Comprehensive experiment platform for gear transmission strength design

A technology of design synthesis and transmission strength, applied in the direction of machine gear/transmission mechanism testing, instruments, teaching models, etc., can solve the problems of insignificant teaching effect, inability to verify experimentally, inability to directly measure gear contact stress and bending stress, etc. Achieve the effect of realistic and ideal experimental effect, real signal transmission process, and improve experimental efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

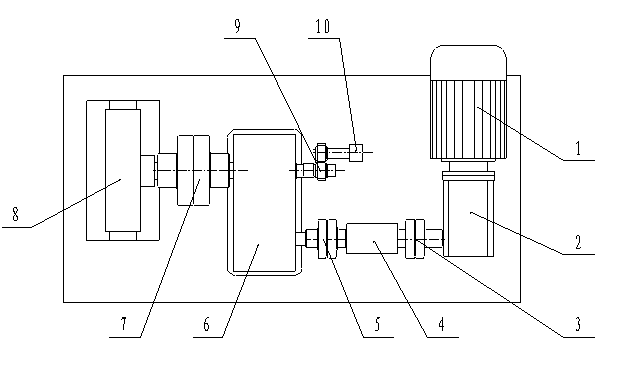

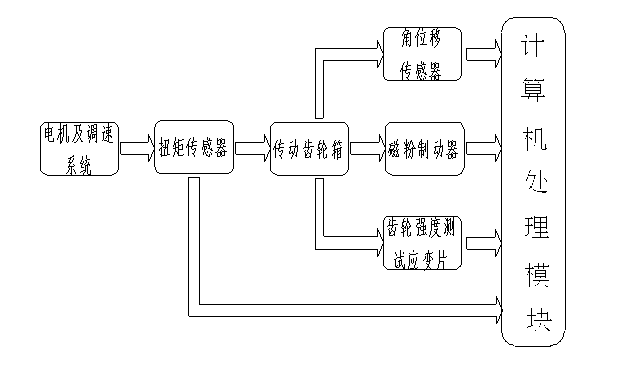

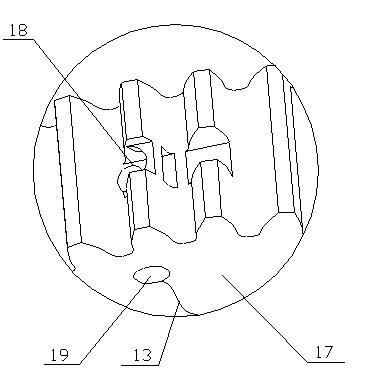

[0022] see figure 1 and figure 2 , the gear transmission strength design comprehensive test bench in this embodiment includes a three-phase asynchronous motor 1, a gearbox 6, a magnetic powder brake 8 and a computer processing module, and the output end of the three-phase asynchronous motor 1 passes through the reducer 2 and the first shaft coupling in turn The torque sensor 3 is connected to one end of the torque sensor 4, the other end of the torque sensor 4 is connected to the input shaft of the gearbox 6 through the second coupling 5, and the output shaft of the gearbox 6 is connected to the magnetic powder brake 8 as a load through the third coupling, see in conjunction image 3 and Figure 4 , the gear to be tested 17 in the gear box 6 is provided with a gear strength test strain gauge, the gear to be tested output shaft 11 that is set with the gear to be tested 17 is connected to the angular displacement sensor 10, the torque sensor 4, the gear strength to test the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com