Non-electrolytic method for metallizing a surface pretreated substrate on-line by spraying and device for implementing the method

A technology of metal plating and electroless plating, which is applied in the field of electroless metal plating and the manufacture of conductive rails, and can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

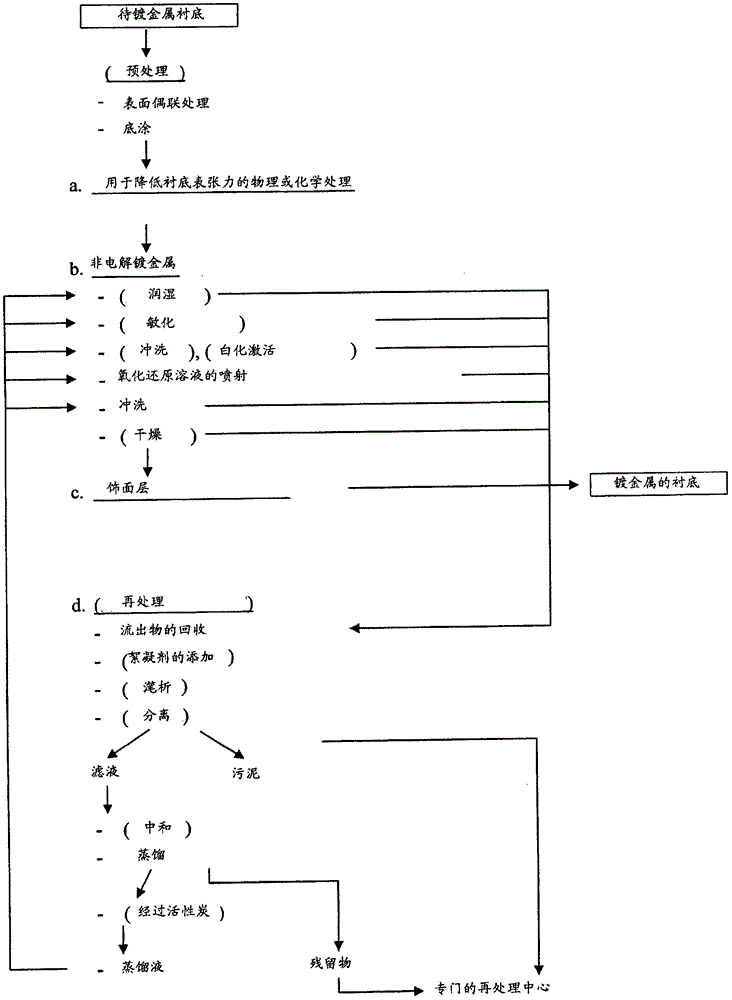

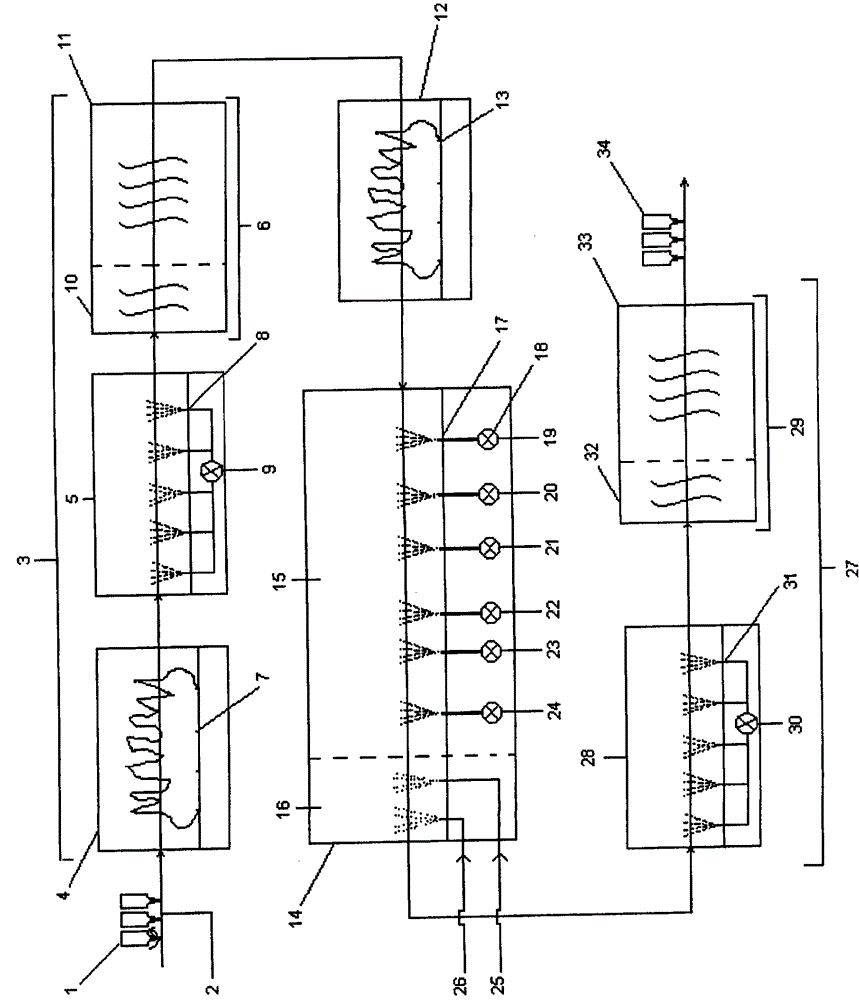

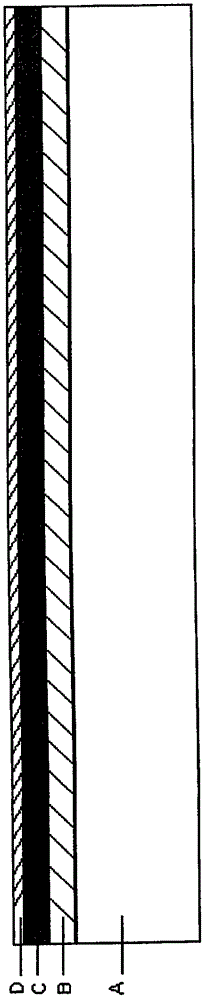

Method used

Image

Examples

Embodiment 1

[0207] Example 1: Silver plating of rigid substrate of insulating glass

[0208] Coating by DEGUSSA on cylindrical glass bottles with a height of 10 cm and an outer diameter of 5 cm by spraying with an HVLP spray gun Sold under the trade name GLYMO 0.1g / l silane-based solution. Then still spray AKZO NOBEL on the rotating bottle with HVLP spray gun Epoxy varnishes sold by companies. Heat for 10 minutes in a heated enclosure at a temperature of 280°C.

[0209] The bottles are then placed in a flame treatment chamber with three natural gas burners. The bottles rotate at 120 rpm. The flame temperature was adjusted to 1400°C, and the flame treatment time was 20 seconds.

[0210] The bottles thus treated are placed in a metallization unit where the bottles go through the following steps in succession:

[0211] § Sensitization of the surface by spraying a stannous chloride based solution with a HVLP spray gun for 5 seconds,

[0212] § Flush the sensitizing solution by sp...

Embodiment 2

[0219] Example 2: Silver plating of rigid substrate of insulating glass

[0220] POLIR-MALIN is spray-coated by HVLP spray gun on a cylindrical glass bottle with a height of 10 cm and an outer diameter of 5 cm. Sold under the trade name GLASSPOLISHING A solution based on cerium oxide at a concentration of 250 g / l, followed by polishing in a polishing chamber consisting of a rotating pad and rinsing by spraying distilled water with an HVLP spray gun.

[0221] The bottles thus treated are placed in a metallization unit in which the following operations are carried out sequentially:

[0222] § Sensitization of the surface by spraying a stannous chloride based solution with an HVLP spray gun for 5 seconds,

[0223] § Flush the sensitizing solution by spraying water with the HVLP spray gun for 5 seconds,

[0224] § Simultaneously spray silver nitrate aqueous solution with a concentration of 2g / l and sodium gluconate aqueous solution with a concentration of 15g / l for 25 secon...

Embodiment 3

[0227] Example 3: Nickel / copper plating of flexible substrates made of polyester fabric

[0228] Apply LA CELLIOSE on a fabric made of polyester with a length of 10 cm, a width of 10 cm and a thickness of 2 mm by spraying with an HVLP spray gun Polyurethane varnishes sold by the company. It was then heated for 40 minutes in a thermally enclosed space at a temperature of 40°C.

[0229] The fabric is then placed in a flame treatment chamber with three natural gas burners. The painted side of the fabric was flame treated at a flame temperature of 1400° C. for 20 seconds. The fabric thus treated is placed in a metallization unit in which the flame-treated lacquered side undergoes the following operations in sequence:

[0230] §Wetting treatment by spraying water with HVLP spray gun for 5 seconds

[0231] §Use the HVLP spray gun to spray nickel sulfate aqueous solution with a concentration of 5g / l and sodium hypophosphite solution with a concentration of 20g / l for 30 seconds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com