Patents

Literature

48results about How to "Adjust interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

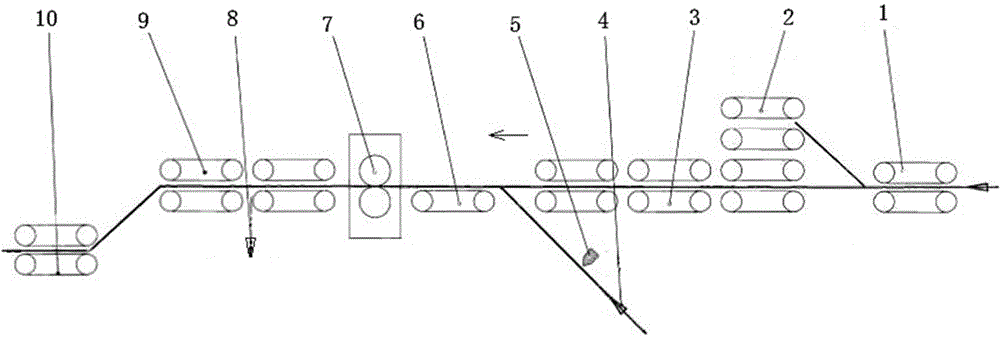

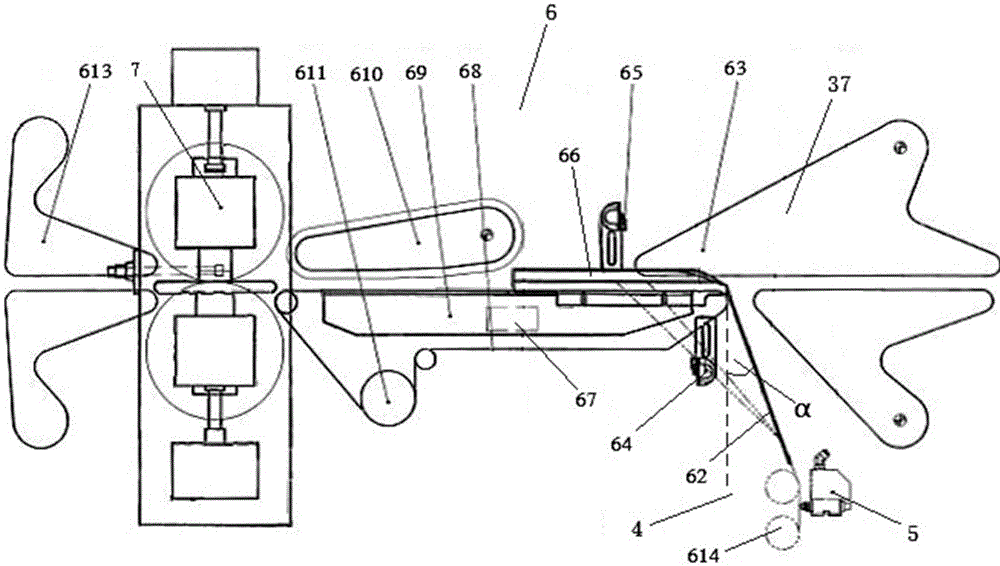

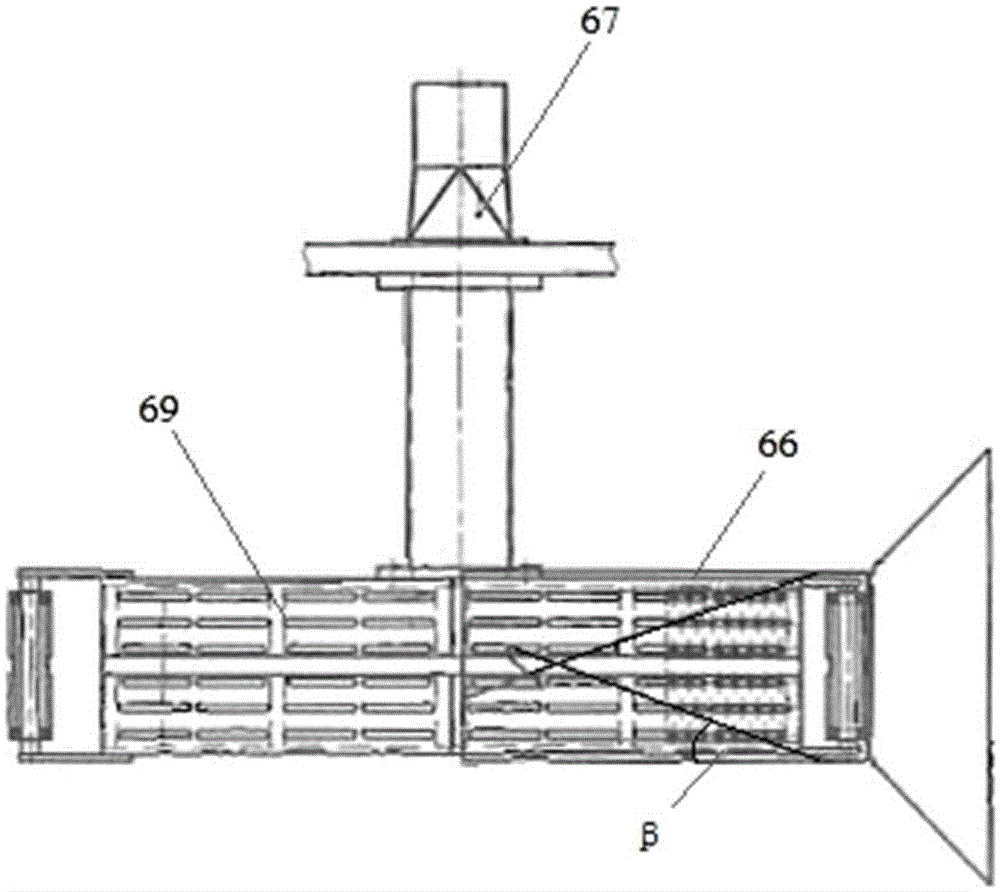

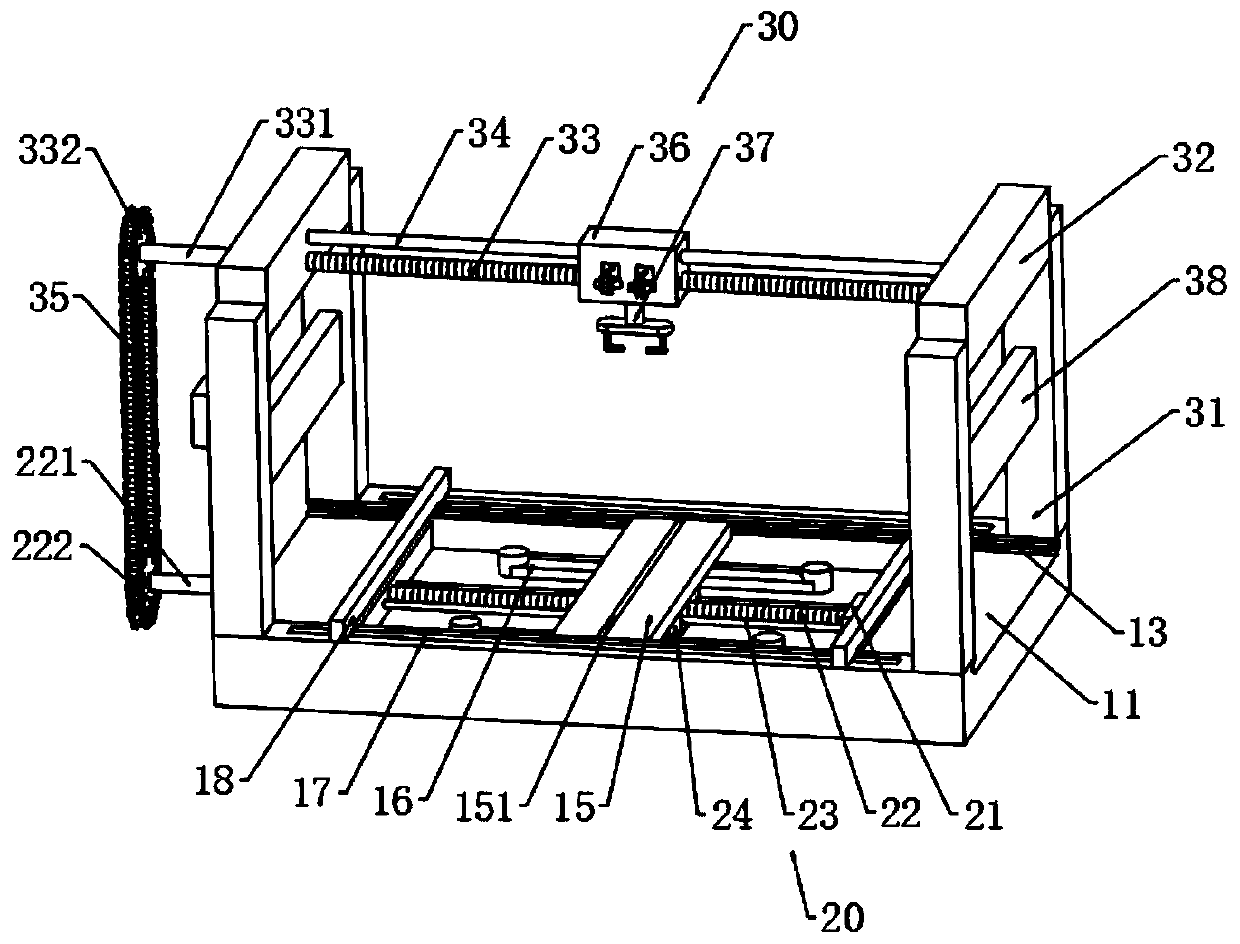

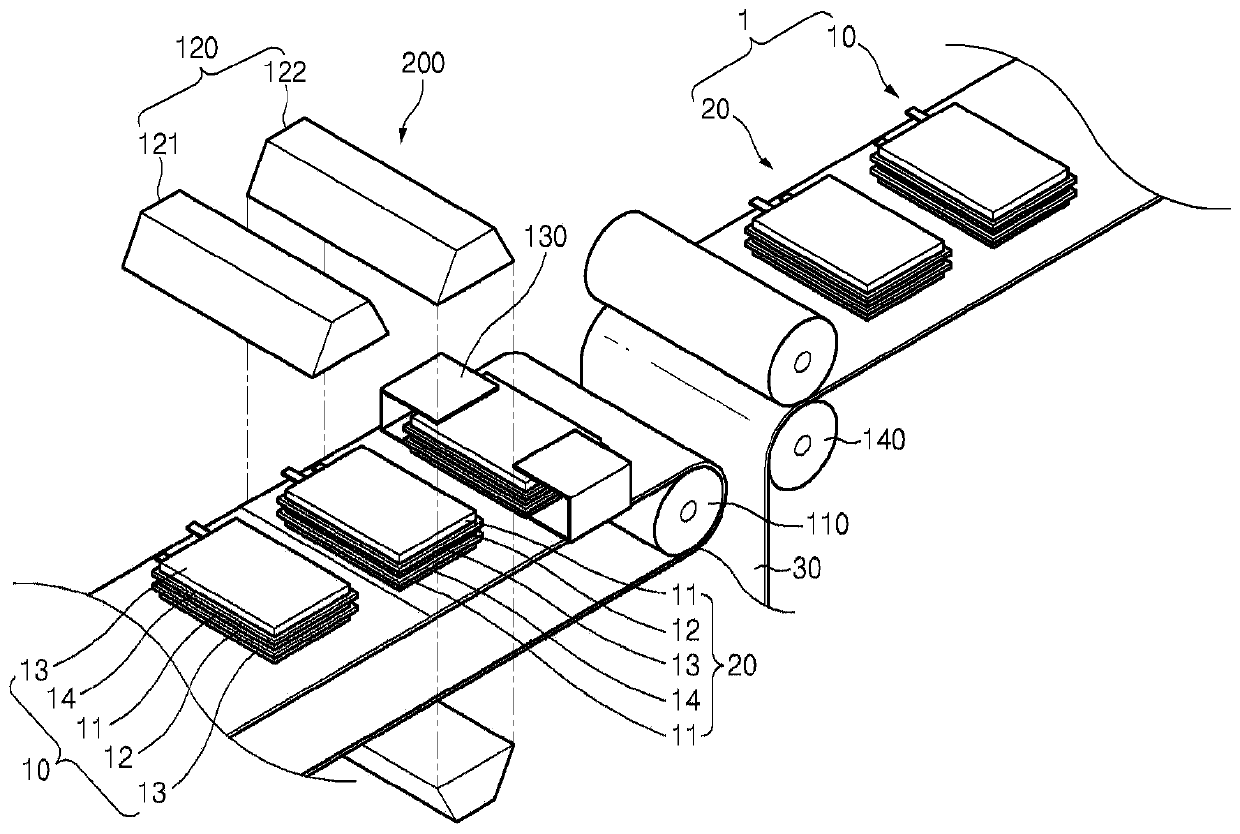

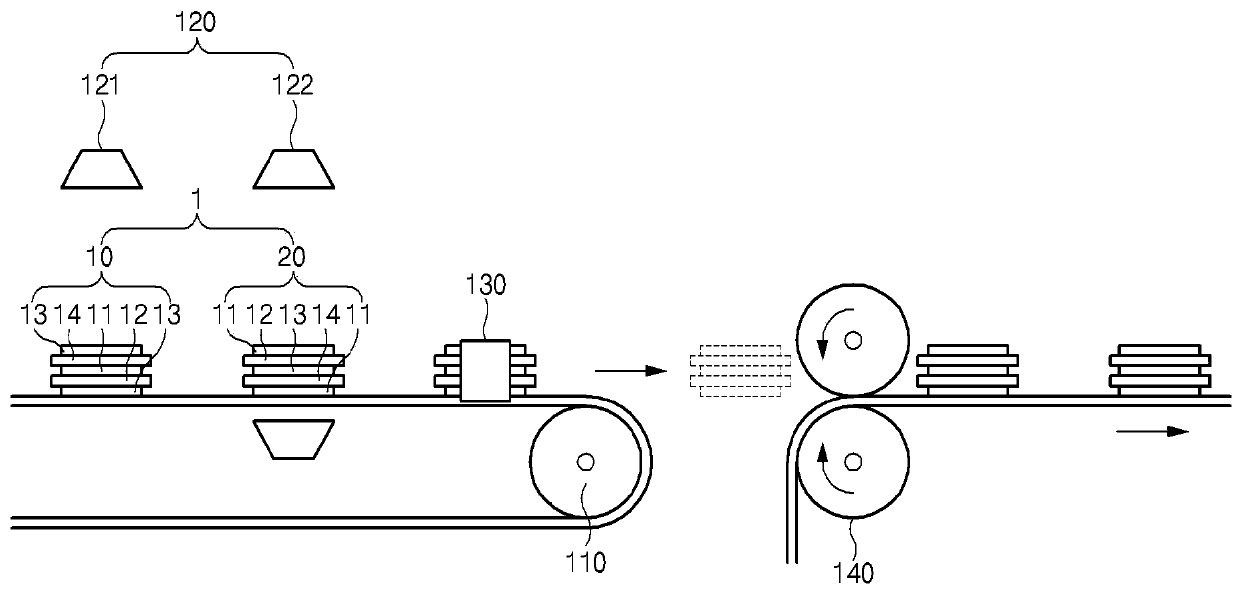

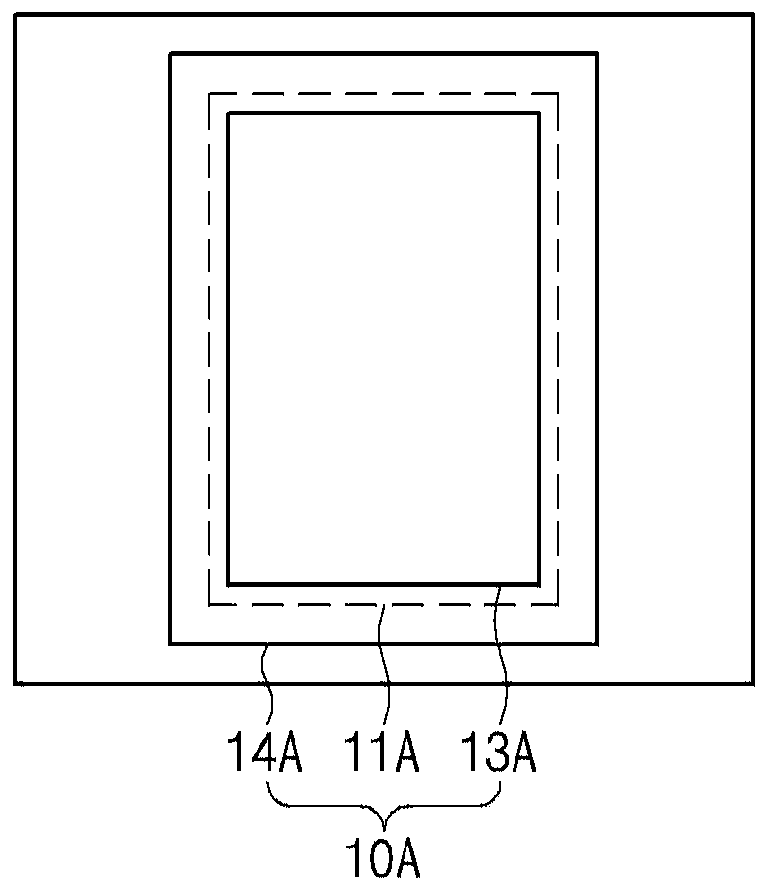

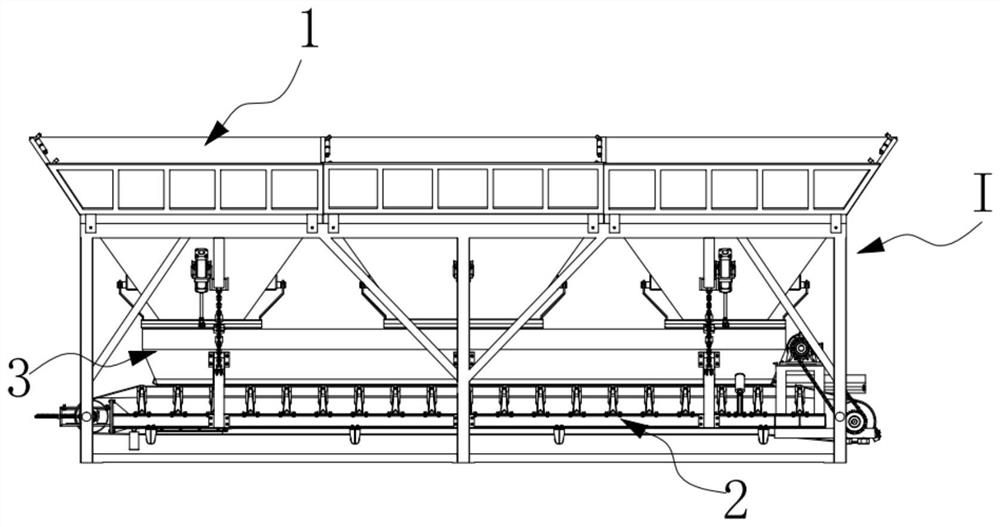

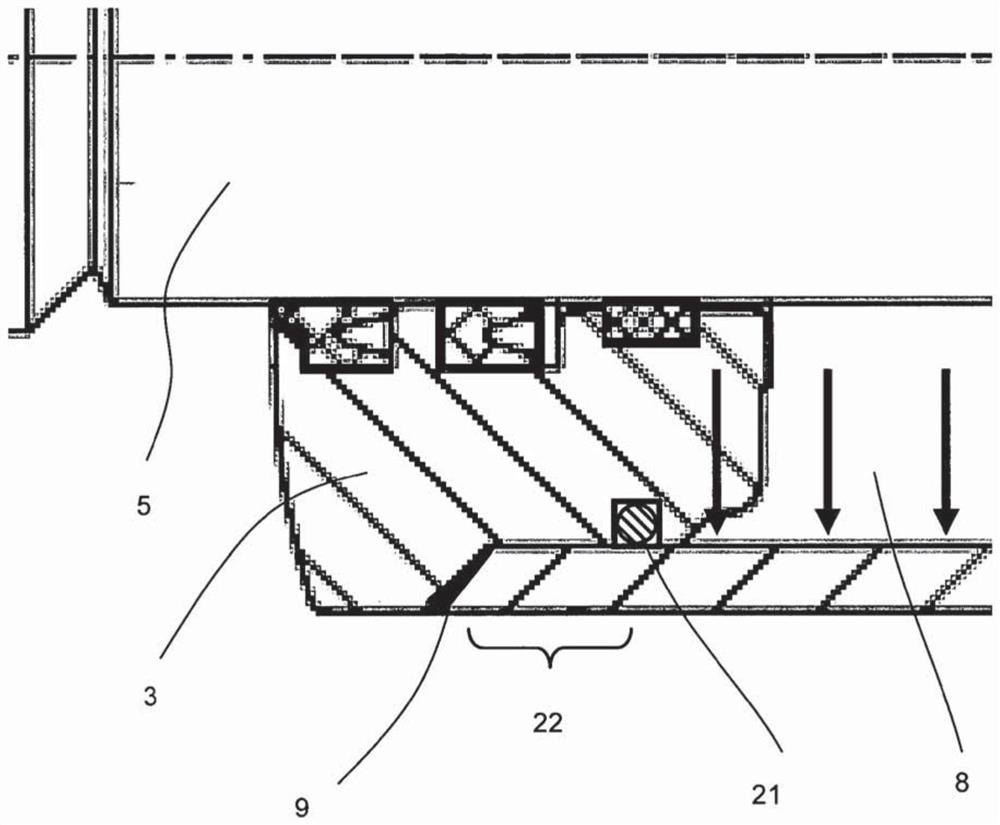

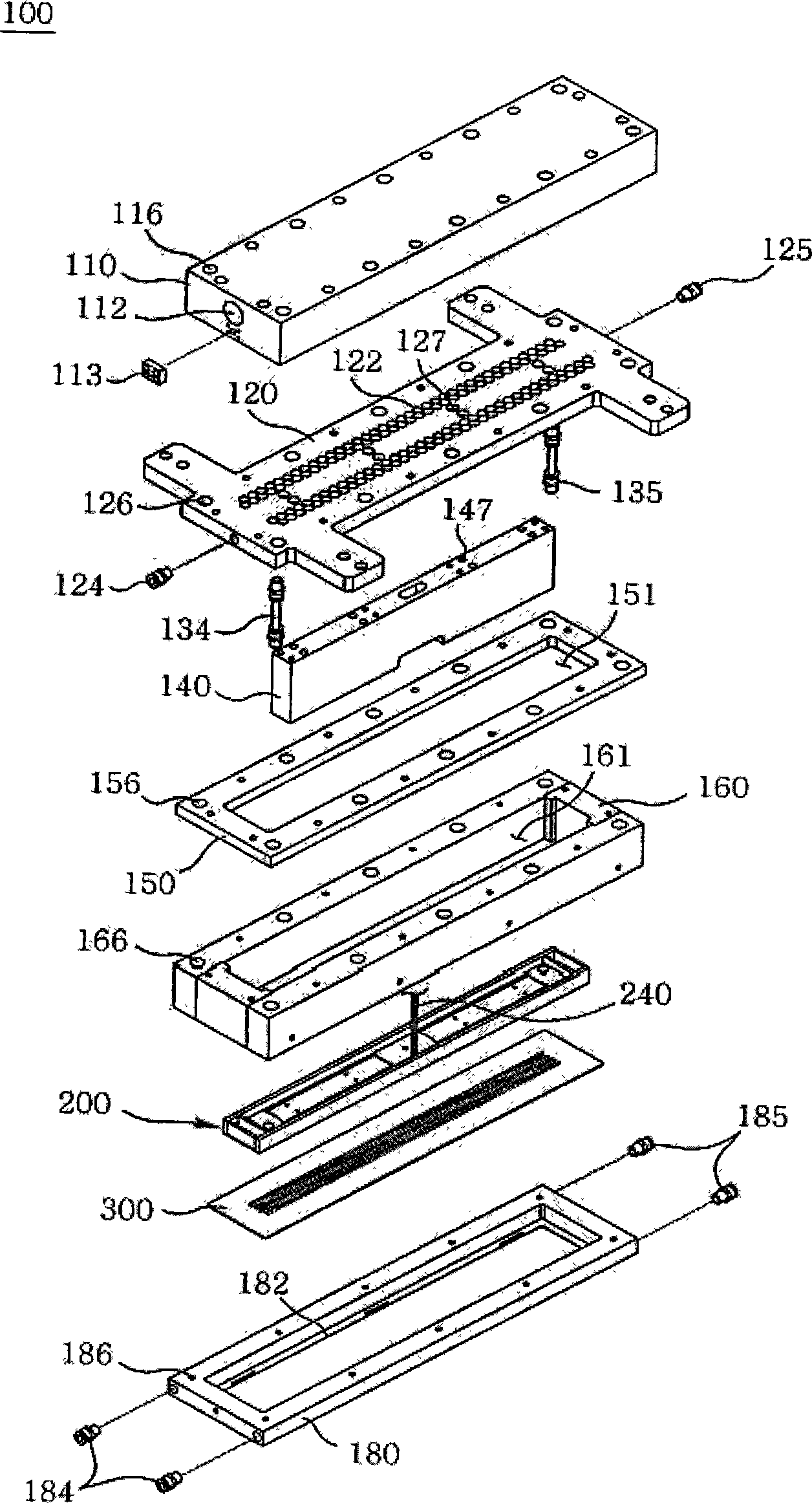

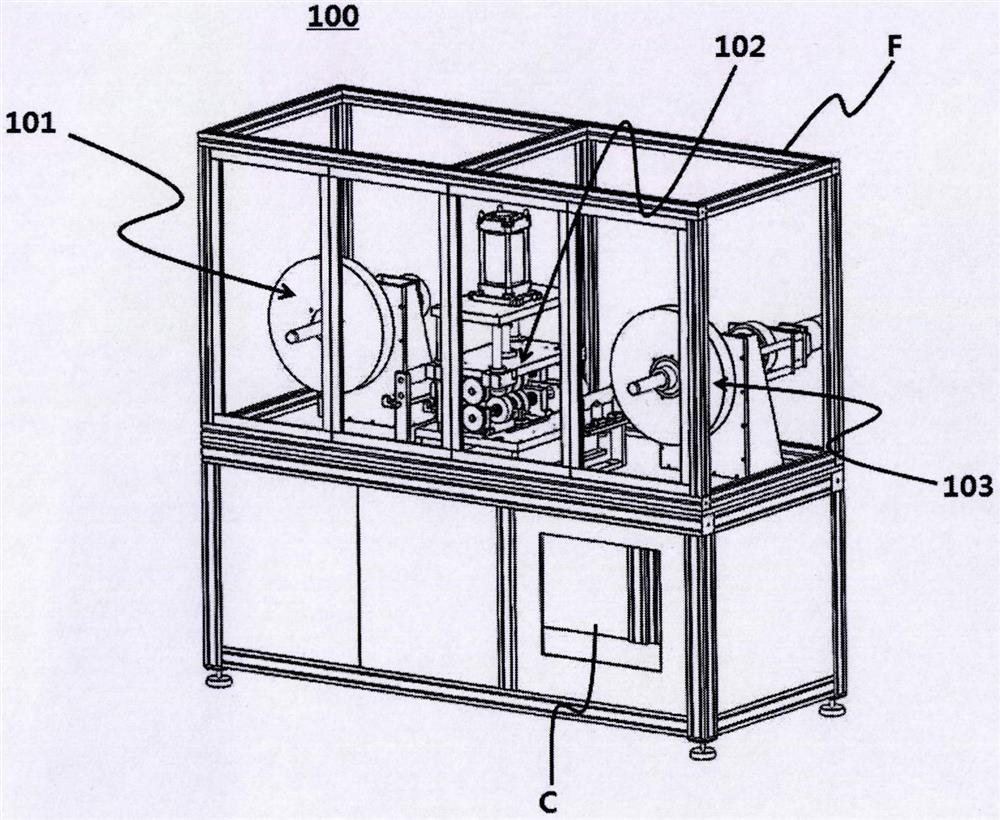

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

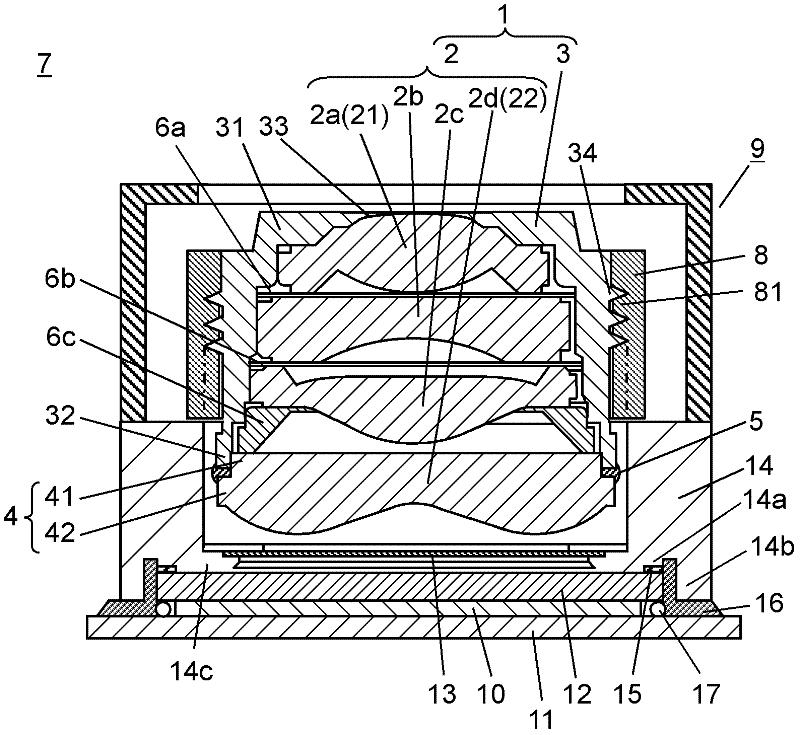

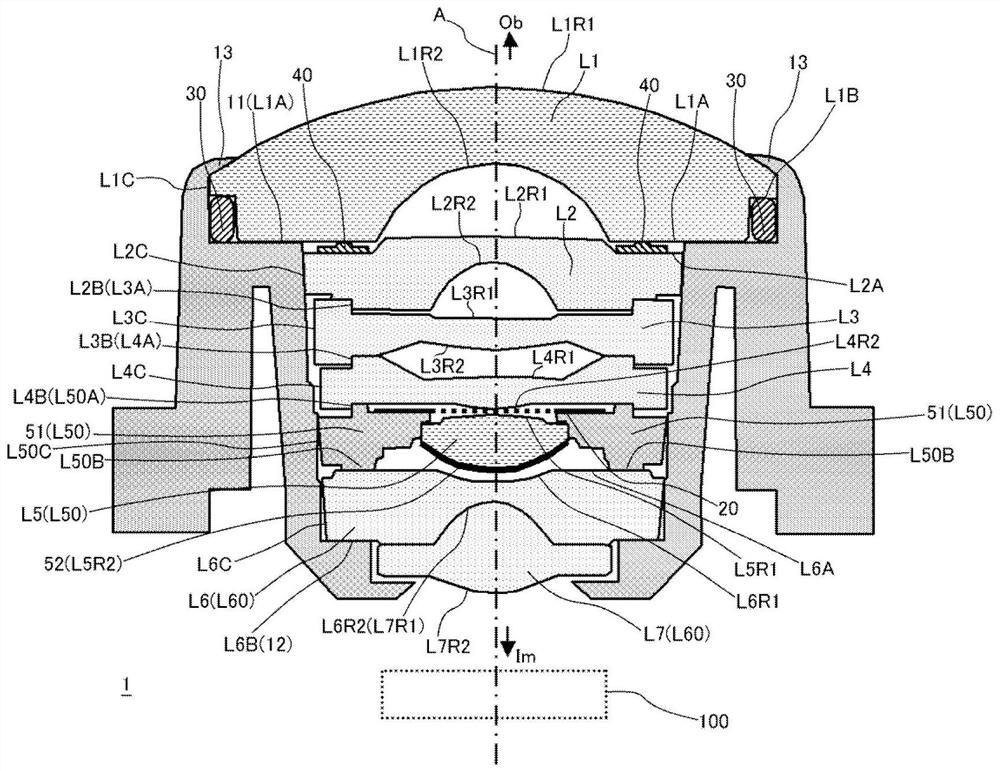

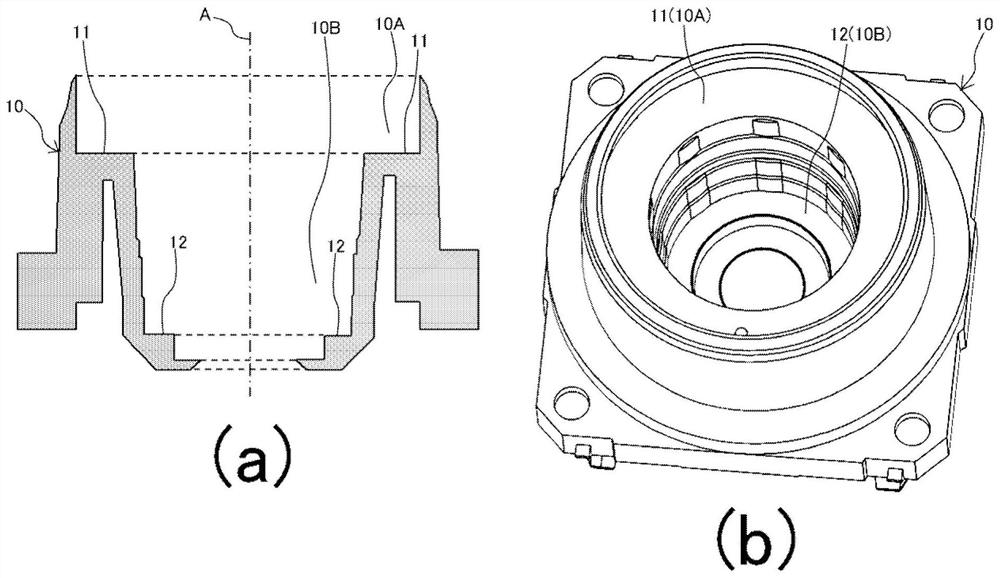

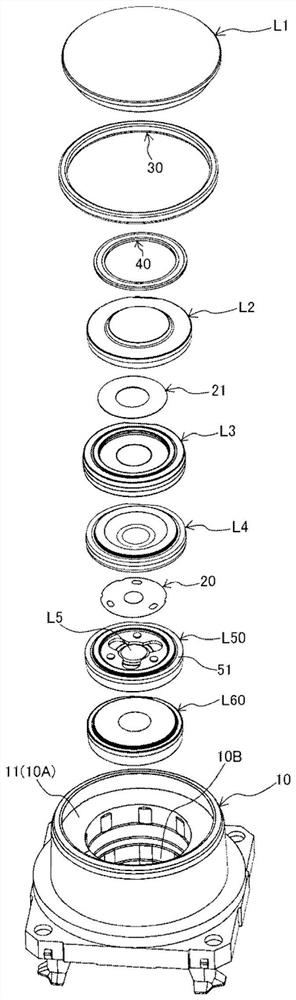

Lens barrel, imaging device and mobile terminal device

InactiveCN102483504ACorrection of curvatureAdjust intervalColor photographyMountingsOptical axisImage resolution

A lens barrel is provided with a lens holder, and an imaging lens composed of a plurality of three or more lenses inserted and fitted into the lens holder. The lens barrel is configured in such a manner that resin spacers having elasticity in the optical axis direction are disposed between the lenses that affect the curvature of field, and a pressing force is applied between the lenses that affect the curvature of field, thereby deforming the resin spacers so as to be fixed in place. Thus, a pressing force is applied between the lenses, which easily affect the curvature of field, thereby elastically deforming the resin spacers in the optical axis direction, enabling the space between the lenses to be adjusted. As a result, the curvature of field can be corrected, and a reduction in resolving power can be prevented.

Owner:PANASONIC CORP

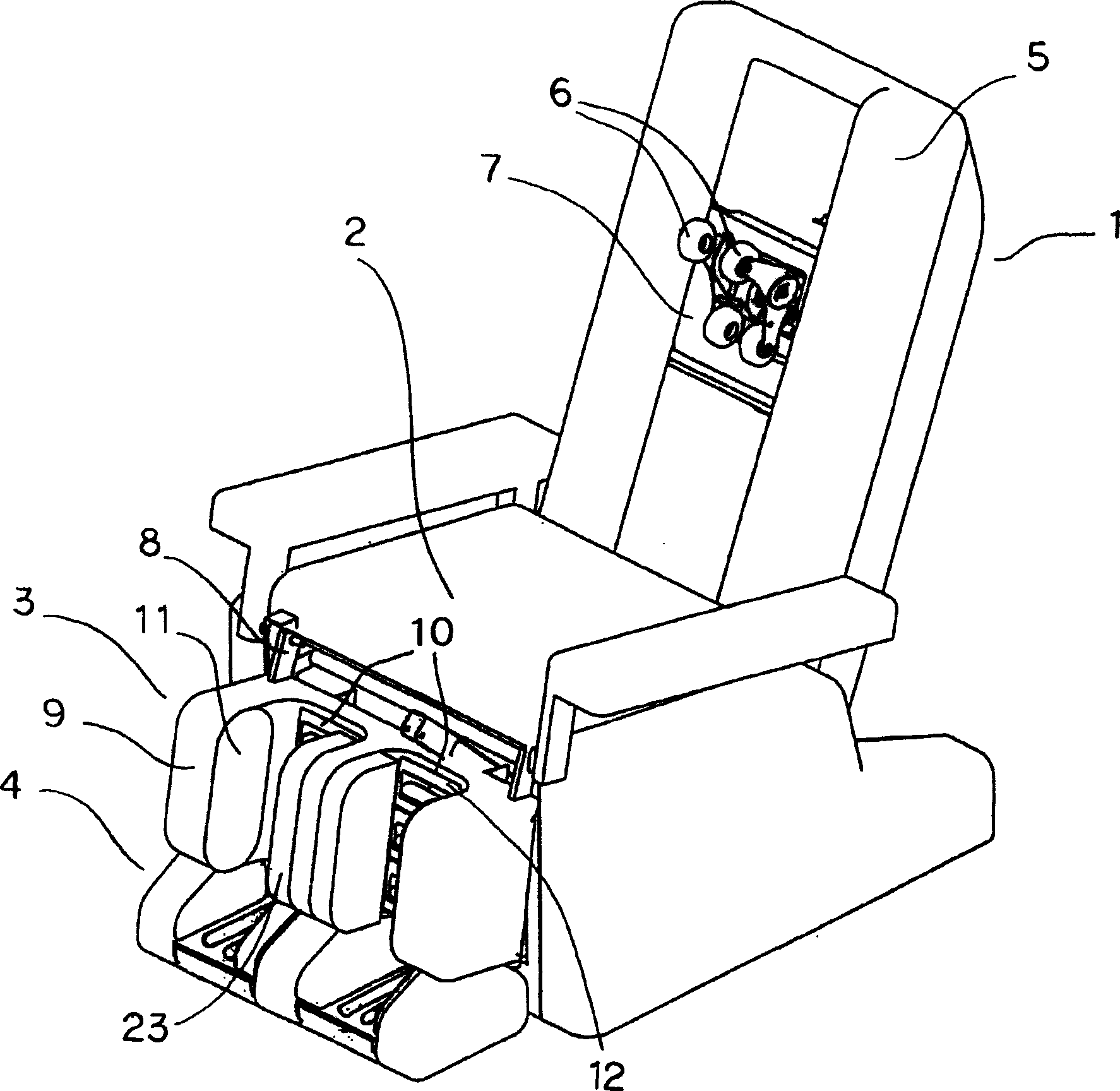

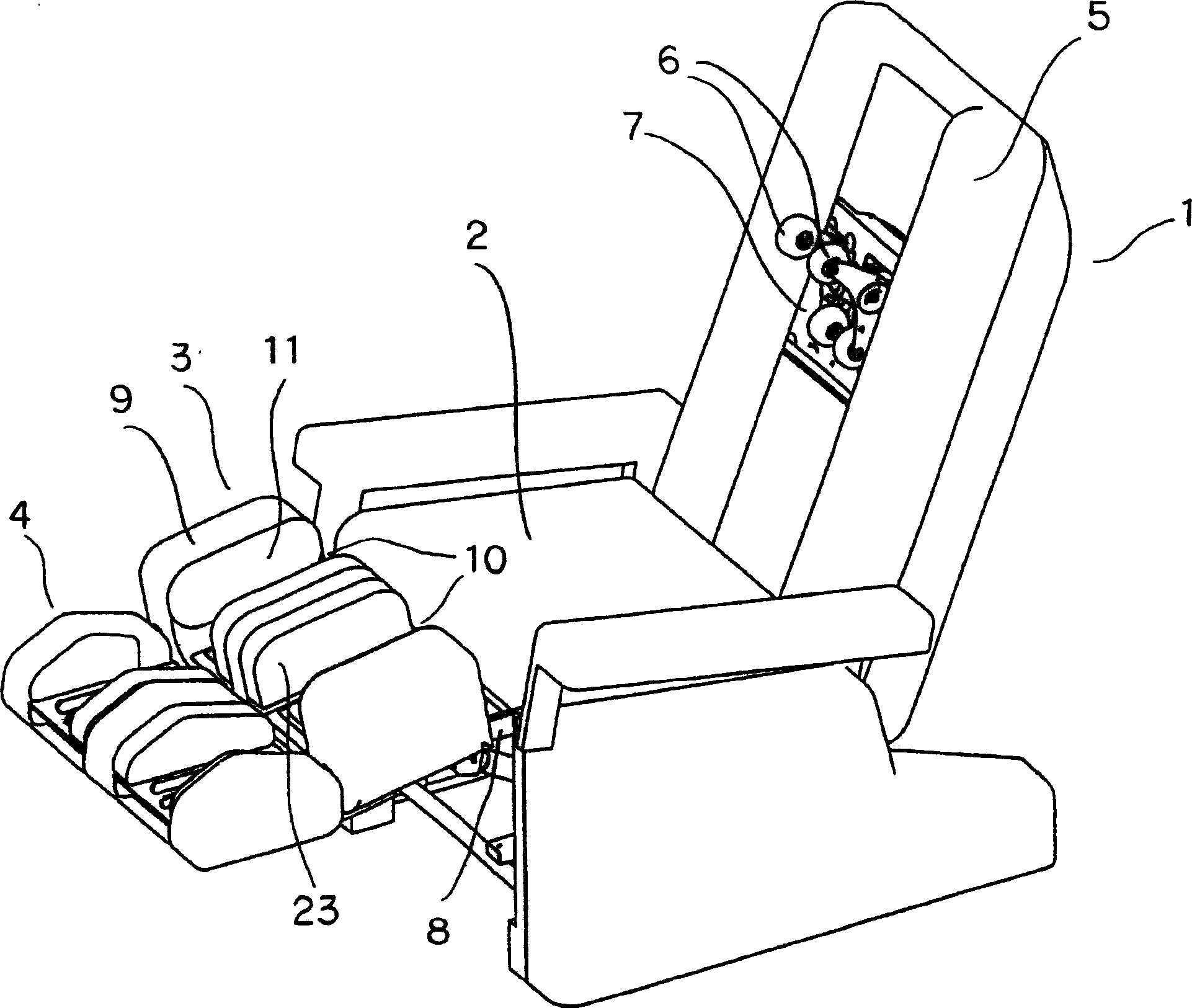

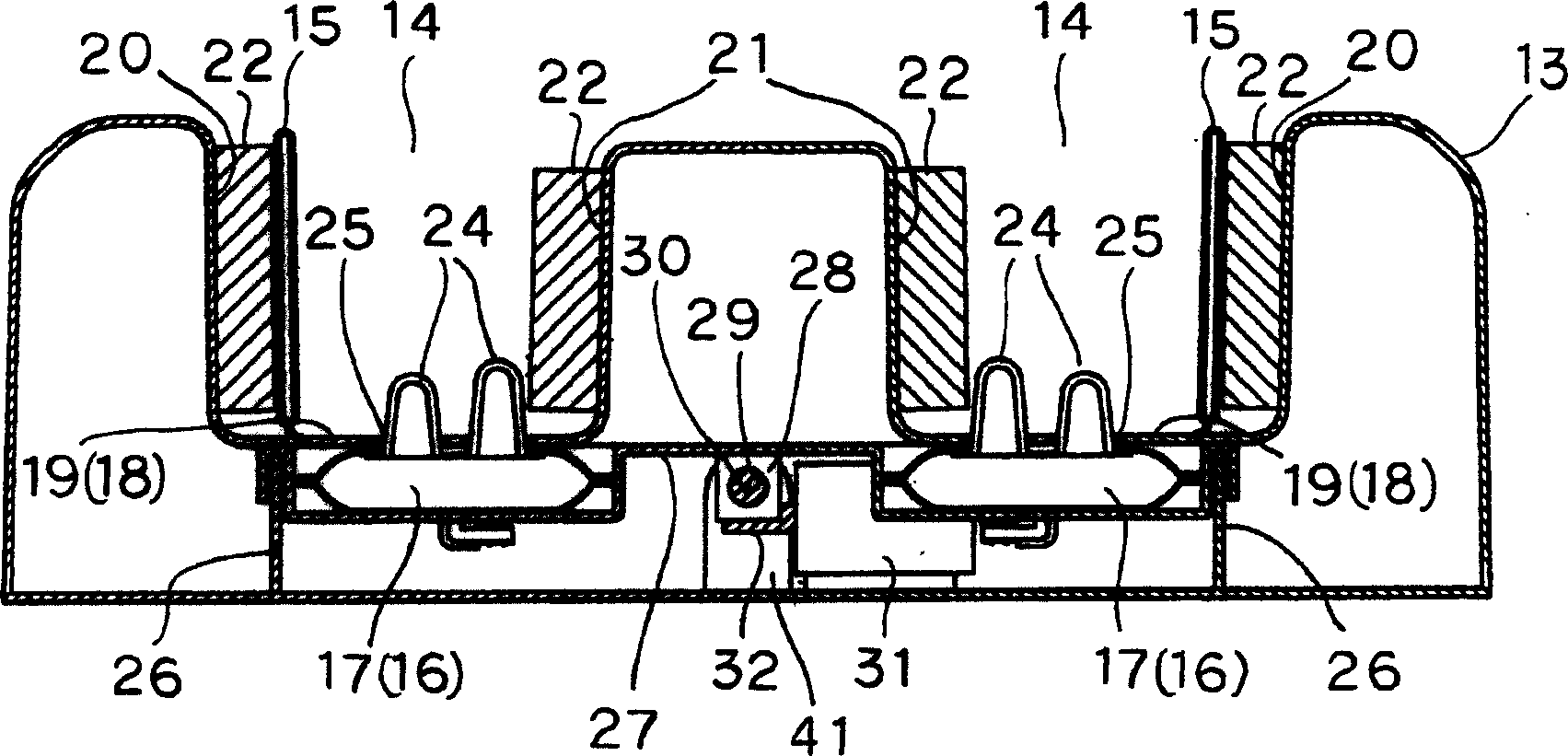

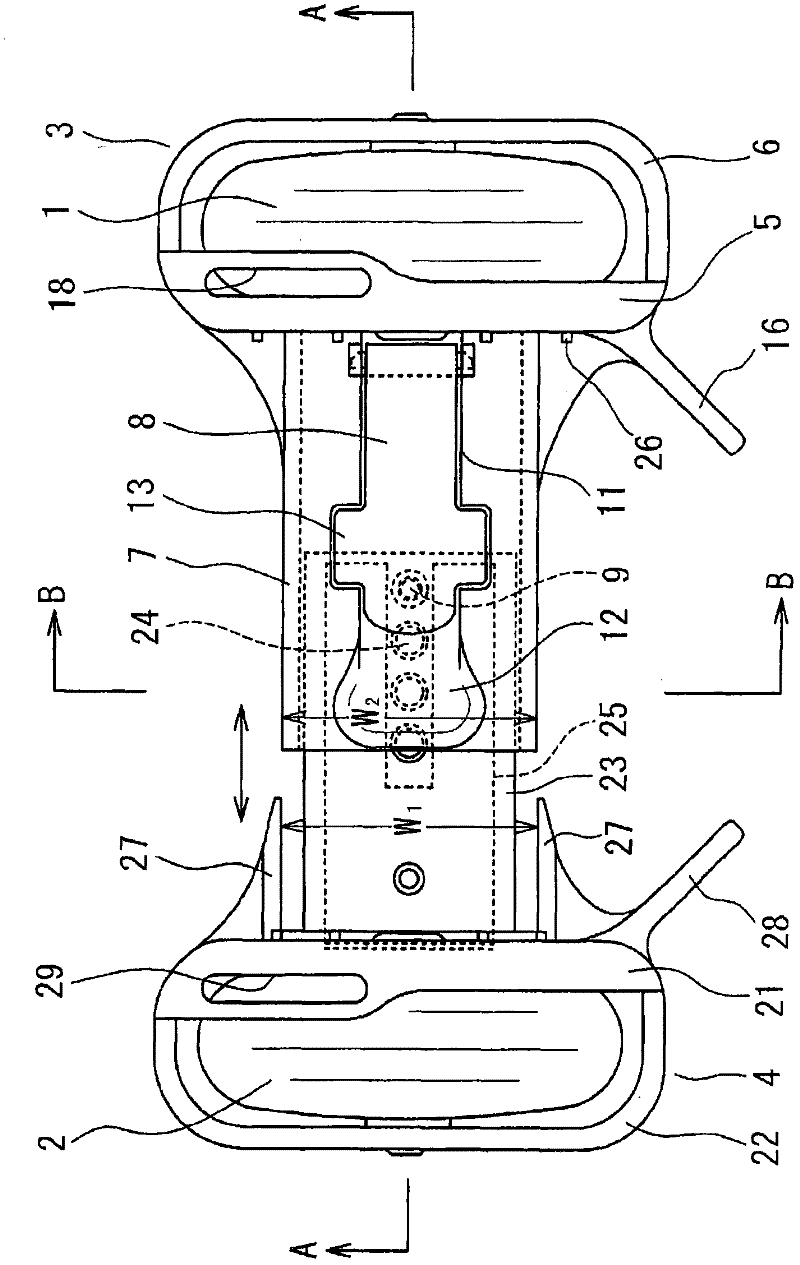

Massage machine

InactiveCN1579356APrevent surrenderMassage evenlyDevices for pressing relfex pointsChiropractic devicesMassagePulp and paper industry

The massage machine includes concave receiving parts 14 housing the parts to be treated and comprising bottom surfaces 18 and side walls stood from both sides of the bottom surfaces 18, an adjusting means 15 for adjusting the distances between the side walls of the concave receiving parts 14, and massage parts 24 disposed on the bottom surfaces 18 of the concave receiving parts 14 and massaging the parts to be treated. The above massage parts 24 are constructed so as to freely move within the concave receiving parts 14.

Owner:SANYO ELECTRIC CO LTD

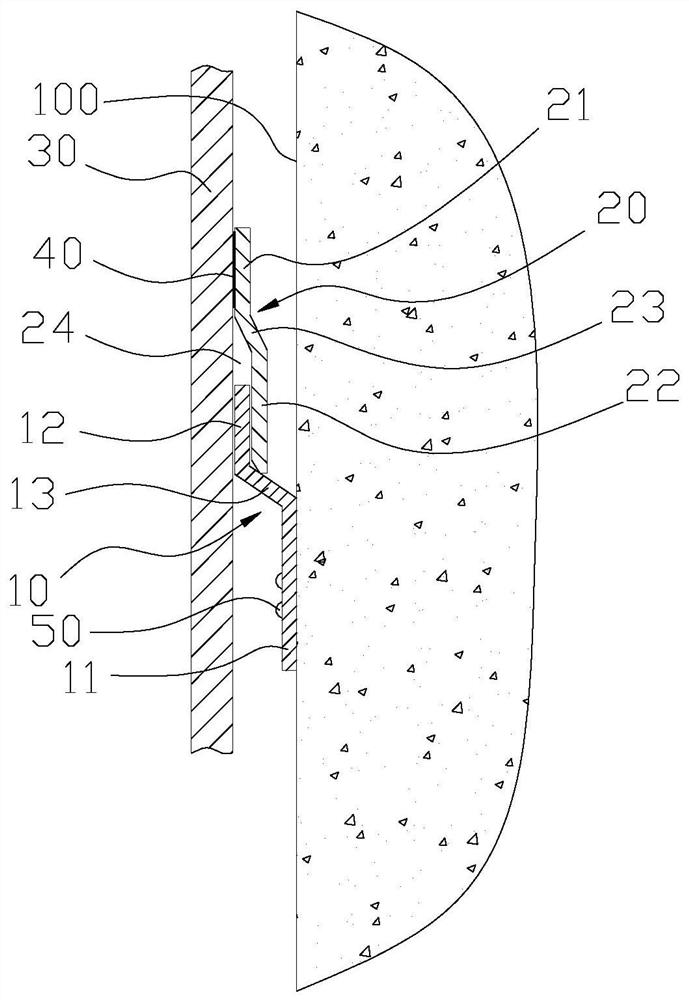

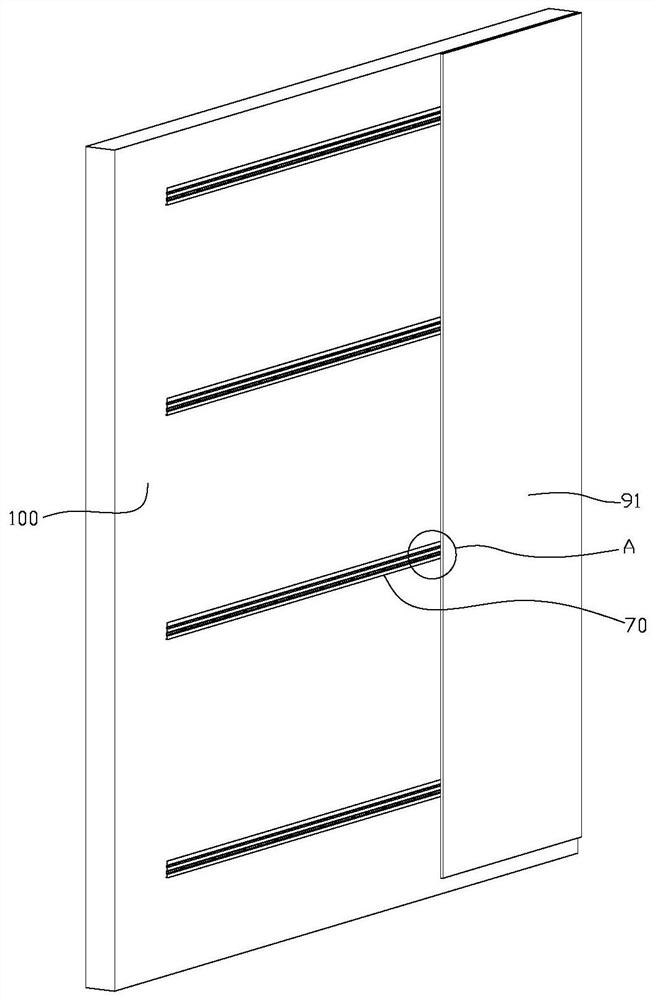

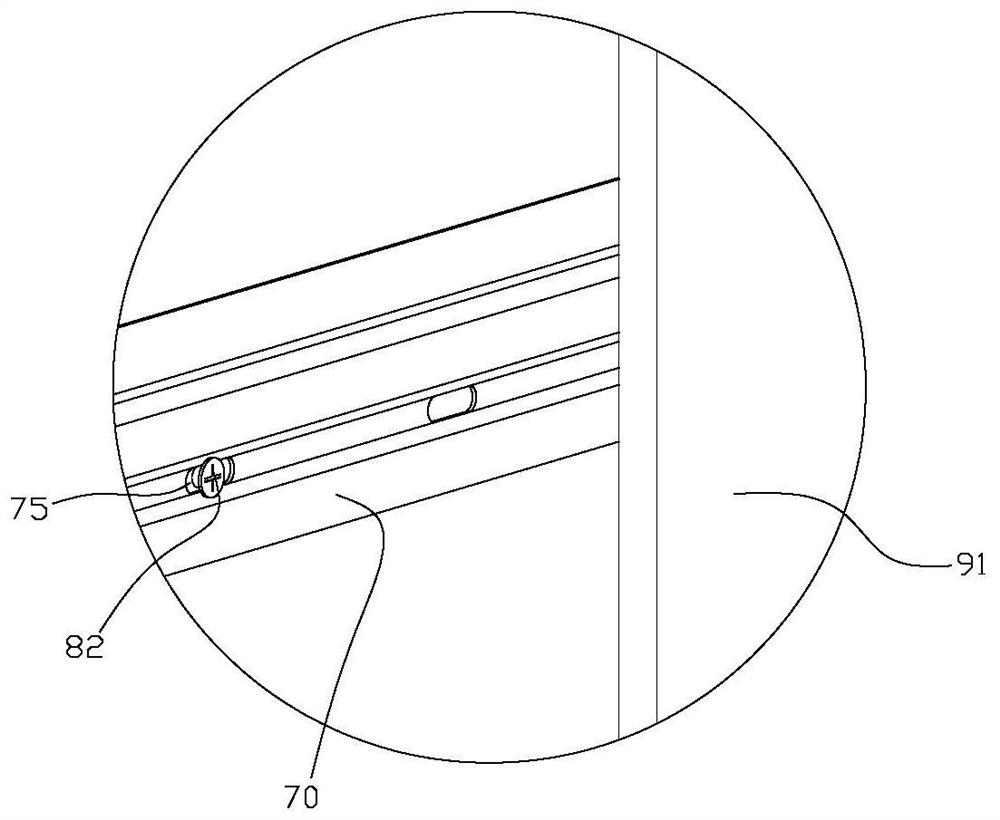

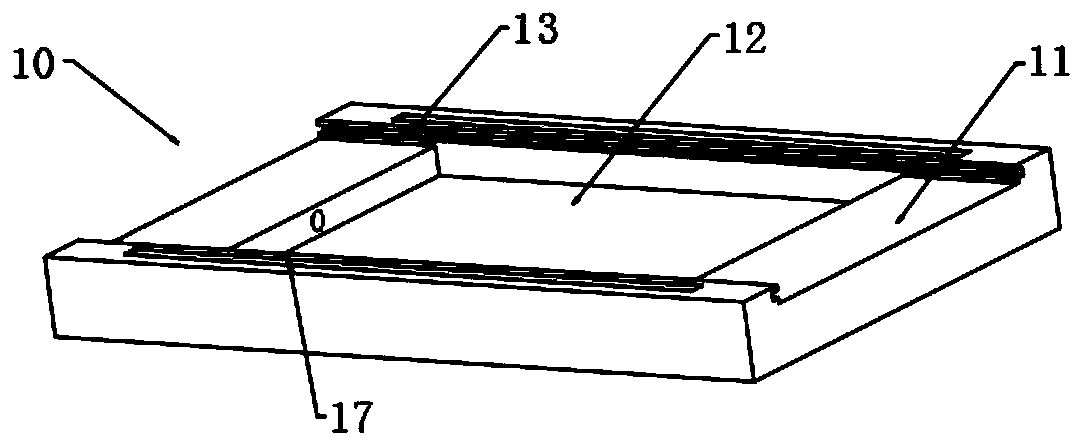

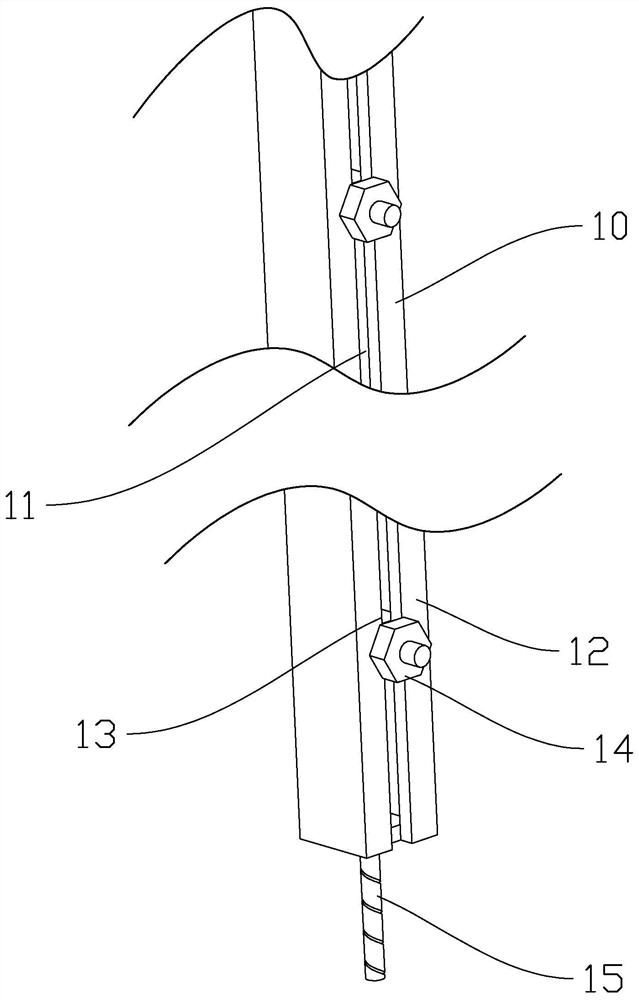

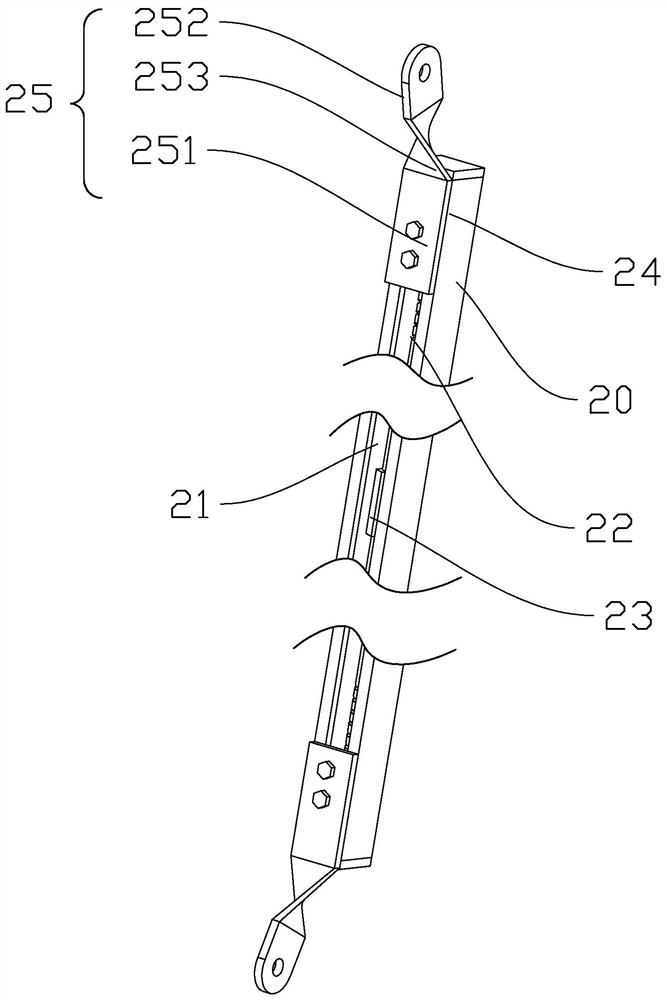

Keel assembly and wall surface assembly

The invention discloses a keel assembly and a wall surface assembly. The keel assembly comprises a lath-shaped keel and a plurality of groups of fastening parts. The plurality of groups of fastening parts are arranged in the extending direction of keels; each fastening part at least comprises an adjusting part, the adjusting parts comprise screw rods used for extending into a structural wall and cushion blocks formed at the tails of the screw rods, and the keels are fixed to the cushion blocks, so that inserting strips are formed on the upper sides of the keels. When the interval between a wallboard and the structural wall needs to be adjusted, the screw rod of each adjusting part is screwed, then the depth of the screw rods extending into the structural wall is changed, the distance between the outer side faces of the cushion blocks and the structural wall can be adjusted, and then the interval between the keels and the structural wall and the interval between the inserting strips onthe upper sides of the keels and the structural wall can be adjusted. The inserting strips are inserted into inserting seams formed by hanging pieces, so that the interval between the wallboard and the structural wall is adjusted certainly.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

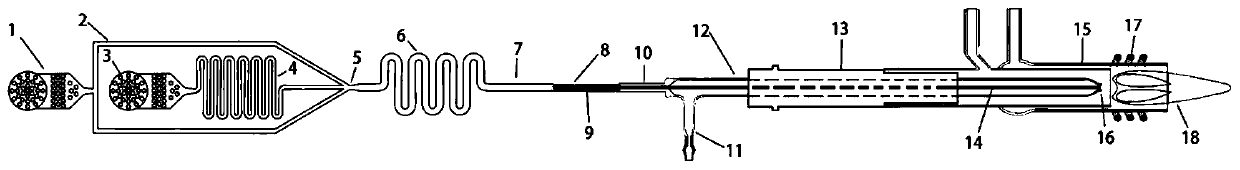

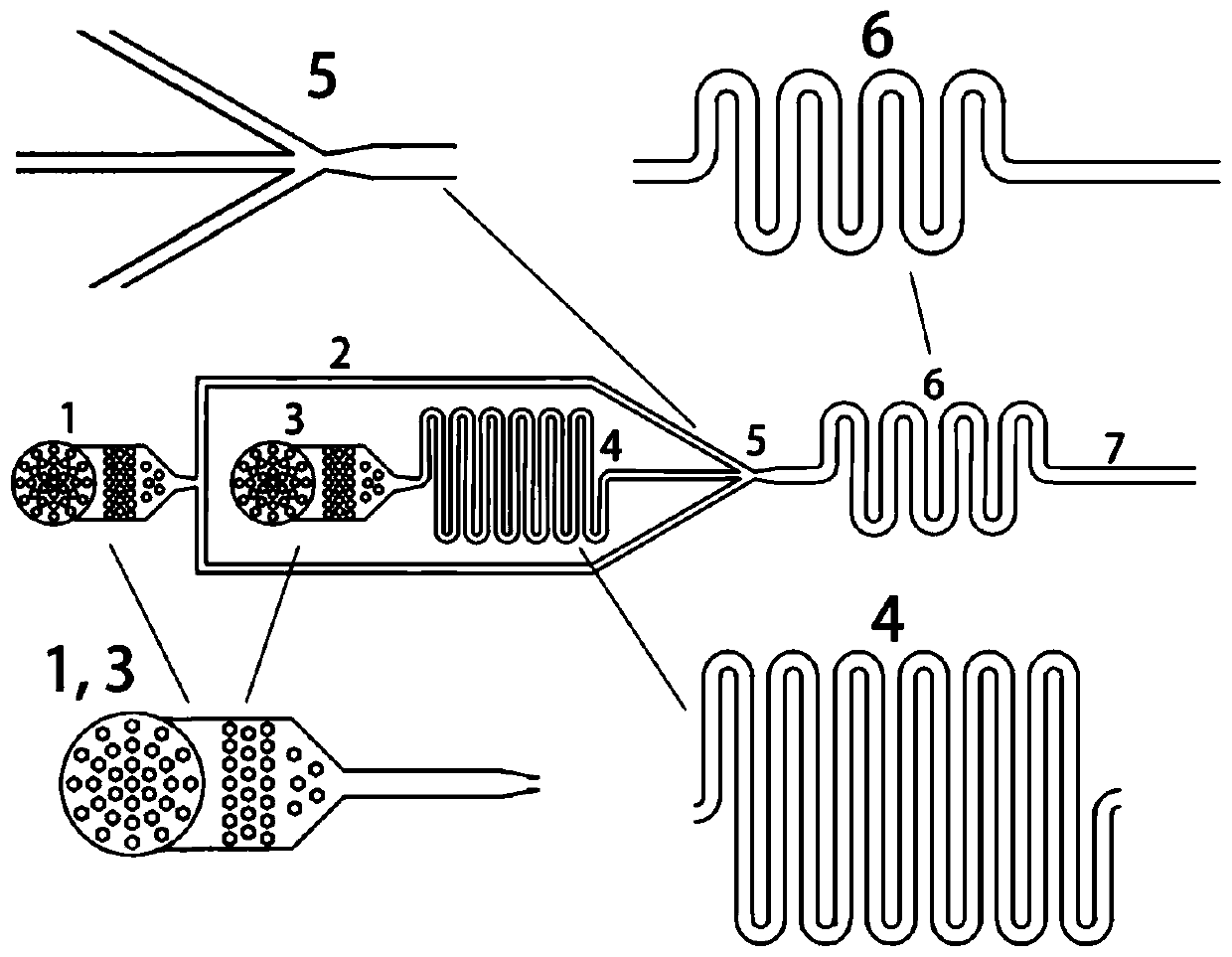

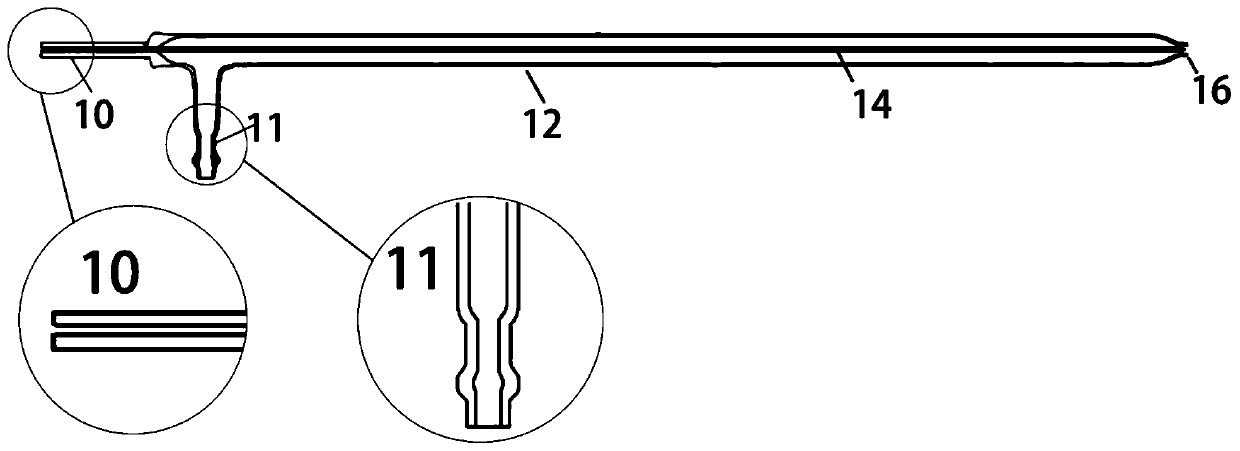

Oil-free sorting-direct injection-ICPMS single cell analysis system

ActiveCN111266140AAdjustable cell intervalAdjust intervalMaterial analysis by electric/magnetic meansLaboratory glasswaresMicrofluidic chipPolyimide

The invention discloses an oil-free sorting-direct injection-ICPMS single cell analysis system, and relates to a single cell analysis platform. A sampling device integrating cell sorting, control andsingle cell direct injection is coupled with ICPMS mass spectrometry detection to perform efficient single cell analysis. The system comprises a double-straight-line-bending-straight-line type micro-fluidic chip body and a direct injection type micro-spraying device. The double-straight-line-bending-straight-line type micro-fluidic chip comprises a buffer solution inlet, a buffer solution channel,a suspension liquid inlet and a two-stage separation channel; a buffer solution and suspension liquid inlet main body is of a cylindrical structure, and a three-fork type connected two-stage separation channel is composed of a plurality of linear-bent-linear structures; the direct injection type micro-spraying device comprises a shell with a carrier gas branch pipe, and the tail end of the shellis gradually thinned to form a nozzle; the sample injection capillary tube is inserted from the tail end of the shell and slightly retracts relative to the nozzle, the polyimide coating on the surfaceof one section of capillary tube is stripped, and a micro cavity is formed on line at the nozzle. An ammonia bicarbonate buffer solution is used in the whole system.

Owner:XIAMEN UNIV

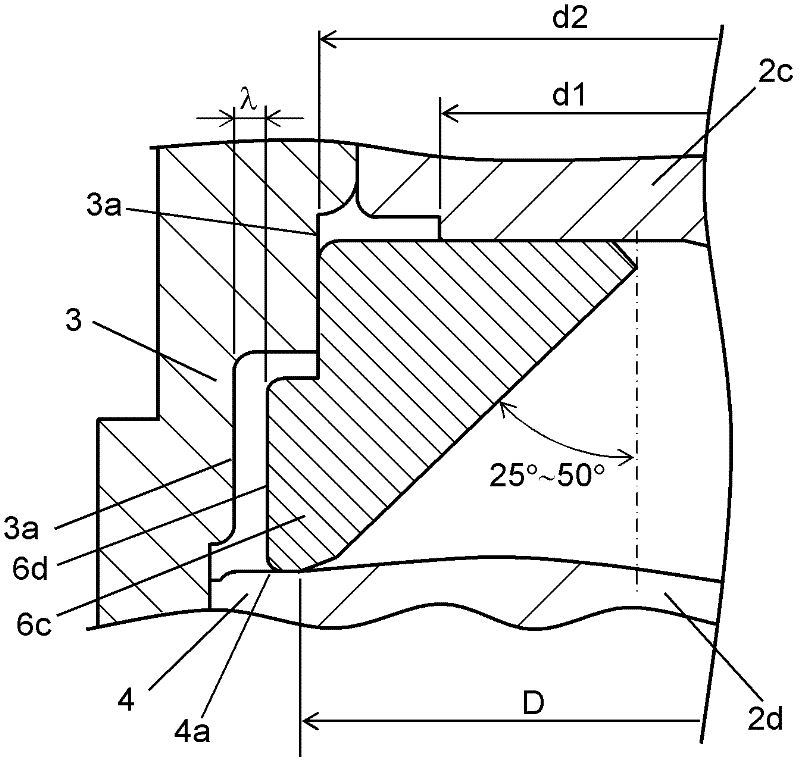

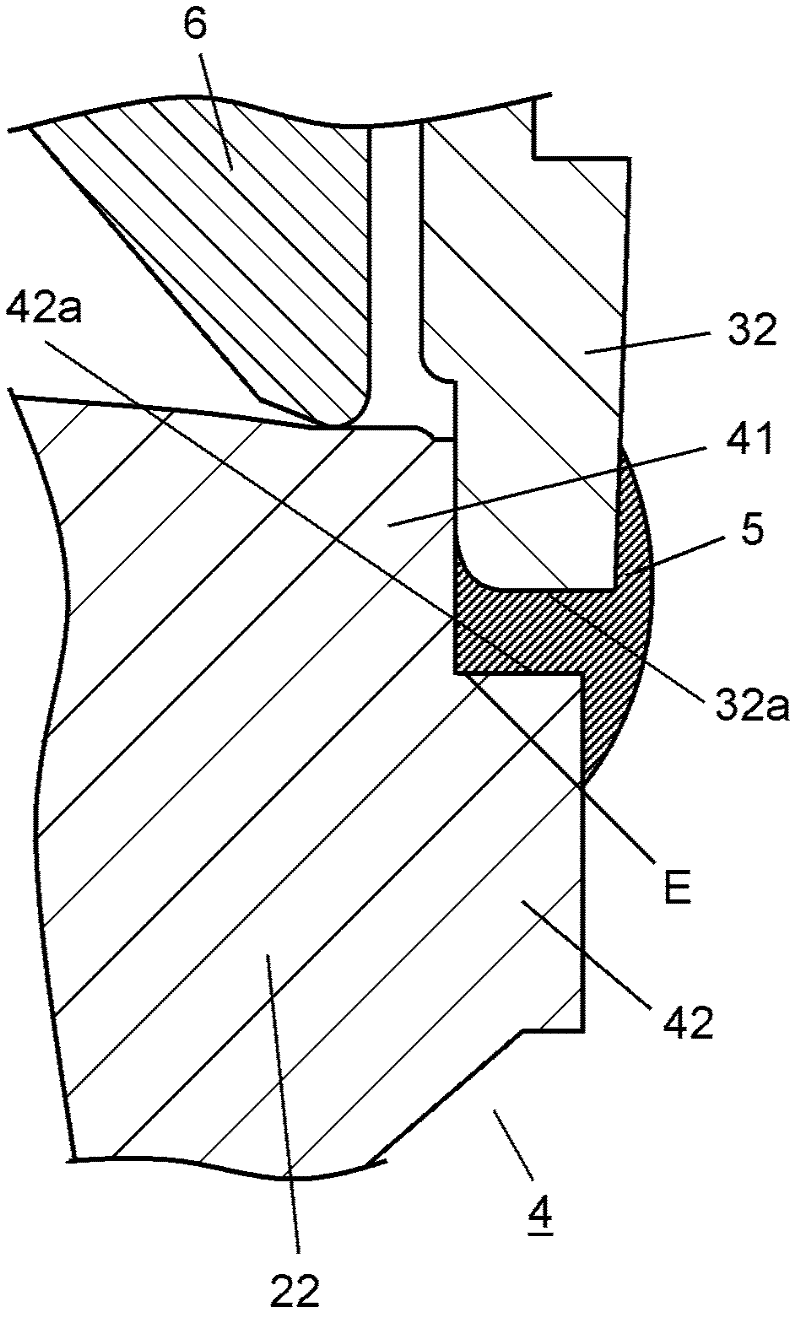

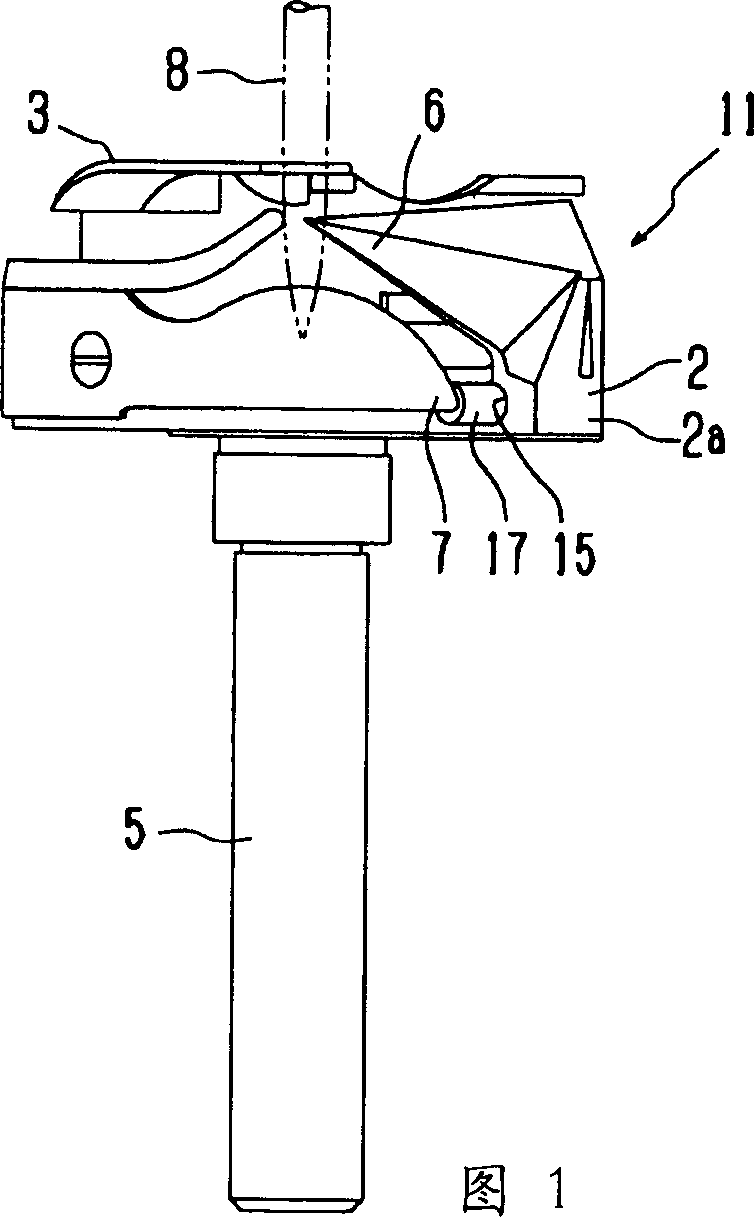

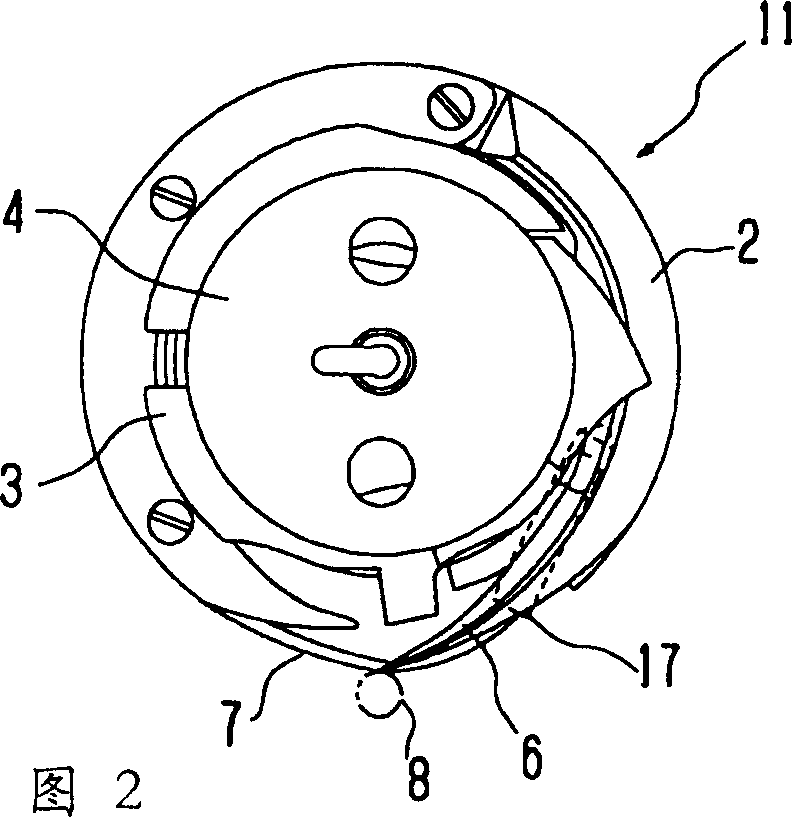

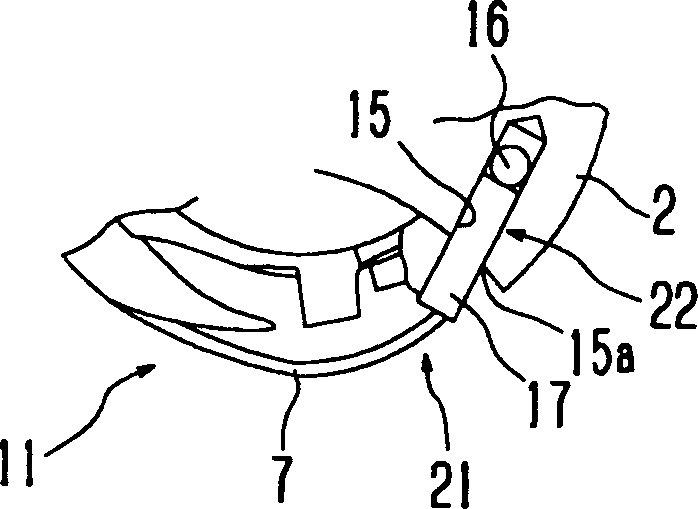

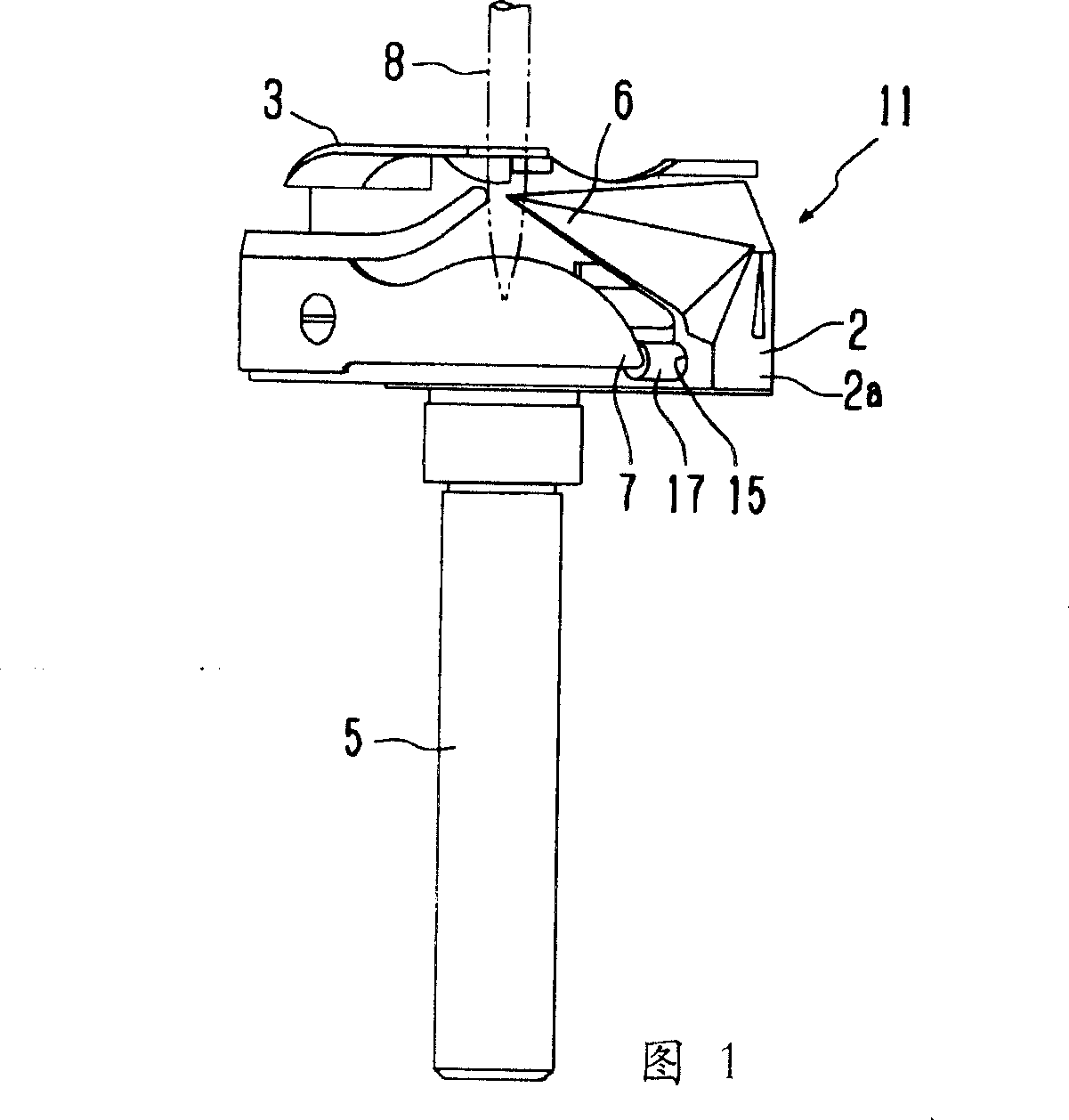

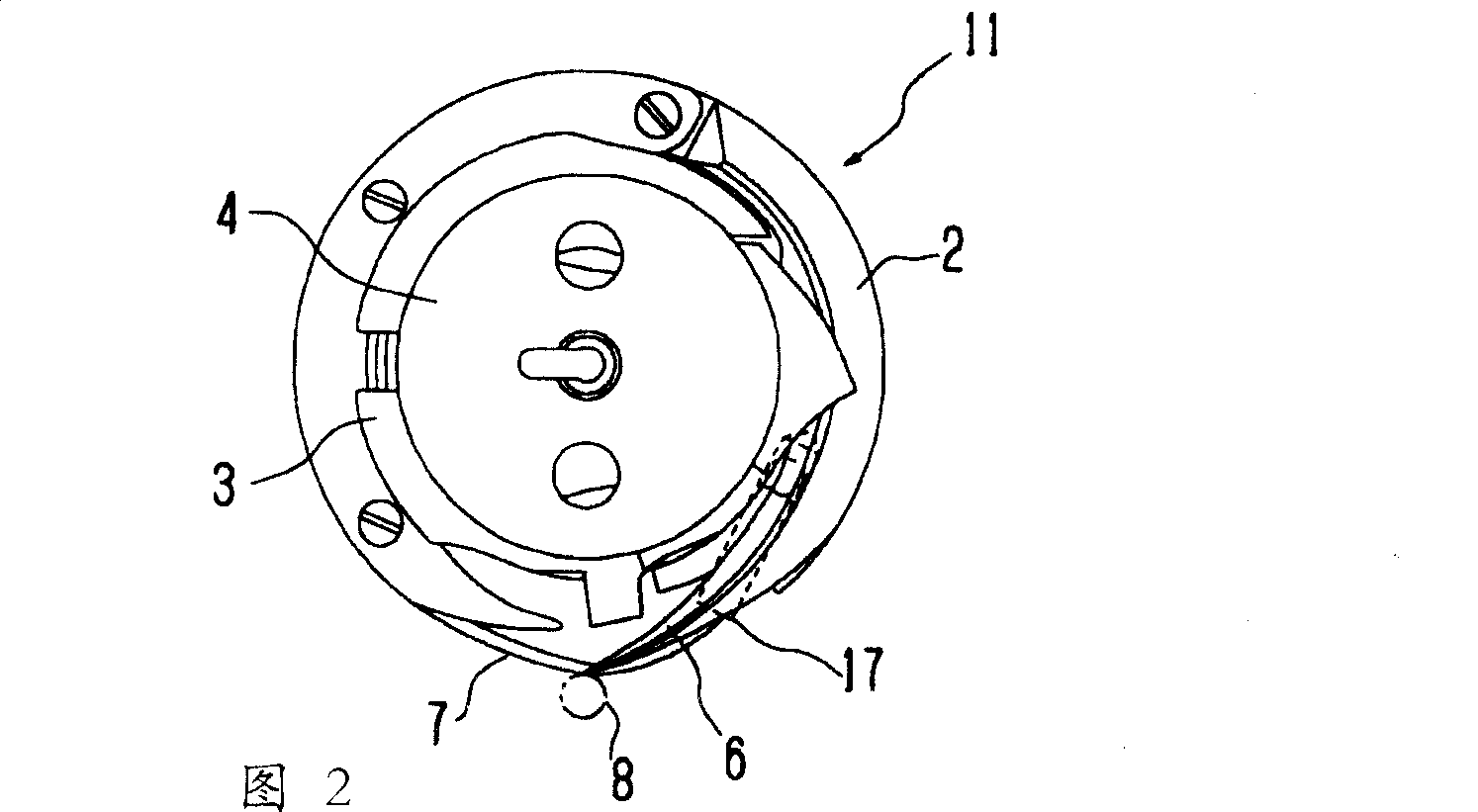

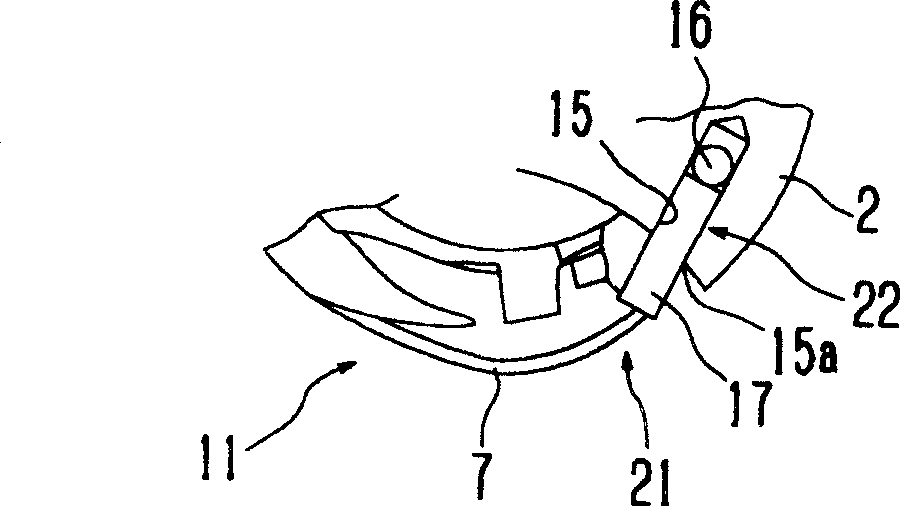

Horizontal bobbin case of sewing machine

A horizontal rotating shuttle of sewing machine having a shuttle hook point, provided on a rotating hook accommodating a rotating hook bobbin case holder rotatably about an axis, tapered along an axial rotational direction of the rotating hook, and a needle guard having a shape distorted along the axial rotational direction, with one end fixed to the rotating hook and the other end as a free end. Adjustment means adjustably displaces the needle guard in a direction to increase / reduce an outer diameter of the rotating hook. In a case where the horizontal rotating shuttle is mounted in a sewing machine, and the clearance between a needle which reciprocates in a vertical direction while holding a needle thread and the needle guard of the rotating hook becomes outside an appropriate range, the adjustment means displaces the needle guard in the direction to increase the outer diameter of the rotating hook or in the direction to reduce the outer diameter of the rotating hook. Thus the clearance between the needle and the needle guard can be adjusted to a value within the appropriate range.

Owner:SABUN KOGYOSHO KK

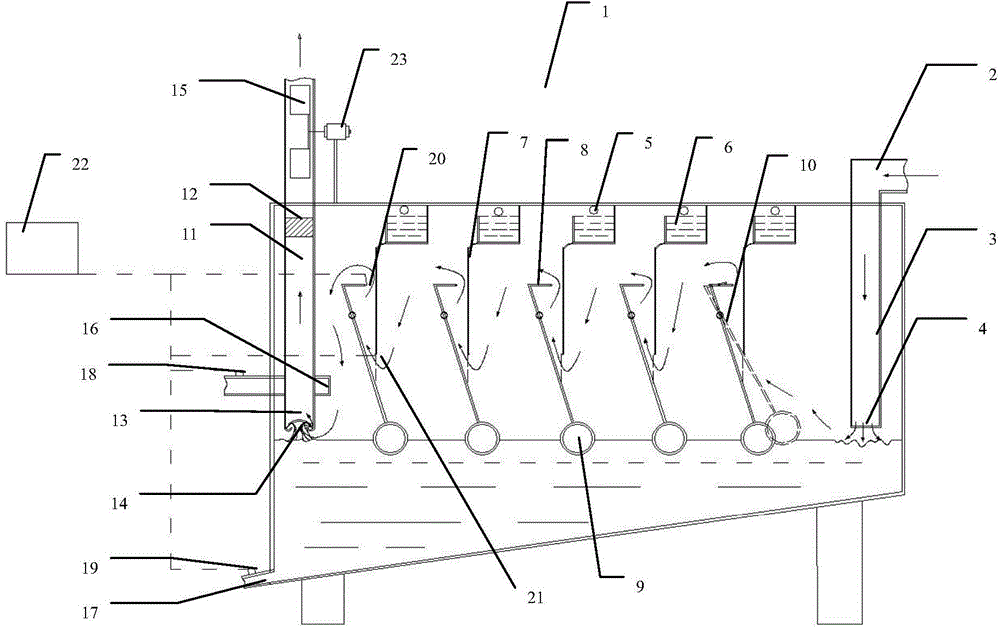

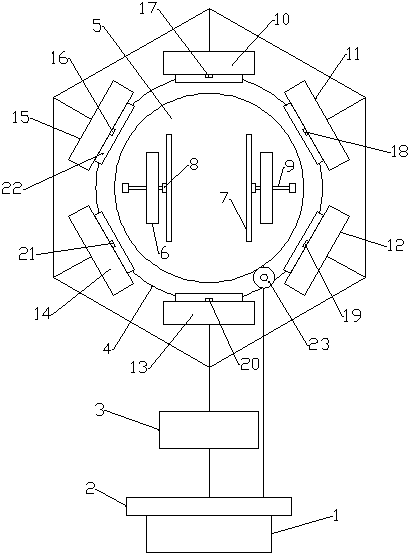

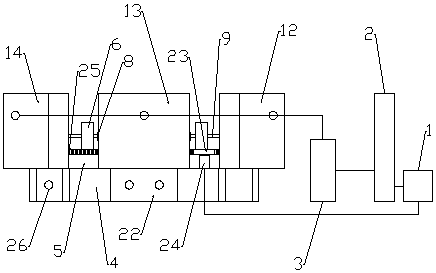

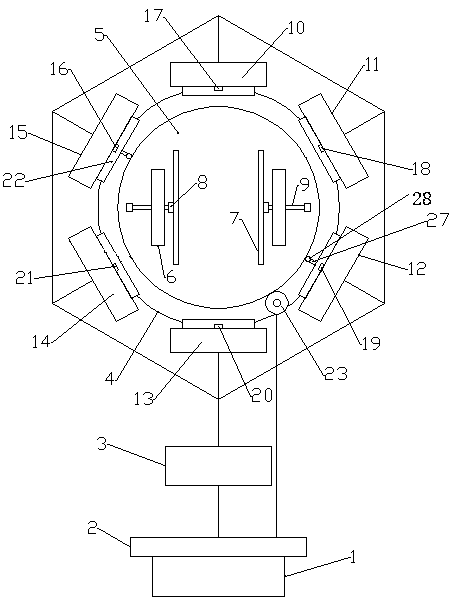

Deduster

InactiveCN104888554ARegulating circulation throughputAdjust intervalUsing liquid separation agentFlue gasFan blade

The invention relates to a deduster, which comprises a housing (1), an air inlet pipe (3), an air outlet pipe (11), overflow channels (6), overflow plates (7), liquid replenishing pipes (5), rotary separators (8), floating drums (9), rotary beams (10), a liquid inlet pipe (16), a liquid outlet pipe (17), a liquid inlet pipe control valve (18), a liquid outlet pipe control valve (19), rotary separator contact points (20), overflow plate contact points (21), a demister (12), fan blades (15), an electrical motor (23), and a controller (22). The rotary separators rotate depending on floating drums below the rotary separators and with the assistance of buoyancy of water, so that intervals between the rotary separators and overflow plates can be adjusted and a flue gas circulation treatment amount can be adjusted. The deduster is beneficial for improving the purification efficiency of gas.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

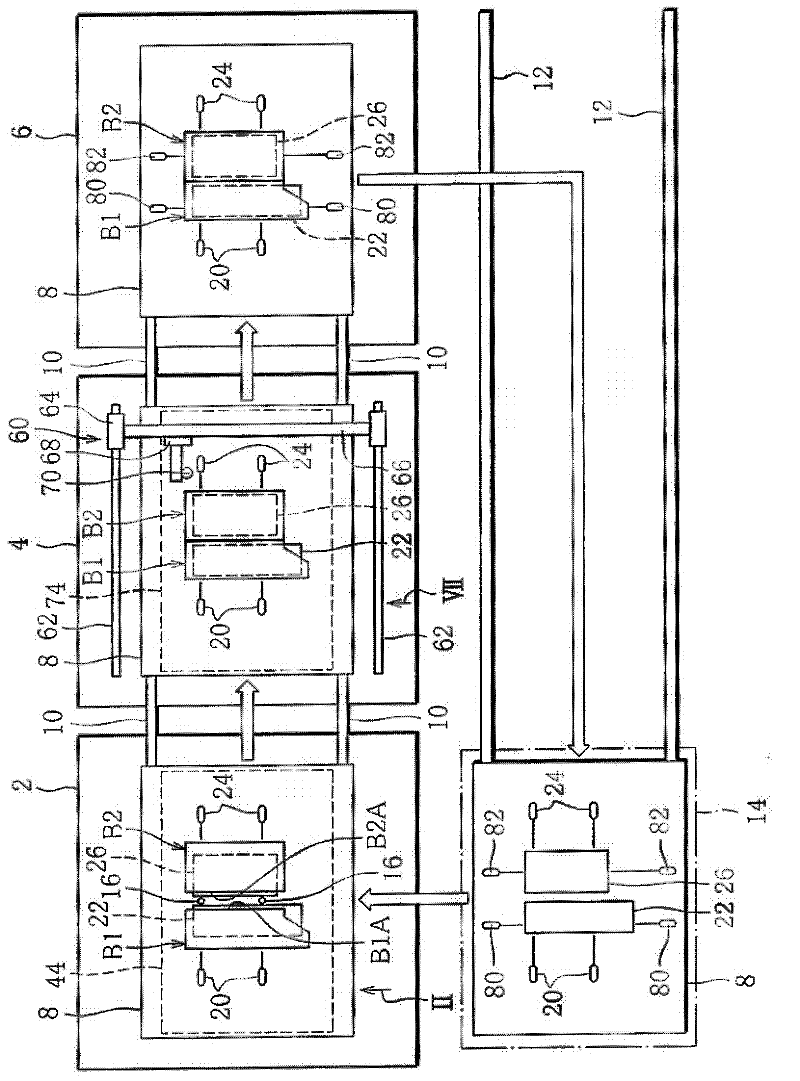

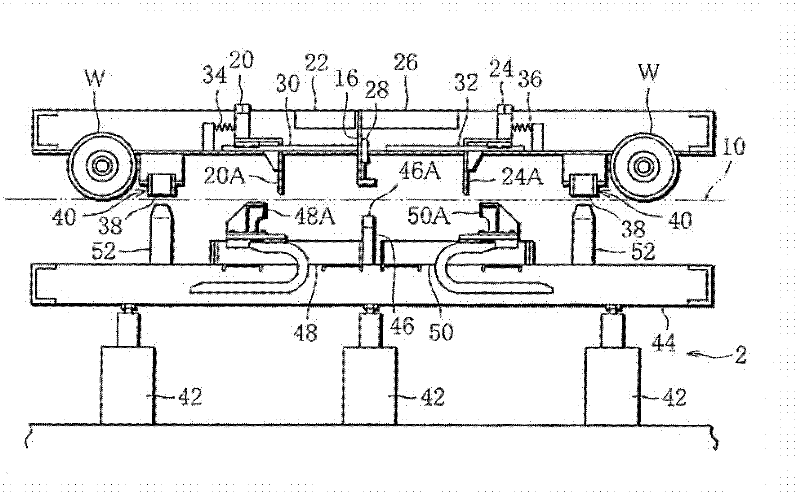

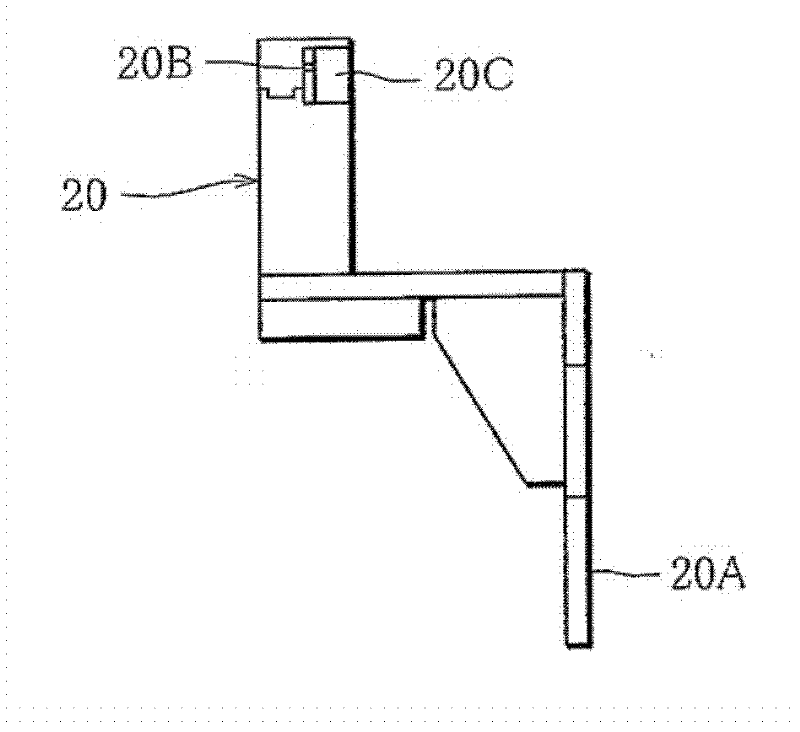

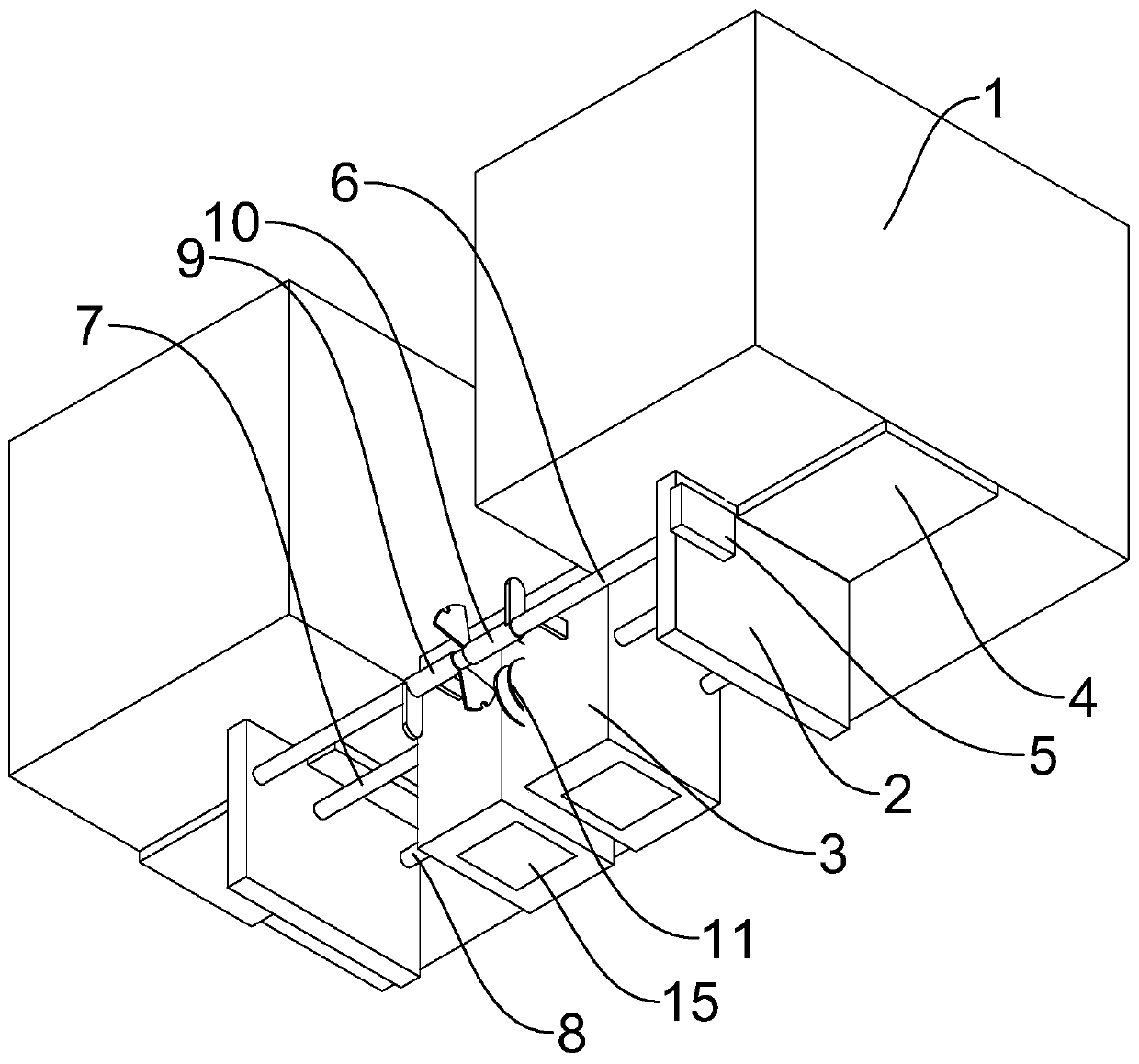

Processing device

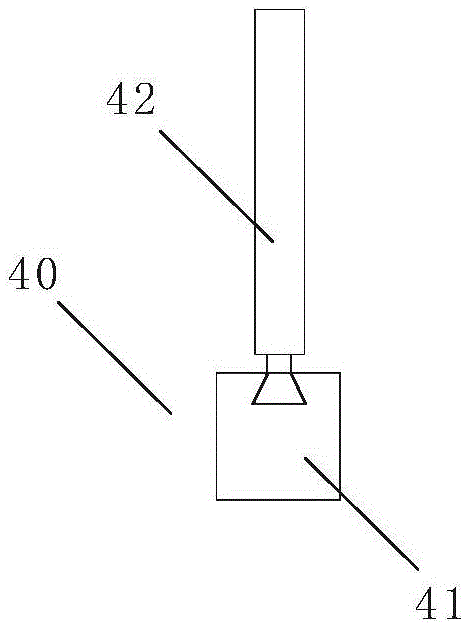

InactiveCN102264506AAvoid cutsPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringActuator

In working equipment comprising a table (8), a positioning station (2) for fixing a workpiece on the table, and a working station (4) for performing a working process on the workpiece, the table (8) includes a stopper (16) for the workpiece to contact, a pressing member (20, 24) for pressing and thereby bringing the workpiece into contact with the stopper, and a fixing device (22, 26) for fixing the workpiece to the table, and the positioning station (2) includes a pressing actuator (48, 50) for moving the pressing member.

Owner:IHI CORP

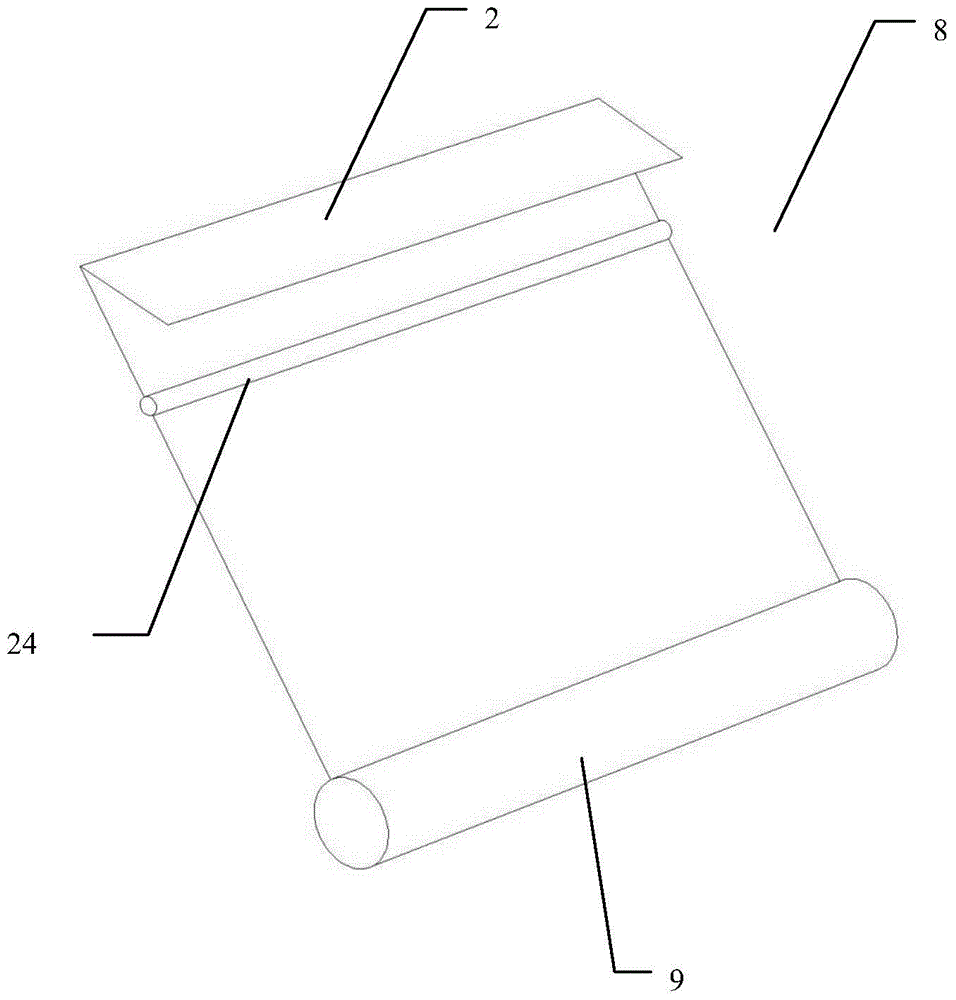

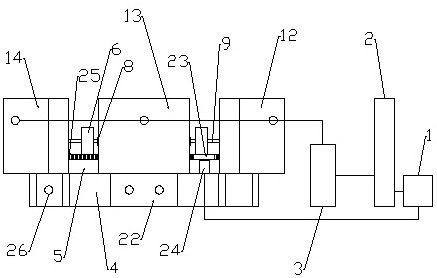

Indentation folding processing method for paper box made of corrugated boards

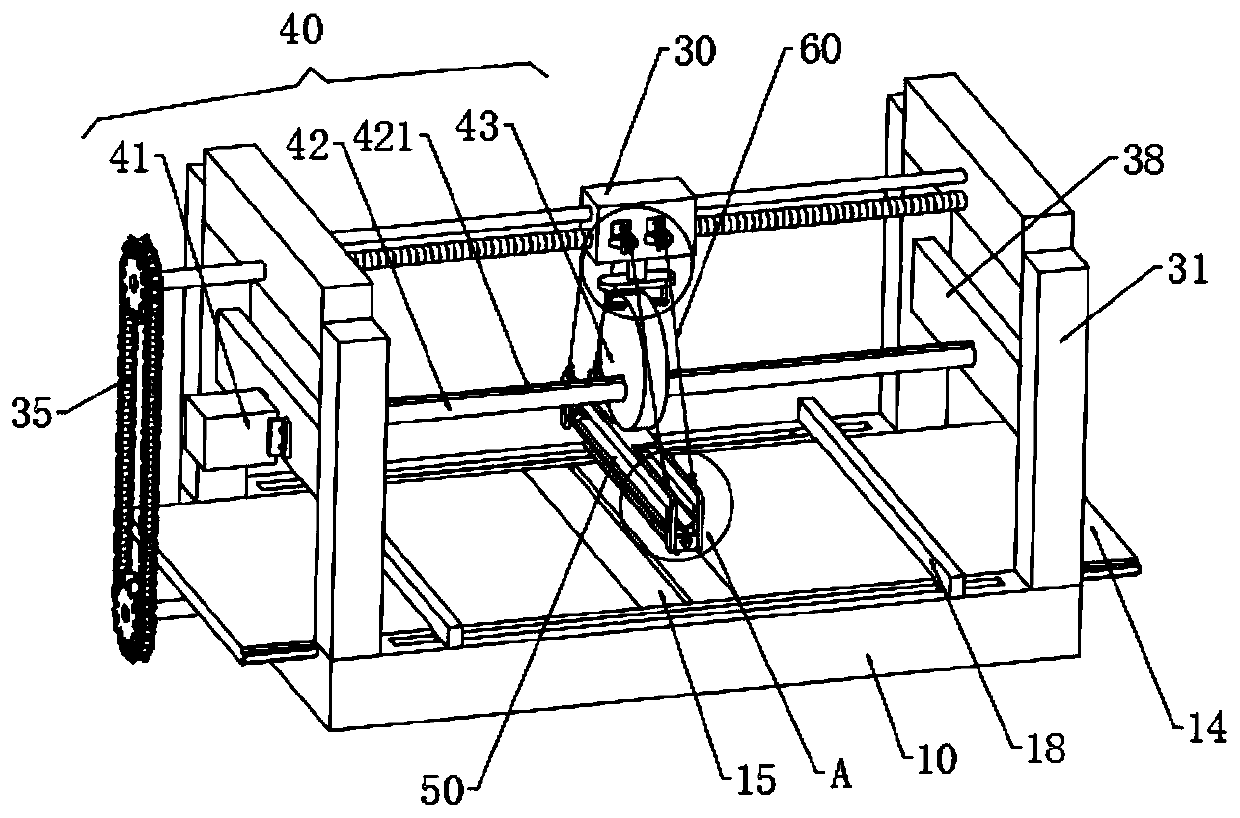

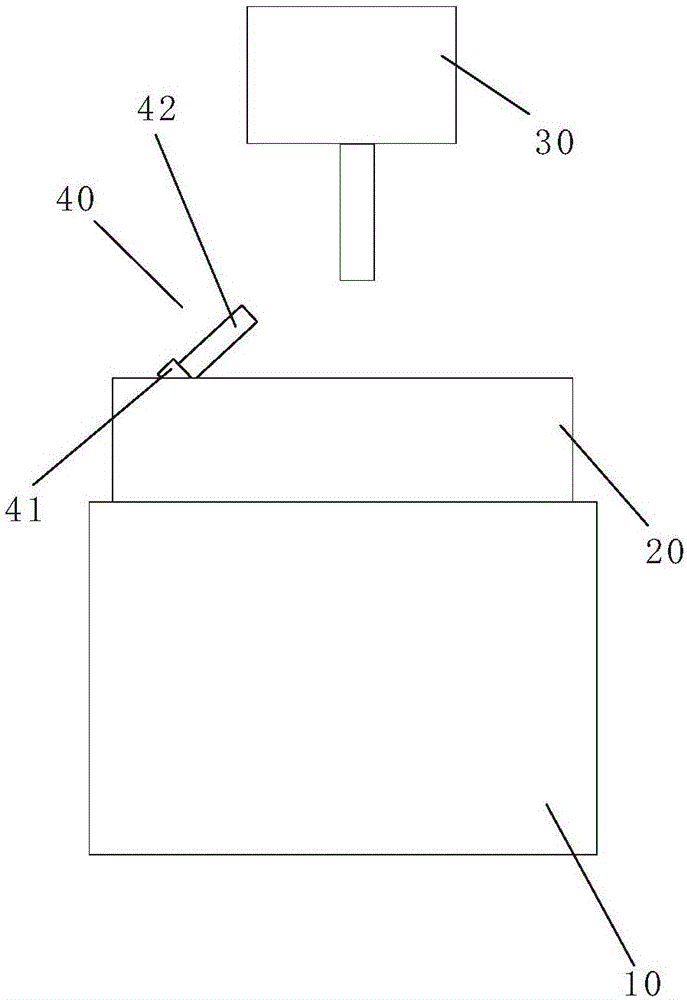

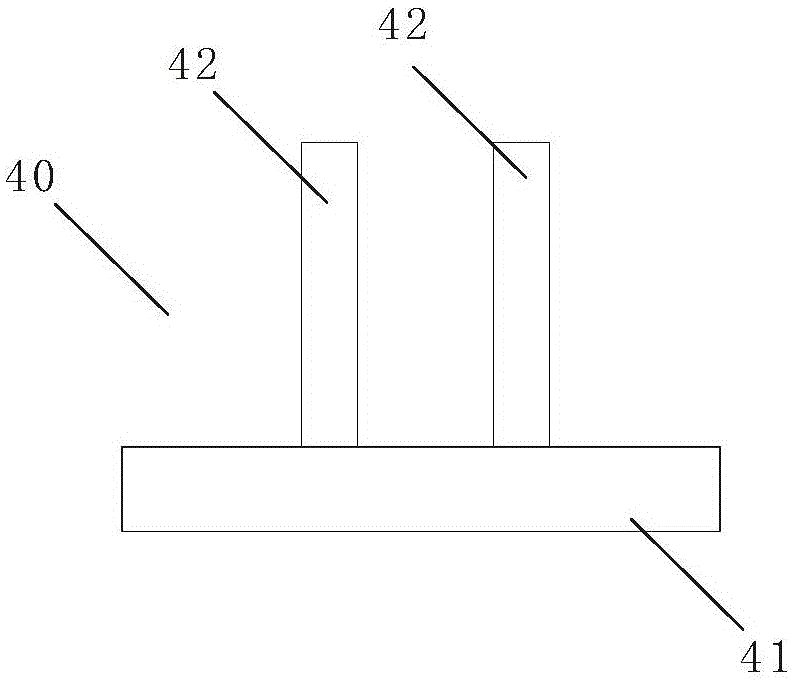

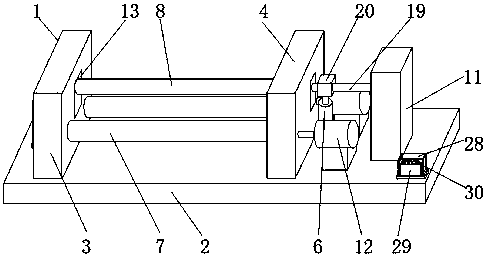

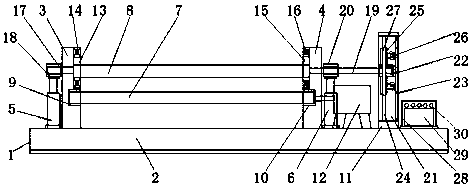

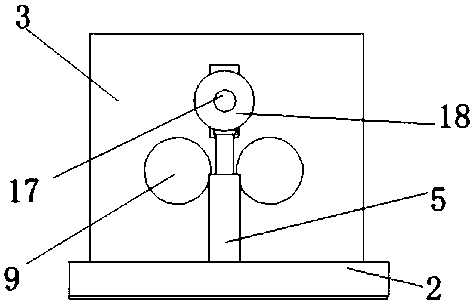

InactiveCN111391404ASimplifies the replacement and fixation processImprove work efficiencyBox making operationsPaper-makingElectric machineryCorrugated fiberboard

The invention relates to an indentation folding processing method for a paper box made of corrugated boards. The indentation folding processing method adopts a following indentation device. The indentation device comprises a bearing mechanism, an indentation mechanism arranged above the bearing mechanism and a cam mechanism arranged above the indentation mechanism, wherein a dial mechanism connected with the indentation mechanism is arranged above the cam mechanism, and a moving plate drive mechanism is arranged in the bearing device. By cooperation of two lead screws, chain wheels and a chain, a stepper motor drive the two lead screws to rotate synchronously, so that two moving seats drive the indentation mechanism and a moving plate to move synchronously respectively, not only can spacing between indentations be adjusted, but also a semi-circular groove can be used for producing a buffer effect on a cutting tool; a round pipe is sleeved with the cutting tool provided with three cutting heads, the corresponding cutting tool can be replaced by rotation, a locking block is used for limiting rotation of a round rod, so that the cutting tool is fixed, and replacing and fixing processes of the cutting tool are simplified.

Owner:李佳佳

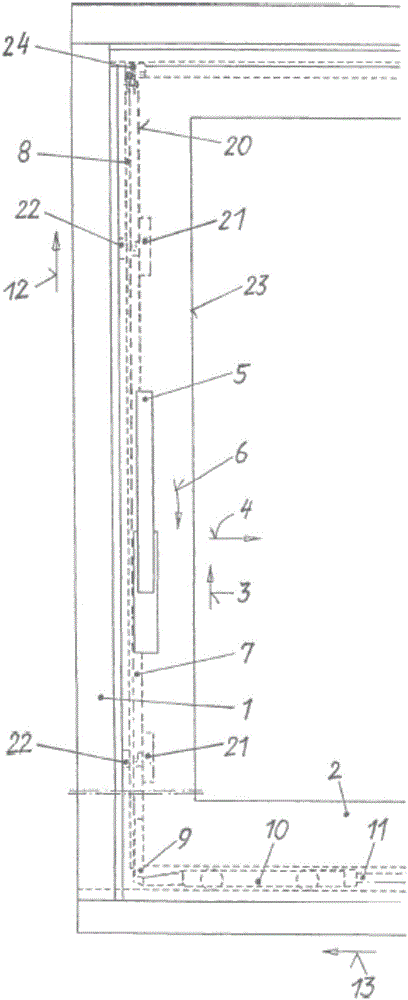

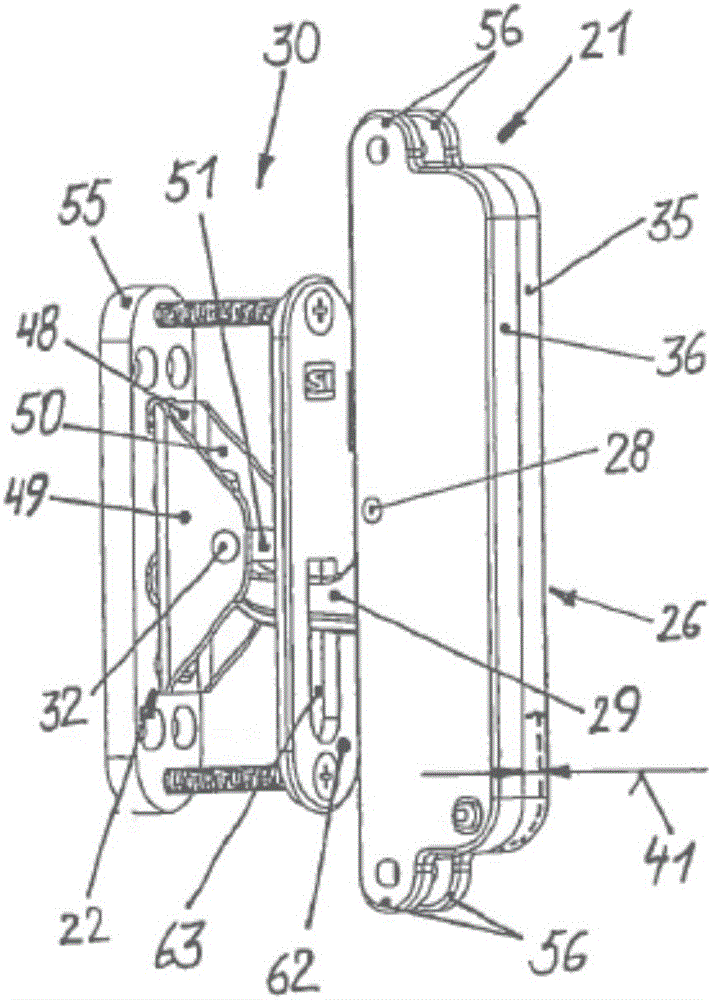

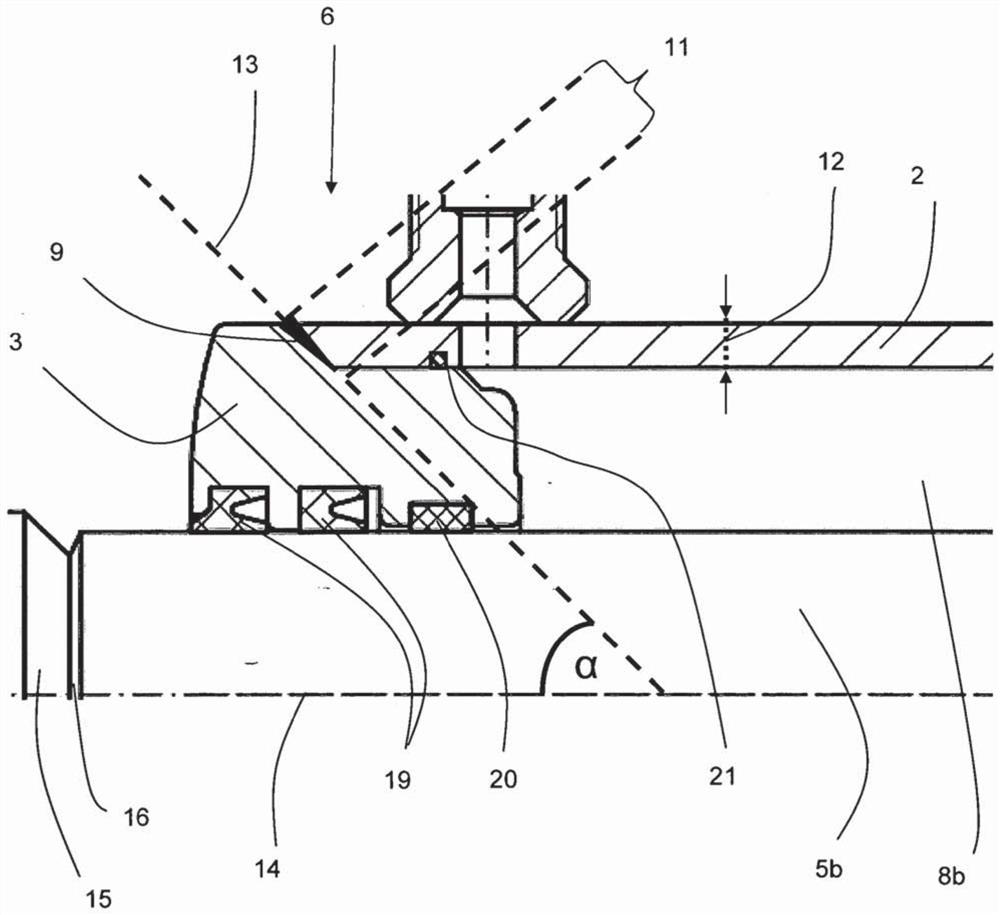

Fitting for an at least liftable, but preferably also slidable window or door leaf

ActiveCN105849345AExtended service lifeFavorable readjustmentBuilding locksWing suspension devicesEngineeringActuator

The invention relates to a fitting for a window or door leaf (2) that can at least be lifted and / or tilted, but preferably also be displaced, and has a guide rail (16), wherein an actuating rod assembly (7) is located on the vertical leaf spar (23) inside a fitting groove (20) of the leaf (2), said actuating rod assembly (7) comprising a drive rod (8) which can slide downwards by means of an actuation member (5) in order for the leaf (2) to be lowered and which transfers the sliding movement to at least one coupled carriage (10) via a corner deflection element (9). The fitting has a locking device (21) which is secured to the actuating rod assembly (7) inside the fitting groove (20) by means of a housing (26) and which can be coupled to the actuating rod assembly (7) by means of a guide part (24). The guide part (24) can be moved by actuating the drive rod (8) of the actuating rod assembly (7), and transfers a pivotable latch (29), which is controlled on the guide part (24) by means of an actuator guide (27) and which is rotatably mounted on the housing (26) of the locking device (21) via a pivot point (28), from an opening position located in a concealed manner in the housing (26) inside the actuating rod assembly (7) against the direction for lowering the leaf (2) into a free operating field (30) of a locked position. When the pivotable latch (29) moves into the locked position, a free end (46) thereof grips a peg (32) that is mounted on the frame (1) and arranged on the locking engagement element (22). The locking engagement element (22) comprises a locking plate (62) which is arranged on the frame (1) in an almost flush manner and which includes a cavity (63) through which the pivotable latch (29) can engage, and an ajar position is created as the free end (46) of the pivotable latch (29) engages into a free space (64) between the peg (32) and the locking plate (62).

Owner:SIEGENIA AUBI KG

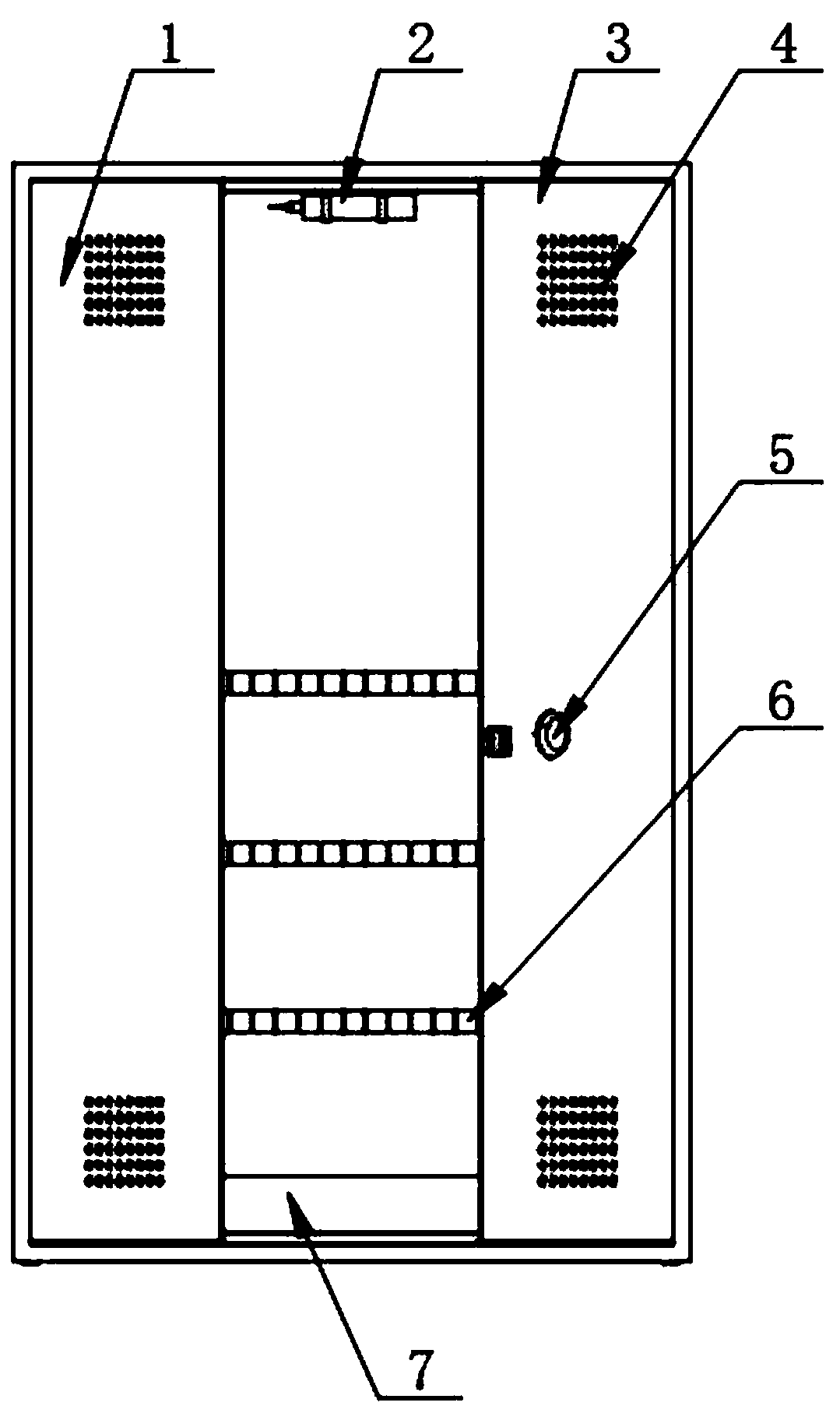

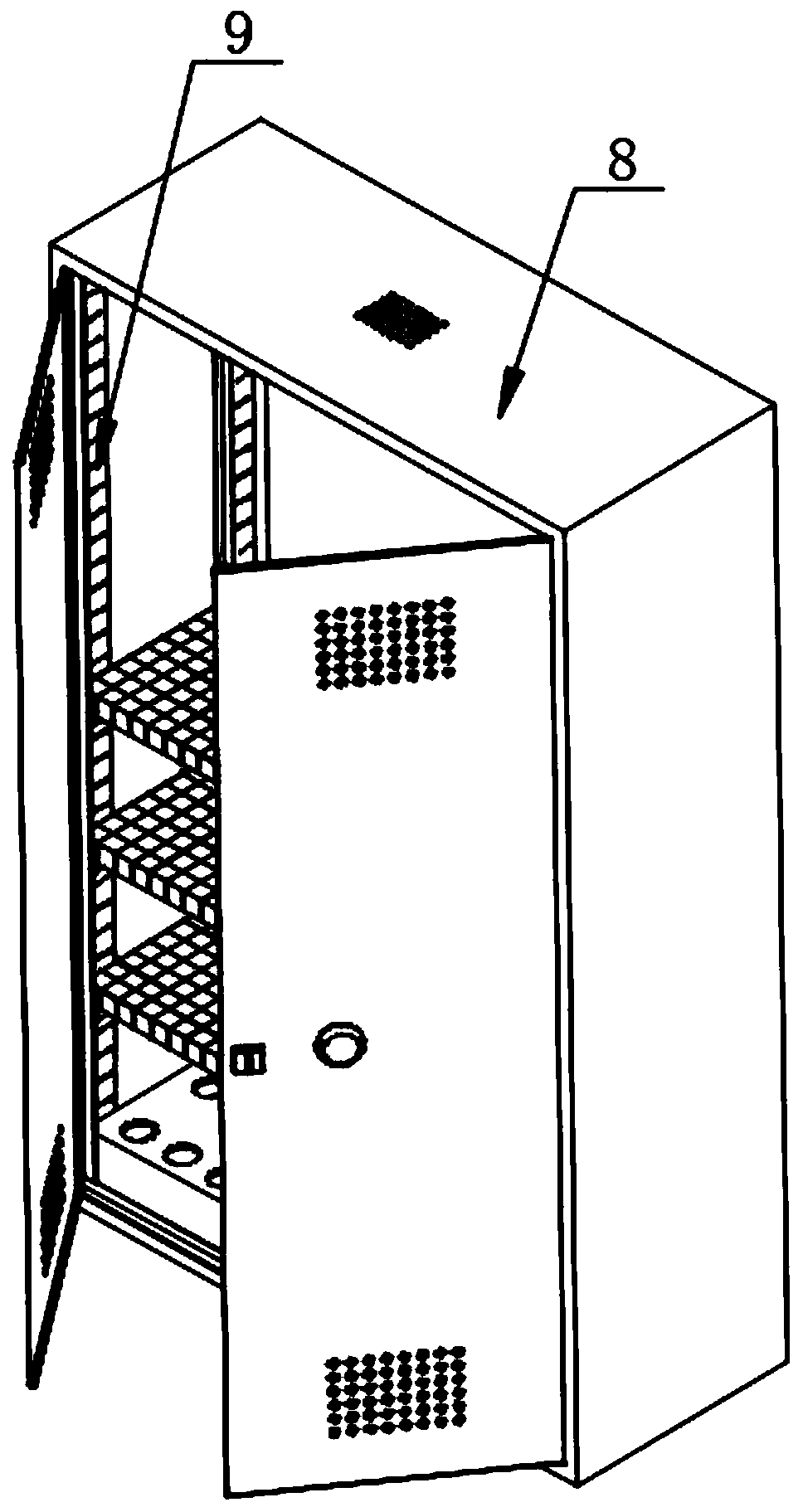

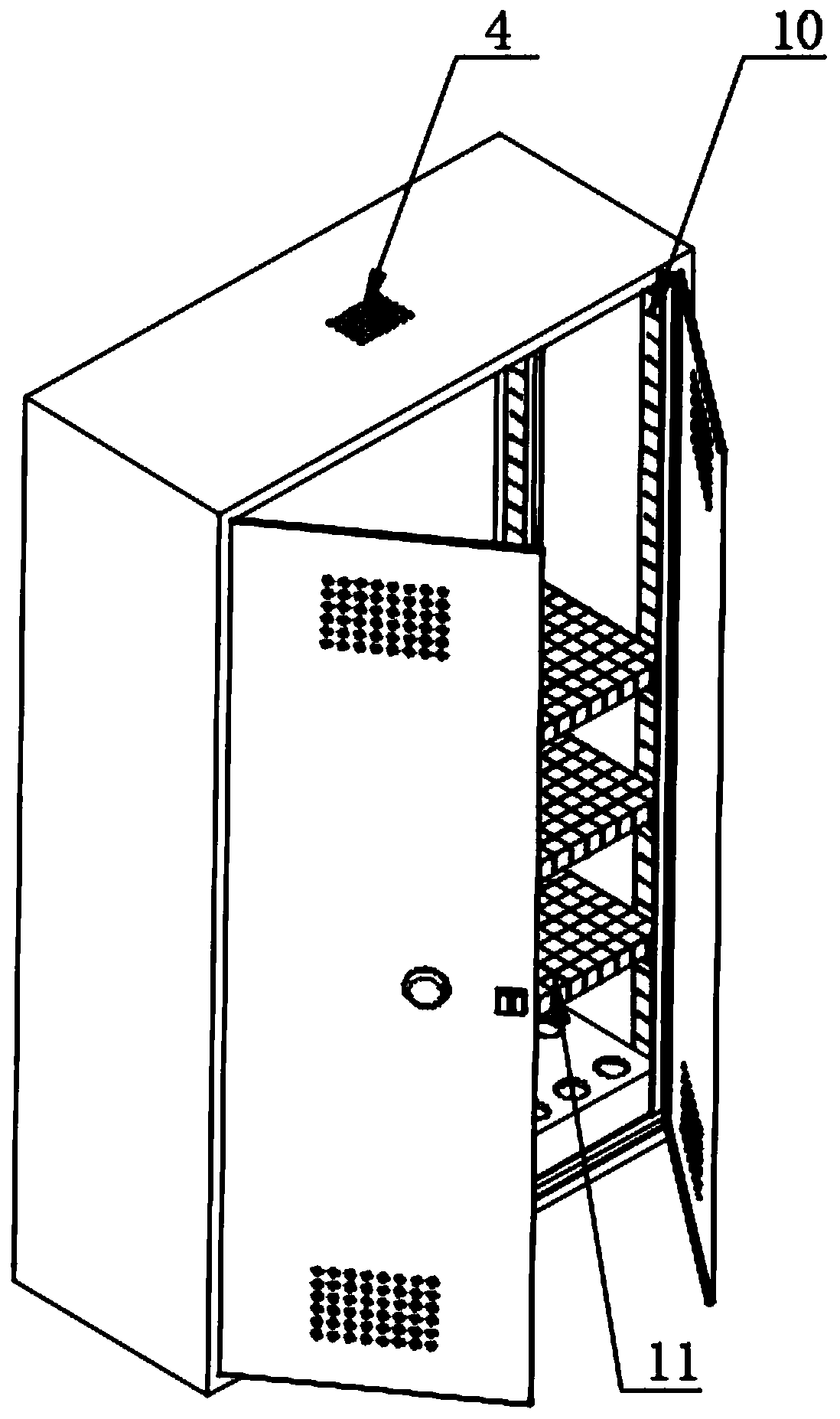

Lithium battery leakage-proof storage cabinet

PendingCN110422494AAdjust intervalAvoid turbulenceConnecting packagesVenting meansObject storageElectrical and Electronics engineering

The invention relates to a lithium battery leakage-proof storage cabinet which comprises a cabinet body and a cabinet door rotatably mounted on the cabinet body. The lithium battery leakage-proof storage cabinet is characterized in that the two side walls of the cabinet body are respectively provided with a left sliding groove and a right sliding groove, a plurality of horizontal object storage plates are arranged between the left sliding groove and the right sliding groove in parallel, liquid leakage holes are formed in the horizontal object storage plates, and a liquid collecting groove is formed in the bottom end of the cabinet body. According to the lithium battery leakage-proof storage cabinet, the arrangement is scientific and reasonable, waste liquid of a waste lithium battery can be collected to prevent explosion of the lithium battery, the distance between the horizontal object storage plates can be adjusted according to the size of the lithium battery, and the application range is wide.

Owner:诚通物流包装有限公司

Apparatus and method for manufacturing secondary battery

ActiveCN110692157AImprove stack qualityAdjust intervalAssembling battery machinesLarge-sized flat cells/batteriesElectrical batteryMechanical engineering

Owner:LG ENERGY SOLUTION LTD

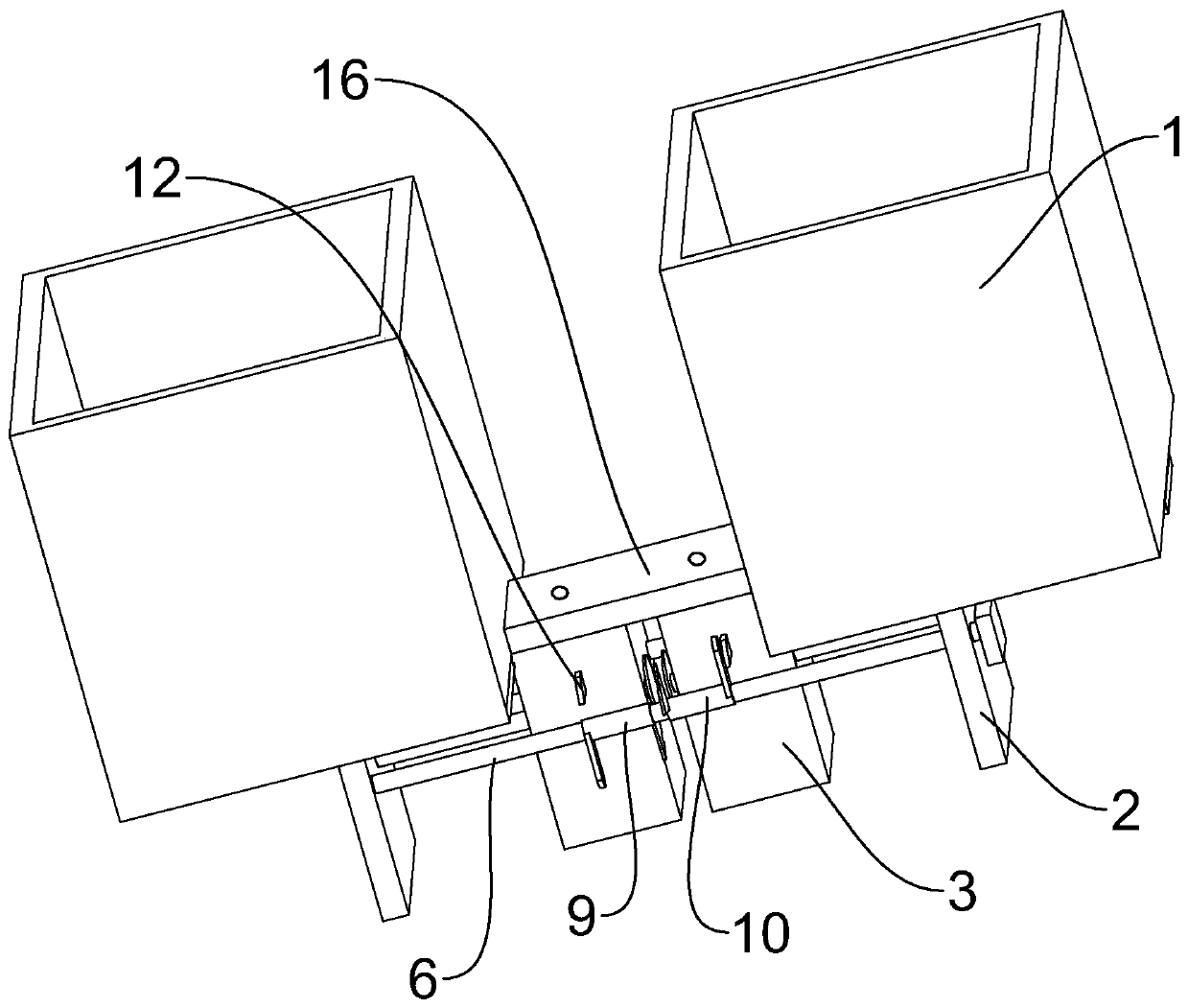

Interval batch liquid adding device

InactiveCN110368873AAdjust intervalImprove work efficiencyFeed devicesEngineeringLeft–right symmetry

The invention discloses an interval batch liquid adding device, which includes storage boxes arranged in left-right symmetry and a cover plate connected with the two storage boxes. Fixing blocks are arranged at the bottoms of the storage boxes, stabilizing blocks are arranged at the lower ends of the storage boxes and the fixing blocks, a long shaft and a limiting rod are arranged between the twostabilizing blocks from front to back, a stepper motor connected with the long shaft in a keyed mode is arranged at the right end of the stabilizing block on the right side, the long shaft is providedwith a left rotating part and a right rotating part, quantitative mechanisms arranged on the limiting rod in a penetrating mode are arranged at the lower end of the cover plate in left-right symmetry, and the quantitative mechanisms on the left and right sides are matched with the left rotating part and the right rotating part correspondingly. The interval batch liquid adding device has the advantages that two liquid can be added in batches at intervals automatically and can be recycled, the interval time of adding of the two liquid is adjusted, the working efficiency is improved, and personal errors are reduced.

Owner:宁波润爵科技有限公司

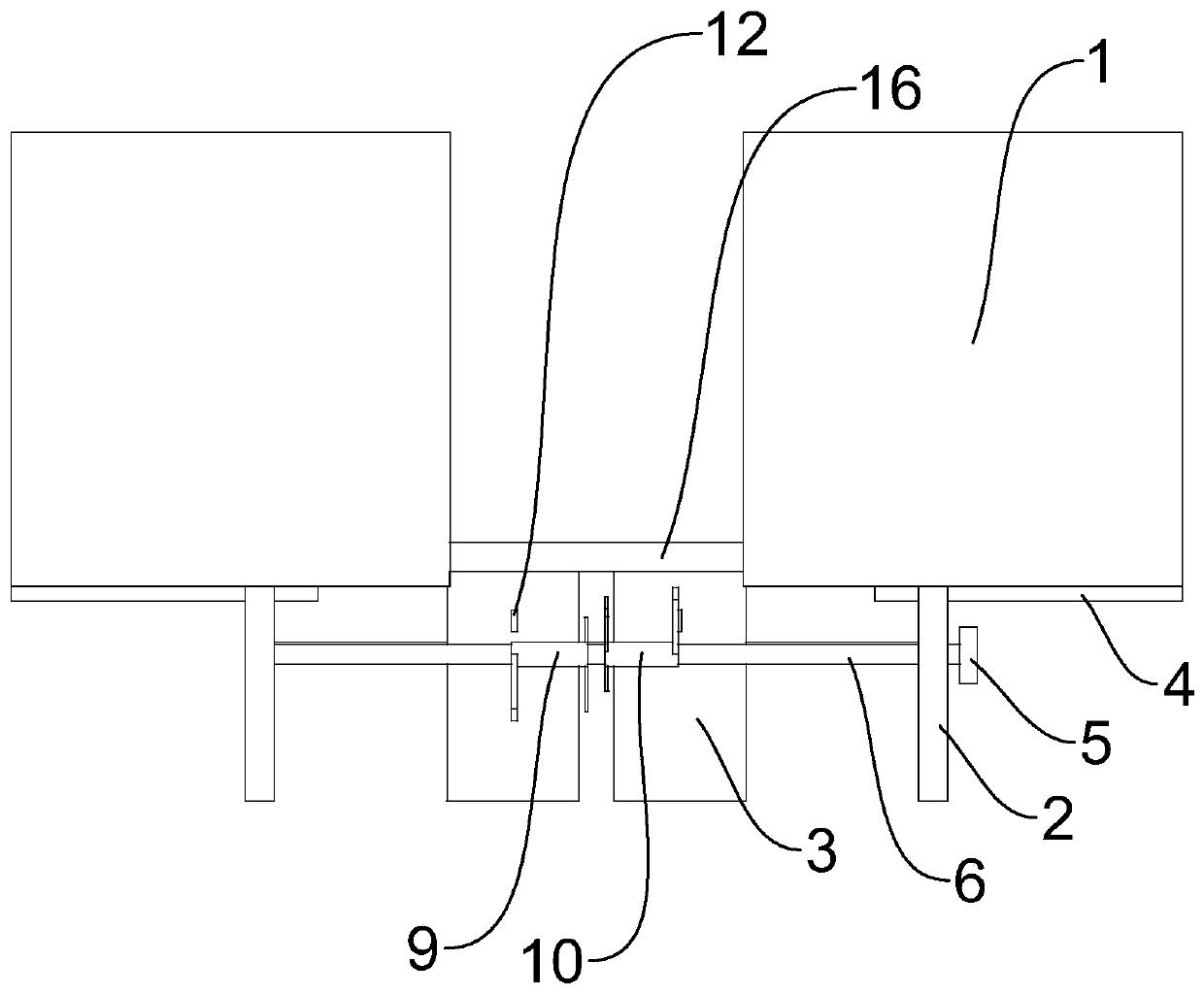

Link automation equipment adopting CCD visual positioning control

The invention discloses Link automation equipment adopting CCD visual positioning control. The Link automation equipment comprises a lower machine body, a workbench is arranged at the position above the lower machine body, a lower mounting groove is formed in the workbench, an upper machine body is arranged at the position above the lower machine body, an upper machine box is arranged at the position, corresponding to the lower mounting groove, of the upper machine body, industrial cameras are arranged in the upper machine box and the lower mounting groove, a gear motor is arranged at the position of on one side of the lower machine body, and a first rotating rod is arranged on the gear motor. The Link automation equipment adopting CCD visual positioning control belongs to the field of automation equipment, qualified products and unqualified products are conveniently treated separately through an arranged first circular containing disc and an arranged second circular containing disc, stacking and disorder of connected products are avoided, the height of a side face table plate is conveniently adjusted, use is convenient, meanwhile, the upper and lower cameras are in cooperation through the industrial cameras at the upper and lower positions, and detection is facilitated.

Owner:深圳市丰源升科技有限公司

Horizontal bobbin case of sewing machine

A horizontal rotating shuttle of sewing machine having a shuttle hook point, provided on a rotating hook accommodating a rotating hook bobbin case holder rotatably about an axis, tapered along an axial rotational direction of the rotating hook, and a needle guard having a shape distorted along the axial rotational direction, with one end fixed to the rotating hook and the other end as a free end. Adjustment means adjustably displaces the needle guard in a direction to increase / reduce an outer diameter of the rotating hook. In a case where the horizontal rotating shuttle is mounted in a sewing machine, and the clearance between a needle which reciprocates in a vertical direction while holding a needle thread and the needle guard of the rotating hook becomes outside an appropriate range, the adjustment means displaces the needle guard in the direction to increase the outer diameter of the rotating hook or in the direction to reduce the outer diameter of the rotating hook. Thus the clearance between the needle and the needle guard can be adjusted to a value within the appropriate range.

Owner:SABUN KOGYOSHO KK

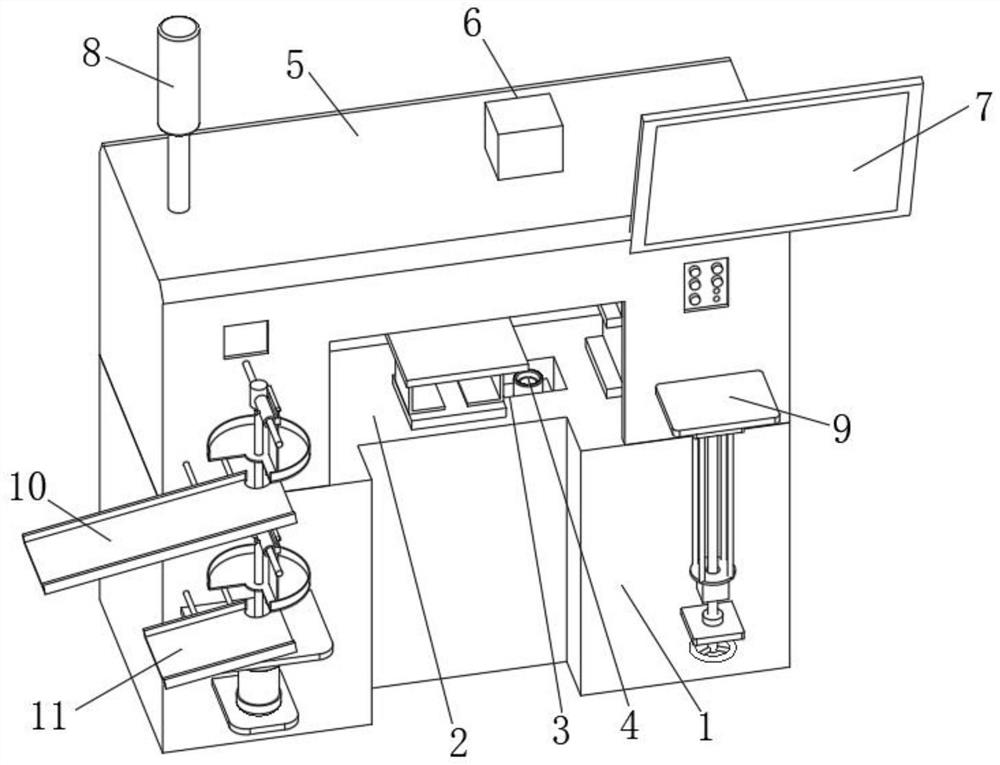

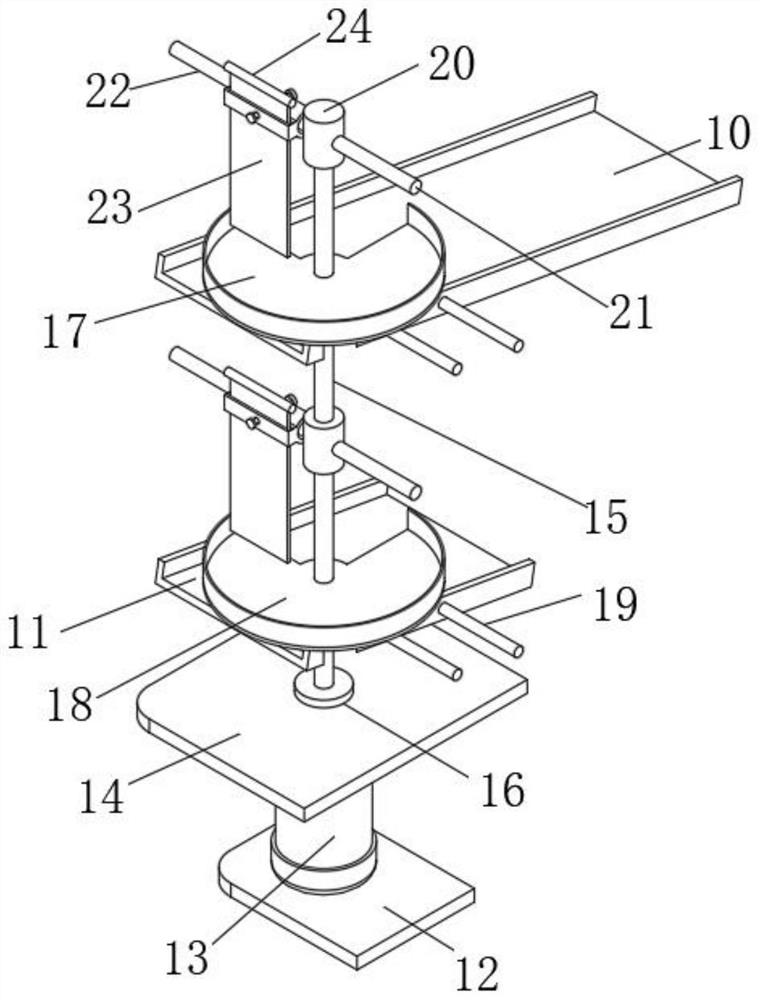

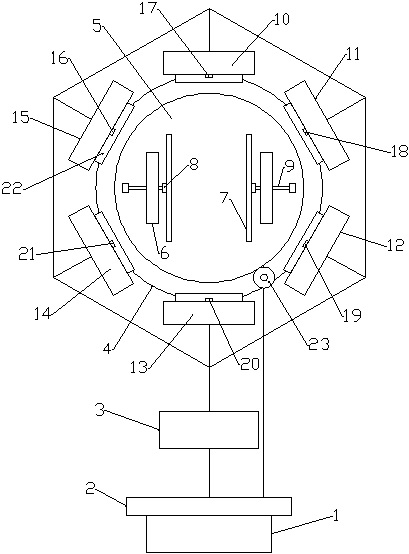

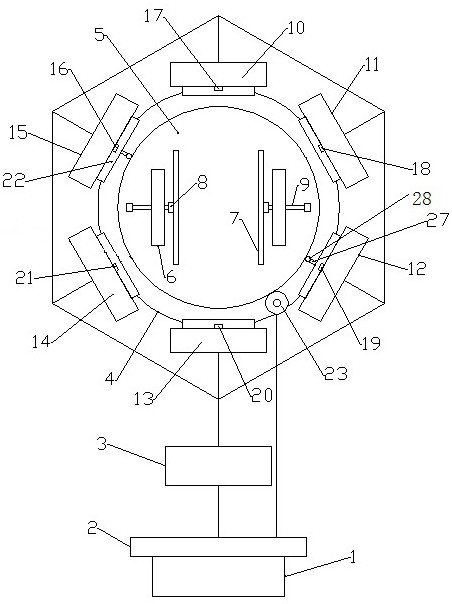

System and method for computer synchronous analysis of learning and memory

ActiveCN110613879AAdjust intervalAchieve consistencyElectrotherapySleep inducing/ending devicesDisplay deviceEngineering

The invention relates to a system and method for computer synchronous analysis of learning and memory. A host is connected with sub-display groups through an AGV screen splitter, the sub-display groups are evenly distributed outside a central platform, and a camera group which is connected with the host in a wireless connection mode is arranged on each sub-display group; a rotary platform is arranged at the center of the central platform, a rotary motor is installed on the side surface of the rotary platform, and the output end of the rotary motor is meshed with a rotary tooth socket which isformed in the side surface of the rotary platform through a driving gear; two limiting support blocks are arranged on the top of the rotary platform symmetrically and fixedly, each limiting support block is sleeved by an adjusting nut, and the interior of each adjusting nut is connected with a limiting clamping plate through a nut sliding block; and the rotary motor is electrically connected withthe host through a wire. Defects of a traditional learning-memory analyzing system are overcome, a plurality of stimulation modes are adopted for stimulation, and the comprehensive stimulation abilityis high, so that test results are comprehensive.

Owner:HUNAN UNIV OF ARTS & SCI

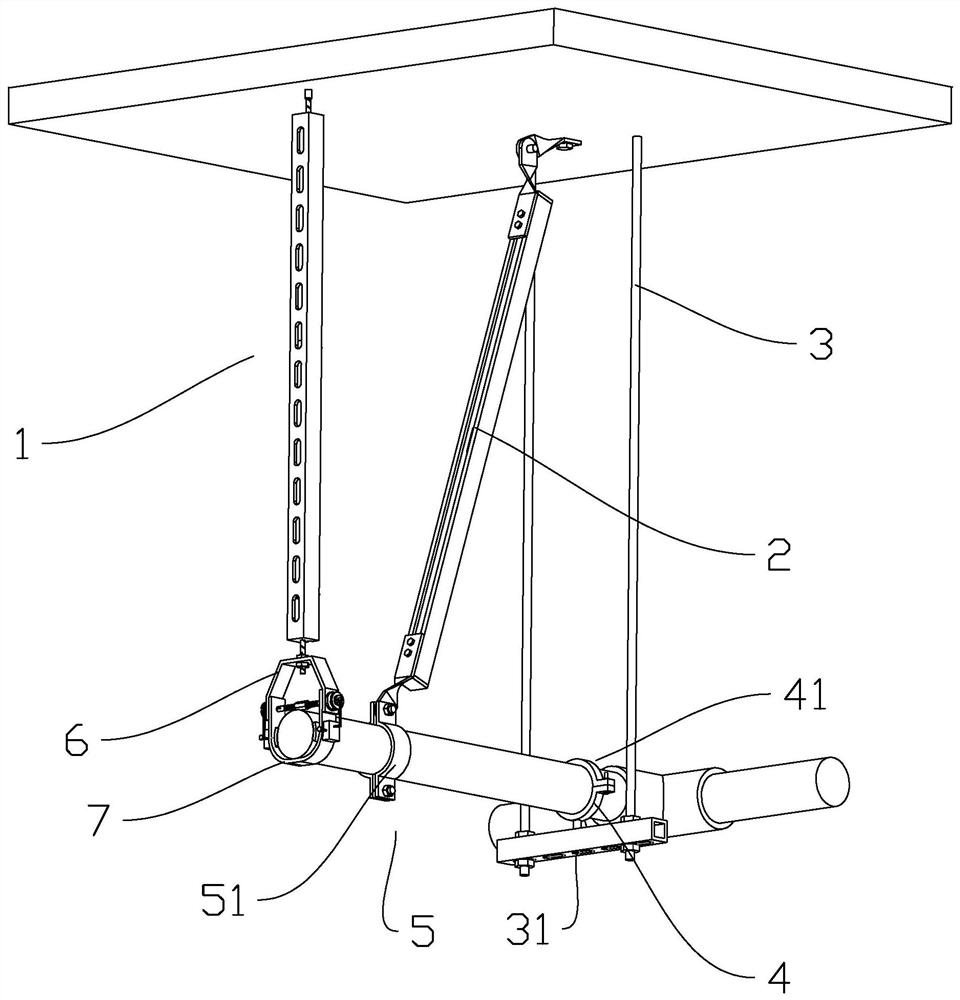

Anti-seismic support and hanger and mounting method thereof

ActiveCN112178279AGood positioning effectImprove seismic performancePipe supportsPipe elementsEarthquake resistantGeotechnical engineering

The invention relates to an anti-seismic support and hanger. The anti-seismic support and hanger comprises a vertical supporting piece, a lateral inclined supporting piece and a door-shaped supportingpiece, wherein the vertical supporting piece comprises a vertical screw rod and channel steel I which sleeves the vertical screw rod; two connecting blocks I are arranged in the channel steel I; theconnecting blocks I sleeve the vertical screw rod; the channel steel I is connected with the vertical screw rod through the connecting blocks I; the lateral inclined supporting piece comprises a lateral screw rod which is obliquely arranged and channel steel II which sleeves the lateral screw rod; two connecting blocks II sleeve the lateral screw rod; the connecting blocks II are abutted against the inner wall of the channel steel II; the door-shaped supporting piece comprises two vertical rods and a transverse plate which is arranged at the bottoms of the vertical rods; the top of the transverse plate and the bottom of the lateral inclined supporting piece are connected with an annular pipe bundle I and an annular pipe bundle II respectively; and the bottom of the vertical supporting piece is connected with a U-shaped pipe bundle. The anti-seismic support and hanger provided by the invention has the effects of improving the anti-seismic capability of the support and hanger and improving the structure stability.

Owner:罗恩(上海)建筑科技有限公司

Rubber parting agent coating device

InactiveCN105127047AImplement bootstrapAdjust intervalLiquid surface applicatorsCoatingsEngineeringCoating

The invention provides a rubber parting agent coating device capable of limiting the conveying position of a rubber strip. The coating device is provided with a supporting table, a parting agent groove, a parting agent supply component and a blocking component, wherein the supporting table is configured on the ground; the parting agent groove is formed in the upper surface of the supporting table and stores a parting agent for coating; the parting agent supply component is arranged above the parting agent groove and supplies the parting agent into the parting agent groove; the blocking component comprises a guiding supporting strip and two blocking rollers, and the guiding supporting strip is installed on the side wall of the parting agent groove in a spanning manner in the direction perpendicular to the rubber conveying direction; and one ends of the blocking rollers are connected with the guiding supporting strip and can be guided by the guiding supporting strip to move along the guiding supporting strip.

Owner:TIANJIN XINZHONGHE RUBBER IND

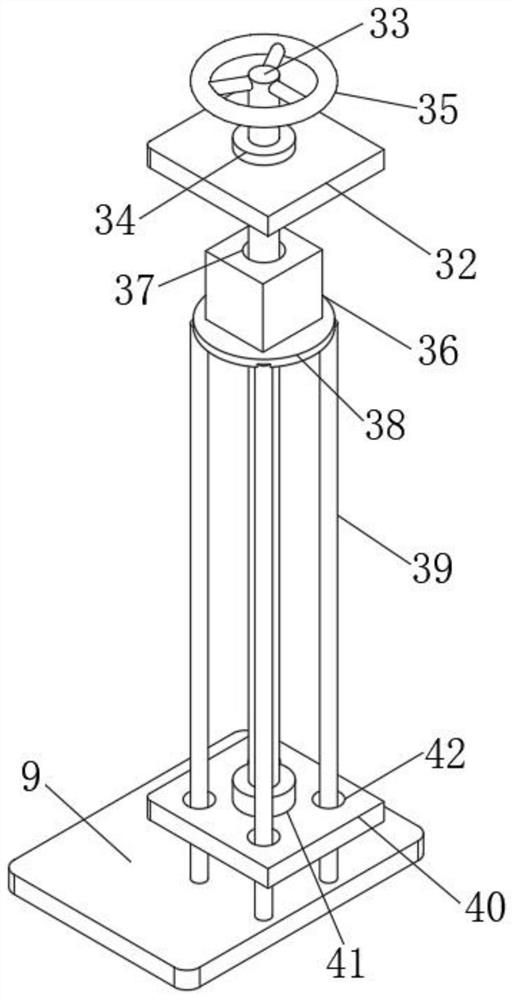

Veneer reeling machine with auxiliary supporting device

ActiveCN110026462AAdjust intervalAdjust processing sizeNon-rotating vibration suppressionEngineeringMechanical engineering

The invention discloses a veneer reeling machine with an auxiliary supporting device. An upper compression roller can be lifted to adjust by arranging a first servo electric cylinder, a second servo electric cylinder, a first supporting plate, a second supporting plate, a first chute and a second chute, so that gaps between the upper compression roller and two lower compression rollers are adjusted, and therefore, the processing dimension of the device is adjusted conveniently. Shock-absorbing and buffering actions can be exerted to the upper compression roller by arranging a first buffer partand a second buffer part, so that the service life of the device can be prolonged; one end of a second rotating shaft can lift to move in a cavity by arranging a third supporting plate and the cavity, so that a second rotating shaft is supported in an auxiliary manner; the lifting and adjusting process of the upper compression roller can be assisted by arranging a rack, a slide rail, a gear and aslider, so that the stability of the device in the adjusting process is enhanced and the service life of the device is prolonged. The veneer reeling machine is excellent in supporting effect, excellent in shock-absorbing effect, excellent in stability and long in service life and does not affect normal production.

Owner:山东森亚信息科技有限公司

Lens unit and method for manufacturing lens unit

Owner:SANKYO SEIKI MFG CO LTD

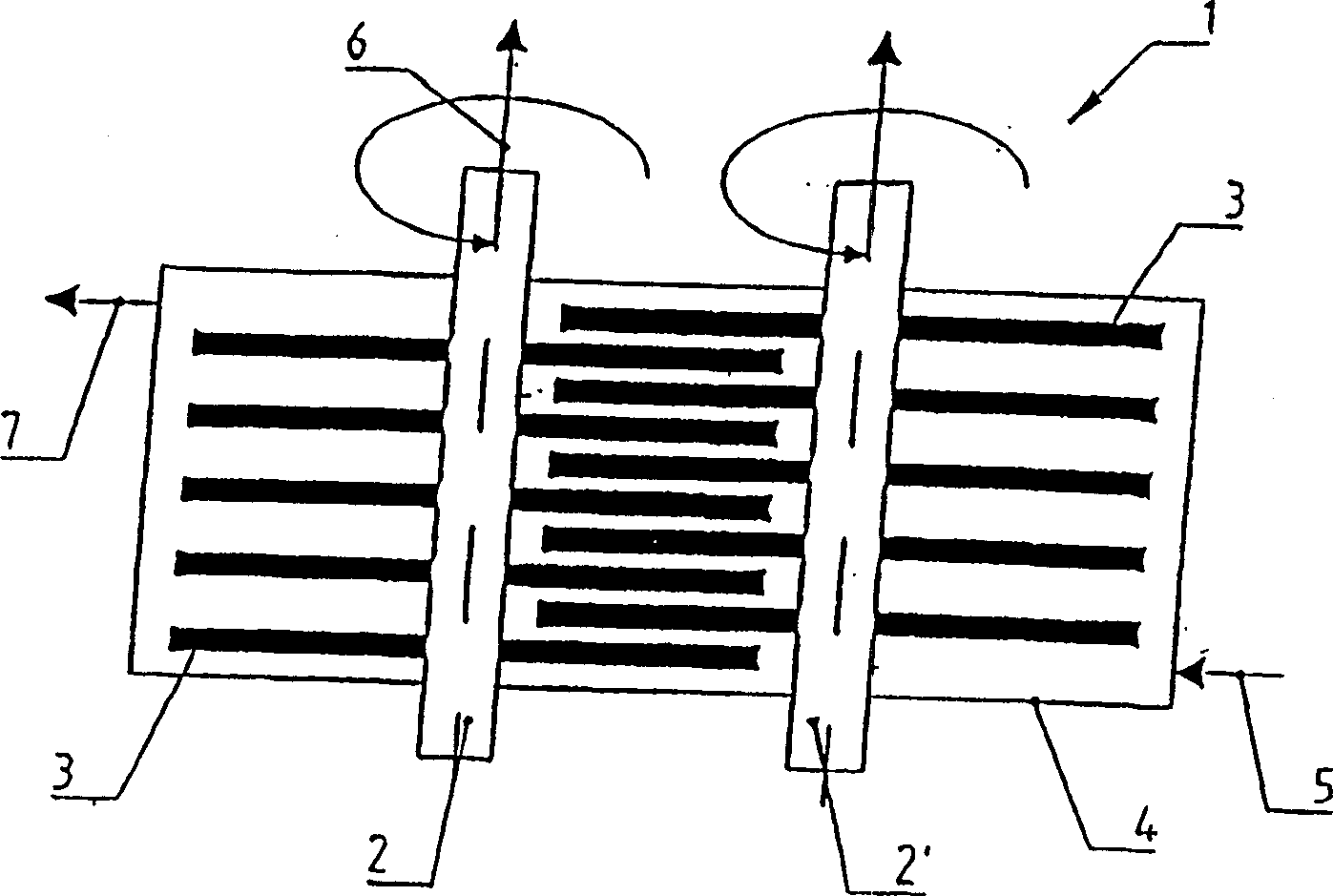

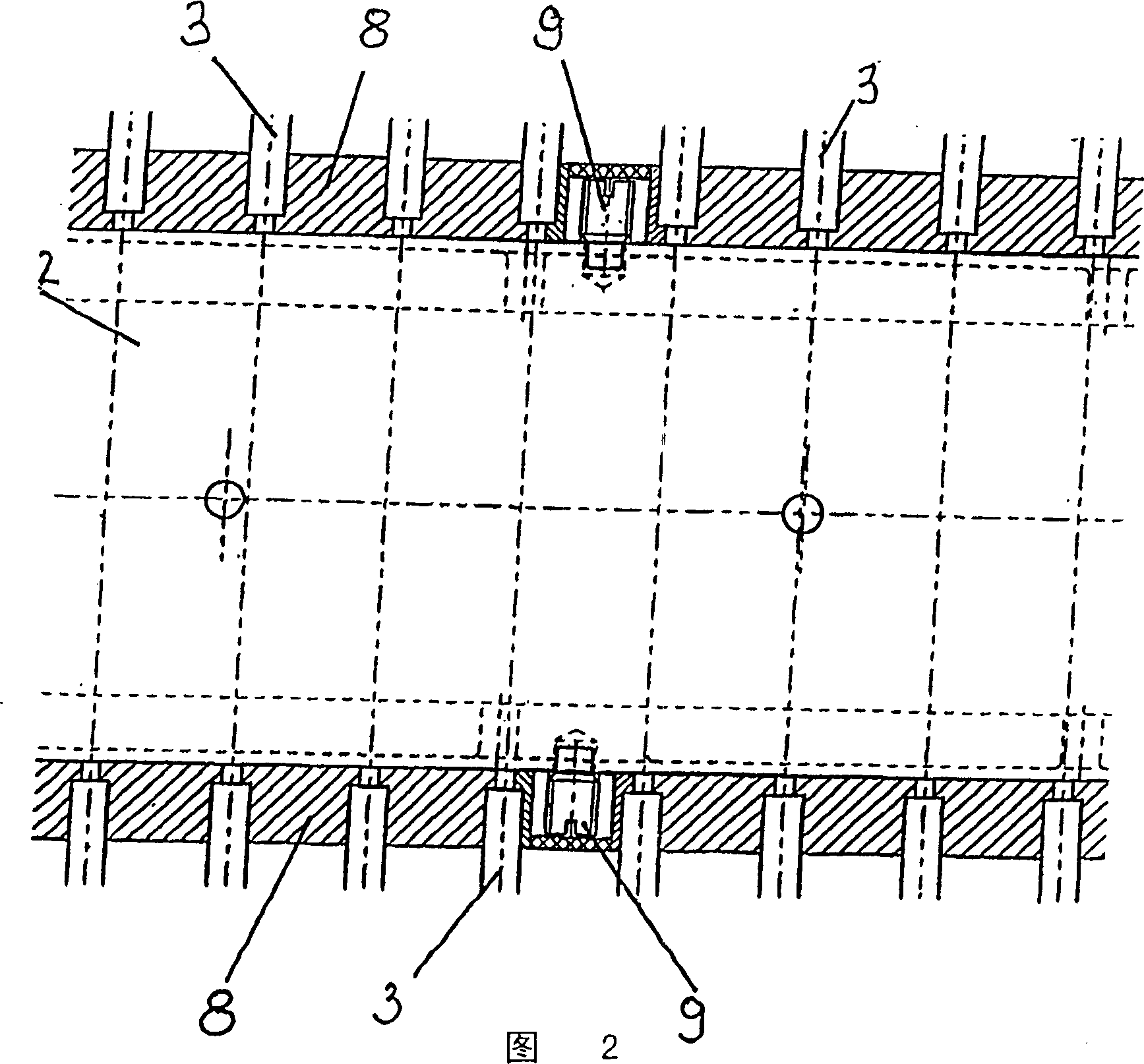

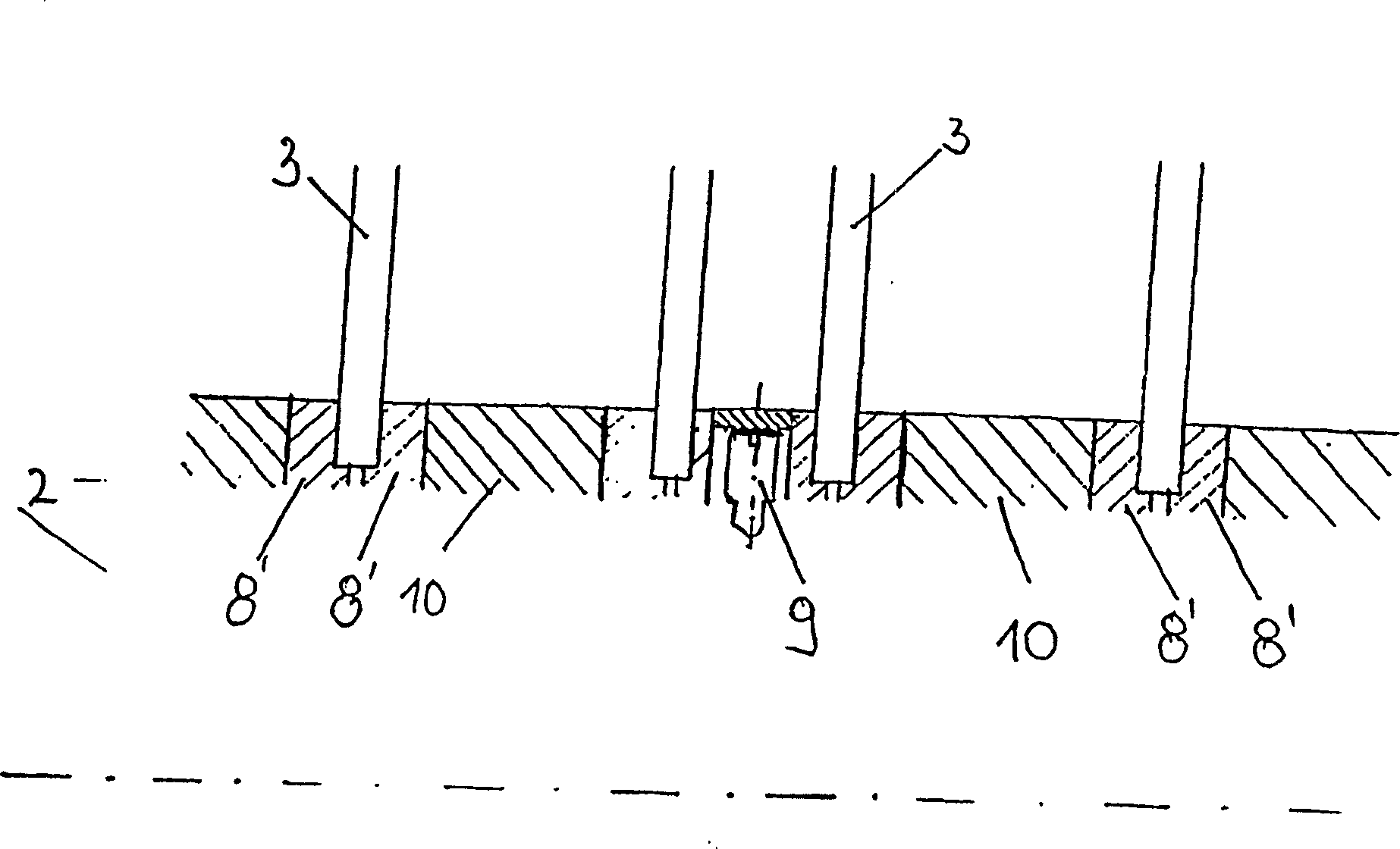

Filter

InactiveCN1258387CImprove stabilityAdjust intervalSemi-permeable membranesTransducer circuitsElastomerFilter media

The invention relates to a filter (1) comprising a plurality of rotating filter discs (3) arranged on a shaft (2) and provided with a porous filter medium. The invention is characterized in that elastomer elements (8, 8') are used as separators and are arranged between each individual filter disc (3) on the shaft (2). The invention also relates to a filter disc (3) for such a filter (1).

Owner:ANDRITZ AG

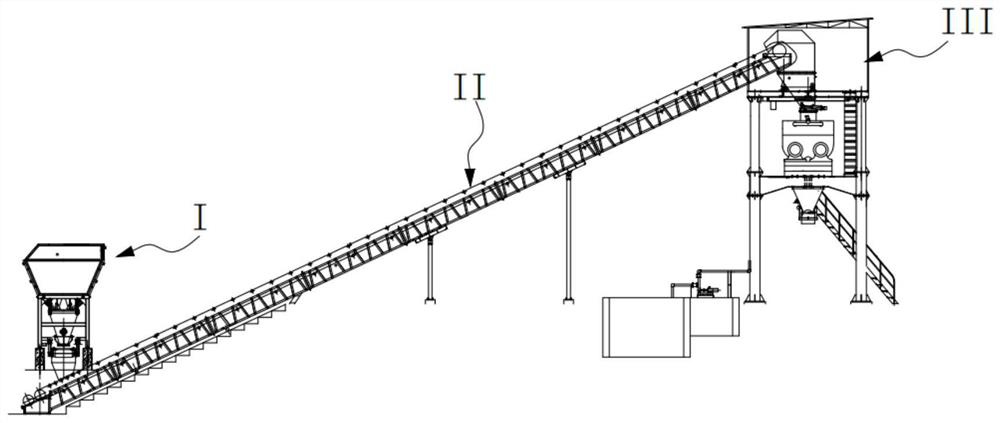

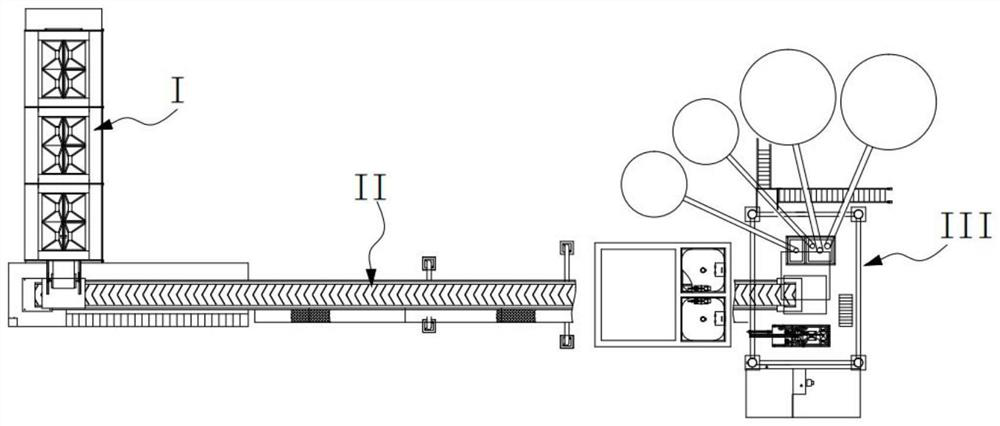

Accurate batching commercial concrete mixing production system

InactiveCN112428439AImprove weighing accuracySolve the inaccurate weighing accuracyMixing operation control apparatusIngredients storageProcess engineeringIndustrial engineering

The invention relates to the technical field of commercial concrete production and preparation, in particular to an accurate batching commercial concrete mixing production system. The accurate batching commercial concrete mixing production system comprises a proportioning device, a lifting device and a mixing device, and weighing equipment comprises a hopper, a weighing bin, a weighing module, a buffer mechanism, an intermittent feeding mechanism and an extrusion mechanism. The suspended extrusion mechanism is arranged in the weighing bin, after stones enter the weighing bin, the stones are transversely extruded by an extrusion ball in the extrusion mechanism to be pushed, so that gaps among the stones are filled, the distribution of the stones in the weighing bin is changed, the weighingprecision of the stones weighed by the weighing module is improved, and the technical problem that the weighing module is inaccurate in weighing precision due to uneven distribution of stones is solved.

Owner:浙江坚塔商砼构件有限公司

A computer synchronous learning and memory analysis system and method

ActiveCN110613879BAdjust intervalAchieve consistencyElectrotherapySleep inducing/ending devicesComputer hardwareElectric machine

The invention relates to a computer synchronous learning and memory analysis system and method. The host computer is connected with sub-display groups through an AGV screen splitter, and the sub-display groups are evenly distributed outside the central platform. The camera group connected to the host computer is provided with a rotating platform at the center of the central platform, and a rotating motor is installed on the side of the rotating platform. The top of the rotary platform is symmetrically fixed with two limit support blocks, and each limit support block is equipped with an adjustment nut. The inner side of the adjustment nut is connected to the limit splint through the nut sliding block. Sexual connection; overcoming many defects of the traditional learning and memory analysis system orientation, adopting a variety of stimulation methods for stimulation, strong comprehensive stimulation ability, so that the measurement results are comprehensive.

Owner:HUNAN UNIV OF ARTS & SCI

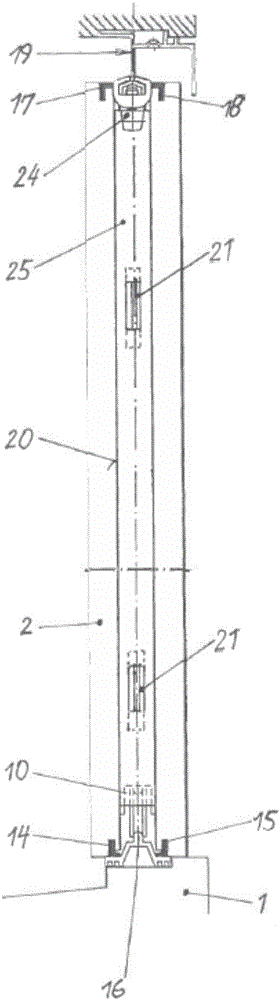

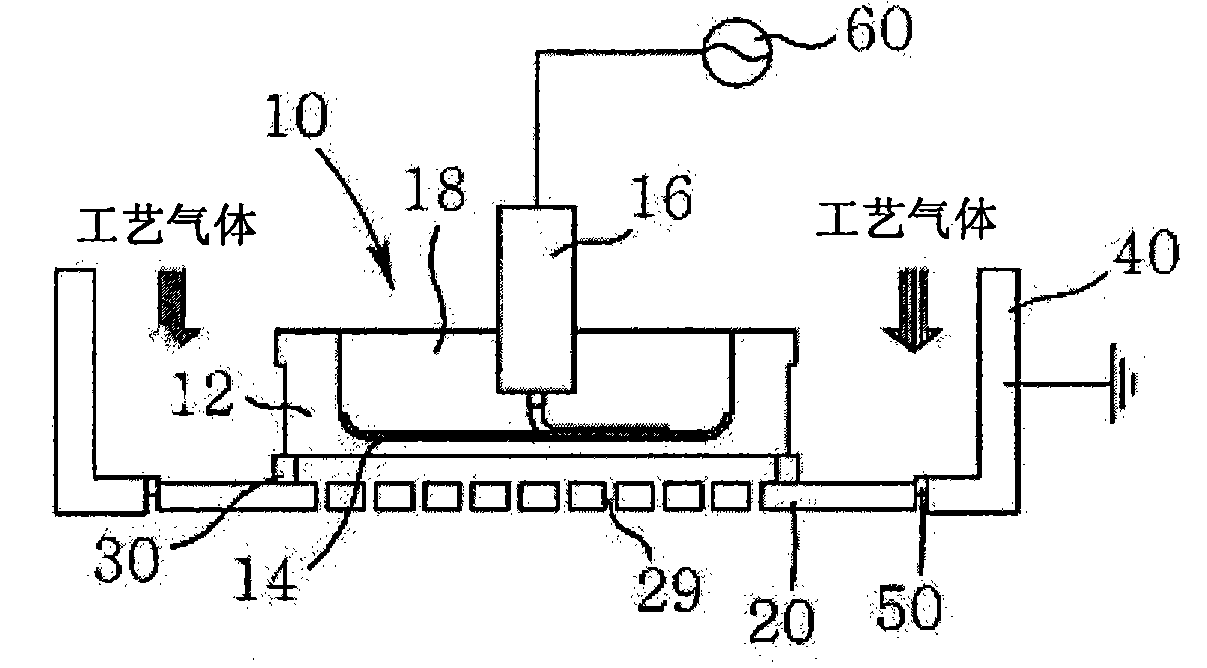

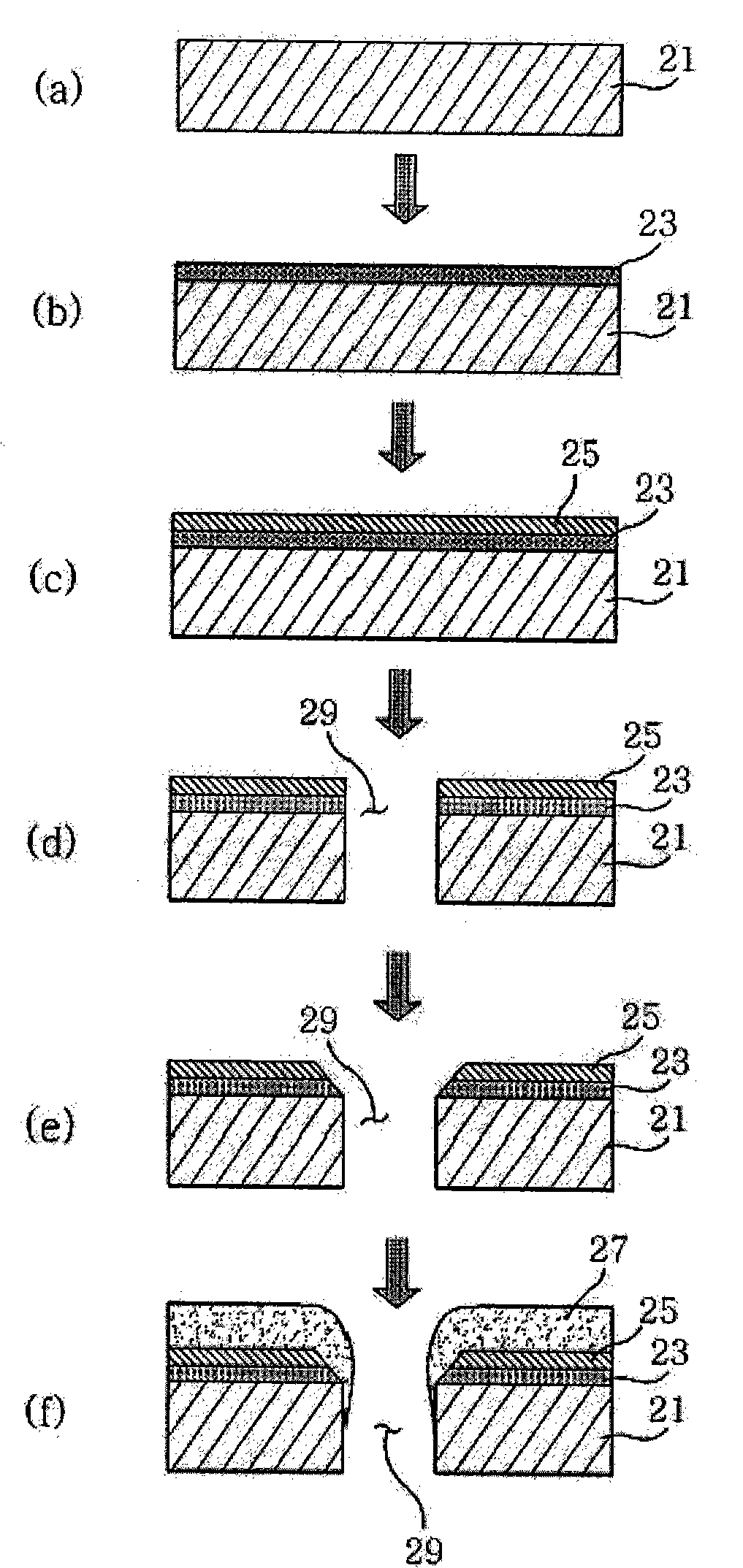

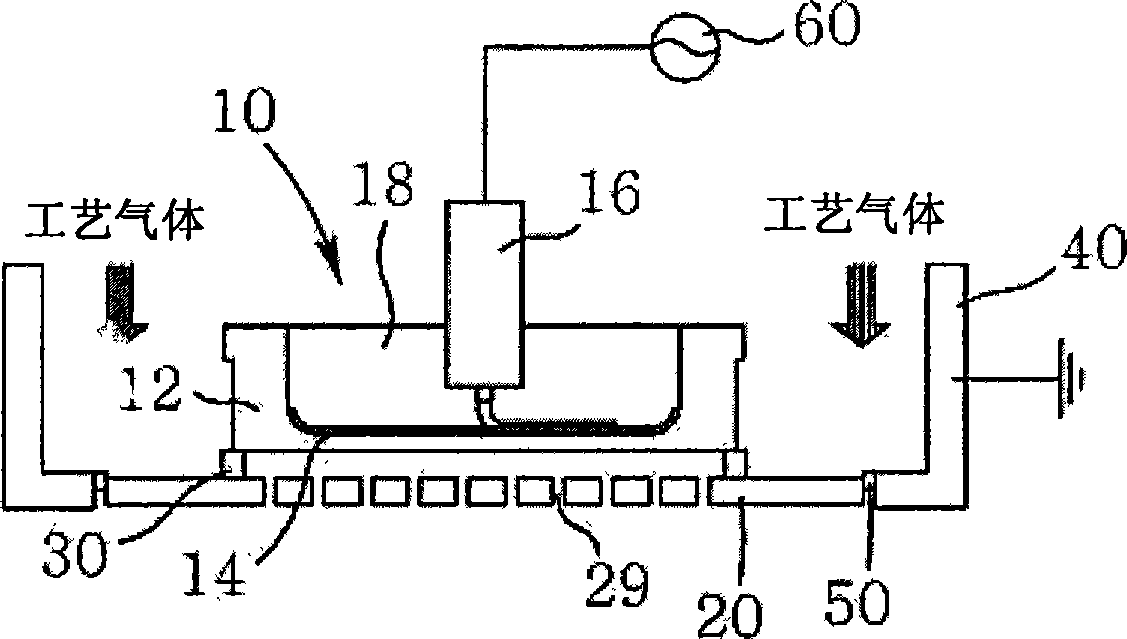

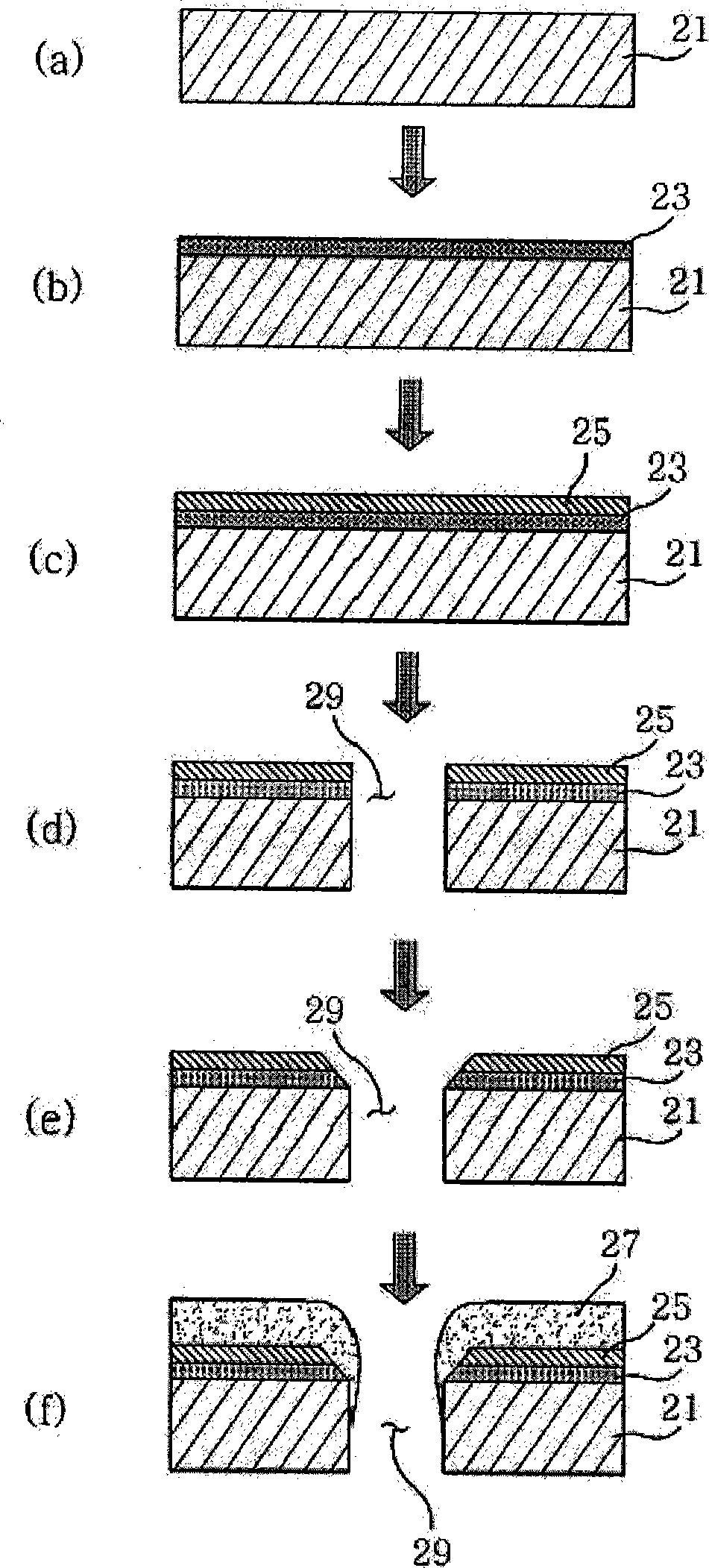

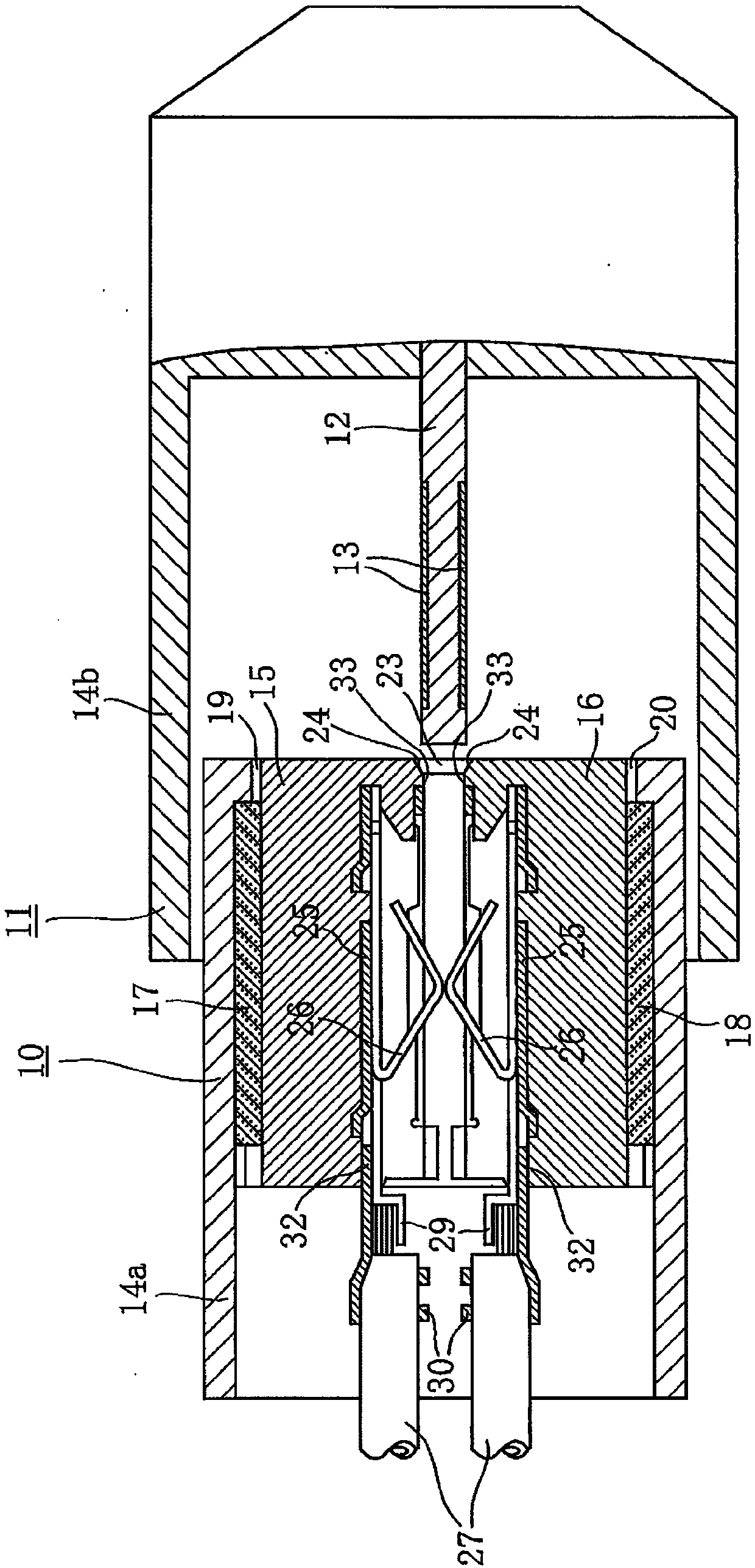

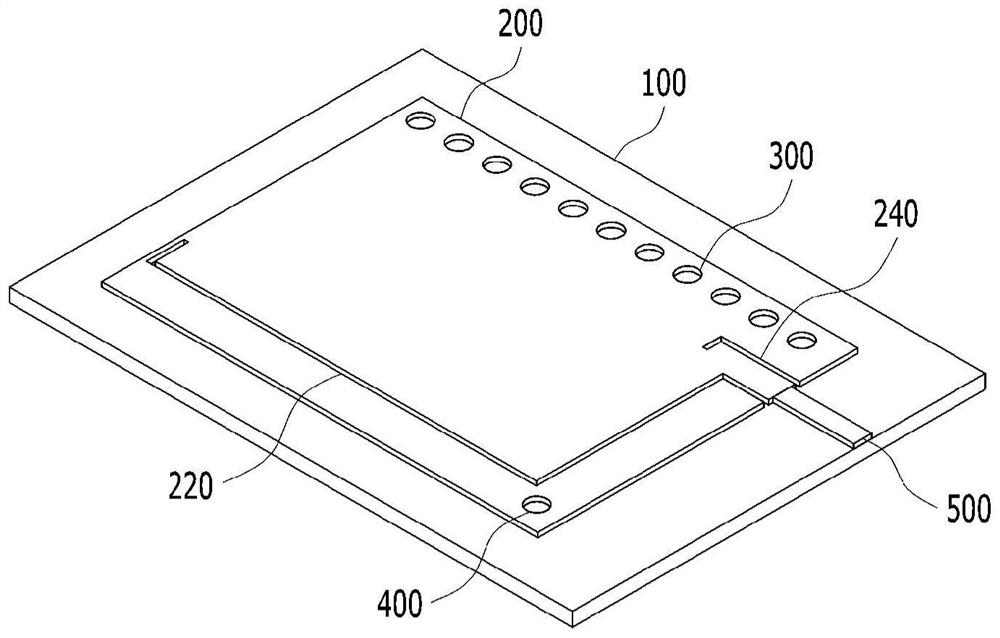

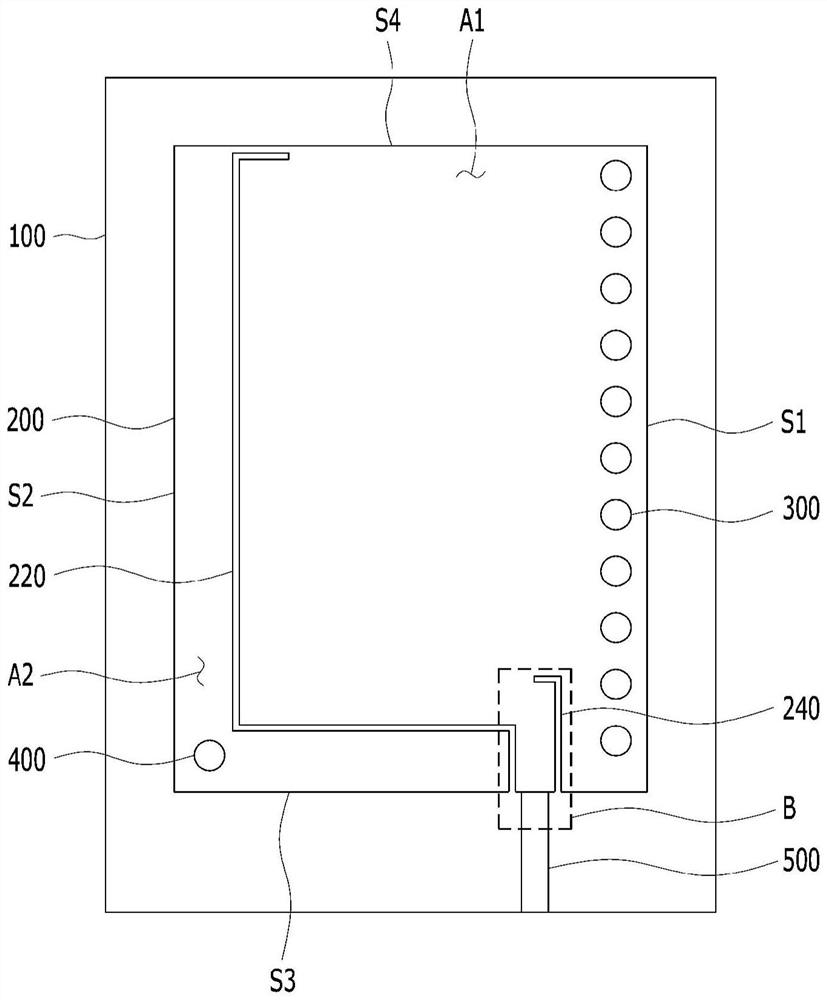

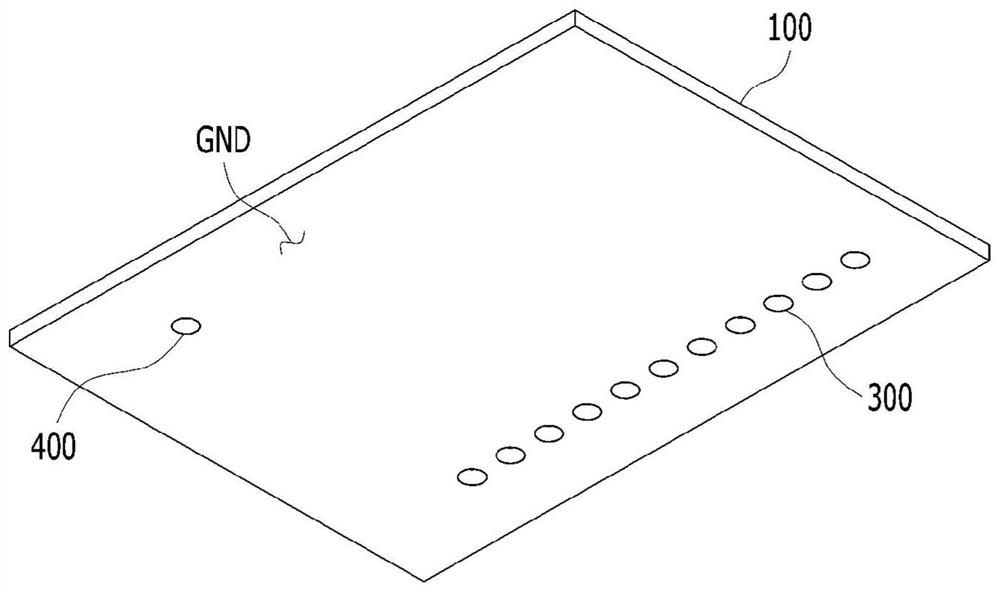

Surface treatment device and manufacture method of lower electrode assembly body of the device

InactiveCN101441986BAdjust intervalArcing phenomenon is minimizedElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

The present invention provides an apparatus for treating the surface of a substrate with plasma in atmospheric pressure and a method for manufacturing a lower electrode assembly thereof, wherein the apparatus for treating the surface is structured as disassembly of structure elements and easy assembly, maintenance such as replacement of electrodes can be easily carried out, and spacing between anupper electrode and a lower electrode is easily adjusted by adjusting thickness of an easily disassembled isolator, furthermore heat generated between the upper electrode and the lower electrode can be efficiently cooled with a cooling system for directly or indirectly cooling the upper electrode and the lower electrode, such that damage caused by heating can be prevented, thus electric arc phenomenon possibly generated on the upper electrode and the lower electrode is minimized.

Owner:LG ELECTRONICS INC

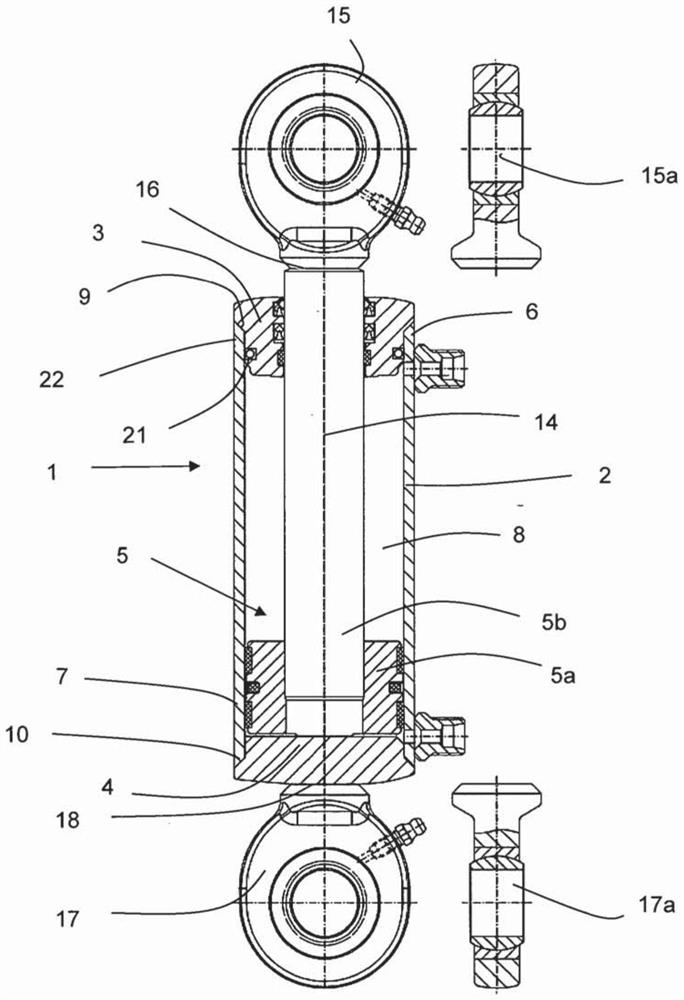

Working cylinder

PendingCN114746657AReduced wall thicknessAdjust intervalFluid-pressure actuatorsLaser beam welding apparatusEngineeringMechanical engineering

The invention relates to a working cylinder having a cylinder liner, a first closing part, a second closing part and a piston unit, the cylinder liner having a cylinder liner first end and a cylinder liner second end, the first closing part being arranged on the cylinder liner first end, the second closing part being arranged on the cylinder liner second end, and the piston unit being arranged on the cylinder liner first end. The first closing part is arranged at the first end of the cylinder liner, the second closing part is arranged at the second end of the cylinder liner, the cylinder liner and the closing parts form a cylinder inner cavity, the piston unit forms at least one working cavity in the cylinder inner cavity, and the piston unit penetrates through the first closing part in a sliding mode. The first closing part is integrally bonded to the cylinder liner by means of an annular first laser circumferential weld, and the second closing part is integrally bonded to the cylinder liner by means of an annular second laser circumferential weld, and the laser circumferential welds each form a fluid-tight sealing plane. An annular sealing ring is arranged axially spaced apart from the respective laser circumferential weld between each closing part and the inner wall of the cylinder liner, the sealing ring forming a pressure-separated ring section between each annular sealing ring and each laser circumferential weld.

Owner:BUMACH ENG INT BV

Surface treatment device and manufacture method of lower electrode assembly body of the device

InactiveCN101441986AAdjust intervalArcing phenomenon is minimizedElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringStructuring element

The present invention provides an apparatus for treating the surface of a substrate with plasma in atmospheric pressure and a method for manufacturing a lower electrode assembly thereof, wherein the apparatus for treating the surface is structured as disassembly of structure elements and easy assembly, maintenance such as replacement of electrodes can be easily carried out, and spacing between an upper electrode and a lower electrode is easily adjusted by adjusting thickness of an easily disassembled isolator, furthermore heat generated between the upper electrode and the lower electrode can be efficiently cooled with a cooling system for directly or indirectly cooling the upper electrode and the lower electrode, such that damage caused by heating can be prevented, thus electric arc phenomenon possibly generated on the upper electrode and the lower electrode is minimized.

Owner:LG ELECTRONICS INC

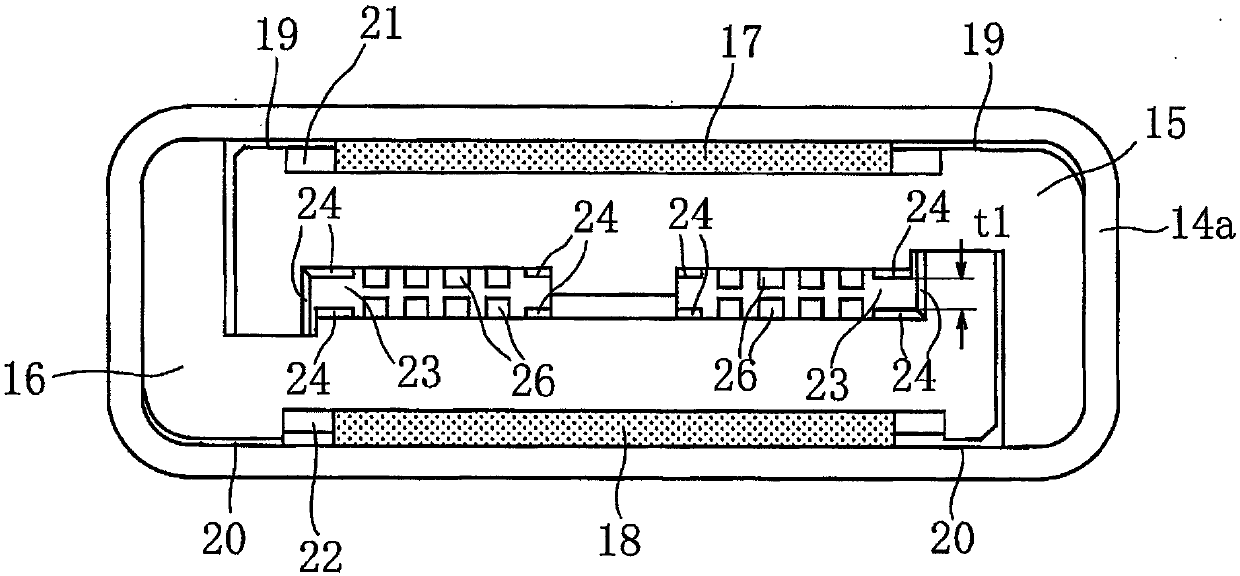

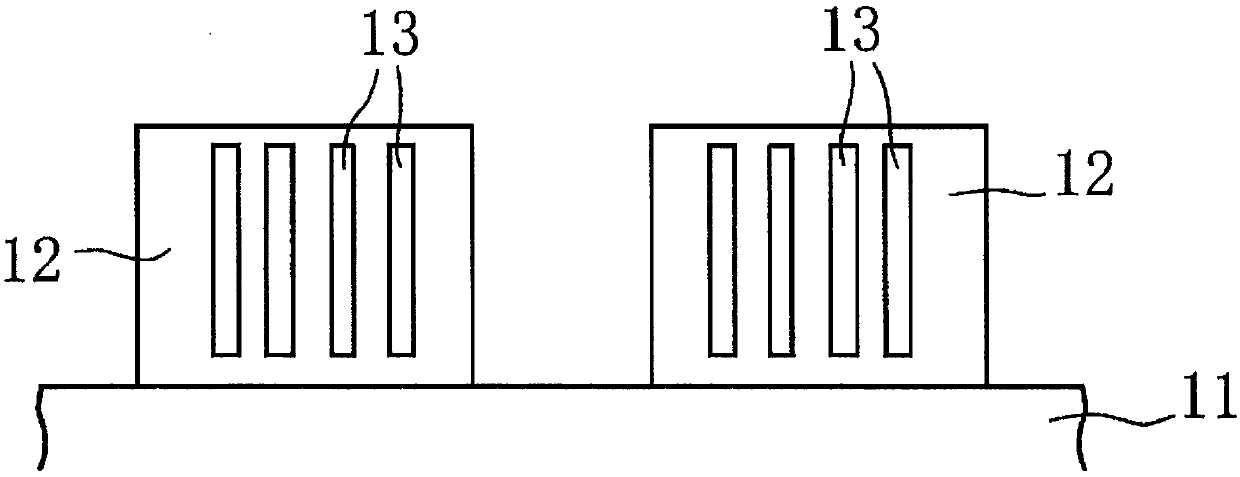

Card edge connection unit

ActiveCN109962354AConstant crimping forceFirmly connectedCoupling contact membersConnections effected by permanent deformationStructural engineeringMechanical engineering

Even when a connection board has a large thickness tolerance, a stable connection is achieved by absorbing the tolerance so as to stabilize a contact pressure between the connection board and contacts. In a unit in which electrode groups (13) of a connection board (12) are in pressure contact with elastic contacts (26) formed integrally with an inner housing (15) to connect thereto, the inner housing (15) is provided inside an outer case (14a) of a card edge connector (10) through an elastic member (17) to be freely movable forward and backward in a thickness direction of the connection board(12). The positions of the elastic contacts (26) are adjusted by forward or backward moving the inner housing (15) in accordance with the thickness of the connection board (12) inserted into board insertion slots (23), so a pressure contact force with the elastic contacts (26) is substantially equalized, irrespective of the size of the thickness of the connection board (12).

Owner:SMK CO LTD

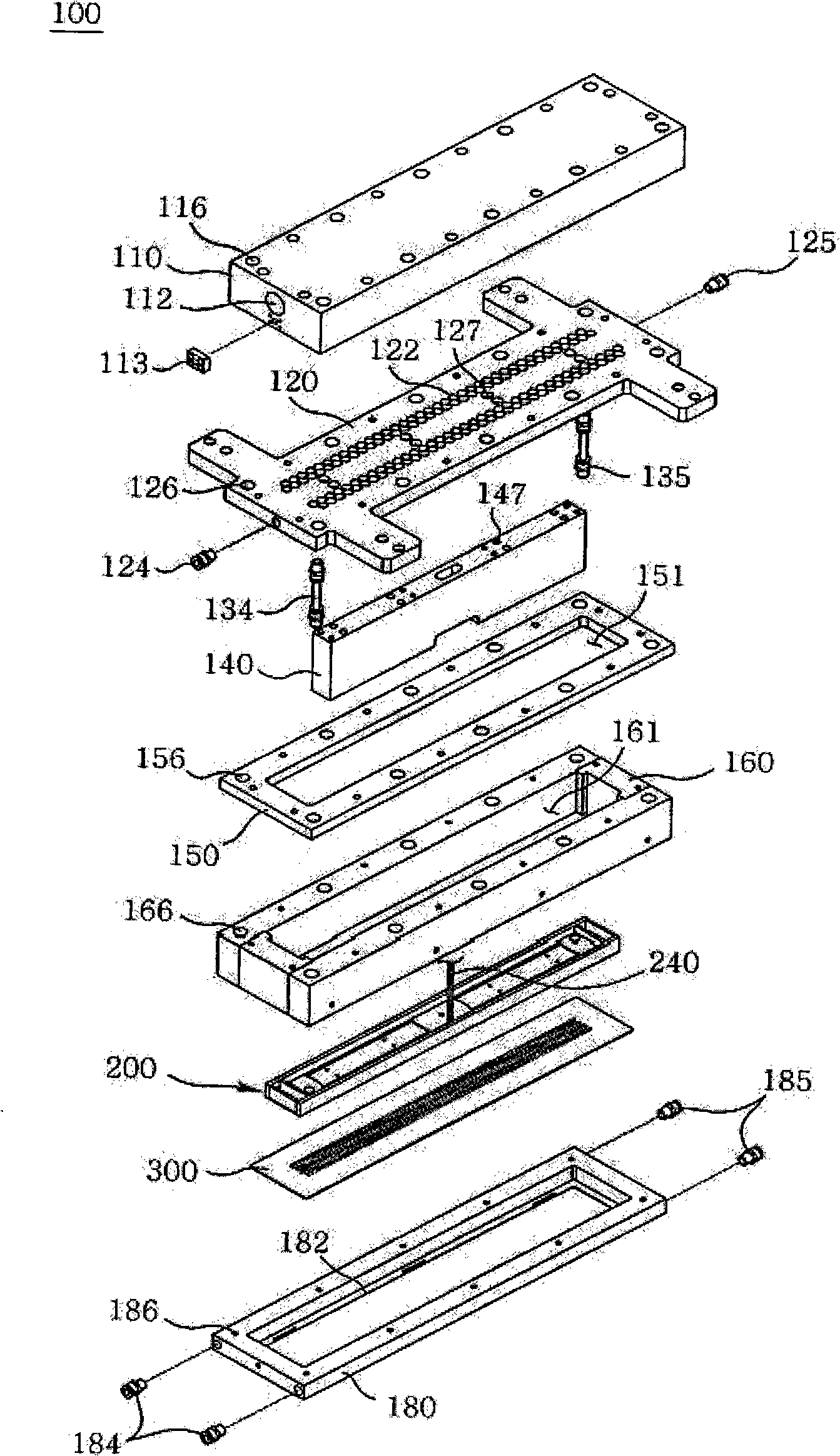

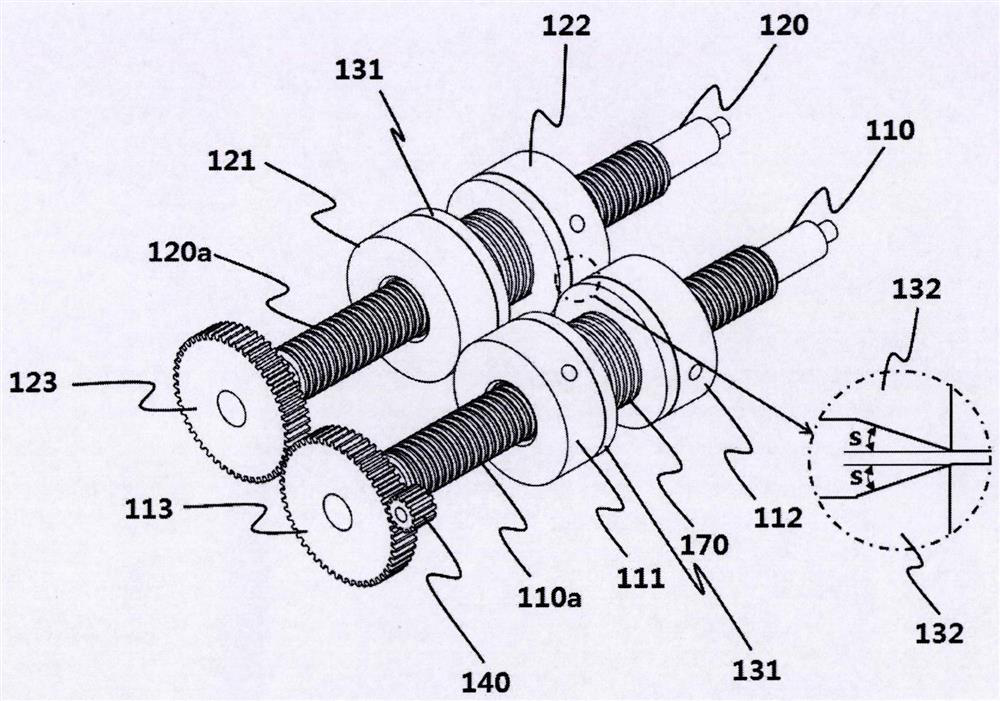

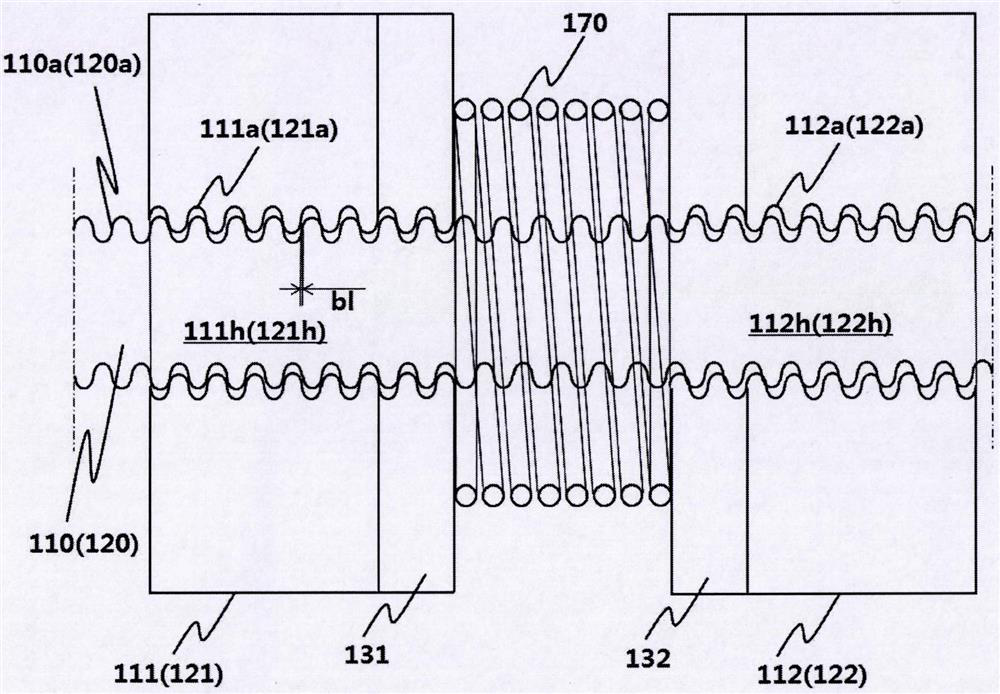

Apparatus for forming edge of lead of secondary battery

ActiveCN108539242BUniform formation qualityAdjust intervalFinal product manufactureSecondary cells manufactureEngineeringScrew thread

An apparatus for forming an edge of a lead of a secondary battery is provided. The first edge and the second edge are formed by performing a pressure application process using a first first pressure roller, a second first pressure roller, a first second pressure roller, and a second second pressure roller, and as a result, the same Compared with the grinding or cutting process in the related art, the uniform formation quality of the first edge and the second edge can be maintained. The first thread and the second thread of the upper shaft and the lower shaft can be used as well as the first first pressure roller, the second first pressure roller, the first second pressure roller and the second second pressure roller respectively The first first screw thread, the second first screw thread, the first second screw thread and the second second screw thread on the first screw to accurately adjust the interval between the pressure rollers, as a result, lead wires with different widths can be formed.

Owner:株式会社POLE

Antenna module

PendingCN114730991AHigh bandwidthAdjust intervalSimultaneous aerial operationsElectrically short antennasSoftware engineeringMechanical engineering

Owner:AMOSENSE

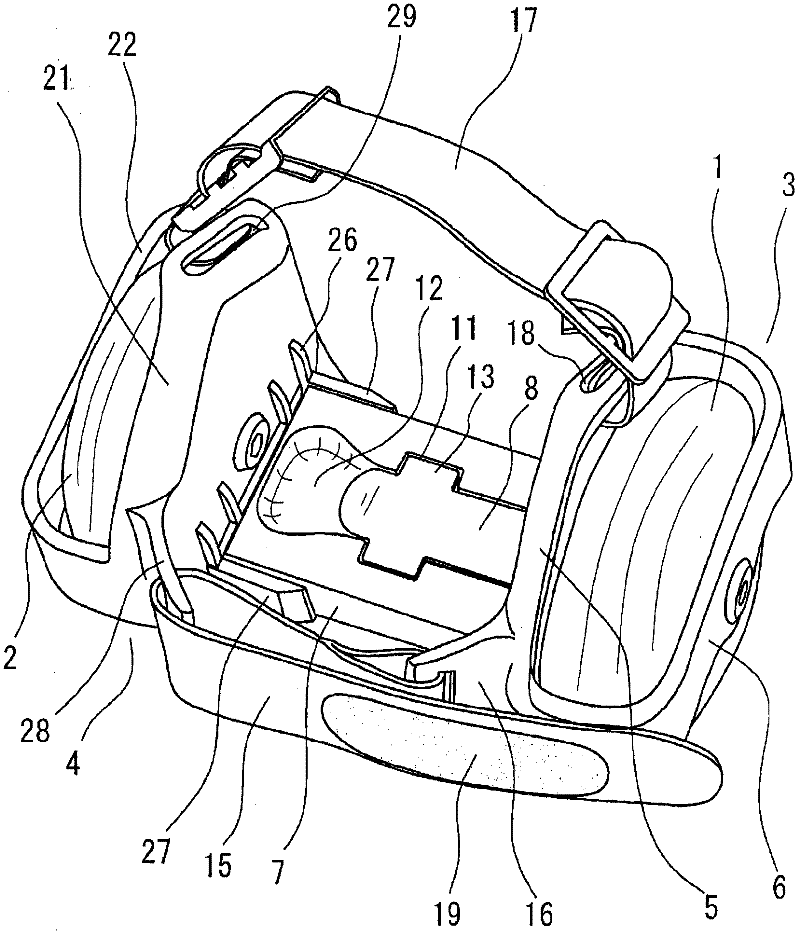

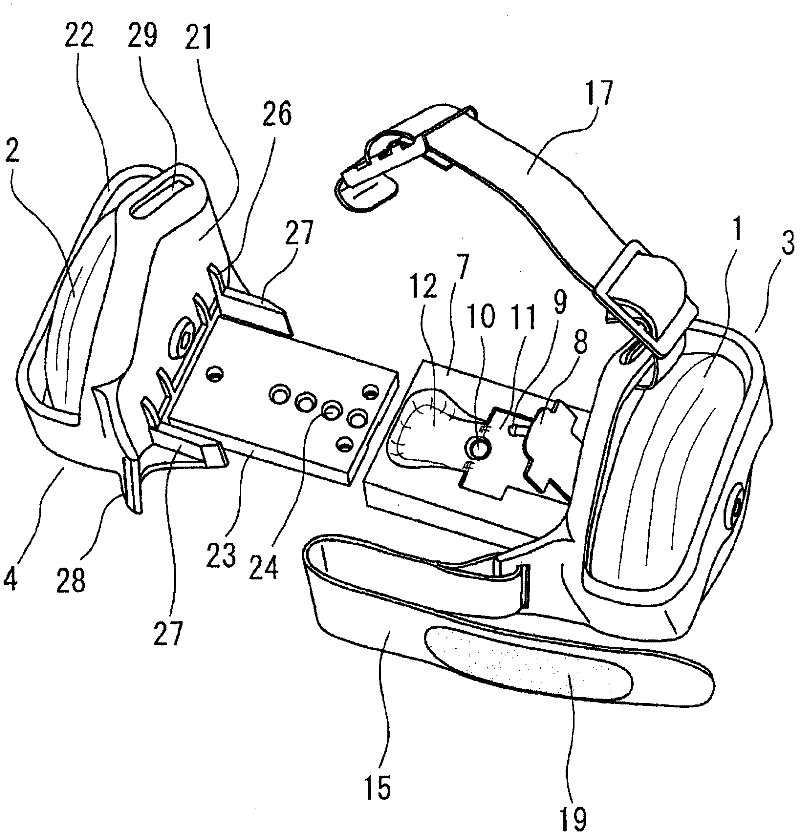

Heel roller for wearing footwear

InactiveCN102341151AAdjust intervalStrong enoughSkate-boardsRoller skatesEngineeringUltimate tensile strength

Disclosed is a heel roller for wearing footwear capable of allowing each wearer to adjust the width of the footwear to fit the size of a foot of the wearer with a simple operation, wherein the tread has sufficient strength to withstand irregular and uneven tread-pressure and does not rattle during use; wherein the heel roller comprises one pair of wheel holders (3 and 4) for holding wheels to be freely rotatable. One of the wheel holders (3) comprises a sidewall (5) for journaling a wheel (1), a wheel guard (6), and a box-shaped body (7) extending horizontally from the sidewall (5); wherein a stopper (8) is provided with a fixation pin (9) atop the box-shaped body (7). The other of the wheel holders (4) comprises a sidewall for journaling a wheel (2), a wheel guard, and an insert plate (23) which extends horizontally from the sidewall and enters into the box-shaped body; wherein upon the insert plate (23) are juxtaposed a plurality of adjustment holes (24) in the insertion direction for selectively inserting the fixation pin (9) of the stopper (8).

Owner:KOMARIYO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com