Fuel tank shell with structural support

a technology of structural support and fuel tank shell, which is applied in the direction of tank vehicles, transportation and packaging, transportation items, etc., can solve the problems of reducing the total mass of the tank, enabling a reduction in the thickness of the entire tank shell, and no teaching of positioning such supports in localized areas of the tank shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention is illustrated in further details by the following non-limiting examples.

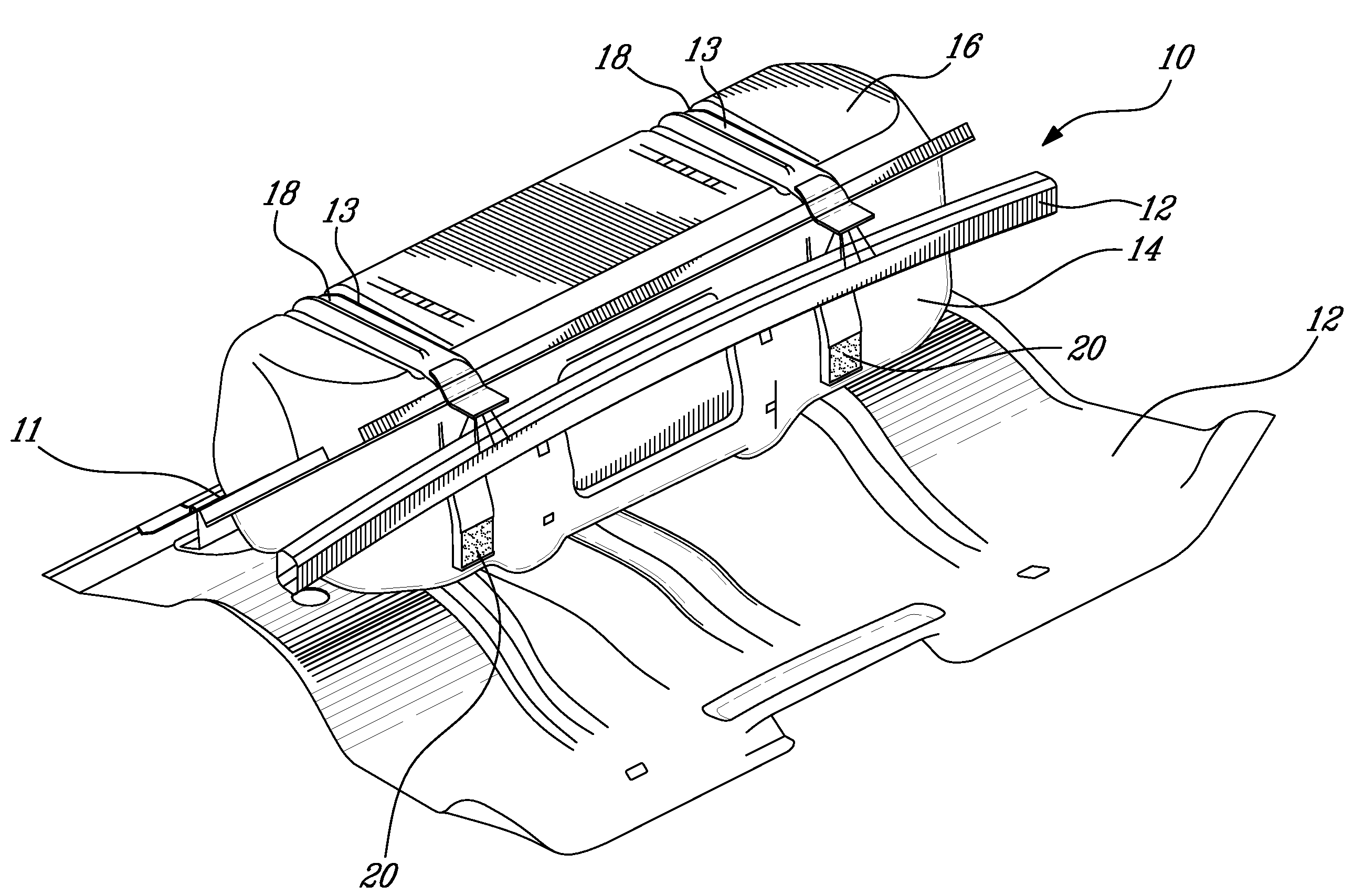

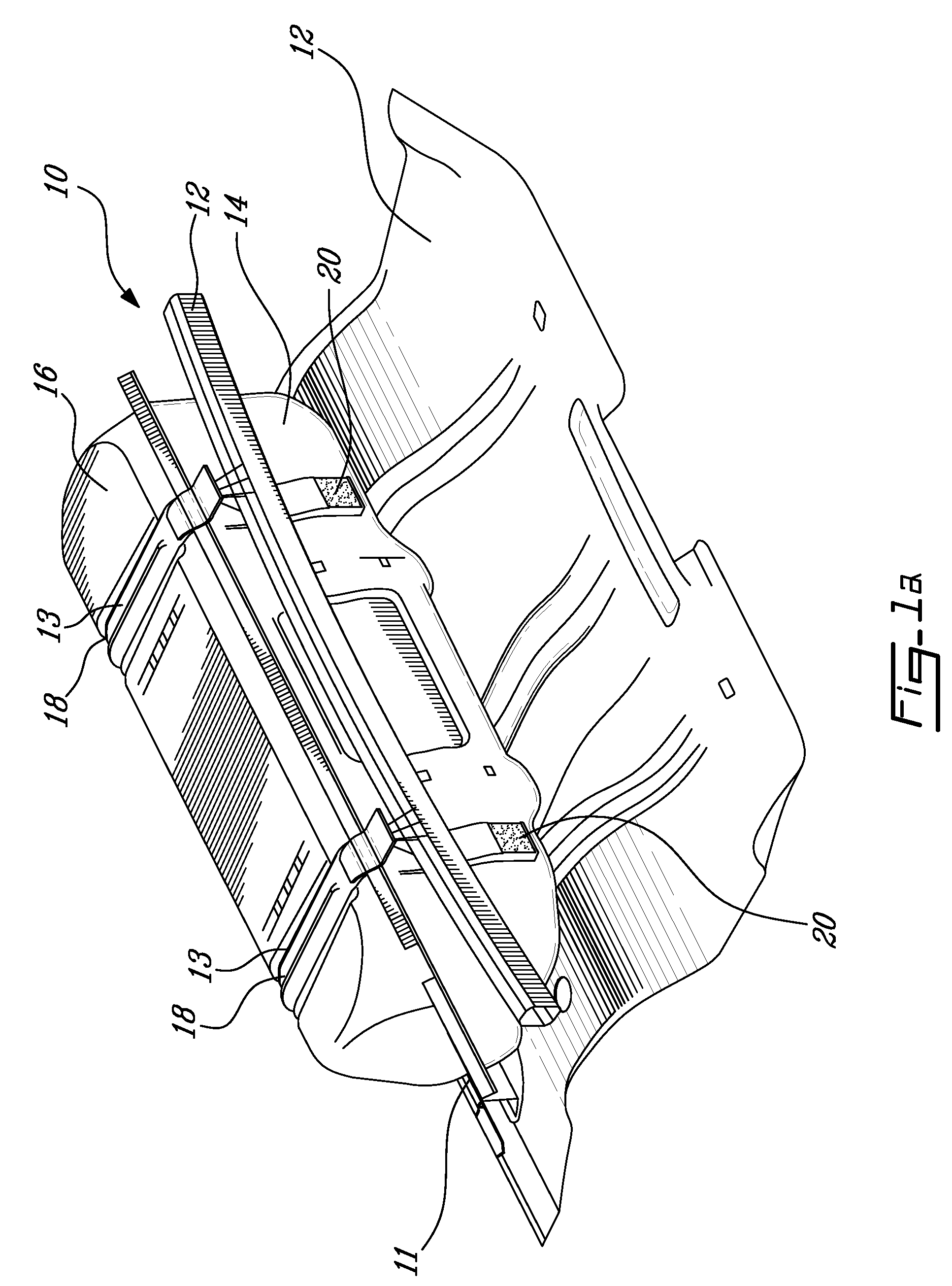

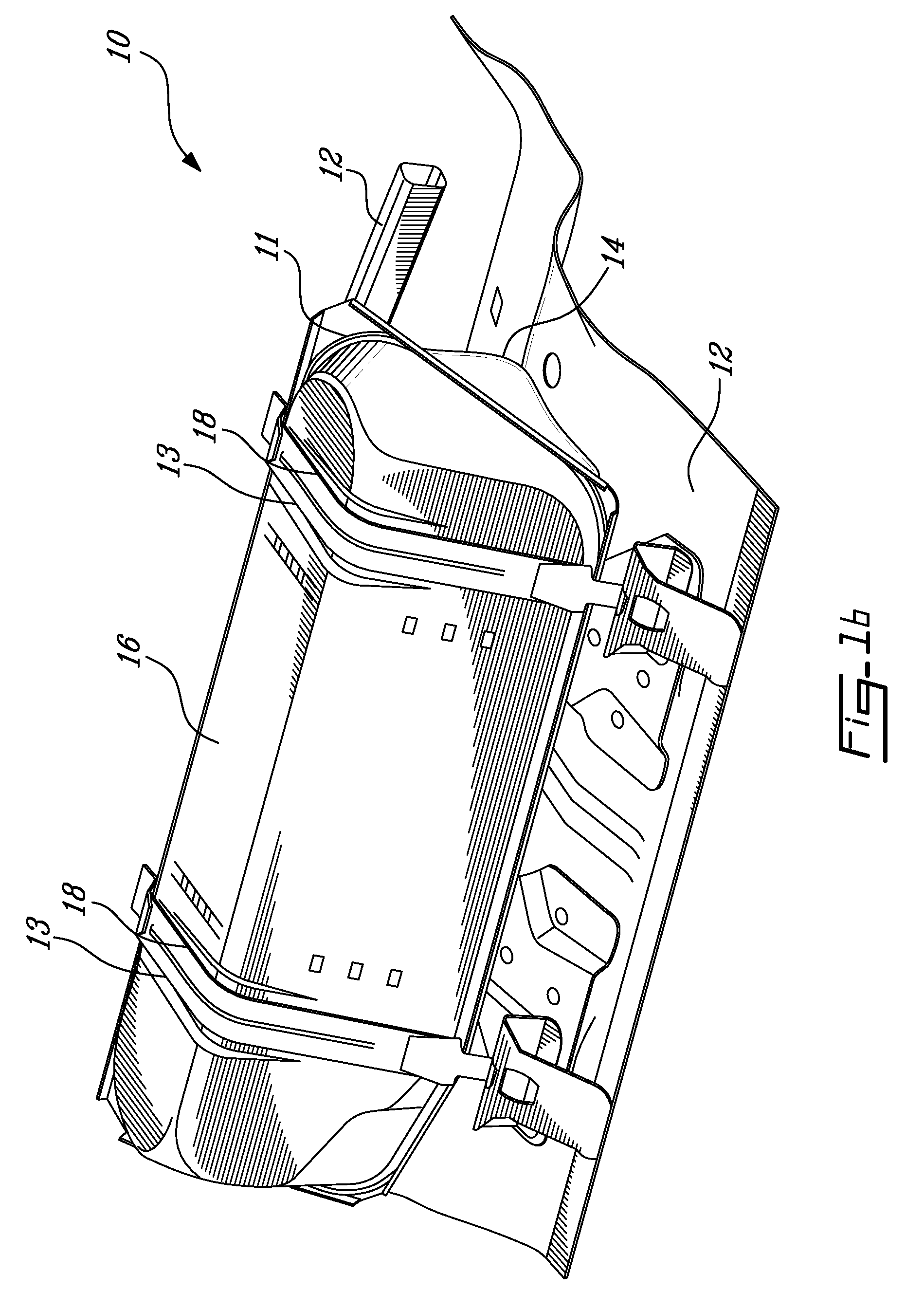

[0021]Referring to FIGS. 1a and 1b, and in accordance with an illustrative embodiment of the present invention, a fuel tank assembly generally referred to using the reference numeral 10, will now be described. The fuel tank assembly 10 is illustratively mounted to a vehicle body 12 (shown in an upside-down configuration). The tank assembly 10 comprises a shell, which may be formed of two halves, illustratively a top half shell 14 and a bottom half shell 16 having a substantially triangular cross-section, which may comprise a flanged border 11 providing a contact area for connecting the shells 14, 16 to one another. Alternatively, the shells 14, 16, which may be made of a metallic material (e.g. steel), may be flangeless and persons skilled in the art will thus understand that various methods of manufacturing an equivalent tank assembly according to the present invention may be used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com