Organic material resistance random access memory element and manufacturing method thereof

A technology of resistive memory and organic materials, applied in the fields of electrical components, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of unsuitability for commercial applications and unstable performance parameters of resistive memory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, an organic material resistive memory element.

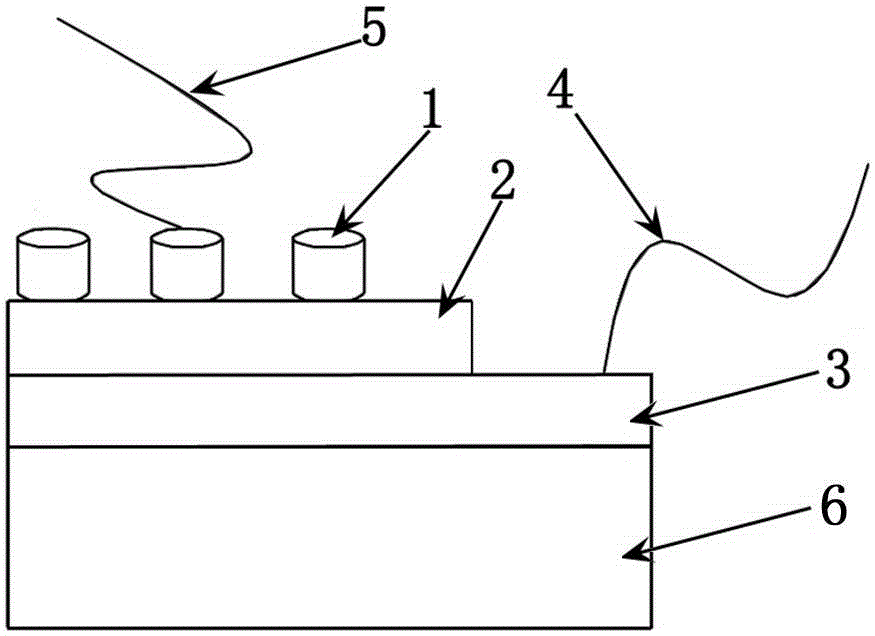

[0024] Such as figure 1 As shown, the structure of the organic material resistive memory element in the present invention includes a lower electrode layer 3, a resistive medium layer 2 and an upper electrode layer 1 arranged in sequence from bottom to top; the lower electrode layer 3 is an ITO (indium tin oxide) layer , the ITO layer can generally be attached to the glass 6 by magnetron sputtering, that is, when preparing the organic material resistive memory element in the present invention, it can be used as The substrate, ITO glass, provides the lower electrode layer 3 . The thickness of the ITO layer on the ITO glass may be 10 nm to 500 nm. The resistive dielectric layer 2 is CH 3 NH 3 PB 3?x Cl 3 layer, the thickness of the resistive medium layer 2 can be set to 10nm-500nm, preferably, can be set to 30nm-200nm. The upper electrode layer 1 is generally composed of several evenly distributed circula...

Embodiment 2

[0026] Embodiment 2, a method for preparing an organic material resistive memory element.

[0027] The preparation method of the organic material resistive memory element in this embodiment includes the following steps:

[0028] a. Select ITO glass as the substrate, the ITO layer on the substrate is the lower electrode layer, and the thickness of the ITO layer is 200nm. Pretreatment of ITO glass: put the ITO glass in acetone and ultrasonically clean it for 1 minute, then put it in alcohol and clean it with ultrasonic wave for 1 minute, then put it in deionized water and clean it with ultrasonic wave for 5 minutes, then take it out and use high-purity ( Purity of 99.99% and above) nitrogen (N 2 ) and blow dry.

[0029] b. Fix the ITO glass pretreated in step a on the spin coater in the glove box, fill the glove box with high-purity (purity of 99.99% and above) nitrogen, and fill the glove box with 0.14 mol / L of PbCl 2 solution, 1.26mol / L of PbI 2 Solution and 1.3mol / L meth...

Embodiment 3

[0037] Embodiment 3, a method for preparing an organic material resistive memory element.

[0038] The method for preparing an organic material resistive memory element in this embodiment also includes four steps a, b, c, and d, wherein, steps a, b, and c are all the same as the corresponding steps in embodiment 2, the difference is Step d, the step d in the present embodiment is as follows:

[0039] d, form CH in step c 3 NH 3 PB 3?x Cl 3 layer and annealed ITO glass is placed on the target platform in the vacuum evaporation growth chamber, and a mask is placed on it. The mask is evenly distributed with 100 μm round holes, and an Al target is placed above the mask. , the vacuum evaporation growth chamber was evacuated to 3×10 -4 Pa, set the sputtering power to 10W, the sputtering distance to 6cm, the sputtering time to 8min, and the rate of 13nm / min in CH 3 NH 3 PB 3?x Cl 3 An Al upper electrode layer with a thickness of about 100nm is deposited on the layer, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com