Patents

Literature

249 results about "Flame treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame treatment is the application of a gas flame to the surface of a material to improve adhesion. Polyolefins, especially polyethylene and polypropylene bond poorly, because they consist of long non-polar molecules. Without special treatment, adhesives, ink, and other coatings cannot be applied to these materials. By rapidly applying intense heat to a surface, molecular chains are broken and polar functional groups are added. Flame treatment also burns off dust, fibers, oils, and other surface contaminants.

Methods of forming multilayer articles by surface treatment applications

InactiveUS20070087131A1Low water vapor transmission rateImprove adhesionPretreated surfacesCoatingsAir treatmentFlame treatment

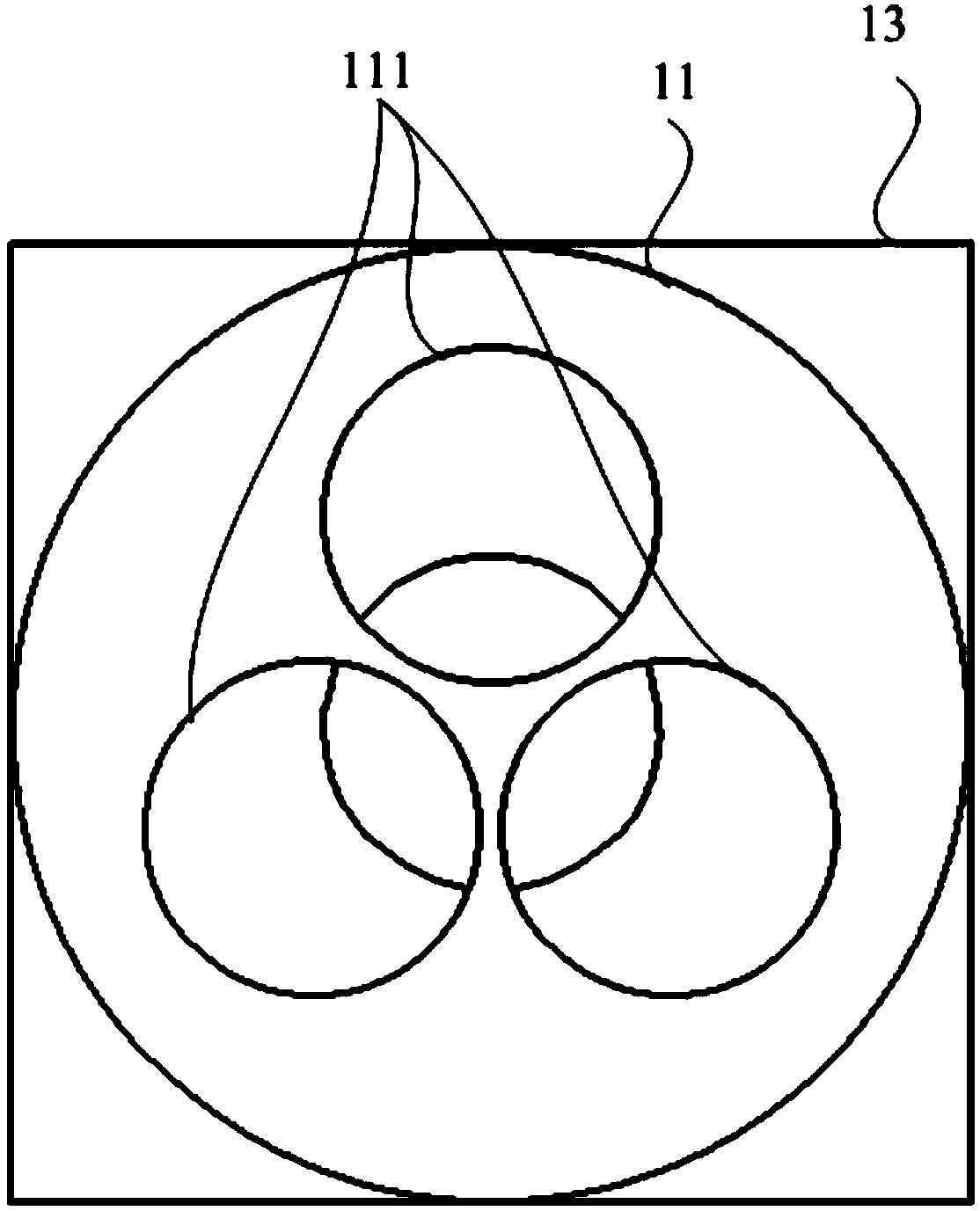

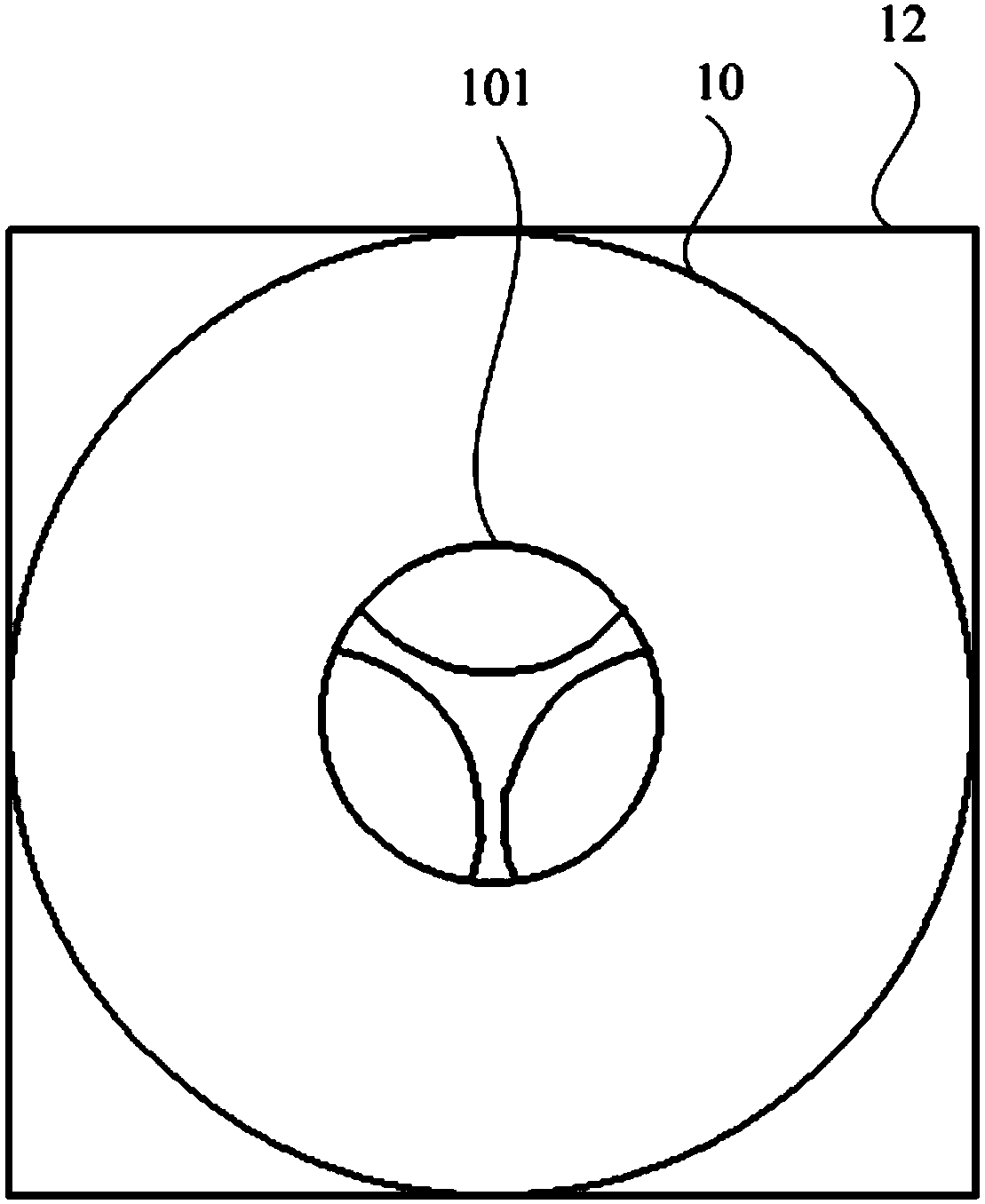

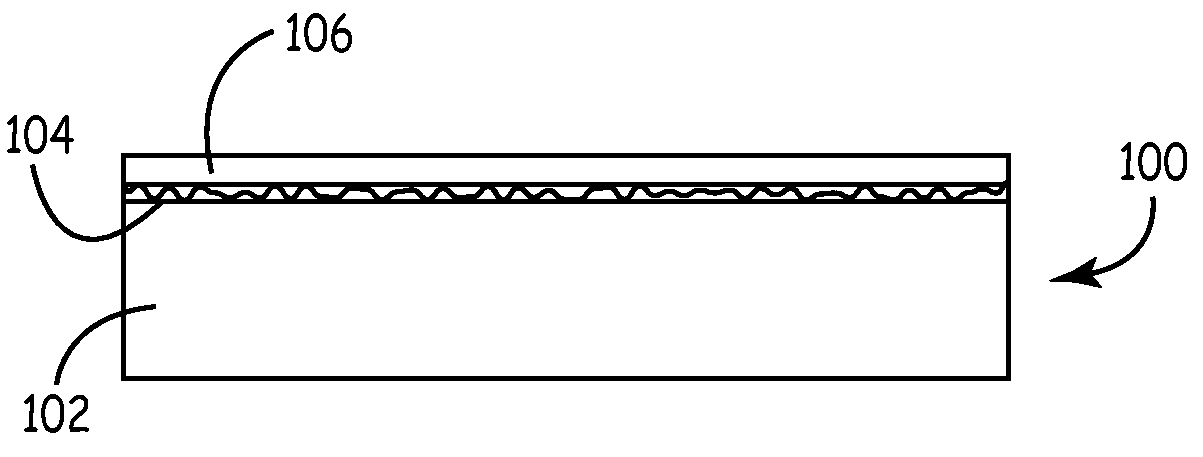

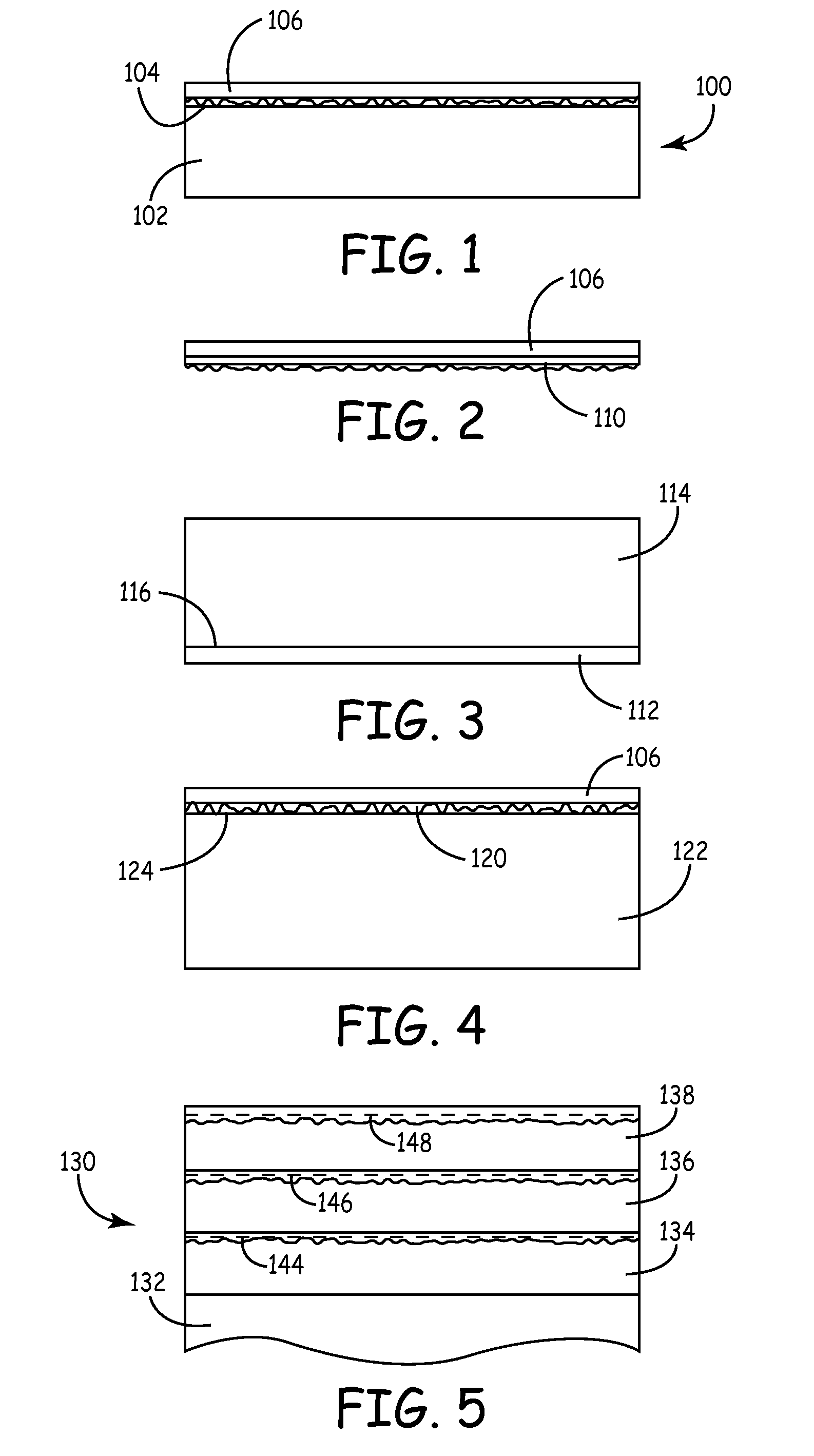

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Ink-receptive foam article

InactiveUS7655296B2Increased durabilityIncrease resistanceDecorative surface effectsSynthetic resin layered productsPolymer scienceFlame treatment

Owner:3M INNOVATIVE PROPERTIES CO

Saloon car bumper special material capable of direct spray coating

The invention discloses a special material for direct spray coating of a bumper, which is prepared by mixing of polypropylene, a rubber toughening agent, a crosslinking agent, grafted polypropylene, inorganic filler, black master bath, an antioxidant and a light stabilizer in proportion, preparation of the master bath, dynamic vulcanization, secondary extrusion, multi-monomer fusing and grafting, etc. The polarity of the special material for the bumper is changed by multi-monomer fusing and grafting modification of methyl methacrylate and so on, and the surface activity of the special material for the bumper is increased; and spray coating paint of the bumper comprises a plurality of chemical compositions, the appetency of various compositions and given functional groups is insufficient, a plurality of active functional groups are formed on the surface of the material by activation of a plurality of functional groups and can simultaneously form physical absorption or chemical bonding with the various chemical compositions in the paint, thereby the special material can perform direct spray coating without flame treating, achieves the optimum spray coating effect, and has good processing fluidity and high toughness.

Owner:CHANGCHUN UNIV OF TECH

Metallized films

InactiveUS6033786AImprove propertiesImprove adhesionSynthetic resin layered productsGlass/slag layered productsButeneMetal coating

A biaxially oriented, heat-set, multilayer film includes a core layer, a bonding layer having a surface adhered to the core layer and a flame treated surface opposite the surface adhered to the core layer. A metal coating for providing oxygen and moisture barrier properties deposited on the flame treated surface and a protective plastic film adhered to said metal coating. The core layer and bonding layer either are free of void-creating additives or include only a quantity of such additives that does not create a matte surface adversely affecting the barrier properties of the metal coating. The bonding layer comprising a mixture including 40 to 100% by weight of propylene / butene-1 copolymer containing up to about 14% by weight of butene-1 (PBC), 0 to 60% of an isotactic polypropylene (PP) and 0 to 50% of a copolymer of ethylene and propylene wherein propylene is the predominant component by weight (EPC).

Owner:APPLIED EXTRUSION TECH

Ink-receptive foam article

InactiveUS20050147807A1Increased durabilityIncrease resistanceOther printing matterDuplicating/marking methodsPolymer scienceFlame treatment

Owner:3M INNOVATIVE PROPERTIES CO

Polypropylene composite material for automobile bumper and prepn. thereof

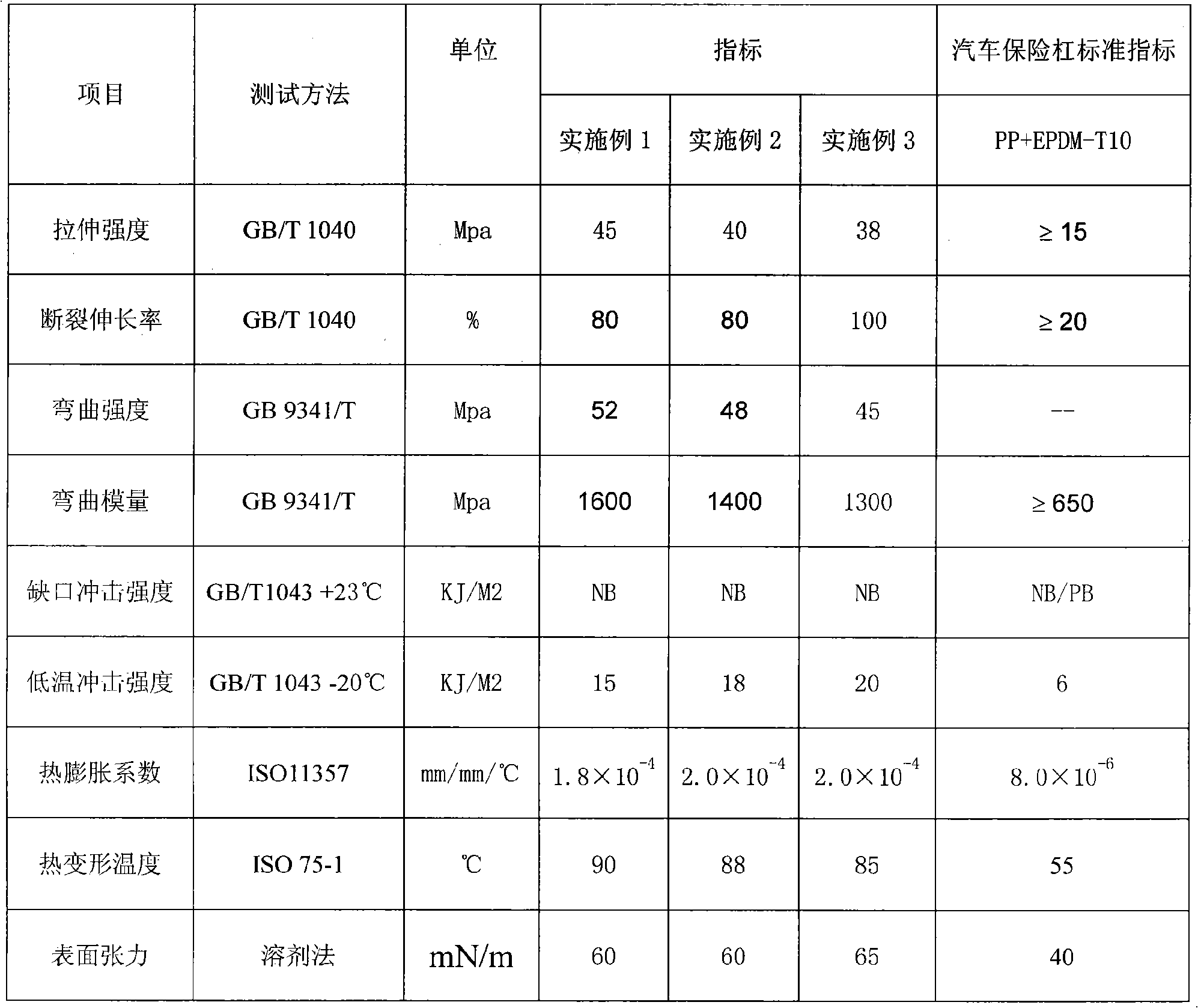

InactiveCN1834145AImprove performanceReduce surface defectsBumpersHeat deflection temperaturePolypropylene composites

This invention discloses a kind of polypropylene composite materials for automobile bumpers and its preparation method. This kind of materials comprises 93.3~56.5wt% polypropylene, 0.2~1.5wt% thermo-stabilizers, 0.3~1wt% photo-stabilizers, 0.2~1% auxiliary reagents, 1~20wt% activating and reinforcing masterbatches and 5~20wt% stuffing masterbatches. The product in this invention has high surface activity, low thermo expansion rate and high thermo expansion temperature. The surface tension is 40mN / m, the linear thermo expansion rate is 10 to the power -6 to 10 to the power -7 mm per mm per deg. C, the thermo deformation temperature is 55 deg. C and some other technological indices all reach or exceed current standards for automobile materials. Thanks to the high surface tension and strong paint-adhesion of the bumpers made of this kind of materials, paints can be directly sprayed rather than flame processing. The thermo expansion rate is low, and therefore, loosening due to significant deformation might not occur with large temperature variation. Besides, it also has the advantages of high the thermo resistant temperature, short baking time and high production efficiency.

Owner:SHANGHAI KINGFA SCI & TECH

Ink-receptive foam article

InactiveUS20060257594A1High crystallinityIncreased durabilityDecorative surface effectsSynthetic resin layered productsPolymer scienceFlame treatment

The present invention is directed an oriented, foamed article having an ink-receptive surface, and a method of making the article. The invention provides a printable substrate comprising at least one high melt-strength, oriented polypropylene foam layer having an ink-receptive surface. The high melt-strength polypropylene having a melt strength of of 25 to 60 cN at 190° C. The ink-receptive surface may comprise and oxidizing treatment, such as corona or flame-treatment of the foam surface, or may comprise an ink-receptive coating, such as a primer coating, on the foam surface. The oriented foam article is particularly useful in the preparation of printed security documents such as currency, stock and bond certificates, birth and death certificates, land titles and abstracts and the like.

Owner:3M INNOVATIVE PROPERTIES CO

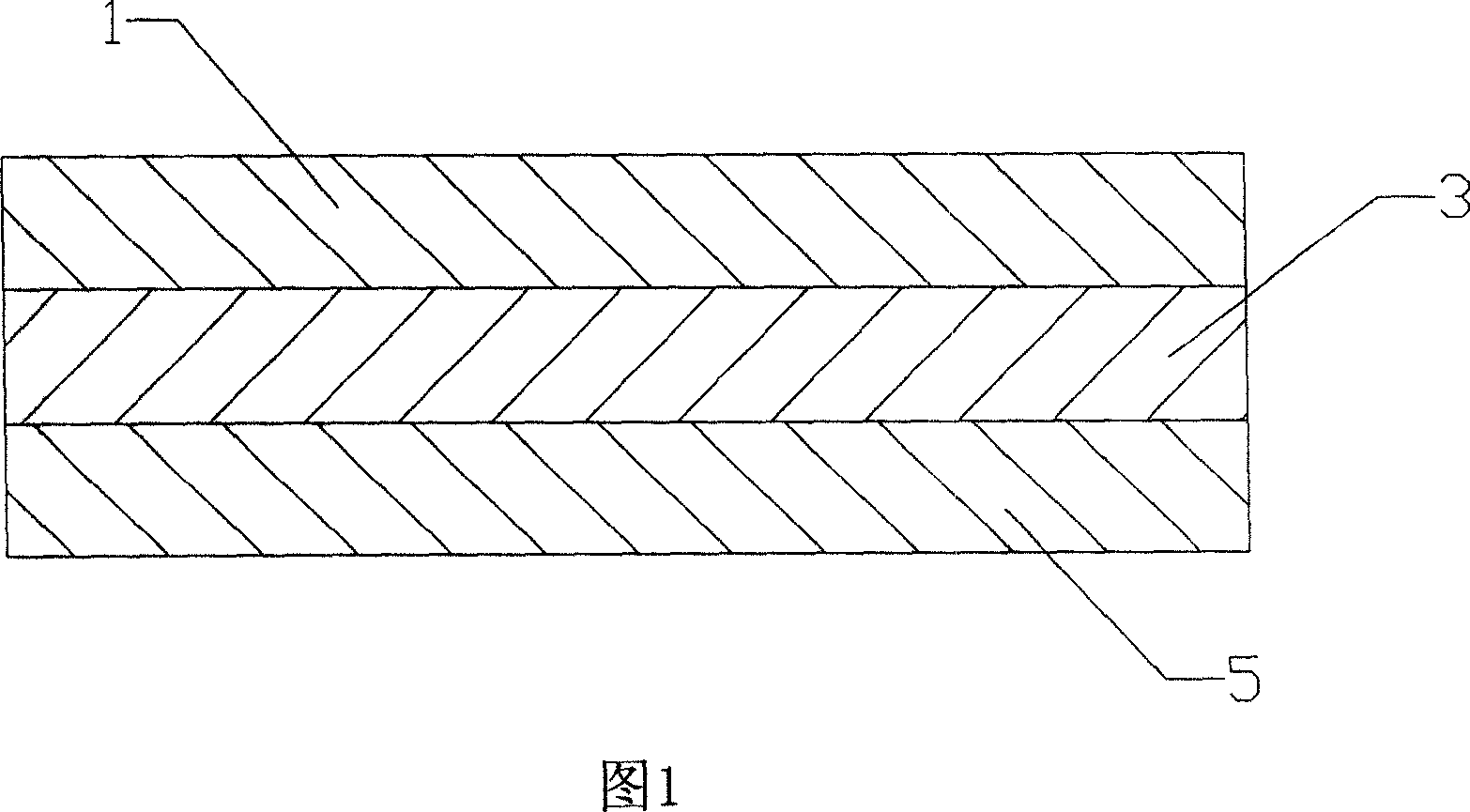

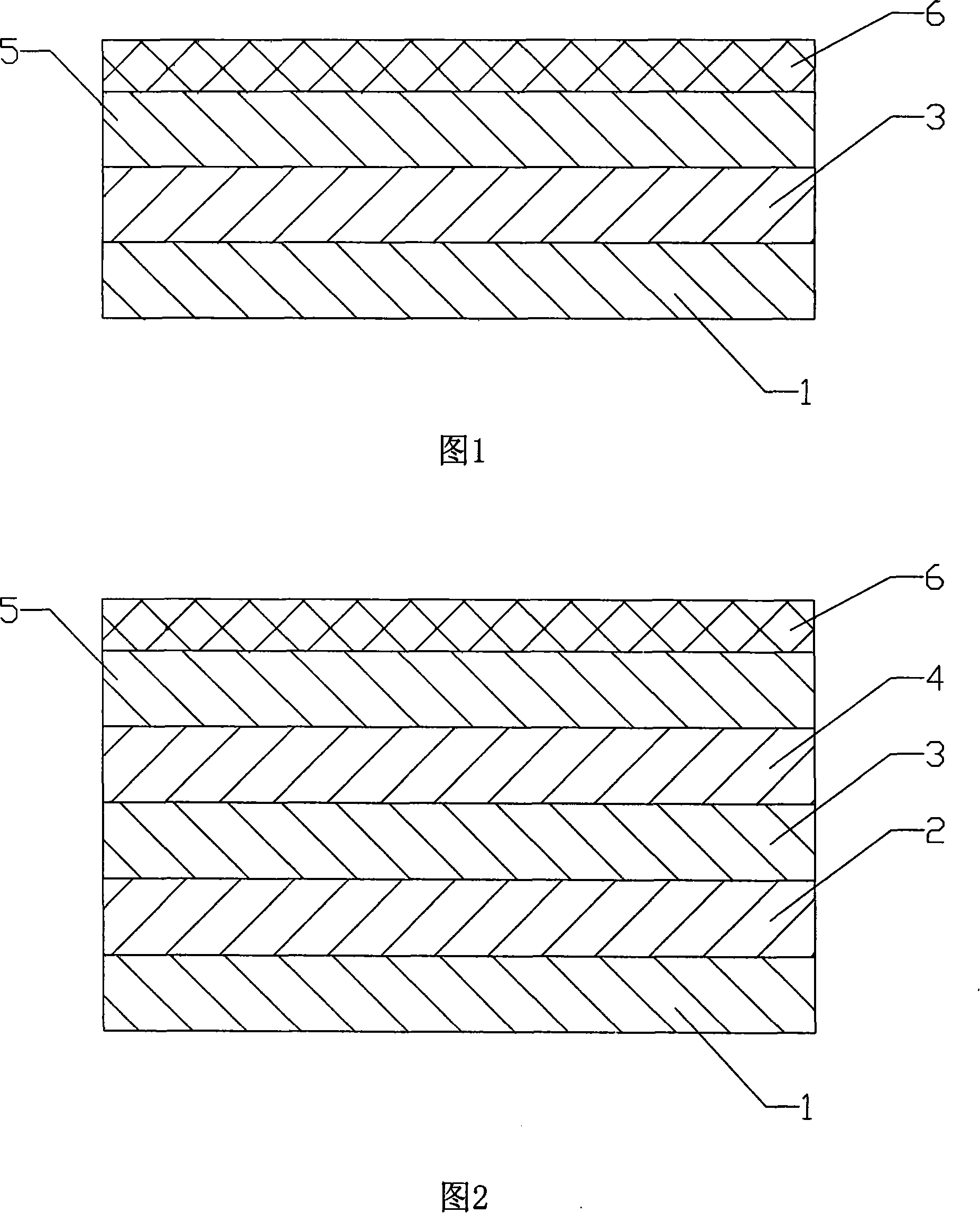

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

ActiveCN101058247ASimple structureHigh heat sealing strengthSynthetic resin layered productsFlat articlesThick plateEngineering

The invention relates to a paper plastic glue free compound bi-directional stretch polypropylene film, which has coextruded surfaced, core layer, functional layer being able to compound with paper, pre-print paper or thin film, with upper sub surface between the surface and core layer, and lower sub surface between the core layer and the functional layer. All of them are extruded through bi-directional stretch. It feeds formulated material into the extruder to melt, which is co-extruded into thick plates through slip cast, then the thick plates being stretched in both directions into thin film, which are processed through corona and flame into mother film, through effective treatment to get the final thin film product. It is simple in structure, strong in thermal sealing, high in stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

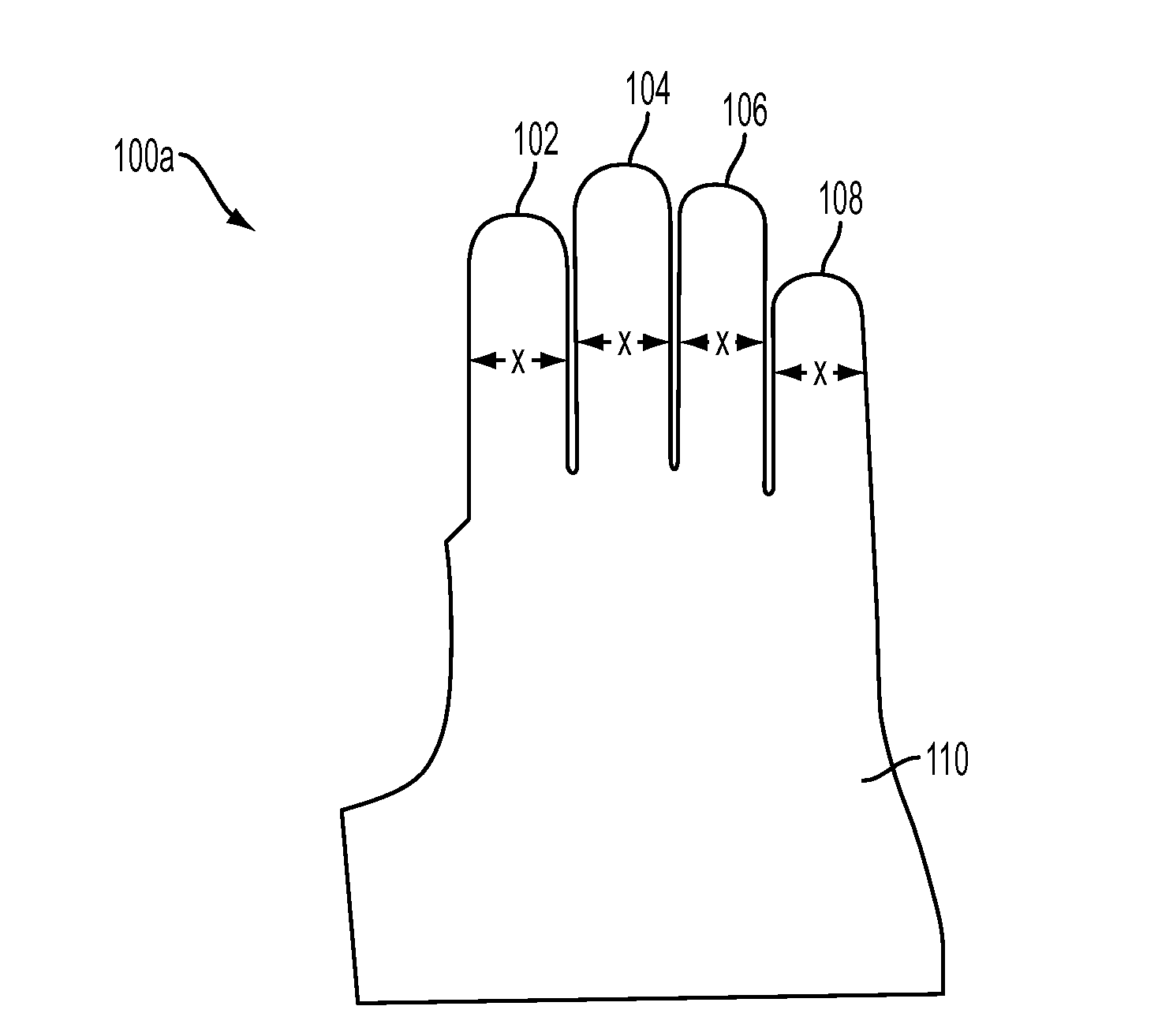

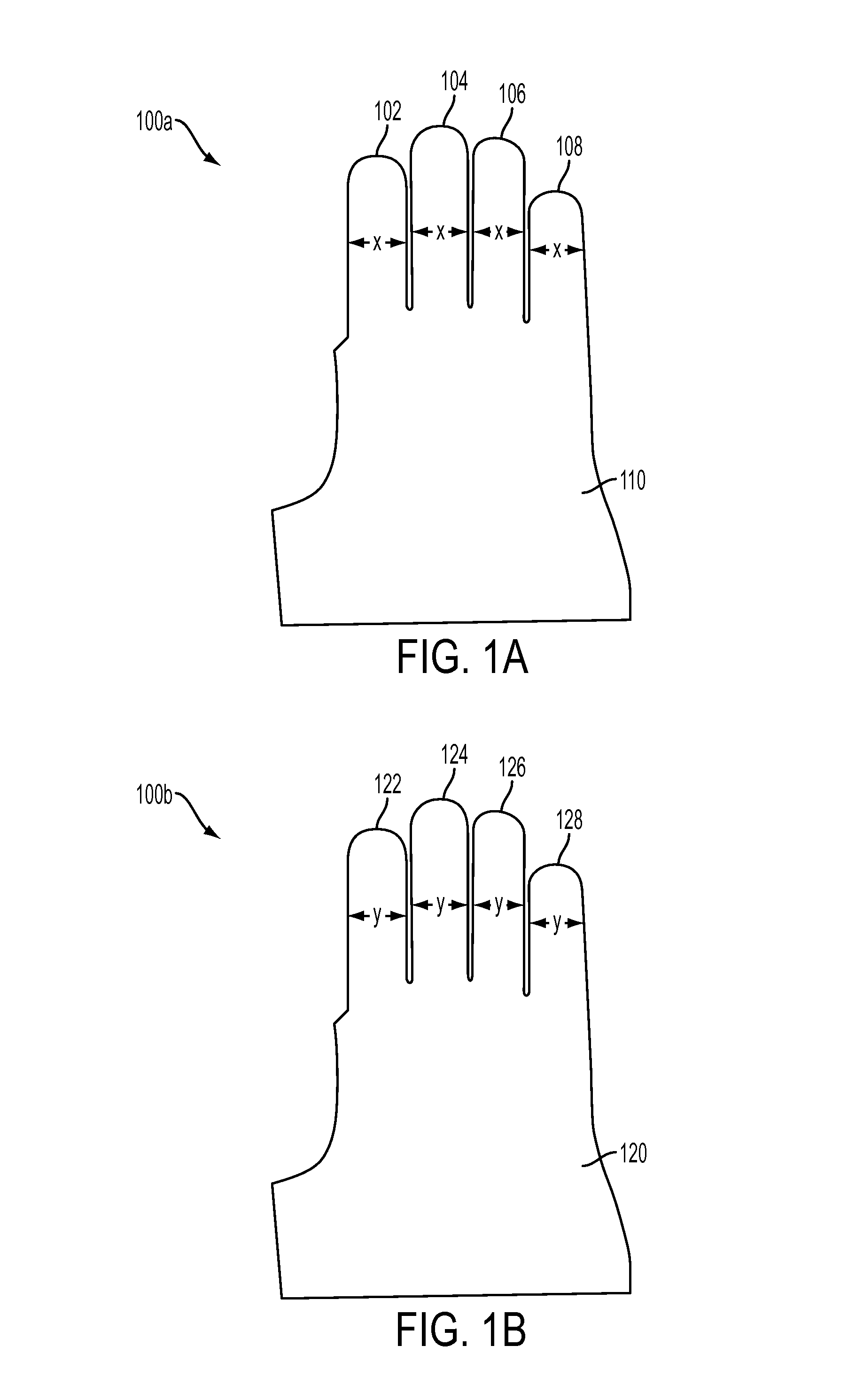

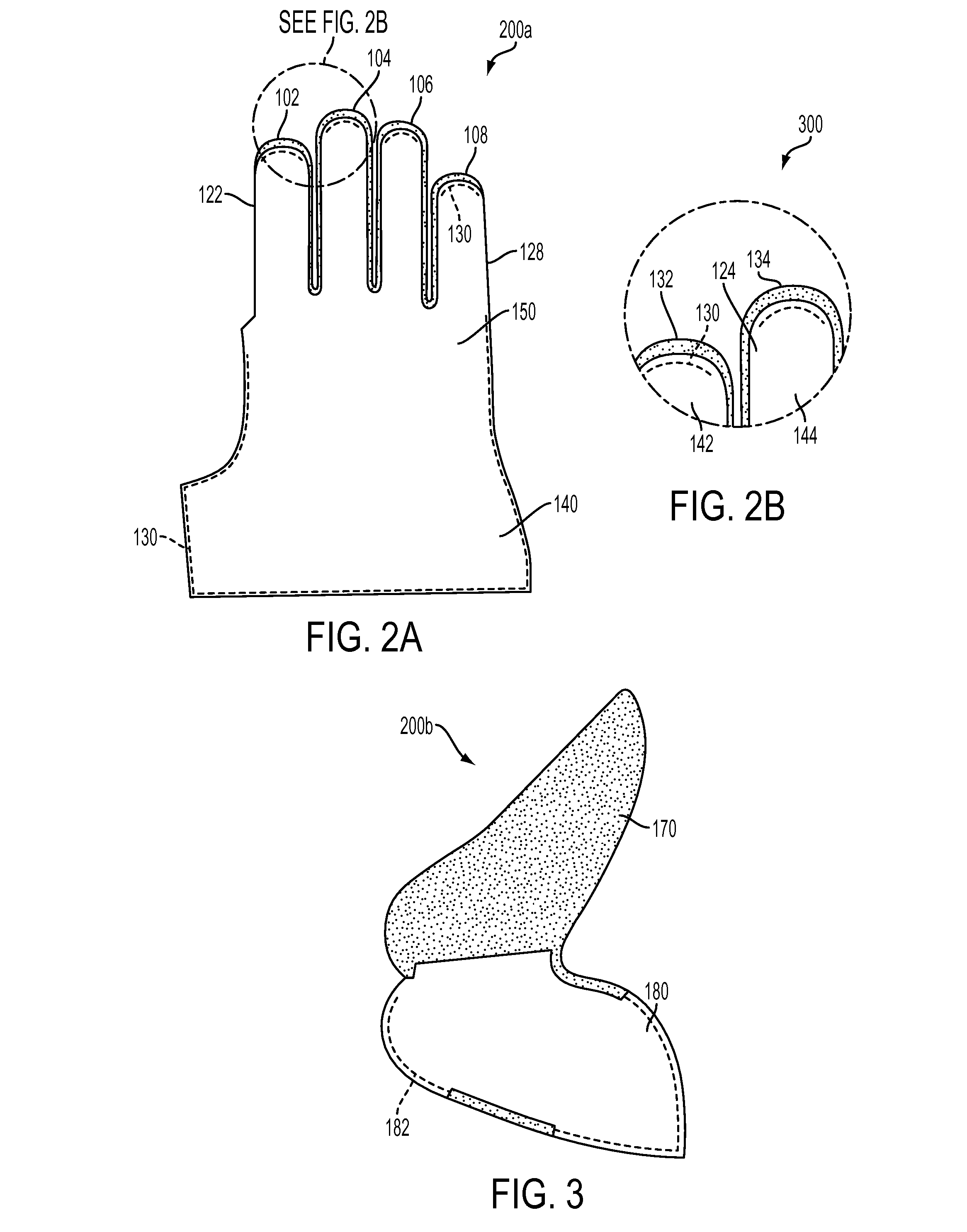

Layered structural fire glove

A flexible, multi-layer glove, including a liner, a glove shell having at least one of a knitted fabric or a flame-treated leather; and / or a floating barrier layer, that includes a plurality of attachment tabs, disposed between the glove shell and the liner, wherein the plurality of attachment tabs attach the barrier layer to the liner and to the glove shell and / or a floating insulation layer is disclosed.

Owner:ANSELL

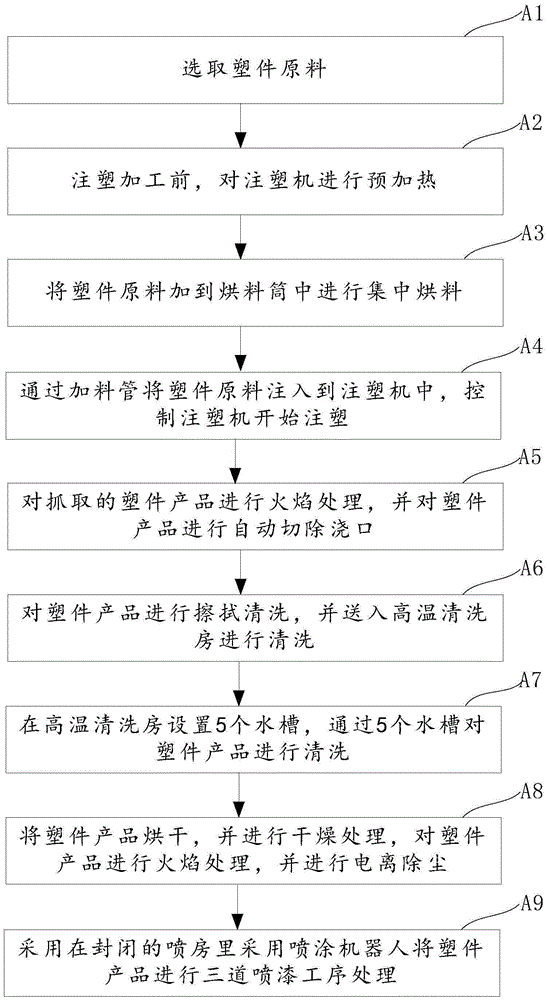

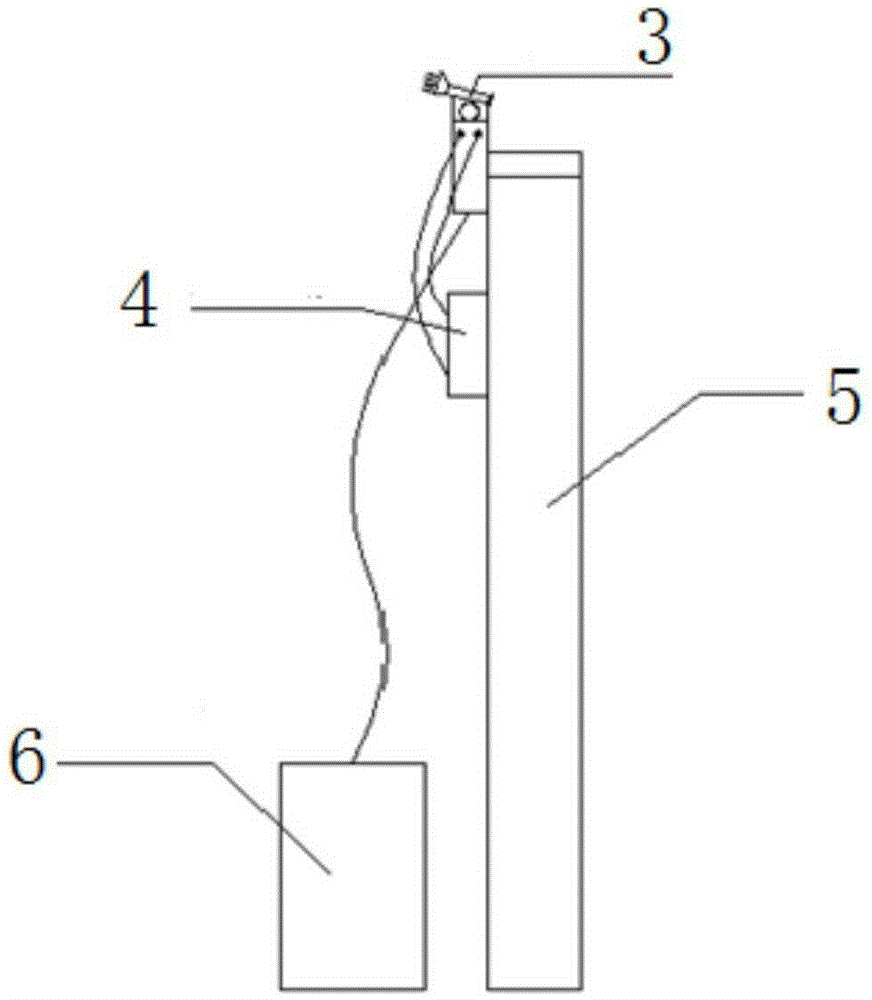

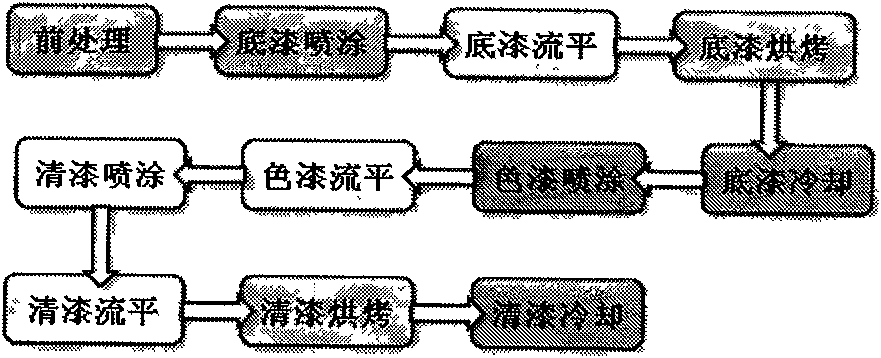

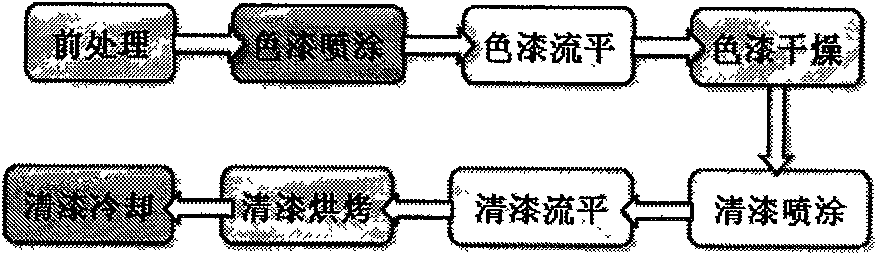

Method for producing colored bumpers

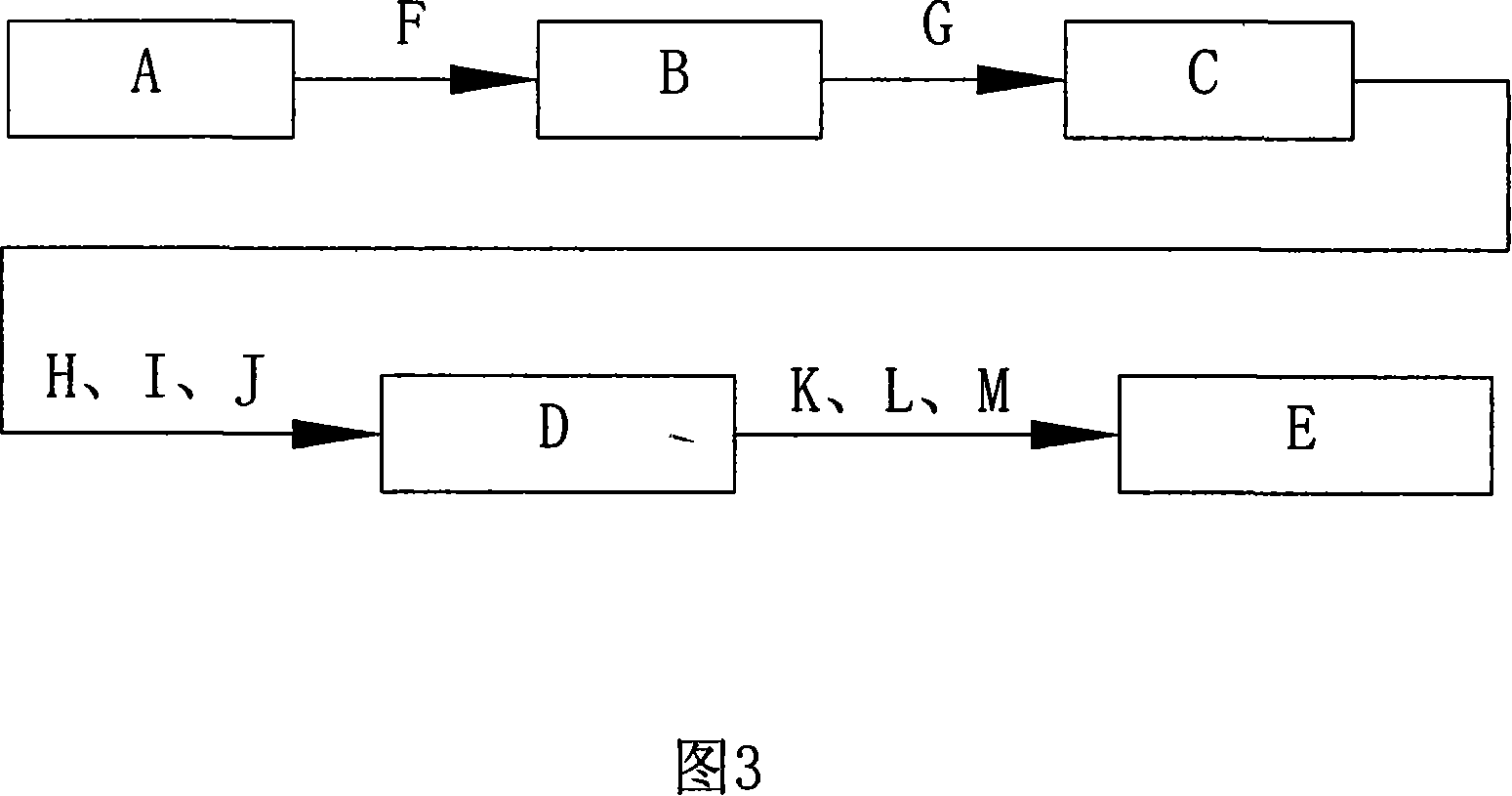

InactiveCN105413979AImprove impact resistanceAvoid defectsPretreated surfacesCoatingsFlame treatmentEngineering

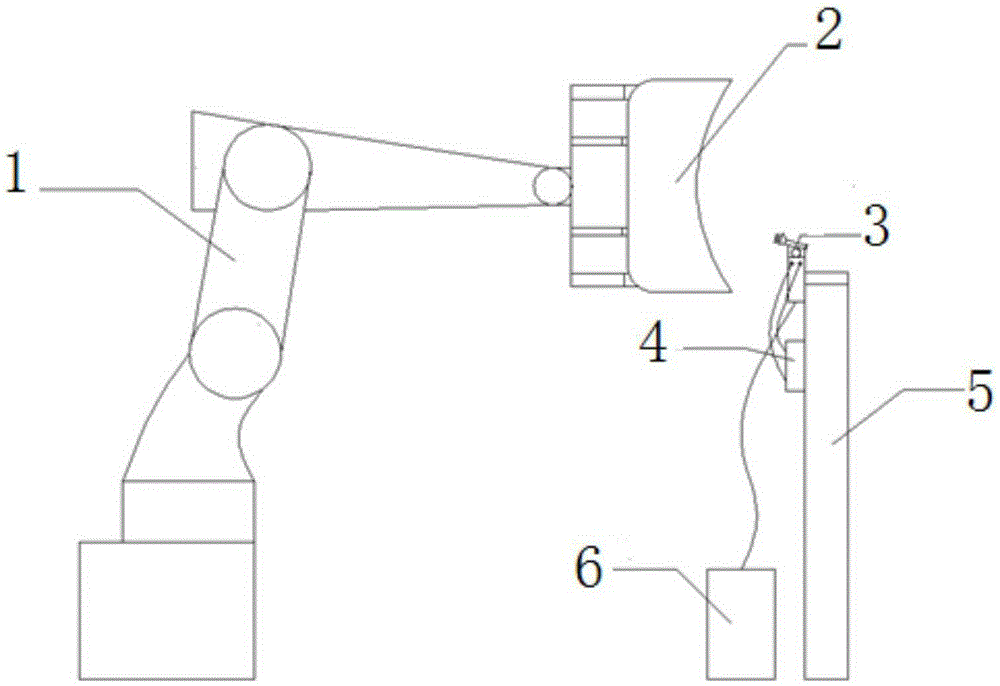

The invention discloses a method for producing colored bumpers. The method includes the steps that A1, plastic part raw materials are selected; A2, an injection molding machine is preheated; A3, the plastic part raw materials are fed into a drying barrel to be dried in a concentrated mode; A4, the injection molding machine is controlled to start injection molding; A5, flame treatment is conducted on a grabbed plastic part product, so that flash and burrs on the surface of the product are removed, and a pouring gate is automatically cut off; A6, the plastic part product is wiped and cleaned and fed into a high-temperature cleaning room to be cleaned; A7, the plastic part product is cleaned; A8, the cleaned plastic part product is dried and fed into a drying room to be dried, then flame treatment is conducted on the plastic part product, and the plastic part product subjected to flame treatment is fed into an ionization dust removal chamber to be subjected to ionization dust removal; and A9, a spraying robot is used for conducting three paint spraying procedures on the plastic part product in a sealed spraying booth. According to the method, the production efficiency is high, the production safety is high, and the percent of pass of products is increased.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

Sprayable polypropylene composite material free of flame treatment and preparation method thereof

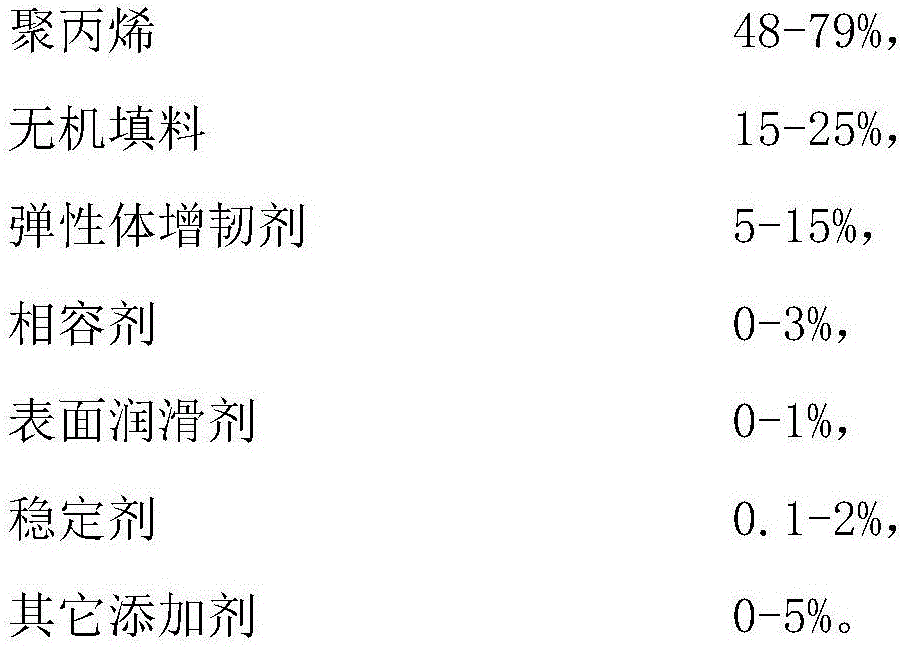

The invention discloses a sprayable polypropylene composite material free of flame treatment and a preparation method thereof. The polypropylene composite material is composed of the following raw materials in percentage by weight: 48-79% of polypropylene, 15-25% of inorganic filler, 5-15% of elastomer toughening agent, 0-3% of compatilizer, 0-1% of surface lubricant, 0.1-2% of stabilizer and 0-5% of other additives. The sprayable polypropylene composite material disclosed by the invention has the following beneficial effects: 1, by means of the synergistic effect of the polypropylene, the inorganic filler, the elastomer toughening agent, the compatilizer and the surface lubricant, the obtained product can be sprayed without the flame treatment, and the paint adhesion is good; and 2, the mechanical performance of the material disclosed by the invention is equivalent to that of the traditional material, the necessary flame treatment process of the paint spraying process can be omitted, and thus the manufacturing costs of paint spraying parts are greatly reduced.

Owner:CHONGQNG PRET NEW MATERIAL +4

Method for surface preparation of solid substances and surface-prepared solid substances

InactiveUS20060222868A1Improve adhesion strengthUniform modificationMolten spray coatingLayered productsAdhesion strengthMaterials science

Owner:MORI YASUHIRO

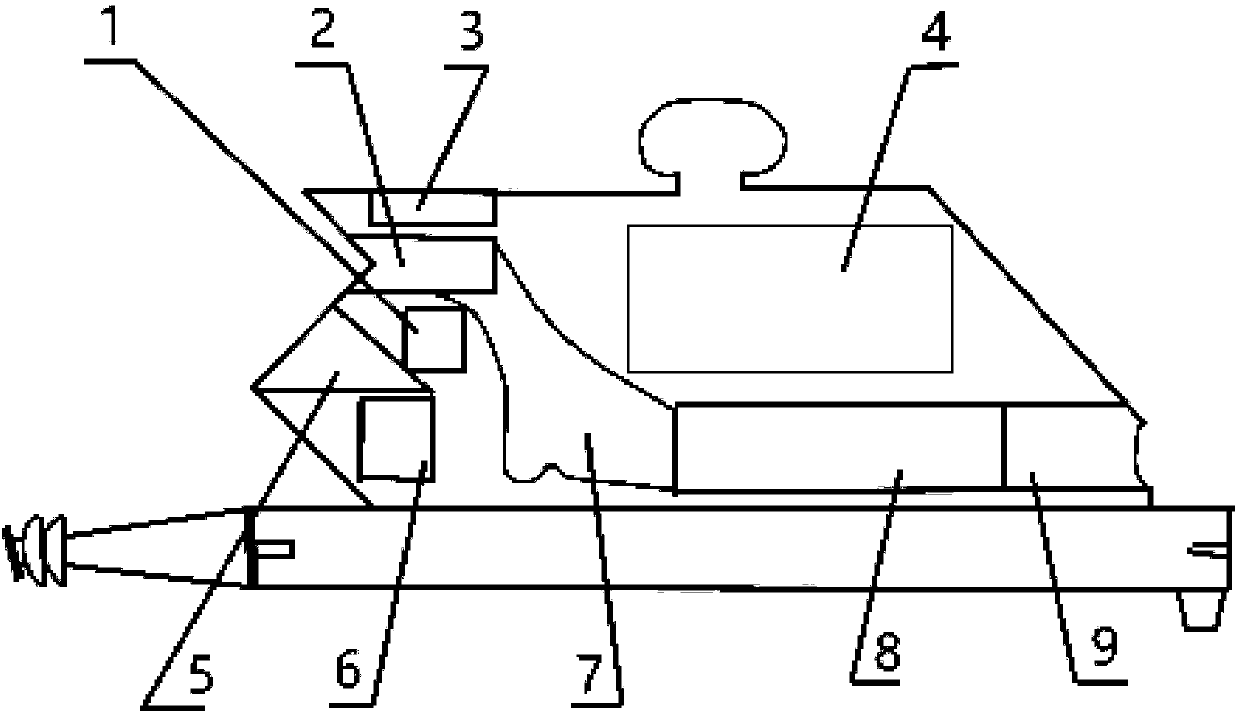

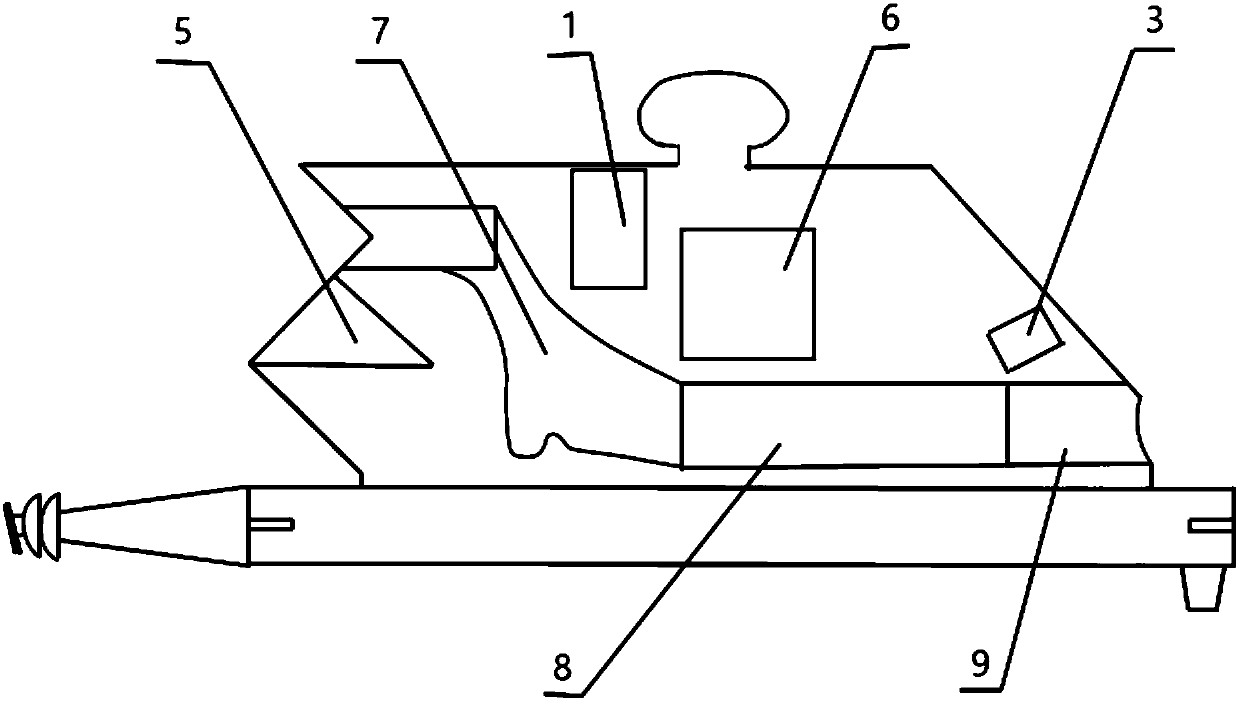

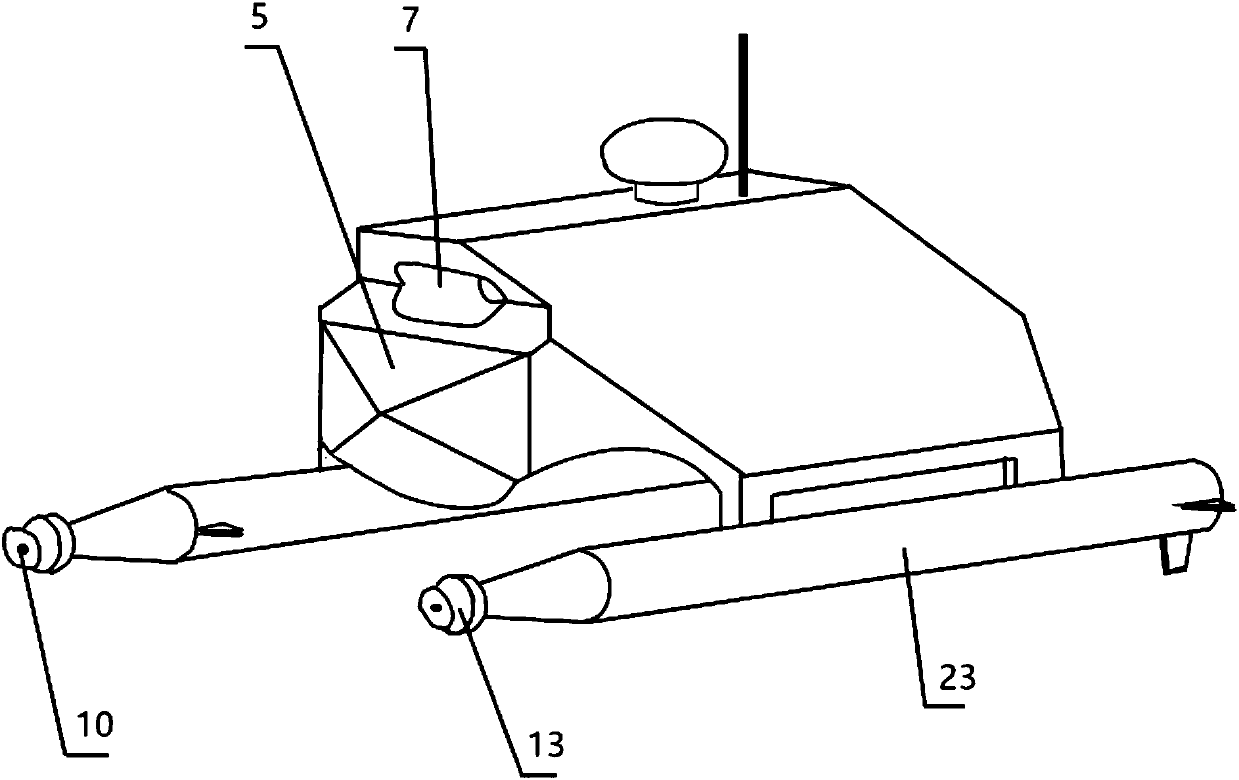

Novel supercavitation water surface high-speed boat

ActiveCN107554684AHigh speed sailingLarge thrustWatercraft hull designPropulsive elementsAir filterAir cavity

The invention discloses a novel supercavitation water surface high-speed boat. The novel supercavitation water surface high-speed boat comprises submerged bodies 23, a support structure, a turbojet engine 8, a driver cabin 5, a steward cabin 4, an S air inlet channel 7, a tail flame treatment nozzle 9, a power source system 1, a central control system 6, an air filter device 2, an air compressionsystem 3 and cavitation generators. The cavitation generators each comprise a cavitator 10, air guiding bushings 13, exhaust holes 14 and air leading grooves 16. Air enters a hull from the air filterdevice 2 and enters the turbojet engine 8 through the S air inlet channel 7 and is finally ejected out through the tail flame treatment nozzle 9. The novel supercavitation water surface high-speed boat takes the turbojet technology as propulsion power, so that compared with an underwater propeller, the propulsion speed and the efficiency are higher; the cavitation generators adopt the supercavitation technology, so that the hull does not make direct contact with water, compared with a traditional vessel, the water resistance of the hull can be reduced, and the navigational speed is increased.

Owner:HARBIN ENG UNIV

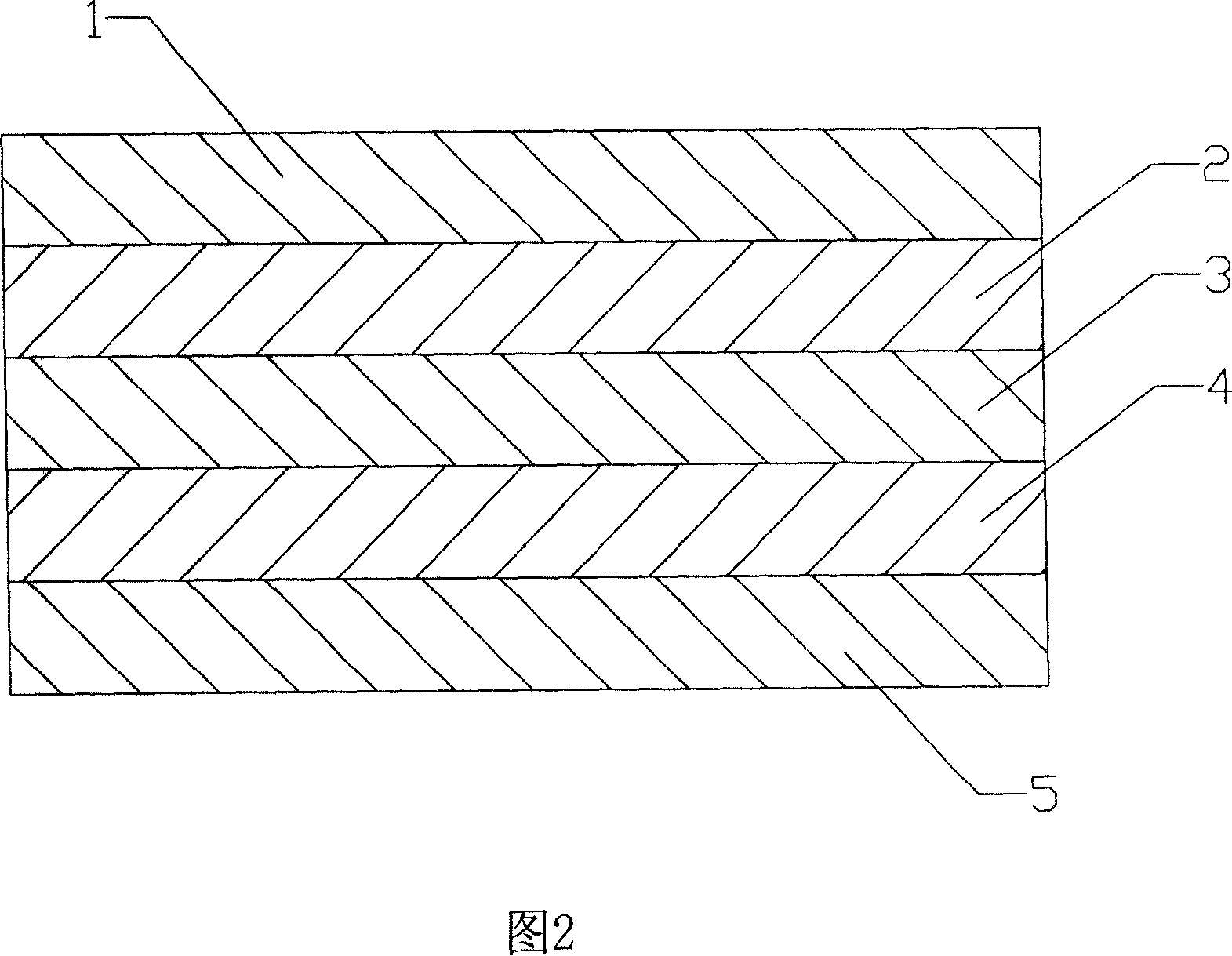

Paper plastic glue-free composite on line repeated spraying bidirectional stretching polypropylene film and its preparation method

ActiveCN101148105ARealize paper-plastic composite without glueComposite process is simpleSynthetic resin layered productsSurface layerEngineering

The present invention discloses one kind of biaxially stretched polypropylene film with on-line leached layer for no-adhesive paper-plastic combination and its preparation process. The film includes one base film comprising one or two biaxially stretched upper surface layers, one core layer and one or two biaxially stretched lower surface layers, and one functional film layer for direct combination with paper material. The film is prepared through forming melt with the material in an extruder, flow casting the melt to form co-extruded thick sheet, biaxially stretching to form film, corona treatment or flame treatment to form mother film, ageing treatment and cutting into the film product. The biaxially stretched polypropylene film with on-line leached layer for no-adhesive paper-plastic combination has low power consumption, environment friendship, high heat sealing strength and high stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

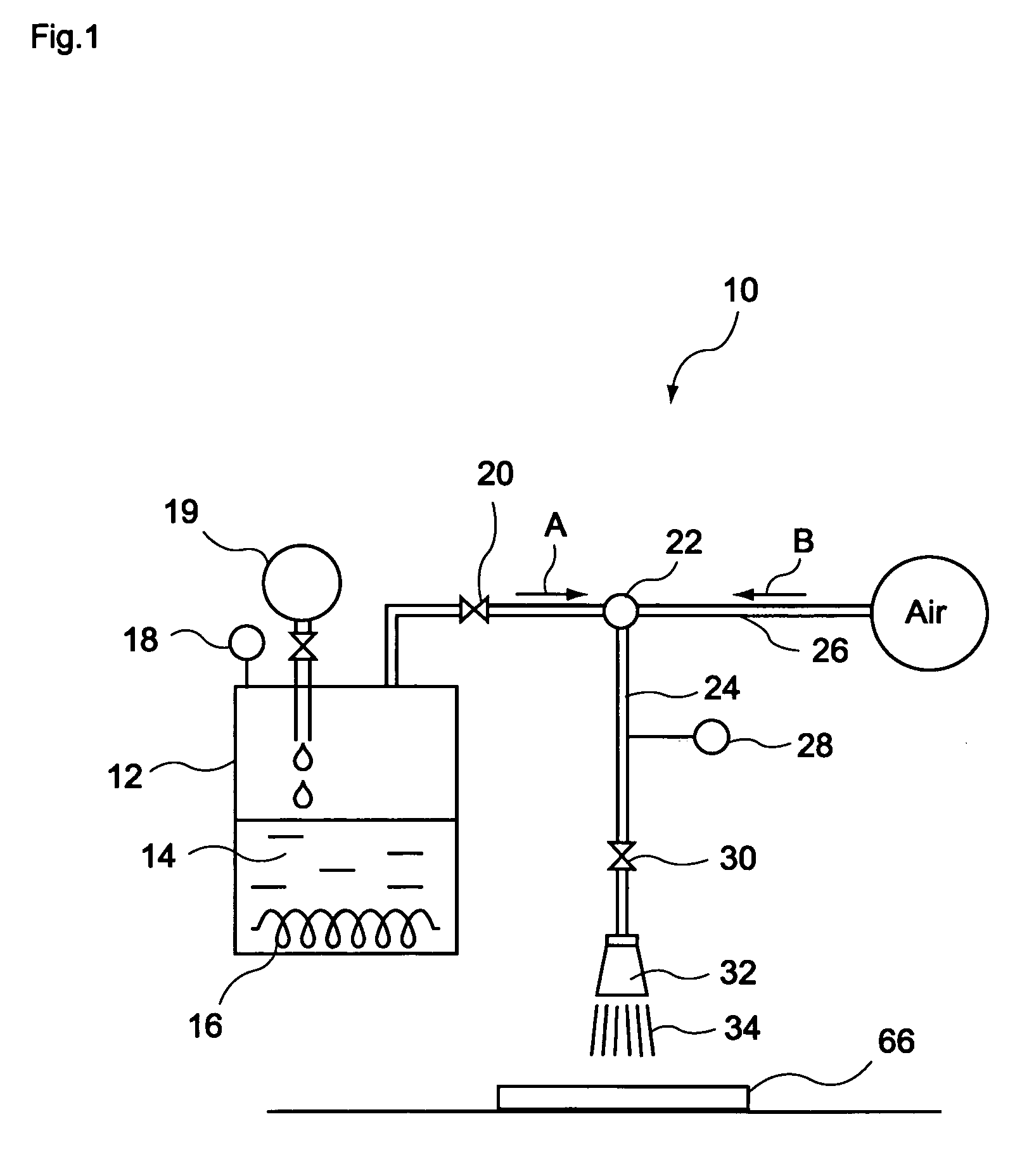

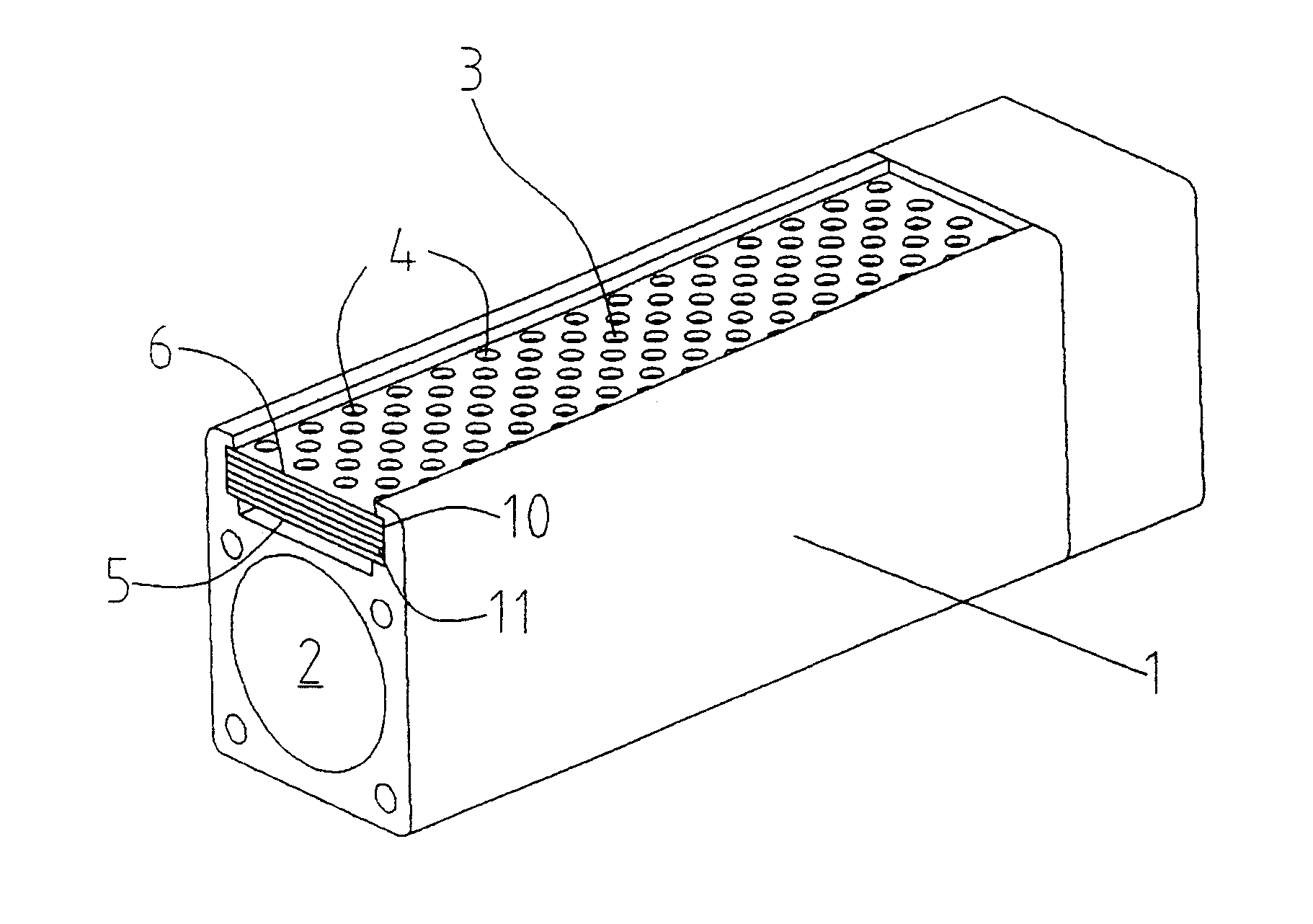

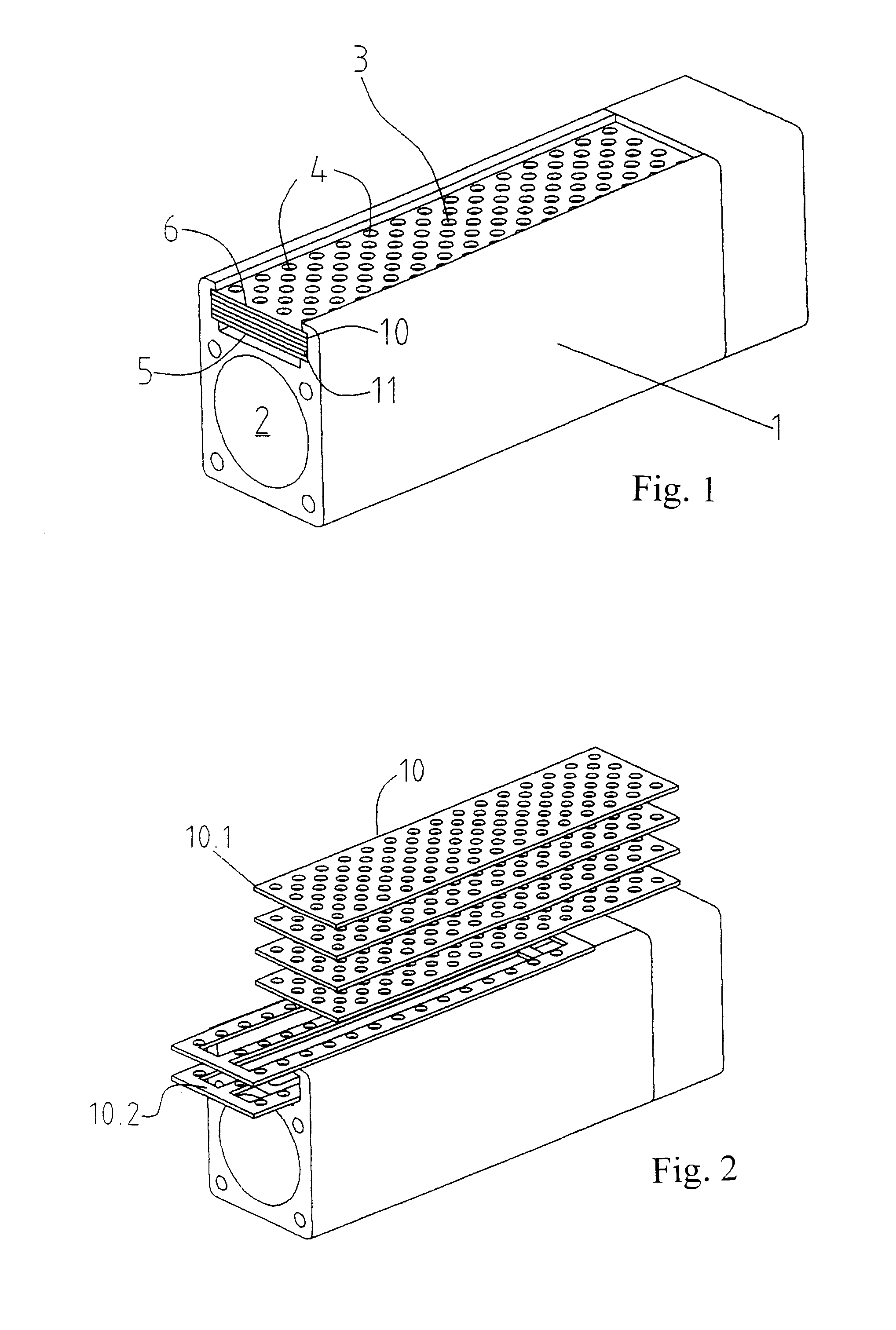

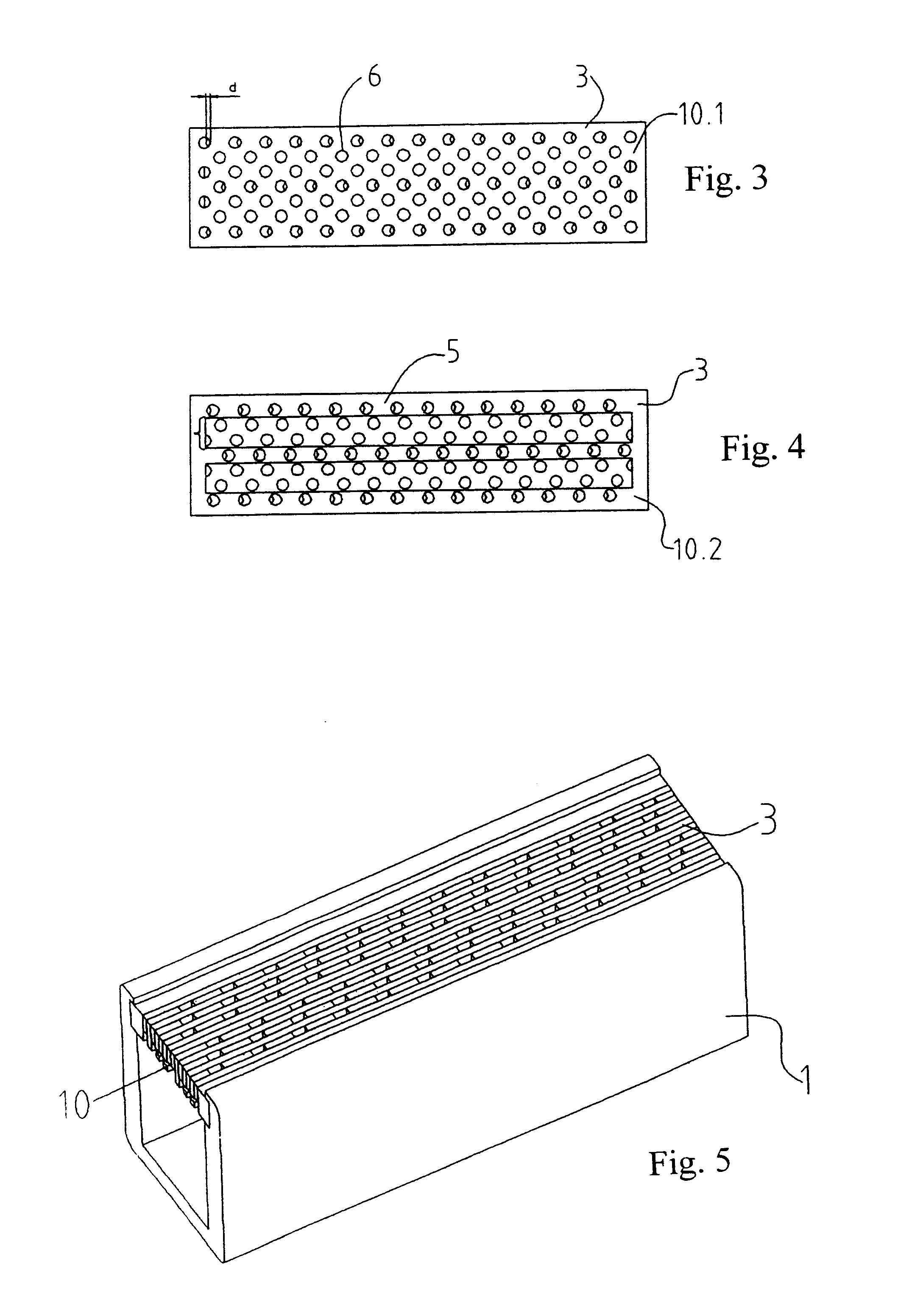

Gas burner

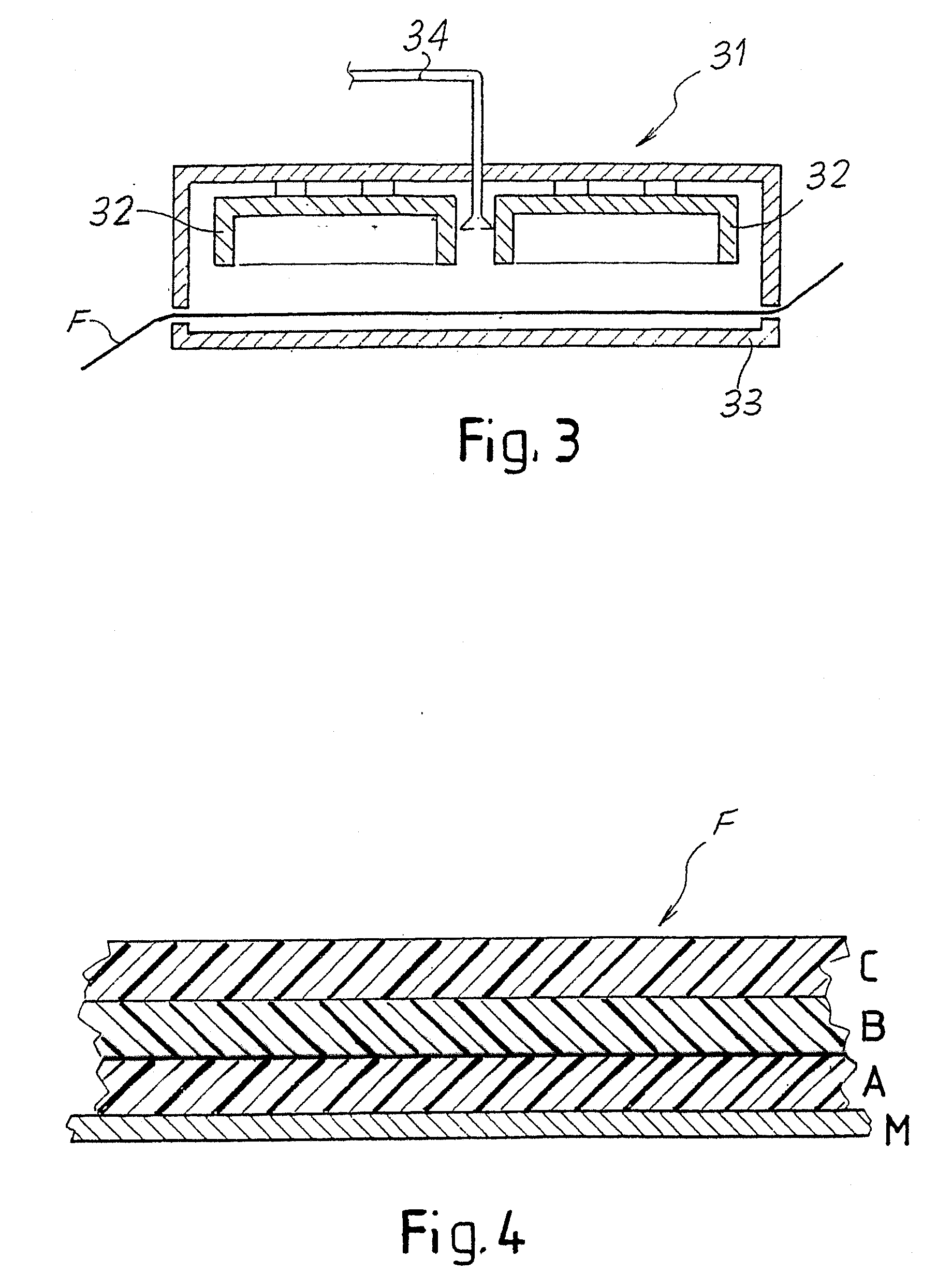

InactiveUS20110244411A1Less productiveIncrease heatChemical vapor deposition coatingGaseous fuel burnerEngineeringFlame treatment

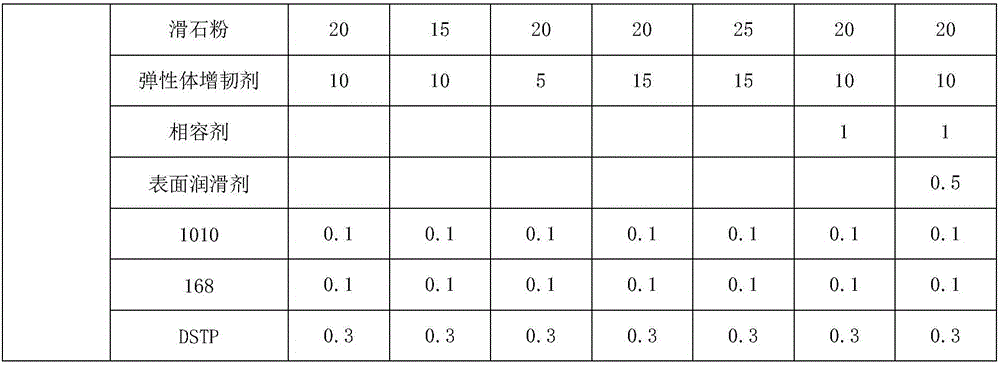

A gas burner, which is particularly suitable for flame treatment of substrates having large surfaces, e.g. for coating such surfaces in a combustion chemical vapor deposition (CCVD) process, includes a burner body with a gas supply connection and a nozzle plate, wherein the burner body and the nozzle plate constitute together a gas plenum and the nozzle plate constitutes a perforated wall section of the plenum. The nozzle plate includes a large number of nozzles extending from a plenum side to a flame side of the nozzle plate and it is made of a plurality of sheets which are arranged in a stack and extend substantially perpendicular or substantially parallel to the nozzle extension. The sheets include through openings, wherein the through openings of all sheets are at least partly aligned with each other, or they have a comb-like form.

Owner:TETRA LAVAL HLDG & FINANCE SA

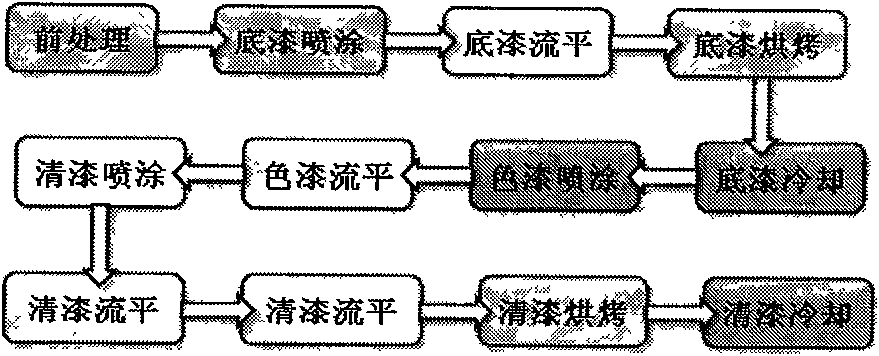

Multilayer Metallized Film and Production Method Description

InactiveUS20080318036A1Improve adhesionHigh oxygen and water vapor barrier effectFilm/foil adhesivesSynthetic resin layered productsButeneFlame treatment

To increase the barrier effect of a metallized film intended for use I the packaging, in particular of food products, a particular composition of the plastic layer (A) is suggested, on which the metal layer (M) is deposited by vacuum evaporation. The plastic layer comprises a polypropylene and butene copolymer and is subjected to a preliminary surface activation treatment, preferably to a flame treatment, and to a subsequent plasma treatment under partial vacuum conditions prior to metallization.

Owner:SYROM 90

PBT/ABS alloy material and method for preparing same

InactiveCN101284932AImprove surface activityColor effects omittedHeat deflection temperatureHigh surface

The invention discloses a PBT / ABS alloy material and a method for manufacturing an automobile bumper. The compositions by weight percentage of the PBT / ABS alloy material are: 45 to 70 percent of PBT, 20 to 45 percent of ABS, 1 to 10 percent of active compatibilizer, 0.1 to 0.6 percent of lubricant, 0.1 to 1.2 percent of chemical inhibitor and 0.1 to 0.6 percent of light stabilizer. The PBT / ABS alloy material has high surface activity, excellent low temperature toughness, excellent dimension stability and high thermal distortion temperature, and other indexes all reaching or exceeding the prior automobile material standards. The bumper molded by the material has high surface activity and strong bonding force with oil paint, can undergo direct spray painting without flame treating, have high thermal distortion temperature and stable dimension, can not cause obvious distortion due to vast-scale variance of the temperature, have smooth and bright surface, good spray painting effect and short baking time, and improve the production efficiency. Moreover, the material can be directly dyed into the same color with a metal part according to the appearance demand of the part, thereby the spray painting technique is saved and the spray painting free effect is achieved.

Owner:SHENZHEN KEJU NEW MATERIAL

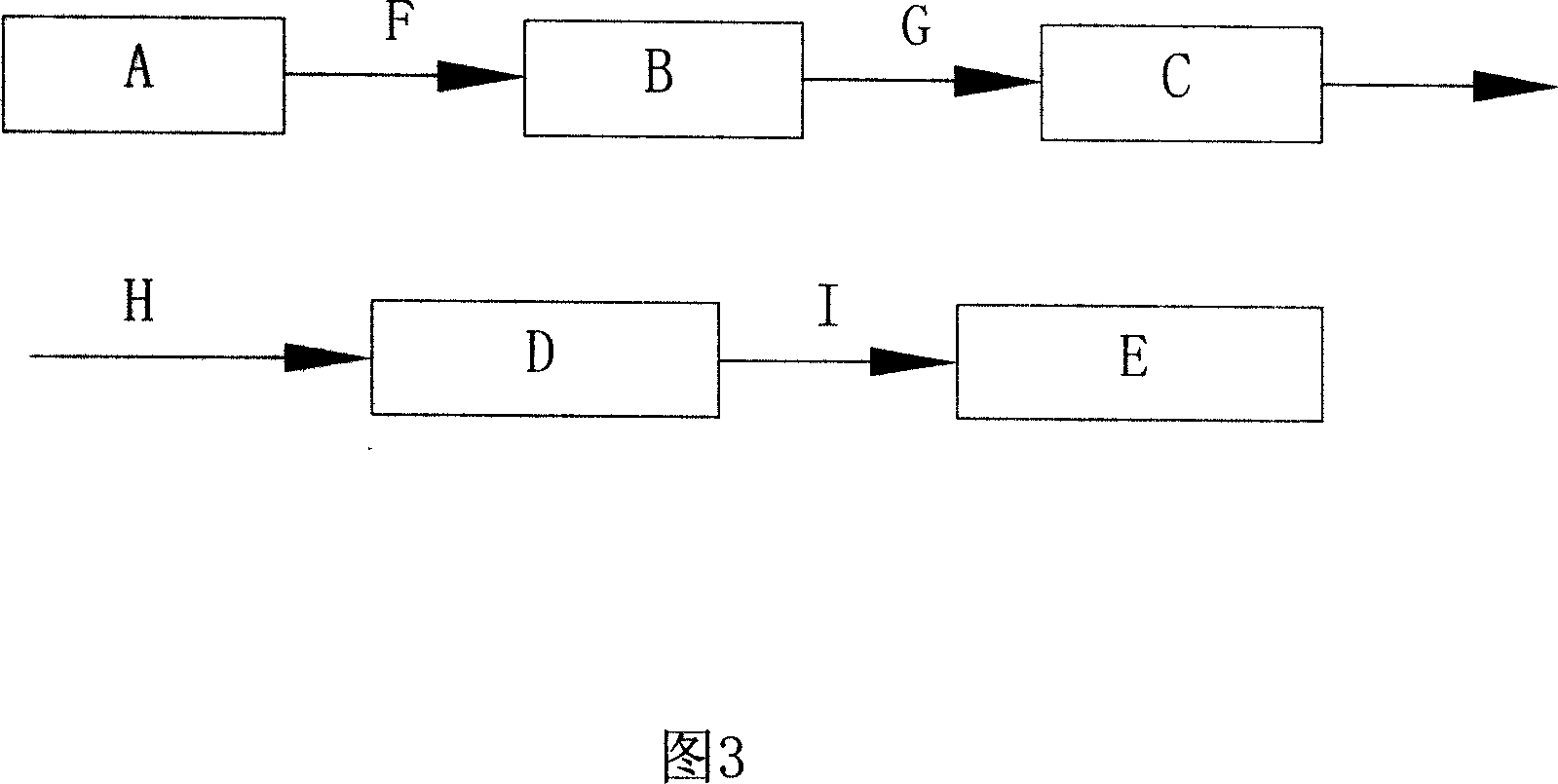

Oil paint coating line-based process for coating water paint in two layers on automotive plastic exterior trimming part

InactiveCN101670332ARealize collinear productionLess investmentPretreated surfacesCoatingsWater basedProduction line

The invention discloses an oil paint coating line-based process for coating water paint in two layers on an automotive plastic exterior trimming part. In the process, to implement two-layer coating technology, an oil / water-based insulation combined system of a robot is imporved and the temperature of a base paint oven in an oil-based production line is regulated by process control of a pretreatment step and by using stable industrial propane (with a purity of more than 95 percent) as a flame treatment fuel and executing base material flame treatment experimental design, base paint spraying isavoided, water-based color paint is directly sprayed on a plastic base material, and a varnish is an oil-based varnish. After equipment improvement is completed, original oil-based paint can still beused in normal production.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

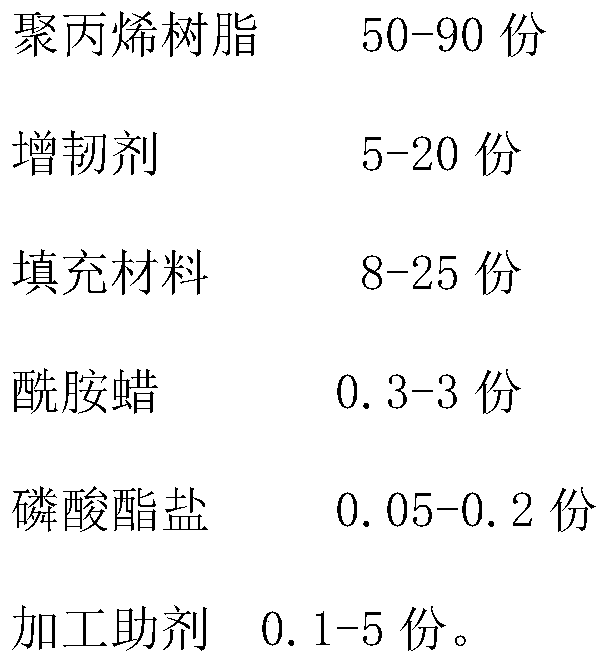

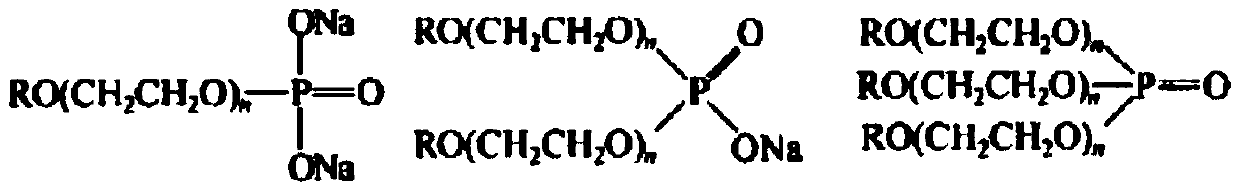

Flame-processing-free waterproof polypropylene composite material which can be coated easily, and preparation method thereof

The invention discloses a flame-processing-free waterproof polypropylene composite material which can be coated easily, and a preparation method thereof. The flame-processing-free waterproof polypropylene composite material which can be coated easily comprises, by weight, 50 to 90 parts of polypropylene resin, 5 to 20 parts of a flexibilizer, 8 to 25 parts of a filling material, 0.3 to 3 parts ofan amide wax, 0.1 to 3 parts of an anti-oxidant, 0.05 to 0.2 part of a phosphate, and 0.1 to 5 parts of a processing auxiliary agent. According to the preparation method, the phosphate and the amide wax are combined, so that rapid crystallization is realized, the higher the crystallization degree, the compacter a compact layer formed on part surfaces is, the better solvent resistance is achieved,the higher material surface tension force is, and the better coating performance is, paint film and PP material tight combination is ensured, a protective film is formed on material surface, penetration of water molecules is prevented, and material water resistance is improved; the particle size of an added filling material is controlled, so that surface tension is improved further, and painting performance and material water resistance are improved.

Owner:WUHAN JINFA TECH CO LTD +1

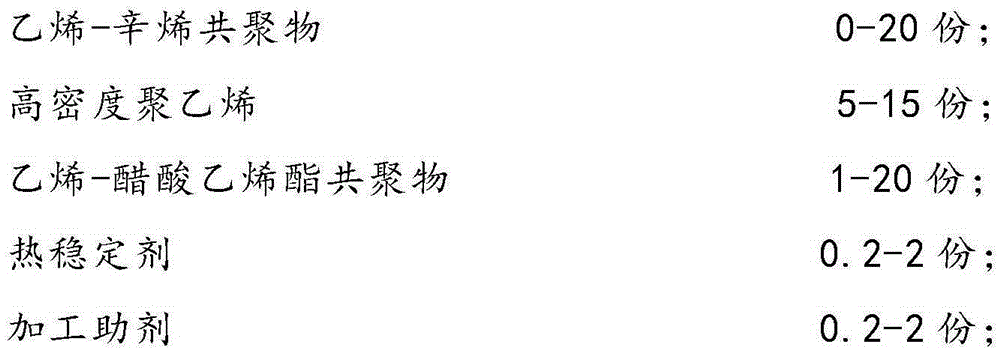

Polypropylene compound free of flame treatment and preparation method thereof

The invention discloses a polypropylene compound free of flame treatment. The polypropylene compound comprises the following components in parts by weight: 65-90 parts of polypropylene, 0-20 parts of ethylene-octene copolymer, 5-15 parts of high density polyethylene, 1-20 parts of ethylene-vinyl acetate copolymer, 0.2-2 parts of a heat stabilizer and 0.2-2 parts of a processing agent; the invention further discloses a preparation method of the polypropylene compound free of flame treatment. Compared with the prior art, the polypropylene compound provided by the invention has the advantages that the compound is free of flame treatment when being used for manufacturing automobile parts, the time is saved and the economic cost is reduced, and manufacturing processes are reduced.

Owner:SHANGHAI KINGFA SCI & TECH

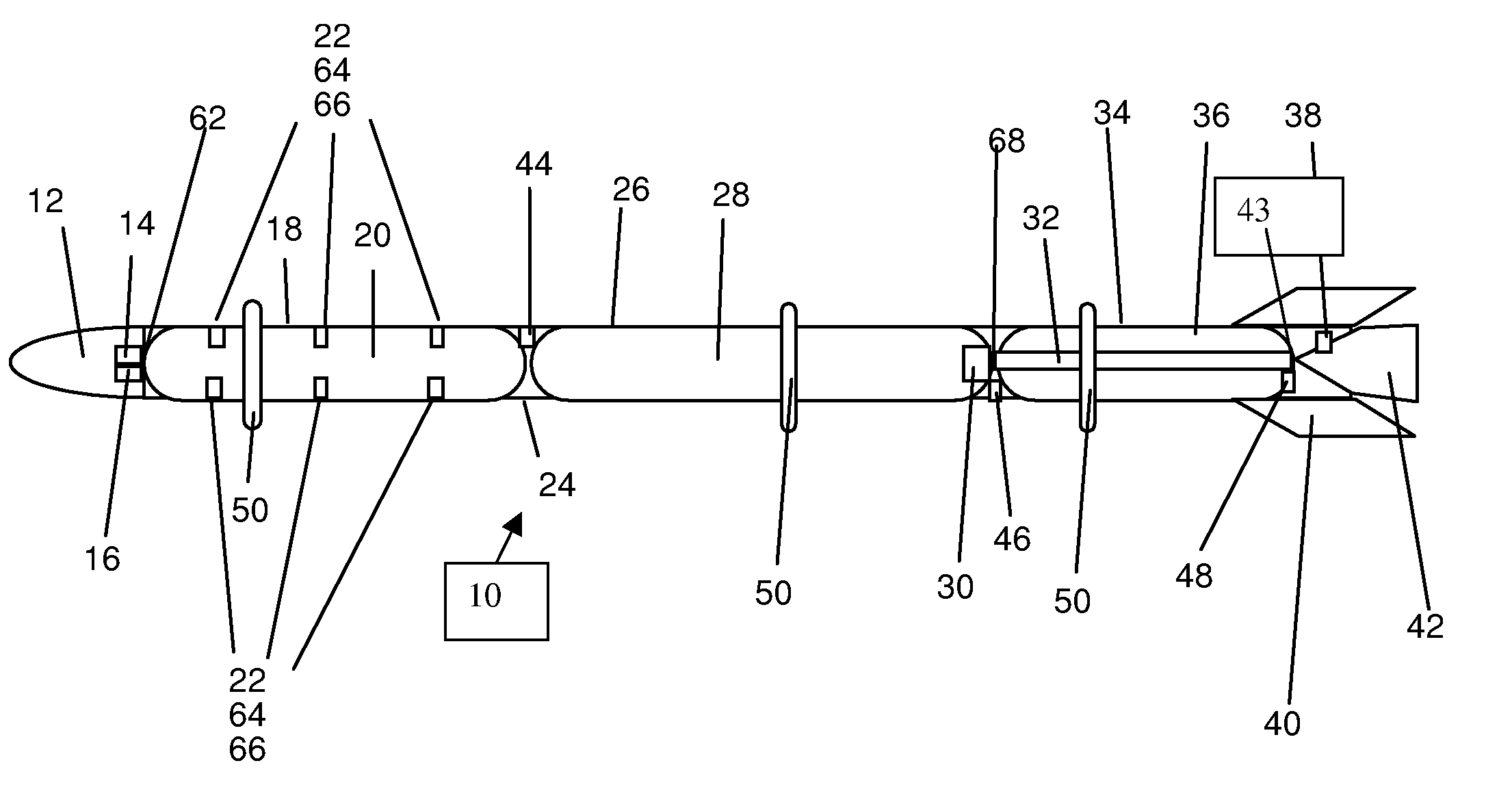

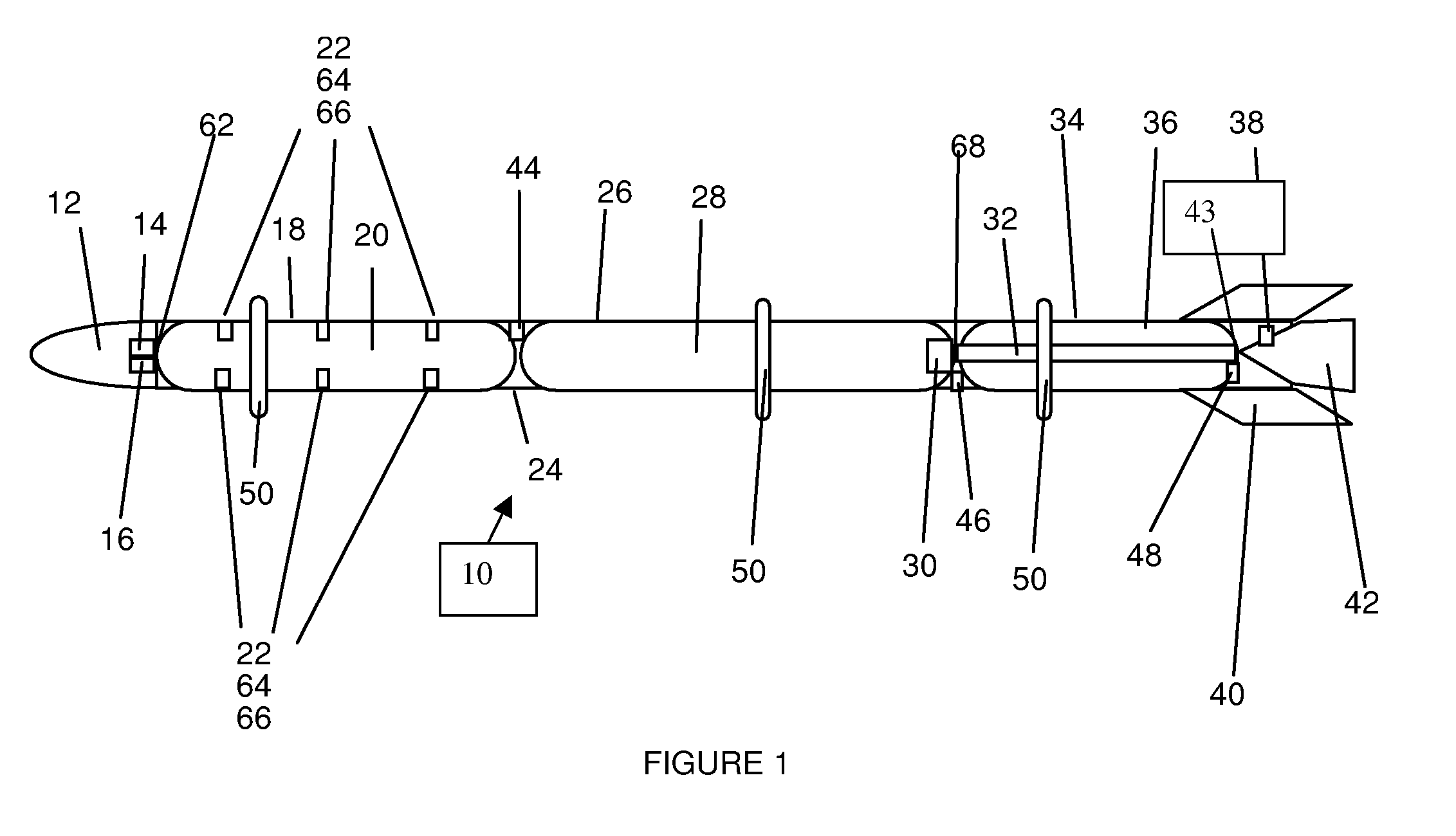

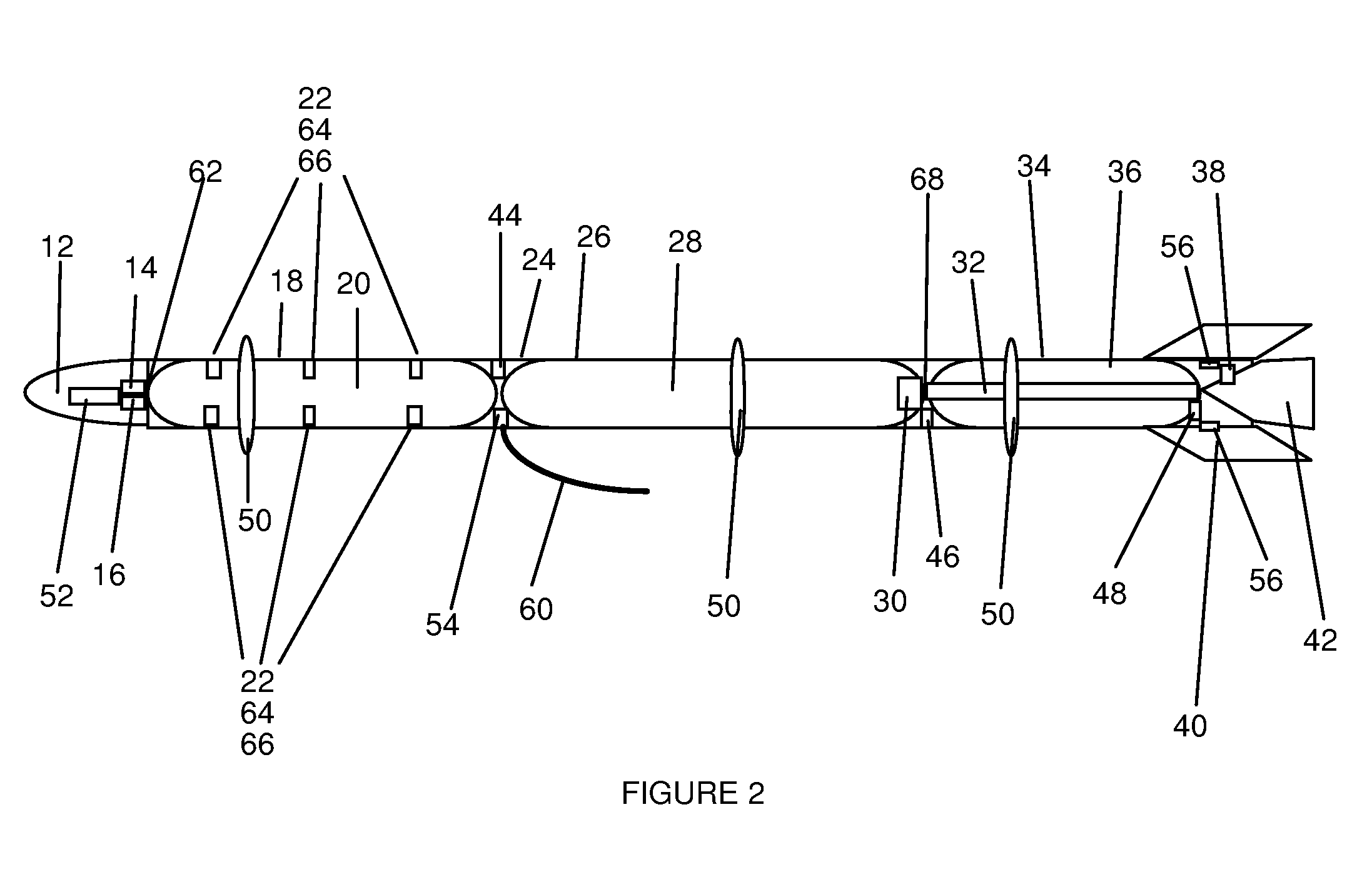

Fire retardation missile system and method

A fire retarding missile and method of use having a unitary construction and containing a propulsion system as well as fire treatment materials. Dispersal of the materials can be initiated both actively and passively, with passive dispersal allowing for a fail safe mode of operation. The fire treatment materials are of the oxygen reduction type, and the method of the invention is to target the hot spot of a fire in order to reduce the spread and intensity thereof. An active guidance system may be of the heat seeking type, or may alternatively be remote controlled video. Stabilizer and guidance fins are controlled in response to signals from the guidance system in order to precisely position the device. The device can be modified for use in fires of specific heat ranges by using nose cones designed to melt in a respective heat range.

Owner:WILLNER BYRON J

Continuous casting manufacturing method for low-carbon high-chromium ferrite corrosion-resisting steel small square billet

The invention discloses a continuous casting manufacturing method for a low-carbon high-chromium ferrite corrosion-resisting steel small square billet. The continuous casting manufacturing method is characterized in that the continuous casting superheat temperature is controlled to be 20-40 DEG C, the drawing speed is 2.2-2.6 m / min, the cooling water volume of a crystallizer is 1750-1950 L / min, the vibration frequency of the crystallizer is 190-220 Hz, the vibration amplitude is 6.5-9.5 mm, the protection slag basicity of the crystallizer is 0.65-0.90, the melting point temperature is 1020-1060 DEG C, and at the temperature of 1300 DEG C, the viscosity is 0.35-0.60 Pa.s; and the M-EMS and F-EMS combined control mode is adopted in the continuous casting process, the current intensity of the M-EMS is 280-320 A, the frequency of the M-EMS is 3-6 Hz, the current intensity of the F-EMS is 400-600 A, and the frequency of the F-EMS is 10-15 Hz. According to the low-carbon high-chromium ferrite corrosion-resisting steel small square billet produced through the method, the low-power acid pickling qualified rate is 95% or over, the surface of the small square billet is free of obvious cracks and other defects, the average depth of oscillation marks is smaller than or equal to 0.24 mm, the small square billet can directly enter the next steel rolling procedure for production without being subjected to surface flame treatment, and the requirements of customers are met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

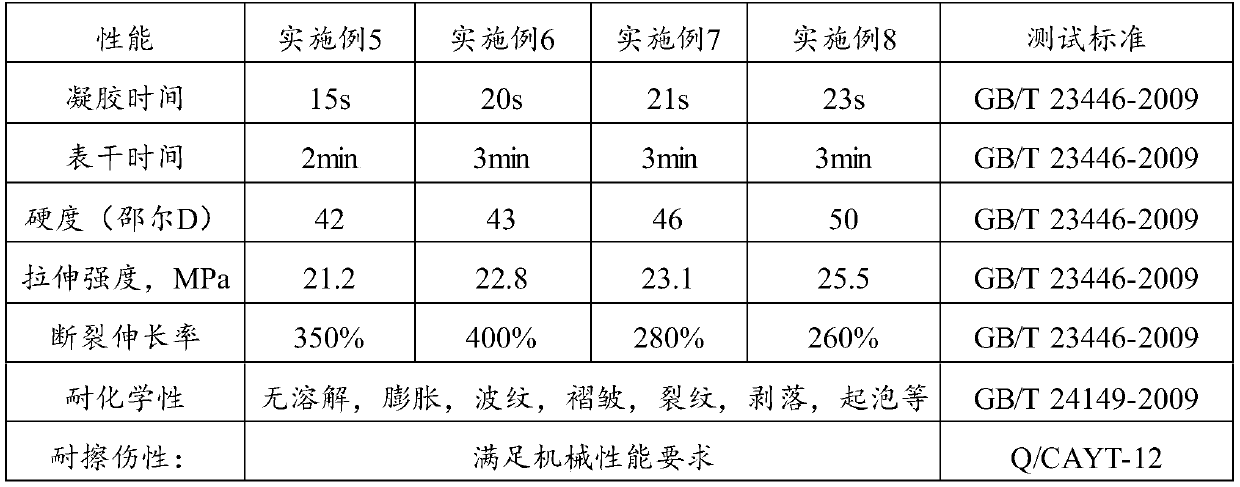

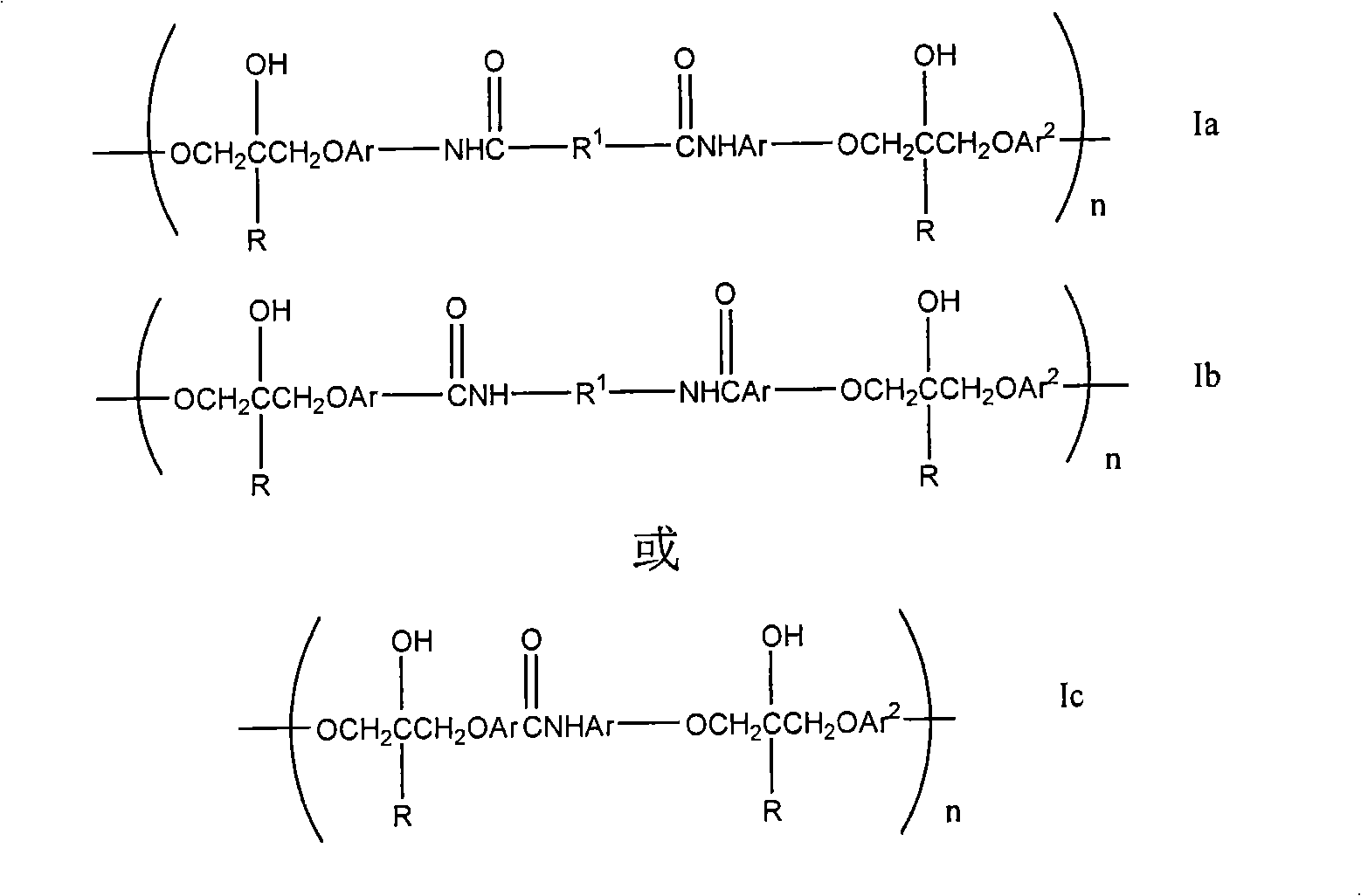

Two-component polyurea coating and application thereof

InactiveCN110564276AImprove scratch resistanceLow VOC contentPretreated surfacesPolyurea/polyurethane coatingsDiluentSpray coating

The invention provides a two-component polyurea coating. The two-component polyurea coating comprises a component A and a component B at a volume ratio of 1: 1, wherein the component A comprises the following components in percentage by weight: 90wt%-100wt% of a semi-prepolymer; 0 to 10 wt% of a diluent; the semi-prepolymer is prepared from an aromatic isocyanate and a hydroxyl-terminated compound, or is prepared from an aliphatic isocyanate and an amino-terminated compound; the component B comprises the following components in percentage by weight: 40 to 75wt% of an amine-terminated polyether; 10 wt%-50 wt% of an amino-terminated chain extender; 0-10 wt% of an auxiliary agent; 0-30 wt% of a pigment; the isocyanate index of the two-component polyurea coating is 1.0 to 1.1. Compared with the prior art, the advantages are that: the bi-component polyurea coating provided by the invention contains specific content components; preferable interaction effect is achieved; the two-component polyurea coating can be used for direct spraying coating onto modified polypropylene bumpers treated through flame treatment and / or primer treatment, and coating layers obtained by spraying can pass alltests of automobile bumper coating and meet the requirements of the coating for automobile bumpers.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

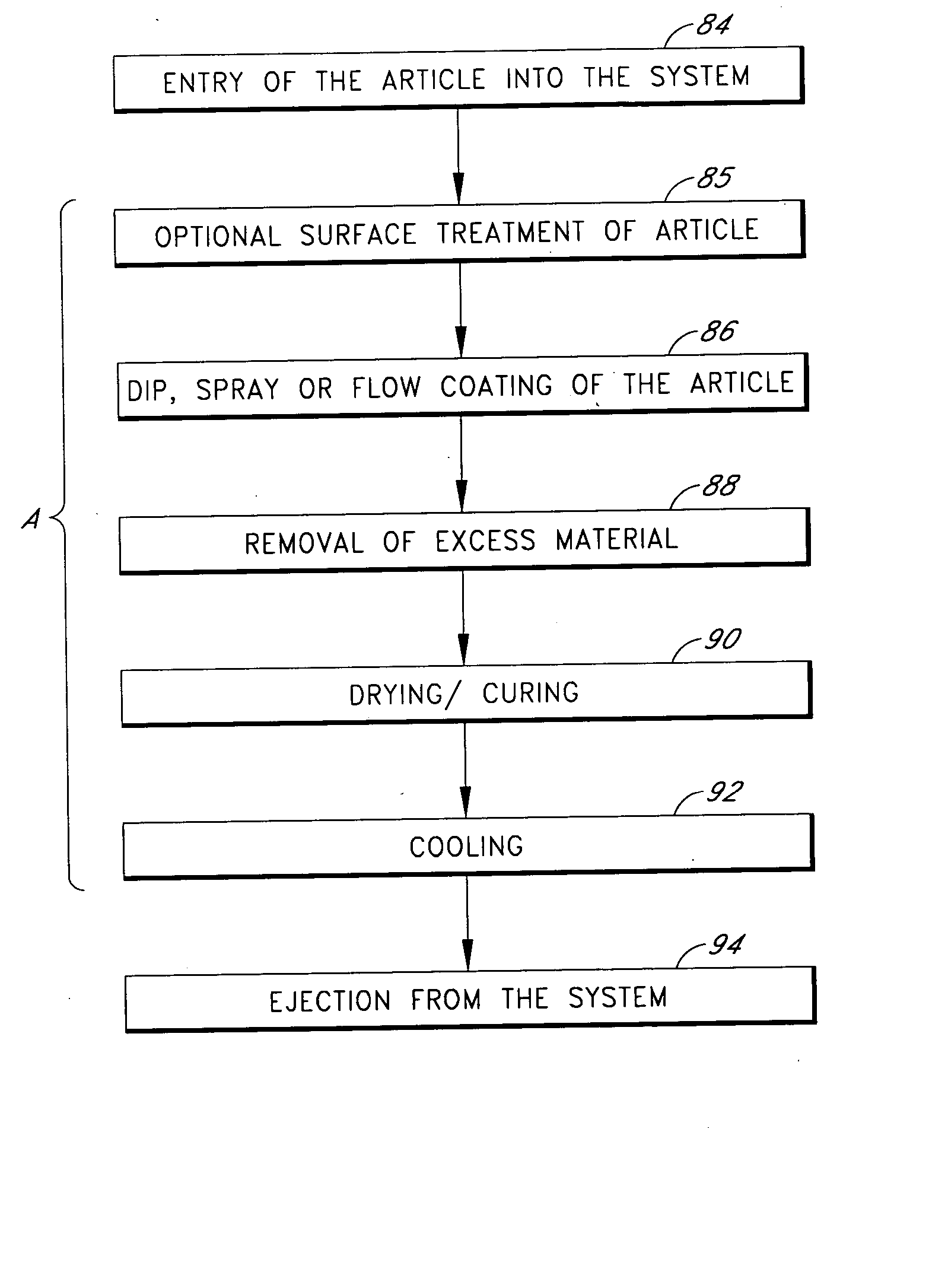

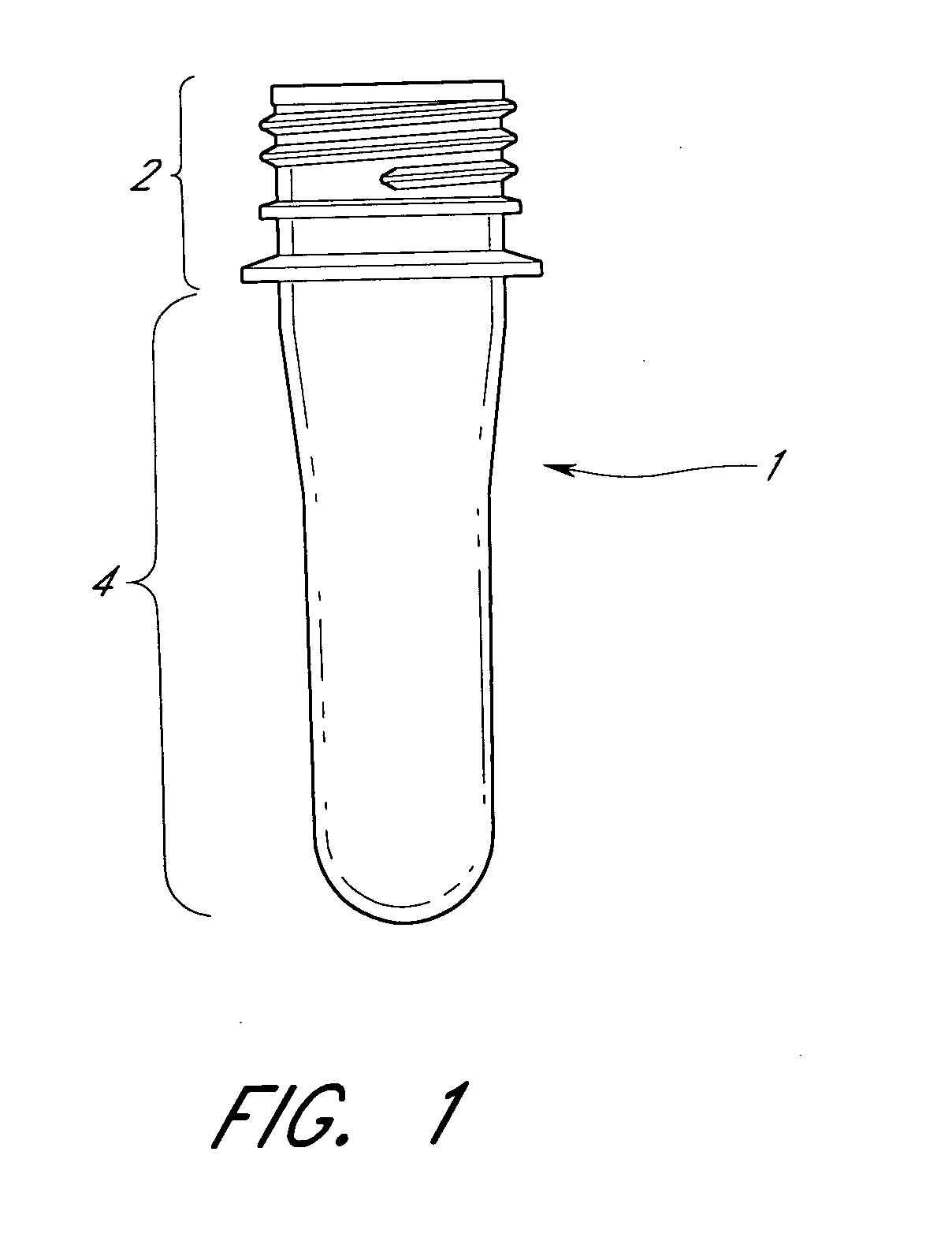

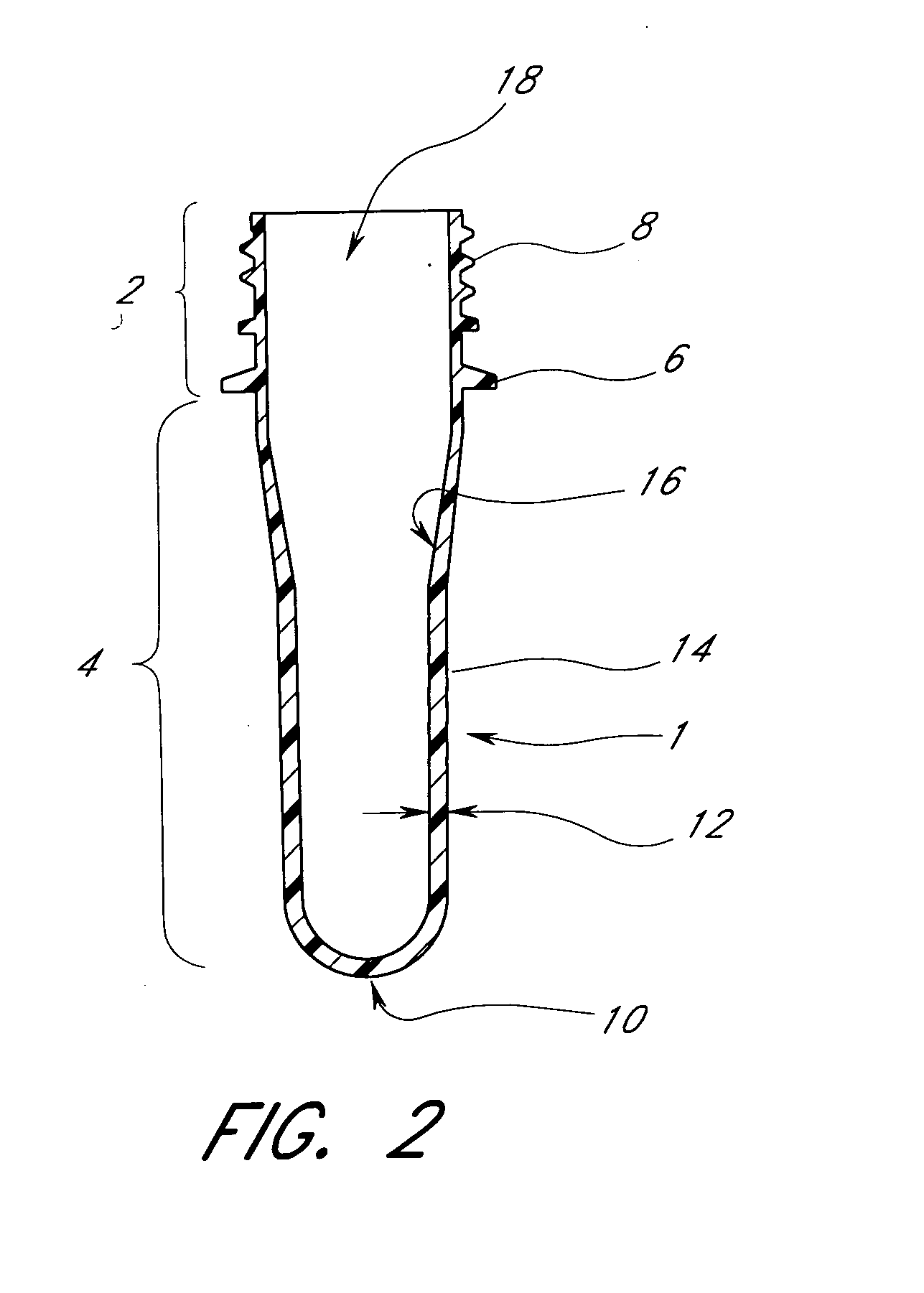

Methods of forming multilayer articles by surface treatment applications

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

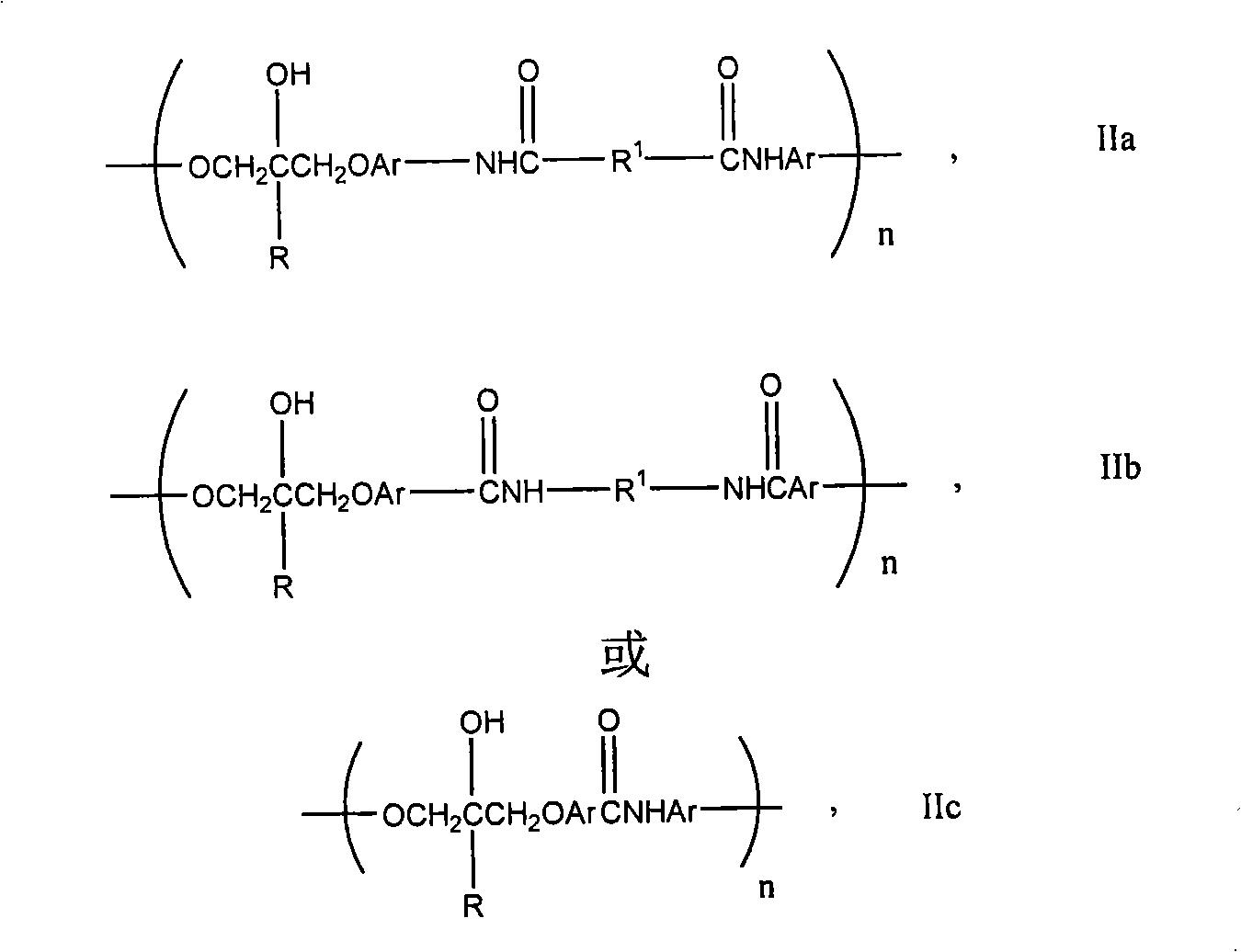

Plastic surface treatment method

InactiveCN103483614AEasy to glueHigh bonding strengthAdhesive processes with surface pretreatmentPotassium dichromateFlame treatment

The invention discloses a plastic surface treatment method. The plastic surface treatment method comprises the following steps: S1, allowing a plastic to be subjected to degreasing treatment by using a degreasing solvent; S2, performing oxidizing flame treatment: roughening the plastic surface by using a piece of abrasive cloth, and then placing the plastic above the oxidizing flame for calcination; S3, impregnating the plastic in a sodium hydroxide solution for 3-5 min, and then flushing the plastic with cold water; S4, performing activation treatment: impregnating the plastic in a mixed solution of chromic acid and concentrated sulphuric acid for 5-10 min; S5, performing oxidation treatment: performing oxidation on the plastic in a mixed solution of potassium dichromate and concentrated sulphuric acid for 5-7 min; S6, drying after washing. The plastic surface treatment method is simple in process; the treated plastic is easy to glue and high in joint strength.

Owner:ZHANGJIAGANG JINFENG RUNERFA HARDWARE PLASTIC FACTORY

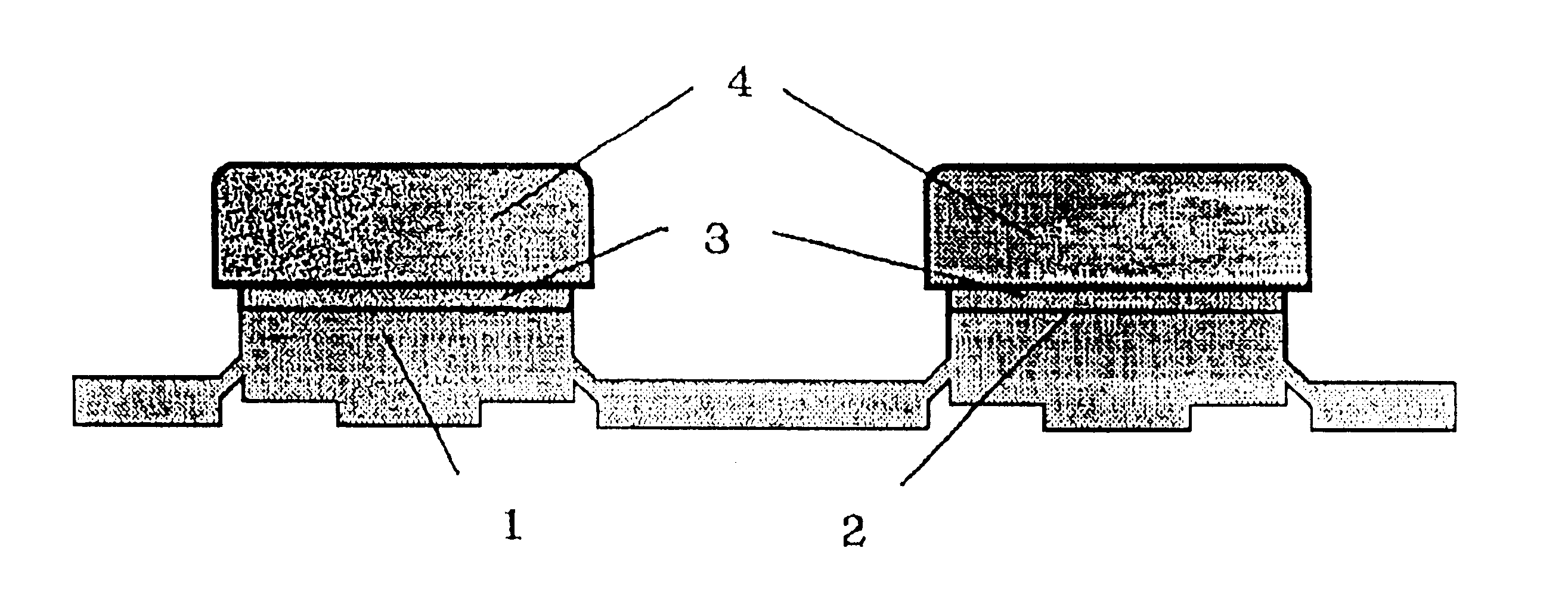

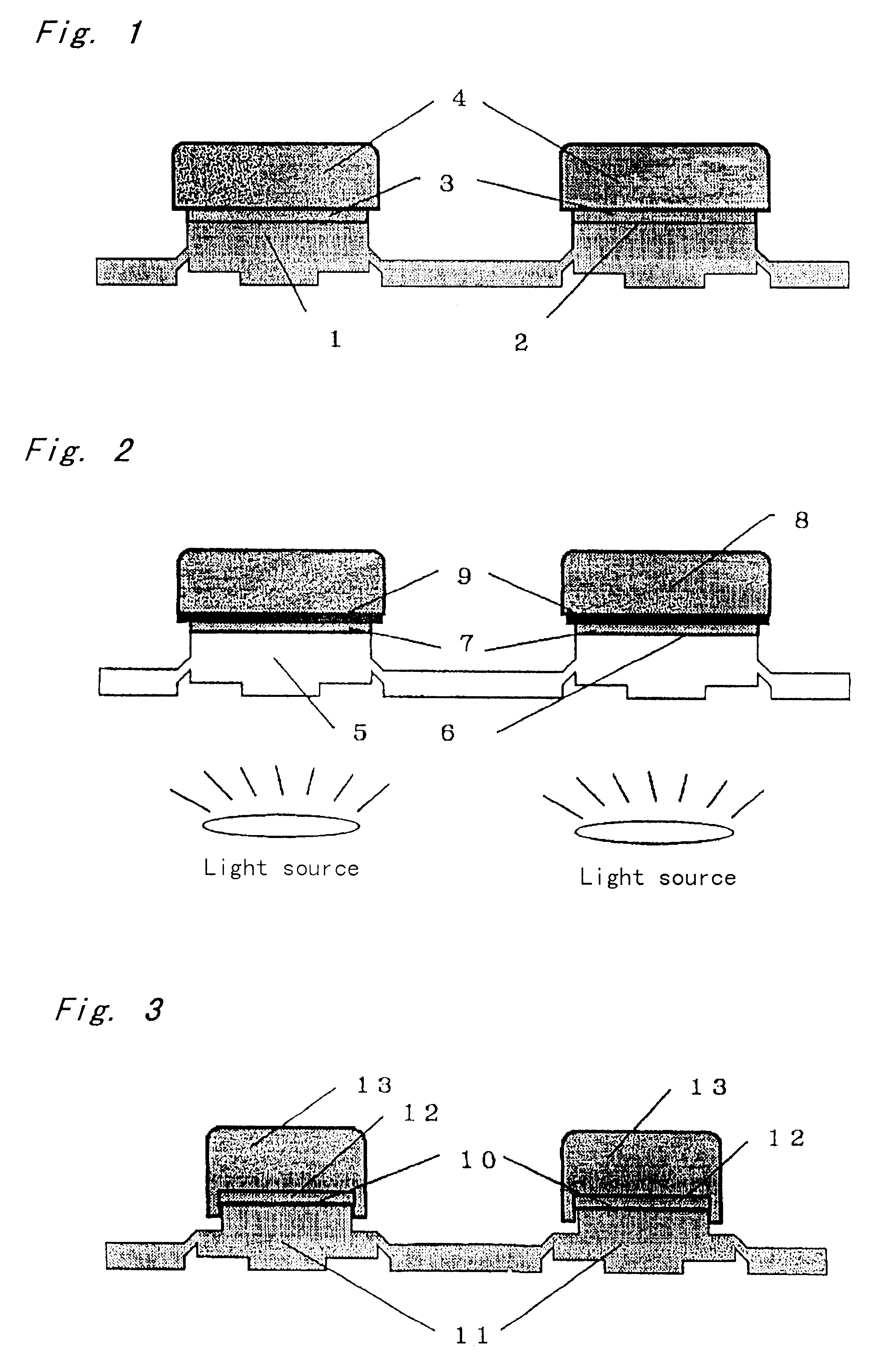

Method for manufacturing key pad with rigid resin key top

InactiveUS6451143B2High linear dilatation coefficientIncrease the number ofLamination ancillary operationsOrnamental structuresEpoxyUltraviolet

Owner:POLYMATECH CO LTD

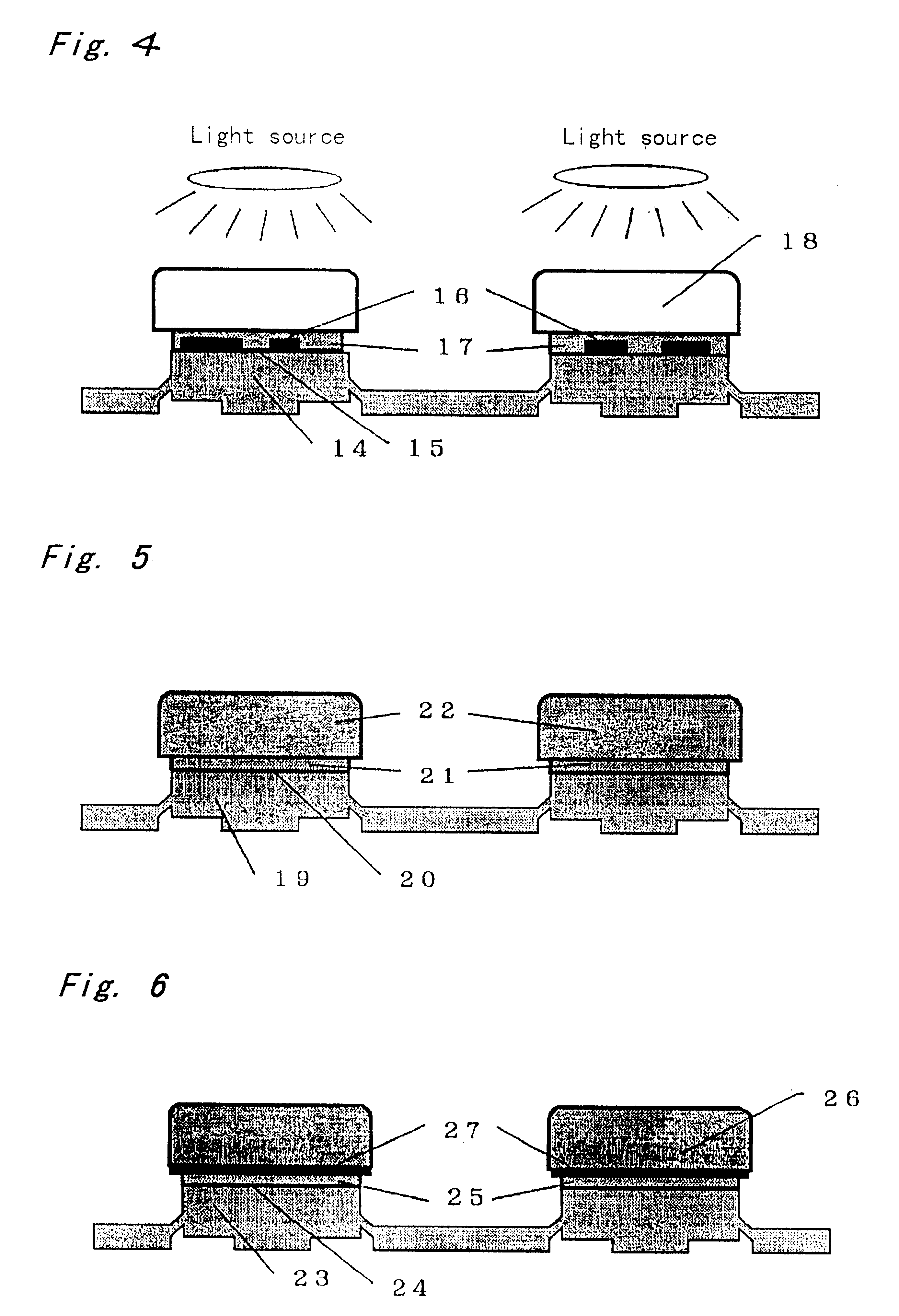

Screen printing technique for polyolefin plastic products

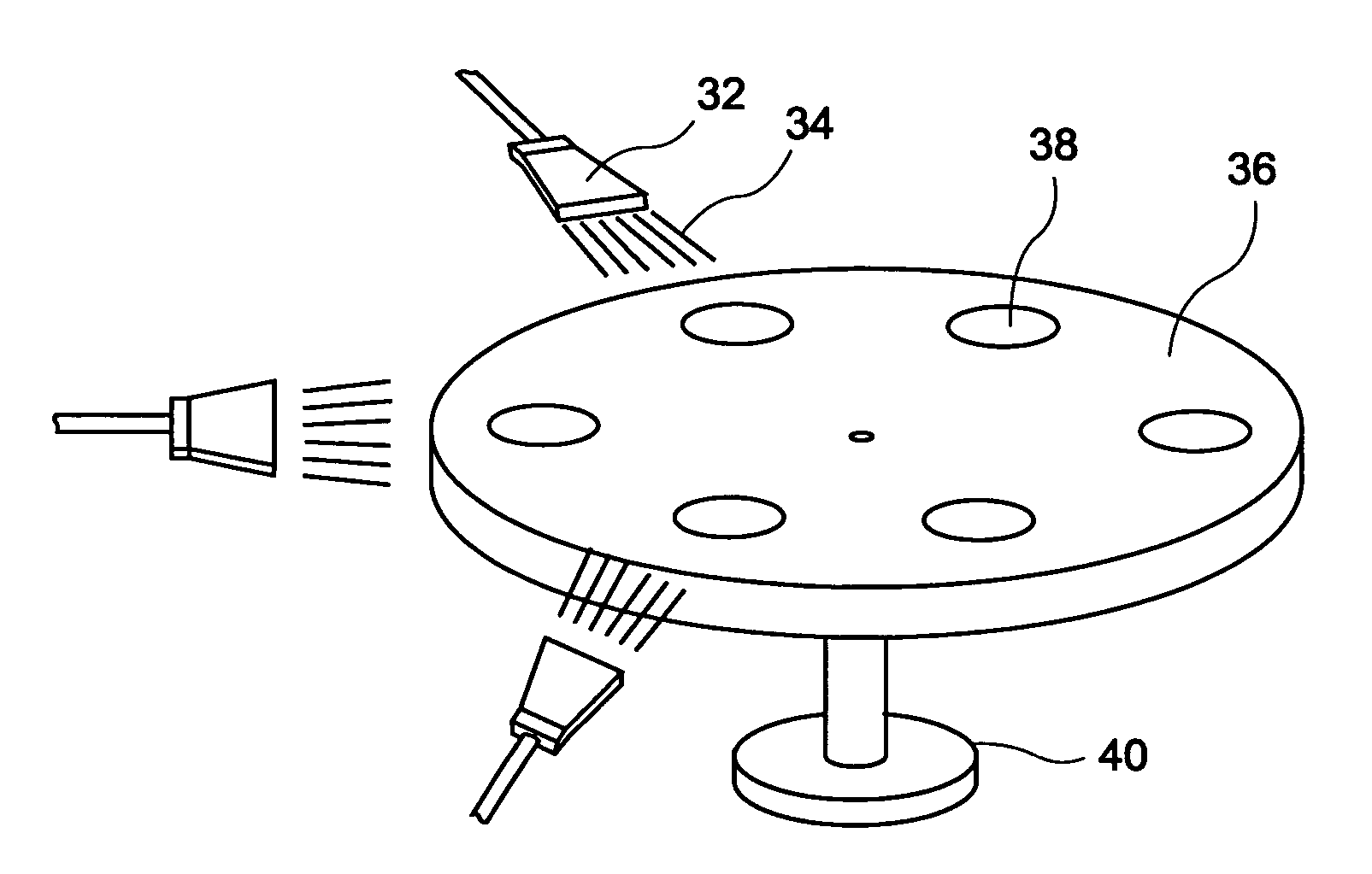

InactiveCN101085578AReduce manufacturing costEase of mass productionScreen printersPhotomechanical exposure apparatusScreen printingUV curing

The fine and highly effective polyolefin silk screening process comprises the silk screen making, oil paint modulation and working piece printing, features in the UV solidified oil paint, working piece silk screen painting composed of the surface flame treatment at the surface to be painted, silk screen painting, ultraviolet solidification treatment, with steady painting and ready for automatic production.

Owner:NINGBO BEIFA GRP CO LTD

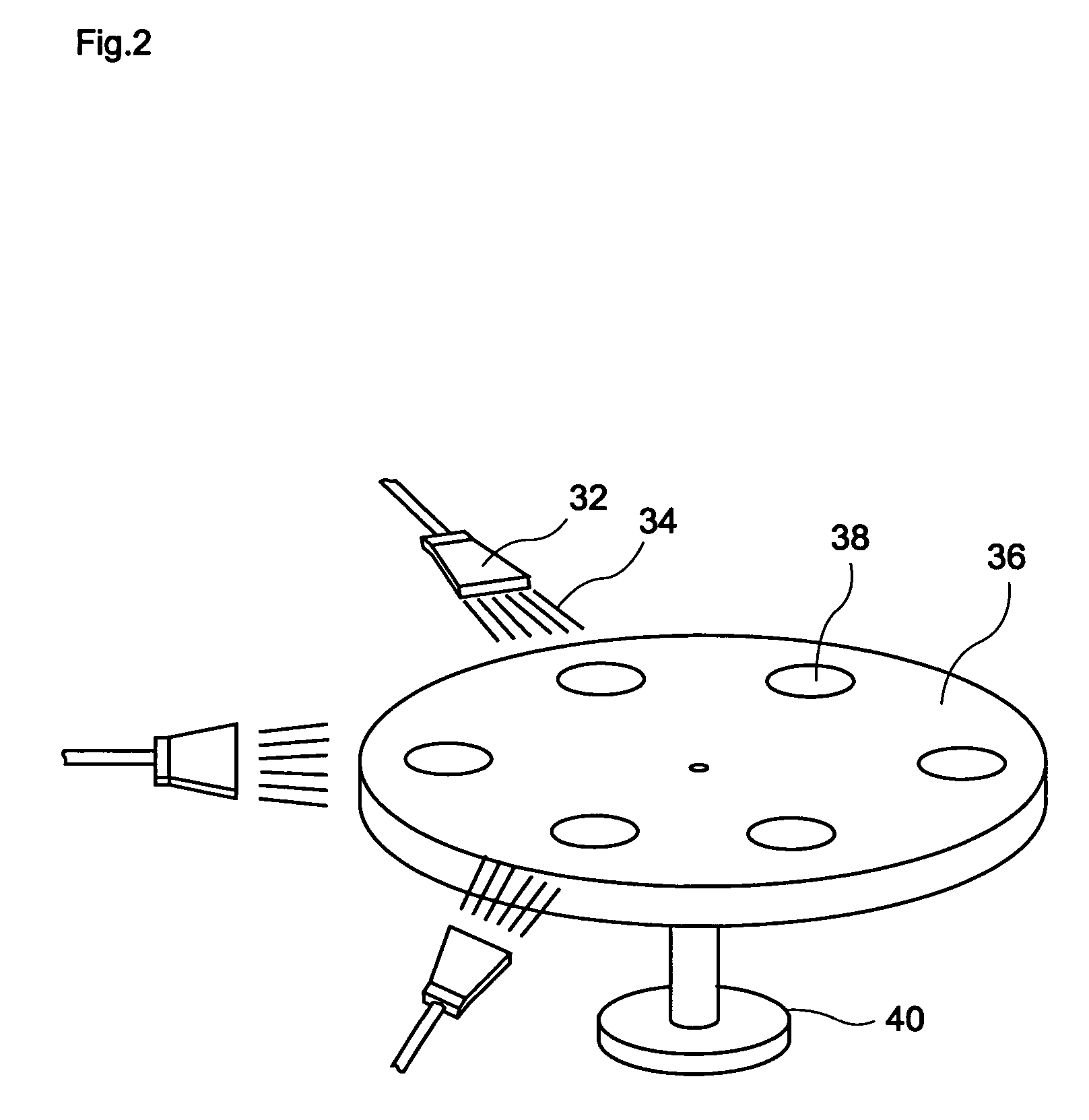

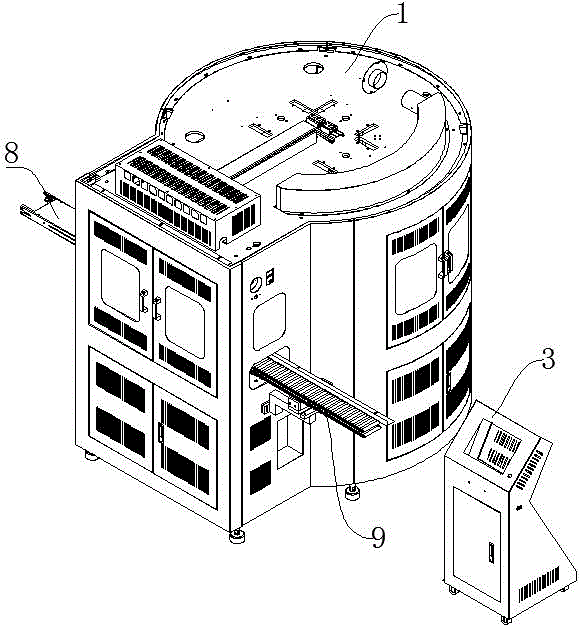

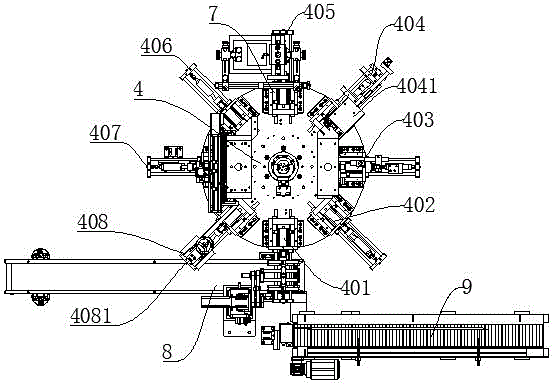

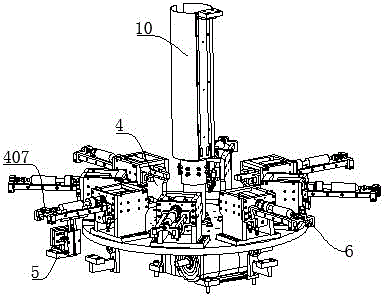

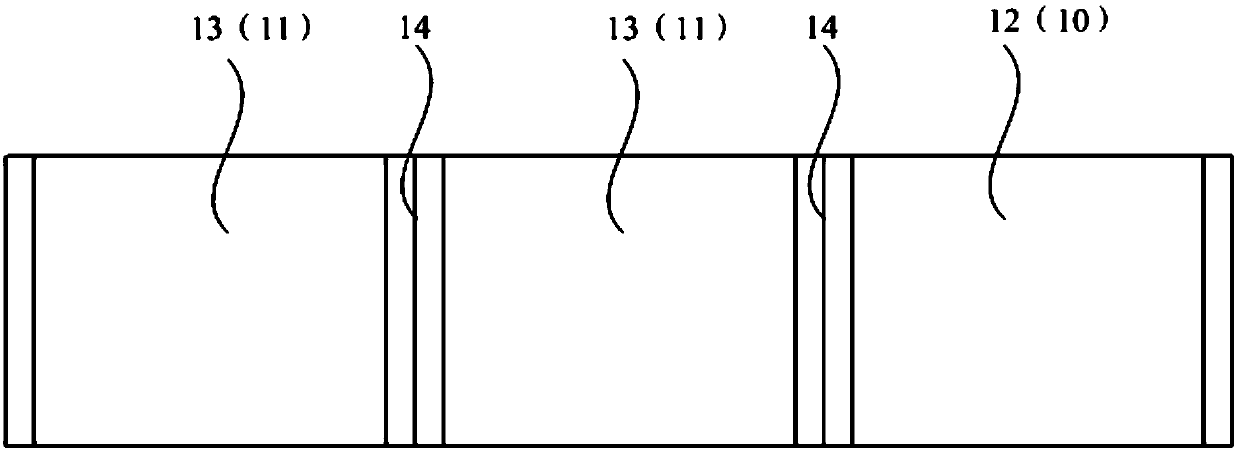

Intelligent screen printing machine for special-shaped bottles

InactiveCN106626736APrevent slippingImprove printing effectScreen printersPrinting press partsScreen printingUV curing

The invention discloses an intelligent screen printing machine for special-shaped bottles. The intelligent screen printing machine comprises a machine frame, a turntable part, a bottle holder part and a movable electric box part. The turntable part is installed inside the machine frame. An electric slip ring part is installed at the center of the turntable part. Eight clamp parts are arranged around the turntable part and comprise eight different stations including the feeding and discharging station, the electrostatic dust removal station, the flame treatment station, the visual positioning station, the first color printing station, the first color printing UV curing station, the second color printing station and the second color printing UV curing station in sequence. An adsorption-type feeding and discharging part is arranged at the position corresponding to the feeding and discharging station. A feeding conveyer belt part is arranged at one side of the adsorption-type feeding and discharging part, and a discharging conveyer belt part is arranged at the other side of the adsorption-type feeding and discharging part. The intelligent screen printing machine has the beneficial effects that bottle holders are additionally arranged at the bottoms of the special-shaped bottles, slipping of bottle bodies in the printing process is avoided, and patterns can be integrally printed onto the surfaces of the bottle bodies; and moreover, dust removal can be performed through the electrostatic adsorption function, the effect dust on the concave-convex surface is cleared up thoroughly can be guaranteed, and the printing effect is improved.

Owner:彭国亮

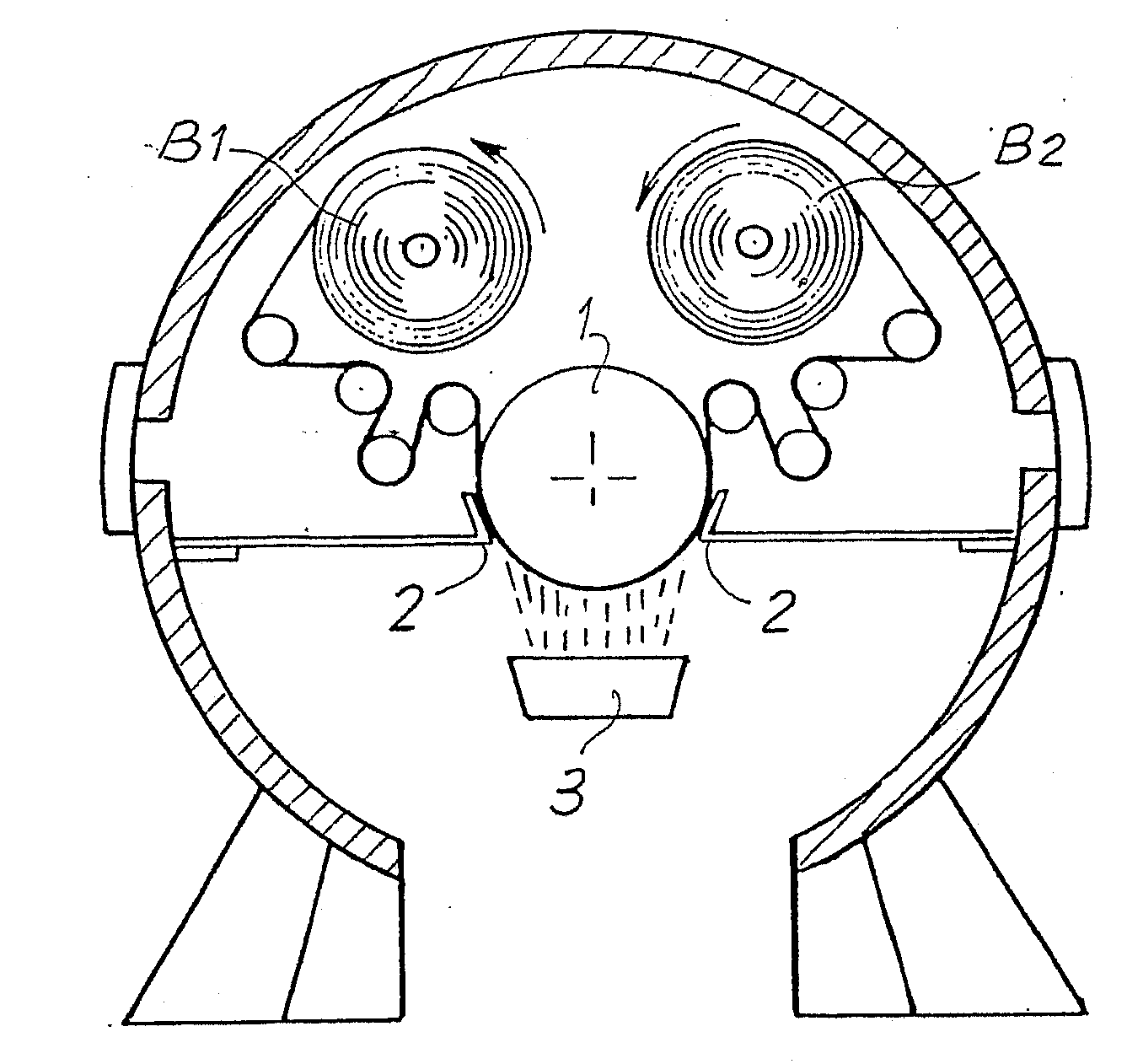

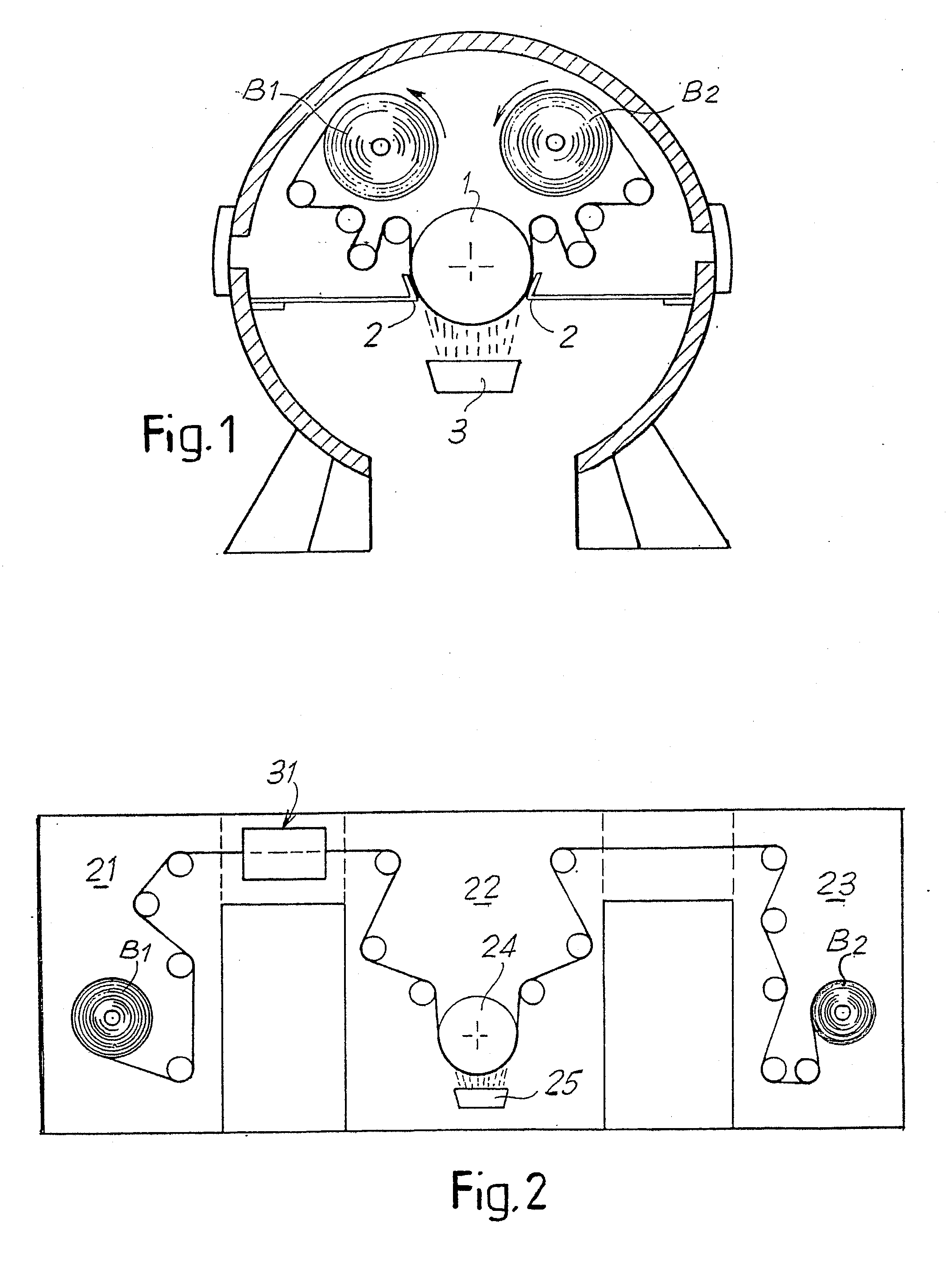

Treatment system for engine gas jet tail flames

PendingCN109538378AImprove cooling efficiencySignificant deceleration and noise reduction effectRocket engine plantsFlame treatmentNoise reduction

The embodiments of the invention provide a treatment system for engine gas jet tail flames used for treating the gas jet tail flames injected by an engine. The engine includes a jet pipe used for gasexpansion and speed increase. The engine gas jet tail flame treatment system includes a cooling device and a supporting device. The cooling device includes at least one introduction module and at least one treatment module. The materials of the introduction module and the treatment module are ice. An introduction channel is arranged in the introduction module. A treatment channel is arranged in the treatment module. The introduction channel is opposite to the jet pipe. The supporting device and the cooling device are connected to each other and is used for supporting the cooling device. The engine gas jet tail flame treatment system can make the cooling device have high temperature reducing and cooling efficiency for the gas jet tail flames, and can make the cooling device have remarkableeffects on deceleration, noise reduction and harmless treatment of the gas jet tail flames.

Owner:XI AN JIAOTONG UNIV

Layer transfer for large area inorganic foils

Layer transfer approaches are described to take advantage of large area, thin inorganic foils formed onto a porous release layer. In particular, since the inorganic foils can be formed from ceramics and / or crystalline materials that do not bend a large amount, approaches are described to provide for gradual pulling along an edge to separate the foil from a holding surface along a curved surface designed to not excessively bend the foil such that the foil is not substantially damaged in the transfer process. Apparatuses are described to perform the transfer with a rocking motion or with a rotating cylindrical surface. Furthermore, stabilization of porous release layers can improve the qualities of resulting inorganic foils formed on the release layer. In particular, flame treatments can provide improved release layer properties, and the deposition of an interpenetrating stabilization composition can be deposited using CVD to stabilize a porous layer.

Owner:NANOGRAM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com