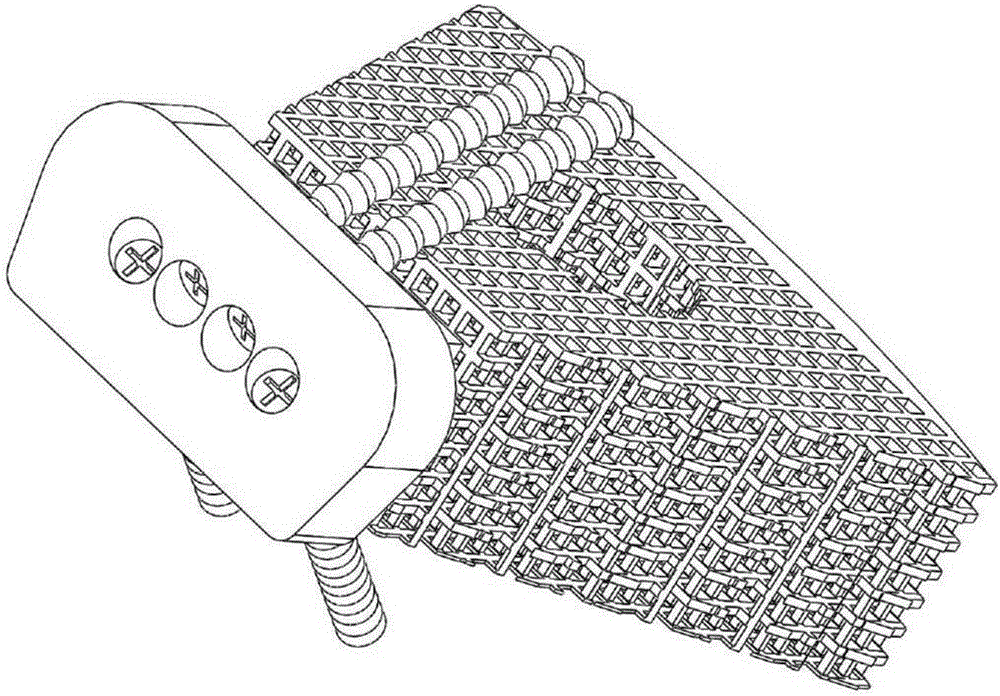

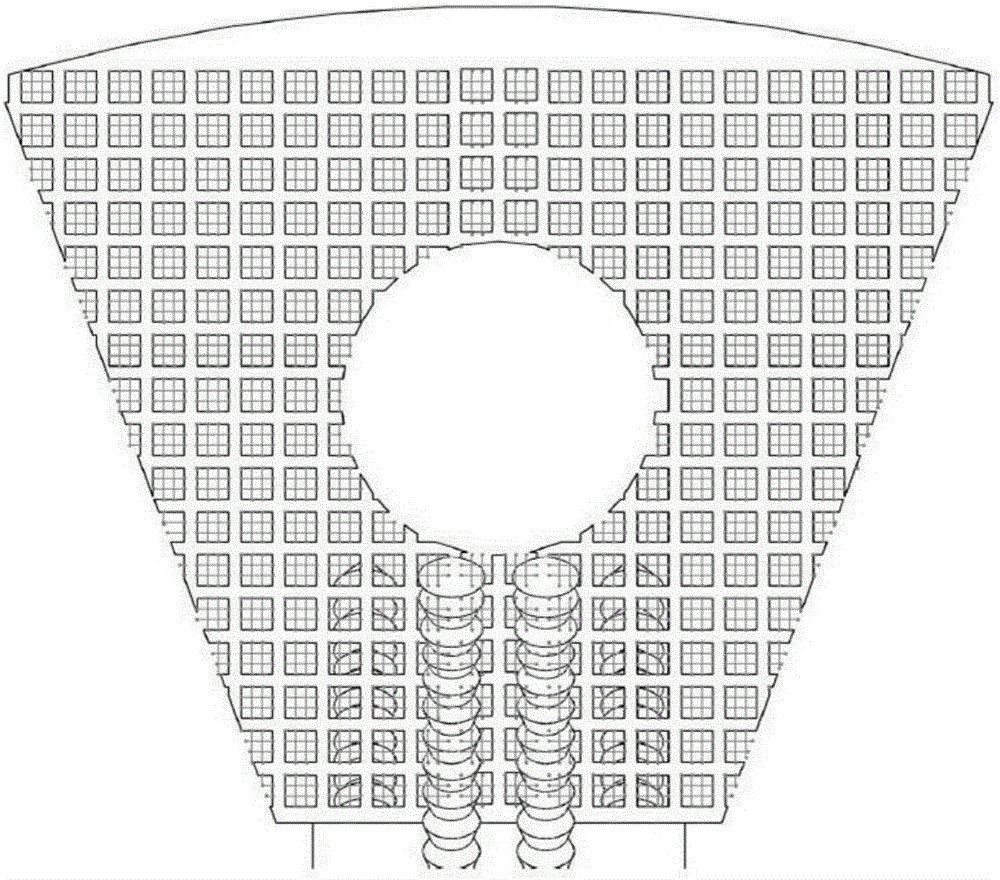

Porous metal cervical interbody fusion cage for directionally and slowly releasing rhBMP-2

ActiveCN105796214AMaintain mechanical strengthLow elastic modulusSpinal implantsBone tissueNatural bone

The invention discloses a porous metal cervical interbody fusion cage for directionally and slowly releasing rhBMP. The cervical interbody fusion cage is manufactured through the following process that firstly, a base body of the porous metal cervical interbody fusion cage is manufactured through the 3D printing technology; then a slow release system carrying rhBMP is injected into the porous metal cervical interbody fusion cage, cooling and drying are conducted, and then the porous metal cervical interbody fusion cage can be obtained. The manufactured cervical interbody fusion cage has the elasticity modulus similar to that of a natural bone, and can directionally and slowly release rhBMP, long-term and stable bone tissue ingrowth induction is achieved accordingly, the combination problem of a bone-material interface is solved, and osseointegration capacity is improved.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

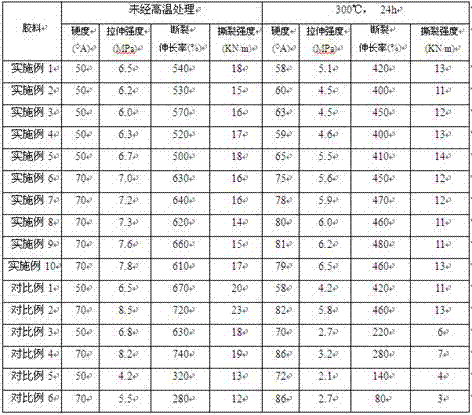

Heat-resistant high-temperature vulcanized silicone rubber and preparation method thereof

The invention relates to heat-resistant high-temperature vulcanized silicone rubber. The heat-resistant high-temperature vulcanized silicone rubber is prepared from, by weight, 100 parts of crude rubber, 10-100 parts of a reinforcing filler, 1-100 parts of a nano-scale heat-resistant filler, 1-100 parts of a micron-scale heat-resistant filler, 0.5-20 parts of a small-molecular heat-resistant agent, 3-15 parts of a structurized control agent, 1-10 parts of a surface-treated agent, 0.1-10 parts of a heat-resistant surface-treated agent and 0.1-10 parts of an internal deformable auxiliary. The heat-resistant high-temperature vulcanized silicone rubber is suitable for multiple product molding processes of mold pressing, extruding, injecting and the like, and high-temperature working devices of various shapes can be molded; the product is good in heat-resistant effect after vulcanization, hardness can be adjusted by synchronous adjustment of formulas and processes, use of different environments is met, good mechanical performance in long-time high-temperature environment can be sustained, working environment is protected, and stable operation of equipment is maintained.

Owner:浙江恒业成有机硅有限公司

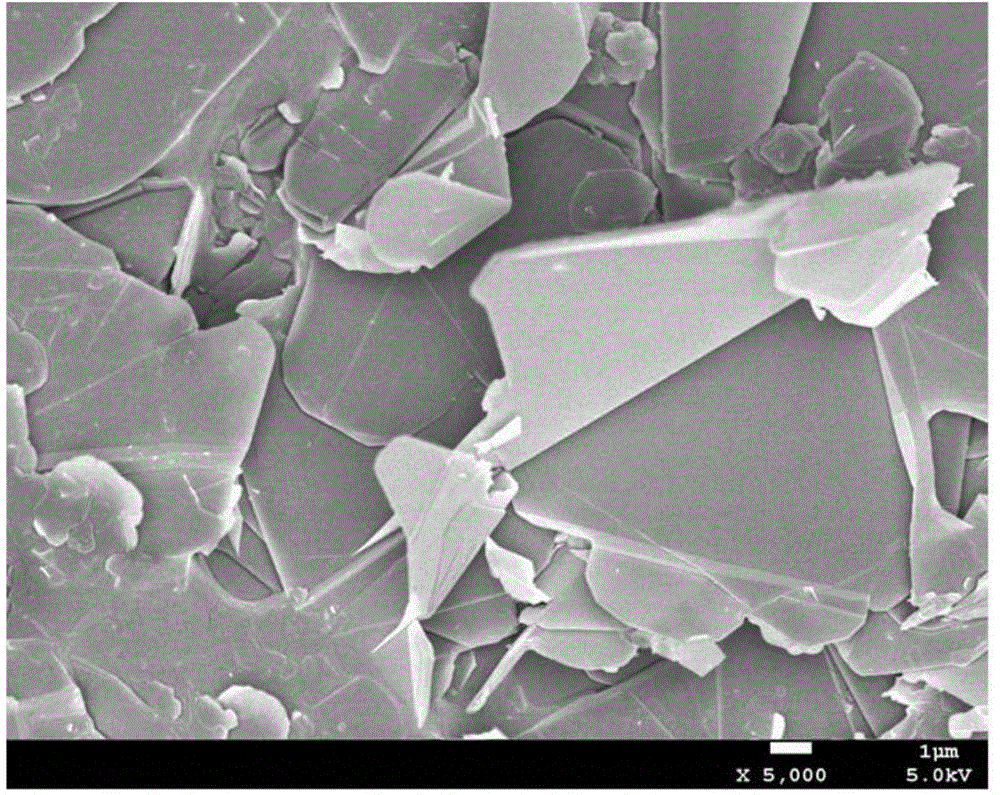

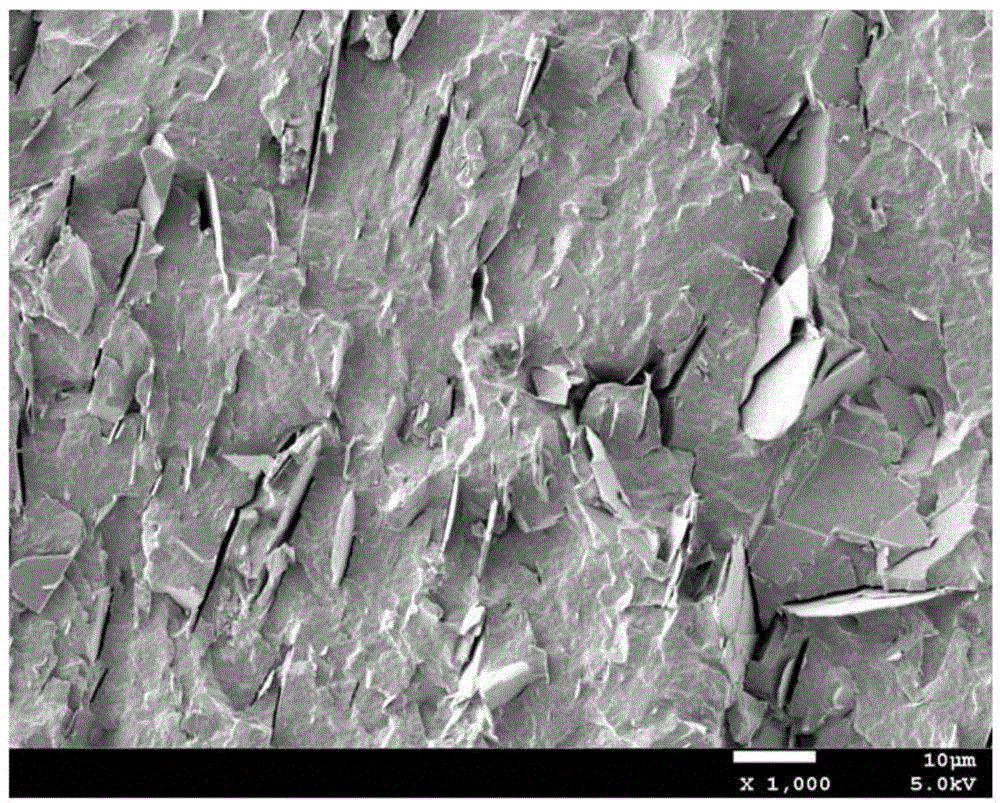

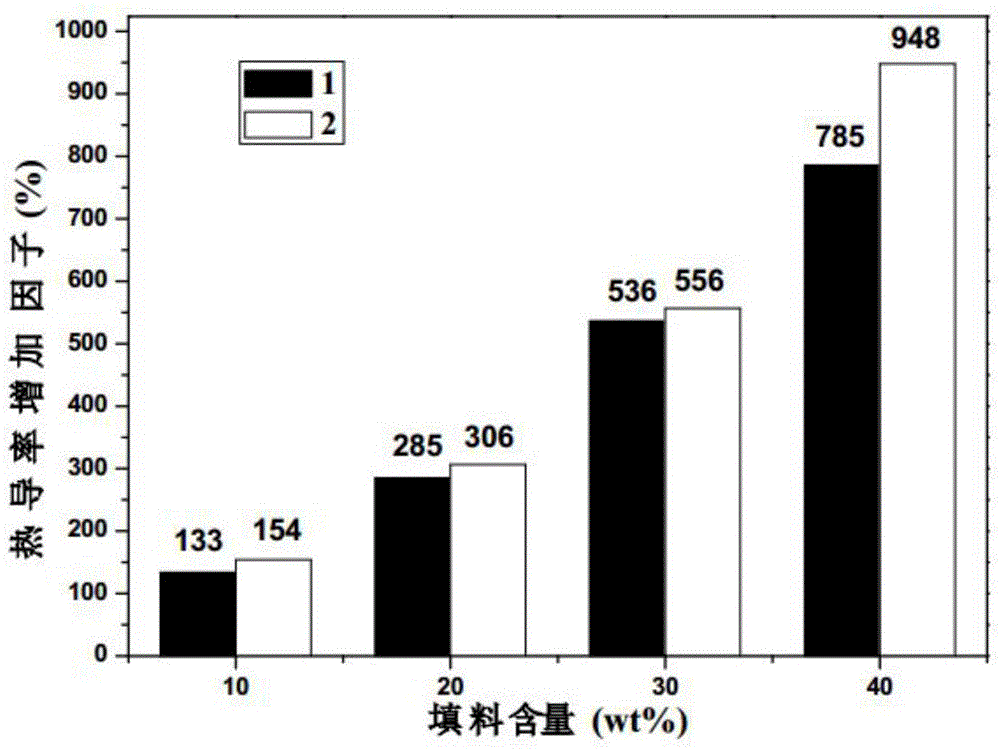

High thermal conductive and insulating polymer composite and preparing method and application thereof

The invention discloses a high thermal conductive and insulating polymer composite and a preparing method and application thereof. The preparing method is characterized in that 0.1-1.0 part of hexagonal boron nitride is evenly stirred and mixed with 50-1000 parts of organic solvent, and is added into an ultrasonic cleaner with the power ranging from 100 w to 1000 w or an ultrasonic cell disruptor, ultrasonic treatment is carried out for 4 hours to 72 hours, and mixed liquor is obtained; standing is carried out on the mixed liquor for 24 hours to 72 hours, after filtering or rotary evaporating is carried out, a product is cleaned for twice to five times by using acetone, and a boron nitride nano-sheet with the higher yield is obtained; 60-90 parts of a polymer matrix and 40-10 parts of the boron nitride nano-sheet are added into a high-speed blender mixer, the temperature ranges from 200 DEG C to 300 DEG C, the rotary speed ranges from 30 rpm to 60 rpm, mixing is carried out for 5 minutes to 10 minutes, and granulates are extruded by a screw extruder; the high thermal conductive and insulating polymer composite can be obtained through smelting and forming. According to the high thermal conductive and insulating polymer composite, the mechanical property can be maintained, and meanwhile the thermal conductivity is improved maximally.

Owner:SICHUAN UNIV

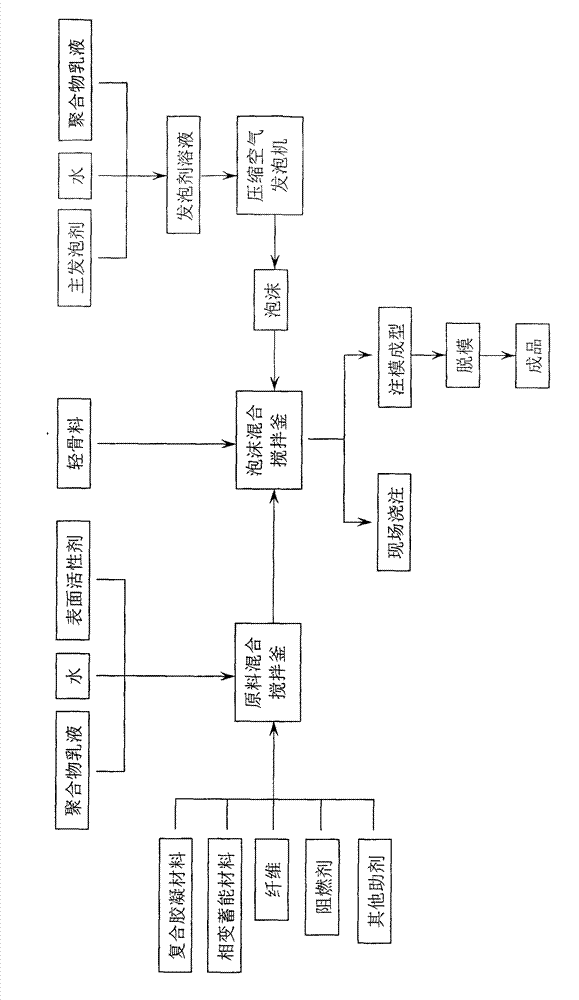

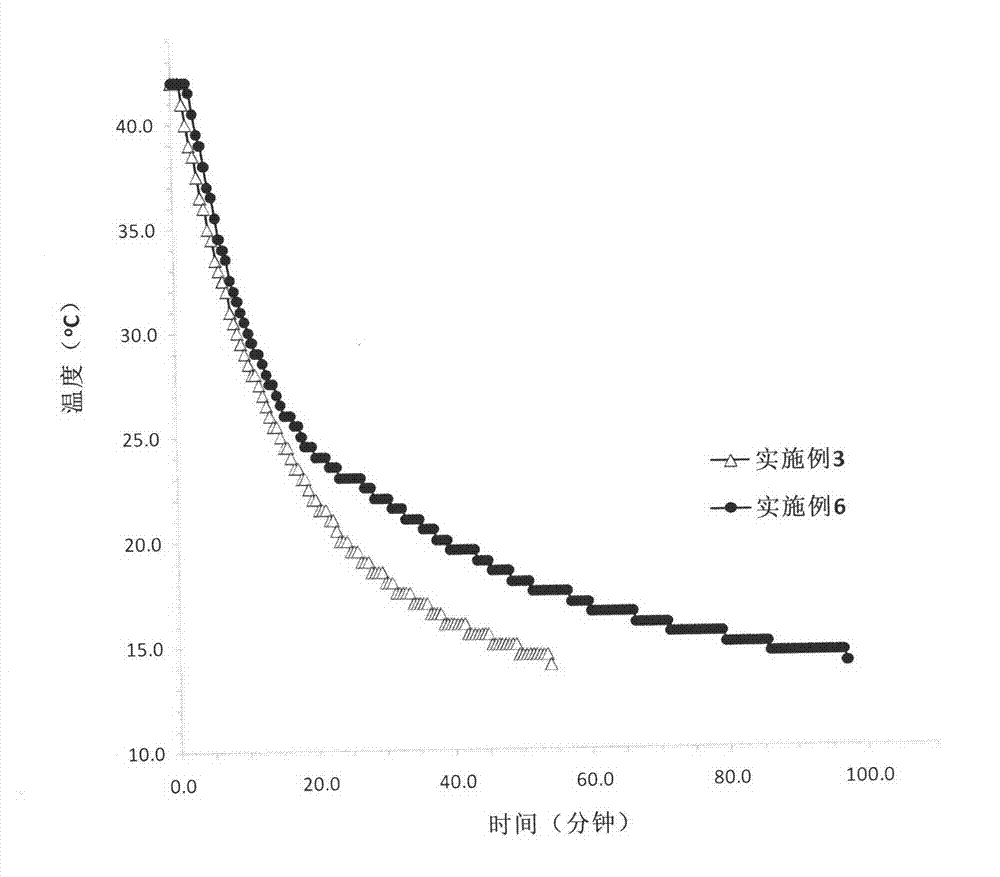

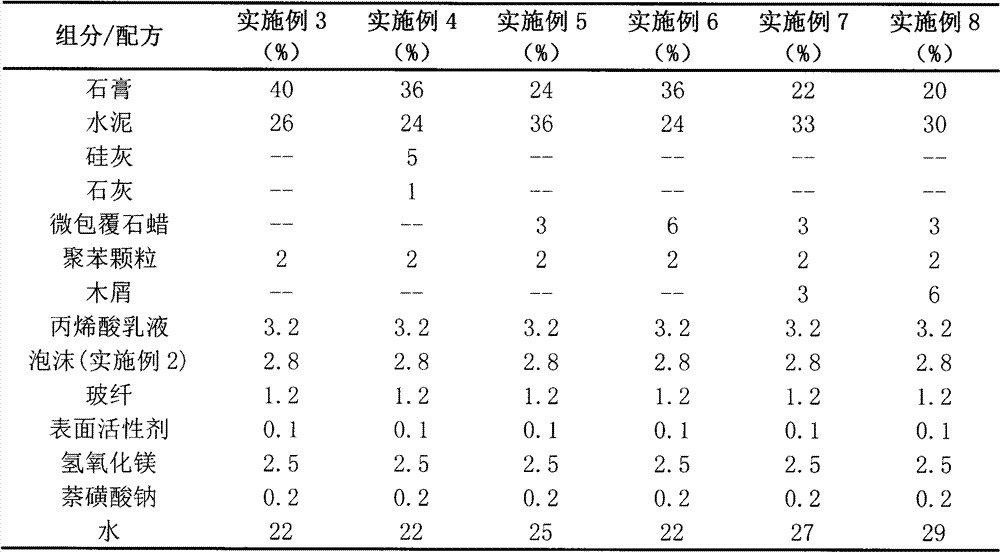

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

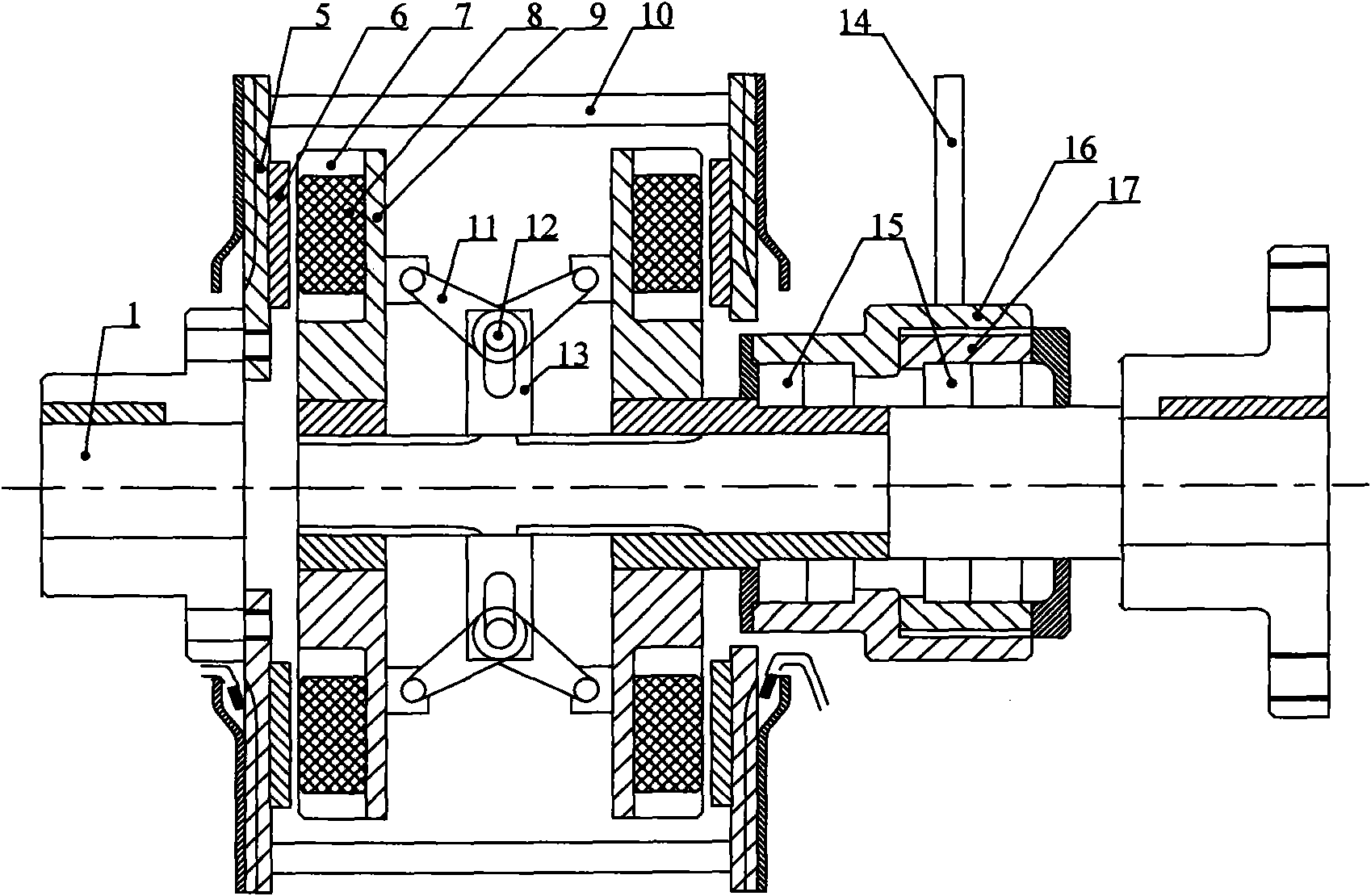

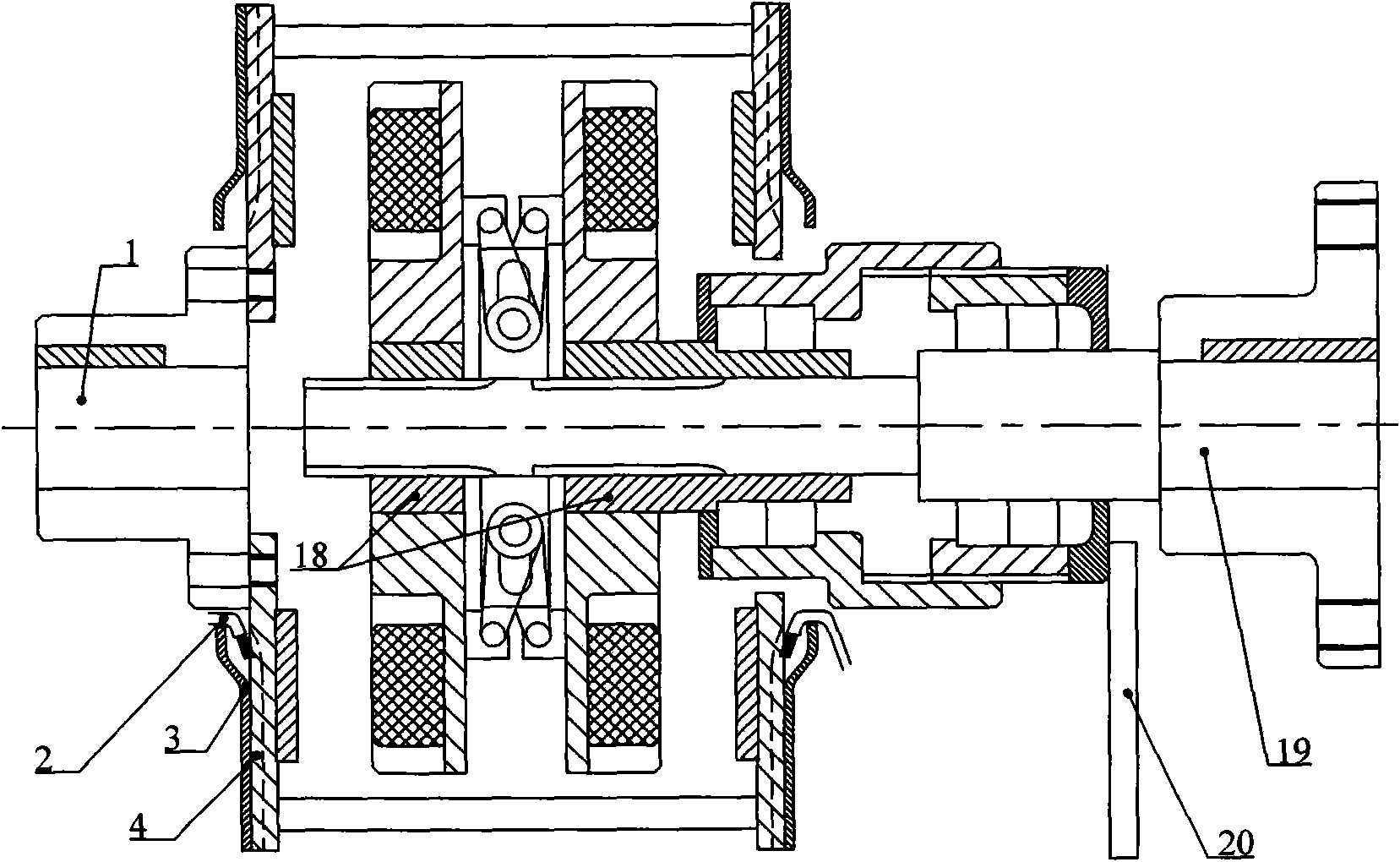

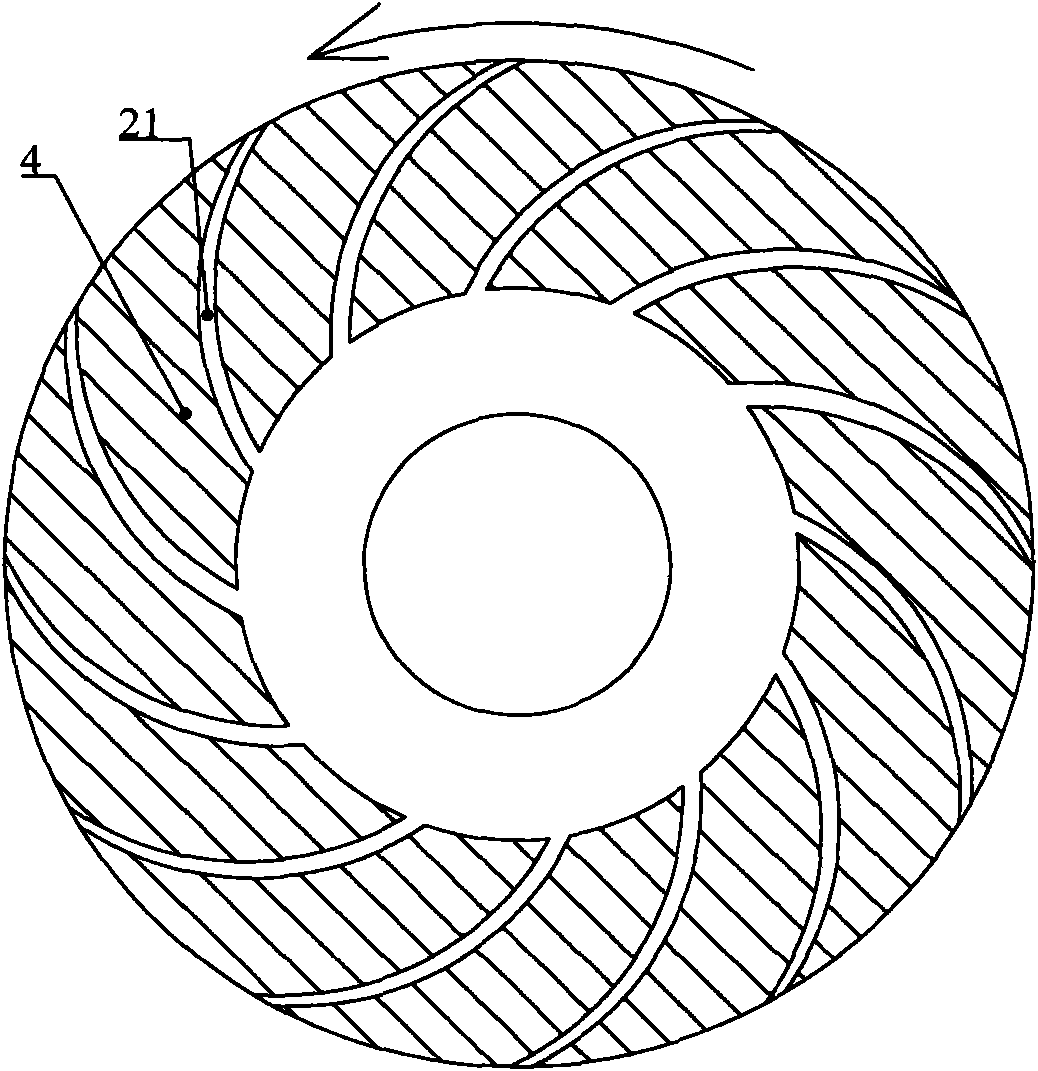

Disc water-cooling permanent magnet eddy current speed regulation device

InactiveCN101982932AAdjustable sizeImplement resizingAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorElectrical conductor

The invention discloses a disc water-cooling permanent magnet eddy current speed regulation device which comprises conductor rotators and permanent magnet rotors and is characterized by also comprising an air gap adjustment mechanism and a water-cooling mechanism, wherein the permanent magnet rotors are arranged between the conductor rotators, the air gap adjustment mechanism is connected with the conductor rotators, and the water-cooling mechanism is arranged on the conductor rotators. In the invention, change of the included angle between connecting bars and the up and down sliding of connecting bar shaft pins in a sliding rail are utilized to adjust distance so as to ensure that the distances between two pairs of permanent magnet rotors and conductor rotators interacting with each other are changed equally, and the structure of the speed regulation device is simple, thereby being convenient to process and install; water piloting ribs, the negative pressure principle and the centrifugal force effect are utilized, water can be piloted by a flume to evenly flow past the back iron surfaces of conductors and then thrown away along with the rotation of the conductor rotators from theoutboards of the conductor rotators, and heat quantity is brought away, thus cooling effect can be obtained; and when a main water supply system has faults, a buffer tank is started to continue supplying water until the faults are removed, thus the normal operation of the device can not be influenced by the faults of the water supply system.

Owner:南京大寰控制系统有限公司 +1

Low-temperature halogen-free lead-free solder paste

InactiveCN102990242AStir wellLow melting pointWelding/cutting media/materialsSoldering mediaRare-earth elementSlag (welding)

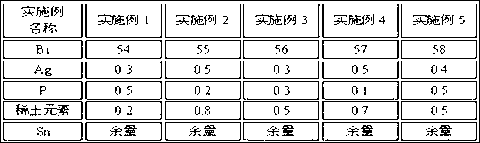

The invention relates to a low-temperature halogen-free lead-free solder paste. The solder paste is mixed by Sn-Ag-Bi-based lead-free solder powder added with P or rare earth elements and a rosin-based soldering flux. The soldering flux is basically composed of, by weight, 30-45% of rosin resin, 2-10% of an organic acid activator, 3-5% of a thixotropic agent, 2-5% of a corrosion inhibitor, 3-5% of a surfactant and the balance solvents. The solder paste has the advantages that the welding temperature is low, slag is reduced, and the solder paste is suitable for manual welding and printing welding with poor thermal shock resistance.

Owner:郴州金箭焊料有限公司

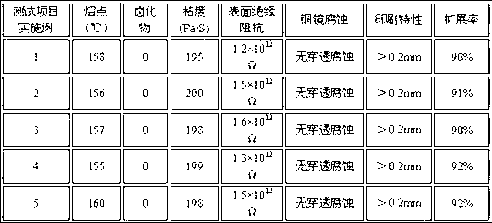

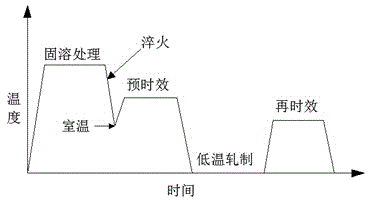

Strain aging method for improving mechanical properties of aluminum alloy

The invention discloses a strain aging method for improving the mechanical properties of aluminum alloy. The strain aging method comprises the following steps: the aluminum alloy is subjected to the solution treatment for 20-60 min at 520-560 DEG C; the aluminum alloy material after the solution treatment is water-cooled and quenched to room temperature; the aluminum alloy is subjected to the pre-aging treatment for 10-30 min at 150-180 DEG C so that the aluminum alloy material is in an underaged state; the aluminum alloy material after the pre-aging treatment is immersed in liquid nitrogen for 20-30 min and then is subjected to the multi-pass low-temperature rolling; finally, the rolled aluminum alloy material is subjected to the low-temperature reaging treatment for 85-100 hours at 100-130 DEG C so as to further strengthen the aluminum alloy. According to the invention, the strain aging method effectively improves the tensile strength and yield strength of aluminum alloy, is simple in process, easy to operate and low in cost, and has good generalizability.

Owner:CHONGQING UNIV

Backlight module

InactiveCN102606960AImprove qualityGuaranteed mechanical strengthMechanical apparatusProtective devices for lightingElastomerLuminous intensity

The invention provides a backlight module. The backlight module comprises a back plate, a light guide plate arranged in the back plate, and a plurality of elastic bodies mounted on the back plate, wherein the back plate includes a bottom plate, and a plurality of side plates vertically connected at the periphery of the bottom plate; the light guide plate includes a bottom surface facing the bottom plate, a top surface away from the bottom plate, and a plurality of side surfaces connected between the bottom surface and the top surface; the plurality of elastic bodies are respectively mounted on the three side plates of the back plate, and butt against the three side surfaces of the light guide plate; and the contact surface between the elastic bodies and the side surfaces of the light guide plate is an arc-shaped surface or a spherical surface. The backlight module provided by the invention can ensure the mechanical strength of the light guide plate by fixing the light guide plate in the back plate through the elastic bodies between the side plates of the back plate and the light guide plate without processing the periphery of the light guide plate by grooving, embossing and so on, and can supply a certain buffer space to prevent extrusion deformation of the light guide plate due to thermal expansion in the prior art, thereby ensuring the luminous intensity and uniformity and reducing the cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

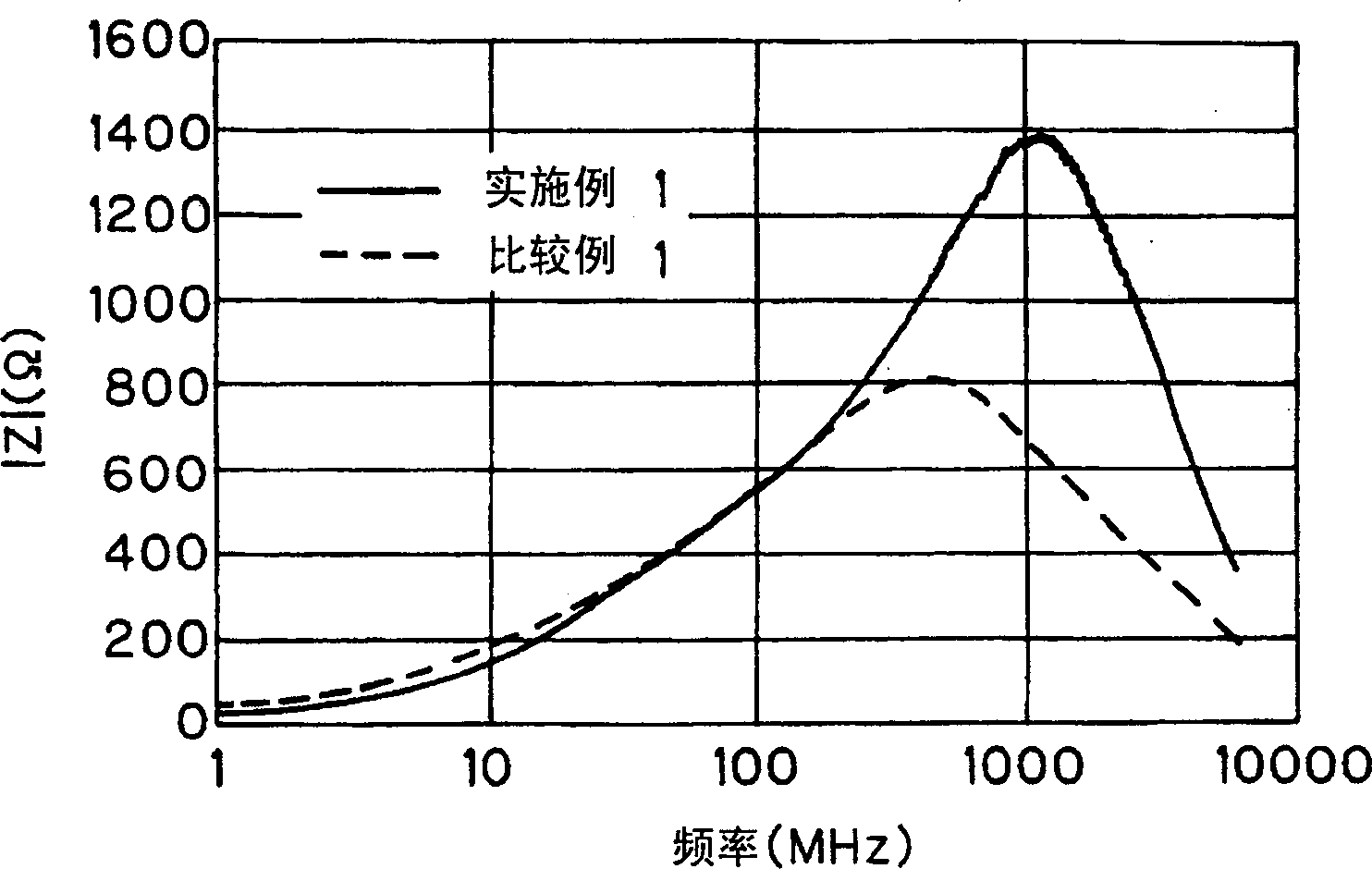

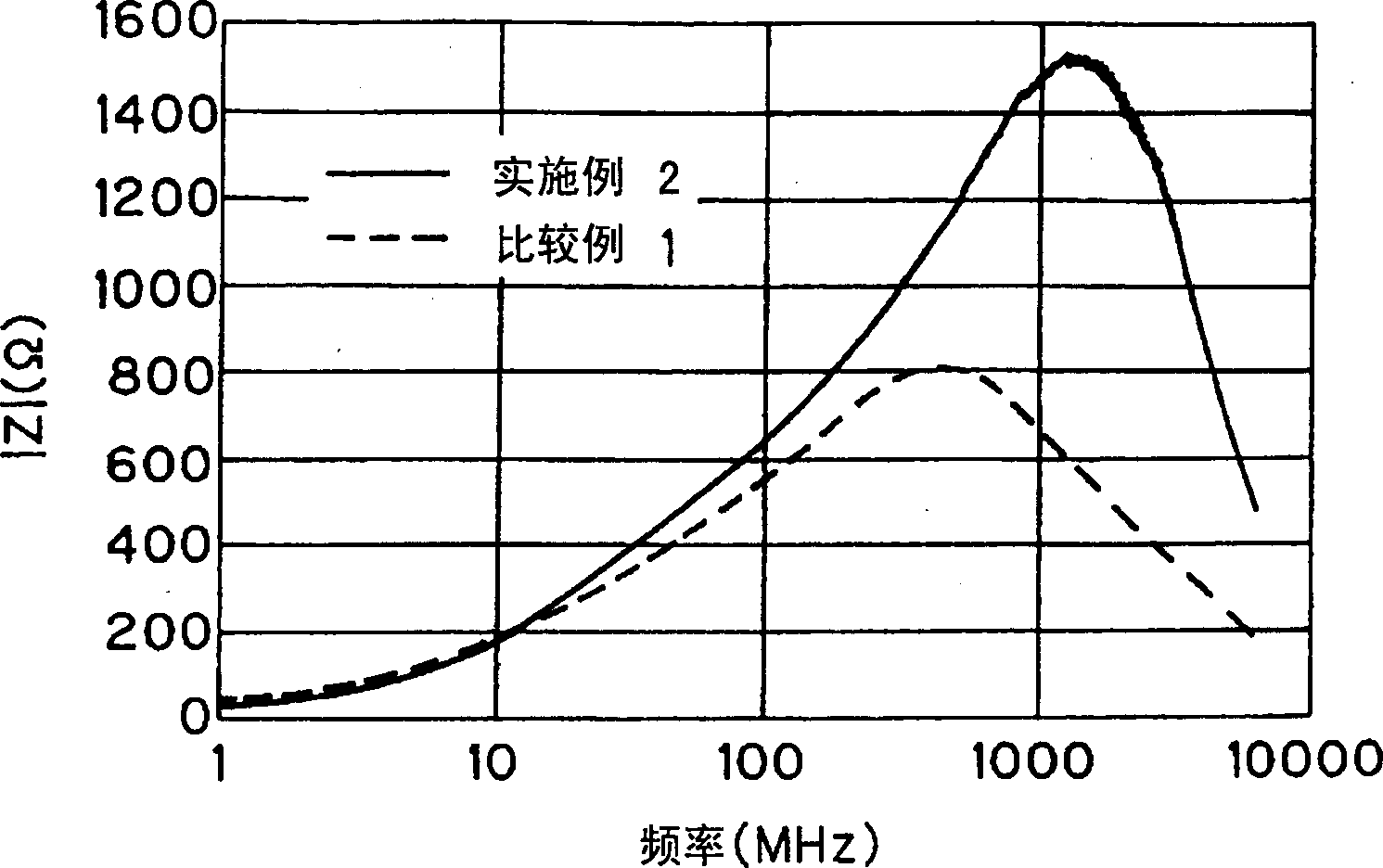

Ceramic electronic component and manufacturing method thereof

InactiveCN1448968ALow dielectric constantImprove reliabilityMultiple-port networksFixed capacitor dielectricCeramic sinteringMetallurgy

The invention provides a ceramic electronic component having the low dielectric constant of a ceramic sintered body and excellent impedance properties in a GHz zone and capable of obtaining high impedance properties in a wide frequency range, and its manufacturing method. This ceramic electronic component is formed by forming a green compact which includes an electrode therein with a ceramic compound comprising a ceramic raw material, a binder and a spherical or granular combustible material having adhesiveness to the binder. The green compact is fired to form the ceramic sintered compact including the electrode and containing about 35 to 80 volume percent pores. The pores of the ceramic sintered compact are filled with resin or glass.

Owner:MURATA MFG CO LTD

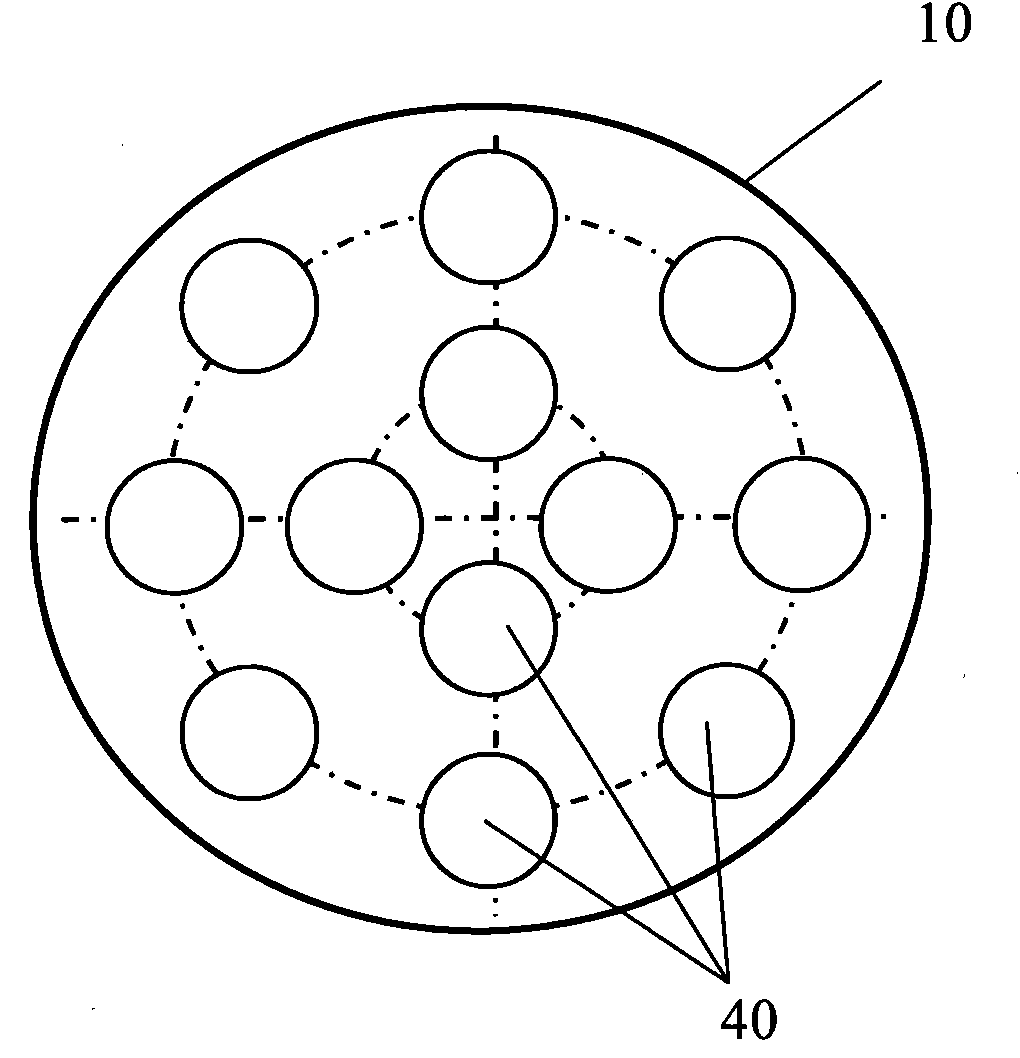

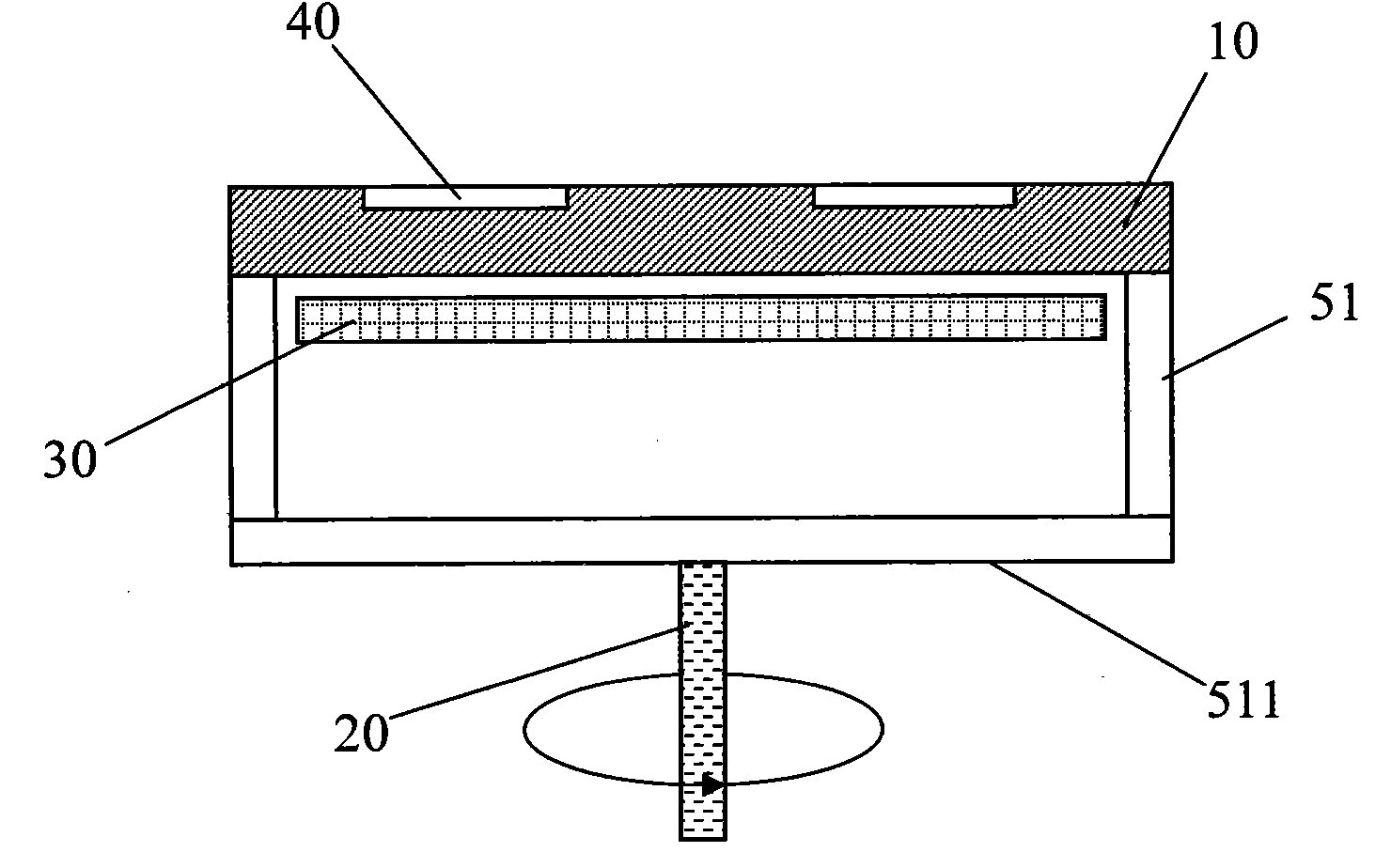

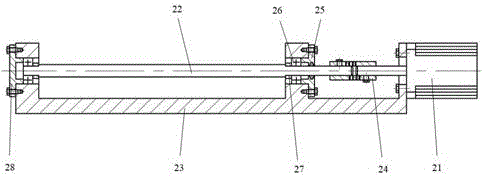

Epitaxial wafer tray and support and rotation connecting device matched with same

ActiveCN101922042AUniform gas concentrationReduce replacementSemiconductor/solid-state device manufacturingFrom chemically reactive gasesDrive shaftEngineering

The invention relates to an epitaxial wafer tray for an MOCVD (Metal Organic Chemical Vapor Deposition) reaction cavity and a support and rotation connecting device matched with same. When the tray is mechanically loaded and unloaded, and a rotating shaft projecting outward from the center of the bottom of the tray is inserted into a counter bore on the top of a drive shaft perpendicular to the rotating shaft. Respectively arranged contact surfaces parallel to the surface of the tray or contact surfaces on the corresponding side face are used for supporting the tray, and the friction transmission between the contact surfaces is used for driving the tray to rotate when the drive shaft rotates. The friction transmission is changed into contact transmission by arranging an axial locating slot and a locating key, the rotation of the tray is ensured to be consistent with that of the drive shaft, and the security of the tray under middle-high speed long-term rotation is improved. The projecting tray rotating shaft is easy to process the surfaces contacted by friction, the entire thickness of the tray is not increased under the condition of ensuring the mechanical strength of the corresponding part on the tray, and the heat capacity of the tray is reduced. Thus, the time required by heating and cooling the tray is shortened, and the production efficiency is improved, which is beneficial to quick temperature adjustment and control required by epitaxial reactions.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

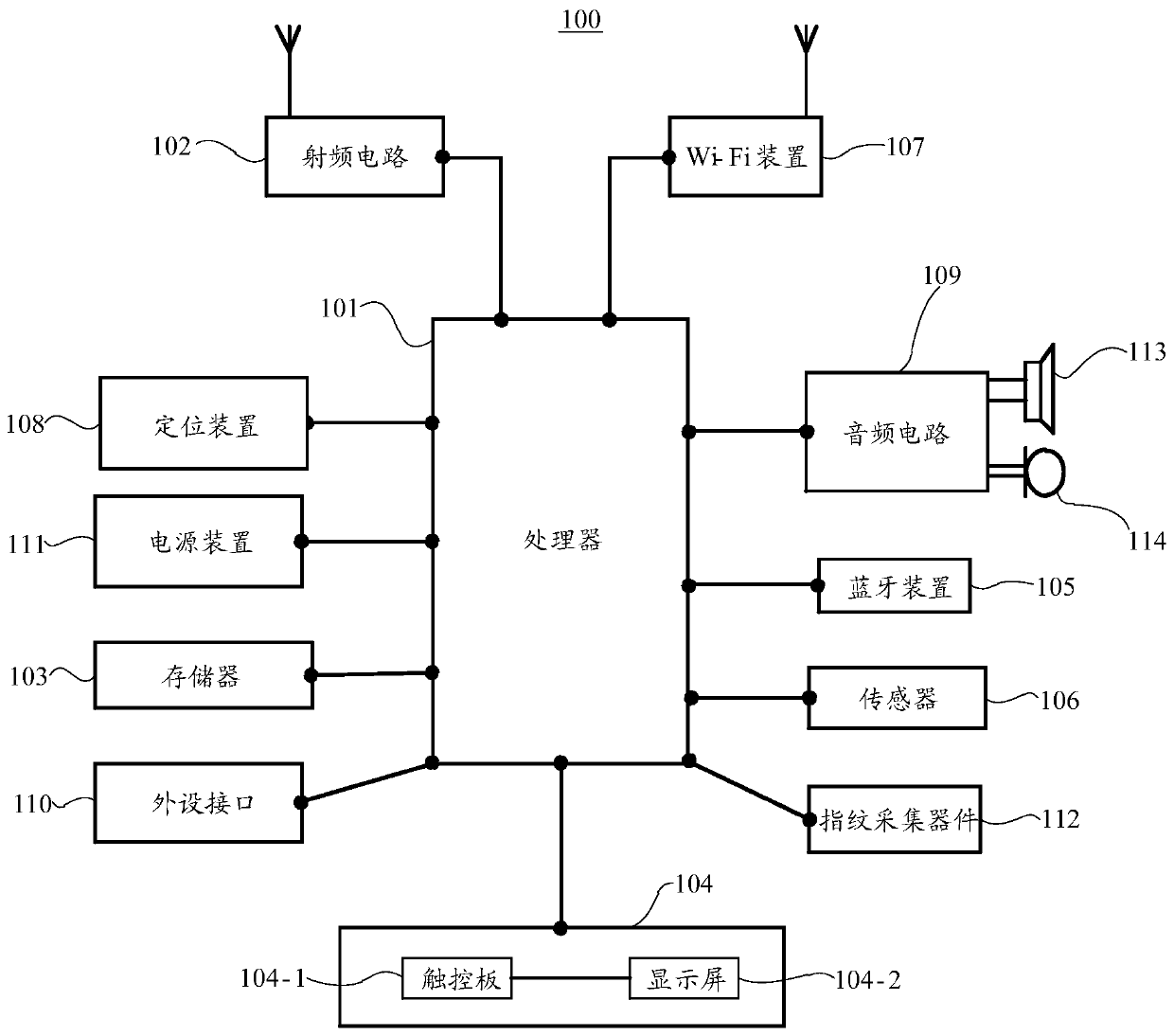

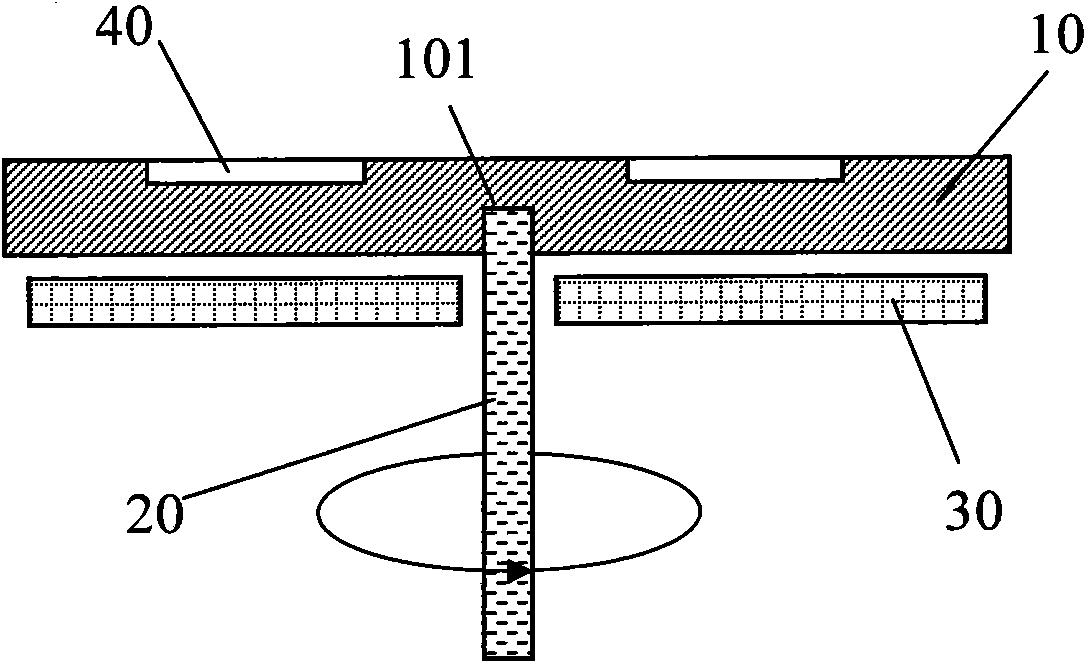

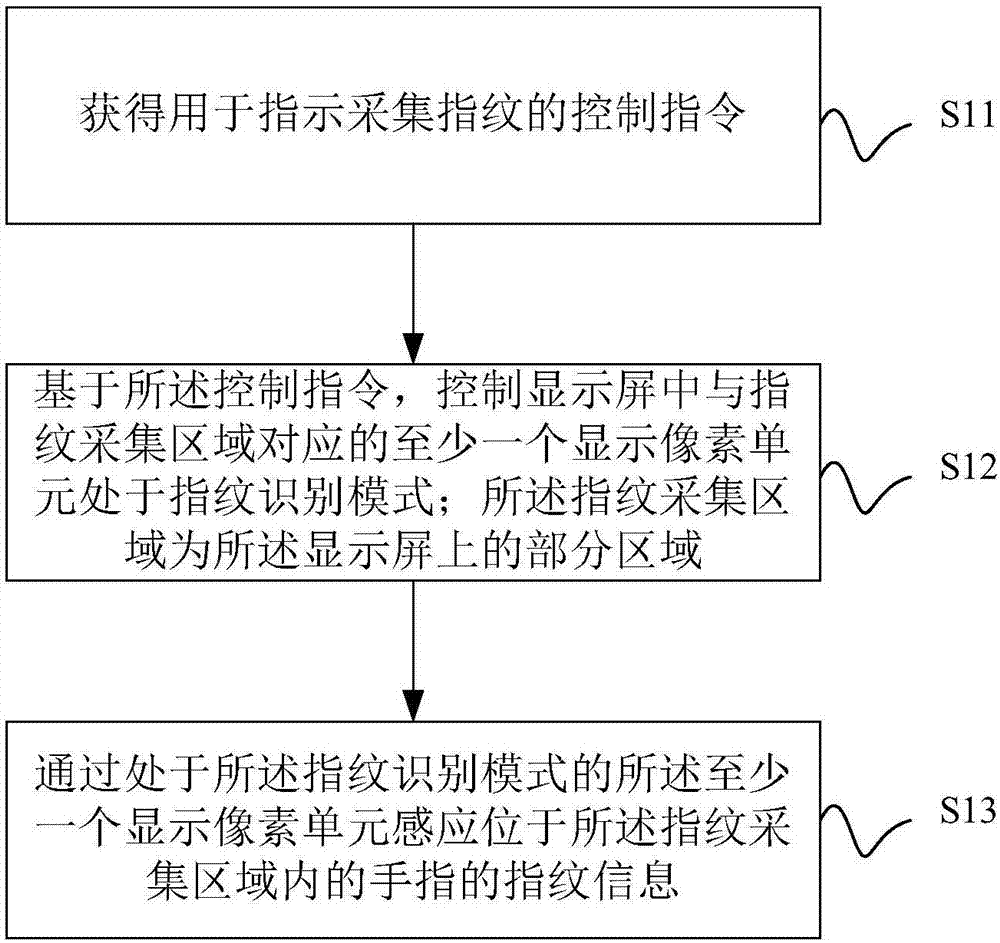

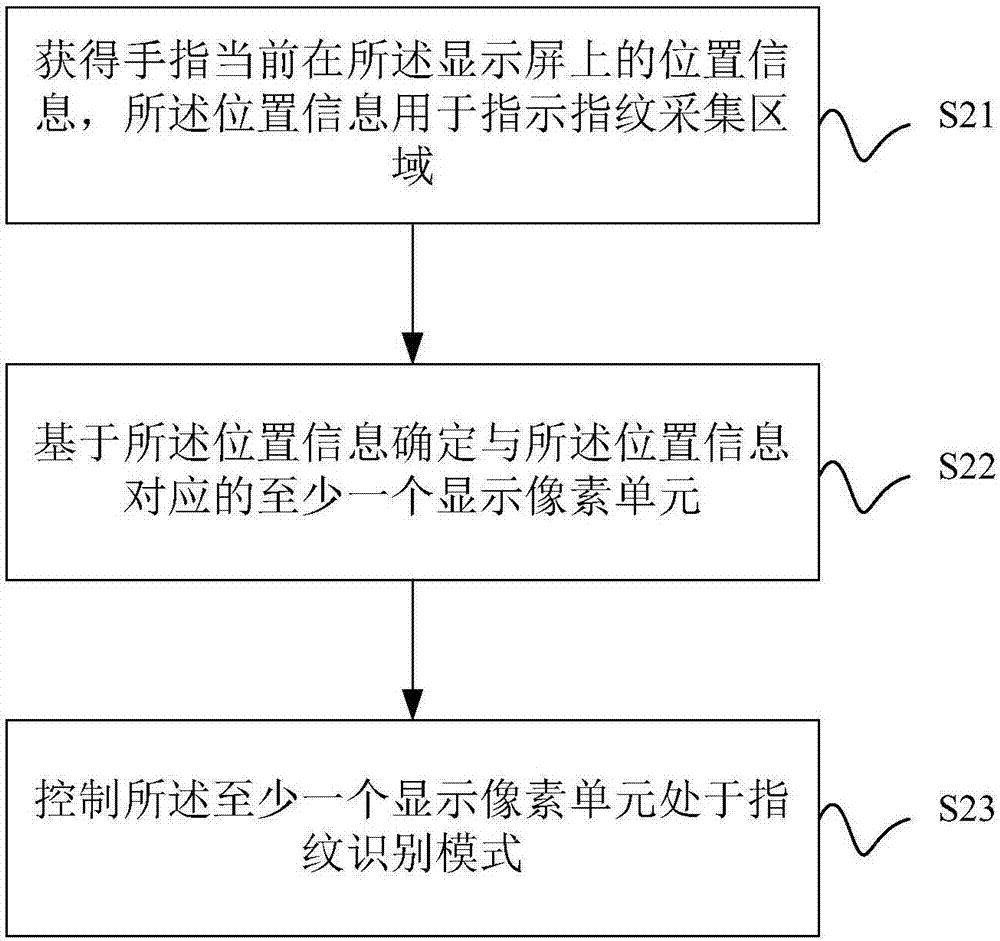

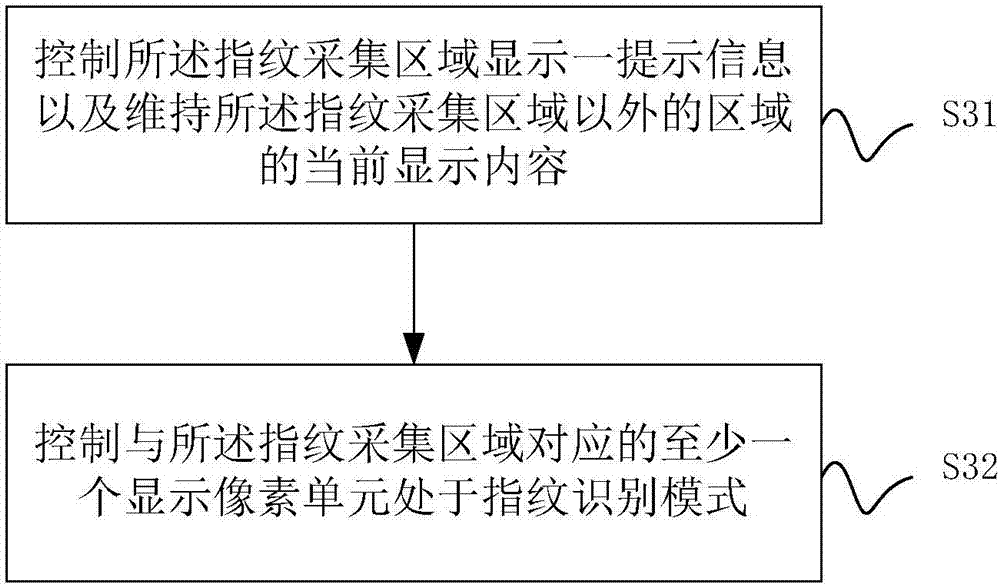

Fingerprint detection method and electronic device

ActiveCN106874892AGuaranteed mechanical strengthSimple preparation processPrint image acquisitionInput/output processes for data processingComputer graphics (images)Computer vision

The invention discloses a fingerprint detection method and an electronic device. The fingerprint detection method comprises the following steps: obtaining a control instruction for indicating to collect fingerprints; executing the control instruction and controlling at least one display pixel unit corresponding to a fingerprint acquisition area in a display screen to be in a fingerprint identification mode, wherein the fingerprint acquisition area is a partial region in the display screen; and sensing fingerprint information of fingers in the fingerprint acquisition area through the at least one display pixel unit in the fingerprint identification mode. According to the technical scheme, the at least one display pixel unit corresponding to the fingerprint acquisition area in the display screen is reused to carry out fingerprint identification, and the fingerprint information of the fingers in the fingerprint acquisition area is sensed through the at least one display pixel unit in the fingerprint identification mode, so that the display screen no longer needs to be bored to install a fingerprint identification module additionally, mechanical strength of the display screen is ensured, production process is simple and production cost is low.

Owner:LENOVO (BEIJING) CO LTD

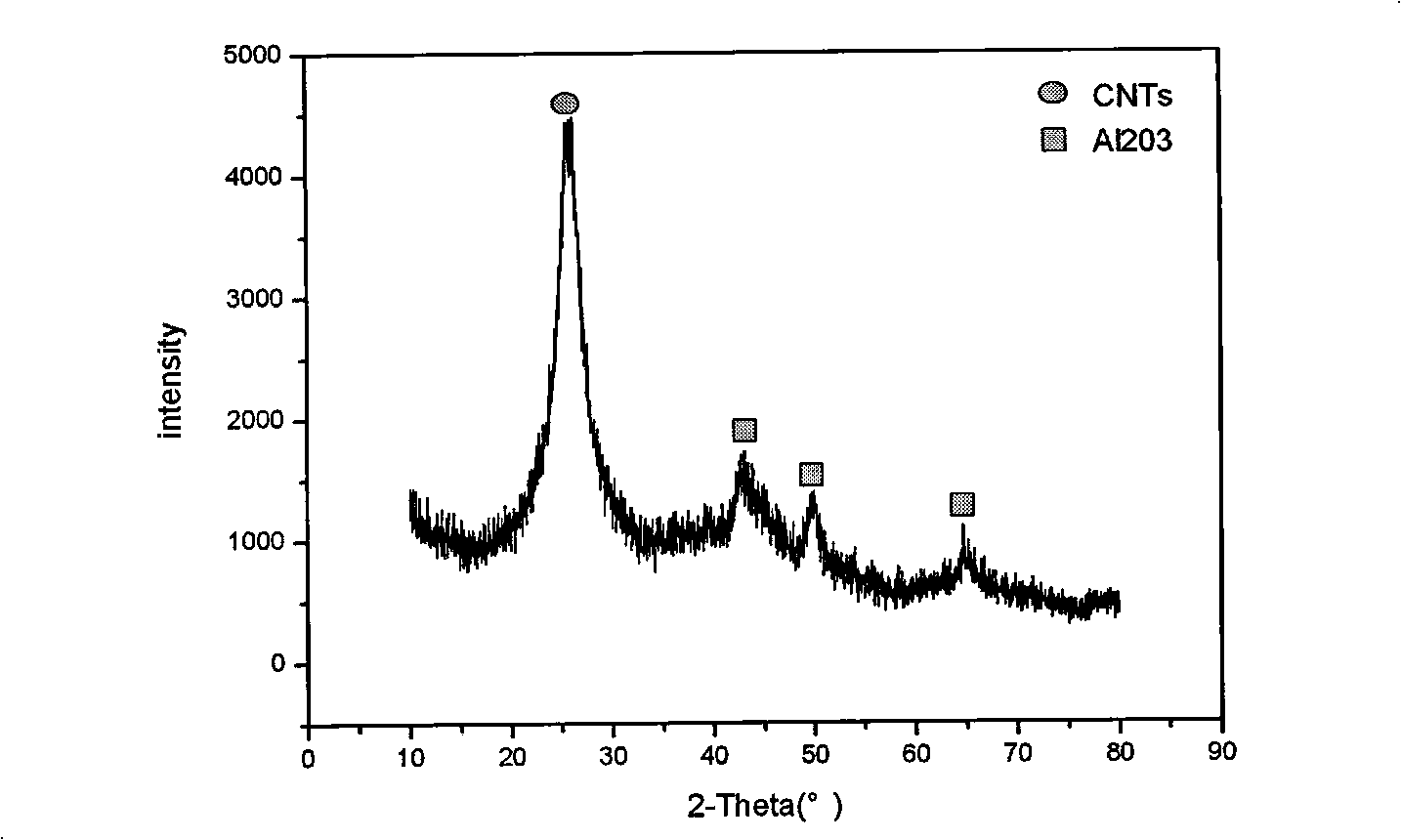

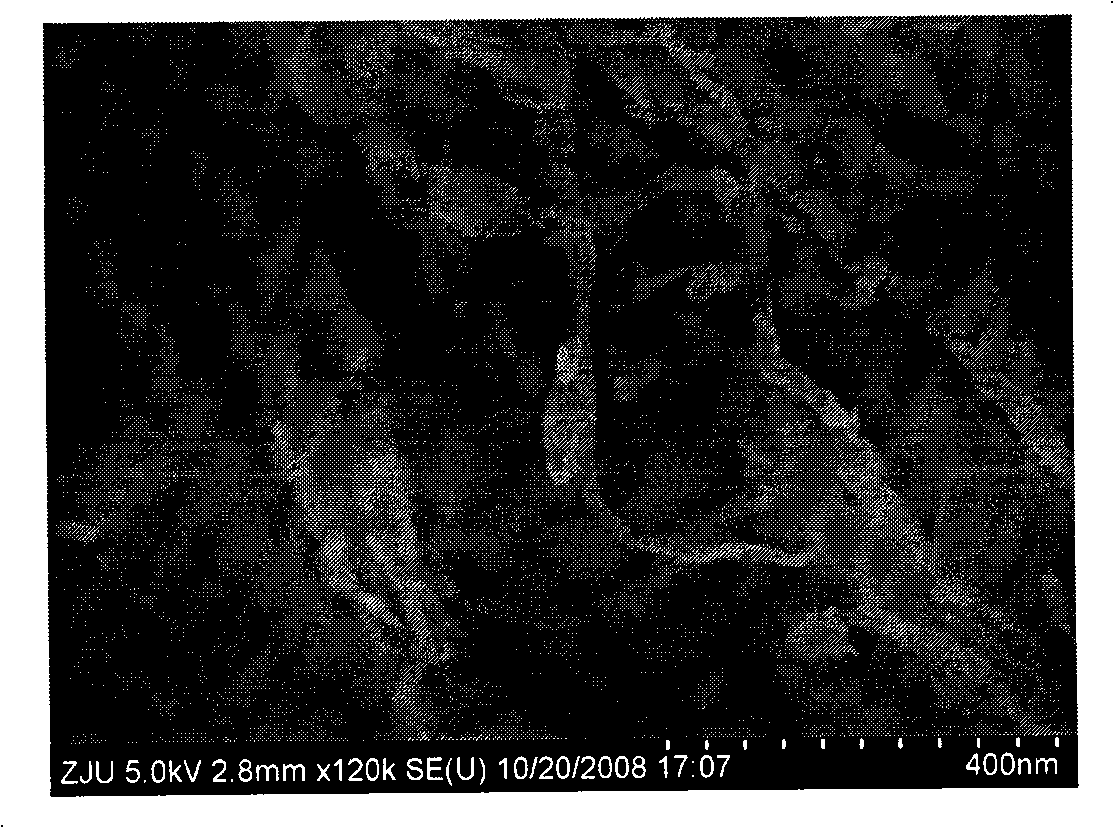

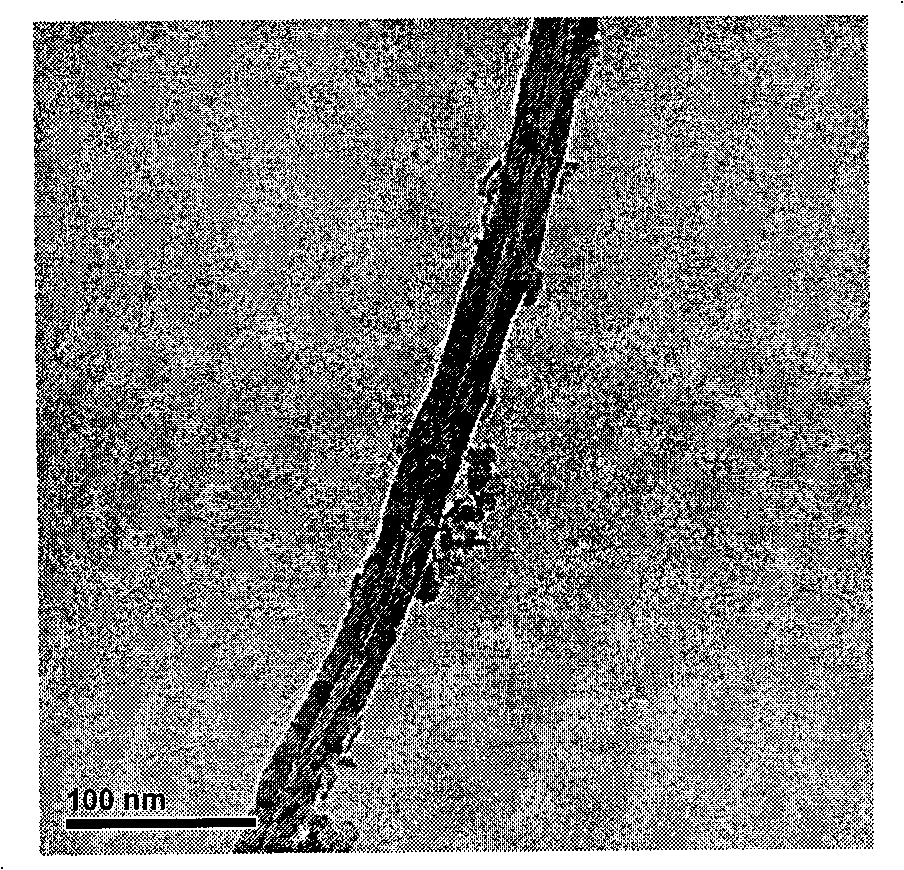

Catalyst for removing nitrogen oxide and organic pollutant discharged in burning and method for preparing same

InactiveCN101513612AGuarantee structureExcellent low temperature SCR characteristicsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChlorobenzeneCarbon nanotube

The invention discloses a catalyst for removing nitrogen oxide and organic pollutant discharged in burning, comprising carbon nanotube and alumina as the carrier and manganese oxide as the active ingredient, the active ingredient in the catalyst accounts for 1 to 10% of the total catalyst mass. The catalyst is prepared by a solvent-thermal method. In the inventive catalyst, CNTs and Al2O3 are simultaneously used as the carrier for the first time, thus the catalyst has big specific surface area and high mechanical strength, at the same tine the temperature of the selective catalytic reaction is reduced, 94.2% of chlorobenzene removing ratio can be obtained at the temperature of 150 DEG C, 88.8% of NOx removing ratio is obtained at the temperature of 200 DEG C. The catalyst can be used for removing the nitrogen oxide (NOx)and dioxin organic pollutant discharged in the high-temperature process in the fire coal power plant, metallurgy industry, garbage burning and the like.

Owner:ZHEJIANG UNIV

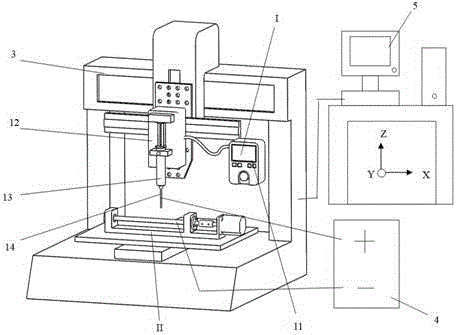

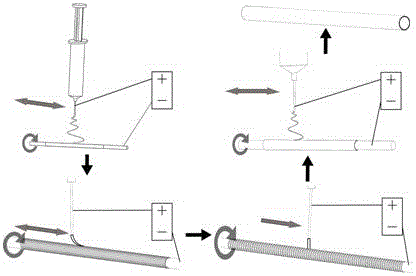

Layered intravascular stent forming system and method based on electrostatic direct writing and electrospinning technology

ActiveCN105839204AGuaranteed mechanical strengthHigh porosityStentsFilament/thread formingFiberSpinning

The invention discloses a layered intravascular stent forming system and method based on an electrostatic direct writing and electrospinning technology. The system comprises a feeding system, a spinning fiber collection system, a three-axis movement platform, a power source and a computer control system. The feeding system drives extrusion of materials through a micro pump execution mechanism. The spinning fiber collection system receives electrospinning fire through rotation of a stepping motor and drive of the three-axis movement platform. The three-axis movement platform drives the spinning fiber collection system to receive electrospinning fiber. The power source forms a high voltage electric field between an injector needle and a core shaft, and electrospinning and electrostatic direct writing processes are achieved. The computer control system drives the three-axis movement platform to move. The advantages of electrostatic direct writing and advantages of electrospinning are combined, electrospinning and the electrostatic direct writing are carried out successively, and finally an intravascular stent of a three-layer structure with good mechanical performance is formed.

Owner:SHANGHAI UNIV

Environmental-friendly recyclable basalt fiber and jute fiber composite plate for automotive interiors and production method thereof

ActiveCN102145553AGuaranteed mechanical strengthGuaranteed molding effectLaminationLamination apparatusEnvironmental resistanceSurface layer

The invention relates to an environmental-friendly recyclable basalt fiber and jute fiber composite plate for automotive interiors and a production method thereof. The environmental-friendly recyclable basalt fiber and jute fiber composite plate is produced by manufacturing a felt by combining a surface layer with a core layer and then carrying out hot-press forming. The core layer is manufactured by lapping and needling two natural fibers, i.e. basalt fibers and jute fibers, and mixtures of two chemical fibers, i.e. polyster fibers and polypropylene fibers; and the core layer comprises the following components in percentage by weight: 10%-30% of the basalt fibers, 10%-30% of the jute fibers, 20%-30% of the polyster fibers and 30%-40% of the polypropylene fibers. The invention has the advantages of low density, light weight, low cost, high strength, good toughness, large deformation, high safety, environment friendliness, recyclability, and the like.

Owner:CHANGCHUN BOCHAO AUTOMOTIVE PARTS CO LTD

Method and apparatus for restoring automobile metal plate work

The method of repairing plate part of automobile includes setting sucking disc in the notched part, pumping out air from the sucking disc, drawing the sucking disc to draw out the notched part and knocking to restore the original shape. Compared with available repairing method, the method of the present invention has the advantages of no need of welding, less deformation and damage of the plate part and simple operation.

Owner:马一爽

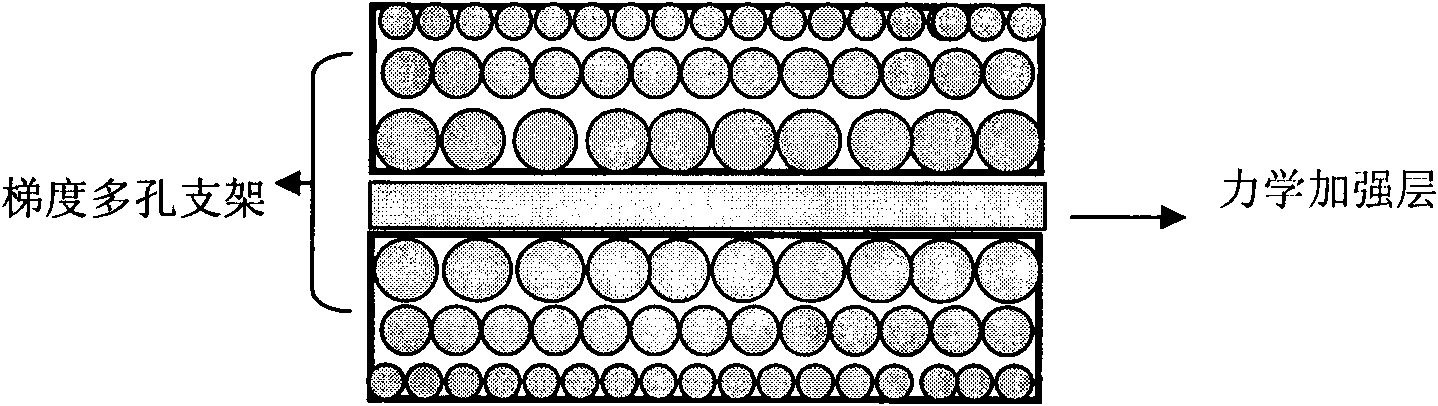

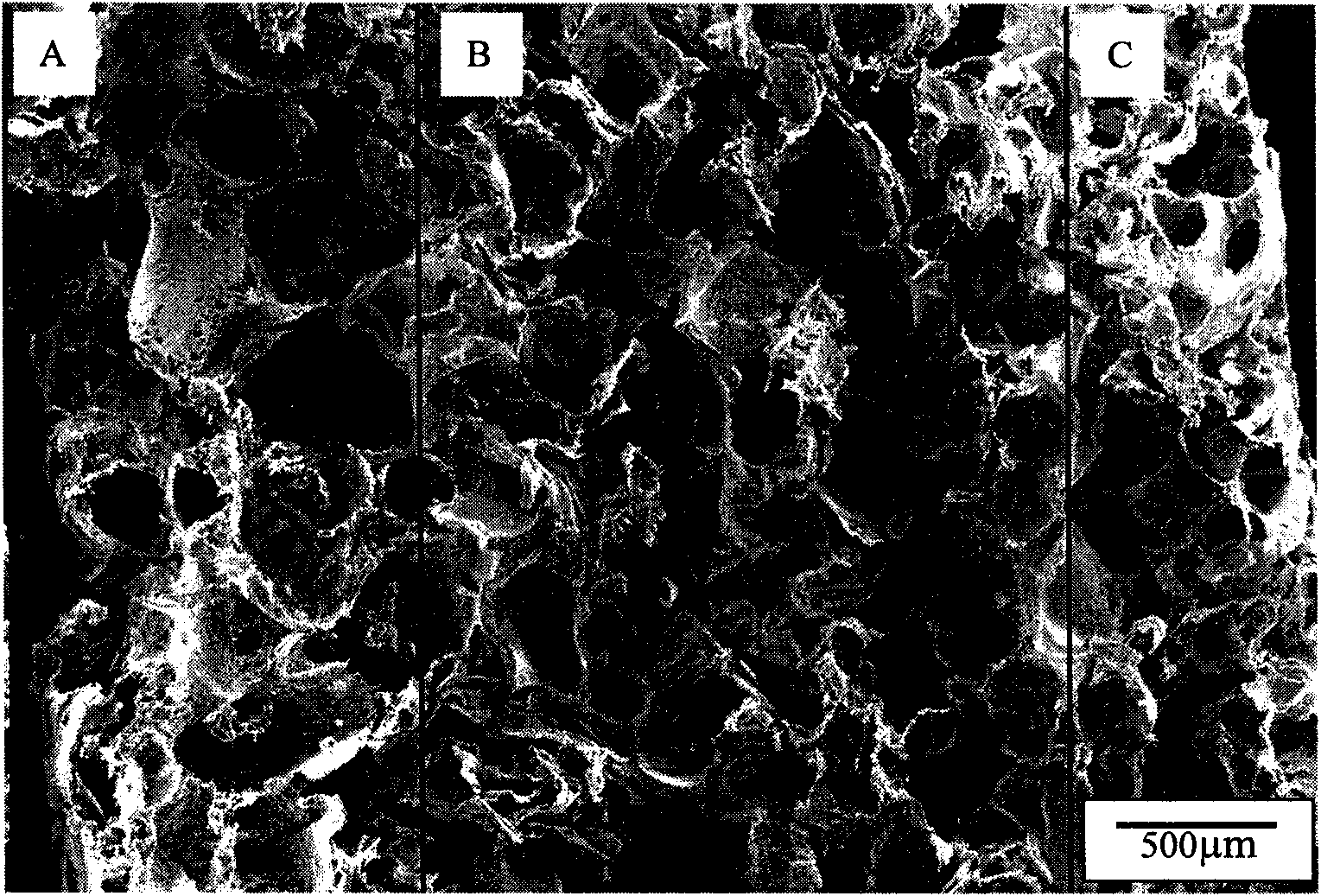

Method for preparing high-strength rib grads multi-aperture bracket

The invention belongs to the technical fields of polymer materials and biomedical engineering, and particularly relates to a method for preparing a high-strength rib grads multi-aperture bracket. The invention can regulate and control apertures and aperture distribution in the bracket by adjusting apertures of porogen, and simulate characteristics of compact and spongy substance apertures of natural bones to prepare the multi-aperture bracket with grads apertures. The invention adopts hydroxylapatite or calcium titanium silicate not only to regulate the relative constant of pH value but also to enhance the biocompatibility and mechanical strength of the material of the bracket; simultaneously, the invention adopts sticking manner to utilize a mechanical property strengthening layer betweentwo layers of grads multi-aperture bracket so as to meet the requirement on the mechanical property of rib bracket.

Owner:TONGJI UNIV

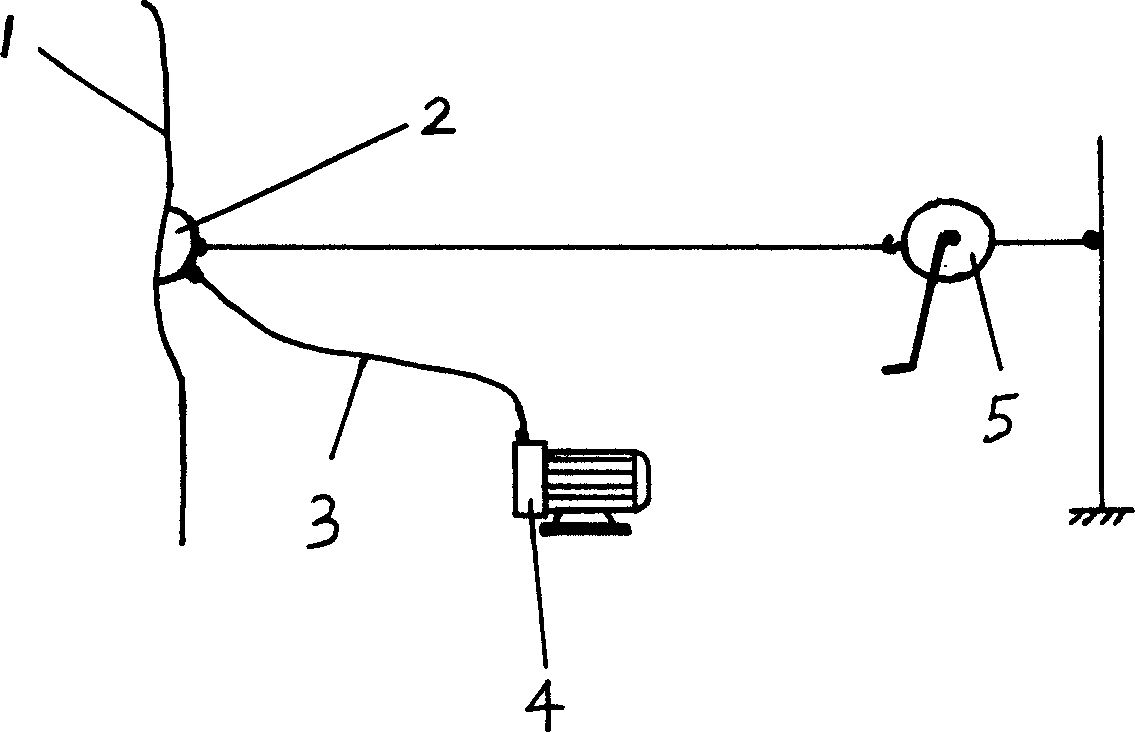

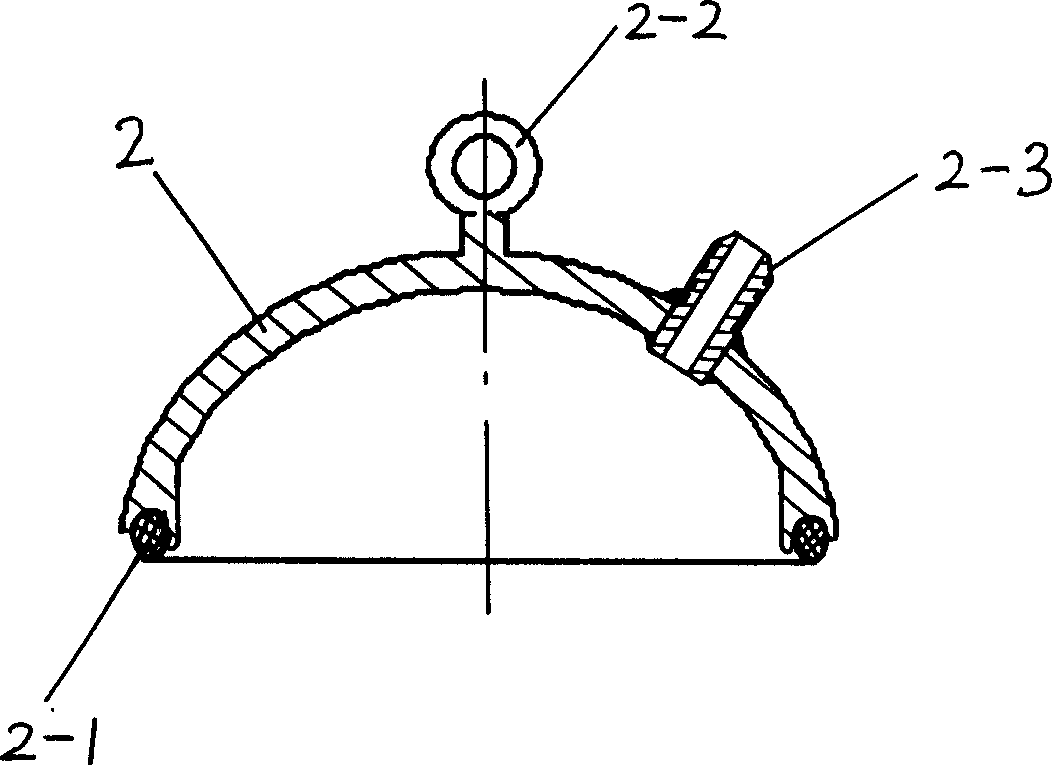

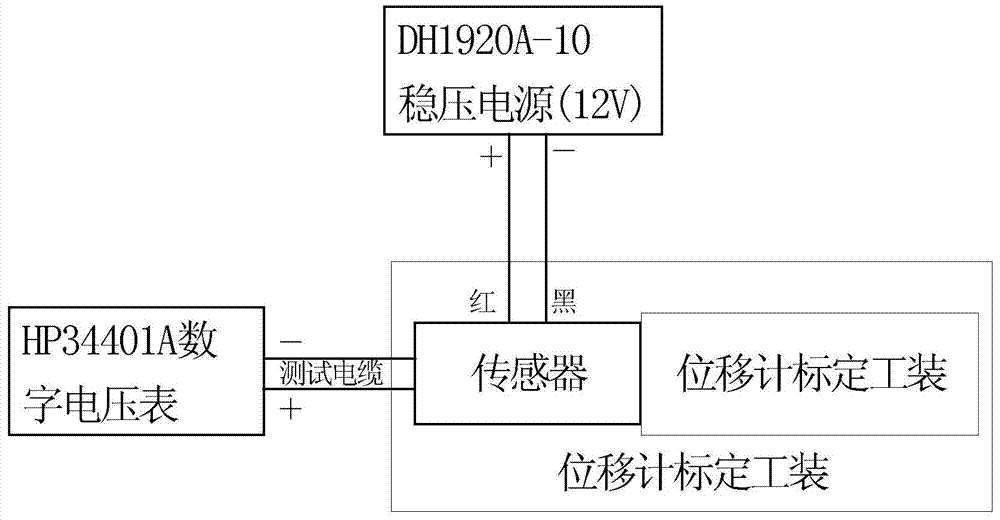

Self-triggering type wide-range displacement sensor

ActiveCN103499269ATimely collectionImprove anti-interference abilityUsing electrical meansEngineeringSelf triggering

The invention discloses a self-triggering type wide-range displacement sensor. The self-triggering type wide-range displacement sensor comprises a multiturn potentiometer (1) and a thread spool (5) and further comprises a rotary encoder (2) and a transmission gear set (7), wherein the multiturn potentiometer (1) is coaxially connected with the thread spool (5), and the transmission gear set (7) comprises a driving gear and a driven gear. The driving gear is coaxially connected with the thread spool (5), the driven gear is coaxially connected with the rotary encoder (2), the rotary encoder (2) is connected with a data collecting and transmitting circuit (3) and is used for triggering the starting of the data collecting and transmitting circuit (3), the rotation of the thread spool (5) can drive the multiturn potentiometer (1) and the driving gear to rotate synchronously, and the rotation of the driven gear can drive the rotary encoder (2) to rotate synchronously. The self-triggering type wide-range displacement sensor can collect variable quantity caused when the displacement changes suddenly, the measuring precision is high, and the self-triggering type wide-range displacement sensor can be suitable for the field work environment.

Owner:航天科工惯性技术有限公司

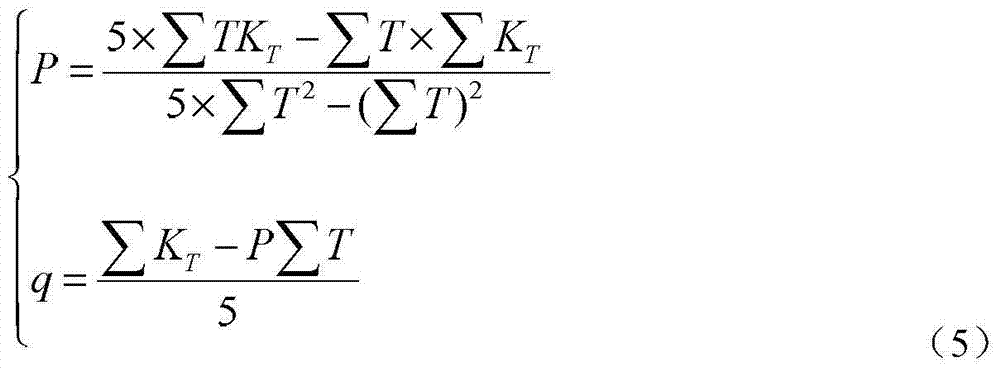

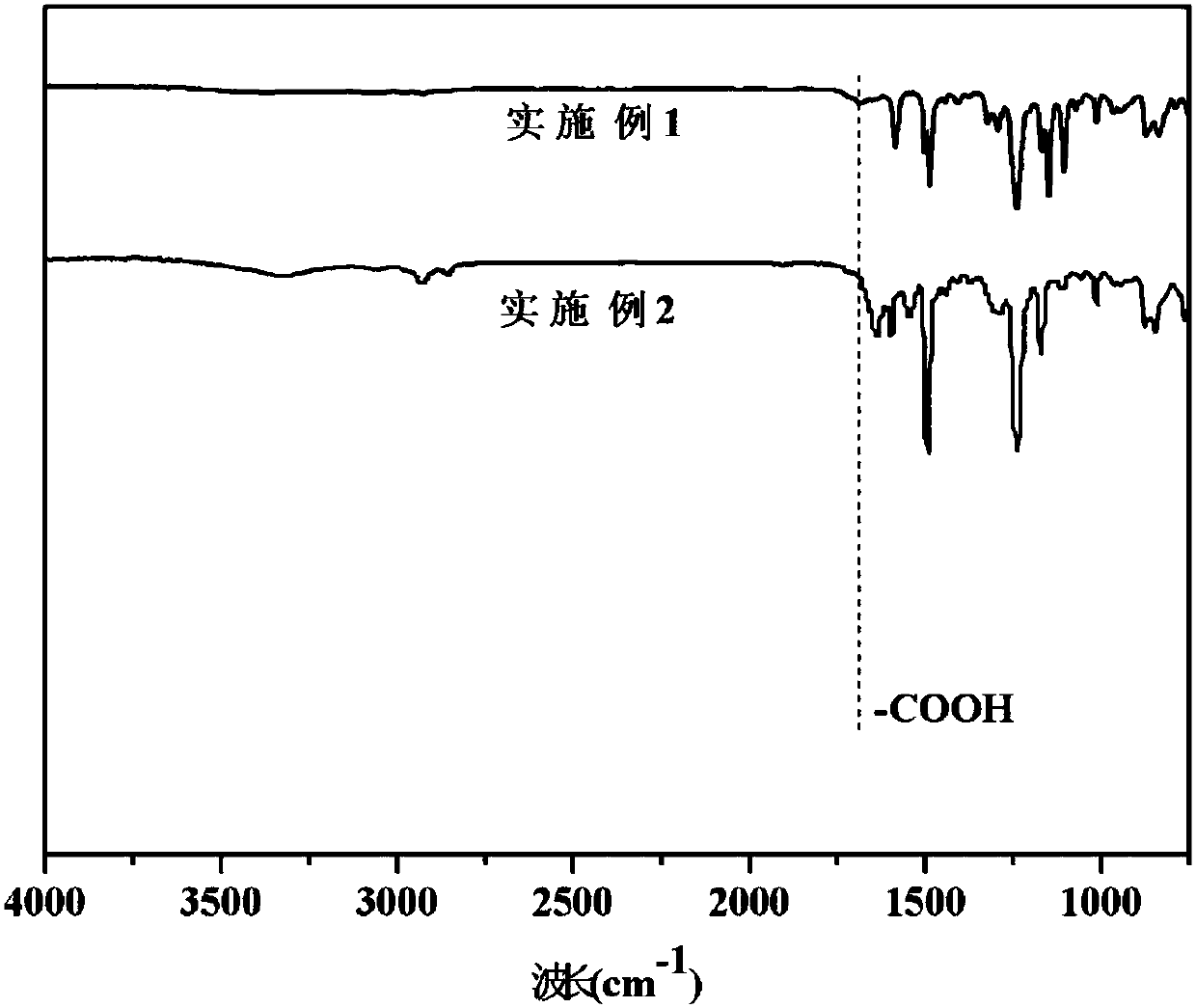

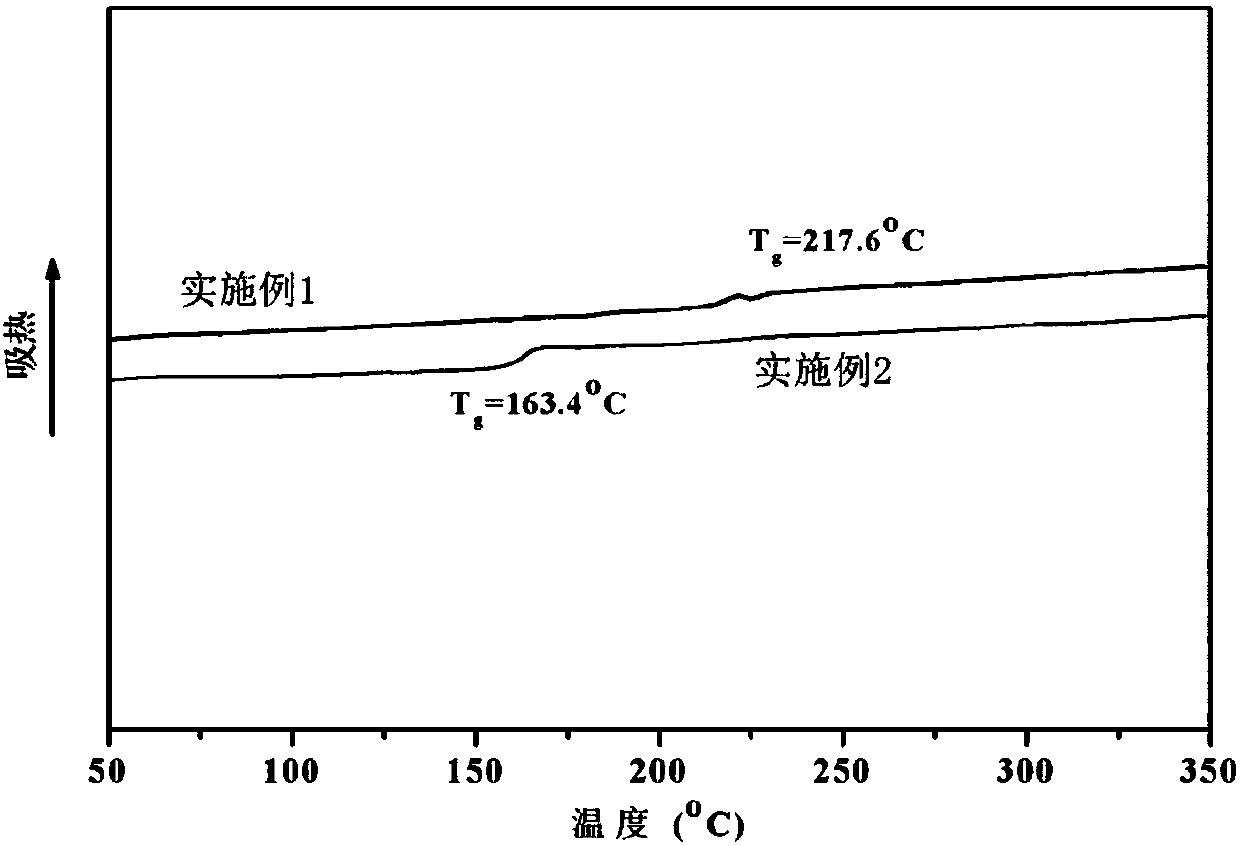

High-temperature-resistant organic-solvent-resistant separating membrane material, separating membrane, and preparation method thereof

ActiveCN107551825AImprove corrosion resistanceImprove temperature resistanceSemi-permeable membranesPolymer scienceOrganic solvent

The invention relates to a high-temperature-resistant organic-solvent-resistant separating membrane material, a separating membrane, and a preparation method thereof, and belongs to the field of highmolecular material. The high-temperature-resistant organic-solvent-resistant separating membrane material is composed of, by weight, 20 to 40 parts of a high-temperature-resistant aromatic ring matrixcontaining resin, 20 to 40 parts of a carboxyl-containing polymer, 0 to 60 parts of a matrix reinforcing material, 0.1 to 10 parts of a water soluble pore forming agent, and 100 to 300 parts of a solvent. The high-temperature-resistant organic-solvent-resistant separating membrane prepared from the high-temperature-resistant organic-solvent-resistant separating membrane material possesses excellent corrosion resistance, heat resistance, mechanical properties, pollution resistance, and high separating efficiency, is a high performance separating membrane, and is promising in application prospect.

Owner:安徽旭云商务咨询有限公司

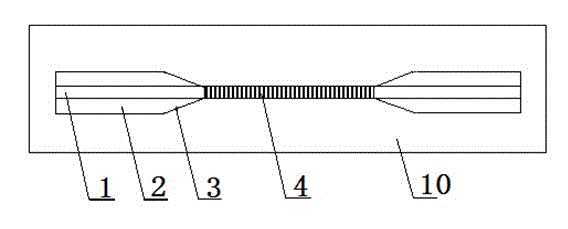

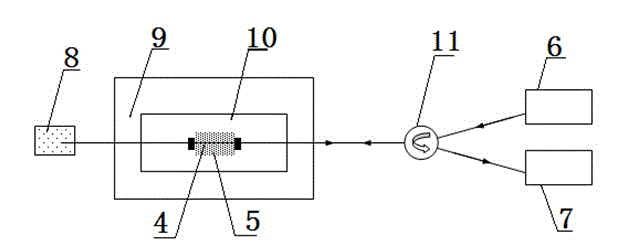

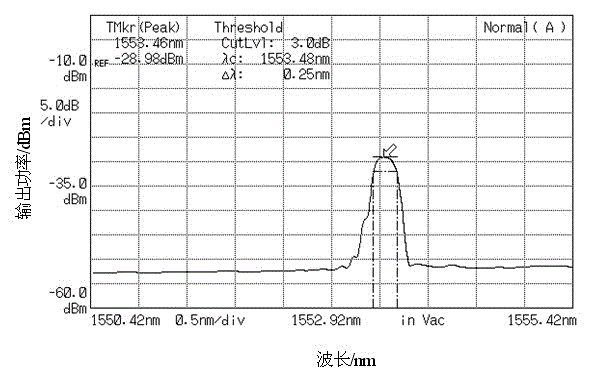

Micro-nano fiber bragg grating refractive index sensor and manufacturing method thereof

InactiveCN102879357AEasy to set upQuick measurementPhase-affecting property measurementsFiberHydrofluoric acid

The invention relates to a micro-nano fiber bragg grating refractive index sensor and a manufacturing method thereof, comprising an organic glass plate which is fixedly connected with two ends of the fiber bragg grating. The middle section of the fiber bragg grating is a clad-free fiber core gate area. The manufacturing method of the micro-nano fiber bragg grating refractive index sensor comprises the steps of 1) fixing two ends of a common fiber bragg grating on an organic glass, putting the organic glass in a temperature-regulated oven, and controlling the temperature at a constant temperature between 17 DEG C and 25 DEG C; 2) dropwise adding 0.8 mL-1.2 mL hydrofluoric acid on the gate area clad of the fiber bragg grating of the step 1), etching for 125-80 minutes, etching off the gate region clad to make the gate area fiber core of the fiber exposed directly; and 3) taking the etched fiber bragg grating of the step 2) together with the organic glass out from the oven, sucking residue etching liquid, cleaning the etched fiber bragg grating, coating a 40% NaOH solution on the etched fiber bragg grating, immersing for 10 minutes to ensure that the residue hydrofluoric acid is neutralized completely, and finally washing the fiber bragg grating with deionized water. The micro-nano fiber bragg grating refractive index sensor has the characteristics of simple structure, accurate measurement and high signal-to-noise ratio.

Owner:XI'AN PETROLEUM UNIVERSITY

High-refractive-index organosilicon material for light-emitting diode (LED) packaging and preparation method of high-refractive-index organosilicon material

ActiveCN102863799AGuaranteed mechanical strengthHigh mechanical strengthSemiconductor devicesPtru catalystSilanes

The invention relates to a high-refractive-index organosilicon material for light-emitting diode (LED) packaging and a preparation method of the high-refractive-index organosilicon material. The technical scheme includes that according to a formula ration, three materials of a phenyl vinyl silicone resin, a phenyl hydrogen silicone resin and nano silicon dioxide (particle size distribution 5-15nm) which is treated by a silane coupling agent are placed in a 2L internal mixer to be internally mixed for one hour, then a platinum catalyst with a platinum content of 200-1000ppm is added to a nitrogen atmosphere, internal mixing is performed for 10 minutes again, finally, an alkynol compound is added, and internal mixing is continuously performed for 10 minutes to obtain the high-refractive-index organosilicon material. Compared with existing high-refractive-index organosilicon materials for LED packaging, the high-refractive-index organosilicon material for LED packaging is higher in drawing strength and larger in cohesive force under the condition of the same refractive index and light transmittance.

Owner:东莞市贝特利新材料有限公司

Railway vehicle side wall and welding method thereof

ActiveCN103010237ASolve the deformationReduce connection partsAxle-box lubricationLaser beam welding apparatusEngineeringSpot welding

The invention relates to a railway vehicle side wall and a welding method thereof. A manner of reducing connecting parts and improving the modularization degree is adopted; and for avoiding generating spot welding indentations, the side wall integrally adopts a laser welding manner to effectively improve welding intensity and control and reduce heat input so as to solve the problem of deformation of a stainless steel side wall. The side wall comprises a plurality of groups of side wall units, a door frame, a side wall upper edge beam and a threshold which are connected into one integral structure. The door frame is in welding connection with the side wall units; above the door frame, each two adjacent side wall units are abutted by a doorway abutting element and meanwhile, the doorway abutting element is in welding connection with the door frame; each side wall unit comprises a plurality of groups of beams and uprights, which are overlapped; and the beams are connected with the uprights in a laser welding manner.

Owner:CRRC QINGDAO SIFANG CO LTD

Preparation method of honeycomb ceramic net through Lu and N co-doped TiO2 photocatalysis

ActiveCN103406136AIncrease costGuaranteed costPhysical/chemical process catalystsDispersed particle separationRare-earth elementMass ratio

The invention relates to a preparation method of a honeycomb ceramic net through Lu and N co-doped TiO2 photocatalysis. The honeycomb ceramic net is regarded as a first carrier, and activity AL2O3 coating with specific surface area of 300 to 400m2 / g and doping with lanthanum, cerium and iron element is loaded on the first carrier and regarded as a second carrier; the mass ratio of AL2O3 to La to Ce to Fe is (100 to 110) to (90 to 115) to (50 to 70) to (5 to 15); the TiO2 photocatalyst films of rare earth element Lu and non-metallic element N are loaded on the second carrier; the mass ratio of Lu to N to TiO2 in the TiO2 photocatalyst film is (0.01 to 0.16) to (0.40 to 1.88) to (97.94 to 99.54). The removal rate of the honeycomb ceramic net prepared through photocatalysis to formaldehyde and toluene in the air is 98.7% and 92.2% respectively, and the removal rate to formaldehyde and toluene in the air is improved by 2.0 times and 1.9 time respectively compared with the application of the TiO2 photocatalyst film only.

Owner:JIANGSU GAOCHUN CERAMICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com