Patents

Literature

96results about How to "Realize stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

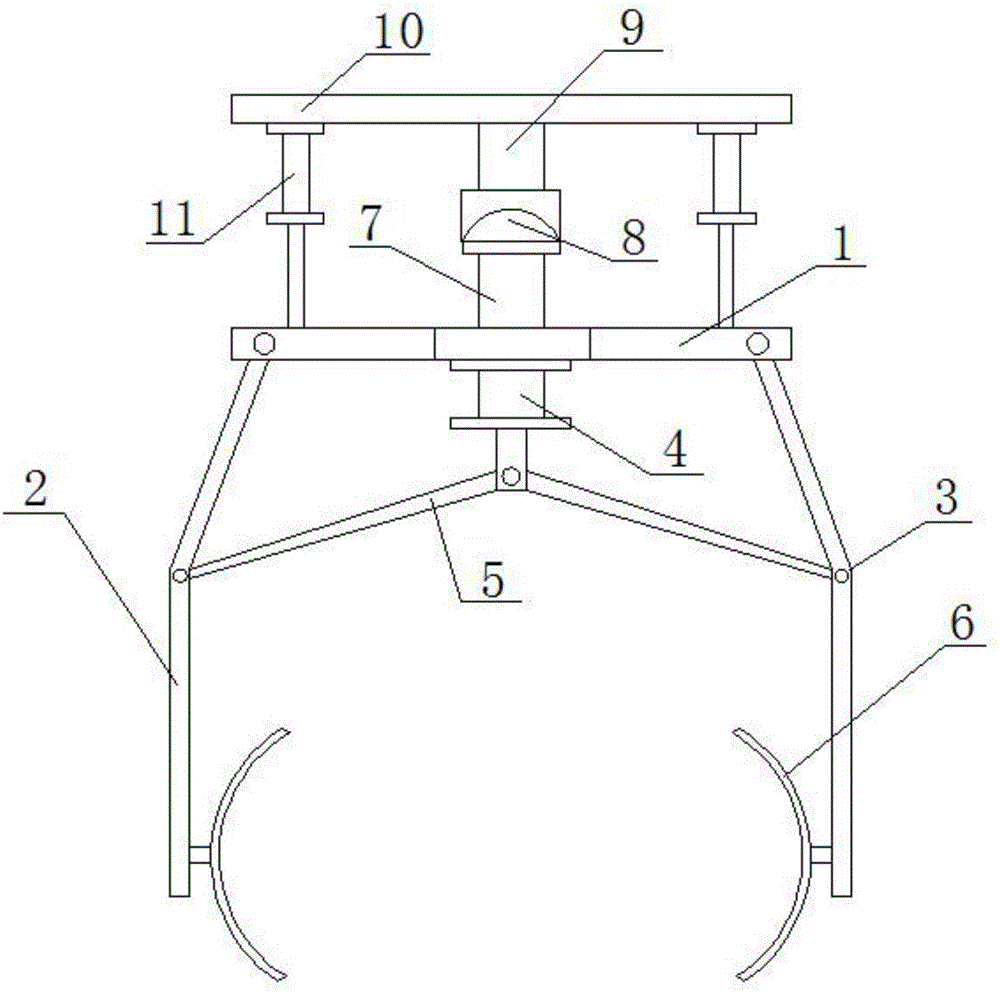

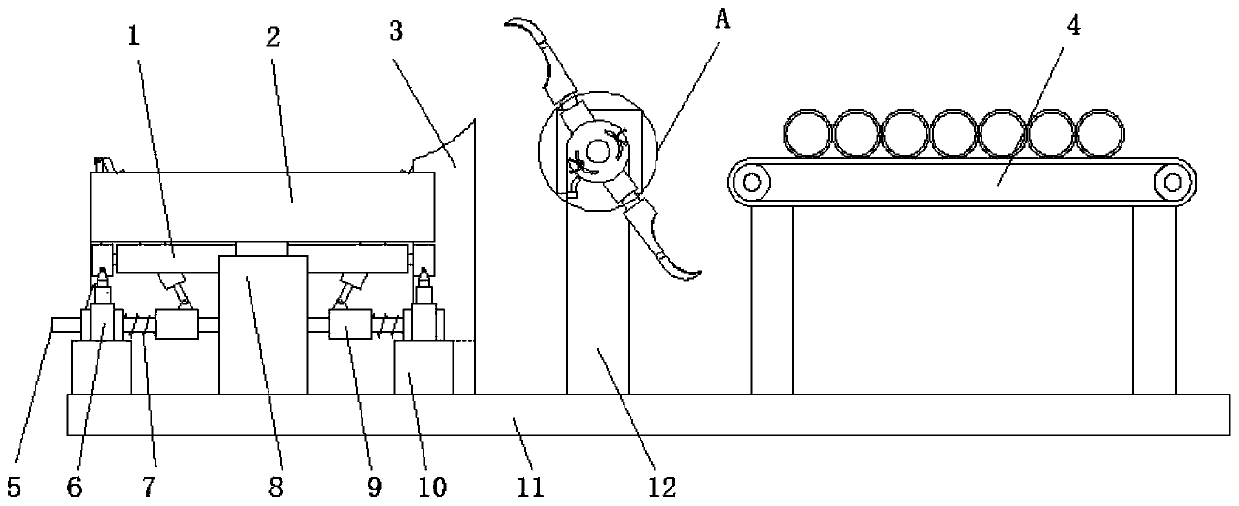

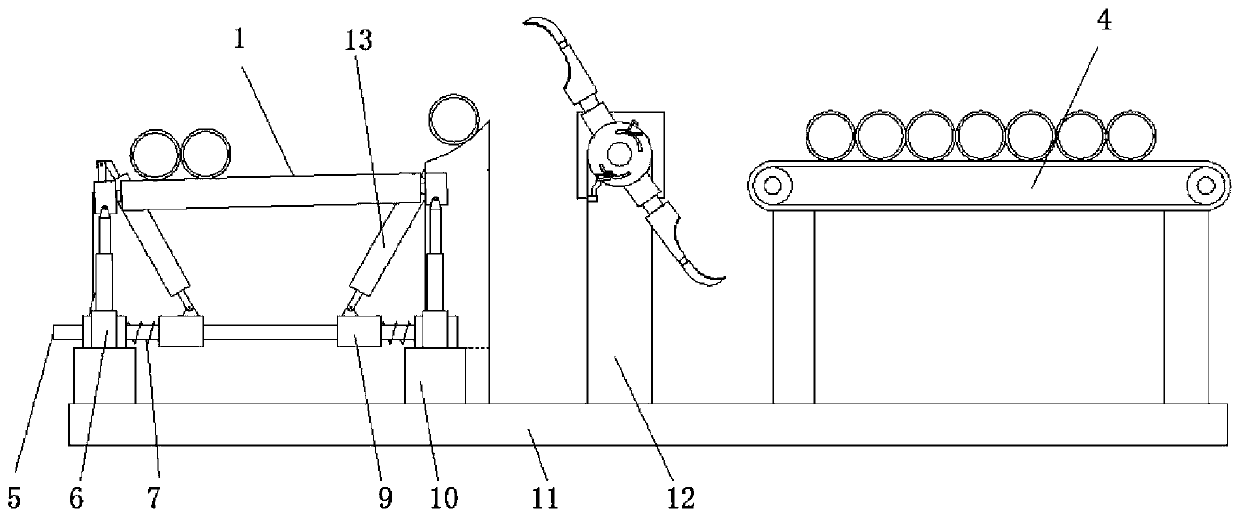

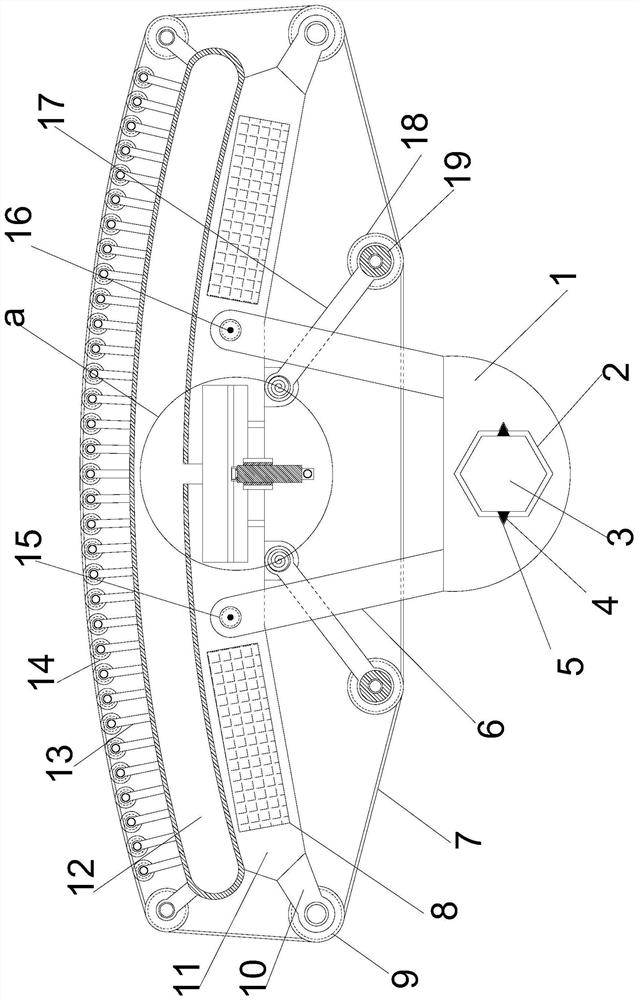

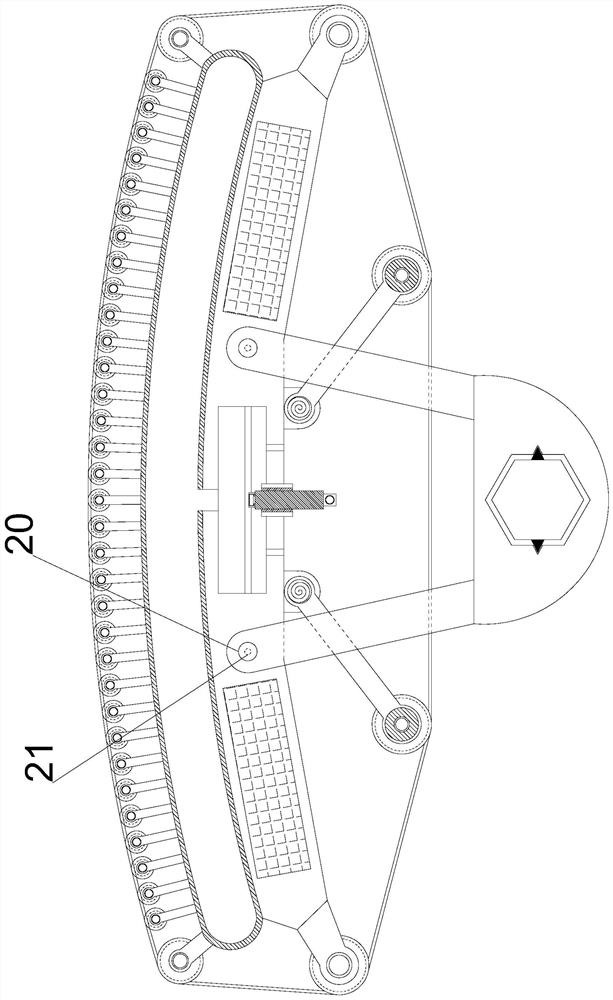

Steel pipe clamping tool

InactiveCN106737783APrevent fallingImplementation angleGripping headsManipulatorPetroleum engineering

The invention discloses a steel pipe clamping tool which comprises a support and a hydraulic oil cylinder. One end of the hydraulic oil cylinder is connected to the lower portion of the support, two connecting rods are hinged to the other end of the hydraulic oil cylinder, and clamping rods are separately hinged to the other ends of the two connecting rods. One ends of the clamping rods are hinged to the support, and the other ends of the clamping rods are provided with clamping claws. A lower connecting rod is arranged on the support and movably connected with an upper connecting rod through a joint bearing. The top end of the upper connecting rod is provided with a rib plate. A plurality of telescopic oil cylinders are connected between the rib plate and the support. According to the steel pipe clamping tool, by arranging the hydraulic oil cylinder for driving and arranging the connecting rods for transmission, the clamping rods are driven for clamping, and the clamping force is strong; by arranging the arc clamping claws for grabbing a steel pipe, the clamping claws are good in adaptability to the steel pipe in outline and shape and high in closing precision, and the steel pipe is prevented from falling off; and by arranging the telescopic oil cylinders for being matched with the joint bearing in movement, multi-angle grabbing and stacking of a manipulator on the steel pipe are achieved, and accuracy is high.

Owner:安徽清水岩生态科技有限公司

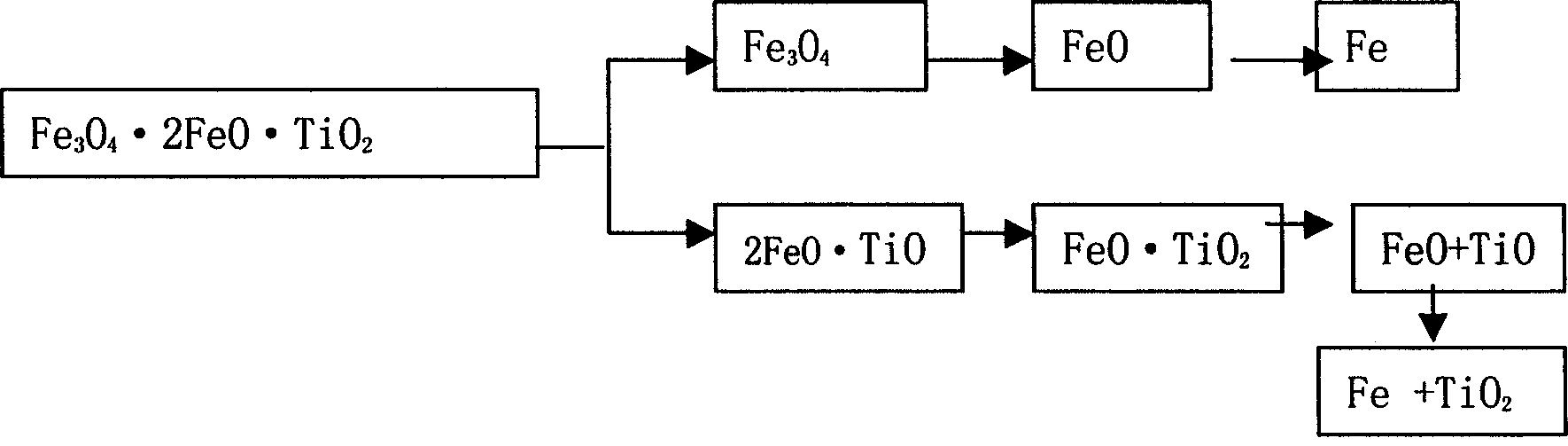

Method for preparing ferro-titantium, steel and ferrovanadium from vanadium-titantium iron headings

This invention provides a method for manufacturing FeTi, steel and FeV with FeVTi mineral concentrate including the following steps: 1, adding alkali metal to recover FeTiV mineral concentrate, 2, smelting and separating recovered Fe, 3, dephosphorizing of iron melt containing V, 4, entering into the steel converter to blow V melting and casting, 5, melting iron melt containing V with steel slag to air-refine V-rich slag with oxygen, 6, melting FeV with the V-rich slag, 7, smelting FeTi by melting slag. The advantages are: 1, avoiding the shortcoming of not recovering Ti in the converter and single-slag return flow and avoiding the shortcoming of low recovery rate of Fe in the Fe first and V second flow, 2, turning slag into the raw material of cement by adjusting composition of the smelted solvent, 3, avoiding complicated V-extraction composition of the technology by immersion.

Owner:梅卫东

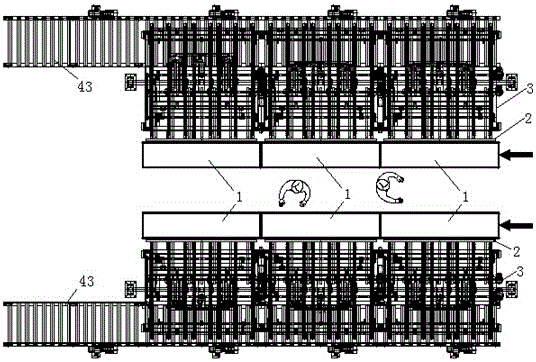

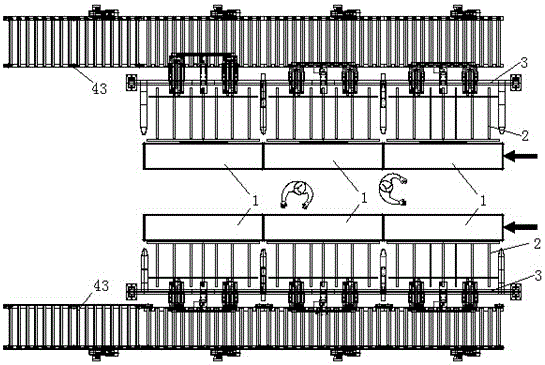

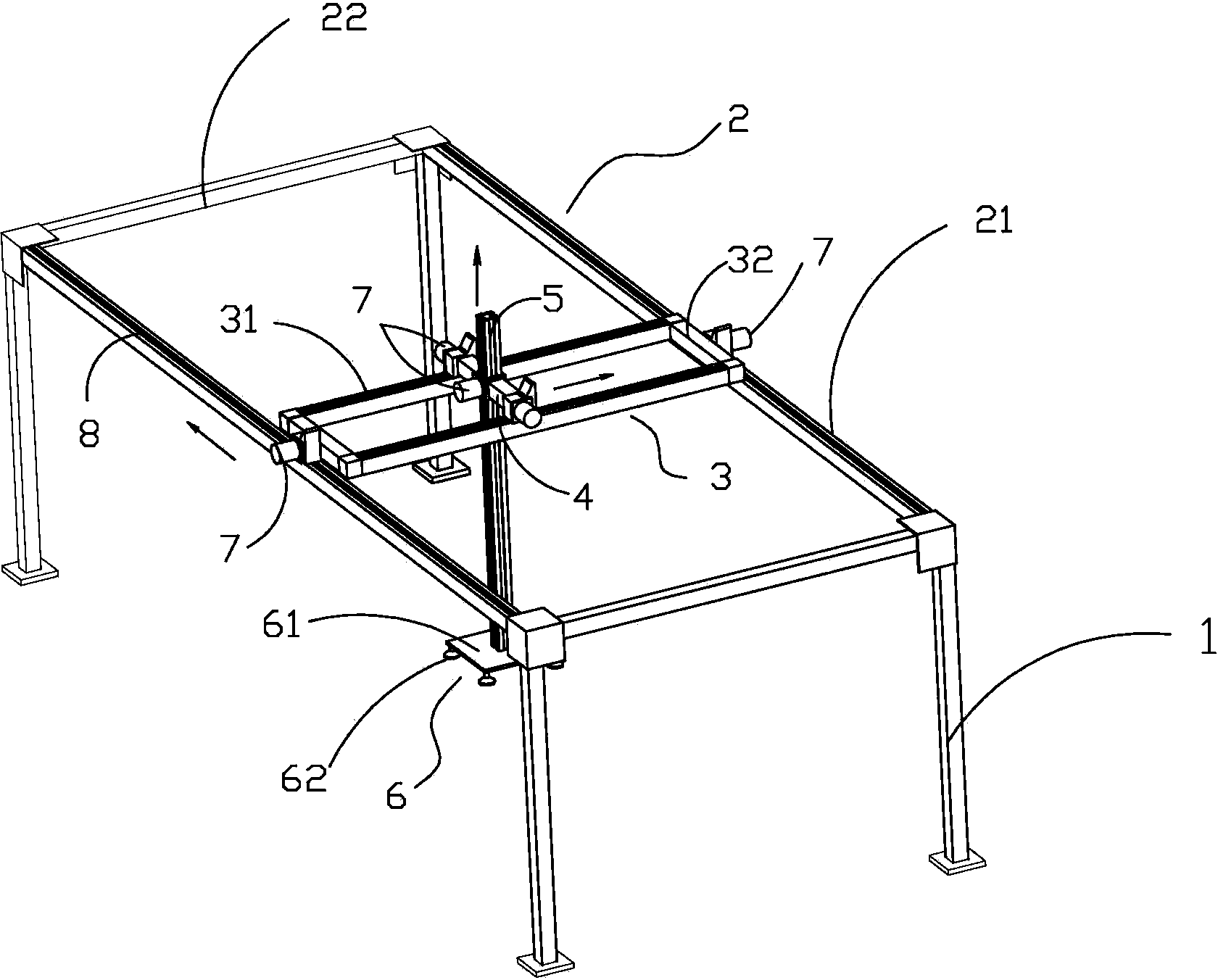

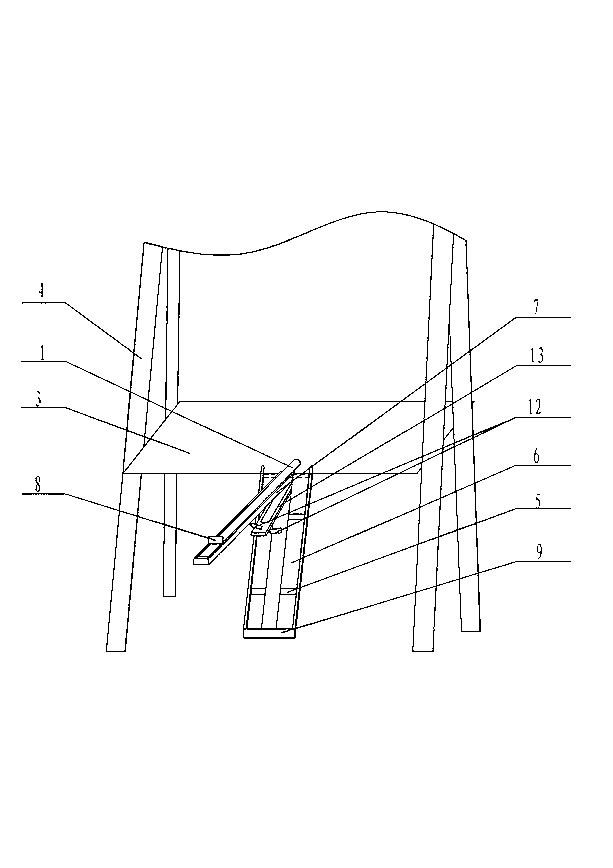

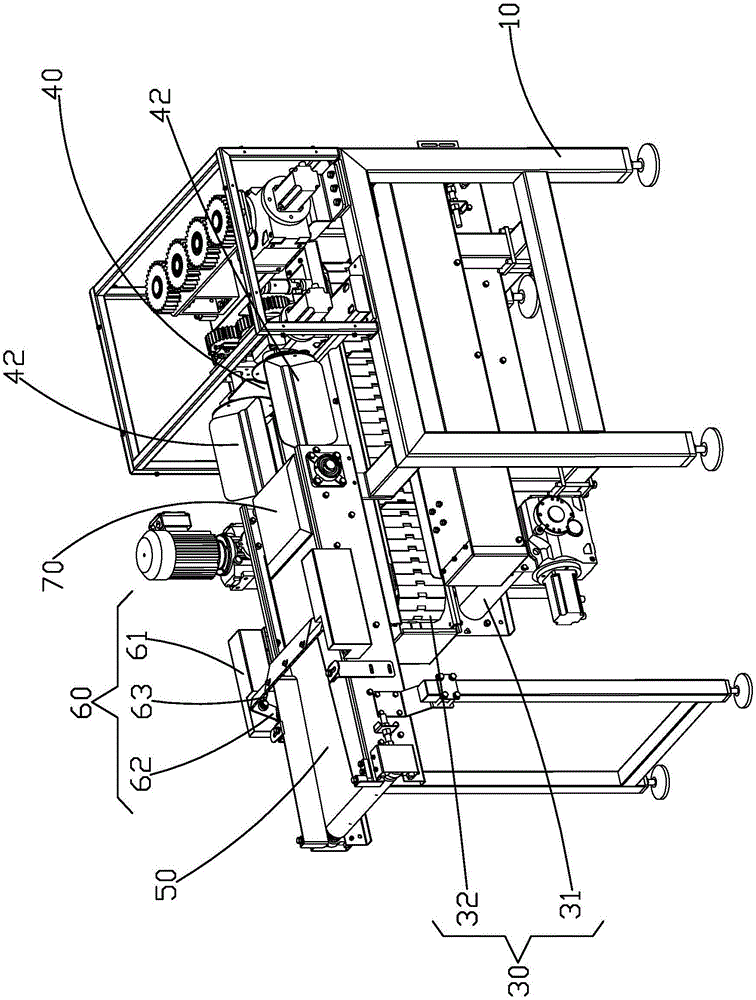

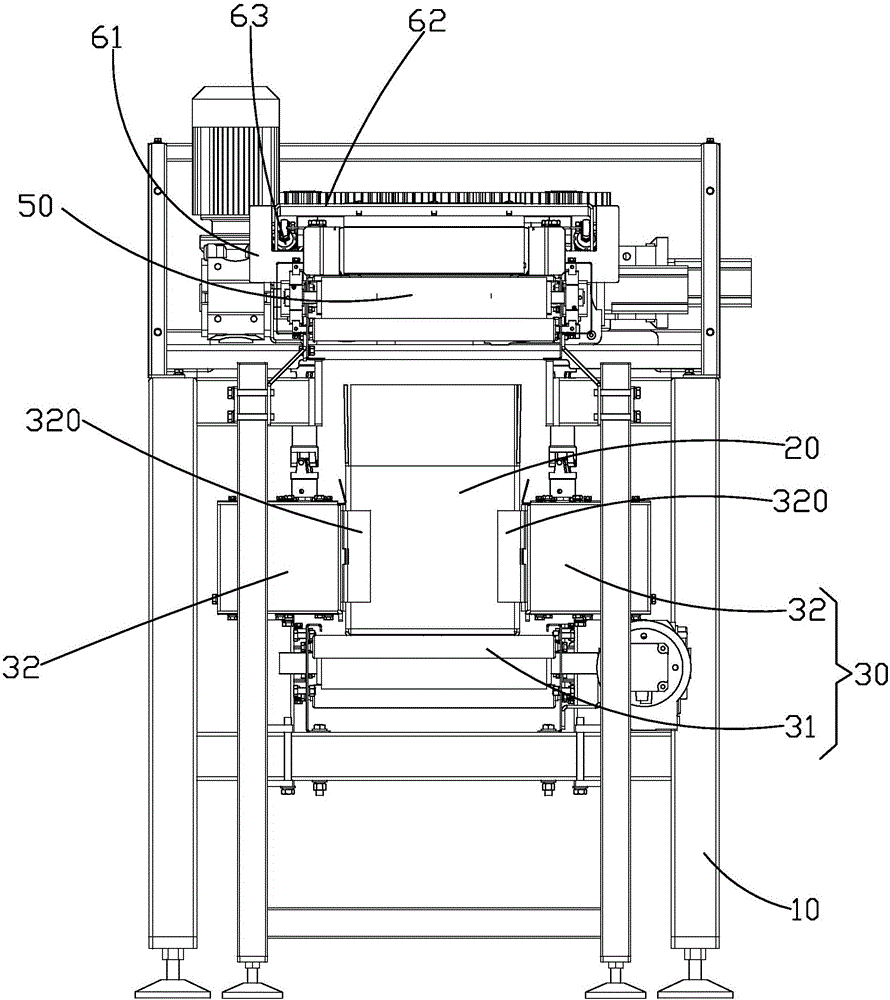

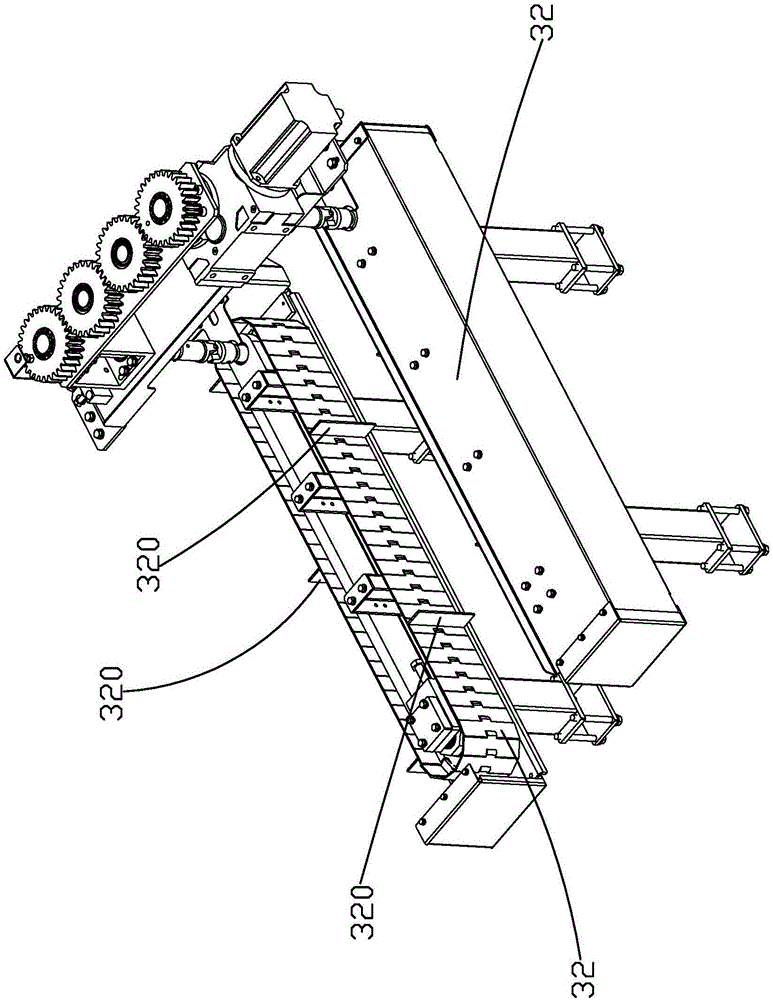

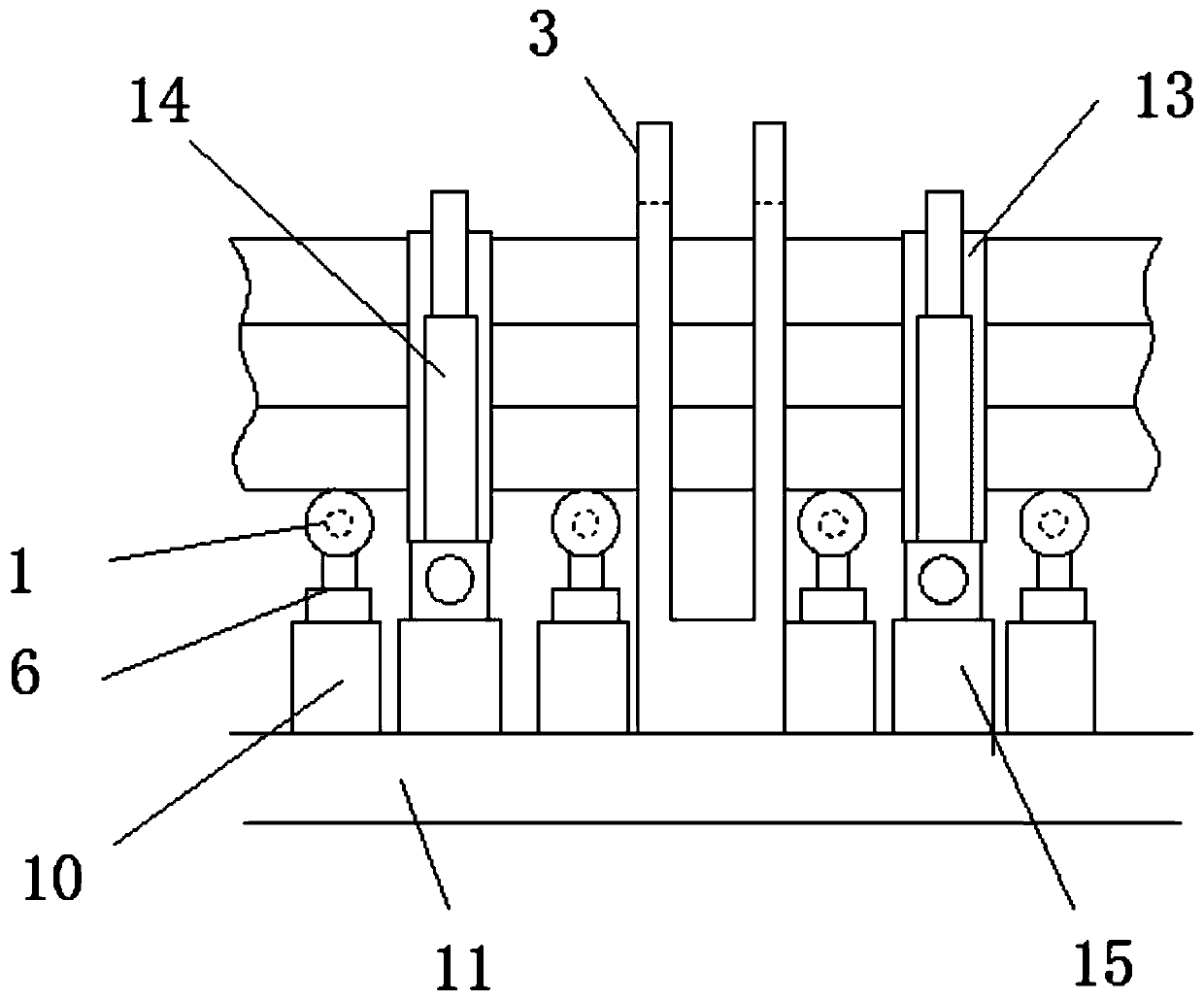

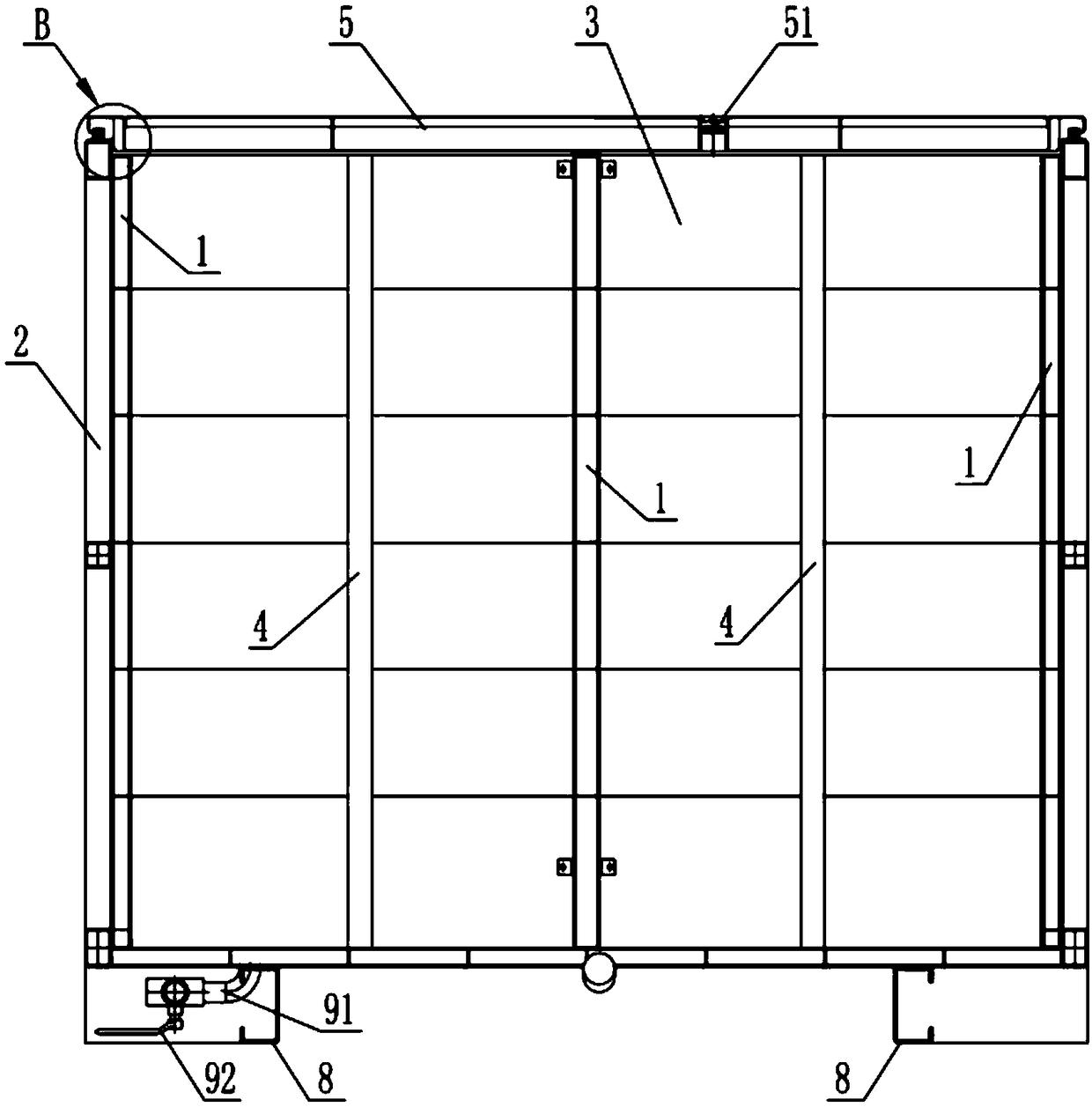

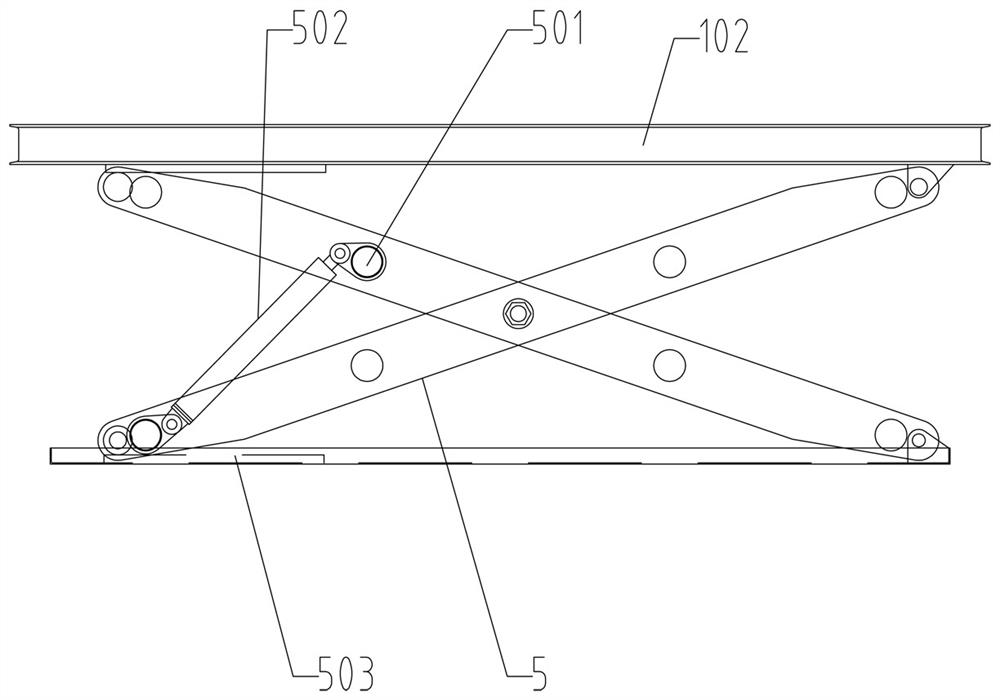

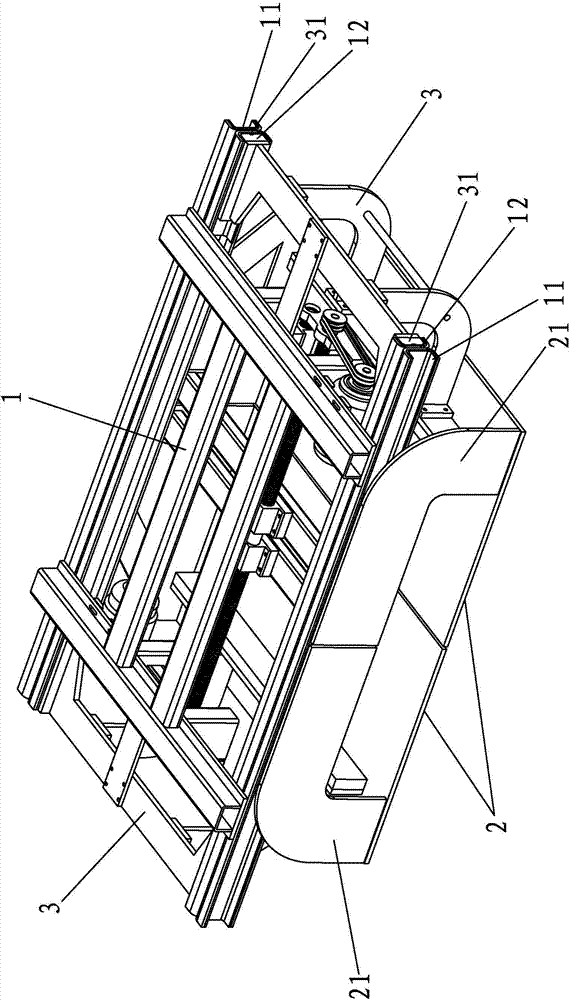

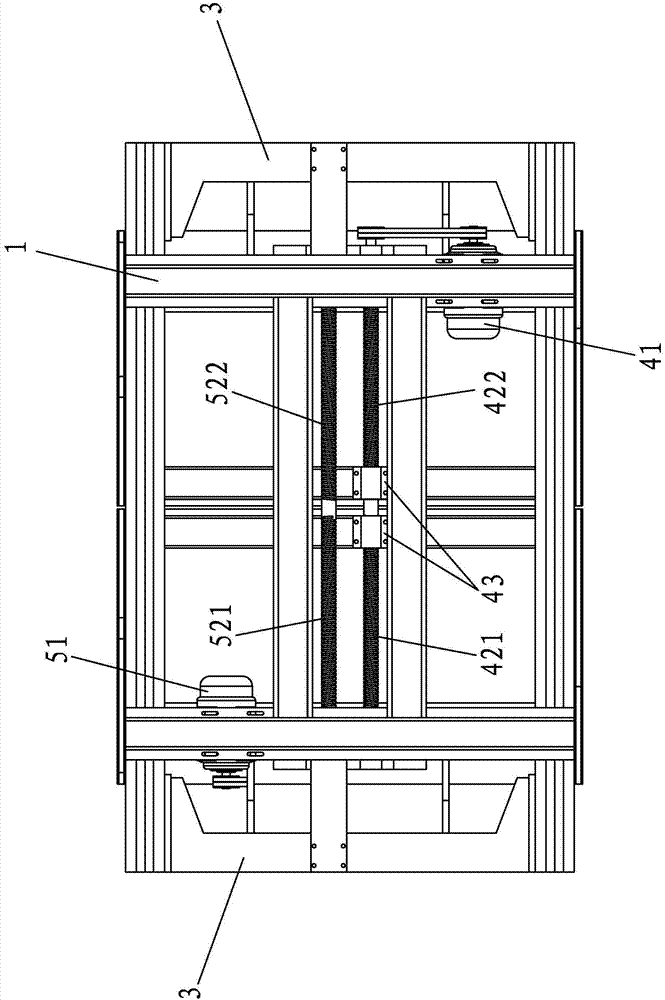

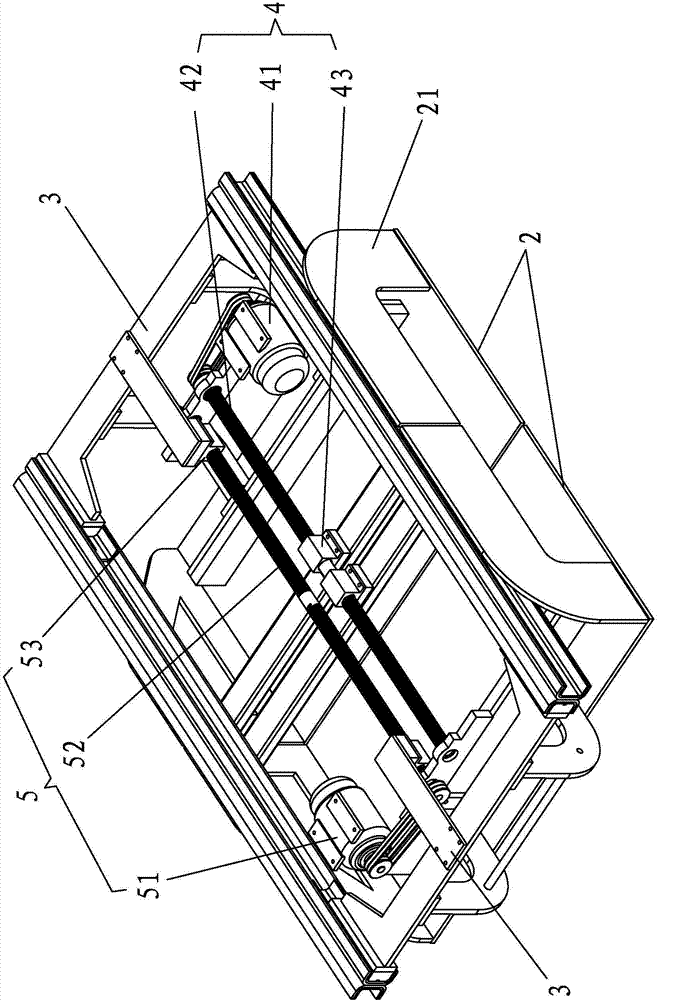

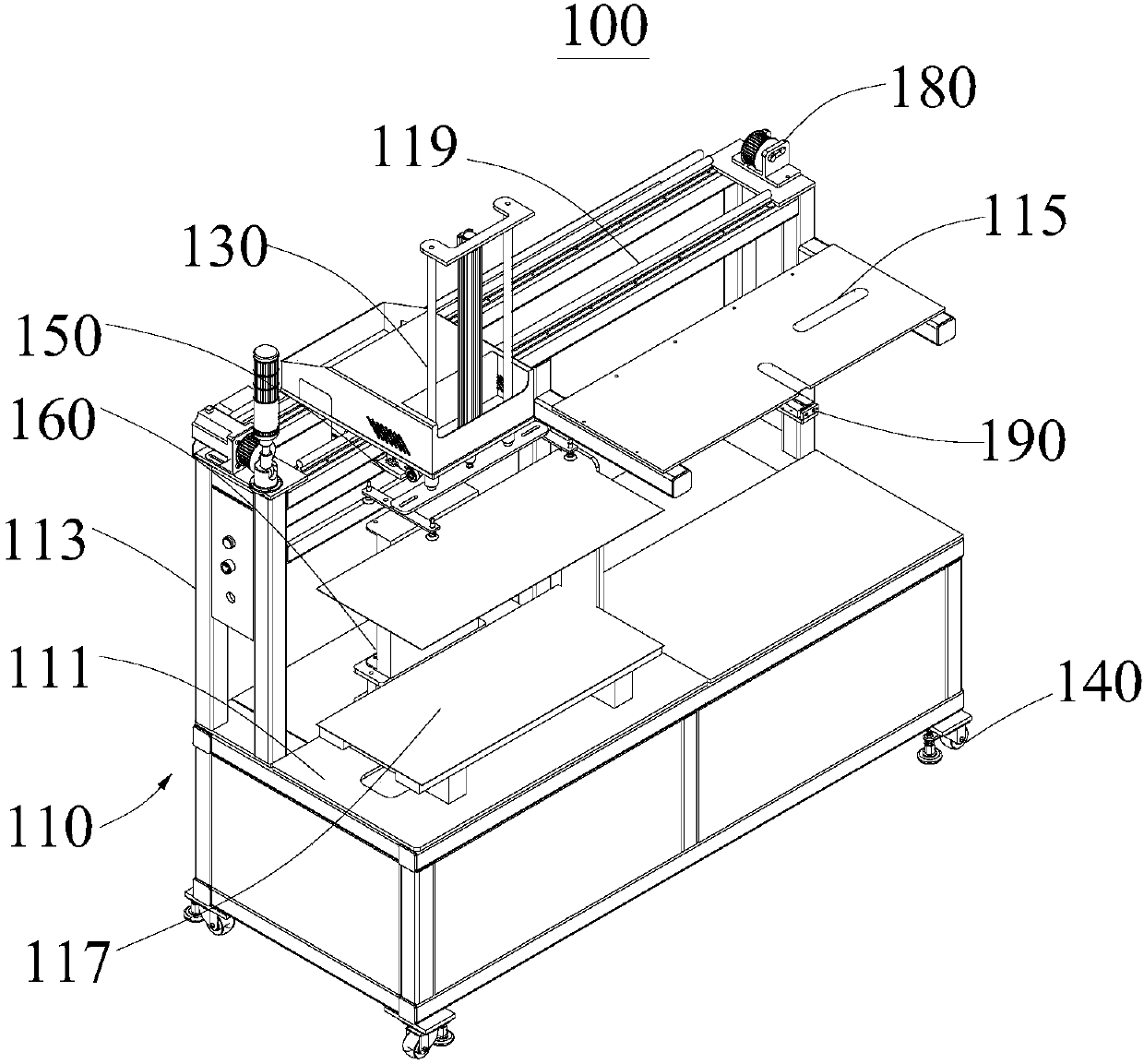

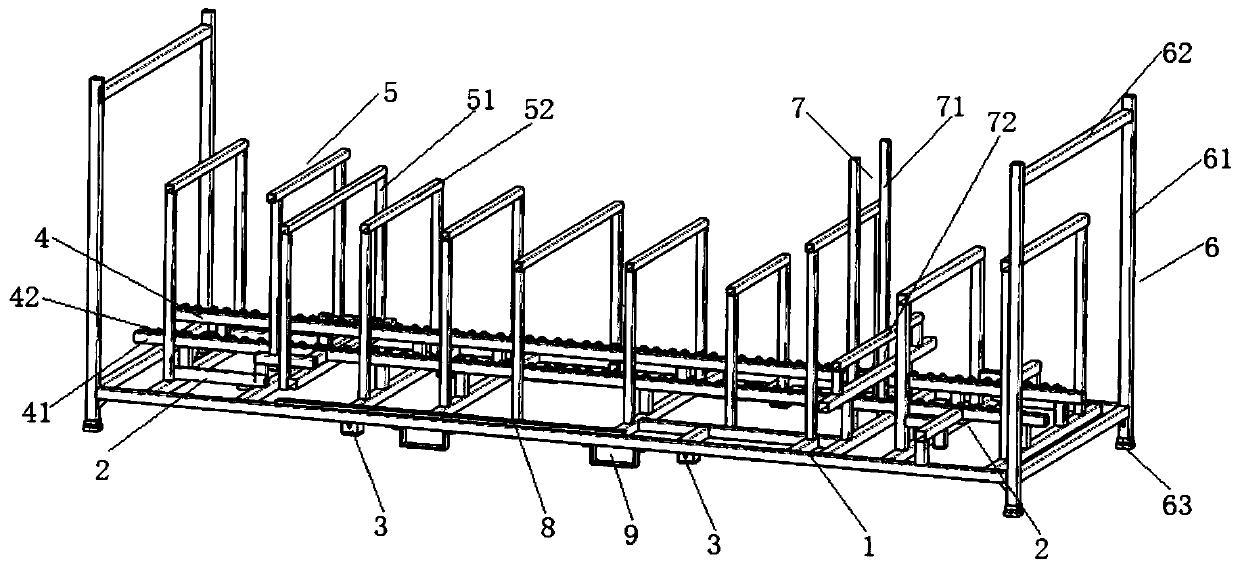

Board stacking system and using method thereof

The invention belongs to the field of board machining, and provides a board stacking system and a using method thereof. The board stacking system comprises a workbench, a lifting platform system and a lane conveying system. The lifting platform system comprises a lifting platform and a lifting control system, and the lifting platform is arranged on one side of the workbench; the lane conveying system is arranged below the lifting platform, the lifting platform comprises a plurality of parallel horizontal rods located at the same horizontal height, and the lane conveying system comprises a lifting conveying system and a conveying system; one end of the lifting conveying system and the horizontal rods of the lifting platform are arranged in a staggered mode, and the other end of the lifting conveying system extends to the conveying system. The problems that at present, cut boards are low in transferring and stacking efficiency, and the overall board machining efficiency is affected are solved.

Owner:JF AUTOMATION SUZHOU CO LTD

Automatic feeding machine structure

InactiveCN103407807ASimple structureEasy to operateArticle feedersArticle deliveryStructural engineeringControl engineering

The invention discloses an automatic feeding machine. The automatic feeding machine comprises a machine frame, wherein the machine frame comprises stand columns, balancing transverse beams arranged on the stand columns, moving racks, moving devices of the moving racks, a lifting beam, a lifting device of the lifting beam and an absorption device, the moving devices are fixed on the moving racks and enable the moving racks to move relative to the transverse beams, the lifting device is fixed onto the moving racks and enables the lifting rack to move vertically relative to the moving racks, and the absorption device is fixed below the lifting beam. The automatic feeding machine is simple and reasonable in structure, convenient to operate and use, safe in operation and usage, good in processing quality and high in work efficiency; meanwhile, saves manpower, reduces labor intensity of operators and is safe and reliable in operation.

Owner:钱旭荣

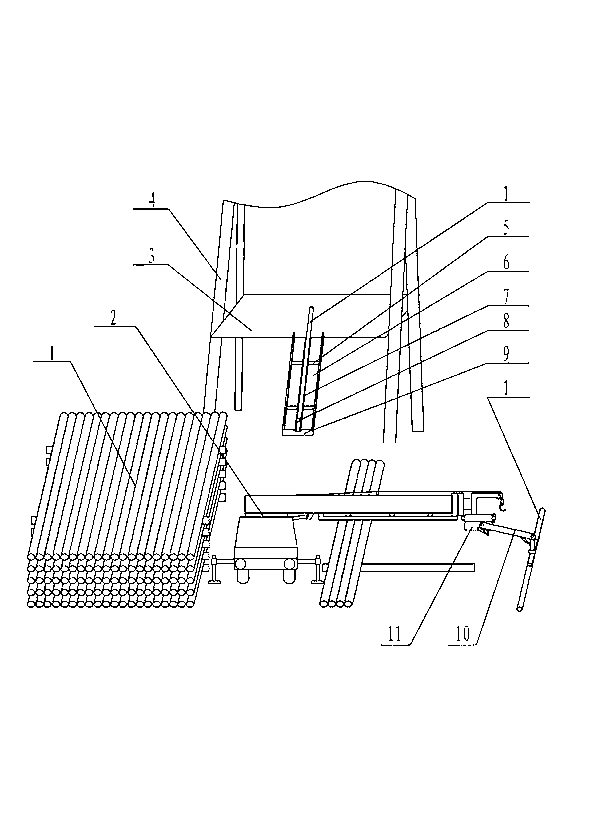

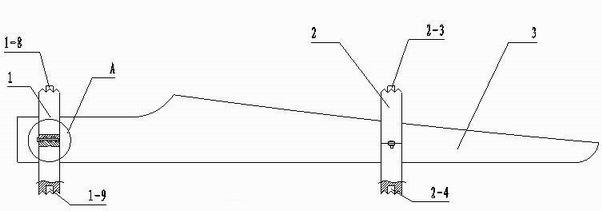

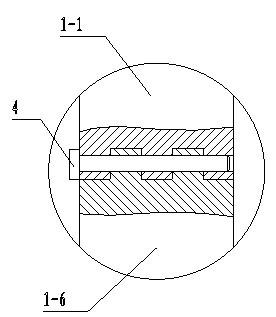

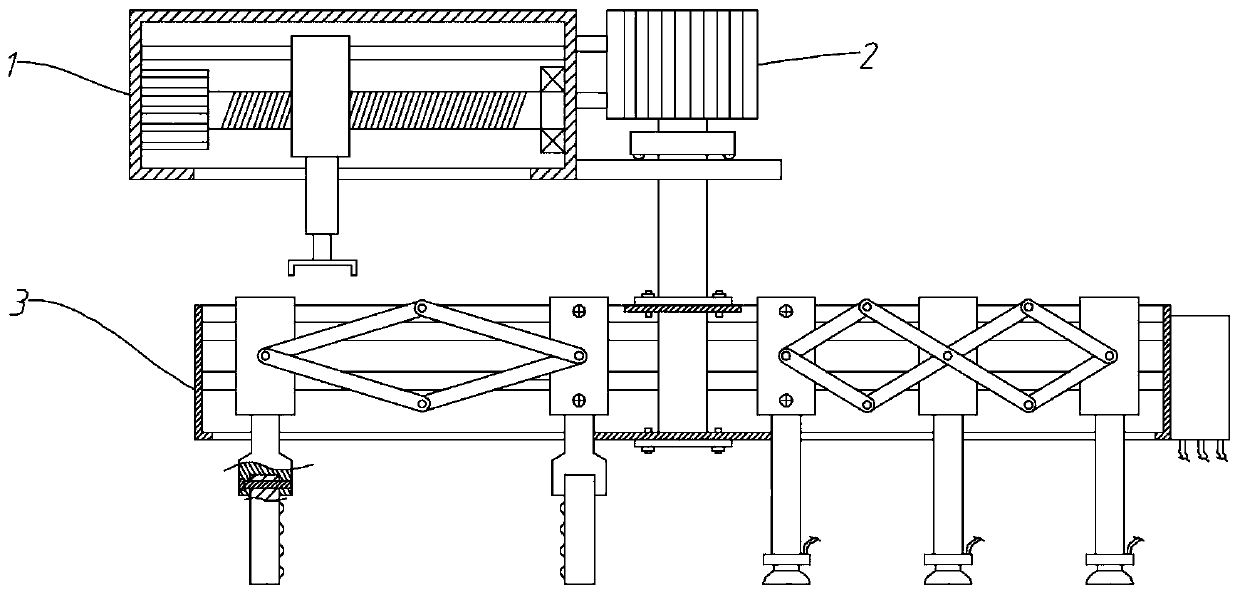

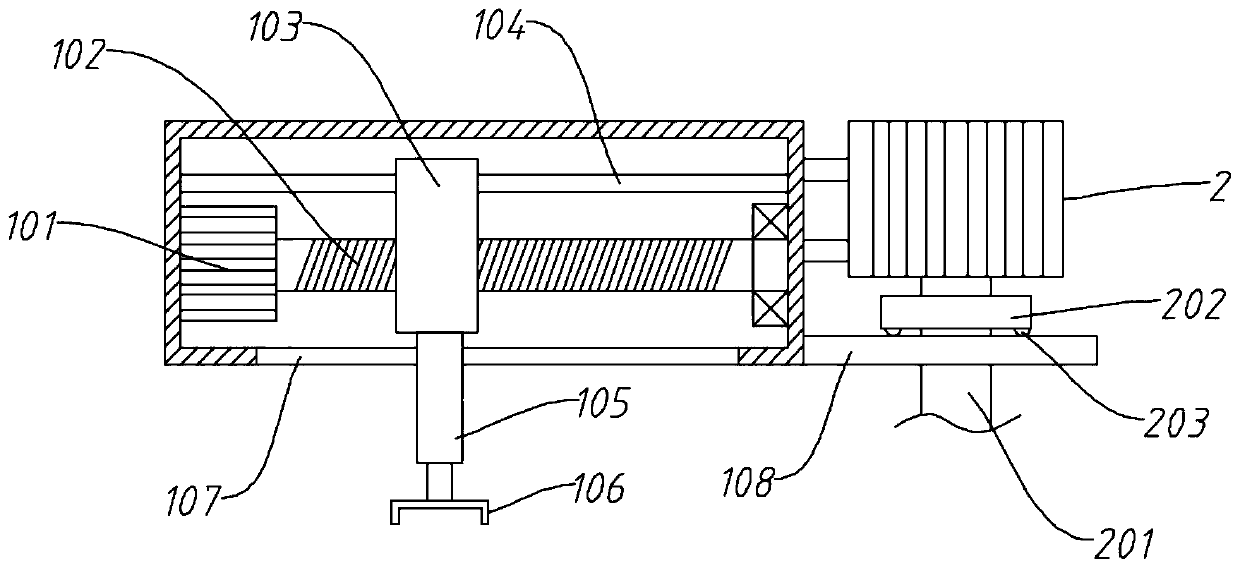

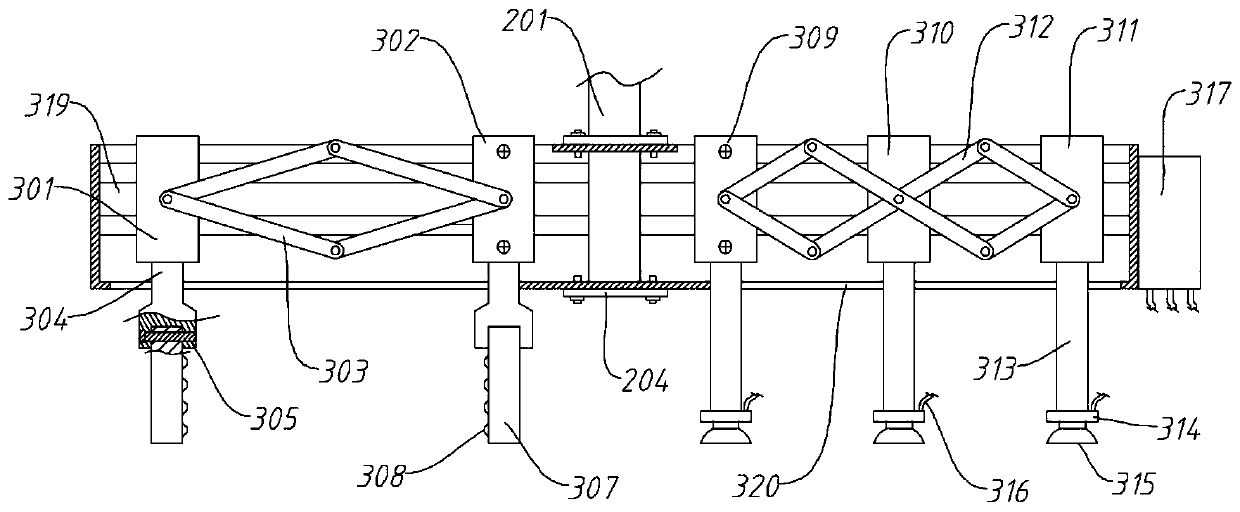

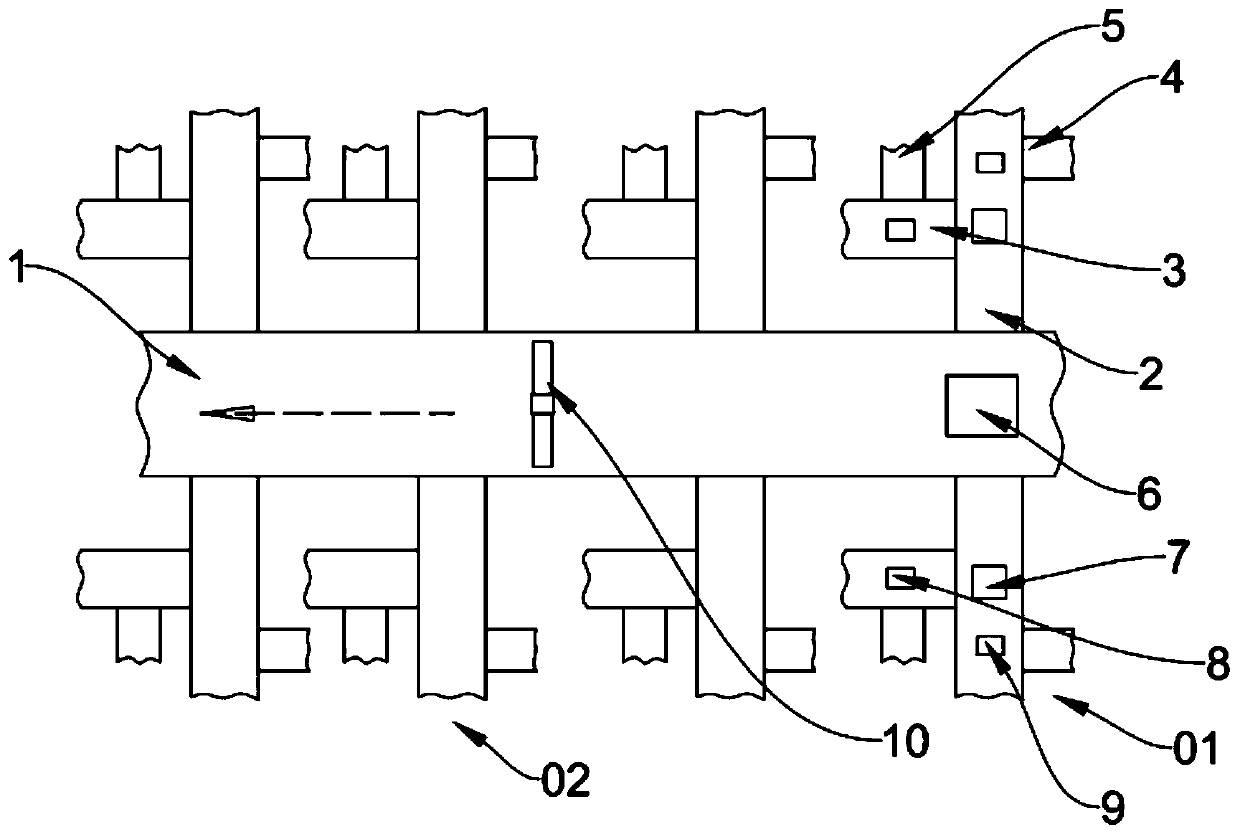

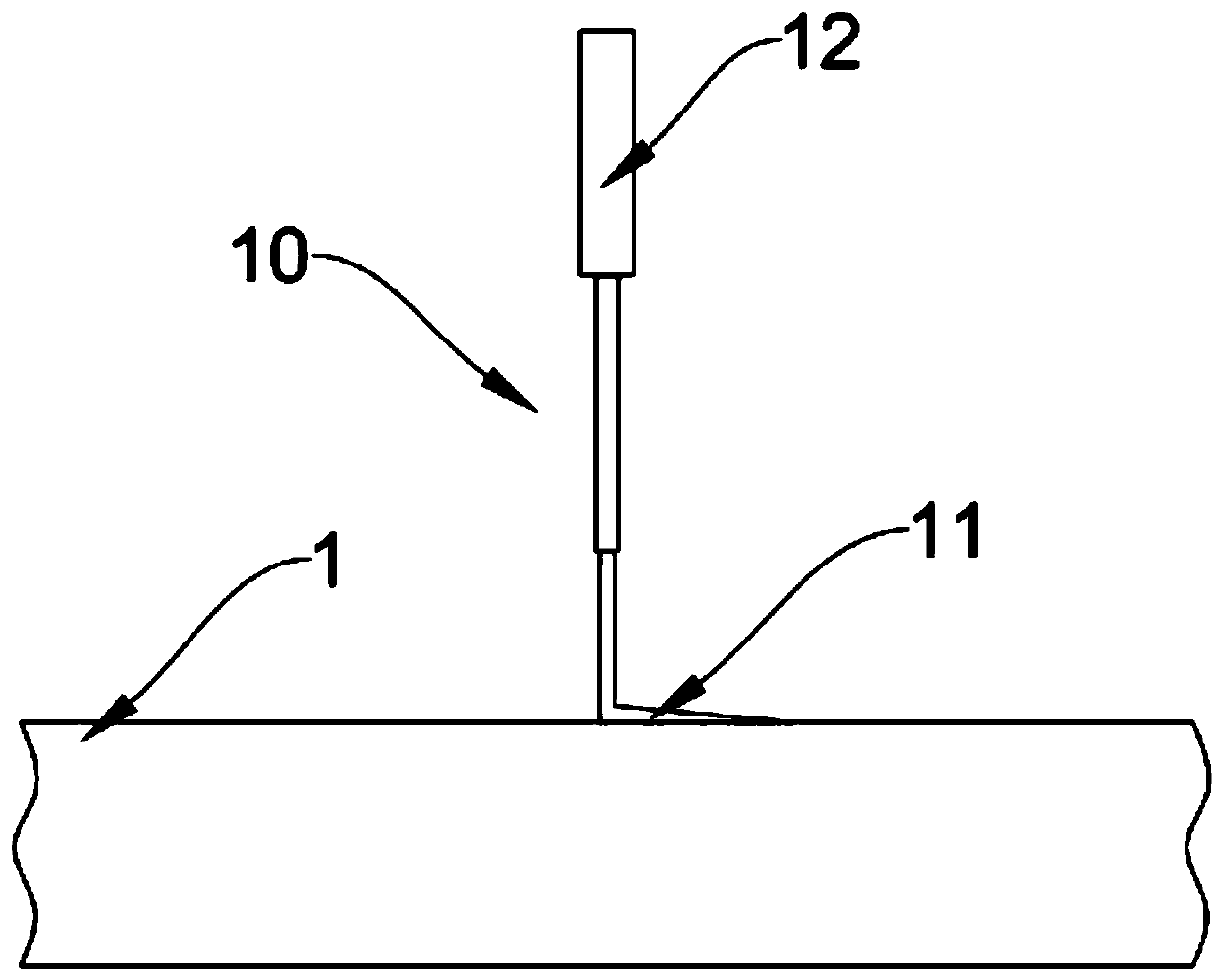

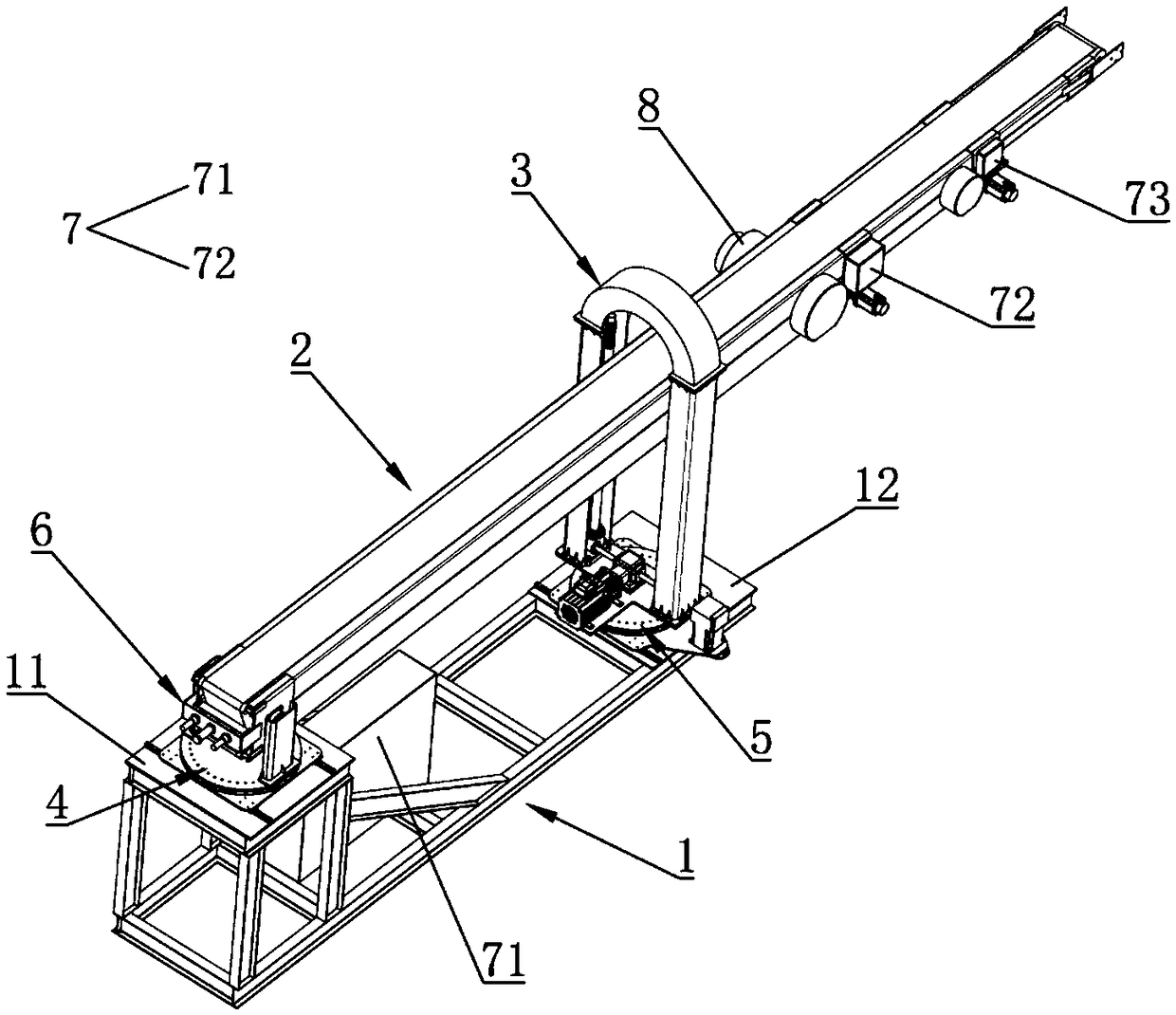

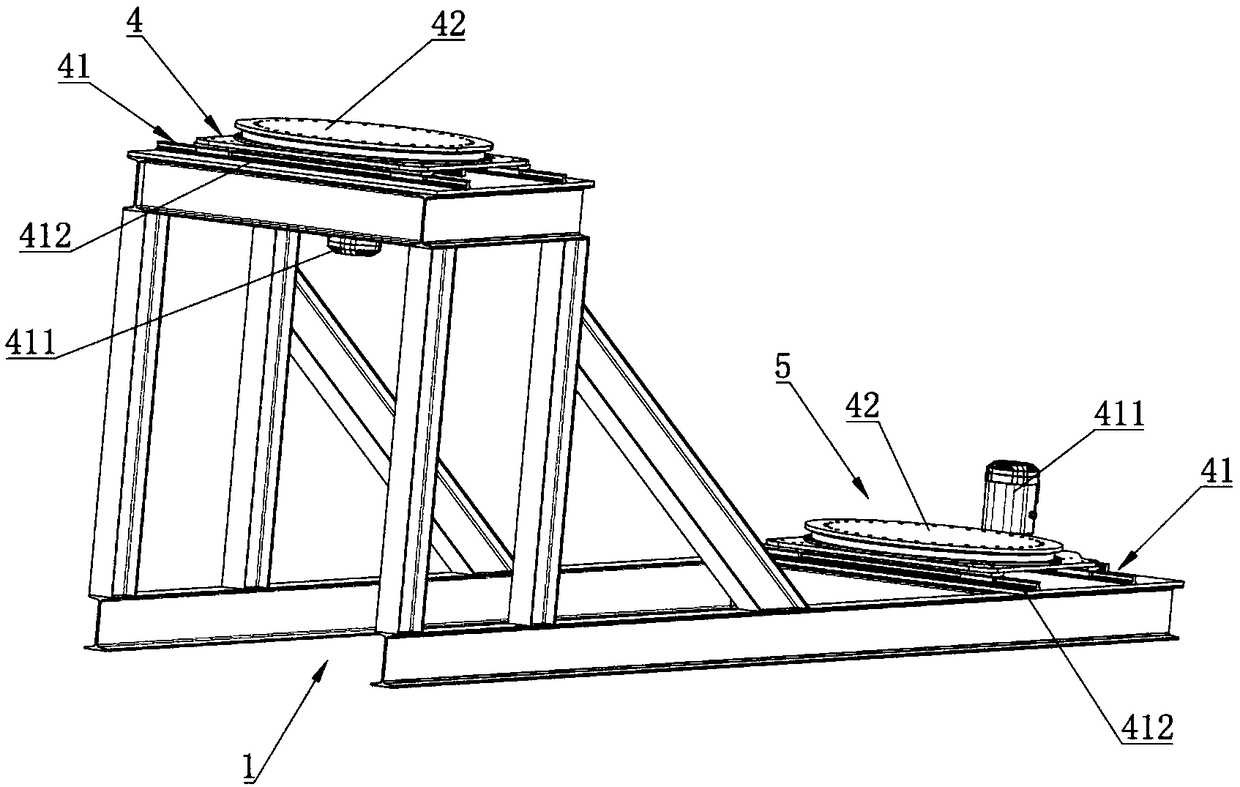

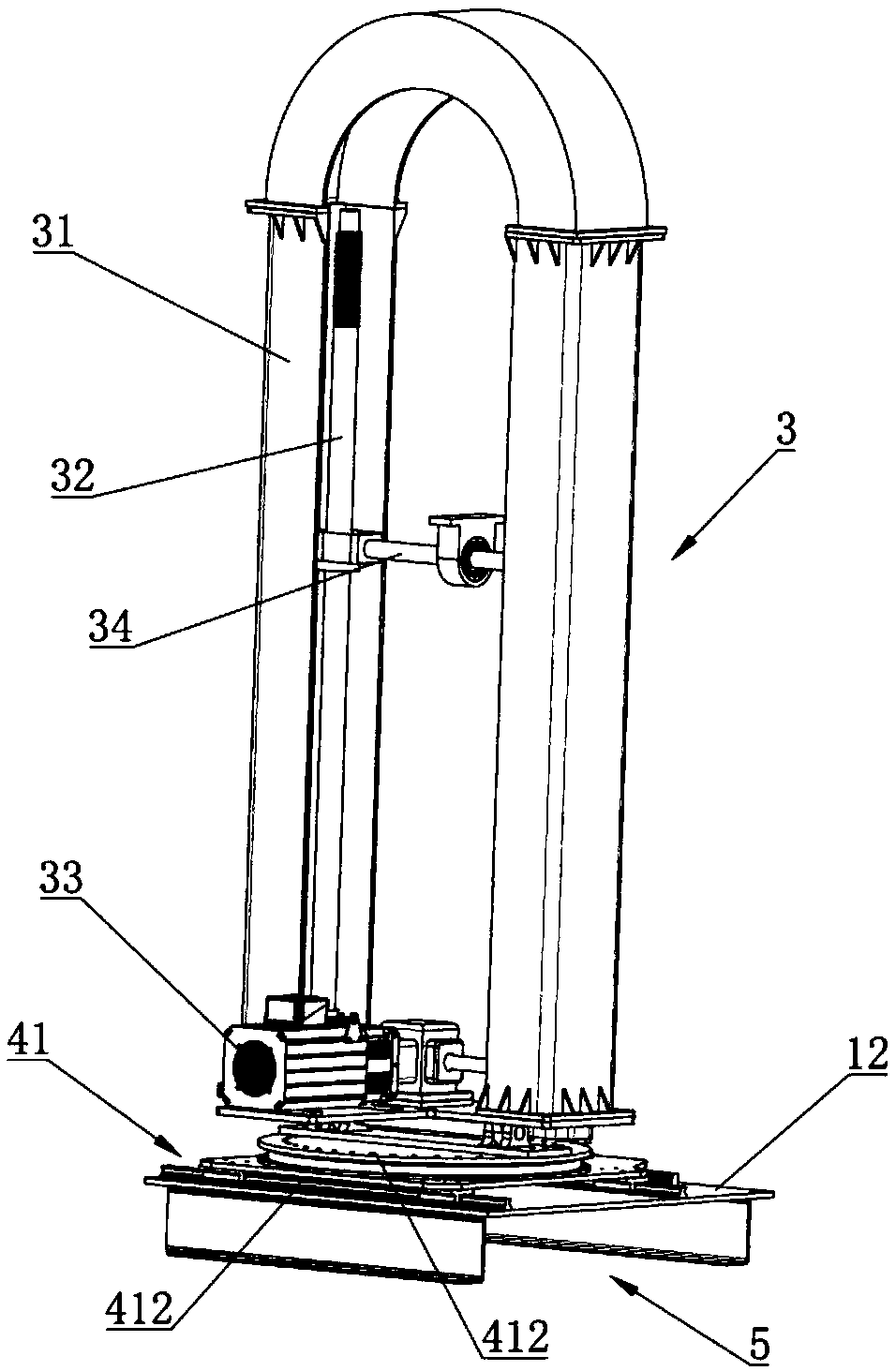

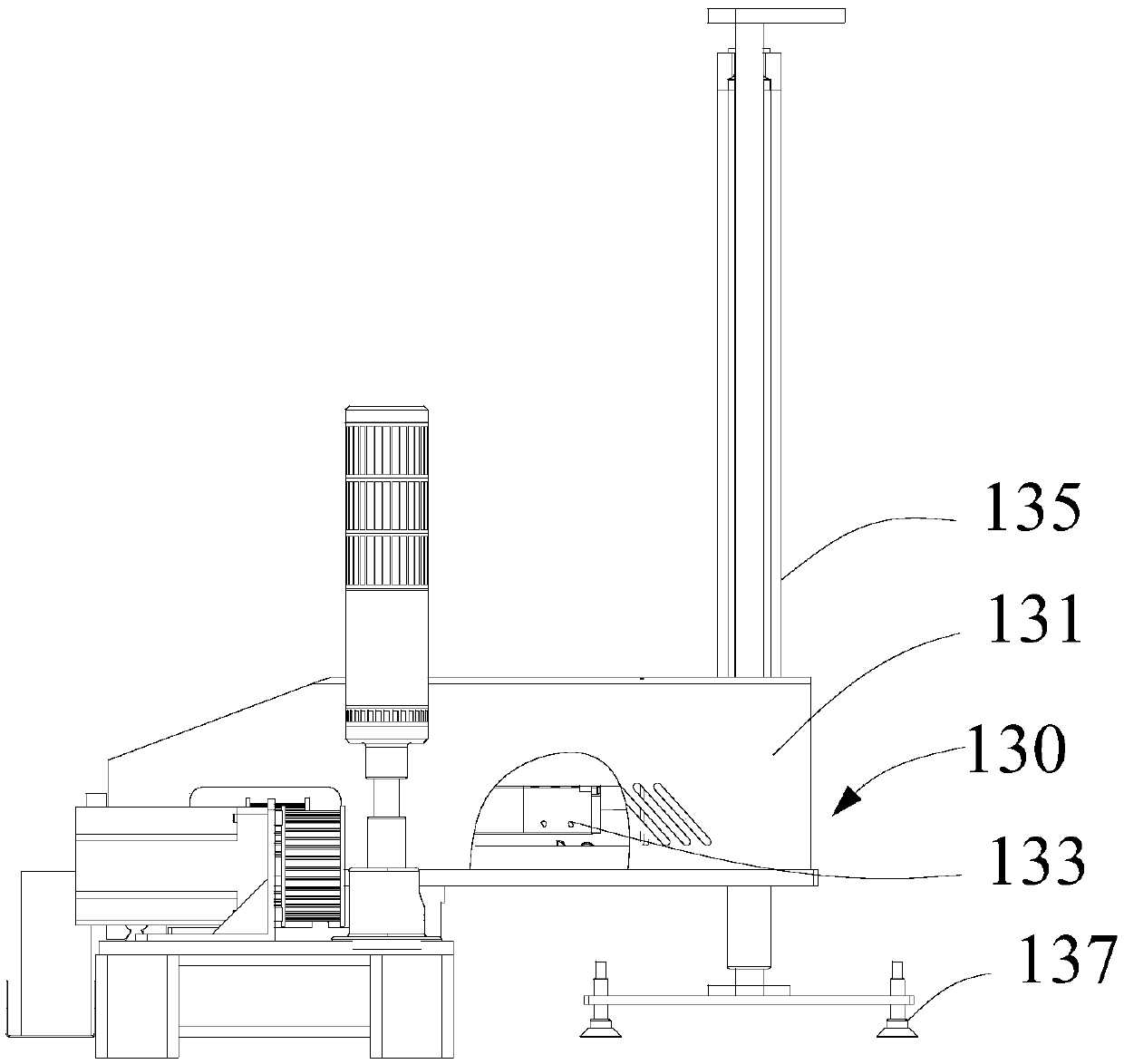

Drill rod automatic stacking and conveying device

InactiveCN103306617ARealize stackingReduce labor intensityDrilling rodsDrilling casingsTraveling blockDrill floor

The invention discloses a drill rod automatic stacking and conveying device, which is mainly composed of a ramp part, a specific crane and a clamping arm and clamping jaw mechanism, wherein a slideway and a trolley are arranged below a suspension arm of the automotive crane; the trolley is provided with the clamping arm and clamping jaw mechanism which can be used for directly grabbing drill rods; a catwalk body provided with a groove is directly fixed on an inclined plane of the ramp; arranged pipe blocks (namely groove entering mechanisms) are arranged at two sides of the catwalk body; when the drill rods are conveyed to a drill floor, one drill rod is suspended to be placed on the arranged pipe blocks on the ramp by the crane, the drill rod rolls into the groove through the arranged pipe blocks, and is pushed to the drill floor through a pulley; when the drill rod is put down by the drill floor, the process is opposite to the above process; the drill rod which glides into the groove and is jacked and pushed onto the arranged tube blocks is automatically suspended onto the ground to be put in order by the crane; the catwalk body is in a fixed type and in a rotary type; the upper end of the rotary-type catwalk body is connected with the upper end of the ramp through a hinge; the lower side of the rotary-type catwalk body can be rotated upwards around a hinge under hydraulic control, and the rear end of the rotary-type catwalk body is lifted up. With the adoption of the drill rod automatic stacking and conveying device, a catwalk machine is leaved out, the arranging and conveying complete automation of the underground drill rods is realized, so that unmanned operation is realized.

Owner:邹永平 +1

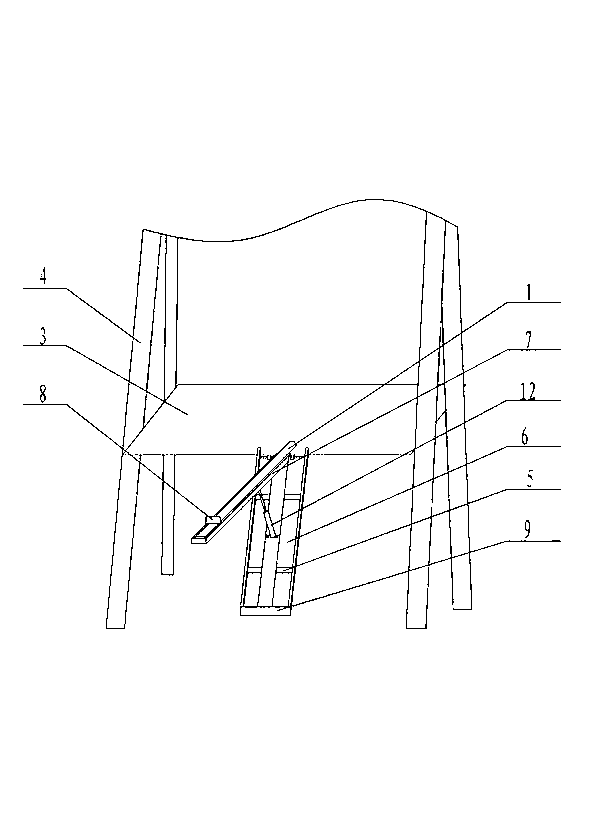

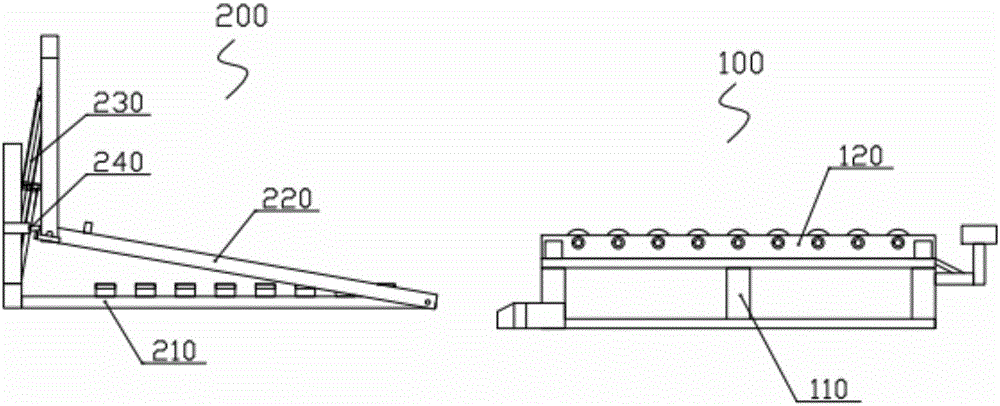

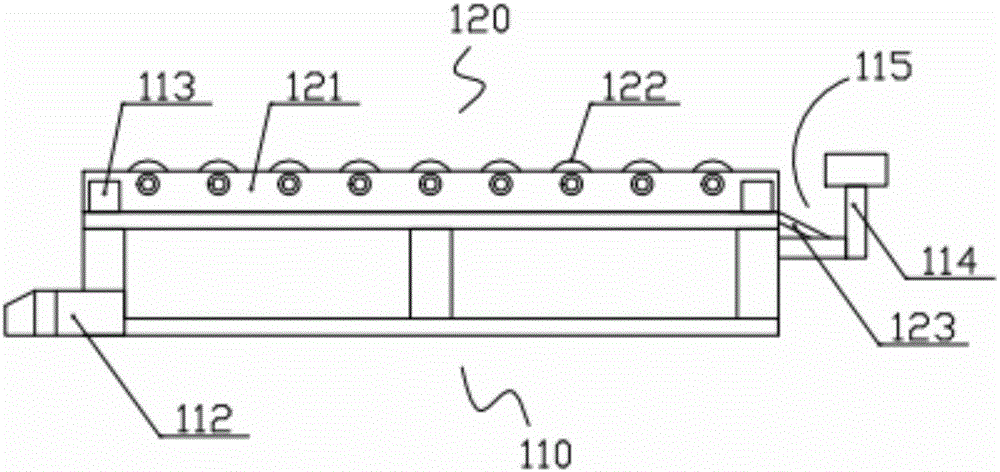

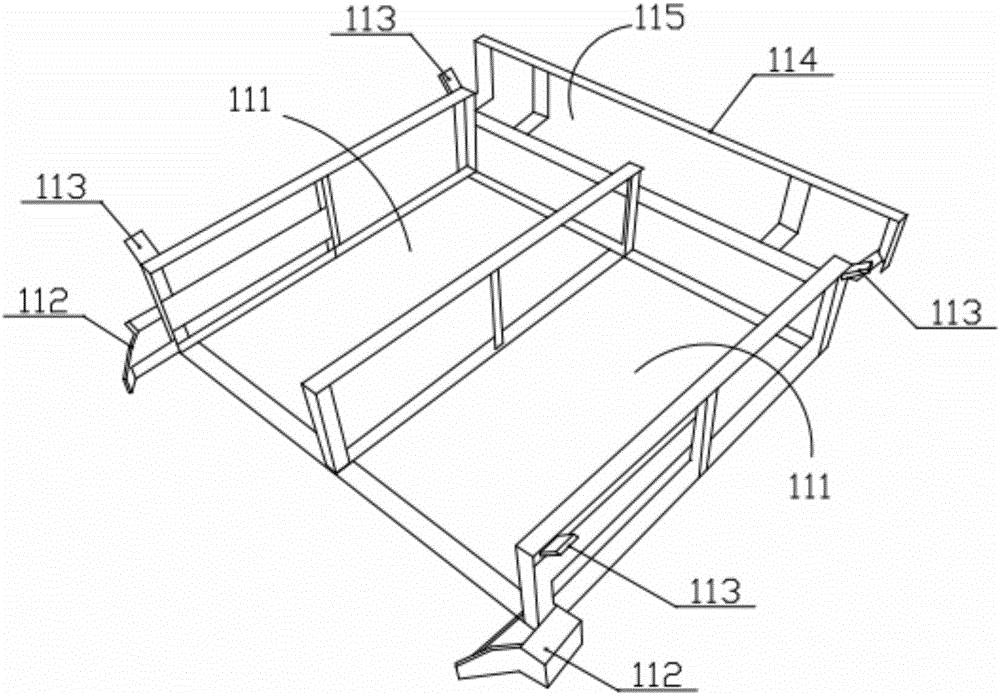

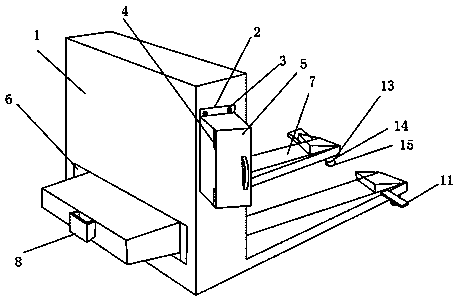

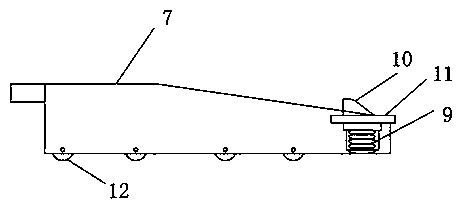

No-pallet loading device and no-pallet loading method

ActiveCN106542466ARealize stackingRealize the loading operationLifting devicesRigid containersLogistics managementPallet fork

The invention relates to a no-pallet loading device and a no-pallet loading method, belongs to the field of goods stacking and logistics transportation, mainly solves the problem that a conventional pallet is low in repeated utilization ratio, and achieves the purposes of lowering the logistics cost and reducing waste of social resources. The no-pallet loading device comprises a pallet component and a fork component, wherein the pallet component comprises a support body and a support platform which can be separated from each other; fork operation spaces are formed on the support body, and the upper parts of the fork operation spaces communicate with the bottom of the support platform; the support platform comprises a framework and a plurality of carrier rollers mounted in the framework side by side; the fork component comprises a fork body and an unloading fork component; the front end of the fork body is hinged to the front end of the unloading fork component; a telescopic part is arranged between the rear part of the fork body and the rear part of the unloading fork component; and a positioning structure is further arranged on the unloading fork component. A novel stacking or loading method is extended based on improvement of the no-pallet loading device.

Owner:郑宜林

Intelligent automatic box falling machine

InactiveCN106184919AQuantitative packingReduce the burden onIndividual articlesEngineeringControl circuit

The invention discloses an intelligent automatic box falling machine. The intelligent automatic box falling machine comprises a rack, wherein a conveying device capable of driving a box body to move and carrying out box packaging is arranged on the lower part of the rack; a material falling mechanism used for bearing materials and controlling the materials to fall off into the box body is further arranged on the rack; the material falling mechanism is arranged above the conveying device; and the conveying device and the material falling mechanism are connected with a control circuit for controlling the conveying device and the material falling mechanism to act or not. According to the intelligent automatic box falling machine disclosed by the invention, because the material falling mechanism located above the conveying device is arranged on the rack, and the materials are accurately controlled to fall off into the box body through the material falling mechanism, manual box packaging of workers can be replaced, the burden of the workers is reduced, the production efficiency is increased, quantitative box packaging for the materials can be realized, and the case of inconsistent box packaging numbers is avoided.

Owner:中山市联拓智能装备科技有限公司

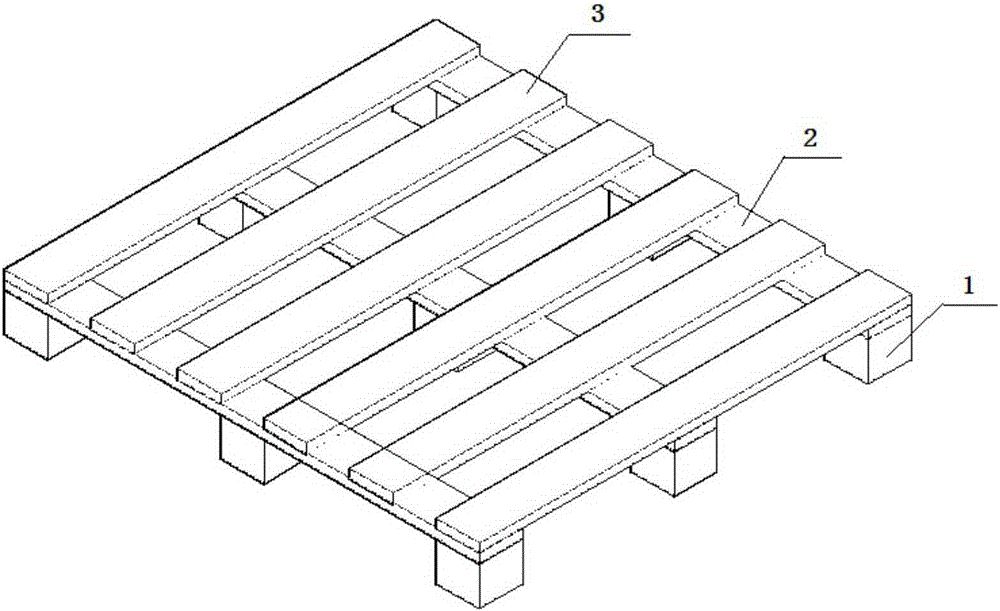

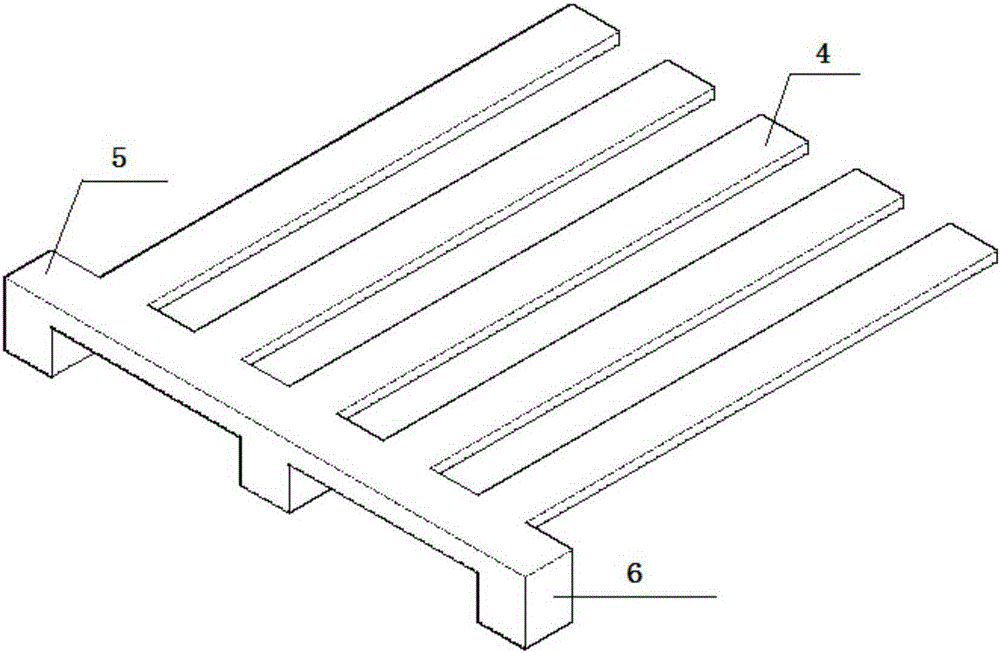

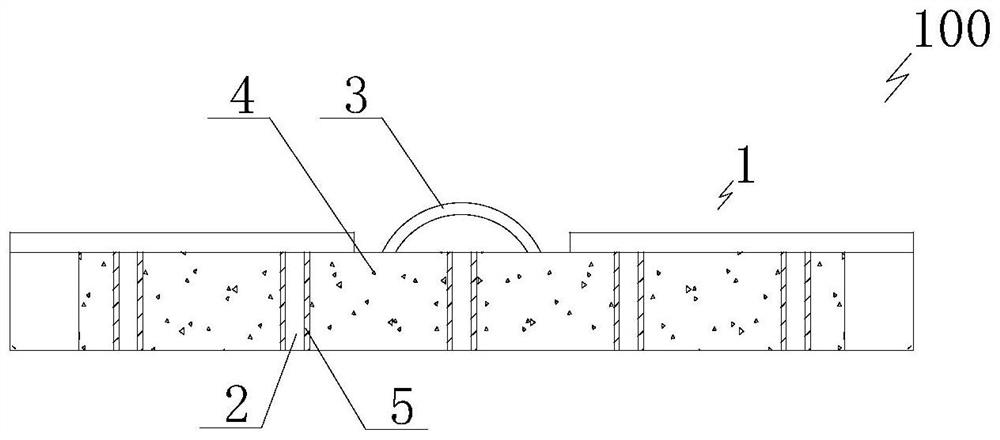

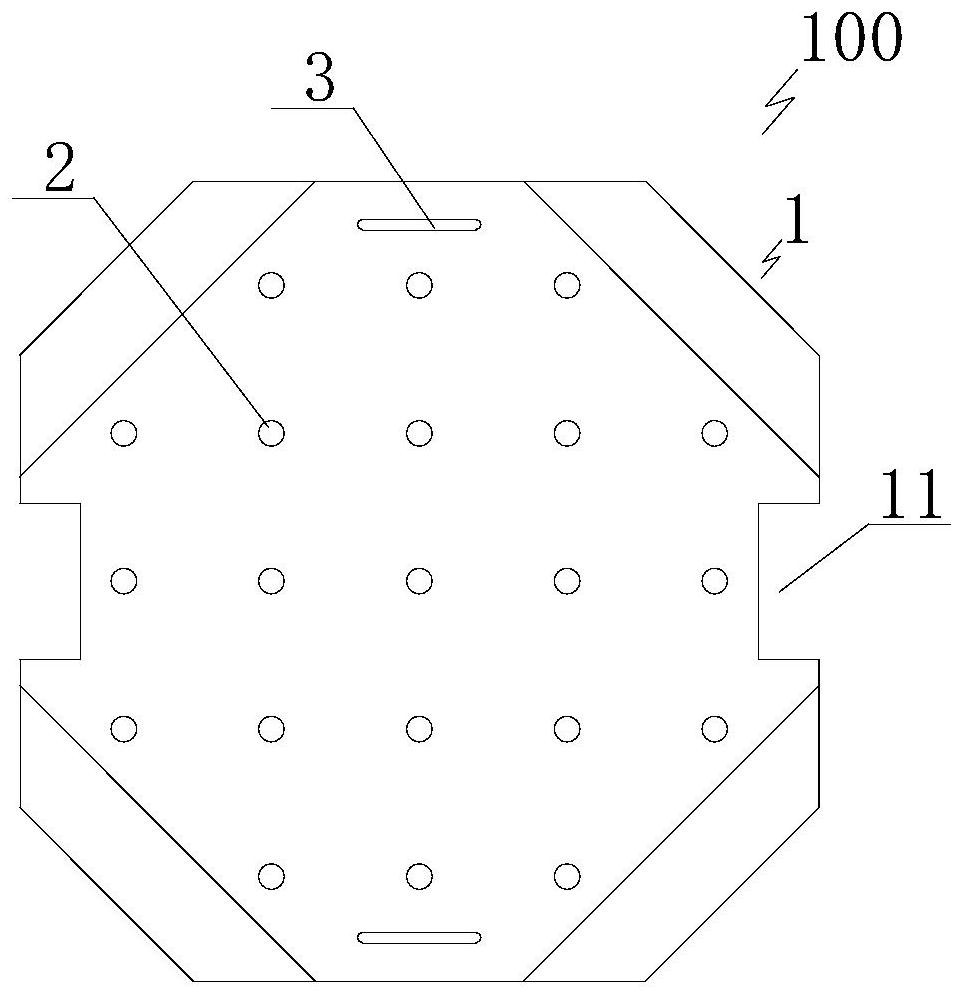

Plastic-wood pallet and information recognizing method thereof

InactiveCN105253426AImprove scalabilityRealize non-contact automatic identificationCo-operative working arrangementsRigid containersEngineeringPallet

The invention provides a plastic-wood pallet and an information recognizing method thereof. The plastic-wood pallet comprises a fixed part and a stretching part. The fixed part comprises a supporting part and fixed carrying plates. The supporting part comprises fixed bottom columns and fixed supporting plates. The fixed bottom columns are arranged at equal intervals in a matrix manner. The supporting plates are arranged on the fixed bottom columns. The fixed carrying plates are arranged on the fixed supporting plates at equal intervals. The stretching part comprises a fixed stretching part and a movable stretching part. The fixed stretching part comprises stretching bottom columns and a stretching supporting plate. The stretching bottom columns are arranged into a line at equal intervals. The stretching supporting plate is arranged on the stretching bottom columns. Stretching carrying plates are arranged on the stretching supporting plate and inserted in the intervals of the fixed carrying plates and connected with each other through a slide rail. By means of cooperation of buckles arranged on the stretching carrying plate and clamping grooves formed in the fixed carrying plates, the stretching size of the stretching part is adjusted. According to the plastic-wood pallet and the information recognizing method thereof, the telescopic adjustment of the plastic-wood pallet and the recognition of information of carried goods can be achieved.

Owner:兰州晨阳启创信息科技有限公司 +1

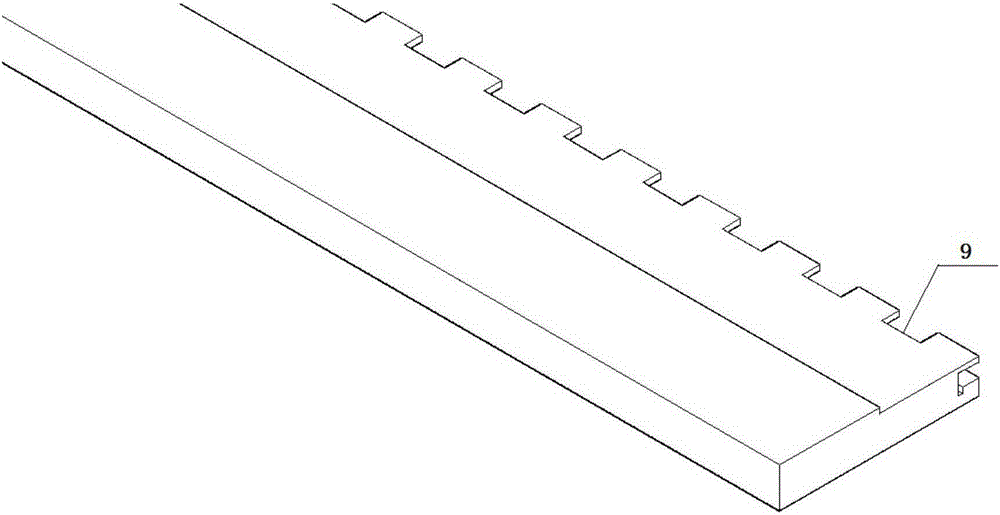

Universal clamp of wind driven generator blades

A universal clamp of wind driven generator blades is used for resolving the problem that the existing wind driven generator blades are high in cost, frequent in replacement and the like in the production, storage, transportation and installation processes. The universal clamp comprises a blade root portion clamp and a blade wing section clamp, the blade root portion clamp is assembled with a root portion cylinder, the blade wing section clamp is assembled with a blade wing portion, a zigzag insertion-connection face with a cylindrical boss is respectively arranged at the top ends of the blade root portion clamp and the blade wing section clamp, a zigzag insertion-connection face with a round hole type groove is respectively arranged at the lower ends of the blade root portion clamp and the blade wing section clamp, and cylindrical bosses at the top ends are matched with the round hole type grooves at the lower ends and the upper zigzag insertion-connection face and the lower zigzag insertion-connection face. The universal clamp is capable of providing clamping effects and stress points for blades in the production, storage and transportation of the blades and the whole process of wind power installation, is capable of achieving stacking of a plurality of blades and suitable for wind driven generator blades of various types and has good generality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

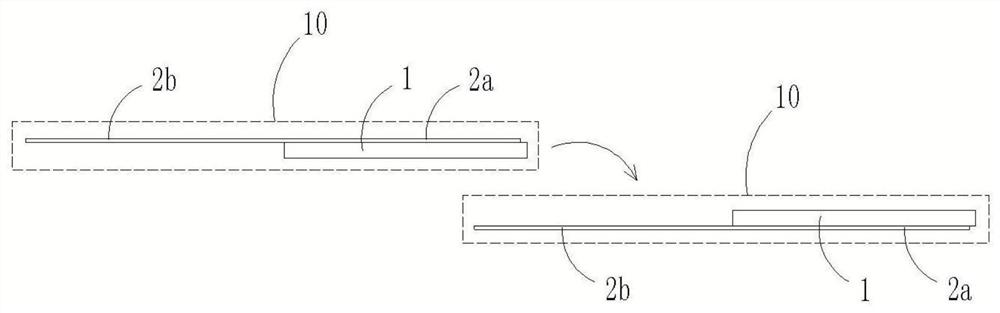

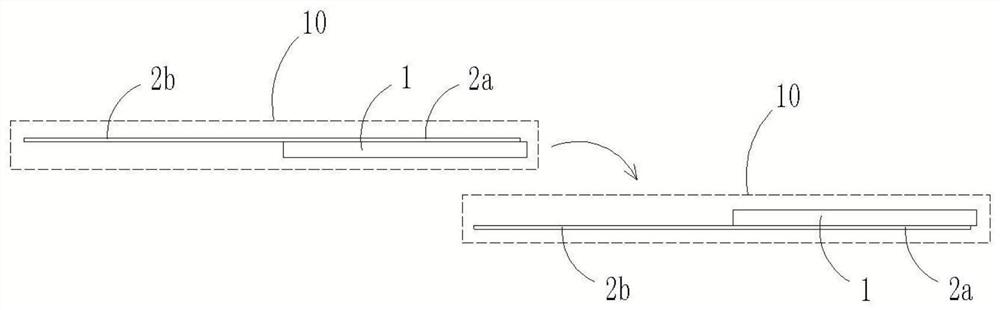

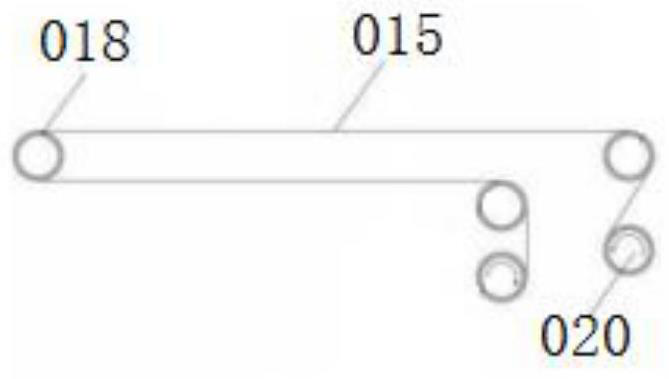

Solder strip feeding device and battery string preparation device

PendingCN111668343AEasy to prepareRealize stackingFinal product manufactureShearing machinesElectrical batteryStructural engineering

The invention discloses a solder strip feeding device which comprises a solder strip unwinding mechanism, a solder strip cutting mechanism and a solder strip traction mechanism. The multiple sets of welding strip cutting mechanisms are arranged at intervals in the linear direction. A welding strip material strip unwound by the welding strip unwinding mechanism is dragged by the welding strip traction mechanism and sequentially penetrates through all the welding strip cutting mechanisms. The solder strip cutting mechanism cuts off the material strips, and multiple sets of solder strips can be obtained. Therefore, the solder strip feeding device can supply multiple sets of material strips at a time, and the preparation efficiency of the battery string is improved. The solder strip feeding device further comprises a solder strip lifting mechanism capable of driving the solder strip cutting mechanism to be close to or away from the material strip so as to facilitate strip conveying or cutting of the material strip. The invention further discloses a battery string preparation device which comprises the solder strip feeding device, a battery piece feeding device and a lamination device.The lamination device can receive the series welding units composed of the battery pieces and the welding strips and can also achieve lamination of the series welding units, and then the battery string can be conveniently prepared.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Manipulator structure and robot capable of achieving switching between adsorption and clamping modes

The invention relates to the technical field of stacking robots, in particular to a manipulator structure and robot capable of achieving switching between adsorption and clamping modes; according to the manipulator structure, a wok box is rotated though a No. 2 servo motor, and the right part of the work box is provided with an adsorption assembly; the left part of the work box is provided with aclamping assembly, right and left switching is performed though rotation of the work box, so that the clamping assembly or the adsorption assembly corresponds to a screw box; the screw box is arranged, and a screw is driven by a No. 1 servo motor to rotate; a movable nut is moved along the axial direction of the screw, so that a clip is driven to move; the up-down position of the clip is regulatedthrough a No. 1 hydraulic cylinder to cooperate with the clamping assembly or the adsorption assembly; when the clamping assembly is rotated to the position below the screw box, the clip is regulatedfor clamping a type I sliding seat II; then, the position of the movable nut is regulated, and the type I sliding seat is changed with the movable nut, so that the spacing between clamping plates ischanged; the clamping of articles is achieved; and the adsorption assembly is kept away based on negative pressure, and used for adsorbing the articles through suction force generated by a negative sucker through a negative pressure pump.

Owner:苏州海翌智能科技有限公司

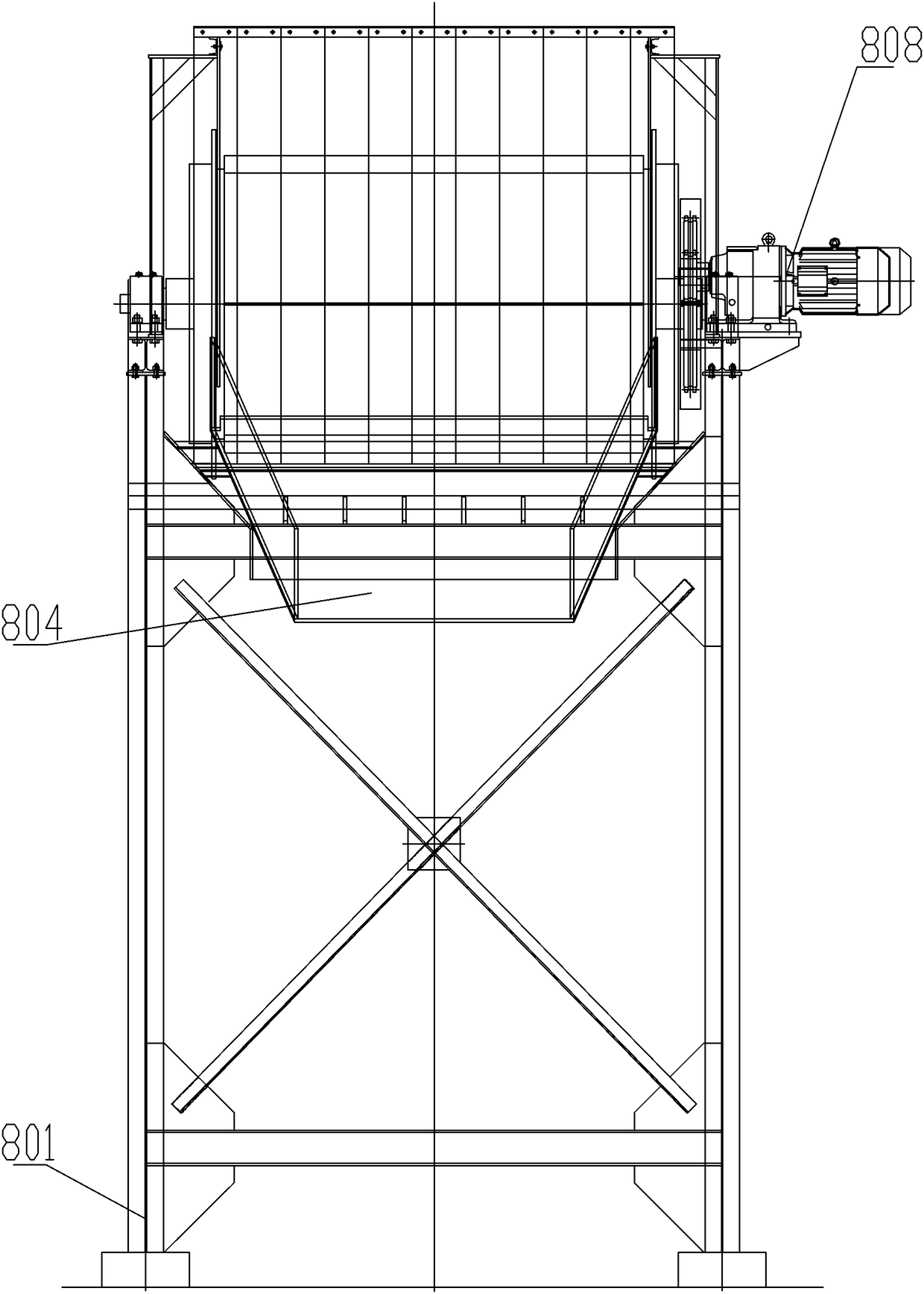

Stacking machine used for stacking steel pipes

ActiveCN111498510AEasy to clamp and supportAchieve magnetic fixationConveyorsStacking articlesElectric machineryPalletizer

The invention discloses a stacking machine used for stacking steel pipes. The stacking machine used for stacking the steel pipes comprises a steel pipe conveying belt, a bottom plate, a stacking mechanism, a material pushing mechanism and a steel pipe magnetic suction device; the material pushing mechanism consists of a push plate and a second electric telescopic rod; the stacking mechanism comprises multiple groups of supporting plates, a limiting frame, multiple groups of first fixing seats, multiple groups of limiting rods and multiple groups of second fixing seats; the steel pipe magneticsuction device comprises an upright, a motor, a rotating seat and a material supporting part; and the material supporting part comprises a third electric telescopic rod, a first placing plate, a cylinder and a second placing plate. According to the stacking machine used for stacking the steel pipes, the magnetic suction fixing of the material supporting part to the steel pipe can be effectively realized through the material supporting part and electromagnetic suction of the material supporting part; the contact between an elastic shifting sheet and an extruding plate can be effectively realized through the position of the elastic shifting sheet in an arc slide groove; the steel pipes can be effectively stacked one by one through obliquely arranged supporting plates; and the steel pipes canbe effectively stacked layer by layer by adjusting the telescopic quantity of a first electric telescopic rod.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

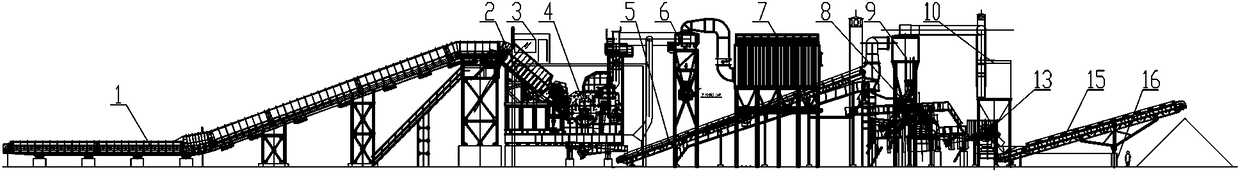

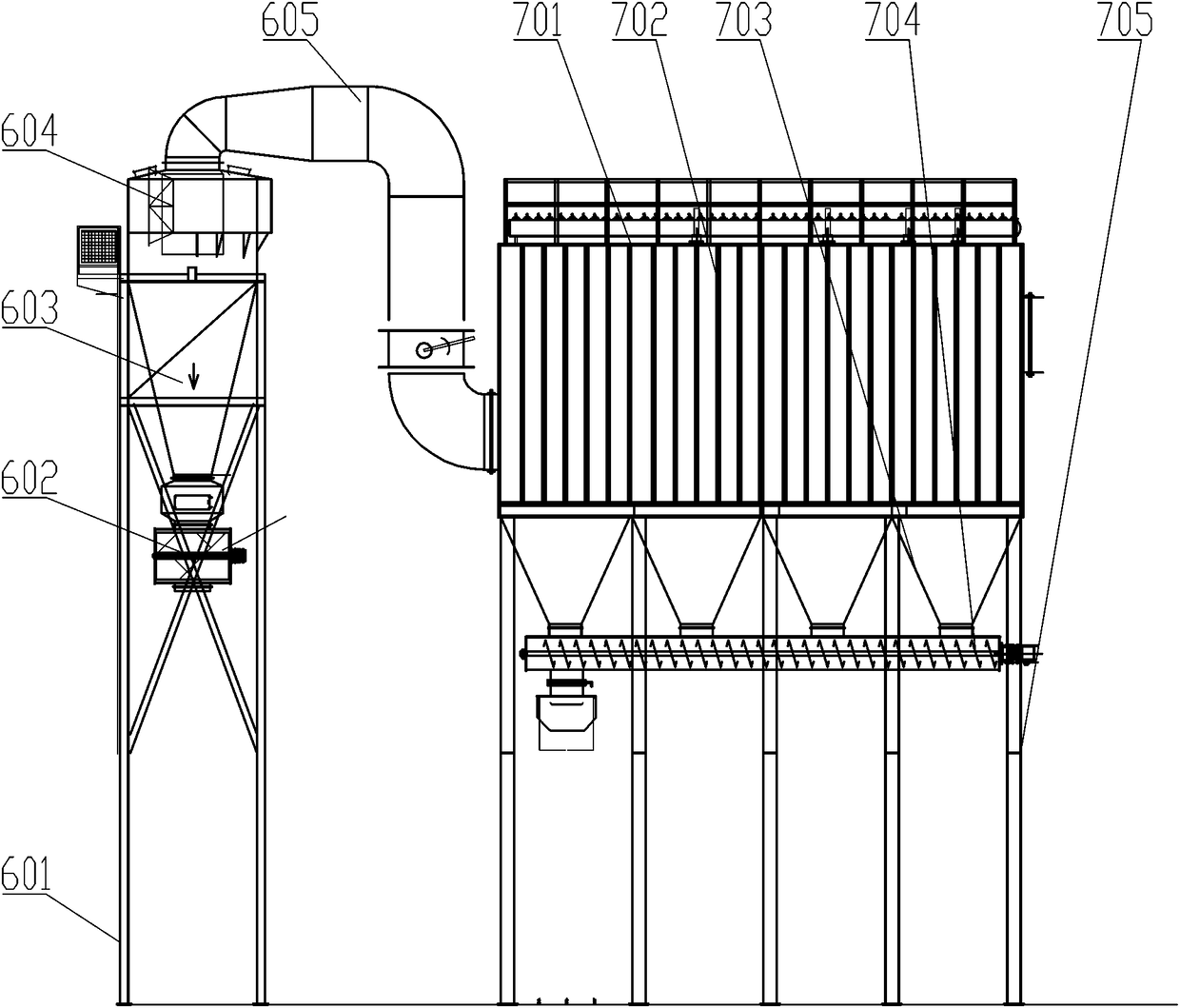

10000HP scrap steel crushing production line

PendingCN109107738AReduce labor intensityIncrease productivityMagnetic separationGrain treatmentsButt jointMagnetic separator

The invention discloses a 10000HP scrap steel crushing production line. The unloading end of a crawler plate conveyor is connected with a feeding hole of a double-drum rolling machine used for rollinga scrap steel raw material; a discharge hole of the double-drum rolling machine is connected with a feeding hole of a crushing machine used for crushing scrap steel rolled blocks in a butt joint manner; a first-stage vibration conveyor used for performing vibration laying and conveying on the crushed material is arranged right below a discharge hole of the crushing machine; a first non-magnetic matter conveyor is arranged right below a falling hopper of a first-stage magnetic separator; an unloading funnel of the first-stage magnetic separator is connected with a second-stage magnetic separator through a second-stage vibration conveyor; a second non-magnetic matter conveyor is arranged right below a falling hopper of the second-stage magnetic separator; and a stacker conveyor used for conveying a metal material after sorting is arranged right below an unloading funnel of the second-stage magnetic separator. The 10000HP scrap steel crushing production line can realize scrap steel crushing production demand in a large scale and thus greatly improves the production efficiency.

Owner:HUBEI LIDI MACHINE TOOL

Space-saving AGV trolley

Owner:上海恒浥智能科技股份有限公司

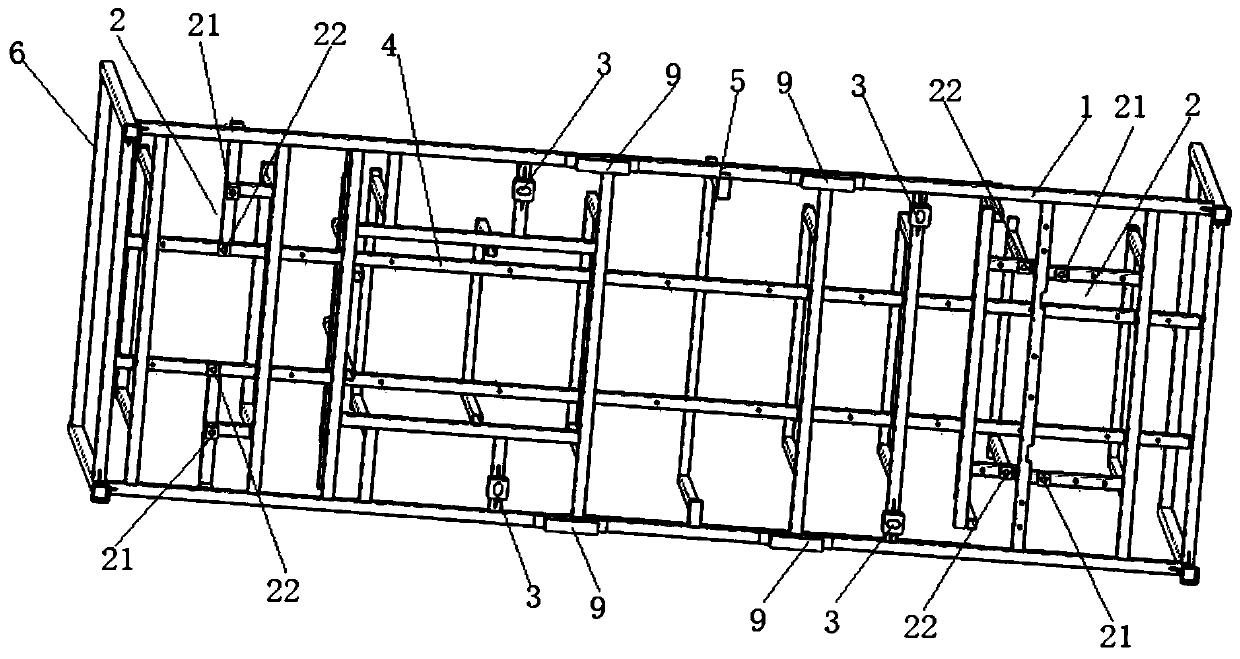

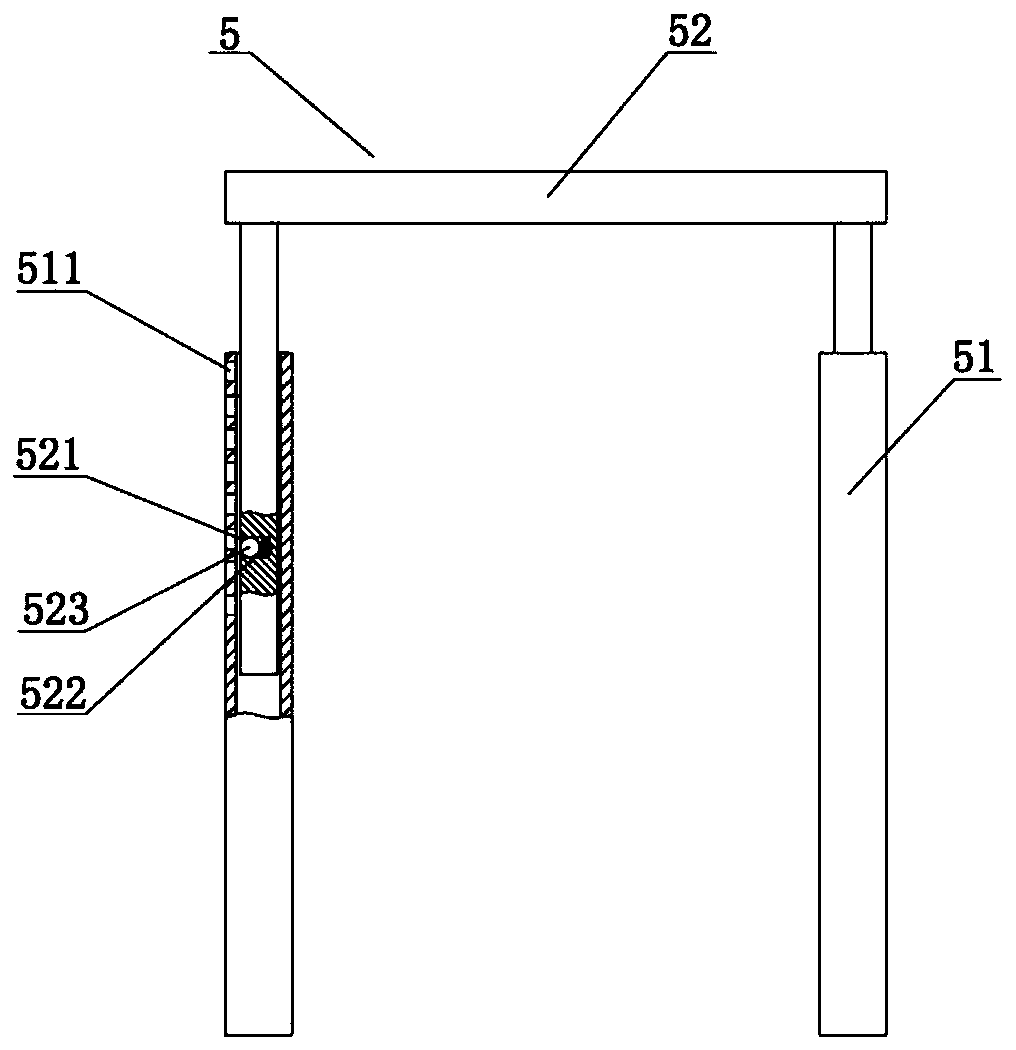

Movable cellar for making baijiu and cellar clay plate components

The invention discloses a movable cellar for making baijiu, belongs to the field of wine making equipment, and provides an independent movable cellar and cellar clay plate components applied to the independent movable cellar. The movable cellar comprises the detachable cellar clay plate components which can be used for making strong-flavor baijiu and aromatic-flavor baijiu respectively. The movable cellar has the advantages that the movable cellar can move integrally, so that baijiu can be put into the cellar, taken out from the cellar and fermenting tanks can be transferred and the like in amanner of mechanized operation, and the movable cellar is suitable for mass production; multiple movable cellars can be stacked layer by layer, the floor space of the movable cellar can be reduced effectively, the limitation of conventional workshop space can be broken through, and the three-dimensional layout of cellars in workshops can be realized; in addition, the cellar clay plate components can be mounted selectively according to different production needs of the strong-flavor baijiu and the aromatic-flavor baijiu to achieve switching, different container devices are not needed, and the equipment costs for producing the strong-flavor baijiu and the aromatic-flavor baijiu are reduced effectively.

Owner:LUZHOU PINCHUANG TECH CO LTD

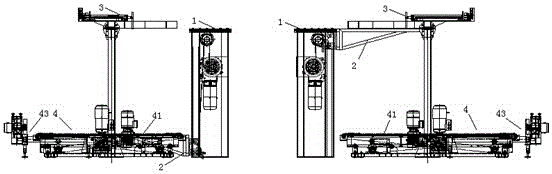

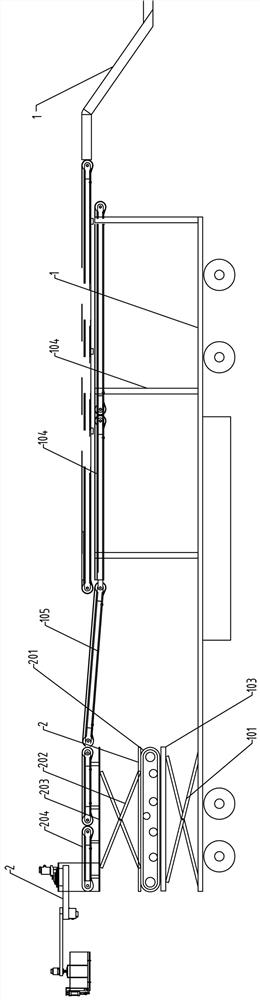

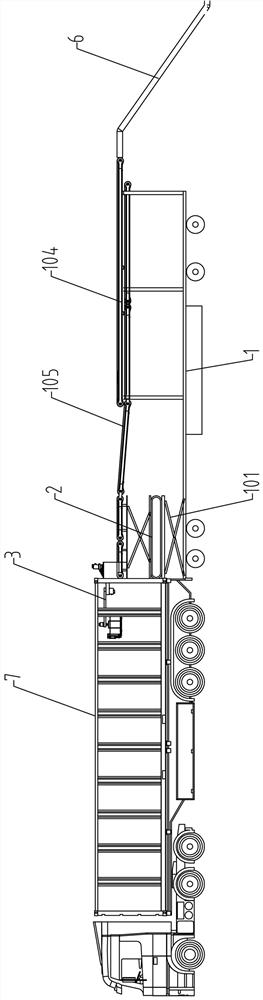

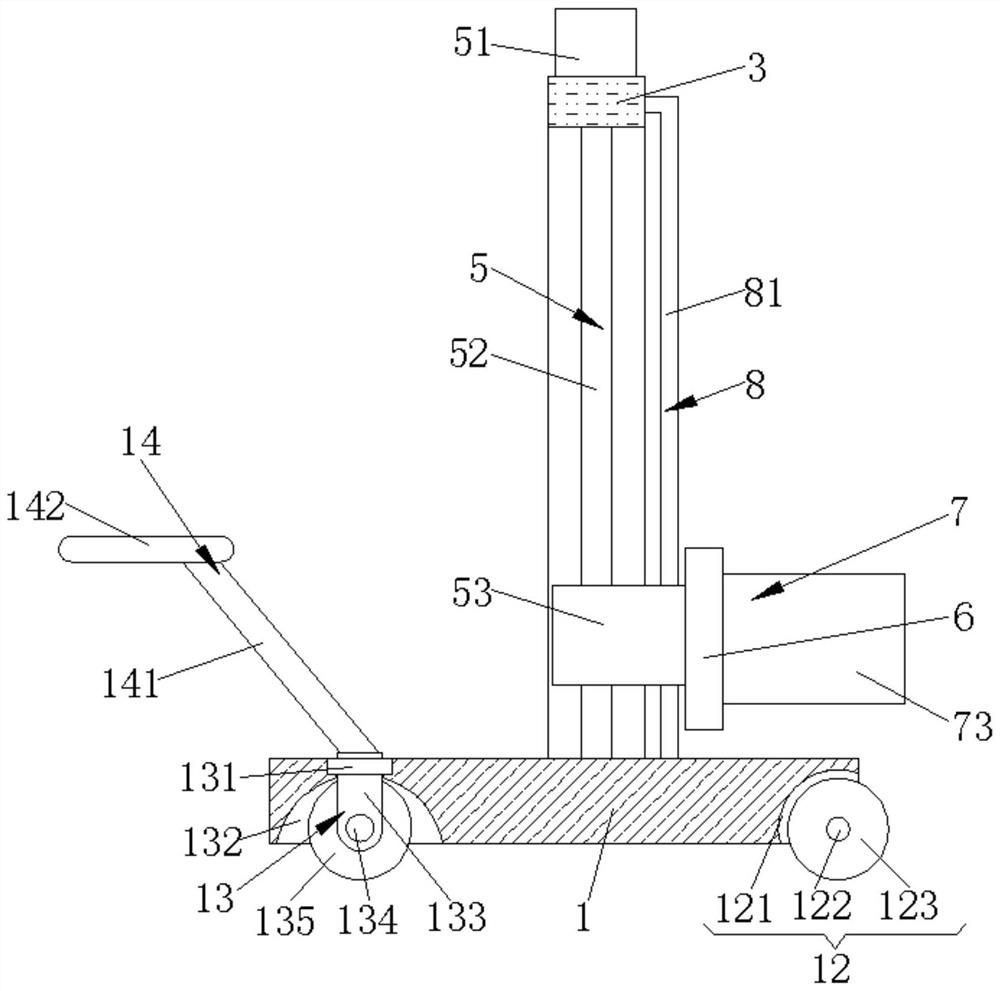

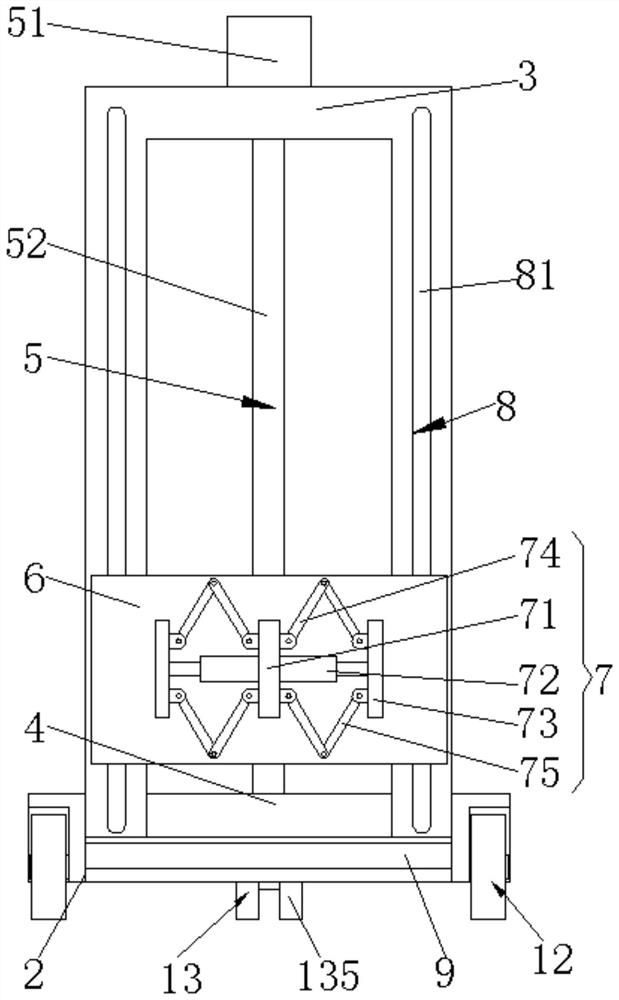

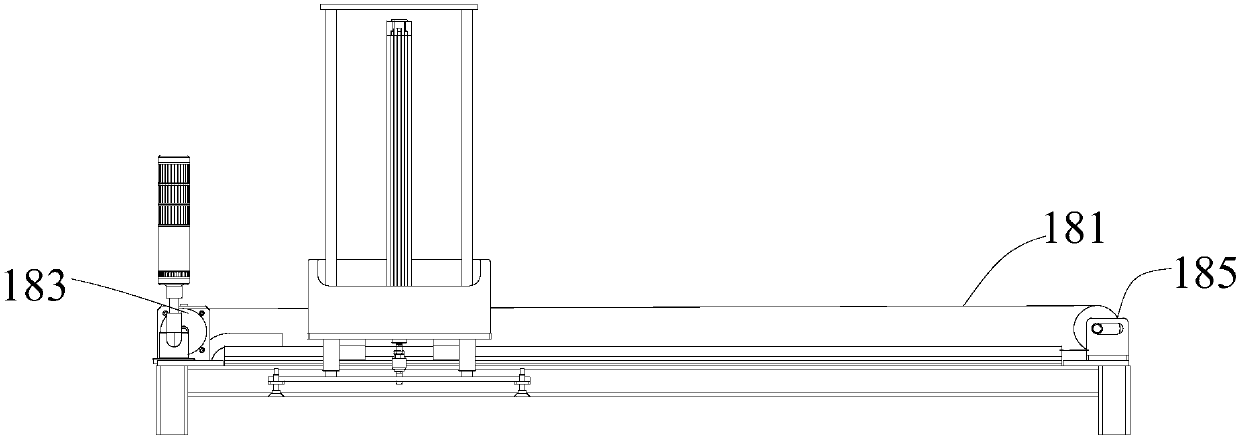

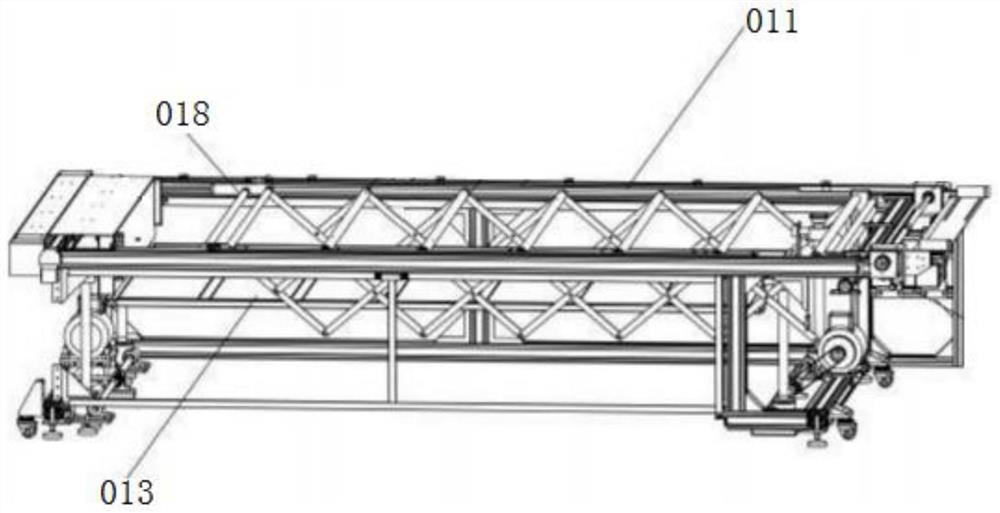

Movable manipulator stacking car loader and goods loading method thereof

PendingCN111908176AEasy to moveRealize stackingStacking articlesDe-stacking articlesPalletizerMachine

The invention relates to a movable manipulator stacking car loader and a goods loading method thereof. The invention adopts the technical scheme that the movable manipulator stacking car loader comprises a forwards-extending moving platform, wherein a lifting mechanism is arranged at the front end of the moving platform; a lifting platform is arranged at the top of the lifting mechanism; a manipulator stacking trolley is arranged on the lifting platform, and comprises a crawler belt moving chassis at the bottom, a trolley lifting machine on the crawler belt moving chassis, and a platform at the top of the trolley lifting machine; a stacking manipulator is arranged at the front end of the platform; a buffer conveyor and a bag feeding conveyor are arranged on the platform behind the stackingmanipulator; the buffer conveyor is connected with a rear slope conveyor; and the rear part of the slope conveyor is connected with a telescopic conveyor. According to the movable manipulator stacking car loader and the goods loading method thereof provided by the invention, the manipulator and the conveyors are combined through a crawler, and the stacking manipulator is arranged on a crawler chassis truck, so that the stability is good, and the purpose of moving the manipulator can be achieved; and through arranging a two-stage lifting structure, a lower lifting structure of the manipulatorstacking trolley is matched with the height of a carriage, so that the the movable manipulator stacking car loader is suitable for carriages with various specifications.

Owner:三维汉界机器(山东)股份有限公司

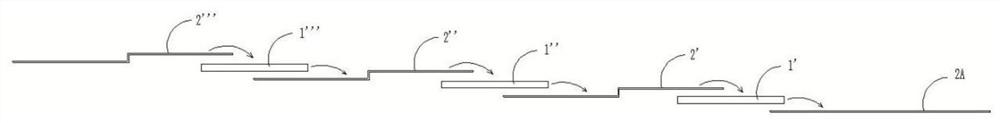

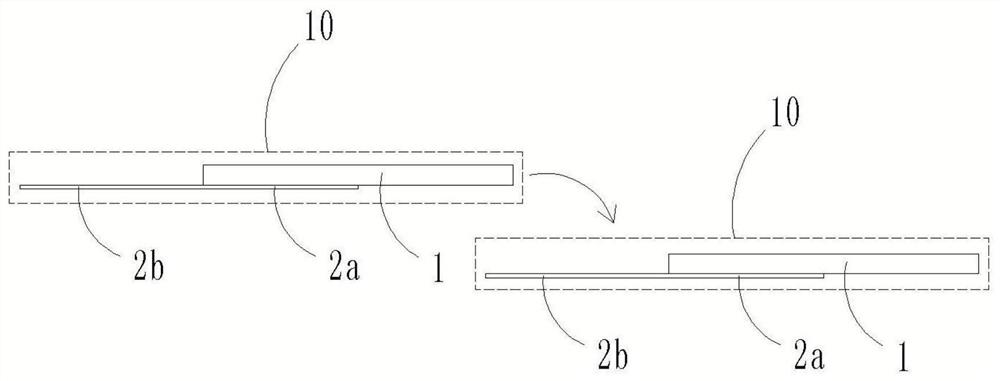

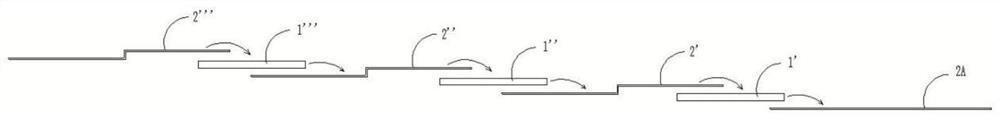

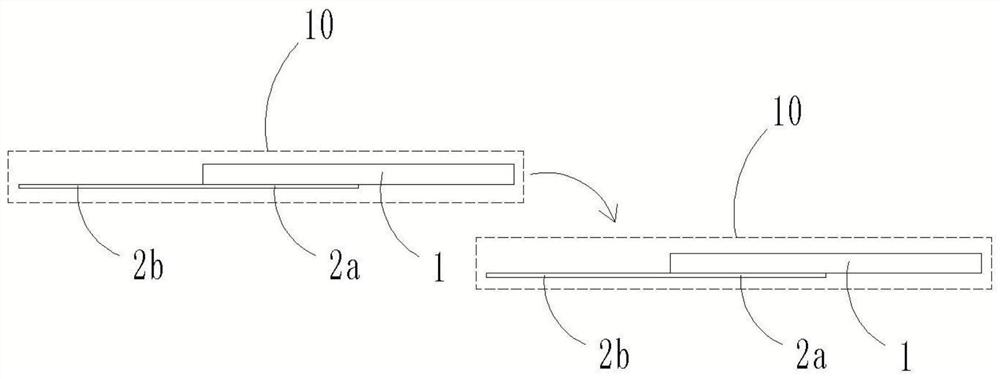

Lamination device and battery string preparation device

PendingCN111697105AEasy to prepareWell laidFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention discloses a laminating device. The laminating device comprises a plurality of laminating tables, a laminating lifting mechanism for driving the laminating tables to move in the verticaldirection, and a laminating translation mechanism for driving the laminating tables to move in the linear direction; through movement in the vertical direction, heights of two adjacent lamination tables can be different, so the lamination tables can move in the horizontal direction, when the horizontal projections of a battery piece and a second end of a welding strip are overlapped, the battery piece is in contact with the second end of the welding strip through movement in the vertical direction, lamination is completed, and then the battery string is rapidly prepared. The invention furtherdiscloses a battery string preparation device which comprises the lamination device, a battery piece feeding device for supplying battery pieces and a solder strip feeding device for supplying solderstrips, the battery pieces and the solder strips form a series welding unit, and the lamination device can further realize lamination of the series welding units, so the battery string can be conveniently prepared.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

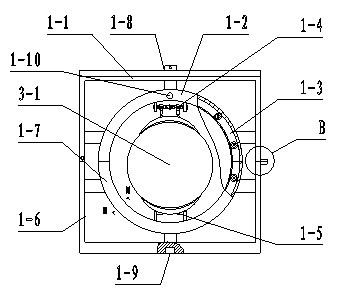

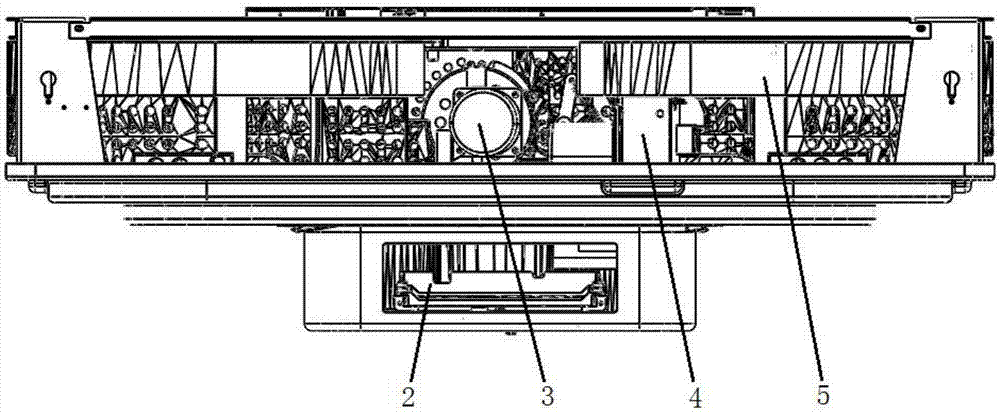

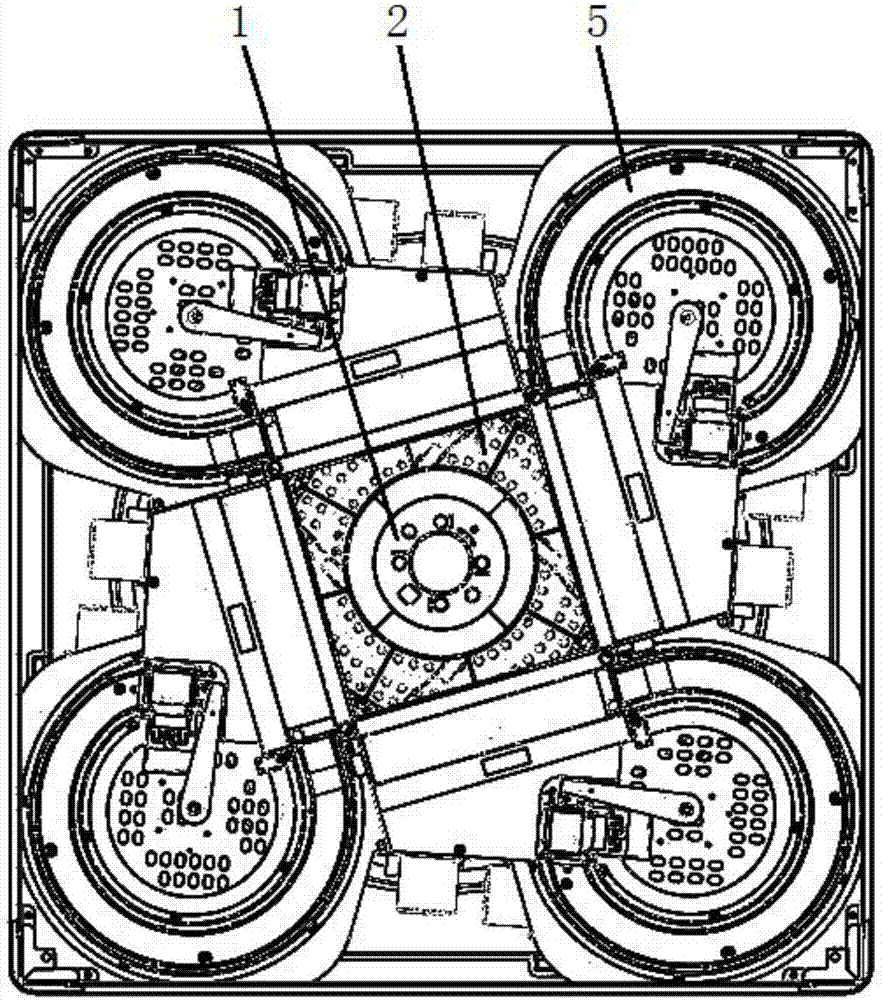

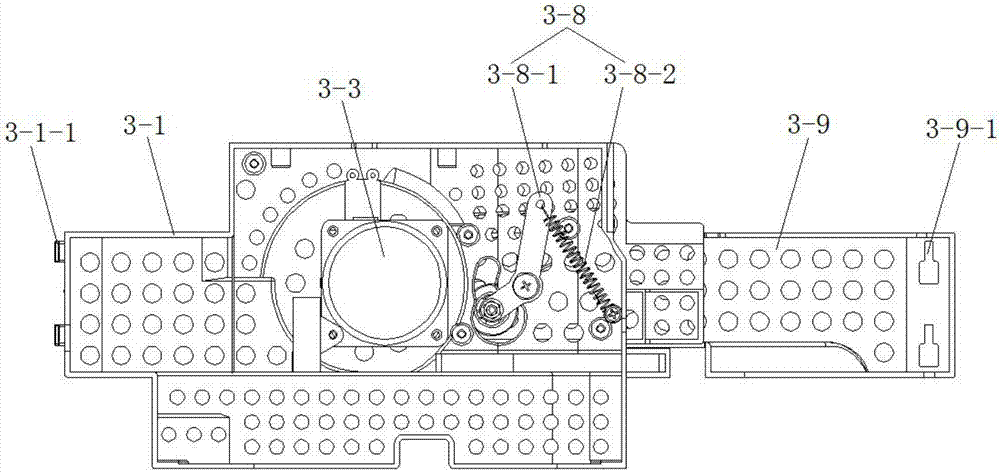

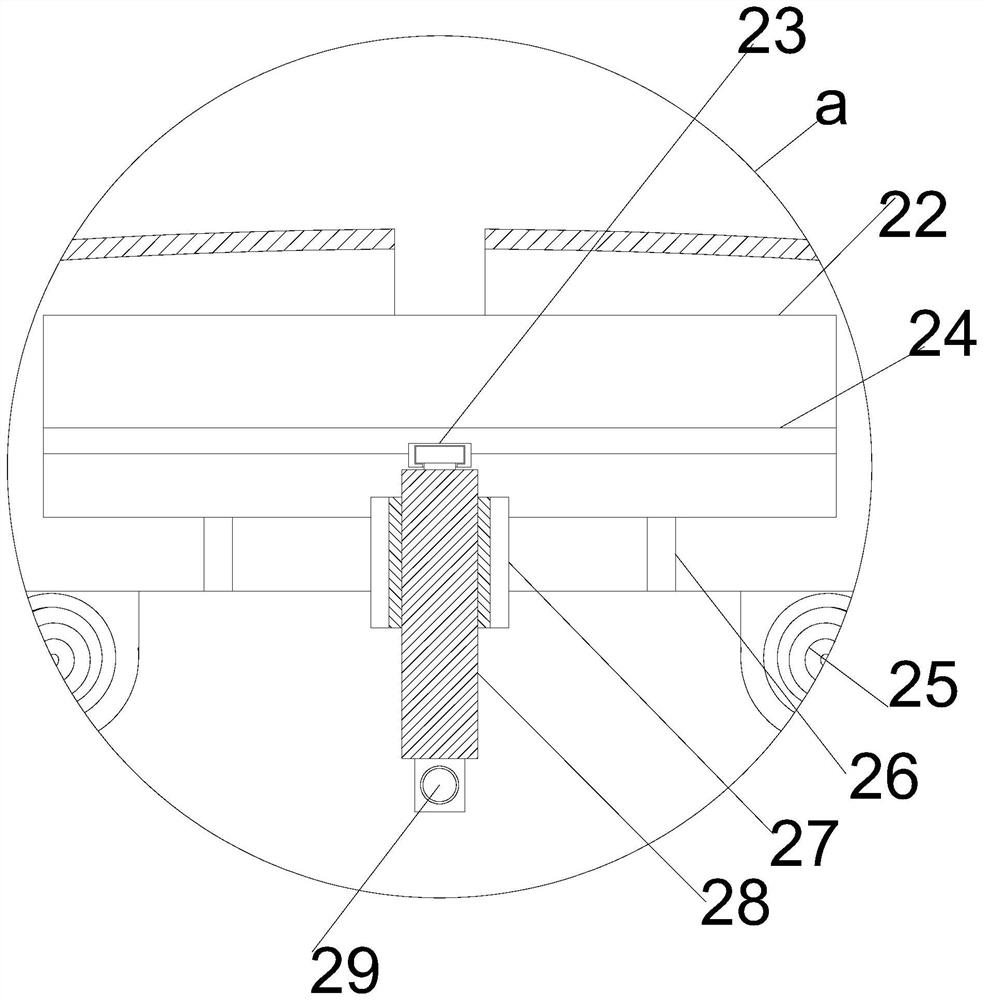

Fully-automatic Mahjong machine

The invention discloses a fully-automatic Mahjong machine. The fully-automatic Mahjong machine comprises an operating disk mechanism, a shuffling mechanism, conveying mechanisms, stacking, lifting and pushing mechanisms and tile feeding mechanisms; the operating disk mechanism is positioned in the center of the Mahjong machine; the shuffling mechanism is positioned at the bottom of the Mahjong machine; the conveying mechanisms, the stacking, lifting and pushing mechanisms and the tile feeding mechanisms are positioned on the four sides of the Mahjong machine; the conveying mechanisms and the stacking, lifting and pushing mechanisms are arranged below the tile feeding mechanism; each tile feeding mechanism comprises a bracket, a tile feeding motor, a tile feeding rocker arm, a tile lifting plate, a tile lifting plate supporting block, a tile lifting motor and a tile lifting rocker arm; a tile feeding rail groove and a tile lifting groove are formed the bracket; the tile feeding rail groove is ring-shaped; and the inlet of the tile lifting groove is communicated with the outlet of the tile feeding rail groove. The conveying mechanisms, the stacking, lifting and pushing mechanisms and the tile feeding mechanisms are small in volume, small in occupied space, small in part quantity and low in cost, and the miniaturization as well as lighting and thinning requirements of the fully-automatic Mahjong machine are met.

Owner:宋拥良

Stacking mechanical arm with brick support plates

InactiveCN103922148ARealize stackingReduce intensityStacking articlesDe-stacking articlesBrickManipulator

The invention discloses a stacking mechanical arm with brick support plates. The stacking mechanism arm comprises a base frame, two brick support plates and two brick clamping plates. An accommodating cavity for accommodating bricks is formed between the two brick support plates and the base frame. A first adjusting mechanism for driving the two brick support plates to synchronously move close to or away from each other is disposed on the base frame. The two brick clamping plates are disposed in the accommodating cavity and are opposite along the parallel direction of the two brick support plates. A second adjusting mechanism for driving the two brick clamping plates to synchronously move close to or away from each other is disposed on the base frame. The stacking mechanical arm with the brick support plates has the advantages that the mechanical arm can stack bricks of optional specifications and is especially suitable for reliably and effectively stacking low-strength, special-shaped and thin bricks, and brick quality is guaranteed; by the stacking mechanical arm with the brick support plates, the product sizes and shapes and low-strength bricks of an automatic linear forming brick making machine are unlimited, product range of the automatic linear forming brick making machine is expanded greatly, and primary brick maintenance strength is lowered greatly.

Owner:FUJIAN EXCELLENCE HONCHA BUILDING MATERIAL EQUIP

Novel pushable fork

The invention discloses a novel pushable fork, comprising a pallet fork plate frame, wherein a containing box body is arranged on the outer surface of one side of the fork plate frame, fastening screws are rotationally arranged on the outer surface of the containing box body, the fastening screws are rotationally arranged on the fork plate frame and the containing box body at the same time, the containing box body is fixedly arranged with the fork plate frame through the fastening screws, a hinge is sleeved on the inner surface of the containing box body, a box body door is fixedly installed on the outer surface of the hinge; a placing movable opening is arranged on the outer wall of the fork plate frame; an additional pushing fork is arranged in the placing movable opening; the outer surface of one side of the additional pushing fork is welded with a hanging plate, a pressure spring is arranged in the additional pushing fork, and a limiter is sleeved on the outer surface of the pressure spring. The novel pushable fork provided by the invention is a push type structure, which can be matched with a push-pull motor to realize the function of stacking goods; and the fork has an anti-slide effect, is convenient to operate and brings better use prospect, etc.

Owner:安徽安鑫货叉有限公司

Continuous intelligent flexibility production method for woolen spinning

ActiveCN108803521AHigh sensitivityReduce stackingContinuous processingTotal factory controlProduction lineYarn

The invention provides a continuous intelligent flexibility production method for woolen spinning and relates to an automatic production method. The continuous intelligent flexibility production method comprises a control unit, an oil centralized blending and conveying unit, a plurality of production units and a cone yarn packaging and storing unit, wherein each production unit comprises a cardingsystem, a combined spinning and winding system and a combined winding and twisting system; subsystems in each production unit have no intersection with subsystems in other production units; the control unit controls the oil centralized blending and conveying unit, the production units and the cone yarn packaging and storing unit for production. With the adoption of the method, continuous single-piece lean production is realized, logistics in a workshop is rapid, efficient and punctual, and material inventory of the workshop is reduced greatly. Quality problems are easy to find by single cheese flow in the processing process of the product, anomaly of a production line can be reflected in real time through data monitoring of a production and execution system of the whole production line, and the product can be traced in the whole process. A digital management mode for the workshop is realized, and synchronization and integration of logistics and information flow in the workshop are realized.

Owner:CONSINEE GRP CO LTD

Intelligent sorting rack for warehousing

The invention discloses an intelligent sorting rack for warehousing. The intelligent sorting rack for warehousing comprises a main conveying belt, a first-stage sorting system and a second-stage sorting system, wherein the first-stage sorting system and the second-stage sorting system are arranged in the conveying direction; the first-stage sorting system and the second-stage sorting system each comprise a plurality of regional sorting modules and a plurality of regional sorting conveying belts arranged on the side face of the main conveying belt; a sorting conveying belt and a weight sortingconveying belt are integrally arranged on the side face of each regional sorting conveying belt; the side face of each volume sorting conveying belt is connected with the corresponding weight sortingconveying belt; a volume sorting module and a weight sorting module are arranged at the joint of each regional sorting conveying belt and the corresponding volume sorting conveying belt and the jointof each regional sorting conveying belt and the corresponding weight sorting conveying belt correspondingly; and each to-be-sorted object is sorted through the corresponding regional sorting module, the corresponding volume sorting module and the corresponding weight sorting module. According to the intelligent sorting rack for warehousing, sorting of the regions, the volumes and the weights of goods is achieved, the goods large in volume and weight are placed in the lower space in a carriage during loading, and the stability of the loaded goods is improved.

Owner:安徽辰讯信息科技有限公司

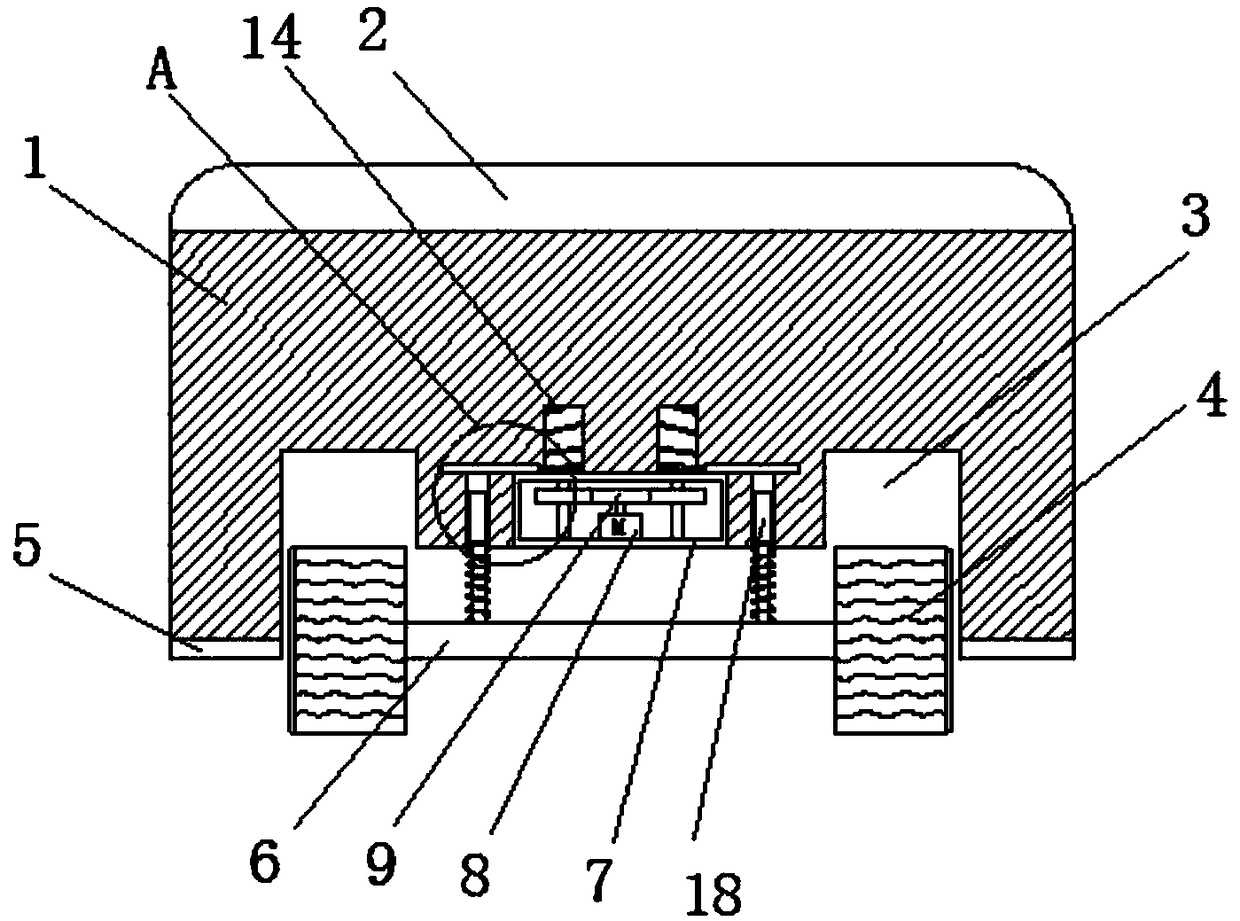

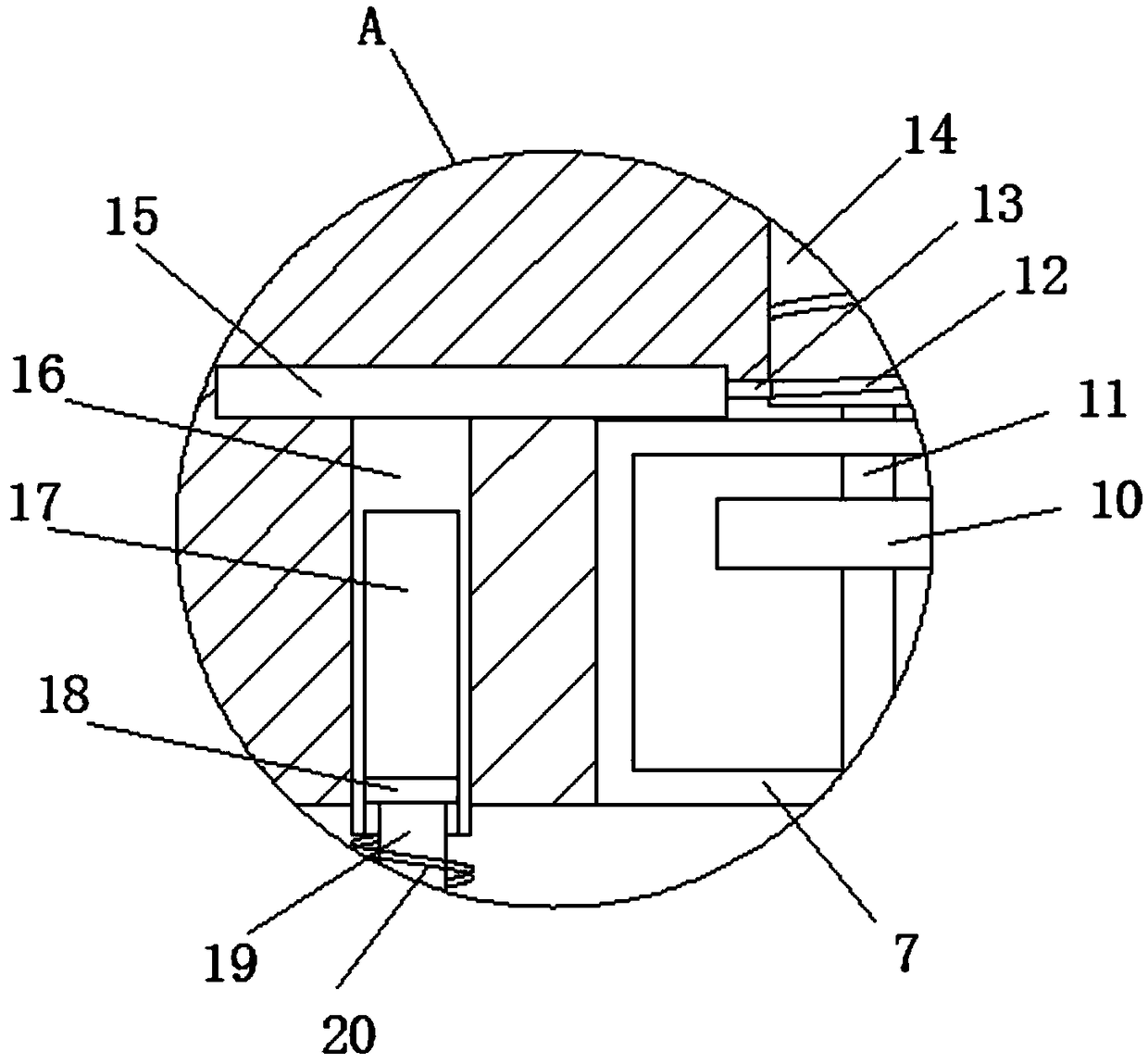

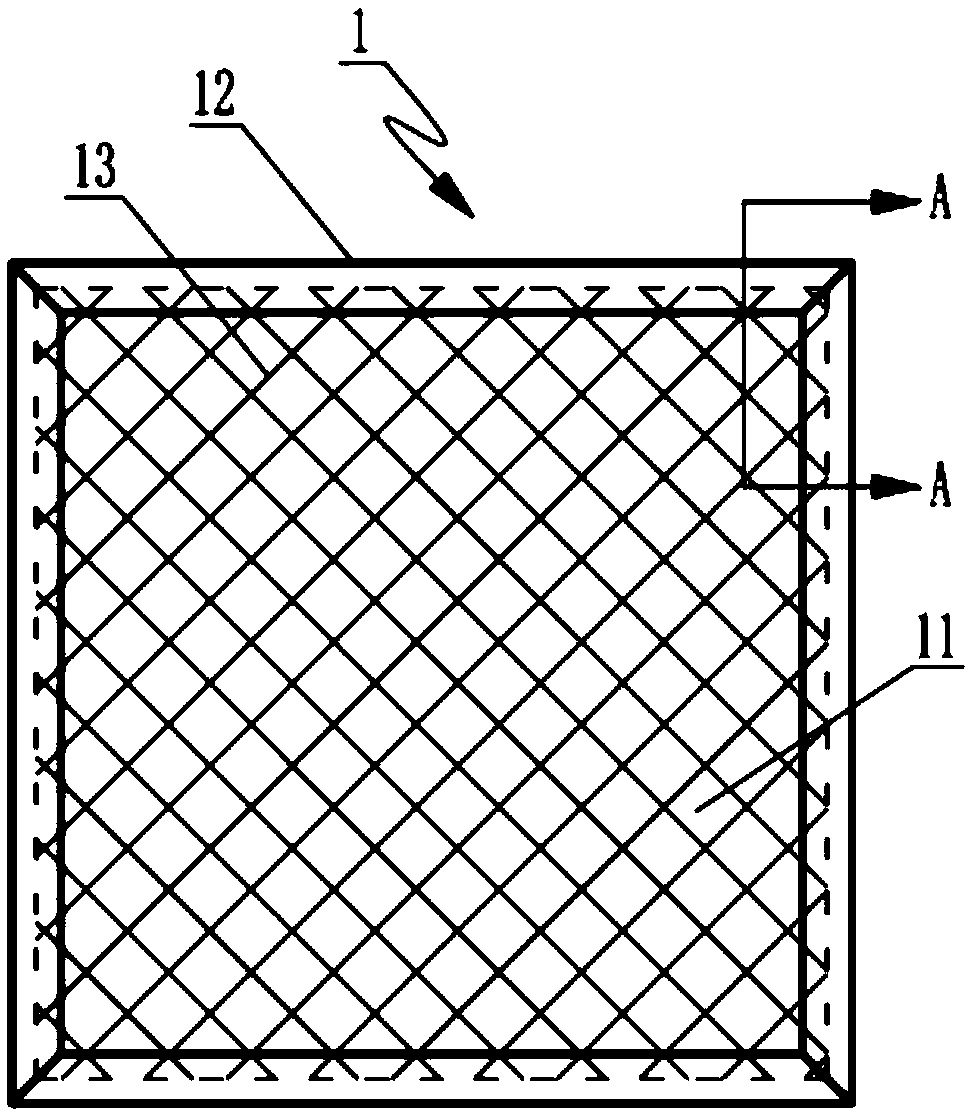

An automatic handling robot

ActiveCN111204687BPrevent dumpingRealize stackingLifting devicesStructural engineeringMechanical engineering

The invention discloses an automatic handling robot, which comprises a base. A tank is provided on the right side of the base. The inner cavity of the tank is provided with a U-shaped frame, and the inner cavity of the U-shaped frame is provided with a lifting mechanism. The right side of the lifting mechanism is provided with a clamping seat, the right side of the clamping seat is provided with a clamping mechanism, the front side and the rear side of the right side of the U-shaped frame are all provided with a limit mechanism, and the tank body The inner cavity of the U-shaped frame is fixedly connected with a cargo placement plate, and the inner cavity of the U-shaped frame is fixedly connected with a fixed plate. The invention solves the problem that the traditional handling robot needs to manually transport the goods to the place where the goods are placed on the robot, and then carry the goods, which is labor-intensive, and the robot may fall when carrying heavy goods. It is inconvenient for the user, and the handling robot does not have the function of stacking the goods, and it is necessary to manually stack the goods to be transported.

Owner:湖南仪路无忧科技有限公司

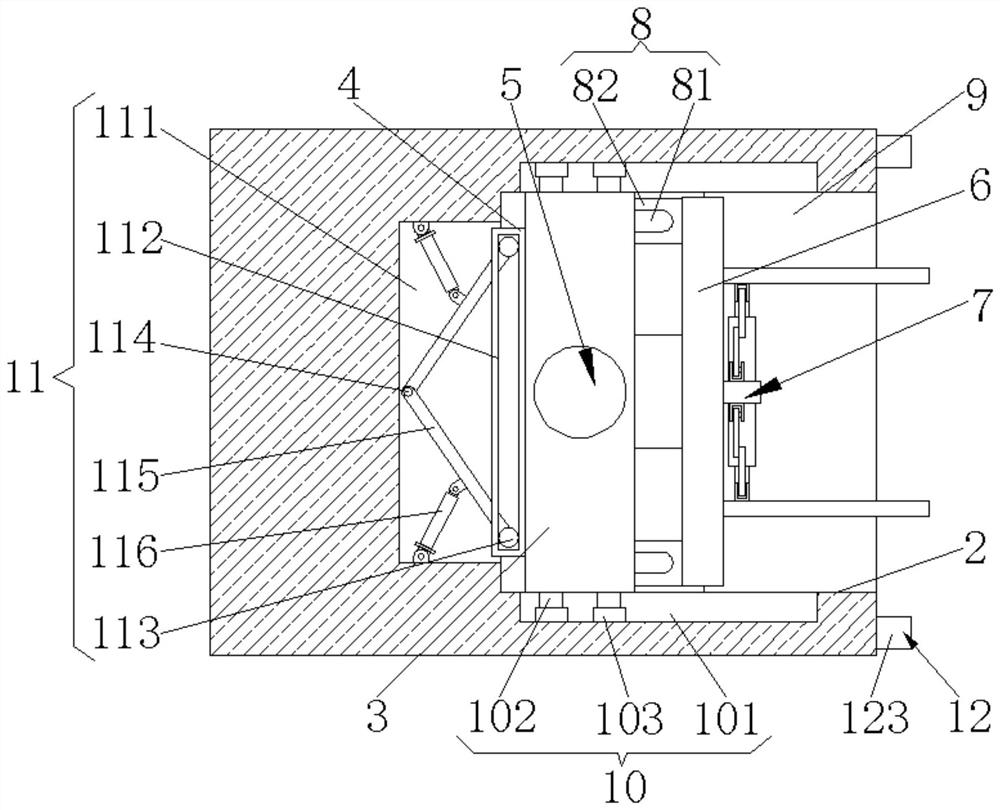

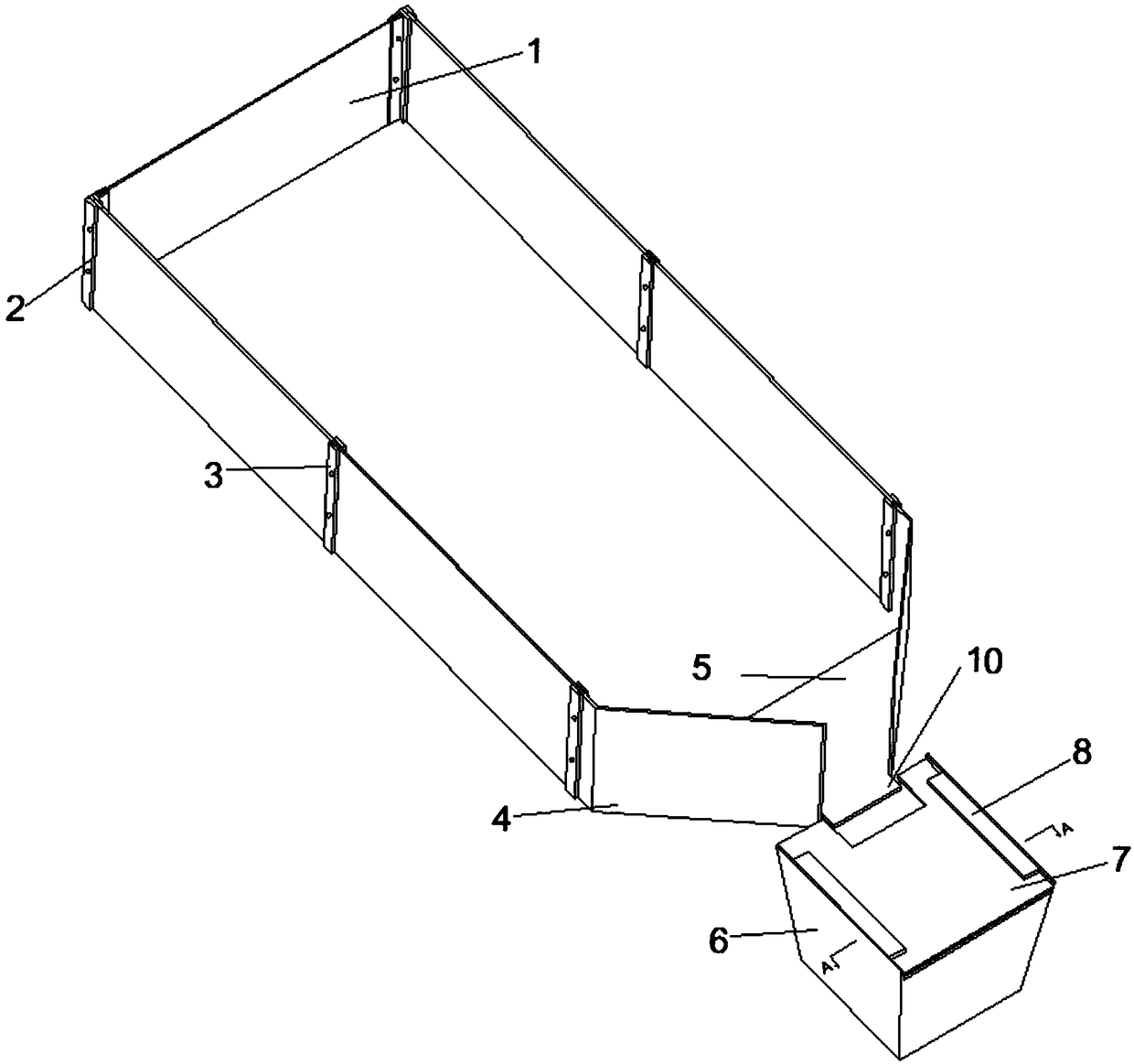

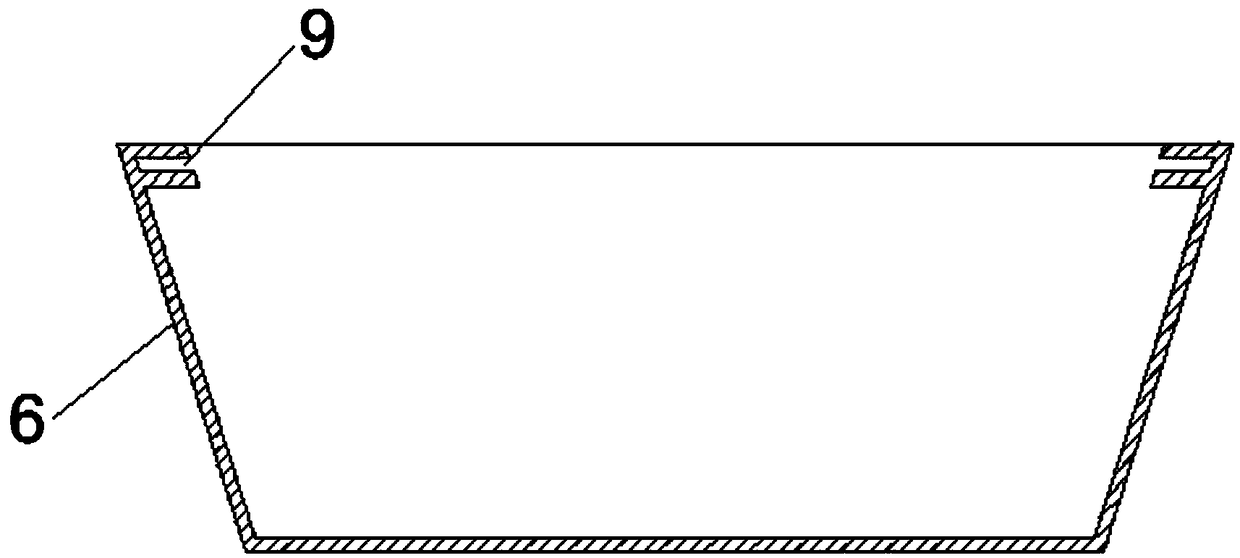

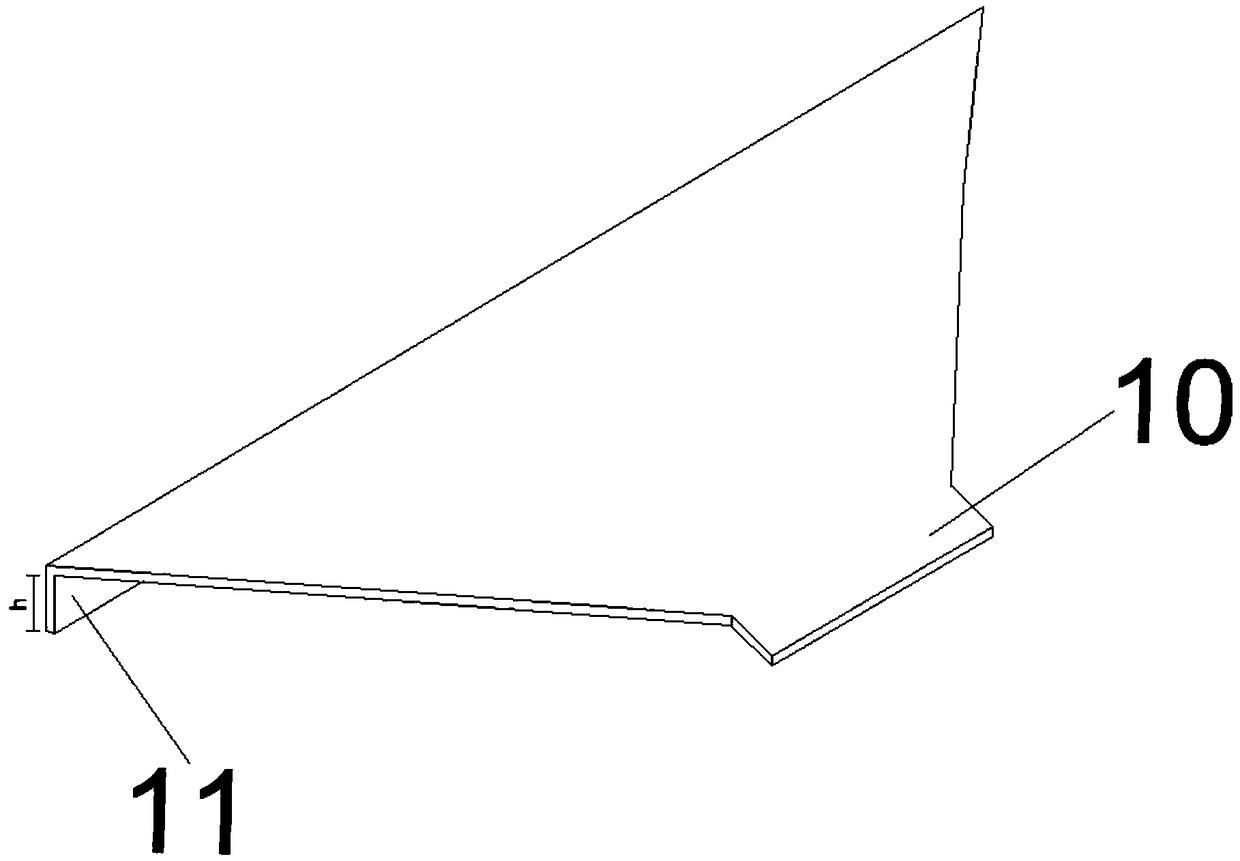

Movable assembled type water and soil conservation field runoff plot and water and soil conservation monitoring method

The invention discloses a movable assembled type water and soil conservation field runoff plot and a water and soil conservation monitoring method, and relates to a runoff plot and a water and soil conservation monitoring method. The invention aims to solve problems that for a runoff plot built by a bricklaying method, buildings are easy to generate frost cracks, weather factor interference is large, runoff sediment samples are difficult to collect and measurement accuracy is low. The runoff plot is formed by a runoff plot main body, a runoff plot diversion trench and a runoff gathering pit; the runoff plot main body is a rectangular frame formed by the surrounding of a plurality of insertion boards; the runoff plot diversion trench is formed by a trapezoid bottom plate and two diversion plates; the runoff gathering pit is formed by the surrounding of four trapezoid plates; and the diversion bottom plate of the runoff plot diversion trench is erected at the upper ends of the trapezoidplates of the runoff gathering pit at one side of a notch. The runoff plot disclosed by the invention is a prefabticated member made of polypropylene; the prefabticated member is assembled in field; the frost cracks cannot be generated; damage of field construction to the environment is avoided; no samples are left in the runoff gathering pit; and acquired monitoring data is accurate. The movableassembled type water and soil conservation field runoff plot and the water and soil conservation monitoring method are applicable to water and soil conservation monitoring.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

Cargo stacking robot

ActiveCN109230578ARealize free adjustmentEasy to stackStacking articlesDe-stacking articlesEngineeringRobot

The invention relates to the technical field of cargo stacking and in particular to a cargo stacking robot comprising a base, a mechanical arm device and a support device, wherein the base comprises afirst platform and a second platform; the first platform is equipped with a first translational rotating device; a second translational rotation device is mounted on the second platform; one end of the mechanical arm device is rotatably connected to the first translational rotation device; one end of the support device is rotatably connected with the second translational rotation device; the mechanical arm device is connected with the support device and comprises a basic arm and a telescopic arm; the basic arm is provided with a telescopic cavity; the telescopic arm sleeves the telescopic cavity of the basic arm to stretch and retract; the first end of the basic arm is rotatably connected with the first translational rotating device; and the position of the basic arm adjacent to the second end is rotatably connected to the support device. The cargo stacking robot improves cargo stacking stability, reduces cargo stacking cost, is flexible to use, and facilitates cargo stacking from different heights and directions.

Owner:GUAGNZHOU SYL AUTOMATIC CONTROL TECH CO LTD

Metal plate intelligent separating and merging machine

ActiveCN107738920ARealize stackingRealize functionControl devices for conveyorsStacking articlesEngineeringManipulator

The invention provides a metal plate intelligent separating and merging machine and relates to the field of metal plate machining equipment. The metal plate intelligent separating and merging machinecomprises a rack, a carrying manipulator, a thickness detecting mechanism, an electromagnetic separator and a plate positioning mechanism, the rack comprises a bearing table, a sliding frame, a plateframe and a stacking frame, and the sliding frame is fixedly connected to the edge of one side of the bearing table. A sliding rail is arranged at the top of the sliding frame, the plate frame is arranged on the bearing table and provided with a plate in-place area, and the stacking frame is fixedly arranged on the bearing table and provided with a plate stacking area. The carrying manipulator isslidably arranged on the sliding rail and oppositely arranged with the plate in-place area or the plate stacking area, the thickness detecting mechanism is fixedly connected to the sliding frame and oppositely arranged with the carrying manipulator, and the electromagnetic separator is fixedly connected to the side, close to the stacking frame, of the bearing table. Compared with the prior art, according to the metal plate intelligent separating and merging machine, the dual functions of stacking and destacking can be achieved, and the very convenient effect is achieved.

Owner:绵阳海迪机器人科技有限公司

Auxiliary polishing device and polishing method for highway traffic guardrail

InactiveCN114734346ARealize stackingIncreased polishing areaBelt grinding machinesPolishingEngineering

The invention discloses a highway traffic guardrail auxiliary polishing device and a polishing method, and relates to the technical field of machining, the polishing device comprises a supporting mounting column, the supporting mounting column is provided with a plurality of combined polishing modules, and each combined polishing module comprises a supporting mounting plate; supporting mounting holes are formed in the supporting mounting plate and the supporting mounting columns, guide conductive columns are symmetrically arranged on the outer sides of the supporting mounting columns, and guide conductive grooves are formed in the inner walls of the supporting mounting holes and the guide conductive columns; an operation mounting plate is arranged right opposite to the supporting mounting plate, fixed mounting columns extend out of the four corners of the side, right opposite to the operation mounting plate, of the supporting mounting plate, the outer ends of the fixed mounting columns are fixed to the operation mounting plate, and a deformation mechanism is arranged on one side of the supporting mounting plate; through a combined modular mounting structure, stacking of the device is achieved, the polishing operation area of the device is remarkably increased, and the device can adapt to polishing operation of different sizes.

Owner:徐州市通泰交通设施有限公司

Automatic sheet material receiving and stacking device

PendingCN113955568ARealize automatic receivingRealize stackingConveyorsFolding thin materialsEngineeringMachine

The invention provides an automatic sheet material receiving and stacking device. The automatic sheet material receiving and stacking device comprises a machine body, a sensor and a controller, wherein the machine body comprises a frame, guide rails fixedly installed at the two sides of the top of the frame, sliding blocks installed on the guide rails in a sliding manner and a lifting table arranged in the middle of the frame, and the machine body is provided with a feeding mechanism used for conveying sheet materials, a material carrying mechanism used for receiving the sheet materials and a material receiving mechanism used for driving the lifting table to do lifting motion so as to achieve stacking of the sheet materials; the sensor is installed on the machine body and used for detecting the existence condition of the sheet materials; and the controller is in communication connection with the sensor, the feeding mechanism, the material carrying mechanism and the material receiving mechanism. The automatic sheet material receiving and stacking device is simple in structure, stable in operation, high in conveying precision and capable of achieving high-precision and automatic sheet material receiving and stacking.

Owner:HANGZHOU ECHO SCI TECH +1

Electrophoresis tool universal for vehicle body sheet metal spare parts

PendingCN110886002ARealize continuous productionReduce labor intensityElectrophoretic coatingsElectrophoresesSpare part

The invention discloses an electrophoresis tool universal for vehicle body sheet metal spare parts, and belongs to the technical field of vehicle sheet metal electrophoresis tools. The electrophoresistool comprises a supporting base, a transfer supporting seat, a lifting appliance positioning seat, a plurality of storing tracks and a plurality of storing handrails, wherein the transfer supportingseat, the lifting appliance positioning seat, the storing tracks and the storing handrails are arranged on the supporting base; and the transfer supporting seat is in positioning fit with a welding skid and a coating skid, the lifting appliance positioning seat is in positioning fit with a coating lifting appliance, the multiple storing tracks are mutually parallel and are arranged in the width direction of the supporting base, and the multiple storing handrails are arranged in the length direction of the supporting base. The electrophoresis tool has the beneficial effects that the electrophoresis tool is suitable for electrophoresis positioning of the different types of vehicle body sheet metal spare parts, positioning operation is easy, fixing is reliable, the type and number of specialelectrophoresis tools are decreased, thus the production cost is saved, continuous production of electrophoresis processes is achieved, manual carrying is not needed, the labor amount of workers is decreased, and the electrophoresis efficiency and quality are improved.

Owner:湖北大冶汉龙汽车有限公司

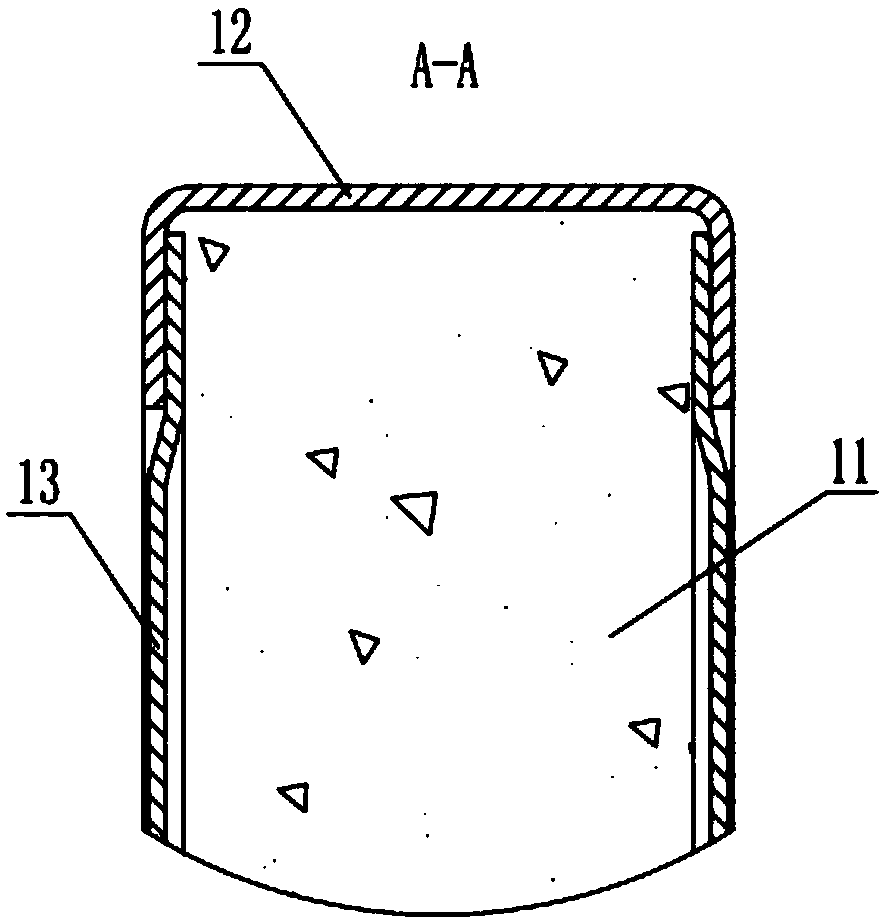

Bearing body structure of ocean electromagnetic node acquisition station

PendingCN112130212AElectromagnetic signal acquisition is reducedImprove delivery accuracyWaterborne vesselsElectric/magnetic detectionMagnetic bearingMechanical engineering

The invention discloses a bearing body structure of an ocean electromagnetic node acquisition station. The bearing body structure comprises a degradable and non-magnetic bearing body, wherein the bearing body is formed by pouring degradable cement; and a plurality of flow guide holes are formed in the bearing body in a penetrating mode in the longitudinal direction. The bearing body structure is made of a degradable and non-magnetic material, so that the influence of exploration on the ocean environment is reduced to the maximum extent, and the influence of the magnetic material on the electromagnetic signal acquisition of the acquisition station is avoided; and due to the design of the flow guide holes, the influence of seawater resistance and ocean current on the acquisition station in the sinking process of the acquisition station can be effectively reduced, and the putting precision of the acquisition station is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com