Patents

Literature

427results about How to "High heat sealing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

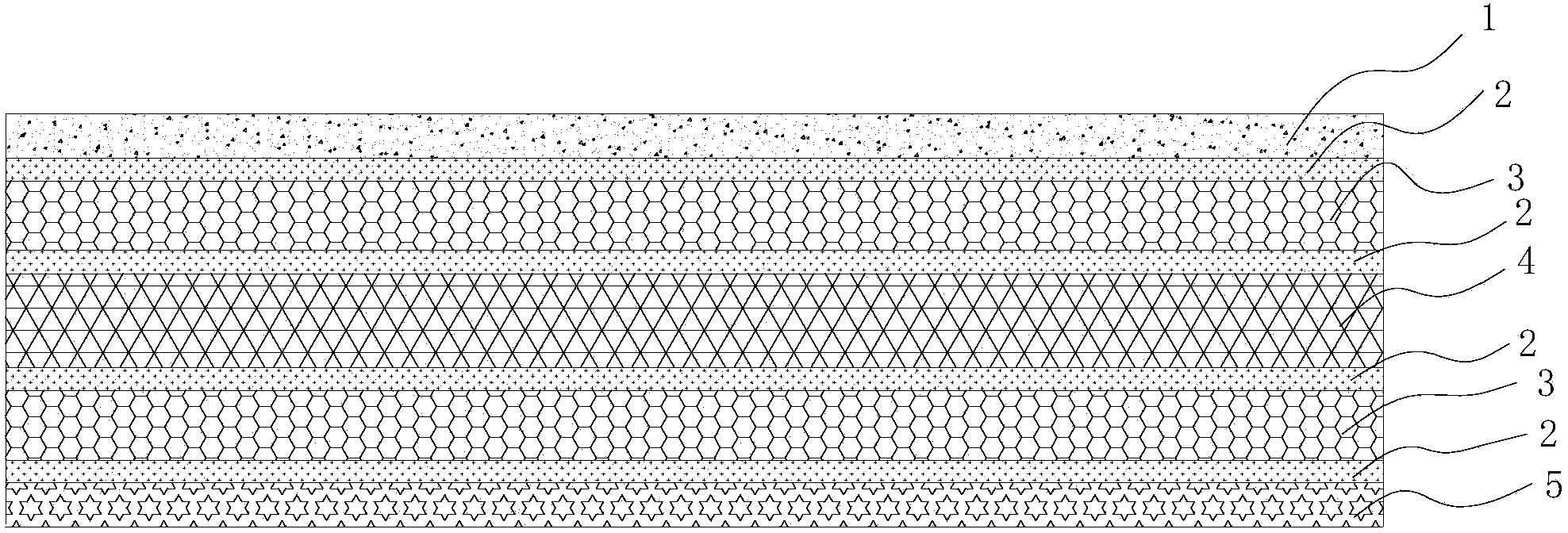

High-separation multilayer joint-extrusion shrink film

InactiveCN102642359AImprove barrier propertiesIncrease oxygenFlexible coversWrappersSurface layerWater vapor

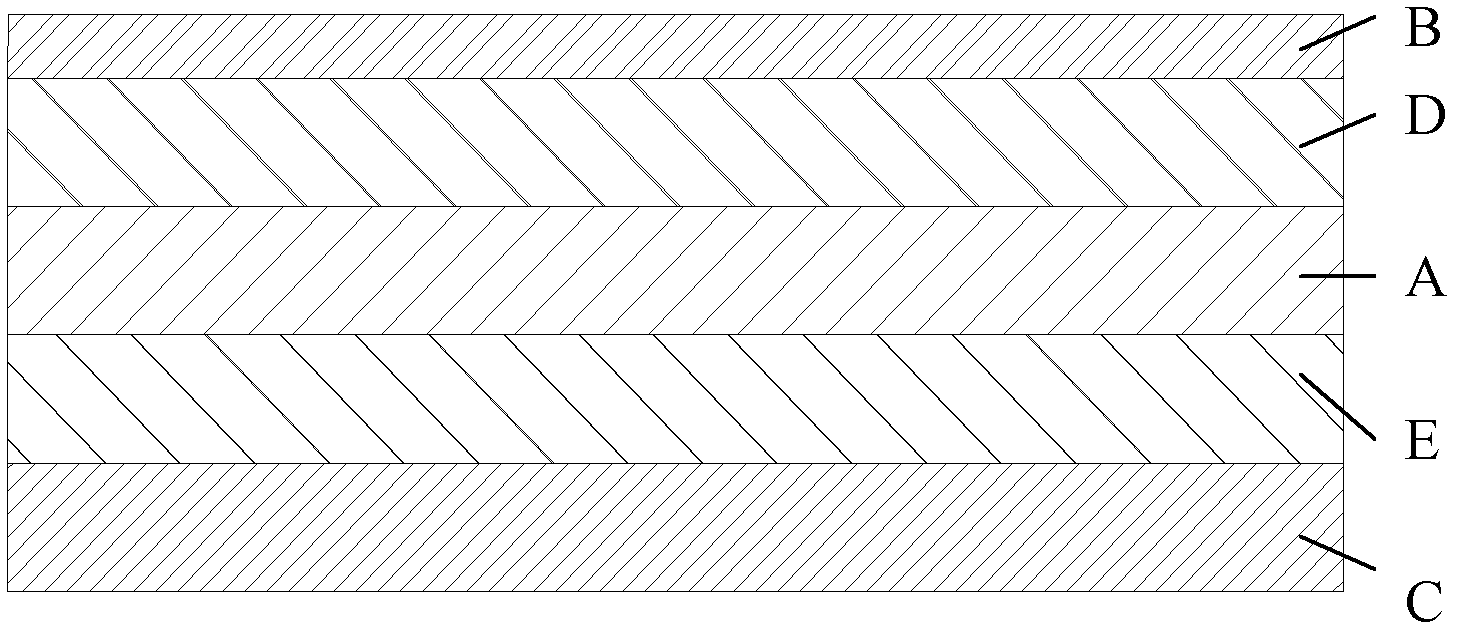

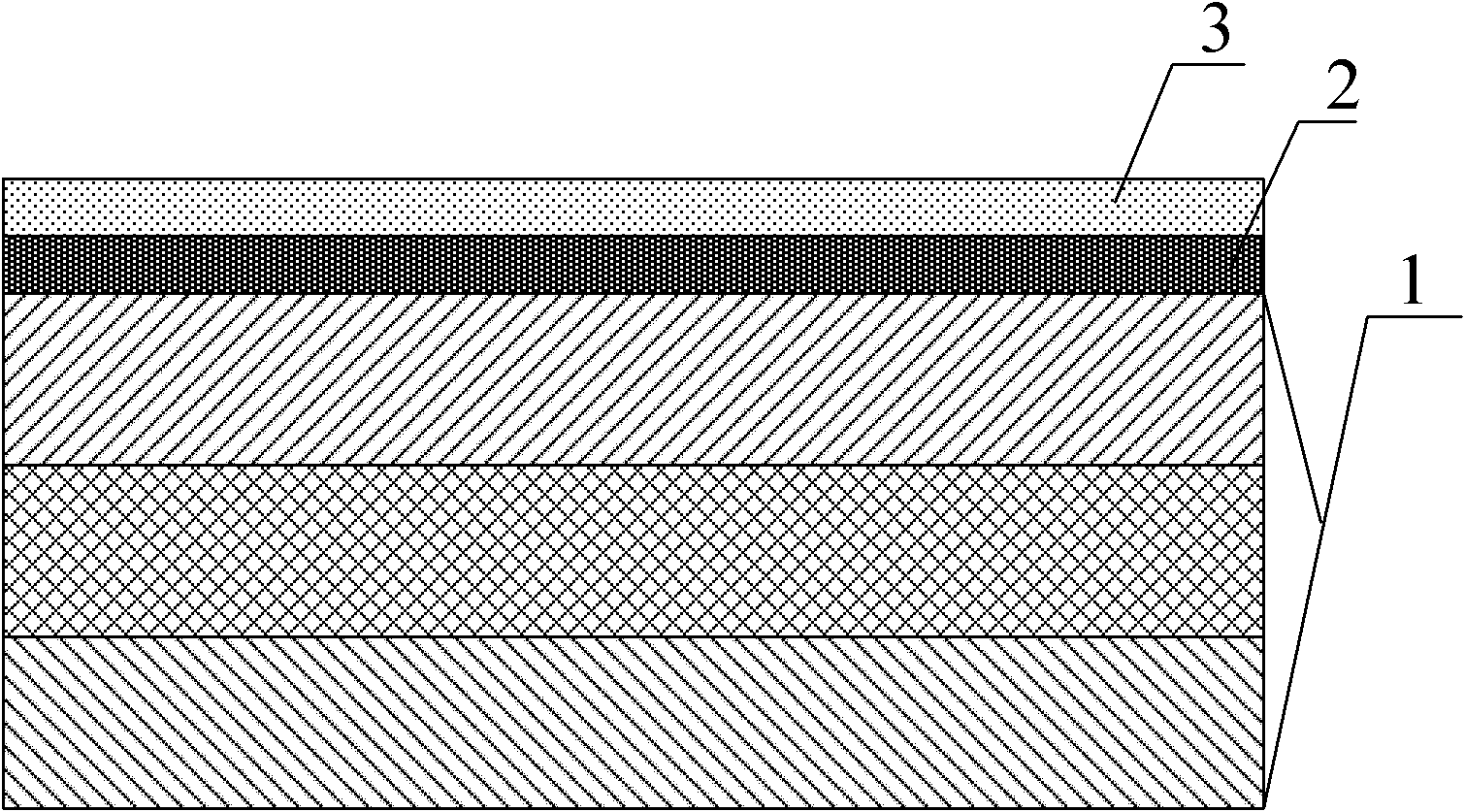

The invention discloses a high-separation multilayer joint-extrusion shrink film, which comprises an outer surface layer, a separation layer, a heat sealing layer and two bonding layers. The two bonding layers are respectively located between the separation layer and the outer surface layer and between the separation layer and the heat sealing layer, the separation layer is made of one of or a combination of two of ethylene vinyl alcohol (EVOH) resin, polyvinylidene chloride resin and modified polyamide resin, the thickness of the separation layer is 10%-45% of the total thickness, the thickness of the outer surface layer is 3%-5% of the total thickness, the thickness of the heat sealing layer is 25%-35% of the total thickness, the thickness of the bonding layers is 10%-30% of the total thickness, and the number of the separation layer is one or three. The outer surface layer of the film is made of high-melting-point resin to overcome the shortcoming that users are easy to burn during a using process of products, simultaneously oxygen and water vapor separation performance are good, the anti-puncturing effect and heat sealing strength are good, and the high-separation multilayer joint-extrusion shrink film can be suitable to vacuum shrink package of chilled pork, cheese products and seafood products.

Owner:张建岭

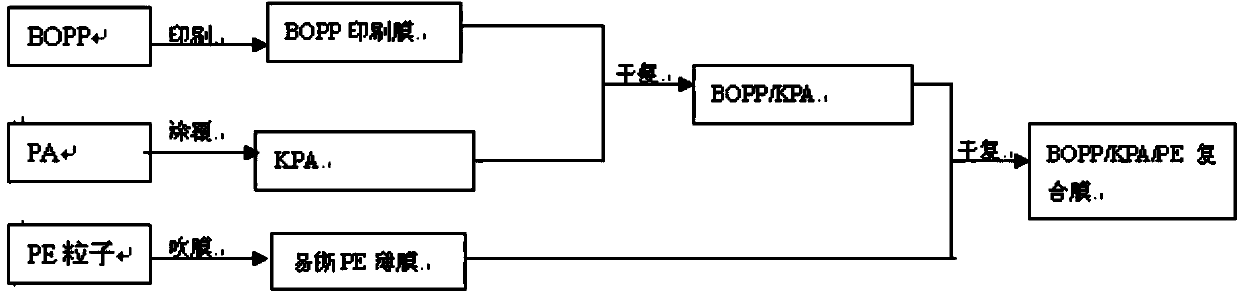

Polyethylene film, packaging composite film and preparation method thereof

InactiveCN104191766AStraight line tearGood linear tearabilitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene film. The polyethylene film orderly comprises a corona layer, a middle layer and a heat sealing layer; the corona layer is prepared from such raw materials as 45wt%-50wt% of linear low density polyethylene and 50wt%-55wt% of high density polyethylene; the middle layer is prepared from such raw materials as 20wt%-25wt% of low density polyethylene and 75wt%-80wt% of high density polyethylene; the heat sealing layer is prepared from such raw materials as 75wt%-80wt% of metallocene linear low density polyethylene and 20wt%-25wt% of low density polyethylene; the polyethylene film is formed by virtue of co-extrusion blow molding of the raw materials of the corona layer, the middle layer and the heat sealing layer; the blowup ratio of the co-extrusion blow molding is less than 2. The invention also provides a packaging composite film and a preparation method thereof; the packaging composite film comprises the polyethylene film, has excellent straight tear property in addition to good heat sealing strength, and can be applied favorably.

Owner:HUANGSHAN NOVEL

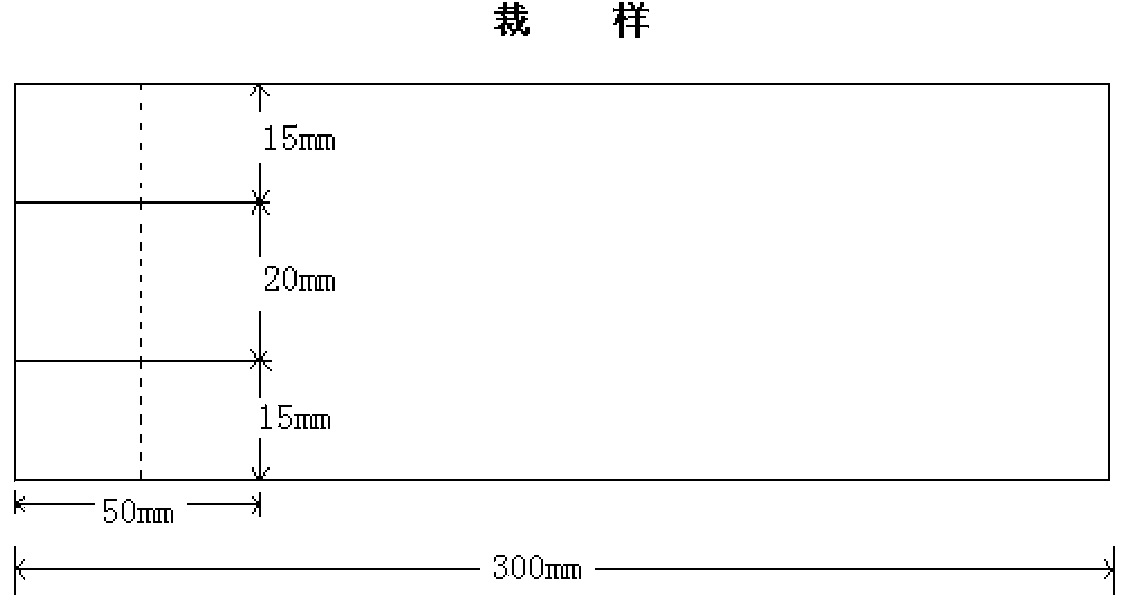

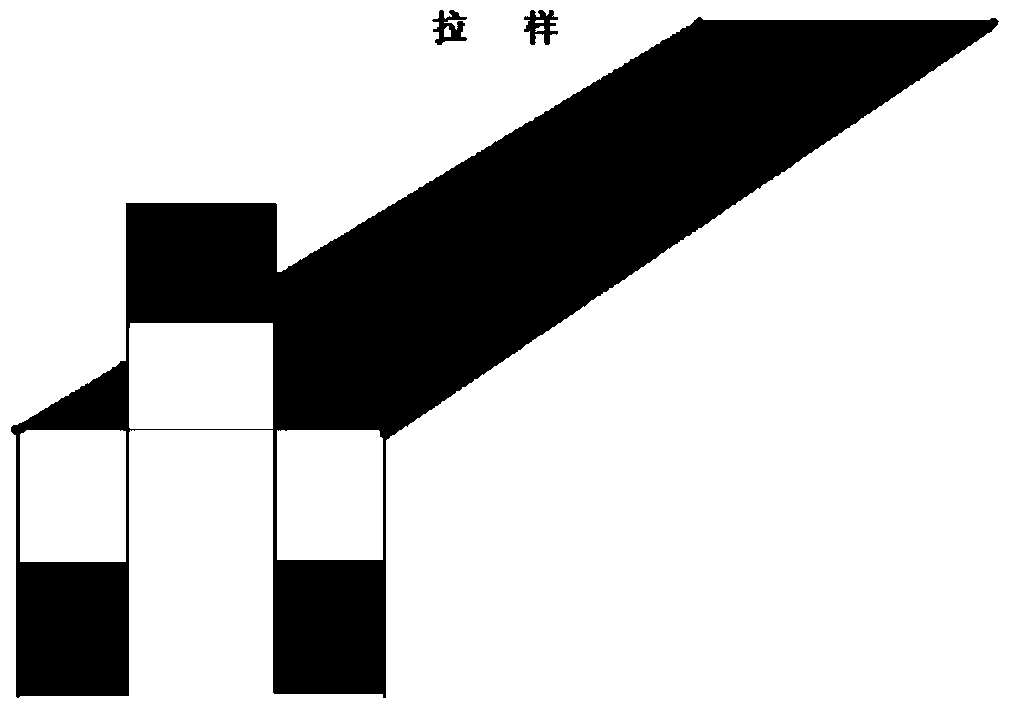

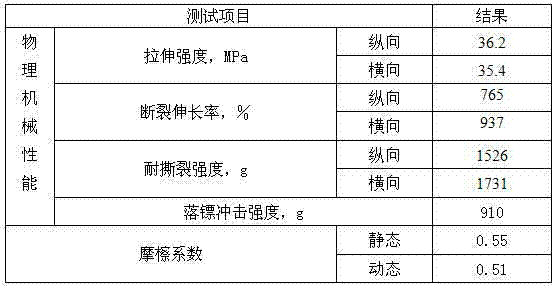

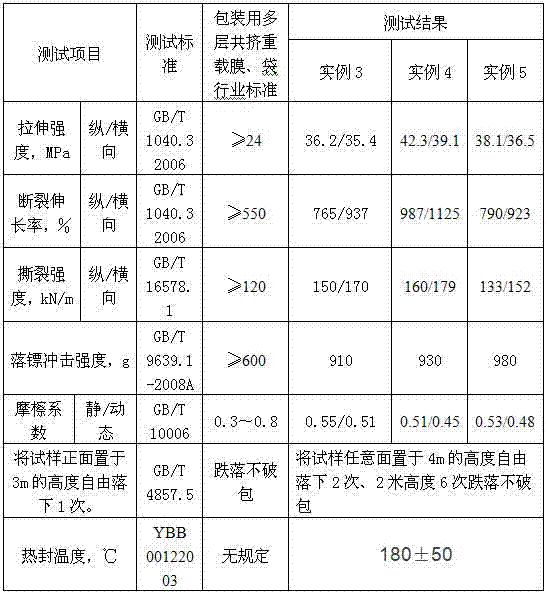

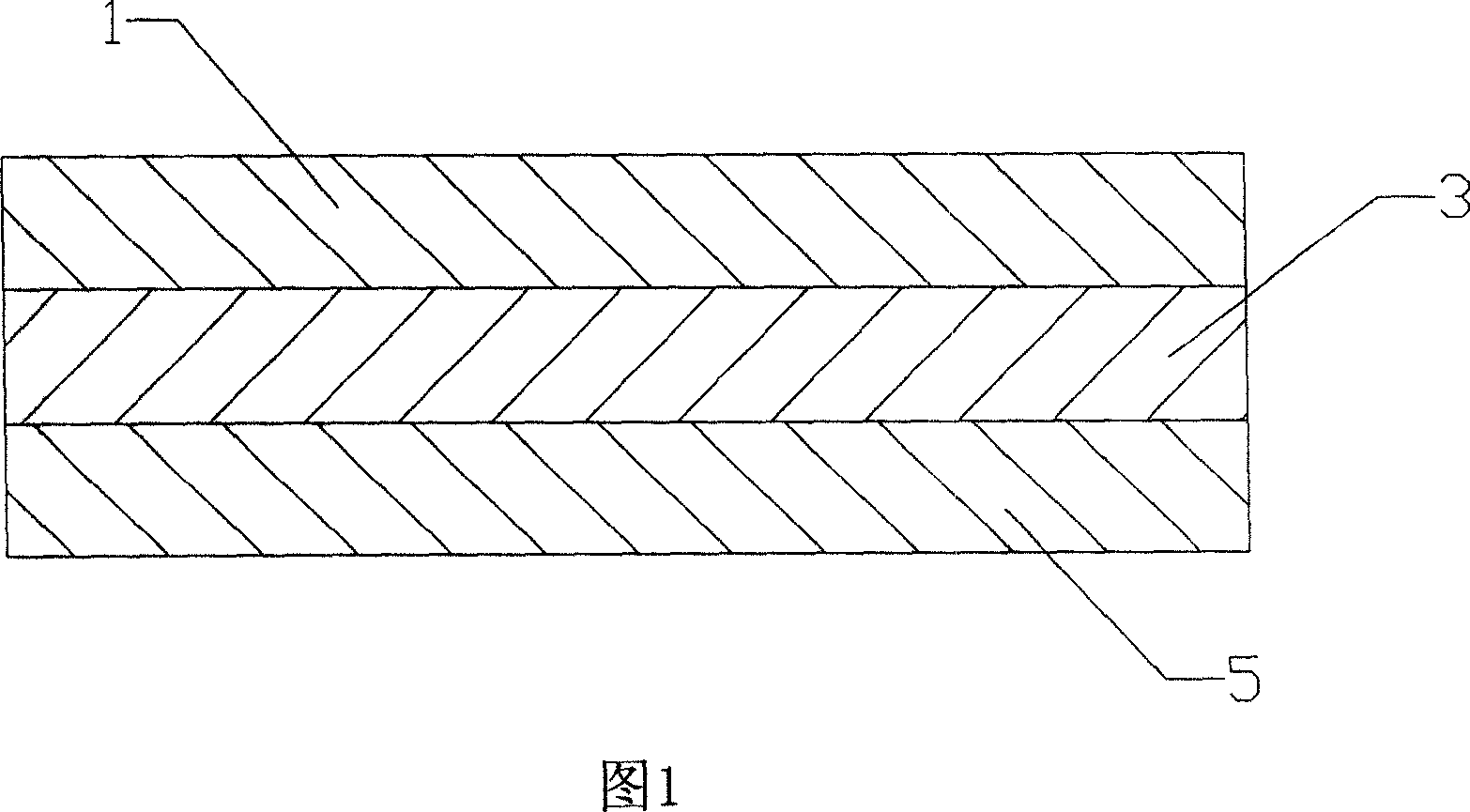

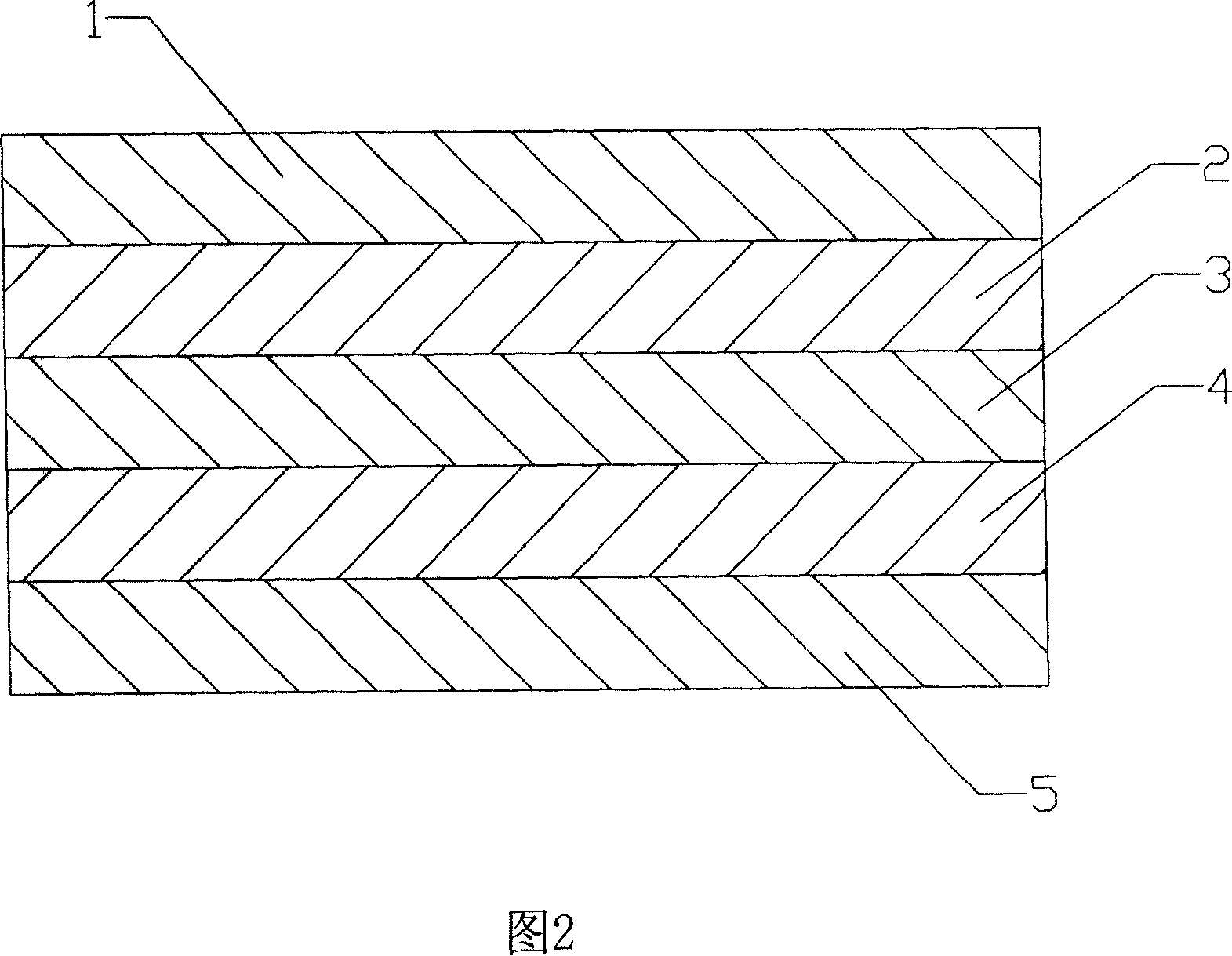

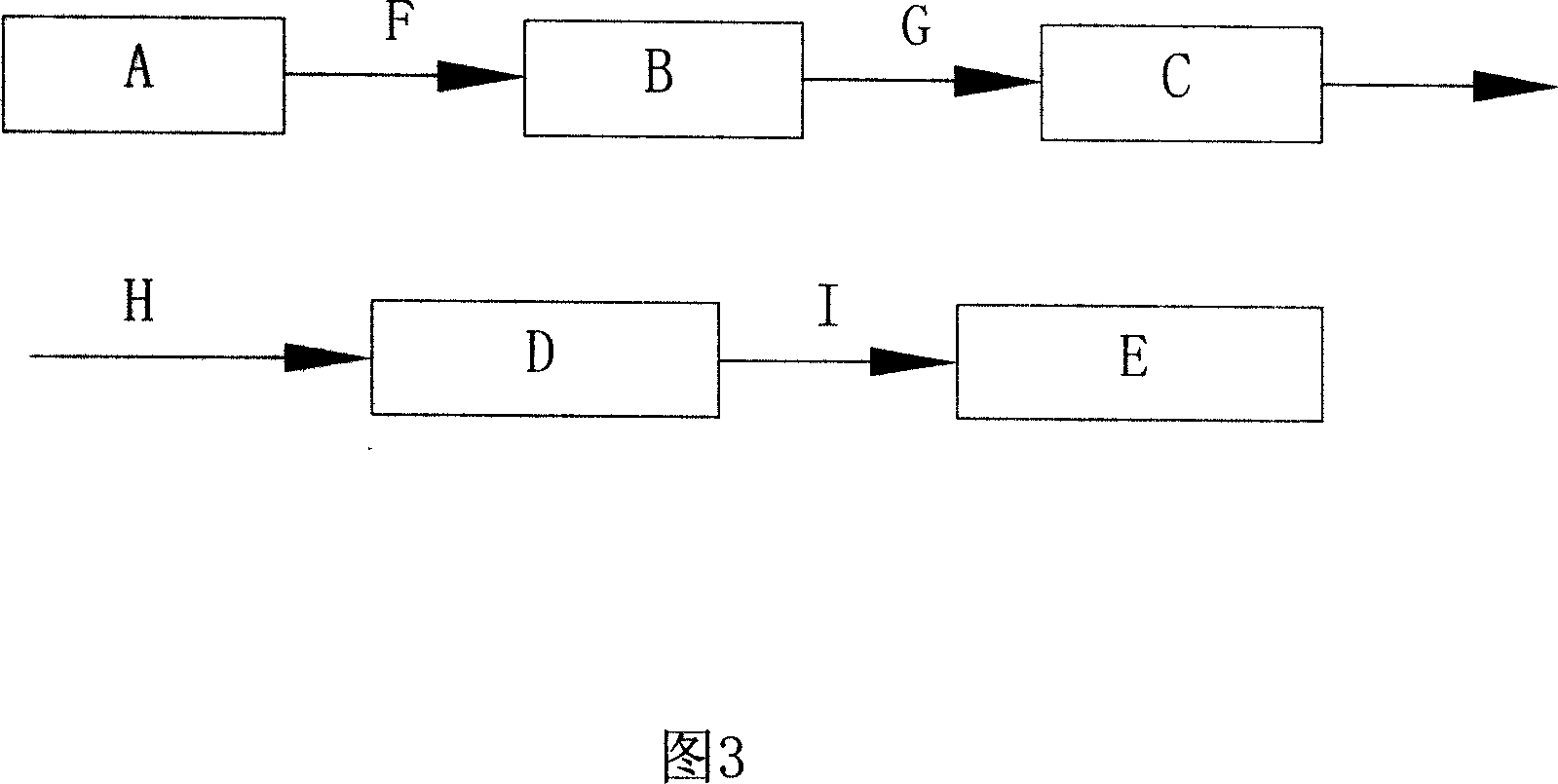

Three-layer coextrusion heavy packaging membrane and fabrication method thereof

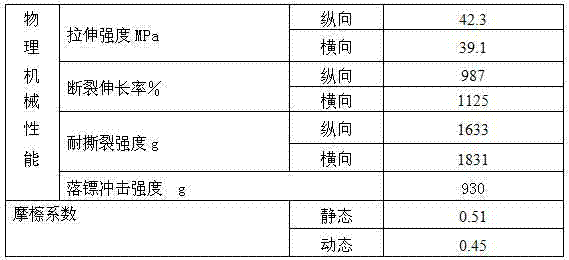

The invention relates to the technical field of heavy packaging membranes, in particular to a three-layer coextrusion heavy packaging membrane and a fabrication method thereof. An inner layer of the three-layer coextrusion heavy packaging membrane contains LLDPE (linear low density polyethylene) and m-LLDPE (metallocene-linear low density polyethylene); a middle layer thereof contains m-LLDPE, LLDPE, MDPE (medium density polyethylene), EVA (ethylene-vinyl acetate) and a color masterbatch; and an outer layer thereof contains LLDPE, LDPE (low density polyethylene) and m-LLDPE. The fabrication method of the three-layer coextrusion heavy packaging membrane adopts the proportioning, and a product is fabricated on a certain technological condition. Compared with the prior art, the membrane has the characteristics that the membrane is excellent in mechanical property and good in deflexion; a skin-friction coefficient of the membrane is moderate; and a heat-seal window can reach 180 minus / plus 50 DEG C. The membrane can fully meet the requirement of normal use of downstream packaging, is particularly suitable for high-speed FFS (form-fill-seal) packaging, and has a good economic benefit and a social benefit.

Owner:GUANGDONG SUNION CHEM & PLASTIC

Capacitor thin film containing modified nano-titanium dioxide and preparation method thereof

InactiveCN103102582AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneCross-link

The invention discloses a capacitor thin film containing modified nano-titanium dioxide and a preparation method thereof. The capacitor thin film comprises the following raw materials in parts by weight: 57-65 of metallocene polypropylene resin, 25-30 of LLDPE (Linear low density polyethylene) resin, 10-15 of low-density polyethylene, 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 0.5-1.5 of poly-4-methyl-1-amylene, 7-9 of modified nano-titanium dioxide, 1.5-2.5 of cross-linking agent TAC, 0.2-0.4 of expoxy butyl oleate, 0.8-1.2 of epoxidation triglyceride, 3-5 of calcium stearate and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

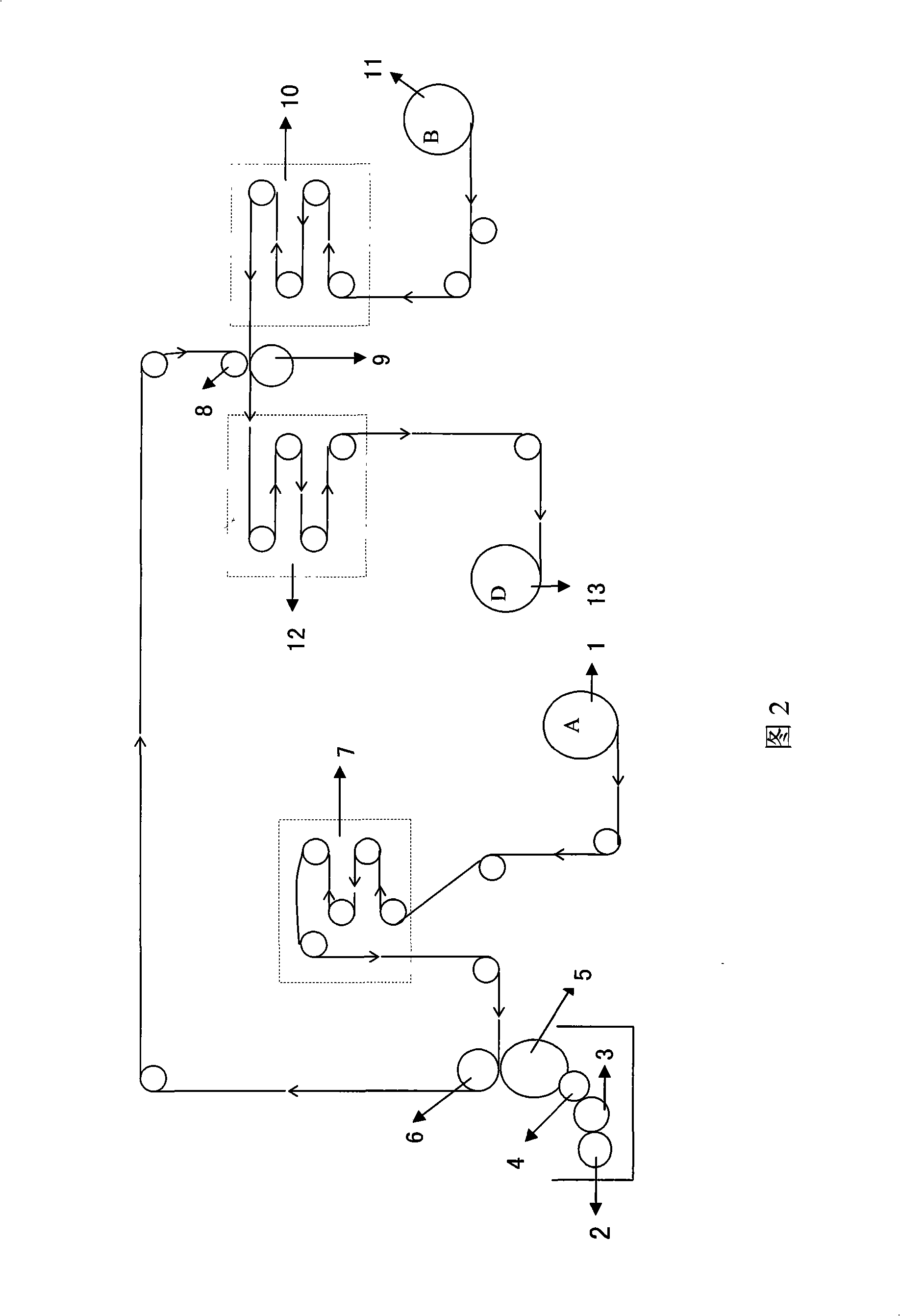

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

ActiveCN101058247ASimple structureHigh heat sealing strengthSynthetic resin layered productsFlat articlesThick plateEngineering

The invention relates to a paper plastic glue free compound bi-directional stretch polypropylene film, which has coextruded surfaced, core layer, functional layer being able to compound with paper, pre-print paper or thin film, with upper sub surface between the surface and core layer, and lower sub surface between the core layer and the functional layer. All of them are extruded through bi-directional stretch. It feeds formulated material into the extruder to melt, which is co-extruded into thick plates through slip cast, then the thick plates being stretched in both directions into thin film, which are processed through corona and flame into mother film, through effective treatment to get the final thin film product. It is simple in structure, strong in thermal sealing, high in stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Capacitor film with low density polyethylene as substrate and preparation method thereof

ActiveCN102964658AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricEpoxyPolyvinyl alcohol

The invention discloses a capacitor film with low density polyethylene as substrate and a preparation method thereof. The capacitor film comprises the following raw materials by weight: 50-55 parts of LDPE (low density polyethylene), 20-25 parts of LLDPE (linear low density polyethylene), 10-15 parts of homo-polymer, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-pentene, 5-10 parts of calcium carbonate, 2-4 parts of hydrotalcite, 1.3-1.8 parts of zinc dialkyl dithiophosphate, 0.4-0.6 part of phthalic acid ester, 0.4-0.7 part of smoke sheet rubber, 1-3 parts of zinc stearate and 0.9-1.3 parts of modified wood ash. The invention mainly adopts low density polyethylene assisted with linear low density polyethylene; and various accessories and additives are subjected to mixing and extrusion, blown film sizing and cutting to prepare the capacitor film. The preparation method is simple; and diatomite, hydrotalcite and modified wood ash are added into the raw materials at the same time to enhance barrier property and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength, and good heat sealing performance.

Owner:安徽芯智达电子科技有限公司

Environment-friendly type aqueous heat sealing glue for medicament blister package and use thereof

ActiveCN101407704AAvoid cost fluctuationsReduce contentFlexible coversWrappersOrganic solventAdhesive

The invention relates to an environment-friendly waterborne hot-seal adhesive for drug bubble cap packages and application thereof. The water-borne heat-seal adhesive is produced with the following substances in the following content proportions (weight portions): waterborne resin: 10-60; assistant: 0-10; auxiliary solvent: 0-30; waterborne pigment: 0-10; deionized water: 30-80; and pH conditioner: 0-5. Compared with the prior art, the invention has the following advantages: the adhesive is environment-friendly and basically free of organic solvents, and the content of volatile organic compounds (VOCs) is extremely low, and the cost advantage is obvious; all indexes including heat-seal strength (can reach as high as 13N / 15mm), after-tack resistance, content of easily oxidized substances and the like comply with drug packing material standards (YBB00132002) of the State Drug Administration, so the waterborne heat-seal adhesive can completely replace the existing solvent-based VC hot-seal adhesives; production of the heat-seal adhesive has simple process and high production efficiency.

Owner:SHANGHAI WEIKAI CHEM

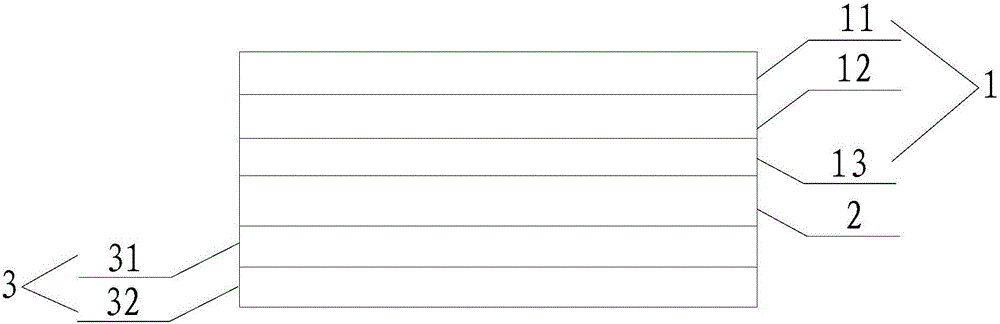

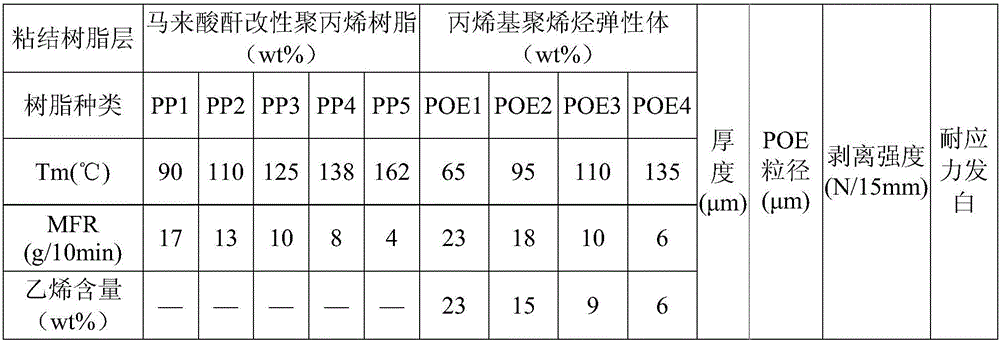

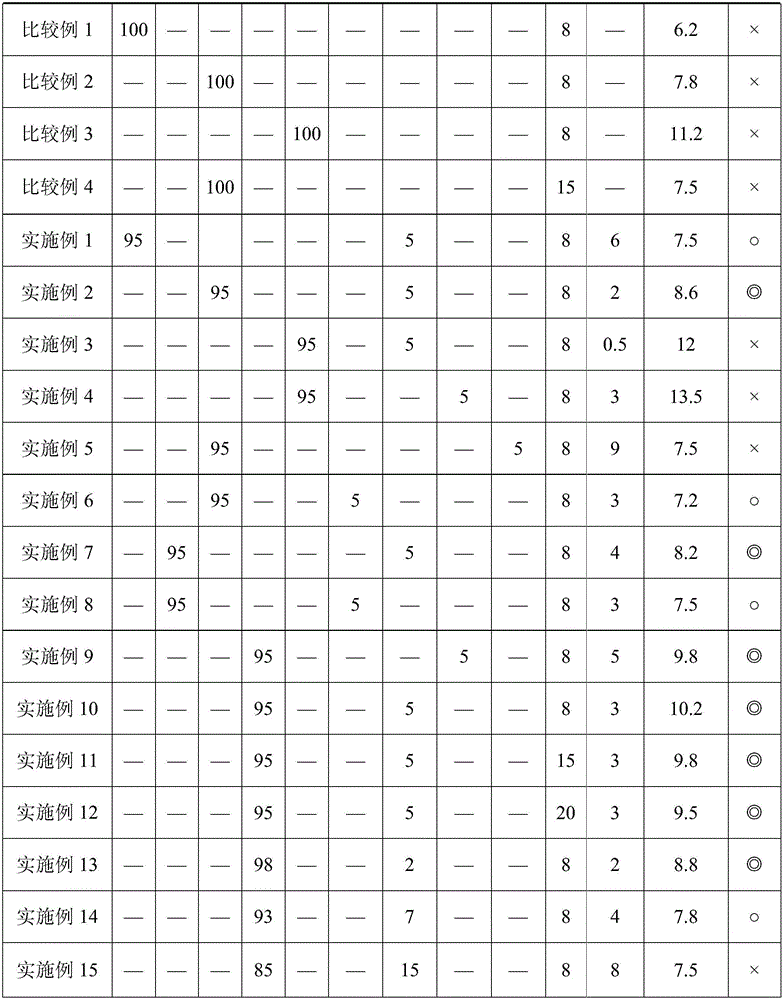

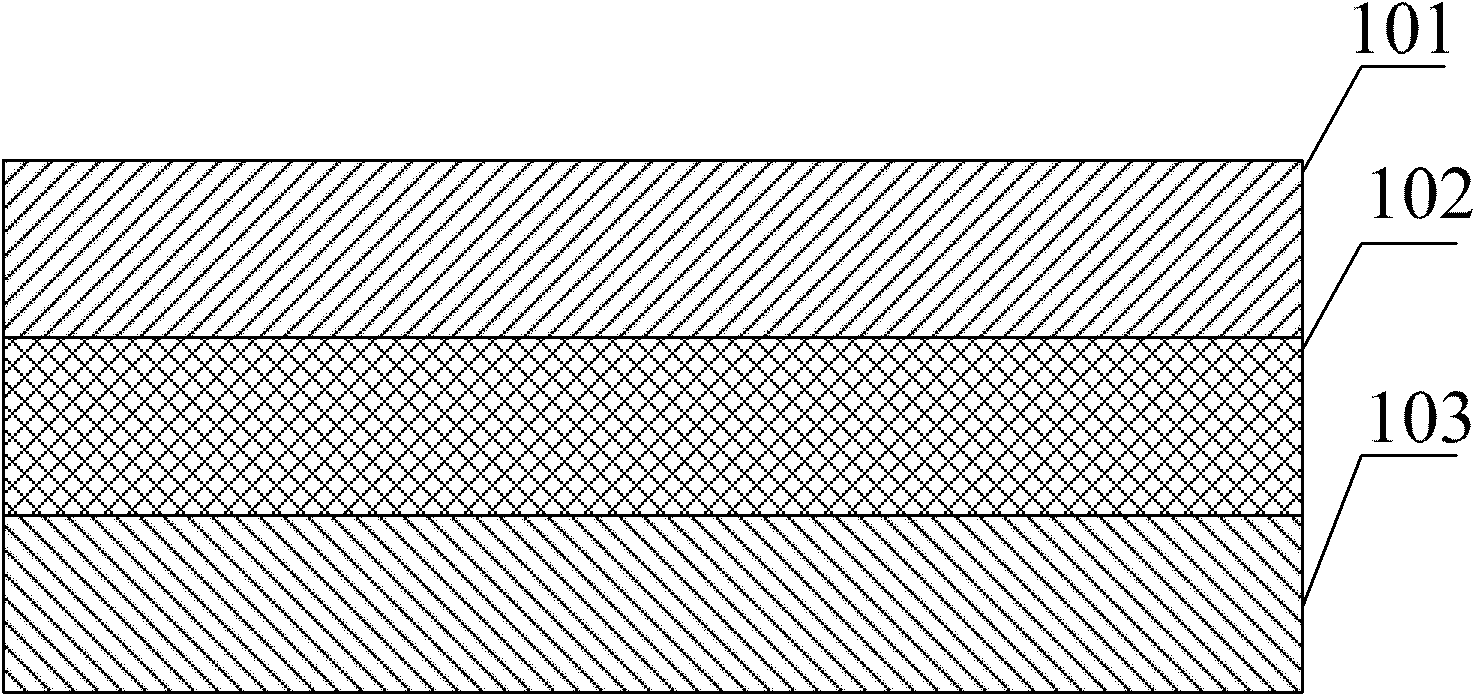

Flexible package material of lithium ion battery

ActiveCN105895833AAvoid breakingHigh bonding strengthSecondary cellsJackets/cases materialsElastomerPolyolefin

The invention relates to a flexible package material of a lithium ion battery. The flexible package material comprises a lamination body, a binding resin layer and sealing layers which are sequentially laminated, wherein the lamination body comprises a heat-resistant resin layer, a binding agent layer and an aluminum foil layer which are sequentially laminated, the melting point of the heat-resistant resin layer is higher than the melting points of the sealing layers made of polyolefin rein, the binding resin layer is polyurethane binding resin, acid-modified polyolefin resin, epoxy binding rein, styrene elastomer binding resin or ethylene acrylic acid binding resin and is laminated on the surface of the aluminum foil layer through hot pressing, and the melt flow rate of a first sealing layer is smaller than the melt flow rates of a second sealing layer and the binding resin layer. The binding resin layer is selected and is used for providing relatively high binding strength between the sealing layer and the aluminum foil layer, and the first sealing layer and the second sealing layer are made of materials with different melt flow rates, and thus, the lithium ion battery can be prevented from being broken due to internal voltage rise; and moreover, the flexible package material has relatively high heat sealing strength, and the resistant stress is bent and whitened.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

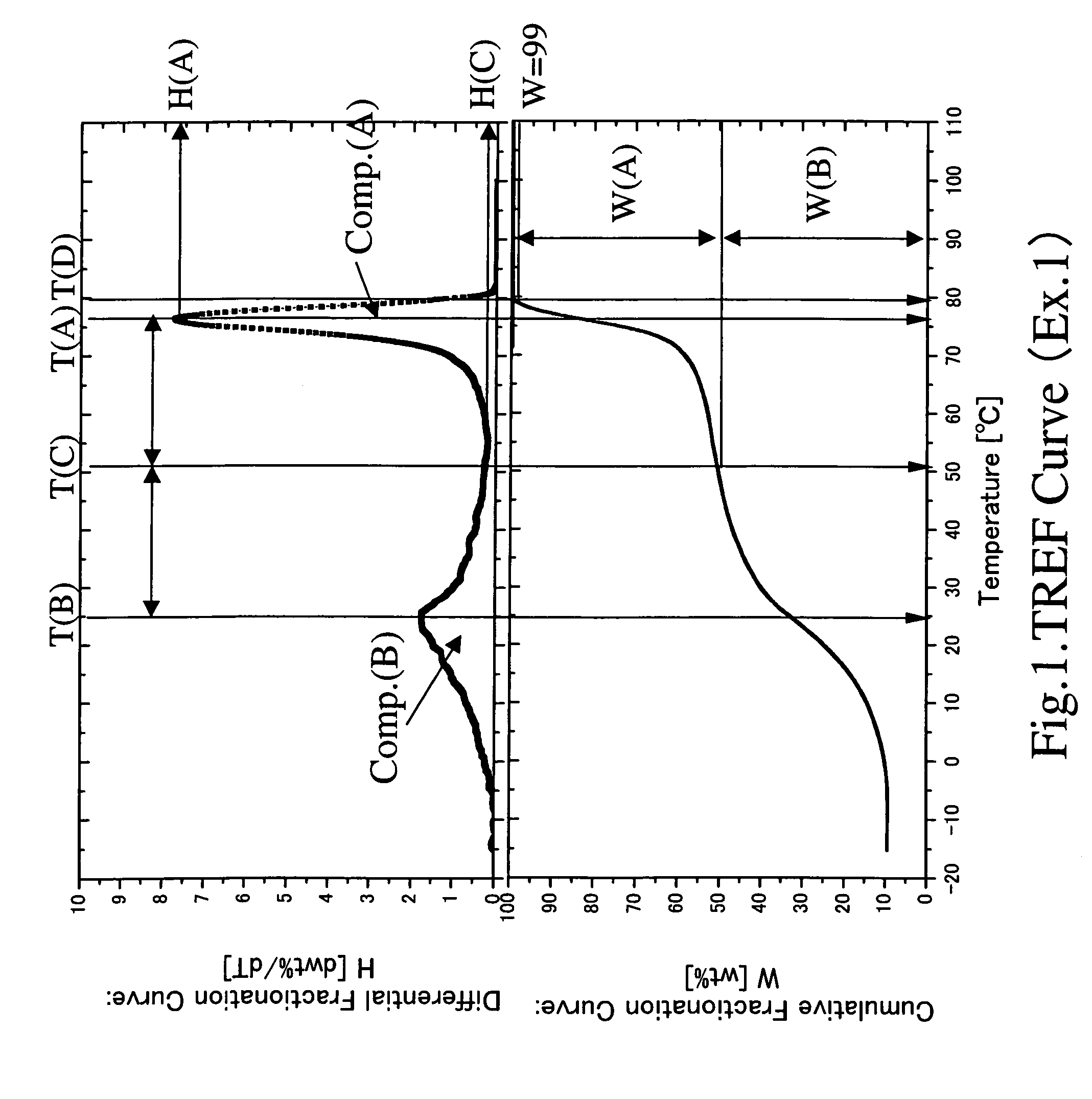

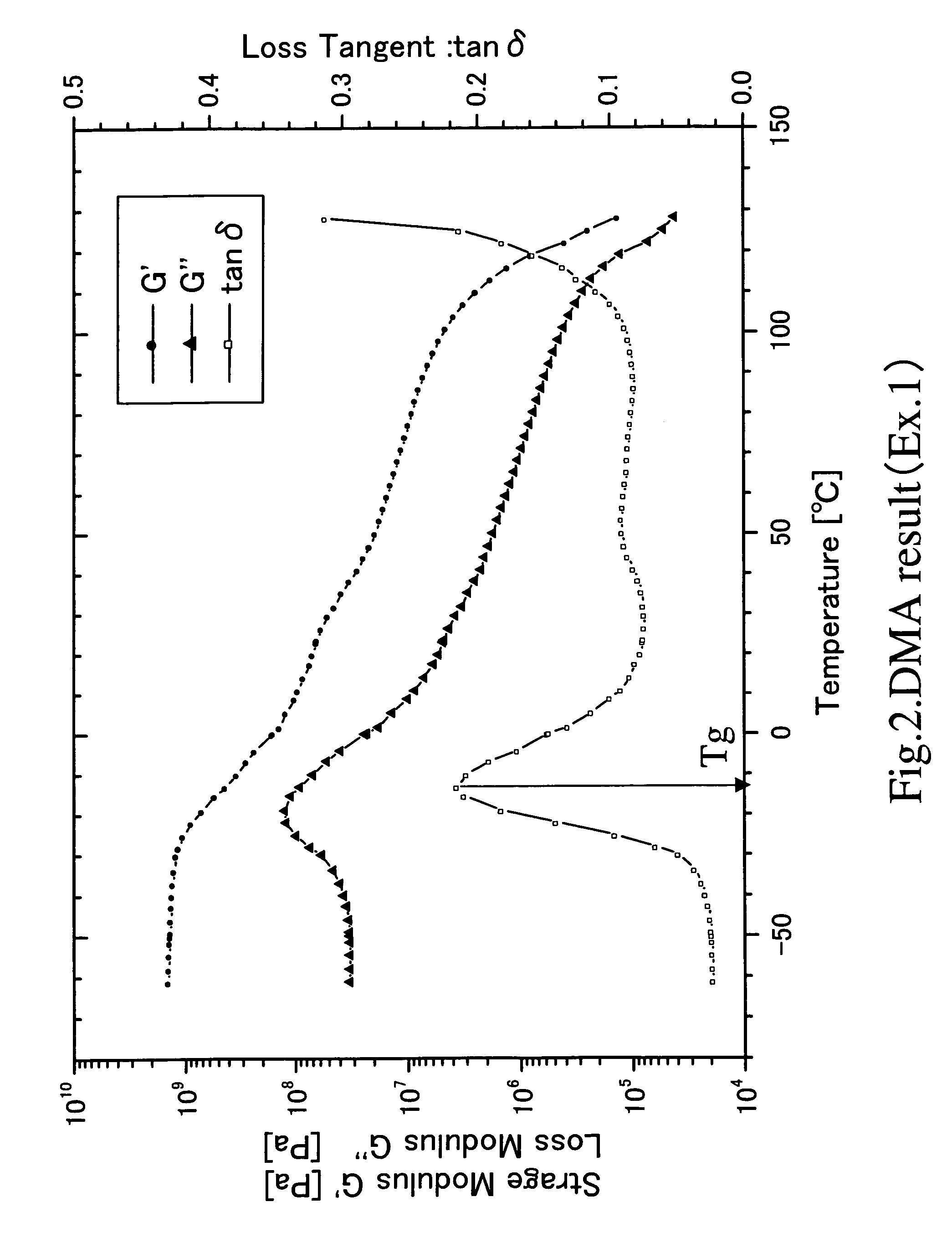

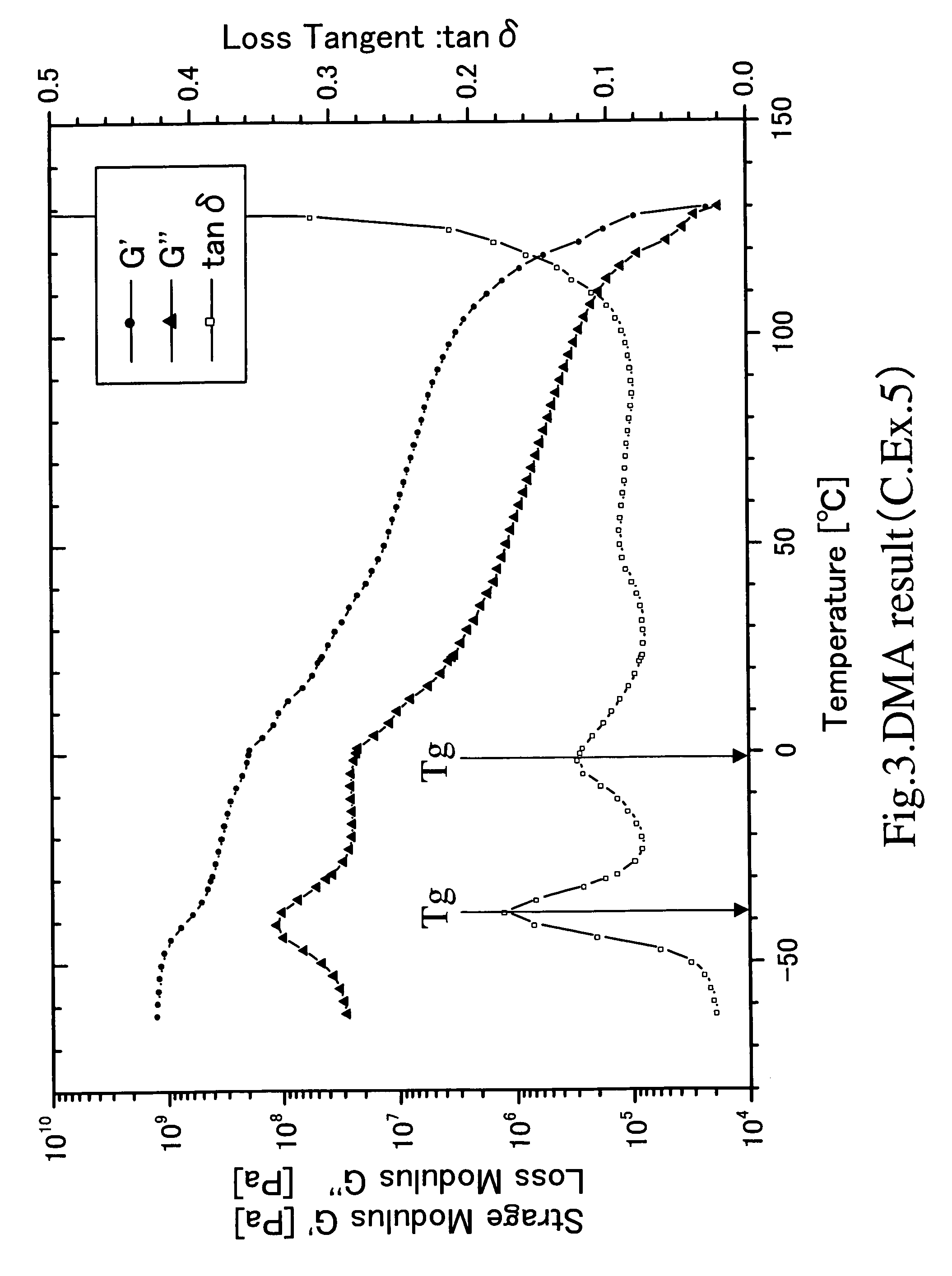

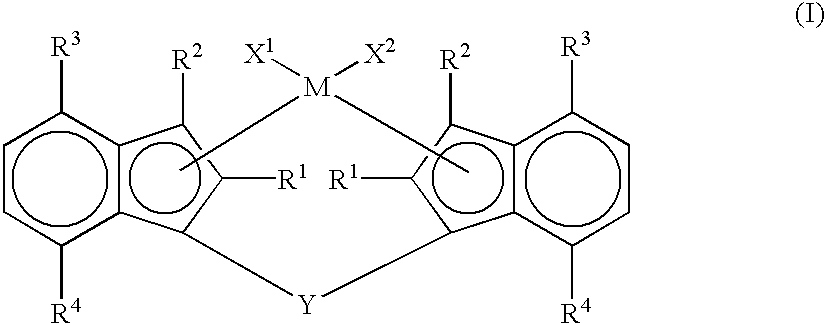

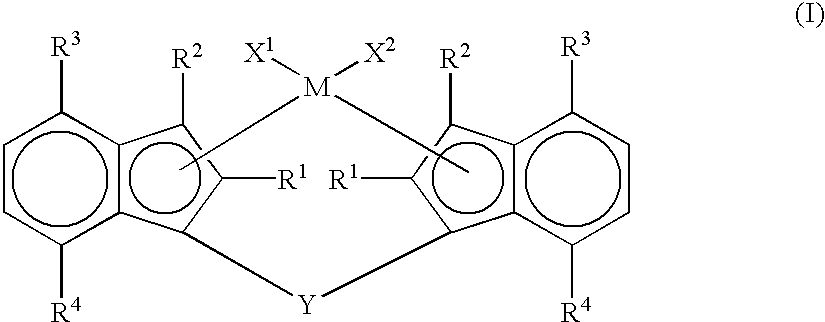

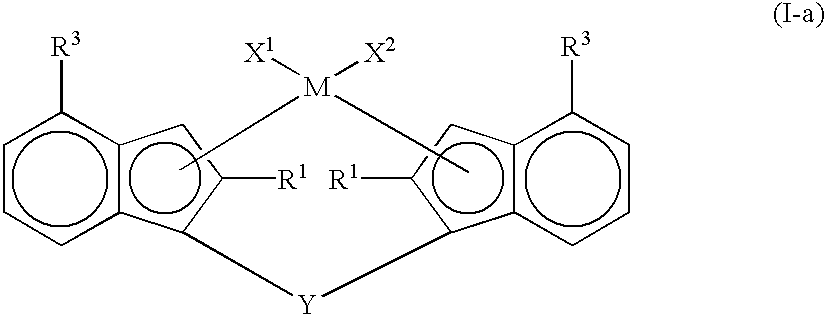

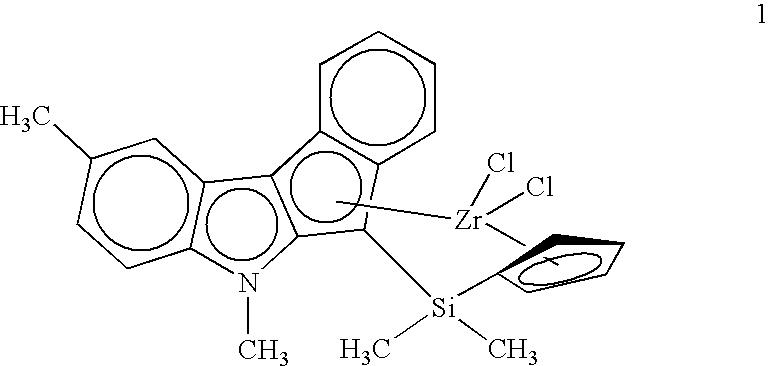

Propylene-ethylene random block copolymer and biaxially oriented multi-layer film using the same as a surface layer

ActiveUS7390575B2Improved transparency and flexibilityNo stickinessSynthetic resin layered productsDomestic containersPolyolefinSurface layer

A polyolefin based biaxially oriented multi-layer film having at least one surface layer comprise of the propylene-ethylene random block copolymer;The propylene-ethylene random block copolymer obtained through sequential polymerization catalyzed by a metallocene component which is composed of 30 to 70 wt % of a propylene-ethylene random copolymer component having an ethylene content of 1 to 7 wt % produced in the first step of the polymerization and from 70 to 30 wt % of a low crystallinity or an amorphous propylene-ethylene random copolymer component produced in the second step of the polymerization having an ethylene content of 6 to 15 wt % higher than that of the polymer component obtained in the first step, wherein that shows a single peak at 0° C. or lower in the temperature-loss tangent (tan δ) curve obtained by dynamic mechanical analysis (DMA).

Owner:JAPAN POLYPROPYLENE CORP

Plastic substrate film for food packing and machining process thereof

InactiveCN102380997AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic substrate film for food packing. The plastic substrate film is formed by performing coextruding and blow molding on an inner layer, a middle layer and an outer layer, wherein the inner layer is made from low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE) and metallocene linear low-density polyethylene (mLLDPE); and both the middle layer and the outer layer are made from LDPE and LLDPE. The plastic substrate film for food packing has the characteristics of high barrier property, high airtightness, high pollution resistance, pressure resistance, impact resistance, high heat-sealing strength and high heat-sealing performance, and is accordant with the national food safety certification.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

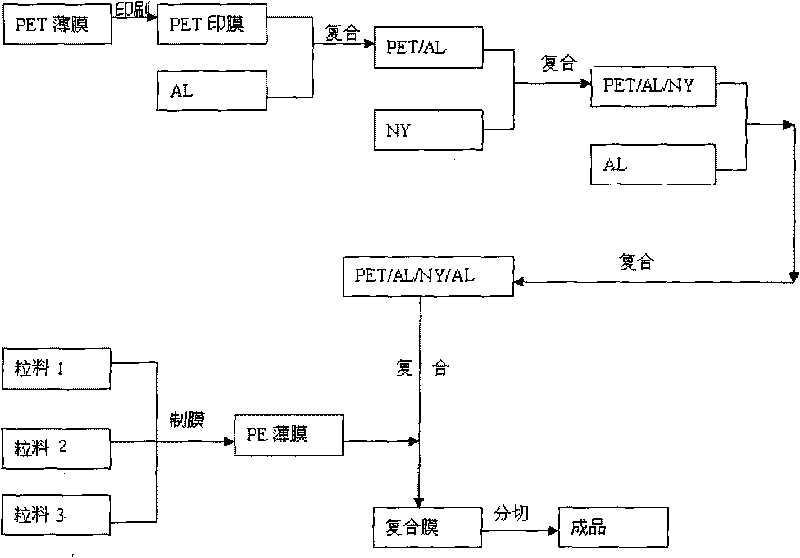

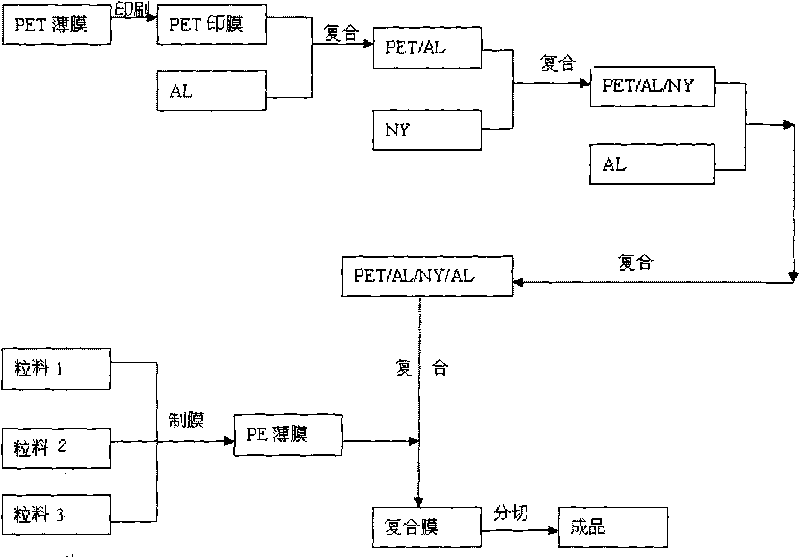

High-blocking corrosion-resisting lithium battery composite packaging film and preparation method thereof

InactiveCN101764199AAvoid prone to creasesAvoid breakingFlexible coversWrappersCorrosion resistantBlock layer

The invention discloses a high-blocking corrosion-resisting lithium battery composite packaging film and a preparation method thereof; the composite packaging film sequentially comprises an outer layer, a middle layer and a heat-sealing layer from outwards to inwards, blocking layers are arranged between the outer layer and the middle layer and between the middle layer and the heat-sealing layer, and the blocking layer is aluminium foil with 7-15mum of thickness; the preparation method comprises the following steps: a. polyethylene terephthalate layer printing; b. composite polyethylene layer preparation; c. dry compound; d. slitting; compared with the prior art, all indexes are completely in accordance to the package standard of the lithium electronic battery, the safety performance is high, the sealing property, blocking performance and corrosion prevention performance are good, transportation and storage are easy, the volume is light, the usage is convenient, and the invention is suitable for the packing development tendency of current batteries.

Owner:HUANGSHAN NOVEL

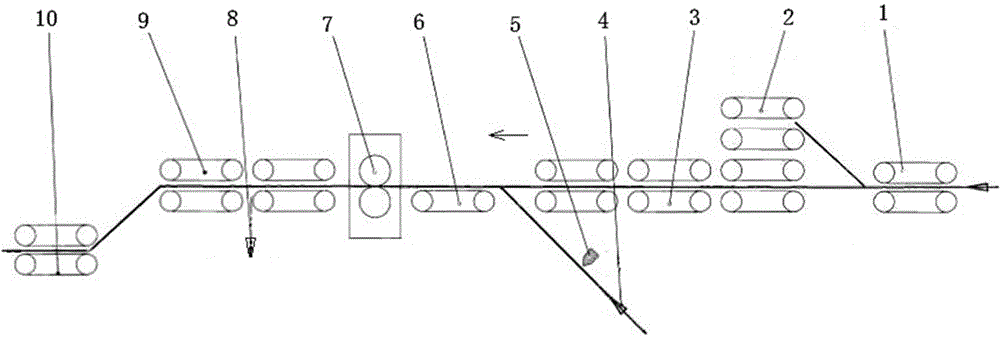

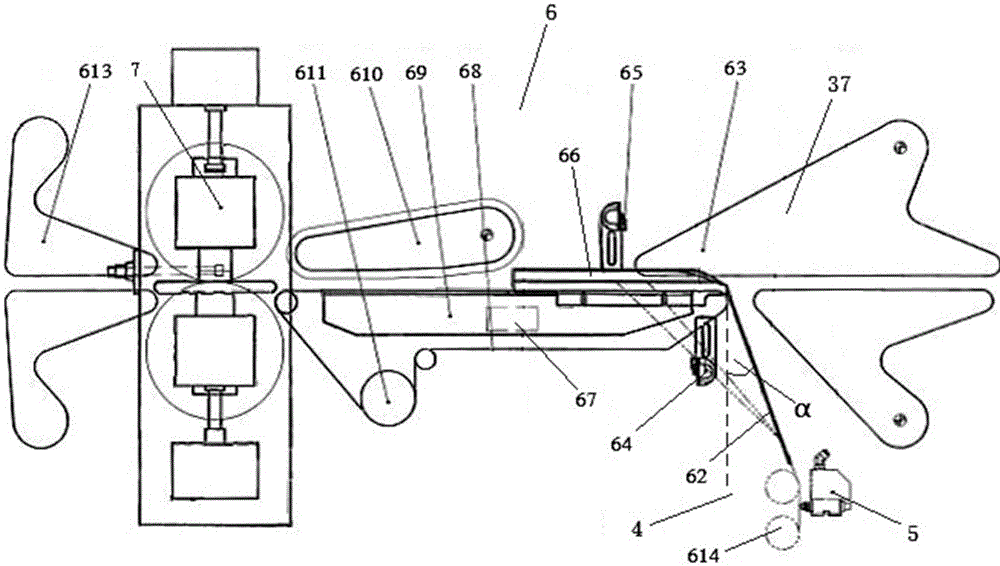

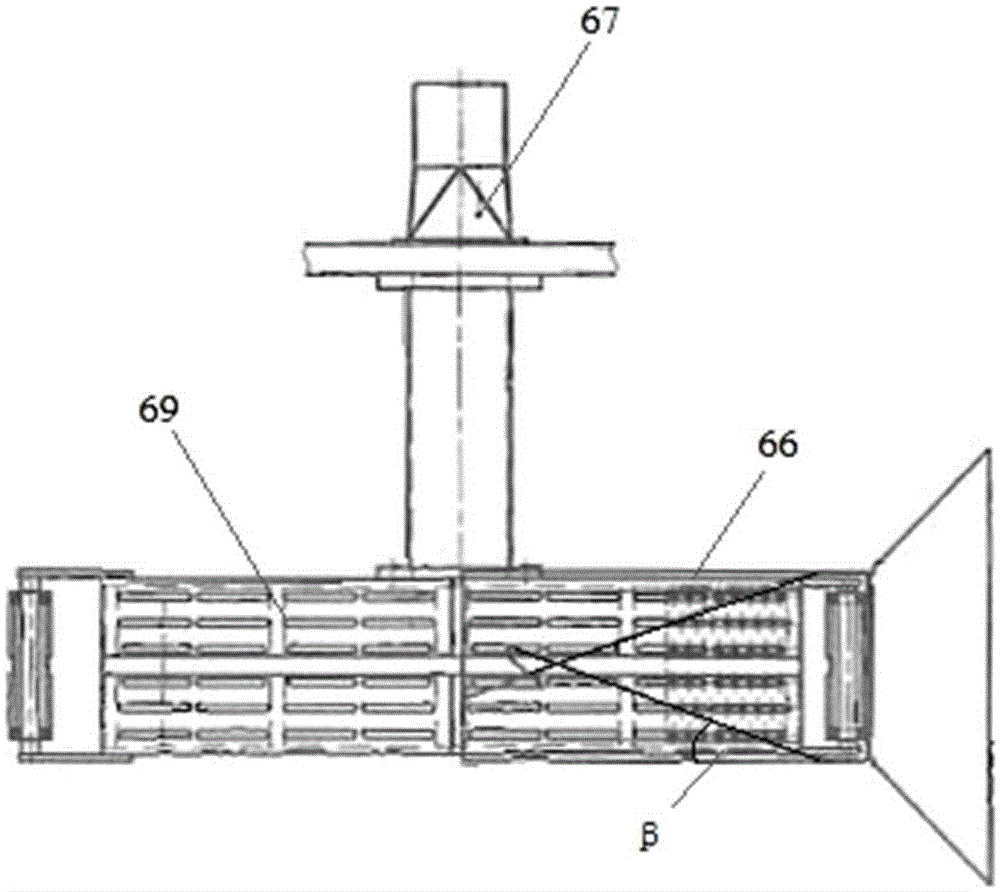

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

Capacitor film with metallocene line-shaped low-density polyethylene resin as base body and preparation method thereof

InactiveCN103102574AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with metallocene line-shaped low-density polyethylene resin as a base body and a preparation method thereof. The capacitor film is prepared from the following raw materials in parts by weight: 45-55 parts of metallocene line-shaped low-density polyethylene resin, 30-35 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy flaxseed oil, 2-3 parts of polyving akohol, 1-2 parts of calmogastrin, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-amylene, 0.1-0.3 parts of polytetrafluoroethene, 9-11 parts of blanc fix, 0.6-0.8 part of antioxygen 1010, 0.3-0.5 part of triethyl acetyl citrate, 0.5-0.7 parts of fumarat, 3-5 parts of calcium stearate, 1.5-2.5 parts of N-2(amino ethyl)-3-ammonia propyl trimethoxy silane, and 1.4-1.8 parts of modified tree ash. The metallocene line-shaped low-density polyethylene resin serving as a primary raw material; the low-density polyethylene resin serving an auxiliary raw material and a plurality of auxiliary material additives are blended, extruded and subjected to film blowing, shaping and cuting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the blanc fixe and the modified tree ash are added to the raw materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

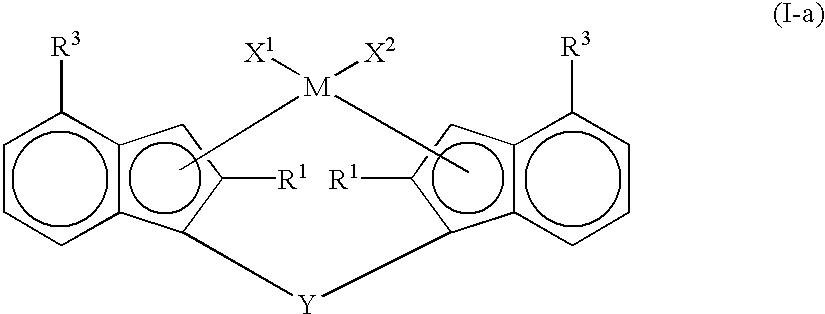

Polypropylene composite film

InactiveUS20020182426A1Good heat sealing performanceHigh heat sealing strengthSynthetic resin layered productsDomestic containersFiberPolymer science

The polypropylene composite film of the present invention comprises (A) a crystalline polypropylene layer and (B) a propylene-1-butene random copolymer layer which is laminated on at least one surface of the crystalline polypropylene layer (A). The propylene / 1-butene random copolymer (B) has the following properties: (1) the copolymer comprises 50 to 95% by mol of constituent units derived from propylene and 50 to 5% by mol of constituent units derived from 1-butene, (2) the intrinsic viscosity is 0.1 to 5 dl / g, (3) the molecular weight distribution (Mw / Mn) is not less than 3, and (4) the parameter B value is 1.0 to 1.5. The crystalline polypropylene layer (A) of this composite film may be unstretched, monoaxially stretched or biaxially oriented. The polypropylene composite film has excellent heat-sealing properties, such as low-temperature heat-sealing properties and heat-sealing strength, and hot tack properties. The polypropylene composite film is almost free from surface tackiness and shows good slip properties and high blocking resistance at high temperatures, so that it is suitable for high-speed packaging. In addition, this composite film also has good transparency and scratch resistance. The polypropylene composite film of the invention having the above-mentioned excellent properties can be favorably used for packaging of foods, fill packaging and fiber packaging.

Owner:MITSUI CHEM INC

Capacitor film containing modified talc and preparation method thereof

The invention discloses a capacitor film containing modified talc and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 57-63 parts of metallocene polypropylene resin, 35-45 parts of bisphenol A polycarbonate, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.0-1.5 parts of poly-4-methyl-1-pentene, 5-7 parts of vermiculite, 3-5 parts of modified talcum powder, 0.7-1.3 parts of an antioxidant 1010, 0.7-0.9 part of propylene glycol adipate polyester, 0.3-0.5 part of di(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate, 3-5 parts of calcium stearate and 2.2-2.6 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:BENGBU LIQUN ELECTRONICS

Bidirectional stretching heat-sealing extinction film used for package and manufacturing method thereof

InactiveCN101125595AReduce manufacturing costReduce pollutionFlexible coversWrappersSurface layerExtinction

The present invention relates to a biaxial tension heat-sealing type extinction membrane used for foods packing and a production method, wherein, a basement membrane of the extinction membrane is provided with an upper surface layer, a middle core layer and a lower surface layer which are packed into a whole through heat melt and jostling together. The upper surface layer is an extinction layer and the lower surface layer is a heat-sealing layer. The production method is mainly that the lower surface of the extinction has the heat-sealing performance by changing the materials that the lower surface uses, and the extinction collects the heat-sealing performance and extinction performance as a whole. Taking the basement membrane as food packing membrane is able to simplify the processing procedure of back procedure, reduce the cost in the backward position production process, decrease the pollution to environments, and simultaneously high heat-sealing intensity and fancy flat gloss pictures are provided.

Owner:DAQING PETROLEUM ADMINISTRATION

Polypropylene composite film

InactiveUS6686055B2Good heat sealing performanceHigh heat sealing strengthSynthetic resin layered productsDomestic containersPolypropylene compositesPolymer science

The polypropylene composite film of the present invention comprises (A) a crystalline polypropylene layer and (B) a propylene-1-butene random copolymer layer which is laminated on at least one surface of the crystalline polypropylene layer (A). The propylene / 1-butene random copolymer (B) has the following properties: (1) the copolymer comprises 50 to 95% by mol of constituent units derived from propylene and 50 to 5% by mol of constituent units derived from 1-butene, (2) the intrinsic viscosity is 0.1 to 5 dl / g, (3) the molecular weight distribution (Mw / Mn) is not less than 3, and (4) the parameter B value is 1.0 to 1.5. The crystalline polypropylene layer (A) of this composite film may be unstretched, monoaxially stretched or biaxially oriented. The polypropylene composite film has excellent heat-sealing properties, such as low-temperature heat-sealing properties and heat-sealing strength, and hot tack properties. The polypropylene composite film is almost free from surface tackiness and shows good slip properties and high blocking resistance at high temperatures, so that it is suitable for high-speed packaging. In addition, this composite film also has good transparency and scratch resistance. The polypropylene composite film of the invention having the above-mentioned excellent properties can be favorably used for packaging of foods, fill packaging and fiber packaging.

Owner:MITSUI CHEM INC

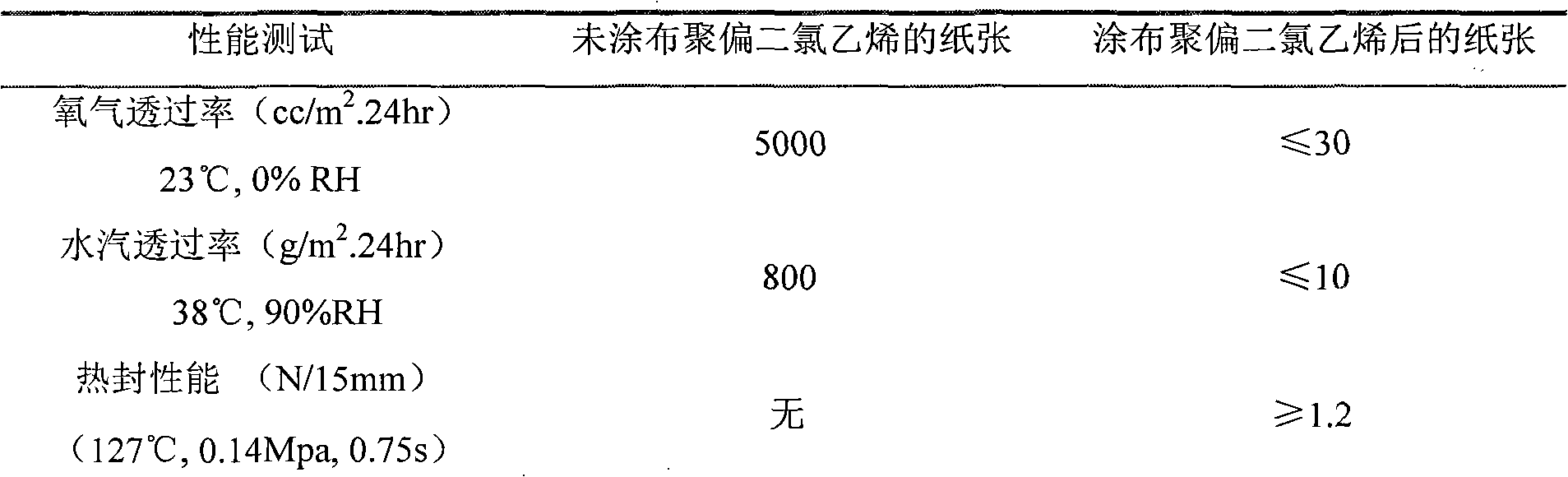

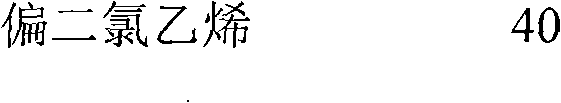

High-solid coating containing polyvinylidene chloride for paper coating and preparation method of coating

InactiveCN102650111AIncrease oxygenHigh water vapor barrierPaper coatingCoatingsFunctional monomerWater vapor

The invention provides a high-solid coating containing polyvinylidene chloride for paper coating and a preparation method of the high-solid coating. The coating is prepared by the following raw materials in percentage by weight: 40-58% of vinylidene chloride, 0.01-2% of acrylate monomer, 0.01-2% of the functional monomer, 0.005-0.02% of oxidation-type initiator, 0.005-0.05% of reduction-type initiator, 0.1-3% of emulsifier, 0.01%-0.1% of electrolyte and 38-45% of deionized water. When the high-solid coating is coated on paper, the physical properties of the paper on separating oxygen and water vapor and heat-seal strength can be improved, and further, the high-solid coating containing polyvinylidene chloride can be widely used in food packaging.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

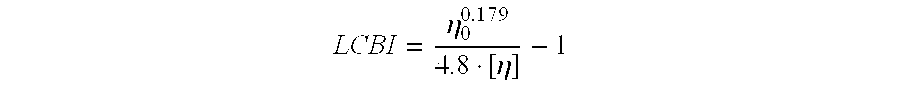

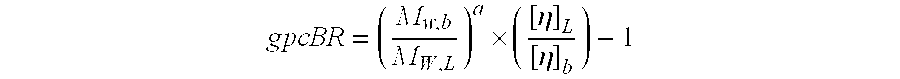

Polyolefin compositions

Owner:EQUSR CHEM LP

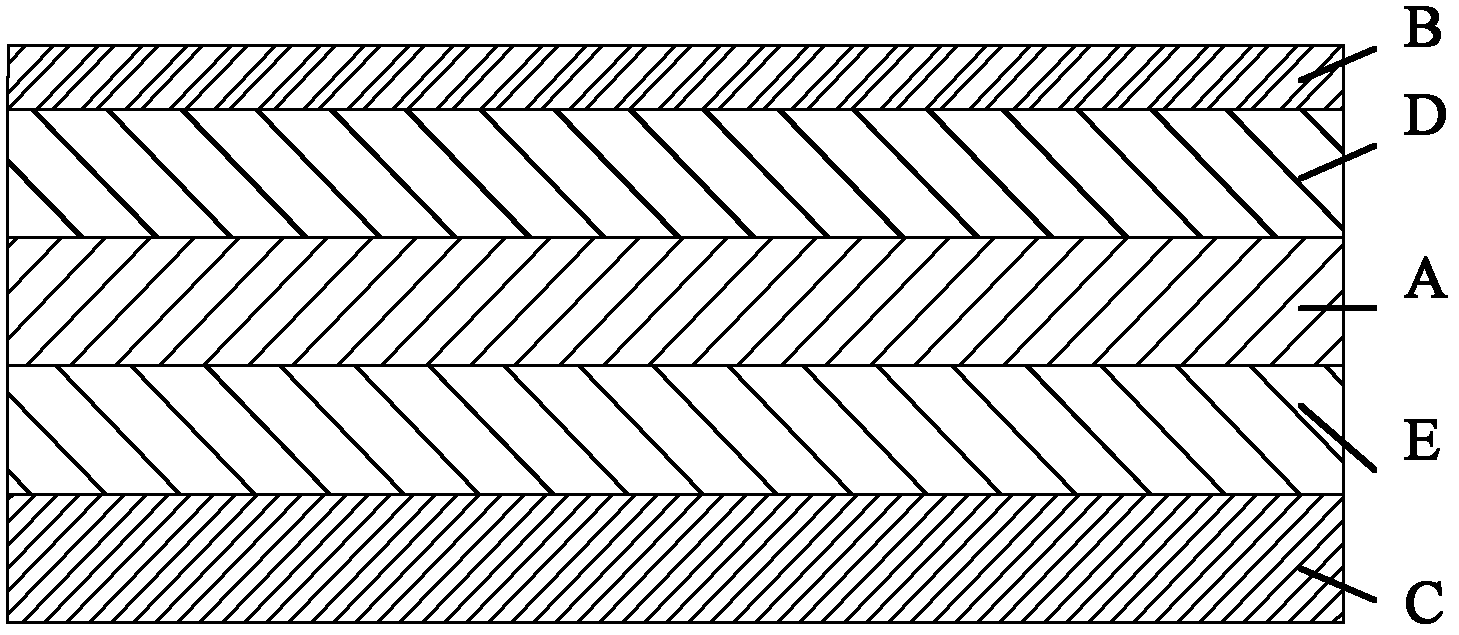

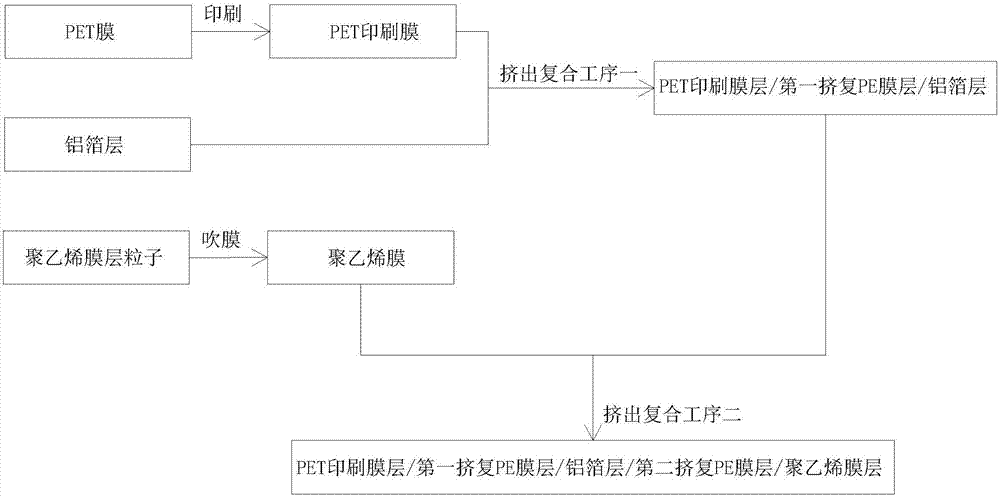

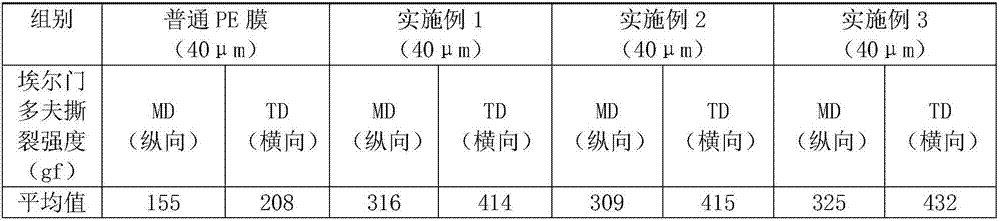

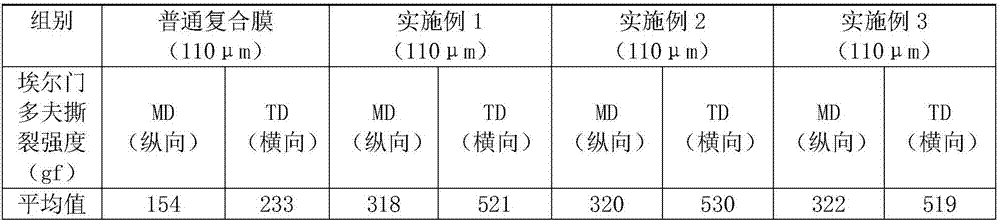

Tear-resistant polyethylene film, composite membrane and preparation method thereof

ActiveCN107323053AHigh peel strengthHigh heat sealing strengthFlexible coversWrappersTear resistanceAluminum foil

The invention relates to a tear-resistant polyethylene film, a composite membrane and a preparation method thereof. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein the corona layer and the middle layer are each composed of first metallocene PE, octa-carbon LLDPE and processing aids, and the heat sealing layer is composed of the first metallocene PE, second metallocene PE, silicone, a slipping agent and an opening agent. The composite membrane is formed by a PET printing membrane layer, a first extruded PE membrane layer, an aluminum foil layer, a second extruded PE membrane layer and a polyethylene membrane layer which are sequentially fitted in the membrane layer thickness direction; the extruded PE membrane layer comprises a first adhesive layer in fit with the aluminum foil layer and a second adhesive layer in fit with the PET printing membrane layer or the polyethylene membrane layer, wherein the first adhesive layer is composed of third metallocene PE and adhesive resin, and the second adhesive layer is composed of the third metallocene PE and color master batch. The polyethylene film and the composite membrane disclosed by the invention have higher tear resistance strength. In addition, the composite membrane has excellent humidity resistance property.

Owner:HUANGSHAN NOVEL

Heat sealing type biaxial-tension polypropylene film

ActiveCN101428699AHigh packaging requirementsReduce manufacturing costFlexible coversWrappersSurface layerAntistatic agent

A heat-sealing type two-way stretching polypropylene film is prepared by forming a heat-sealing layer with a heat-sealing strength on the surface layer of the two-way stretching polypropylene film by a co-extrusion process. The heat-sealing layer can be formed above or below the two-way stretching polypropylene film, or formed on both the upper and the lower surfaces of two-way stretching polypropylene film at the same time. The adopted heat-sealing material comprises mixing materials of heat-sealing type materials like biopolymer polypropylene or terpolymer polypropylene, propylene-butylene copolymer or known alkene copolymer and the like; heat-sealing materials like 3% to 60% of propylene butylene copolymer or known alkene copolymer and the like, or elastic body, 40% to 97% of homopolymerization polypropylene, and 1% to 20% of an anti-static agent are added to a core layer. The interface heat-seal package or the couple-seal package can be directly performed to the product without being compounded with the PE or CPP heat-sealing film; the surface of the product can be printed and coated, or coated after being printed according to the operating requirements; the product integrates package and decoration as a whole, and can replace partial composite products. The product has the remarkable advantage of low cost, and reduces the environmental pollution.

Owner:HAINAN SHINER IND

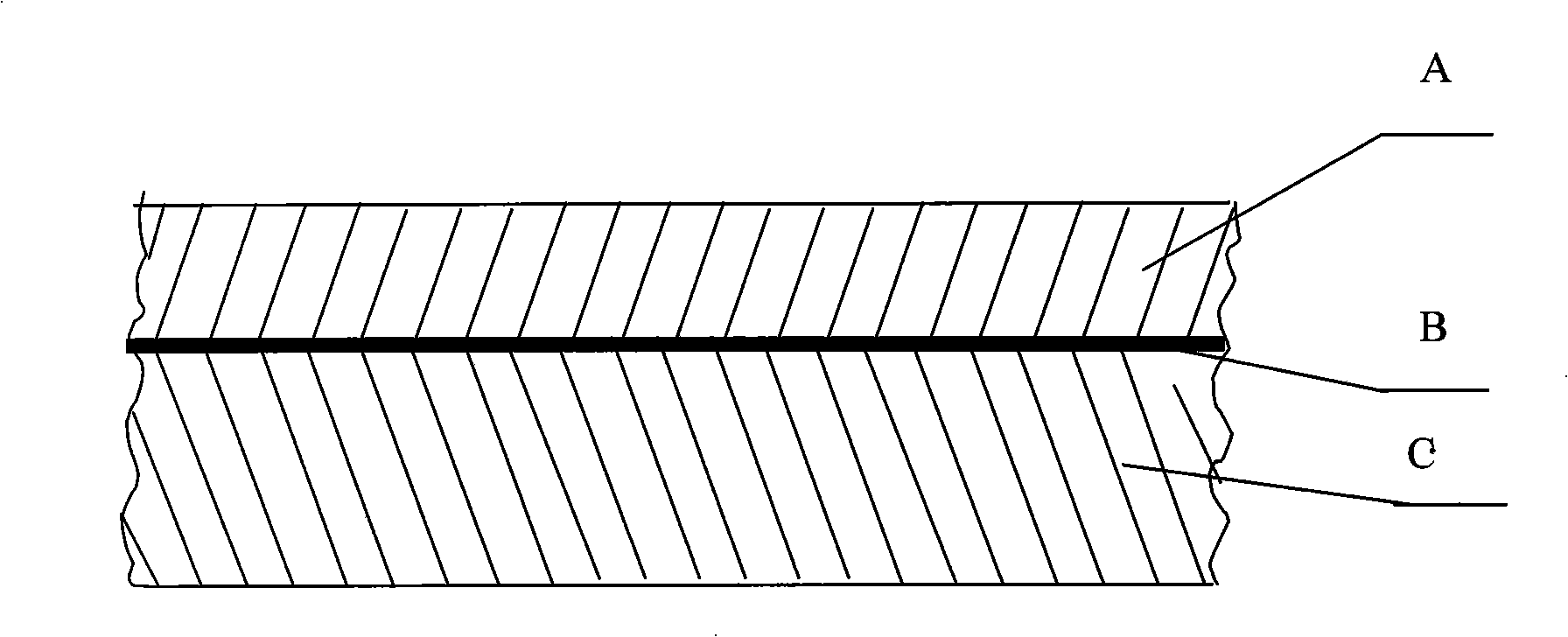

Flexible package aluminum-plastic film material for lithium battery

InactiveCN104241556AImprove ductilityGood mechanical propertiesSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPolyesterElectrolytic agent

The invention relates to a flexible package aluminum-plastic film material for a lithium battery. The flexible package aluminum-plastic film material for the lithium battery comprises a layer structure, wherein the layer structure comprises an aluminum-based layer (AL) in the middle and layers on the inner side and the outer side of the aluminum-based layer, wherein a novel functional adhesive resin layer (AD), a polyester layer (PET), a novel functional adhesive resin layer (AD) and a copolymer propylene layer (CPP) are sequentially distributed on the inner side from inside to outside; a polyester layer (PET), a novel functional adhesive resin layer (AD) and a homopolymer propylene layer (PP) are sequentially distributed on the outer side from inside to outside. The polyester layer (PET) is used as a functional barrier layer and has the stable chemical performance and high electrolyte resistance; the copolymer propylene layer (CPP) is used as a functional material layer and has the high electrolyte resistance, heat-sealing performance and high heat-sealing strength; the novel functional adhesive resin layer (AD) is made of a PP material and has the strong adhesive fastness with the aluminum-based layer (AL), the polyester layer (PET), the homopolymer propylene layer (PP) and the copolymer propylene layer (CPP). The layering can not occur by adopting a casting process technology.

Owner:广东赛洋科技有限公司

Capacitor thin film containing modified sepiolite powder and preparation method thereof

InactiveCN103102581AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolymer science

The invention discloses a capacitor thin film containing modified sepiolite powder and a preparation method thereof. The capacitor thin film containing modified sepiolite powder comprises the following raw materials in parts by weight: 40-45 of metallocene polypropylene resin, 35-40 of LDPE (Linear low density polyethylene), 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 2.2-2.5 of poly-4-methyl-1-amylene, 7.5-9.5 of modified sepiolite powder, 3.5-5 of zeolite, 1.2-1.5 of antioxidant DSTP, 0.9-1.1 of acetylcitric acid tris(2-ethylhexyl) ester, 0.8-1.2 of di-n-butyl maleate, 3-5 of calcium stearate, 2.5-3 of N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane (triethoxysilane), and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

Packaging film for milk and method for manufacturing same

InactiveCN101306743ALow shrinkageAvoid deformationFlexible coversWrappersComposite filmChemical reaction

A milk packaging film is a composite film formed by binding an outer film and an inner film via a binder layer. The outer film is a polyvinylidene chloride film, the binder is mono-component or two-component polyurethane solvent binder or non-solvent binder, and the inner film is a black and white polyethylene film. The manufacturing method of the milk packaging film comprises the steps of heating the outer polyvinylidene chloride film via a heating device; placing on an unwinding shaft of a film-coating machine; passing through an unwinding machine; adjusting via a flattening device, a tension control device and an edge guide device; coating binder; and laminating with the inner film treated by the flattening device, the tension control device and the edge guide device. The inventive milk packaging film has the advantages of high heat-sealing strength, high mechanical strength, stable chemical properties, resistance to oil and fat, solvent, acids, bases and salts, no chemical reactions with foods, good food sanitation performance, high-temperature steaming resistance, no deformation, no cracking, good printability, and low cost.

Owner:河南双汇投资发展股份有限公司

Self-supporting bag and composite film thereof

ActiveCN104924712AGood heat sealingGuaranteed leak-proof effectSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film. The polyethylene film comprises a composite layer, a middle layer and a heat sealing layer which are sequentially overlapped. The composite layer comprises 60-70wt% of metallocene polyethylene and 30-40wt% of low-density polyethylene; the middle layer comprises 30-35wt% of high-density polyethylene, 30-35wt% of linear low-density polyethylene and 30-35wt% of low-density polyethylene; the heat sealing layer comprises 33-35% of low-density polyethylene, 63-65% of reinforcing polyethylene resin, 0.5-0.8wt% of slipping agent and 1.3-2.0wt% of anti-blocking agent. A melting point of the composite layer is higher than that of the middle layer, and the melting point of the middle layer is higher than that of the heat sealing layer. The invention further provides a composite film and a self-supporting bag which are prepared through the polyethylene film. By the adoption of the PE film, PE melting of the heat sealing portion can be effectively avoided, the heat sealing performance of the PE film is greatly improved, and the polyethylene film has excellent adaptation, pressure resistance and falling resistance and meets the requirement of actual production.

Owner:河北永新包装有限公司

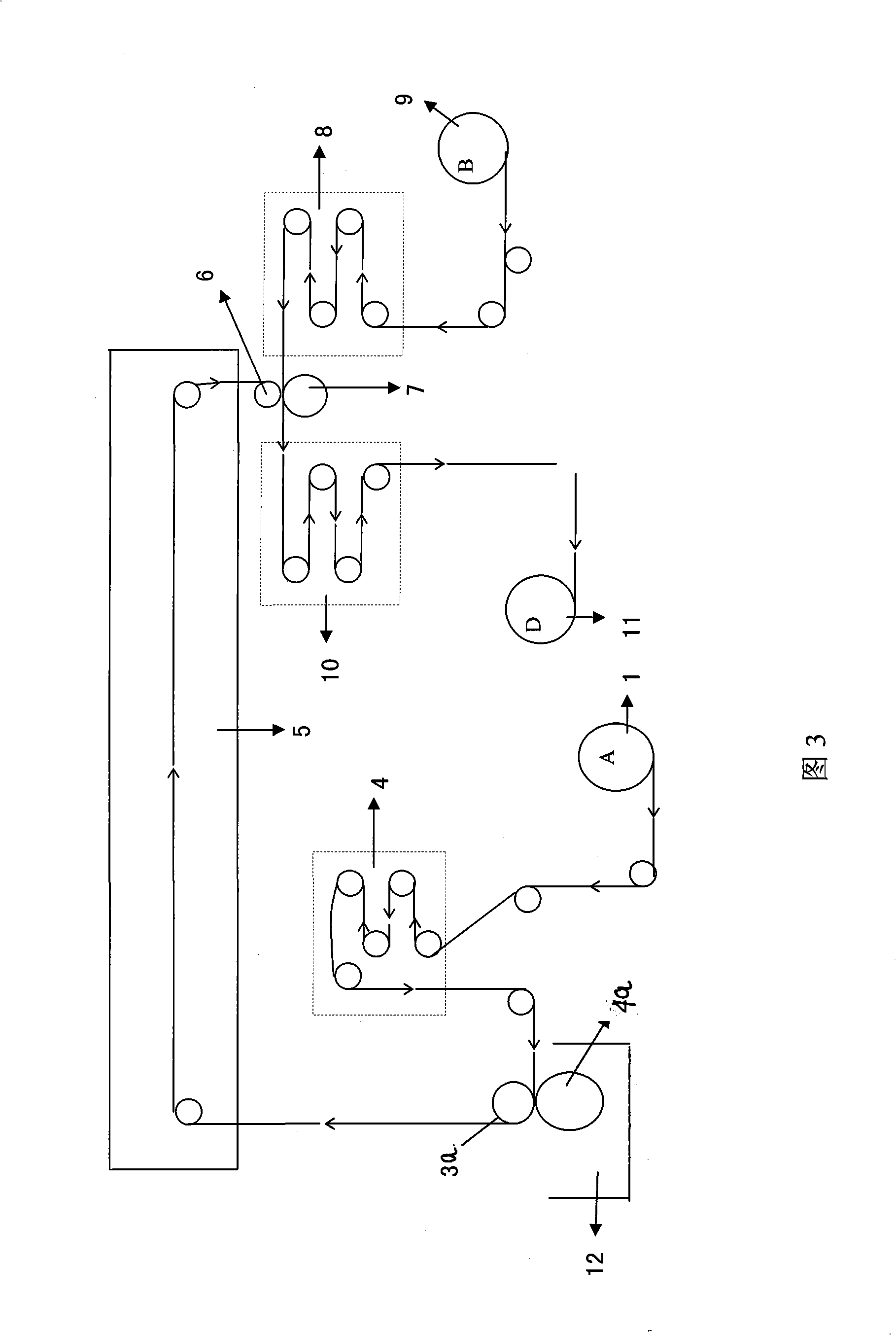

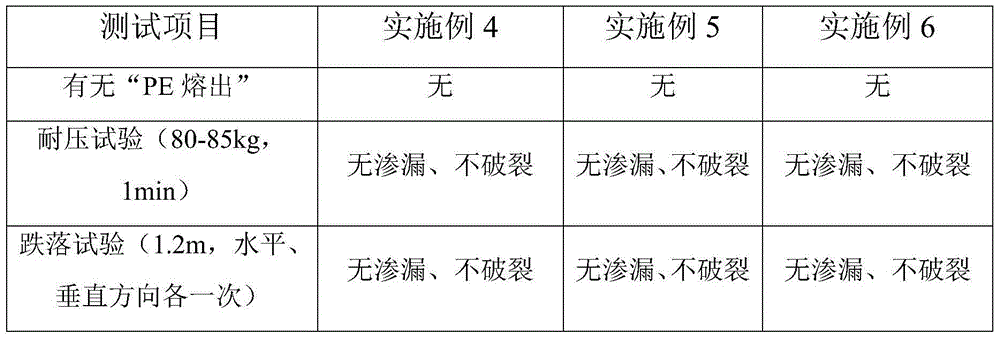

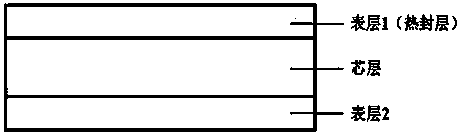

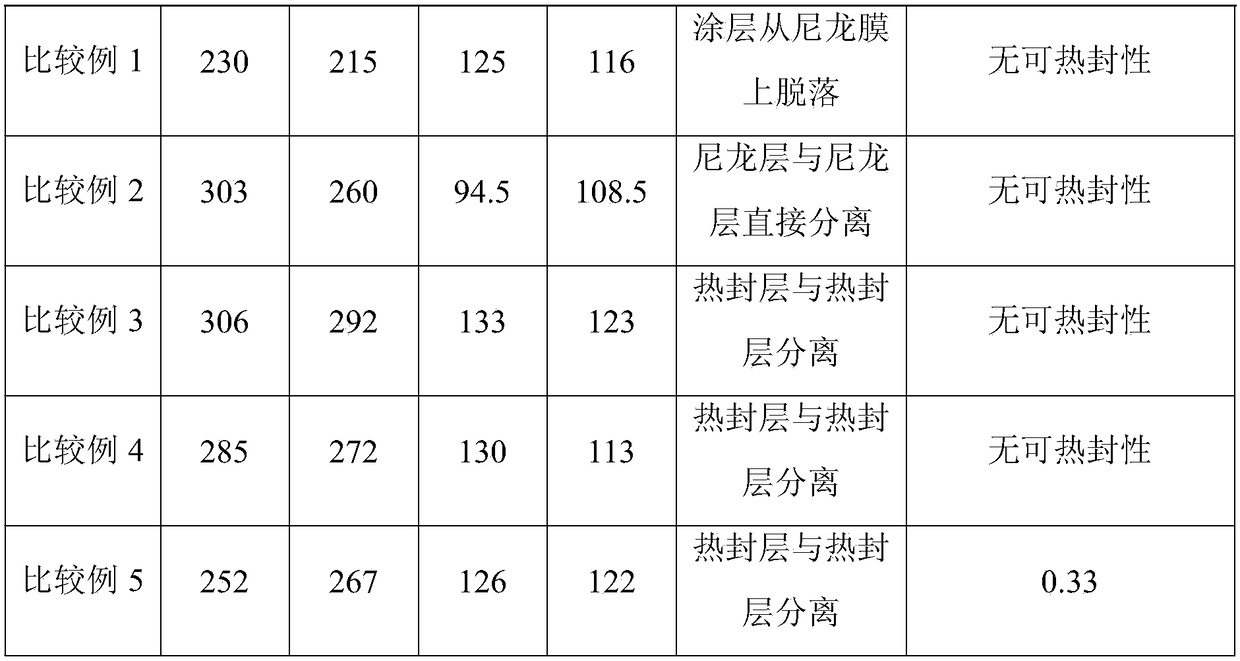

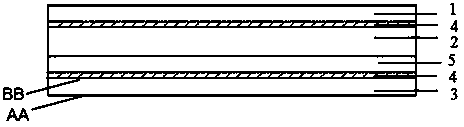

Two-way stretching nylon film capable of being heat sealed and preparation method thereof

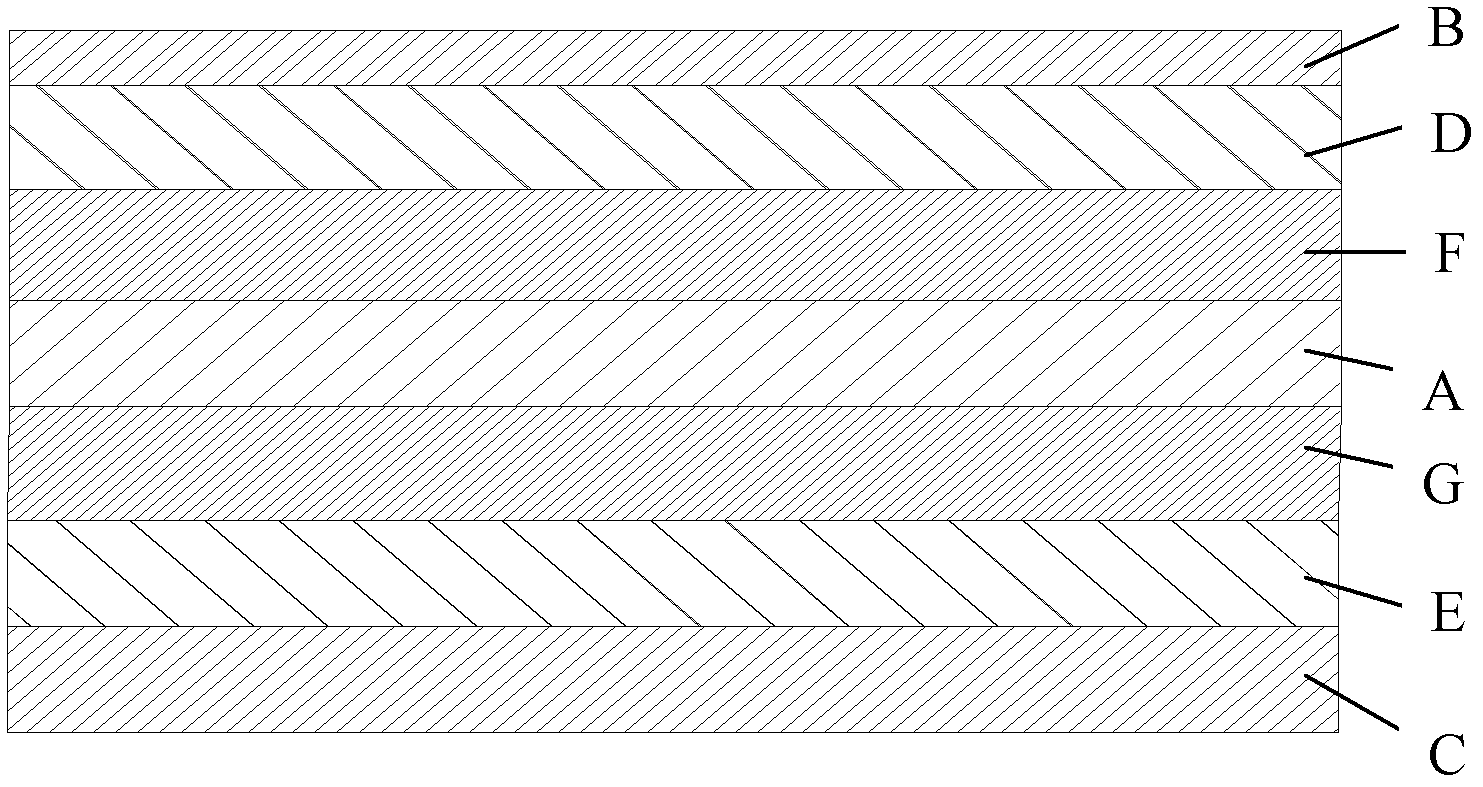

ActiveCN108481866ASimple compositionEasy to prepareSynthetic resin layered productsLaminationSurface layerNylon 6

The invention relates to a two-way stretching nylon film capable of being heat sealed and a preparation method thereof. The two-way stretching nylon film capable of being heat sealed is of a three-layer structure composed of a surface layer 1, a core layer and a surface layer 2. The surface layer 1 is prepared from the following raw materials: 70-100% of copolymer nylon and 0-30% of nylon-6 resin;the core layer is prepared from 100% of nylon-6 resin; and the surface layer 2 is prepared from the following raw materials: 0-1% of antiblocking agent, 0-1% of slipping agent and 98-100% of nylon-6resin. The two-way stretching nylon film capable of being heat sealed is formed through fusion co-extrusion, sheet flow-casting and synchronous two-way stretching. The prepared two-way nylon film capable of being heat sealed is simple in production technology, the heat sealing layer is even in thickness, the obtained film has the high heat sealing strength, is environmentally friendly and free oftoxicity, and can be applied to fields of food, medical treatment, electronic packaging and the like.

Owner:厦门长塑实业有限公司

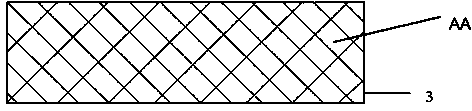

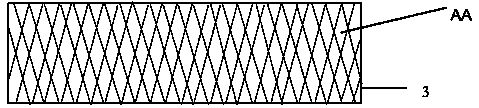

Lithium battery aluminum-plastic film and preparation method thereof

ActiveCN103647029AImprove corrosion resistanceIncrease heat seal specific surface areaDomestic sealsJackets/cases materialsPlastic packagingHeat resistance

The invention belongs to the field of an aluminum-plastic packaging film composite material, and particularly relates to a lithium battery aluminum-plastic film and a preparation method thereof. The lithium battery aluminum-plastic film sequentially comprises a heat-resisting polyimide (PI) layer, an adhesive layer, an aluminum foil layer, an anticorrosion coating, an adhesive layer and a heat-seal layer from outside to inside, and the lithium battery aluminum-plastic film is characterized in that the surface of the heat-seal layer is provided with a concave-convex gridding structure. Compared with the prior art, the specific surface area of heat sealing is greatly increased through the concave-convex gridding of the heat-seal layer, a powerful mechanical lock is formed in heat sealing, the high heat-seal strength can be realized, and the application safety of a lithium battery can be reliably guaranteed.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Liquid package composite membrane and preparation method thereof

ActiveCN102673882AHigh heat sealing strengthExcellent drop resistance and pressure resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a liquid package composite membrane and a preparation method thereof and belongs to the technical field of plastic package. The composite membrane comprises a surface layer, an obstruction layer, a reinforced layer and a heat seal layer, wherein the surface layer is a polyethylene terephthalate film layer; the obstruction layer is an aluminum foil layer; the reinforced layer is a polyethylene terephthalate film layer; and the heat seal layer consists of the following materials: 40-60wt% of eight-carbon linear low-density polyethylene, 35-50wt% of polyvinyl acetate and 5-10wt% of low-density polyethylene. The liquid package composite membrane provided by the invention has excellent break-resistant and pressure-resistant performances; break-resistant performance test shows that the liquid package composite membrane does not break while falling to a cement floor from a height of 10 meters once; and pressure-resistant performance test shows that the liquid package composite membrane has no leakage within 24 hours when the static pressure is 20MPa.

Owner:ZHEJIANG GOLDSTONE PACKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com