Board stacking system and using method thereof

A palletizing system and plate technology, which is applied in the field of palletizing systems, can solve problems such as low efficiency and affect the overall efficiency of plate processing, and achieve high efficiency, promote the automation process, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

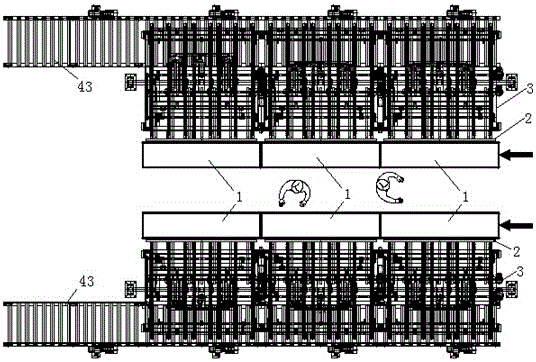

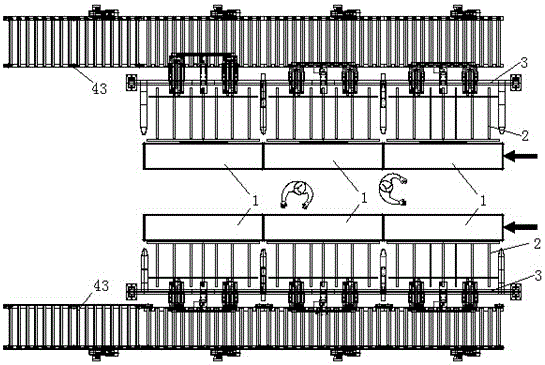

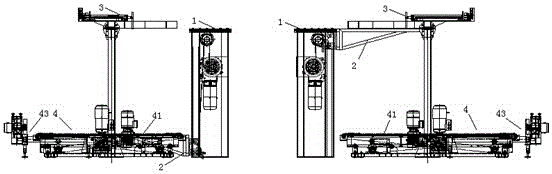

[0032] refer to Figure 1 to Figure 12 , this embodiment provides a plate palletizing system, including a workbench 1, a lifting platform system 2, a positioning baffle system 3, a lane-separating conveying system 4 and a control unit 6, and the upper end surface of the workbench 1 is a pneumatic floating ball The working platform, the lifting platform system 2 includes a lifting platform 21 and a lifting control system 22, the lifting platform 21 is arranged on one side of the workbench 1, the lane-dividing conveying system 4 is arranged under the lifting platform 21, and the lifting platform 21 includes a plurality of mutually parallel And the crossbar 211 at the same level, the lane-dividing conveying system 4 includes a lifting conveying system 41 and a conveying system 43, one end of the lifting conveying system 41 is interlaced with the crossbar 211 in the lifting platform 21, and the lifting conveying The other end of the system 41 leads to a delivery system 43 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com