Patents

Literature

30results about How to "Less resolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

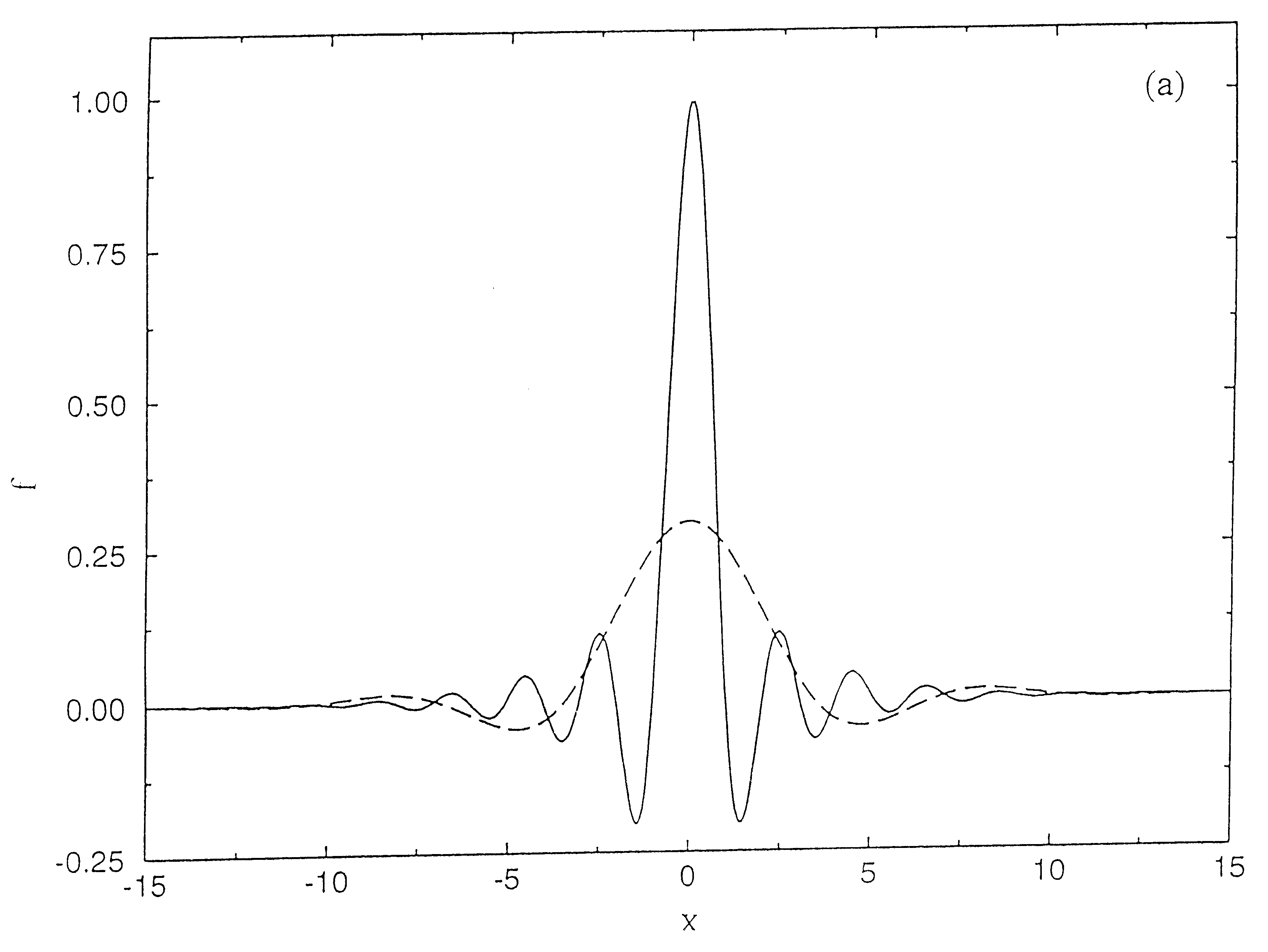

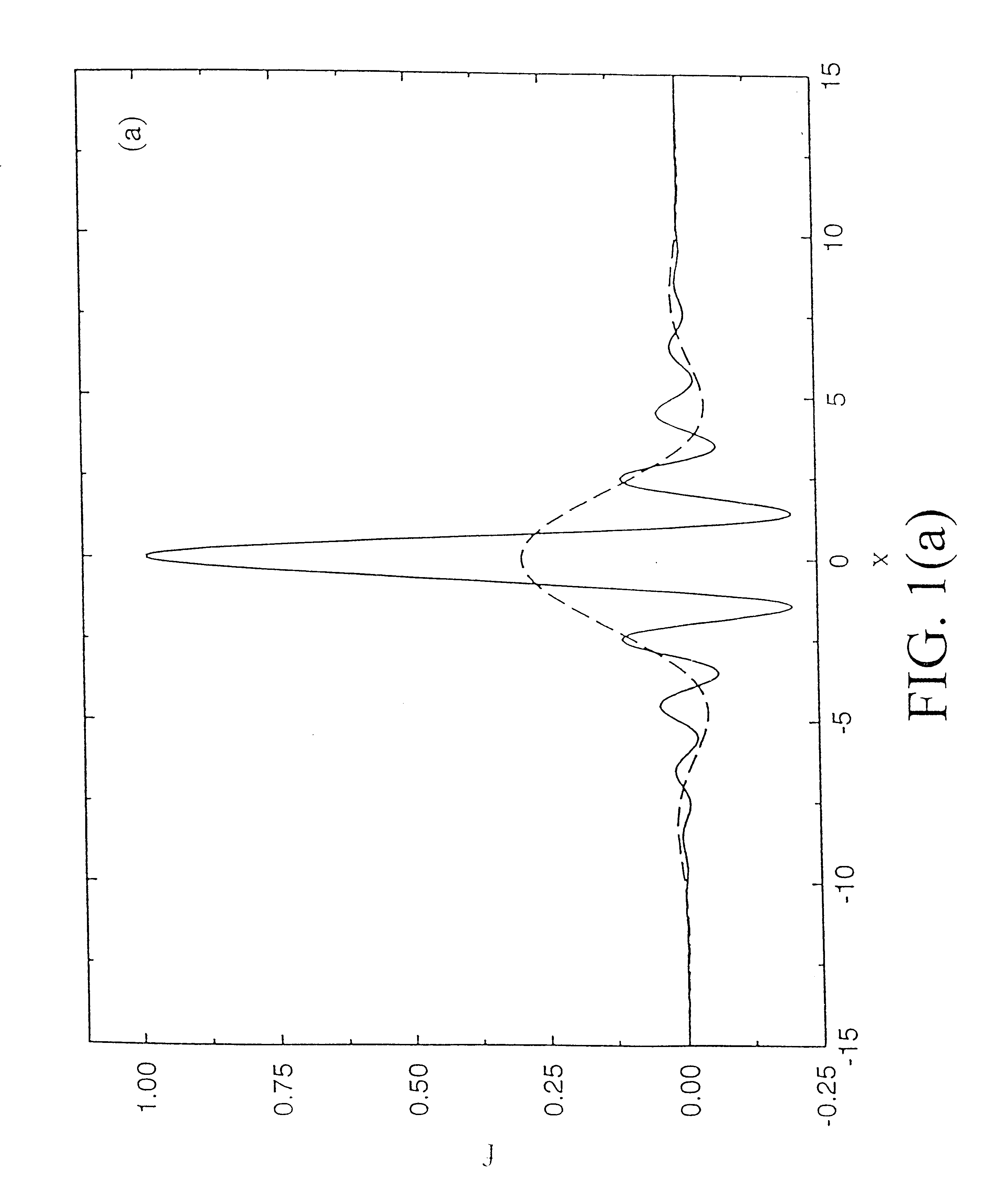

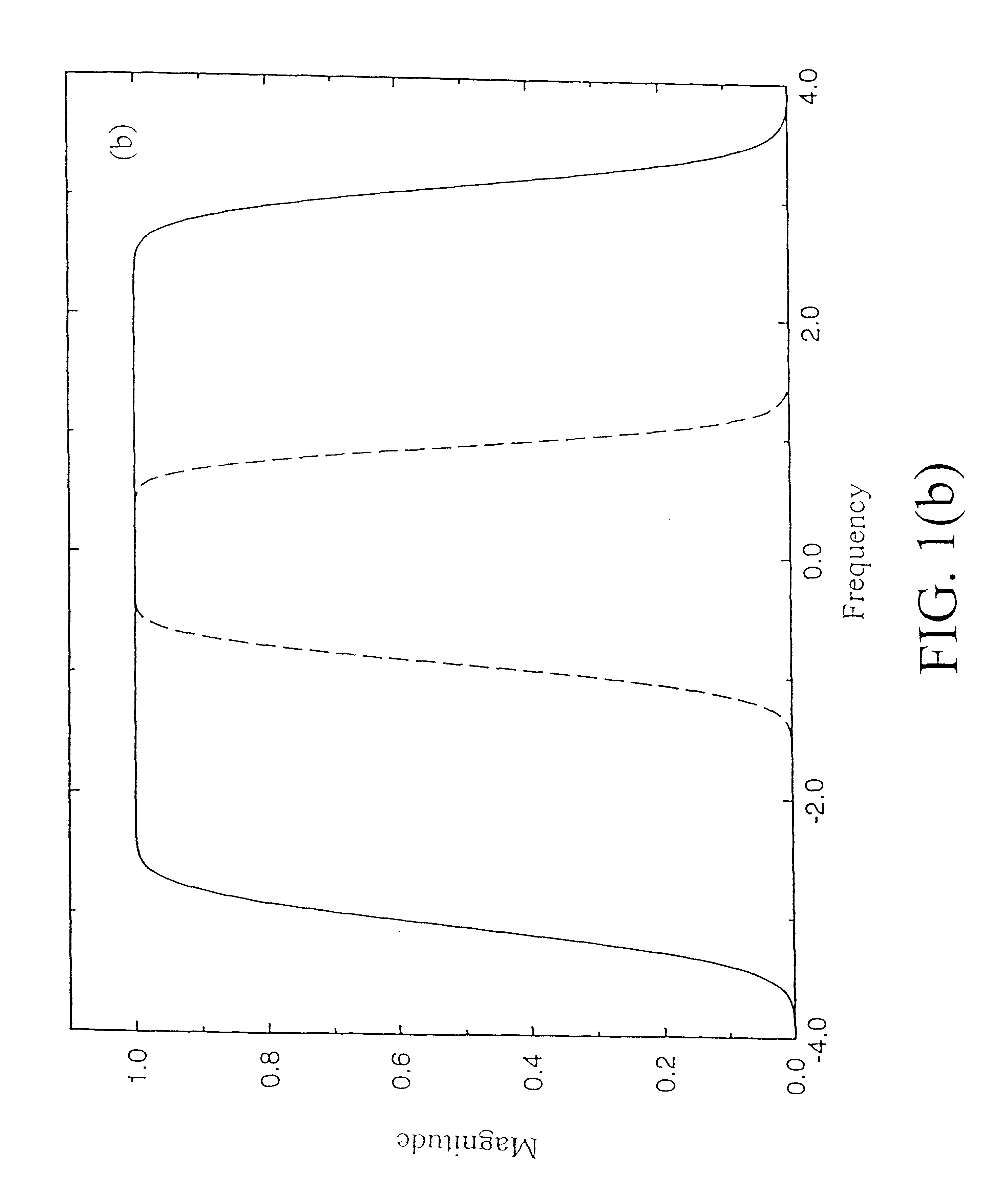

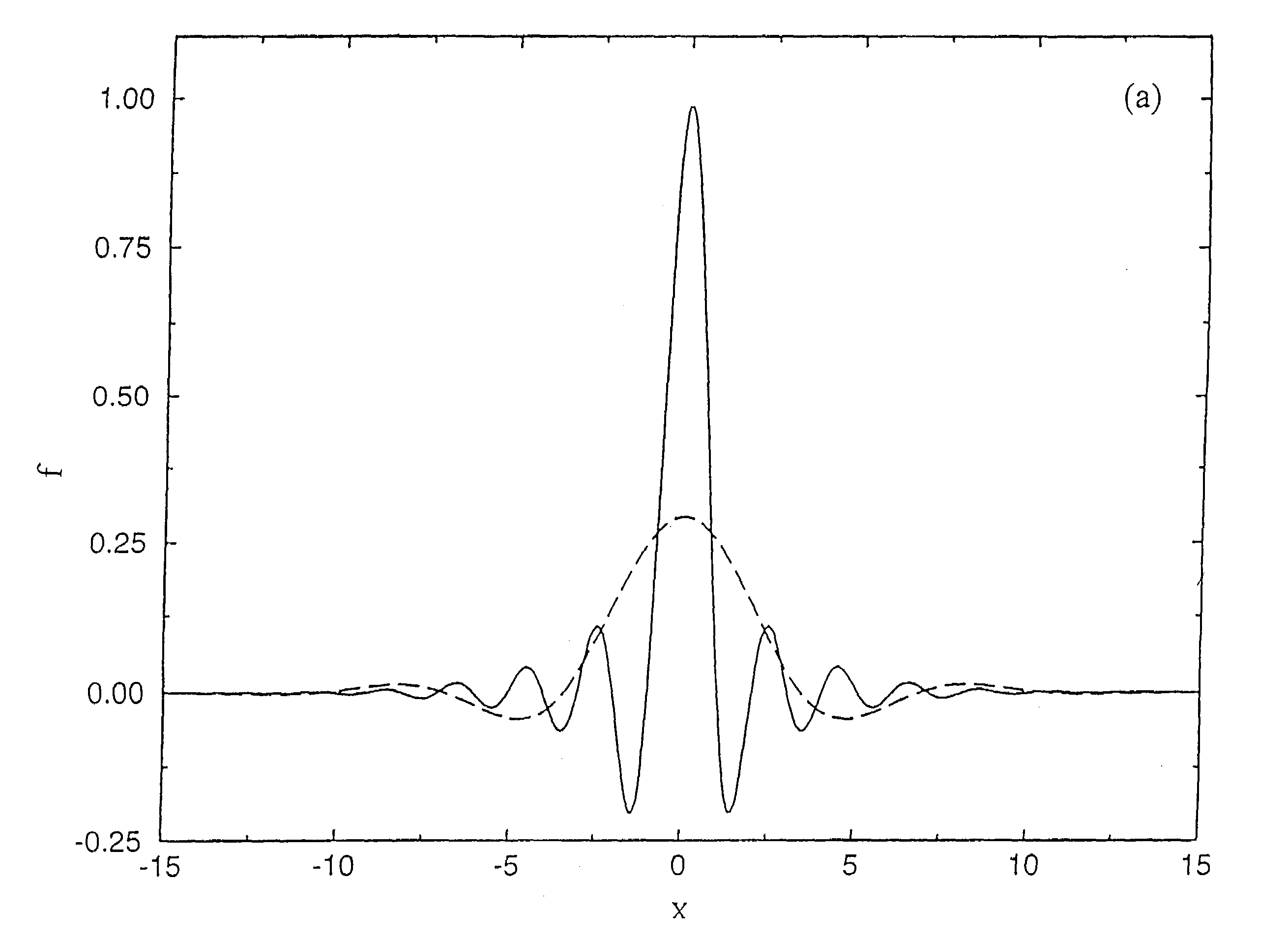

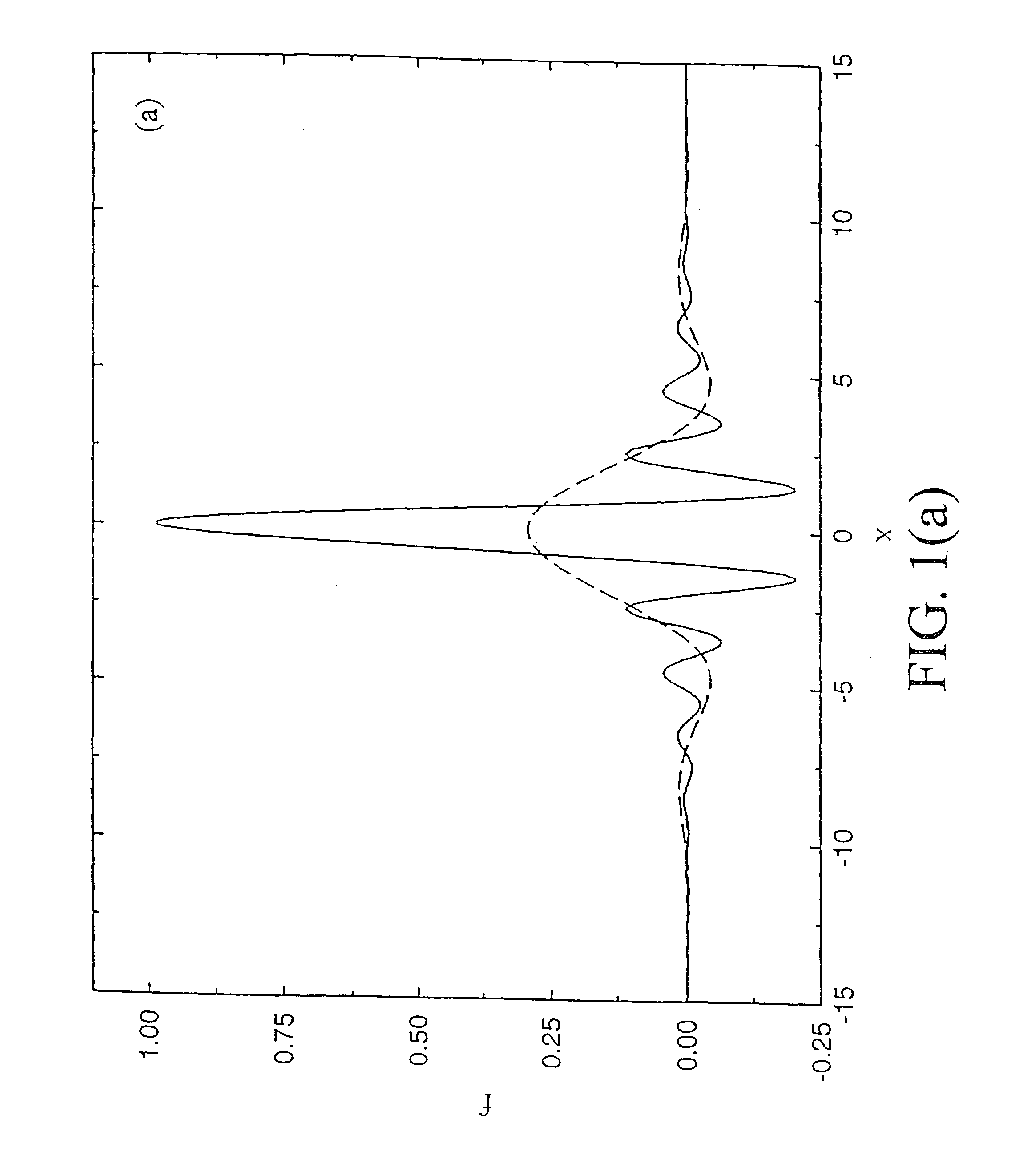

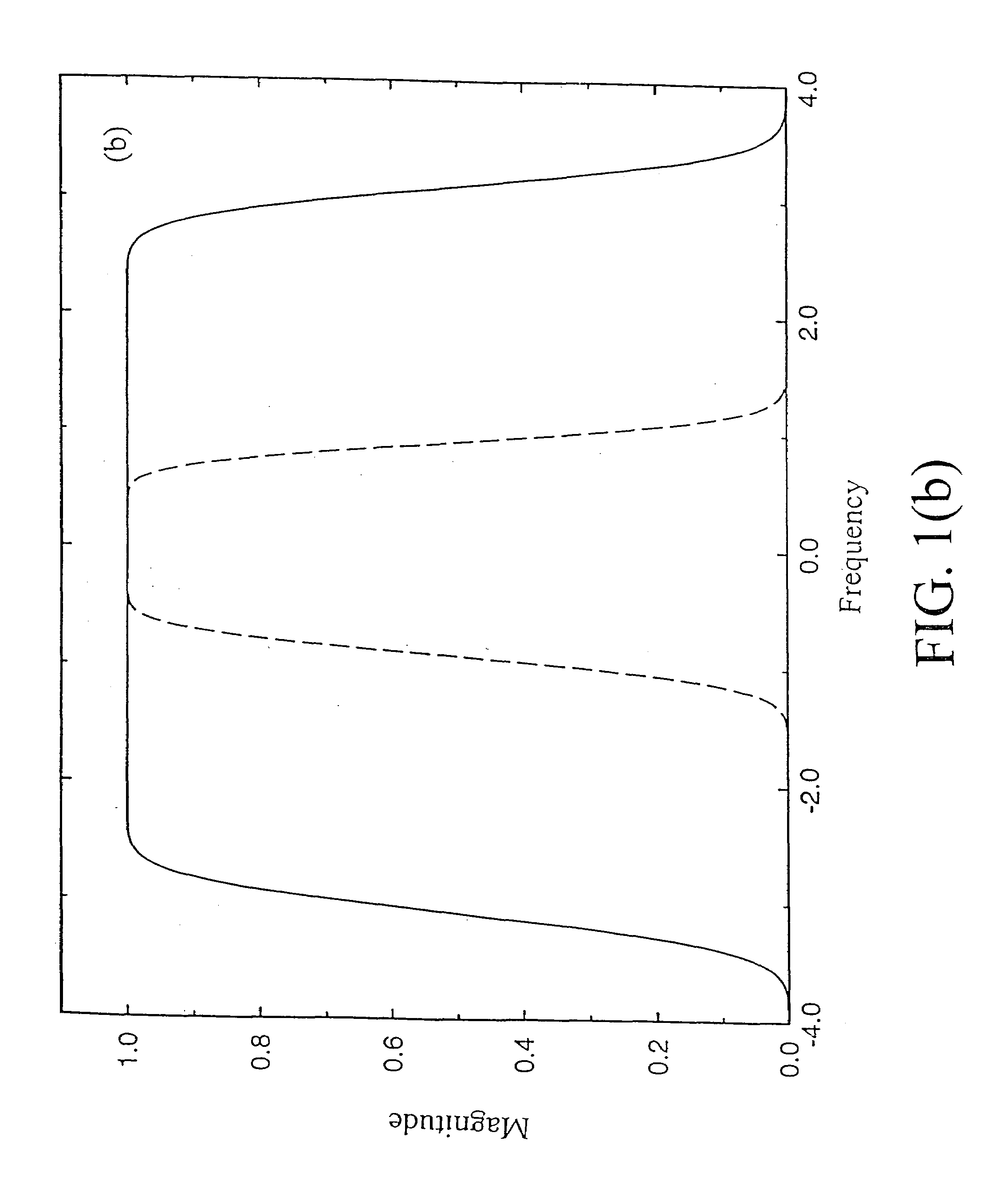

Methods for performing DAF data filtering and padding

InactiveUS6847737B1Reduce acquisition timeEnhance and improve imageImage enhancementImage analysisPattern recognitionData set

A method for padding, filtering, denoising, image enhancing and increased time-frequency acquisition is described for digitized data of a data set where unknown data is estimated using real data by adding unknown data points in a manner that the padding routine can estimate the interior data set including known and unknown data to a given accuracy on the known data points. The method also provides filtering using non-interpolating, well-tempered distributed approximating functional (NIDAF)-low-band-pass filters. The method also provides for symmetric and / or anti-symmetric extension of the data set so that the data set may be better refined and can be filtered by Fourier and other type of low frequency or harmonic filters.

Owner:IOWA STATE UNIVERSITY +1

Methods for performing DAF data filtering and padding

InactiveUS7272265B2Reduce acquisition timeEnhance and improve imageImage enhancementImage analysisPattern recognitionData set

A method for padding, filtering, denoising, image enhancing and increased time-frequency acquisition is described for digitized data of a data set is described where unknown data is estimated using real data by adding unknown data points in a manner that the padding routine can estimate the interior data set including known and unknown data to a given accuracy on the known data points. The method also provides filtering using non-interpolating, well-tempered distributed approximating functional (NIDAF)-low-band-pass filters. The method also provides for symmetric and / or anti-symmetric extension of the data set so that the data set may be better refined and can be filtered by Fourier and other type of low frequency or harmonic filters.

Owner:IOWA STATE UNIV RES FOUND

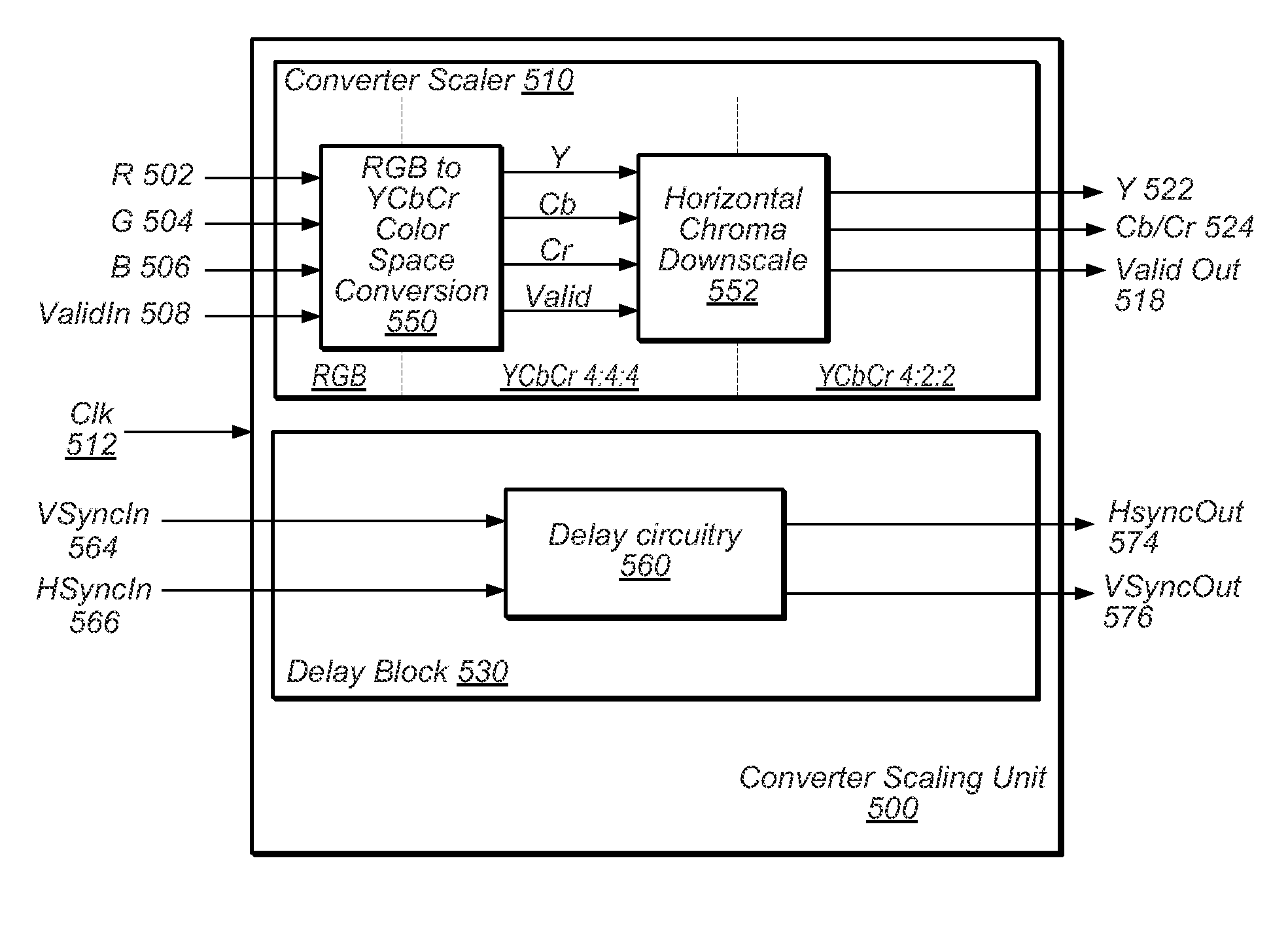

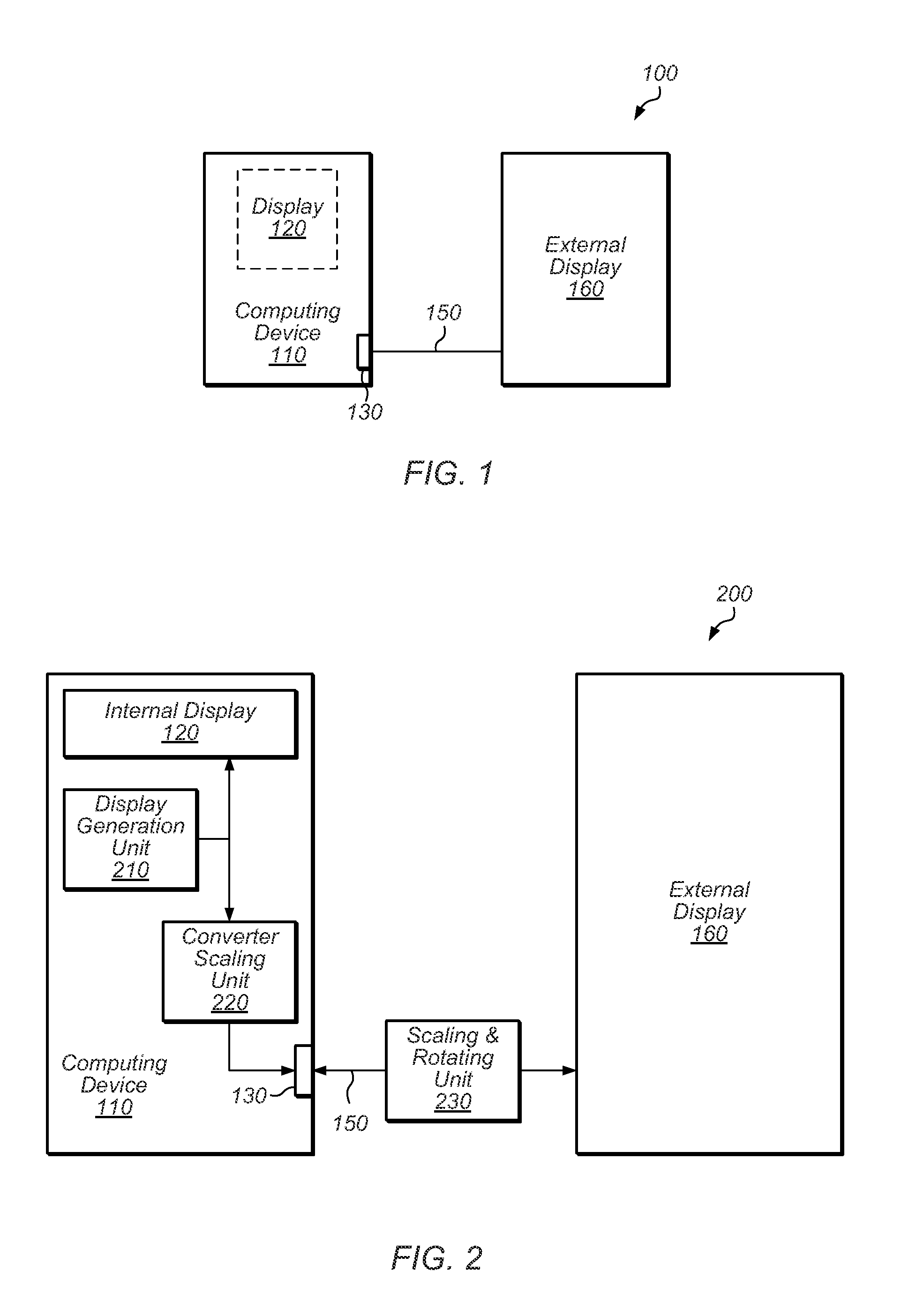

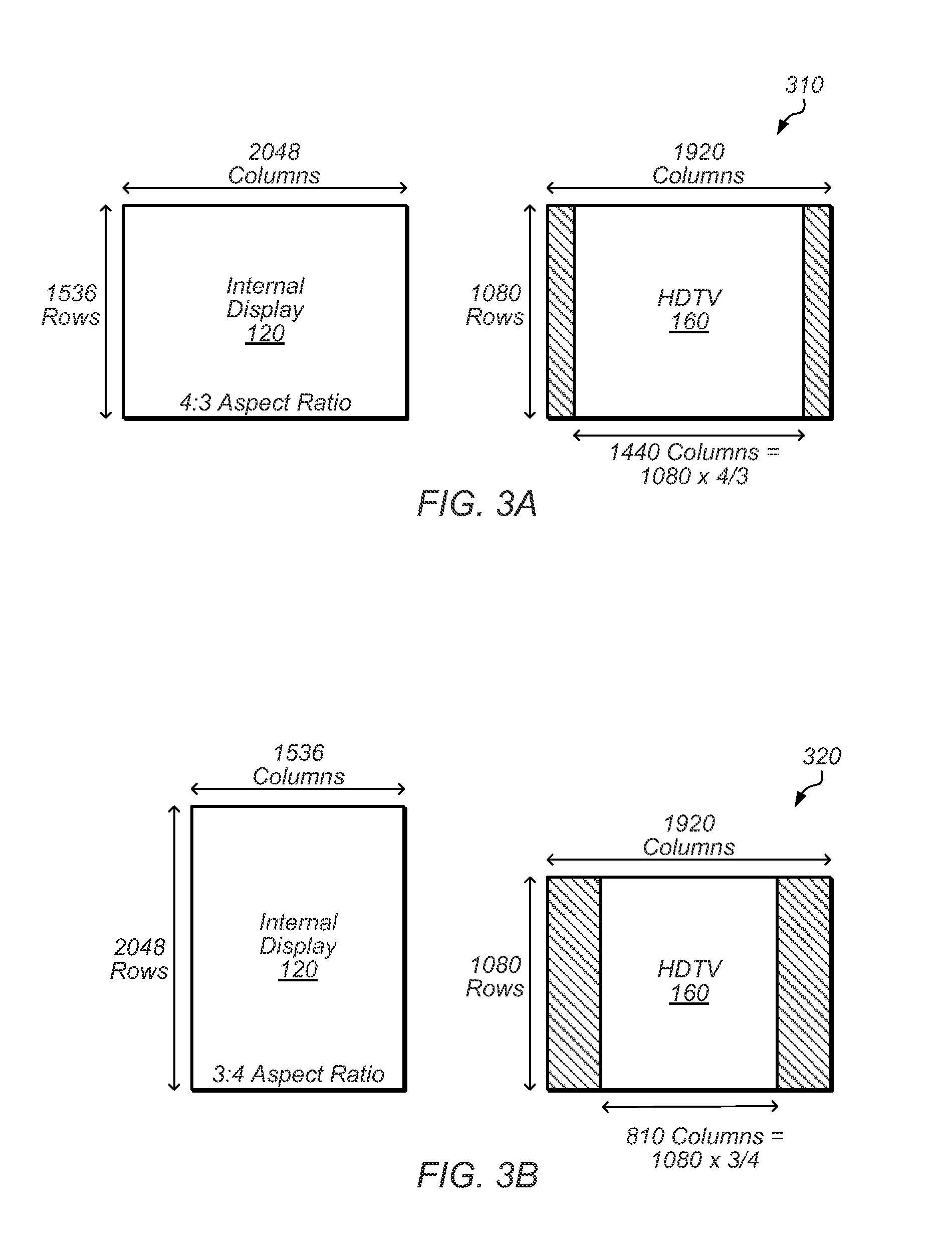

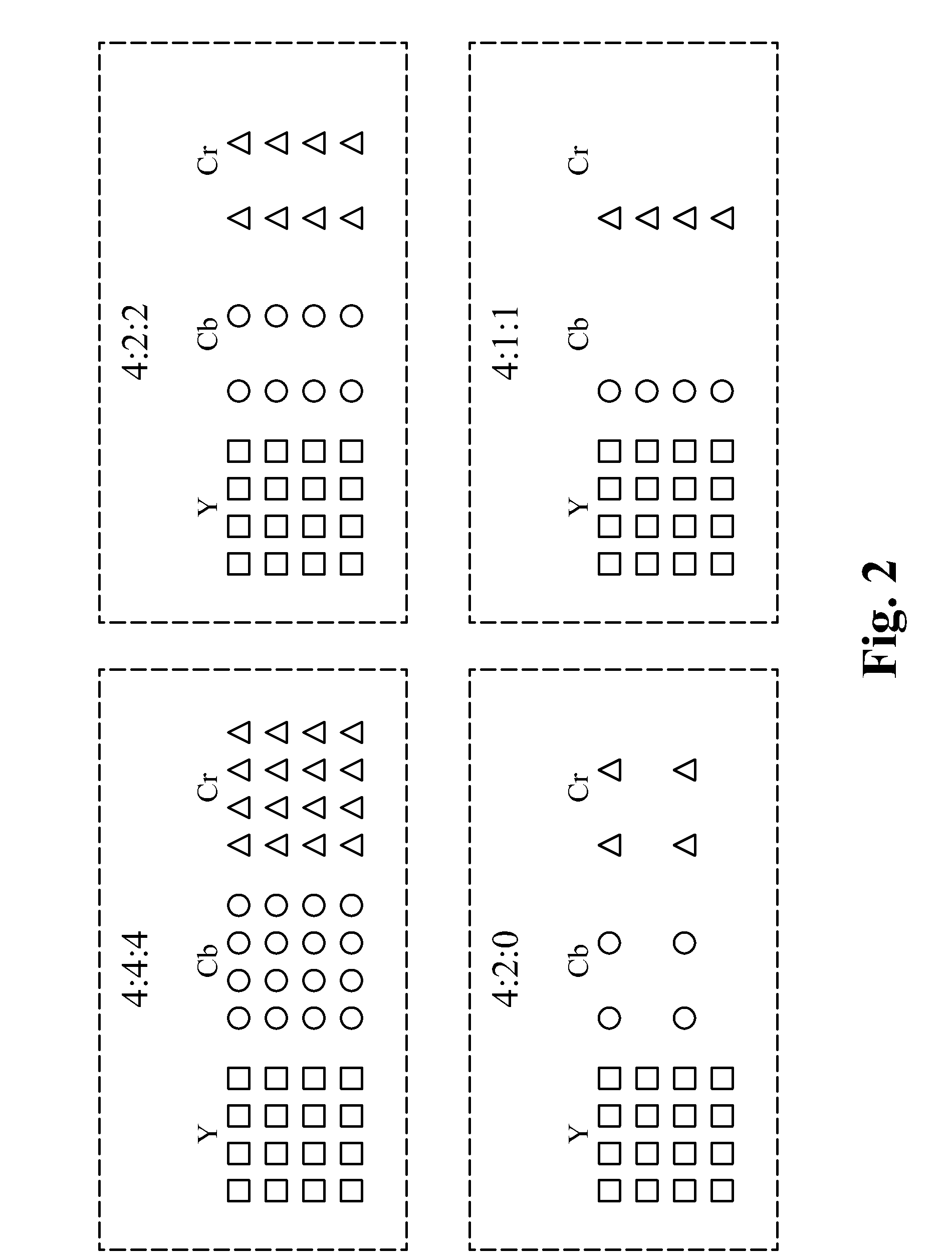

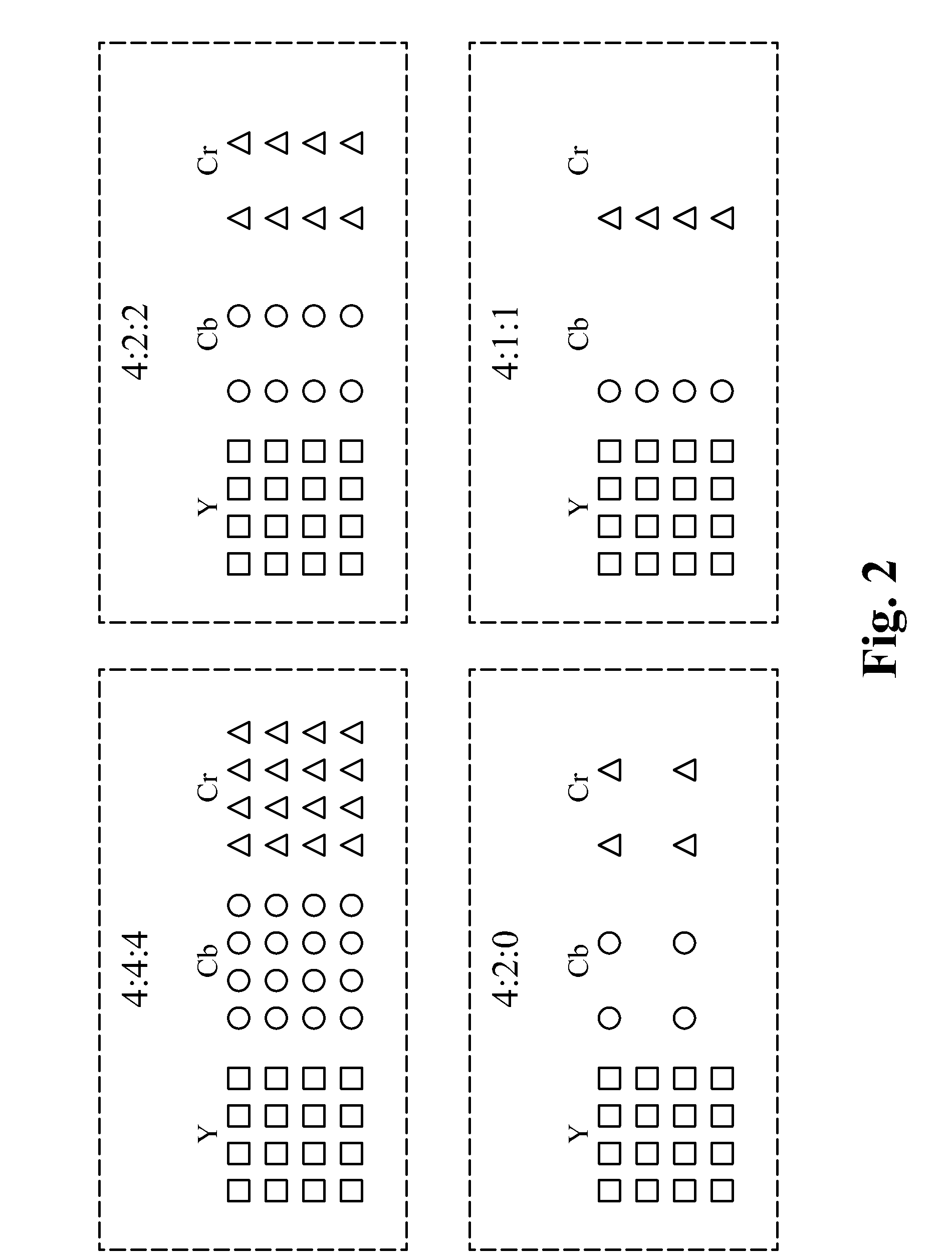

Color Space Conversion for Mirror Mode

InactiveUS20130057567A1Less resolutionLow acuityCathode-ray tube indicatorsInput/output processes for data processingAspect ratioImage resolution

The same pixel stream may be displayed on an internal display and an external display while maintaining the original aspect ratio corresponding to the internal display dimensions. A connector with limited number of pins may only support a two-wire display port interface to the external display, which may not provide enough bandwidth to transmit the full resolution image to the external display. To transmit the full resolution image, a color space conversion from RGB space to YCbCr color space may be performed. The Luma component may be transmitted at full resolution, while the chroma components may be scaled. Accordingly, there is no loss of image resolution, while some amount of color resolution may be lost. However, there is no need to retime frames within the system on chip (SOC), and the same pixel stream may be used as the basis for display on both the internal and the external display.

Owner:APPLE INC

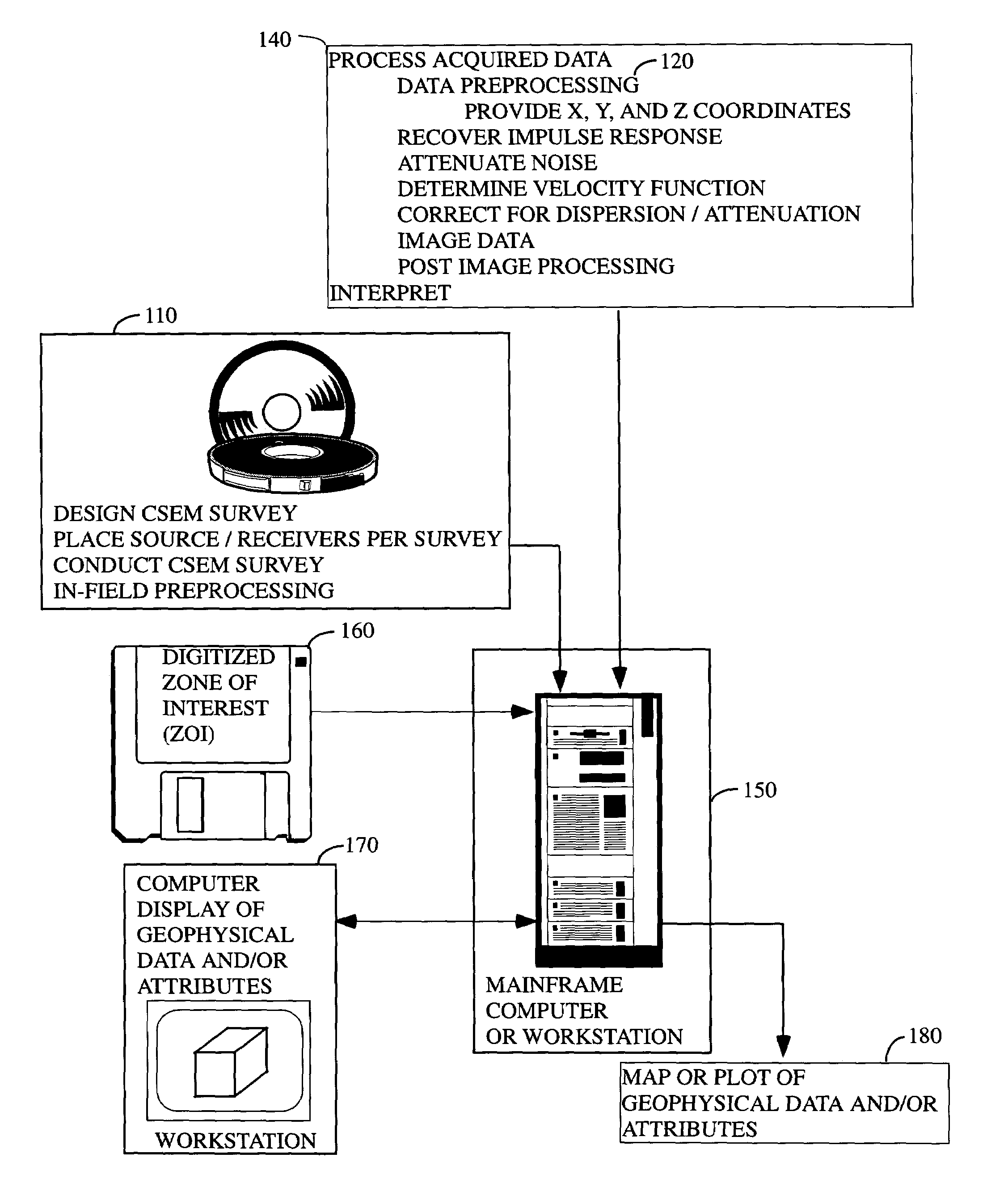

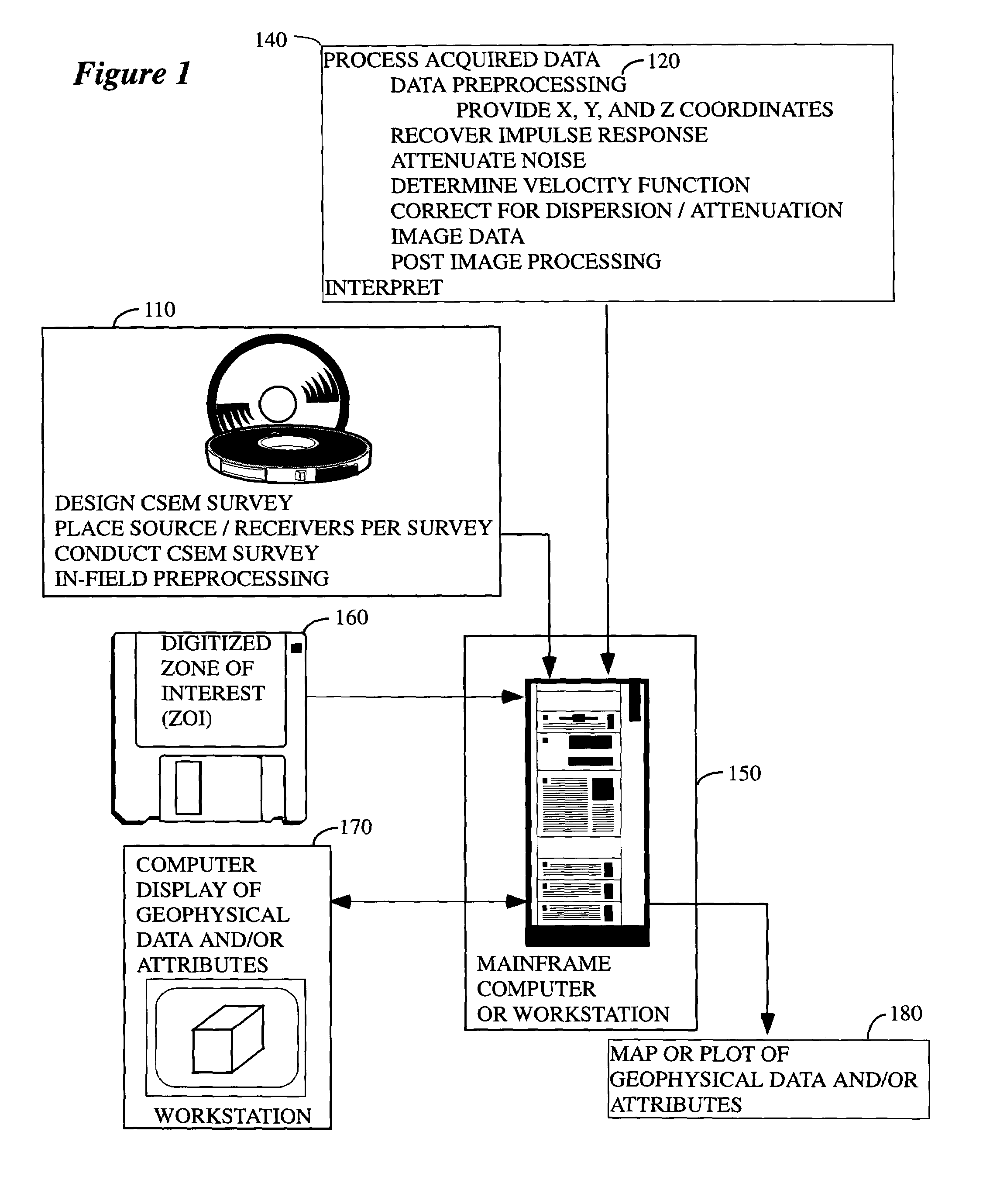

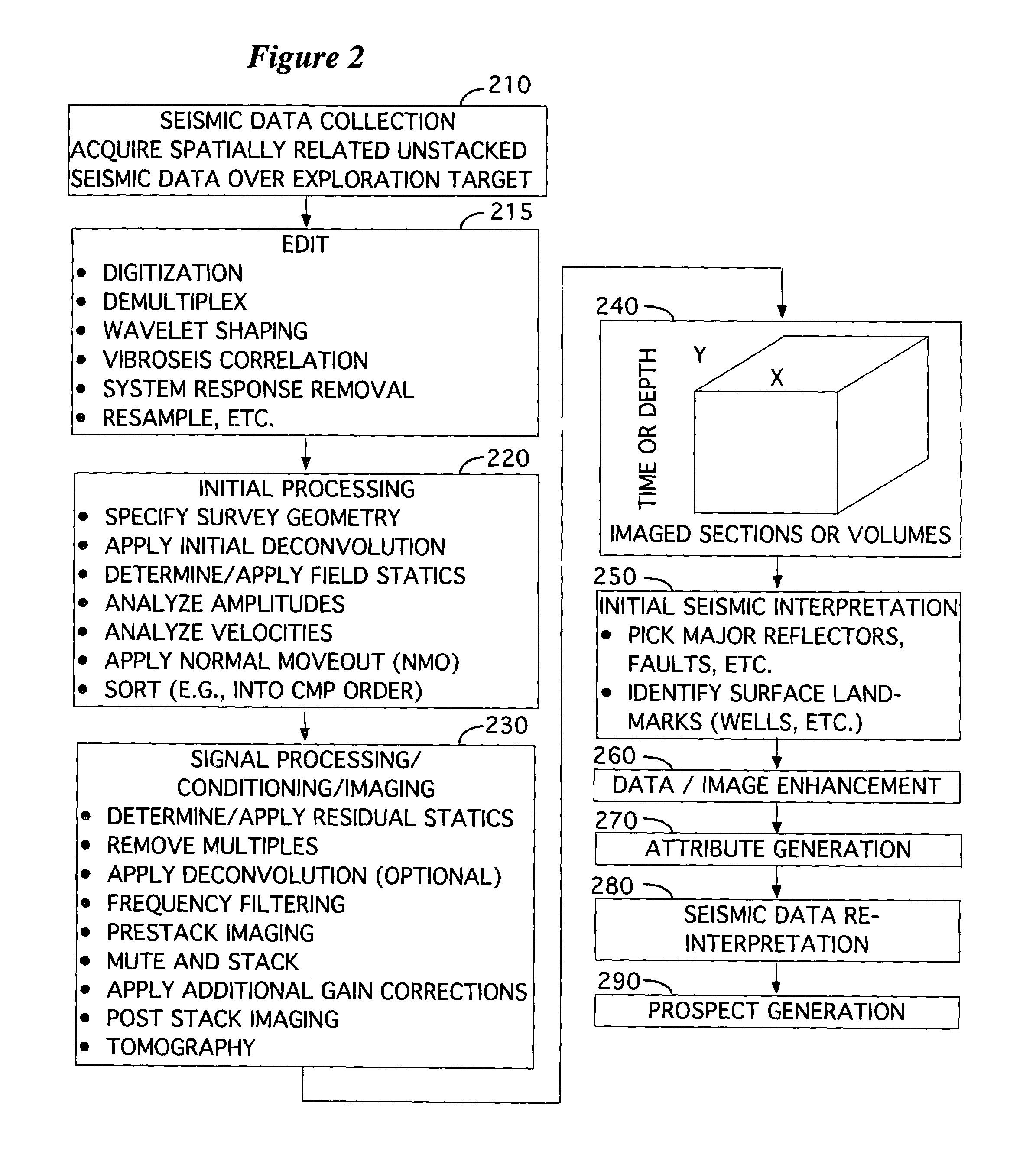

System and method for using time-distance characteristics in acquisition, processing, and imaging of t-CSEM data

InactiveUS7502690B2Enhance the imageEasy to processSeismic signal processingSeismology for water-covered areasUltrasound attenuationControlled source electro-magnetic

There is provided herein a system and method of acquiring, processing, and imaging transient Controlled Source ElectroMagnetic (t-CSEM) data in ways that are similar to those used for seismic data. In particular, the instant invention exploits the time-distance characteristics of t-CSEM data to permit the design and execution of t-CSEM surveys for optimal subsequent processing and imaging. The instant invention illustrates how to correct t-CSEM data traces for attenuation and dispersion, so that their characteristics are more like those of seismic data and can be processed using algorithms familiar to the seismic processor. The resulting t-CSEM images, particularly if combined with corresponding seismic images, may be used to infer the location of hydrocarbon reservoirs.

Owner:BP CORP NORTH AMERICA INC

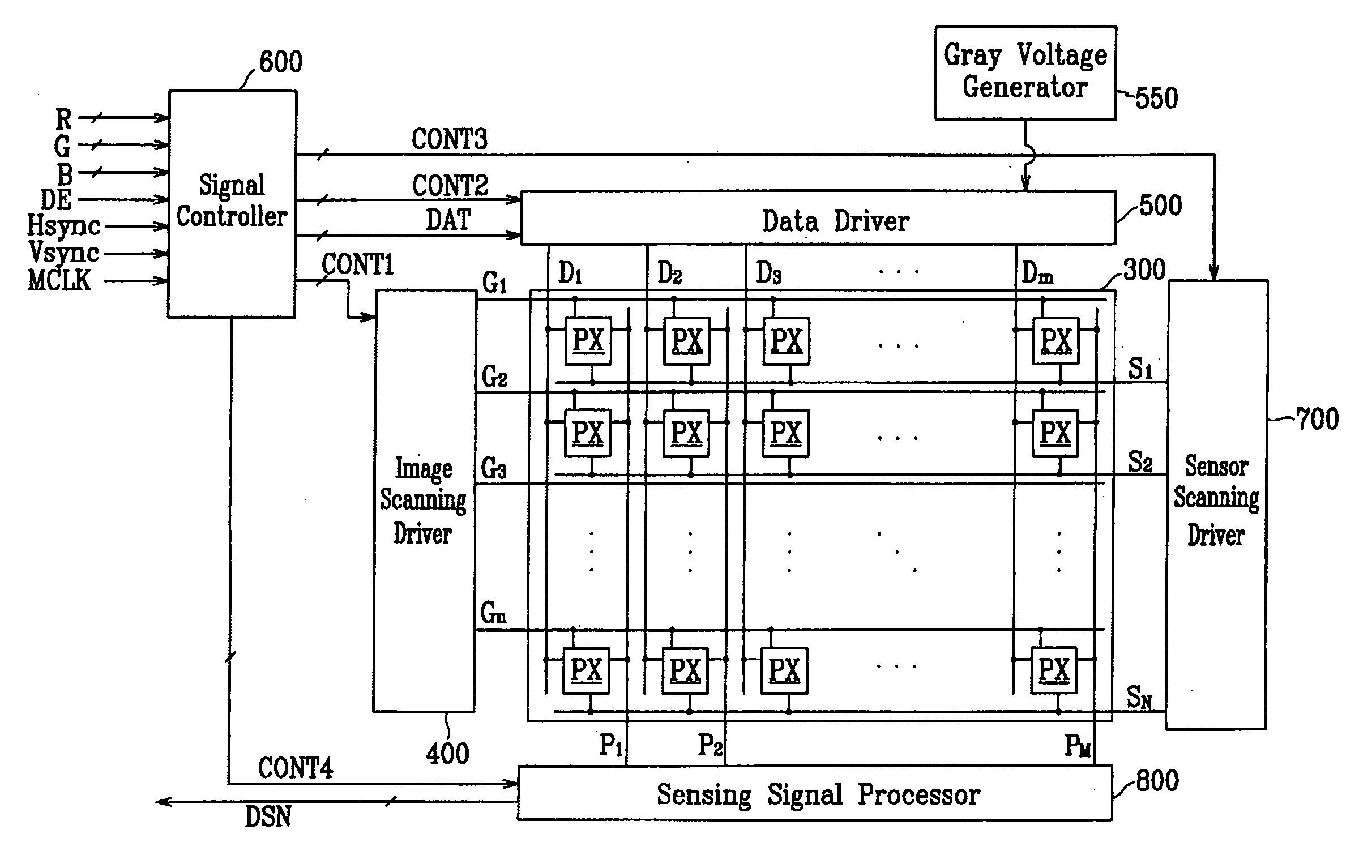

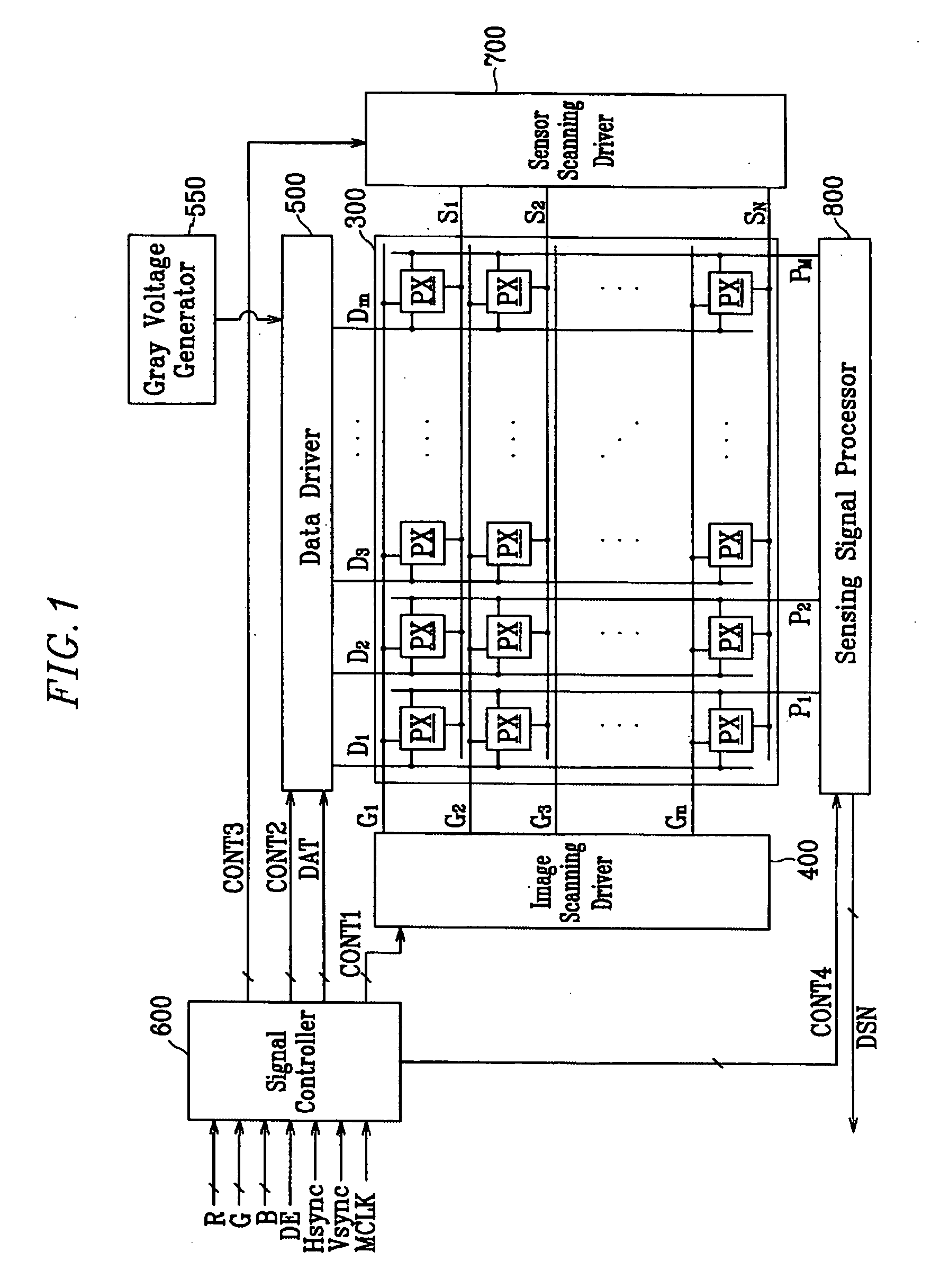

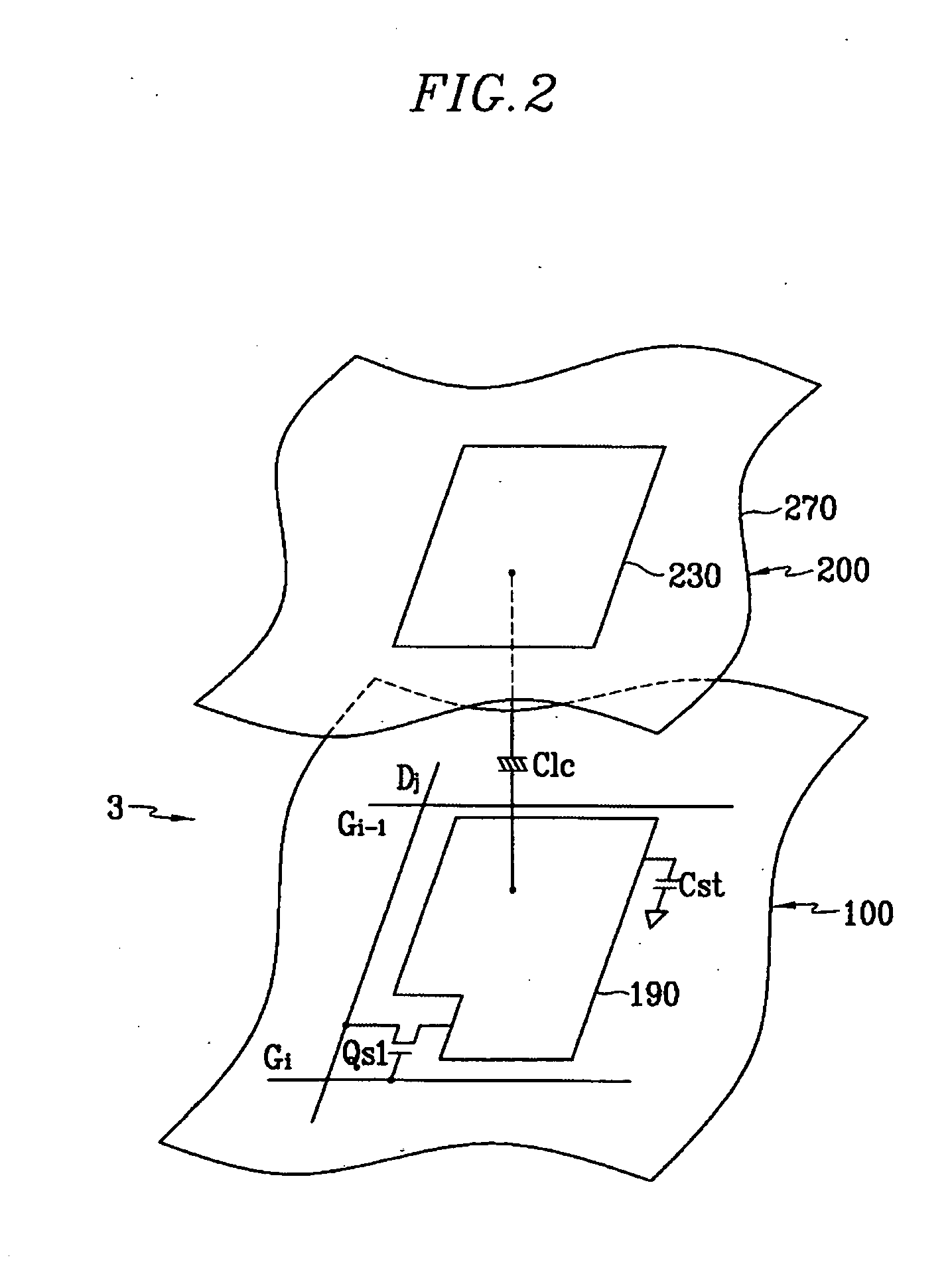

Display device including sensing elements

InactiveUS20060097975A1Less resolutionStatic indicating devicesNon-linear opticsEngineeringDisplay device

A display device is provided, which includes: a display panel unit; a first sensor formed on the display panel unit and generating a first sensing signal based on an external light; and a second sensor formed on the display panel unit and generating a second sensing signal in response to a touch.

Owner:SAMSUNG DISPLAY CO LTD

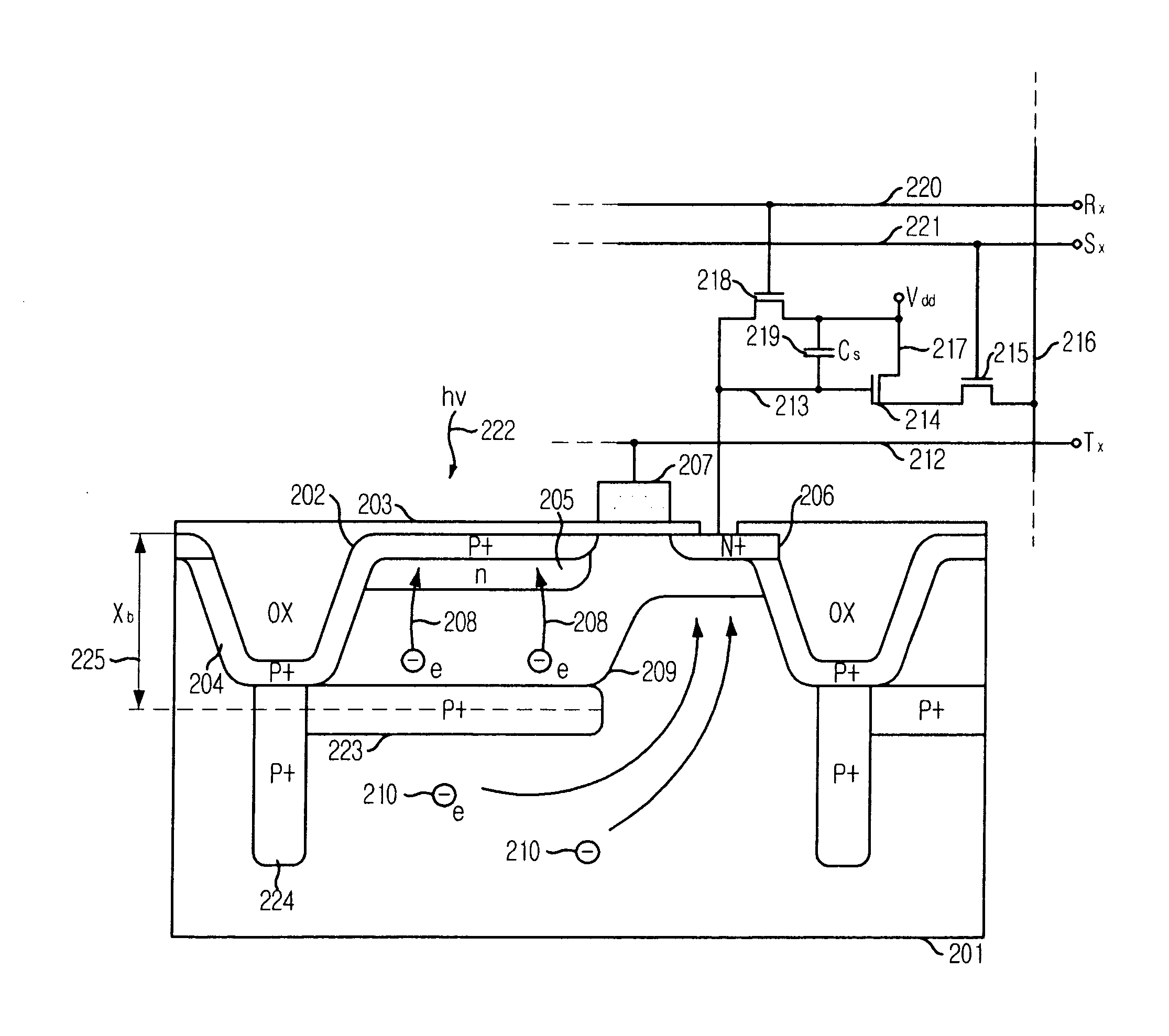

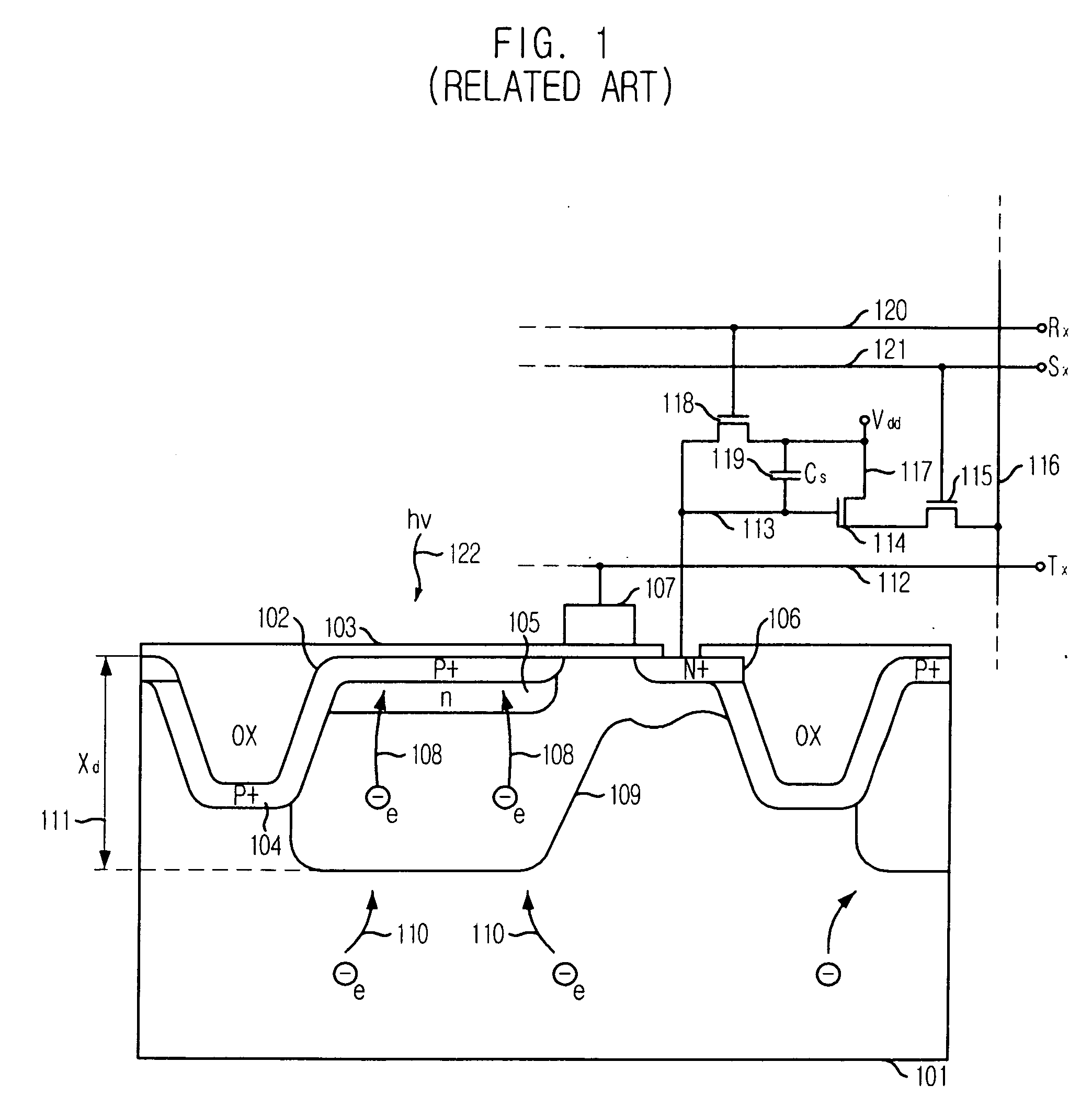

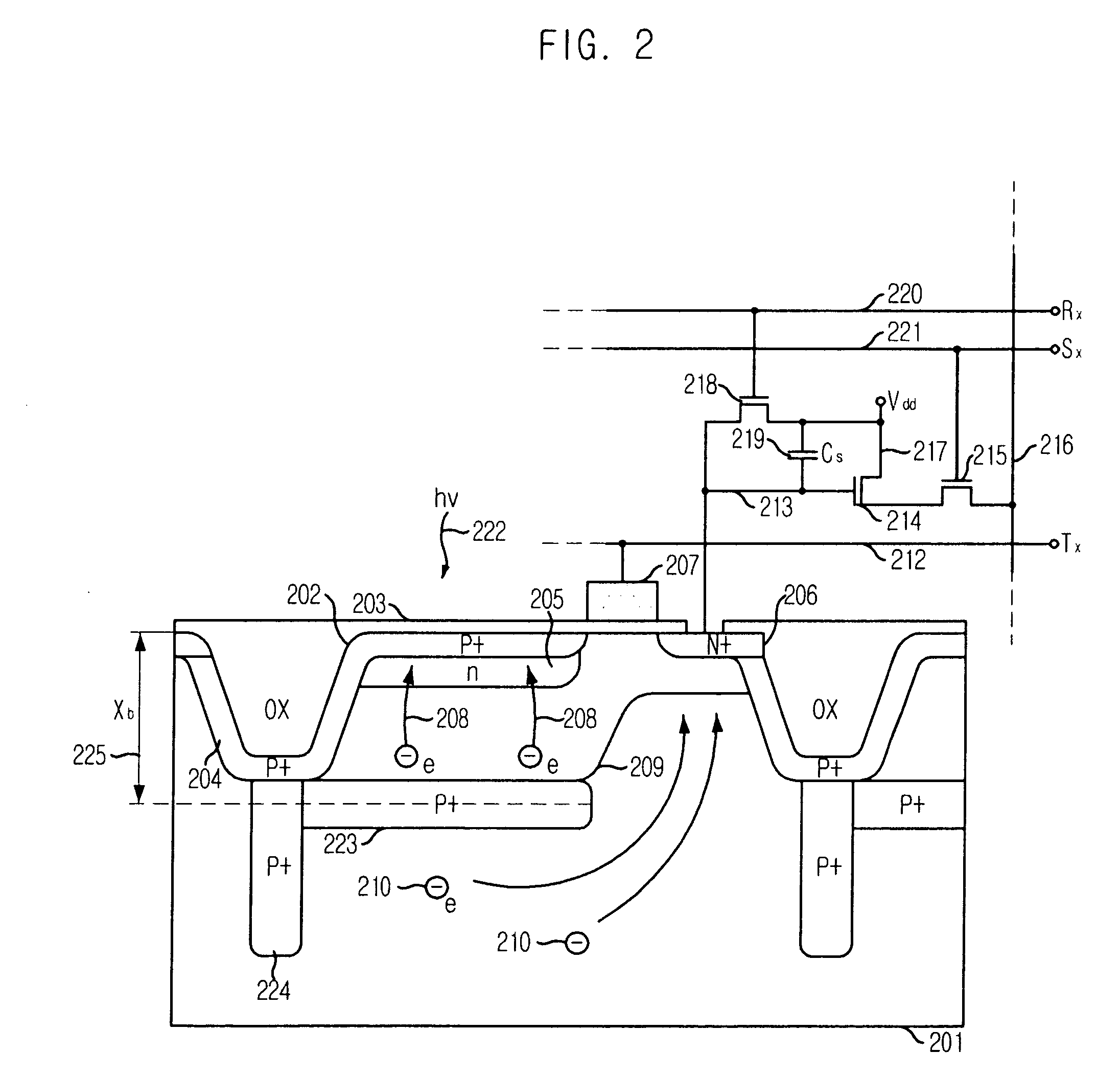

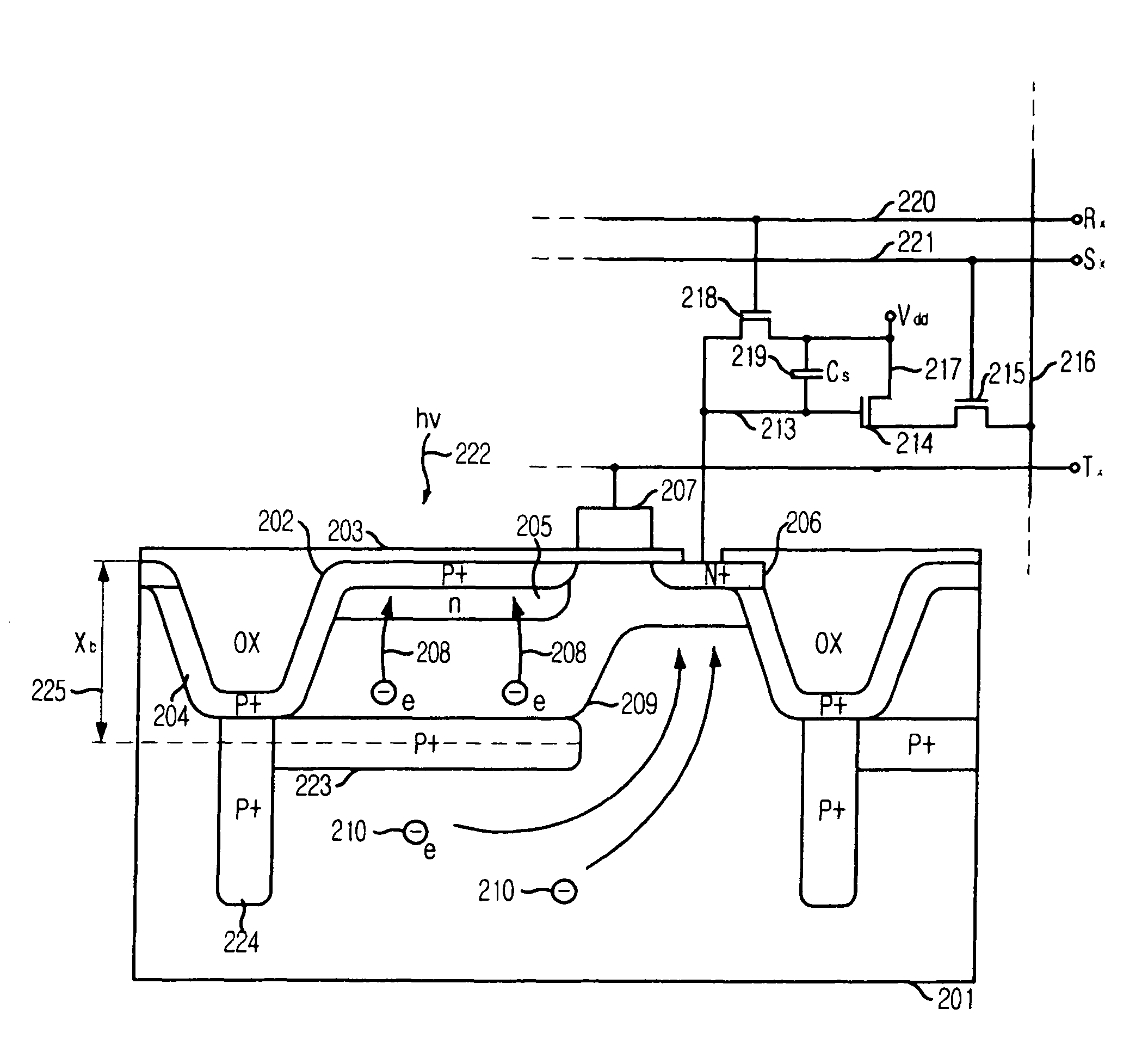

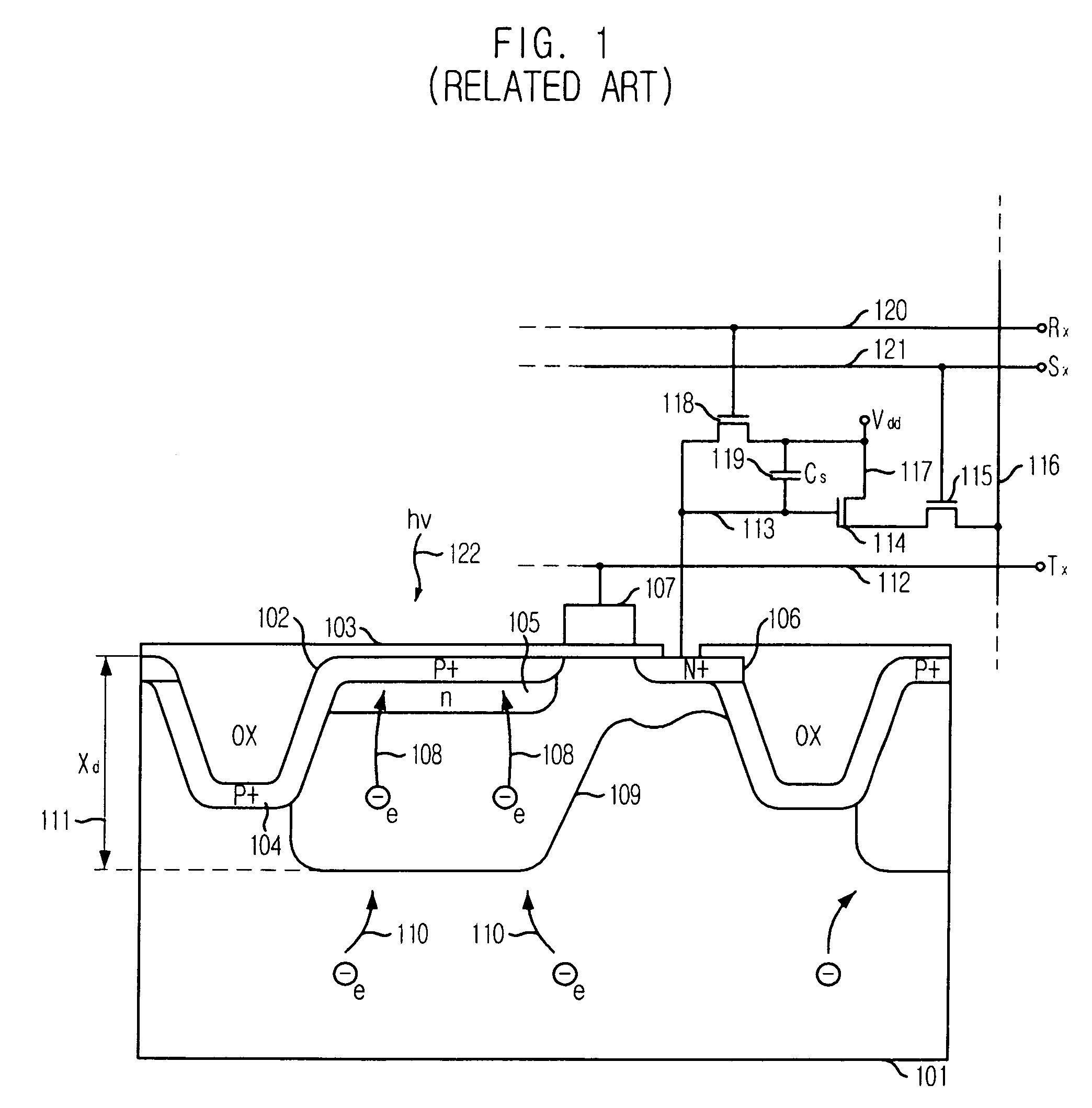

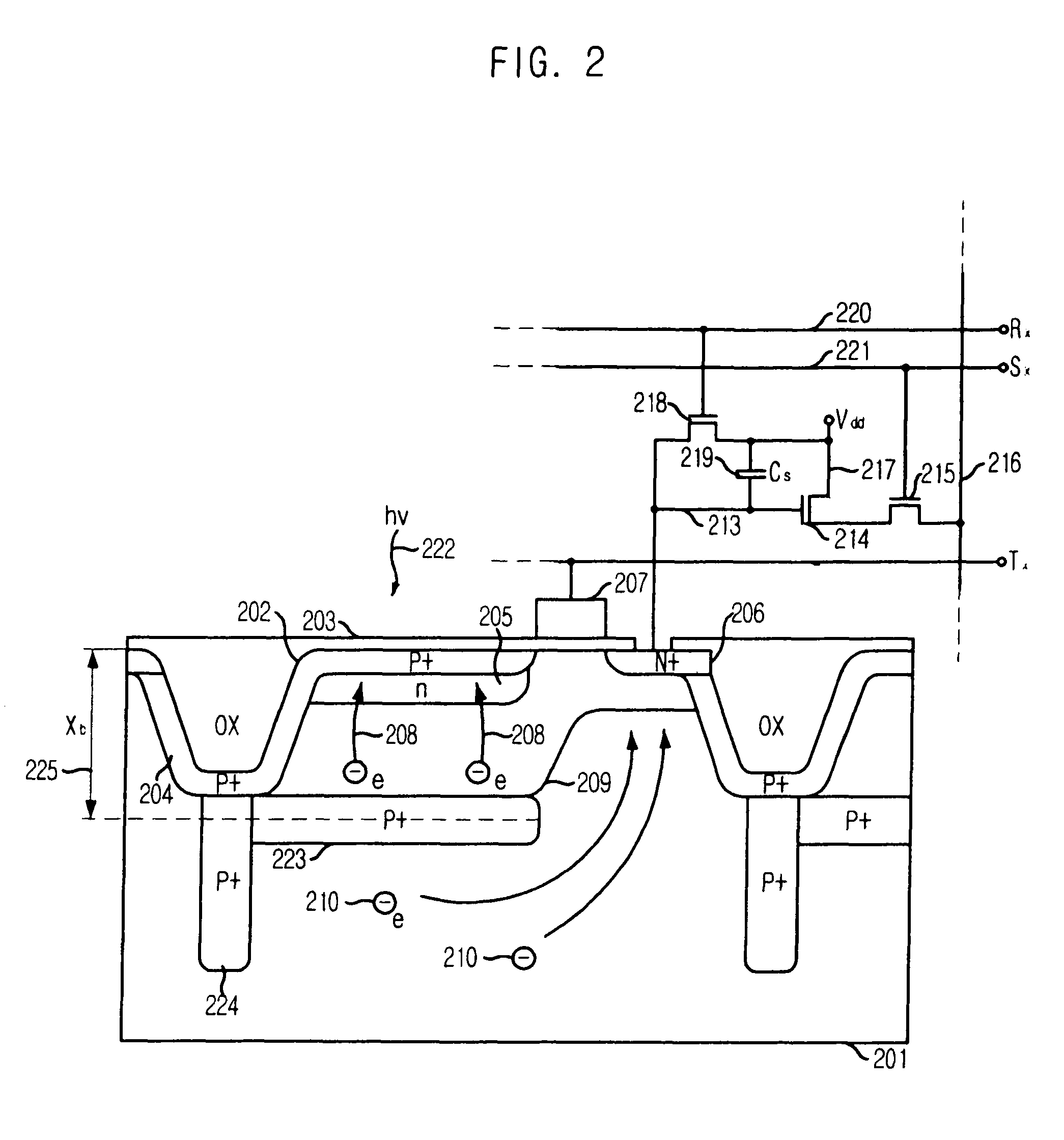

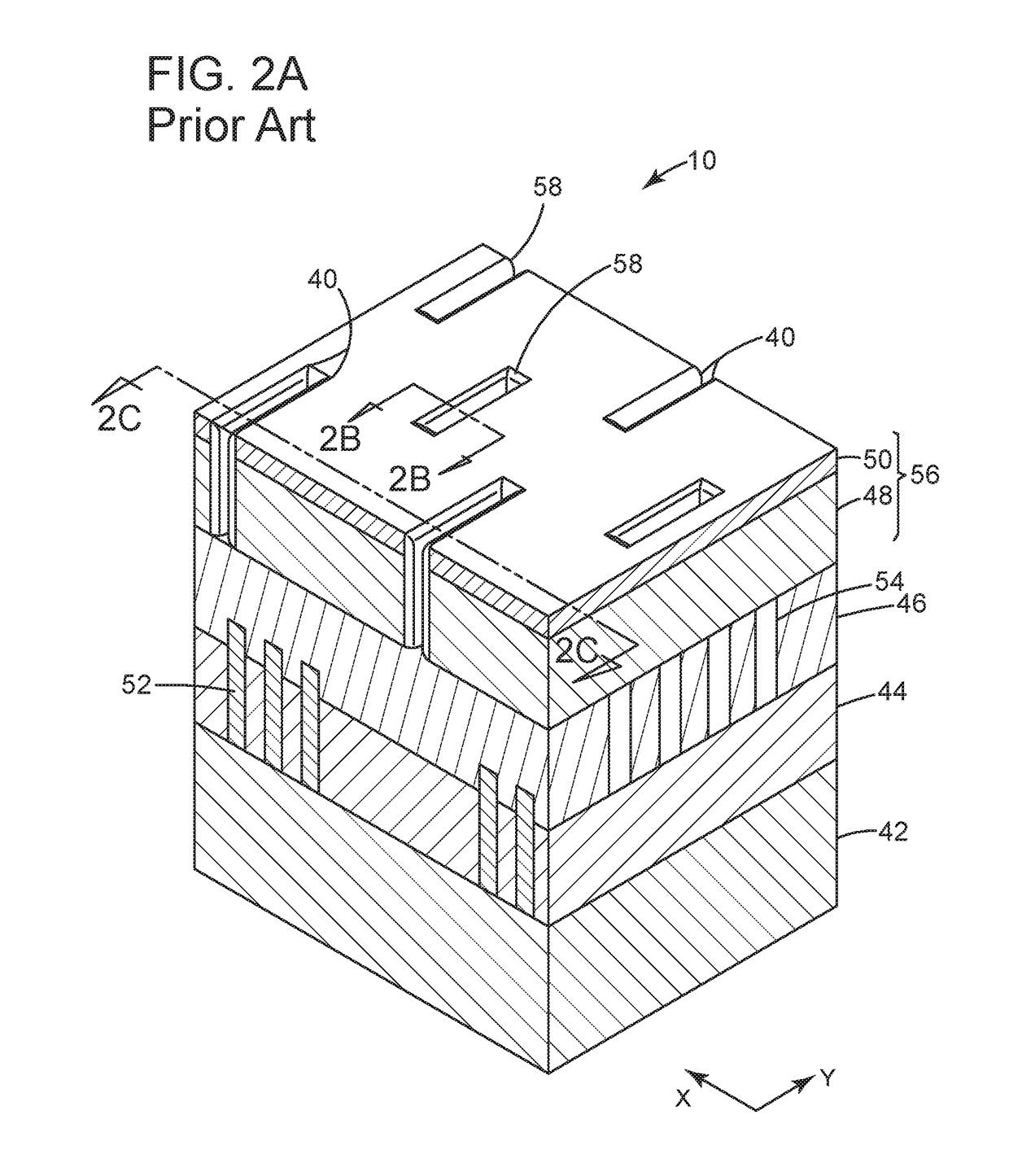

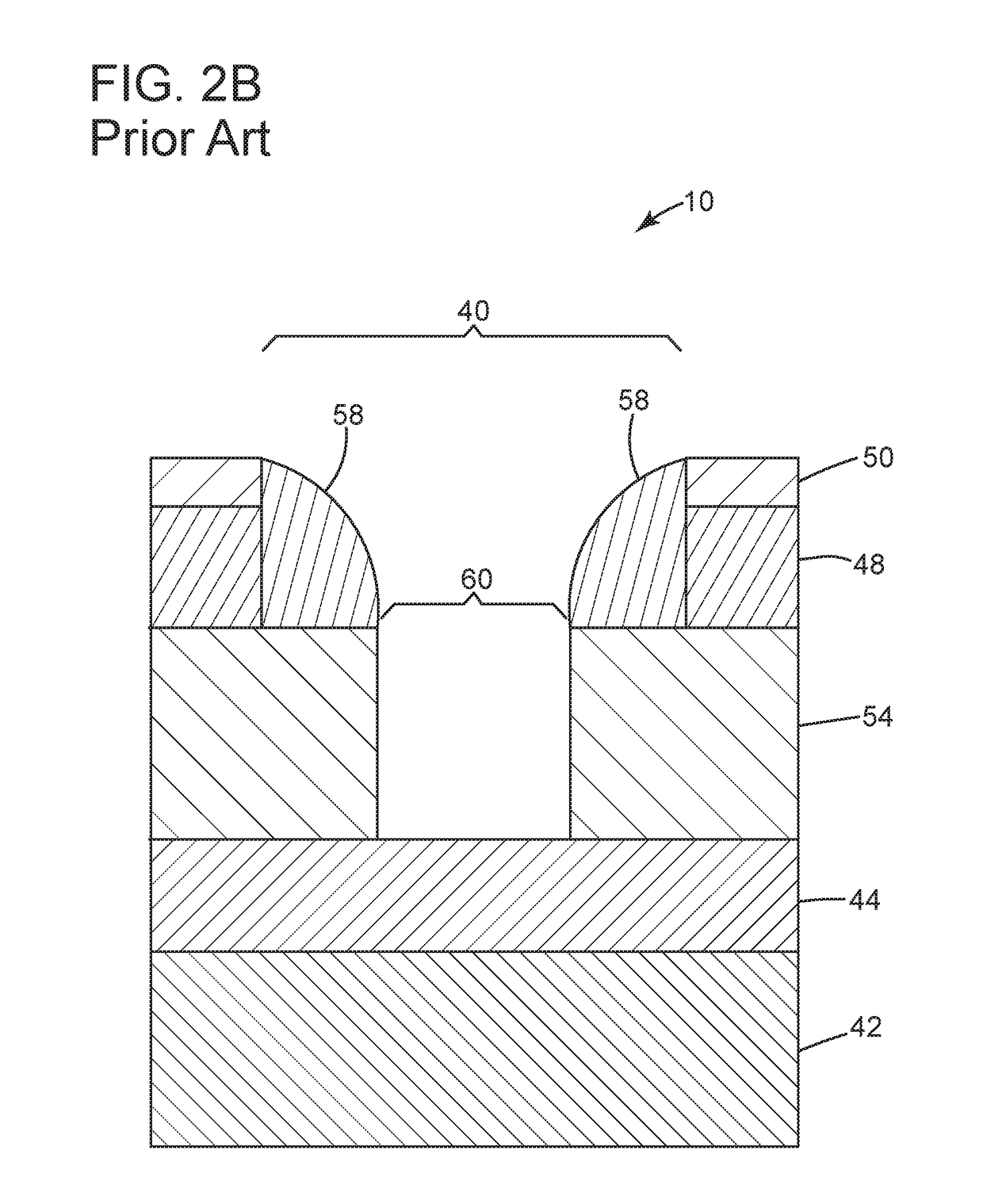

Stacked pixel for high resolution CMOS image sensor

ActiveUS20070023801A1Simpler and more practical solutionLess resolution lossTelevision system detailsSolid-state devicesCMOSHigh resolution

Provided is a solid-state CMOS image sensor, specifically a CMOS image sensor pixel that has stacked photo-sites, high sensitivity, and low dark current. In an image sensor including an array of pixels, each pixel includes: a standard photo-sensing and charge storage region formed in a first region under a surface portion of a substrate and collecting photo-generated carriers; a second charge storage region formed adjacent to the surface portion of the substrate and separated from the standard photo-sensing and charge storage region; and a potential barrier formed between the first region and a second region underneath the first region and diverting the photo-generated carriers from the second region to the second charge storage region.

Owner:INTELLECTUAL VENTURES II

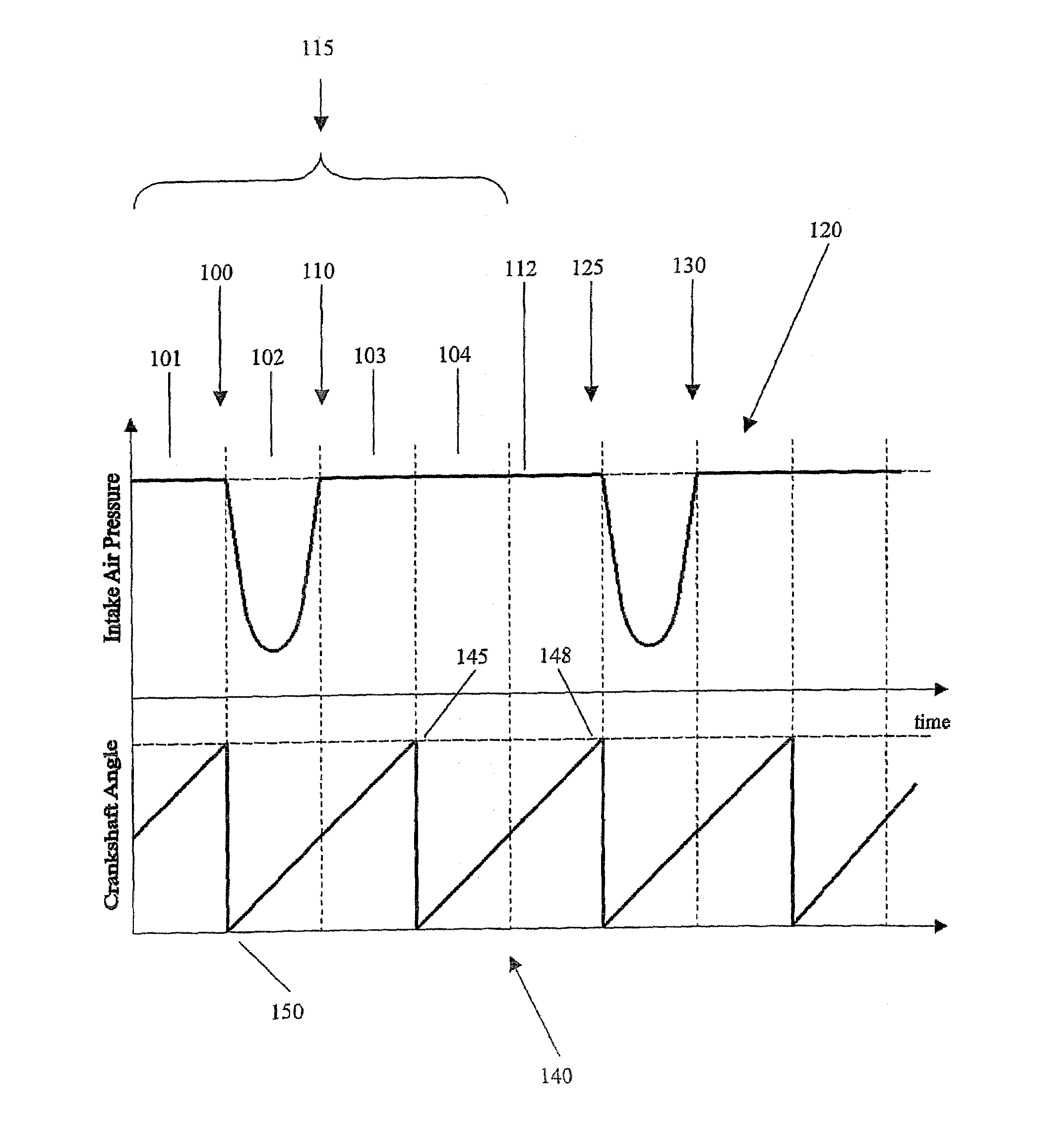

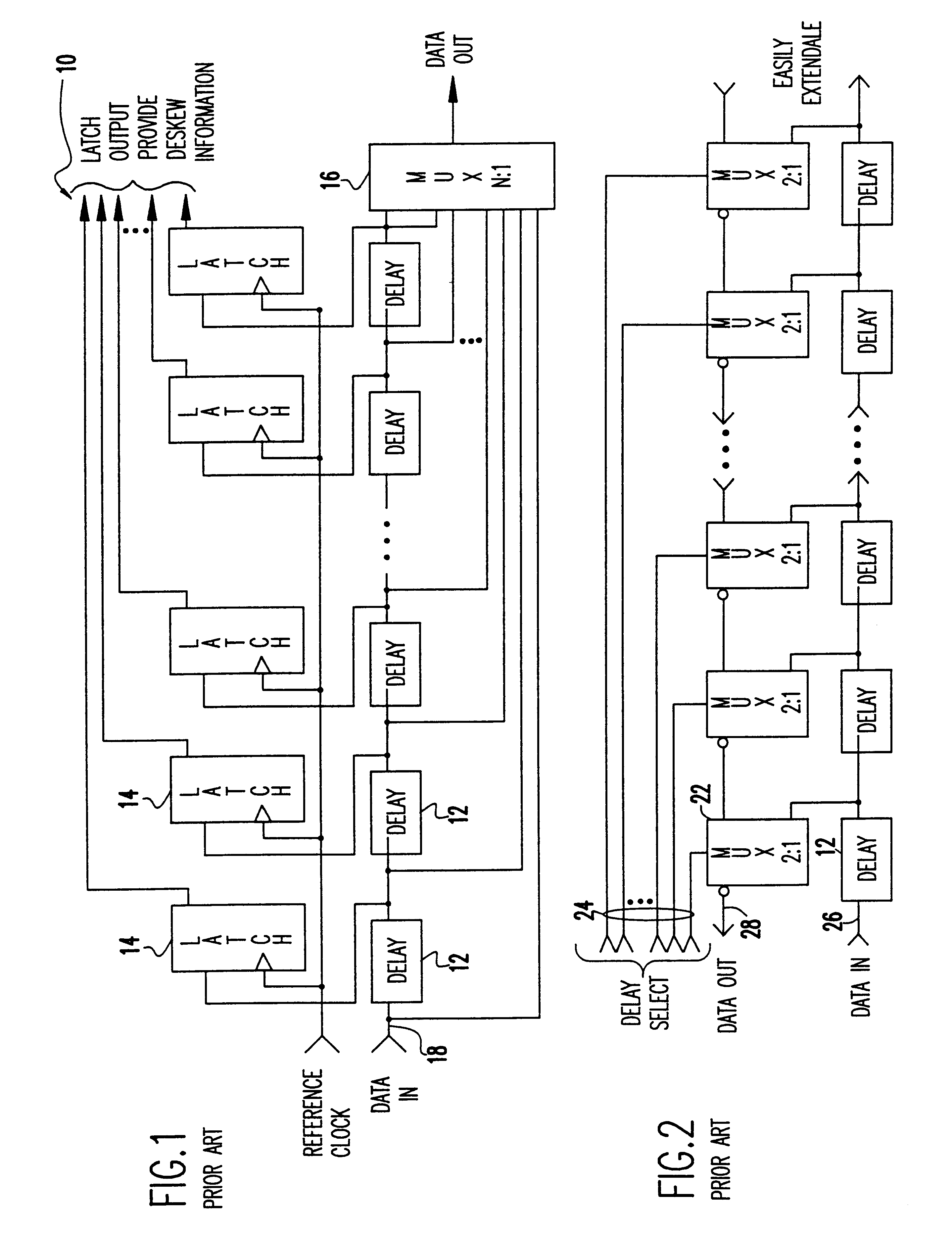

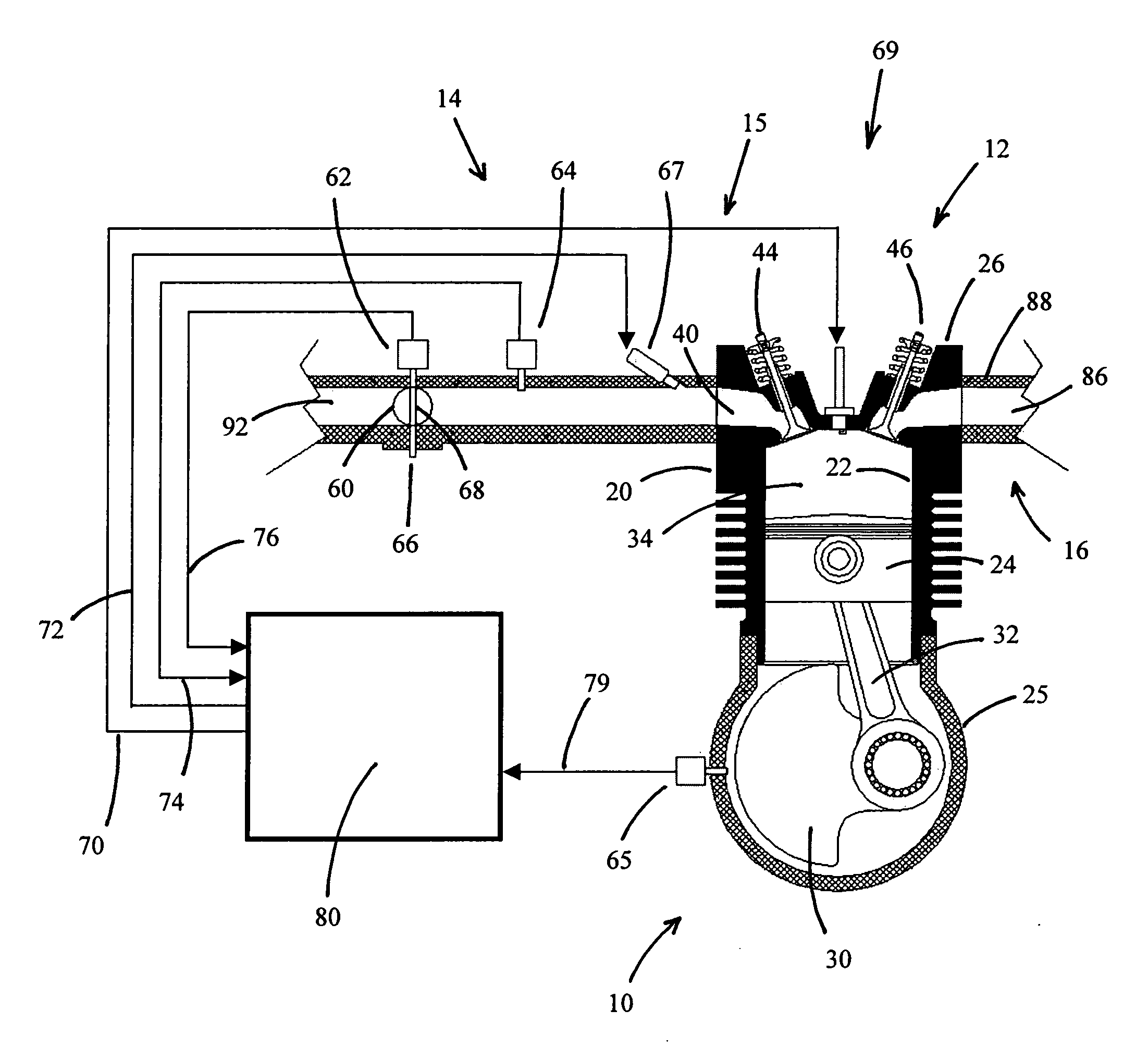

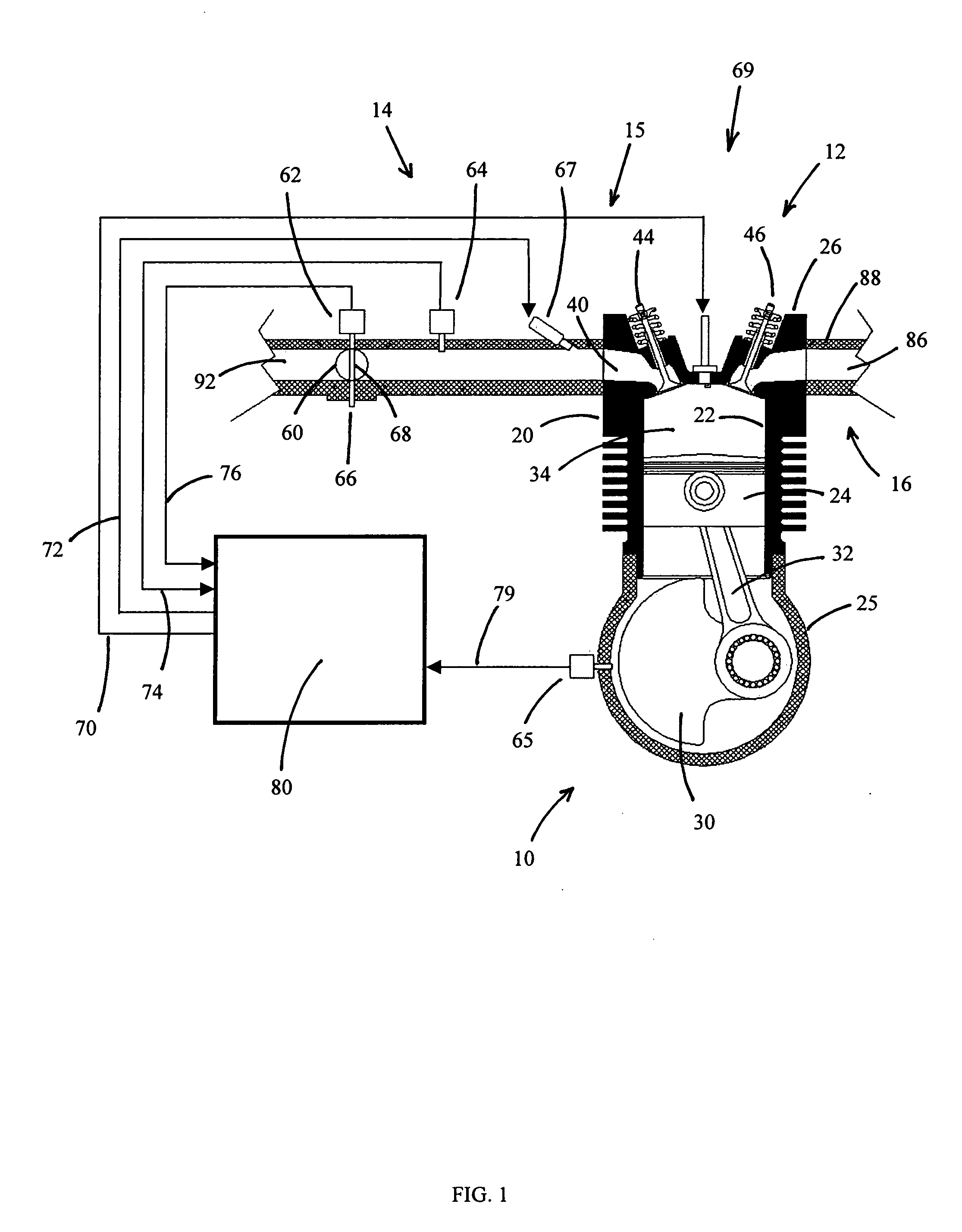

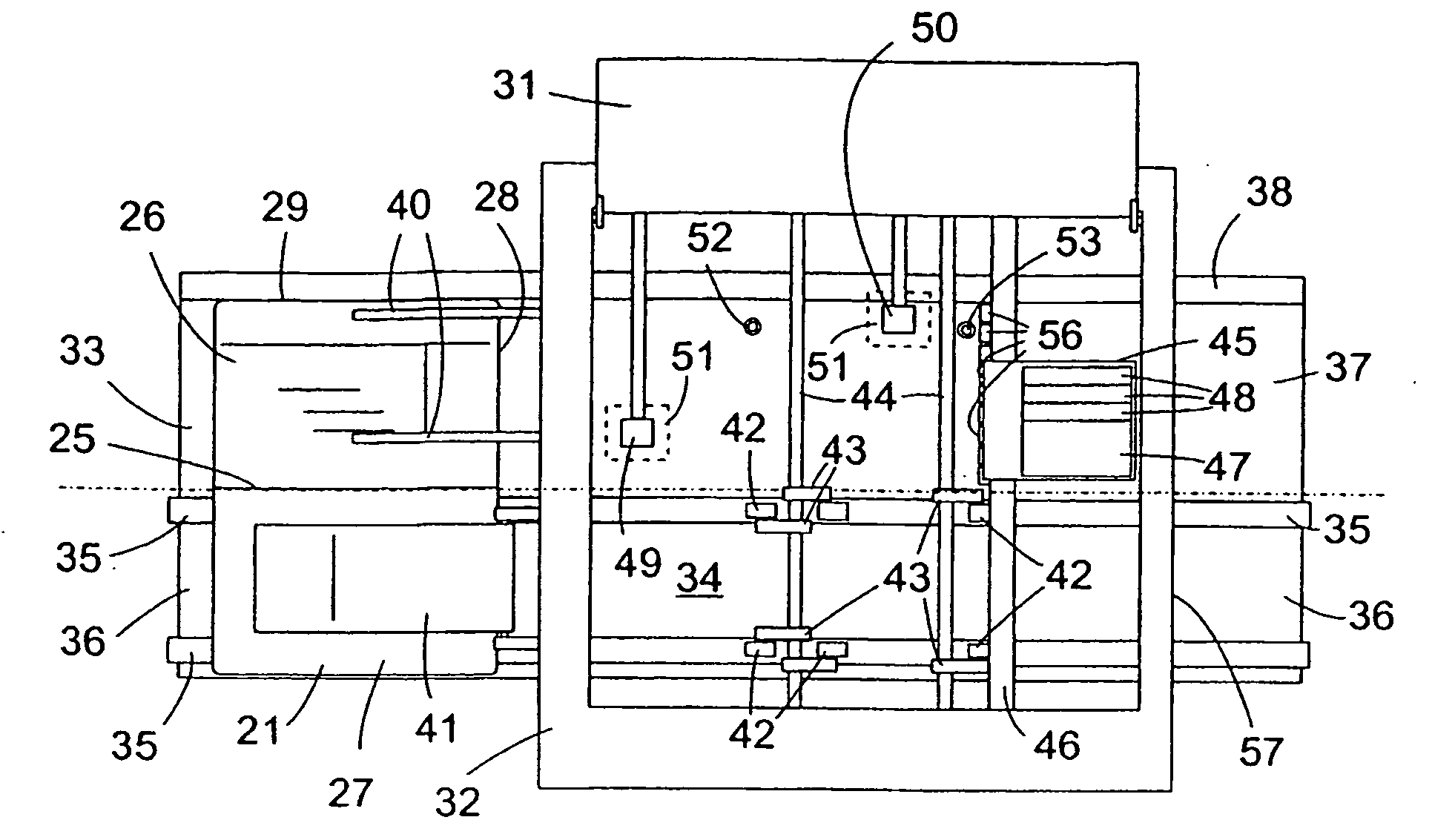

Engine timing control with intake air pressure sensor

InactiveUS7225793B2Reduce complexityLow costElectrical controlVolume/mass flow by thermal effectsExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

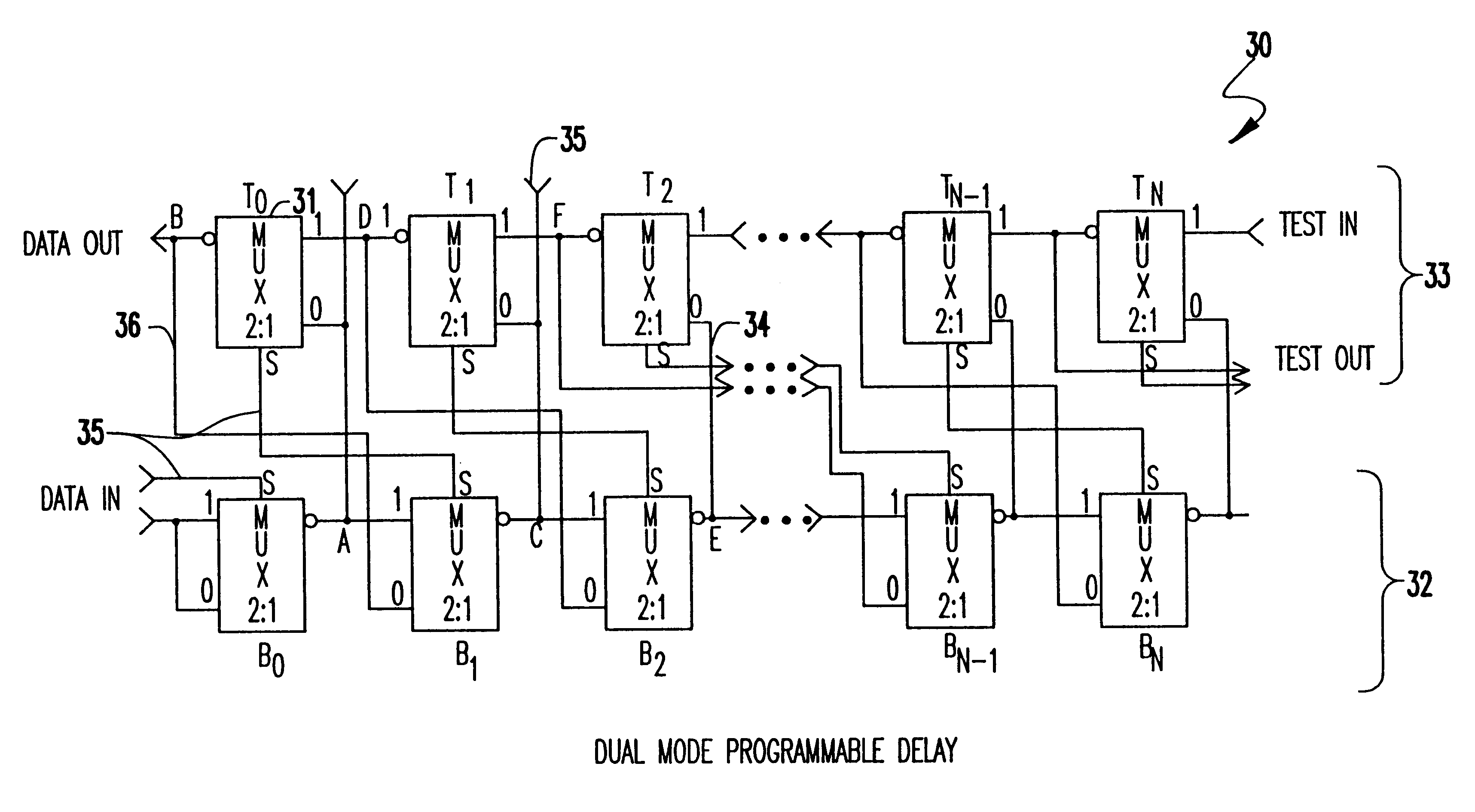

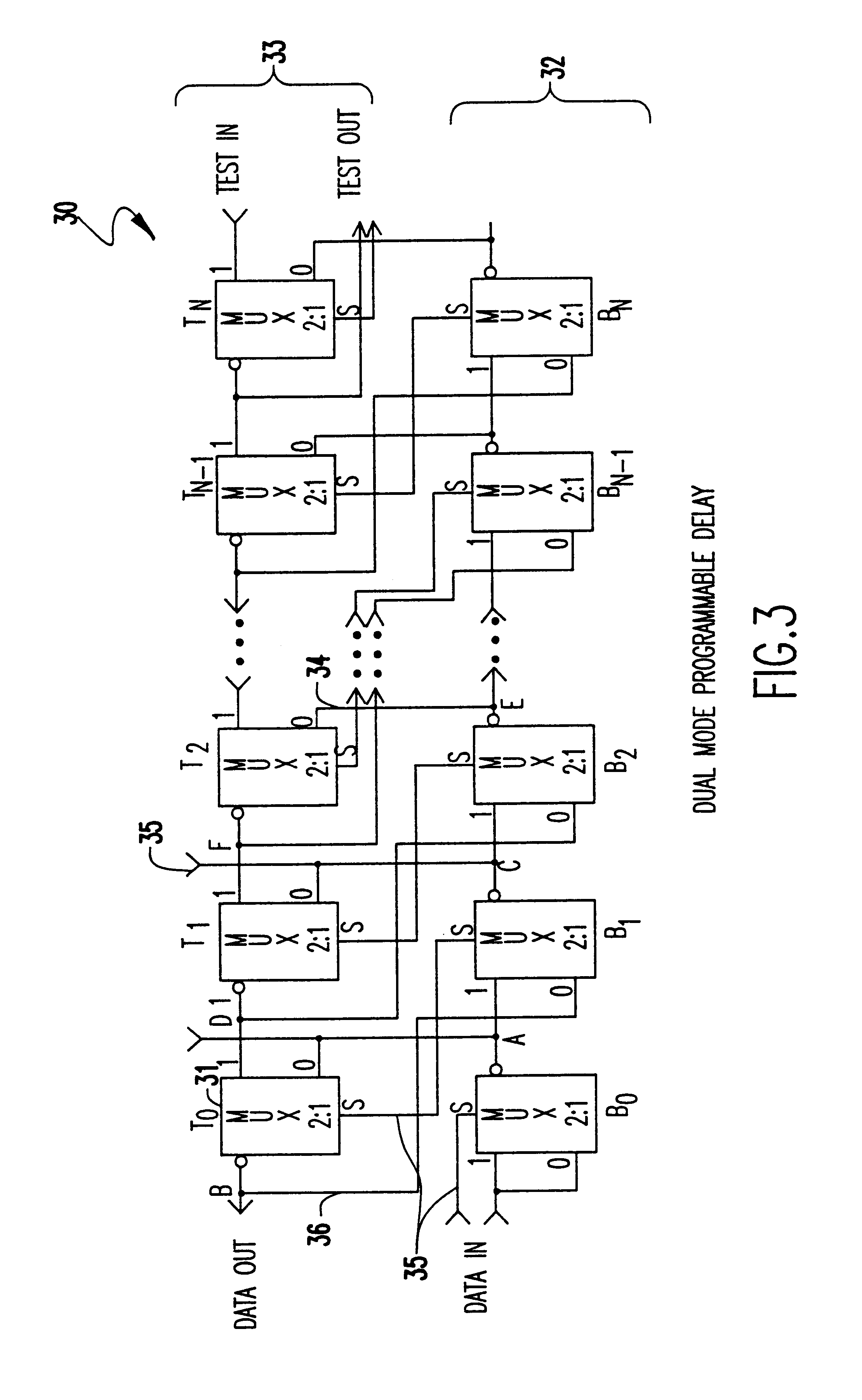

Dual mode programmable delay element

InactiveUS6222407B1Less resolutionSingle output arrangementsTime-delay networksMultiplexingMultiplexer

Rapid set-up is achieved in a programmable delay element having identical pairs of positionally corresponding delay stages in parallel arrays. The pairs of delay elements include identical arrangements of circuit elements and are replicable in a step-and-repeat fashion to simplify delay element manufacture for any arbitrary maximum delay time to be provided. Delay stages of the delay element are comprised of multiplexers. Outputs of respective delay stages are simultaneously stored as a signal transition is propagated through the delay stages in a first order to program the delay element. Thereafter, signals are propagated through selected delay stages in a second order controlled by the simultaneously stored outputs of respective delay stages during the propagation of the signal transition. The selected stages through which a signal is propagated in the second order are the same stages through which the signal transition had propagated in the first order at the time the delay stage outputs were simultaneously stored.

Owner:IBM CORP

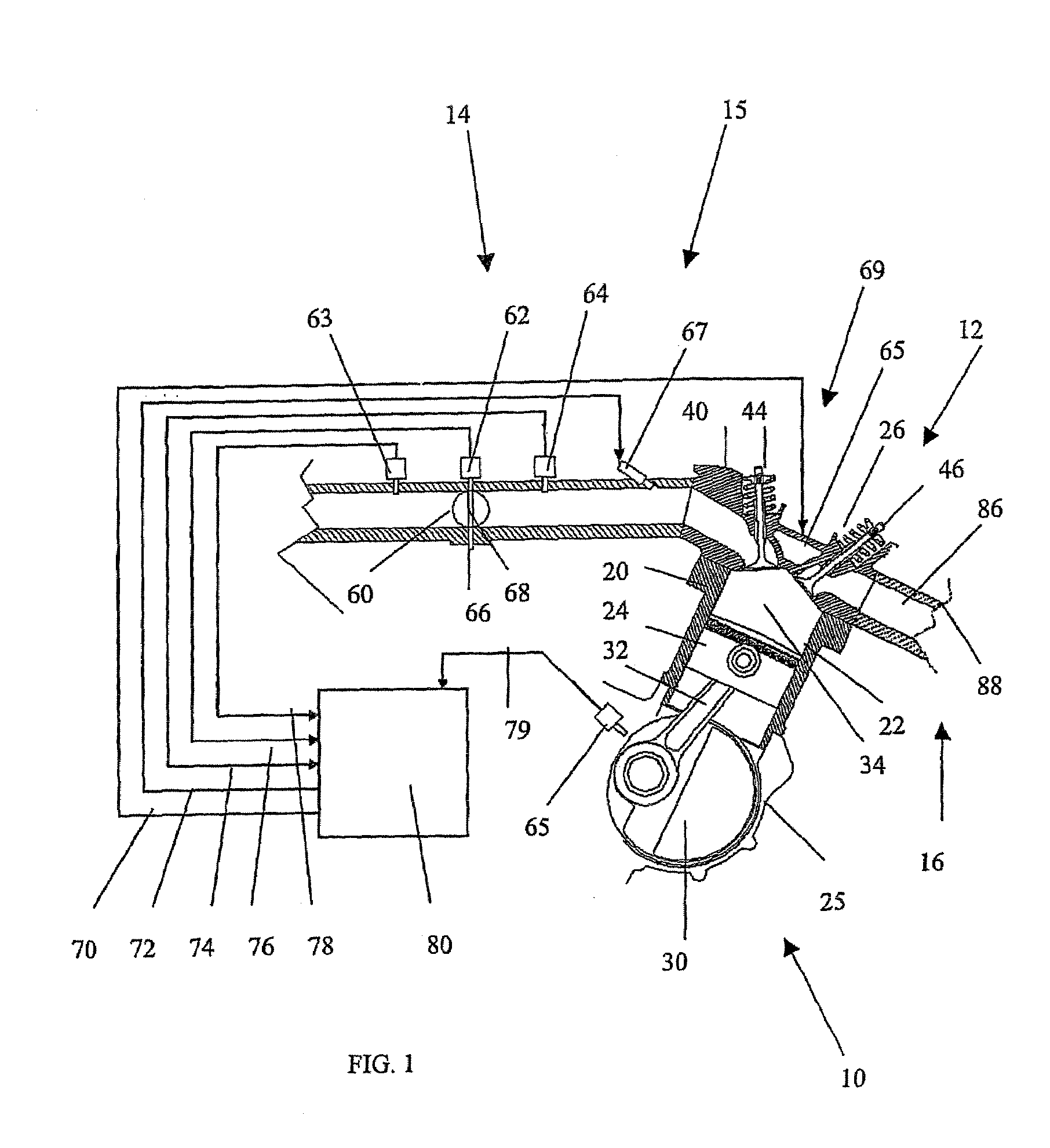

Electronic engine control with reduced sensor set

InactiveUS20050039526A1Low costReduce complexityElectrical controlEngine testingImage resolutionFour-stroke engine

An engine control apparatus is disclosed for determining crankshaft position, engine phase, engine loading, and intake air mass of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. Intake air pressure is used to determine intake air mass and loading of the engine. This combination results in a single sensor used in a system to determine intake air mass, engine loading, injected fuel mass, and to determine timing for fueling and ignition events. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure over time to increase resolution in the determination of crankshaft position.

Owner:ELECTROJET TECH INC

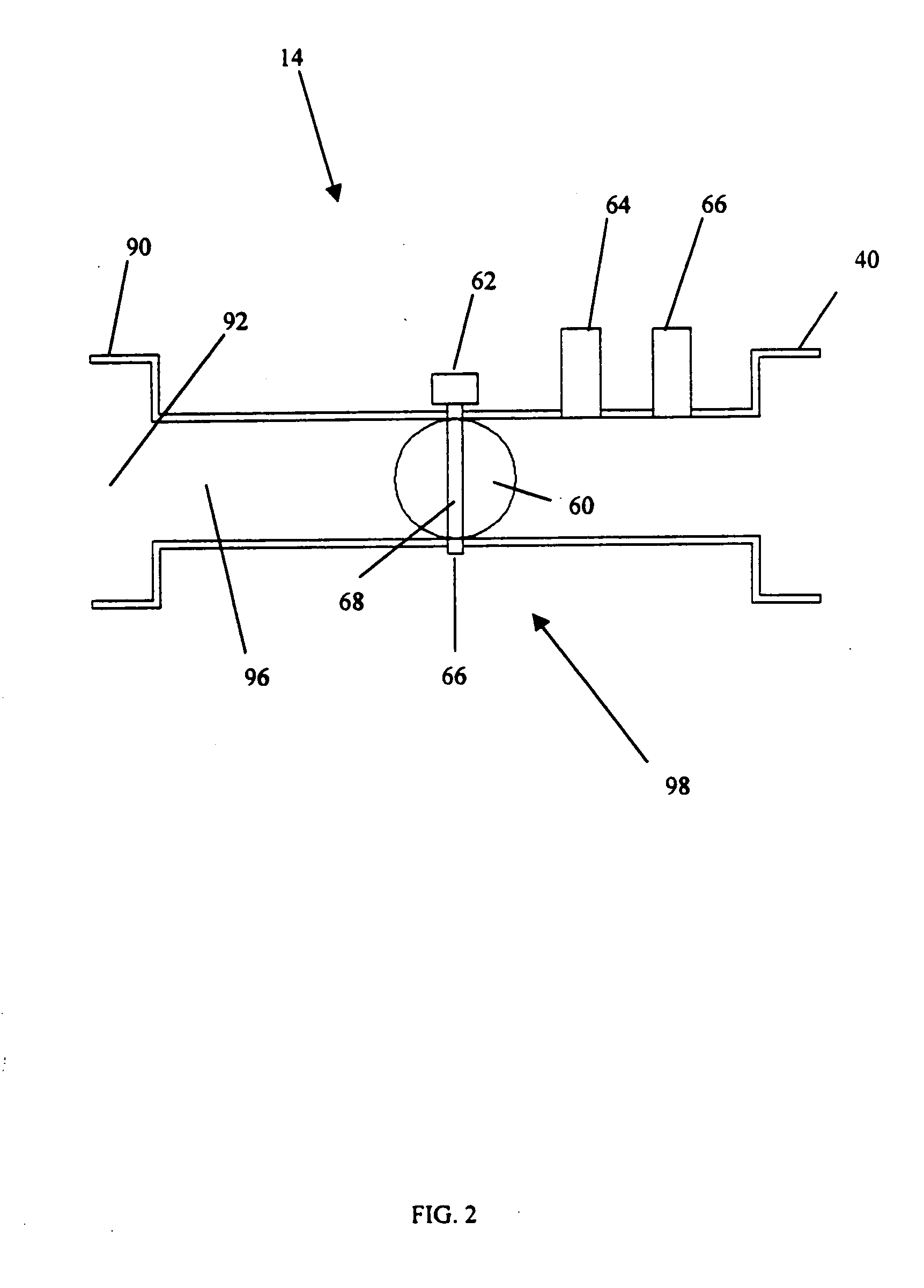

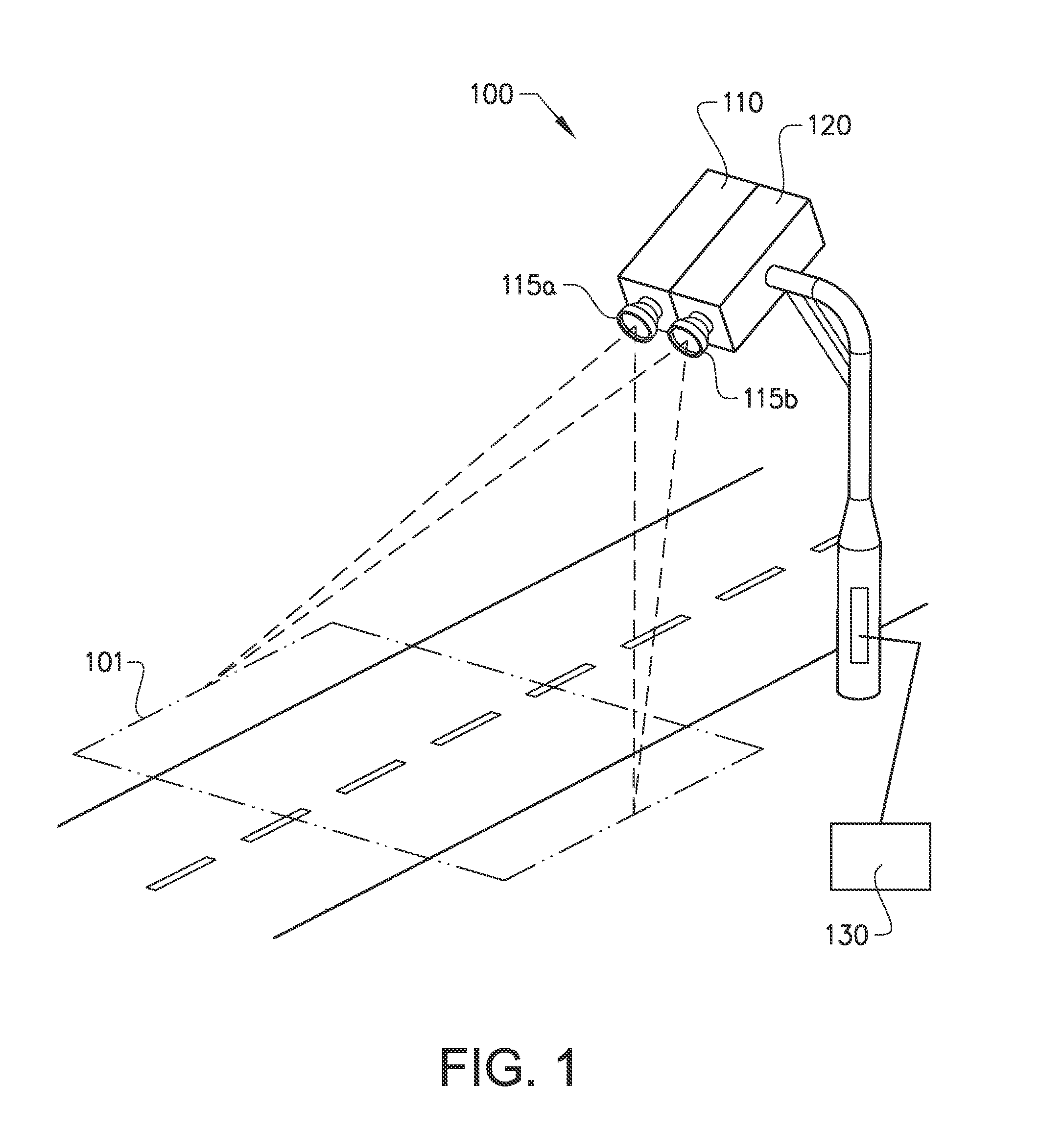

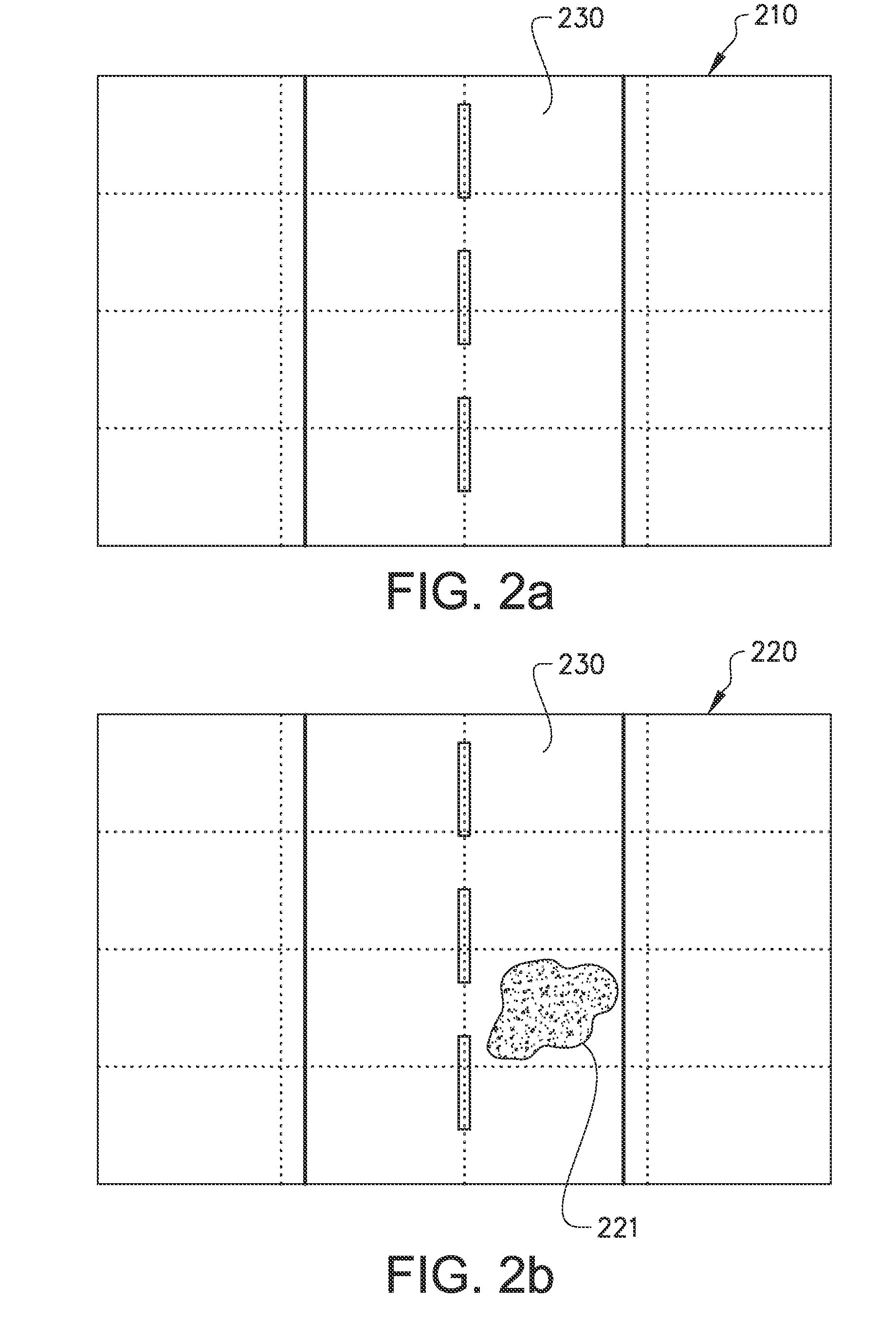

Method for identification of contamination upon a lens of a stereoscopic camera

ActiveUS20150009296A1Reduce needLess accuracyImage enhancementImage analysisCamera lensComputer graphics (images)

A method for identifying contamination upon a lens of a stereoscopic camera is disclosed. The stereoscopic camera is arranged such that it has the same capturing area over time, and is provided with a first camera providing first images of said capturing area and a second camera providing second images of said capturing area. The first and second images are divided into at least one evaluation area correspondently located in respective image. A traffic surveillance system is also disclosed where contamination upon a lens of a stereoscopic camera is identified according to said method.

Owner:KAPSCH TRAFFICCOM AB

Stacked pixel for high resolution CMOS image sensor

ActiveUS7737475B2Excessive signalingMinimum lossTelevision system detailsSolid-state devicesCMOSHigh resolution

Provided is a solid-state CMOS image sensor, specifically a CMOS image sensor pixel that has stacked photo-sites, high sensitivity, and low dark current. In an image sensor including an array of pixels, each pixel includes: a standard photo-sensing and charge storage region formed in a first region under a surface portion of a substrate and collecting photo-generated carriers; a second charge storage region formed adjacent to the surface portion of the substrate and separated from the standard photo-sensing and charge storage region; and a potential barrier formed between the first region and a second region underneath the first region and diverting the photo-generated carriers from the second region to the second charge storage region.

Owner:INTELLECTUAL VENTURES II

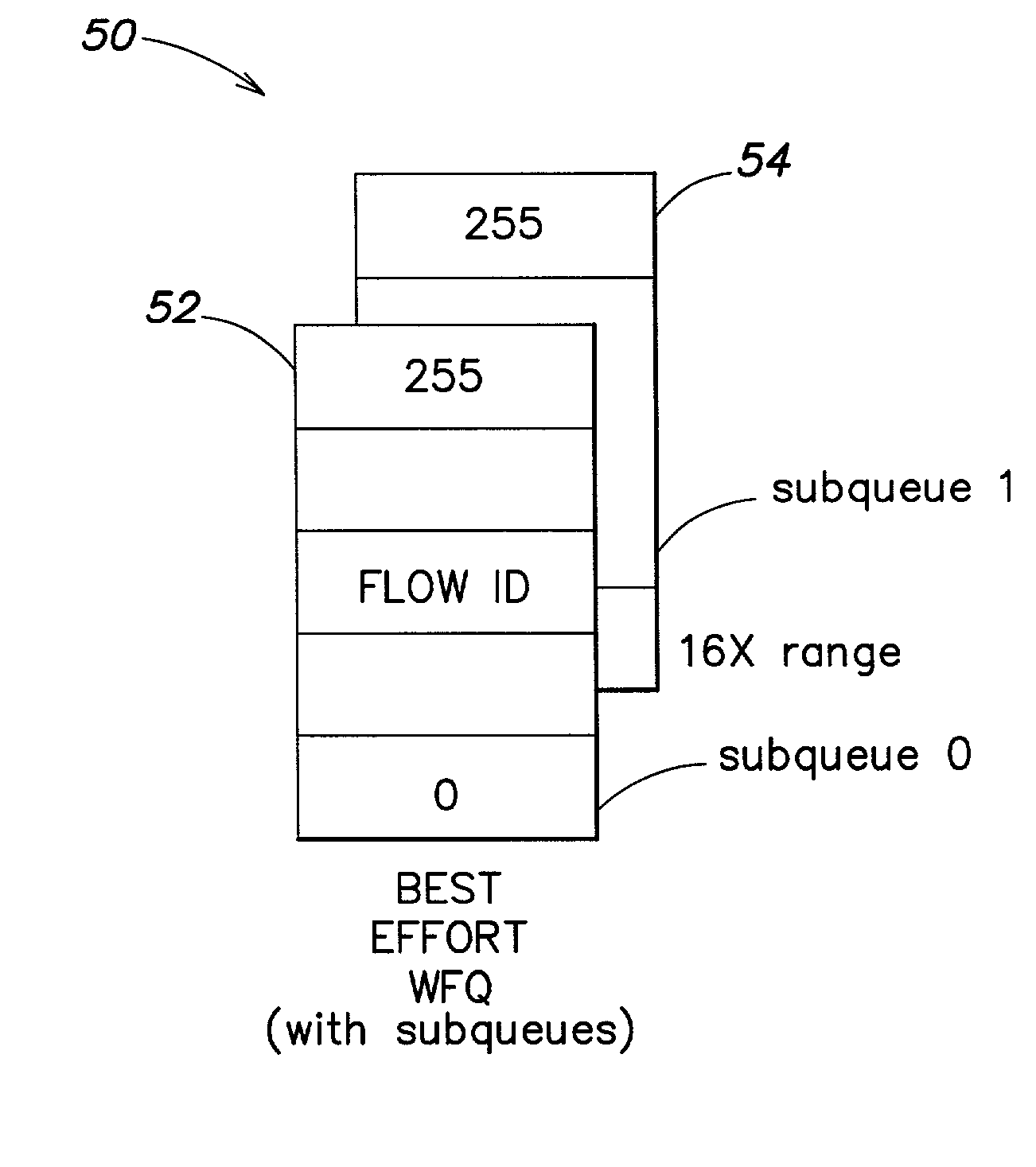

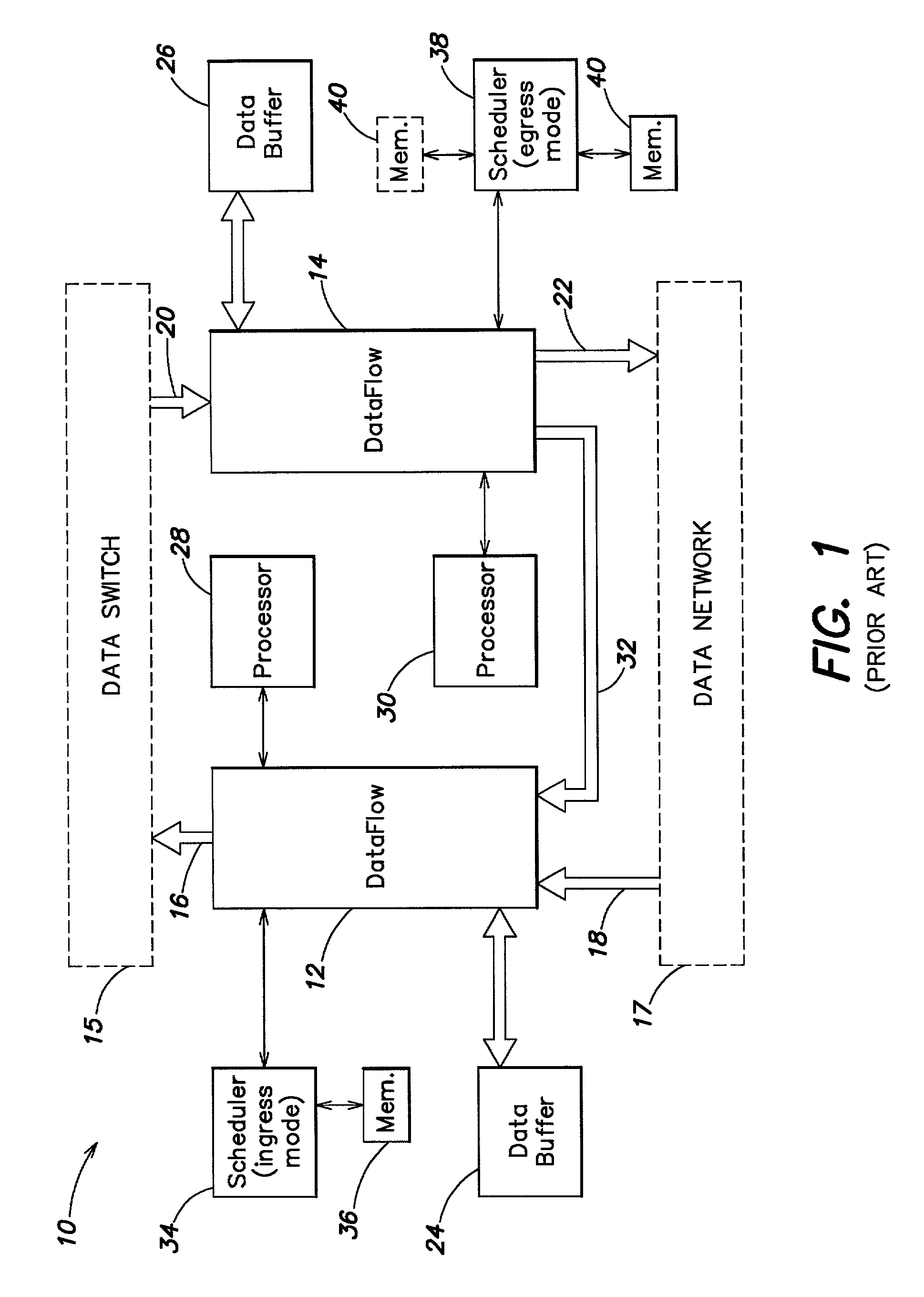

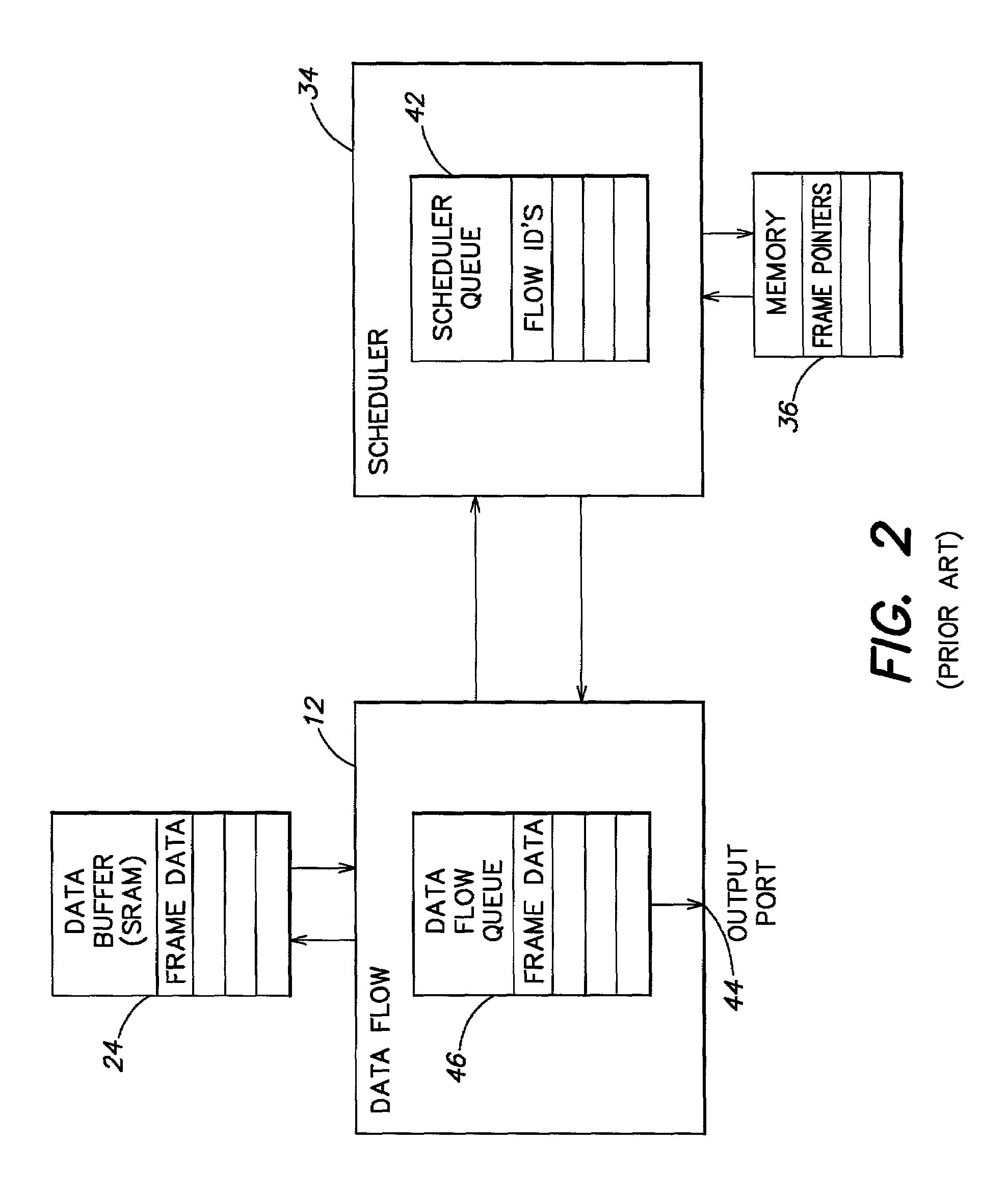

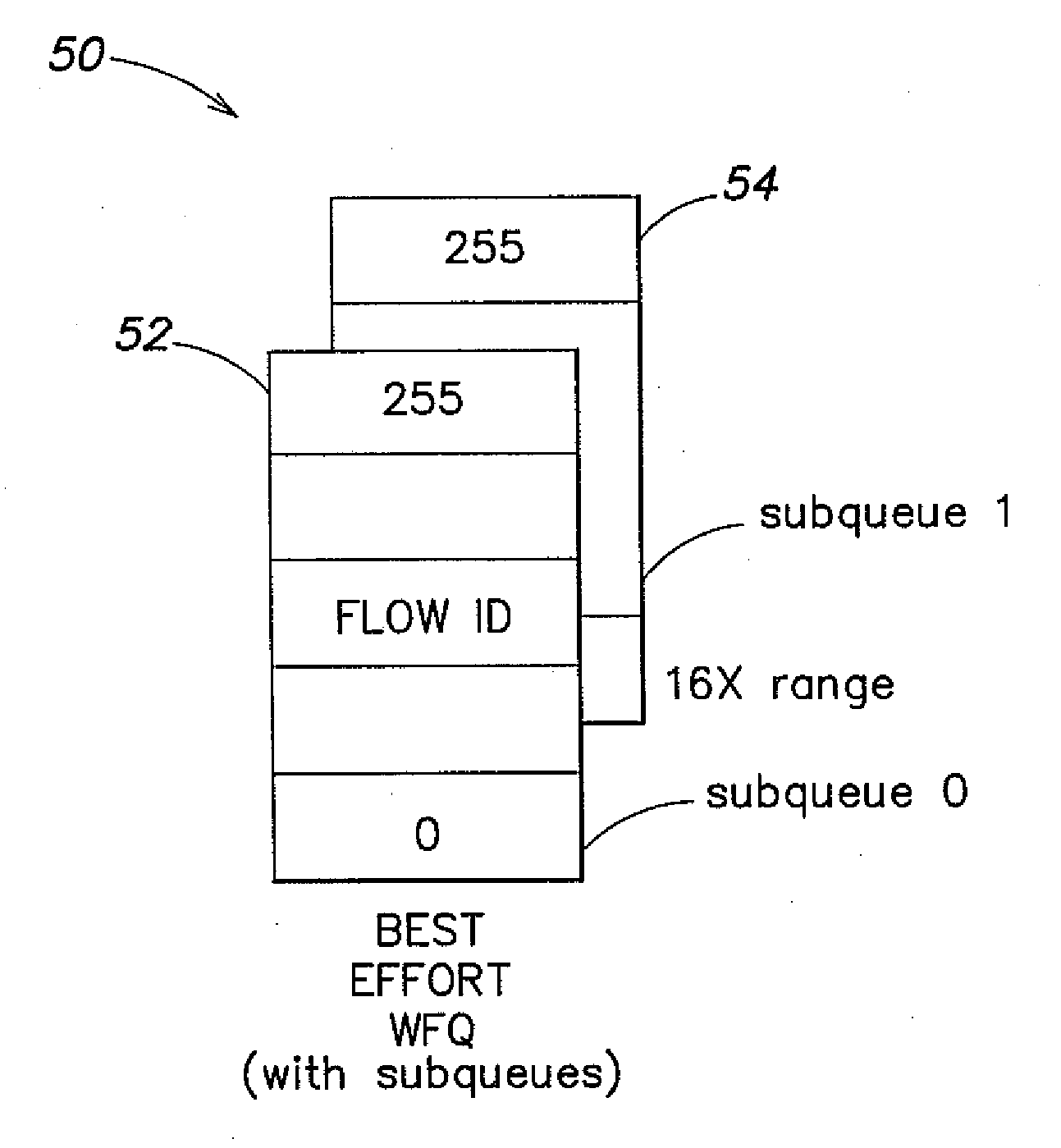

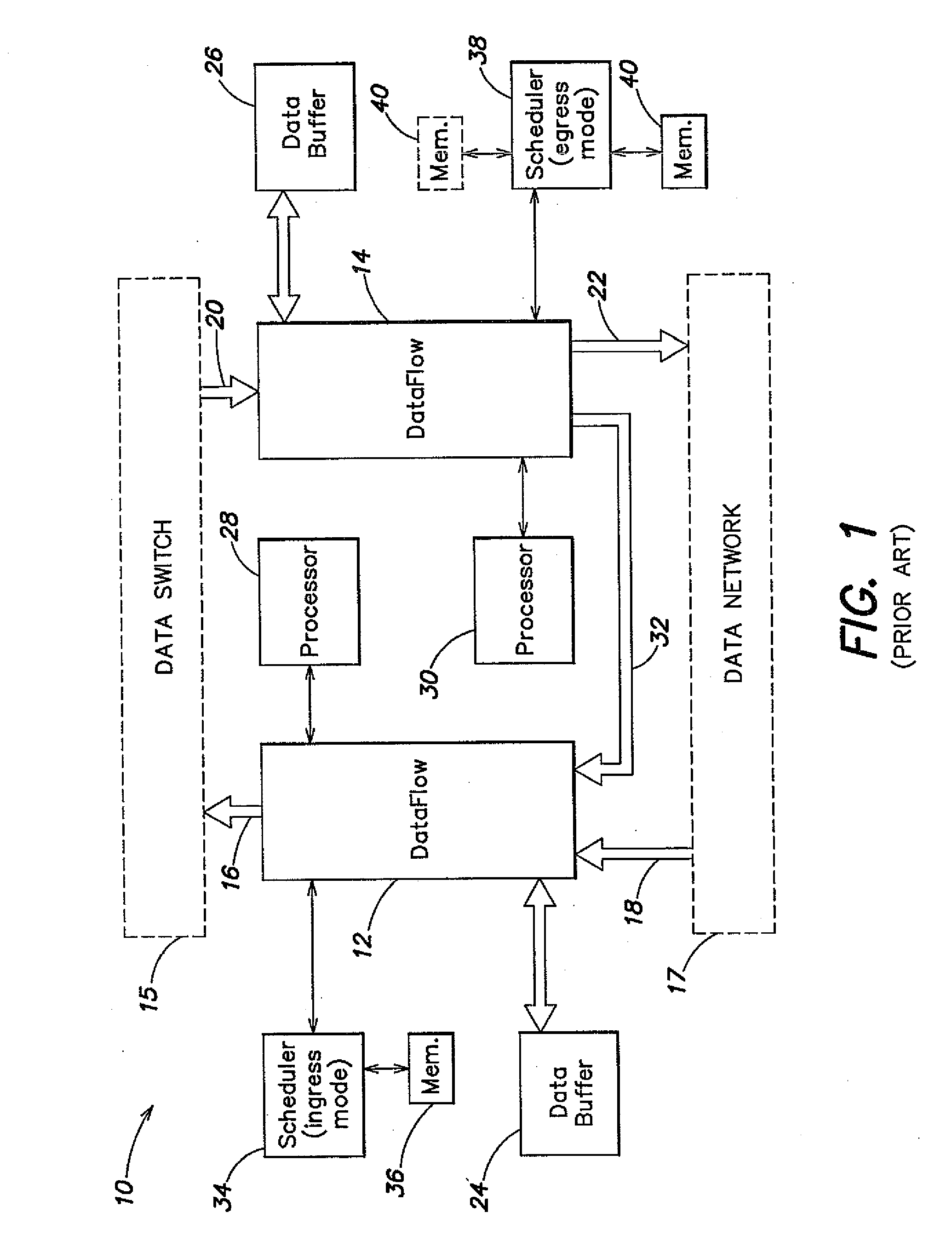

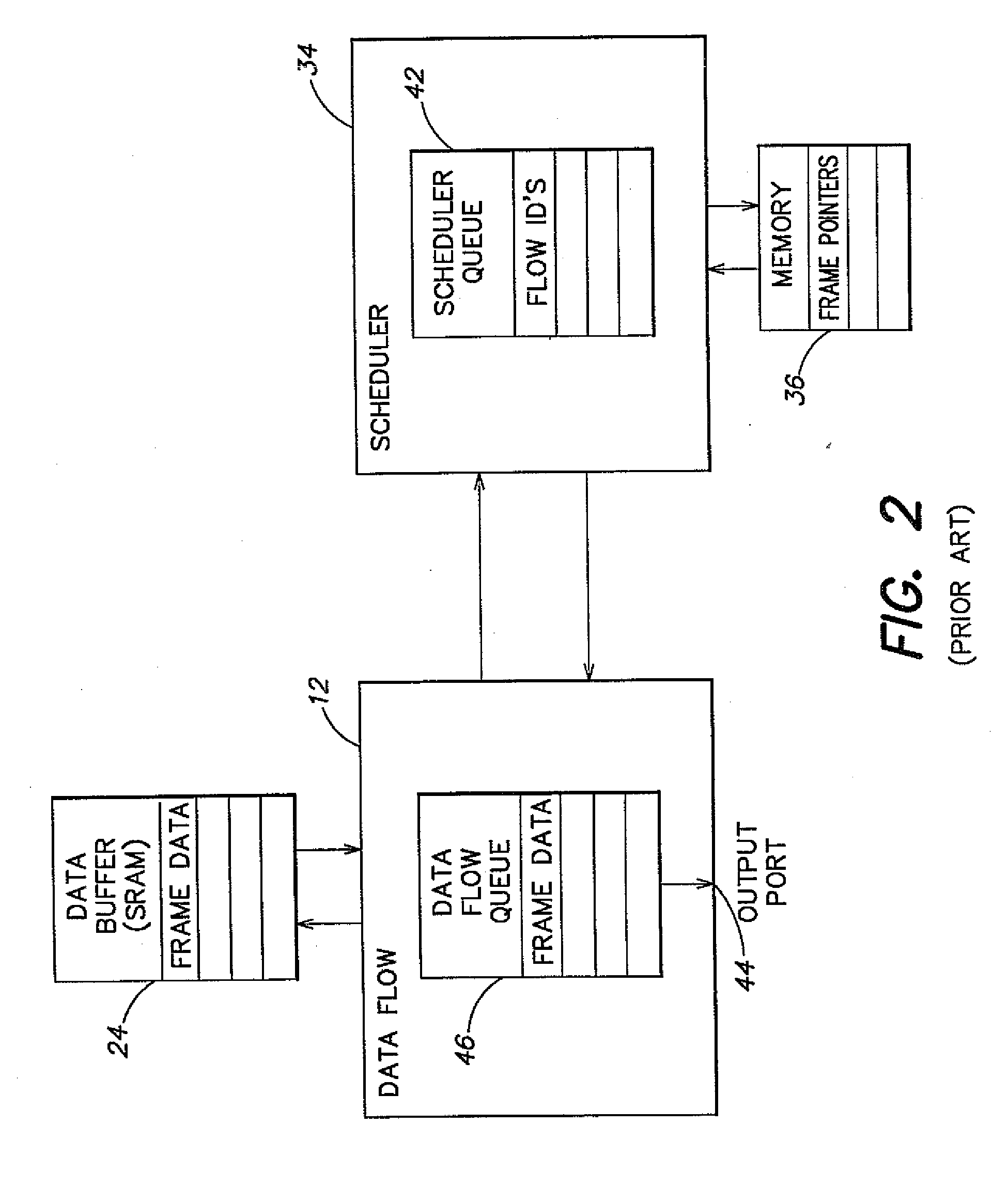

Weighted fair queue having extended effective range

InactiveUS7187684B2High resolutionIncrease rangeError preventionFrequency-division multiplex detailsExtended coverageImage resolution

A scheduler for a network processor includes a scheduling queue in which weighted fair queuing is applied to define a sequence in which flows are to be serviced. The scheduling queue includes at least a first subqueue and a second subqueue. The first subqueue has a first range and a first resolution, and the second subqueue has an extended range that is greater than the first range and a lower resolution that is less than the first resolution. Flows that are to be enqueued within the range of highest precision to the current pointer of the scheduling queue are attached to the first subqueue. Flows that are to be enqueued outside the range of highest precision from the current pointer of the scheduling queue are attached to the second subqueue. Numerous other aspects are provided.

Owner:IBM CORP

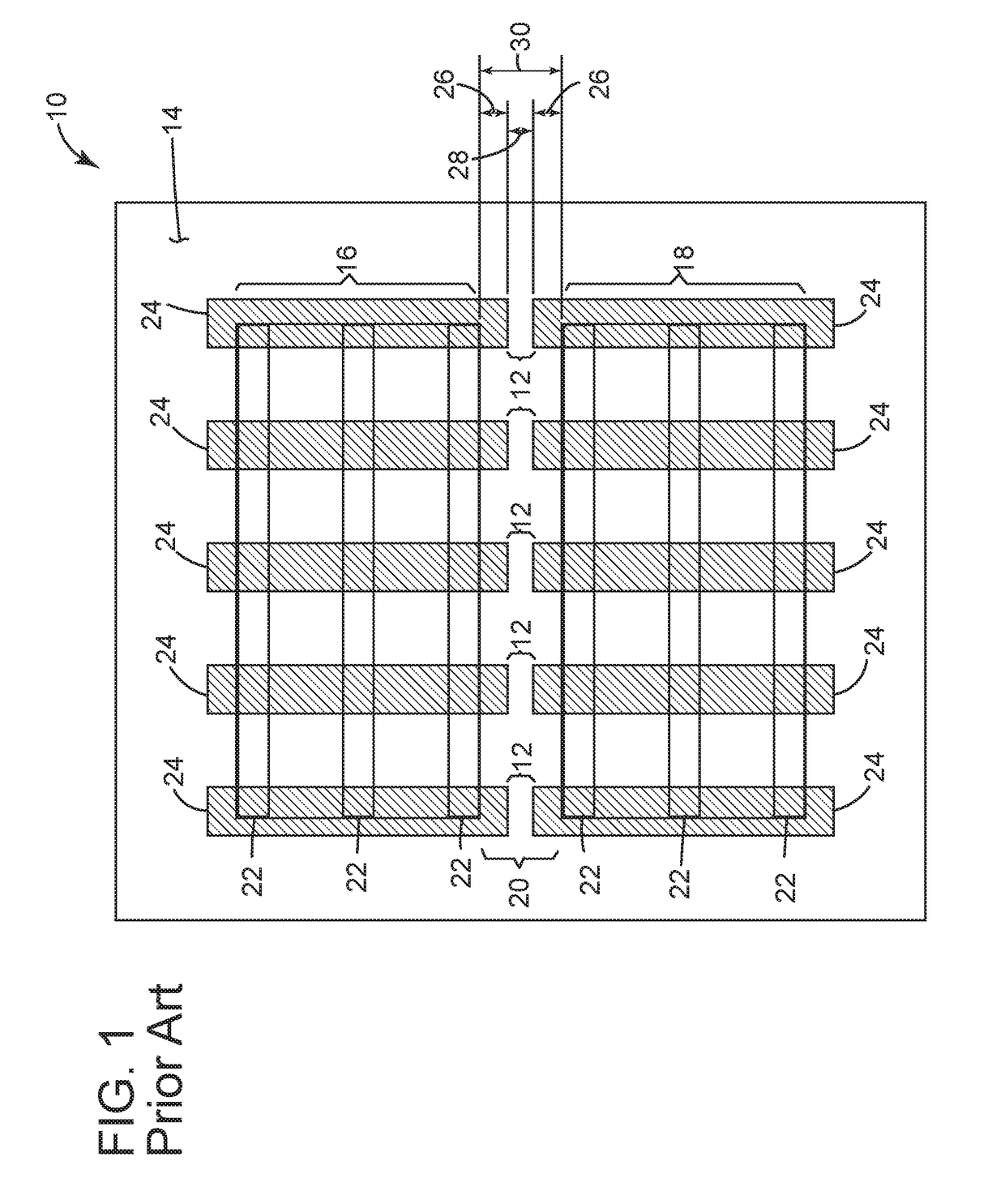

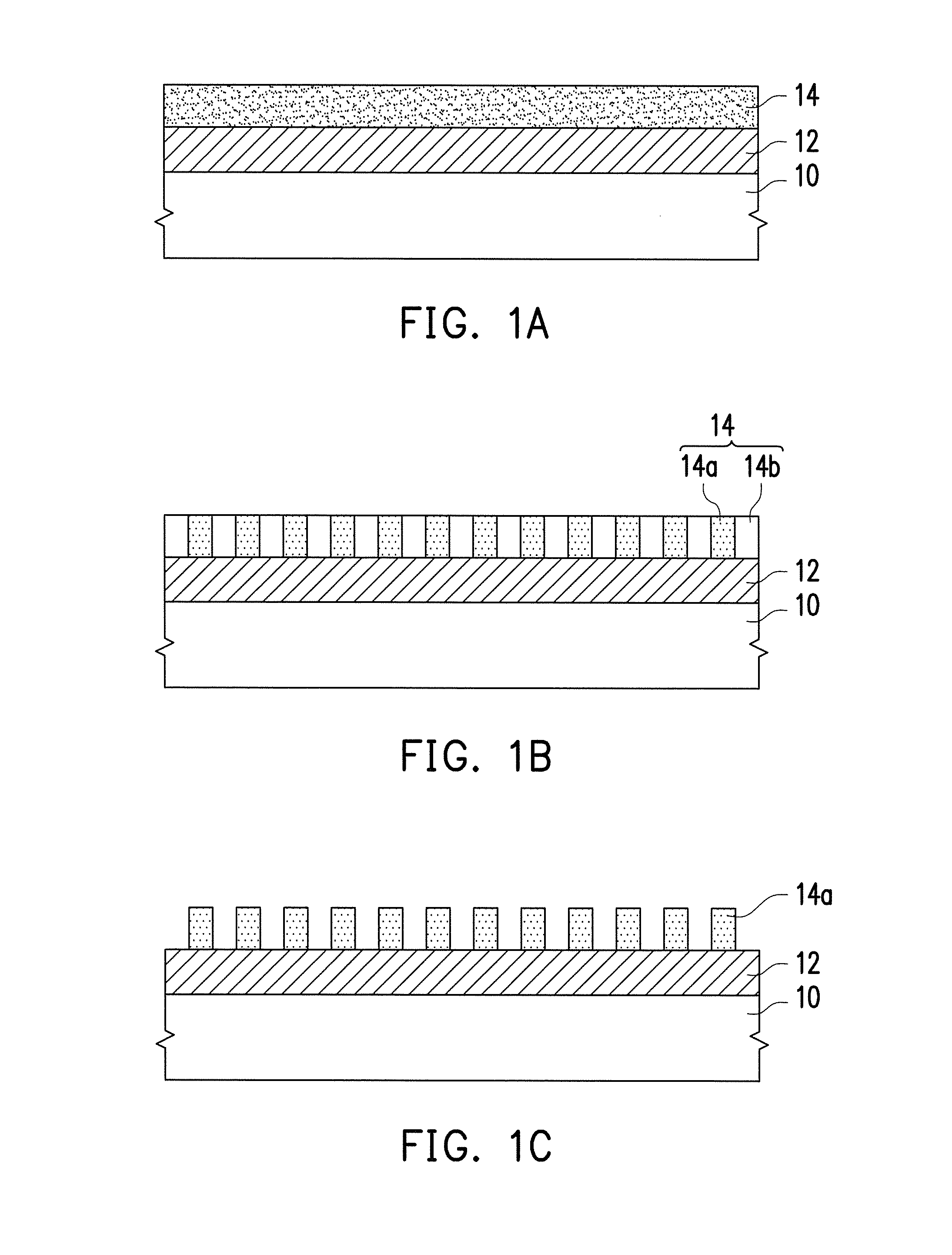

Methods of forming a CT pillar between gate structures in a semiconductor

ActiveUS10177037B2High aspect ratioLess resolutionTransistorSolid-state devicesSemiconductor structureEngineering

A method includes providing a semiconductor structure having a substrate and a plurality of fins extending upwards from the substrate. A CT pillar layer is disposed over the semiconductor structure. A CT mask is lithographically patterned over the CT pillar layer. The CT mask is anisotropically etched to remove exposed portions of the CT pillar layer and to form a CT pillar between the fins. A dummy gate structure is disposed across the CT pillar. The dummy gate structure is replaced with first and second metal gate structures that are electrically isolated from each other by the CT pillar.

Owner:GLOBALFOUNDRIES U S INC

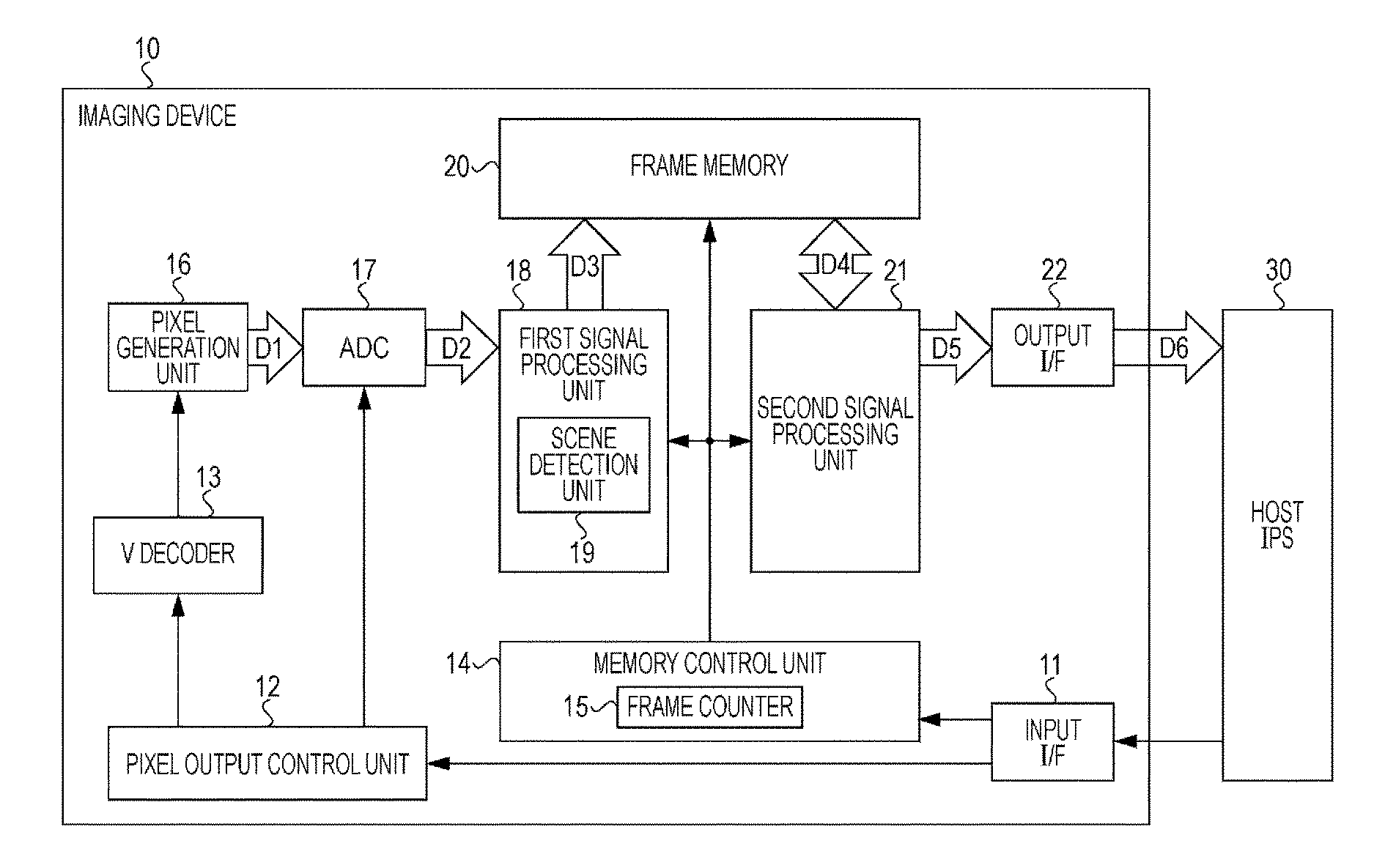

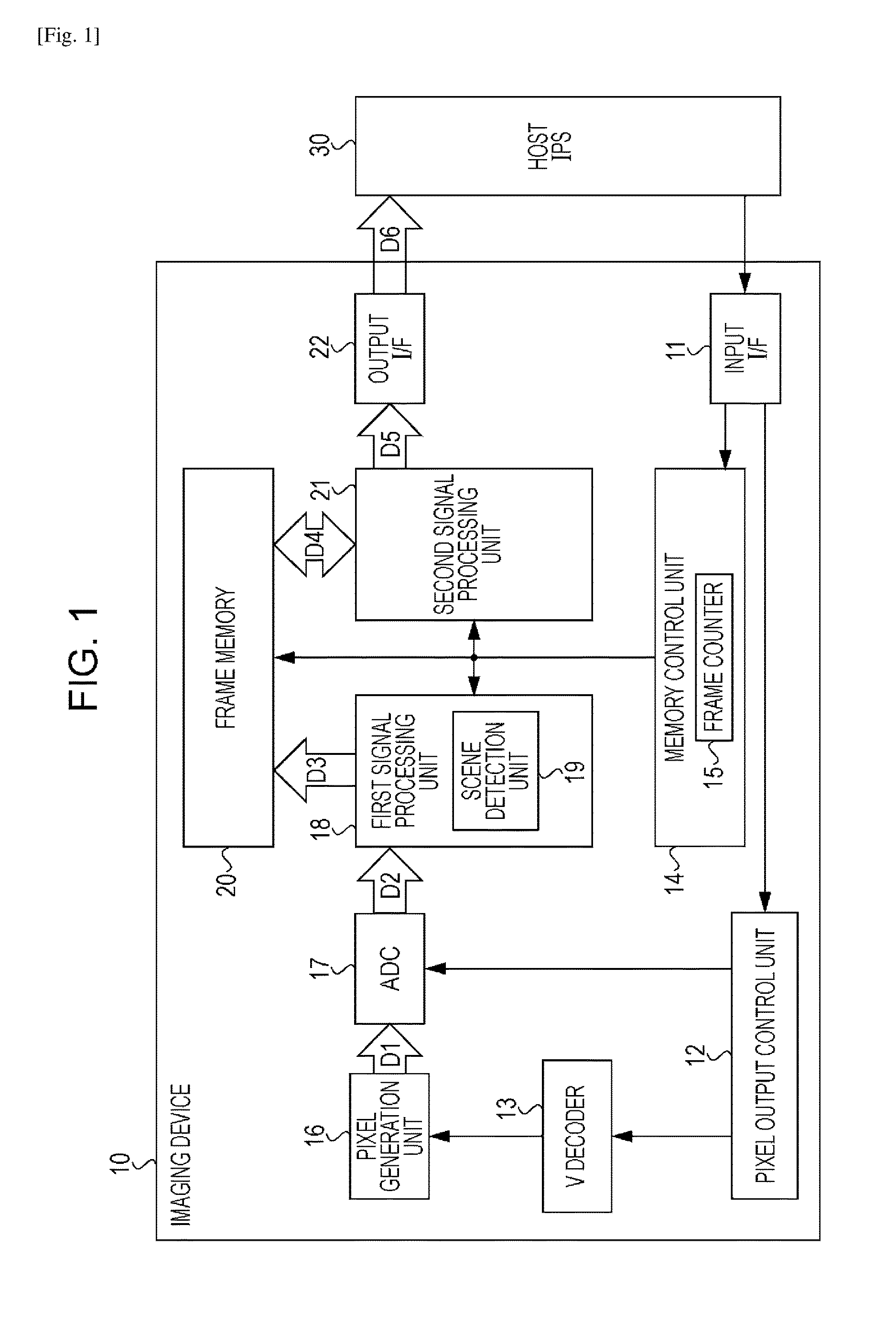

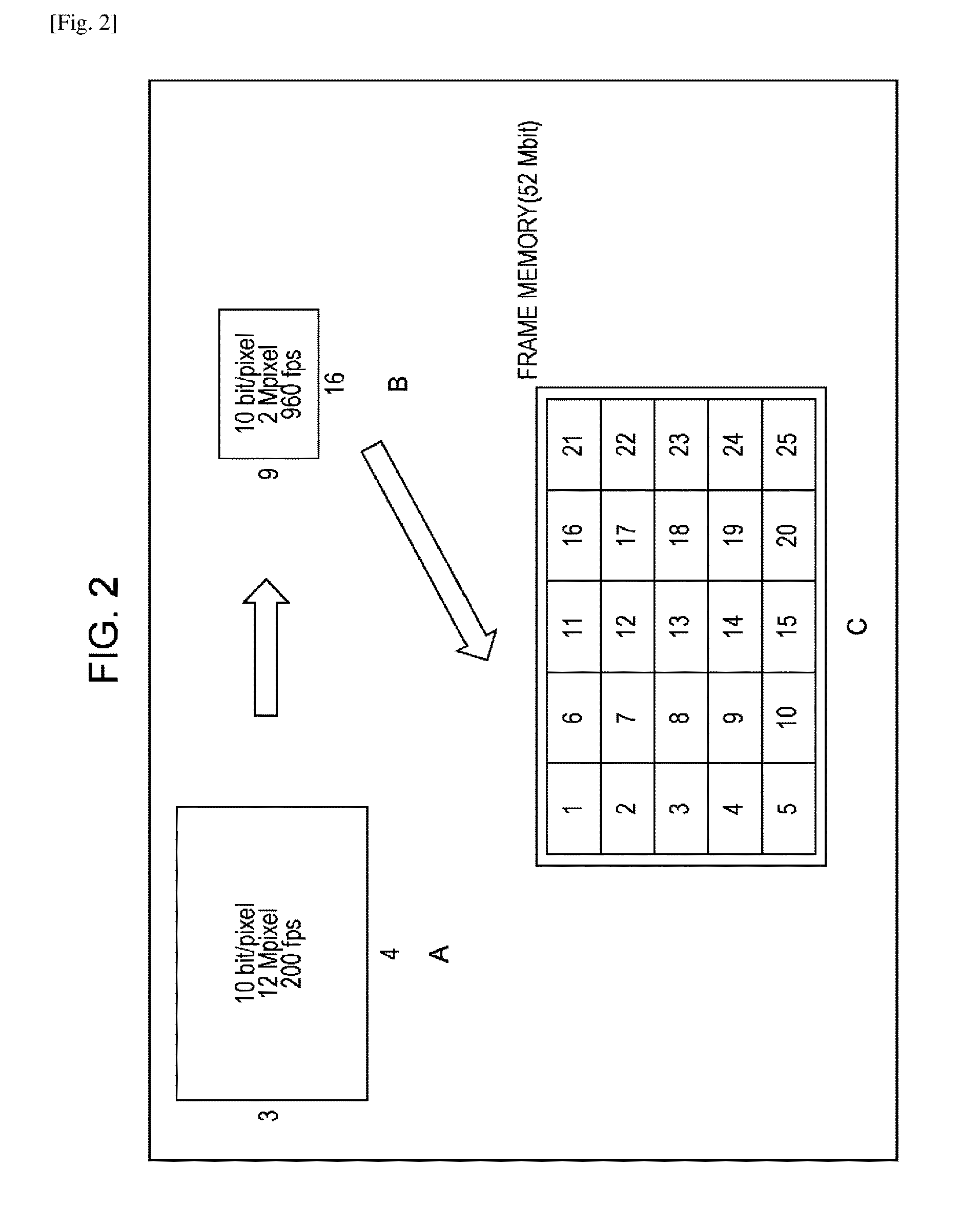

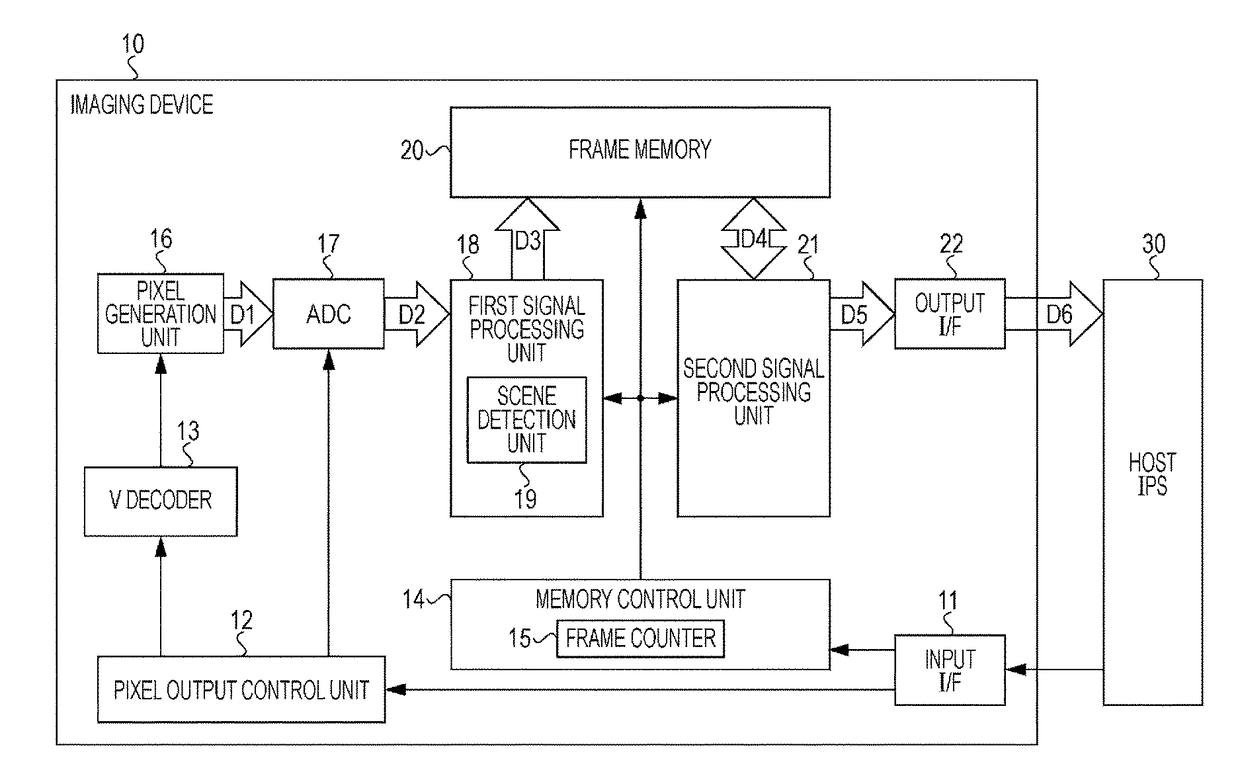

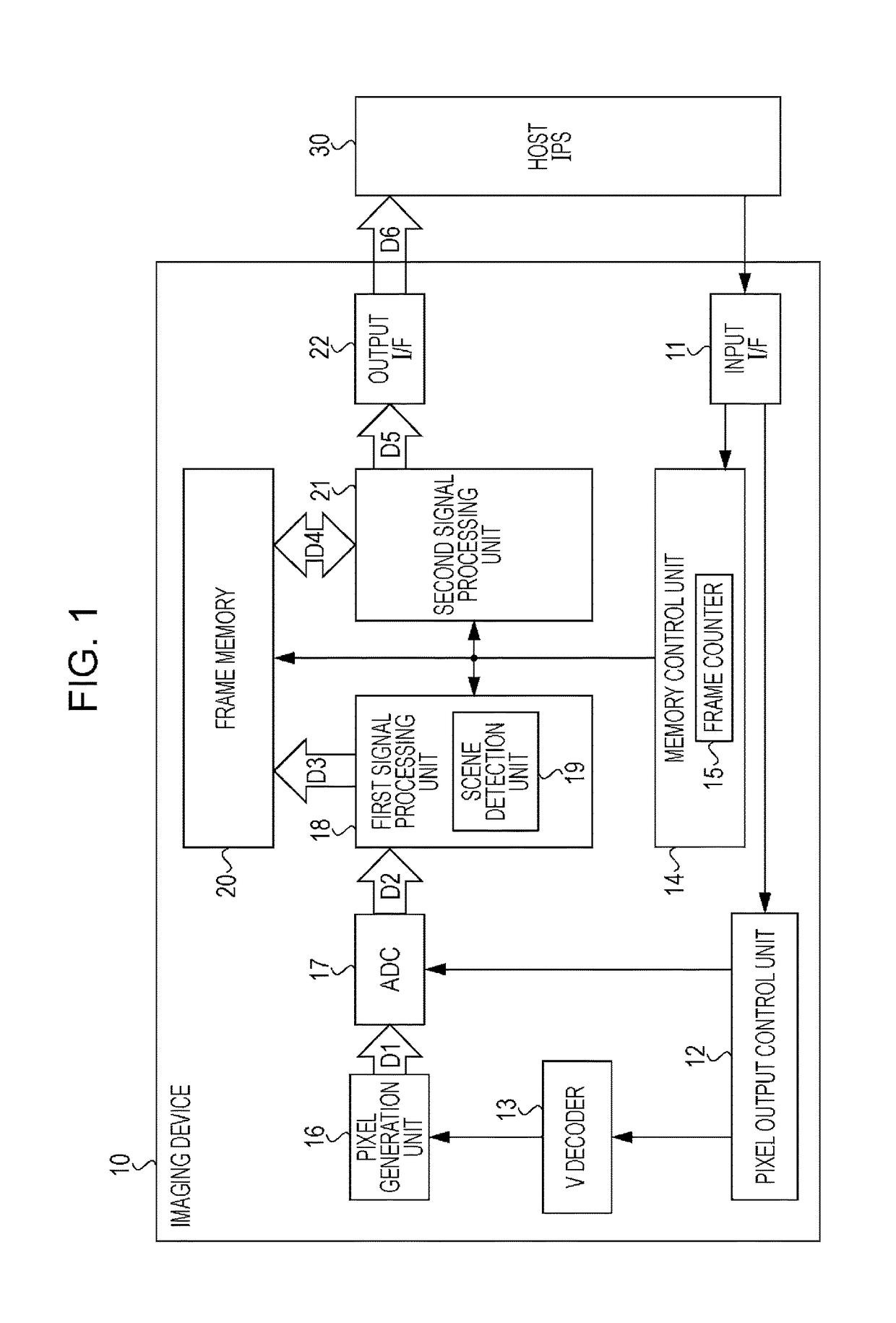

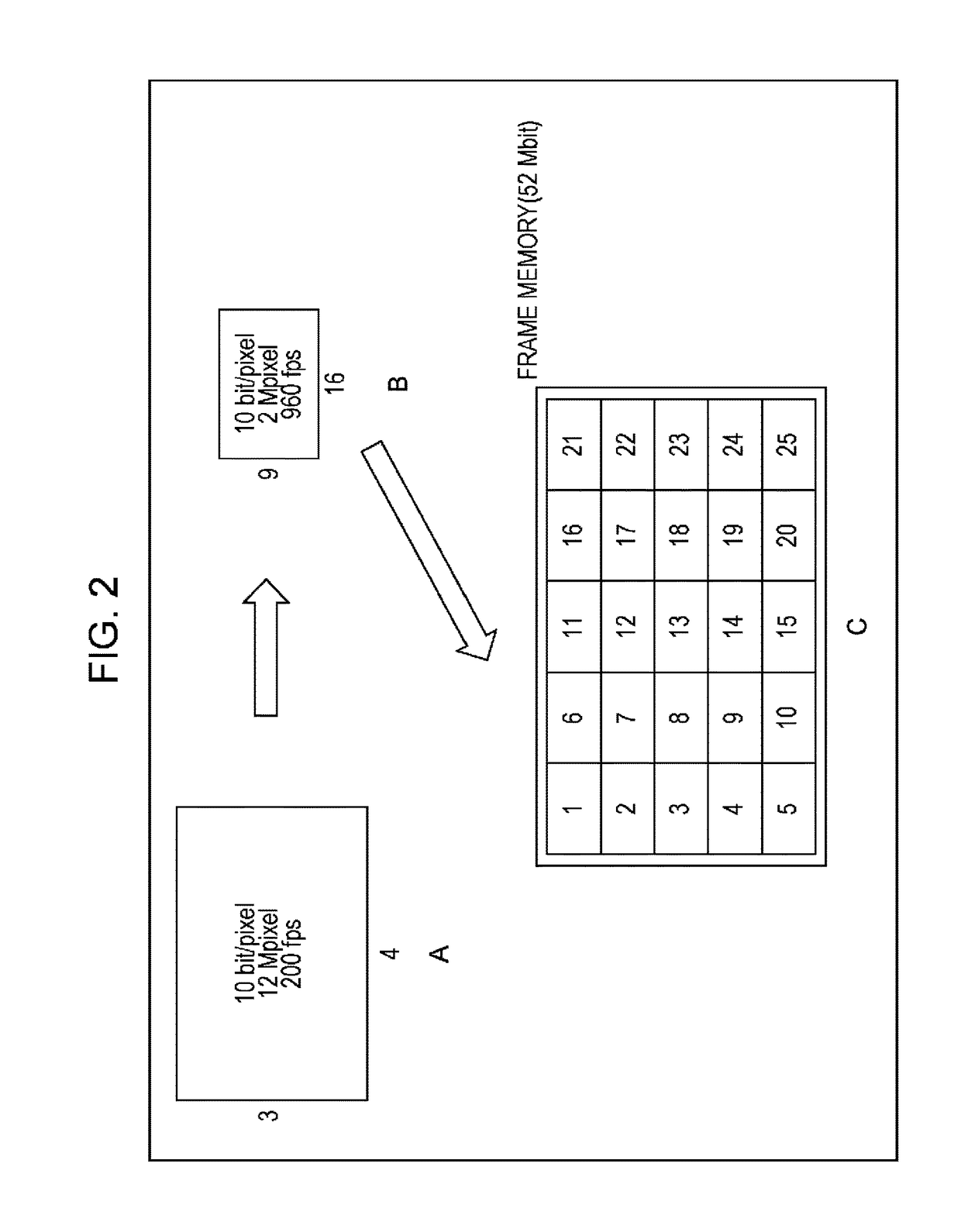

Imaging device, imaging apparatus, and electronic apparatus

ActiveUS20160381319A1Less resolutionHeat suppressionTelevision system detailsColor television detailsElectric devicesComputer science

There is provided an imaging device that includes a pixel generation unit that generates an image signal formed from a plurality of pixel signals according to incident light, and a frame memory that stores the image signal of a plurality of frames.

Owner:SONY CORP

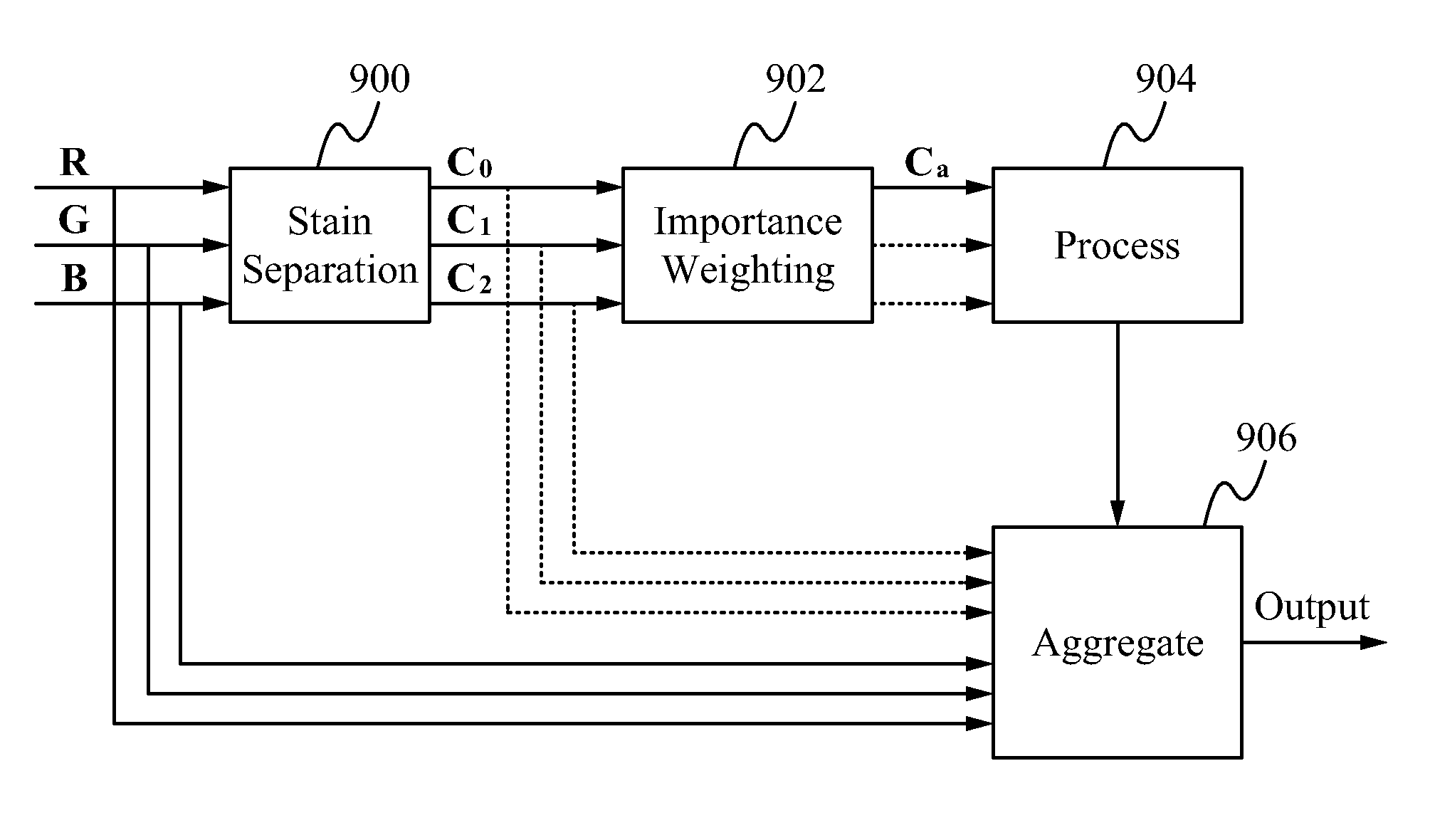

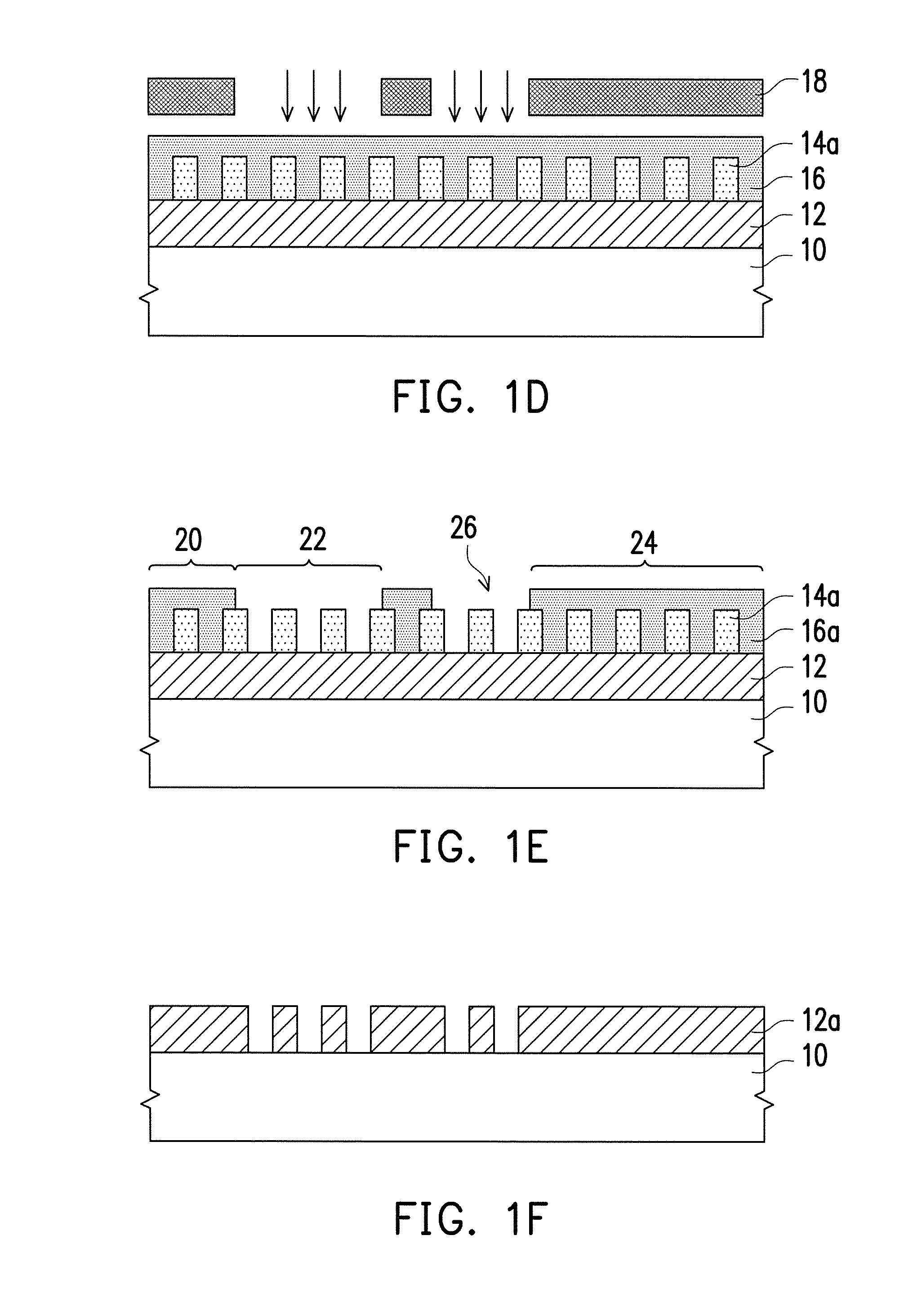

Method for efficient representation and processing of color pixel data in digital pathology images

ActiveUS20120263356A1Accurate representationEfficient compression of imageCharacter and pattern recognitionImage codingImage resolutionImage compression

Efficient representation of color digital pathology images (DPI) is described herein, which is accomplished by exploiting properties unique to such images. The method decomposes the data into constituent parts whose relative importance is able to be specified, allowing the data to be accurately represented with less bit precision, less spatial resolution or less spectral resolution. Two specific areas where the method is able to be utilized include: (1) more-efficient image compression; and (2) more efficient processing of the data. Efficient image compression is accomplished by assigning fewer bits to less-important colors. Efficient data processing is accomplished by processing only those colors, or combinations of colors, that are deemed important.

Owner:SONY CORP

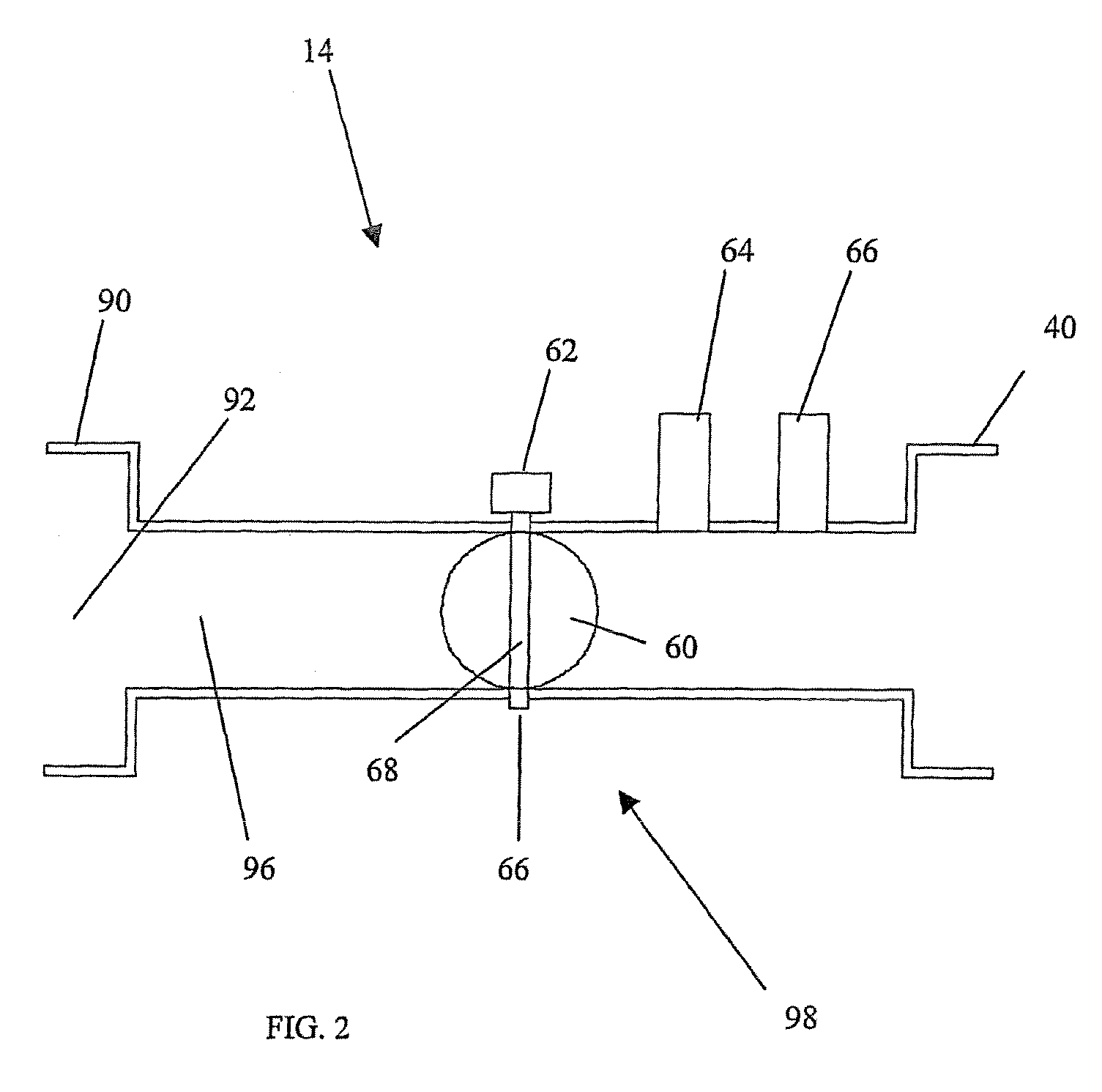

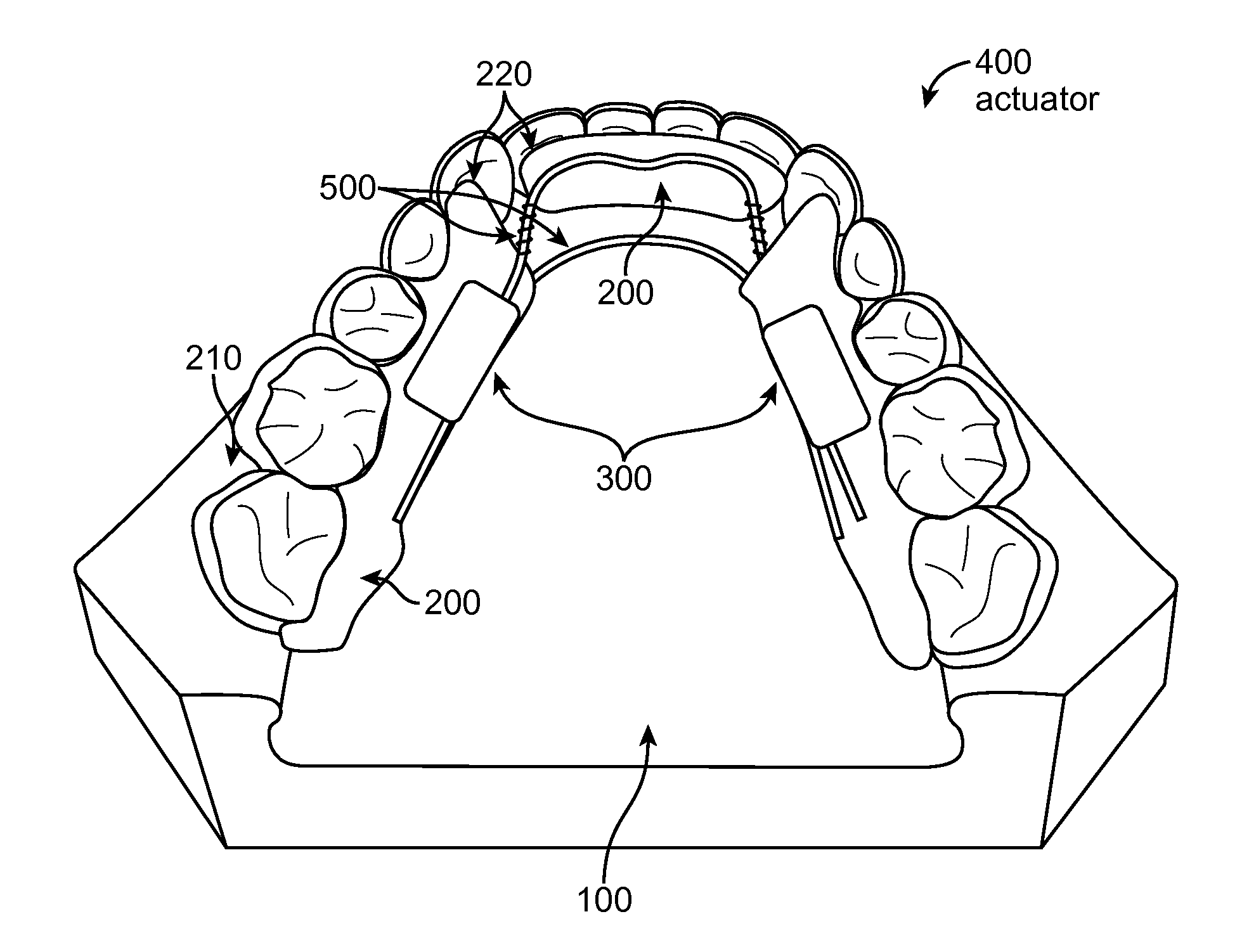

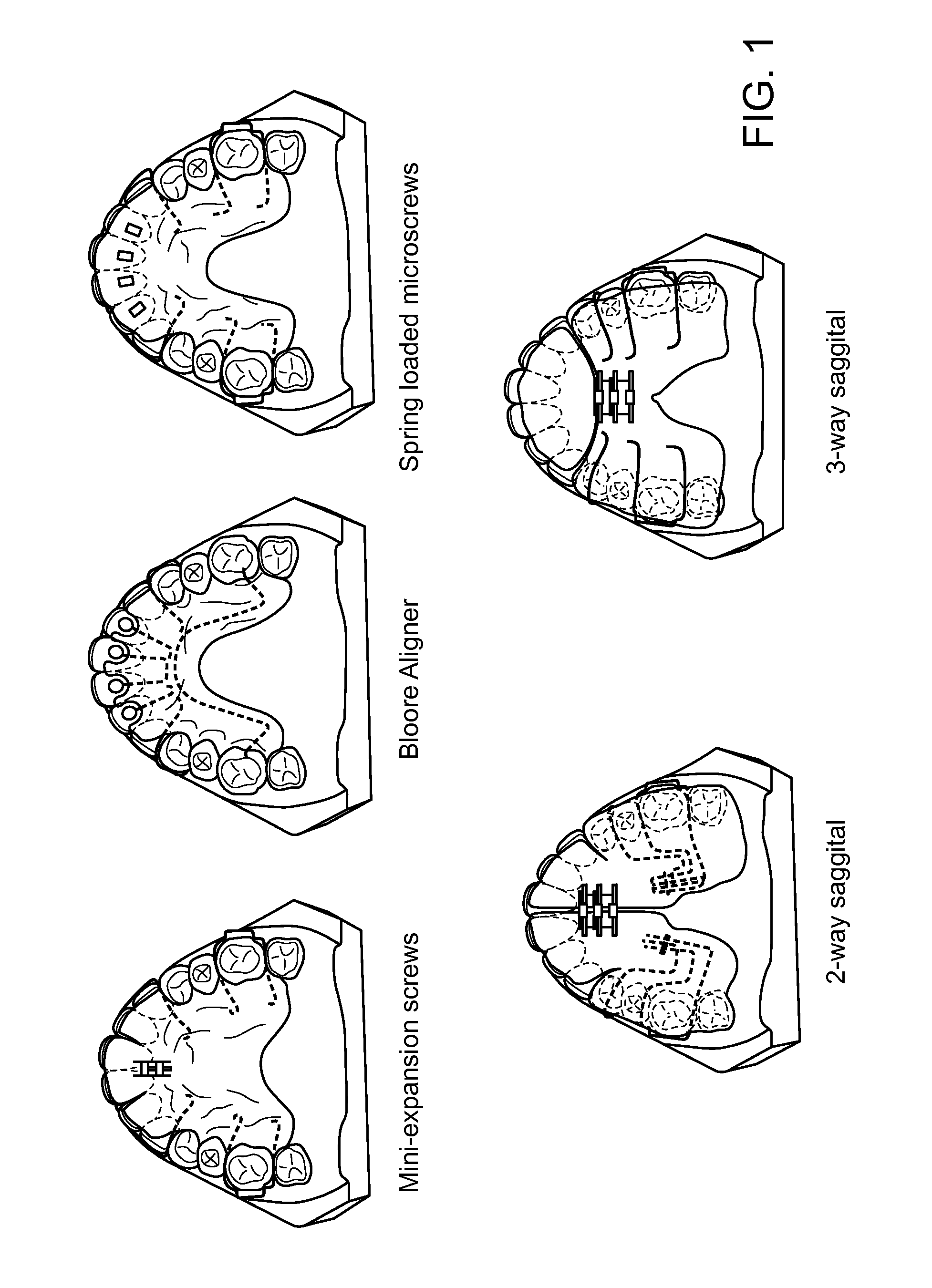

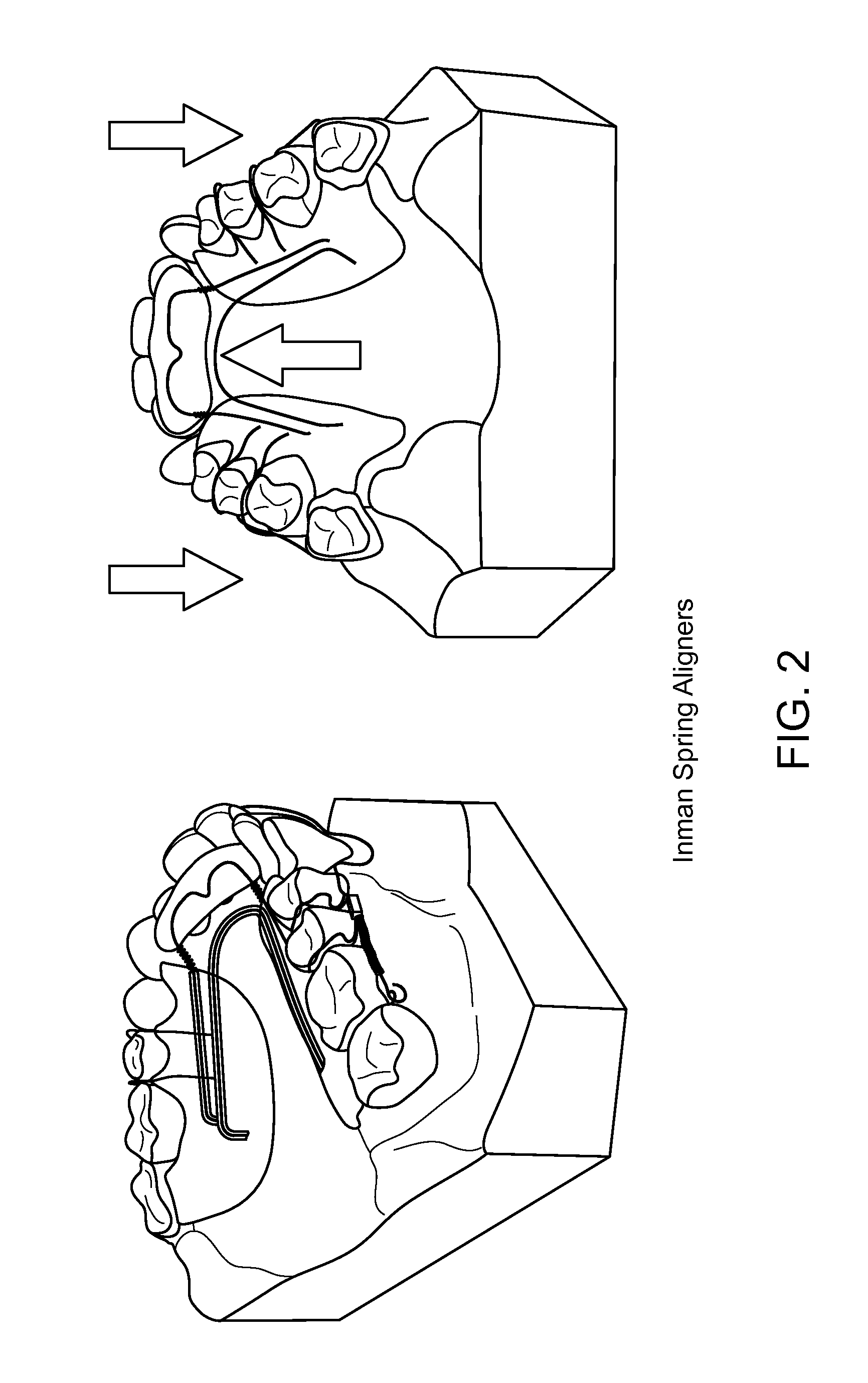

Cyclic interruptive force orthodontic device and system

Provided herein is a cyclic interruptive force orthodontic device and a system comprising the same. Methods of making and using the same are also provided.

Owner:RGT UNIV OF CALIFORNIA

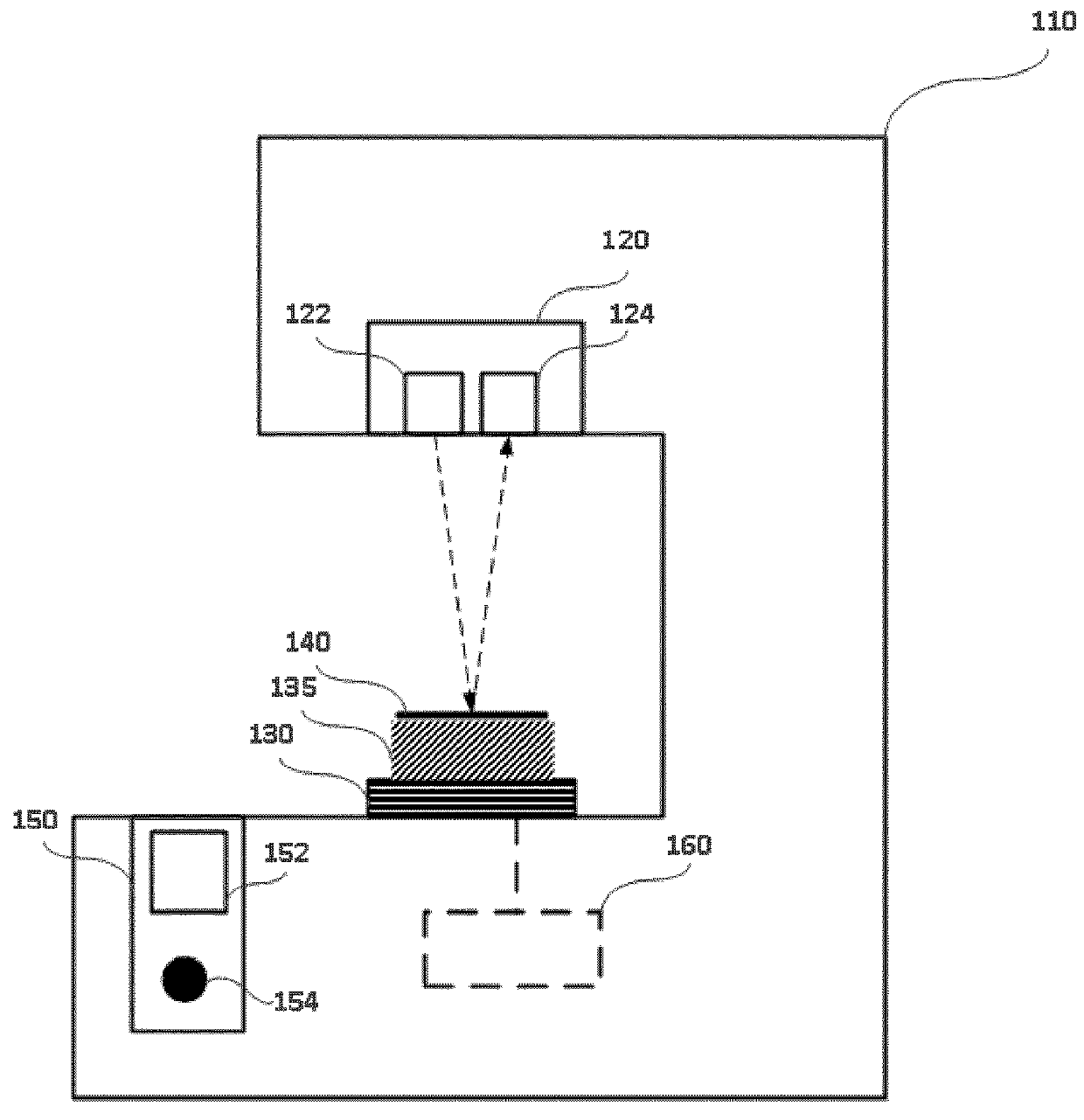

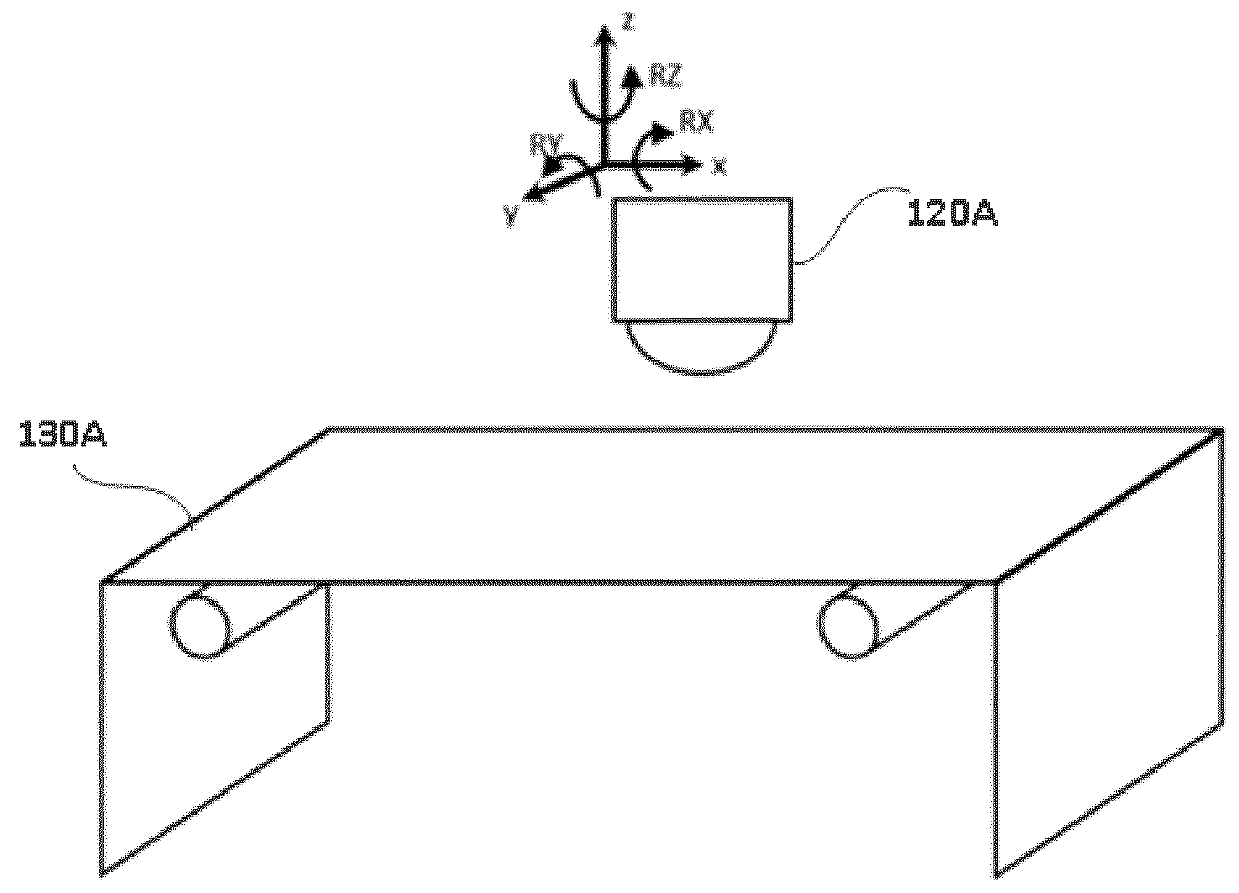

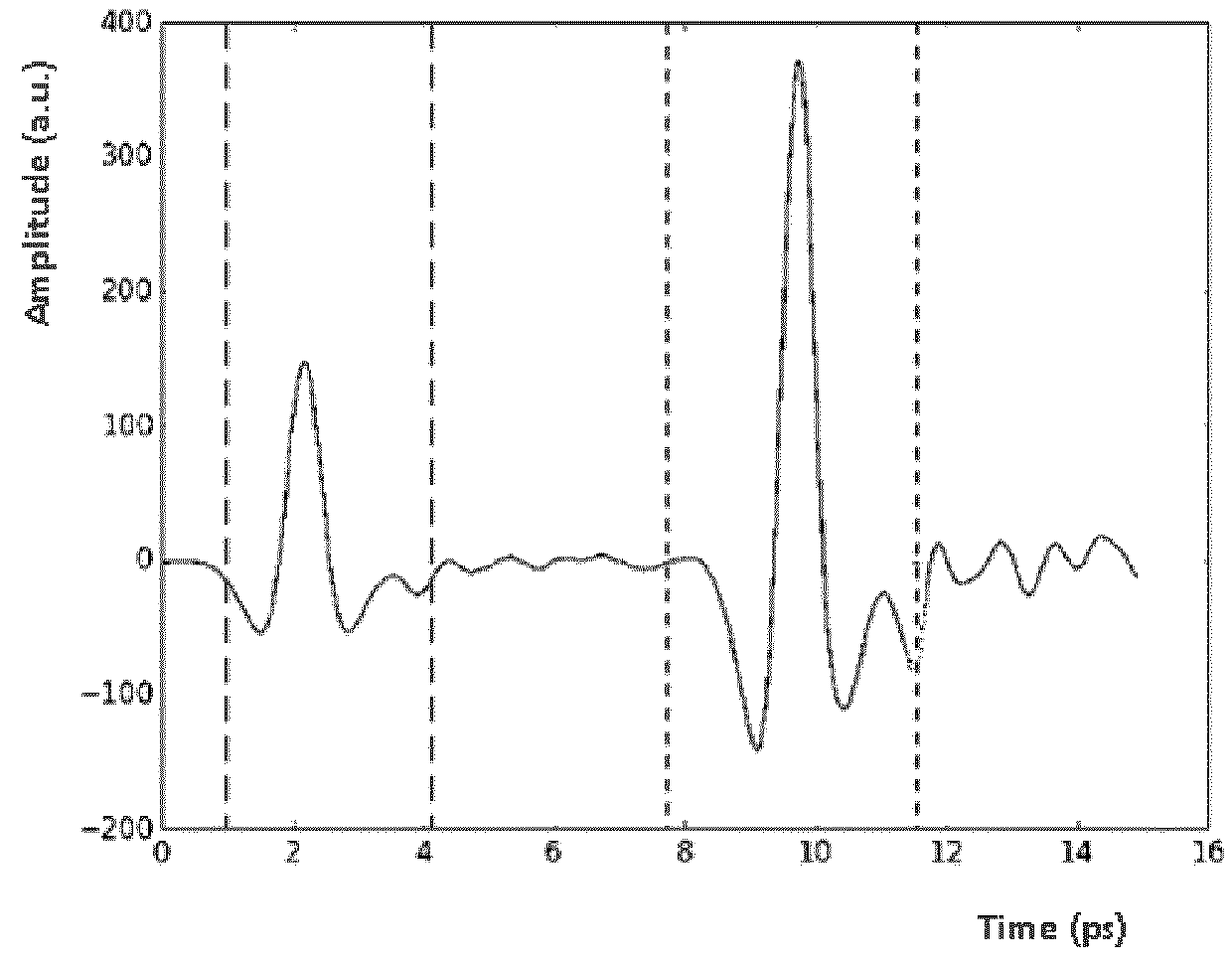

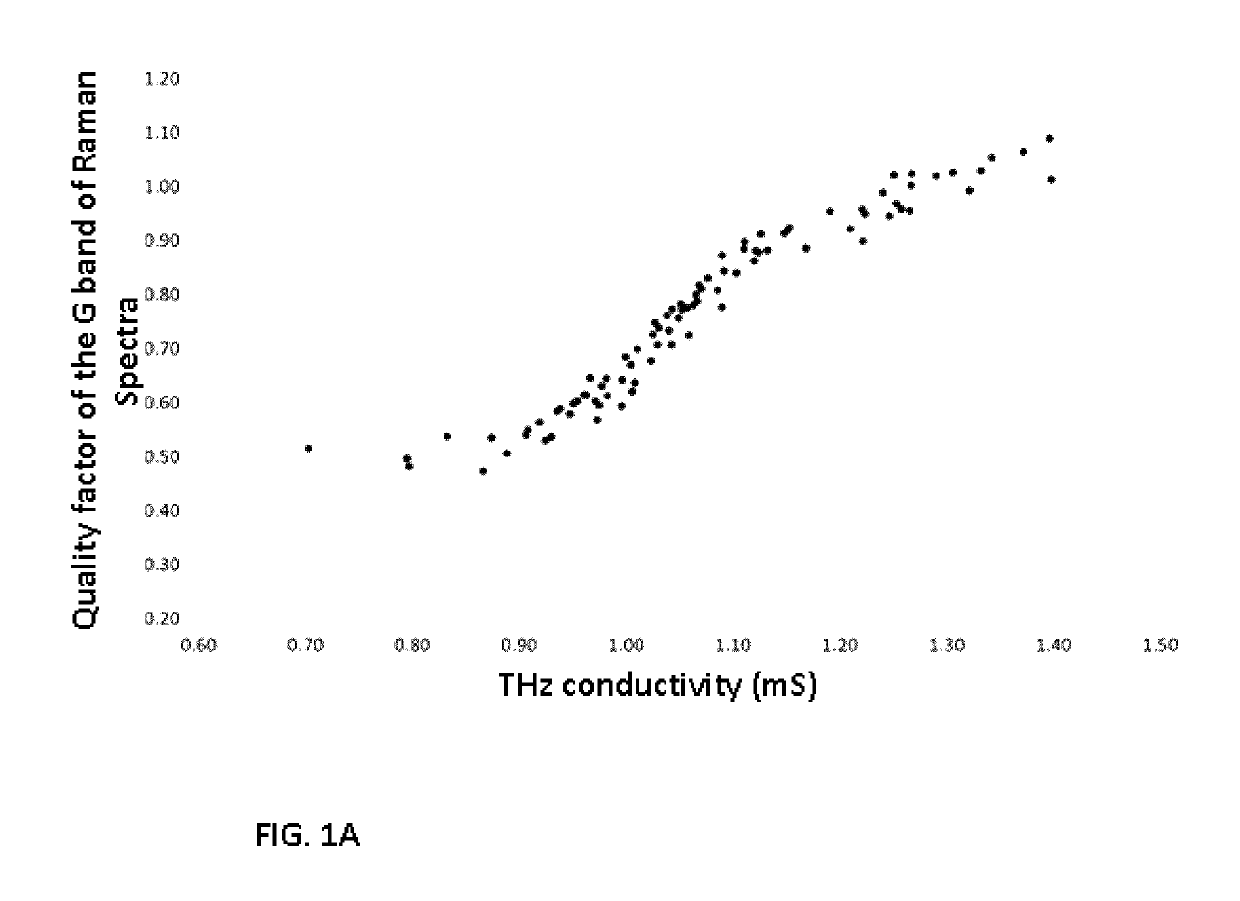

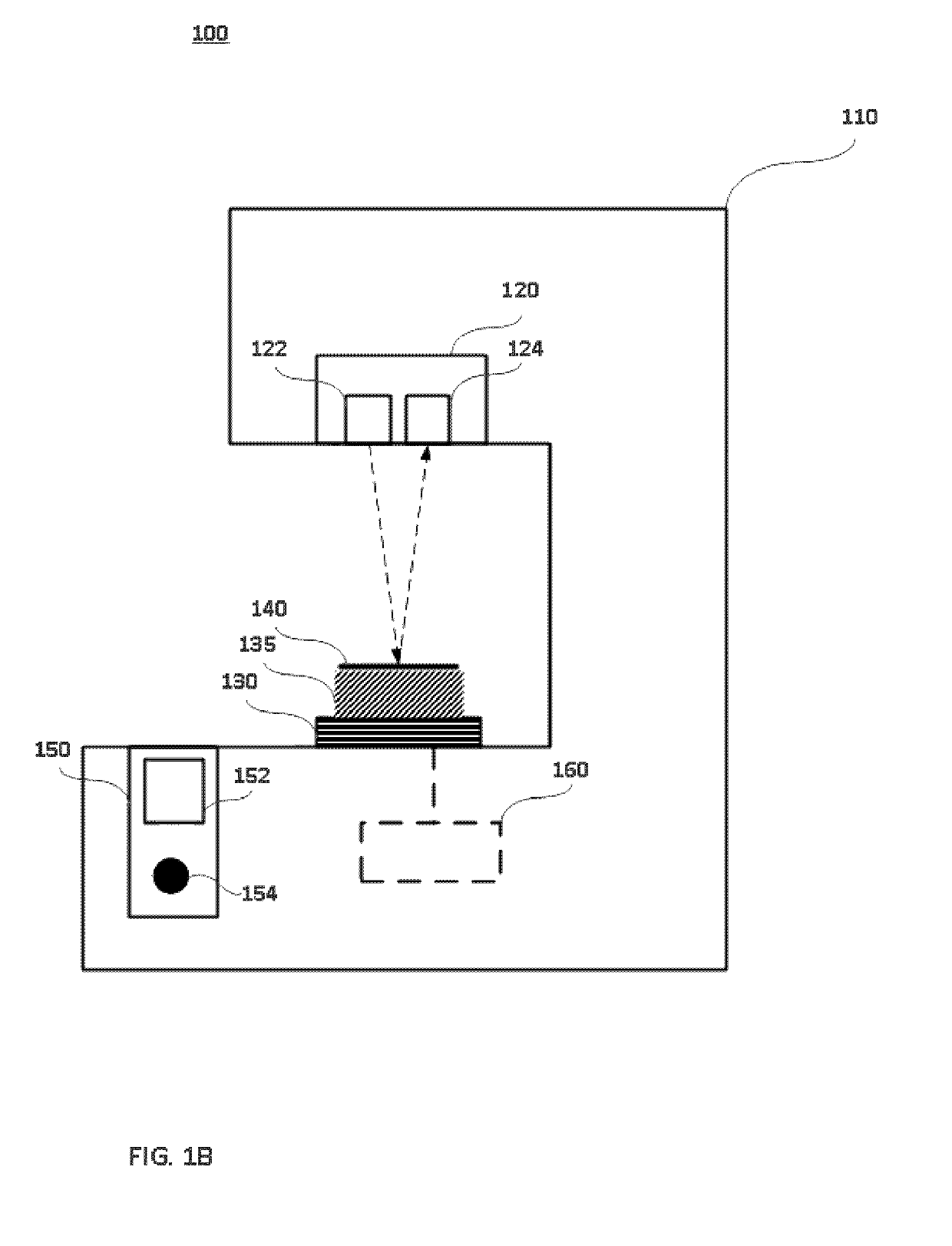

Quality inspection of thin film materials

ActiveUS20180164354A1Measurement result is affectedEffective electricalMethods for obtaining spatial resolutionResistance/reactance/impedenceIrradiationFilm material

Devices and methods for determining the quality thin film materials are disclosed. The thin film materials are provided on substrates forming thin film material structures. The devices comprise a housing, a THz module with a THz source emitter and a THz detector,and a reflective base moveable relative to the THz module and configured to support the thin film material structures. The THz source emitter is configured to irradiate the thin film materials. The THz detector is configured to measure at least one reflection of the irradiation. The device is configured to calculate a parameter indicative of the quality of the thin film material based on said reflection measurements.

Owner:ASSOC CENT DE INVESTIGACION COOP & NANOCIENCIAS CIC NANOGUNE +2

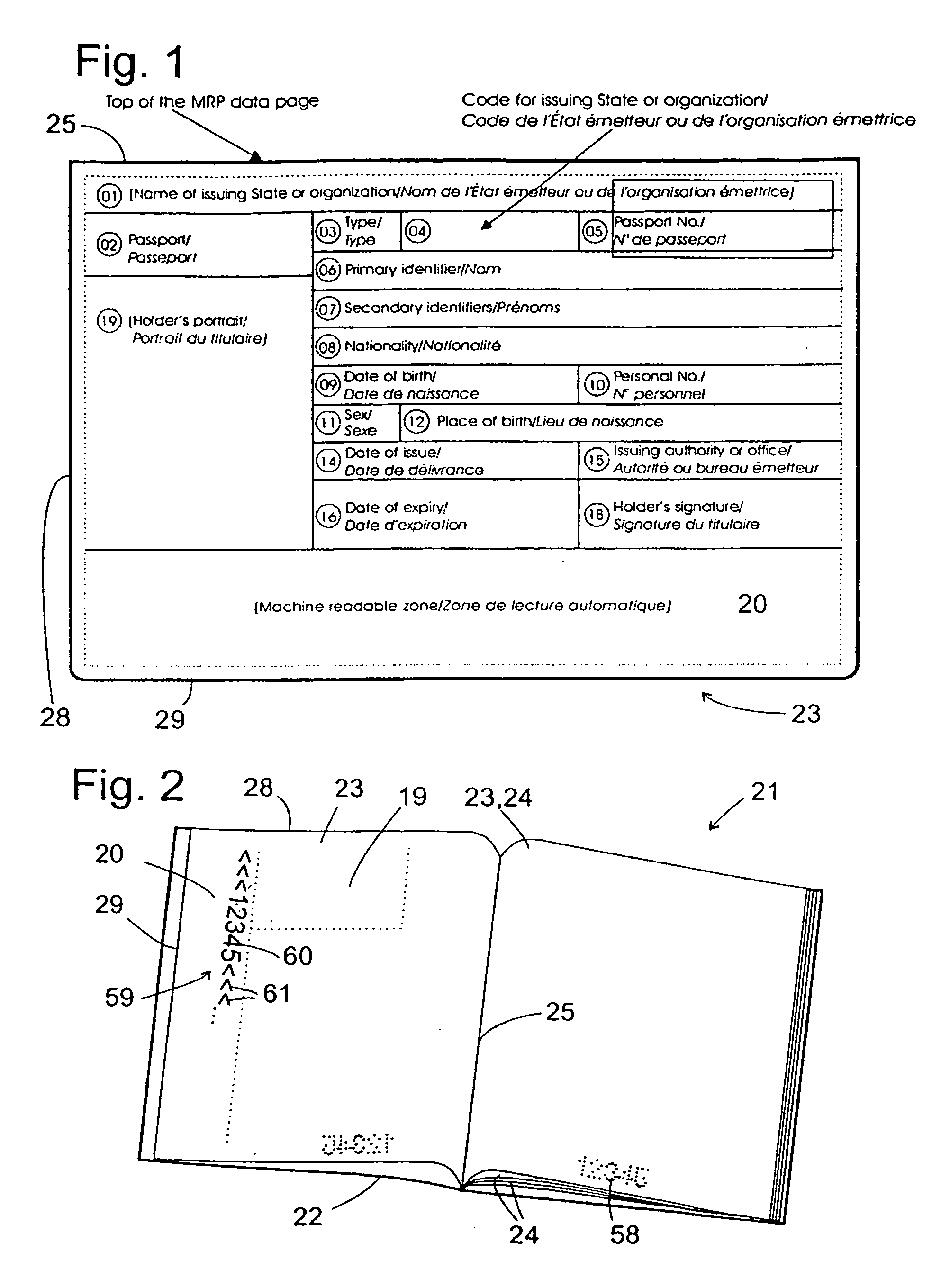

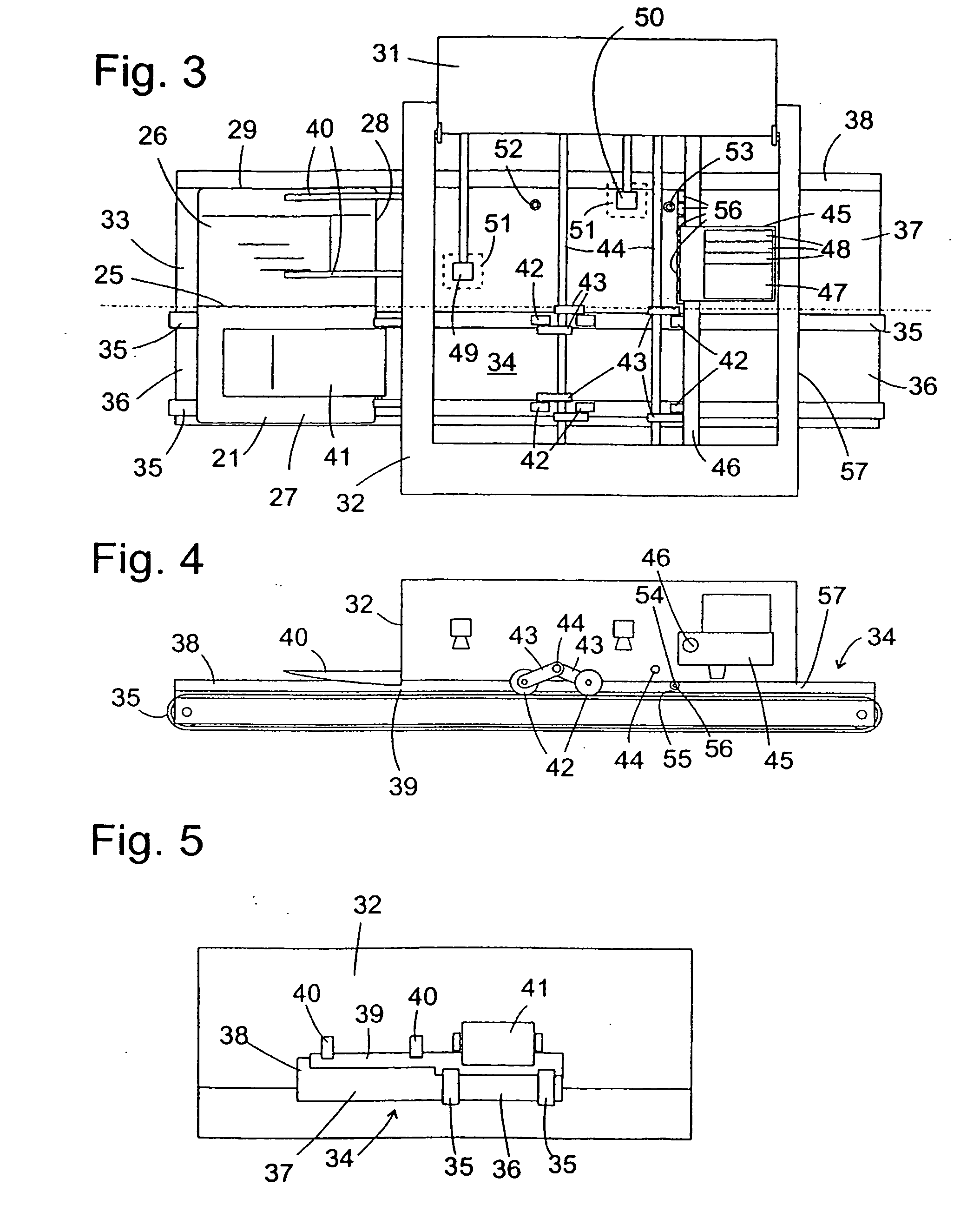

Method and device for printing details onto a document

InactiveUS20090096820A1Good machine readabilityInformation amount of becomes largeDigitally marking record carriersOther printing matterGraphicsDocumentation

Owner:SAFE ID SOLUTIONS

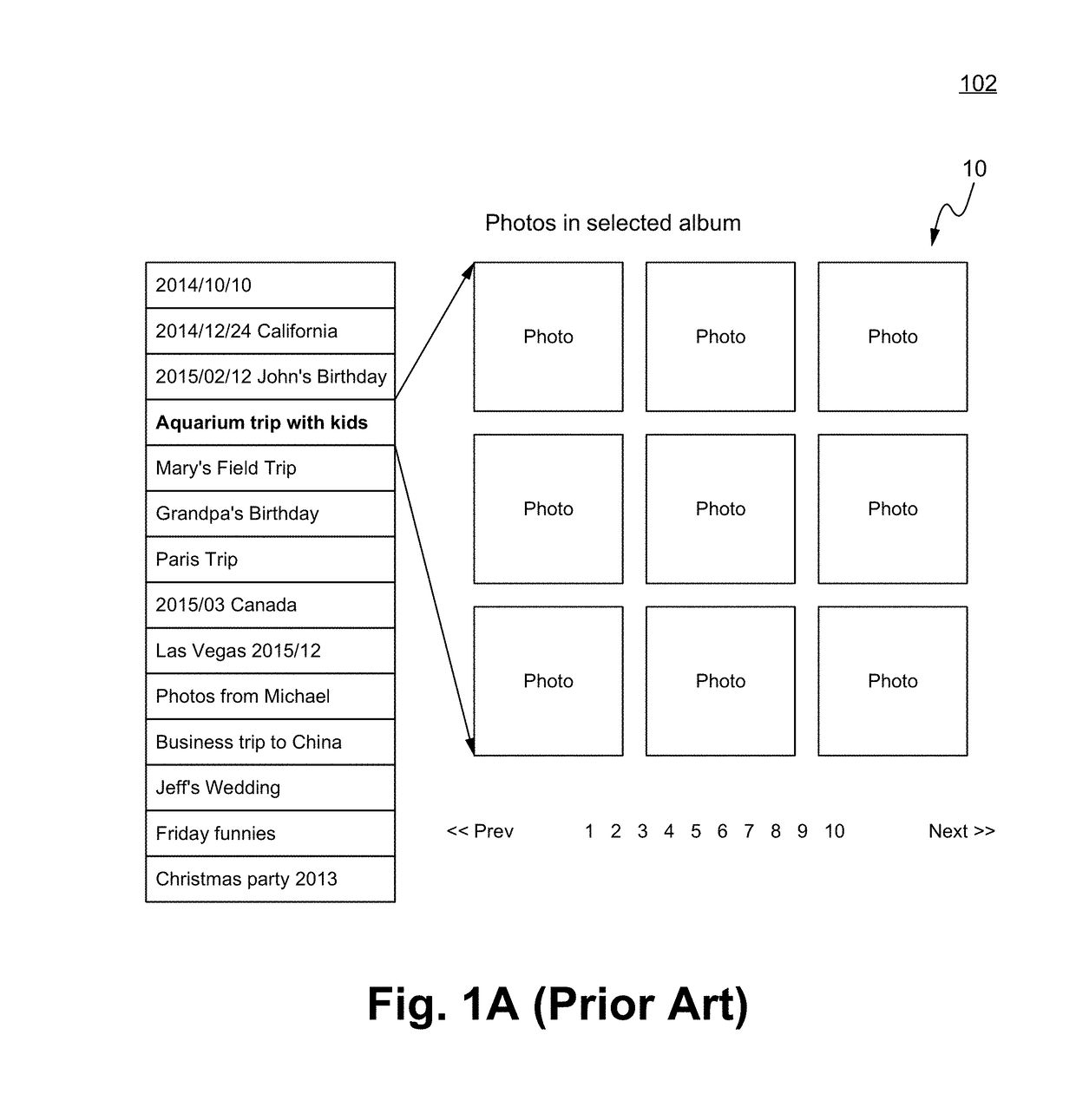

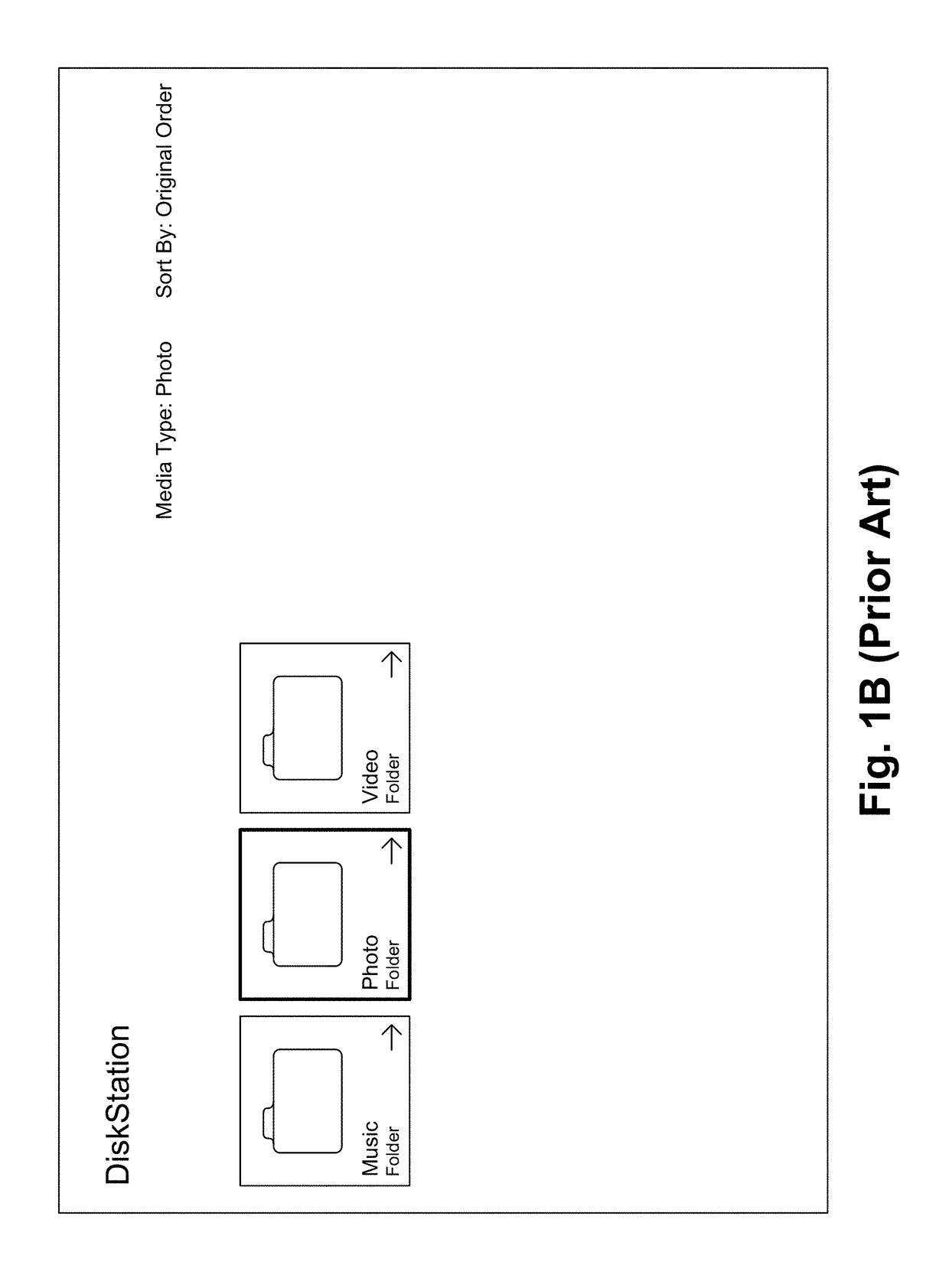

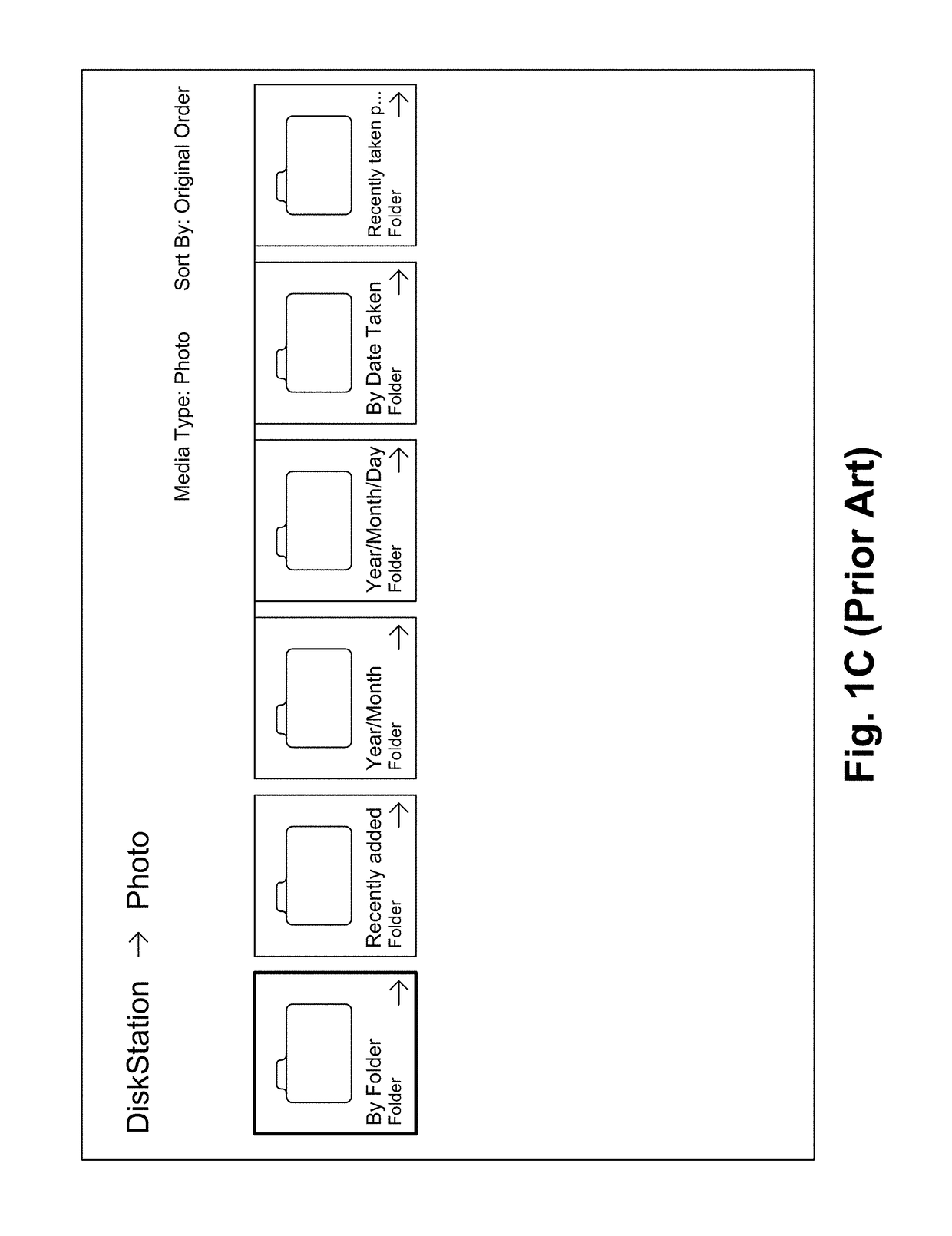

Systems for and methods of browsing and viewing huge and heterogeneous media collections on TV with unified interface

InactiveUS20180367838A1Few pixelLess resolutionDigital data information retrievalDigital data protectionRemote controlDisplay device

The system and method comprise an Internet-connected defice configured to receive media files of a person from different media sources from a local network or Internet, a smart computing software, with or without hardware assist, configured to sort and categorize the media files and automatically generate a media presenting structure including one or more media channels as a primary layer and one or more media programs as a secondary layer based on an intelligent media content analysis of at least two factors. At least one of the factors includes a media content that is of the person. A display that the device is coupled to is configured to display the sorted media files on a unified user interface having the one or more media channels and the one or more media programs as a media presenting structure. A remote control is used to navigate the media presenting structure to find photos of interests on the display.

Owner:ATRIVA MEDIA INC

Weighted fair queue having extended effective range

InactiveUS20070140285A1Increase the areaLess resolutionData switching by path configurationStore-and-forward switching systemsImage resolutionFair queuing

A scheduler for a network processor includes a scheduling queue in which weighted fair queuing is applied to define a sequence in which flows are to be serviced. The scheduling queue includes at least a first subqueue and a second subqueue. The first subqueue has a first range and a first resolution, and the second subqueue has an extended range that is greater than the first range and a lower resolution that is less than the first resolution. Flows that are to be enqueued within the range of highest precision to the current pointer of the scheduling queue are attached to the first subqueue. Flows that are to be enqueued outside the range of highest precision from the current pointer of the scheduling queue are attached to the second subqueue. Numerous other aspects are provided.

Owner:IBM CORP

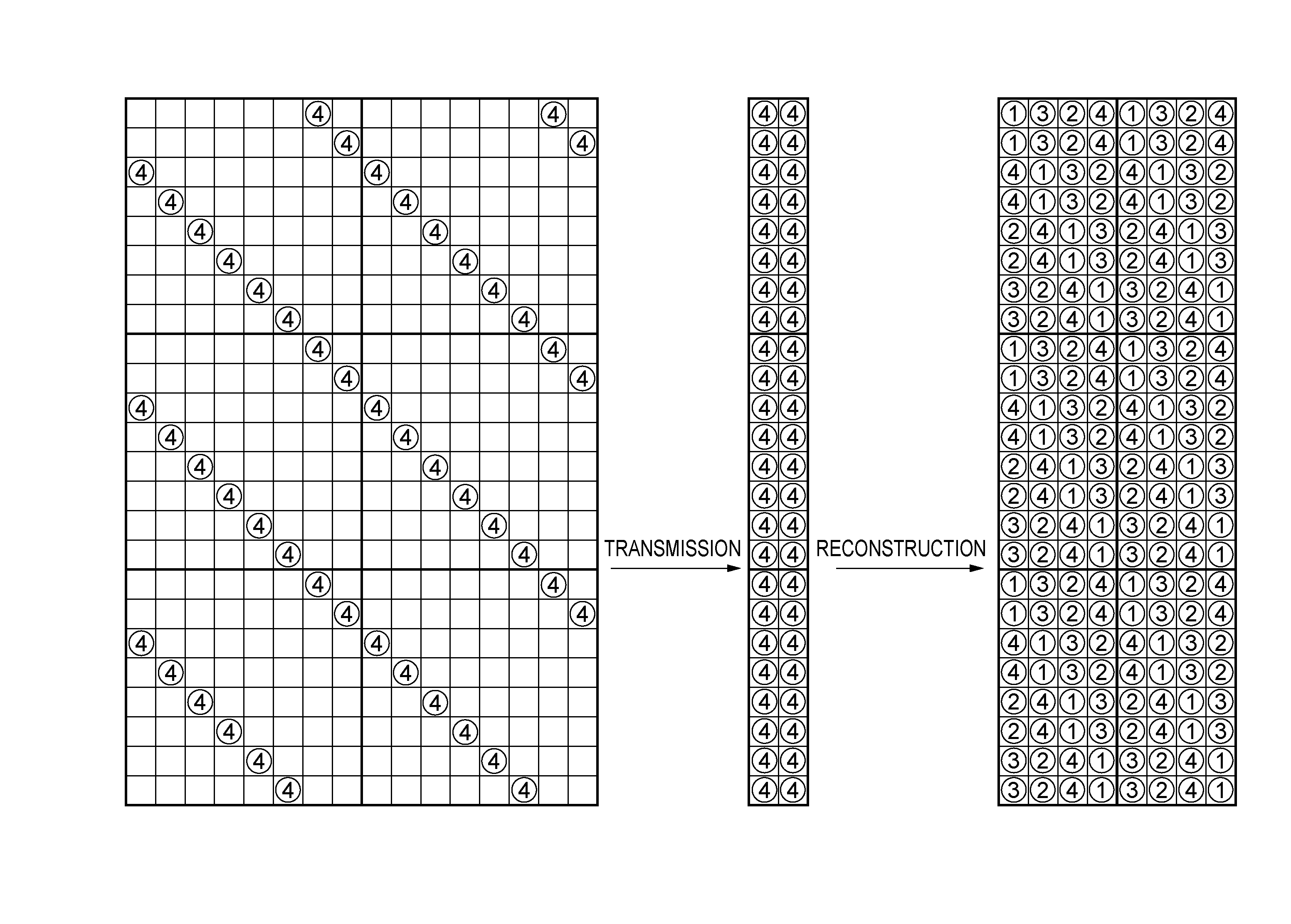

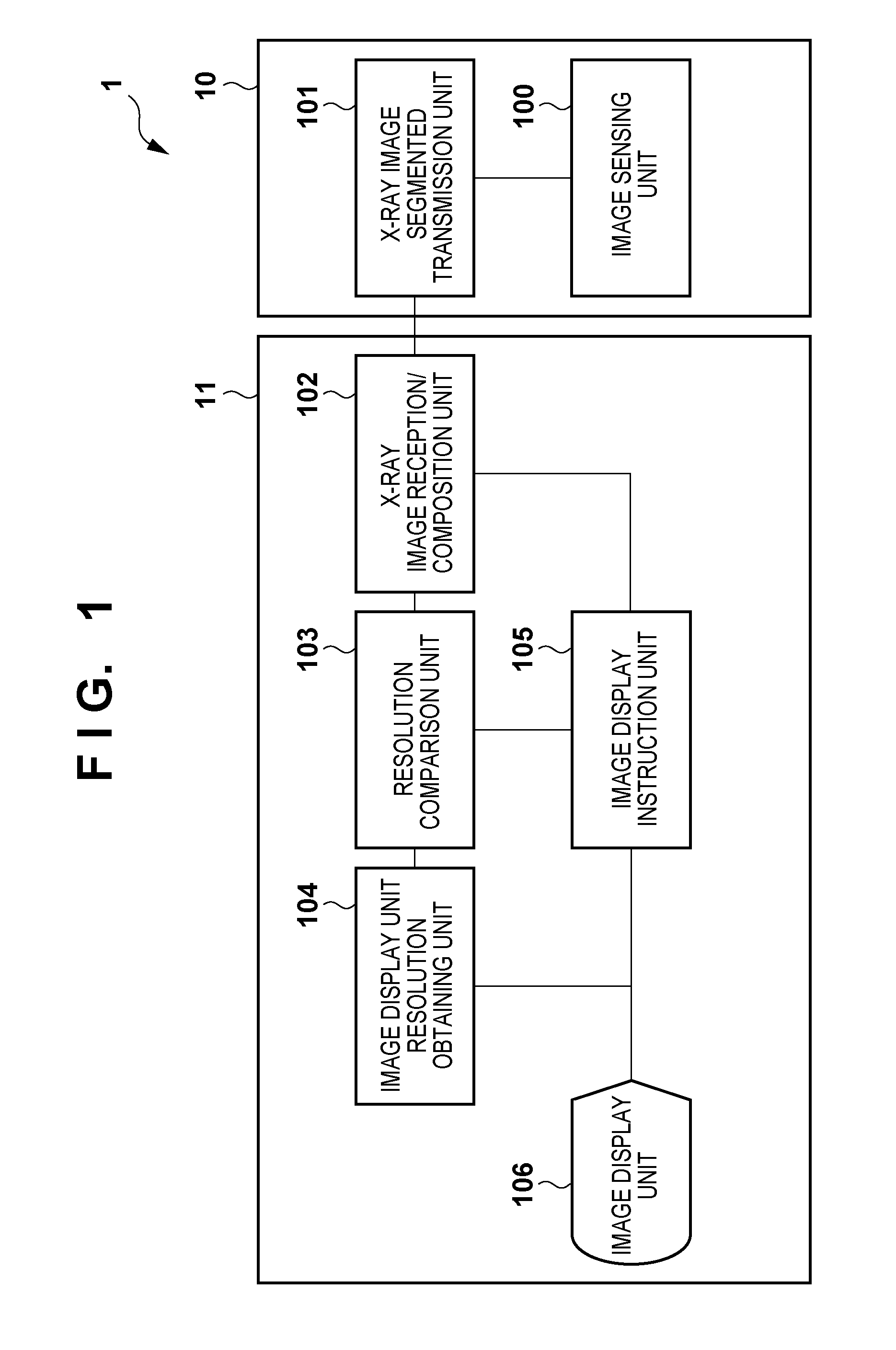

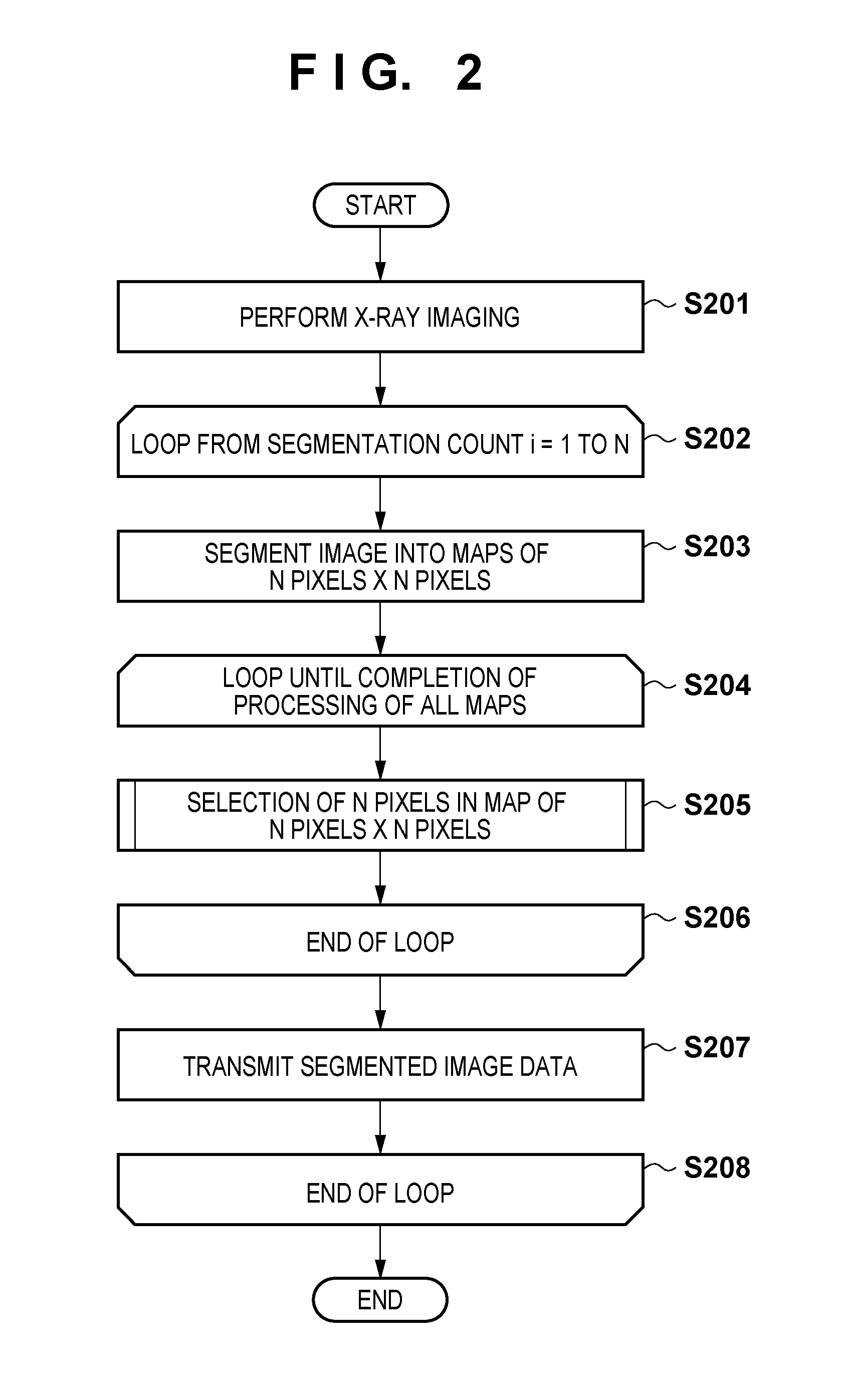

X-ray imaging system, method of controlling x-ray imaging system, information processing apparatus, and x-ray imaging apparatus

InactiveUS20120243663A1Less resolutionRadiation diagnosis data transmissionTelevision system detailsInformation processingSoft x ray

An X-ray imaging system comprising an X-ray imaging apparatus which captures an X-ray image and an information processing apparatus which receives and composes the X-ray image, the X-ray imaging apparatus comprising a transmission unit configured to segment a X-ray image into images and sequentially transmit the images, and the information processing apparatus comprising a reception / composition unit configured to sequentially receive and compose the X-ray images, a determination unit configured to determine, every time the X-ray images are sequentially composed, whether a resolution of the composed X-ray image is not less than a predetermined value, and a display control unit configured to perform control to display the composed X-ray image on a display unit, when the determination unit determines that the resolution is not less than the predetermined value.

Owner:CANON KK

Imaging device, imaging apparatus, and electronic apparatus

ActiveUS9906753B2Less resolutionHeat suppressionTelevision system detailsColor television detailsImage signalElectron

Owner:SONY CORP

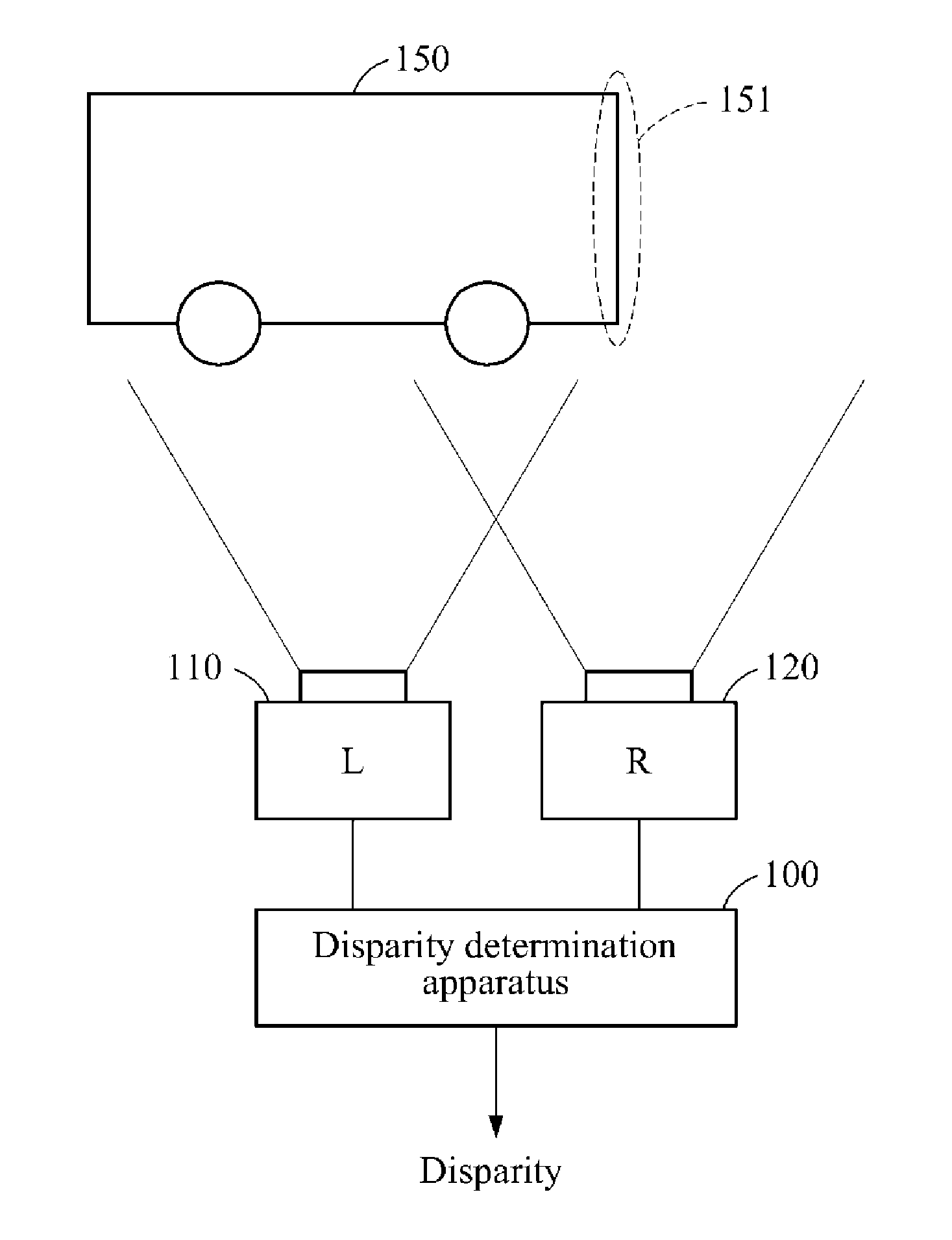

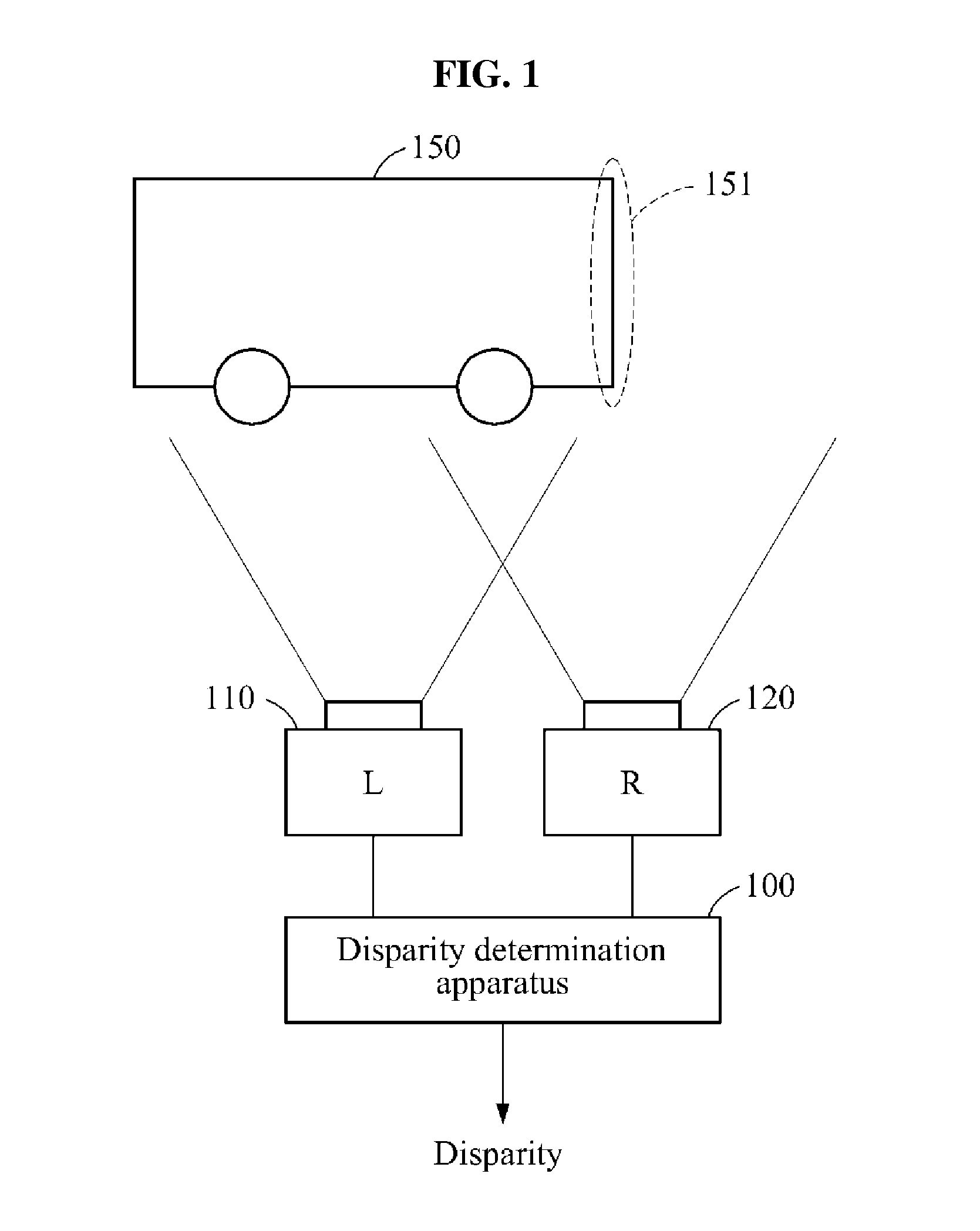

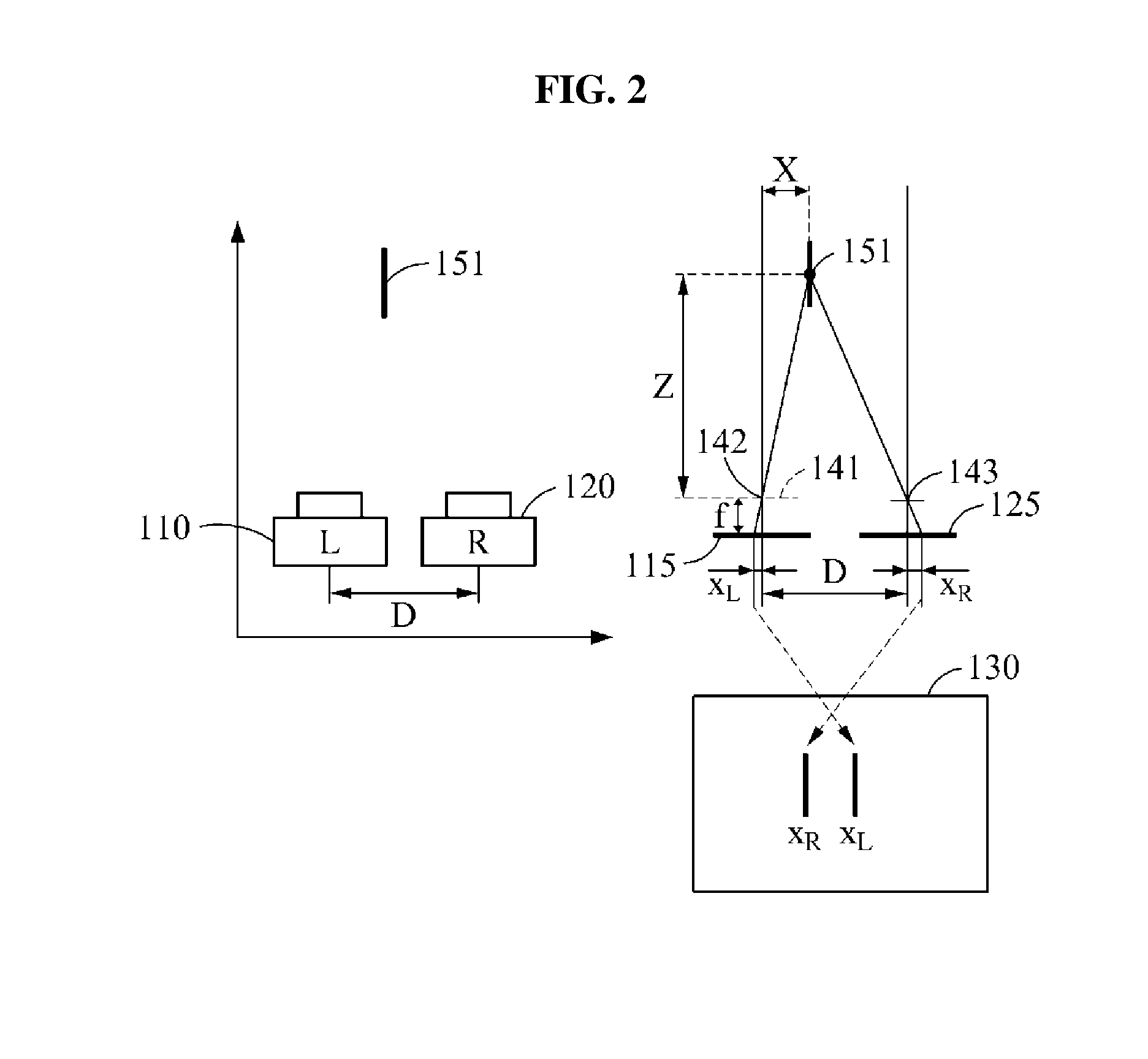

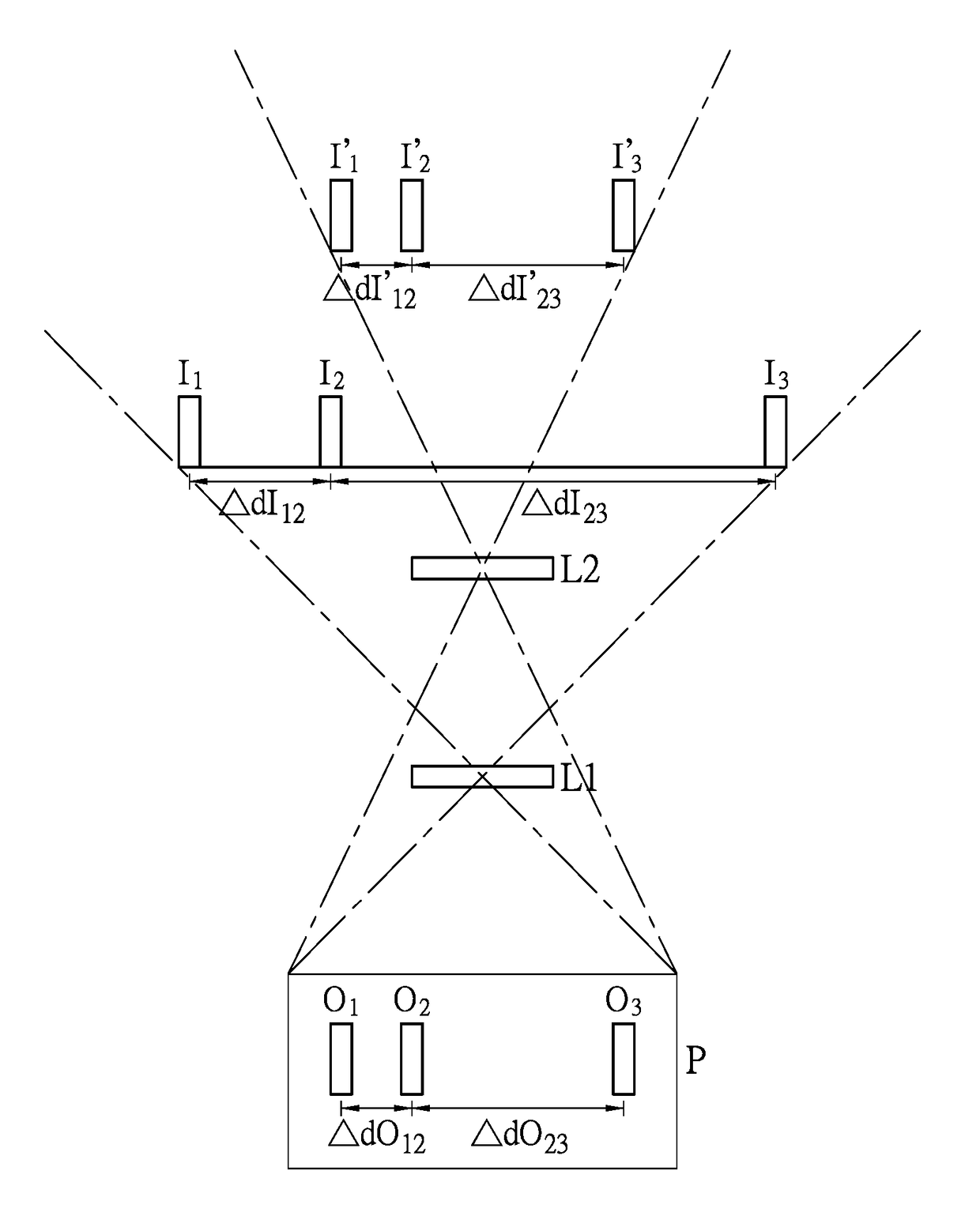

Method and apparatus for determining disparity

ActiveUS20160217584A1Less resolutionImage enhancementImage analysisPattern recognitionComputer vision

Owner:SAMSUNG ELECTRONICS CO LTD

Probe card with different permutations and combinations

ActiveCN113791335AShort threadLower resistancePrinted circuit testingMeasurement instrument housingProbe cardEngineering

The invention provides a probe card with different permutations and combinations, which is provided with 2N-1 probe holes, the number of the probe holes in the first column is 2N-1-1, the number of the probe holes in the second column is 2N-1, and in addition, the outer side of the second column is provided with no less than 2N-1 flat cable holes; and each probe hole is provided with a lead connected with one flat cable hole. The sum of the number of the probe holes has a complete natural number sequence, and the probe holes and the leads are arranged clearly.

Owner:南通芯盟测试研究院运营管理有限公司

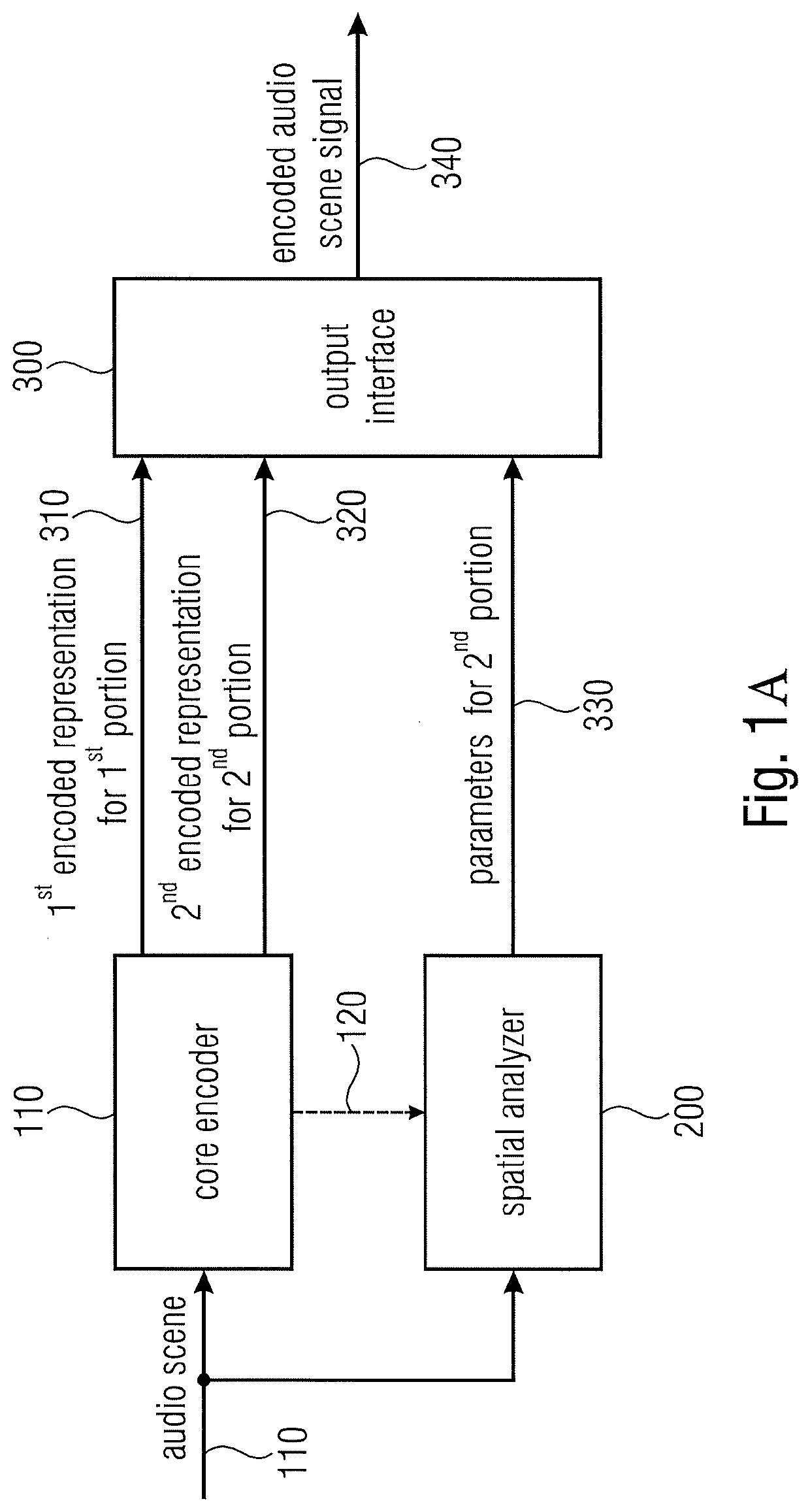

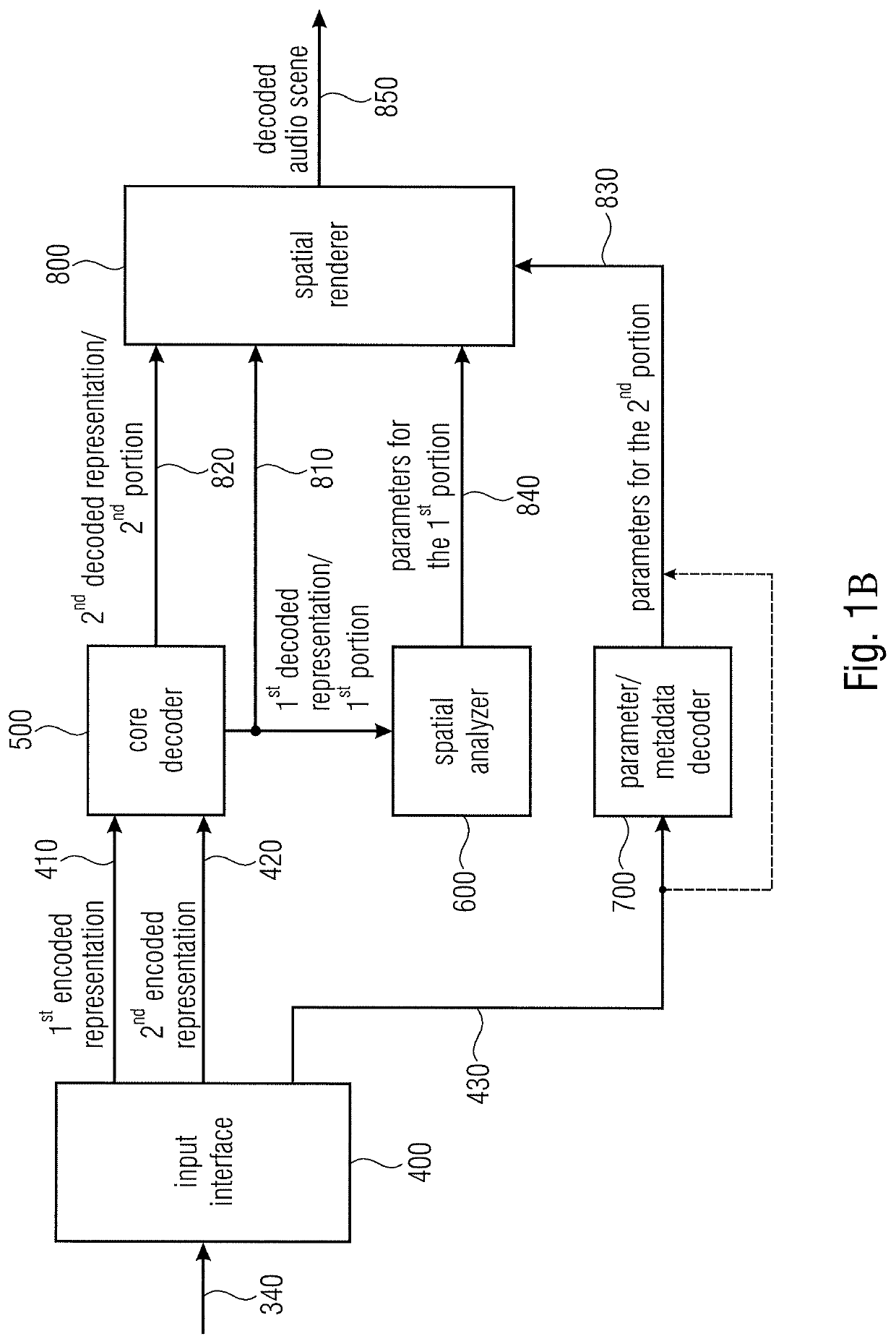

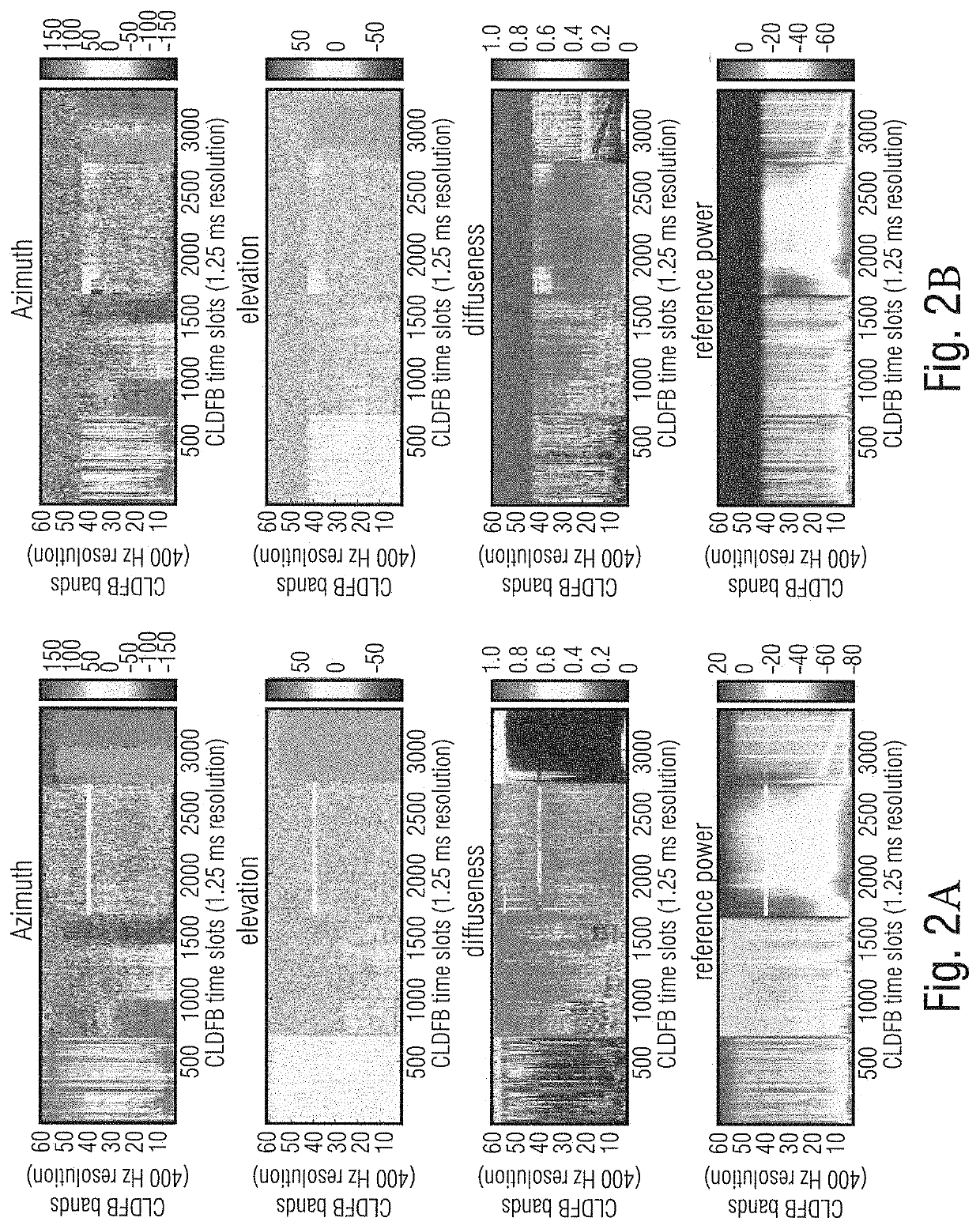

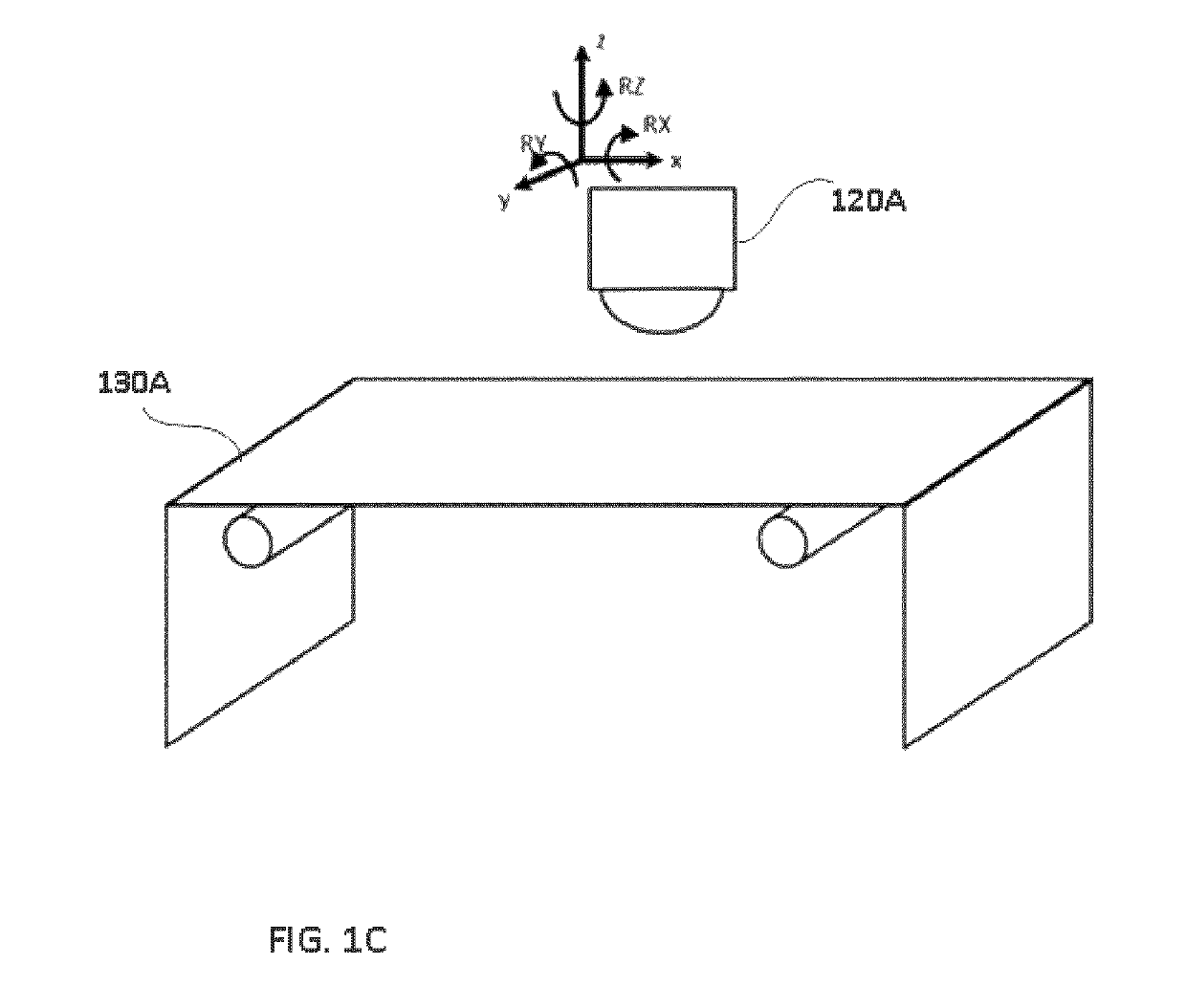

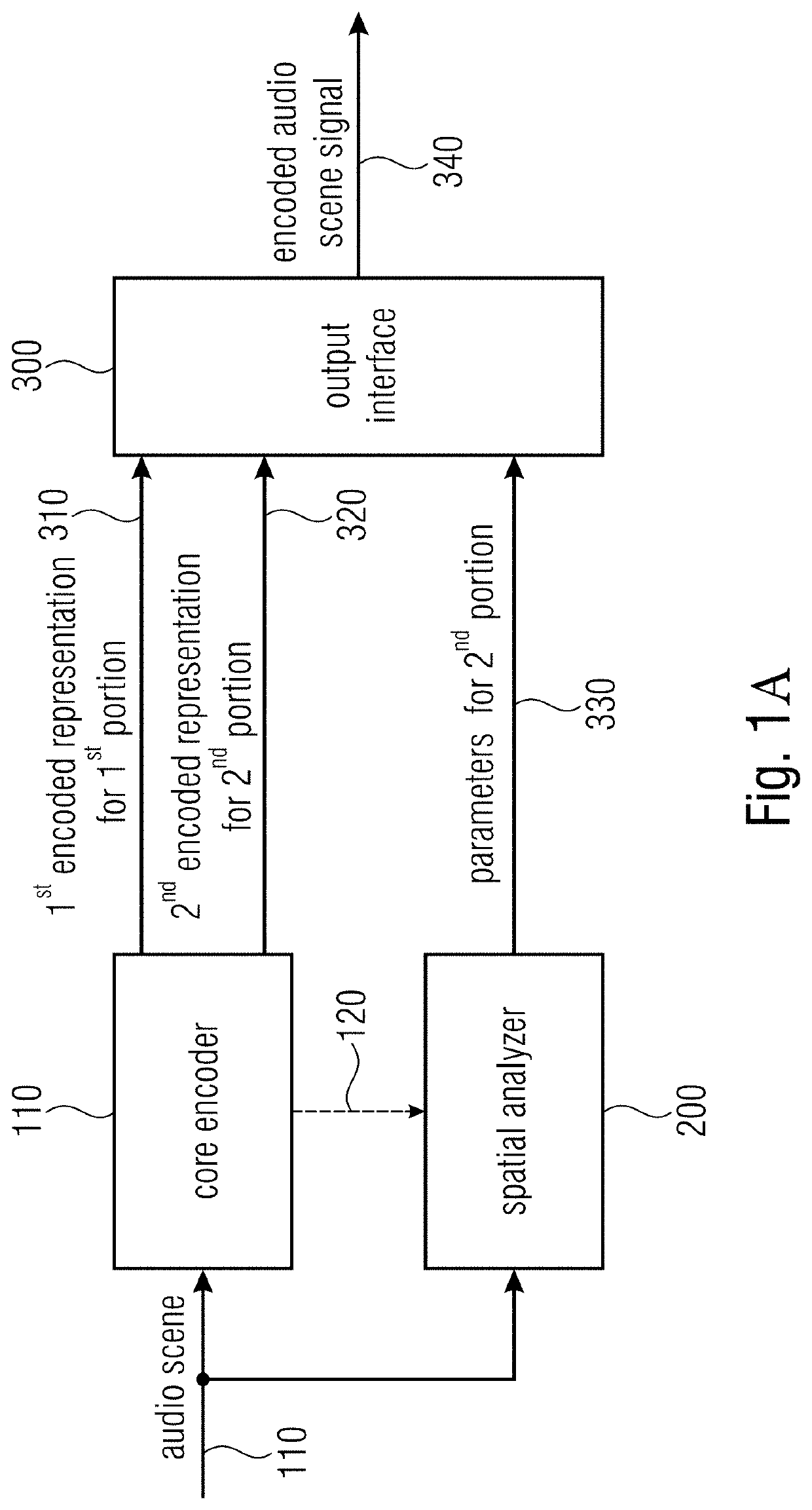

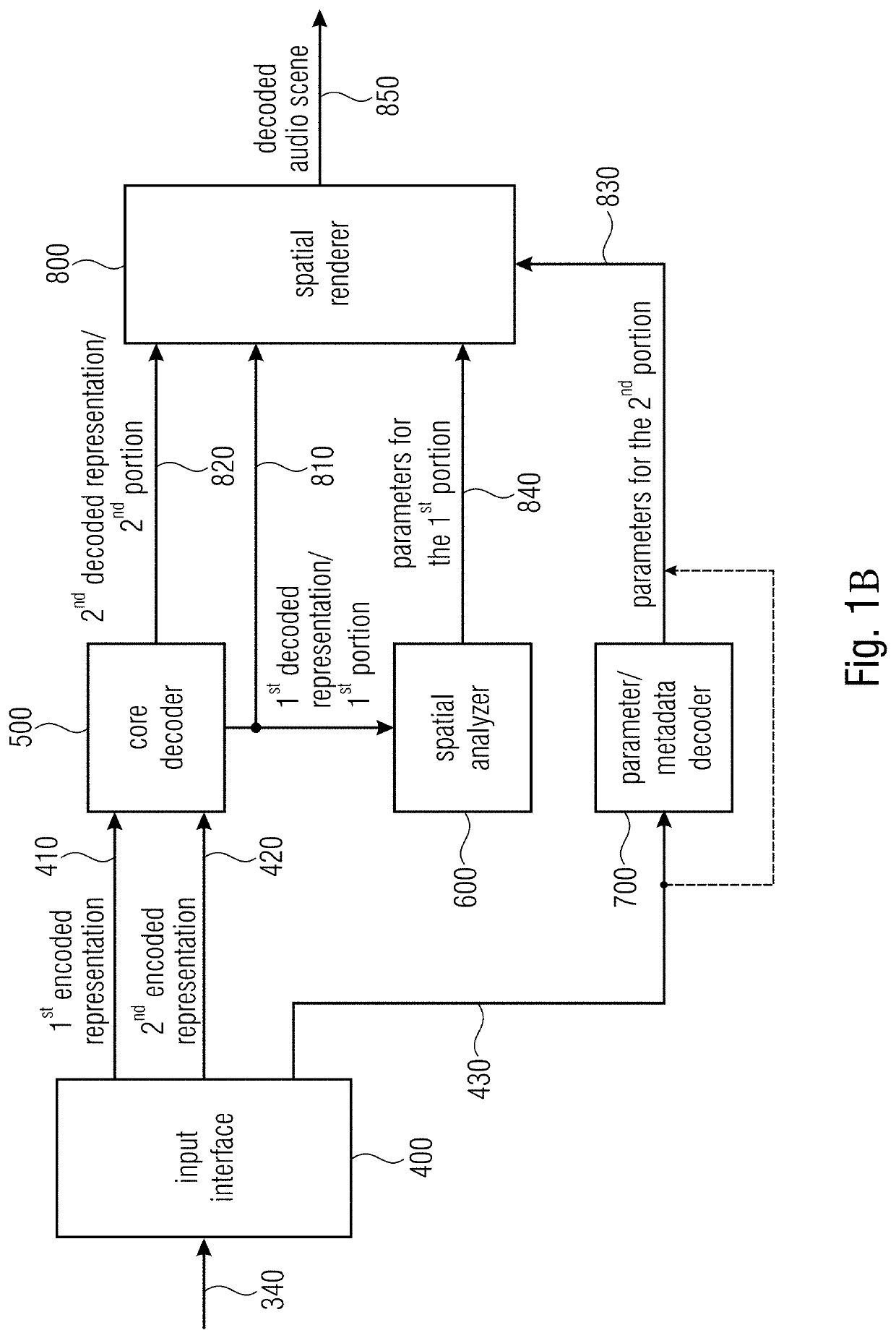

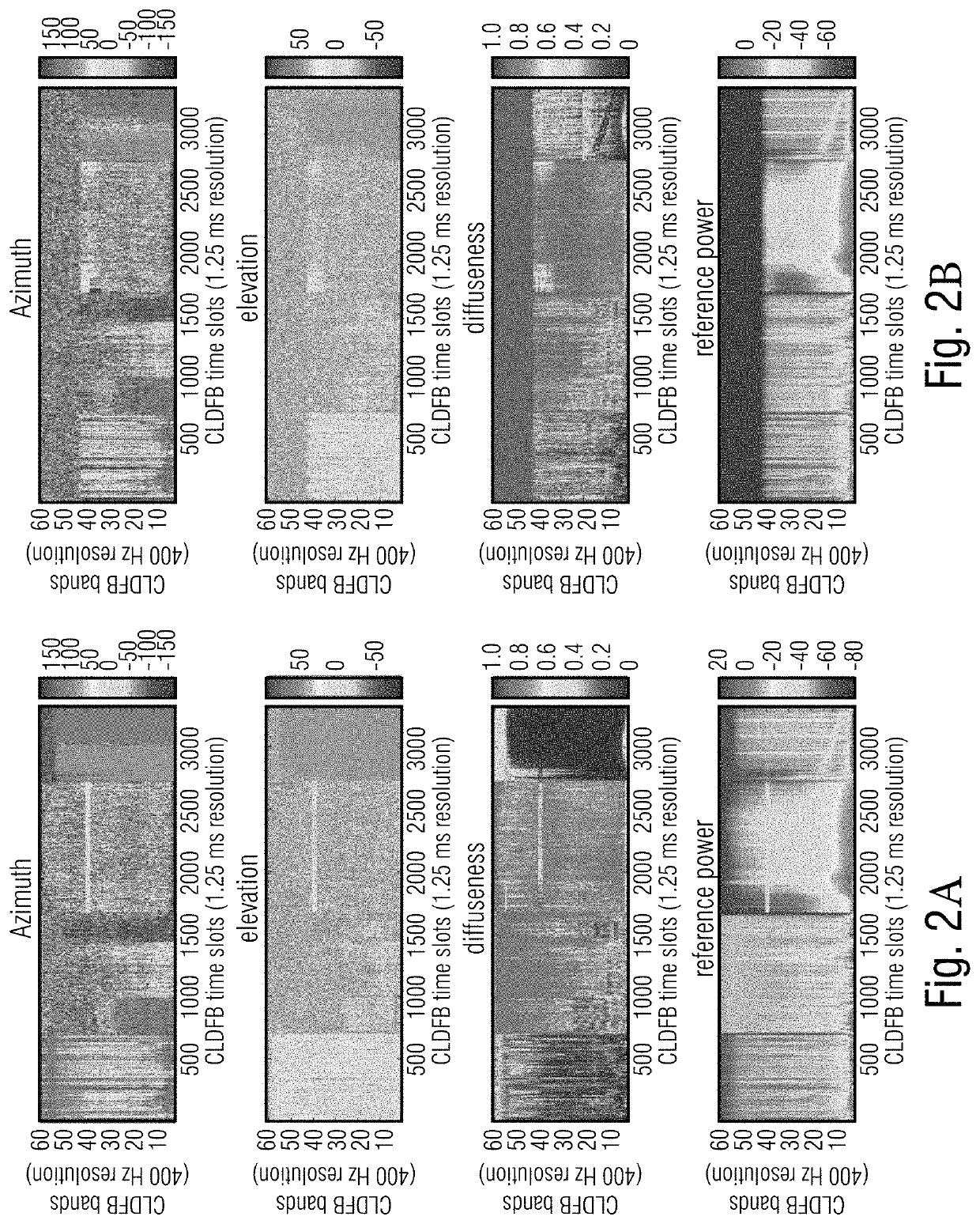

Audio scene encoder, audio scene decoder and related methods using hybrid encoder-decoder spatial analysis

ActiveUS20200357421A1Improve audio qualityIncrease flexibilityStereophonic circuit arrangementsSpeech analysisPattern recognitionComputer vision

An audio scene encoder for encoding an audio scene, the audio scene having at least two component signals, has: a core encoder for core encoding the at least two component signals, wherein the core encoder is configured to generate a first encoded representation for a first portion of the at least two component signals, and to generate a second encoded representation for a second portion of the at least two component signals, a spatial analyzer for analyzing the audio scene to derive one or more spatial parameters or one or more spatial parameter sets for the second portion; and an output interface for forming the encoded audio scene signal, the encoded audio scene signal having the first encoded representation, the second encoded representation, and the one or more spatial parameters or one or more spatial parameter sets for the second portion.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Quality inspection of thin film materials

ActiveUS10267836B2Less time-consumingEffective electricalMethods for obtaining spatial resolutionResistance/reactance/impedenceIrradiationMaterials science

Devices and methods for determining the quality thin film materials are disclosed. The thin film materials are provided on substrates forming thin film material structures. The devices comprise a housing, a THz module with a THz source emitter and a THz detector, and a reflective base moveable relative to the THz module and configured to support the thin film material structures. The THz source emitter is configured to irradiate the thin film materials. The THz detector is configured to measure at least one reflection of the irradiation. The device is configured to calculate a parameter indicative of the quality of the thin film material based on said reflection measurements.

Owner:ASSOC CENT DE INVESTIGACION COOP & NANOCIENCIAS CIC NANOGUNE +2

Audio scene encoder, audio scene decoder and related methods using hybrid encoder-decoder spatial analysis

PendingUS20220139409A1Improve audio qualityIncrease flexibilityStereophonic circuit arrangementsSpeech analysisPattern recognitionComputer vision

An audio scene encoder for encoding an audio scene, the audio scene having at least two component signals, has: a core encoder for core encoding the at least two component signals, wherein the core encoder is configured to generate a first encoded representation for a first portion of the at least two component signals, and to generate a second encoded representation for a second portion of the at least two component signals, a spatial analyzer for analyzing the audio scene to derive one or more spatial parameters or one or more spatial parameter sets for the second portion; and an output interface for forming the encoded audio scene signal, the encoded audio scene signal having the first encoded representation, the second encoded representation, and the one or more spatial parameters or one or more spatial parameter sets for the second portion.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

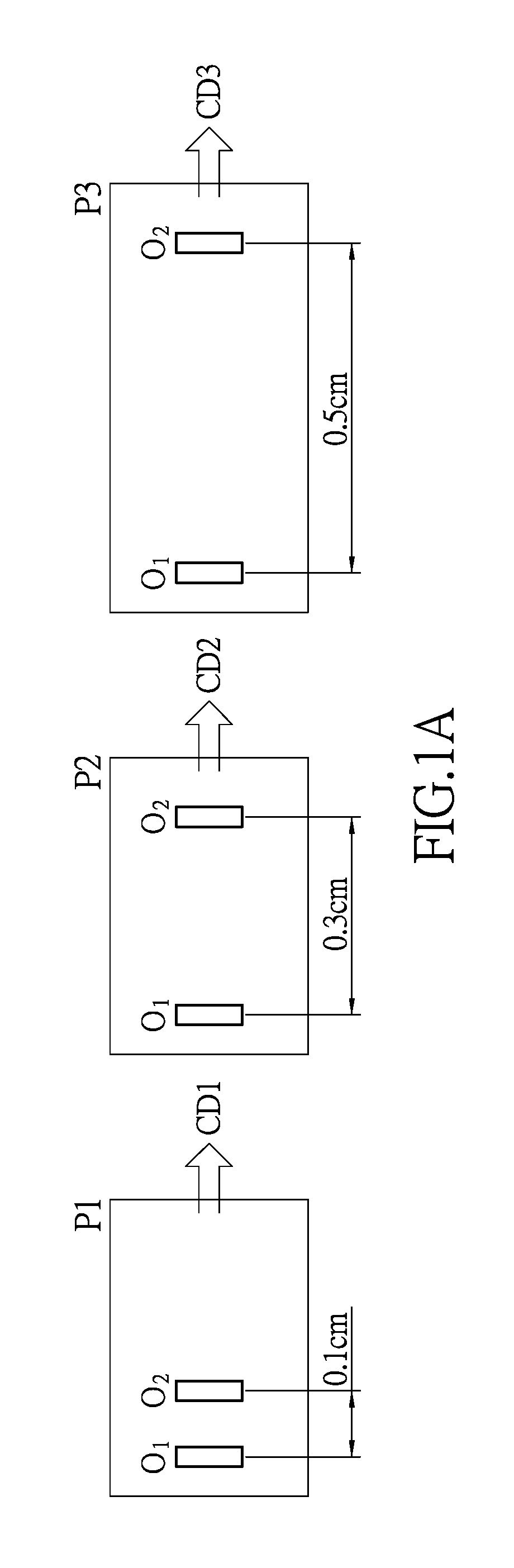

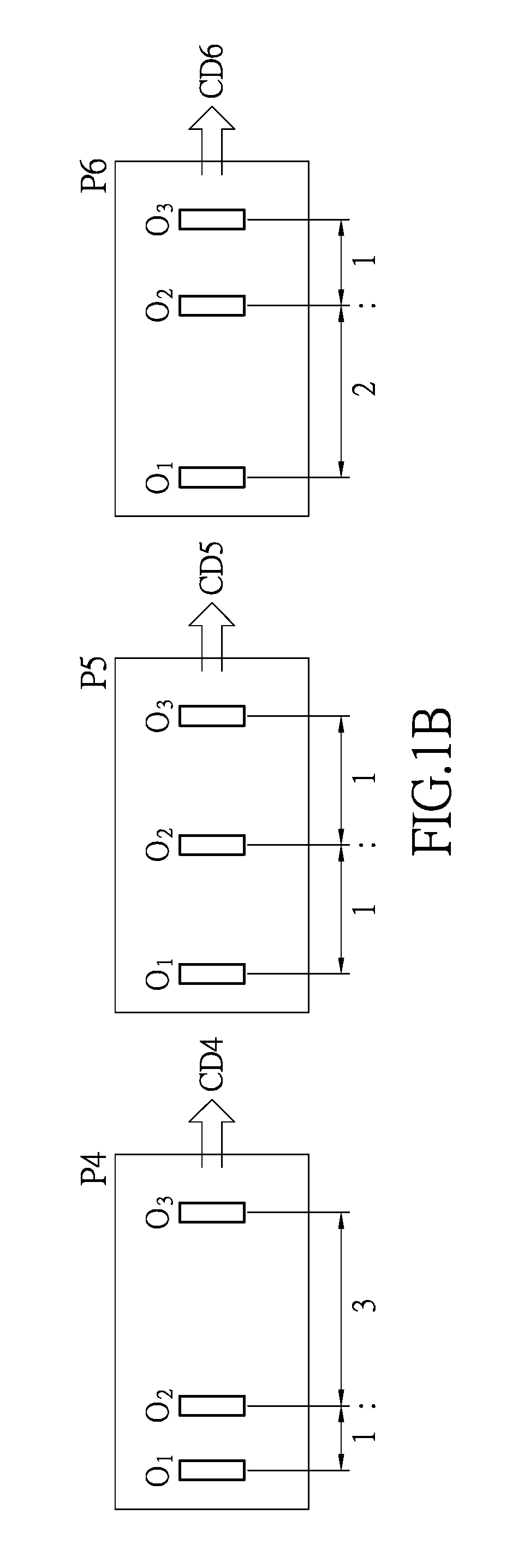

Coding and decoding method using patterns and system thereof

ActiveUS9805236B2Less resolutionRecord carriers used with machinesSensing by electromagnetic radiationDecoding methodsComputer science

Disclosed are coding and decoding methods using patterns and a system thereof. The object-images are obtained via detecting a pattern comprising objects. The distances between the object-images are obtained and a code is found based on the obtained distances between the object images. The distances between the object-images are defined as distances between centers of the object-images. As there are at least three objects in a pattern, a code is obtained based on a ratio of distances between object-images, which equals to a ratio of distances between objects. As there are at least four objects in a pattern, it is first determined whether a first ratio of object-images equals to a predetermined ratio of object-images. If no, a second ratio of object-images is obtained via a correcting factor and the first ratio of object-image, and finally a code is obtained based on the second ratio of object-images.

Owner:PIXART IMAGING INC

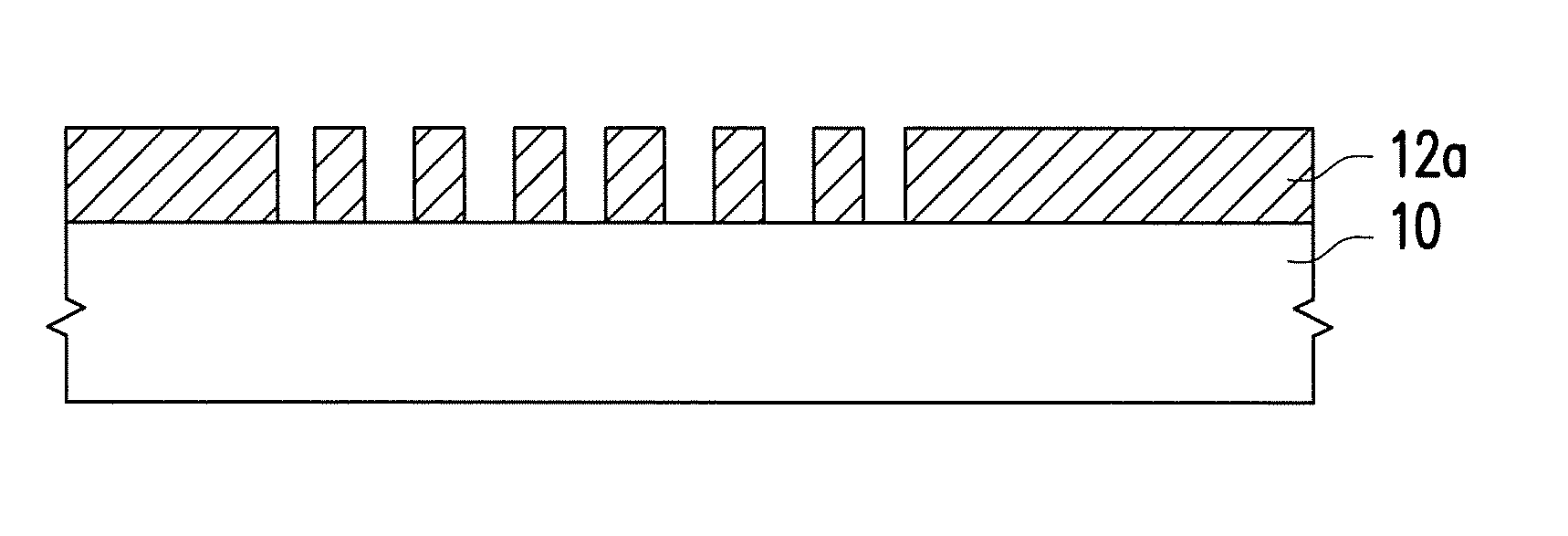

Patterning method

ActiveUS20150072532A1Less resolutionSemiconductor/solid-state device manufacturingLithography processEngineering

A patterning method is provided. First, a material layer is formed over a substrate. Thereafter, a plurality of directed self-assembly (DSA) patterns are formed on the material layer. Afterwards, a patterned photoresist layer is formed by using a single lithography process. The patterned photoresist layer covers a first portion of the DSA patterns and exposes a second portion of the DSA patterns. Further, the material layer is patterned by an etching process, using the patterned photoresist layer and the second portion of the DSA patterns as a mask.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com