Paper plastic glue-free composite on line repeated spraying bidirectional stretching polypropylene film and its preparation method

A polypropylene film, biaxial stretching technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of no disclosure of the preparation method of film layer components, difficulty in production reproduction, difficulty, etc., Achieve the effect of being beneficial to manufacturing and promotion, high heat sealing strength and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

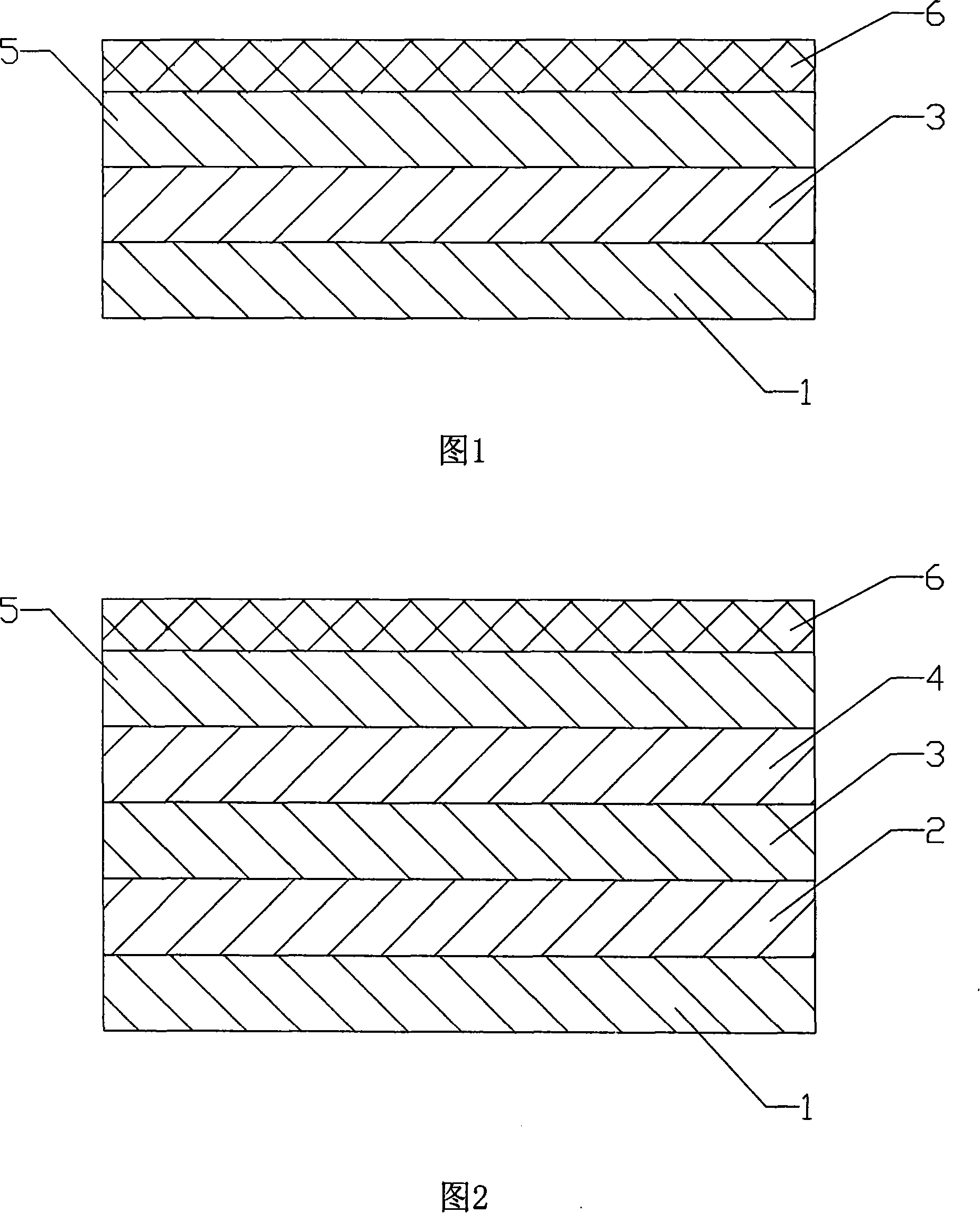

Embodiment 1

[0035] The composition of functional layer 6 is: 70% ethylene-butene copolymer, maleic anhydride graft modified product of 30% ethylene-butene copolymer, wherein, the content of butene in the ethylene-butene copolymer is 30%, and the graft ratio of the maleic anhydride graft modified product of ethylene-butene copolymer is 0.5%.

[0036] The composition of the upper surface layer 5 is: 100% isotactic polypropylene (the isotacticity is 95%, and the melt index is 3 grams / 10 minutes);

[0037] The composition of the core layer 3 is: 99.75% isotactic polypropylene (97% isotacticity, 3 g / 10 minutes melt index), 2500 ppm glyceryl monostearate;

[0038] The composition of the lower surface layer 1 is: a total of high-density polyethylene (melt index is 0.05 g / 10 minutes) and ethylene-propylene copolymer (melt index is 7 g / 10 minutes) which accounts for 99.2% of the surface layer according to the configuration of 9:11. Mixture, 8000ppm of antioxidant 1010.

[0039] The total thickne...

Embodiment 2

[0052] The components of functional layer 6 are: 50% ethylene-butene copolymer, 20% maleic anhydride graft modification of ethylene-butene copolymer, 30% P-125, wherein ethylene-butene copolymer The content of butene in the product is 10%, and the graft ratio of the maleic anhydride graft modified product of ethylene-butene copolymer is 1.2%.

[0053] The composition of the upper surface layer 5 is: 100% isotactic polypropylene (the isotacticity is 95%, and the melt index is 3 grams / 10 minutes);

[0054] The ingredients of the next surface layer 2 and the last surface layer 4 are: 99.8% isotactic polypropylene (96% isotacticity, 2.5 grams / 10 minutes melt index), 2000ppm glyceryl monostearate;

[0055] The composition of core layer 3 is: the isotactic polypropylene of 99.7% (isotacticity is 96%, melt index is 2.5 grams / 10 minutes), the glyceryl monostearate of 2000ppm, the methylenebisstearamide of 1000ppm ;

[0056] The composition of lower surface layer 1 is: 99.8% isotacti...

Embodiment 3

[0075] The components of the functional layer 6 are: 80% ethylene-octene copolymer, 19% maleic anhydride graft modification of ethylene-butene copolymer, 1% P-125, wherein ethylene-octene copolymer The content of octene in the product is 20%, and the graft rate of the maleic anhydride graft modified product of ethylene-butene copolymer is 2%.

[0076] The composition of the upper surface layer 5 is: 100% isotactic polypropylene (the isotacticity is 95%, and the melt index is 3 grams / 10 minutes);

[0077] The ingredients of the next surface layer 2 and the last surface layer 4 are: 99.8% isotactic polypropylene (95% isotacticity, 2 grams / 10 minutes melt index), 2000ppm glyceryl monostearate;

[0078] The composition of the core layer 3 is: 99.75% isotactic polypropylene (95% isotacticity, 2 g / 10 minutes melt index), 2000 ppm glyceryl monostearate, 500 ppm erucamide;

[0079] The composition of lower surface layer 1 is: 99.8% isotactic polypropylene (isotacticity is at 95%, mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com