Patents

Literature

230 results about "Bending strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bending Strain. Loss of ground support (e.g., geological faults, river or sea bed movement, etc.) can result in strain in the pipe wall. These strains can result in geometric defects such as ovality, dents, wrinkles etc. that can affect the structural integrity of the pipeline and, potentially, lead to failure. In the Offshore Pipeline market,...

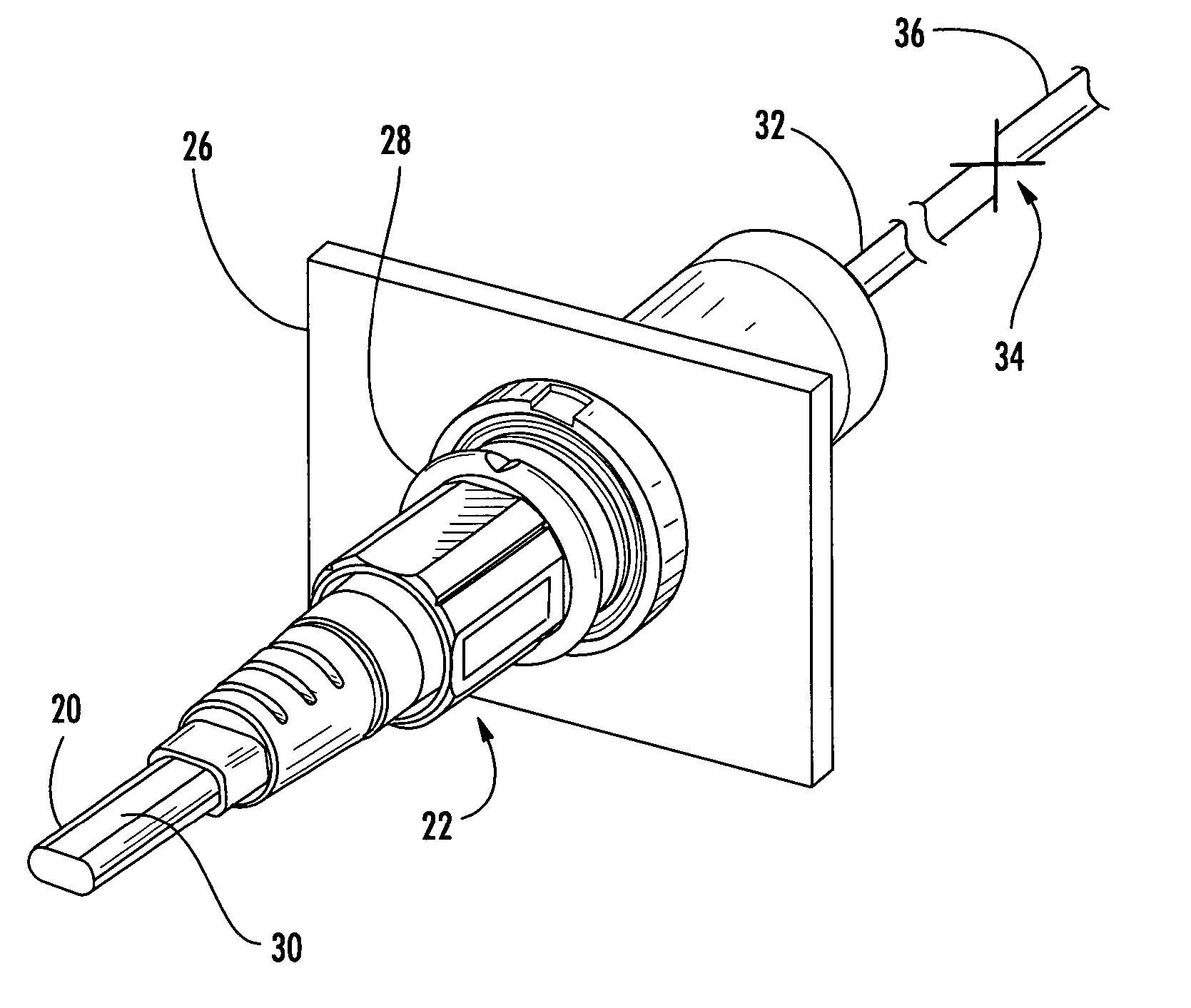

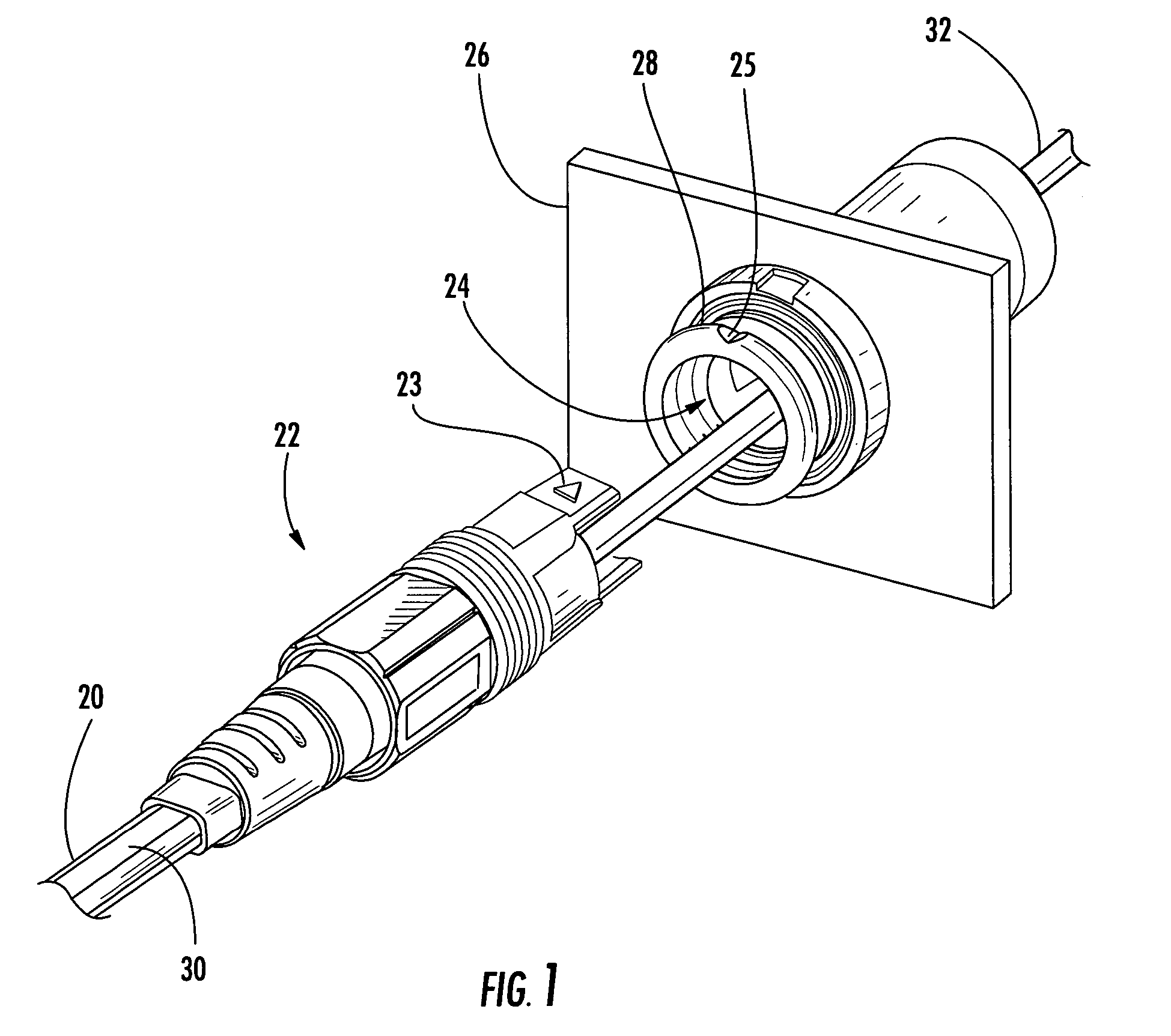

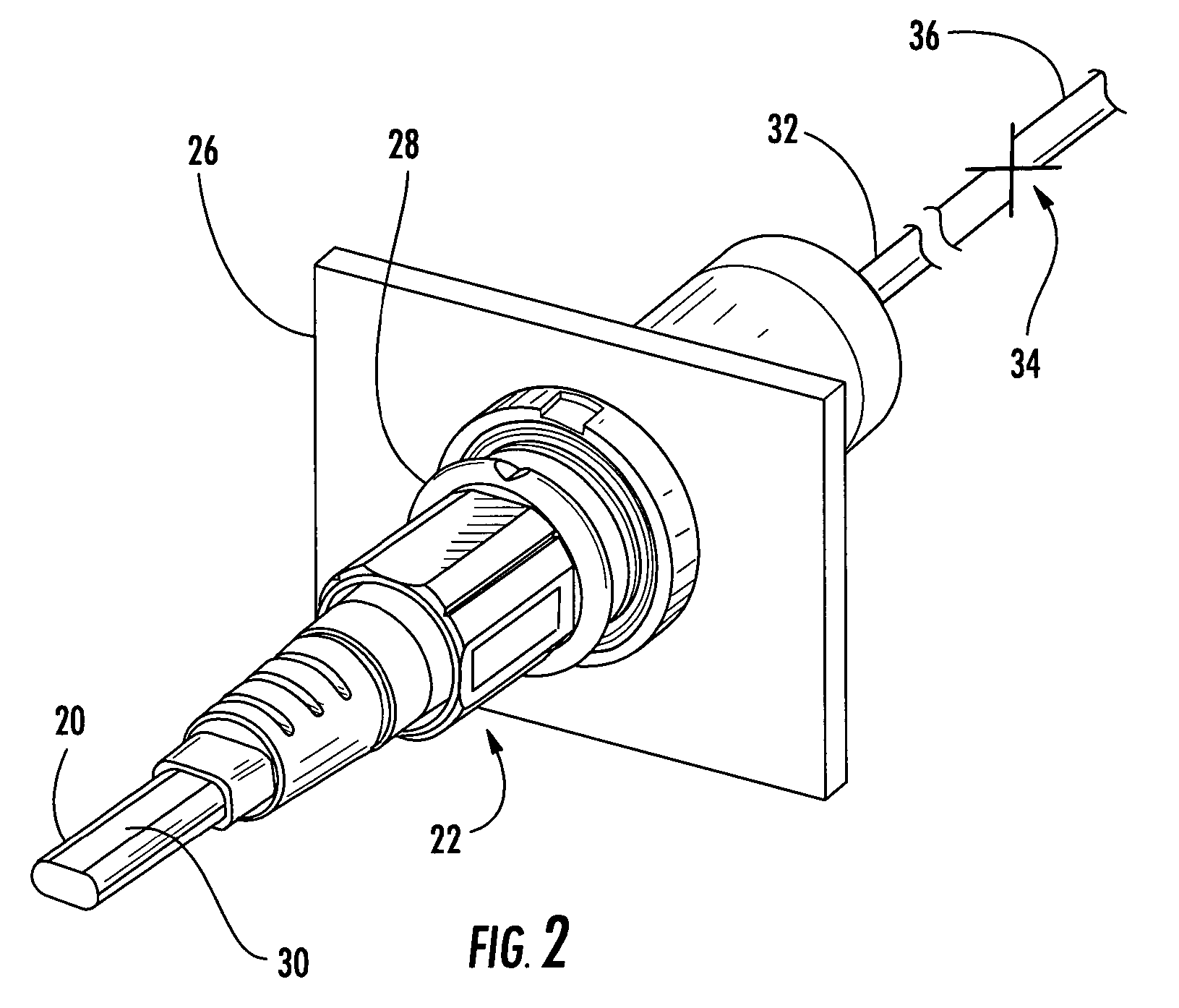

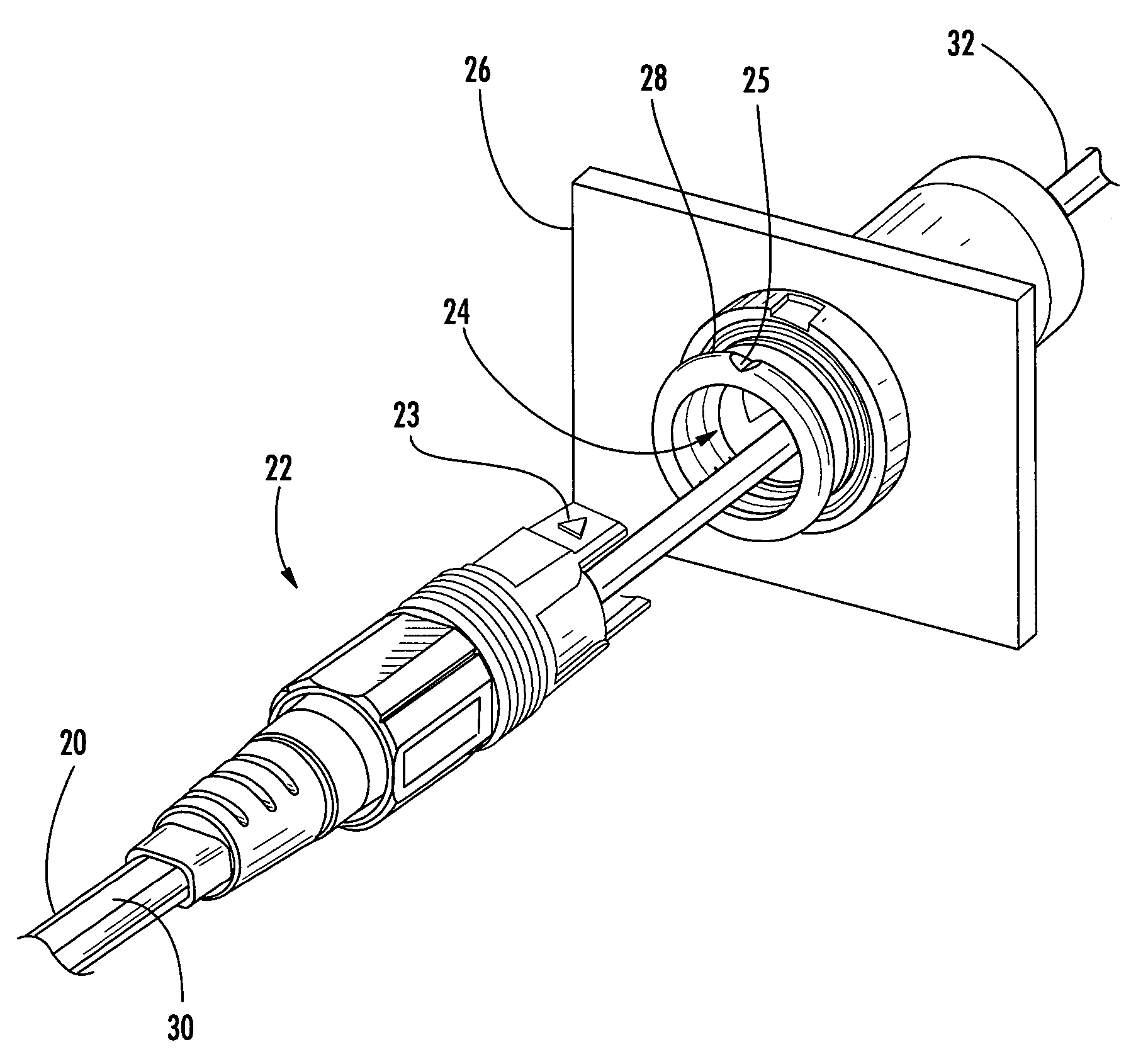

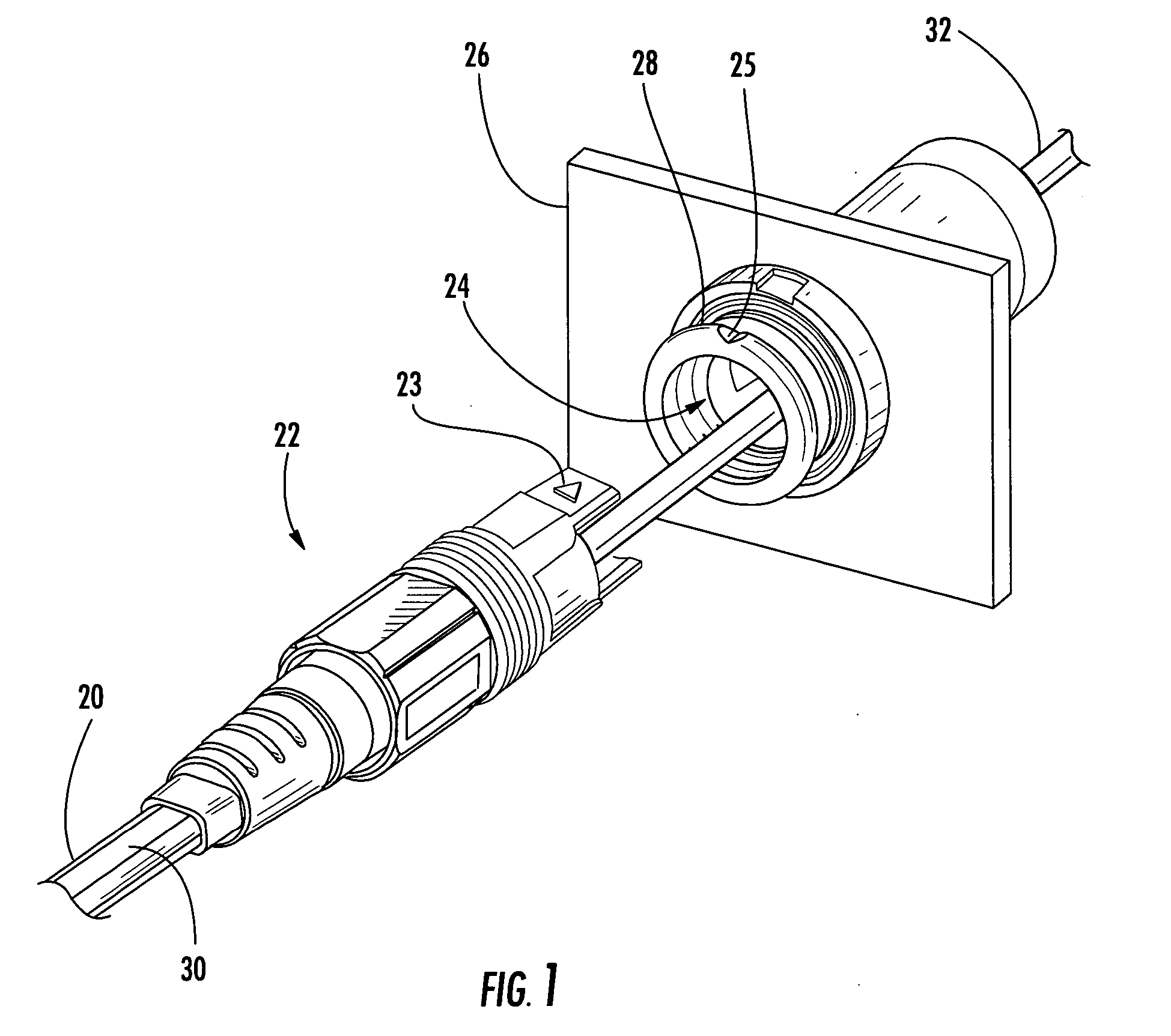

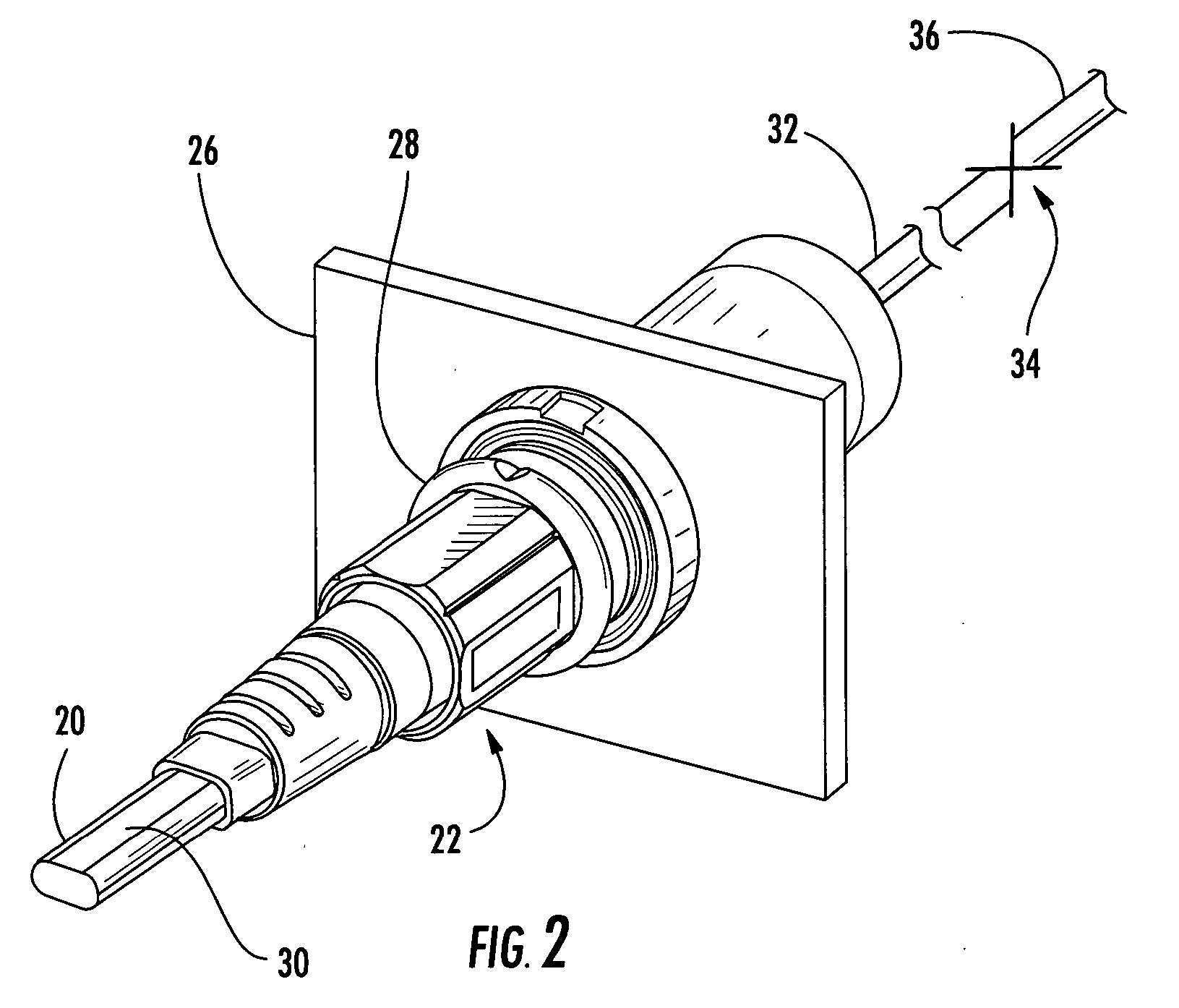

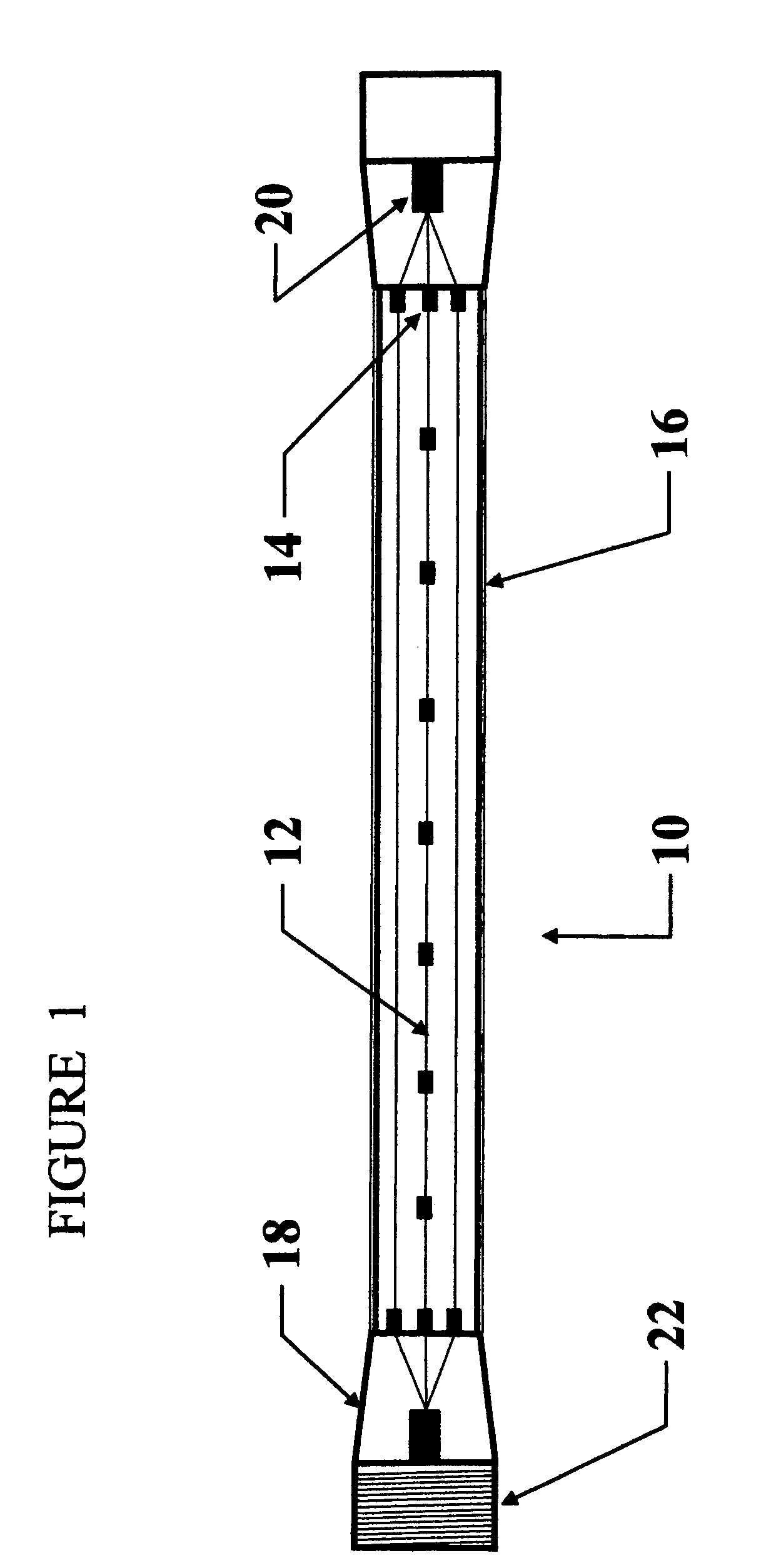

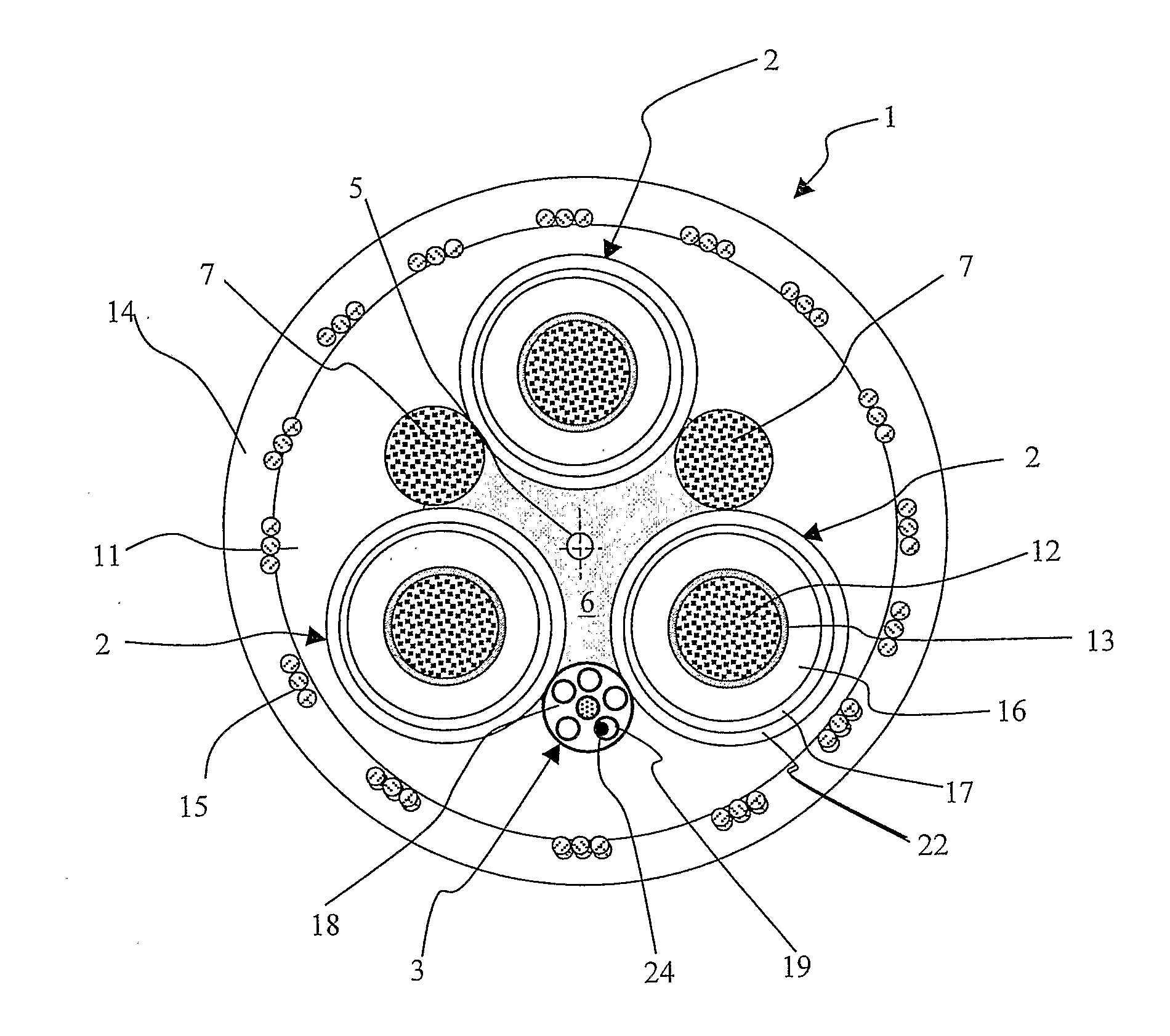

Fiber optic cable and plug assembly

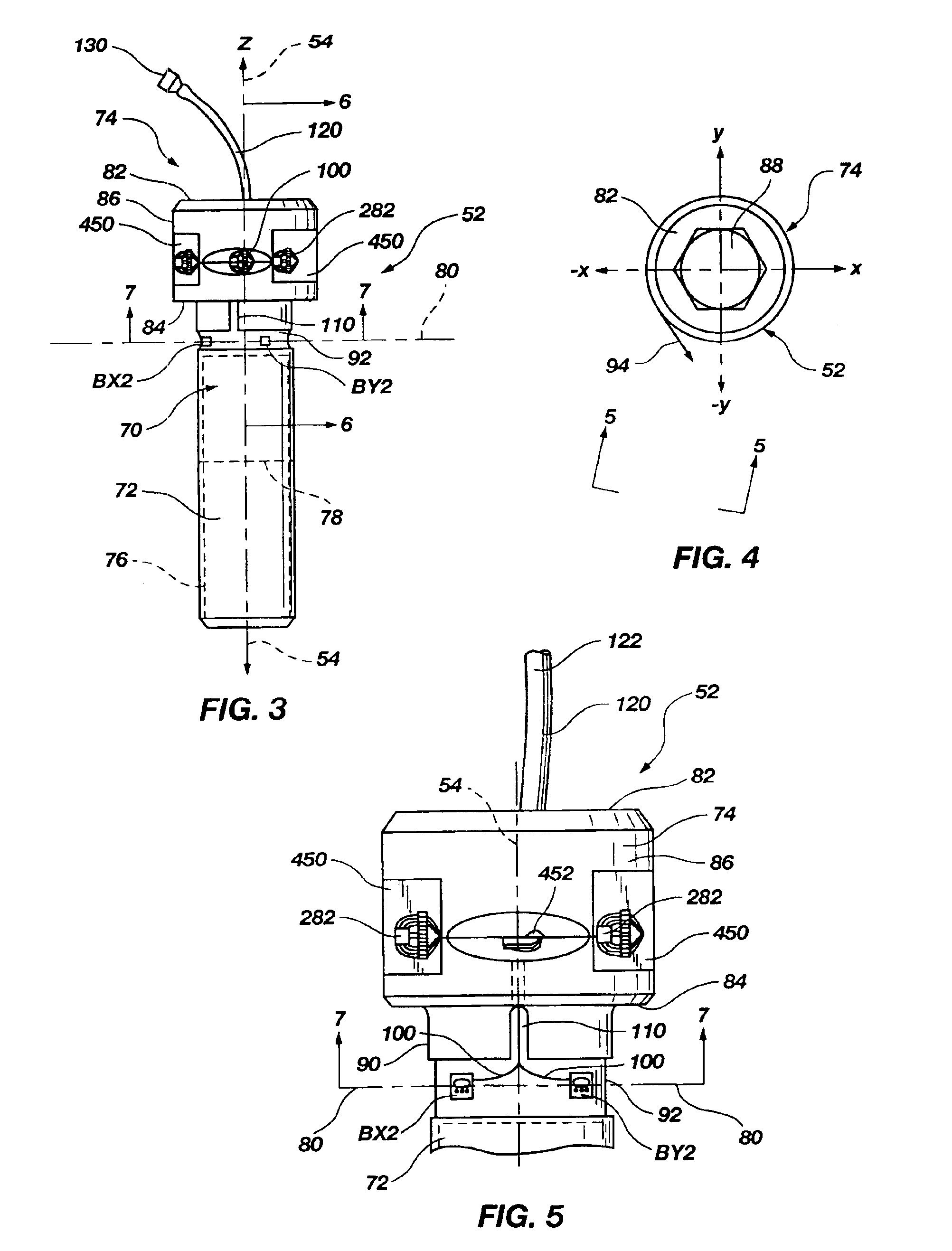

A fiber optic cable has a plug assembly that may be positioned and secured at any desired location along the length of the cable to engage a receptacle disposed within a connector port provided in a wall of a connection terminal. The plug assembly includes a shroud, a coupling nut, a heat shrink tube for sealing the cable and a boot for providing bending strain relief. At least a portion of the cable passes through the connector port for interconnection with optical fibers of a distribution cable or optical equipment. A method for routing a fiber optic cable into a connection terminal includes using a connector port provided in a wall of the terminal, determining a desired length of the cable, positioning and securing a plug assembly at a desired location along the length of the cable, and mating the plug assembly with a receptacle disposed within the connector port.

Owner:CORNING OPTICAL COMM LLC

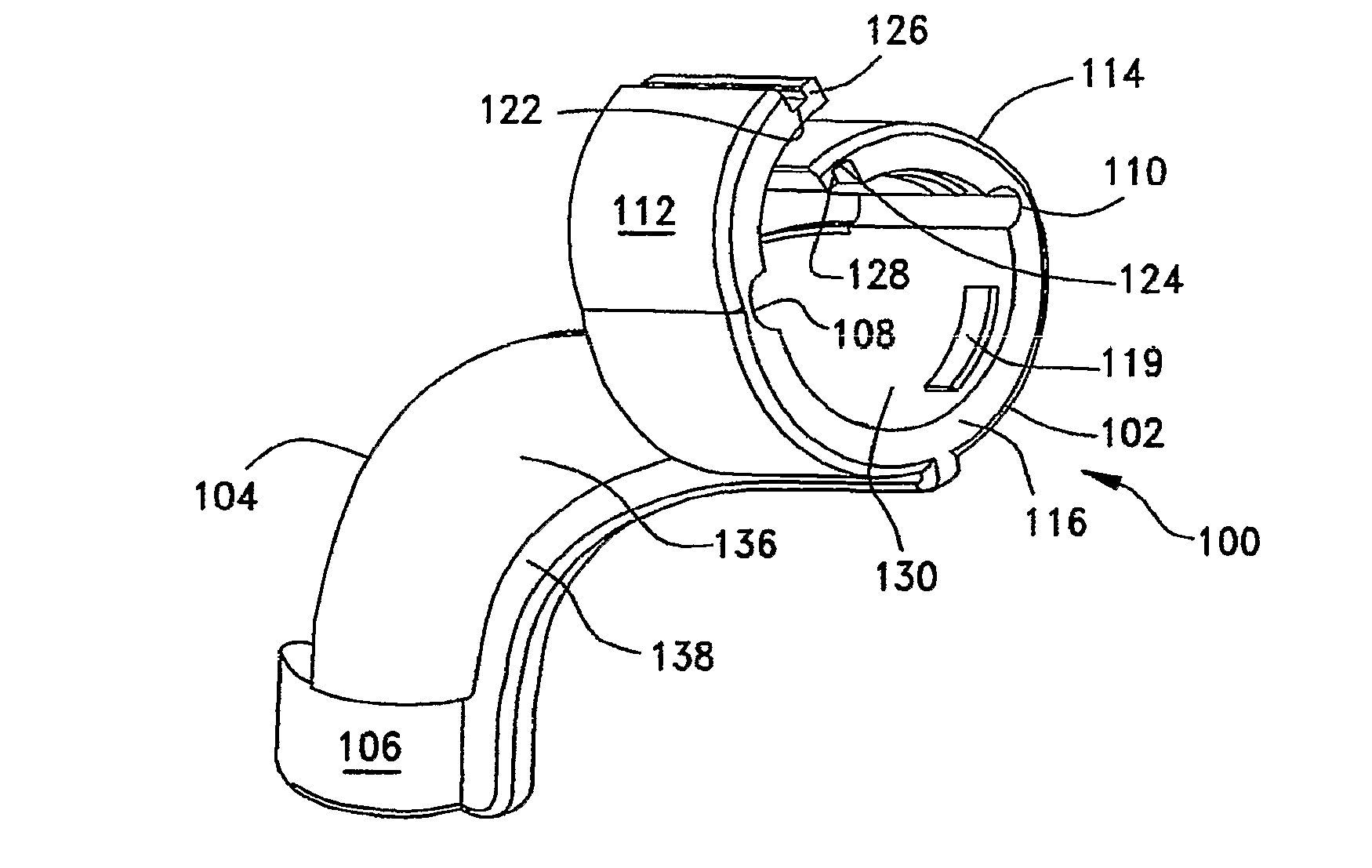

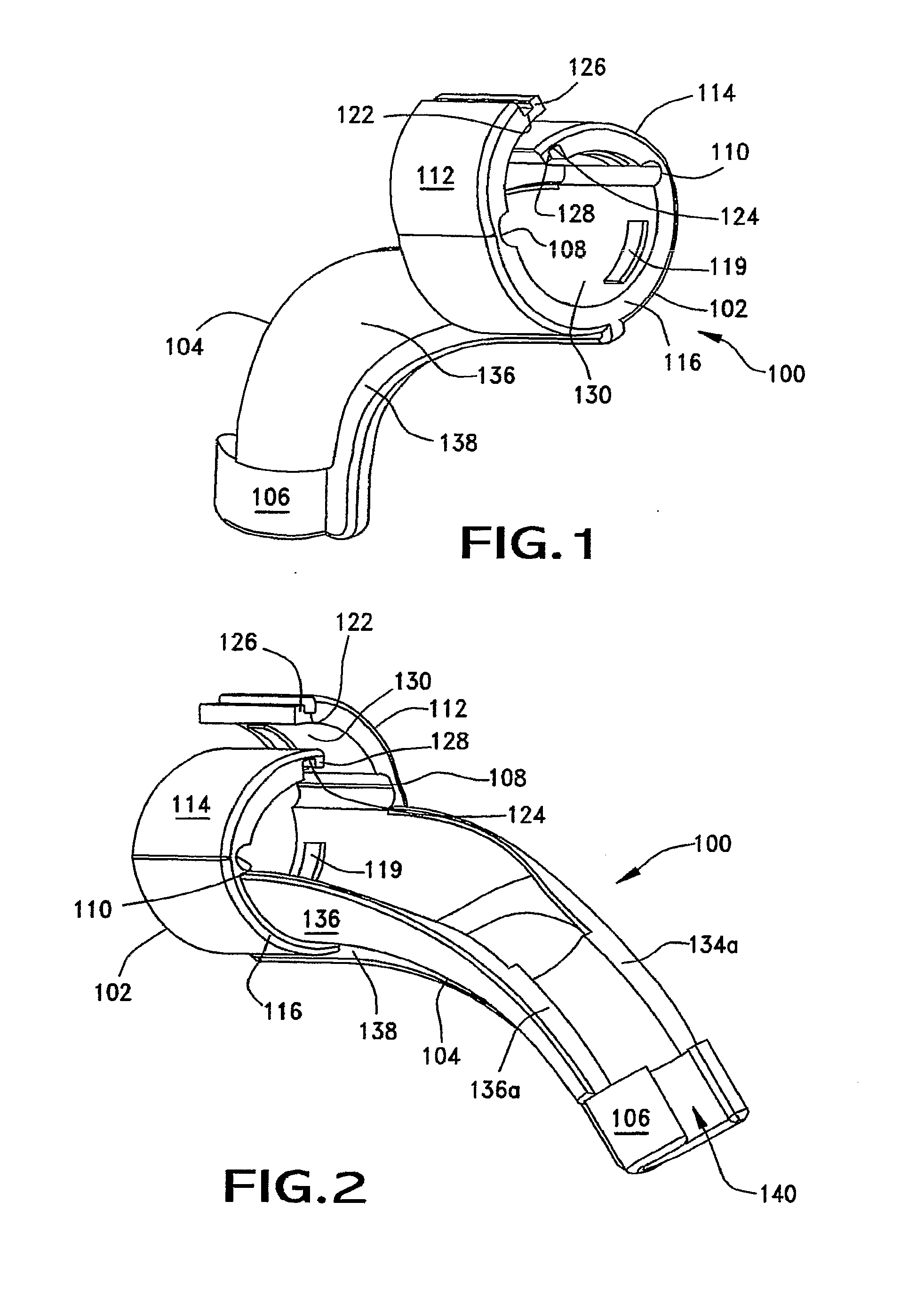

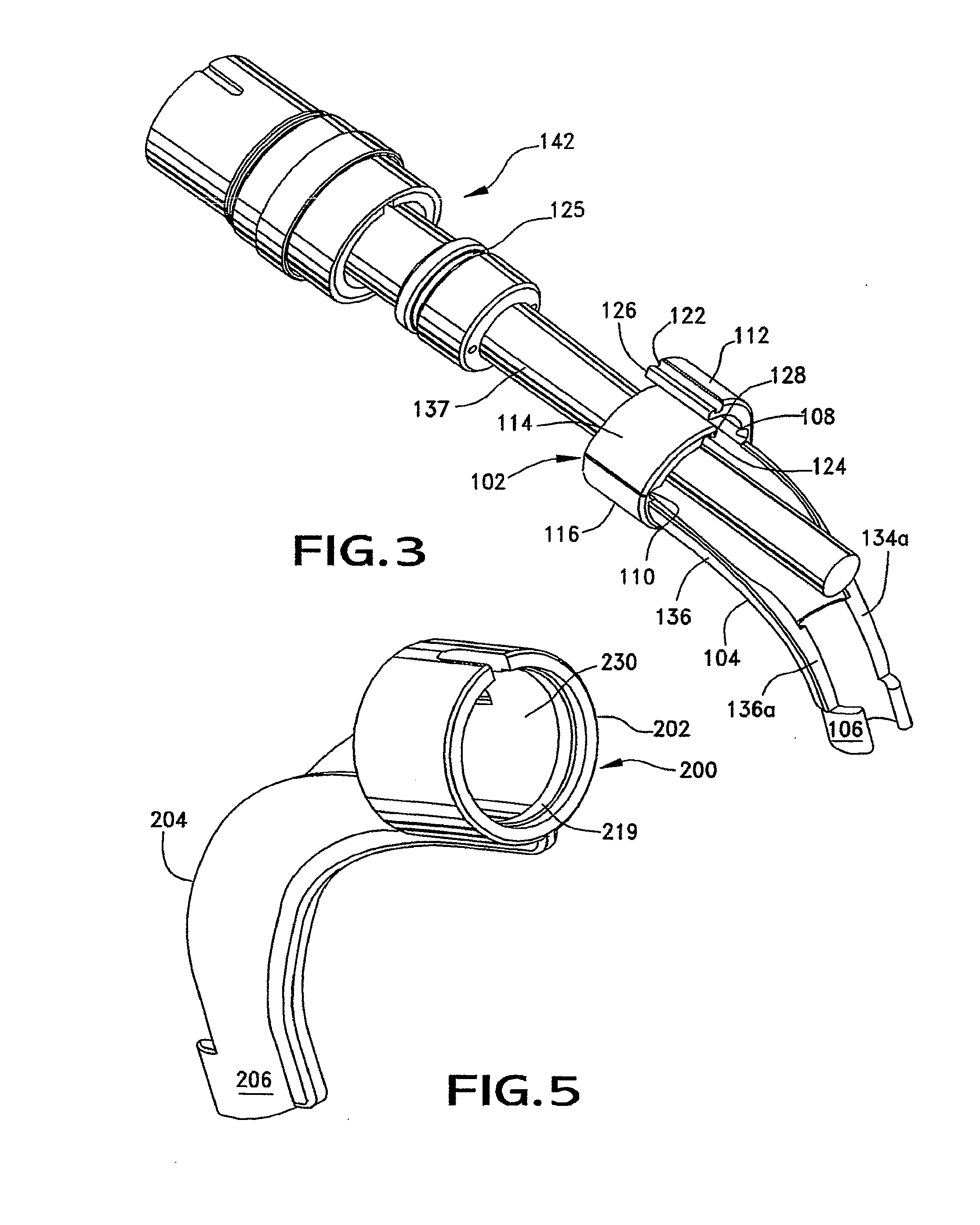

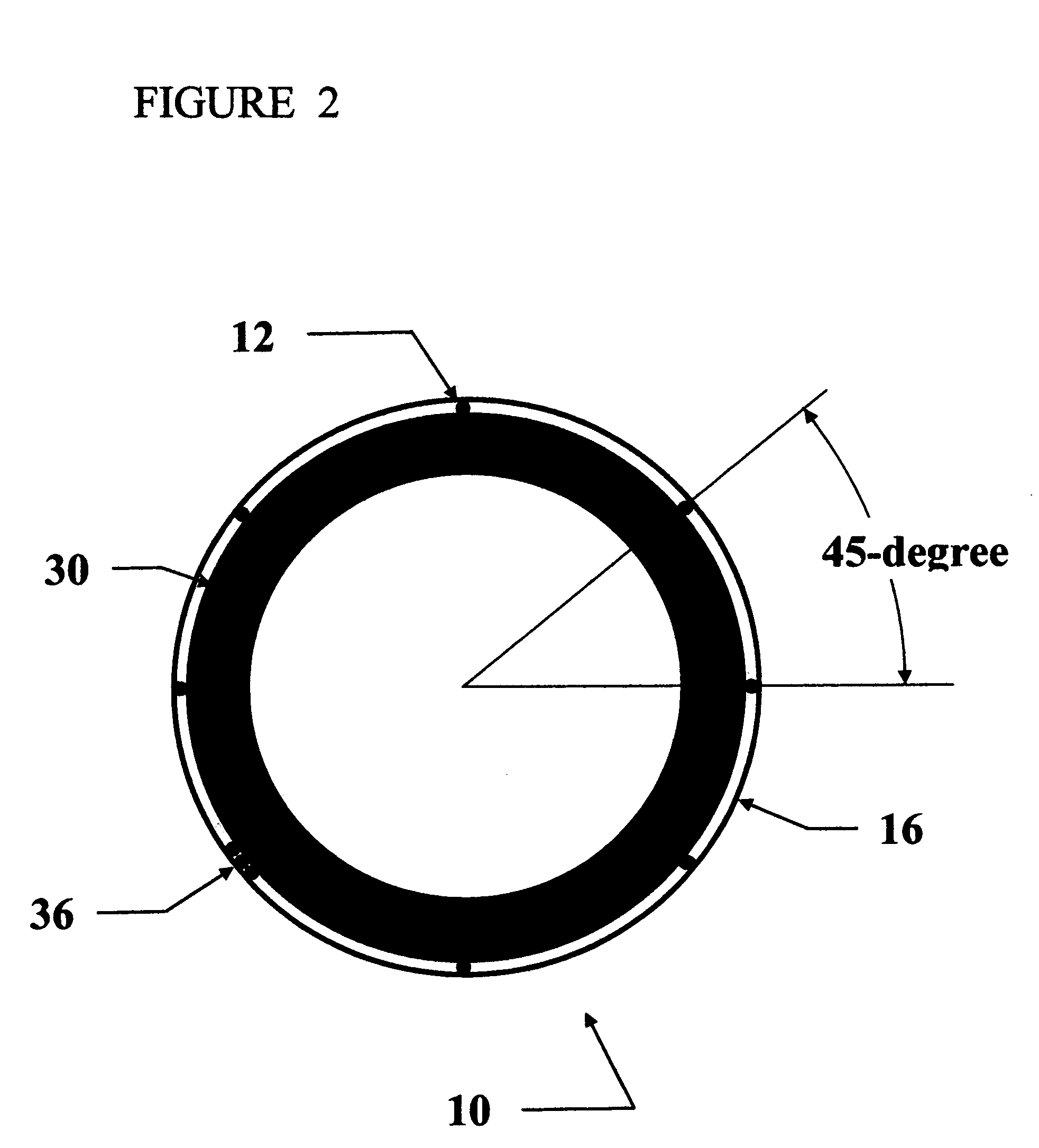

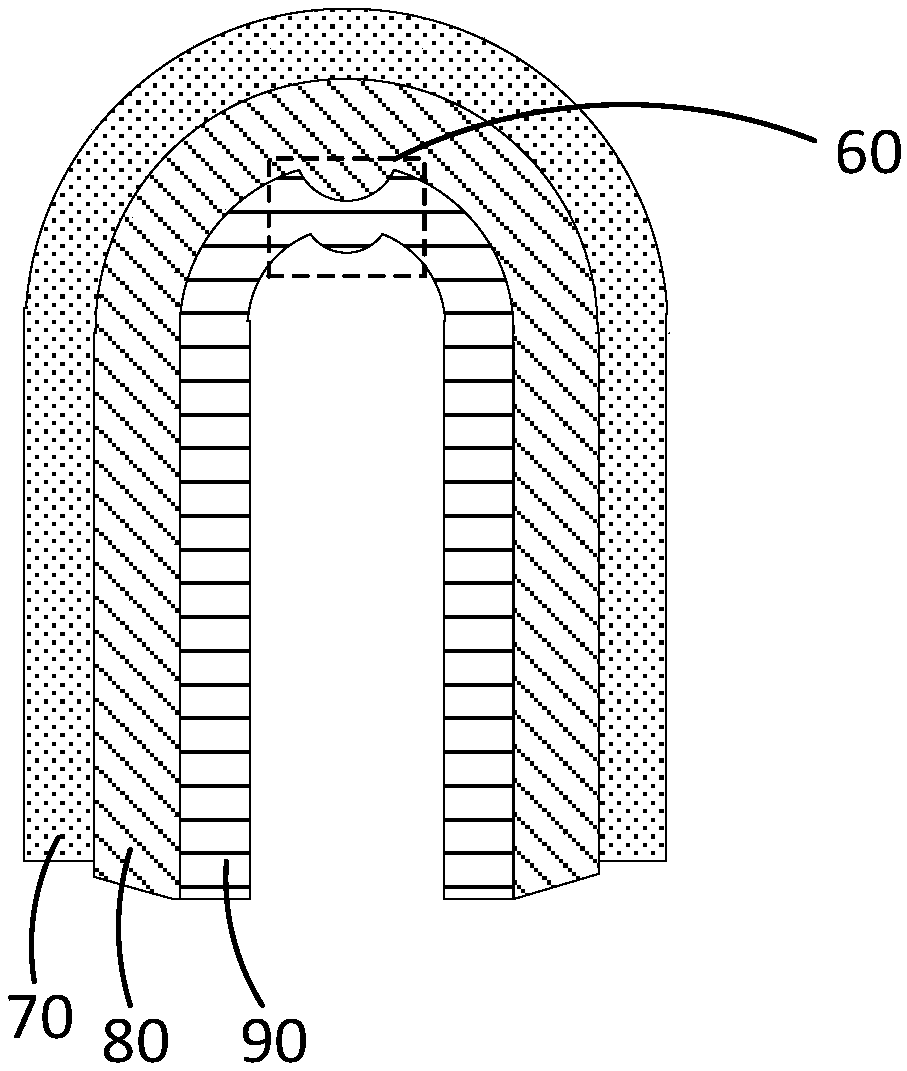

Retrofittable Bend Strain Relief With A Latching Ring

ActiveUS20100247041A1Rerouting of the cableReduce and eliminate service disruptionCoupling light guidesBending strainEngineering

A bend limiting system (strain relief (200)) that may be retrofit onto a cable connector (142). The bend limiting system includes a latching ring (102) configured to fit over the cable connector's mating face so that the bend limiting system may be placed into position after the connector is connected to another device. The bend limiter (200) includes three sections. These sections include a latching ring (202) in the front, an elongated cable guide (204) in the middle and a cable retainer (206) at the end. The latching ring portion (202) is of a generally circular shape to engage the mating face of a round complementary connector.

Owner:MOLEX INC

Fiber optic cable and plug assembly

ActiveUS20050281510A1Easy to adjustCoupling light guidesFibre mechanical structuresFiberBending strain

A fiber optic cable has a plug assembly that may be positioned and secured at any desired location along the length of the cable to engage a receptacle disposed within a connector port provided in a wall of a connection terminal. The plug assembly includes a shroud, a coupling nut, a heat shrink tube for sealing the cable and a boot for providing bending strain relief. At least a portion of the cable passes through the connector port for interconnection with optical fibers of a distribution cable or optical equipment. A method for routing a fiber optic cable into a connection terminal includes using a connector port provided in a wall of the terminal, determining a desired length of the cable, positioning and securing a plug assembly at a desired location along the length of the cable, and mating the plug assembly with a receptacle disposed within the connector port.

Owner:CORNING OPTICAL COMM LLC

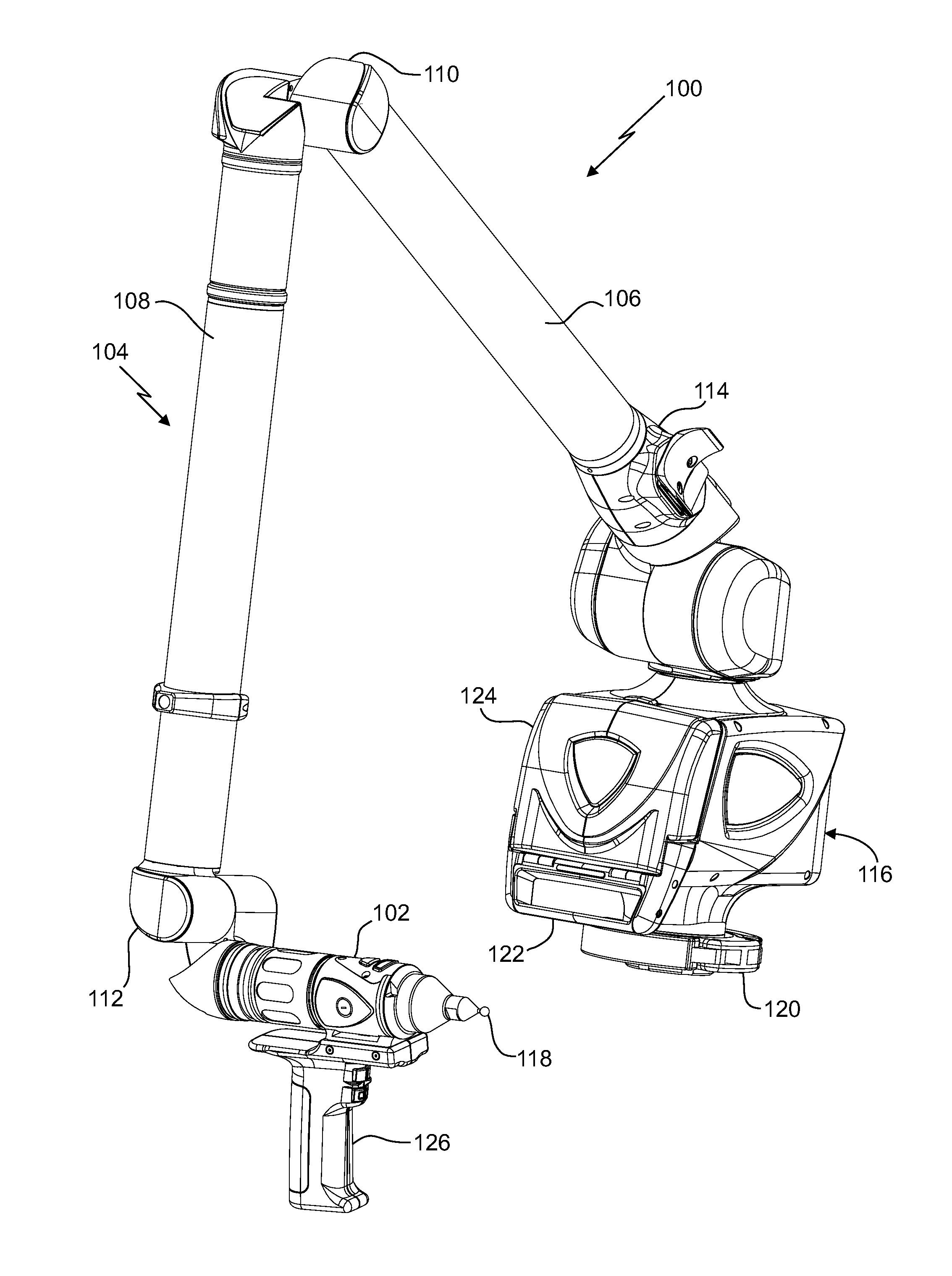

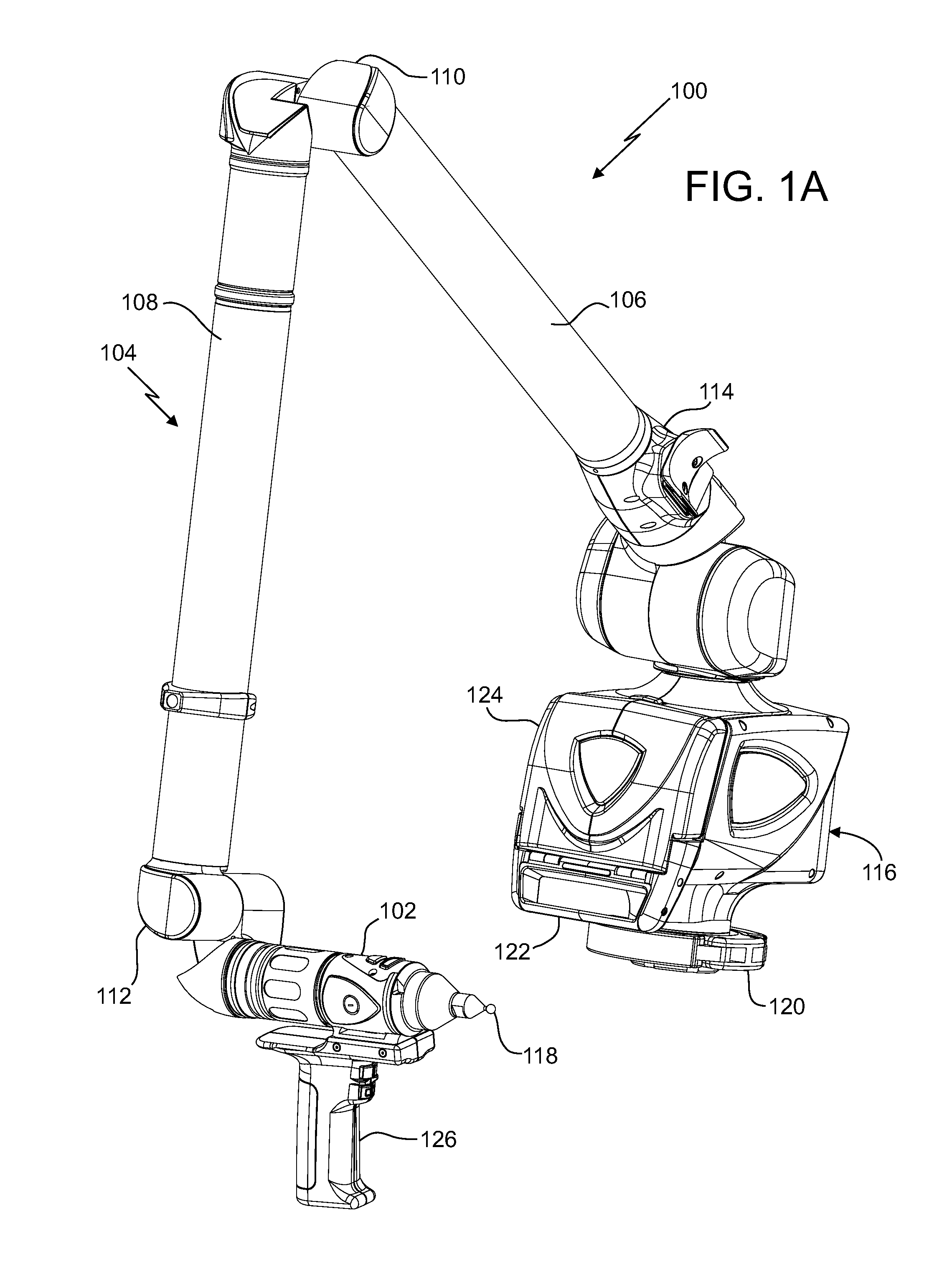

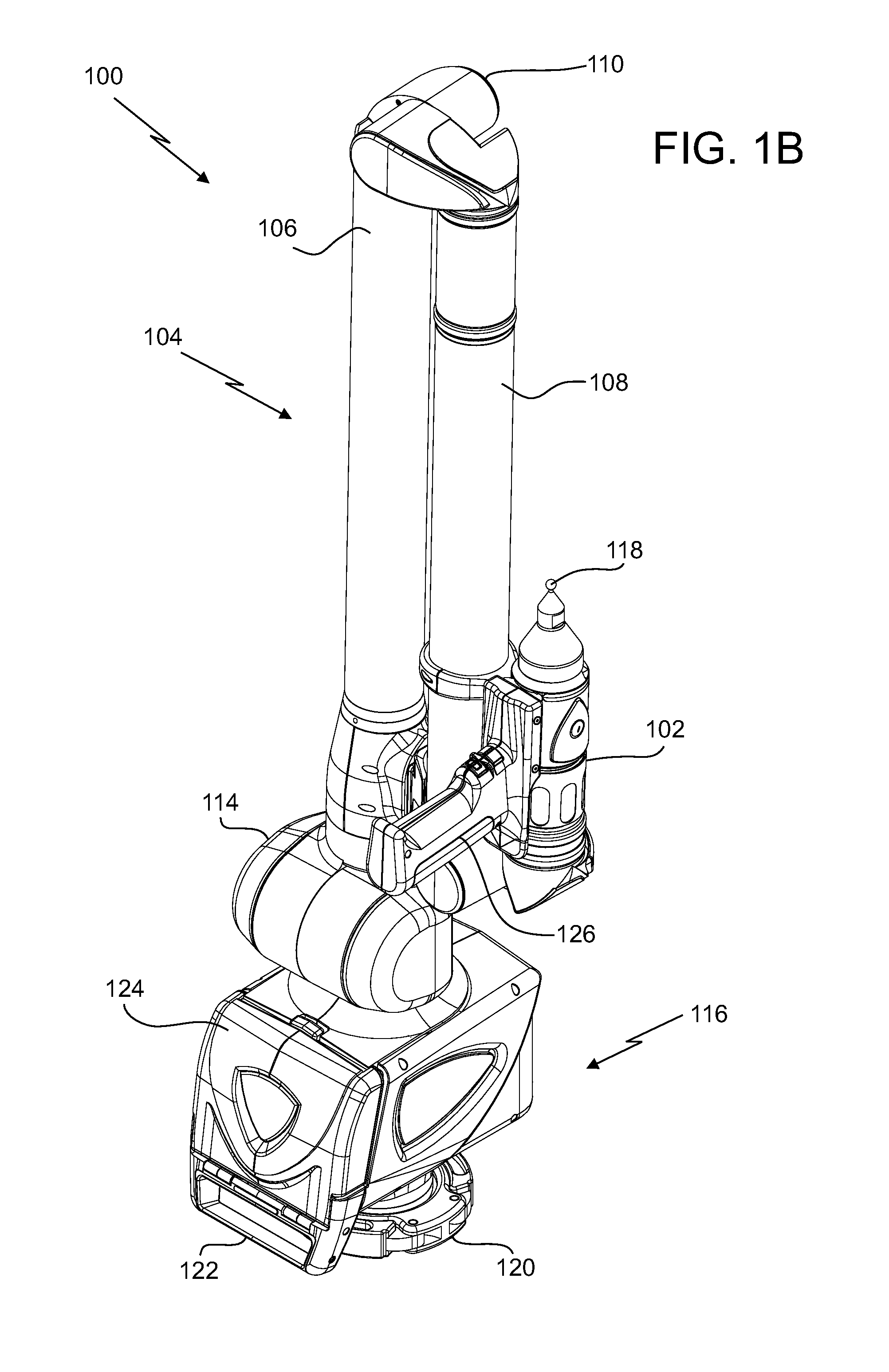

Embedded arm strain sensors

InactiveUS20110175745A1Programme controlTesting/monitoring control systemsMeasurement deviceTransverse plane

A portable articulated arm coordinate measurement machine (AACMM) can include a manually positionable articulated arm portion, a measurement device attached to the first end, a structural component of the AACMM, wherein the structural component has an axial direction, at least three strain gage sensors, each having a sensitive axis, coupled to the structural component, wherein the sensitive axis of each strain gage sensor is oriented approximately parallel to the axial direction, each strain gage sensor is approximately intersected by a transverse plane perpendicular to the axial direction, each strain gage sensor produces an analog strain gage signal, and the strain gage sensors are disposed to provide data sufficient to determine a bending strain at any point residing on both the structural component and the transverse plane and an electronic circuit that receives the position signal and provides data corresponding to a position of the measurement device.

Owner:FARO TECH INC

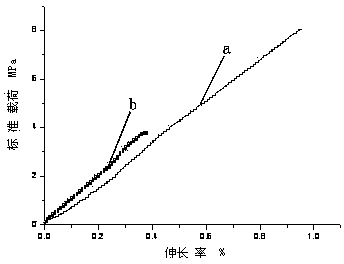

Graphene oxide/light cured resin composite and its preparation method and application

The invention provides a graphene oxide / light cured resin composite and its preparation method and application, the graphene oxide / light cured resin composite comprises two phases of graphene oxide and light cured resin, the graphene oxide is evenly dispersed in the light curing resin, the content of the graphene oxide is 0.1-1wt%, and the light cured resin comprises an oligomer, a light initiator and an active diluent. A graphene oxide nano material is dispersed in the light curing resin to obtain the graphene oxide / light cured resin nano composite, elongation at break and maximum bending strain of ordinary light cured resin is improved to a certain extent, and the impact strength of a coating film is increased by 2 times, so that a part printed by a 3D printer has better mechanical property.

Owner:QINGDAO UNIV OF SCI & TECH

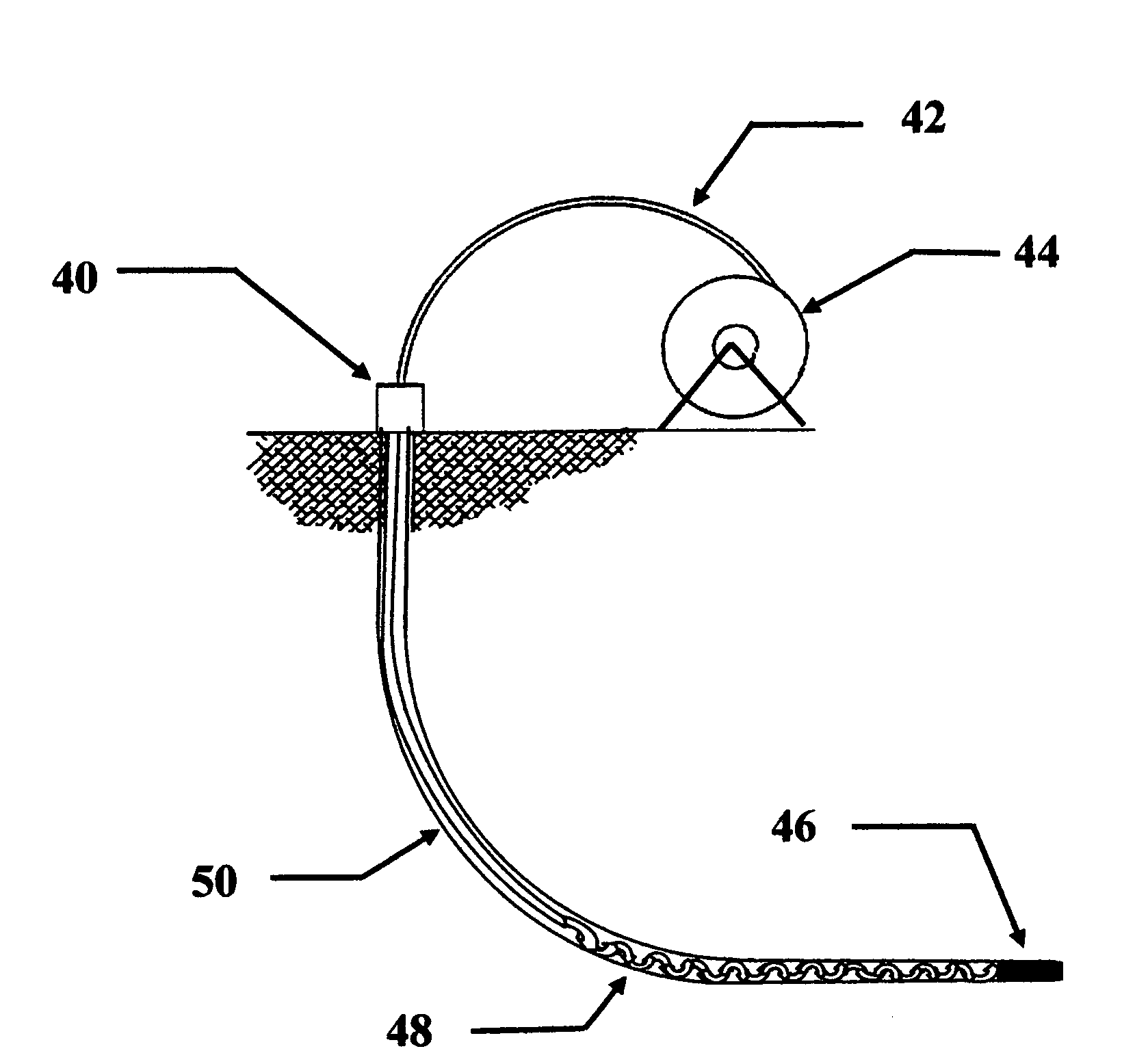

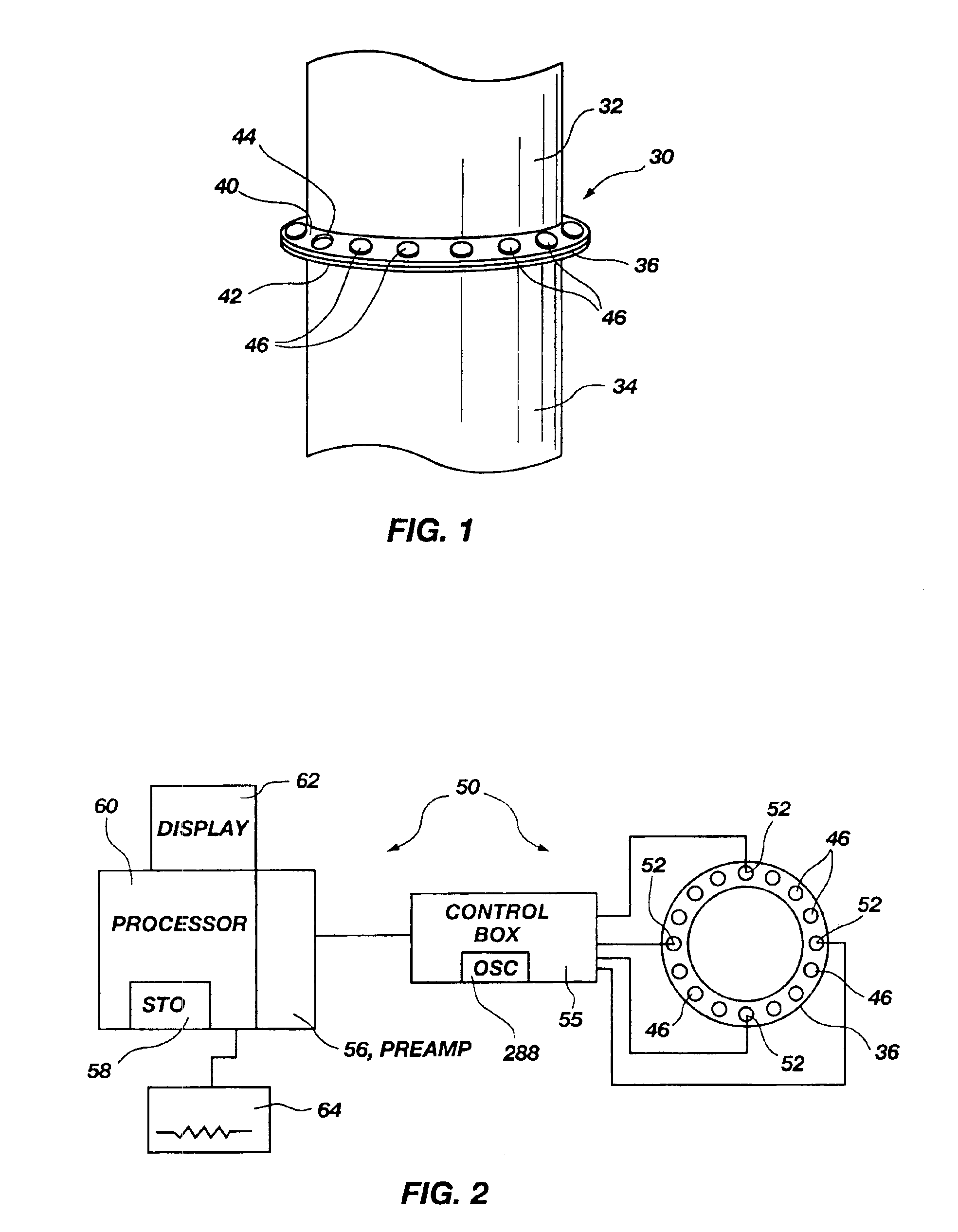

Dynamic performance monitoring of long slender structures using optical fiber strain sensors

A method is described using optical fiber technology to measure the vibration characteristics of long slender structures subjected to dynamic disturbances imposed by water or wind generated loads. The method is based on making bending strain measurements at selected locations along the length of long slender structures such as marine risers or large ropes using fiber optics technology including Optical Time Domain Reflectometry and Bragg diffraction gratings. Engineering interpretation of information obtained from bending strains determines the vibration characteristics including frequency, amplitude, and wave length. Maximum bending strain measurements assess pending structural damage. One application is measurement of vortex induced vibrations (VIV) response of marine risers. The fiber optics based method is also applicable to the measurement of the bending characteristics of spoolable pipe using plastic optical fibers which can be interpreted to assess the pipe structural integrity and to prevent lock-up during deployment into a small diameter annulus.

Owner:WILLIAMS JERRY GENE

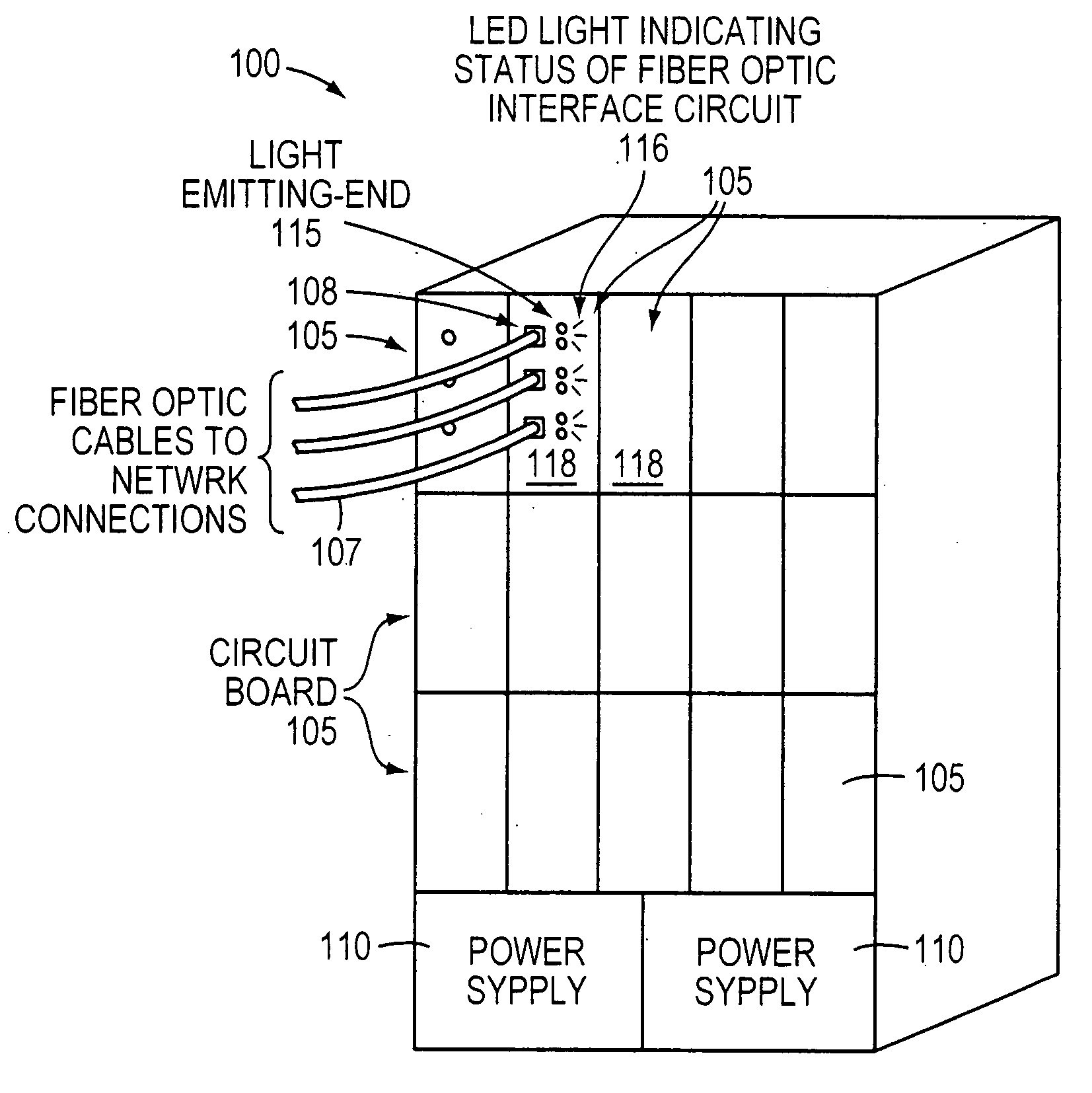

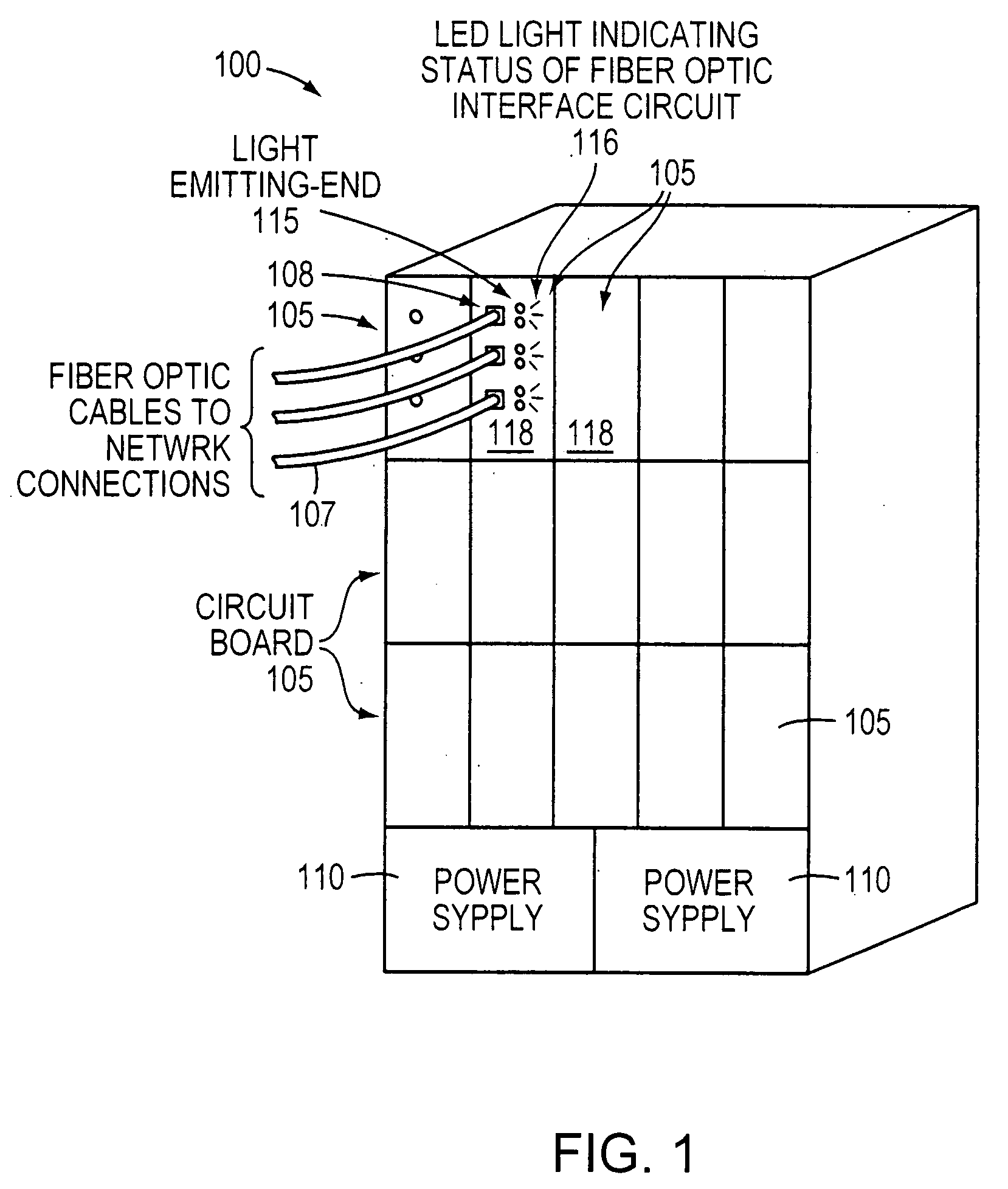

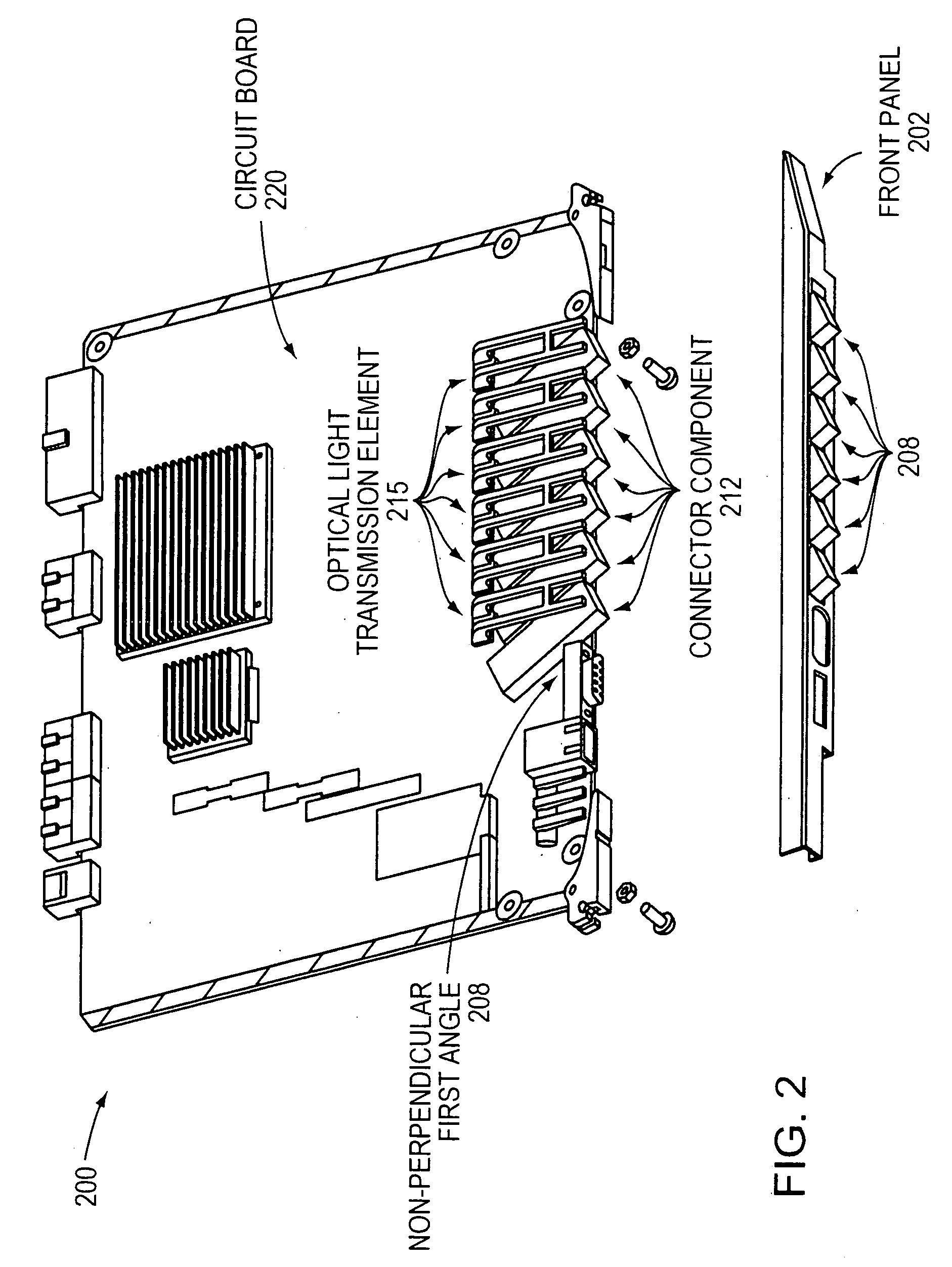

Method and apparatus for providing optical indications about a state of a circuit

InactiveUS20090051558A1Electric/electromagnetic visible signallingAlarmsTotal internal reflectionSmall form factor

An apparatus or corresponding method according to an embodiment of the invention provides optical indications about the state of a circuit on a circuit board. A standard Small Form-Factor Pluggable (SFP) connector component and an optical light transmission element are arranged at different angles relative to an edge of the circuit board, with the connector component being angled other than perpendicular to an edge of the circuit board to increase the density of connector components per circuit board or relieve bending strain on an external cable connected to the connector component. The optical light transmission element may include at least three mounting features to attach the transmission element to the circuit board. The optical light transmission element includes a light propagating region, supporting total internal reflection, and a light-emitting end to output light at a front panel of the circuit board near the associated connector component. A single piece embodiment eliminates a separate clip, thereby increasing ease of manufacture, assembly, and repair while decreasing cost.

Owner:TELLABS BEDFORD

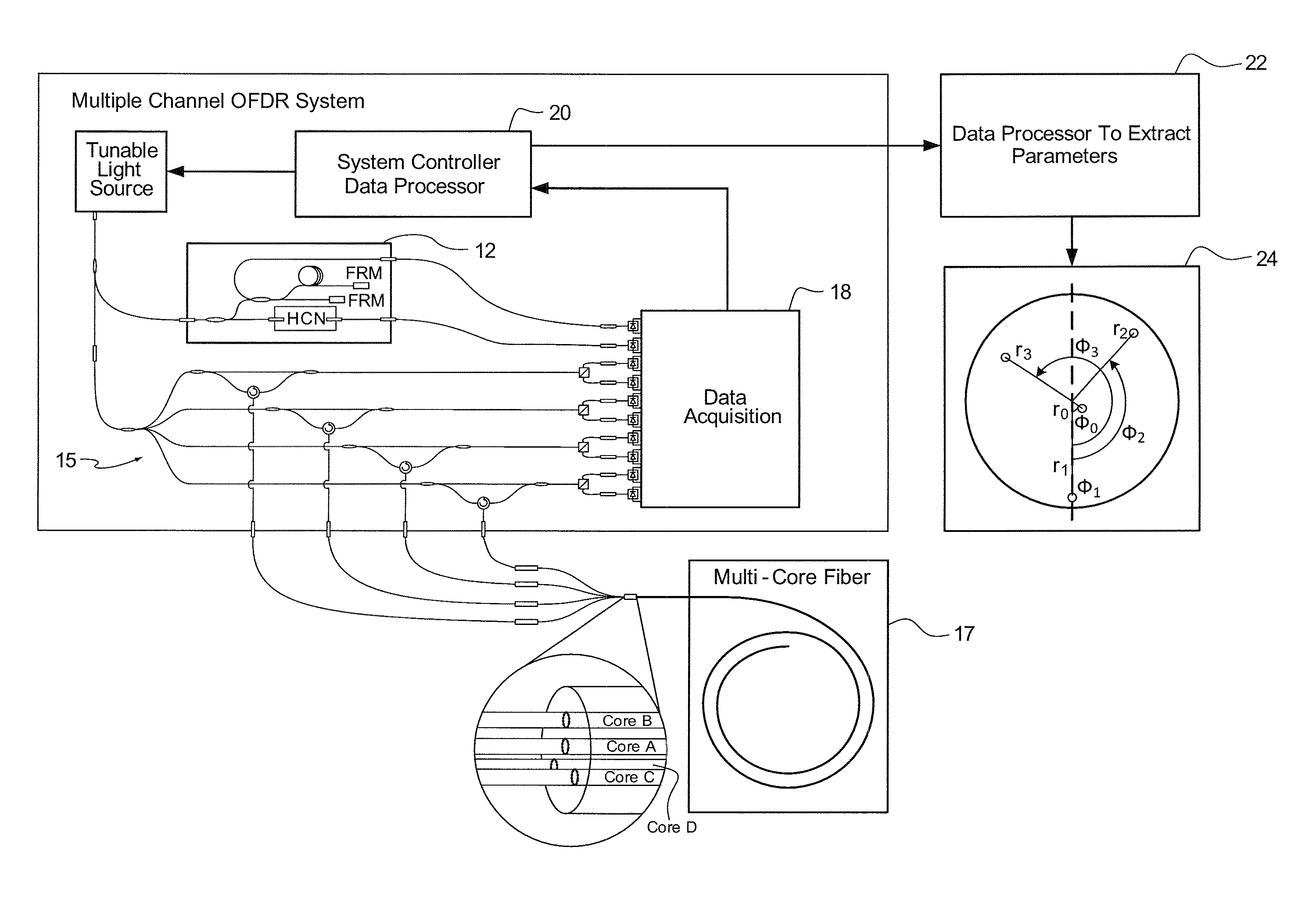

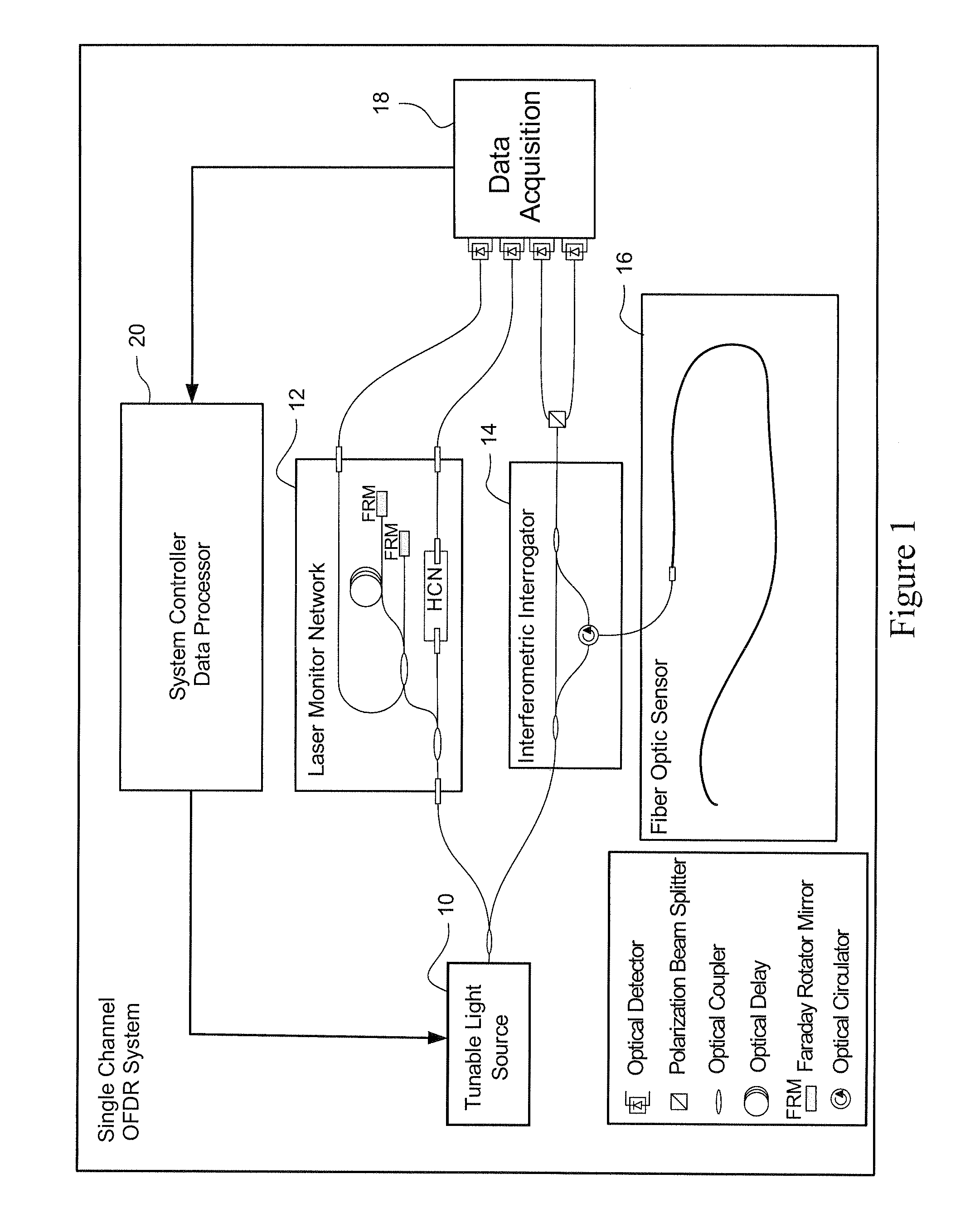

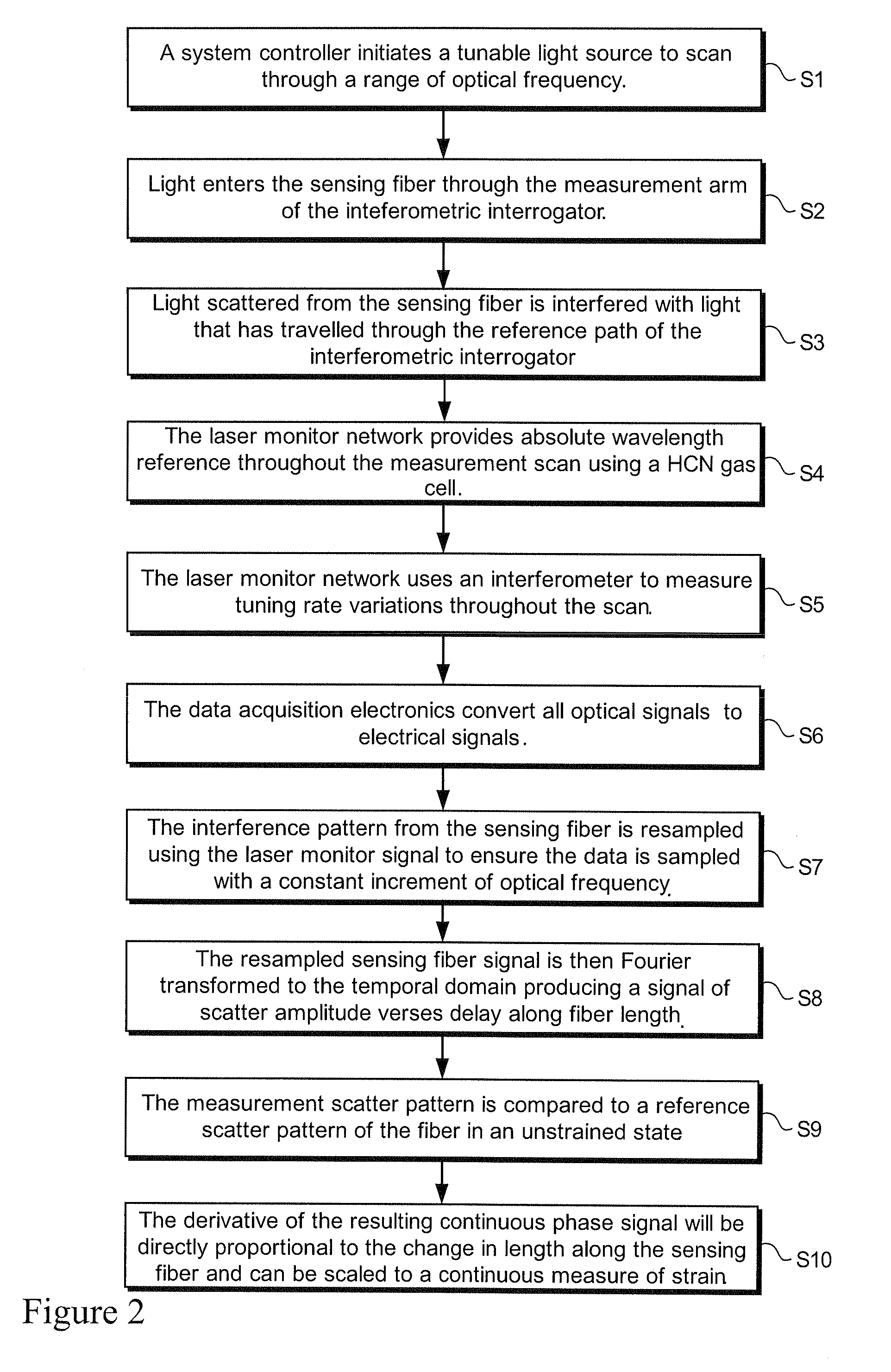

Compensating for non-ideal multi-core optical fiber structure

ActiveUS8531655B2Without loss in positional accuracyAccurately determinedForce measurementMaterial analysis by optical meansFiberBending strain

Owner:INTUITIVE SURGICAL OPERATIONS INC

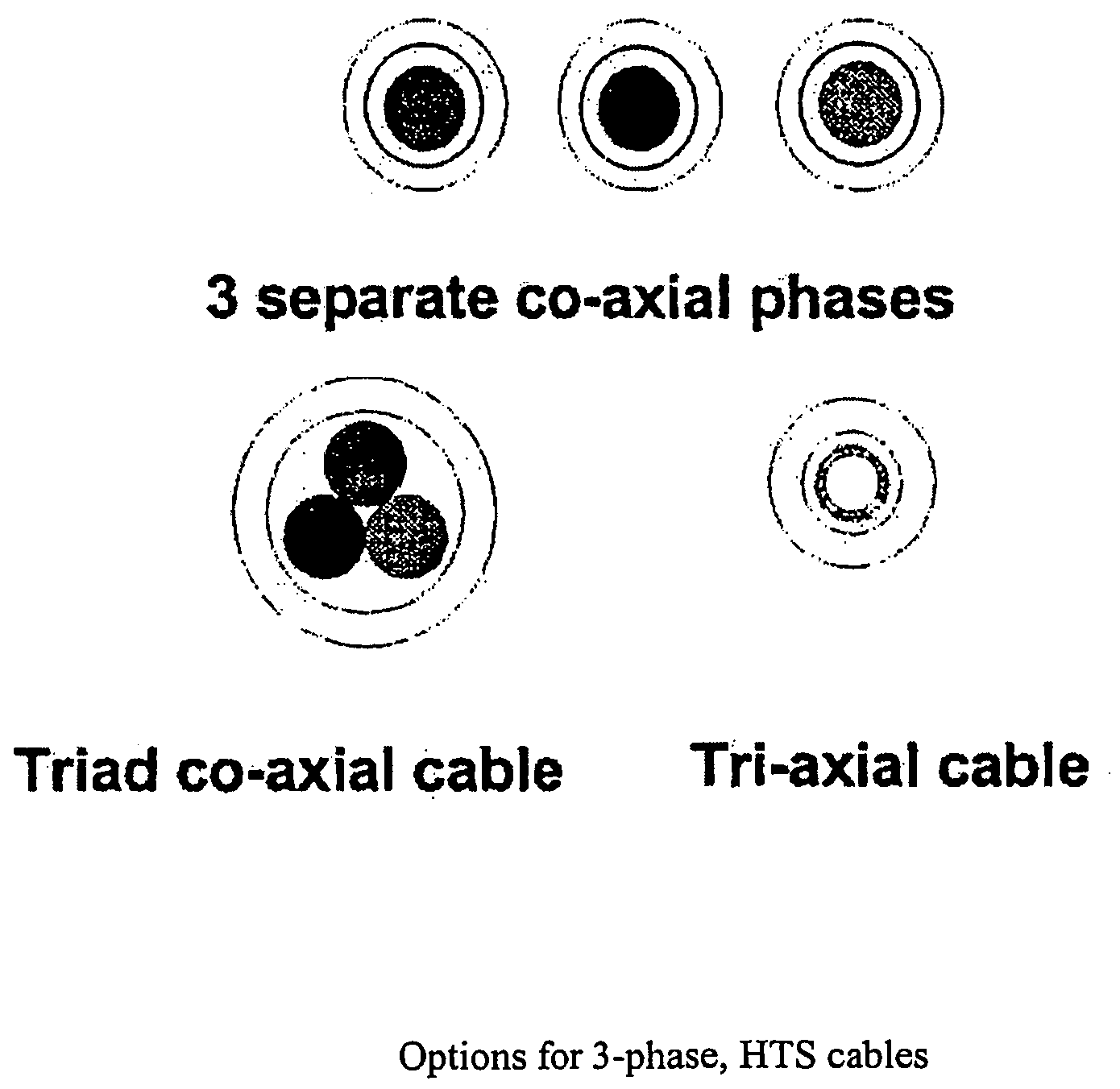

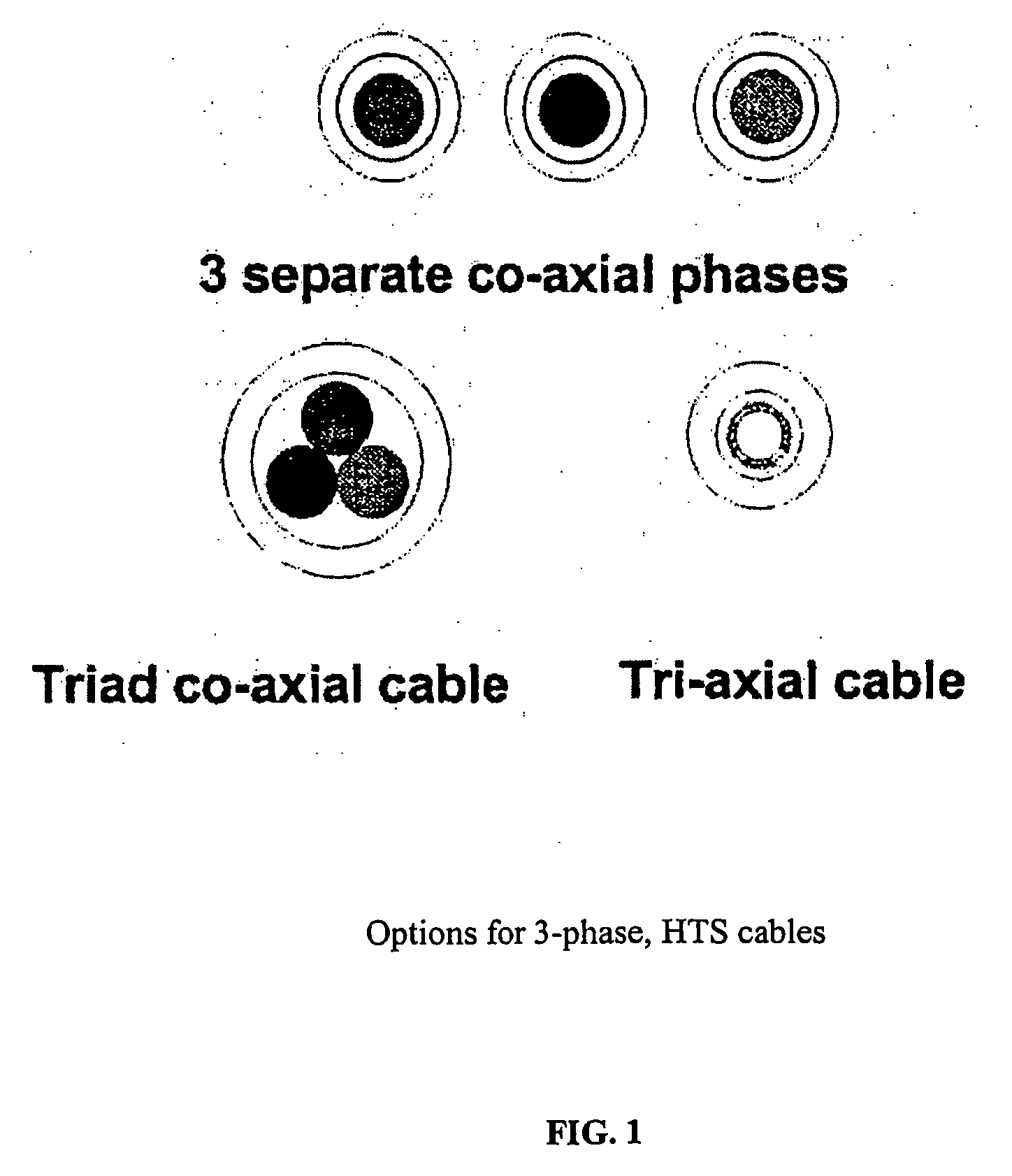

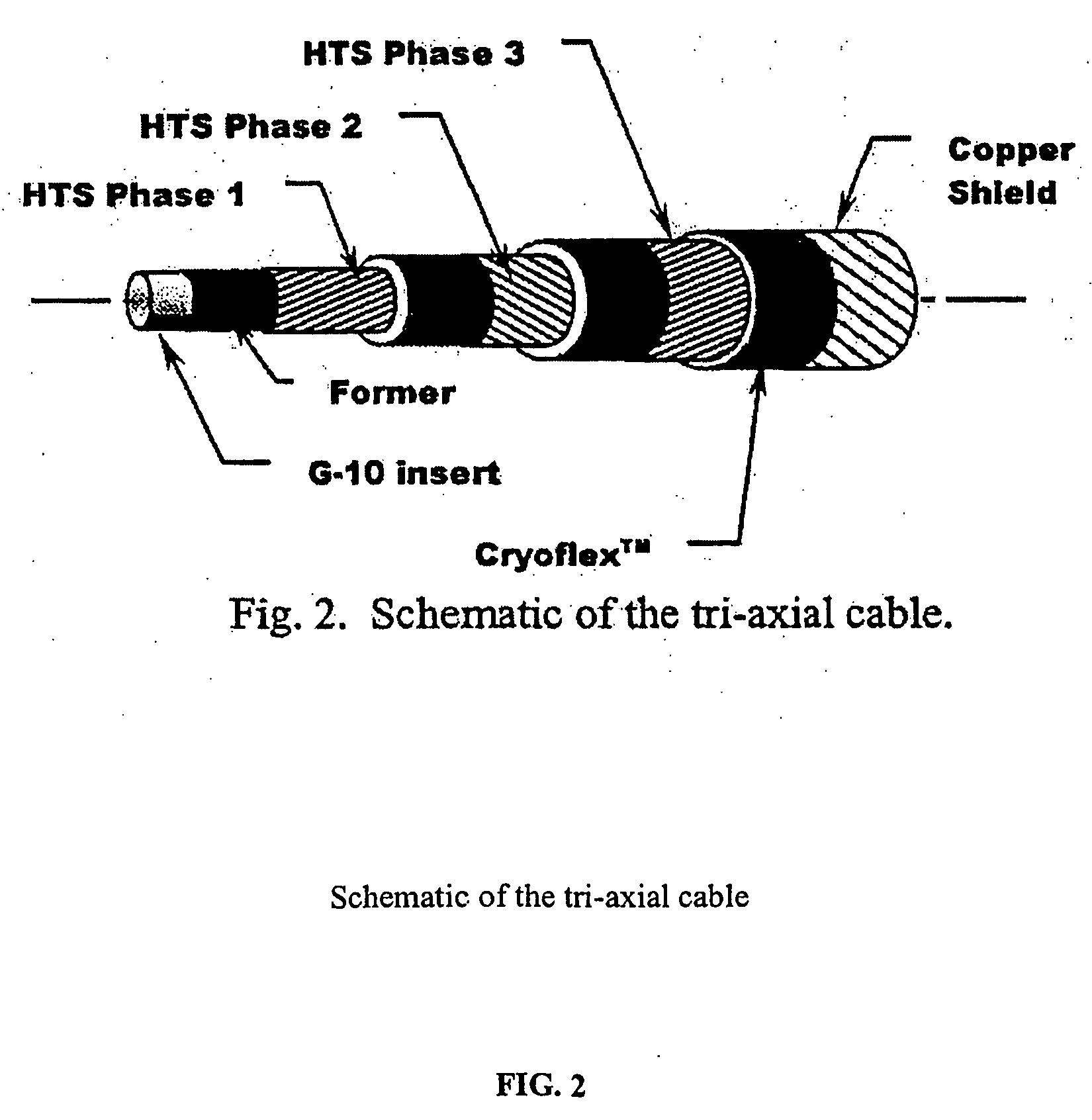

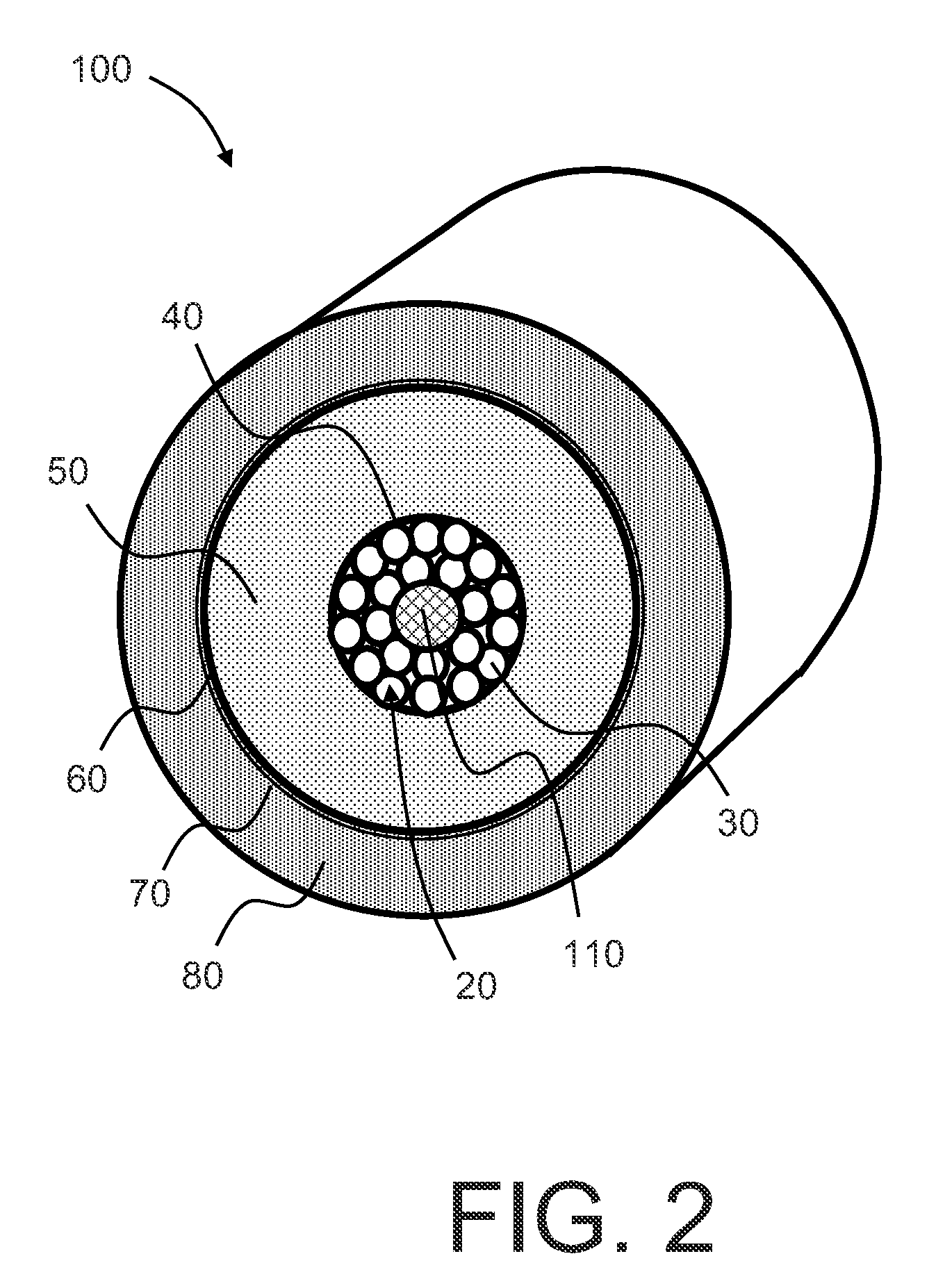

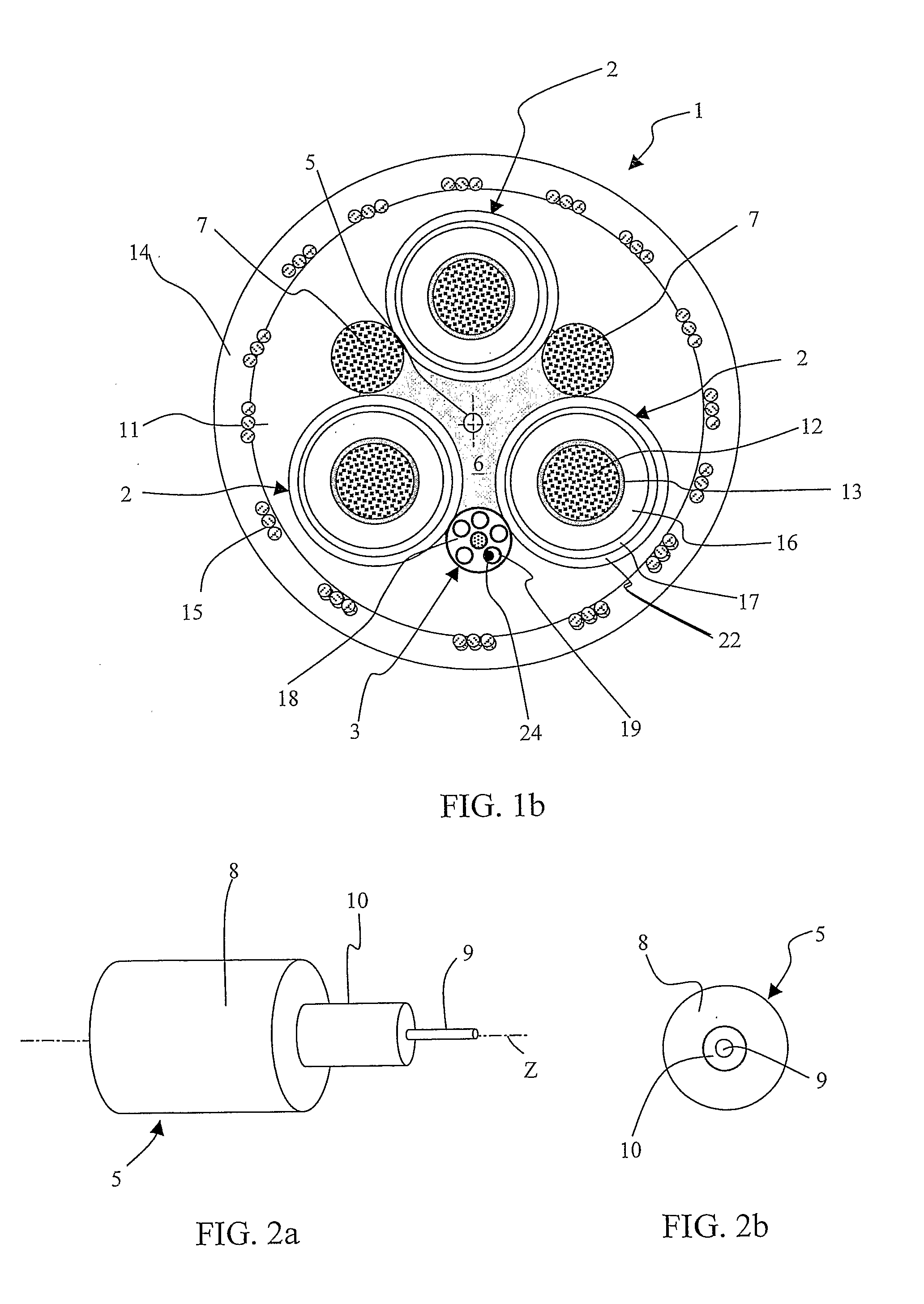

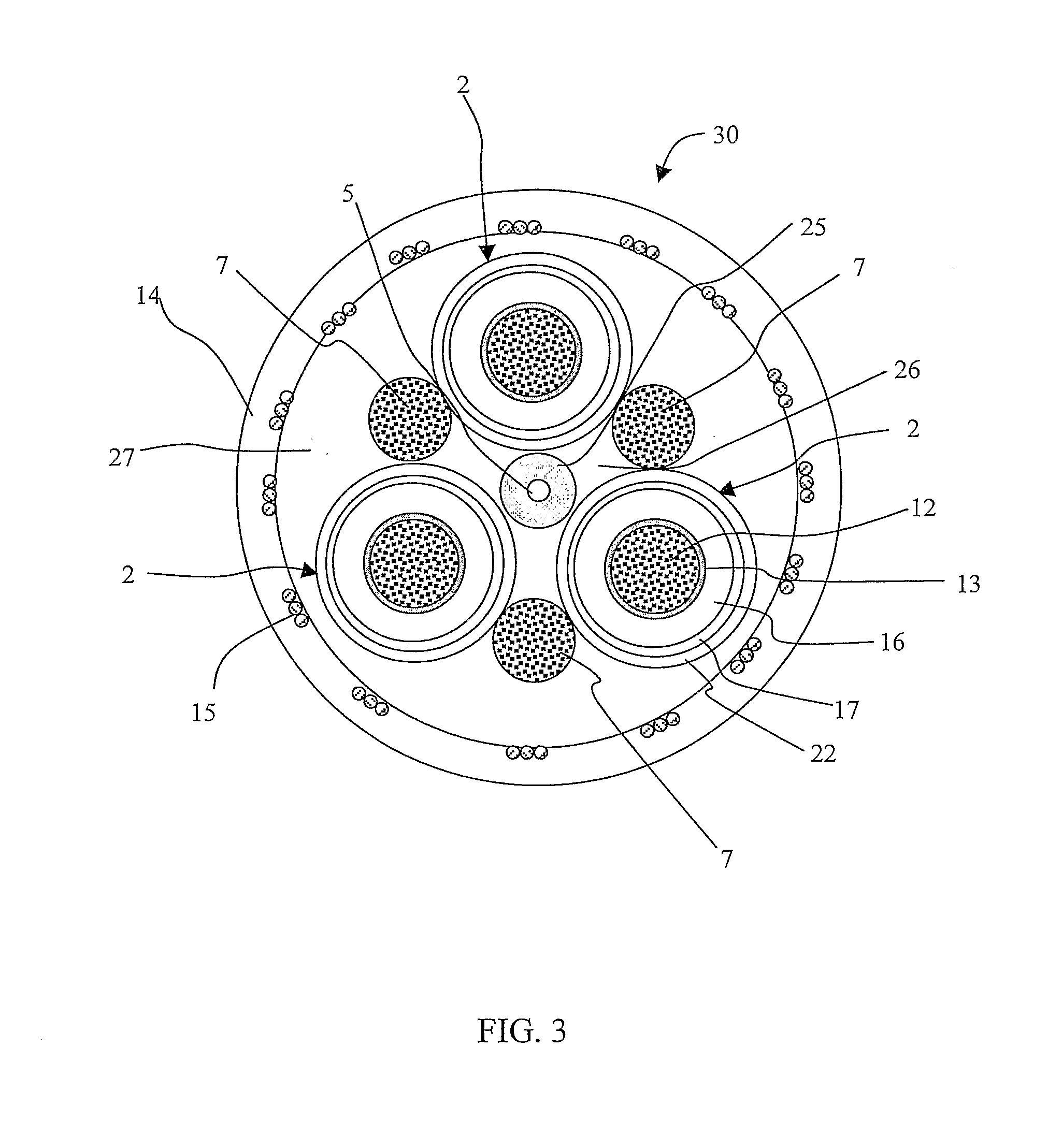

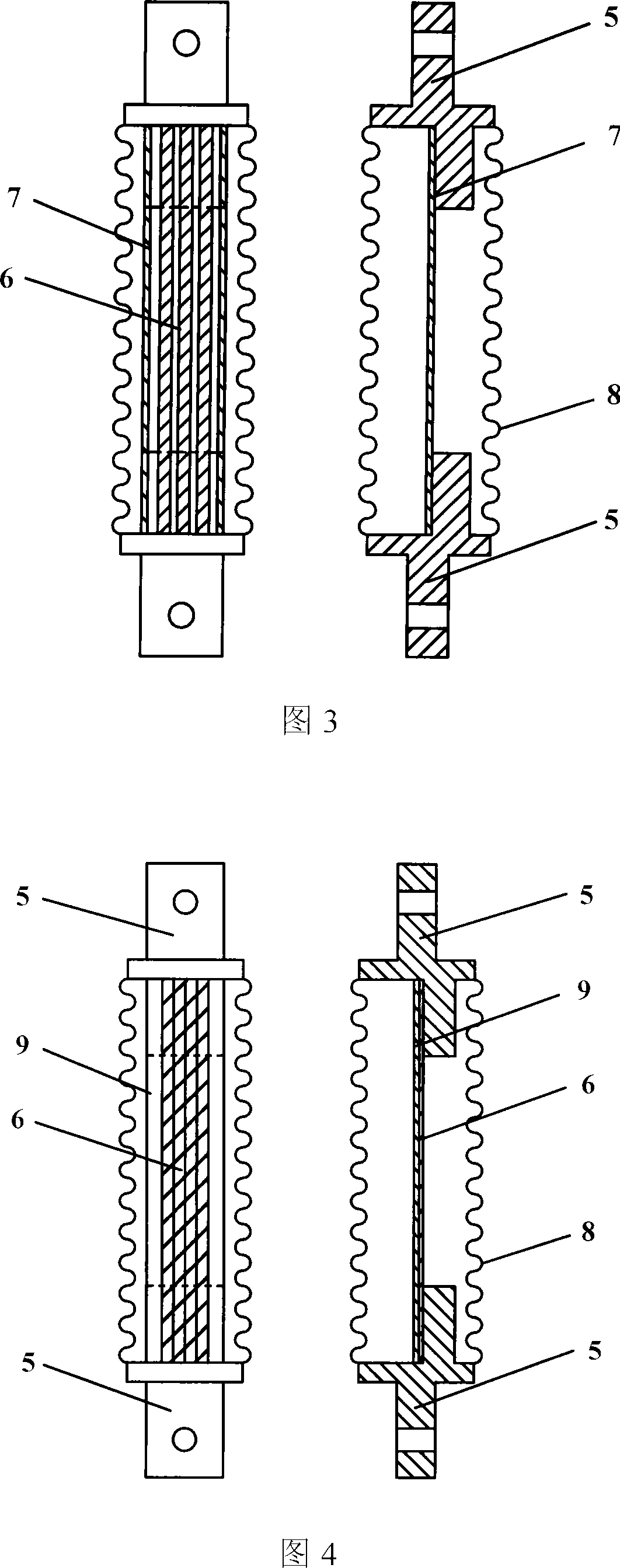

Triaxial superconducting cable and termination therefor

InactiveUS20050173149A1Improve superconductivityIncrease the critical currentSuperconductors/hyperconductorsCable fittings for cryogenic cablesBand shapeBending strain

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith. Methods of forming and terminating a triaxial superconductor are disclosed.

Owner:SOUTHWIRE CO LLC

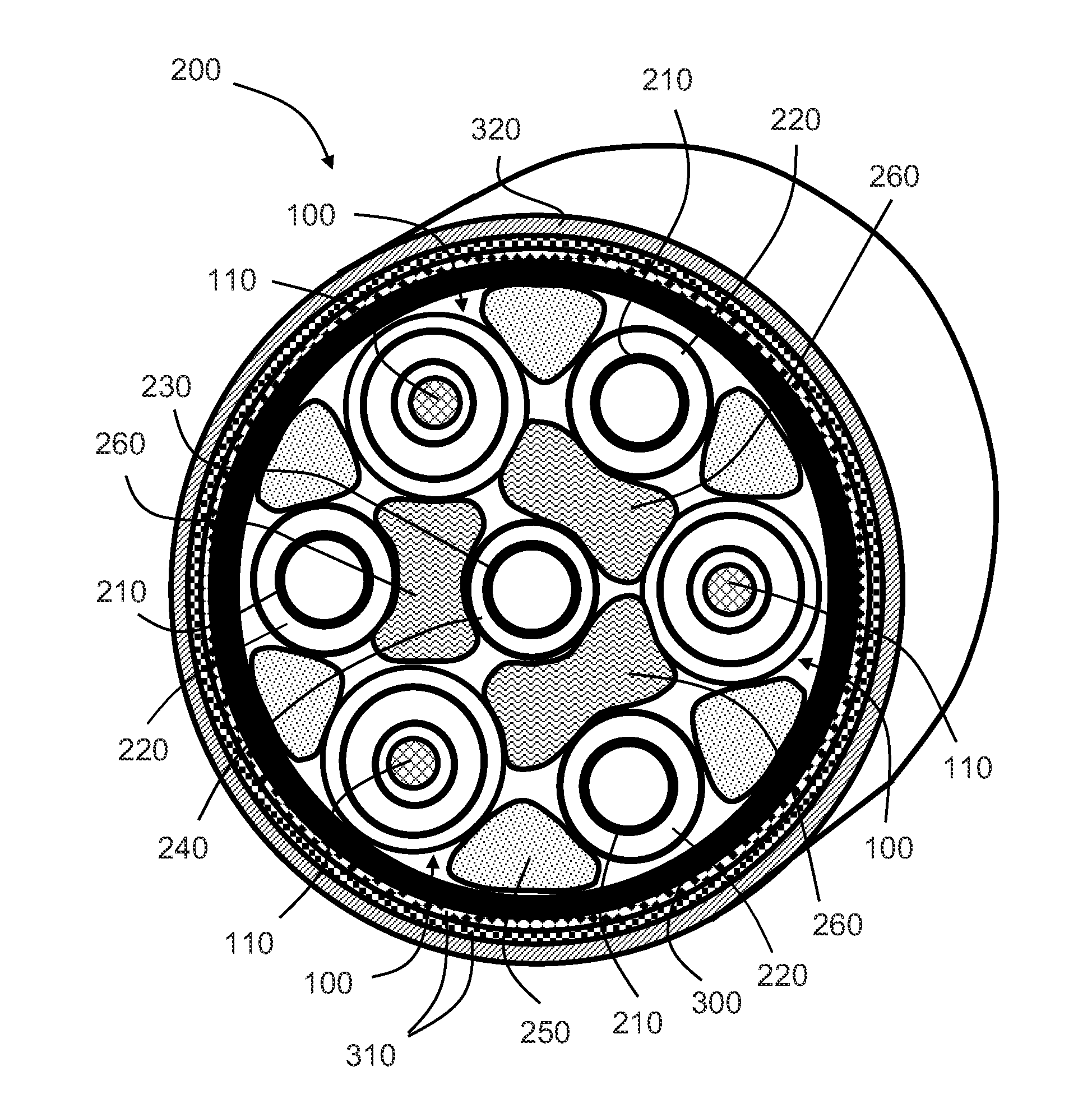

Elastic high voltage electric phases for hyper depth power umbilical's

InactiveUS20120234596A1Less materialImprove carrying capacityLine/current collector detailsInsulated cablesElectricityBending strain

A power umbilical cable includes one or more axial elongate phases for conducting electrical current, and one or more axial elongate structural components adapted to undergo stress to withstand axial and bending strain applied to the power umbilical cable in operation. The umbilical cable has an outer protection layer, each of the phases having a conductive core made of a plurality of metal wires. Each current conducting core includes at a central portion therein, and surrounded by the plurality of conductive metal wires, a flexible element to enable the wires to move in a radial direction to reduce their strain when the umbilical cable is subject in operation to stress causing the one or more elongate structural components to be axially strained.

Owner:NEXANS

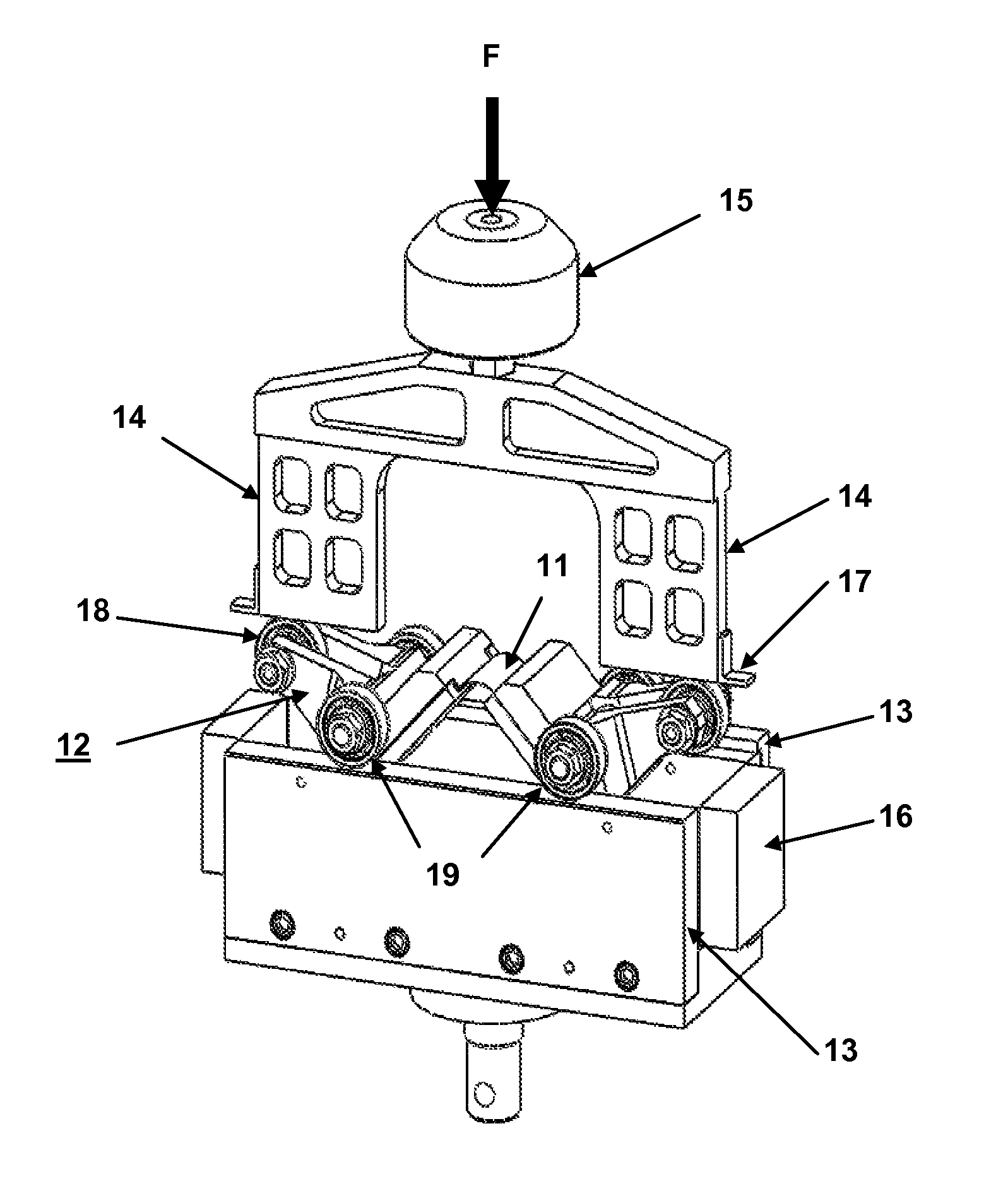

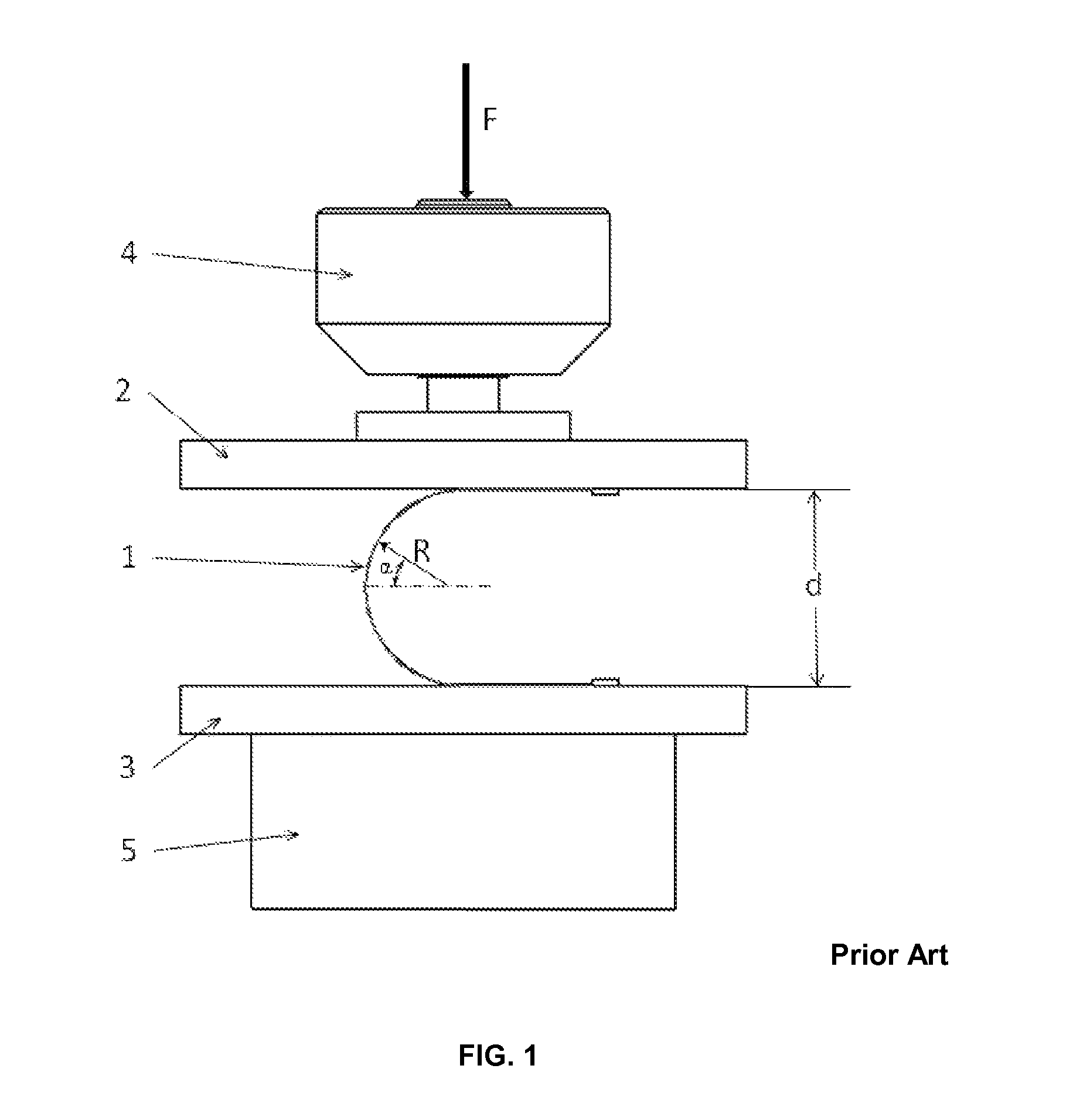

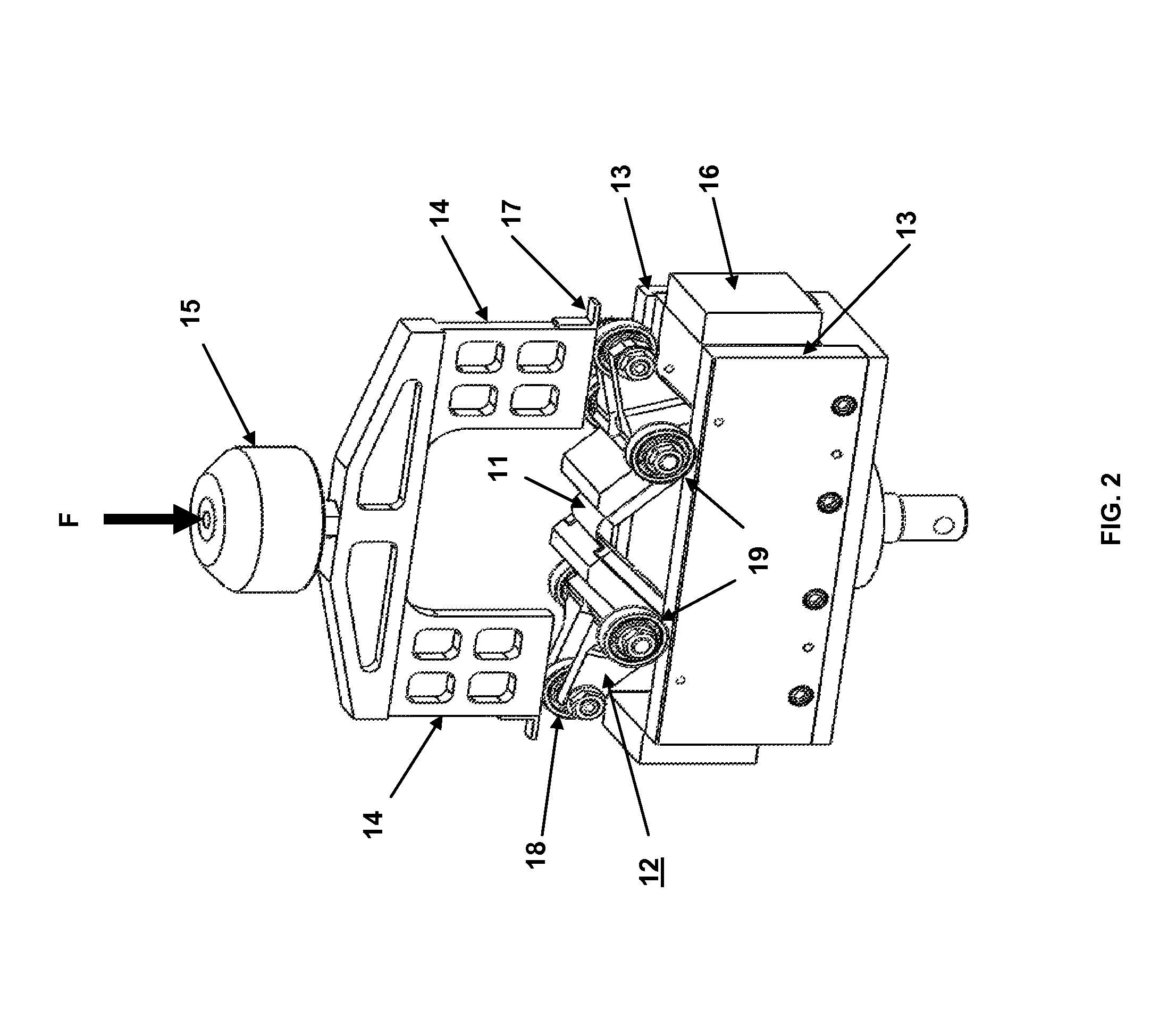

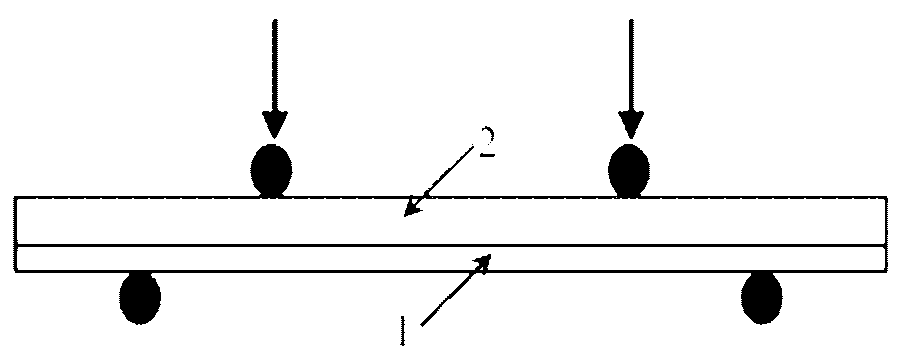

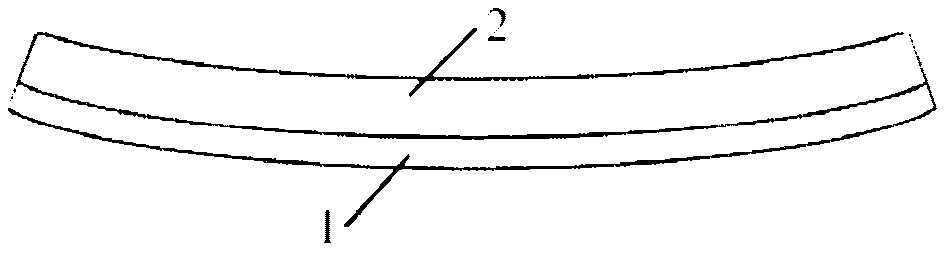

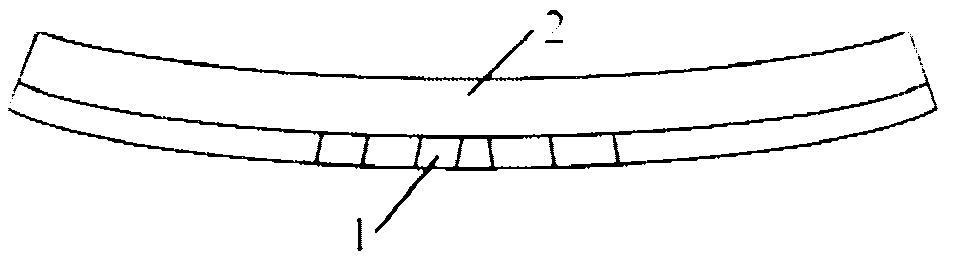

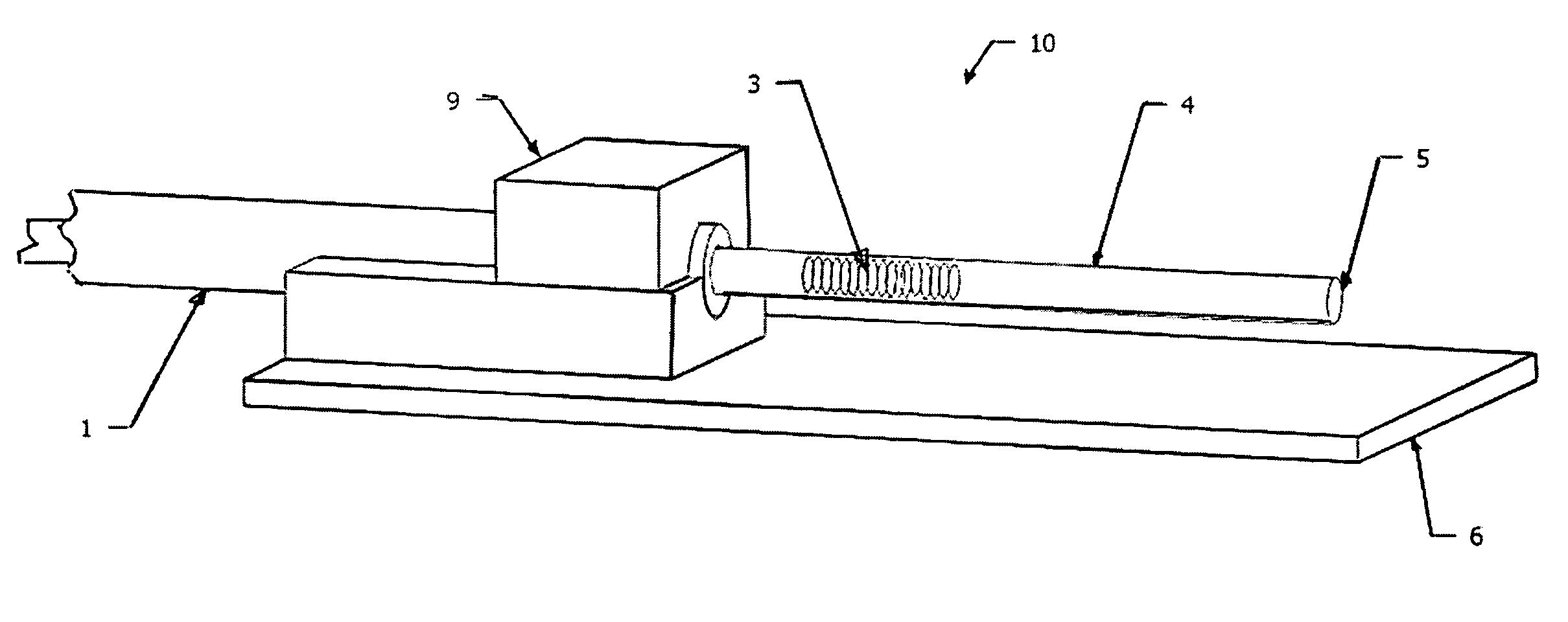

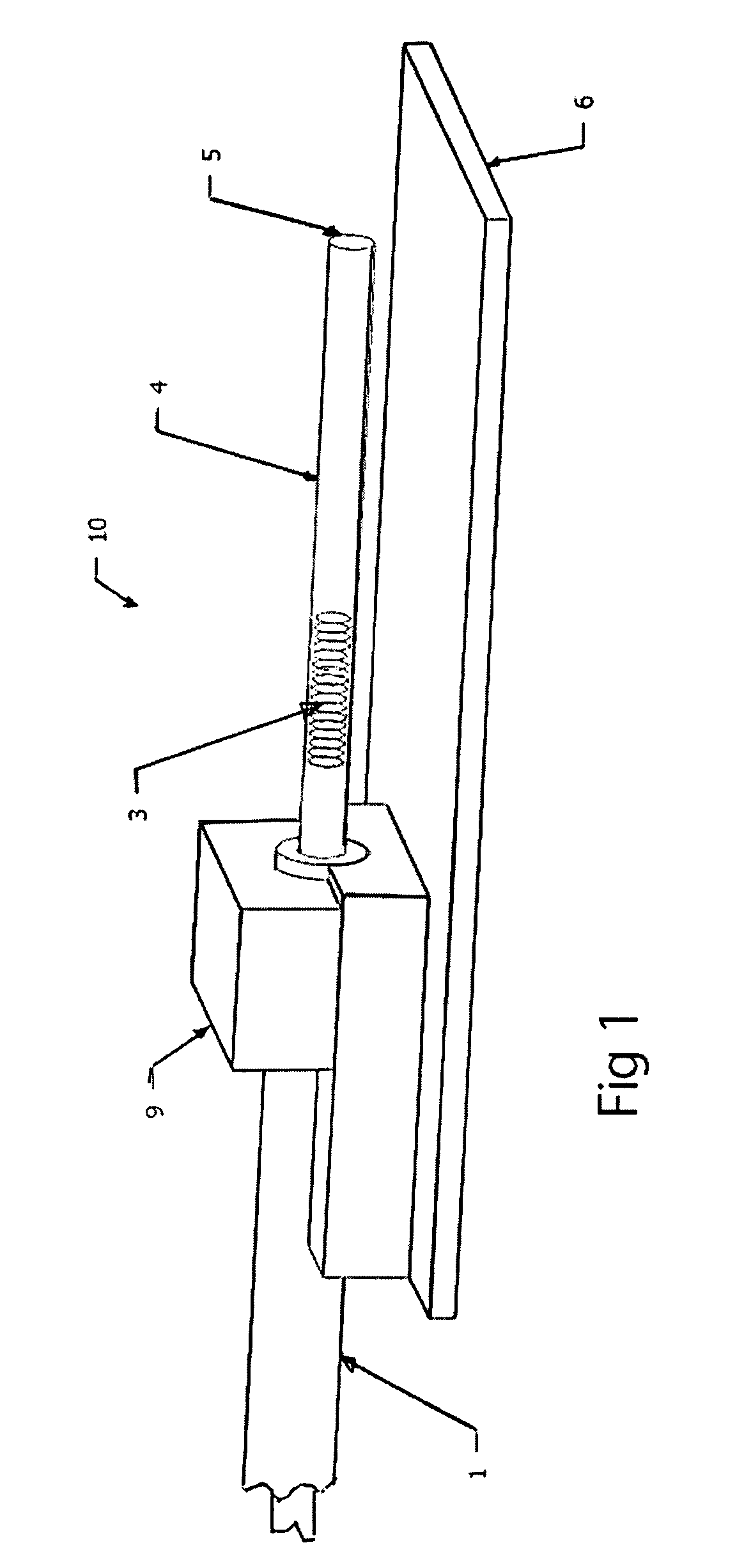

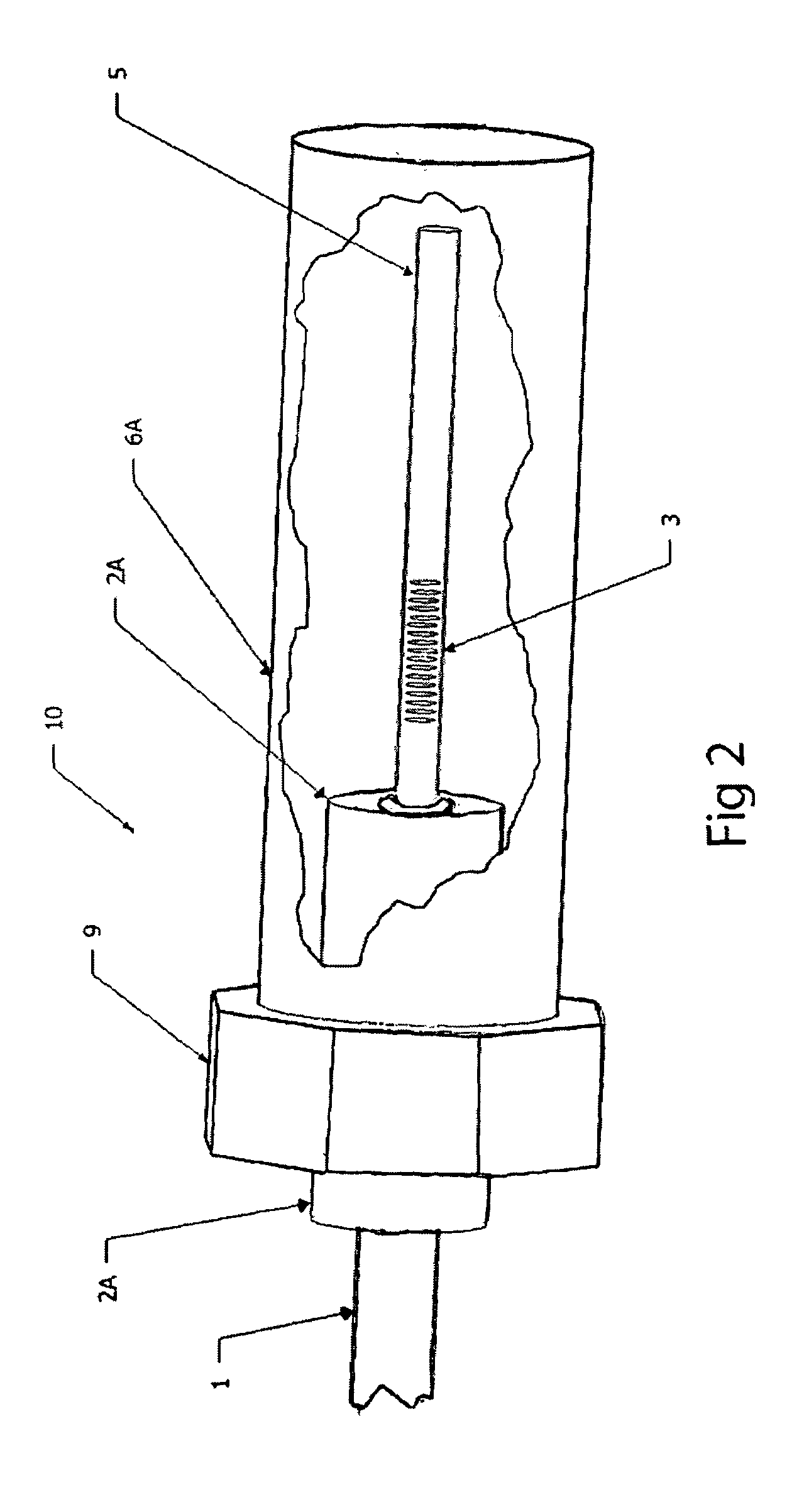

Device for testing thin specimens in pure bending

An improved test fixture to evaluate thin composite laminates commonly used in deployable space structures. The fixture is designed to impart a pure moment into the coupon, a necessary improvement to prior test methods where results are obtained by fitting material properties in a nonlinear structural analysis of the test. Fixture mechanics allow for direct calculation of the coupon flexural modulus and allowable flexural strain based on two key measurements, fixture displacement and applied load.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Bending beam load cell with torque sensitivity compensation

InactiveUS6910392B2Weighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementElectricityBending strain

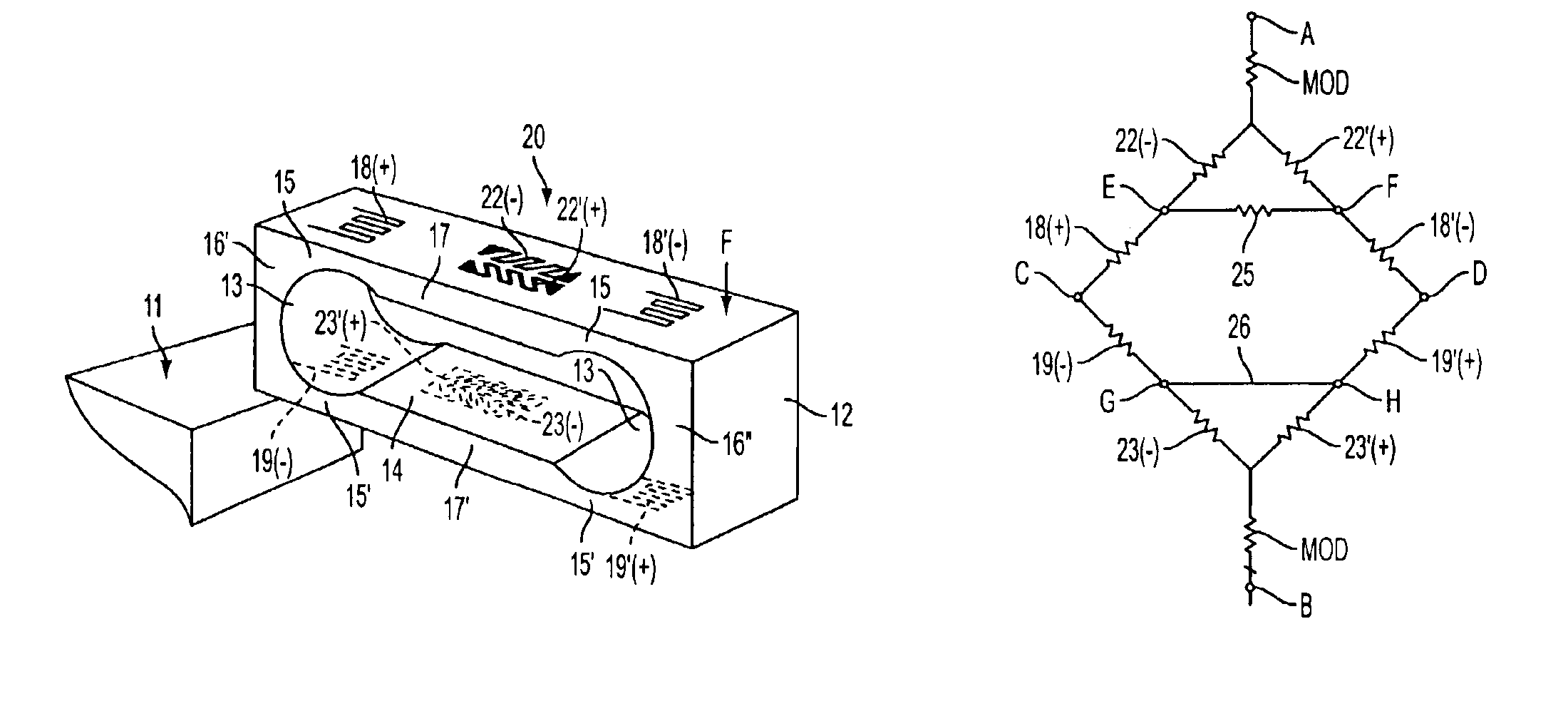

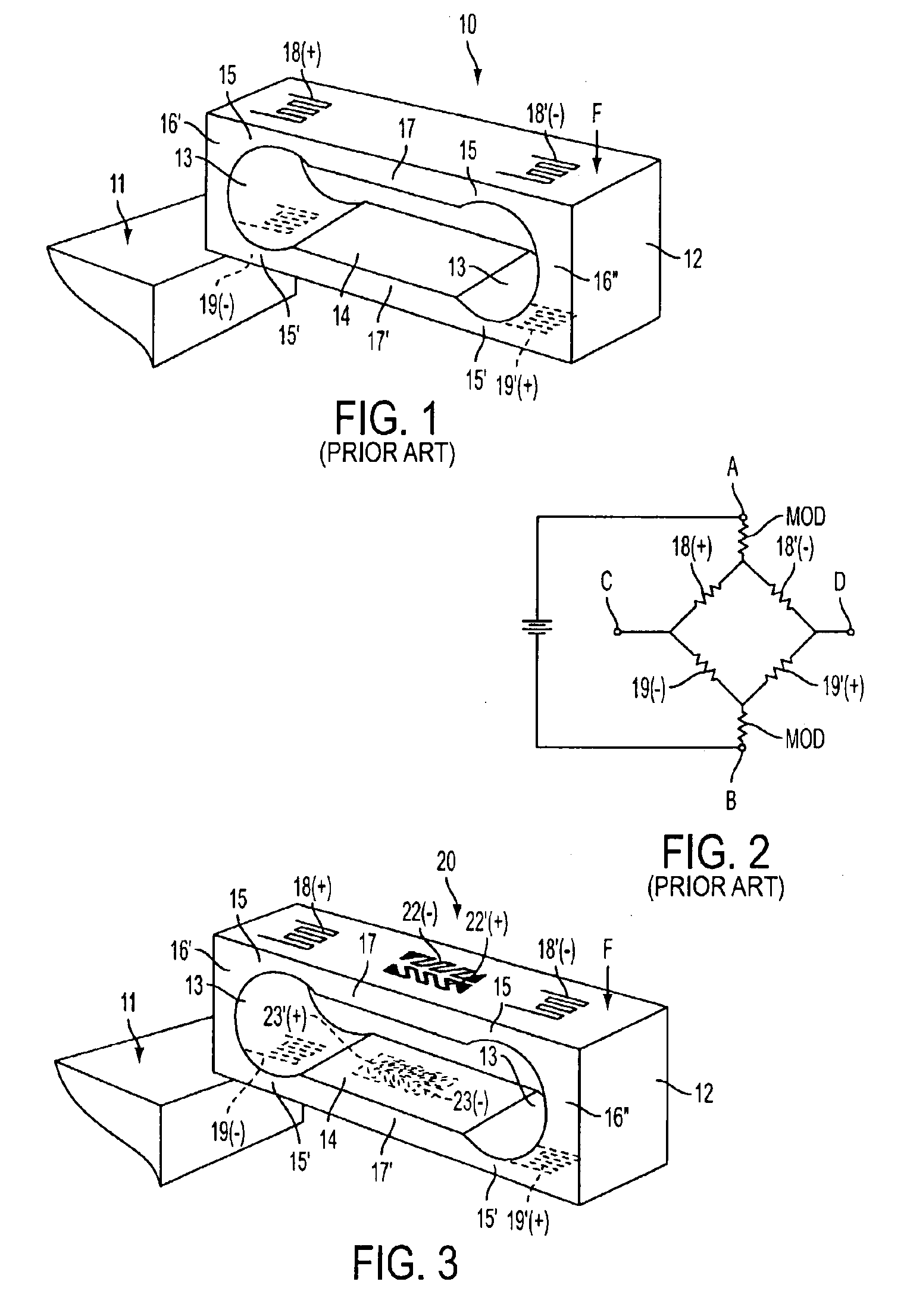

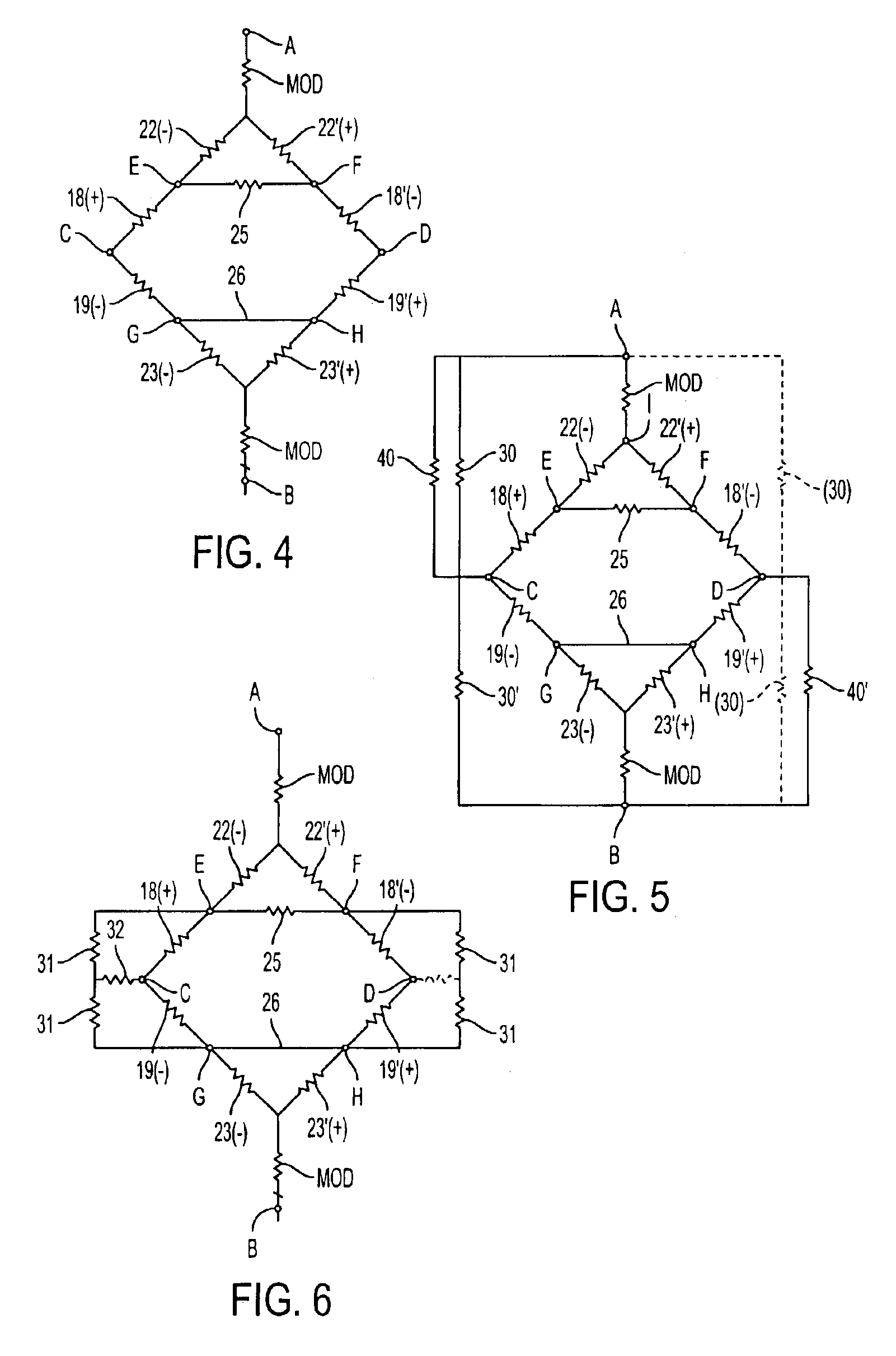

A bending beam load cell can be compensated for side-to-side off center load sensitivity by simple electrical adjustments if a pair of shear sensing strain gages are bonded to each bending beam midway between axial strain gages used to measure bending strains. The shear sensing strain gages measure torque on the load cell, and are incorporated in bridge circuits that make it possible to vary the amount of torque sensitivity correction by changing the value of a trimming resistor. The bridge circuits also include circuit components for compensation of front-to-back off center load error and for zero adjustment. Four strain gages on each bending beam can be part of a single composite strain gage element, so the shear sensing strain gages do not add any cost to the load cell. Such a load cell can also be hermetically sealed before any compensation of offset load errors is done.

Owner:FLINTEC GROUP

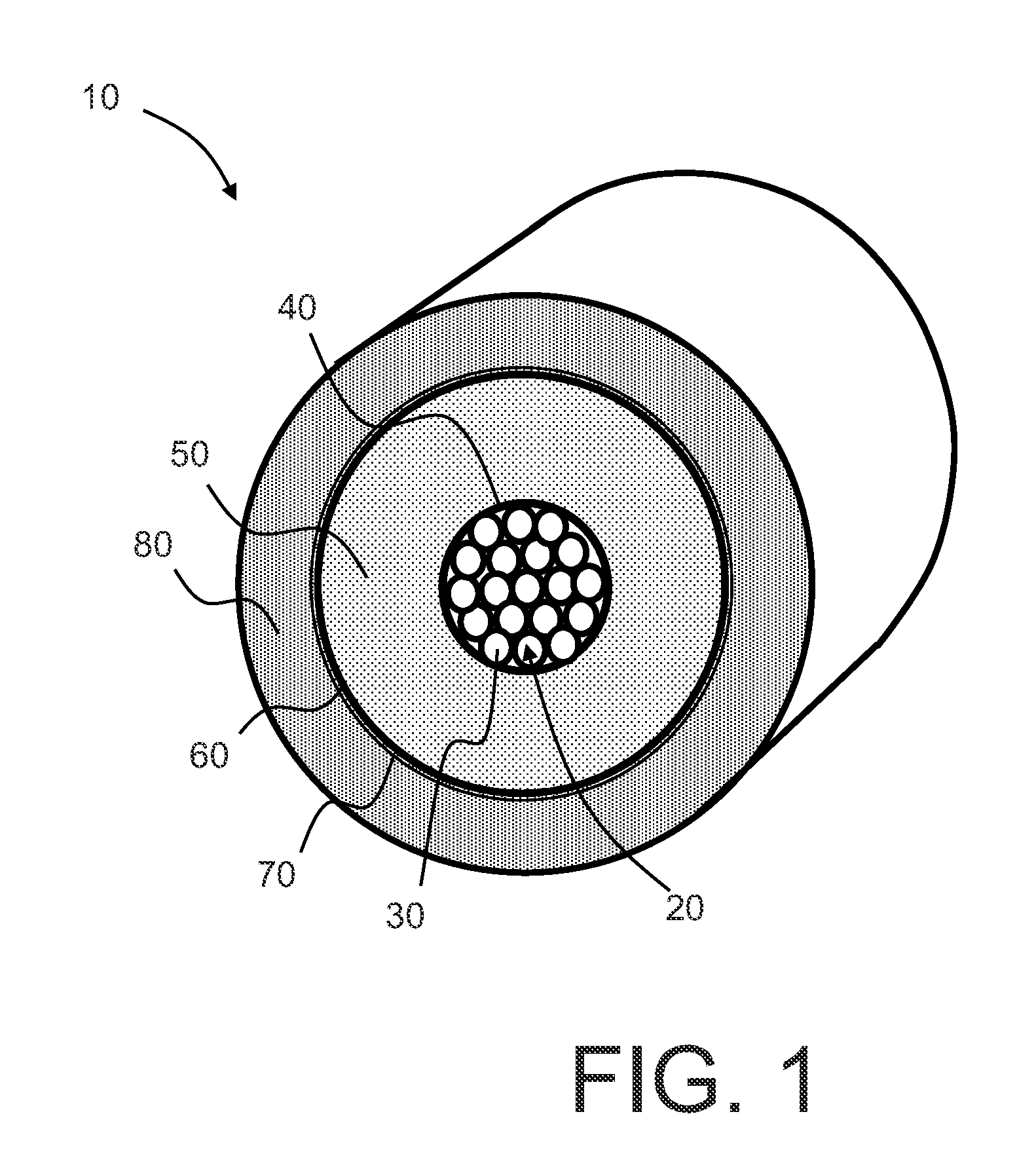

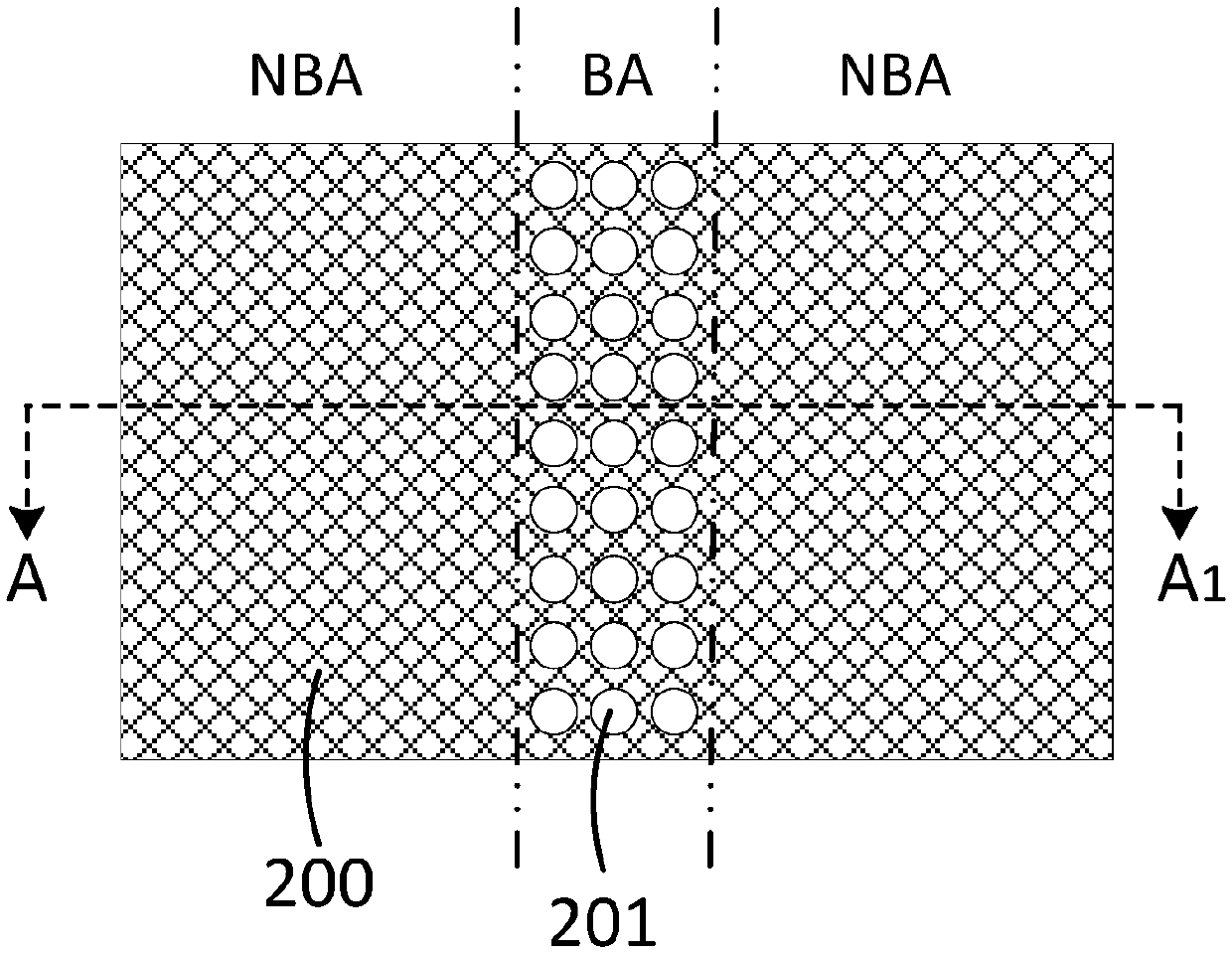

Electric cable with bending sensor and monitoring system and method for detecting bending in at least one electric cable

ActiveUS20120174683A1Effective periodic maintenanceHigh mechanical stressControlForce measurement by measuring optical property variationNon symmetricMonitoring system

A method for monitoring at least the bending strain of at least one electric cable provided with at least one peripheral mechanically non-symmetric strength member is provided.

Owner:PRYSMIAN SPA

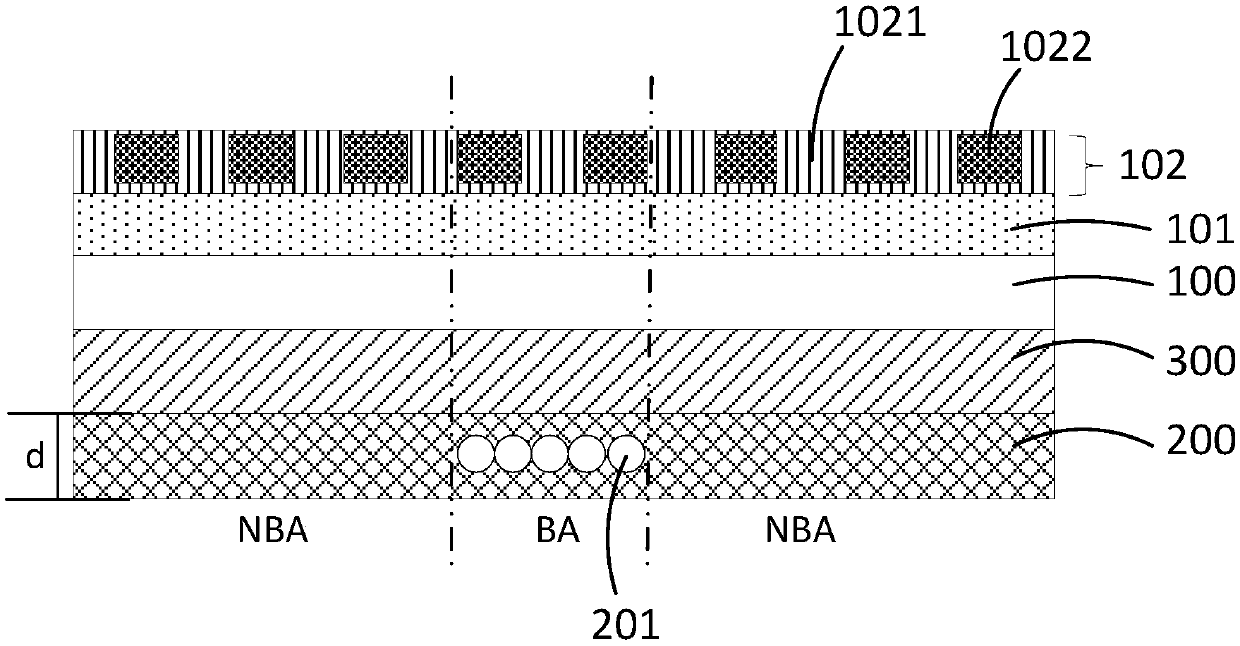

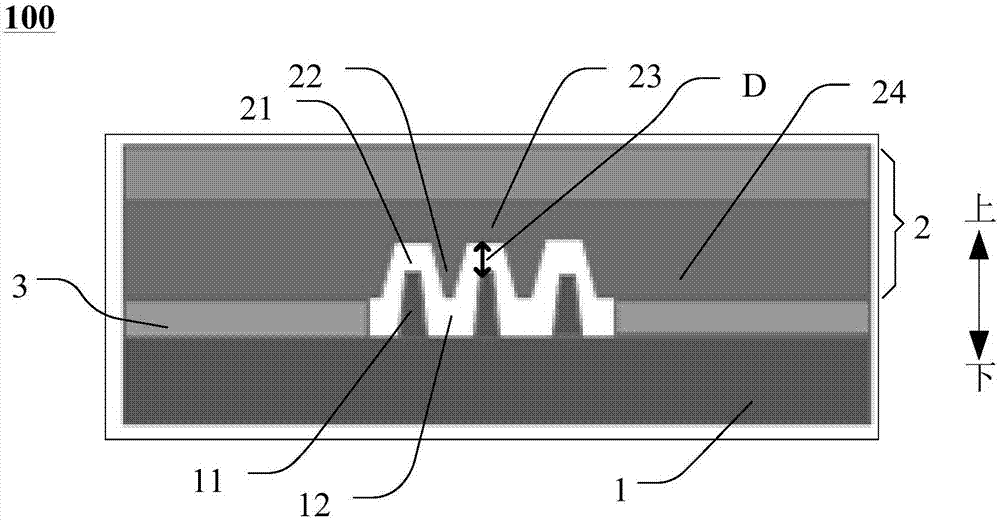

Flexible display panel and display device

ActiveCN109523921AGuaranteed bending resistanceImprove bending resistanceSemiconductor/solid-state device detailsPhotovoltaic energy generationDisplay deviceBending strain

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a flexible substrate, an array layer which is located above the flexible substrate, a display layer which is located on the side, away from the flexible substrate, of the array layer and comprises multiple illuminating members, and a shielding membrane located on the side, away from the array layer, of the flexible substrate; the flexible display panel comprises a bendable region, and at least multiple hollowed-out parts are arranged on the part, located on the shielding membrane, of thebendable region. The flexible display panel has the advantages that the bending strain when the flexible display panel is bent can be relieved to prevent bending lines from being generated by the flexible display panel in the bending region, and therefore the reliability of the performance of the flexible display panel is ensured.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

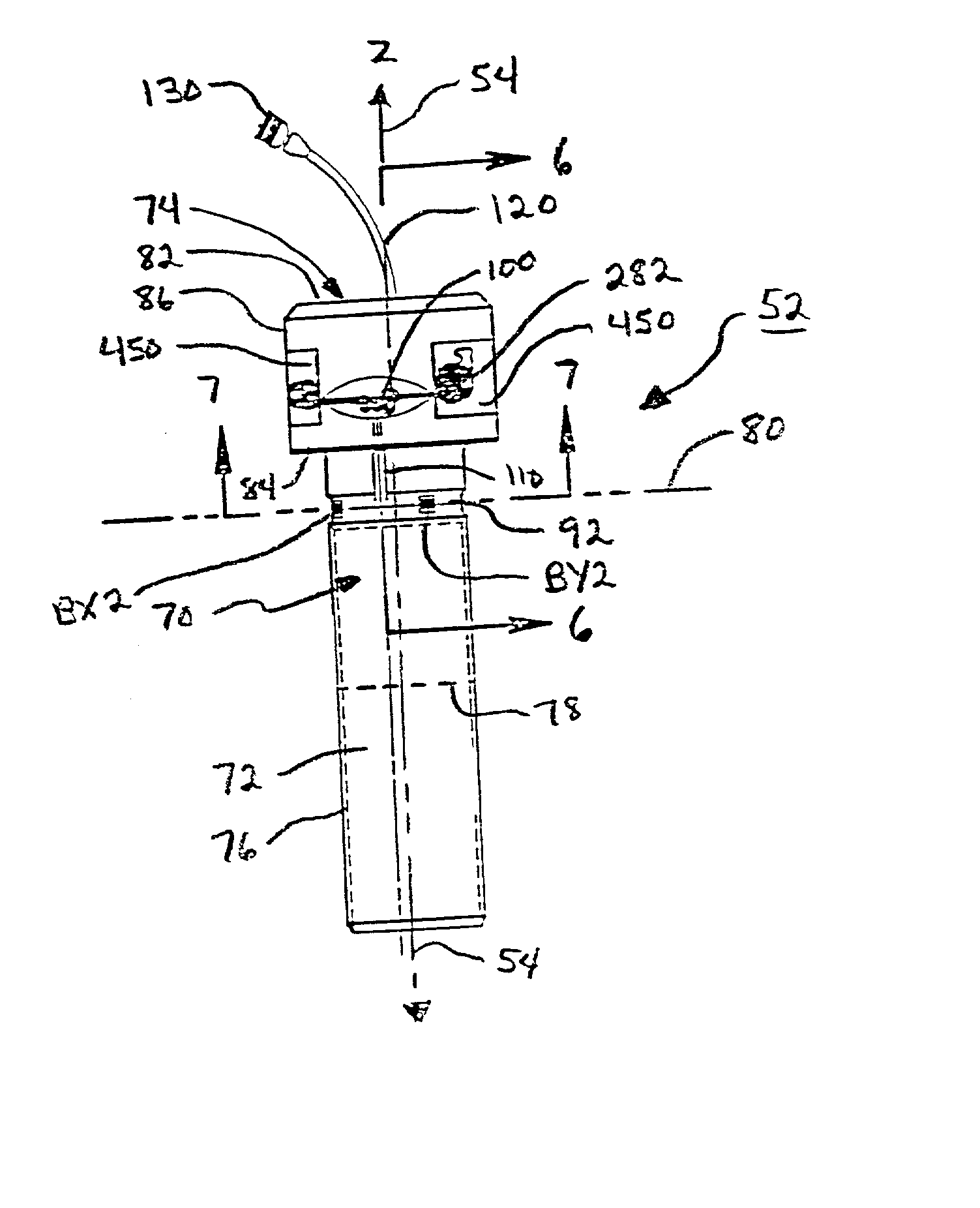

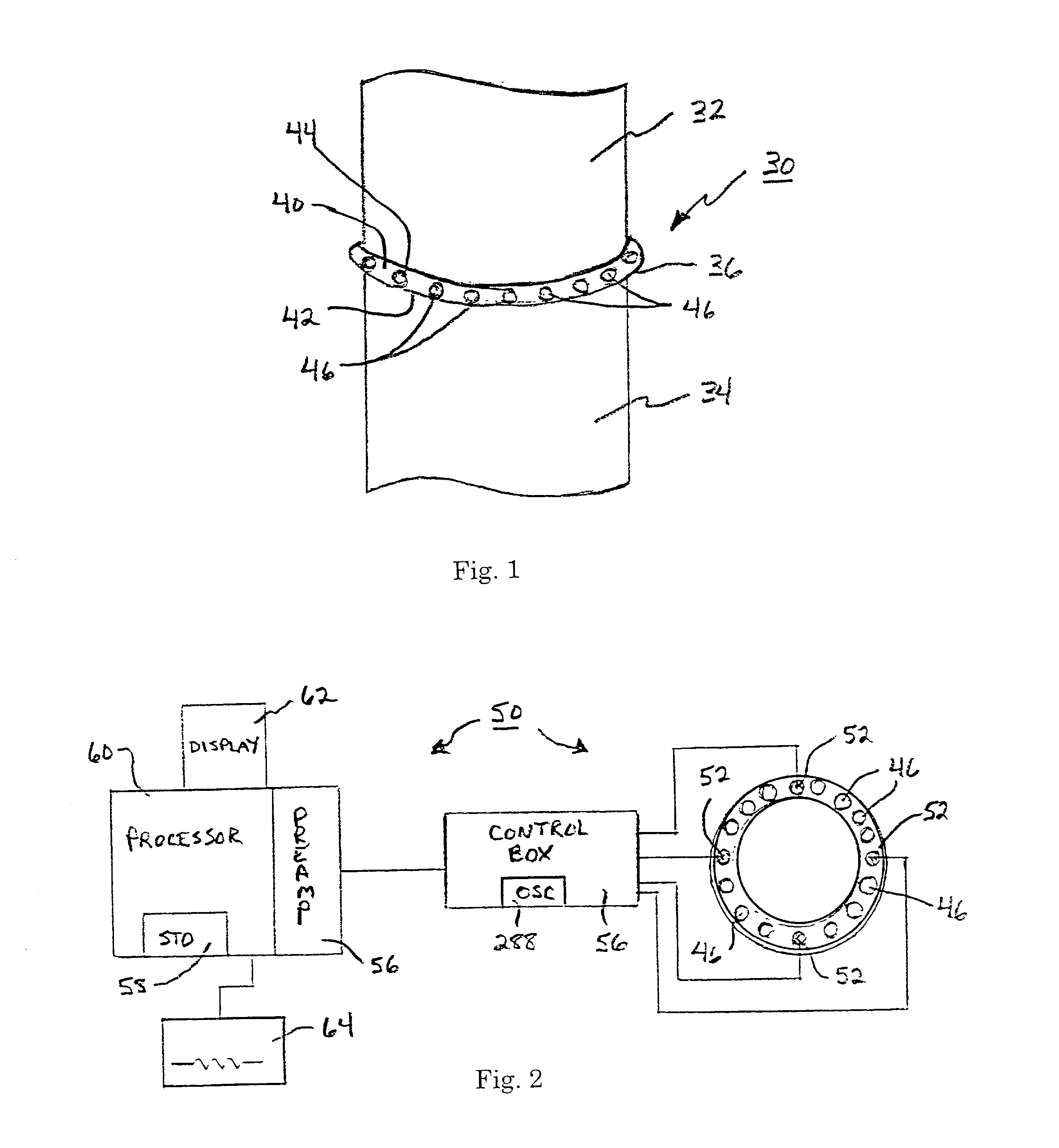

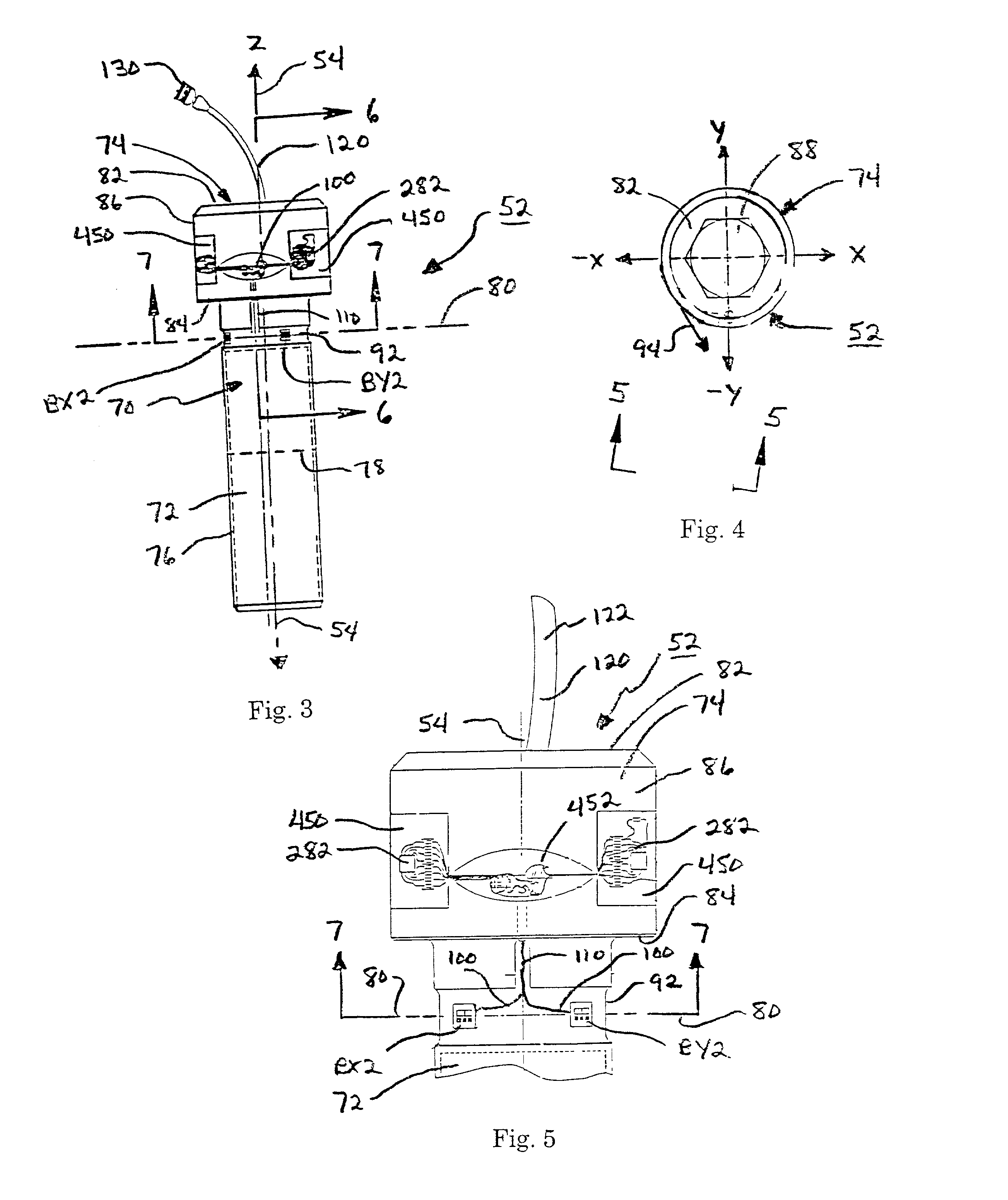

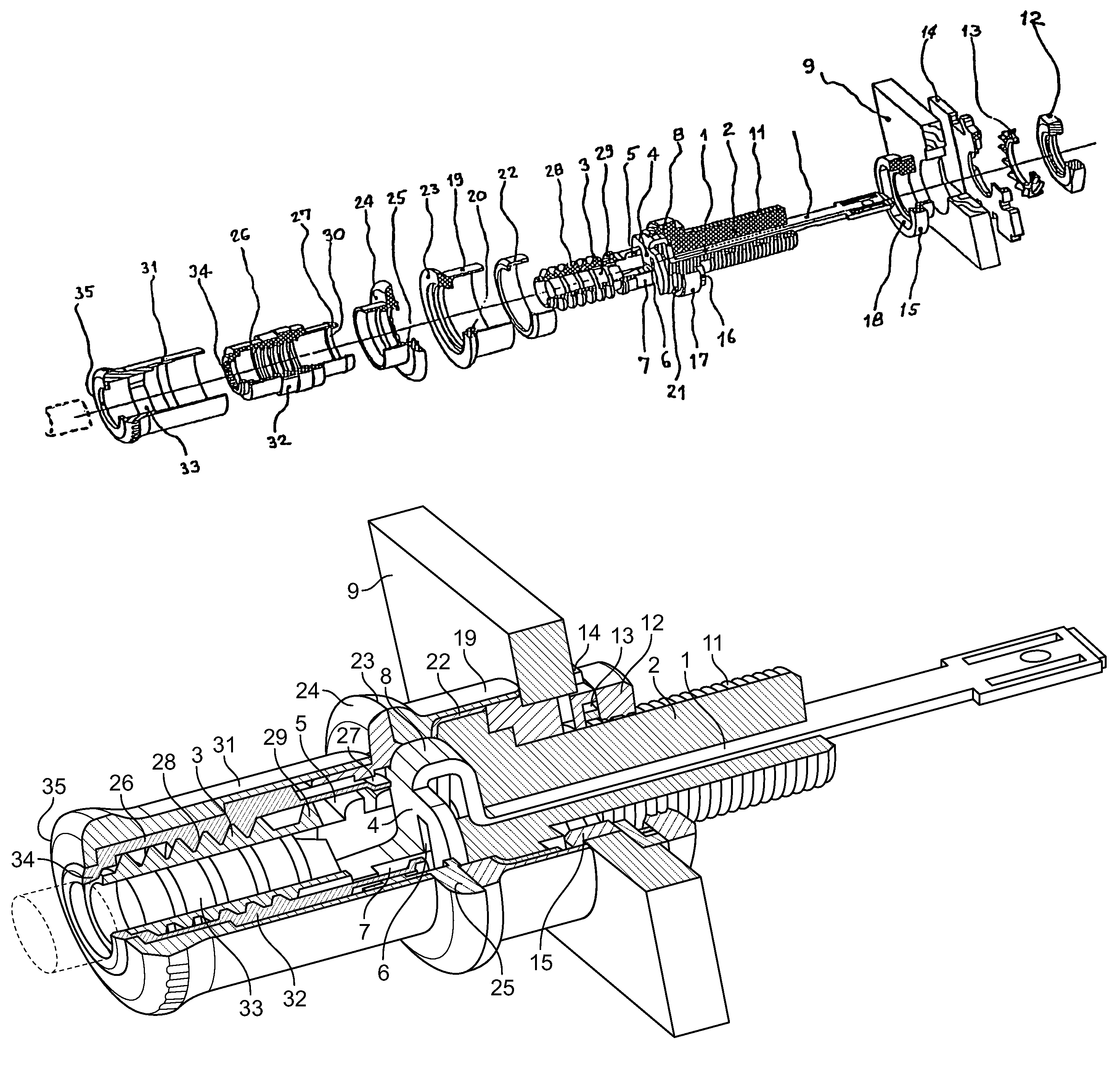

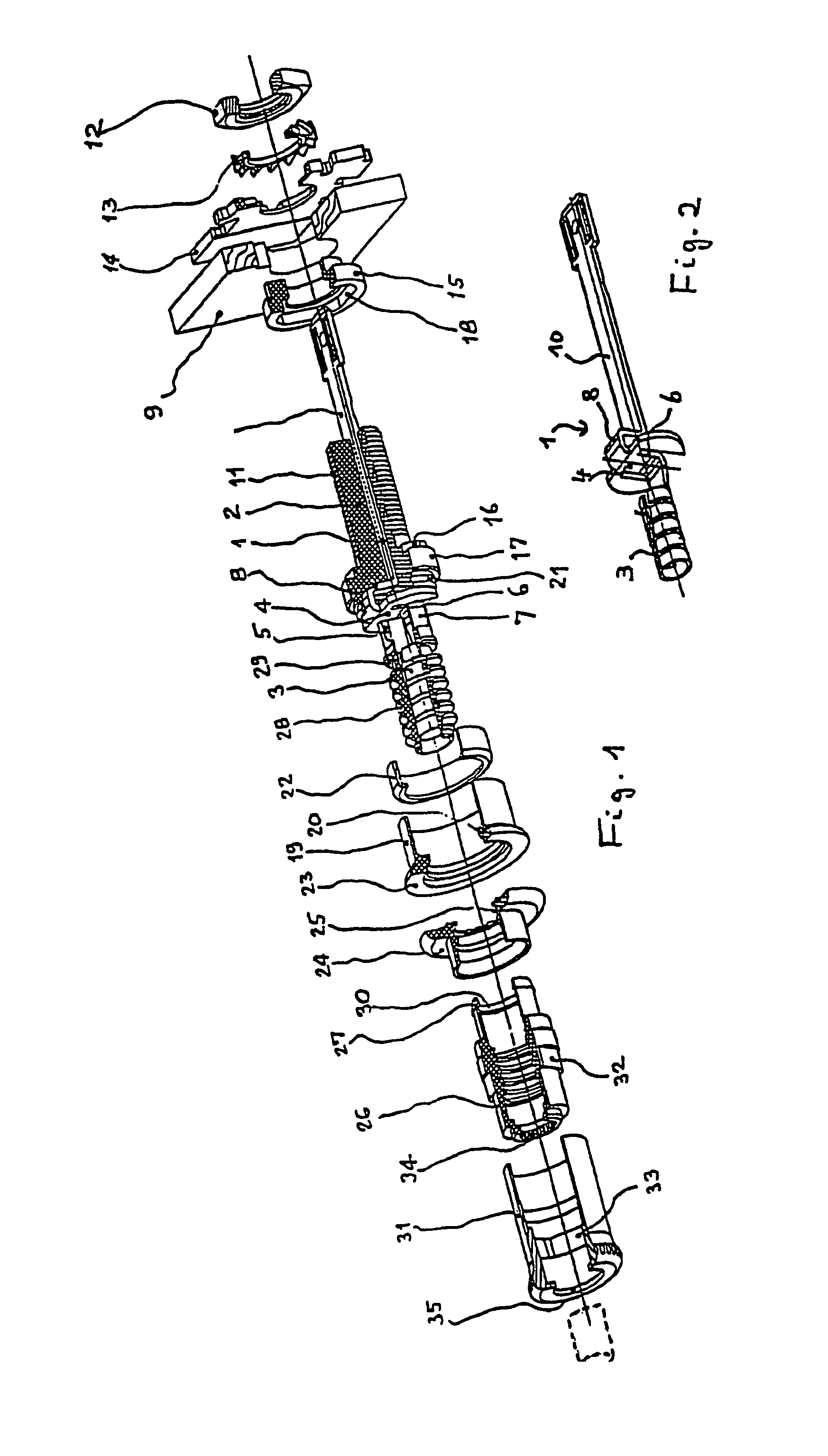

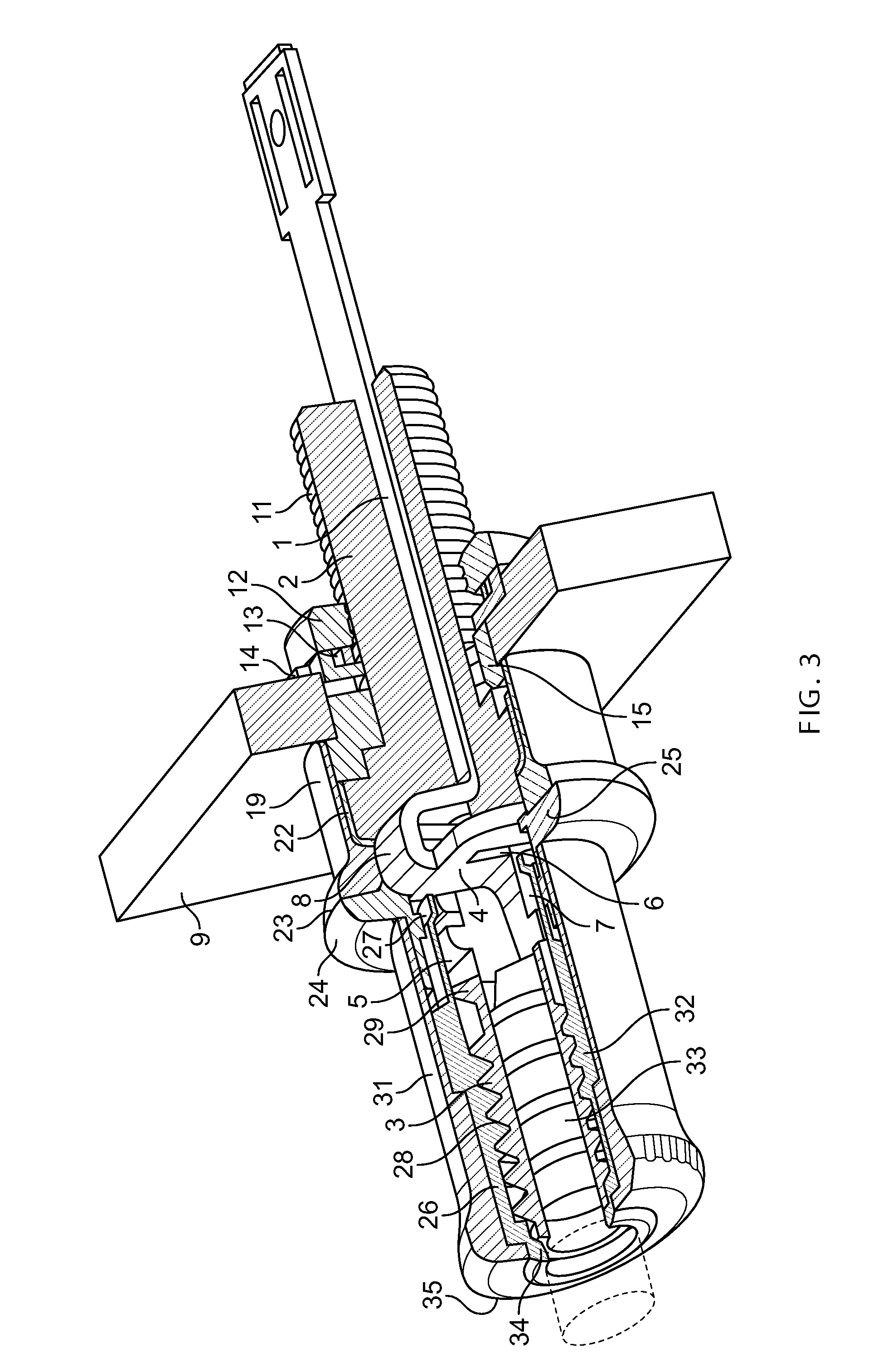

System and method for measuring bending in a pin member

InactiveUS20030000314A1Reliably accurately measureHighly accurate bending moment informationLoad modified fastenersForce measurementOutput deviceBending strain

An instrumented pin member is provided that is capable of measuring bending moments, and optionally of measuring bending and axial strain in real or near real time. The instrumented pin member includes a pin member body disposed about a pin member axis, wherein the pin member body includes a bending portion. A sensing device is positioned at the pin member body within the bending portion for sensing a bending strain in the bending portion exclusive of a net axial strain, and for outputting a sensor measurement signal representative of the bending strain. A sensor measurement signal output device is provided for outputting the sensor measurement signal from the sensor device. A related system includes a plurality of pin members, among other things. Related methods also are disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Prediction method for surface thin film residual stress

ActiveCN102426068AAccurate prediction of residual stressEasy to operateForce measurementBending strainOptoelectronics

The invention discloses a prediction method for surface thin film residual stress. The method comprises the following steps of: A, obtaining a relation curve for variation of density of internal cracks of a thin film along with a bending strain value by using a four-point bending experiment; B, establishing a theoretical prediction model for the relation of the density of the internal cracks of the thin film and the bending strain value based on the stress transfer condition in a thin film structure under the action of four-point bending load; C, establishing a theoretical relation curve for the density of the internal cracks of the thin film and the bending strain value at different residual stress values according to the theoretical prediction model in the step B; and D, selecting the theoretical relation curve in the step C which has the most matching degree with the relation curve in the step A, wherein the residual stress value corresponding to the theoretical relation curve is the predicted surface thin film residual stress. The method provided by the invention is easy to operate, can also be used for accurately predicting the residual stress of the thin film without being limited to the thin film material, and particularly has obvious advantages in the case of small thin film thickness.

Owner:EAST CHINA UNIV OF SCI & TECH

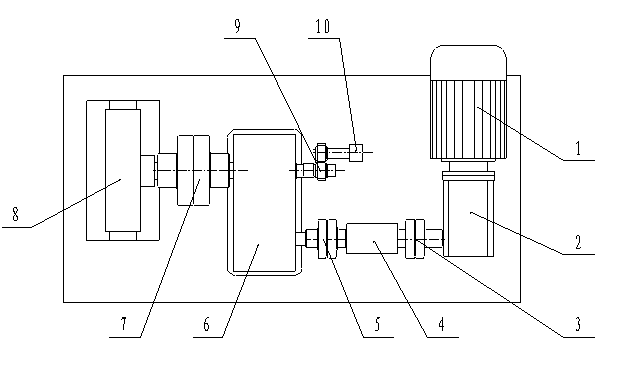

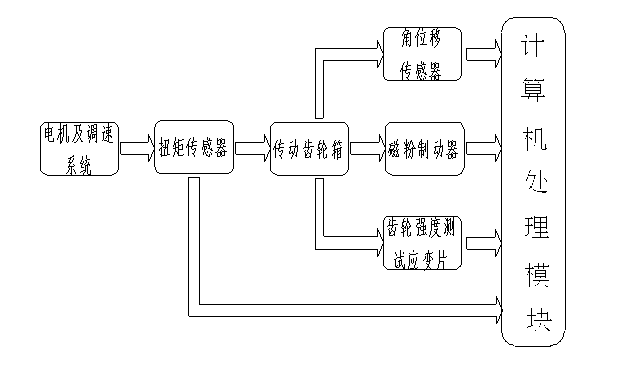

Comprehensive experiment platform for gear transmission strength design

InactiveCN103076172AThe experimental effect is idealFor quick replacementMachine gearing/transmission testingEducational modelsOutput deviceStrength design

The invention discloses a comprehensive experiment platform for gear transmission strength design, which comprises a motor, a gearbox, a load and a computer processing module; the motor is connected with the load by the input shaft of the gearbox and the output shaft of the gearbox; a torque sensor is arranged on the transmission line between the motor and the gearbox, a gear to be tested in the gearbox is provided with gear strength test strain gauges, a to-be-tested gear output shaft on which the gear to be tested is mounted is connected with an angular displacement sensor, and the torque sensor, the gear strength test strain gauges and the angular displacement sensor are electrically connected with the computer processing module. By reasonably arranging the bending stress test strain gauge and the contact stress test strain gauge, the comprehensive experiment platform for gear transmission strength design can accurately measure out the contact stress and bending stress of the gear; because an attenuation-less rotary union is adopted as a signal output device, the contact stress signal and the bending stress signal can be more really, stably and reliably transmitted; and the replaceable gearbox ensures that the experimental teaching effect is more remarkable.

Owner:湖南长庆机电科教有限公司 +1

Dental restorative composition

InactiveUS6221931B1Improve surface activityImprove toughnessImpression capsSynthetic resin layered productsNatural toothMethacrylate

A dental restorative composition is disclosed, comprising: (a) a methacrylate or acrylate monomer, (b) an organic-inorganic composite filler prepared by curing a mixture of a particulate filler having a mean particle size of 20 nm or less with a methacrylate or acrylate monomer having a viscosity of 60 cP or more and pulverizing the cured mixture, (c) a particulate filler having a mean particle size of 20 nm or less, and (d) a polymerization initiator, and further, if desired, (e) a glass powder having a maximum particle size of 5 mum or less and having a mean particle size of from 0.5 to 2 mum. The dental restorative composition according to the invention gives restorations having surface smoothness and transparency similar to natural teeth, having superior esthetics and superior physical properties such as bending strength and bending strain energy characteristics, and being provided with easy polishing.

Owner:GC CORP

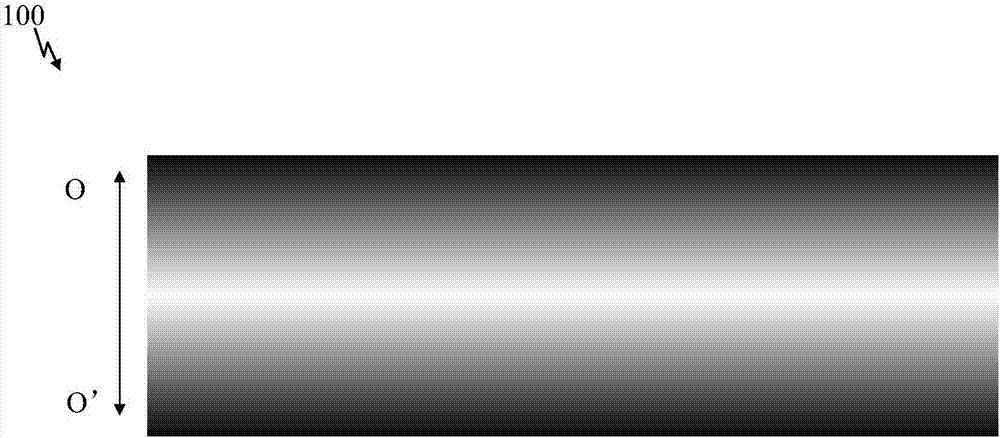

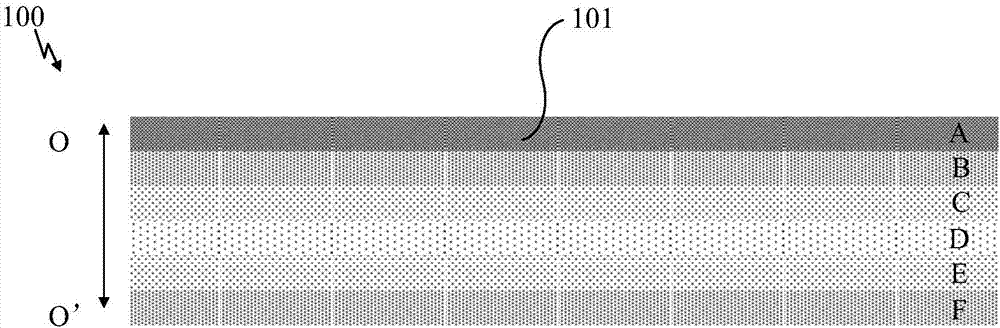

Adhesive film and preparation method thereof and flexible display module

ActiveCN107216819AGuaranteed strengthImprove reliabilityFilm/foil adhesivesIdentification meansAdhesiveBending strain

The embodiment of the invention provides an adhesive film and a preparation method thereof and a flexible display module and relates to the technical field of adhesives. By providing the adhesive film with gradually varied elasticity modulus, when the adhesive film is applied to the flexible display module, the module has enough bending strain under a proper stress. The double-sided adhesive film is distributed in a manner that the elastic modulus of the double-sided adhesive film is small in the middle but great in two sides along the thickness direction of the double-sided adhesive film.

Owner:BOE TECH GRP CO LTD

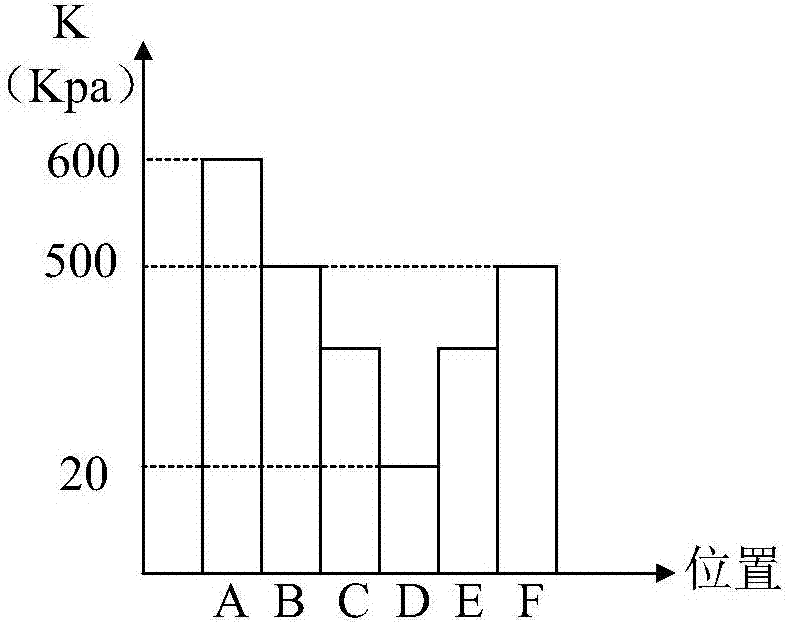

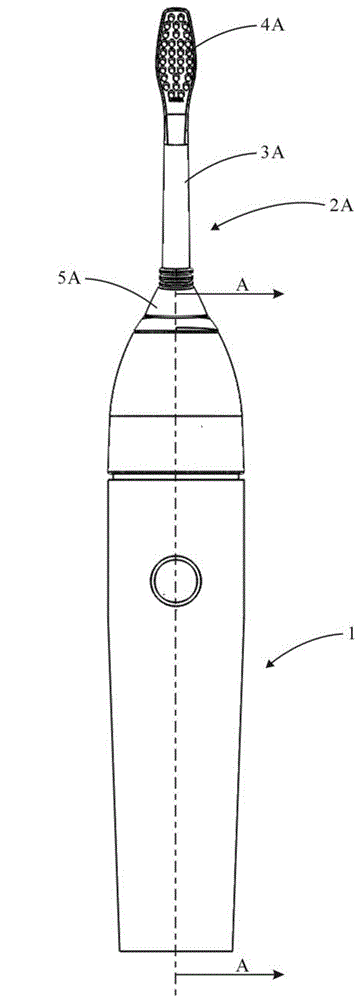

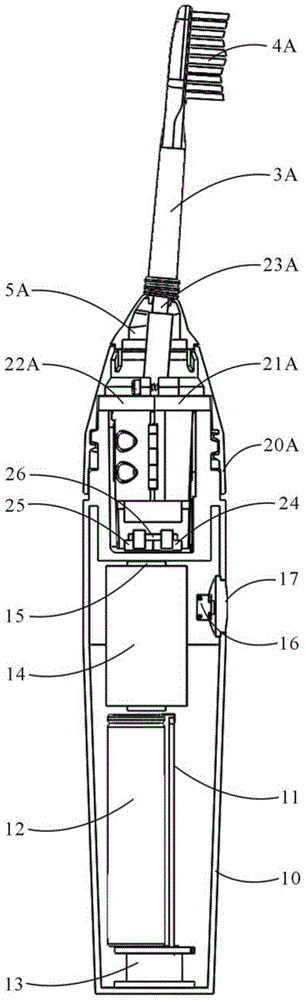

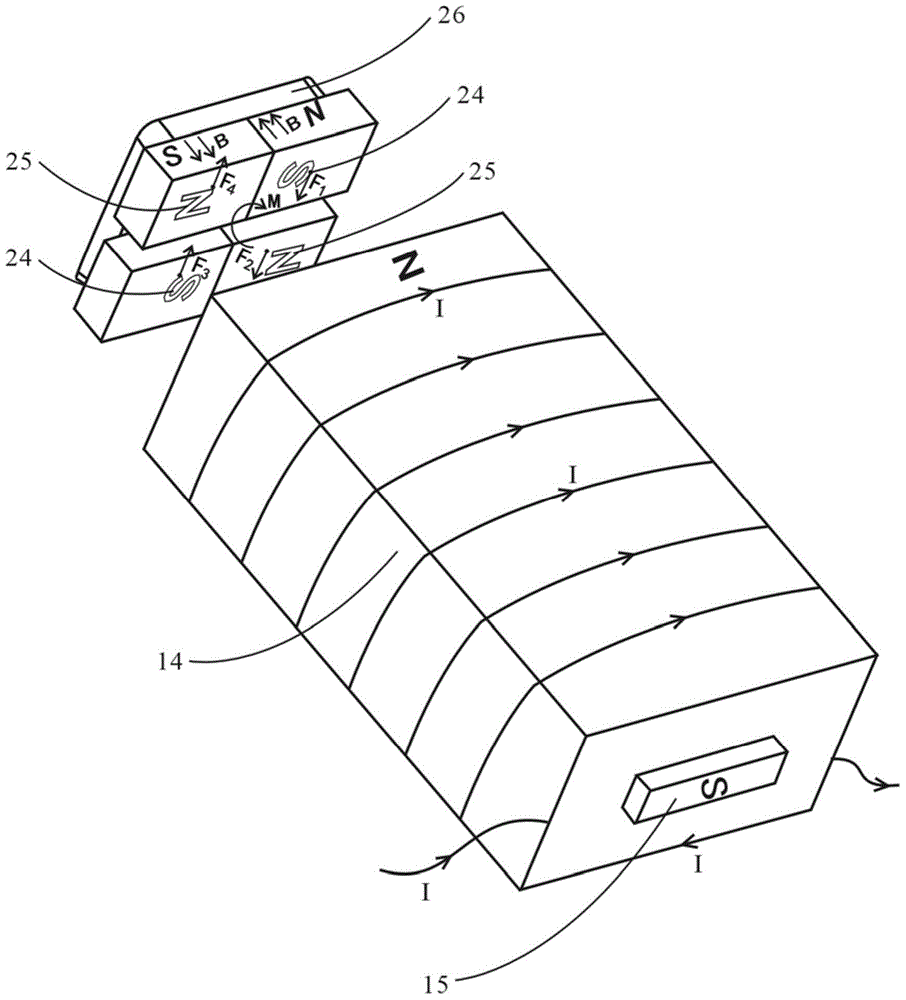

Cleaning device

The invention discloses a cleaning device for personal cleaning and nursing. The cleaning device comprises a cleaning device housing detachably connected with a handle housing, a bracket supporting the cleaning device, a cleaning element carrier as well as a cleaning element, a passive component and a cleaning device transducer which are distributed on the cleaning element carrier. The cleaning device transducer comprises at least two transducer elastic parts, wherein one end of each transducer elastic part is fixedly connected with a corresponding transducer elastic part fixing part; the other end of each transducer elastic part is fixedly connected with a transmission arm of the transducer bracket linking elastic part; bending strain of the elastic material is utilized to form the cleaning device with vibrating frequency of f (inherent frequency), so that the inherent frequency f of the cleaning device ranges from 100 Hz to 400 Hz; a relationship between the inherent frequency f (inherent frequency) and electromagnetic force frequency f0 generated in a drive coil in the handle meets that: f (inherent frequency) is larger than 0.85f0 and smaller than 1.05f0. The cleaning device provided by the invention is relatively compact in structure, relatively attractive in appearance, relatively stable to rotate and relatively small in noise.

Owner:SHANGHAI SHIFT ELECTRIC CO LTD

Simple fiber optic seismometer for harsh environments

InactiveUS7714271B1Suitable accuracySuitable sensitivityRadiation pyrometrySubsonic/sonic/ultrasonic wave measurementGratingBending strain

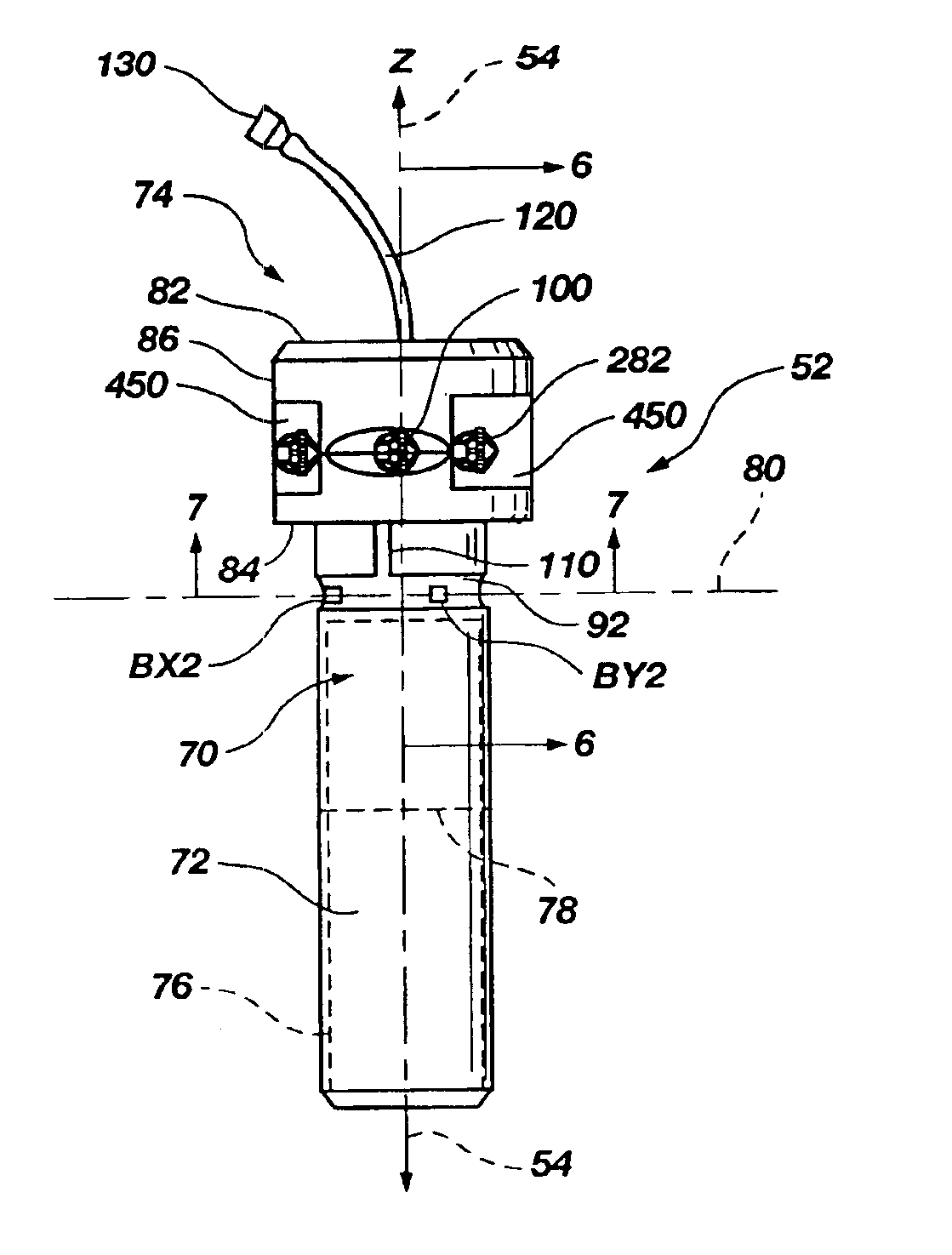

Disclosed is a sensor capable of measuring motion in a harsh environment. The sensor uses a fiber optic sensor element formed within a core of an optical fiber that is disposed within an enclosure made of a high strength, corrosion-resistant material. The optical fiber is attached to a supporting fixture in a cantilever fashion so that the intrinsic internal mass of the optical fiber has the freedom to be affected by gravity so that an environmental disturbance acting on the sensor results in a bending strain being applied to the optical fiber. A Bragg grating is located at the bending portion of the optical fiber. The modulation of an optical signal promulgating through the optical fiber is sensed using conventional means and used to measure the magnitude of the environmental disturbance.

Owner:US OIL & GAS CORP

Display assembly and mobile device with same

The invention discloses a display assembly and a mobile device with the same. The display assembly can be bent and comprises a mounting substrate and a flexible display module which is mounted on the mounting substrate. A groove is formed in one of the mounting substrate and the flexible display module, the other is provided with a bulge suitable for being matched in the groove, and when the display assembly is not bent, a gap between the groove and the bulge is formed to absorb strains generated when the display assembly is bent. According to the display assembly, the flexible display module and the mounting substrate are matched through the groove and the bulge, the gap between the groove and the bulge is formed when the display assembly is not bent, so that when the whole device is bent, the bending strains are absorbed through the connecting mode between the flexible display module and the mounting substrate, and borders of the flexible display module are not added at the same time, and therefore the problem is solved that a film layer of the flexible display module cracks when the whole device is bent.

Owner:BOE TECH GRP CO LTD

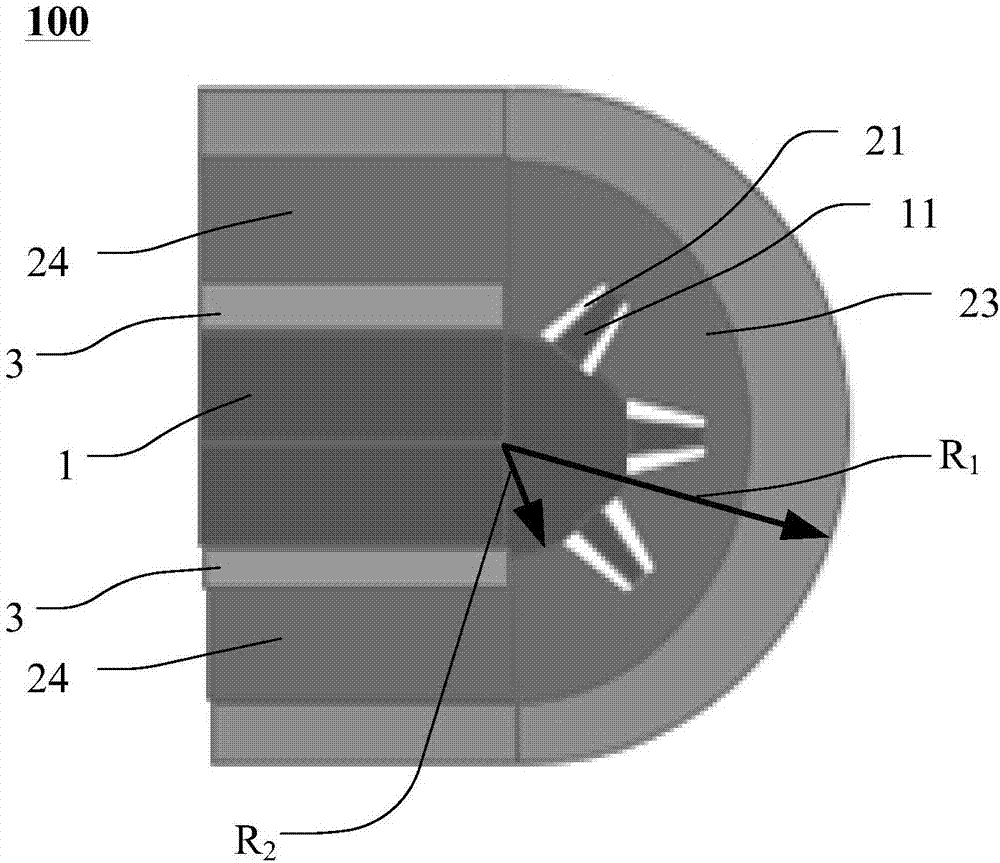

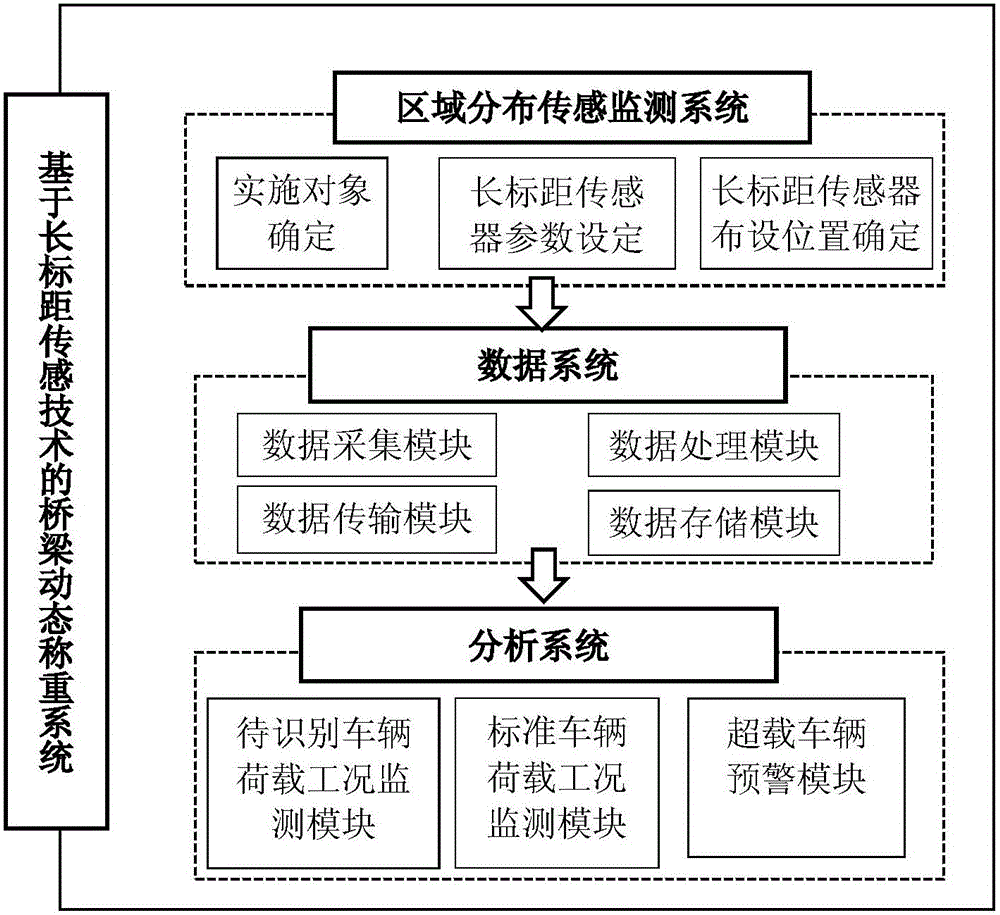

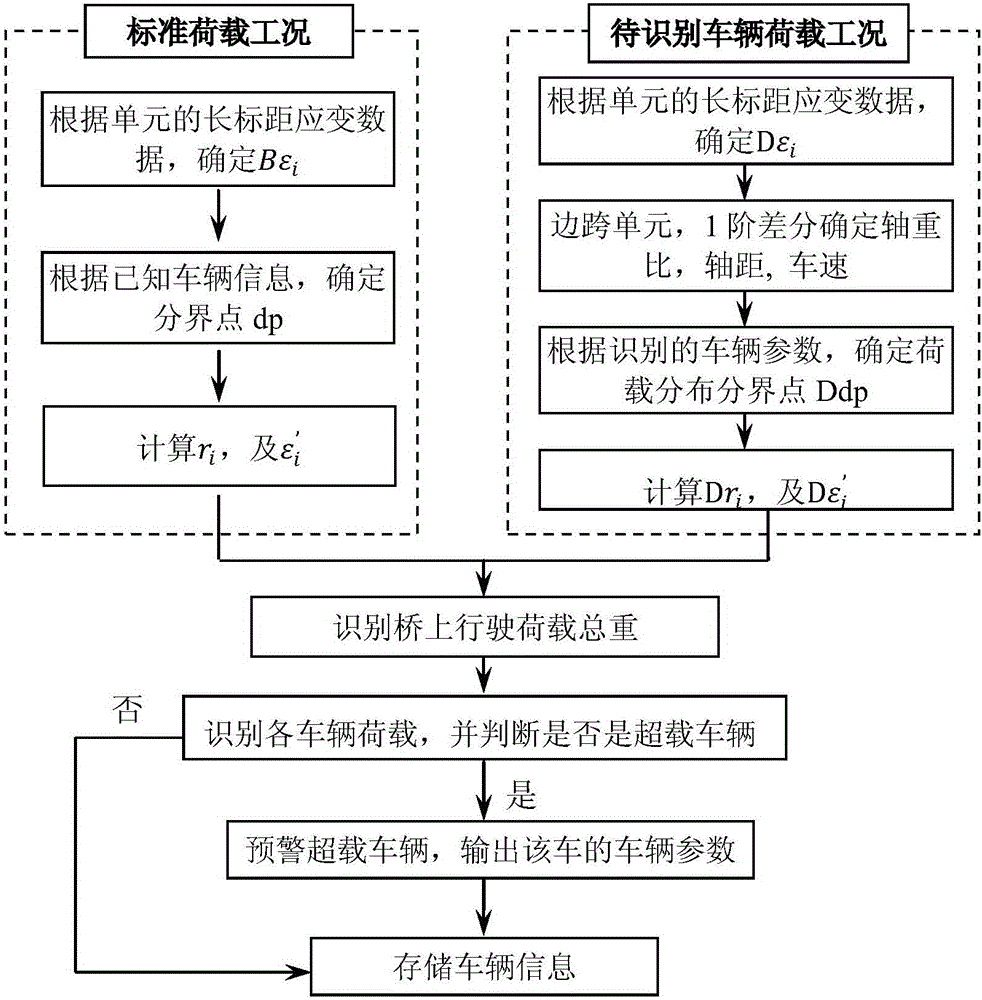

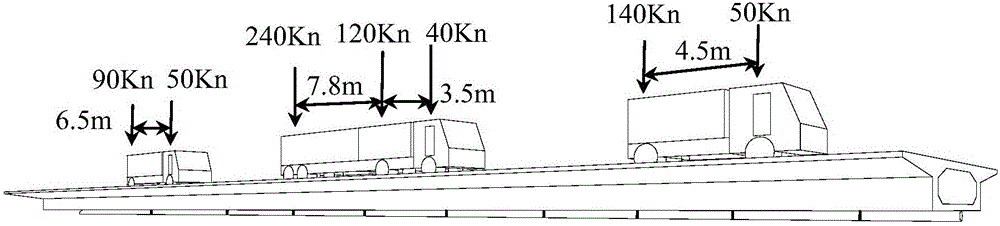

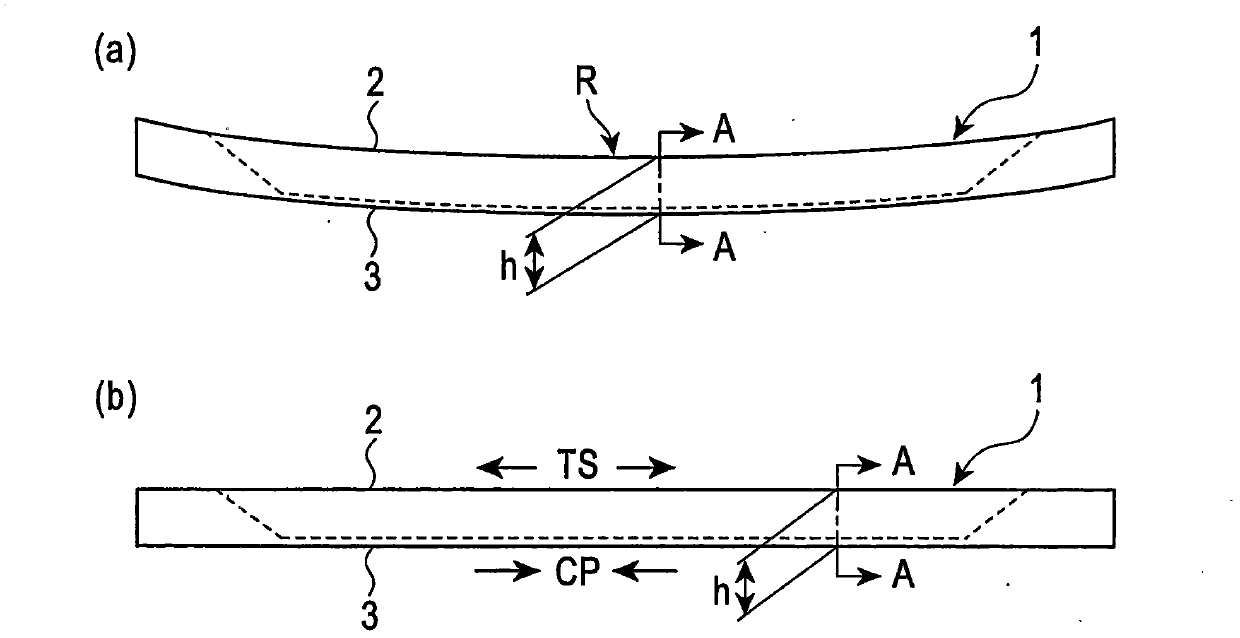

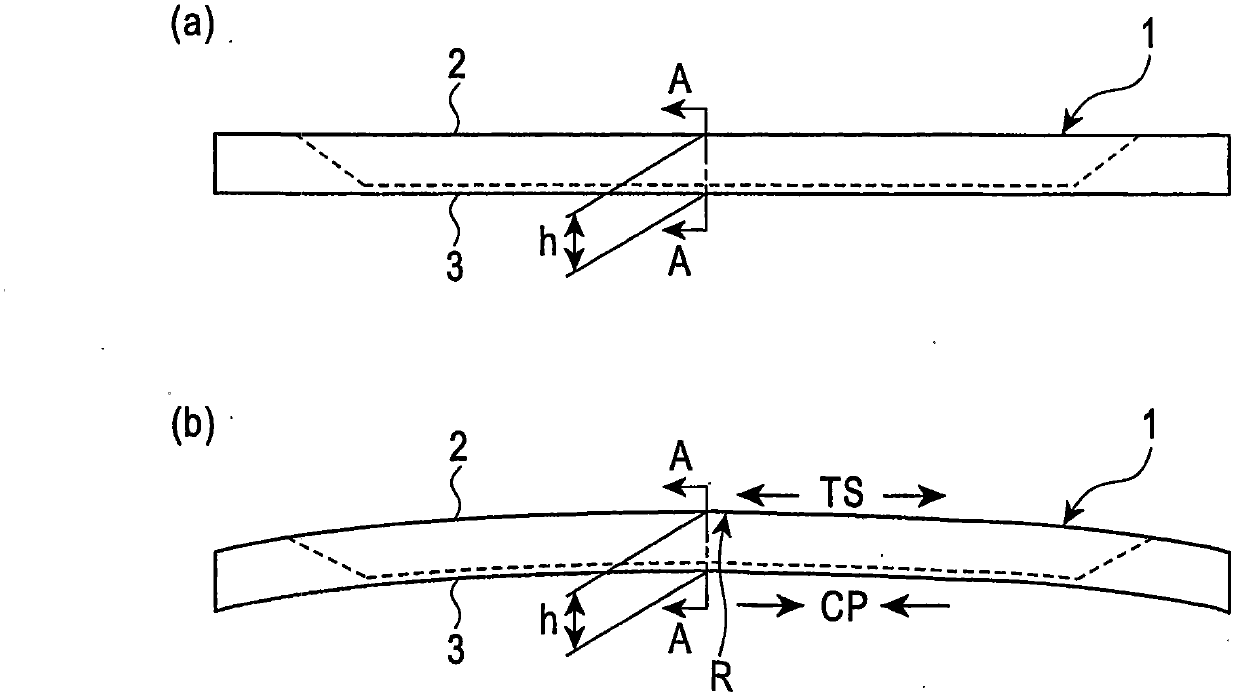

Bridge dynamic weighing method based on long-gauge fiber grating sensing technology and dynamic weighing system thereof

ActiveCN106441530AAvoid damageReduce maintenance costsWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusFiberGrating

The invention discloses a bridge dynamic weighing method based on the long-gauge fiber grating sensing technology and a bridge dynamic weighing system thereof. The dynamic weighing method comprises the steps that long-gauge sensors are arranged: the long-gauge sensors are arranged on the initial entering and final exiting side span units of a vehicle and the part between the two side span units along the length direction of the bridge; load condition monitoring of a vehicle to be identified and load condition monitoring of a standard vehicle are performed: the vehicle of which various parameters are known acts as the standard vehicle, the strain response data of each sensing unit under the load condition of the standard vehicle are acquired, and the maximum strain of each sensing unit only caused by the axle load is calculated; and vehicle load identification under the load condition of the vehicle to be identified is performed. The maximum bending strain value only caused by the axle load under the load condition of the standard vehicle is analyzed and compared with the corresponding value under the load condition of the standard value so that the total weight of the driving load on the bridge and the load of each vehicle can be identified, the overload vehicle can be effectively pre-warned and thus damage to the big long-span bridges can be avoided.

Owner:SOUTHEAST UNIV

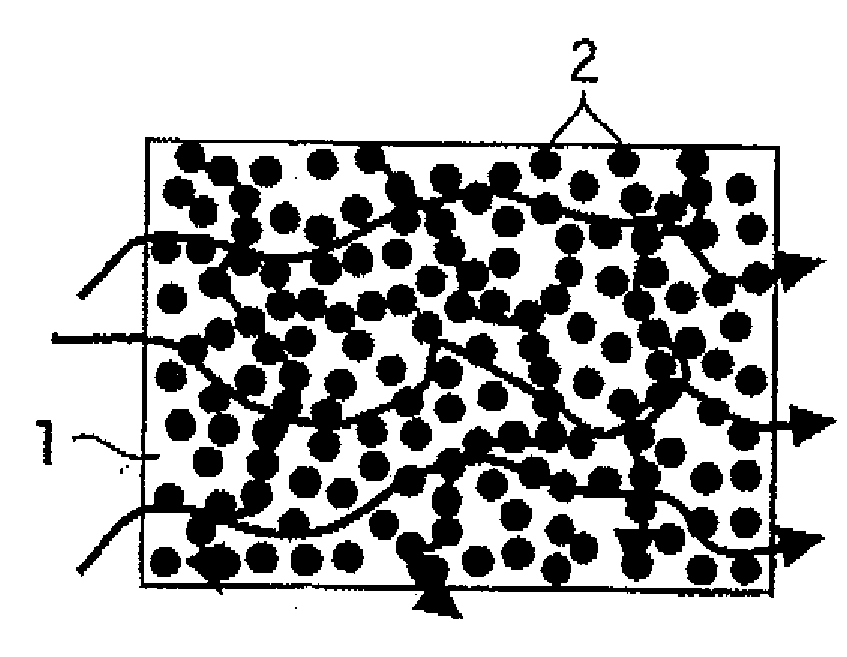

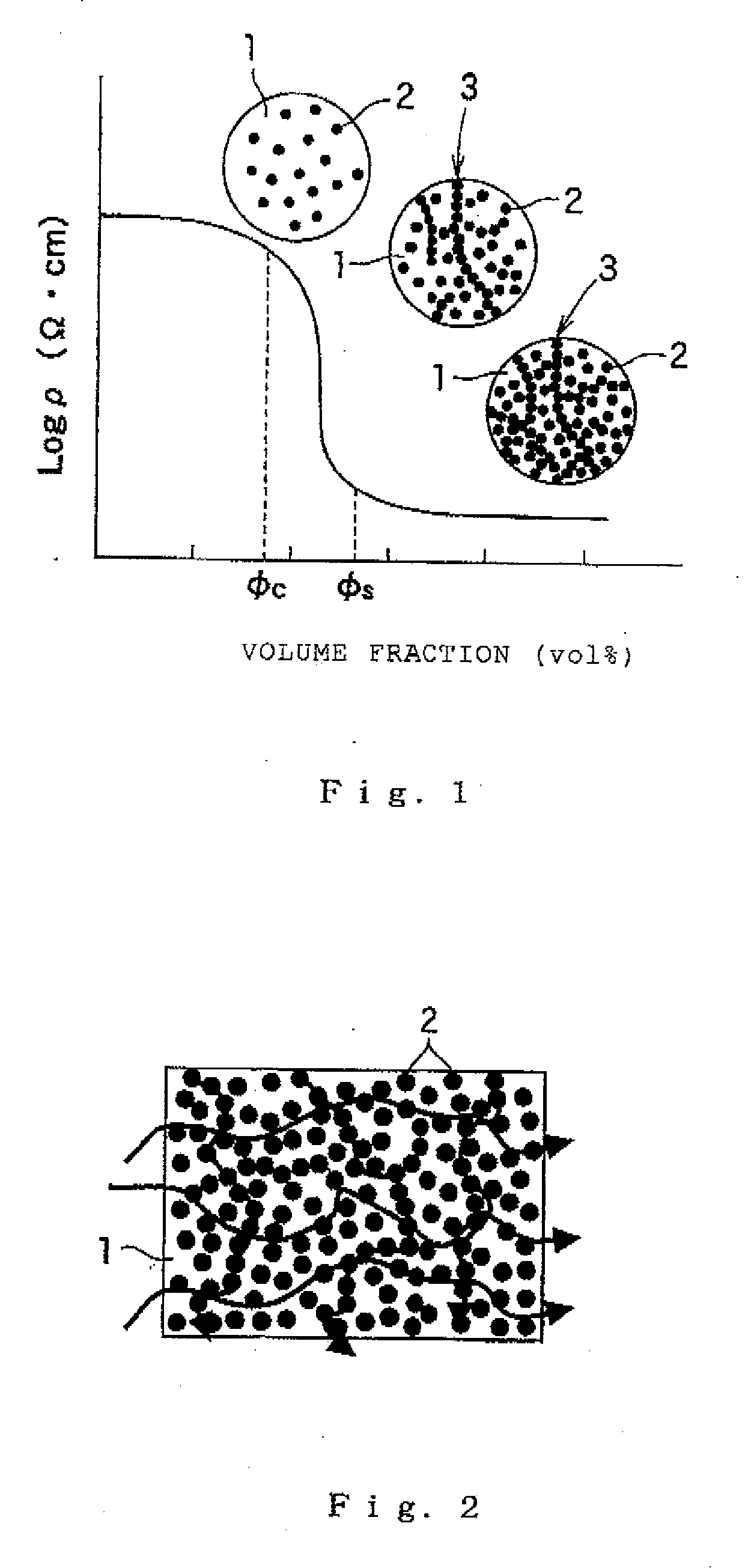

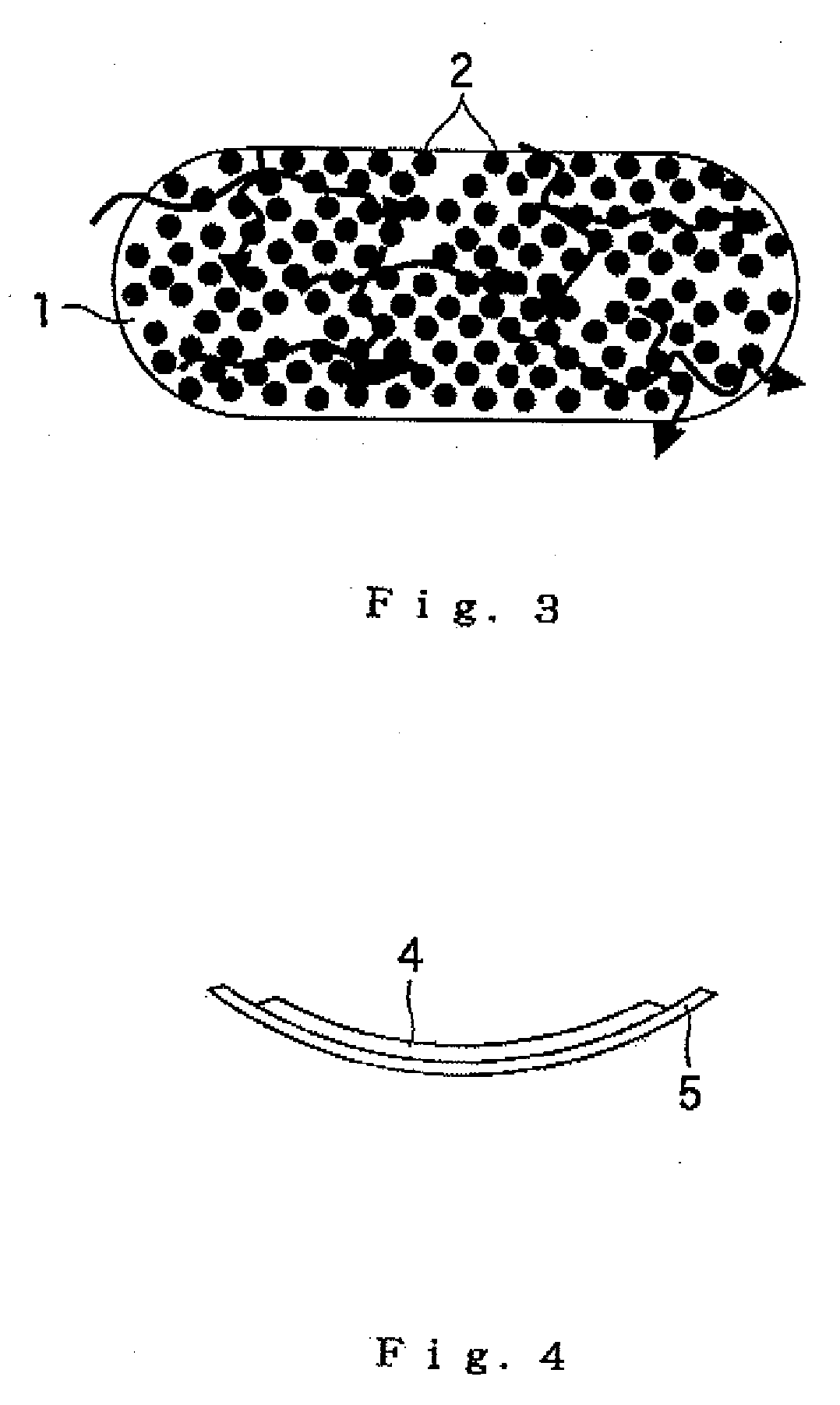

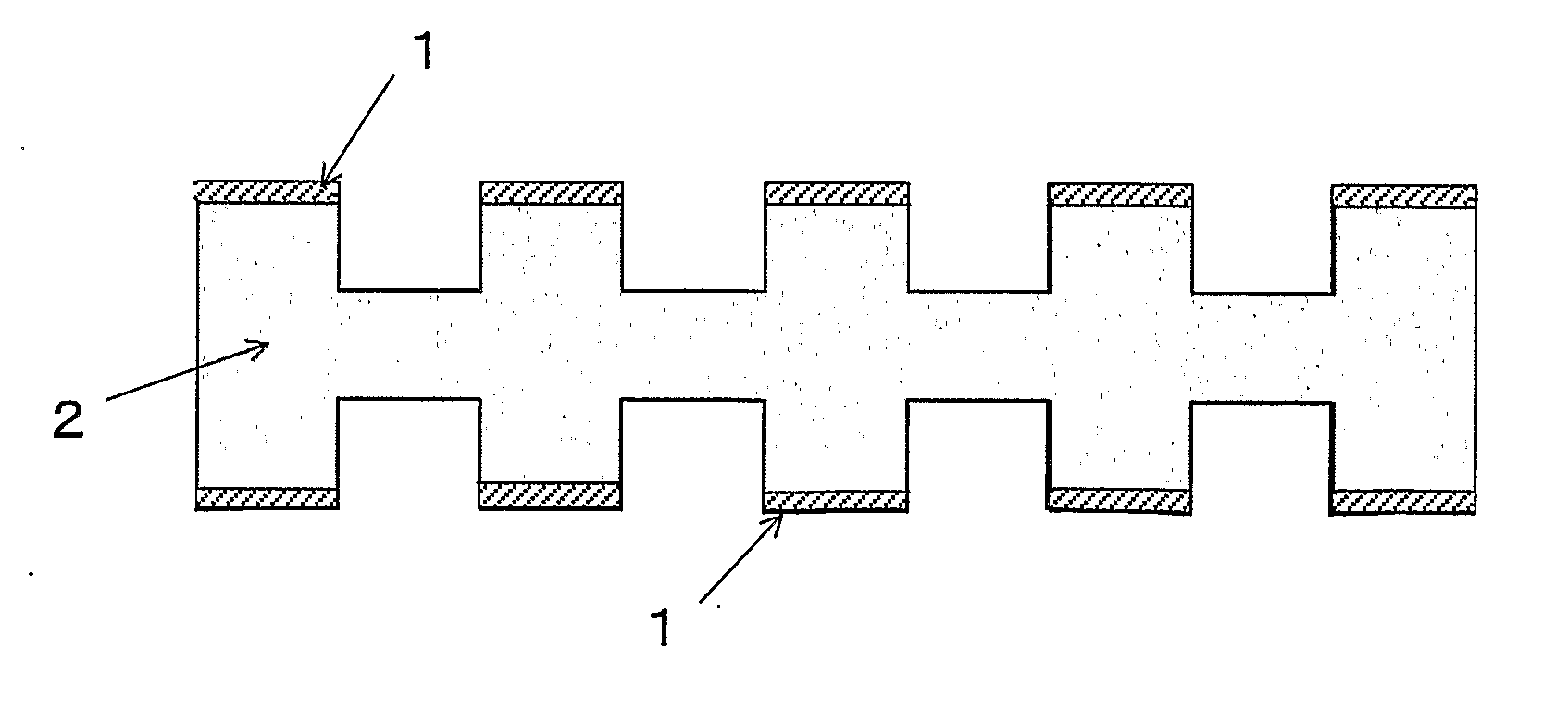

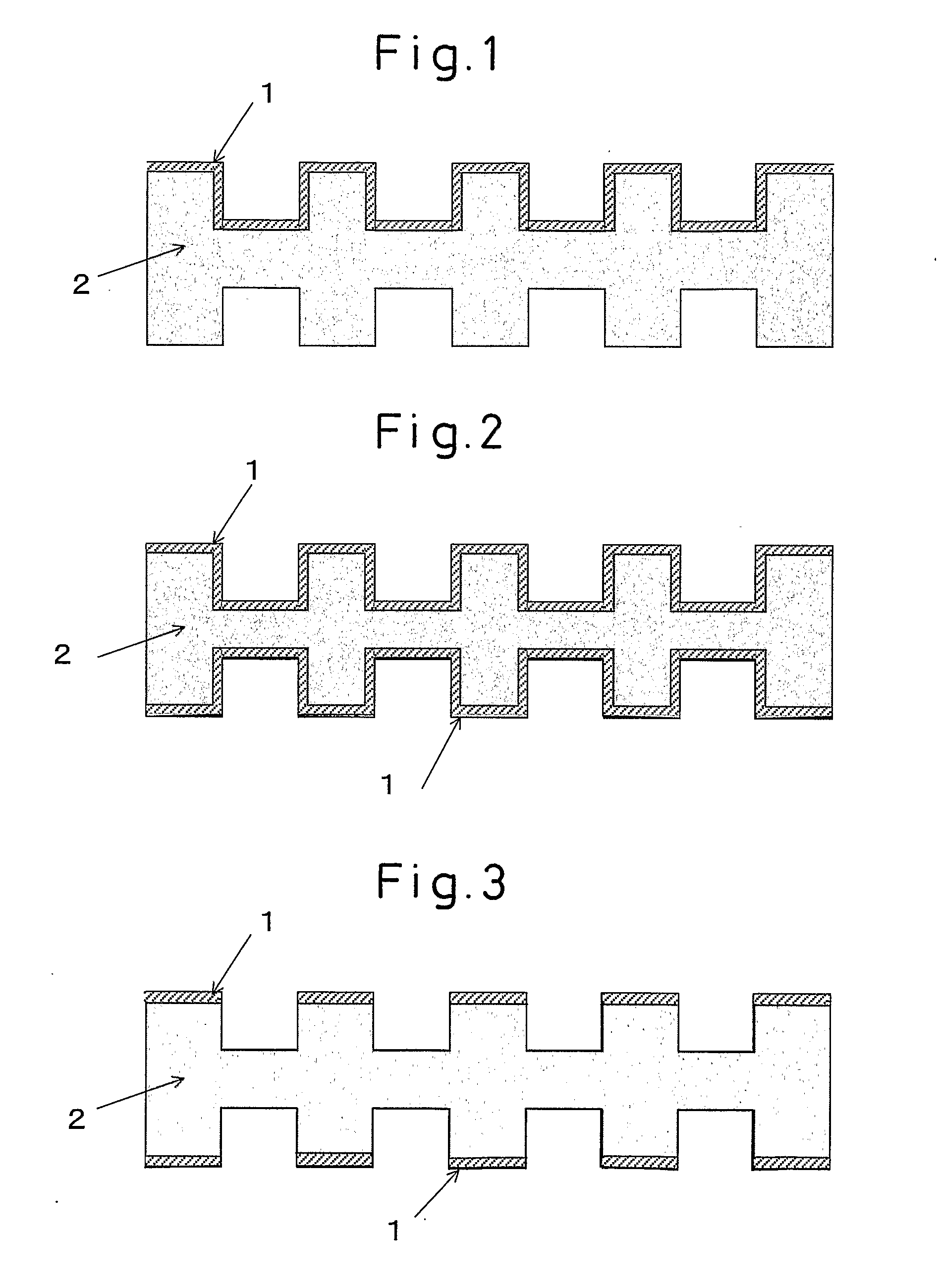

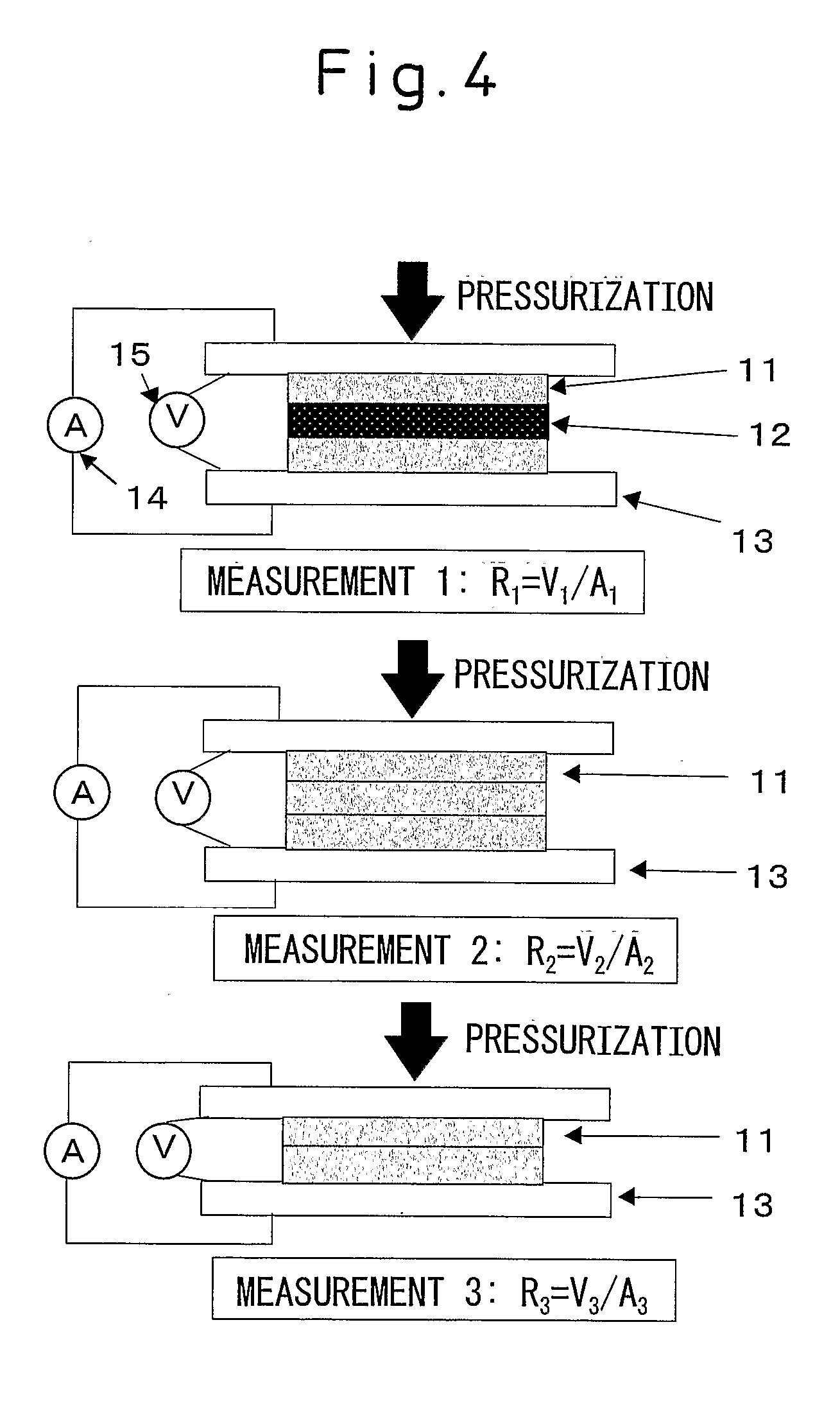

Crosslinked elastomer body for sensor, and production method therefor

InactiveUS20080067477A1High shape design flexibilityGood molding effectConductive materialNon-conductive material with dispersed conductive materialElastomerParticulates

A crosslinked elastomer body is composed of an electrically conductive composition comprising an electrically conductive filler and an insulative elastomer (matrix). The electrically conductive tiller is in a spherical particulate form and has an average particle diameter of 0.05 to 100 μm. The electrically conductive filler has a critical volume fraction (φc) of not less than 30 vol % as determined at a first inflection point of a percolation curve at which an insulator-conductor transition occurs with an electrical resistance steeply reduced when the electrically conductive filler is gradually added to the elastomer. A resistance observed under compressive strain or bending strain increases according to the strain over a resistance observed under no strain when the electrically conductive filler is present in a volume fraction not less than the critical volume fraction (φc) in the composition.

Owner:SUMITOMO RIKO CO LTD

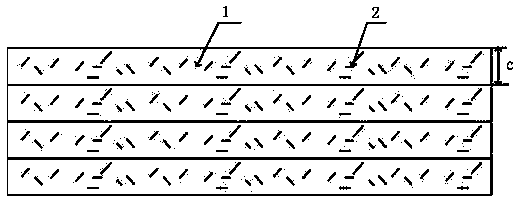

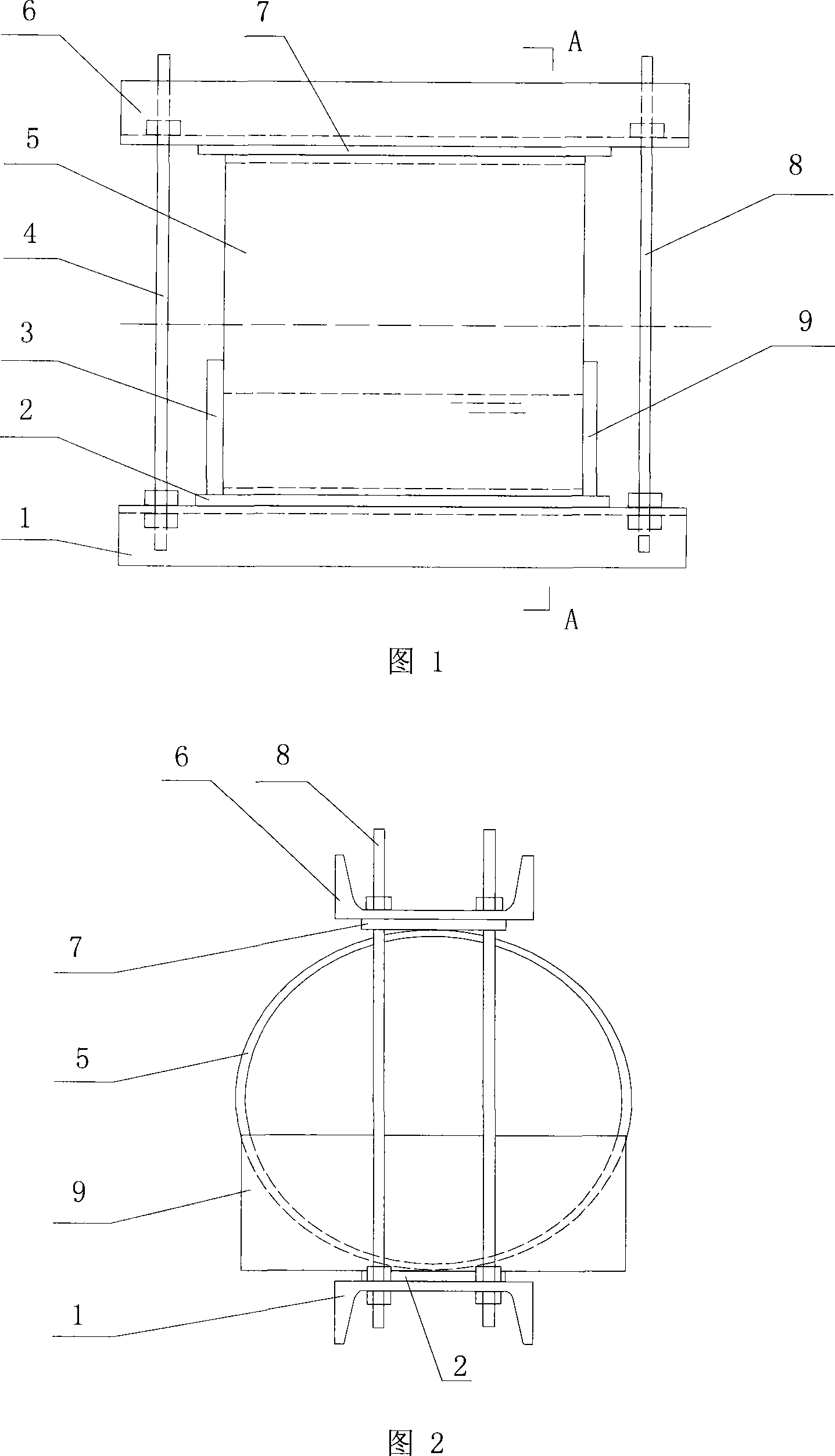

Test method of sample destroy time in tube of glass fibre reinforced plastic long-term performance test

InactiveCN101118203AReduce labor intensityImprove accuracyWeather/light/corrosion resistanceStrength propertiesEngineeringBending strain

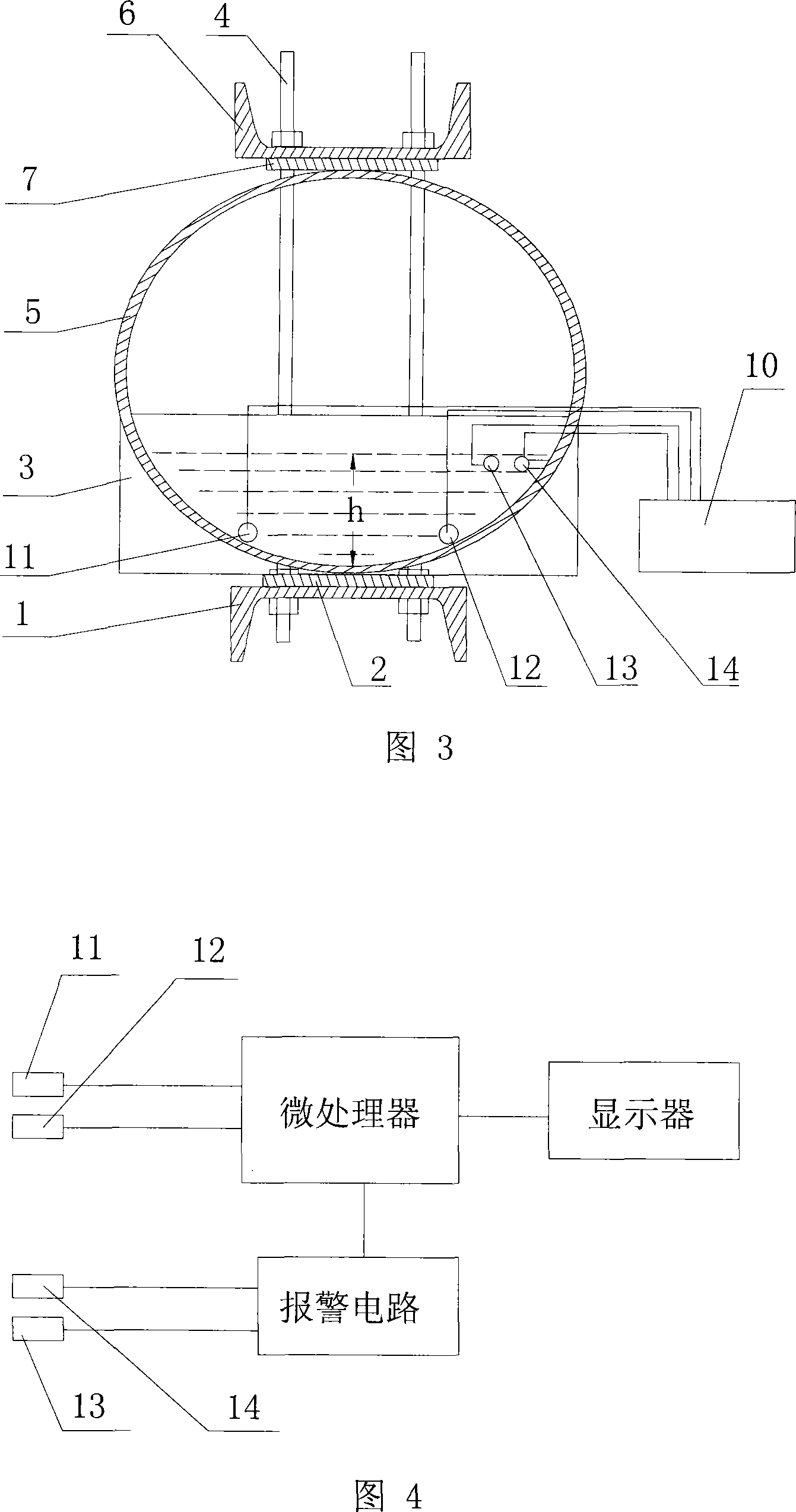

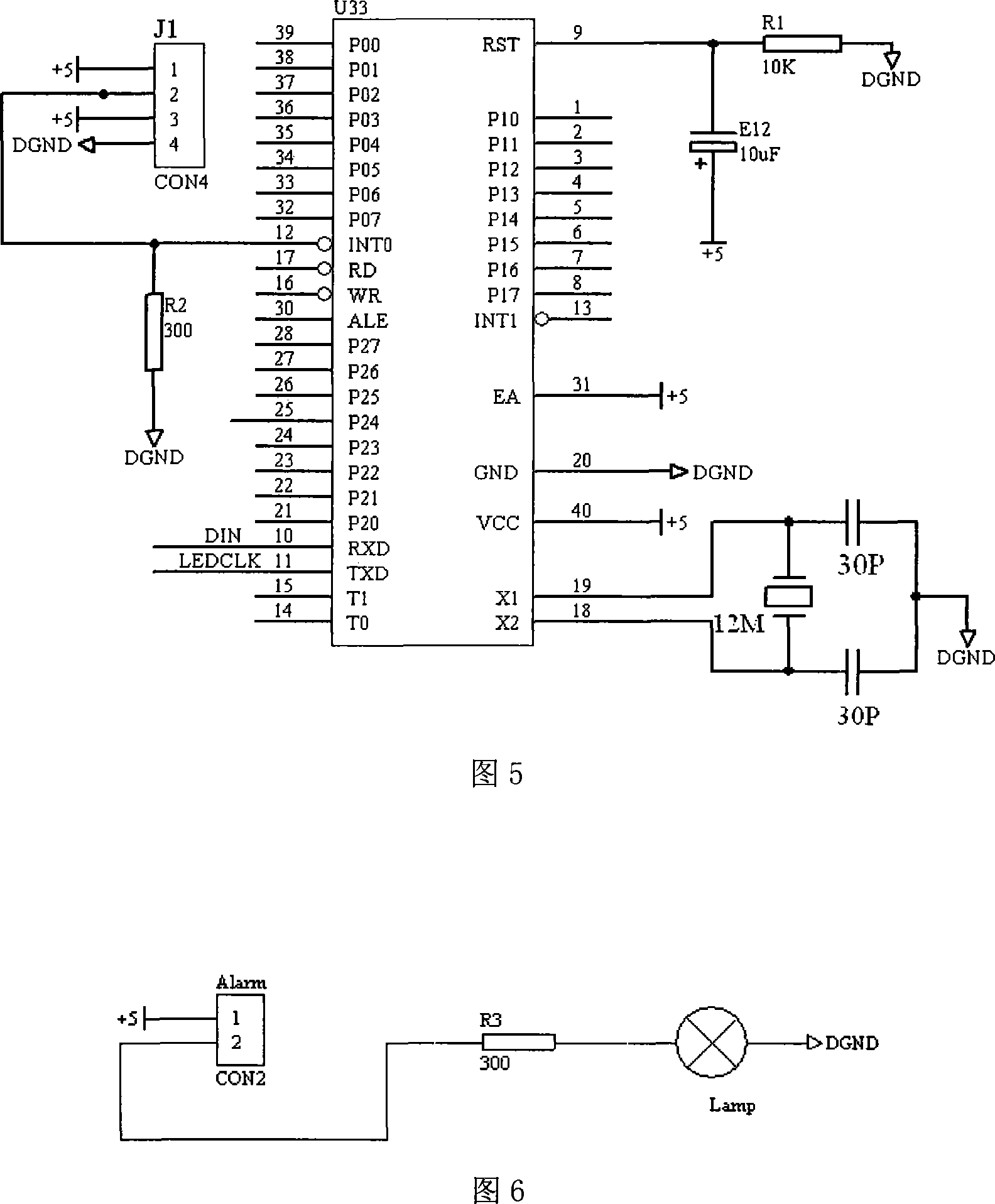

The present invention relates to a test method of a test piece destruction time in a glass-reinforced plastic pipe long-term ring-bending strain test, in particular to a test method of a test piece destruction time in a glass-reinforced plastic pipe long-term performance test. The present invention is characterized in that with the help of the conductive characteristic of corrosive liquor, a corrosion resistant and conductive first interruption electrode 11 and a second interruption electrode 12 are arranged on the two sides of the bottom pipe wall in a glass-reinforced plastic pipe test piece 5; when the glass-reinforced plastic pipe test piece 5 is charged with sulfuric acid corrosive liquor, the first interruption electrode 11 and the second interruption electrode 12 are connected through corrosive liquor, the conductive characteristic of the sulfuric acid corrosive liquor is utilized to make the external interruption pin of a microporocessor in a high level, and the microporocessor starts to record power on time; when the glass-reinforced plastic pipe test piece 5 is broken under the effect of distortion and sulfuric acid corrosion, the sulfuric acid flows out of the glass-reinforced plastic pipe test piece 5 along the fracture, the first interruption electrode 11 and the second interruption electrode 12 are disconnected, the external interruption of the microporocessor is in a low level, and the microporocessor stops timing, thus the test piece destruction time is obtained. The present invention has the advantages of reduced labor intensity, and high accuracy.

Owner:SHENZHEN KANGQIANG CONSTR NEW TECH ENG

Method and apparatus for measuring bending in a pin member

InactiveUS6951137B2Efficient measurementReliably accurately measureLoad modified fastenersForce measurementBending strainOutput device

An instrument pin member is provided that is capable of measuring bending moments and optionally of measuring bending and axial strain in real or near real time. The instrumented pin member includes a pin member body disposed about a pin member axis, wherein the pin member body includes a bending portion. A sensing device is positioned at the pin member body within the bending portion for sensing a bending strain in the bending portion exclusive of a net axial strain, and for outputting a sensor measurement signal representative of the bending strain. A sensor measurement signal output device is provided for outputting the sensor measurement signal from the sensing device. A related system includes a plurality of pin members, among other things. Related methods also are disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Pole terminal

InactiveUS7354306B2Reduce material thicknessImprove conductivityOne pole connectionsElectrically conductive connectionsElectrical connectionBending strain

The invention relates to a pole terminal for producing an electrical connection. Said pole terminal comprises a metallic conductive body which is surrounded by an insulating body which can be fixed to the housing of an electrical appliance, and on which a tensioning nut can be screwed, said tensioning nut clamping the electrical conductor to be connected against the conductive body, establishing an electrical contact. The aim of the invention is to improve one such pole terminal in such a way that the conductive body can be produced from a material which is highly conductive, such as silver or copper. To this end, the conductive body is produced from a material exhibiting higher conductivity, by means of noncutting deformation, and is connected to the surrounding insulating body to form a composite body. Preferably, the conductive body is embodied as a stamped part which is machined by bending strain.

Owner:THORNER WOLFGANG B

Fuel cell separator and production process thereof

InactiveUS20070178349A1Reduce contact resistanceImprove conductivityMaterial nanotechnologyFinal product manufactureFuel cellsSurface layer

A fuel cell separator having a surface layer on one side or both sides thereof. The surface layer includes at least two layers, wherein the surface layer includes a low-elastic modulus layer (1) having a bending elastic modulus of 1.0×10<sp>1< / sp>-6.0×10<sp>3< / sp> MPa, and a bending strain of 1% or more; and a high-elastic modulus layer (2) having a bending elastic modulus exceeding 6.0×10<sp>3< / sp> MPa, as at least one layer constituting the surface layer, other than the low-elastic modulus layer (1).

Owner:SHOWA DENKO KK

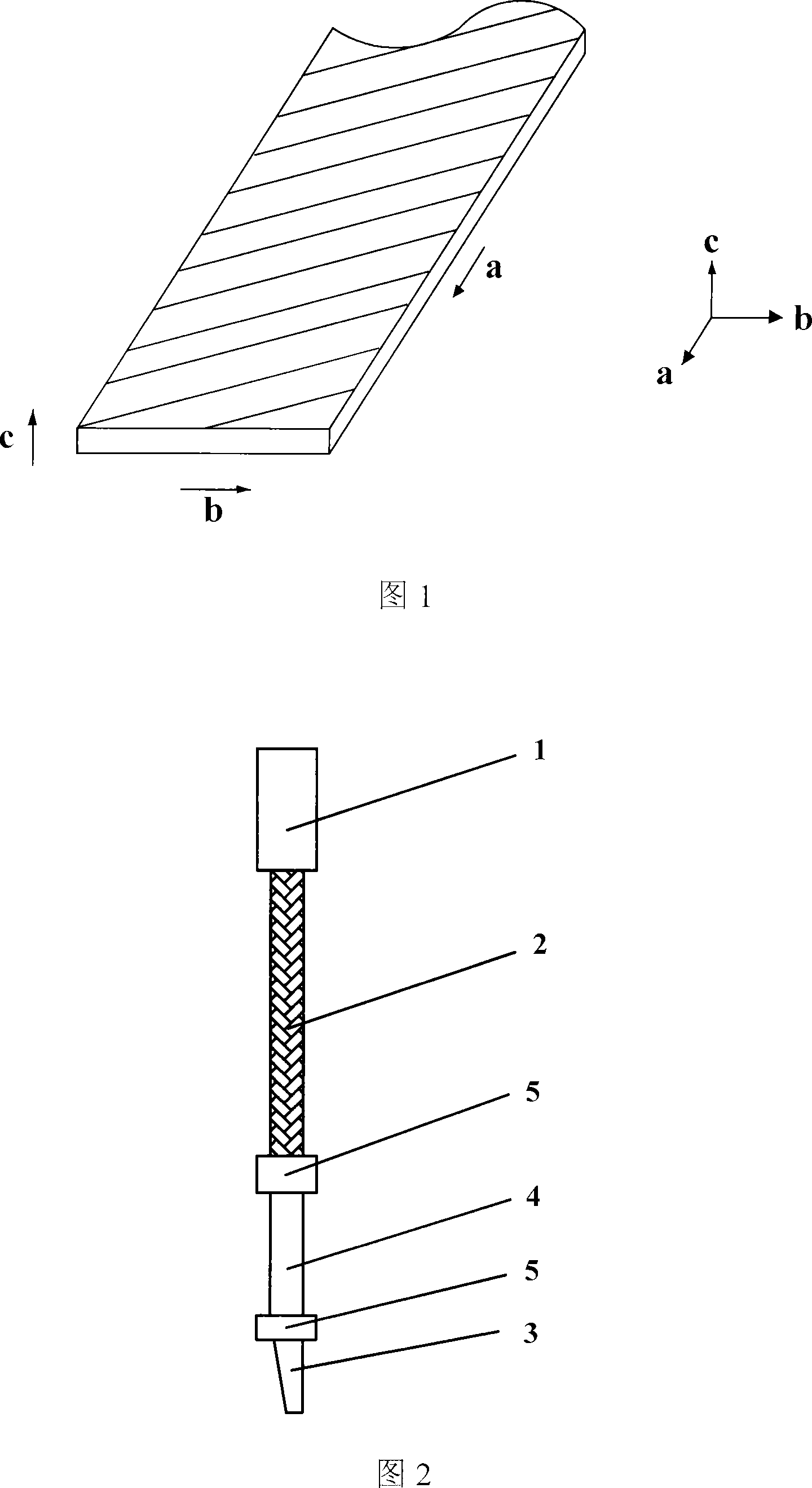

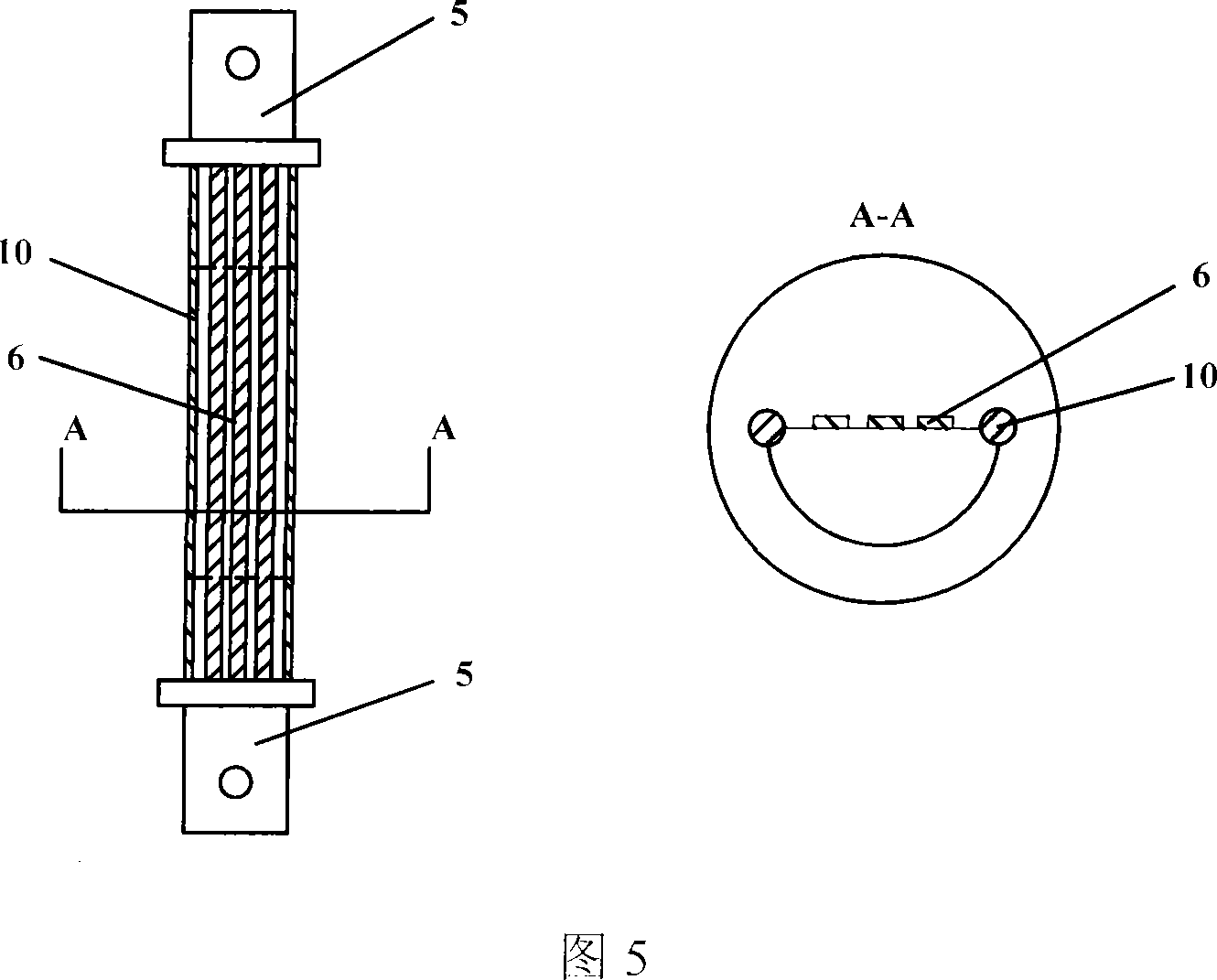

High-temperature superconductive lead wire

ActiveCN101221848ASo as not to damageGuaranteed structural strengthSuperconducting magnets/coilsHigh-temperature superconductivityBending strain

The invention relates to a current lead for a high temperature super conducting device, comprising a high temperature super conduction segment and a heat exchanger, wherein the high temperature super conduction segment consists of at least one super conducting element and two end heads, the super conducting element comprises at least one high temperature super conducting wire with super conducting capability and at least one elastic skeleton, when the super conducting element comprises more than two high temperature super conducting wires with super conducting capability, the width surfaces of wires are in parallel; when the bending strain of the whole high temperature super conduction segment is less than 0.5 percent, the critical current of the high temperature super conducting wire is no less than 95 percent of the critical current of the wire which does not receive the strain; by the method, the high temperature super conduction current lead can be bent in a certain range, thereby the invention is more flexible in practical use and more easily realizes the standardizing industrial production.

Owner:INNOVA SUPERCONDUCTOR TECH

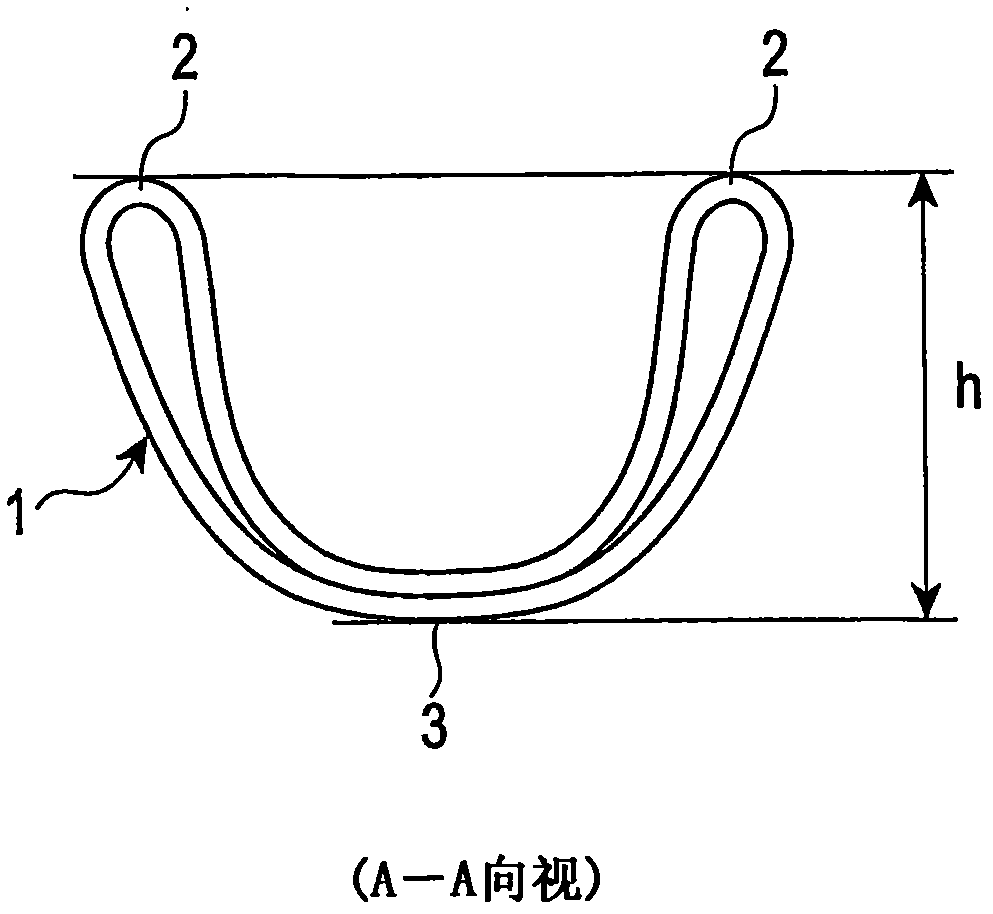

Method for manufacturing torsion beam and torsion beam

ActiveCN102387876AReduce tensile residual stressImprove fatigue strengthInterconnection systemsResilient suspensionsEngineeringBending strain

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com