Connector for connecting two pipes

A technology of connecting parts and connecting pieces, which is applied in the direction of mechanical equipment, couplings, etc., and can solve problems such as unsealed connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

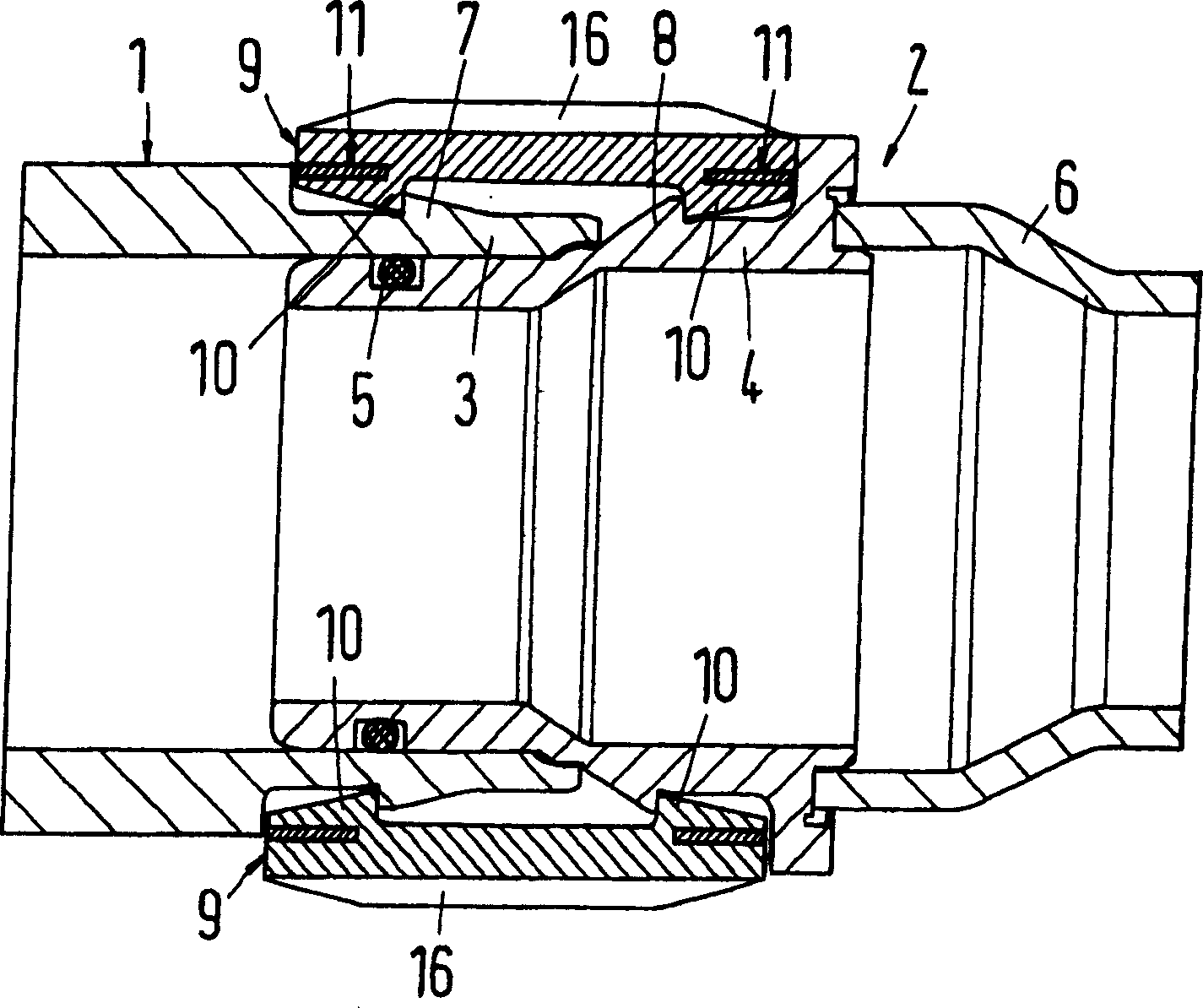

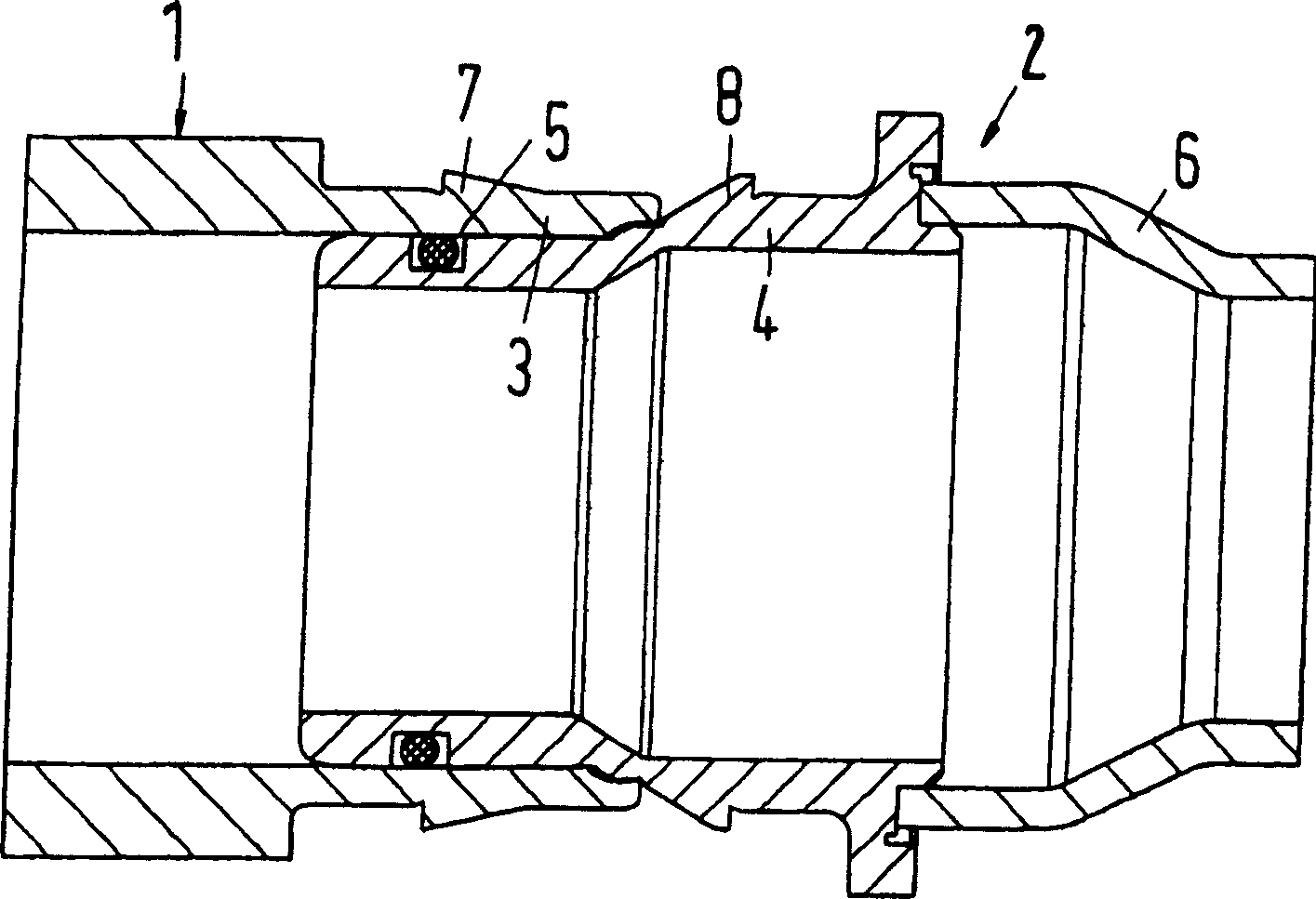

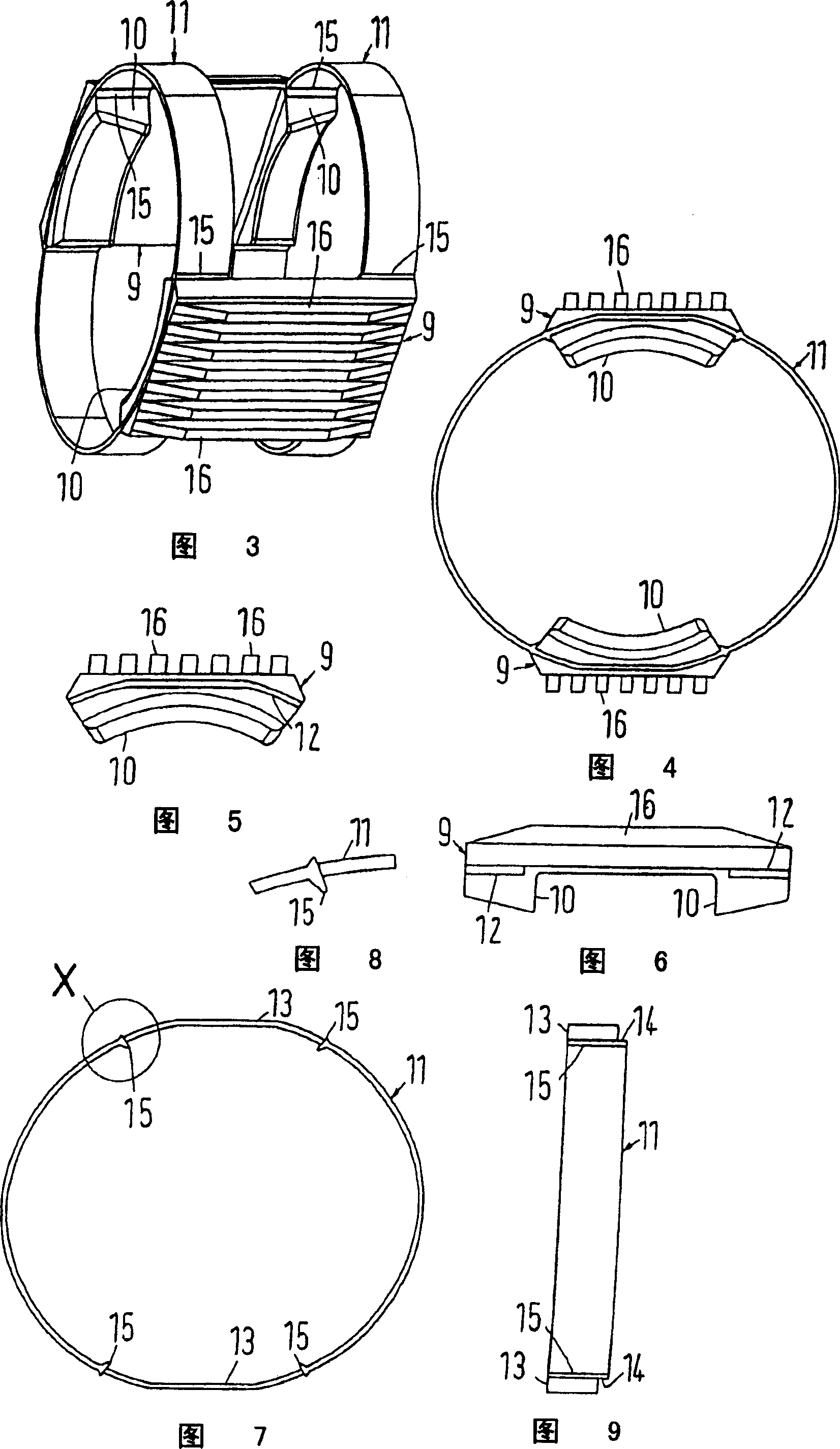

[0058] figure 1 Embodiments of connectors and parts thereof according to the present invention are shown in and 3-9. This connecting piece is used to connect two pipes 1 and 2, only partially shown, made of thermoplastic material or metal. Tubes 1 and 2 are in figure 2 Connectors are not shown. The end sections 3 and 4 of the tubes 1 and 2 are inserted into the connector and joined together. The region where the end sections 3 and 4 join each other is sealed relative to each other by a sealing ring 5 . The end section 4 is welded to the remainder 6 of the tube 2 . Each end section 3 and 4 has an annular positioning rib 7 or 8 respectively.

[0059] The connecting piece has a radially inwardly protruding positioning lug 10 at the axial end of the bending-rigid connecting piece 9 . The positioning lugs 10 lock or snap behind the positioning ribs 7 and 8 when the end sections 7 and 8 are inserted into the connecting piece and are simultaneously joined together. For this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com