Patents

Literature

41results about How to "Fast stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

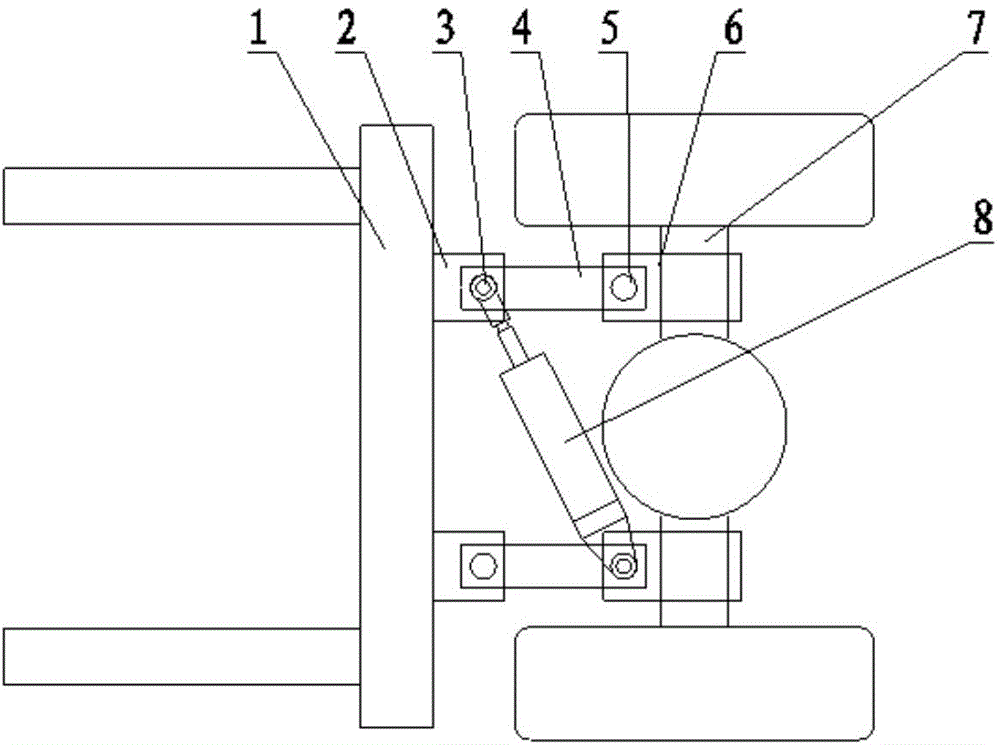

Automatic output device of rotary cutter veneer production line

ActiveCN104003235ANovel structureHigh degree of automationArticle deliveryControl engineeringElectric machinery

The invention discloses an automatic output device of a rotary cutter veneer production line. The automatic output device is provided with a conveyor frame and is characterized in that a cylinder positioning frame is arranged in a top frame of a classification frame; the outer side of the top frame is provided with a conveyor motor; a swing frame is arranged under the top frame; a supporting frame is arranged between pillars of the classification frame; the pillars are provided with photoelectric switches; the lower portions of two ends of a cylinder seat are provided with swing cylinders; the upper ends of the swing cylinders are connected with the cylinder positioning frame; the lower ends of the swing cylinders are hinged to the swing frame; the supporting frame is corresponding to the conveyor frame; a rotating shaft is arranged above the supporting frame; two ends of the rotating shaft are fixedly connected with the supporting frame; driving belt pulleys are arranged on the rotating shaft separately; the rotating shaft is driven by the conveyor motor; one end of the swing frame is connected with the rotating shaft through a support; belt pulleys are arranged at the other end of the swing frame separately; a classification conveyor belt winds around the swing frame, one end of the classification conveyor belt is connected with the driving belt pulleys, and the other end of the classification conveyor belt is connected with the belt pulleys. According to the automatic output device of the rotary cutter veneer production line, the structure is novel, the degree of automation is high, the veneer qualified rate is high, the working efficiency is high, the time and the labor are saved, and the like.

Owner:SHANDONG BAISHENGYUAN GRP

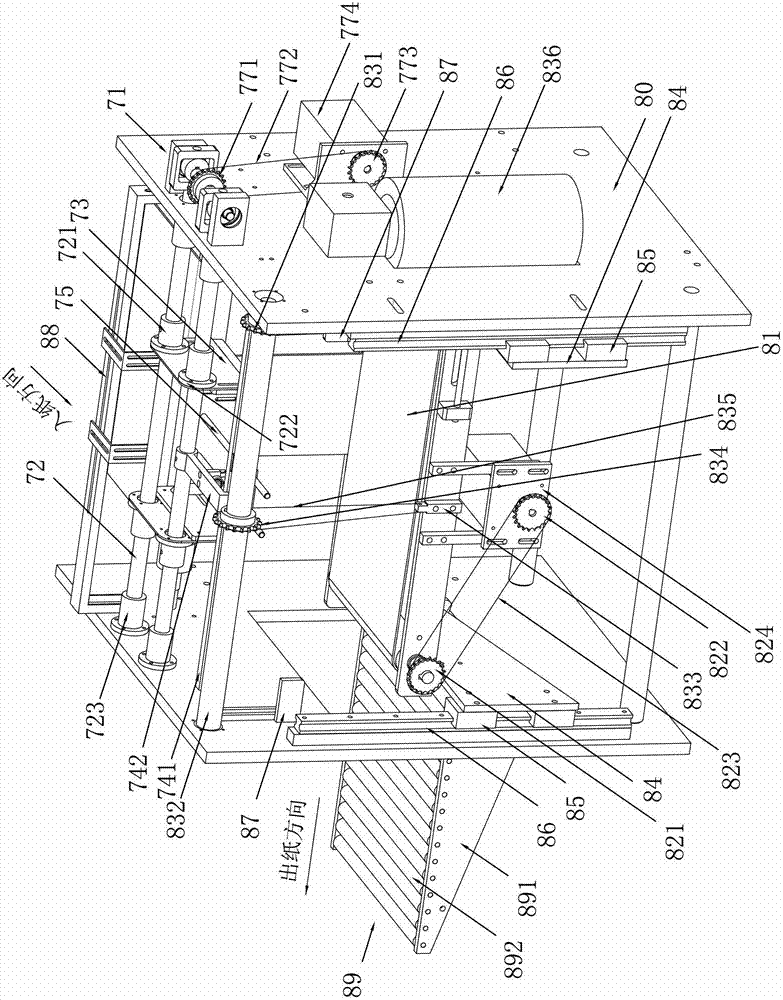

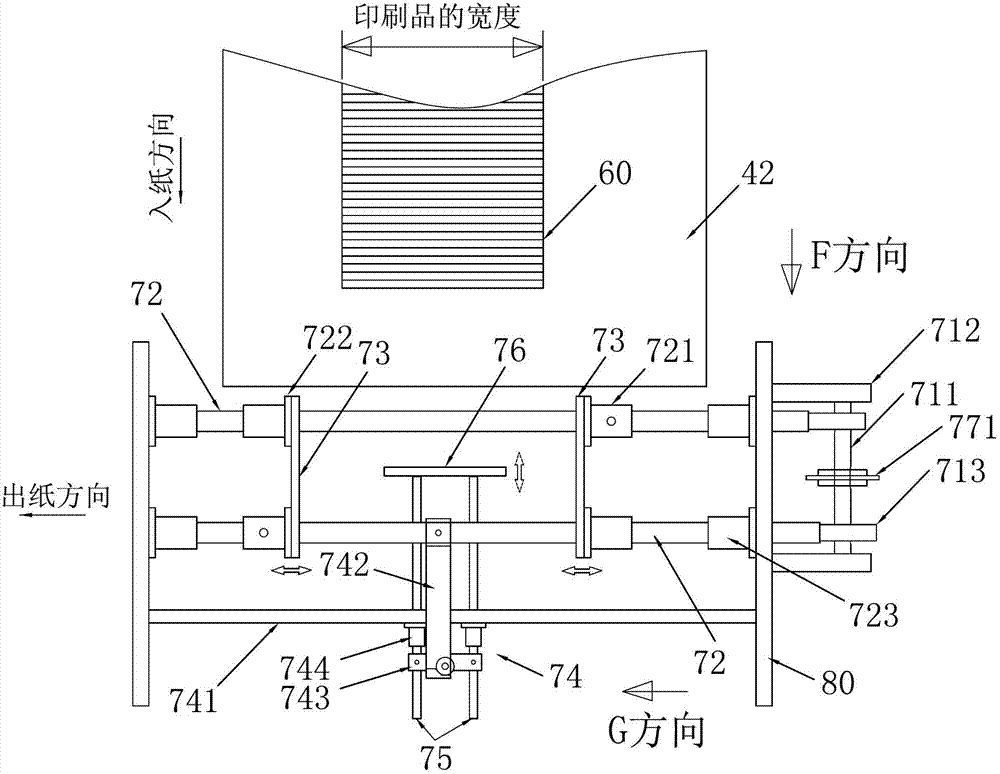

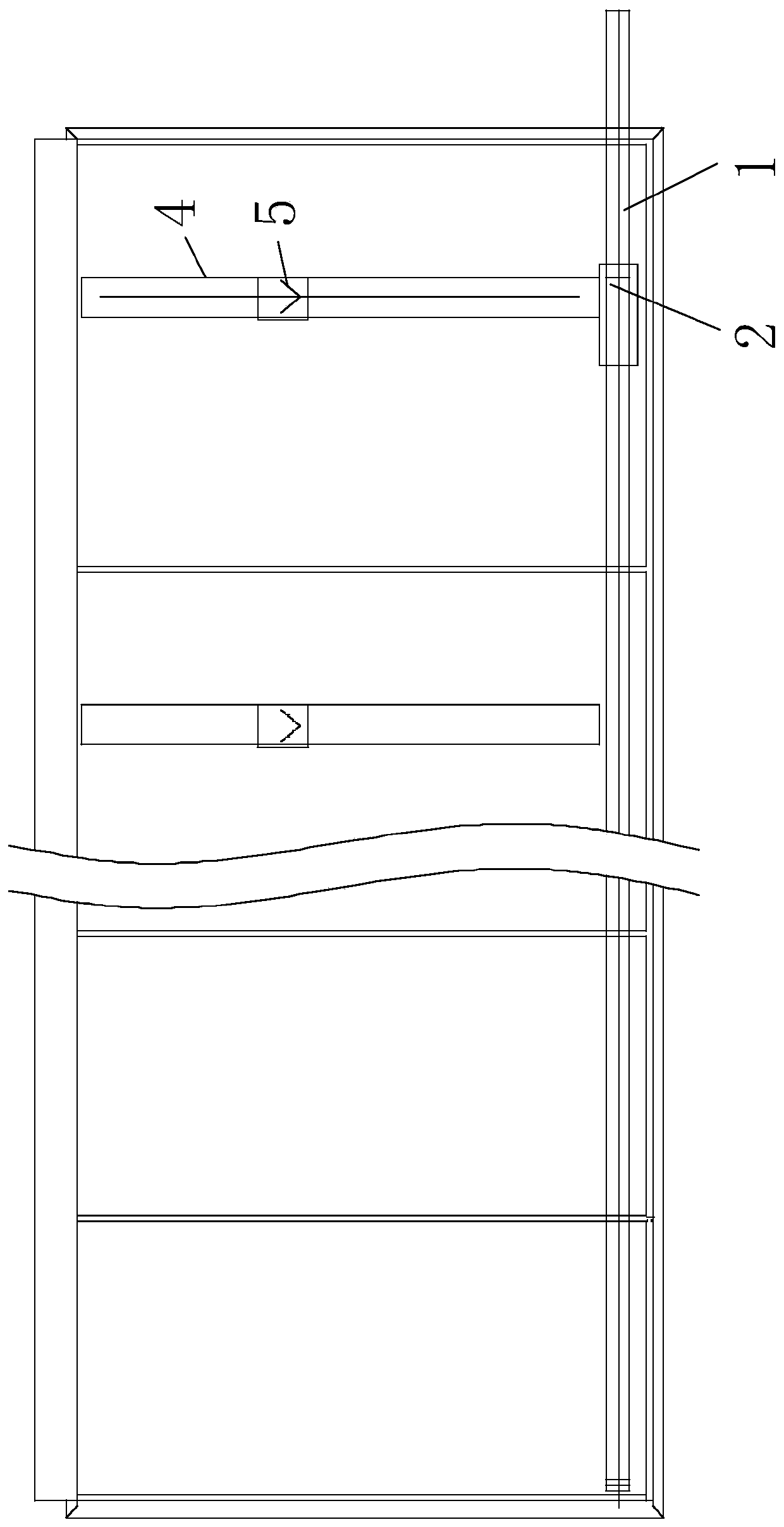

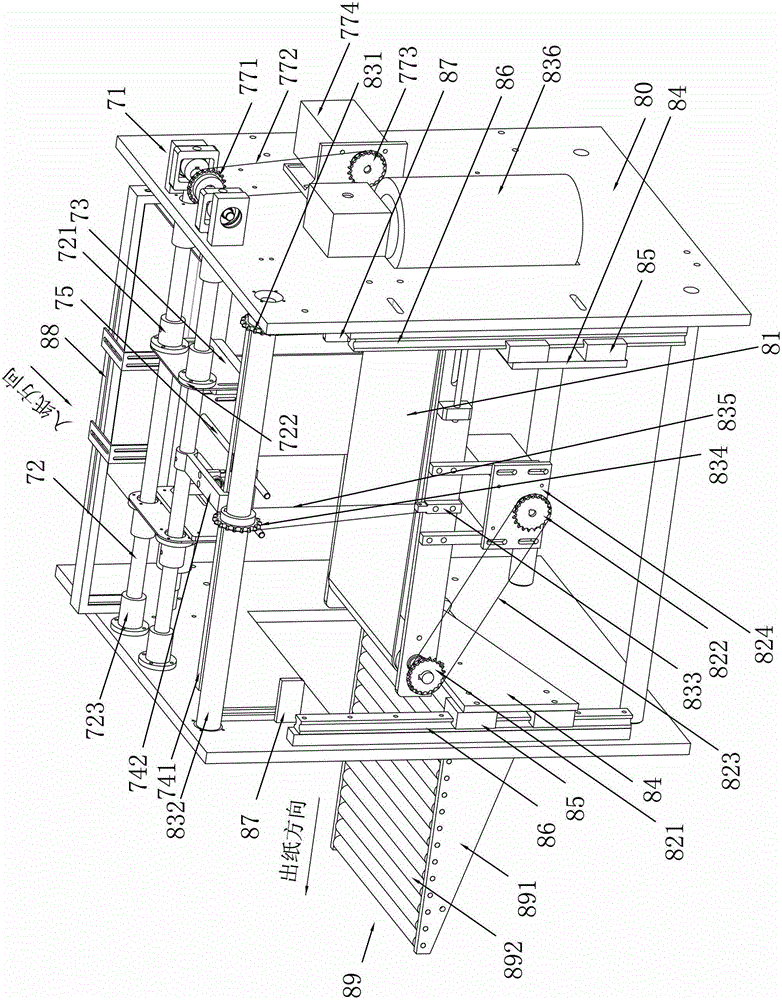

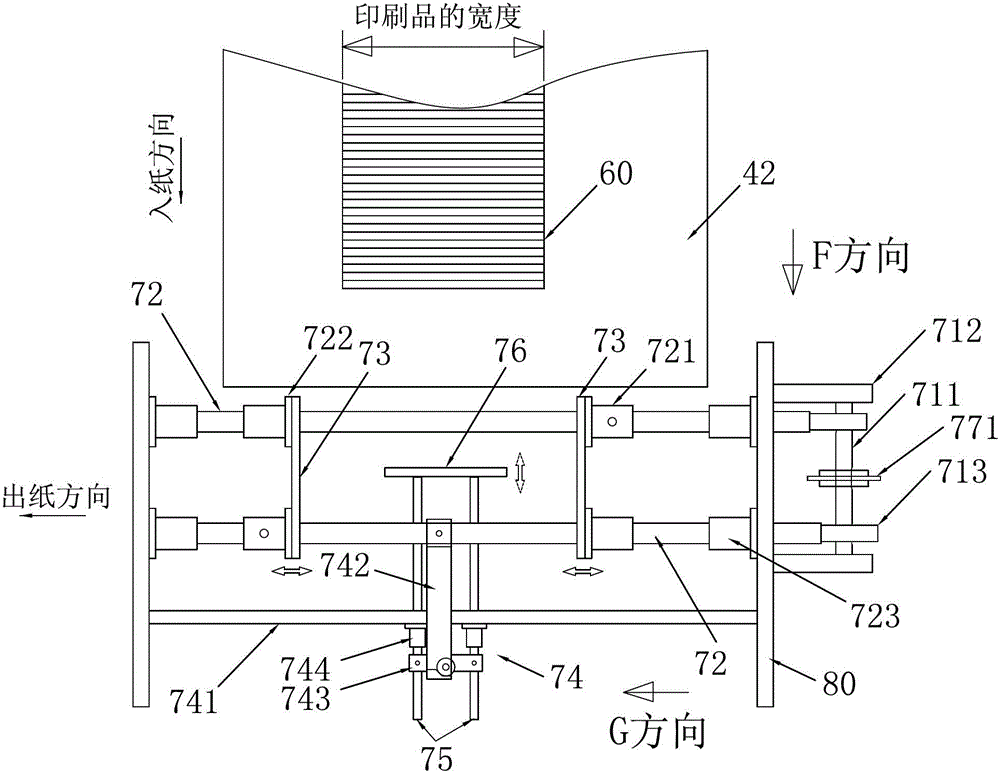

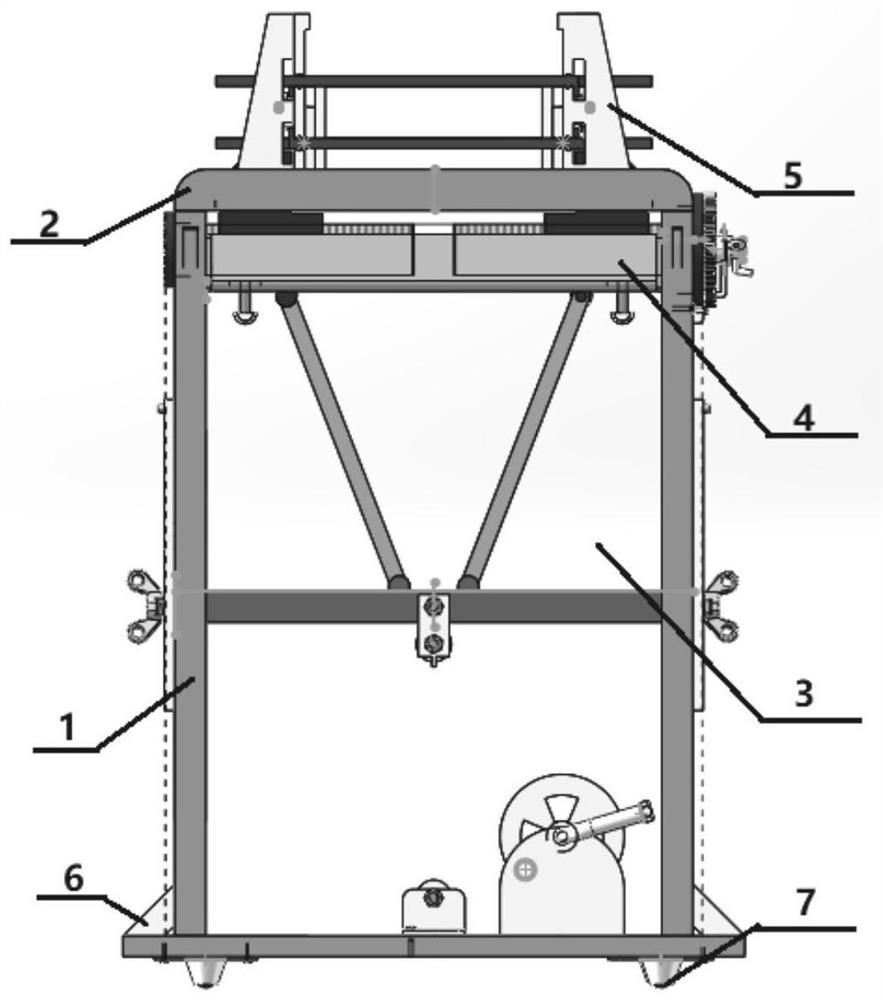

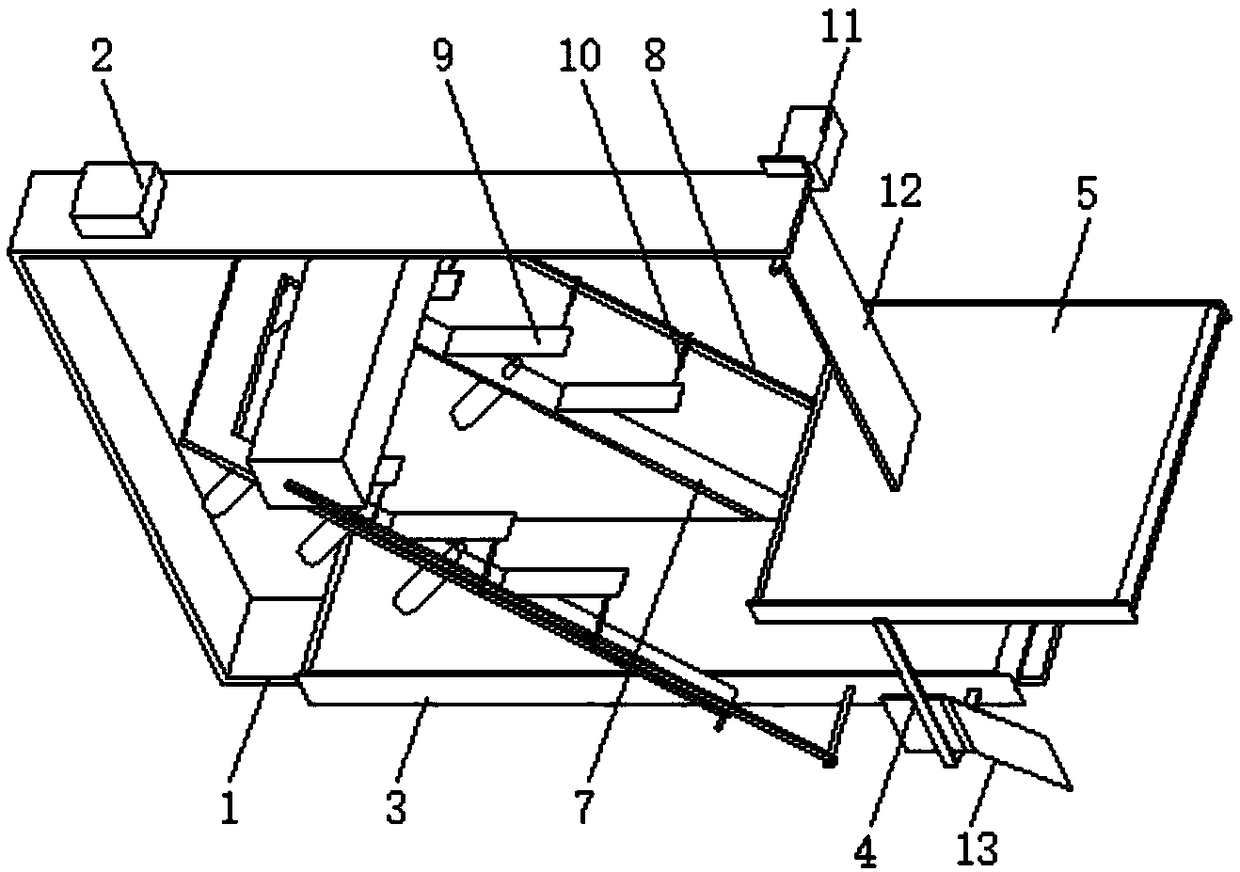

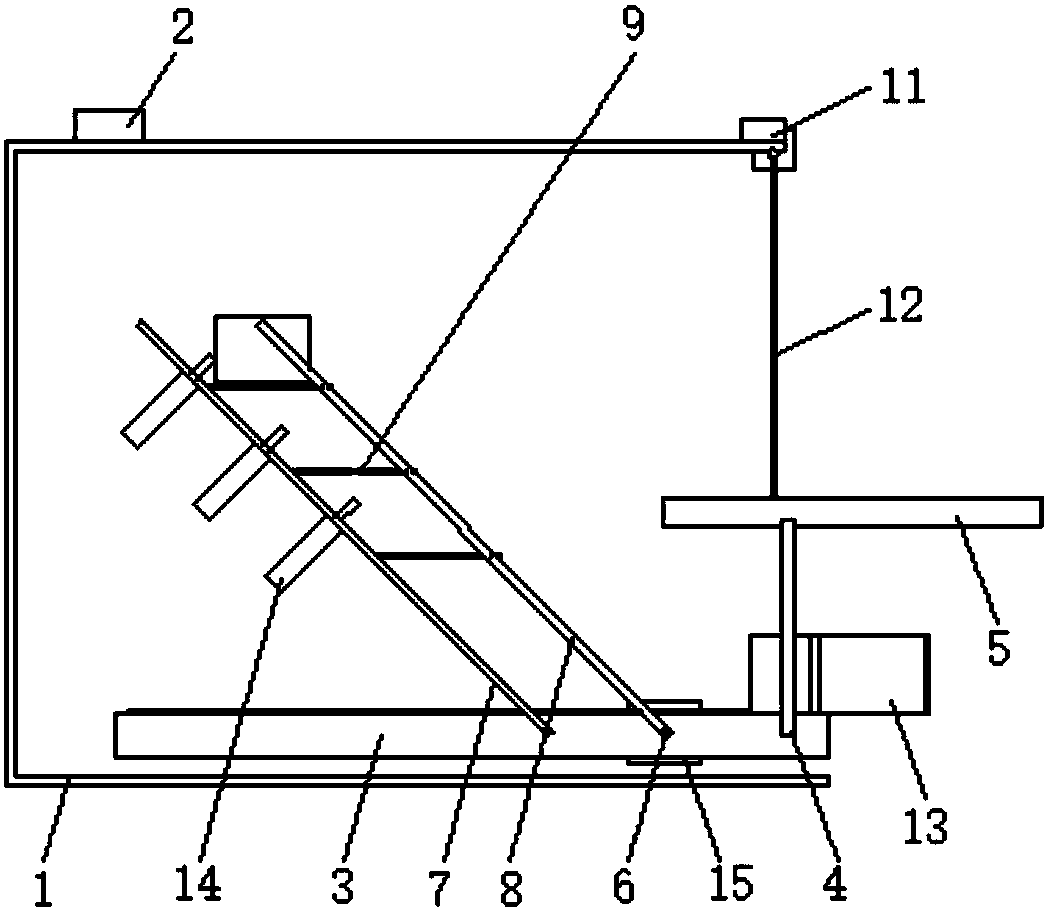

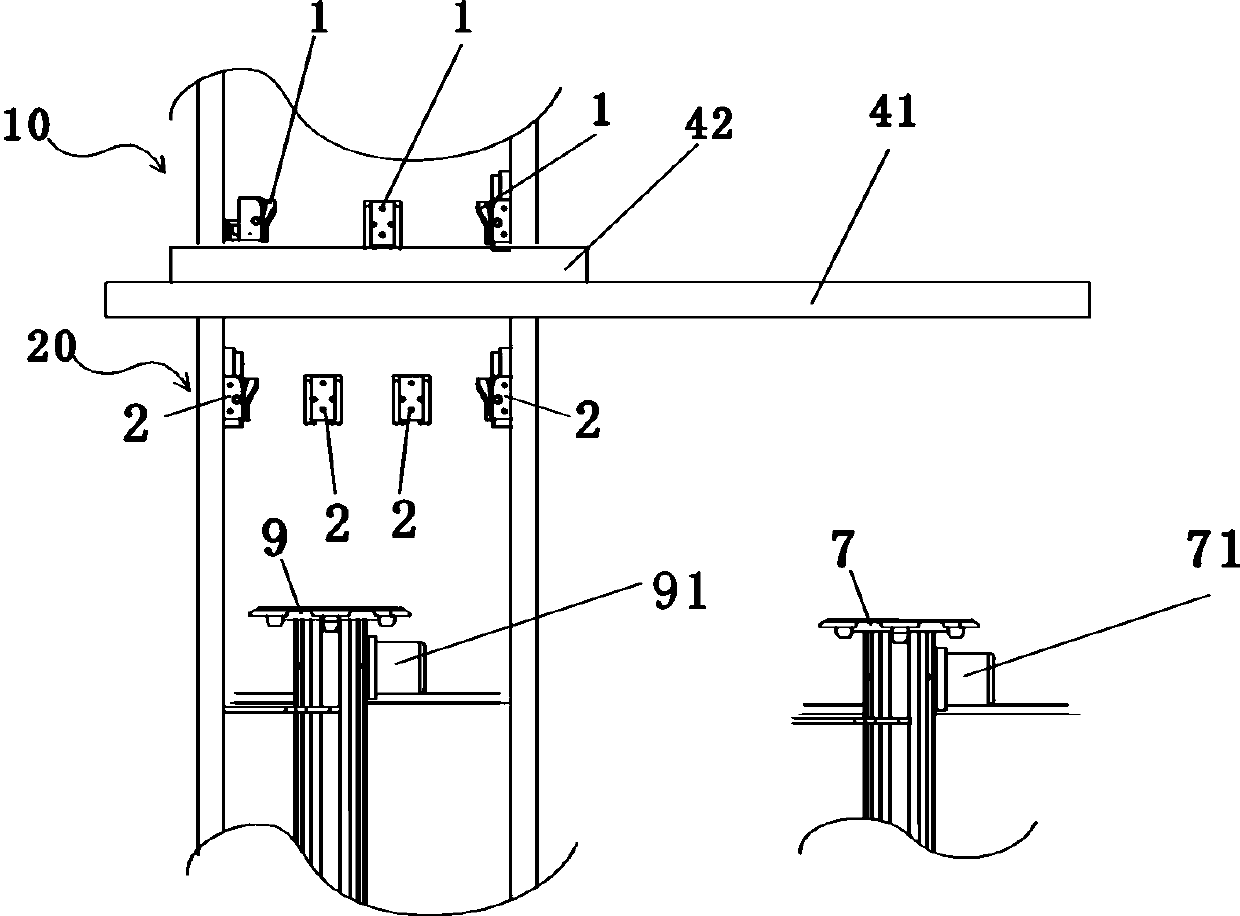

Stacking and collecting mechanism, stacking and collecting method and quality testing machine for small-size prints

The invention discloses a stacking and collecting mechanism, a stacking and collecting method and a quality testing machine for small-size prints. The stacking and collecting mechanism comprises two main wallboards. The two main wallboards are partially provided with clapping devices. A stacking output device is arranged under the clapping device. The clapping device comprises a supporting beam mounted between the two main wallboards. One end of the supporting beam is connected with a cam mechanism. A pair of lateral pushing boards is mounted on the supporting beam, and is used for pushing two lateral sides of prints. A rear pushing board is arranged between two lateral pushing boards, is connected with the supporting beam through a supporting rod and a slope driving mechanism, and is used for hooking-in and clapping the upper surface of the prints. The stacking output device comprises a lifting platform which is driven to move up and down by a lifting motor through a lifting conveying mechanism. The stacking and collecting method and the quality testing machine for small-size prints are realized based on the stacking and collecting mechanism. Automatic stacking and collecting of the small-size prints are realized at a high speed in high efficiency with low vibration and noise.

Owner:HEBEI TIANYUHENG TECH CO LTD

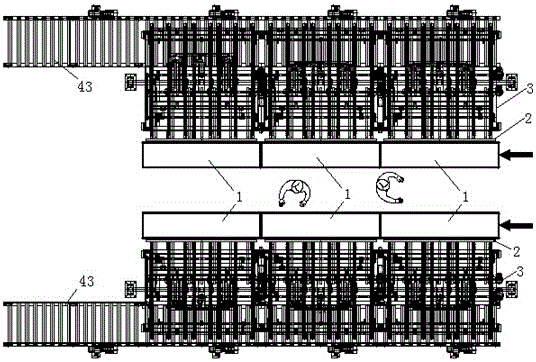

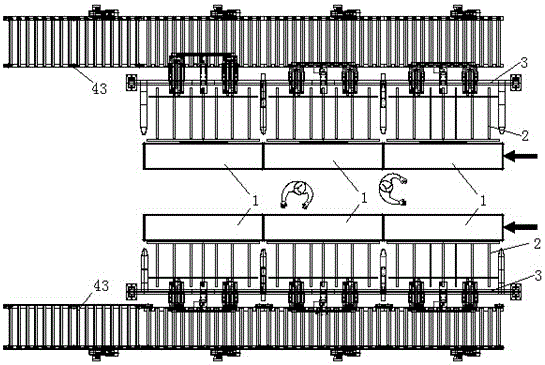

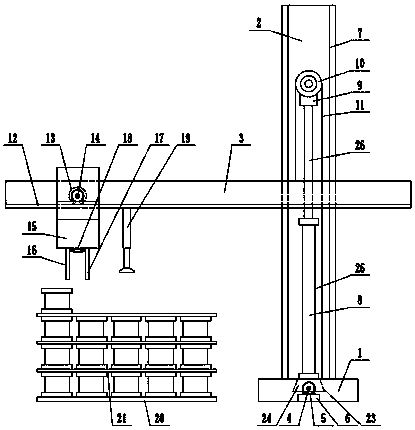

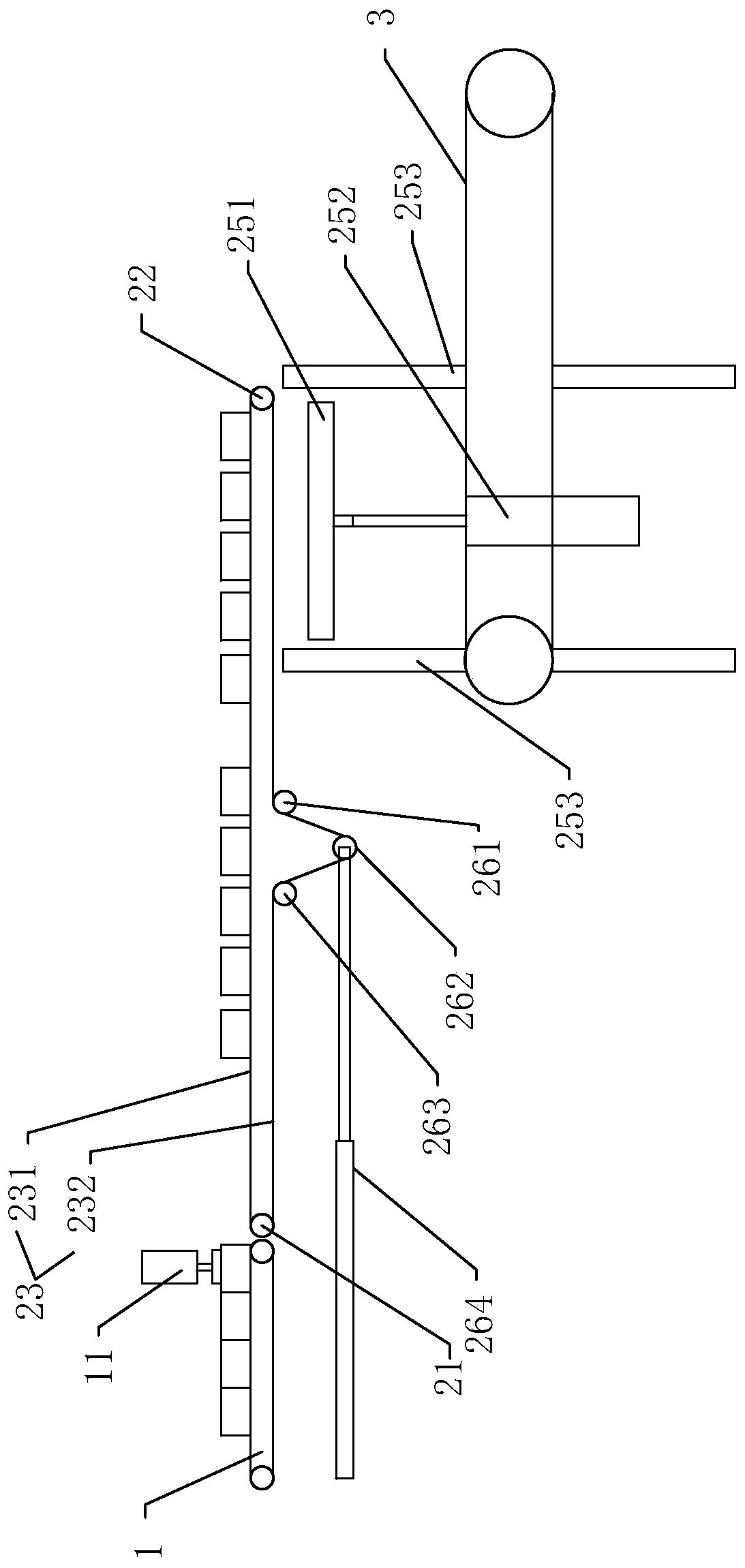

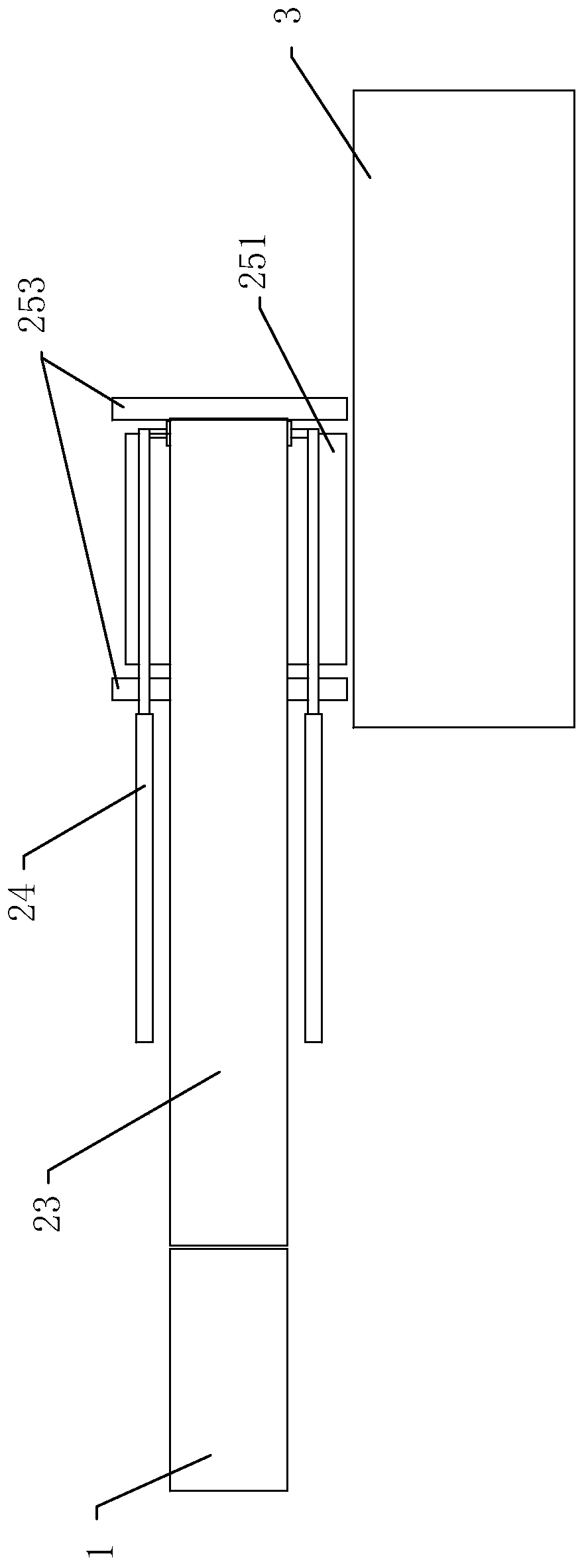

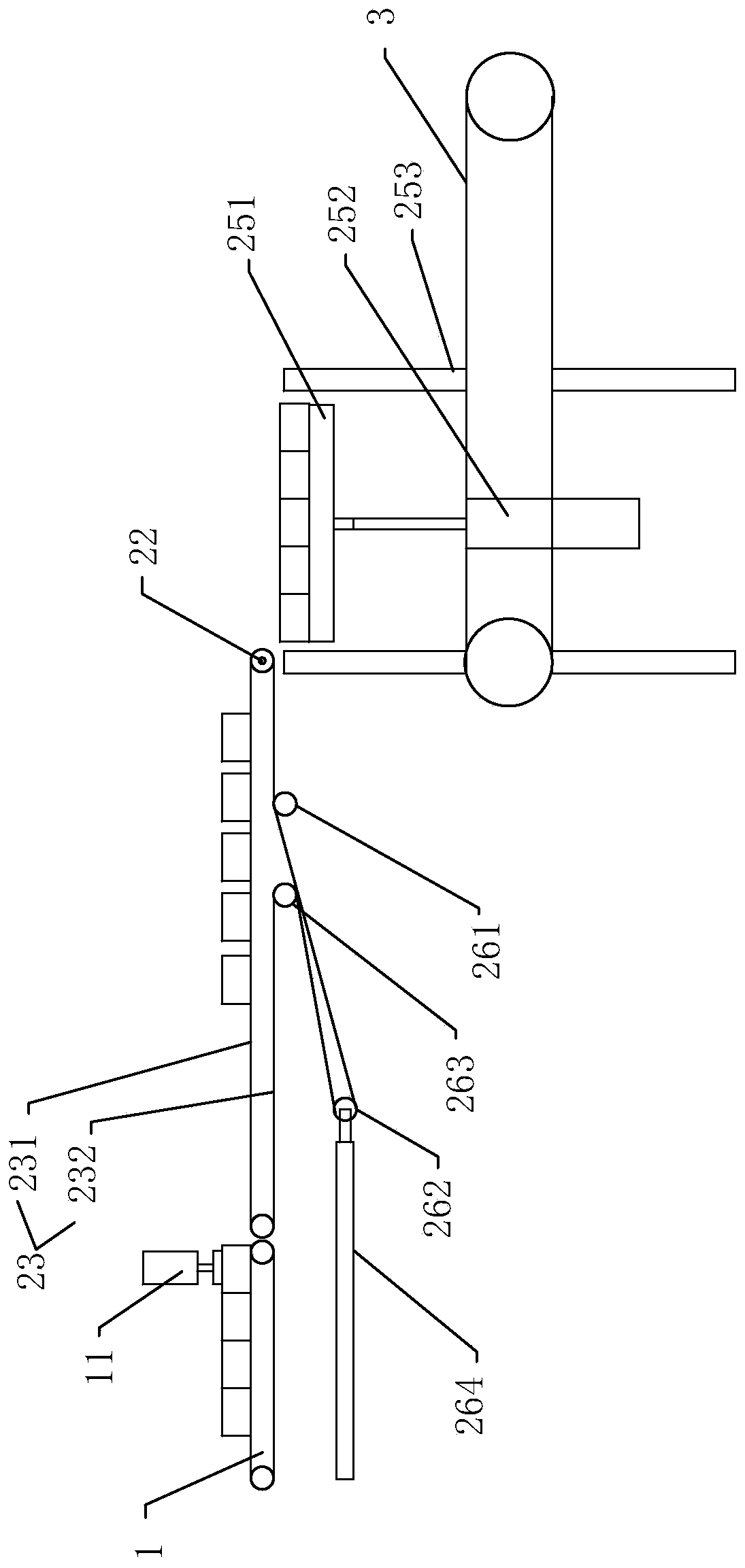

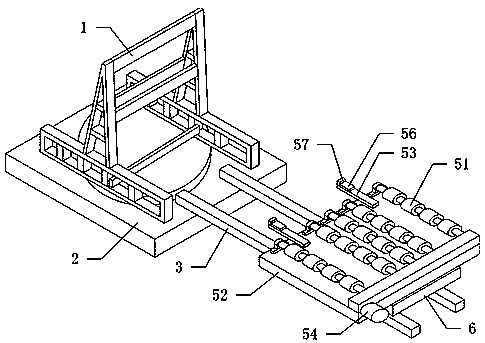

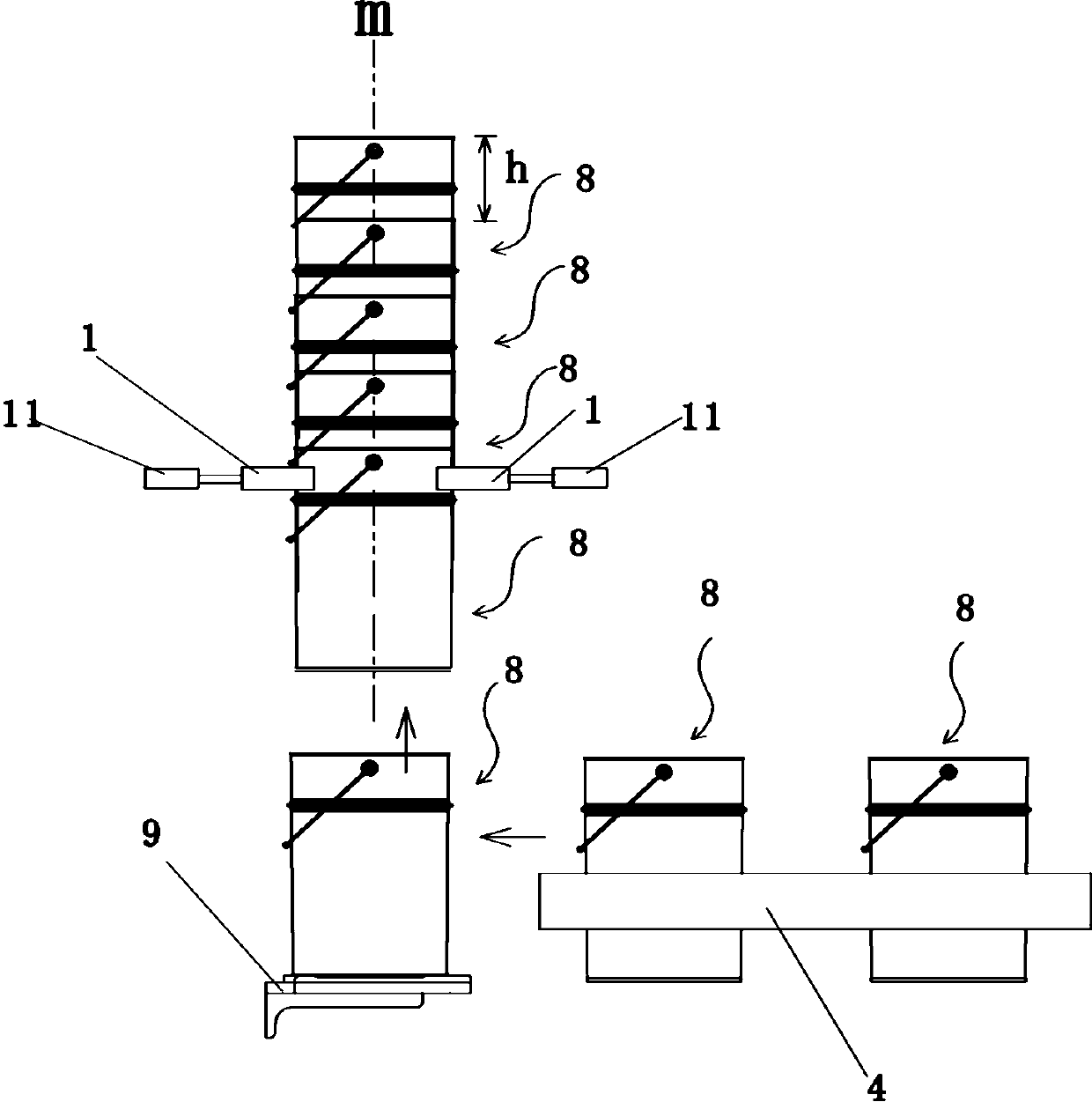

Board stacking system and using method thereof

The invention belongs to the field of board machining, and provides a board stacking system and a using method thereof. The board stacking system comprises a workbench, a lifting platform system and a lane conveying system. The lifting platform system comprises a lifting platform and a lifting control system, and the lifting platform is arranged on one side of the workbench; the lane conveying system is arranged below the lifting platform, the lifting platform comprises a plurality of parallel horizontal rods located at the same horizontal height, and the lane conveying system comprises a lifting conveying system and a conveying system; one end of the lifting conveying system and the horizontal rods of the lifting platform are arranged in a staggered mode, and the other end of the lifting conveying system extends to the conveying system. The problems that at present, cut boards are low in transferring and stacking efficiency, and the overall board machining efficiency is affected are solved.

Owner:JF AUTOMATION SUZHOU CO LTD

Chemical fiber cone yarn stacking device

The invention provides a chemical fiber cone yarn stacking device and belongs to the technical field of chemical fiber processing. The chemical fiber cone yarn stacking device comprises a vertical beam frame, a horizontal beam frame and a clamping jaw support; the vertical beam frame is slidably arranged on a dovetail-shaped sliding chute of a base through a slider; a screw has threaded connectionwith the slider positioned at the lower end of the vertical beam frame; the horizontal beam frame is arranged on a vertical guide rail of the vertical beam frame in a manner of sliding up and down; the lower end of a lifting cylinder body is fixed to the vertical beam frame; the upper end of a lifting piston rod is connected with a chain wheel support; a chain wheel is rotationally arranged on the chain wheel support; a chain is arranged on the chain wheel in a surrounding manner; one end of the chain is connected with the horizontal beam frame; the other end of the chain is connected with the base; the clamping jaw support is slidably arranged on the horizontal beam frame; a gear is meshed with a gear rack; a first clamping jaw and a second clamping jaw are slidably arranged on the clamping jaw support; the two ends of a clamping jaw cylinder are separately connected with the first clamping jaw and the second clamping jaw; and a lift type sucking disc is installed at the lower side of the horizontal beam frame. The chemical fiber cone yarn stacking device provided by the invention can be used for quickly implementing stacking of chemical fiber cone yarns and is high in automationdegree.

Owner:浙江银汇高纤材料股份有限公司

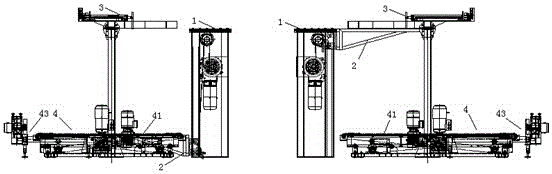

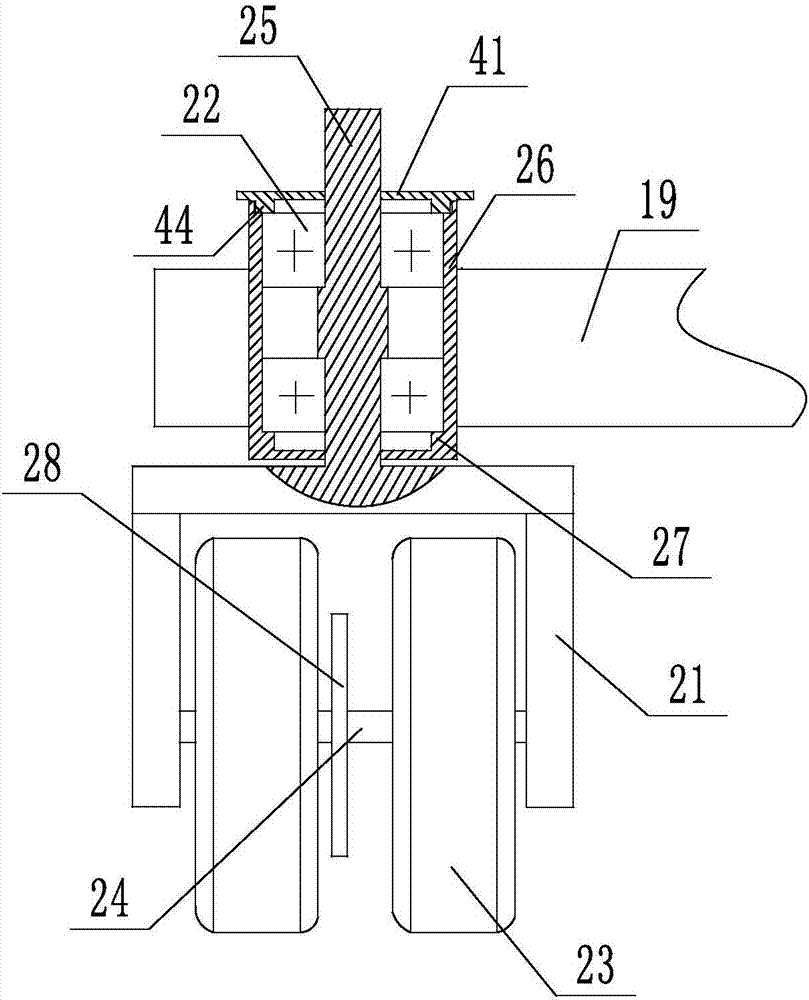

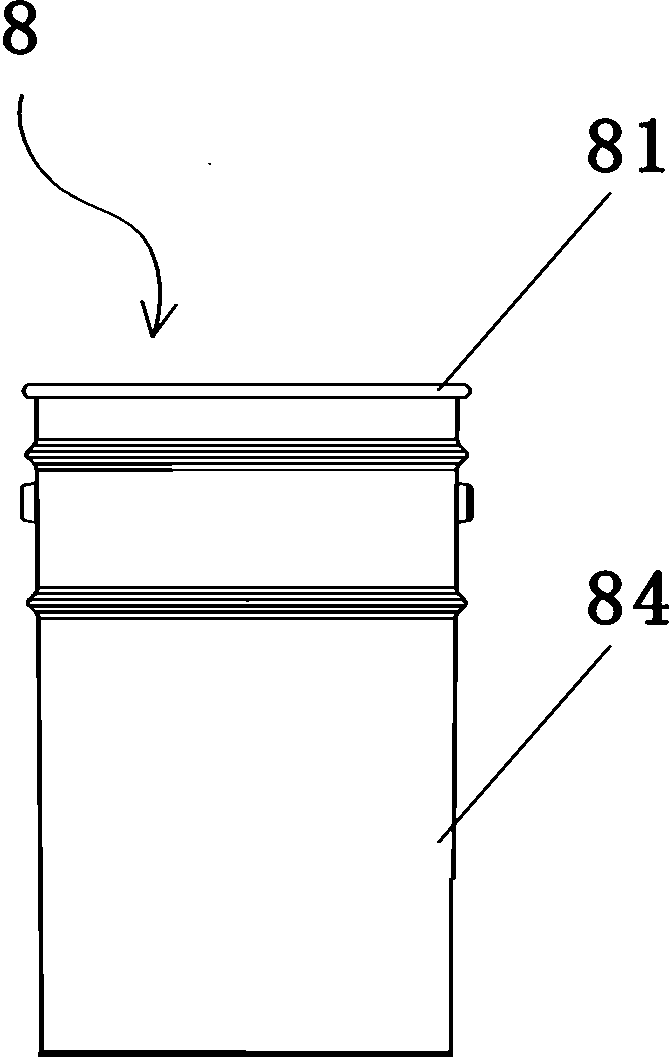

Automatic stacking equipment for metal drums

ActiveCN107324061AHandles in the same directionTowards the sameStacking articlesEngineeringPower component

Automatic stacking equipment for metal drums comprises a circumferential arranging mechanism and a drum supporting plate used for supporting a metal drum stack. A first-grade turnover mechanism is arranged in front of the drum supporting plate. A horizontal delivery mechanism for delivering metal drums which are not stacked is arranged between the circumferential arranging mechanism and the first-grade turnover mechanism. A second horizontal clamping and delivering mechanism is arranged in front of the first-grade turnover mechanism. A second-grade turnover mechanism is arranged in front of the second horizontal clamping and delivering mechanism. The first-grade turnover mechanism comprises a first magnet block capable of rotating, and a rotary shaft of the first magnet block extends in the left-right direction. The first-grade turnover mechanism is further provided with a first-grade turnover power component for driving the first magnet block to rotate clockwise. The drum supporting plate is located below a second-grade blocking component. By means of the automatic stacking equipment for the metal drums, the stacking speed can be improved, the automatic paper-feeding mode can be adopted, and it is ensured that the directions of handles are coincident after stacking.

Owner:汕头市澄海区正益设备有限公司

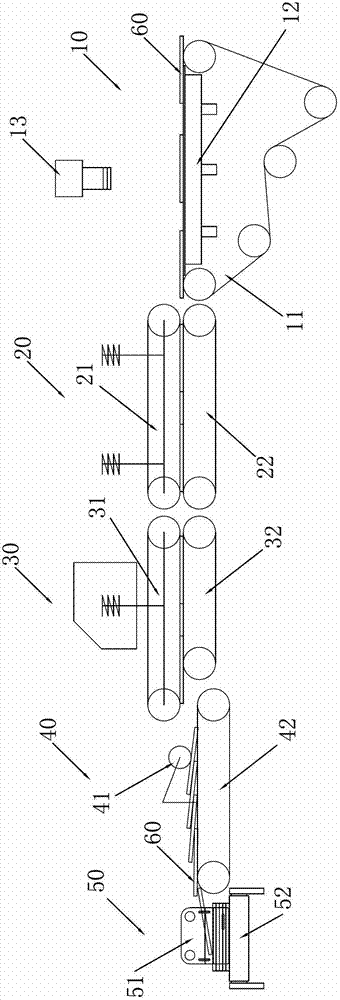

Phenolic paper automatic proportioning and stacking system

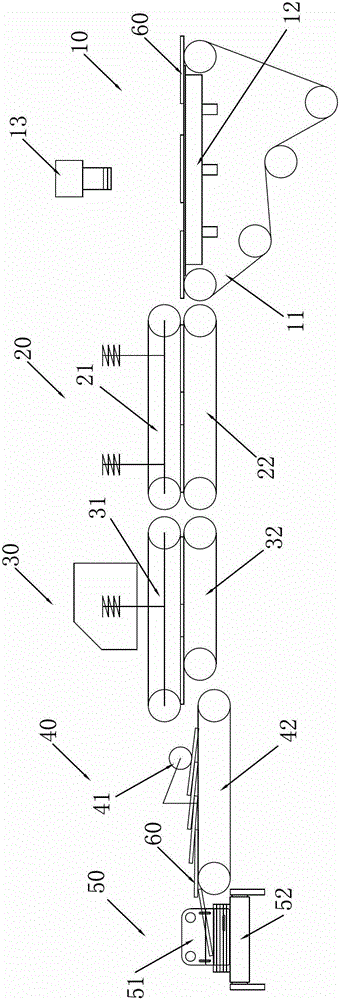

ActiveCN104291145AFully automatedImprove stack qualityArticle feedersConveyor partsPulp and paper industryPaper sheet

The invention discloses a phenolic paper automatic proportioning and stacking system. A first separation pusher and a second separation pusher are located on two opposite sides of a first guide table, a third separation pusher is located on one side of a second guide table, paper limit devices can guide and correct the positions of paper on the tables, paper pushing mechanisms on the first separation pusher, the second separation pusher and the third separation pusher can push out single pieces of paper on respective paper delivery devices to the first guide table or the second guide table corresponding to the paper pushing mechanisms, phenolic paper pushed out by the first separation pusher and phenolic paper pushed out by the second separation pusher are different in height, a first counting device and a second counting device count paper on the first guide table and the second guide table respectively and transmit signals to controllers, a labeling machine can label paper on the labeling workbench, a first grabbing and delivering device can sequentially deliver the paper on the first guide table to the second guide table and the labeling workbench, a second grabbing and delivering device can enable a mirror plate to cover the surface of the labeled paper, and the controllers control the first grabbing and delivering device, the second grabbing and delivering device, the paper pushing mechanisms and the labeling machine to work. The phenolic paper automatic proportioning and stacking system saves labor and improves stacking quality.

Owner:KUNSHAN JUHONG MACHINERY TECH

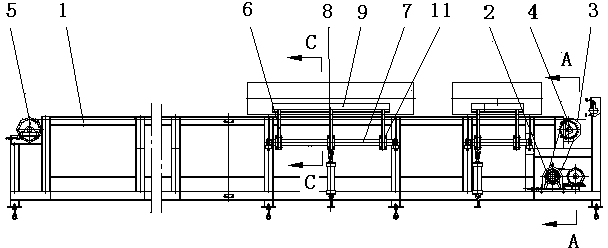

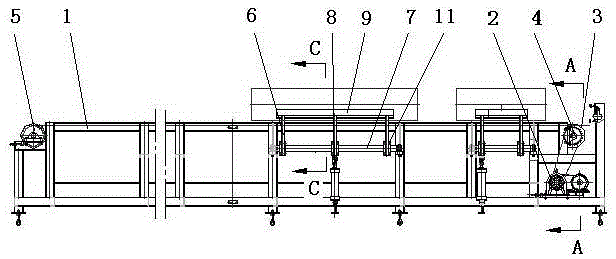

Strip cigarette stacking conveying device

The invention relates to the field of strip cigarette packaging equipment, in particular to a strip cigarette stacking conveying device. The strip cigarette stacking conveying device comprises a rack,a control system, an input device, a stacking device and an output device, the control system is arranged on the rack, and the input device, the stacking device and the output device are sequentiallyarranged on the rack and electrically connected with the control system separately; the stacking device comprises a driving roller, a driven roller, a stacking conveying belt, a first horizontal displacement device and a receiving device; the stacking conveying belt is arranged on the driving roller and the driven roller, then a top layer and a bottom layer of the stacking conveying belt are formed, the driven roller moves back and forth in the conveying direction of the stacking conveying belt through the first horizontal displacement device, and the bottom layer of the stacking conveying belt is provided with a tensioning device for making the stacking conveying belt maintain a certain tension; and the receiving device is arranged at the output end of the stacking conveying belt. The strip cigarette stacking conveying device can achieve stacking conveying of various special-shaped cigarettes.

Owner:曾国耀

Stacking system

The invention discloses a stacking system which comprises a fixed frame, a roll chain, a roll chain driving device, a box pulling rod and a clamping device, wherein the fixed frame is provided with a frame structure by taking the using direction as reference; the roll chain driving device is used for driving the roll chain to make telescopic action from one end of the frame structure of the fixed frame to the other end; the two sides above the frame structure of the fixed frame are completely covered by the two sides vertical to the movement direction of the roll chain; two clamping mechanisms are respectively and symmetrically fixed above the fixed frame and positioned at the two sides vertical to the movement direction of the roll chain; the two opposite sides of the two clamping mechanisms are capable of making relative motion along the directions vertical to the movement direction of the roll chain; one end of the box pulling rod can move along the movement direction of the roll chain and is located on the fixed frame; and the lower side surface of the other end of the box pulling rod is fixedly provided with a convex baffle. The stacking system is simple in structure, high in stacking speed, small in occupied space, wide in application scope, convenient to use, safe and reliable.

Owner:苏州澳昆智能机器人技术有限公司

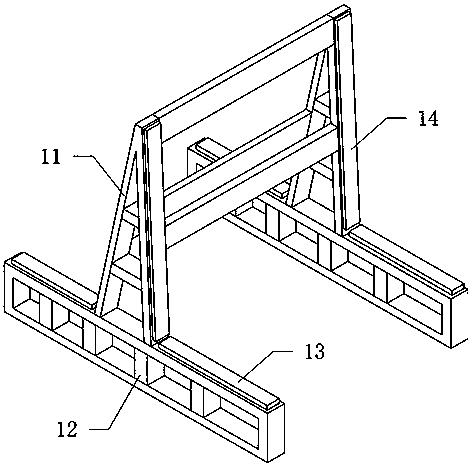

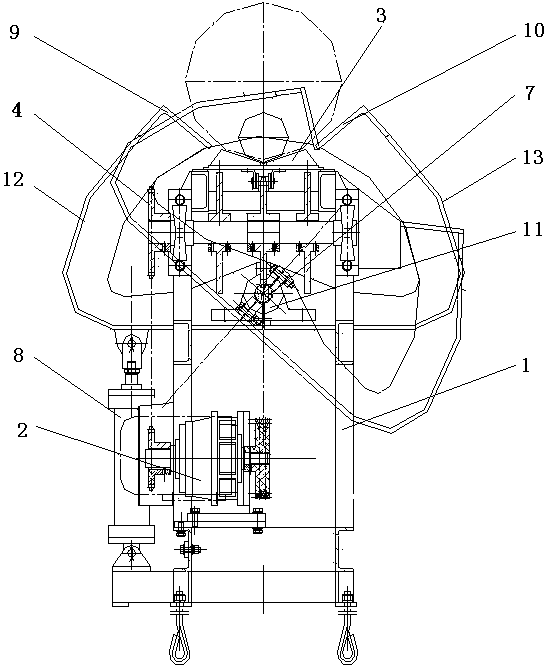

Plate overturning and stacking device

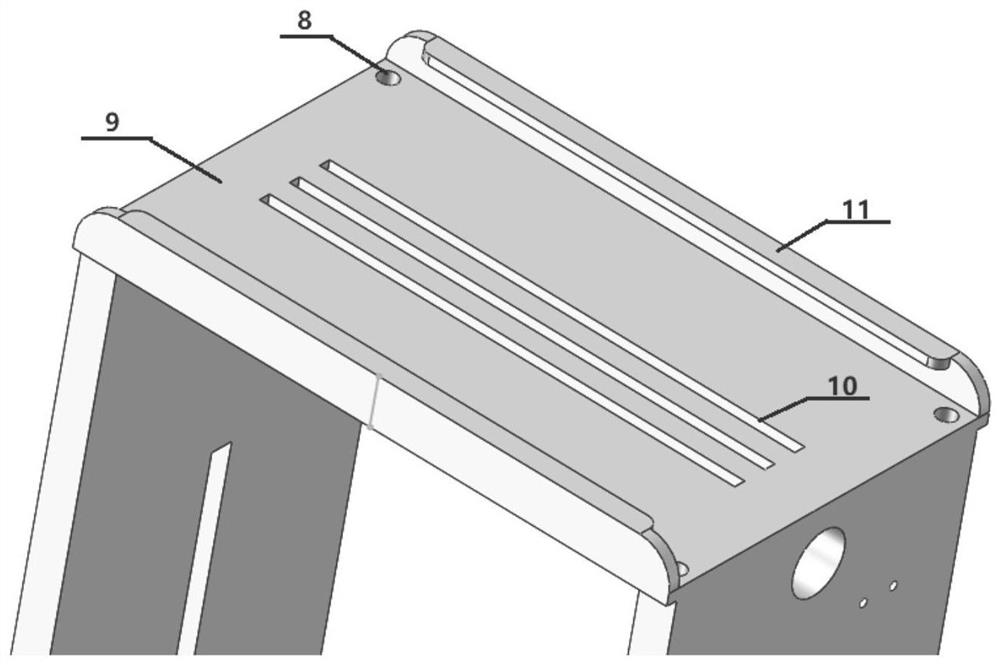

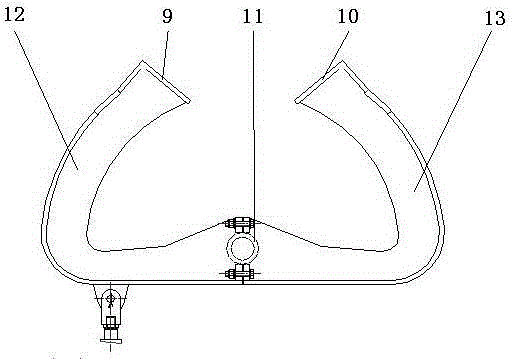

PendingCN109928218AEasy to stackSo as not to damageStacking articlesConveyor partsEngineeringH shaped

Disclosed is a plate overturning and stacking device. The device comprises a horizontally arranged roller bracket, a plurality of rollers which are rotatably arranged on the roller bracket and uniformly distributed, a roller motor, a stacking frame which can be rotated along a vertical straight line and is used for placing plates, an overturning frame which is arranged below the roller bracket andused for supporting the roller bracket and driving the roller bracket to overturn and a control device. Every two adjacent rollers are in chain connection, and the roller motor is in power connectionwith any roller. The stacking frame comprises an underframe with an H-shaped horizontal projection shape, an inverted V-shaped supporting frame arranged in the middle of the underframe and a rotatingdevice arranged at the bottom of the underframe, and the overturning frame can be horizontally moved back and forth relative to the stacking frame so as to stack the plates to the stacking frame. Twosupporting plates with the top surfaces lower than the top surfaces of the rollers are arranged on the side, close to the stacking frame, of the roller bracket, and convex blocks with the top surfaces higher than the top surfaces of the rollers are formed on the convex surfaces of the supporting plates. The control device is used for controlling the overturning frame, the roller motor and the rotating device to work. The plate overturning and stacking device is unique in design and used for overturning the plates and finishing stacking.

Owner:肇庆爱博新材料科技有限公司

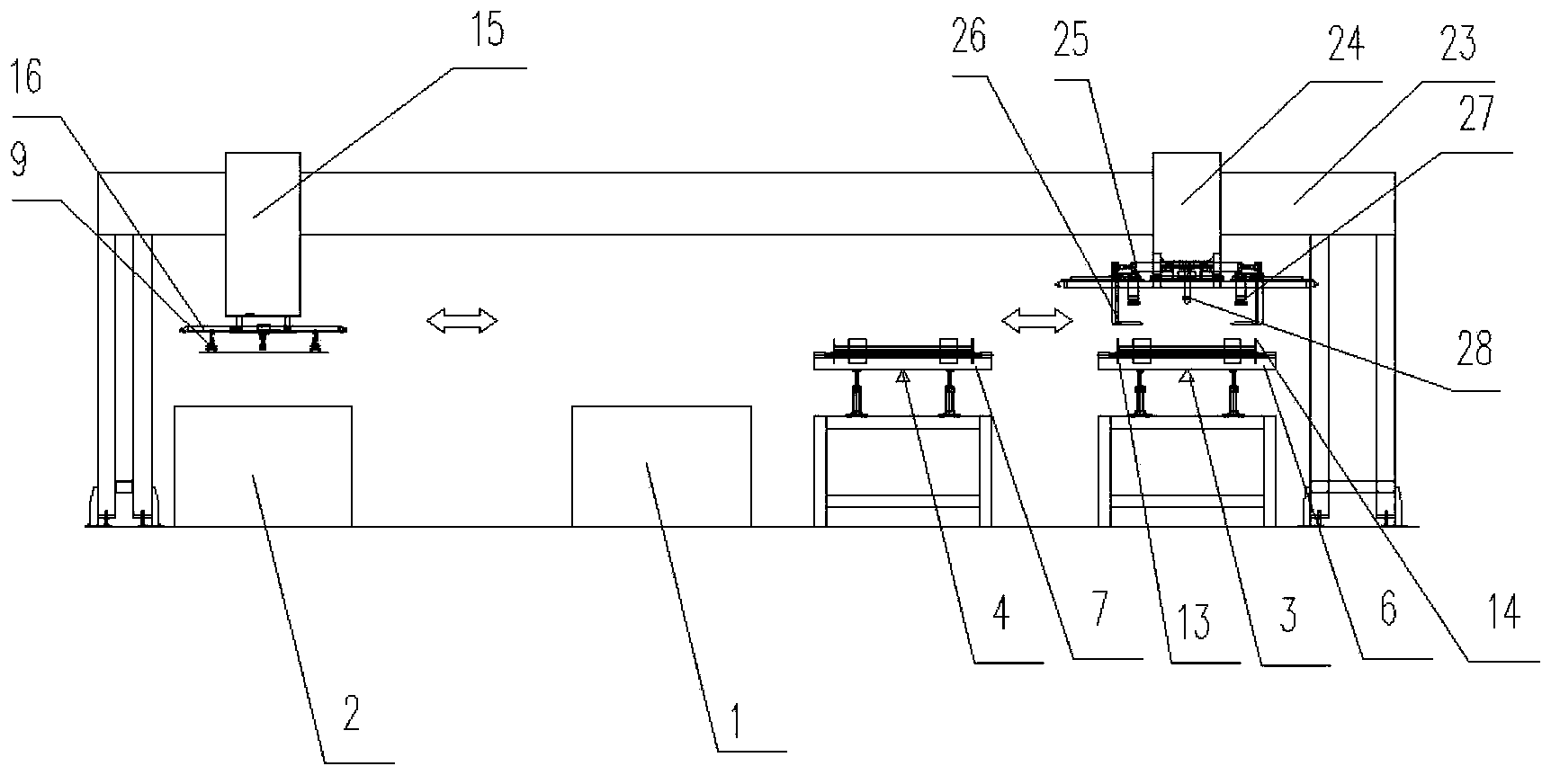

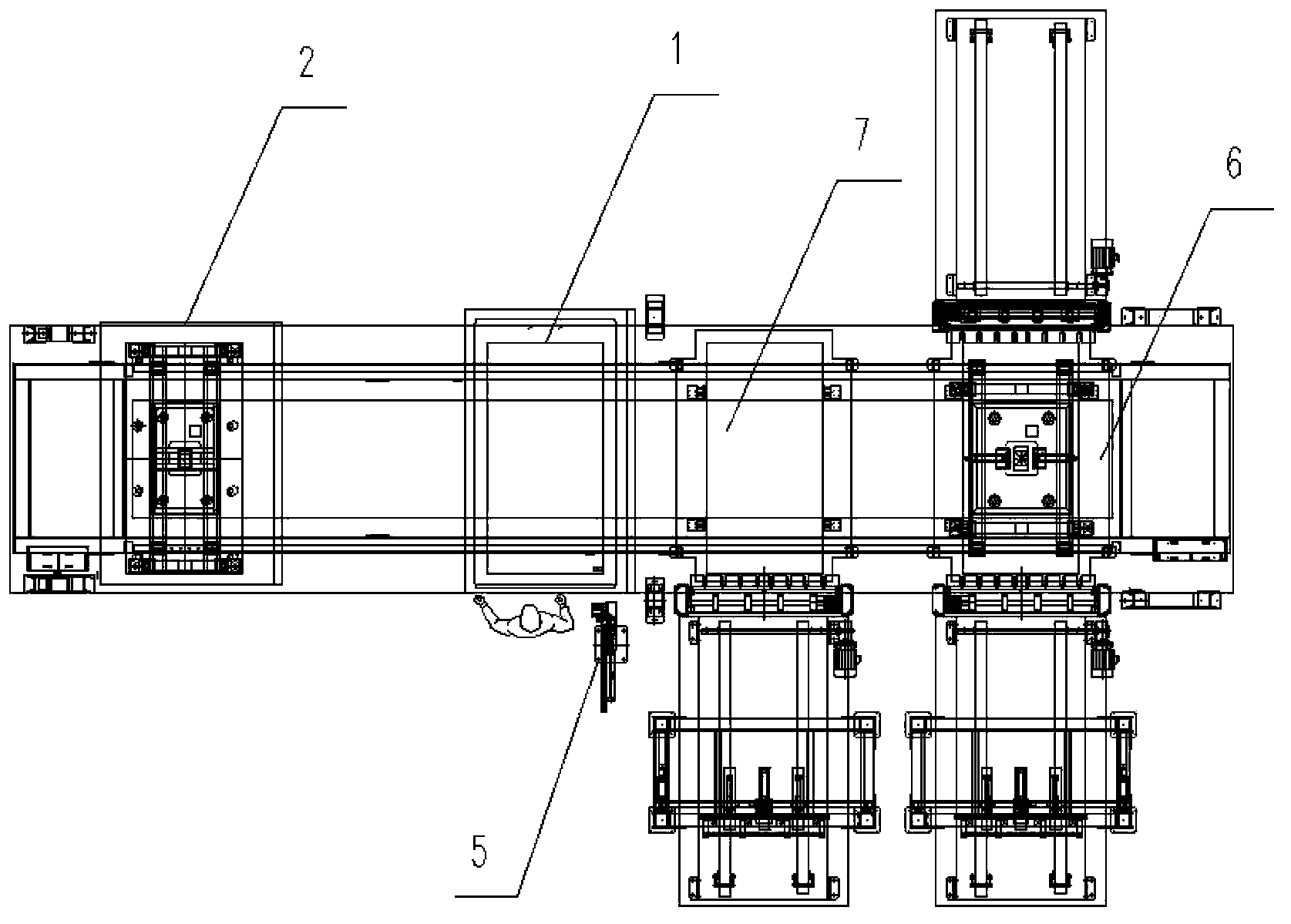

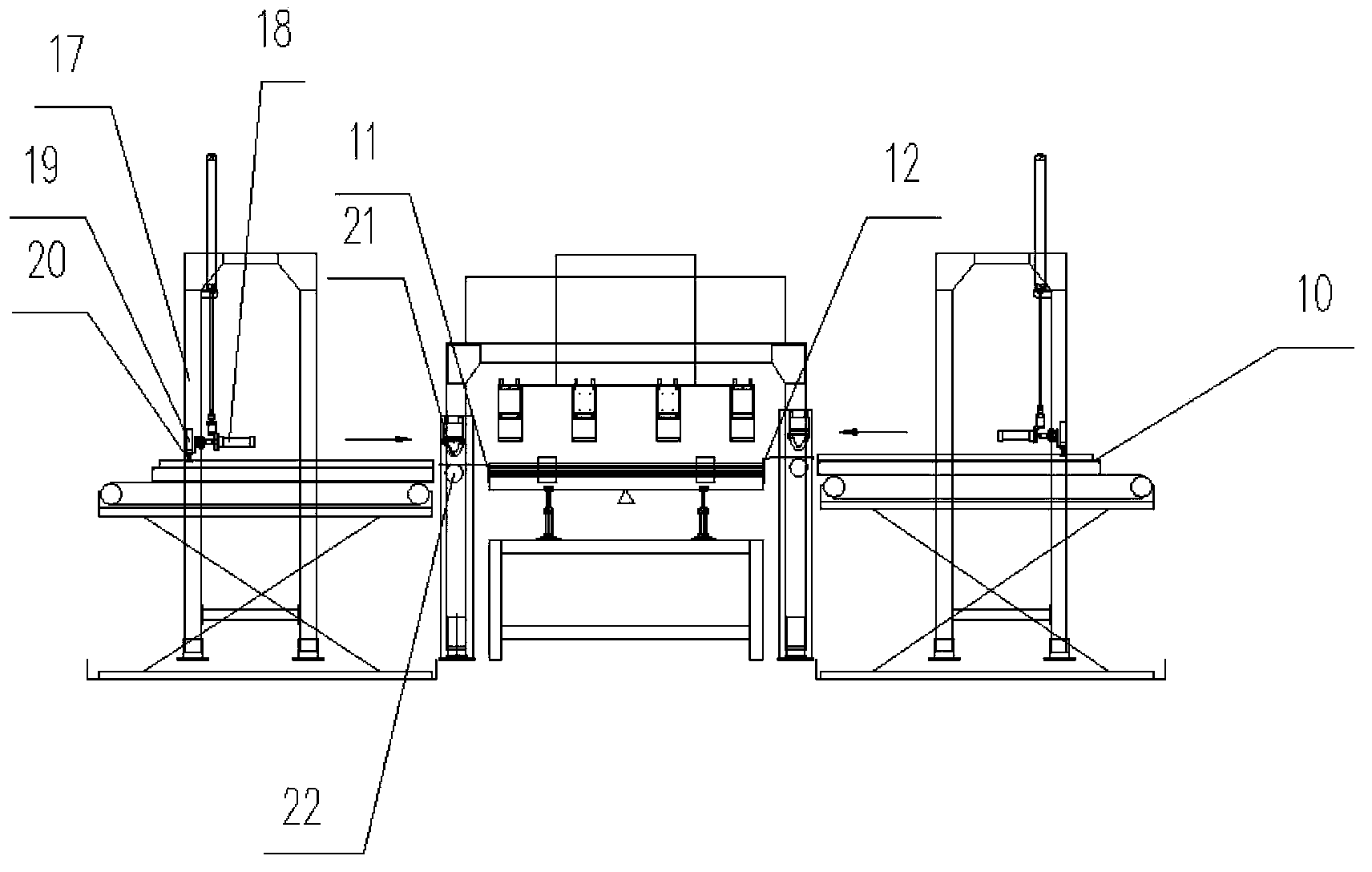

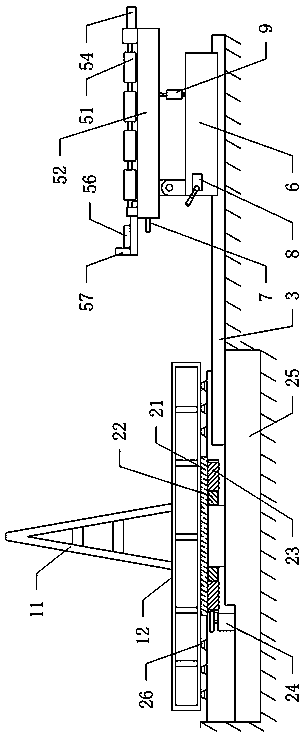

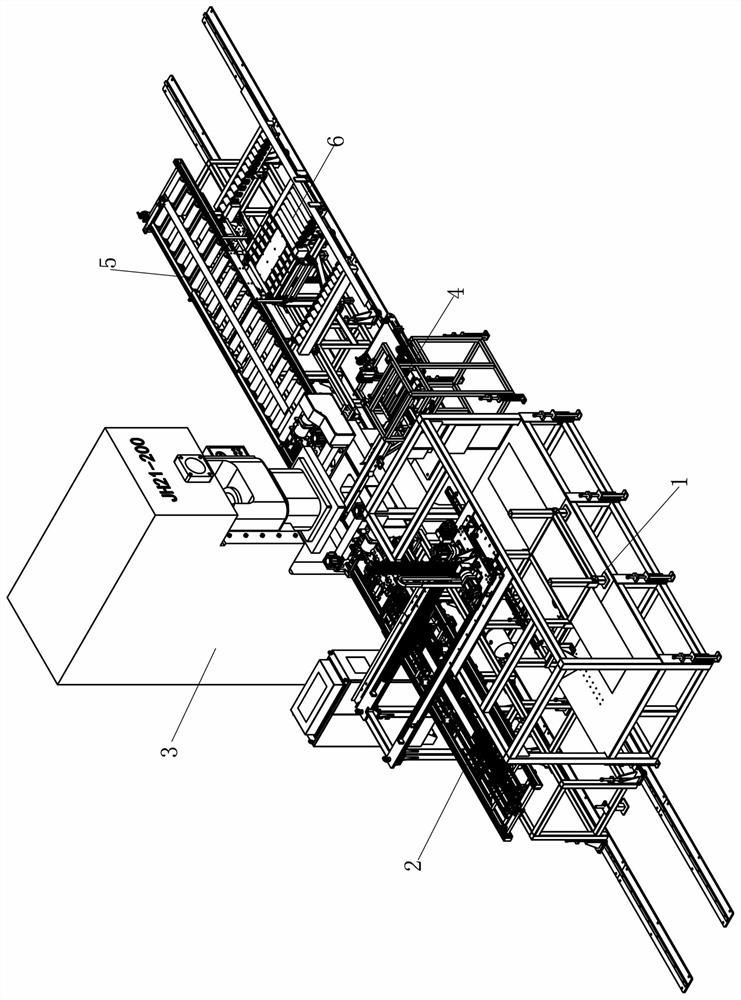

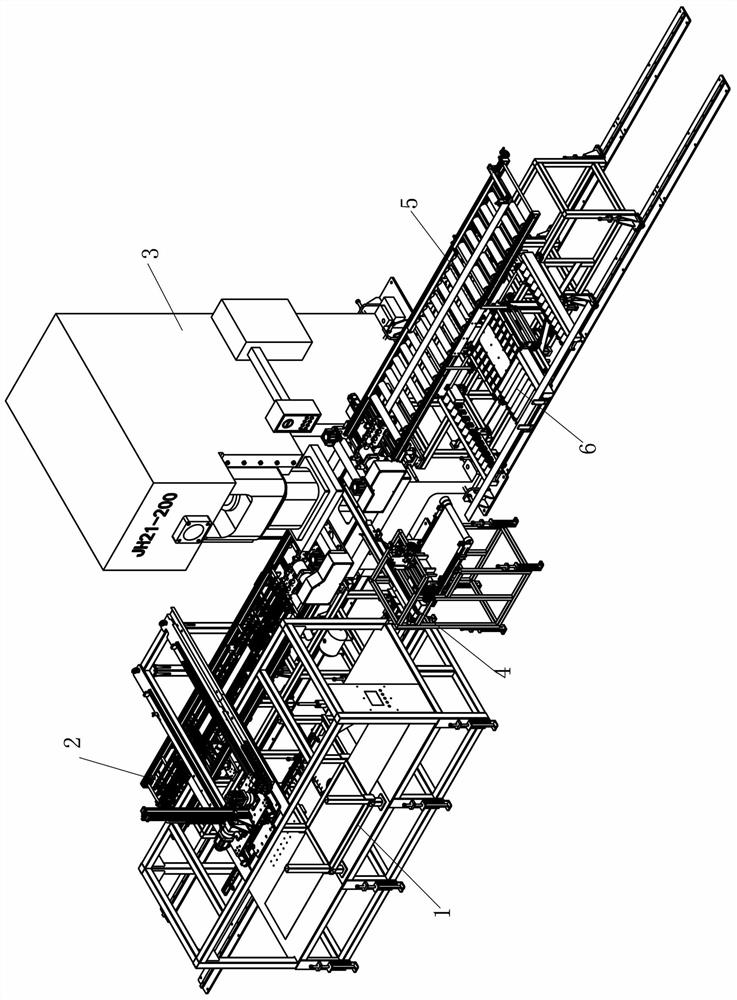

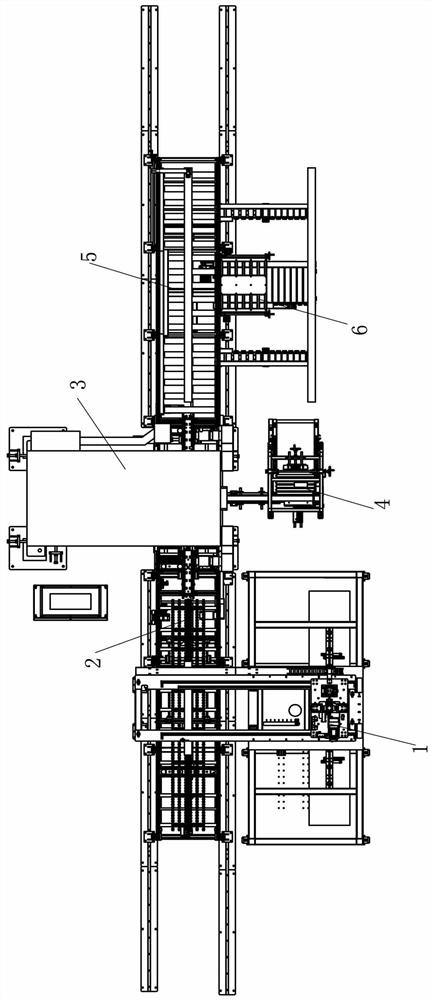

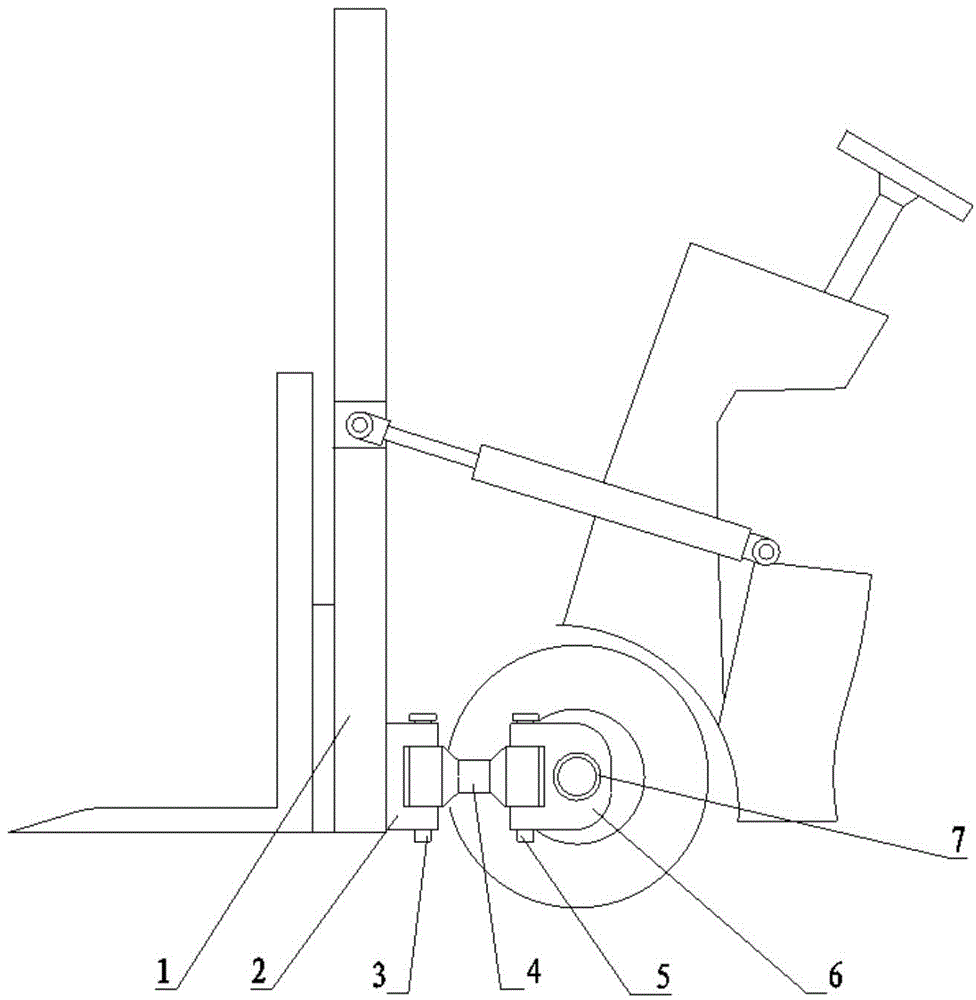

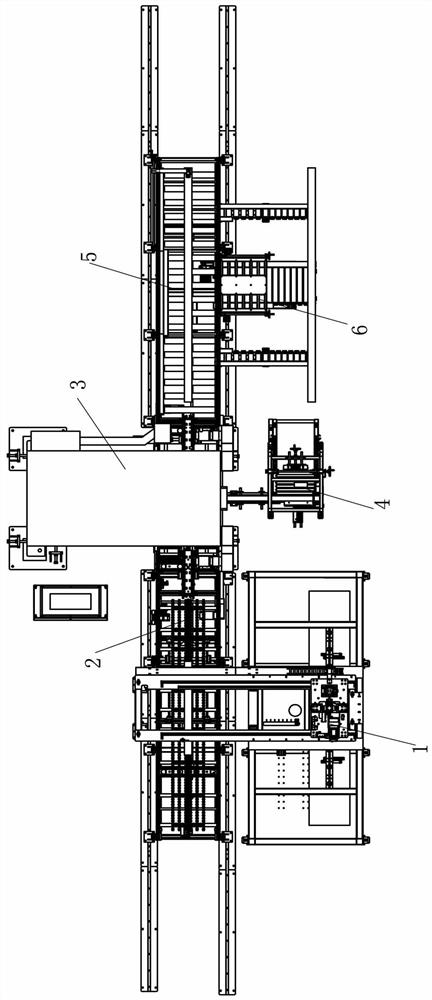

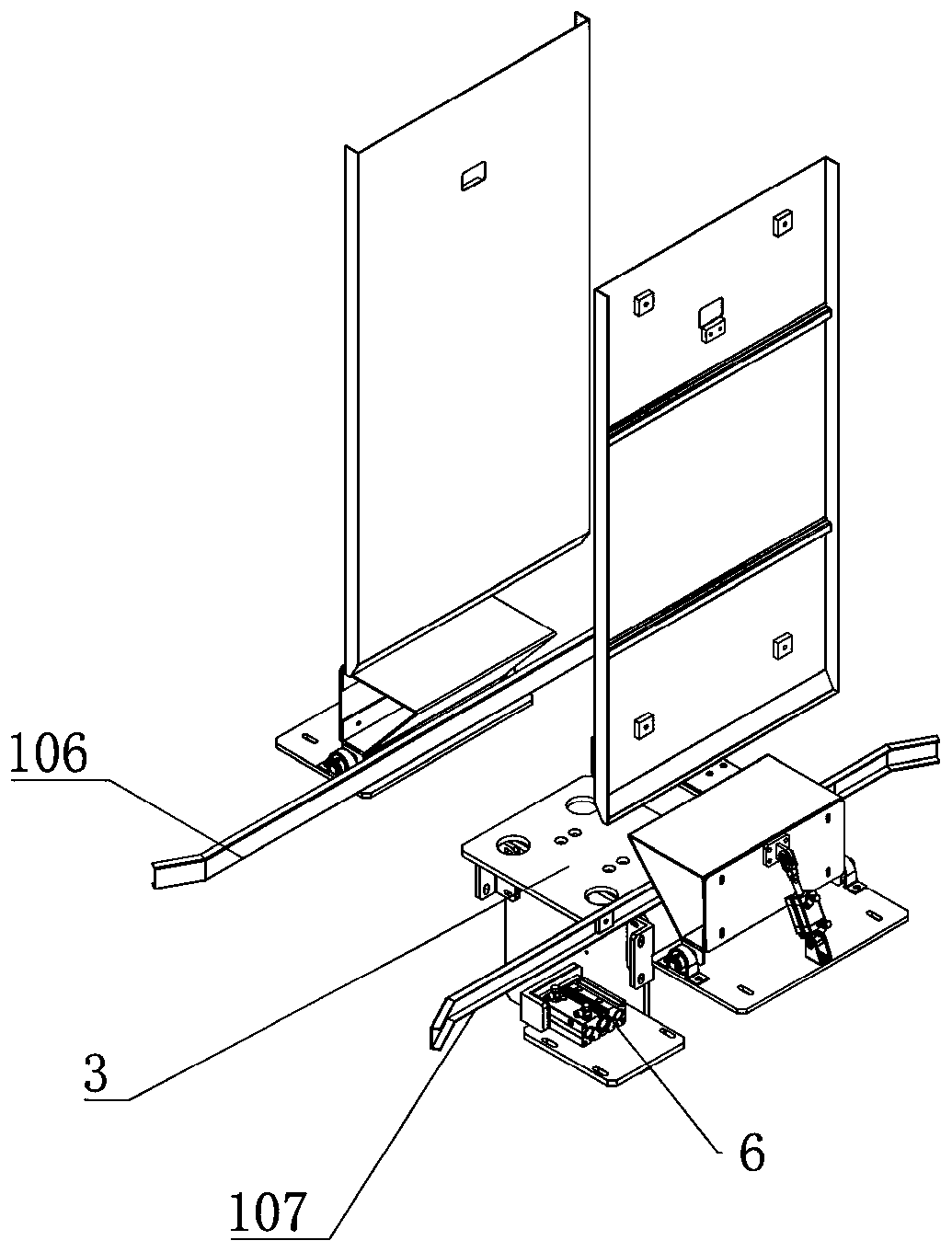

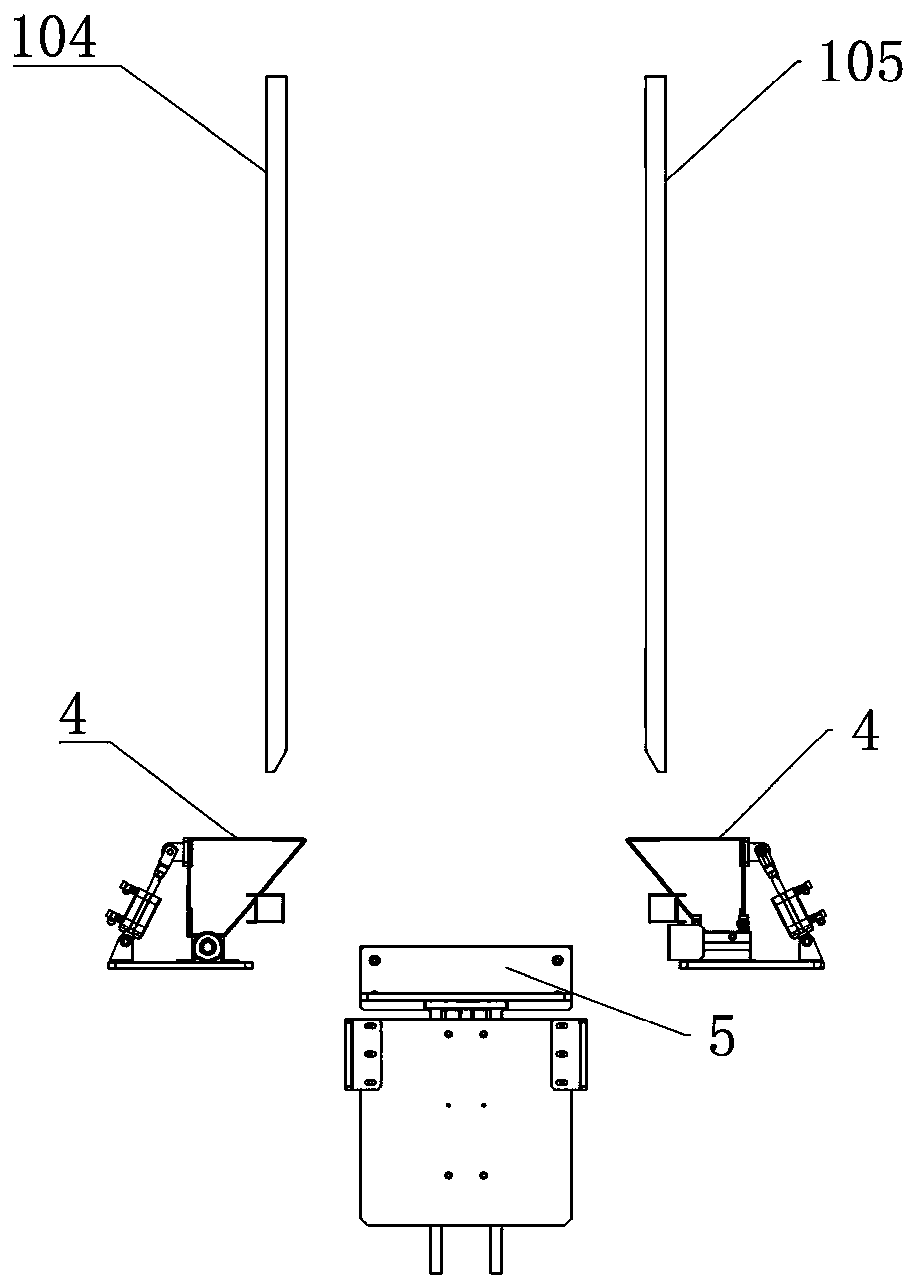

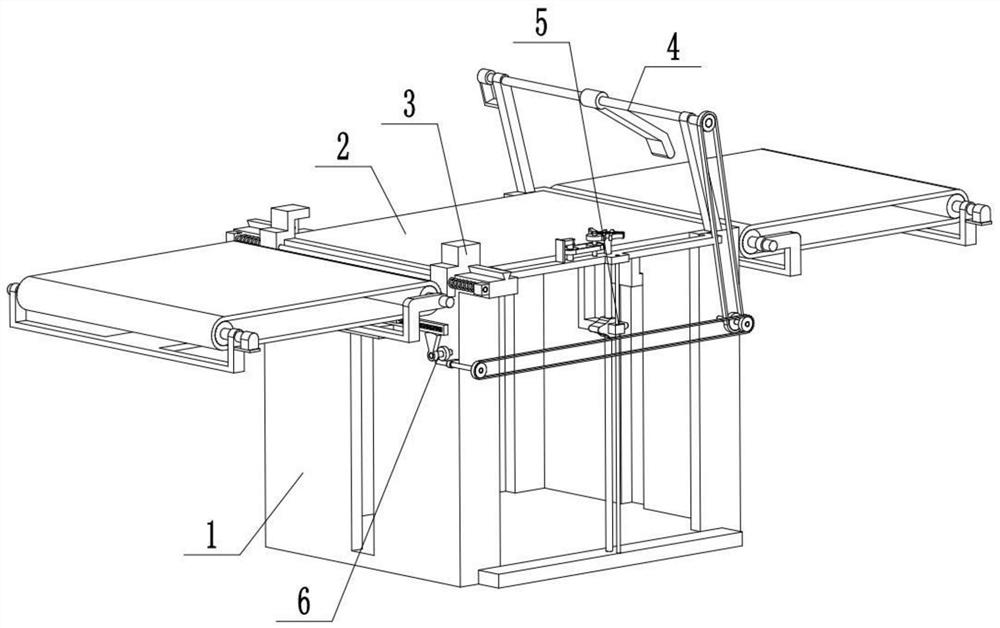

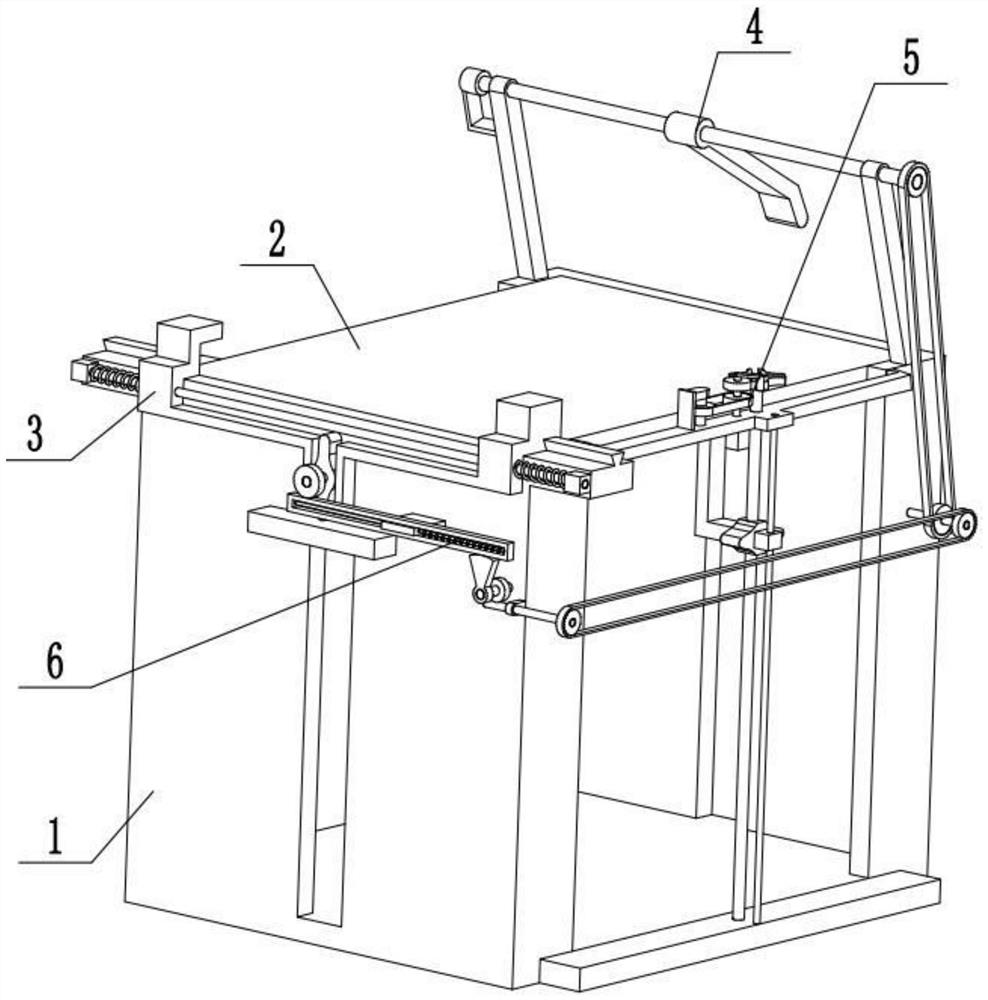

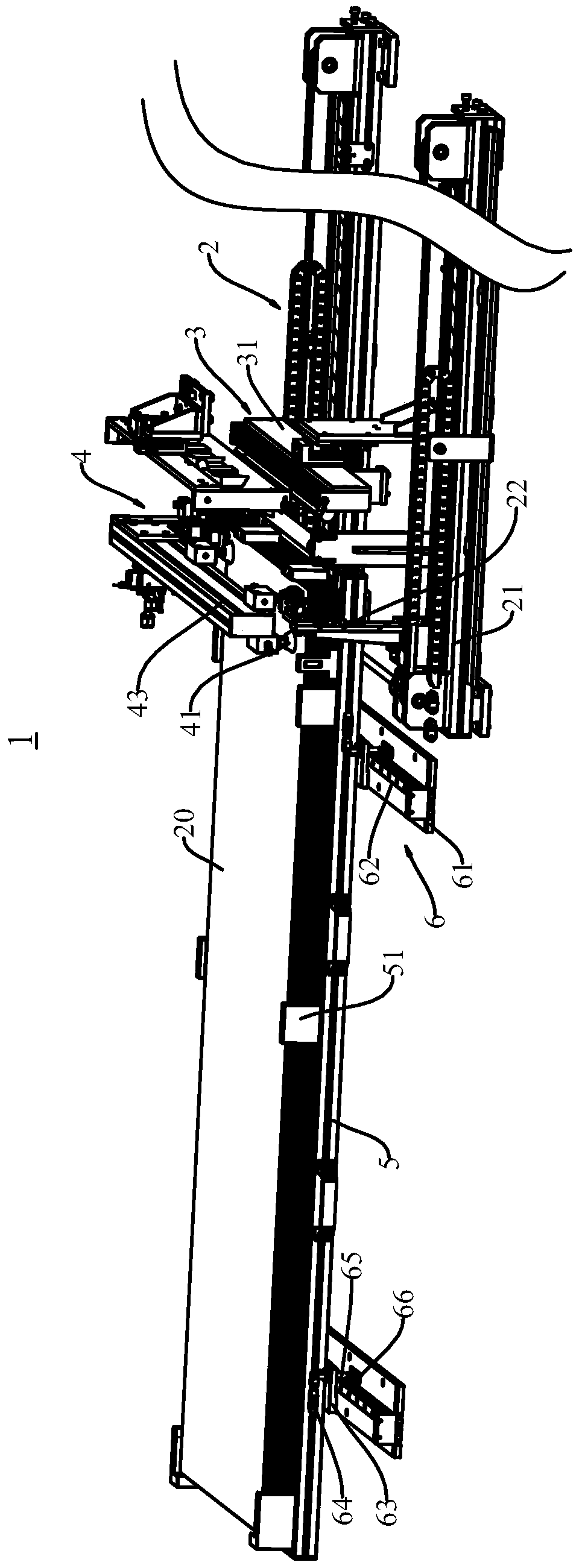

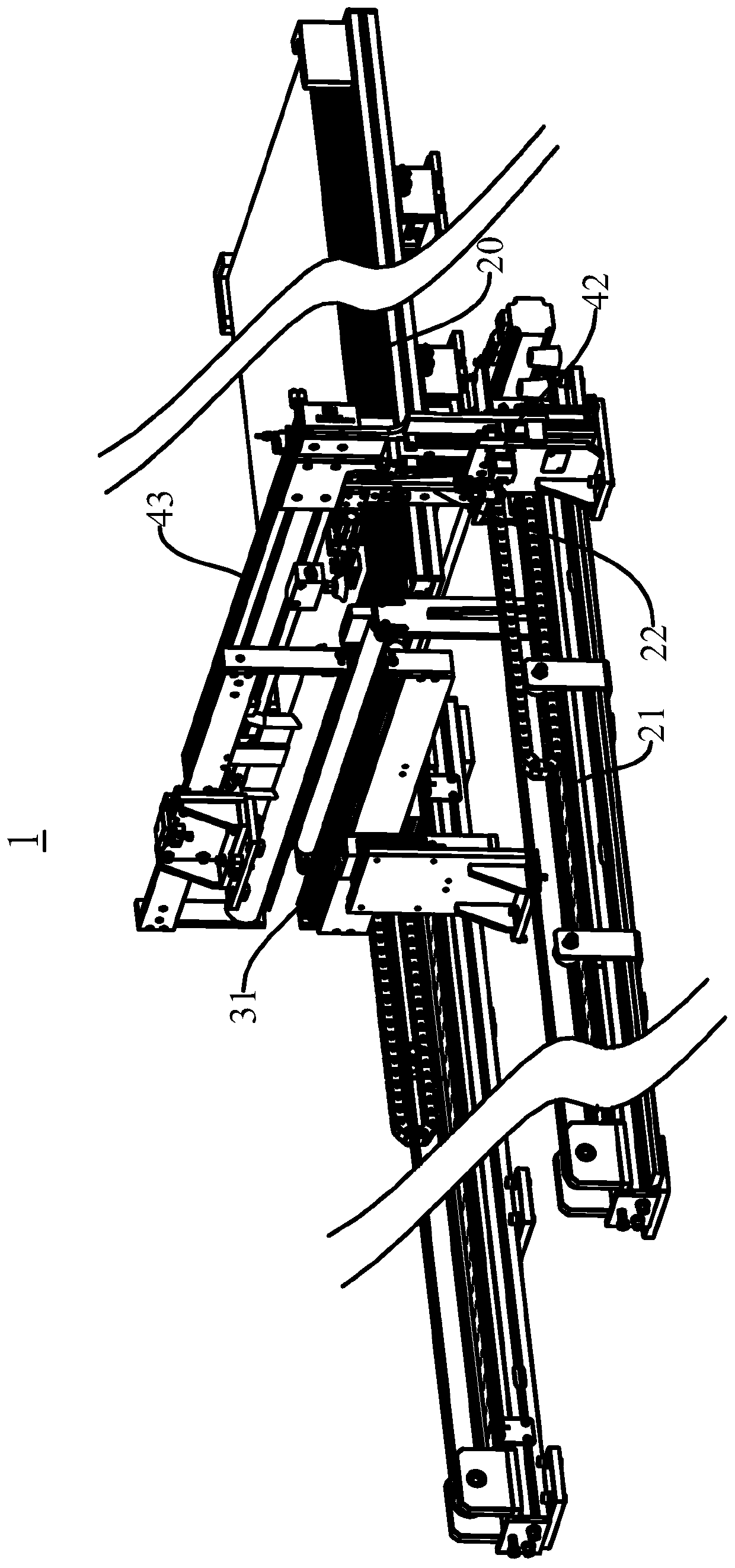

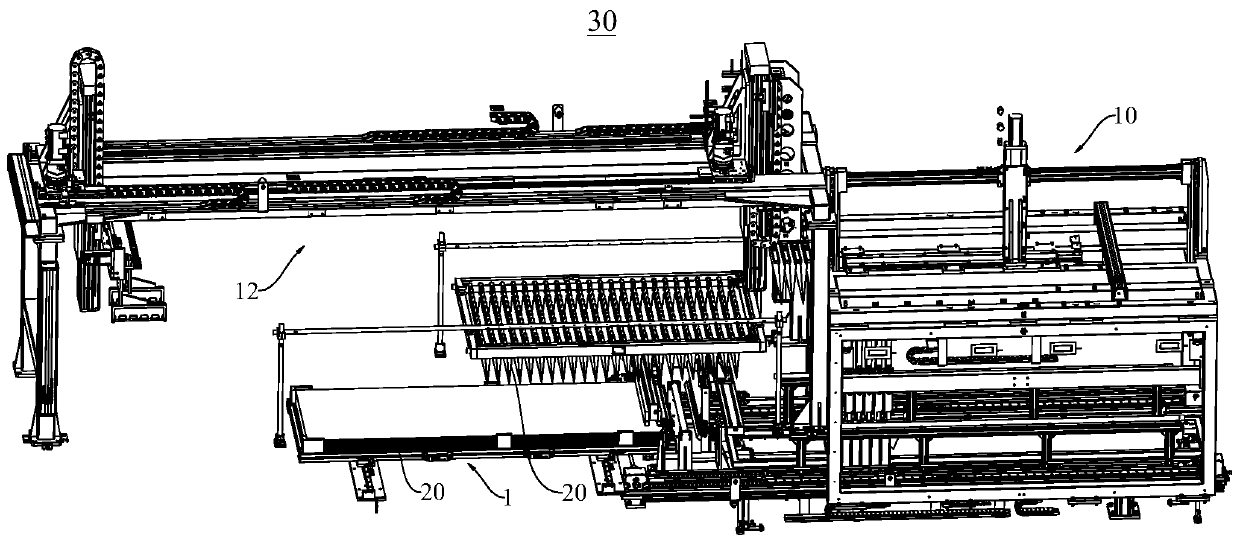

Automatic blanking and punching production line for sheets

ActiveCN113426895AMatch punch rhythmIncrease productivityMetal-working feeding devicesPositioning devicesProduction linePunching

The invention relates to the technical field of sheet punching, in particular to an automatic blanking and punching production line for sheets. The automatic blanking and punching production line comprises a sheet feeding device, a sheet inlet device, a sheet punching die, a sheet discharging device and a punched part receiving device. The sheet feeding device is used for grabbing single sheets to the sheet inlet device, the sheet inlet device is used for intermittently and horizontally conveying the single sheets into the sheet punching die, the sheet punching die is used for punching holes in the sheets, and the sheet discharging device is used for conveying out the punched sheets and stacking the punched sheets. According to the automatic blanking and punching production line for the sheets, the sheet feeding device, the sheet inlet device, the sheet punching die, the sheet discharging device and the punched part receiving device are used for achieving the procedures of sheet feeding, intermittent material inlet, sheet punching, discharging, stacking, punched part stacking and the like of the sheets, and therefore the automatic blanking and punching production line is high in production efficiency and can be matched with the punching rhythm of the sheet punching die. The automatic blanking and punching production line is suitable for continuously punching sheets.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

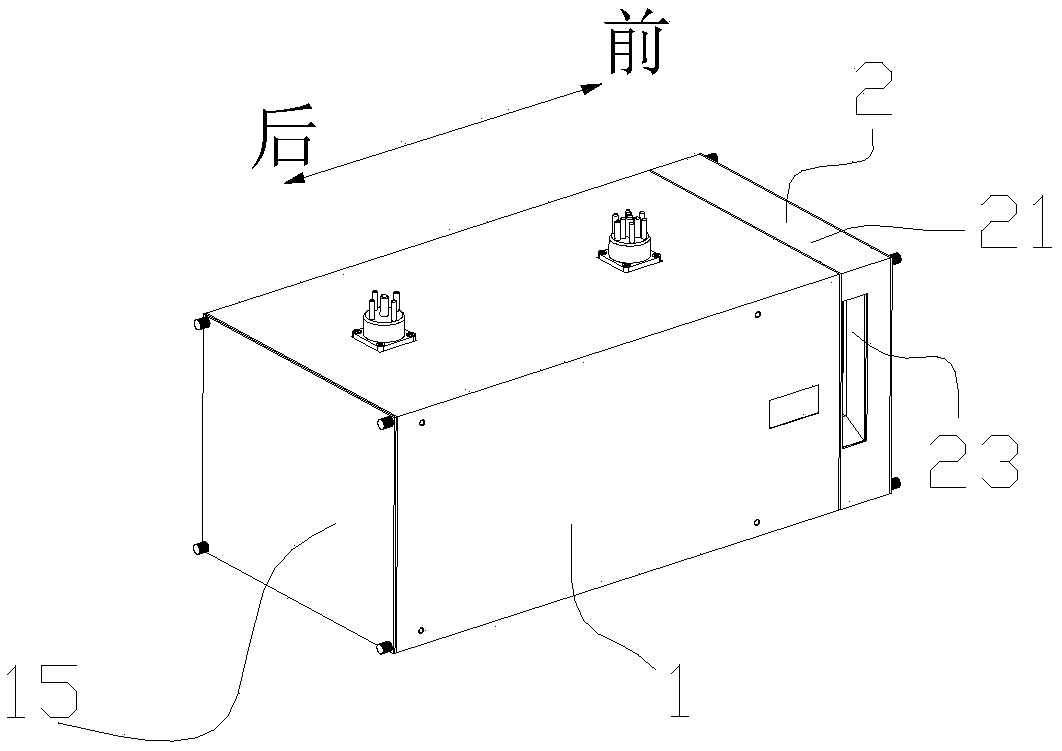

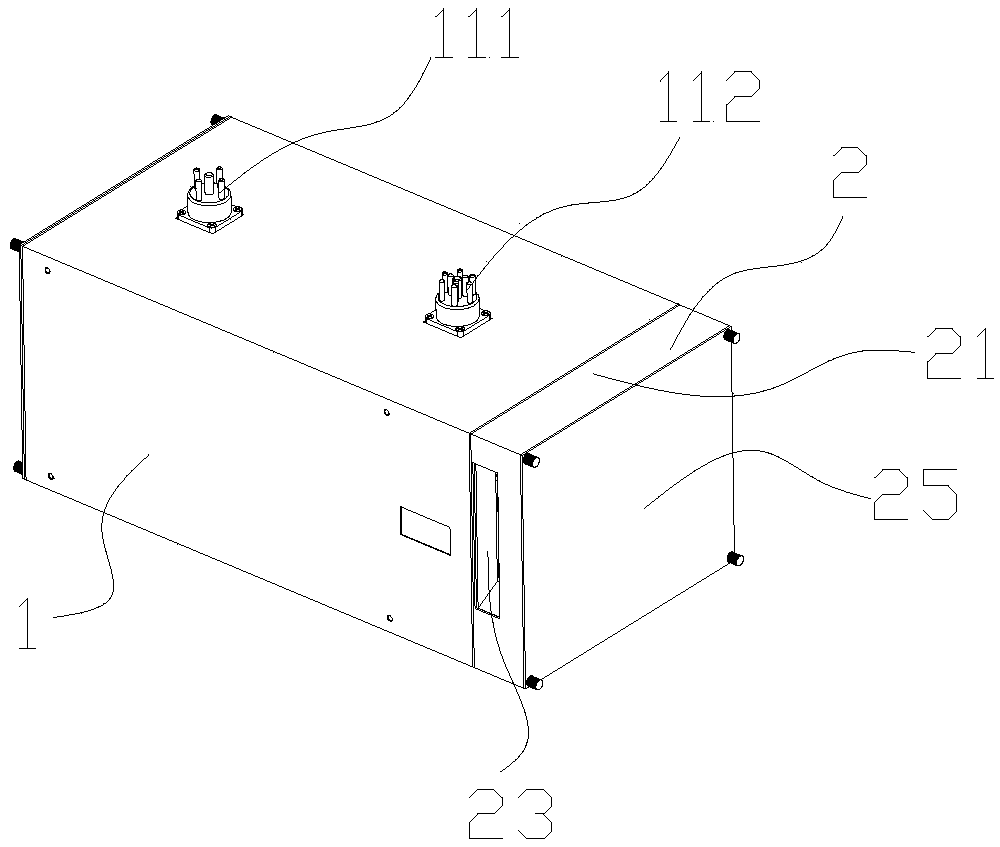

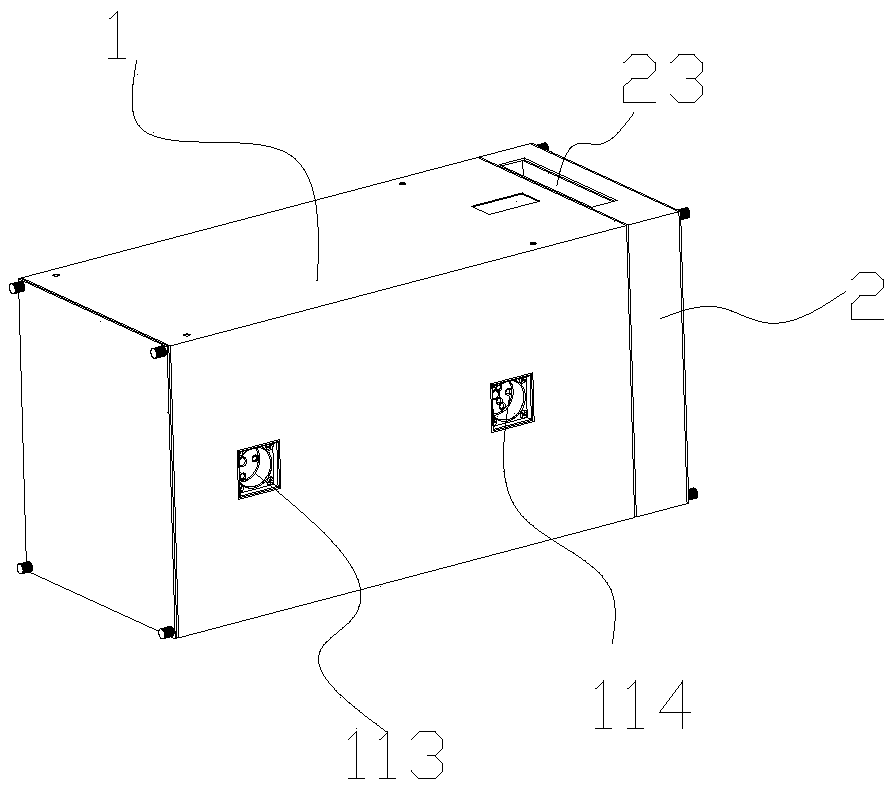

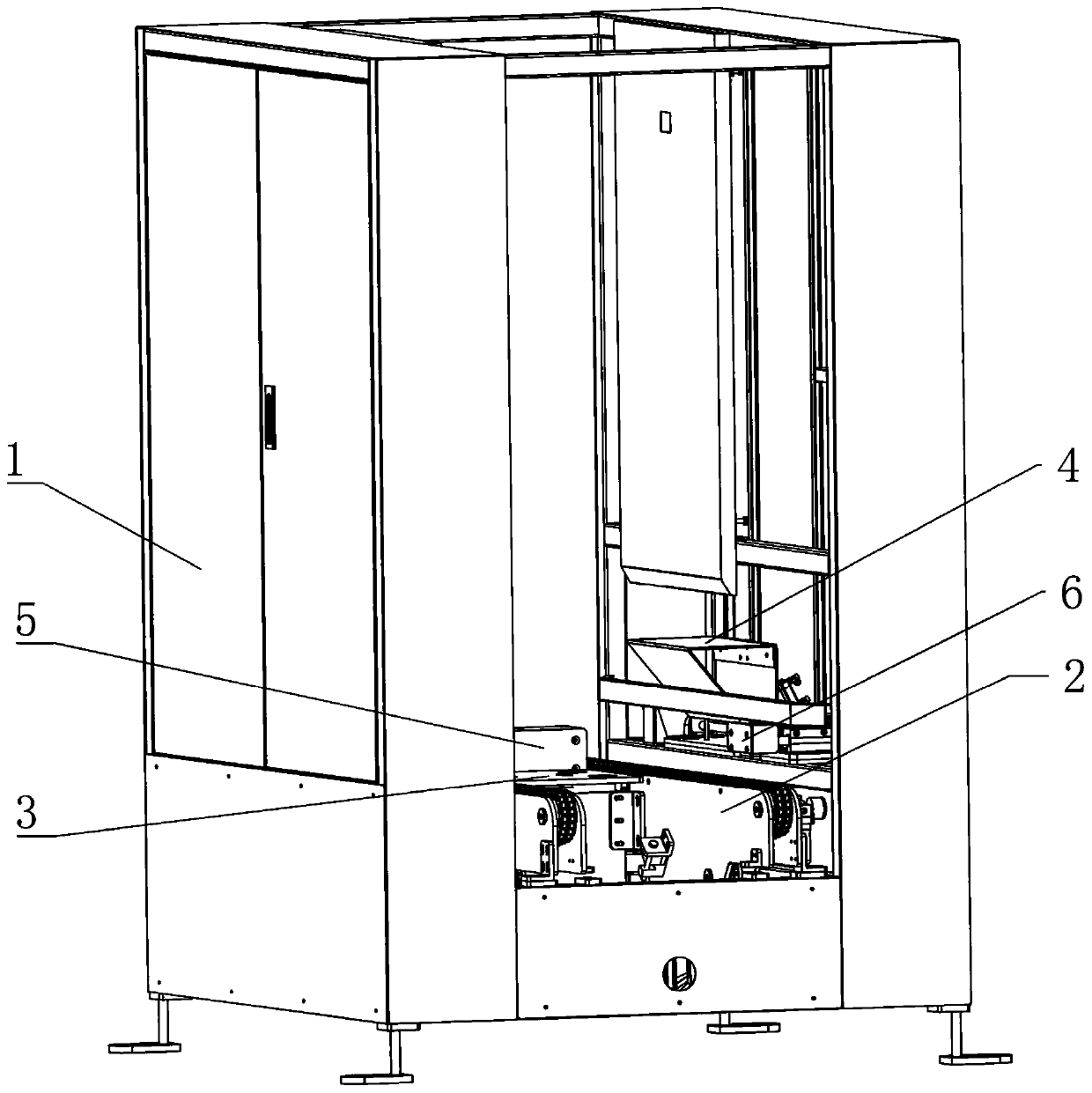

Vending machine

PendingCN108665624ASquare shapeEasy to transportCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectrical and Electronics engineeringEngineering

The invention relates to the technical field of vending, in particular to a vending machine. The vending machine comprises a panel and a sealing plate, wherein the panel is provided with a touch screen and a material taking opening, at least one goods storage cabinet is arranged between the panel and the sealing plate and comprises a rack, two sides of the rack are provided with side doors, the two side doors are internally installed on vending units installed on the rack in a stacked way, the middle of each goods storage cabinet is provided with a conveyer for conveying materials popping outof the vending units to the material taking opening, and the vending machine can achieve automatic position selectin and quick stacking and piling and is high in timeliness.

Owner:张旭

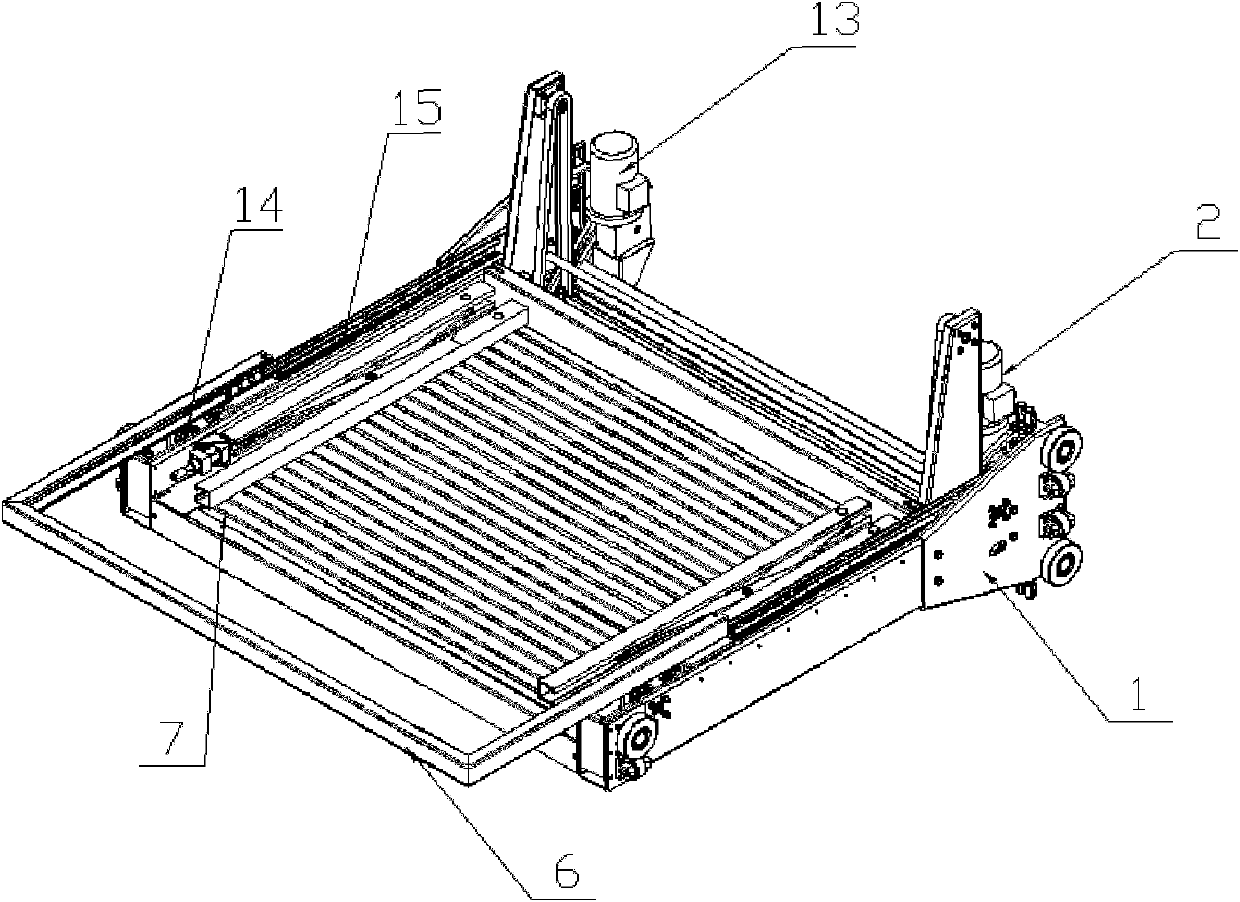

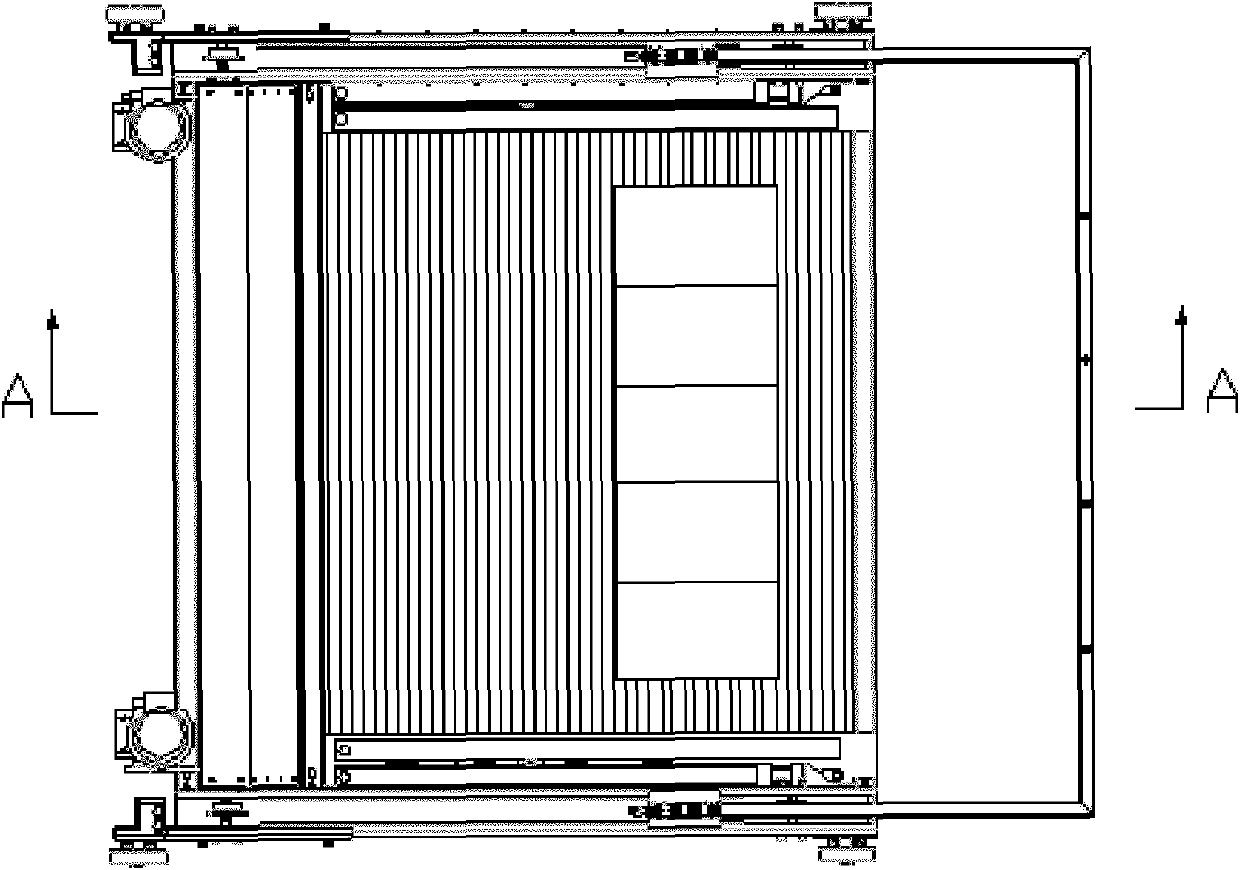

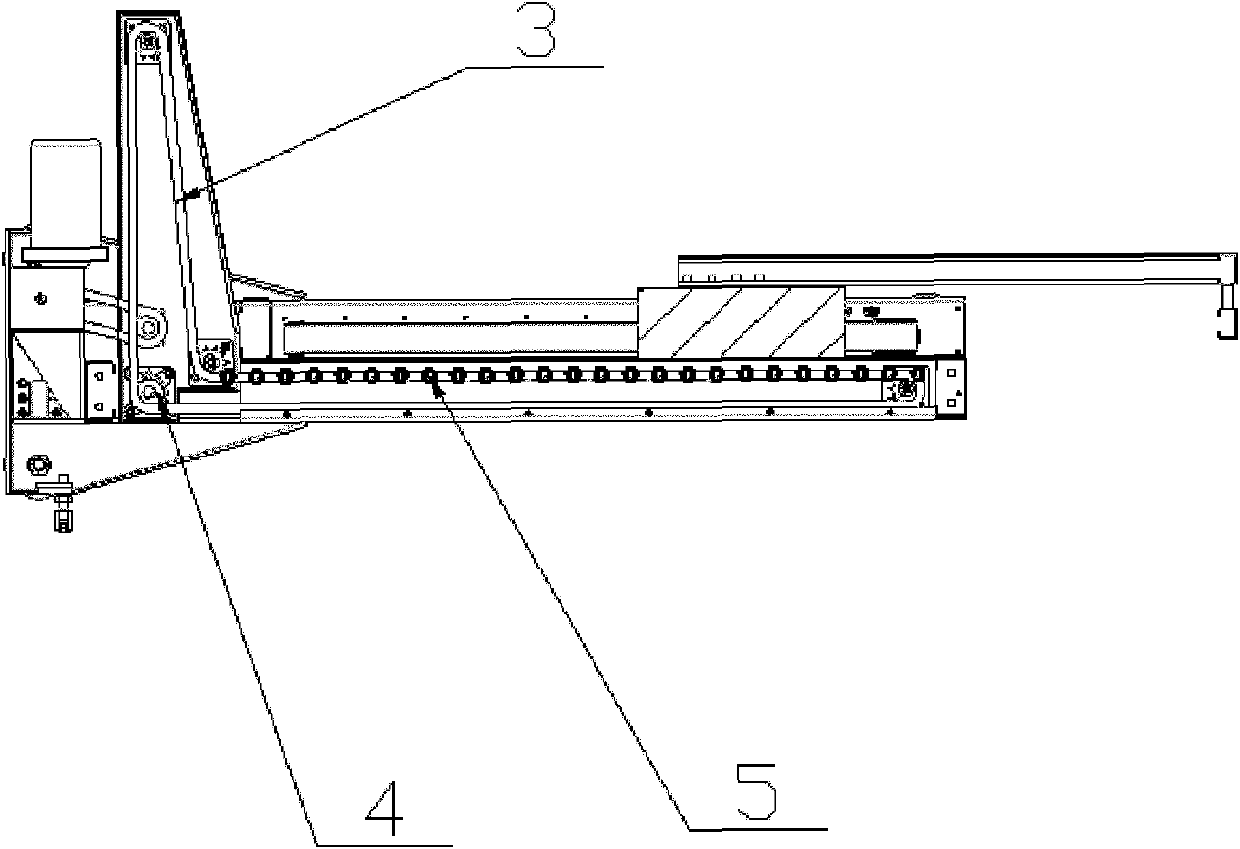

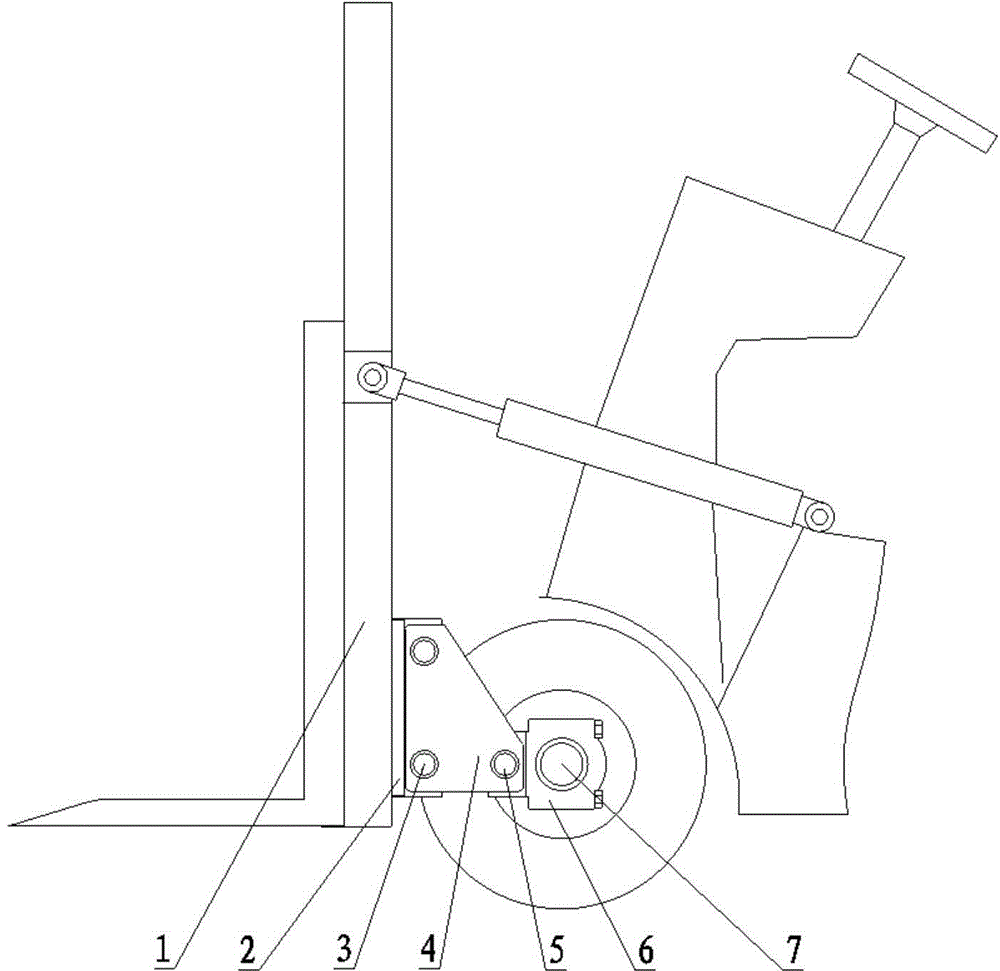

Automatic raw wood stacking device

ActiveCN103625830ANovel structureHigh degree of automationConveyor partsRoller-waysElectric machineDrive shaft

The invention relates to an automatic raw wood stacking device and belongs to the technical filed of wood-working machinery. The automatic raw wood stacking device is characterized in that the device is provided with a rack, wherein the rack is provided with a linear moving device and a turnover device, the linear moving device comprises a moving motor, a riding wheel, a riding wheel shaft, a driving shaft, a driven shaft, a driving chain wheel, a driven chain wheel and a chain, the turnover device comprises a turnover frame, a turnover shaft, a turnover cylinder, an outer turnover support plate, and an inner turnover support plate, the riding wheel shaft is arranged on the rack, the riding wheel is arranged on the riding wheel shaft, the turnover shaft is arranged below the riding wheel, the turnover frame is composed of a shaft sleeve, an outer turnover frame and an inner turnover frame, the shaft sleeve is arranged on the turnover shaft, one side of the shaft sleeve is fixedly connected with the outer turnover frame, and the other end of the shaft sleeve is fixedly connected with the inner turnover frame; the upper end of the outer turnover frame is fixedly connected with the outer turnover support plate, the lower end of the outer turnover frame is connected with the rack through the turnover cylinder, and the upper and of the inner turnover frame is fixedly connected with the inner turnover support plate. The automatic raw wood stacking device provided by the invention has the advantages of being novel in structure, high in automation degree, quick in stacking speed, safe to operate, low in employment cost, and the like.

Owner:SHANDONG BAISHENGYUAN GRP

Transporting vehicle goods translation device

InactiveCN106144962AFast stackingAvoid repeated shift operationsLifting devicesAutomotive engineering

Owner:范红兵

Saline-alkaline removing and dewatering combined treatment method for waste residue with characteristics of high water content and low permeability

The invention discloses a saline-alkaline removing and dewatering combined treatment method for waste residue with high water content and low permeability, and belongs to the field of waste residue treatment. The saline-alkaline removing and dewatering combined treatment method is characterized in that a plurality of pipe-like or strip-like electrodes with characteristics of electric conduction and water permeation are horizontally arranged in parallel at a certain interval to form electrode groups, and the electrode groups and waste residue layers are stacked alternately; an appropriate amount of a liquid containing appropriate components is injected through the electrodes; direct current is applied through the electrodes to generate an electric field in the waste residue; under the action of the electric field, the soluble ions contained in the saline-alkaline in the waste residue migrate to the electrodes with the opposite polarity, and are carried out by the appropriate liquid through the water permeation pipelines of the electrodes so as to remove the saline-alkaline from the waste residue; the water in the waste residue migrate to the electrodes so as to be discharged from the water permeation pipelines; and under the pressure of the overlying waste residue, the water in the waste residue is further squeezed to the electrodes so as to be discharged from the water permeation pipelines. According to the present invention, the saline-alkaline removing and dewatering combined treatment method can simultaneously perform saline-alkaline removing and dewatering, and furtherhas characteristics of short treatment time and small construction occupation area.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

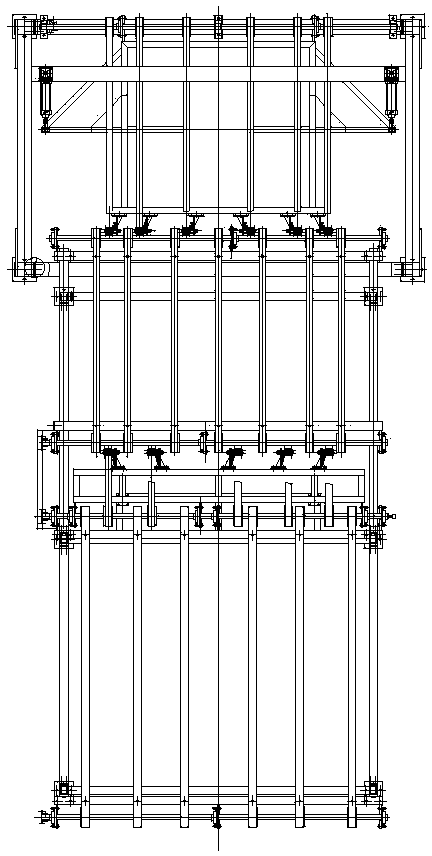

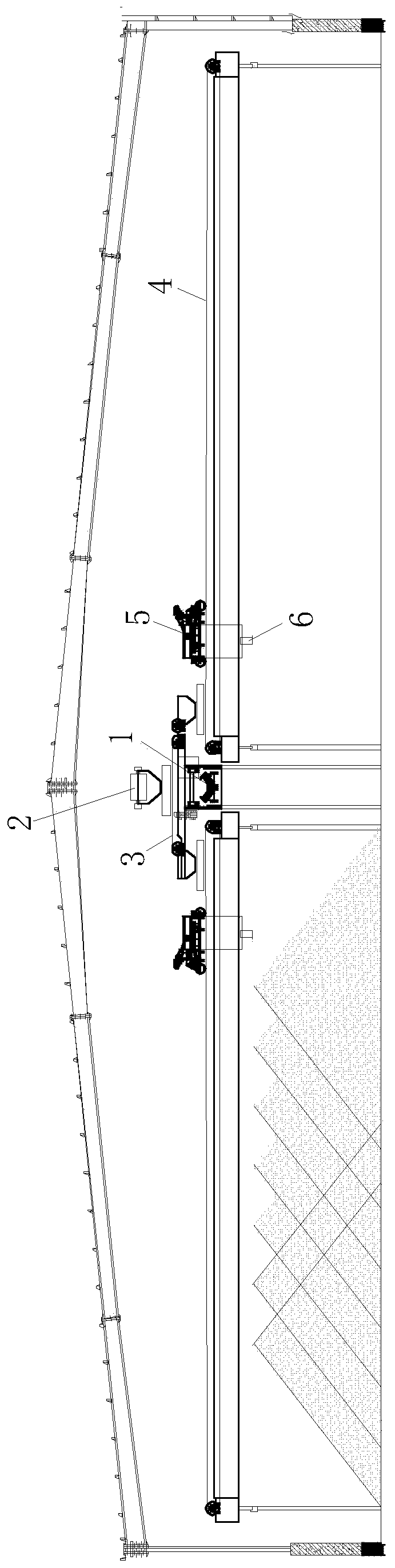

Automatic material distribution system for intelligent large material stacking yard

InactiveCN110980312AFast stackingReduce manual interventionLoading/unloadingConveyor partsEngineeringStructural engineering

The invention discloses an automatic material distribution system for an intelligent large material stacking yard. The automatic material distribution system comprises a material stacking yard, a mainbelt conveyor and a material distribution belt conveyor system, wherein the main belt conveyor is distributed in the material stacking yard along a length direction of the material stacking yard, andis far away from the ground for a certain height. The material distribution system comprises a movable discharger, the material distribution belt conveyor, a movable plow discharger and a feeding belt conveyor, wherein the material distribution belt conveyor is adaptive to the movable discharger and synchronously moves with a long-side rail arranged along the length of the material stacking yard;the movable plow discharger is arranged on a truss rail; and the feeding belt conveyor is fixedly arranged on the movable discharger. By use of the automatic material distribution system disclosed bythe invention, the multi-degree-of-freedom movable stacking and material distribution of materials can be realized, the materials can be quickly stacked and subjected to material distribution, manualintervention is greatly reduced, the automatic material distribution system is convenient in use and is simple in maintenance, and a great quantity of manpower, material resources and financial resources can be saved.

Owner:芜湖起运机械制造有限公司

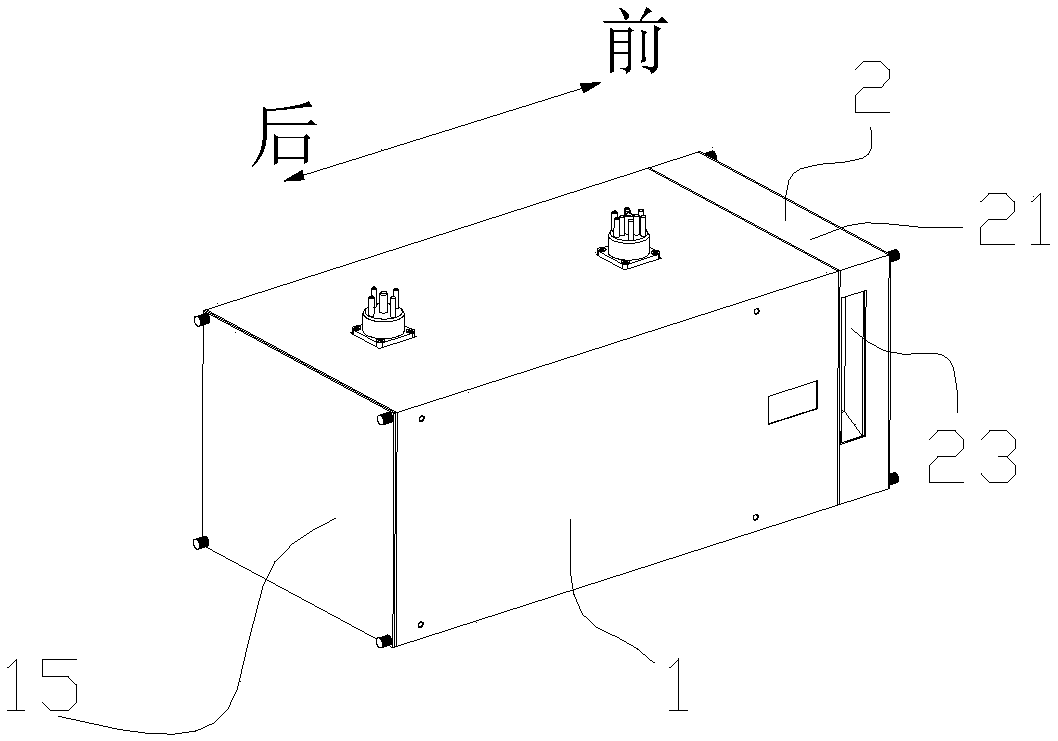

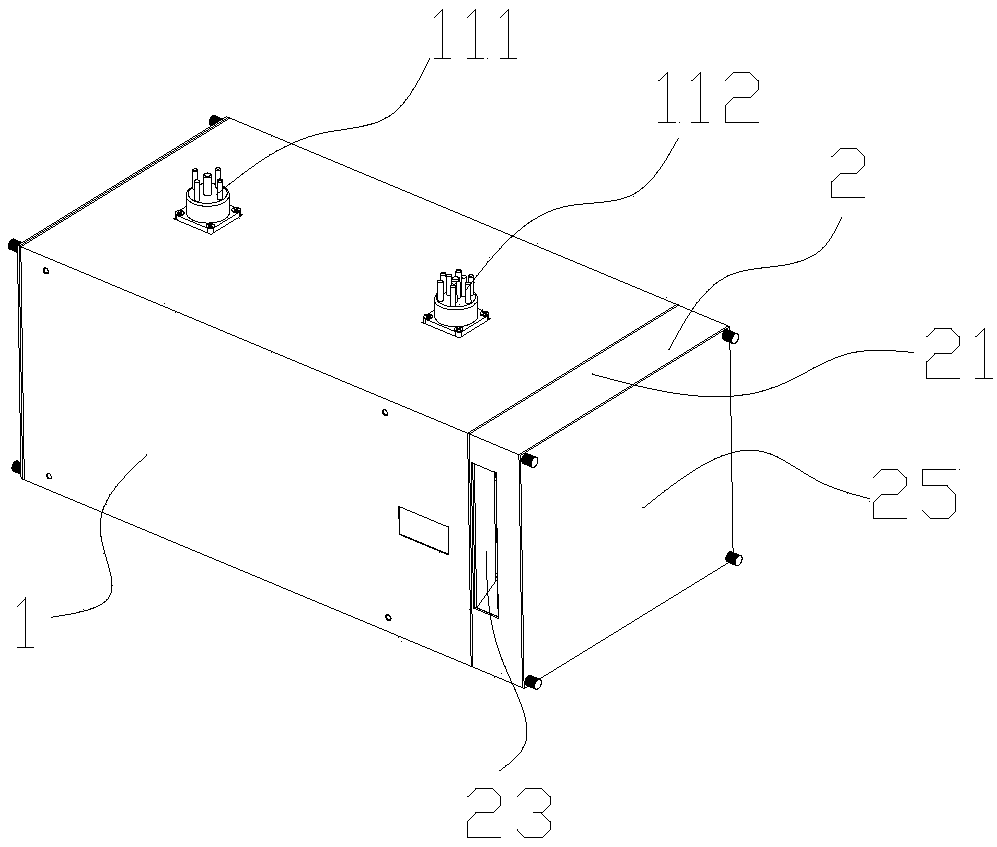

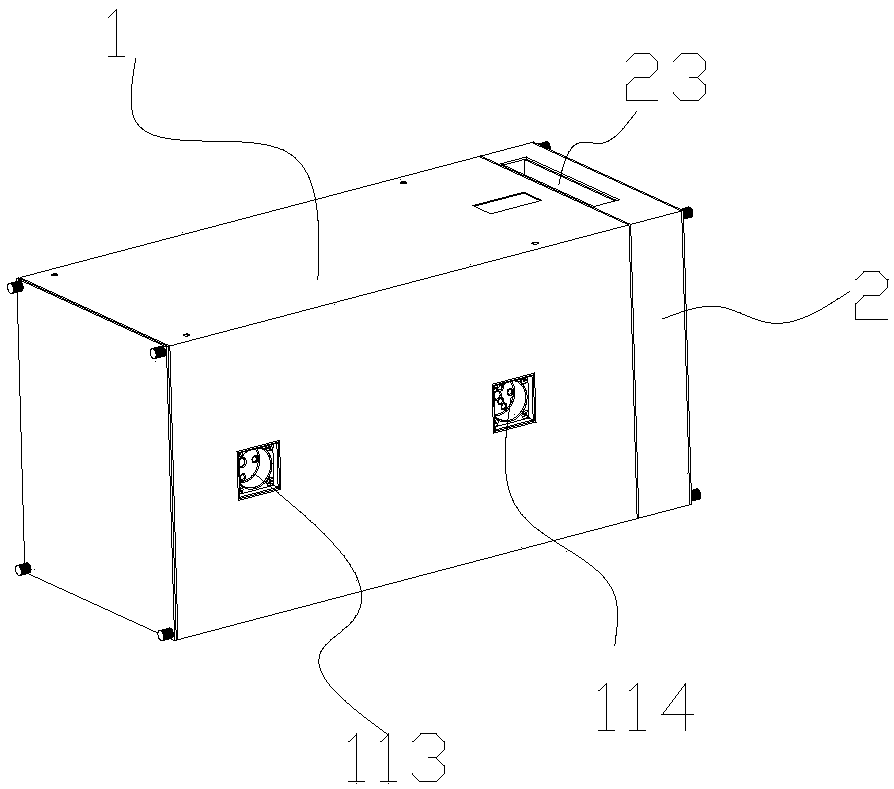

Automatic vending unit

PendingCN108537961ASquare shapeFast StackingCoin-freed apparatus detailsApparatus for dispensing discrete articlesColletCarton

The invention relates to the technical field of loading and unloading machinery equipment, in particular to an automatic vending unit. The automatic vending unit comprises a storing device and a flipping device; the storing device comprises feed box, a feed collet is fixedly embedded in the feed box, a feed guiding channel used for guiding feed is arranged in the feed collet, and the rear end of the feed guiding channel is closed while the front end of the same leads to the flipping device; the flipping device comprises a pop-up box located at the front end of the feed box and fixedly connected with the same, a discharging chamber continuously communicated with the feed guiding channel is arranged in the pop-up box, the front end of the pop-up box is closed, a discharging hole communicatedwith the discharging chamber is arranged in one side of the pop-up box, and a flipping mechanism used for flipping the feed from the discharging chamber to the discharging hole is arranged on one side of the pop-up box and opposite to the discharging hole; the feed in the feed collet is arranged side by side, a push plate used for pushing all the feed forward is arranged at the rear end of the feed farthest from the discharging hole, and an elastic device is arranged between the push plate and the feed collet. The automatic vending unit can serve as a packing material to replace a carton or arefrigerated cabinet.

Owner:张旭

Stacking and collecting mechanism, stacking and collecting method and quality testing machine for small-size prints

ActiveCN103112747BReduce false detection rateReduce work intensityPile receiversOther printing apparatusOutput deviceEngineering

The invention discloses a stacking and collecting mechanism, a stacking and collecting method and a quality testing machine for small-size prints. The stacking and collecting mechanism comprises two main wallboards. The two main wallboards are partially provided with clapping devices. A stacking output device is arranged under the clapping device. The clapping device comprises a supporting beam mounted between the two main wallboards. One end of the supporting beam is connected with a cam mechanism. A pair of lateral pushing boards is mounted on the supporting beam, and is used for pushing two lateral sides of prints. A rear pushing board is arranged between two lateral pushing boards, is connected with the supporting beam through a supporting rod and a slope driving mechanism, and is used for hooking-in and clapping the upper surface of the prints. The stacking output device comprises a lifting platform which is driven to move up and down by a lifting motor through a lifting conveying mechanism. The stacking and collecting method and the quality testing machine for small-size prints are realized based on the stacking and collecting mechanism. Automatic stacking and collecting of the small-size prints are realized at a high speed in high efficiency with low vibration and noise.

Owner:HEBEI TIANYUHENG TECH CO LTD

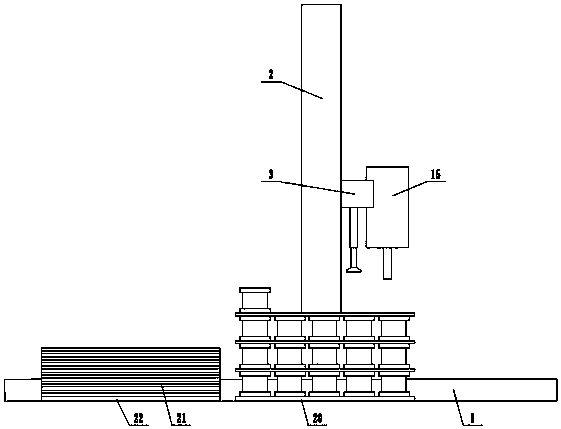

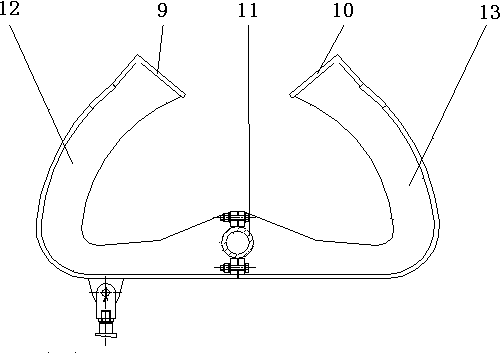

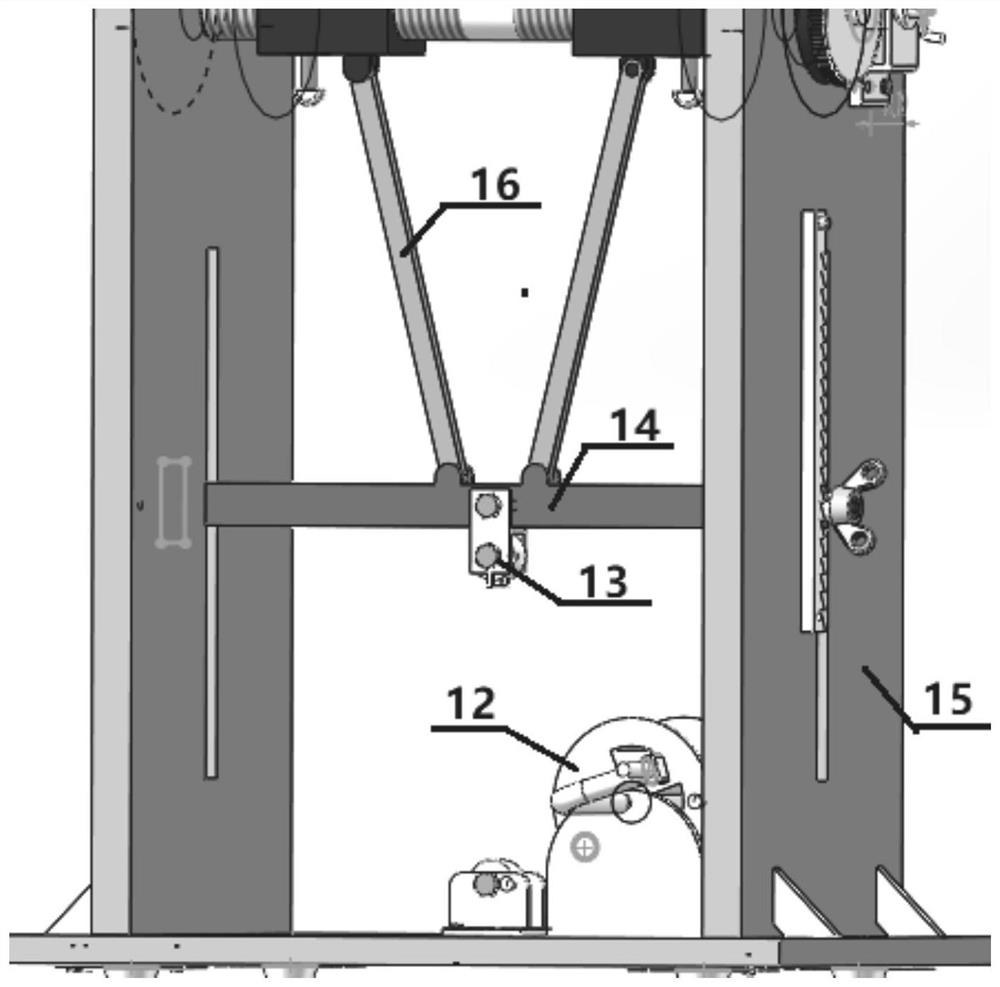

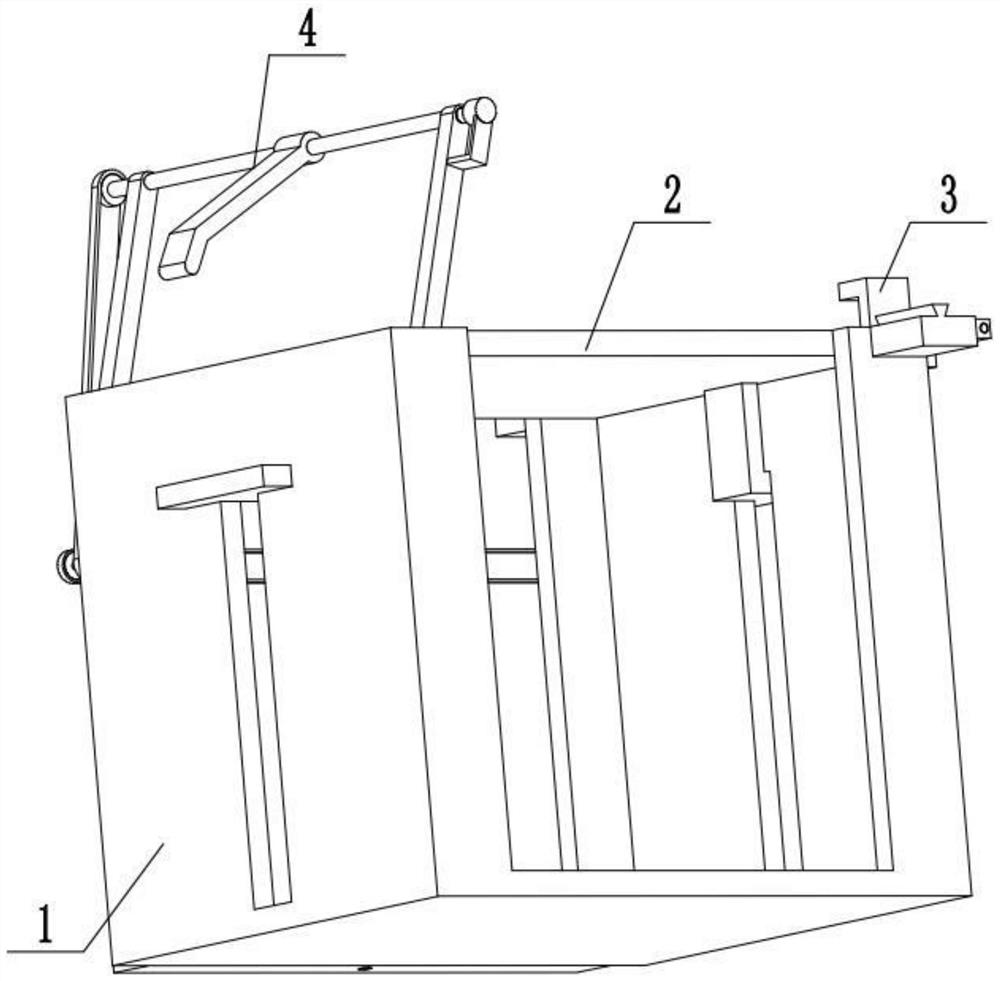

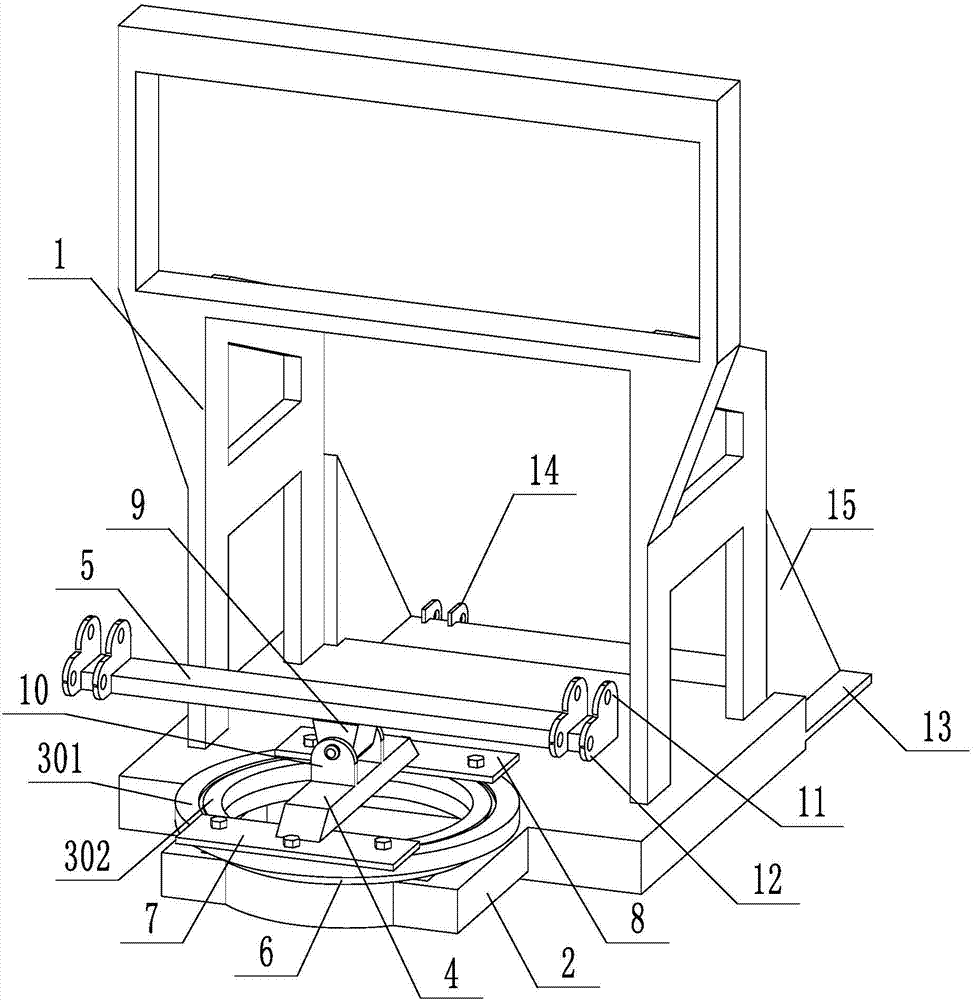

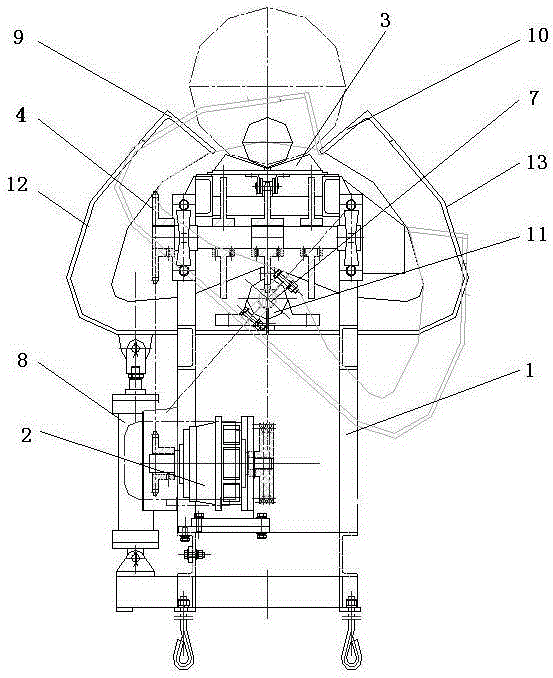

A stacking device for proton exchange membrane fuel cells

ActiveCN109449471BFast stackingAvoid damageFuel cells groupingEngineeringProton exchange membrane fuel cell

The invention discloses a stacking device for a proton exchange membrane fuel cell, comprising: a frame, a workbench, a primary pressure-applying mechanism, a secondary pressure-applying mechanism, a slider group, and a pressure-applying plate group; the workbench is fixed on the frame The upper part; the slider group includes two sliders that can move toward each other on the workbench; the primary pressure-applying mechanism is arranged on the frame and connected with the slider group, and can drive the two sliders to move toward each other to perform primary pressure; the second The secondary pressure-applying mechanism is connected to the slider group, which can drive the two sliders to move toward each other after the primary pressure application to perform secondary pressure application; the pressure-applying plate set includes two pressure-applying plates, and each pressure-applying plate is connected to a slider. Through the two modes of the slider group and the design of the two pressure-applying structures, two different pressure-applying methods, fast stacking and slow strong pressure, can be realized during the battery stacking process, so that both ends of the battery can be evenly applied. The precision of applying the force is high, avoiding the damage of the fuel cell in the process of applying the force, and facilitating assembly.

Owner:WUHAN POLYTECHNIC UNIVERSITY

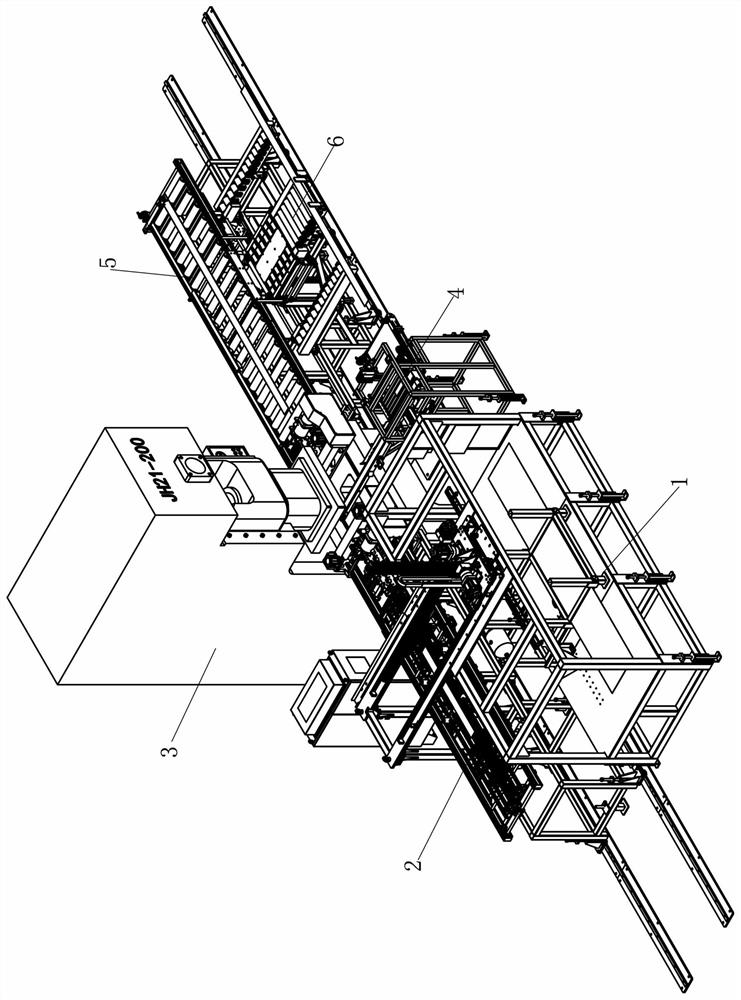

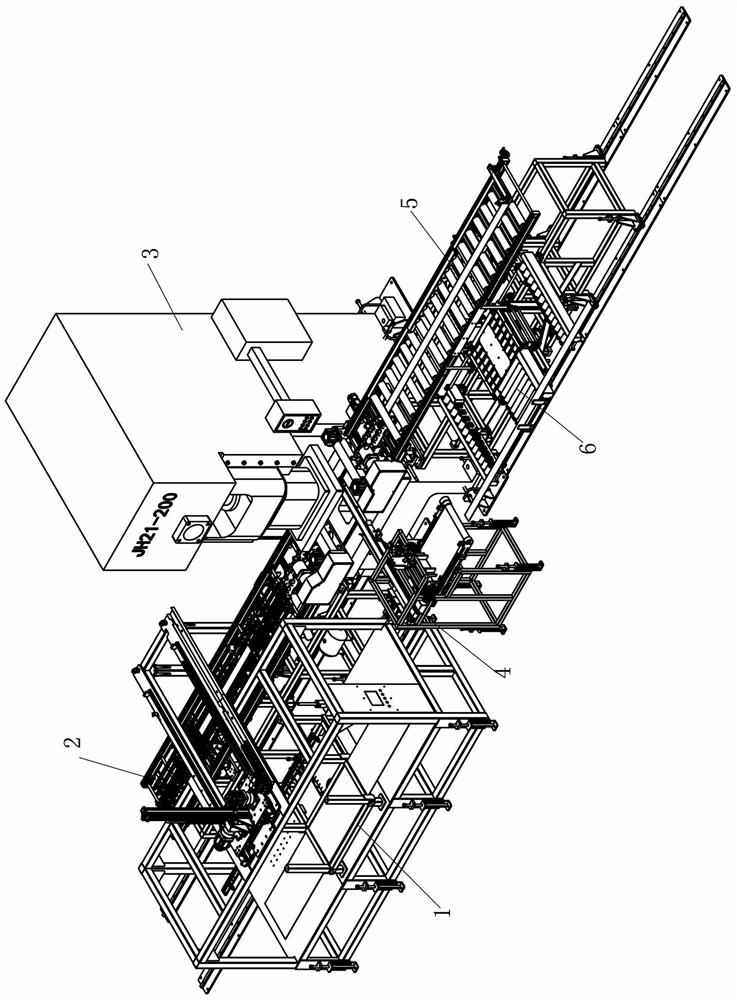

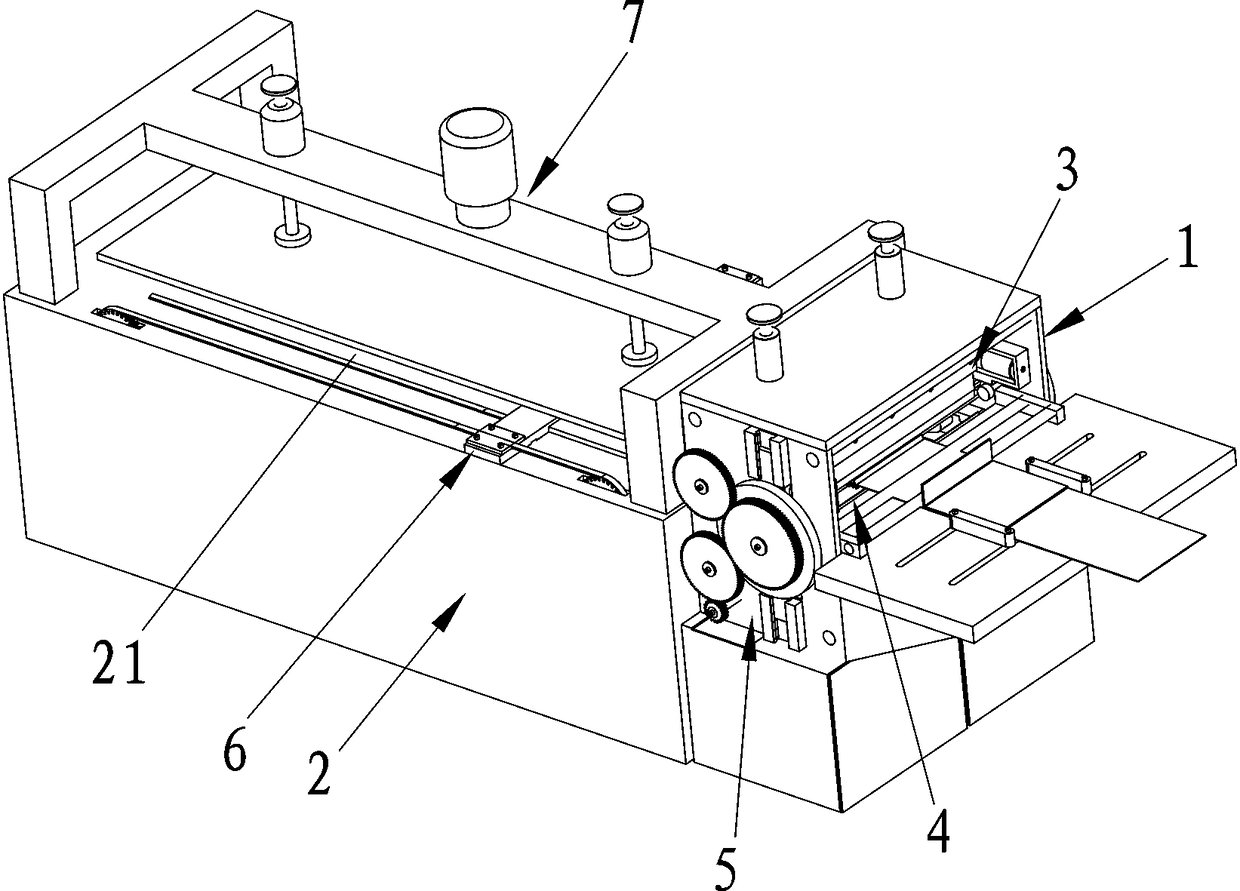

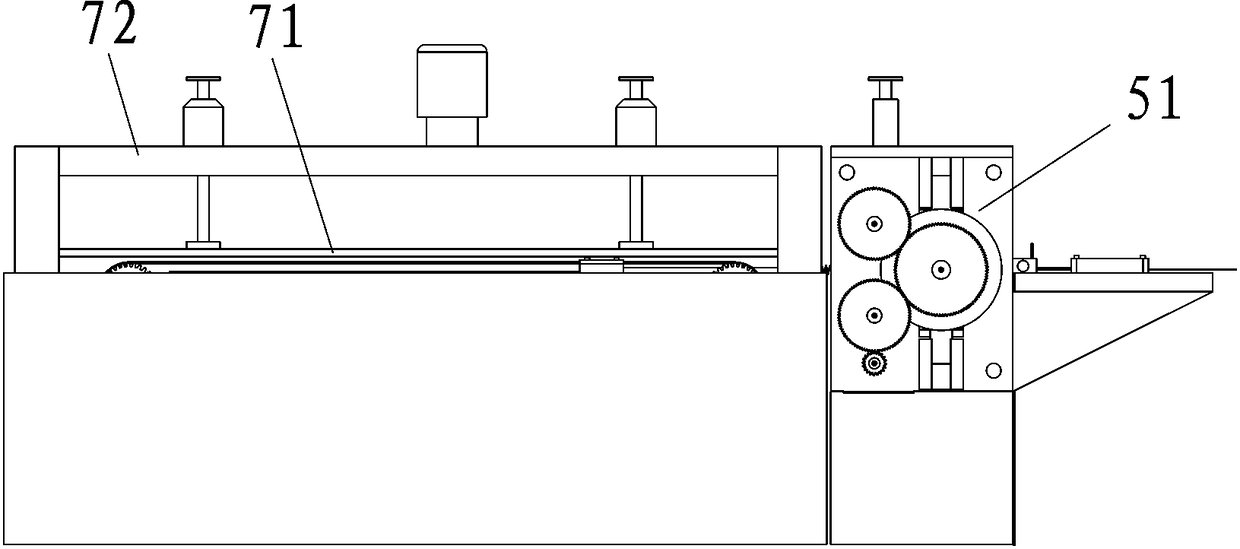

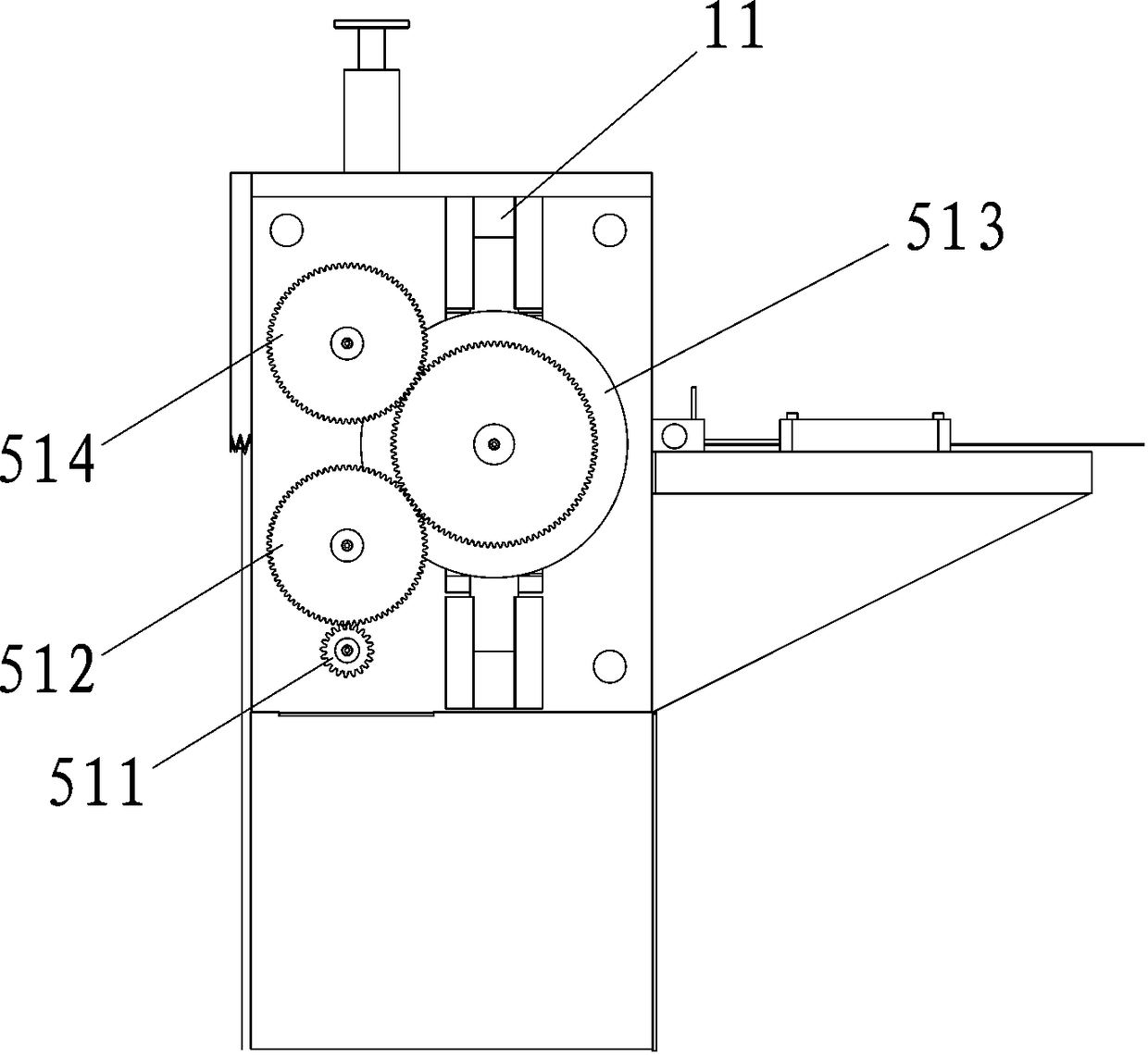

A sheet automatic blanking and punching production line

ActiveCN113426895BMatch punch rhythmIncrease productivityMetal-working feeding devicesPositioning devicesProduction linePunching

The invention relates to the technical field of sheet material punching, in particular to an automatic blanking and punching production line for sheet materials. It includes a sheet material feeding device, a sheet material feeding device, a sheet material stamping die, a sheet material discharging device and a blanking piece receiving device. The sheet material feeding device is used for grabbing a single sheet to the On the sheet material feeding device, the sheet material feeding device is used to convey a single sheet material intermittently and horizontally into the sheet material stamping die, and the sheet material stamping die is used to punch out holes on the sheet material, and the sheet material The material discharging device is used to convey the punched sheet and stack them. The present invention realizes sheet material feeding, intermittent feeding, sheet punching, sheet material feeding, Therefore, the production efficiency of the present invention is high and can match the punching rhythm of the sheet stamping die, and the present invention is suitable for continuous punching of sheets.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

Raw material one-way limiting stacking mechanism for machining

The invention discloses a raw material one-way limiting stacking mechanism for machining. The mechanism comprises a mounting frame, the mounting frame is a right-angel C-shaped plate with a rightwardopening, a control switch is arranged at the left end of the horizontal part on the upper side of the mounting frame, and the input end of the control switch is electrically connected with the input end of an external power supply. According to the raw material one-way limiting stacking mechanism for machining, the structure is simple, stacking of raw materials for machining can be rapidly carriedout, through the turnover of a first connecting plate and a second connecting plate, the single raw material is pushed to be in a vertical stacked mode by using hinged plates which are parallel to each other, the raw materials are pushed to a second conveying device through electric telescopic rods, so that the disorder of the raw materials is avoided under the combination with baffles; and the hinged plates are always in a horizontal state in the reverse rotation process, and the adjacent raw materials are not extruded and collided, so that the abrasion of the mechanical raw materials is avoided, the subsequent machining quality is guaranteed, the efficiency is improved, and the use is more convenient.

Owner:苏州圣凡自动化科技有限公司

Automatic stacking device

PendingCN110304430AEasy to operateFast stackingConveyorsControl devices for conveyorsComputer moduleMechanical engineering

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

A polymer sheet stacking conveying device

Owner:ZHEJIANG FENGBANG MACHINERY TECH CO LTD

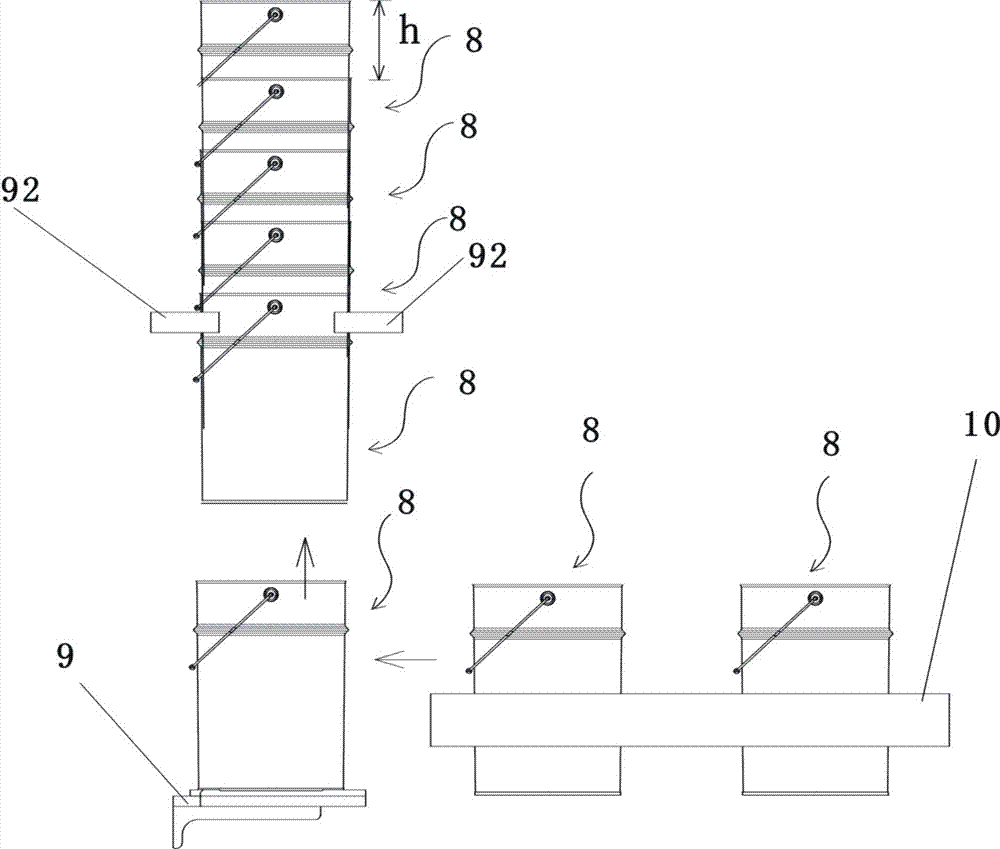

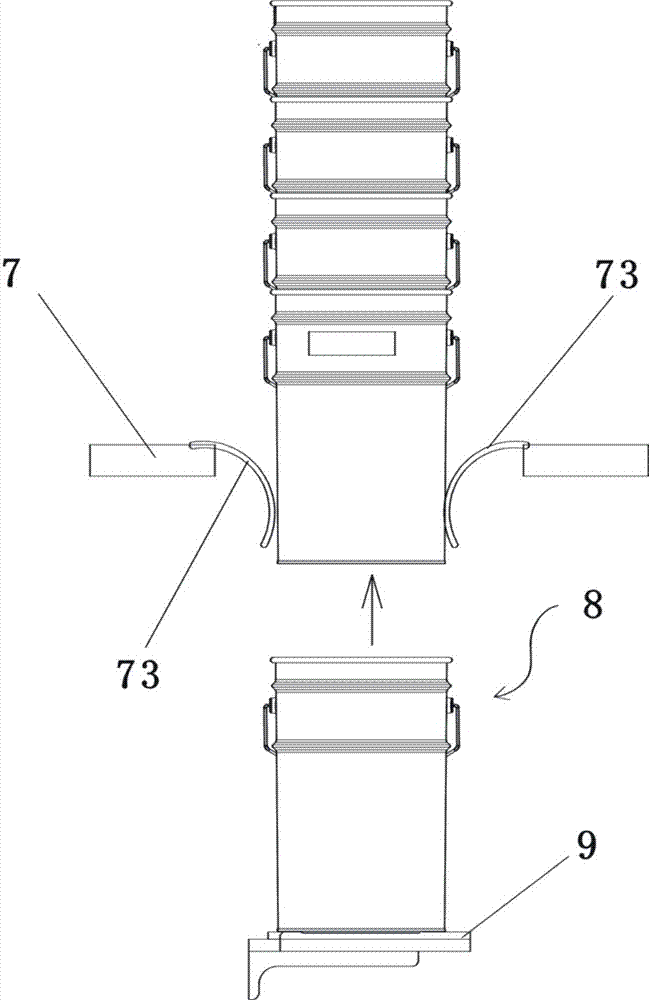

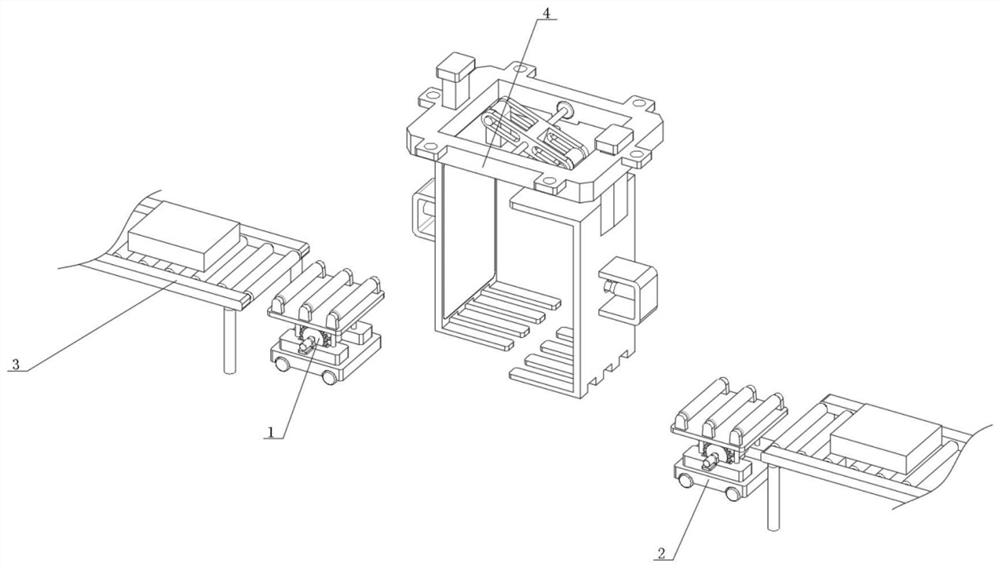

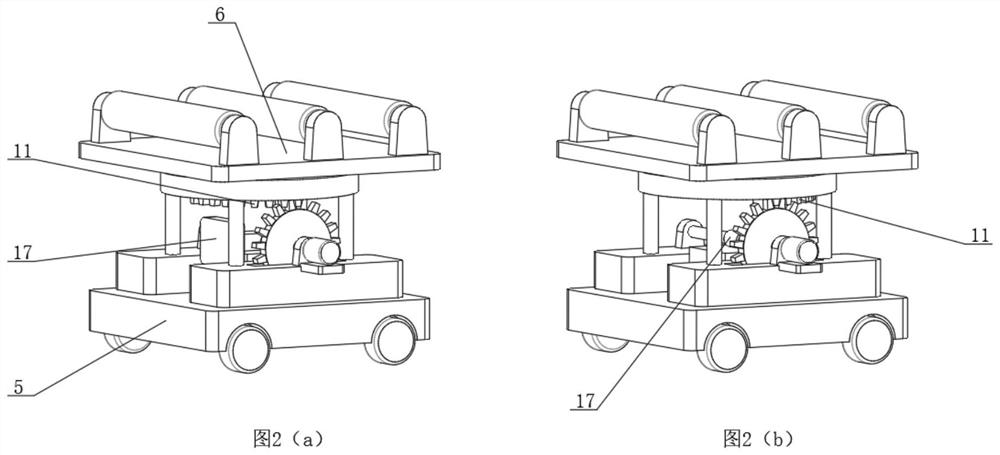

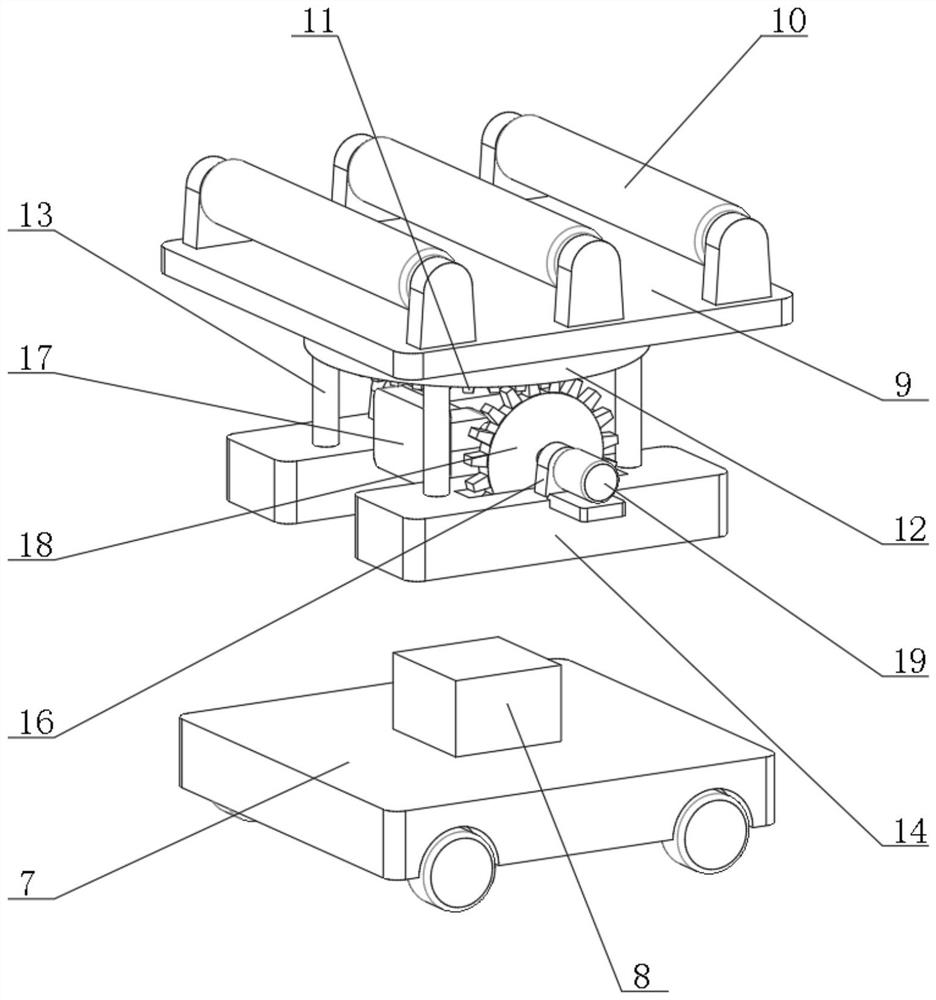

Elevator for stacking box-shaped materials in batches up and down for material boxing

PendingCN113620066AFast stackingEfficient stackingPackagingStacking articlesElectric machineryManufacturing engineering

The invention discloses an elevator for stacking box-shaped materials in batches up and down for material boxing. A first conveying trolley and a second conveying trolley are included, conveying devices are correspondingly arranged on one side of the first conveying trolley and one side of the second conveying trolley, and an automatic stacking mechanism is arranged between the first conveying trolley and the second conveying trolley. Each of the first conveying trolley and the second conveying trolley comprises a driving mechanism and a carrying mechanism arranged at the top of the driving mechanism, each carrying mechanism comprises a transmission plate, three electric rollers are mounted at the top end of each transmission plate, and every three electric rollers synchronously rotate in the mode that a motor drives a gear set to drive a chain to rotate. The automatic stacking mechanism comprises a fixing base, and a left side stacking plate and a right side stacking plate are symmetrically arranged on the two sides of the lower portion of the fixing base. The whole device can efficiently stack materials in sequence, operation is reliable, the stacking efficiency and quality of the materials can be ensured, the stacking automation degree of the materials is improved, and the production and use requirements are met.

Owner:QIBU CO LTD

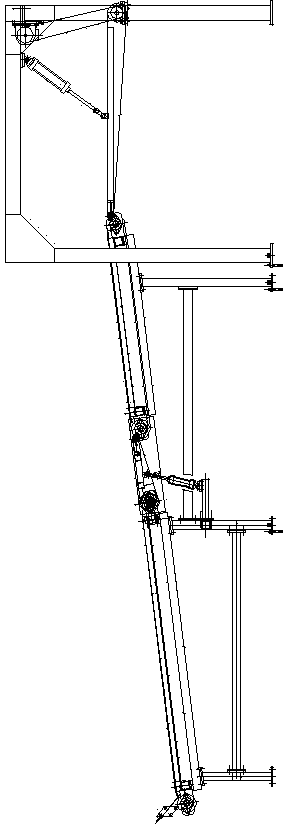

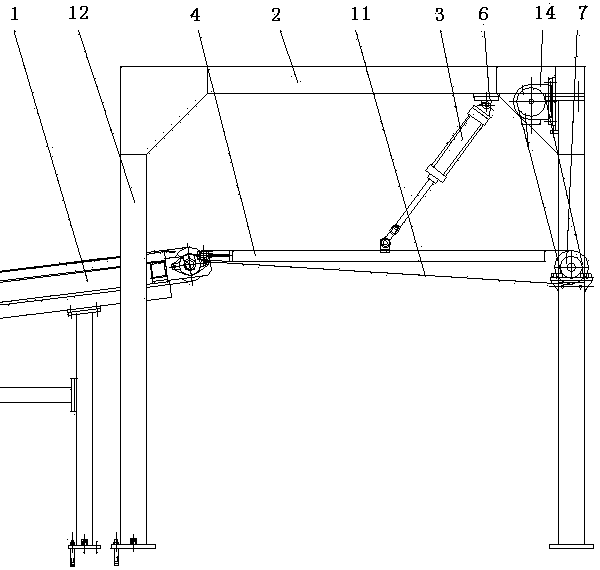

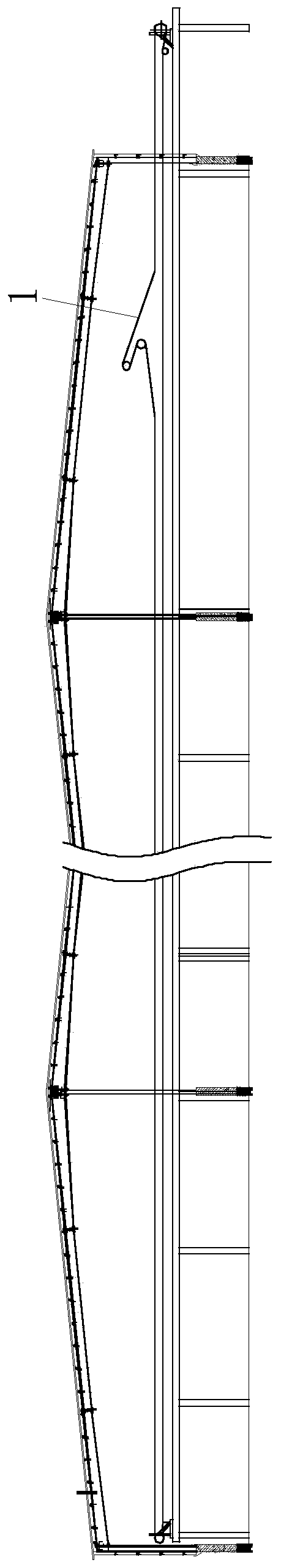

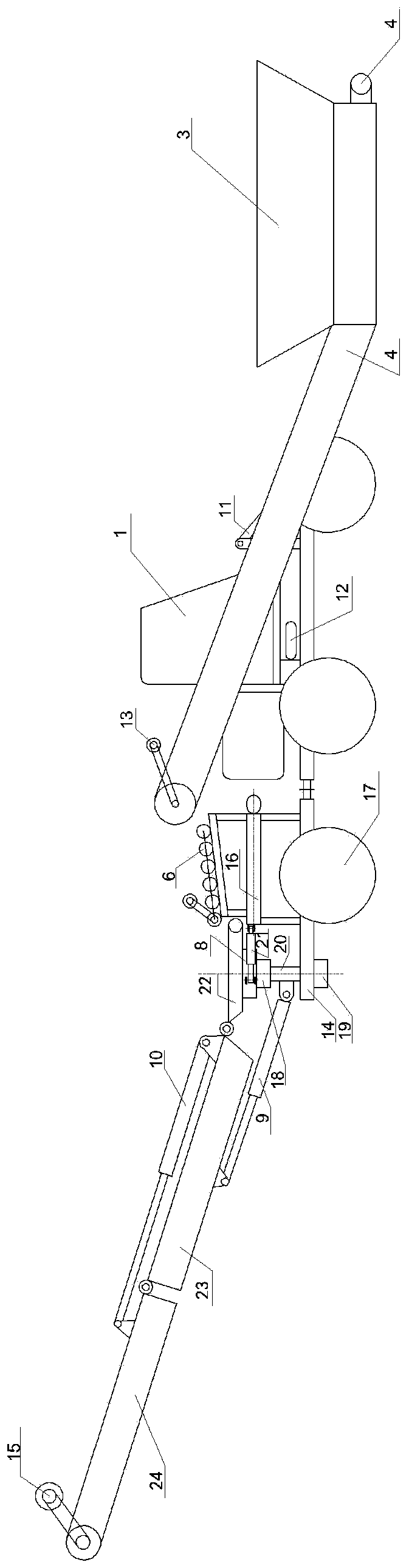

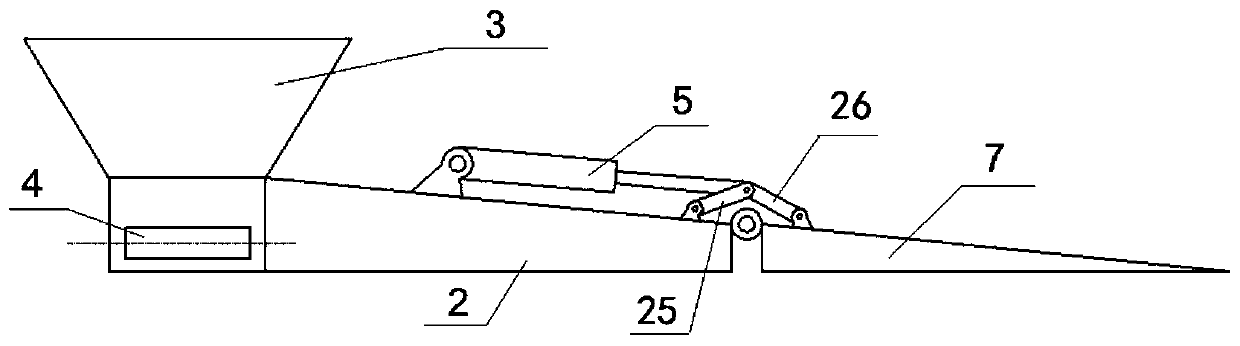

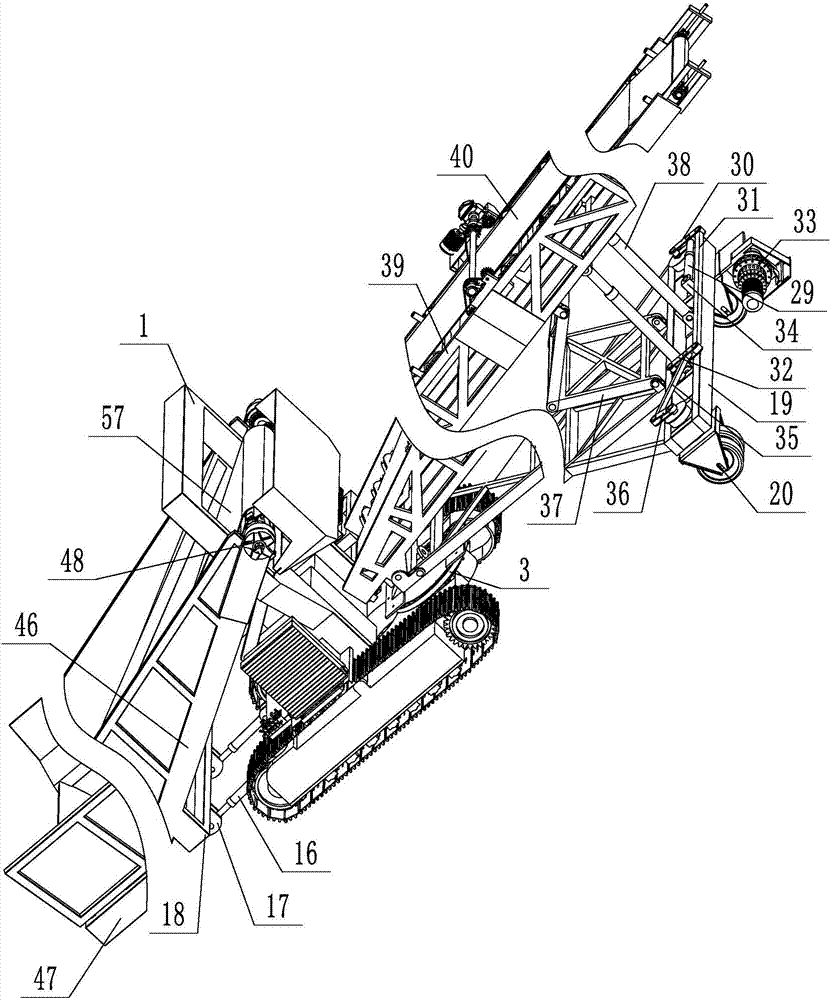

Self-propelled sugarbeet stacking and truck loading dual-purpose equipment

PendingCN111591787AStacked in orderFast stackingConveyorsStacking articlesAgricultural engineeringTruck

The invention discloses self-propelled sugarbeet stacking and truck loading dual-purpose equipment, and relates to the technical field of agricultural machinery. The equipment comprises a loading machine, a foldable get-on table, a sugarbeet unloading hopper, a main conveying belt device, an impurity and soil removal device, a foldable stacking conveying belt device, a lifting large arm, a power device, a traction chassis, an impurity and soil receiving conveying belt device and a thrust wheel. The lifting large arm is arranged at the front end of the loading machine, and the lower end of thelifting large arm is connected with the foldable get-on table. The sugarbeet unloading hopper is fixed to one side of the foldable get-on table. One end of the main conveying belt device is mounted below the sugarbeet unloading hopper, and the other end of the main conveying belt device is arranged obliquely upwards. The rear end of the loading machine is connected with the traction chassis. The impurity and soil removal device and the impurity and soil receiving conveying belt device are arranged at the upper end of the traction chassis. The impurity and soil receiving conveying belt device is located under the impurity and soil removal device. The foldable stacking conveying belt device is rotationally mounted at the rear end of the traction chassis. The stacking speed of the equipment is high, storage space is saved, impurity removal and soil removal can be carried out on sugarbeet conveniently, and the phenomenon that sugarbeet is rotten is avoided.

Owner:乌兰浩特市群兴机械制造有限公司 +1

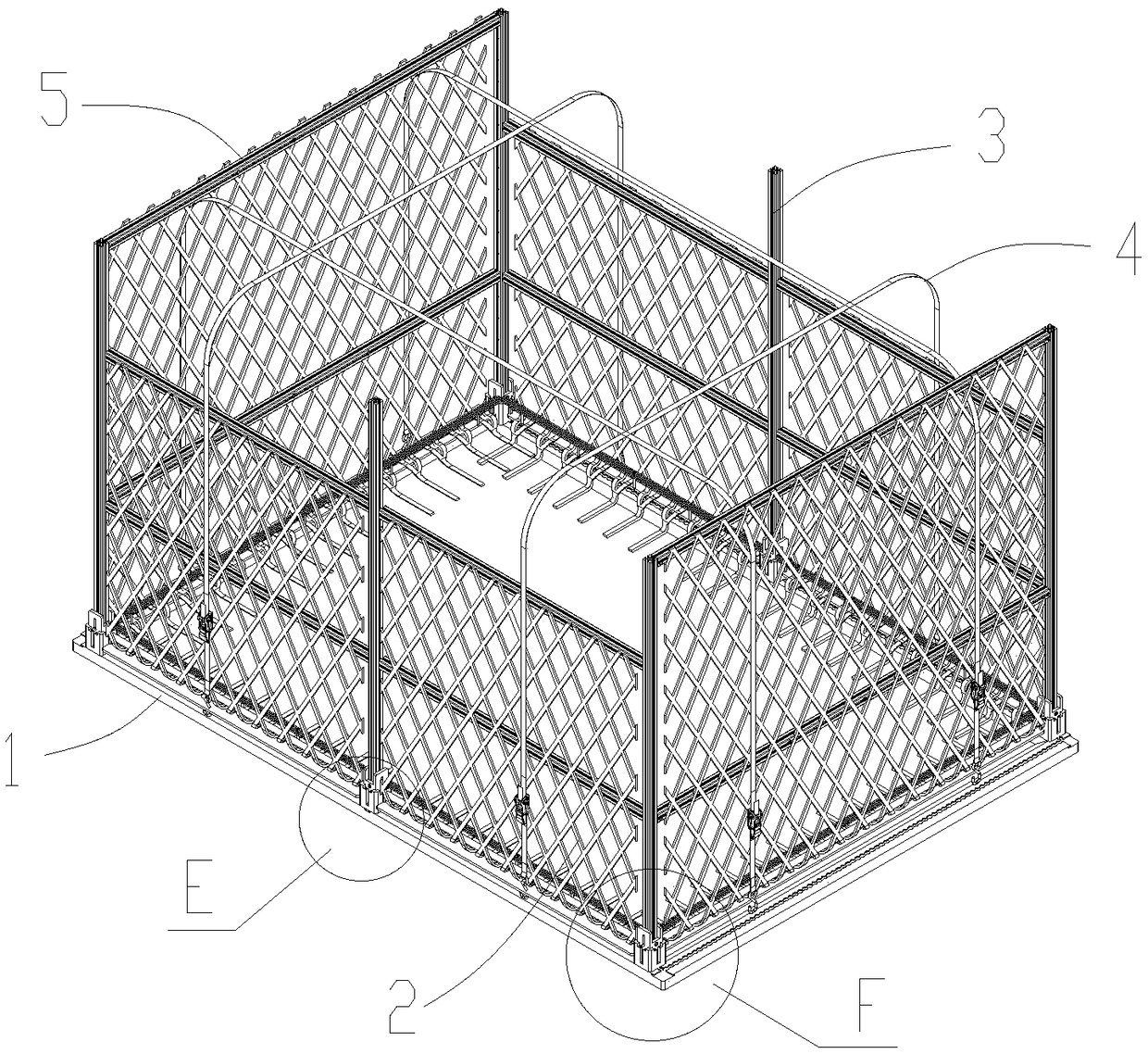

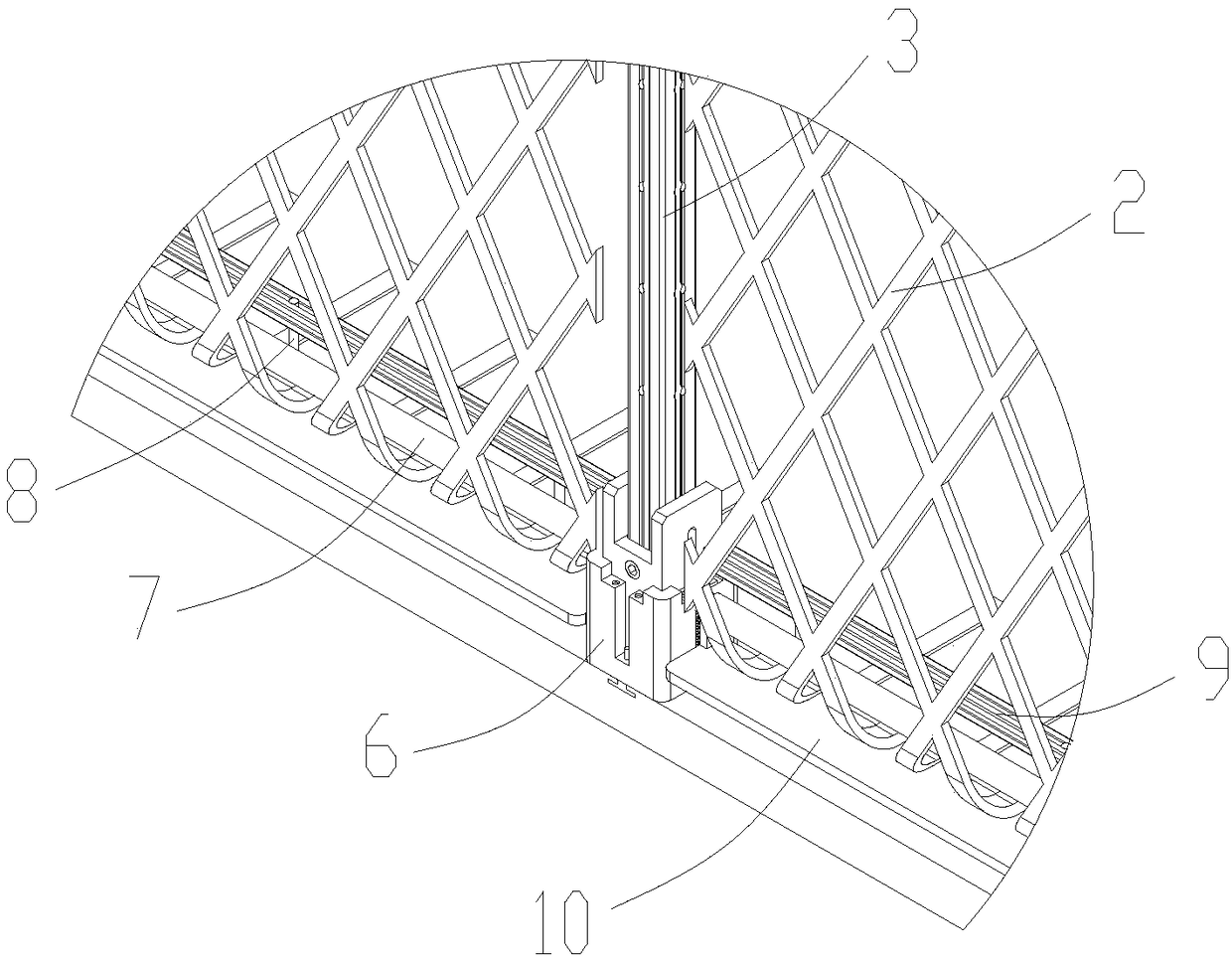

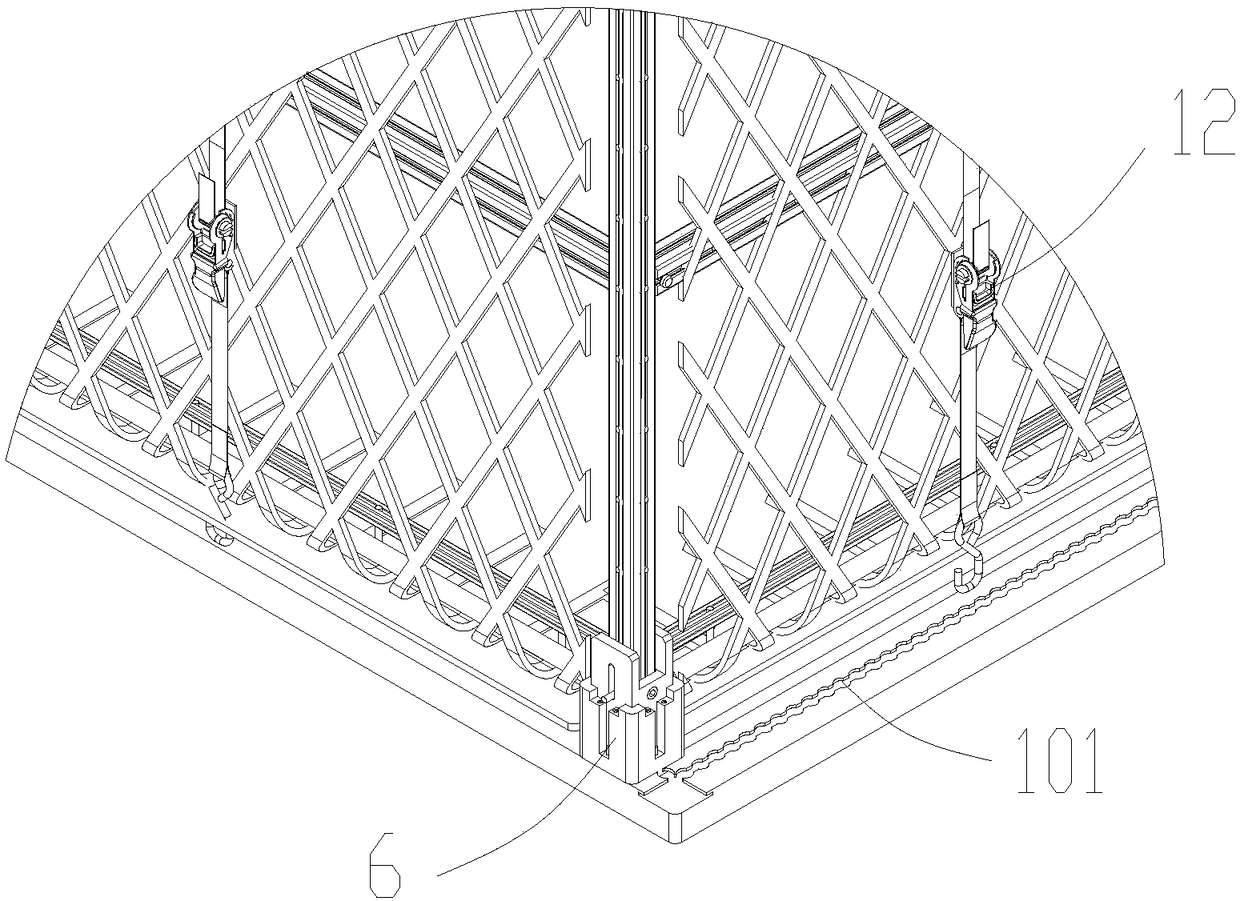

Aviation packaging plate servo stacking device

The invention discloses an aviation packaging plate servo stacking device which comprises a supporting bottom plate. The aviation packaging plate servo stacking device is characterized in that a plurality of upright columns are arranged at the peripheral parts of the supporting bottom plate; a liftable static force rope net is arranged between every two adjacent upright columns; rolling mechanismsare arranged at the bottom edges of the static force rope nets; and rigid fastening mechanisms are arranged at the top edges of the static force rope nets. The aviation packaging plate servo stackingdevice which is open and can limit is designed, and a maximum goods stacking space is obtained within the range of an existing supporting bottom plate; with the application of the static force rope nets, the technical specification requirements of aviation goods stacking are met, and stacking and fixing of goods at any height are achieved; a quick and convenient unloading mode is provided; the stability of the goods is improved; a goods stacking speed is raised substantially; and the aviation packaging plate servo stacking device is simple in structure and long in service life and is safe andreliable.

Owner:杭州宝函科技有限公司

Novel hopper loading and unloading vehicle

The invention discloses a novel hopper loading and unloading vehicle. The vehicle comprises a loading structure, a rotary steering device and a support rotating mechanism; the loading structure, the rotary steering device and the support rotating mechanism are movably connected; an output end of the loading structure is corresponding to an input end of the rotary steering device; the support rotating mechanism includes a loading and unloading vehicle body, a first rotating set and a second rotating set; the first rotating set is positioned at the front end of the loading and unloading vehicle body; the second rotating set is positioned at the back end of the loading and unloading vehicle body; the rotary steering device includes a rotary steering mechanism; the rotary steering mechanism includes a support frame, rotating wheel sets and a transmission mechanism; the transmission mechanism drives two rotating wheel sets to rotate in a splayed form; the loading structure includes a support mechanism; and the support mechanism includes a support beam, a rolling mechanism and a deviation preventing mechanism. The loading structure realizes no-landing stacking of materials and high bearing capacity; and the rotary steering device is convenient to steer the device.

Owner:山东大军机械有限公司

Paper processing equipment

PendingCN110697459ACompact structureSave spaceFolding thin materialsStacking articlesProcess engineeringBattery cell

The invention discloses paper processing equipment, and relates to the technical field of battery producing and processing. The paper processing equipment comprises a paper feeding device, a forming device and a stacking device. The paper feeding device is used for conveying paper. The forming device is used for folding and forming the paper conveyed by the paper feeding device. The stacking device is used for stacking and fixing the folded and formed paper. The paper processing equipment can fast and stably carry out paper feeding, forming, stacking and discharging work, safe processing and finished product quality of the paper are guaranteed, and the work efficiency of all the processing procedures is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

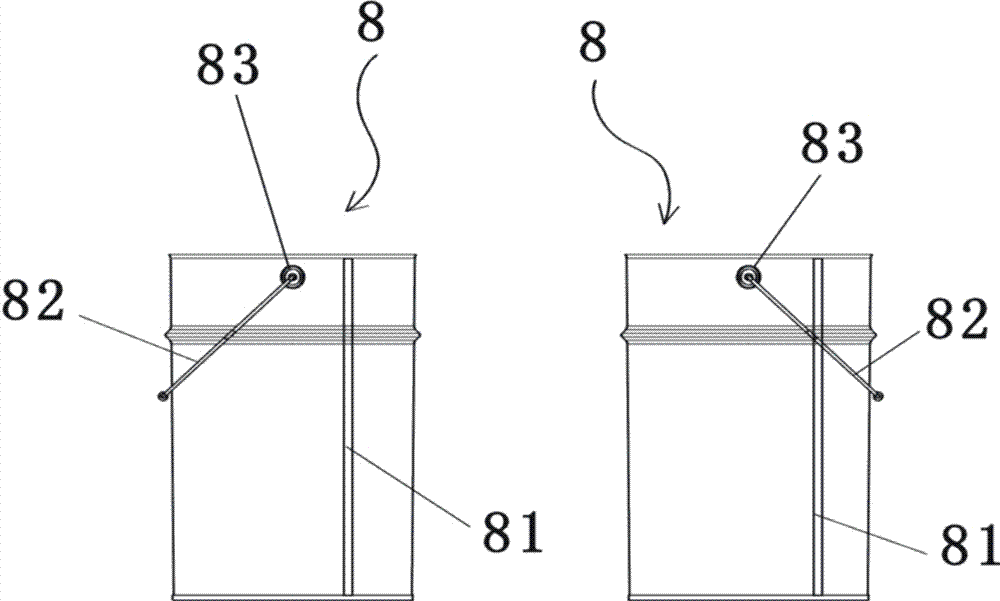

Automatic stacking equipment for metal drums without stopping the machine

ActiveCN109264414BSimple action coordinationImprove matchConveyorsStacking articlesEngineeringStructural engineering

The invention relates to an automatic stacking equipment for metal buckets without stopping for stack-changing, which is characterized in that a first group of bucket clamping block assemblies are arranged above a bucket supporting plate, a second group of bucket clamping block assemblies are also arranged above the bucket supporting plate, and the vertical position of the second group of bucket clamping block assemblies is lower than that of the first group of bucket clamping block assemblies; a horizontal longitudinal guide rail is also fixedly arranged, a sliding support is arranged on thehorizontal longitudinal guide rail, and the first group of bucket clamping block assemblies are arranged on the sliding support; a longitudinal driving mechanism for driving the sliding support to longitudinally move back and forth along the horizontal longitudinal guide rail is also arranged; when the first group of bucket clamping block assemblies and the sliding support are driven down to the rear end of the longitudinal movement track of the first group of bucket clamping block assemblies by a longitudinal driving mechanism and each elastic bucket clamping block of the first group of bucket clamping block assemblies is in a closing state, and each elastic bucket clamping block of the first group of the barrel clamping block assemblies is positioned above the barrel supporting plate. Bymeans of the invention, the stacking action is simple, the stacking speed is high, and the stacking process can be continued while stack-changing.

Owner:汕头市澄海区正益设备有限公司

Log automatic stacking device

ActiveCN103625830BNovel structureHigh degree of automationConveyor partsRoller-waysDrive shaftAgricultural engineering

The invention relates to an automatic raw wood stacking device and belongs to the technical filed of wood-working machinery. The automatic raw wood stacking device is characterized in that the device is provided with a rack, wherein the rack is provided with a linear moving device and a turnover device, the linear moving device comprises a moving motor, a riding wheel, a riding wheel shaft, a driving shaft, a driven shaft, a driving chain wheel, a driven chain wheel and a chain, the turnover device comprises a turnover frame, a turnover shaft, a turnover cylinder, an outer turnover support plate, and an inner turnover support plate, the riding wheel shaft is arranged on the rack, the riding wheel is arranged on the riding wheel shaft, the turnover shaft is arranged below the riding wheel, the turnover frame is composed of a shaft sleeve, an outer turnover frame and an inner turnover frame, the shaft sleeve is arranged on the turnover shaft, one side of the shaft sleeve is fixedly connected with the outer turnover frame, and the other end of the shaft sleeve is fixedly connected with the inner turnover frame; the upper end of the outer turnover frame is fixedly connected with the outer turnover support plate, the lower end of the outer turnover frame is connected with the rack through the turnover cylinder, and the upper and of the inner turnover frame is fixedly connected with the inner turnover support plate. The automatic raw wood stacking device provided by the invention has the advantages of being novel in structure, high in automation degree, quick in stacking speed, safe to operate, low in employment cost, and the like.

Owner:SHANDONG BAISHENGYUAN GRP

A push-and-stack paper stacking equipment and forming process

ActiveCN106273671BLabor savingFast stackingPaper/cardboard articlesManufacturing technologyPulp and paper industry

The invention relates to the technical field of filter element manufacturing, and discloses a pushing-folding paper folding device. The pushing-folding paper folding device comprises a supporting base and a carrying table for containing folded paper, and also comprises an upper pushing plate device, a lower pushing plate device, a driving device and a damping sliding device for abutting against formed filter paper; the driving device drives the upper pushing plate device and the lower pushing plate device to alternately push and fold filter paper to be formed, the upper pushing plate device and the lower pushing plate device push and fold the filter paper, the filter paper pushes the damping sliding device to slide in the carrying table, and the upper pushing plate device, the lower pushing plate device and the driving device are connected with the supporting base. When the paper folding device works, the filter paper is in a stacked shape with an arc transition through alternate pushing and folding of the upper pushing plate device and the lower pushing plate device; labor can be reduced through the pushing-folding paper folding device, the pushing-folding speed is high, the forming standard is more uniform, and the forming quality is better. The invention also provides a forming technology of the paper folding device, and the forming technology has the advantages that the production efficiency can be improved, and the forming quality can be guaranteed.

Owner:东莞市盛联滤清器制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com