Patents

Literature

30results about How to "Avoid Soldered Connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

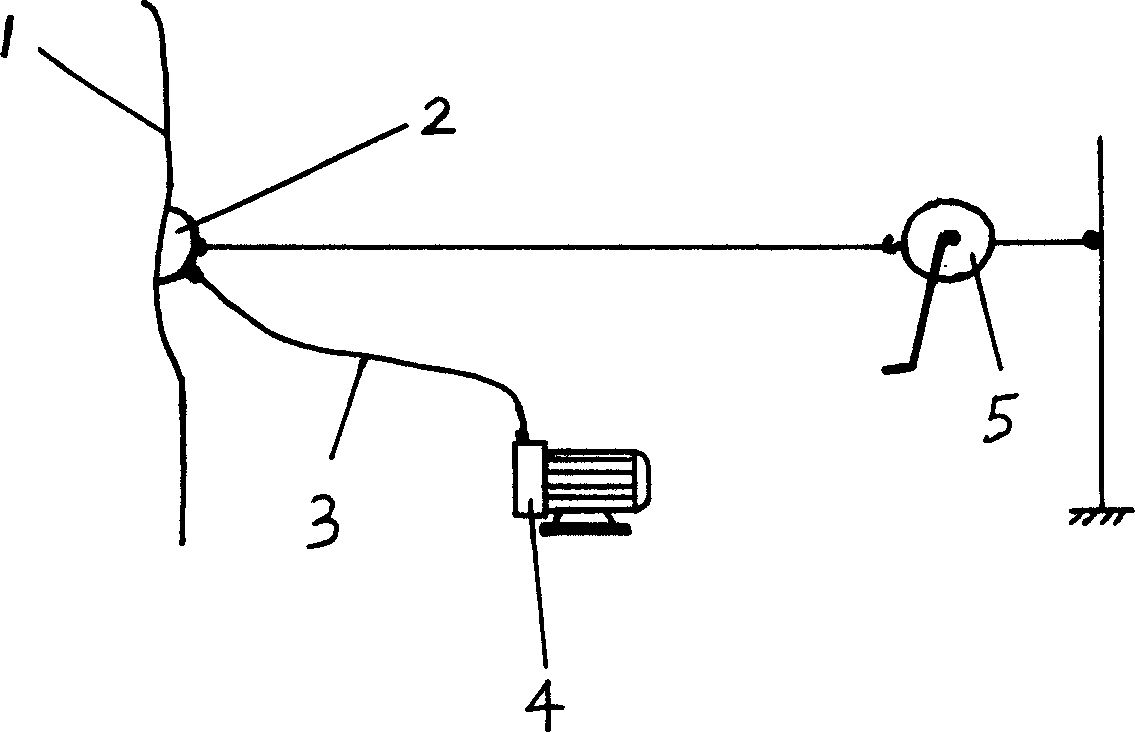

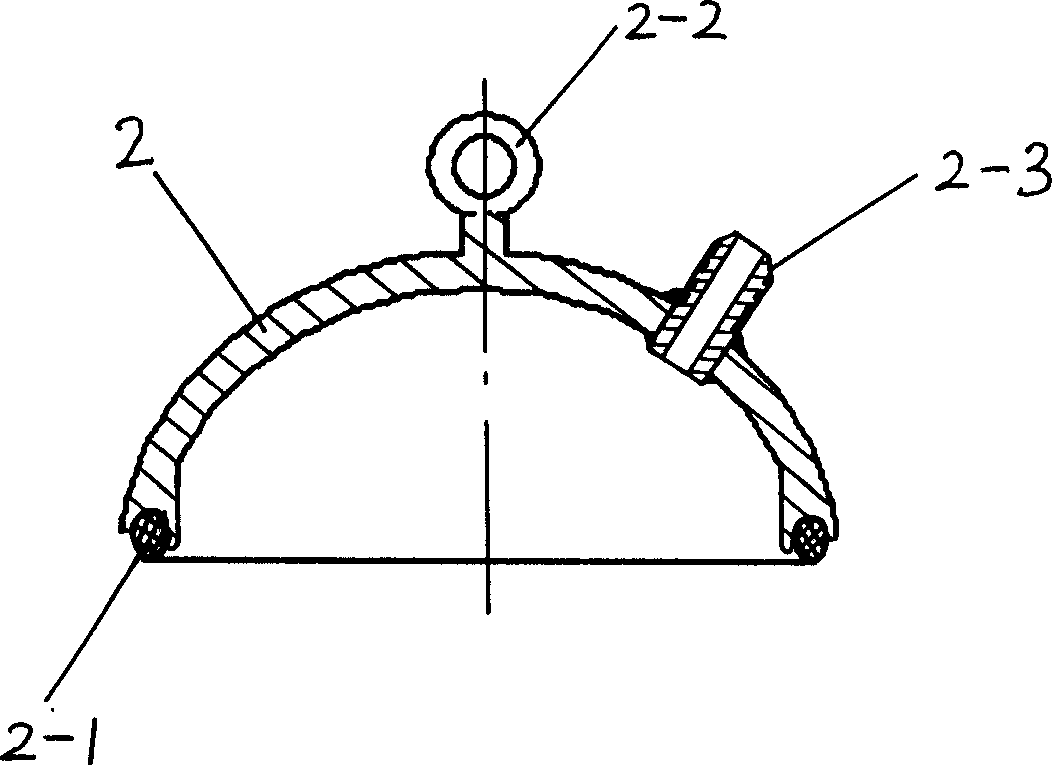

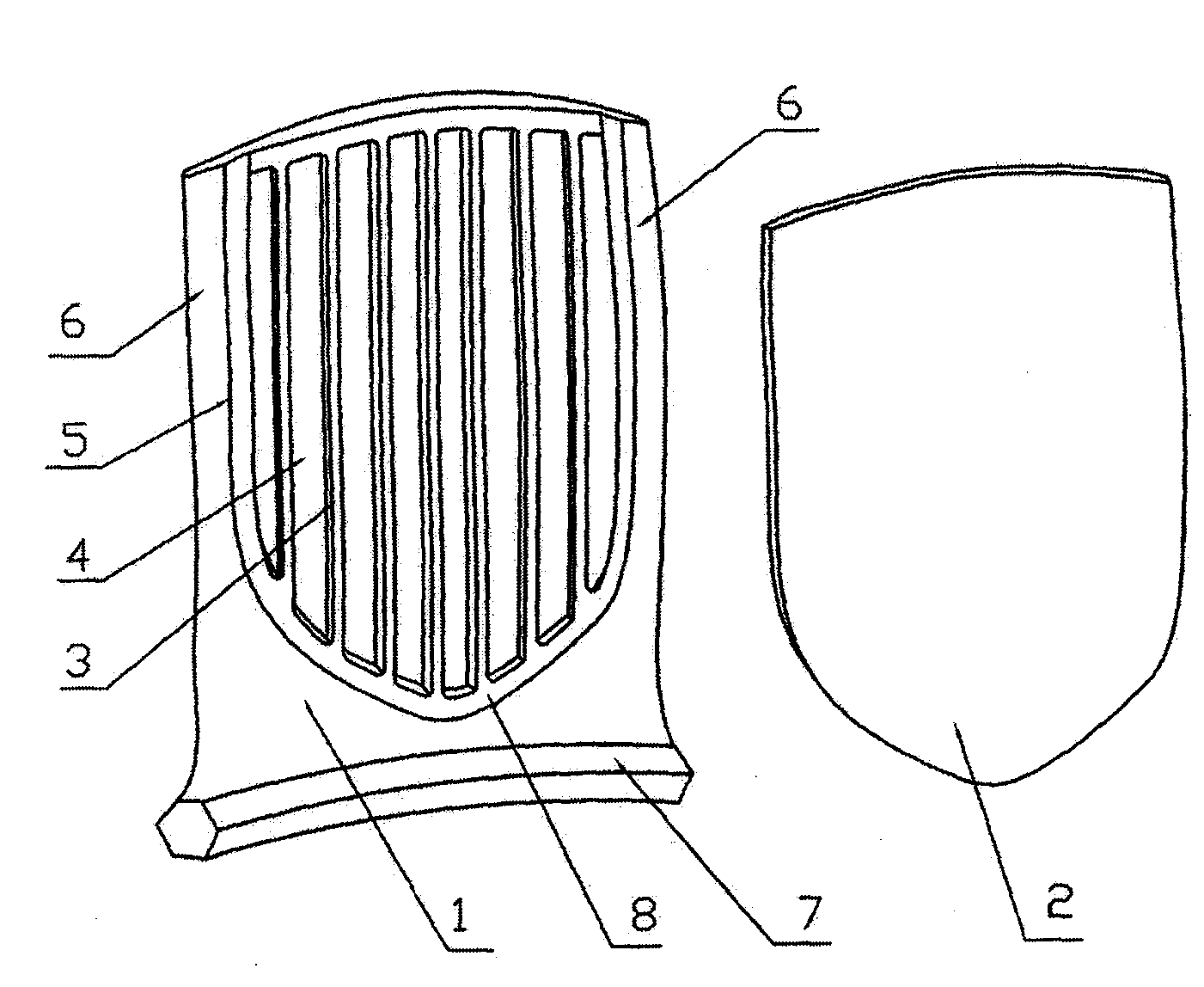

Method and apparatus for restoring automobile metal plate work

The method of repairing plate part of automobile includes setting sucking disc in the notched part, pumping out air from the sucking disc, drawing the sucking disc to draw out the notched part and knocking to restore the original shape. Compared with available repairing method, the method of the present invention has the advantages of no need of welding, less deformation and damage of the plate part and simple operation.

Owner:马一爽

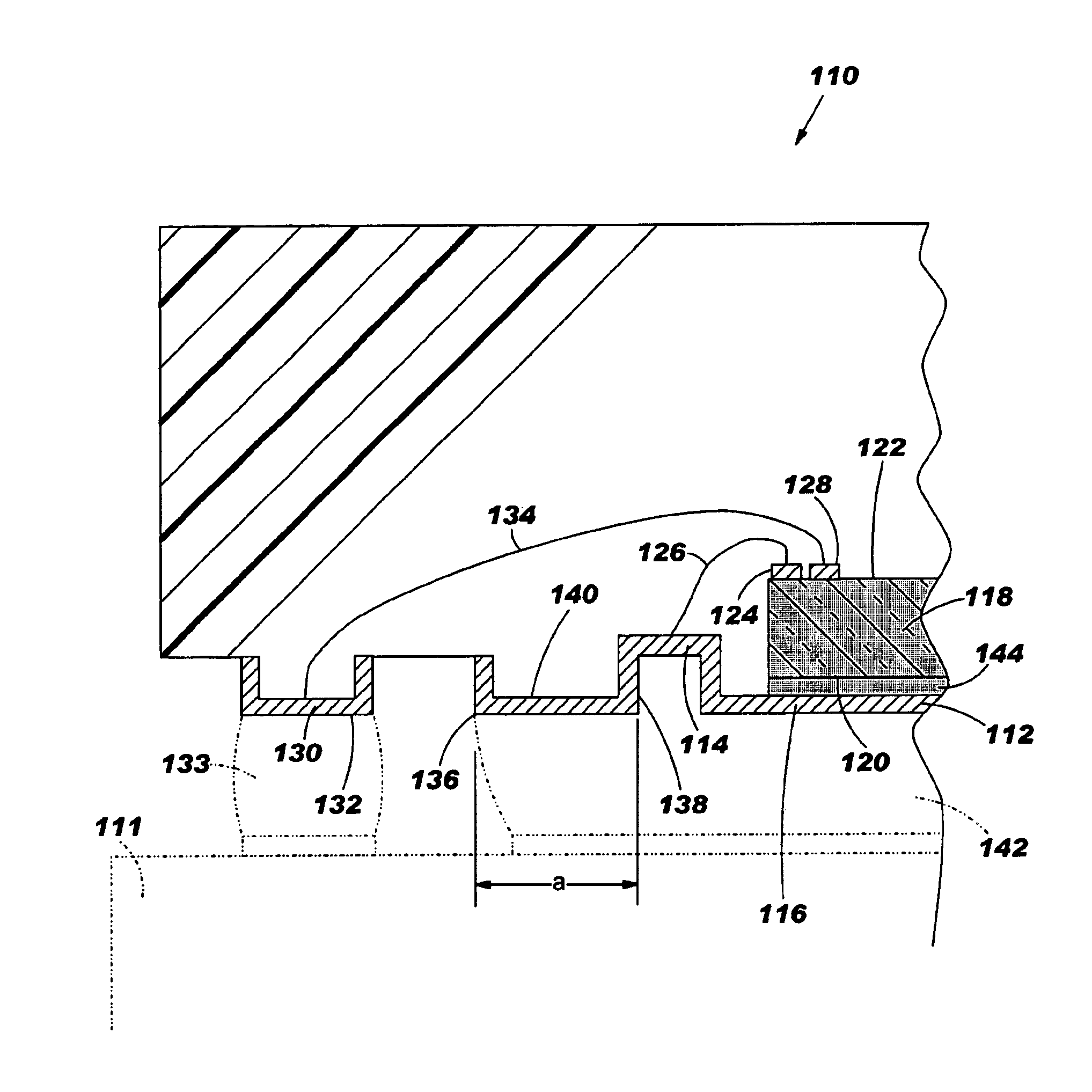

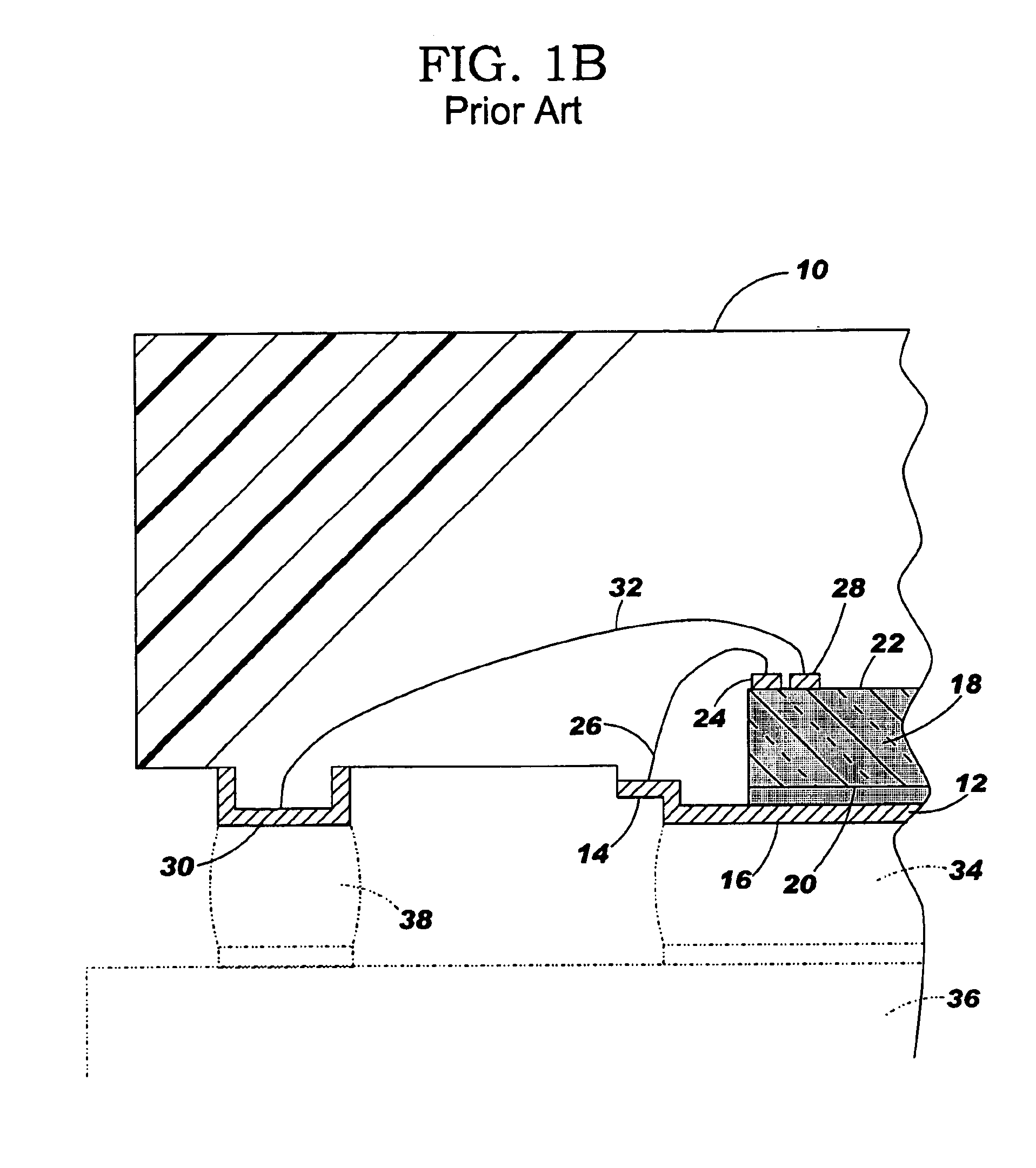

Optimized electronic package

InactiveUS6894382B1Increase productionLow costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

An electronic package for use with a printed circuit board is provided. The electronic package includes a ground layer having an upper and lower section, a semiconductor chip, a conductive signal layer and a ground plane having a first section electrically connected to the upper section of the ground layer and a second section substantially planar with said lower section of said ground layer, the second section of the ground plane having an additional area to prevent cracking of a solder connection between the ground layer, the ground plane and the printed circuit board.

Owner:IBM CORP

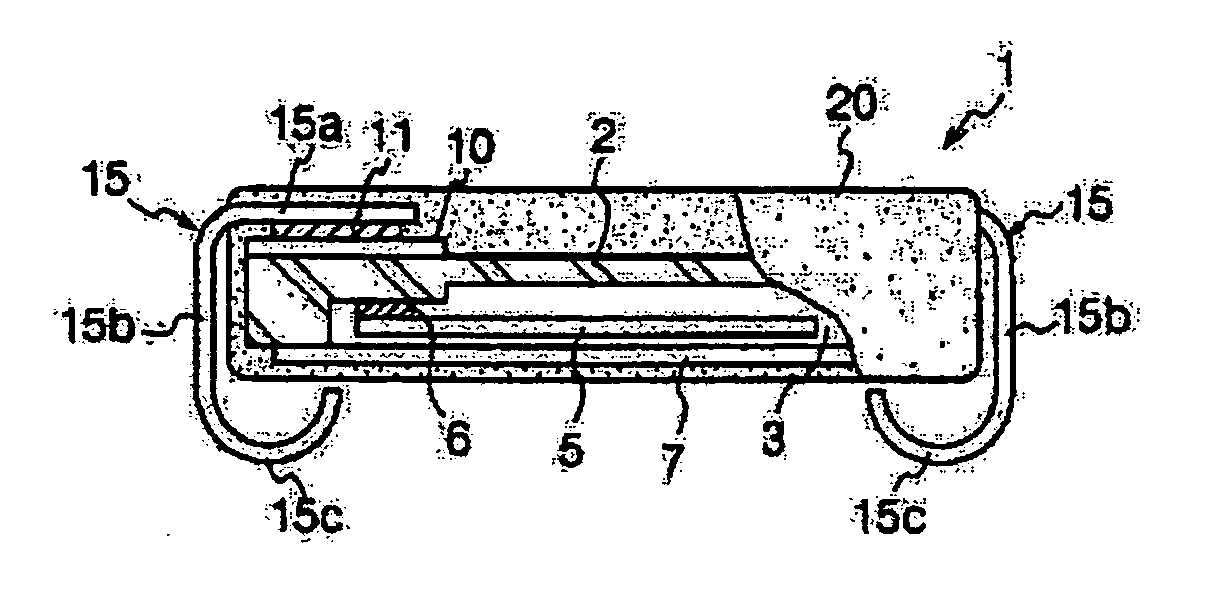

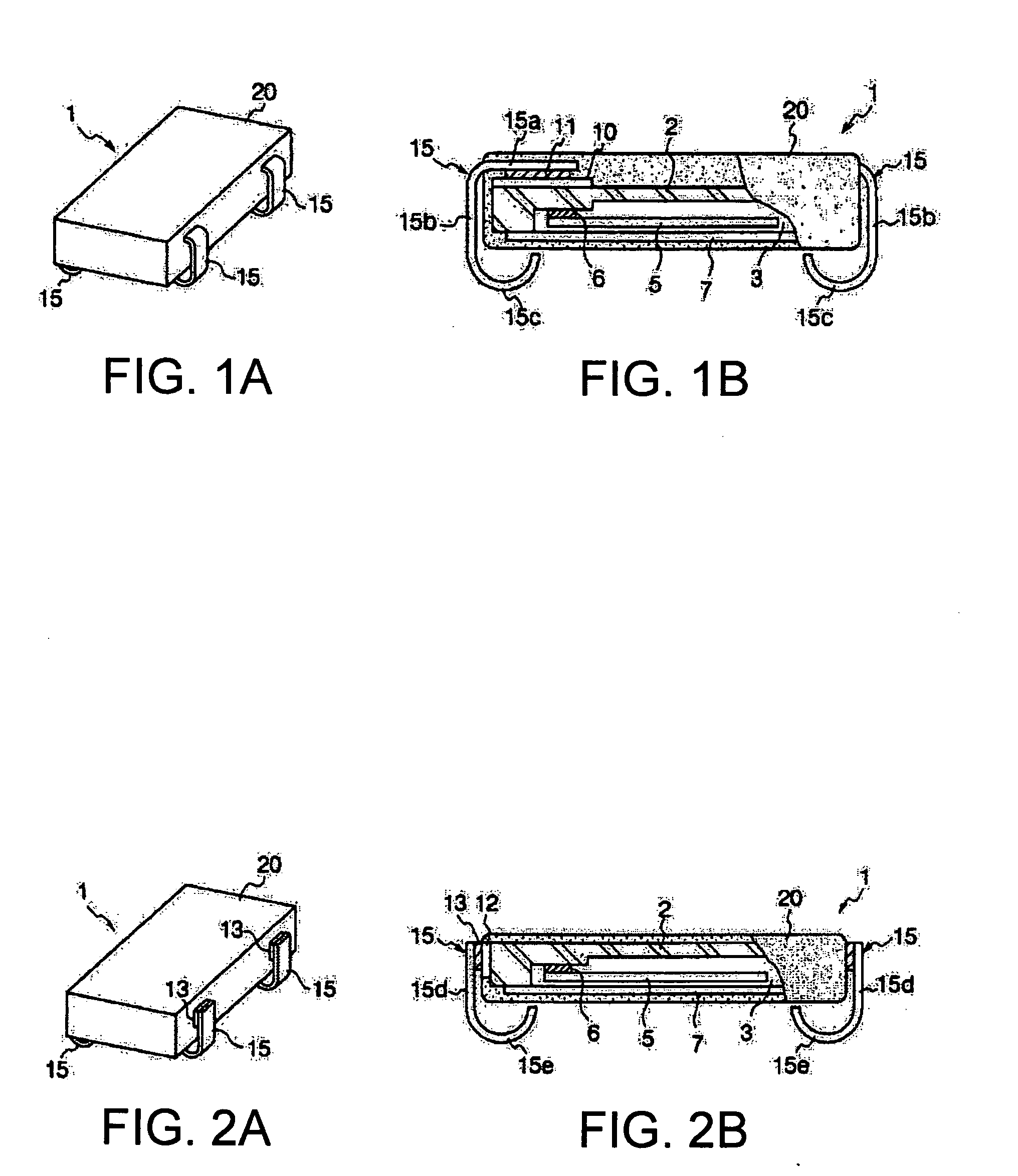

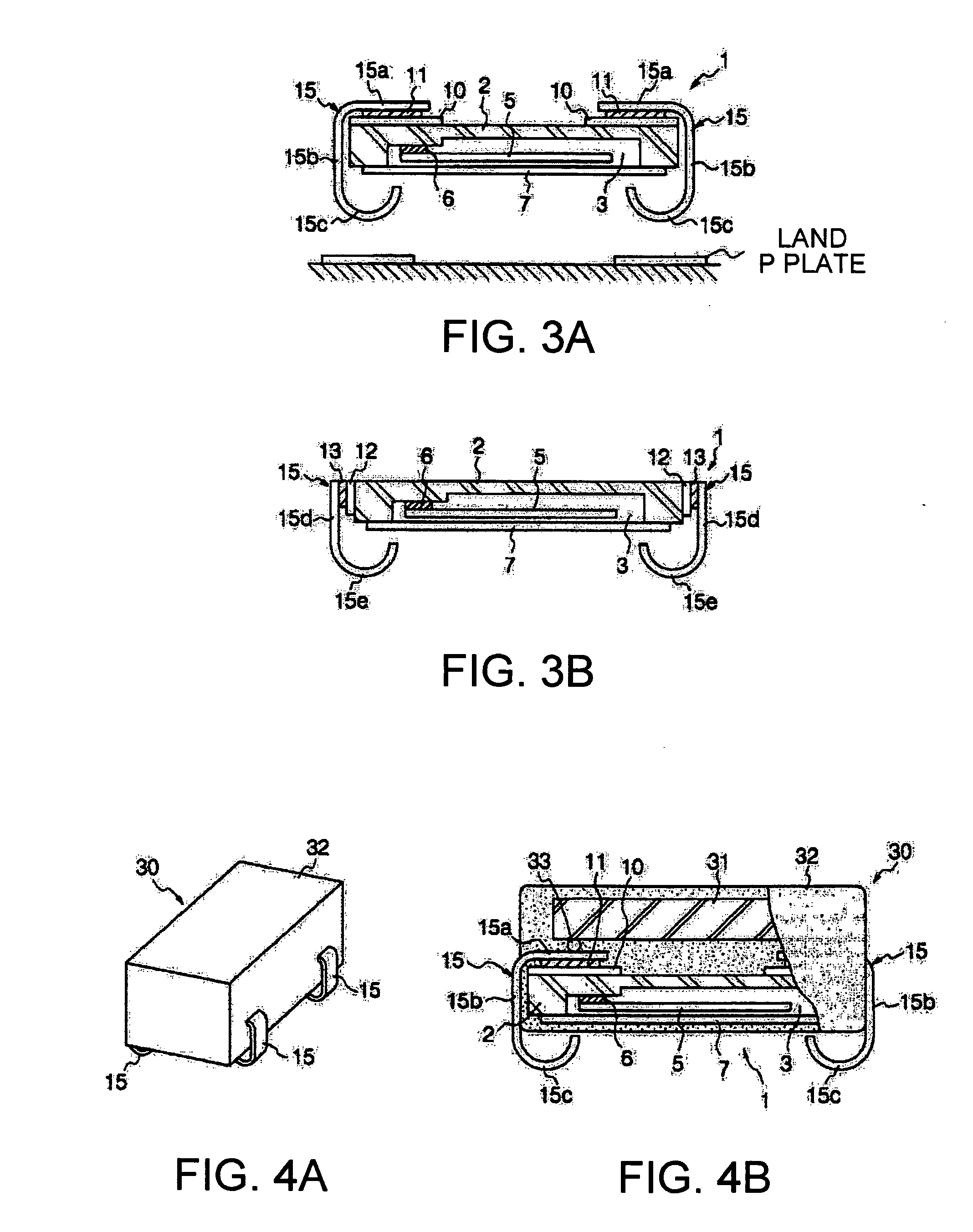

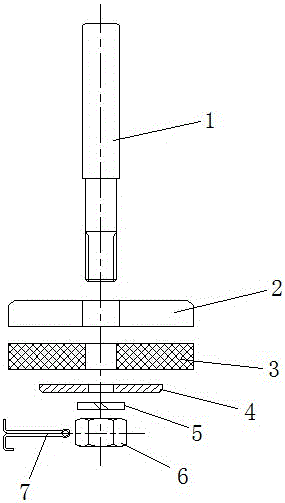

Piezoelectric resonator and piezoelectric oscillator

InactiveUS20060244344A1Avoid Soldered ConnectionsReduce the overall heightPiezoelectric/electrostriction/magnetostriction machinesFinal product manufactureMetalPiezoelectric resonators

A piezoelectric resonator comprises: an insulating package provided with a concave portion at a lower region thereof, an piezoelectric resonator installed within the concave portion of the insulating package; a lid sealing a lower opening of the concave portion; and a metal lead terminal of which a upper region is electromechanically connected and fixed to the outer terminal installed at the outer surface of the insulating package, and a lower region thereof is projected downward from the lid. The metal lead terminal includes a drooping portion extending along the side surface of the insulating package and a connecting member extending from the lower part of the drooping portion. The drooping portion is not constrained from the connecting member, and the drooping portion and the connecting member are capable of elastically deformed.

Owner:TOYO TSUSHINKI

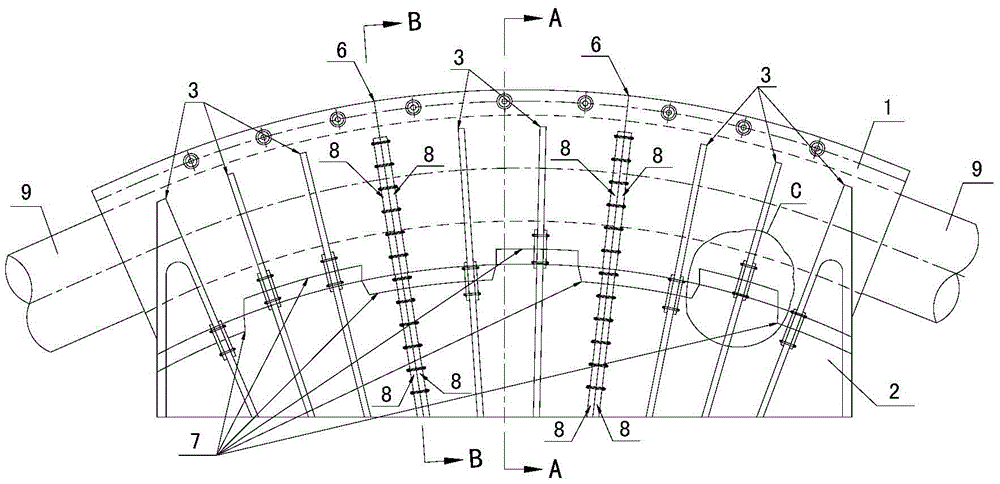

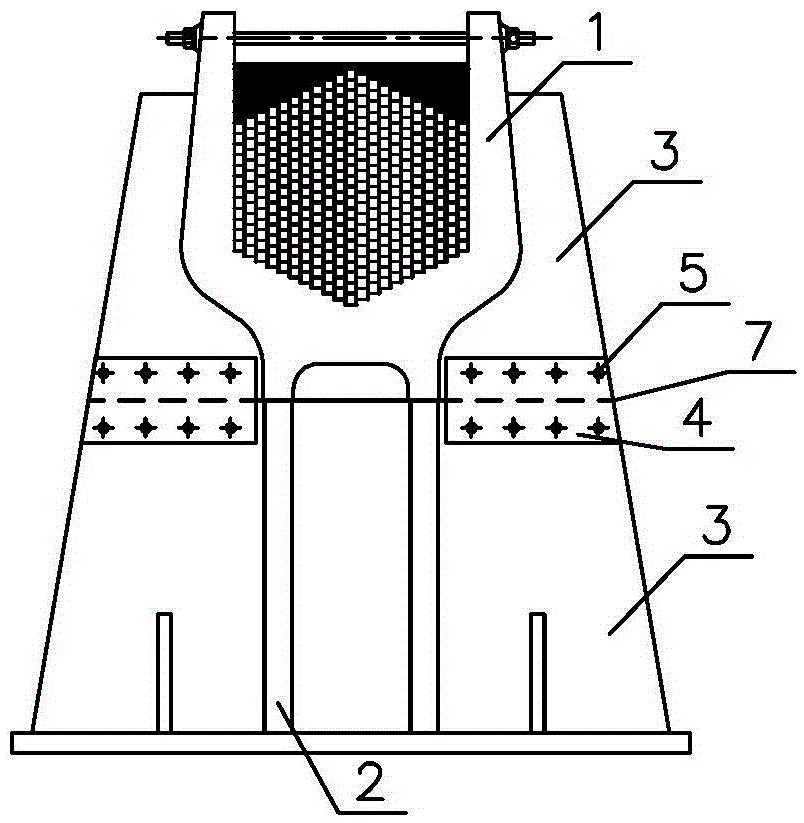

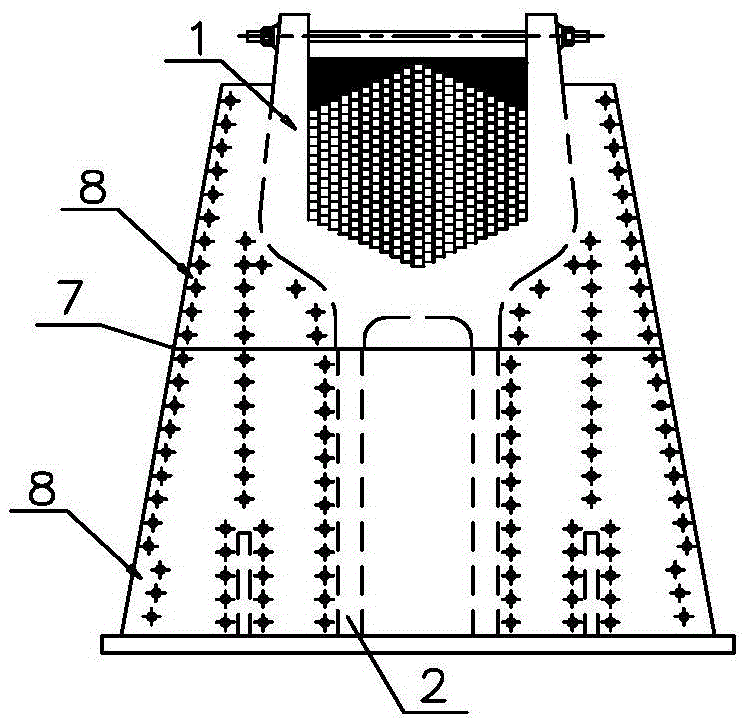

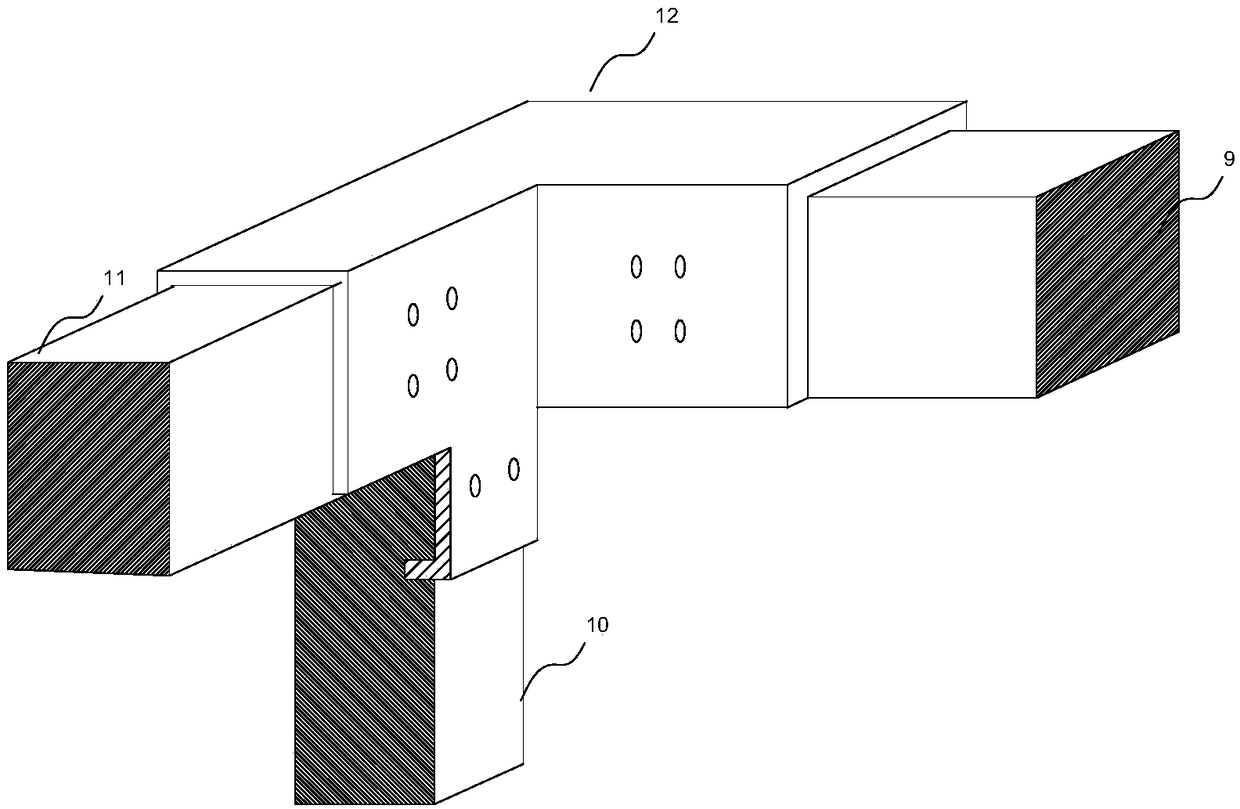

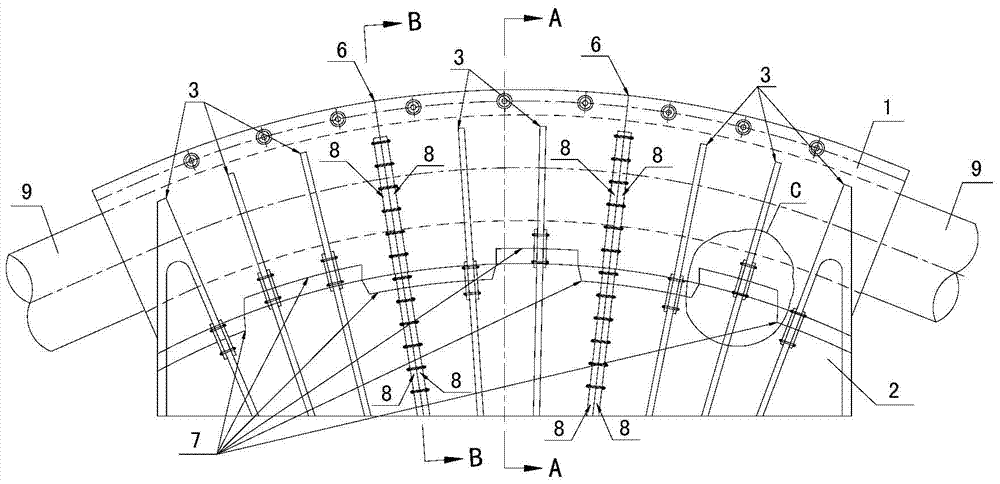

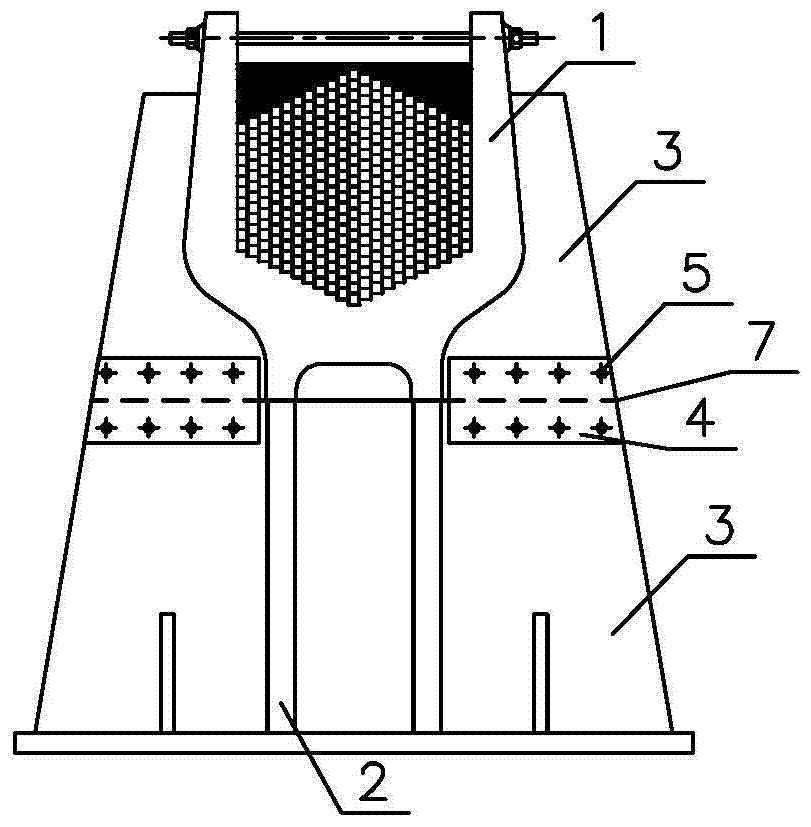

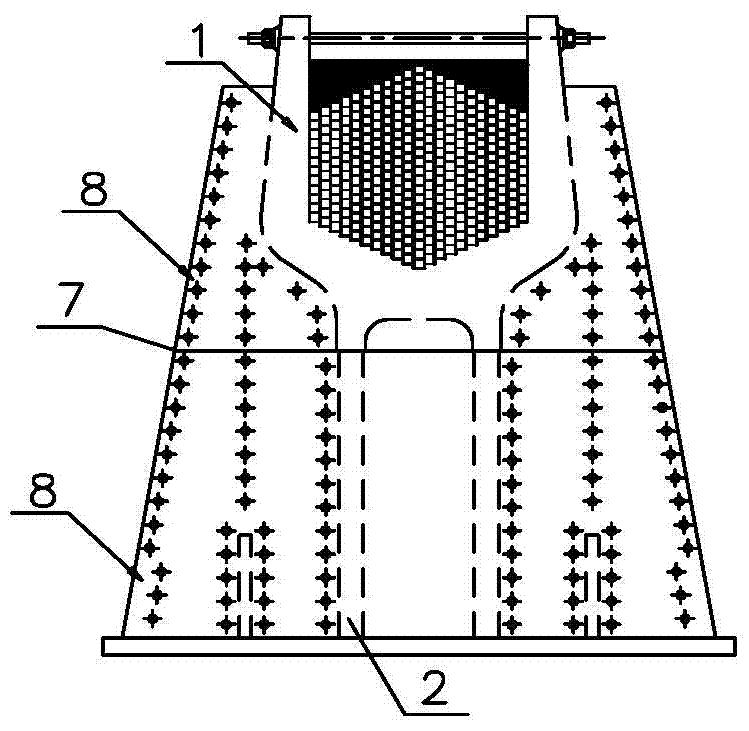

Multi-block main cable saddle structure

ActiveCN105421229AQuick installationAvoid Welding Residual StressBridge structural detailsThick plateWelding residual stress

The invention relates to a multi-block main cable saddle structure. The main cable saddle of a suspension bridge is divided into an upper saddle head and a lower saddle head through partitioning interfaces. The partitioning interfaces are located in the position 30+ / -5cm below a cable bearing trough bottom plate for a main cable. Concave-convex seams are adopted at the partitioning interfaces. End transverse ribs at the partitioning interfaces are connected through splice plates and high-strength bolts at the concave-convex seams. The upper saddle head and the lower saddle head are each equally divided into three blocks through the transverse partitioning interfaces in the longitudinal direction. The two end transverse ribs are arranged on the two sides of each transverse partitioning interface respectively and connected through the high-strength bolts. By means of the multi-block main cable saddle structure, the partitioned blocks can be quickly mounted on site; residual welding stress caused by super-thick plate welding is avoided through the partitioned blocks in the height direction, the upper saddle head and the lower saddle head are tightly connected together under the action of the powerful vertical main cable pressure; the concave-convex seams facilitate high-altitude hoisting and splicing and can also resist unbalanced horizontal shear force; by adopting the partitioned blocks, the weight of a single saddle body is reduced, casting, transporting and hoisting are facilitated, and the multi-block main cable saddle structure is particularly applicable to large-span suspension bridges in mountainous areas where transportation condition limitations exist.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

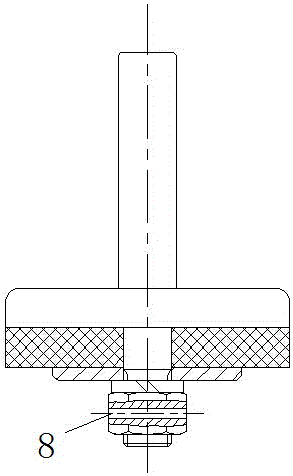

Novel one-way valve element structure

InactiveCN105697825AAvoid Soldered ConnectionsAvoid breakingCheck valvesLift valveStress concentrationFiber

A new check valve spool structure belongs to the technical field of valves and is composed of a valve stem, a valve plate, a sealing gasket, a pressure plate and a nut. The valve stem is a stepped shaft, and the shaft head of the stepped shaft is processed with external threads. Placed on the shoulder of the stepped shaft, the gasket is placed under the valve plate, the pressure plate is placed under the gasket, the nut is tightened under the pressure plate, and a pin hole through the valve stem is opened on the tightened nut. A latch is arranged in the pin hole. The invention has simple structure and clear working principle. Compared with the traditional valve core structure, it avoids the welding connection between the valve stem and the valve plate, and the fracture of the root of the valve stem is caused by the stress concentration; the setting of the gasket can play a buffering and sealing effect , prolonging the service life of the sealing surface; the use of cylindrical pins can avoid the entanglement of fibrous substances and affect the matching of the sealing surface, further improving the sealing performance.

Owner:YANGZHOU SIQI ENVIRONMENTAL PROTECTION EQUIP CO LTD

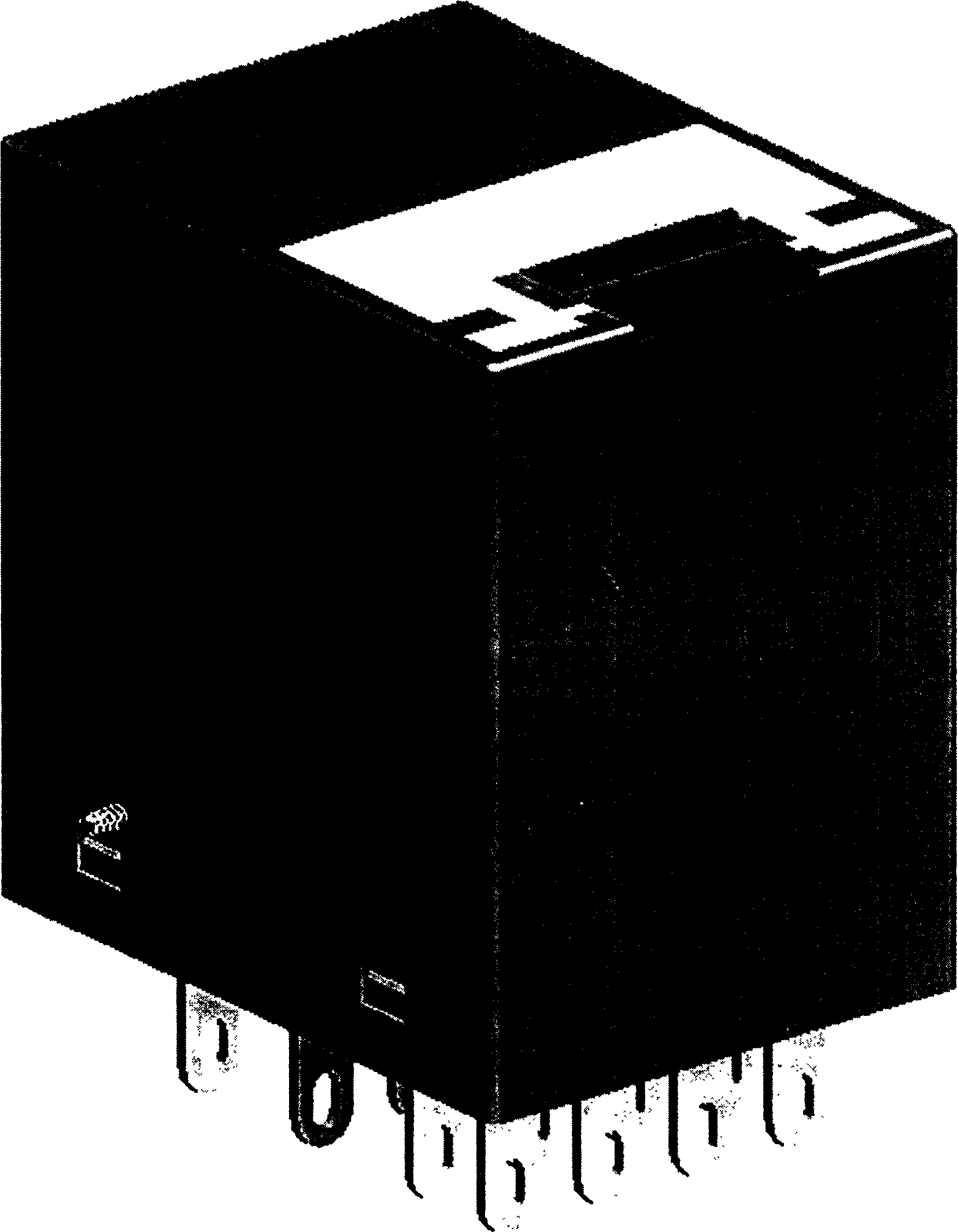

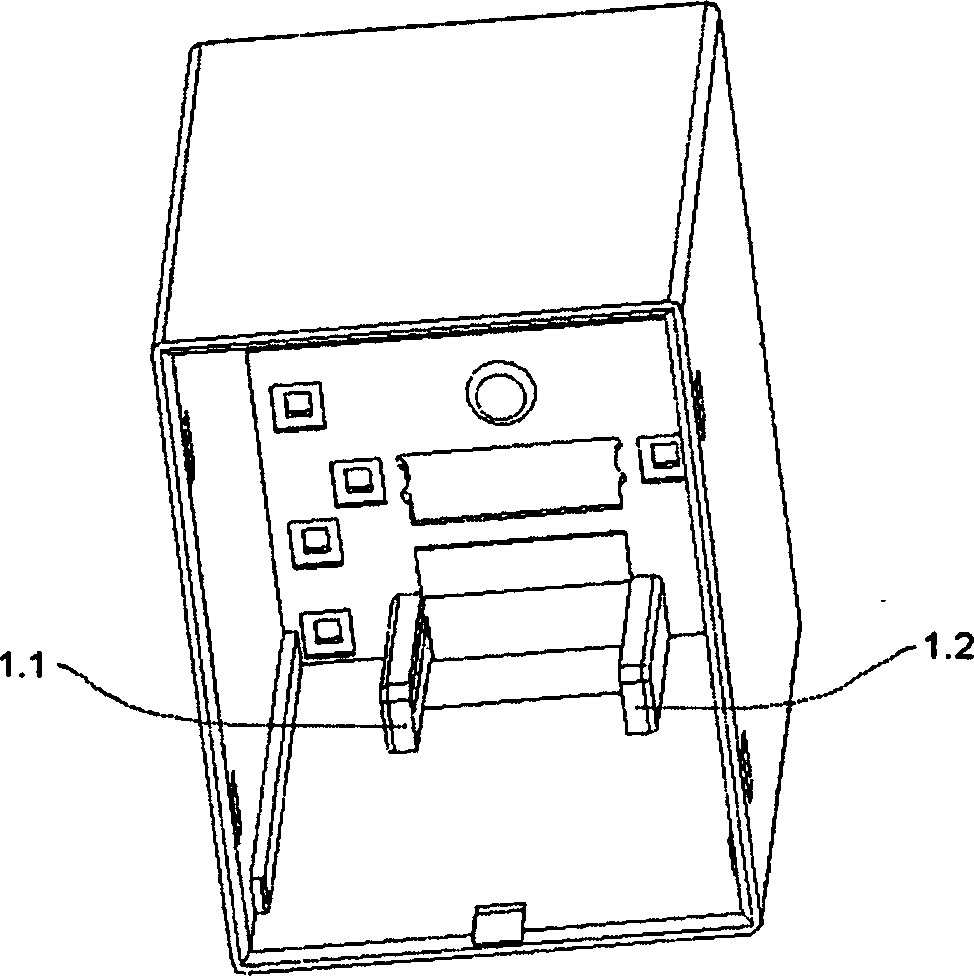

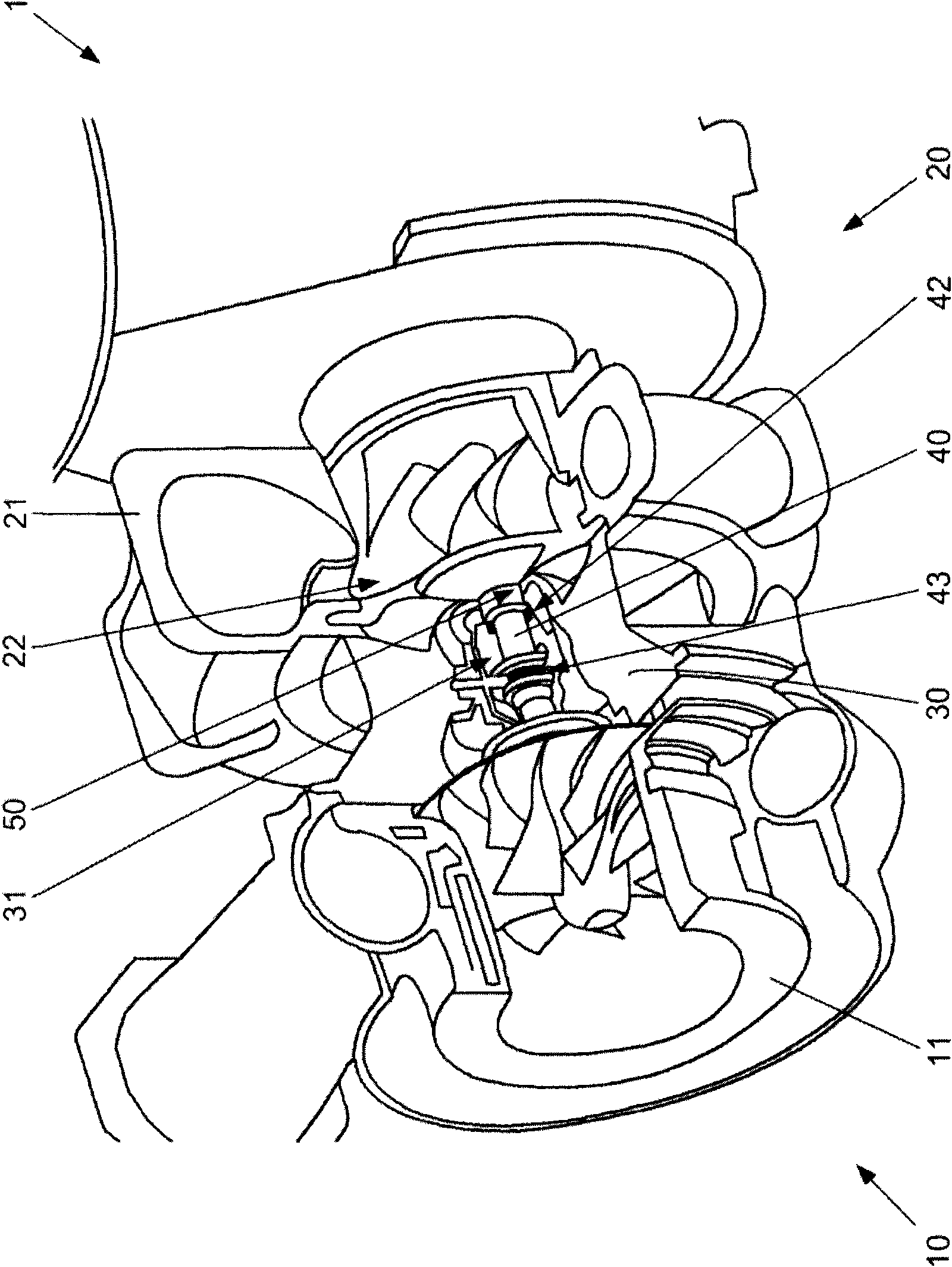

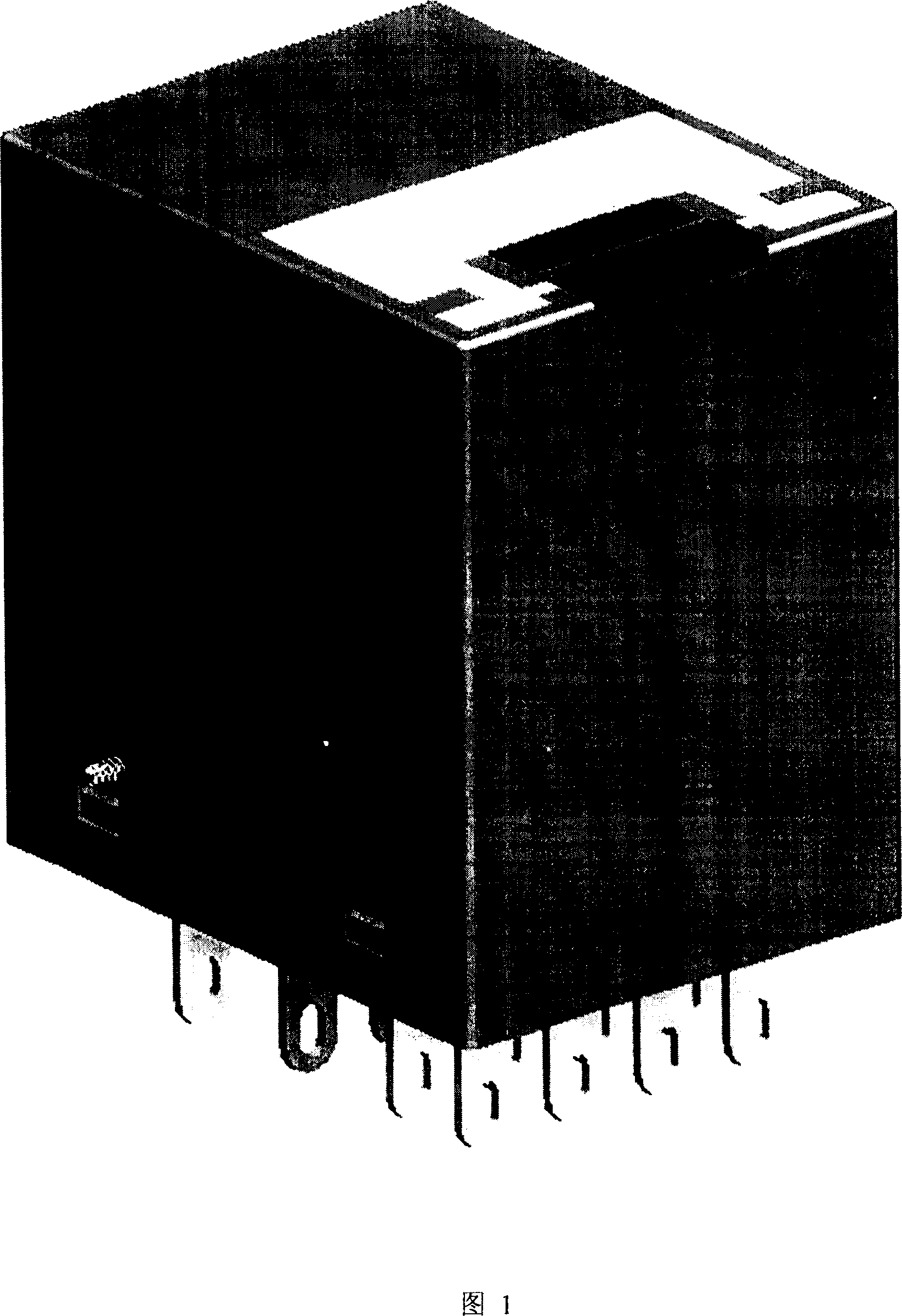

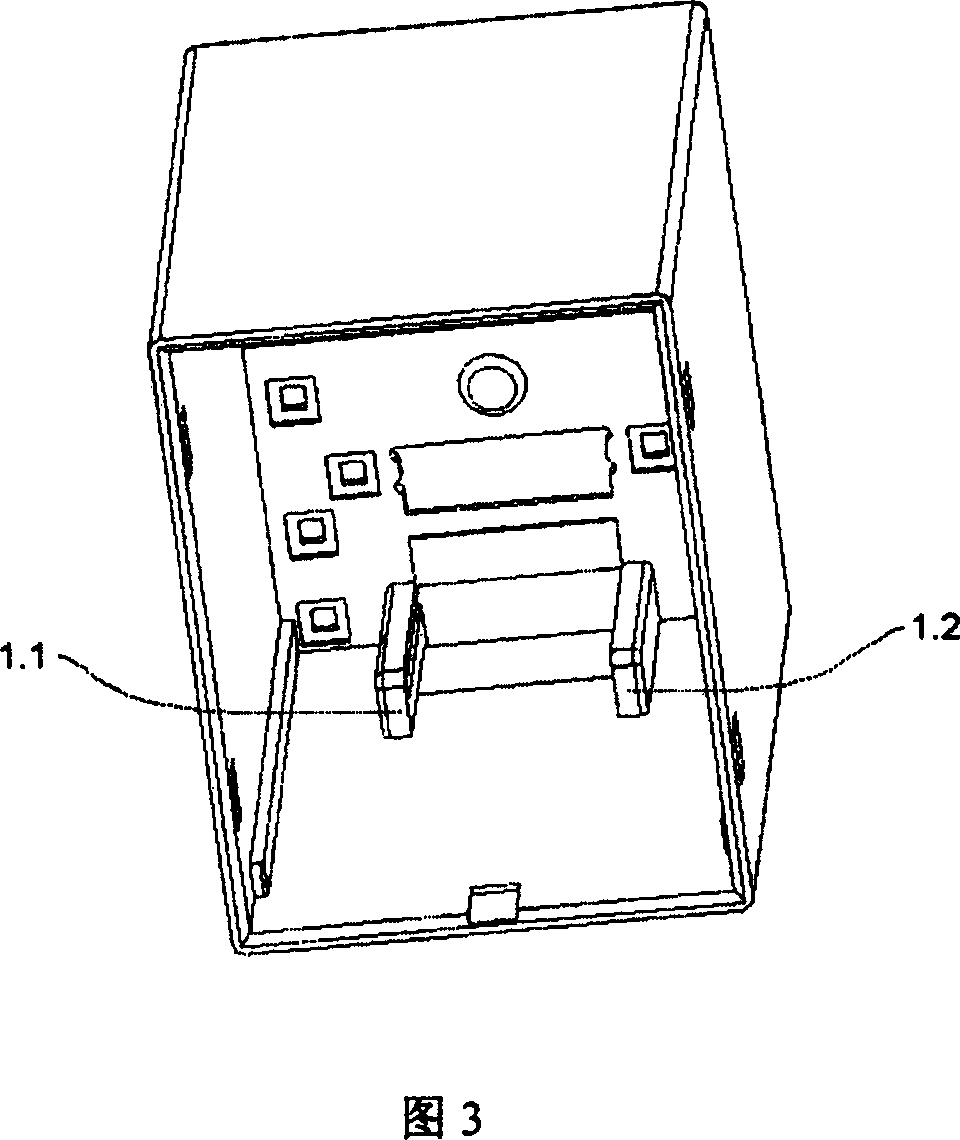

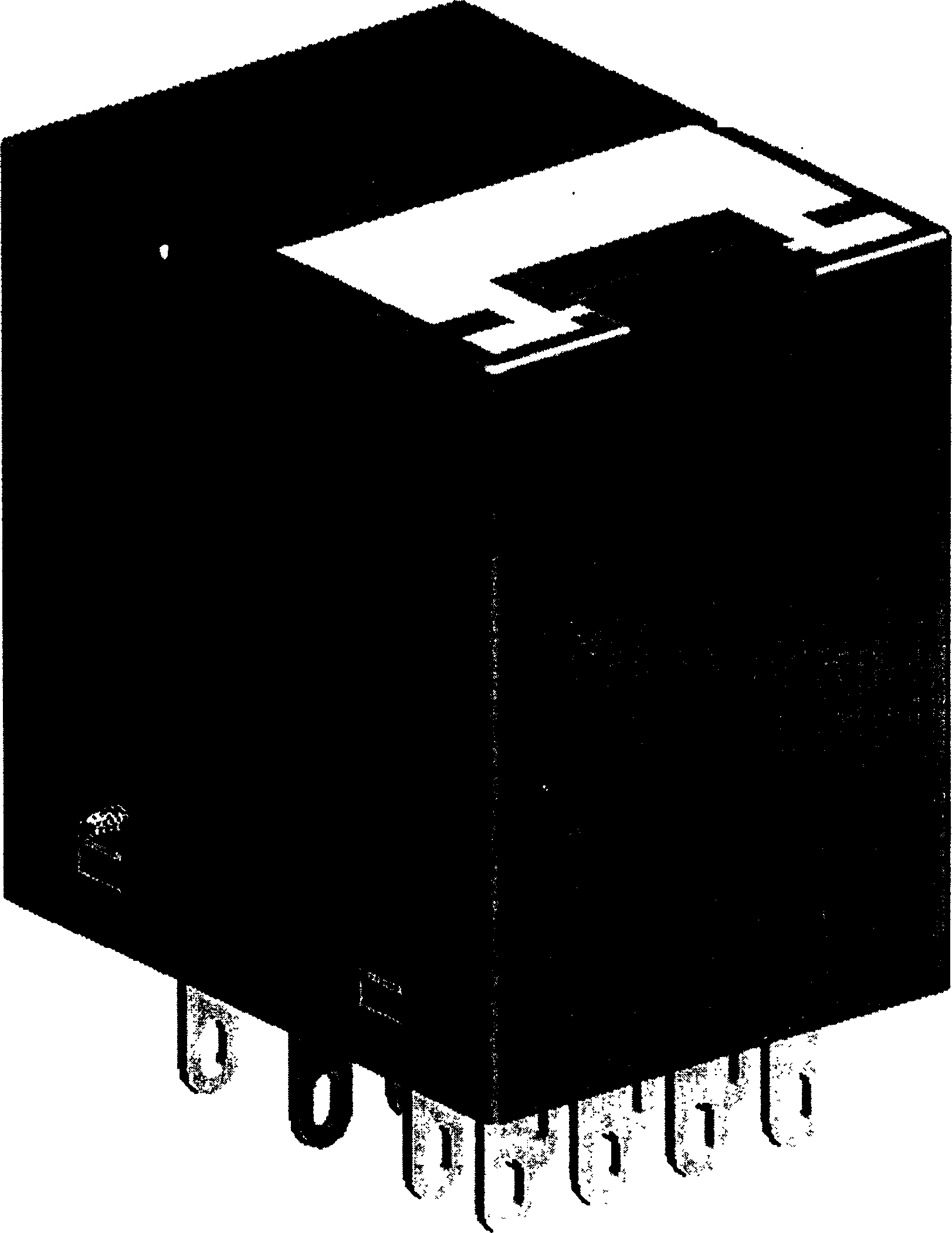

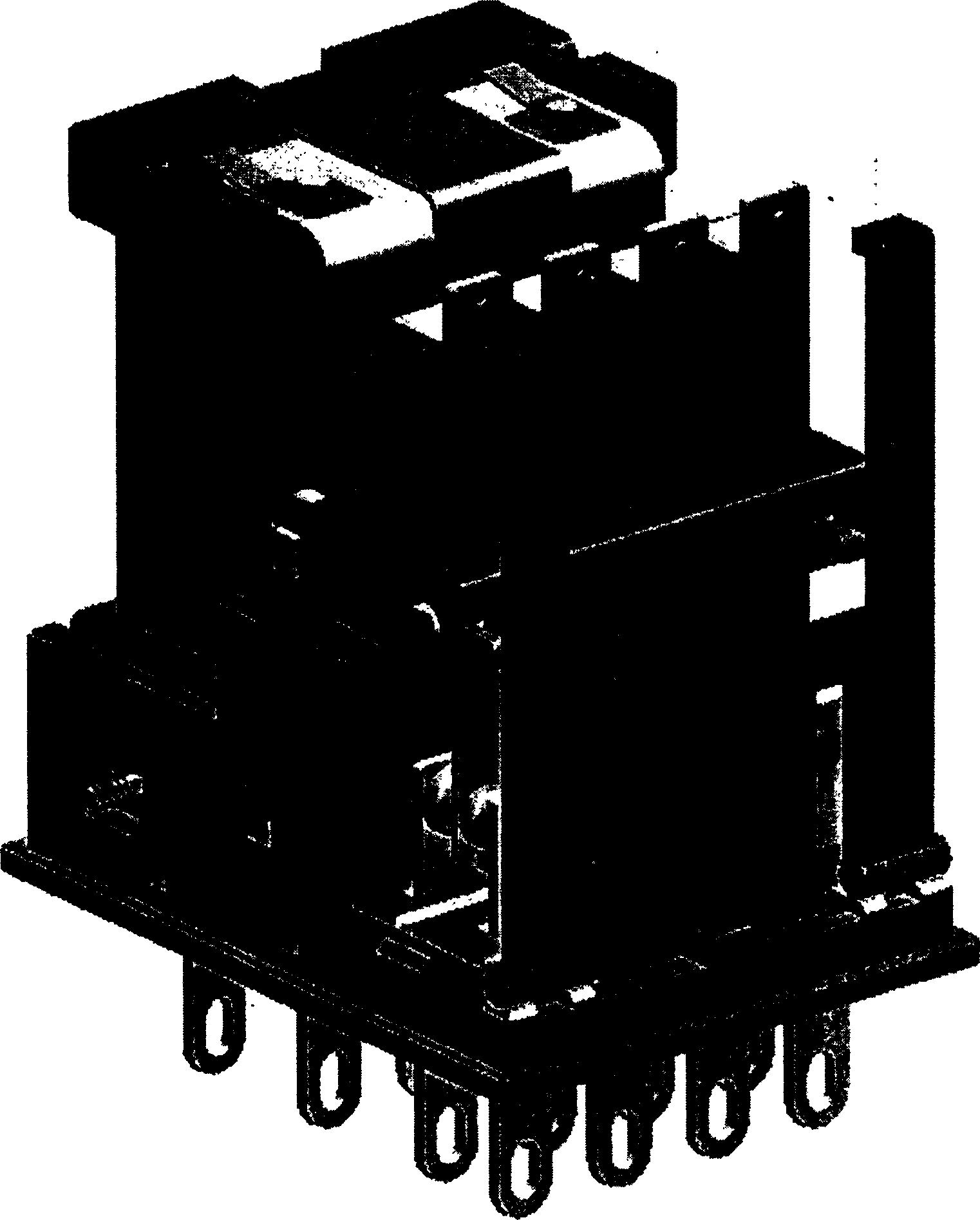

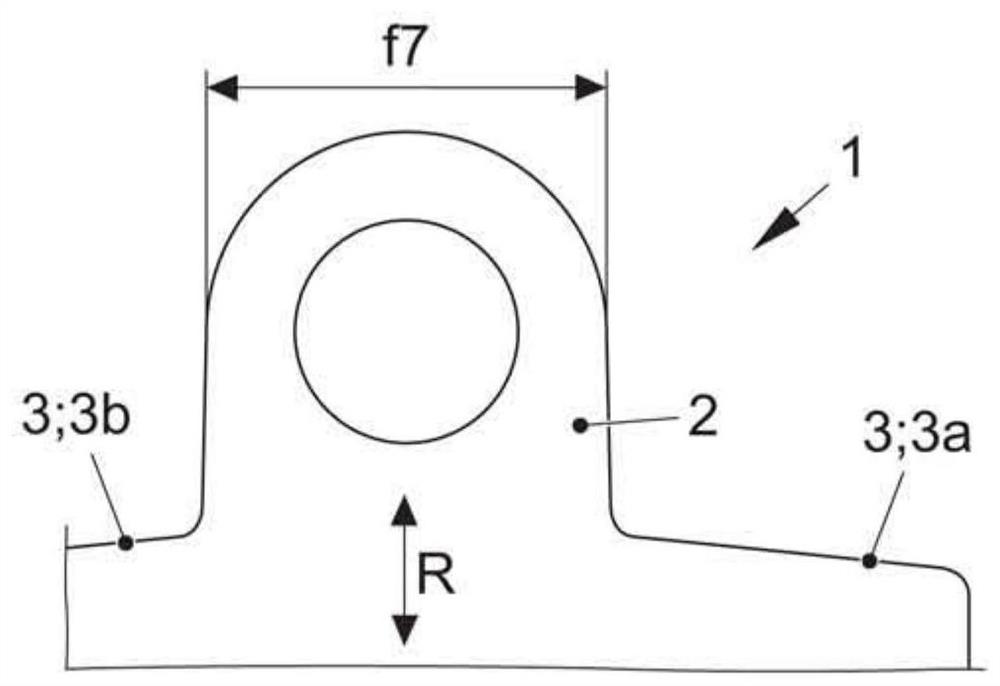

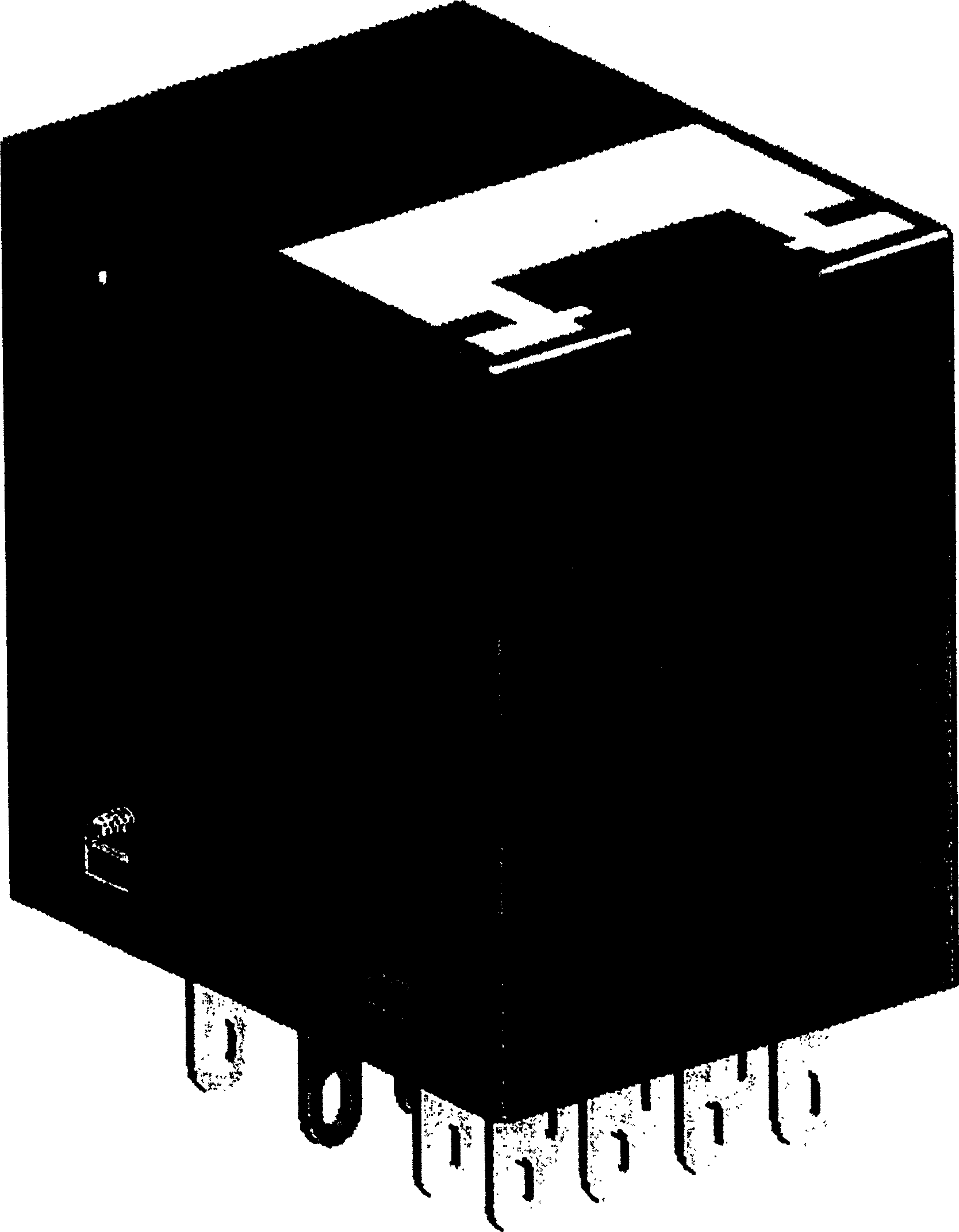

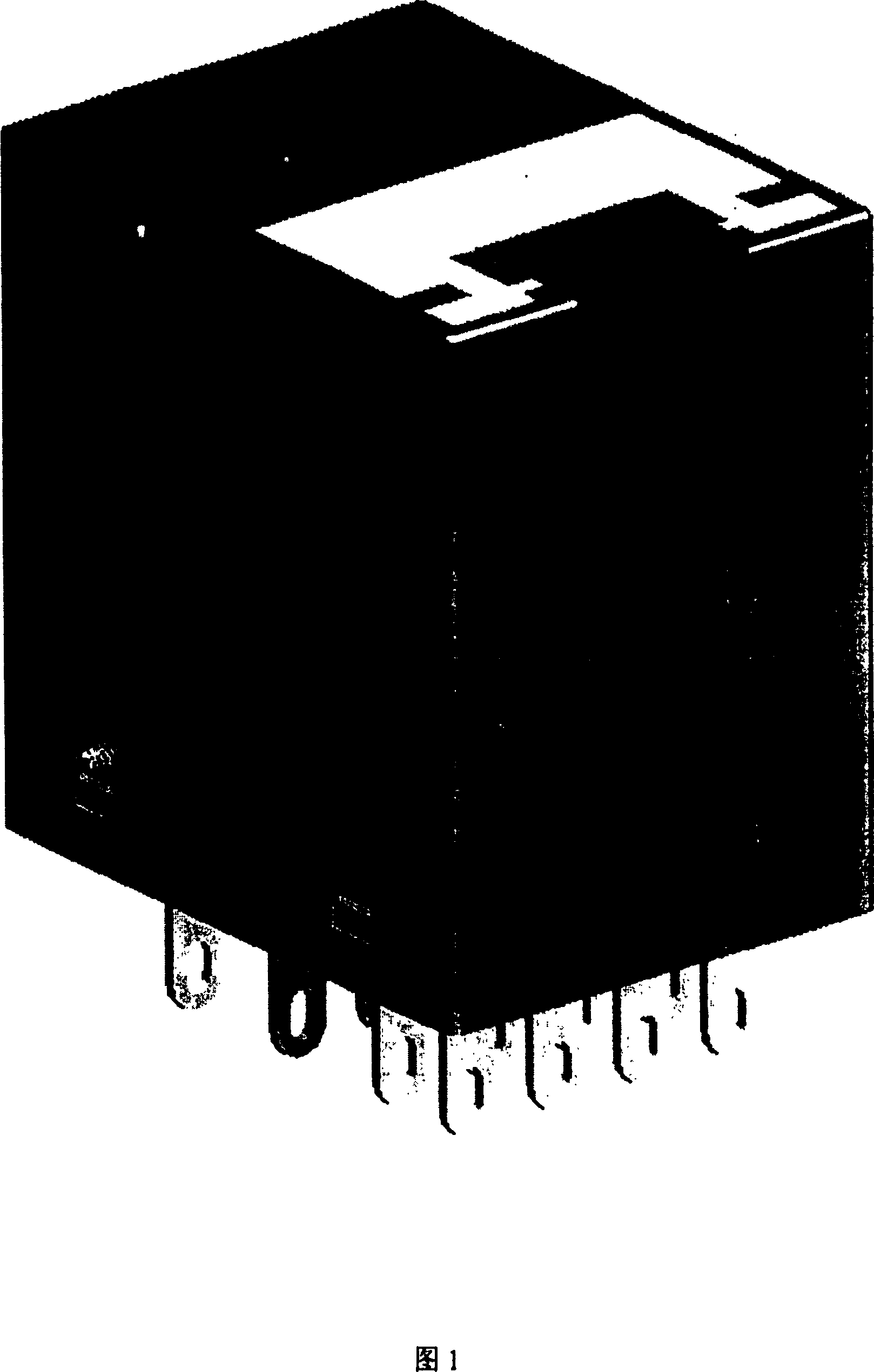

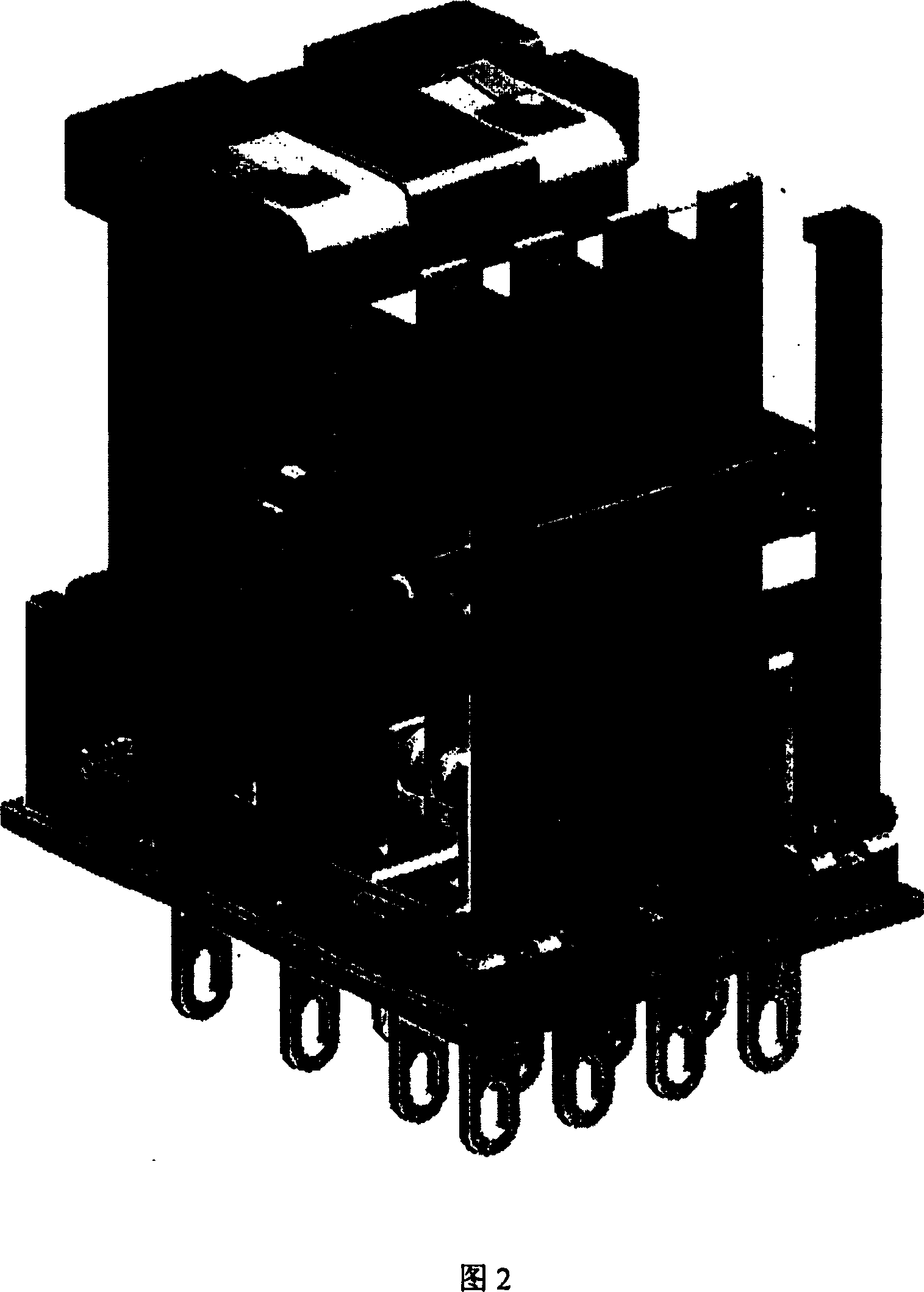

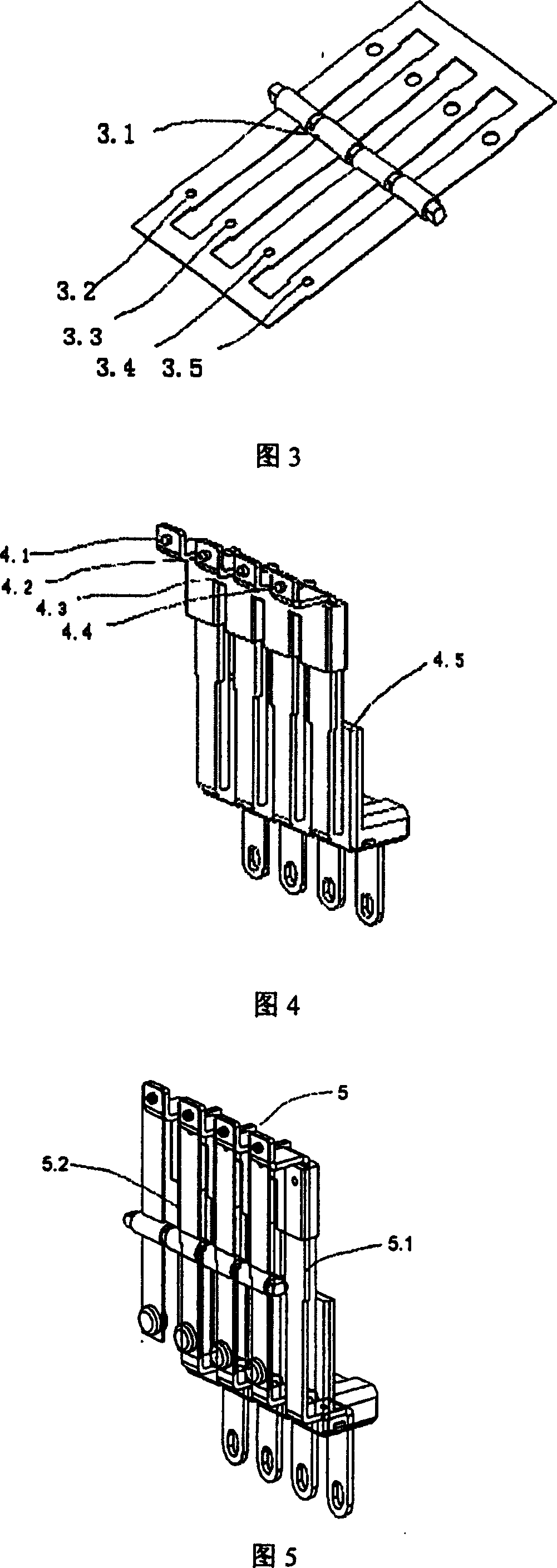

Low height press-button type small-sized large power AC-DC electromagnetic relay

ActiveCN1558436AAvoid soldered connectionsAvoid pollutionElectromagnetic relay detailsEngineeringRivet

in particular a low height small-sized high power AC, DC electromagnetic relay with a plurality of contacts by utilizing a press-button arrangement, wherein a seesaw structure press-button mechanism is arranged on the top of the outer casing, one end will move forward and backward through the press-button, the other end of the press-button will drive the moving reed row of the relay, thus realizing the contact conversion. The moving reed lead-out sheets are also linked into lead-out row through the insulation member, and are connected through rivet compression, the press-button is mounted on the side surface of the outer casing, a support rotation shaft is arranged at the center of the press-button.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

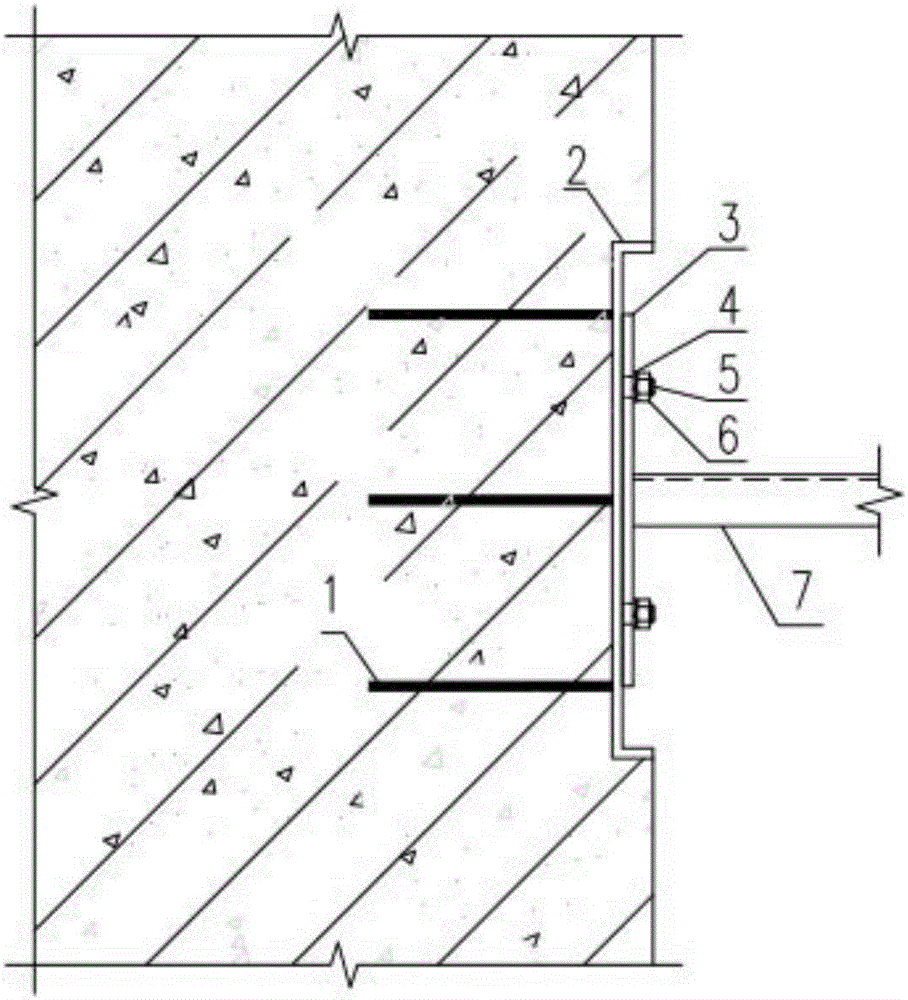

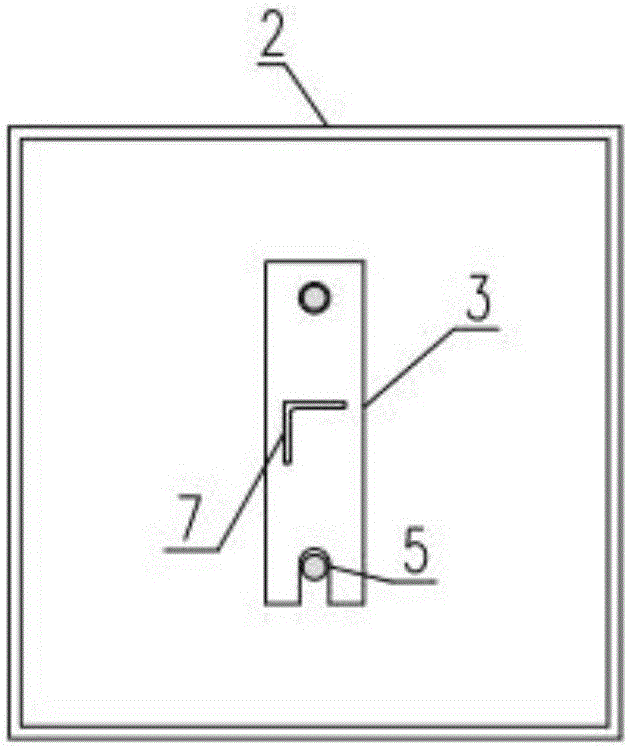

Demountable support device and assembling method thereof

InactiveCN106436922AAvoid Soldered ConnectionsShorten the construction periodBuilding constructionsArchitectural engineeringBuilding construction

Owner:HUATIAN ENG & TECH CORP MCC

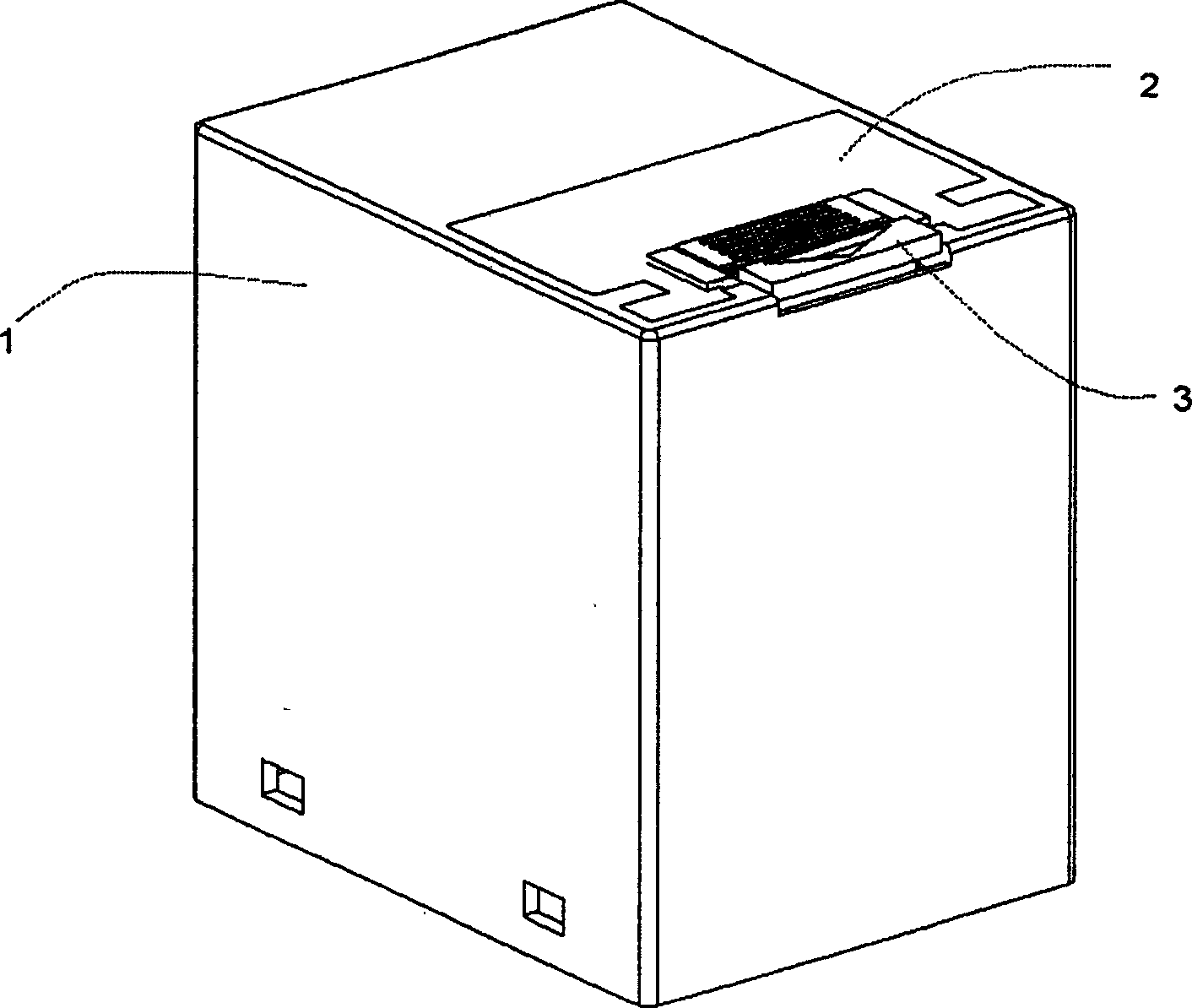

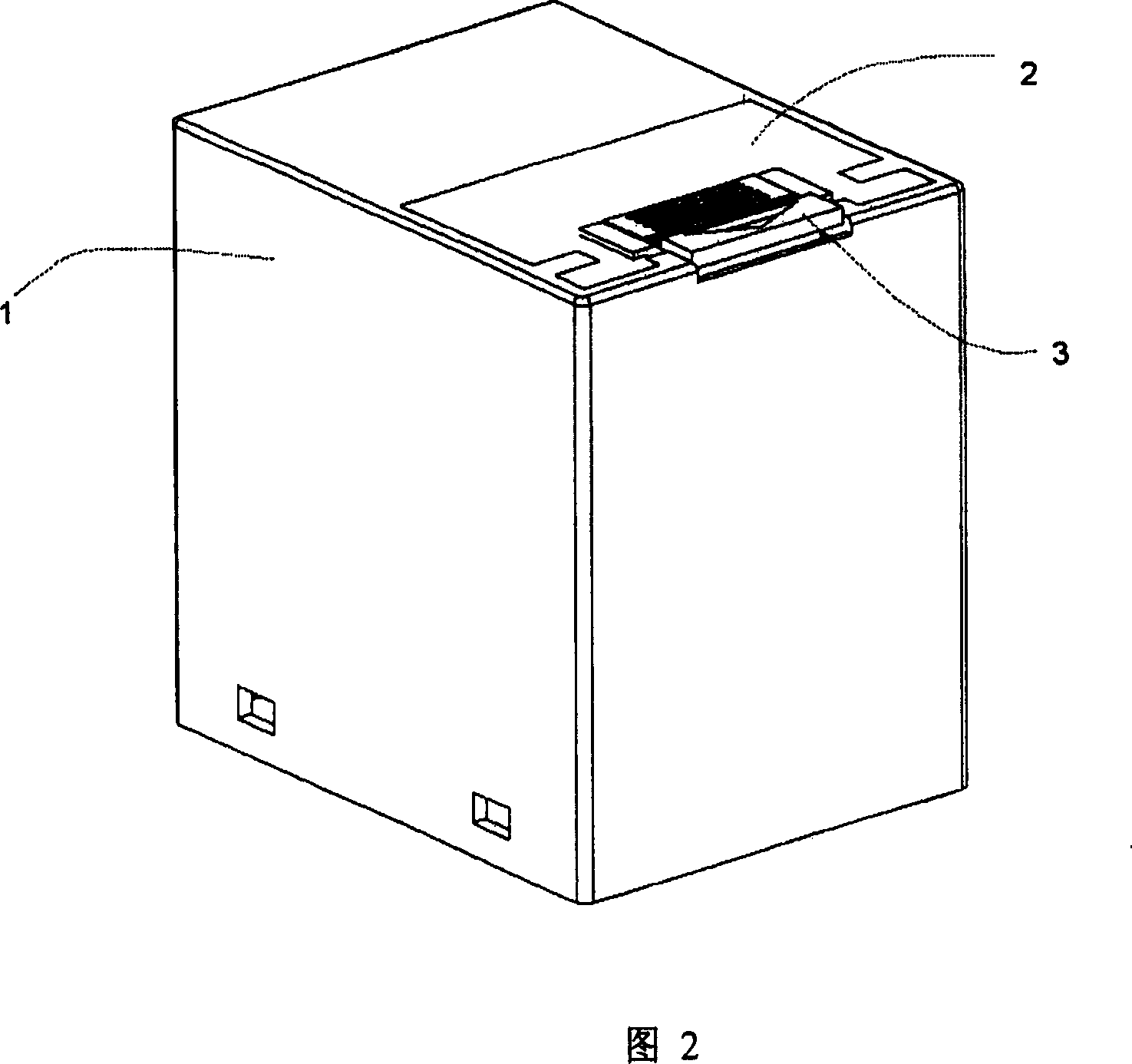

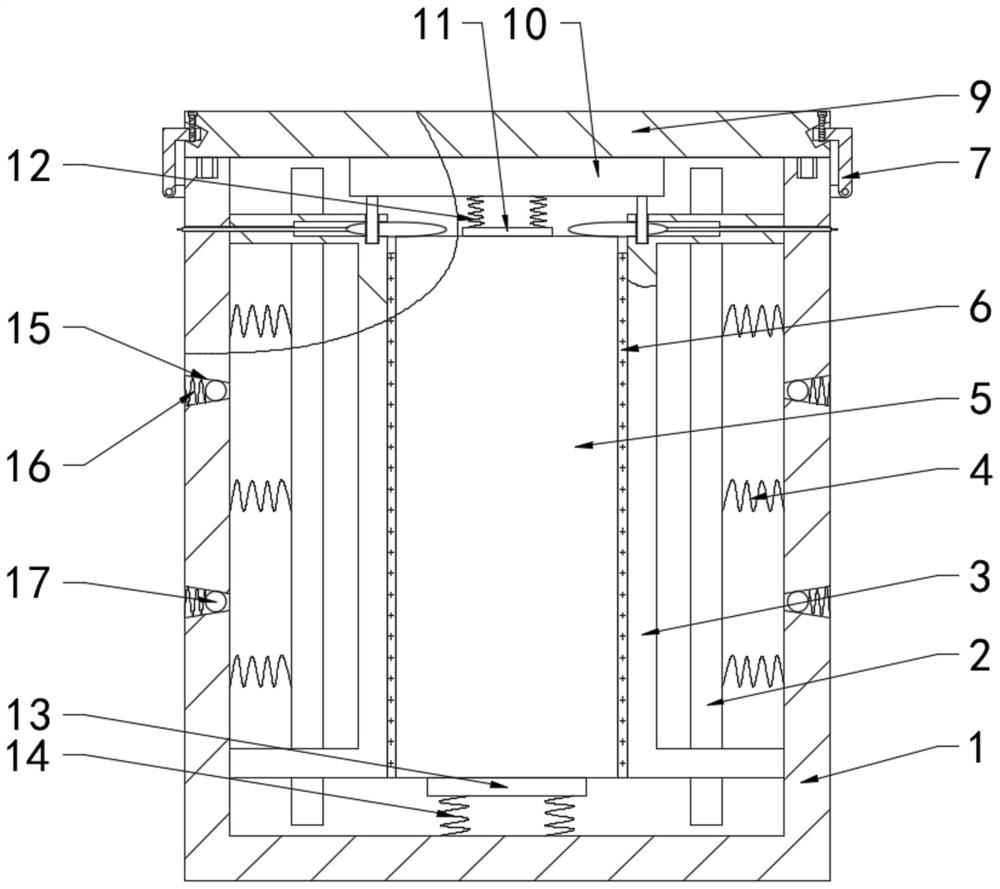

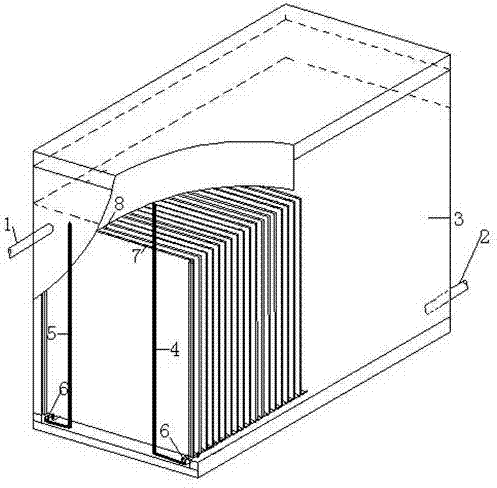

Assembling-facilitating cabinet frame

PendingCN108966580AEasy to installAvoid Soldered ConnectionsPrinted circuit board receptaclesRack/frame constructionEngineering

The invention discloses an assembling-facilitating cabinet frame. The cabinet frame is a square frame and comprises an upper square frame, a lower square frame and vertical beams connecting the uppersquare frame and the lower square frame. The upper square frame and the lower square frame comprise two first crossbeams and two second crossbeams. The first crossbeams and the second crossbeams and the vertical beams connected with the first crossbeams and the second crossbeams are connected through three-way connectors. The first crossbeam and the second crossbeams and the vertical beams connected with the first crossbeams and the second crossbeams and the three-way connectors are connected through screws. When the cabinet frame is used, the two upper crossbeams are inserted into the first connection ends and the second connection ends, insertion of the vertical beams is limited through the convex edges and the bumps of the extension pieces, the corresponding grooves are arranged on thevertical beams, the convex edges and the bumps are clamped into the grooves, the screws are applied to penetrate through the first crossbeam connection holes, the second crossbeam connection holes andthe vertical beam connection holes and then the three beams are fixed so that the structure can be used for quick and convenient installation, welding connection is avoided and the environment is protected.

Owner:天津正本自控系统有限公司

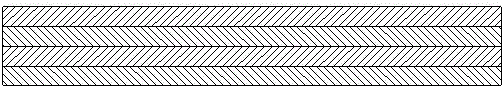

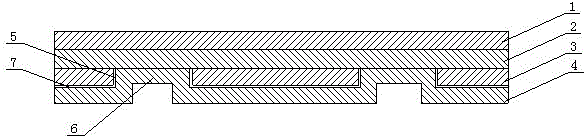

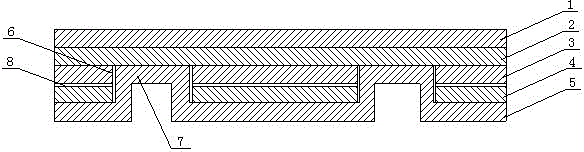

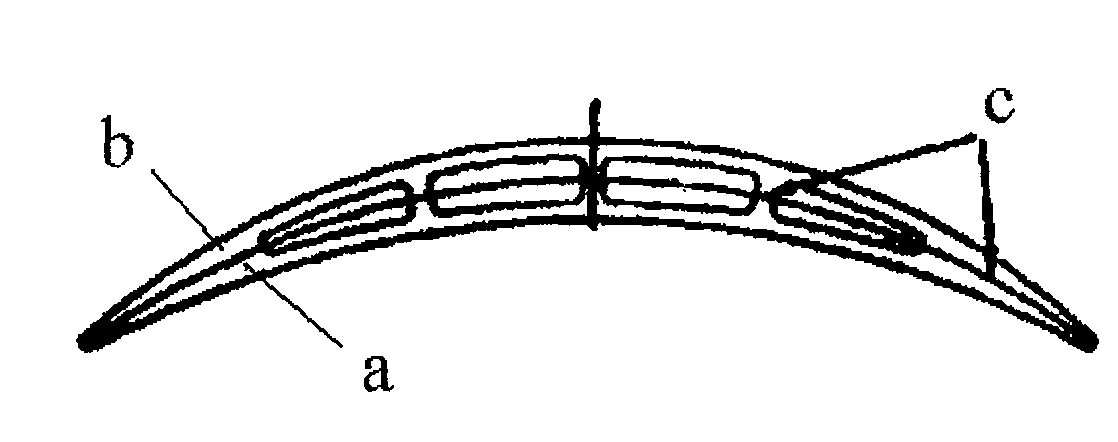

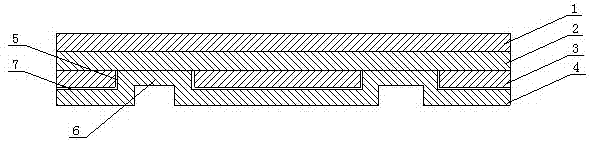

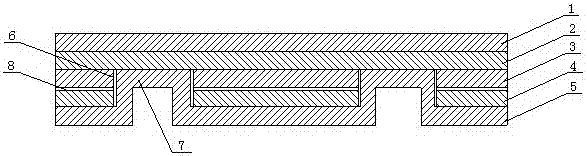

Car body multi-layer board overlapping structure

ActiveCN103332226AEasy to manufactureUniform distribution of intensitySuperstructure connectionsEngineeringSecondary layer

The invention aims to provide a car body multi-layer board overlapping structure which is used for solving the problems of high production cost, insufficient welding strength and loose structure which are caused by the defects such as cold solder joint, weak solder joint or splashing due to the local thick material of the conventional car body multi-layer board overlapping structure. The car body multi-layer board overlapping structure comprises a first layer of board, a second layer of board, ellipsis, an (N-1)th layer of board and an Nth layer of board, wherein N is more than or equal to 4. The structure is characterized in that the first layer of board, the second layer of board and the third layer of board are sequentially overlapped, welded and fixed so as to form a primary finished product welding assembly; the third layer of board, ellipsis and the (N-1)th layer of board are sequentially overlapped, and a plurality of through notches are formed in same positions; and projection parts are formed on the Nth layer of board and correspond to the notches, the projection parts of the Nth layer of board are inserted into the notches, and the Nth layer of board is welded and fixed with the primary finished product welding assembly so as to form the car body multi-layer board overlapping structure.

Owner:CHERY AUTOMOBILE CO LTD

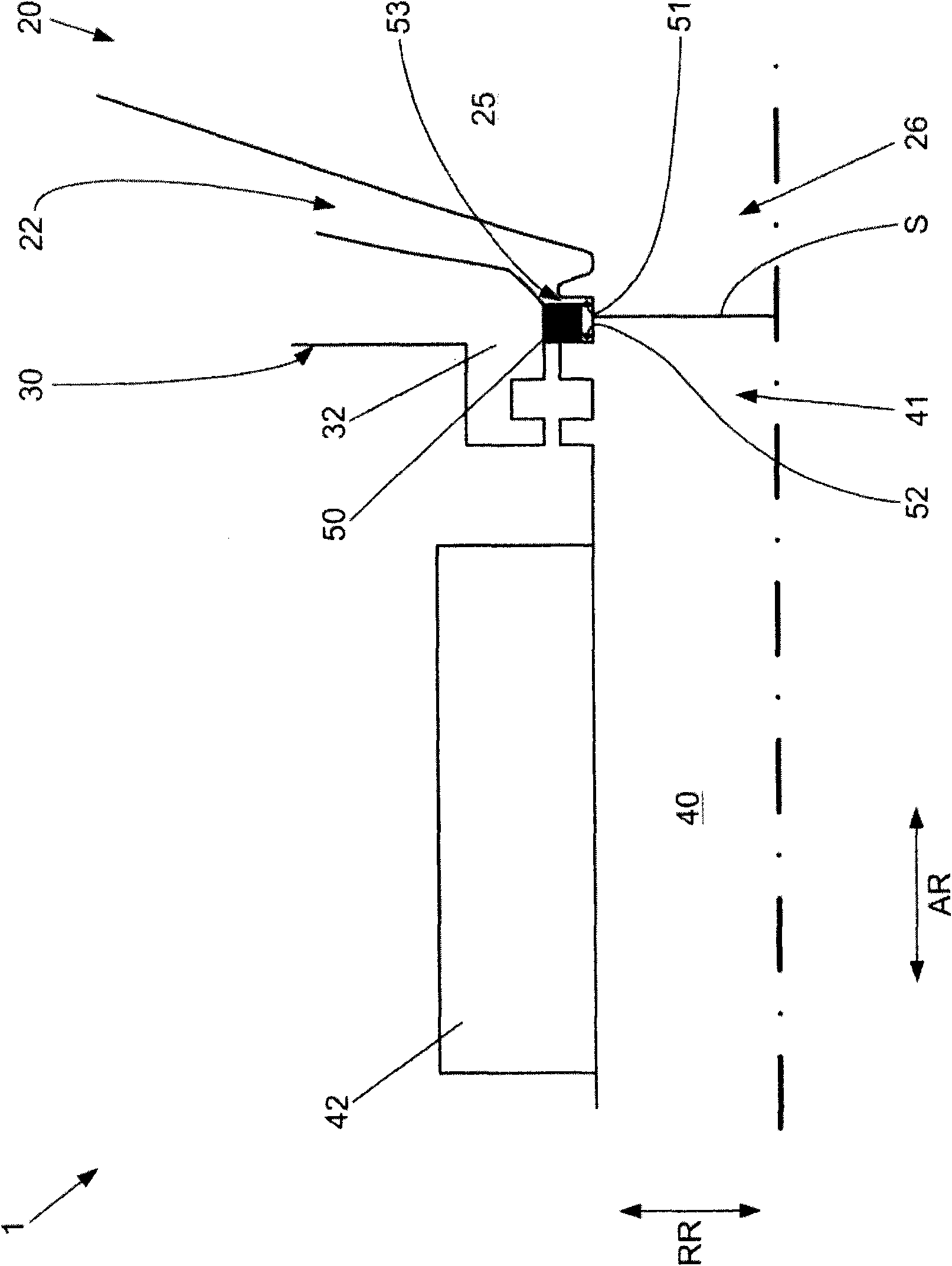

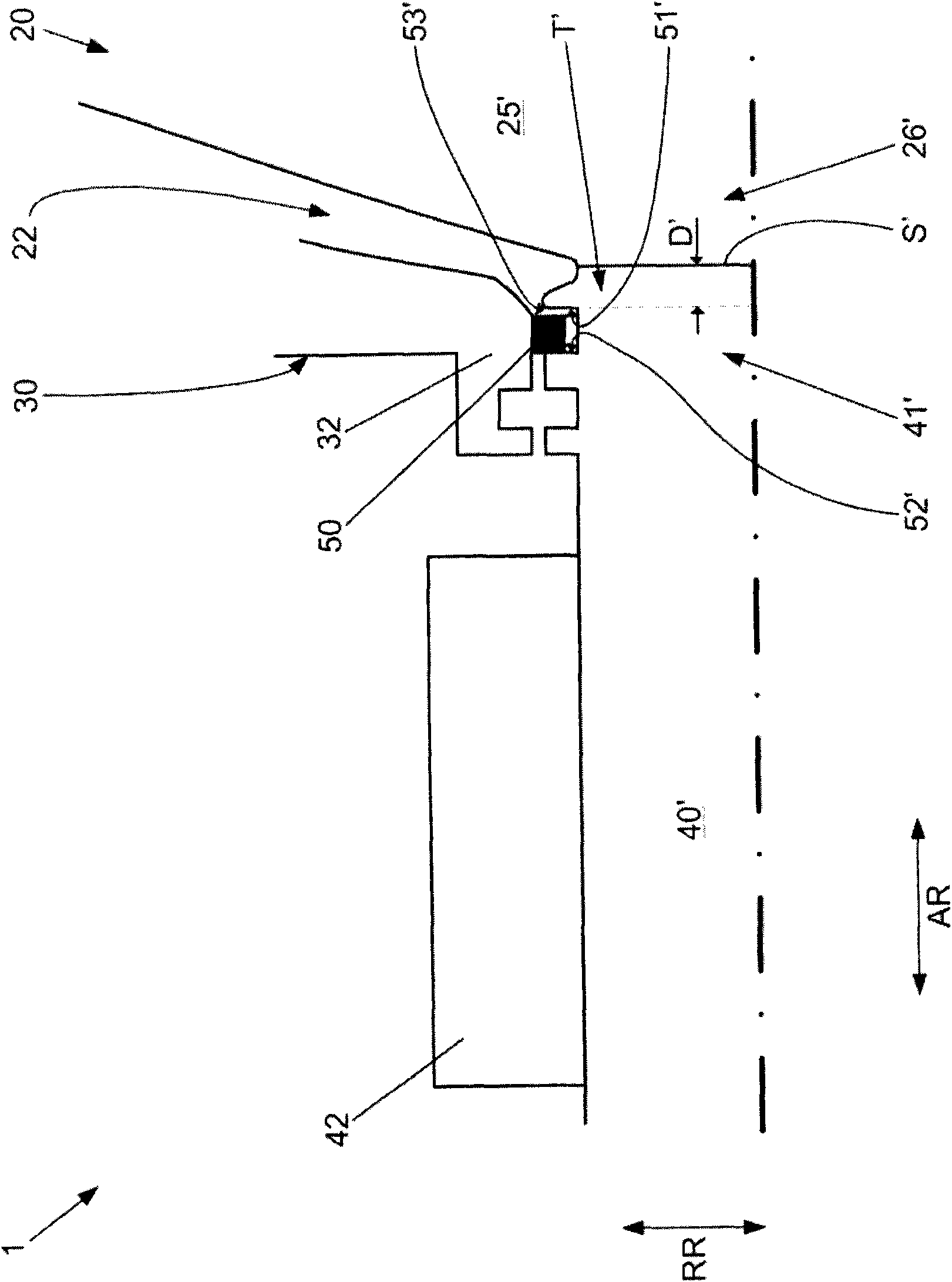

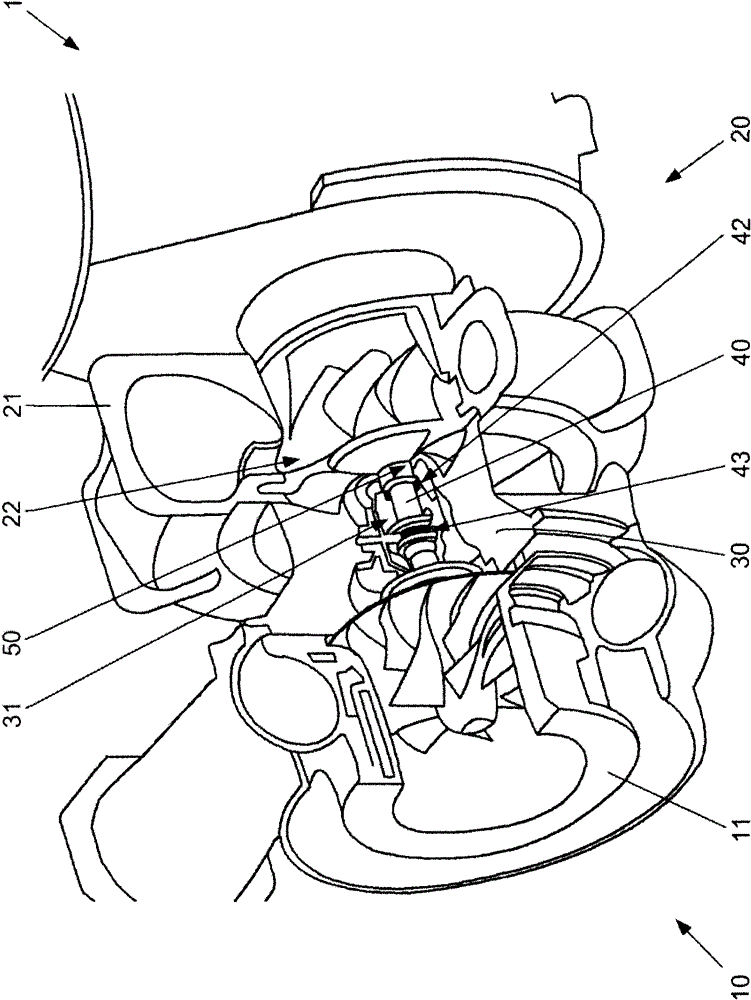

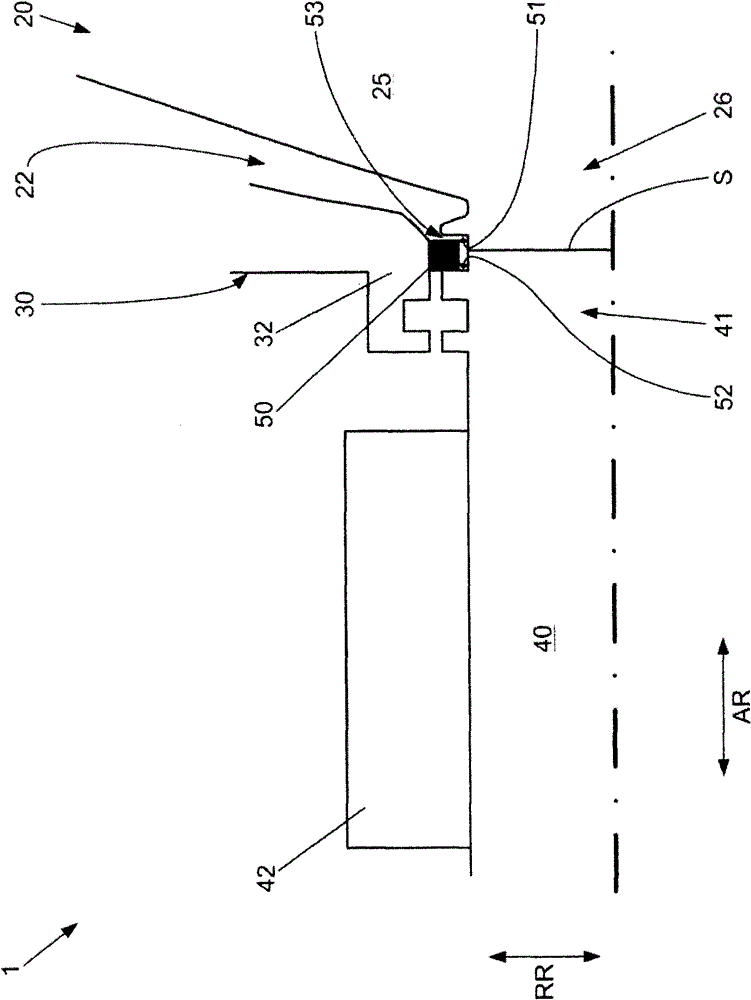

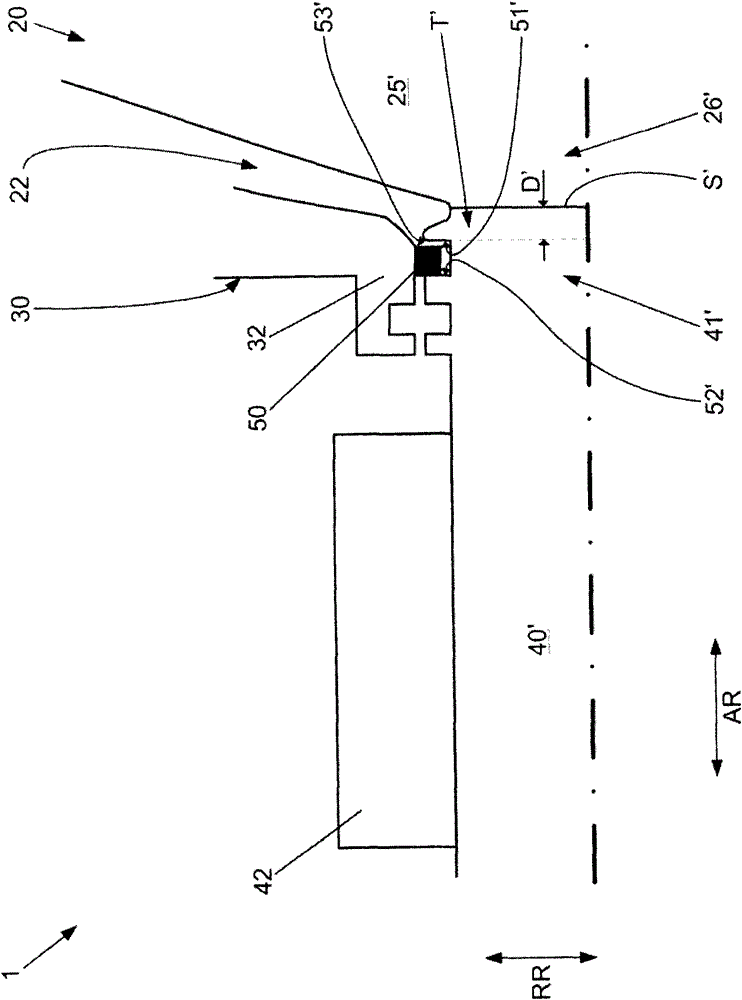

Turbo machine

InactiveCN102322304ALow melting pointReduce rotational frictionBlade accessoriesGas turbine plantsImpellerEngineering

The invention relates to a turbo machine (1), comprising a bearing housing (30), shafts (40',40'') supported on an inner chamber(31) of the bearing housing (30) rotatably, working impellers(25',25'') connected with longitudinal end parts(41',41'') of the shafts (40',40'') on a material and arranged on the outside of the inner chamber(31) and in a working impeller chamber(22), and a seal member(50) arranged on the circumferences of the shafts (40',40'') to thereby seal the inner chamber(31) relative to the working impeller chamber(22); wherein, the seal member is used for sealing the common effect of two seal surfaces(51',52',51'',52'') rotated oppositely. The invention aims to provide a turbo machine which prevents an undesired welded loose release between the working impellers and the shafts reliably by forming and arranging the seal surface materials of at least one seal surface of the two seal surfaces on isolation layers(T',T'') between the seal member and the working impellers.

Owner:MAN ENERGY SOLUTIONS SE

Low height press-button type small-sized large power AC-DC electromagnetic relay

ActiveCN1303627CAvoid Soldered ConnectionsAvoid pollutionElectromagnetic relay detailsEngineeringRivet

in particular a low height small-sized high power AC, DC electromagnetic relay with a plurality of contacts by utilizing a press-button arrangement, wherein a seesaw structure press-button mechanism is arranged on the top of the outer casing, one end will move forward and backward through the press-button, the other end of the press-button will drive the moving reed row of the relay, thus realizing the contact conversion. The moving reed lead-out sheets are also linked into lead-out row through the insulation member, and are connected through rivet compression, the press-button is mounted on the side surface of the outer casing, a support rotation shaft is arranged at the center of the press-button.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

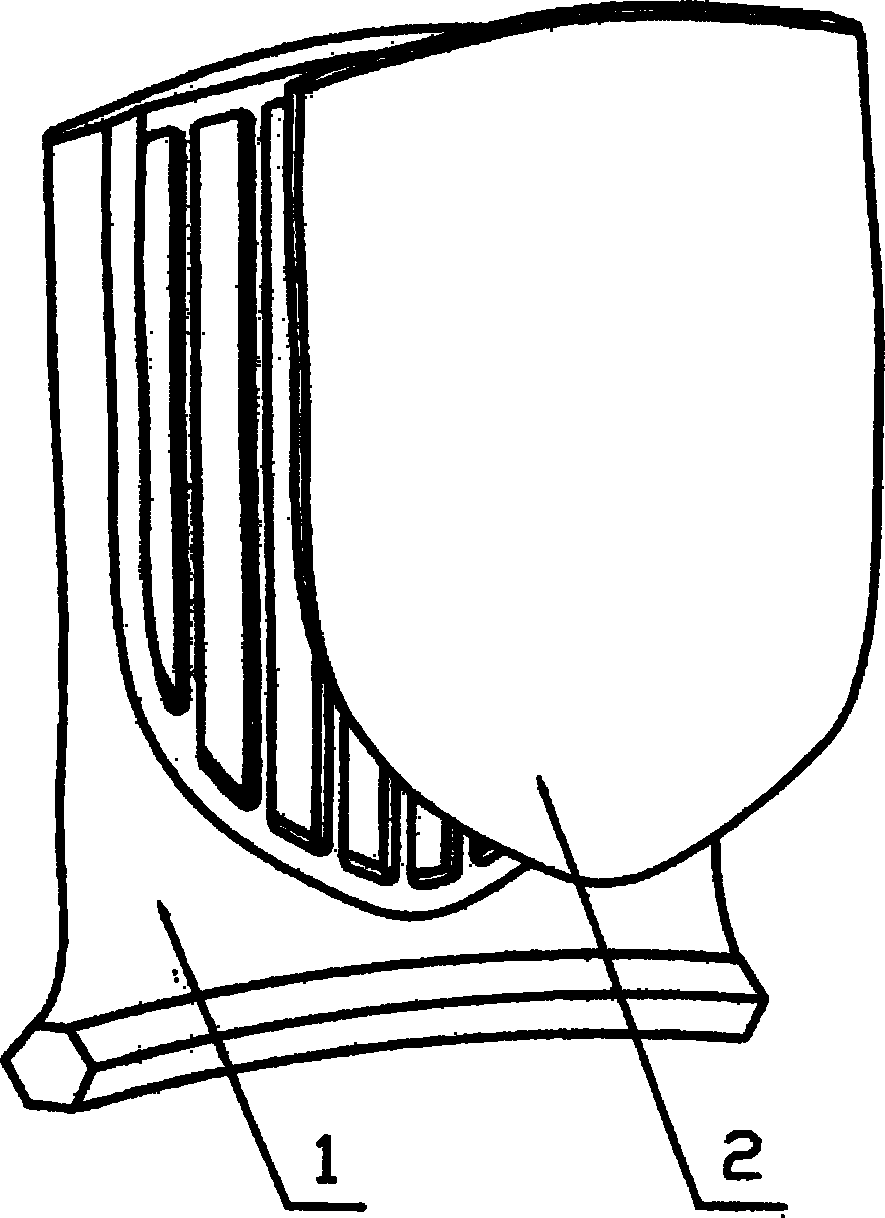

Hollow fan blade for aircraft engine

ActiveCN101418811BImprove the safety of useSimple preparation processPump componentsPumpsAviationEngineering

The invention belongs to the field of fan blade of turbofan engine, relating to an aeroengine hollow fan blade. The blade is a combined structure composed of a blade main body and a local panel, the blade main body comprises a blade body and a complete tenon, one side of the blade body is provided with a groove at the center, the edge of the blade body is solid, the local panel is a curved flat plate corresponding to the shape of the groove area of the blade main body, and the ribs of the groove on the blade body of the blade main body and the edge of the groove area are welded with the localpanel to form the hollow blade. Compared with the conventional titanium alloy hollow fan blade manufacturing scheme, the invention has the outstanding advantage of simple manufacturing process, and the blade use safety is also effectively improved. Compared with solid blade, the weight of the blade of the invention is obviously reduced.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

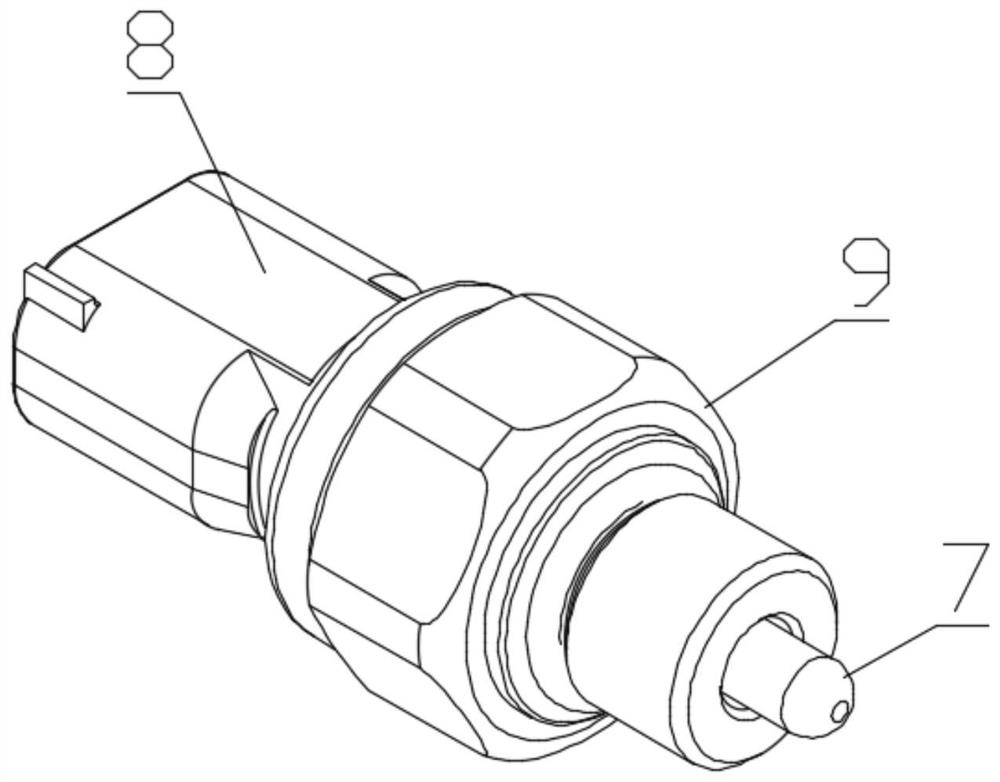

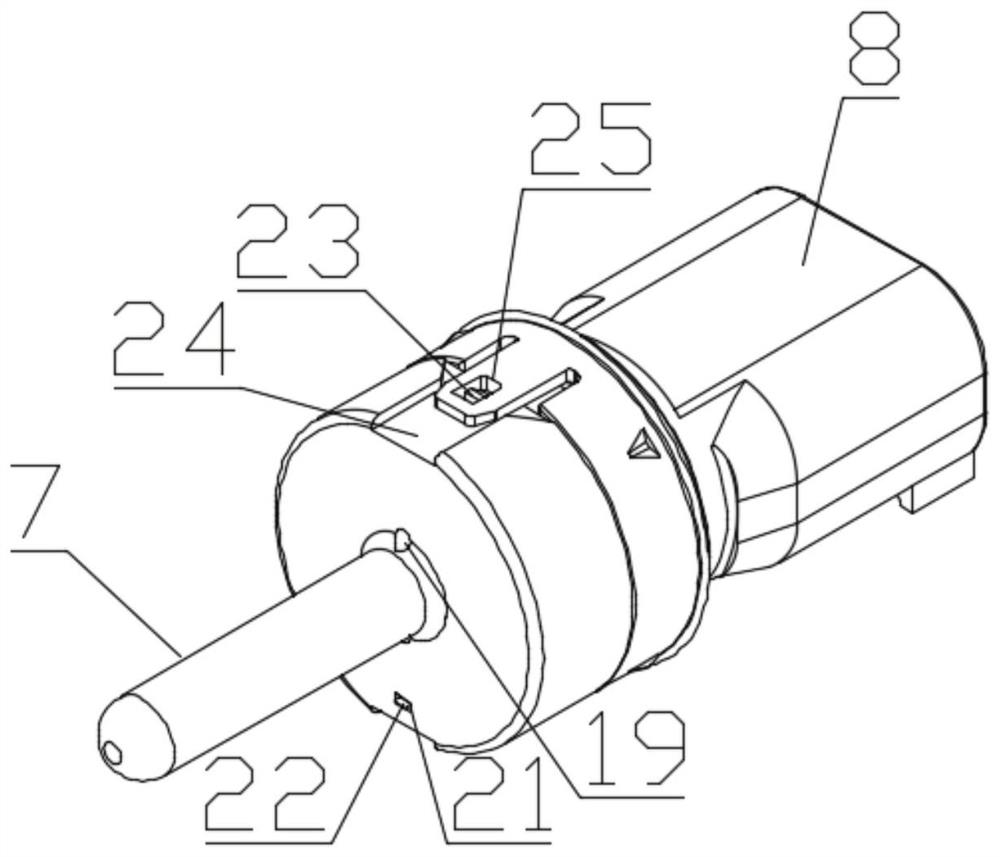

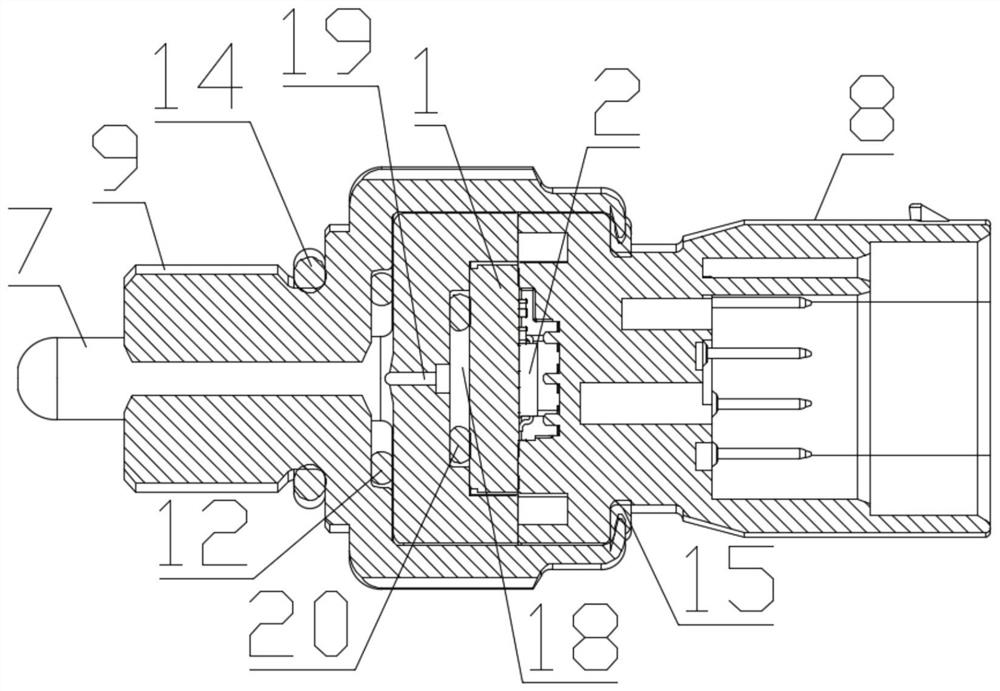

Pressure and temperature sensor for oil

PendingCN113514189AAvoid hidden harmReduce dependenceThermometers using electric/magnetic elementsFluid pressure measurementProcess engineeringElectronic component

Owner:无锡华阳科技有限公司

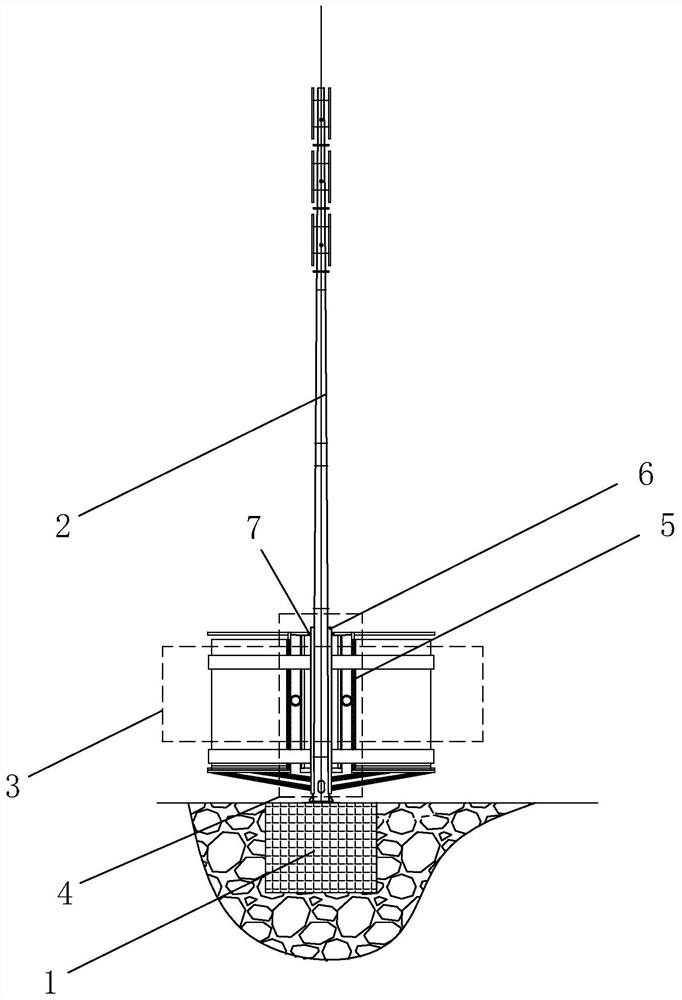

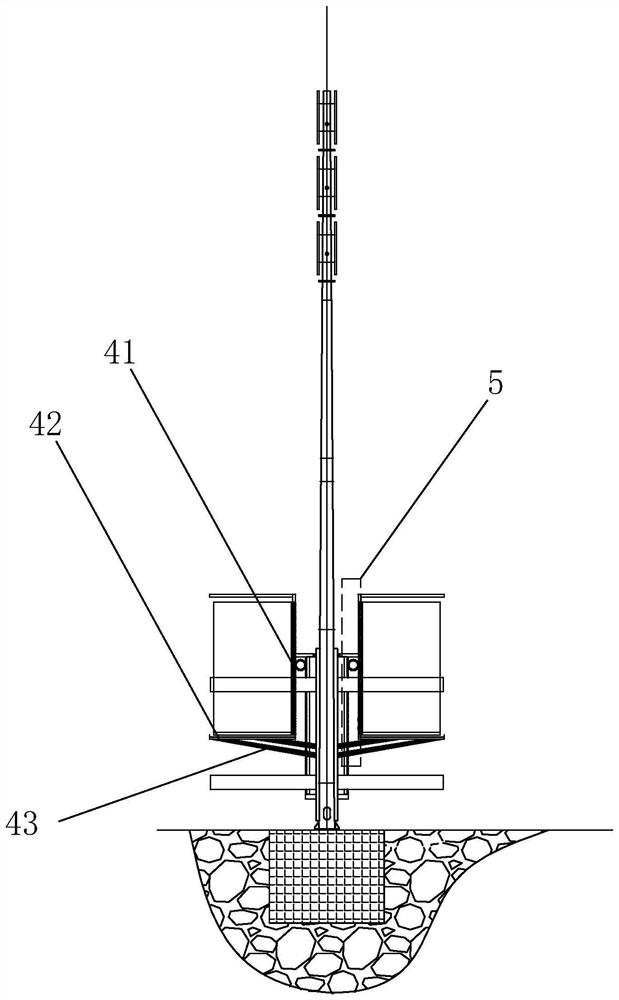

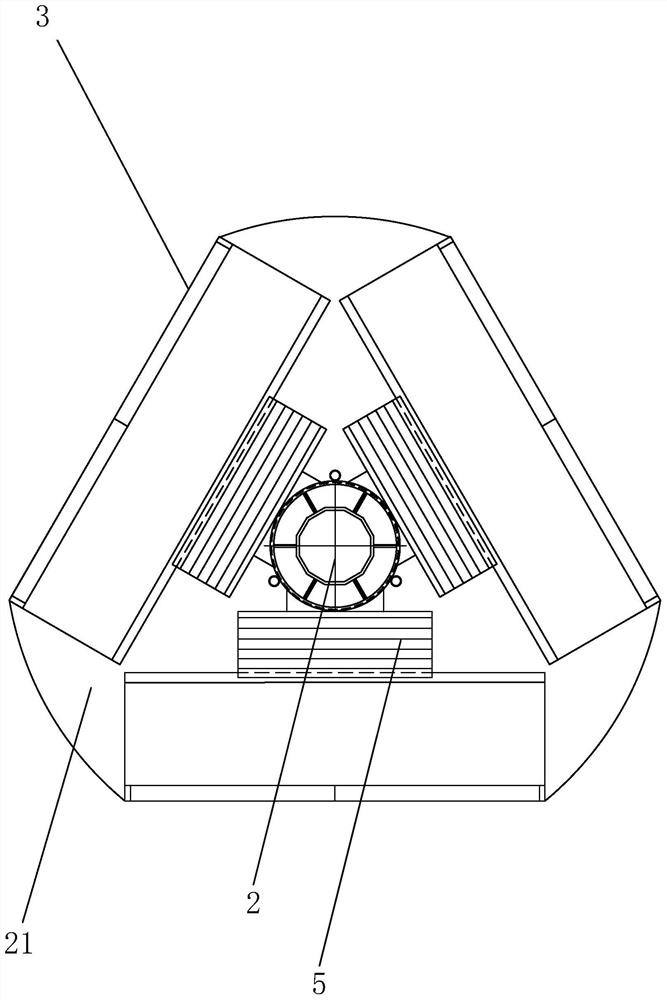

Tower and cabinet integrated communication base station

InactiveCN111677361AReduce space consumptionImprove ventilation and cooling conditionsFoundation engineeringTowersWater leakTower

The invention discloses a tower and cabinet integrated communication base station which comprises a foundation base, a communication pipe tower and a suspended type cabinet set. The communication pipetower is connected to the foundation base, and the suspended type cabinet set is arranged on a tower body of the communication pipe tower. Due to the fact that the suspended type cabinet set arrangedon the communication pipe tower, the cabinet set can get away from the ground surface to be arranged in the air, the space occupation of the communication base station can be effectively reduced, andmeanwhile the ventilation and heat dissipation conditions of the cabinet set are improved; and after the suspended type cabinet set is attached to the communication pipe tower, the problem that in atraditional communication base station which is integrally formed by tower and cabinet welding, due to wobbling of a pipe tower, the welding gap between the pipe tower and a cabinet is likely to be damaged can be solved effectively, the structure that the pipe tower is attached to the independent suspended type cabinet set is adopted, the welding connecting manner is omitted, and the phenomena ofwater leakage and dustproof failure are avoided.

Owner:浙江德宝通讯科技股份有限公司

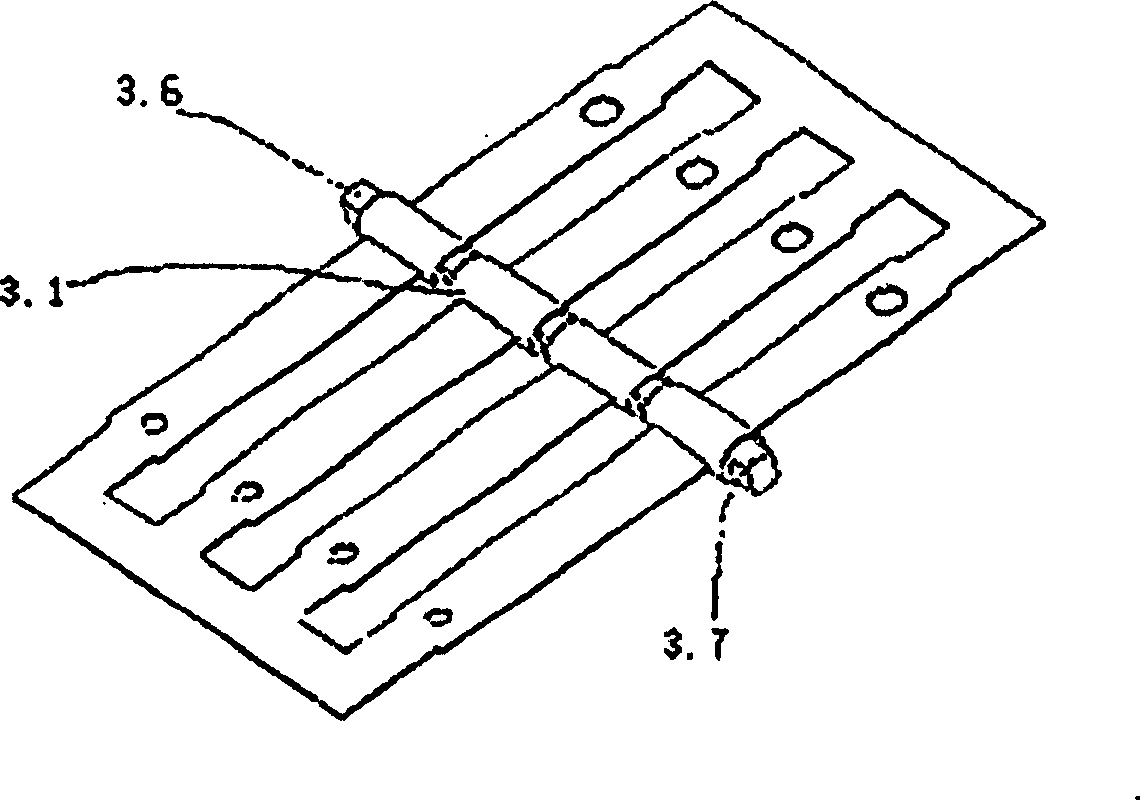

Low height small-sized large power AC-DC electromagnetic relay with multiple contact sets

ActiveCN1558434AAvoid soldered connectionsAvoid pollutionElectromagnetic relay detailsContact systemHigher Power

The invention relates to an electromagnetic relay, in particular a low height small-sized high power AC, DC electromagnetic relay with a plurality of contacts, which comprises a magnetic circuit system, a contact system and a chassis portion, wherein at least a group of moving reeds of the contact system are linked into moving reed row through an insulation member, the moving reed lead-out sheets are linked into lead-out row through the insulation member, the moving reed lead-out row and the moving reed row are linked into the moving reed portion of the relay.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

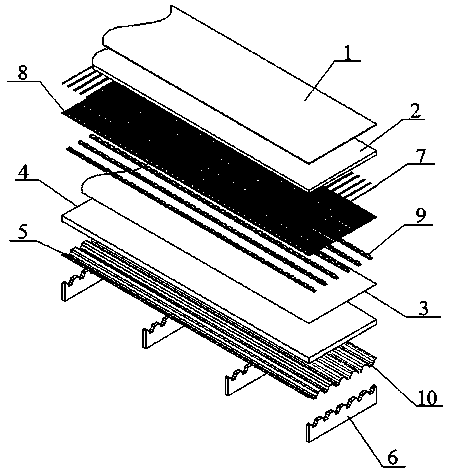

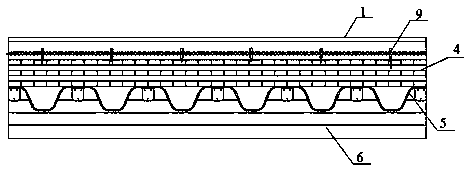

A COCS combine bridge deck structure

PendingCN109024268AStrong shock absorption and shock resistanceHigh strengthBridge structural detailsClimate change adaptationStress concentrationSheet steel

The invention discloses an A COCS combine bridge deck structure which comprises an asphalt abrasion layer, a UHPFRC layer, a Waterproof layer, CLT top board, a corrugated sheet steel board and a diaphragm board, all of which are orderly arrayed from the top to the bottom. The UHPFRC layer is provided with a ribbed reinforcing steel mesh, the asphalt abrasion layer is laid on the surface of the UHPFRC layer, the waterproof layer is laid on the surface of the CLT top plate, and the UHPFRC layer is connected with the CLT top plate through a shear connector. A CLT top board, the c corrugated sheet steel board and the UHPFRC layer are combined organically, A PZ-type shear connector and a screw connector are used to effectively combine that parts, The advantages of each material are further brought into play to avoid the welding connection of the traditional structure, to overcome the problem of stress concentration at the vulnerable position caused by the number and collection of the structural weld seams, to improve the fatigue resistance of the orthotropic plate, to improve the integrity of the assembled building, to facilitate the manufacture and installation, to be simple in maintenance and to be low in production cost.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Lap joint structure of multi-layer boards of car body

ActiveCN103332226BEasy to manufactureUniform distribution of intensitySuperstructure connectionsEngineeringOpen structure

The purpose of the present invention is to propose a new type of lap joint structure of multi-layer boards of the car body to solve defects such as virtual welding, weak welding or spatter caused by the local material thickness of the traditional multi-layer board lap joint structure of the car body, and the manufacturing problems brought about High cost, insufficient welding strength, loose structure and other problems. The overlapping structure of the multilayer panels of the vehicle body of the present invention includes the first layer, the second layer, ..., the (N-1)th layer and the Nth layer, the said N is greater than or equal to 4, the key lies in the said first layer The first layer, the second layer, and the third layer are stacked in sequence and welded and fixed to form the welding assembly of the initial product; the third layer, ..., the (N‑1)th layer are stacked in sequence, and Several through gaps are set at the same position; the Nth layer board is provided with a convex part at the position corresponding to the gap, and the convex part of the Nth layer board is inserted into the gap, and the Nth layer board and the initial The finished welding assembly is welded and fixed to form an overlapping structure of multi-layer panels of the car body.

Owner:CHERY AUTOMOBILE CO LTD

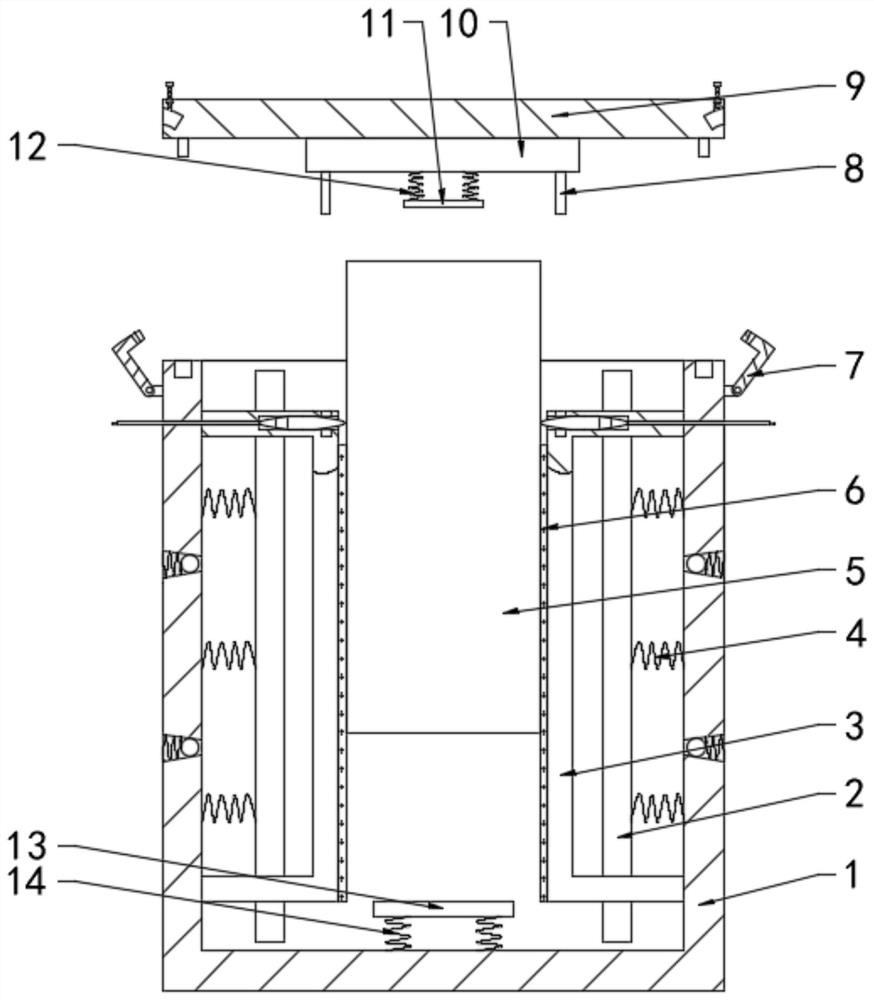

Secondary explosion-proof battery steel shell

PendingCN113571825AReduce impactPlay the role of secondary explosion protectionVent arrangementsCell lids/coversElectrical batteryEngineering

A secondary explosion-proof battery steel shell disclosed by the present invention comprises an outer shell and a roll core, C-shaped plates are fixedly connected to the periphery of the interior of the outer shell, and first sliding grooves are formed in the top and the bottom of each C-shaped plate; buffer plates are slidably connected to the first sliding grooves, and a plurality of first springs are fixedly connected between the outer shell and the buffer plates; a plurality of conical holes are formed in the outer shell, and sealing balls tangent to the conical holes are arranged in the conical holes. In the invention, under the action of the first springs and the buffer plates, the impact force of airflow generated during explosion to the outer shell is buffered; meanwhile, the plurality of through holes are formed in the buffer plates, and one stream of airflow is dispersed into a plurality of streams of direct-current airflow, so that the impact force of the airflow to the outer shell is further reduced; and then the airflow applies the impact force to the sealing balls through the small ends of the conical holes, the sealing balls are pushed to open the conical holes, and the air pressure generated by explosion in the outer shell is rapidly relieved, so that the secondary explosion-proof effect is achieved, and the situation of chain explosion is avoided.

Owner:安徽捷盛科技有限公司

Turbine

InactiveCN102322304BLow melting pointReduce rotational frictionBlade accessoriesLeakage preventionImpellerWeld seam

The invention relates to a turbomachine (1) having a bearing housing (30), a shaft (40', 40") rotatably supported in an inner chamber (31) of the bearing housing (30), through a weld (S' , S") is materially connected to the longitudinal end (41', 41 ") of the shaft (40', 40") and is arranged in the working impeller chamber (22) outside the inner chamber (31) ( 25', 25") and a seal (50), which is arranged on the circumference of the shaft (40', 40"), thereby sealing the inner chamber (31) relative to the working impeller chamber (22), wherein the seal For sealing, it cooperates with two mutually oppositely rotating sealing surfaces (51', 52'; 51", 52"). The object of the present invention is to provide a turbomachine in which undesired loosening of the welded connection between the impeller wheel and the shaft is reliably prevented. This is achieved in that the sealing surface material of at least one of the two sealing surfaces forms an insulating layer (T', T") arranged between the seal and the impeller.

Owner:MAN ENERGY SOLUTIONS SA

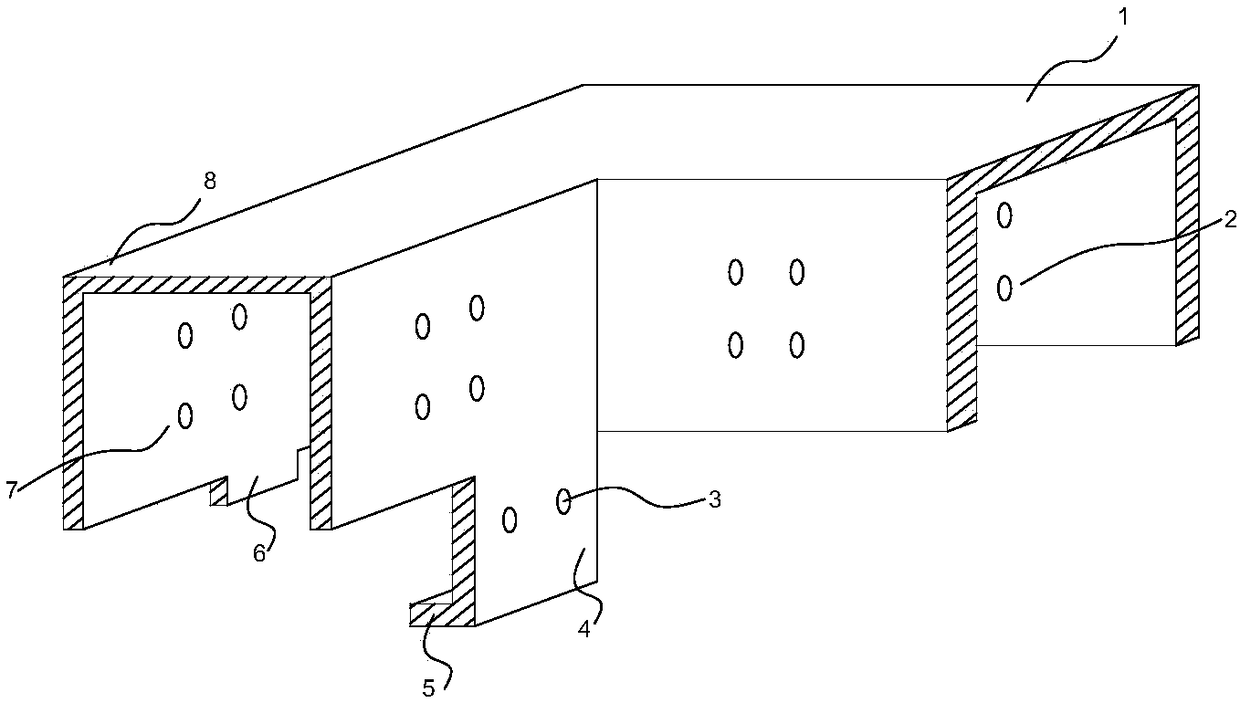

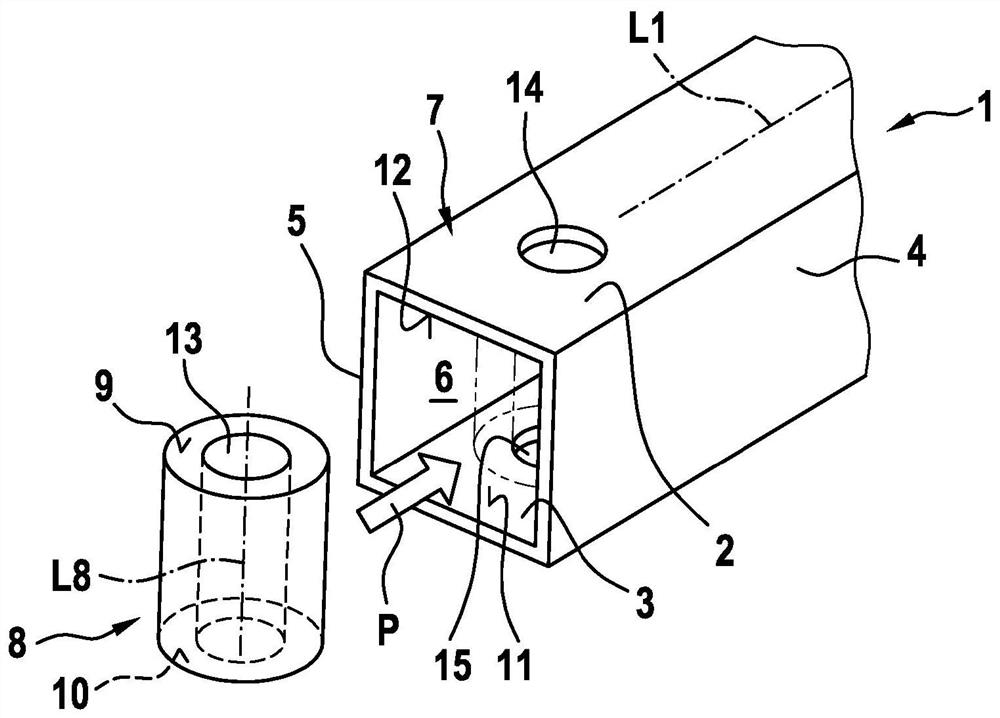

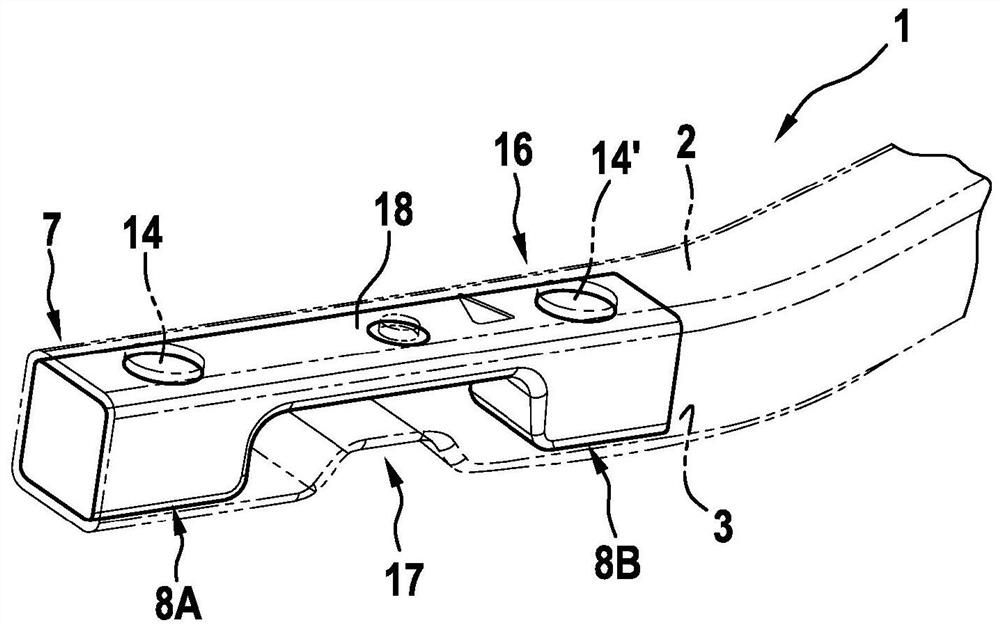

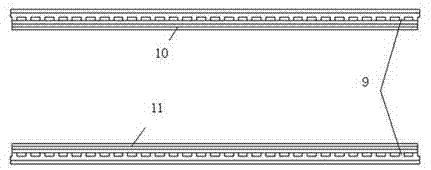

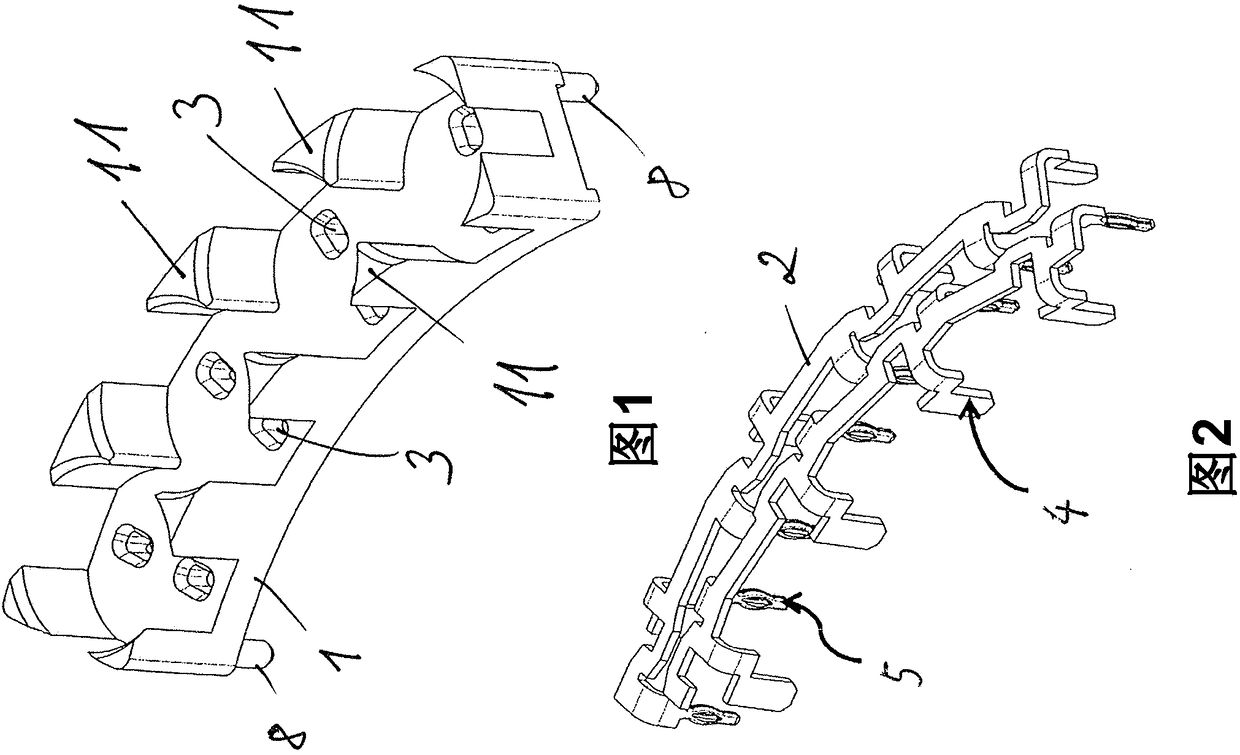

Profiled brace, in particular for motor vehicle

ActiveCN112996698ANo stiffness lossMaximize clamping lengthUnderstructuresSuperstructure subunitsClassical mechanicsStructural engineering

The invention relates to a profiled brace (1), in particular for a motor vehicle, comprising a top chord (2); a bottom chord (3); two mutually spaced lateral walls (4, 5) which together with the top chord (2) and the bottom chord (3) delimit an interior (6); two profiled ends (7, 16); and an end piece (8A, 8B) which is arranged in each profiled end (7, 16), the end pieces being connected together by means of a connecting web (18), wherein the end face (9, 10) of each end piece (8A, 8B) rests against adjacent inner wall regions (11 and 12) of the bottom chord (3) and the top chord (2), respectively, and an intermediate region (17) which is designed as a tunnel that is introduced into the bottom chord (3) is formed between the profiled ends (7, 16).

Owner:BAYERISCHE MOTOREN WERKE AG

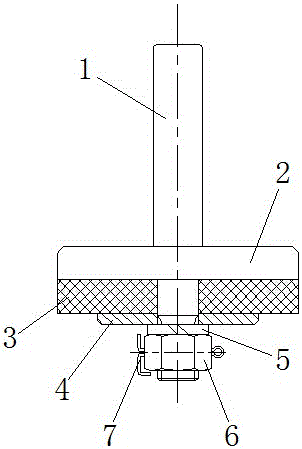

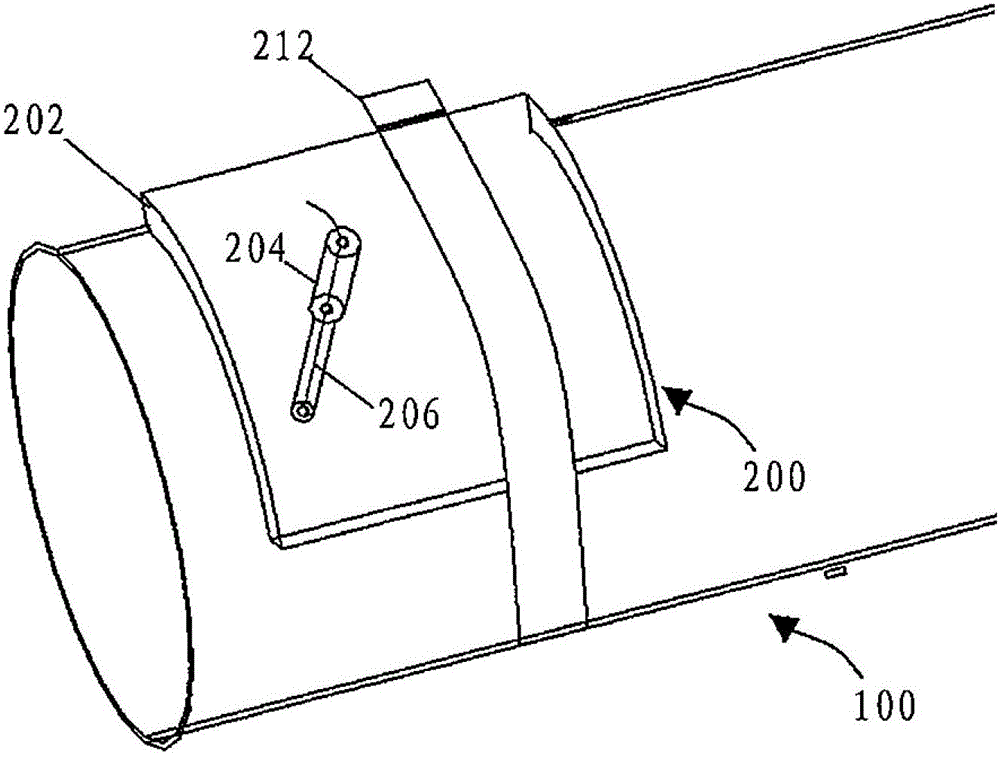

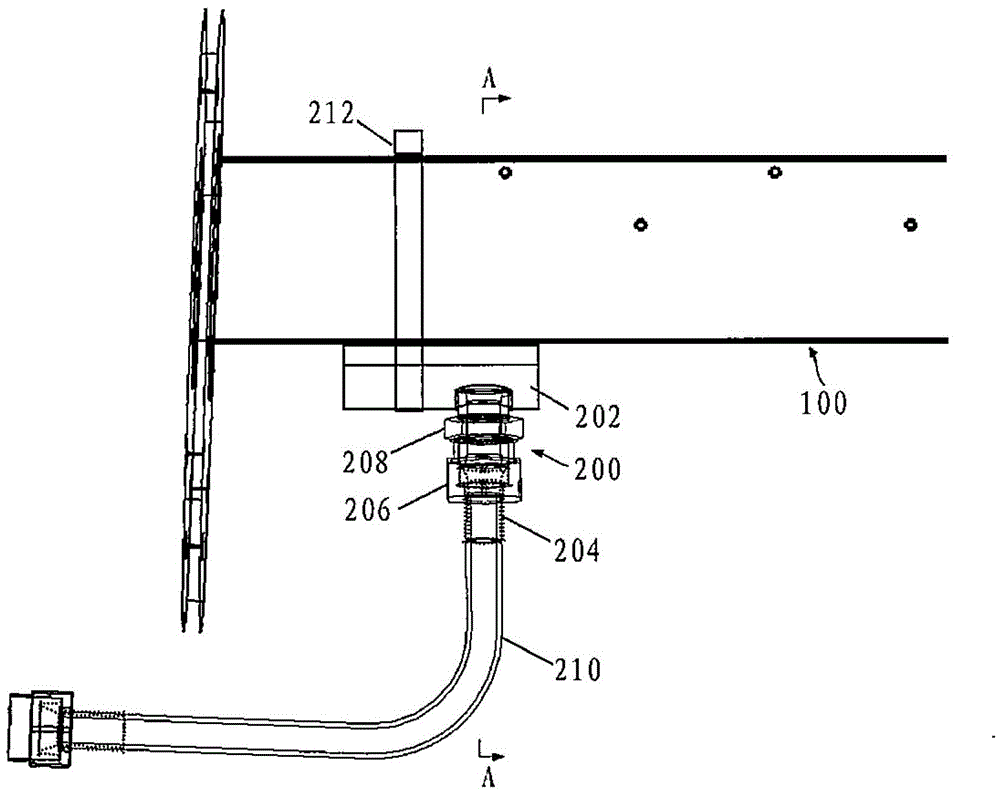

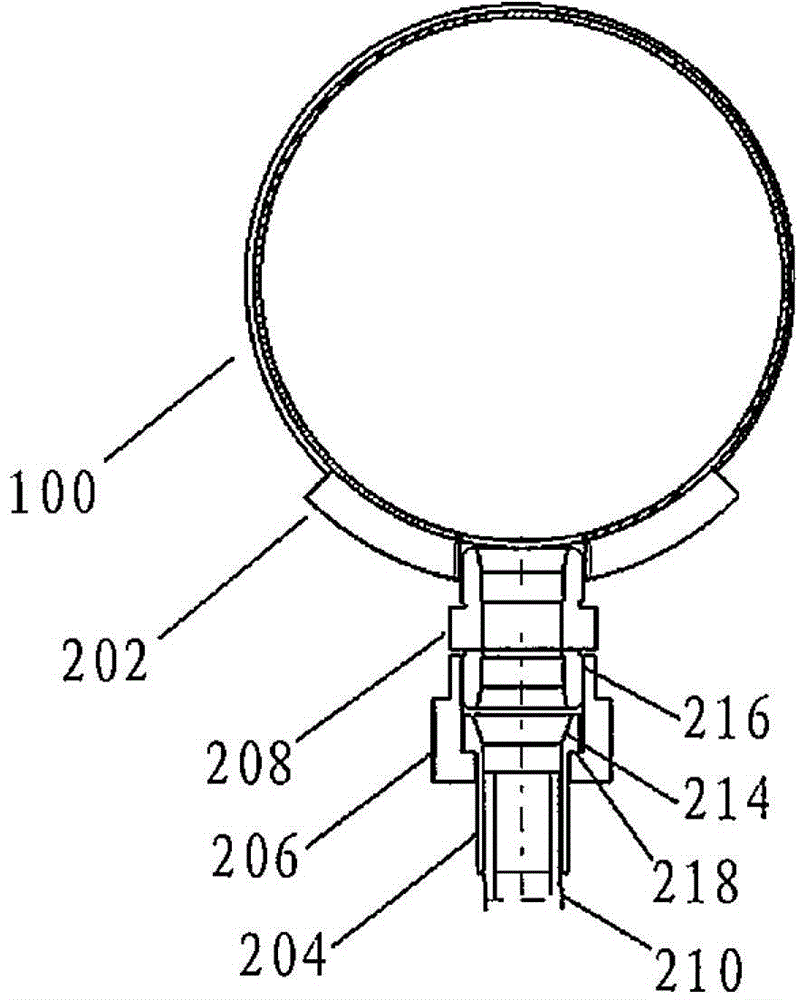

A temperature measuring component installed in a flute tube

ActiveCN103017924BAvoid fitAccurate measurementThermometer detailsThermometers using electric/magnetic elementsReducerEngineering

The invention discloses a temperature measuring assembly arranged in a flute pipe. The flute pipe comprises a first through hole, and comprises a base and a tubular bearing piece, wherein the base comprises a joint surface which is matched with an outer surface of the flute pipe; a second through hole is formed in the joint surface; the base is fixed to the flute pipe in a non-welded mode, so that the joint surface is attached to the outer surface of the flute pipe, and the second through hole is aligned with the first through hole; and because the outer diameter reducer of the tubular bearing piece has a boss which can be clamped on the base, a thermocouple is fixed on the tubular bearing piece, and a probe of the thermocouple is exposed from a thin end of the tubular bearing piece, the tubular bearing piece is fixed in the second through hole and the first through hole, and the probe of the thermocouple is approximately positioned in the center of the flute pipe. The thermocouple is born by the tubular bearing piece, so that the probe of the thermocouple can be prevented from being attached to the pipe wall due to the high-flow velocity hot-gas impact in the flute pipe; and therefore, the hot-gas temperature at the central position in the flute pipe can be accurately measured.

Owner:COMAC +1

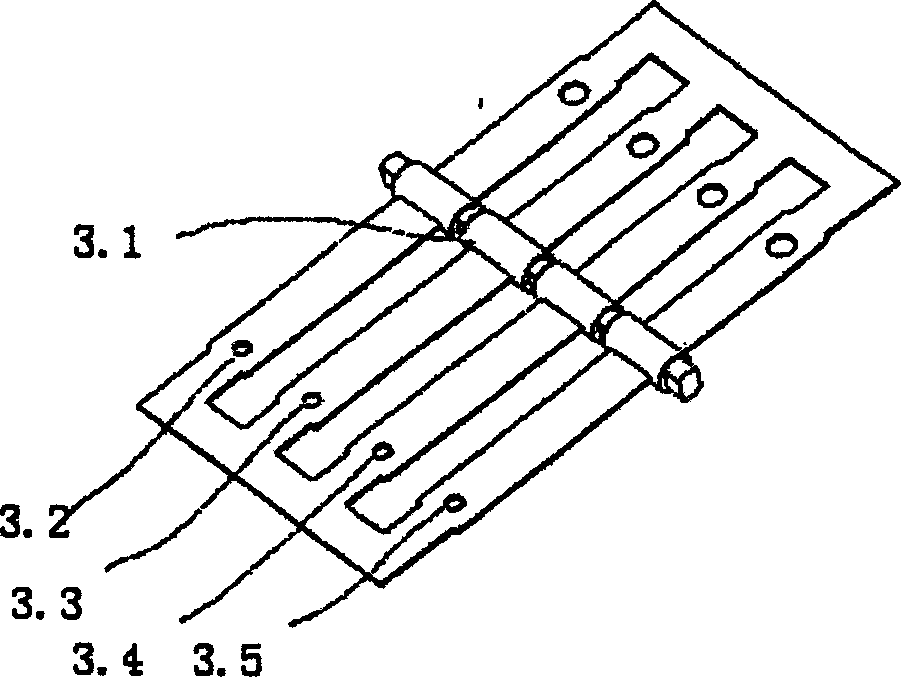

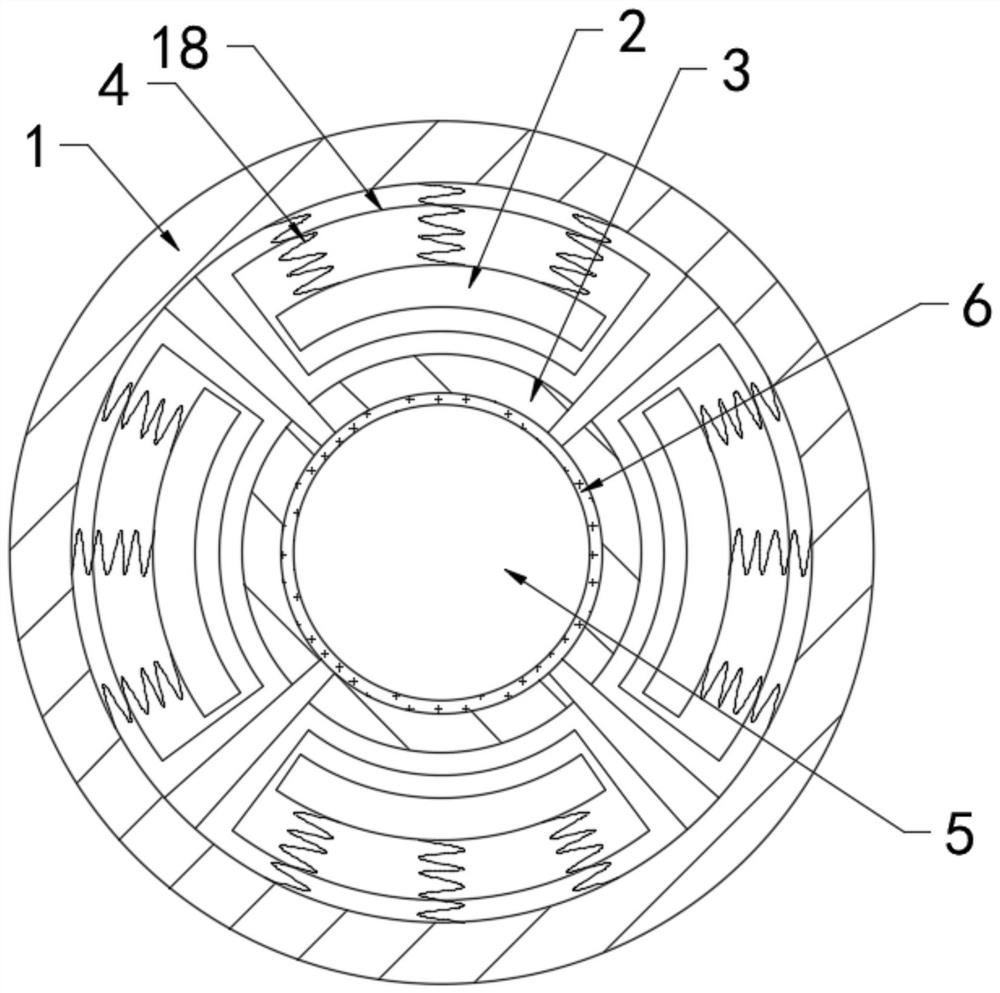

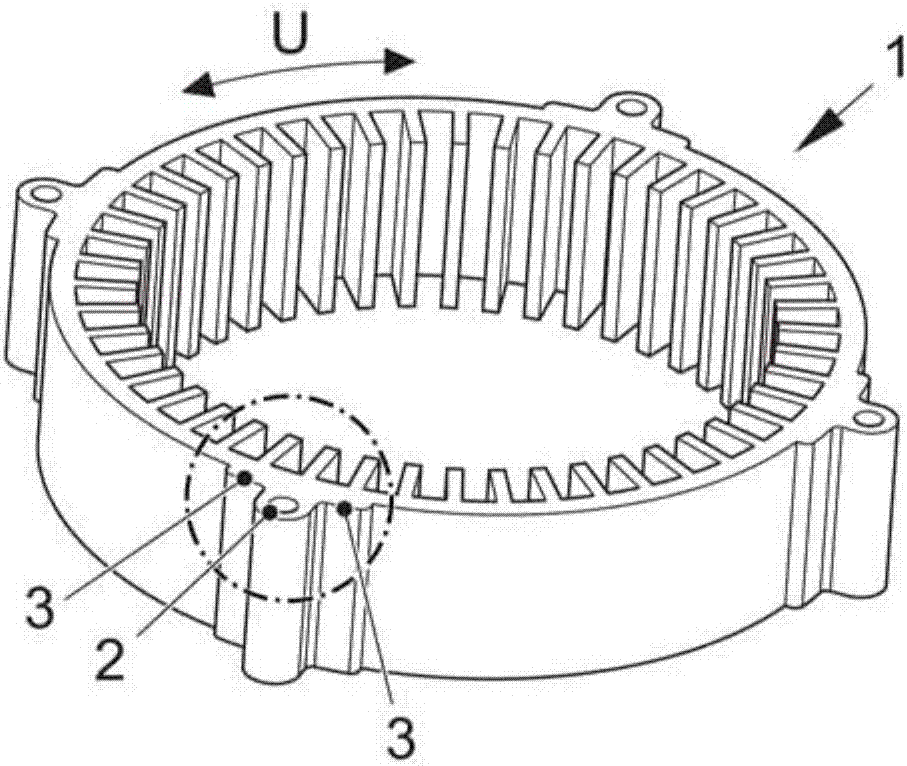

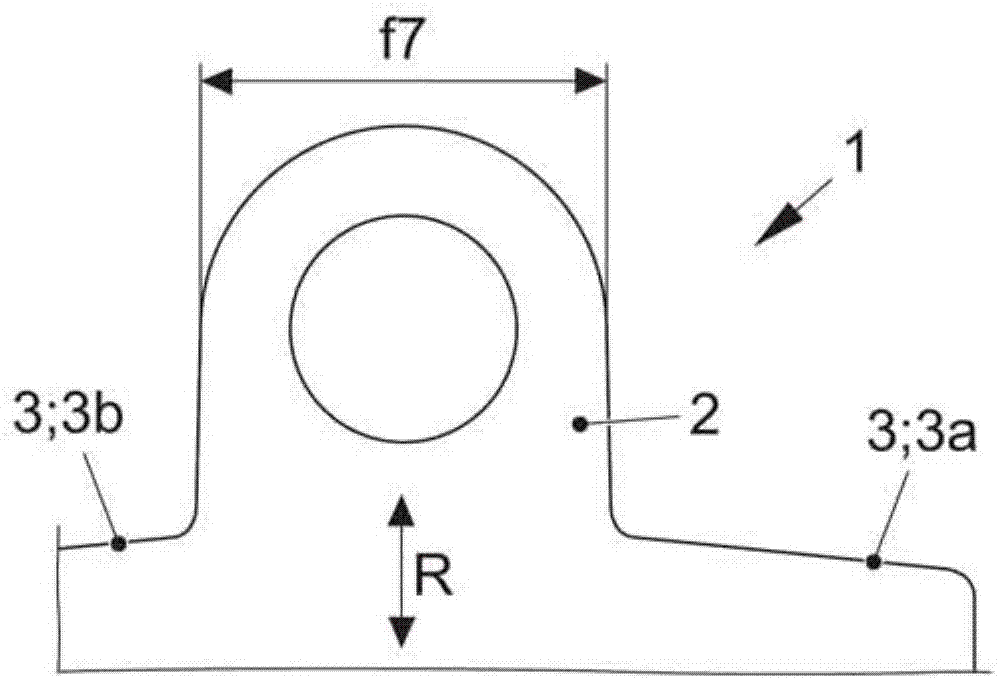

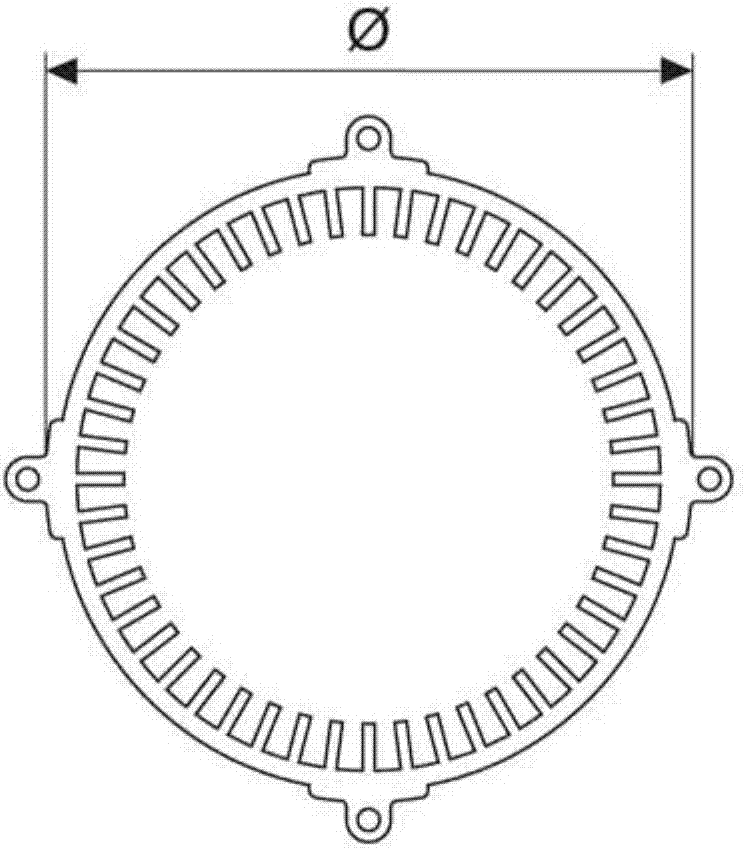

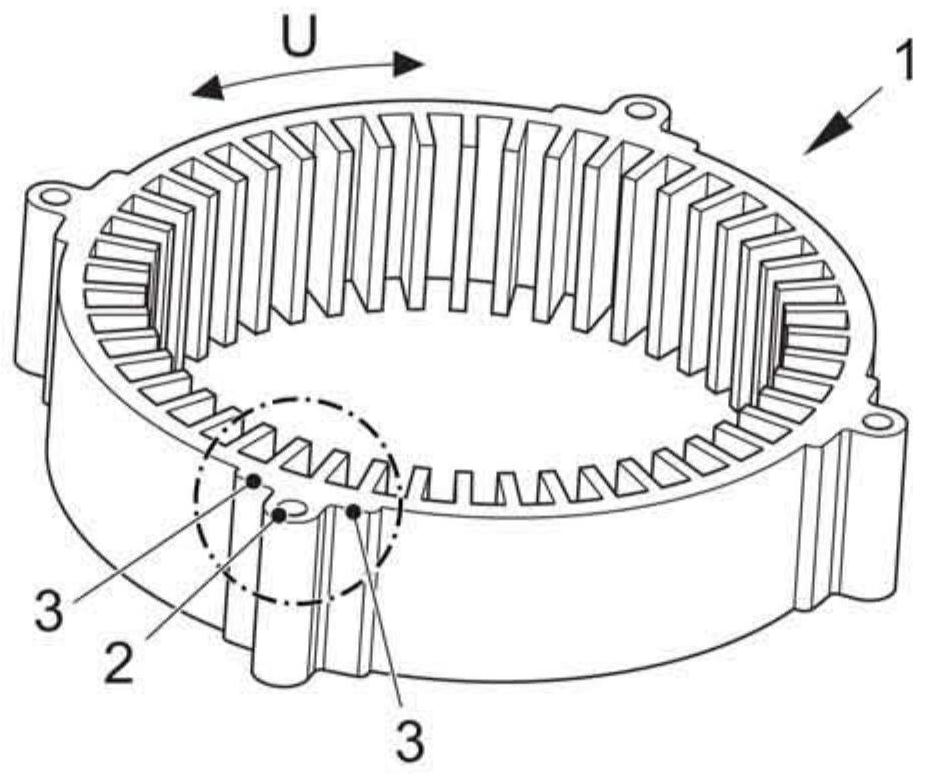

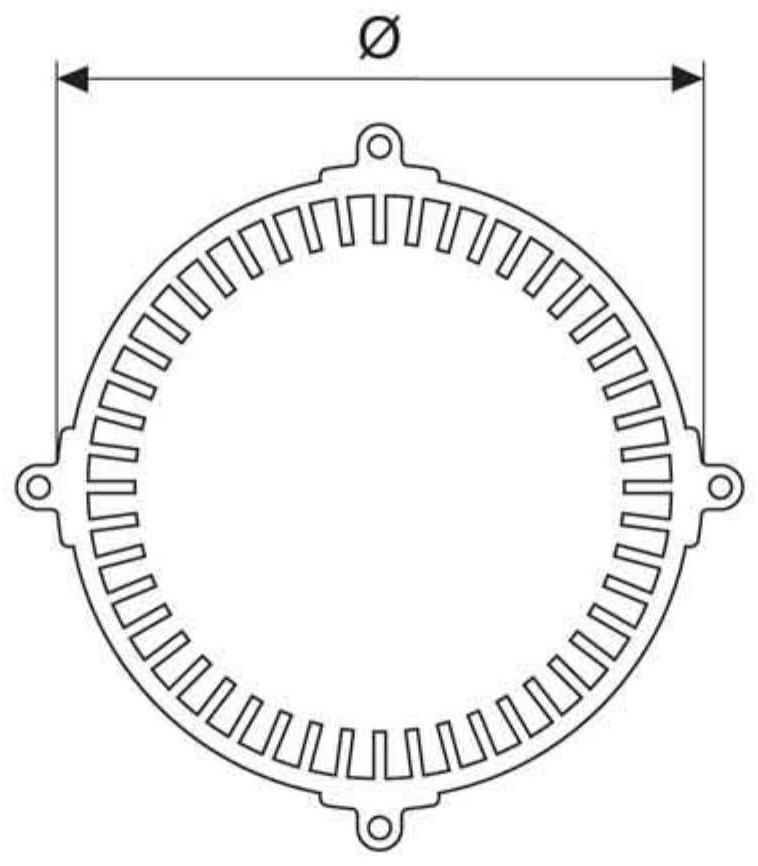

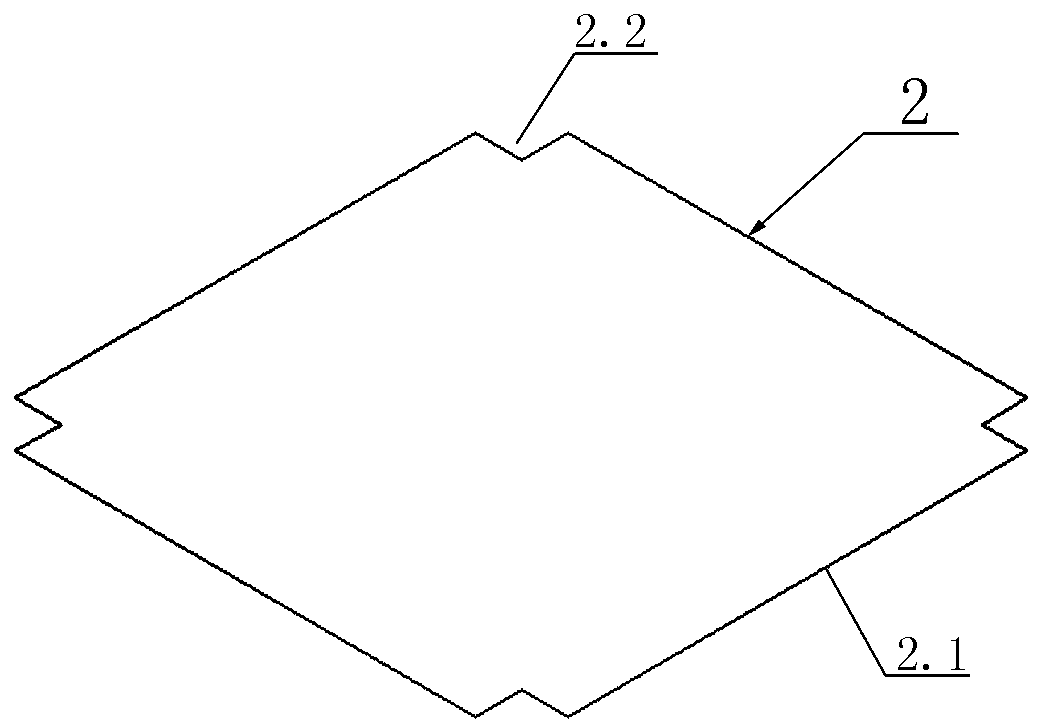

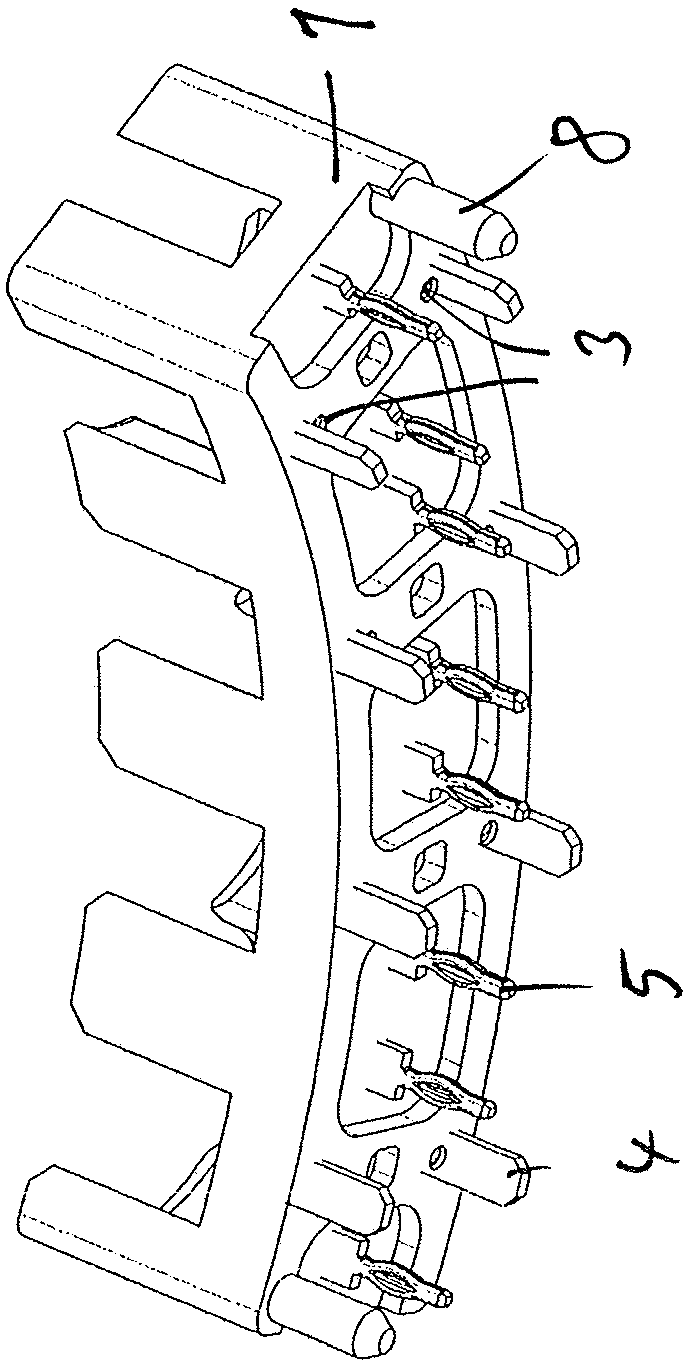

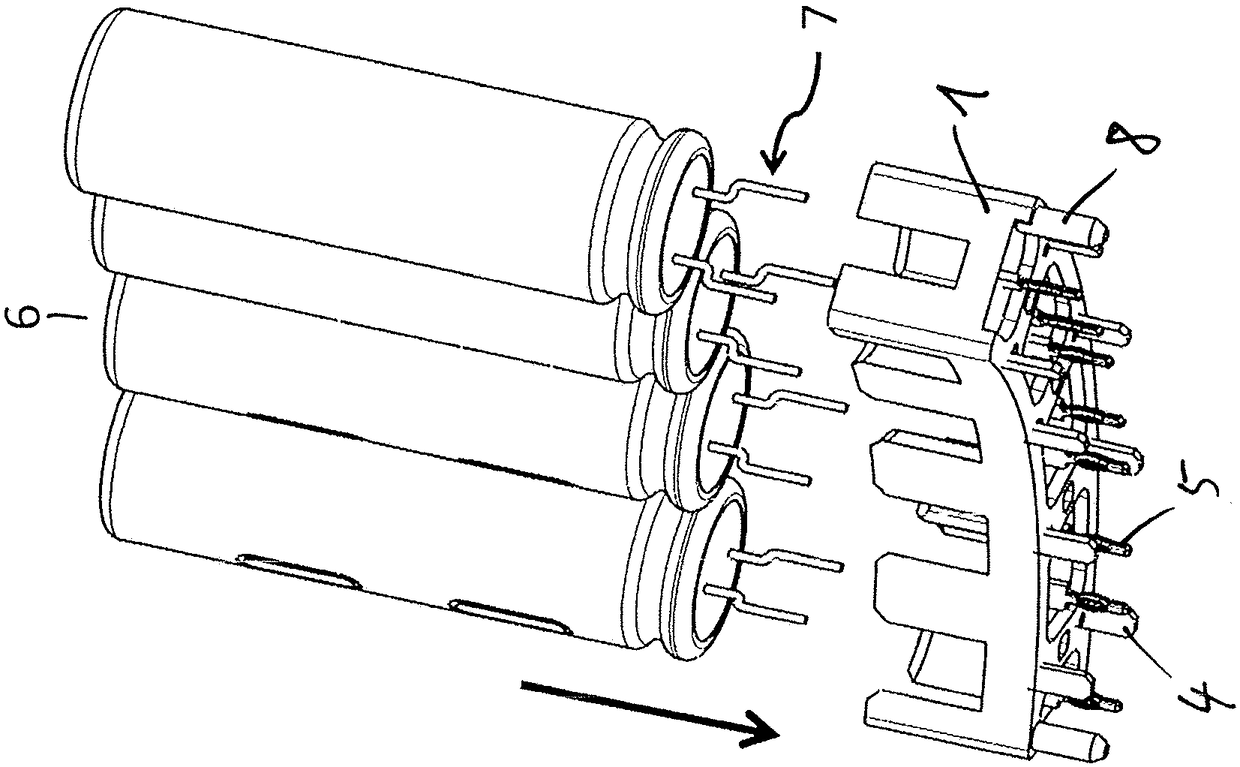

Stator-plate assembly, motor and method for manufacturing motor

ActiveCN107294236AAvoid Soldered ConnectionsReduce usageMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineBiomedical engineering

The invention relates to a stator-plate assembly for a vehicle motor, in particular for an electric motor, and to a method for producing such a motor. The stator-plate assembly (1) can be arranged in a housing (10), especially a clutch and / or a transmission housing. The manufacture and installation are simplified through the following method. The stator-plate assembly (1) has at least one circumferential form fit element (2) and at least one radial form fit element (3) on outer circumferential area of the stator-plate assembly. The circumferential form fit element is used to form shape cooperatoin type connection along the circumference of the stator-plate assembly between the stator-plate assembly (1) and the housing (10). The radial form fit element is used to form radial shape cooperation type connection between the radial form fit element (3).

Owner:VOLKSWAGEN AG

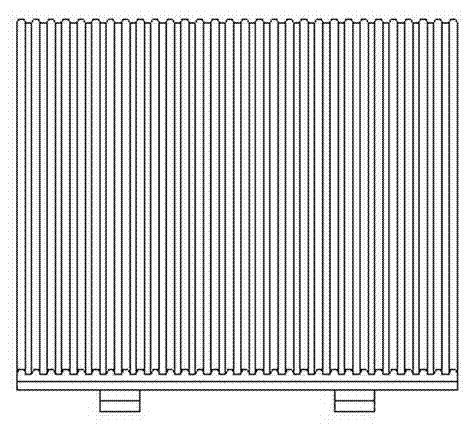

Electrochemical reactor and method for processing organic pollutant in water

InactiveCN102603038BReduce spacingIncrease the areaWater/sewage treatmentElectrochemical responseElectrolysis

Owner:TIANJING YIRONG TECH

Stator lamination stack, electric machine and method for manufacturing such electric machine

ActiveCN107294236BAvoid Soldered ConnectionsReduce usageMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineClutch

The invention relates to an electric machine, for example for a motor vehicle, in particular a laminated stator pack for an electric motor, such an electric machine and a method for producing such an electric machine, wherein the laminated stator pack (1) can be arranged in a housing (10), especially in the clutch and / or transmission housing. Production and assembly are simplified in that the stator lamination stack (1) has at least one circumferential form-fit element (2) and at least one radial form-fit element (3) in its outer peripheral region, said circumferential form Fitting elements for forming a form-fitting connection between the stator lamination stack (1) and the housing (10) in the circumferential direction of the stator lamination stack (1), said radial form fitting elements for A radial form-fitting connection is formed between the sheet pack (1) and the housing (10).

Owner:VOLKSWAGEN AG

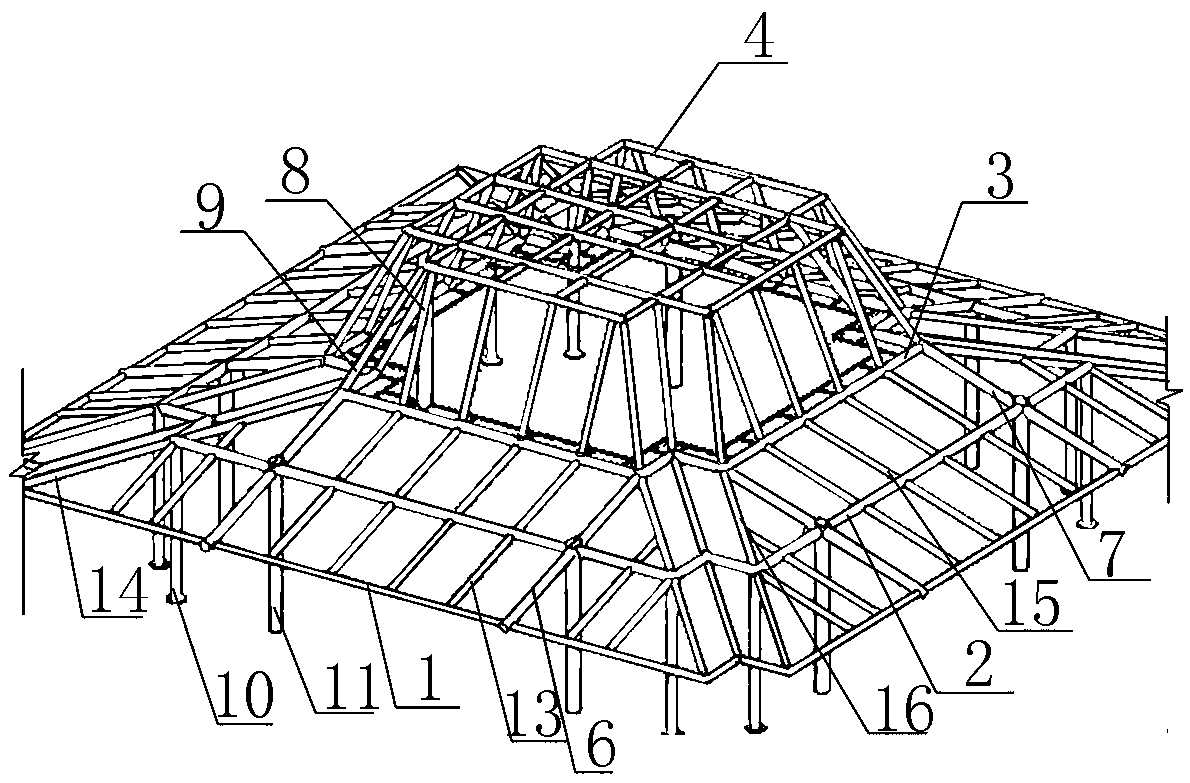

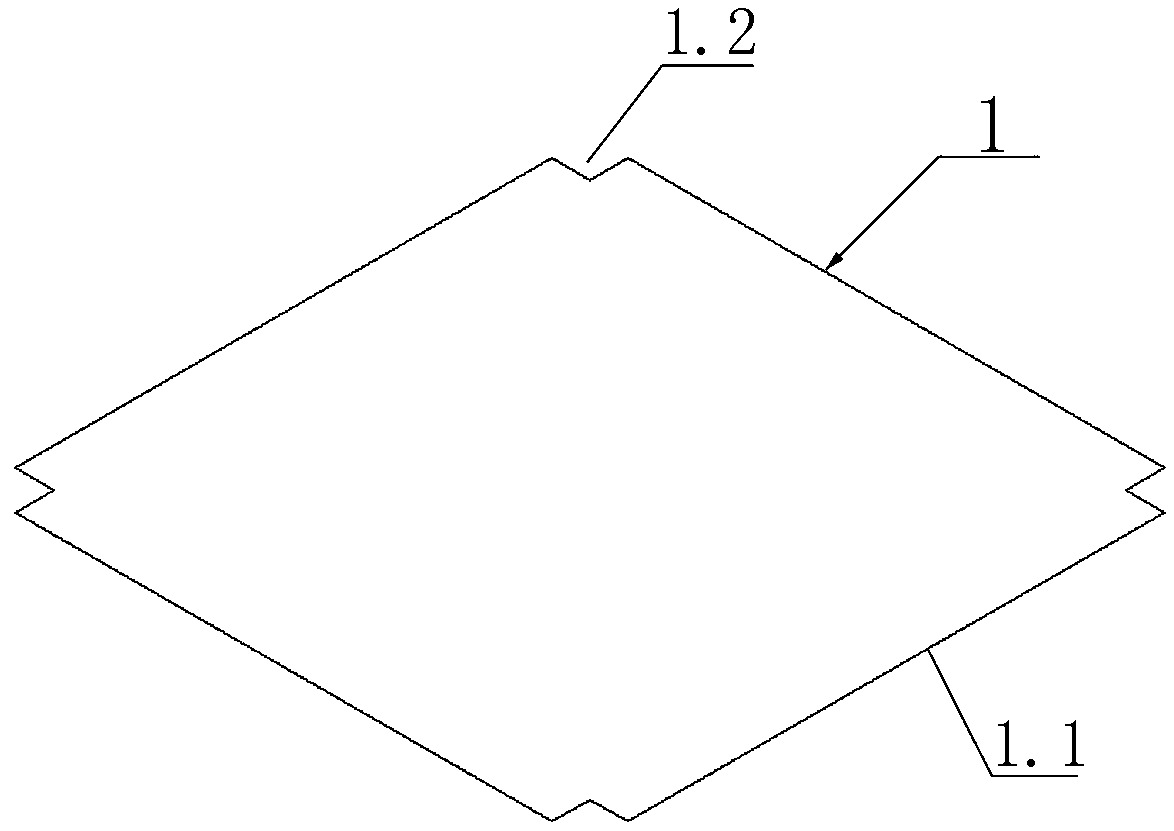

Intersecting space steel pipe truss structure of Tibetan style golden roof and construction method of intersecting space steel pipe truss structure

The invention provides an intersecting space steel pipe truss structure of a Tibetan style golden roof and a construction method of the intersecting space steel pipe truss structure. The intersectingspace steel pipe truss structure comprises a first-layer chord member structure, a second-layer chord member structure, a third-layer chord member structure and a top face grid structure. The outer edge of the top face grid structure is in a rectangular shape. The four corners of the rectangular shape are each concave inwards to form a fourth concave right-angle corner. The third-layer chord member structure, the second-layer chord member structure and the first-layer chord member structure are closed annular frames correspondingly. The shape of each annular frame is the same as the shape of the outer edge of the top face grid structure. The three annular frames are concentrically enlarged in an equal proportion manner from top to bottom. The first-layer chord member structure and the second-layer chord member structure are connected through first connection rods. The second-layer chord member structure and the third-layer chord member structure are connected through second connectionrods. The third-layer chord member structure and the top face grid structure are connected through third side diagonal web members and third corner diagonal web members. The intersecting space steel pipe truss structure and the construction method solve the technical problems that a traditional steel pipe truss structure is poor in force bearing capacity and not attractive in modelling.

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +2

Low height small-sized large power multiple contacts AC-DC electromagnetic relay with a winding shaft pushing mechanism

ActiveCN1300817CAvoid Soldered ConnectionsAvoid pollutionElectromagnetic relay detailsEngineeringContact system

The invention relates to a low height small-sized high power AC, DC electromagnetic relay with a plurality of contacts and winding shaft pushing mechanism, wherein at least a group of moving reeds of the contact system are linked into moving reed row through an insulation member, the insulation member is provided with a rotation shaft on the two ends, a corresponding shaft hole is arranged on the pushing block, thus forming a hinge connection and pushing the rotation shaft hole on the block to be fastened on the boss of the armature, the movement of the armature drives the moving contact portion of the relay for actuation through the pushing block transmission action. The invention realizes lowered relay height, high electric distance, creepage distance, penetration insulating distance and dielectric pressure resistance.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Low height small-sized large power AC-DC electromagnetic relay with multiple contact sets

ActiveCN1332407CReduce usageLower the altitudeElectromagnetic relay detailsContact systemHigher Power

The invention relates to an electromagnetic relay, in particular a low height small-sized high power AC, DC electromagnetic relay with a plurality of contacts, which comprises a magnetic circuit system, a contact system and a chassis portion, wherein at least a group of moving reeds of the contact system are linked into moving reed row through an insulation member, the moving reed lead-out sheets are linked into lead-out row through the insulation member, the moving reed lead-out row and the moving reed row are linked into the moving reed portion of the relay.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Mounting aid and method for mounting electrical components on printed circuit board

PendingCN108574151AHigh mechanical reliabilityReduce the impact of exposureCoupling contact membersCouplings bases/casesBusbarEngineering

The invention relates to a mounting aid and method for mounting electrical components on a printed circuit board. The mounting aid for mounting electrical components (6) onto the printed circuit board(9) includes a body (1) comprising compartments for receiving the electrical components (6), with the compartments having a base with openings (3) for the insertion of connection wires (7) of the electrical components (6), and metal parts (2) fastened to the body (1), wherein the metal parts (2) each form at least one contact pin (5) on the underside of the body (1) and each from a busbar for connection to electrical components (6) in a plurality of compartments of the body (1).

Owner:BORGWARNER BERU SYST

Pressure guiding module mounted in flute-shaped pipe

ActiveCN103010482BAvoid Soldered ConnectionsReduce defective rateAircraft components testingFluteEngineering

Owner:COMAC +1

A multi-block main cable saddle structure

ActiveCN105421229BAvoid Soldered ConnectionsReduce adverse effectsBridge structural detailsThick plateWelding residual stress

The invention relates to a multi-block main cable saddle structure. The main cable saddle of a suspension bridge is divided into an upper saddle head and a lower saddle head through partitioning interfaces. The partitioning interfaces are located in the position 30+ / -5cm below a cable bearing trough bottom plate for a main cable. Concave-convex seams are adopted at the partitioning interfaces. End transverse ribs at the partitioning interfaces are connected through splice plates and high-strength bolts at the concave-convex seams. The upper saddle head and the lower saddle head are each equally divided into three blocks through the transverse partitioning interfaces in the longitudinal direction. The two end transverse ribs are arranged on the two sides of each transverse partitioning interface respectively and connected through the high-strength bolts. By means of the multi-block main cable saddle structure, the partitioned blocks can be quickly mounted on site; residual welding stress caused by super-thick plate welding is avoided through the partitioned blocks in the height direction, the upper saddle head and the lower saddle head are tightly connected together under the action of the powerful vertical main cable pressure; the concave-convex seams facilitate high-altitude hoisting and splicing and can also resist unbalanced horizontal shear force; by adopting the partitioned blocks, the weight of a single saddle body is reduced, casting, transporting and hoisting are facilitated, and the multi-block main cable saddle structure is particularly applicable to large-span suspension bridges in mountainous areas where transportation condition limitations exist.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com