High strength automobile aluminium alloy wheel rim

A high-strength, aluminum alloy technology, applied in the direction of rims, vehicle parts, transportation and packaging, etc., can solve the problems of low strength and narrow application range, and achieve the effect of good mechanical properties, low production cost and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

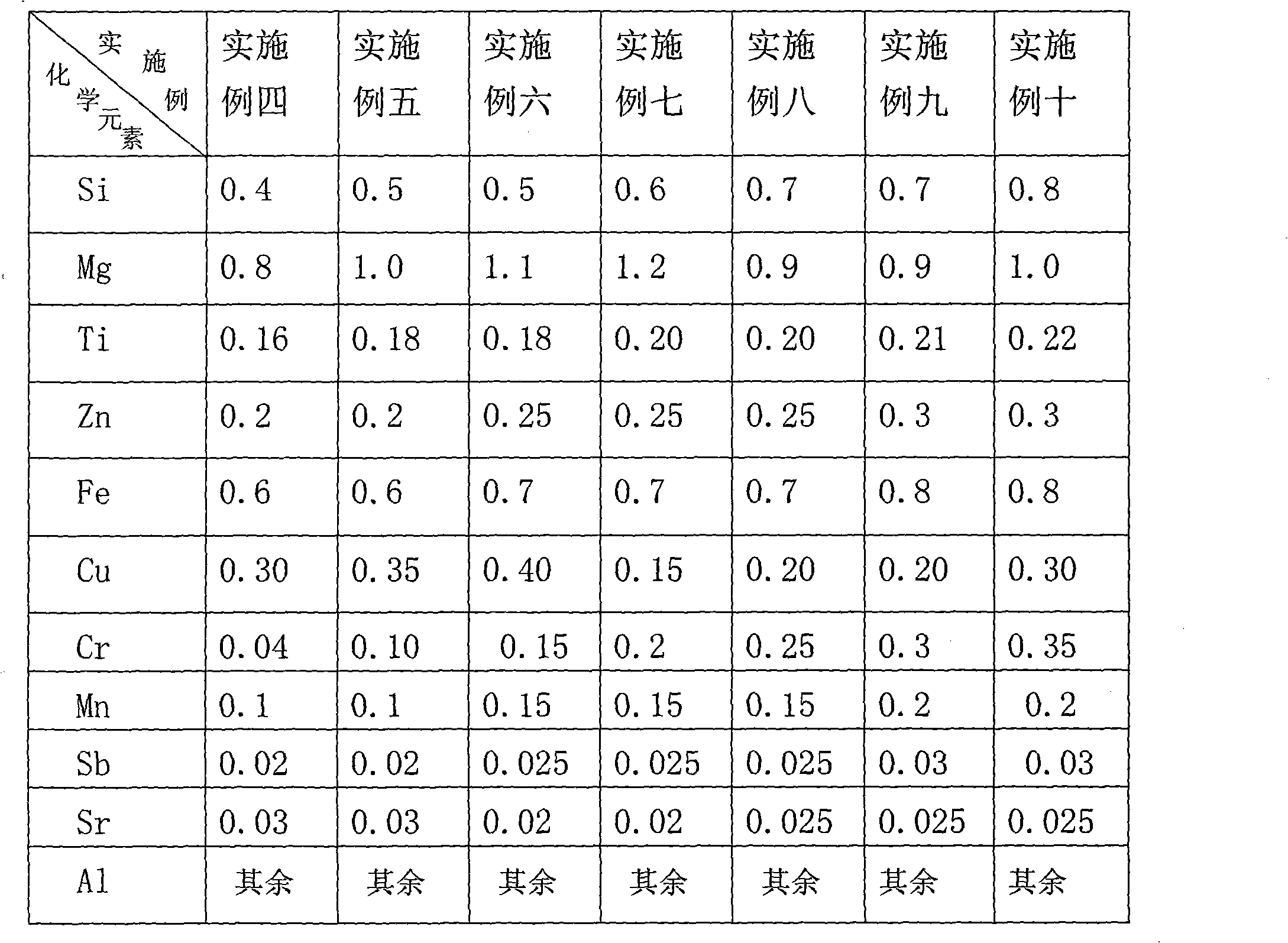

Embodiment 1

[0030] A high-strength automotive aluminum alloy wheel rim, which is made of high-strength aluminum alloy material. The chemical elements and their mass percentage contents of the high-strength aluminum alloy material are: Si 0.4%, Mg 0.8%, Ti 0.16%, Zn 0.2%, Fe 0.6%, Cu 0.15%, Cr 0.04%, Mn 0.1%, Sb 0.02%, Sr 0.02%, and the rest is Al.

Embodiment 2

[0032] A high-strength automotive aluminum alloy wheel rim, which is made of high-strength aluminum alloy material. The chemical elements and their mass percentage contents of the high-strength aluminum alloy material are: Si 0.6%, Mg 1.0%, Ti 0.2%, Zn 0.25%, Fe 0.7%, Cu 0.25%, Cr 0.2%, Mn 0.15%, Sb 0.025%, Sr 0.025%, and the rest is Al.

Embodiment 3

[0034] A high-strength automotive aluminum alloy wheel rim, which is made of high-strength aluminum alloy material. The main chemical elements and their mass percentage contents of the high-strength aluminum alloy material are: Si 0.8%, Mg 1.2%, Ti 0.22%, Zn 0.3%, Fe 0.8%, Cu 0.4%, Cr 0.35%, Mn 0.2%, Sb 0.03%, Sr 0.03%, and the rest is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com