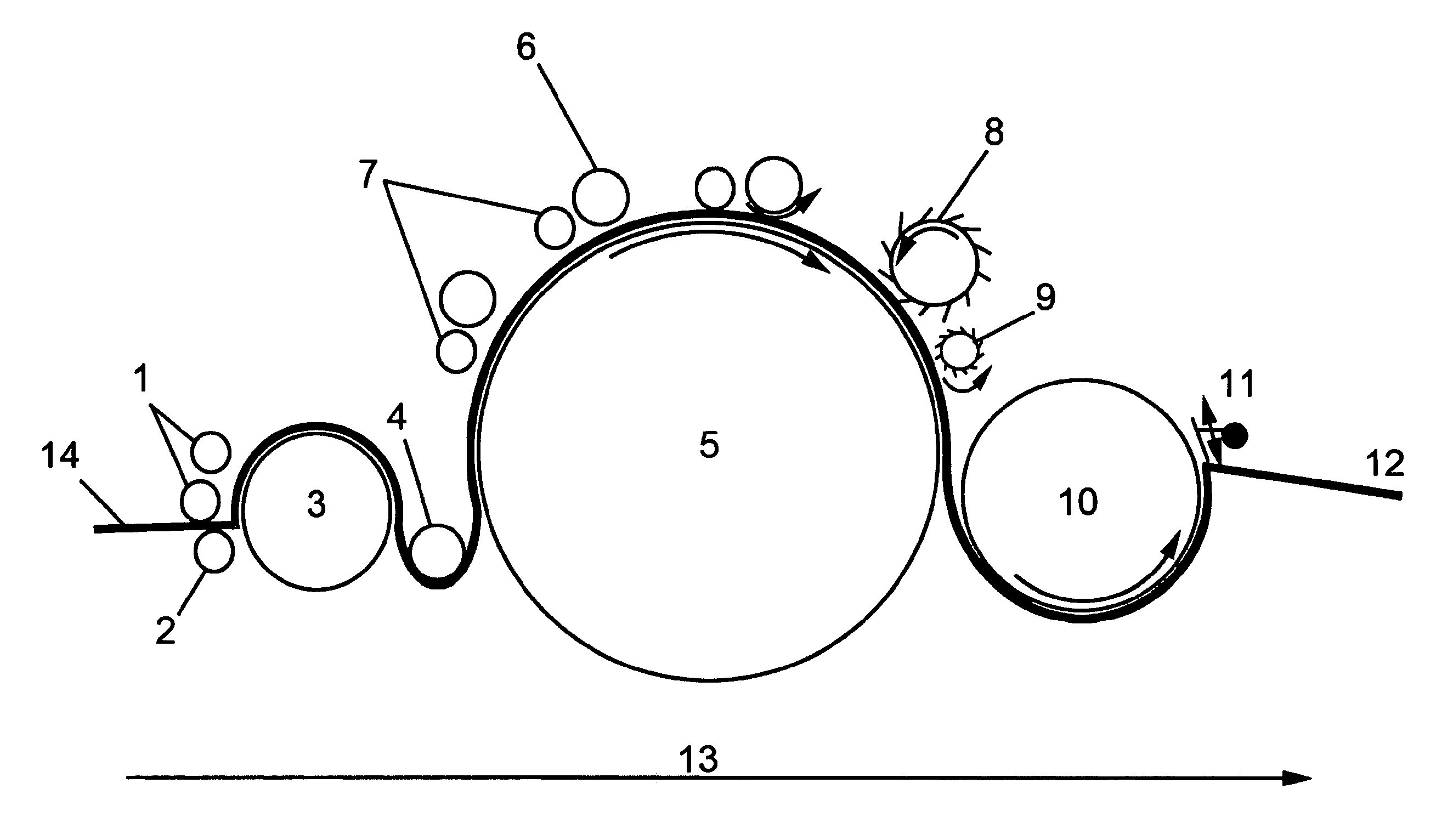

Patents

Literature

92results about How to "High mechanical load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

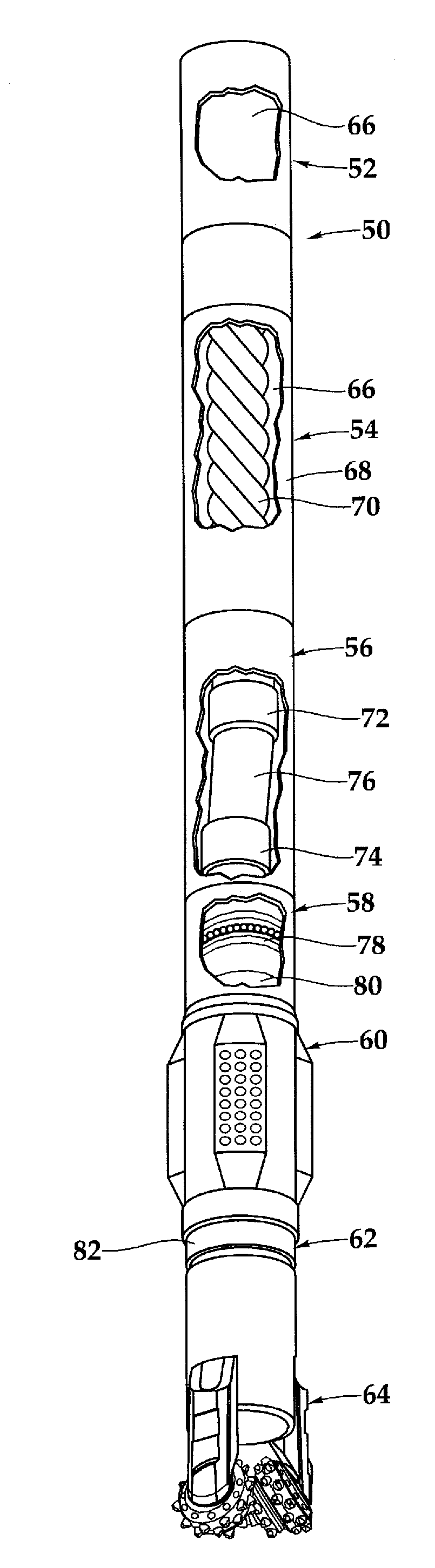

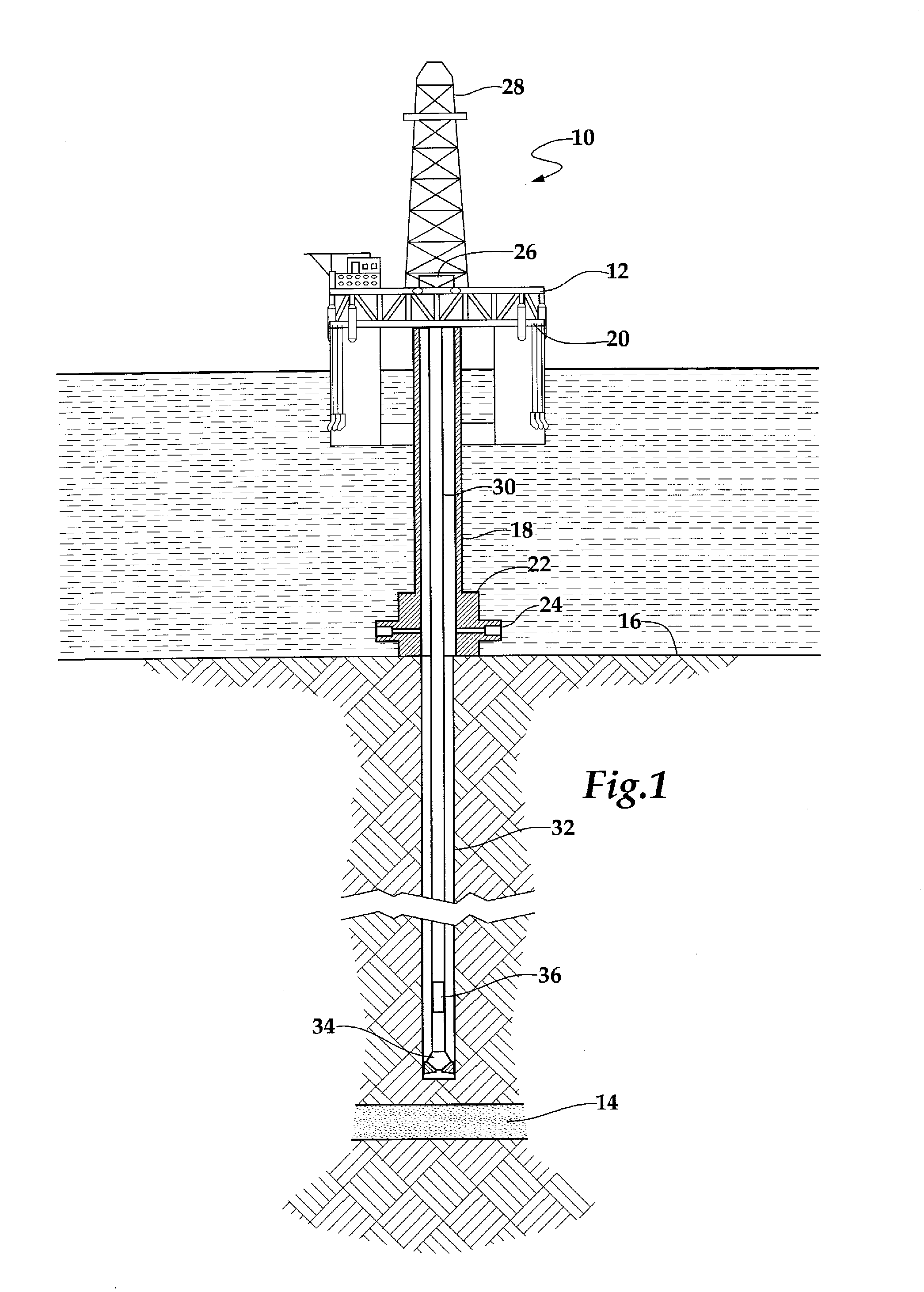

Apparatus and method for high temperature drilling operations

InactiveUS20100038142A1High mechanical loadPump componentsOscillating piston enginesEngineeringWellbore

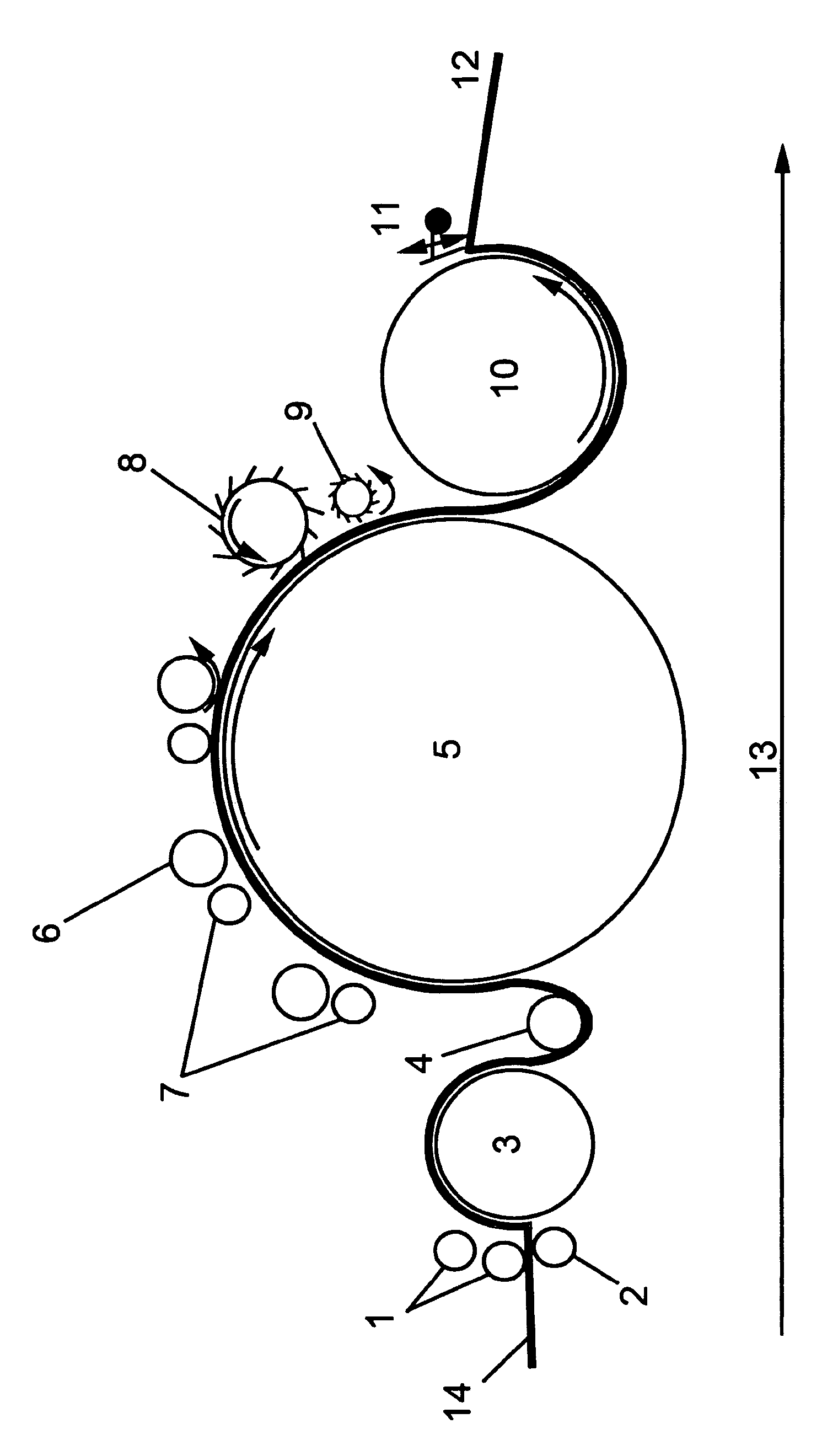

An apparatus (50) for drilling a wellbore that transverses a subterranean hydrocarbon bearing formation. The apparatus (50) includes a drill string (52) having an inner fluid passageway (66). A drill bit (64) is disposed at a distal end of the drill string (52) and is operable to rotate relative to at least a portion of the drill string (52). A fluid motor (54) is disposed within the drill string (52) and is operable to rotate the drill bit (64) in response to a circulating fluid received via the inner fluid passageway (66) of the drill string (52). The fluid motor (54) has a stator (68) with (n) lobes and a rotor (70) with (n−1) lobes. The stator (68) includes an inner surface formed from a first material and the rotor (70) includes an outer surface formed from a second material that is dissimilar to the first material.

Owner:HALLIBURTON ENERGY SERVICES INC

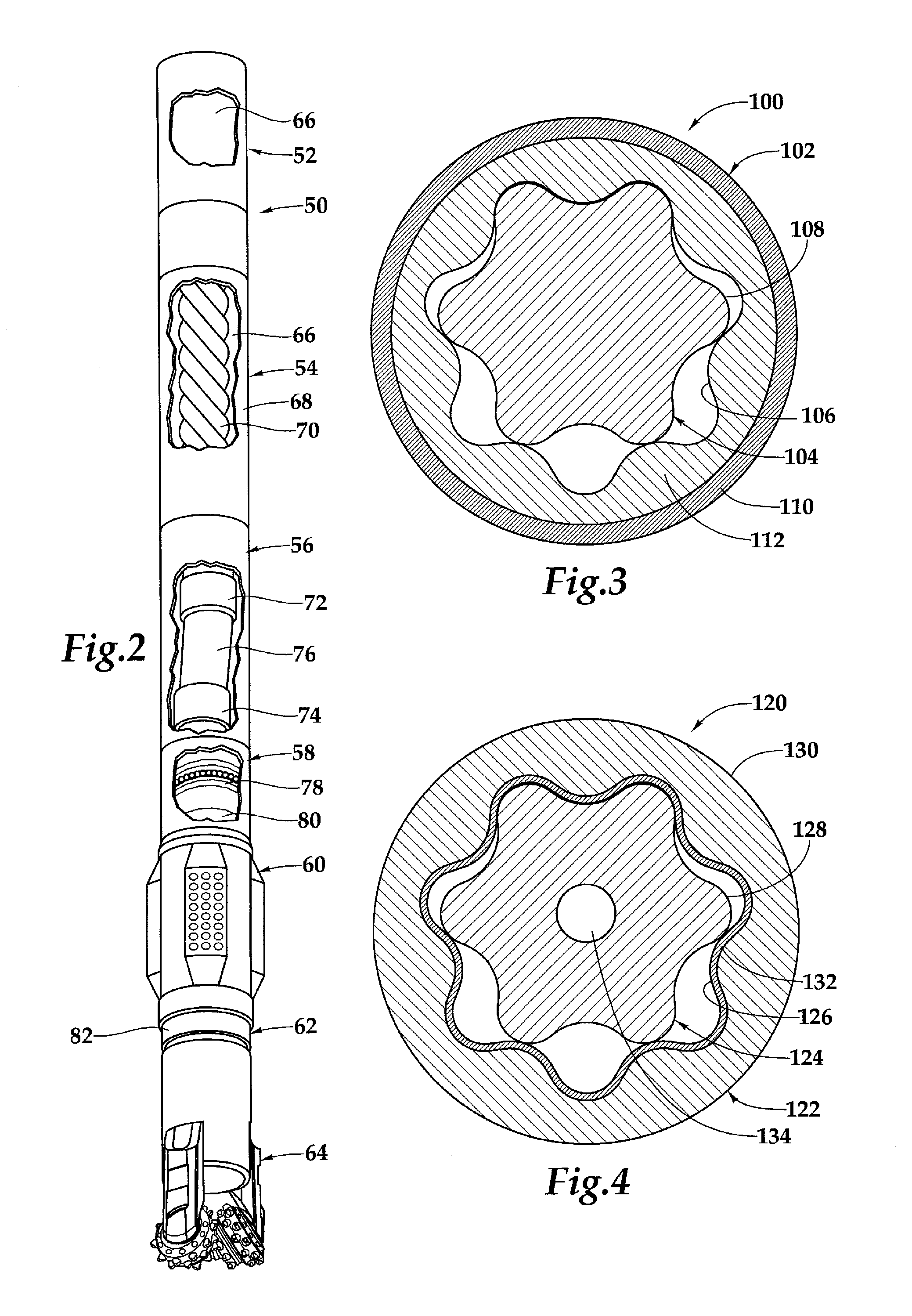

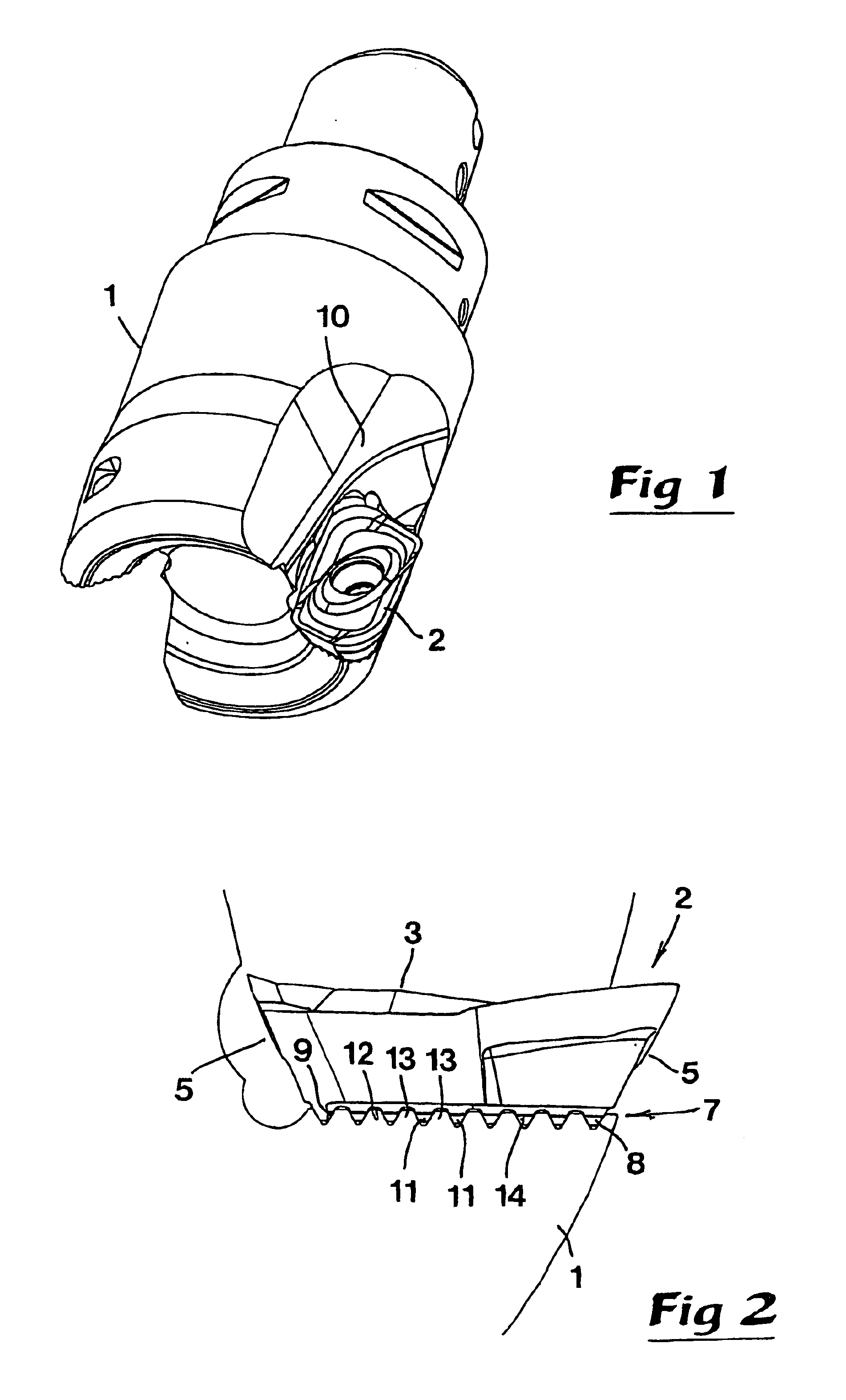

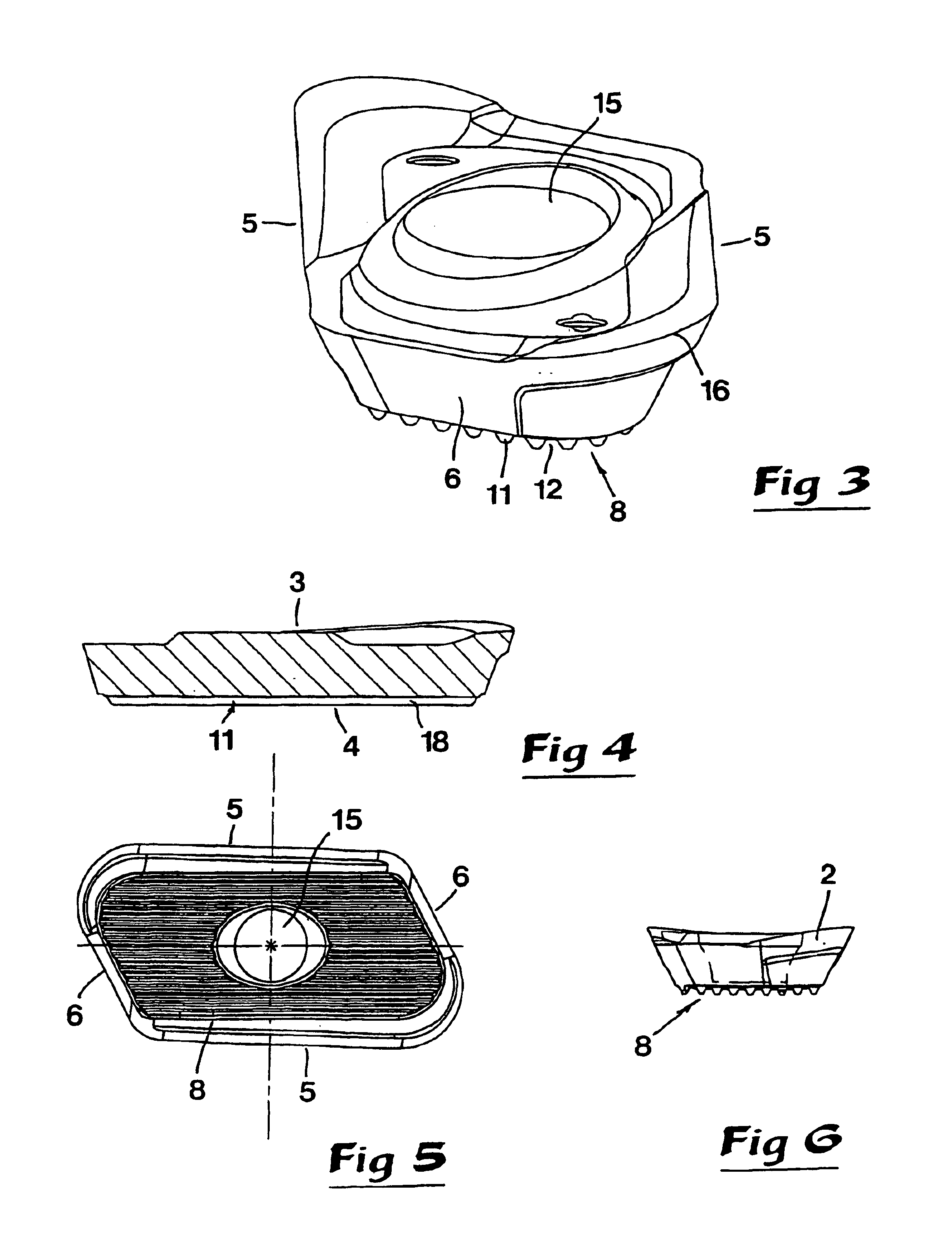

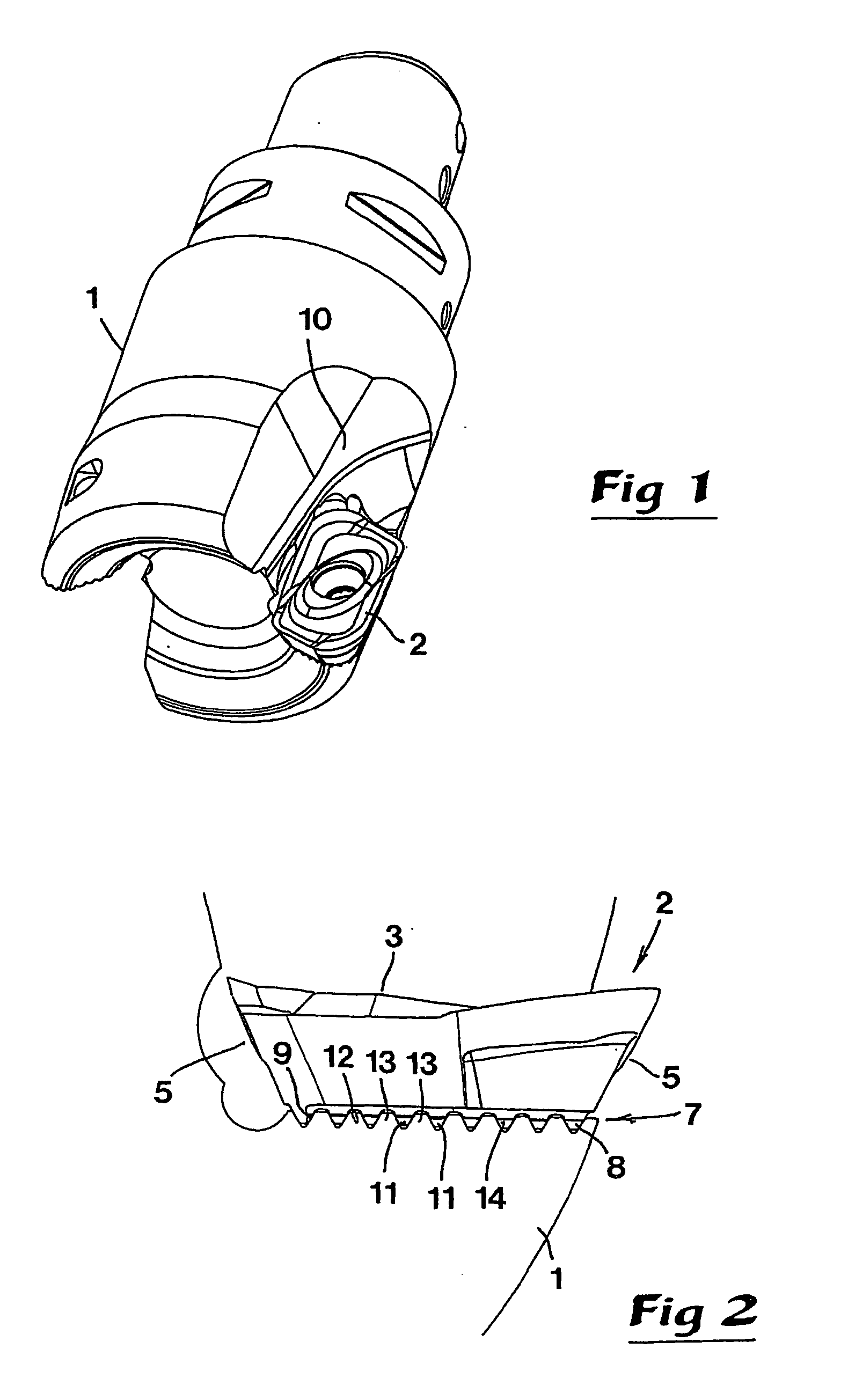

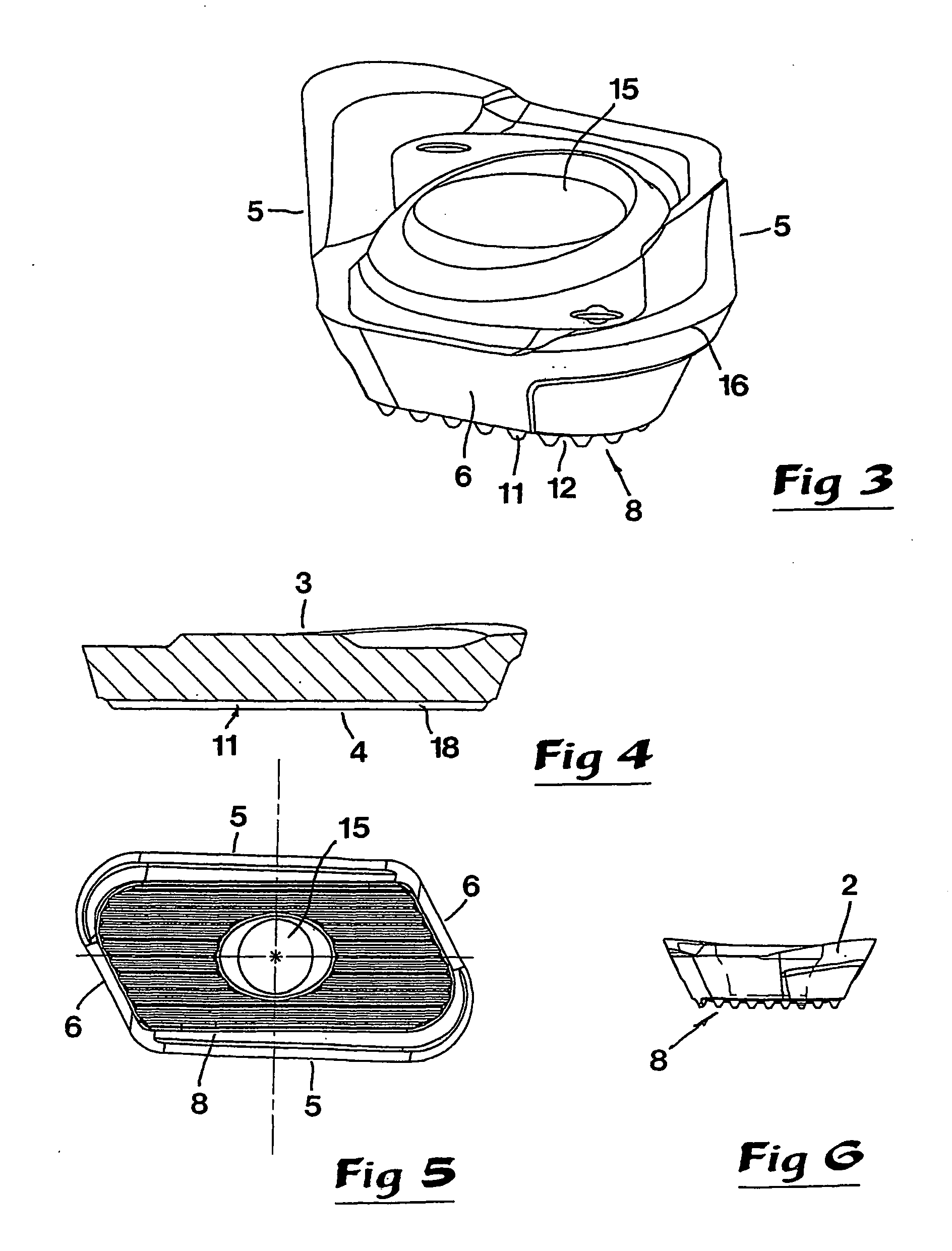

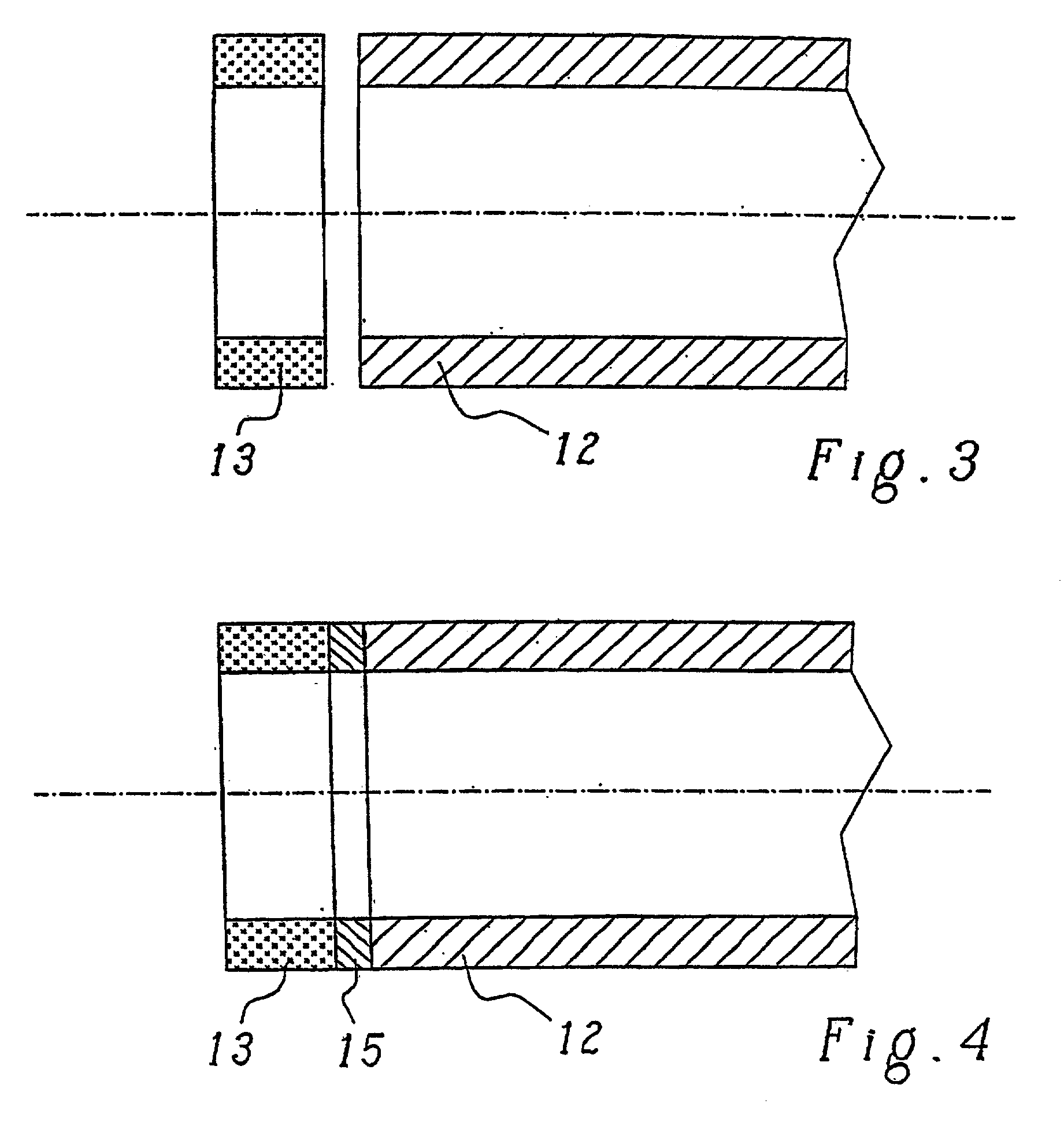

Tool and toolholder for chip forming machining

InactiveUS6921234B2Simple interfaceHigh mechanical loadTransportation and packagingMilling cuttersEngineeringSupport surface

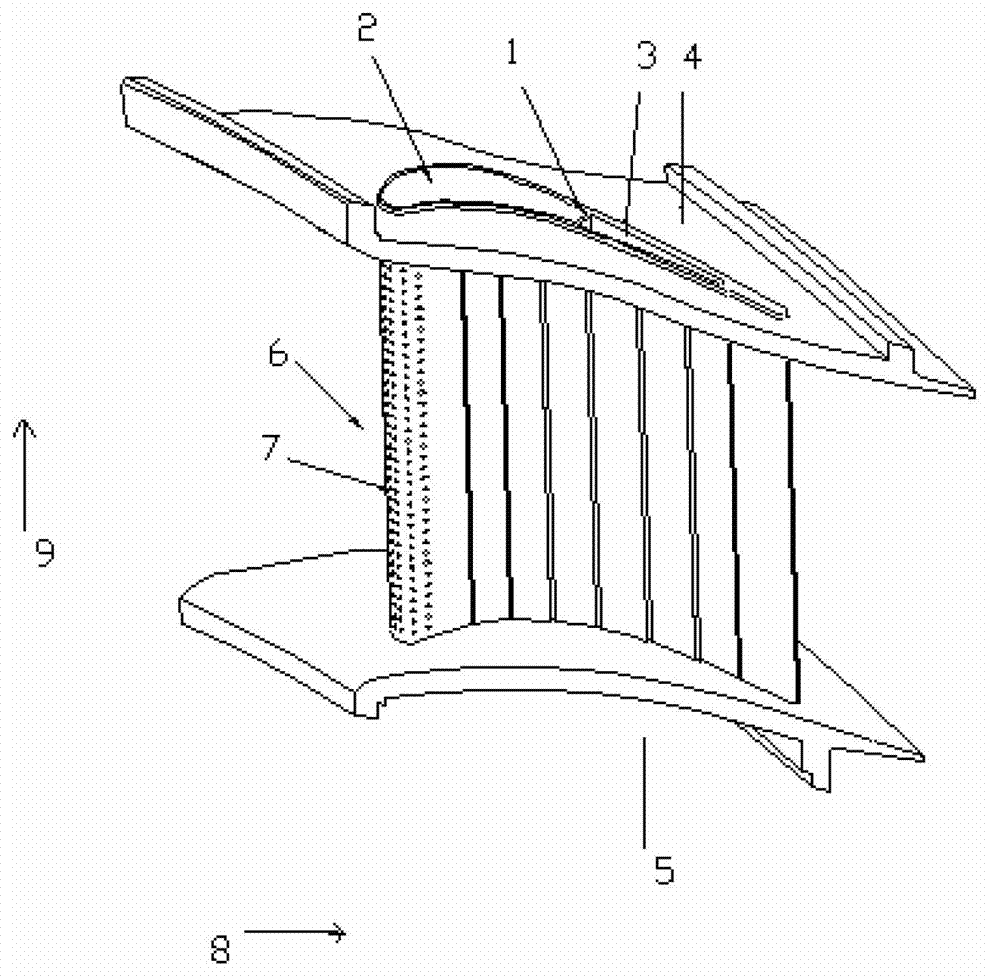

An indexible cutting insert has a connecting surface formed by alternating parallel ridges and grooves. Each ridge is defined by a pair of flanks which converge in an outward direction. Each ridge includes a convexly curved surface portion for making line contact with a corresponding ridge of a support surface. The convexly curved surface is spaced from outer and inner ends of the respective flank.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

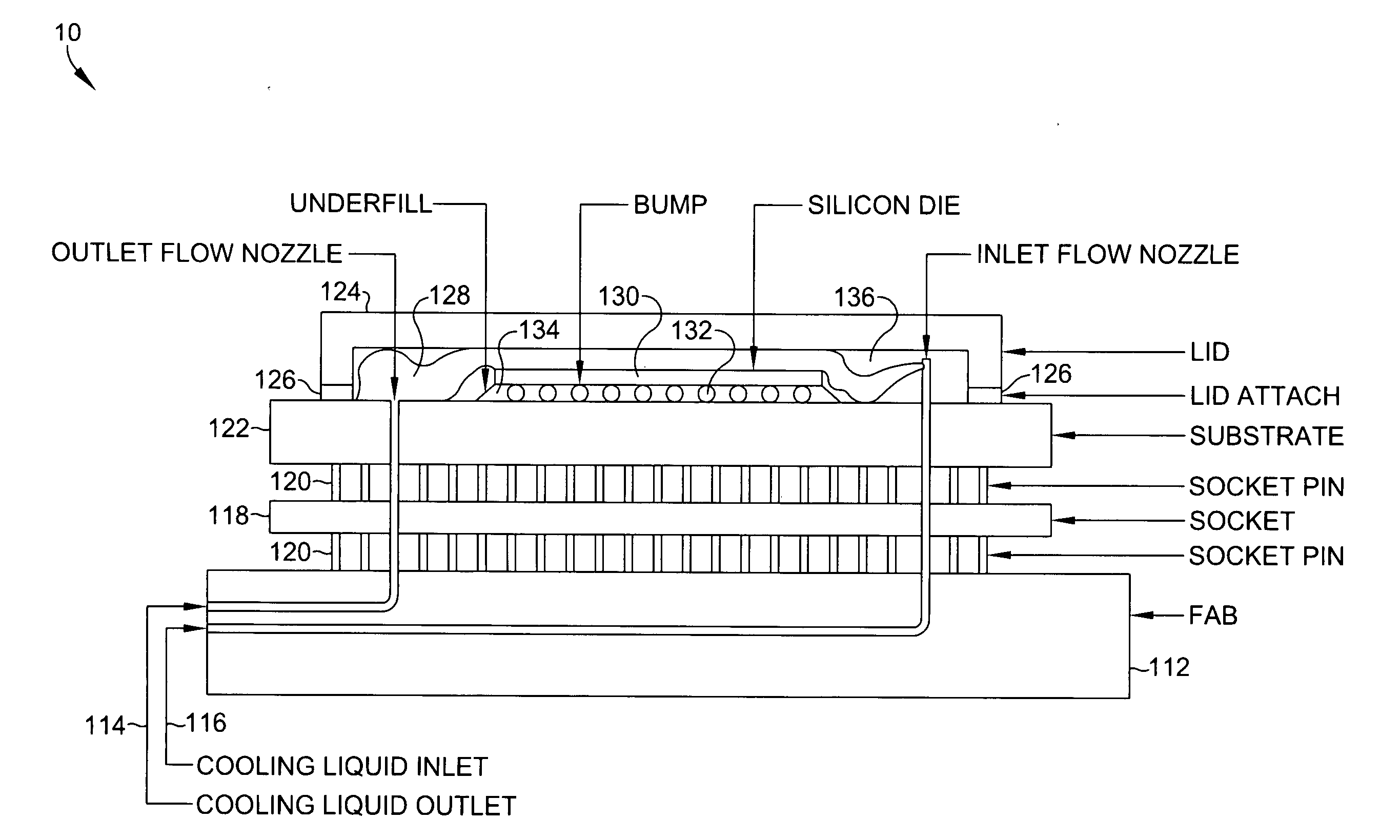

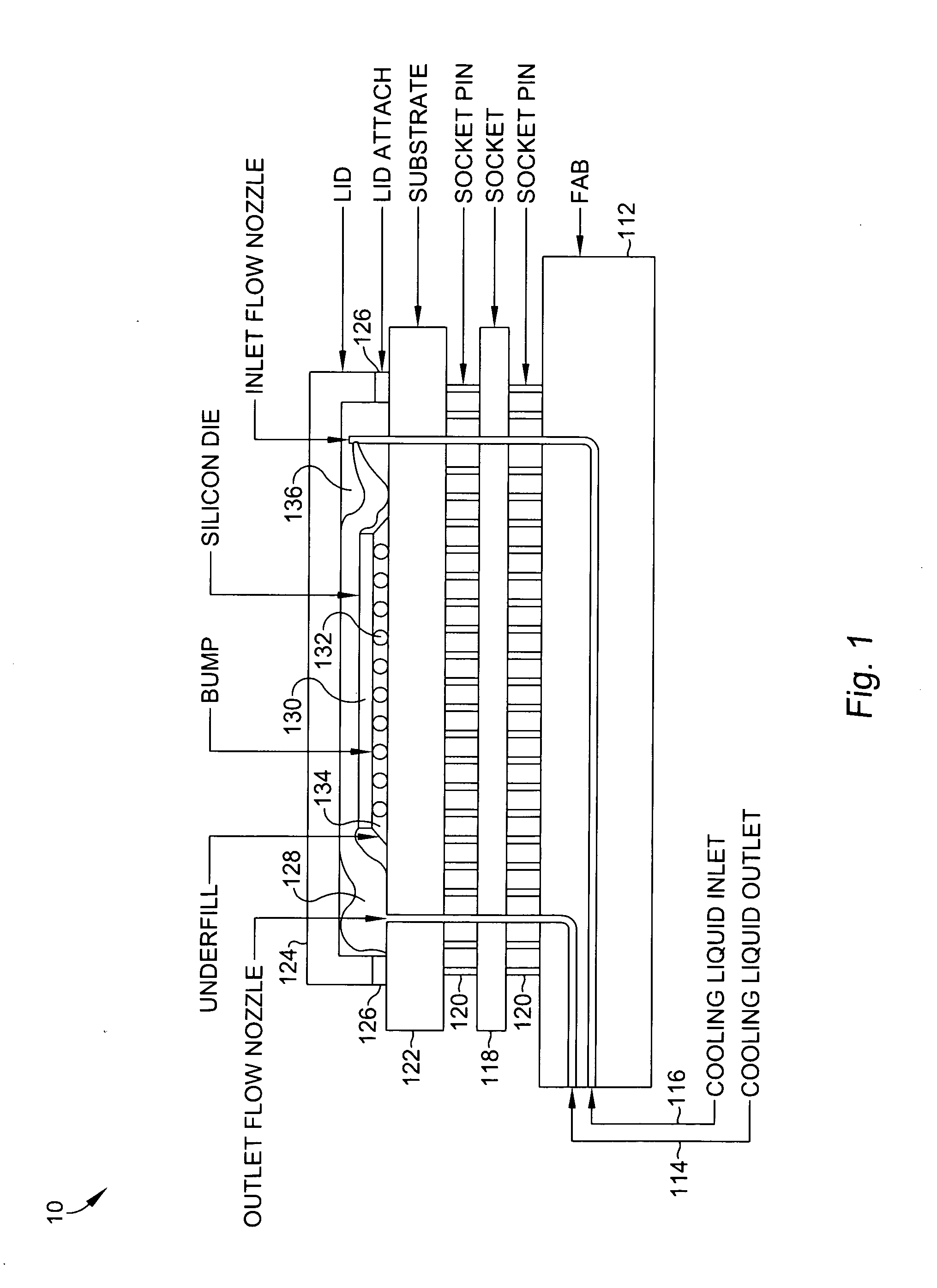

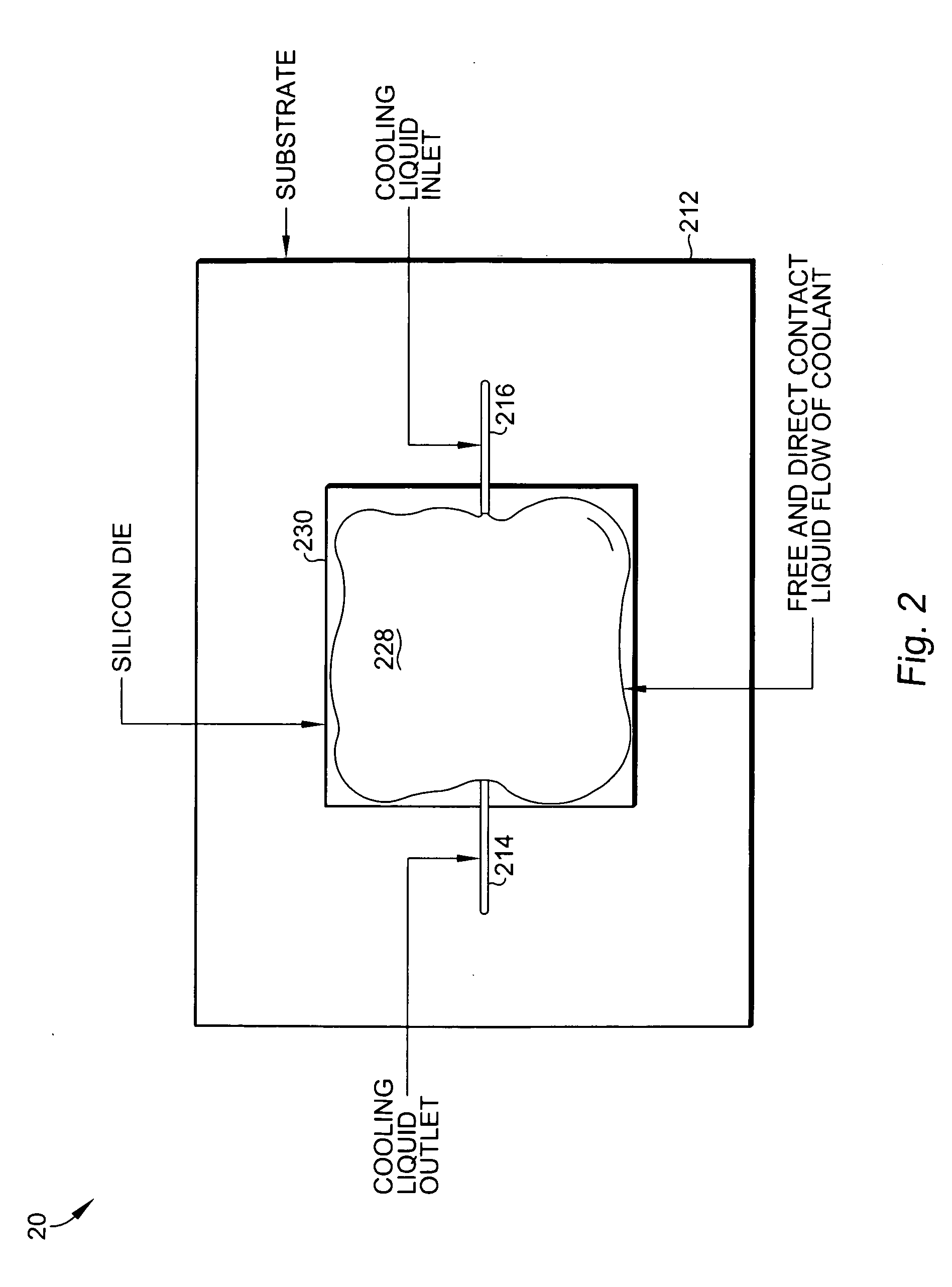

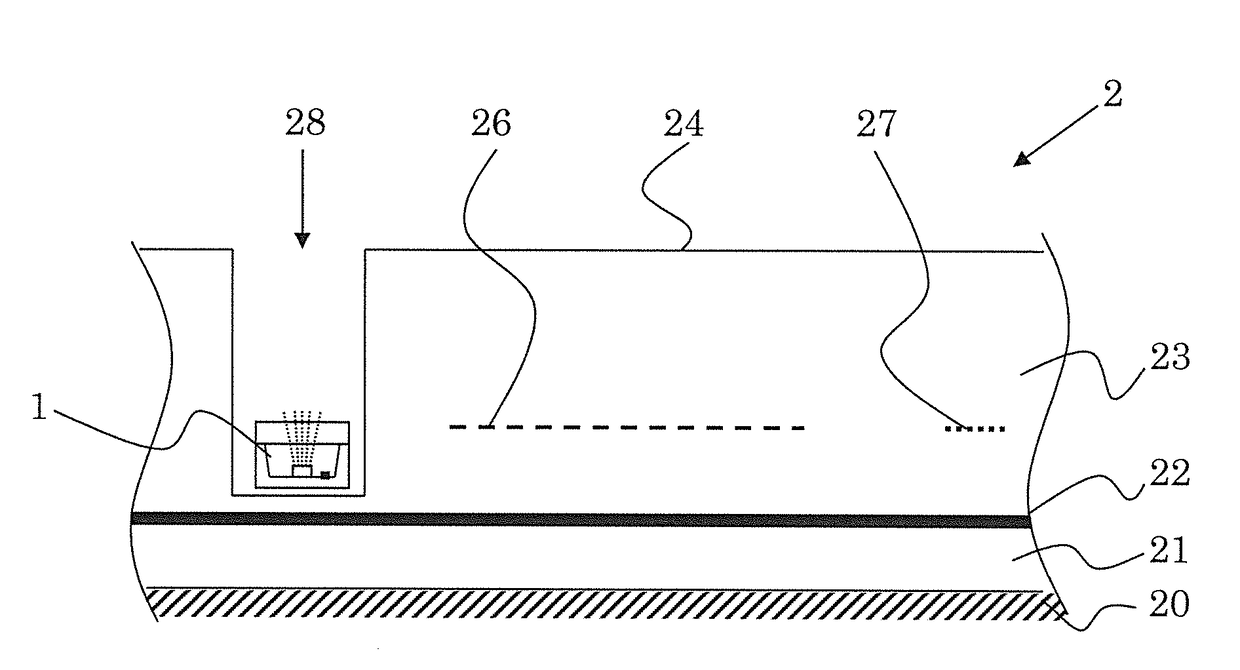

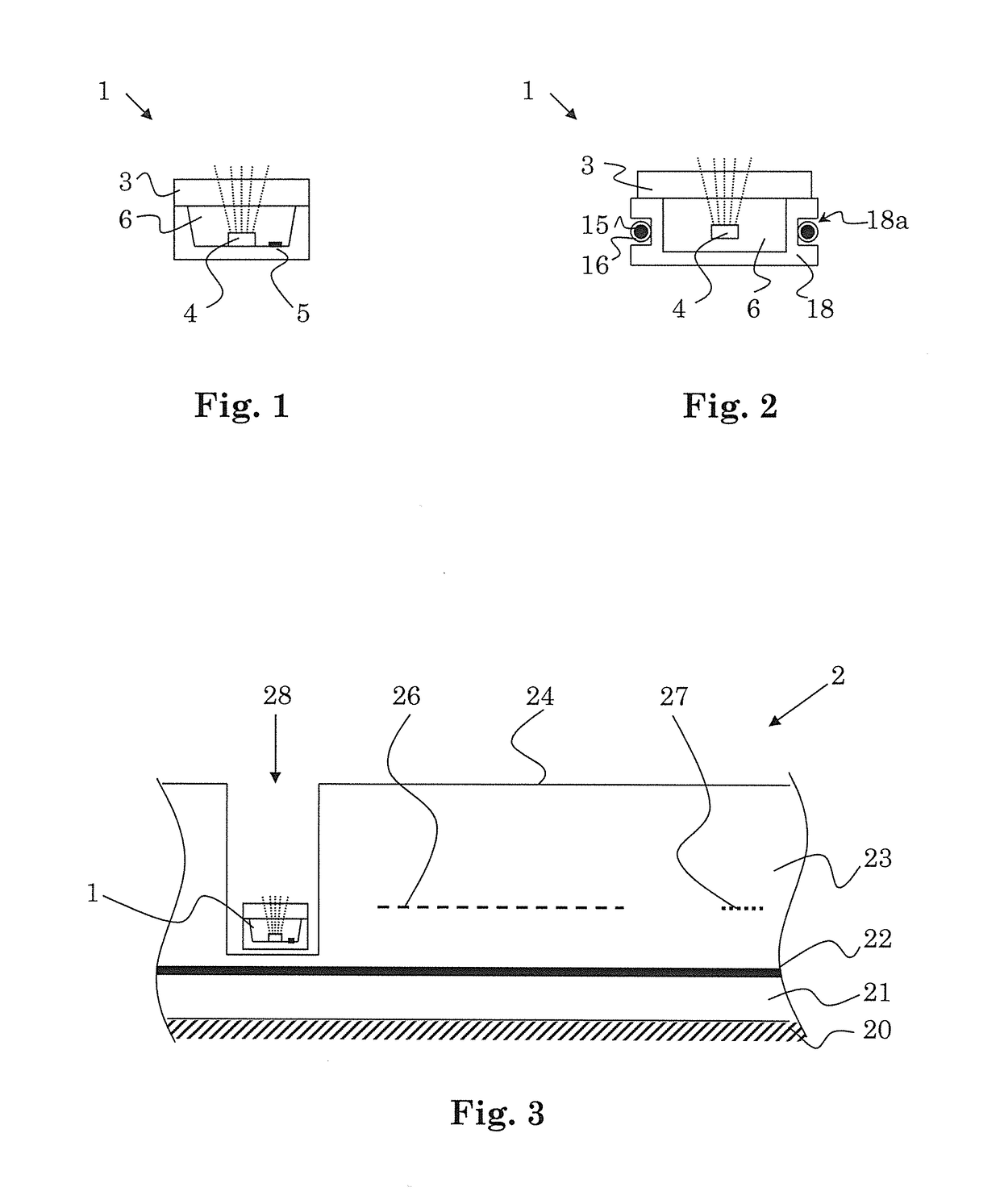

Direct contact cooling liquid embedded package for a central processor unit

ActiveUS20070177352A1Avoid a lotAvoid introducingSemiconductor/solid-state device detailsSolid-state devicesCouplingPackage design

A direct contact cooling liquid embedded package design for use with a computer central processor unit is suitable for thermal management of high heat dissipation electronic components such as server processors. The direct contact cooling liquid embedded packaged CPU has mechanical coupling and embedded plumbing that attaches to the board pumped liquid supply and direct contact cooling liquid of the heat-generating portion of the CPU. A direct contact cooling liquid embedded packaged CPU removes higher levels of heat directly from the core of the processors by convective cooling. Cooling liquid is introduced into the package of the server CPU by mechanically attaching the CPU to the board through a socket interconnect. Pins of the socket serve to provide electrical connection between the board and the CPU, while a few pins are designed for the purpose of inlet and outletting cooling liquid into and out of the CPU package.

Owner:ORACLE INT CORP

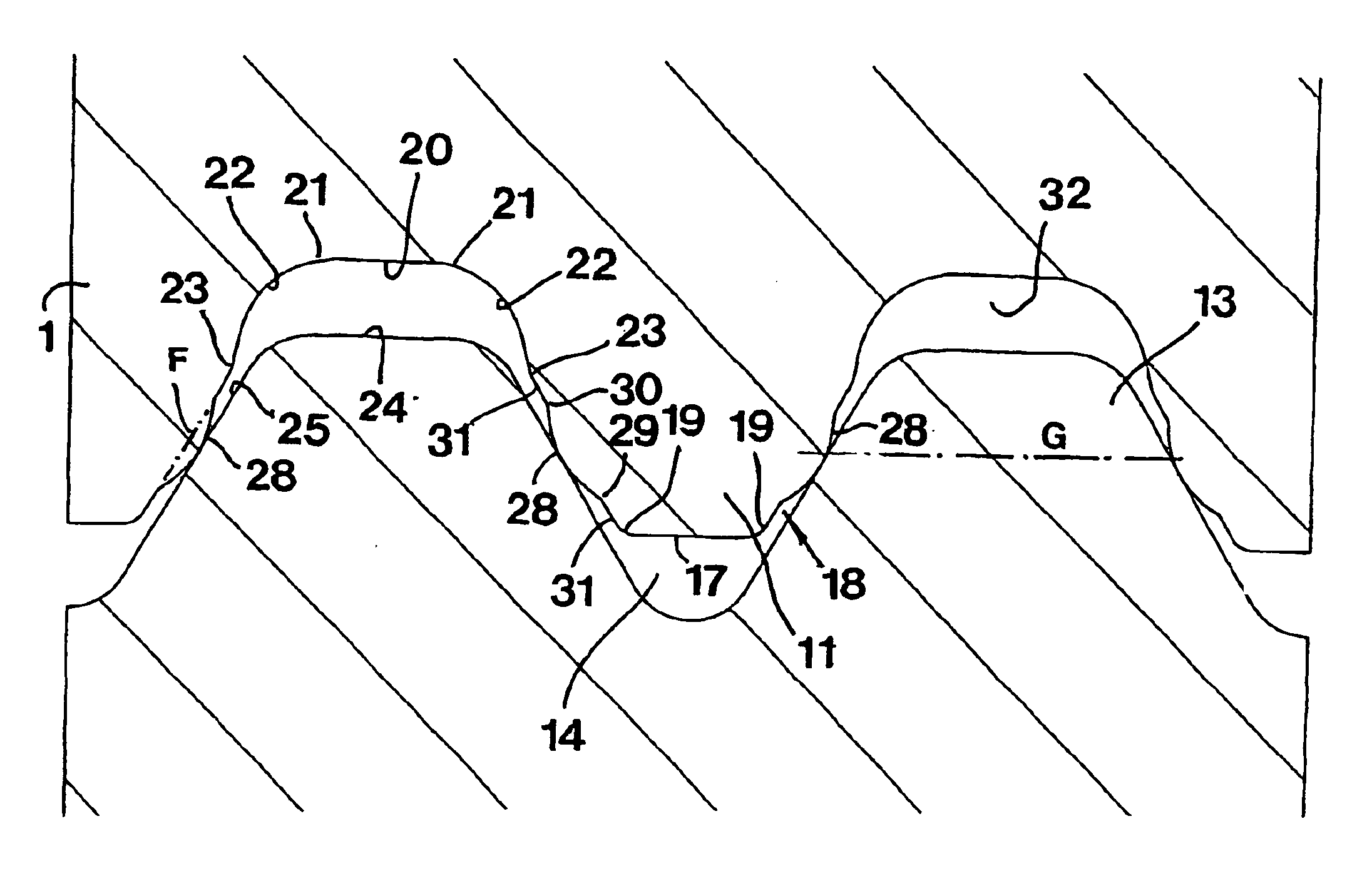

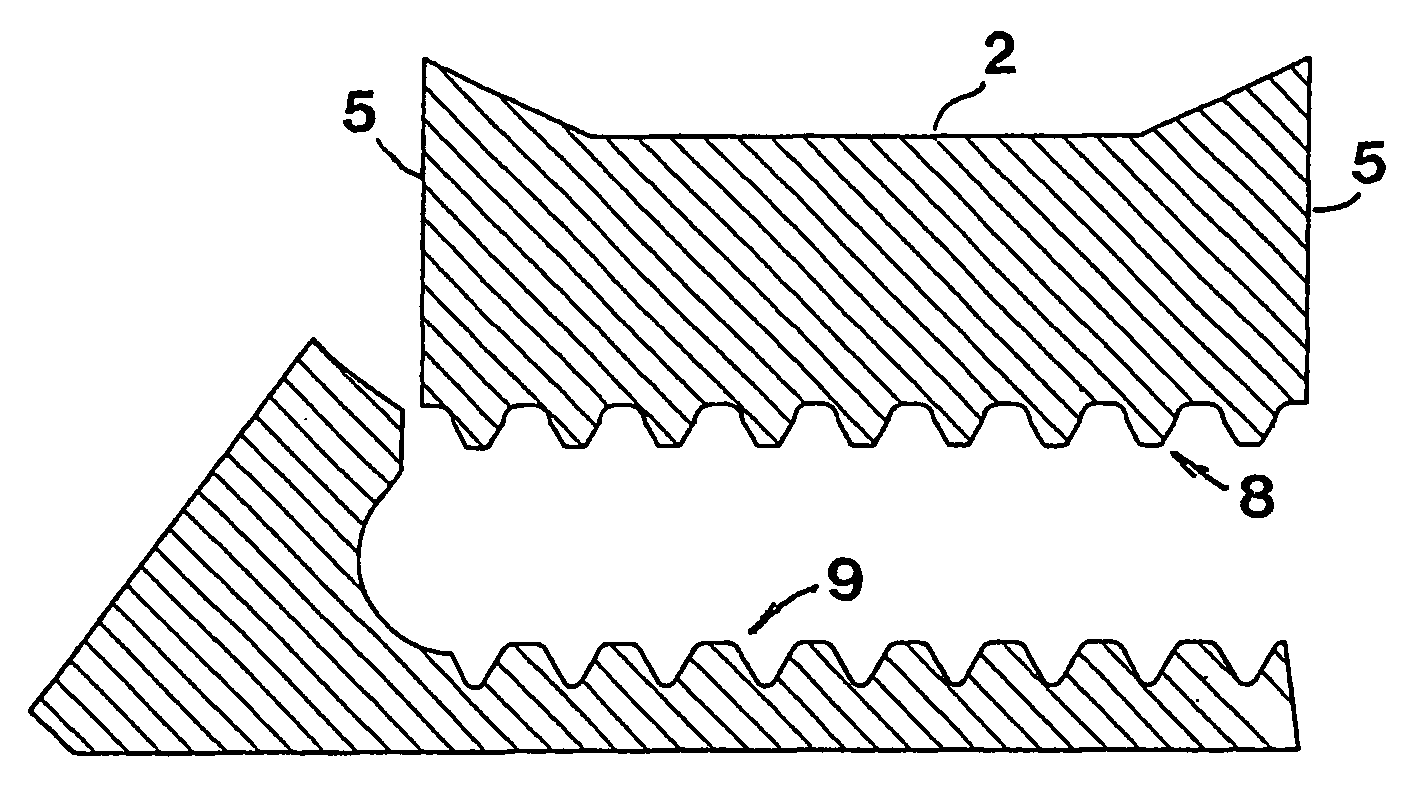

Tool and toolholder for chip forming machining

InactiveUS20040101371A1Simple interfaceHigh mechanical loadTransportation and packagingMilling cuttersContact lineBiomedical engineering

This invention relates to a tool intended for chip removing machining together with a cutting insert therefor. The cutting insert is formed having a connecting surface or serrations that comrises ridges (11) and intermediate grooves. The flanks (18) which delimit the ridge (11) have a convexly curved surface (28), the contact point of which to a co-operating flank (25) of a co-operating ridge consists of a line (G), which extends axially along the length extension of the flank and is situated in an area approximately halfway between on teh one hand an outer transition (19) between the flank (18) and an apex (17) and on the other hand an inner transition (23) between the flank and a groove bottom. The convexley curved surface extends inwards as well as outwards from said contact line (G), in order to guarantee that practical contact between the flanks of the co-operating ridges is attained via surface contact at an indifferent place between the outer and inner limiting edges (29, 30) of the curved surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

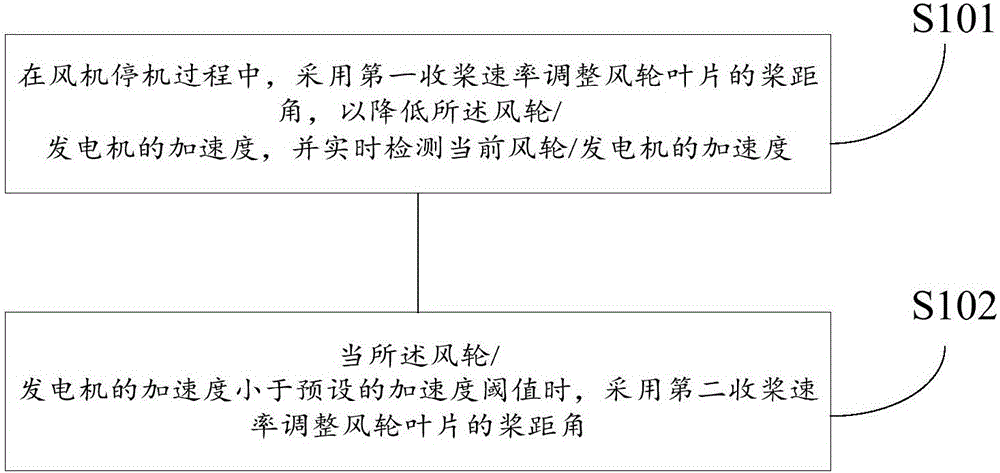

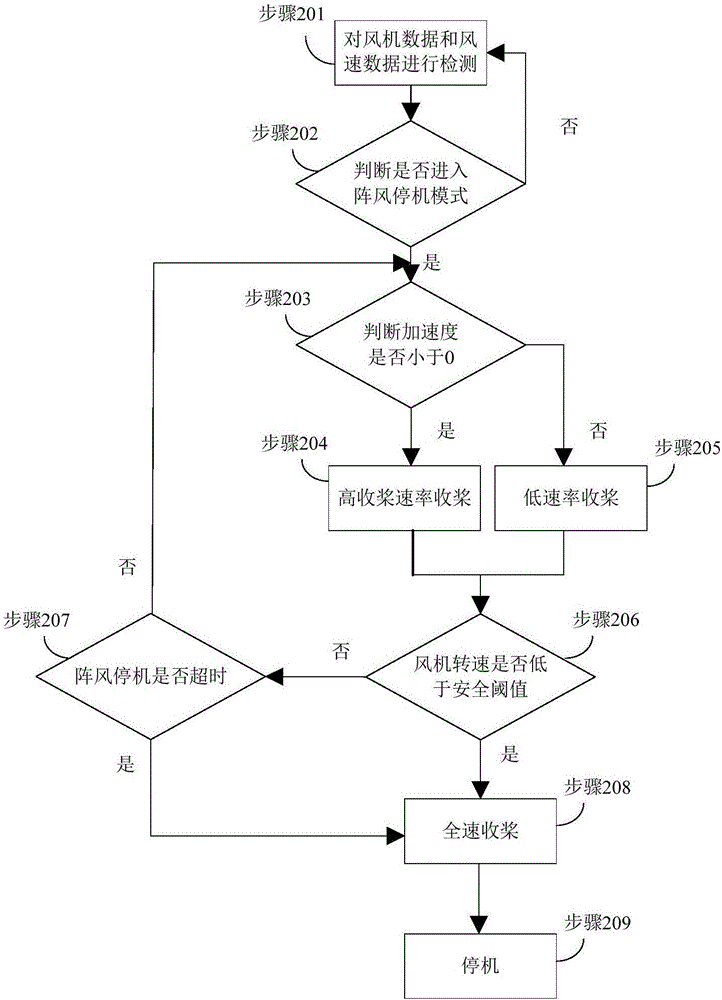

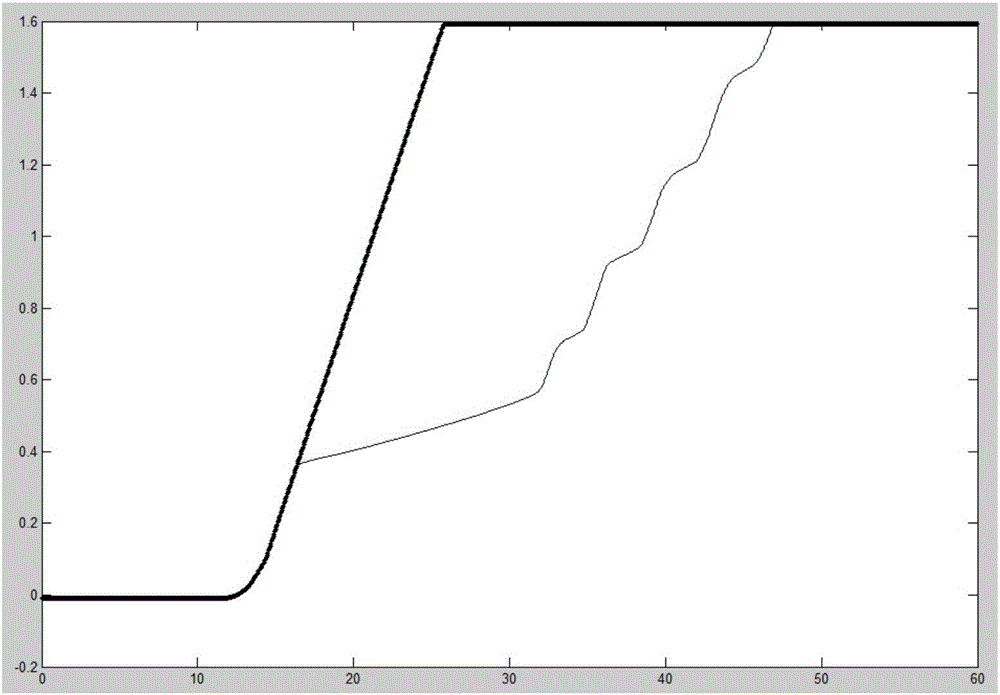

Halting method and system for fan in extreme state

ActiveCN106121914AAvoid damageReduce accelerationWind motor controlActive/predictive/anticipative controlEngineeringMechanical load

The invention provides a halting method and system for a fan in an extreme state, and relates to the field of fan control. The method provided by the invention comprises the steps that a paddle collecton speed changing manner is adopted, before gust halt, firstly, a pitch angle of a wind wheel is adjusted at a high paddle collecton speed, so as to avoid the problem that the wind wheel overspeeds; and then, the pitch angle of the wind wheel is adjusted at a low paddle collecton speed, so as to avoid the problem that the overall mechanical load of the fan is too large. Through the adoption of the control method, the fan can avoid the situation that the fan overspeeds and flies and the situation that the fan structure breaks due to the fact that the mechanical load of the fan is too large at the same time, and the safety of the fan during the gust halt process is improved.

Owner:SANY ELECTRIC CO LTD

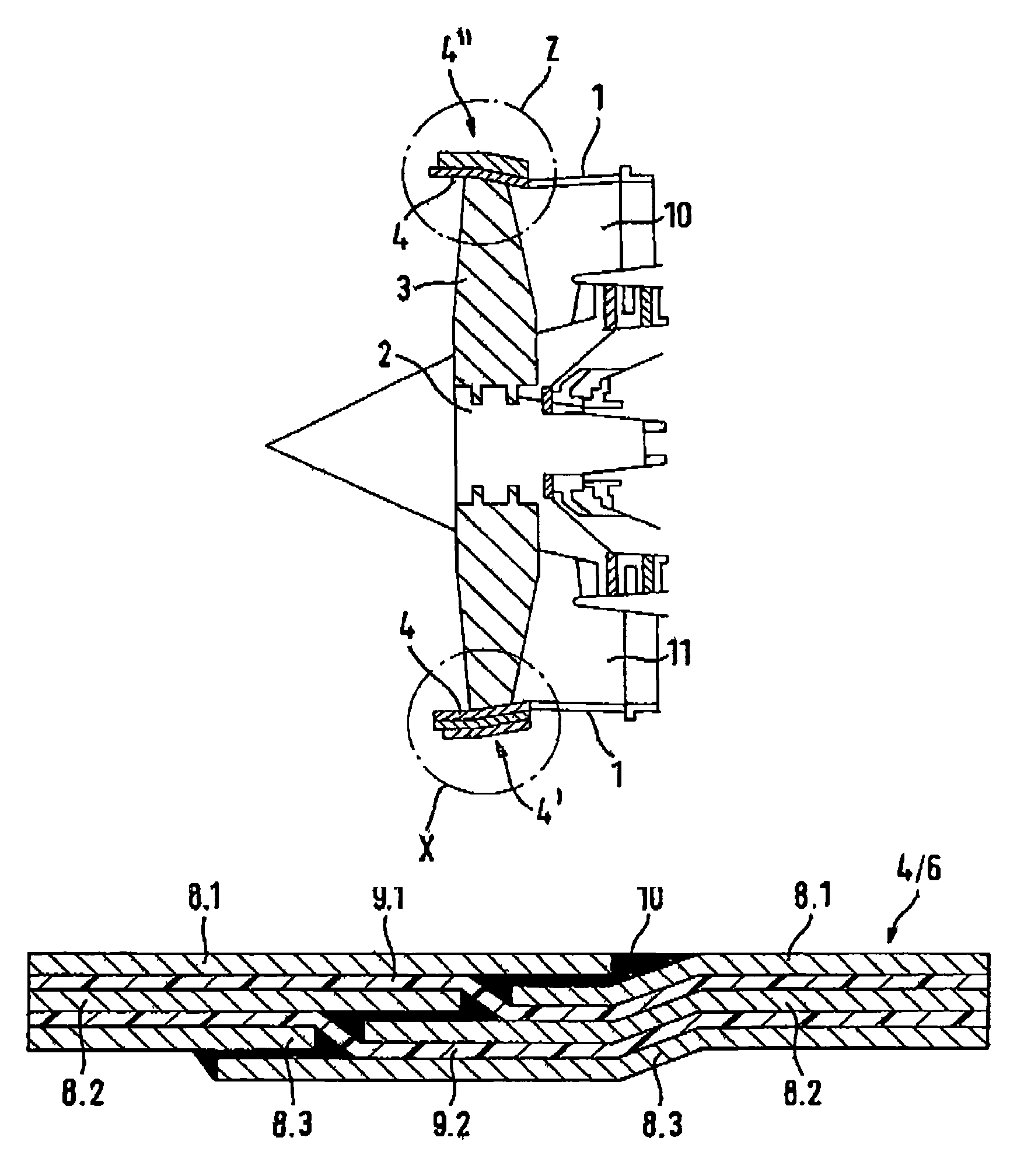

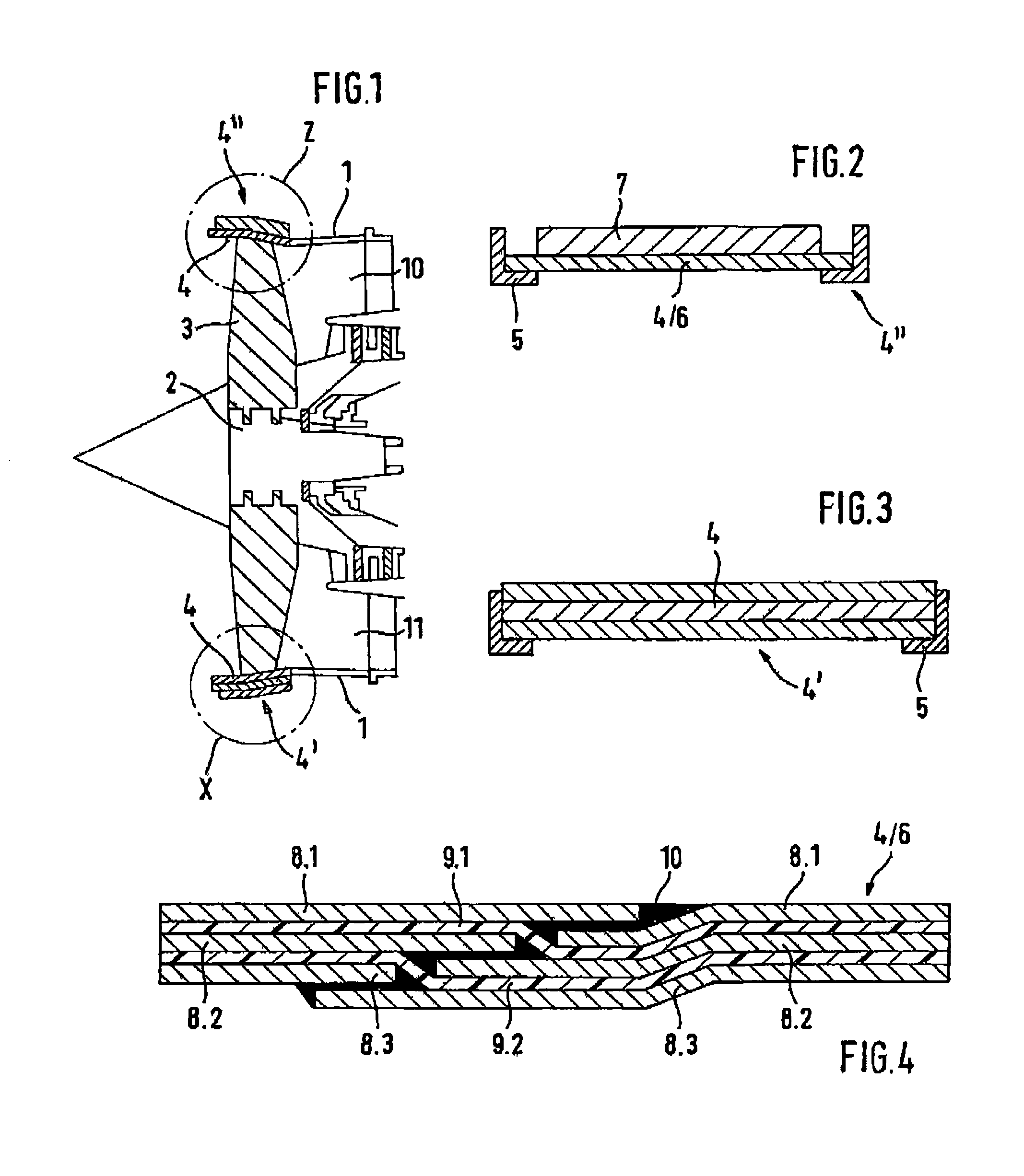

Protective ring for the fan protective casing of a gas turbine engine

InactiveUS7076942B2Improve impact absorption performanceReduce weightEfficient propulsion technologiesSafety/regulatory devicesFiberAbsorption capacity

A protective ring (4) for the fan blades (2, 3) of a gas turbine engine includes a material combination of metal bands and polymer-bonded fiber-weave layers interconnected in alternating arrangement. The protective ring thus formed, which is characterized by tough-elastic properties and low weight, can be used as a full containment (4′) with sufficiently large wall thickness or as a penetration containment (4″) with smaller wall thickness and with a trapping layer arranged on the outer circumference. As a full containment, the protective ring has impact-absorption capacity, as a penetration containment it prevents a further destruction of the broken-through protective ring.

Owner:ROLLS ROYCE DEUT LTD & CO KG

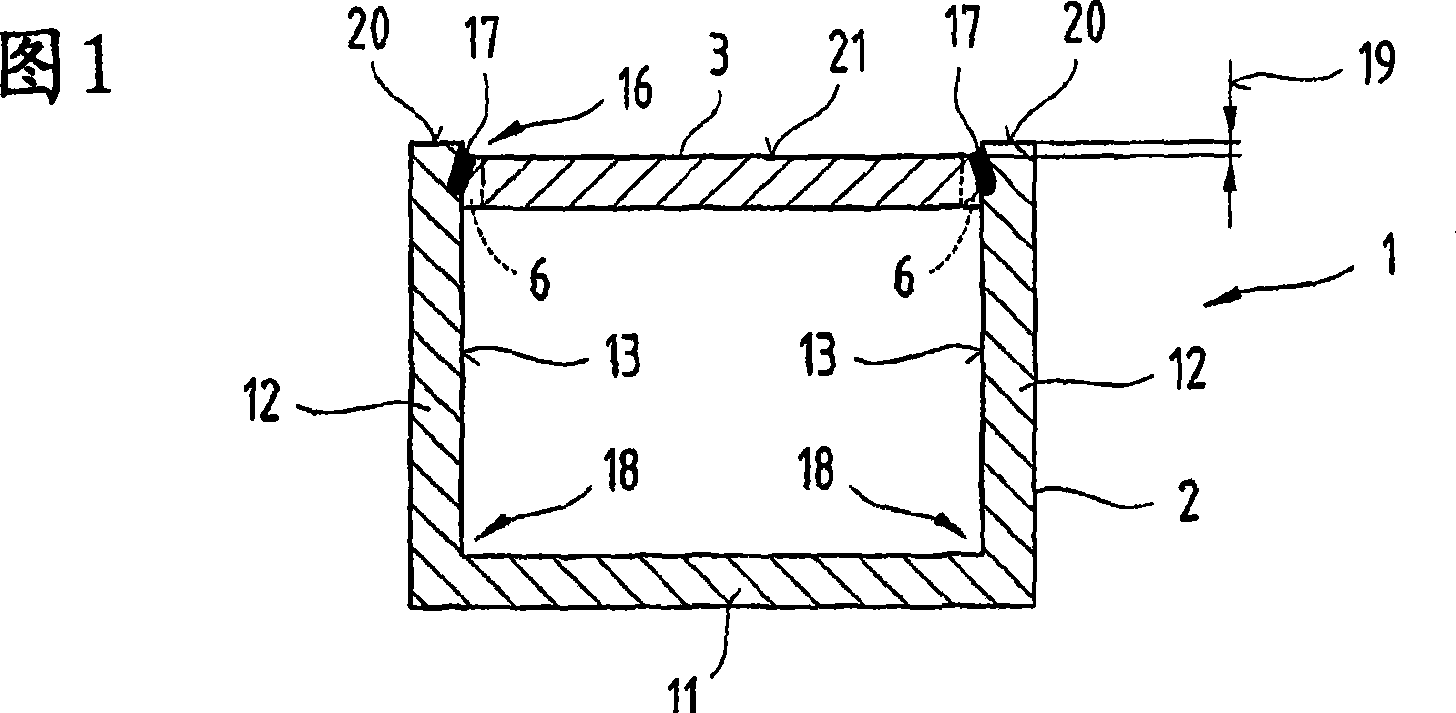

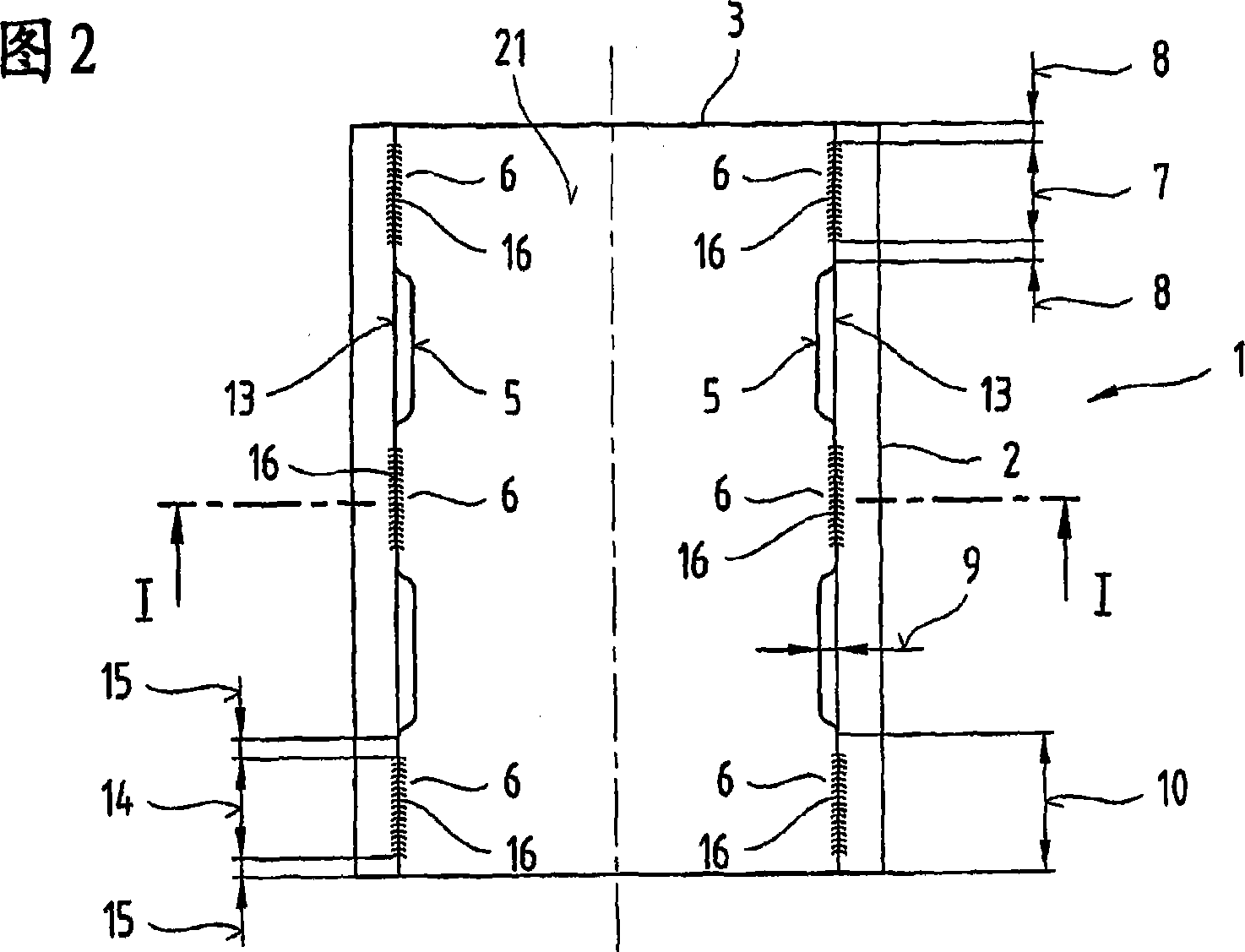

Multi-piece part composed of metal element and manufacturing method thereof

InactiveCN101048257APrevent agingAvoid brittlenessThin material handlingLaser beam welding apparatusCold formedButt joint

The invention relates to a subassembly (1) and a method for the production thereof. Said subassembly (1) comprises a first and a second part (2, 3), the first (2, 3) of which is cold-formed. Said parts (2, 3) are provided with parallel planar pieces (20, 21) and contact areas that extend at an angle therefrom in order to place the two parts (2, 3) against each other without leaving a gap therebetween while being joined to each other at the butt joint (16) via a welded seam (17) created by means of beam welding. The planar pieces (20, 21) are disposed so as to be misaligned relative to each other by an offset (19). One of the parts (2, 3) is provided with a contacting projection (6) which embodies the contact area of the first part (2). The parts (2, 3) are positioned relative to each other in such a way that the second part (3) forms the butt joint (16) along with the first part (2) in the section of the first part (2) in which an offset thickness of the basic material is smaller than the offset thickness of the structure in a deformation zone (18) created on the first part (2) by cold forming.

Owner:STIWA HLDG

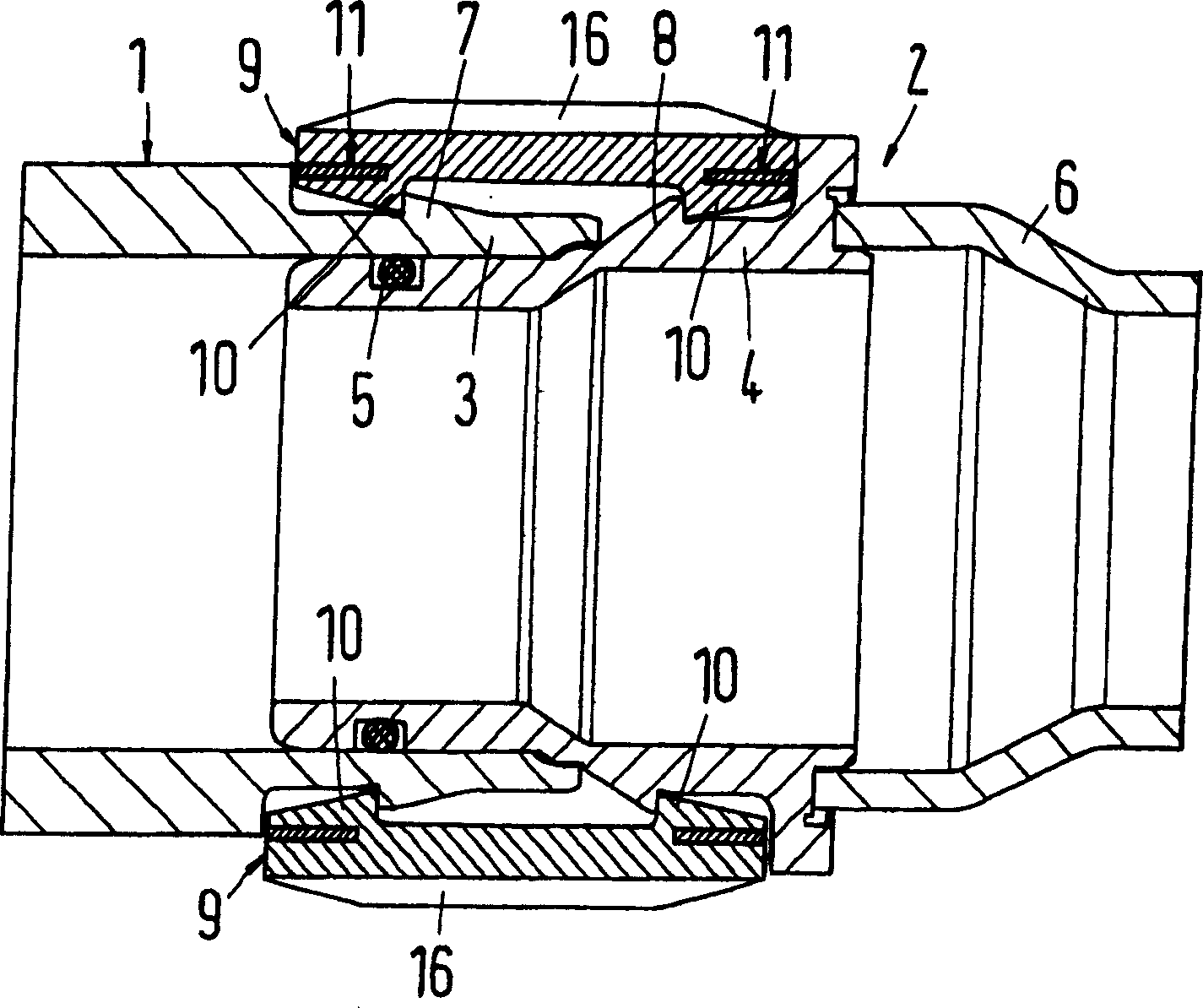

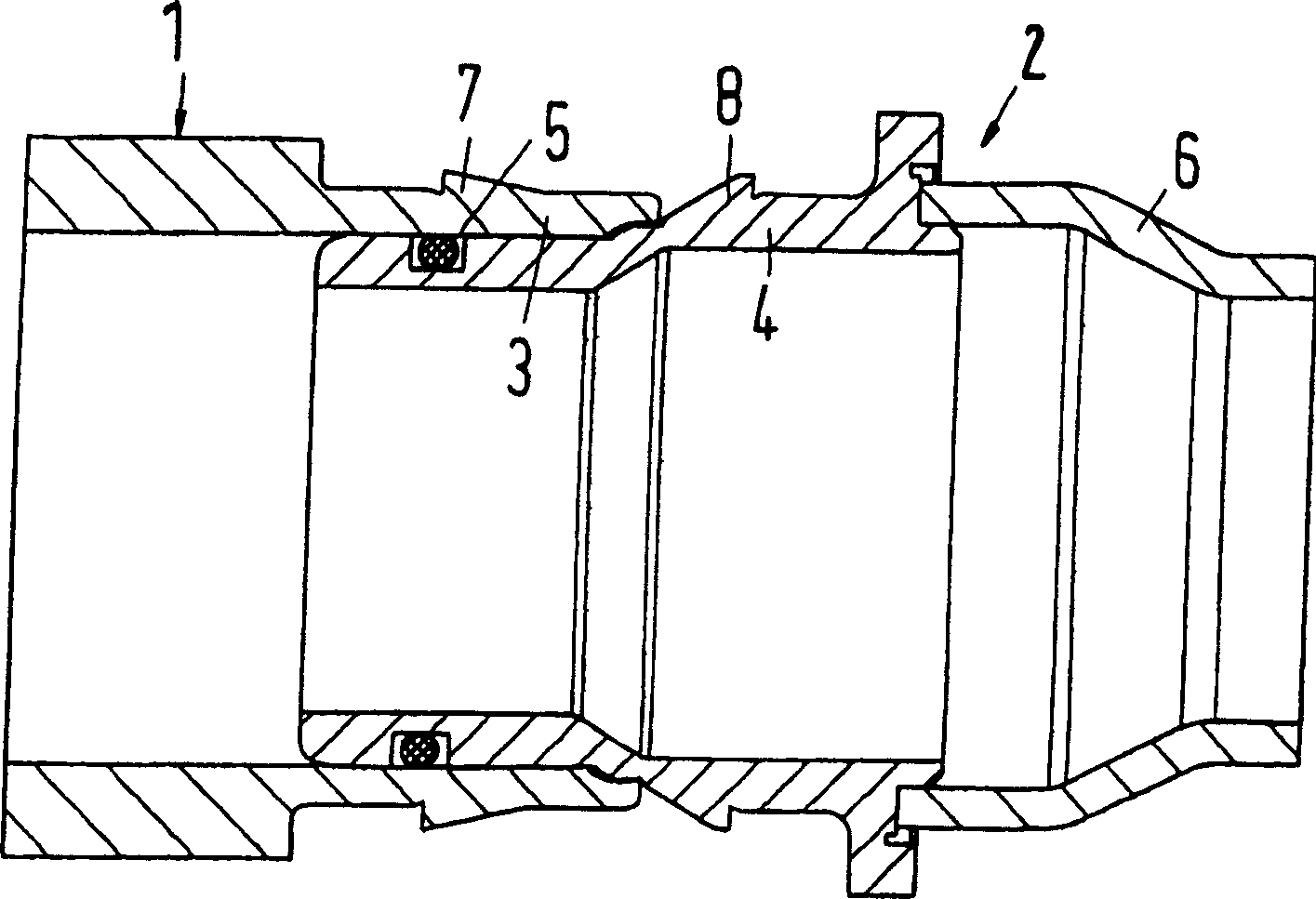

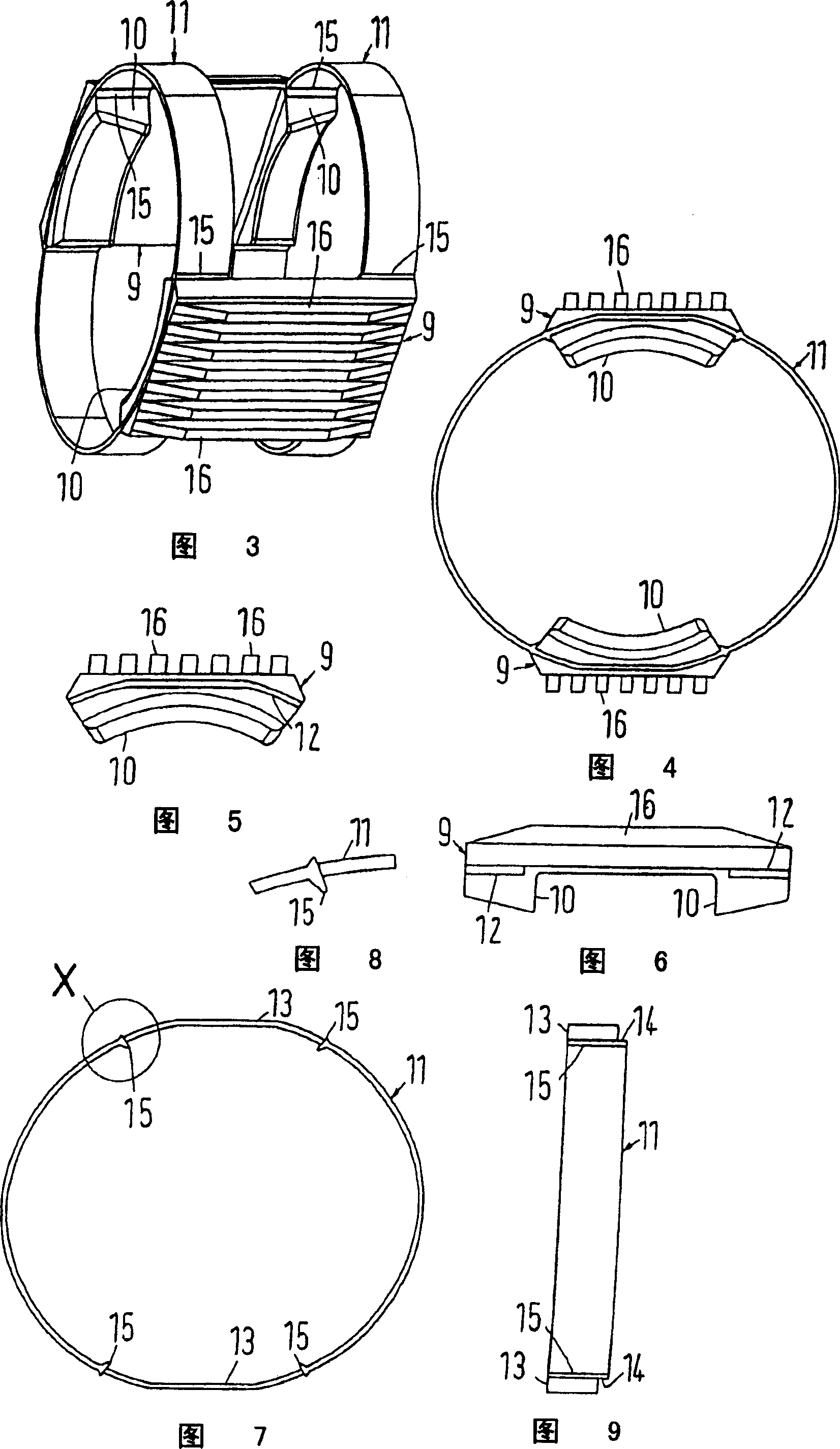

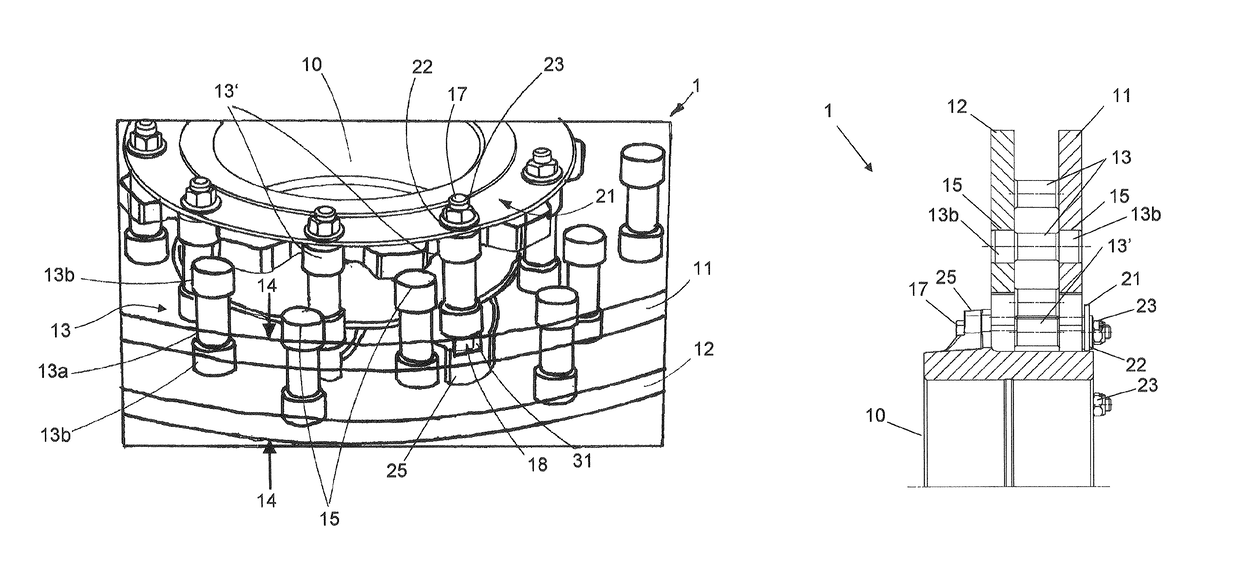

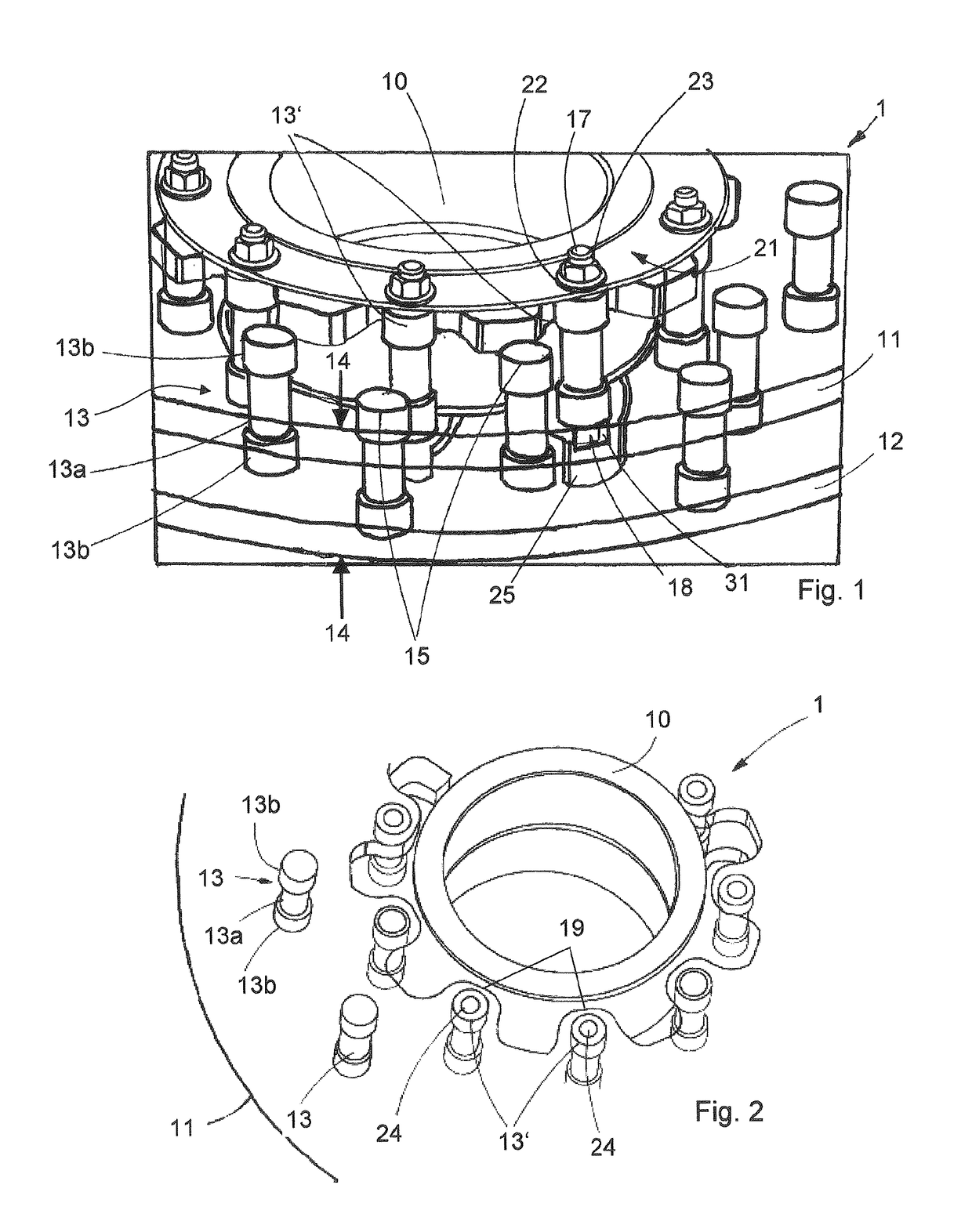

Connector for connecting two pipes

The invention relates to a coupling for joining two pipes (1, 2) having end sections (3, 4) which are respectively provided with circumferential locking ribs (7, 8) to be inserted into the coupling, wherein the coupling has at least one elastic ring (11) that joins at least two longitudinally elongated webs (9). The coupling has a stop projecting part (10) which is locked in the rear of the lock ribs (7, 8) when the end sections (3, 4) are inserted into the coupling and can be unlocked to release the connection of the pipes (1, 2) by expanding at least one ring (11). Each ring (11) is manufactured separately from the webs (9).

Owner:NORMA GERMANY GMBH

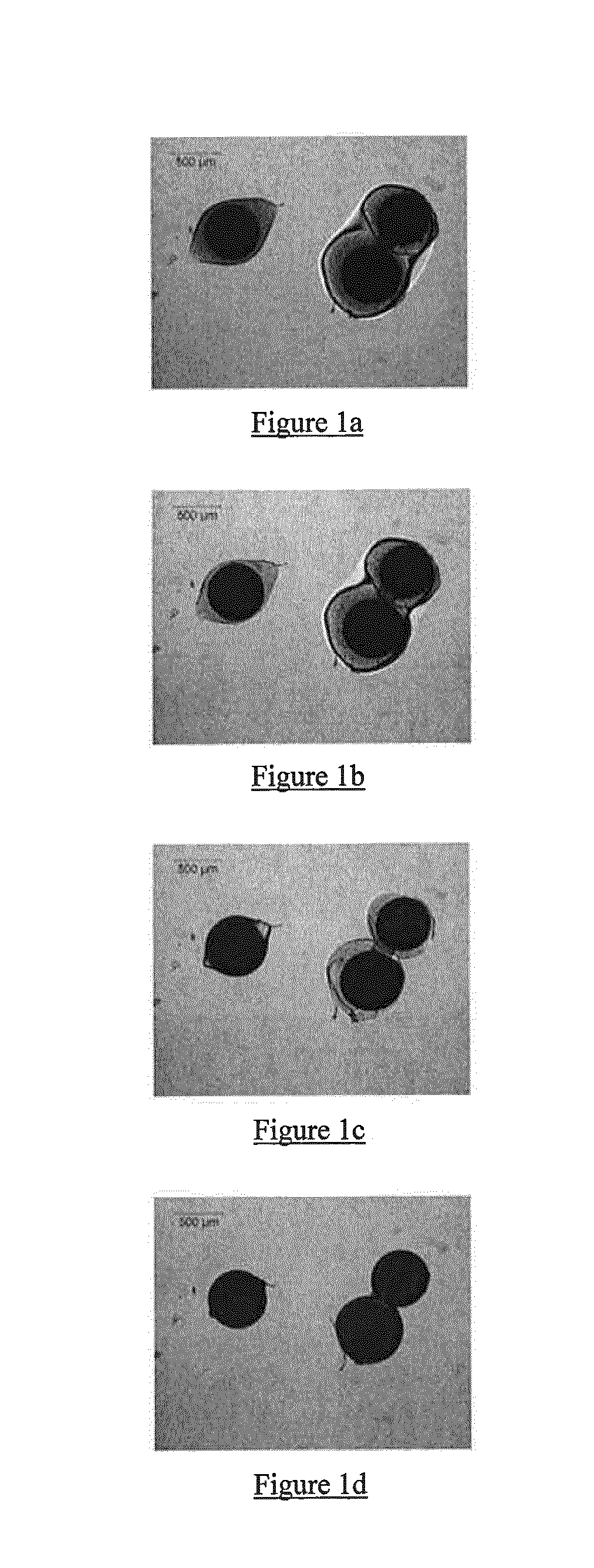

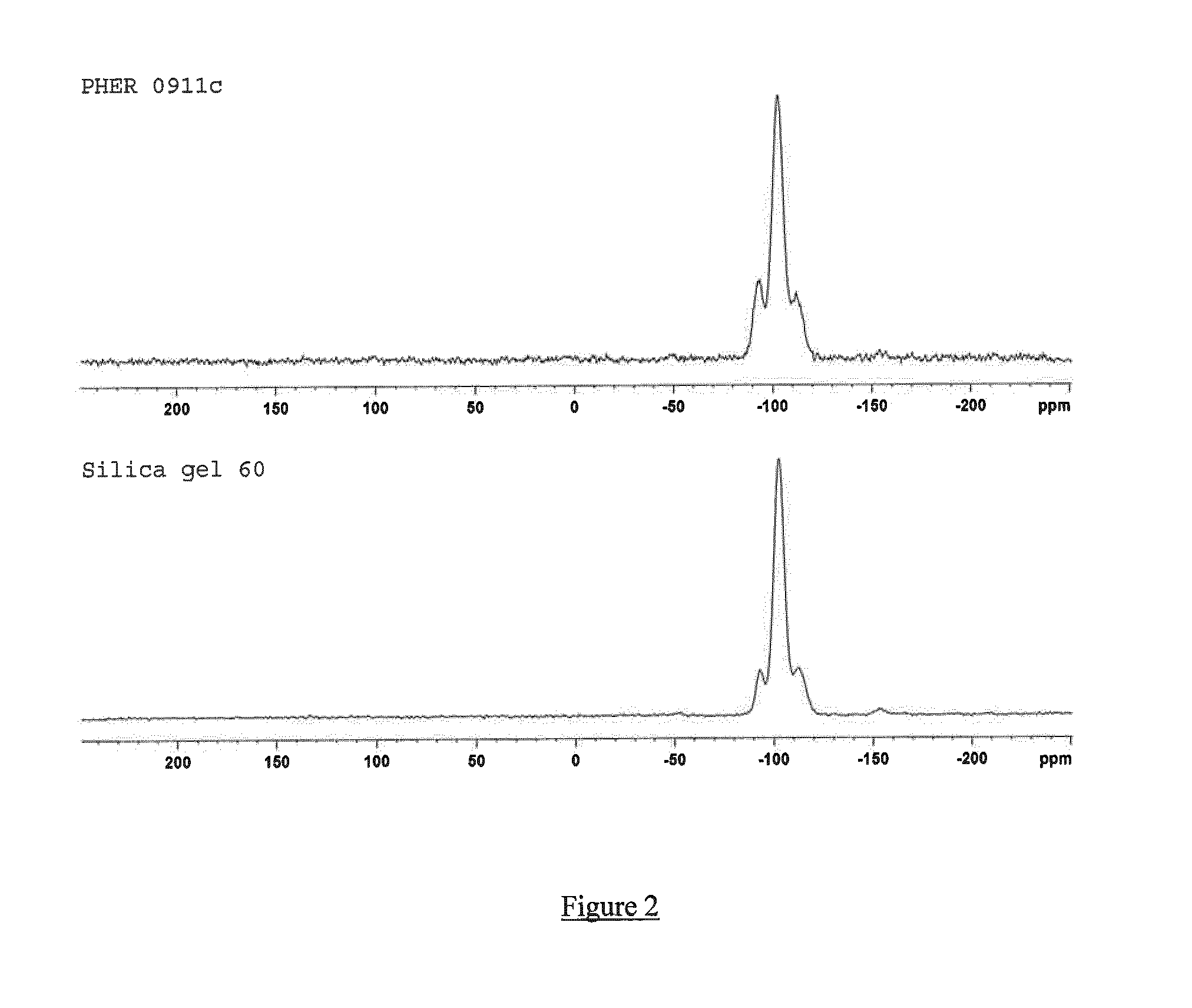

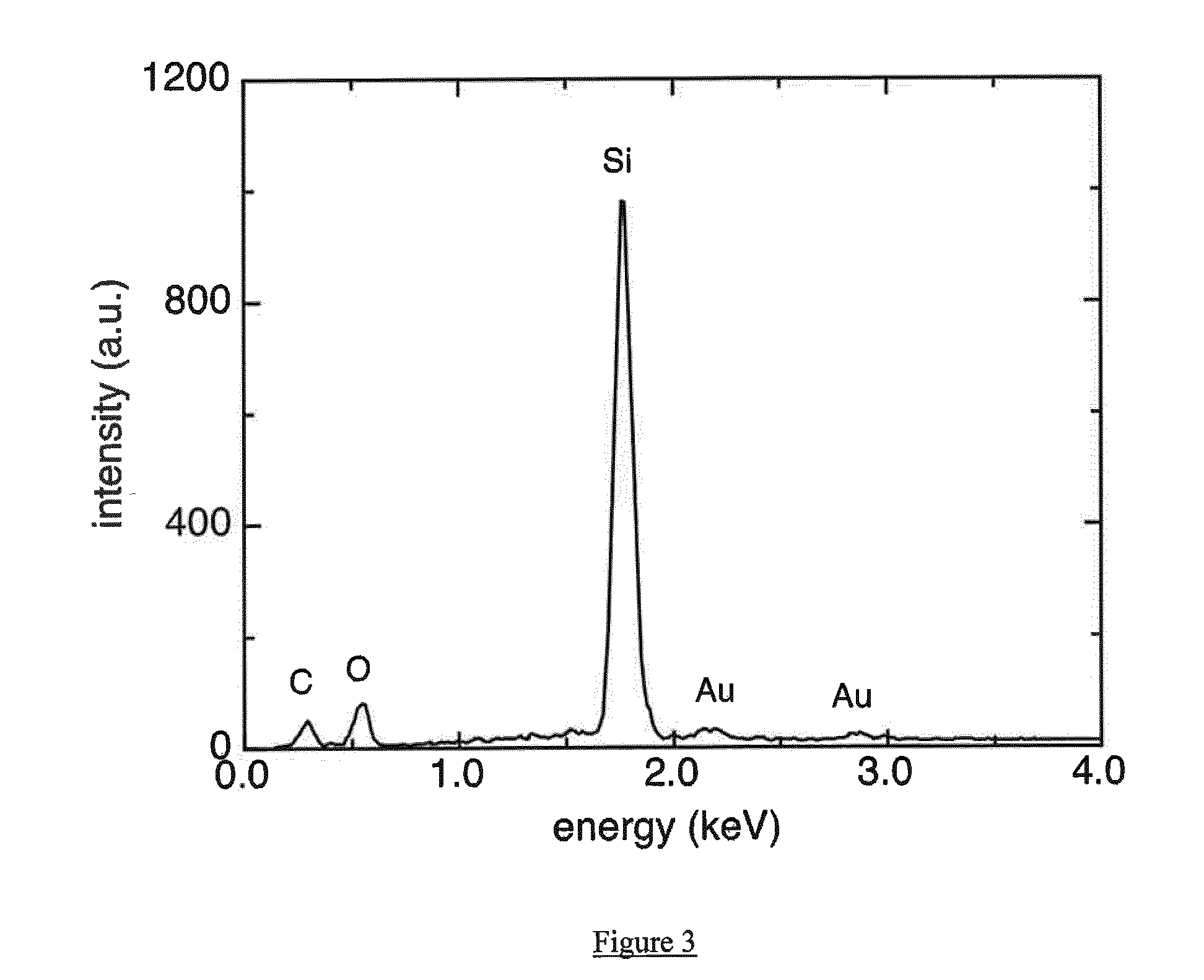

Core-shell capsules

InactiveUS20140106032A1Environmental lossImprove mechanical stabilityEssential-oils/perfumesGaseous substancesCross-linkHydrogel scaffold

The invention provides a process for preparing a core-shell capsule comprising the steps of (i) mixing a solid active ingredient and / or an oily liquid active ingredient with a polymeric material capable of forming a hydrogel shell around the active ingredient(s), (ii) forming a shell comprising a hydrogel scaffold formed of a polymeric lattice around the core, (iii) optionally cross-linking the polymeric lattice; and (iv) contacting the optionally cross-linked core-shell hydrogel shell with a liquid silica precursor so as to cause precipitation of silica within the scaffold structure thereby forming a composite shell of silica interspersed between the polymeric lattice.

Owner:FIRMENICH SA

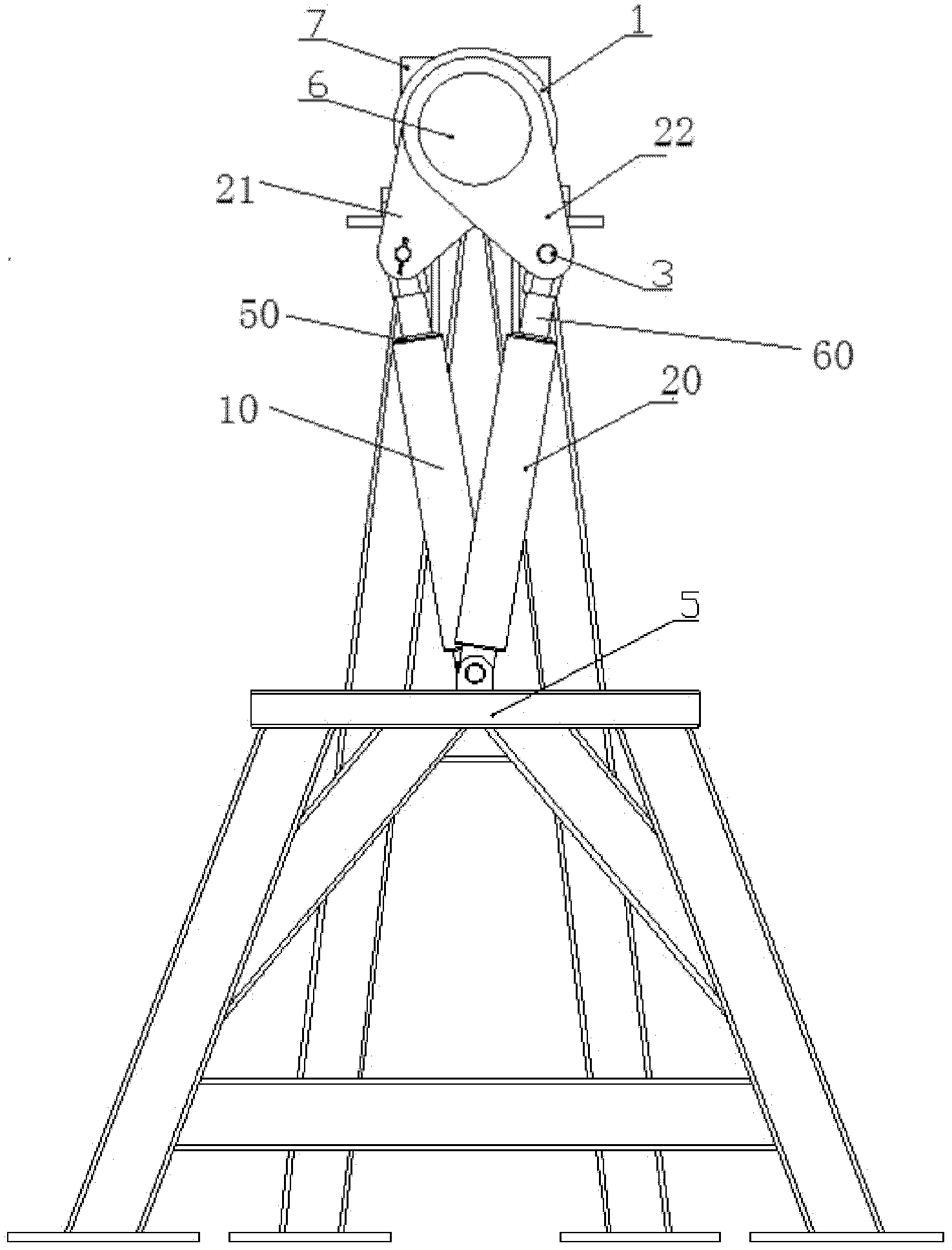

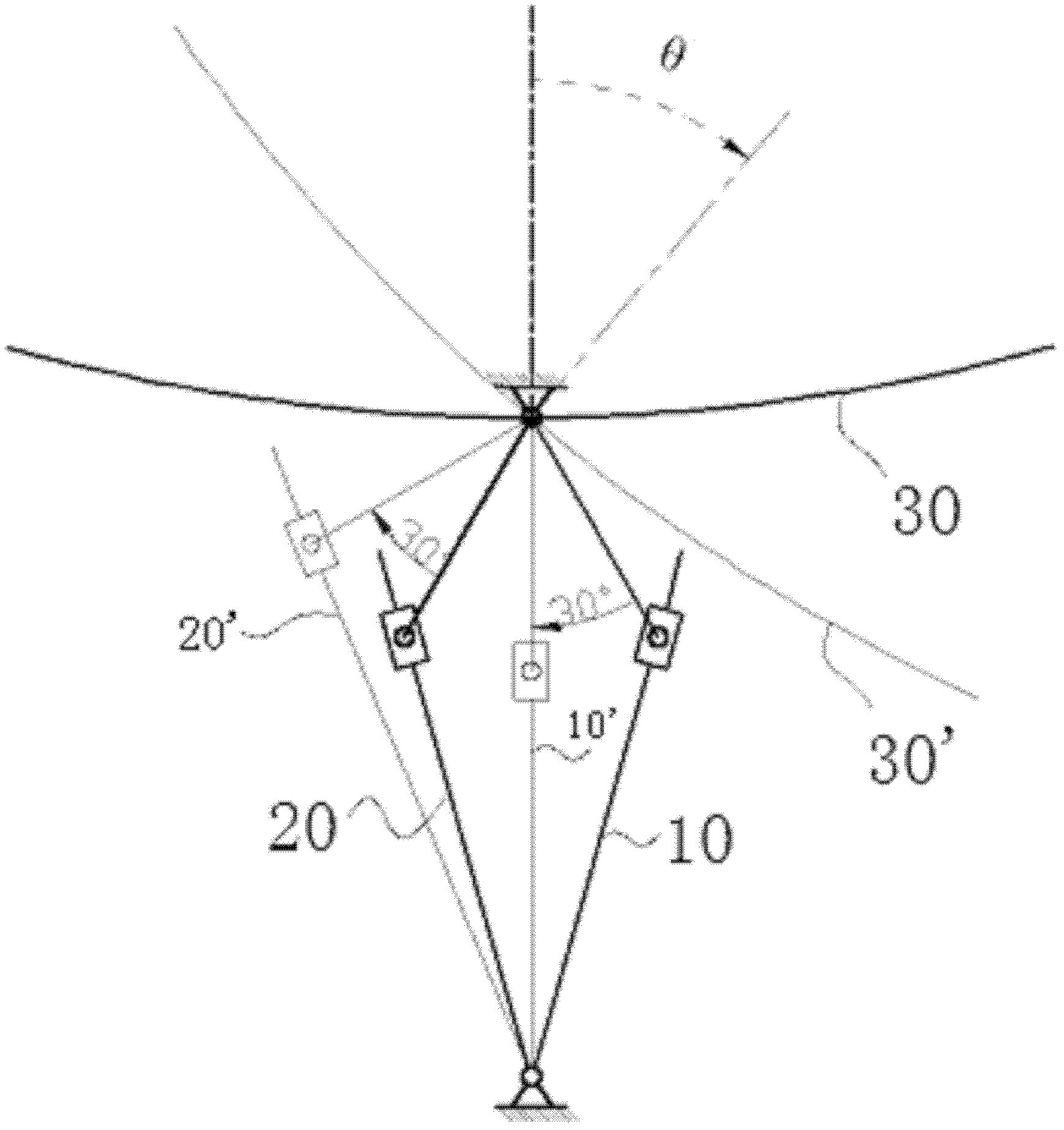

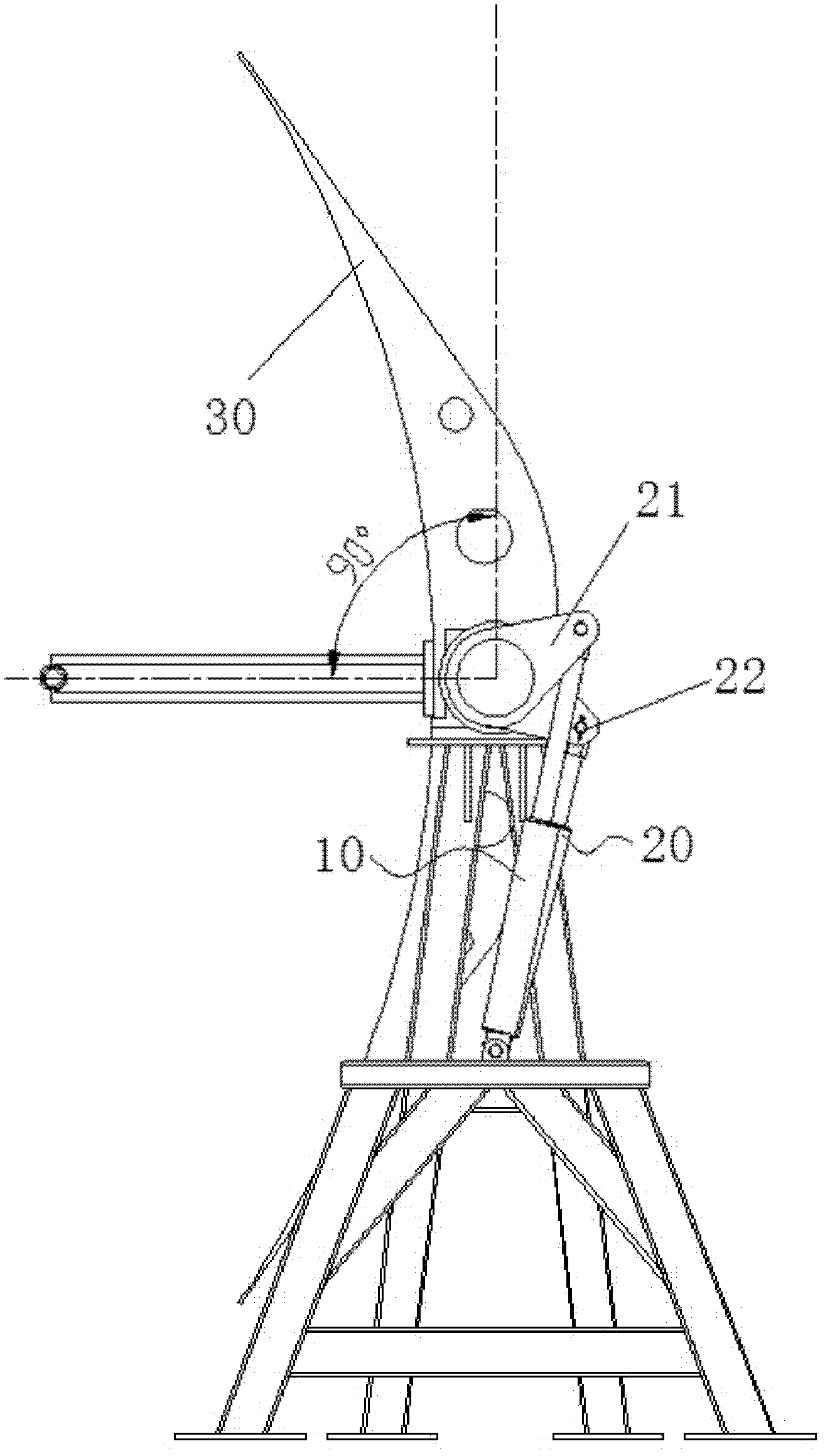

A solar heat collection focus tracking drive mechanism

ActiveCN102269481ASimple mechanical structureEasy to processSolar heating energySolar heat collector controllersHydraulic cylinderEngineering

The invention discloses a solar energy collection focusing tracking driving mechanism which is applied to slot solar thermal power generation engineering. The mechanism is characterized by comprising a flange shaft, connection rods, pin rolls, a single piston hydraulic cylinder, a driving mechanism support frame, a parabolic condenser main shaft, and a parabolic condenser main shaft support frame. The flange shaft is concentrically connected with the parabolic condenser main shaft; the connection rods are connected with the piston hydraulic cylinder; and the pin rolls are connected with a connection piece and the hydraulic cylinder. The single piston hydraulic cylinder mainly comprises a cylinder barrel and a piston rod. Only one end of the single piston rod is provided with the piston rod, oil is pressed or returned by an oil pump, the piston rod is pushed to be extended or contracted from the cylinder barrel slowly, then the connection piece swings, and finally the flange shaft is rotated, so that a slot paraboloid is driven to rotate. The solar energy collection focusing tracking driving mechanism has a simple structure, rotates stably and is large in load capacity, and is usedas a slot heat collection paraboloid focusing tracking mechanism structure which has the characteristics of reliability and stability, and can be applied to a large-scale slot solar thermal power station.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

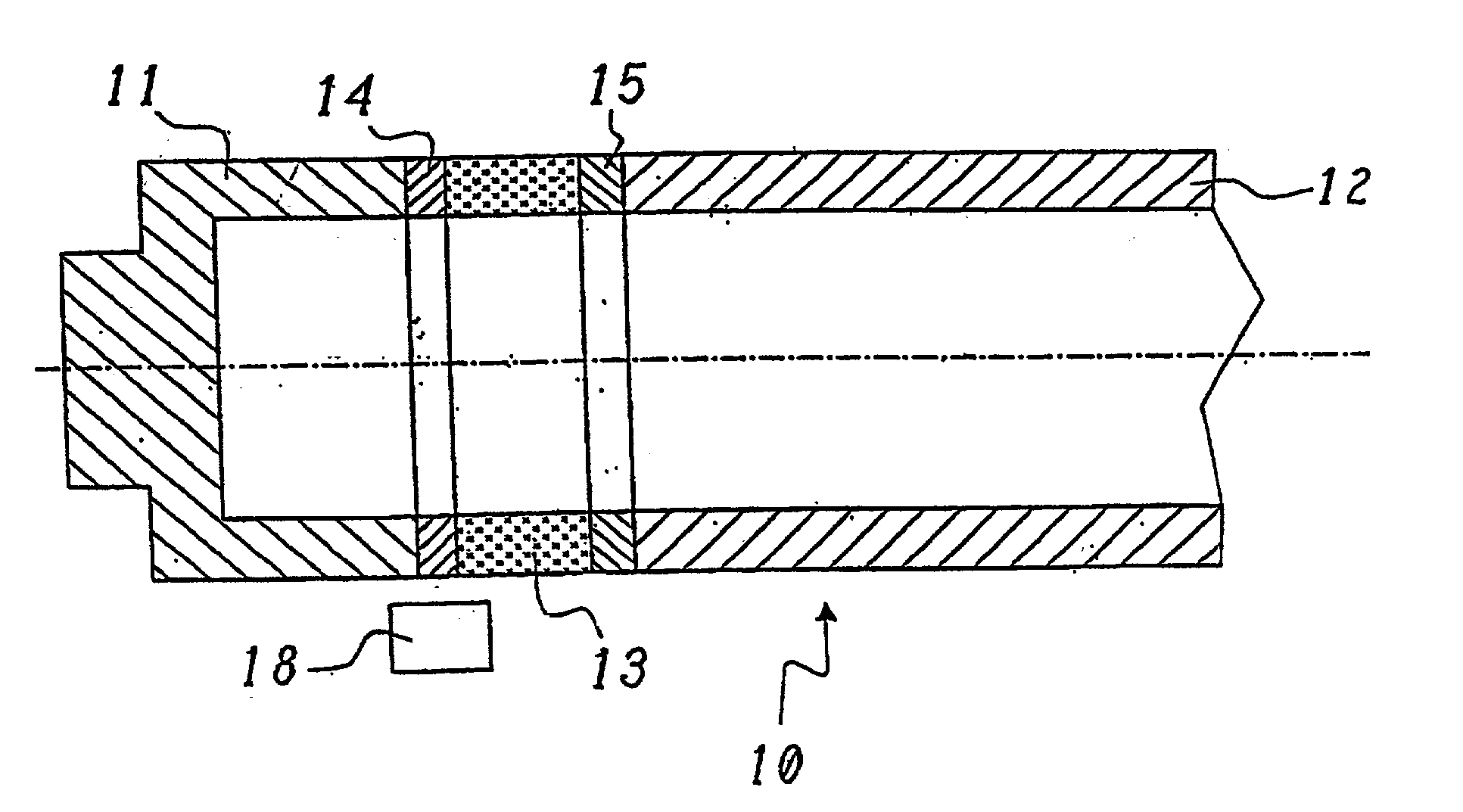

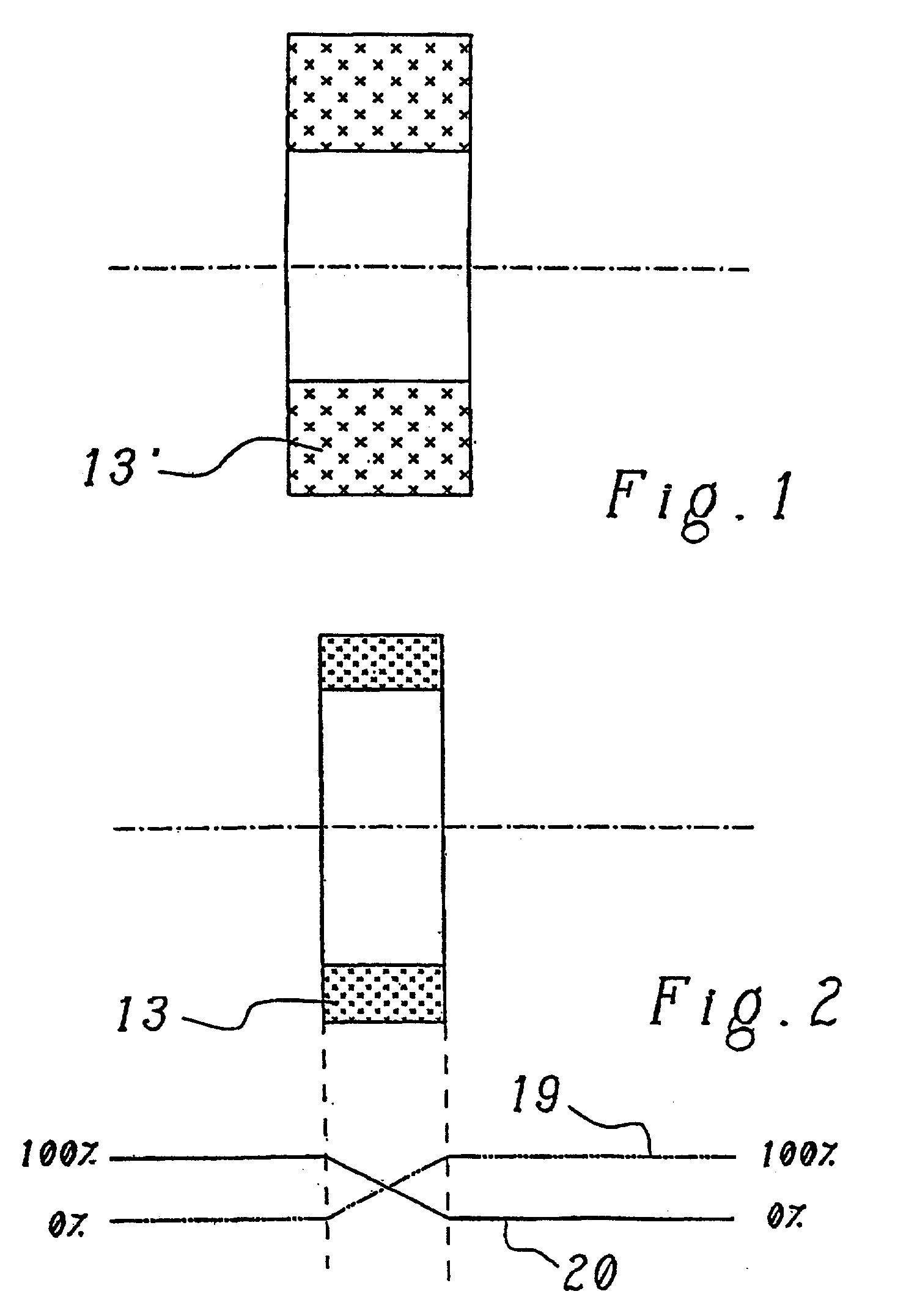

Rotor for a turbomachine, and process for producing a rotor of this type

InactiveUS20020136659A1Less creep-resistantHigh mechanical loadTurbinesPump componentsOperating temperaturePowder metallurgy

A rotor (10) for a turbomachine, comprising at least one first, preferably disk-like rotor section (12), which is exposed to high operating temperatures and consists of a particularly creep-resistant material, in particular a nickel-based alloy, and at least one second, preferably disk-like rotor section (11), which is exposed to lower operating temperatures and consists of a less creep-resistant material, in particular steel, the first and second rotor sections (11, 12) being joined to one another by welding. In a rotor of this type, a crack-free welded joint is achieved by the fact that, to join the two rotor sections (11, 12), a transition region (13) is arranged between the two rotor sections (11, 12), which transition region is produced by powder metallurgy, is welded to one of the two rotor sections (11, 12) at least on one side, and on this side has the same composition as the rotor section to which it is welded.

Owner:ALSTOM TECH LTD

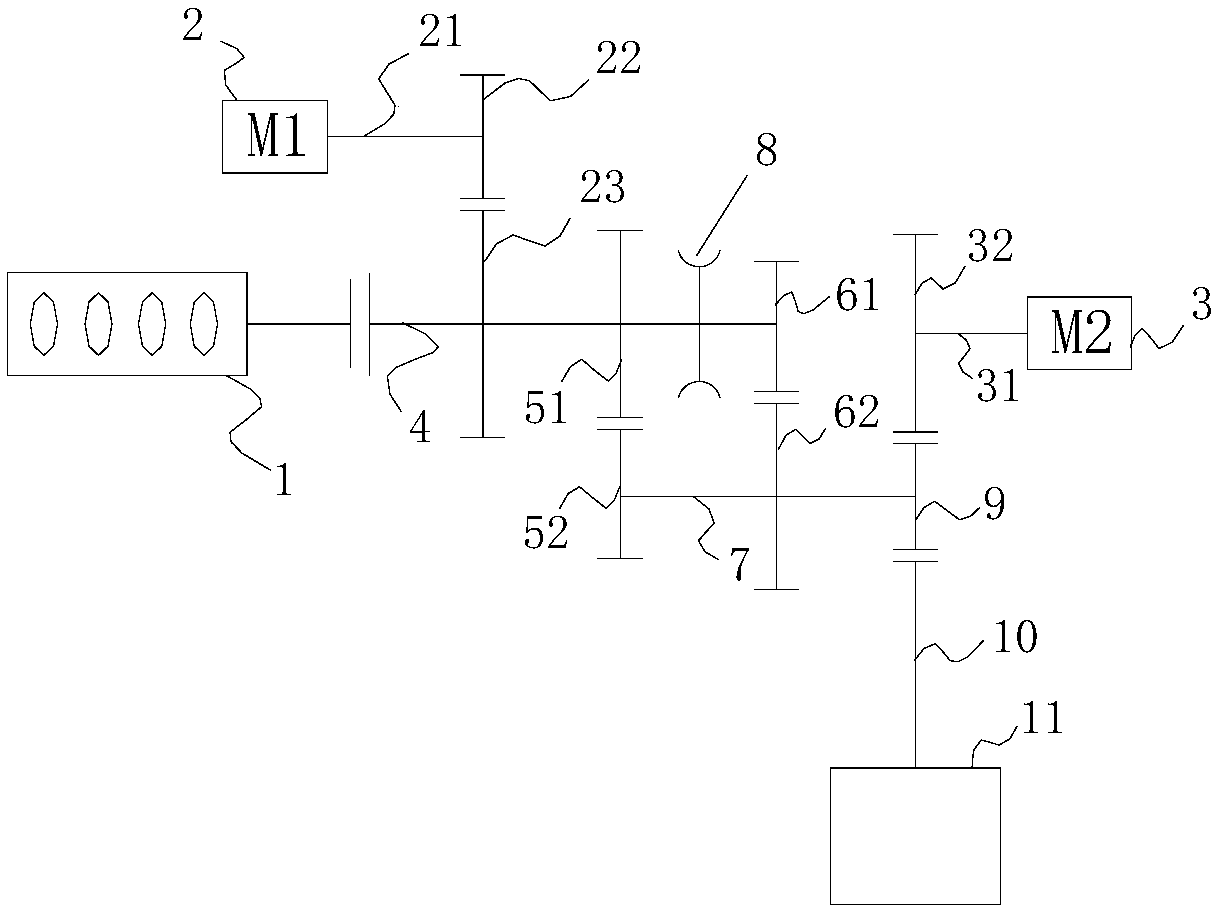

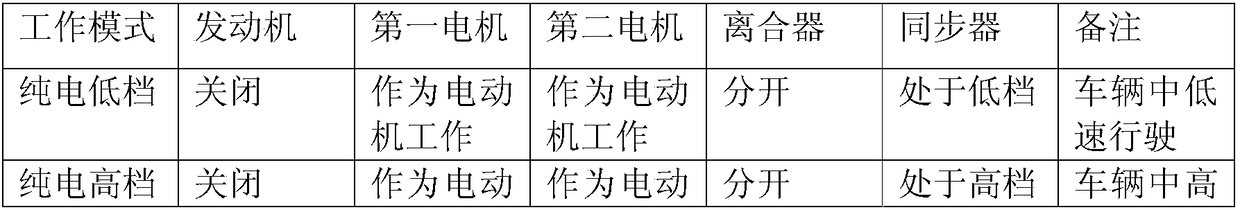

Transmission system, transmission method and corresponding vehicle

InactiveCN108128137ALow powerUnit Efficiency/Cost ImprovementHybrid vehiclesGas pressure propulsion mountingAutomotive engineeringReverse mode

The invention discloses a transmission system comprising an engine, a first motor and a second motor. The engine, the first motor and the second motor are connected with a transmission separately. Thetransmission comprises a first input drive shaft, as well as a first gear set and a second gear set which are jointly connected in series on the first input drive shaft and an intermediate shaft. Theend of the intermediate shaft is connected with a gear pair. The gear pair is separately connected with a third input drive shaft and a deceleration driven gear. The third input drive shaft is connected with the second motor. The deceleration driven gear is connected with a differential. The invention also discloses a transmission method. The pure electric mode, the series mode, the parallel mode, the reversing mode and the parking mode can be realized. The invention also discloses a vehicle capable of realizing the multiple modes and the multiple gears. Through the technical solution, the efficiency of the engine in the mechanical drive can be optimized and the power of the engine and powers of the motors are reduced.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

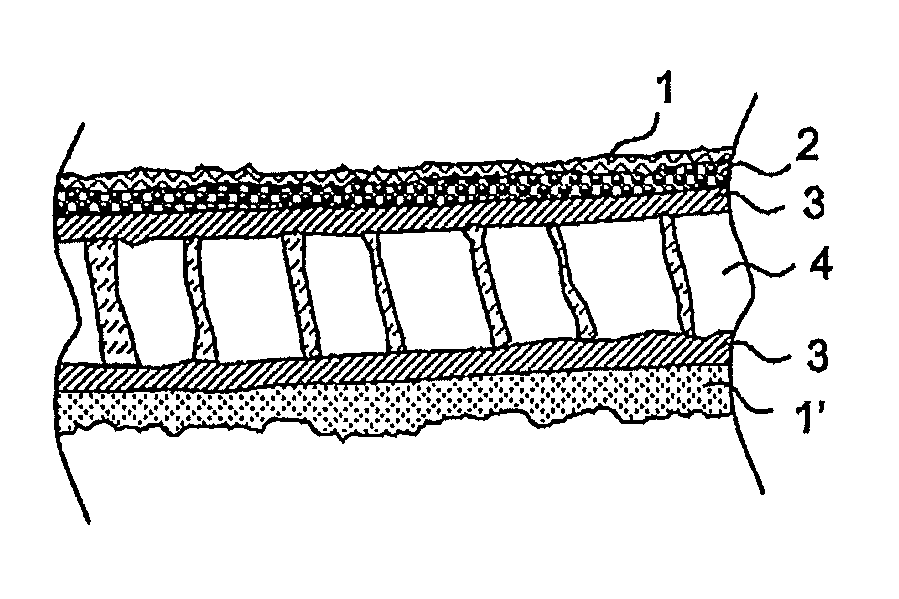

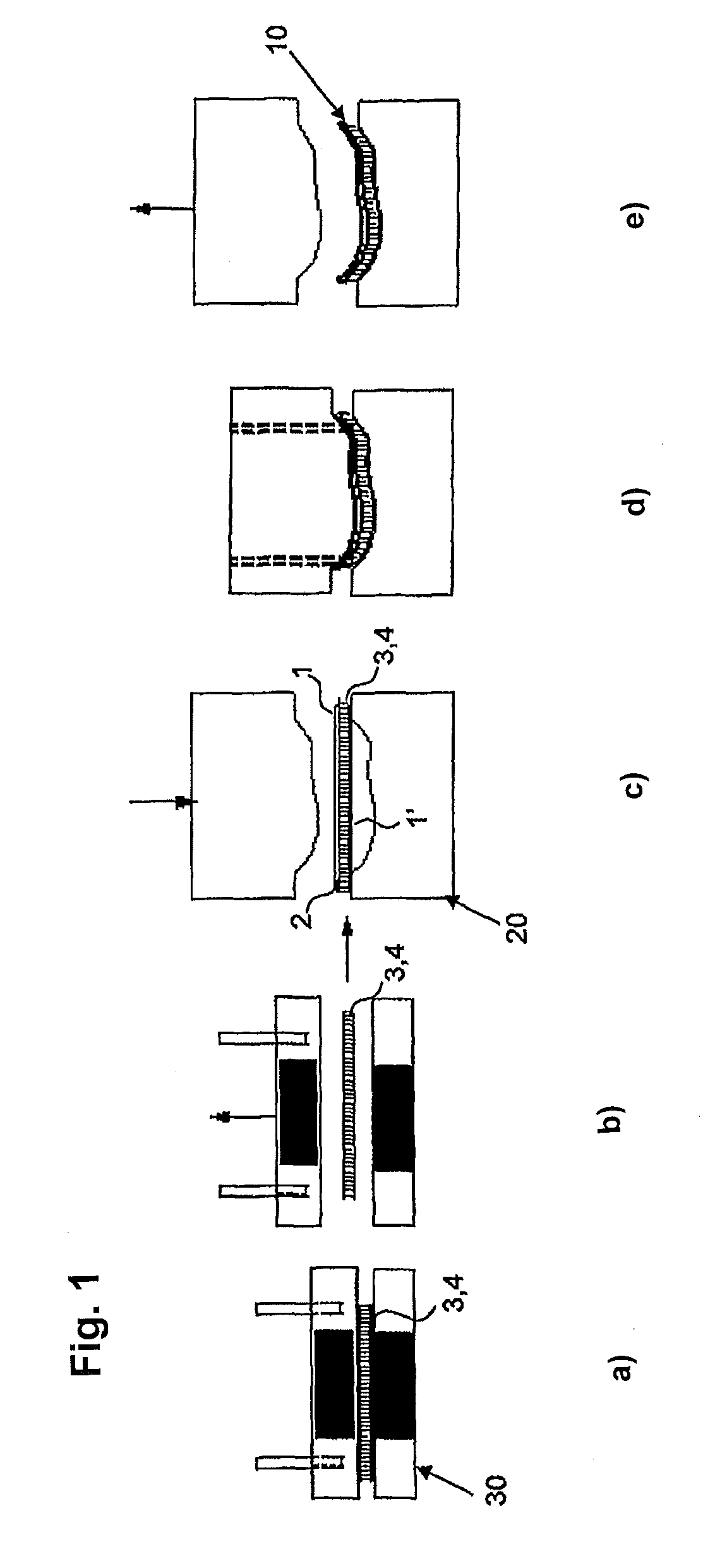

Method for producing a flat semi-finished product from a fiber composite material and flat semi-finished product

InactiveUS20130210298A1Low priceHigh mechanical loadWeft knittingLayered productsTextile fiberFiber bundle

A method produces a flat semi-finished product from a fiber composite material that contains individual carbon fibers, carbon fiber bundles, or a mixture thereof in a defined anisotropic fiber orientation and a thermoplastic matrix material. The anisotropy of the carbon fibers is created in a carding process using the high orientability of admixed non-carbon textile fibers, at least some of the non-carbon textile fibers being thermoplastic, and the carbon fibers having been isolated from waste or used parts. The flat fibrous web which is produced by a carding process and which has a specific orientation of the carbon fibers in the longitudinal direction is compressed into a sheet material under the effect of heat. This enables the use of carbon fibers, for example from production waste, as reinforcing fibers, whereby a less expensive raw material is provided and the carbon fibers are contained in the waste materials are recycled.

Owner:SGL AUTOMOTIVE CARBON FIBERS

Turbine air cooling blade

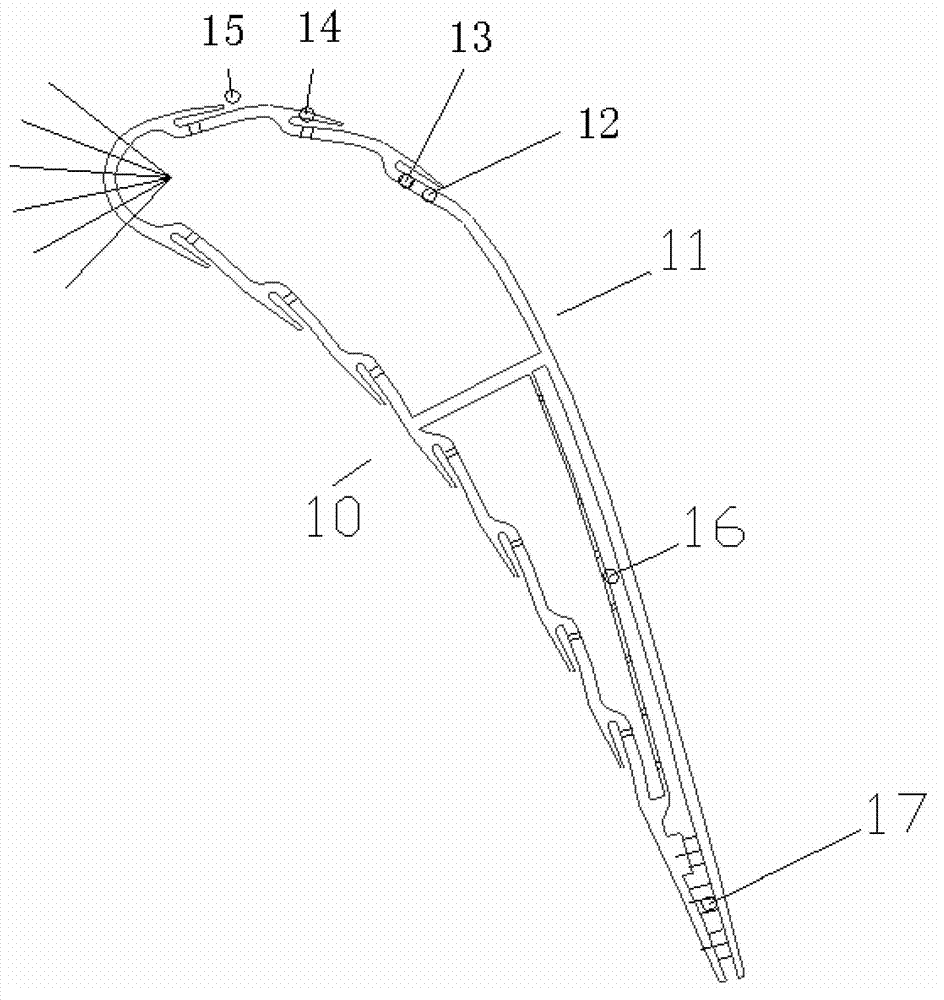

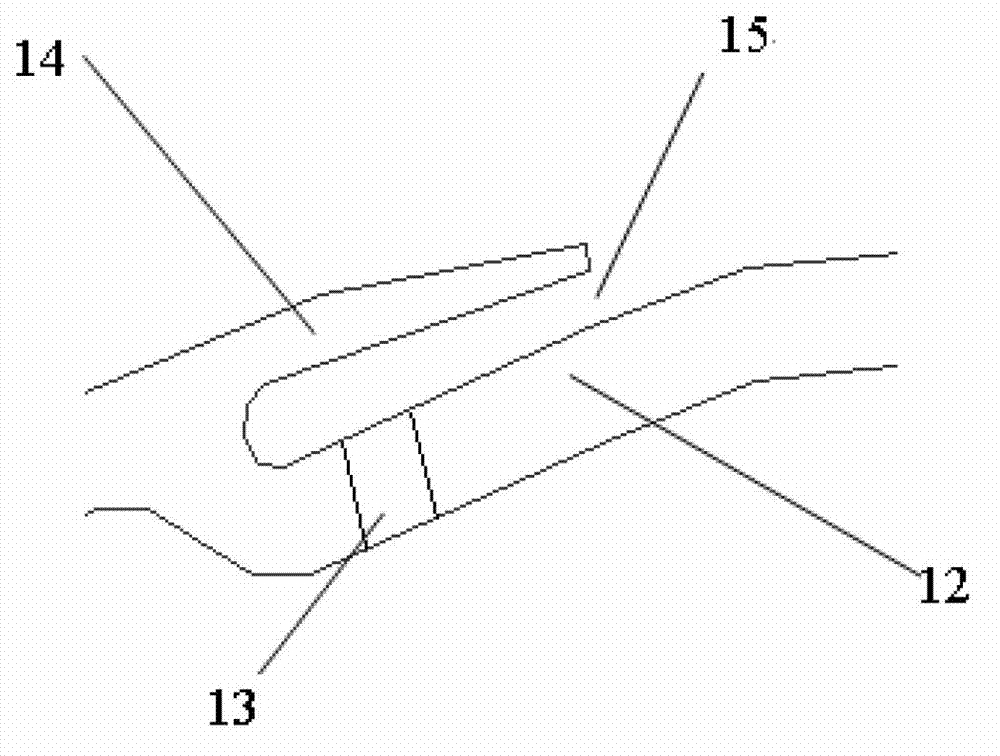

InactiveCN103046967AIncrease coverageReduce spacingBlade accessoriesMachines/enginesTurbine bladeFront edge

The invention belongs to the field of an aero engine, in particular to a turbine air cooling blade. An inner cavity is divided into by a front cavity 2 and a rear cavity 3, the front cavity 2 is cooled by air supplied by an upper end 4 and a lower end 5, multiple rows of exhaust membrane holes 7 are reserved on a front edge 6 of the cooling blade, and a plurality of scale-shaped cooling structure units are arranged on the surface of the blade. Compared with a conventional cooling structure, the air cooling blade with the scale-shaped cooling structure units is higher in cooling efficiency, lower in temperature on the outer surface and capable of bearing higher temperature load, and under the same working condition, utilization amount of cooling air can be reduced, and efficiency of an engine can be improved. Since a scale-shaped cooling structure body is separated from scales, the scale-shaped cooling structure body is less influenced by gas, lower in temperature and capable of bearing high mechanical load, and on the other hand, the scale-shaped cooling structure body can be thinner and consume fewer cooling air, so that by the air of the turbine blade in scale-shaped cooling structure, performance and efficiency of the engine can be improved.

Owner:CHINA GAS TURBINE ESTAB

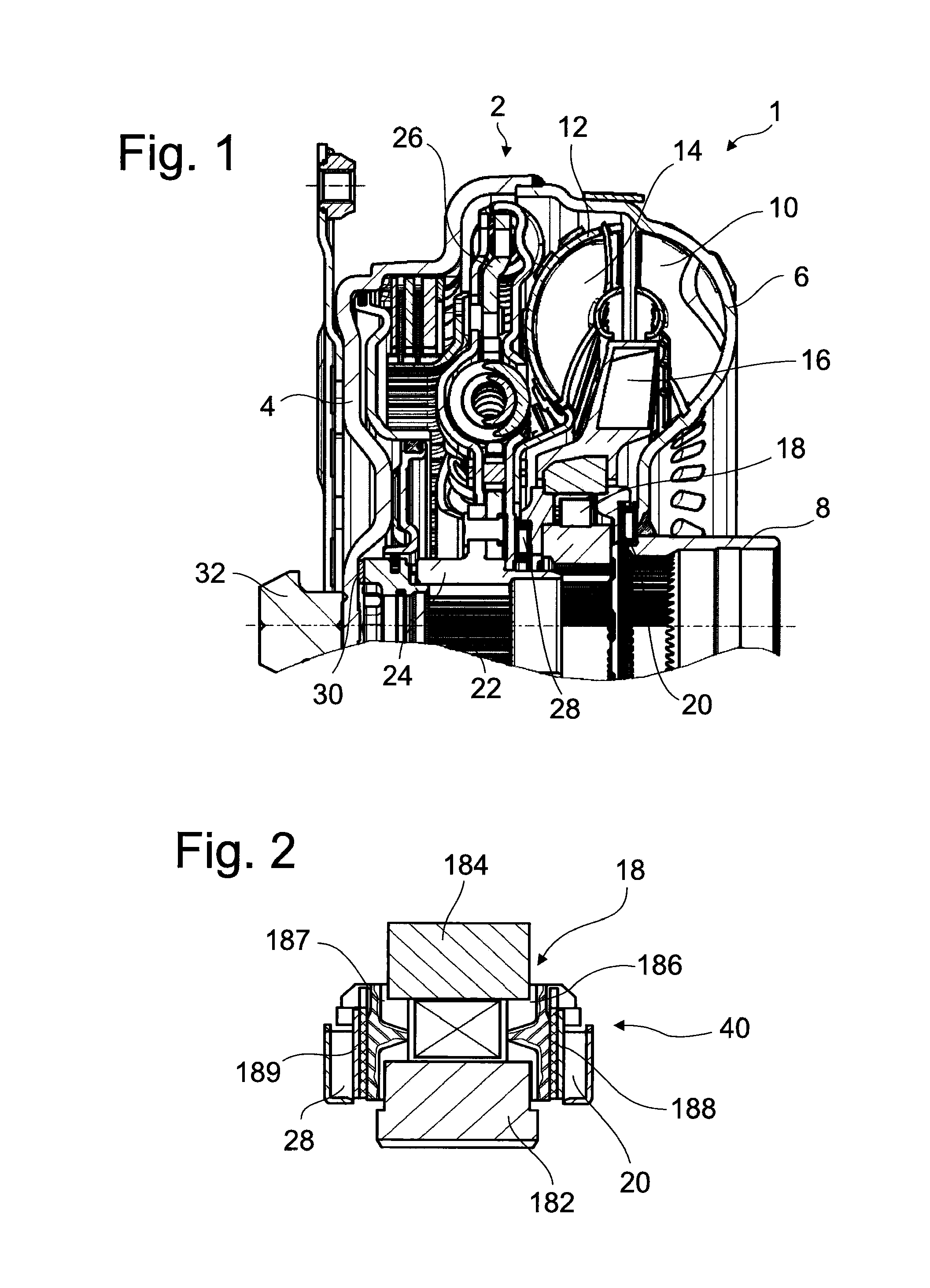

Assembled undular brake disc

ActiveUS20140339027A1Save installation spaceIncrease the diameterBraking discsActuatorsContact pressureEngineering

The invention relates to an assembled undular brake disc having a hub on which two friction rings which are produced from a steel material are arranged parallel to and spaced apart from one another. The assembled undular brake disc can withstand high mechanical loads and permits good internal ventilation. Supporting bolts for absorbing an axially acting pad contact pressure force are arranged between the friction rings.

Owner:FAIVELEY TRANSPORT WITTEN GMBH

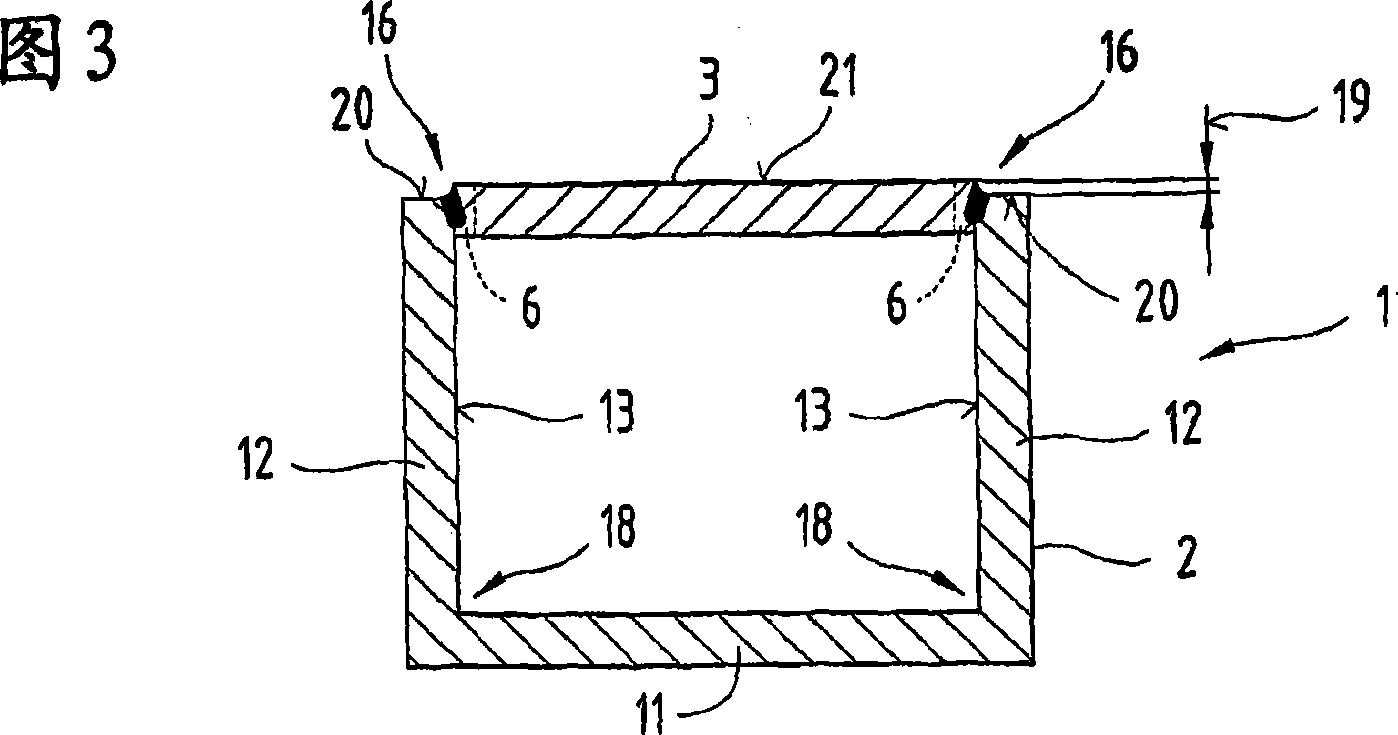

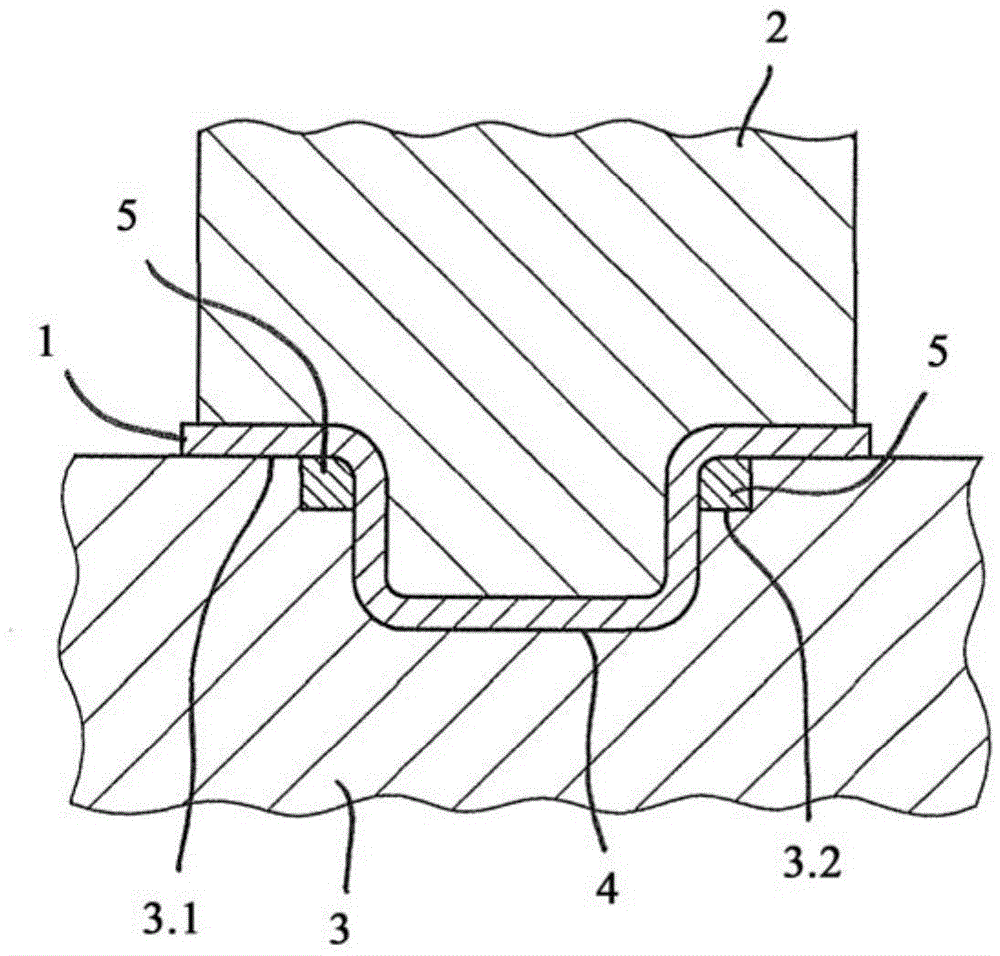

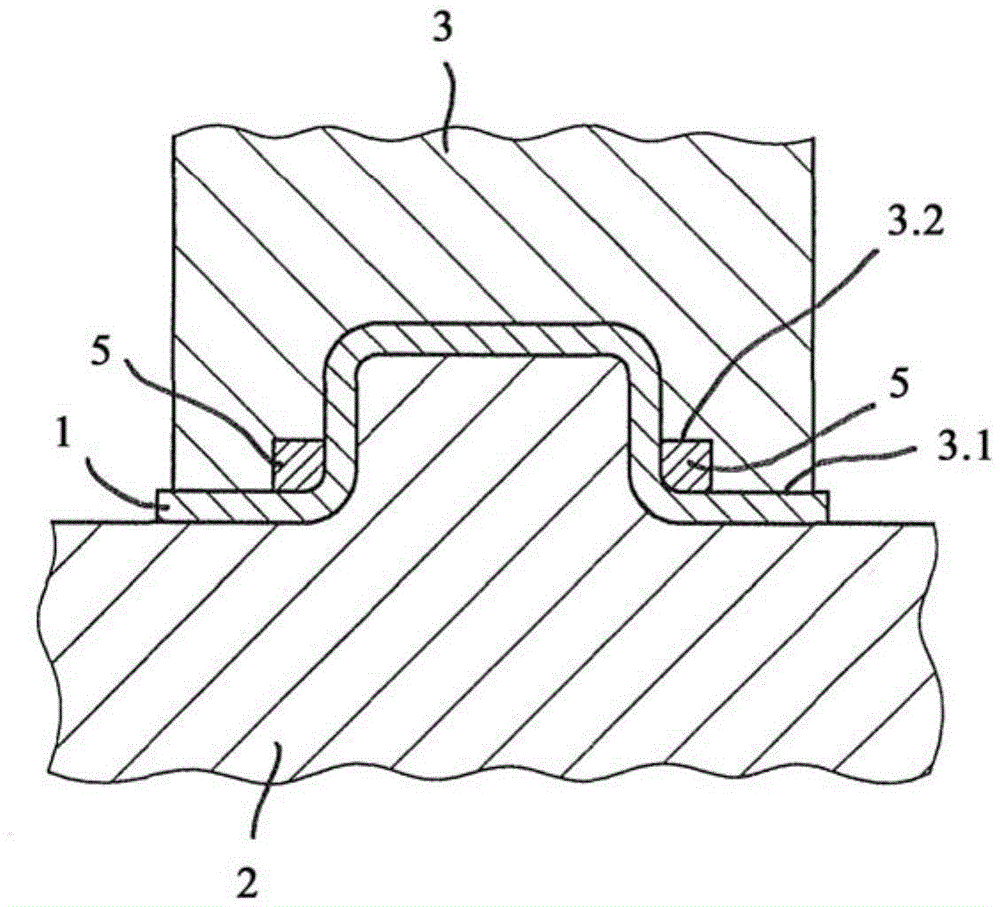

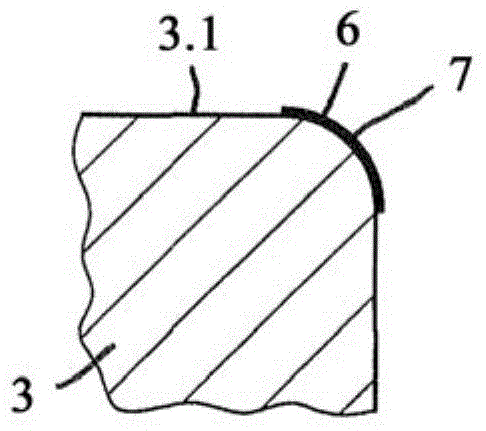

Method and forming tool for hot forming and press hardening work pieces made of sheet steel, in particular galvanized sheet steel

InactiveCN103958087AReduce or prevent damageReduce heat lossShaping toolsQuenching devicesSheet steelBond coating

The invention relates to a method for hot forming and press hardening plate-shaped or preformed workpieces made of sheet steel, in particular galvanized workpieces (1) made of sheet steel, in which the workpiece (1) is heated to a temperature exceeding the austenitizing temperature and subsequently formed and quenched in a cooled forming tool comprising a stamp (2) and a die (3), characterized in that the drawing edge region, which is defined by a positive die radius, of the die (3) used for hot forming and press hardening is provided with a materially bonded coating of a material (6, 6') and / or is provided with an insert (5) having a thermal conductivity that is lower than the thermal conductivity of section (3.1) of the die (3), which is adjacent to the drawing edge region, by at least 10 W / (m*K), which section comes into contact with the workpiece (1) during hot forming and press hardening of the same. The surface of the material (6, 6') applied to the drawing edge region and facing the workpiece (1) or the surface of the provided insert (5) has a lateral dimension extending across the drawing edge (7), which is in the range of 1.6 times to 10 times the positive die radius of the die (3). The invention also relates to a corresponding forming tool.

Owner:THYSSENKRUPP STEEL EURO AG

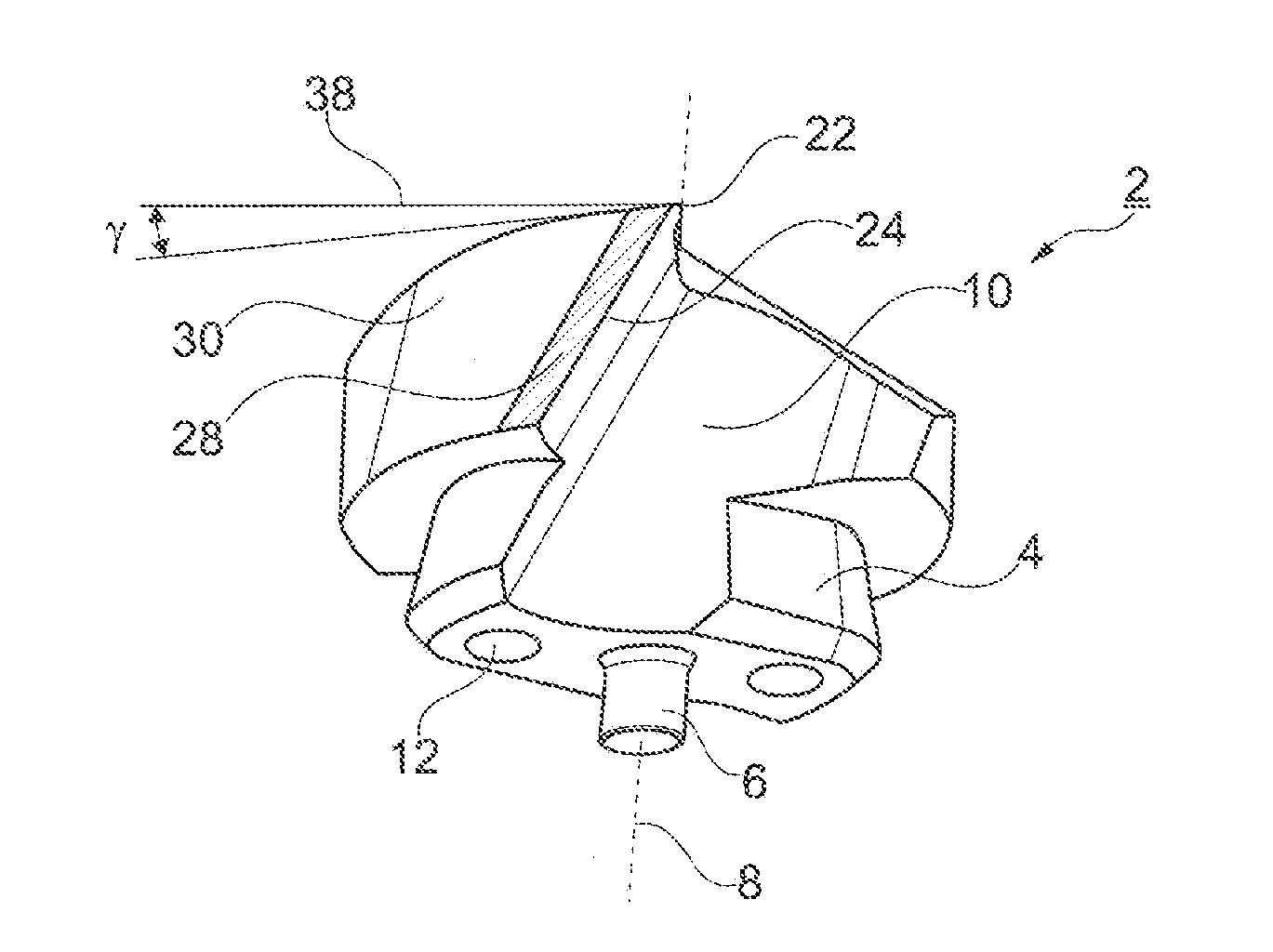

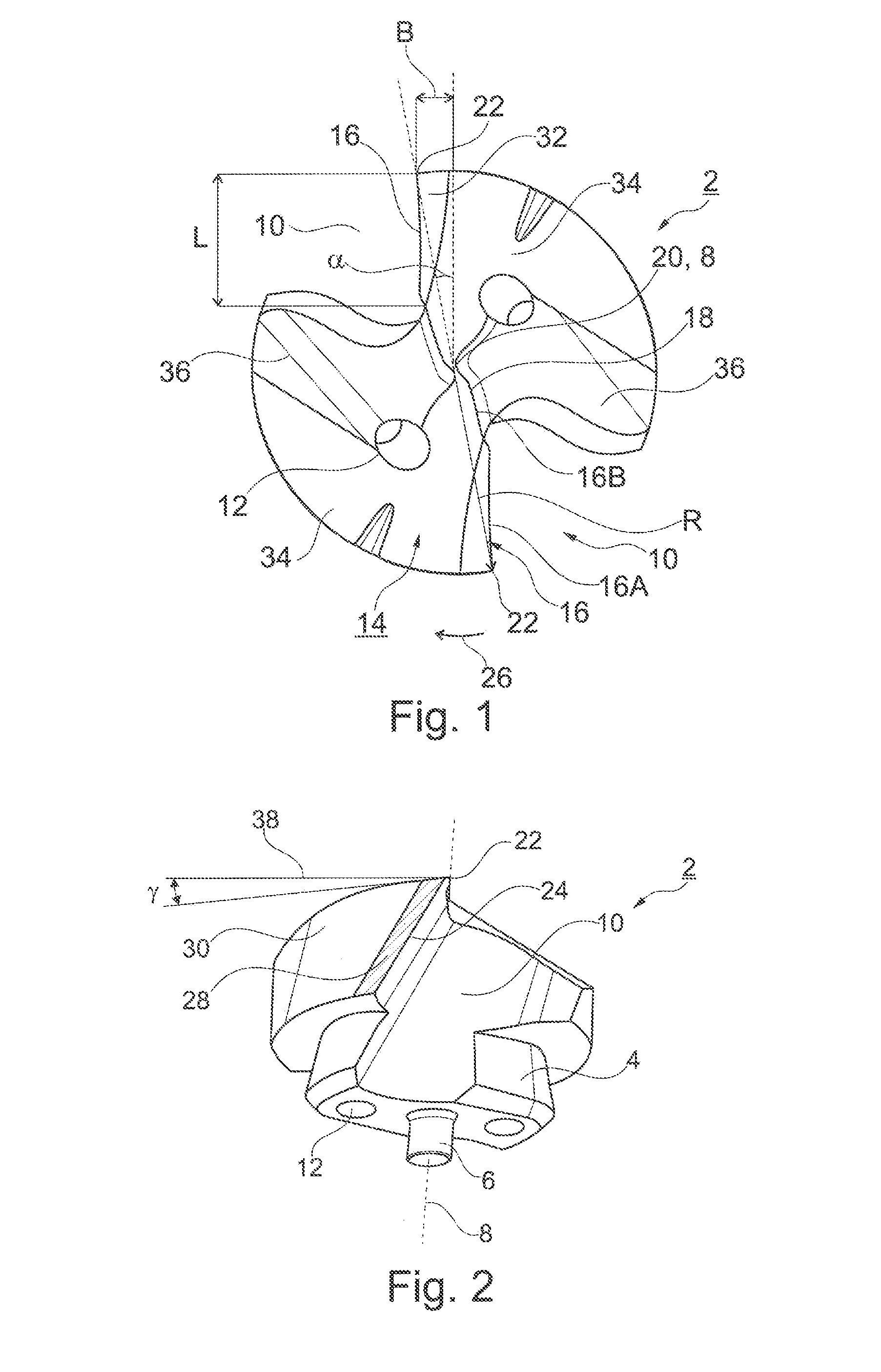

Rotary tool and method for manufacturing

ActiveUS20160263663A1Improve propertiesImprove wear characteristicsWorkpiecesTurning toolsEngineeringMechanical engineering

A rotary tool, in particular drilling tool, extends along a longitudinal axis and has an end surface; a brad point; and at least one major cutting edge extending outward up to an edge corner. A first free surface segment adjoins the major cutting edge, and a second free surface segment in turn adjoins said first free surface segment. To keep the stress, in particular the wear, low in the region of the end surface, the first free surface segment has a lower average abrasiveness than the second free surface segment.

Owner:KENNAMETAL INC

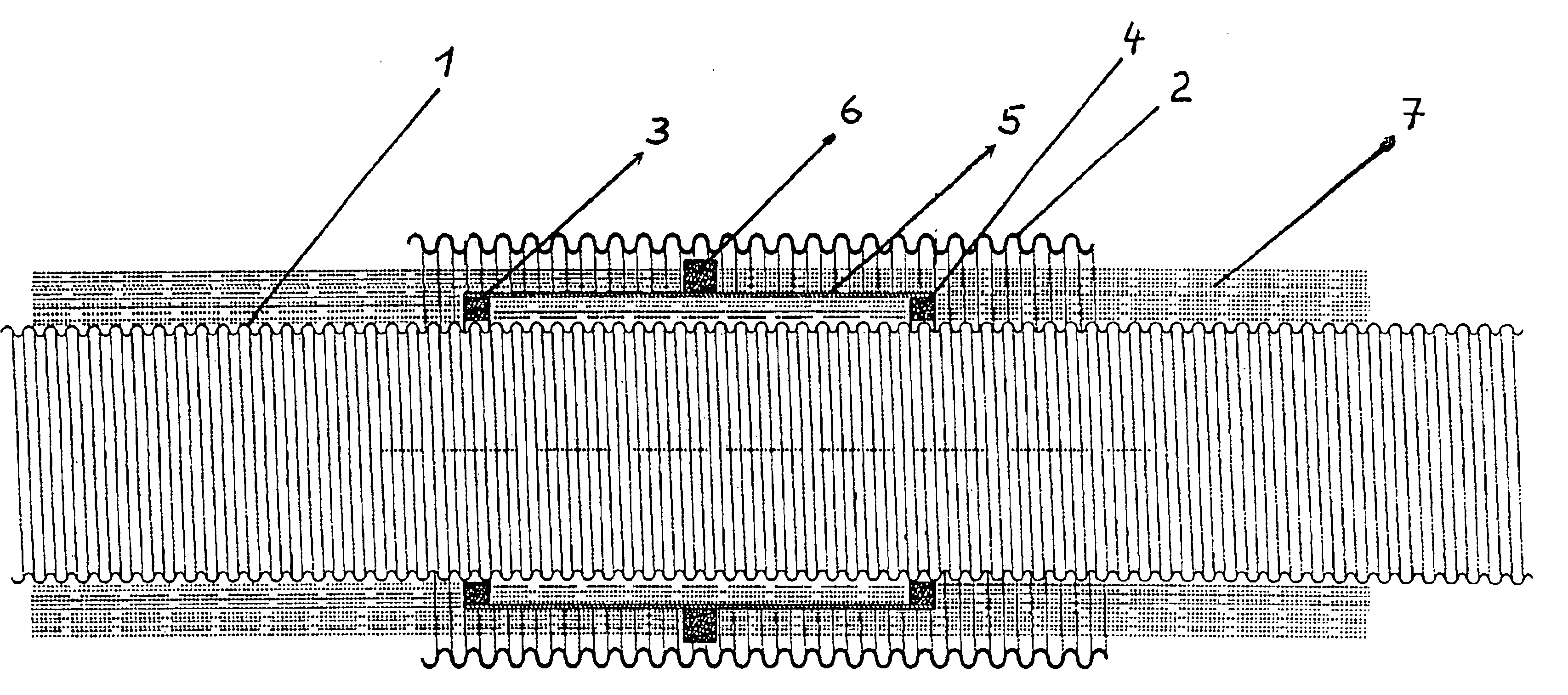

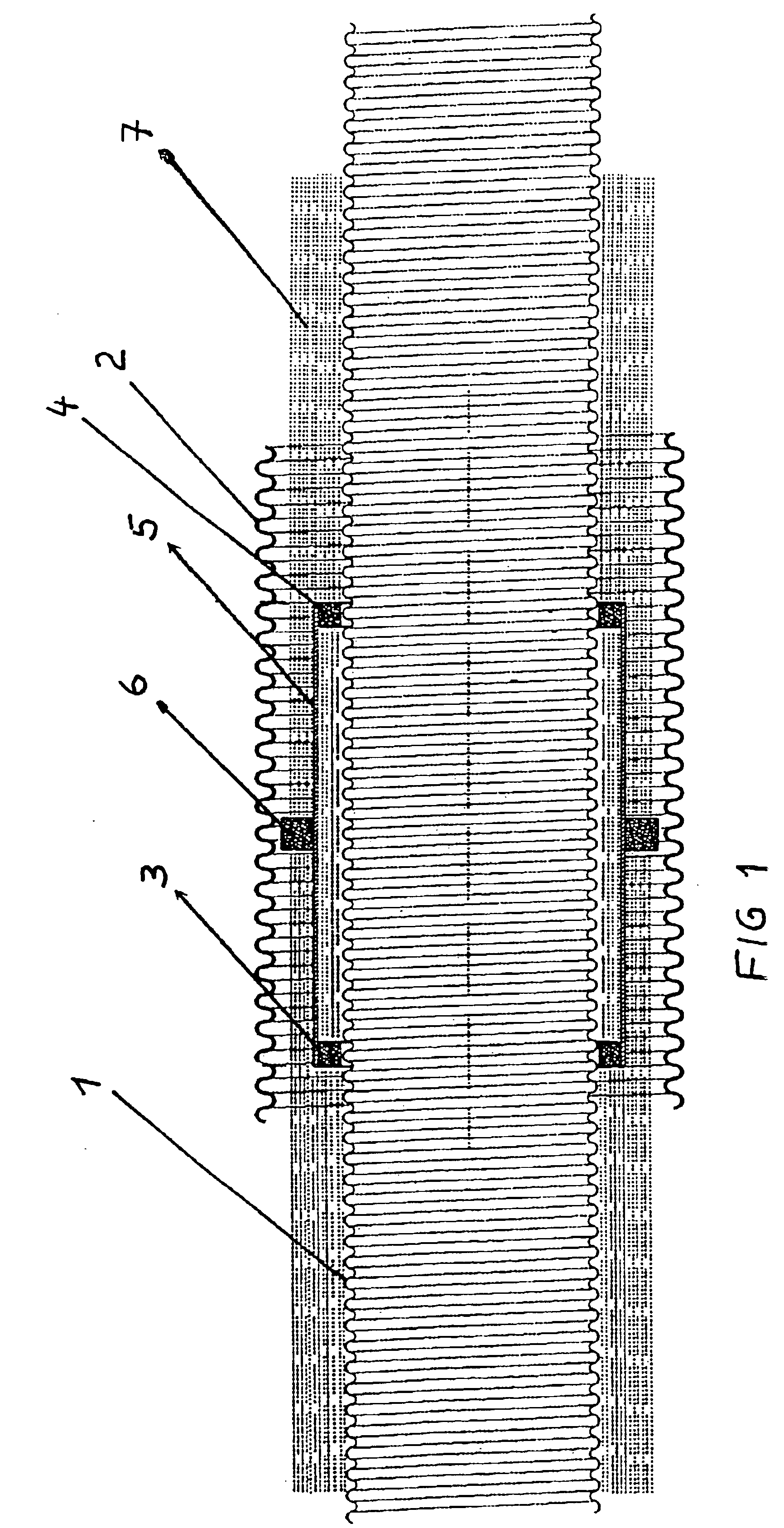

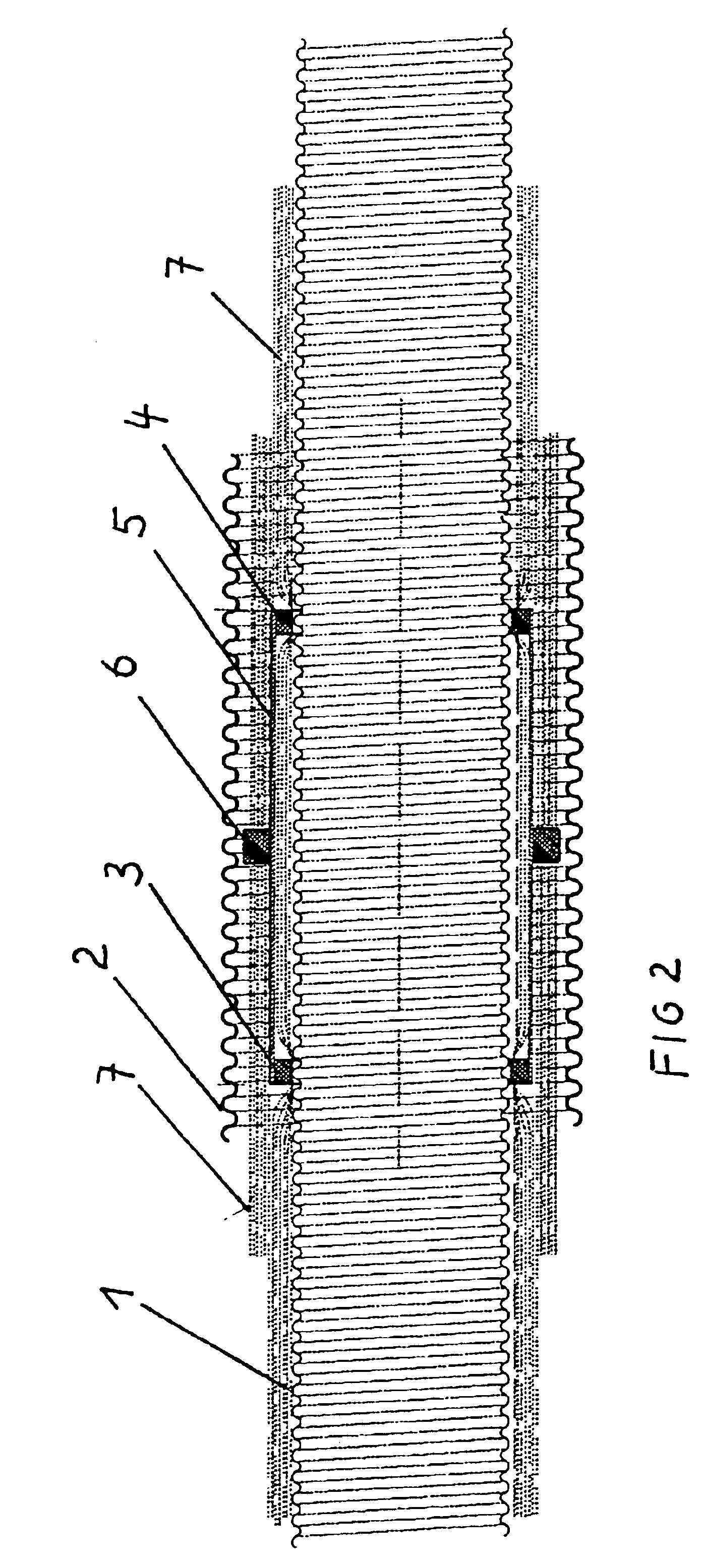

Spacer for a long substrate

InactiveUS6883548B2Good heat insulationHigh mechanical loadThermal insulationFlexible pipesEngineeringAxial distance

A spacer for a long substrate in the interior of a long tube, with a superinsulation material being disposed between the substrate and the tube. The spacer includes two rings (3, 4) seated on the substrate (1) and spaced apart from each other at a longitudinal axial distance, a tube section (5) supported on the rings (3, 4) and a second ring (6) disposed on the tube section (5). The first rings (3, 4), the tube section (5) and the second ring (6) are made of a material with poor thermal conductivity and high mechanical strength.

Owner:NEXANS

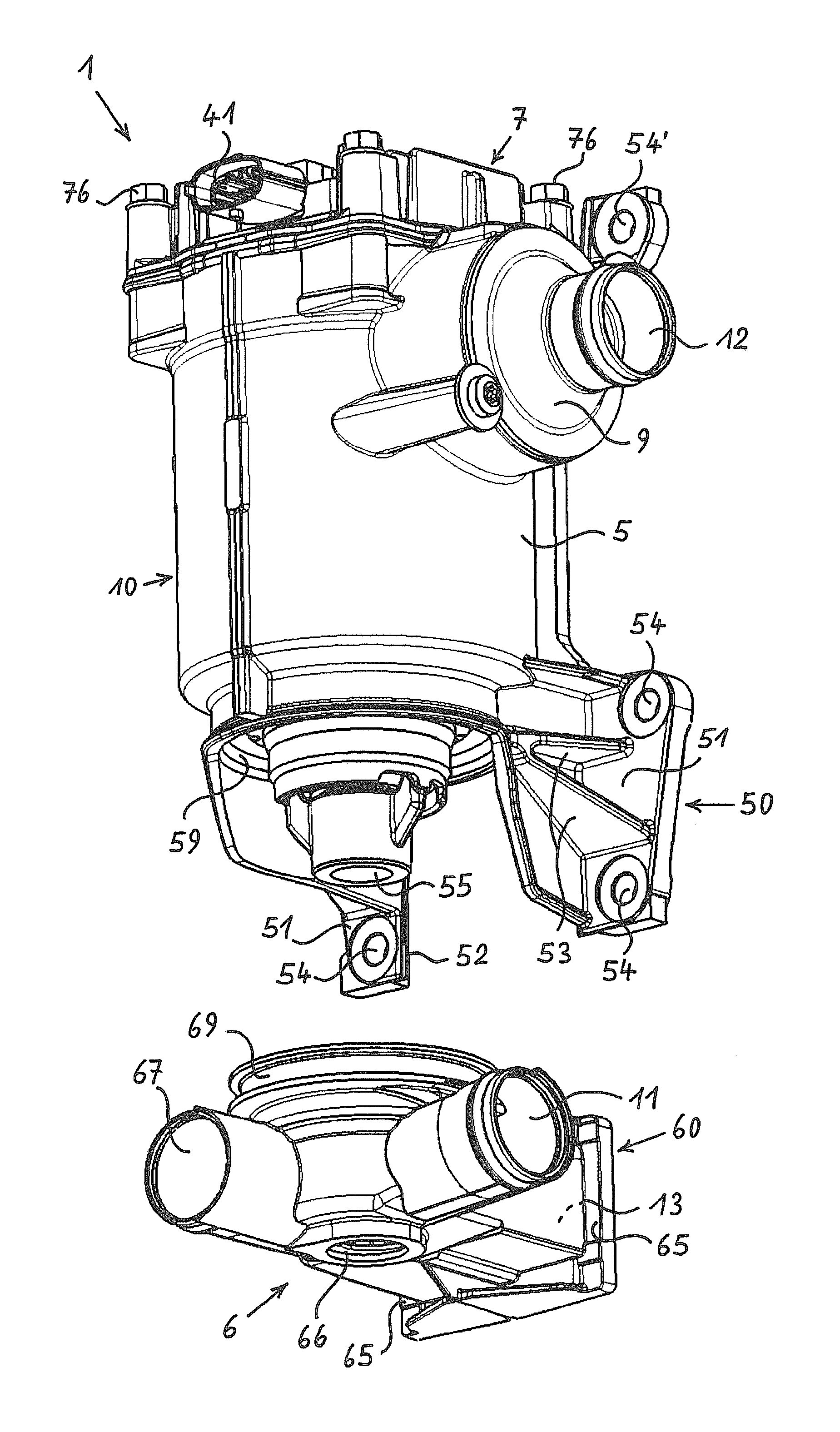

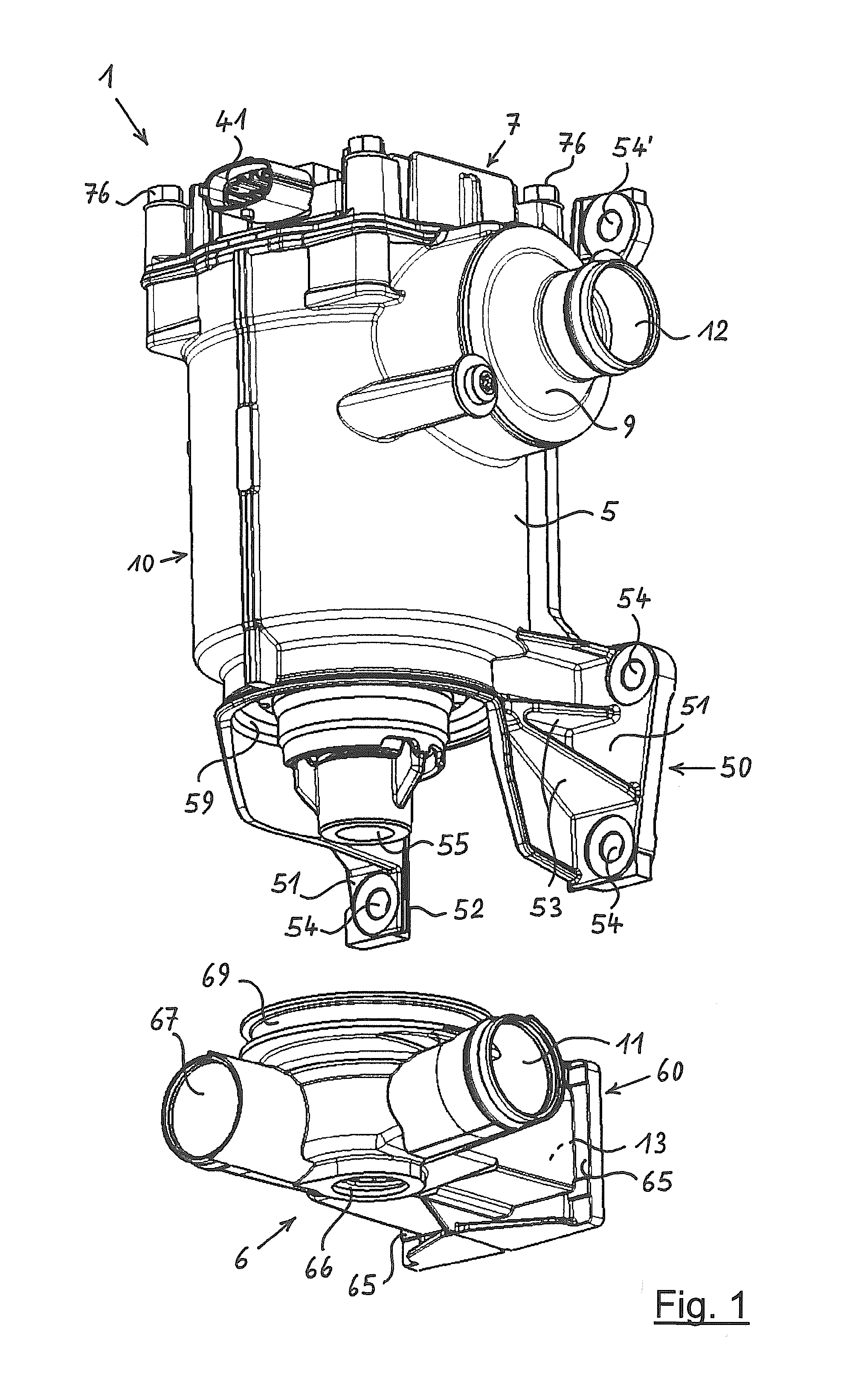

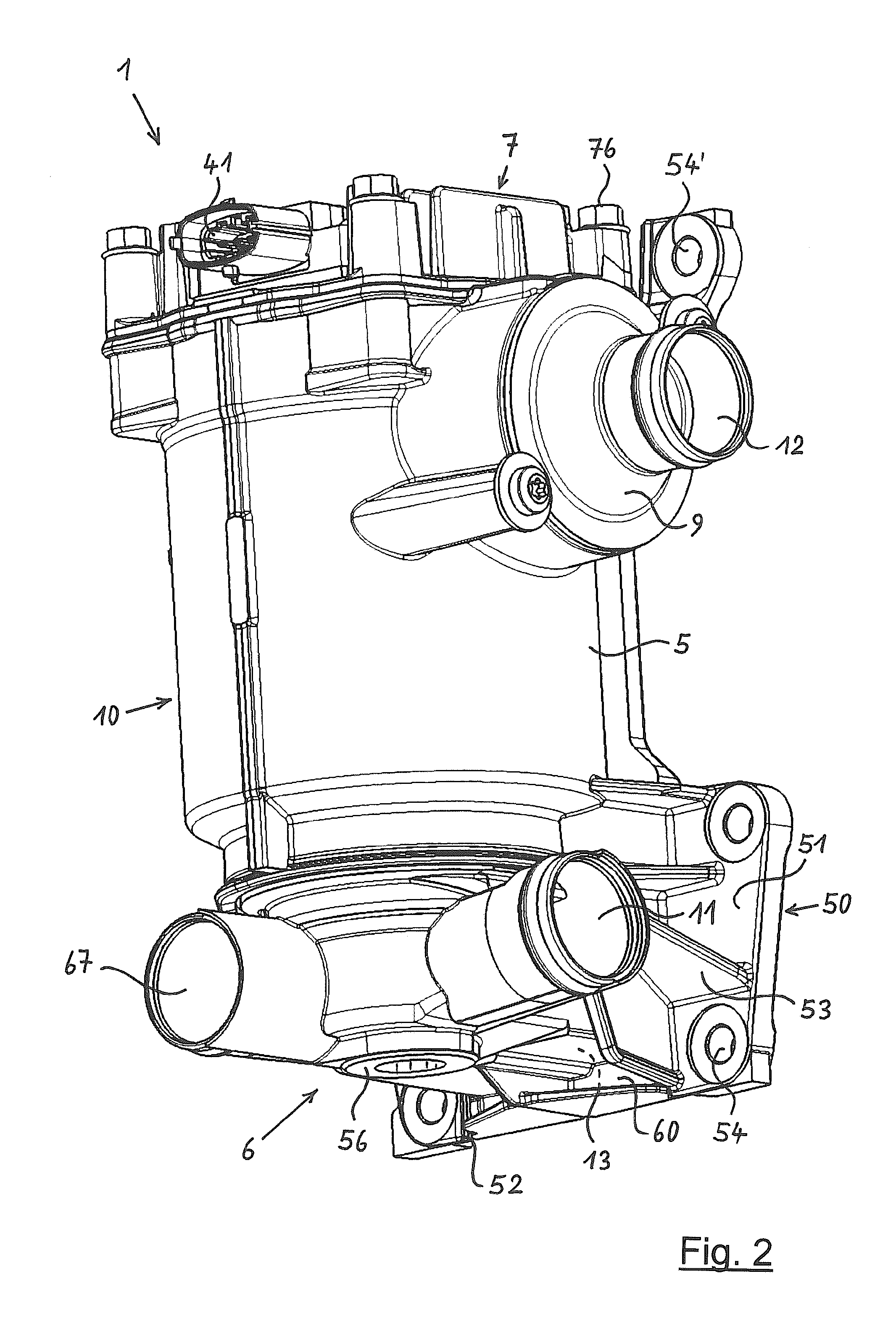

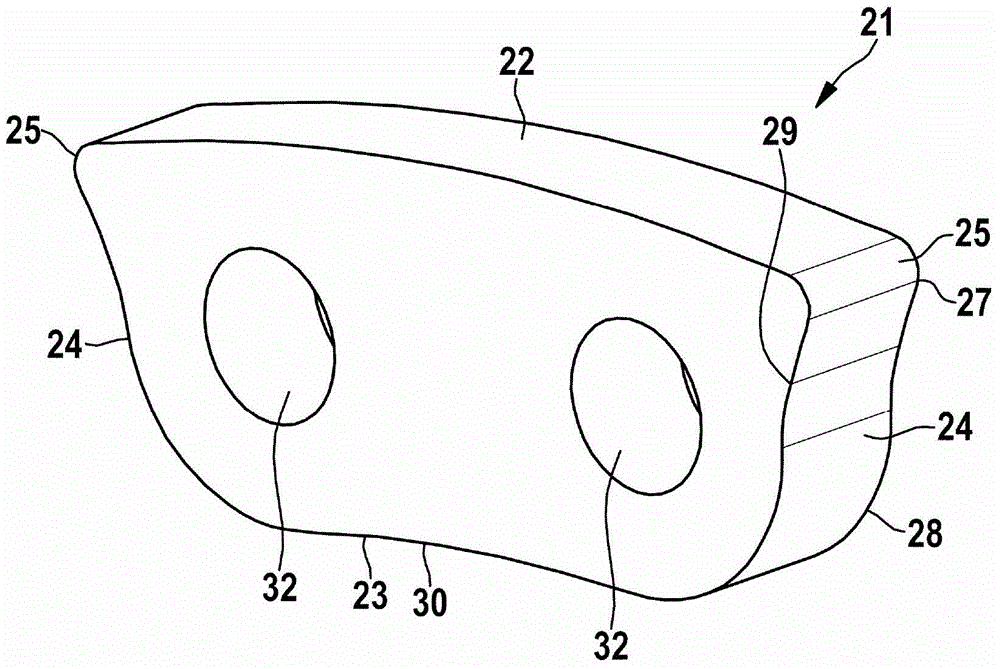

Centrifugal precipitator for precipitating oil mist from the crankcase ventilation gas from an internal combustion engine

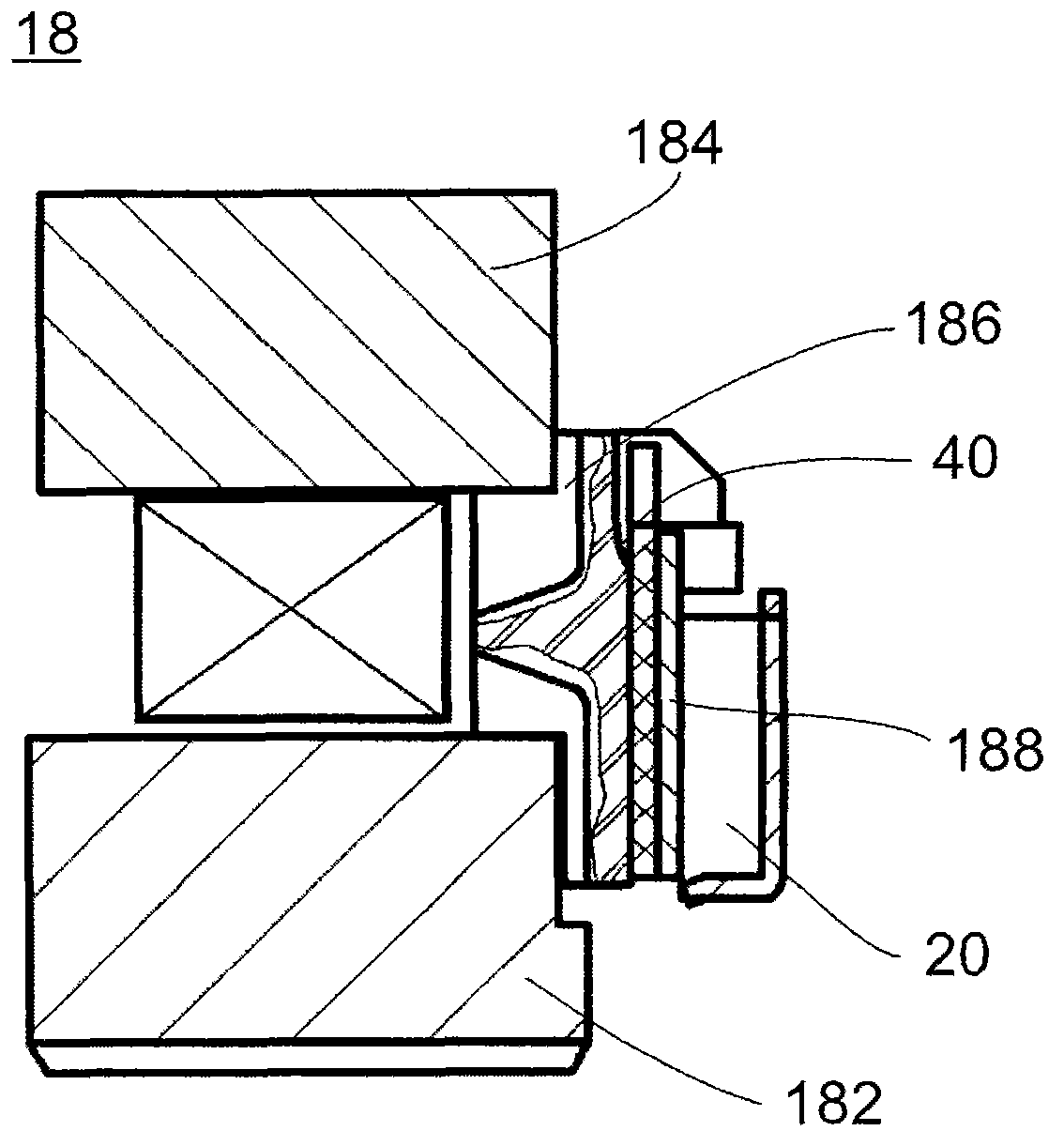

ActiveUS20140069398A1Low costCertain movabilityNon-fuel substance addition to fuelDispersed particle separationExternal combustion engineCrankcase

A centrifugal precipitator having a housing and a rotatable driven rotor for precipitating oil mist from crankcase ventilation gas of an internal combustion engine. The housing has an inlet for gas to be deoiled, a deoiled gas outlet and an oil outlet. The housing includes a metallic main element surrounding the rotor and carrying the rotor bearing. A housing bottom is built onto the main element from below. The housing attaches with a flange to a counterflange or module of the engine. The housing flange is formed on the main element and the housing. The oil outlet runs through a first flange part of the housing bottom and this flange part has a circumferential rim. A second flange part of the main element has a collar engaging over part of its periphery behind the rim and can be clamped with the rim in between against the counterflange.

Owner:HENGST WALTER

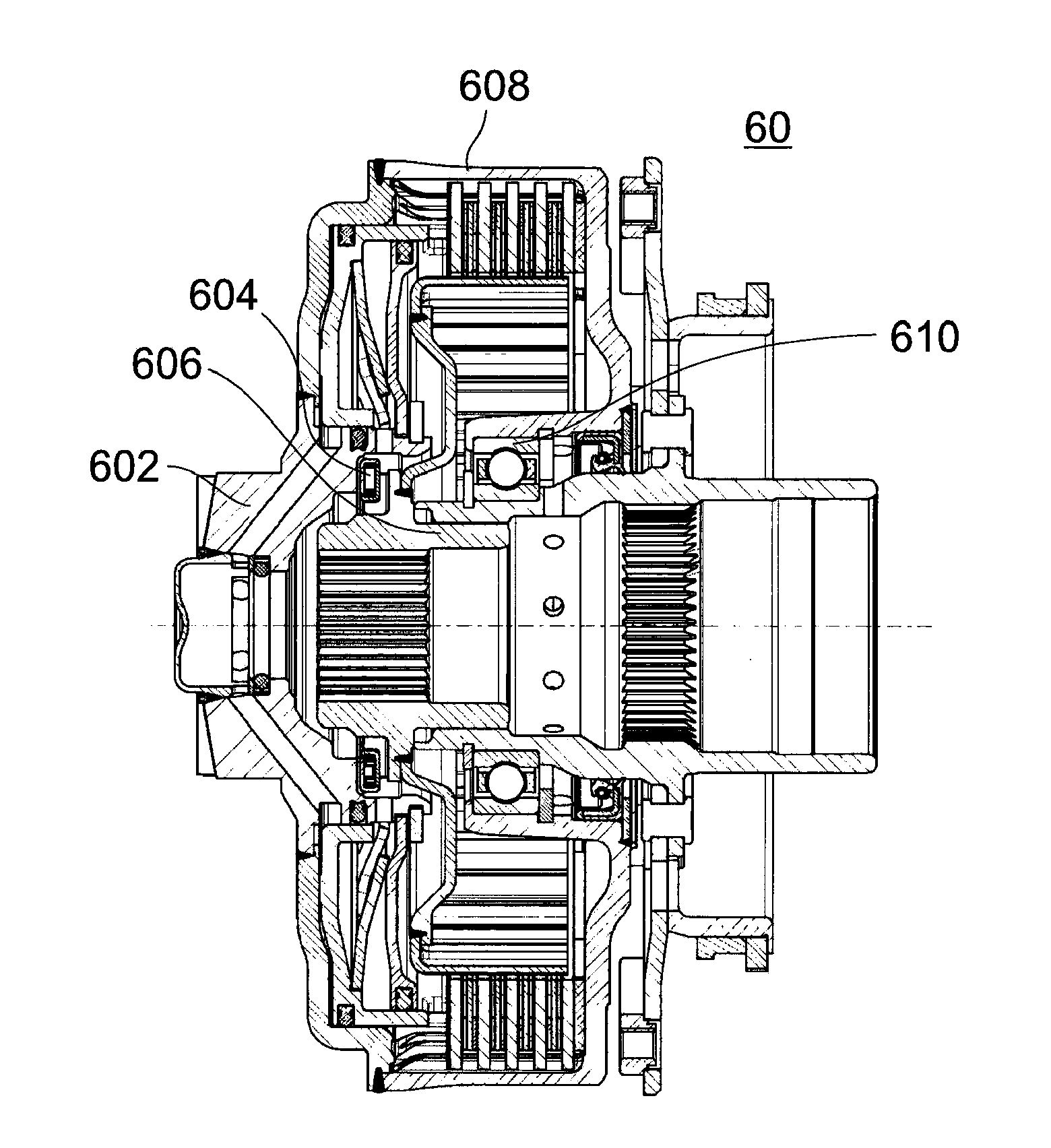

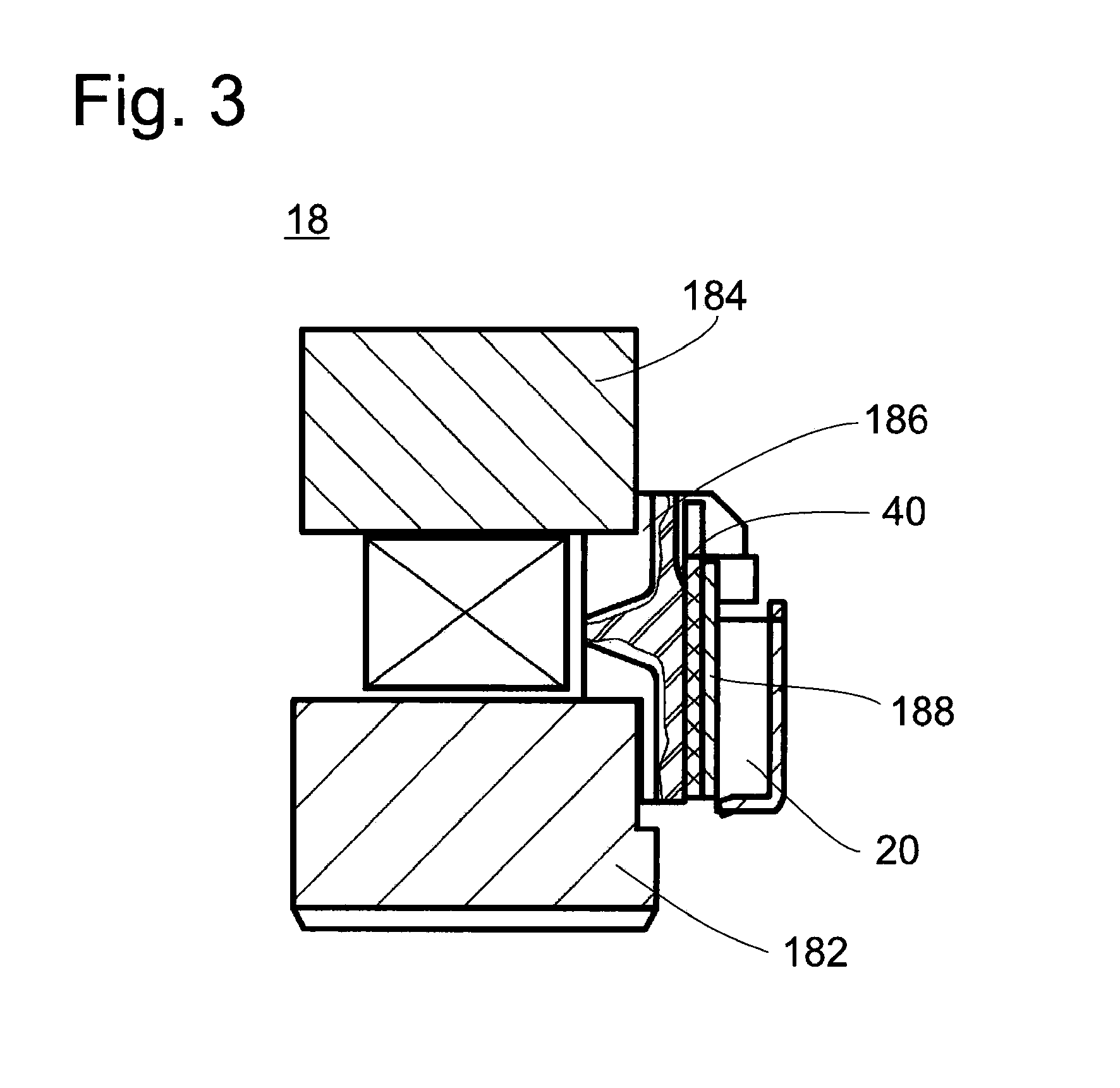

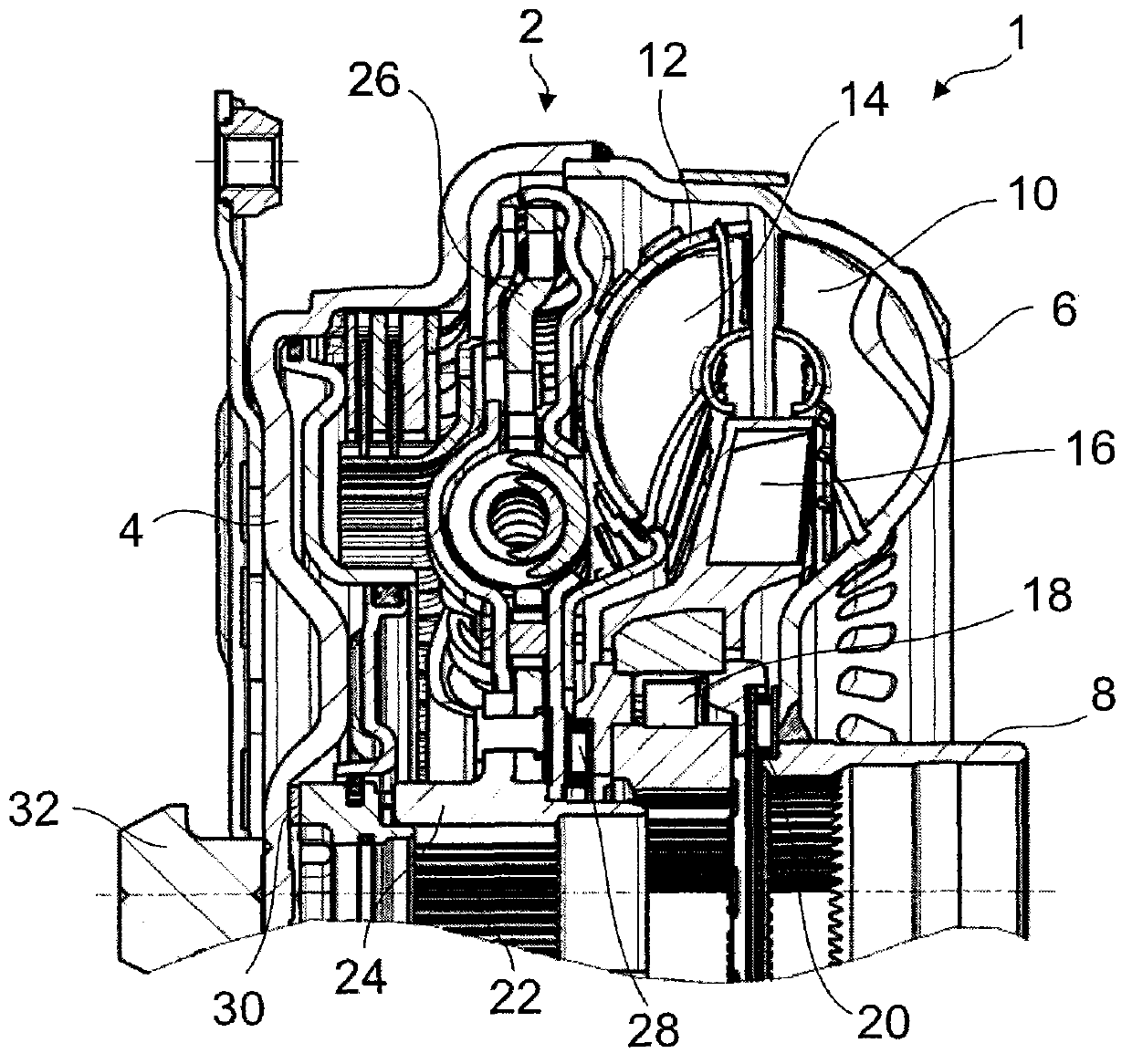

Torque Transmission Device With Electrical Insulation

InactiveUS20130125538A1Improve insulation performanceHigh mechanical loadRotary combination bearingsRoller bearingsExternal combustion engineTorque transmission

A torque transmission device, particularly for a motor vehicle, for the transmission of a torque from a driving unit, particularly from an internal combustion engine, to a driven unit, particularly a transmission, has at least one bearing location which has at least one bearing support acting in axial and / or radial direction, wherein an insulation element preventing a flow of electric current is provided in the region of the at least one bearing location.

Owner:ZF FRIEDRICHSHAFEN AG

Composite material and composite component, and method for producing such

InactiveUS20100152015A1Improve thermal conductivityImprove relationshipPretreated surfacesCoatingsCeramic compositeMetallurgy

A composite material, a composite component made thereof, and a method for producing a metal-ceramic composite material or a composite component are provided. The composite material or the composite component is produced by the method described in the following. In a first step, a porous ceramic preform is produced from a ceramic starting mass, and in a second step the infiltration of the porous ceramic preform with a molten metal takes place, the ceramic starting mass having a ceramic main component and a ceramic minor component that reacts with this main component, and the minor component reacts at least partially with the main component during the first and / or second step.

Owner:ROBERT BOSCH GMBH

Wheel for a road vehicle

ActiveUS20190023118A1Control deformationEfficient loadingAssociation with control/drive circuitsMagnetic circuit rotating partsElectromagnetElectric motor

Disclosed is road vehicle wheel with an in-wheel electric motor that includes a rim configured for mounting at least one tire on the rim; a rim support configured for supporting the rim on a non-rotating wheel part to allow rotation of the rim with respect to the non-rotating wheel part; a stator of the in-wheel electric motor, the stator including electromagnets and being supported on the non-rotating wheel part; and a rotor of the in-wheel electric motor, the rotor including permanent magnets and being supported on the rim support such that any forces exerted on the rim do not act on the rotor. The rim is supported such that any forces exerted on the rim are directly born by the rim support and is not in direct contact with the rotor.

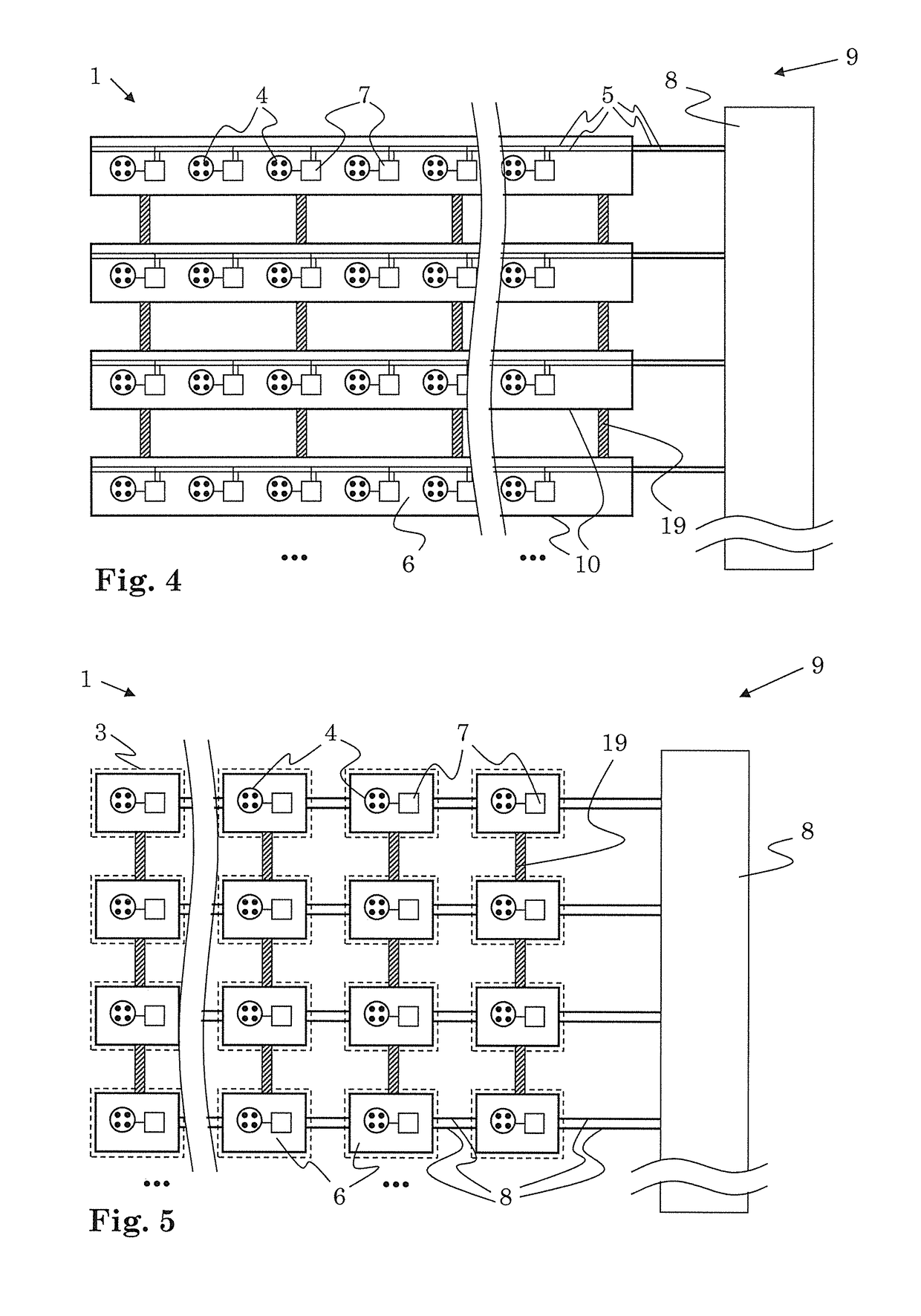

Ice rink illumination

ActiveUS20170326435A1Precise positioningHigh mechanical loadSki bindingsPlanar light sourcesElectrical connectionEngineering

The illuminants arrangement includes a plurality of LED-based light sources that are encased in a water-tight manner by way of one or more encasings, wherein the light sources are, at least in a group-wise manner, operationally interconnected by way of electrical connection leads. The connection leads include voltage supply leads. The illuminants arrangement as a protection of the one or more encasings and the light sources from mechanical damage includes at least one protective overlay for being placed onto the one or more encasings, so that light emitted by the light sources can be emitted through the at least one protective overlay. The illuminants arrangement can include a heating device. Each of the light sources can be suitable for emitting light of a variable color, wherein the color of each of the light sources can be individually selected by way of a control unit.

Owner:HS TECHNICS

Assembled shaft brake disk

ActiveUS9709108B2High mechanical loadImprove ventilationBraking discsBraking membersContact pressureEngineering

The invention relates to an assembled undular brake disc having a hub on which two friction rings which are produced from a steel material are arranged parallel to and spaced apart from one another. The assembled undular brake disc can withstand high mechanical loads and permits good internal ventilation. Supporting bolts for absorbing an axially acting pad contact pressure force are arranged between the friction rings.

Owner:FAIVELEY TRANSPORT WITTEN GMBH

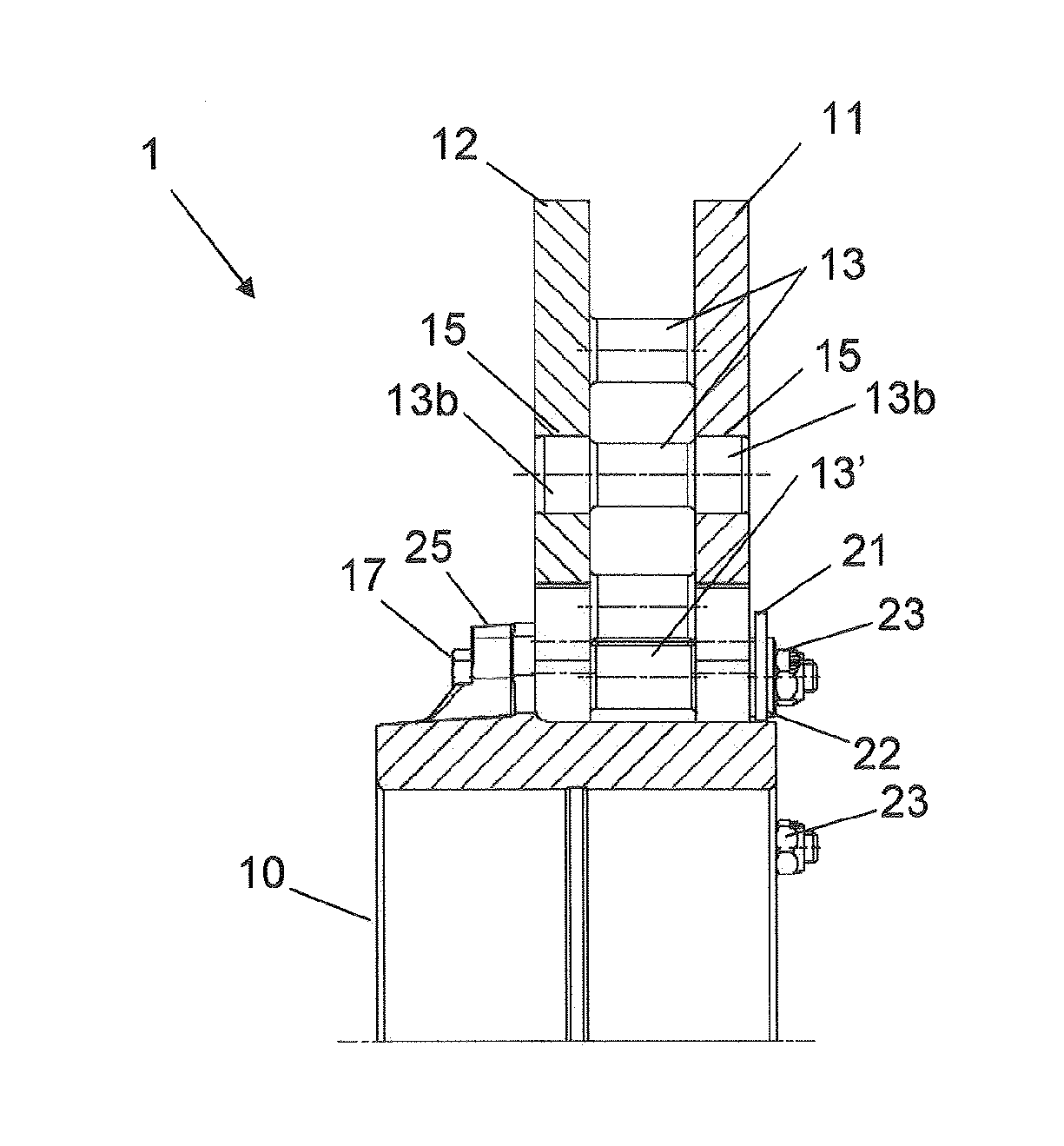

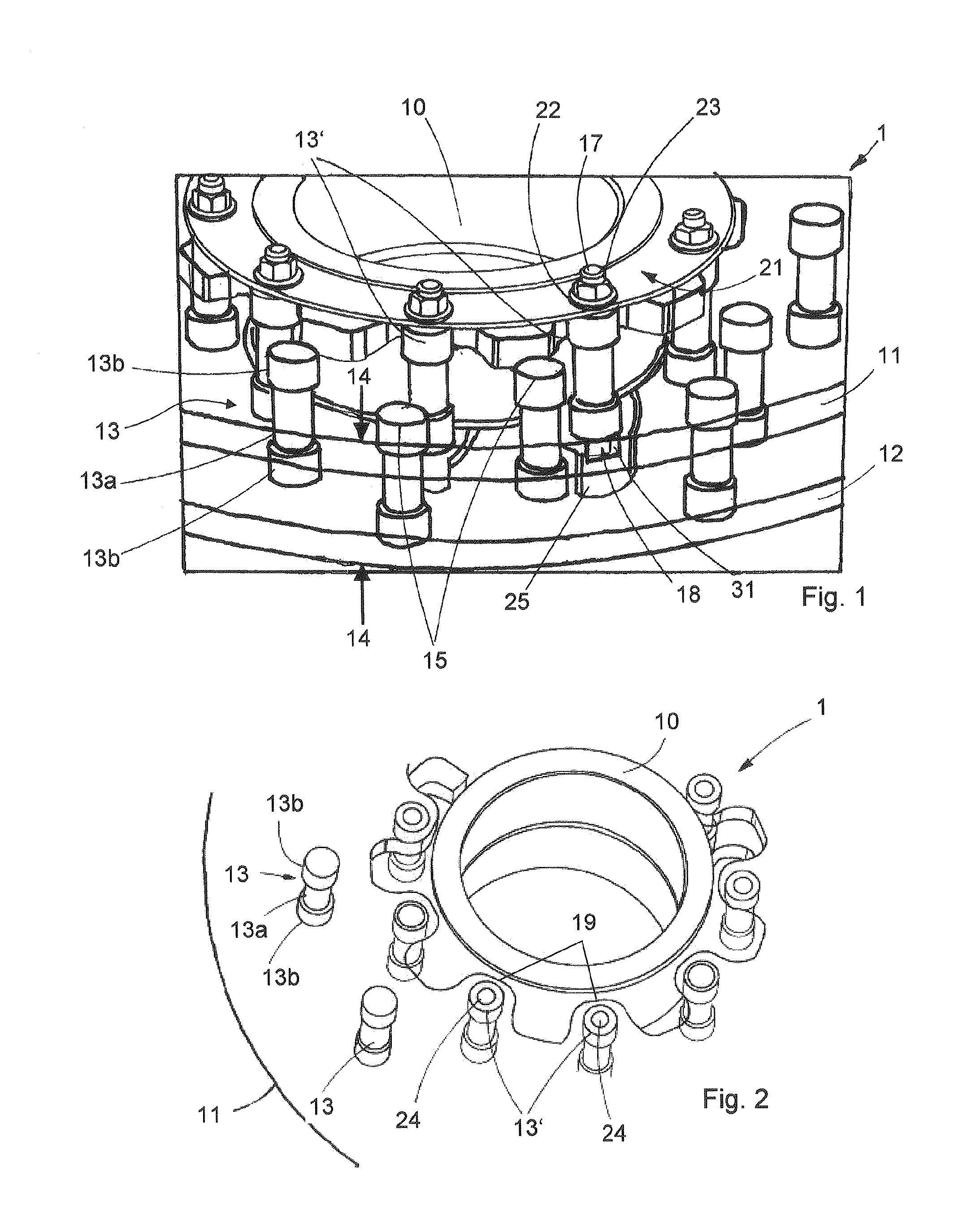

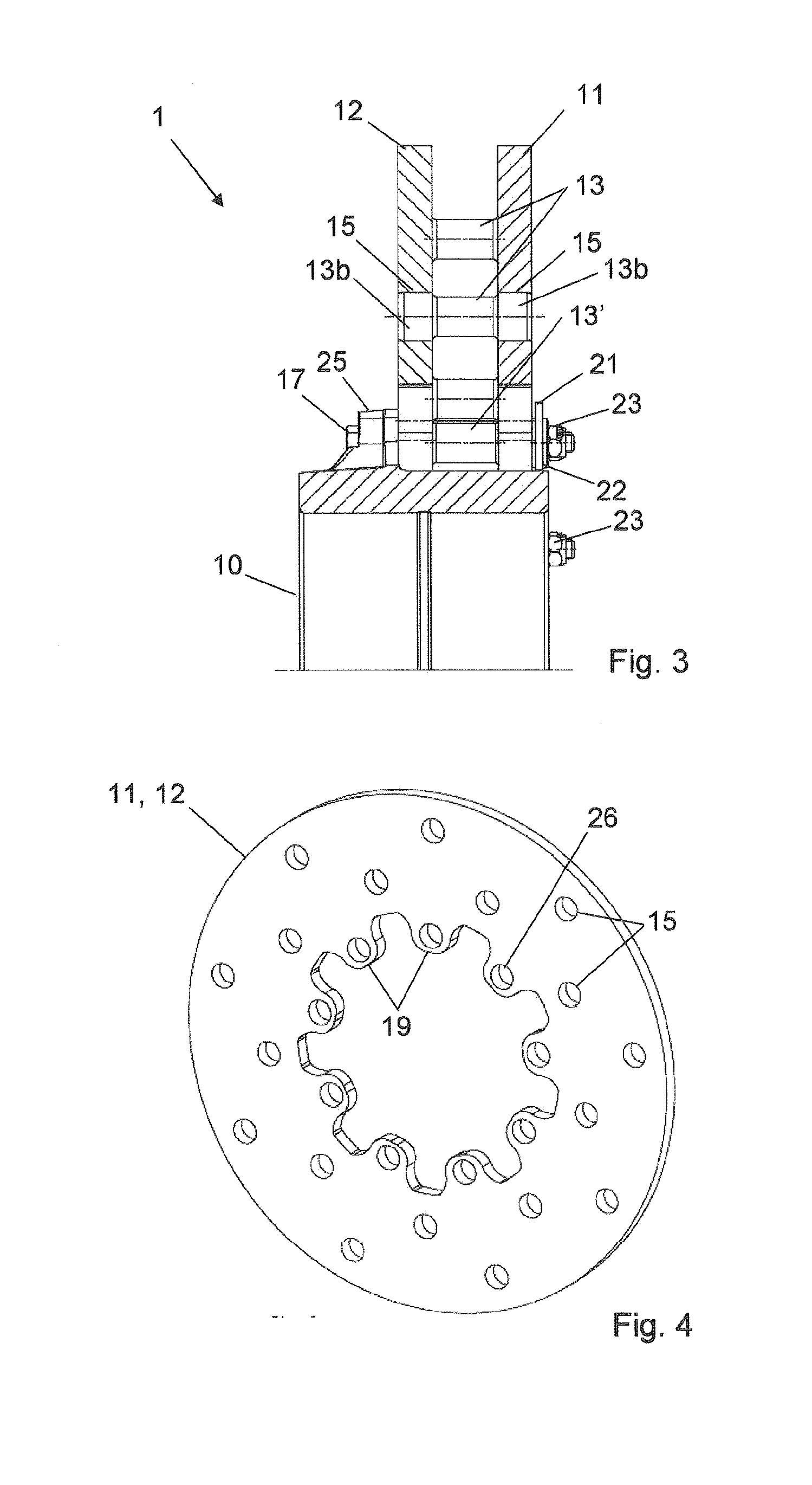

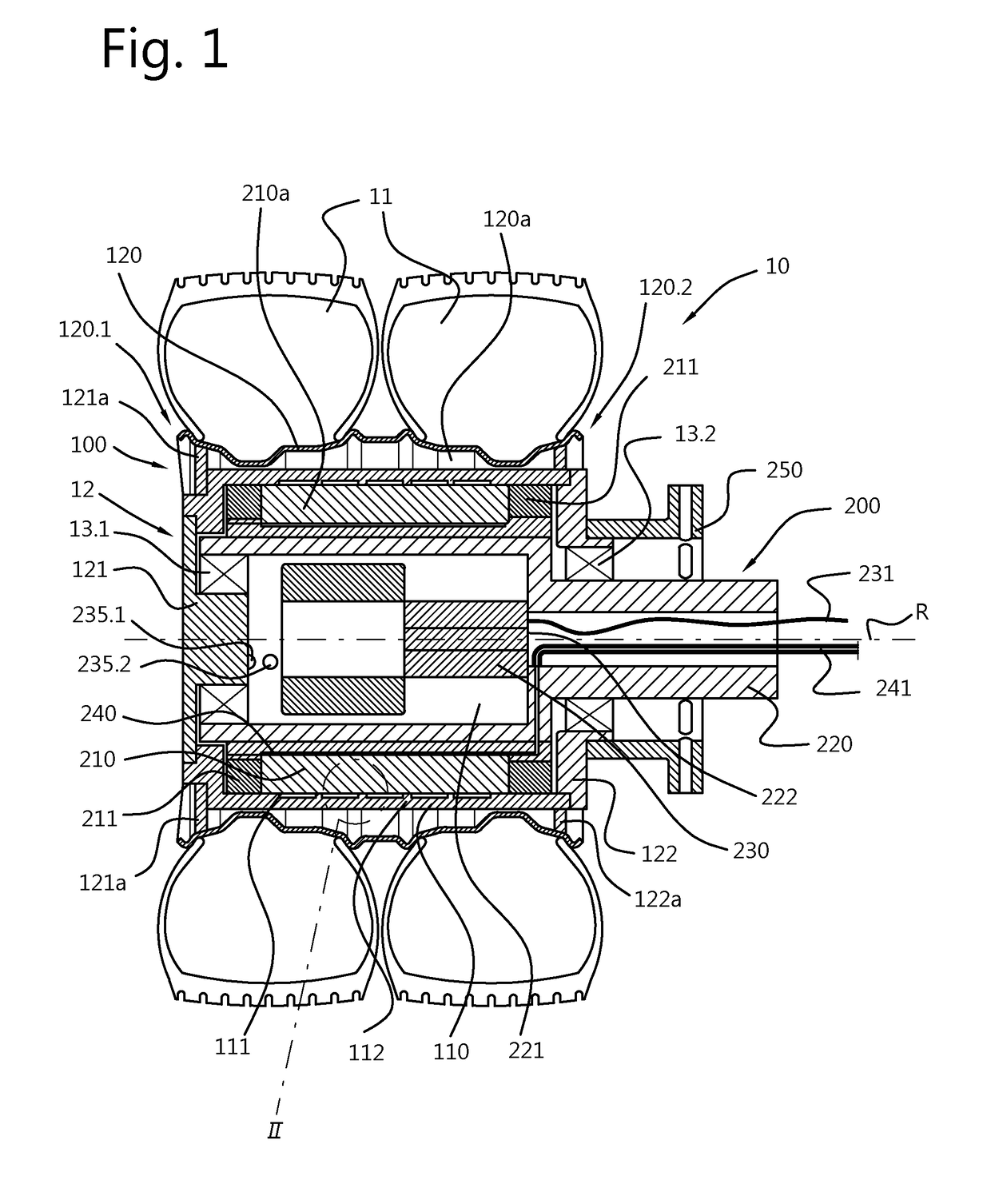

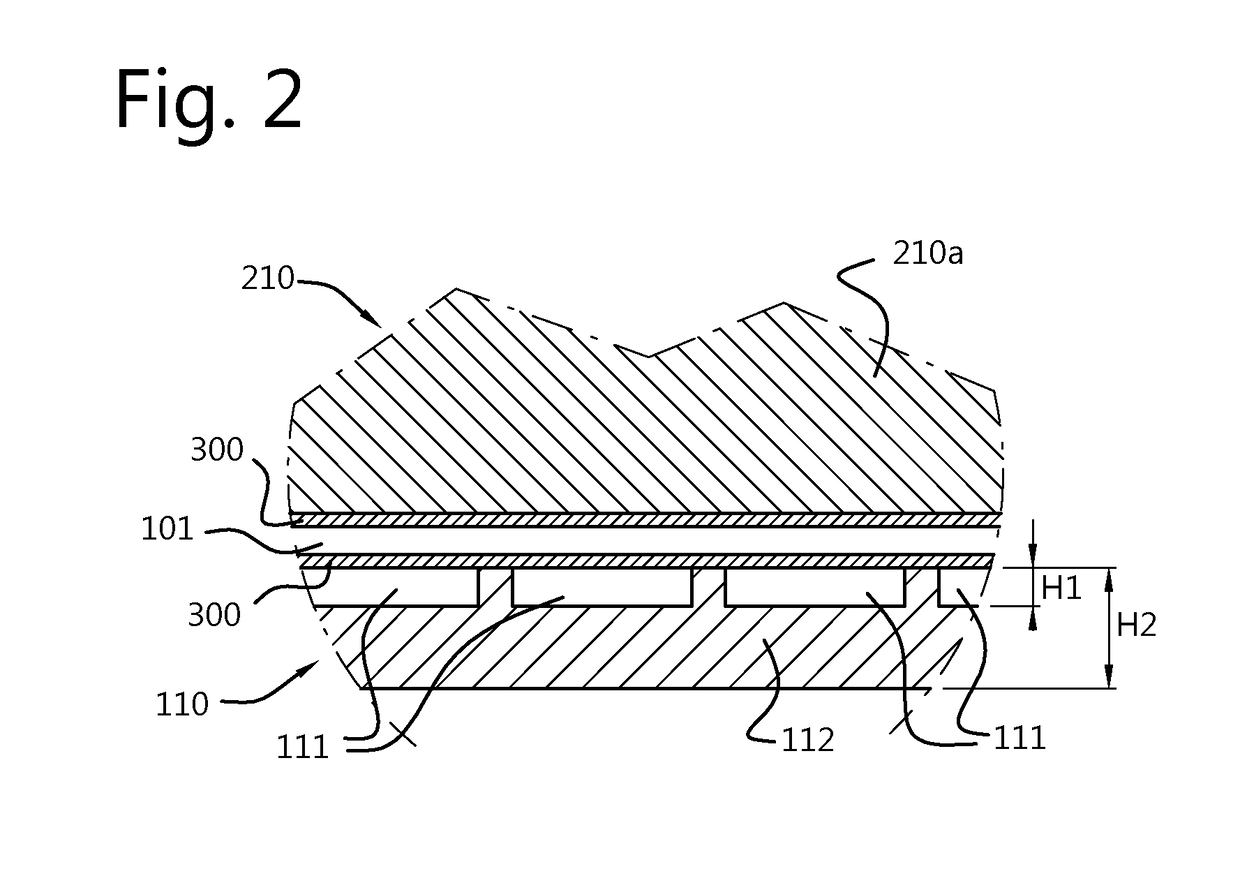

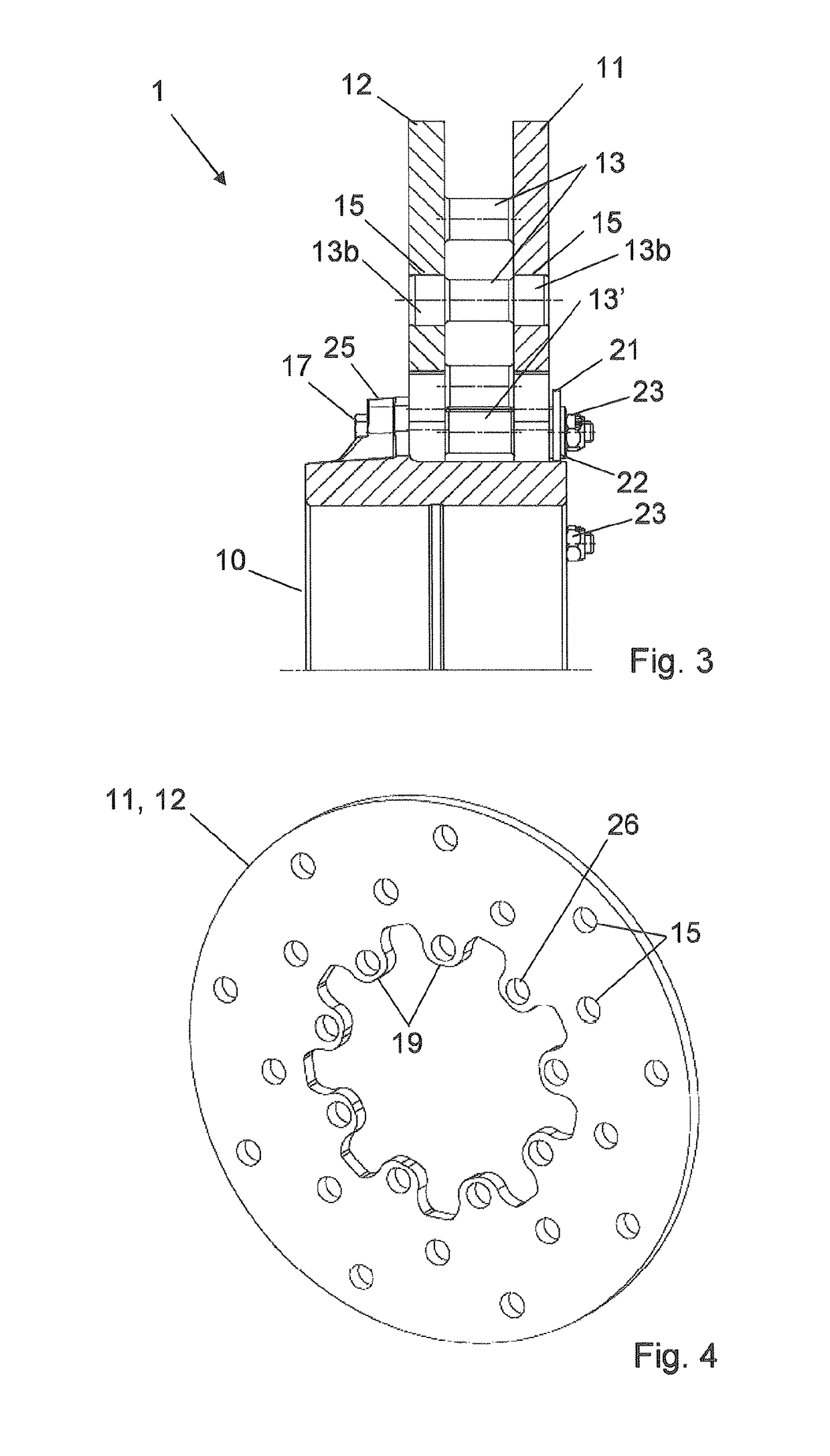

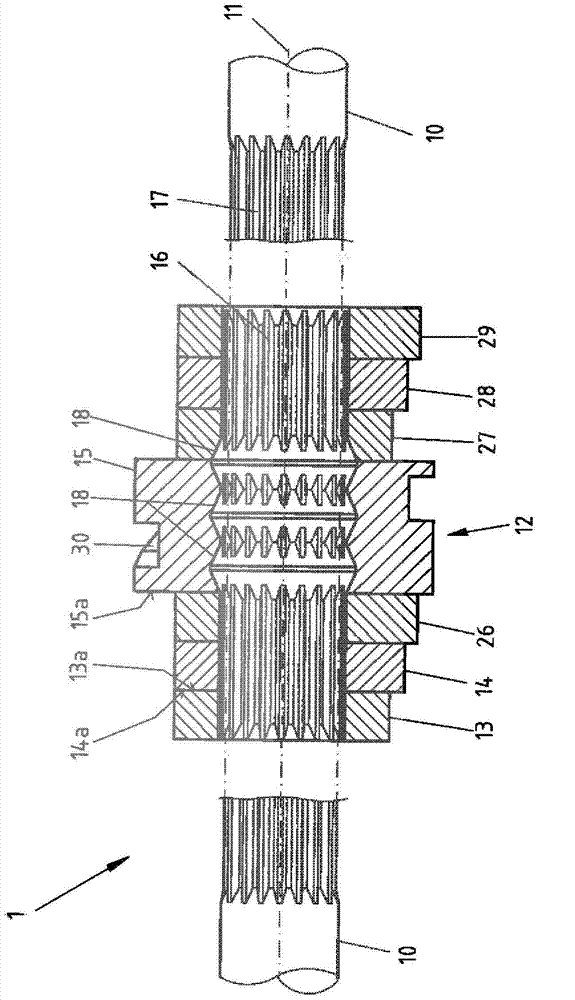

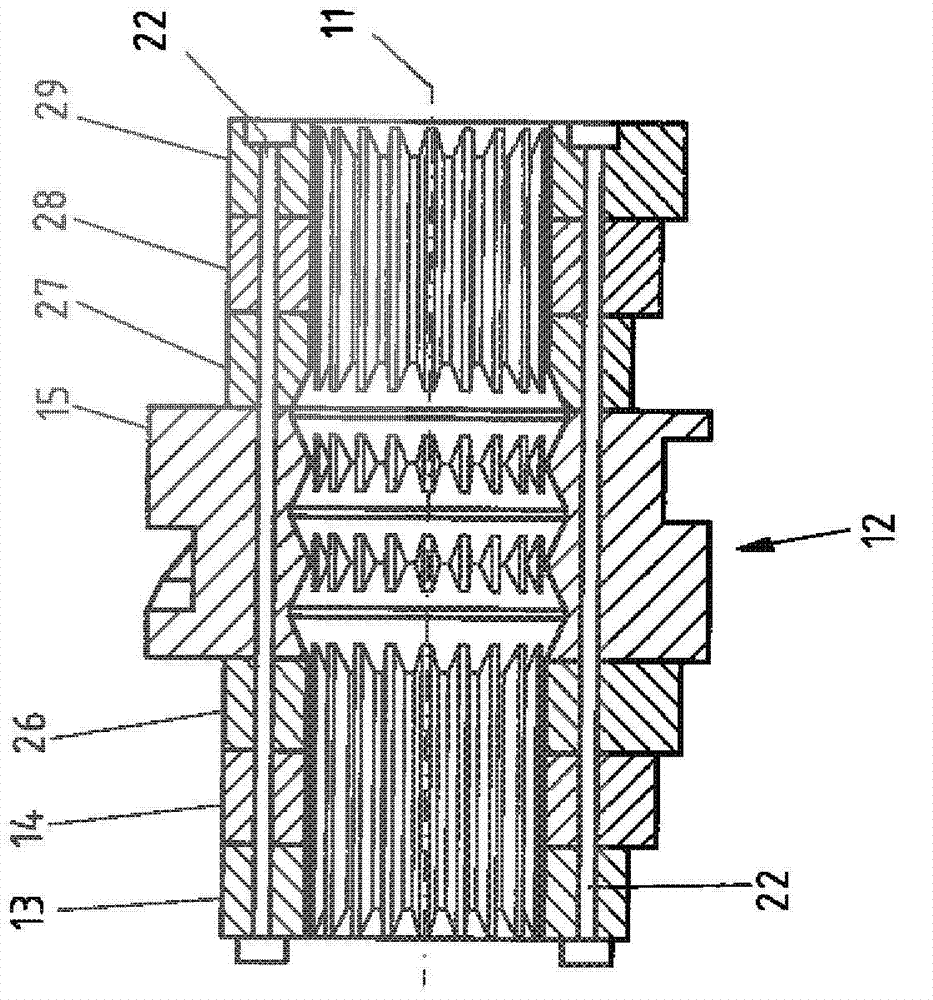

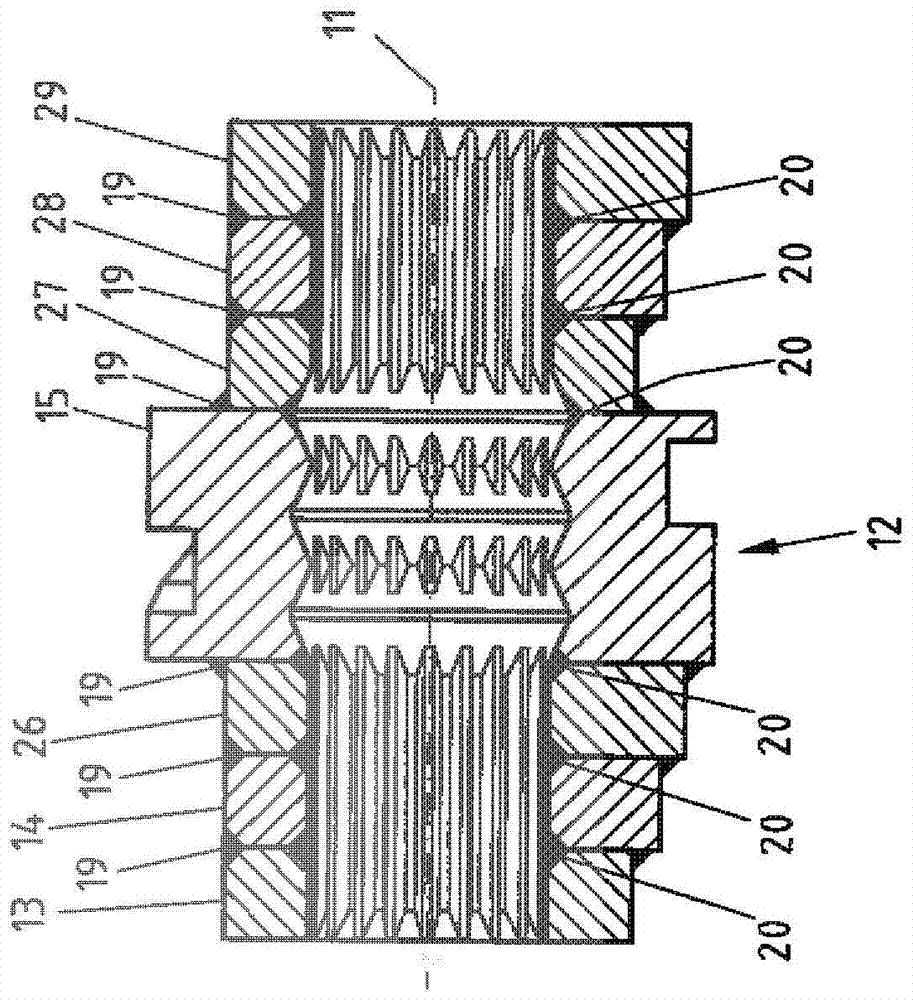

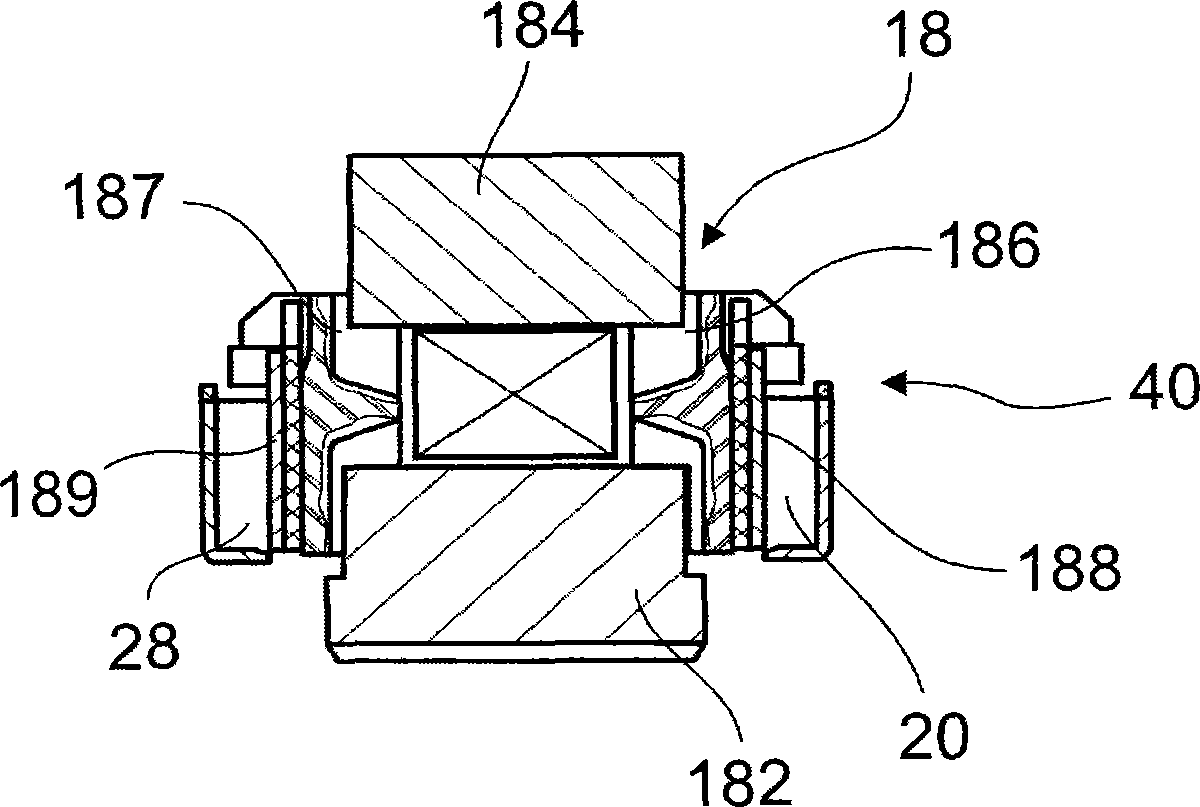

Camshaft with an axially displaceable cam pack

The invention relates to a camshaft (1) and a method for producing a camshaft (1) having a support shaft (10) which is rotatably mounted in a shaft axis (11), at least one cam pack (12) being axially displaceably mounted on the support shaft (10), and the cam pack (12) comprising at least two cams (13, 14, 26, 27, 28, 29, 32, 33, 34) and at least one adjusting element (15) for axially adjusting the cam pack (12). According to the invention, the cams (13, 14, 26, 27, 28, 29, 32, 33, 34) and the at least one adjusting element (15) are interconnected axially adjacent to each other and can be accommodated directly on the support shaft (10) as a combined entity by means of a rolling body guide with rolling bodies (31) such that the combined entity can be axially displaced.

Owner:THYSSENKRUPP PRESTA TECCENTER AG

Light and efficient photovoltaic module

InactiveCN106159013AReduce weightHigh mechanical loadPhotovoltaic supportsPhotovoltaic energy generationLight reflectionEngineering

Owner:建开阳光新能源科技有限公司

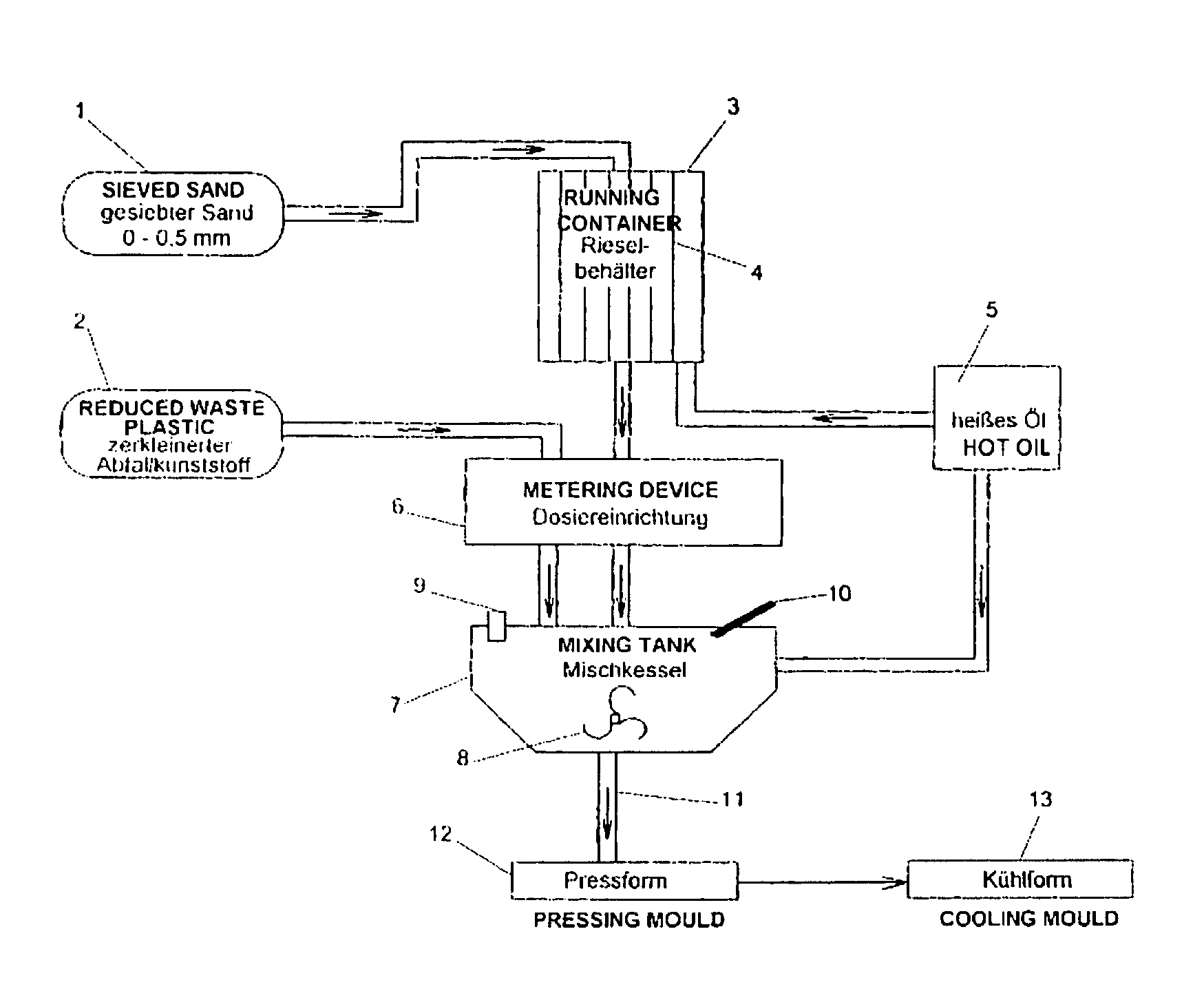

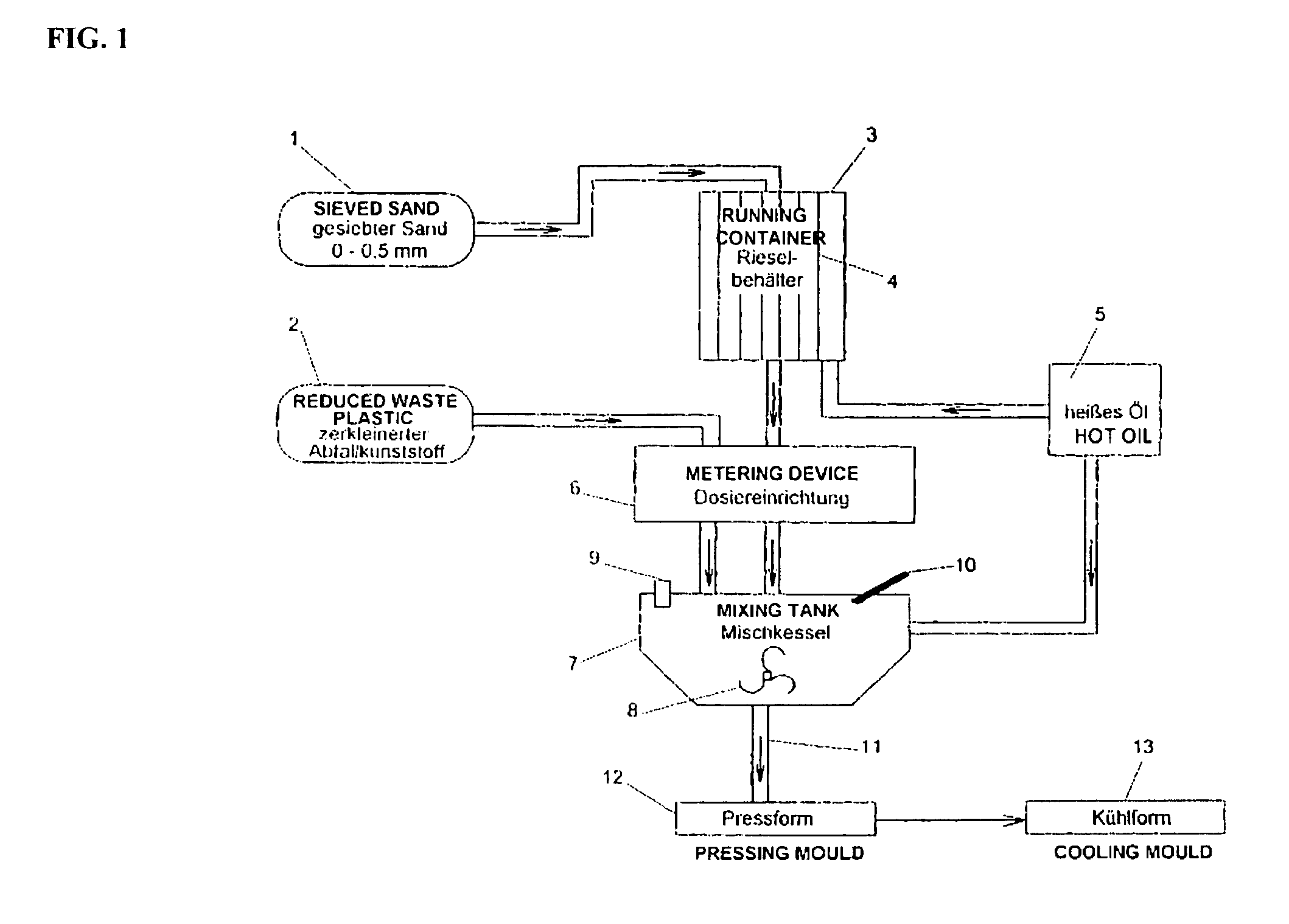

Material and method and device for producing the same

InactiveUS7345107B2Reduce manufacturing costImprove flame retardant performanceSpecial tyresWood working apparatusMetallurgyHot melt

The invention relates to a material which consists essentially of sand and polymers as well as optionally, a small quantity of aggregates. The invention also relates to a method for producing this material, comprising the following steps: producing a hot molten mixture consisting of sand and polymers; introducing said molten mixture into a mould; cooling the molten mixture under pressure until the molten mixture hardens in the mould. The material can be used e.g. for producing building blocks, pavement slabs, manhole covers, housings in electrical engineering and insulators for high-voltage applications.

Owner:POLY BLOCK GREEN TECH GMBH

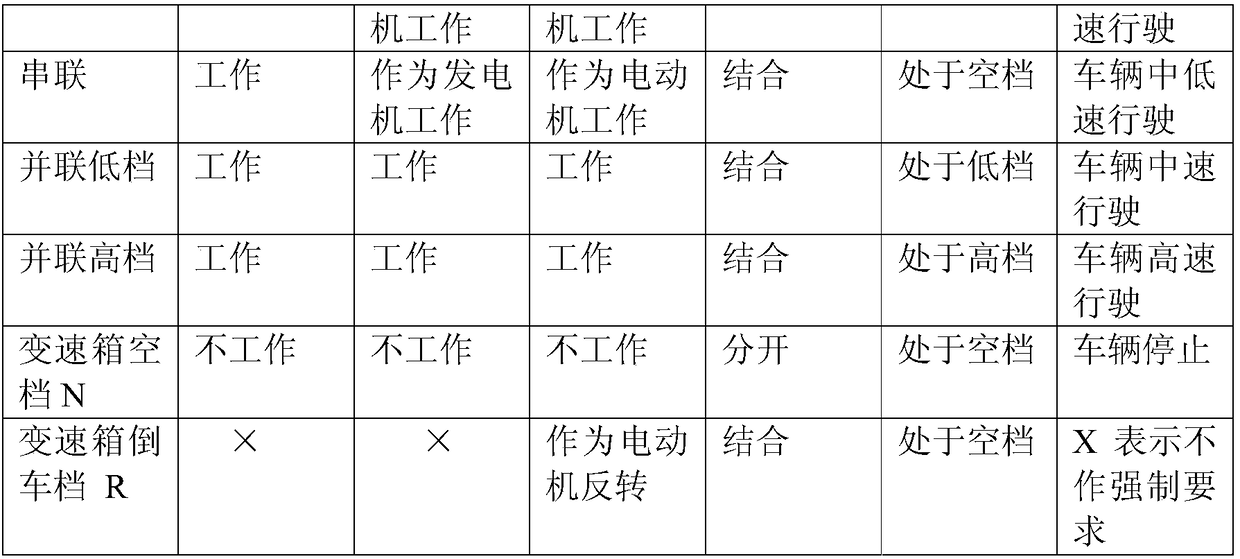

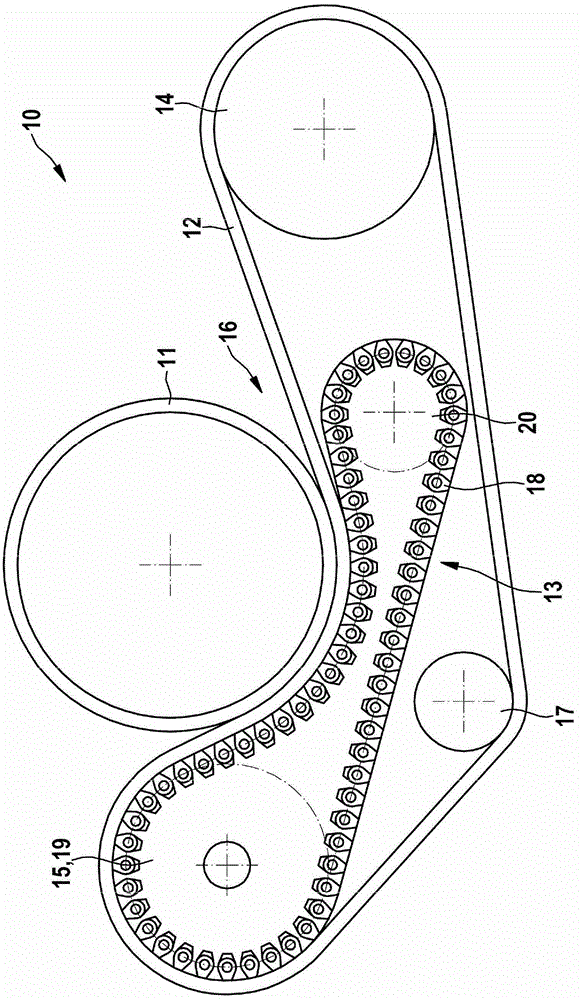

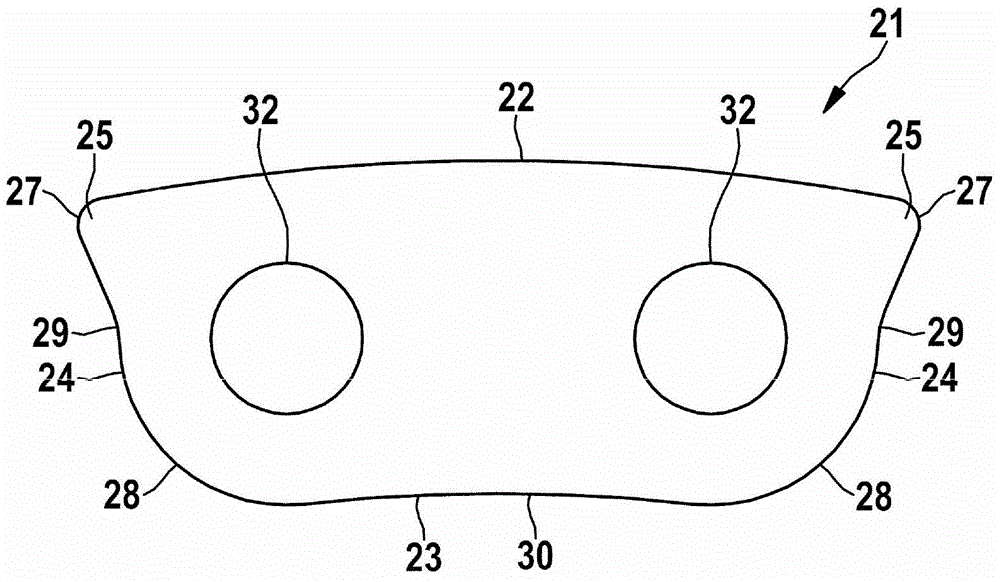

Chain link, support chain, and support device

ActiveCN104487235AReduce processing costsHigh mechanical loadConveyorsPoultry deboningMechanical engineeringEngineering

The invention relates to a chain link (21) for a support chain (18) for supporting a press belt (12) in a separating device (10) for separating materials of different flowability. The chain link (2) has a support surface (22) and an inner surface (23) opposite the support surface (22) and is characterized in that a protruding support element (25) is arranged on at least one end face (24) of the chain link (21) so as to form an undercut. The invention further relates to a support chain (18) for a support device for supporting a press belt (12) in a separating device (10) for separating materials of different flowability. The support chain (18) is an articulated chain, which has individual chain links (21) connected to each other in an articulated manner. The chain links (21) are threaded onto chain pins extending perpendicular to the conveying direction F. The invention further relates to a support device having the support chain according to the invention.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

Torque transmission device with electrical insulation

ActiveCN103089829AAvoid passingGood insulation propertiesRoller bearingsGearboxesElectricityMobile vehicle

Owner:ZF FRIEDRICHSHAFEN AG

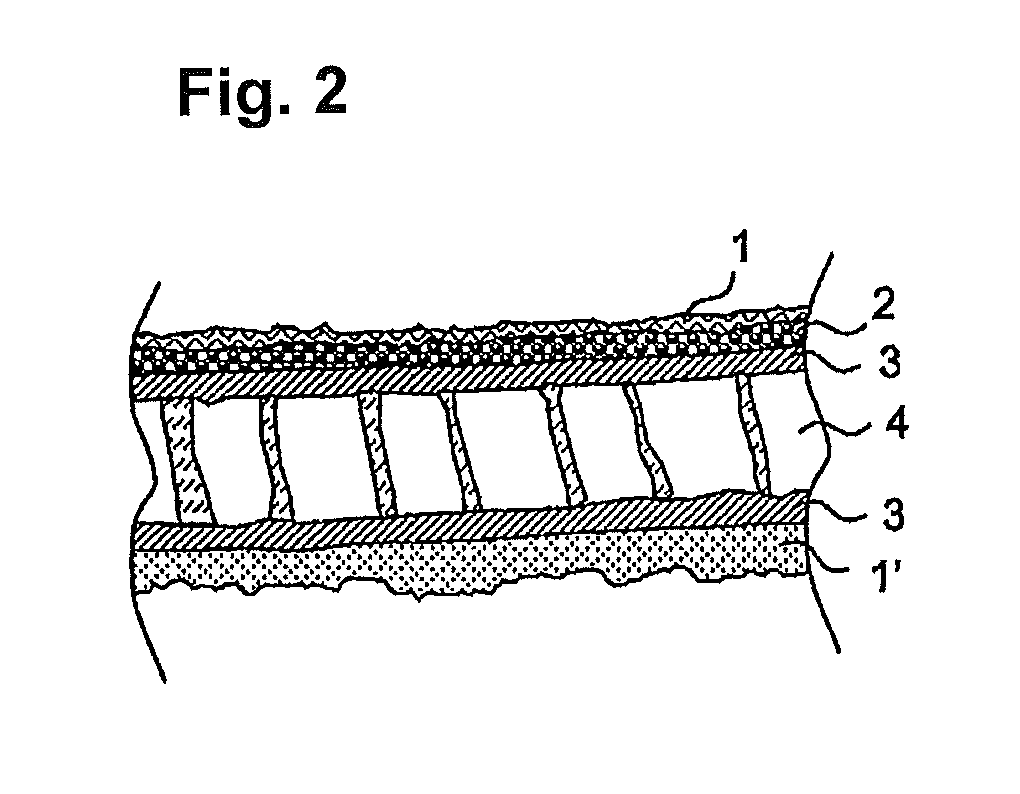

Sandwich composite component and production process therefor

ActiveUS9662854B2Increase contactIncrease pressureSynthetic resin layered productsLaminationFiberHoneycomb

A sandwich component (10) having a honeycomb core layer (4) and at least one fiber-reinforced thermoplastic outer layer (3) and the corresponding production method. The outer layer (3) is connected to the honeycomb core layer (4) by a thermoplastic material. At least one side of the sandwich component (10 has a decorative layer (1,1′), which is arranged on the outer layer (3). The sandwich component (10) furthermore has at least one foam layer (2), which is arranged between the outer layer (3) and the decorative layer (1,1′), and which is connected to the outer layer (3) and the decorative layer (1,1′).

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com