Solder strip feeding device and battery string preparation device

A technology for welding ribbons and battery sheets, which is applied in shearing devices, circuits, photovoltaic power generation, etc., can solve the problems of low battery string preparation efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

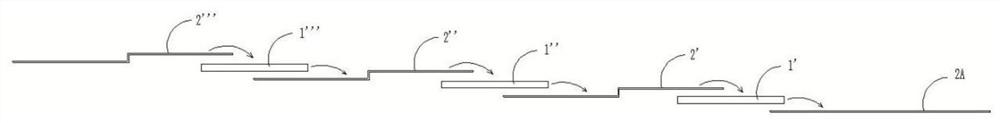

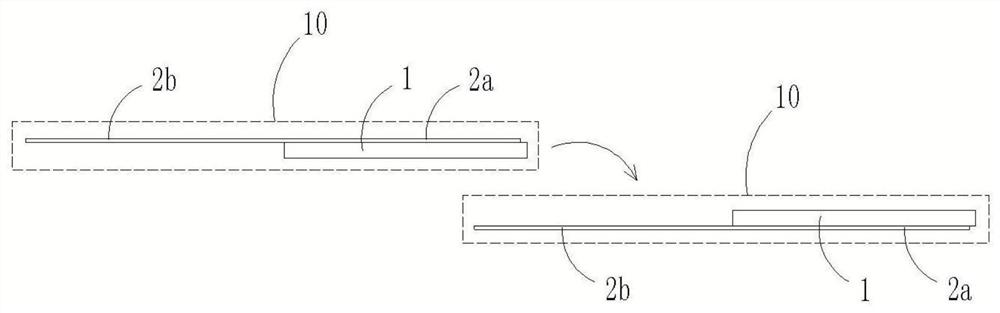

[0070] The ribbon loading device 200 transports the finished ribbon 2 to contact with the battery sheet 1 to construct the stringer unit 10 .

[0071] In this embodiment, the finished ribbon 2 is a ribbon material segment that meets the technical requirements and can be directly used to construct the stringer unit 10 .

[0072] When multiple welding ribbons 2 need to be laid on one battery sheet 1 , the welding ribbon feeding device 200 can move each welding ribbon 2 one by one to contact the battery sheet 1 . Alternatively, the ribbon feeding device 200 can transport multiple ribbons 2 to contact the battery sheet 1 at the same time.

[0073] Wherein, the ribbon feeding device 200 includes a ribbon extractor (not shown) and a ribbon extractor (not shown); Driving components such as linear modules and robots; after the ribbon extractor is extracted to the finished ribbon 2, the ribbon extractor drives the ribbon extractor to move towards the construction station of the string...

Embodiment 2

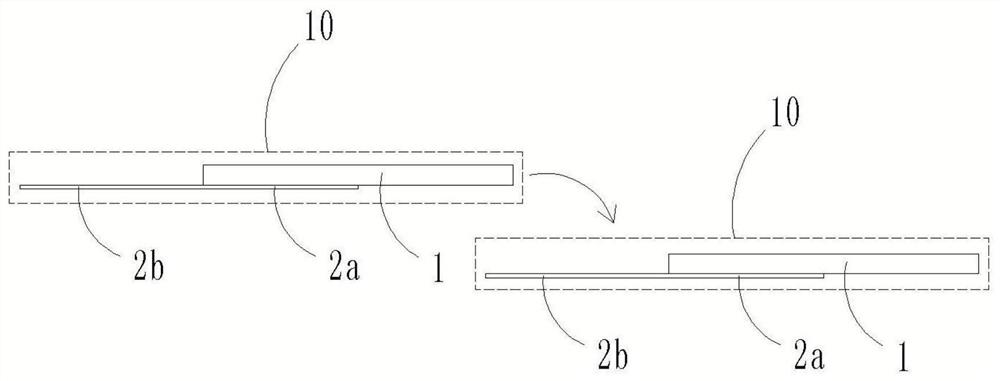

[0075] In order to facilitate the continuous operation of the equipment, the ribbon feeding device 200 can prepare the finished ribbon 2 and then transport the finished ribbon 2 to the construction station of the stringer unit 10 .

[0076] In one embodiment, the ribbon loading device 200 includes: a ribbon unwinding mechanism 210 for releasing the ribbon material; a ribbon cutting mechanism 220 located downstream of the ribbon unwinding mechanism 210 and capable of cutting the ribbon material Ribbon; the ribbon pulling mechanism 230 can pull out the ribbon material strip from the ribbon unwinding mechanism 210, and pull the ribbon material ribbon through the ribbon cutting mechanism 220 so that the ribbon cutting mechanism 220 can cut the ribbon material bring.

[0077] refer to Figure 11 , The ribbon unwinding mechanism 210 includes an unwinding shaft 211 and an unwinding driver that drives the unwinding shaft 211 to rotate; The unwinding shaft 211 rotates to release the ...

Embodiment 3

[0083] The battery string preparation device is provided with multiple sets of welding ribbon feeding devices 200 described in Embodiment 2, which are respectively used to prepare a set of welding ribbons 2 .

[0084] Alternatively, the battery string preparation device is provided with only one set of welding ribbon feeding device 200 described in Embodiment 2, and multiple sets of welding ribbons 2 are prepared one by one through the welding ribbon feeding device 200 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com