Phenolic paper automatic proportioning and stacking system

An automatic batching and phenolic paper technology, which is applied in thin material handling, conveyor objects, object supply, etc., can solve the problems of high labor intensity, low quality of paper stacking, and low production efficiency, so as to save labor, increase production capacity, The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

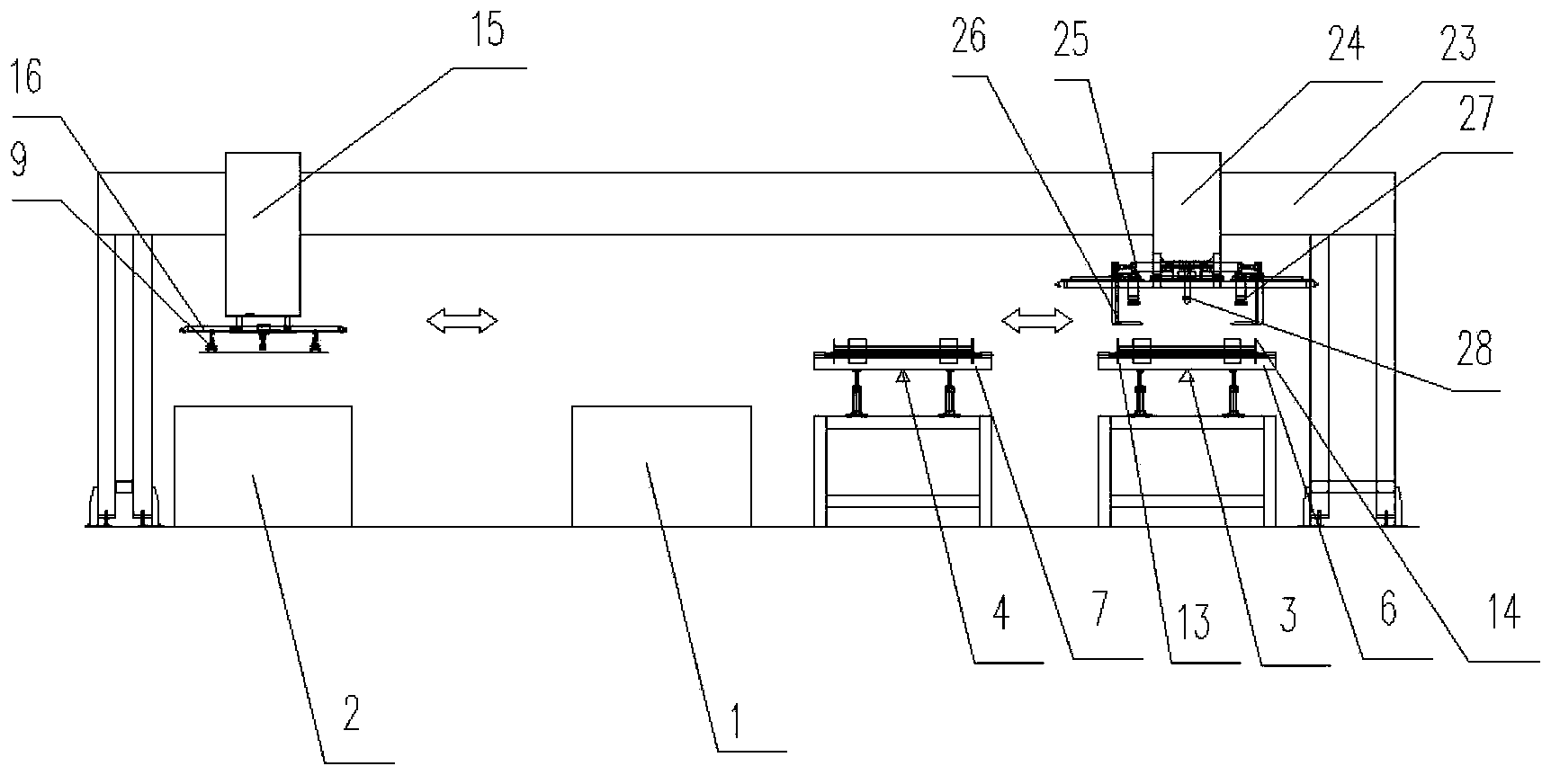

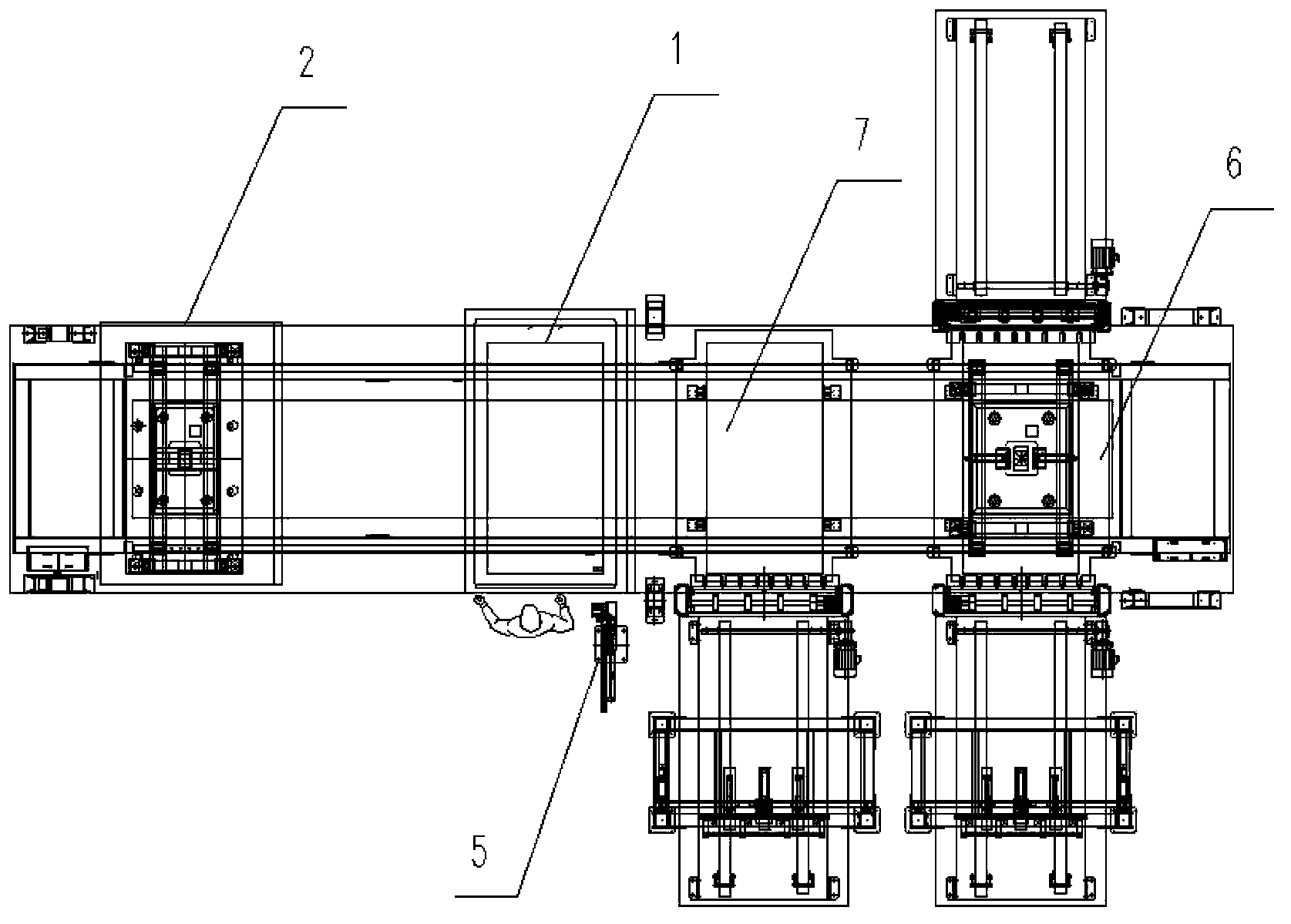

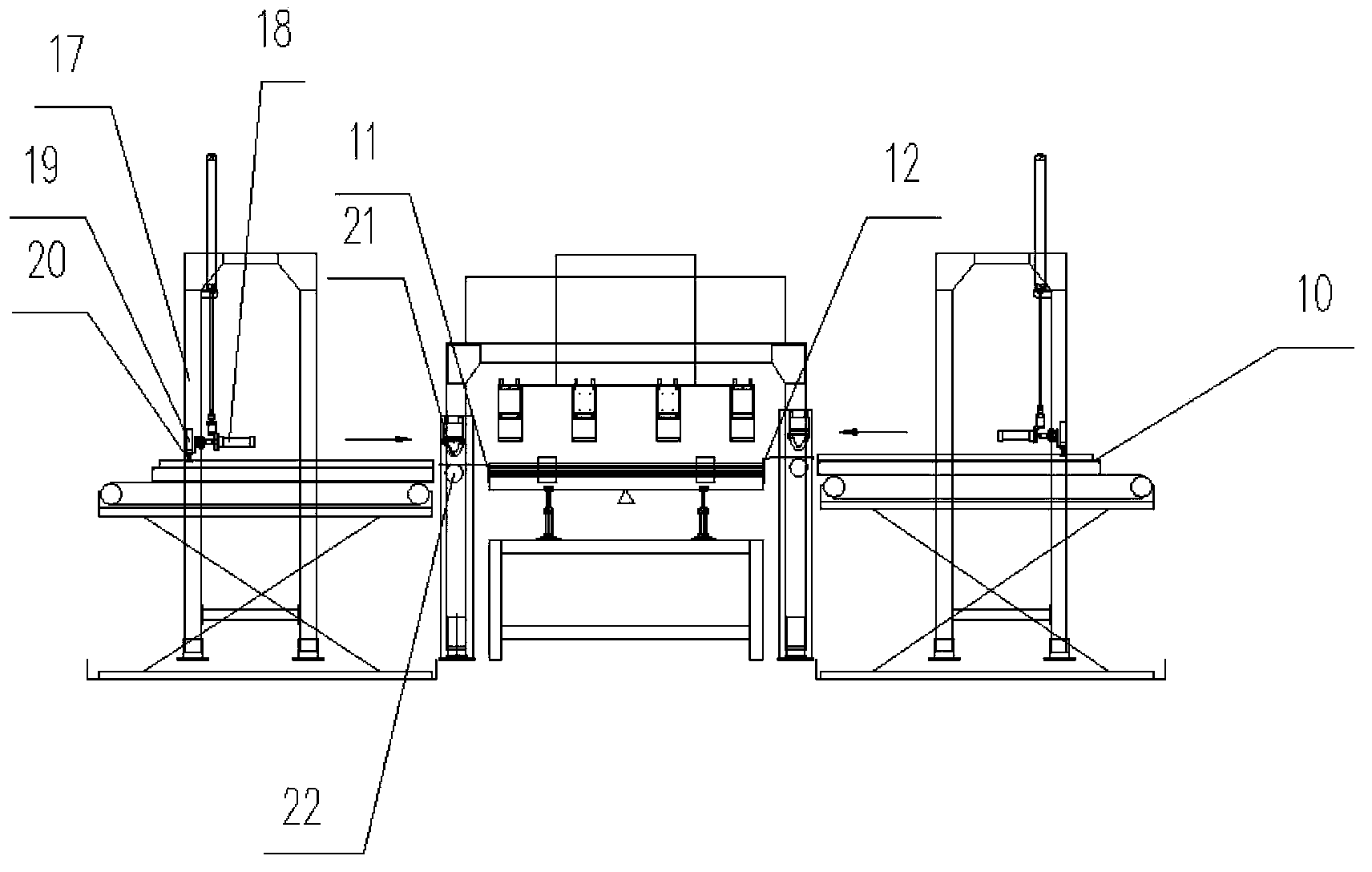

[0019] Embodiment: An automatic batching and stacking system for phenolic paper, including a labeling workbench 1, a mirror plate placement platform 2, the first and second grabbing and conveying devices, the first, second and third separating pushers, the paper conveying device 10, the second One and two metering equipment 3, 4, the first and second guide table, labeling machine 5 and controller, the first and second guide table 6, 7, labeling workbench 1 and mirror plate placement table 2 respectively Placed in the working area, the first and second separation pushers are opposite to the first alignment table and are symmetrically located on opposite sides of the first alignment table, and the third separation pusher is opposite to the second alignment table and located on one of them. side, wherein the first and second guiding tables include the table body and the paper limit device respectively, and the paper limit device can guide the position of the paper on the table bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com