Camshaft with an axially displaceable cam pack

A technology of camshafts and cam groups, applied in the direction of elements with teeth, cams, belts/chains/gears, etc., can solve the problems of expensive design and expensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

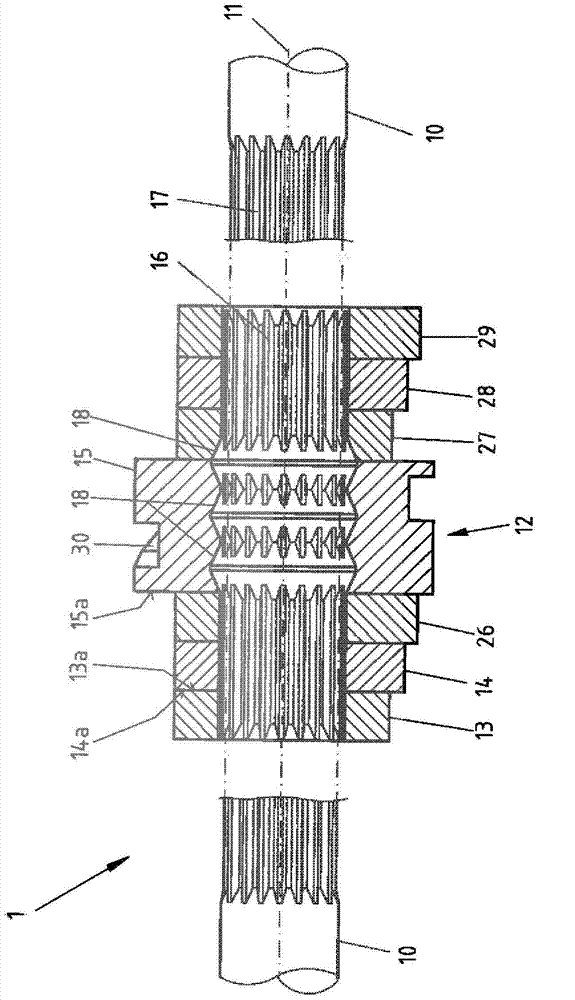

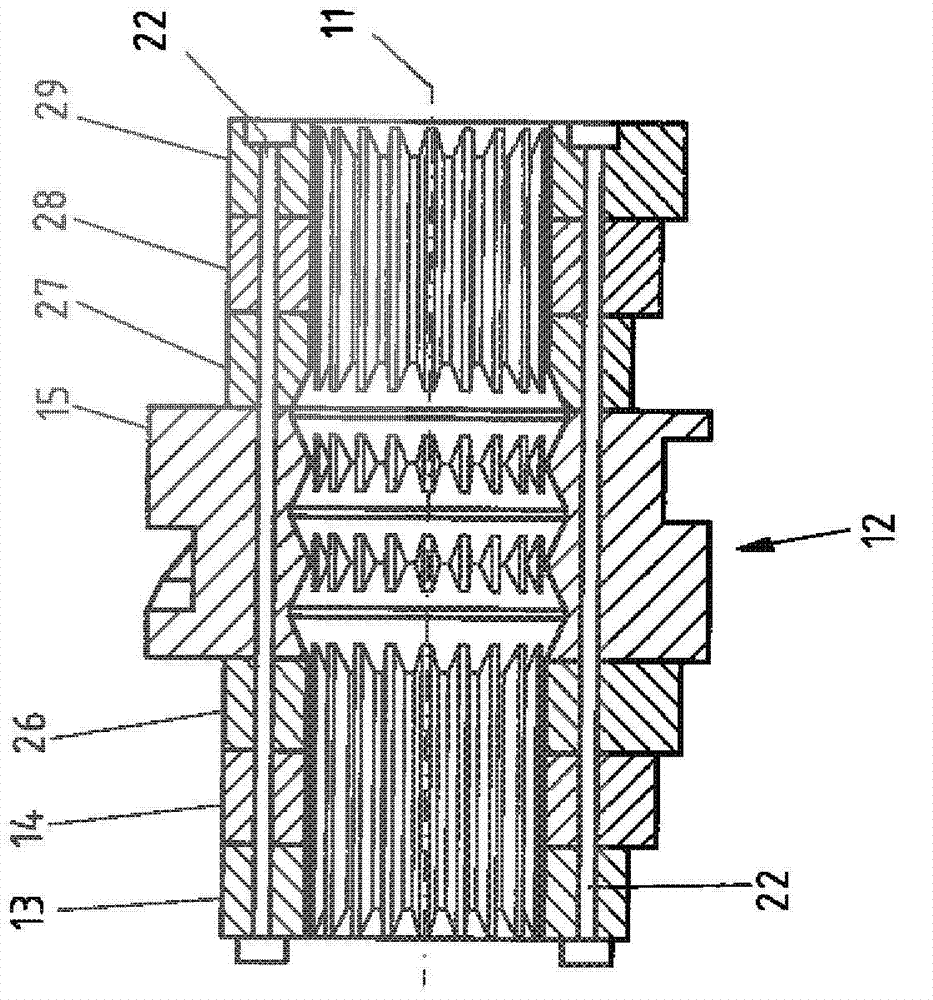

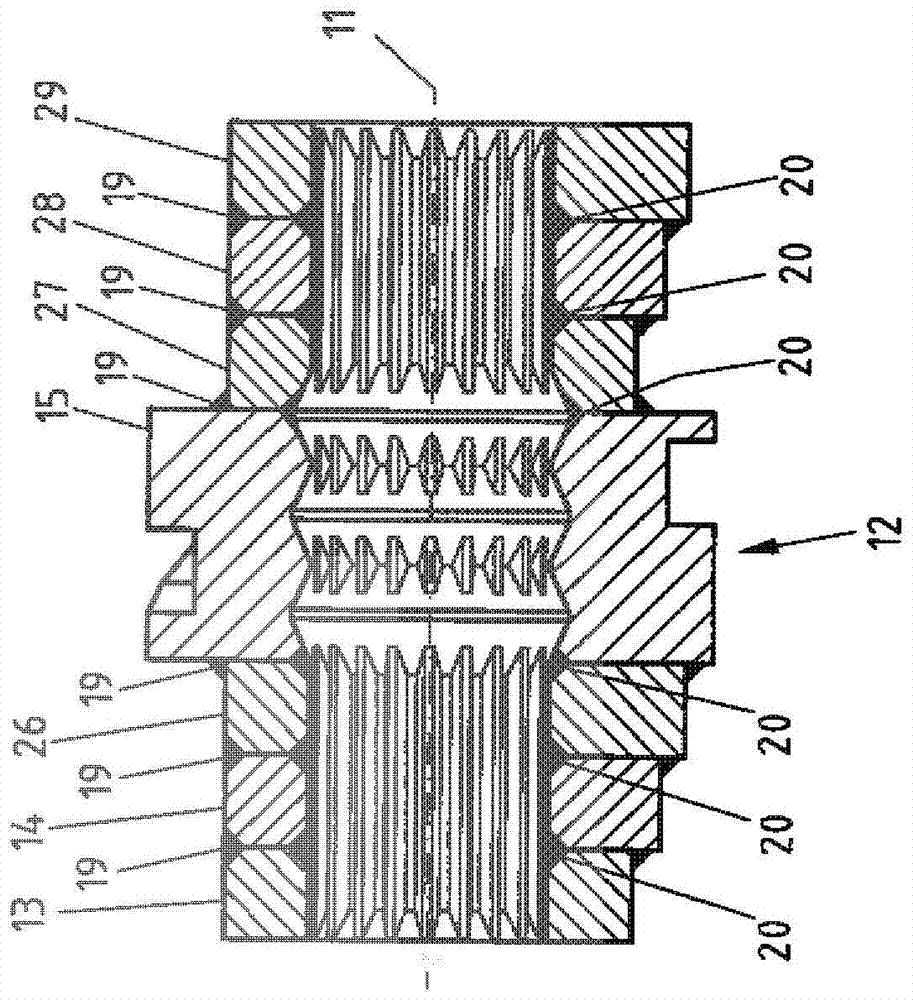

[0075] figure 1 An exemplary embodiment of a camshaft 1 with a cam set 12 is shown, which is embodied with the features of the invention. The camshaft 1 comprises a carrier shaft 10 which is shown interrupted in the seating area of a cam set 12 . The carrier shaft 10 can be mounted to rotate about an axis 11 , for example in a cylinder head of an internal combustion engine.

[0076] The cam set 12 comprises, for example, six cams 13 , 14 , 26 , 27 , 28 and 29 , in which the adjustment element 15 is provided and into which guide grooves 30 are introduced at the outer periphery of the adjustment element 15 . Cams 13 , 14 and 26 are located on a first side of adjustment element 15 and cams 27 , 28 and 29 are located on a second, opposite side of adjustment element 15 . Through holes extend through the cams 13 , 14 , 26 , 27 , 28 , 29 and through the adjustment element 15 , through which the carrier shaft 10 passes. Inserted into this through-bore formed by the individual com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com