High-temperature superconductive lead wire

A high-temperature superconducting, current lead technology, applied in superconducting magnets/coils, circuits, electrical components, etc., to achieve the effects of improving work stability, easy standardization of industrial production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

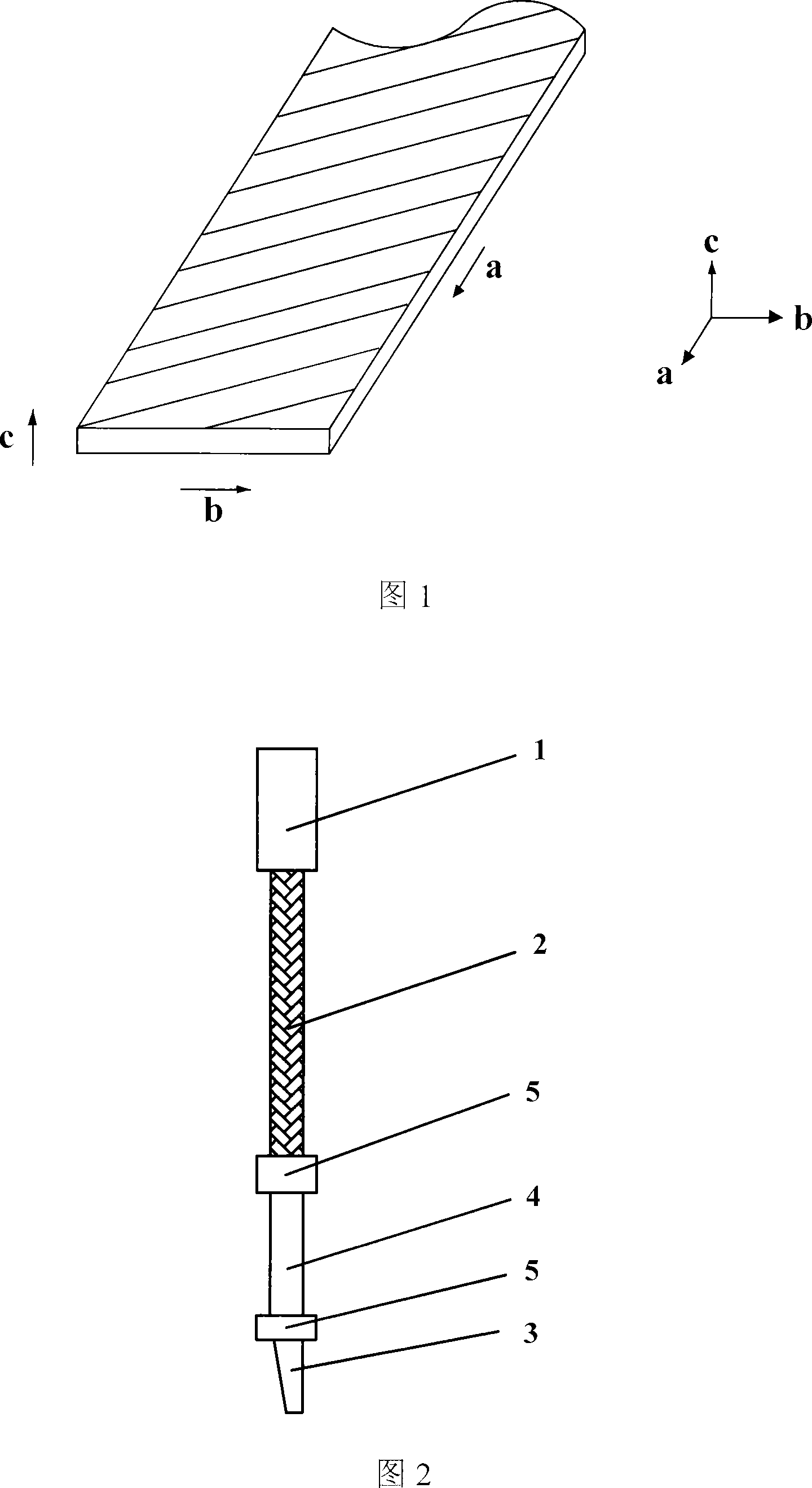

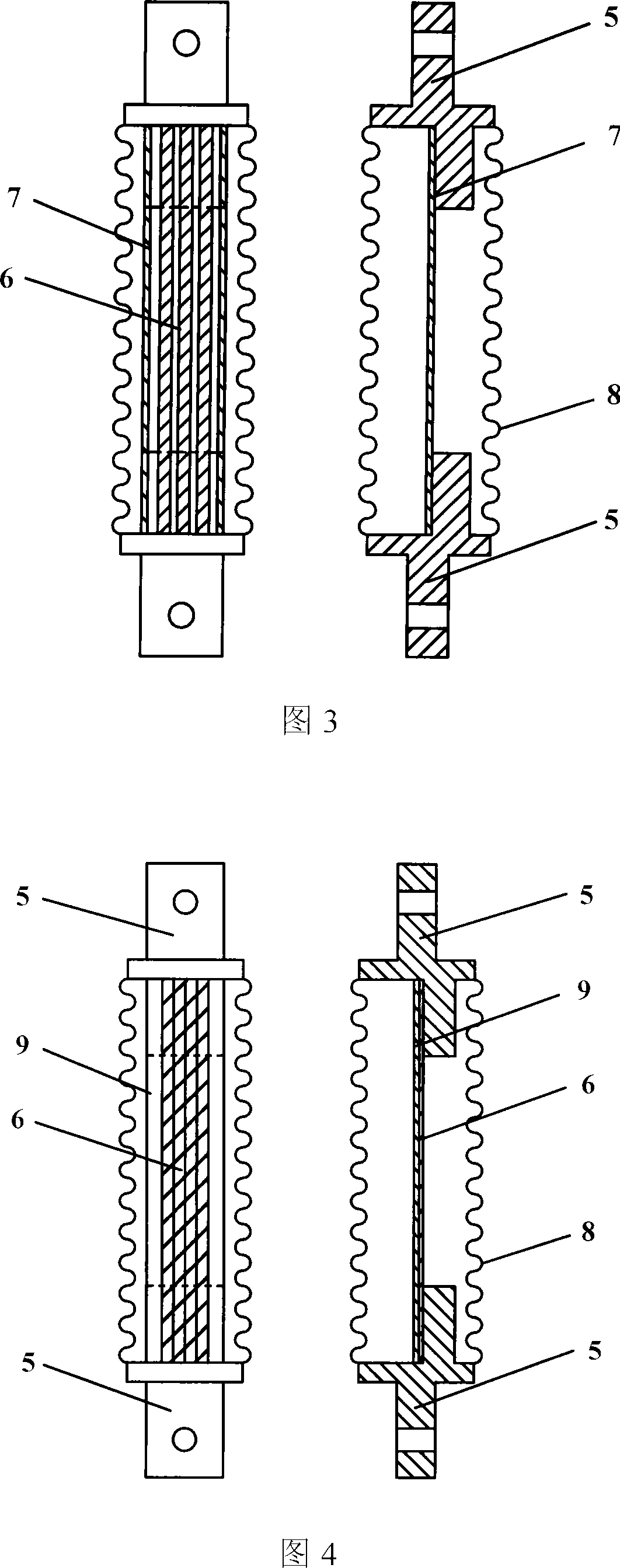

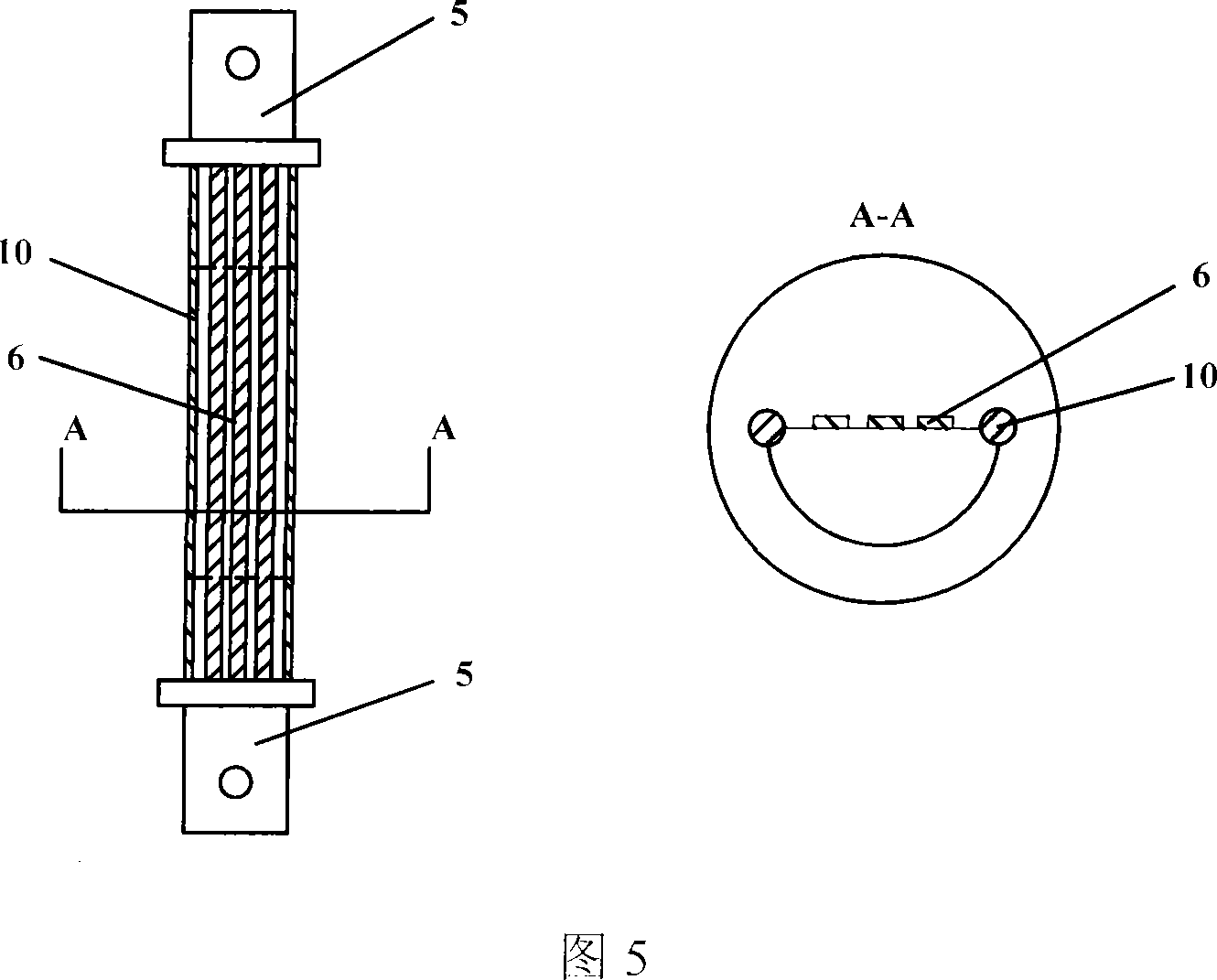

[0021] As shown in Figure 2, the high-temperature superconducting current leads are welded together by a room temperature terminal 1, a heat exchanger 2, a high-temperature superconducting section, and a connecting wire 3, wherein the high-temperature superconducting section is composed of a high-temperature superconducting element 4 and two Composed of copper terminals 5, wherein the superconducting element includes 3 high-temperature superconducting wires 6 with superconducting properties and 2 stainless steel thin plates 7 with certain elasticity as shown in Figure 3, which are welded side by side on the copper terminals 5 at both ends, When the width of two stainless steel thin plates is 6cm, the length is the same as 6cm, and the thickness is 10mm, when the bending strain of the entire high-temperature superconducting section is within 0.5%, the critical current of the high-temperature superconducting wire is not lower than when the wire is not under strain 95% of the crit...

Embodiment 2

[0023] As shown in Figure 2, the high-temperature superconducting current lead is composed of a room temperature terminal 1, a heat exchanger 2, a high-temperature superconducting section and a connecting wire 3, wherein the high-temperature superconducting section part consists of a high-temperature superconducting element 4 and two copper terminals 5 components, wherein the superconducting element includes three high-temperature superconducting wires 6 with superconducting properties and a stainless steel sheet 9 with certain elasticity as shown in Figure 4, the width surfaces of the high-temperature superconducting wires are parallel to each other, and the stainless steel sheet When the thickness is 0.005mm, the high-temperature superconducting wire is welded to the stainless steel sheet, the outer sleeve of the current lead is a bellows 8, and when the bending strain of the entire high-temperature superconducting section is within 0.5%, the critical current of the high-tempe...

Embodiment 3

[0025] As shown in Figure 4, the superconducting section of the high-temperature superconducting current lead is composed of a high-temperature superconducting element and two copper terminals 5, and the superconducting element includes three high-temperature superconducting wires 6 with superconducting properties and one with Certain elastic epoxy resin 9, the width surfaces of the high-temperature superconducting wires are parallel to each other, the thickness of the epoxy resin plate is 1mm, the high-temperature superconducting wires and the epoxy resin are bonded with epoxy adhesive, and the outer sleeve of the current lead For the bellows 8, when the bending strain of the entire high-temperature superconducting section is within 0.5%, the critical current of the high-temperature superconducting wire is not lower than 95% of the critical current when the wire is not subjected to strain. The heat exchanger part of the high-temperature superconducting current lead uses a gold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com