Torque transmission device with electrical insulation

A technology of torque transmission device and insulating element, applied in the direction of transmission device, fluid transmission device, transmission device parts, etc., can solve the problems of increased duration, difficult assembly of torsional shock absorbers, etc., and achieve the effect of increasing the structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Similar or similarly acting elements are identified below with the same reference numerals.

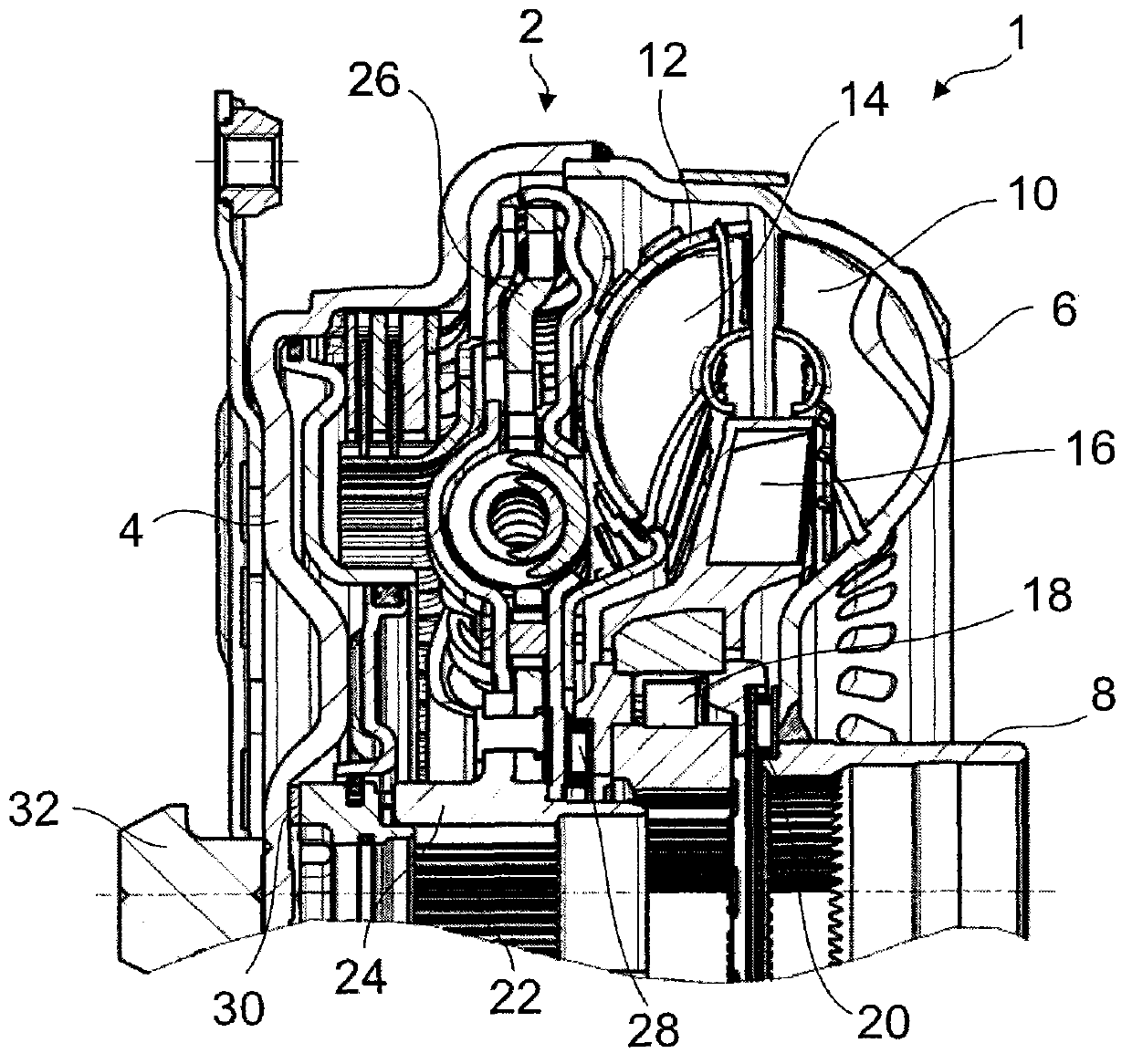

[0052] figure 1 A wet-running clutch assembly 1 in the form of a hydraulic torque converter is shown. On its side facing the drive (not shown), the housing 2 has a housing cover 4 which is fixedly connected to the impeller housing 6 . The impeller housing 6 merges into the impeller hub 8 in the radially inner region.

[0053] The impeller casing 6 together with the impeller blades forms a pump impeller 10 which cooperates with a turbine 14 having a turbine casing 12 with turbine blades and a stator 16 with stator blades. The pump wheel 10 , the turbine wheel 14 and the guide wheel 16 form a hydraulic circuit in a known manner.

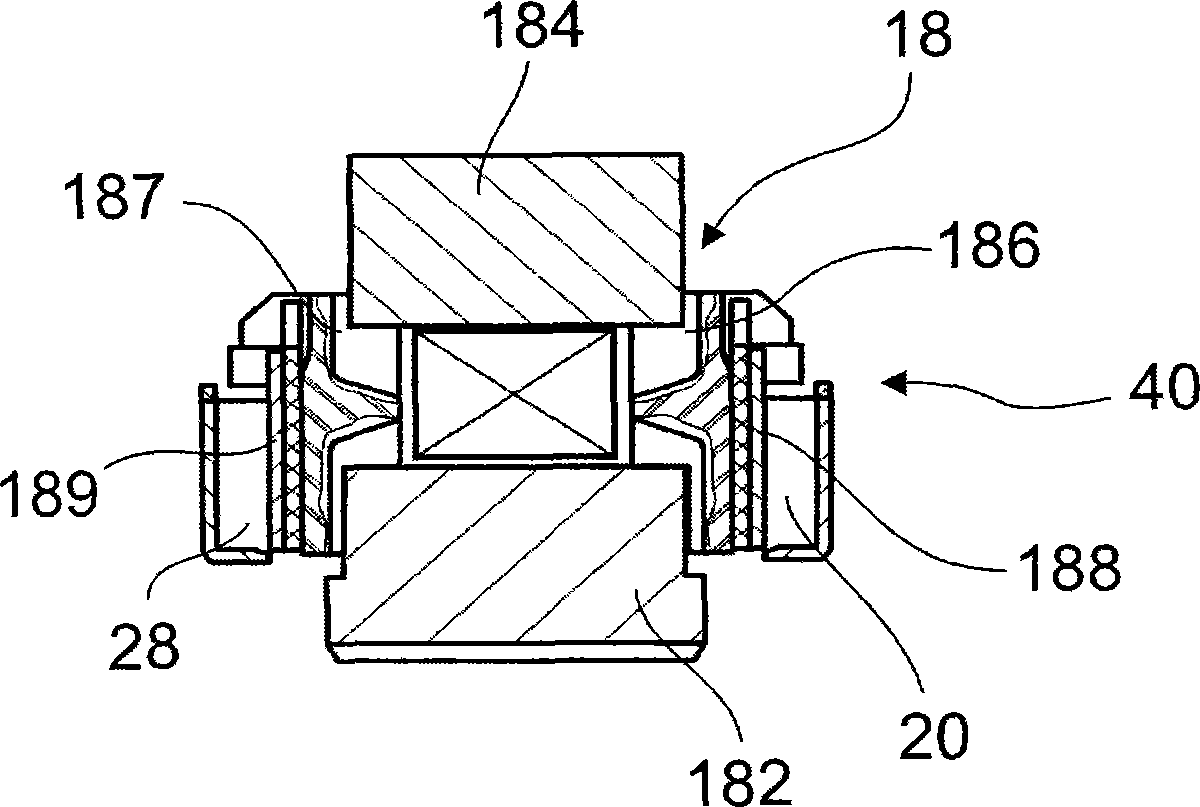

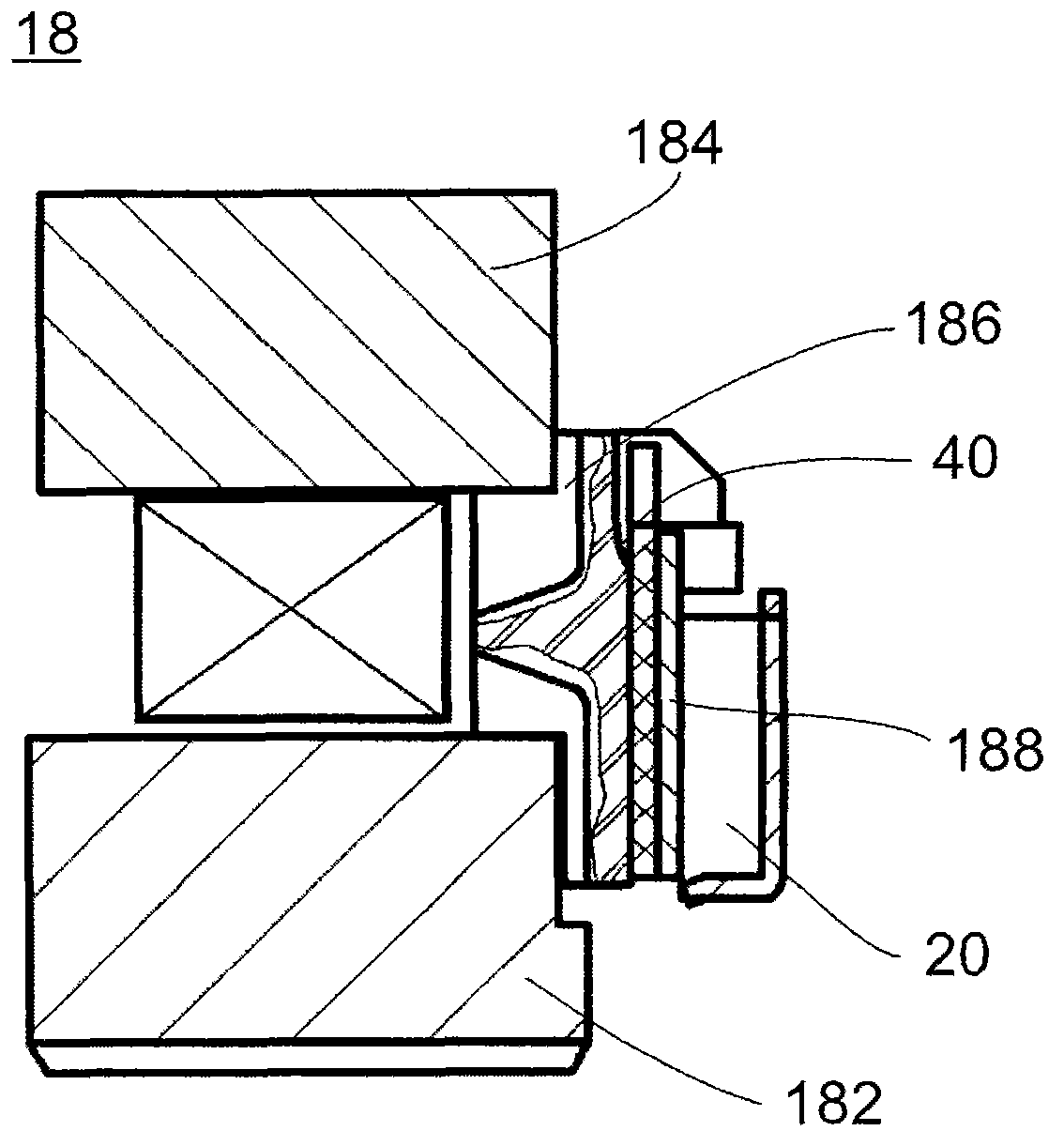

[0054] The guide wheel 16 is arranged on a freewheel 18 which is supported axially on the pump hub 8 via an axial bearing 20 . The pump hub 8 is hollow and therefore accommodates the transmission input shaft 22 in its interior.

[0055] The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com