Patents

Literature

225 results about "Crankshaft position sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crank sensor is an electronic device used in an internal combustion engine, both petrol and diesel, to monitor the position or rotational speed of the crankshaft. This information is used by engine management systems to control the fuel injection or the ignition system timing and other engine parameters. Before electronic crank sensors were available, the distributor would have to be manually adjusted to a timing mark on petrol engines.

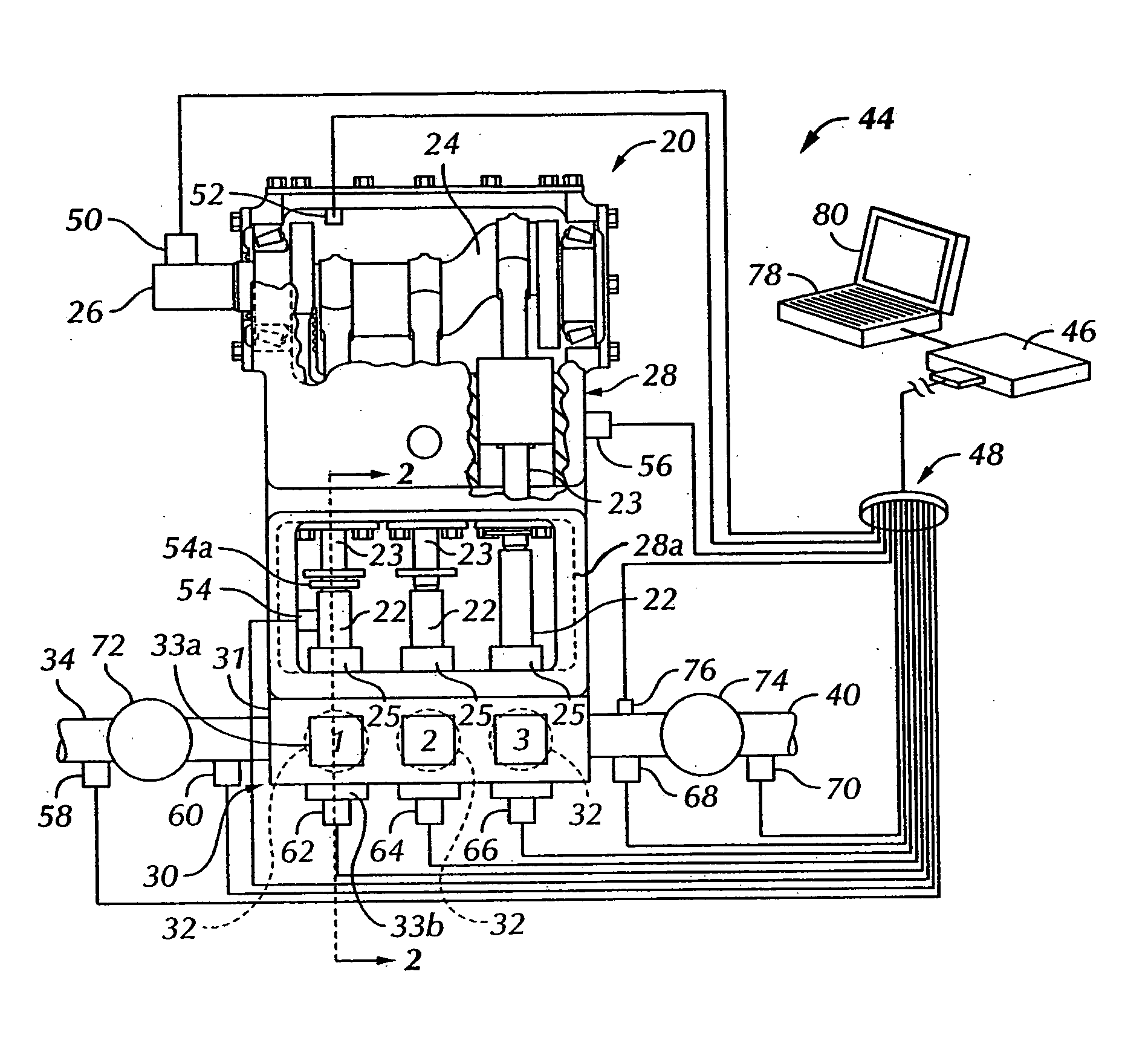

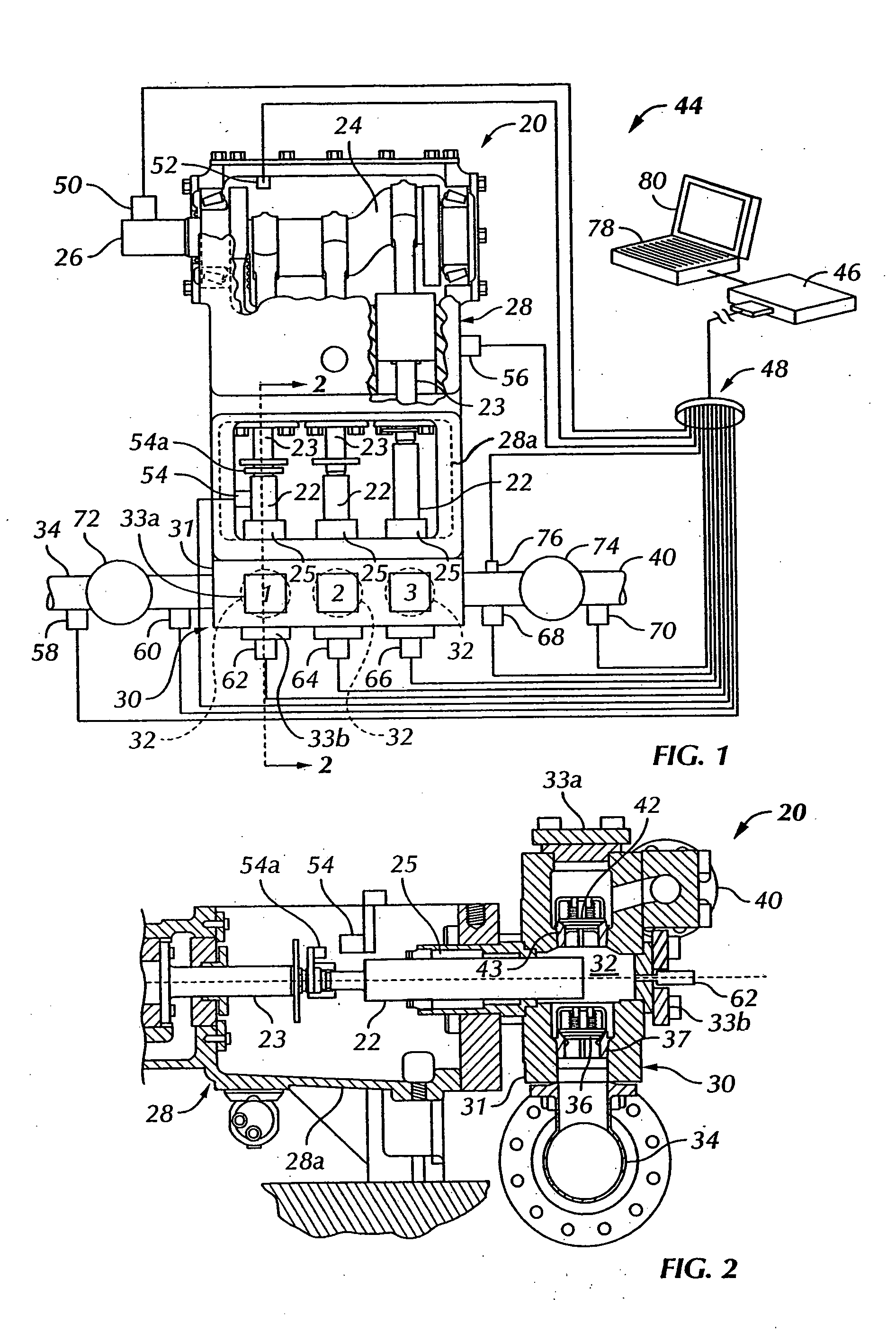

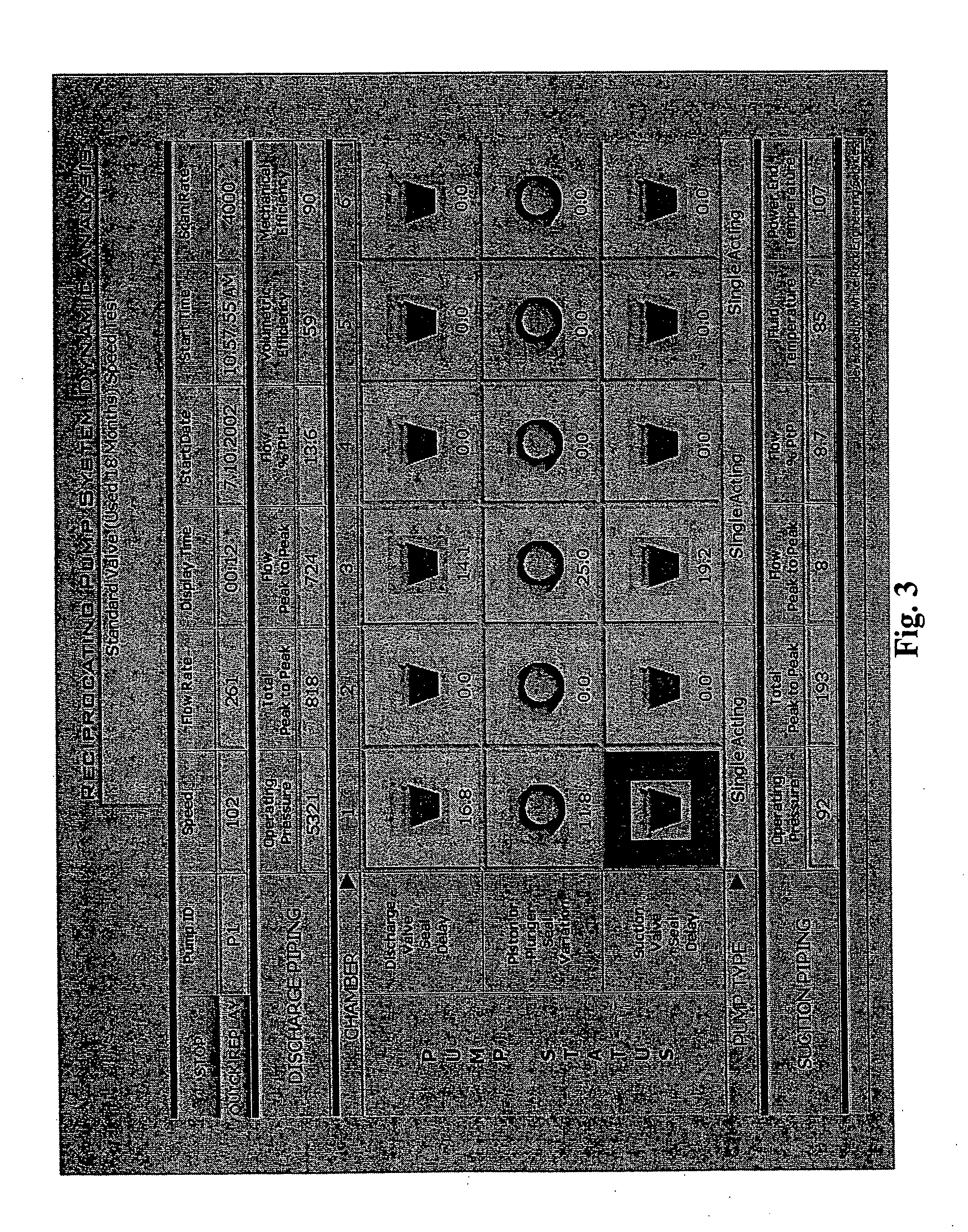

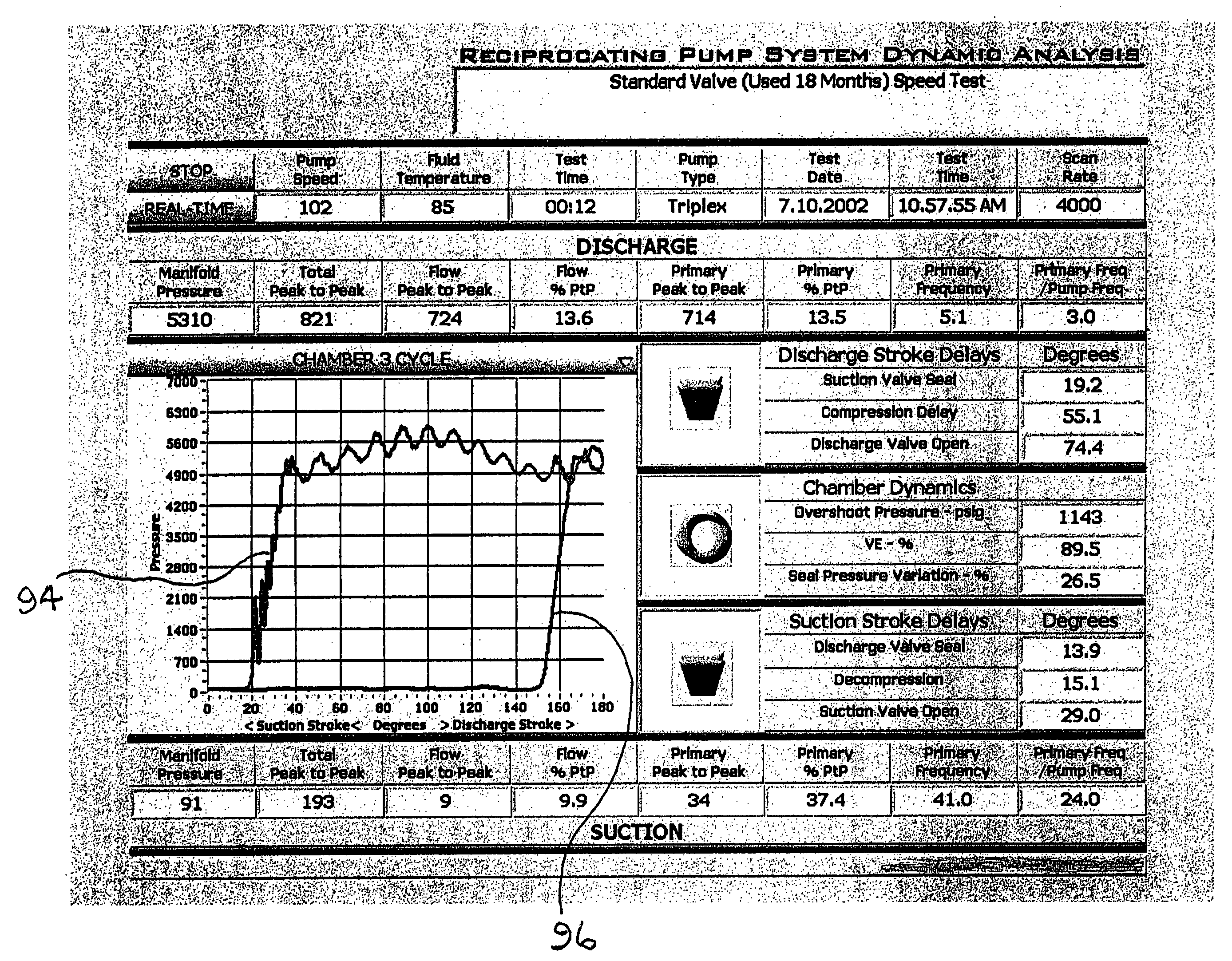

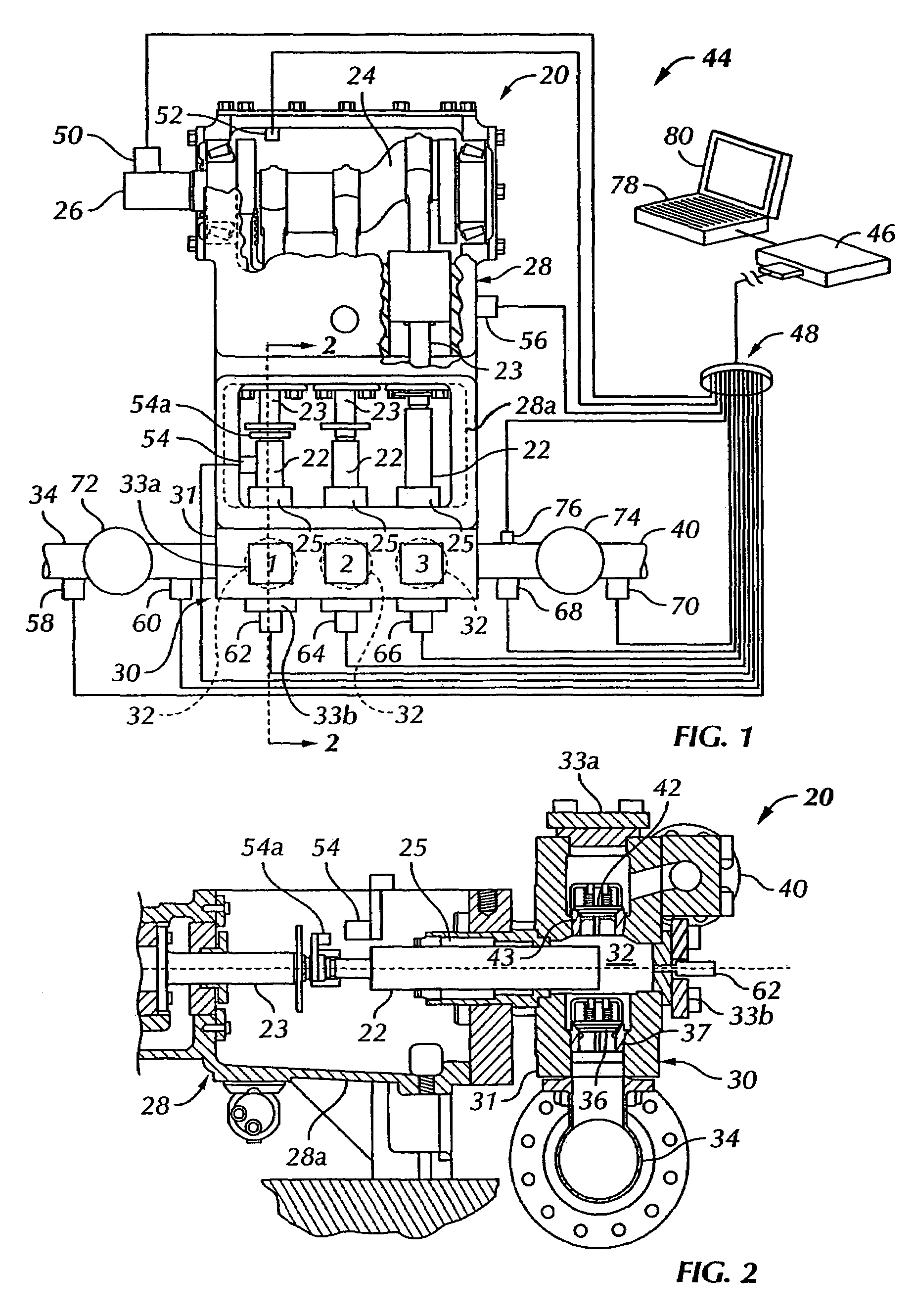

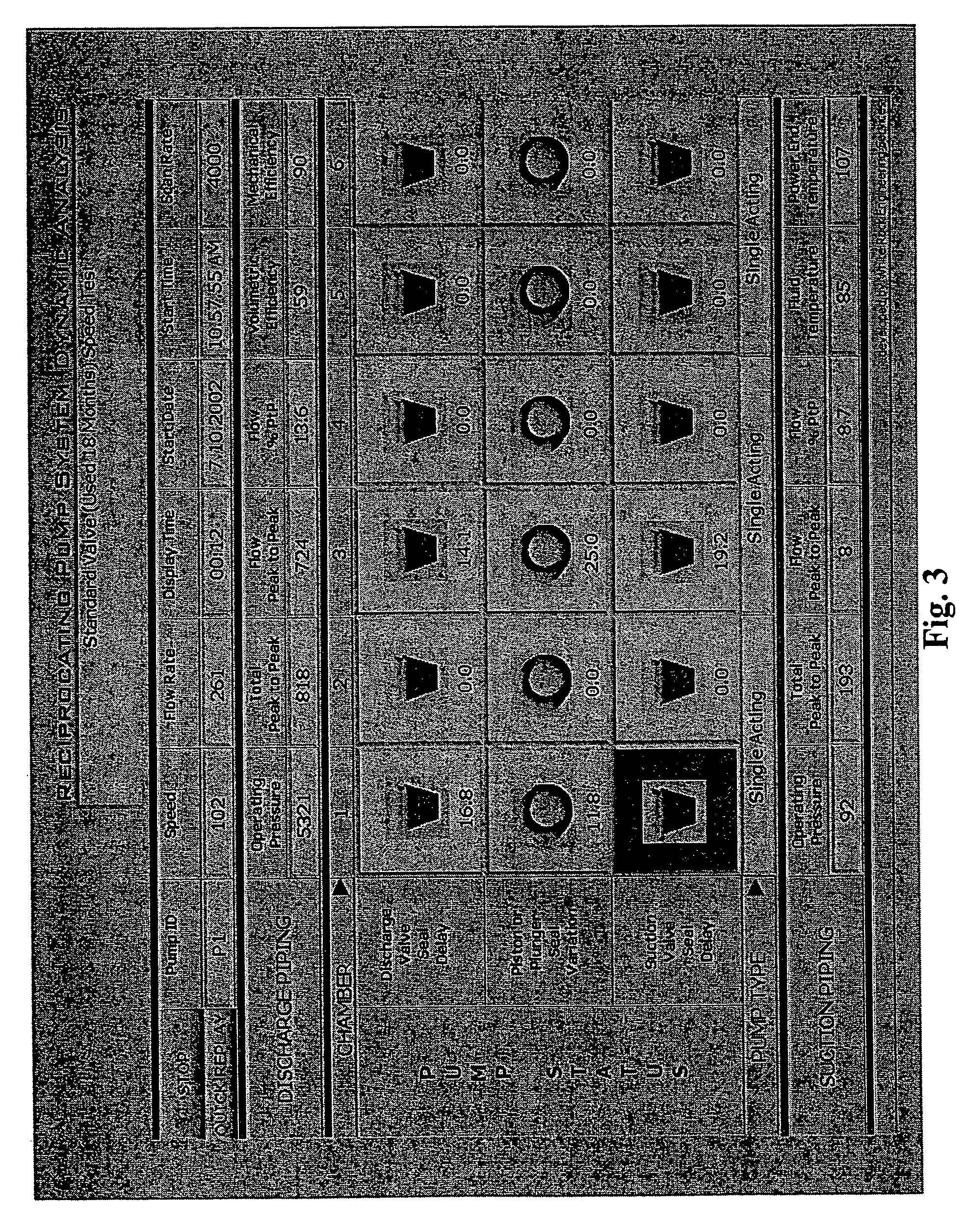

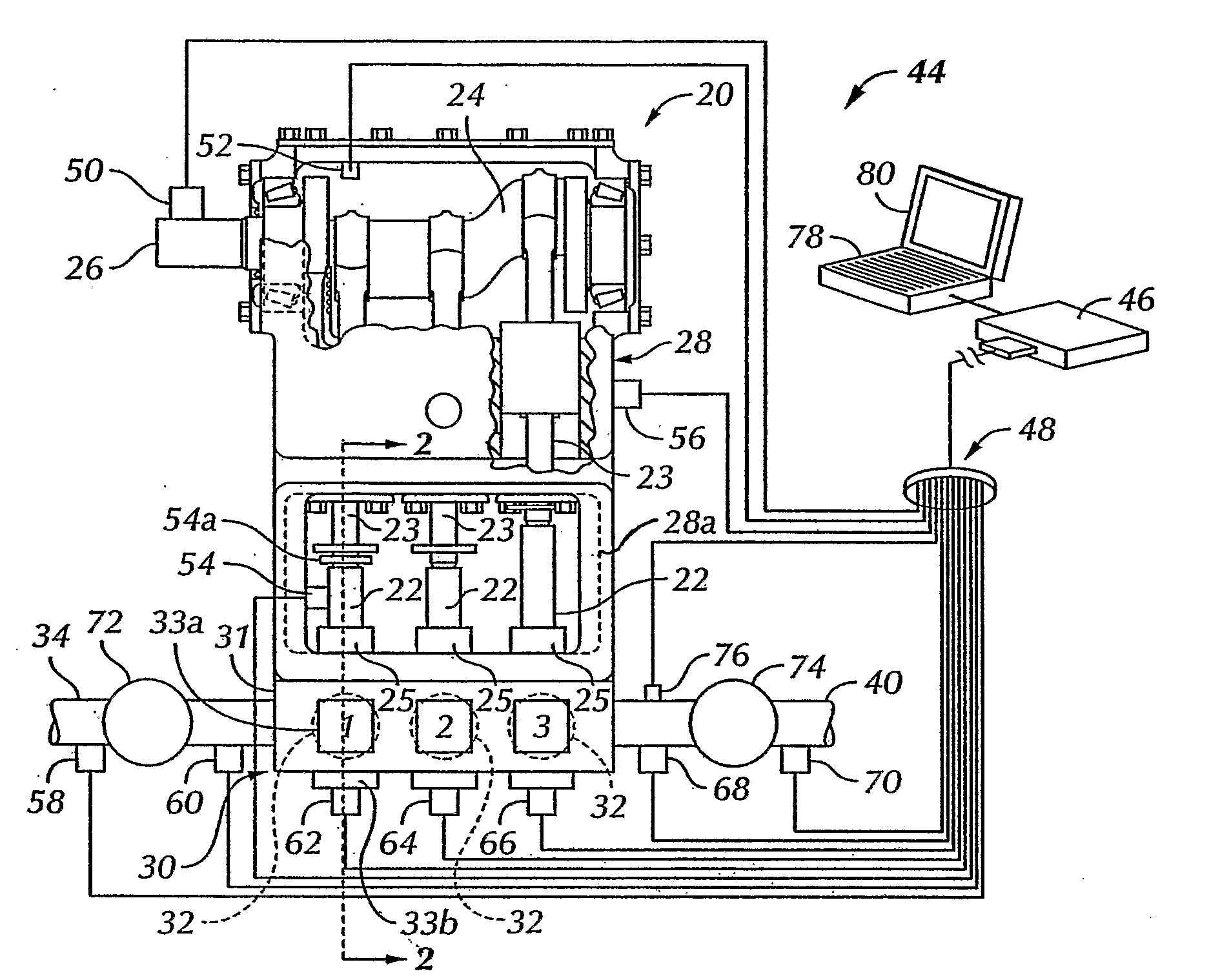

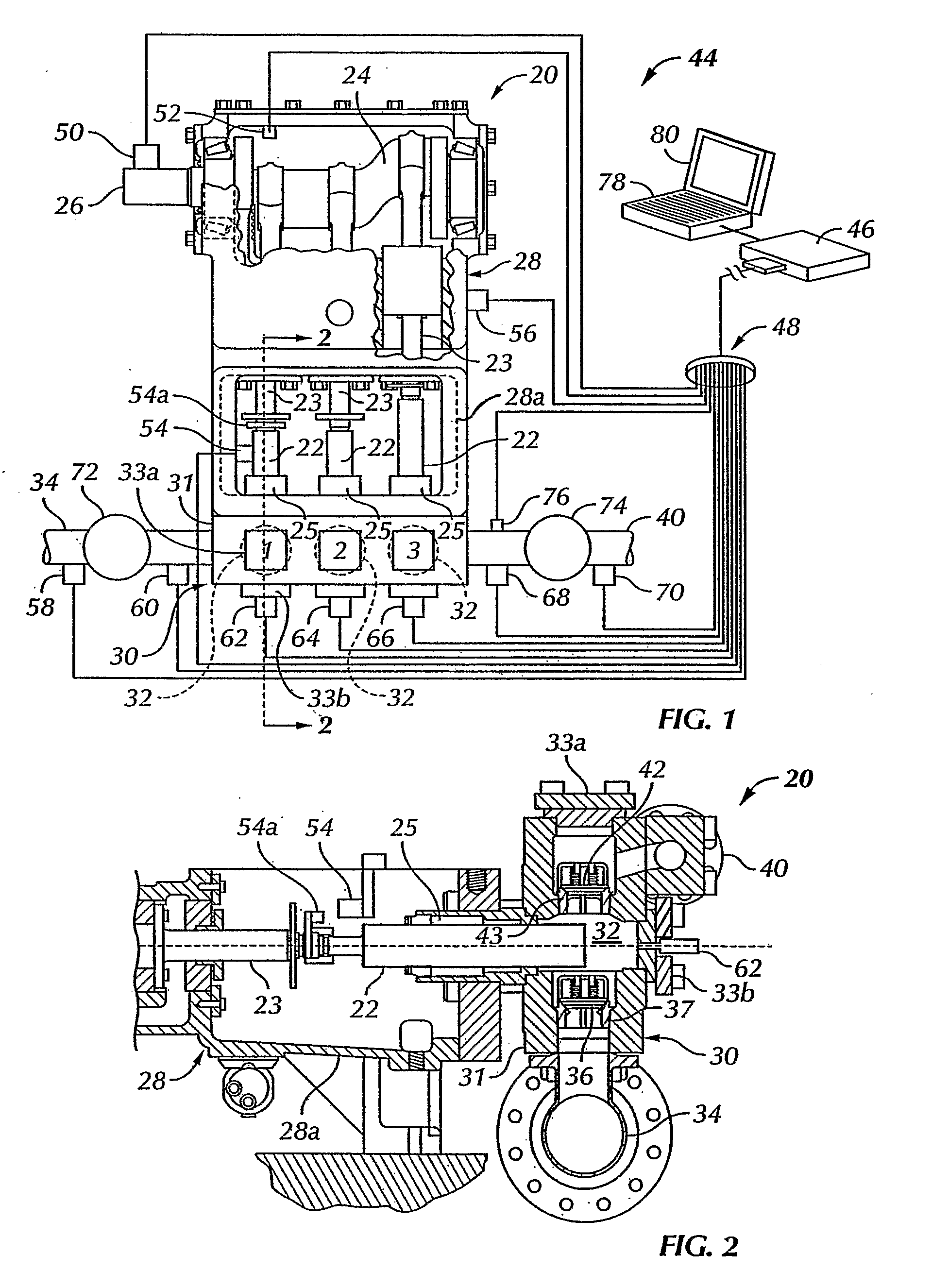

System and method for power pump performance monitoring and analysis

InactiveUS20050180868A1Easy to useEasy to provideTime indicationProgram control using stored programsDisplay deviceEngineering

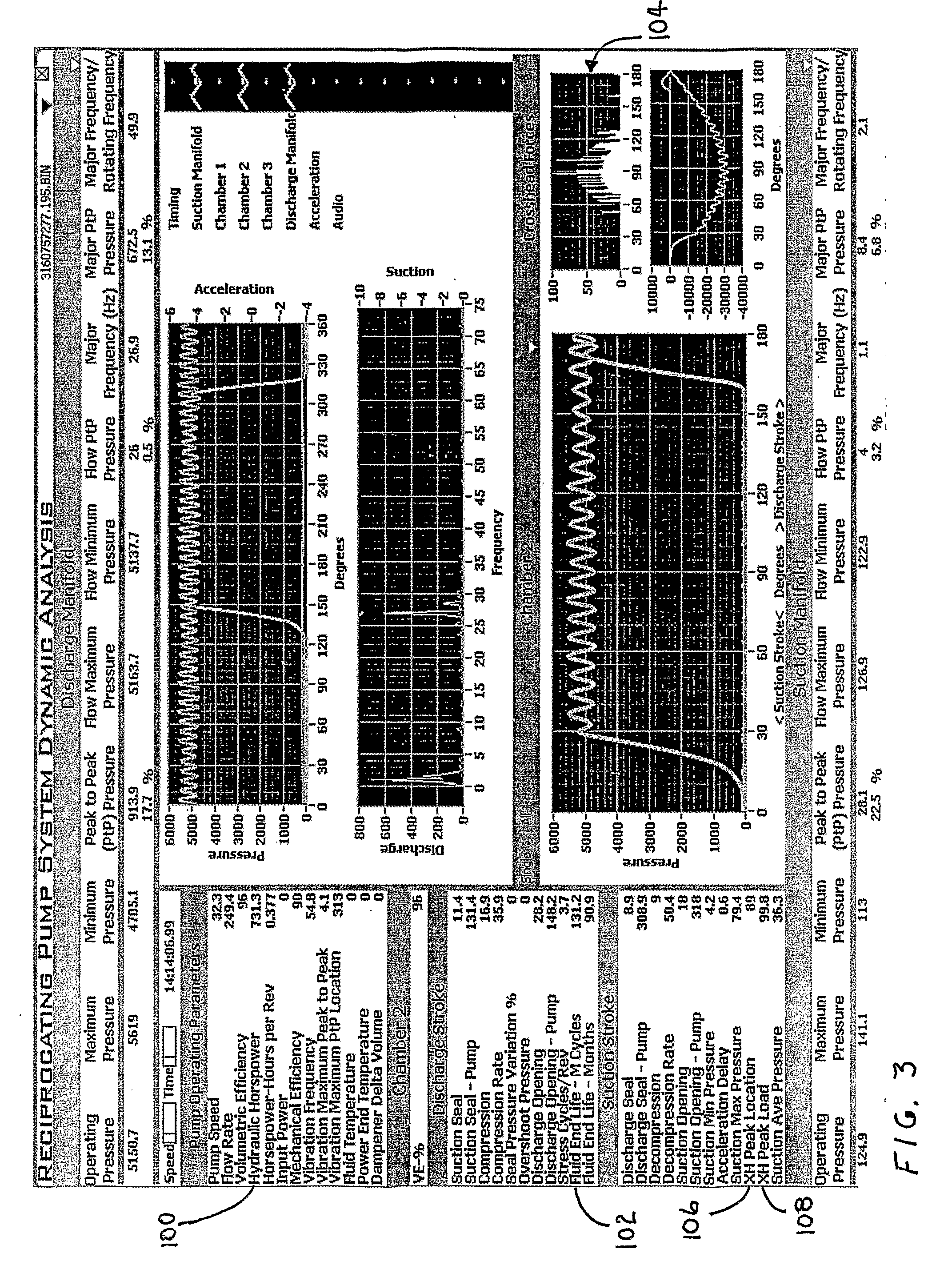

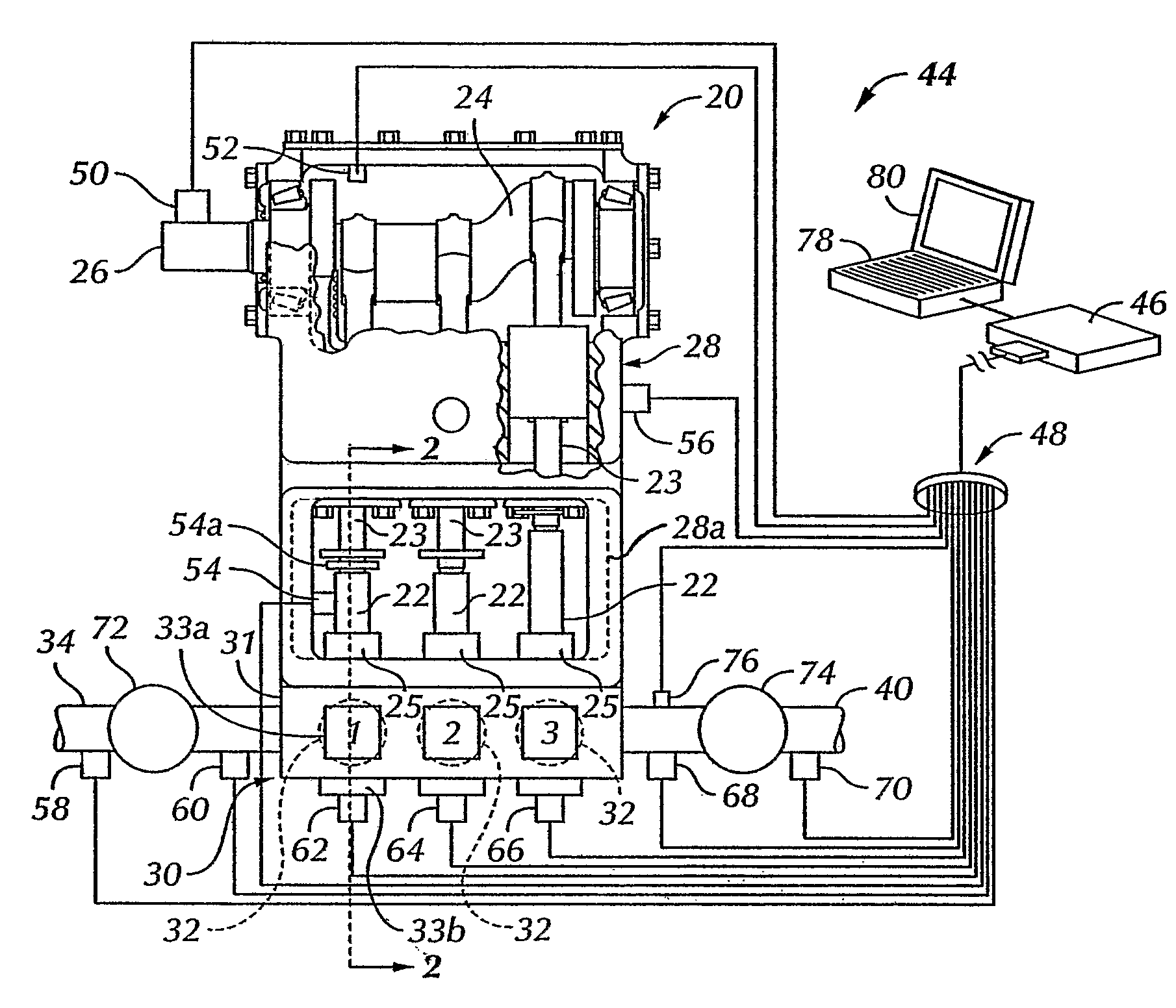

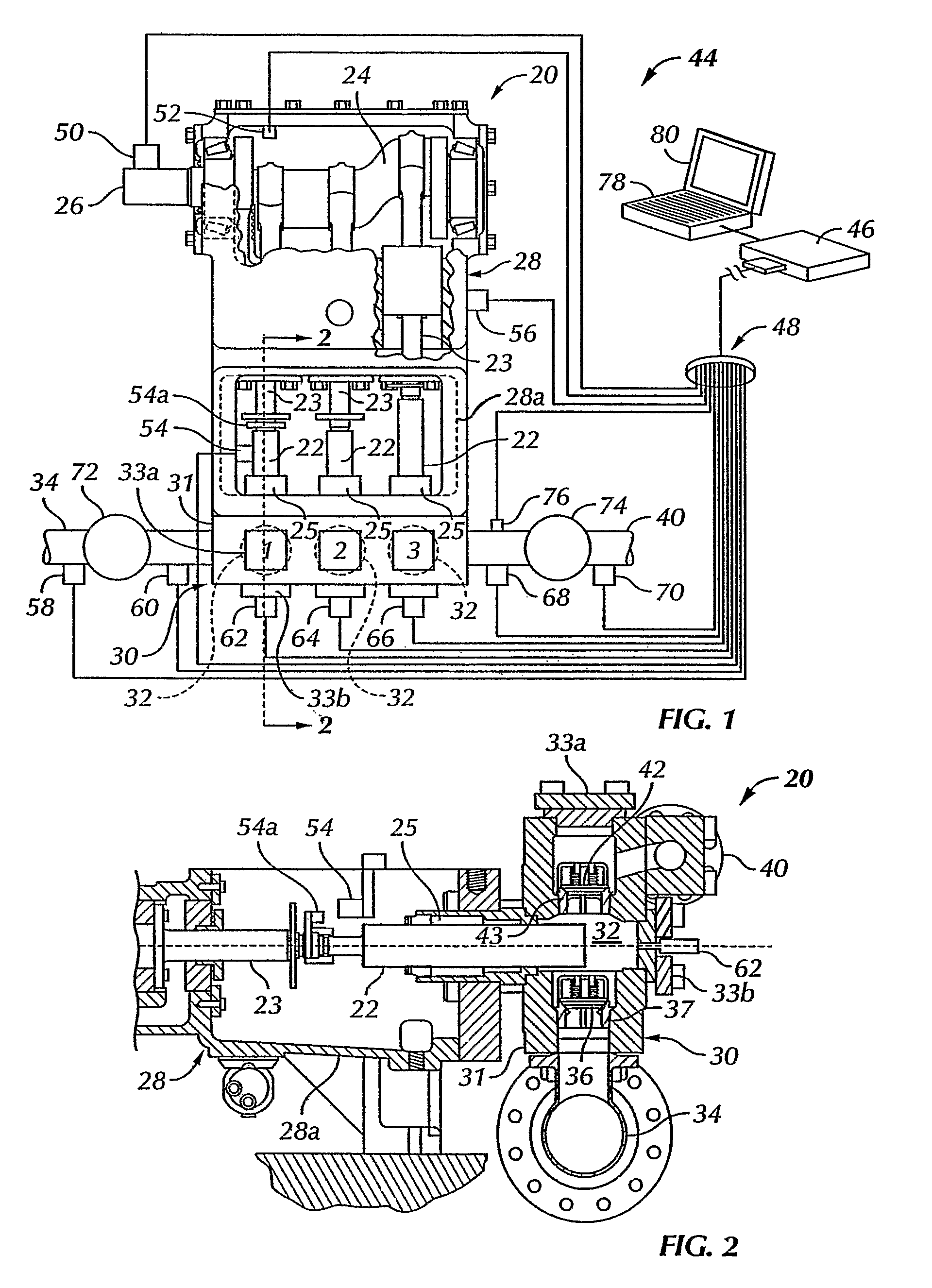

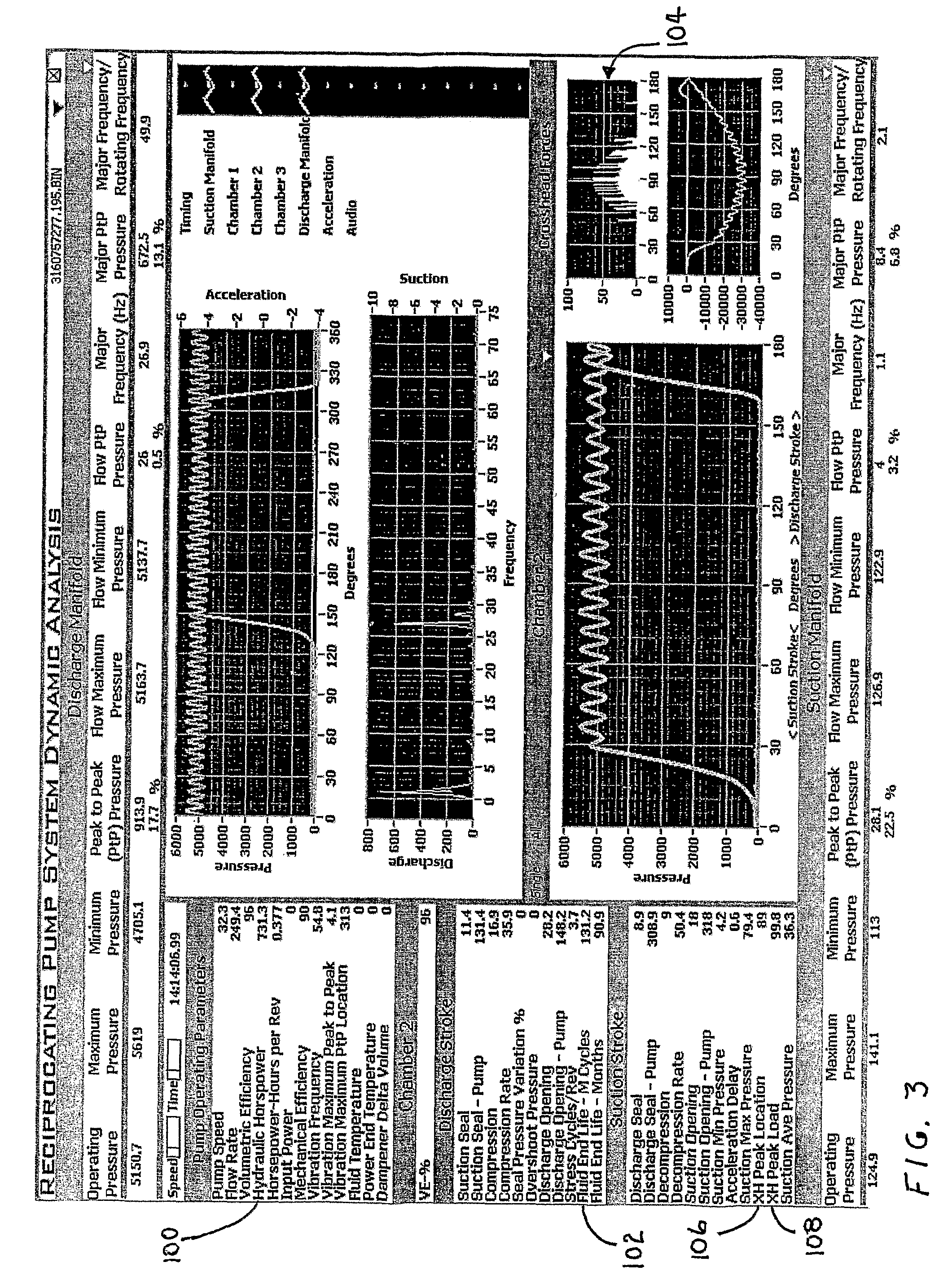

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

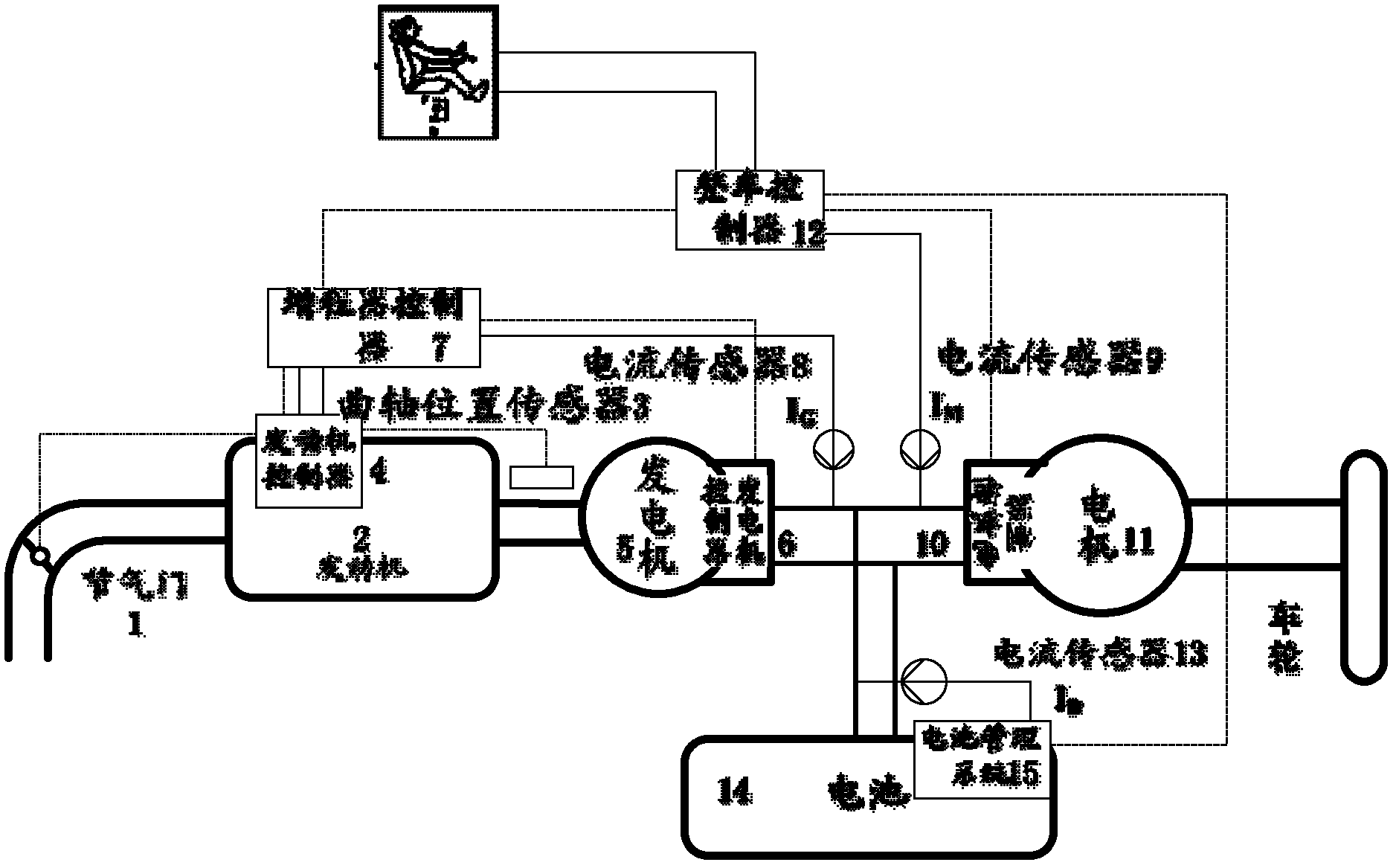

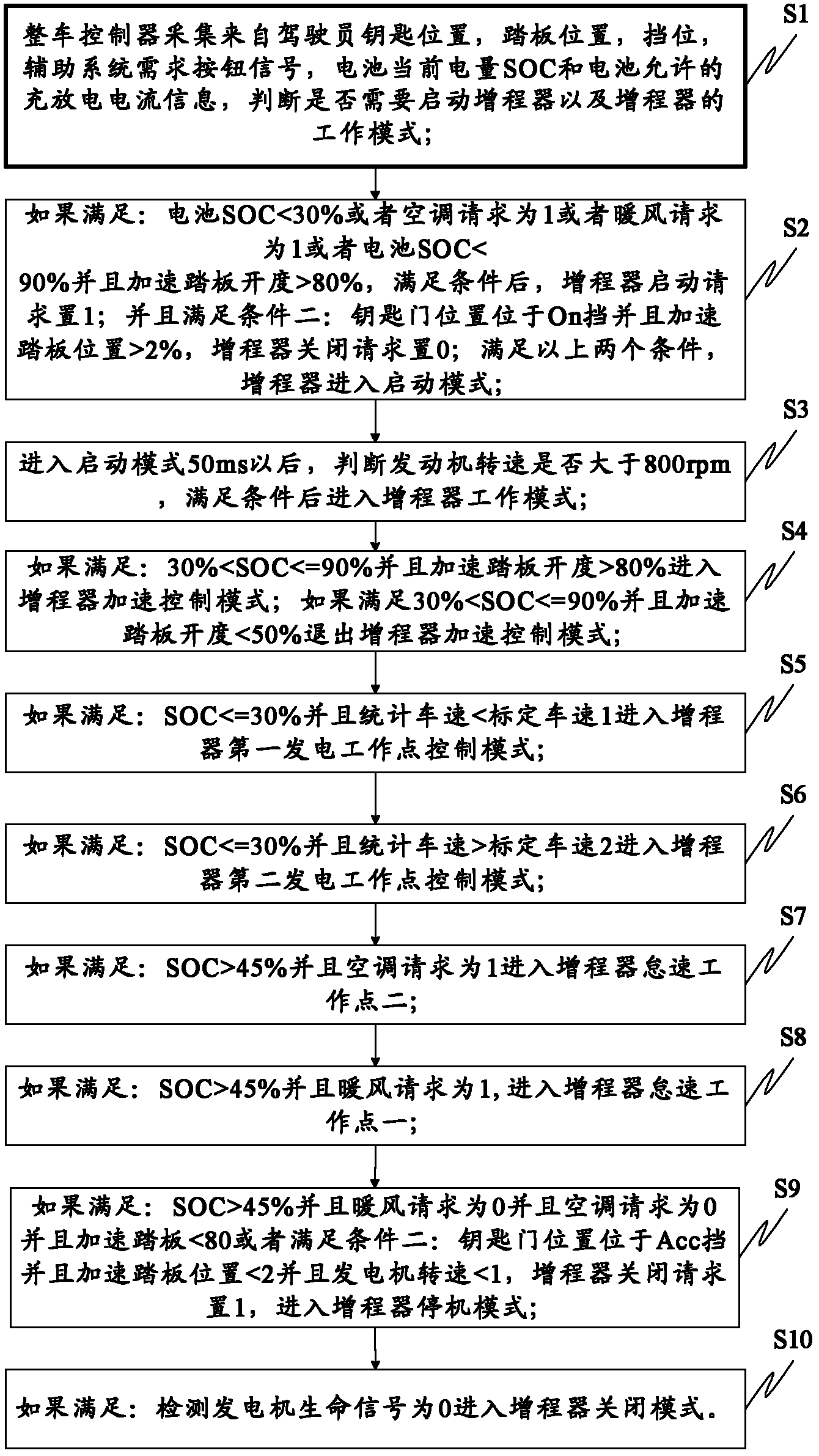

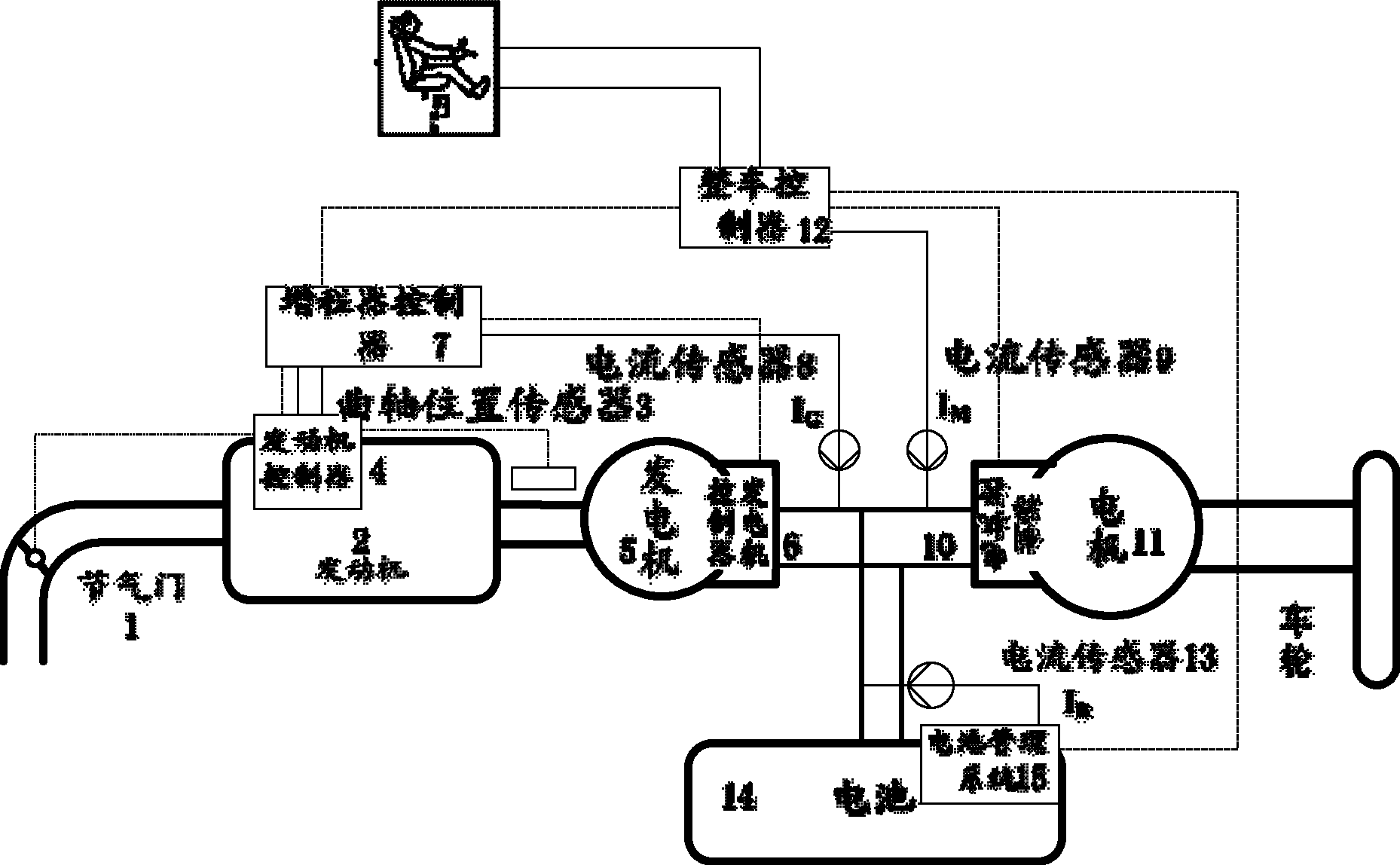

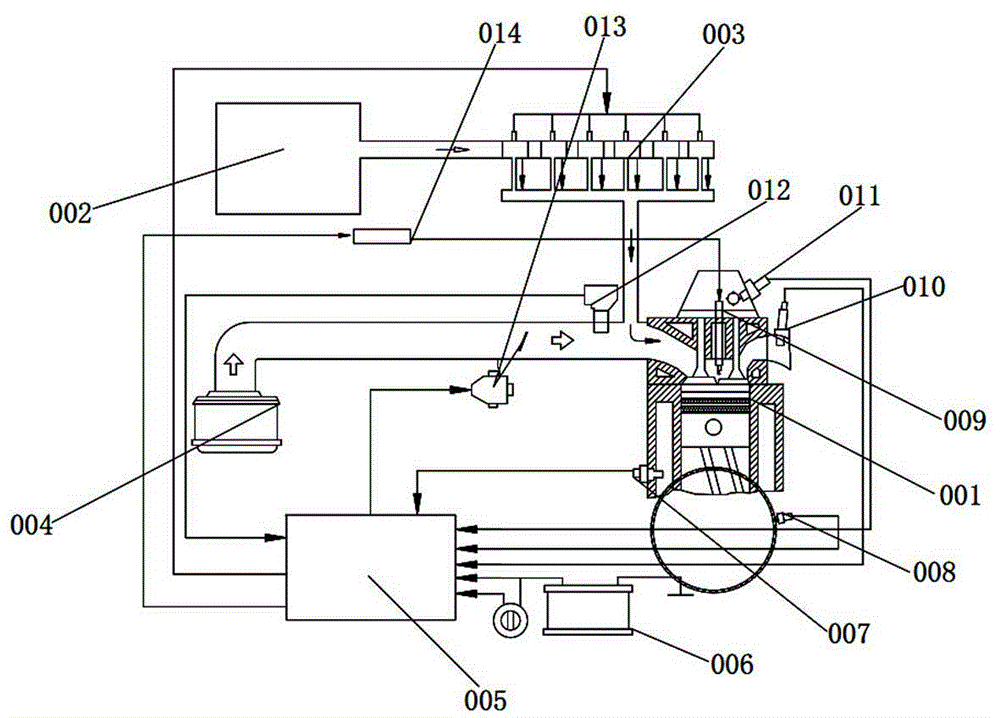

Range extended electric vehicle control system and method

ActiveCN102616148AMeet functional requirementsReduce fuel consumptionSpeed controllerElectric machinesDrive wheelElectrical battery

The invention discloses a range extended electric vehicle control system, and relates to a whole vehicle control system. The range extended electric vehicle control system comprises an engine controlled by the conventional throttling valve, a generator which is integrally connected with a crank shaft of the engine and has functions of generating power and driving, a vehicle-mounted power battery, a whole vehicle controller, a range extender controller, a battery management system, a battery direct current sensor, an engine controller unit, a generator controller unit, a generator end direct current sensor and a permanent magnet synchronous driving motor, wherein the permanent magnet synchronous driving motor, the power battery and the generator are connected to a power line and used for driving wheels, a motor controller, a motor direct current sensor, the throttling valve and a crank shaft position sensor; the range extender controller communicates with the engine controller unit and the generator controller unit and sends a control instruction; and the range extender controller manages power generation energy and controls an auxiliary system according to a demand of a driver and a state of a range extender system. The invention also discloses a range extended electric vehicle control method. The range extended electric vehicle control system and the range extended electric vehicle control method can be used for electric automobiles.

Owner:BEIJING ELECTRIC VEHICLE

System and method for power pump performance monitoring and analysis

InactiveUS7623986B2Easy to useEasy to provideTime indicationProgram control using stored programsEngineeringStreamflow

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

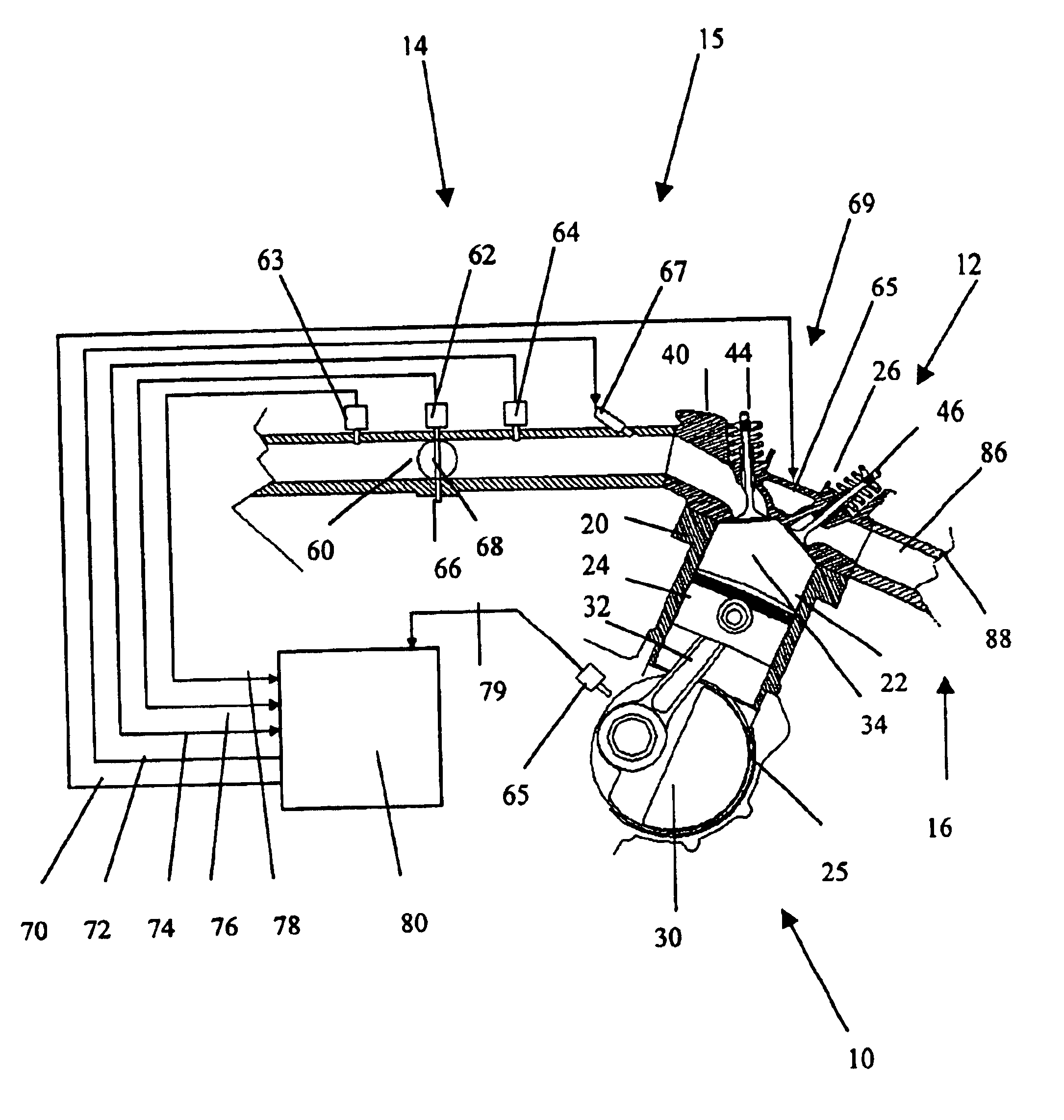

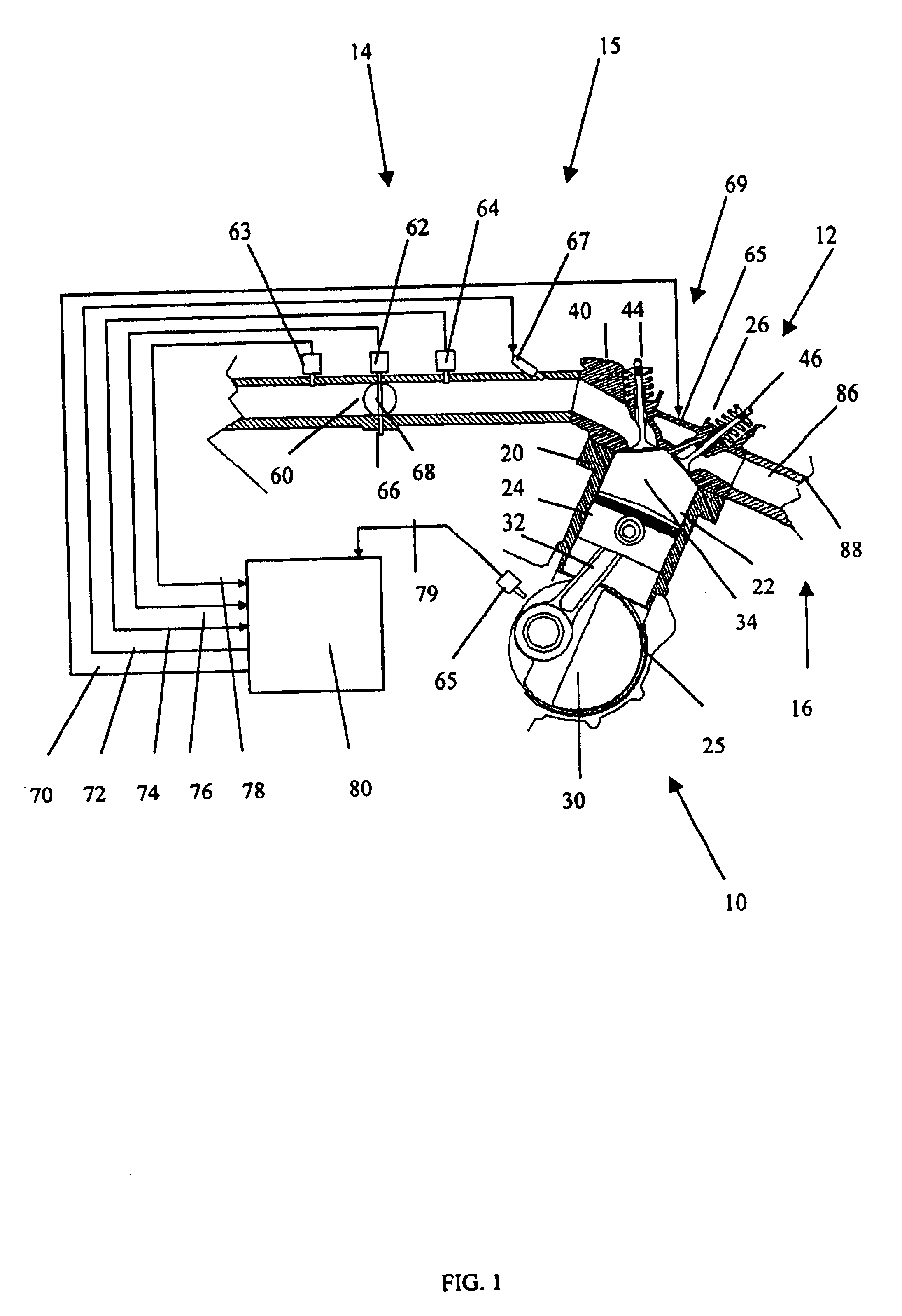

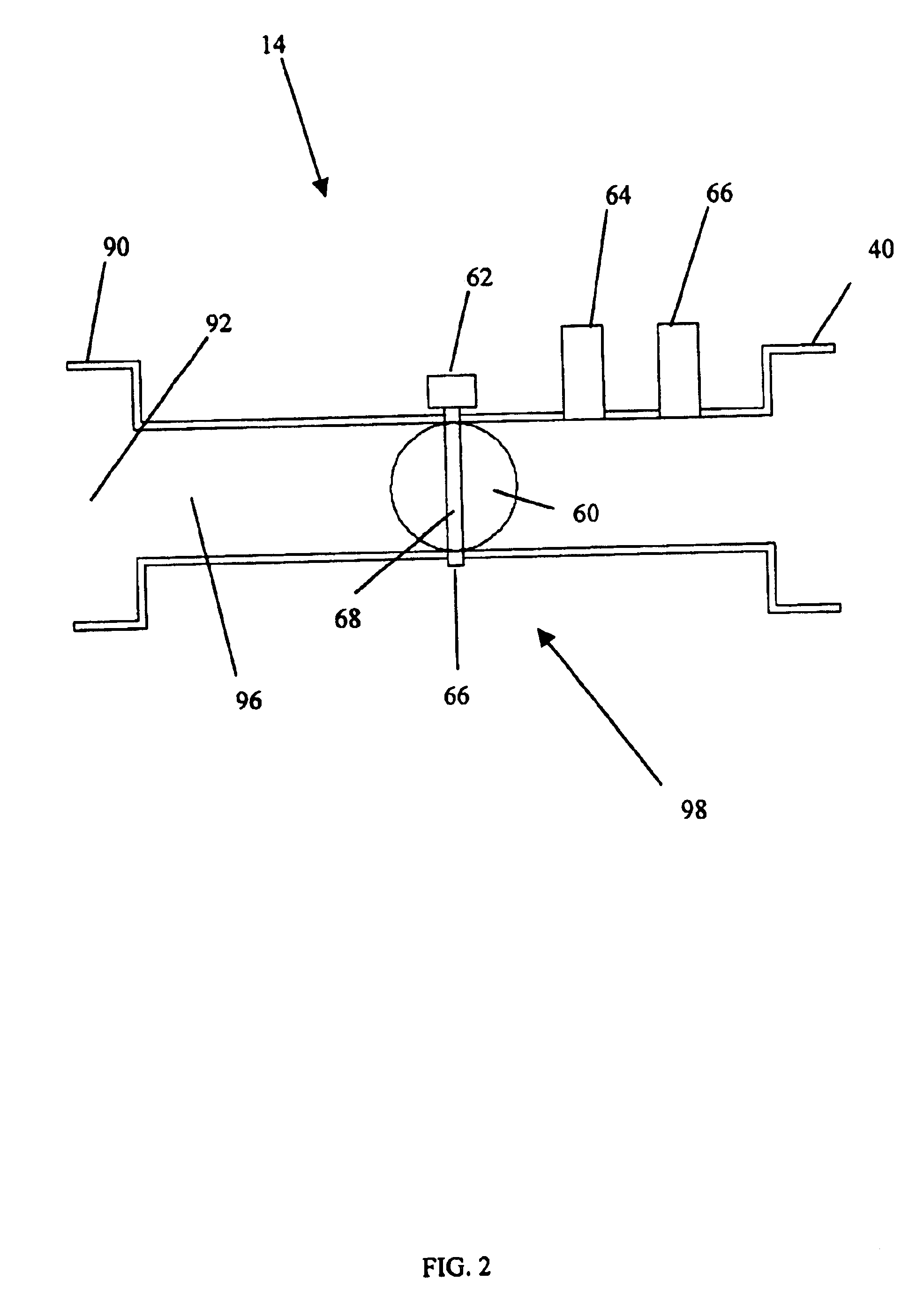

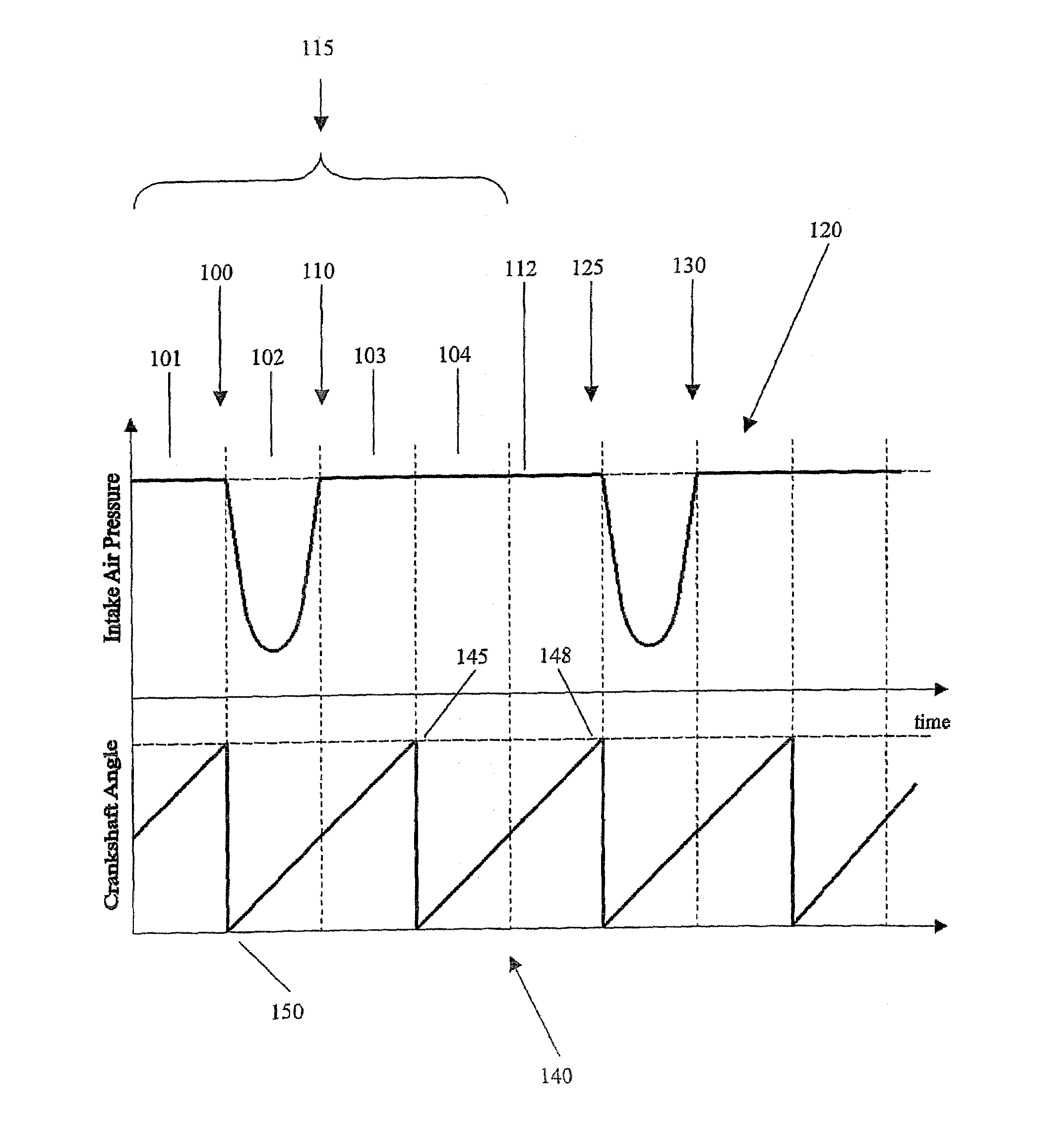

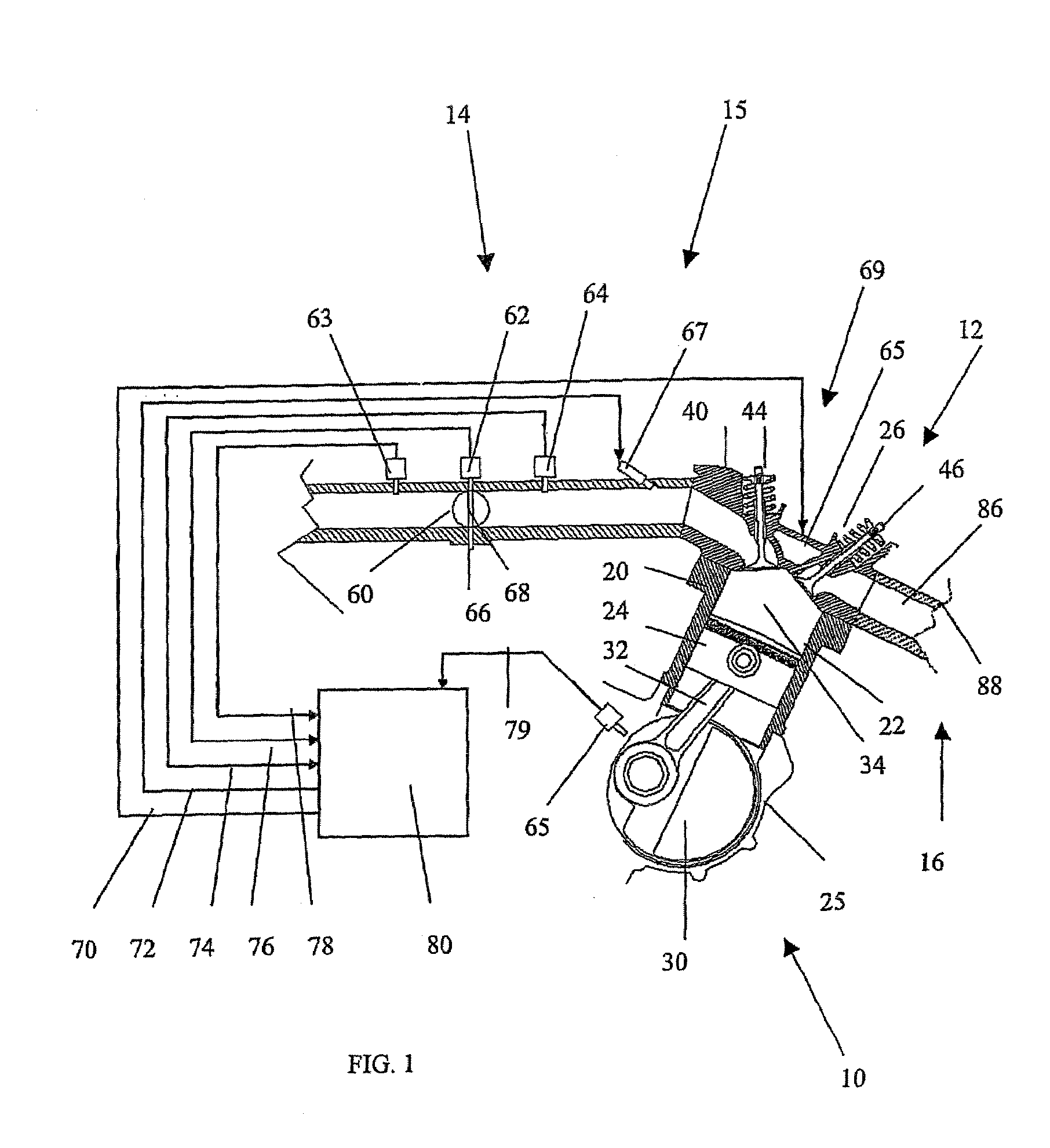

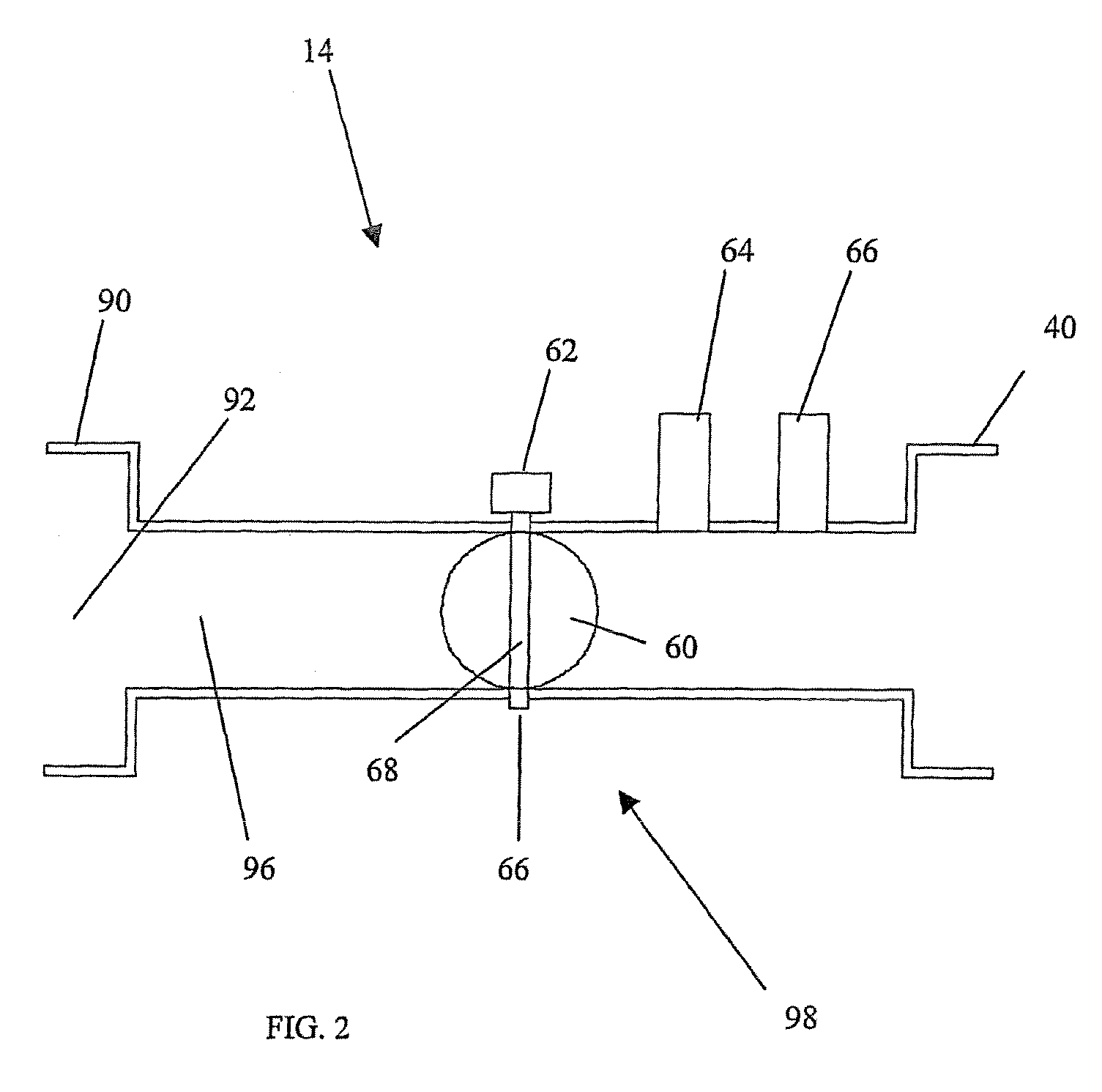

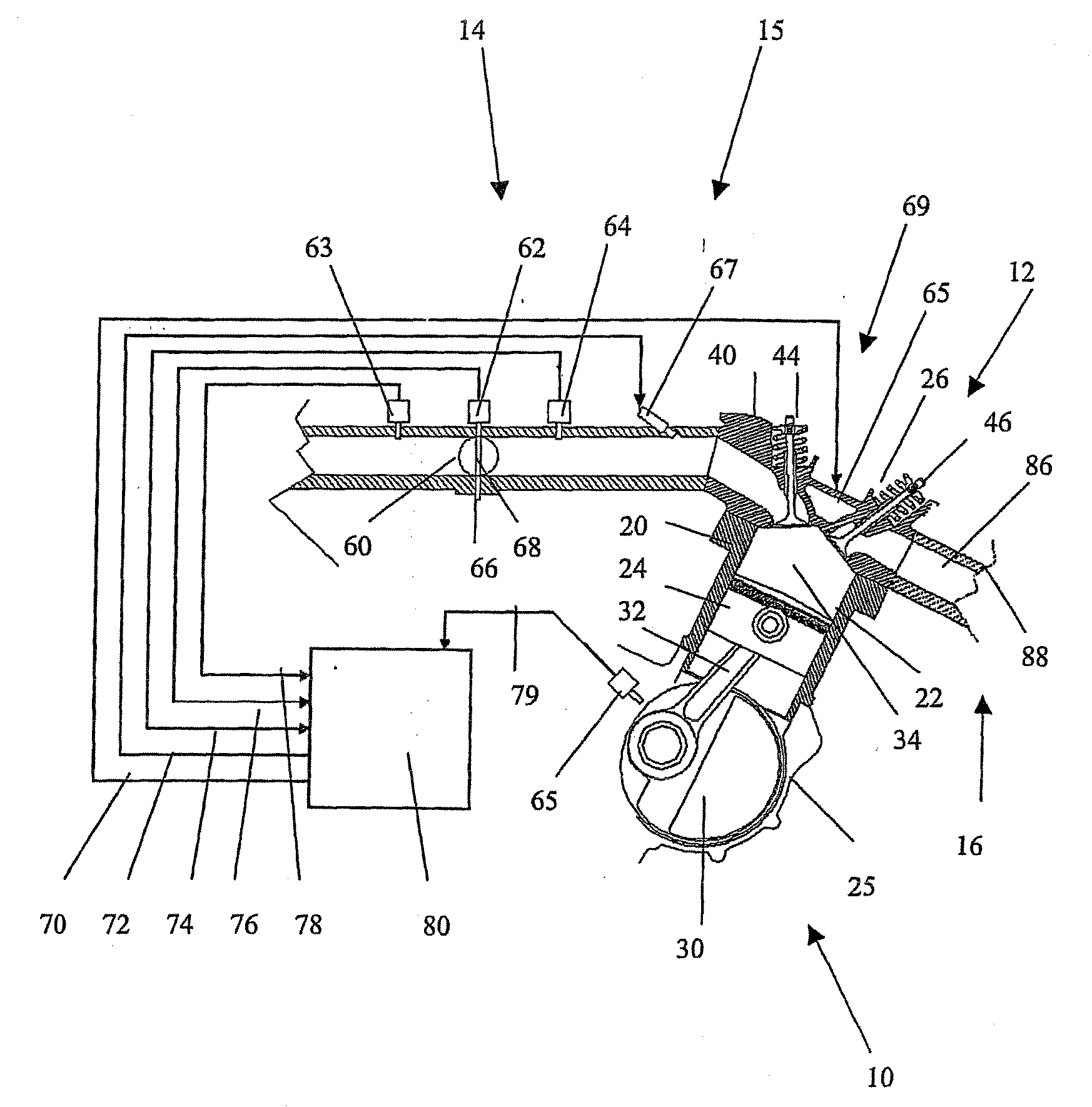

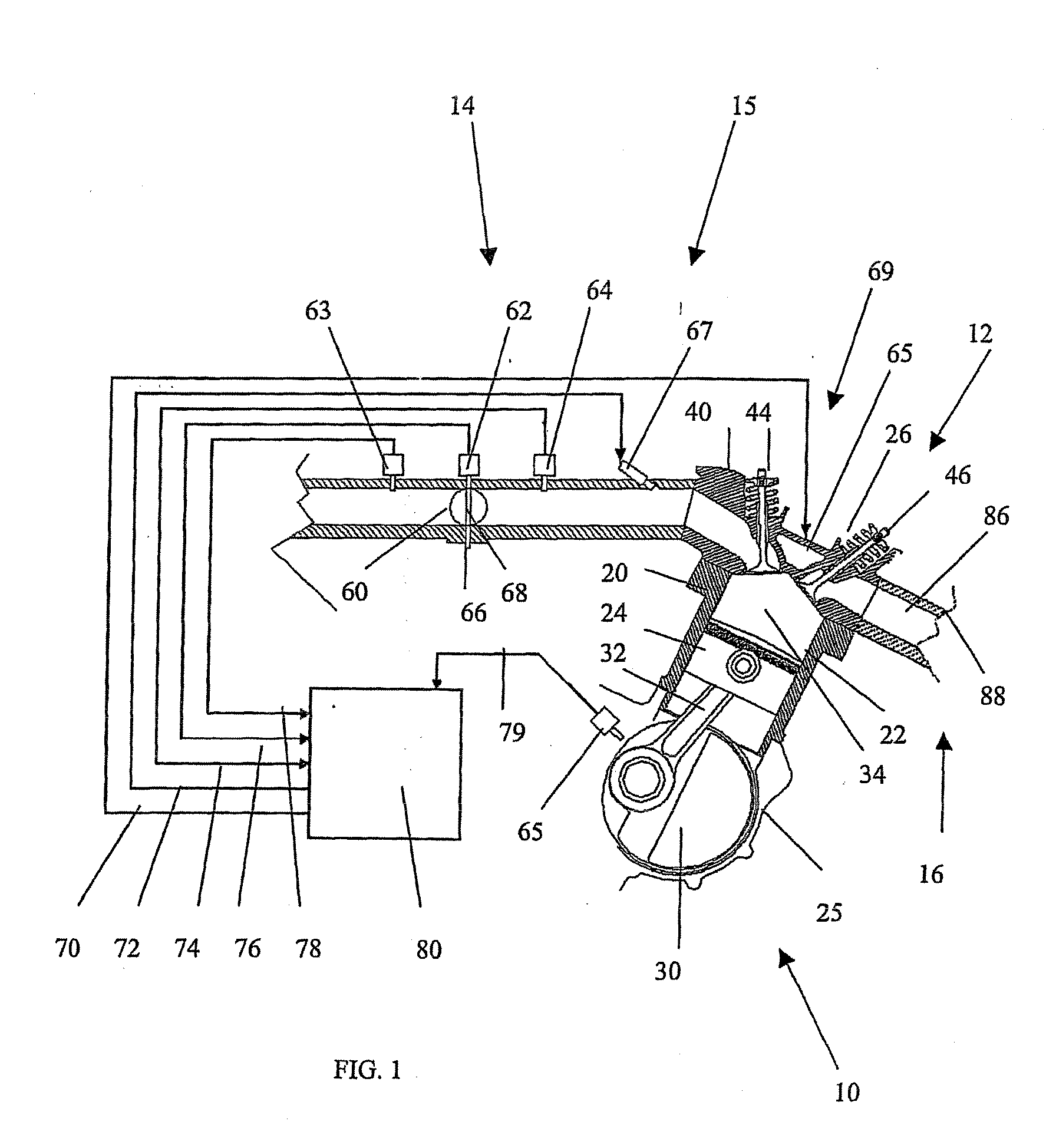

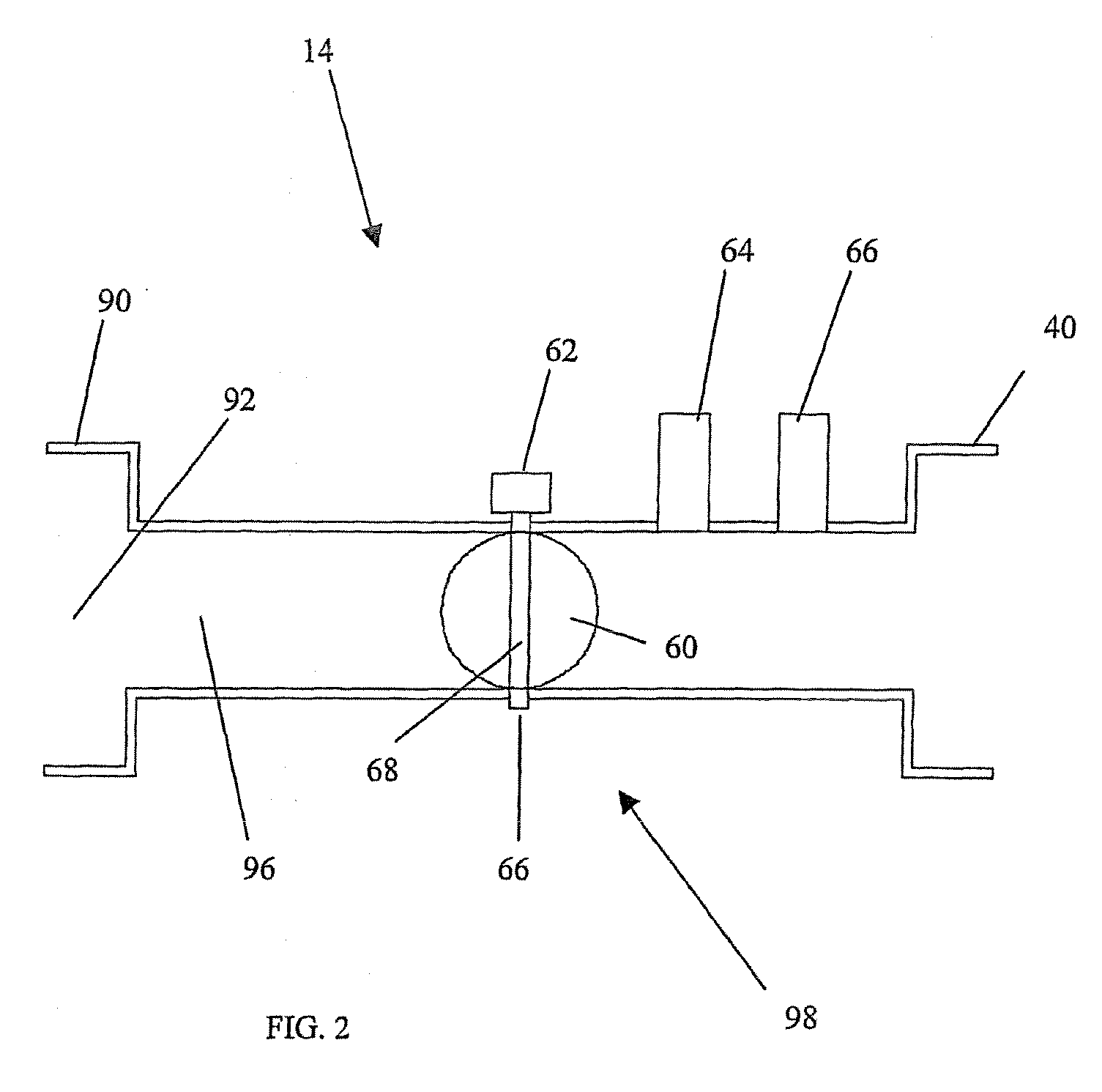

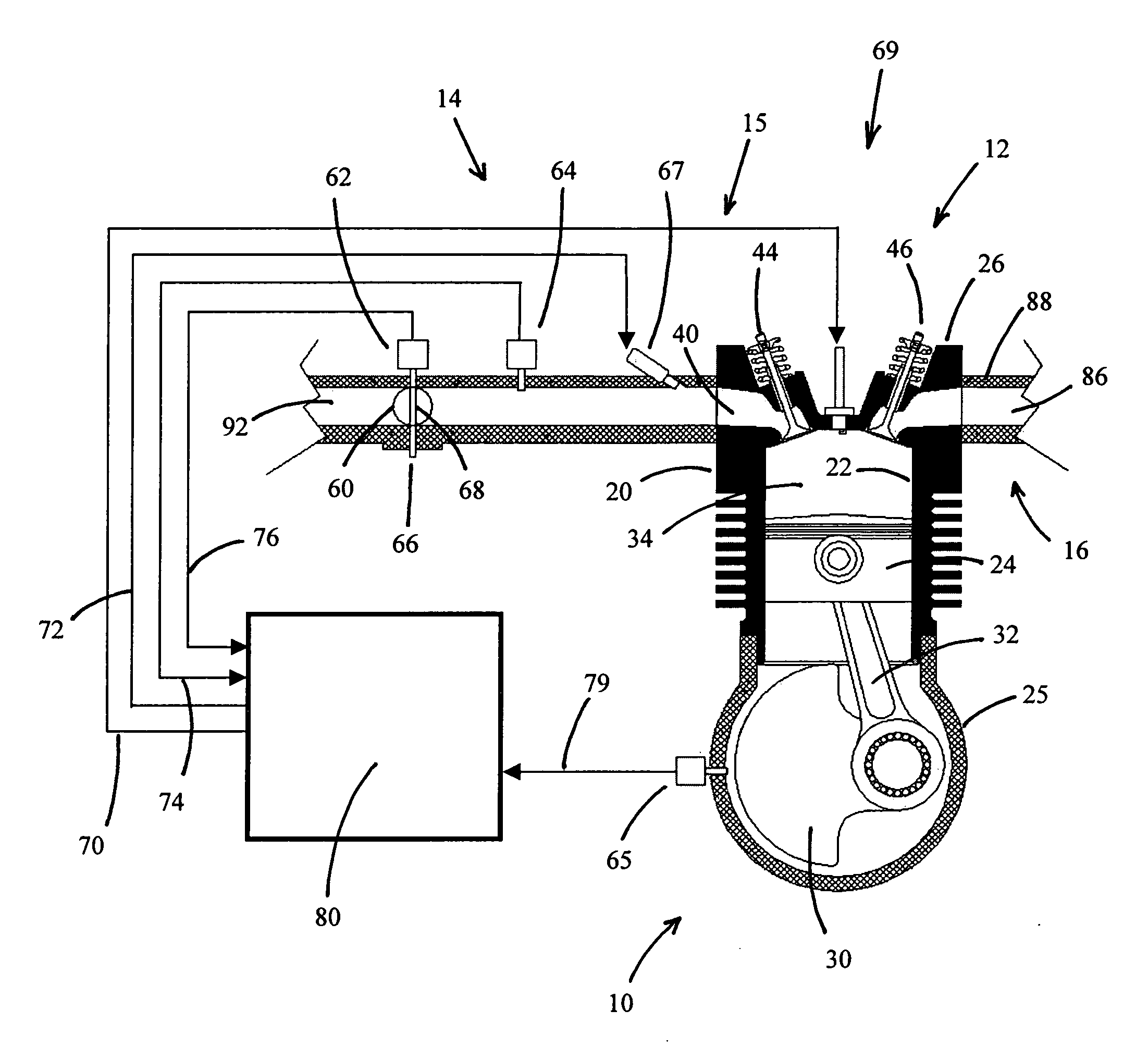

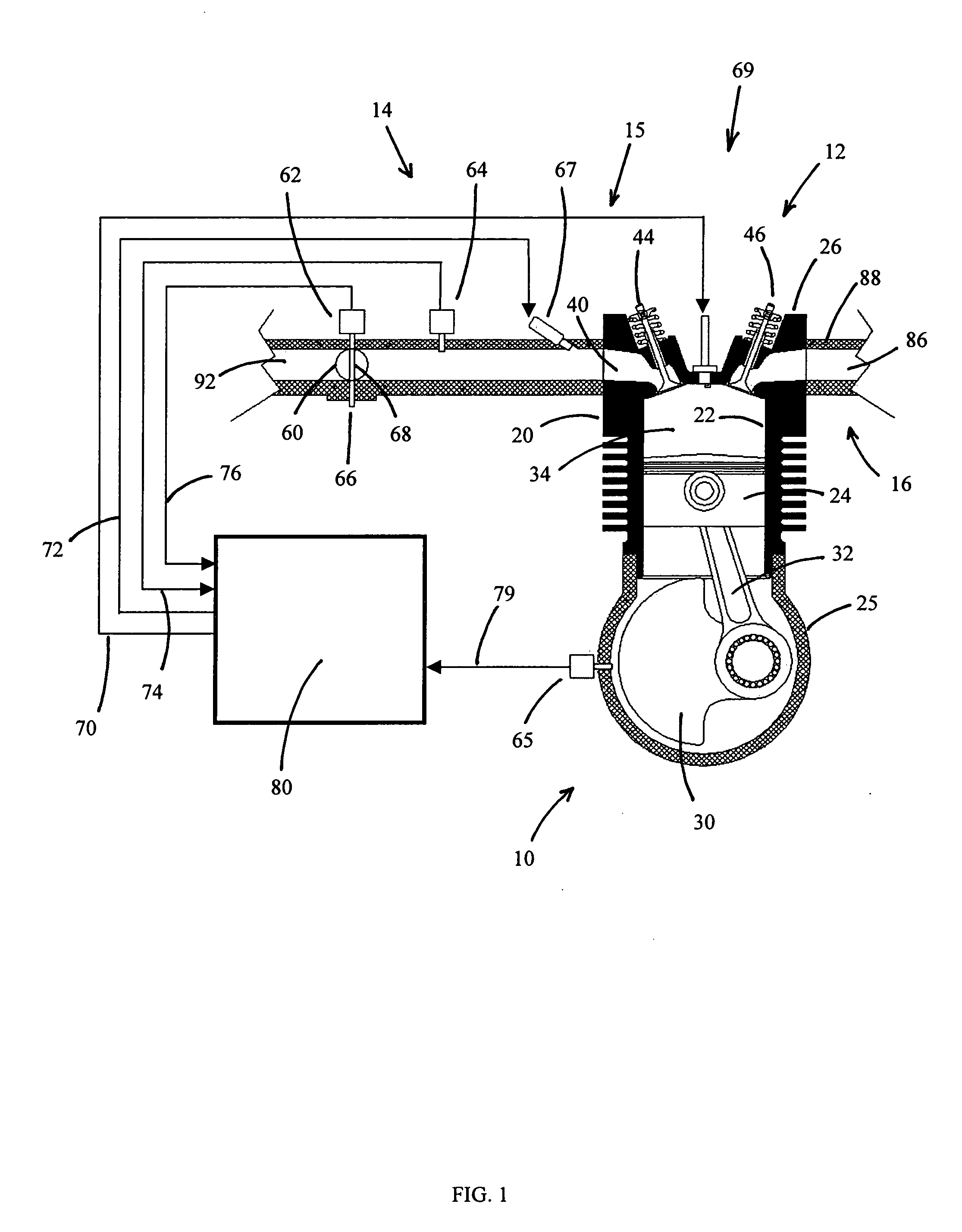

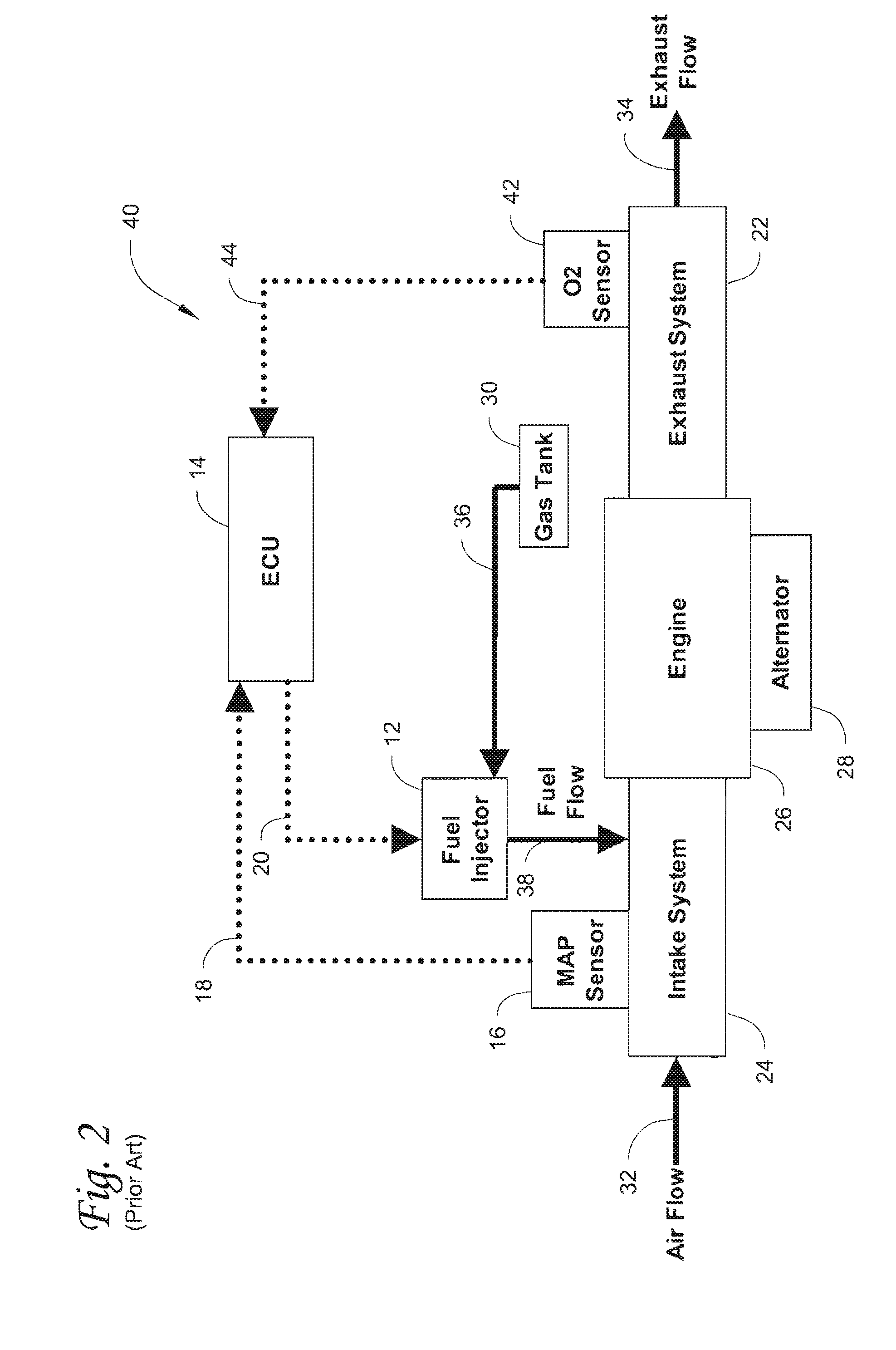

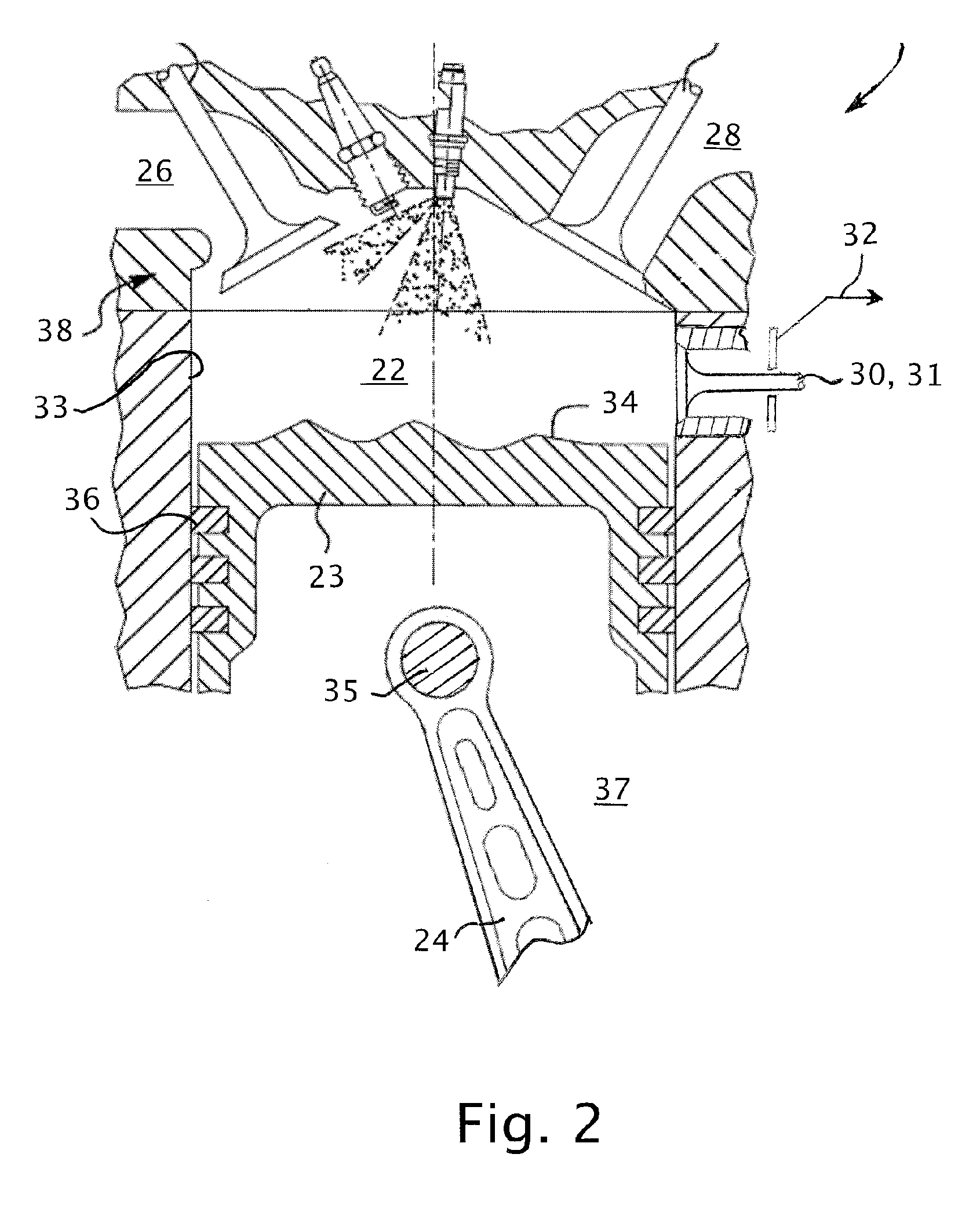

Engine timing control with intake air pressure sensor

InactiveUS6804997B1Reduce in quantityRobust implementationElectrical controlEngine testingExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position.

Owner:ELECTROJET TECH INC

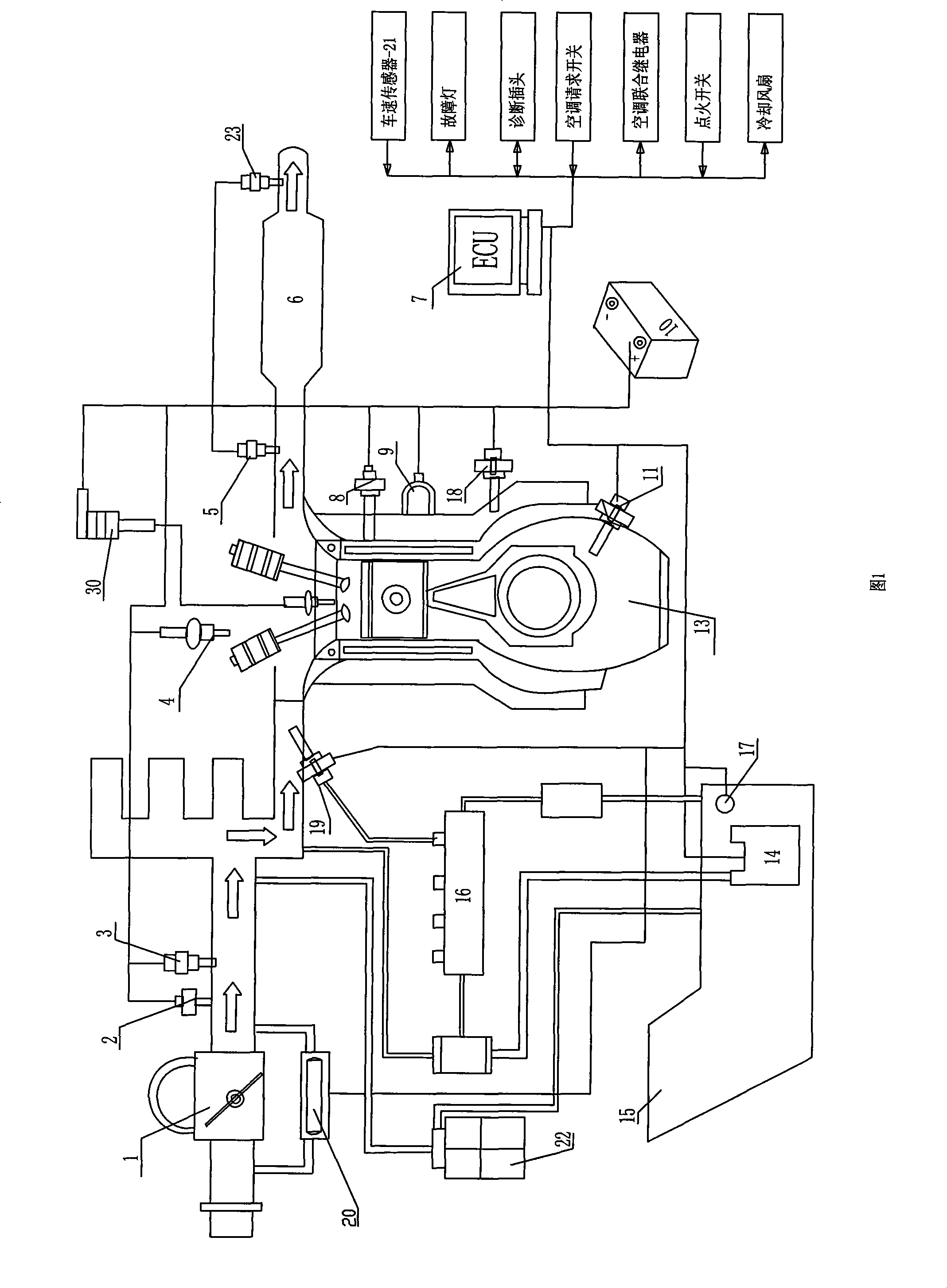

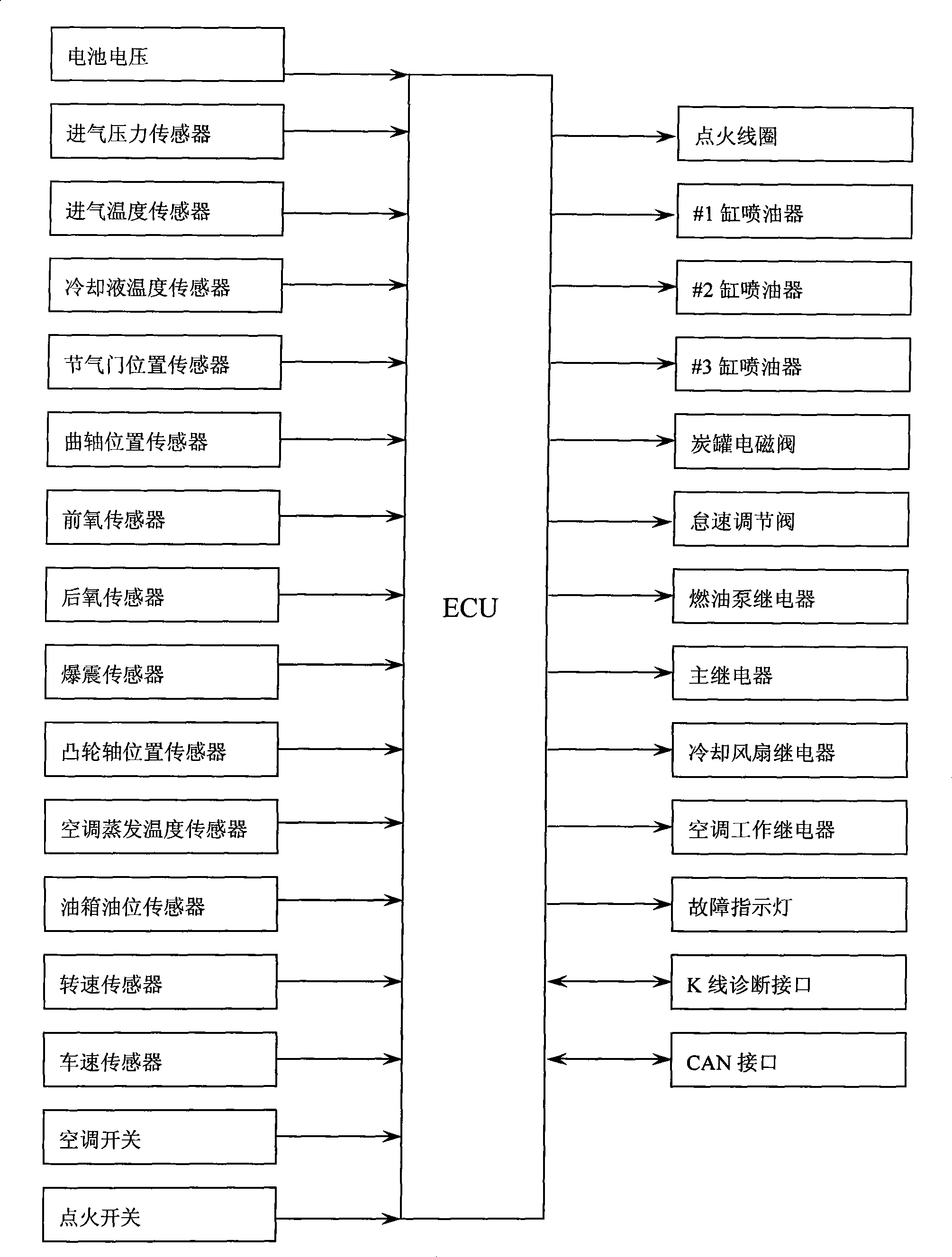

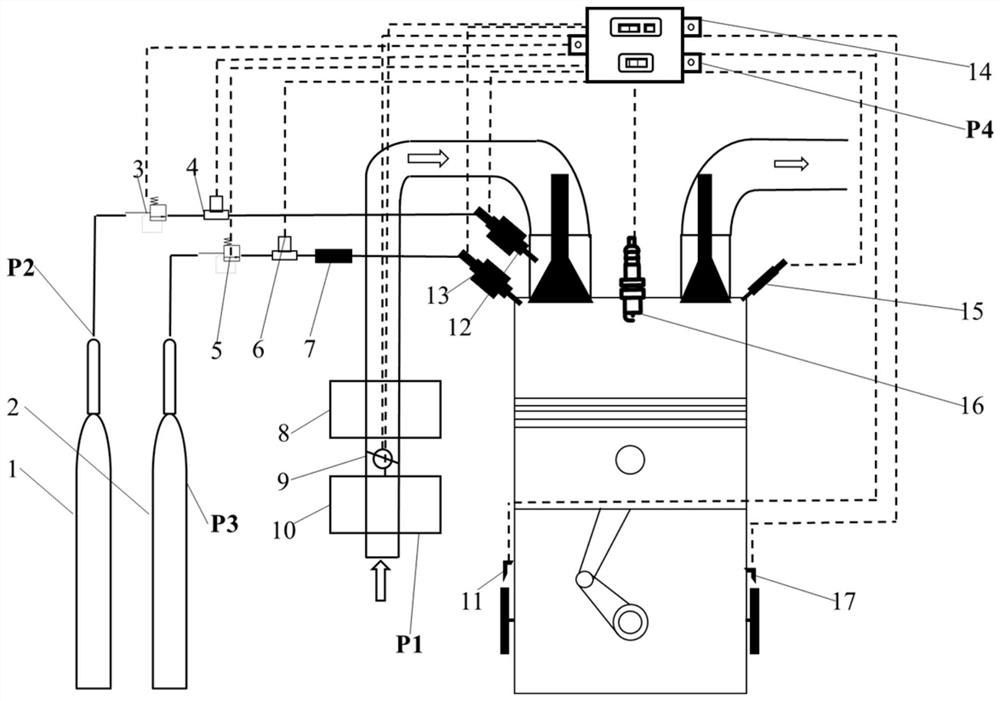

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

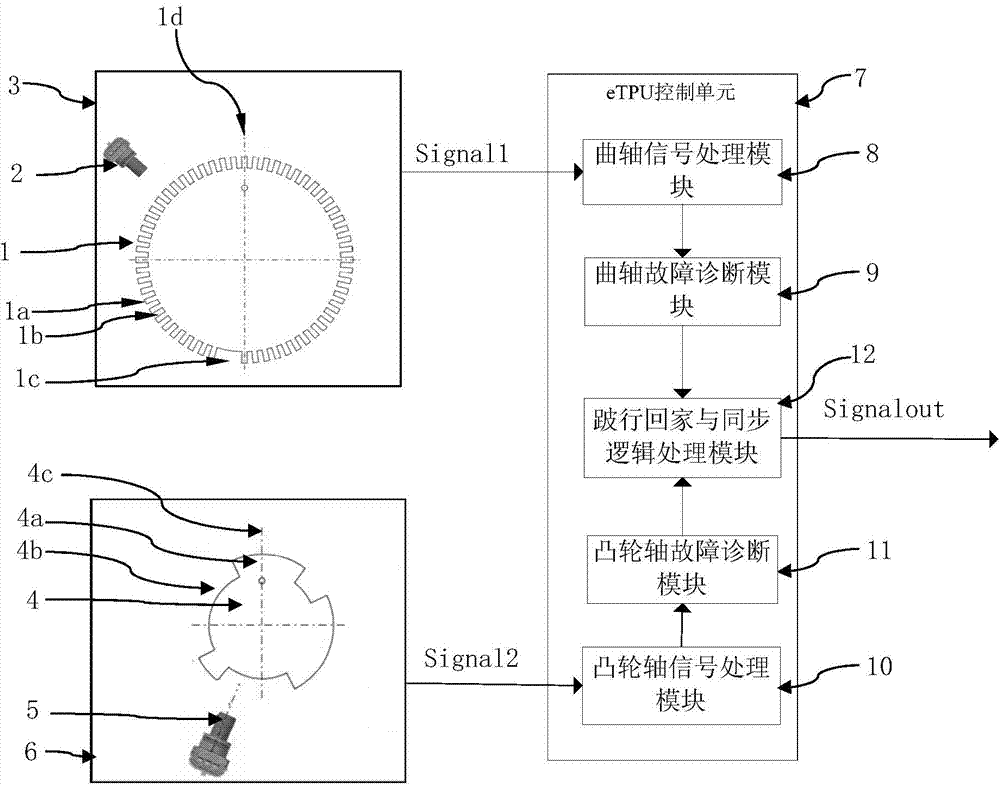

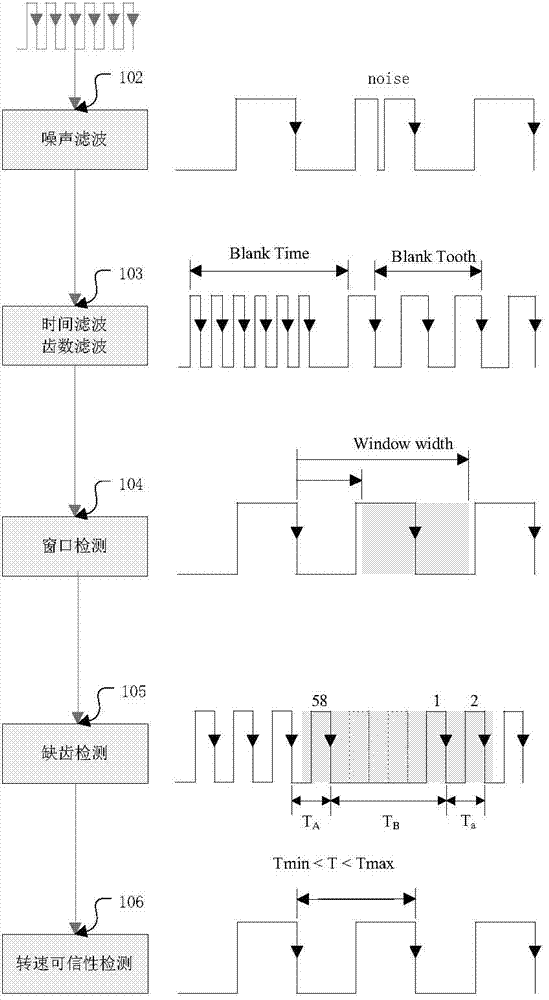

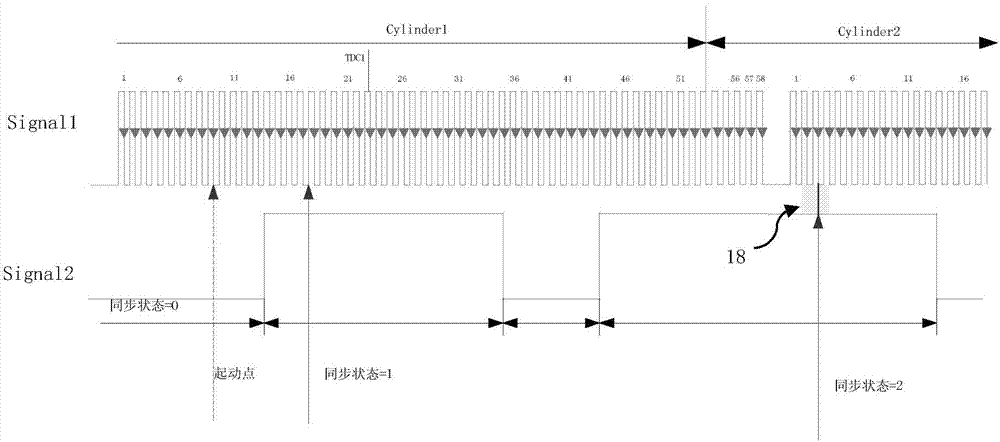

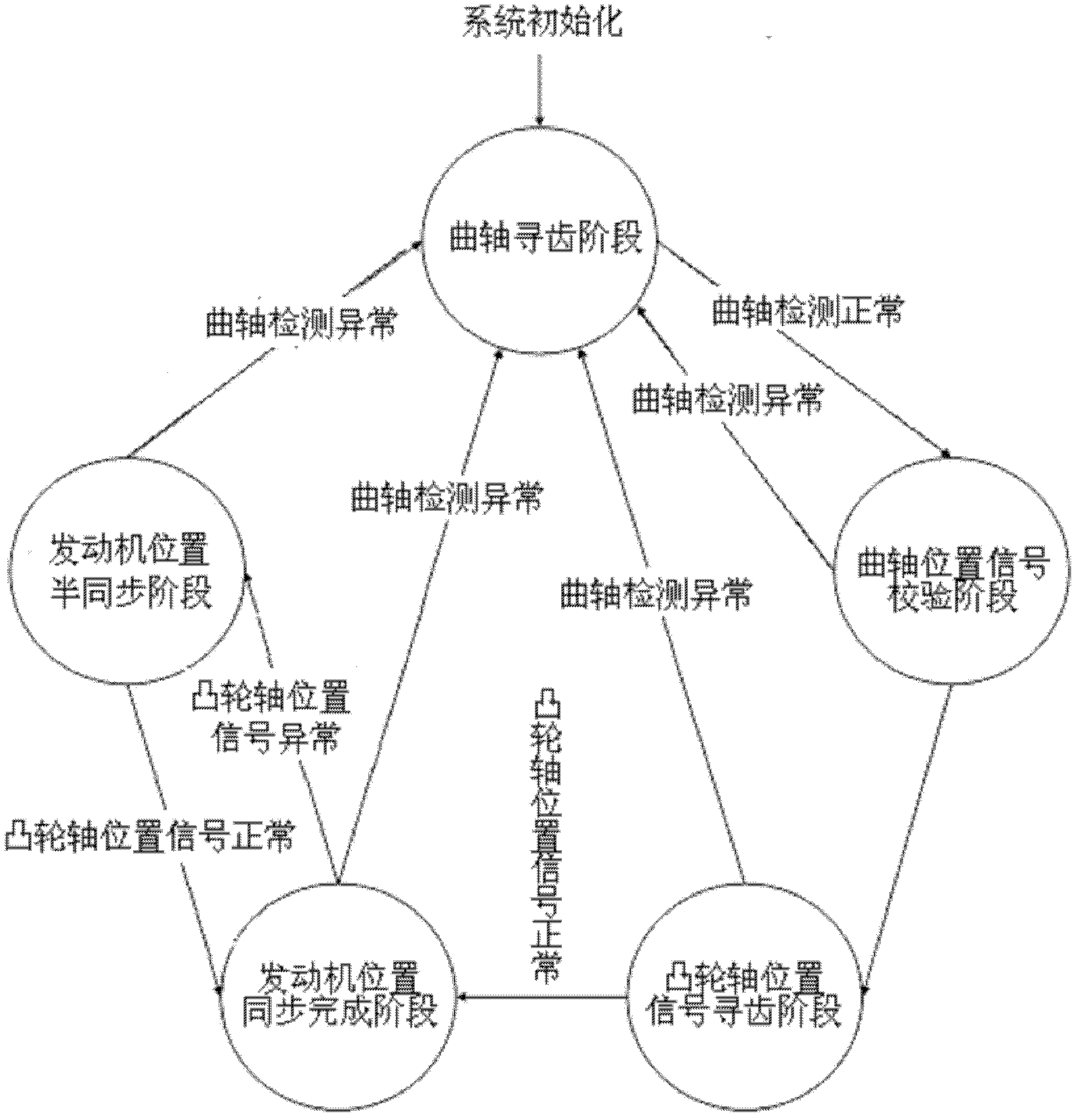

Engine position management system and management method

ActiveCN104747309AAchieve limp homeSync fastElectrical controlMachines/enginesLarge toothPosition sensor

The invention discloses an engine position management system. The engine position management system comprises a crankshaft signal panel, a crankshaft position sensor, a camshaft signal panel, a camshaft position sensor and an eTPU control unit, wherein the crankshaft signal panel comprises multiple convex teeth and tooth gaps; the tooth gaps have a large tooth gap for positioning; and the camshaft signal panel comprises three convex teeth with different central angles and tooth gaps. The eTPU control unit comprises a crankshaft signal processing module, a crankshaft fault diagnosis module, a camshaft signal processing module, a camshaft fault diagnosis module and a limp return and synchronous logic processing module. The engine position management system can use crankshaft signals and camshaft signals for realizing quick cylinder judgment and synchronization of an engine when the camshaft position sensor and the camshaft position sensor are normal, and can use another sensor for realizing the cylinder judgment synchronization and providing the angle information with limited precision to realize the limb return of the engine when one sensor is broken down. The invention further provides a management method of the engine position management system.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

Engine timing control with intake air pressure sensor

InactiveUS7225793B2Reduce complexityLow costElectrical controlVolume/mass flow by thermal effectsExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

Engine timing control with intake air pressure sensor

InactiveUS20060118086A1Low costReduce complexityElectrical controlVolume/mass flow by thermal effectsBridge typeImage resolution

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

Electronic engine control with reduced sensor set

InactiveUS20050039526A1Low costReduce complexityElectrical controlEngine testingImage resolutionFour-stroke engine

An engine control apparatus is disclosed for determining crankshaft position, engine phase, engine loading, and intake air mass of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. Intake air pressure is used to determine intake air mass and loading of the engine. This combination results in a single sensor used in a system to determine intake air mass, engine loading, injected fuel mass, and to determine timing for fueling and ignition events. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure over time to increase resolution in the determination of crankshaft position.

Owner:ELECTROJET TECH INC

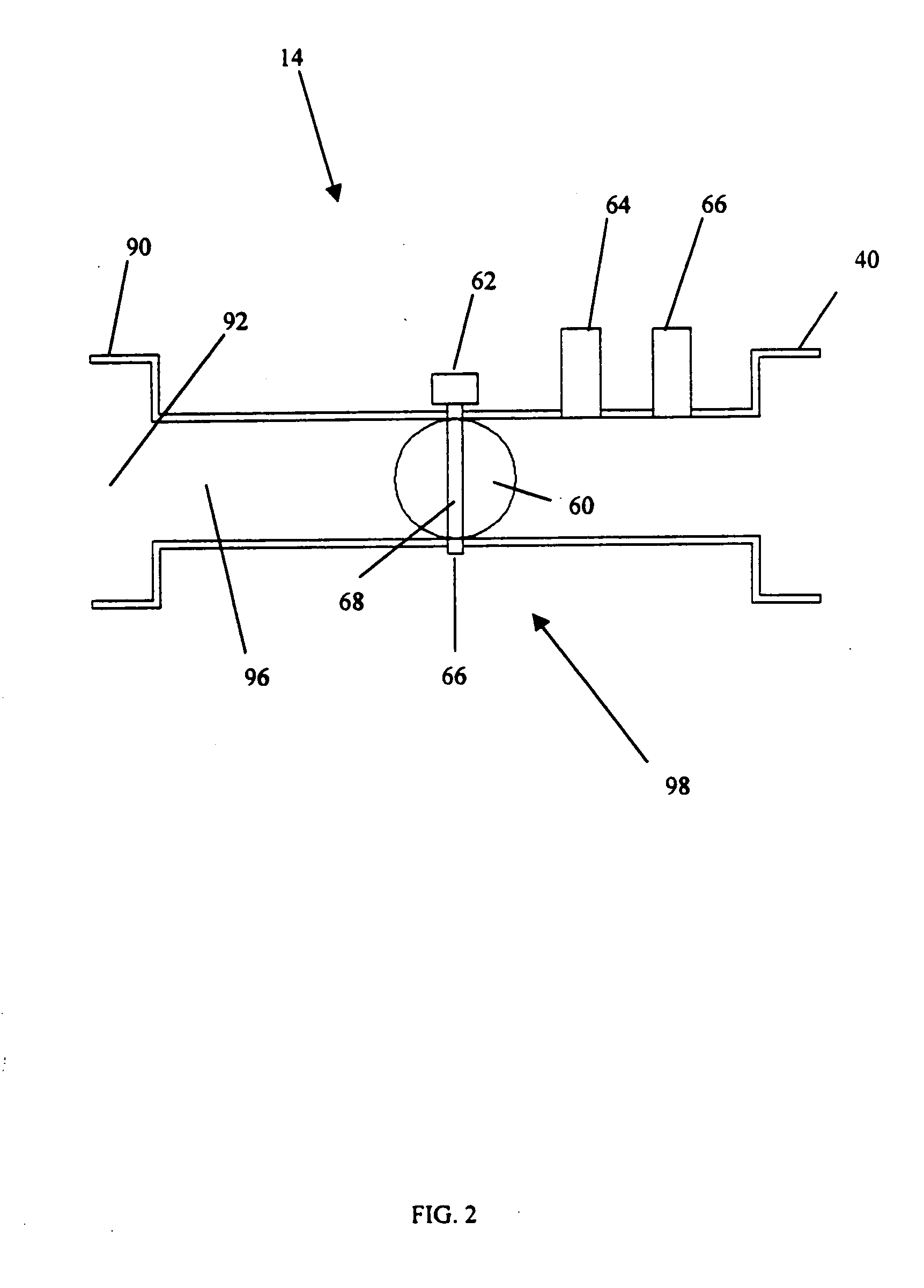

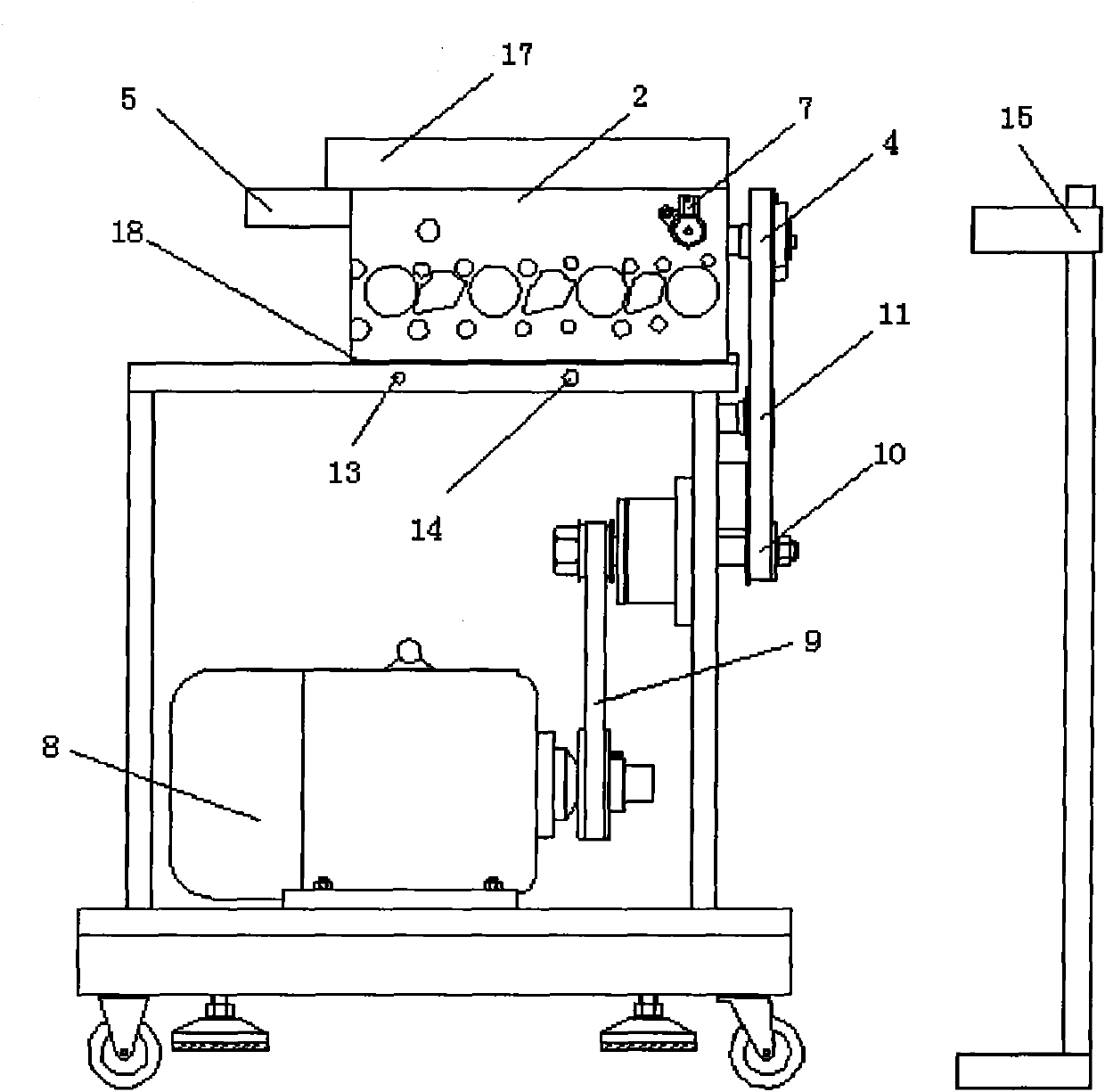

Bench test device for power assembly of mixed power electric vehicle

The invention relates to mixed power electric automobile power assembly bench test device. Front, back, left, and right frames are formed bench according to the mounting means of engine, torque sensor, electric machine, gear box and the sensor fixing position at the crank shaft. Power assembly is set at the bench. Power measuring machine is connected with the power output end of the gear box. Torque sensor is set between the engine and the electric machine or power measuring machine. The connected power assembly, torque sensor, and power measuring machine are connected with each controller unit and related wiring harness to constructer CAN network, adjust system communicating, verify reliability and system function for engine, electric machine, battery, HCU multi energy sources controller, BMS battery management unit, MCU electric machine controller, EMS engine controller etc.

Owner:CHERY AUTOMOBILE CO LTD

Engine variable valve timing system performance testboard

ActiveCN101907519ASimple structureImprove general performanceInternal-combustion engine testingVariable valve timingDrive motor

The invention discloses an engine variable valve timing system performance testboard, relating to an engine variable valve timing system performance test device. The invention aims to solve the problems of engine variable valve timing system performance detection and has simple structure, strong universality, easier installation and more accurate and reliable measured data. The invention has the technical scheme that the testboard comprises a cylinder cover. A cam shaft is arranged in the cylinder cover; the front end of the cam shaft is connected with a phase shifter and the rear end thereof is connected with a cam angle sensor; a valve assembly is arranged in the cylinder cover and actuates along with the rotation of the cam shaft; the cylinder cover is provided with an engine oil control valve; a drive motor drives a crankshaft sprocket through a transmission synchronous belt; the crankshaft sprocket drives the phase shifter through a chain; a crankshaft position sensor is arranged below the crankshaft sprocket; and hydraulic oil enters from the oil inlet arranged on the cylinder cover and flows out from the oil outlet. The invention is mainly applied to the performance test of an engine variable valve timing system.

Owner:MIANYANG FULIN PRECISION MACHINING

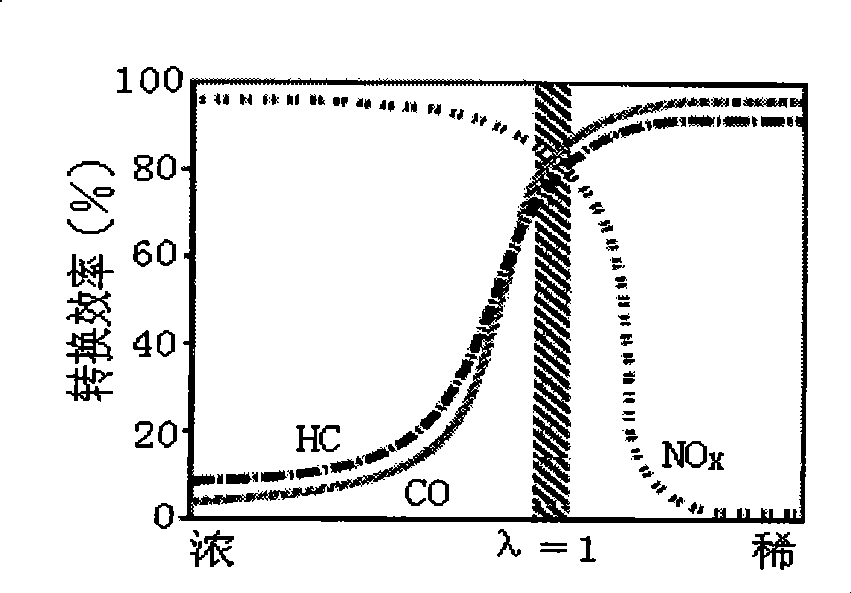

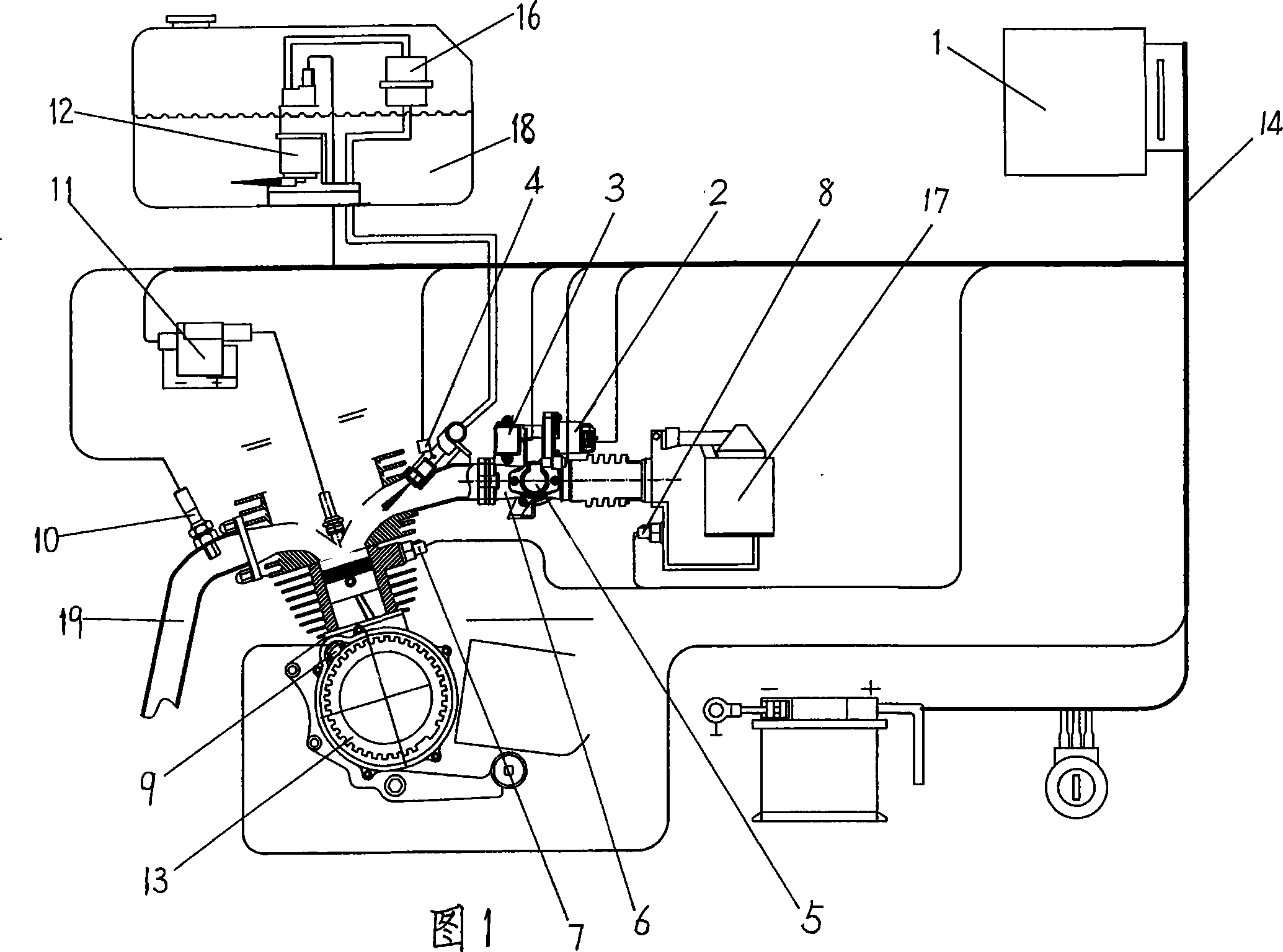

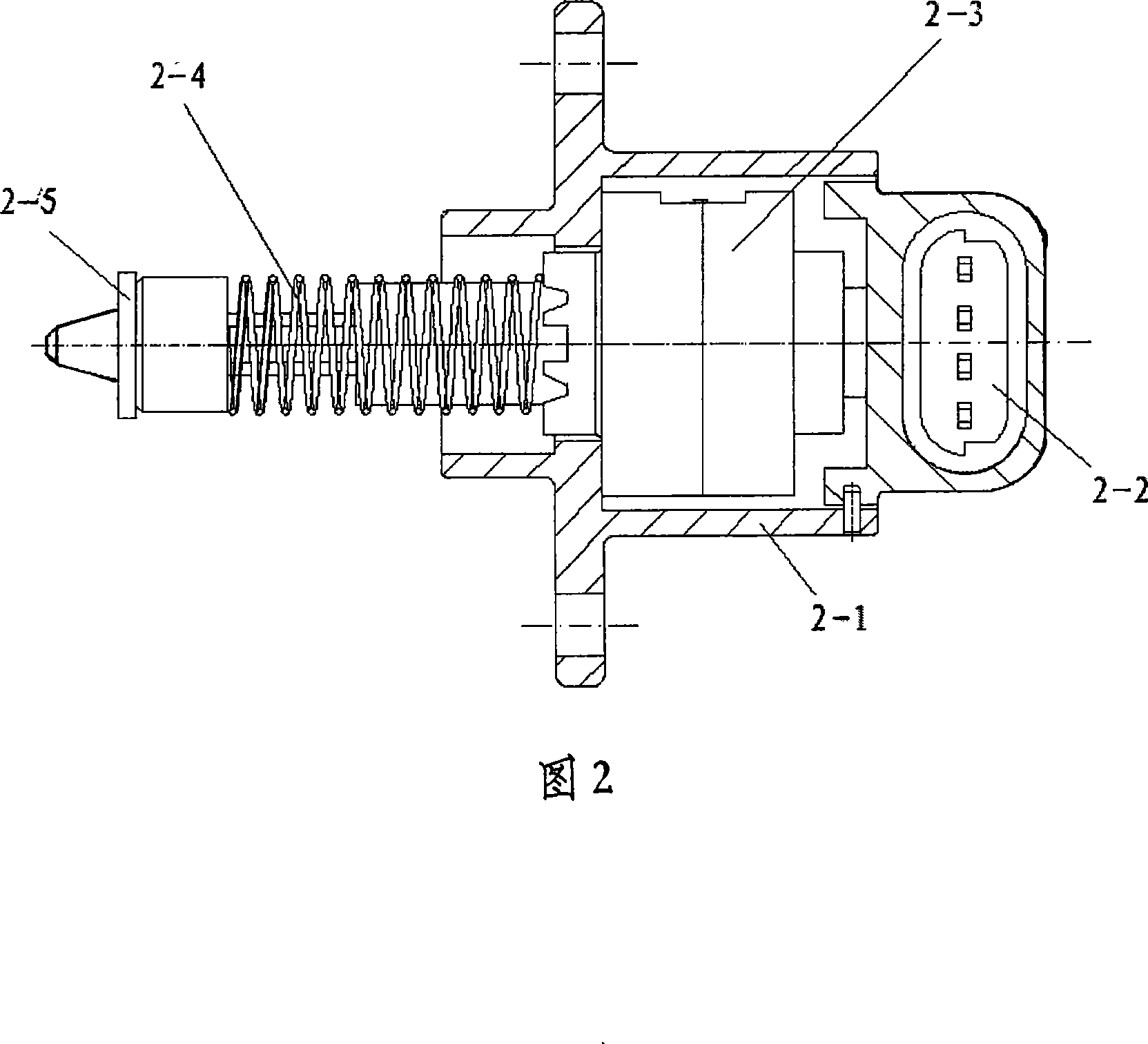

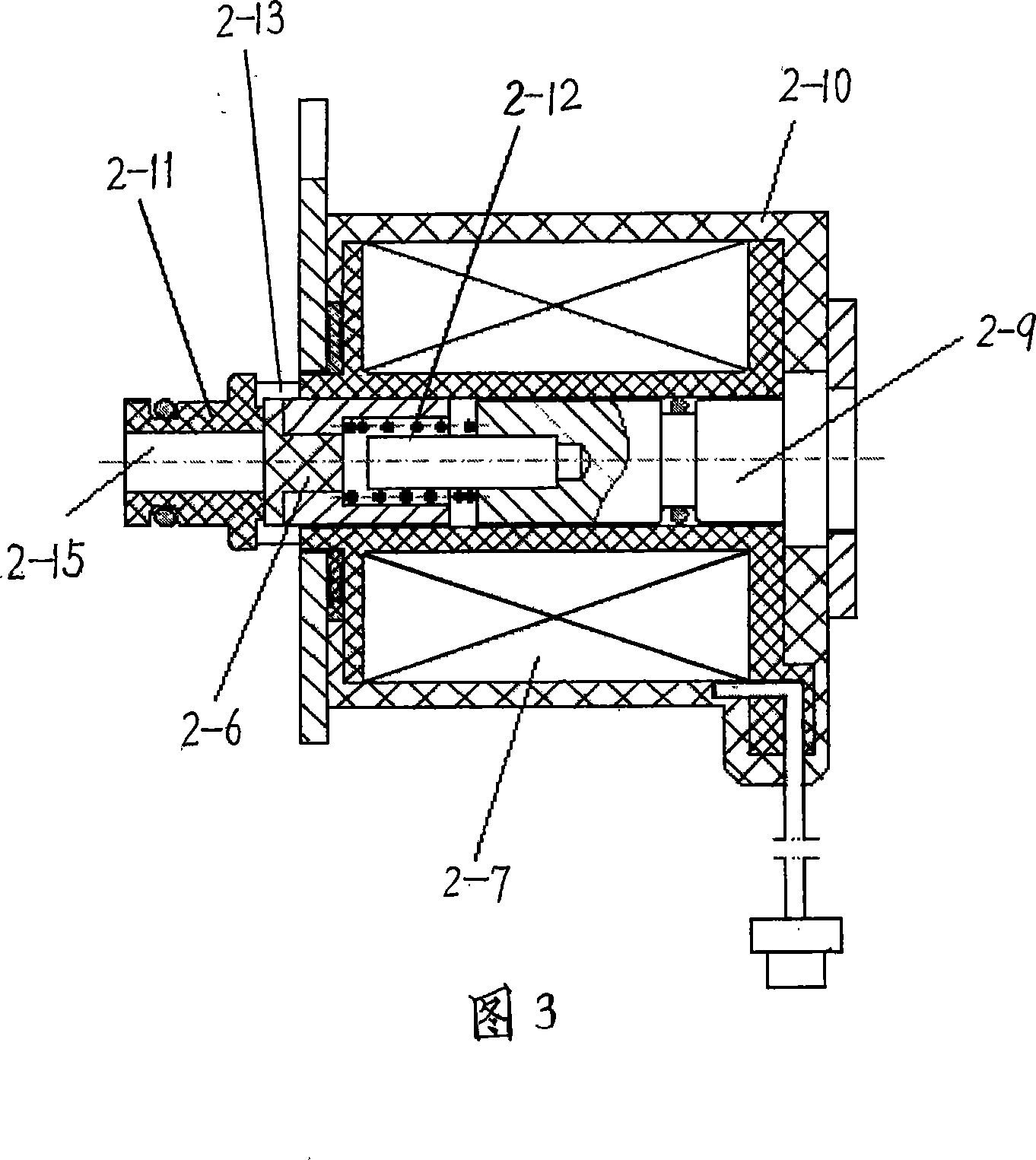

Motor engine electric control fuel oil spraying system

InactiveCN101144437AReasonable designSimple structureElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention discloses a motorcycle engine electronic control fuel injection system, and comprises an electronic control unit, and a sensor and an executive mechanism connected with the electronic control unit; the sensor comprises a crankshaft position signal generator, a crankshaft position sensor and a throttle position sensor corresponding to the crankshaft position signal generator, an intake pressure sensor communicated with an air intake tube, an intake air temperature sensor communicated with the air intake tube, a cylinder body temperature sensor installed on the engine body, and an oxygen sensor arranged on an exhaust tube, wherein, the executive mechanism comprises an idle speed control valve, an electric fuel pump, a fuel pressure regulator, an oil ejector and an ignition coil. The invention has the advantages that the design is reasonable, the structure of the system is perfect, the operating performance is stable and reliable, and the engine combines the electronic control system with the exhaust gas aftertreatment technology, to lead the exhaust gas emission to meet the requirements of the motorcycle country more than three issues emission regulation as well as the more than Euro III exhaust emission regulation.

Owner:西安易道汽车电器有限责任公司 +2

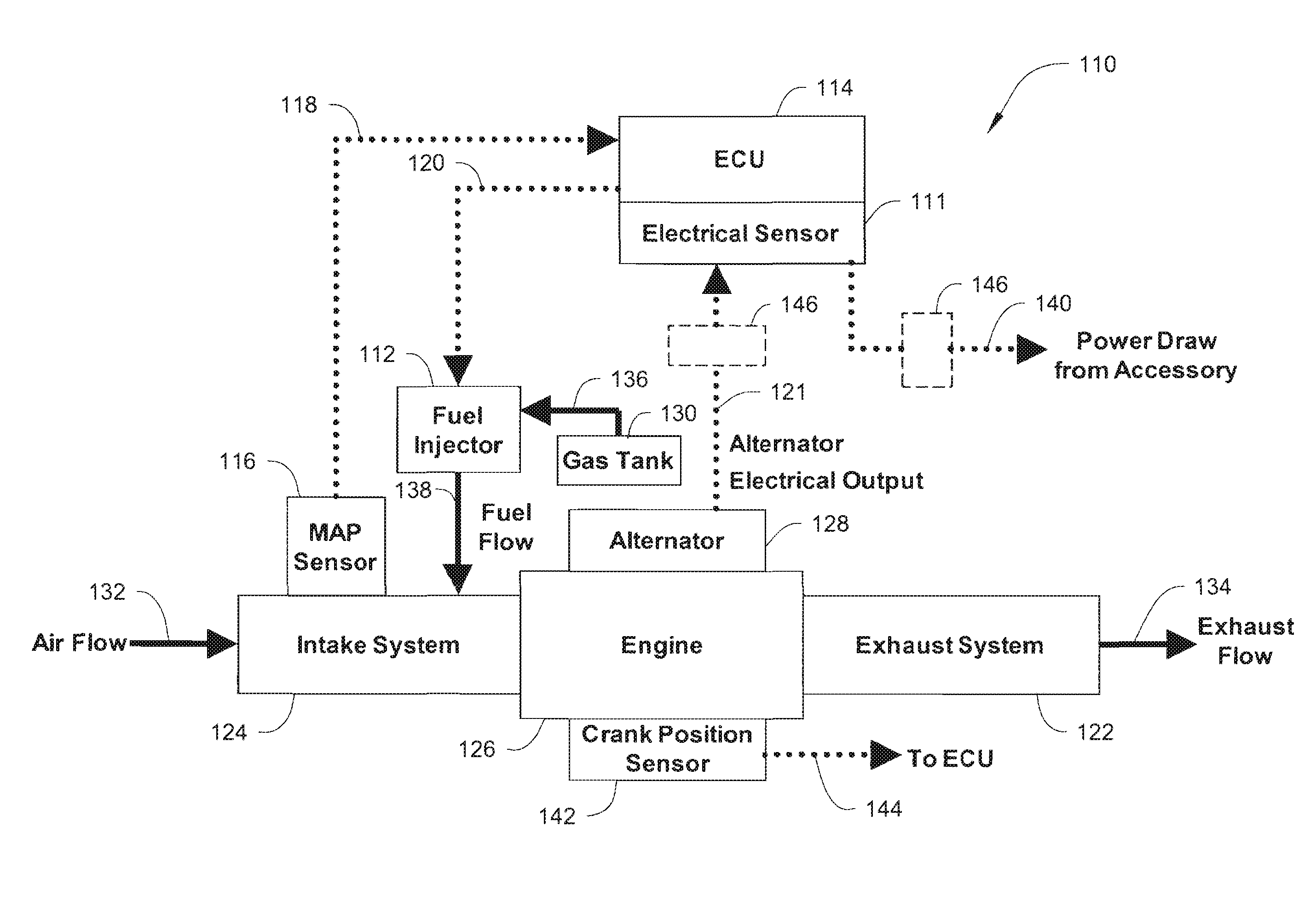

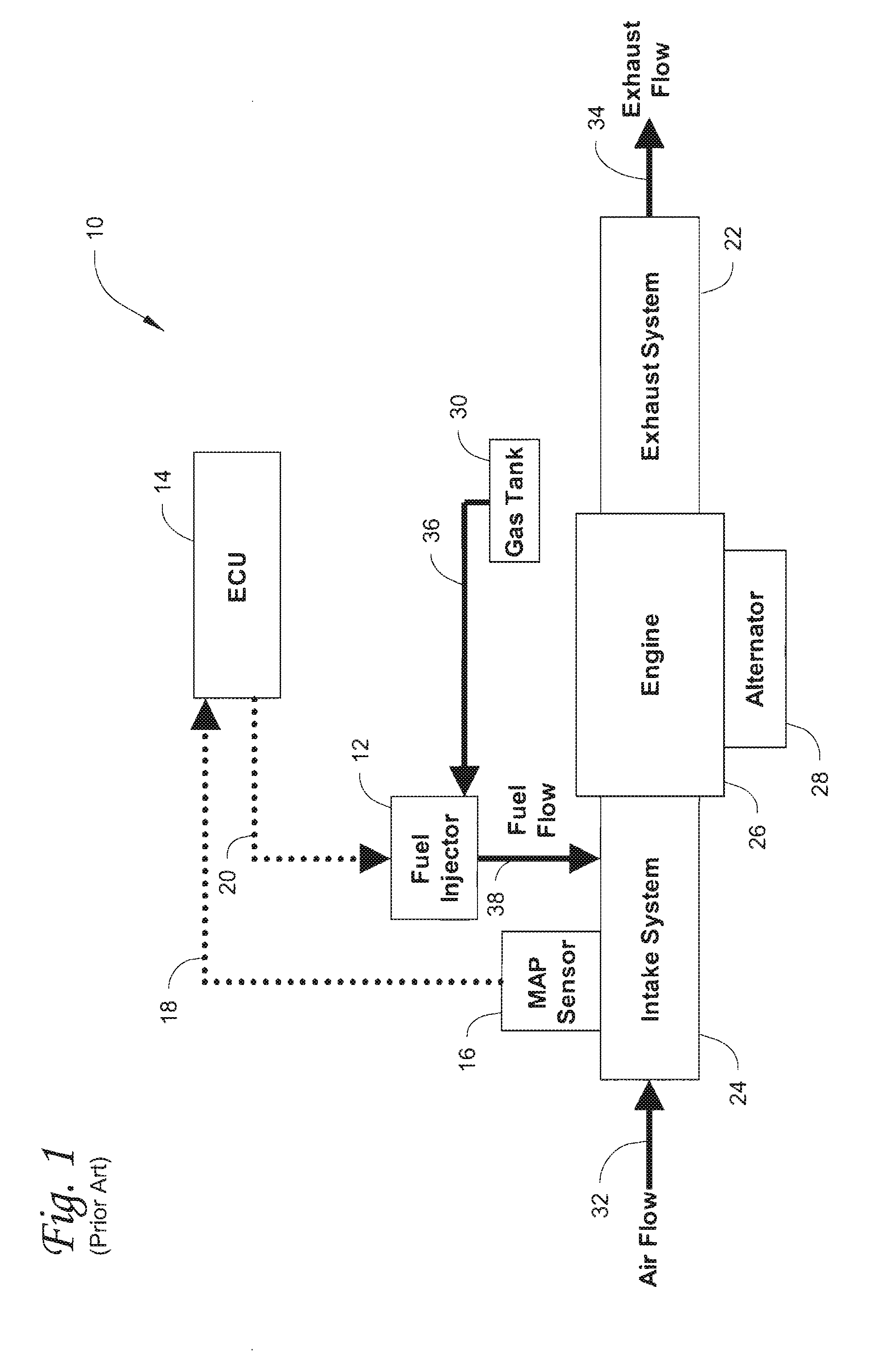

Genset engine with an electronic fuel injection system integrating electrical sensing and crank position sensing

ActiveUS20110180043A1Convenient timeImprove efficiencyElectrical controlDigital data processing detailsElectricityClosed loop

An open or closed loop EFI system, integrated on a genset engine or any internal combustion engine, with an electrical sensor and crank position sensor is described. Since a genset engine's exhaust emissions and general performance are a function of spark timing, integration of electrical and crank position sensors on a genset engine provides optimal engine performance and efficiency when the electrical draws fluctuate. The electrical sensor and crank position sensor send data to the electronic control unit (ECU), and this data is used to determine the optimal air-to-fuel ratio (AFR) and optimal spark timing. The ECU varies the spark timing in accordance with the speed and load of the engine and actuates the fuel injector to send the correct amount of atomized fuel to mix with the air flow to be combusted allowing the engine to meet performance.

Owner:CUMMINS POWER GENERATION

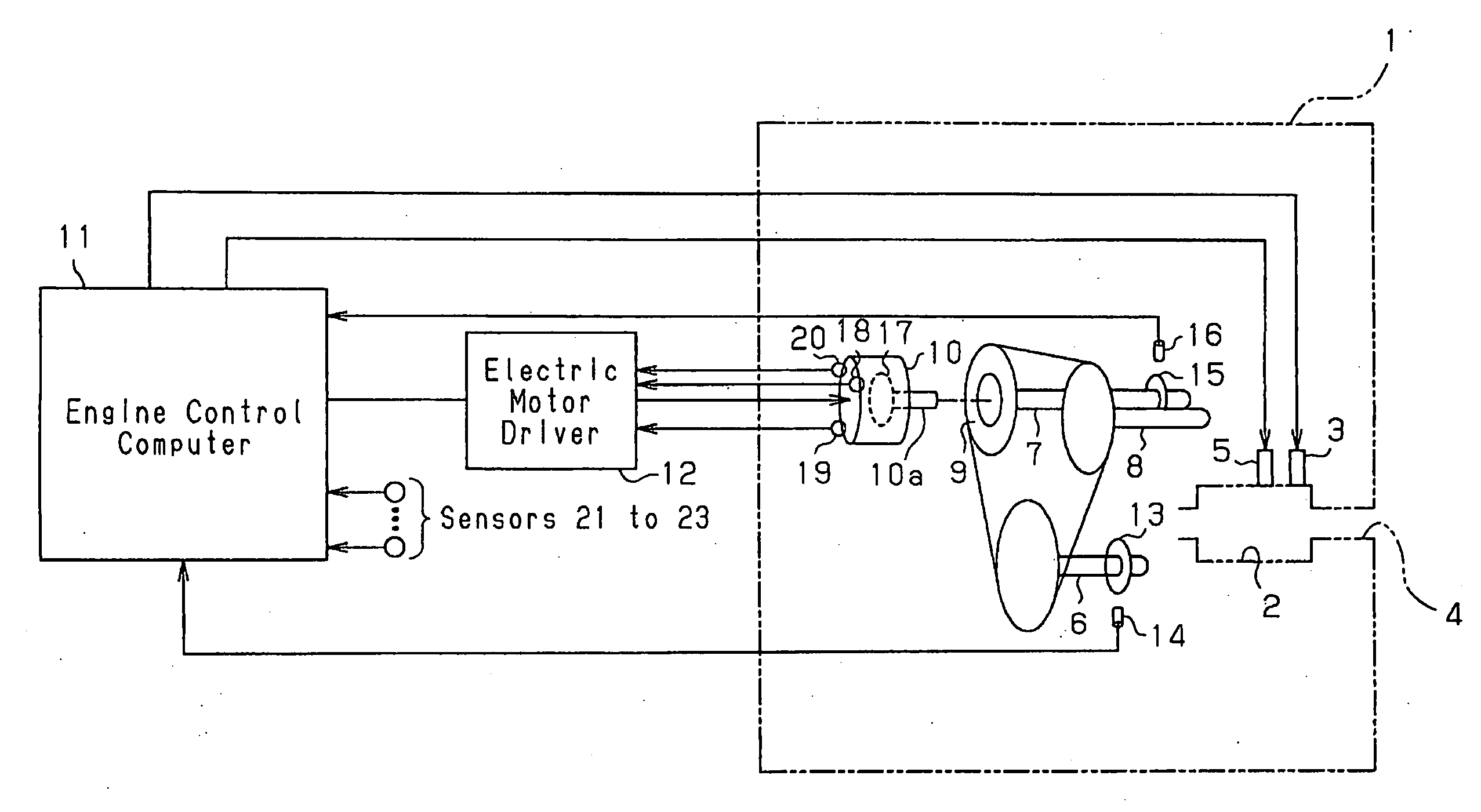

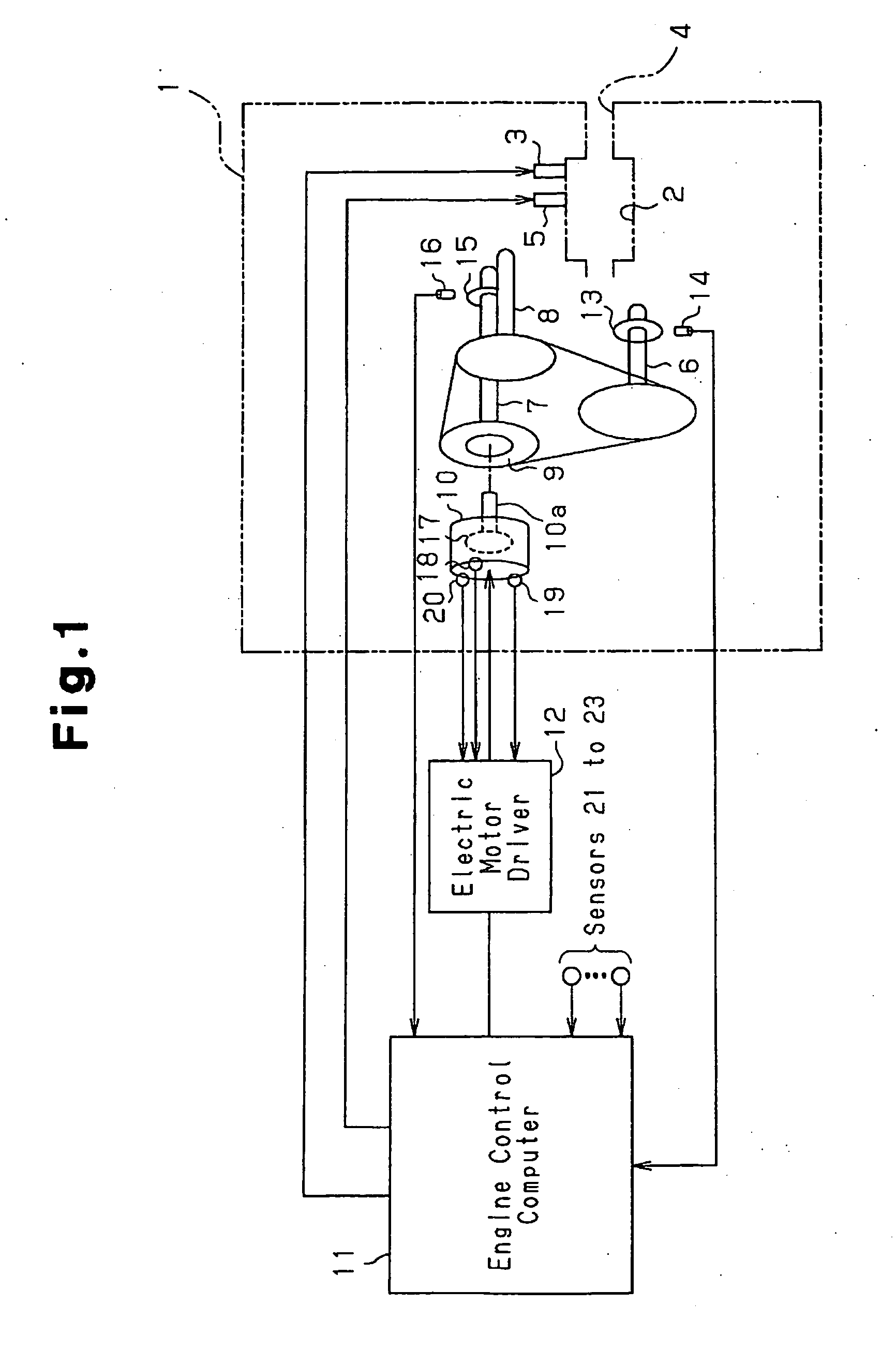

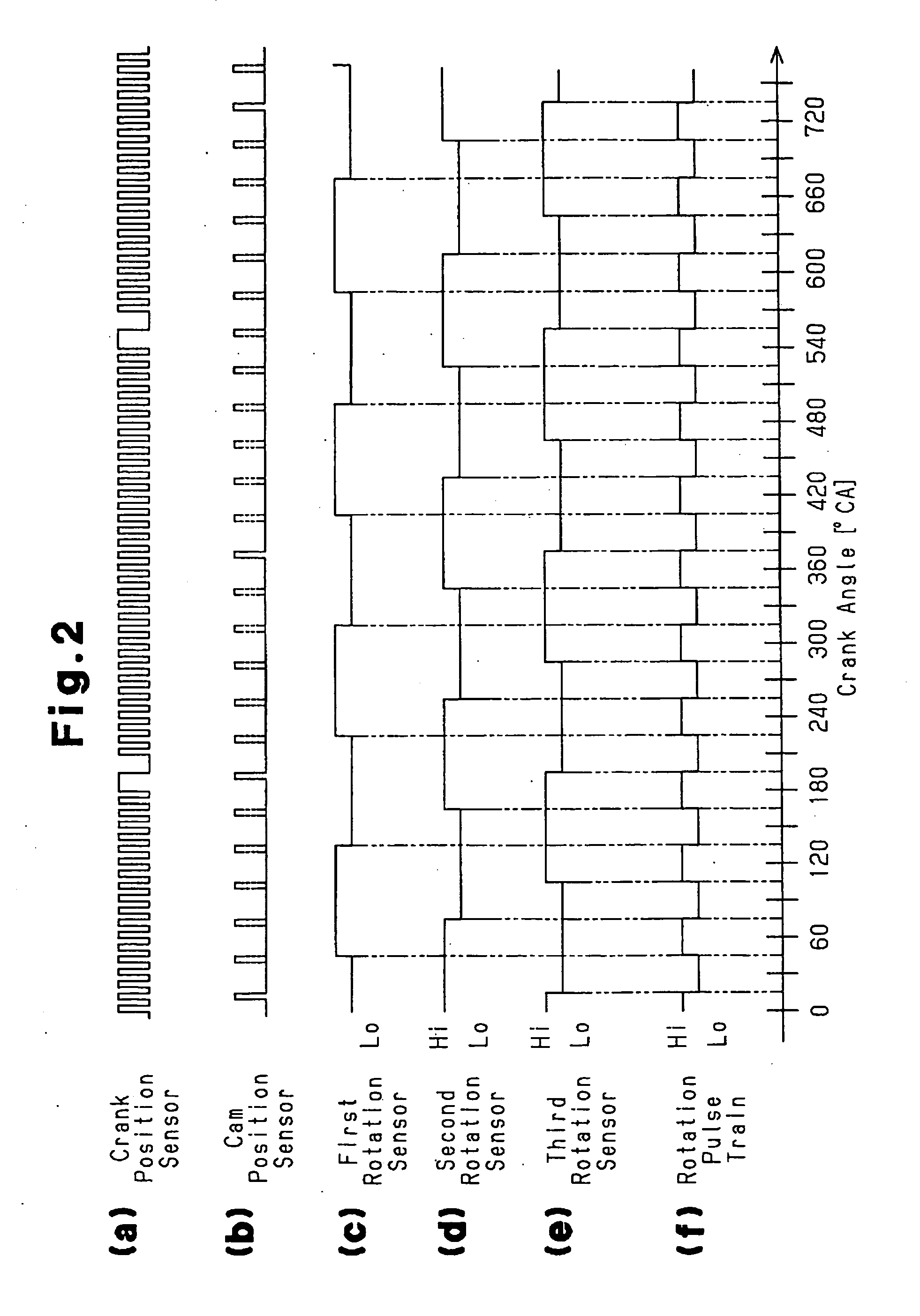

Control apparatus and method for internal combustion engine

InactiveUS20060178803A1Analogue computers for vehiclesValve arrangementsInternal combustion engineControl theory

A control apparatus for an internal combustion engine includes a crankshaft, a camshaft for actuating an intake valve of the engine, a crank position sensor that outputs a crank signal every time the crankshaft rotates 10° of crank angle, an electric motor that is coupled to the camshaft, and an engine control computer that, based on the crank signal, controls the engine every time the crankshaft rotates 30° of crank angle. The motor includes a rotor and three rotation sensors. Each sensor outputs a signal corresponding to induced voltage generated by rotation of the rotor. The computer controls the rotating motor based on the signals from the rotation sensors. When the crank position sensor malfunctions, the computer controls the engine every time the crankshaft rotates 30° of crank angle based not on the crank signal but on a rotation pulse train generated based on the signals from the rotation sensors.

Owner:TOYOTA JIDOSHA KK

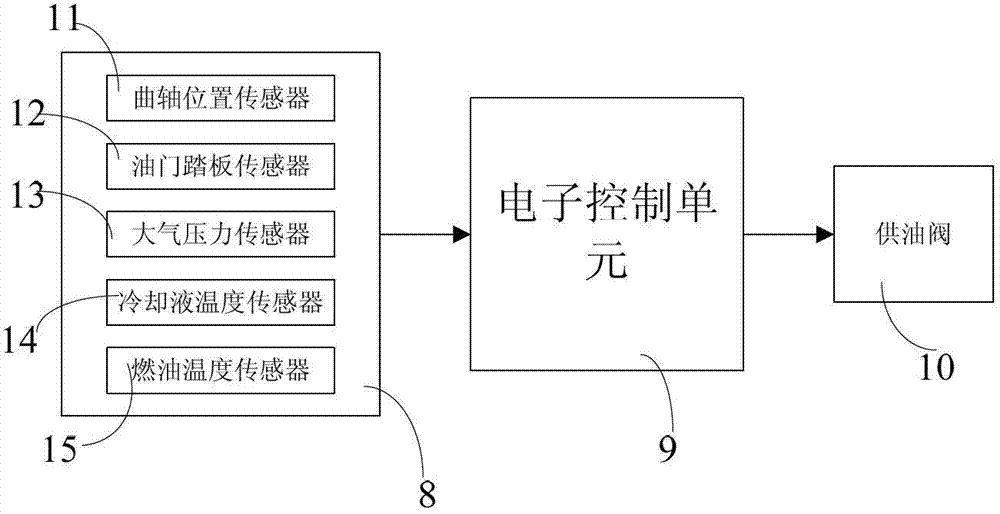

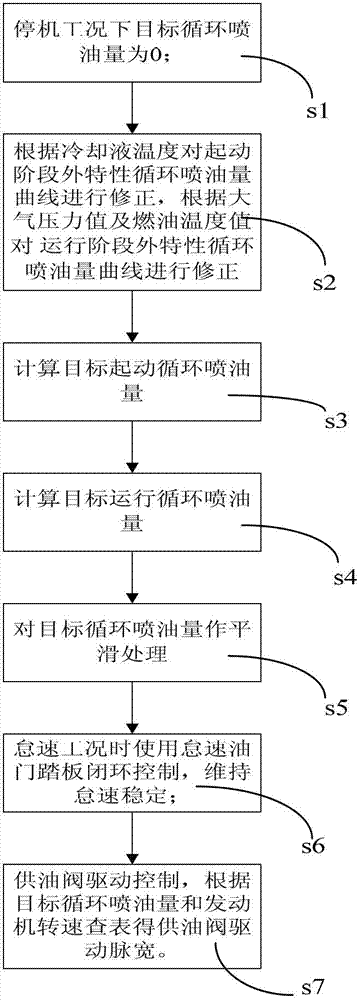

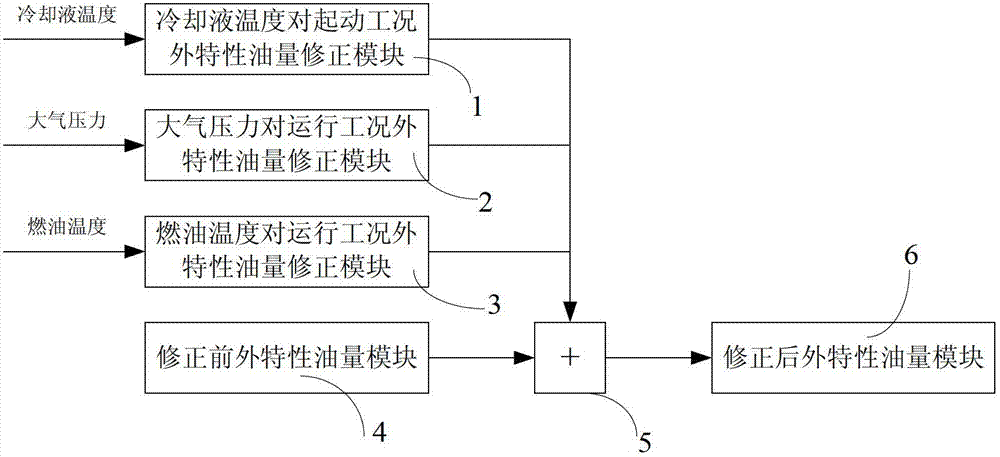

Oil quantity management control system and method for diesel engine electric control voltage accumulation distributed type common rail system

ActiveCN103161594ACompact structureOil volume control with high precisionElectrical controlMachines/enginesAtmospheric airFuel oil

The invention relates to an oil quantity management control system and a method for a diesel engine electric control voltage accumulation distributed type common rail system, and belongs to the technical field of diesel engine oil quantity control. According to the technical scheme, the oil quantity management control system for the diesel engine electric control voltage accumulation distributed type common rail system comprises an oil supply valve and an electronic control unit. The electronic control unit is used for driving and controlling working conditions of the oil supply valve. The electronic control unit is connected with a sensor module. The sensor module is used for detecting conditions of a diesel engine and environment conditions. The sensor module comprises a crankshaft position sensor, an accelerator pedal sensor, a barometric pressure sensor, a coolant temperature sensor and a fuel oil temperature sensor. External characteristic circulating oil-injection quantity curves are pre-stored inside the electronic control unit. The external characteristic circulating oil-injection quantity curves comprise a start-up phase external characteristic circulating oil-injection quantity curve and a run phase external characteristic circulating oil-injection quantity curve. The oil quantity management control system for the diesel engine electric control voltage accumulation distributed type common rail system is simple and compact in structure, high in accuracy of oil quantity control, good in applicability, safe and reliable.

Owner:WUXI WEIFU HIGH TECH CO LTD

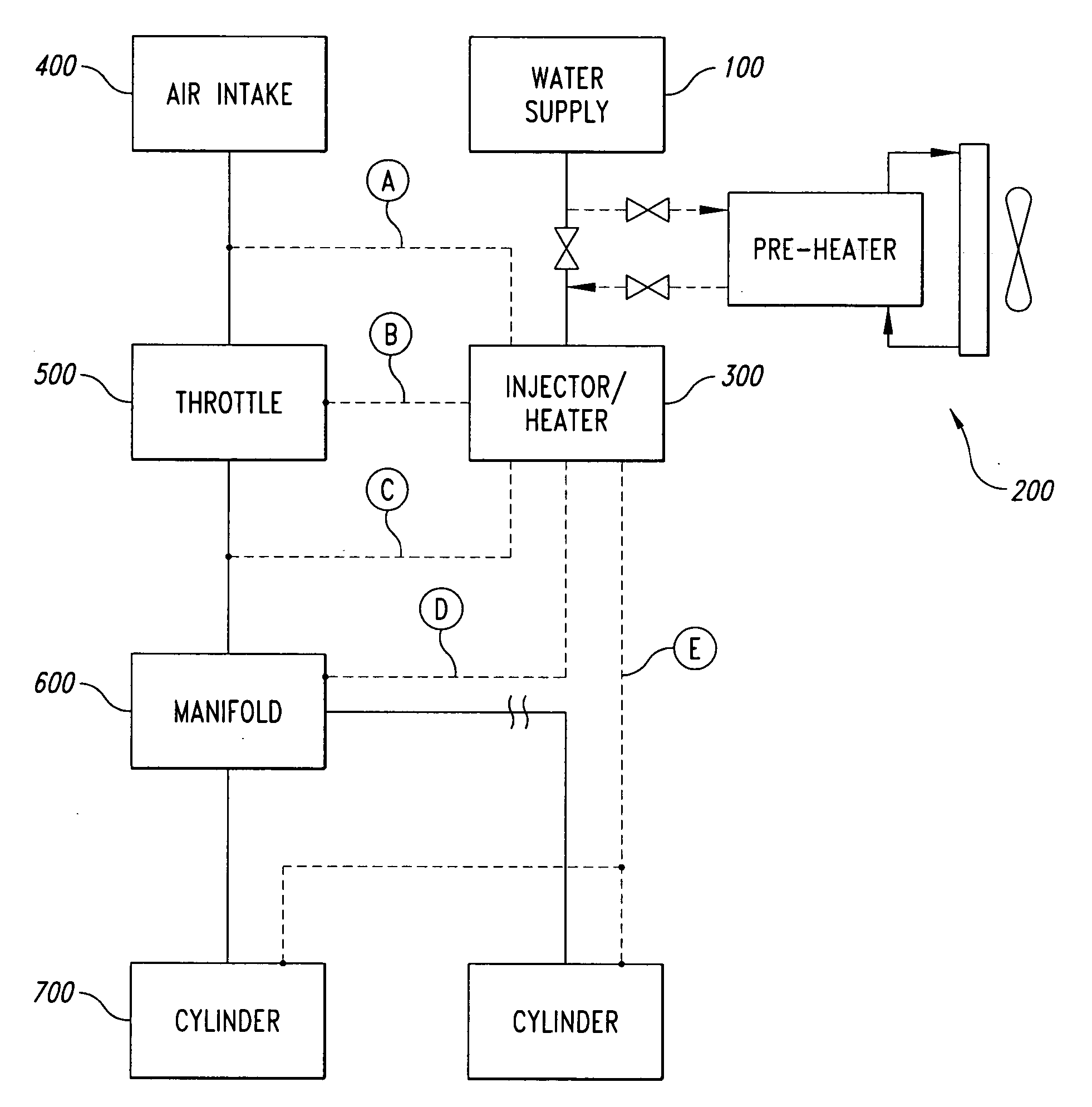

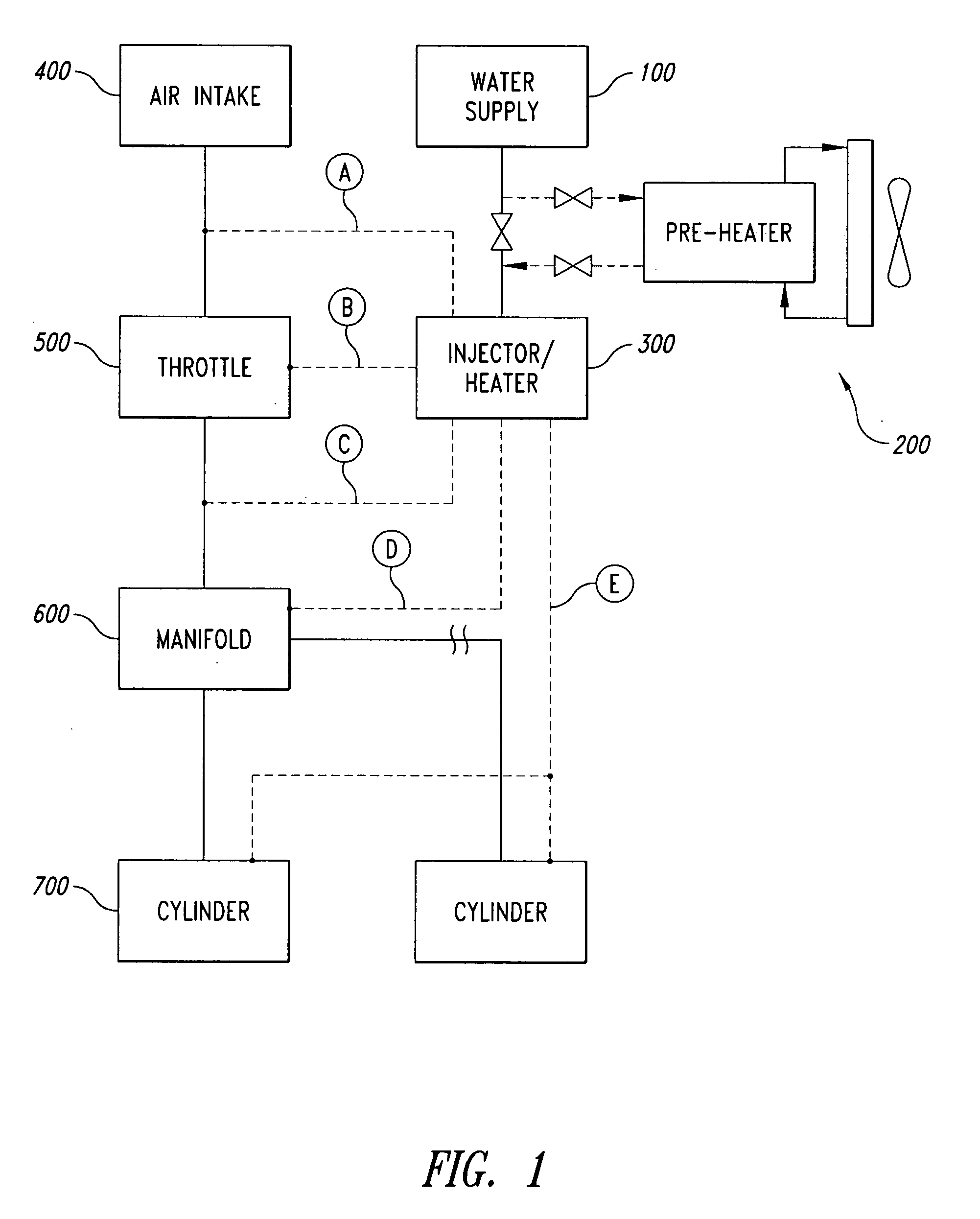

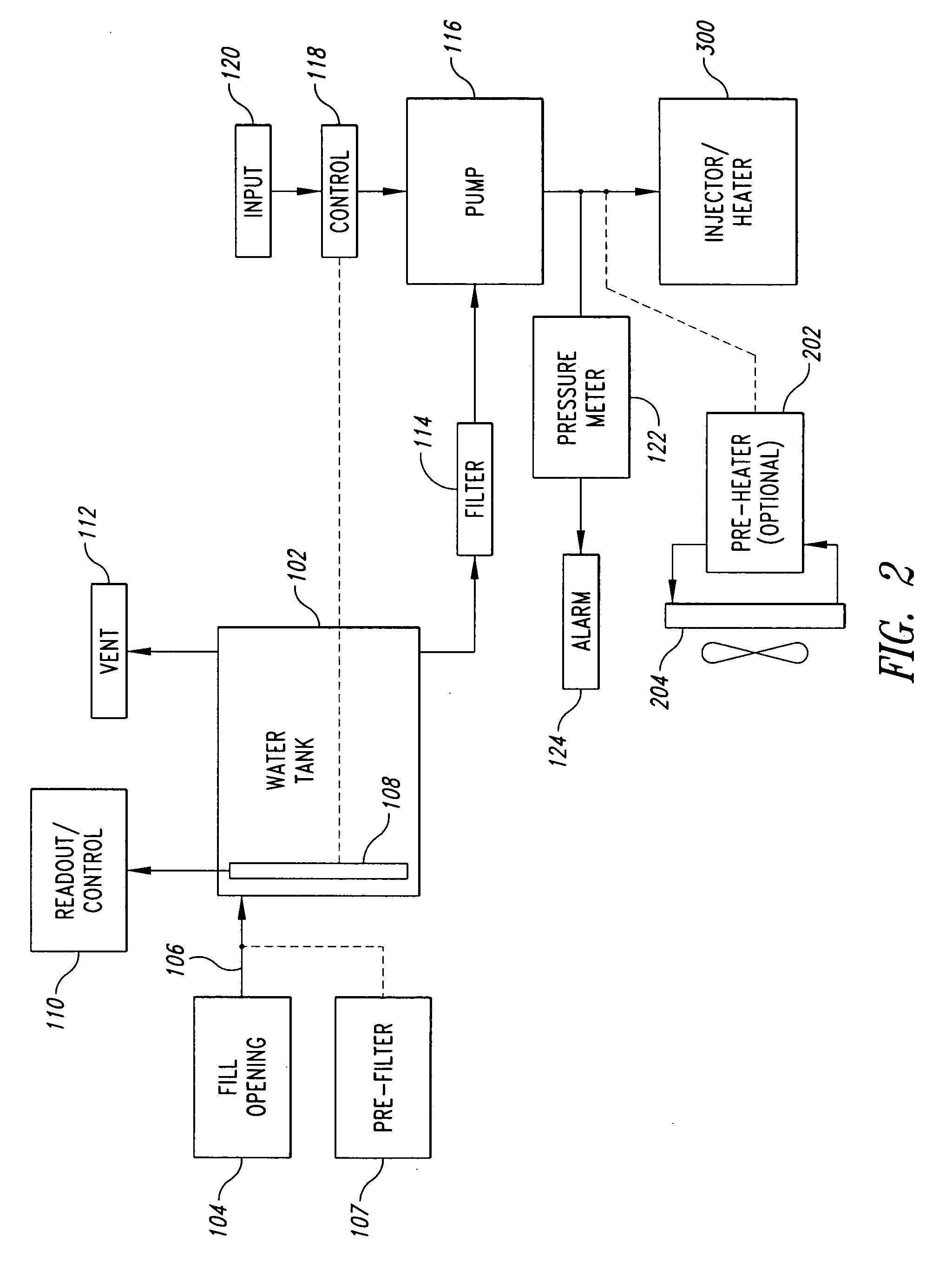

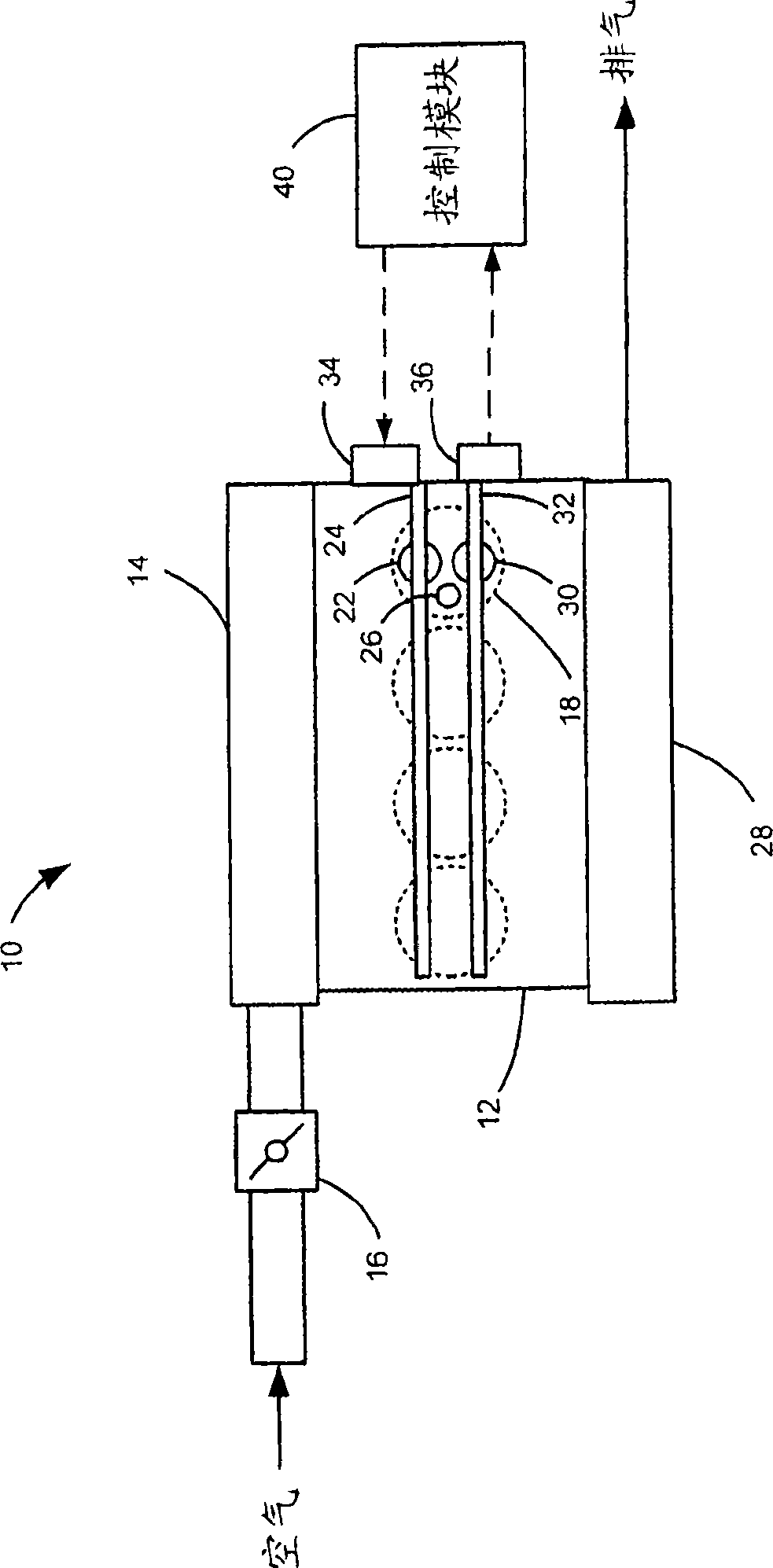

Devices, systems and methods for controlling introduction of additives into an internal combustion engine

InactiveUS20060249102A1Internal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineControl signal

A water injection control system includes a control unit adapted to receive one or more of a plurality of sensor signals from sensors provided as standard equipment in a vehicle, and to provide one or more control signals configured to control the operation of a water injection system associated with an engine of the vehicle. The received sensor signals may include signals from sensors such as an O2 sensor, an engine coolant temperature sensor, a mass air flow sensor, a manifold absolute pressure sensor, a crankshaft position sensor, a vehicle speed sensor, an intake air temperature sensor, and a throttle position sensor. The control signals provided by the controller may include signals for controlling functions such as water injector pulse rate and pulse width, water pump operation, water heater power, dashboard indicators, and PCU O2 sensor input.

Owner:S I S POWER

System And Method For Power Pump Performance Monitoring And Analysis

ActiveUS20080196512A1Accurate methodFluid parameterFluid pressure measurement using pistonsEngineeringCrankshaft position sensor

A power pump performance analysis system and methods includes a signal processor connected to certain sensors for sensing pressures and stresses in the cylinder chambers and the inlet and discharge piping of a single or multicylinder pump. Pump speed and pump piston position may be determined by a crankshaft position sensor. Performance analyses for pump work performed, pump cylinder chamber stress, pump fluid end useful cycles to failure, and crosshead loading and shock analysis are provided for estimating pump component life and determining times for component replacement before failure.

Owner:MHWIRTH

System and method for power pump performance monitoring and analysis

ActiveUS7581449B2Accurate methodFluid parameterFluid pressure measurement using pistonsEngineeringCrankshaft position sensor

Owner:MHWIRTH

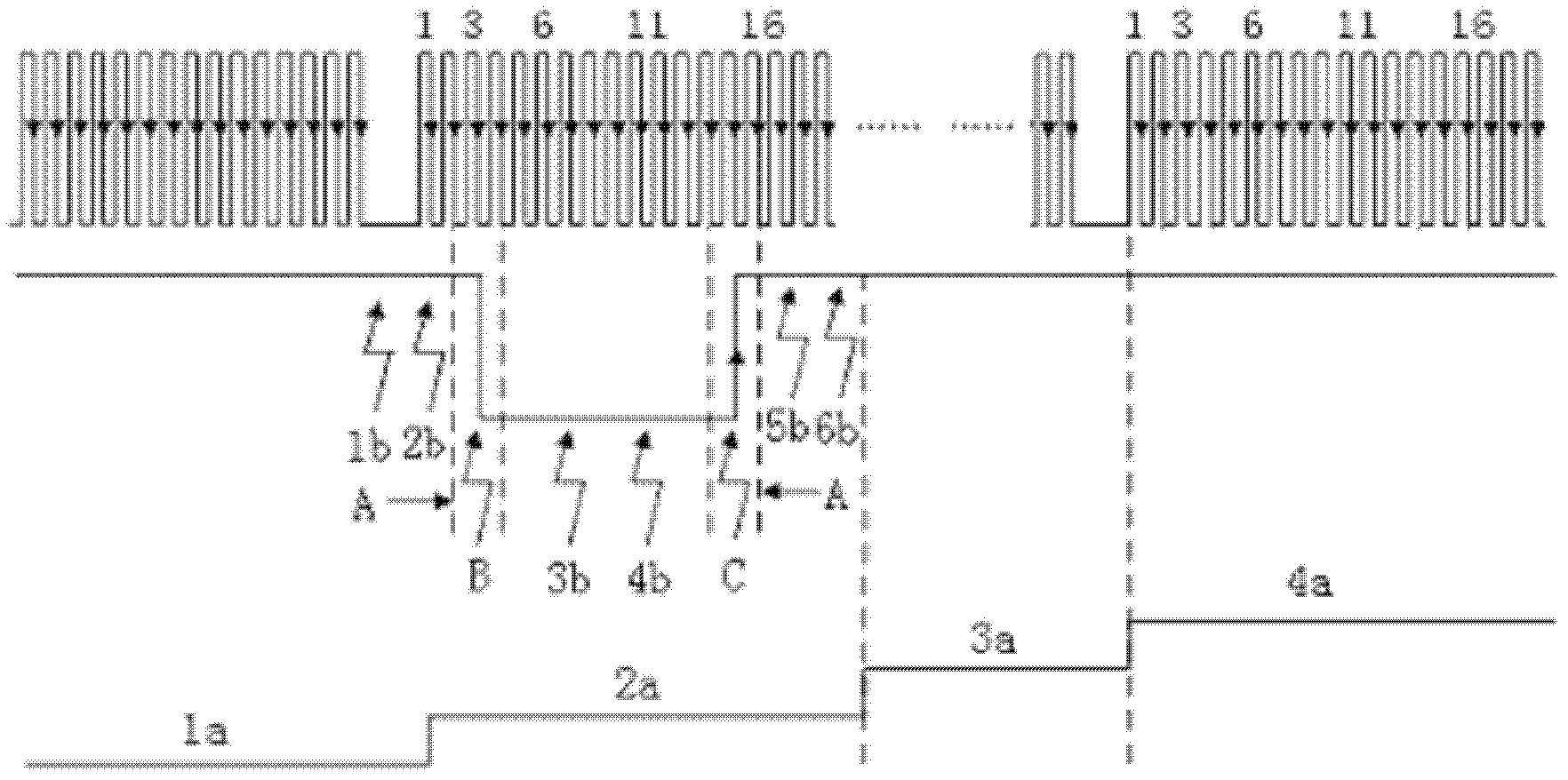

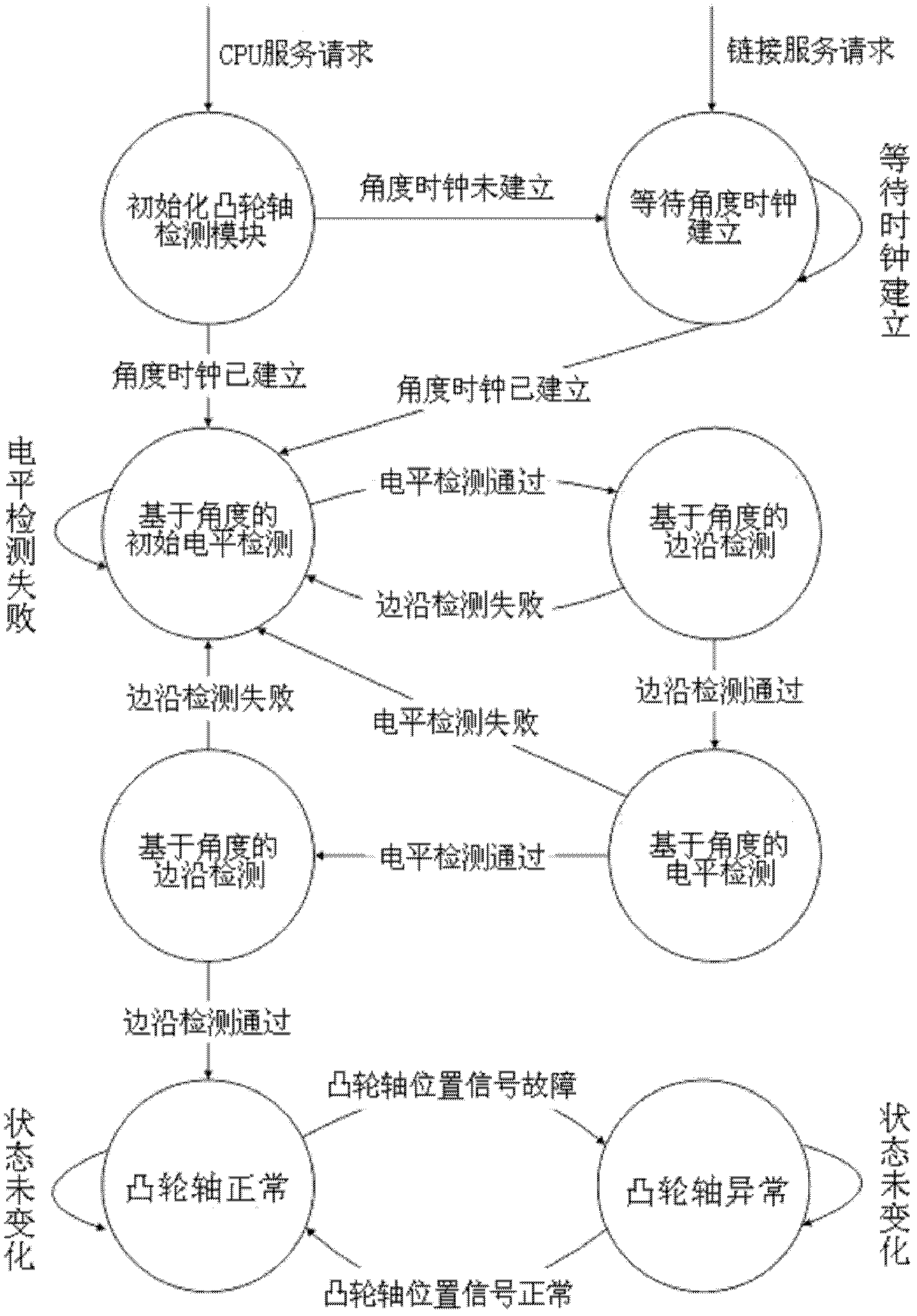

System and control method of engine position management

ActiveCN103133169AReduce utilizationImprove fault toleranceElectrical controlMachines/enginesFault toleranceComputer module

The invention discloses a system of engine position management. According to the system of the engine position management, an enhancement mode time processing unit (ETPU) is adopted to achieve rapid and synchronic fault-tolerance. According to a crank signal processing module, a jumping edge of a crank position signal detected by an input crank position sensor is collected for several times. According to a cram shaft signal processing module, electrical level and a jumping edge of a cram shaft position signal detected by an input cram shaft position sensor are collected for several times in a mixing mode. According to a synchronous logical processing module, a crank state quantity signal output by the crank signal processing module and a cram shaft state quantity signal output by the cram shaft signal processing module are processed and analyzed and a synchronous state quantity signal is output so that an engine state can be changed in real time and synchronism of a crank and a cram shaft is finally achieved. The invention further discloses a control method for the engine position management. The system and the method are capable of achieving the process of the synchronism of an engine rapidly and steadily.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

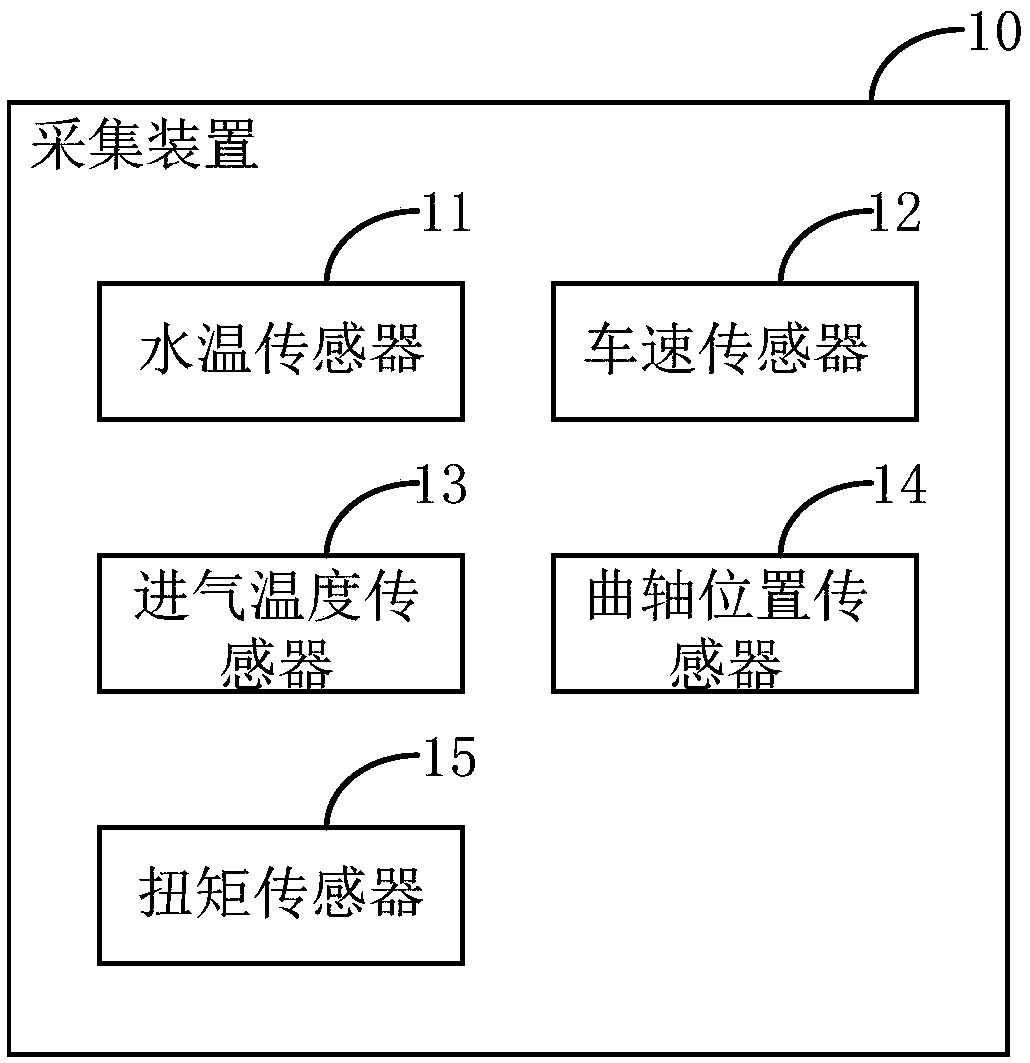

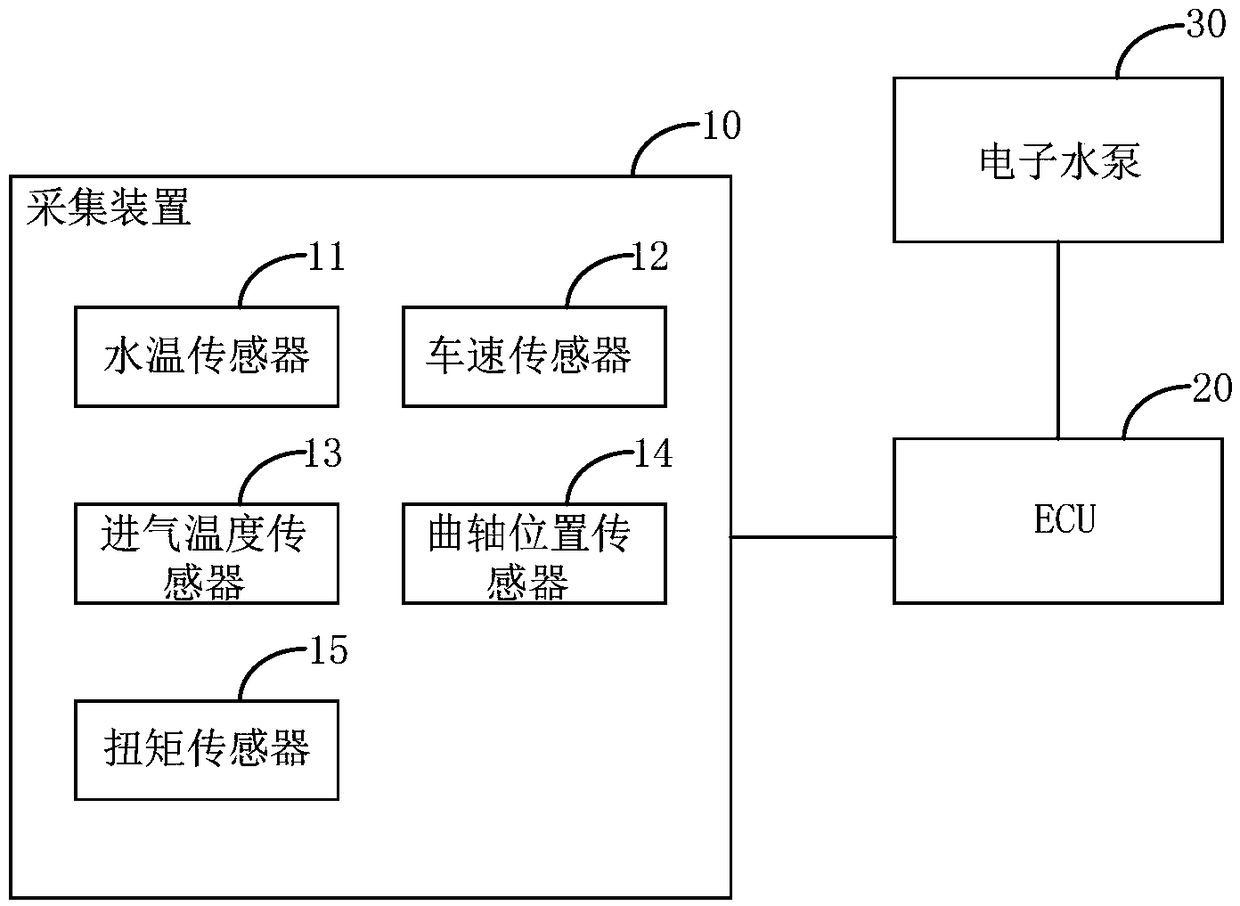

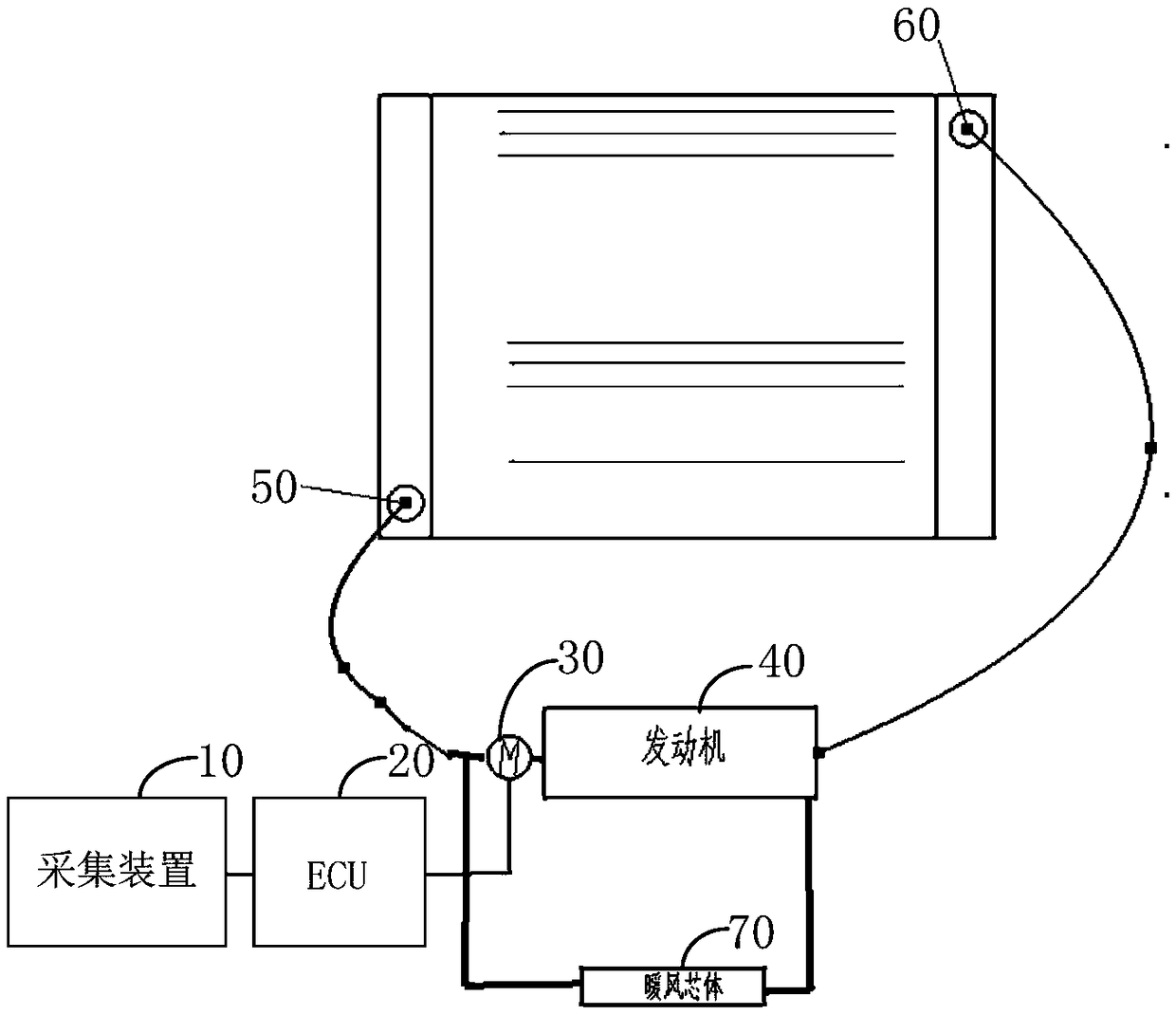

Variable-flow engine cooling system and method

The invention provides a variable-flow engine cooling system and a method. The system comprises a water temperature sensor, a vehicle speed sensor, an intake air temperature sensor, a crankshaft position sensor, a torque sensor and an ECU. The water temperature sensor is used to collect the water temperature of the engine. The vehicle speed sensor is used for collecting the vehicle speed of the engine; the intake air temperature sensor is used for collecting the intake air temperature of the engine; the crankshaft position sensor is used to collect the rotational speed of the engine; the torque sensor is used to collect the load of the engine; the ECU is used for obtaining duty cycle accord to water temperature, vehicle speed, intake air temperature, rotational speed and / or load, and controlling the flow rate of the electronic pump according to the duty cycle; an external electronic pump can be arranged; when the engine warm-up is started, the electric water pump is controlled not to run or to run at low speed; when the engine is in the medium speed load condition, the flow rate of the electronic pump is controlled; the flow rate of the cooling system is increased to speed up the rapid cooling of the engine.

Owner:北京长城华冠汽车技术开发有限公司

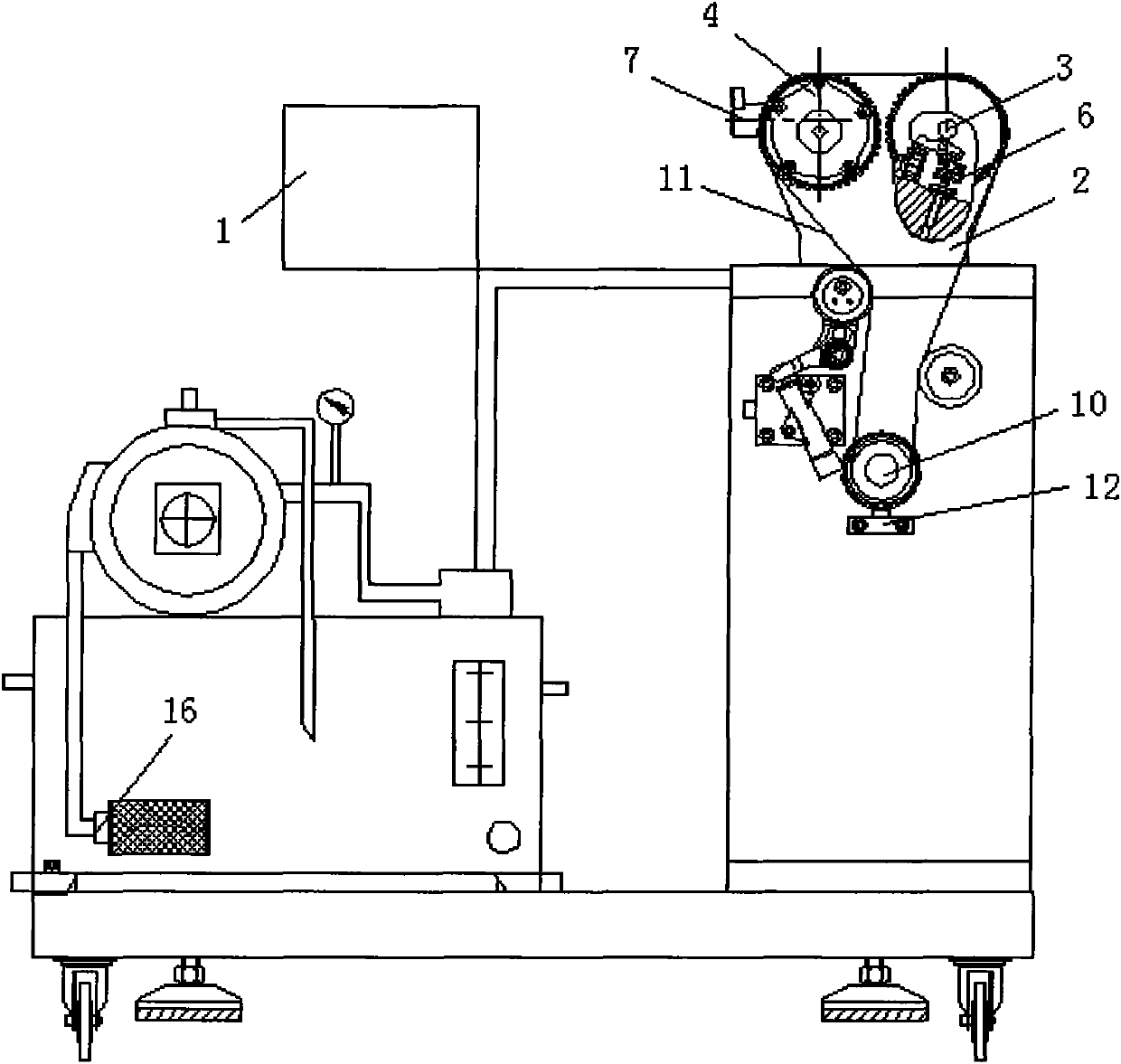

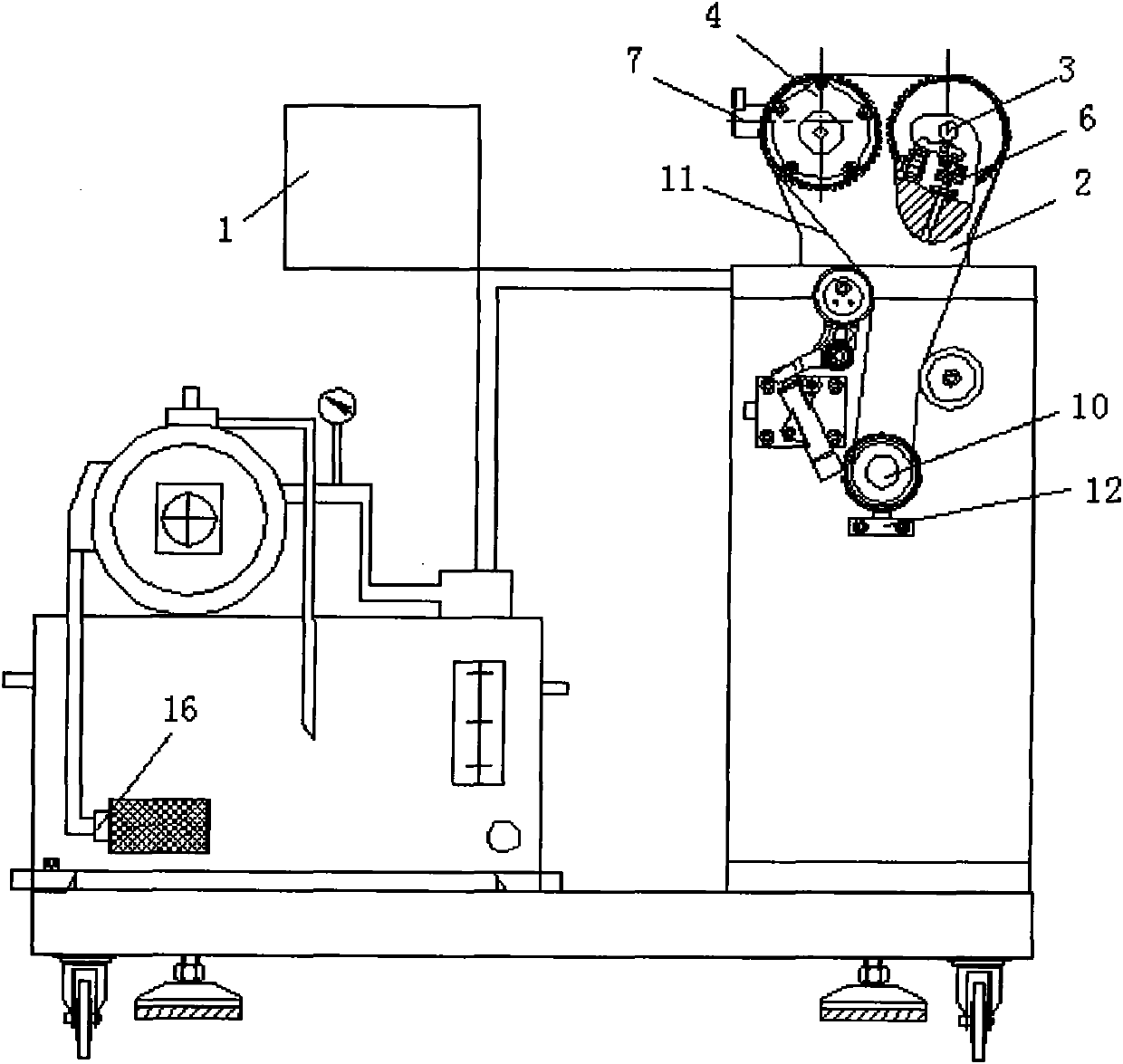

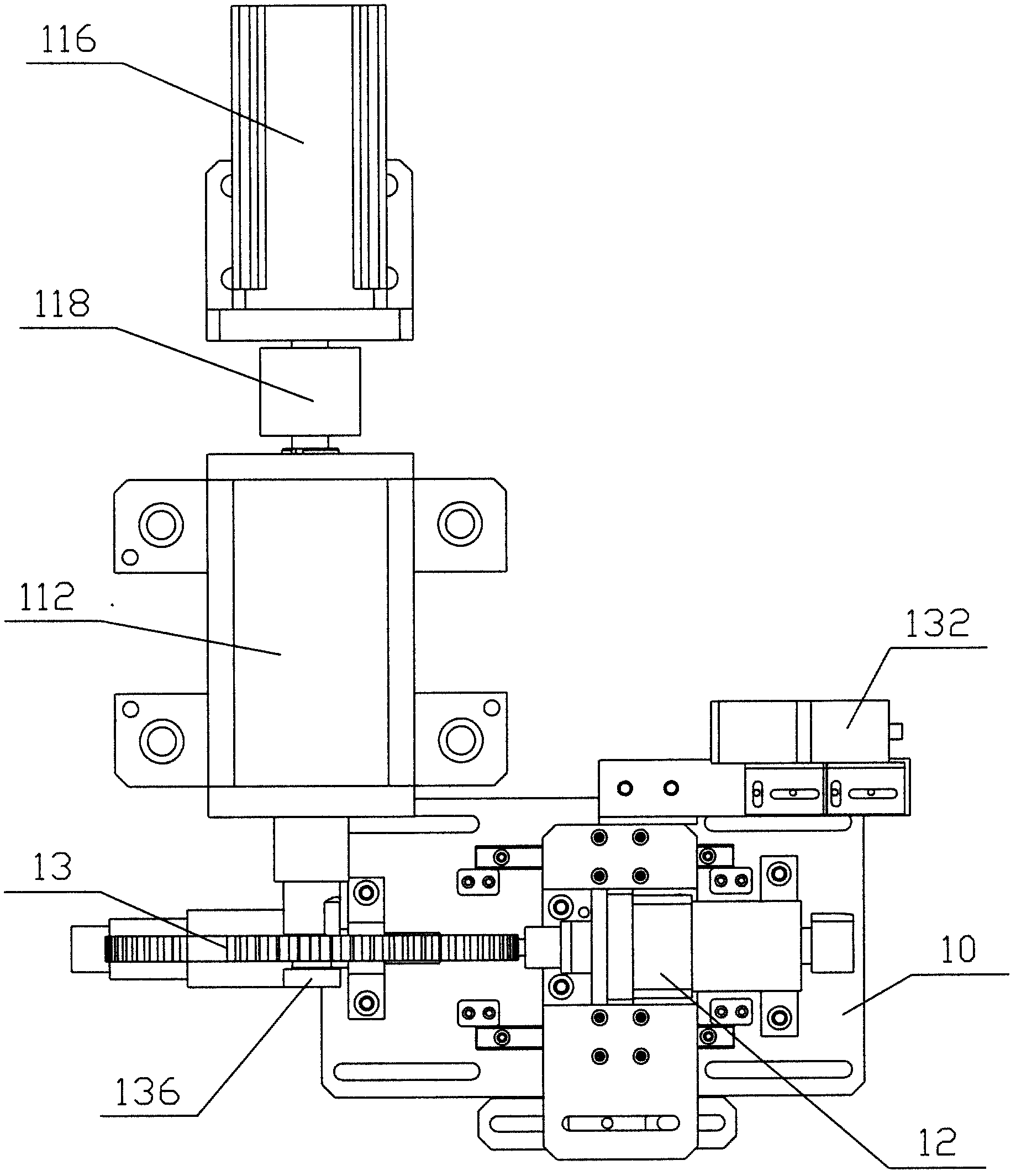

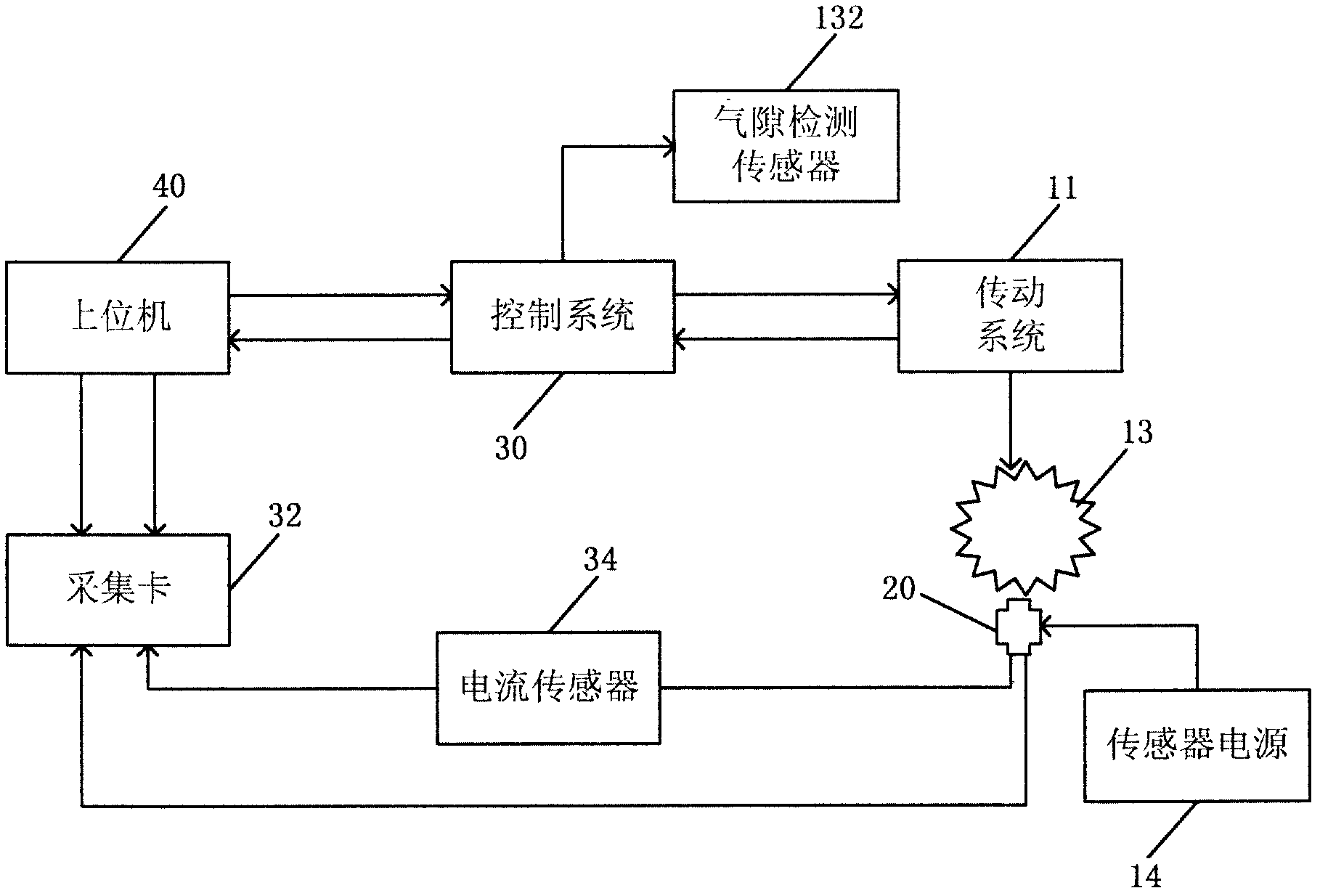

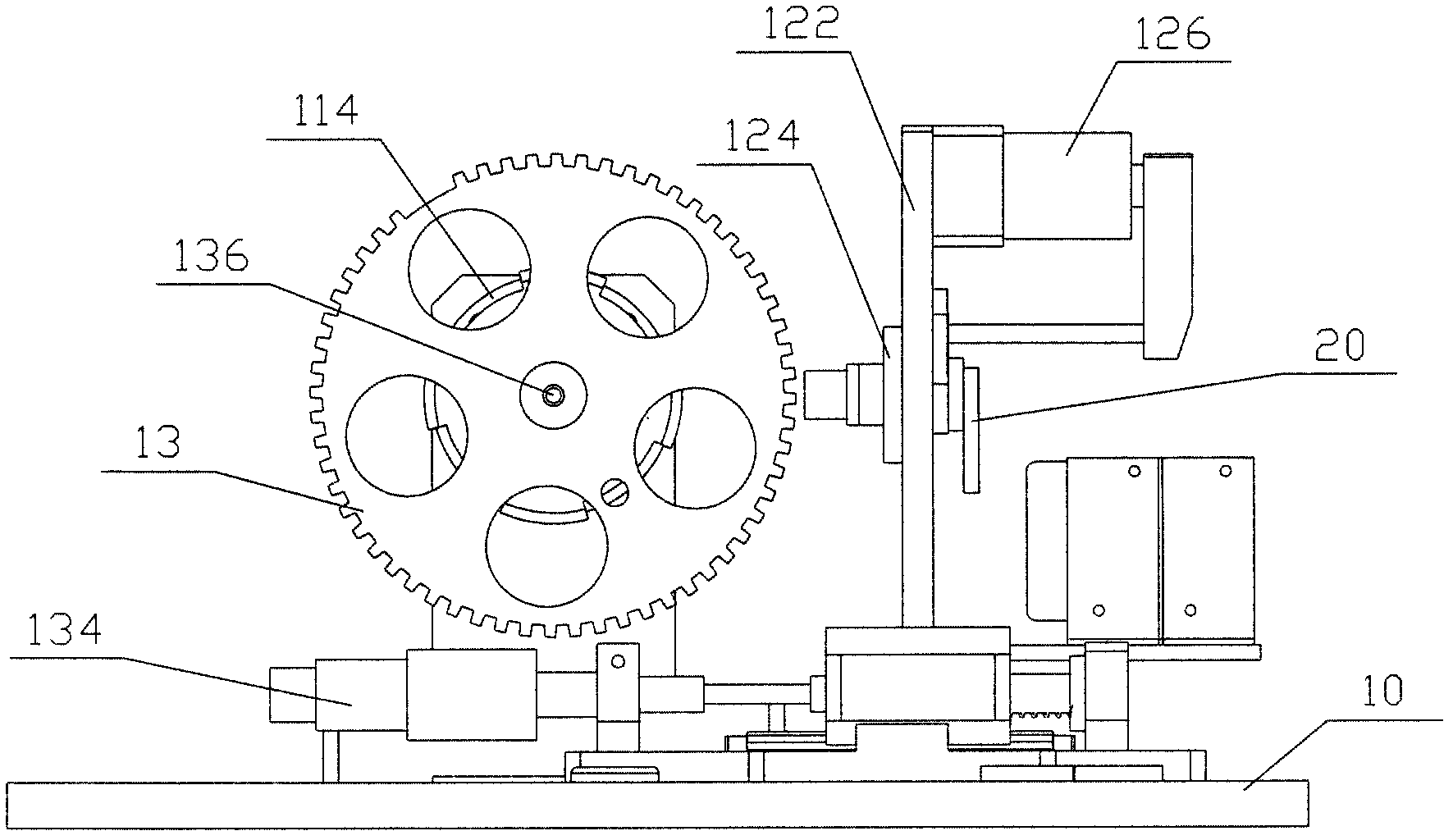

Automobile sensor detection equipment and method for detecting performance of sensor by utilizing same

The invention discloses automobile sensor detection equipment and a method for detecting the performances of sensors by utilizing the same. The automobile sensor detection equipment comprises a working table, a digital circuit transmission system, a workpiece clamping mechanism, a detection-air-gap regulating and detection mechanism, a signal system, a control system, a data acquisition system and a signal analysis system, wherein the digital circuit transmission system is arranged on the working table; the control system is arranged in the working table; a signal wheel and a sensor power supply are arranged in the signal system; and an acquisition card and a current sensor are arranged in the data acquisition system. According to the invention, the performances of a crankshaft position sensor, an ABS (Anti-lock Brake System) sensor, a camshaft position sensor, a vehicle speed sensor and the like can be subjected to comprehensive and automatic detection; the performances of the sensors can be comprehensively and automatically detected; the automobile sensor detection equipment not only has high precision, high stability and high efficiency and is easy to operate, but also is not influenced by the subjectivity of an operator; and the requirement on the optimal control of the performances of the sensors in the development and manufacturing of the sensors can be met.

Owner:重庆坤恩机电技术有限公司

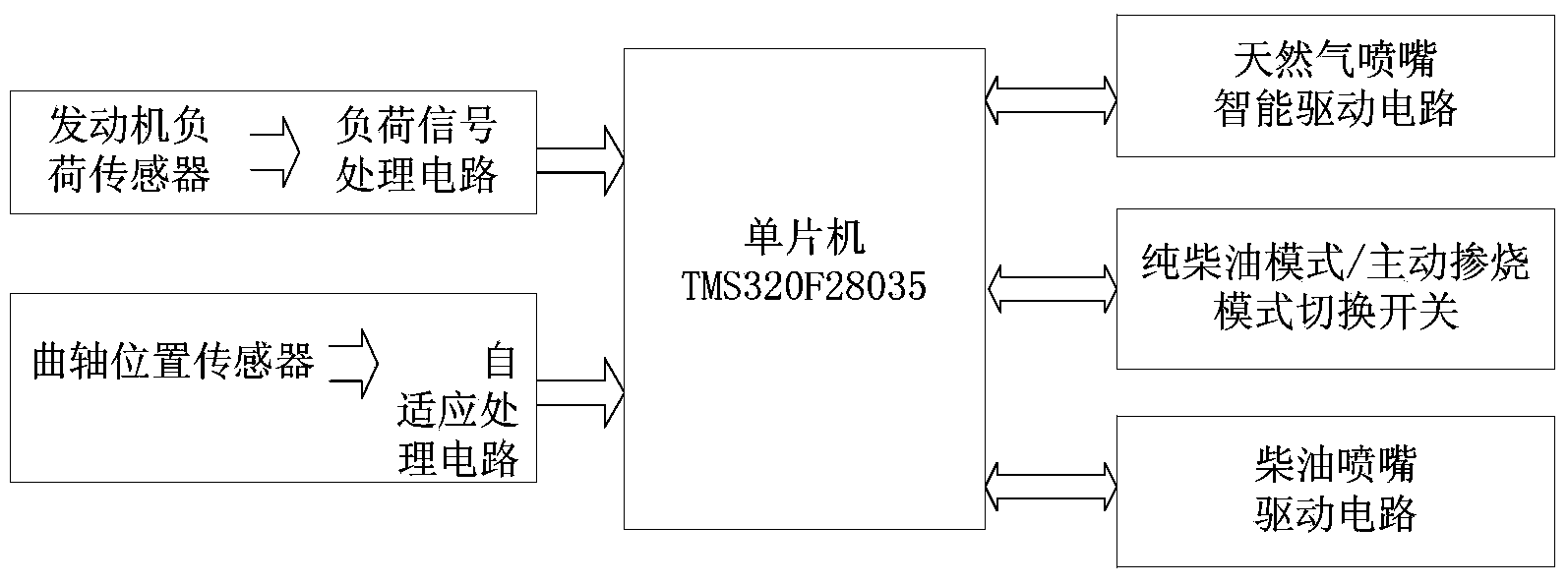

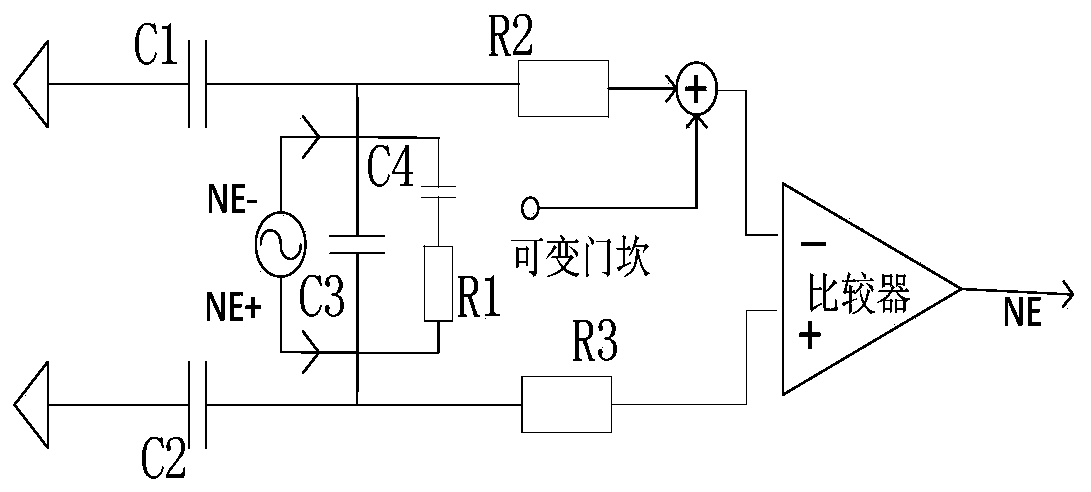

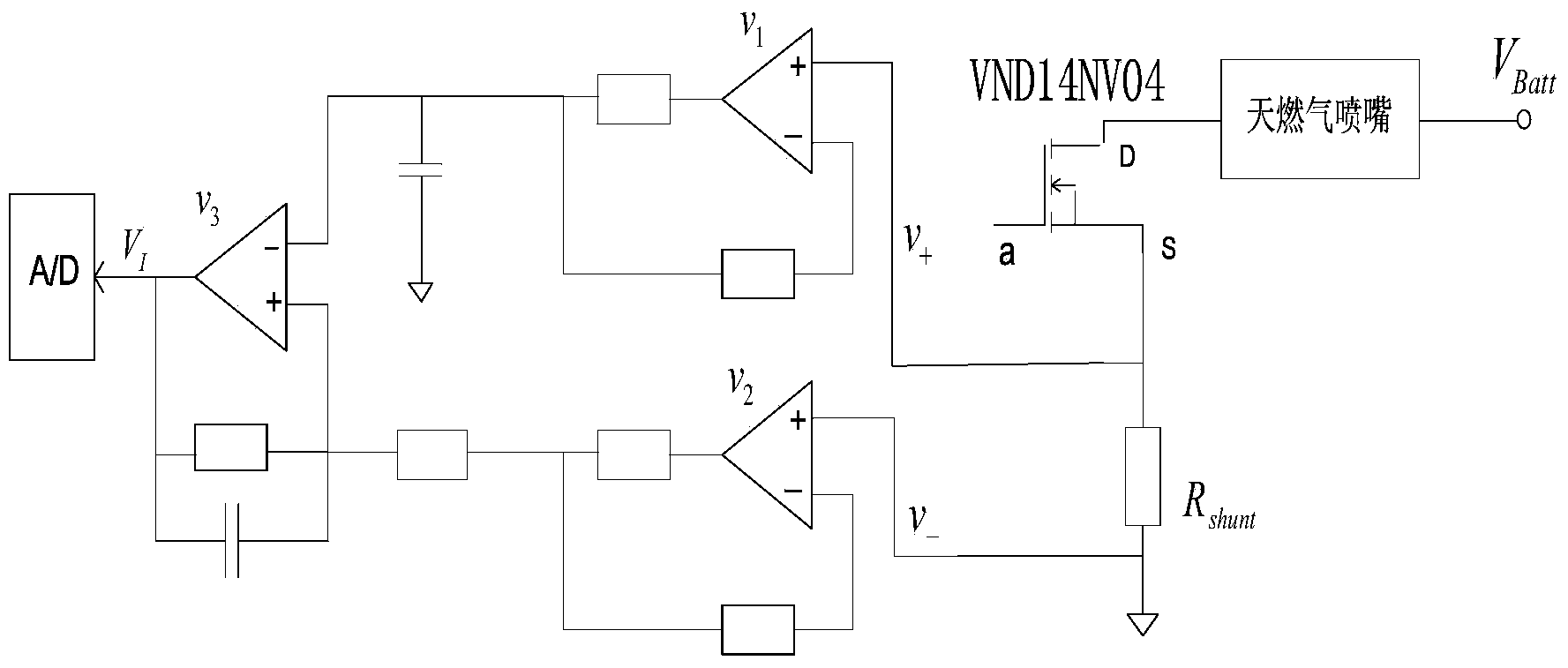

Diesel/natural gas active blending combustion electronic control system and method

InactiveCN104005863AProtect mechanical partsAvoid knockingEngine controllersMachines/enginesMicrocontrollerDetonation

The invention discloses a diesel / natural gas active blending combustion electronic control system and method. The electronic control system comprises a single-chip microprocessor, a natural gas nozzle intelligent drive circuit, a diesel nozzle drive circuit, a pure diesel mode / active blending combustion mode diverter switch, a load signal processing circuit and a self-adapting processing circuit, wherein the natural gas nozzle intelligent drive circuit, the diesel nozzle drive circuit, the pure diesel mode / active blending combustion mode diverter switch, the load signal processing circuit and the self-adapting processing circuit are respectively connected with the single-chip microprocessor. The load signal processing circuit receives a detection signal of an engine load sensor. The self-adapting processing circuit receives a detection signal of a crankshaft position sensor. The crankshaft position sensor measures the rotating position and the rotating speed of an engine crankshaft. The electronic control system is connected with an original diesel engine electronic control system in parallel and does not depend on the original diesel engine electronic control system, and therefore the optimal control over fuel-injection quantity, gas-injection quantity and fuel injection timing for blending combustion is achieved; besides, the detonation phenomenon which may occur in the passive blending combustion process of dual fuel is avoided fundamentally, and the reliability of long-term work of a dual-fuel engine is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

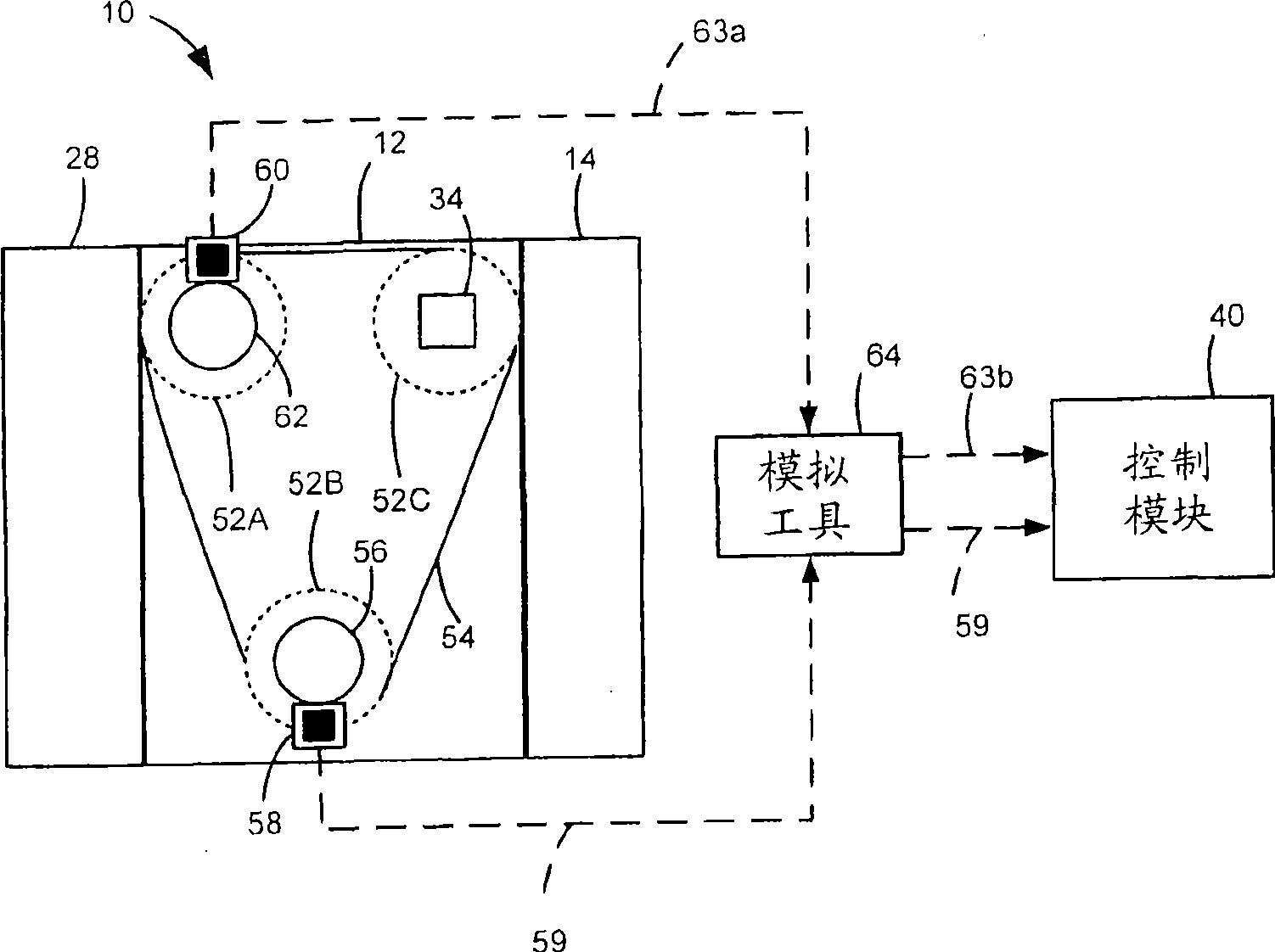

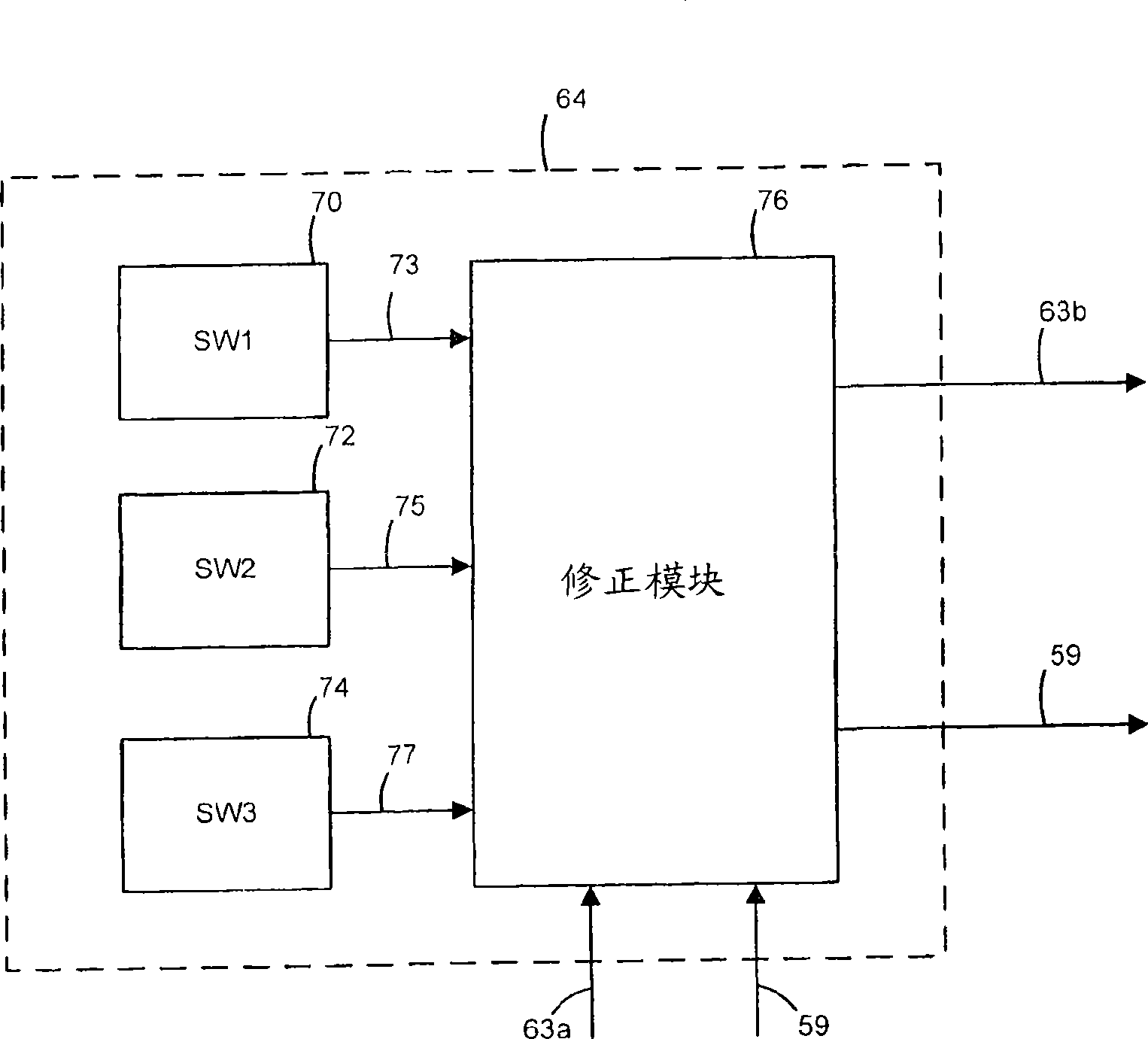

Camshaft and crankshaft position correlation simulation methods and systems

The invention relates to a camshaft and crankshaft position relevance analogy method and a system, which is aimed at providing a system designed for simulating an internal combustion engine when incorrect valve timing exists. The analogy system is aimed at calibrating and / or verifying a special camshaft-crankshaft relevance diagnosis algorithm. The analogy system comprises an analogy module which is communicated with a crankshaft position sensor, a camshaft position sensor and a motor control module; wherein the analogy module comprises a first selector selected for processing the lapse value of a periodic signal, and a correction module for receiving the camshaft position signal from the camshaft position sensor and generating corrected camshaft position signal based on the crankshaft position signal and the lapse value.

Owner:GM GLOBAL TECH OPERATIONS LLC

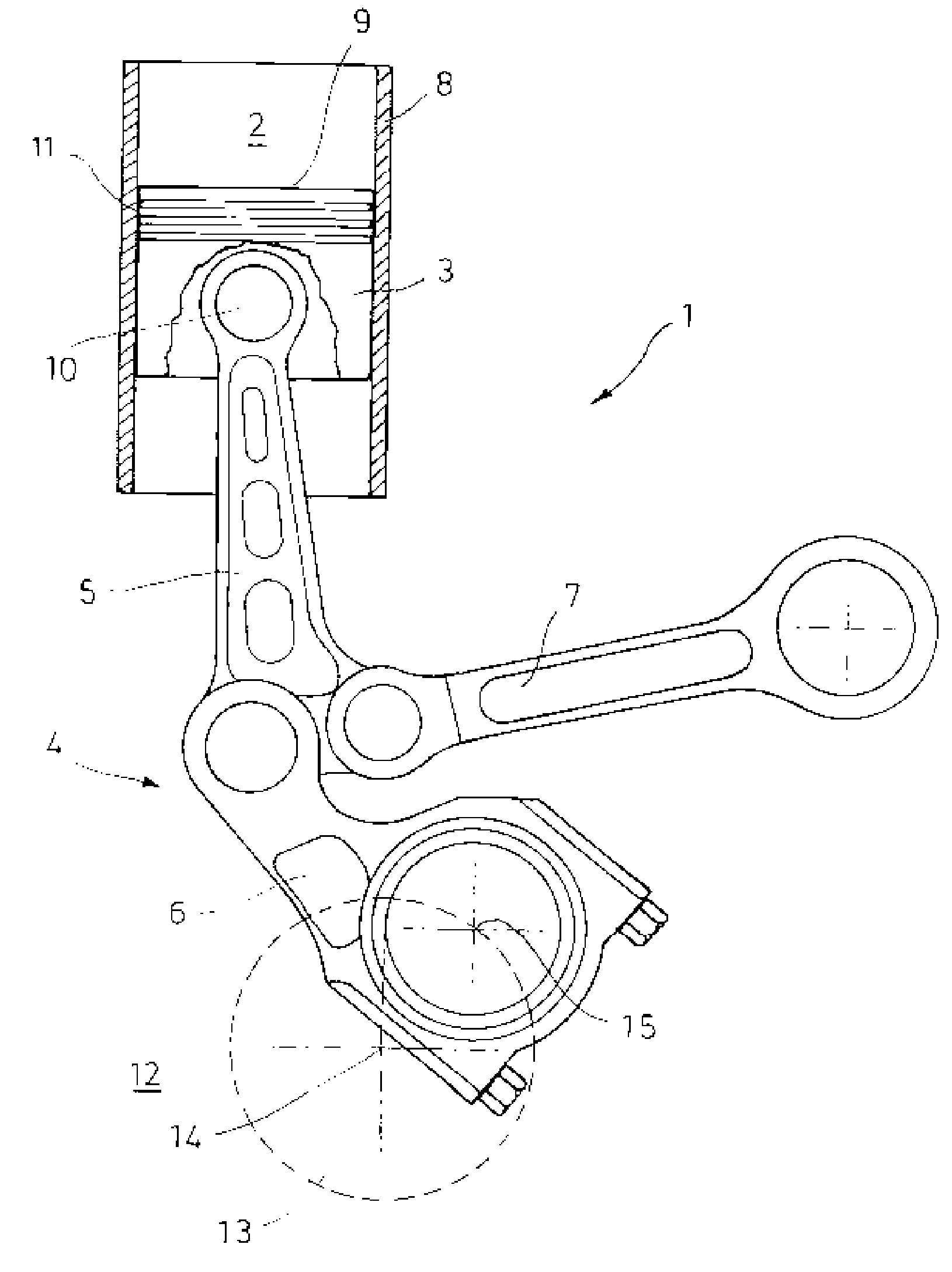

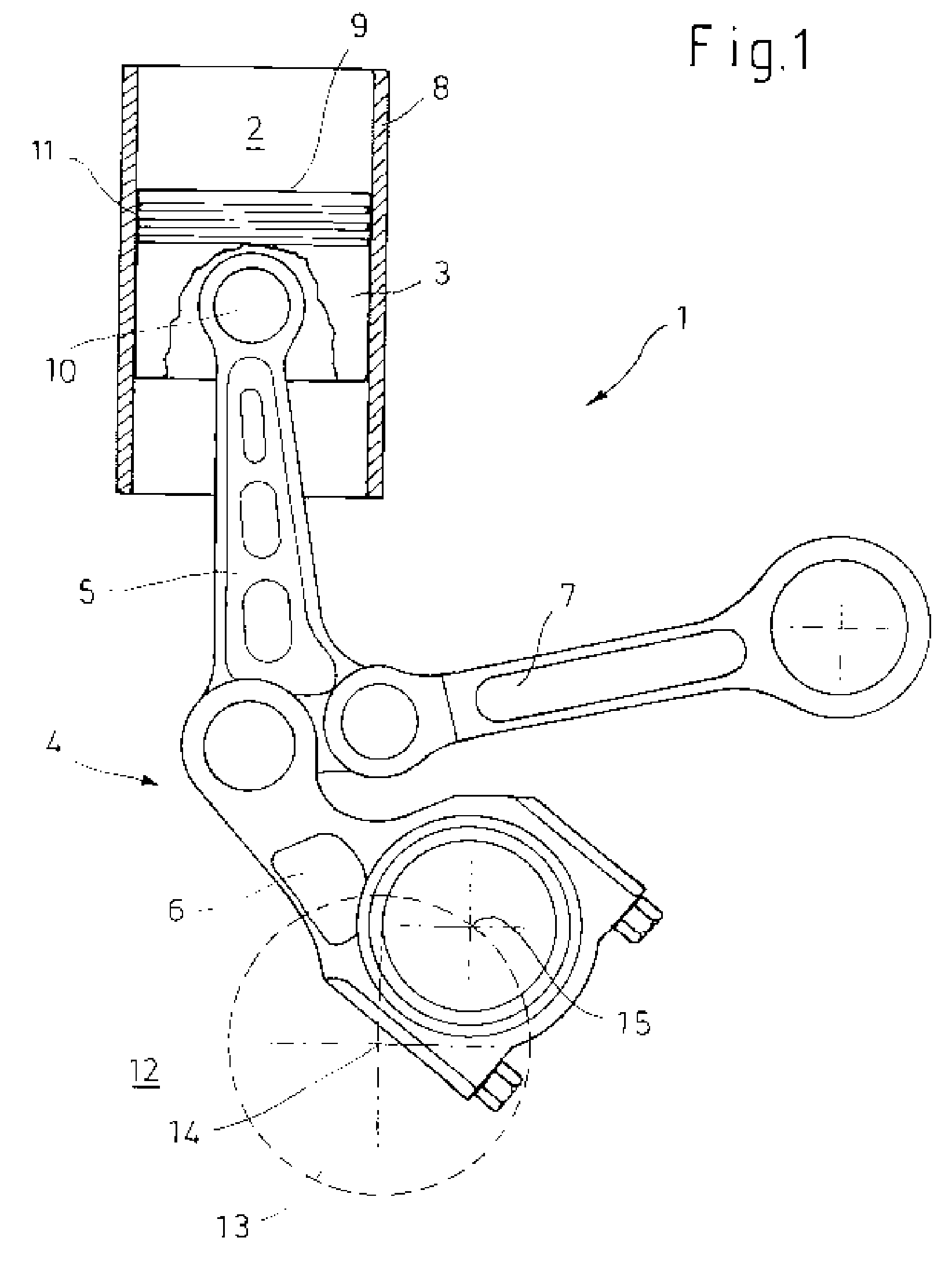

System and method for controling crankshaft position during engine shutdown using cylinder pressure

ActiveUS7191756B2Reduce energy consumptionSpeed sensing governorsMachines/enginesExhaust valveControl valves

Owner:FORD GLOBAL TECH LLC

Hydrogen generator set

InactiveCN104989519ANo damageNo pollution in the processElectrical controlInternal combustion piston enginesAir filterVolumetric Mass Density

The invention discloses a hydrogen generator set. The hydrogen generator set comprises a generator body which comprises an energy supply system, an energy transduction system and a control unit. The energy supply system comprises a hydrogen supply unit and a fuel gas injection valve connected with the hydrogen supply unit. The energy transduction system comprises an air filter and a plurality of sensors connected with the air filter. The control unit is composed of an electronic control unit (ECU). The sensors comprise the intake air temperature and pressure sensor, the water temperature sensor, the crankshaft position sensor, the oxygen sensor and the phase sensor. Hydrogen is effectively used as energy, the product of combustion is water and no pollution is caused; the quantity of heat of combustion is high and more heat is released; hydrogen has extensive sources and is renewable; the defects that hydrogen is low in density and high in flow speed are overcome, the hydrogen generator set effectively protects an engine against backfire, damage to components is avoided, and energy conservation and environmental protection are effectively achieved.

Owner:DONGGUAN SHENGDONG NEW ENERGY TECH CO LTD

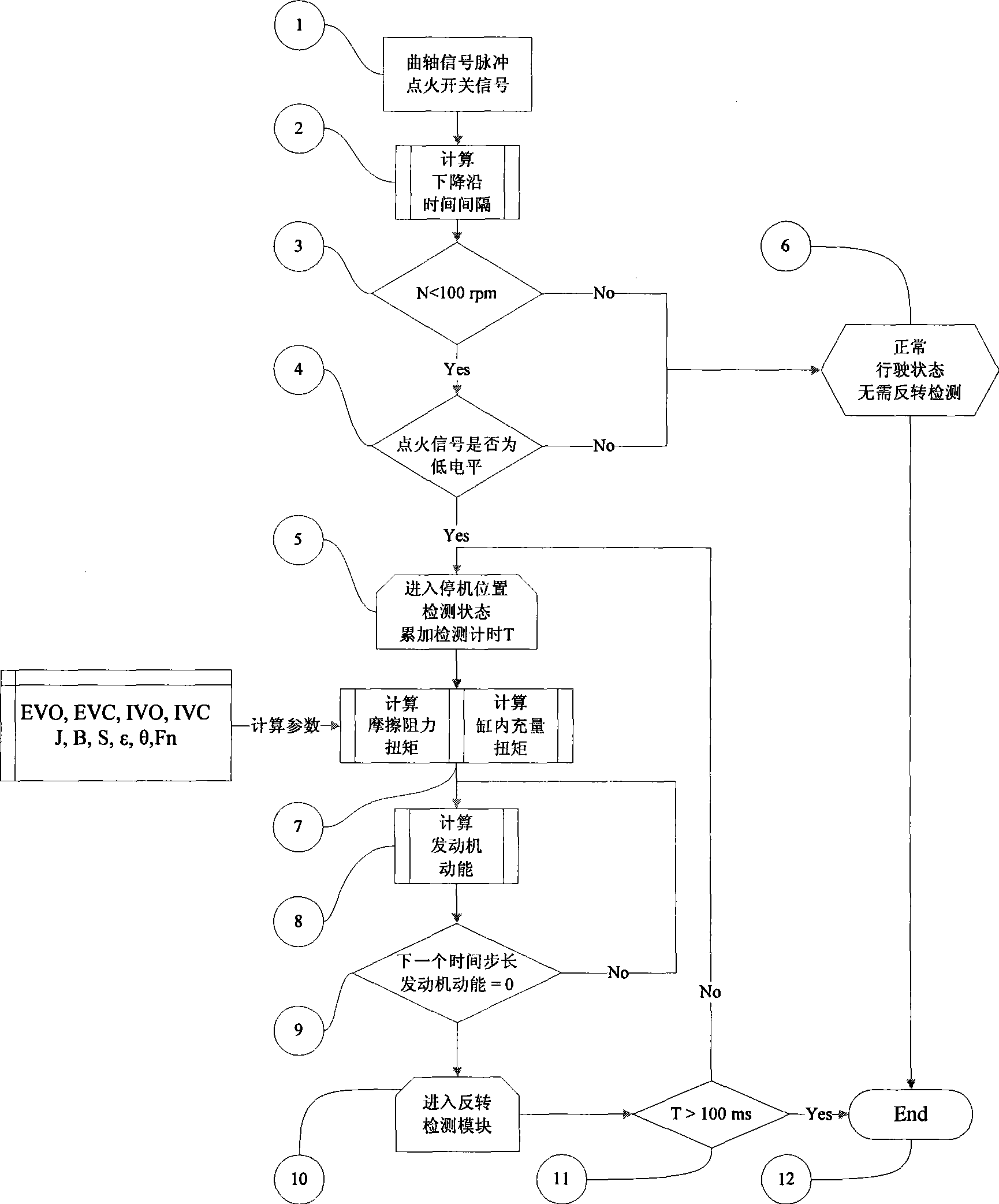

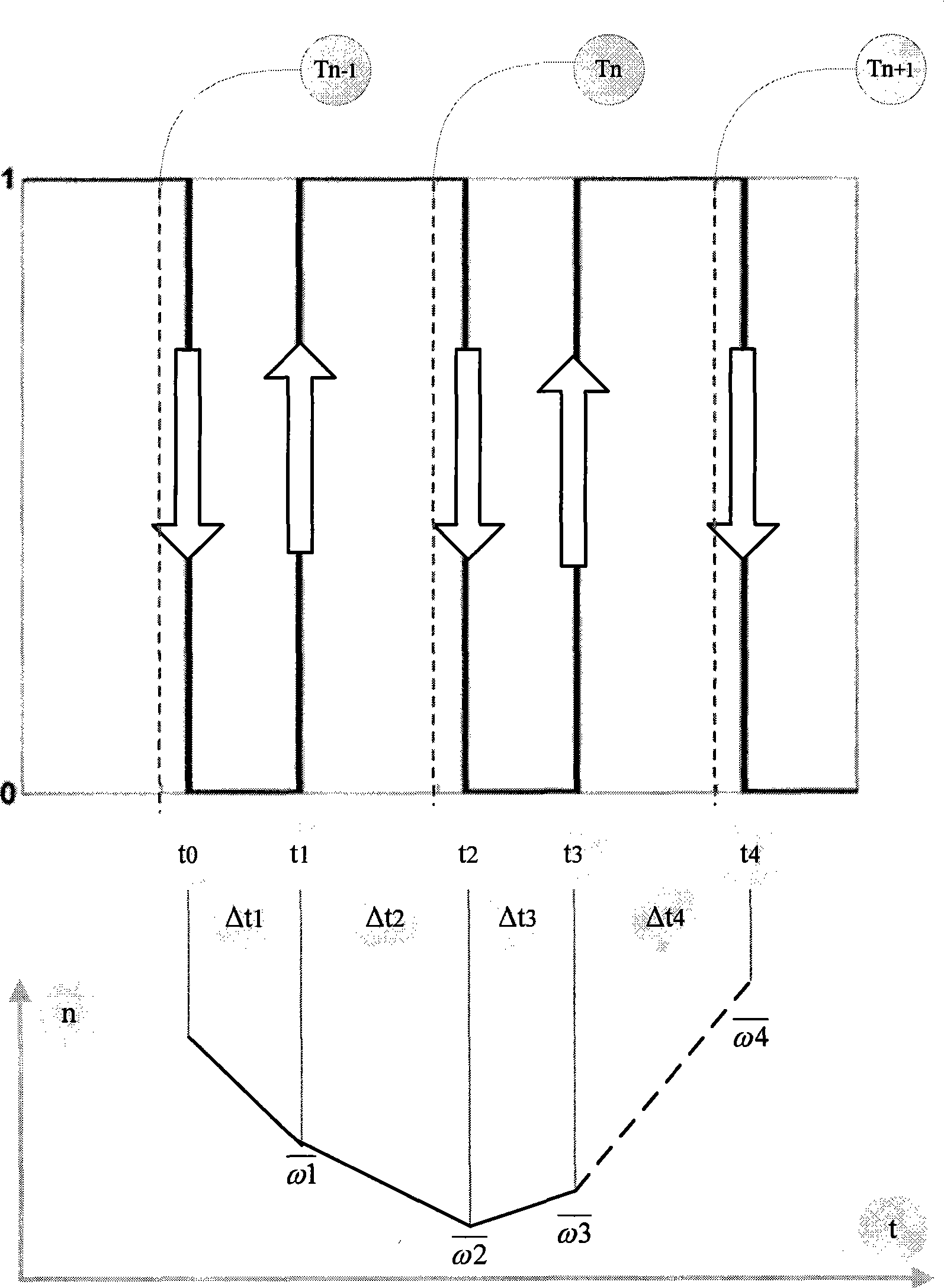

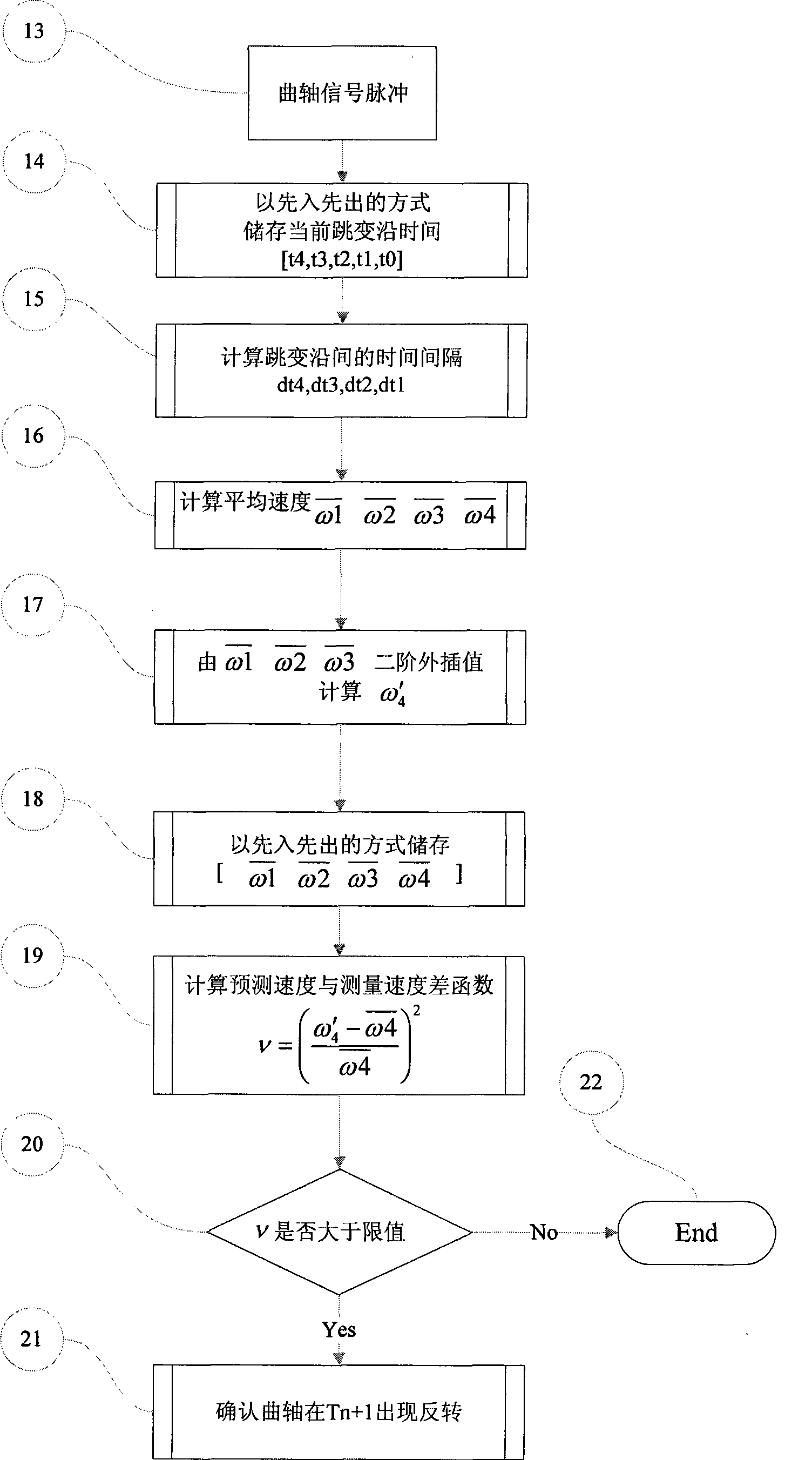

Method for determining engine crankshaft position

ActiveCN101457700ADetermine where to stopAccurately determine the reversal positionElectrical controlMachines/enginesFriction torqueControl theory

The invention relates to a method for detecting the position of an engine crankshaft. Under the condition of using an original non-directional crank position judgment sensor, on the basis that the concepts of engine friction torque and inner cylinder charging torque are introduced, and the variation tendency of the engine dynamic power is calculated; on the moment that all dynamic power are zero, the crankshaft inverse rotation position can be probably generated, and by checking the pulse interval of rotational speed signals before and after the probable inverse rotation point, whether the inverse rotation is generated or not and the concrete time of the inverse rotation are finally determined. The method can judge the switching number of the rotation direction of the crankshaft in the shutdown process to the utmost extent and can determine rotated angles in different rotation directions, so that the stop position of the engine crank is finally determined accurately.

Owner:CHERY AUTOMOBILE CO LTD

Hydrogen/ammonia dual-fuel engine and control method

ActiveCN113586261AInternal combustion piston enginesEngine controllersControl systemHydrogen pressure

The invention discloses a hydrogen / ammonia dual-fuel engine and a control method. The invention relates to an ammonia-hydrogen engine and a control method thereof, in particular to an engine capable of adjusting the mixing ratio of hydrogen and ammonia according to the working condition of the engine and a control method, and aims at achieving high-efficiency and high-power output and controlling knocking. The engine mainly comprises a gas inlet system, a hydrogen supply system, an ammonia supply system and a control system. An ECU judges the position and the rotating speed of a crankshaft through a crankshaft position sensor and a rotating speed sensor, judges the occurrence of knocking according to a knocking sensor, and adjusts the injection time and the injection pulse width of a hydrogen pressure reducing valve and a hydrogen injector of the hydrogen supply system according to requirements; and meanwhile, the injection time and the injection pulse width of an ammonia pressure reducing valve and an ammonia injector of the ammonia supply system are adjusted, so that the ammonia-hydrogen mixing ratio is determined. The engine and the control method can eliminate the knocking phenomenon of the hydrogen engine and improve the working range of the hydrogen engine.

Owner:BEIJING UNIV OF TECH

Fault diagnosis method of engine crankshaft position sensor

A fault diagnosis method of an engine crankshaft position sensor is composed of a data acquisition system, a fuzzy processing system and a neural network system, and mainly diagnoses faults of Hall type and magnetic induction type crankshaft position sensors. According to the method, wave shape eigenvalues of fuzzified electronic signals of the crankshaft position sensor serve as input values of the neural network system, the fault diagnosis of the crankshaft position sensor is completed by a back propagation (BP) neural network in a multi-input and multi-output structure. The fault diagnosis method of the engine crankshaft position sensor has the advantages of being capable of diagnosing a plurality of faults of the crankshaft position sensor rapidly and accurately, providing technological help for automobile repair enterprises, and being widely used in the fault diagnosis of various kinds of automobile sensors.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

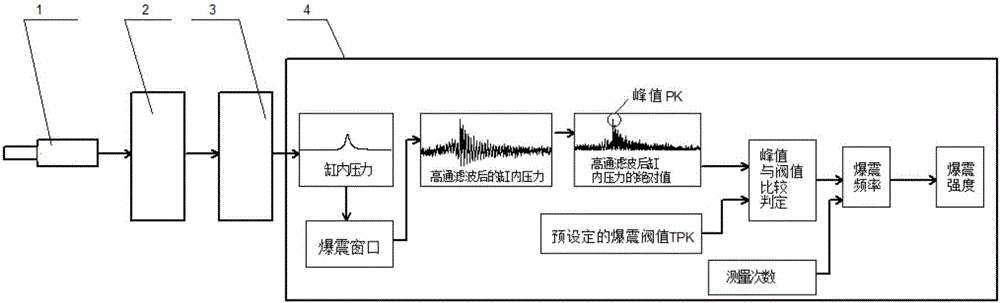

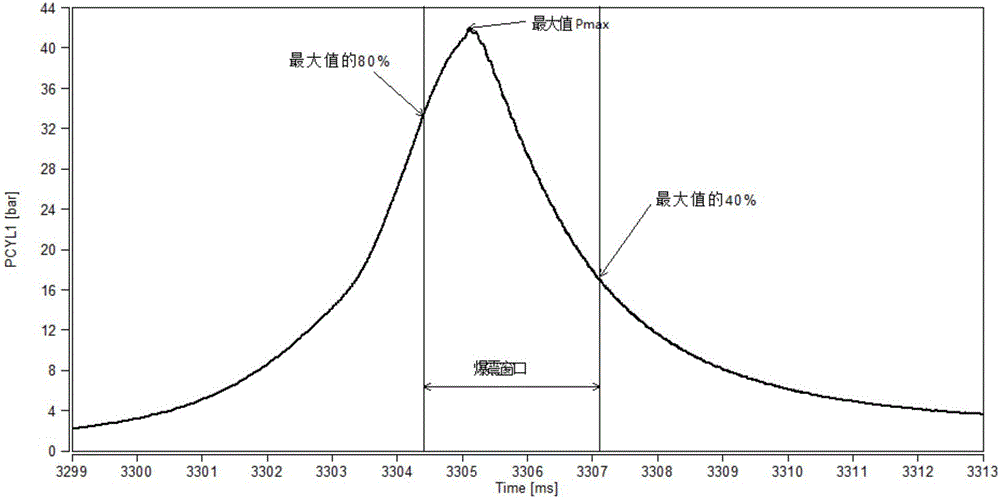

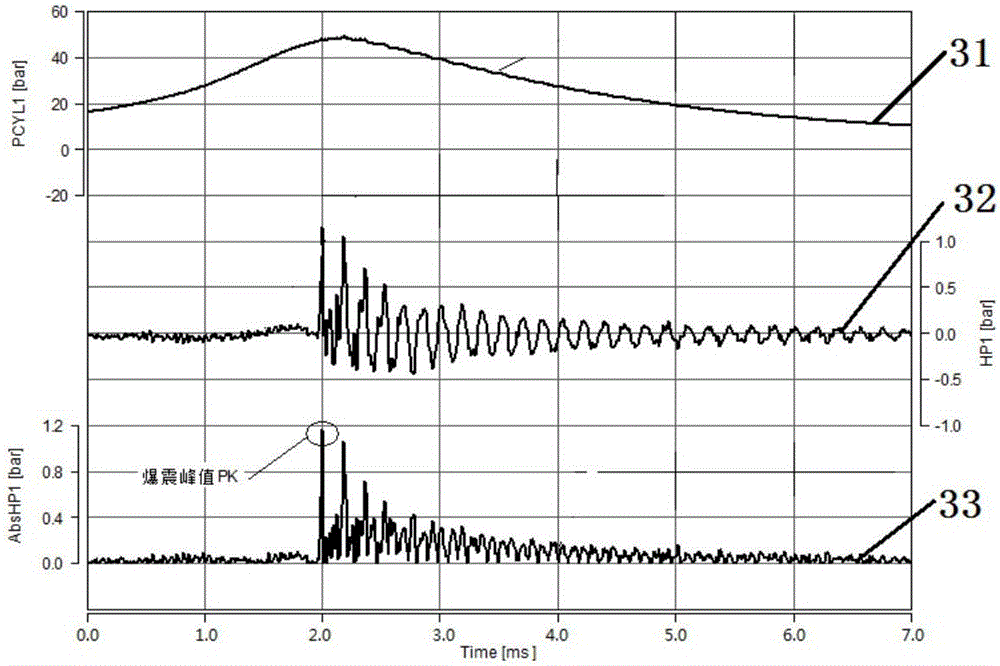

Engine knocking measurement device

InactiveCN106768613AReduce testing costsImprove test efficiencyRapid change measurementCombustion chamberMeasurement device

The invention discloses an engine knocking measurement device. The device comprises a cylinder pressure sensor which is installed on an engine with a cylinder pressure sensor installation hole and is used for sensing the cylinder pressure in a combustion chamber, a charge amplifier which is used for converting a charge signal sensed by the cylinder pressure sensor into a voltage signal, a data collection card which is used for collecting the voltage signal output by the charge amplifier, and a knocking judger which is used for getting a knocking peak PK according to a cylinder pressure signal collected by the data collection card, comparing the knocking peak PK with a preset knocking threshold TPK, judging that engine knocking is carried out if the knocking peak PK is greater than the knocking threshold TPK, and judging that engine knocking is not carried out if the knocking peak PK is smaller than the knocking threshold TPK. The device only needs the cylinder pressure sensor, and does not need a crankshaft position sensor. Therefore, the test cost in the process of engine research and development process is reduced, and the test efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

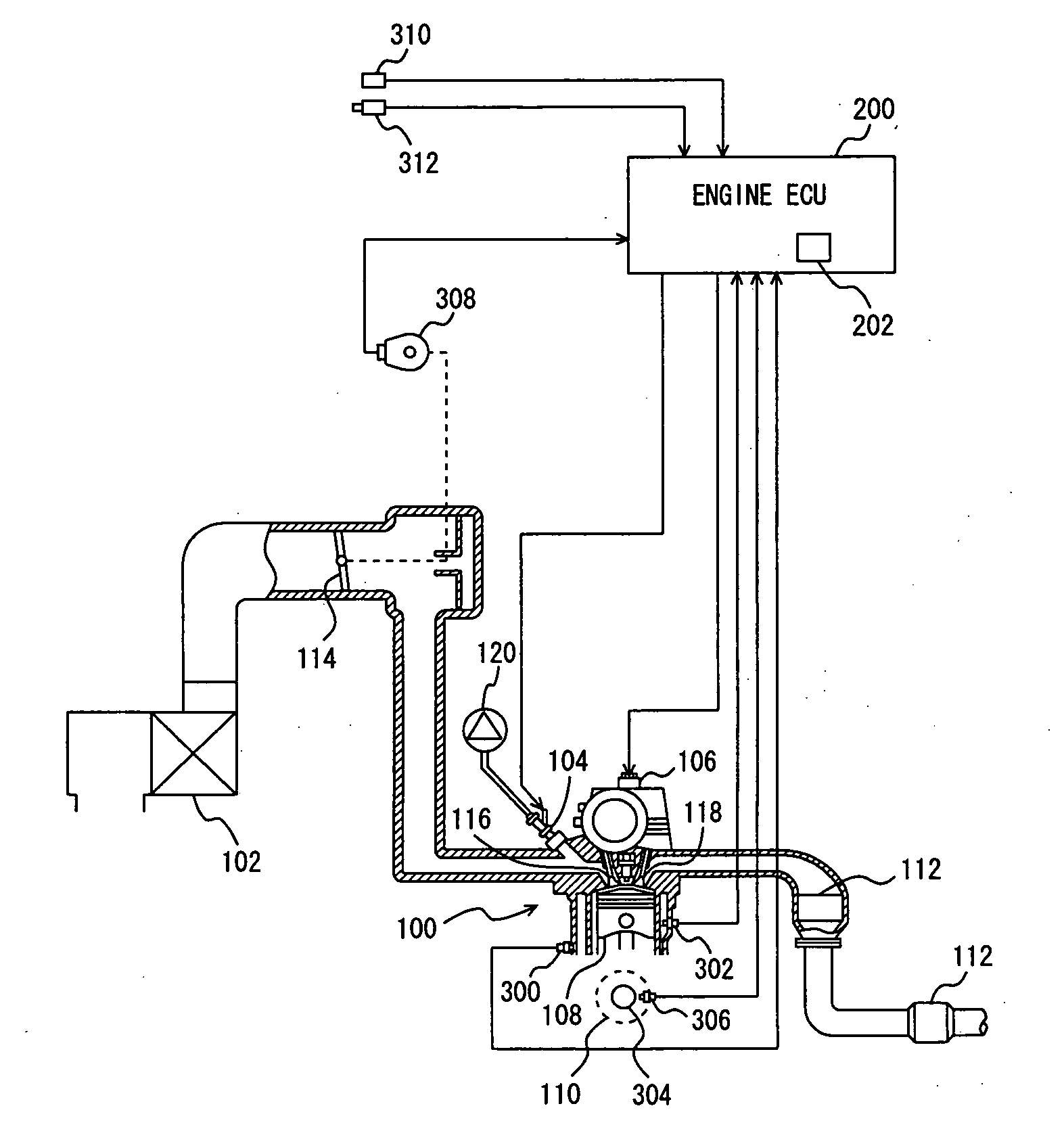

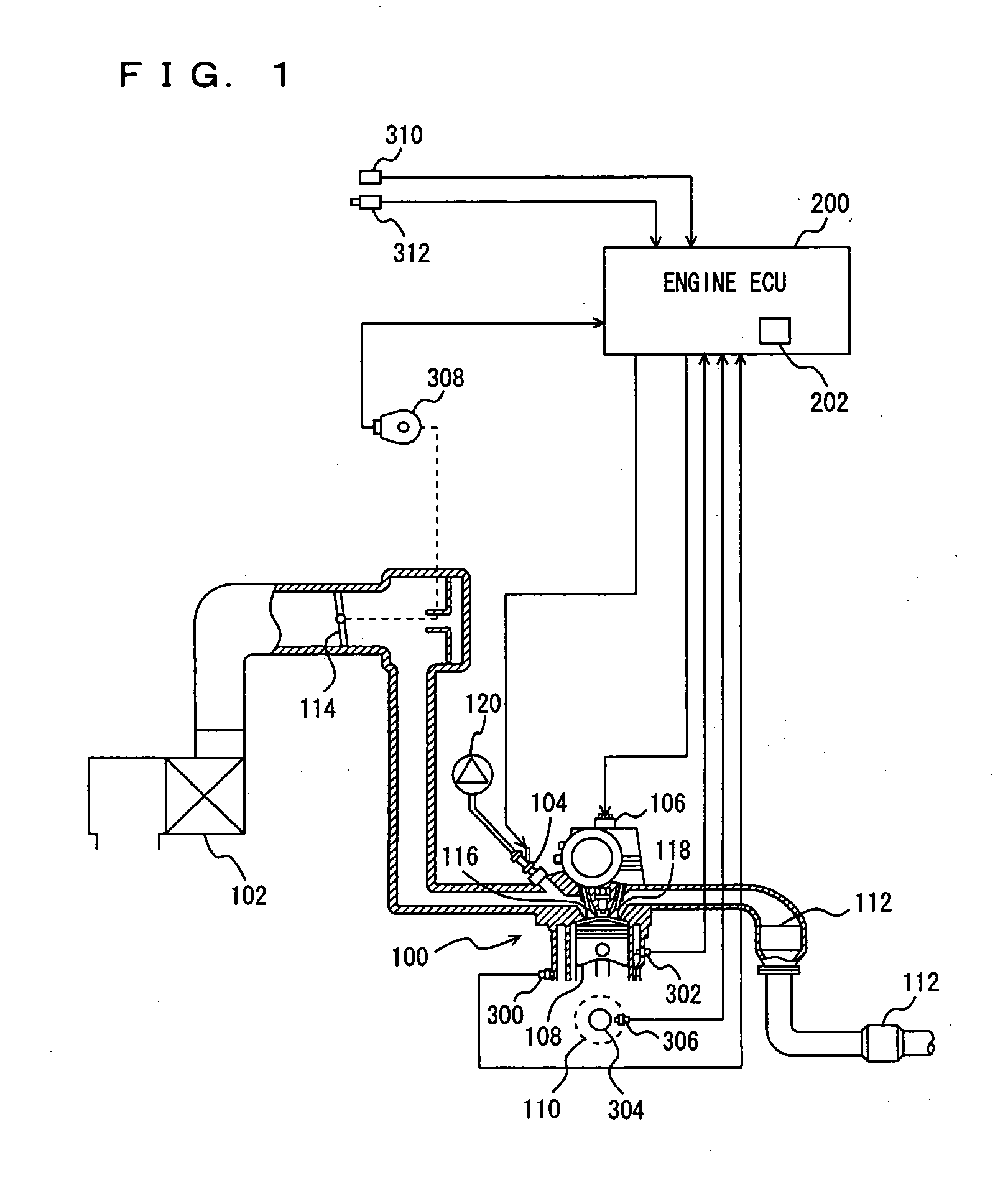

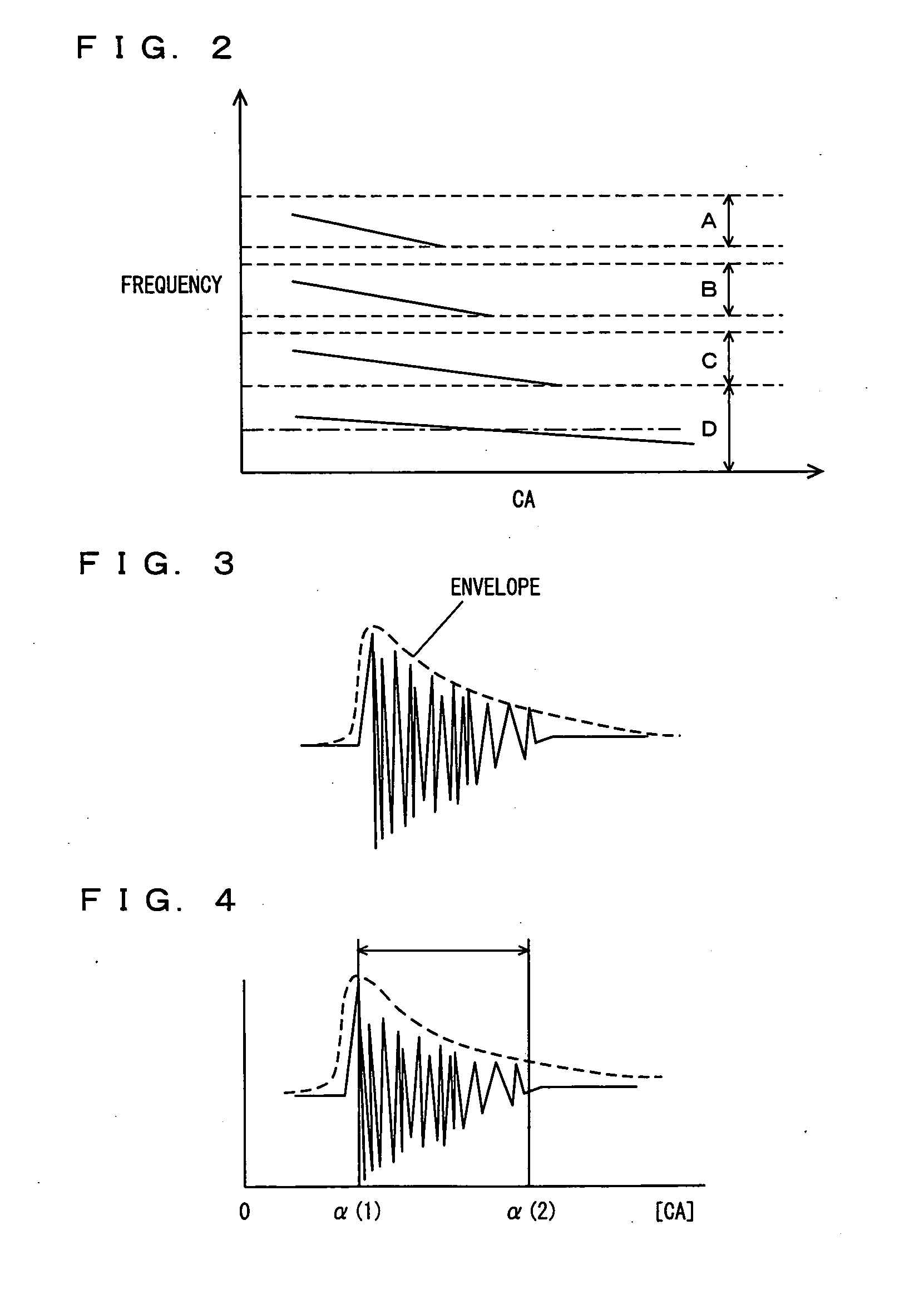

Internal combustion engine knock determination device

ActiveUS20060236754A1Improve accuracyInternal-combustion engine testingRapid change measurementInternal combustion enginePosition sensor

An engine ECU executes a program including the steps of: setting a knock waveform model corresponding to engine speed sensed by a crank position sensor; calculating knock intensity N based on the result of comparison between a detected waveform and the set knock waveform model; when the knock intensity N is larger than a predetermined reference value, determining that knocking has occurred; and when the knock intensity N is not larger than the predetermined reference value, determining that knocking has not occurred.

Owner:TOYOTA JIDOSHA KK +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com