Diesel/natural gas active blending combustion electronic control system and method

A natural gas and control system technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as the inability to actively control diesel injection, achieve the best combustion economy and avoid knocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

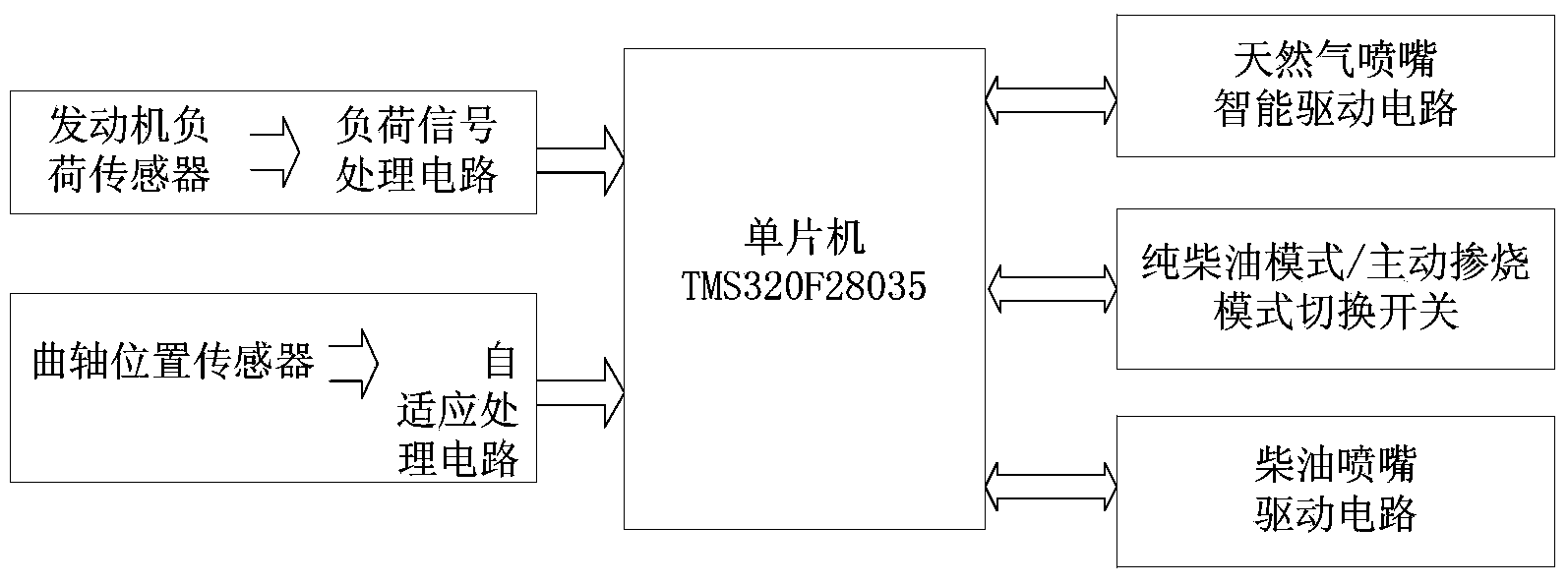

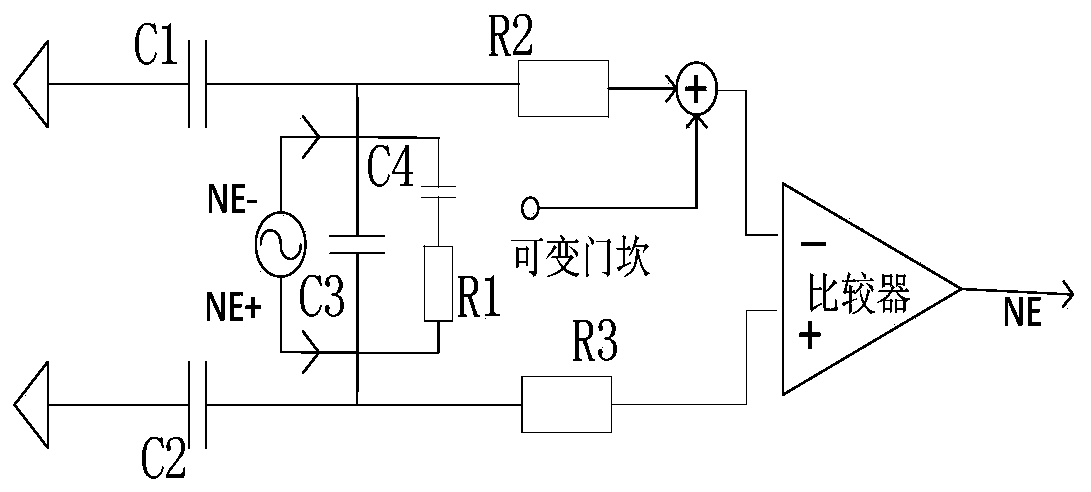

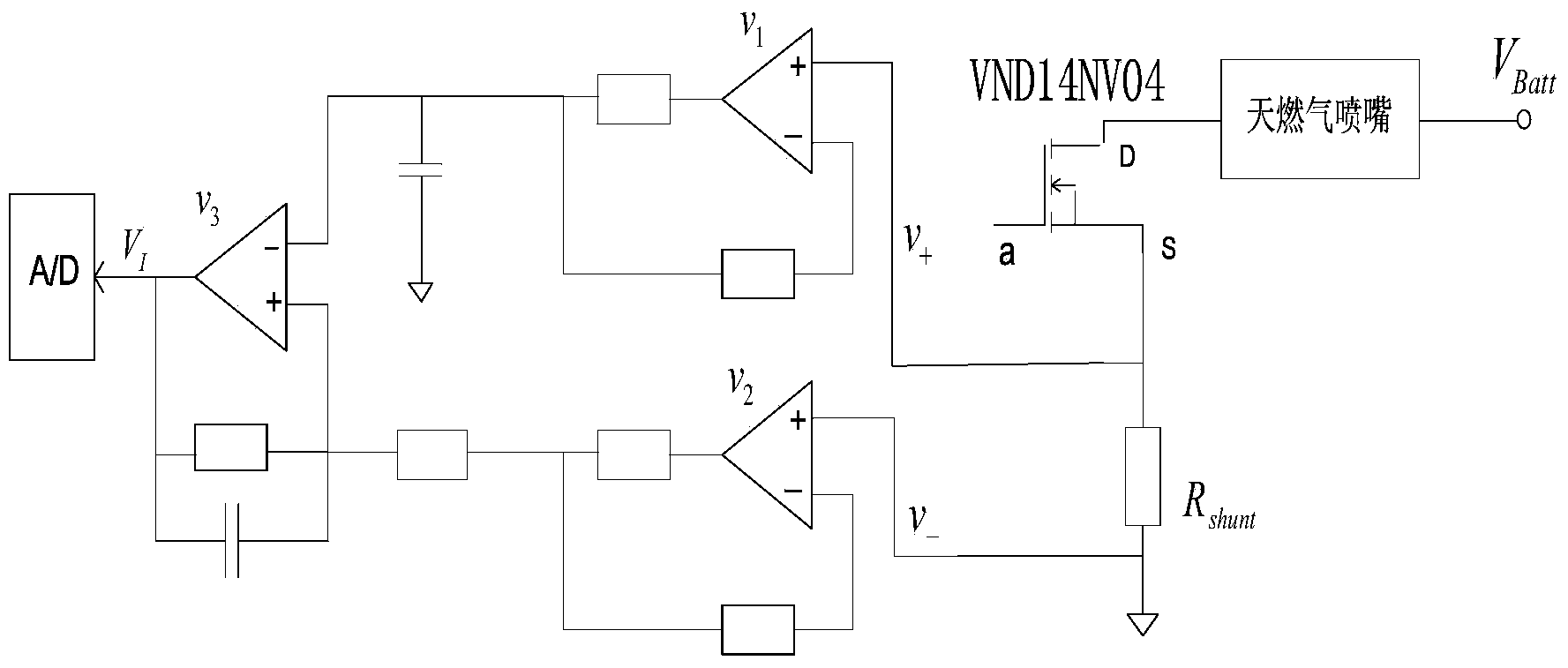

[0027] like figure 1 As shown, a diesel / natural gas dual-fuel active blending electronic control system includes a single-chip microcomputer, and a natural gas nozzle intelligent driving circuit, a diesel nozzle driving circuit, a pure diesel mode / active blending mode switch, a load A signal processing circuit and an adaptive processing circuit, the load signal processing circuit receives the detection signal of the engine load sensor, the adaptive processing circuit receives the detection signal of the crankshaft position sensor, and the crankshaft position sensor measures the rotational position and rotational speed of the engine crankshaft.

[0028] The engine load sensor adopts an intake pressure / intake temperature integrated sensor, and the crankshaft position sensor is an electromagnetic induction sensor.

[0029] The load signal processing circuit is a second-order Butterworth low-pass filter composed of operational amplifiers, which adjusts and filters the intake press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com