Patents

Literature

54results about How to "Improve stack quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

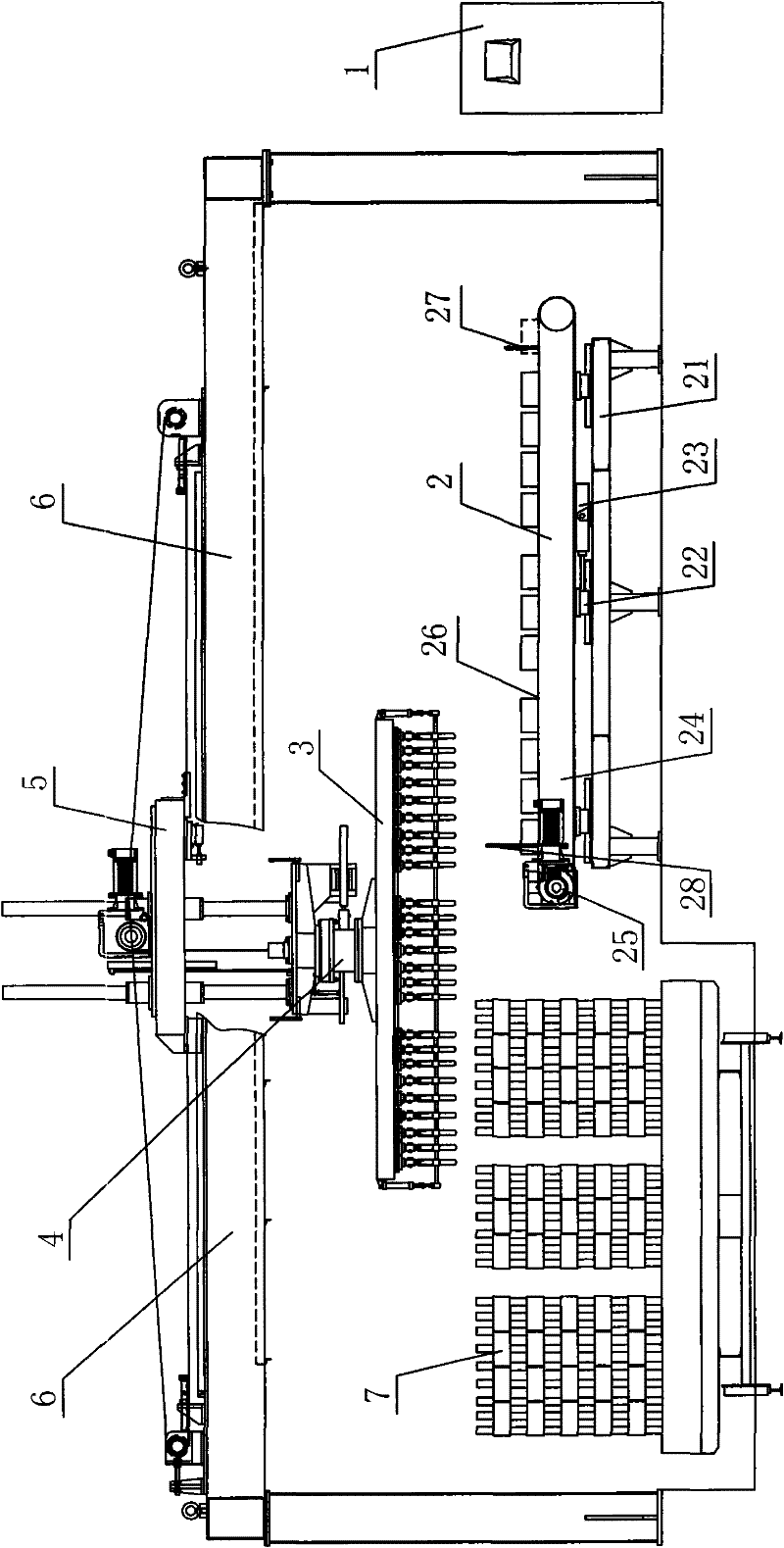

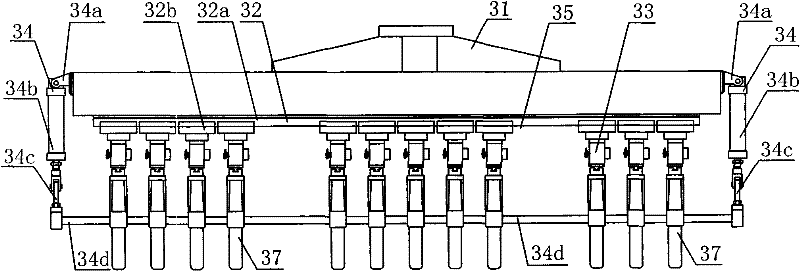

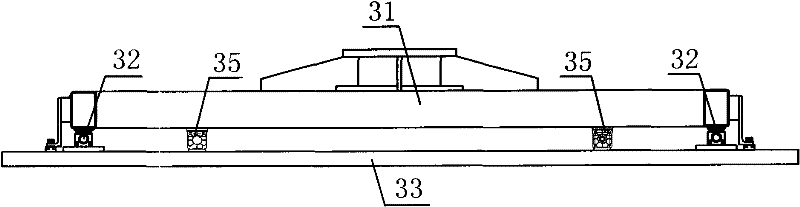

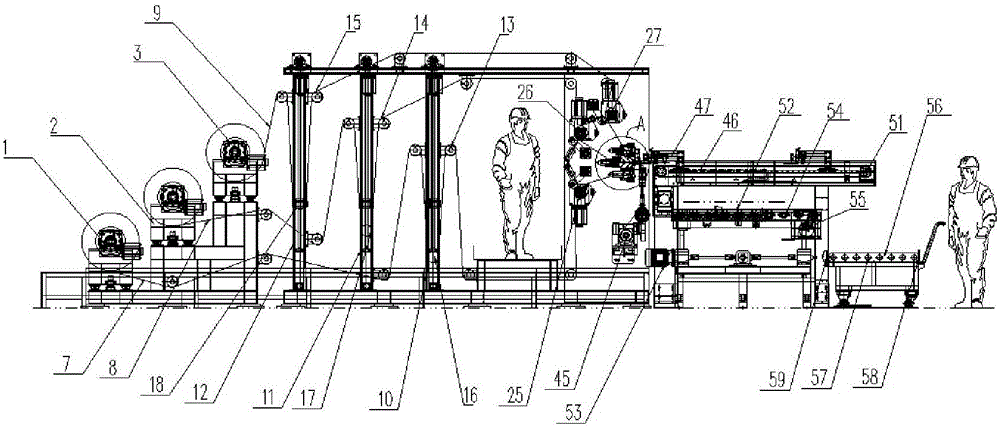

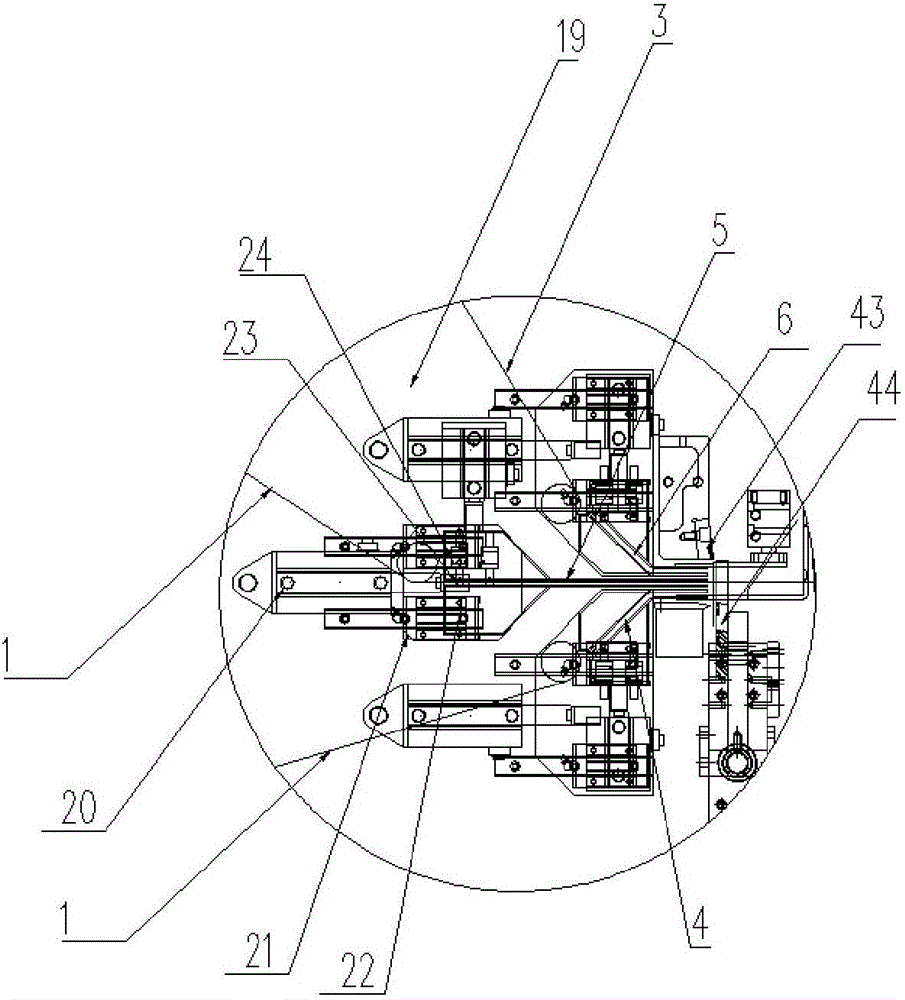

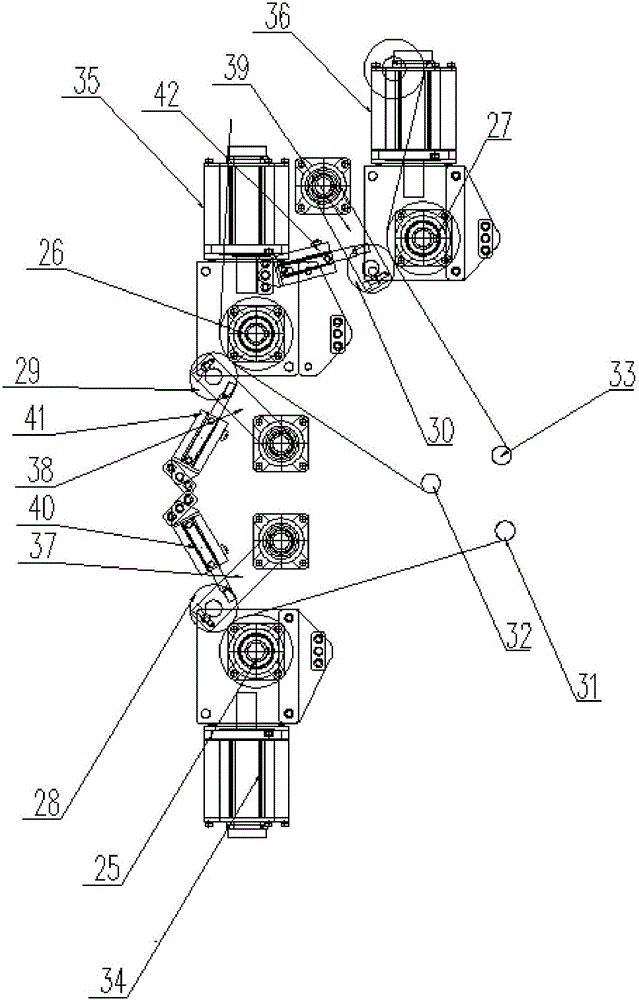

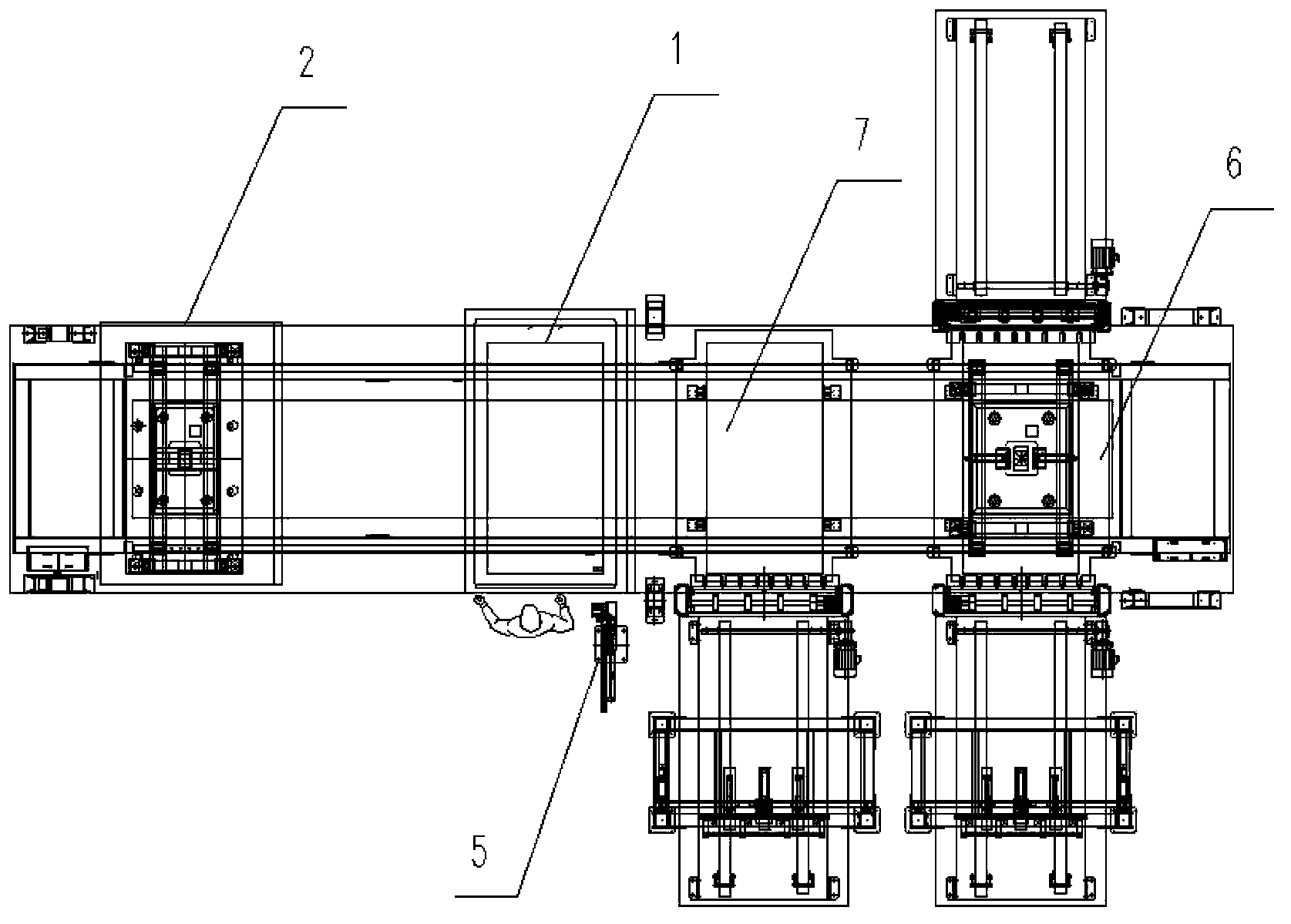

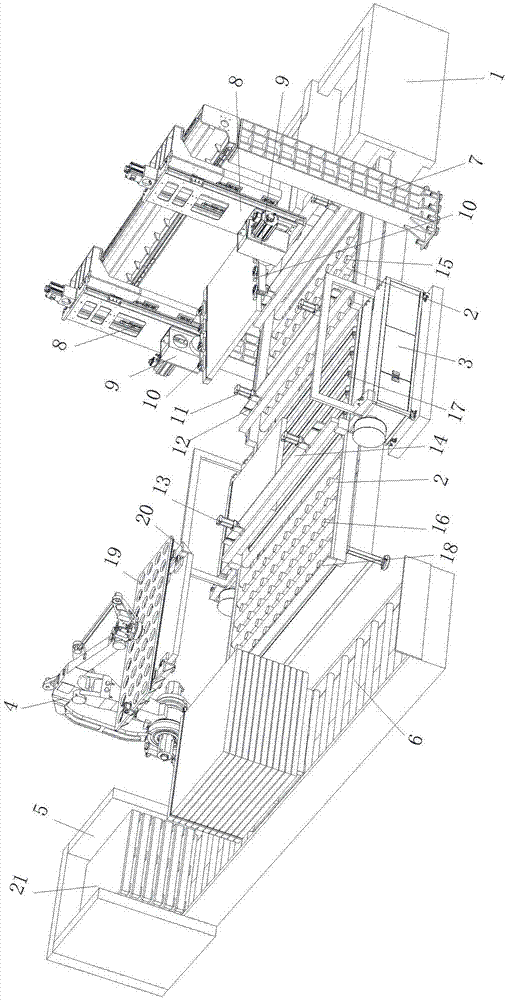

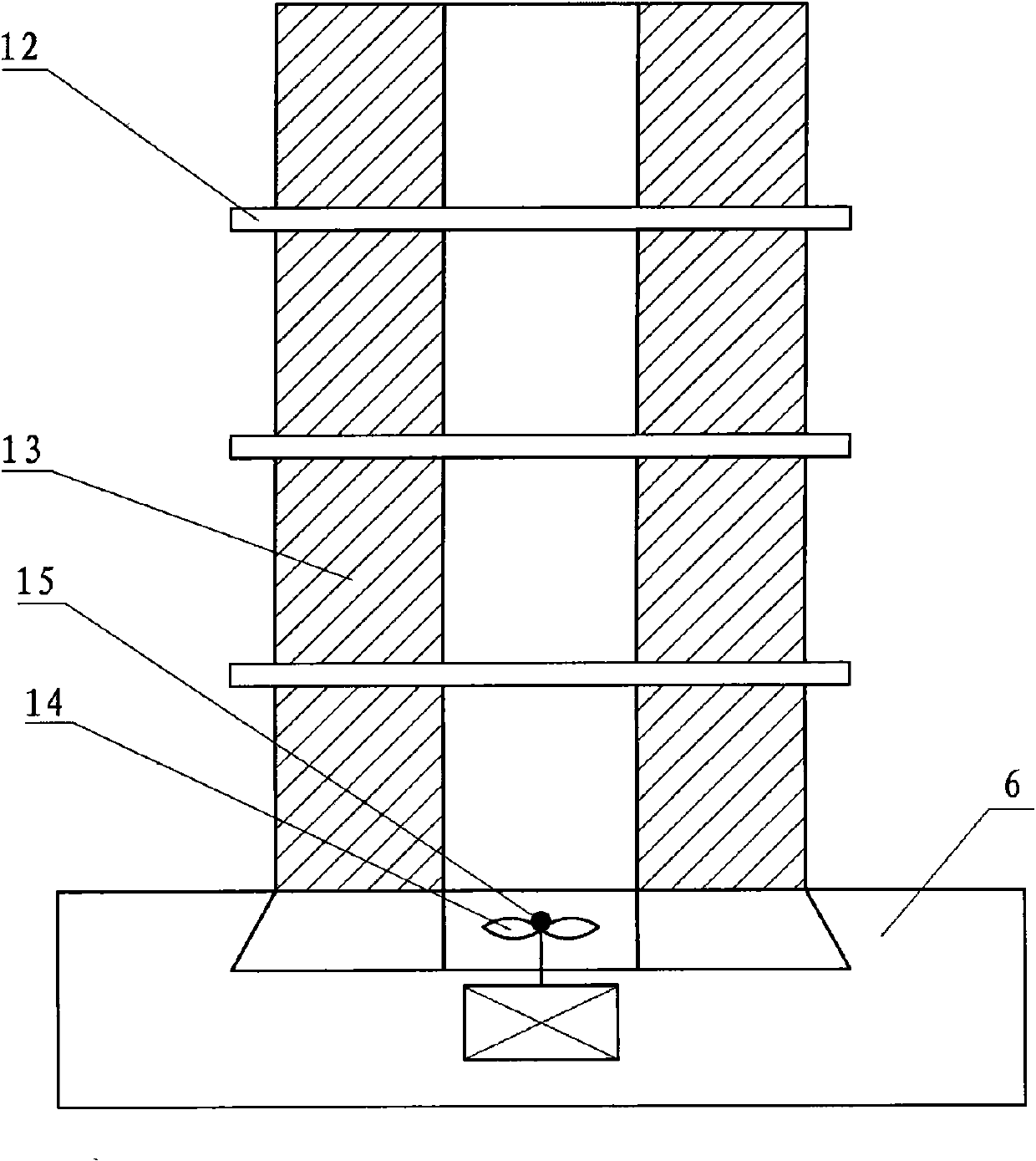

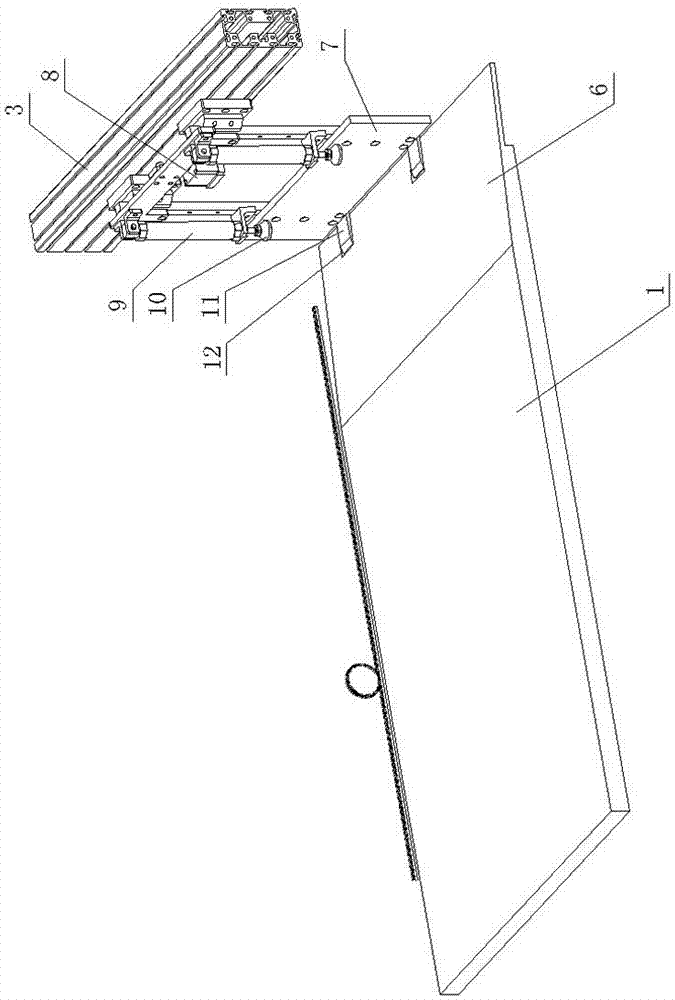

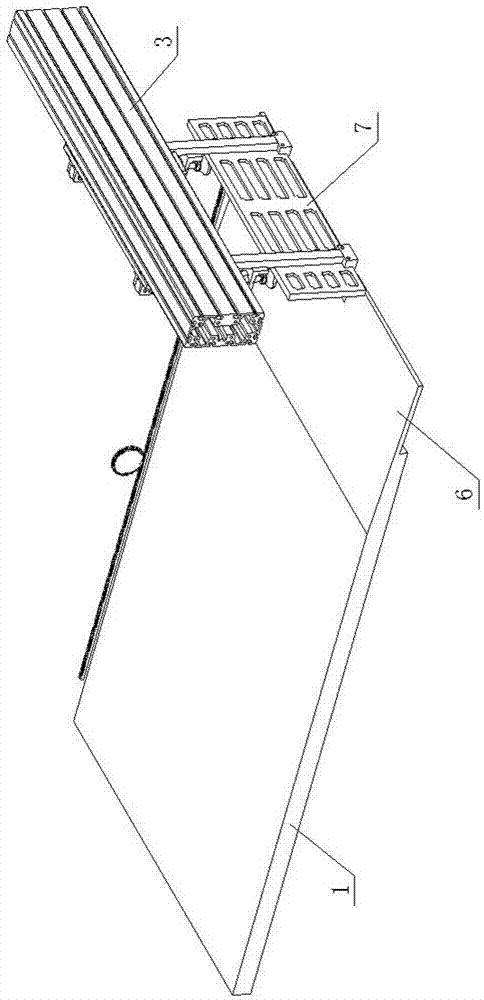

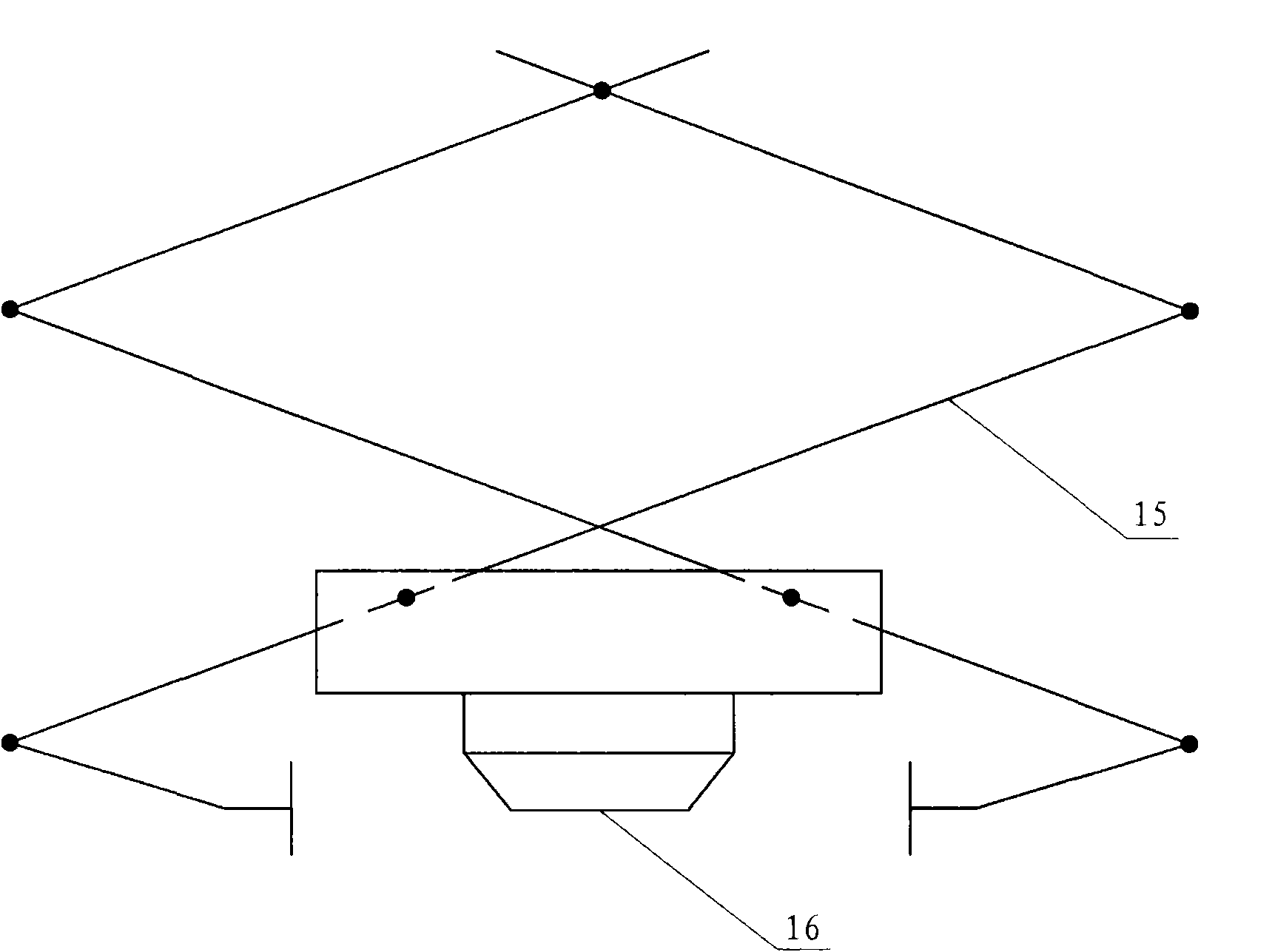

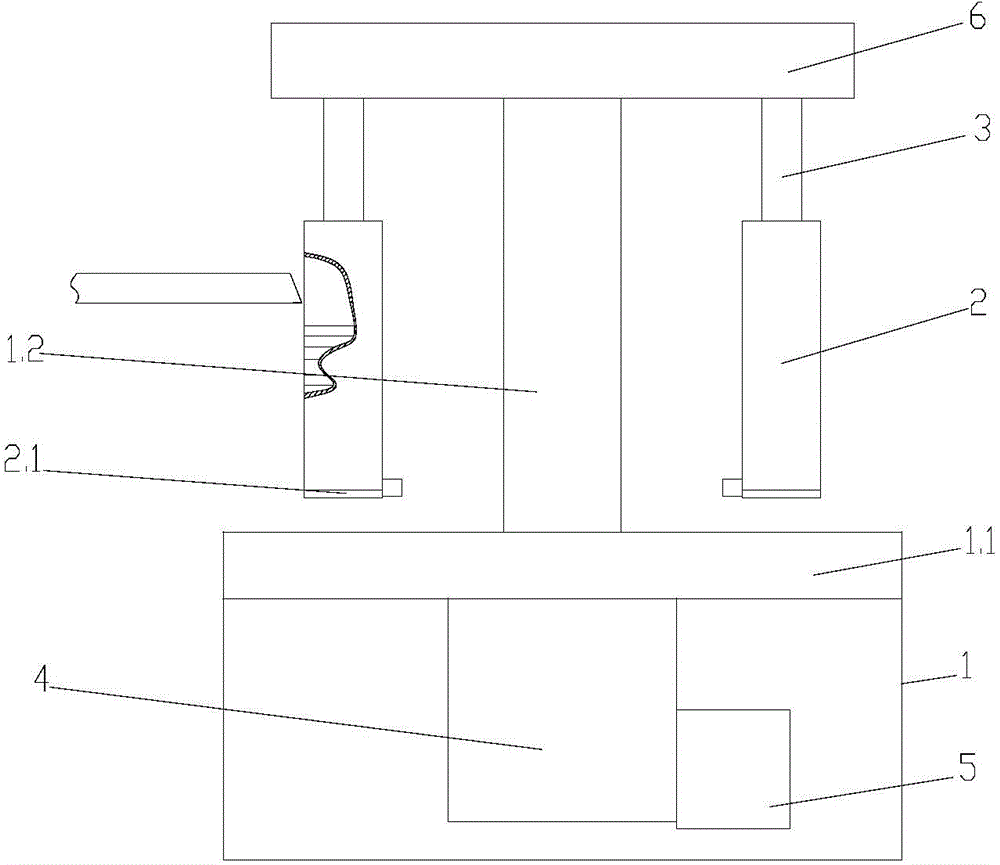

Automatic adobe stacking device

ActiveCN102225719AIncrease productivityImprove stack qualityDischarging arrangementStacking articlesAutomatic controlMechanical engineering

The invention provides an automatic adobe stacking device. The device comprises an automatic control device, an adobe group conveying mechanism, a horizontal travelling mechanism, a vertical lifting mechanism arranged on the horizontal travelling mechanism, a rotation mechanism fixed on the lower end of the vertical lifting mechanism and an adobe grabbing mechanism fixed on the lower end of the rotation mechanism, wherein the adobe group conveying mechanism is arranged below the adobe grabbing mechanism; and the automatic control device is respectively connected with the adobe group conveyingmechanism, the horizontal travelling mechanism, the vertical lifting mechanism, the rotation mechanism and the adobe grabbing mechanism so as to control the operation of the mechanisms. The adobe automatic stacking device has the advantages of accurate positioning, stable direction steering, neatly stacked adobes, firmly overlapped upper and lower adobes, simple structure, high automatic degree and easiness for operation, so that the labor intensity of workers is reduced, the production efficiency of stacking is greatly improved, and the stacking quality of adobe stacks is improved.

Owner:信阳雄狮装备科技股份有限公司

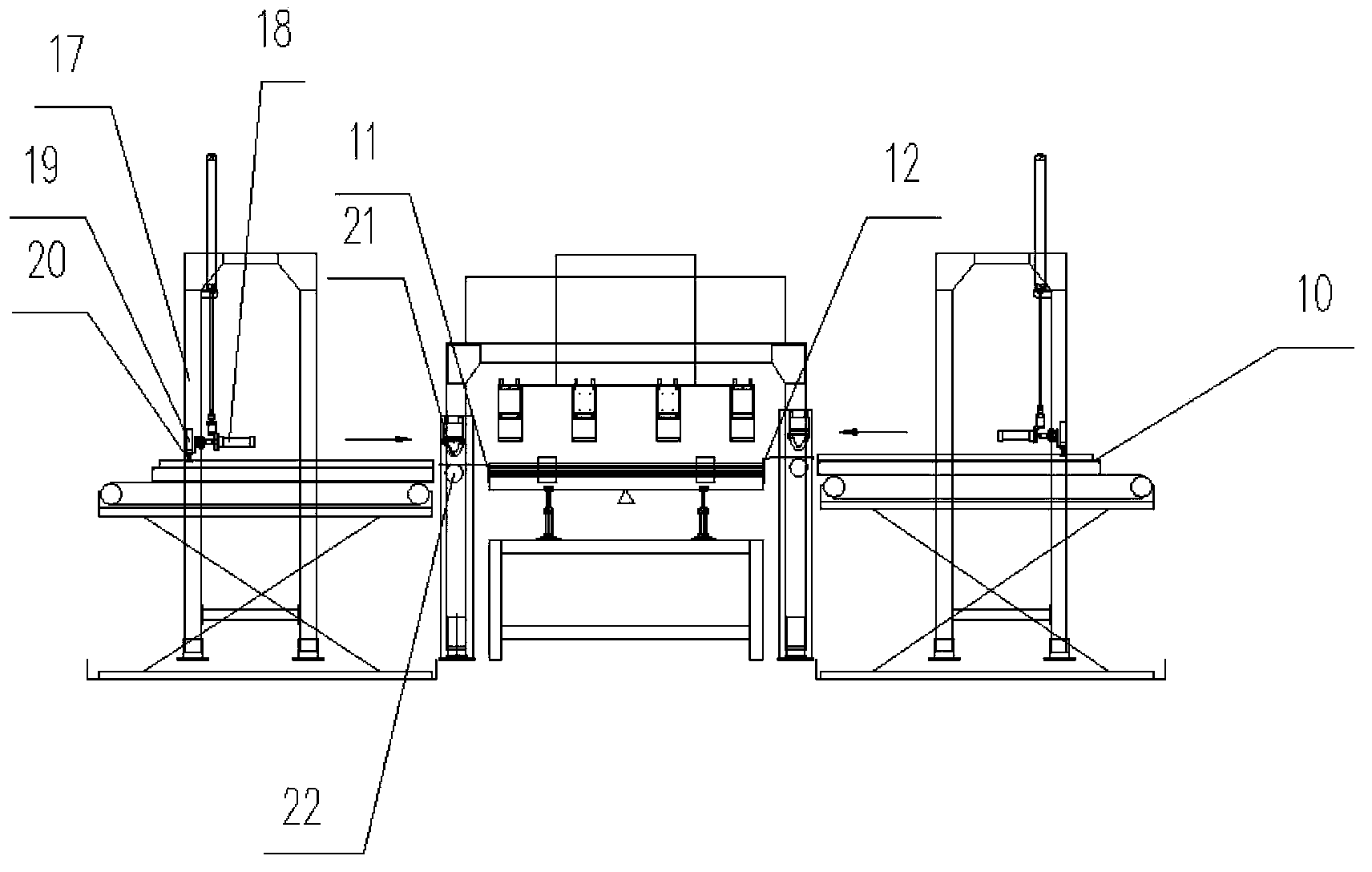

Automatic paper lamination stacking machine

The invention discloses an automatic paper lamination stacking machine which comprises a rack, wherein a paper lifting plate and a paper conveying belt are arranged in the rack; the paper conveying belt is arranged in front of the paper lifting plate; the upper plane of the paper conveying belt is lower than the upper end surface of the paper lifting plate; a paper support plate is arranged in front of the paper conveying belt; a movable paper pushing arm is arranged at the corresponding position of the paper support plate; a counting sensor is arranged in the rack at the end of the paper support plate close to the paper conveying belt and electrically connected with a control device of the machine; a lifting device is arranged on the rack and is in transmission connection with a turnover frame; a paper holding arm and a paper blocking arm are arranged on the turnover frame; a paper moving plate capable of sliding along the horizontal direction and a movable stacking paper support plate capable of going up and down in the vertical direction are mounted on the rack; the paper moving plate is located at the top of the lifting device; the movable stacking paper support plate is arranged in front of the paper moving plate; a stacking transition platform is arranged between the movable stacking paper support plate and the lifting device; a paper aligning plate is also arranged on the rack; and the paper aligning plate is located above the movable stacking paper support plate. The automatic paper lamination stacking machine disclosed by the invention has the advantages of high production efficiency and good stacking quality.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD

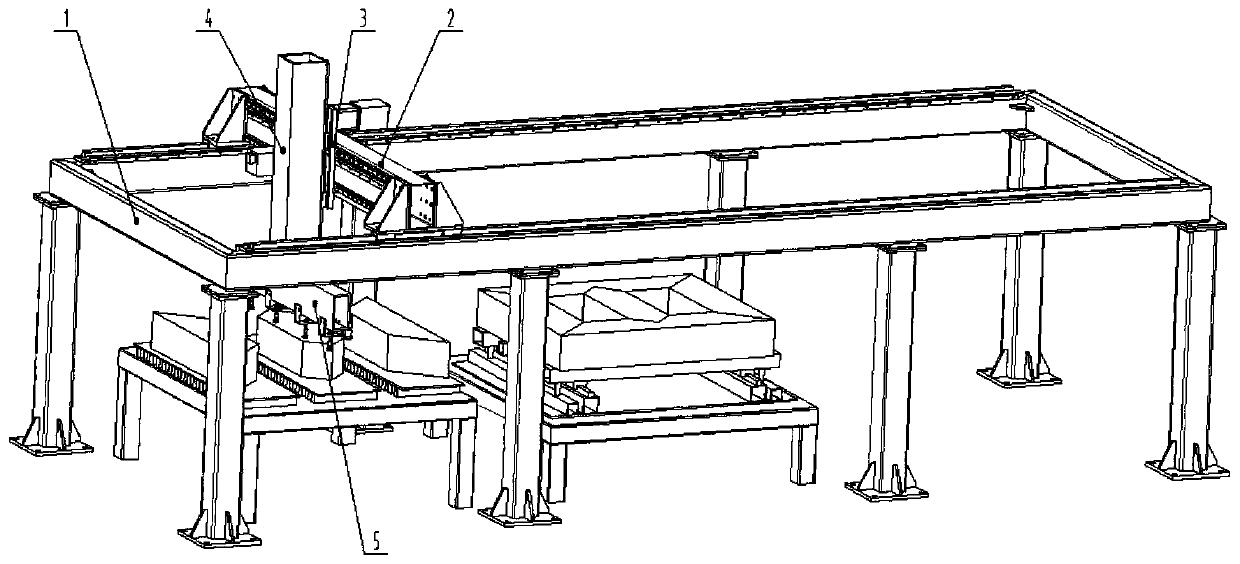

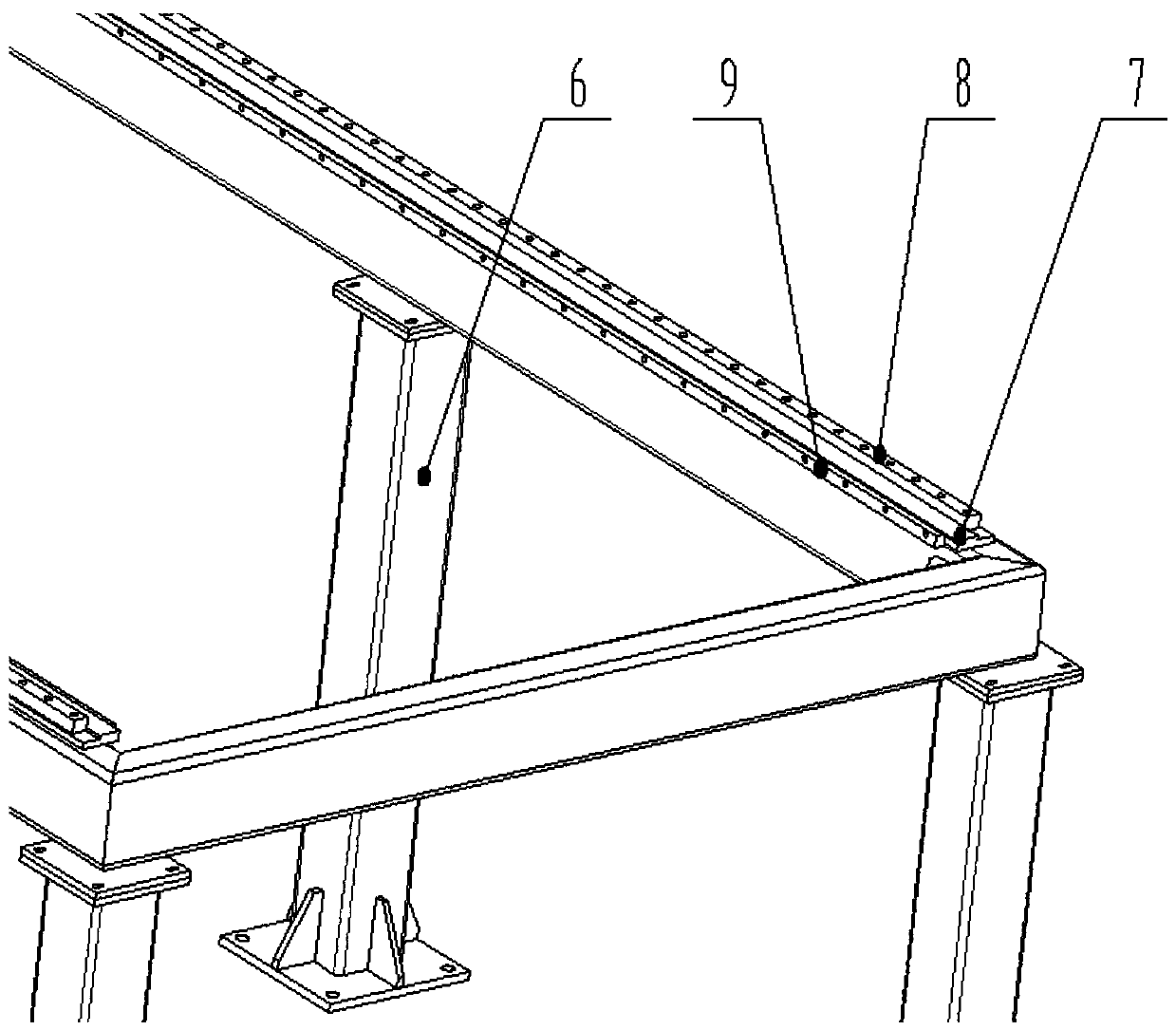

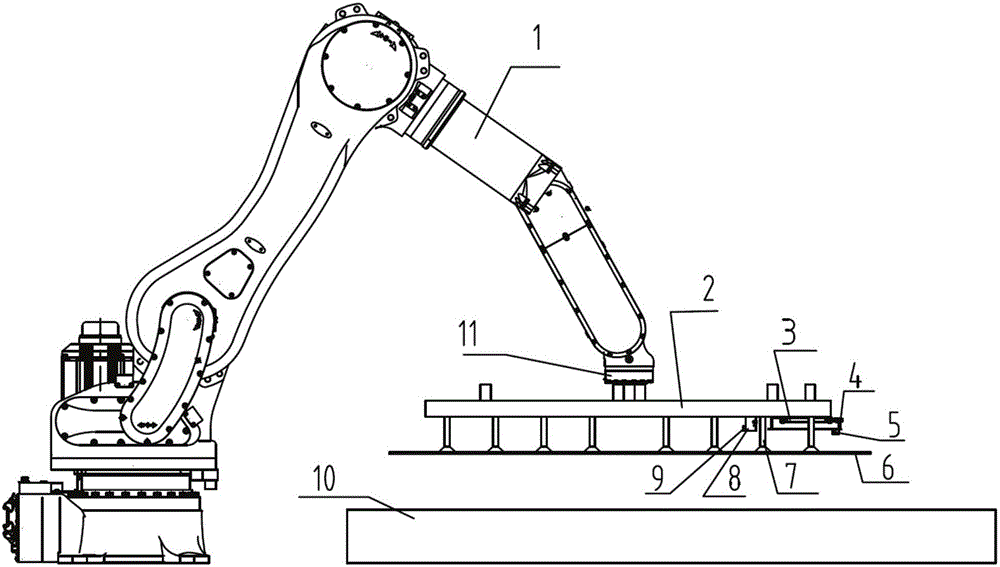

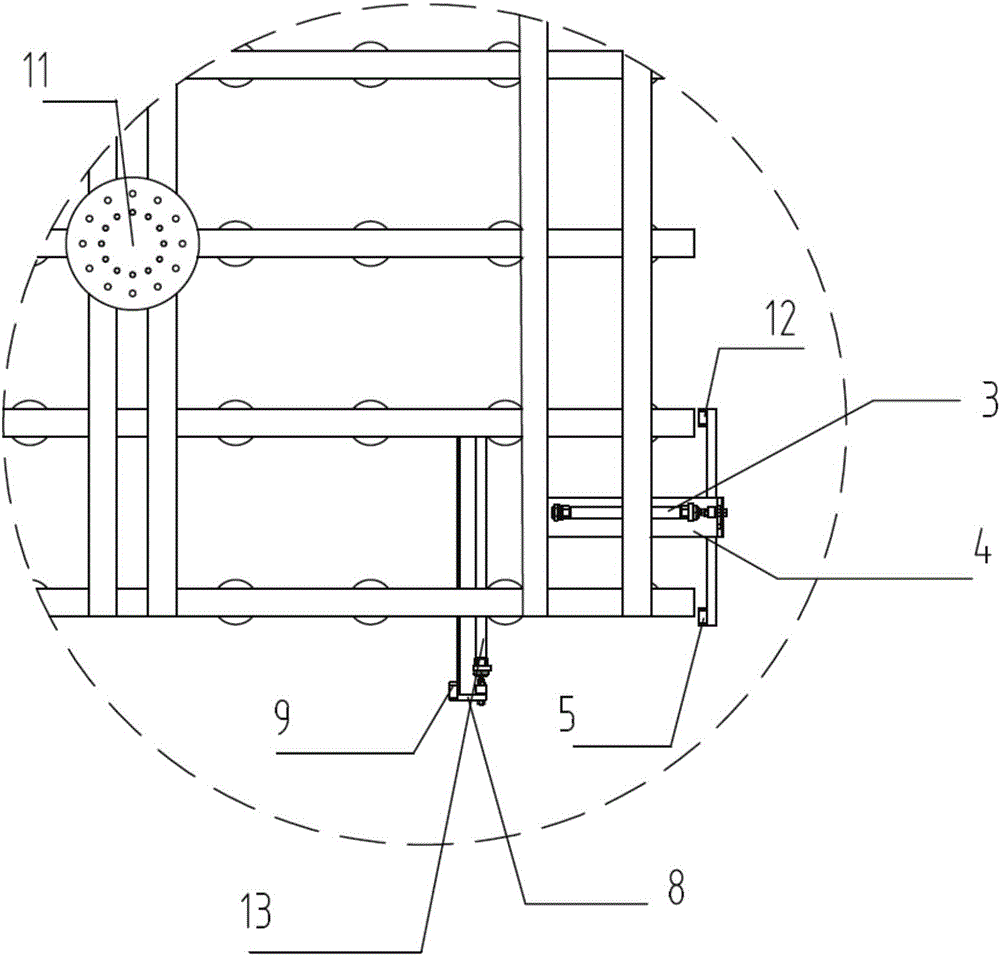

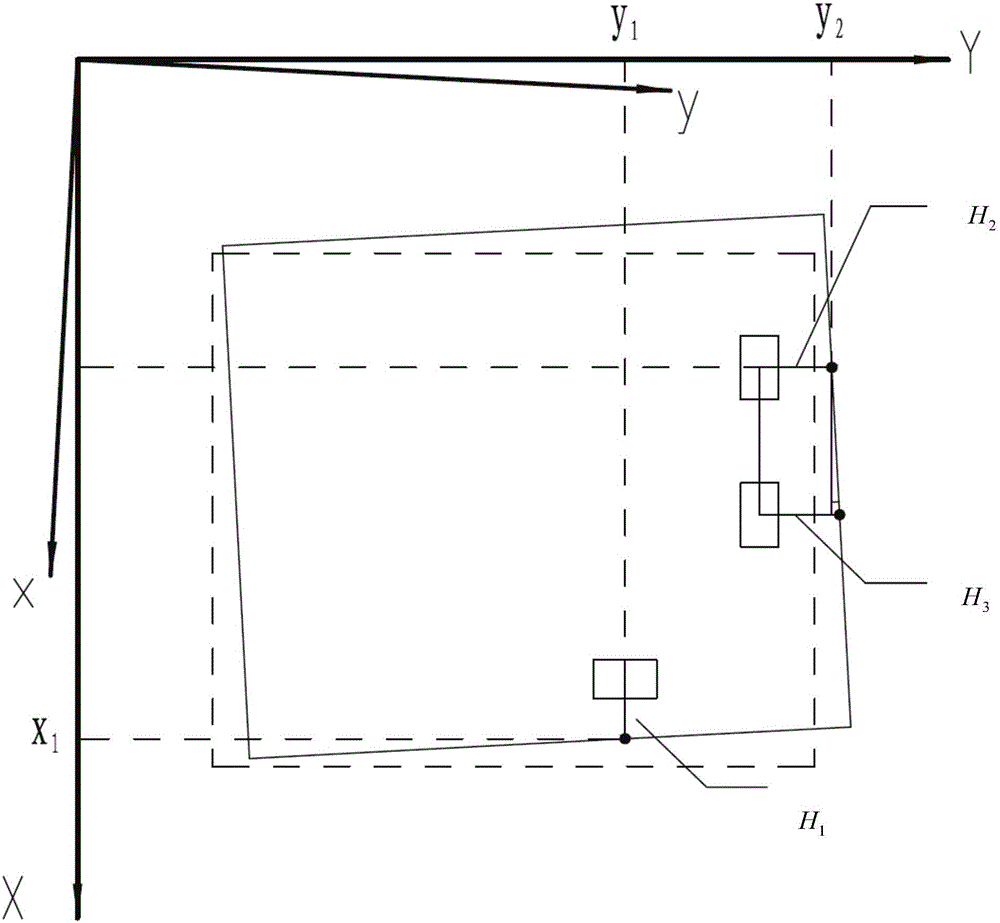

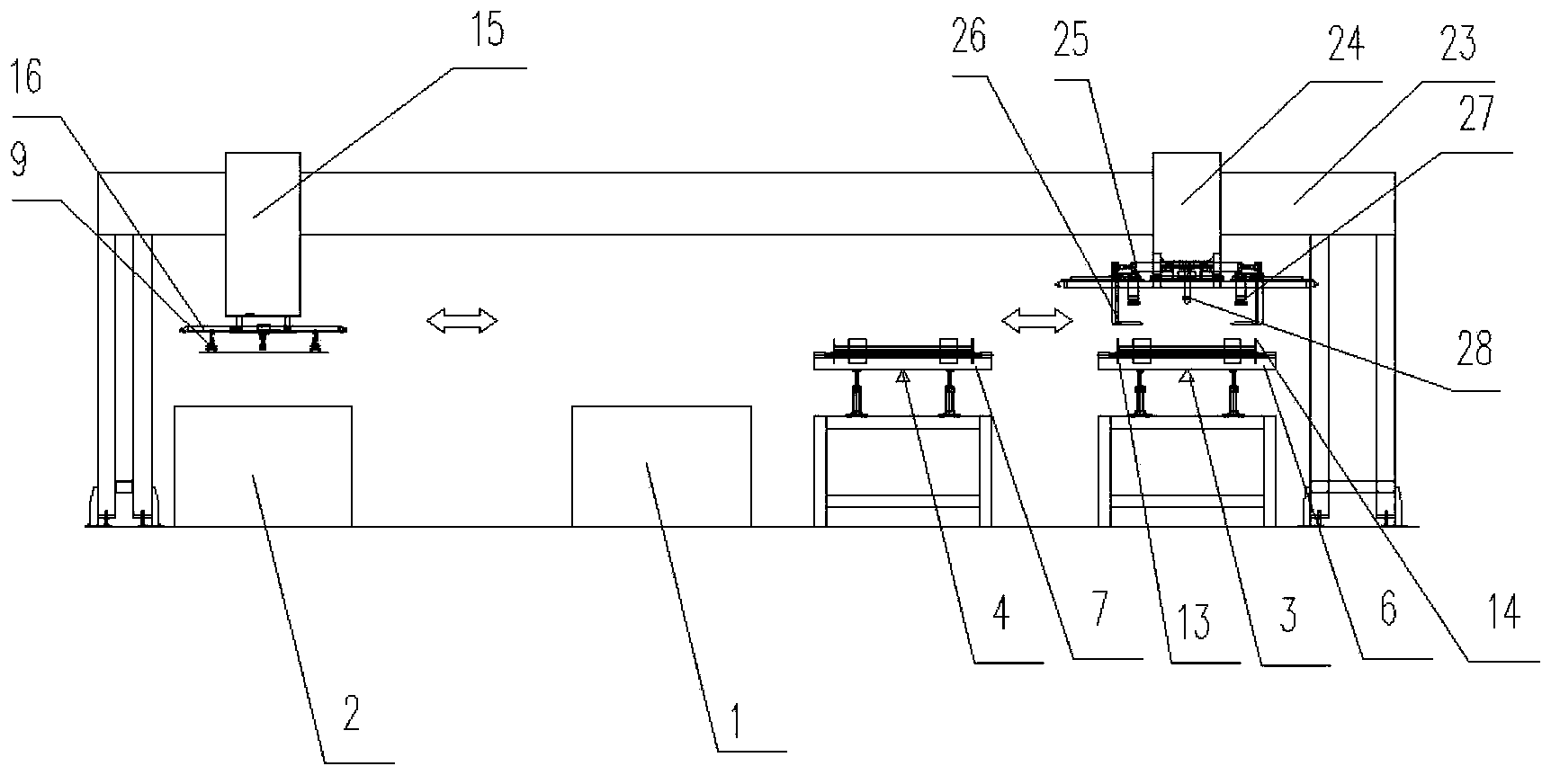

Automatic lamination robot for transformer iron core

PendingCN110534334ASolve efficiency problemsAddress the degree of automationProgramme-controlled manipulatorGripping headsImaging processingFree rotation

The invention discloses an automatic lamination robot for a transformer iron core and can solve technical problems of low efficiency, light labor and high intensity of the transformer iron core lamination process in the prior art. The robot comprises a main frame supporting large cross beam assembly, wherein the large cross beam assembly can move front and back on a main frame, a transverse movingassembly is installed on the large cross beam assembly and can move left and right, a longitudinal moving assembly is installed on the transverse moving assembly and can move up and down, and a rotating assembly is installed at a tail end of the longitudinal moving assembly and can rotate freely. An industrial camera installed at the tail end of the rotating assembly can shoot an overall pictureof a feeding area, the position of a silicon steel sheet to be sucked by a mechanical arm is determined through image processing and identification, the position of the mechanical arm is adjusted to just face the to-be-sucked silicon steel sheet, and thereby the truss mechanical arm is controlled for completing single-sheet suction of the silicon steel sheet. The robot is advantaged in that the required silicon steel sheet can be automatically identified in an image identification mode, the position of the mechanical arm is automatically corrected, the silicon steel sheet is grabbed and placedat the designated position of a lamination table, the lamination quality and efficiency are improved, and labor intensity of workers is reduced.

Owner:HEFEI YUANZHEN ELECTRIC POWER TECH +1

Glass stacking device and control method thereof

InactiveCN106395383AImprove stack qualityIncrease productivityCharge manipulationConveyor partsEngineeringGlass production

The invention relates to a glass stacking device and a control method thereof. The glass stacking device comprises a stacking robot and a tray, wherein the stacking robot comprises a mechanical arm, a chuck frame and a sensor; the mechanical arm is mounted at a stacking grabbing area through a base; the chuck frame is mounted at the tail end of the mechanical arm; the sensor is mounted on the chuck frame, comprising two horizontal photoelectric sensors and a vertical photoelectric sensor; the three sensors are pushed through cylinders to realize the measuring of glass to be grabbed; the position, relative to the chuck frame, of the glass, can be obtained through the measuring; the glass grabbing direction of the mechanical arm and an included angle in the marching direction of a glass production line can be corrected through the displacement data of the photoelectric sensors, and the glass can be accurately stacked through the correcting. With the adoption of the method for stacking the glass, the stacked glass can be arranged regularly to prepare for the next operation link.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

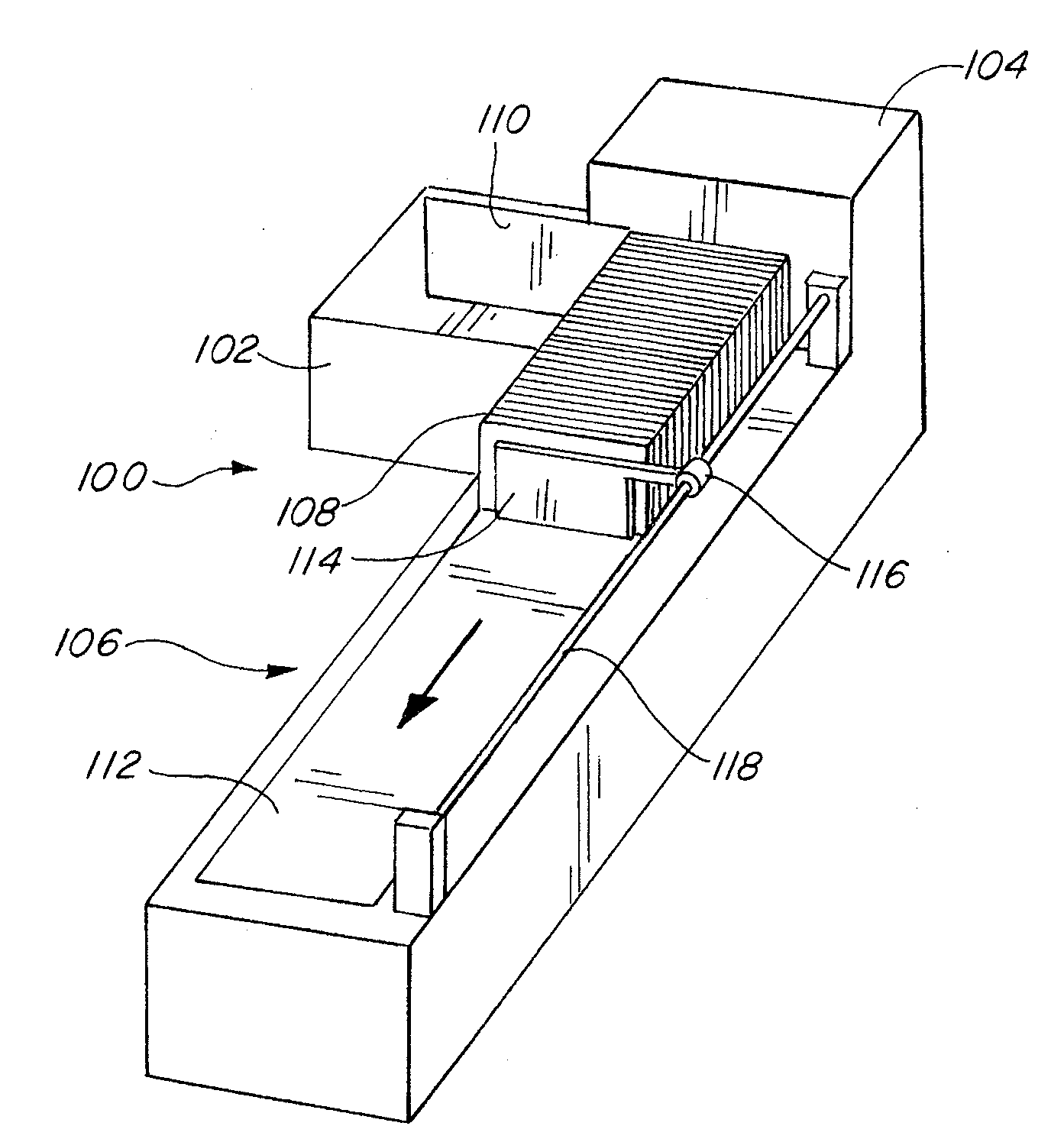

Apparatus for singling of sheet material

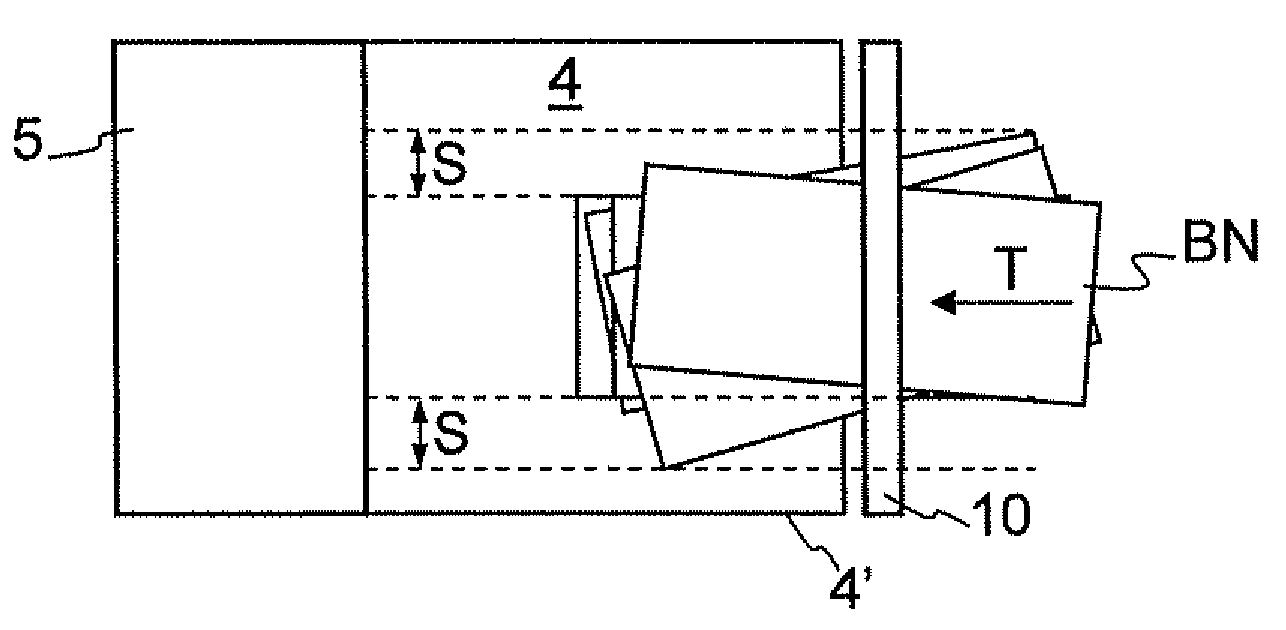

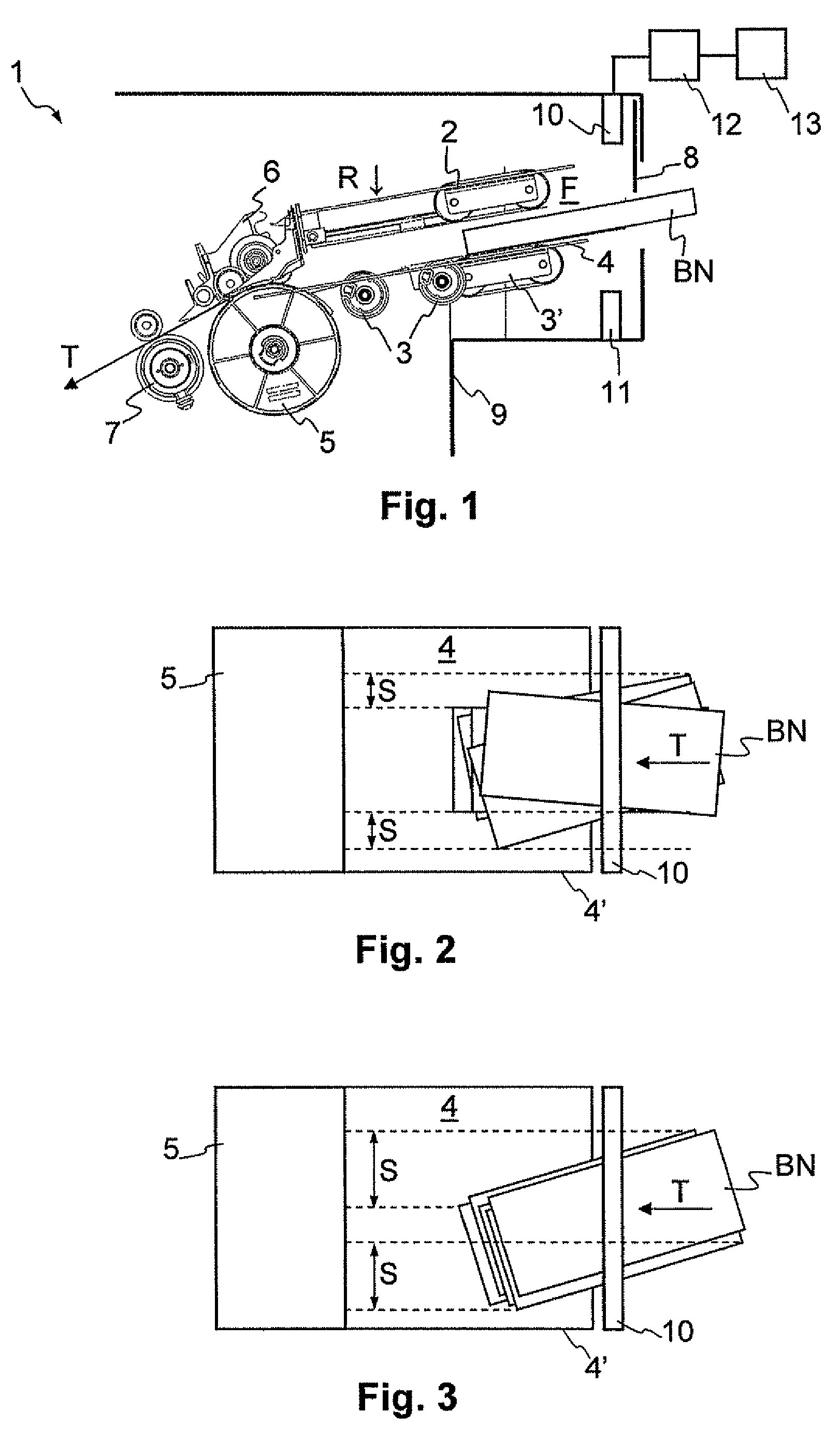

InactiveUS20090206541A1Improve stack qualityEasy alignmentFunction indicatorsCoin/currency accepting devicesTransport systemEngineering

Apparatus for singling sheet material, in particular bank notes, which is inputted into an input area of the apparatus as a stack and is transported up to a singler, which transfers individual pieces of sheet material of the stack of sheet material to a sheet transport system, which transports the singled sheet material in a transport direction, a sensor disposed in transport direction upstream of the singler, which substantially extends over the width of the input area, generating signals which specify whether and in which area of the width of the input area the sheet material is present, and a control device evaluating the signals of the sensor during a transport of the stack of sheet material to the singler and comparing occurring fluctuations and changes of the signals of the sensor regarding the presence or absence of sheet material with predetermined threshold values for fluctuations and changes of the signals of the sensor, in order to derive a statement from the occurring fluctuations and changes of the signals of the sensor, whether the pieces of sheet material forming the stack of sheet material are aligned to each other with respect to their edges, and whether the stack of sheet material has an alignment which substantially is in parallel to the transport direction of the transport system.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

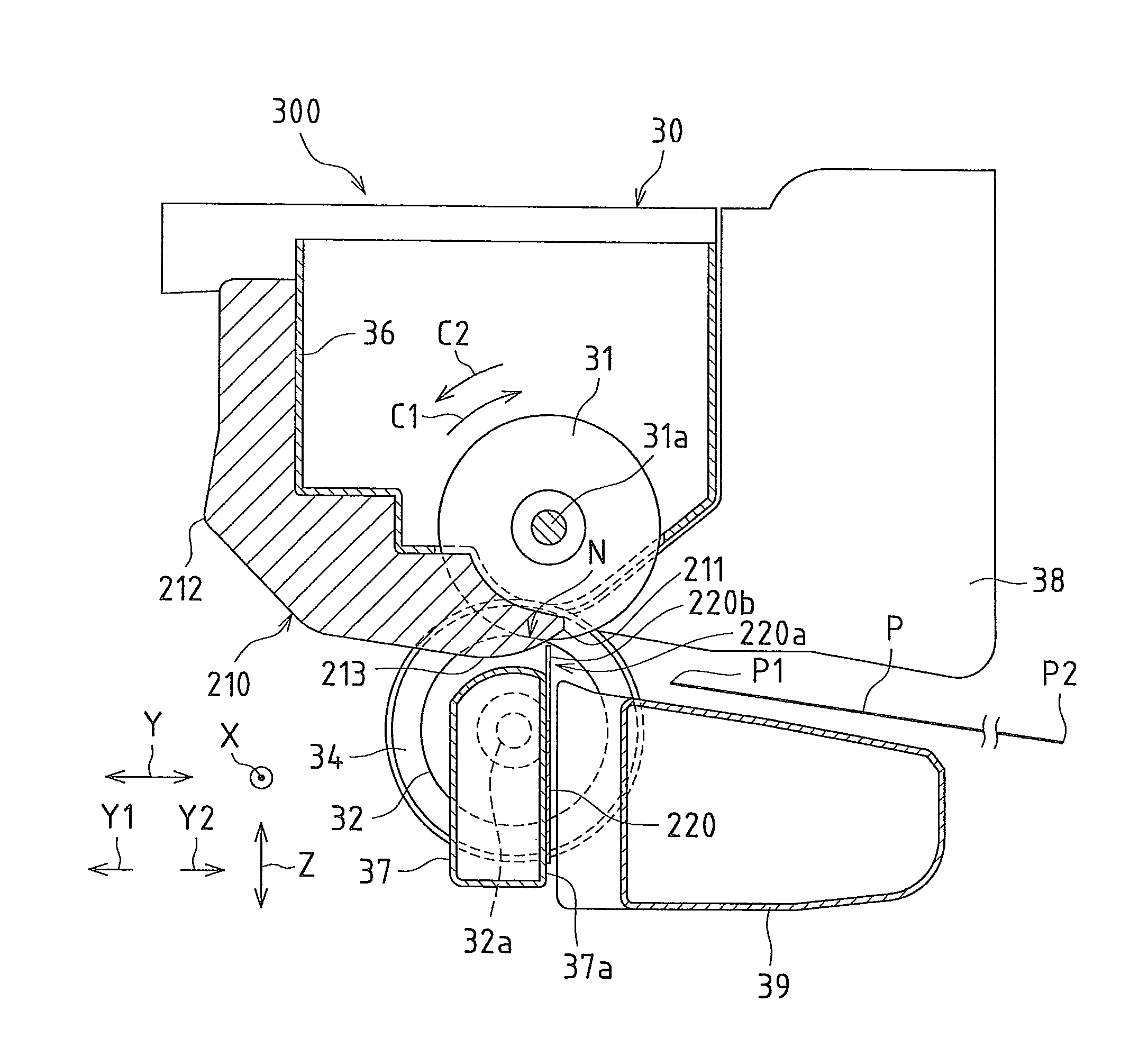

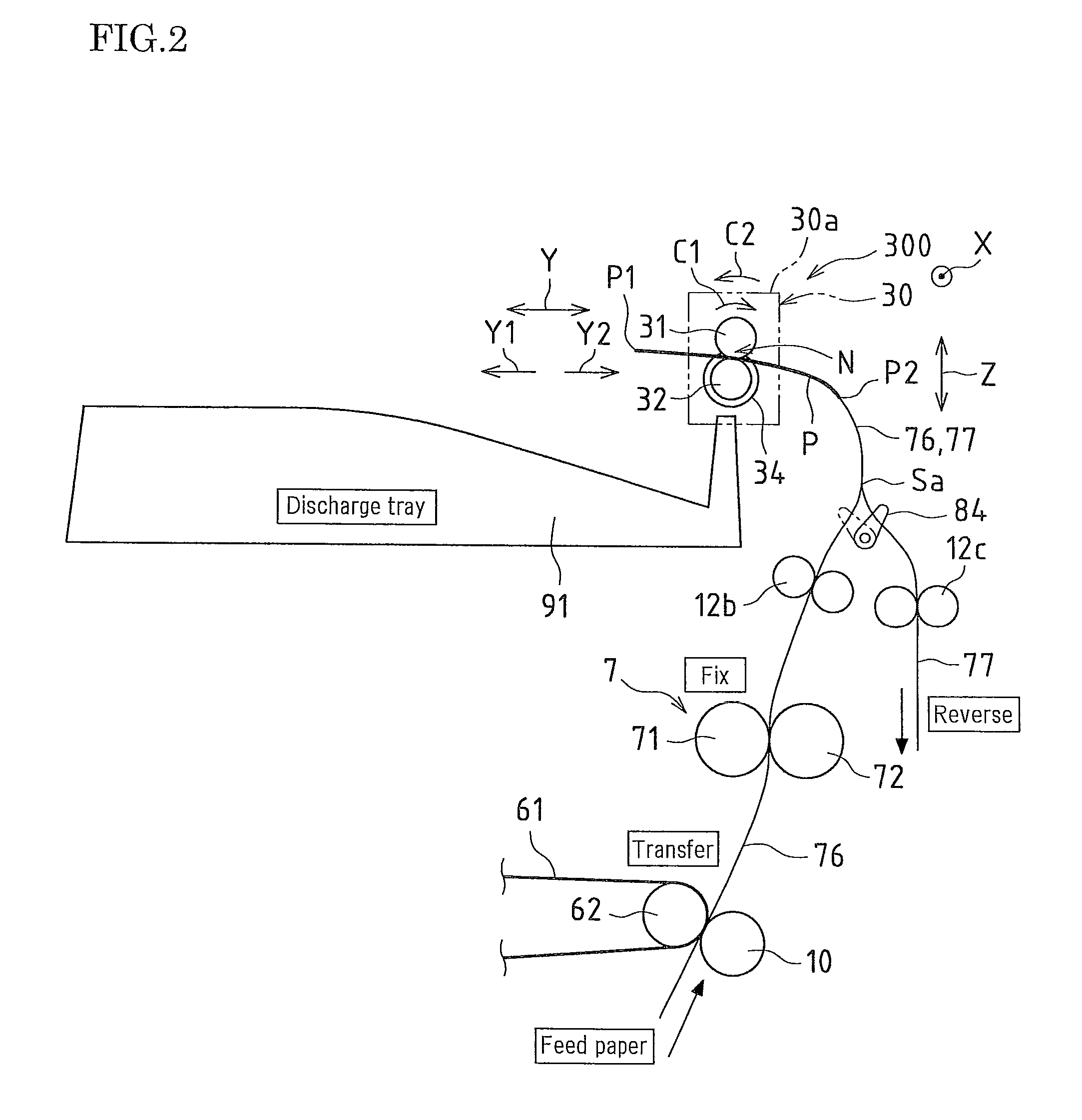

Sheet transport apparatus and image forming apparatus including the same

ActiveUS8523175B2InhibitionImprove stack qualityArticle feedersArticle deliveryEngineeringPerpendicular direction

A sheet transport apparatus includes a sheet transport portion that transports a sheet in a first transport direction and a second transport direction, a bending member that bends without breaking the sheet by corrugating the sheet in an orthogonal direction, and a restriction member that restricts, in a perpendicular direction, a corrugation in the sheet bent by the bending member. The restriction member is provided on an upstream side in the first transport direction of the bending member.

Owner:SHARP KK

Piece sorting machine

ActiveCN103659889AImprove smooth performanceIncrease profitMetal working apparatusCopper foilEngineering

The invention discloses a piece sorting machine. The piece sorting machine comprises a stacking platform, two feeding platforms, two cutting devices, at least two feeding shafts, a guide rail, a first material moving device and a second material moving device; the two feeding platforms are arranged on the bilateral sides of the stacking platform in turn respectively; the guide rail is straddled above the stacking platform and the feeding platforms; the first material moving device and the second material moving device can move along the guide rail. According to the piece sorting machine, pieces after cutting can be taken by the first material moving device and the second material moving device from one of the feeding platforms simultaneously and placed on the stacking platform, the pieces are stacked according to the type and number of the pieces required by every copper foil substrate in a staggered mode directly, and accordingly every group of pieces after being stacked can be conveyed for combination operation directly and accordingly the stacking efficiency is greatly improved, the manual work is saved, the stacking quality is improved, meanwhile the spaced required by the pieces to be stored and stacked can be saved, and the utilization rate of the factory space can be improved.

Owner:KUNSHAN JUHONG MACHINERY TECH

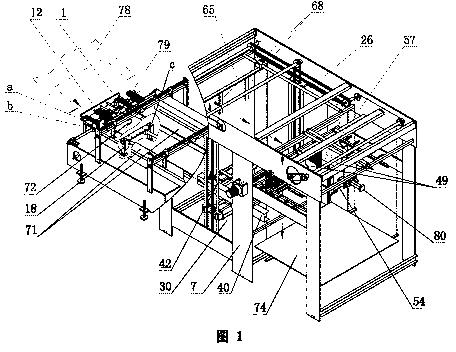

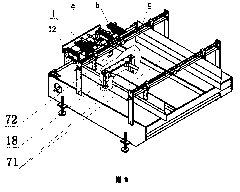

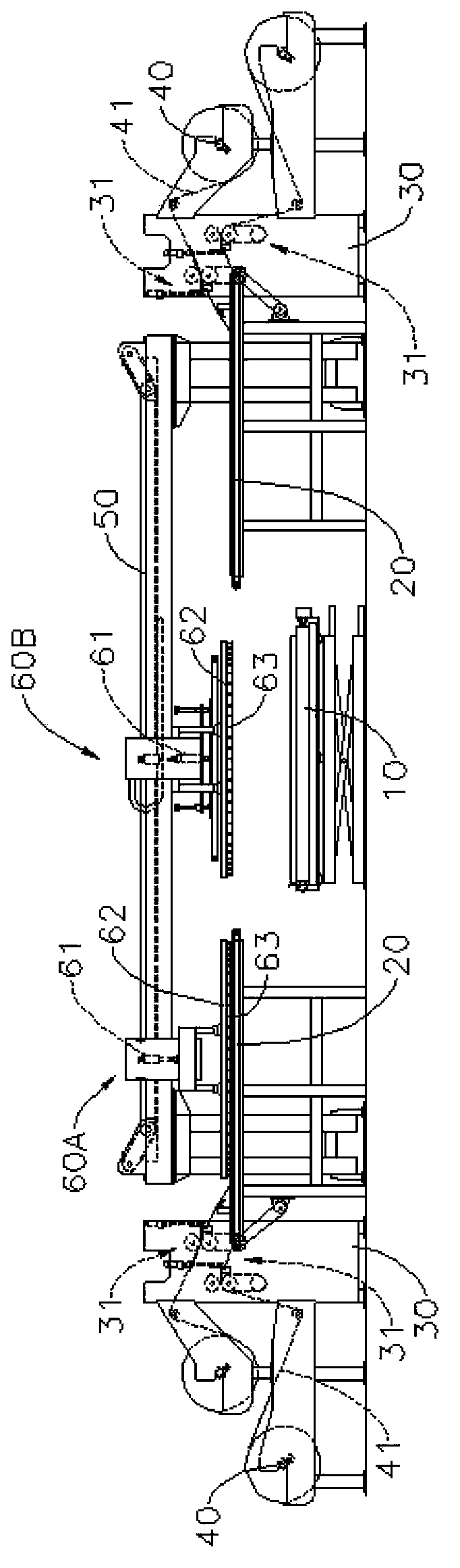

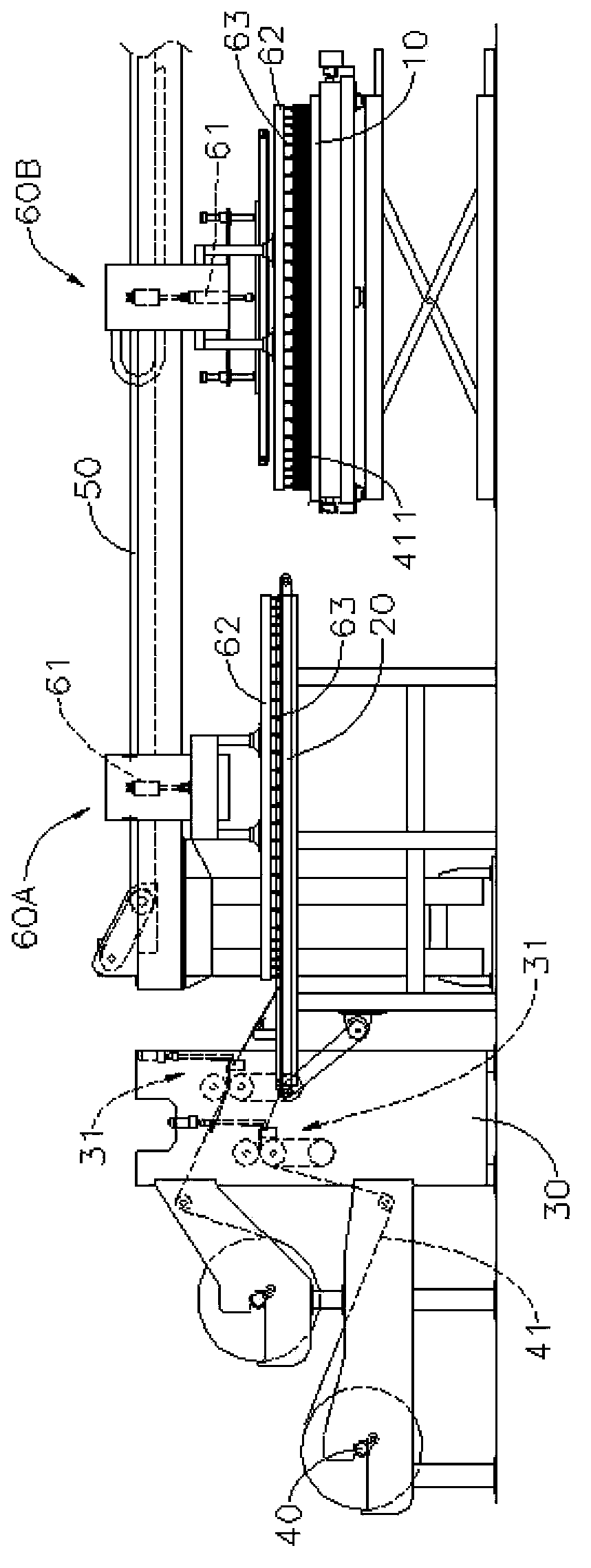

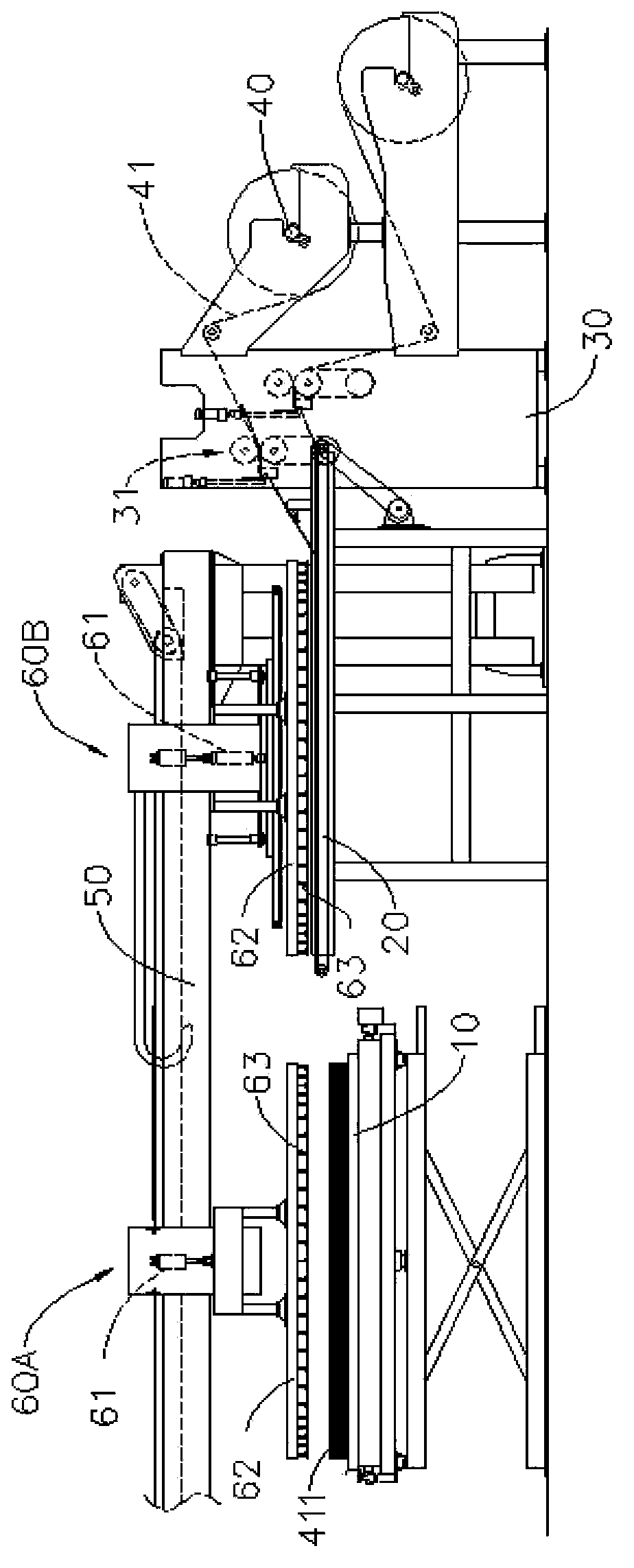

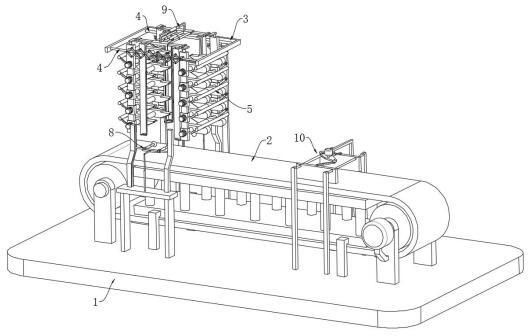

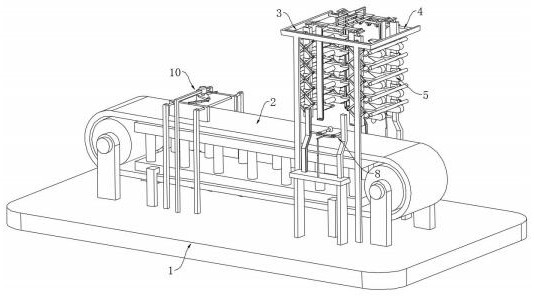

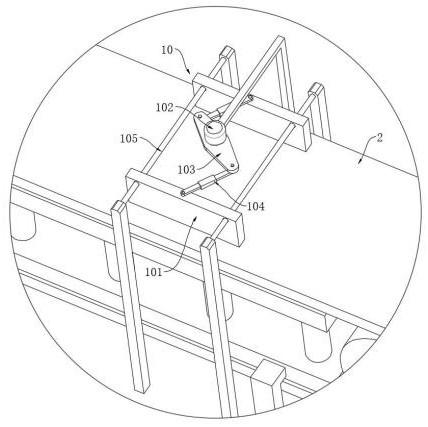

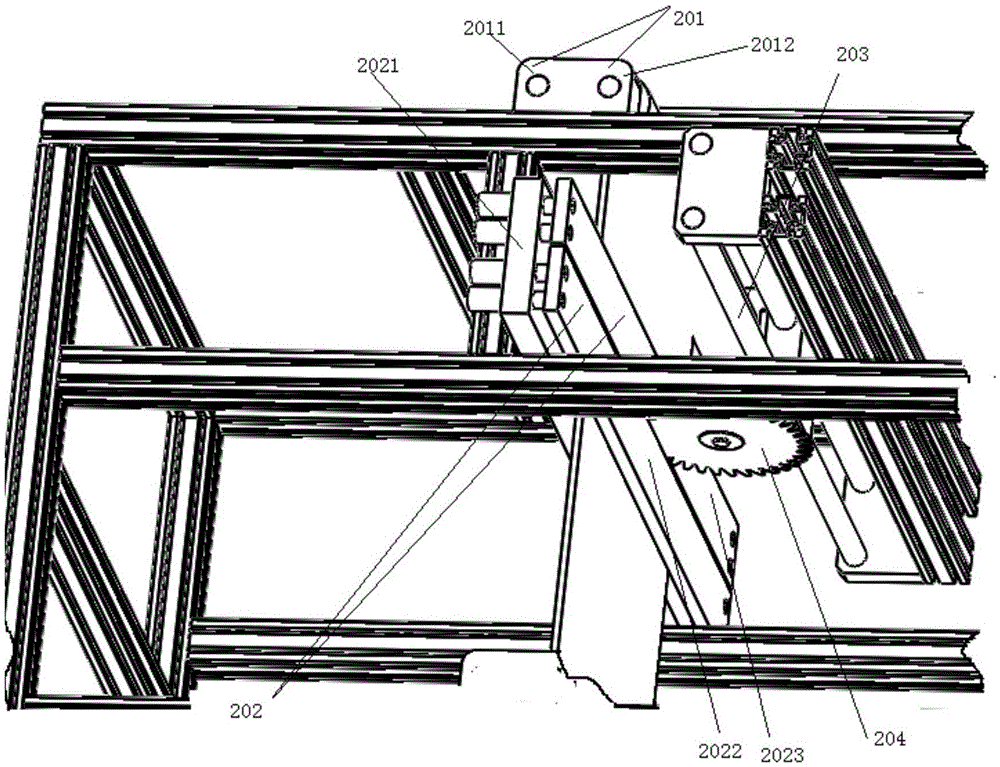

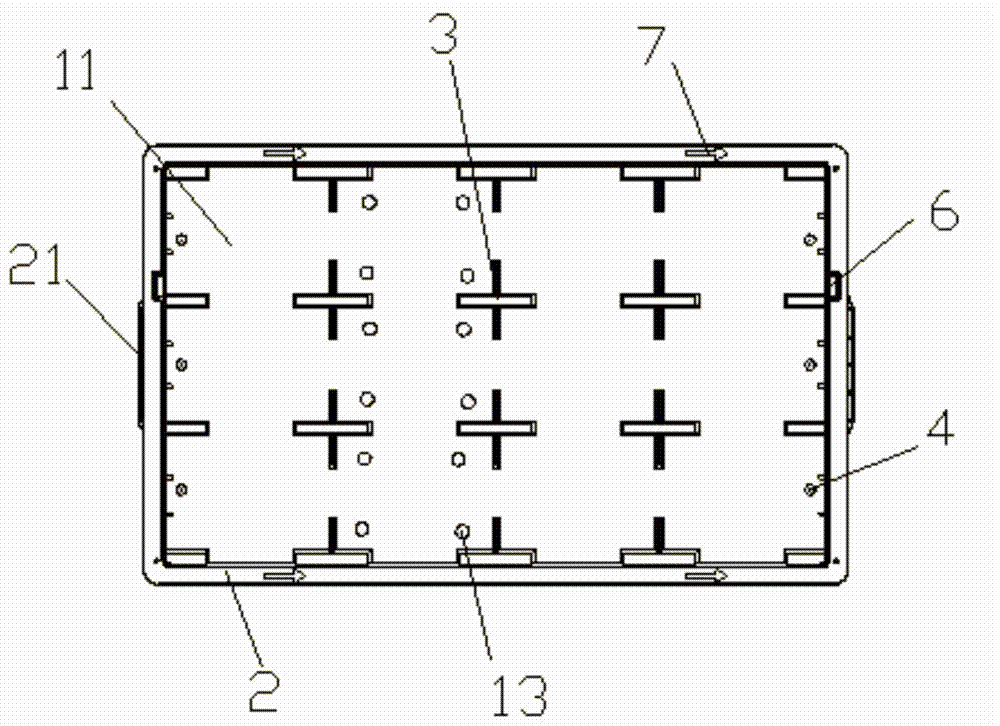

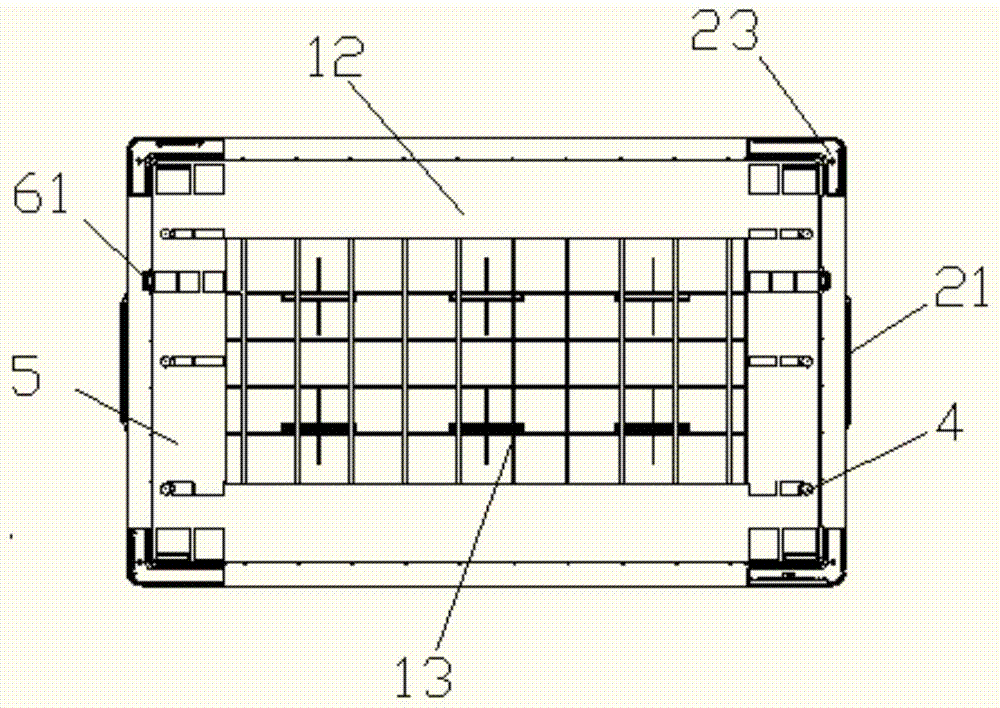

Three-axis type PP cropping and stacking machine

ActiveCN105775882AAvoid formingHighly consistent cutting sizePile receiversArticle deliveryStack machineEngineering

The invention discloses a three-axis type PP cropping and stacking machine. A first material strip sent by a first sending mechanism is guided into a first material strip conveying channel through a first material strip guiding and taking mechanism. A second material strip sent by a second sending mechanism is guided into a second material strip conveying channel through a second material strip guiding and taking mechanism. A third material strip sent by a third sending mechanism is guided into a third material strip conveying channel through a third material strip guiding and taking mechanism. The first material strip conveying channel, the second material strip conveying channel and the third material strip conveying channel are arranged in the longitudinal direction at intervals. The tail ends of the first material strip conveying channel, the second material strip conveying channel and the third material strip conveying channel are aligned, and material strip cropping mechanisms are right located at the tail ends of the first material strip conveying channel, the second material strip conveying channel and the third material strip conveying channel. Cropping cutters of the material strip cropping mechanisms ascend and descend in the longitudinal direction to achieve simultaneous cutting off of the first material strip, the second material strip and the third material strip. A lifting staggered stacking mechanism comprises a table top capable of ascending and descending in the longitudinal direction and a lifting drive device. The lifting drive device drives the table top to longitudinally ascend and descend. At least one material piece clamping, moving and loading mechanism can clamp and convey a first cropped material piece, a second cropped material piece and a third cropped material piece to the table top of the lifting staggered stacking mechanism for stacking. According to the three-axis type PP cropping and stacking machine, the three kinds of PP material strips can be fed at the same time and are combined to be synchronously cropped and stacked, the production efficiency is high, and the stacking quality is high.

Owner:KUNSHAN JUHONG MACHINERY TECH

Phenolic paper automatic proportioning and stacking system

ActiveCN104291145AFully automatedImprove stack qualityArticle feedersConveyor partsPulp and paper industryPaper sheet

The invention discloses a phenolic paper automatic proportioning and stacking system. A first separation pusher and a second separation pusher are located on two opposite sides of a first guide table, a third separation pusher is located on one side of a second guide table, paper limit devices can guide and correct the positions of paper on the tables, paper pushing mechanisms on the first separation pusher, the second separation pusher and the third separation pusher can push out single pieces of paper on respective paper delivery devices to the first guide table or the second guide table corresponding to the paper pushing mechanisms, phenolic paper pushed out by the first separation pusher and phenolic paper pushed out by the second separation pusher are different in height, a first counting device and a second counting device count paper on the first guide table and the second guide table respectively and transmit signals to controllers, a labeling machine can label paper on the labeling workbench, a first grabbing and delivering device can sequentially deliver the paper on the first guide table to the second guide table and the labeling workbench, a second grabbing and delivering device can enable a mirror plate to cover the surface of the labeled paper, and the controllers control the first grabbing and delivering device, the second grabbing and delivering device, the paper pushing mechanisms and the labeling machine to work. The phenolic paper automatic proportioning and stacking system saves labor and improves stacking quality.

Owner:KUNSHAN JUHONG MACHINERY TECH

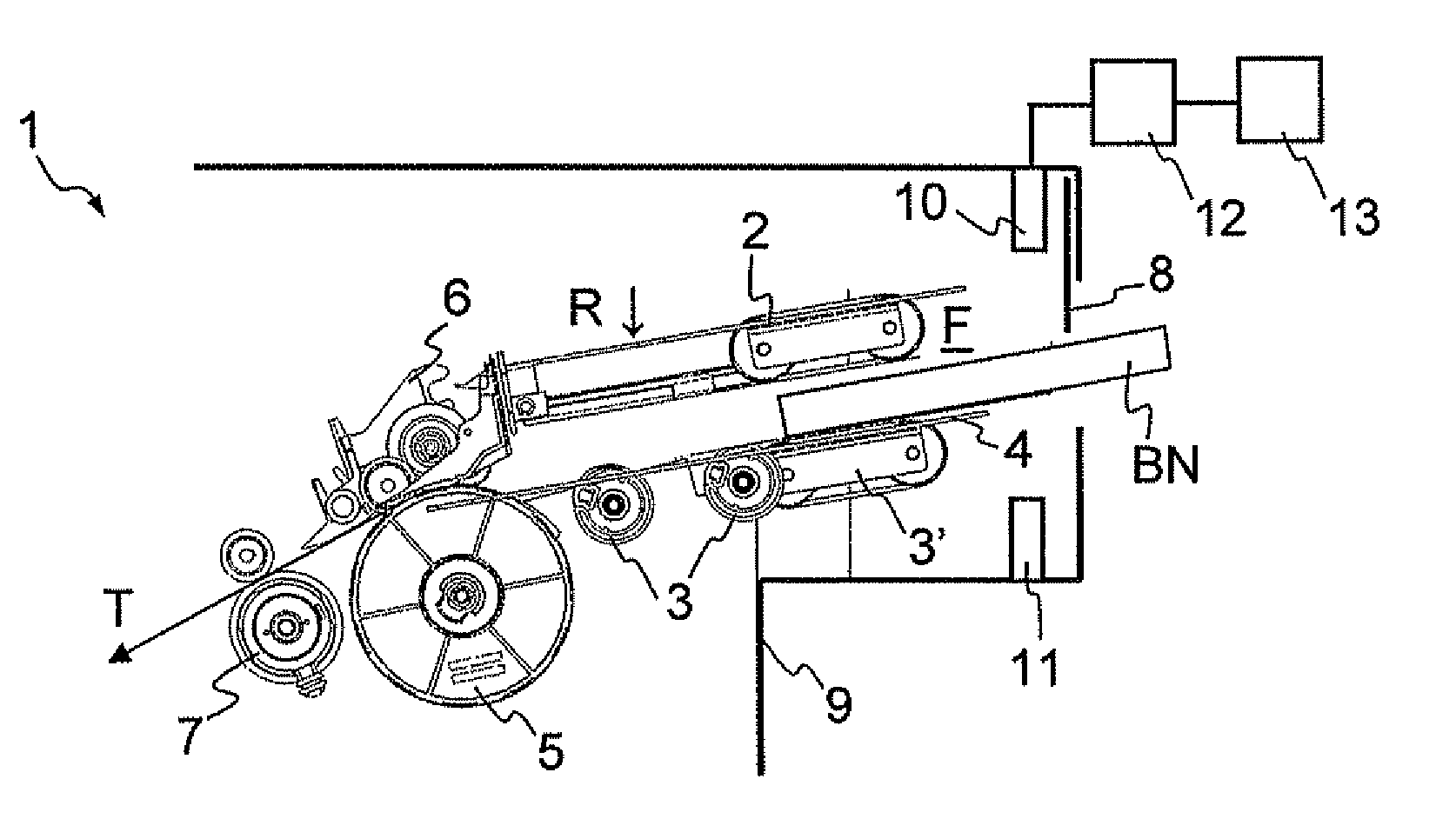

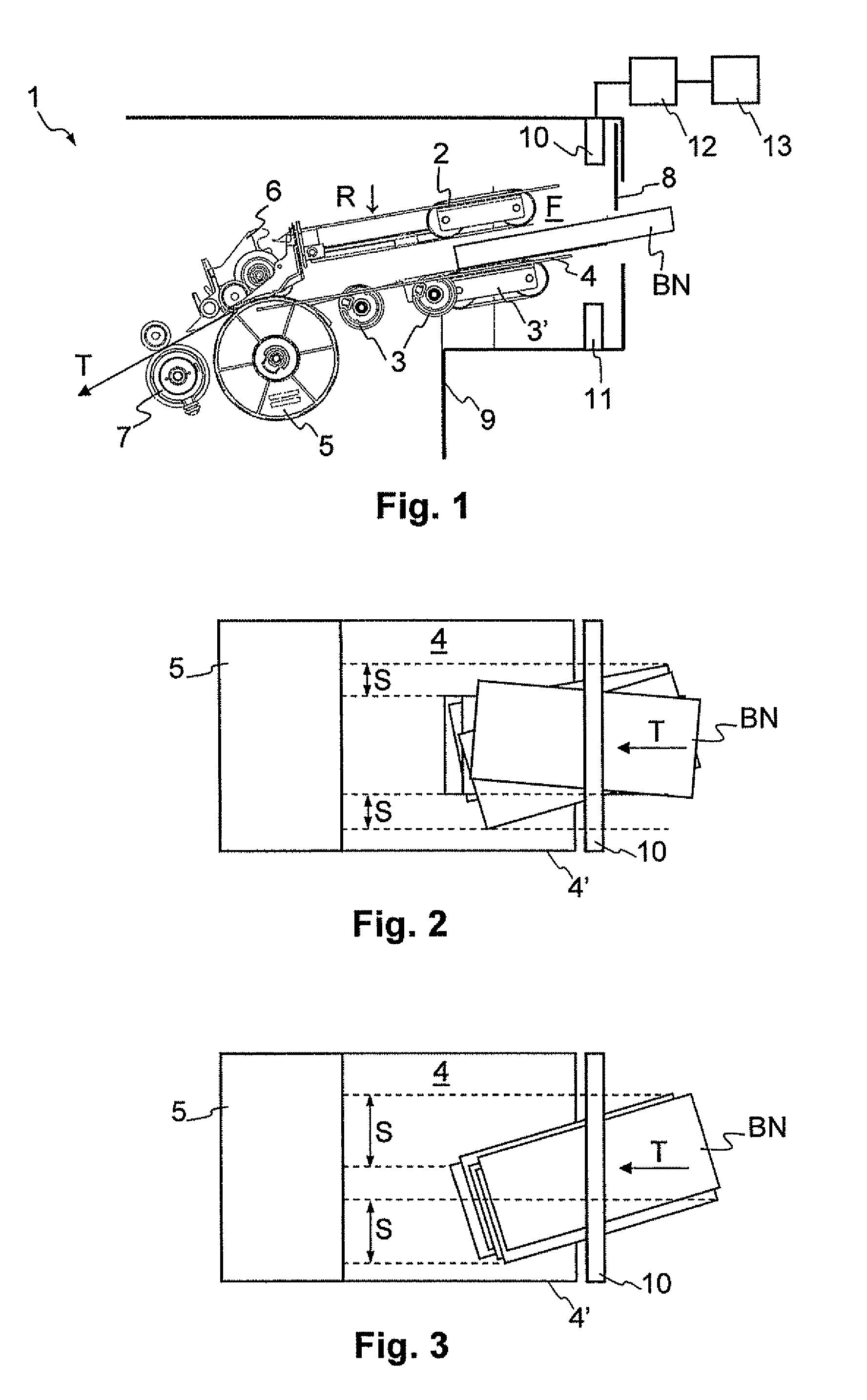

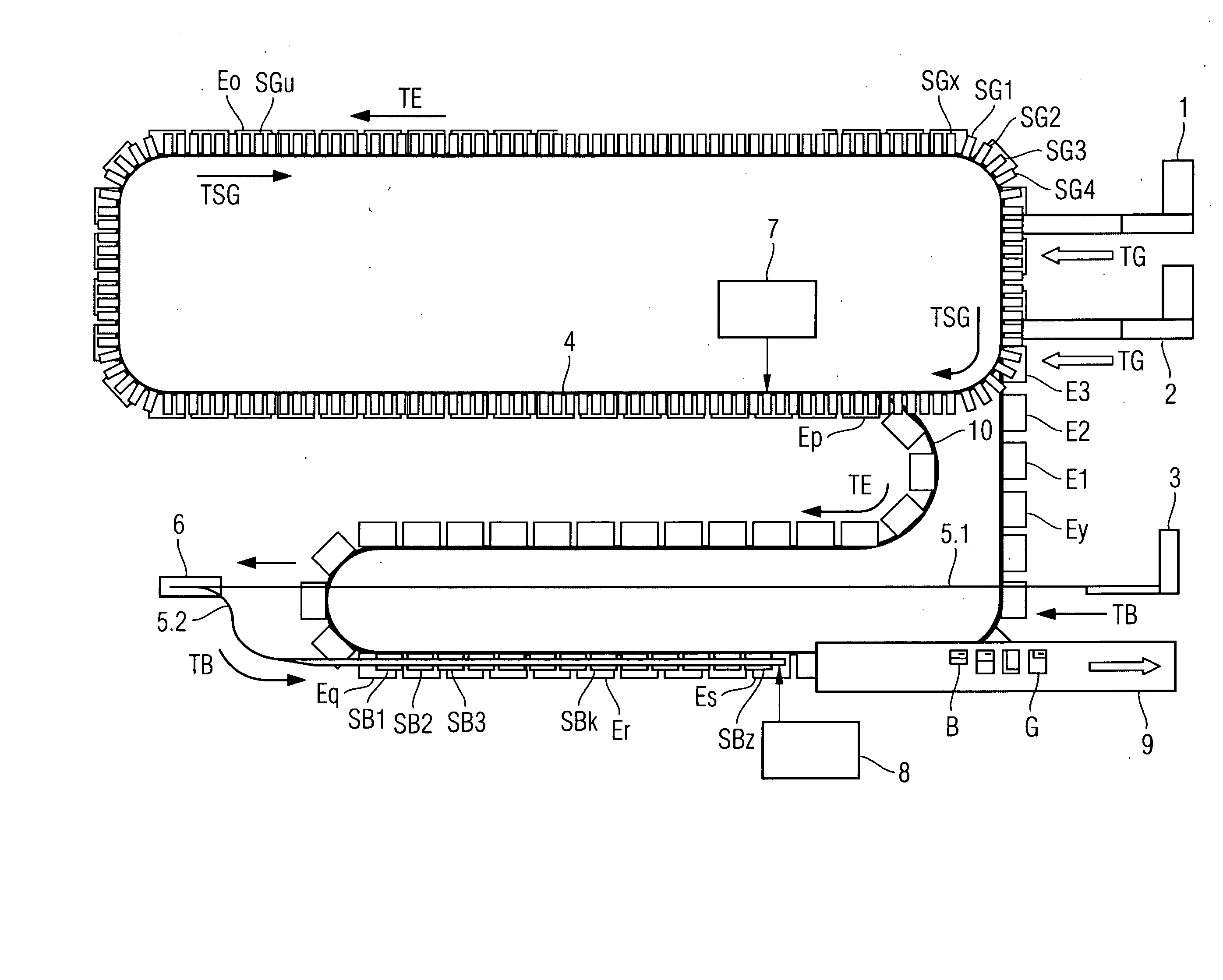

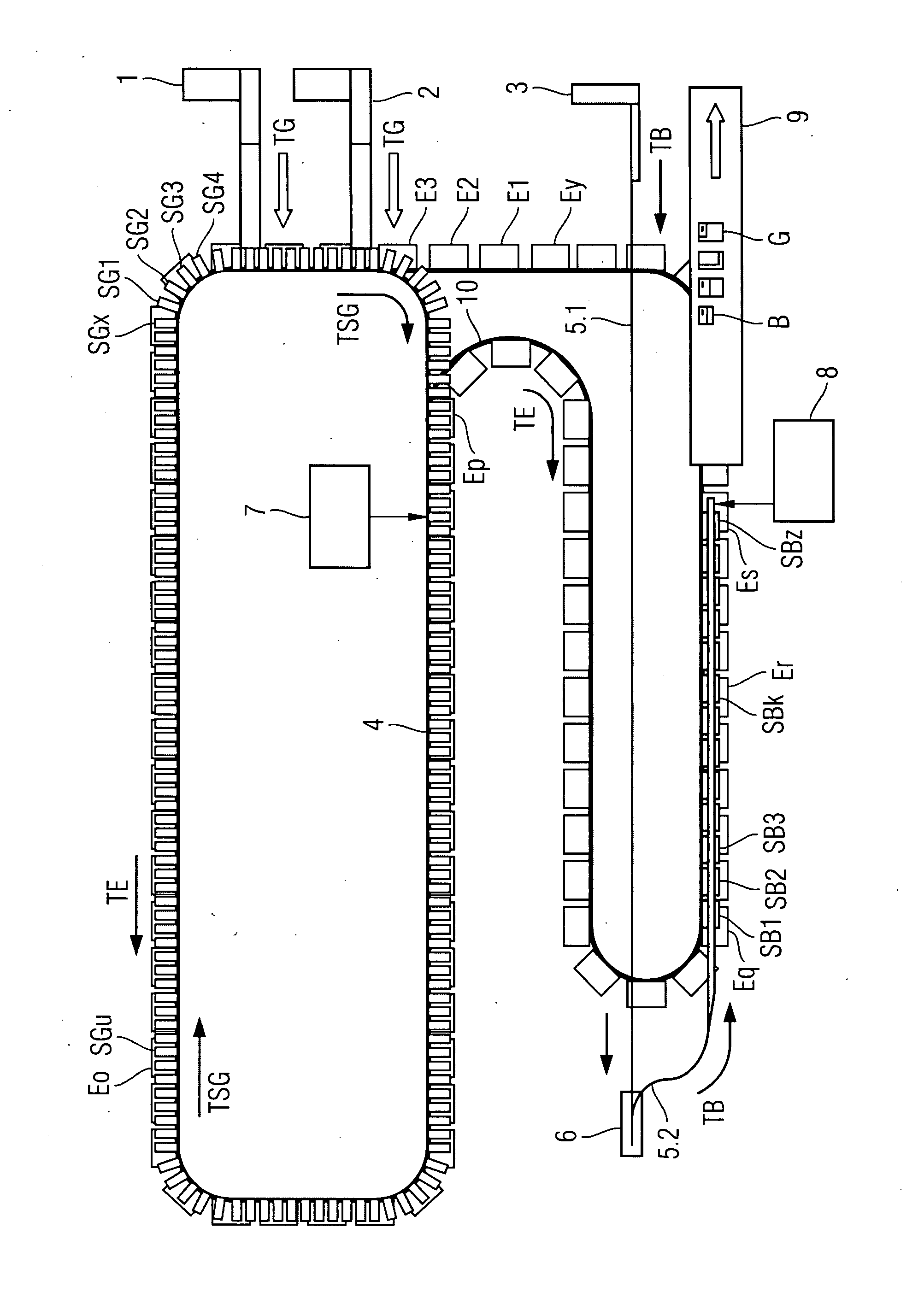

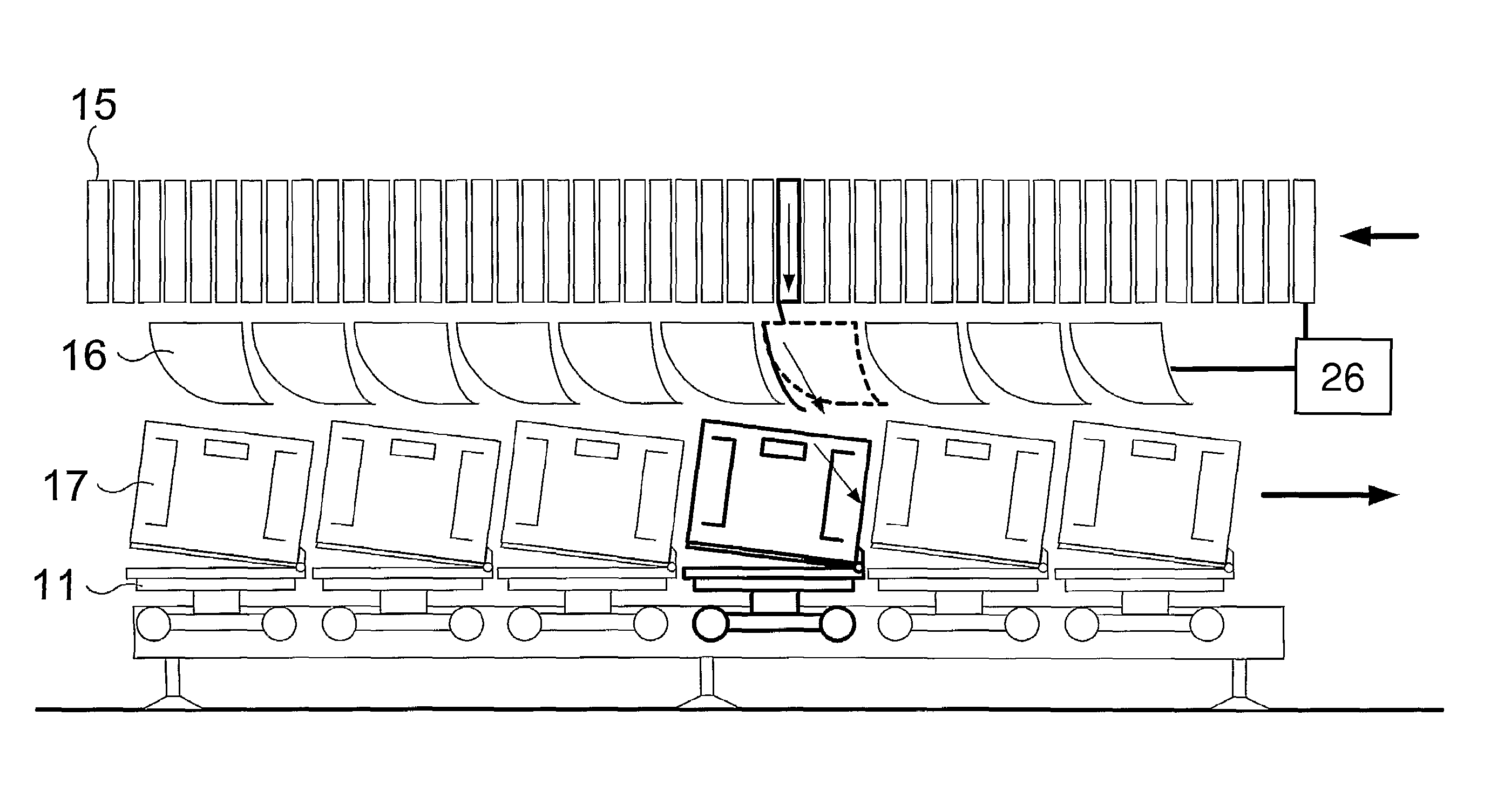

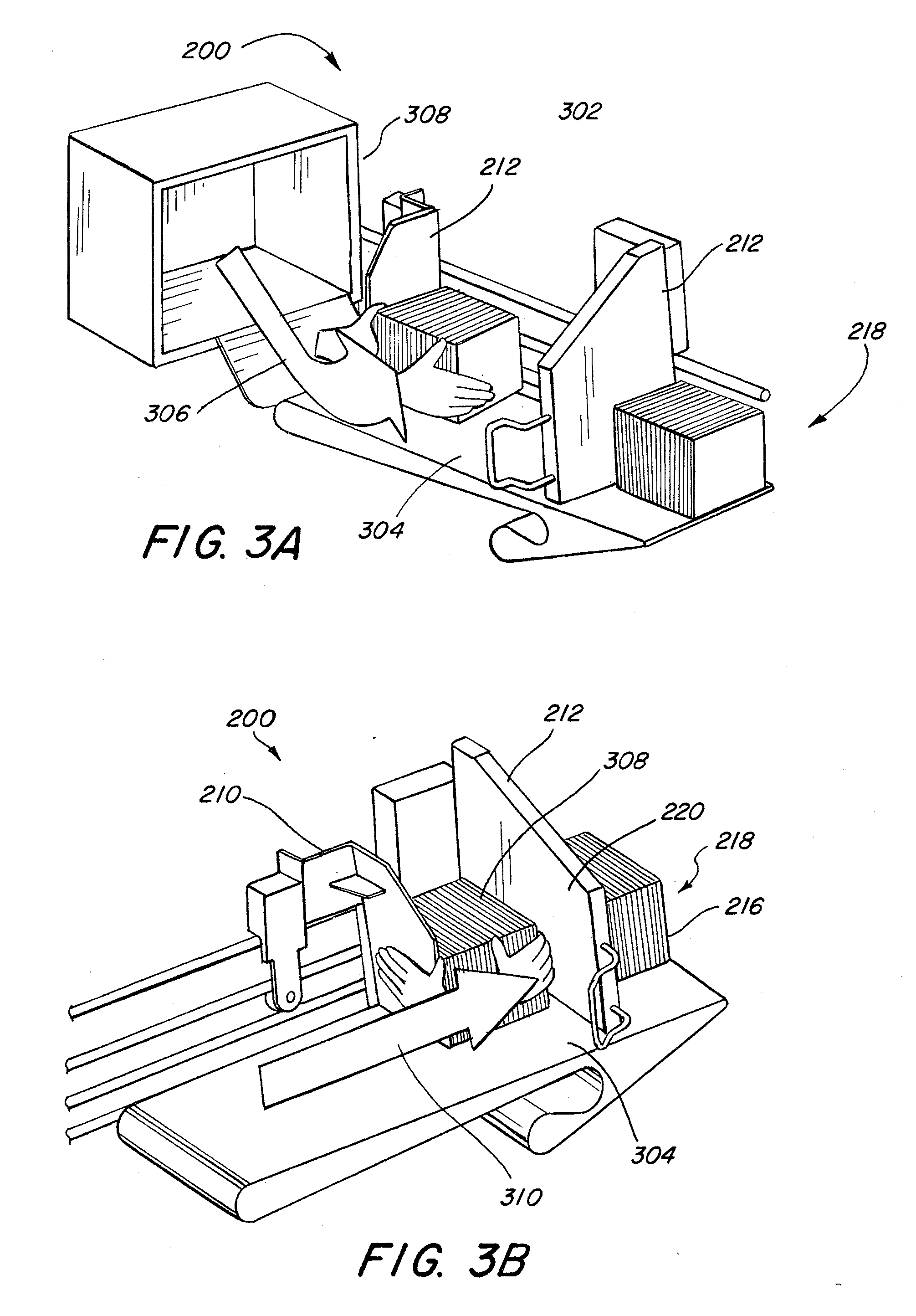

Sorting installation and sorting method for letters and large letters

InactiveUS20080060981A1Reducing locationImprove stack qualitySeparation devicesCharacter and pattern recognitionEngineeringLettering

Owner:SIEMENS AG

Full-automatic paperboard stacking equipment and paperboard stacking method

PendingCN107879120AImprove stacking accuracyImprove stack qualityOverturning articlesStacking articlesPaperboardPalletizer

The invention discloses full-automatic paperboard stacking equipment. The full-automatic paperboard stacking equipment is characterized by comprising a paperboard machine, a laminating mechanism, a binding mechanism, a stacking mechanism and a conveying mechanism which are sequentially connected from back to front, wherein the laminating mechanism, the binding mechanism and the stacking mechanismare sequentially connected through a conveying line, the laminating mechanism comprises a laminating mechanical arm, a first positioning device and a first jacking device, the binding mechanism comprises a binding machine, a second positioning device and a lifting conveying device, the stacking mechanism comprises a second jacking device and a stacking mechanical arm, and the conveying mechanism comprises a pallet machine and a pallet conveying line. The invention further discloses a stacking method for the paperboard stacking equipment.

Owner:DONGGUAN ALFA AUTOMATION TECH CO LTD

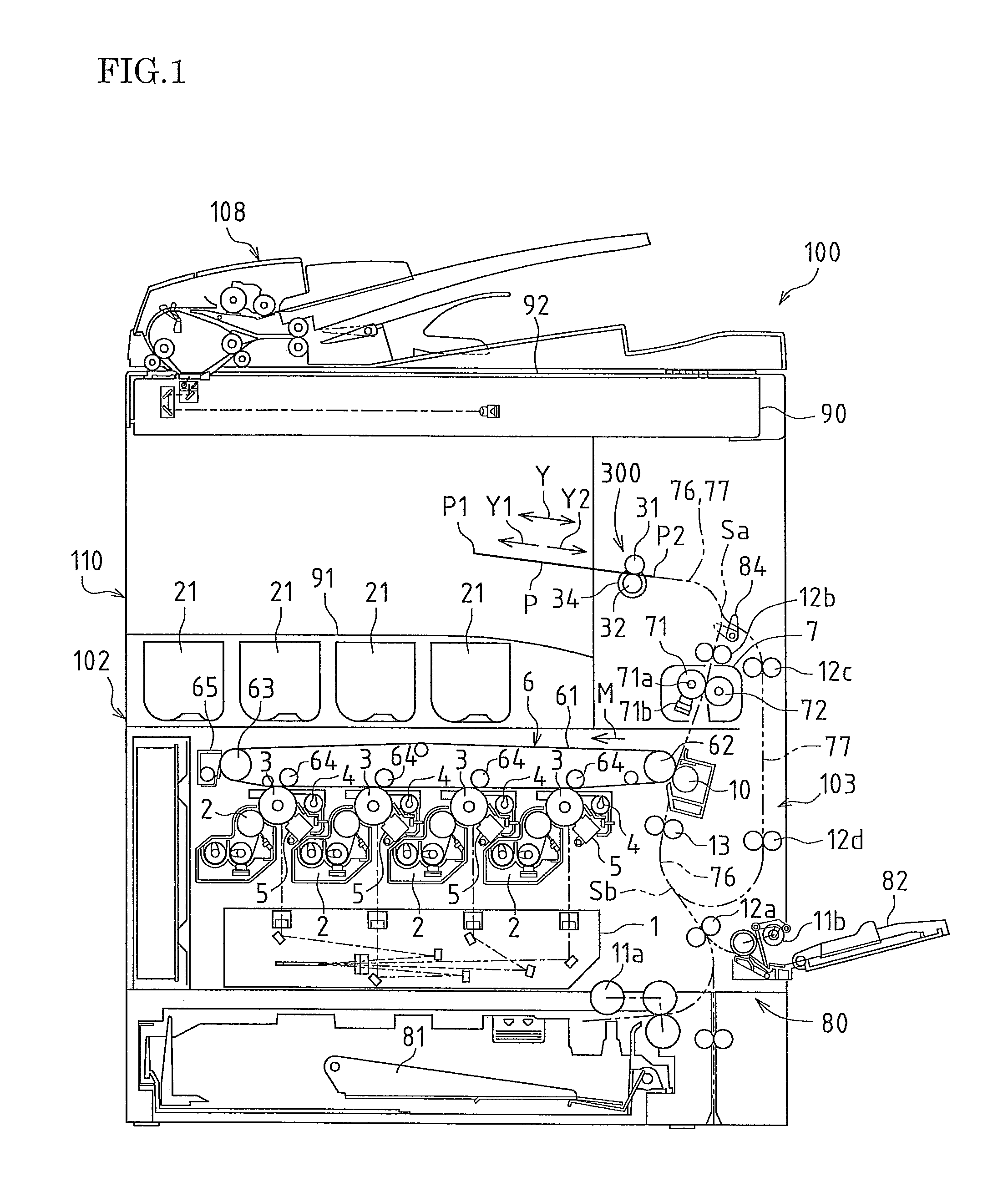

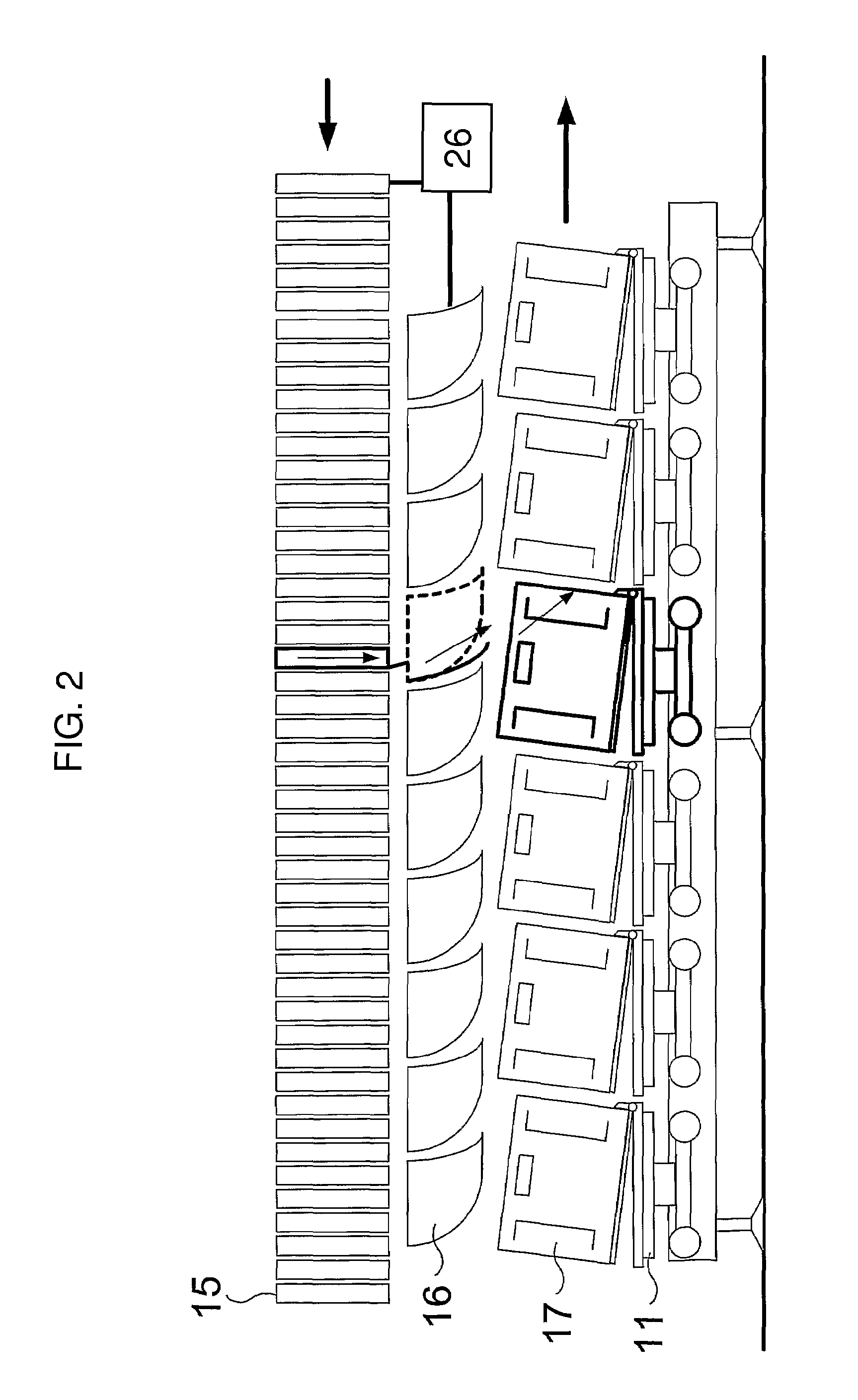

Sorting device for flat mail items

InactiveUS7683284B2Occupancy level can be reducedLower Level RequirementsSeparation devicesCharacter and pattern recognitionEngineeringIntermediate storage

The sorting device according to the present invention has at least one mail item buffer receptacle, a number of storage pockets for mail items arranged one after another and circulating continuously in a conveyor belt and moved past one or more loading stations. Below straight transfer sections of the conveyors fixed intermediate storage receptacles open at the top are arranged to accept one or more mail items from the loaded storage pockets to be opened under control in the transfer sections. On a transport path below the intermediate storage receptacles there are also continuously circulating mail item containers open at the top as sorting end points assigned to the destination addresses or destination address groups. In the mail item containers the mail items are unloaded downwards in a horizontal position in accordance with their read destination address through controllable opening of the relevant intermediate storage receptacle at the point, in which the mail item container assigned to the address is located in the corresponding position below the intermediate storage receptacle with mail items for this mail item container.

Owner:SIEMENS AG

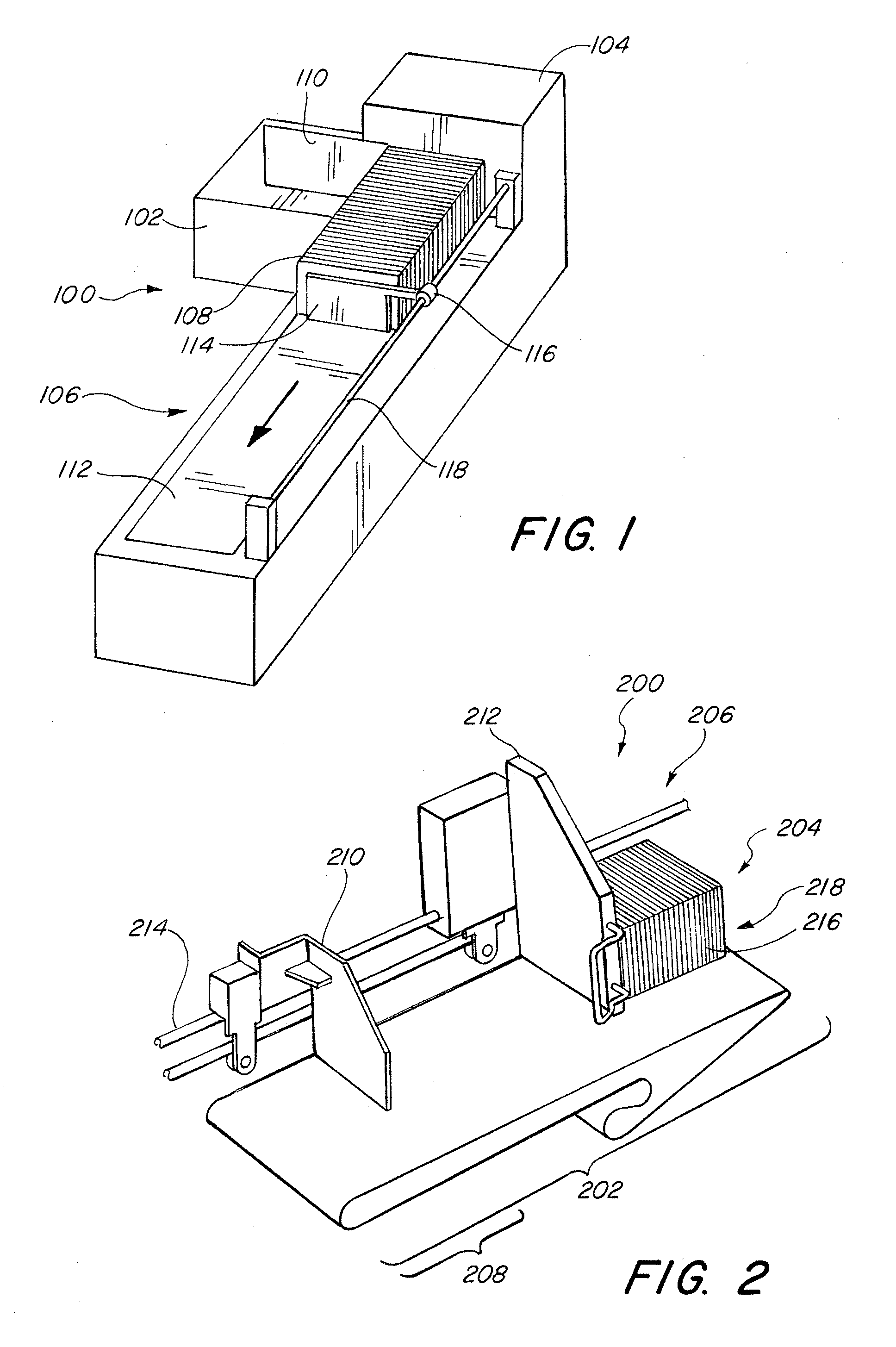

Mail feeder auxiliary paddle

InactiveUS20090242464A1Maintain integrityImprove stack qualityPile receiversSortingMechanical engineeringEngineering

A mail sorter including a conveying surface and a main paddle movably disposed on a slide member for supporting a first end of a main stack of mail pieces while traversing along the conveying surface to apply a first stacking pressure to the mail pieces. An auxiliary paddle is also disposed on the slide member for segregating an auxiliary stack of mail pieces from the main stack of mail pieces. The auxiliary paddle is moveable between a first position where the auxiliary paddle is free of contact with any of the mail pieces and a second position where the auxiliary paddle supports the auxiliary stack of mail pieces against the main paddle to apply a second stacking pressure to the auxiliary stack of mail pieces, the second stacking pressure being less than the first stacking pressure.

Owner:NORTHROP GRUMAN CORP

Accessory system for fast stacking of annealed steel coil and operation method thereof

InactiveCN101948081AImprove stacking efficiencyImprove stacking qualityLoad-engaging elementsSight lineElectricity

The invention discloses an accessory system for fast stacking of annealed steel coil and an operation method thereof. The system comprises an embedding sleeve, an image pickup system, an illuminating system, a viewer-sight indicating system, a display, and a position indicating mark, wherein the embedding sleeve is arranged at the center of the lower end face of a guide cone of a steel coil lifting appliance; the image pickup system is arranged at the center of the lower surface of the embedding sleeve in a sunk manner; the illuminating system is arranged at the lower surface of the embedding sleeve and adjacent to the image pickup system; the viewer-sight indicating system is arranged in the embedding sleeve in a sunk manner and adjacent to the image pickup system and the illuminating system; the display is electrically connected with the image pickup system and used for displaying images shot by the image pickup system and the viewing field mark central point; and the position indicating mark is arranged at the center of the upper surface of a starting fan on a steel coil stacking platform; and the center line of the embedding sleeve coincides with the center lien of the guide cone, the viewer-sight indicating system sends out two mutually vertical light rays from the viewing field, so that mutually vertical viewer-sight lines are displayed on the display, the point of the intersection of the viewer-sight lines coincides with the central point of the viewing field. The system and the method of the invention can improve stacking efficiency and quality.

Owner:SHANDONG IRON & STEEL CO LTD

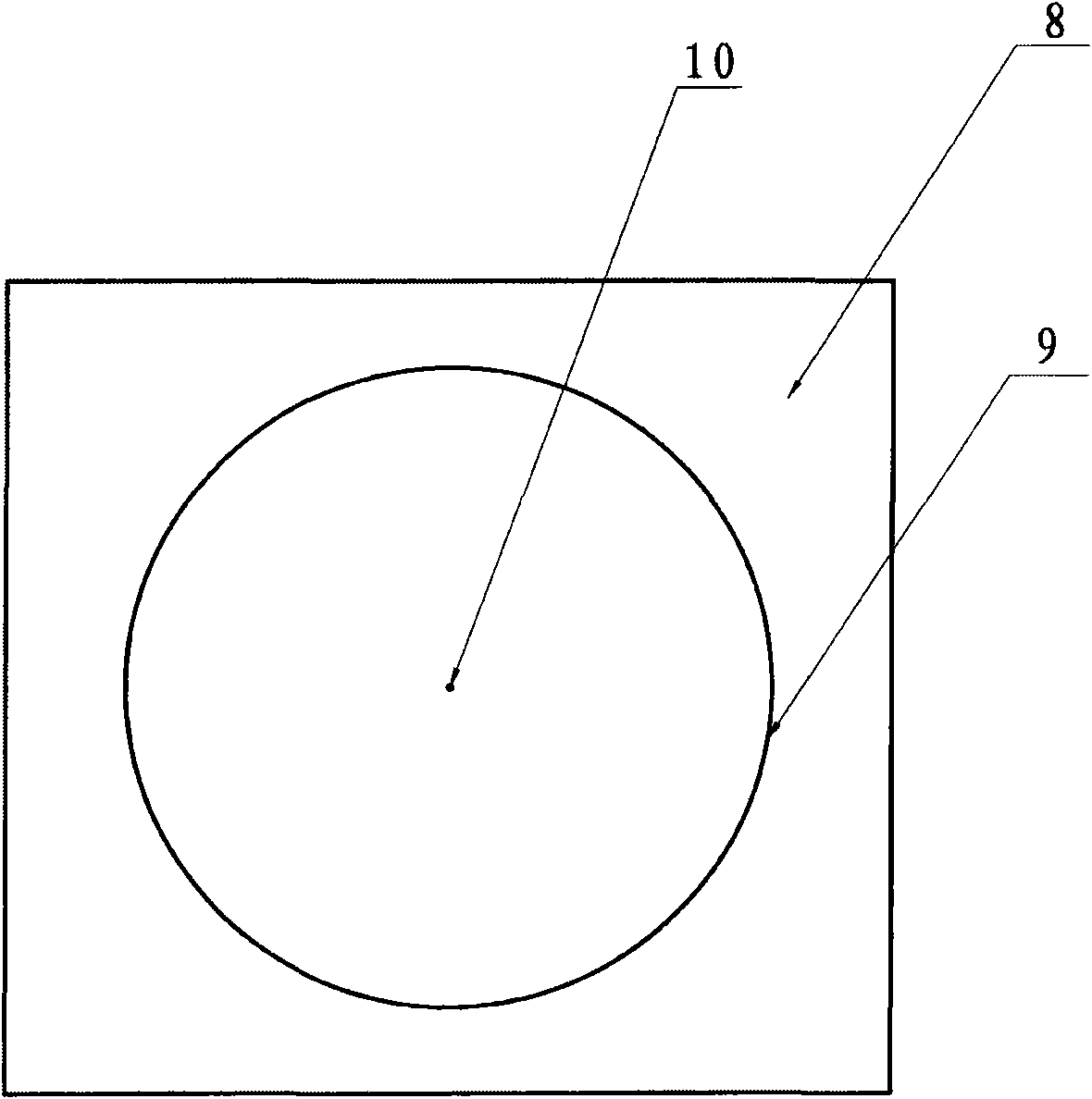

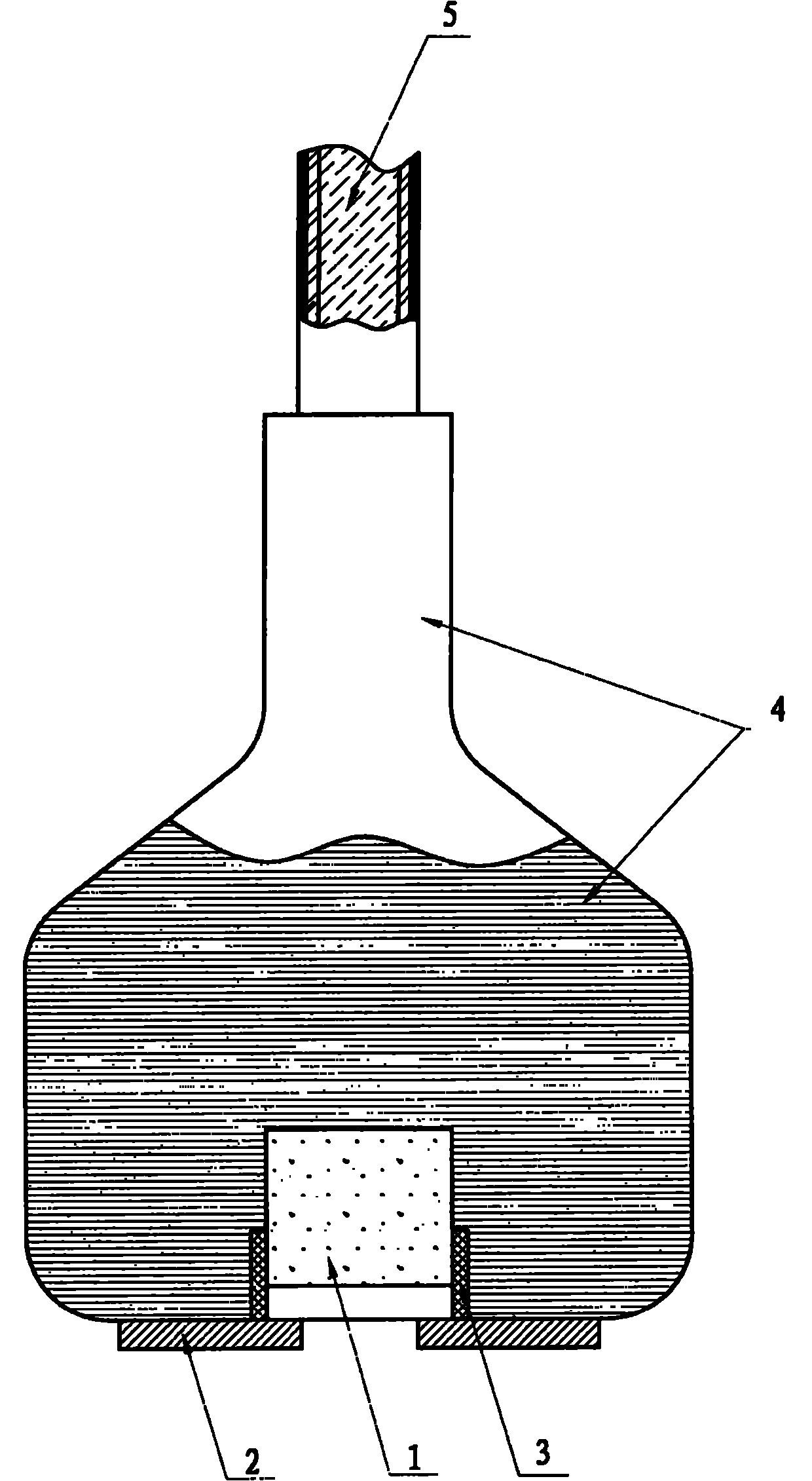

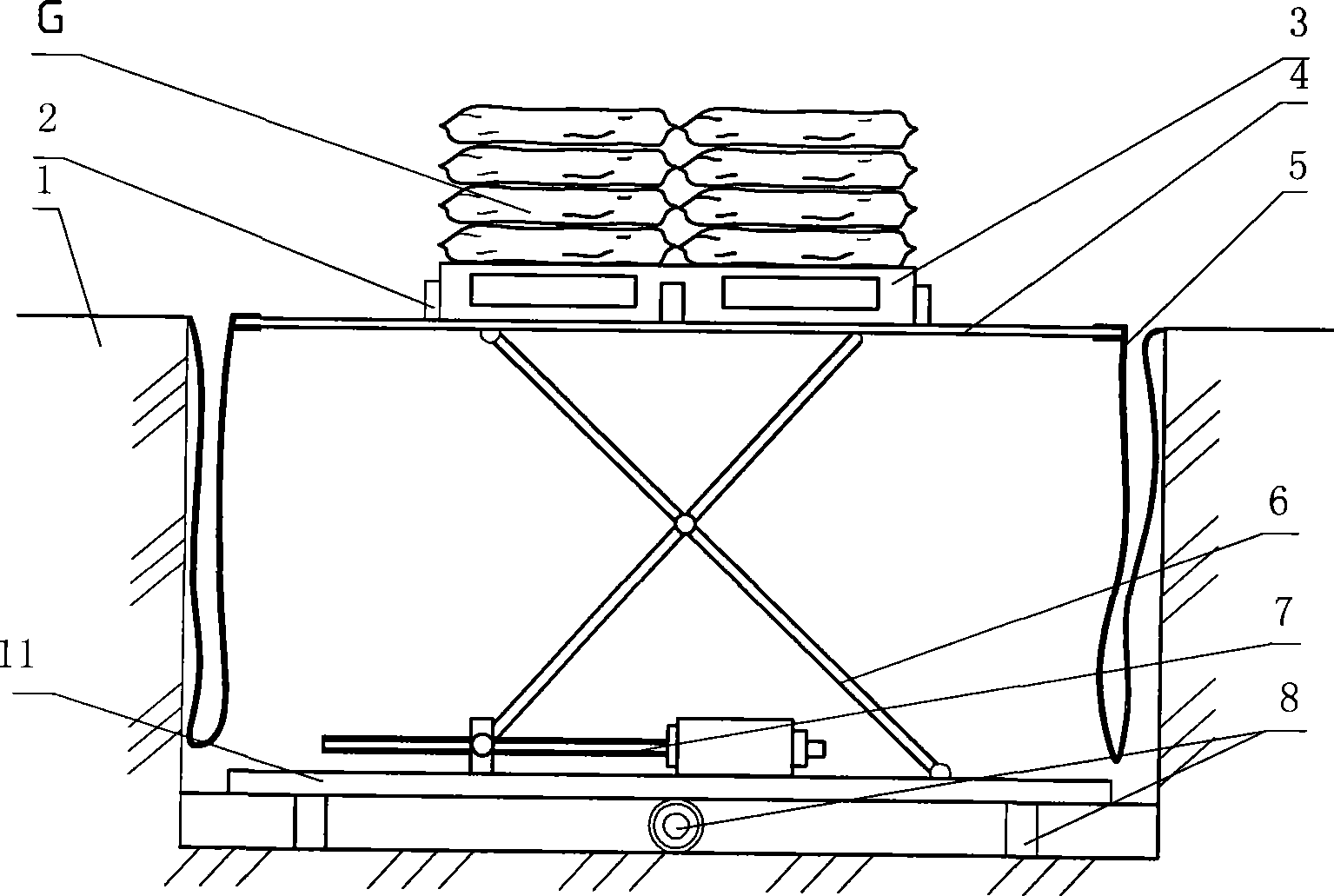

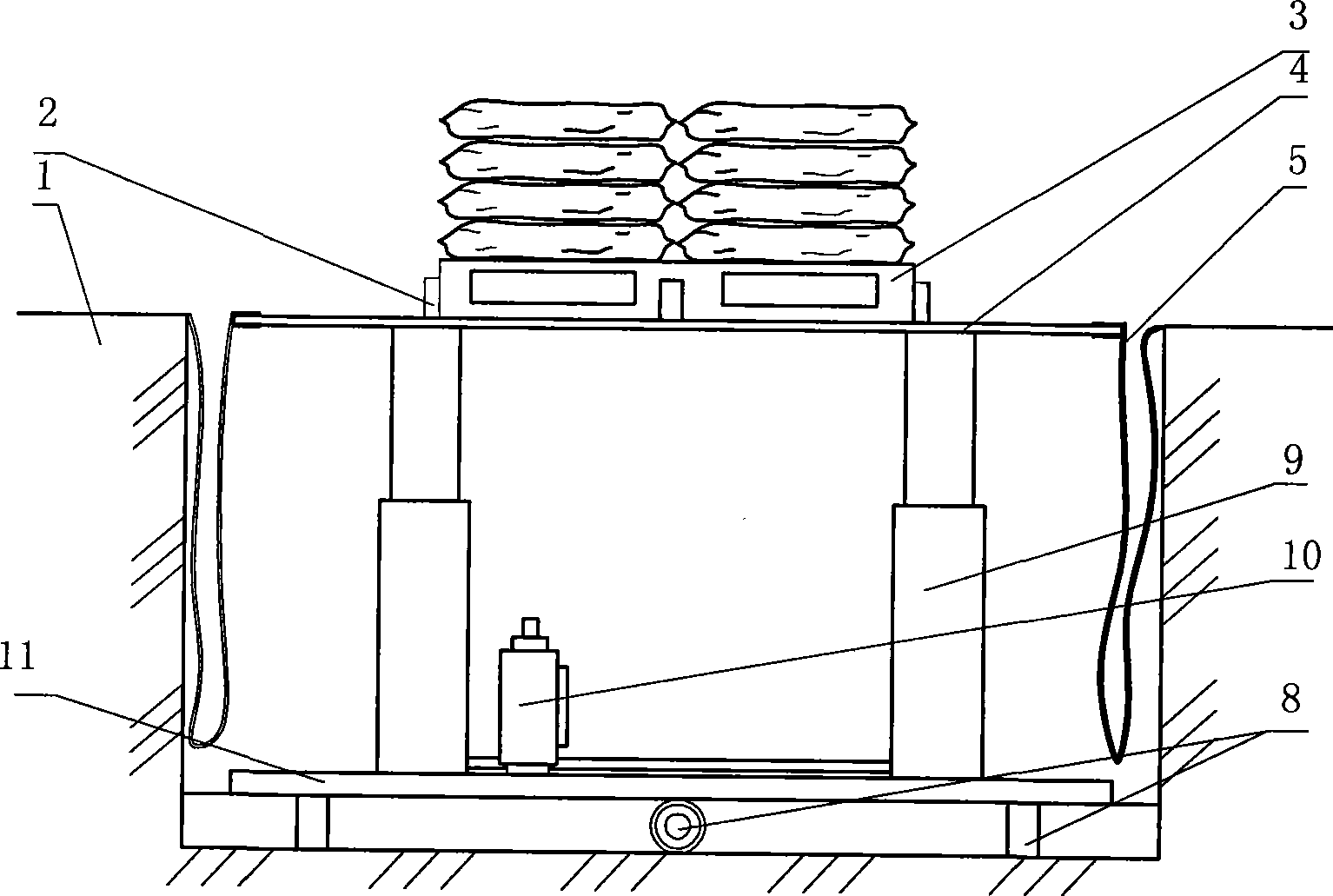

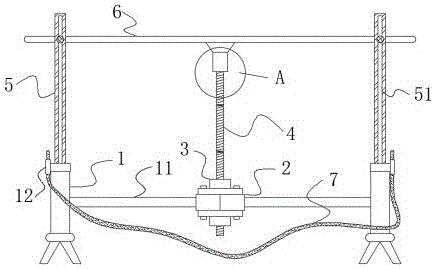

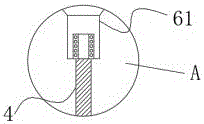

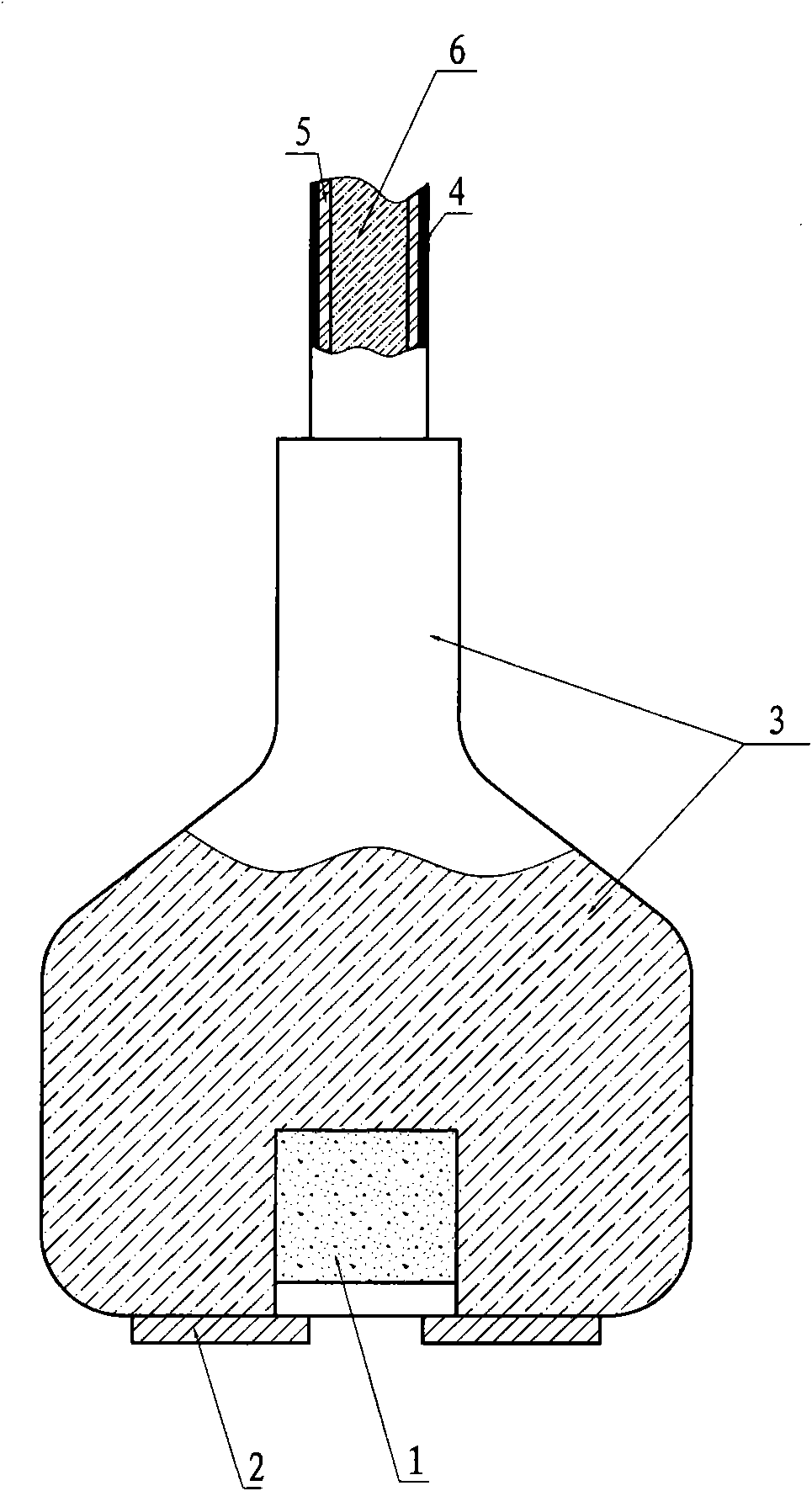

Plate stacking device for bagged materials

InactiveCN101544343AImprove stacking qualityGood for healthLifting devicesStacking articlesRotary stageElectric machinery

The invention relates to a plate stacking device for bagged materials, in particular to the plate stacking device for material bags of the bagged materials. The plate stacking device for the bagged materials comprises ground and a floor rack, and is characterized in that: the ground is provided with a circular pit of which the bottom is provided with a rotating platform; a lifting mechanism is arranged on the rotating platform; the top part of the lifting mechanism is provided with a plate stacking platform which is matched with the diameter of the circular pit; and the lifting mechanism is a hydrocylinder which is vertically arranged and driven by a hydraulic oil pump, and also can be screw rod pairs which is horizontally arranged and driven by a motor to change the included angle of cross supports up and down. The invention provides the plate stacking device which is suitable for the principle of human engineering; operators need not frequently change too low or too high positions of waists, and can handily lift the material bags and easily stack the material bags; and the plate stacking device greatly improves work speed and efficiency and stacking quality.

Owner:SHANGHAI KINGFA SCI & TECH +1

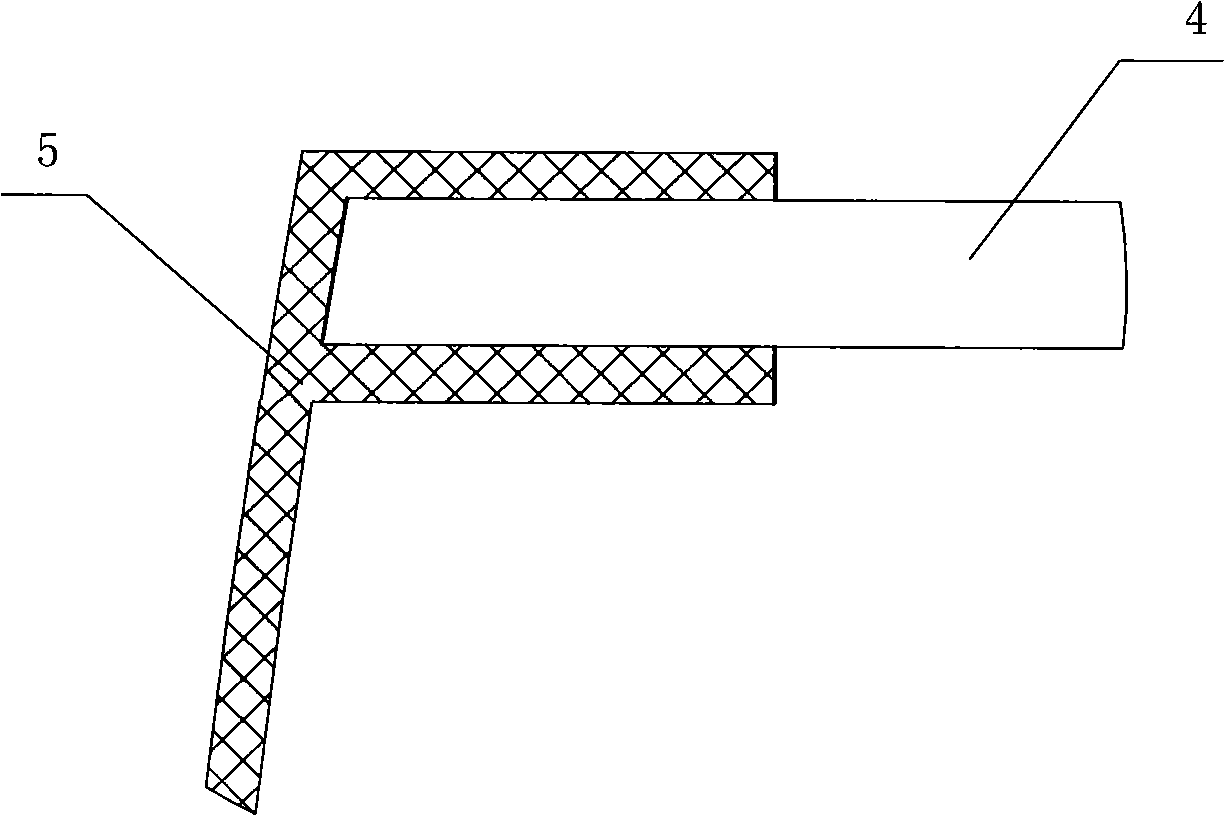

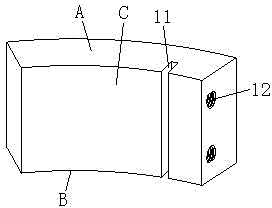

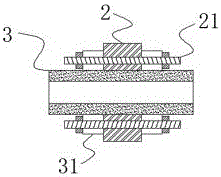

Method for guaranteeing stack mounting precision of straight-slot iron cores of motor and stack mounting die employed in method

InactiveCN104659979AIncrease stiffnessImprove stack qualityManufacturing stator/rotor bodiesElectric machineryProcessing accuracy

The invention discloses a method for guaranteeing the stack mounting precision of straight-slot iron cores of a motor and a stack mounting die employed in the method. According to the method, at least three key boards are adopted for performing positioning during stack mounting of the iron cores, so that the concentricity of the iron cores are improved; limiting blocks are clamped on the key boards between an upper pressure plate and a lower pressure plate, bending deformation of the key boards is limited through clamping grooves of the limiting blocks, and the verticality between the key boards and positioning surfaces of the upper pressure plate and the lower pressure plate is guaranteed through the processing precision of two end surfaces of each of the clamping grooves and the limiting blocks. The method is high in stack mounting efficiency; stacked layers of iron core stamping sheets are regular in a stack mounting process and unlikely to deform, so that the motor quality can be remarkably improved.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Automatic conveying and stacking equipment for lithium batteries

ActiveCN114379986ANeatly stackedRealize automatic stackingConveyorsFinal product manufactureStructural engineeringTransfer mechanism

The invention relates to the technical field of lithium battery manufacturing, and discloses automatic conveying, stacking and stacking equipment for lithium batteries. The automatic lithium battery conveying, stacking and stacking equipment comprises a bearing plate, a conveying belt mechanism is fixedly installed on the upper end face of the bearing plate, and a transferring mechanism used for transferring lithium battery panels to a stacking mechanism from the conveying belt mechanism is installed on the left portion of the upper end face of the bearing plate and located below the stacking mechanism. The upper end faces of the multiple stages of telescopic mounting plates are jointly connected with a collecting frame mechanism in a clamped mode, and the right portion of the upper end face of the bearing plate is fixedly connected with a straightening mechanism used for adjusting the positions of the lithium battery panels through a supporting rod. And the stacking quality and the stacking efficiency can be effectively improved, the distance between the clamping plates can be adjusted according to the lithium battery panels of different lengths and thicknesses, and the application range is widened.

Owner:徐州林泰新能源有限公司

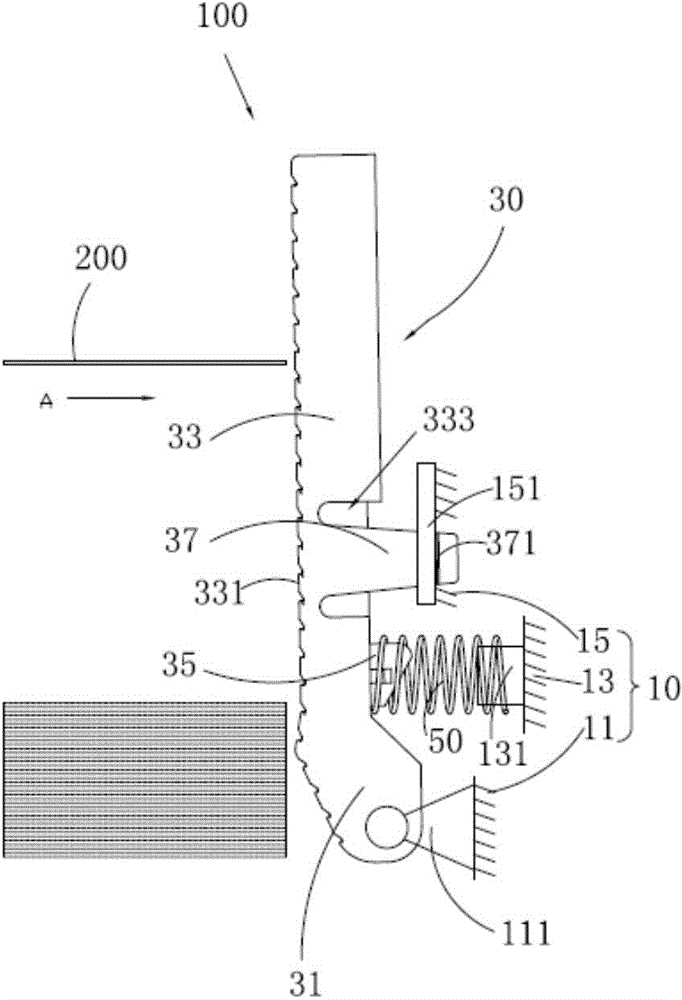

Stacking mechanism

A stacking mechanism is used for stacking piece-shaped mediums. The stacking mechanism comprises a support and a buffering part arranged on the support. A buffering face is formed on the buffering part, the buffering part is rotatably installed on the support, and the stacking mechanism further comprises an elastic part arranged between the support and the buffering part. When the piece-shaped mediums impact on the buffering part in the direction perpendicular to the piece-shaped mediums, the buffering part can push the elastic part and rotate relative to the support so as to buffer impact of the piece-shaped mediums, the piece-shaped mediums descend under their own gravity effect so as to achieve stacking. Due to the fact that the stacking mechanism is provided with the elastic part between the support and the buffering part, the buffering part can press the elastic part to move, adsorption of impact of the piece-shaped mediums is improved, and stacking quality is improved.

Owner:SHENZHEN YIHUA COMP +2

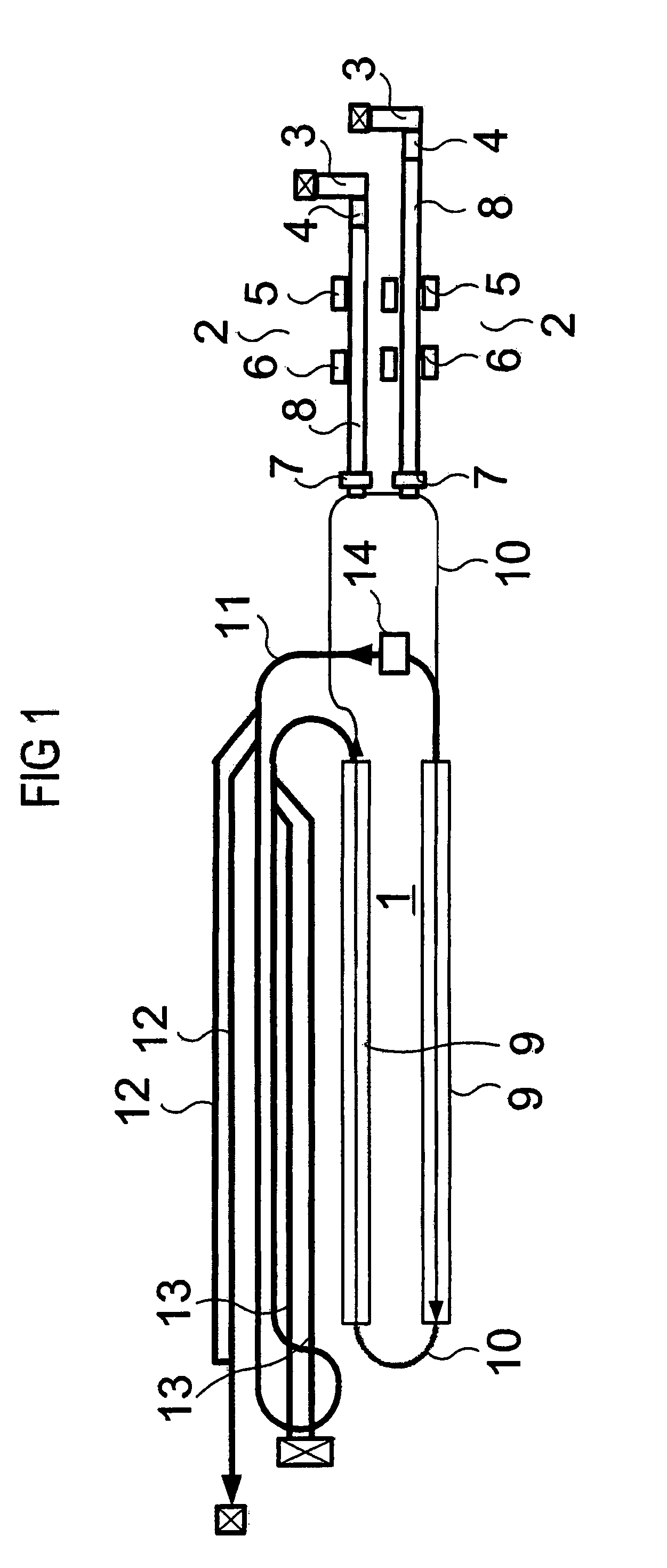

Apparatus for singling of sheet material

InactiveUS7883088B2Improve stack qualityEasy alignmentFunction indicatorsCoin/currency accepting devicesTransport systemEngineering

Apparatus for singling sheet material, in particular bank notes, which is inputted into an input area of the apparatus as a stack and is transported up to a singler, which transfers individual pieces of sheet material of the stack of sheet material to a sheet transport system, which transports the singled sheet material in a transport direction, a sensor disposed in transport direction upstream of the singler, which substantially extends over the width of the input area, generating signals which specify whether and in which area of the width of the input area the sheet material is present, and a control device evaluating the signals of the sensor during a transport of the stack of sheet material to the singler and comparing occurring fluctuations and changes of the signals of the sensor regarding the presence or absence of sheet material with predetermined threshold values for fluctuations and changes of the signals of the sensor, in order to derive a statement from the occurring fluctuations and changes of the signals of the sensor, whether the pieces of sheet material forming the stack of sheet material are aligned to each other with respect to their edges, and whether the stack of sheet material has an alignment which substantially is in parallel to the transport direction of the transport system.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

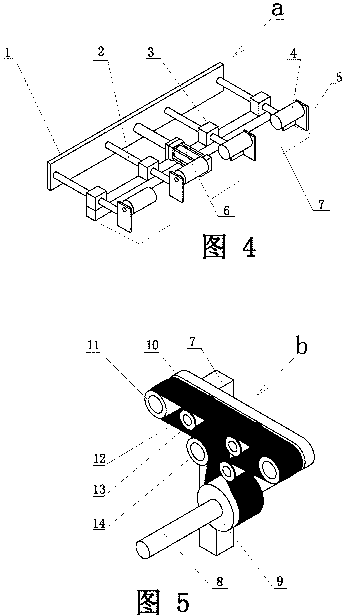

Paper grabbing mechanism of paper unloading machine

The invention discloses a paper grabbing mechanism of a paper unloading machine. The paper grabbing mechanism comprises a lifting cross beam, a paper transfer table and a right paper blocking arm. The paper transfer table and the right paper blocking arm are mounted on the lifting cross beam and driven by respective drive motors to move left and right independently. A downwards-inclining paper unloading guiding face is arranged at the right end of the table surface of the paper transfer table, and the right paper blocking arm is connected with a right paper baffle. The paper grabbing mechanism is characterized in that a notch is formed in the rightmost end of the paper unloading guiding face, a paper grabbing block is movably arranged in the notch and arranged at the bottom of the right paper baffle, the paper grabbing block is pushed by a paper grabbing cylinder to move up and down, a paper pressing block is arranged above the paper grabbing block and pushed by a right cylinder to move up and down, and the paper grabbing cylinder and the right cylinder are connected to the right paper blocking arm. Paper stacking consistency during paper unloading can be guaranteed, the paper stacking quality is improved, and subsequent packaging is facilitated.

Owner:ZHEJIANG HUAYUE PACKING MACHINERY

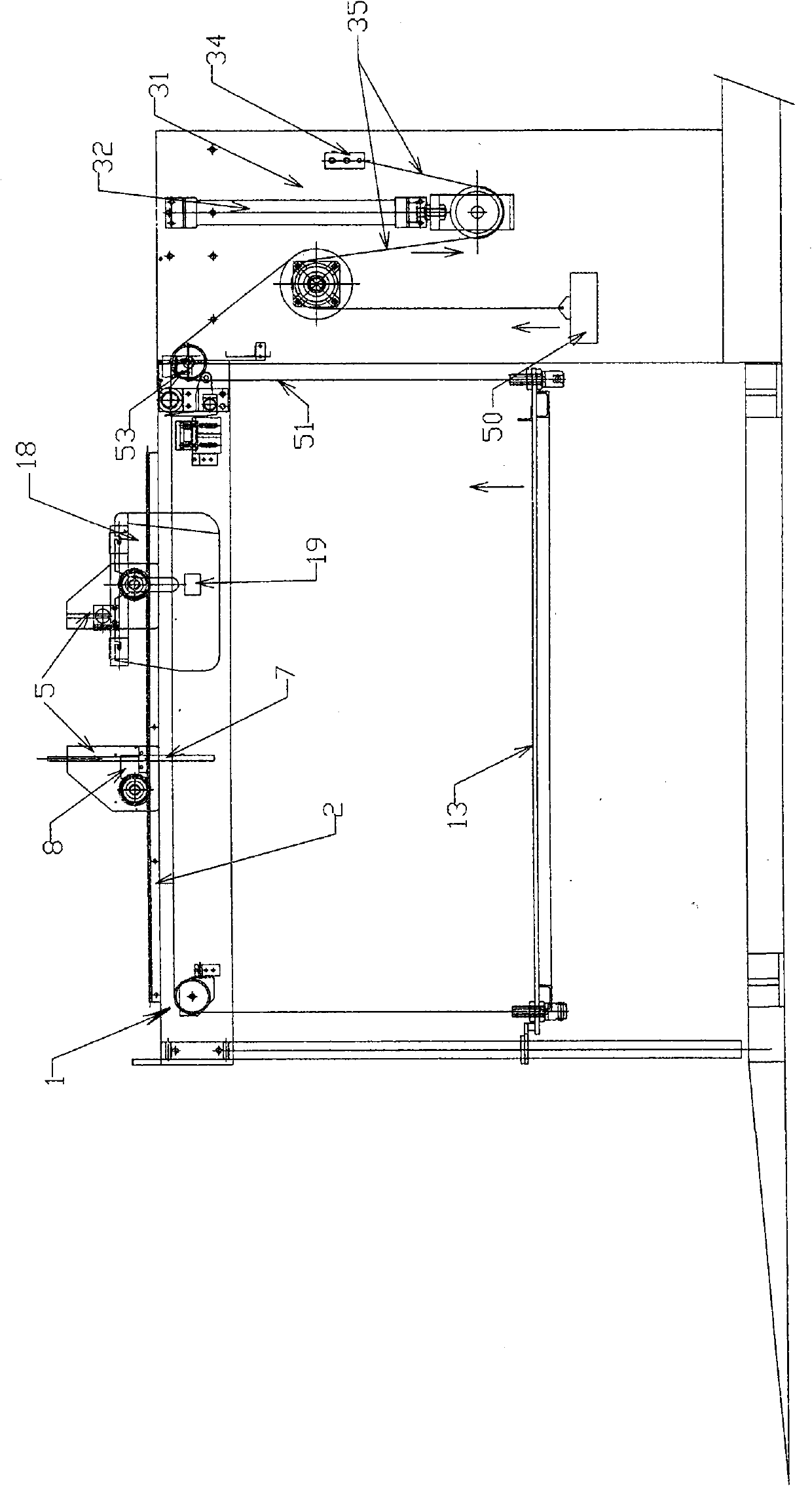

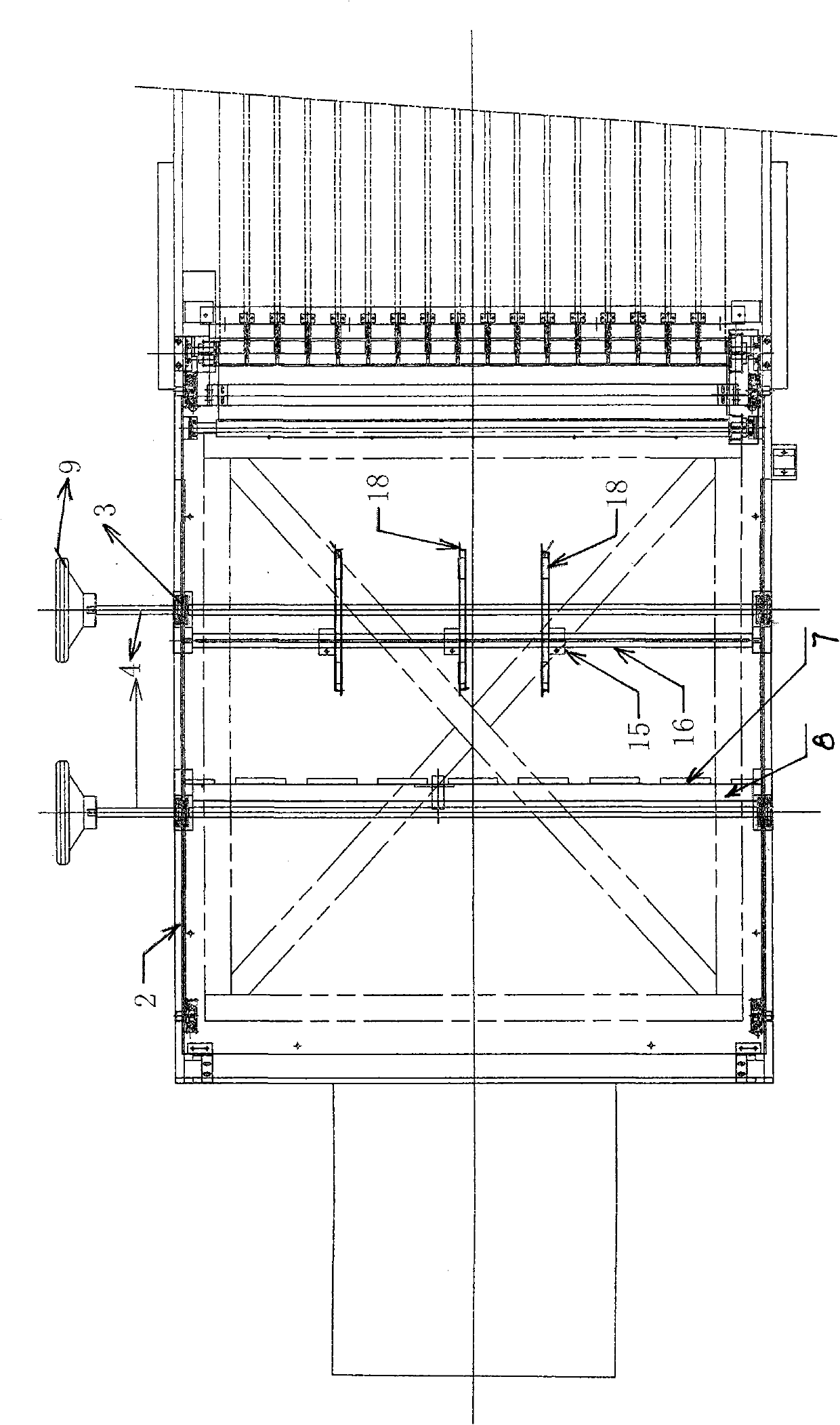

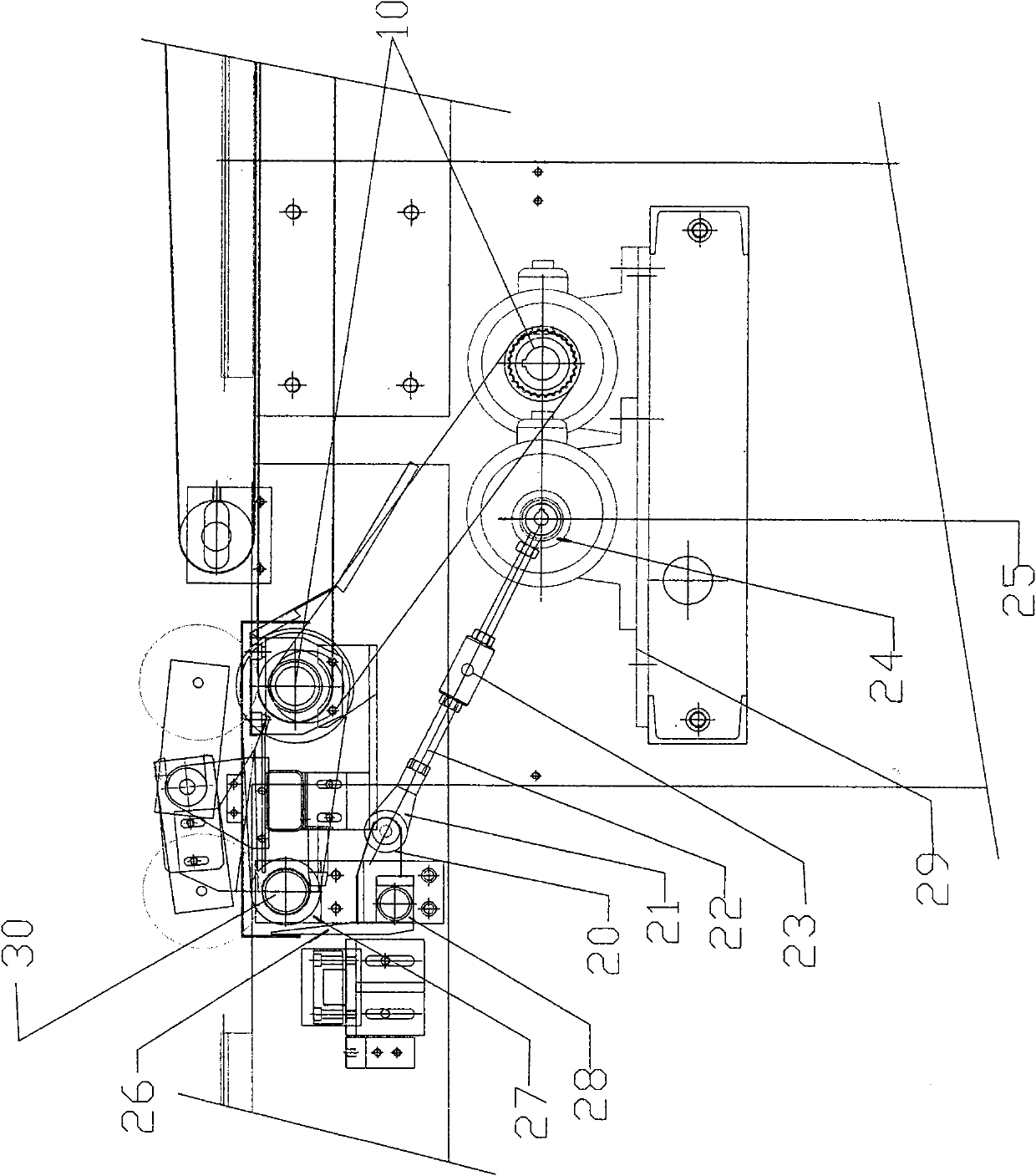

Automatic paper-gathering device of roll paper splitting machine

The invention discloses an automatic paper-gathering device of a roll paper splitting machine. A lifting delivery board (13) is arranged at the lower part of a rack (1) of the automatic paper-finishing device and is connected with a lifting control mechanism; the top part of the rack is provided with two sets of pressing board back seats (5), a transverse pressing board seat (8) and a transverse pressing board (7) are arranged between one set of the pressing board back seats, and a paper blocking piece shaft (16) is arranged between the other set of the pressing board back seats; and the paper blocking piece shaft is equipped with a vertical pressing board (18) provided with a vibrator (19). The transverse sides of finished product paper are gathered by the transverse pressing board while the vertical sides thereof are gathered by the vertical pressing board, and the finished product paper is placed on the lifting delivery board; and the lifting delivery board is controlled by the lifting control mechanism and can automatically descend along with the increment of the finished product paper. The automatic paper-gathering device in the invention has the advantages of high stacking quality, orderly gathered paper, high working efficiency and lowered stacking and processing cost.

Owner:瑞安市瑞阳印刷机械有限公司

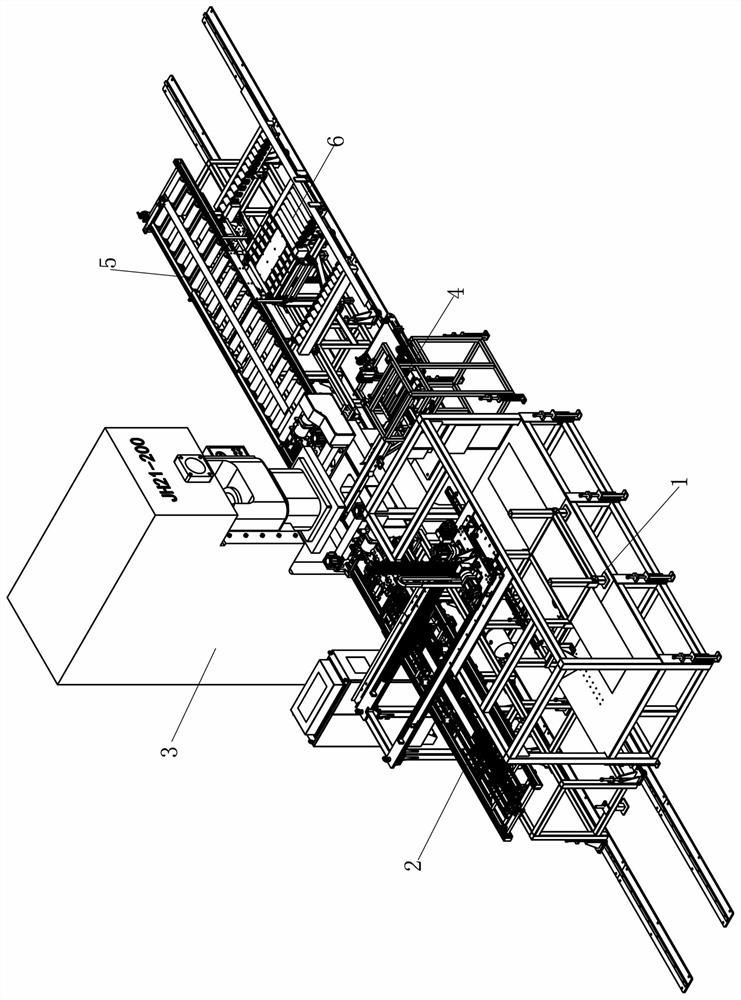

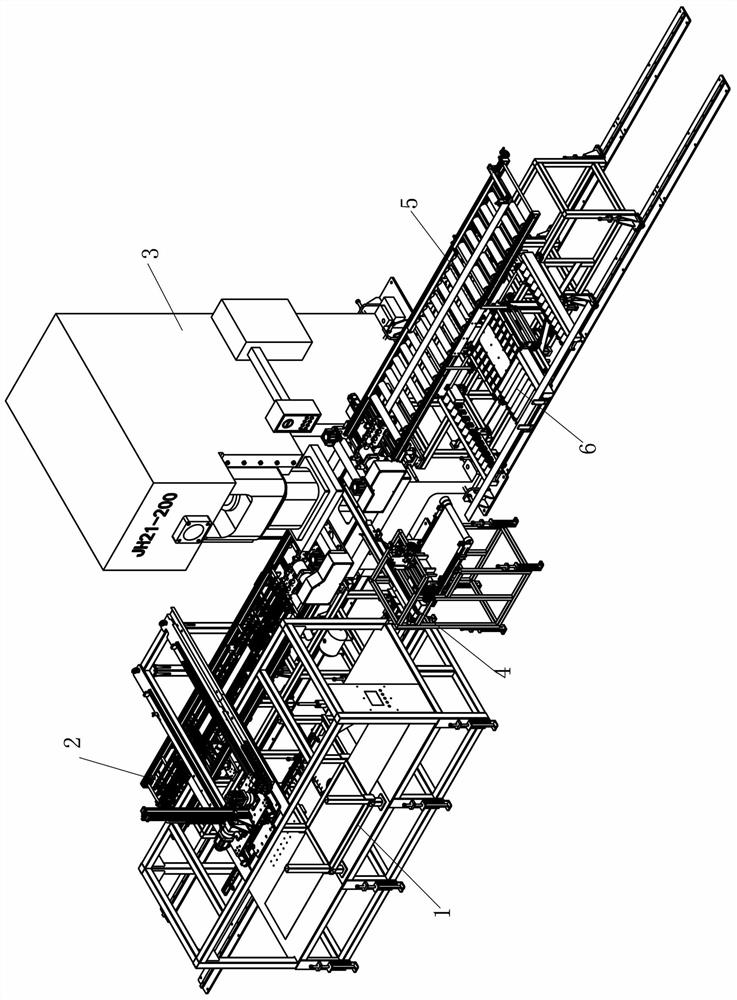

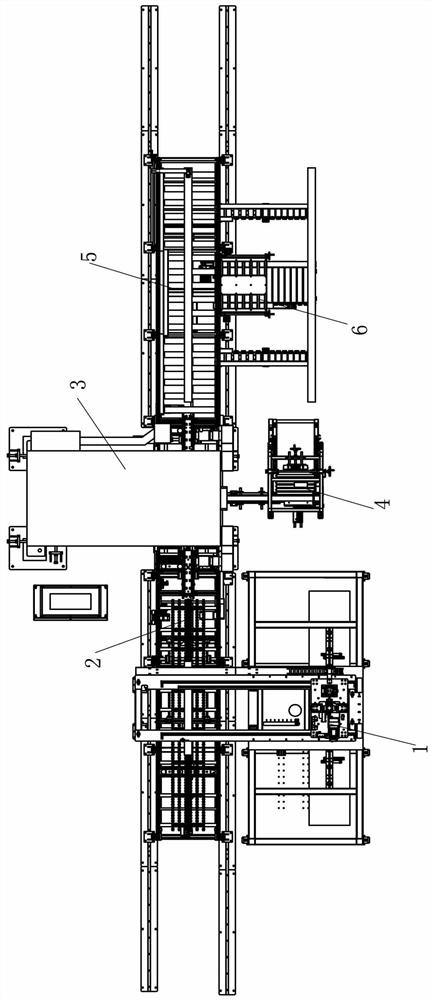

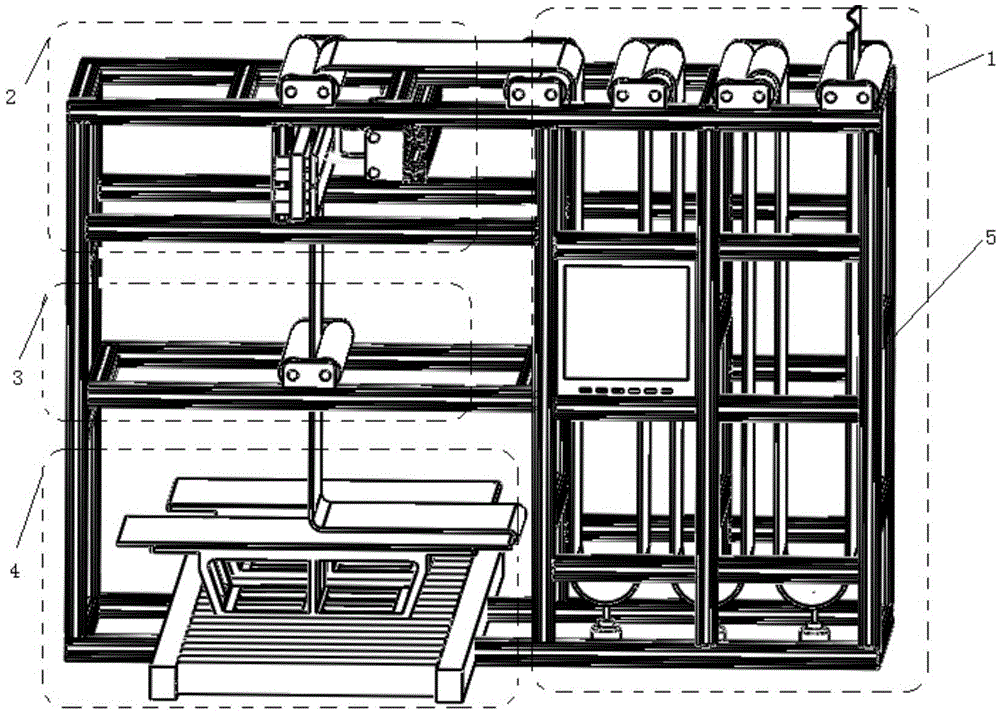

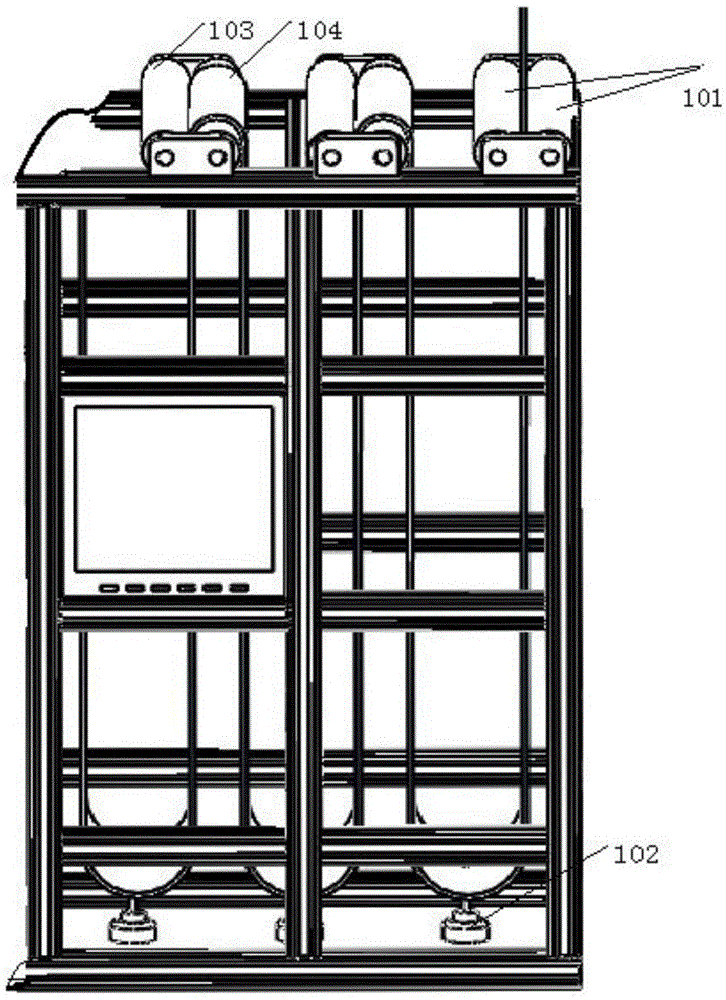

Automatic blanking and punching production line for sheets

ActiveCN113426895AMatch punch rhythmIncrease productivityMetal-working feeding devicesPositioning devicesProduction linePunching

The invention relates to the technical field of sheet punching, in particular to an automatic blanking and punching production line for sheets. The automatic blanking and punching production line comprises a sheet feeding device, a sheet inlet device, a sheet punching die, a sheet discharging device and a punched part receiving device. The sheet feeding device is used for grabbing single sheets to the sheet inlet device, the sheet inlet device is used for intermittently and horizontally conveying the single sheets into the sheet punching die, the sheet punching die is used for punching holes in the sheets, and the sheet discharging device is used for conveying out the punched sheets and stacking the punched sheets. According to the automatic blanking and punching production line for the sheets, the sheet feeding device, the sheet inlet device, the sheet punching die, the sheet discharging device and the punched part receiving device are used for achieving the procedures of sheet feeding, intermittent material inlet, sheet punching, discharging, stacking, punched part stacking and the like of the sheets, and therefore the automatic blanking and punching production line is high in production efficiency and can be matched with the punching rhythm of the sheet punching die. The automatic blanking and punching production line is suitable for continuously punching sheets.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

Multi-perception rubber lamination robot device

ActiveCN105480729AFully automatedImprove stack qualityStacking articlesDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses a multi-perception rubber lamination robot device. The device comprises a buffer mechanism, a cutting mechanism, a lamination mechanism, a loading mechanism and a support; the buffer mechanism is arranged at one end of the support, and the cutting mechanism, the lamination mechanism and the loading mechanism are arranged at the other end of the support and are sequentially arranged from top to bottom. By means of the device, automatic lamination can be achieved, and the lamination efficiency and quality are improved.

Owner:SOUTHEAST UNIV

Level calibration mechanism for house building

InactiveCN106150107AReal-time adjustmentThere will be no loosenessBuilding material handlingBrickThreaded pipe

The invention discloses a level calibration mechanism for house building. The level calibration mechanism comprises two support seats and a threaded pipe, a front sliding groove is formed in one side of each guide rail in a penetrating mode, a side sliding groove is formed in the other side of each guide rail in a penetrating mode, the top ends of support rods are both fixedly connected with the middle of the outer side wall of a semi-ring, an adjusting threaded rod is inserted into the threaded pipe, the end, close to a connecting seat, of the adjusting threaded rod is provided with a cylinder, the adjusting threaded rod is composed of multiple connecting threaded rods, one end of each connecting threaded rod is provided with a support pin, and the end, close to the corresponding support pin, of each connecting threaded rod is provided with an installing groove; the top end of the outer side wall of each support seat is provided with a support ring, the support rings are connected with the two ends of a U-shaped pipe in an inserting mode respectively, and the two ends of the U-shaped pipe both extend to the upper portions of the support rings. The level calibration mechanism for house building is reasonable in structural design and high in practicability, not only can improve the stacking quality and efficiency of wall bricks, but also can avoid a resource waste phenomenon and has the very high practicability.

Owner:TIANJIN SENRAN ENG COST CONSULTING

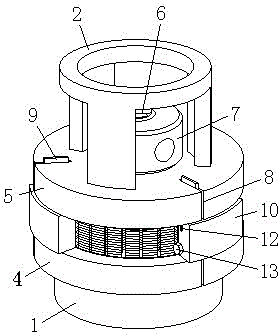

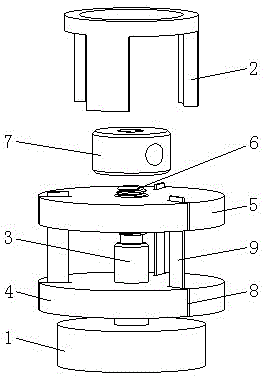

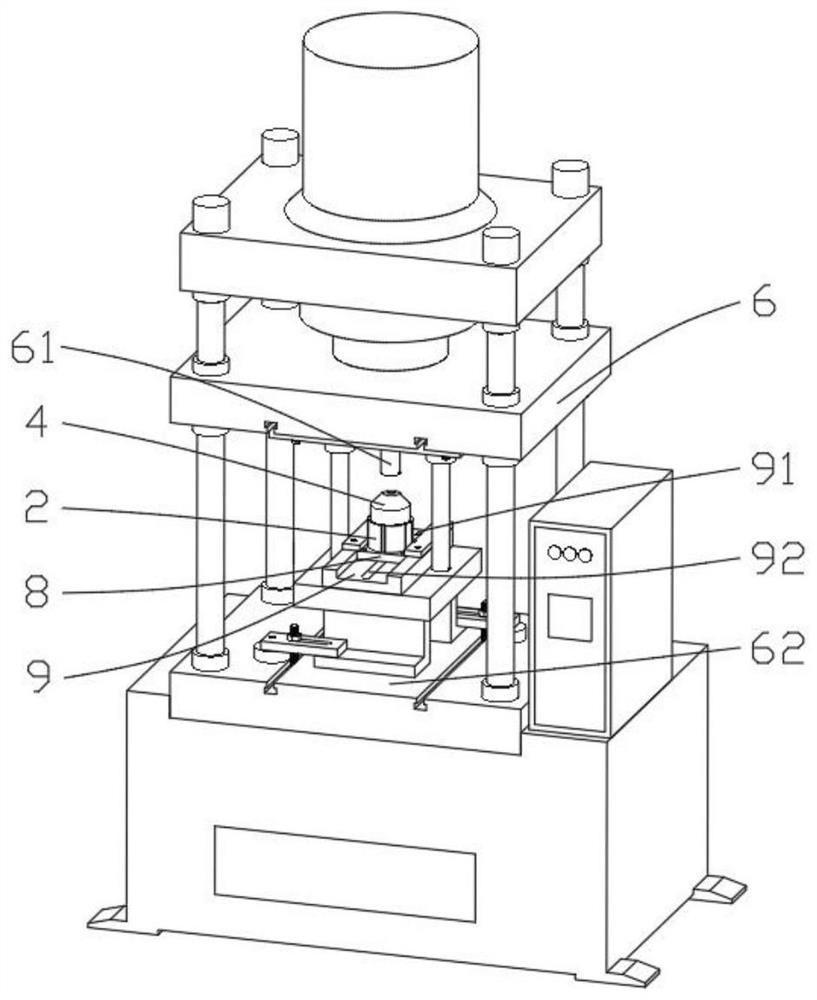

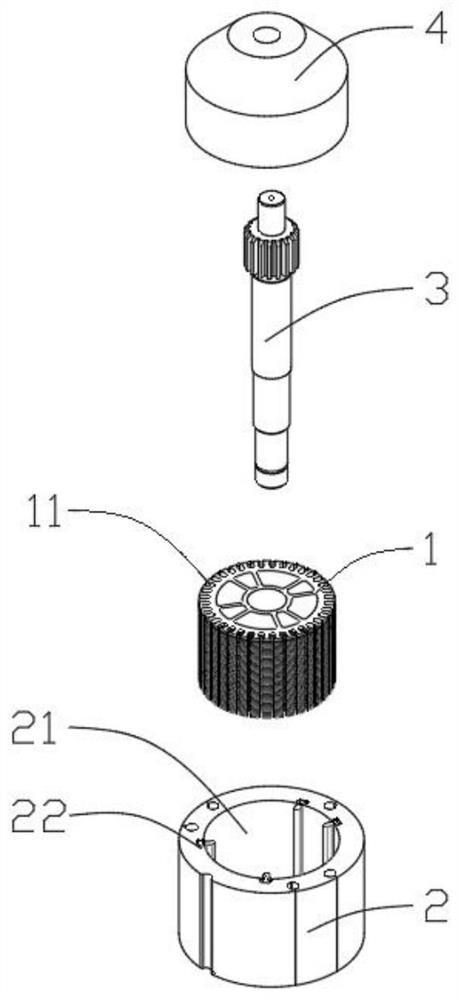

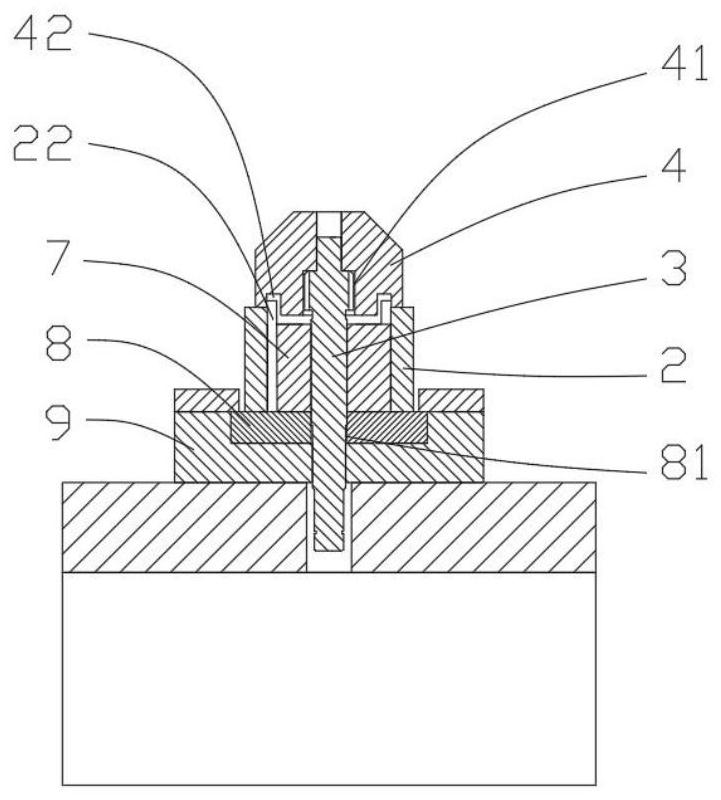

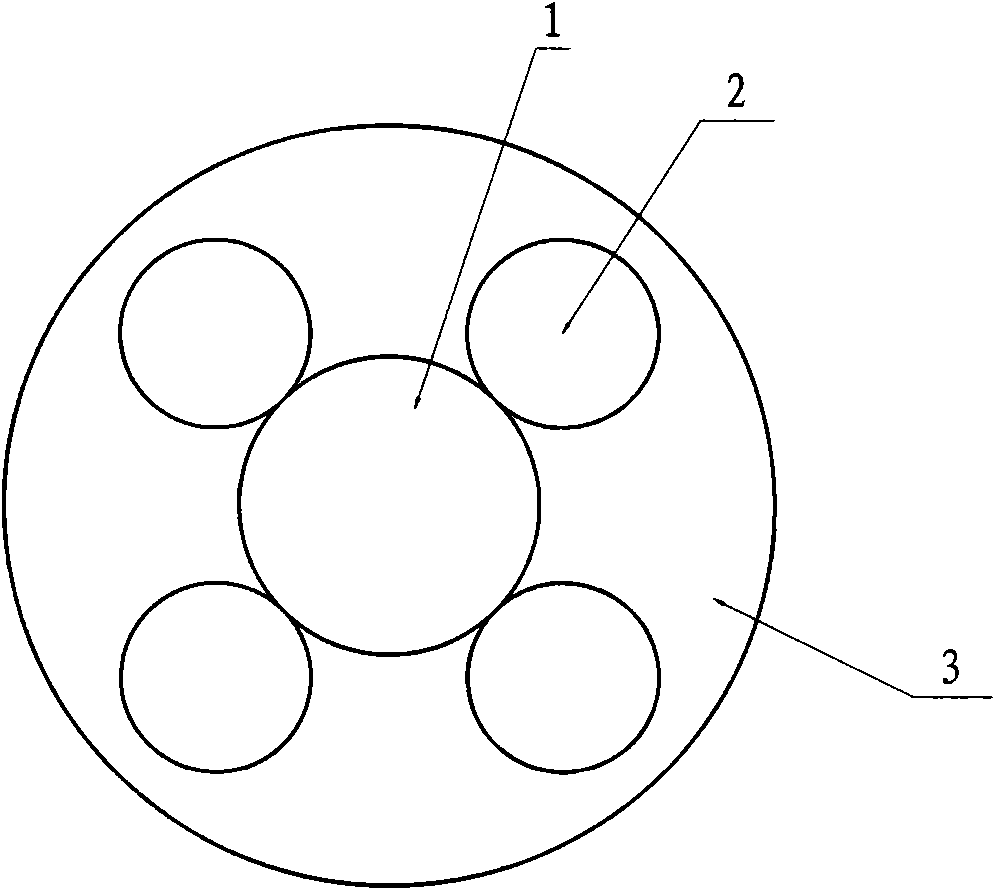

Rotor iron core stacking die

PendingCN113270984AFlat surfaceTightly boundManufacturing stator/rotor bodiesEngineeringStructural engineering

The invention relates to the technical field of rotor iron core production, and discloses a rotor iron core stacking die which comprises an iron core punching sheet positioning seat, a rotor shaft pressing seat and an iron core punching sheet pressing seat. The rotor shaft pressing seat and the iron core punching sheet pressing seat are located above the iron core punching sheet positioning seat. According to the invention, the laminated rotor iron core punching sheets are circumferentially positioned through the iron core punching sheet positioning seat, the positions of the winding grooves of the rotor iron core punching sheets are ensured to be in one-to-one correspondence, the subsequent off-line operation is facilitated, and the rotor shaft pressing seat and the iron core punching sheet pressing seat axially press the rotor shaft and the rotor iron core punching sheets respectively, so that the rotor iron core punching sheets are tightly connected with the rotor shaft, all layers of rotor iron core punching sheets are tightly attached, it is guaranteed that the size of the stacked rotor iron core is matched with the set size, and meanwhile after stacking, the surface of each rotor iron core punching sheet is smooth, the stacking process is simple, the efficiency is high, the size precision is high, and the quality is good.

Owner:湖北信友汽车零部件有限公司

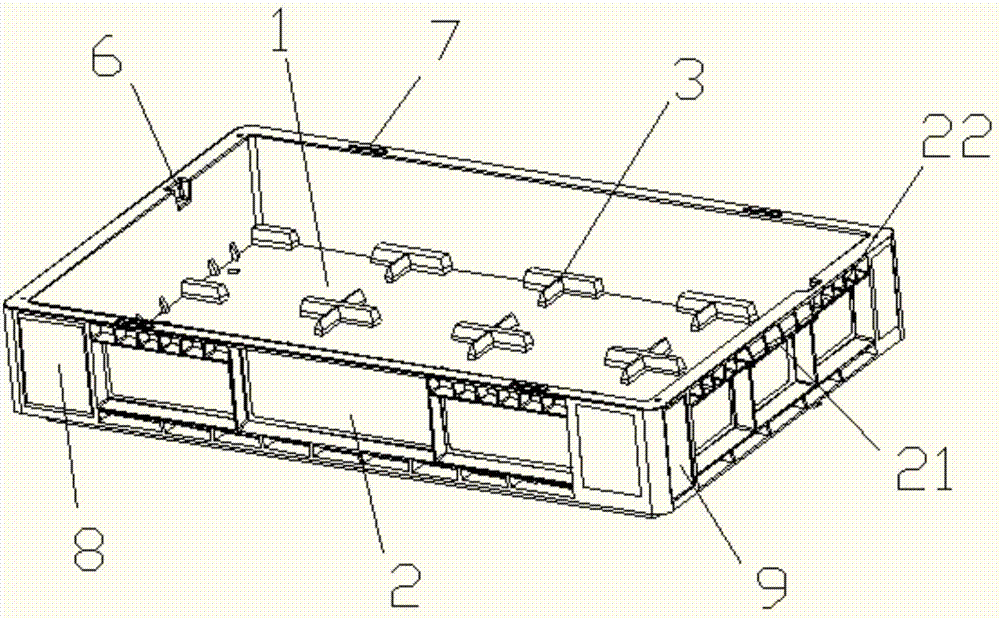

Integrated type electric turnover box and production method

PendingCN107458687AReduce connectionsIncrease productivityContainers to prevent mechanical damageRigid containersCustomer requirementsInjection moulding

The invention discloses an integrated type electric turnover box and a production method applied to the electric field. The integrated type electric turnover box is characterized by structurally comprising a bottom plate and side plates, wherein the bottom plate comprises an upper surface and a lower surface; the side plates are perpendicularly arranged on the upper surface; the side plates are enclosed to form a placing region; and the bottom plate and the four side plates are injection-molded integrally. The integrated type electric turnover box is injection-molded integrally, so that a connecting process of the side plates and the bottom plate is reduced, production efficiency is improved and production cost is reduced. Changes of the structure of the turnover box finished product can be realized by changing a mould shape according to different customer requirements, so that production efficiency of the turnover box is improved. The turnover box is manufactured through a model, so that the product dimension is more precise, structural dimension difference, caused by the connecting process of the bottom plate and the side plates, of the turnover box finished product is avoided, structural consistency of the turnover boxes produced in batch is effectively improved, stacking effect of the turnover box is guaranteed, stacking stability is improved, and guarantee is provided for a follow-up operation process.

Owner:SUZHOU YING CHUANG POWER TECH

Annealed steel coil quick stacking device and operation method thereof

InactiveCN101967550AEasy to adjustReduce injuriesFurnace typesHeat treatment furnacesVisual field lossElectricity

The invention provides an annealed steel coil quick stacking device and an operation method thereof. The annealed steel coil quick stacking device comprises a steel coil hanger, an embedding sleeve, a pick-up system, an illumination system, a display, a steel coil stacking platform and a position indicating marker, wherein the steel coil hanger is provided with a guide cone; the embedding sleeve is arranged in the center of the lower end face of the guide cone; the pick-up system is concavely arranged in the center of the lower surface of the embedding sleeve; the illumination system is arranged on the lower surface of the embedding sleeve and is close to the pick-up system; the display is electrically connected with the pick-up system and is used for displaying images shot by the pick-upsystem and visual field mark center points of the pick-up system; a forced draught fan is arranged on the steel coil stacking platform; and the position indicating marker is arranged in the center ofthe upper surface of the forced draught fan, wherein the center line of the embedding sleeve coincides with the center line of the guide cone. The annealed steel coil quick stacking device has simplestructure and low investment cost and can effectively improve the stacking efficiency and equality.

Owner:SHANDONG IRON & STEEL CO LTD

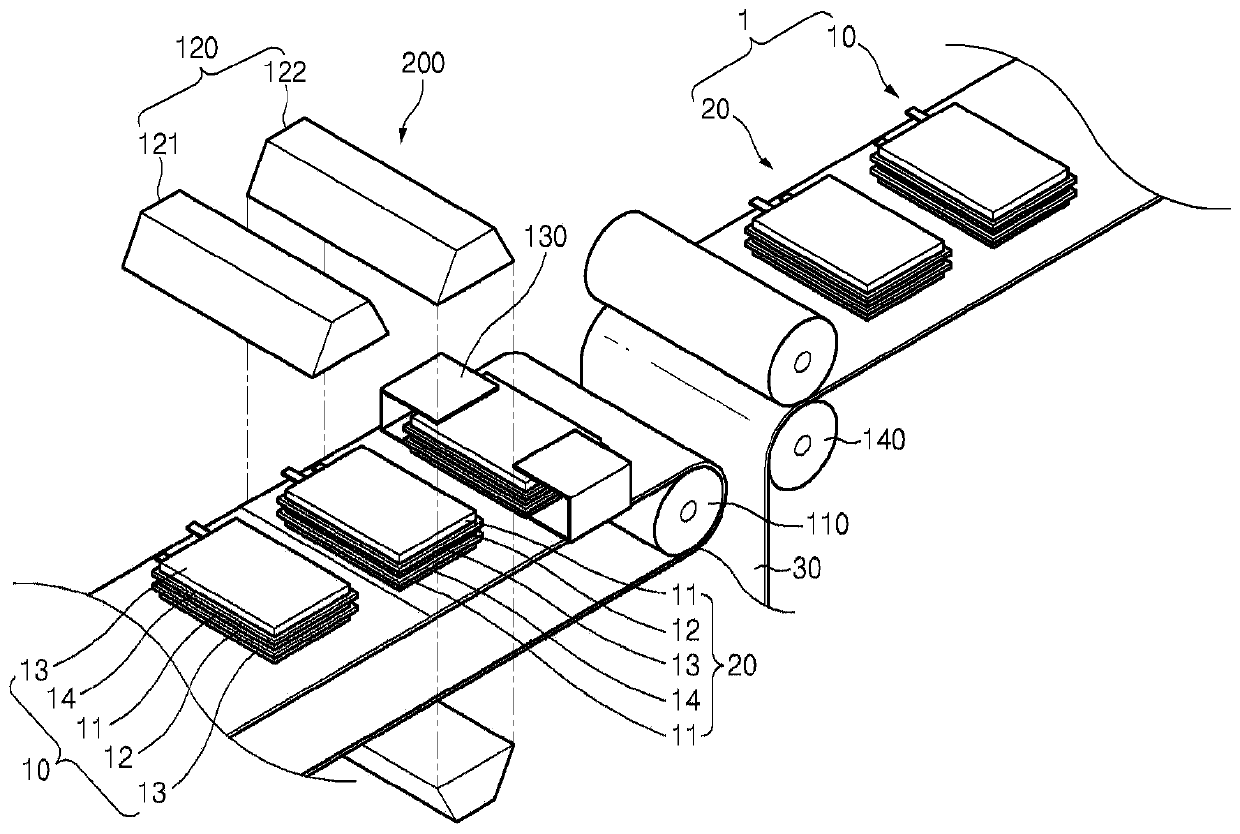

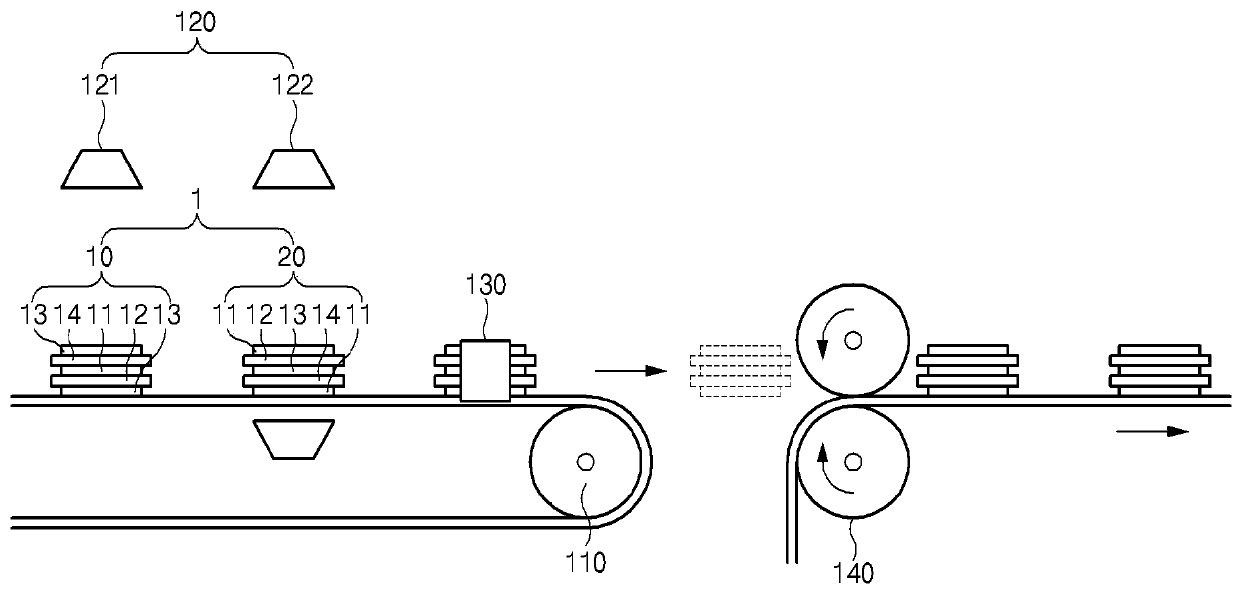

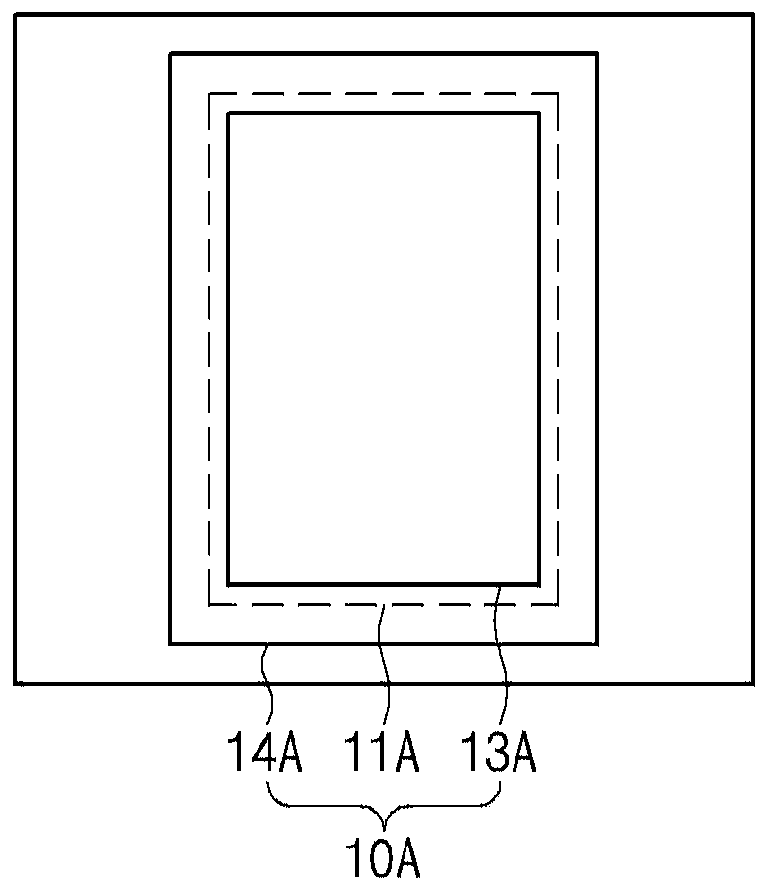

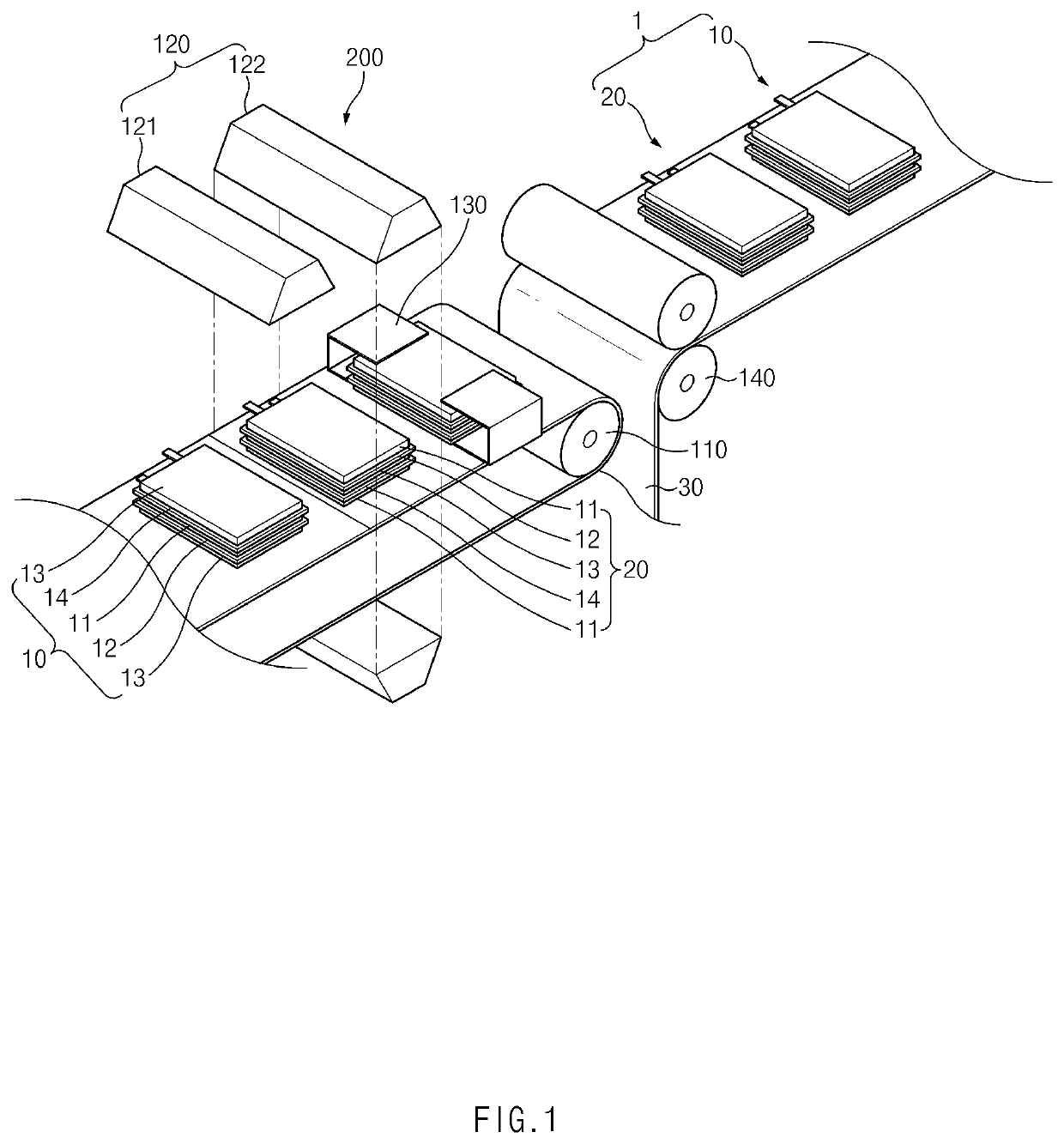

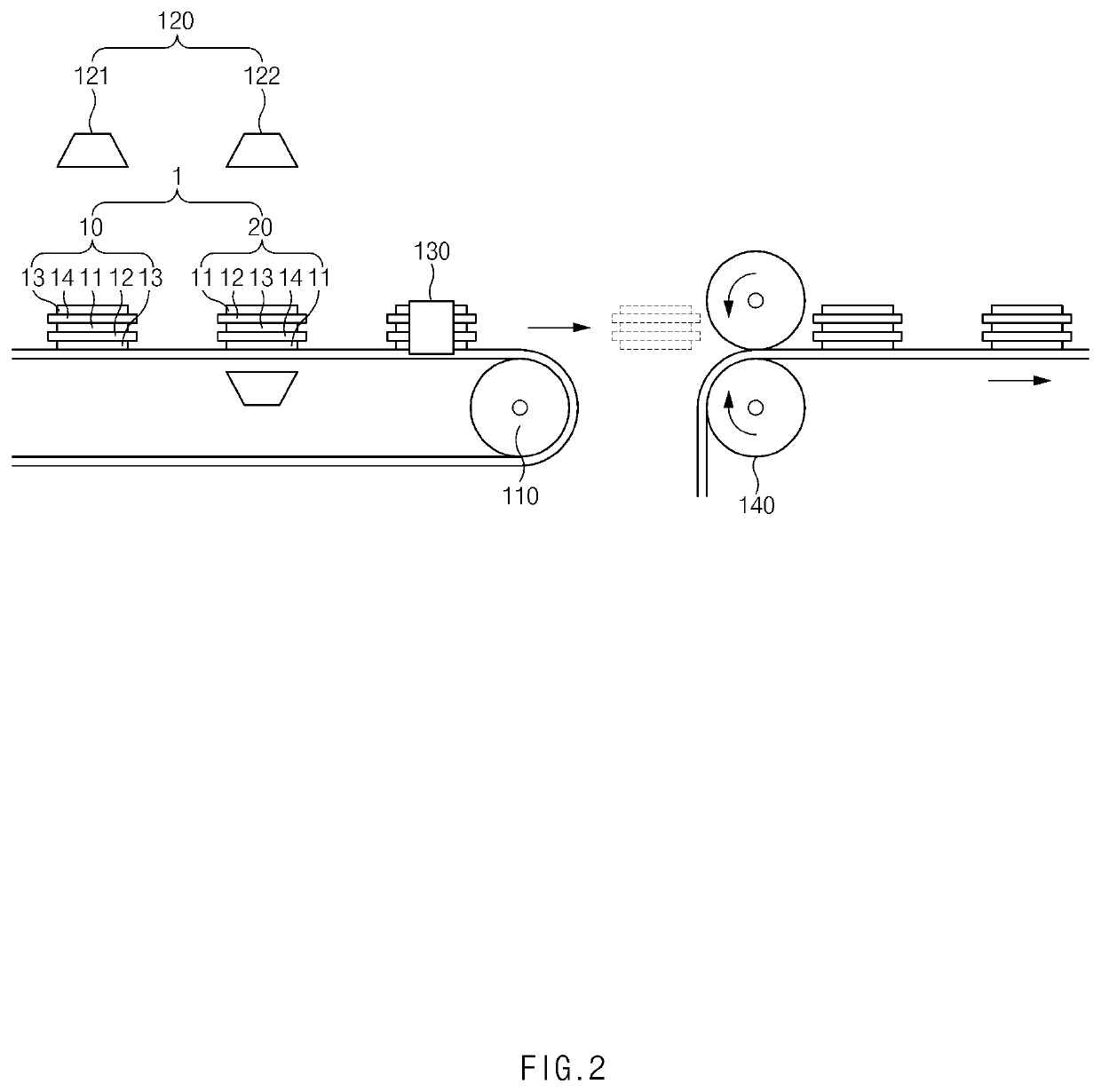

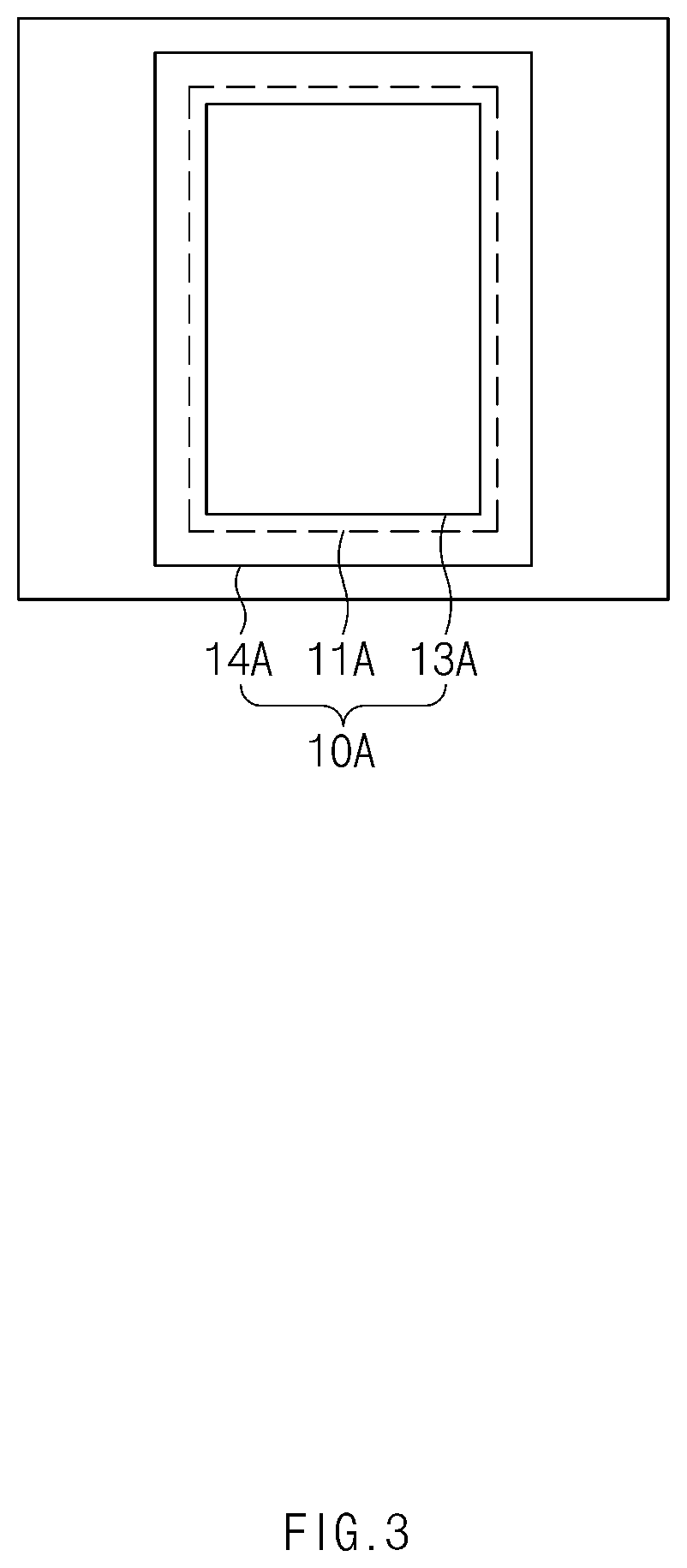

Apparatus and method for manufacturing secondary battery

ActiveCN110692157AImprove stack qualityAdjust intervalAssembling battery machinesLarge-sized flat cells/batteriesElectrical batteryMechanical engineering

Owner:LG ENERGY SOLUTION LTD

Rotary quantitative material stacking system

The invention relates to the technical field of quantitative material stacking mechanisms, in particular to a rotary quantitative material stacking system. The rotary quantitative material stacking system comprises a stand, groove type hoppers, elastic force sensors, a motor and a controller used for driving the motor to rotate, the motor is arranged at the axle center in the stand, the output end of the motor runs through a workbench of the stand to connect with a rotating shaft arranged at the axle center of the top of the workbench, the controller is arranged at one side of the motor, a turn plate is arranged at the top of the rotating shaft, the hoppers are suspended on the turn plate by the elastic force sensors, a plurality of hoppers are uniformly distributed along the circumferential direction of the turn plate, a feed hole is formed in the side wall of the upper part of each hopper, an electric discharge gate controlled by the controller is arranged at the bottom end of each hopper, and the elastic force sensors are connected with the controller. The rotary quantitative material stacking system automatically controls ordered material stacking, the material stacking quality is good, the efficiency is high, the structure is simple, and the cost is low.

Owner:常州市兰迪电器有限公司

Apparatus and method for manufacturing secondary battery

PendingUS20200212494A1Improve stack qualityAvoid defectsAssembling battery machinesLarge-sized flat cells/batteriesElectrical polarityMechanical engineering

An apparatus for manufacturing the secondary battery includes a first measurement part photographing unit cells, which are continuously transferred, to measure a position of a first electrode having a relatively large size of the first electrode and a second electrode, which are provided in the unit cells and have polarities opposite to each other, from an image of each of the photographed unit cells; and a first arrangement part disposing the unit cell passing through the first measurement part at a preset position of the separation sheet to adjust an interval between the unit cells disposed on the separation sheet on the basis of the position of the first electrode, which is measured by the first measurement part.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com