Railway vehicle side wall and welding method thereof

A rail vehicle side wall, welding method technology, applied in welding equipment, laser welding equipment, railway car body and other directions, can solve the problem of stainless steel side wall deformation and other problems, to solve the spot welding indentation, ensure mechanical strength and safety, The effect of a high degree of modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

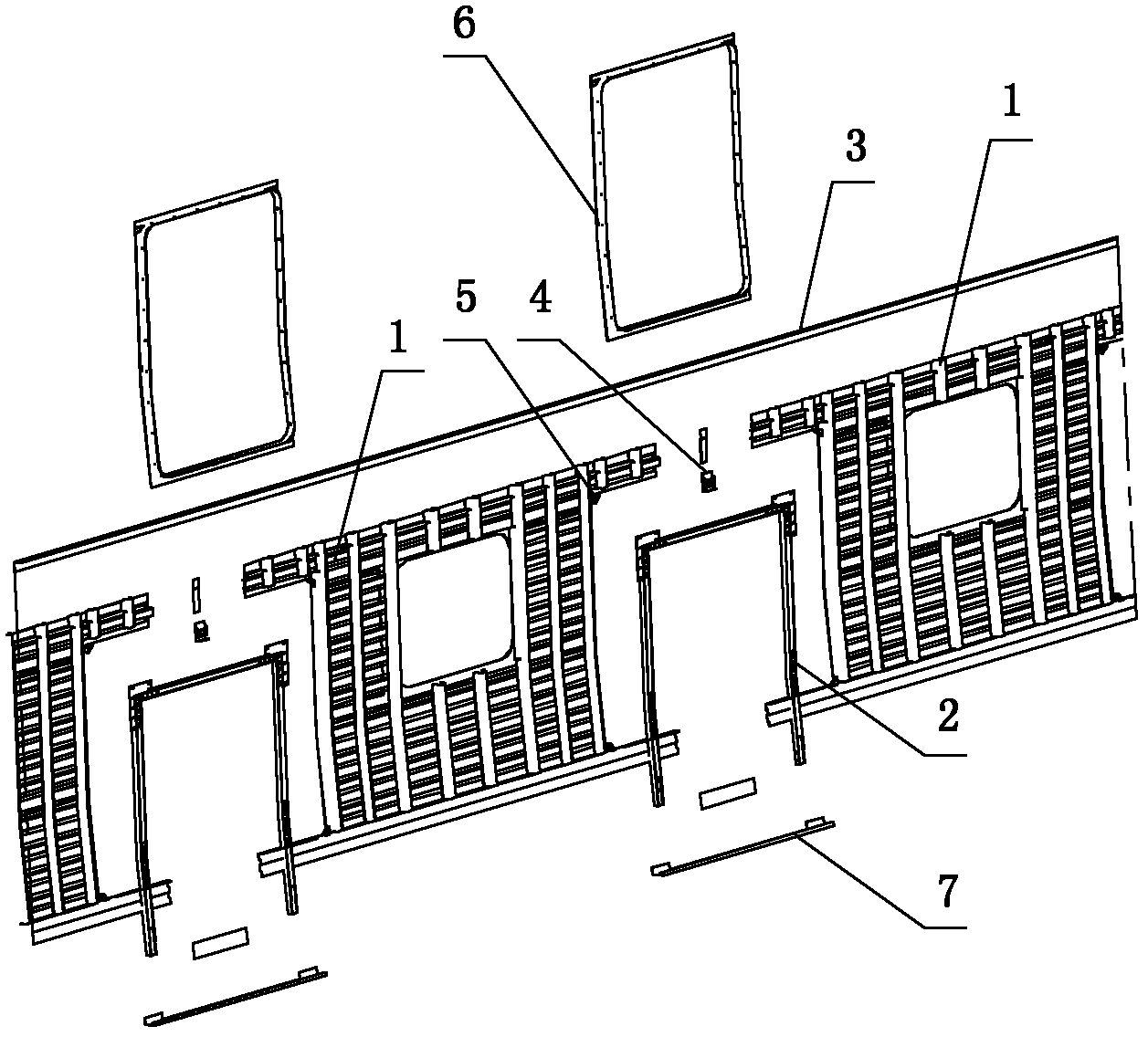

[0048] Embodiment 1, combining Figure 1 to Figure 6 , the rail vehicle side wall mainly includes:

[0049] Several groups of side wall units 1, door frames 2, side wall side beams 3 and threshold 7 are connected into an integral structure. in,

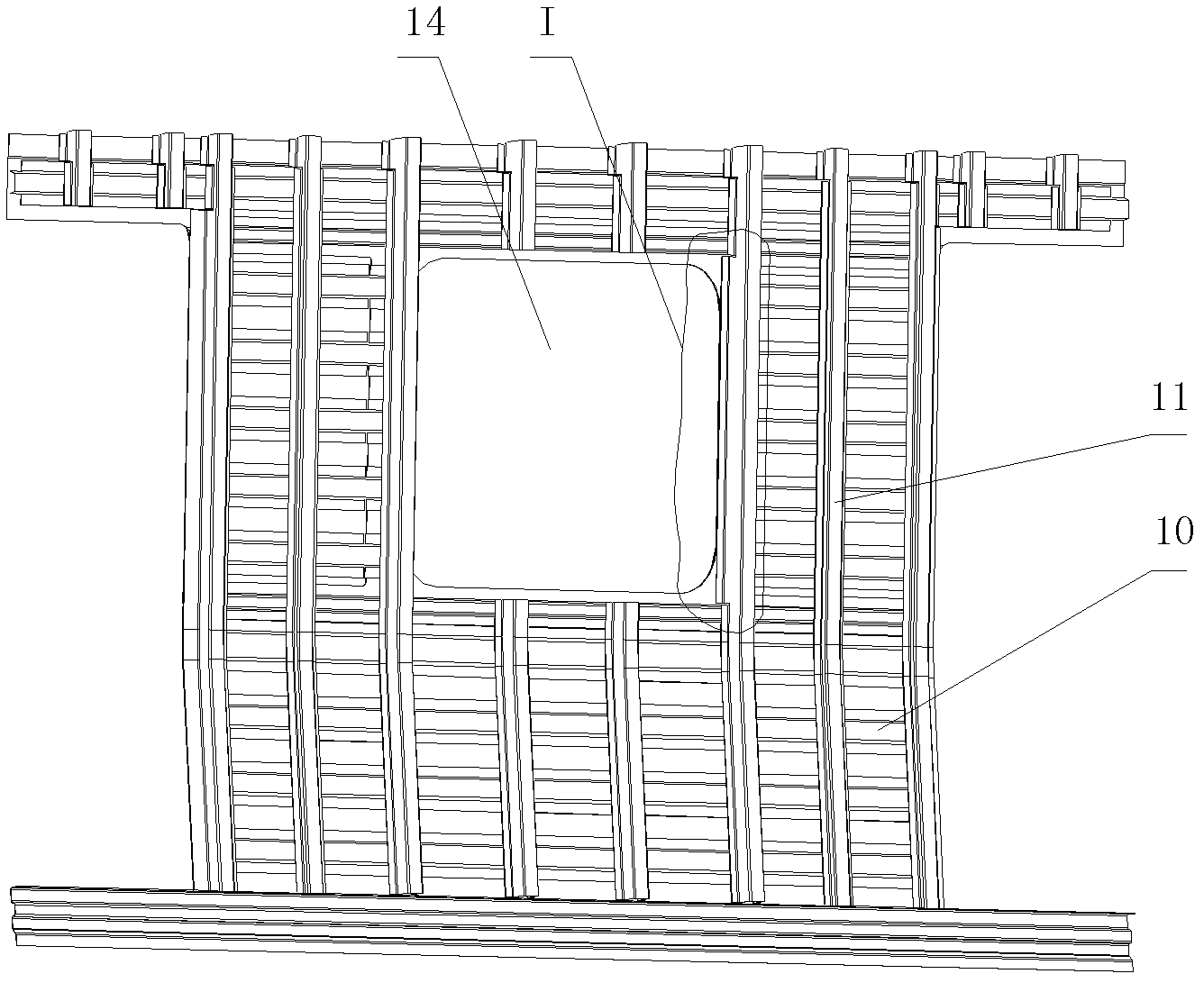

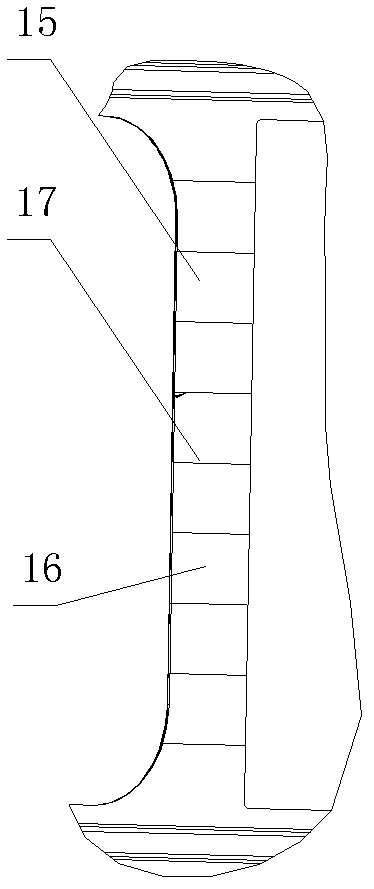

[0050] The side wall unit 1 includes several sets of overlapping beams 10 and columns 11 , the beams 10 and the exterior wall panels are connected by laser welding, and the beams 10 and columns 11 are connected by laser welding.

[0051]The door frame 2 has an overall structure in which the doorway beam 8 and the doorway columns 9 on both sides are connected by tailor welding.

[0052] The door frame 2 and the side wall unit 1 are connected by welding;

[0053] At the center line above the door frame 2 , two adjacent side wall units 1 are butted with a gap through the door butt joint element 4 .

[0054] At the same time, the door butt joint element 4 is connected with the door frame 2 by means of plug welding;

[0055] At the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com