Automatic stacking equipment for metal drums without stopping the machine

An automatic stacking and metal barrel technology, applied in the field of metal barrel stacking, can solve the problems of reducing the stacking speed, time-consuming, unable to continue stacking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

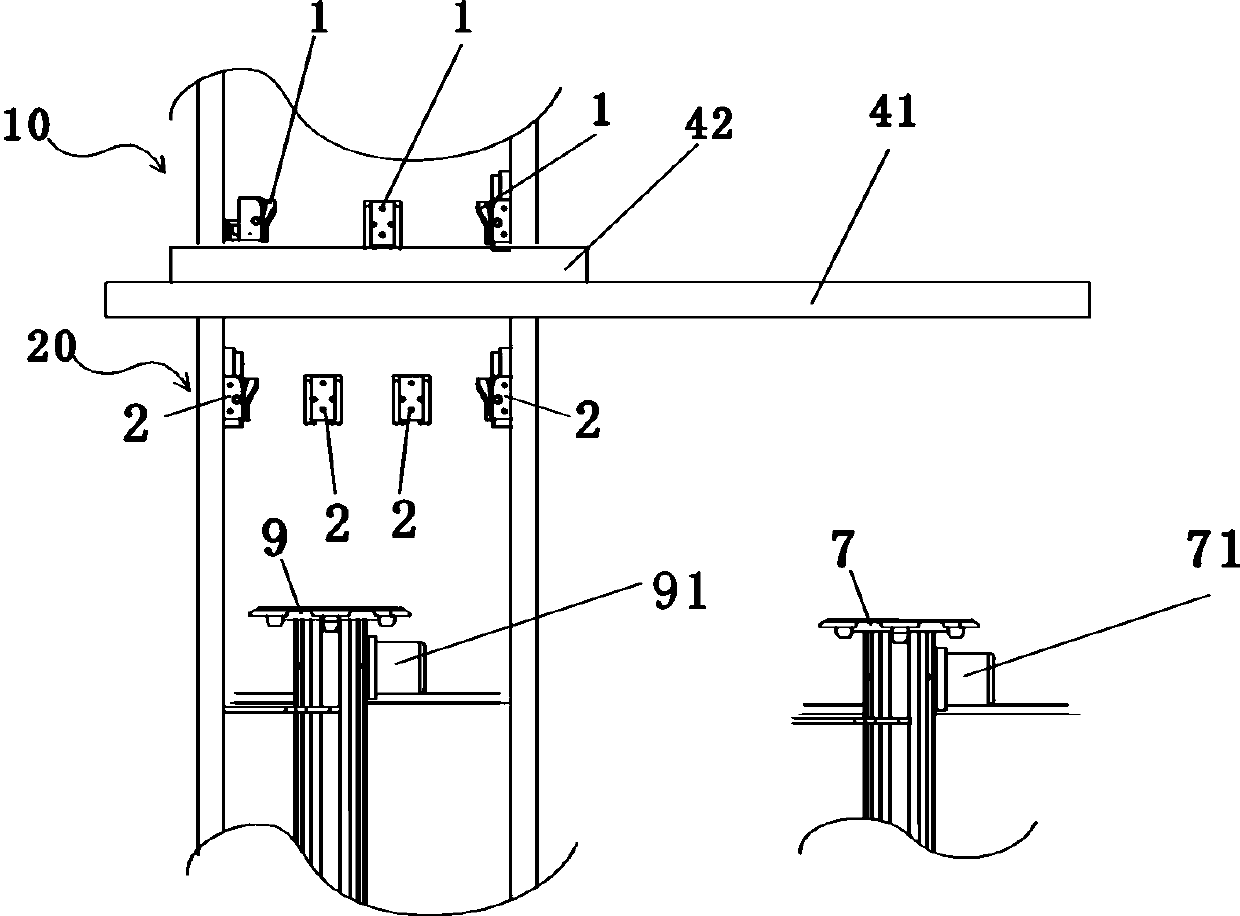

[0066] The difference between the second embodiment and the first embodiment mainly lies in the different structures of the elastic bucket holding clamps. In the second embodiment, in the first set of bucket holding clamp assembly 10 and the elastic bucket holding clamp block of the second set of bucket holding clamp assembly 20, each clamp body 31 can be radially slidably installed on the corresponding clamp block On the support 32, and the clamping block body 31 clamps the clamping block support 32 from the up and down direction to form a clamping rail of the clamping block support, such as Figure 13 shown in . The rest of the structure of the second embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com