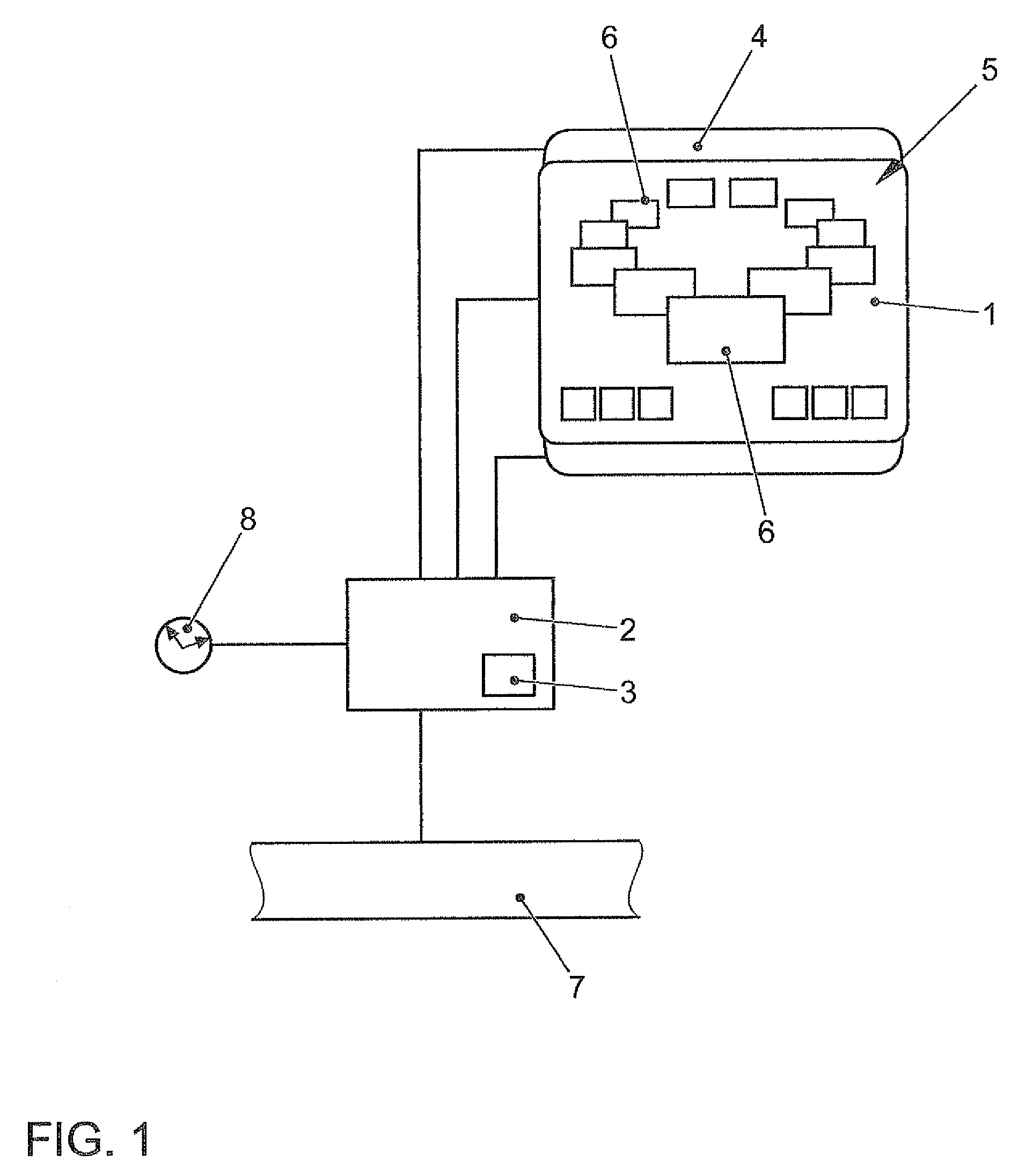

Patents

Literature

448results about How to "Large spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrospun fibers and an apparatus therefor

InactiveUS6753454B1Optimal spacingMaintain spacingNanotechFilament/thread formingFiberPolymer solution

A novel fiber comprising a substantially homogeneous mixture of a hydrophilic polymer and a polymer which is at least weakly hydrophobic is disclosed. The fiber optionally contains a pH adjusting compound. A method of making the fiber comprises electrospinning fibers of the substantially homogeneous polymer solution. A method of treating a wound or other area of a patient requiring protection from contamination comprises electrospinning the substantially homogeneous polymer solution to form a dressing. An apparatus for electrospinning a wound dressing is discosed.

Owner:AKRON THE UNIV OF +2

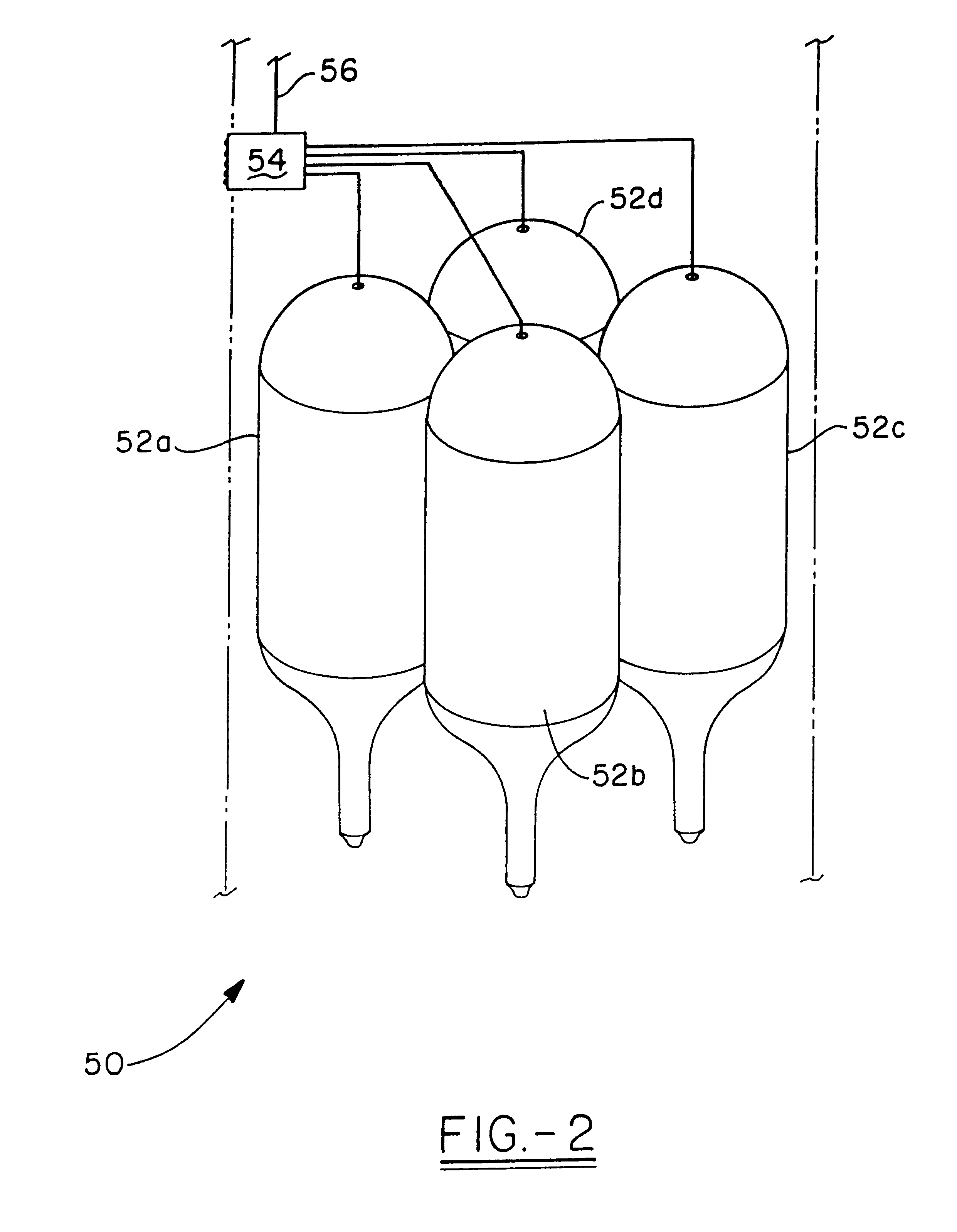

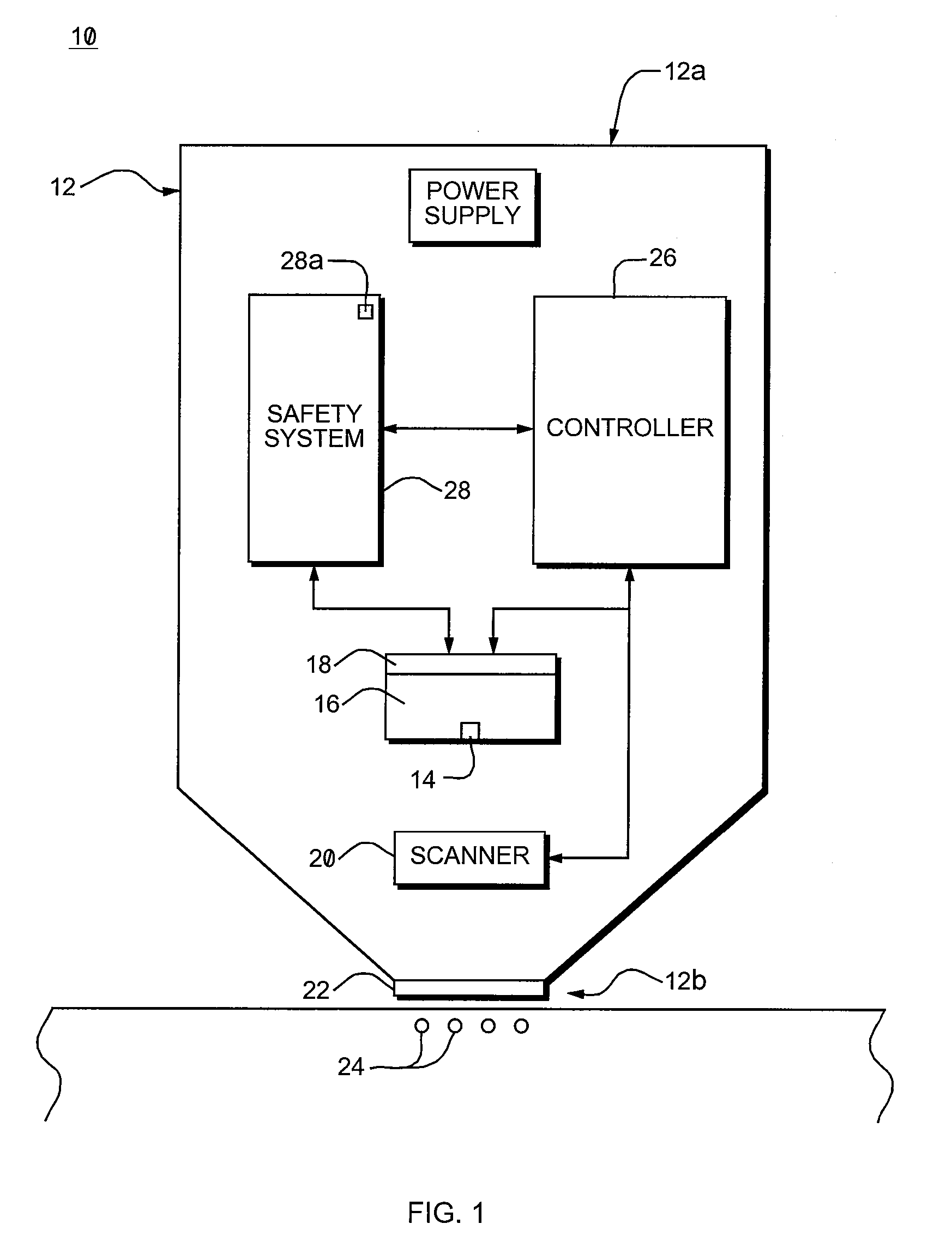

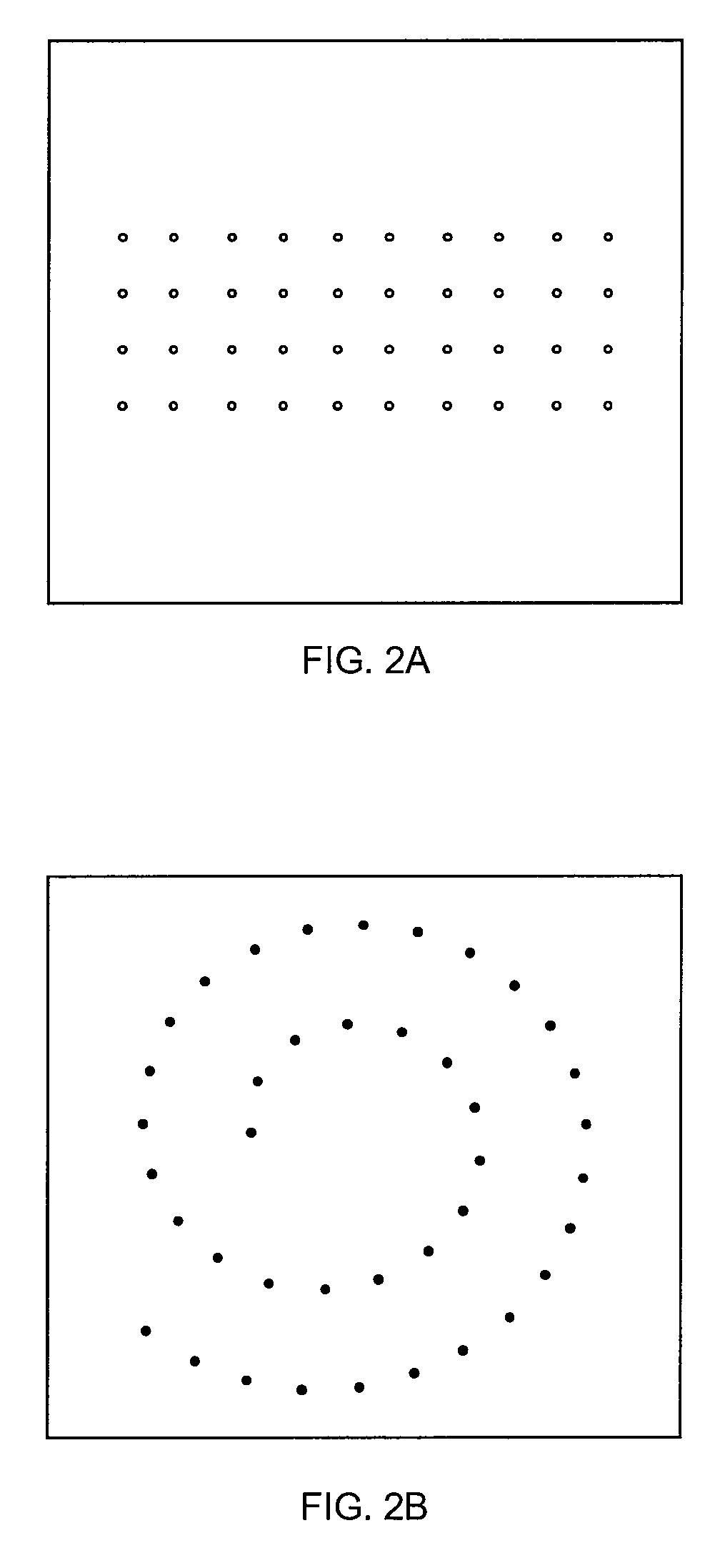

Handheld Photocosmetic Device

InactiveUS20080058783A1Maintain and improve benefitSimple designDiagnosticsControlling energy of instrumentHand heldDermatology

The present invention discloses handheld photocosmetic devices that can be utilized to apply EMR to the skin, e.g., to achieve fractional treatment of the skin. The invention discloses effective fractional photocosmetic devices for use in by a consumer in a non-medical and or non-professional setting. Thus, embodiments of such devices are disclosed herein that have one or more of the following attributes: capable of performing one or more cosmetic and / or dermatological treatments; efficacious for such treatments; durable; relatively inexpensive; relatively simple in design; smaller than existing professional devices (with some embodiments being completely self-contained and hand-held); safe for use by non-professionals; and / or not painful to use (or only mildly painful).

Owner:PALOMAR MEDICAL TECH

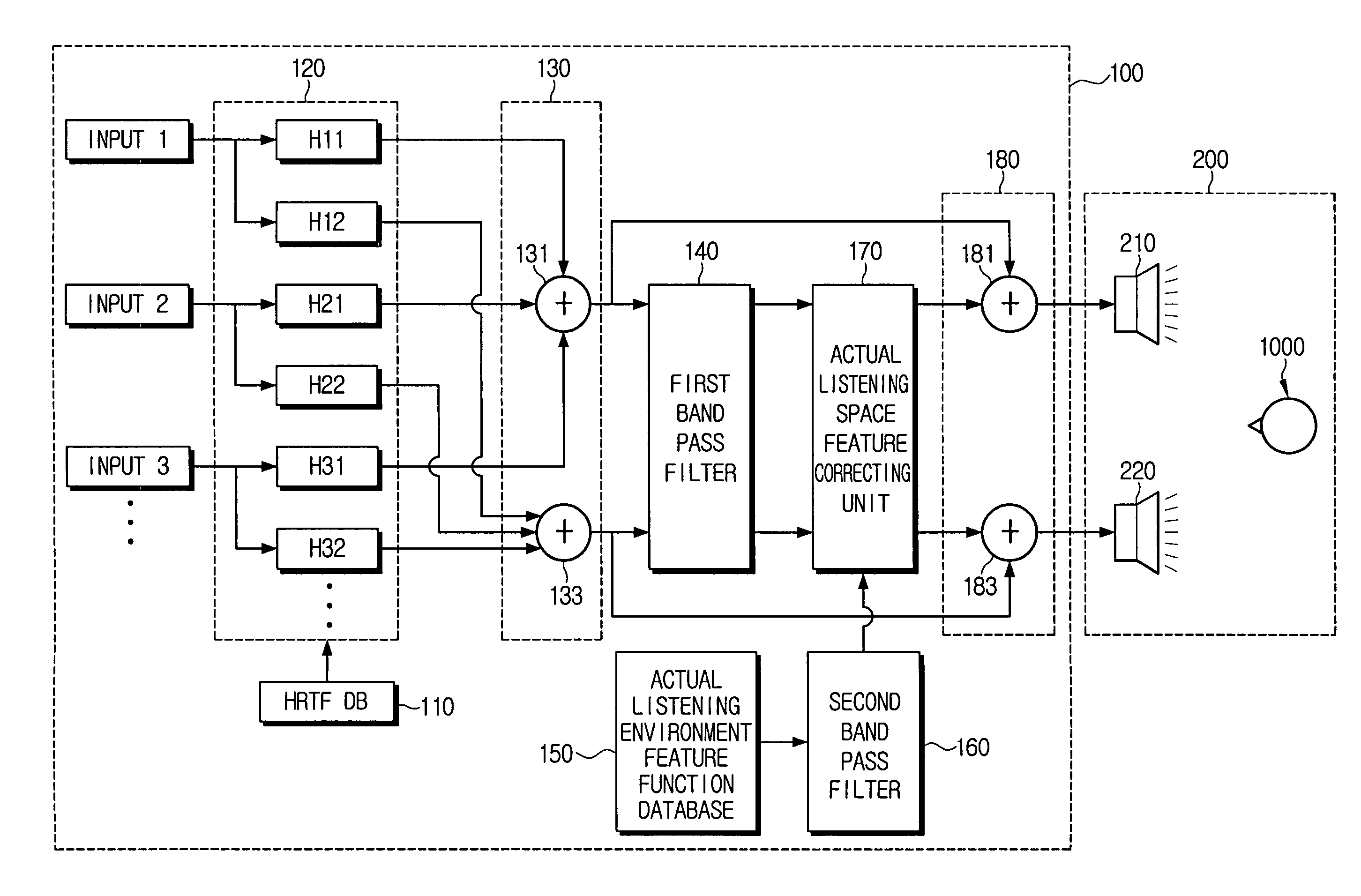

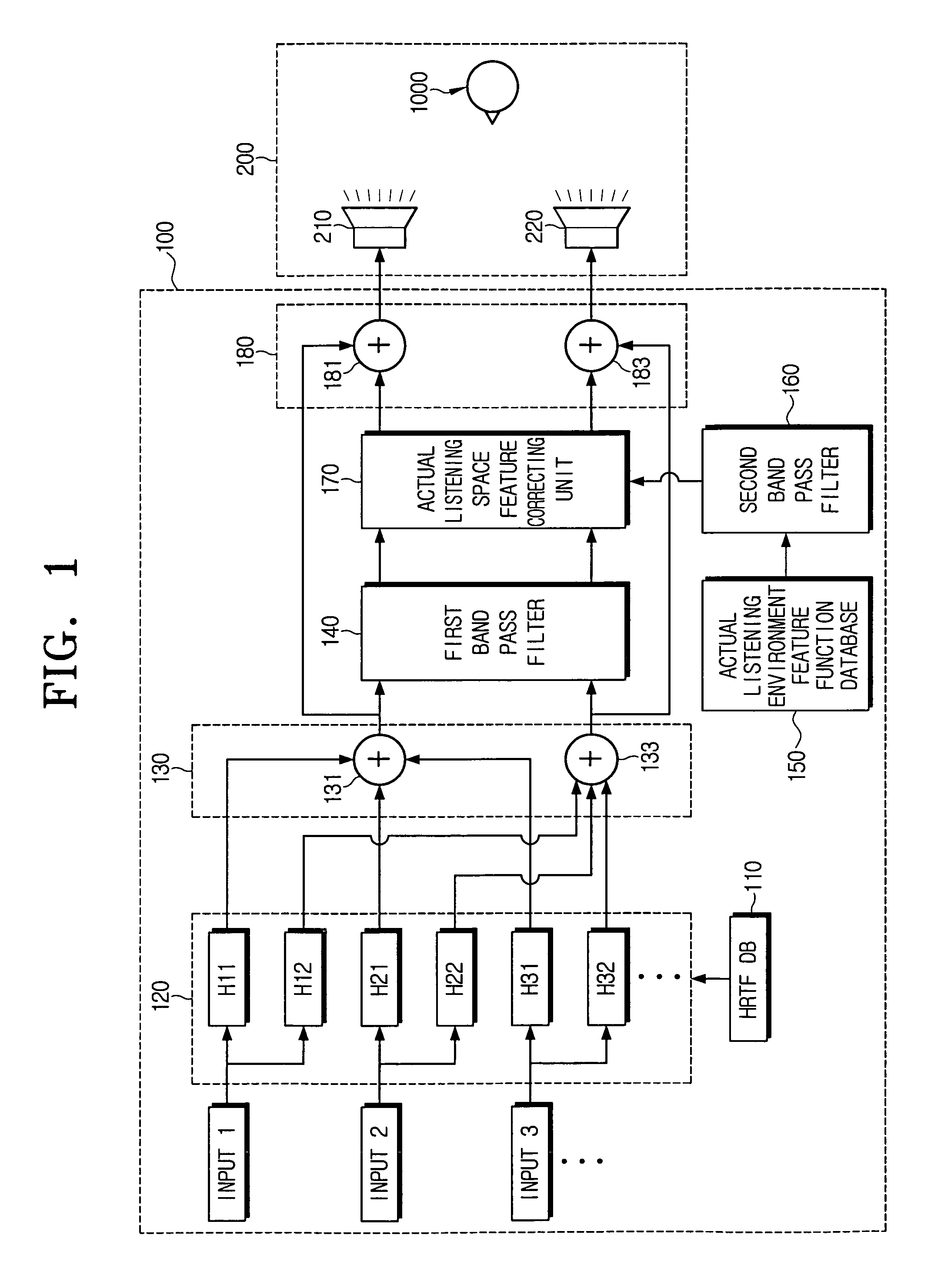

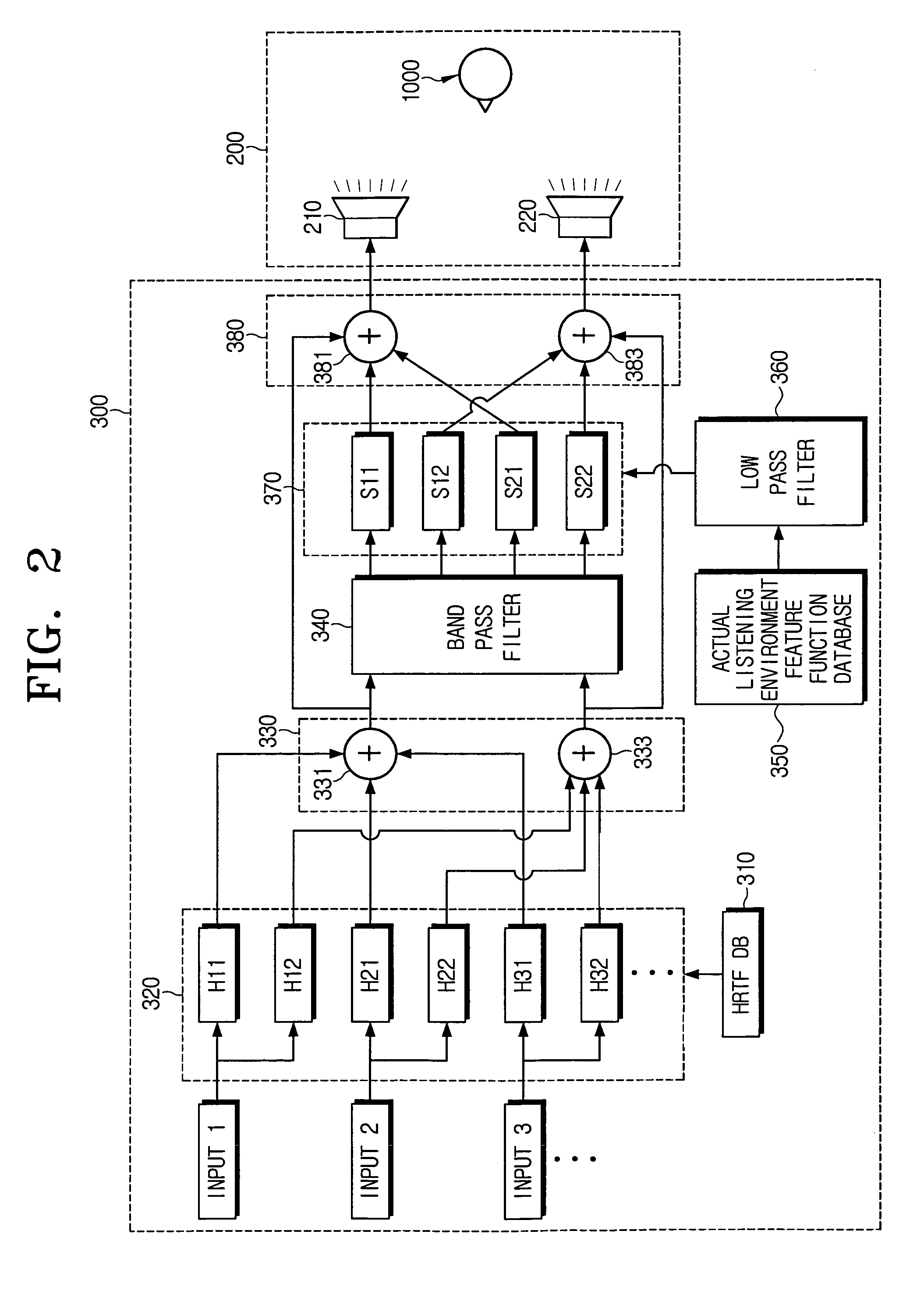

Sound reproducing apparatus and sound reproducing method

InactiveUS8160281B2Accurate featuresLarge spacingTransducer acoustic reaction preventionLoudspeaker spatial/constructional arrangementsComputer scienceDistortion

A sound reproducing apparatus and a sound reproducing method. The sound reproducing apparatus includes an actual listening environment feature function database where an actual listening space feature function is stored for correcting the virtual source in response to a feature of an actual listening space provided at the time of listening; and an actual listening space feature correcting unit of reading out the actual listening space feature function stored in the actual listening environment feature function database, and correcting the virtual source based on the reading result. Accordingly, causes of each distortion may be removed to provide sounds having the best quality.

Owner:SAMSUNG ELECTRONICS CO LTD

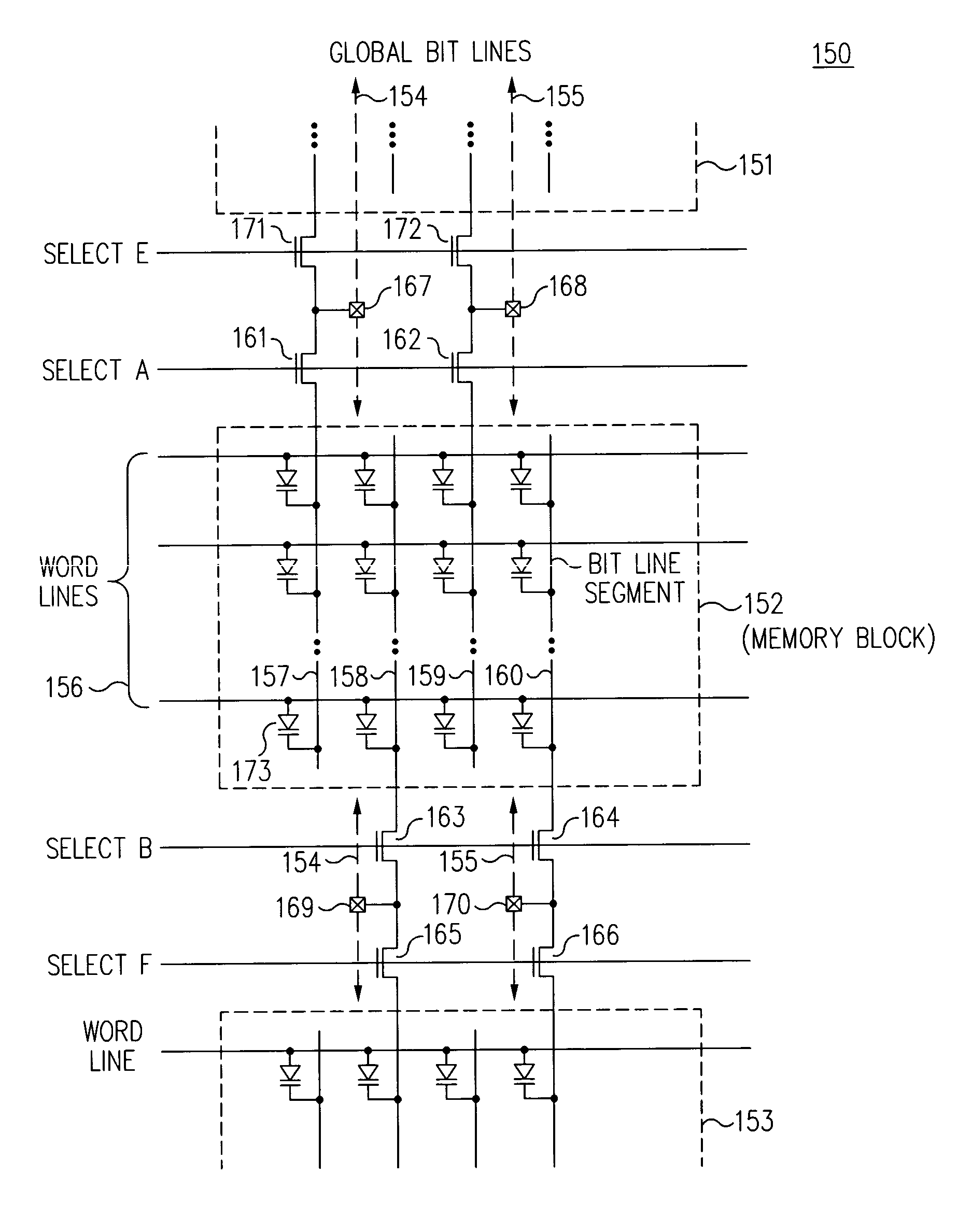

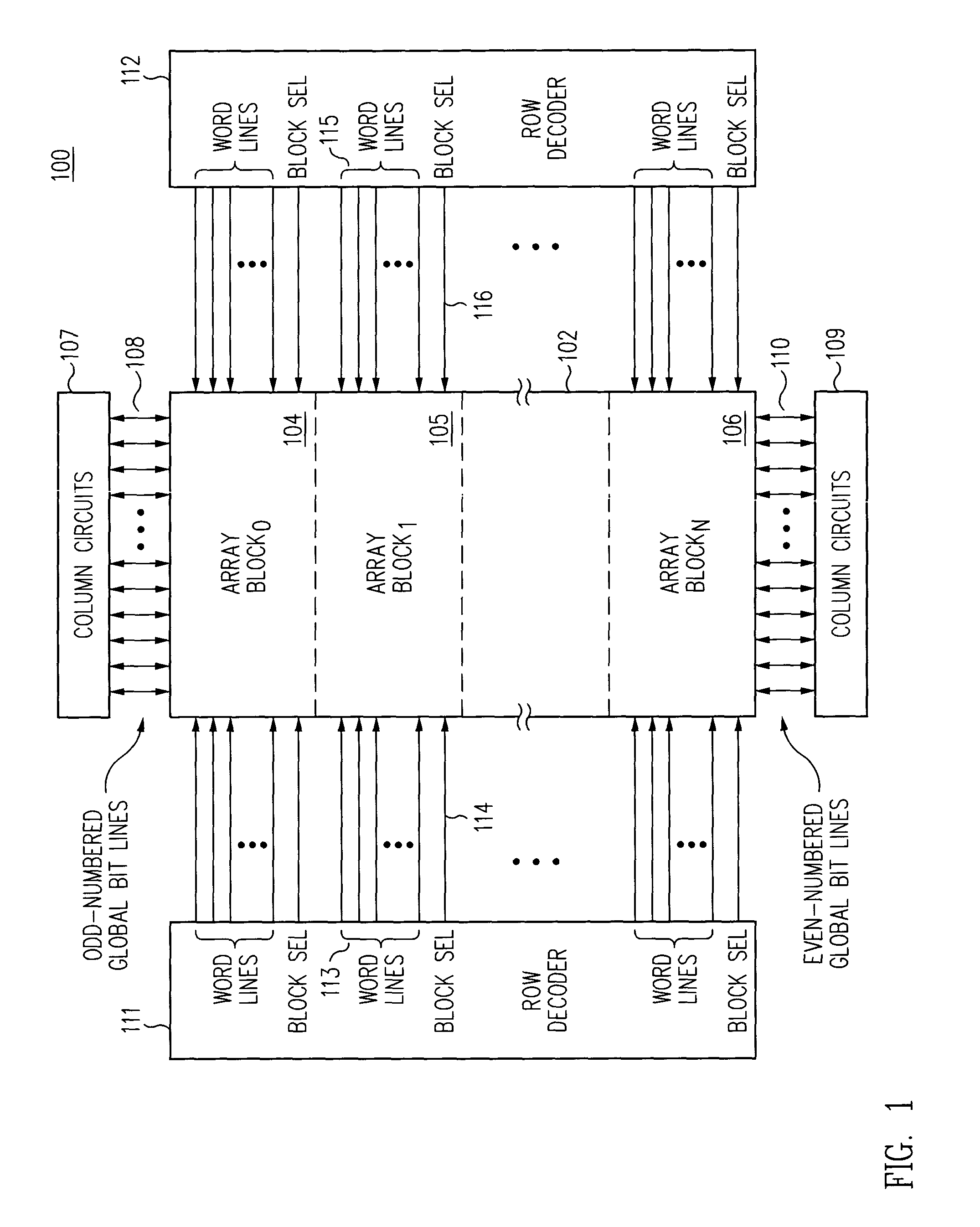

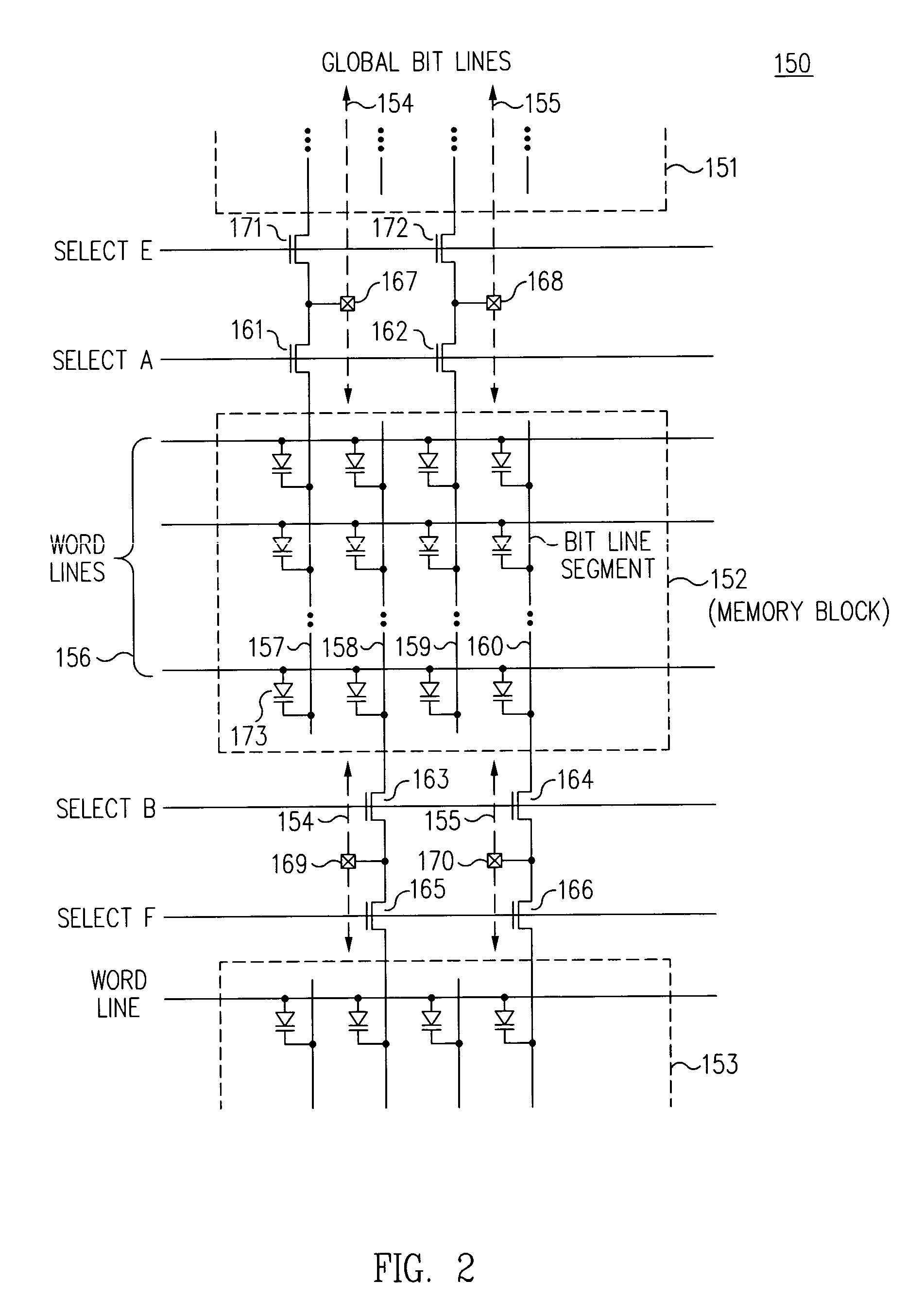

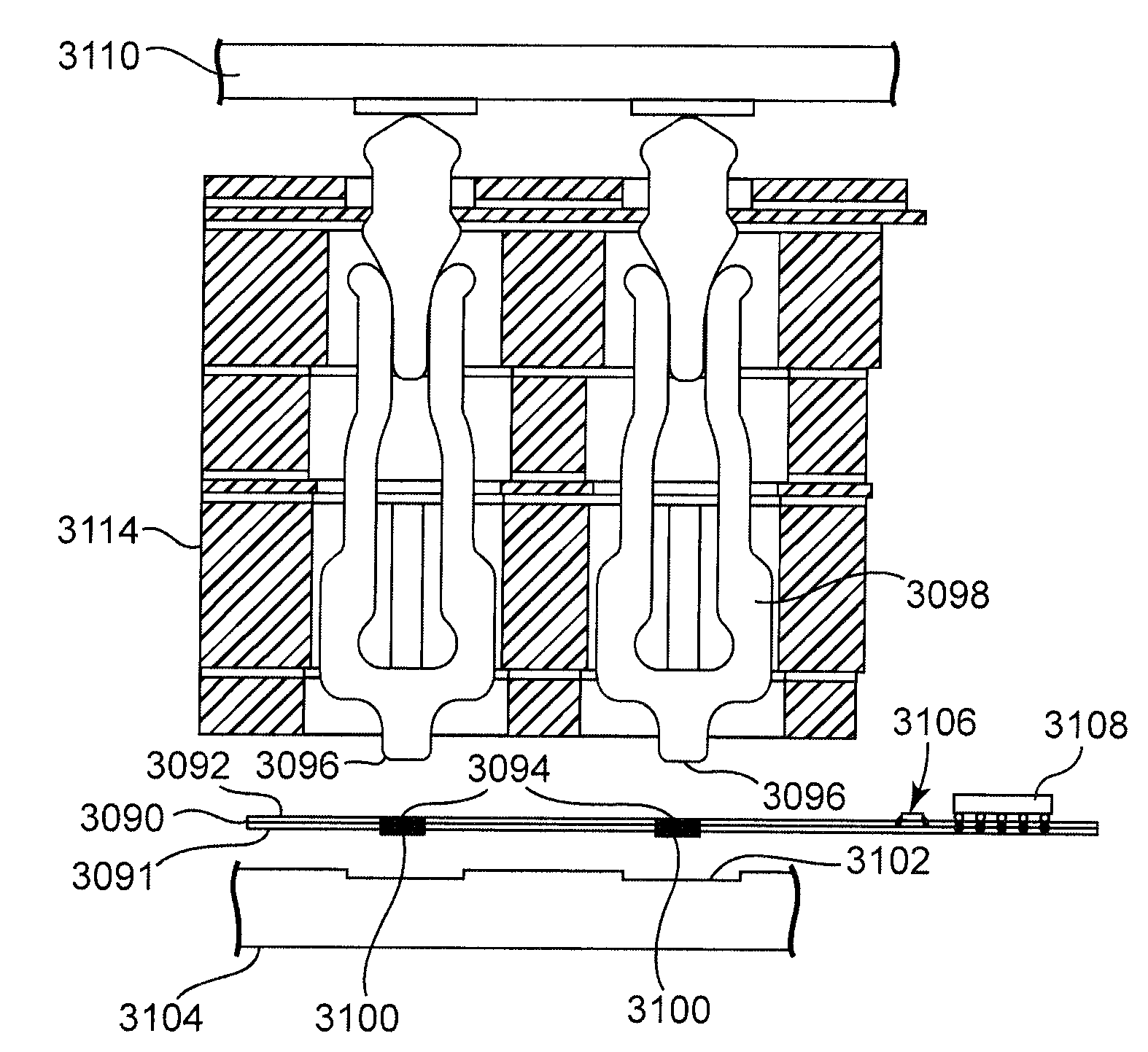

Three-dimensional memory device incorporating segmented bit line memory array

InactiveUS7233024B2Reduce capacitanceShorten overall length of unitSolid-state devicesRead-only memoriesBit lineHigh density

A three-dimensional (3D) high density memory array includes multiple layers of segmented bit lines (i.e., sense lines) with segment switch devices within the memory array that connect the segments to global bit lines. The segment switch devices reside on one or more layers of the integrated circuit, preferably residing on each bit line layer. The global bit lines reside preferably on one layer below the memory array, but may reside on more than one layer. The bit line segments preferably share vertical connections to an associated global bit line. In certain EEPROM embodiments, the array includes multiple layers of segmented bit lines with segment connection switches on multiple layers and shared vertical connections to a global bit line layer. Such memory arrays may be realized with much less write-disturb effects for half selected memory cells, and may be realized with a much smaller block of cells to be erased.

Owner:WODEN TECH INC

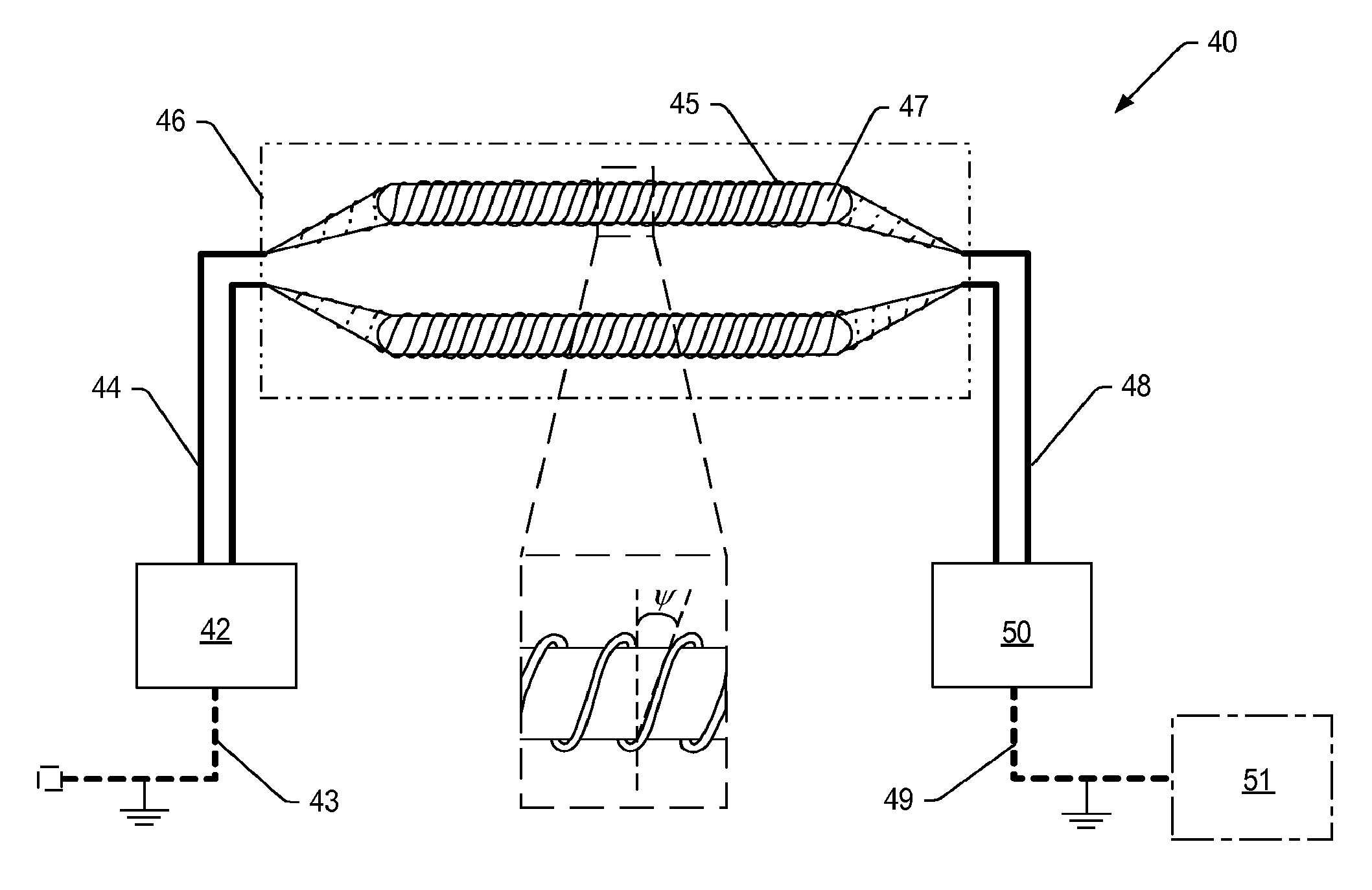

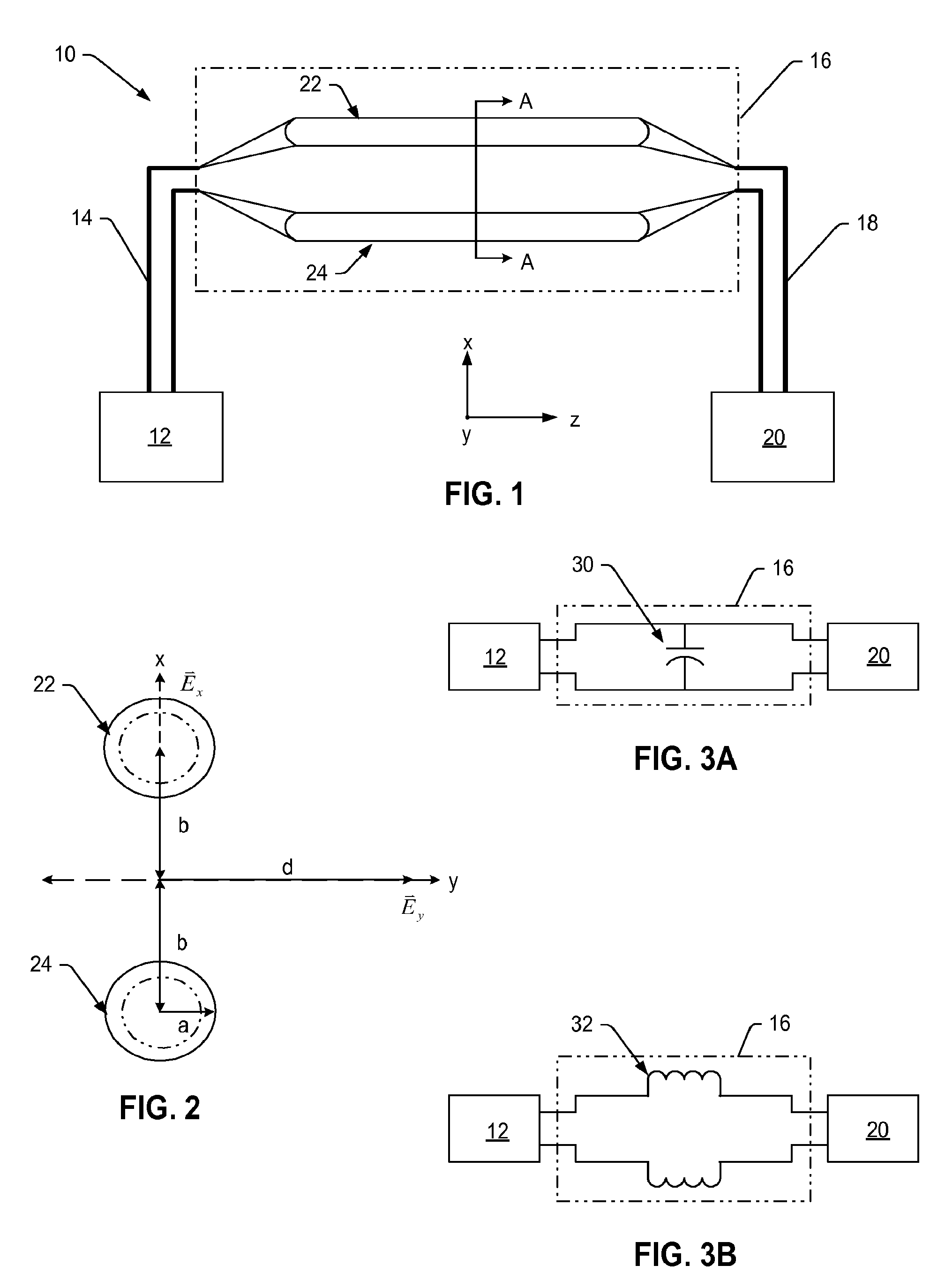

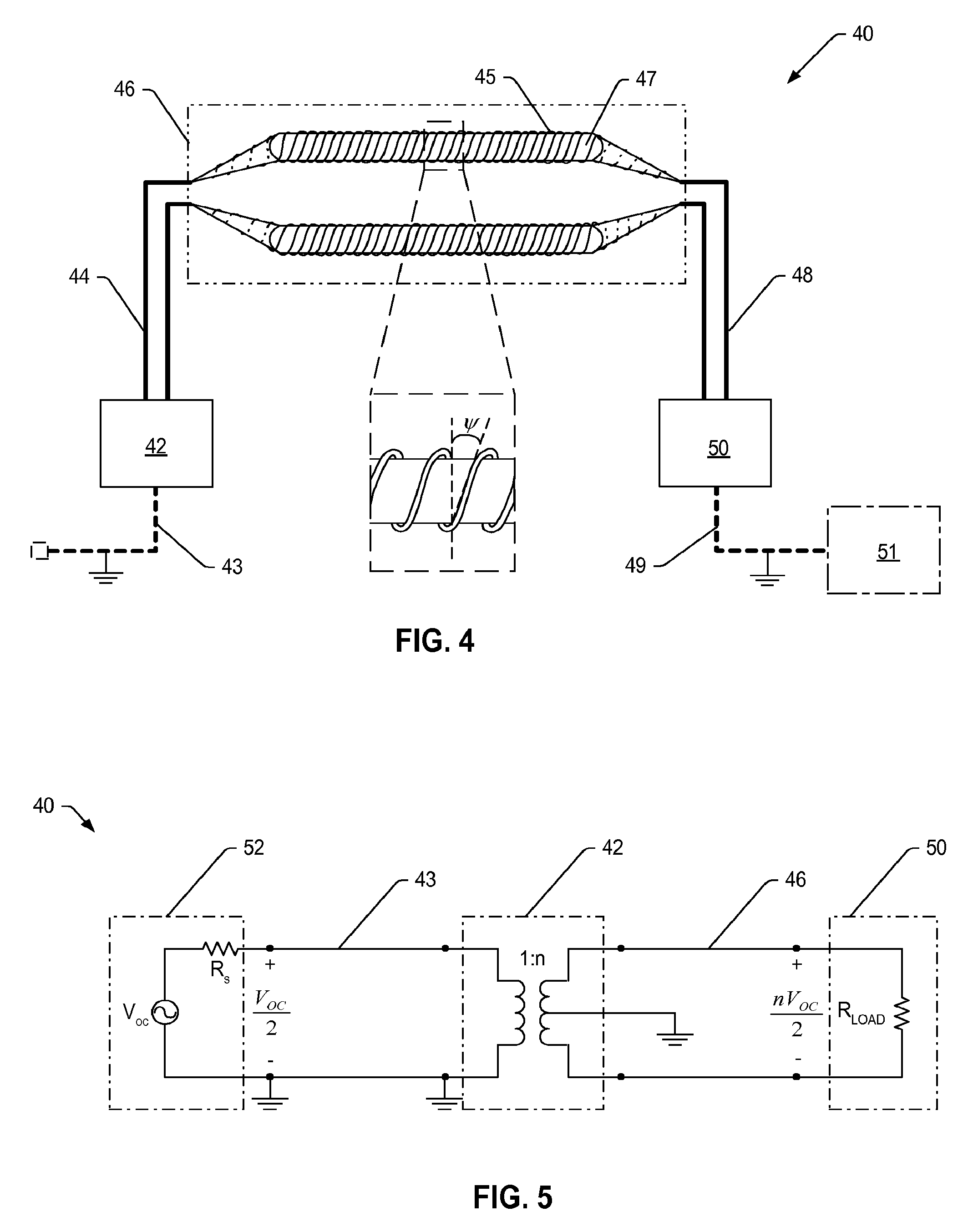

Electric field generator incorporating a slow-wave structure

InactiveUS7656167B1Increase the lengthReduced phase velocityResistance/reactance/impedenceDelay linesWave structureEngineering

An improved E-field generator including a slow-wave transmission line structure is provided herein. In some cases, the improved E-field generator may include an inductively-loaded slow-wave transmission line structure driven by a power source at one end of the structure and terminated by a load at the other end of the structure. In other cases, the improved E-field generator may include a capacitively-loaded slow-wave transmission line structure. In either case, the improved E-field generator provides a frequency-independent, significantly increased electric field at a distance spaced from the generator without altering the dimensions of the generator and / or the input power supplied to the generator. The increase in generated field intensity is achieved by decreasing the phase velocity of the electromagnetic wave propagating along the parallel elements of the generator.

Owner:TDK CORPARATION

Light Management for Image and Data Control

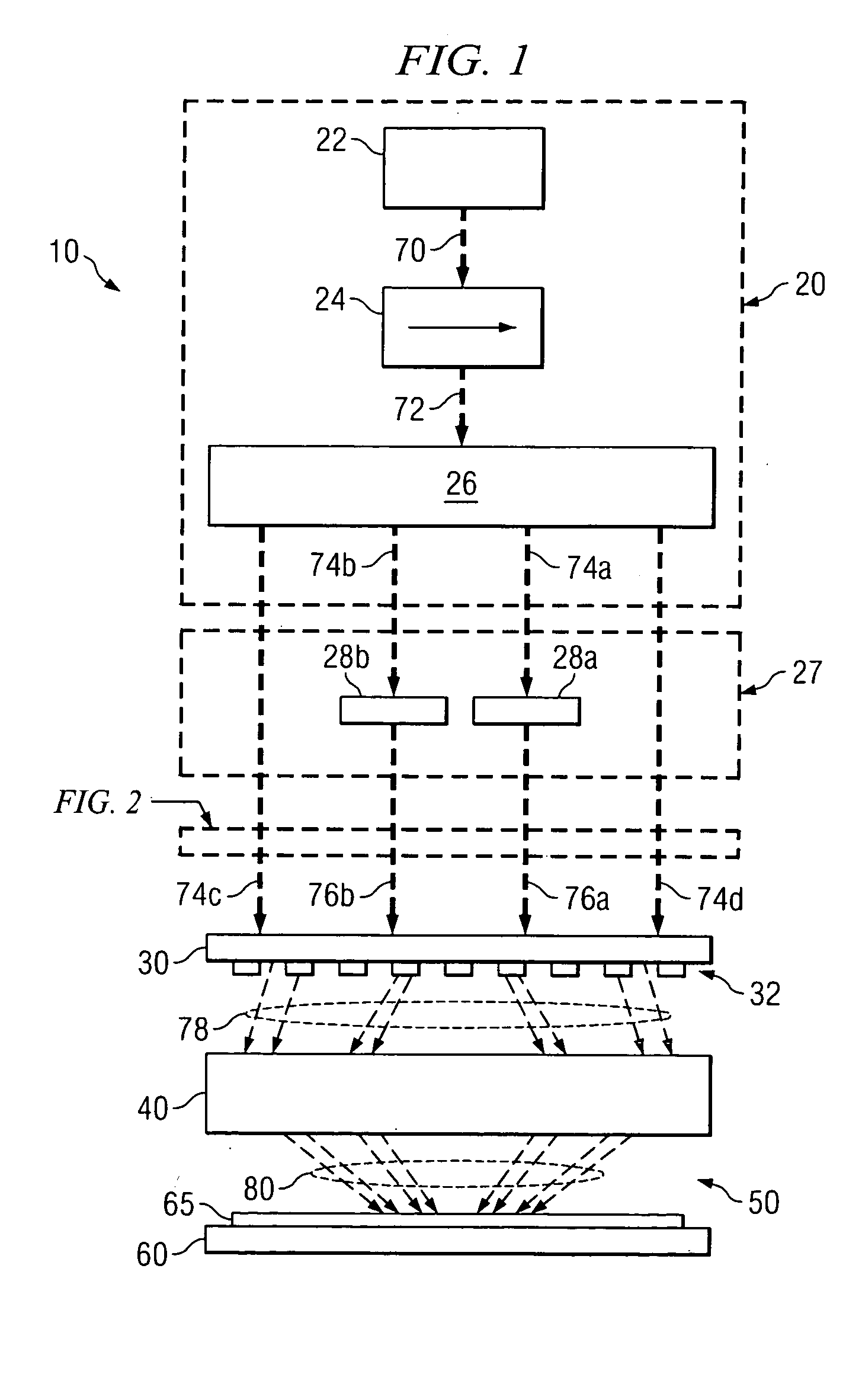

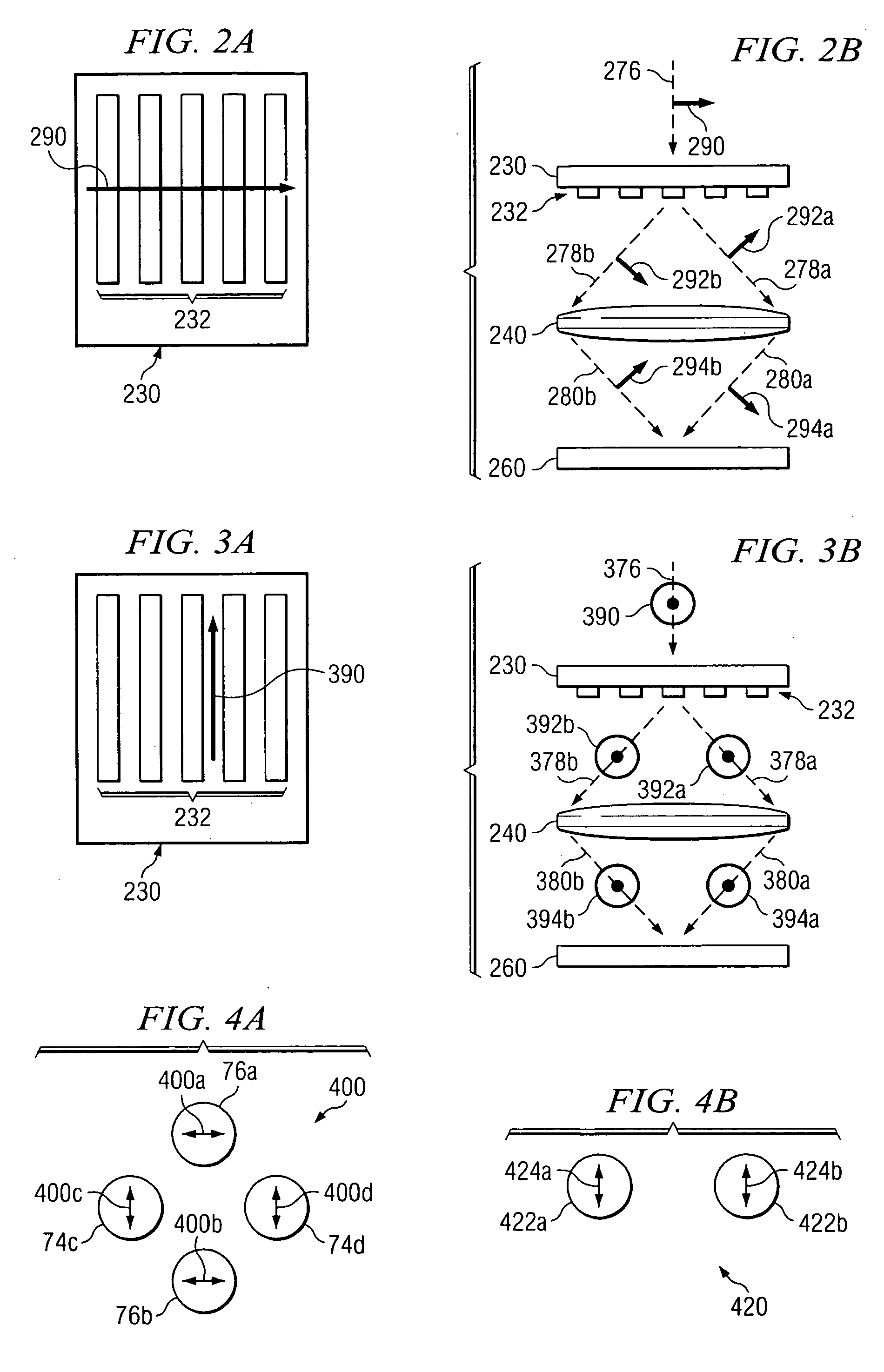

ActiveUS20140285429A1Improve display characteristicsImproved hand-eye coordinationInput/output for user-computer interactionTelevision system detailsData controlNight driving

A light control and display technology applicable to light redirection and projection with the capacity, in a number of embodiments modified for particular applications, to produce managed light, including advanced images. Applications include miniature to very large scale video displays, optical data processing, 3-dimensional imaging, and lens-less vision enhancement for poor night-driving vision, cataracts and macular degeneration.

Owner:SIMMONS JOHN CASTLE

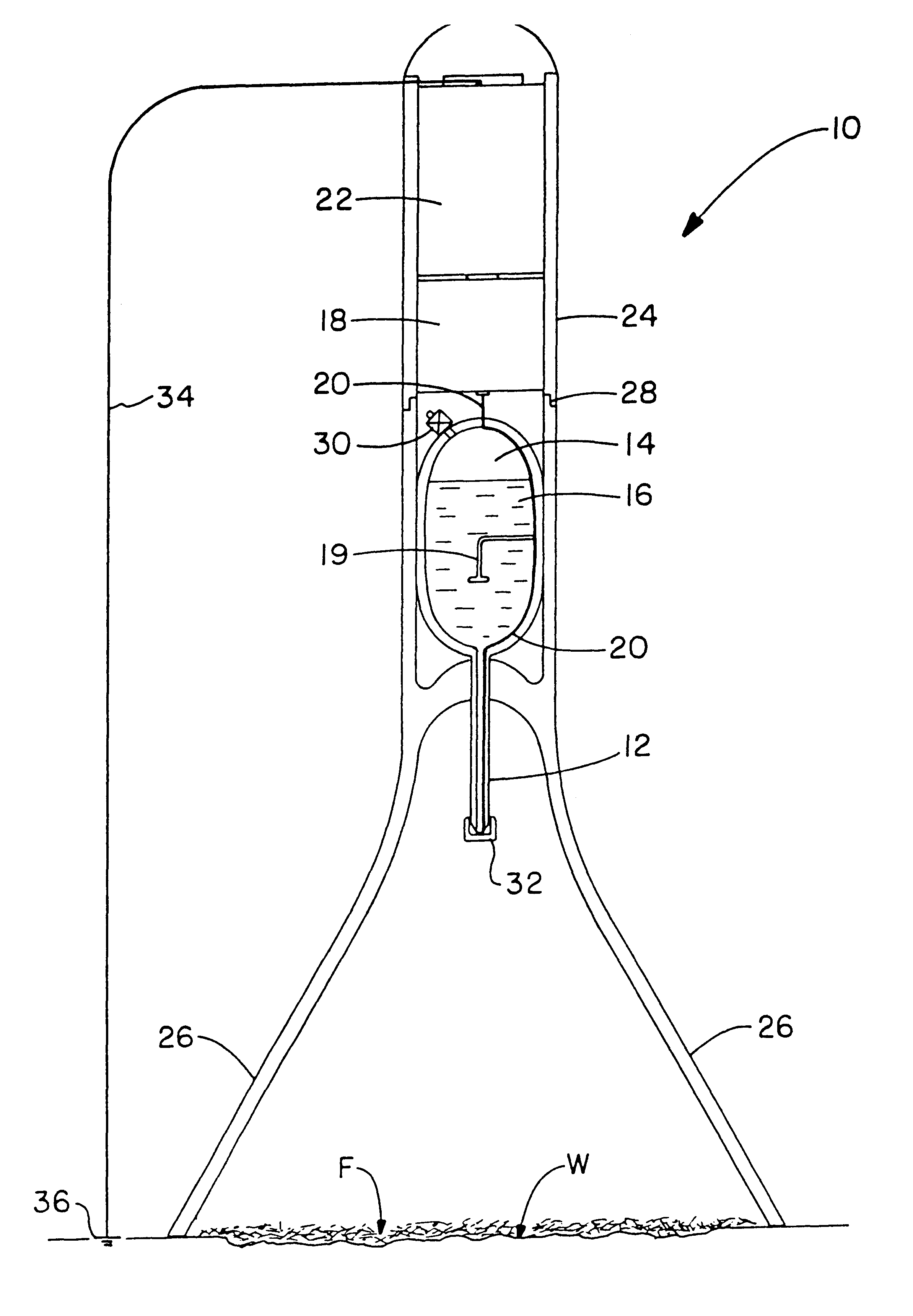

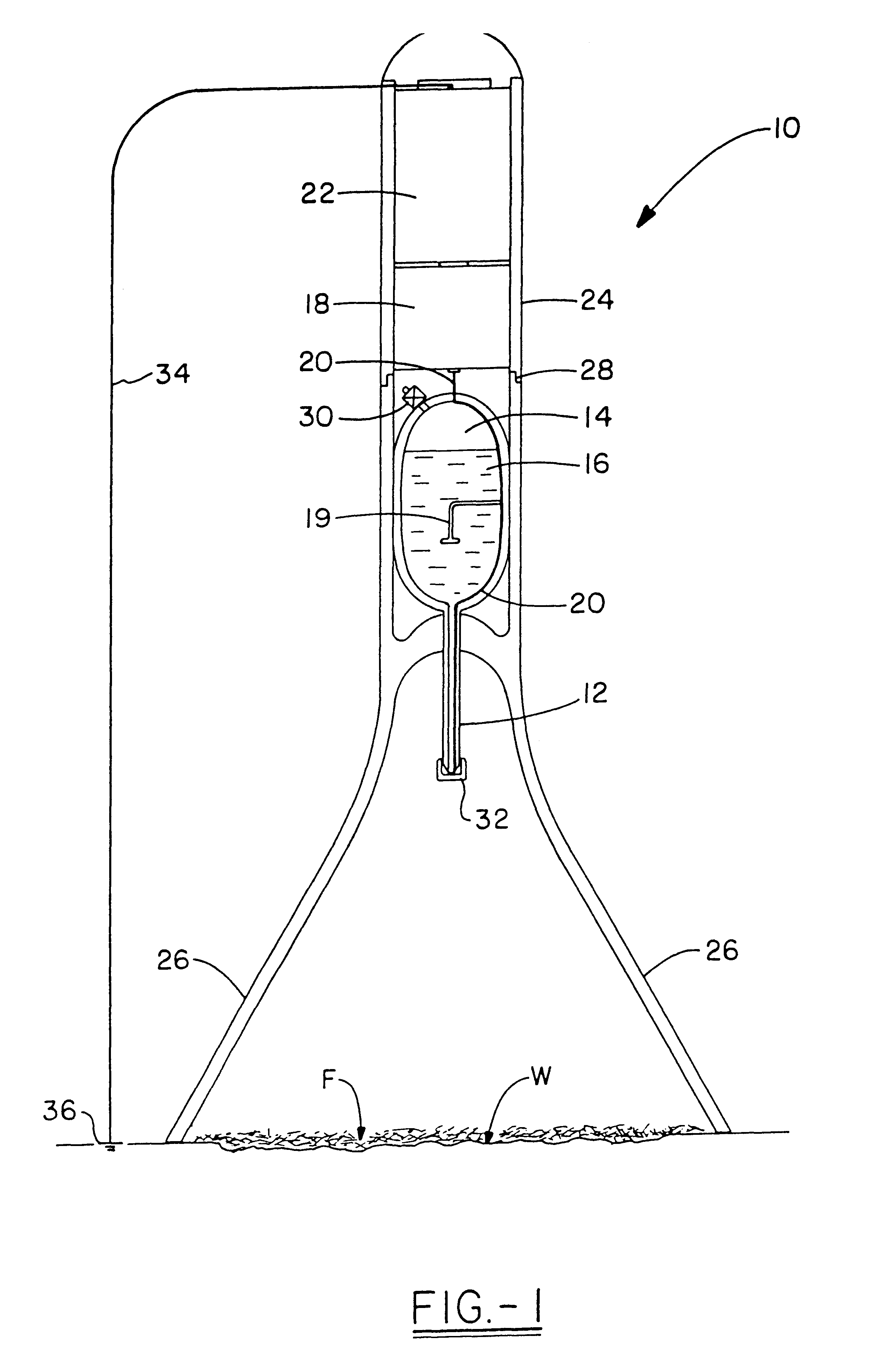

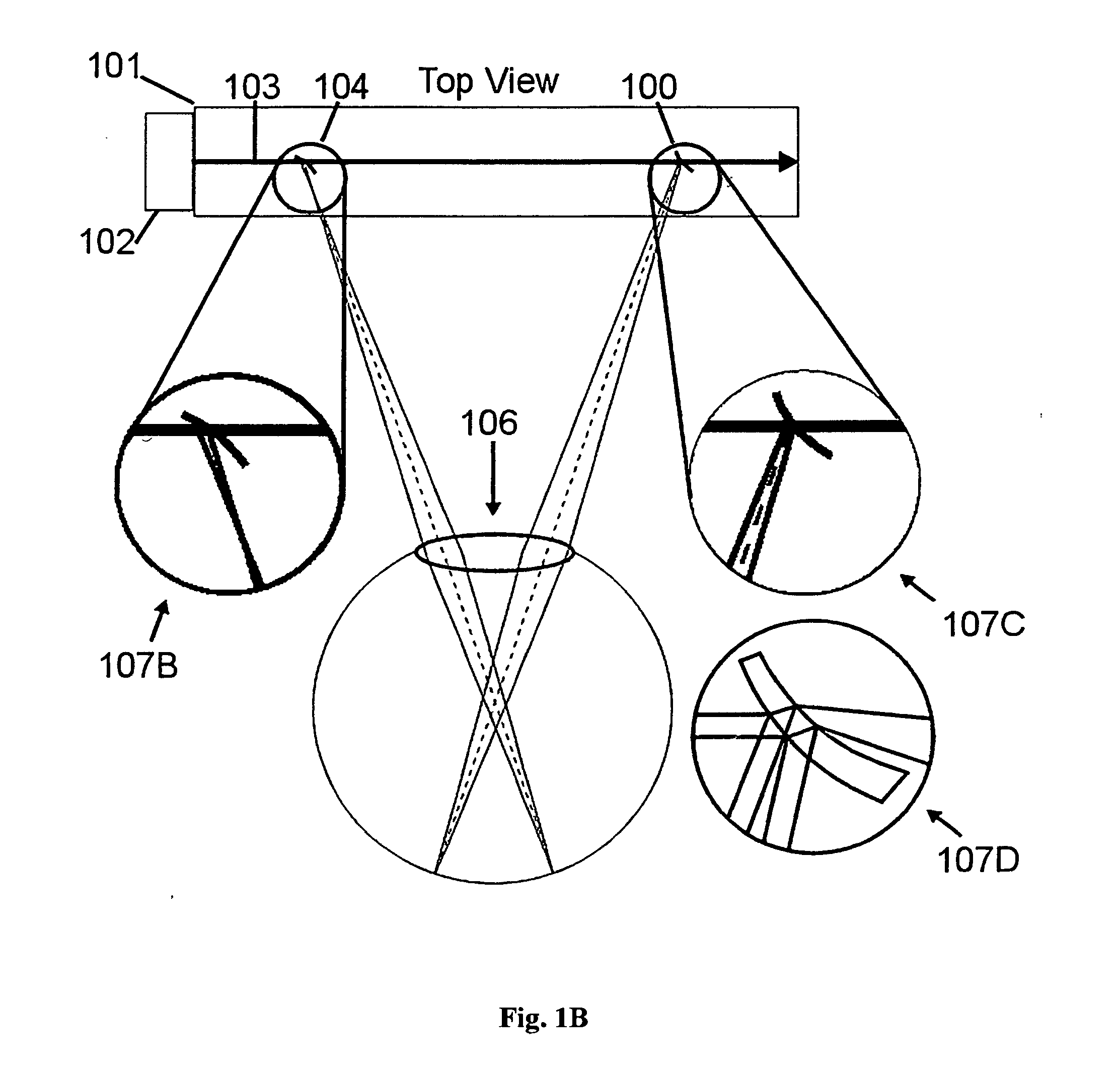

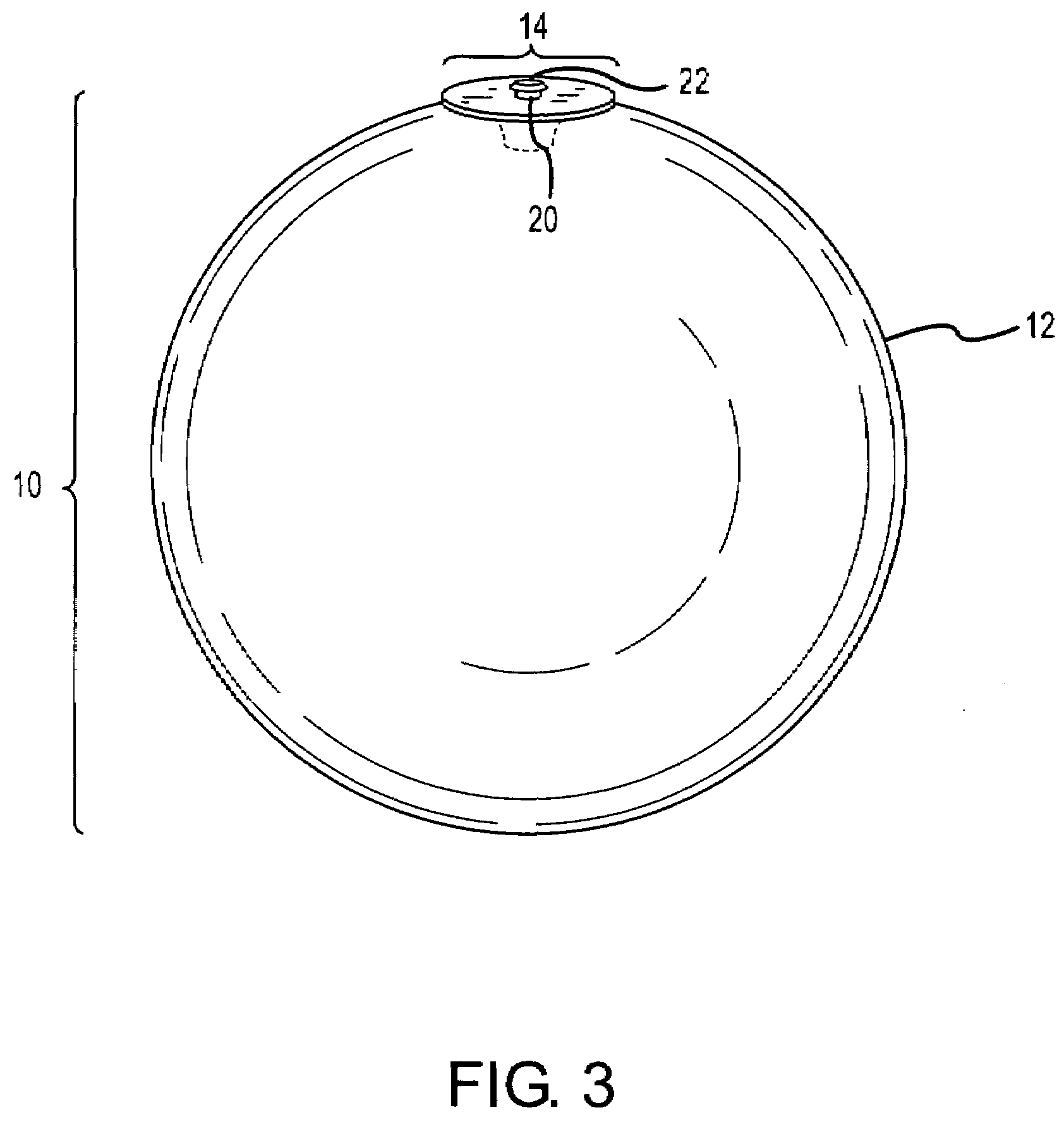

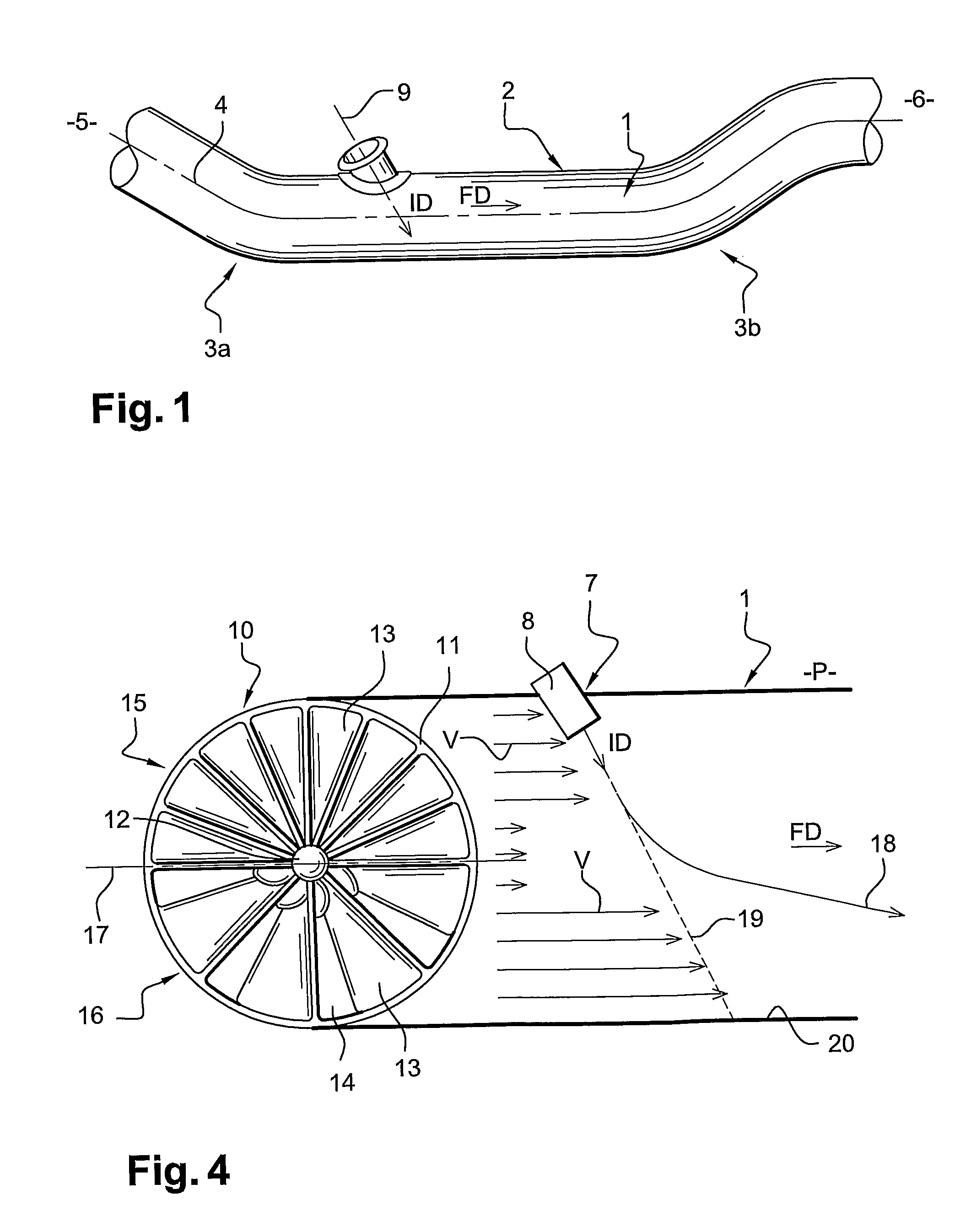

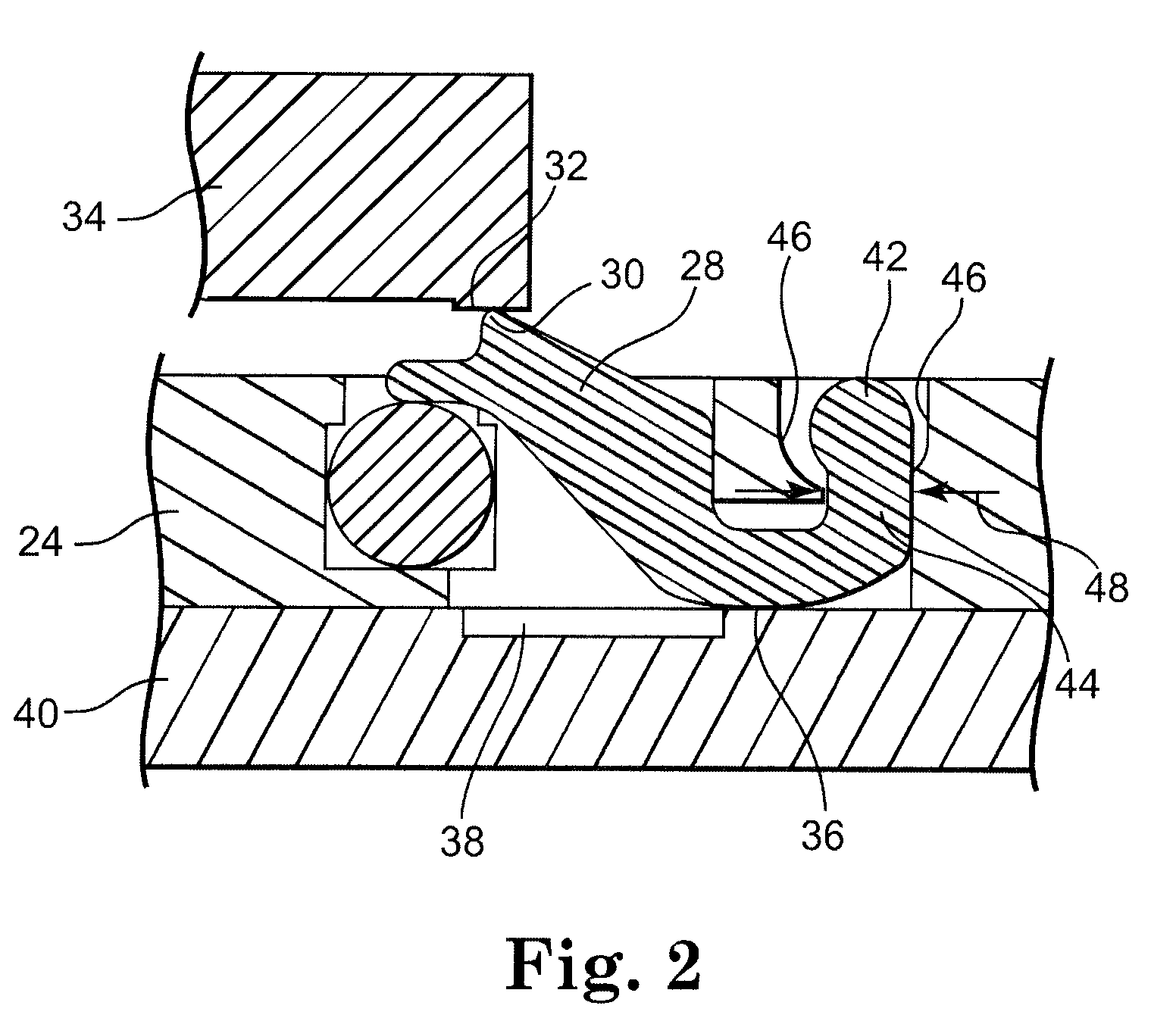

Apparatus and method for intragastric balloon with in situ adjustment means

ActiveUS20080172079A1Good for weight lossEncourage early satietySurgeryDilatorsSurgeryInstrumentation

An intragastric balloon and method of adding and / or removing fluid therefrom are disclosed. The intragastric balloon includes a shell, a grasping tab, and a self-sealing portion. A gastroscopic instrument which includes a grasping tool is inserted into the stomach of a patient and used to grasp the grasping tab located on the surface of the shell. Using the grasping tool, the intragastric balloon is securely fastened to the gastroscopic instrument. A filling instrument, such as a needle, is advanced through the self-sealing portion of the shell for the filling or deflating of the intragastric balloon. After inflation or deflation is complete, the filling instrument is then withdrawn from the balloon and the gastroscopic instrument withdrawn from the stomach.

Owner:APOLLO ENDOSURGERY INC

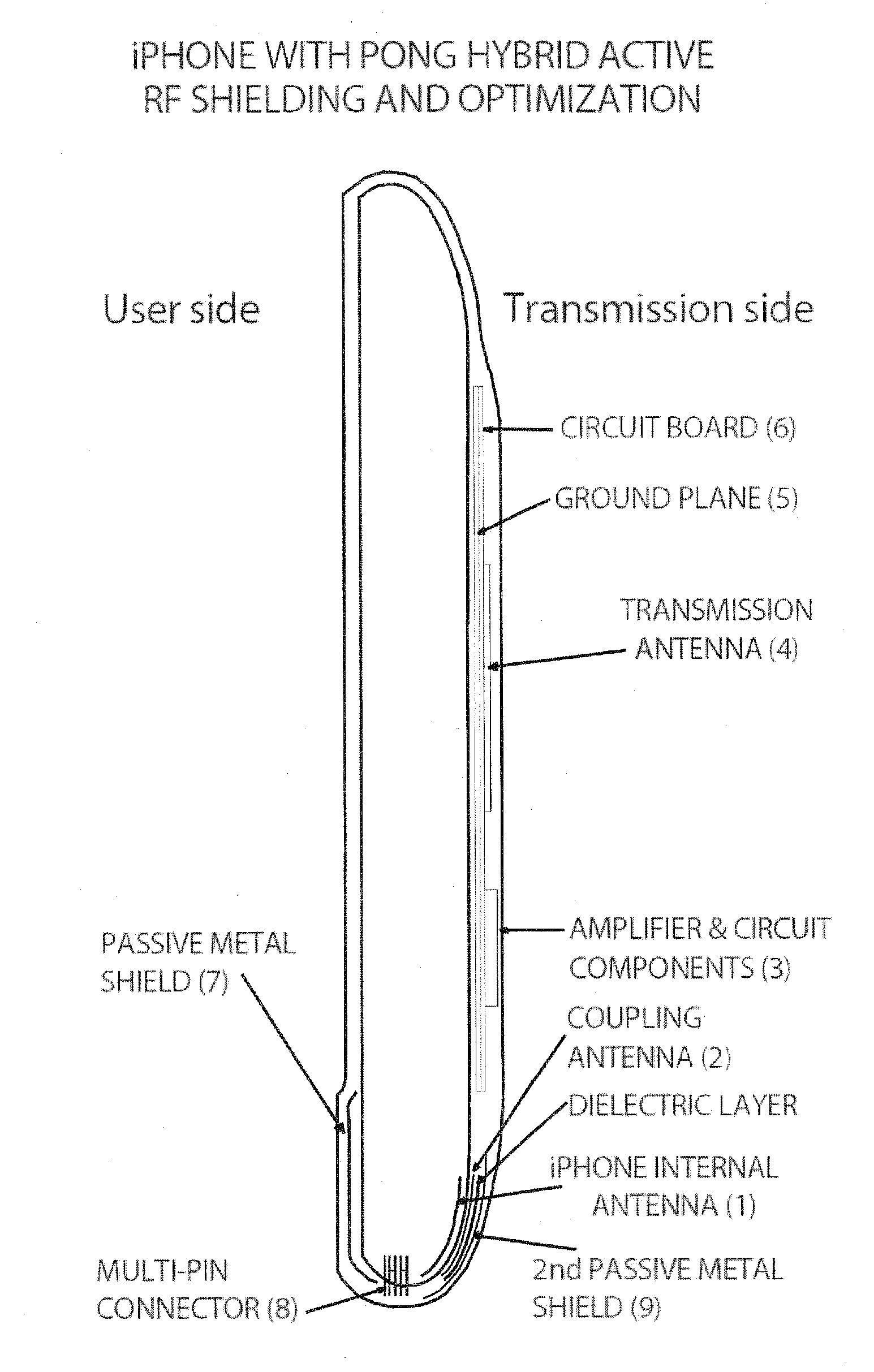

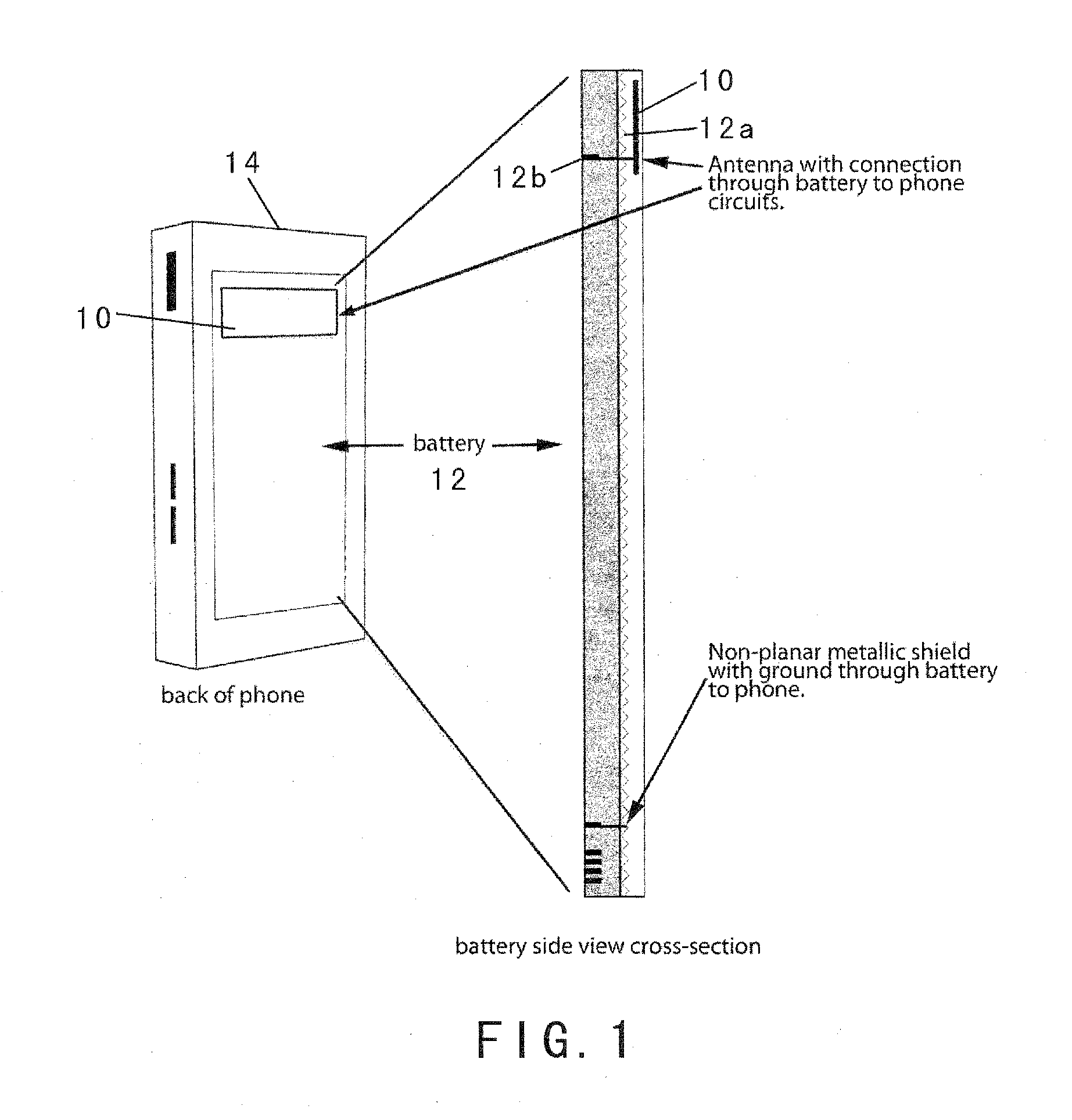

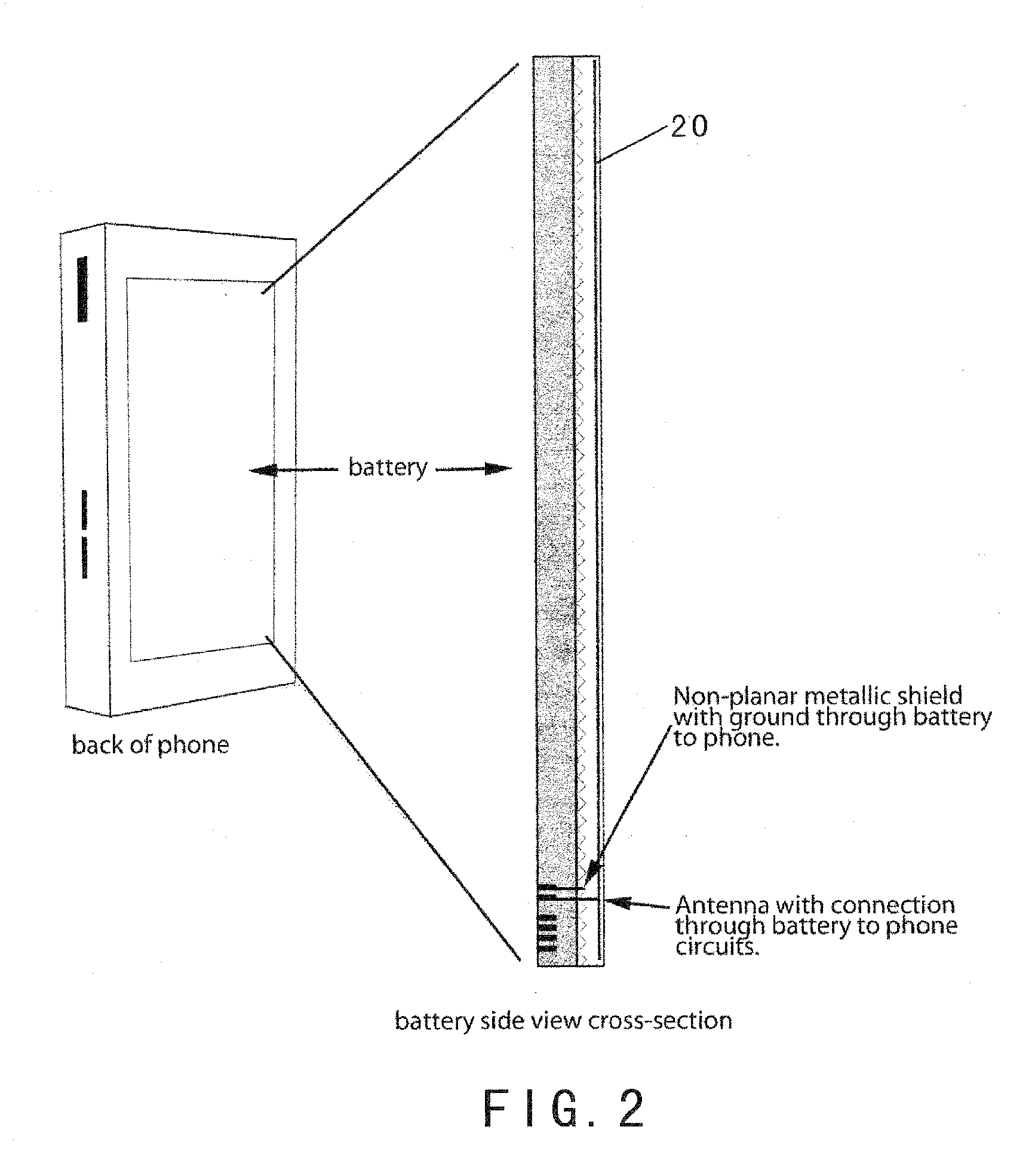

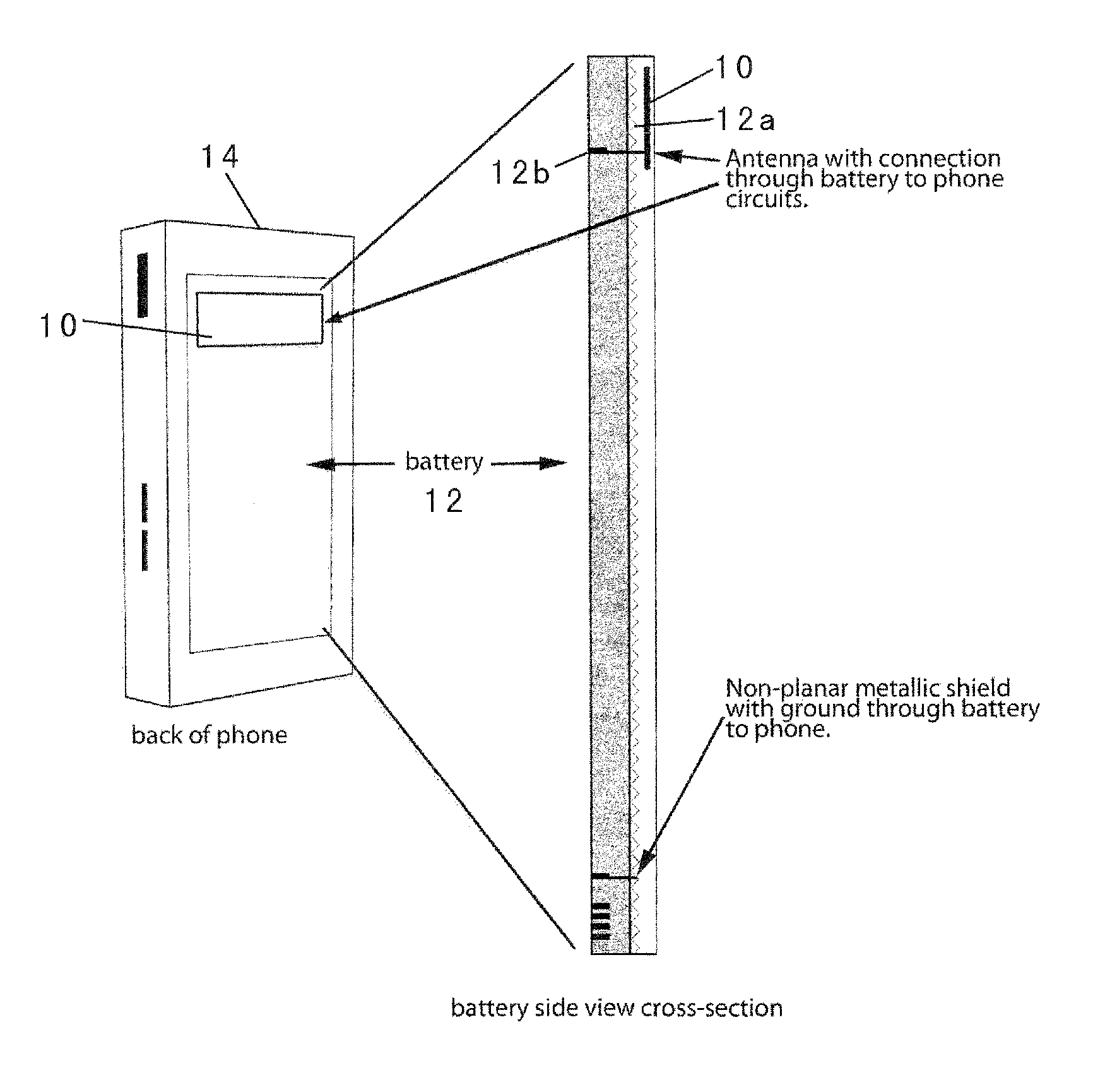

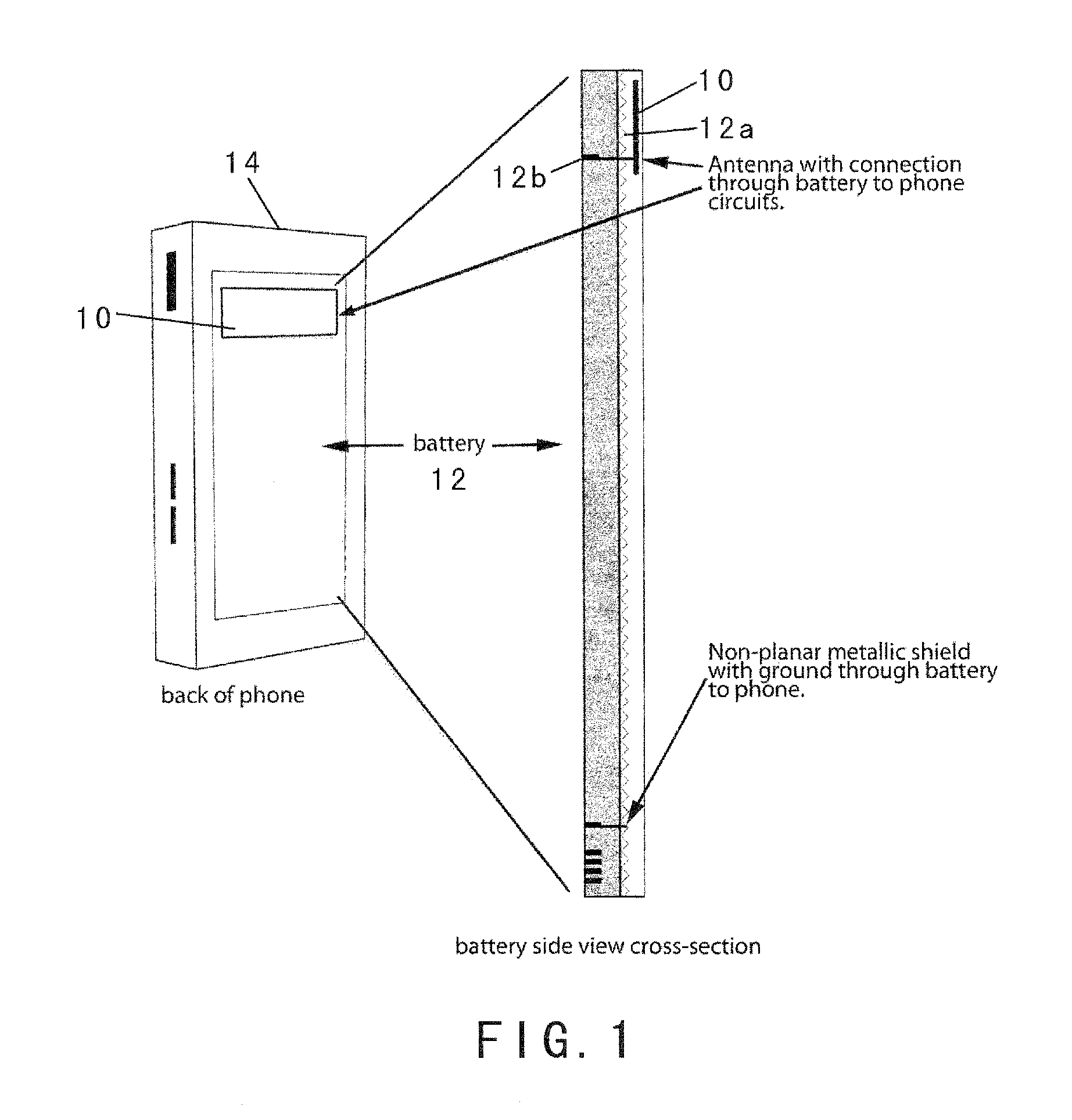

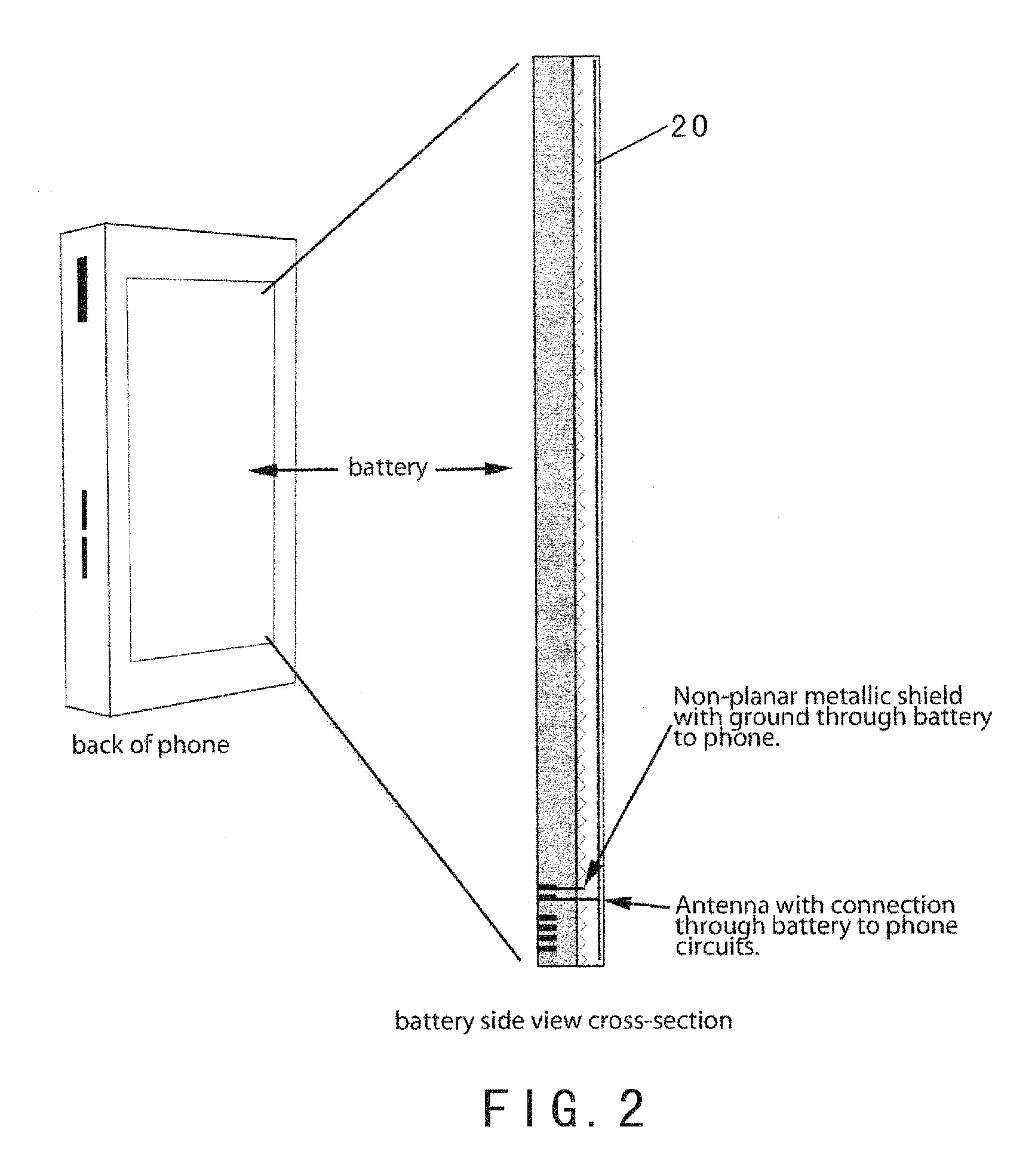

Radiation Redirecting External Case For Portable Communication Device and Antenna Embedded In Battery of Portable Communication Device

ActiveUS20100113111A1Increase effective spaceEffective redirectingSimultaneous aerial operationsMagnetic/electric field screeningAntenna designMulti band

An advanced antenna or set of antennae for a wireless device is provided by embedding the antennae into the battery case or generally the largest surface area of a wireless phone. The antenna connections are made through the battery's connections to the wireless device. The antenna design can be compact and located in any area of the battery. The antenna design can be thin and flat, located at the back surface of the battery or the large rear surface of a wireless phone, facing away from the user. An RF shielding device can be embedded into the battery and configured in relation to the antenna such that the RF field intensity and the consequent specific absorption rate for the user is lowered while the outgoing signals of the wireless device remain fully adequate for the function of the wireless device. This feature is preserved for a multi-band operation because a digital phase shifter is used between two radiating antennae. An external case is used as a complement to the wireless phone to provide additional antennae, power and capability.

Owner:PENUMBRA BRANDS LLC

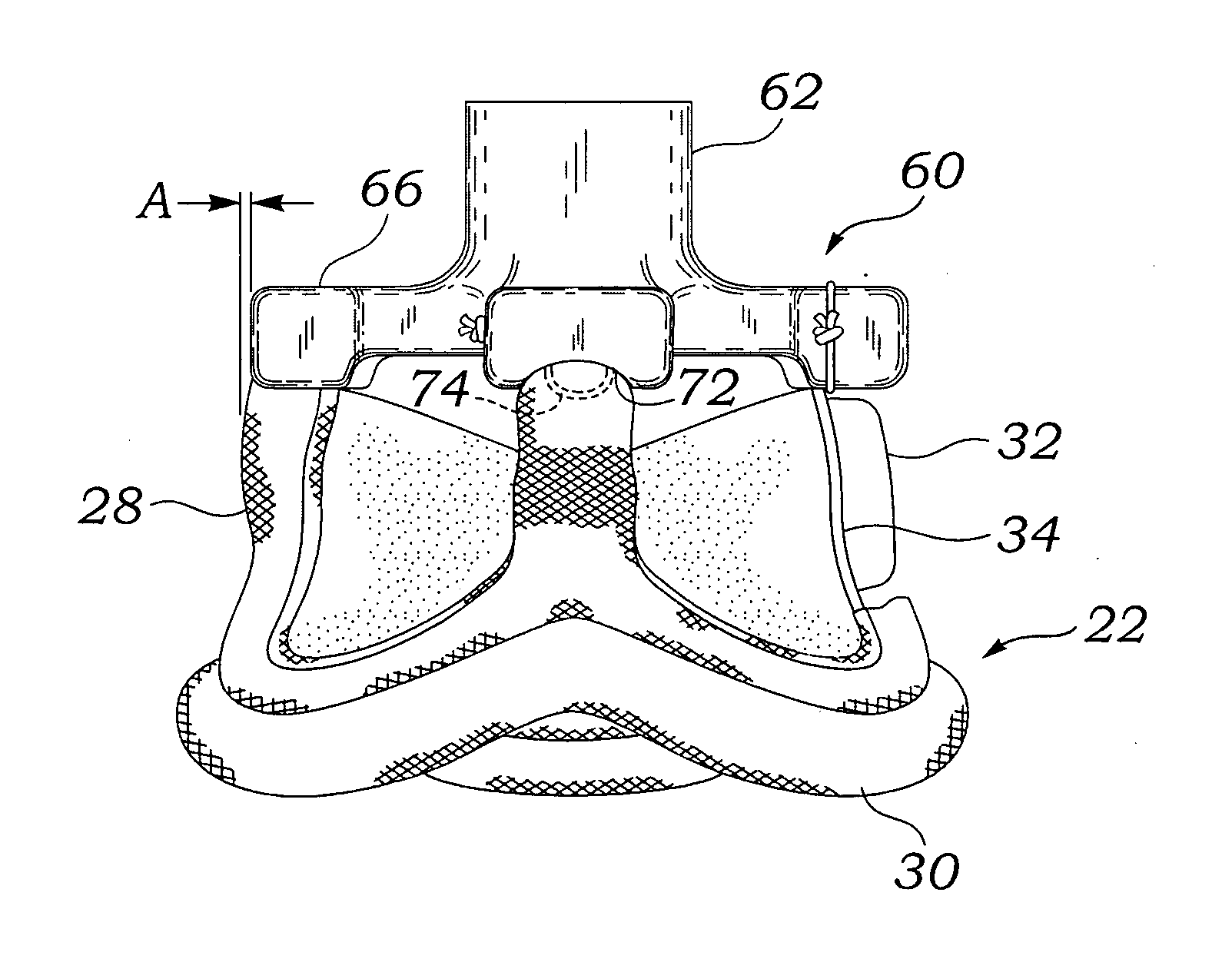

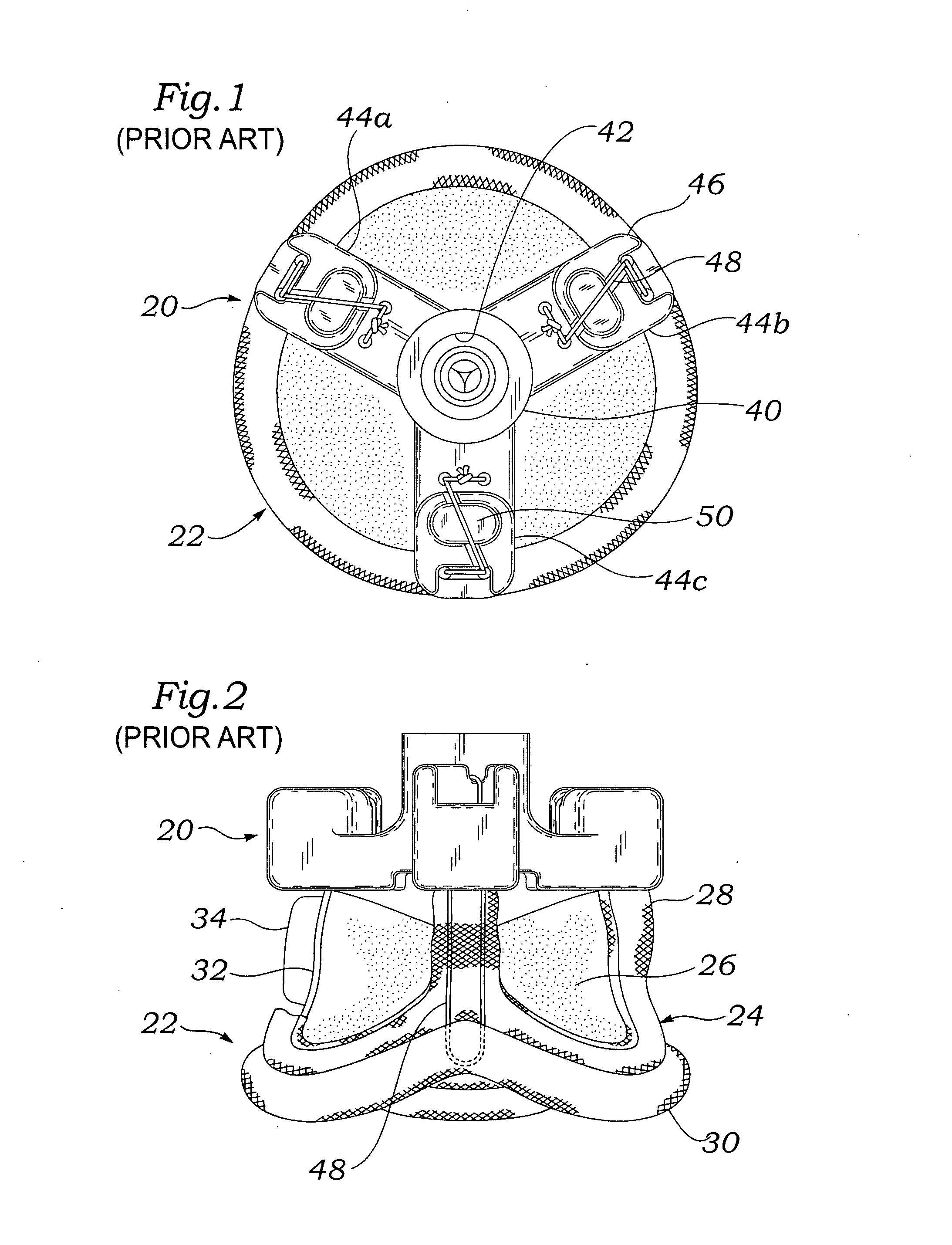

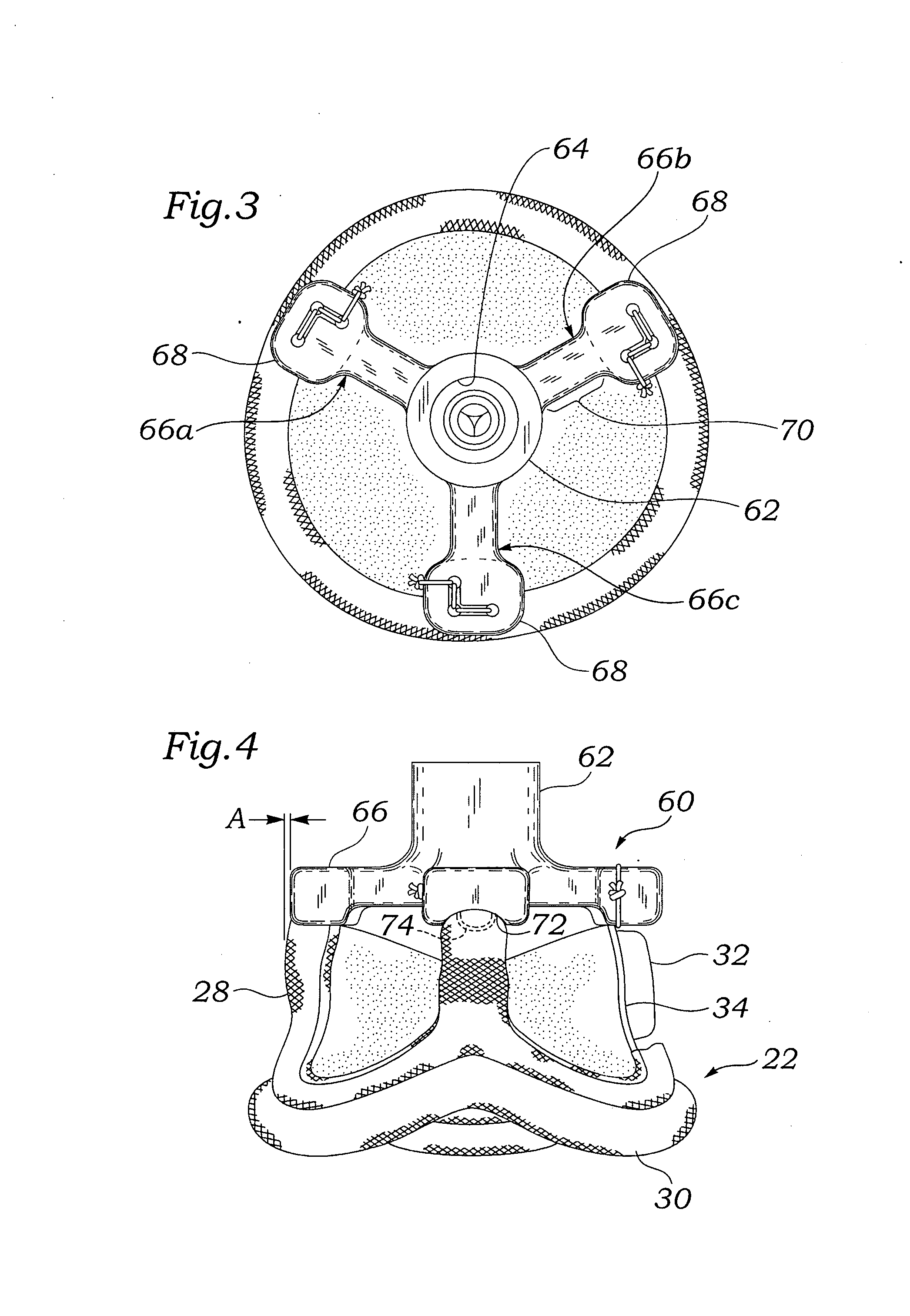

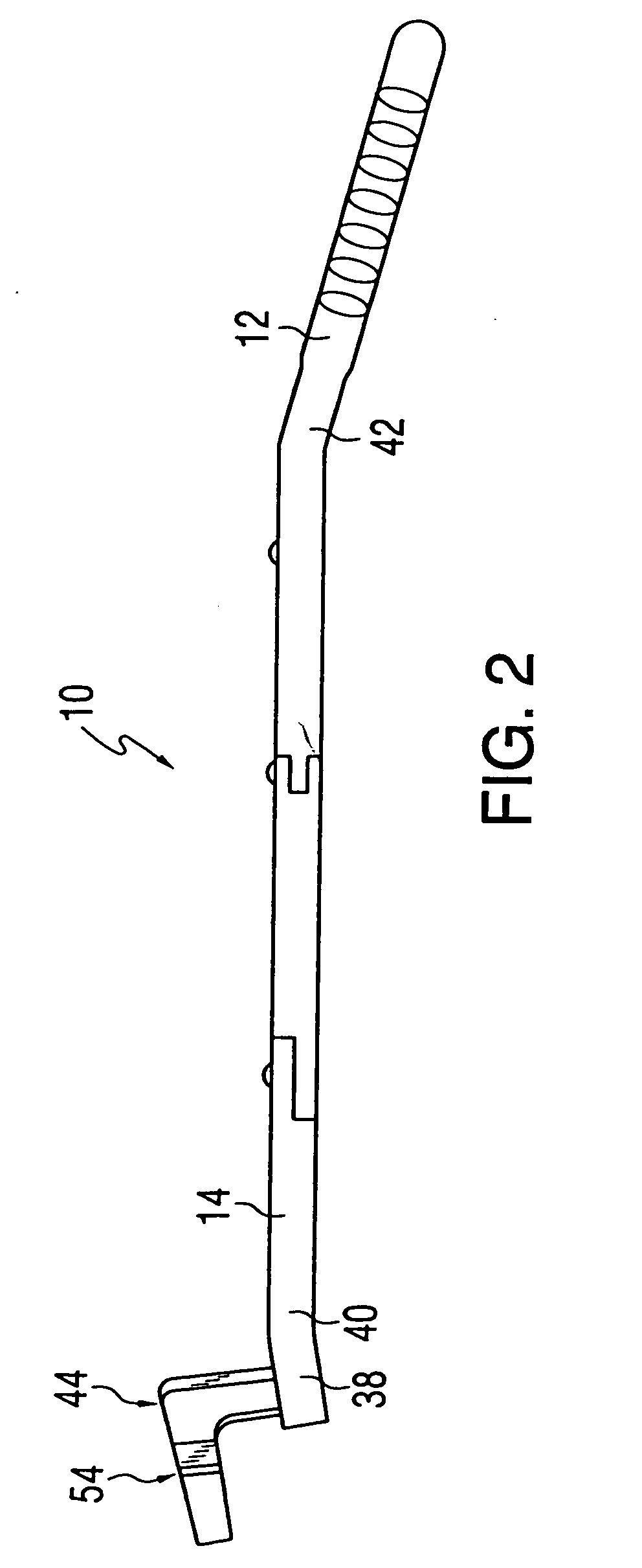

Holders for prosthetic aortic heart valves

A holder for a flexible leaflet prosthetic aortic heart valve that is less bulky than earlier holders and minimizes obstructions to vision and working space around the valve to facilitate implantation thereof. The holder may have a central hub and three outwardly extending legs that connect directly and exclusively to tips of the commissures of the aortic heart valve for better tactile feedback when parachuting and seating the valve in the annulus. The legs are sized so that they do not overlap the commissure tips and therefore afford a better view of the sewing ring adjacent the commissures. The legs may be narrow in the midsection or split into two rails to increase visibility of the valve leaflets. The hub may be vaulted axially upward relative to the outer ends of the legs to further increase visibility of the valve. A more secure engagement between the central hub and a delivery handle is also provided to ensure the holder / handle connection does not become loose during suture placement through the sewing ring and fewer handle revolutions are required to screw in and unscrew the handle from the holder.

Owner:EDWARDS LIFESCIENCES CORP

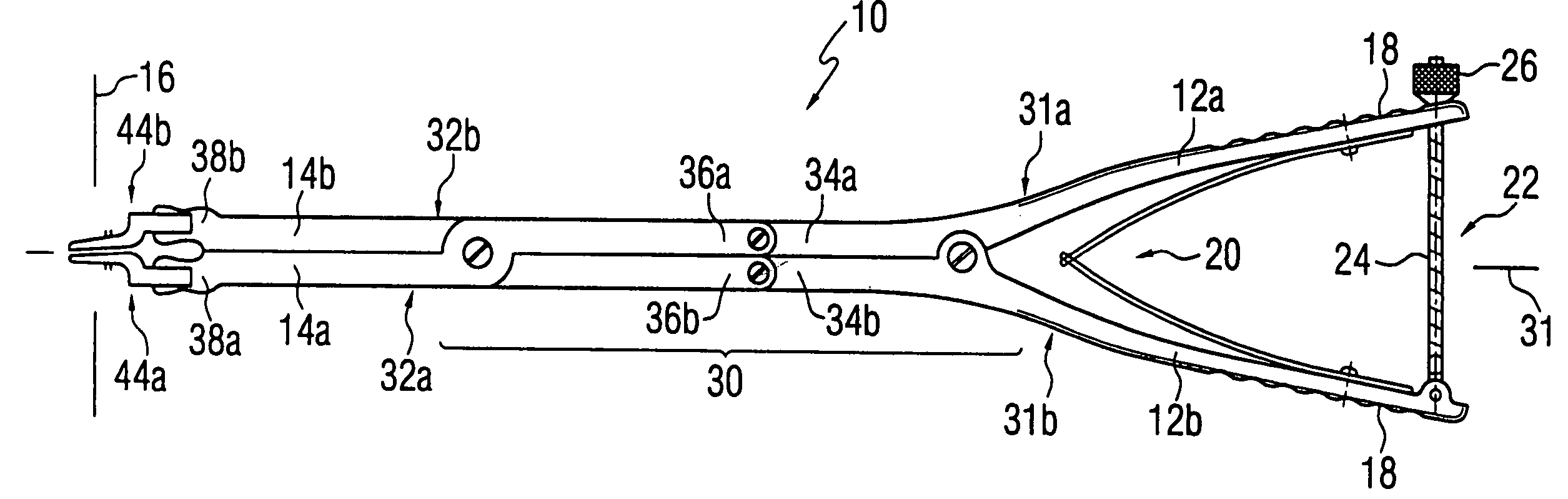

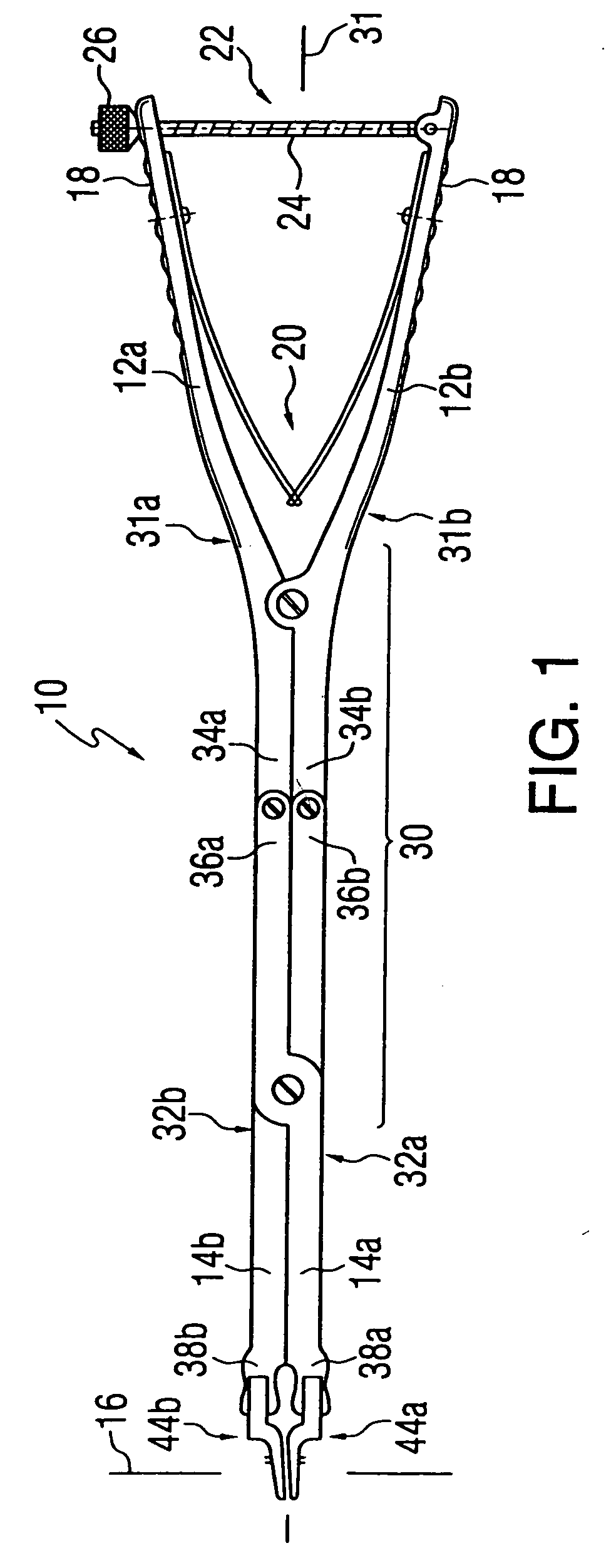

Spinal disc space distractor

InactiveUS20050177173A1Improve stabilityAccurate placementBone implantJoint implantsBiomedical engineeringDisc space

A distractor for separating adjacent elements, such as vertebrae. The distractor preferably has a scissors-type distracting mechanism, either in a simple scissors or double-acting scissors configuration. A set of blades is provided on each jaw such that an implant may be inserted between the spaced apart blades. The set of blades includes at least two blades.

Owner:DEPUY SYNTHES PROD INC

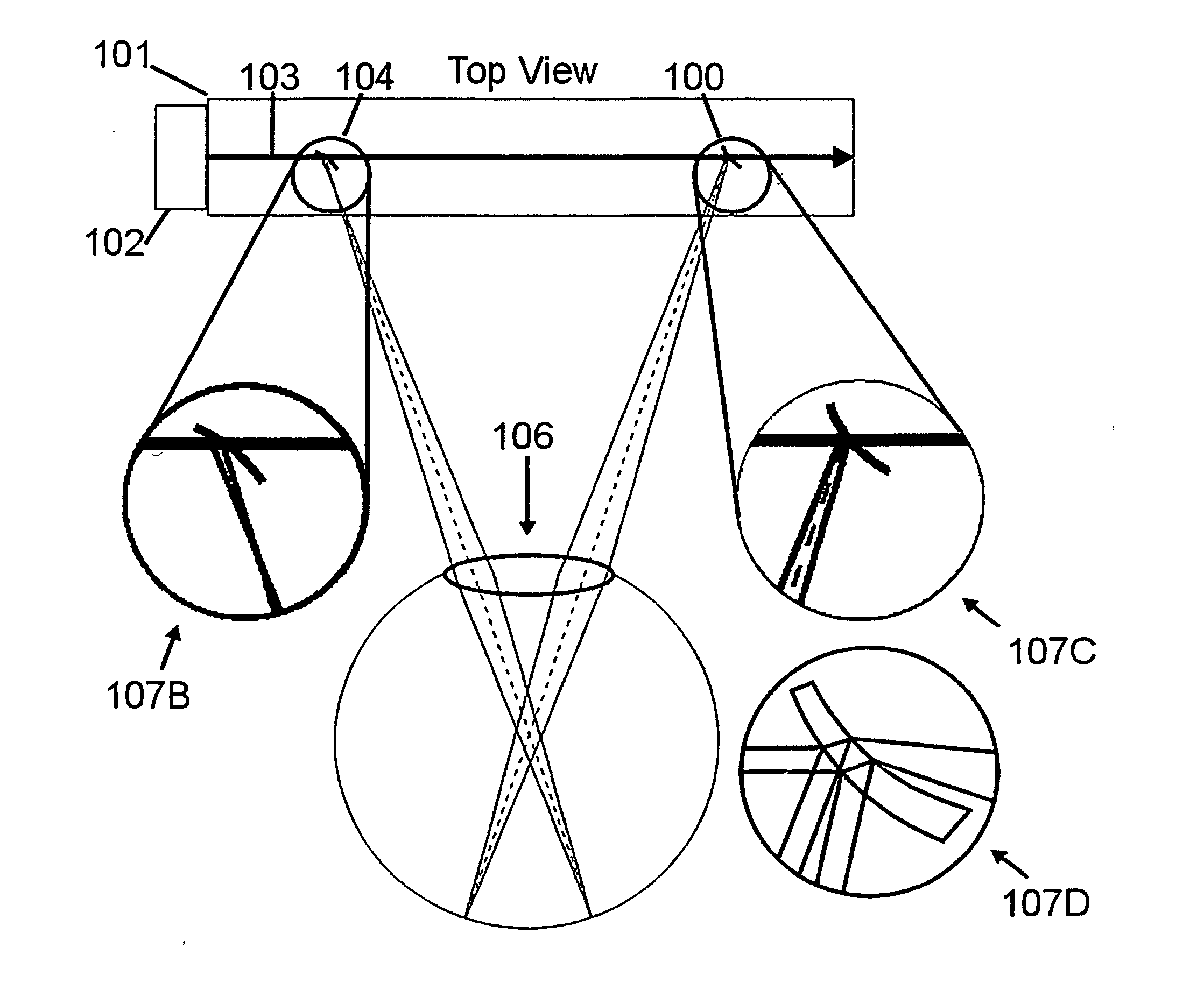

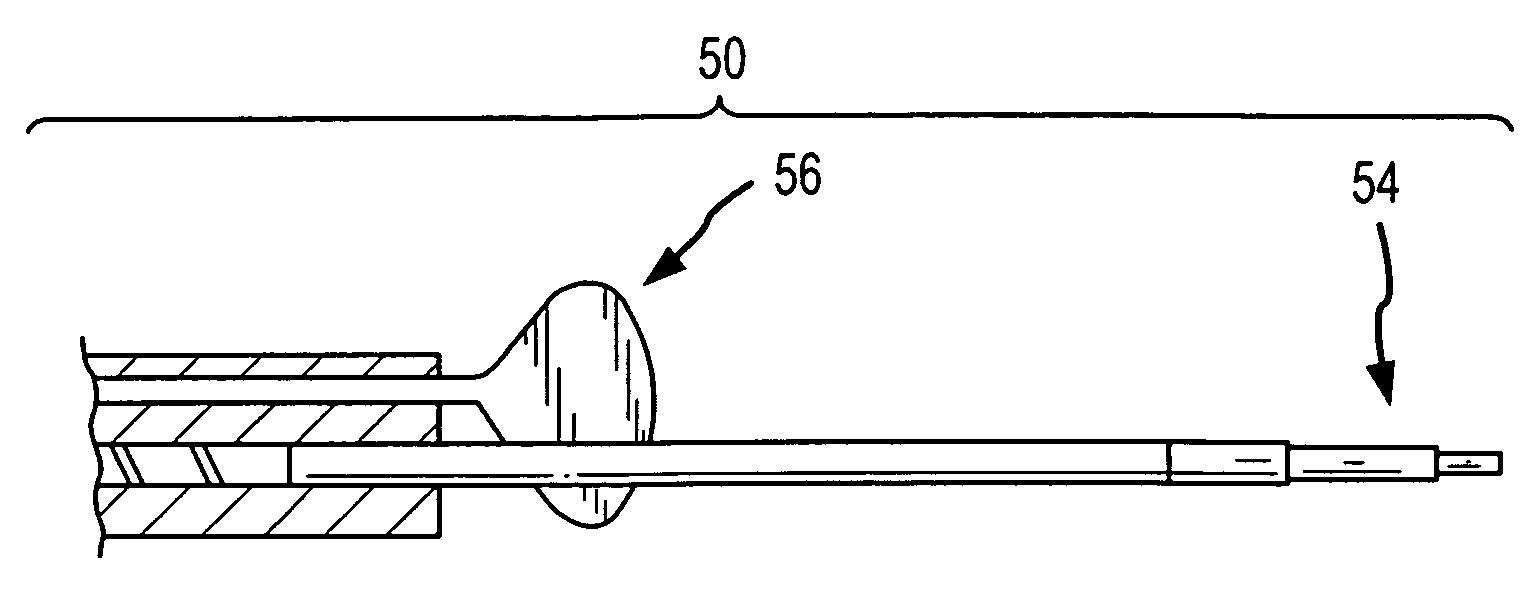

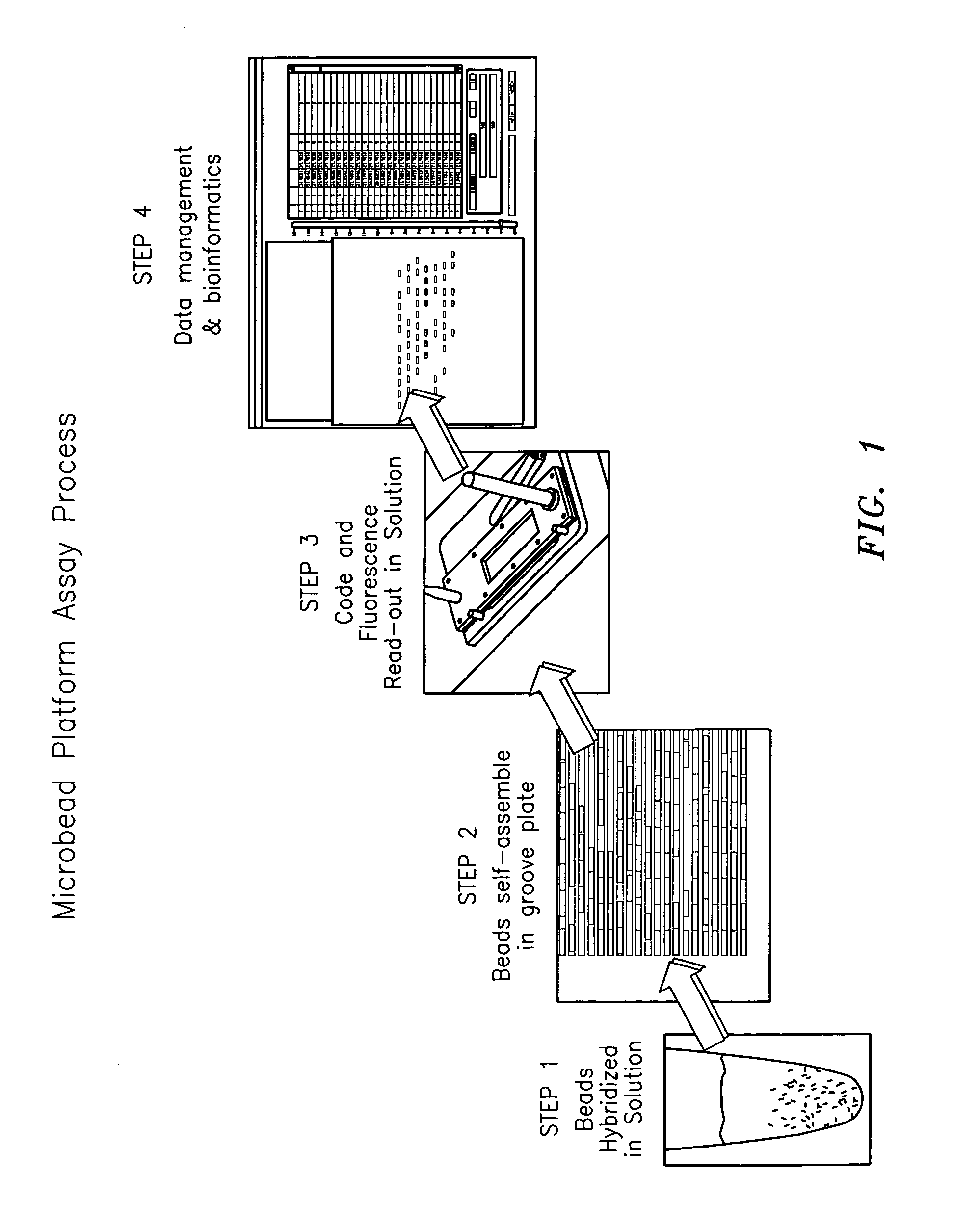

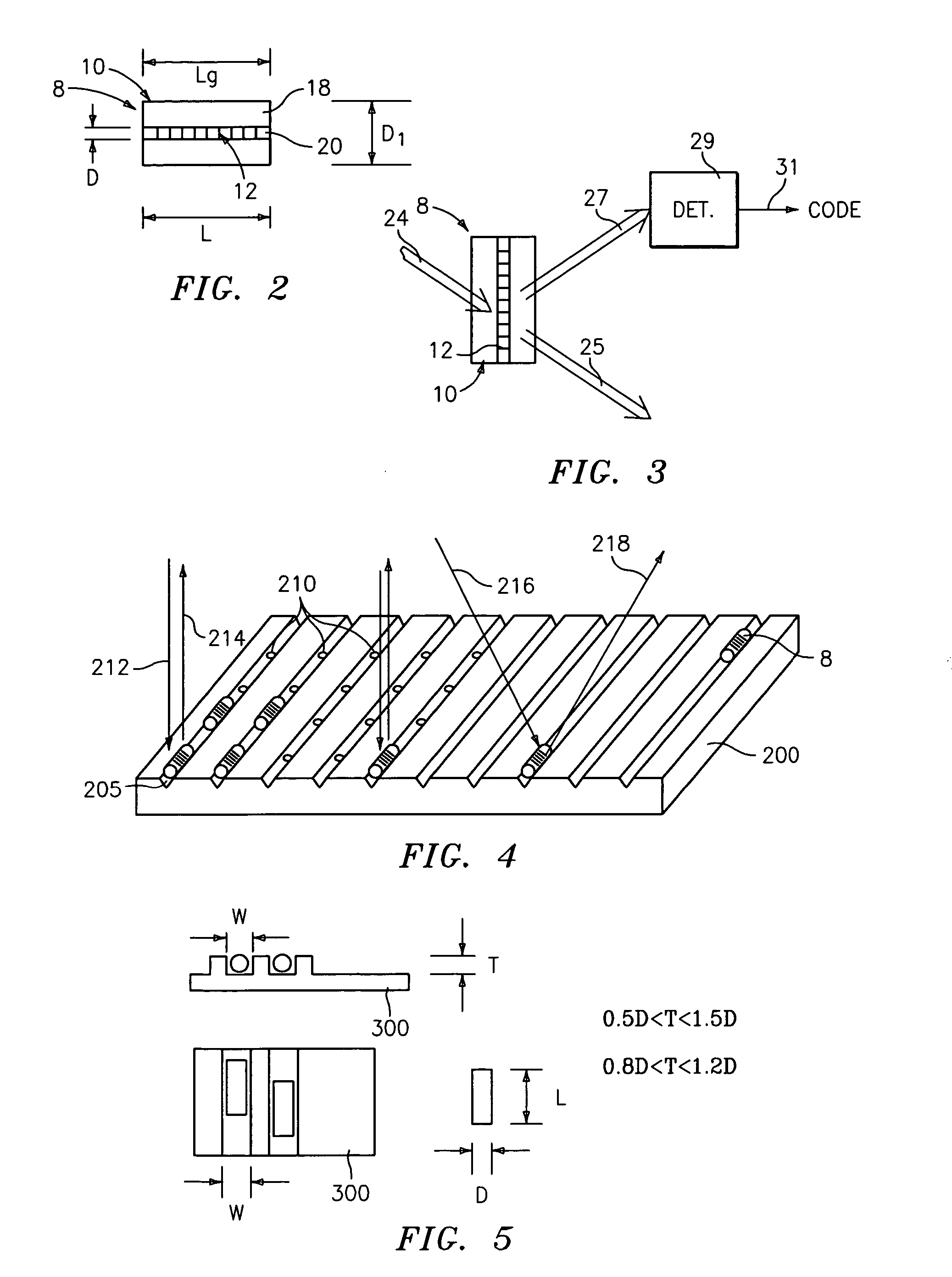

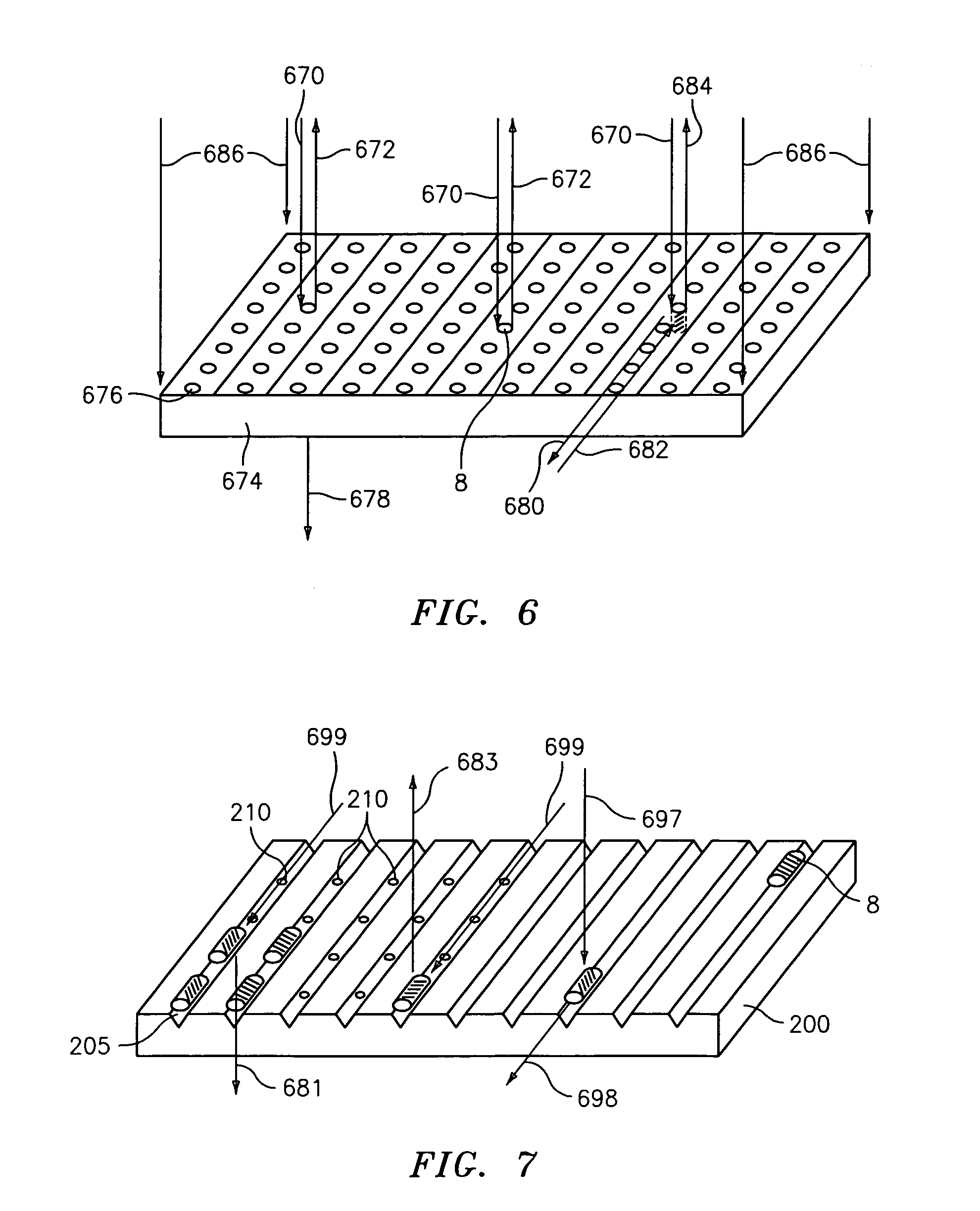

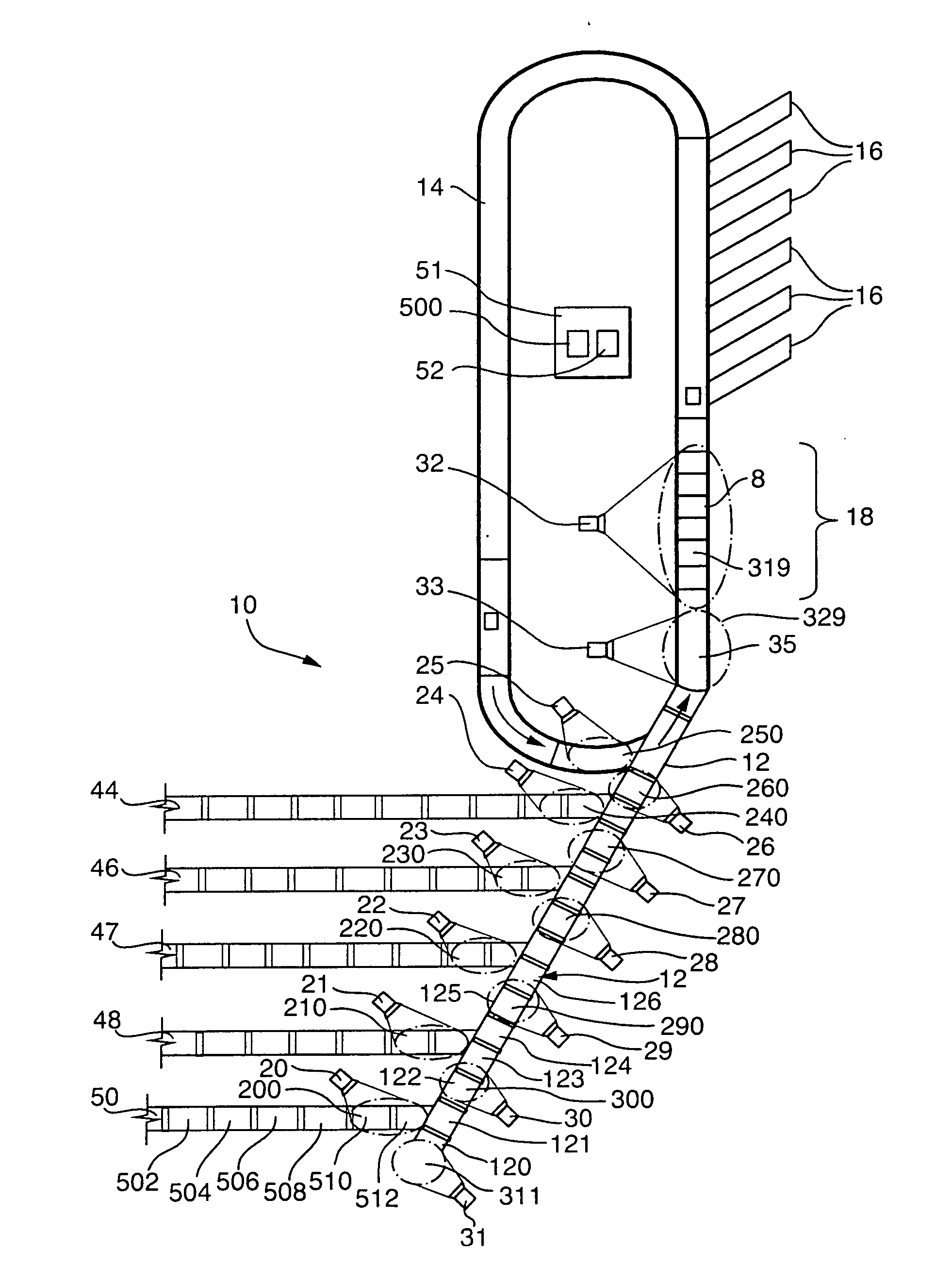

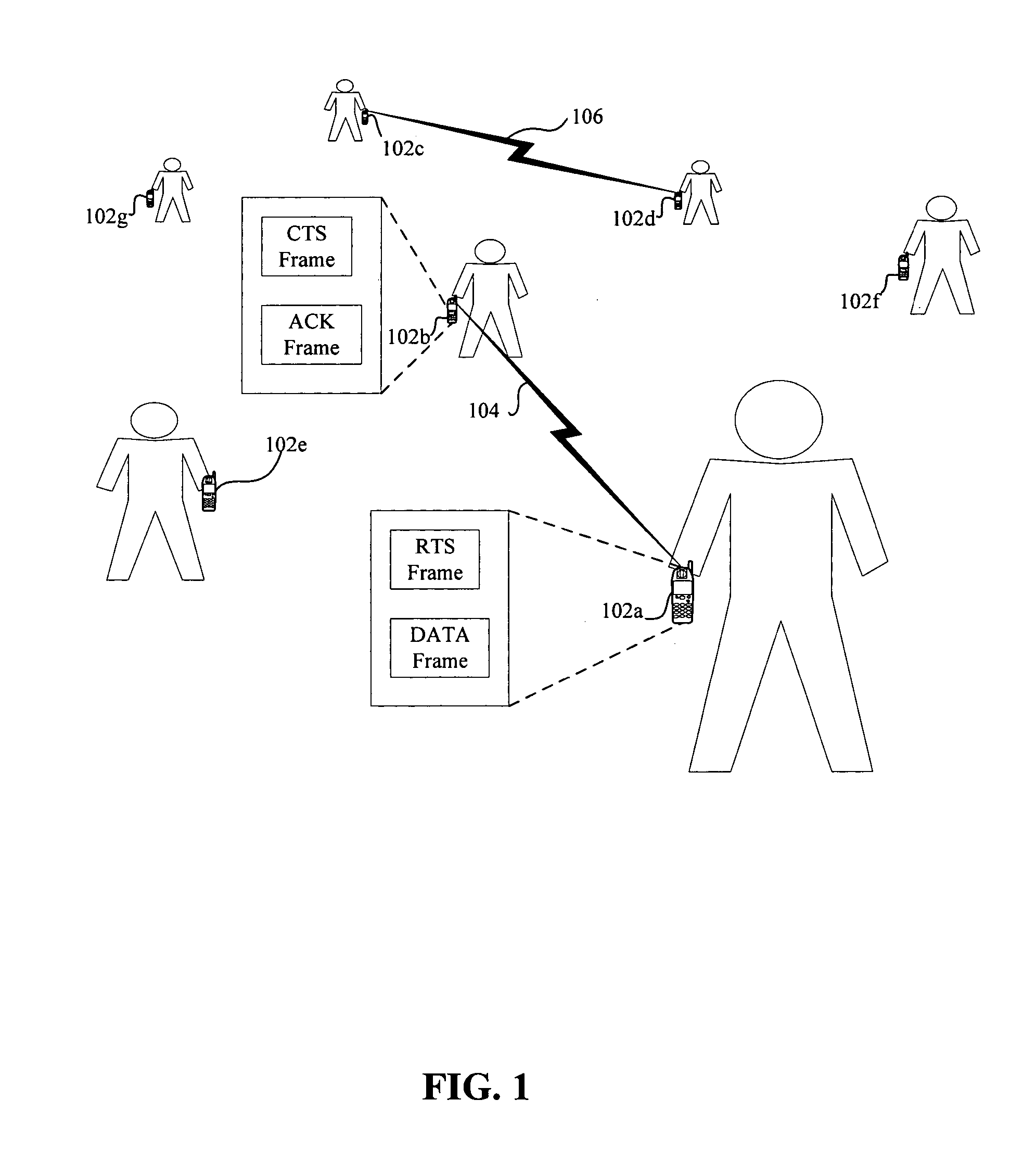

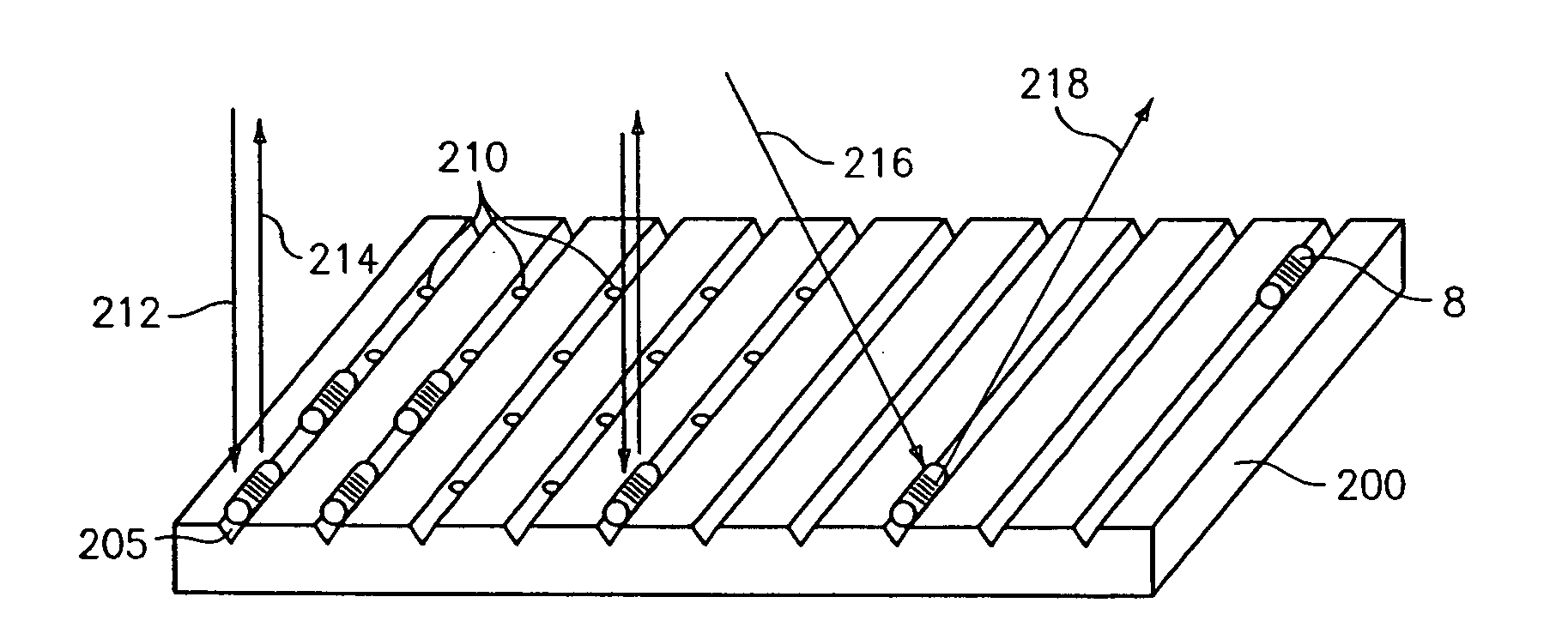

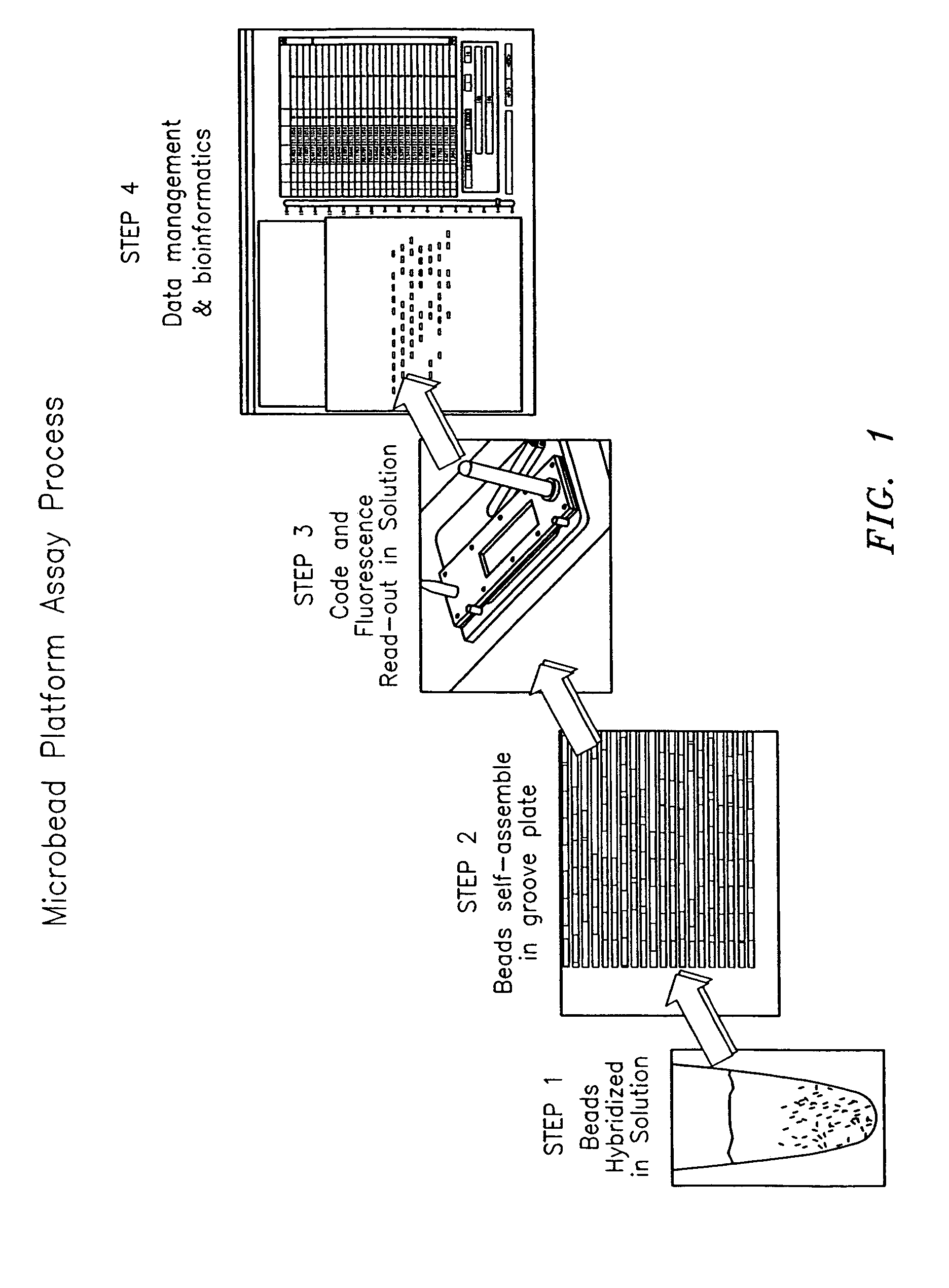

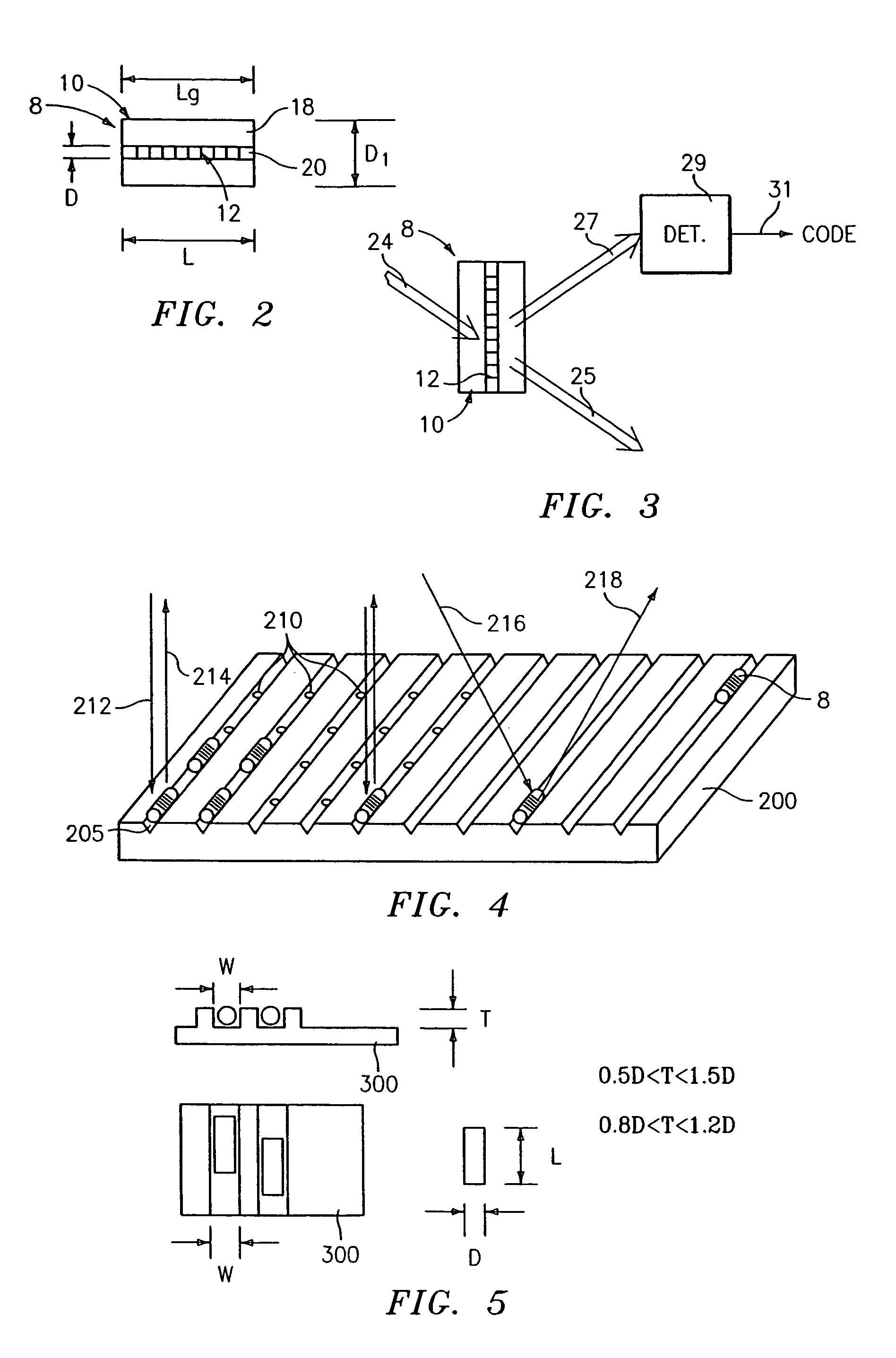

Method and apparatus for aligning microbeads in order to interrogate the same

InactiveUS20060063271A1Fast readoutQuick alignmentSamplingLaboratory glasswaresRotational axisEngineering

A method and apparatus are provided for aligning optical elements or microbeads 8, wherein each microbead has an elongated body with a code embedded therein along a longitudinal axis thereof to be read by a code reading device. The microbeads 8 are aligned with a positioning device (or cell) 500 having a plate or platform 200, 1252 with grooves 205, 1258 so the longitudinal axis of the microbeads is positioned in a fixed orientation relative to the code reading device. The microbeads 8 are typically cylindrically shaped glass beads having a diffraction grating-based code embedded in the bead 8 disposed along an axis, which requires a predetermined alignment between the incident code readout laser beam and the code readout detector in two of three rotational axes. The geometry of the grooves 205 are designed to allow for easy loading and unloading of beads from a cell, and the grooves 205 may be straight or curved. Also, the cell may be segmented into regions each associated with a different reaction or used for a different identification process / application, and may have many different geometries depending on the application.

Owner:ILLUMINA INC

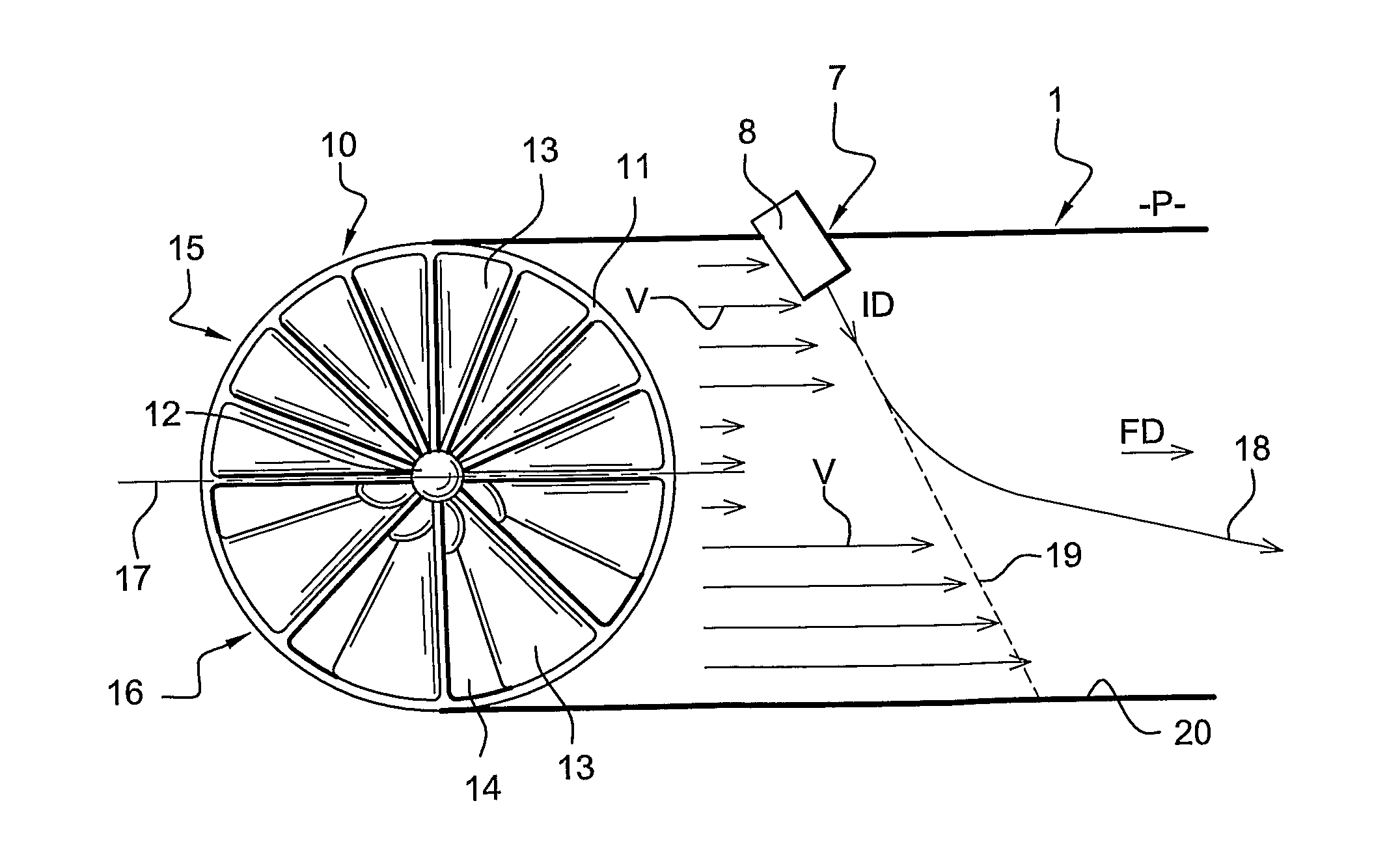

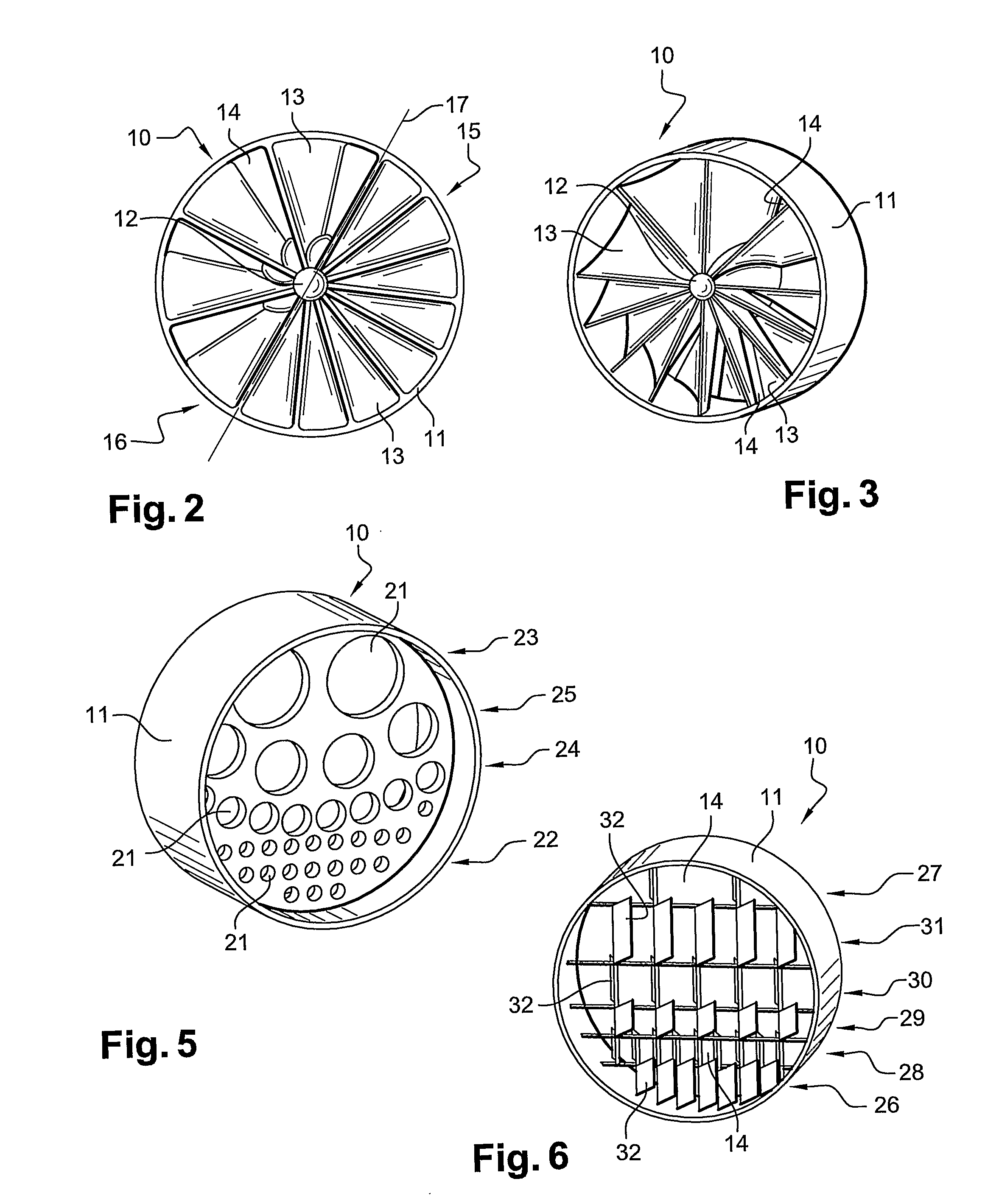

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

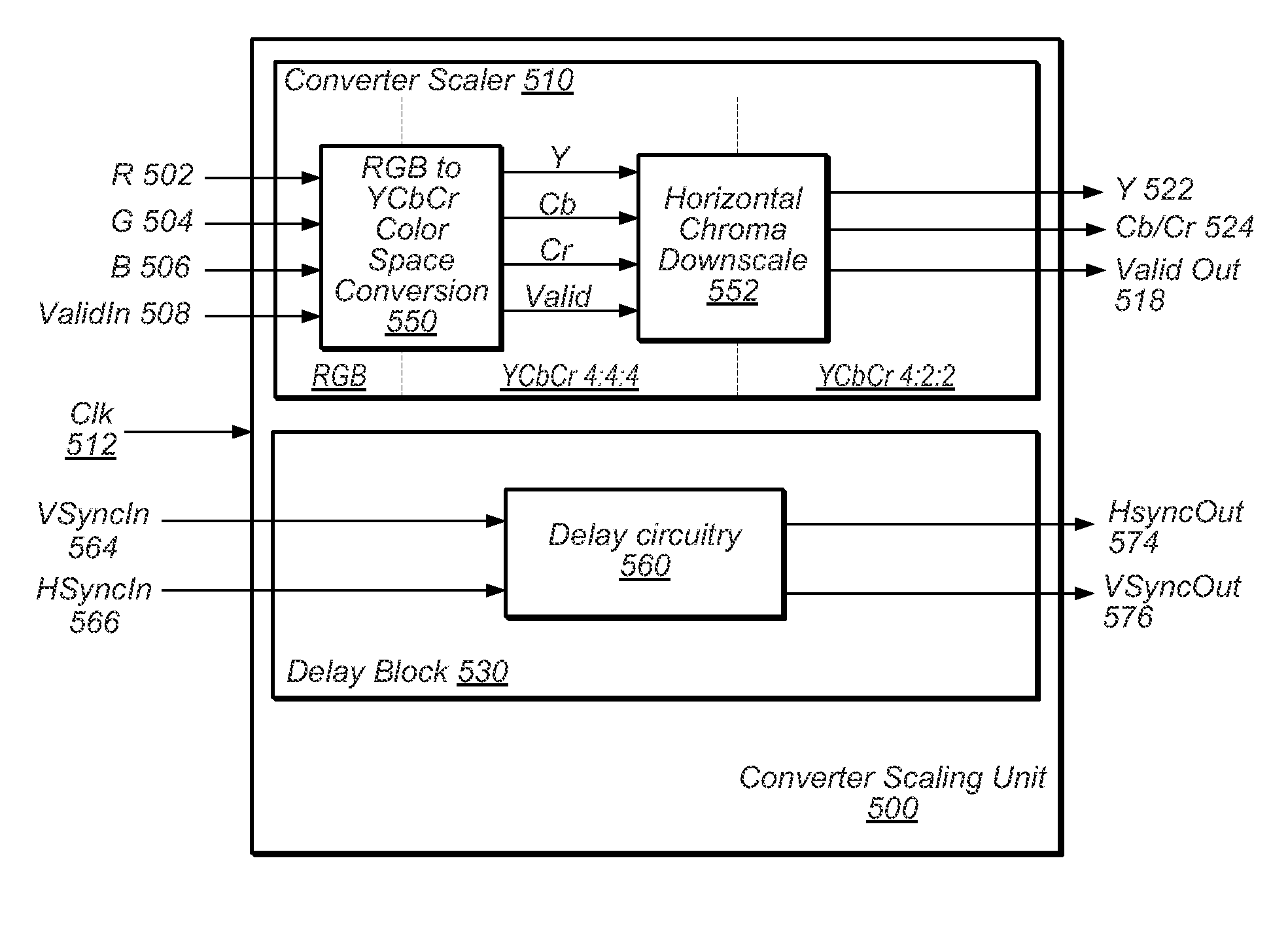

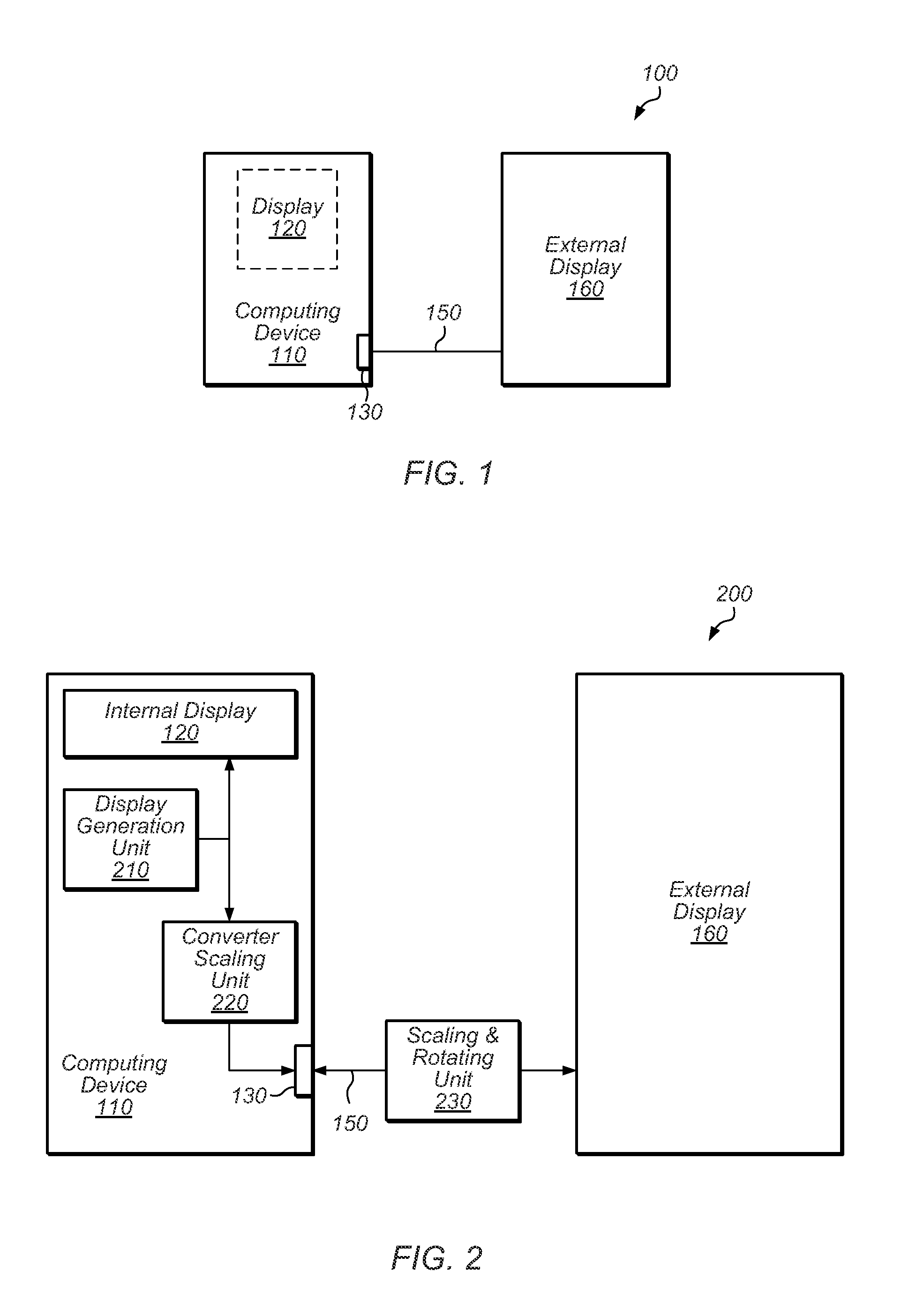

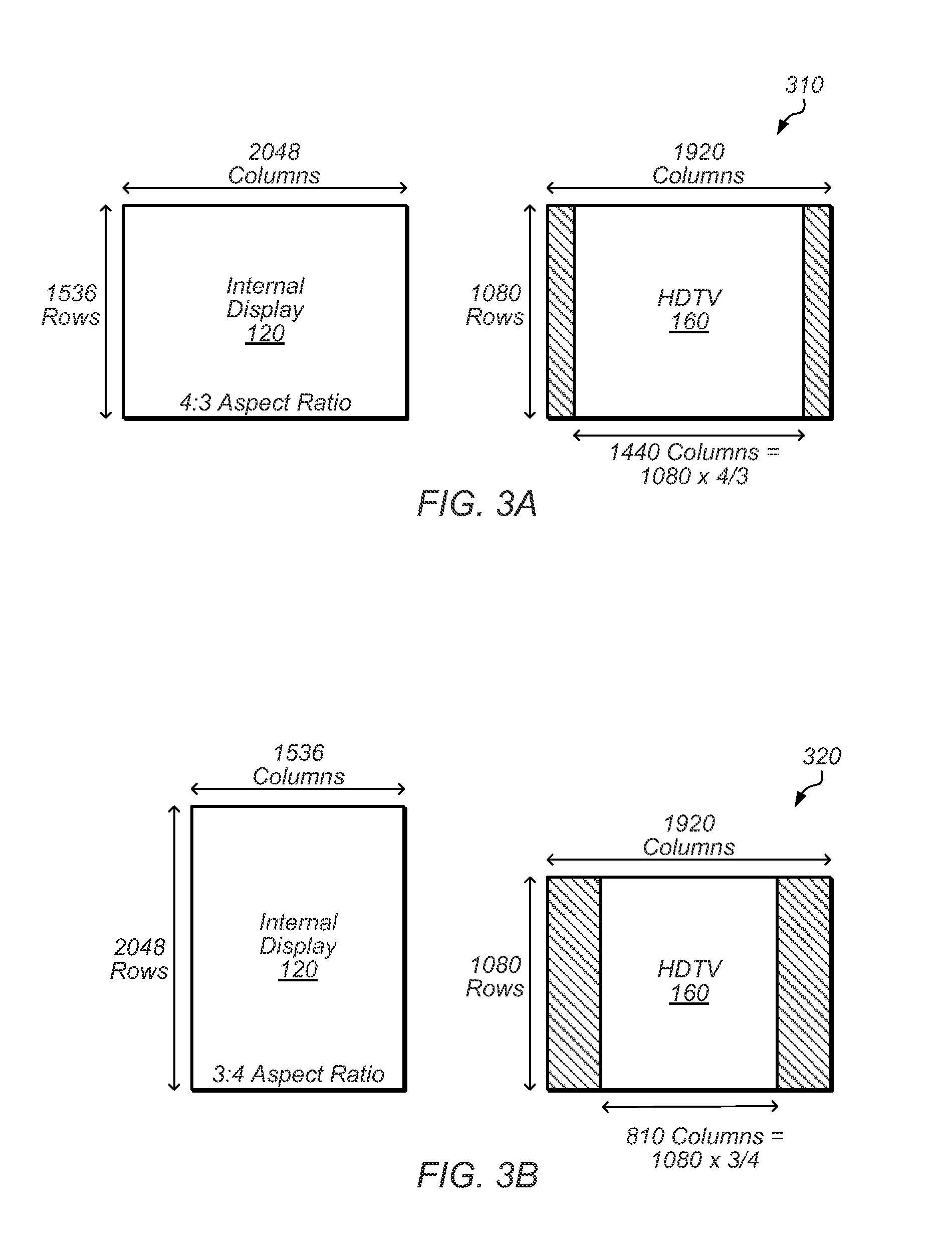

Color Space Conversion for Mirror Mode

InactiveUS20130057567A1Less resolutionLow acuityCathode-ray tube indicatorsInput/output processes for data processingAspect ratioImage resolution

The same pixel stream may be displayed on an internal display and an external display while maintaining the original aspect ratio corresponding to the internal display dimensions. A connector with limited number of pins may only support a two-wire display port interface to the external display, which may not provide enough bandwidth to transmit the full resolution image to the external display. To transmit the full resolution image, a color space conversion from RGB space to YCbCr color space may be performed. The Luma component may be transmitted at full resolution, while the chroma components may be scaled. Accordingly, there is no loss of image resolution, while some amount of color resolution may be lost. However, there is no need to retime frames within the system on chip (SOC), and the same pixel stream may be used as the basis for display on both the internal and the external display.

Owner:APPLE INC

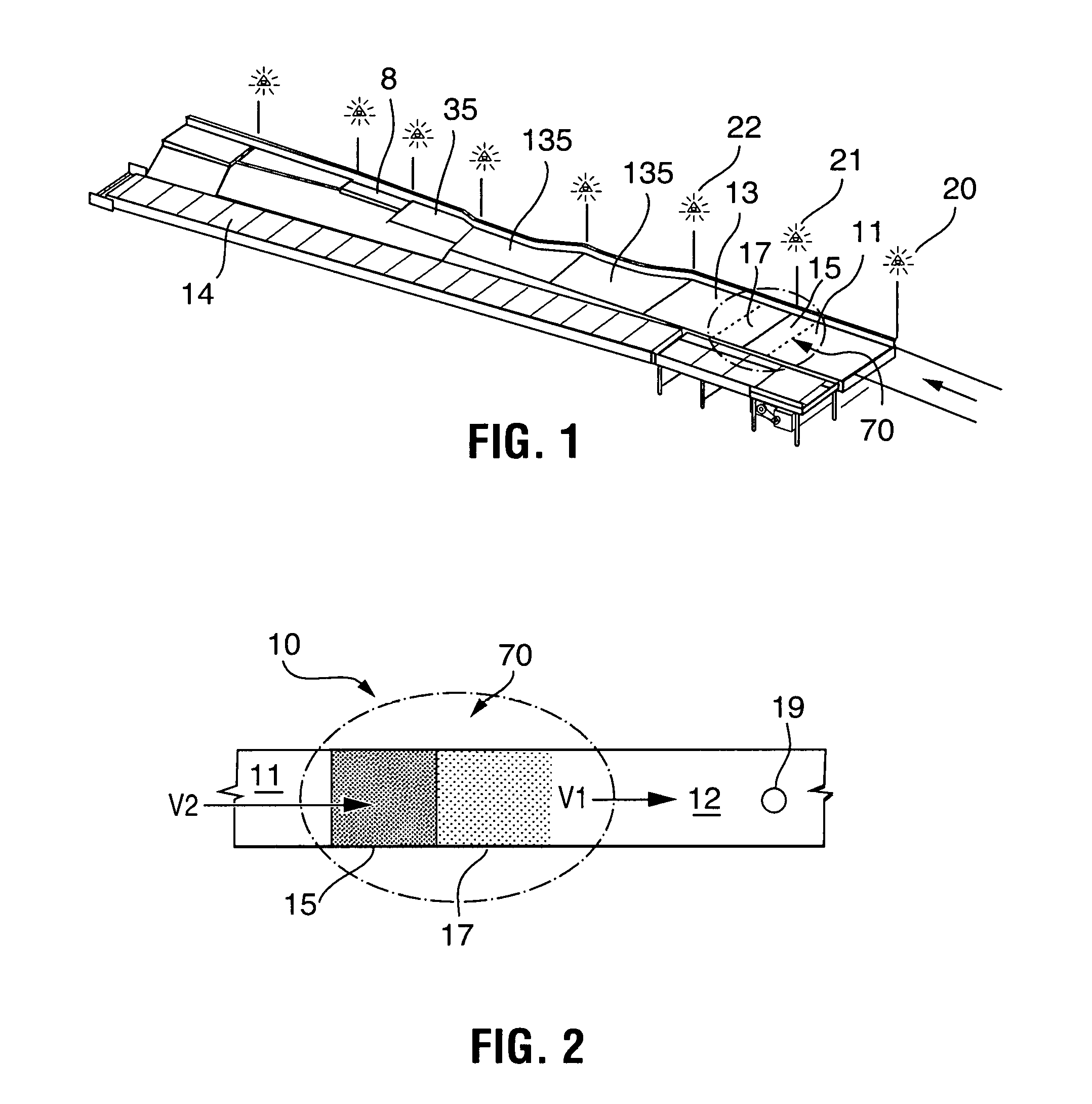

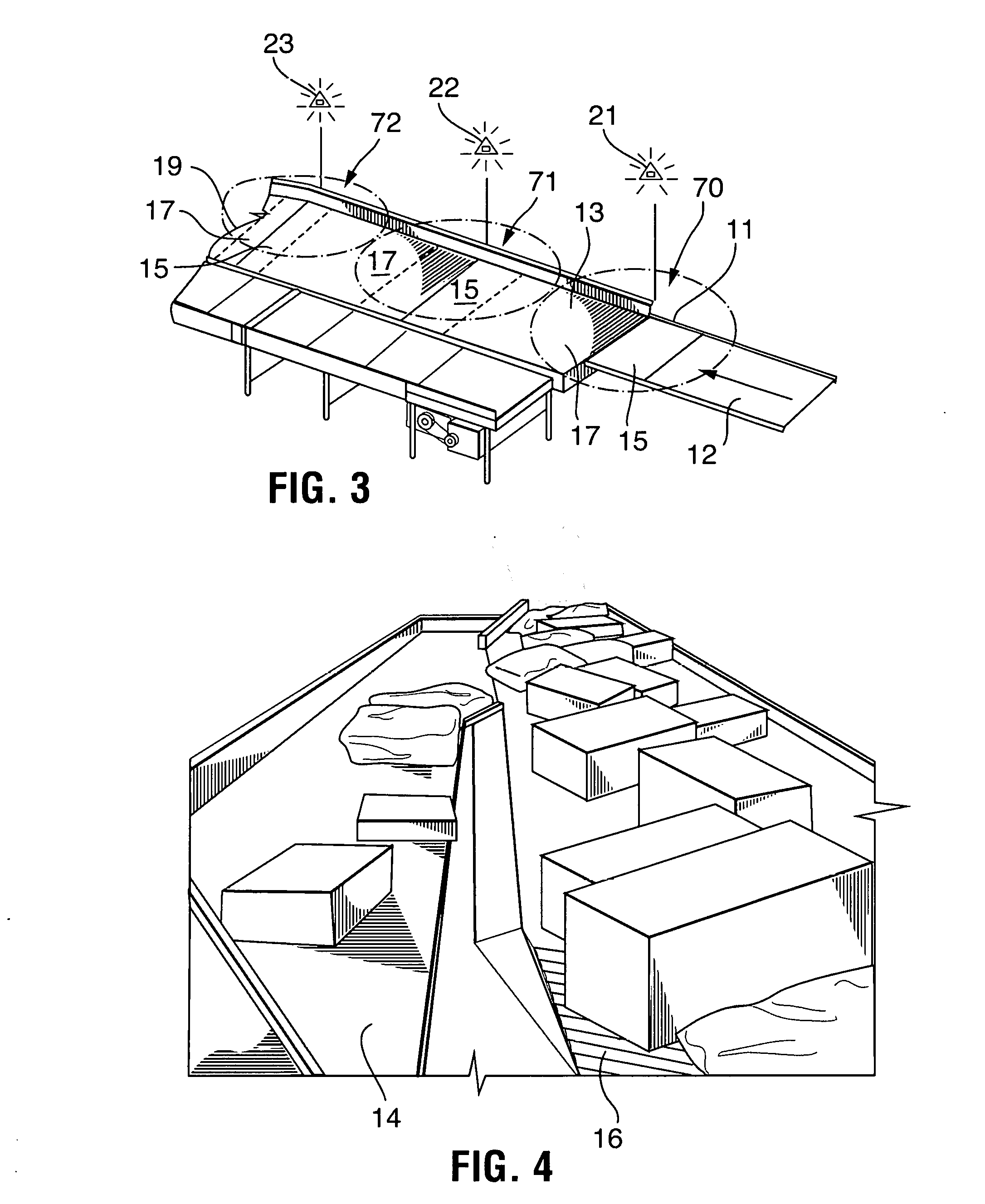

Vision based conveyor package flow management system

ActiveUS20160221762A1Improve efficiencyMaximize packing densityConveyorsControl devices for conveyorsIndividual itemEntry point

A camera based vision system that recognizes and maximizes belt area utilization. A plurality of cameras are positioned at flow entry points of feed conveyors and at the singulator. The control algorithm recognizes individual items area, the rate at which individual objects are passing, and the area utilization of the collector belt. The video camera and computer based conveyor package management system monitor and control the number and size of the packages present on the infeed conveyors, collector conveyor, singulator conveyor and sorting conveyor in a package handling system wherein the camera data is used to measure the available area or space on the conveyors to maintain a desired density of packages on selected conveyor(s). The conveyor speed is controlled as a function of occupancy on a collector or just prior to a singulator or receiver.

Owner:FIVES INTRALOGISTICS SA

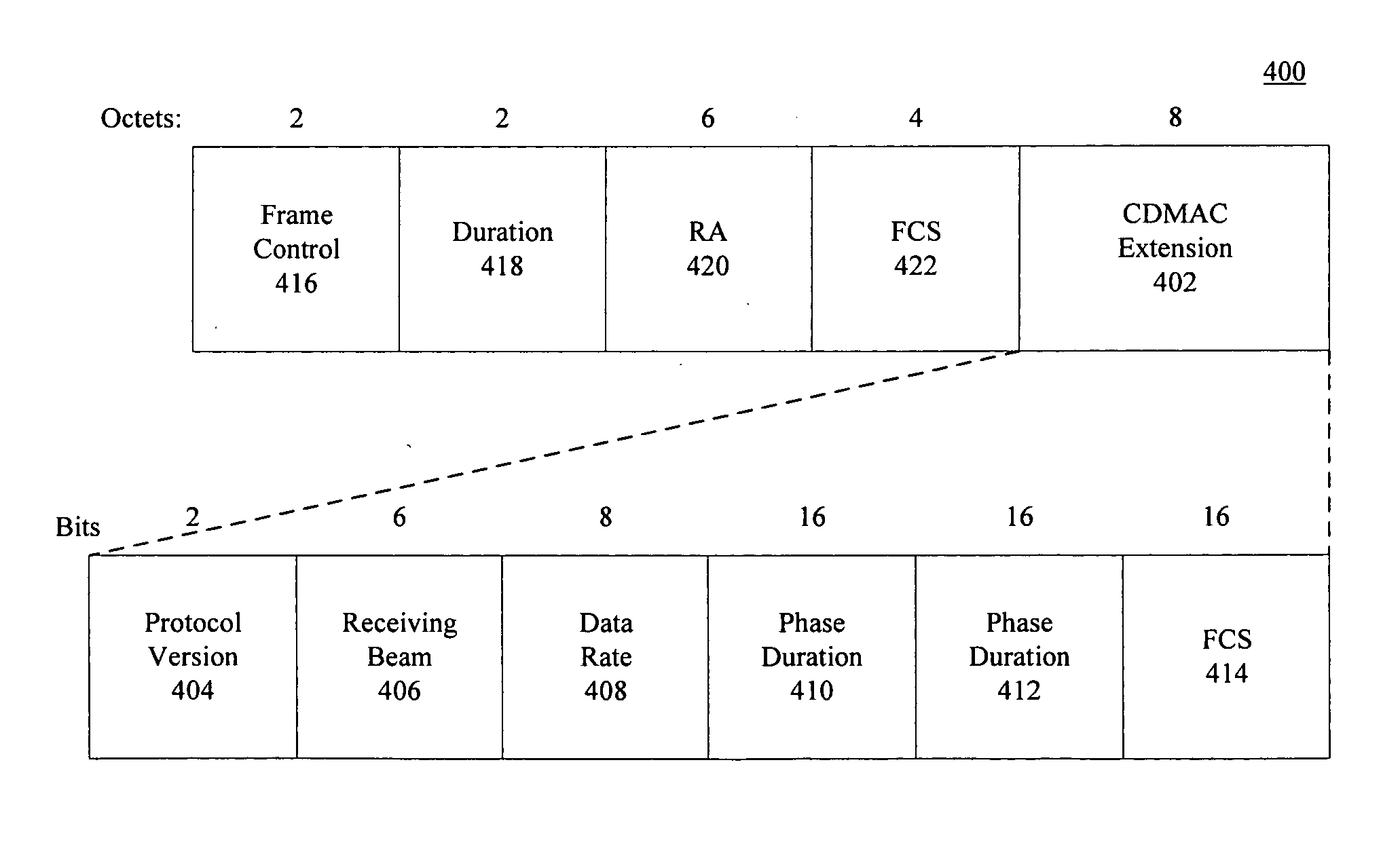

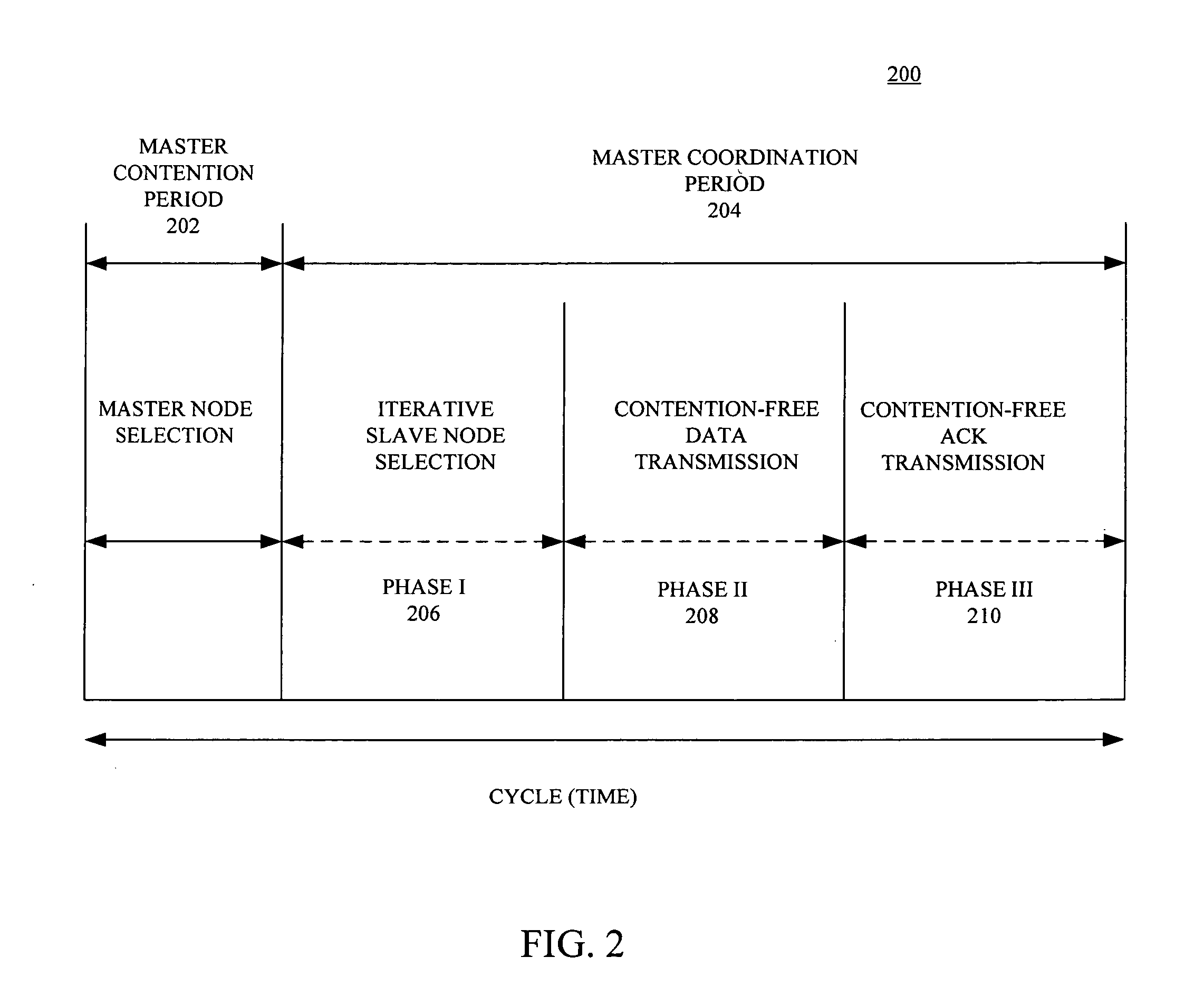

Coordinated directional medium access control in a wireless network

InactiveUS20060209772A1Reception-higher throughputImprove energy efficiencyNetwork topologiesRadio/inductive link selection arrangementsMedia access controlData transmission

A method of simultaneously transmitting and receiving multiple data packets over wireless channels among the nodes of a wireless network is provided. The method includes automatically selecting a master sending node and corresponding master receiving node in response to an omni-directionally transmitted request to send during a contention period. The method also includes selecting a slave sending node and corresponding slave receiving node if a spatial reuse ratio correspond to the master-node pair is less than a predetermined threshold and if directional data transmissions between the slave sending node and corresponding slave receiving node avoid interfering with directional data transmissions between the master nodes and other pairs of slave nodes. The method further includes causing the master sending node and slave sending node to directionally transmit data packets during a coordination period.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

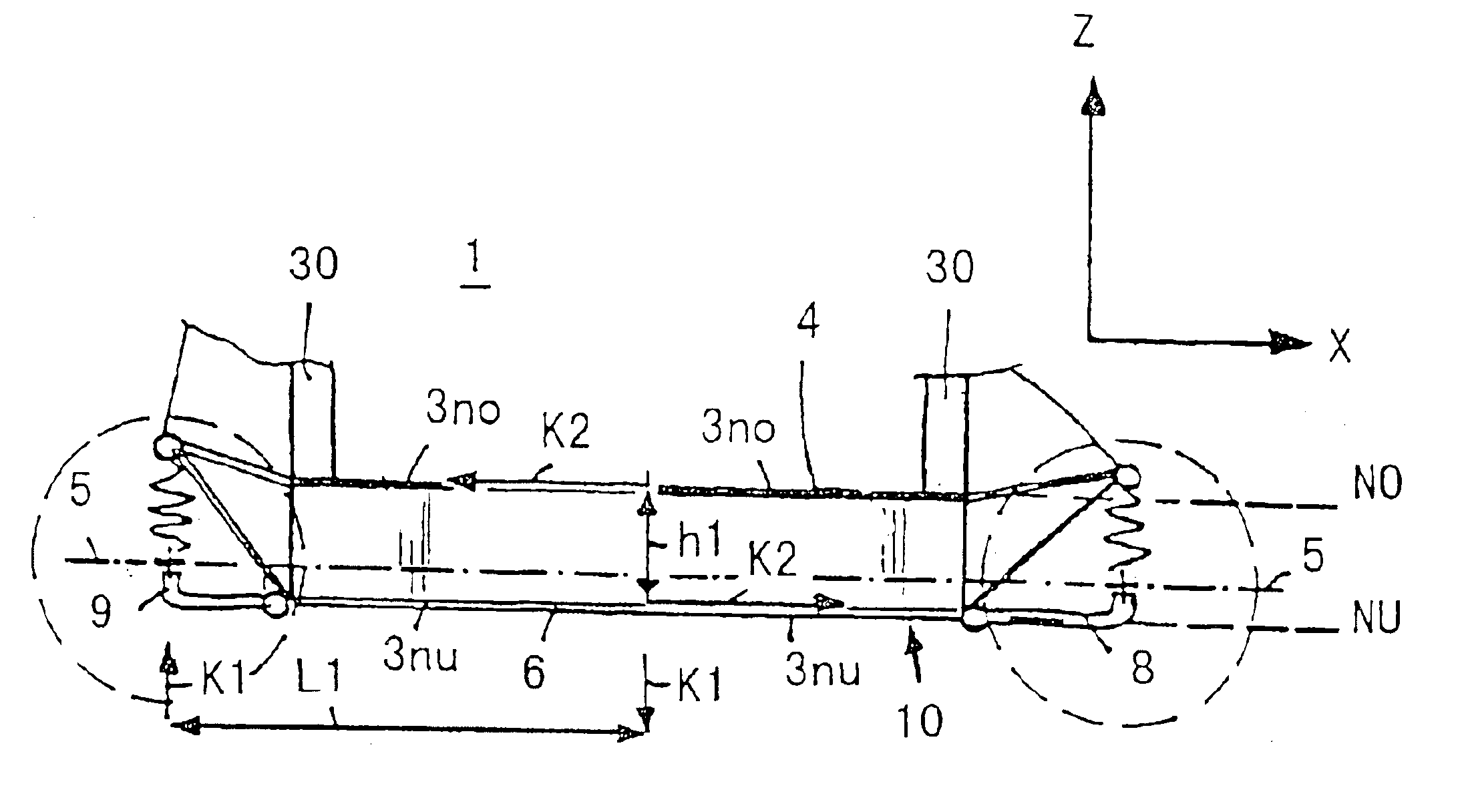

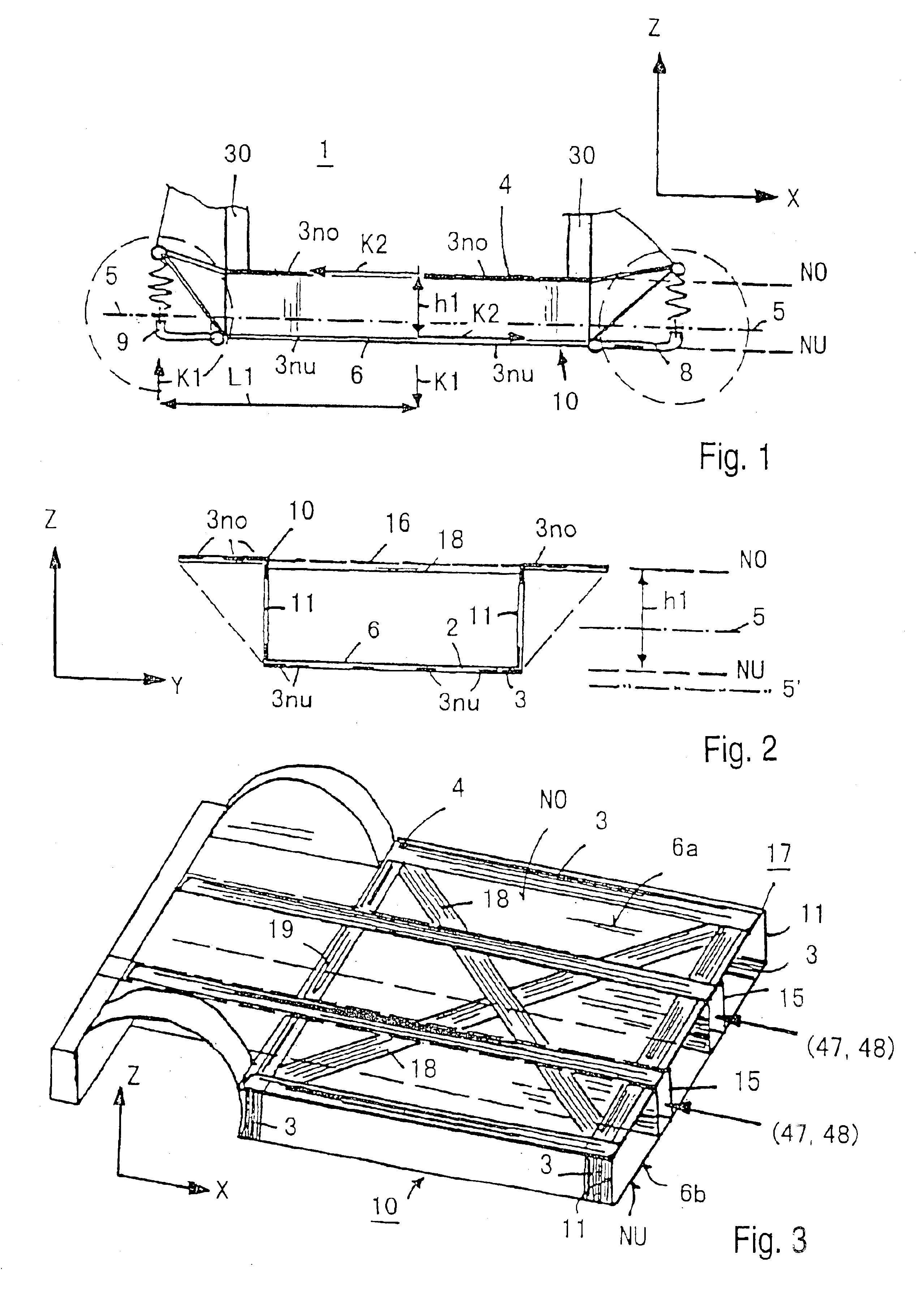

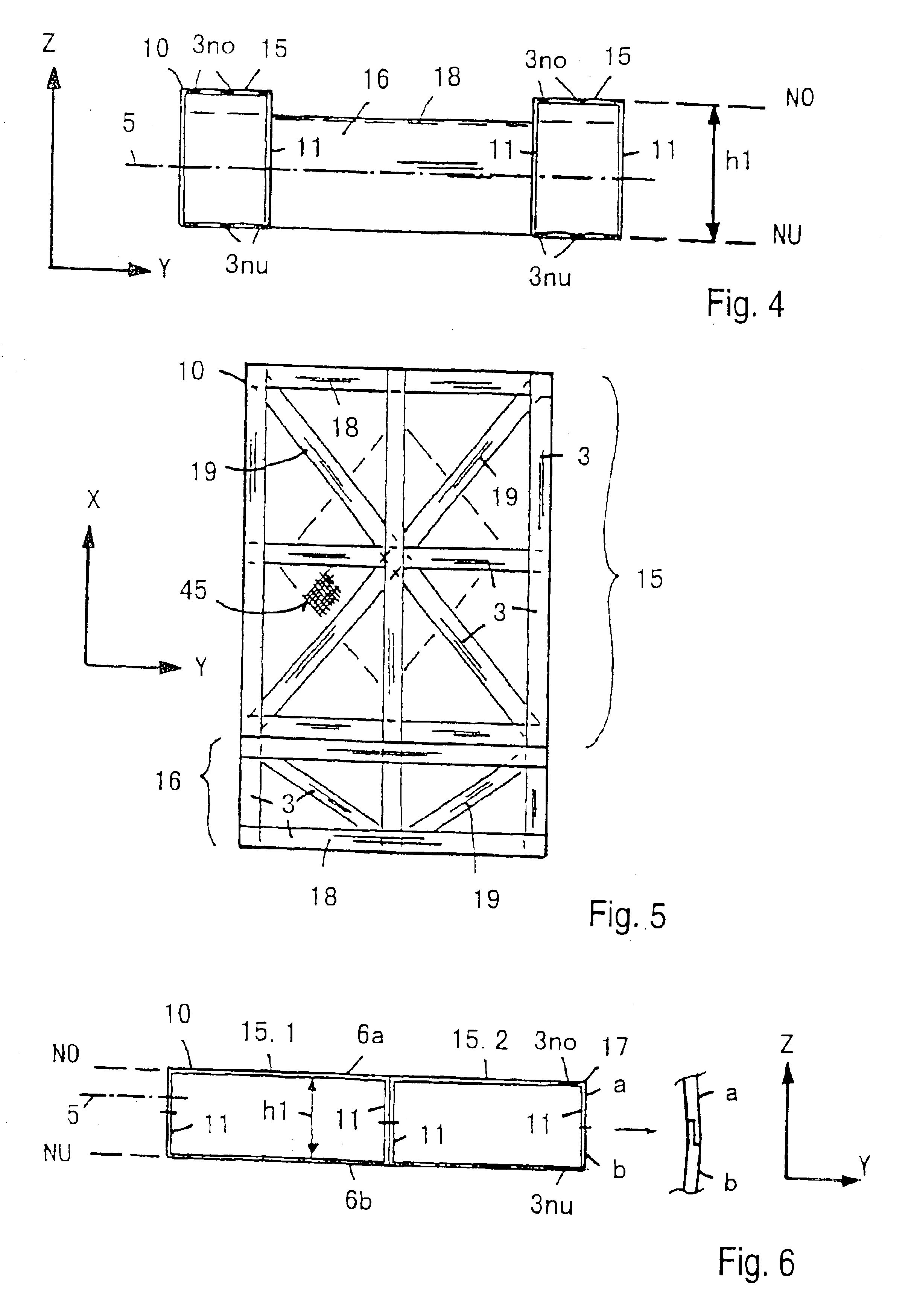

Fiber-reinforced thermoplastic vehicle cell

InactiveUS6854791B1Good long-term stabilityExcellent mechanical propertiesVehicle seatsUnderstructuresEngineeringThermoplastic matrix

A vehicle cell made of reinforced—reinforced thermoplastic material includes a shape-defining, long-reinforced-reinforced thermoplastic matrix (2) with integrated continuos fiber strands or strips (3). In a base structure (10), which includes a base plate (6), uninterrupted continuous fiber strands running longitudinally (3no) in an upper base area (NO) and continuous fiber strands running longitudinally (3nu) in a lower base area (NU). The upper and the lower base areas are connected with vertical walls (11). This results in an economically manufacturable, light-weight, rigid and safe vehicle cell.

Owner:RCC REGIONAL COMPACT CAR

Radiation redirecting external case for portable communication device and antenna embedded in battery of portable communication device

ActiveUS8208980B2Increase effective spaceAvailable spaceSimultaneous aerial operationsMagnetic/electric field screeningAntenna designMulti band

An advanced antenna or set of antennae for a wireless device is provided by embedding the antennae into the battery case or generally the largest surface area of a wireless phone. The antenna connections are made through the battery's connections to the wireless device. The antenna design can be compact and located in any area of the battery. The antenna design can be thin and flat, located at the back surface of the battery or the large rear surface of a wireless phone, facing away from the user. An RF shielding device can be embedded into the battery and configured in relation to the antenna such that the RF field intensity and the consequent specific absorption rate for the user is lowered while the outgoing signals of the wireless device remain fully adequate for the function of the wireless device. This feature is preserved for a multi-band operation because a digital phase shifter is used between two radiating antennae. An external case is used as a complement to the wireless phone to provide additional antennae, power and capability.

Owner:PENUMBRA BRANDS LLC

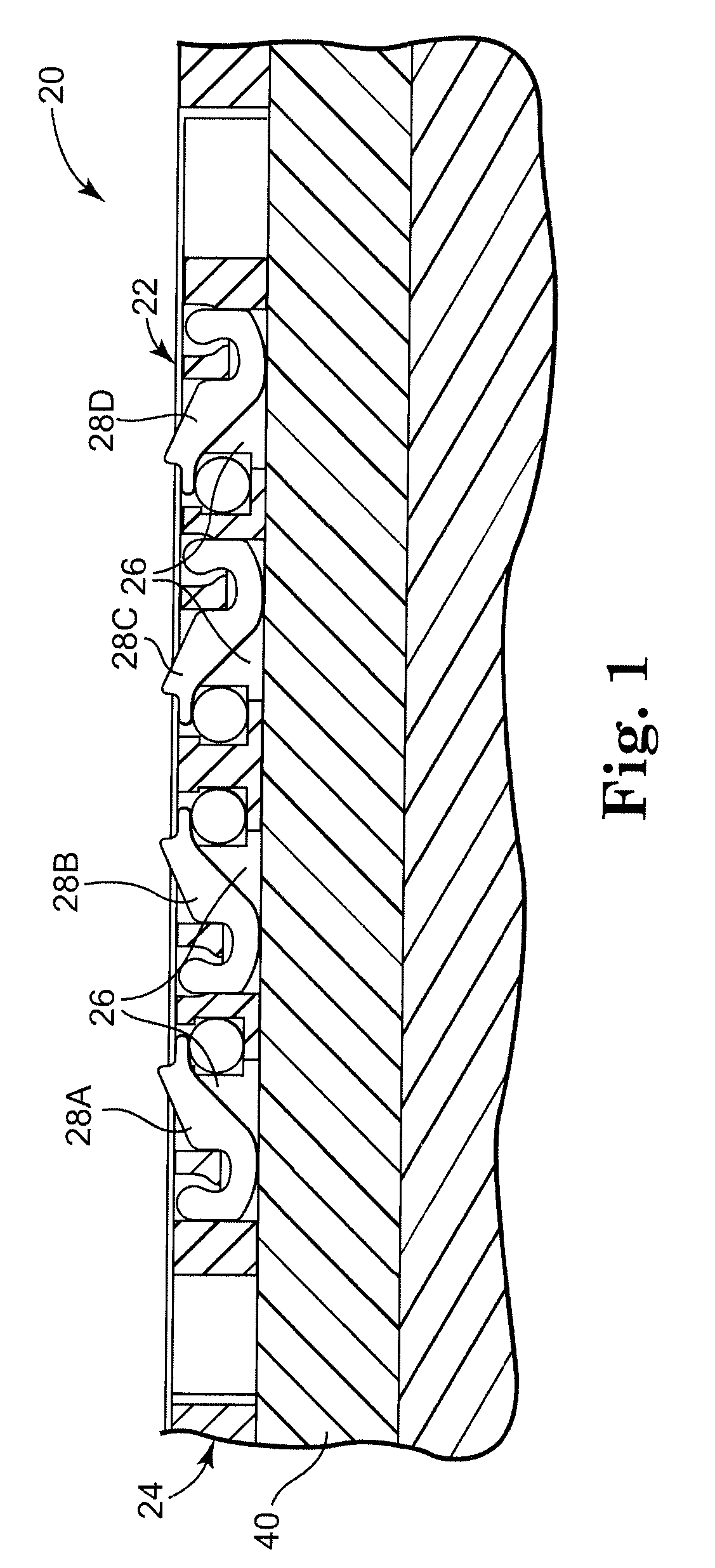

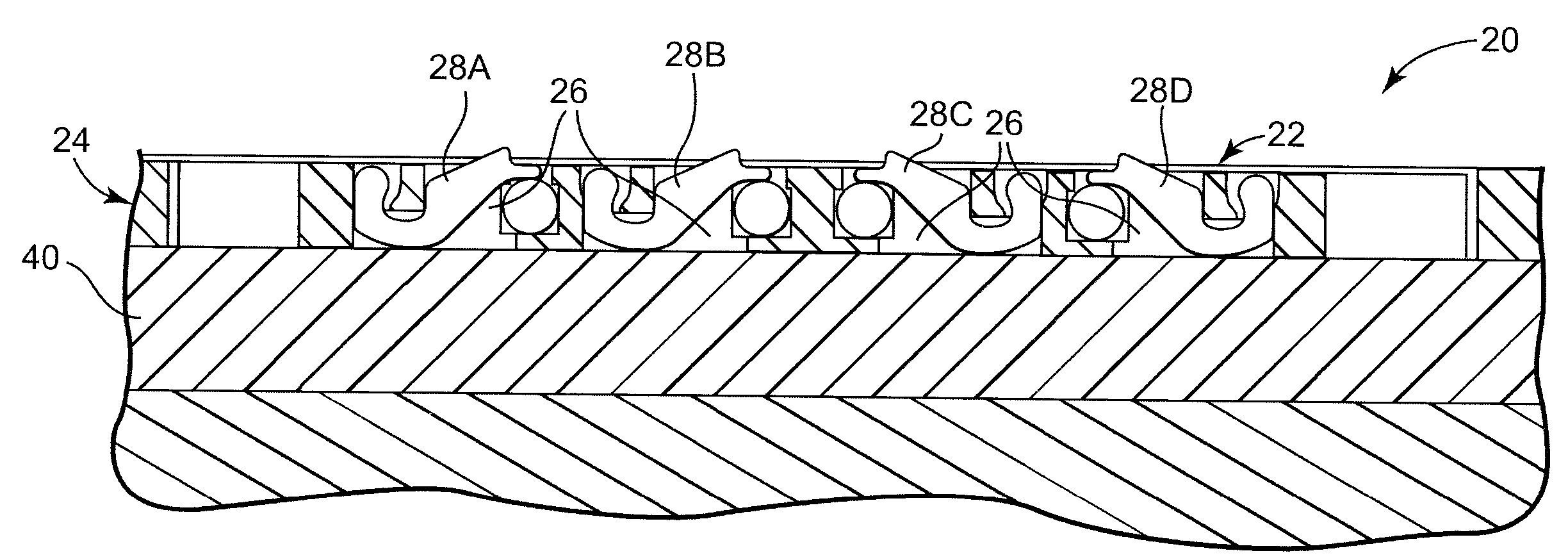

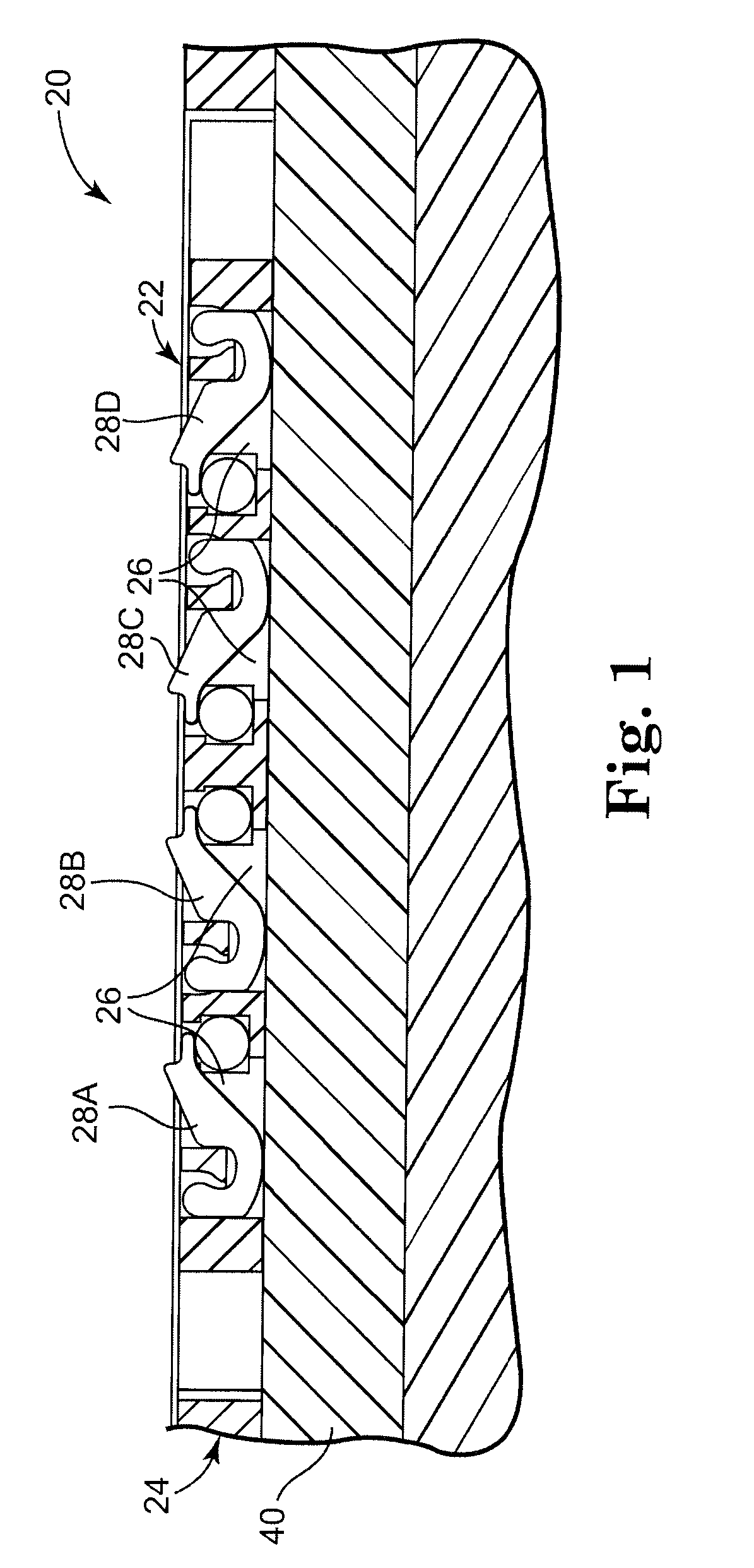

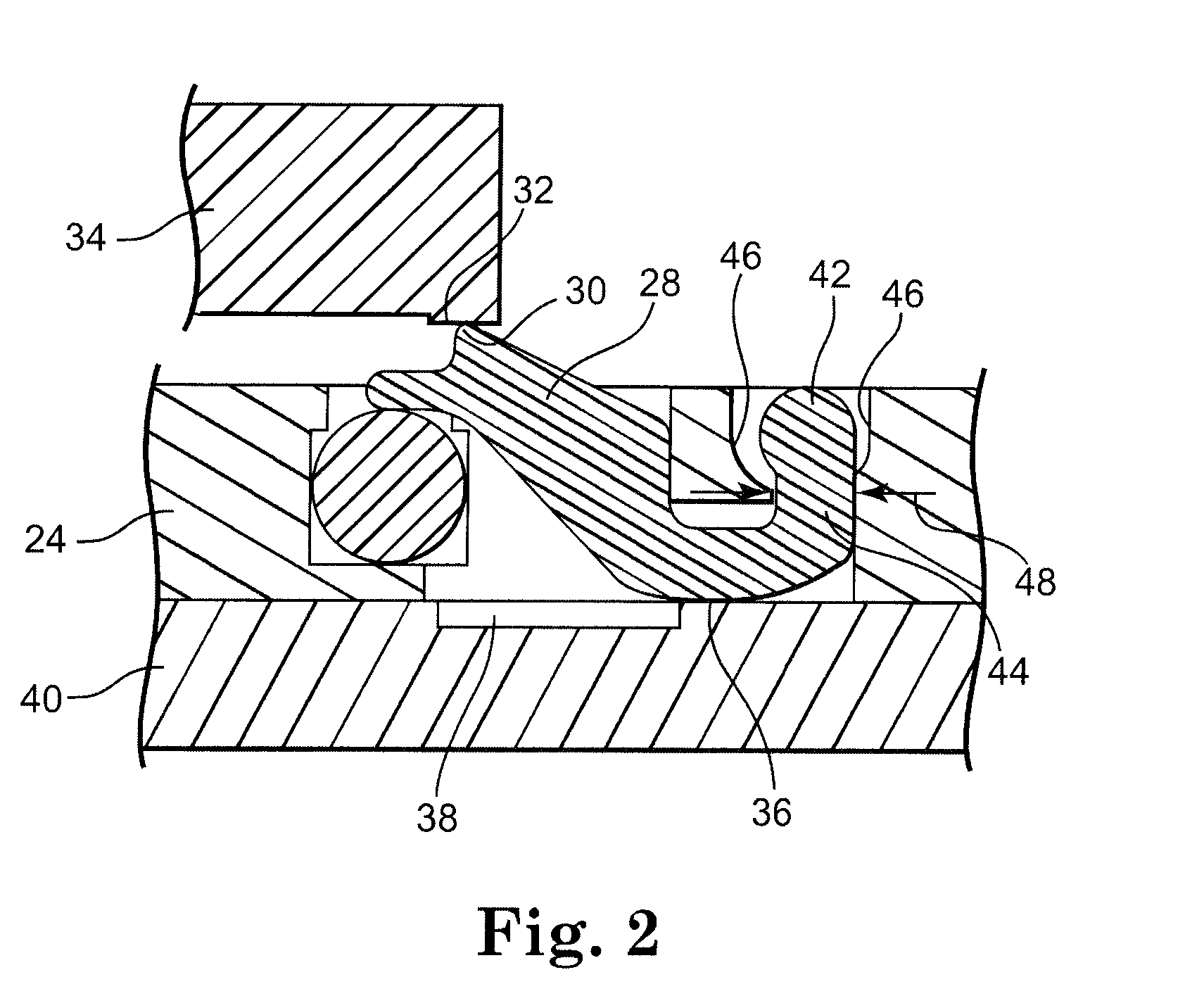

Fine pitch electrical interconnect assembly

ActiveUS7537461B2Low costLarge spacingElectrically conductive connectionsFinal product manufactureFlexible circuitsFine pitch

An electrical assembly including a socket assembly, a first circuit member electrically coupled to contact members along a first side of a socket assembly, and a second circuit member electrically coupled to the contact members along a second side of the socket assembly. A flexible circuit member is interposed between the socket assembly and the second circuit member. The flexible circuit member comprises a plurality of electrical traces electrically coupled with the contact members on the socket assembly. In one embodiment the flexible circuit member comprises a distal portion extending the electrical traces beyond the socket assembly.

Owner:R&D SOCKETS INC

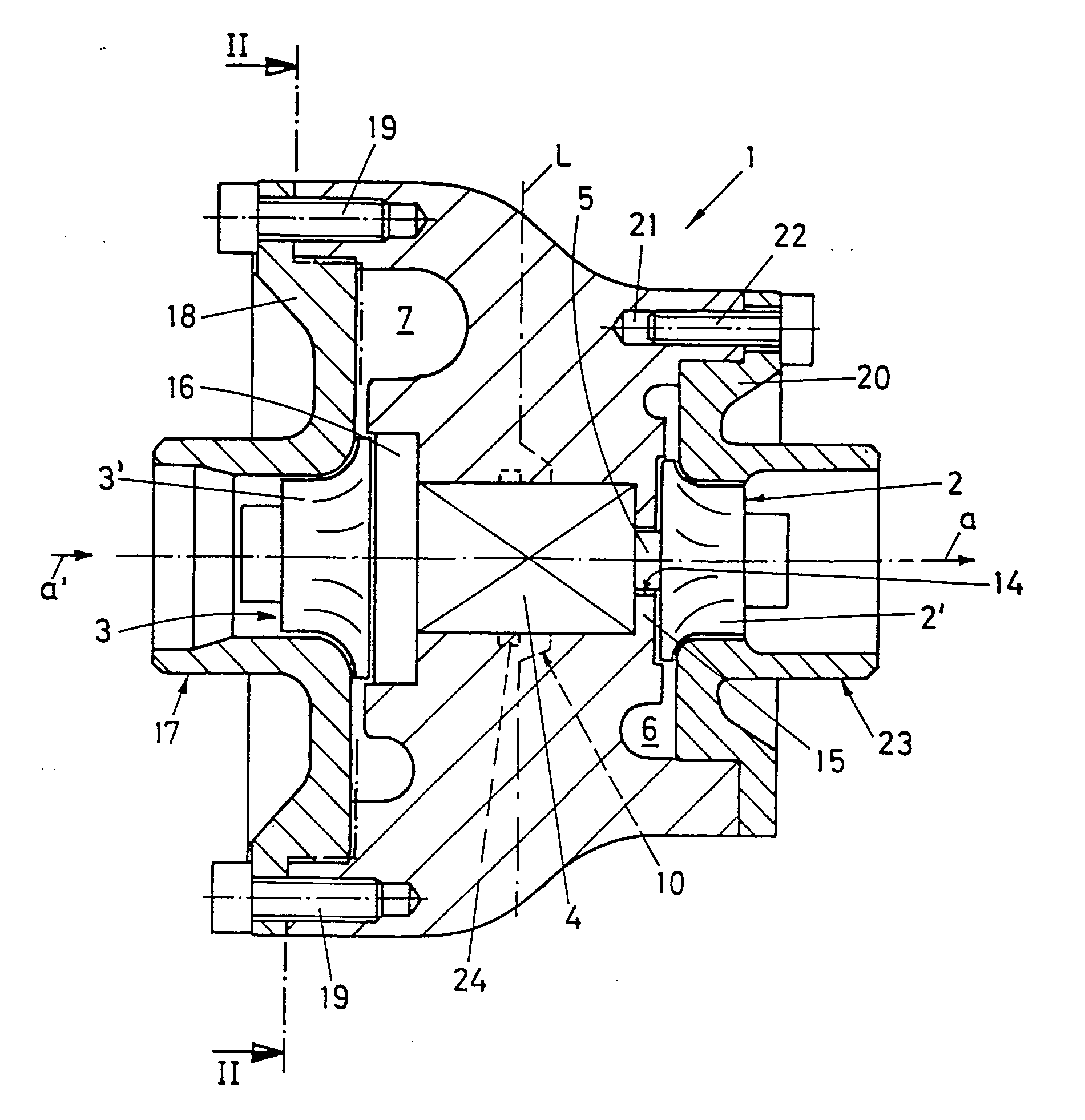

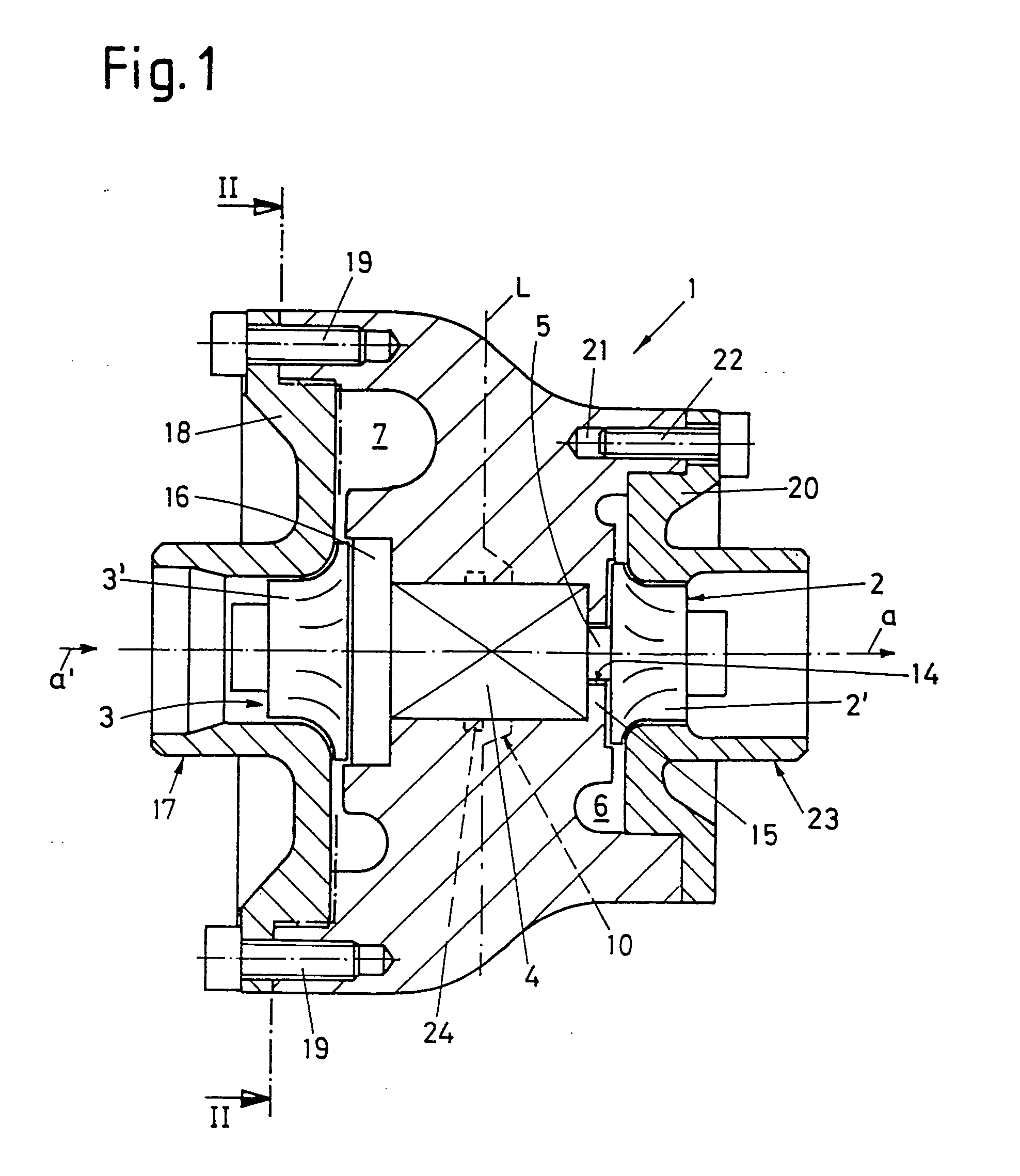

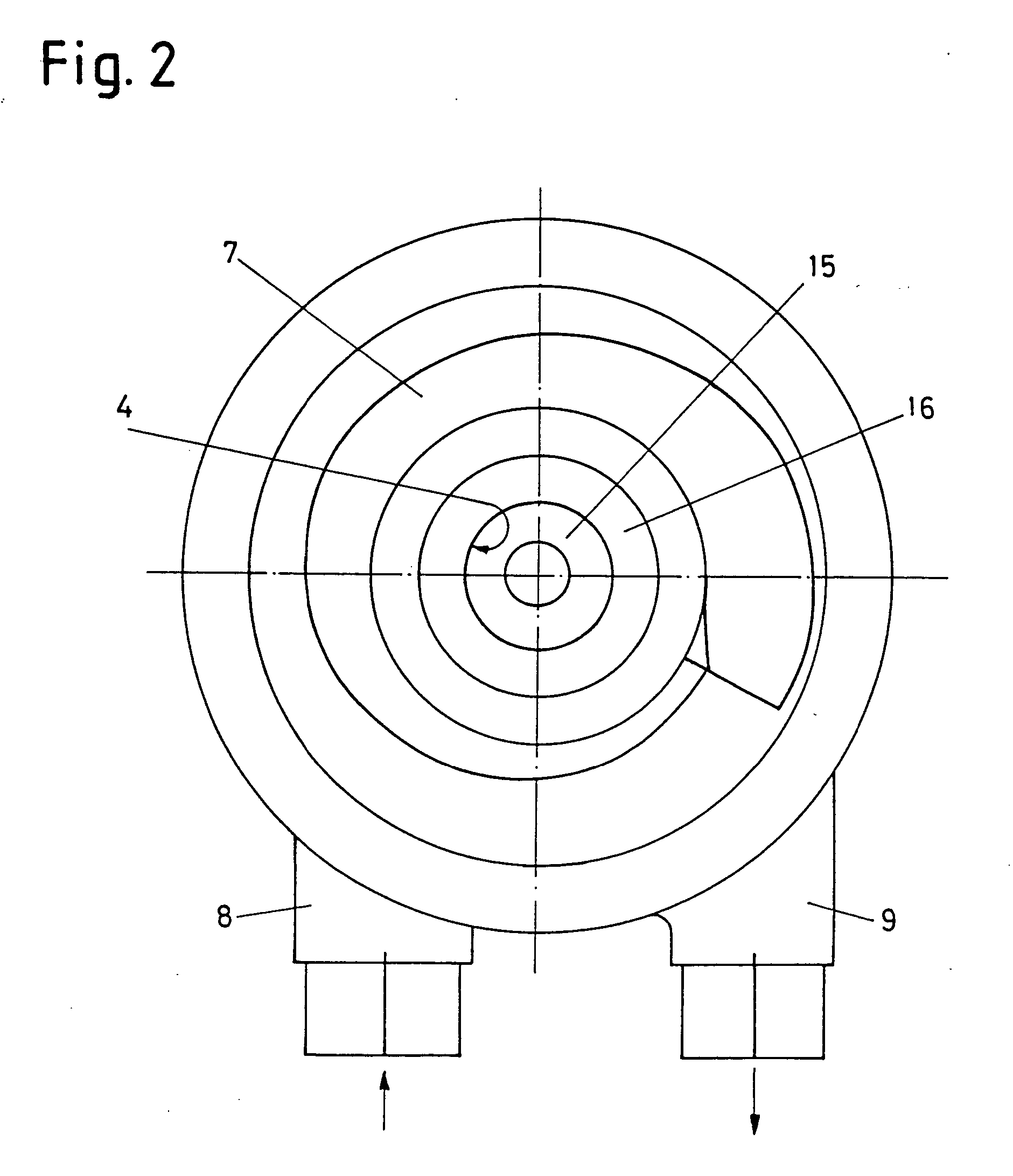

Housing for a fluid flow engine

InactiveUS20050069427A1Large spacingLess cumbersomePump componentsStatorsEngineeringMechanical engineering

A housing (1) for a fluid flow engine comprises a first rotor space (2) for receiving and housing a turbine rotor, a bearing space (4) to house a shaft (5) of said turbine rotor, and a second rotor space (3) for receiving and housing a compressor rotor. The housing portions, which surround the bearing space (4), are integrally formed at least in part with those portions that surround at least one of the rotor spaces (2,3).

Owner:BORGWARNER INC

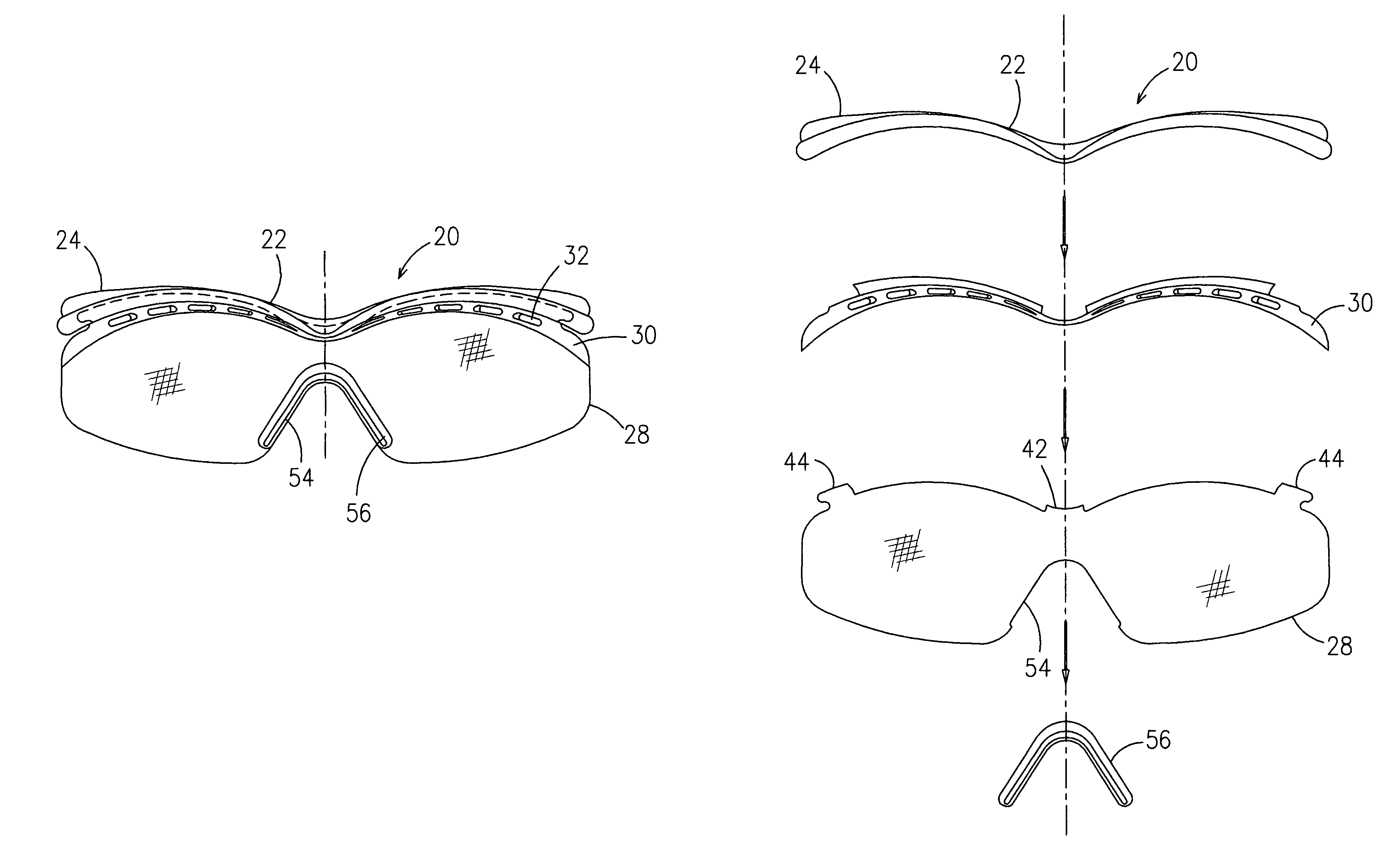

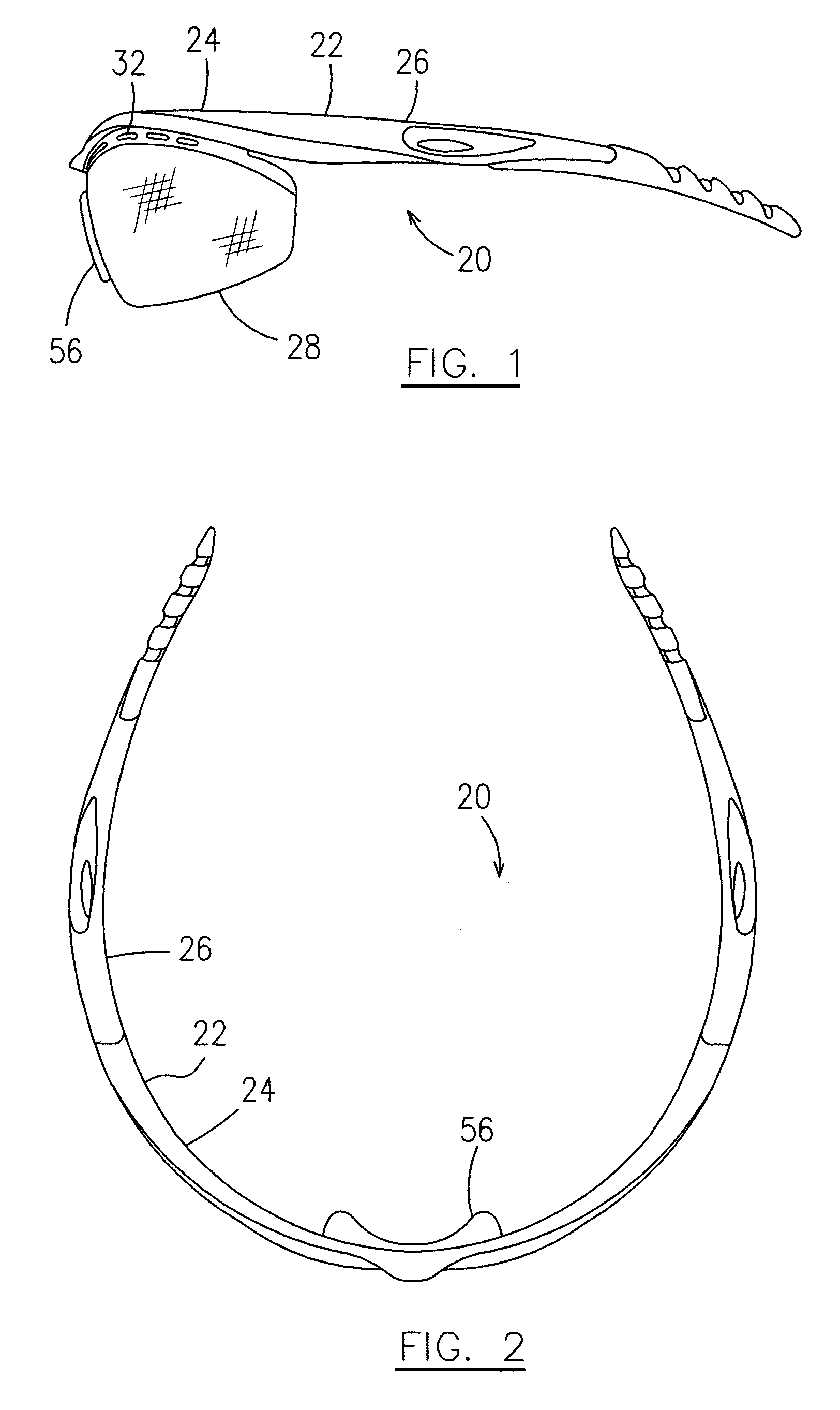

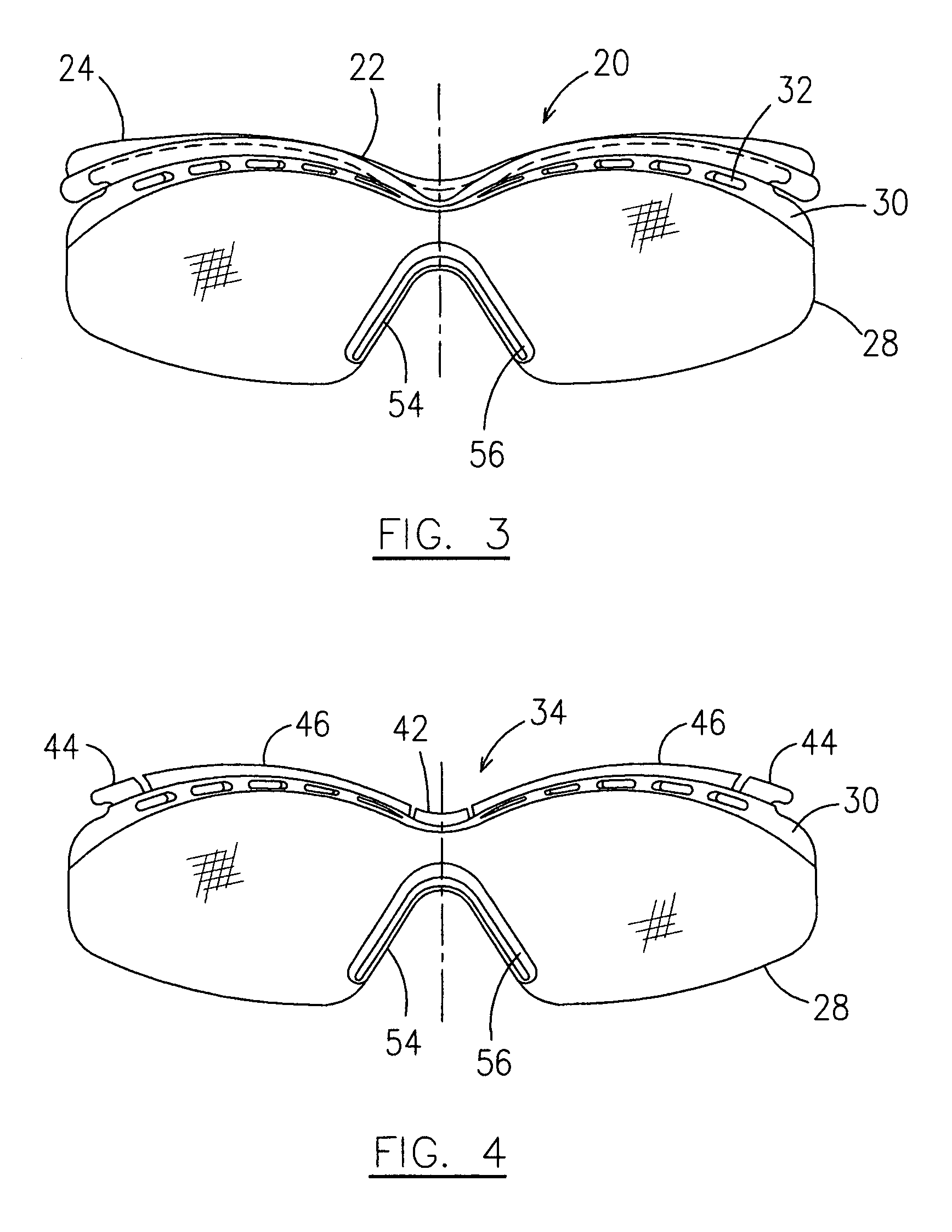

Eyewear having detachable lens retaining member

Eyewear is provided with an exchangeable lens retaining member which is removably attached to a lens to form a lens unit. The lens unit is detachably secured to the main frame of the eyewear such that the lens unit extends downwardly from the main frame. At least a section of the lens retaining member provides a spacing between a bottom of the main frame and the lens, where vent passages are defined.

Owner:SHELDON BRENT

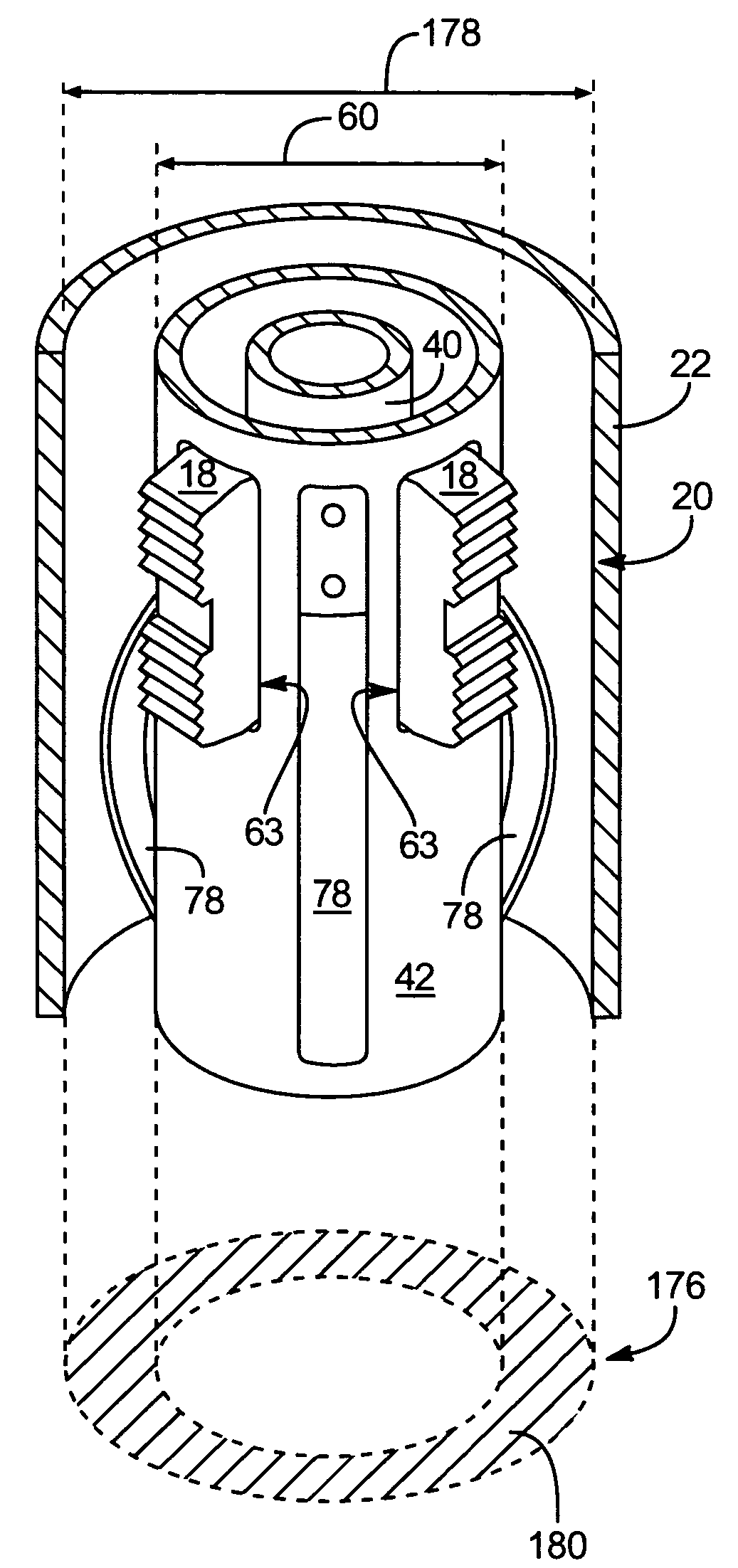

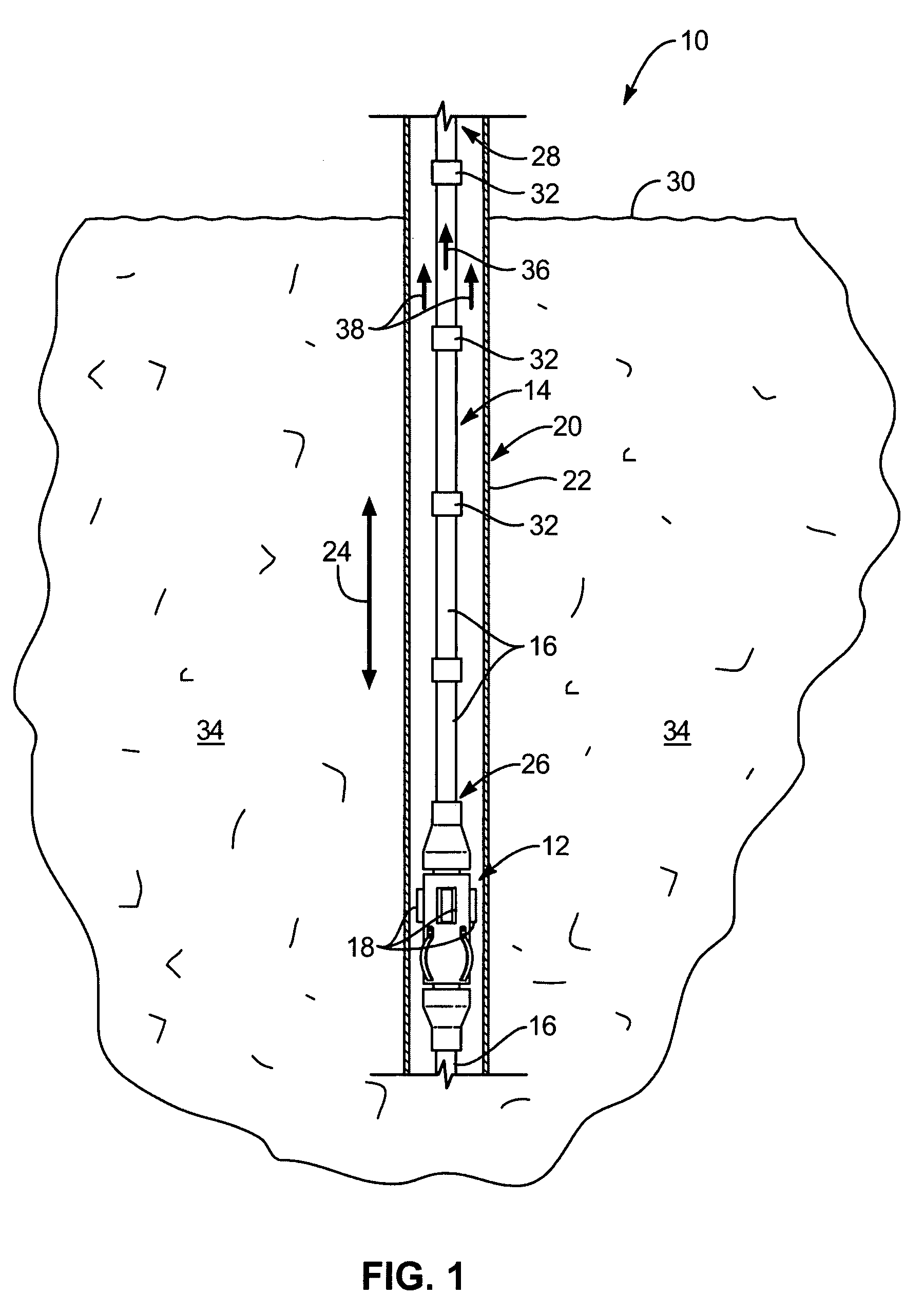

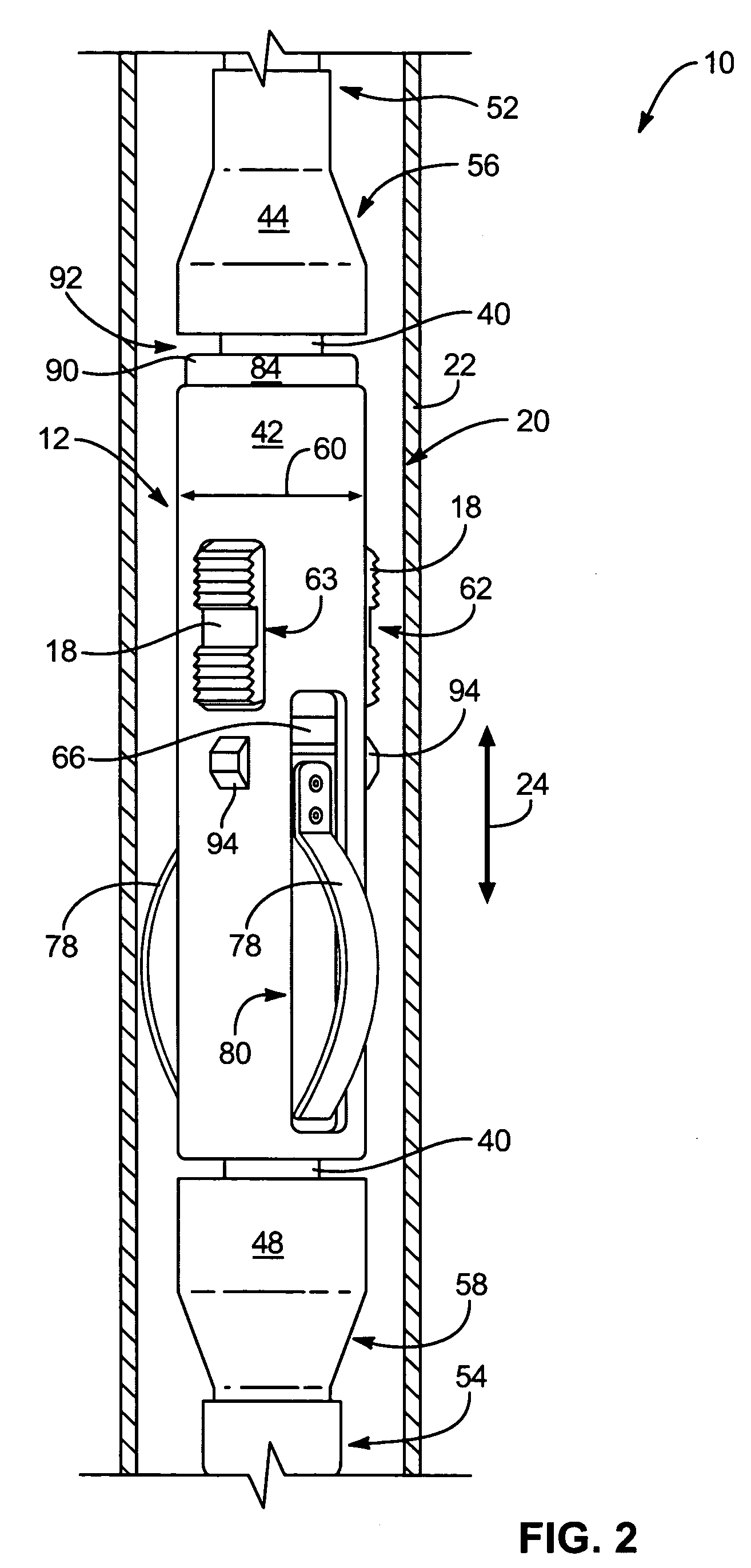

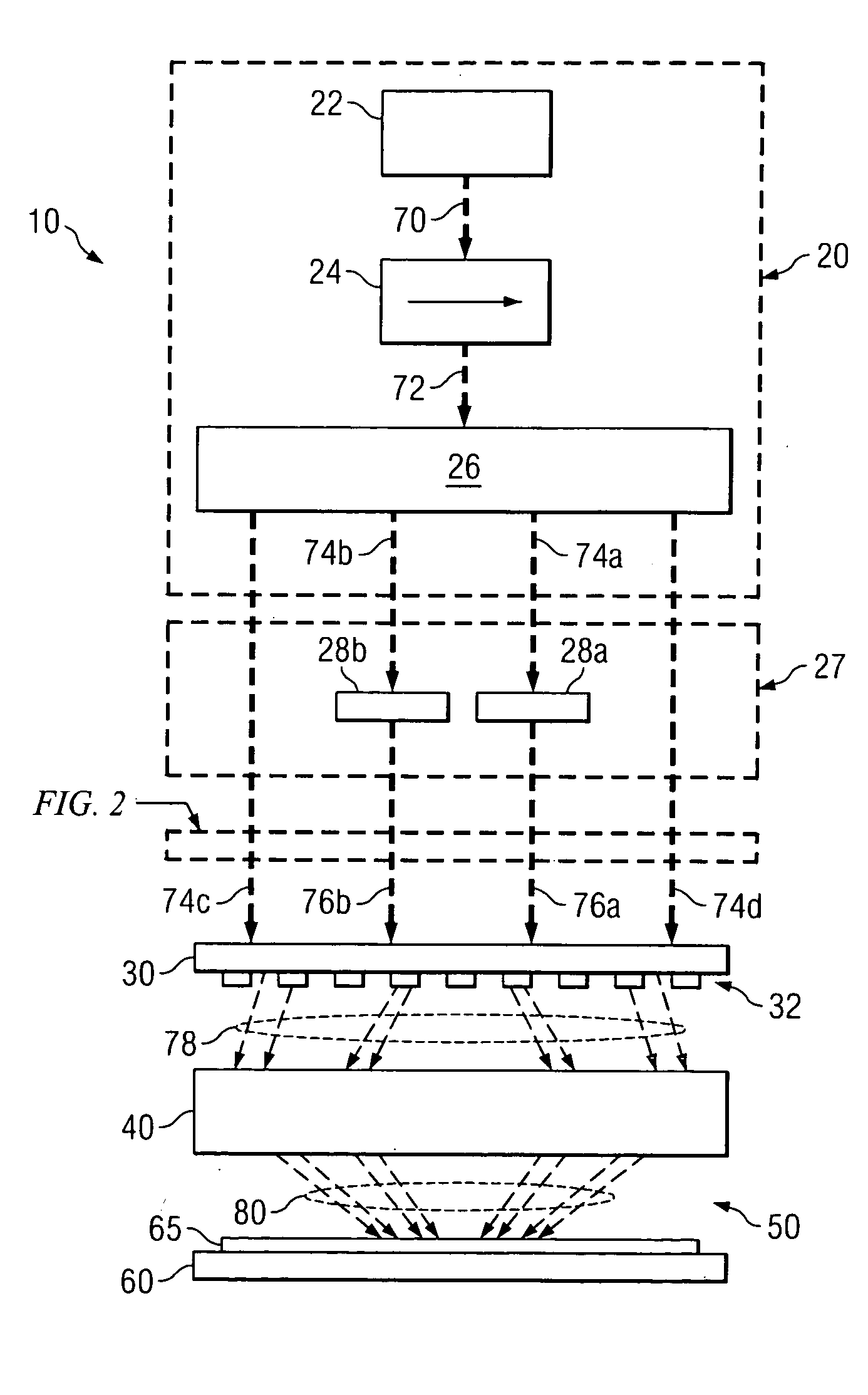

Hydrodynamic, down-hole anchor

ActiveUS7255172B2Facilitate their admittanceIncrease gas productionDrilling rodsFluid removalMechanical engineeringWellbore

A method of removably anchoring well tubing in a well bore may include selecting a well having a bore diameter and an anchor positioned therein. The anchor may have a housing defining an anchor diameter and extension members extending therefrom toward the bore diameter. The bore diameter and anchor diameter may be spaced apart a distance defining an annulus therebetween and extending along the well. A tool sized to cut substantially exclusively within the annulus may be selected. The tool may be positioned within the annulus, rotated, and advanced to drive past the housing to remove the extension members between the housing and the bore diameter to free the anchor.

Owner:TECH TAC

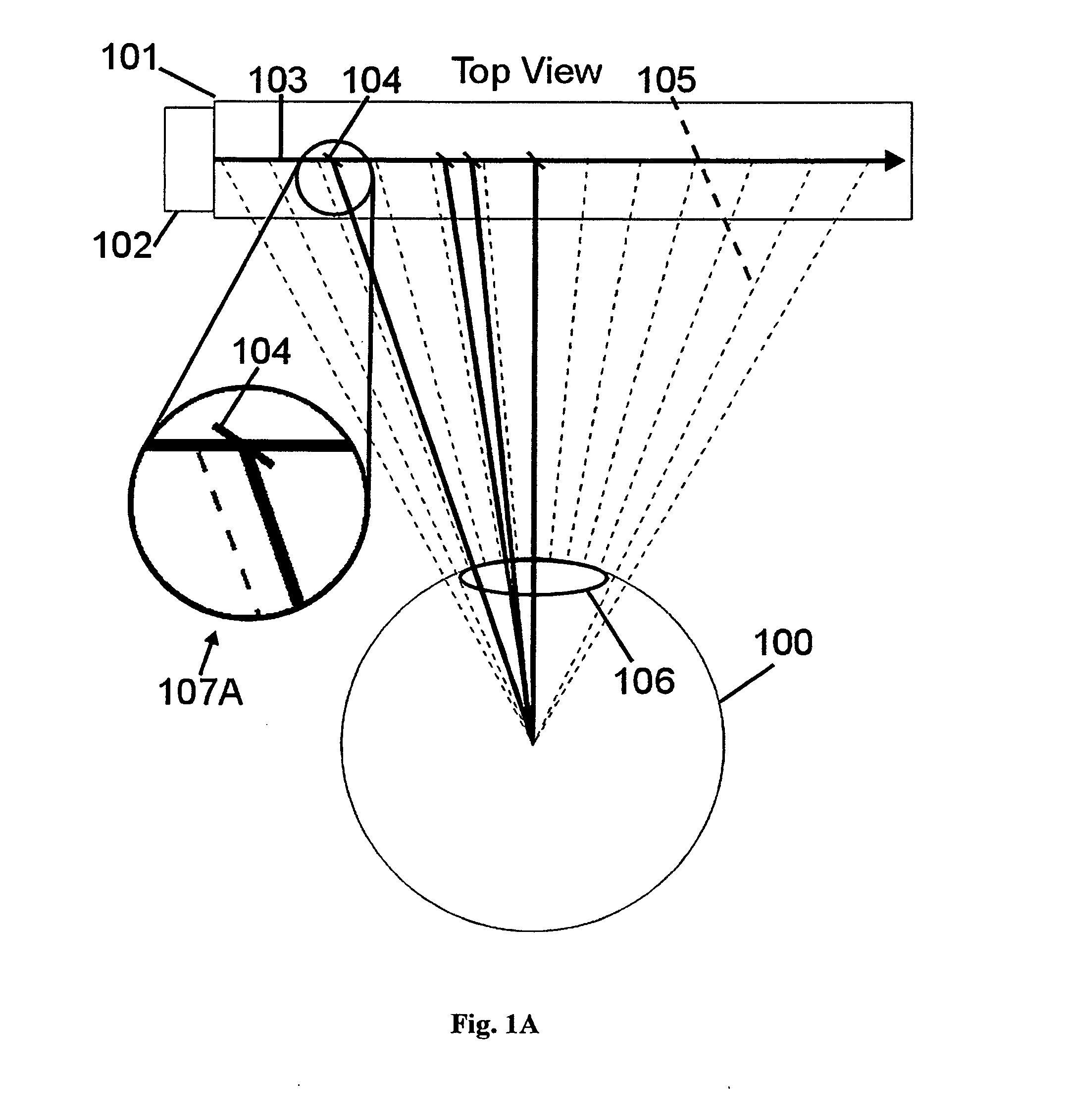

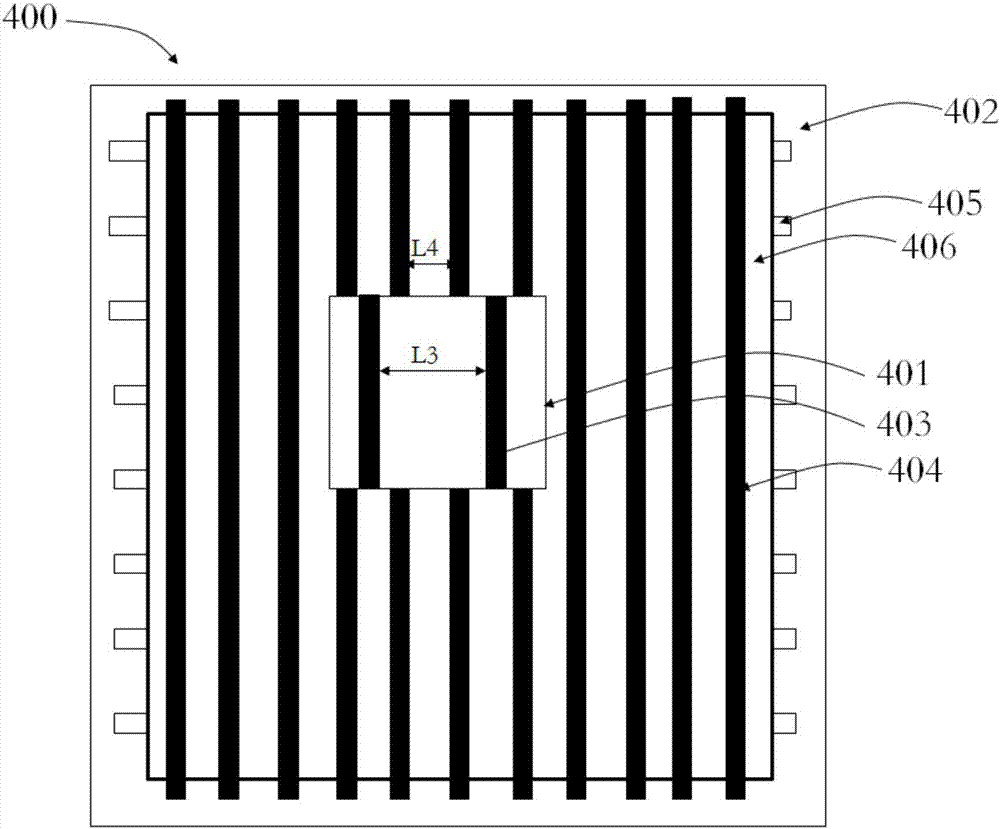

System and method for custom-polarized photolithography illumination

ActiveUS20050128458A1Image is often very smallLarge spacingSemiconductor/solid-state device manufacturingPolarising elementsPolarizerPhotolithography

In one embodiment, a system for custom-polarized photolithography illumination includes an illuminator operable to generate an illumination pattern of light, a polarizer unit operable to variably polarize the light, and a mask pattern defining photolithographic pattern features in two dimensions. The mask pattern is associated with a mask capable of transmitting at least a portion of the variably polarized light through the mask pattern.

Owner:TEXAS INSTR INC

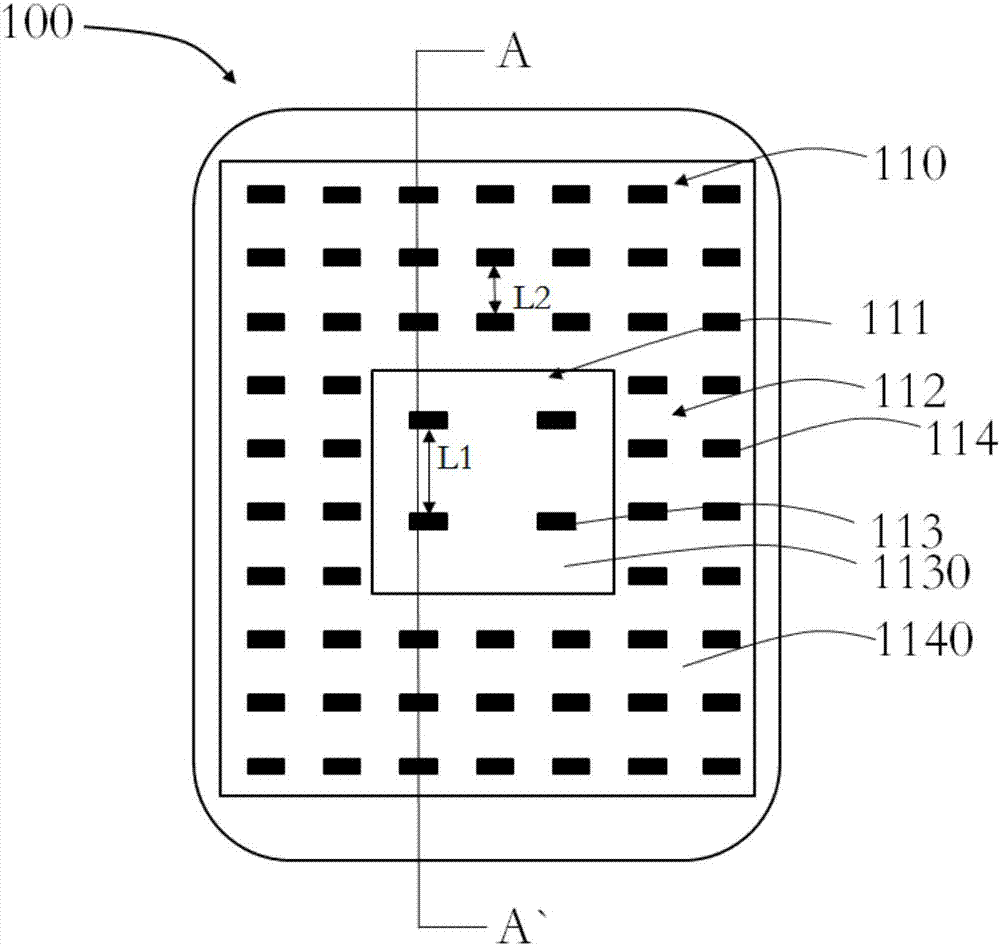

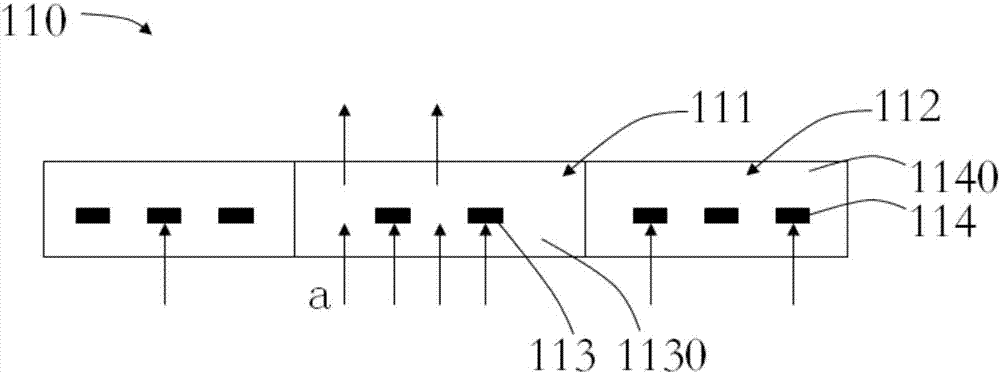

Display screen, display device and mobile terminal

ActiveCN107194321AImprove accuracyLarge spacingStatic indicating devicesSolid-state devicesDisplay deviceComputer terminal

The invention provides a display screen. The display screen comprises a display layer, wherein the display layer comprises a fingerprint recognition area and a peripheral area adjacent to the fingerprint recognition area; the fingerprint recognition area is provided with first driving devices; the peripheral area is provided with second driving devices; and the arrangement space of the first driving devices is greater than the arrangement space of the second driving devices. The invention provides a display device which comprises the display screen and an optical fingerprint module, wherein the optical fingerprint module is located at one side, deviating from the users, of the display screen; and the optical fingerprint module is arranged at a position corresponding to the fingerprint recognition area so as to conveniently transmit and receive optical signals through the fingerprint recognition area. The invention furthermore provides a mobile terminal. Through arranging the driving devices with large arrangement spaces in the fingerprint recognition area of the display area and arranging the optical fingerprint module under the fingerprint recognition area, the fingerprint recognition correctness of the optical fingerprint module is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

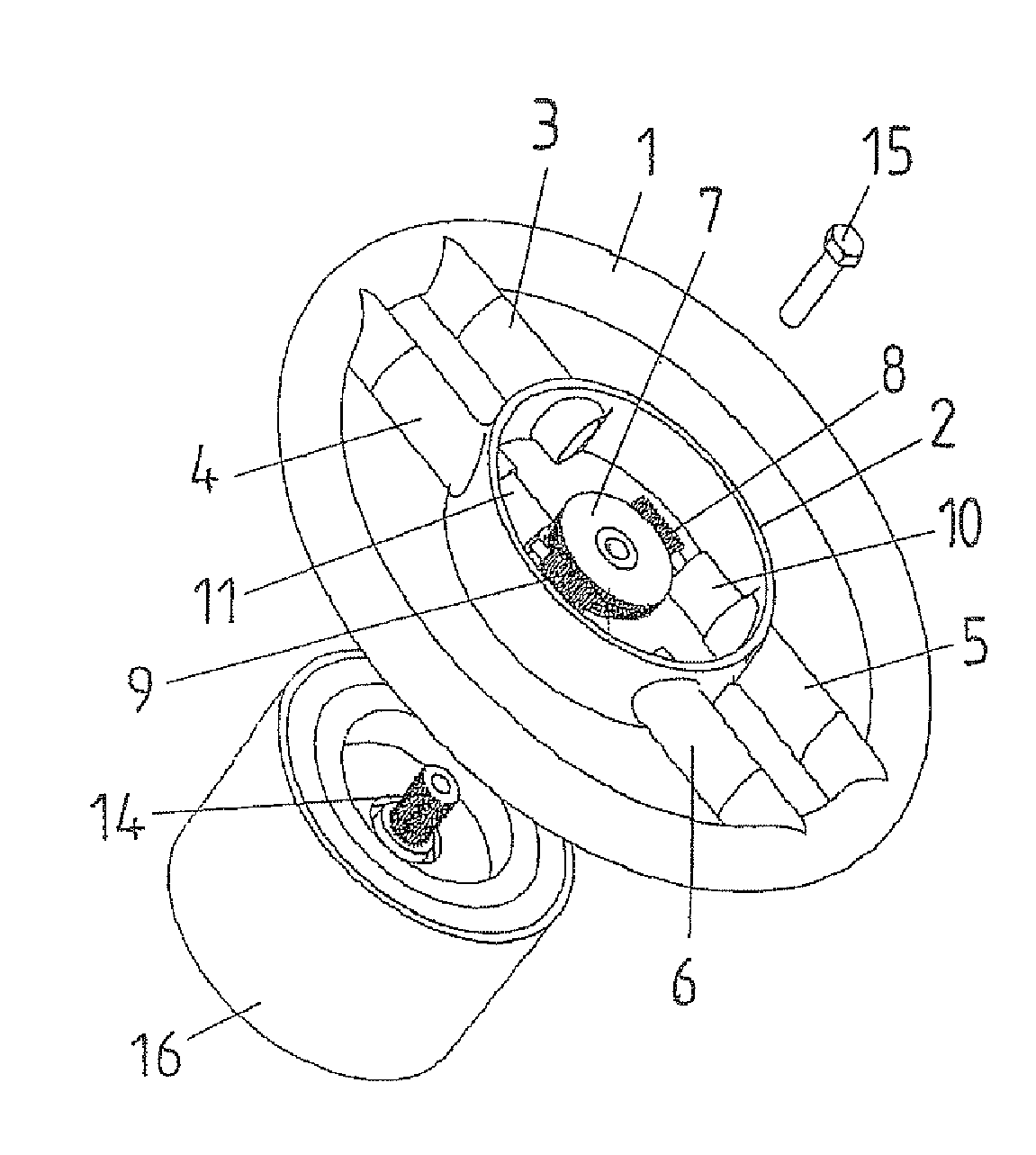

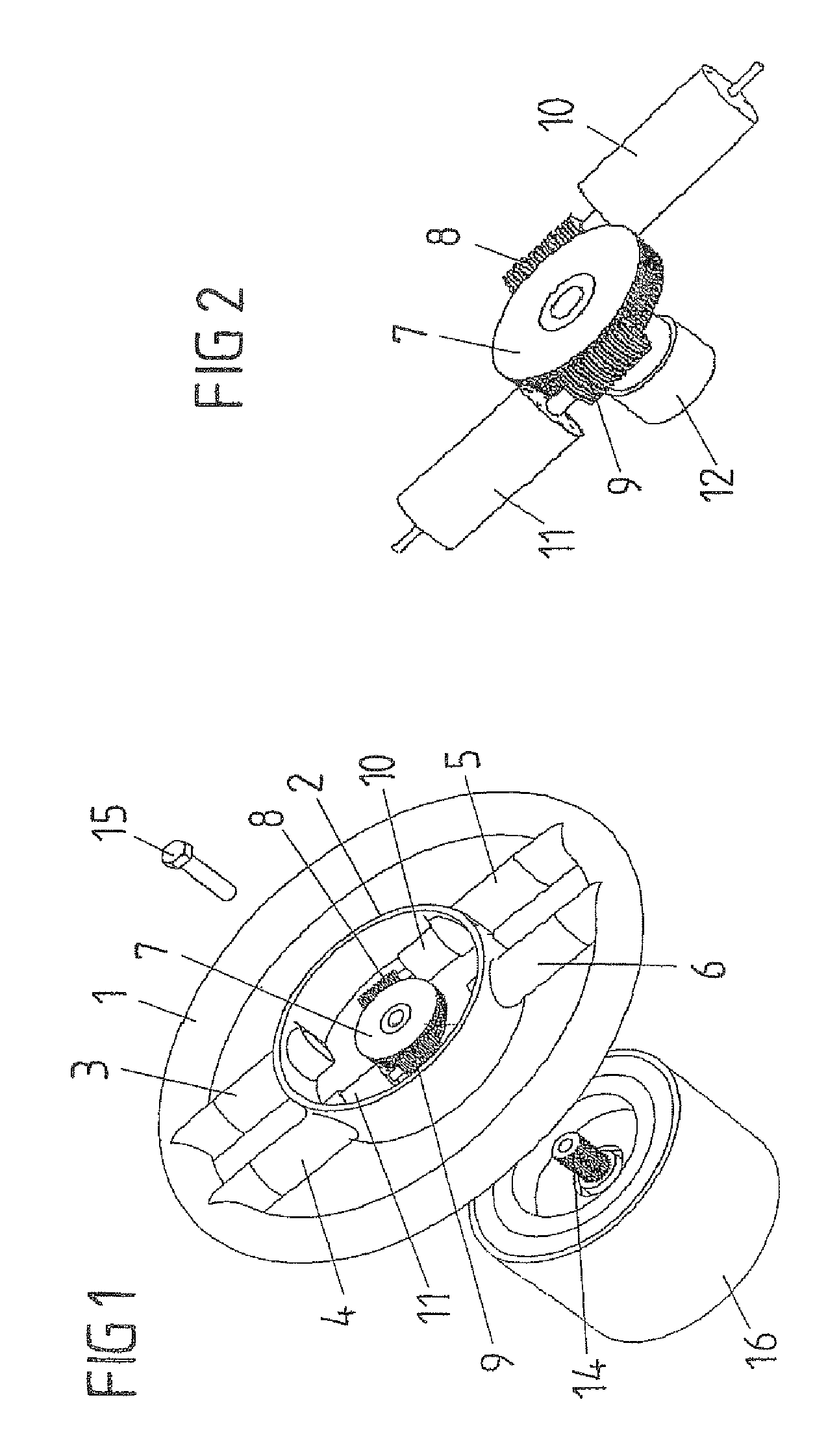

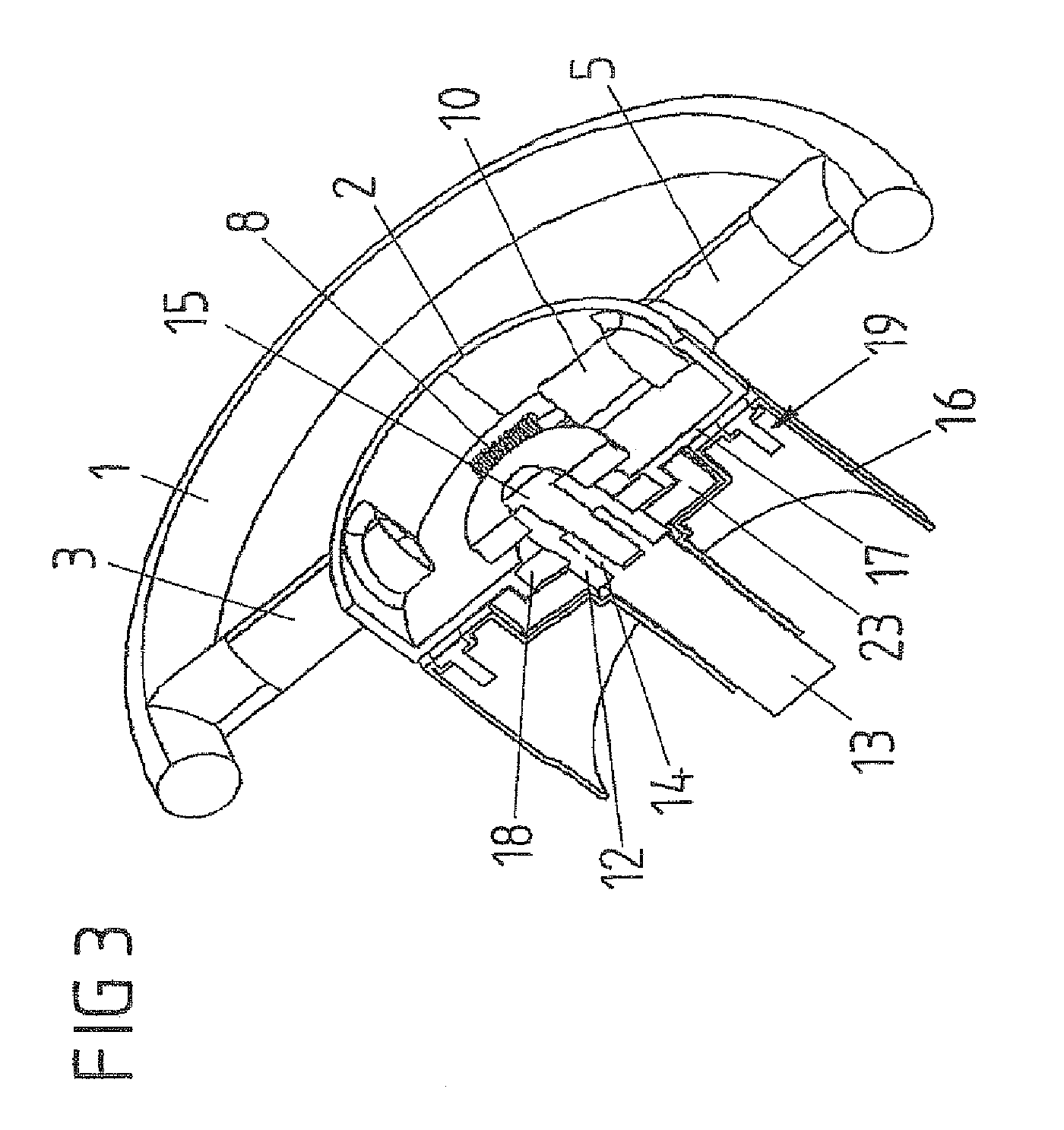

Steering device for a superposition steering system

A steering device for a superposition steering system is provided using at least one actuator. The device is based on the object of producing a superposition steering system which requires no additional installation space in the steering column. The actuator for the superposition steering system is therefore arranged in the steering wheel.

Owner:JOYSON SAFETY SYST GERMANY GMBH

Fine pitch electrical interconnect assembly

ActiveUS20080182436A1Low costLarge spacingElectrically conductive connectionsFinal product manufactureFlexible circuitsEngineering

An electrical assembly including a socket assembly, a first circuit member electrically coupled to contact members along a first side of a socket assembly, and a second circuit member electrically coupled to the contact members along a second side of the socket assembly. A flexible circuit member is interposed between the socket assembly and the second circuit member. The flexible circuit member comprises a plurality of electrical traces electrically coupled with the contact members on the socket assembly. In one embodiment the flexible circuit member comprises a distal portion extending the electrical traces beyond the socket assembly.

Owner:R&D SOCKETS INC

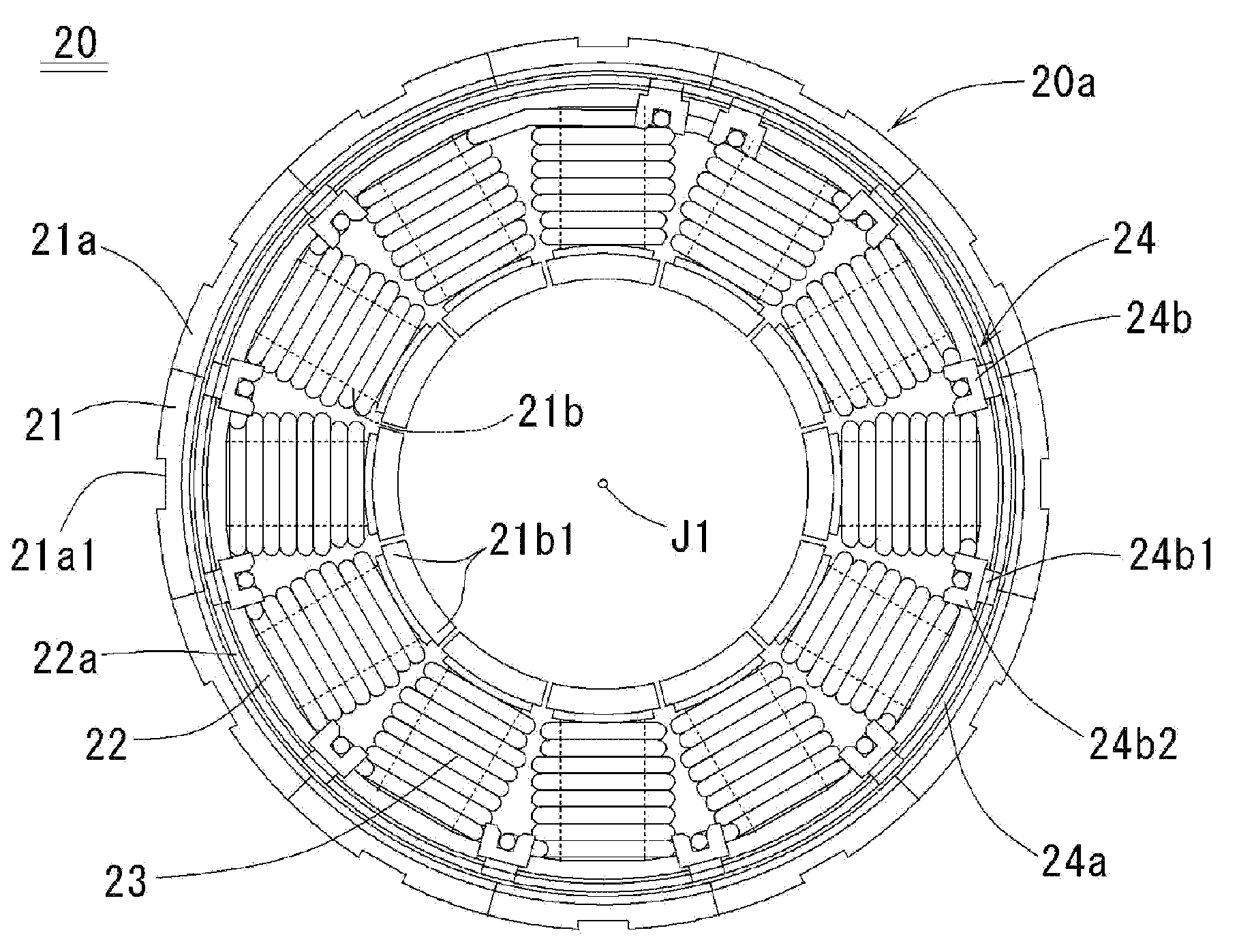

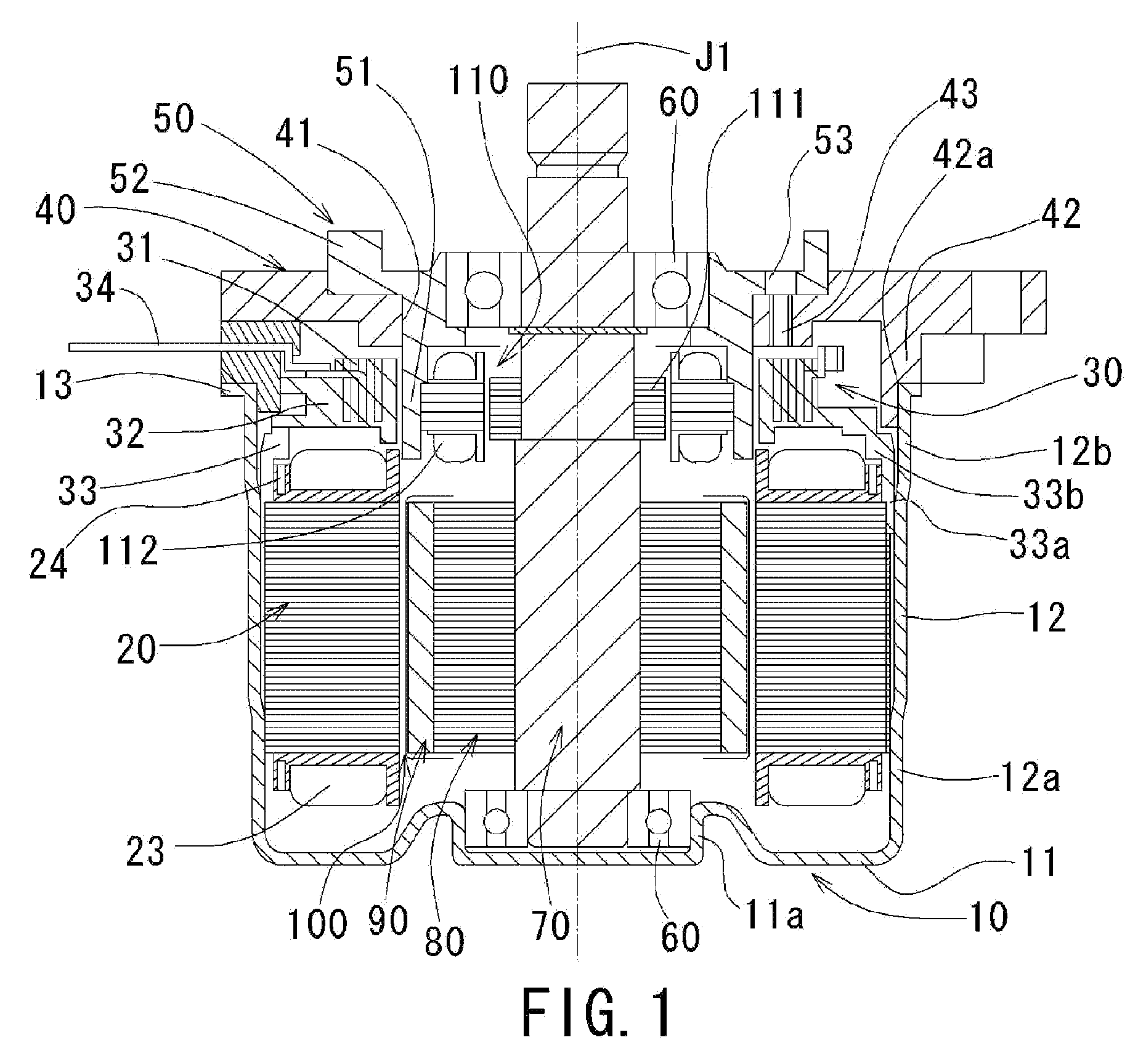

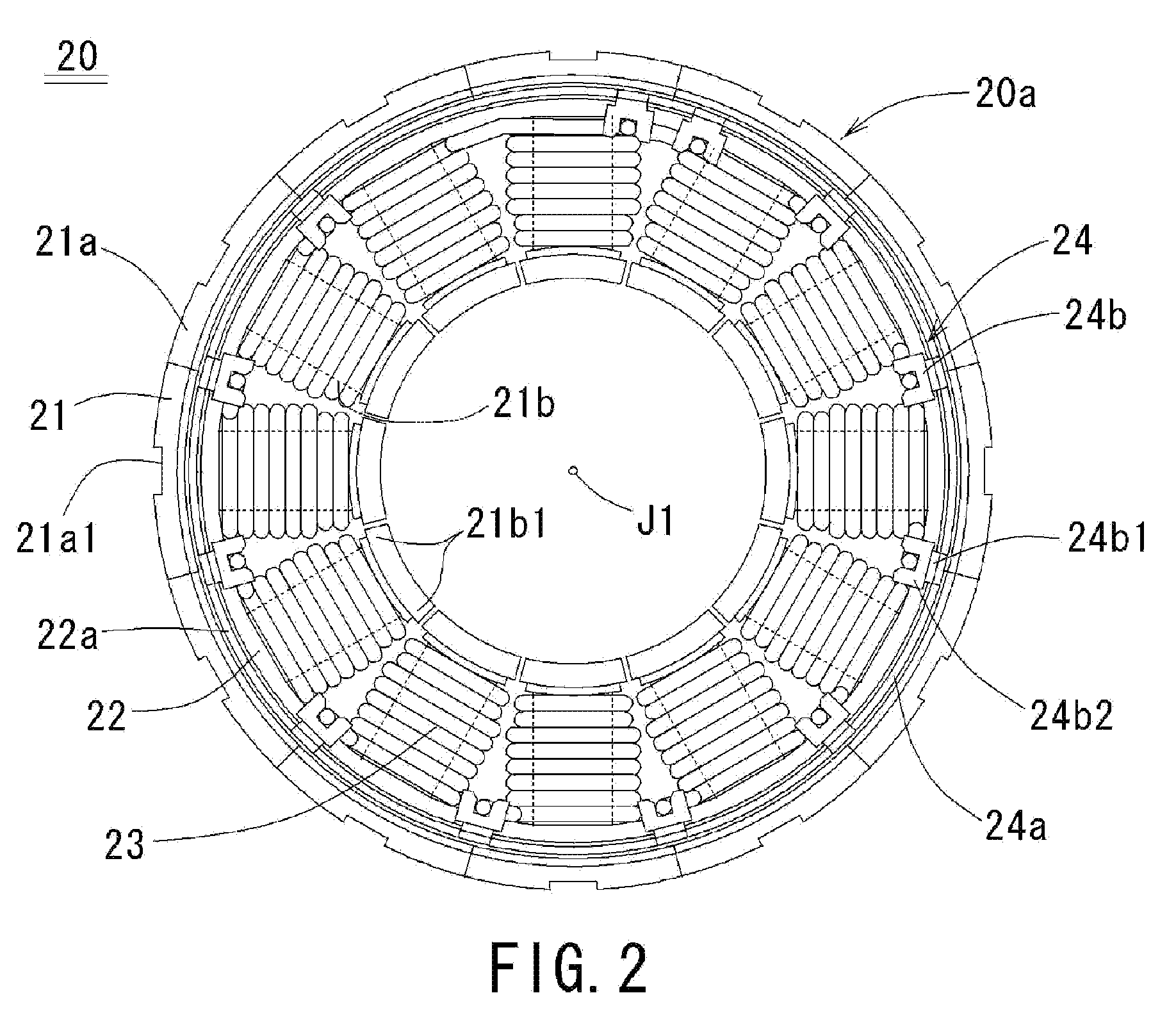

Motor

ActiveUS20070278875A1Preferable workability of connectingSpaceSynchronous generatorsWindingsElectric motorStator

A motor includes a stator including a core back having a circular or substantially circular shape, a plurality of tooth portions extending radially inwardly from the core back, a plurality of insulators covering the tooth portions, a plurality of coils formed by winding wires around the tooth portions via the insulators. The motor also includes a bus bar arranged axially above the stator. The bus bar supports a first conductor plate having a plurality of first terminals to which first end portions of the wires from each phases of the coils are connected. The insulators include a guiding groove and support therein the second conductor plate to which second end portions of the wires are connected. Through the second conductor plate, the second end portions of the wires are connected to the neutral point.

Owner:NIPPON DENSAN CORP

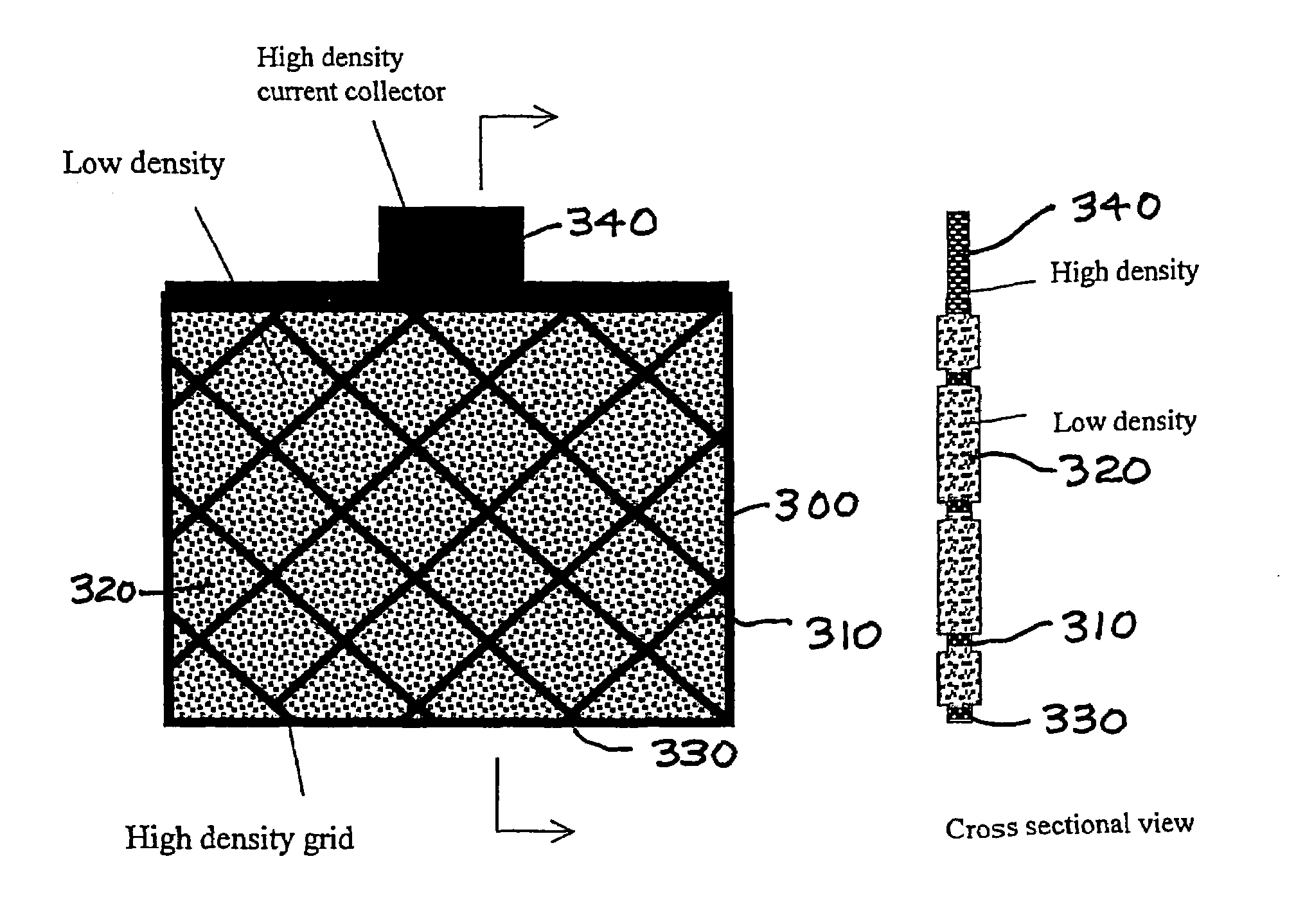

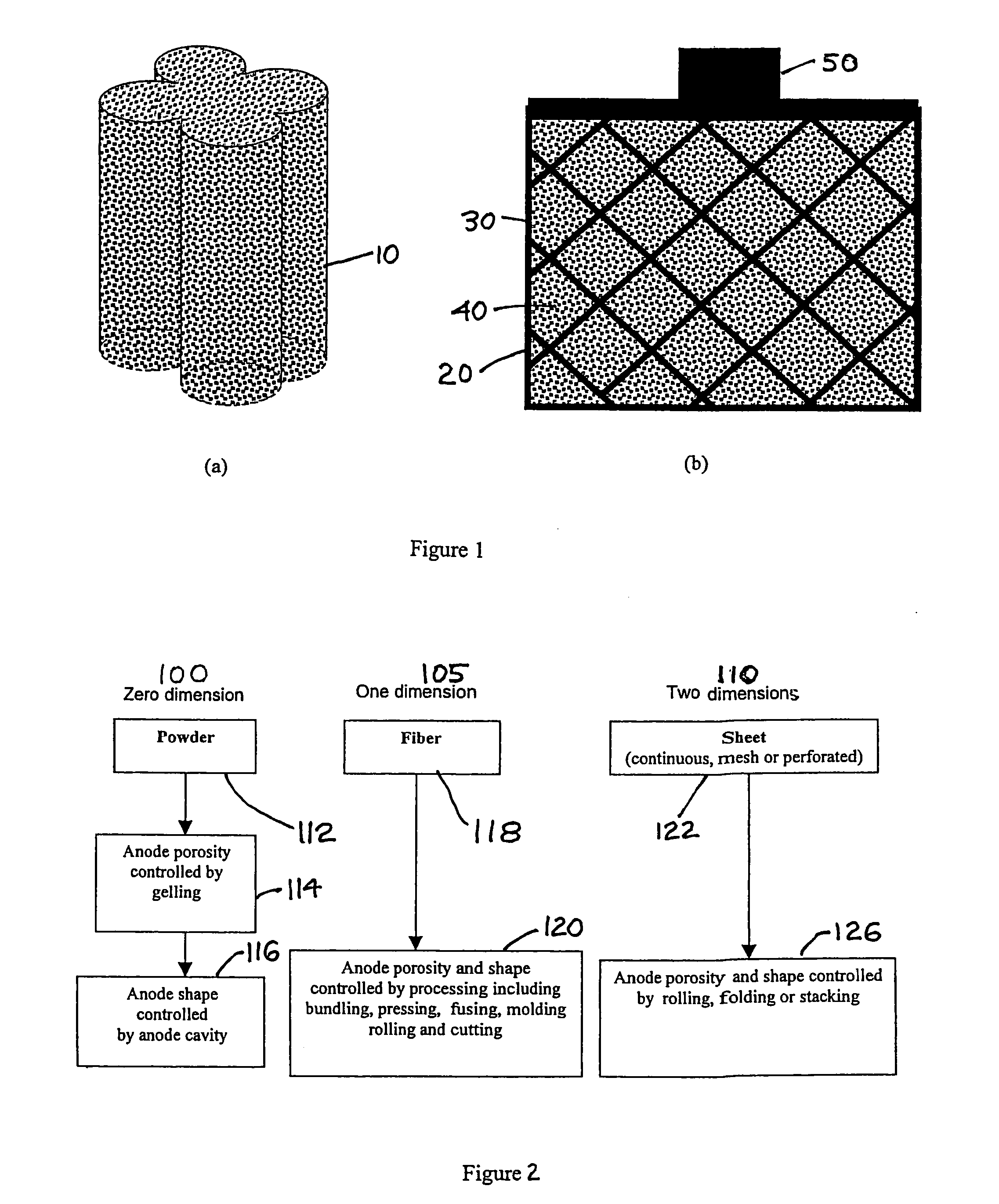

Solid porous zinc electrodes and methods of making same

InactiveUS7291186B2Improve conductivityImprove stabilityFuel and primary cellsAlkaline accumulatorsPorosityFiber

A solid porous zinc electrode for use in alkaline-zinc batteries, zinc-air batteries and fuel cells is provided which comprises specific zinc filaments, fibers, threads or strands compressed into a physically-stable wooly mass to form the electrode with a controlled geometrical shape and porosity distribution. Differential densification incorporates ribs, borders, grids or tabs for good structural integrity, mechanical strength, electrochemical behavior, and electrical conductivity. Pressing in a mold or rolling of a compressed sheet can also provide an anode with a large anode / cathode interface area and a complex geometry. The filaments of controlled dimension and composition are preferably made by spin forming from molten zinc alloys. Such anodes are not susceptible to breakage, have a long storage life and can be used in high rate discharge applications.

Owner:TECK METALS

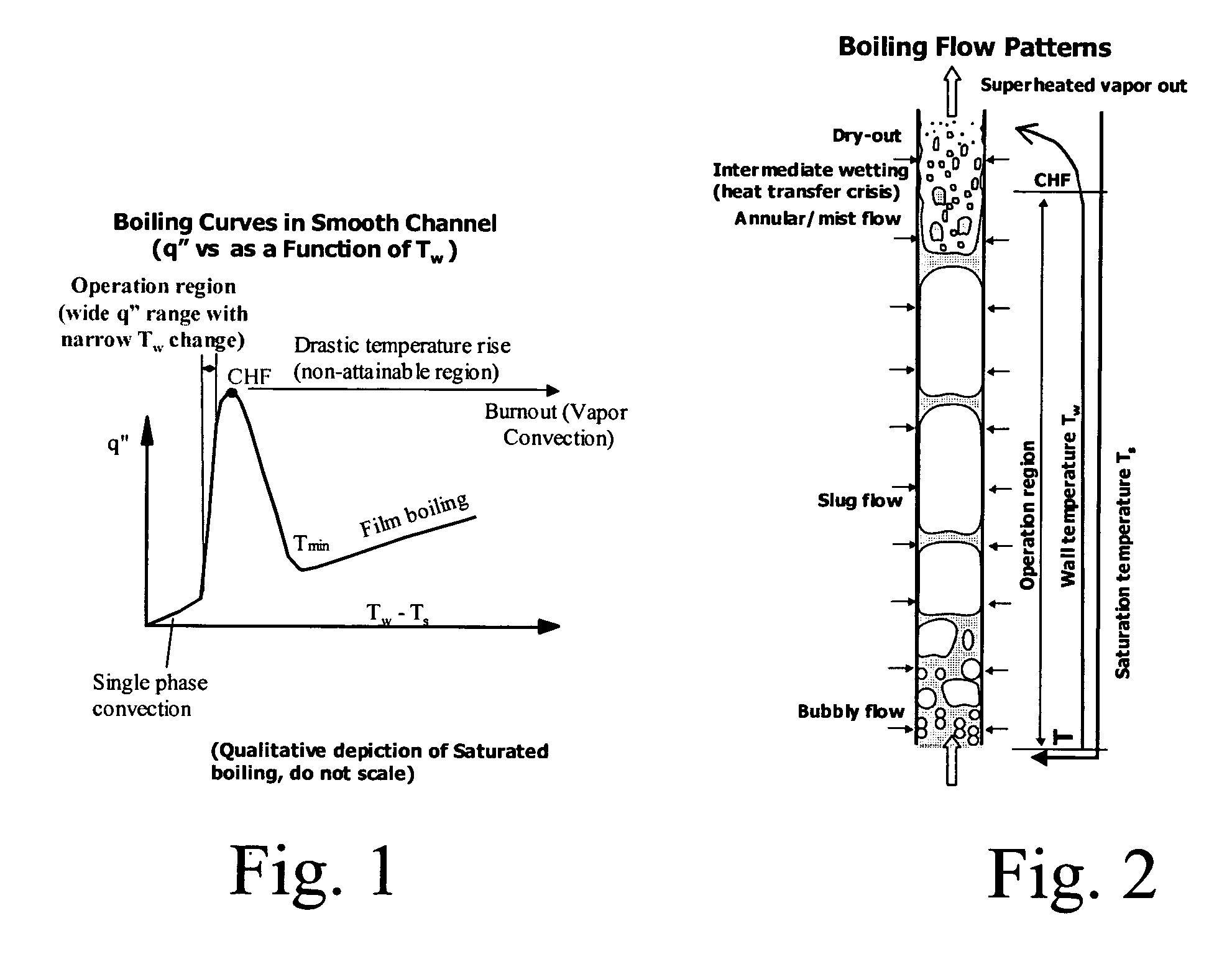

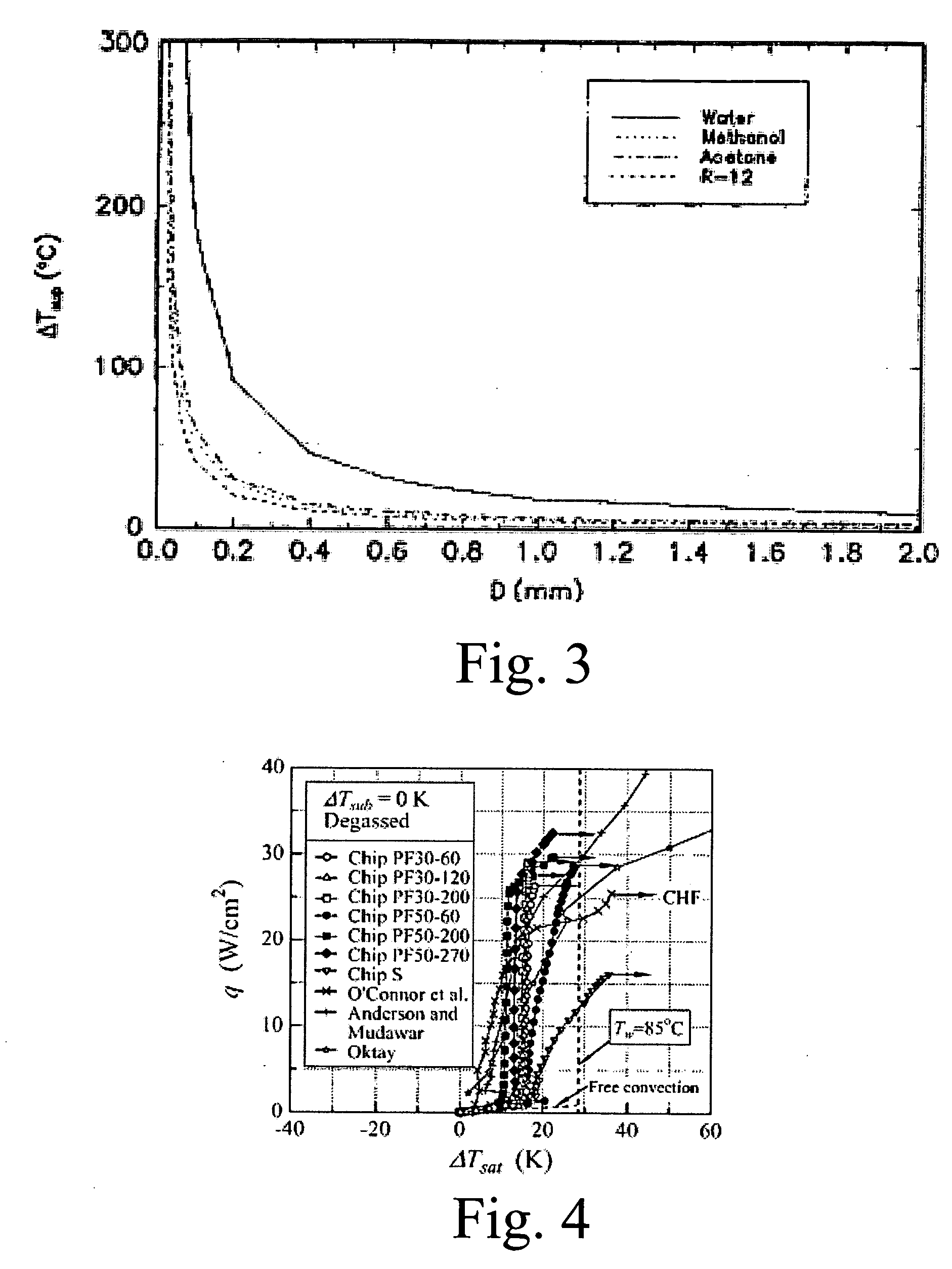

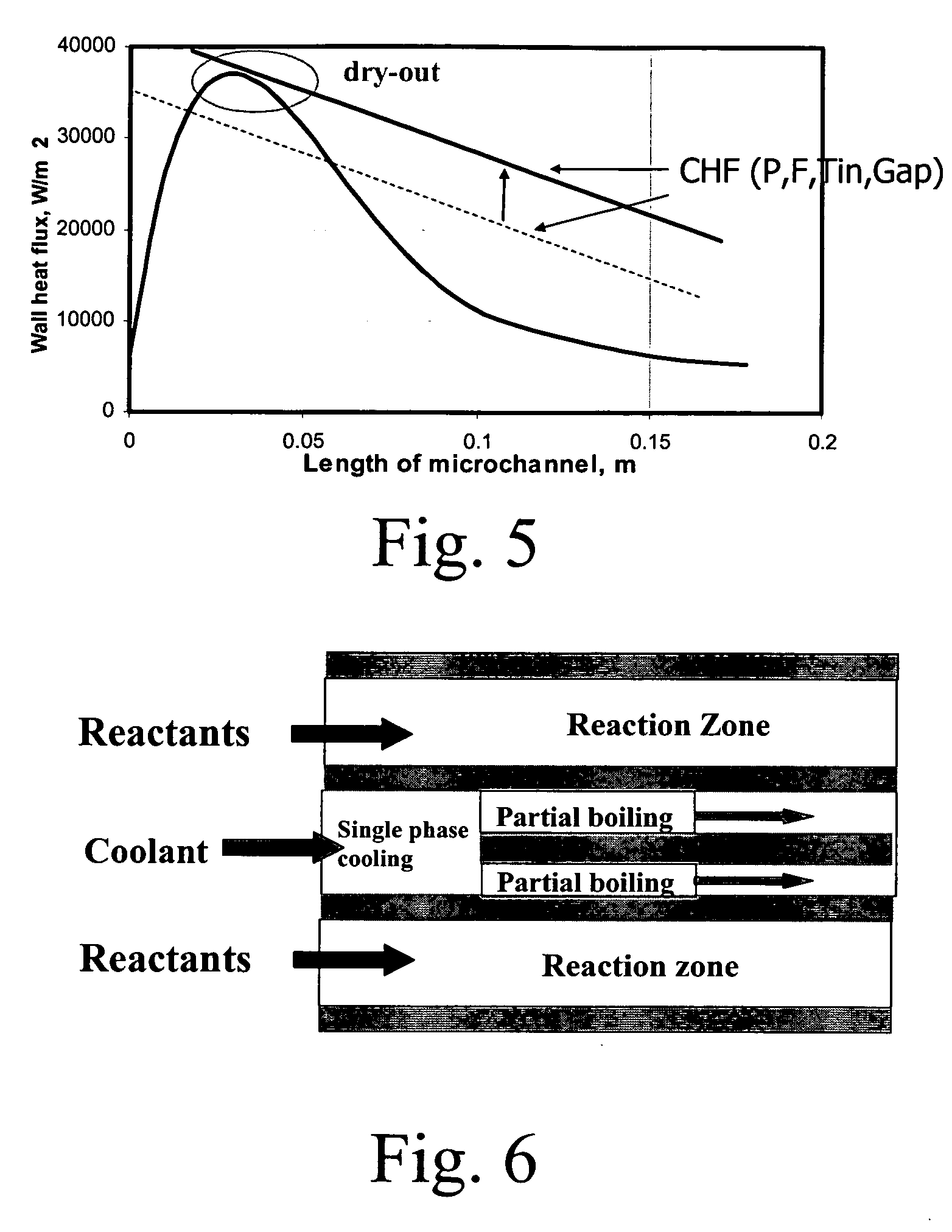

Partial boiling in mini and micro-channels

ActiveUS20060142401A1Less bubbleHigh densityOrganic compounds purification/separation/stabilisationOrganic compound preparationExothermic processChemistry

The invention provides methods, apparatus and systems in which there is partial boiling of a liquid in a mini-channel or microchannel. The partial boiling removes heat from an exothermic process.

Owner:VELOCYS CORPORATION

Method and apparatus for aligning microbeads in order to interrogate the same

A method and apparatus are provided for aligning optical elements or microbeads, wherein each microbead has an elongated body with a code embedded therein along a longitudinal axis thereof to be read by a code reading device. The microbeads are aligned with a positioning device so the longitudinal axis of the microbeads is positioned in a fixed orientation relative to the code reading device. The microbeads are typically cylindrically shaped glass beads between 25 and 250 microns (μm) in diameter and between 100 and 500 μm long, and have a holographic code embedded in the central region of the bead, which is used to identify it from the rest of the beads in a batch of beads with many different chemical probes. A cross reference is used to determine which probe is attached to which bead, thus allowing the researcher to correlate the chemical content on each bead with the measured fluorescence signal. Because the code consists of a diffraction grating typically disposed along an axis, there is a particular alignment required between the incident readout laser beam and the readout detector in two of the three rotational axes. The third axis, rotation about the center axis of the cylinder, is azimuthally symmetric and therefore does not require alignment.

Owner:CYVERA CORP

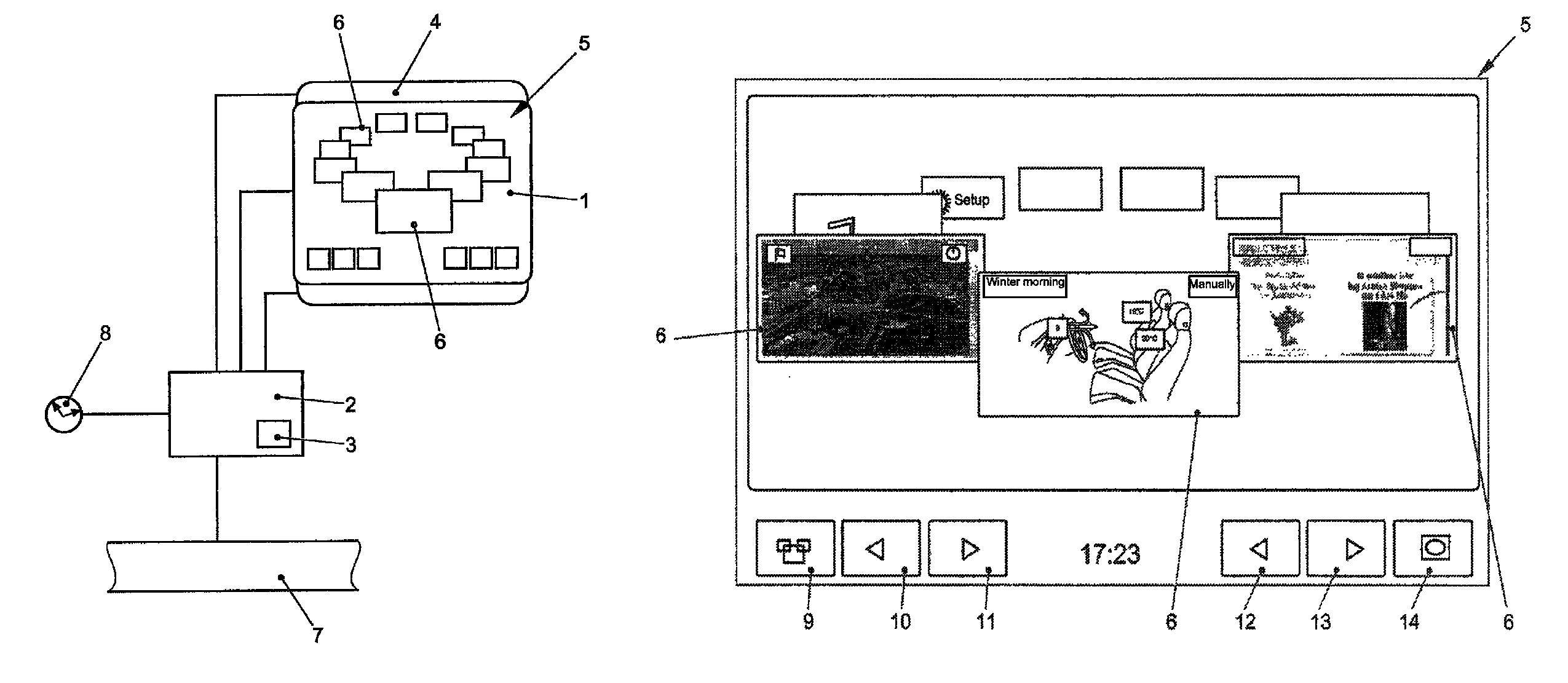

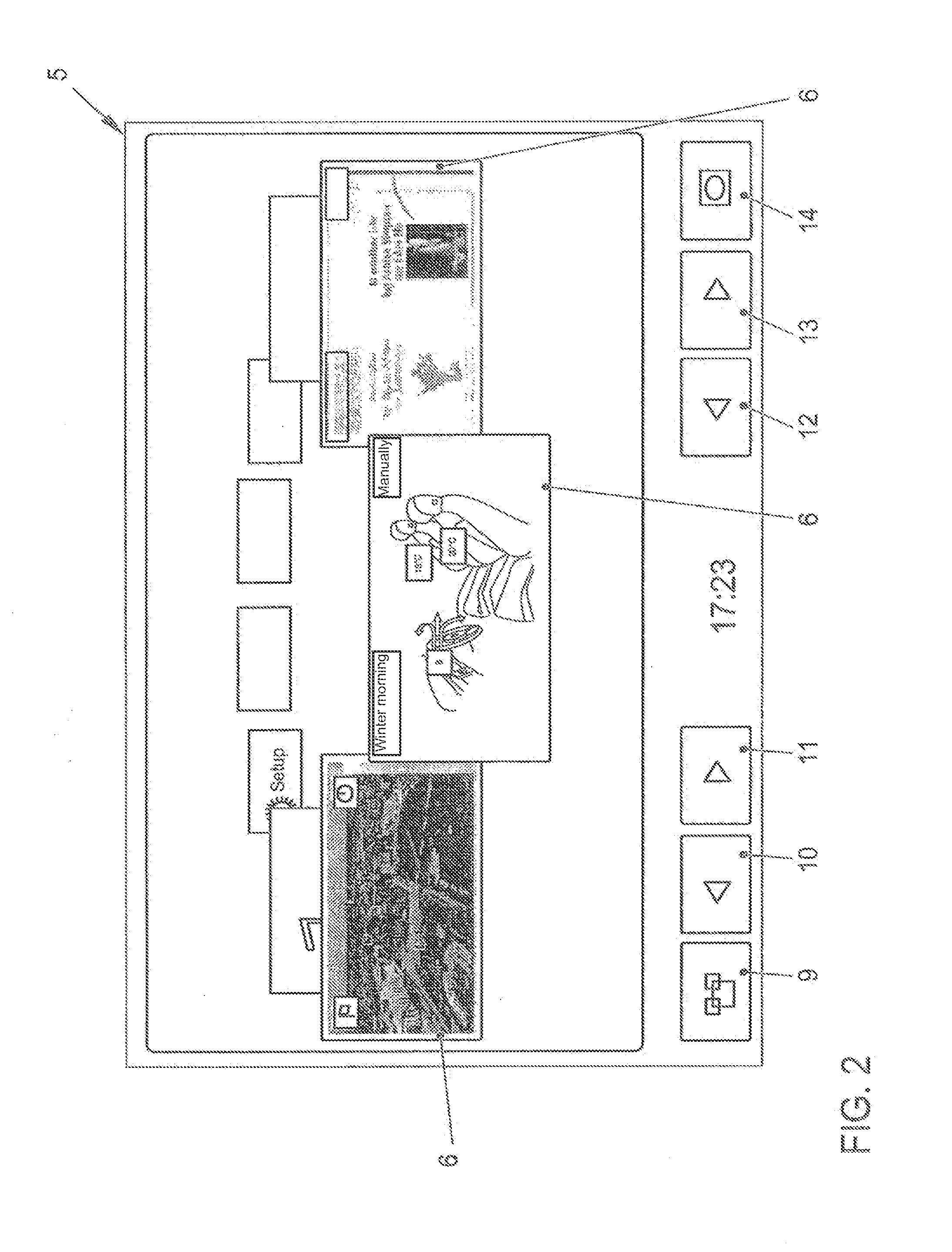

Method for displaying information in a vehicle and display device for a vehicle

ActiveUS8477108B2Rapid and intuitive and simple operator controlSafety is not impairedInstrument arrangements/adaptationsCathode-ray tube indicatorsGraphicsArithmetic logic unit

In a method for displaying information in a motor vehicle, a plurality of objects are represented graphically with the aid of a display mounted in a motor vehicle. A user-interface device generates graphics data which control the display such that the graphical objects are shown disposed on a virtual, perspectively displayed ring, and that in response to an input with the aid of an input device, an arithmetic logic unit of the user-interface device alters the graphics data such that the graphical objects on the virtual ring rotate like a carousel. A corresponding display device is provided.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com