Patents

Literature

231results about How to "Reduce material thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

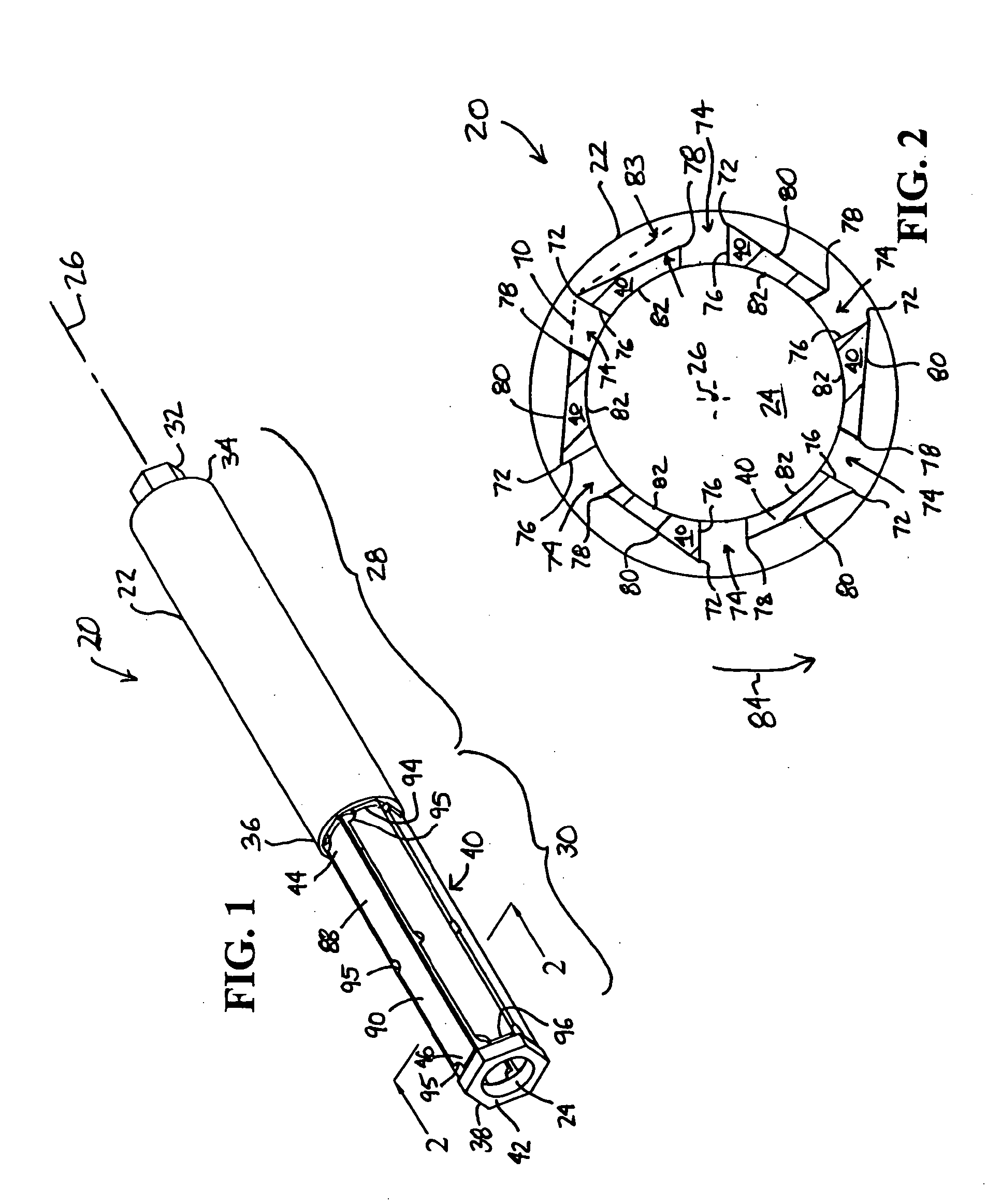

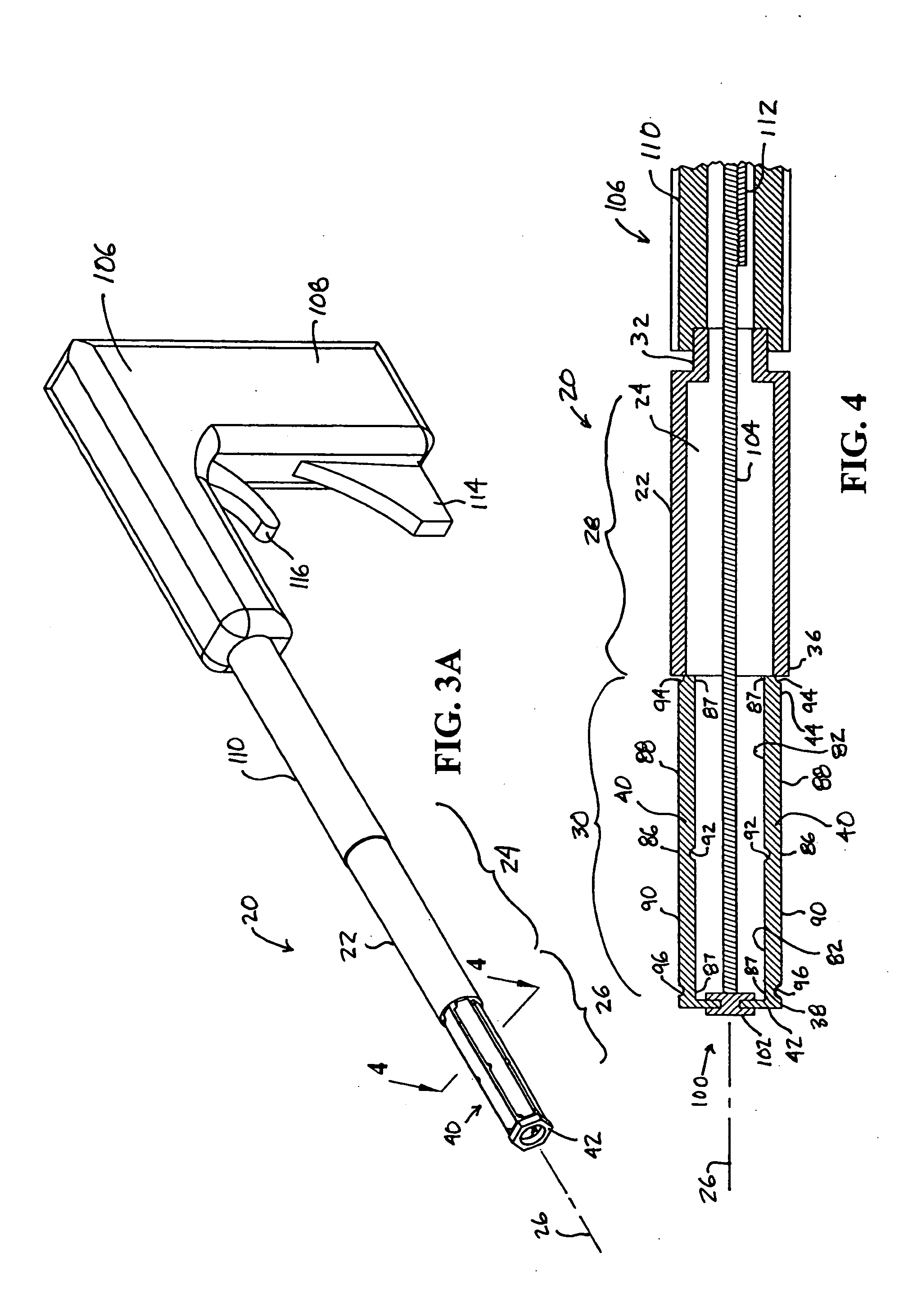

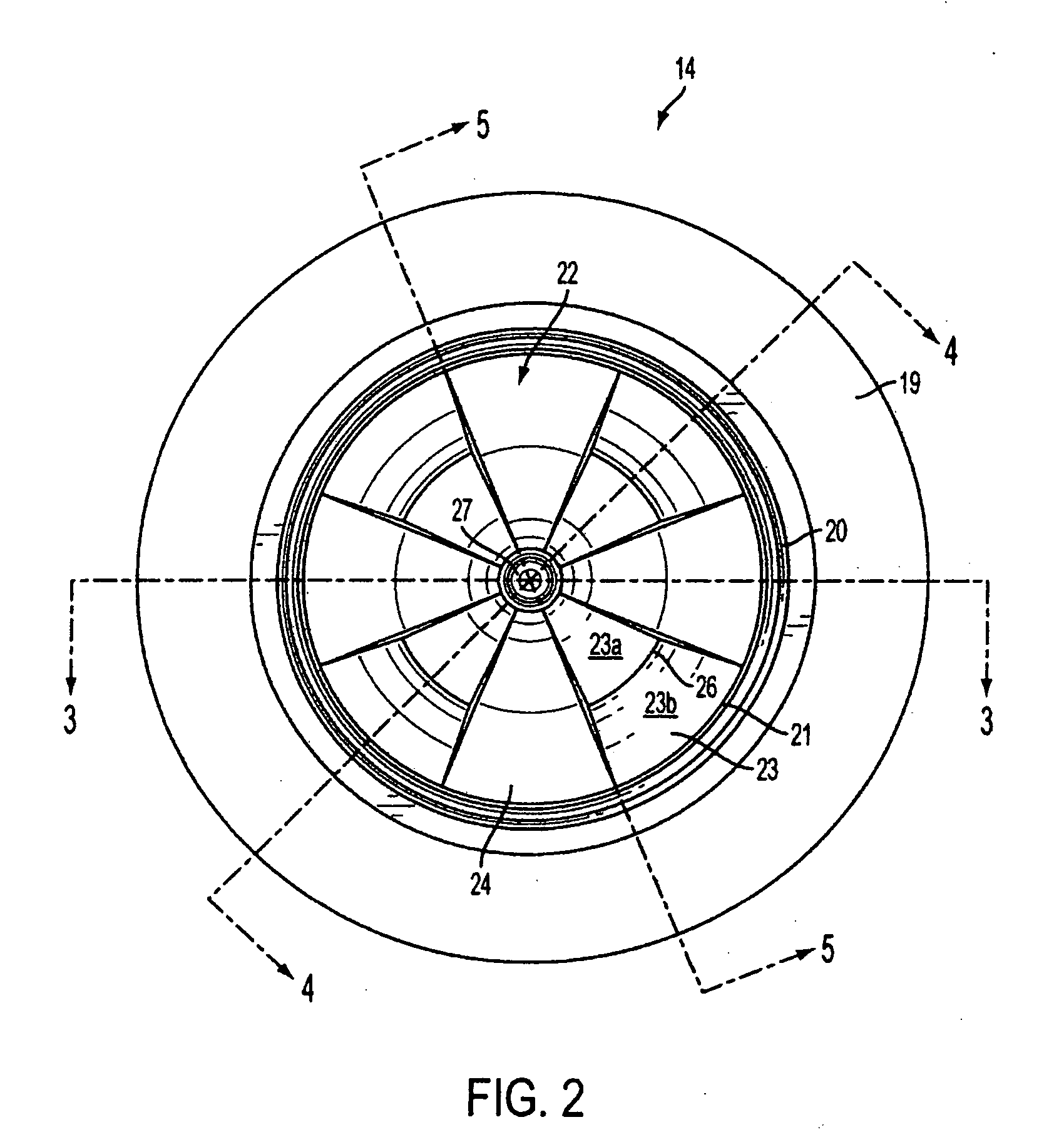

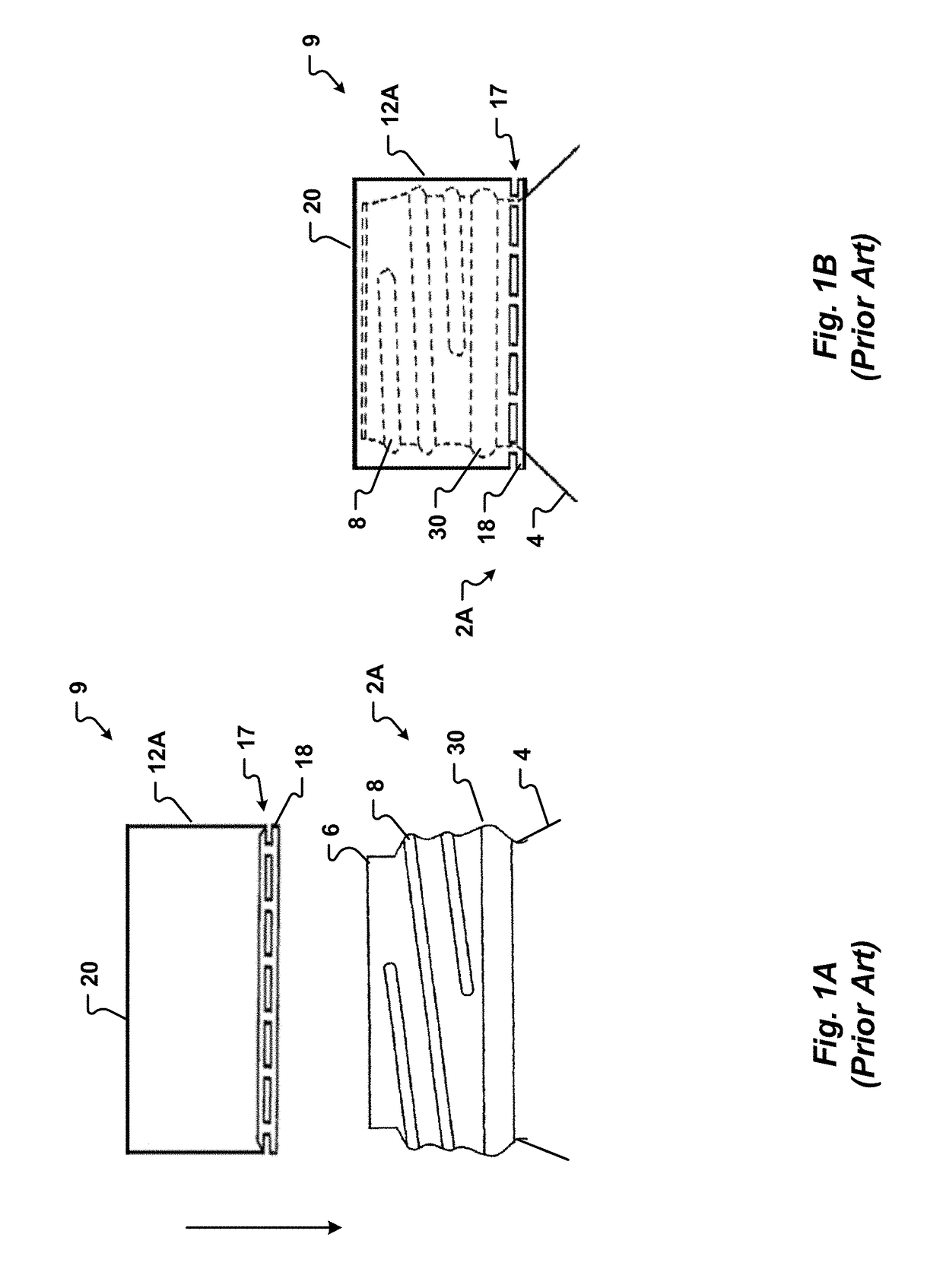

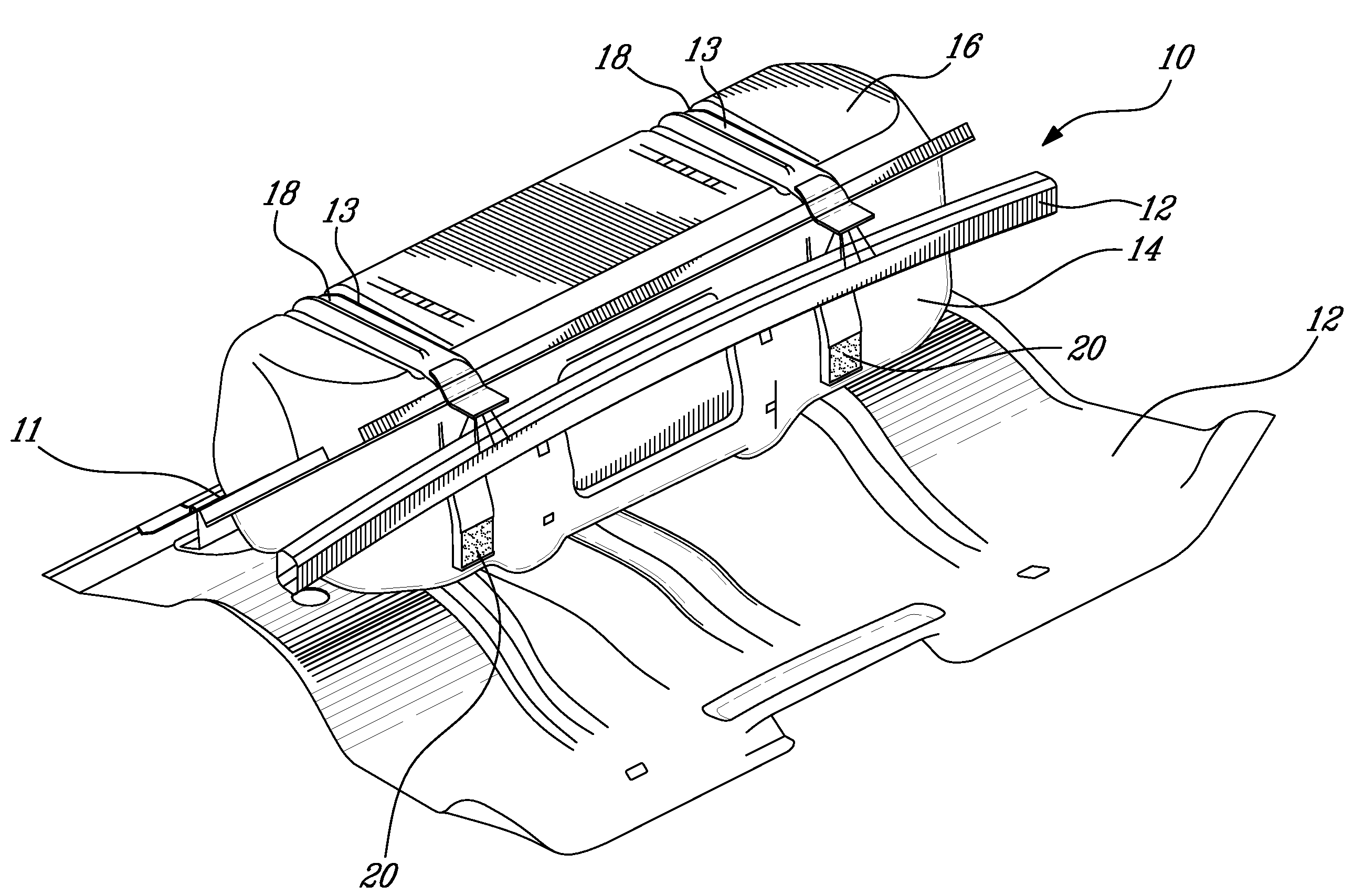

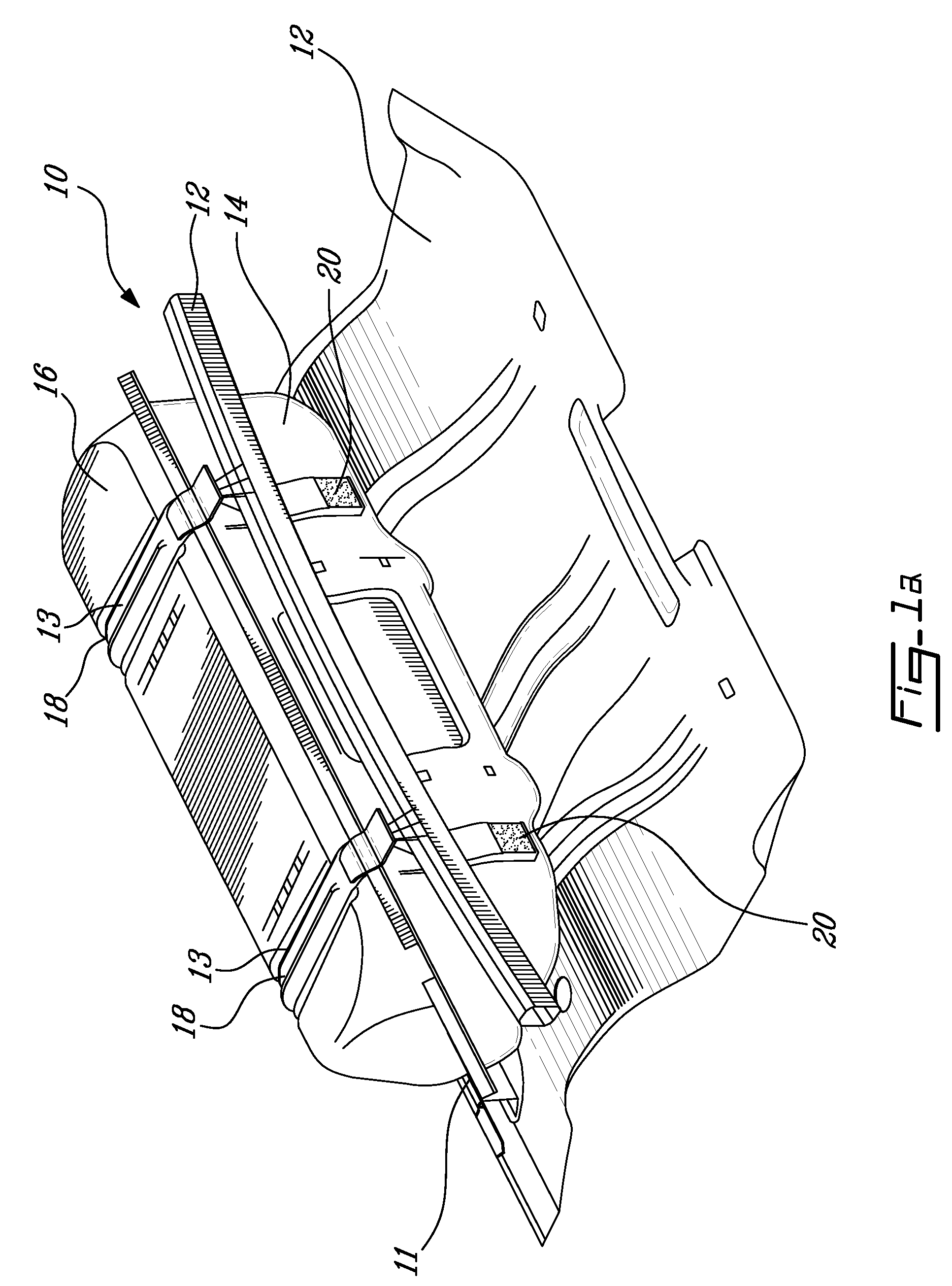

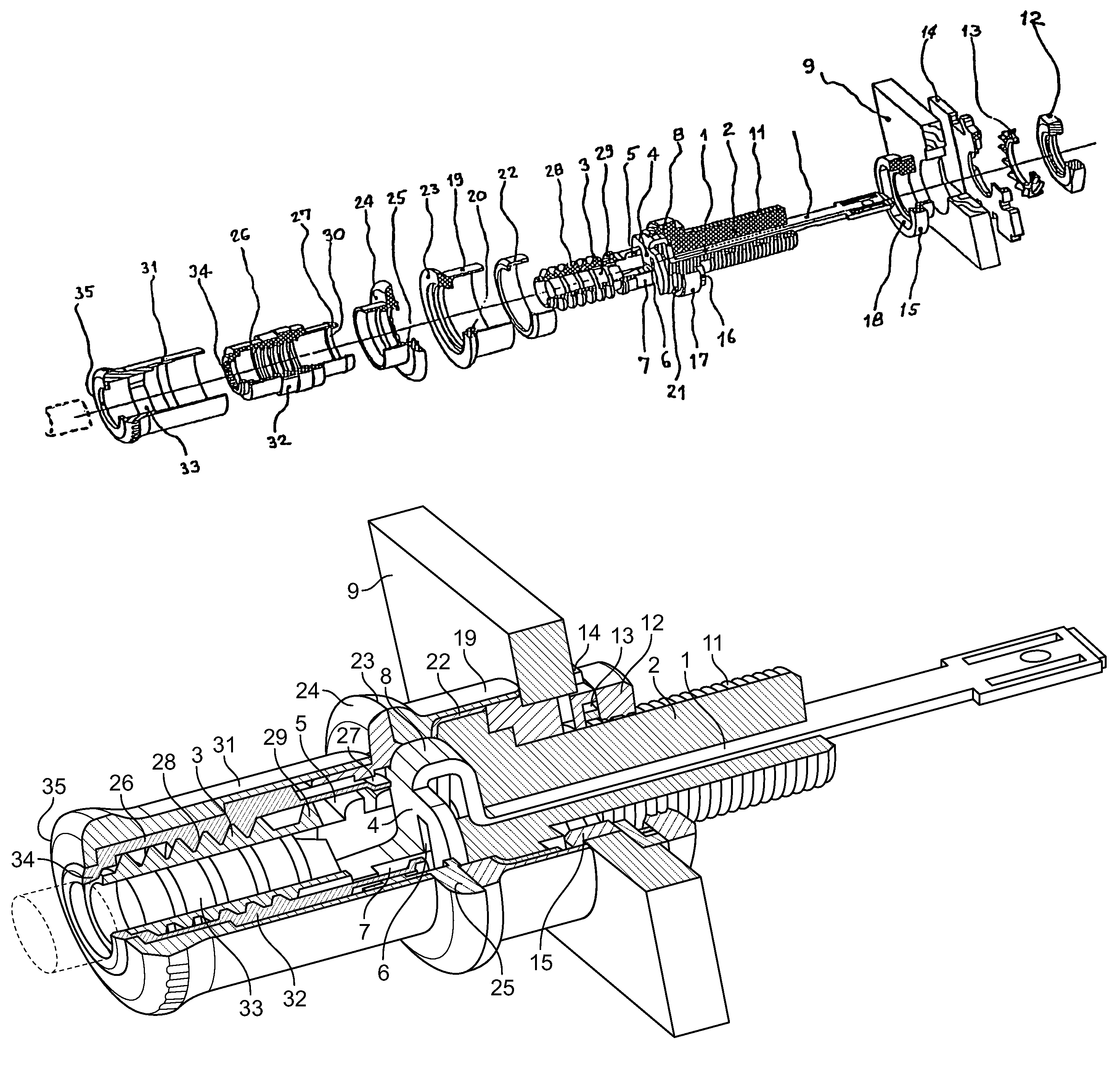

Expandable reamer

An expandable reamer includes, in one exemplary embodiment thereof, a cannulated shaft and a plurality of straight cutting blades having deformable points. The blades are hingably outwardly rotatable at the deformation points between a contracted position and an expanded position. In the contracted position, the blades are substantially parallel to the longitudinal axis of the cannulated shaft and, in the expanded position, the blades have at least a portion oriented radially outward from the longitudinal axis, thereby forming a larger diameter cutting surface in the expanded position and in the contracted position. The blades are formed from a portion of the cannulated shaft by, e.g. milling longitudinally extending slots through the wall of the cannulated shaft, the slots serving as flutes dividing the cutting edge and trailing edge of each adjacent blade. Each blade may also include more than one segment arranged along its length, the segments coupled by deformation points. The expandable reamer may be used for cutting a cavity in a bone or other structure that is larger than the diameter of the entry point into the bone and greater than the diameter of the contracted reamer.

Owner:ZIMMER TECH INC

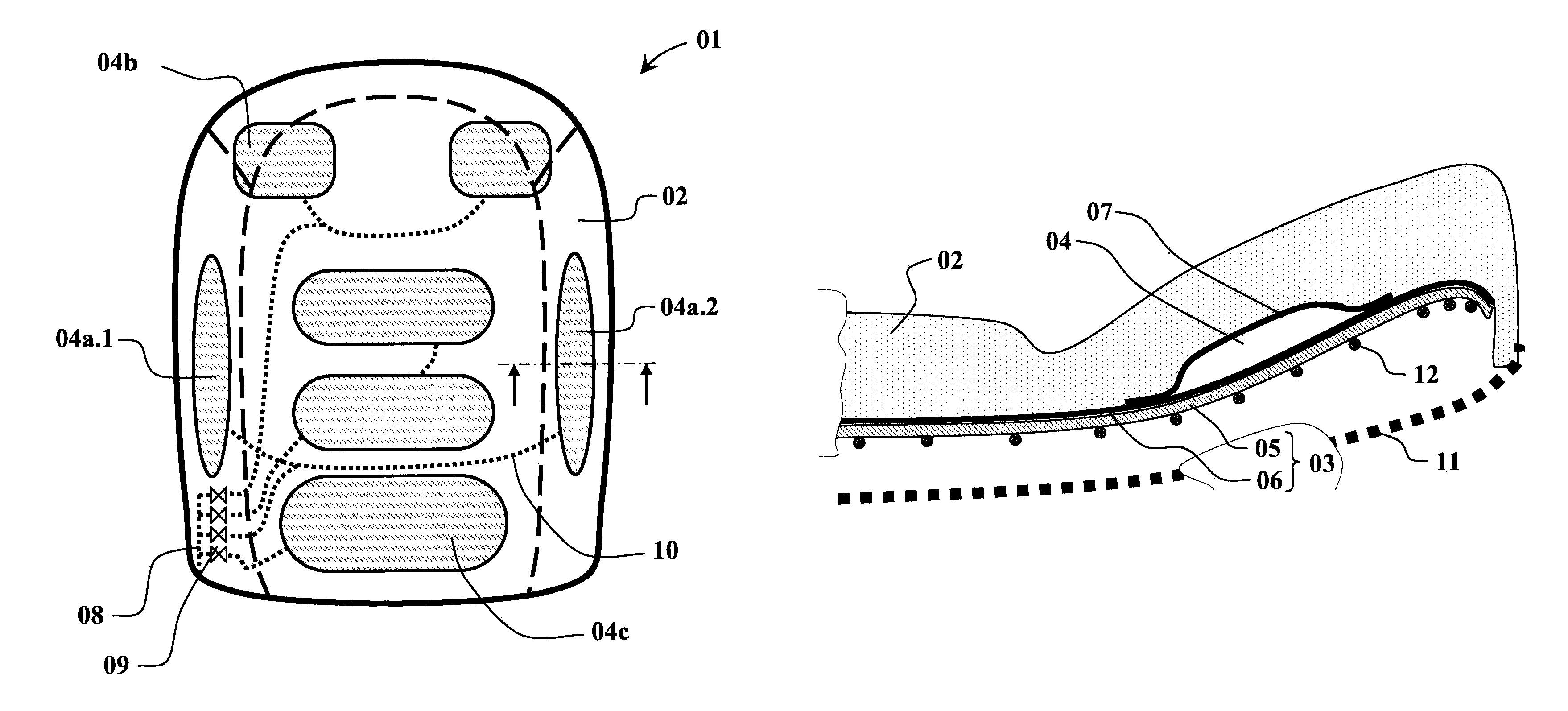

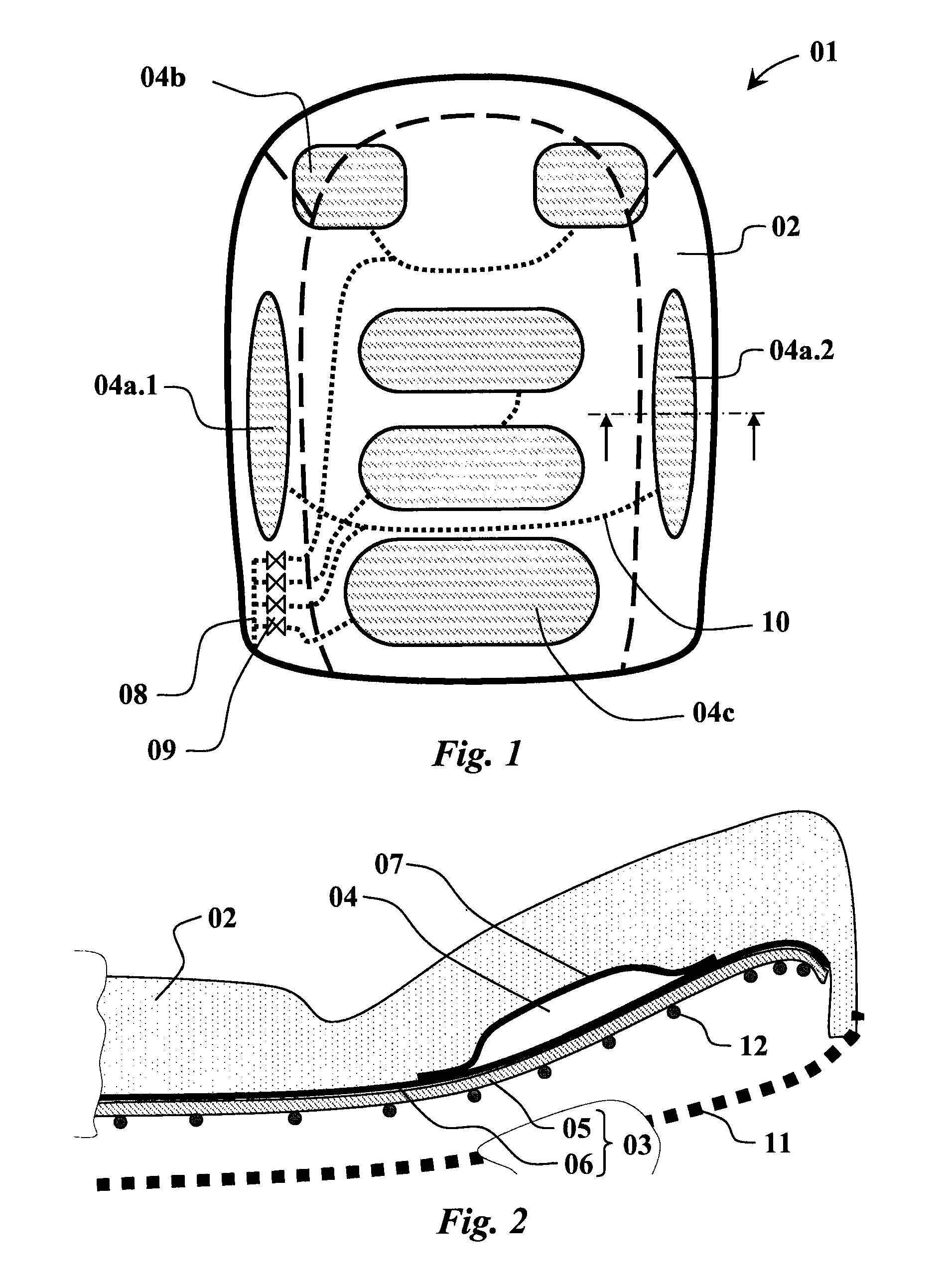

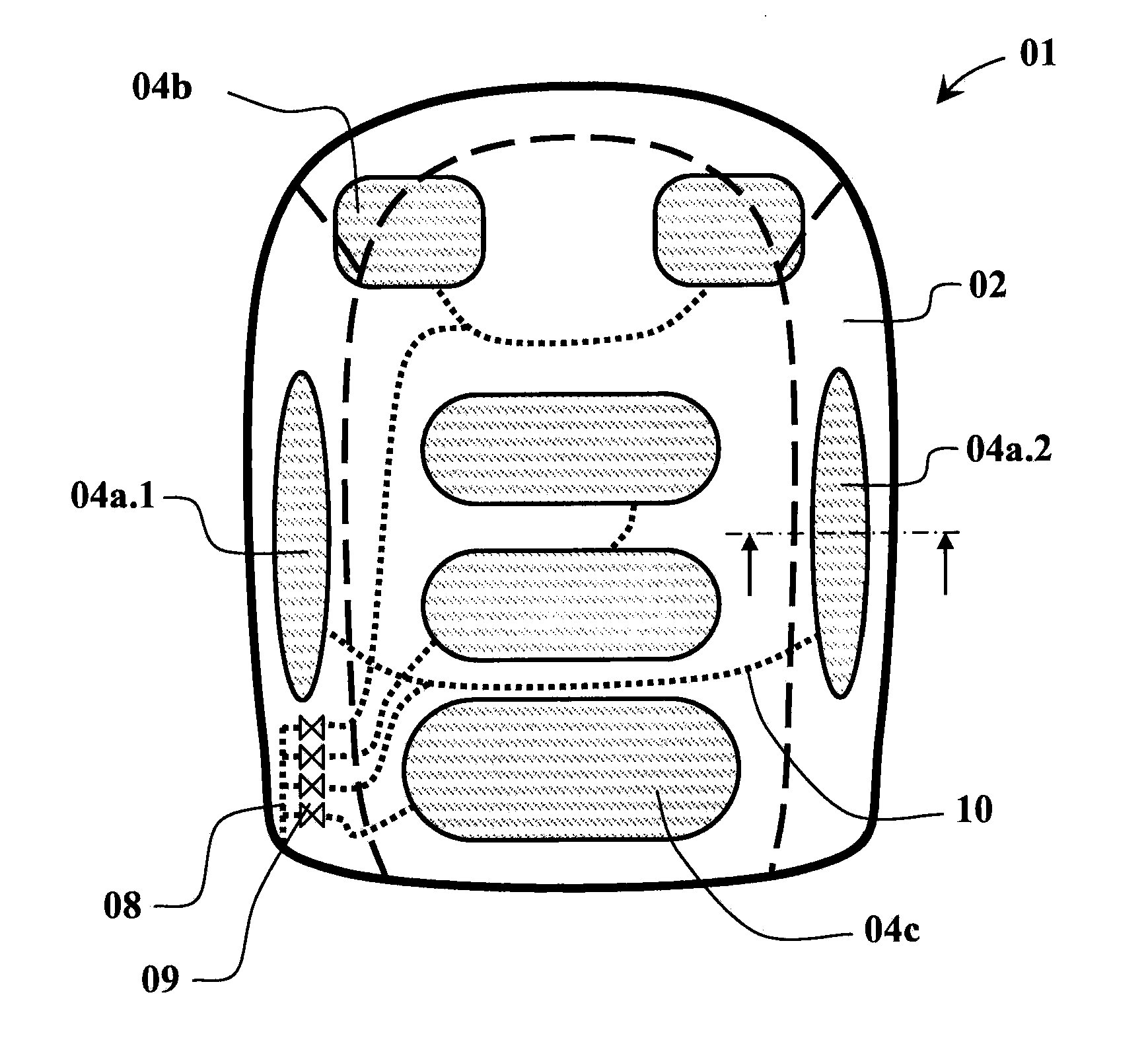

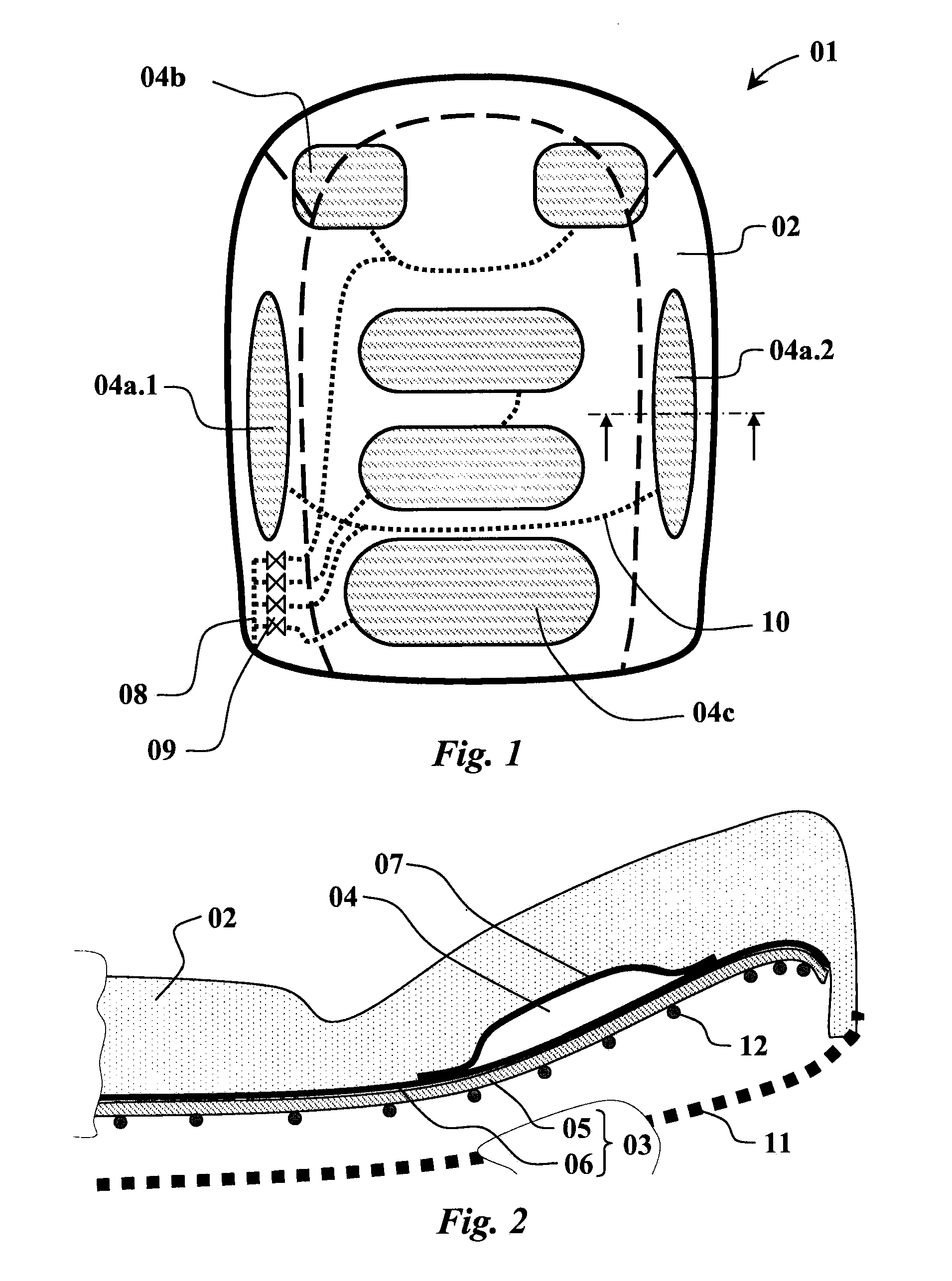

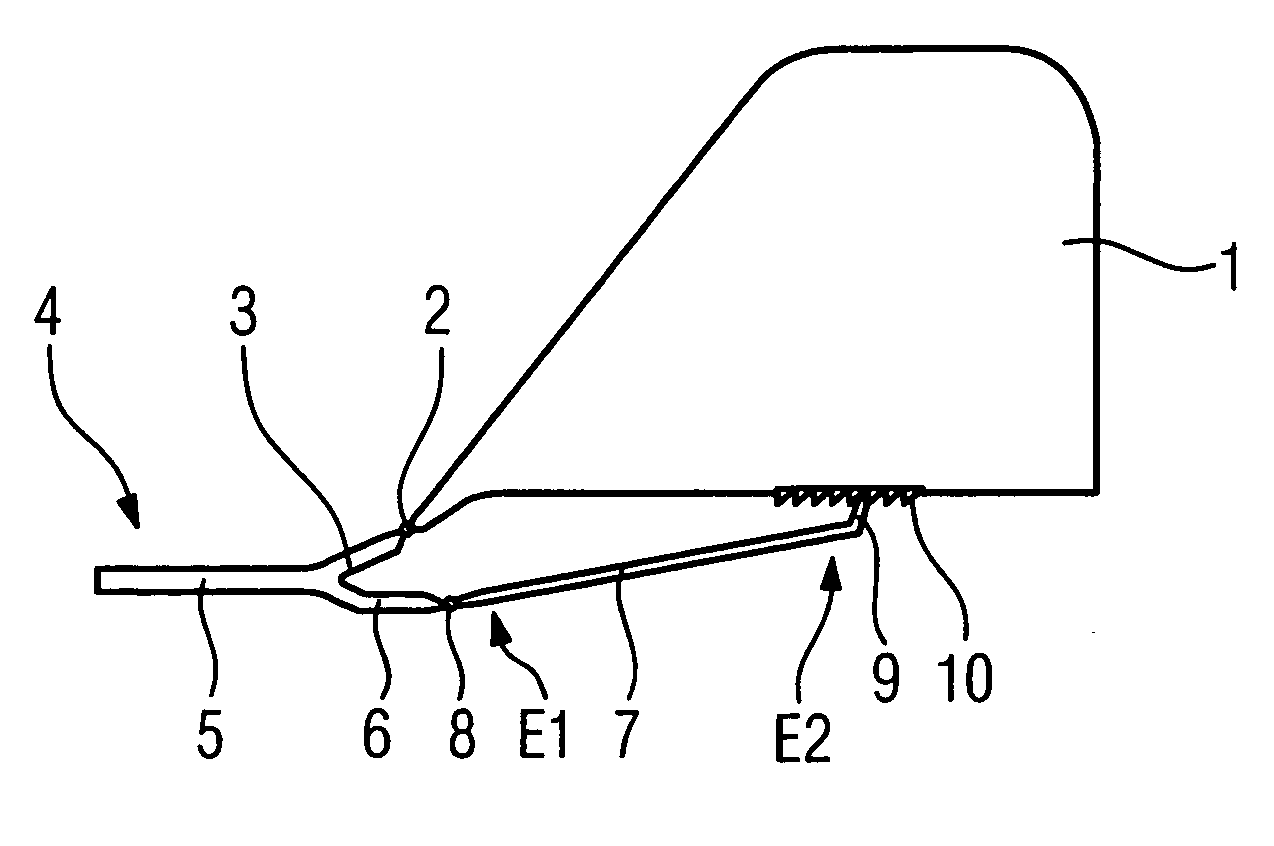

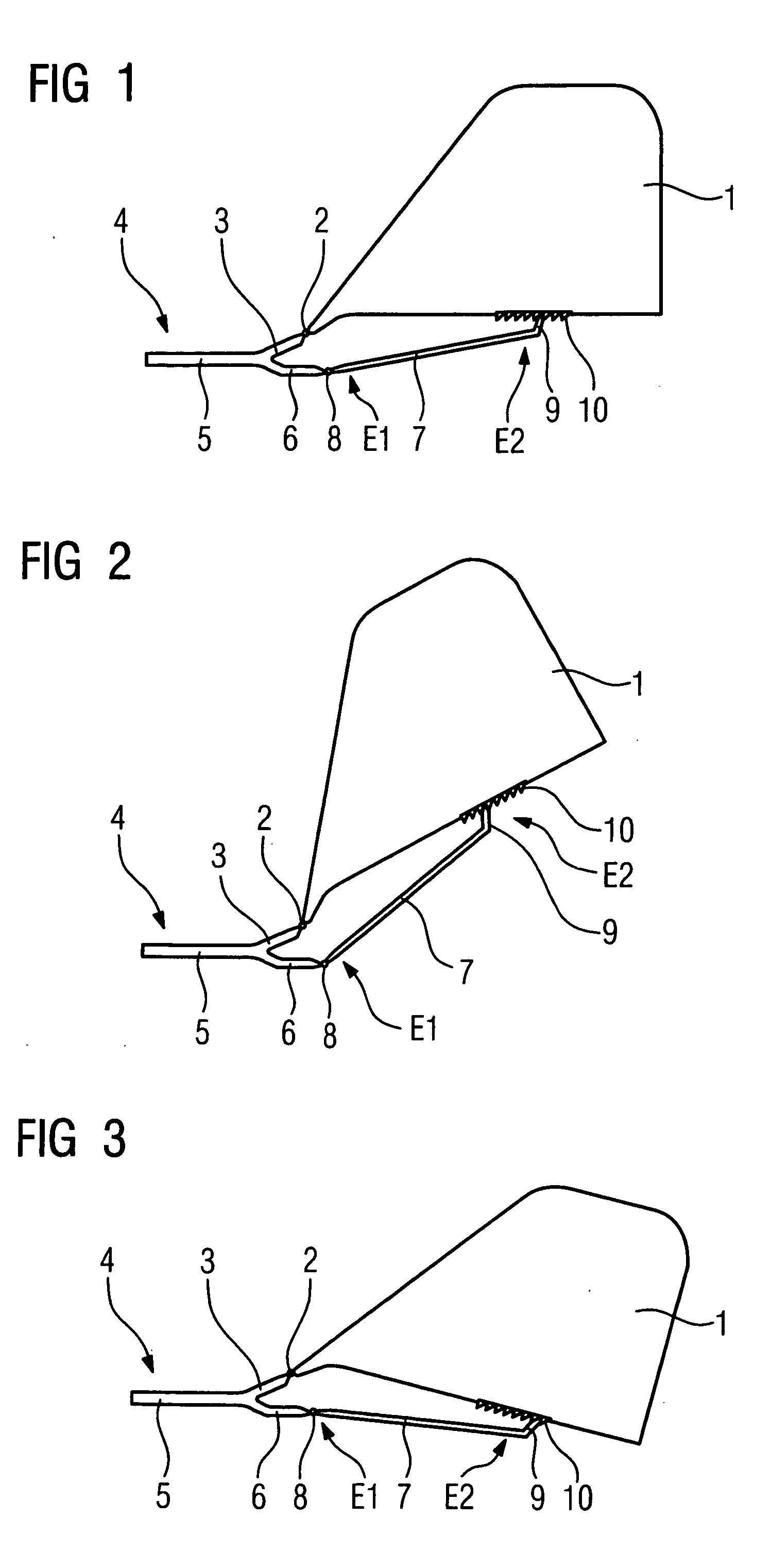

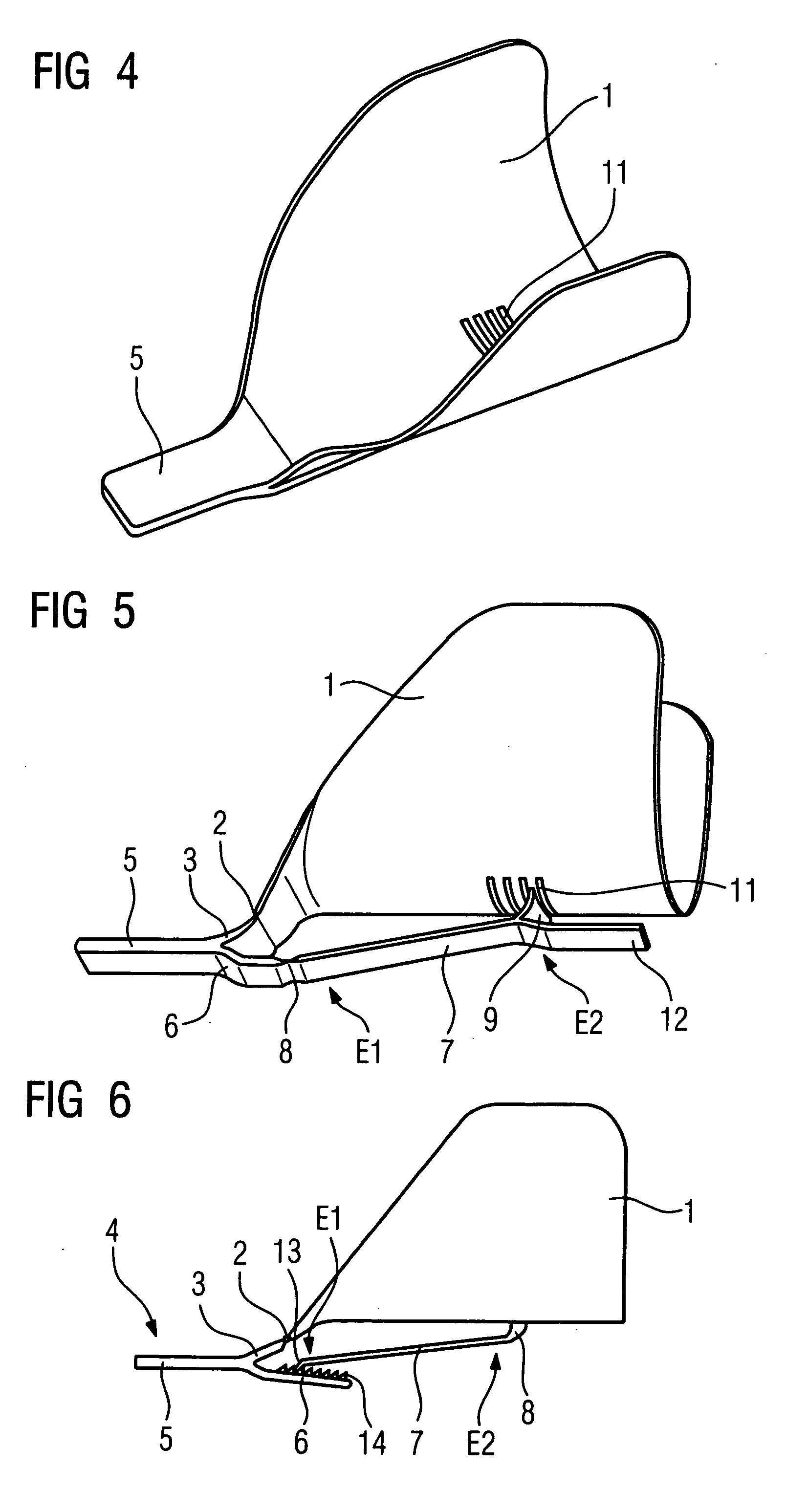

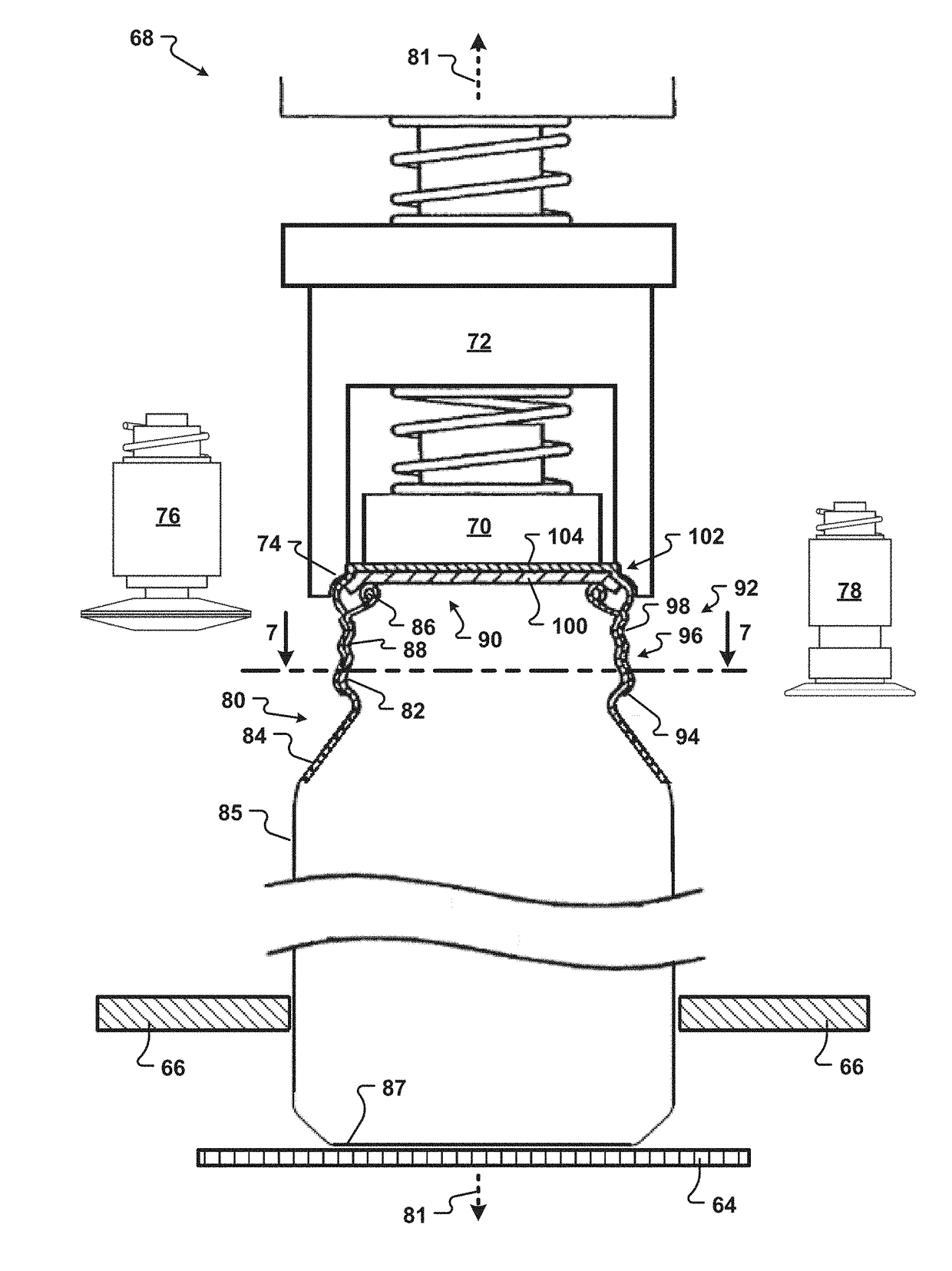

Seat cushion with bubble elements

InactiveUS8342607B2Avoid damageAvoid displacementVehicle seatsDismountable chairsHermetic sealEngineering

A seat cushion for the production of a vehicle seat has a foam body and a carrier element. The carrier element is disposed on the back side of the foam body and provides mechanical support to the foam body on the back side thereof. At least one bubble element is disposed between the foam body and the carrier element and can be supplied with compressed air via an air inlet. The carrier element features an air-impermeable barrier layer on the side facing towards the foam body. The bubble element is composed of two bubble halves that are connected to one another by means of an airtight sealing joint, and wherein the bubble half facing away from the foam body is formed by a surface section of the barrier layer of the carrier element, and wherein the second bubble half facing towards the foam body is fastened at the assigned surface section of the barrier layer while forming the airtight sealing joint.

Owner:FS FEHRER AUTOMOTIVE GMBH

Plastic container base structure and method for hot filling a plastic container

Owner:GRAHAM PACKAGING CO LP

Aqueous binder for inorganic fiber and thermal and/or acoustical insulation material using the same

InactiveUS20100098947A1Maintain physical propertiesReduce material thicknessSynthetic resin layered productsGlass/slag layered productsFiberAcrylic resin

Provided is an aqueous binder for inorganic fibers, which is formaldehyde-free, has excellent strength, and is suitable for use under conditions of weakly acidic to weakly basic, and by which a cured product composed of the binder having excellent strength is obtained, and an thermal and / or acoustical insulation material made of inorganic fiber using the same. The thermal and / or acoustical insulation material is molded by using an aqueous hinder for inorganic fibers including: an acrylic resin with an acid value of 350 to 850 mgKOH / g; a crosslinking agent containing at least one dialkanolamine; and a curing accelerator, in which a molar ratio of the total number of the hydroxyl groups and imino groups in the crosslinking agent to the total number of carboxyl groups in the acrylic resin is 0.8:1 to 1.5:1, and in which pH of the hinder is adjusted to 6.0 to 8.0 with a volatile basic compound.

Owner:ASAHI FIBER GLASS CO LTD

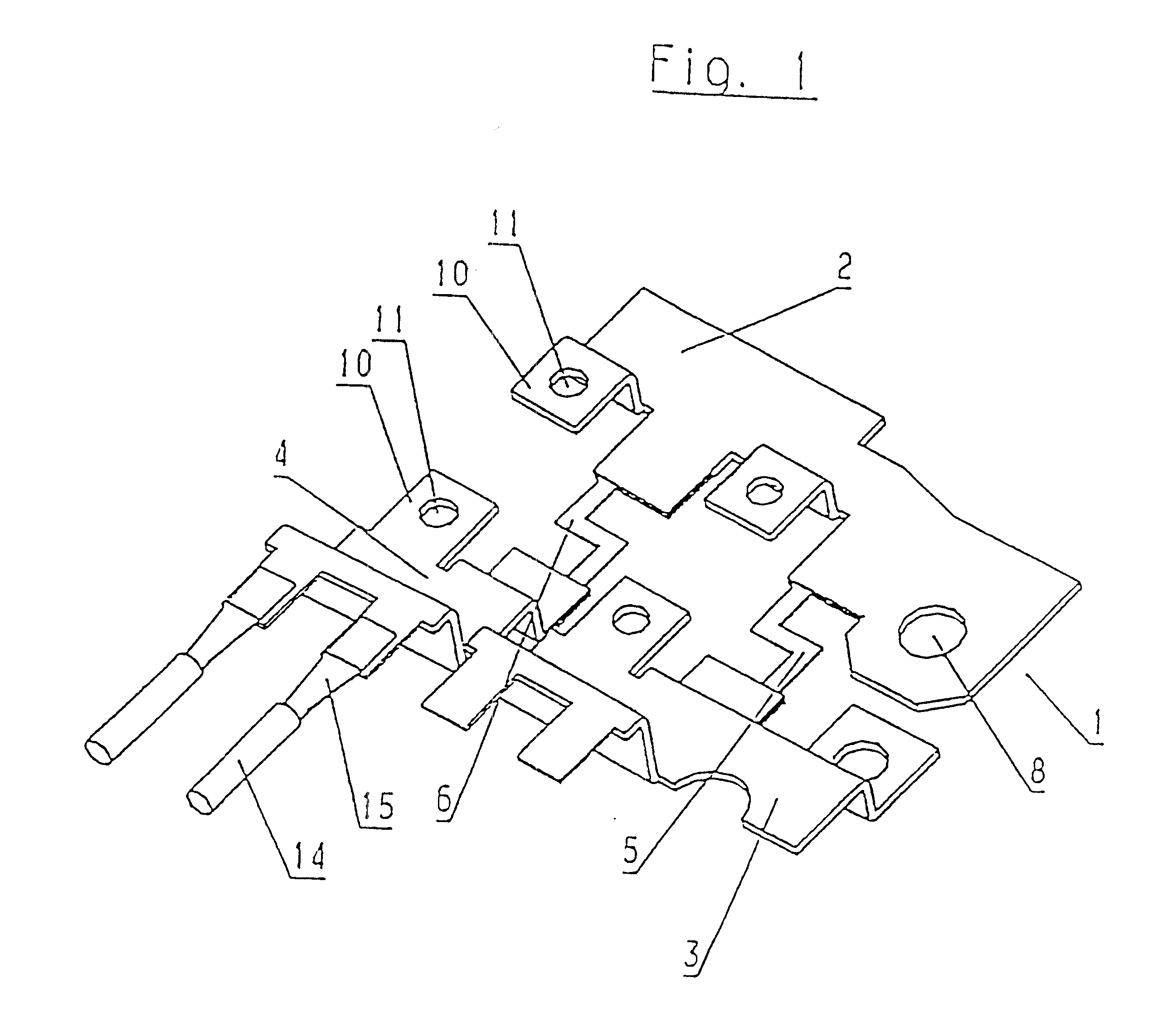

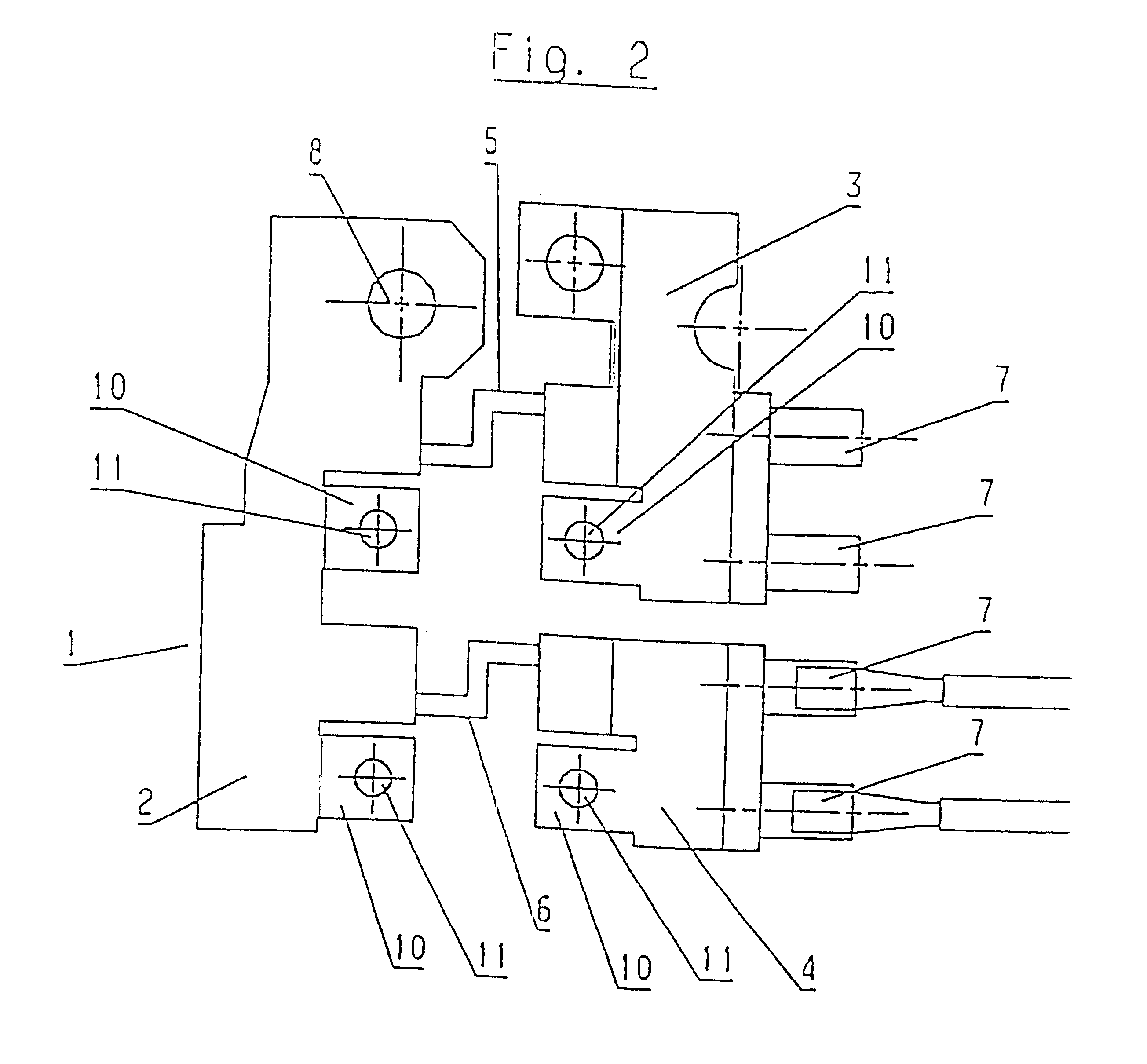

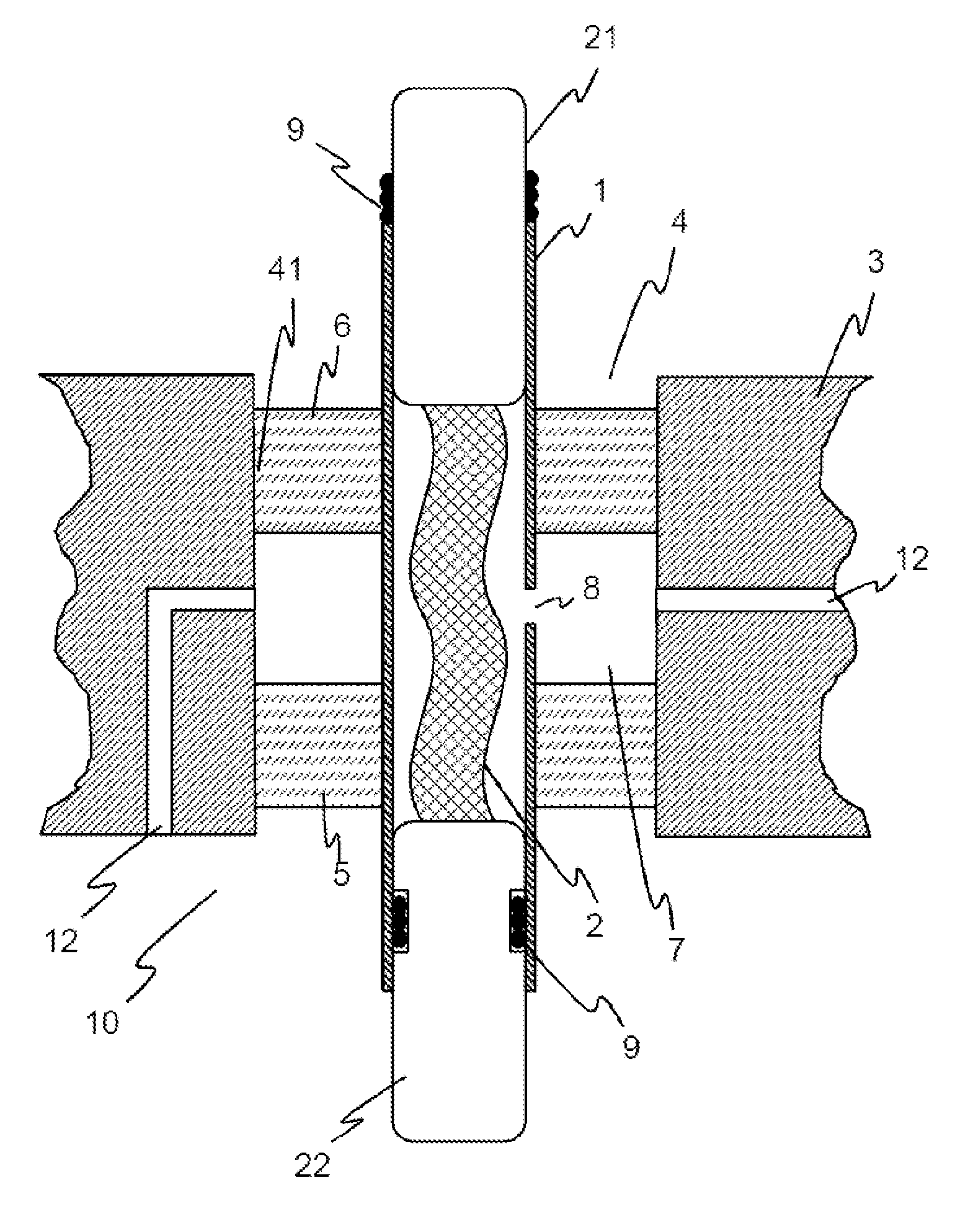

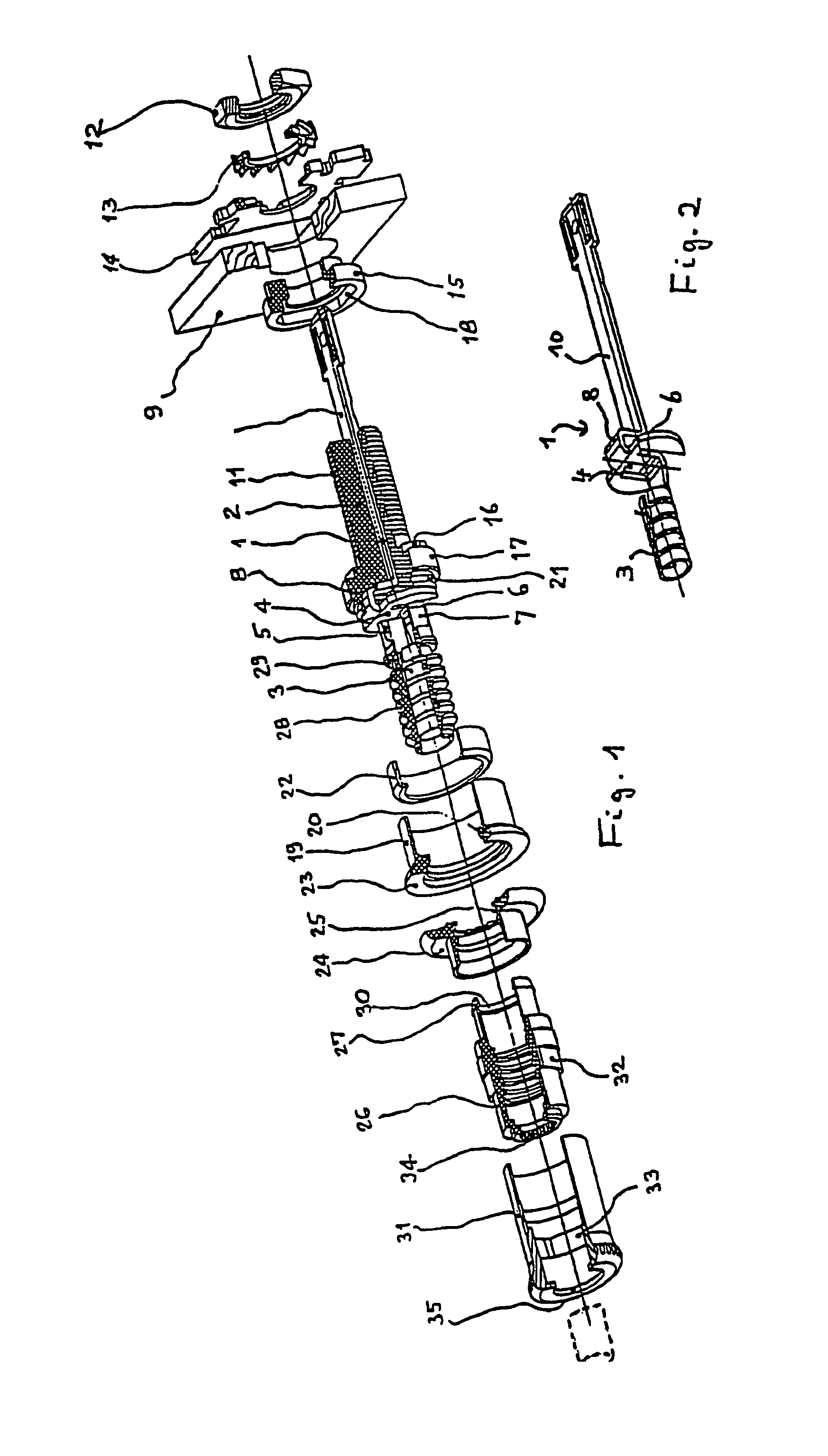

Current distribution device

InactiveUS6476705B1Production of the current distribution device is correspondingly simplifiedCompact and weight-saving current distribution devicesBus-bar/wiring layoutsCoupling device detailsCurrent distributionElectrical connection

A voltage distribution device for use especially in motor vehicles, includes a first area (2) made of conductive material and fitted with at least one electrical connection (8), at least two separate second areas (3, 4) made of conductive material and fitted with at least one electrical connection each (7), and bridge-like fuse areas (5, 6) made of conductive material, which each link the second areas (3, 4) with the first (2) and are inseparably connected to the first and associated second area. The bridge-like fuse areas (5, 6) each have a cross-section of material calibrated along a longitudinal section according to material thickness and / or depth. In another embodiment of the invention, in a voltage distribution device for use especially in motor vehicles, a first area (2) made of conductive material and with at least one electrical connection (8), and at least two second areas (3B) made of conductive material and with at least one electrical connection each (4), are linked by bridge-like fuse areas made of conductive material (3), whereby these fuses (3) are inseparably connected to the first area (2) by deep-draw sleeves (5).

Owner:AUDIO OHM DI TONANI CATERINA E C +1

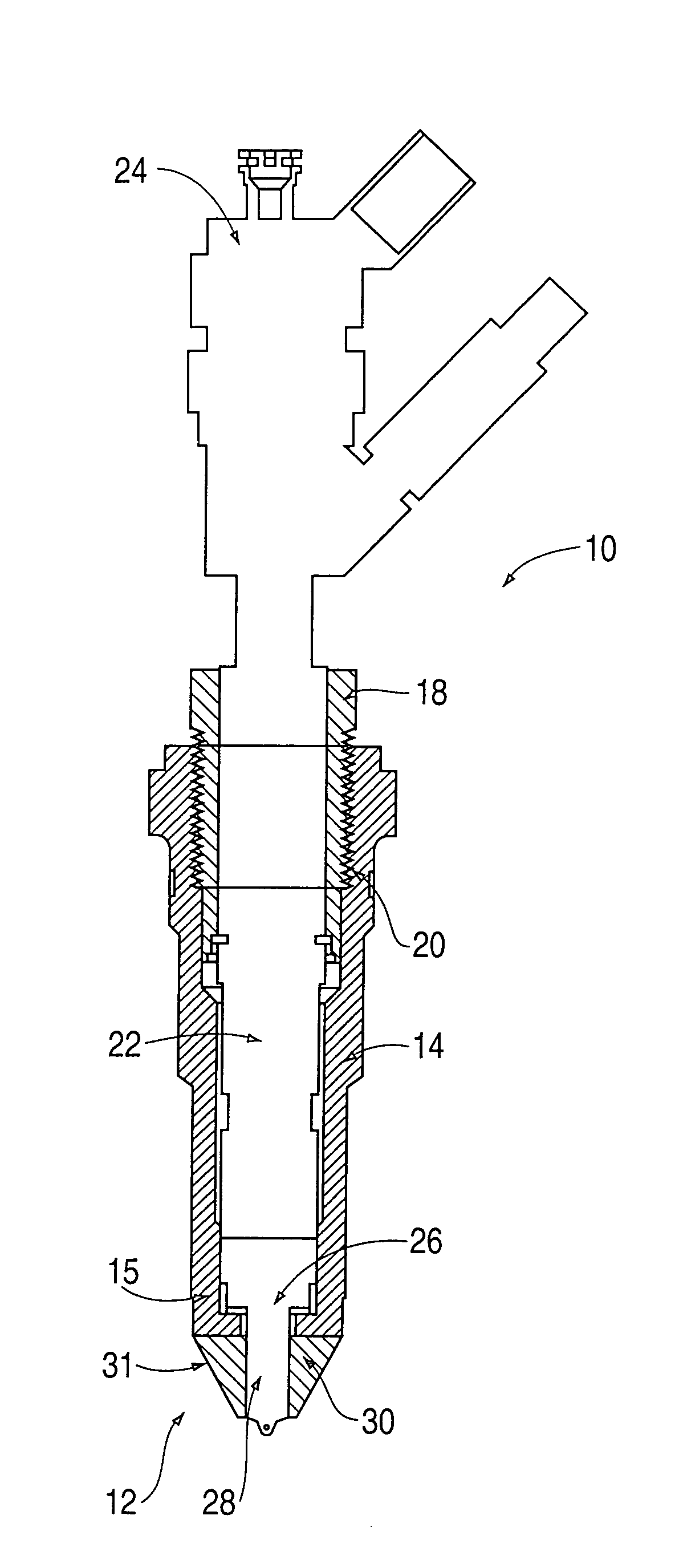

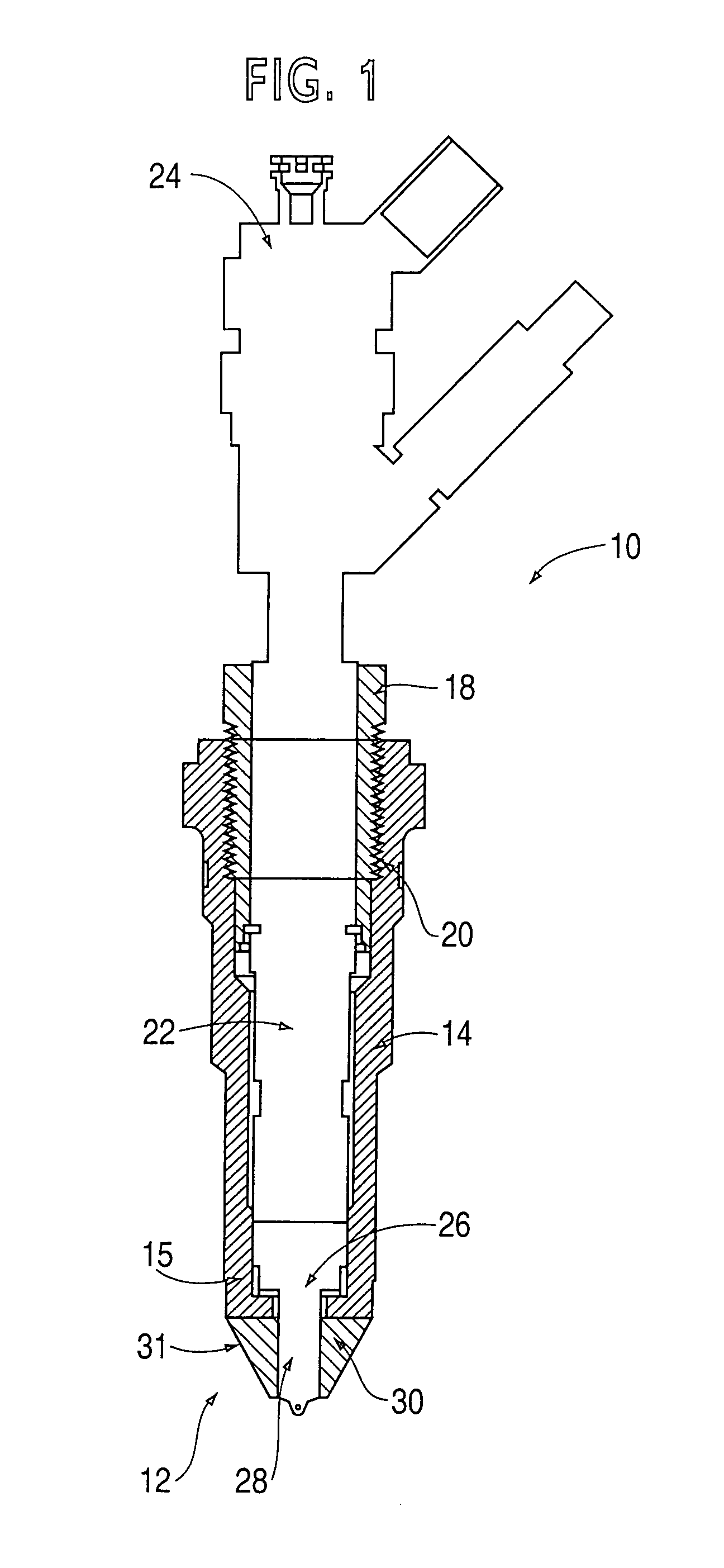

Fuel injector having a nozzle with improved cooling

InactiveUS7028918B2Improve reliabilityImprove performanceSpray nozzlesMachines/enginesInterference fitEngineering

A fuel injector having a nozzle with improved cooling including a retainer and a nozzle housing received therein. The nozzle housing includes a nozzle shank, an outer peripheral surface and at least one injection hole at a tip of the nozzle shank. The nozzle shank is positioned in a nozzle support portion of the retainer. In one embodiment, the outer peripheral surface of the nozzle shank is tapered, and the inner peripheral surface of the nozzle support portion is correspondingly tapered and sized to engage the outer peripheral surface of the nozzle shank along a tapered interface. In another embodiment, the inner peripheral surface of the nozzle support portion has a diameter smaller than a diameter of the outer peripheral surface of the nozzle shank so that an interference fit exists at a seal interface. In yet another embodiment, a nozzle seal seals an interface between the inner peripheral surface of the retainer and the outer peripheral surface of the nozzle shank to thereby prevent entry of hot gases into the interface. In another embodiment, the nozzle support portion is provided on a nozzle sleeve.

Owner:CUMMINS INC

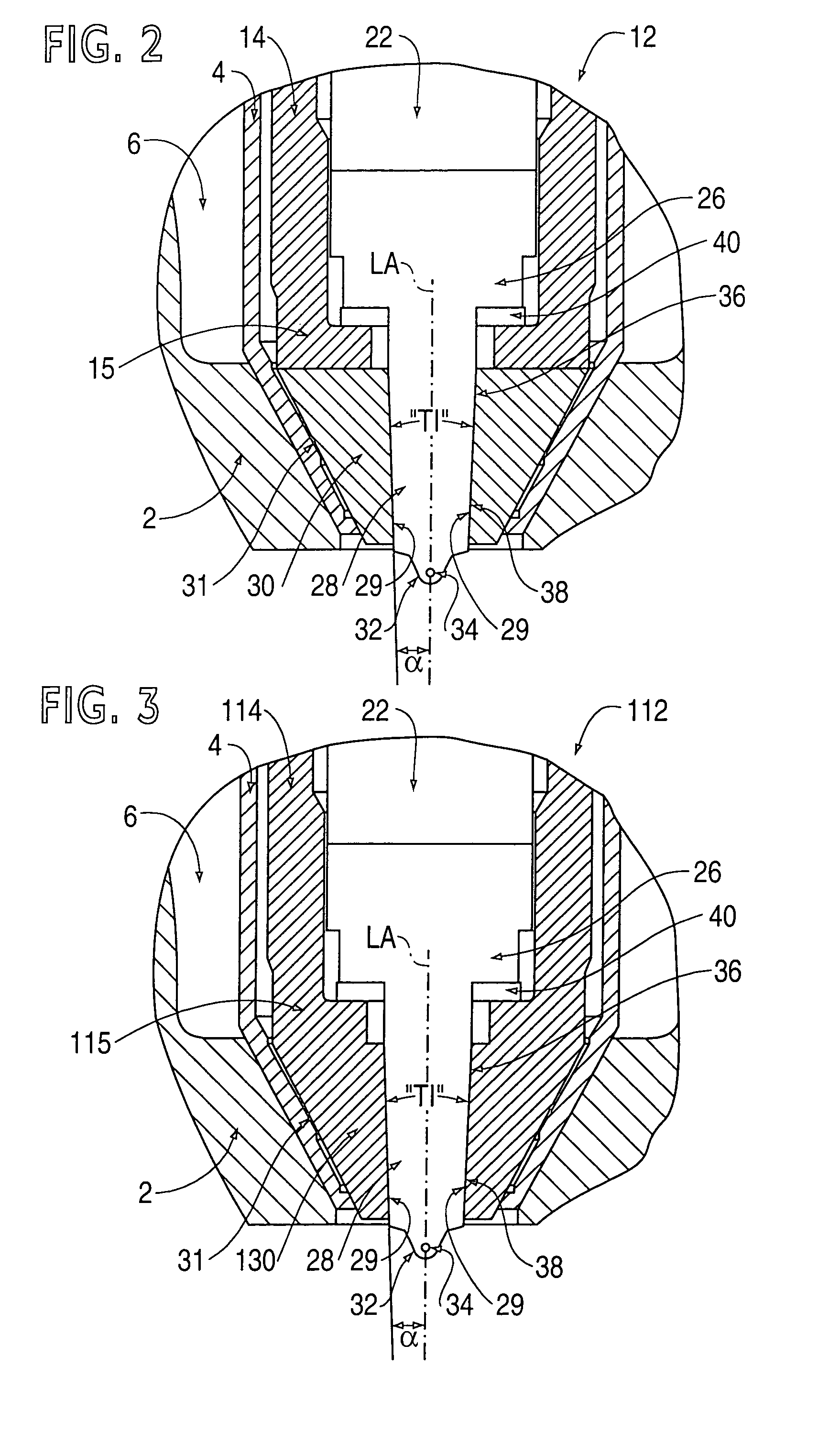

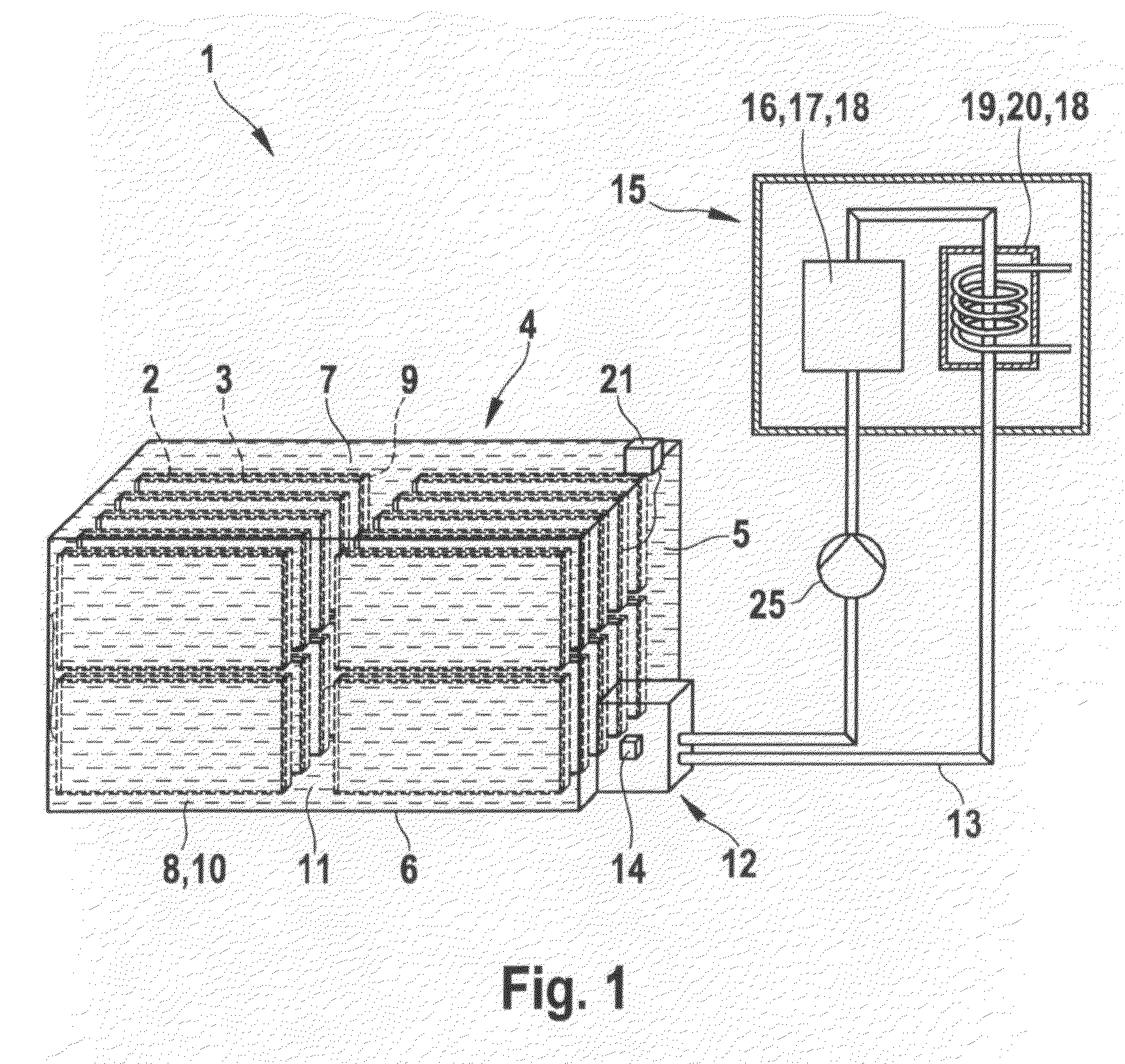

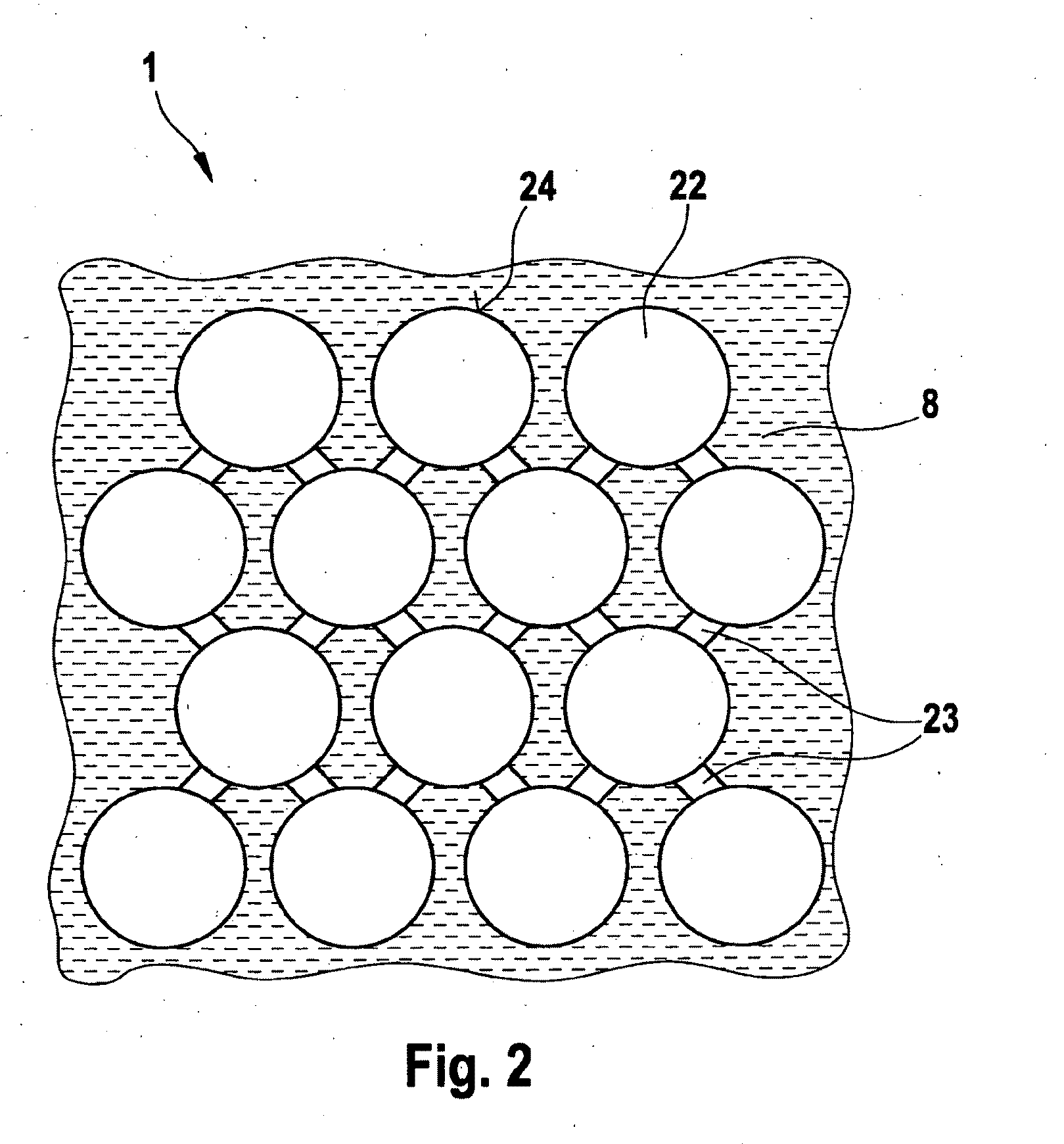

Temperature-controlled battery device and method for it

InactiveUS20110027631A1WideAvoid disadvantagesCell temperature controlBattery isolationTemperature controlElectrical battery

A battery device having at least one battery and having at least one heating and / or cooling device temperature-controlling the battery. It is provided that the battery, submerged in an heating and / or cooling medium, is situated in a housing that accommodates the heating and / or cooling medium. The present invention also relates to a corresponding method.

Owner:ROBERT BOSCH GMBH

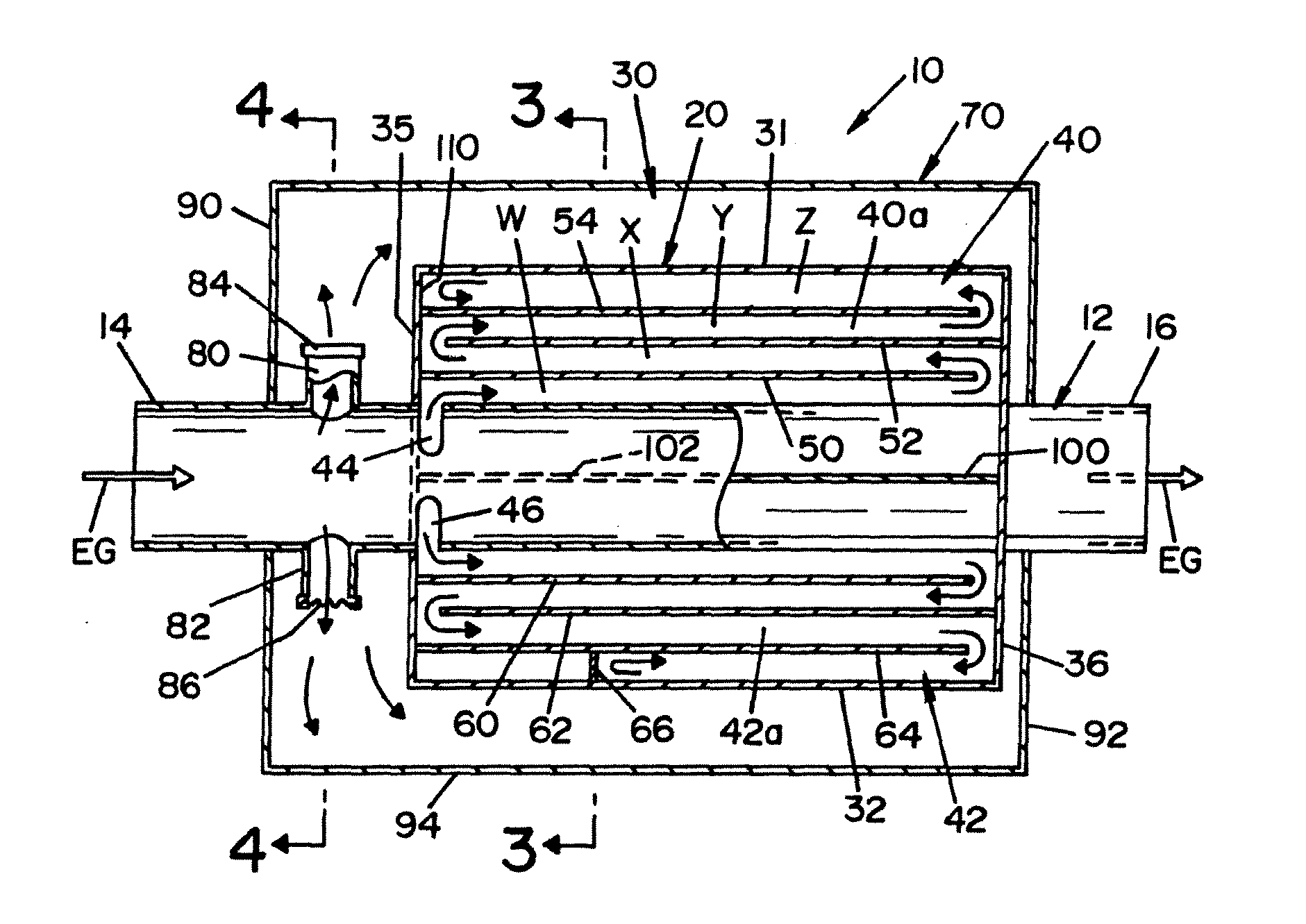

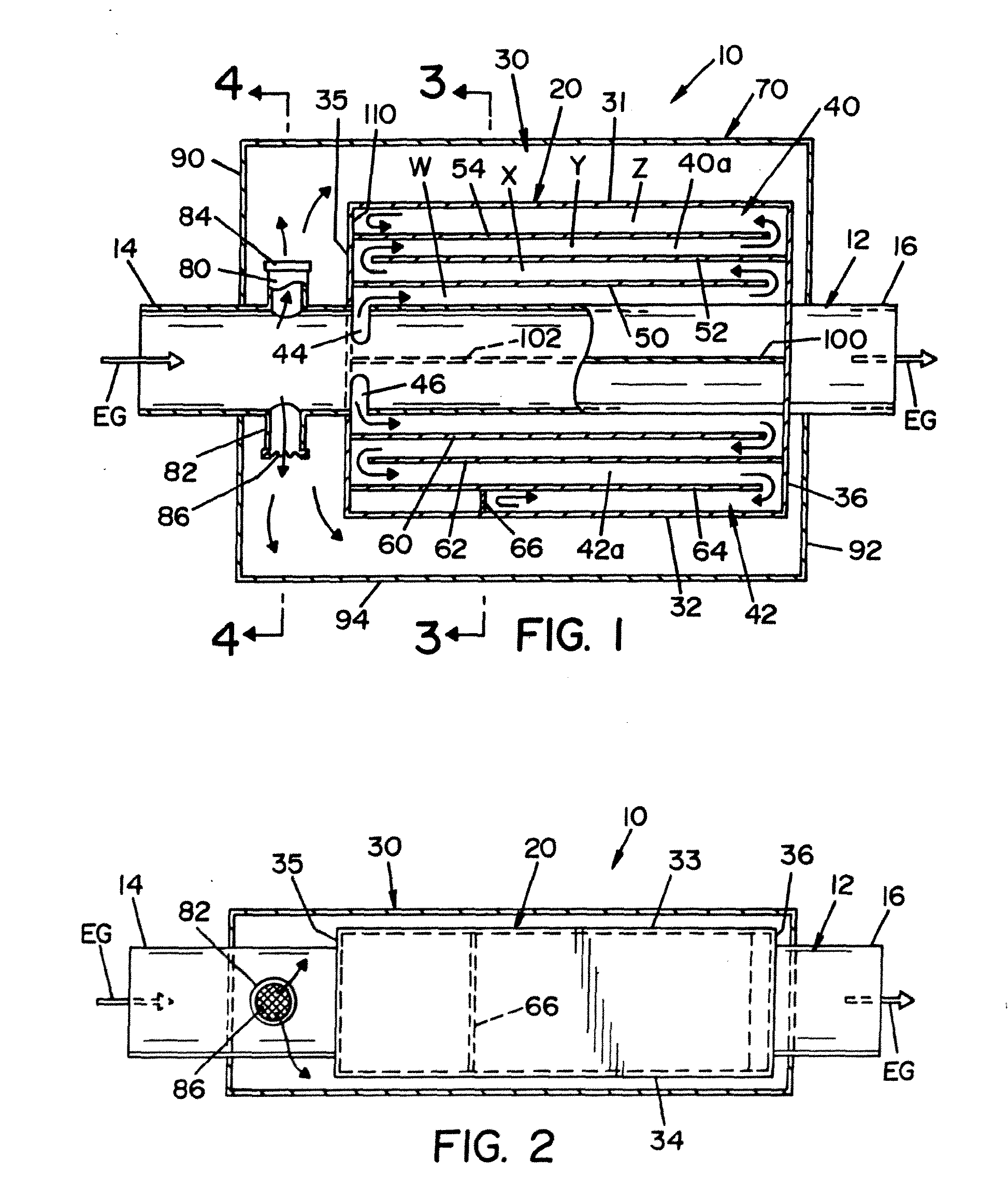

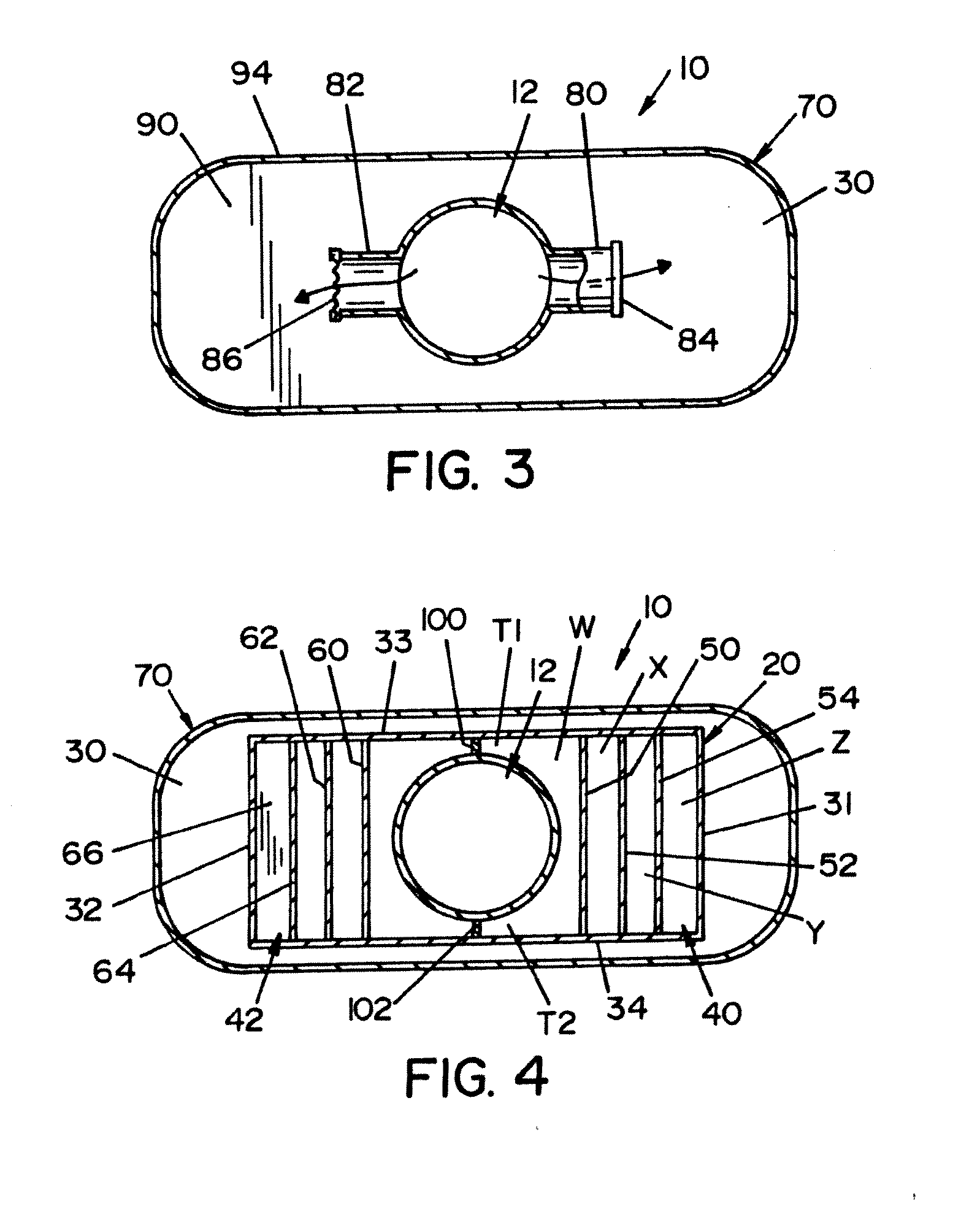

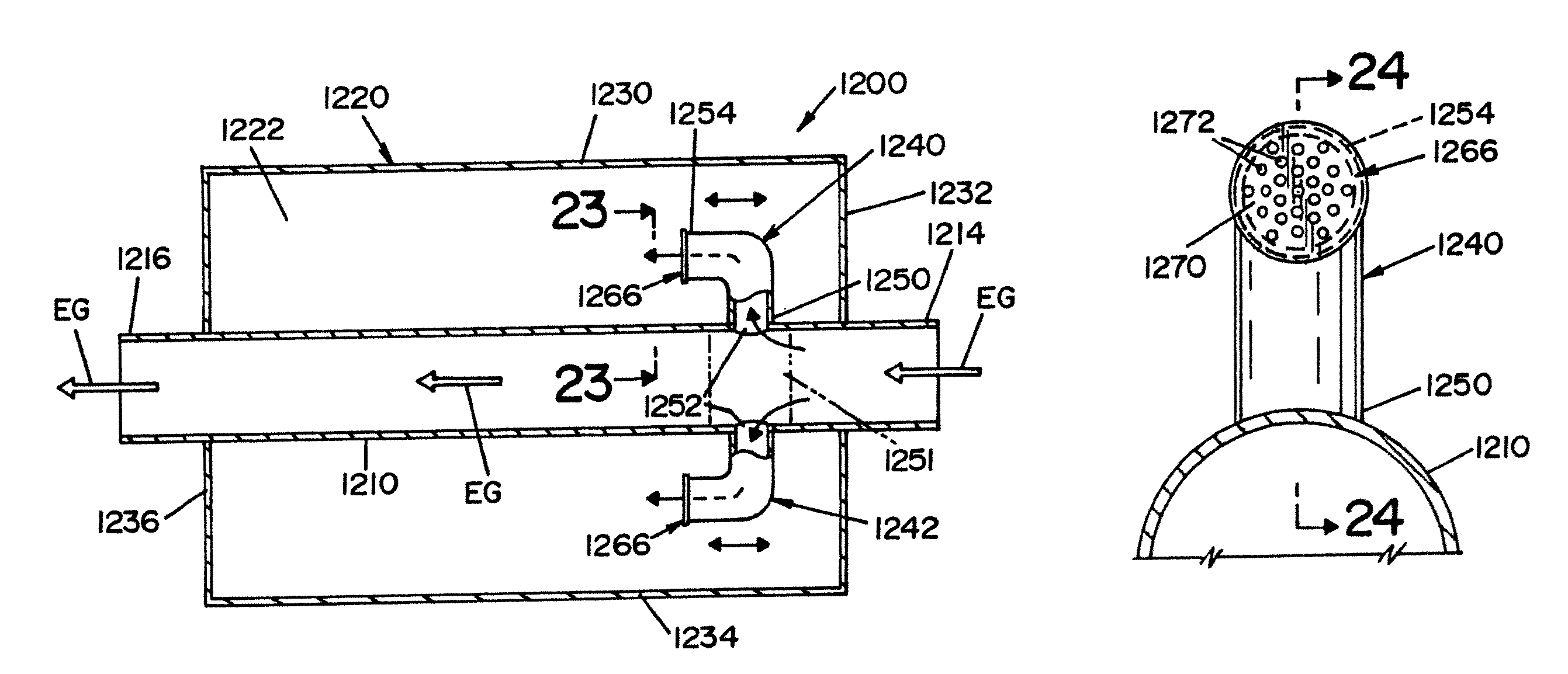

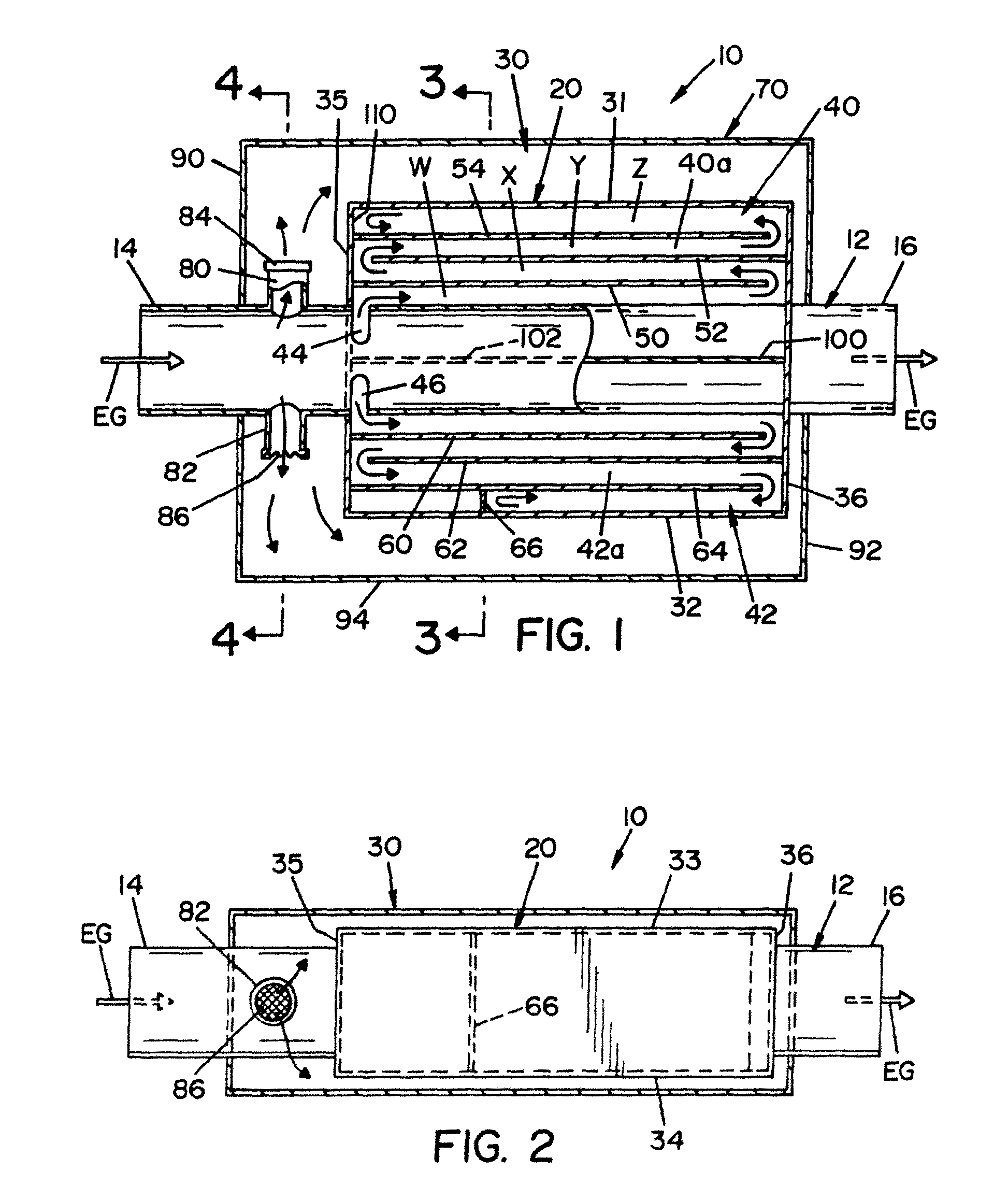

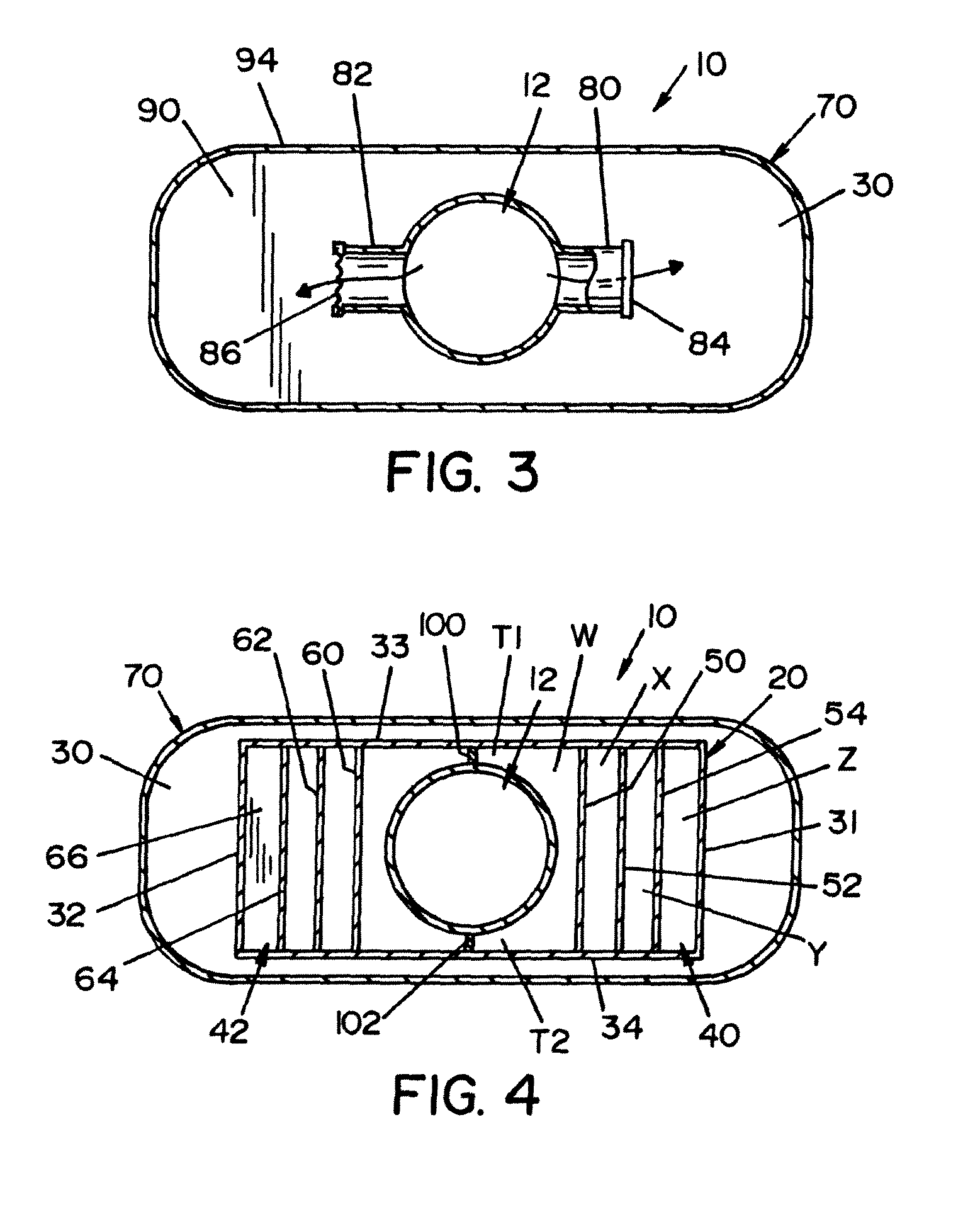

Exhaust muffler

ActiveUS20100270103A1Easy to adjustMaximizes performance characteristicSilencing apparatusMachines/enginesCombustionEngineering

A muffler for reducing the sounds of combustion gases exhausted from an internal combustion engine including an elongated fluid passage extending between an inlet and an outlet such that the outlet is in fluid communication with the inlet. Further, the inlet being connectable with the gases exhausted from the engine and the outlet being connectable with the atmosphere. The muffler further including an outer tank surrounding the passage and a tubular connector having a first end in fluid connection with the passage and a second end in fluid connection with the tank such that the connector produces a fluid connection between the passage and the tank. The connectors having a perforated resistance plate to restrict the fluid flow between said passage and said sound chamber thereby reducing the severity of the sound or fluid pulses entering and exiting said sound chamber, perforations in said perforated plate forming an open portion of said plate and said open portion being less than 60 percent.

Owner:TMG PERFORMANCE PRODS

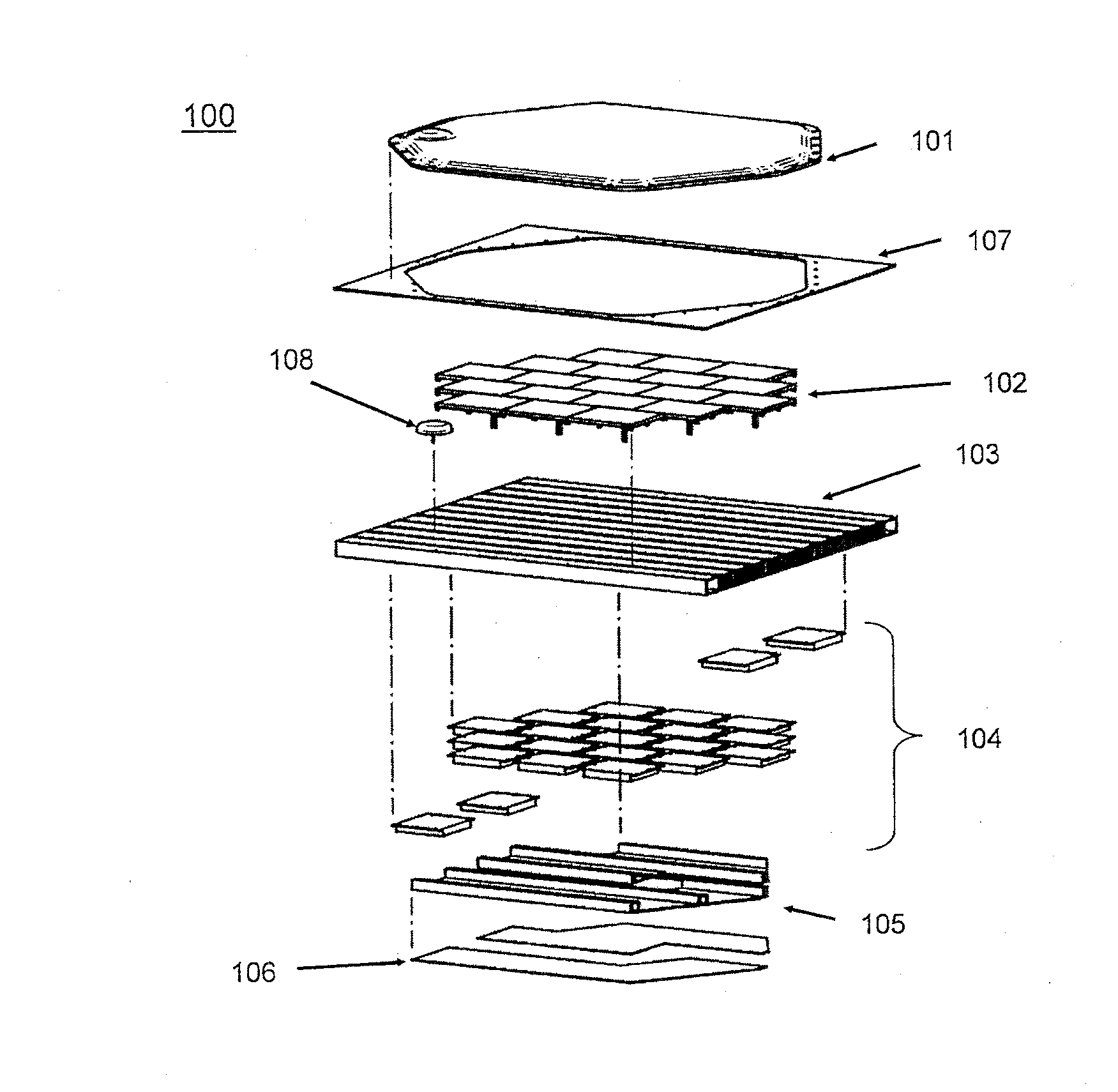

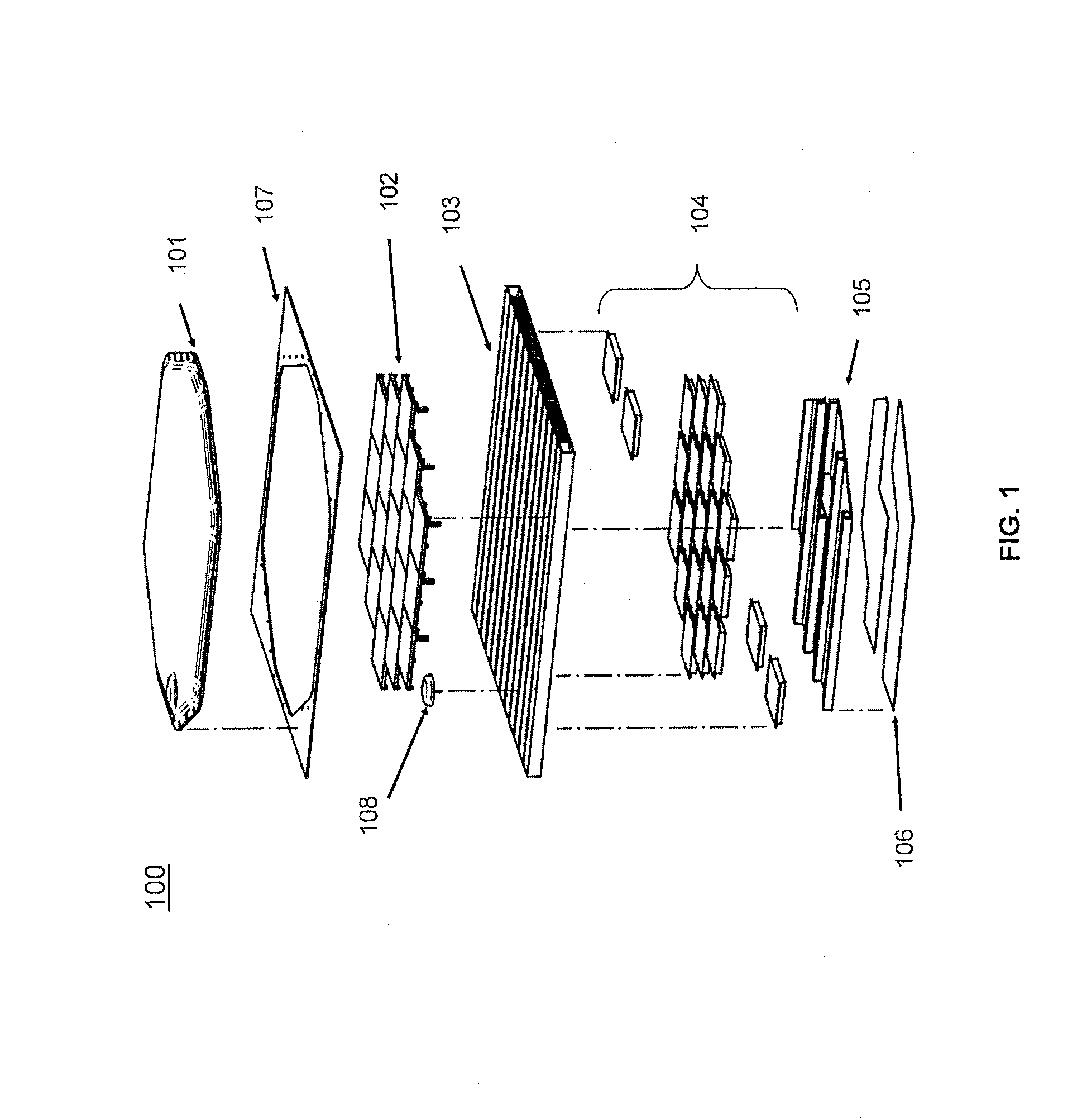

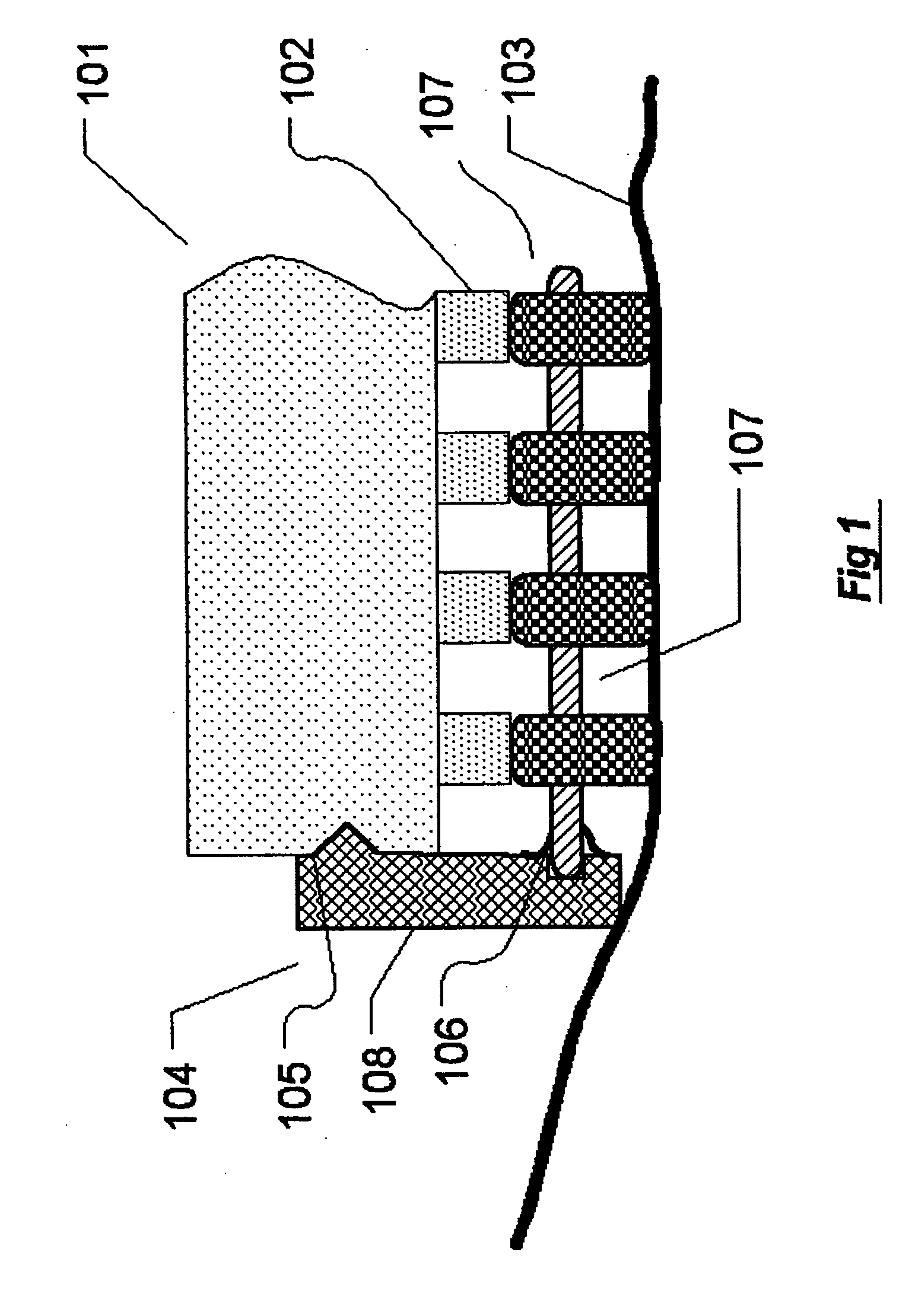

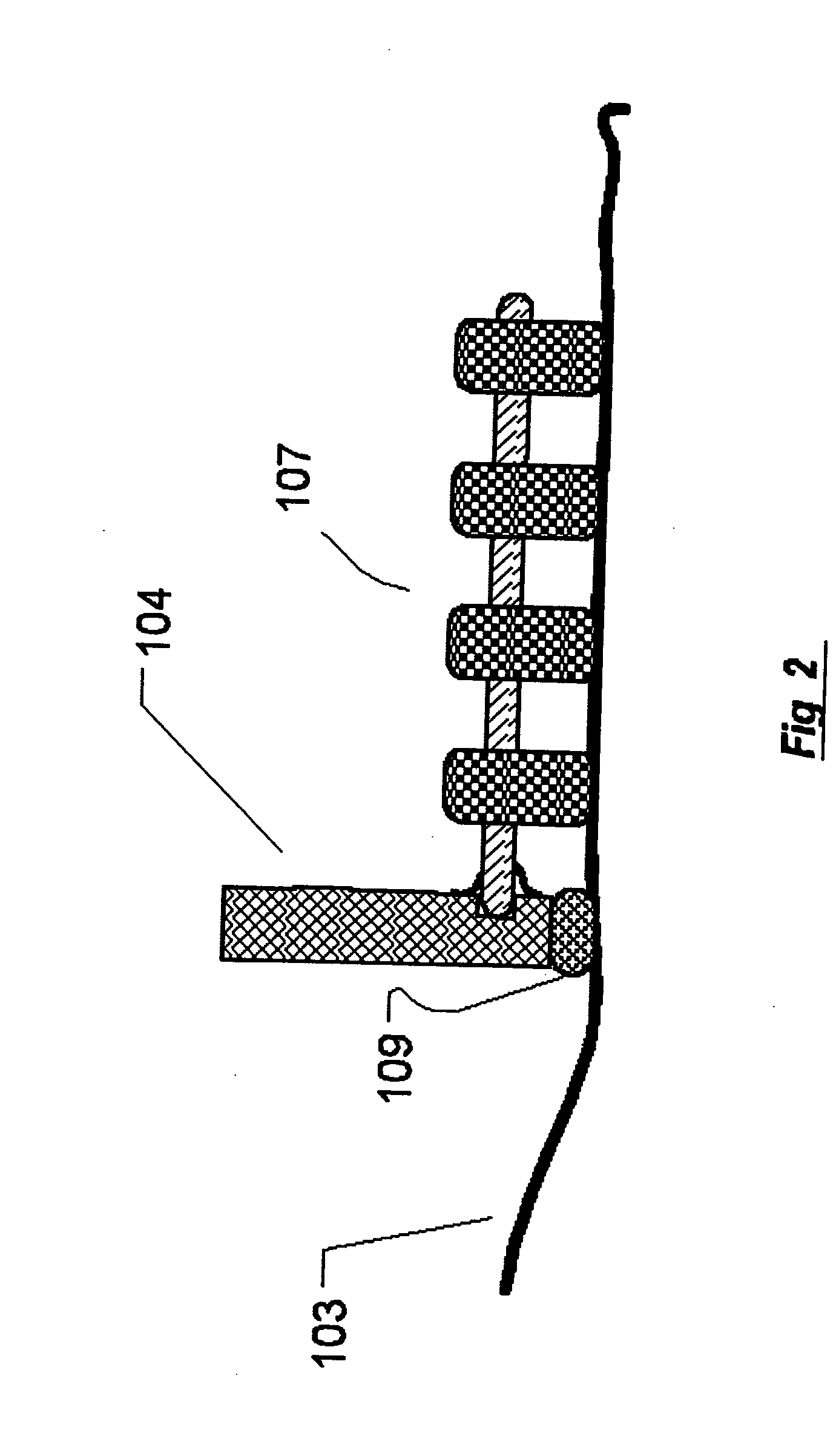

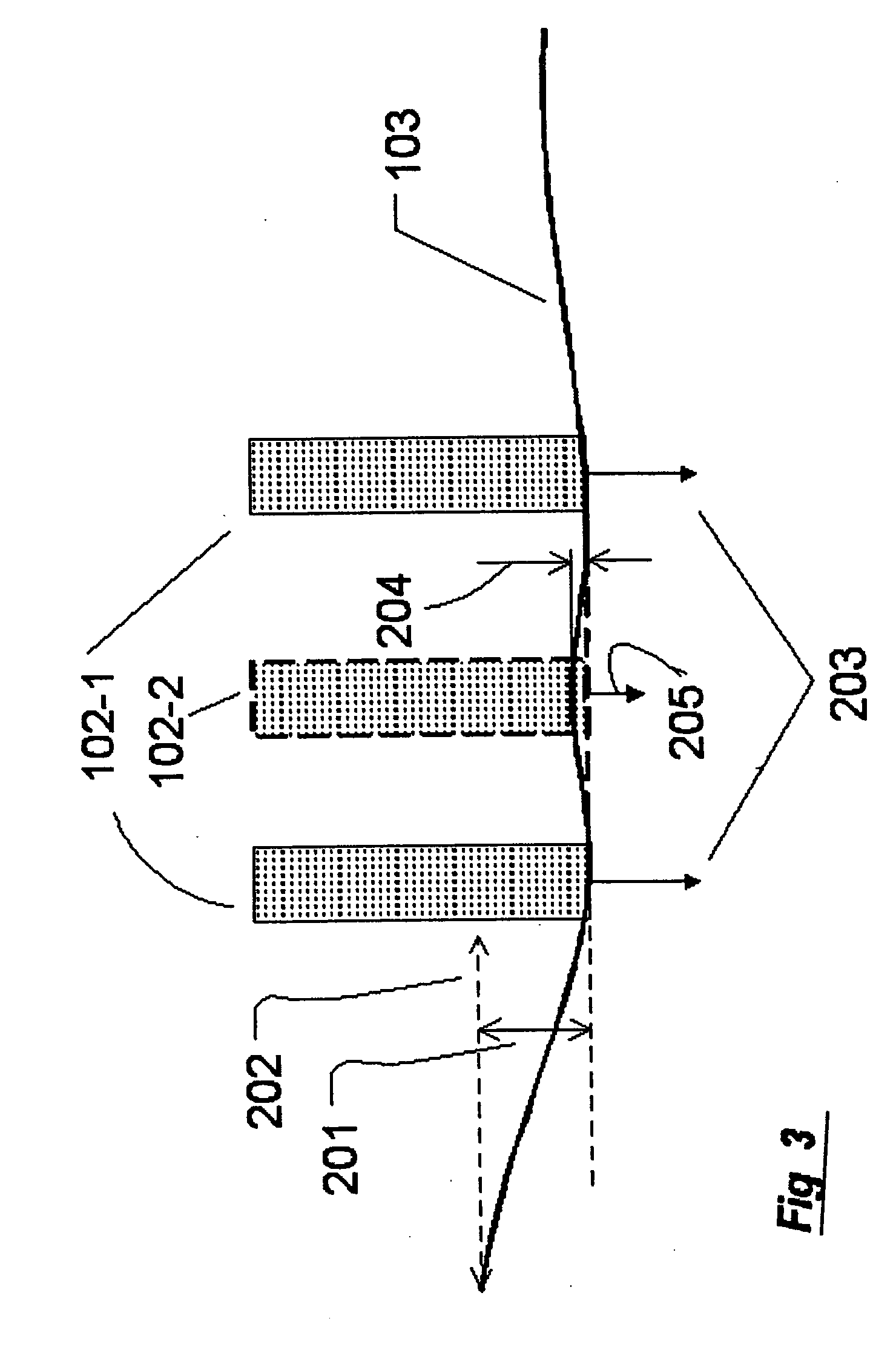

Antenna tile device and cold plate

ActiveUS20140139400A1Simple structureHigh frequencyAntenna arraysAntenna adaptation in movable bodiesDigital signal processingComputer module

A method, system, and device relating to a broad-band fragmented aperture tile and antenna system are disclosed. In one exemplary embodiment, an aperture tile comprises a plurality of unit cells. The plurality of unit cells individually comprise a driven radiating element layer, a module layer having a printed circuit board, wherein the module layer comprises one or more of a time delay module, a radio frequency distribution module, a radio frequency module, or a digital signal processor. Furthermore the aperture tile is coupled to a cold plate configured for heat transfer.

Owner:VIASAT INC

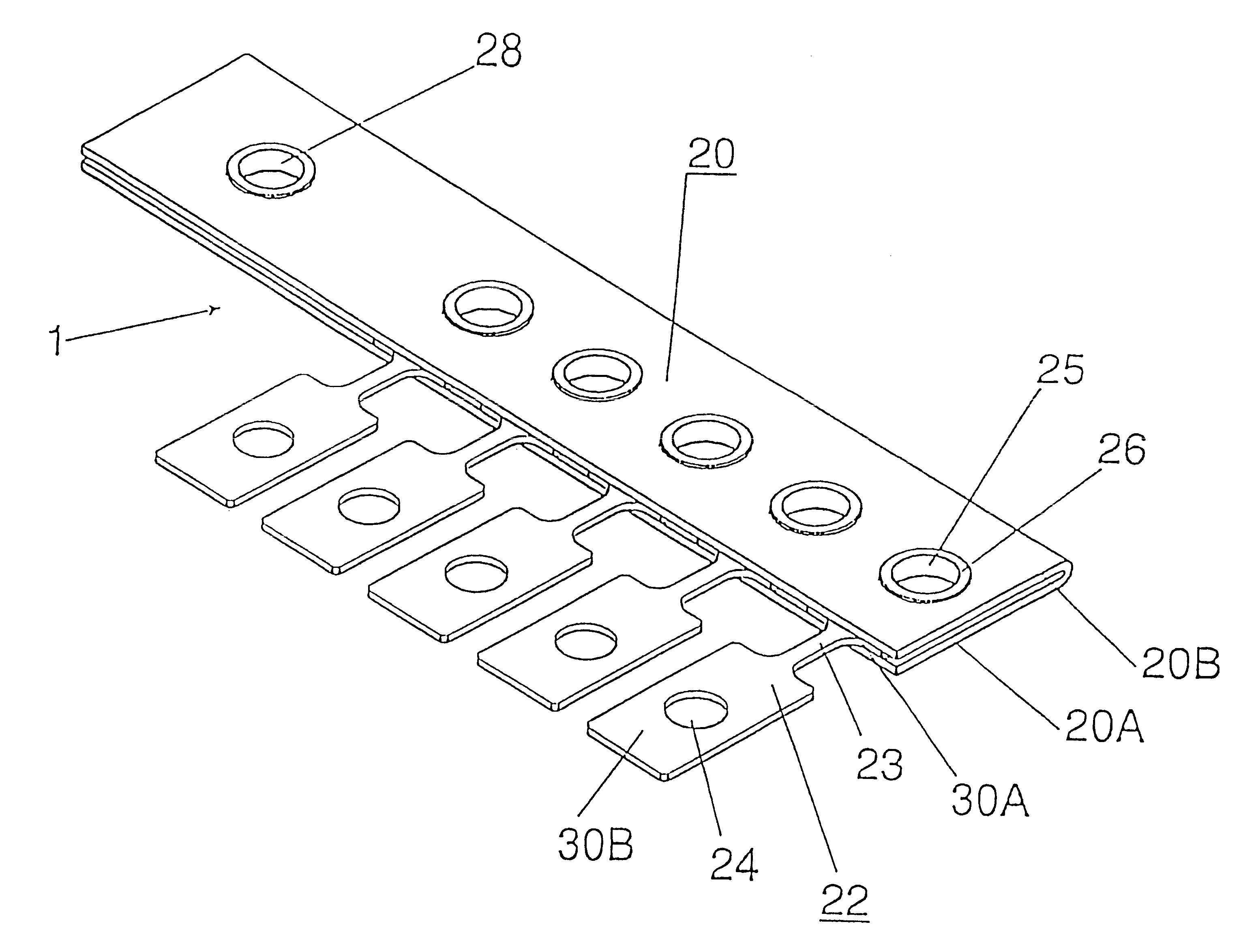

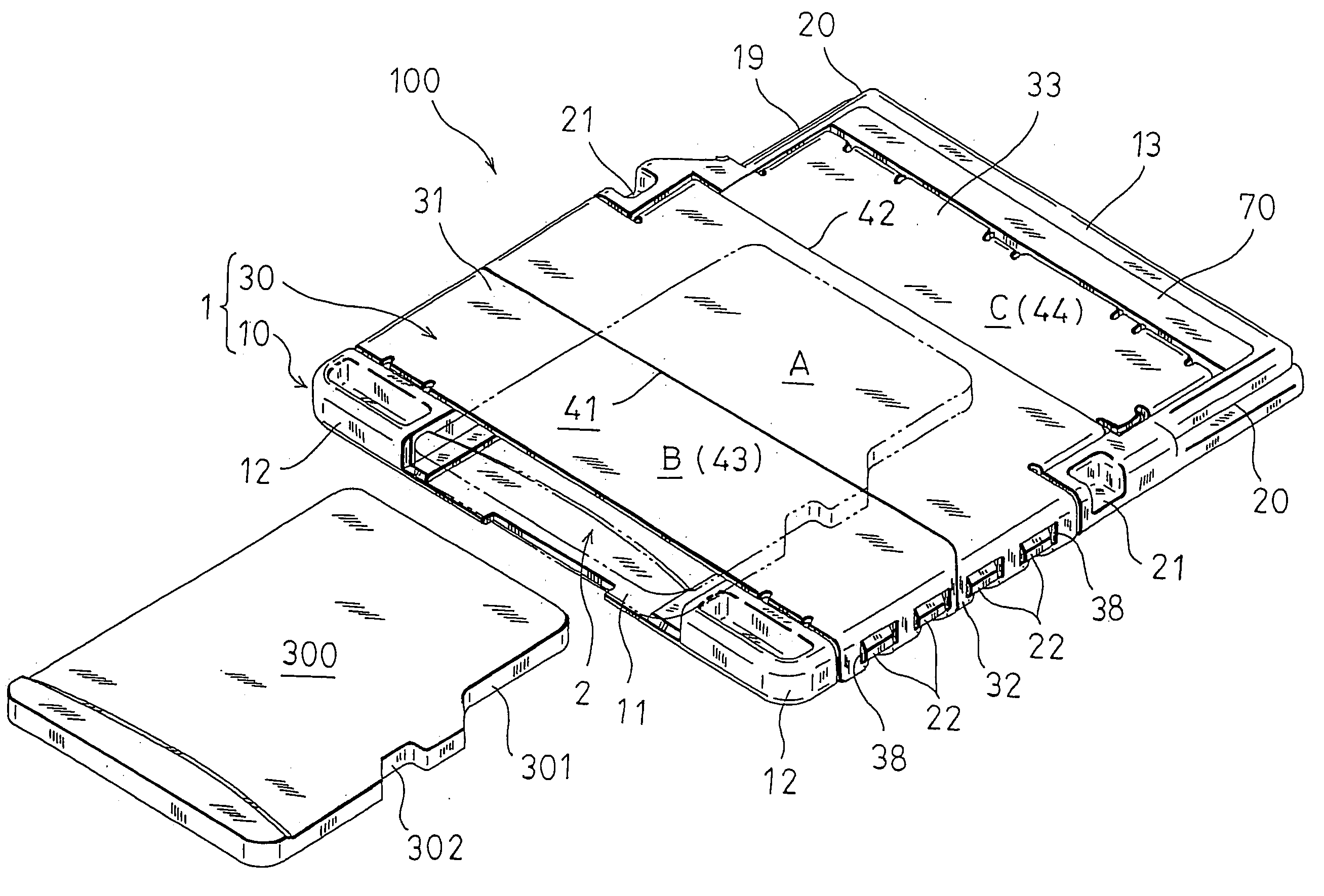

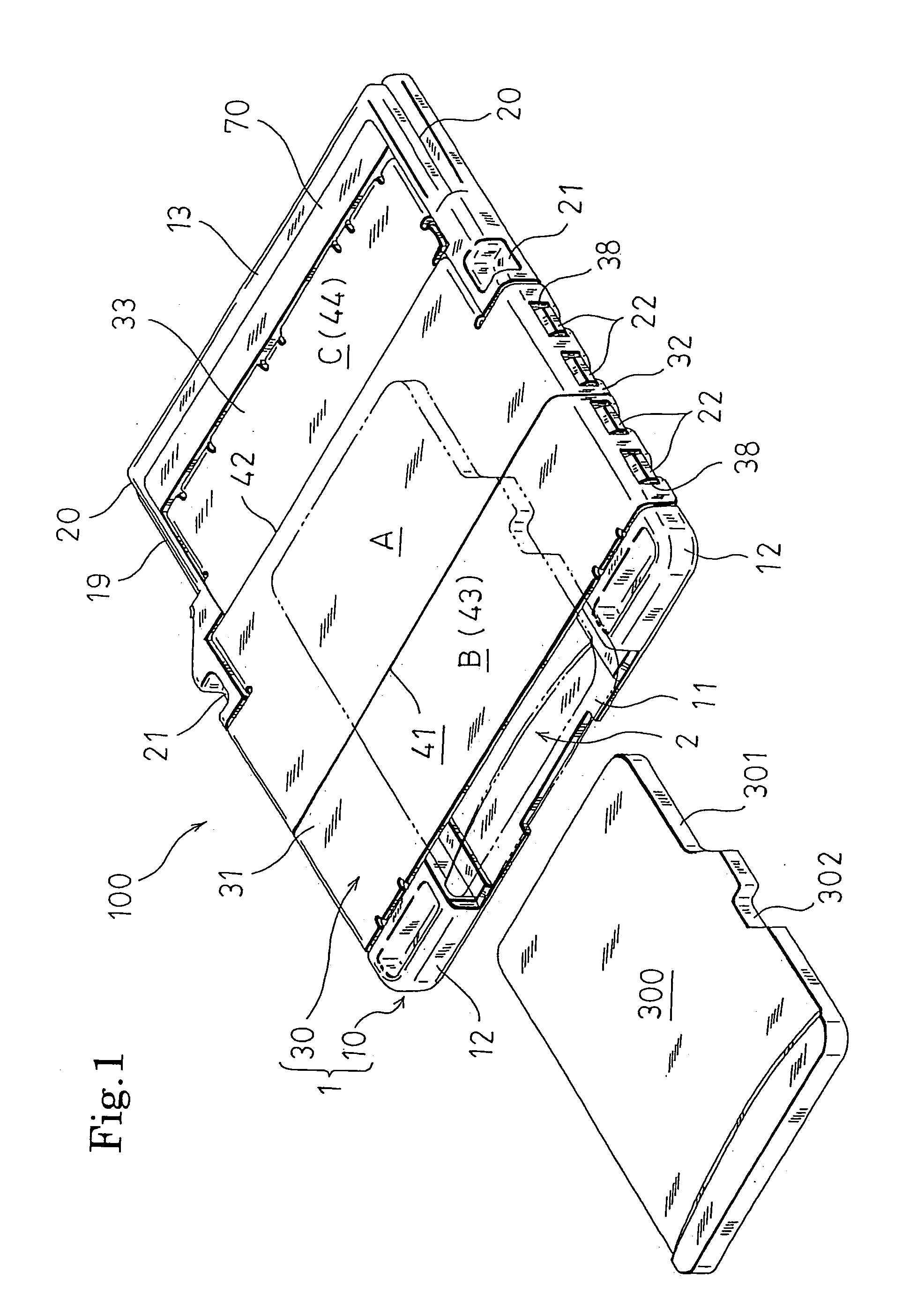

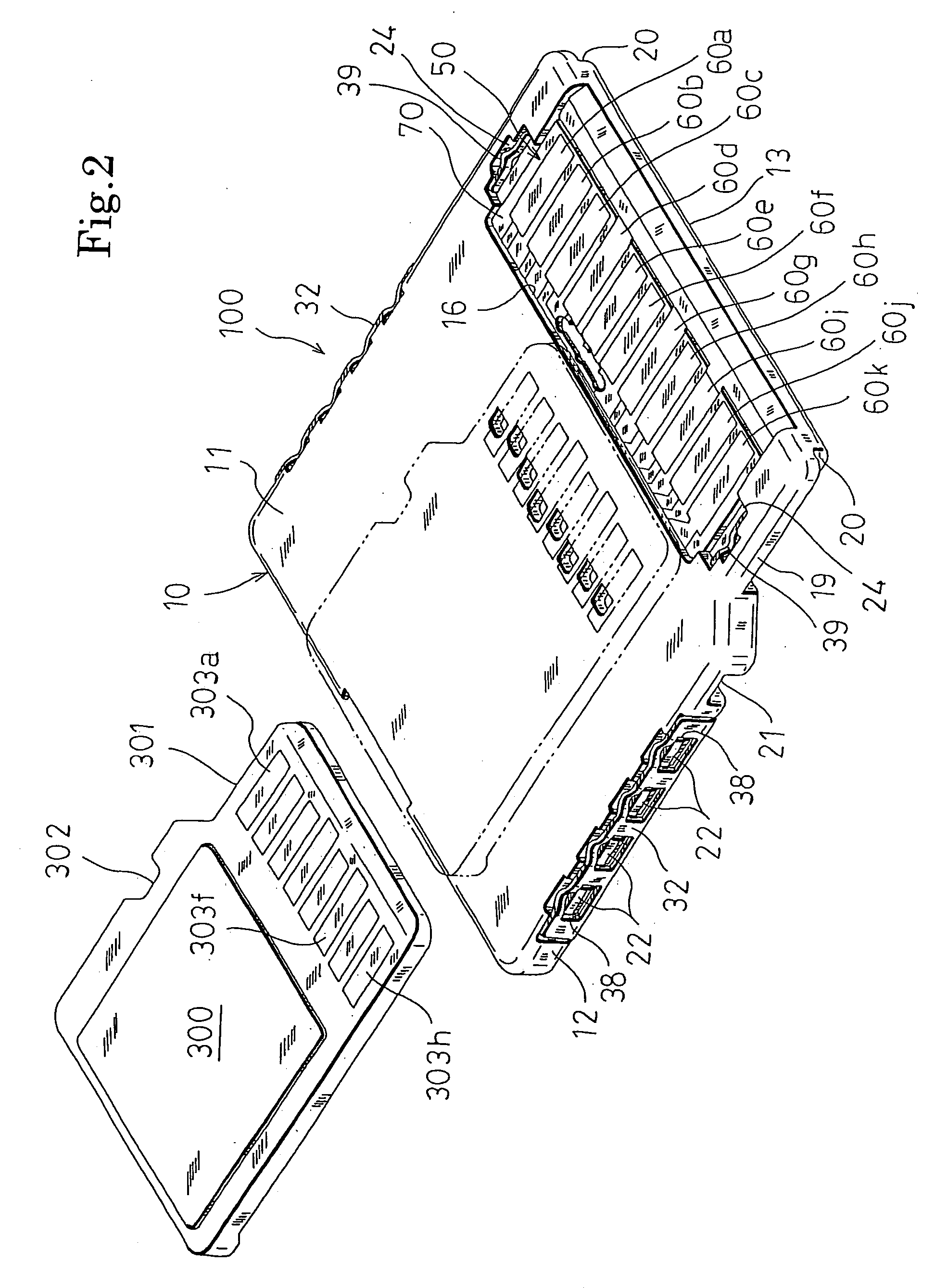

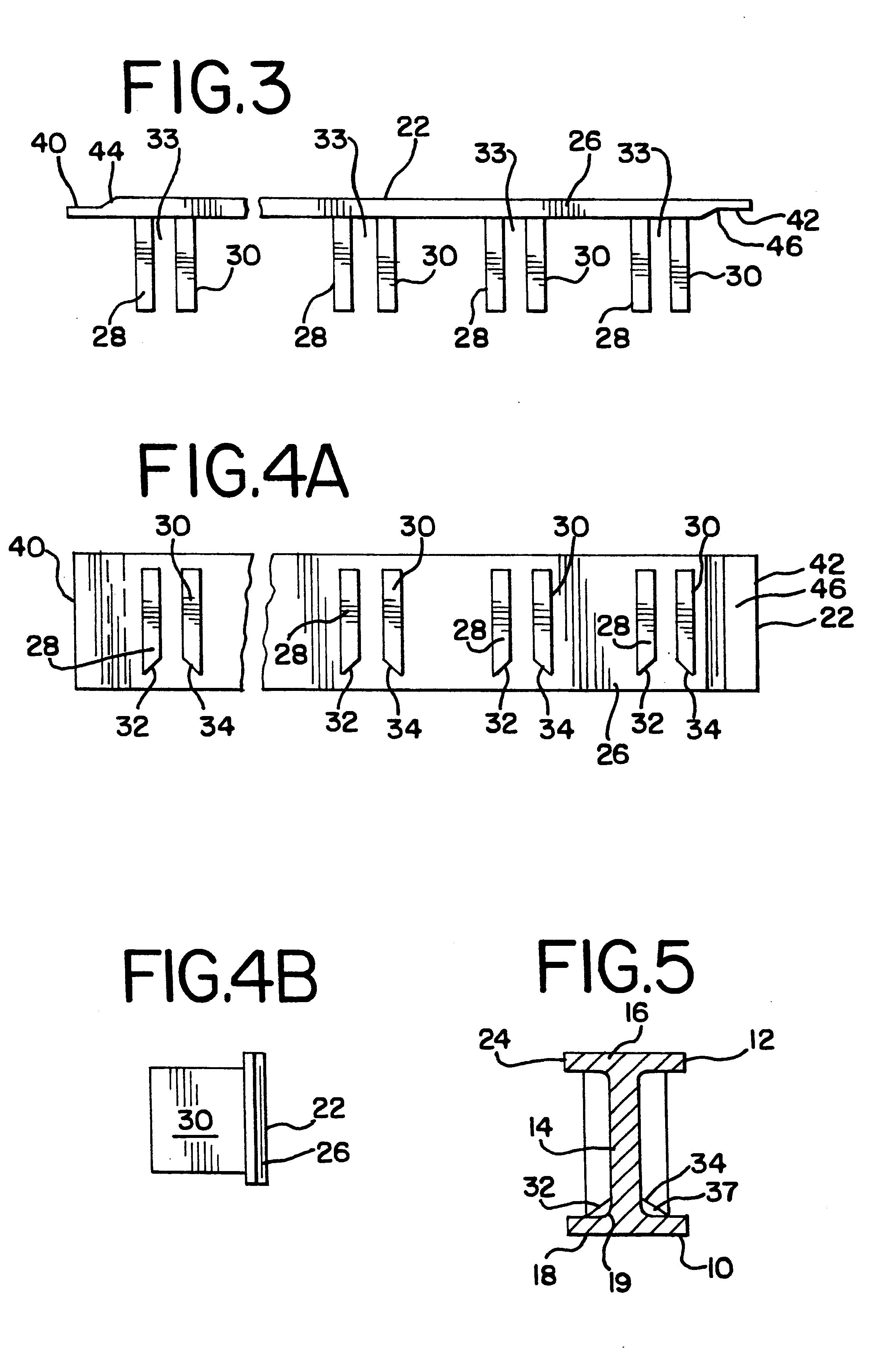

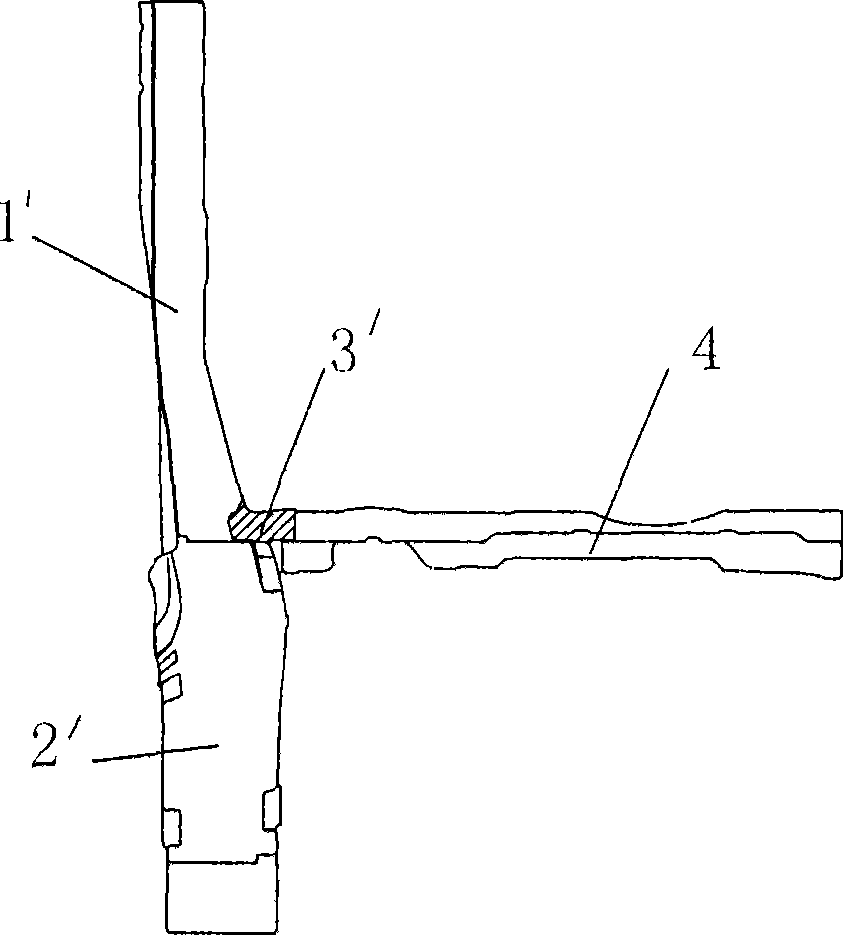

Memory card adaptor

InactiveUS20070077822A1Reduce material thicknessIncreasing the thicknessElectric discharge tubesTwo-part coupling devicesEngineeringMemory cards

The invention relates to a memory card adaptor which enables a small memory card to be used in a card connector for a large memory card that is larger than the small memory card. In the surface of a metal cover 30 which cooperates with a resin base 10 to constitute an adaptor body having a shape corresponding to an outer shape of a large memory card, steps 41, 42 are disposed by partly reducing the material thickness of the cover 30. Insulating layers 43, 44 the thickness of which is equal to less than the steps 41, 42 are formed on the surface of the thinned cover 30 to dispose insulation areas B, C on the side of one face of the adaptor, whereby the insulation areas are arbitrarily set on the side of the one face of the adaptor without increasing the thickness of the adaptor, and while maintaining the rigidity of the adaptor.

Owner:HOSIDEN CORP

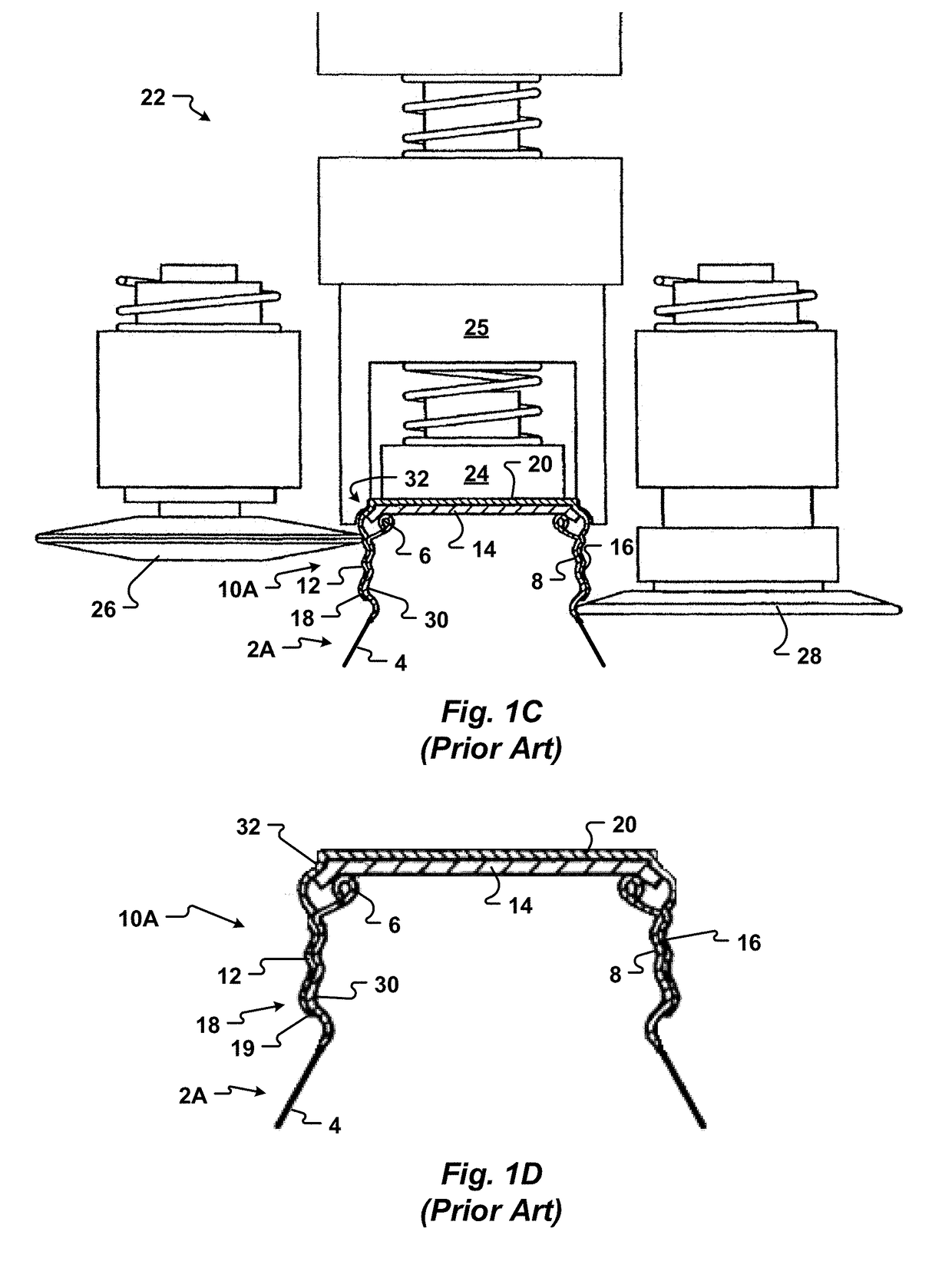

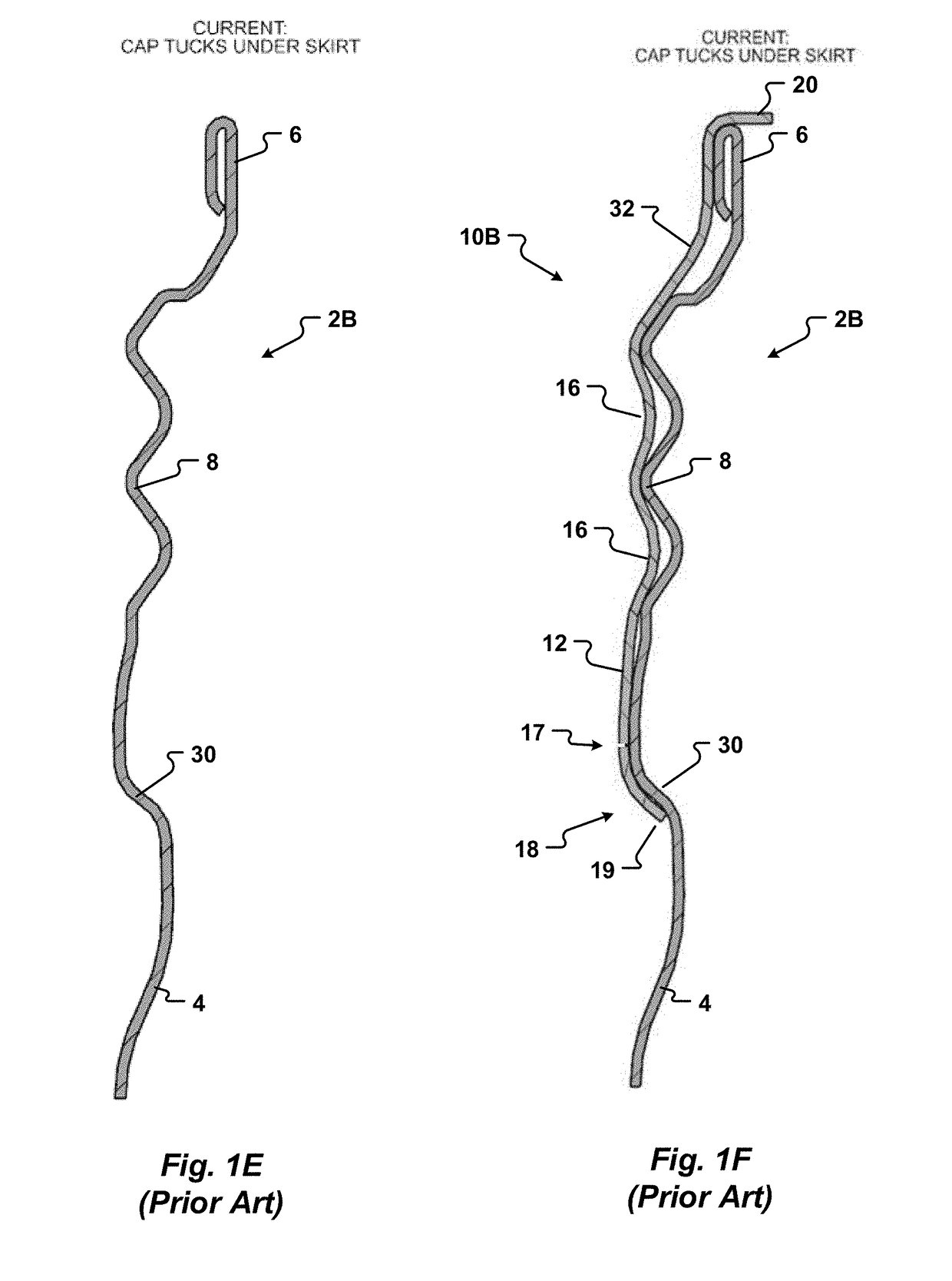

Tamper evidence device for roll-on pilfer proof closures

Methods and apparatus of sealing bottles with Roll-on Pilfer Proof (ROPP) closures and providing tamper evidence are provided. More specifically, the present invention relates to novel ROPP closures that may be used to seal a bottle shaped container which can subsequently receive a tamper evidence device. The bottle can have a neck portion formed without a skirt portion. Optionally, the bottle can include an annular ring. The ROPP closure generally includes a body portion. In one embodiment, the body portion has a curl. A tamper evidence device can be applied to a bottle sealed with a ROPP closure by a capping apparatus. The tamper evidence device may be visually altered when the ROPP closure is rotated in an opening direction. In one embodiment, the ROPP closure cannot be rotated while the tamper evidence device is associated with the bottle. In another embodiment, the tamper evidence device includes at least one protrusion which extends inwardly at least partially into the bottle annular ring.

Owner:BALL CORP

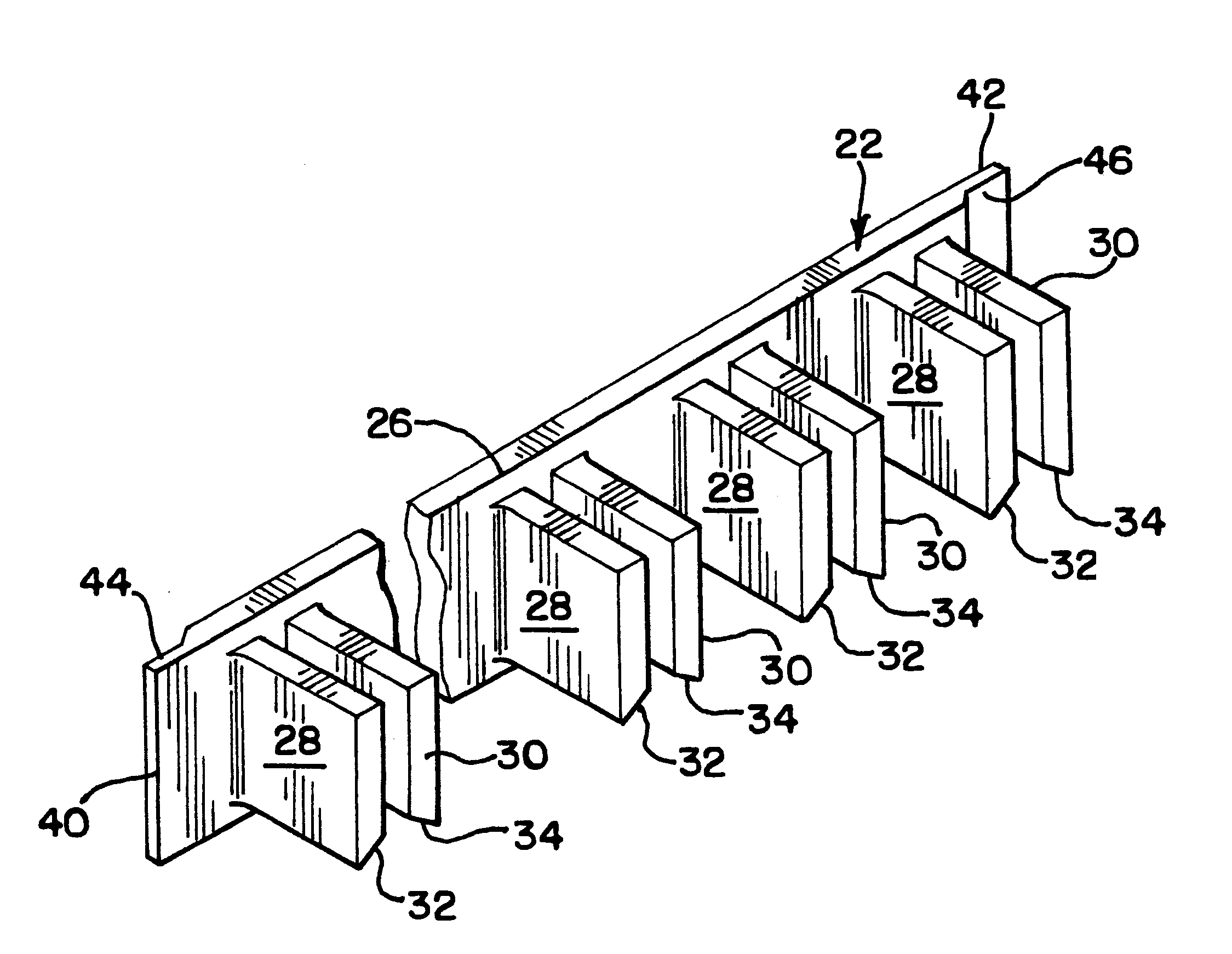

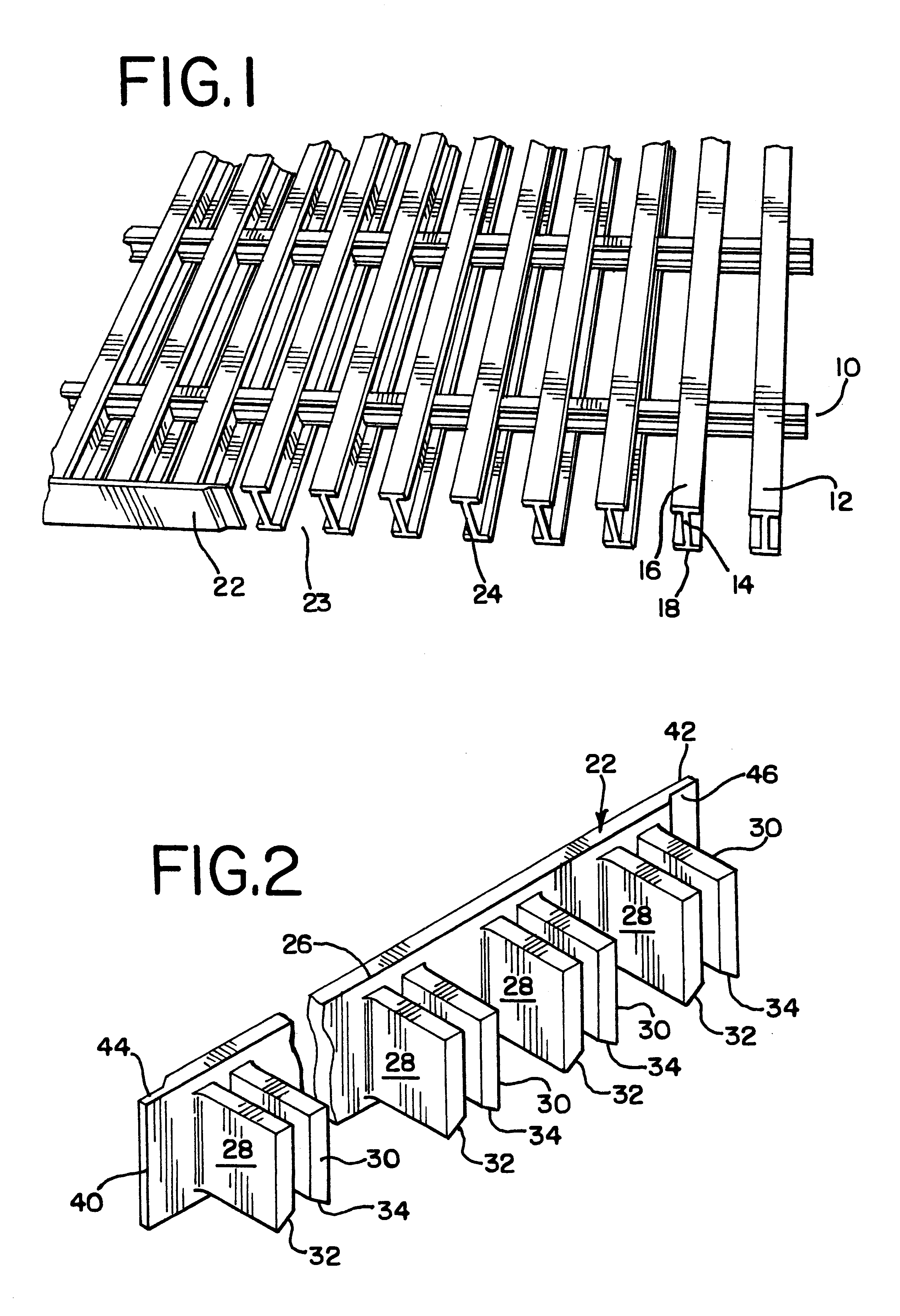

Endcaps for fiberglass running boards

InactiveUS6219987B1Complementing strengthComplementing economyBuilding reinforcementsFlooringGlass fiberMarine engineering

An arrangement of endcaps particularly formed and arranged for use in connection with composite deck beams particularly adapted to use on rail car running boards but is also suitable to other beam type decks such as those used on semi-trailers, in marine applications or as industrial catwalks. The endcaps close the ends of fiberglass reinforced plastic running boards, complementing the strength, economy and durability of such materials.

Owner:HOLLAND CO

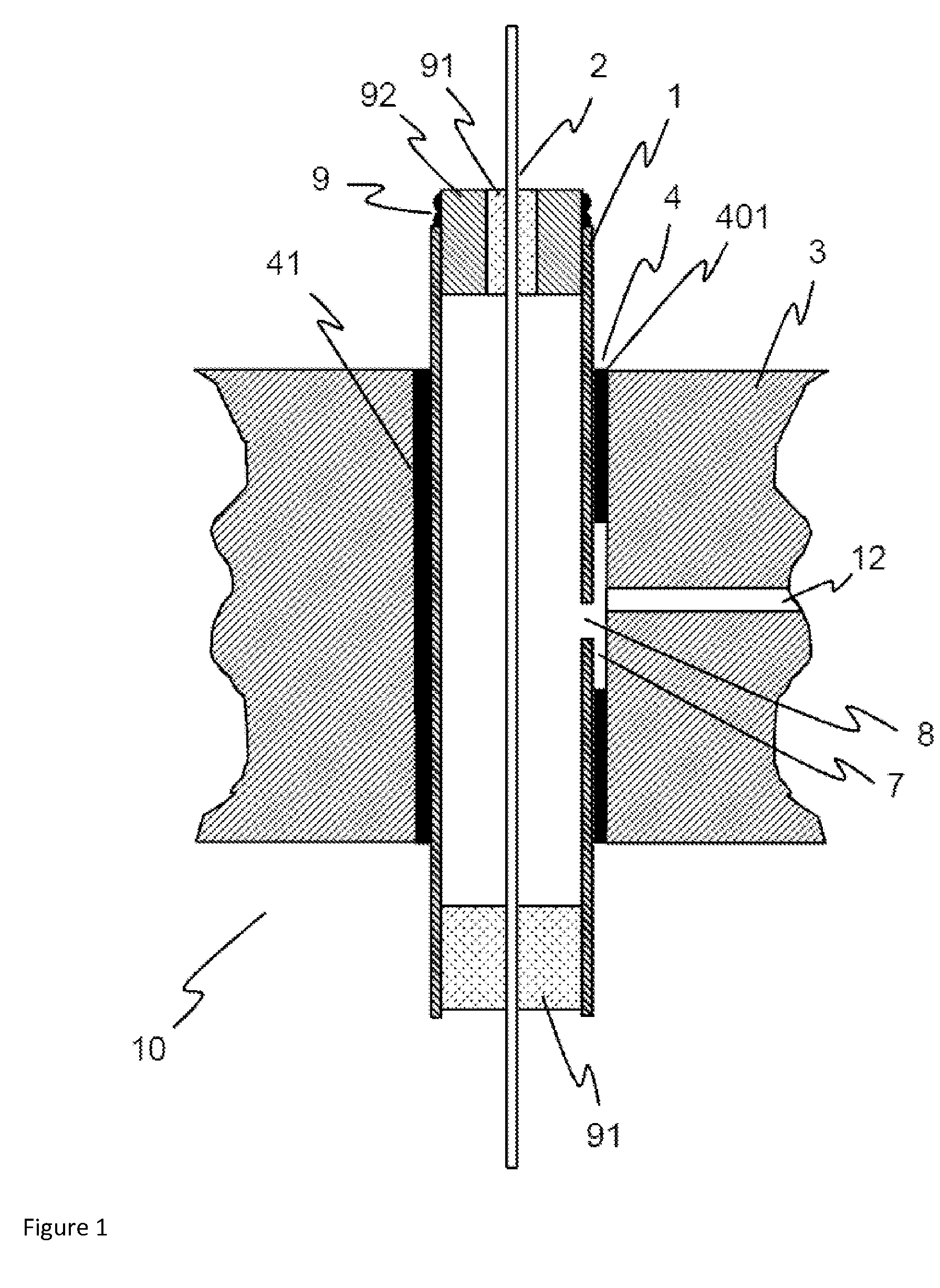

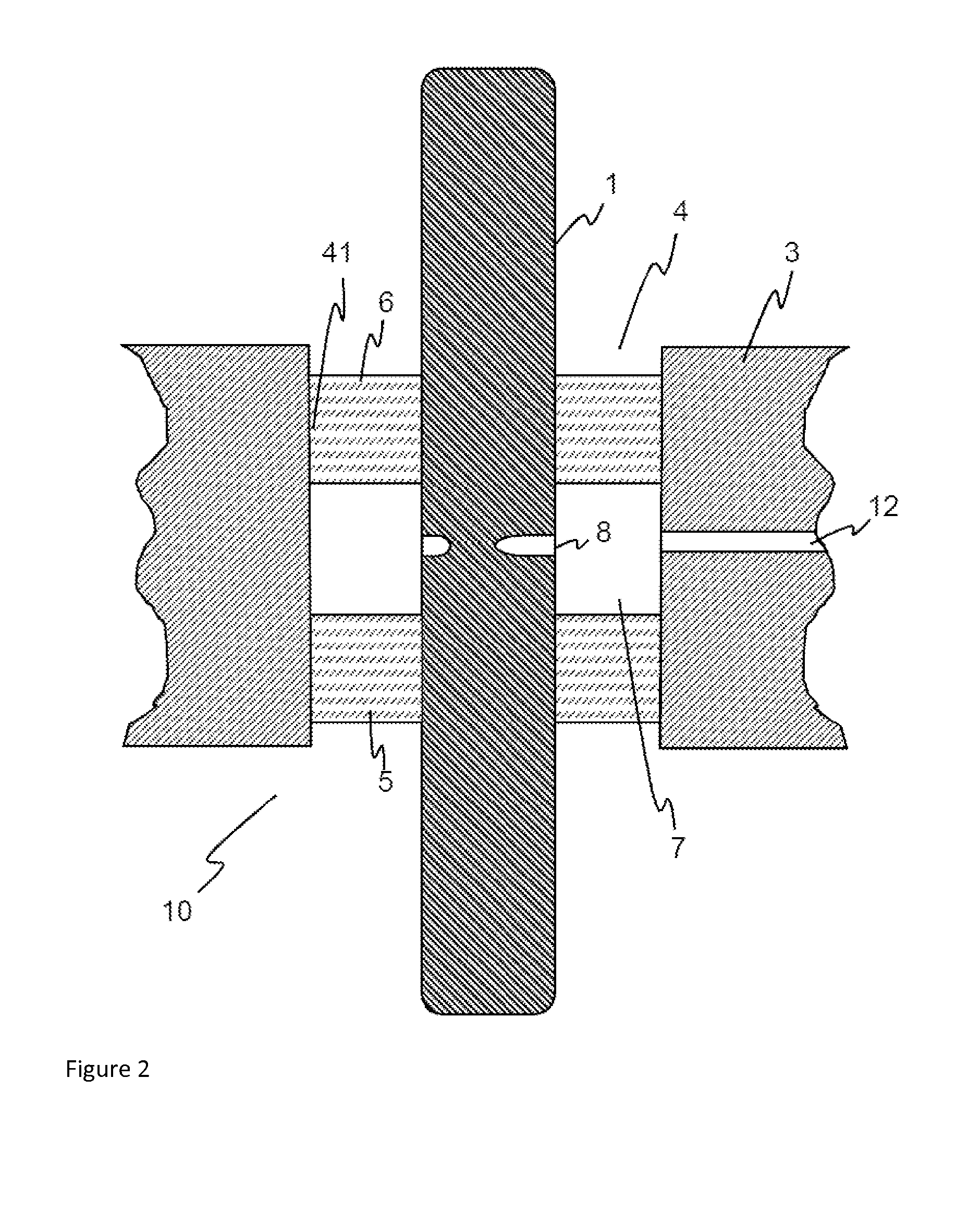

Fault-proof feed-through device

ActiveUS20140231133A1High mechanical loadEfficient productionElectrical apparatusNuclear energy generationMechanical stabilityEngineering

A feed-through is provided that includes a flange and a first functional component. The flange has a through-opening in which the first functional component is arranged and is connected to the flange such that the through-opening is sealed. The first functional component has at least one deformation region, in which a recess is provided such that the mechanical stability of the first functional component is reduced in the deformation region. In this manner, the first functional element can be deformed in the deformation area when mechanical load is applied.

Owner:SCHOTT AG

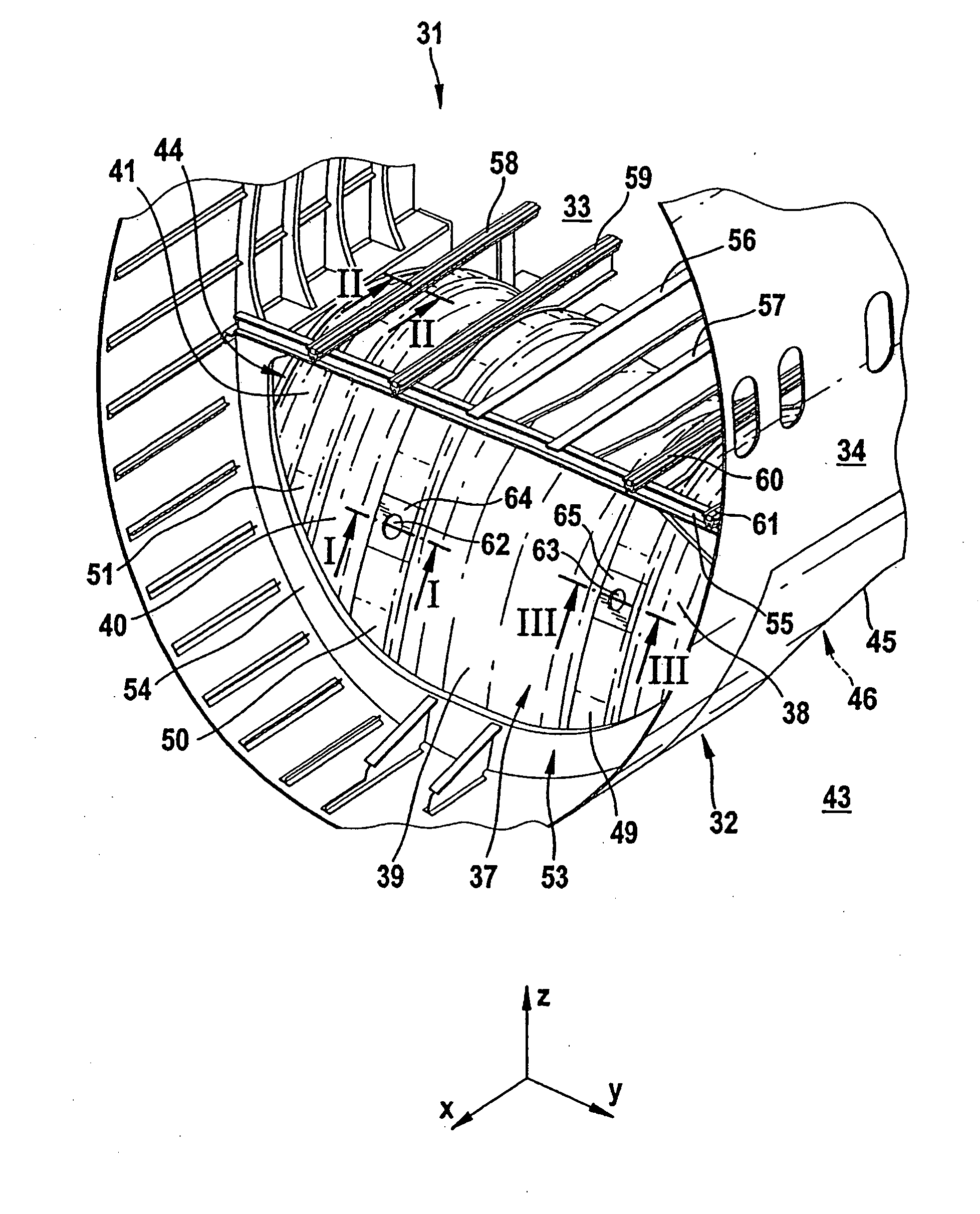

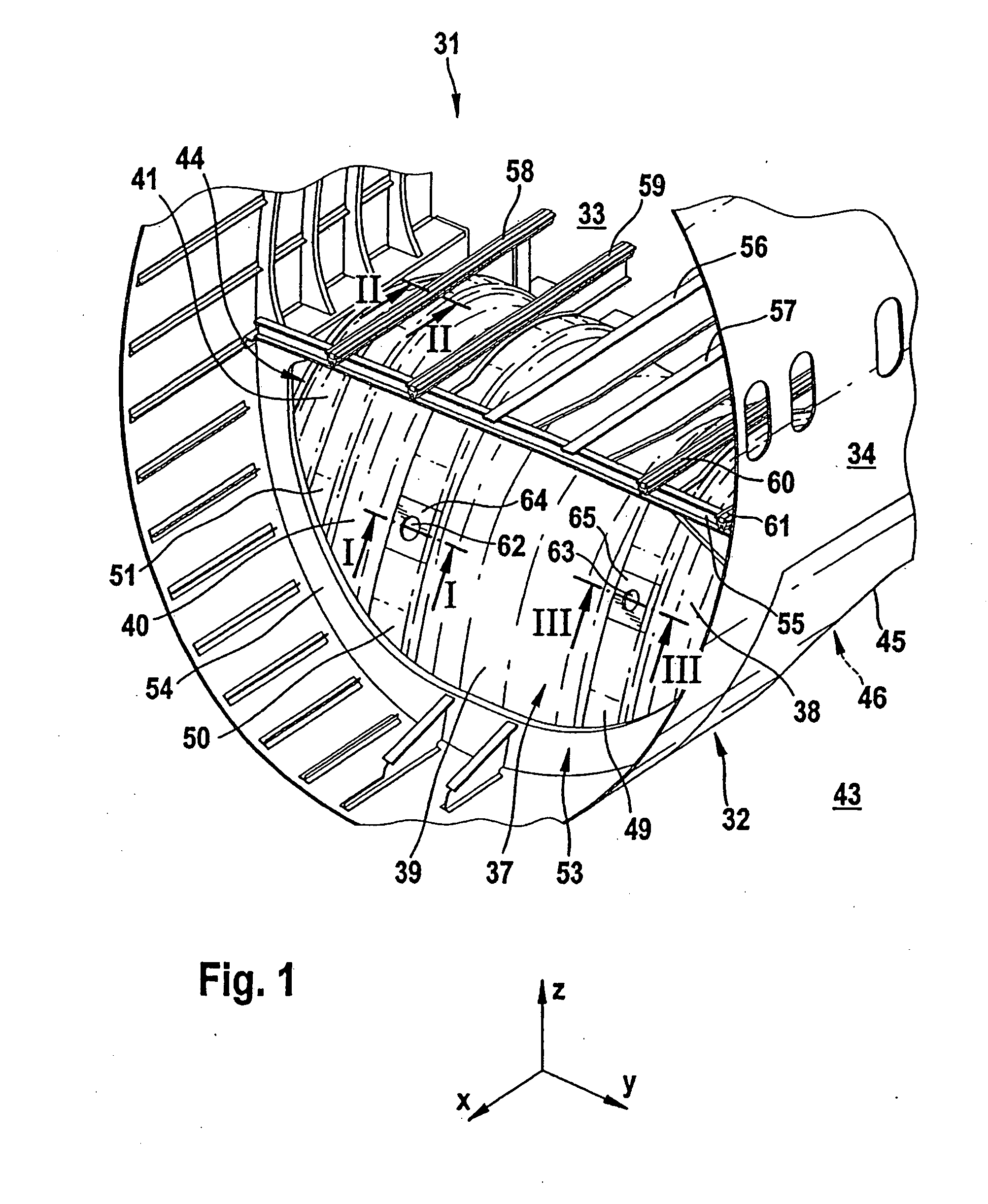

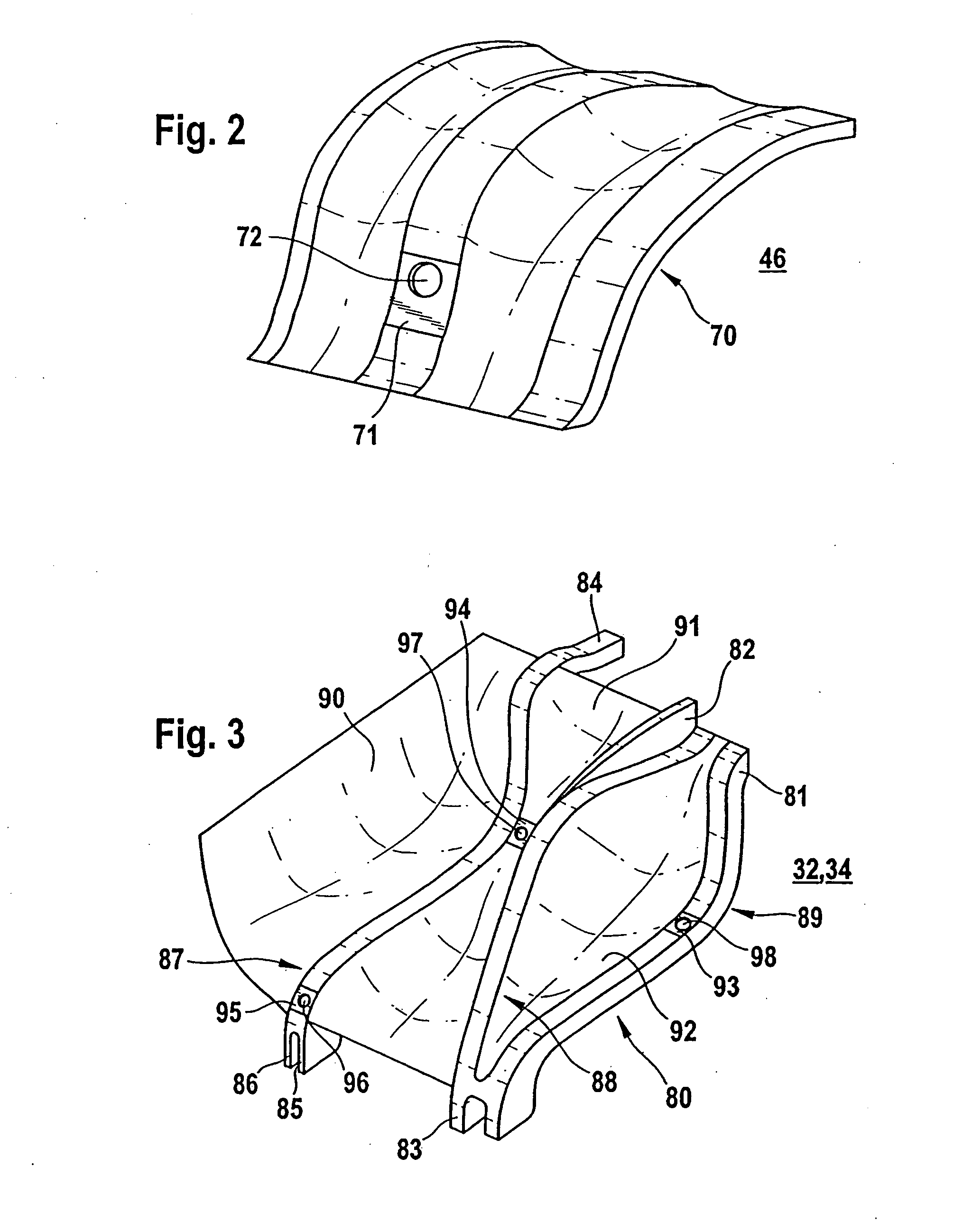

Airframe structure of an aircraft or spacecraft

InactiveUS20080173765A1Force fluxReduce stressCosmonautic vehiclesCosmonautic partsInternal pressureFlight vehicle

The present invention provides an airframe structure of an aircraft or spacecraft, with: a hollow body section which can be subjected to an internal pressure; a membrane arrangement which has at least one single-part, multi-curved membrane component for sealing off the internal pressure from an external pressure which acts on the hollow body section and differs from the internal pressure; and a joining structure for a pressuretight joining of the membrane arrangement to a region of the hollow body section; wherein the membrane arrangement forms a receiving well which is accessible from outside the hollow body section, extends at least partially into the hollow body -section and is for receiving a component of the aircraft or spacecraft.

Owner:AIRBUS OPERATIONS GMBH

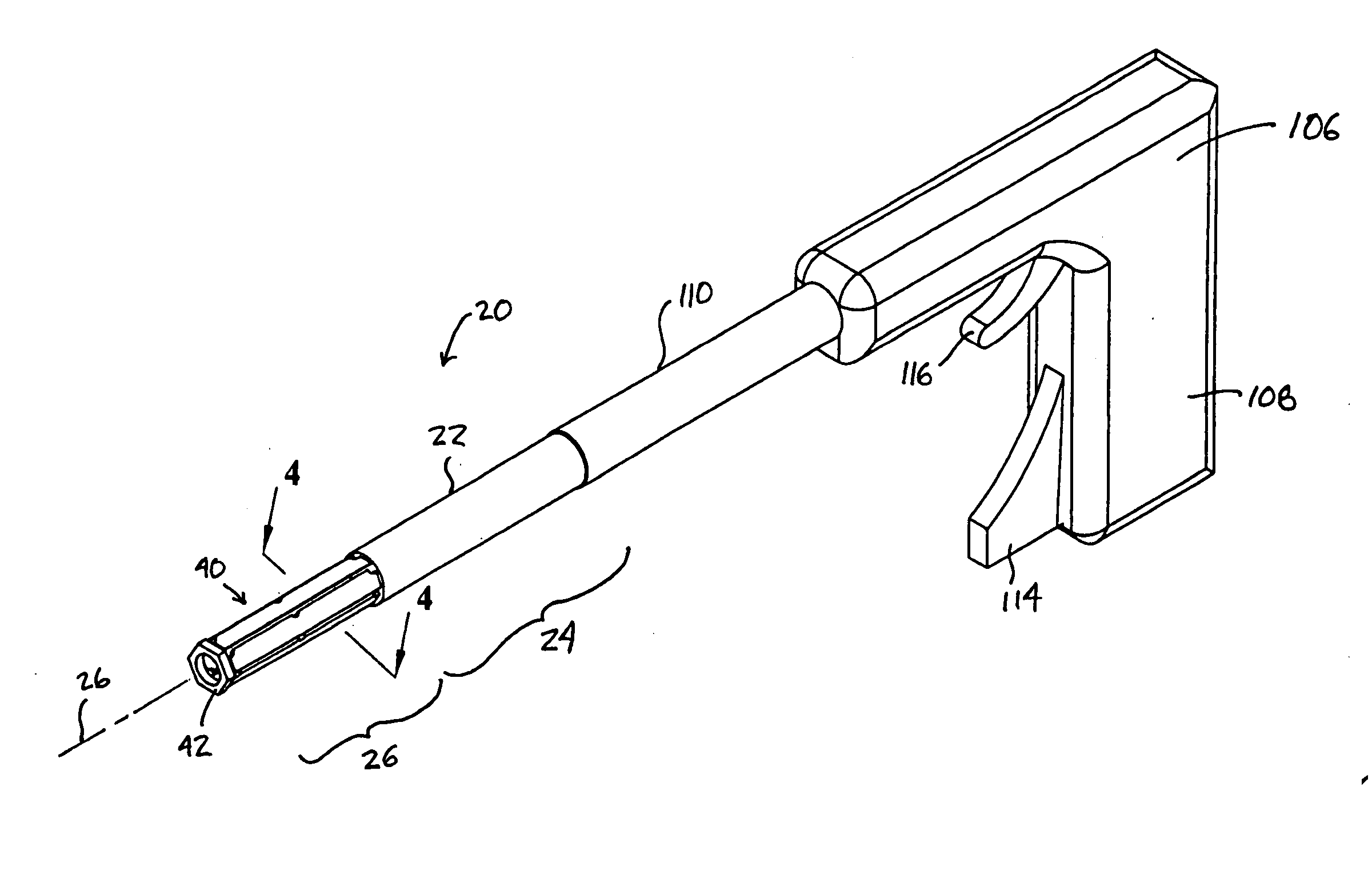

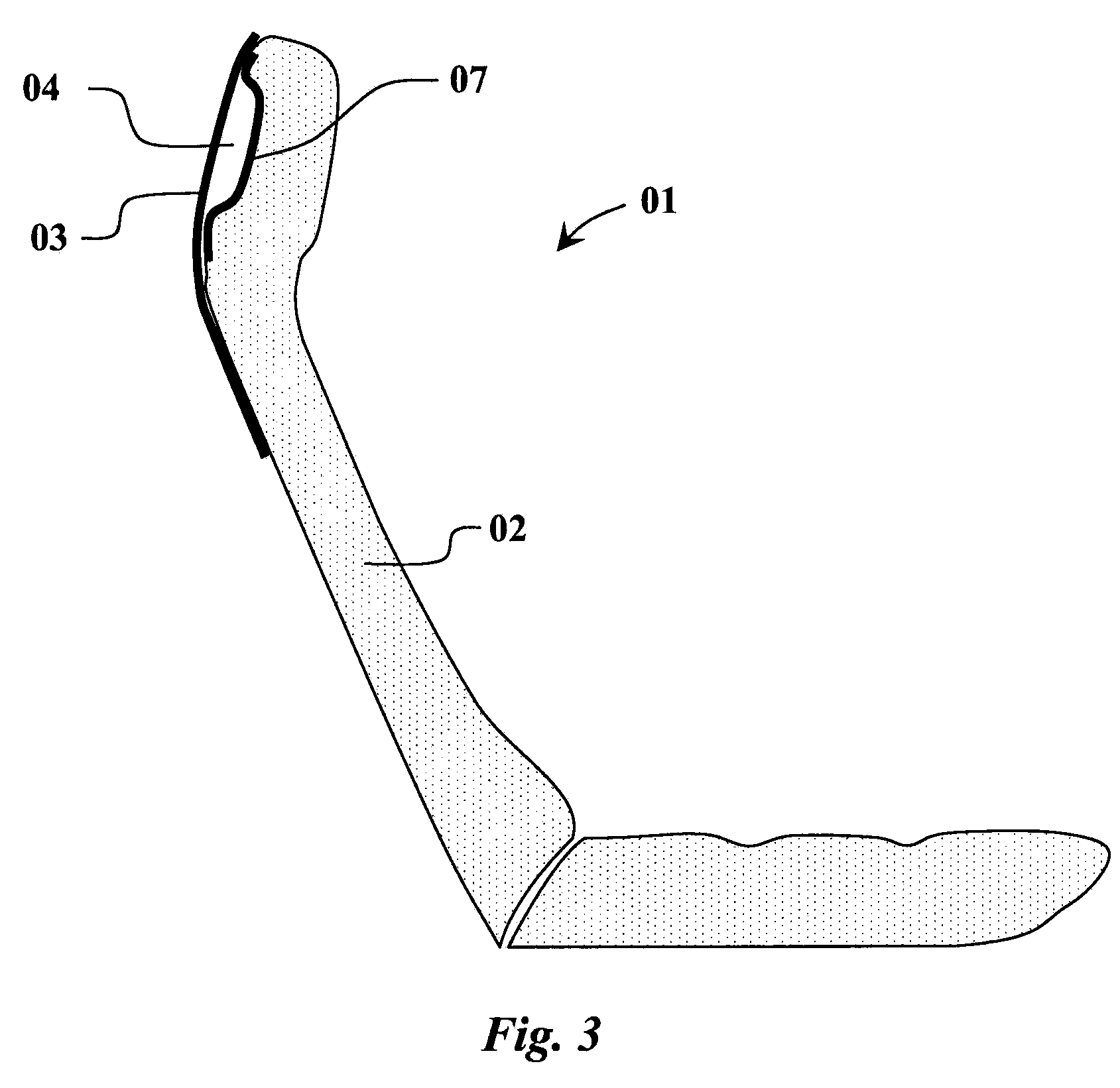

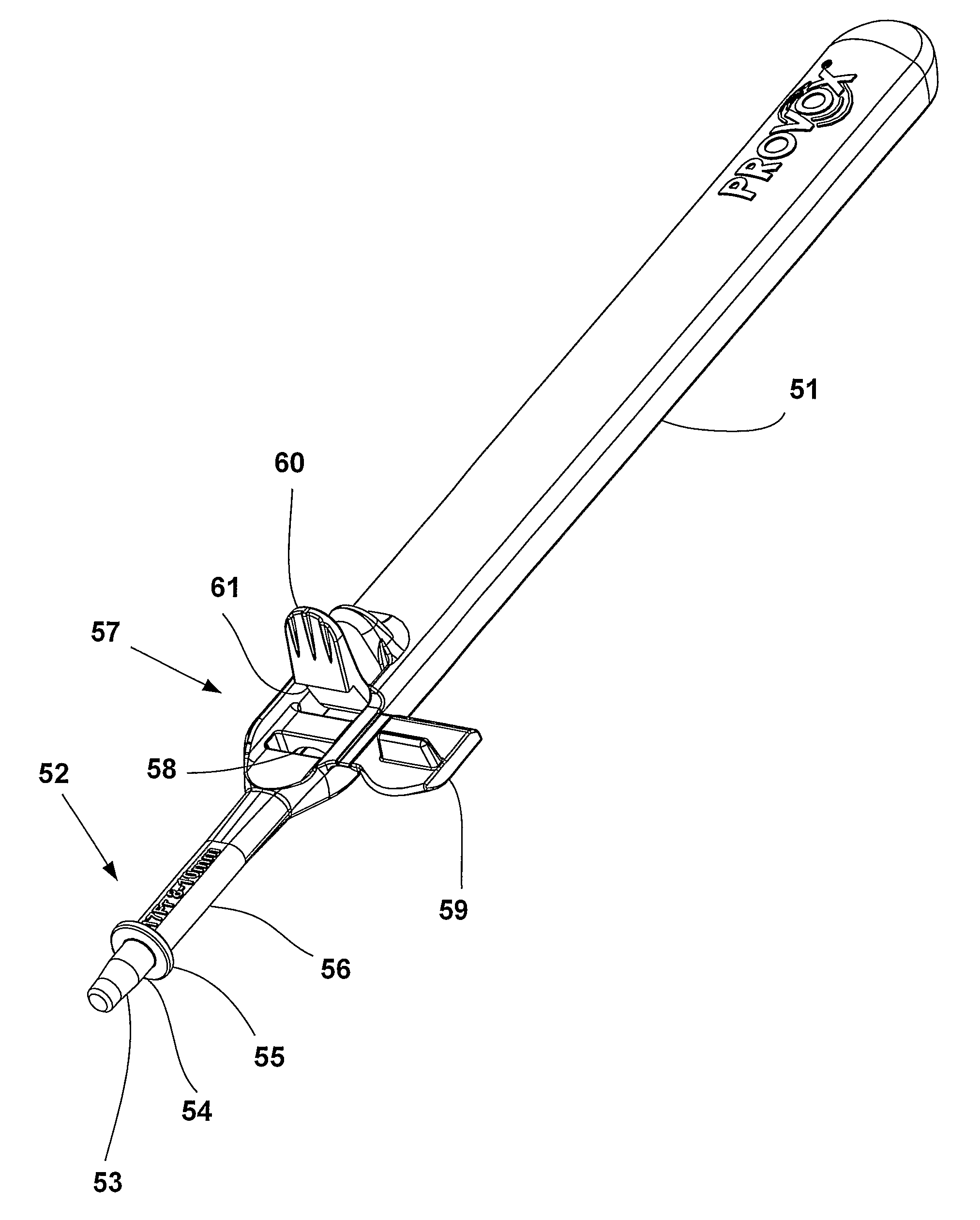

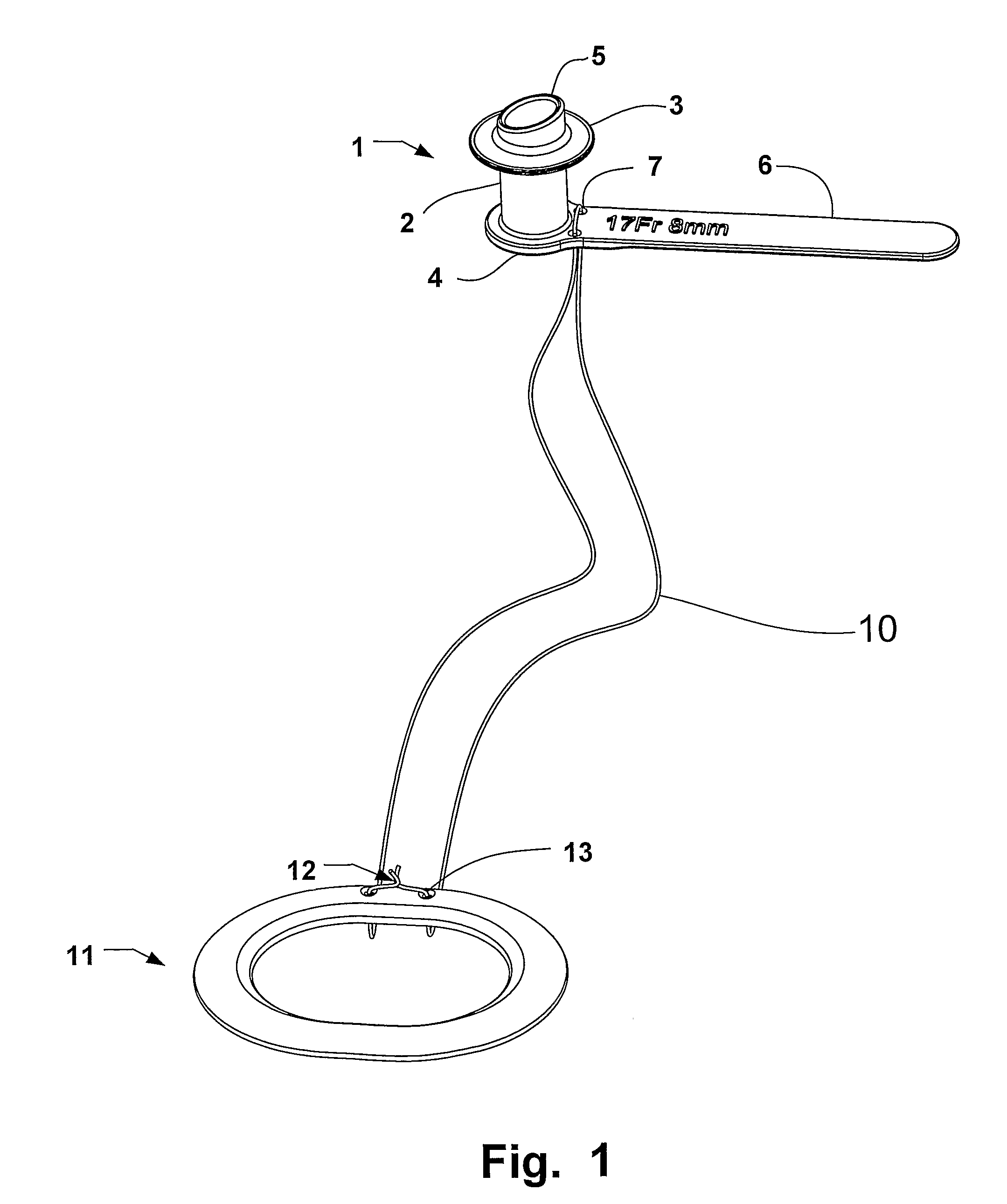

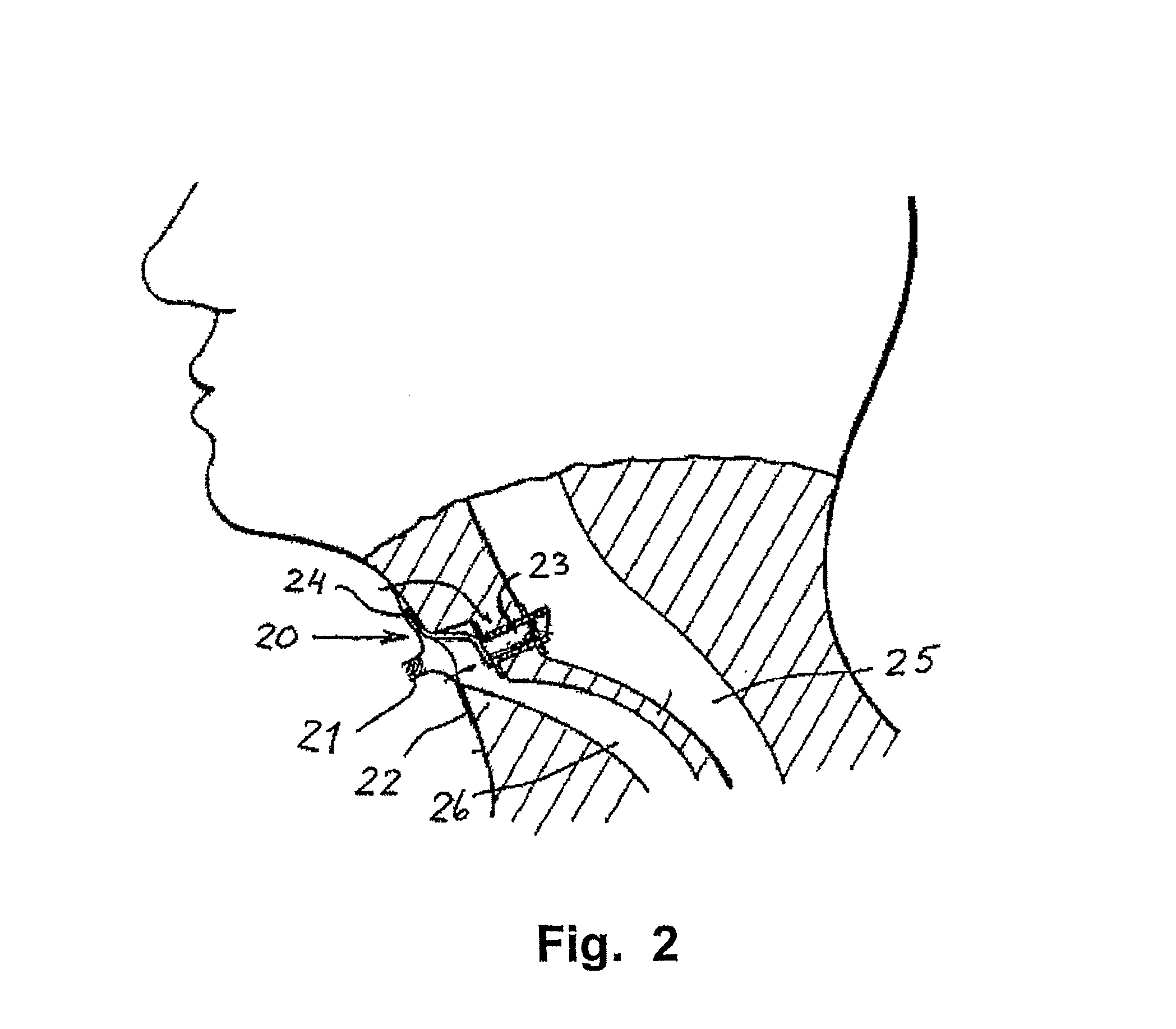

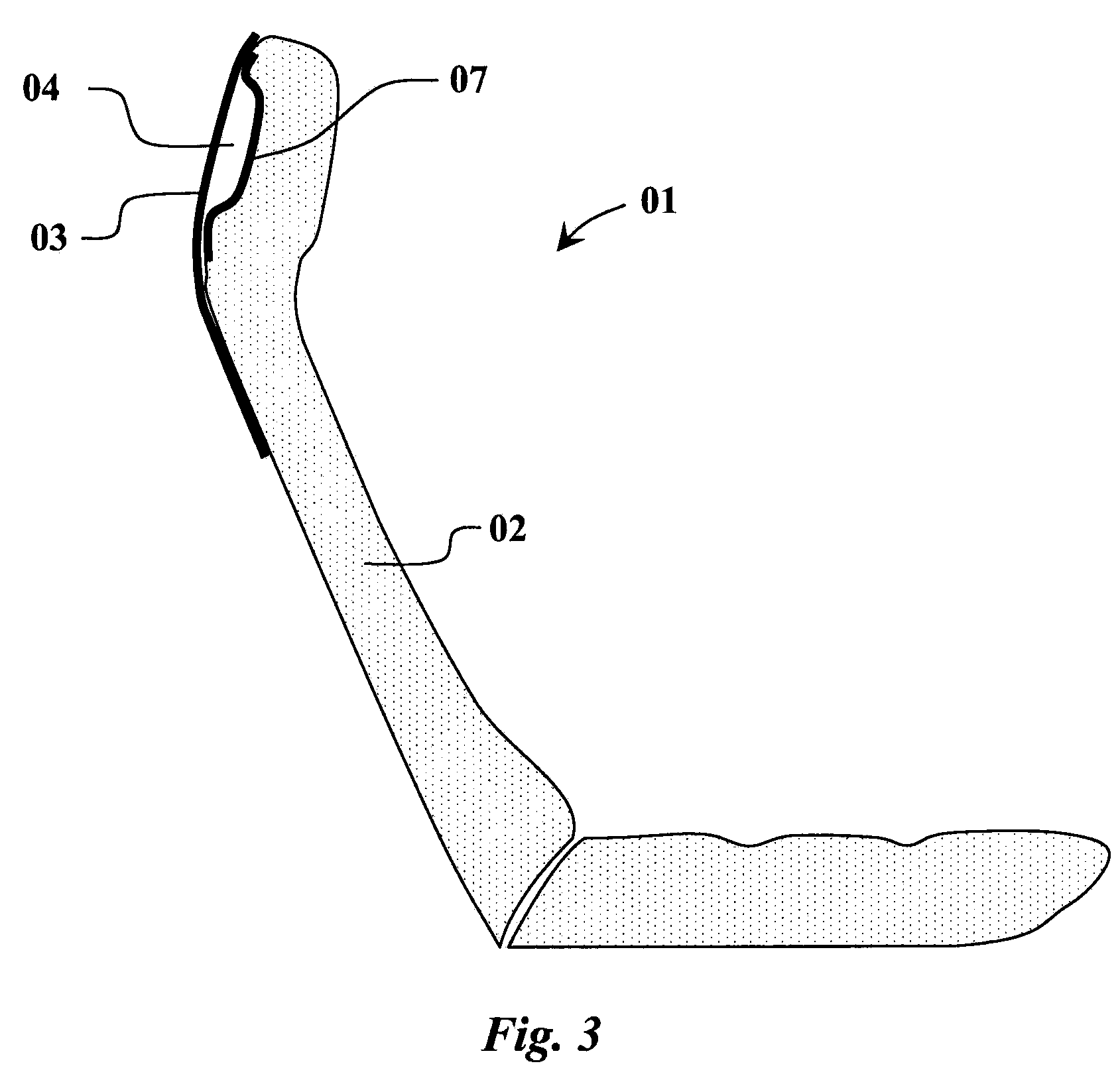

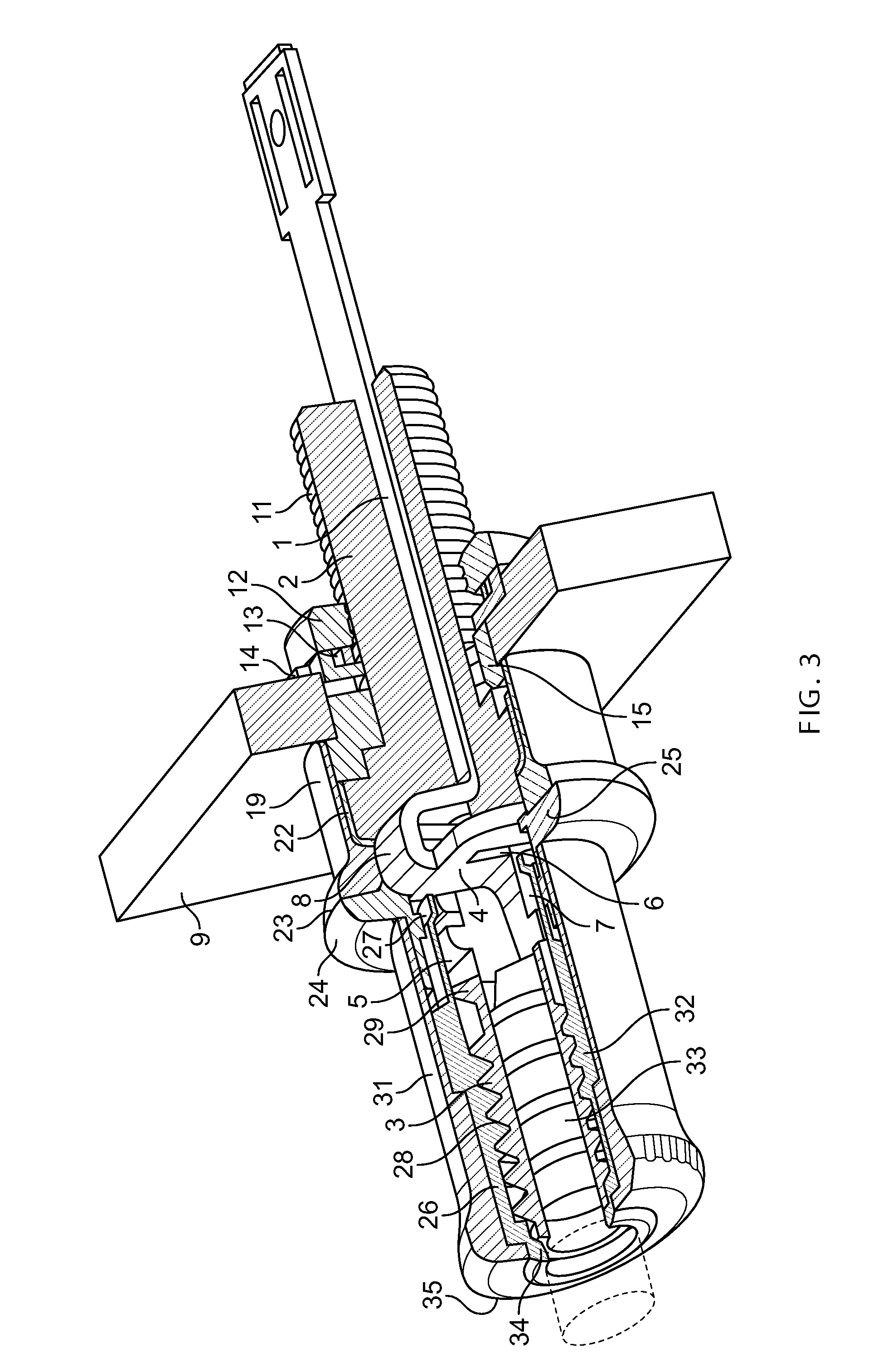

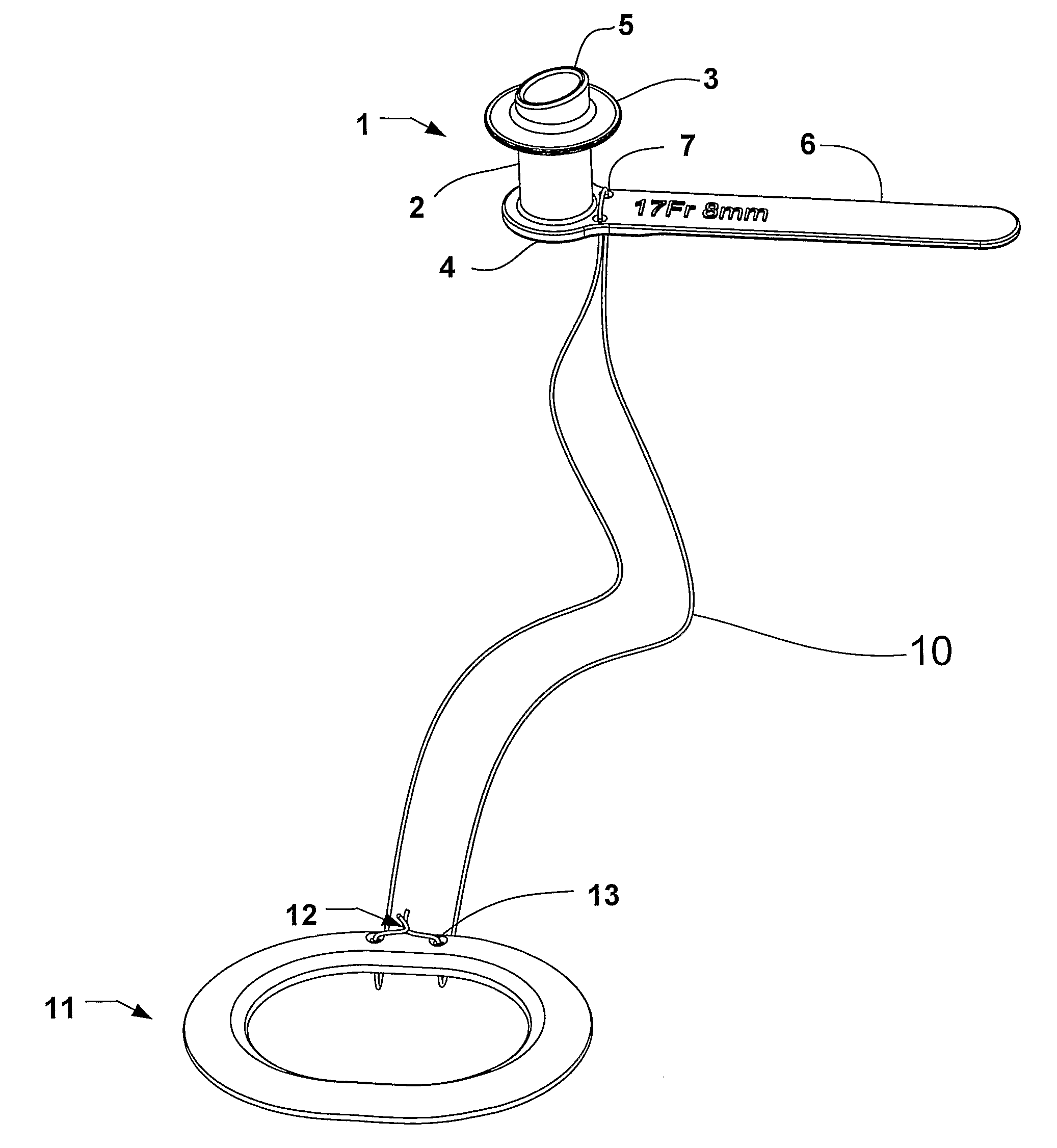

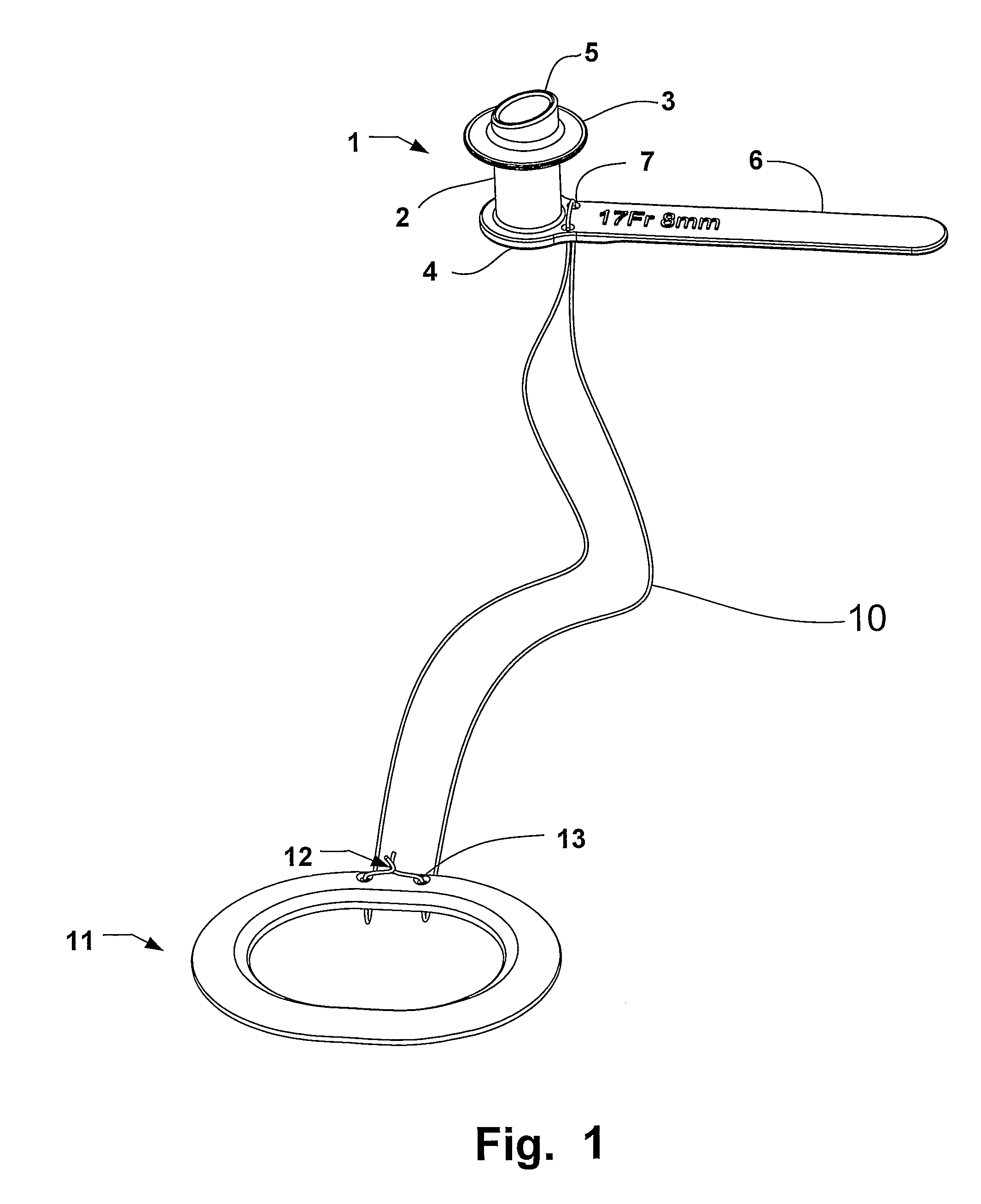

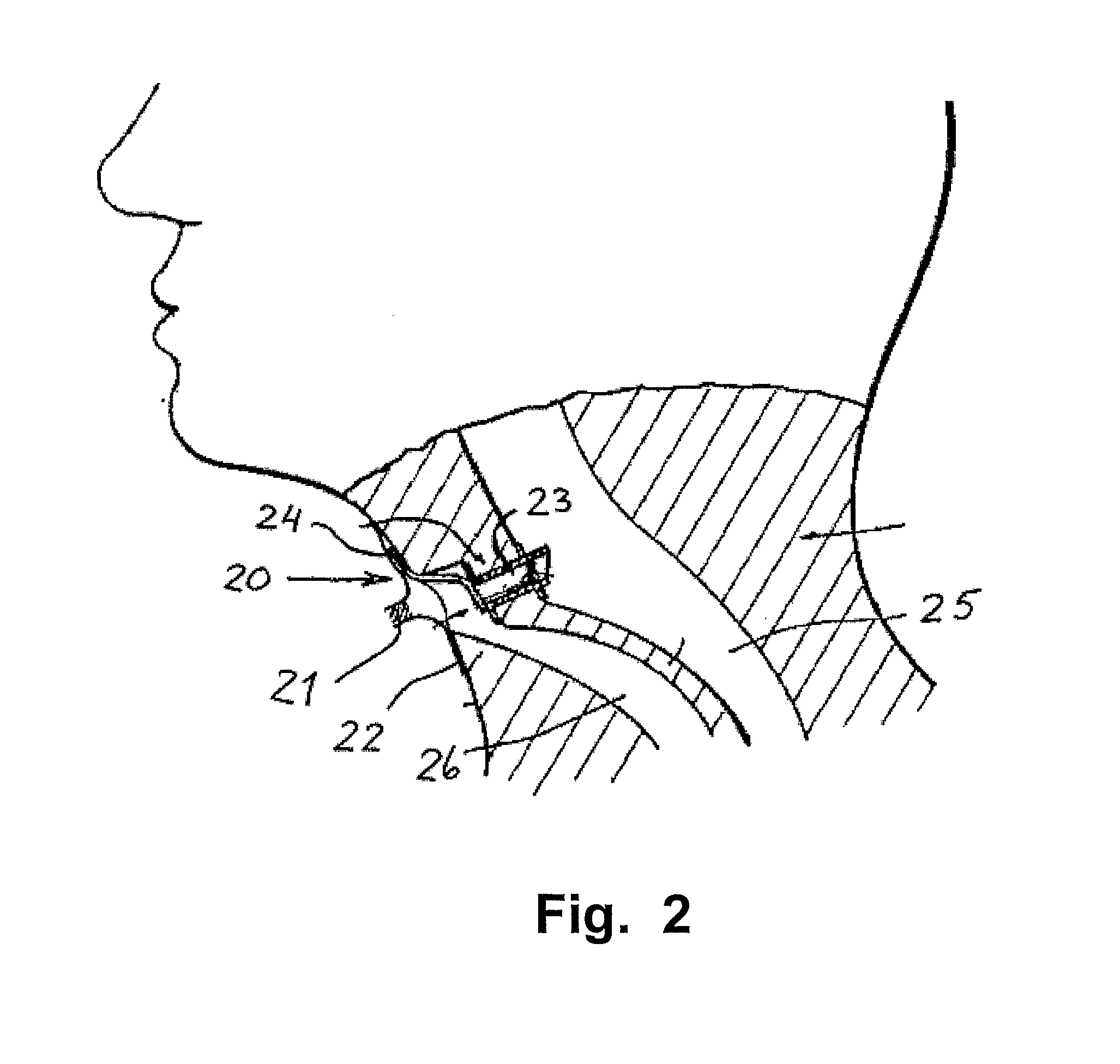

Voice prosthesis, insertion tool and method

An insertion tool for inserting a tracheostoma voice prosthesis member into a fistula between oesophagus and trachea. The insertion tool includes an engagement portion for engaging and retaining said tracheostoma voice prosthesis member to be inserted into the fistula, a gripping portion for gripping a safety strap of said member in a firm grip, a shaft portion adapted to be held by one hand of a user, and a release lever arrangement adjacent said shaft portion for operation by a finger of the same hand as is holding said shaft portion, whereby said release lever, after said member being positioned in place in said fistula by operation of said insertion tool by means of said shaft, is adapted to be operated for releasing said member by one-hand operation. A tracheostoma voice prosthesis member and a method for applying said tracheostoma voice prosthesis member are also provided.

Owner:COLOPLAST AS

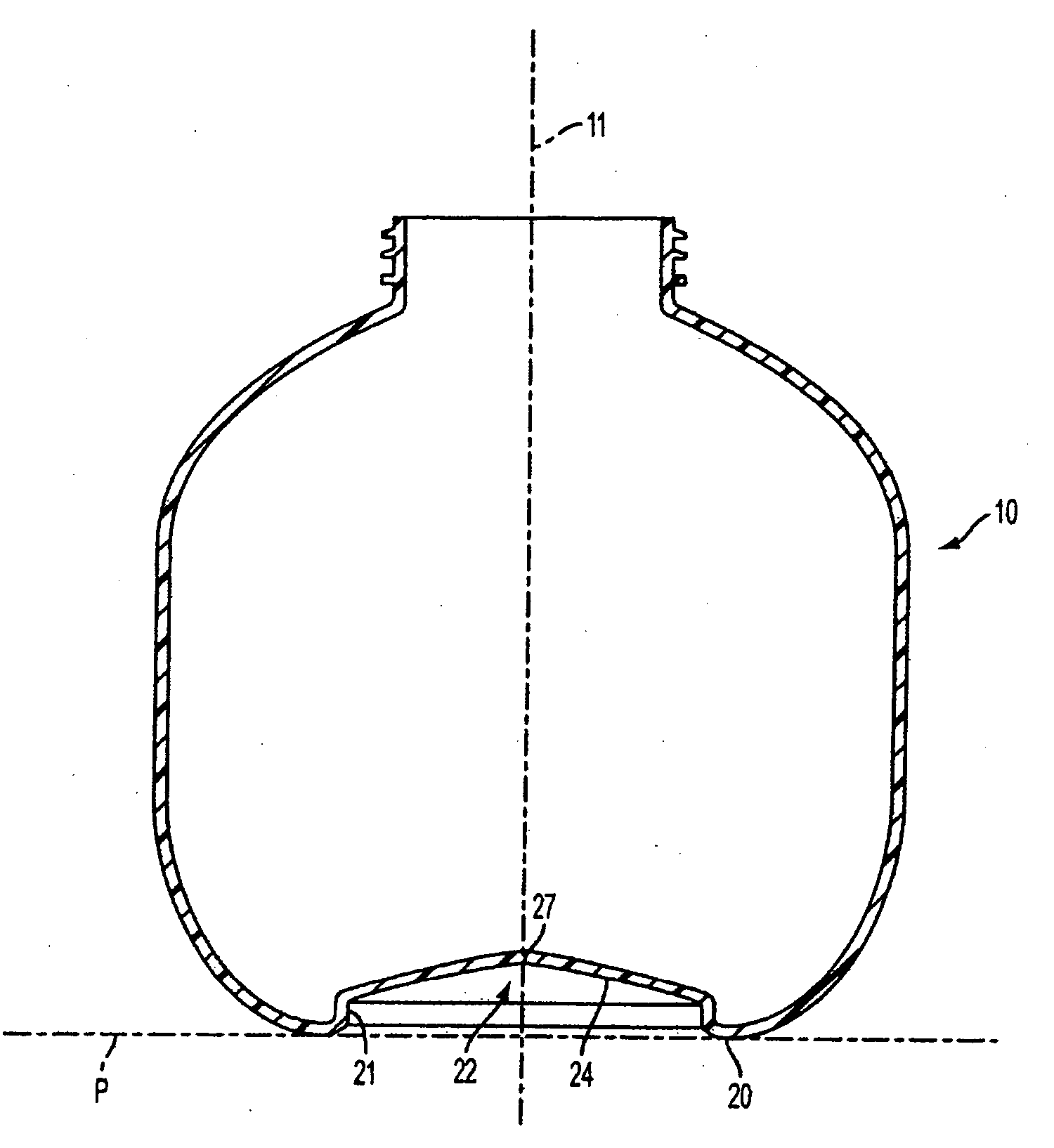

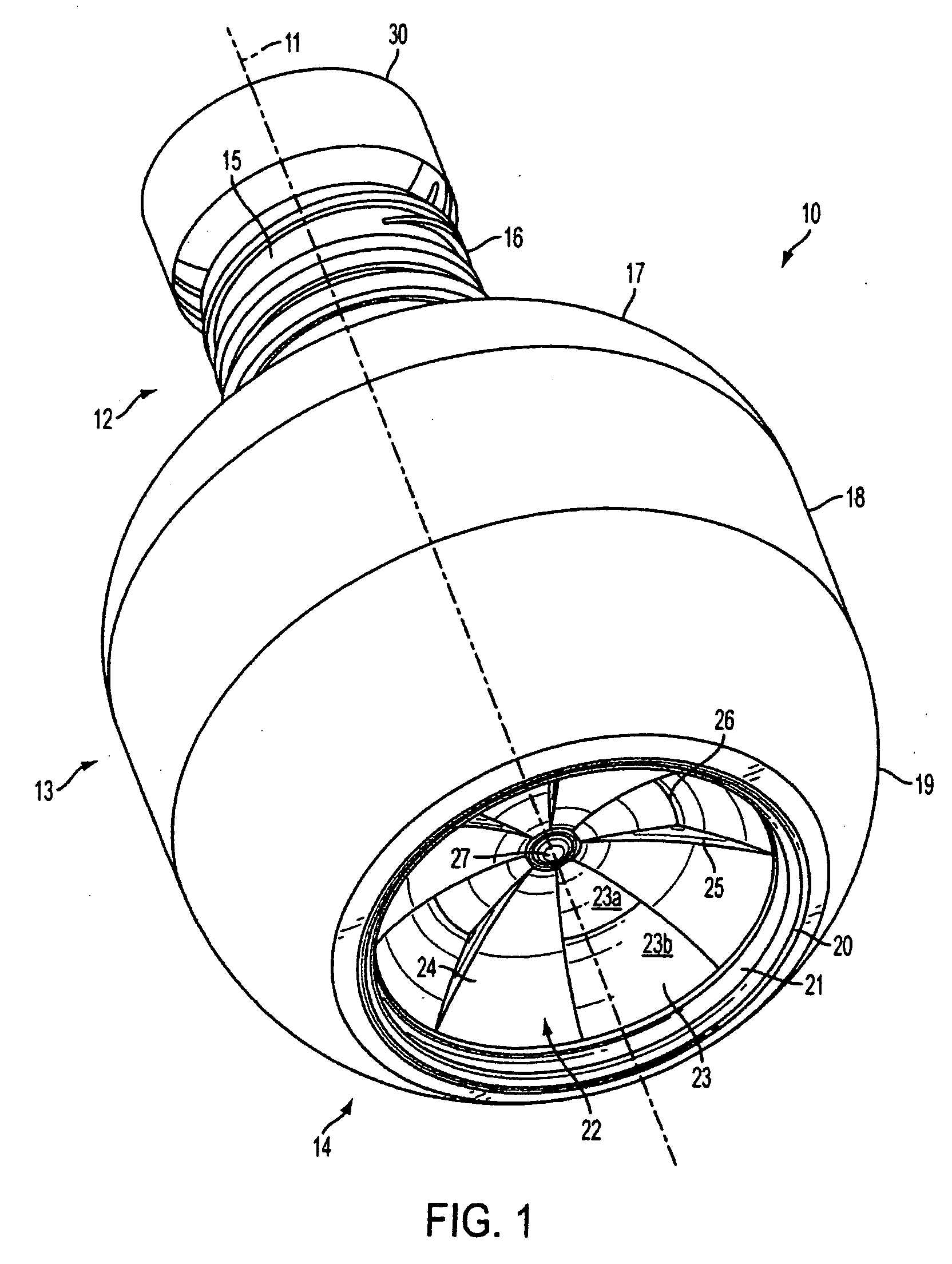

Fuel tank shell with structural support

ActiveUS20090189384A1Provide supportReduce thicknessTank vehiclesItem transportation vehiclesStress levelFuel tank

A fuel tank assembly for vehicles comprising a fuel tank shell having reduced wall thickness, accordingly resulting in a reduced total mass of the tank assembly. The fuel tank shell comprises two half shells connected to one another and having at least one support member attached thereto for providing structural support to the fuel tank shell. In particular, the support member may be positioned internally or externally to the fuel tank with such a positioning being selected so as to offer support in at least one area where the stress level exerted on the fuel tank shell is maximum.

Owner:SPECTRA PREMIUM MOBILITY SOLUTIONS CANADA LTD +1

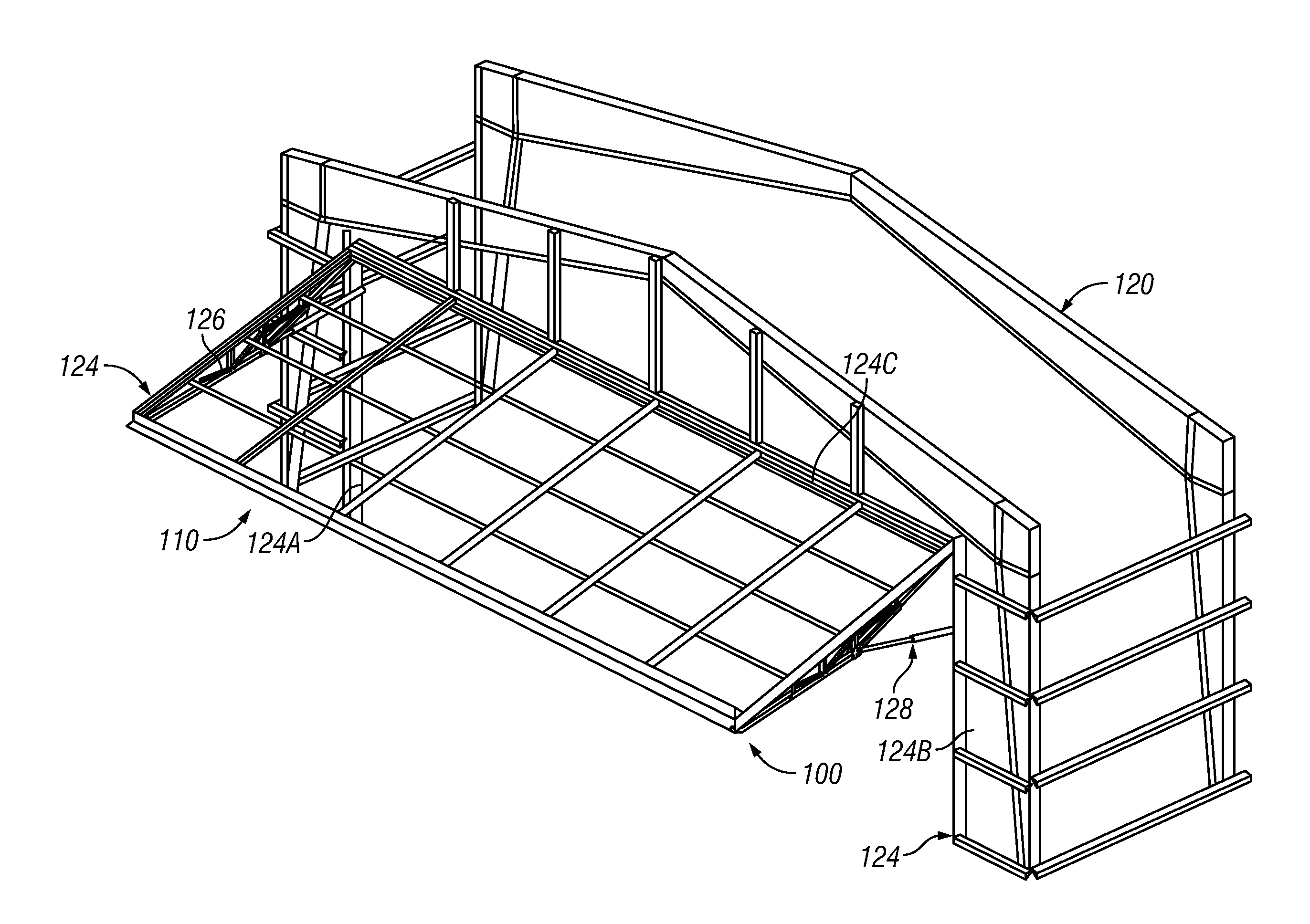

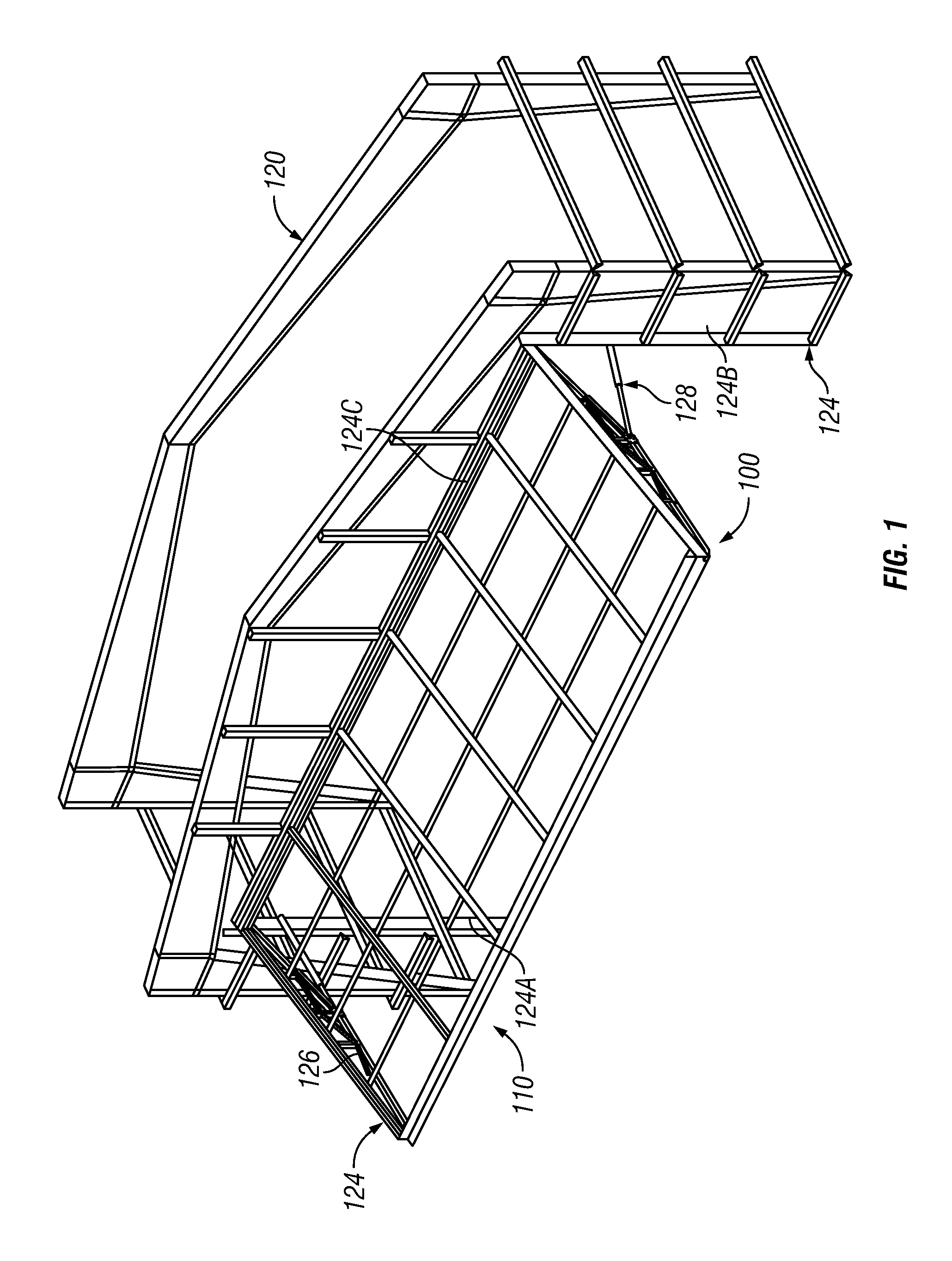

Support Truss for Hinged Overhead Door

InactiveUS20110232196A1High strengthReduce material thicknessMan-operated mechanismPower-operated mechanismHydraulic ramEngineering

An overhead door for closing a building opening has load distributing support trusses extending along spaced vertical members of the door or door frame. Each support truss is secured to a respective door vertical member to extend transverse to the door in a generally downward direction when the door is in an overhead, open position. The trusses are substantially V-shaped. Each truss has first and second rails extending from respective ends of the truss to an apex. One or more trusses may be side trusses secured to vertical members defining opposite sides of the door. Each side truss has a pivot mount configured for pivotal connection to one end of a hydraulic ram for opening and closing the door.

Owner:VGENSYS

Exhaust muffler

ActiveUS7942239B2Easy to adjustMaximizes performance characteristicSilencing apparatusMachines/enginesCombustionEngineering

A muffler for reducing the sounds of combustion gases exhausted from an internal combustion engine including an elongated fluid passage extending between an inlet and an outlet such that the outlet is in fluid communication with the inlet. Further, the inlet being connectable with the gases exhausted from the engine and the outlet being connectable with the atmosphere. The muffler further including an outer tank surrounding the passage and a tubular connector having a first end in fluid connection with the passage and a second end in fluid connection with the tank such that the connector produces a fluid connection between the passage and the tank. The connectors having a perforated resistance plate to restrict the fluid flow between said passage and said sound chamber thereby reducing the severity of the sound or fluid pulses entering and exiting said sound chamber, perforations in said perforated plate forming an open portion of said plate and said open portion being less than 60 percent.

Owner:TMG PERFORMANCE PRODS

Seat Cushion With Bubble Elements

InactiveUS20110084539A1Reduced stabilityAvoid damageVehicle seatsDismountable chairsHermetic sealEngineering

A seat cushion for the production of a vehicle seat has a foam body and a carrier element. The carrier element is disposed on the back side of the foam body and provides mechanical support to the foam body on the back side thereof. At least one bubble element is disposed between the foam body and the carrier element and can be supplied with compressed air via an air inlet. The carrier element features an air-impermeable barrier layer on the side facing towards the foam body. The bubble element is composed of two bubble halves that are connected to one another by means of an airtight sealing joint, and wherein the bubble half facing away from the foam body is formed by a surface section of the barrier layer of the carrier element, and wherein the second bubble half facing towards the foam body is fastened at the assigned surface section of the barrier layer while forming the airtight sealing joint.

Owner:FS FEHRER AUTOMOTIVE GMBH

Pole terminal

InactiveUS7354306B2Reduce material thicknessImprove conductivityOne pole connectionsElectrically conductive connectionsElectrical connectionBending strain

The invention relates to a pole terminal for producing an electrical connection. Said pole terminal comprises a metallic conductive body which is surrounded by an insulating body which can be fixed to the housing of an electrical appliance, and on which a tensioning nut can be screwed, said tensioning nut clamping the electrical conductor to be connected against the conductive body, establishing an electrical contact. The aim of the invention is to improve one such pole terminal in such a way that the conductive body can be produced from a material which is highly conductive, such as silver or copper. To this end, the conductive body is produced from a material exhibiting higher conductivity, by means of noncutting deformation, and is connected to the surrounding insulating body to form a composite body. Preferably, the conductive body is embodied as a stamped part which is machined by bending strain.

Owner:THORNER WOLFGANG B

Device for support of the head

InactiveUS20060083355A1Avoid disadvantagesProduced simply and cost-effectivelySofasBedsX-rayImage Artifact

A device for supporting the head of a patient is accommodated on a patient bed of an x-ray apparatus. To prevent image artifacts, the device has a head shell mounted on a fastening part by means of a joint, and a support is provided between the head shell and the fastening part for adjustment of the angle of inclination of the head shell.

Owner:SIEMENS HEATHCARE GMBH

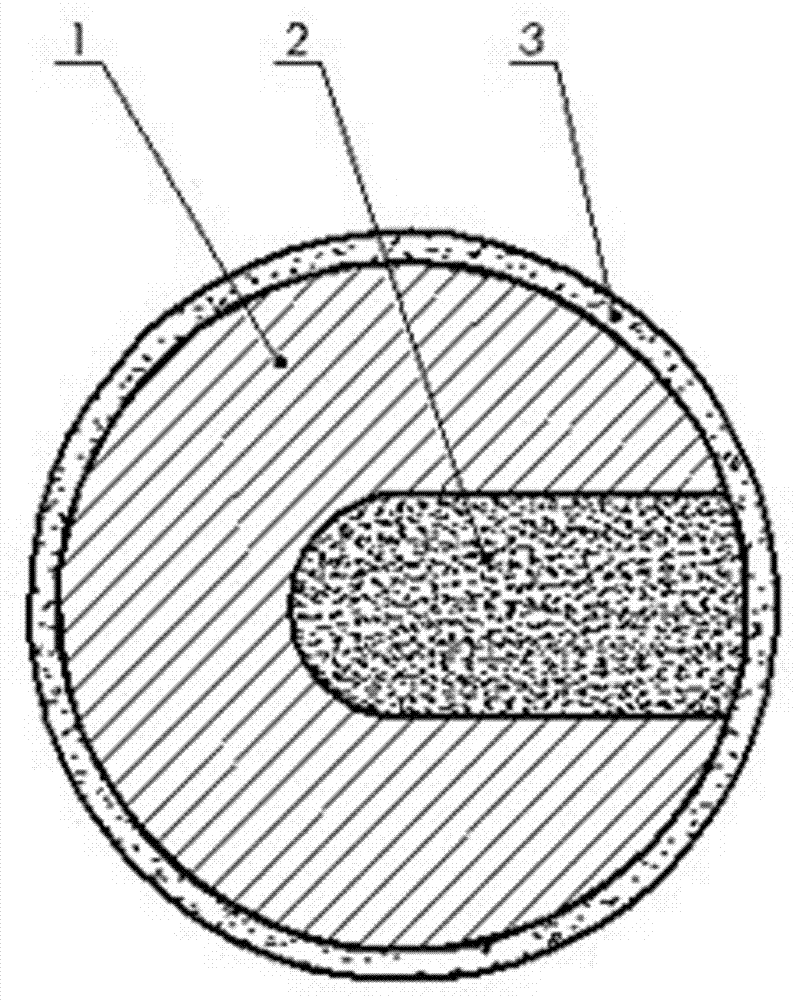

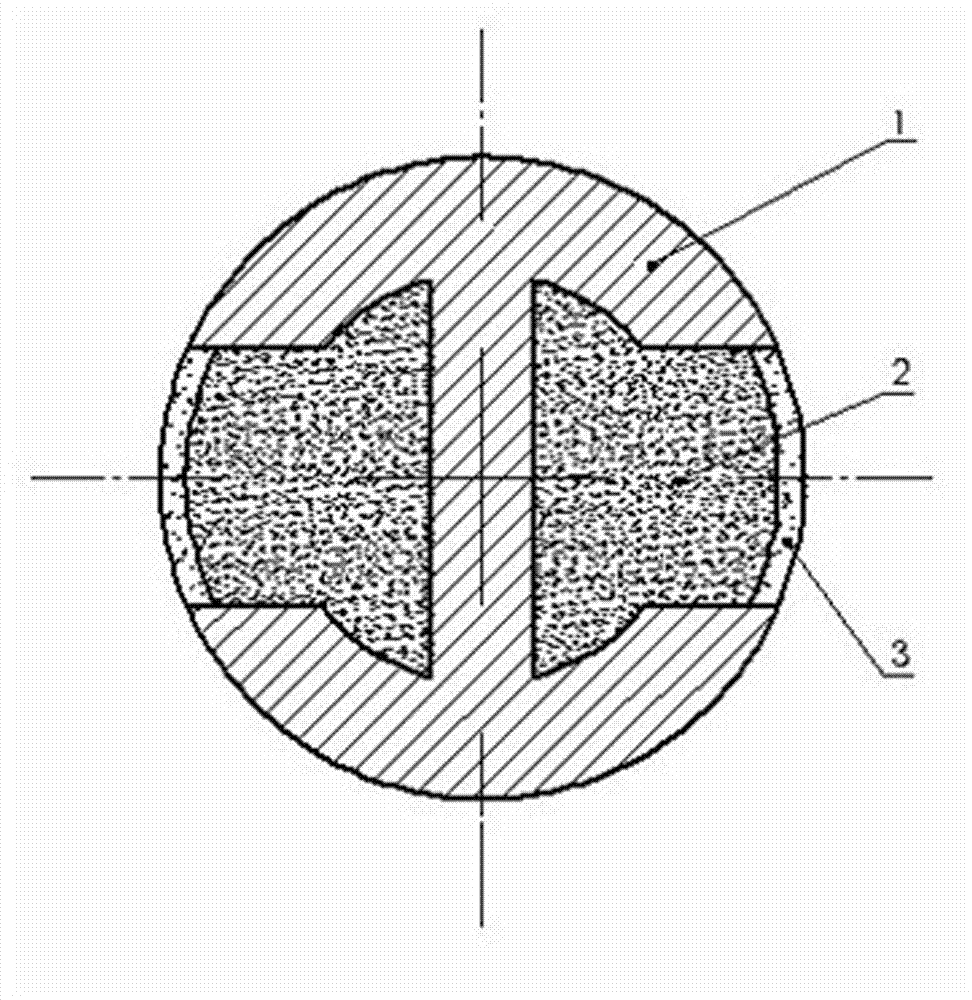

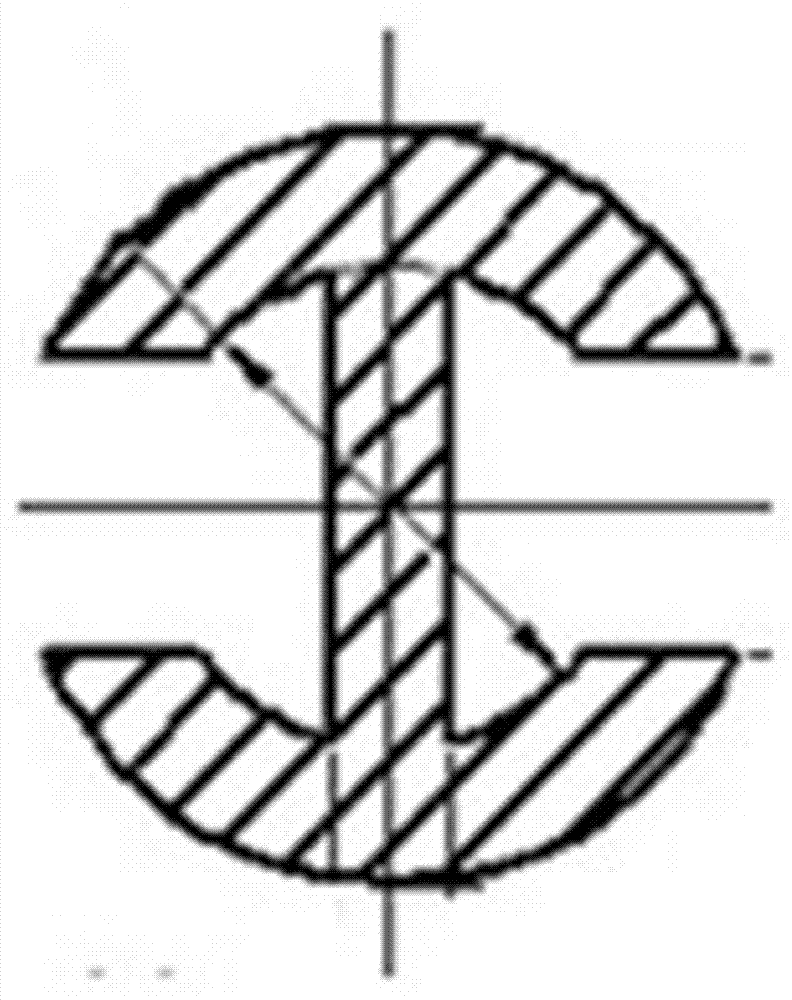

Composite aluminum-base brazing wire for continuously brazing aluminum alloy and method for manufacturing composite aluminum-base brazing wire

InactiveCN103203560AReasonable structureThe joint performance is stable and goodWelding/cutting media/materialsSoldering mediaFiller metalSilicon

The invention discloses a composite aluminum-base brazing wire for continuously brazing aluminum alloy and a method for manufacturing the composite aluminum-base brazing wire. The aluminum-base brazing wire comprises a section of aluminum-base brazing filler metal, non-corrosive brazing fluxes for aluminum and silicon powder coating layers; the section of the aluminum-base brazing filler metal is provided with grooves, the non-corrosive brazing fluxes for the aluminum are composited in the grooves of the section, and the silicon powder coating layers are coated on surfaces of the brazing fluxes; and the section side of the section of the brazing filler metal can be provided with one groove or two grooves or three grooves. The method includes smelting and casting the brazing filler metal of the brazing wire during manufacture and squeezing a blank which is a rod; manufacturing the section of the brazing filler metal of the brazing wire by means of rolling and squeezing; compositing the section of the brazing filler metal with the non-corrosive brazing fluxes for the aluminum; and coating the silicon powder coating layers on the surfaces of the composite brazing fluxes. The composite aluminum-base brazing wire and the method have the advantages that the local composite aluminum-base brazing wire for continuously brazing the aluminum alloy is suitable for intelligent brazing equipment provided with a laser brazing system, so that the intelligent brazing equipment can be used for continuously brazing various medium and large aluminum alloy structural parts with over-burning temperatures higher than 580 DEG C, the quality of brazing seams is stable, and the efficiency is high.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Adapter for multi-element contact-probe

InactiveUS20050003518A1Maintaining their functionalityReduce material thicknessBioreactor/fermenter combinationsUltrasound therapyTarget surfaceContact force

The disclosed invention describes an Adaptor structure, used in conjunction with a multi-element contact-probe, for protecting the probe elements and the Target surface from wearing and contamination, while maintaining probe functionality including the probe elements contact force exerted on the corresponding Target surface points. The provided Adaptor structure is removable and suitable for disposable applications. The invention constitutes also a method in which the mediating Adaptor structure physically buffers between the Contact probe front-end and Target surface. Further the invention constitutes also a kit comprising at least one Contact probe and at least one Adaptor structure.

Owner:AVIRAM DAVID +1

Voice prosthesis, insertion tool and method

ActiveUS20090043386A1Reduce complicationsImprove voice qualityEar treatmentTracheaeProsthesisFistula

A tracheostoma voice prosthesis member (1) intended for insertion into a fistula between oesophagus and trachea. The member comprises a tubular body portion (2) with a proximal end opening into the trachea and a distal end opening into the oesophagus. A one-way flap valve covers a through opening of the tubular body portion (2) for allowing air to pass through the tubular body portion (2) from the proximal end to the distal end but preventing air and other matter from passing in the reverse direction. A support ring (8) supports the one-way valve and / or stiffens the tubular body portion (2) adjacent the one-way valve. The ratio between the smallest inner diameter of the through opening and the largest outer diameter of the tubular body portion (2) is larger than 58%. A safety strap (6) extends from the proximal end and is attached to the skin outside the tracheostoma by a plaster. The cross-section of the safety strap is convex so that substantially no space is formed along the side edges of the safety strap (6) between the skin, plaster and the edges of the safety strap. A safety medallion (11) may be attached to the member by a cord (10). The medallion (11) is sufficiently large for being unable to pass down into the trachea and the lungs of the user, if accidentically dropped. A device and a method for applying said tracheostoma voice prosthesis member (1) are also provided.

Owner:COLOPLAST AS

Apparatus and Methods of Capping Metallic Bottles

InactiveUS20180044155A1Less simultaneous forceReduce side loadCapsThreaded caps applicationEngineeringBottle

An apparatus and methods of sealing a metallic container are provided. More specifically, the present invention relates to capping apparatus and methods that reduce the amount of force applied to a metallic bottle to seal the metallic bottle with a ROPP closure. The capping apparatus may include more thread rollers than known capping apparatus. Optionally, the thread rollers may use more forming passes to form threads on the ROPP closure. The capping apparatus may also rotate one or more of the ROPP closure and the metallic container in a closing direction before the metallic container is discharged. In one embodiment, the thread rollers form the closure threads before or after a pilfer roller applies a sideload to the ROPP closure.

Owner:BALL CORP

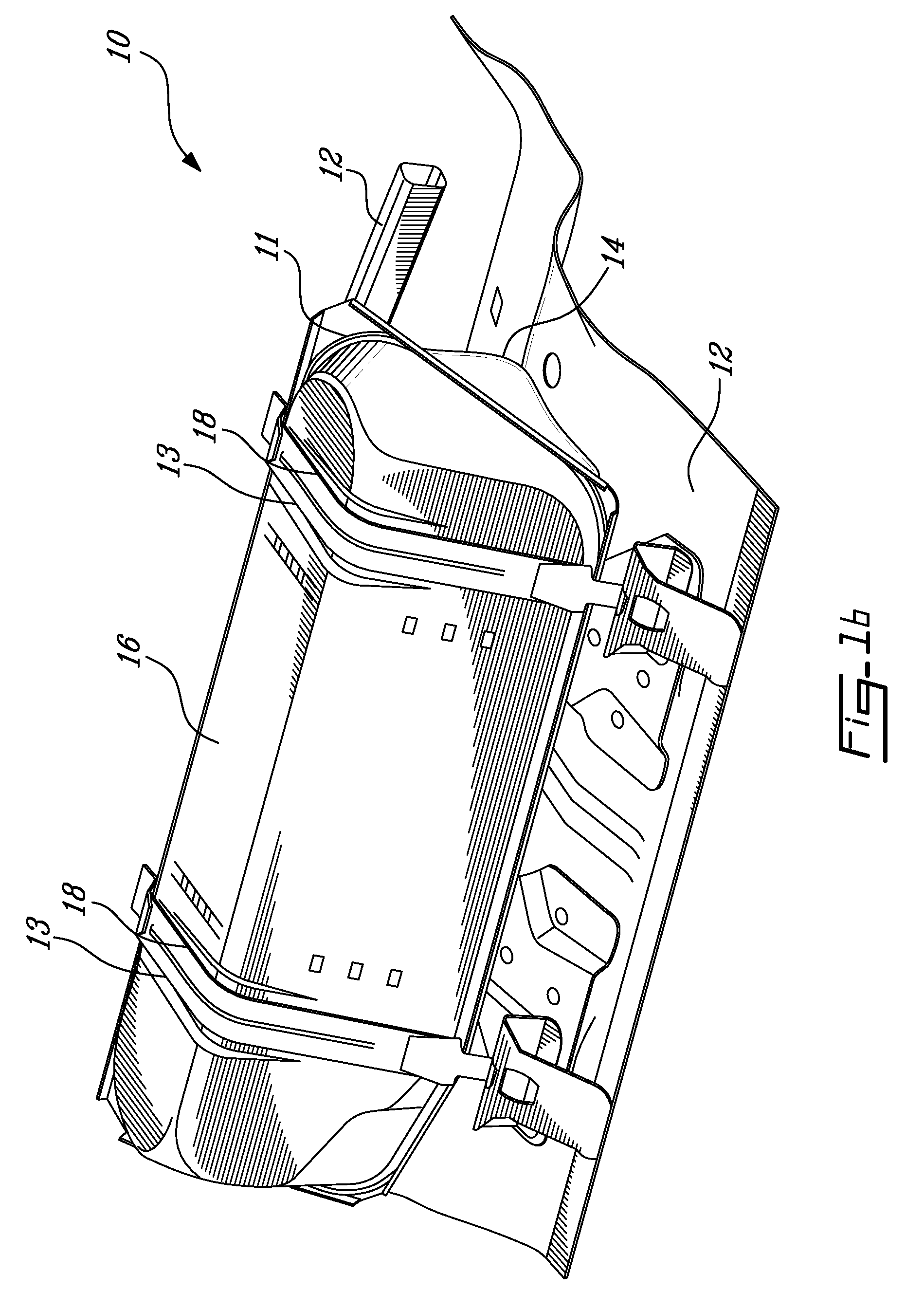

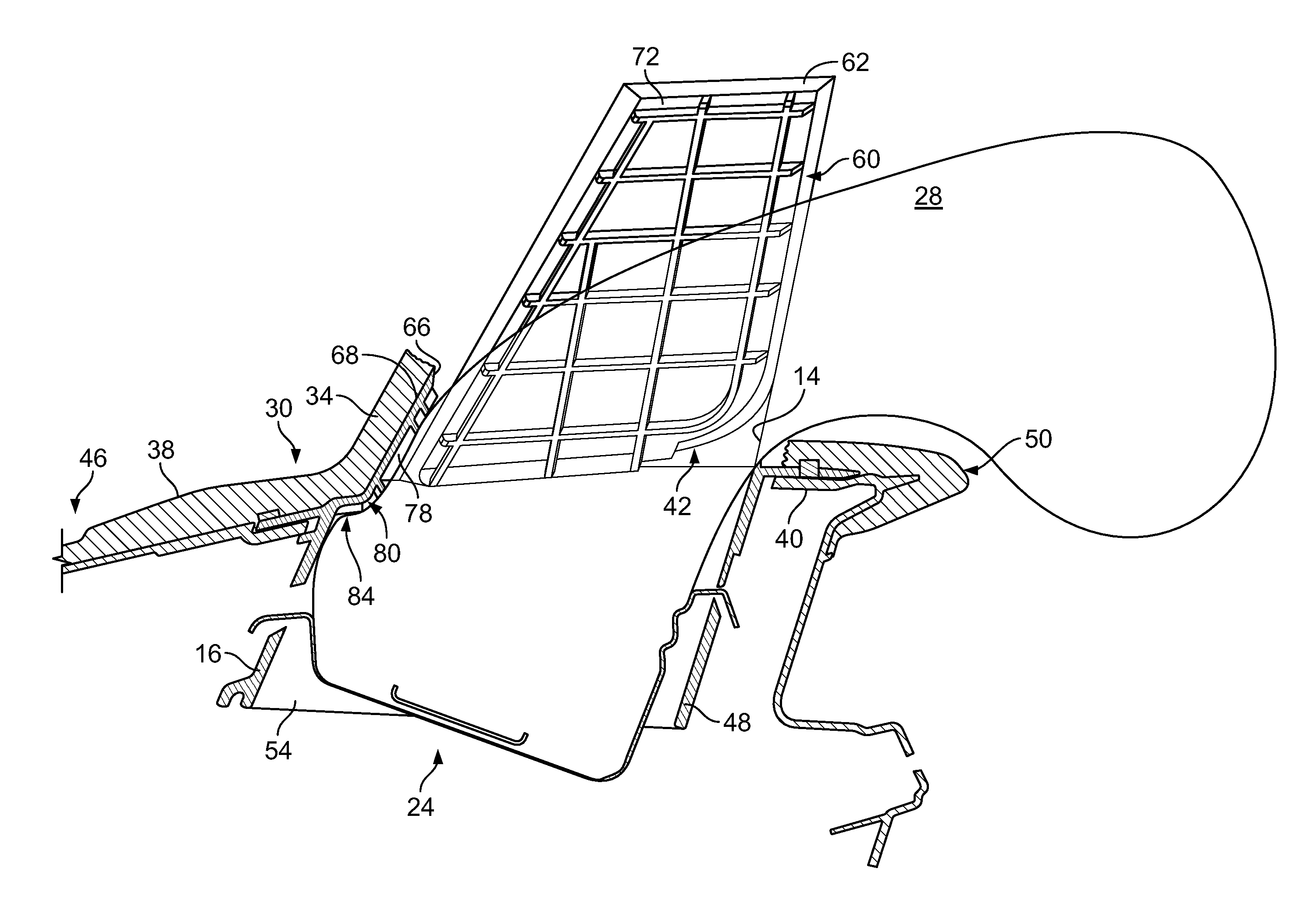

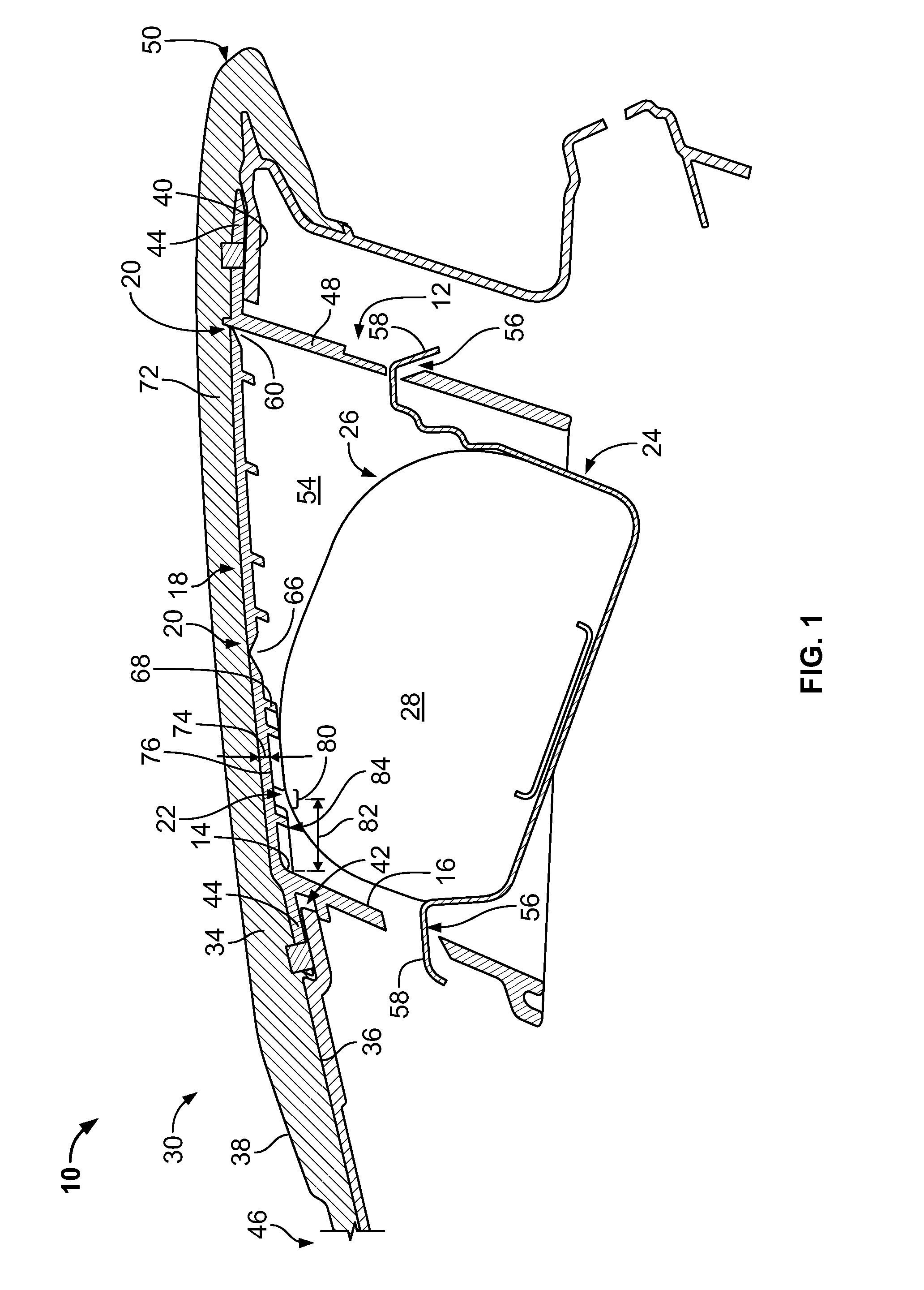

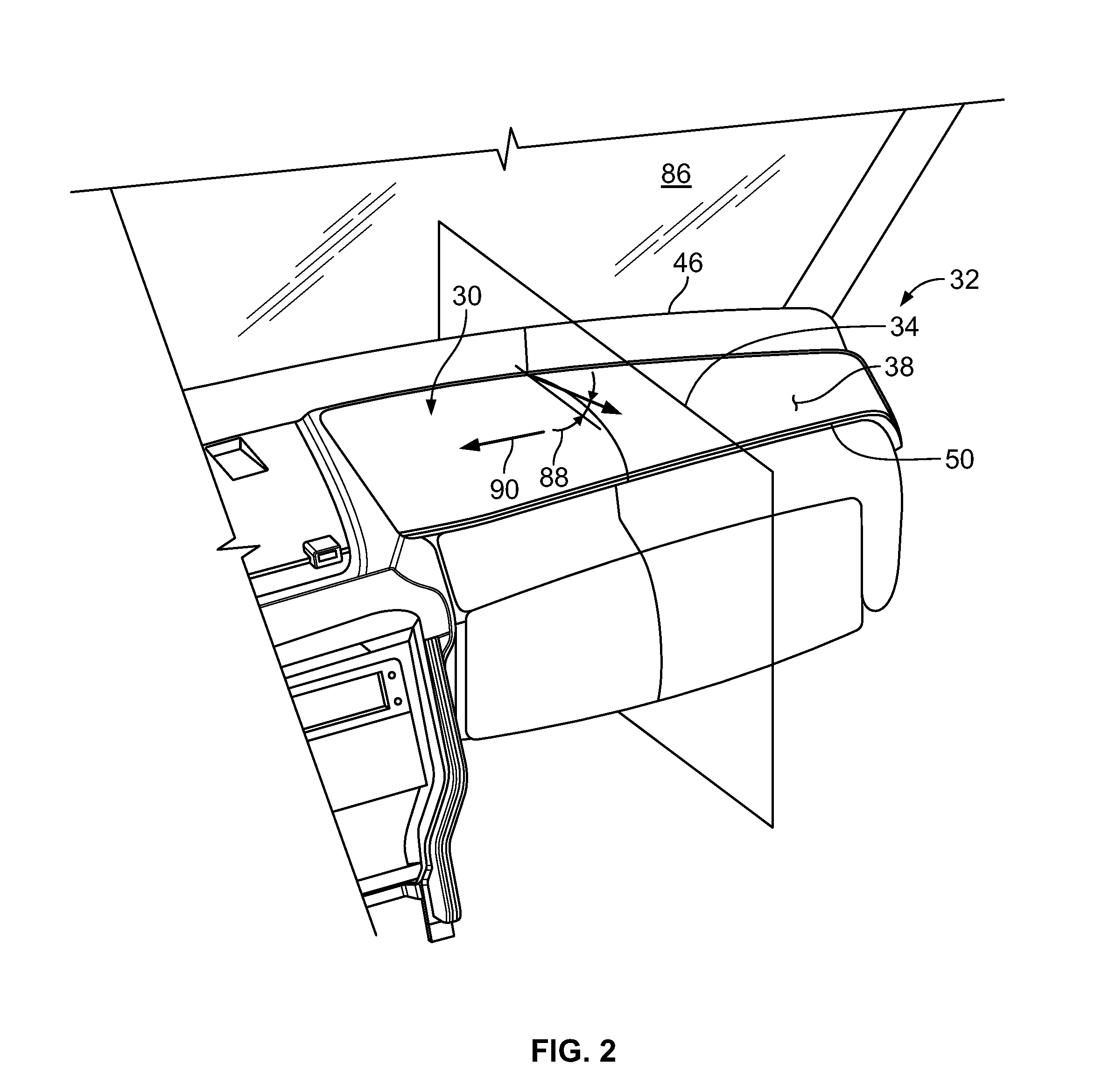

Seamless instrument panel passenger air bag door

Owner:FORD GLOBAL TECH LLC

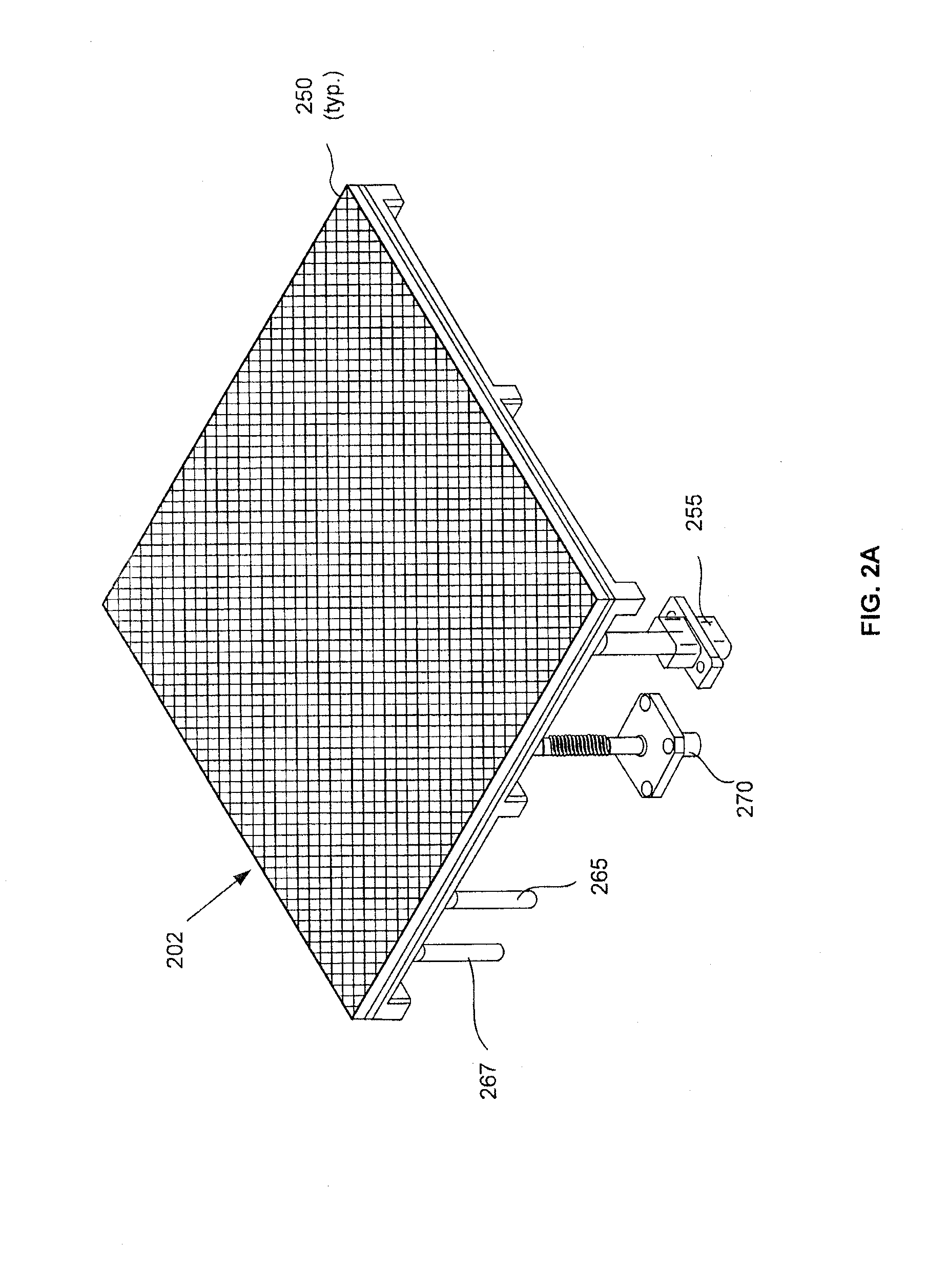

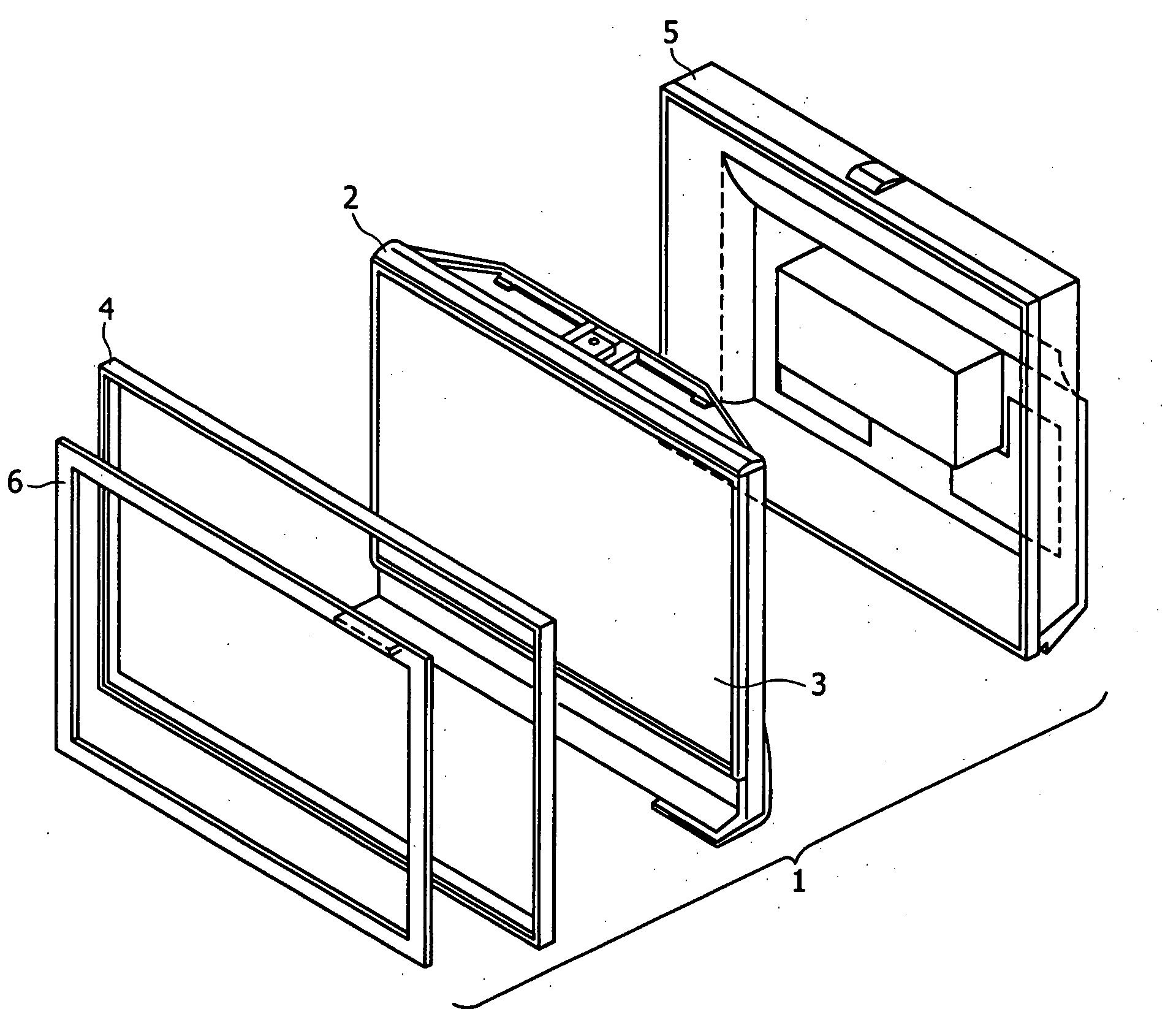

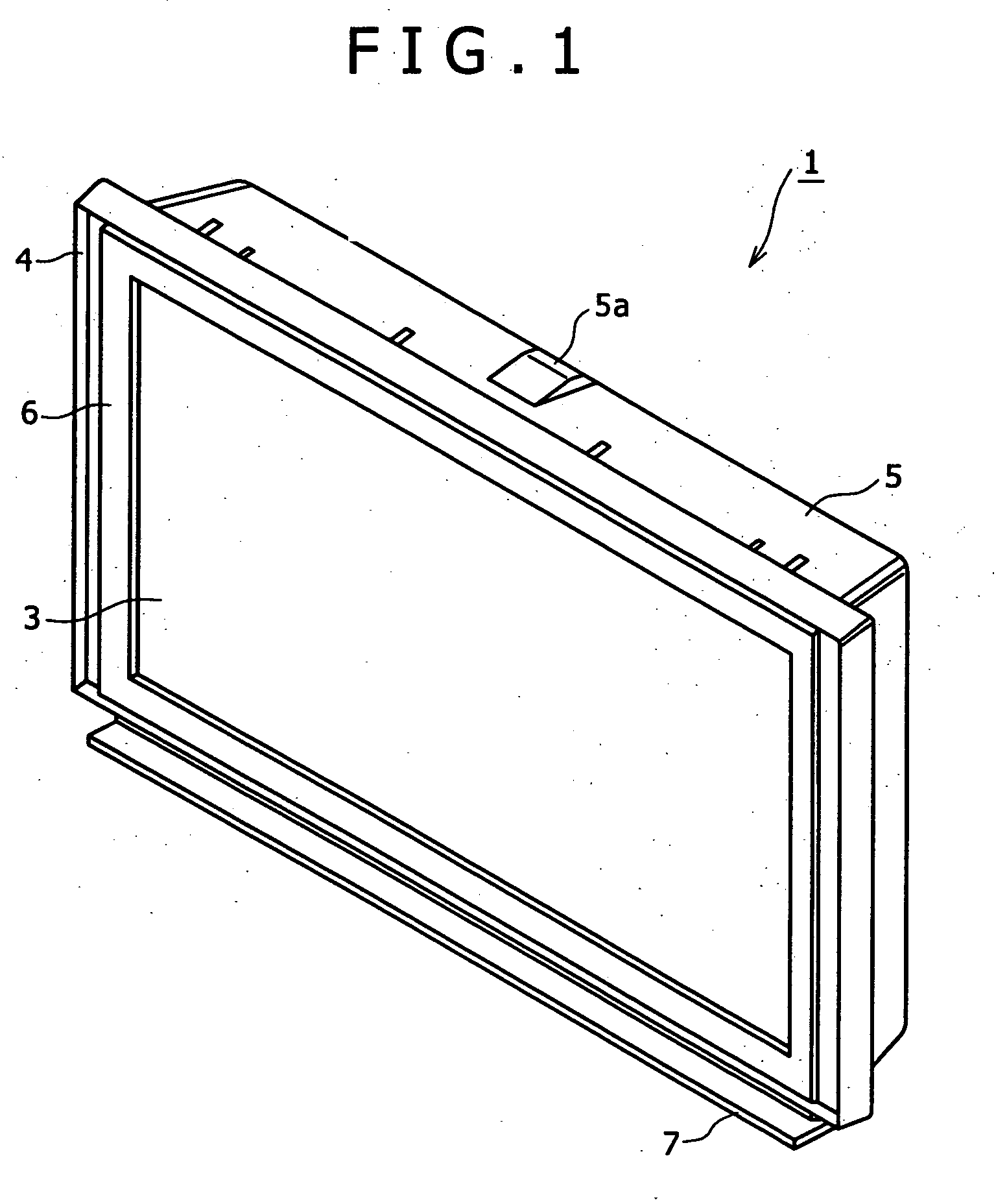

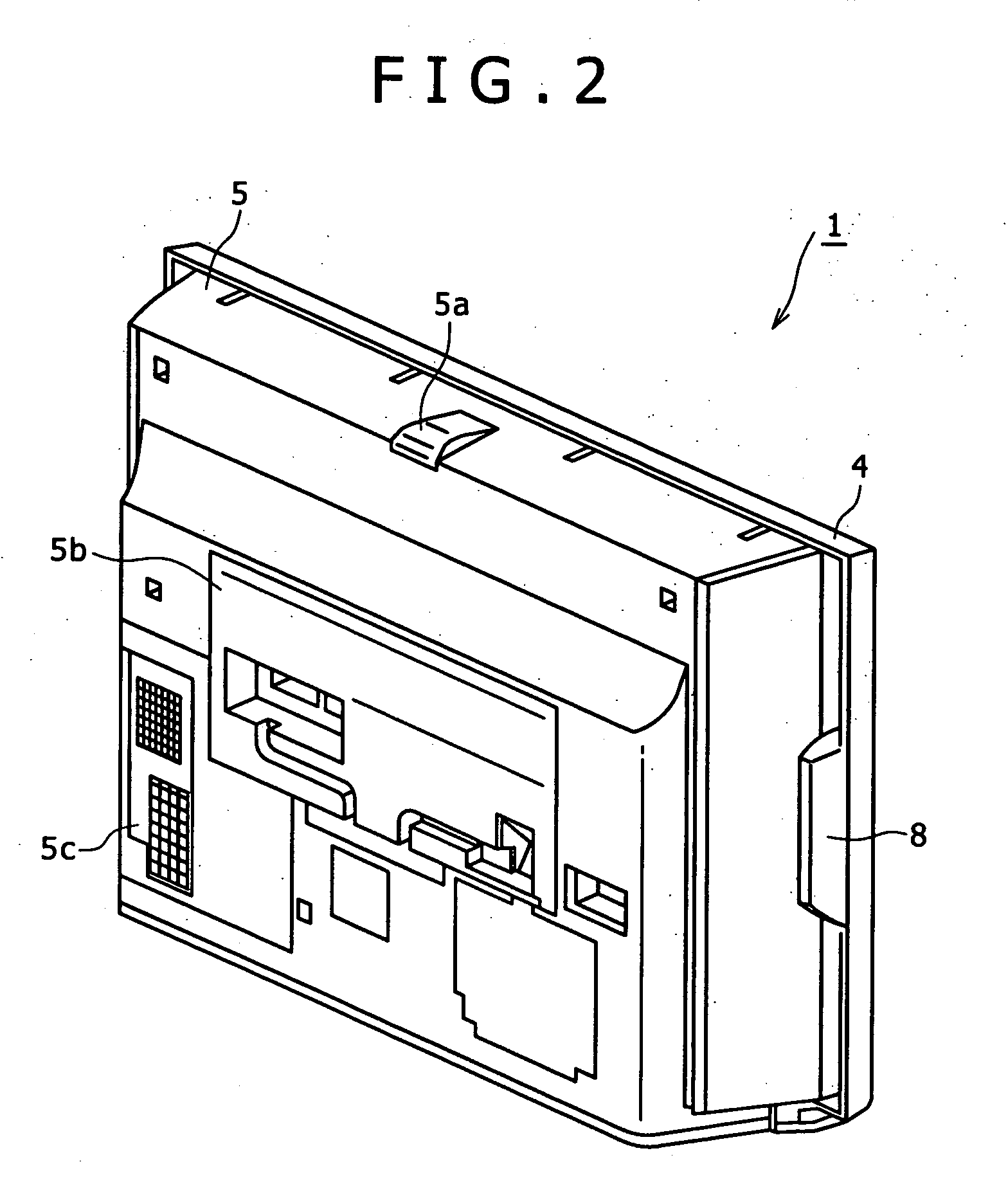

Rear projection display apparatus

InactiveUS20070177063A1Reduce material thicknessIncrease stiffnessBuilt-on/built-in screen projectorsPicture reproducersEngineeringProjection lens

Disclosed herein is a rear projection display apparatus including, a screen, a projection mirror, a video apparatus for projecting a picture, an optical unit including a projection lens, a light source, a drive and control circuit, and a structure body for holding the screen, the structure body having, a frame body formed from an extruded metal member, and a reinforcement member formed from a sheet metal, the frame body including, a bottom frame constituting a bottom surface, left and right side frames erected at both ends on the front side of the structure body, of the bottom frame, and a top frame bridgingly disposed between the upper ends of the left and right side frames, and the reinforcement member including, at least a frame support for connecting between the bottom surface of the bottom frame and the right side frame, or connecting between the bottom surface of the bottom frame and the left side frame.

Owner:SONY CORP

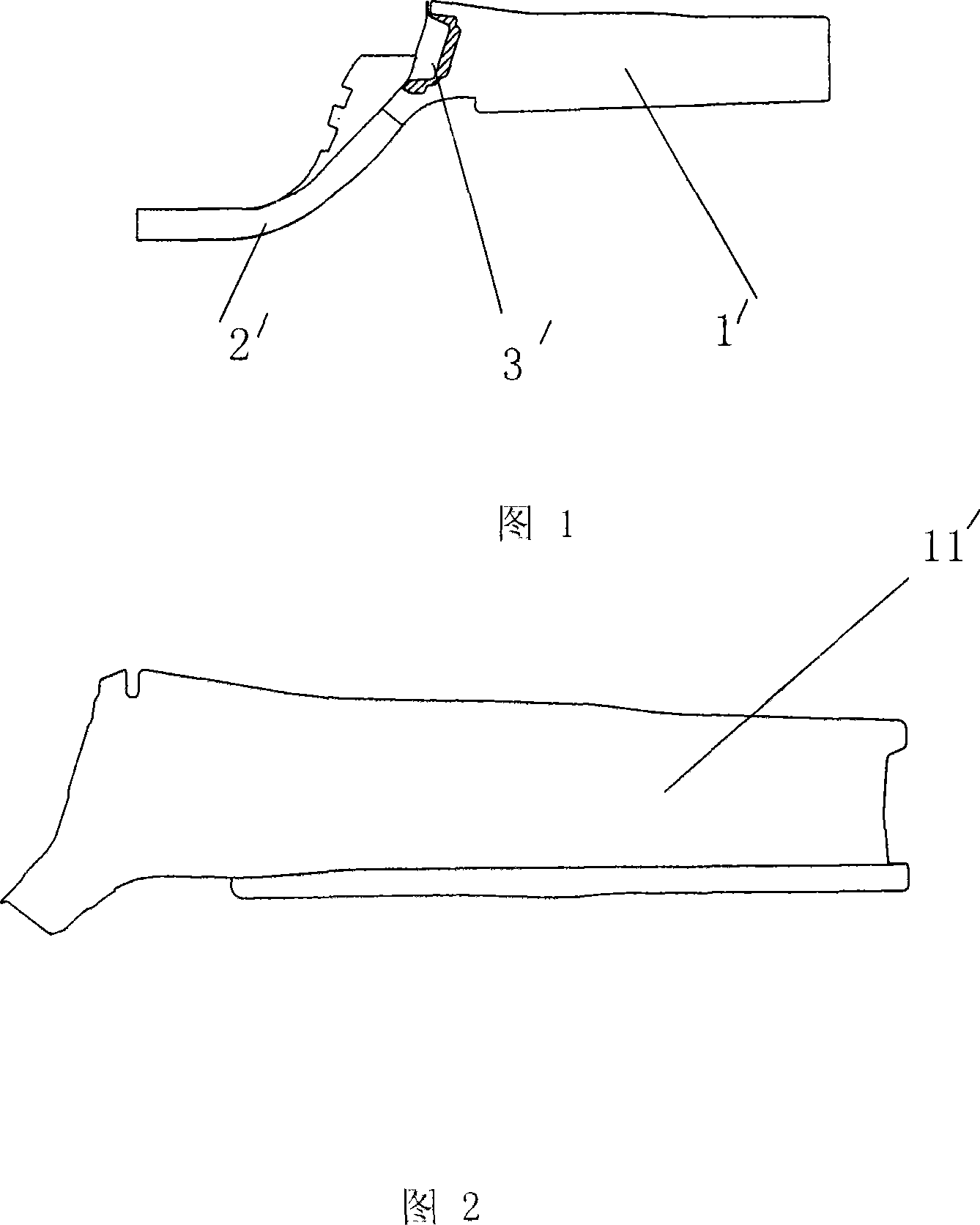

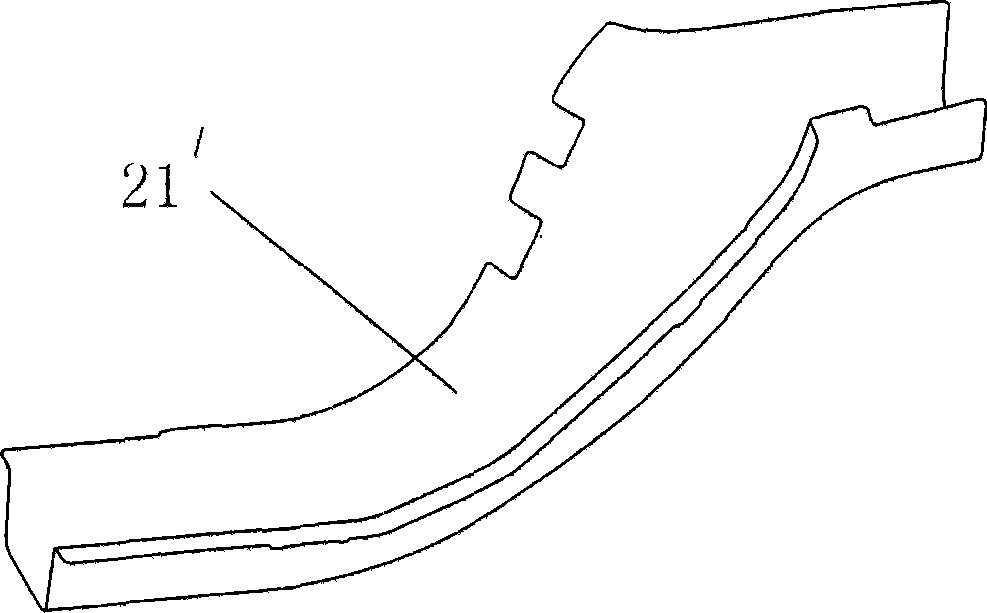

Front stringpiece of vehicle body

ActiveCN101367410AEasy to processGuaranteed Continuity of DeliverySuperstructure subunitsMonocoque constructionsEngineeringClosed cavity

The invention discloses a front longeron of an automobile body, which comprises a front part of the front longeron connected with a front bumper of the automobile and a rear part of the front longeron connected with a front baffle of the automobile, wherein the front part of the front longeron comprises a sealed cavity structure welded by a front body plate of the front longeron and a front outer plate of the front longeron; the rear part of the front longeron comprises a sealed cavity structure welded by a rear body plate of the front longeron; the front lengeron also comprises a connecting piece which connects the front part of the front longeron and the rear part of the front longeron; the connecting piece is in a three-way groove shape; one end of the connecting piece is provided with a connector welded with the front part of the front longeron; and the other end of the connecting piece is provided with a connector welded with the rear part of the front longeron and a connector welded with a middle crossbeam of the front baffle. As the front longeron of the automobile body is designed into three parts, and a bending surface and a welded surface are integrated on the connecting piece, thereby improving the whole strength and proper force dividing transfer; in addition, the front longeron has the advantages of convenient processing and low welding difficulty.

Owner:CHERY AUTOMOBILE CO LTD

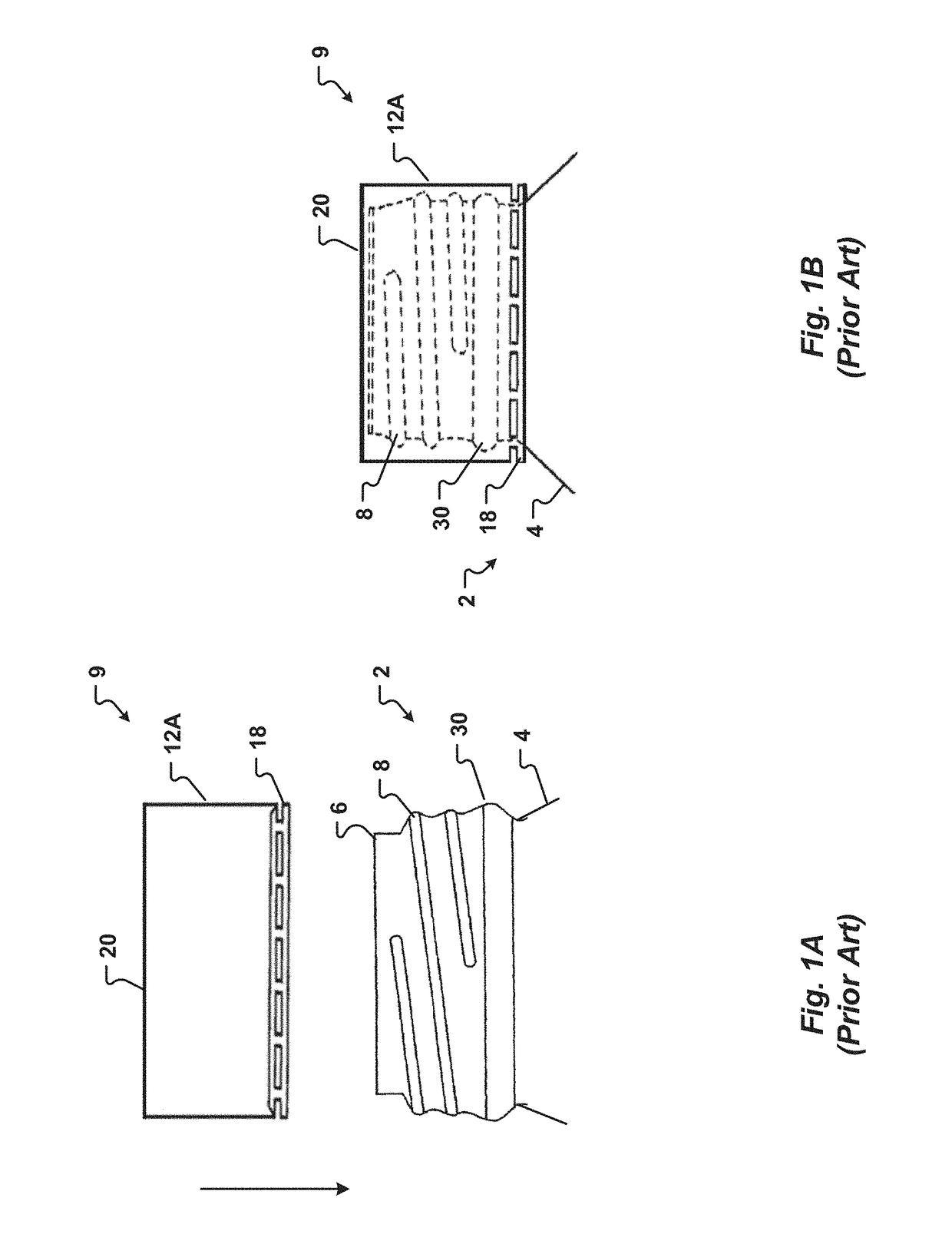

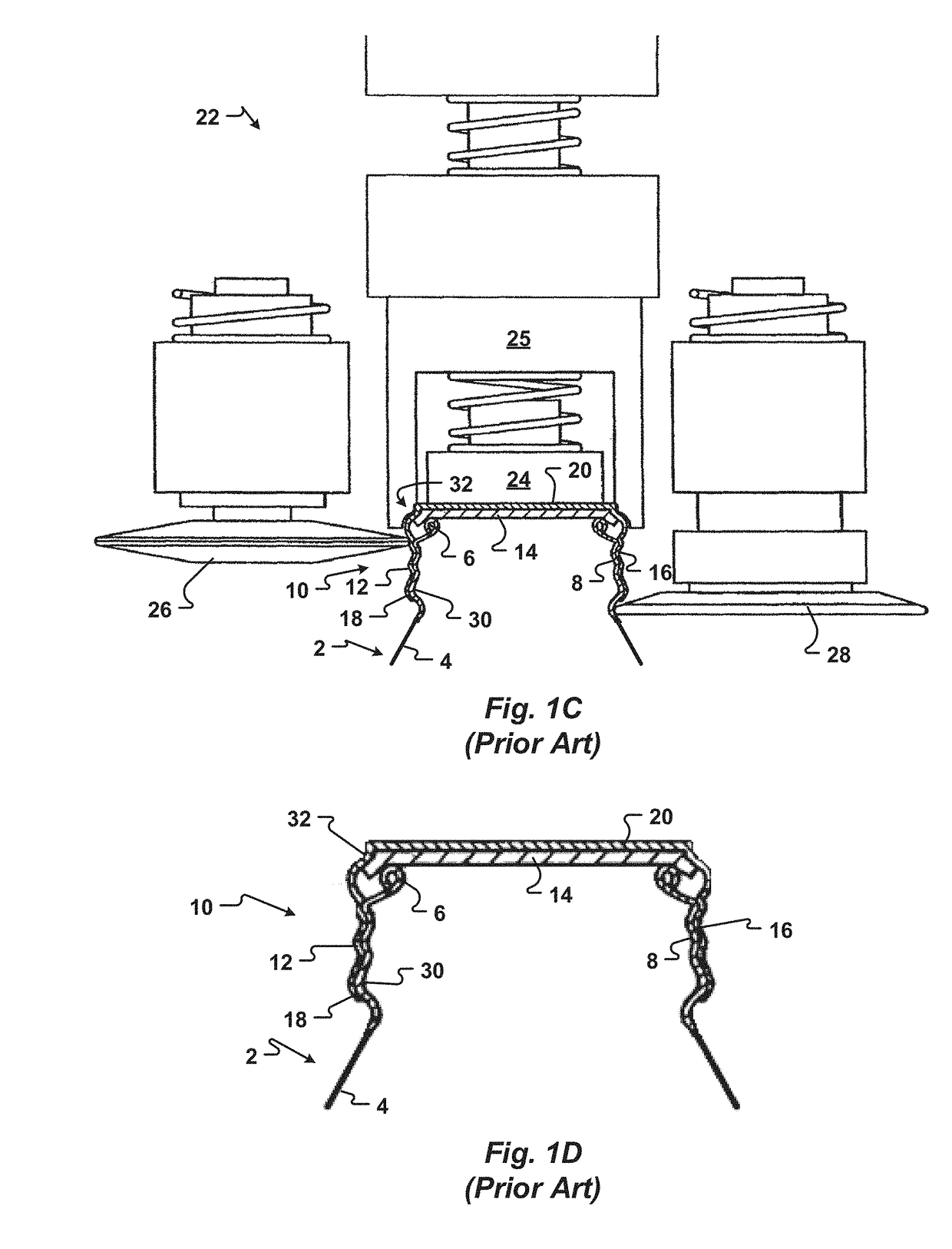

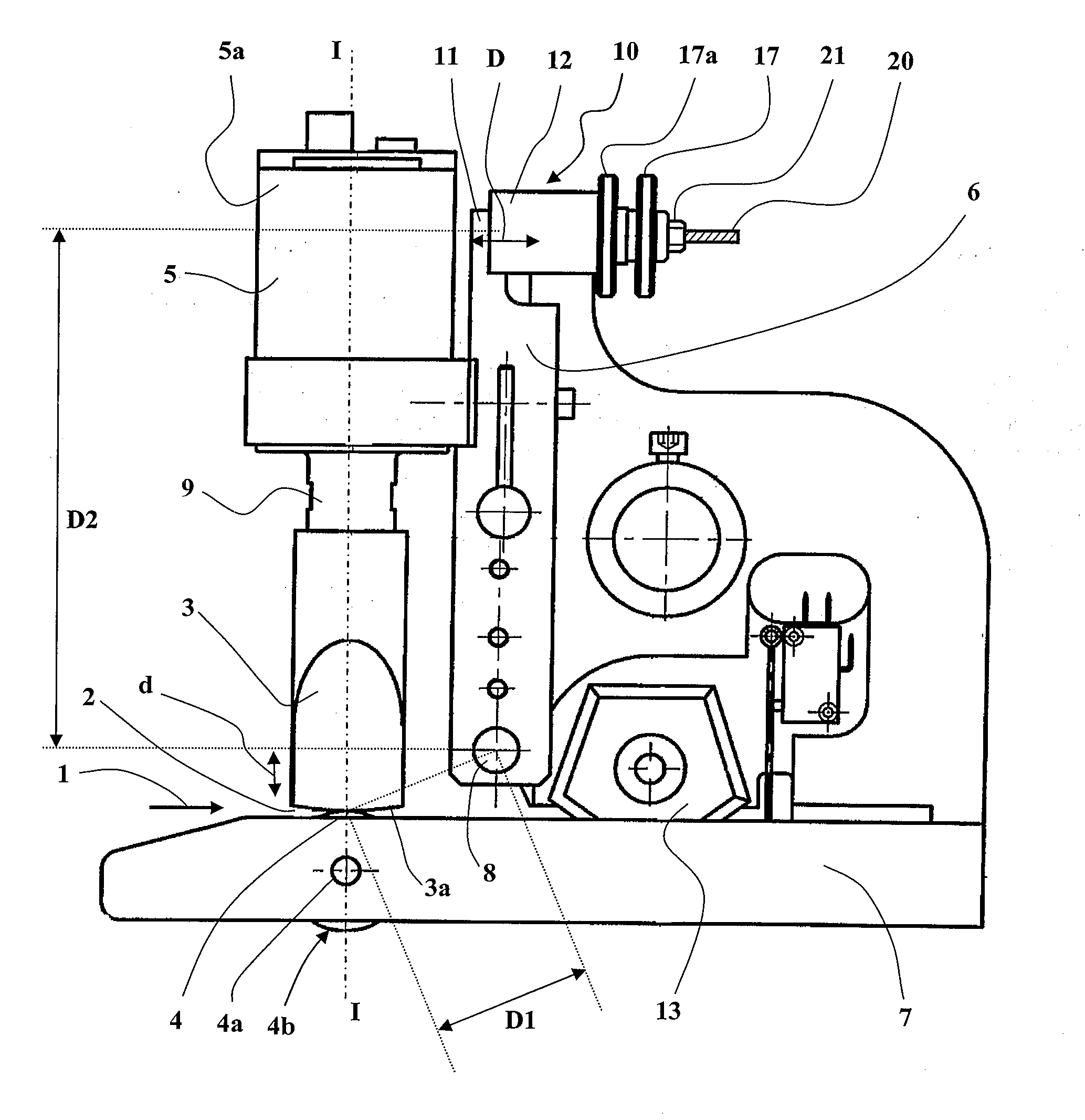

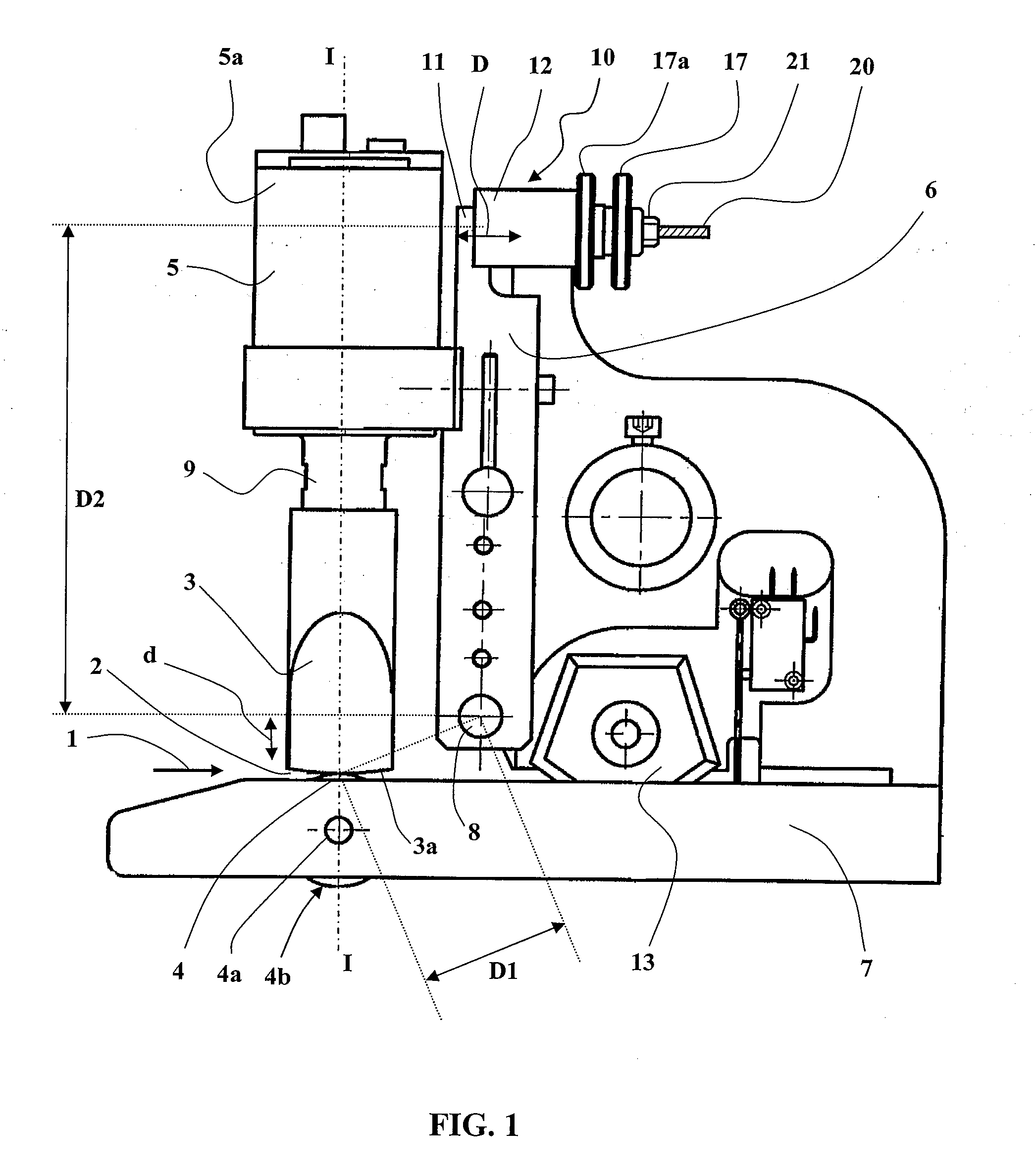

Method and device for ultrasound processing of a material web

ActiveUS20090025853A1Easy to adjustHigh adjustment accuracyLaminationLamination apparatusEngineeringSonotrode

A sonotrode and an anvil have a spacing determined by a manually adjustable mechanical device. The adjustable mechanical device includes an abutment device which maintains the distance between the sonotrode and the anvil greater than the minimum space, and which is provided with an elastic device for elastically attracting the sonotrode and the anvil to each other. Thus, it is possible to control efficiently the melting of material between the sonotrode and the anvil, for reliable welding, or for efficient cutting, or for welding along the cutting line.

Owner:TEXTI SONICS SAS

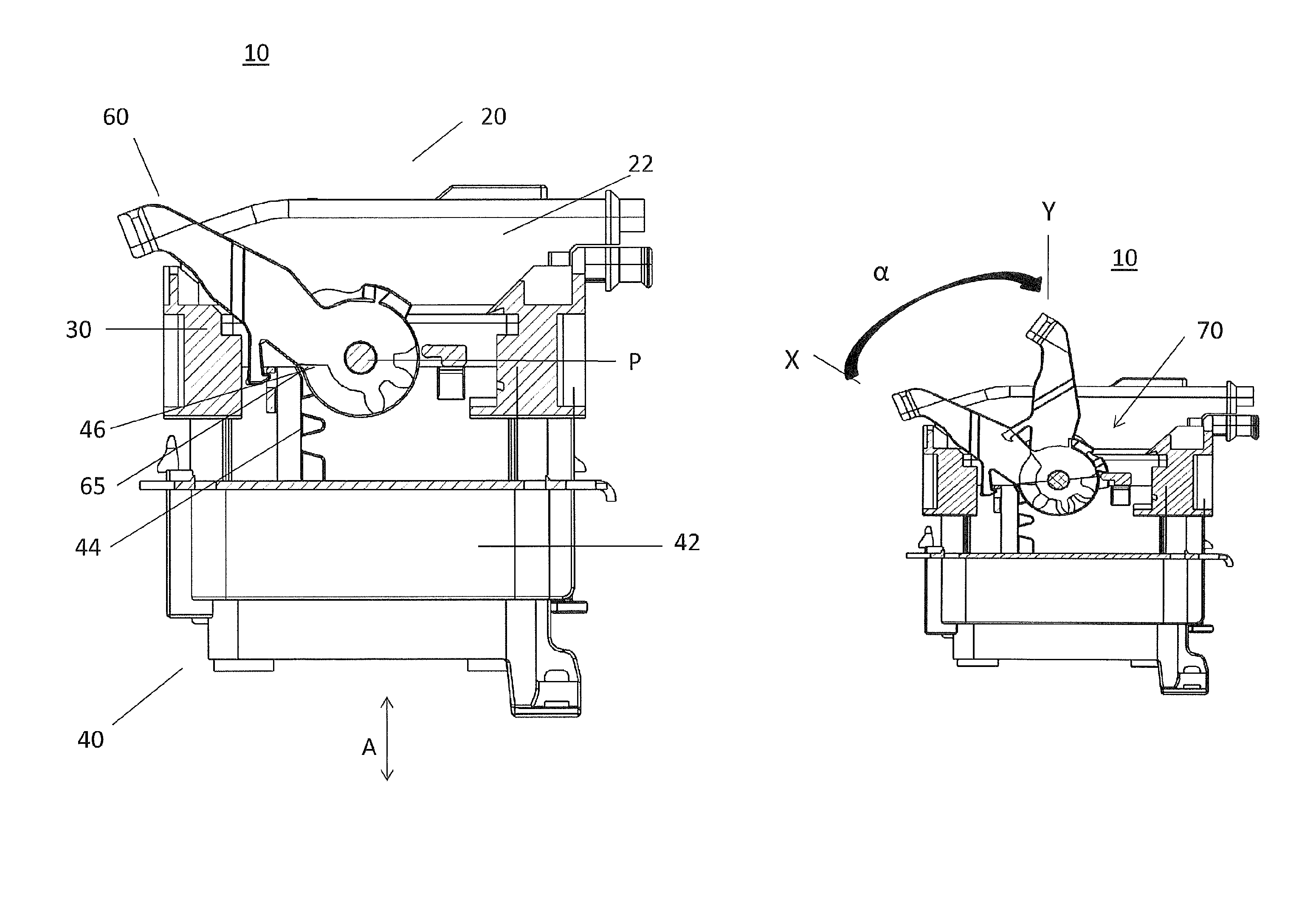

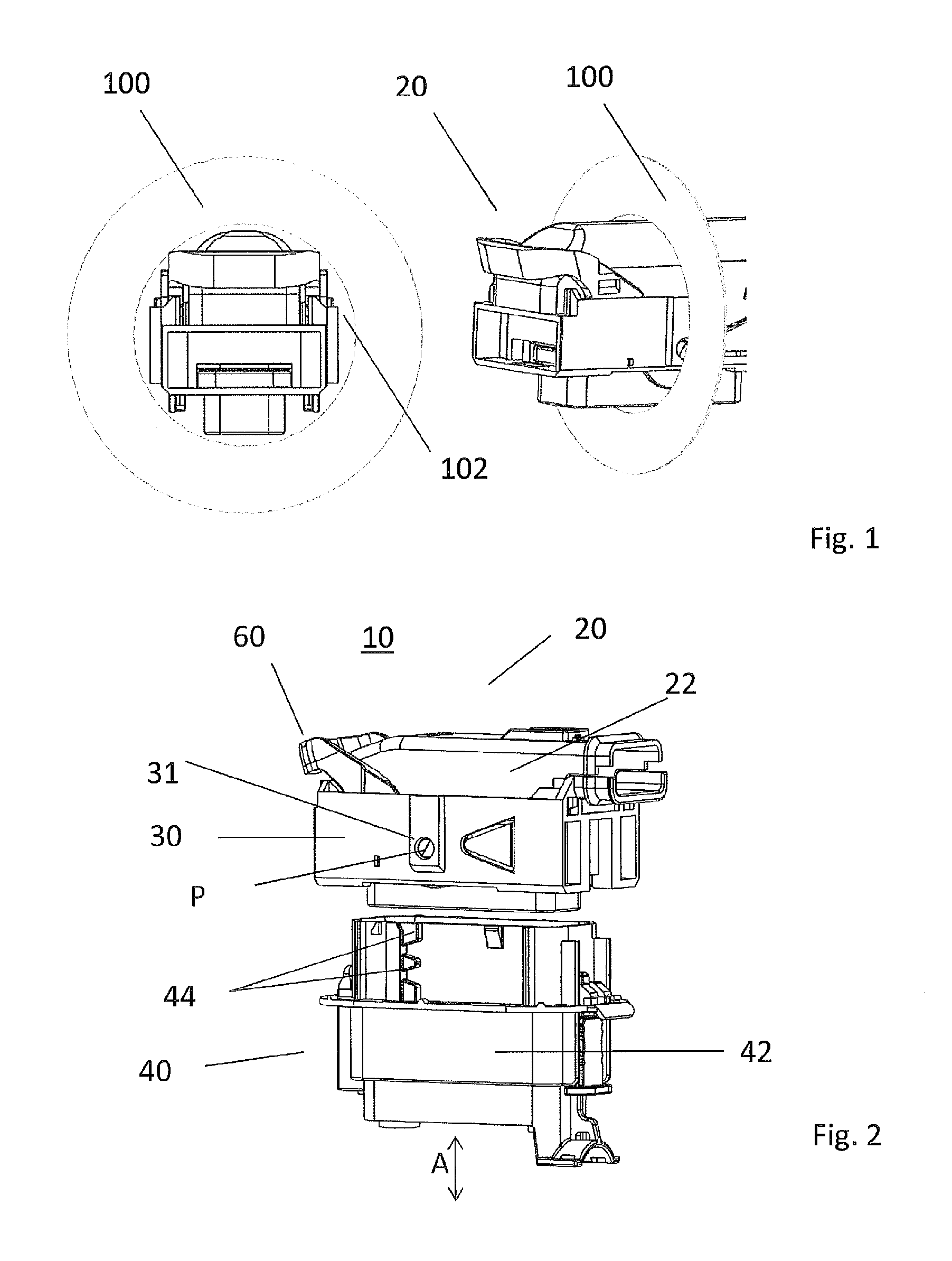

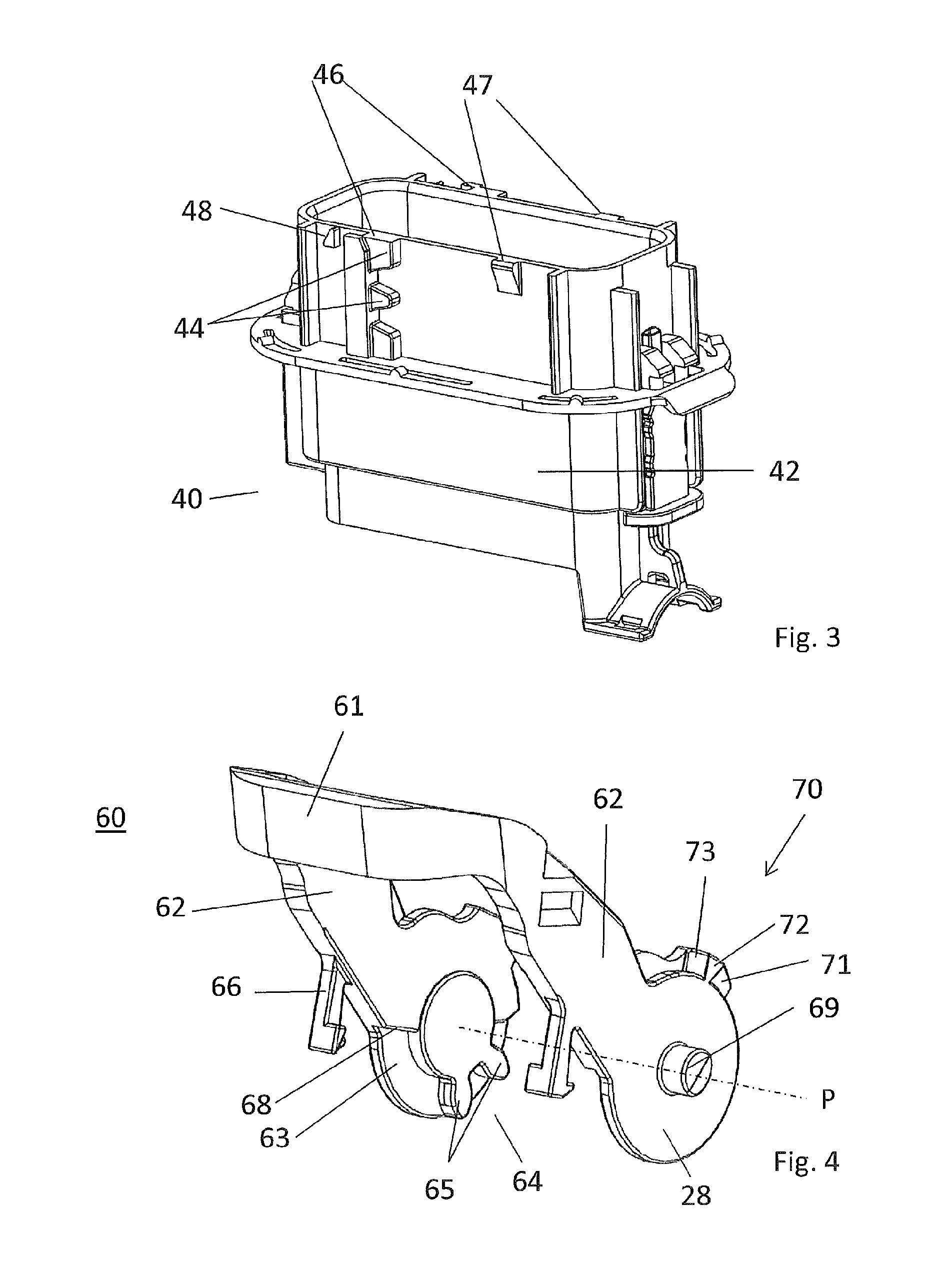

Connector having a housing with a first tooth system actuated by a second tooth system on a lever

InactiveUS9178307B2Easy to installEasy to engageEngagement/disengagement of coupling partsEngineeringMechanical engineering

A connector system having a first connector and a second connector. The first and the second connector are moveable relative to one another along an axis in order to connect and disconnect the contacts of the first connector and the second connector. The first connector has a lever mounted at the pivot point and is pivotal around an angle. The lever has a surface extending in the circumferential direction and which extends substantially through the essentially along the same angle. The surface has a first planar section and a second section having a radially extending tooth system. The lever is movable from a first, second, and third position. The housing of the second connector has a complementary tooth system. The tooth systems become engaged when the lever is moved from the second to third position, thus moving the first connector and the second connector toward one another along the axis.

Owner:DELPHI TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com