Method and apparatus for aligning microbeads in order to interrogate the same

a technology of microbeads and interrogation, which is applied in the field of methods and apparatus for processing information contained on microbeads, can solve the problems of insufficient different codes, inability to withstand harsh temperature, chemical, nuclear and/or electromagnetic environments, and insufficient existing technologies such as bar codes, to achieve reliable and repeatable transportation of all beads, and low cost. , the effect of fast and effective/reliable movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

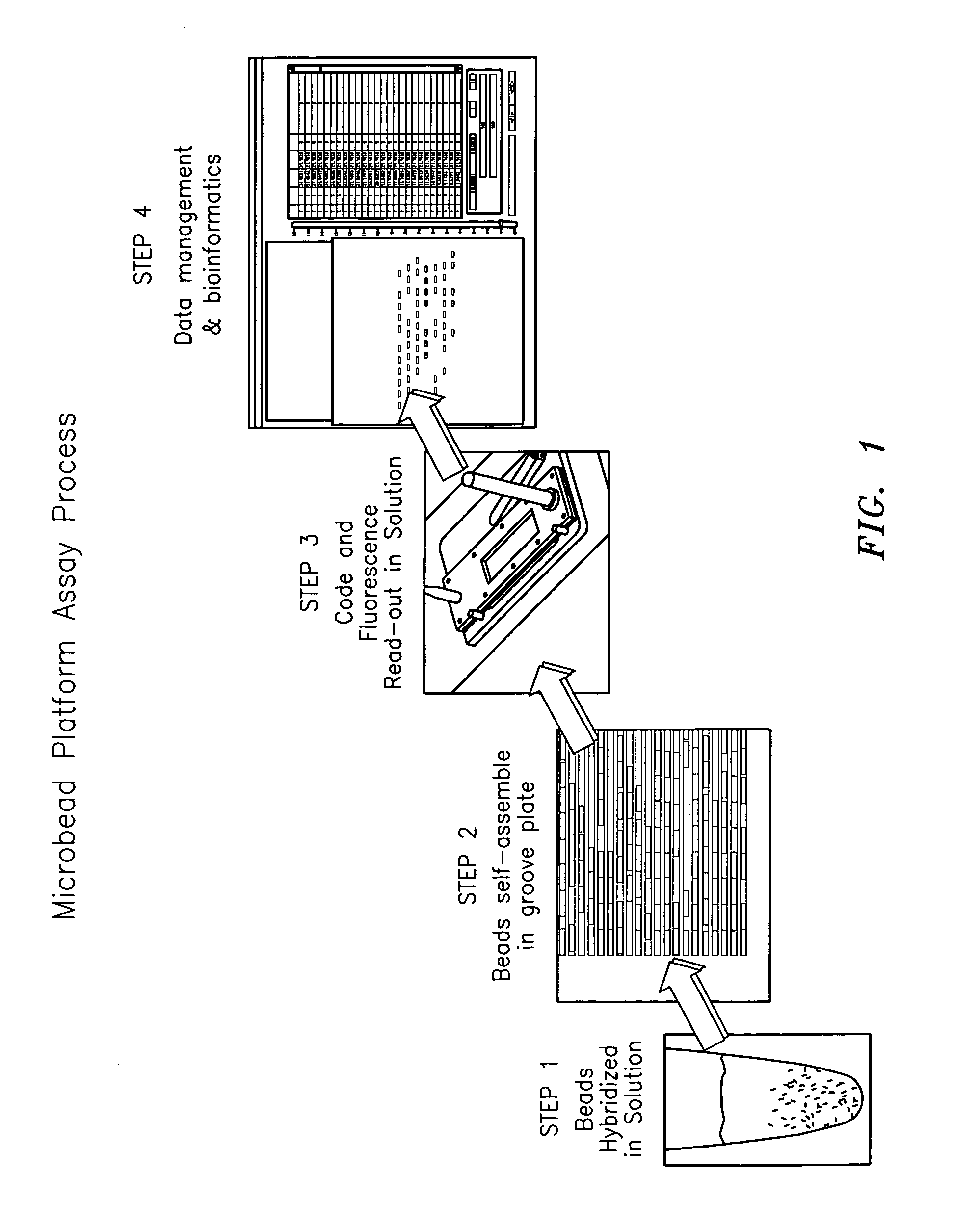

[0089]FIG. 1 shows, by way of example, steps of a microbead assay process which uses the microbead technology of the present invention. The steps of the assay process shown in FIG. 1 include a first step in which the microbeads are used in a solution; a second step in which the microbeads are aligned in a desired manner; a third step in which the code and florescence in and / or on the microbeads are read-out; and a fourth step in which the information related to the code and florescence is processed in relation to data management and bioinformatics. The present invention primarily relates to step 2 wherein the microbeads are uniquely aligned so the longitudinal axis of the microbeads is positioned in a fixed orientation relative to the code and florescence reading device, as well as relating to a lesser extent to step 3. It is important to note that the scope of the present invention is not intended to be limited to any particular type or kind of assay process or other process in whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com