Lap joint structure of multi-layer boards of car body

A multi-layer board and joint structure technology, which is applied to the upper structure, the connection between the upper structure sub-assemblies, vehicle components, etc., can solve the problems of high manufacturing cost, weak welding, and insufficient welding strength, and improve driving comfort Performance and customer satisfaction, reduce the probability of failure, improve the effect of manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

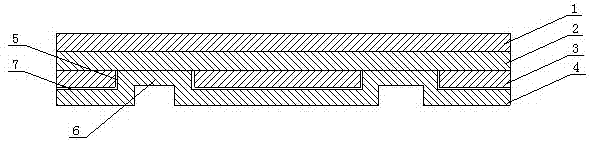

[0018] Such as figure 2 As shown, the overlapping structure of the four-layer panels of the vehicle body in this embodiment includes a first laminate 1, a second laminate 2, a third laminate 3 and a fourth laminate 4, wherein the first laminate 1, the second laminate The board 2 and the third layer board 3 are stacked and welded in sequence to form the welding assembly of the initial product; the third layer board 3 is evenly distributed with several gaps 5 penetrating the third layer board 3, and the fourth layer board 4 A protruding part 6 is provided at a position corresponding to the notch 5, and the cross section of the notch 5 conforms to the cross-sectional shape of the protruding part 6; the protruding part 6 of the fourth layer plate 4 is inserted into the notch 5 of the third layer plate 3; The four-layer board 4 is only welded and fixed with the second layer board 2 in the welding assembly of the preliminary product at the convex portion 6 to form an overlapping st...

Embodiment 2

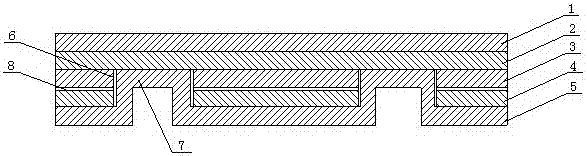

[0021] Such as image 3 As shown, the overlapping structure of the vehicle body without laminates in this embodiment includes a first laminate 1, a second laminate 2, a third laminate 3, a fourth laminate 4 and a fifth laminate 5, wherein the first laminate The plate 1, the second layer plate 2, and the third layer plate 3 are stacked and welded in sequence to form a welding assembly of the initial product; the third layer plate 3 and the fourth layer plate 4 are evenly distributed with several through gaps 6, so The fifth layer plate 5 is provided with a convex portion 7 at a position corresponding to the notch 6, and the cross section of the notch 6 is consistent with the cross-sectional shape of the convex portion 7; the convex portion 7 of the fifth layer plate 5 is inserted into the third layer plate 3 , In the gap 6 of the fourth laminate 4, the fifth laminate 5 is only welded and fixed with the second laminate 2 in the welding assembly of the preliminary product at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com