Paper plastic glue-free composite off line repeated spraying bidirectional stretching polypropylene film

A polypropylene film, biaxial stretching technology, applied in the direction of synthetic resin layered products, coatings, layered products, etc., can solve the problems of difficulty, difficulty in production and reproduction, and the composition of the film layer and its preparation method are not disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

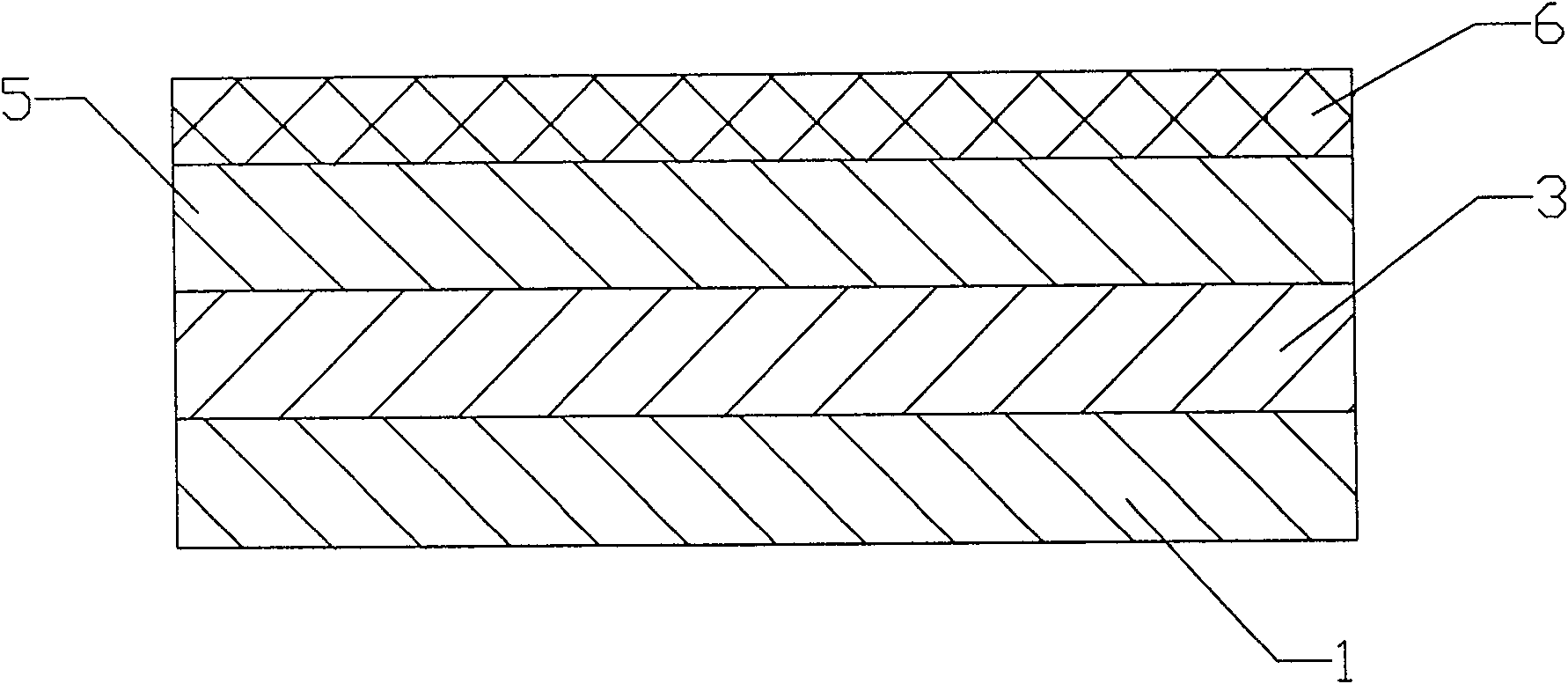

[0029] The composition of functional layer 6 is: 70% ethylene-butene copolymer, maleic anhydride graft modified product of 30% ethylene-butene copolymer, wherein, the content of butene in the ethylene-butene copolymer is 30%, and the graft ratio of the maleic anhydride graft modified product of ethylene-butene copolymer is 0.5%.

[0030] The base film is biaxially oriented polypropylene matting film, which is a three-layer co-extruded structure.

[0031] The total thickness of the prepared product is 20 μm, the thickness of the functional layer 6 is 6 μm, and the functional layer 6 accounts for 30% of the total weight of the film.

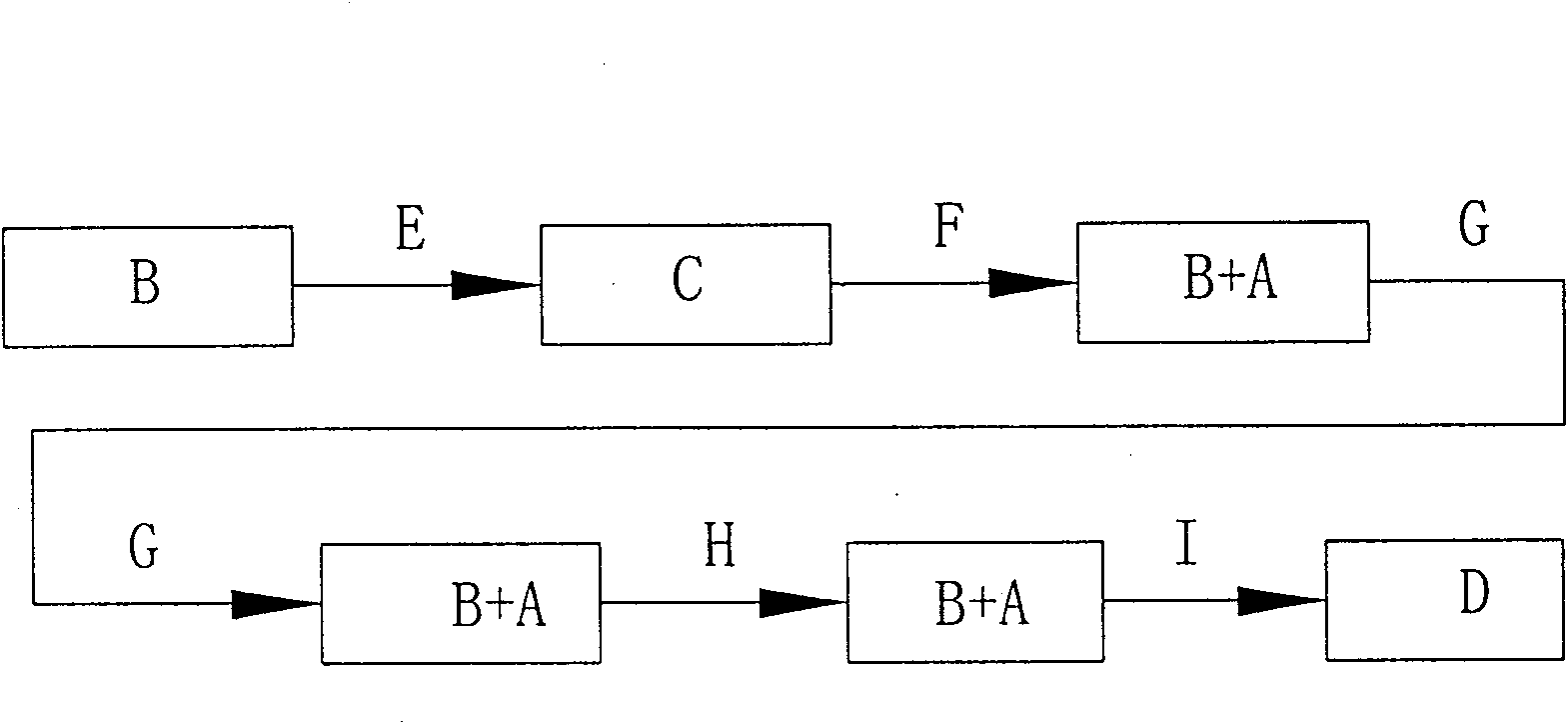

[0032] The preparation method is as follows: the raw material of the functional layer 6 is coated on the upper surface layer 5 of the base film A through the off-line coating process F (including extrusion, die head and cooling roll), and the lower surface layer 1 at this time is a matte layer. Then the functional surface is subjected to corona trea...

Embodiment 2

[0043] The components of functional layer 6 are: 50% ethylene-butene copolymer, 20% maleic anhydride graft modification of ethylene-butene copolymer, 30% P-125, wherein ethylene-butene copolymer The content of butene in the product is 10%, and the graft ratio of the maleic anhydride graft modified product of ethylene-butene copolymer is 1.0%.

[0044] The base film is a biaxially oriented polypropylene light film with a three-layer co-extruded structure.

[0045] The total thickness of the prepared product is 18 μm, the thickness of the functional layer 6 is 5 μm, and the functional layer 6 accounts for 27.8% of the total weight of the film.

[0046] In the preparation method, other is identical with embodiment 1 except following two:

[0047] 1. The lower surface layer 1 is a transparent layer;

[0048] 2. Off-line lamination extrusion, die head temperature 260°C, cooling roll temperature 30°C; corona treatment power 25w min. / m 2 .

[0049] The properties of the manufactu...

Embodiment 3

[0059] Functional layer 6 is 80% ethylene-octene copolymer, 19% maleic anhydride graft modification of ethylene-butene copolymer, 1% P-125, wherein the ethylene-octene copolymer inner octane The ethylene content was 20%, and the graft ratio of the maleic anhydride graft-modified ethylene-butene copolymer was 2%.

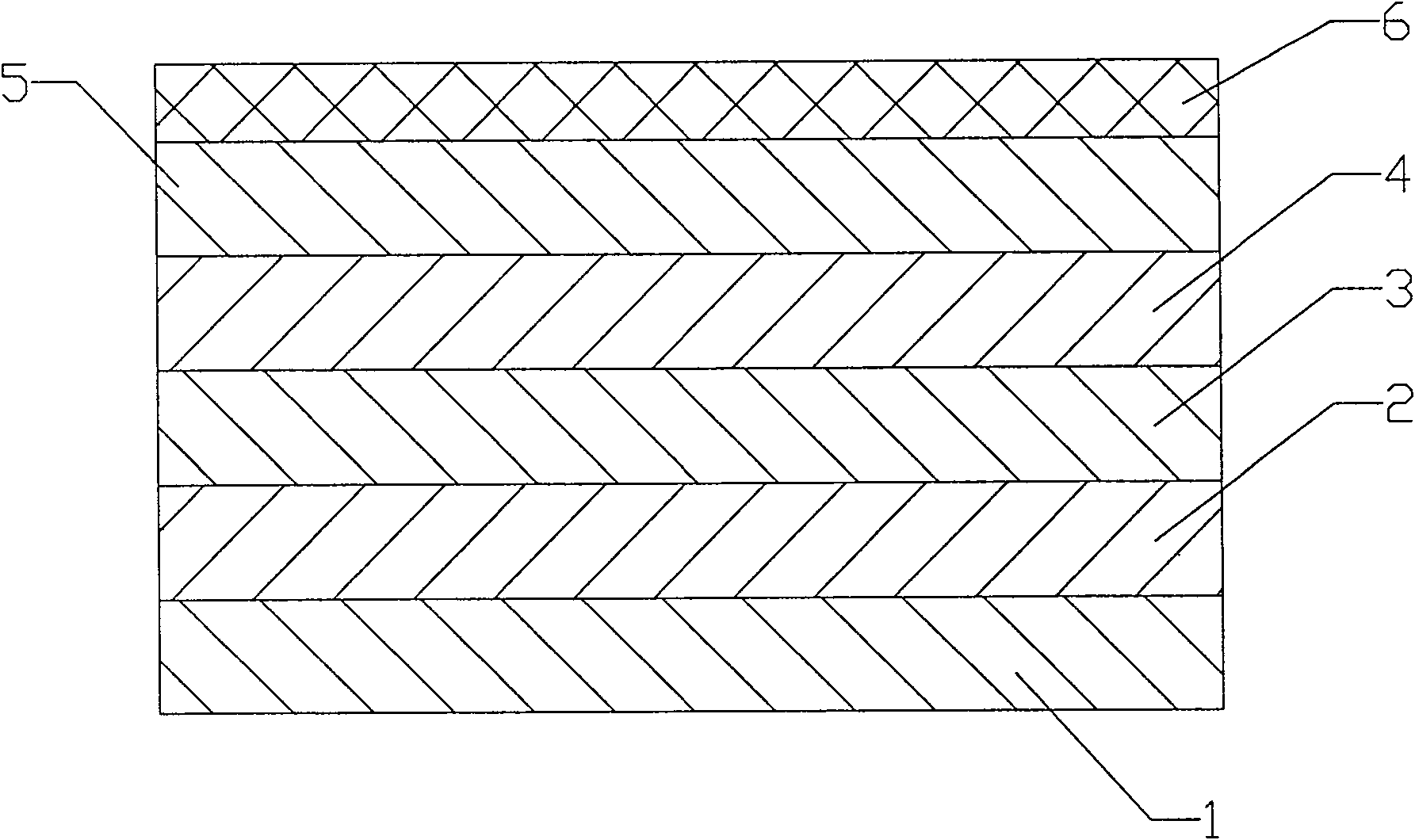

[0060] The base film is a biaxially oriented polypropylene light film with a five-layer co-extrusion structure.

[0061] The total thickness of the prepared product is 18 μm, the thickness of the functional layer 6 is 5.4 μm, and the functional layer 6 accounts for 30% of the total weight of the film.

[0062] In the preparation method, other is identical with embodiment 1 except following two:

[0063] 1. The lower surface layer 1 is a transparent layer;

[0064] 2. Off-line lamination extrusion, die head temperature 220°C, cooling roll temperature 25°C; corona treatment power 35w min. / m 2 .

[0065] The properties of the manufactured products are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com