Method and apparatus for restoring automobile metal plate work

A technology for automobile sheet metal parts and equipment, which is applied in the field of improvement of repair methods for automobile sheet metal parts, can solve the problems of large local repeated deformation, affect mechanical strength, and reduce strength, and achieve reduced repeated deformation, simple operation, and low The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

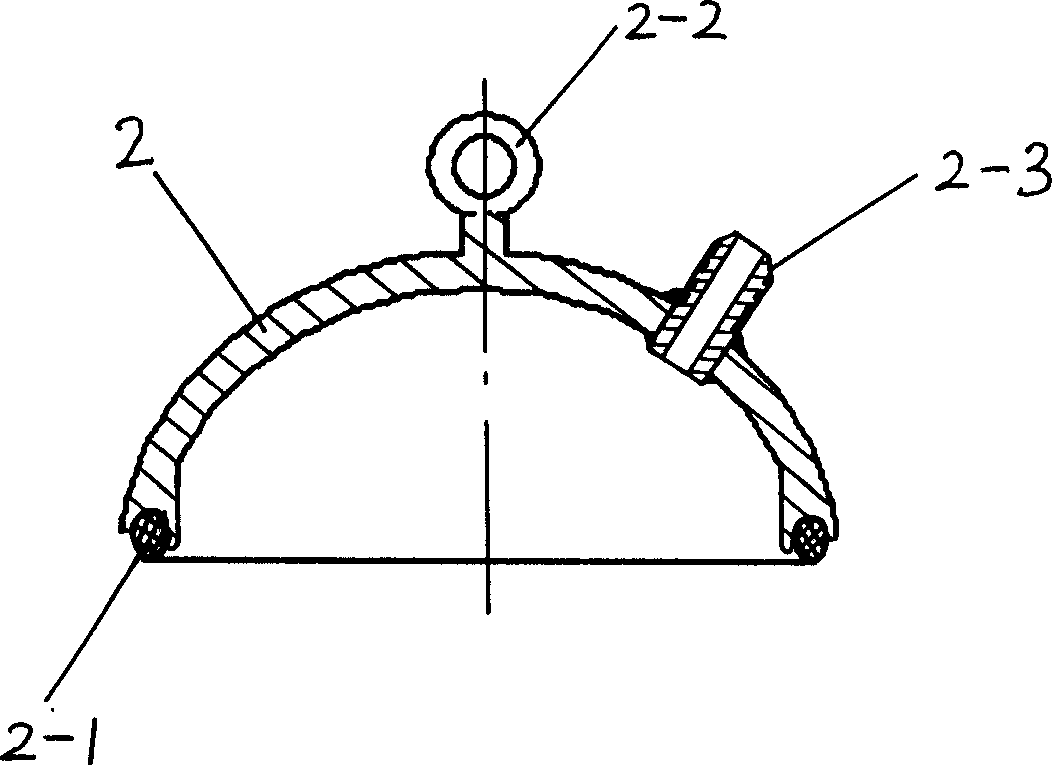

[0010] Such as figure 2 As shown, the suction cup 2 of this device is made of metal, and its center is provided with a pull ring 2-2, which can be connected during traction, and a rubber sealing ring 2-1 is provided along the mouth, which acts as a seal, and the suction cup is provided with an air outlet 2-3, for connecting the vacuum pump to extract the air inside the suction cup.

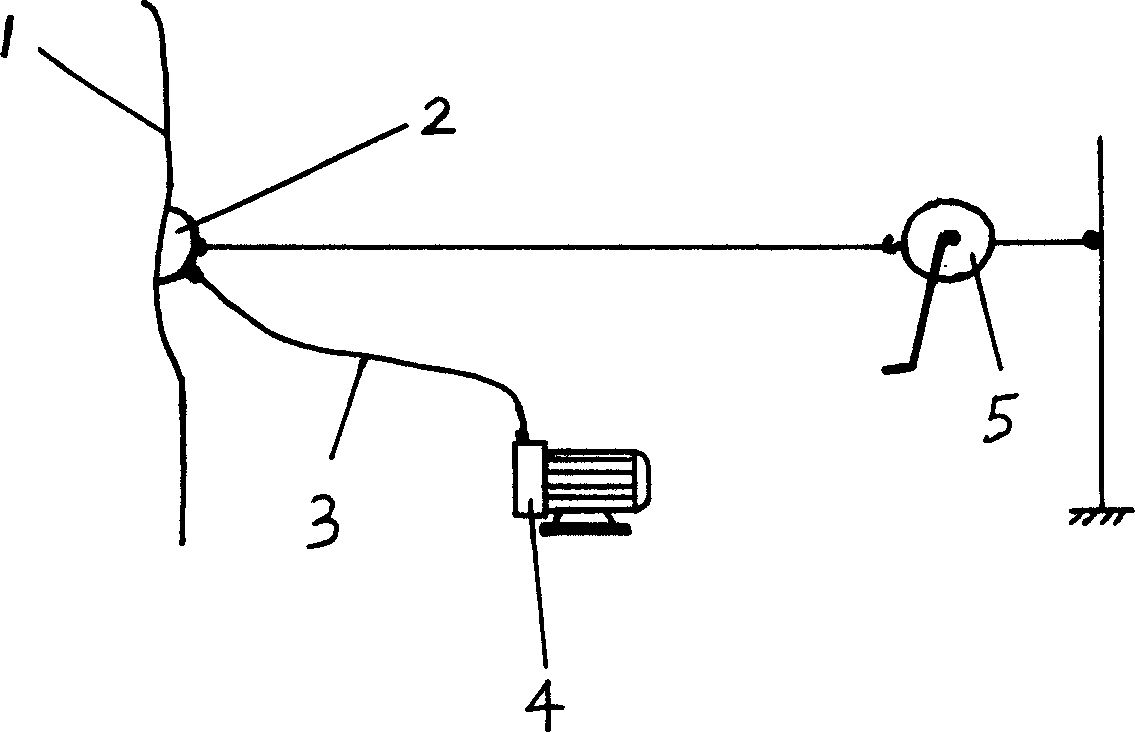

[0011] When using the connection as figure 1 As shown, the equipment used includes a vacuum pump 4, a suction cup 2, and a tractor 5. The suction cup 2 is connected to the vacuum pump 4 through a pipeline 3, and the suction cup 2 is connected to the tractor 5 through a pull ring.

[0012] When repairing, place the suction cup 2 on the concave part of the sheet metal part 1, vacuum the air in the suction cup with the vacuum pump 4, then pull the suction cup 2 through the tractor 5, pull out the concave part, and restore it by beating. The vacuum pump used is a piston type with a vacuum degree of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com