Patents

Literature

534results about How to "Avoid recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

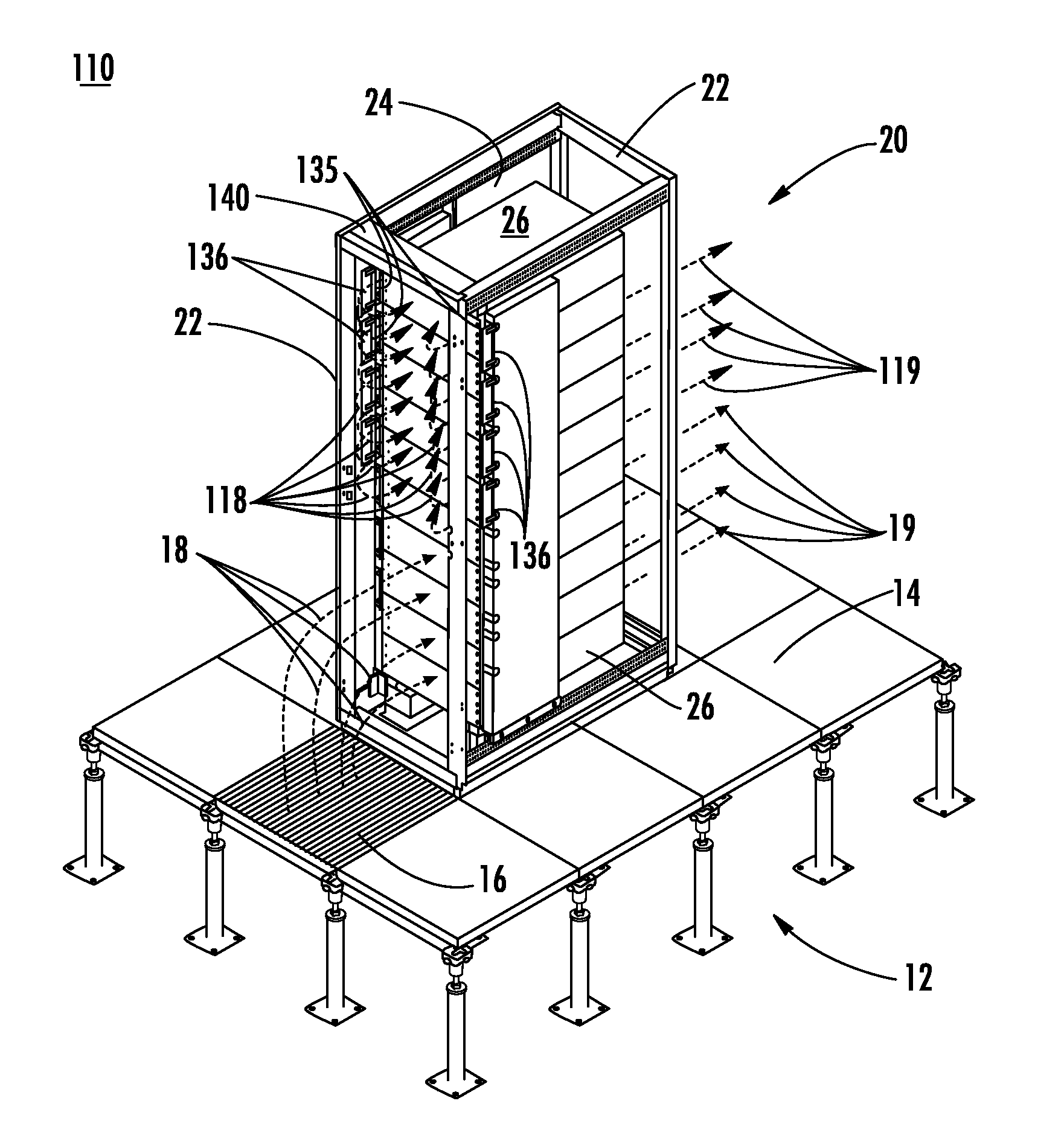

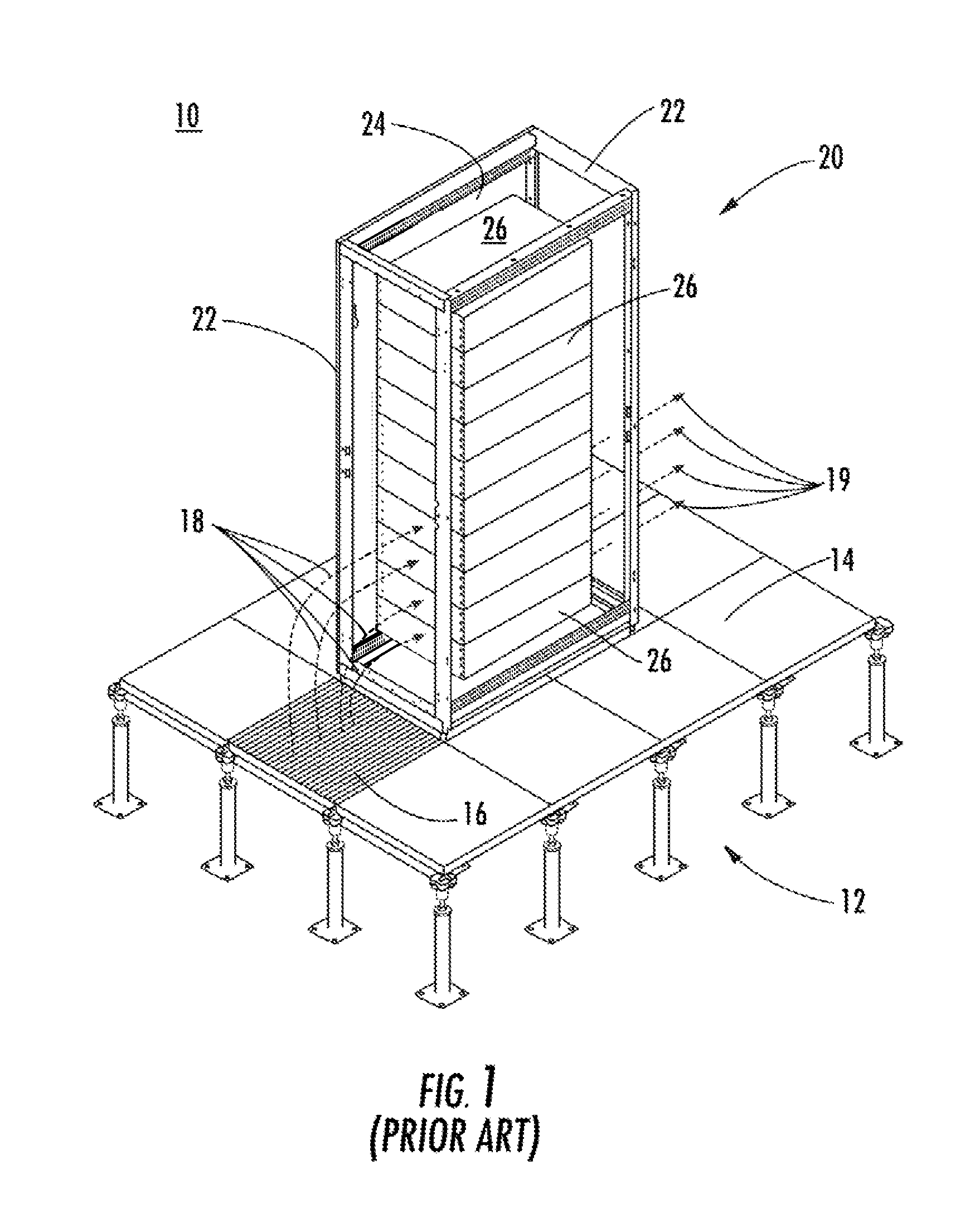

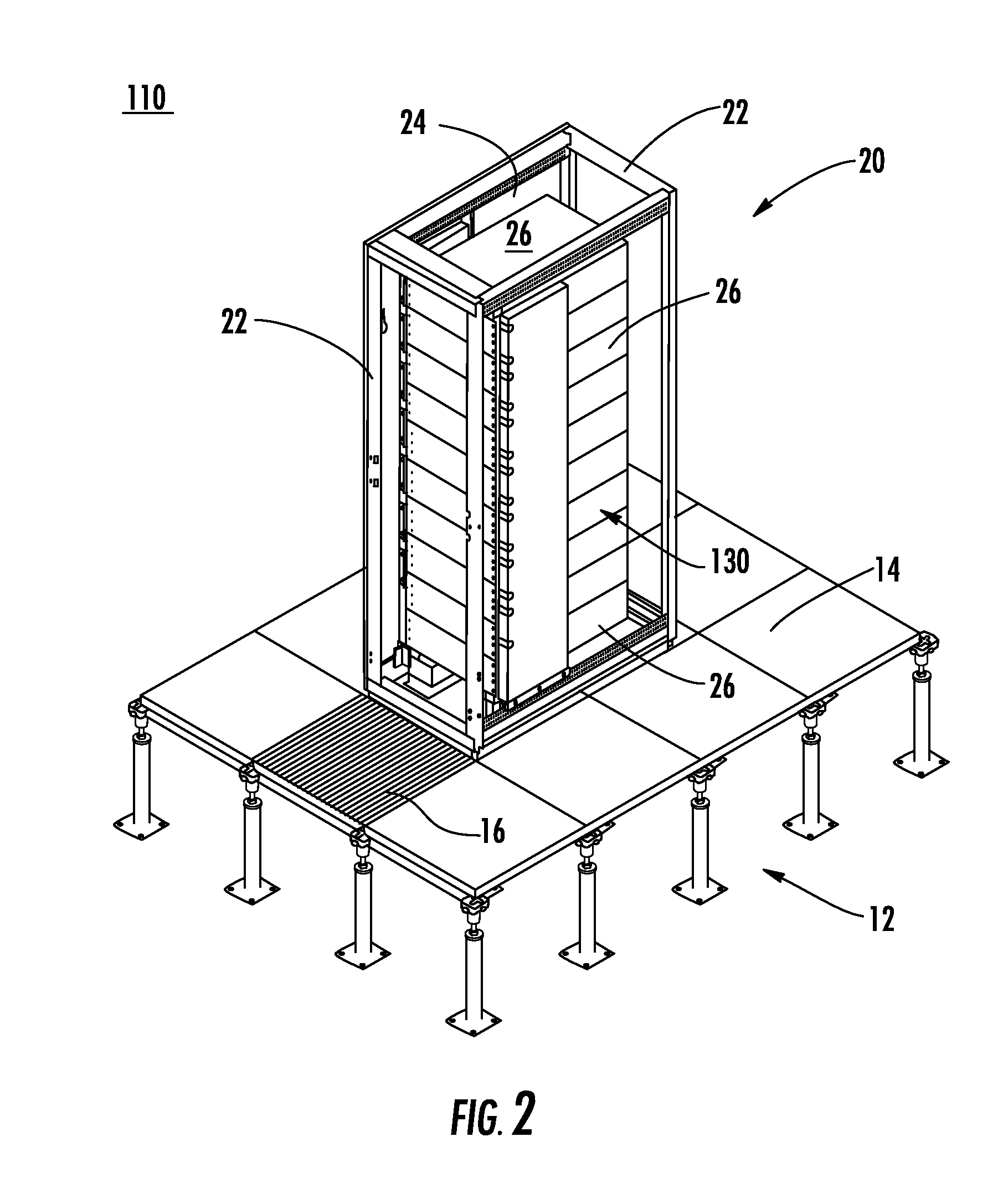

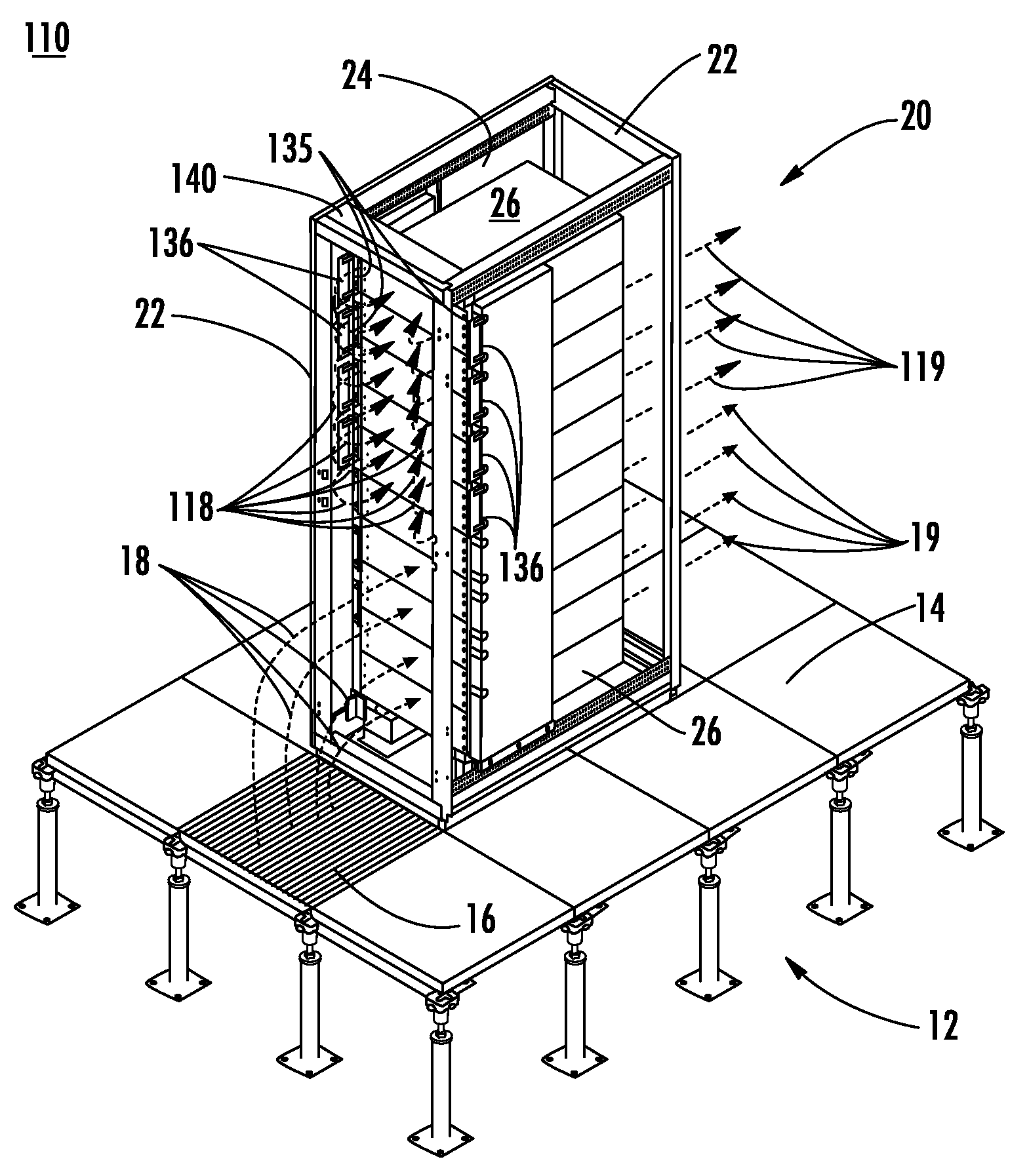

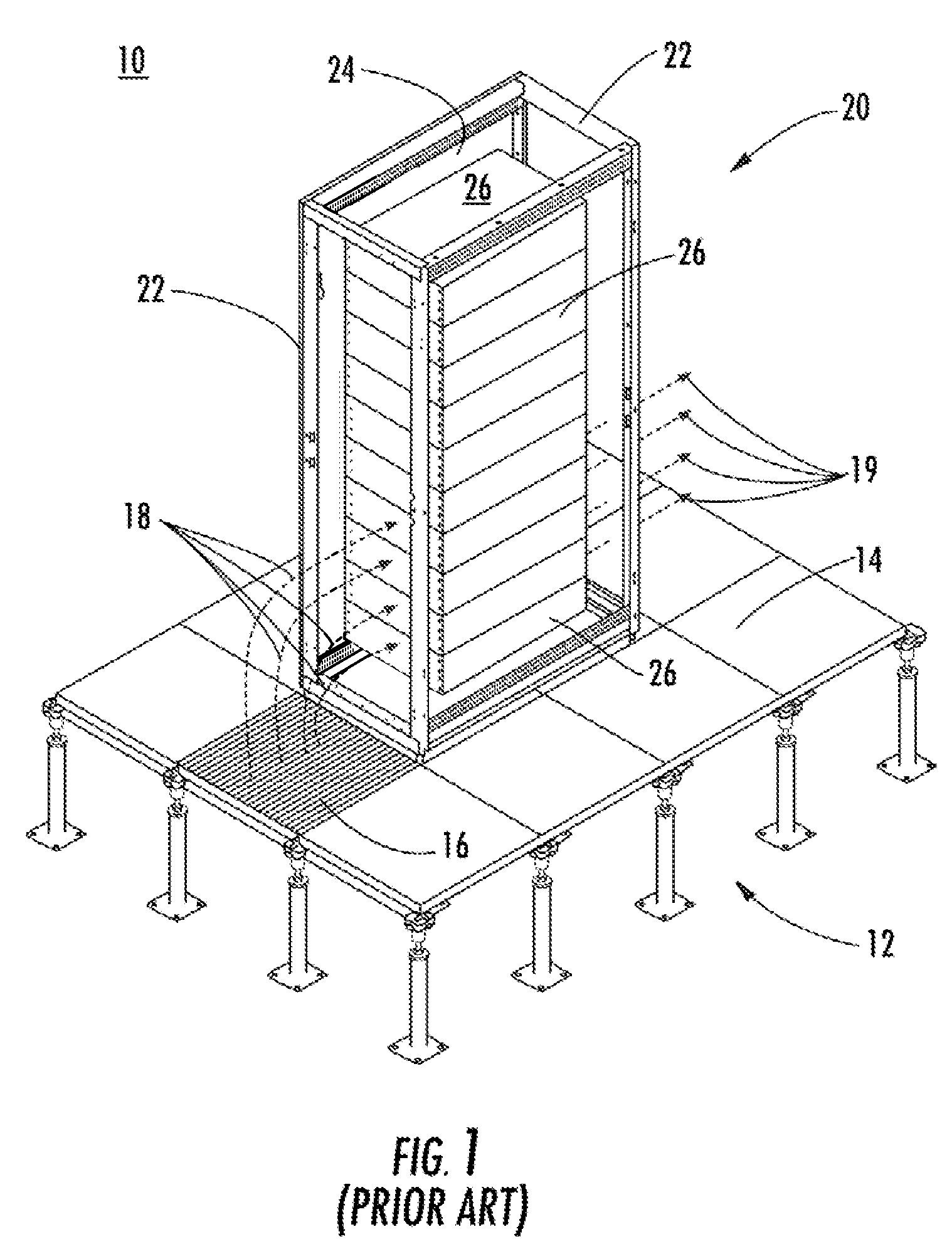

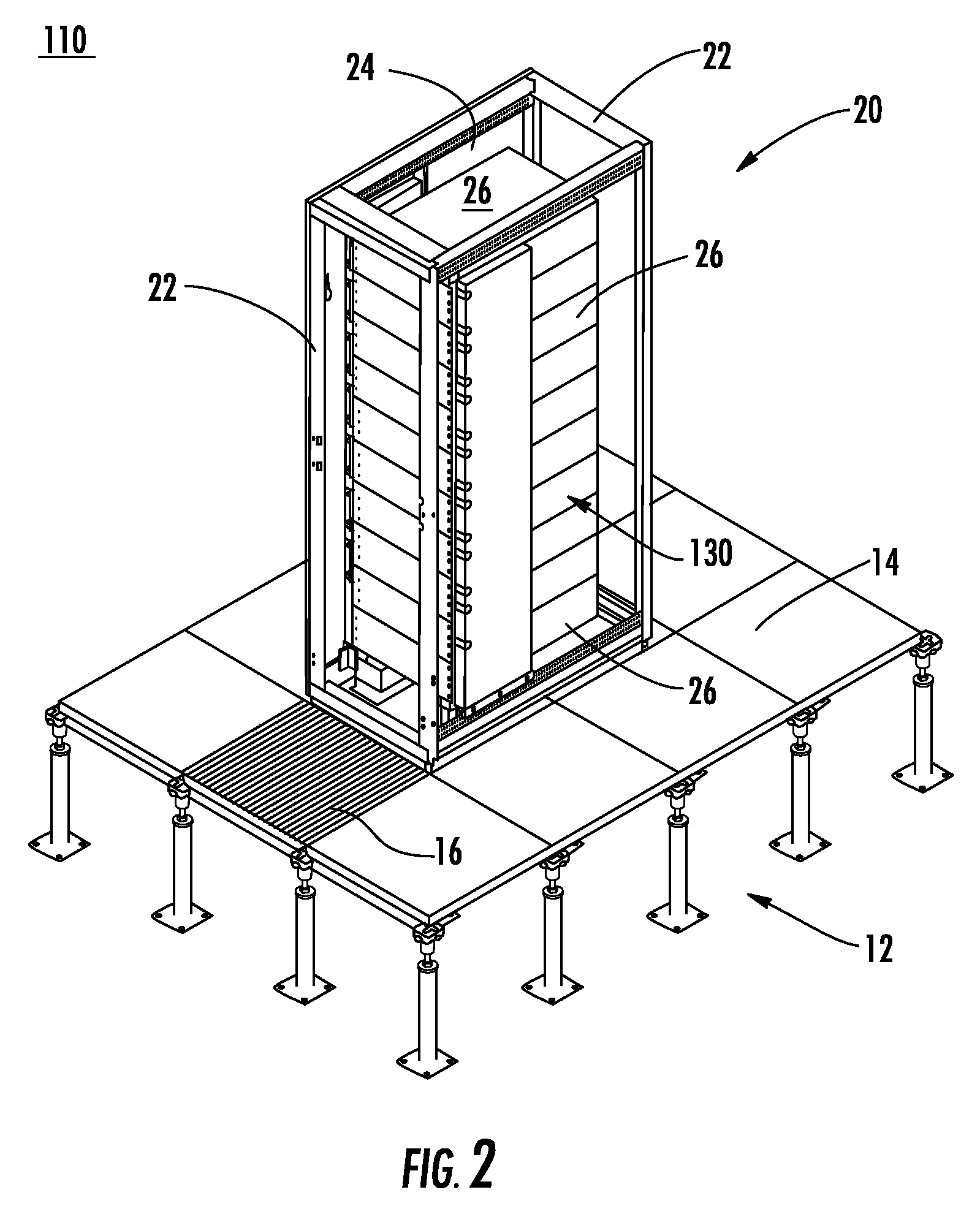

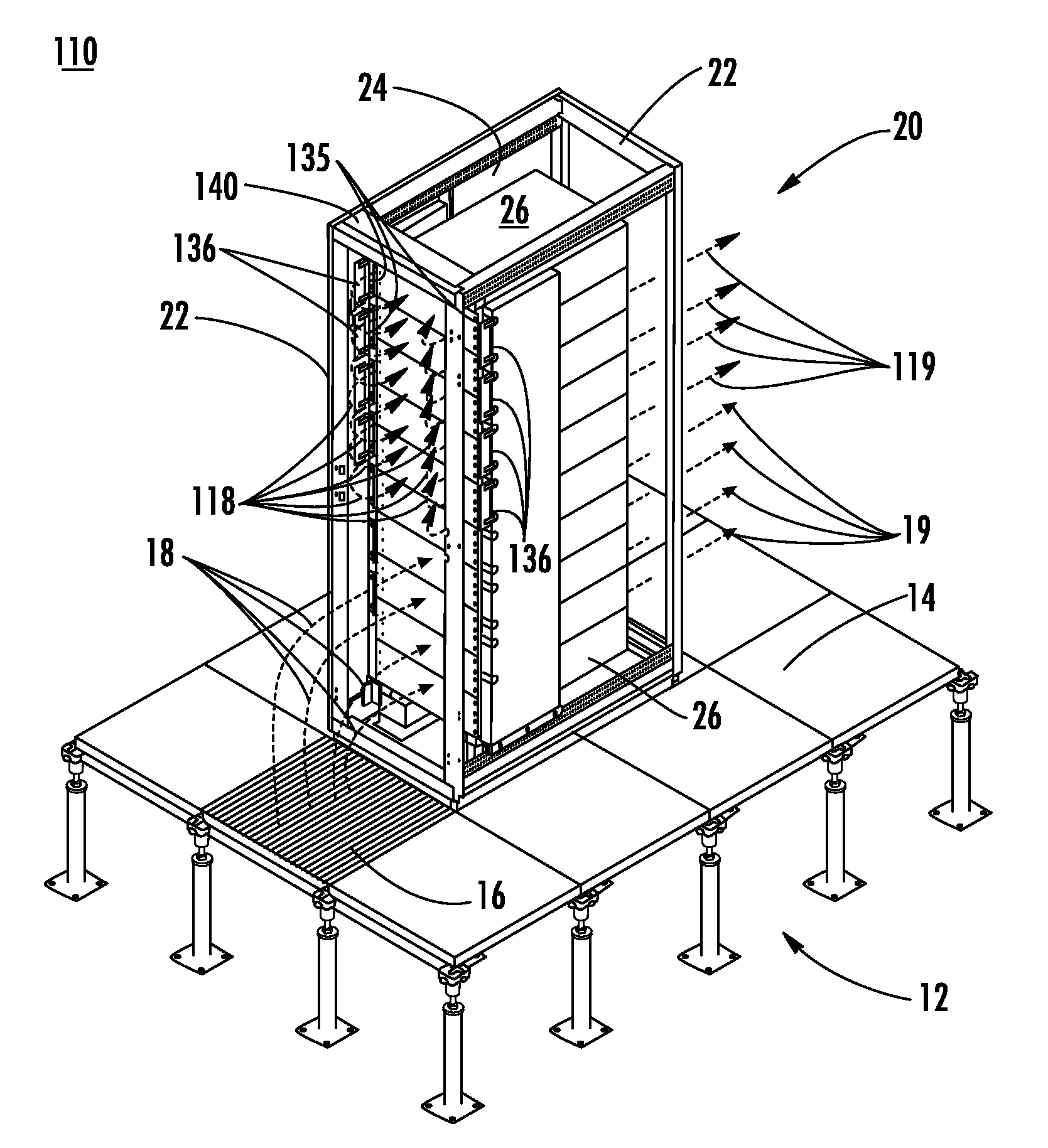

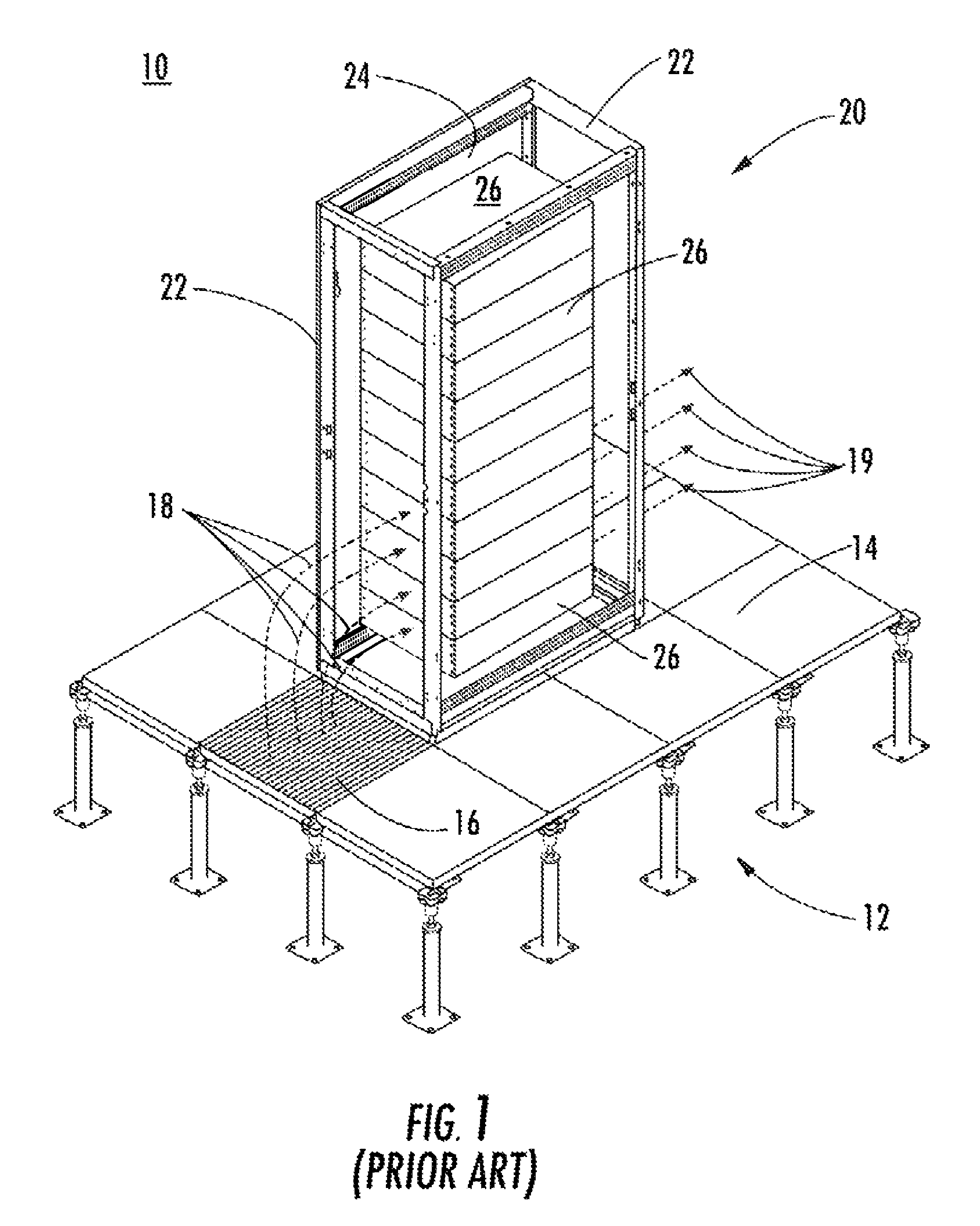

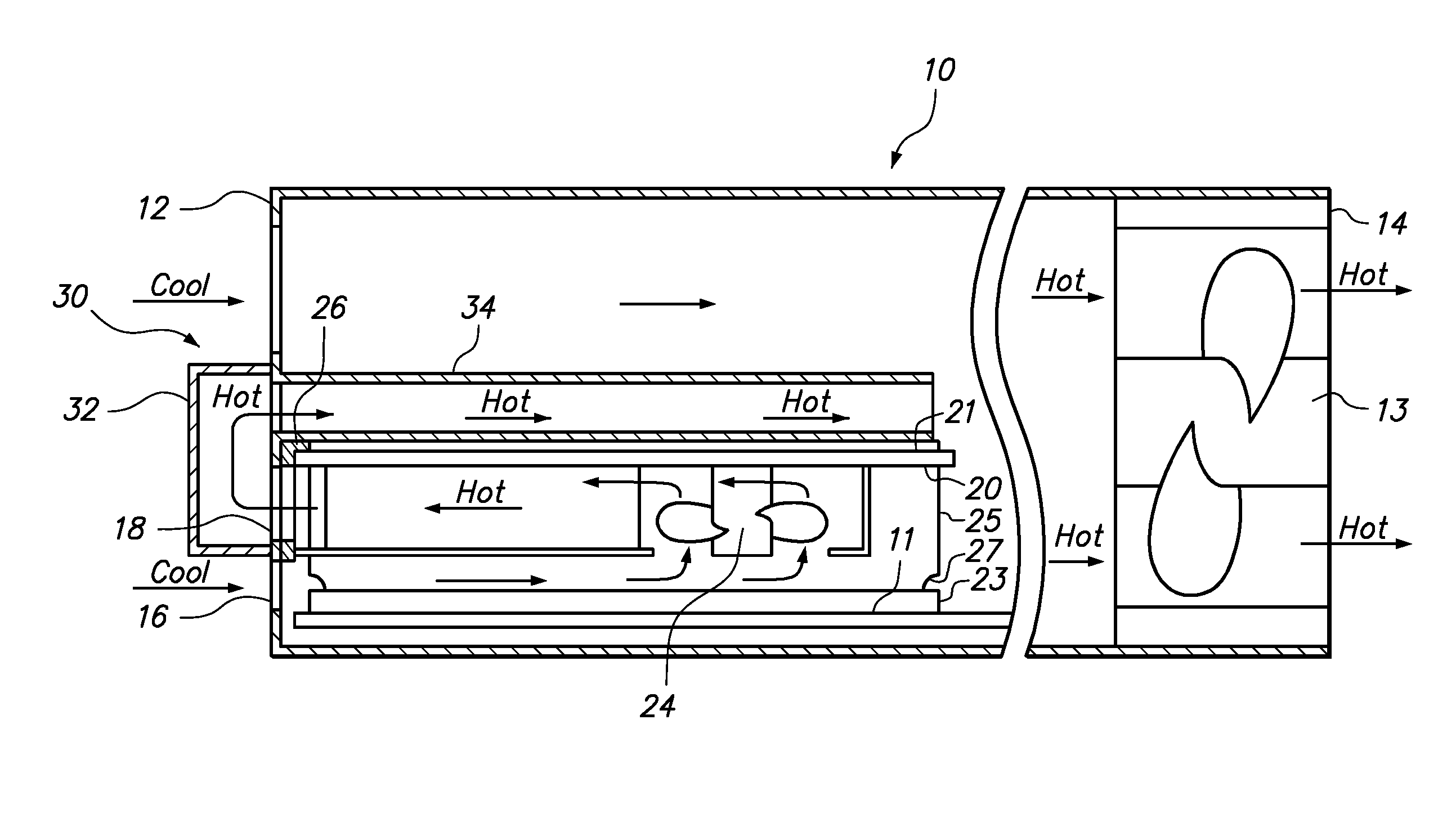

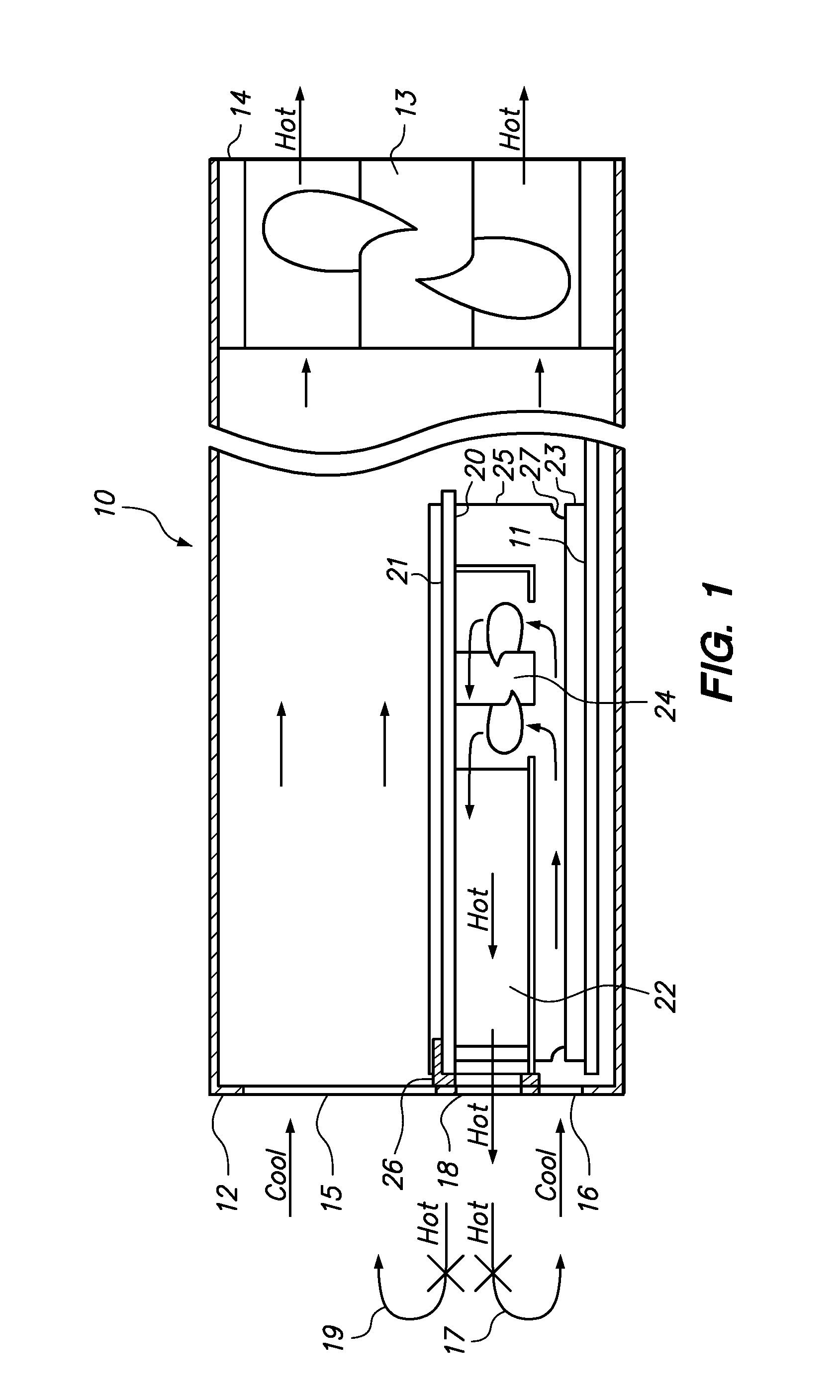

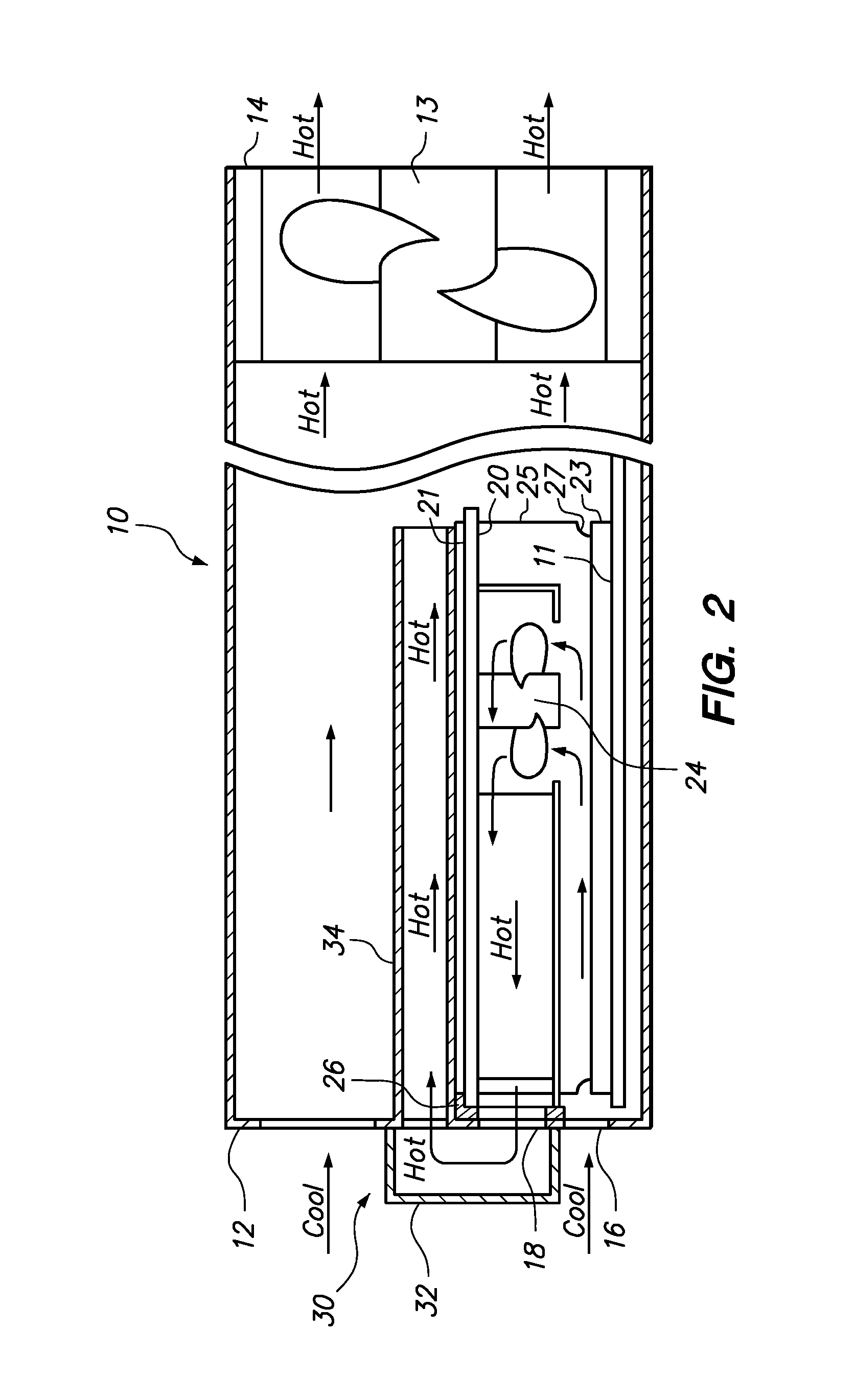

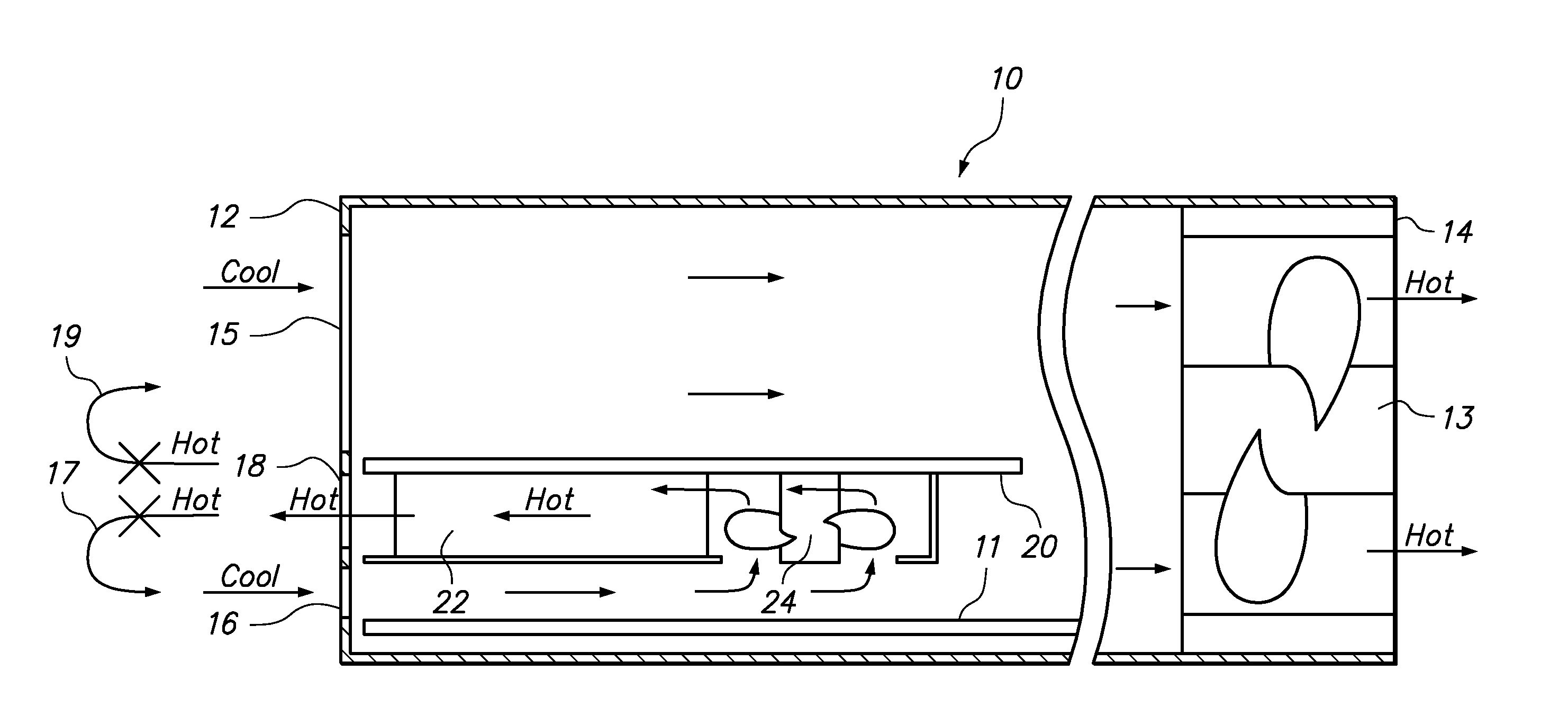

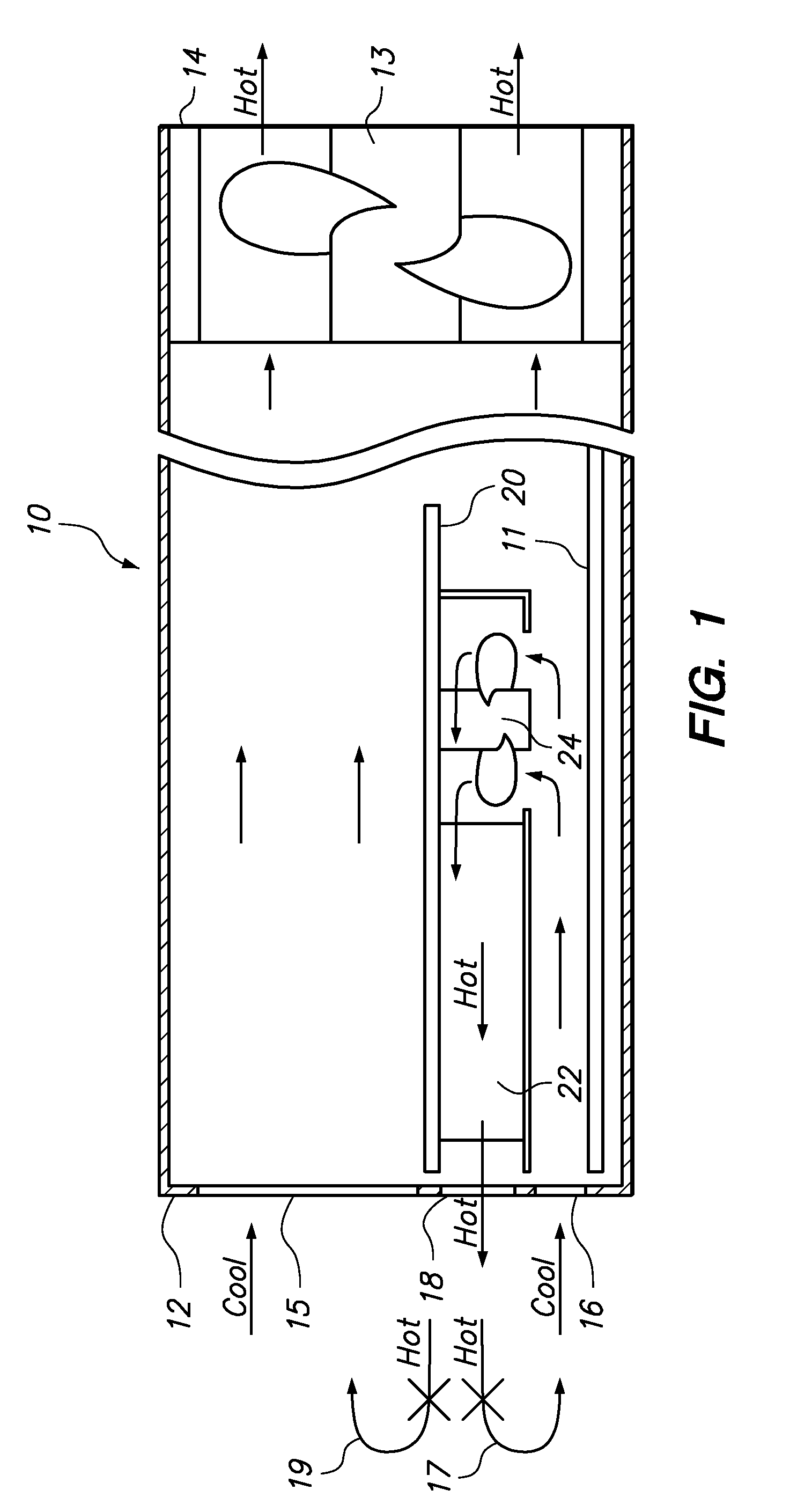

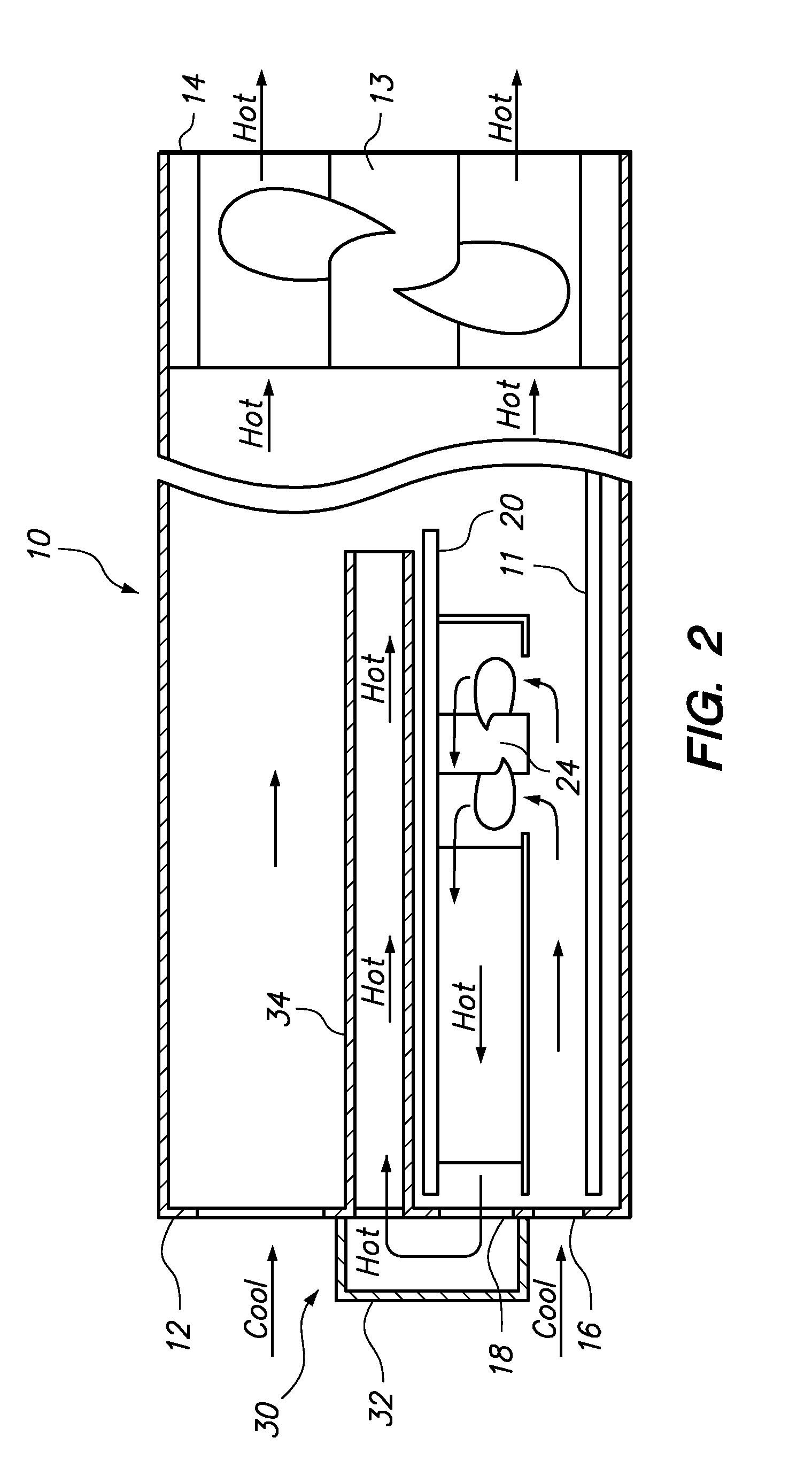

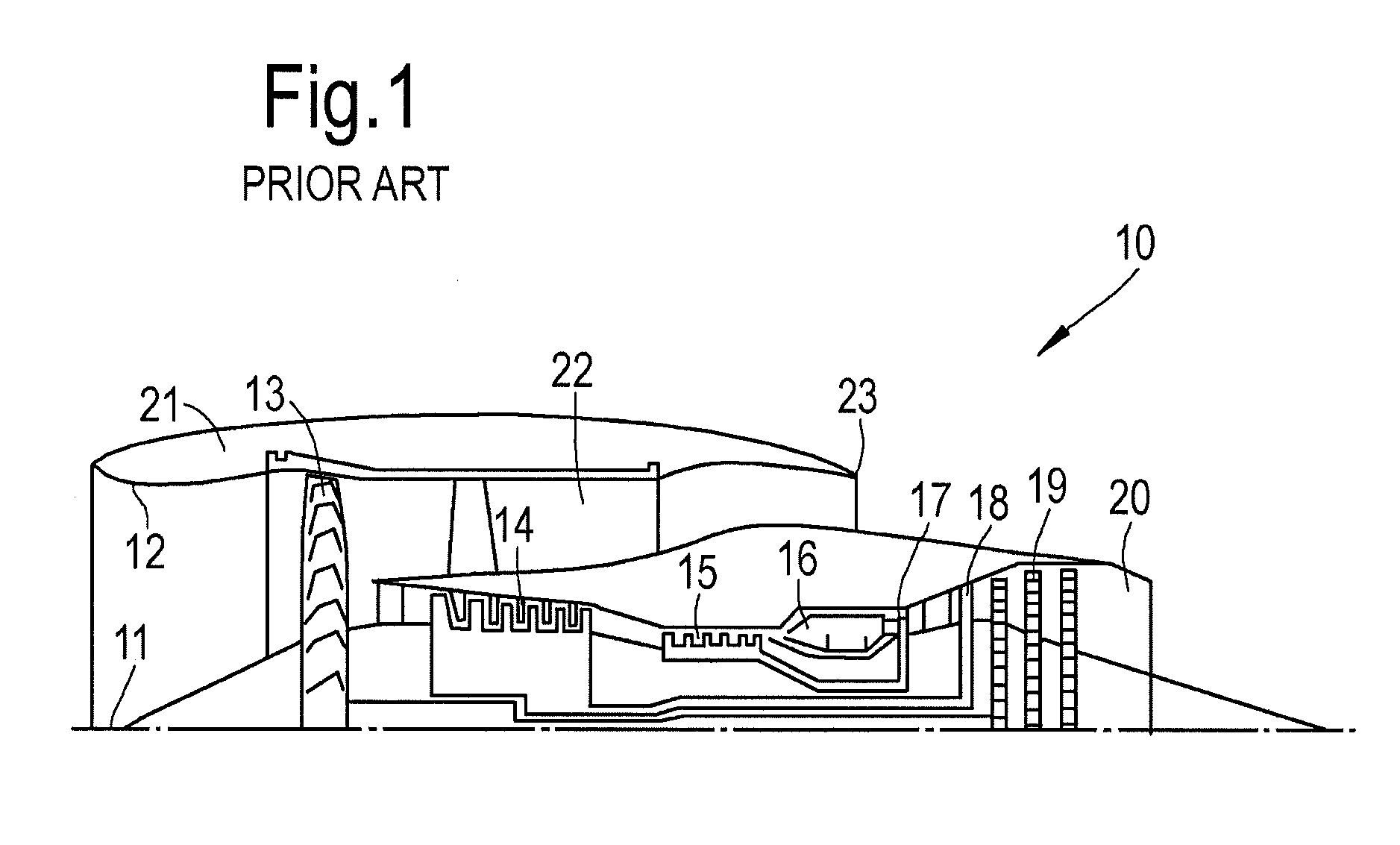

Selectively routing air within an electronic equipment enclosure

InactiveUS20070173189A1Speed up the flowImprove liquidityModifications using gaseous coolantsElectrical apparatus casings/cabinets/drawersEngineeringAir temperature

A method of cooling electronic equipment mounted in an enclosure includes routing air from beneath the enclosure to an upper portion of the enclosure, selectively routing air to electronic equipment mounted in the upper portion of the enclosure, and exhausting heated air from the electronic equipment to an enclosure outlet. In addition, preventing recirculation includes installing and arranging an internal air duct within an enclosure in such a manner that recirculation is prevented, and balancing air temperature around an enclosure includes using an internal air duct.

Owner:CHATSWORTH PROD INC

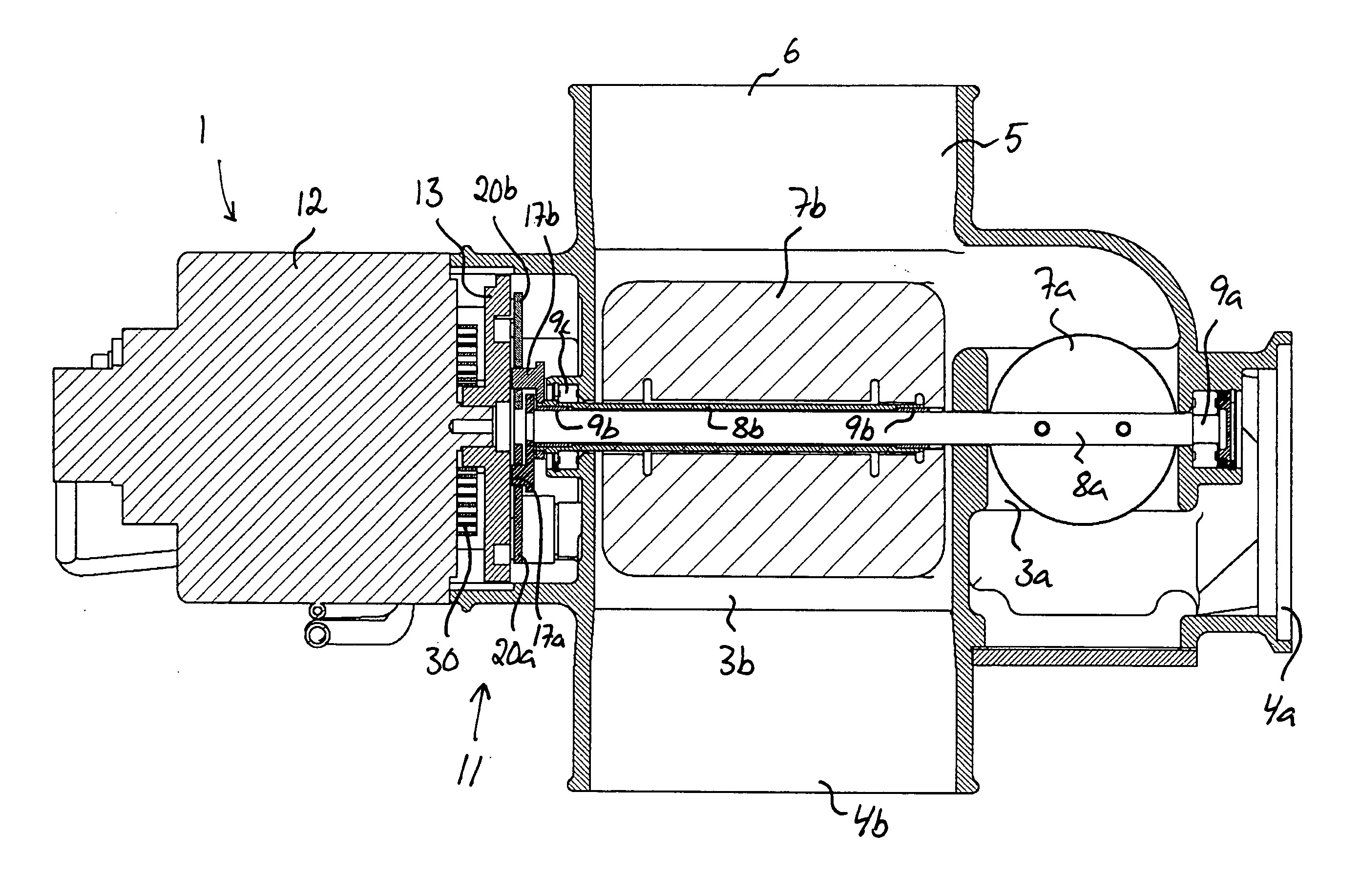

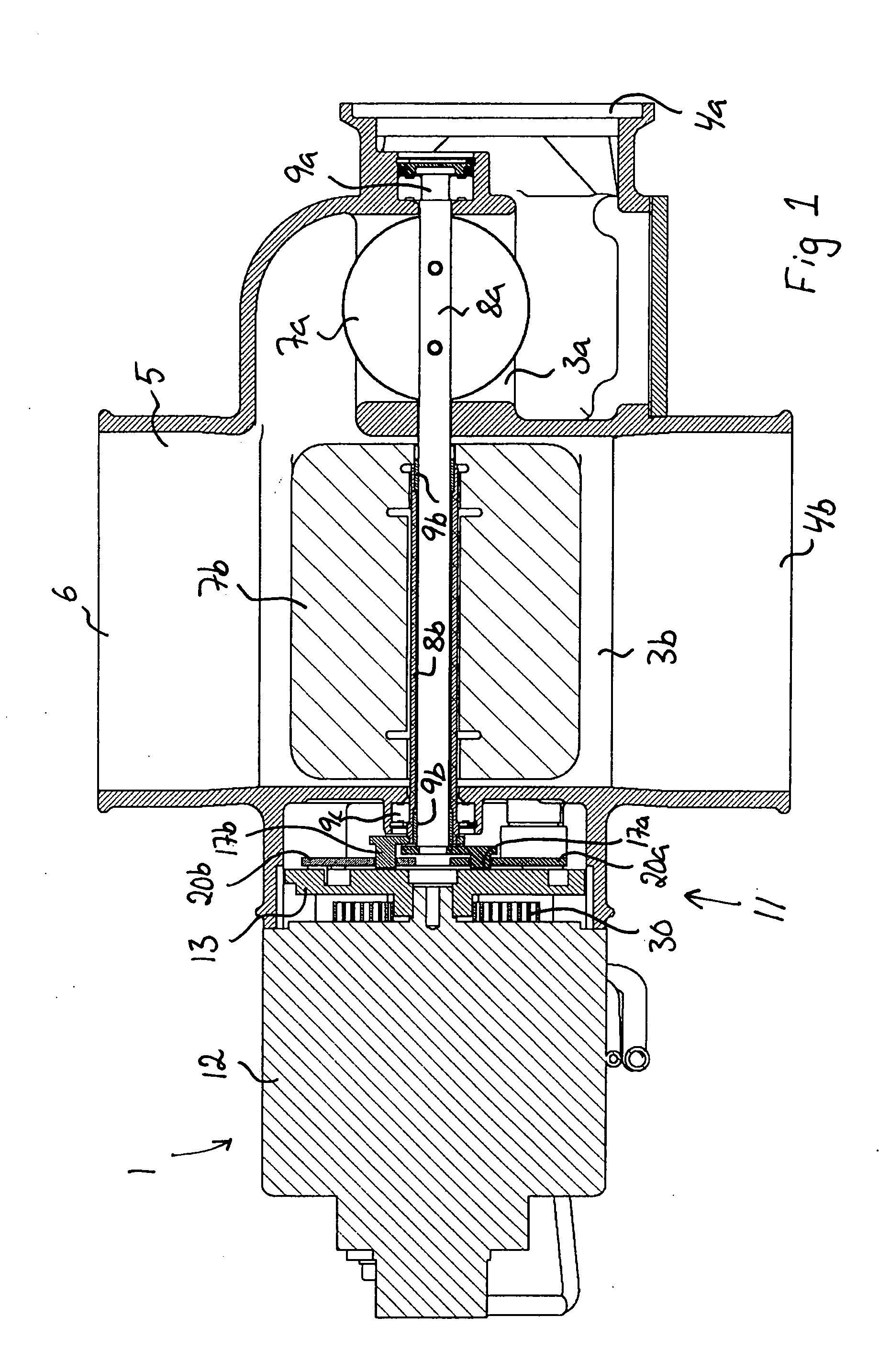

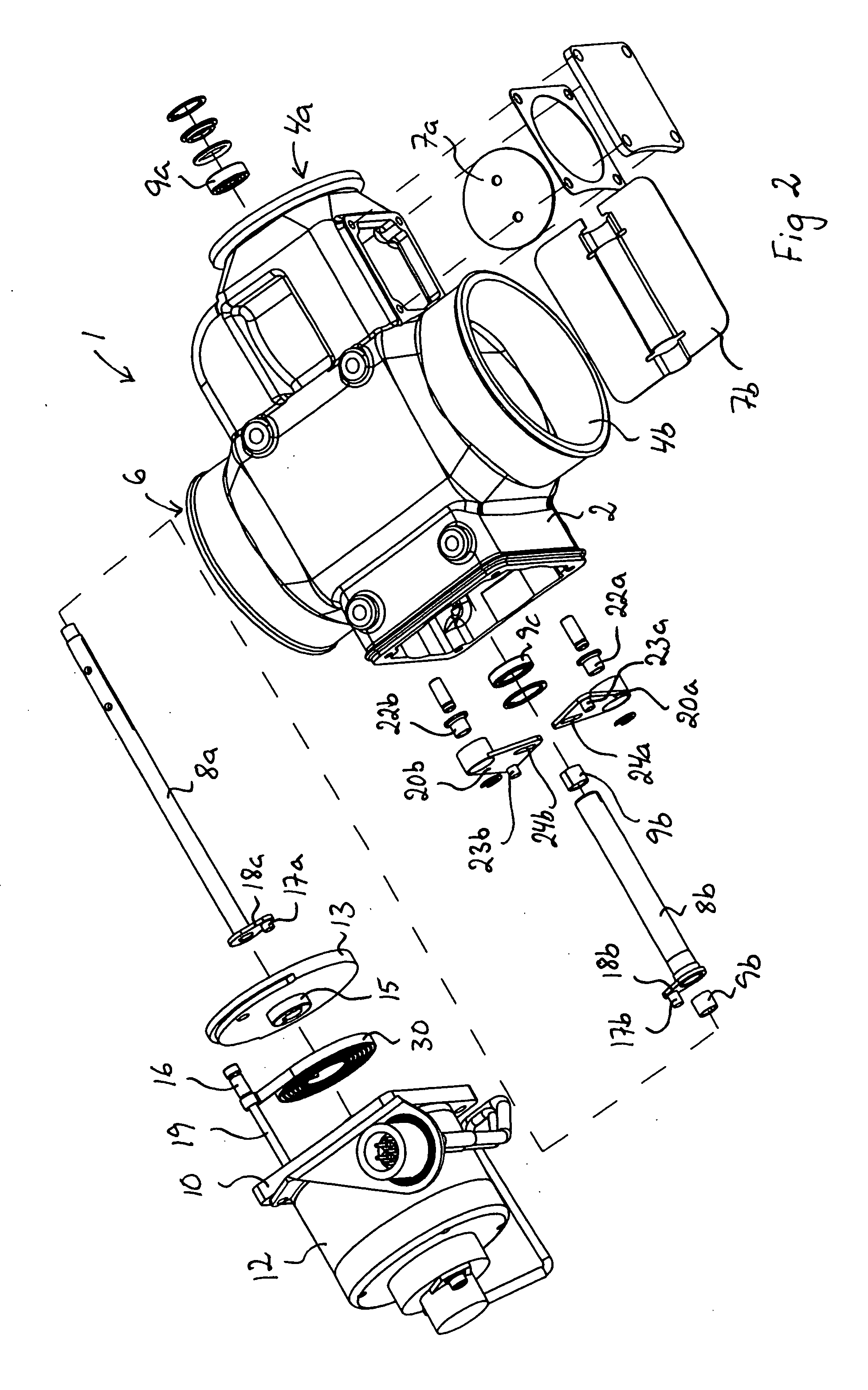

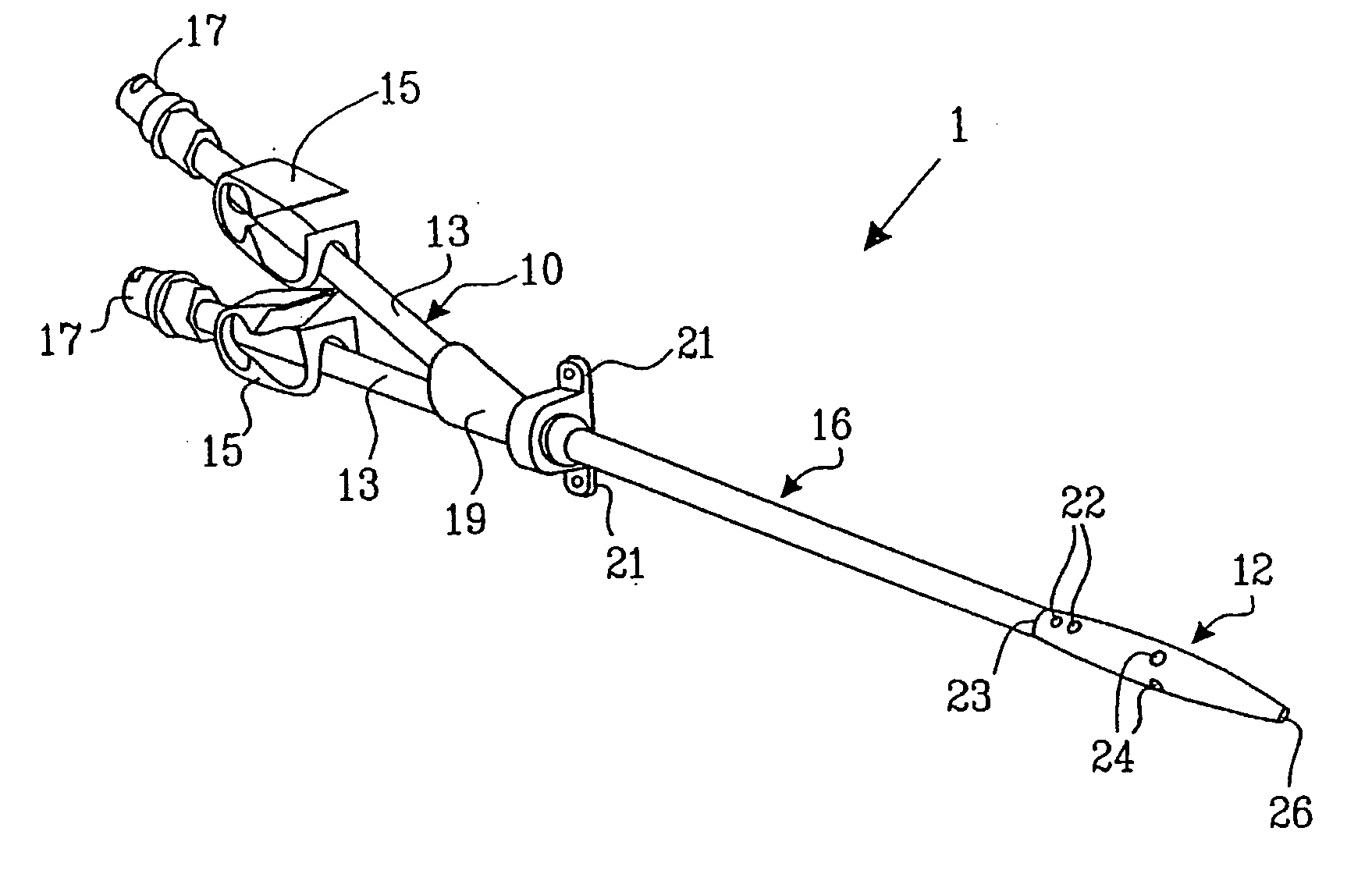

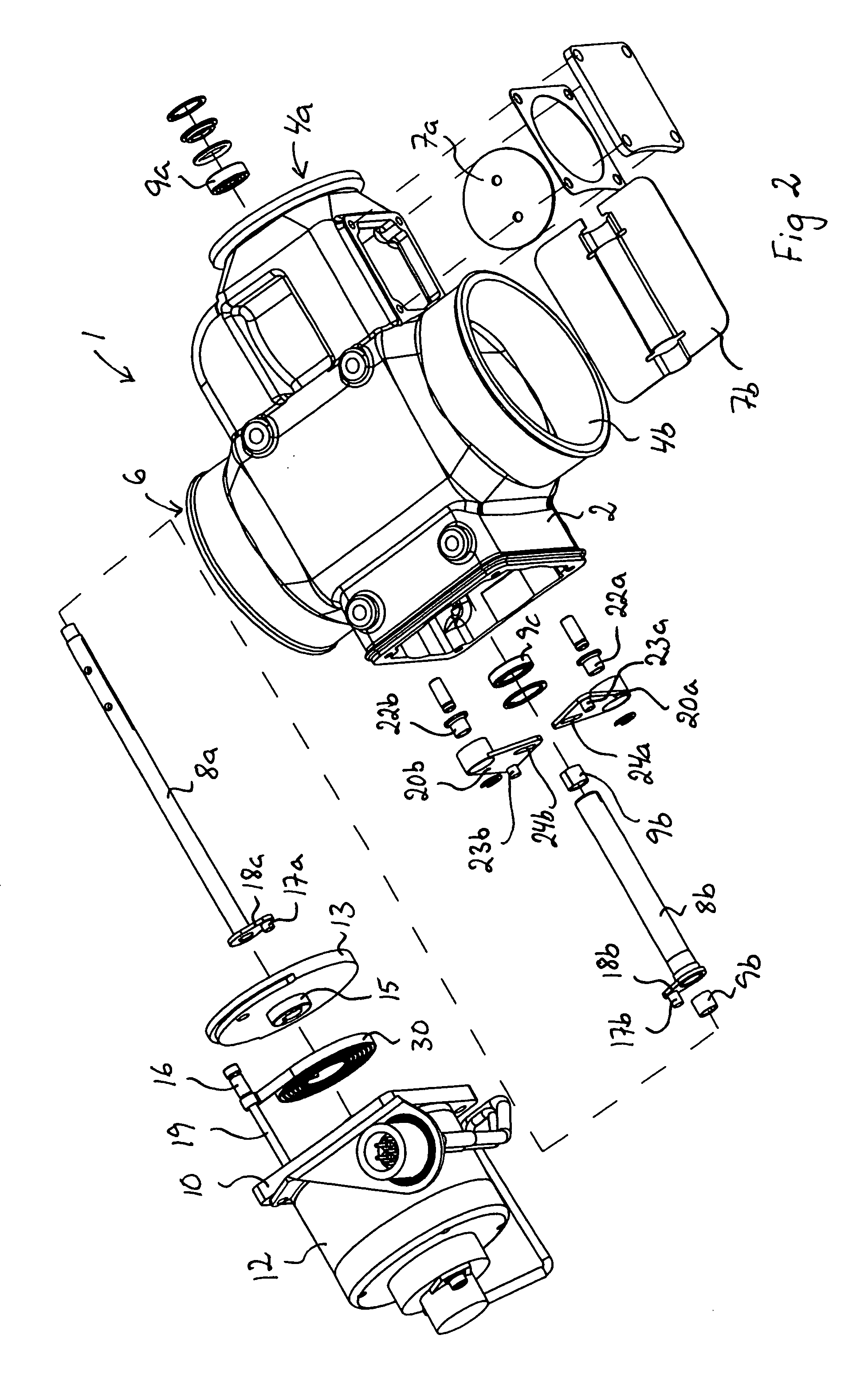

Valve device

InactiveUS20050241702A1Function increaseEasy to adjustInternal combustion piston enginesEngine operationsControl theoryMotion transfer

The invention relates to a valve device comprising a valve housing (2) with a first and a second flow channel (3a, 3b), and a first and second damper shaft (8a, 8b), which are rotatable relative to the valve housing (2). A first damper (7a) is arranged in the first flow channel (3a) fixed to the first damper shaft (8a) and a second damper (7b) is arranged in the second flow channel (3b) fixed to the second damper shaft (8b). A rotatable regulating member (13) is arranged to control the rotational position of the damper shafts (8a, 8b) via two motion transfer members (20a, 20b), the respective motion transfer member (20a, 20b) being in engagement with a guiding (21) of the regulating member (13) so that the rotational position of the motion transfer member and thereby the rotational position of the associated damper shaft (8a, 8b) is controlled by the rotational position of the regulating member via this guiding (21).

Owner:STT EMTEC AB

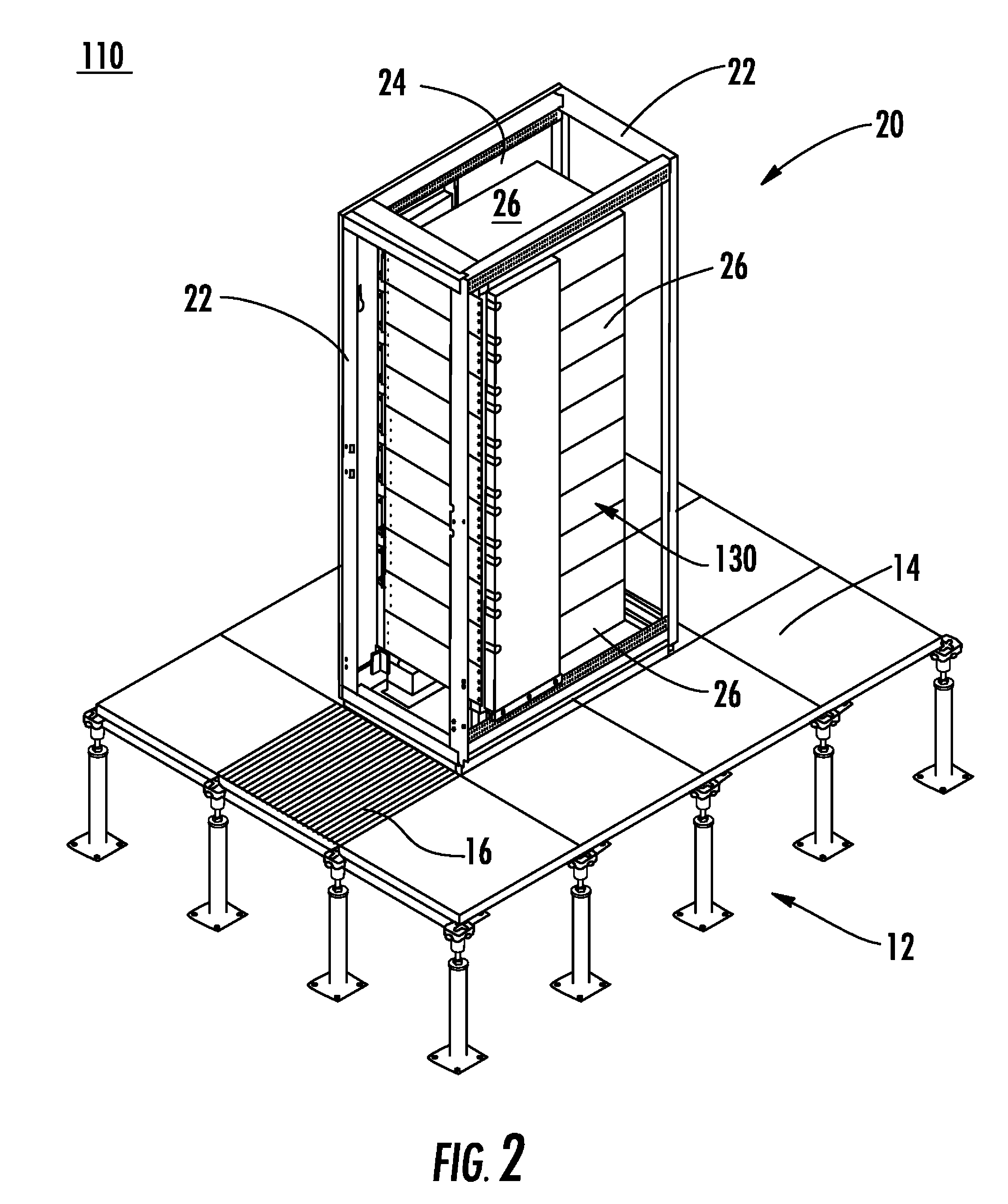

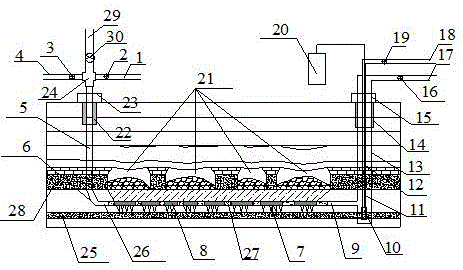

Internal air duct

InactiveUS20070171610A1Avoid recyclingSpeed up the flowDomestic cooling apparatusLighting and heating apparatusEngineeringElectronic equipment

An internal air duct for an electronic equipment enclosure comprises a collector that is adapted to receive cool air and at least one riser that has an interior in fluid communication with an interior of the collector. The riser is adapted to be mounted within an electronic equipment enclosure and has a port for routing the cool air received from the collector to an interior of the enclosure.

Owner:CHATSWORTH PROD INC

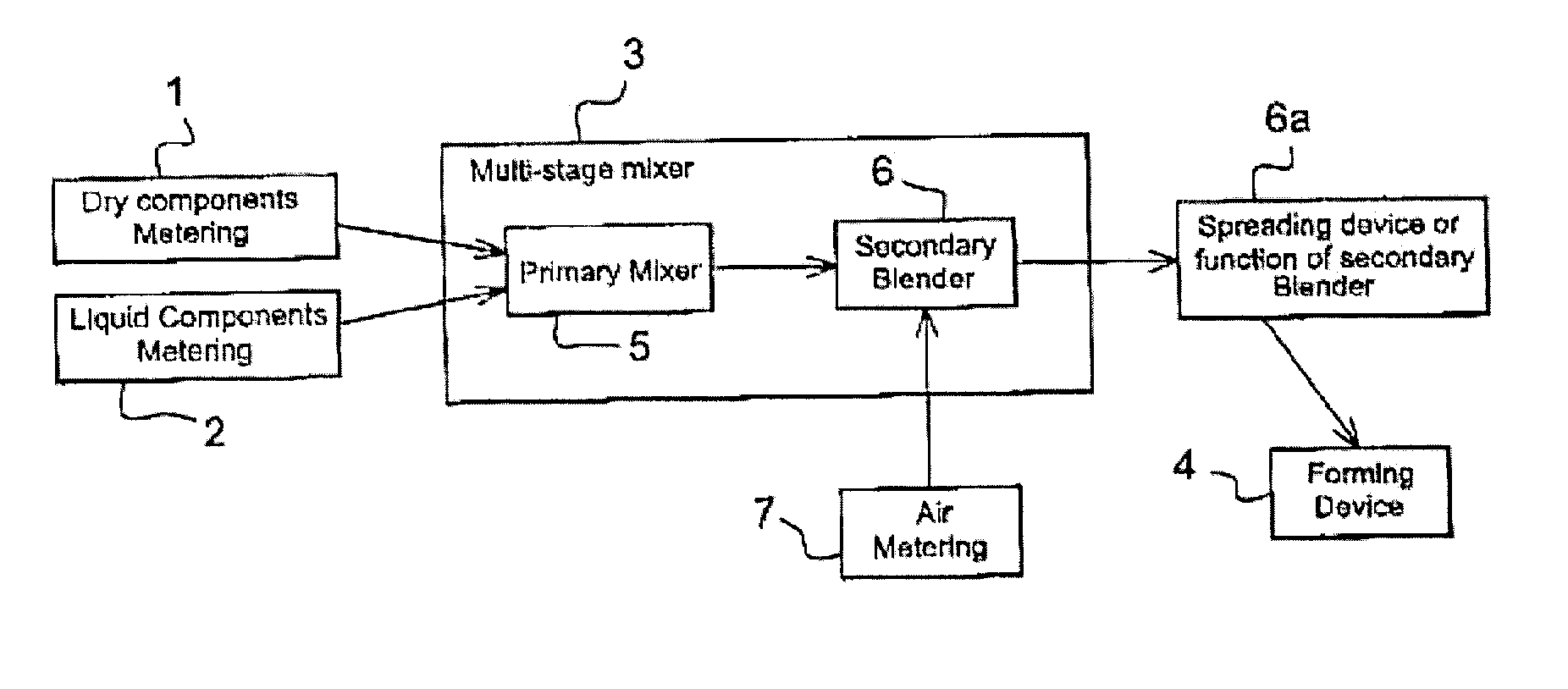

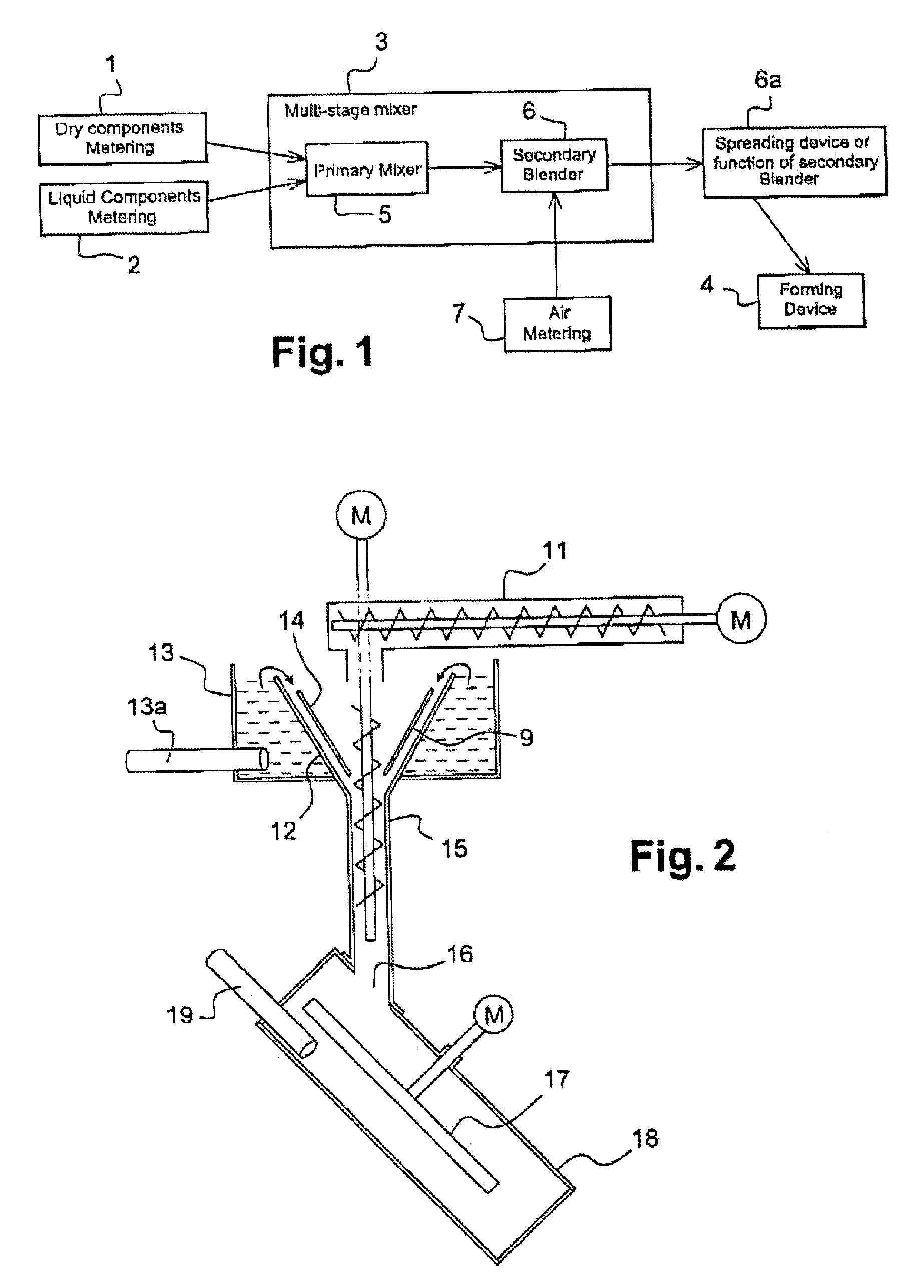

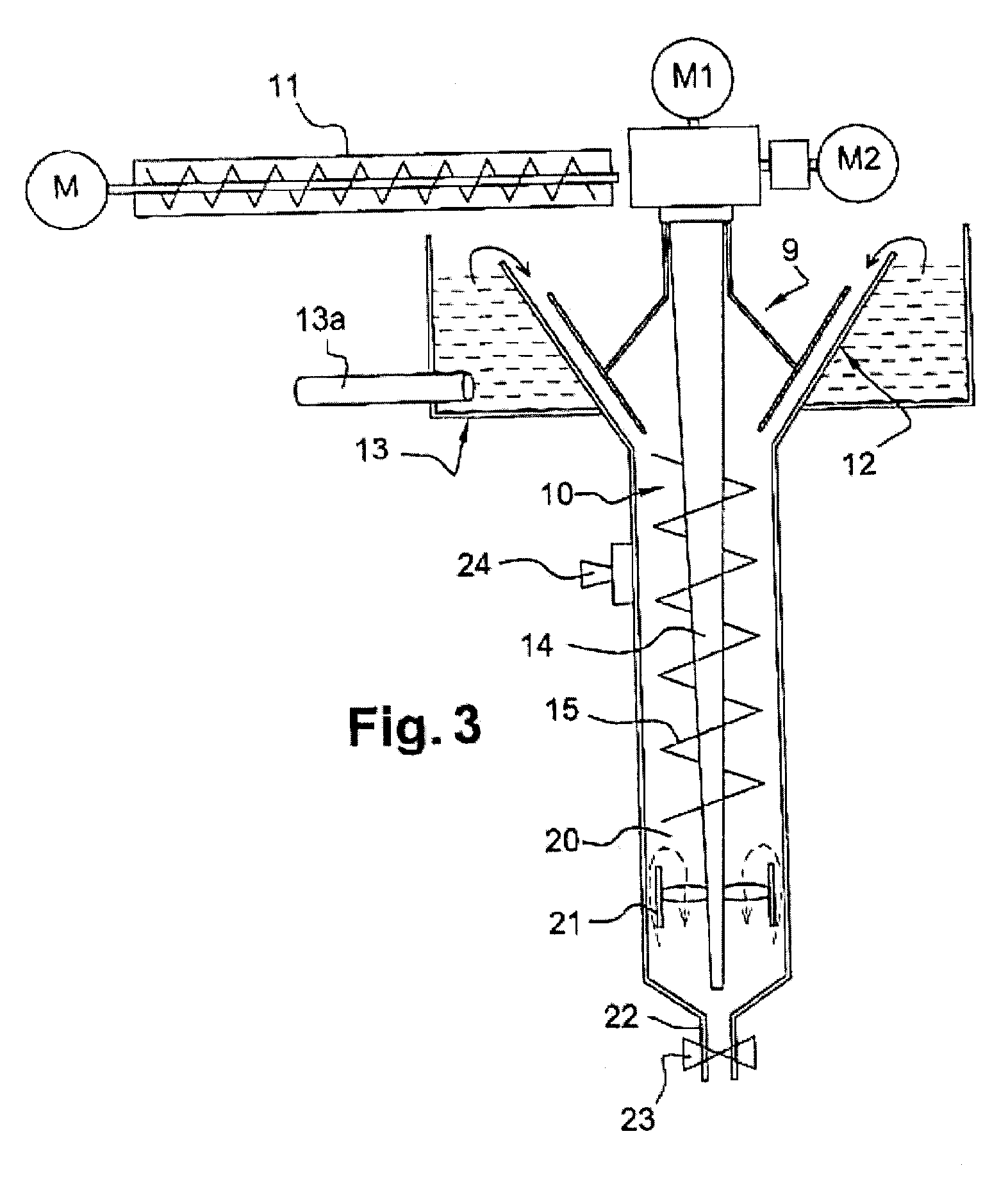

Process And Apparatus For Manufacturing Set Cellular Cement

ActiveUS20050219938A1Less foaming agentLess waterLiquid surface applicatorsTransportation and packagingFoaming agentSlurry

A process for manufacturing set cellular cement, including the steps of: (i) mixing cementitious material, water, foaming agent and optionally additives into a free flowing slurry having a slump of at least 100 mm; subsequently (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently (iii) casting the cellular slurry of step (ii); and finally allowing the cellular slurry to set. And, an apparatus for carrying out the process.

Owner:ETEX BUILDING PERFORMANCE INT SAS

Selectively routing air within an electronic equipment enclosure

InactiveUS8257155B2Speed up the flowImprove liquidityModifications using gaseous coolantsElectrical apparatus casings/cabinets/drawersAir temperatureWaste management

Owner:CHATSWORTH PROD INC

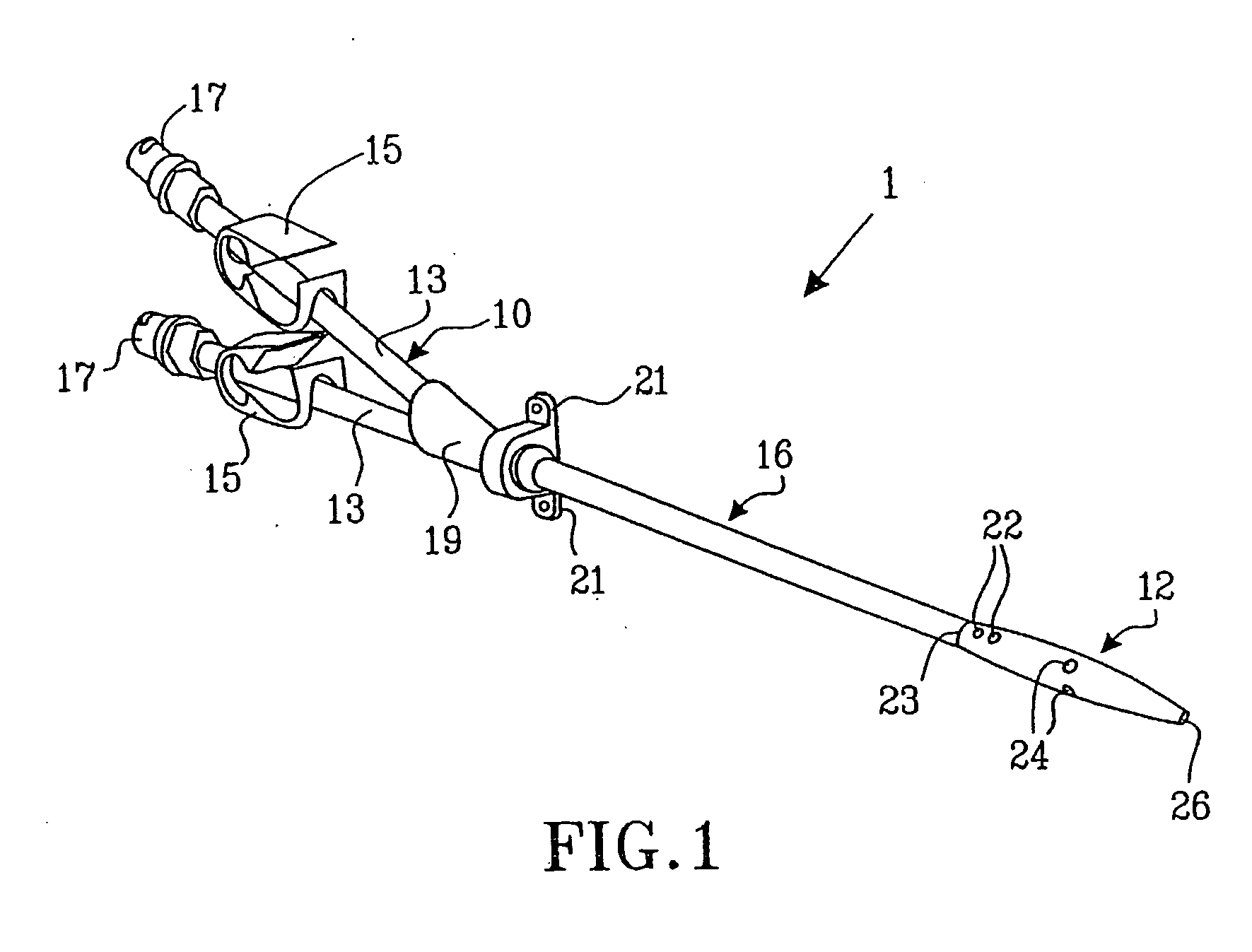

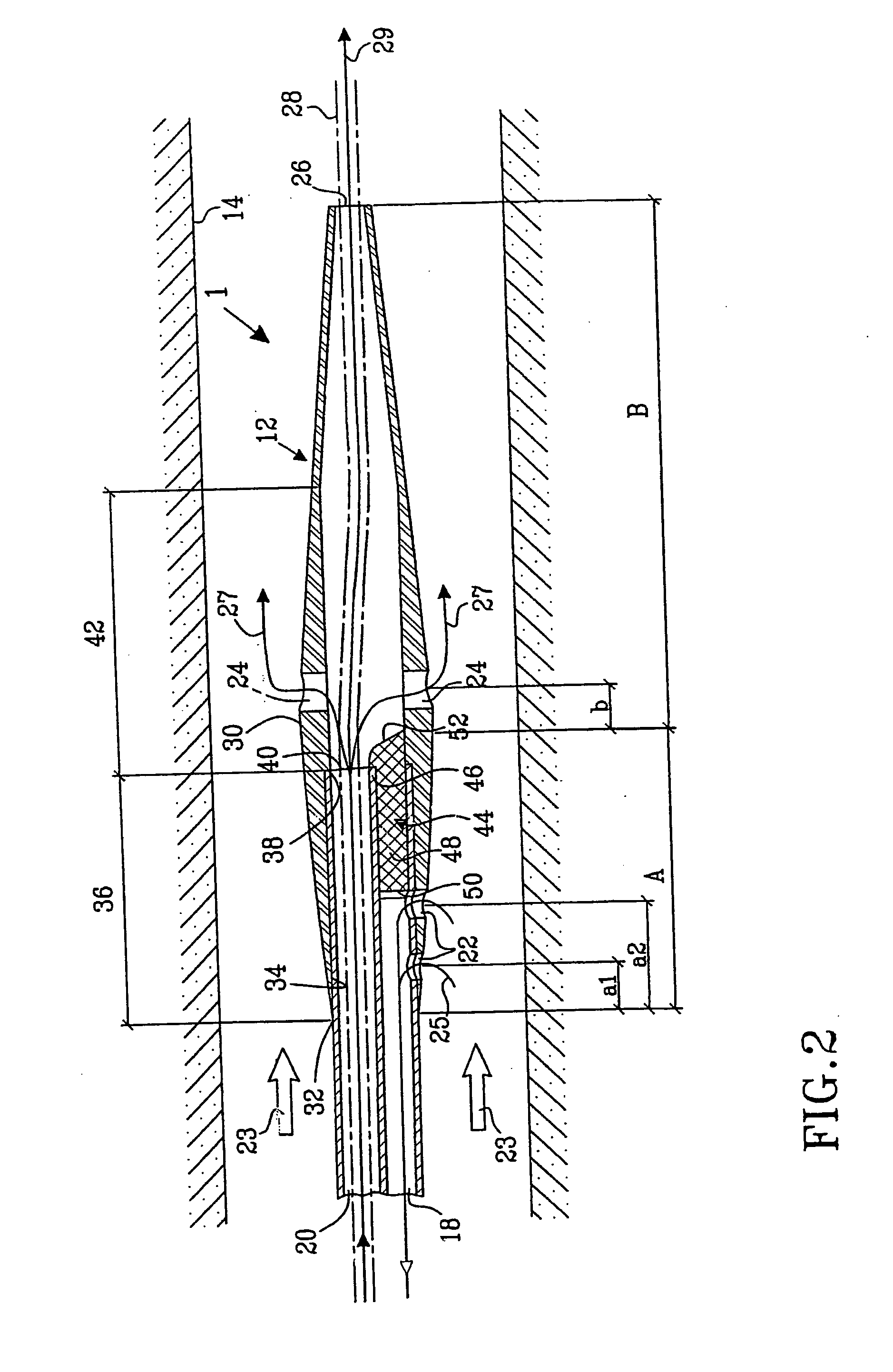

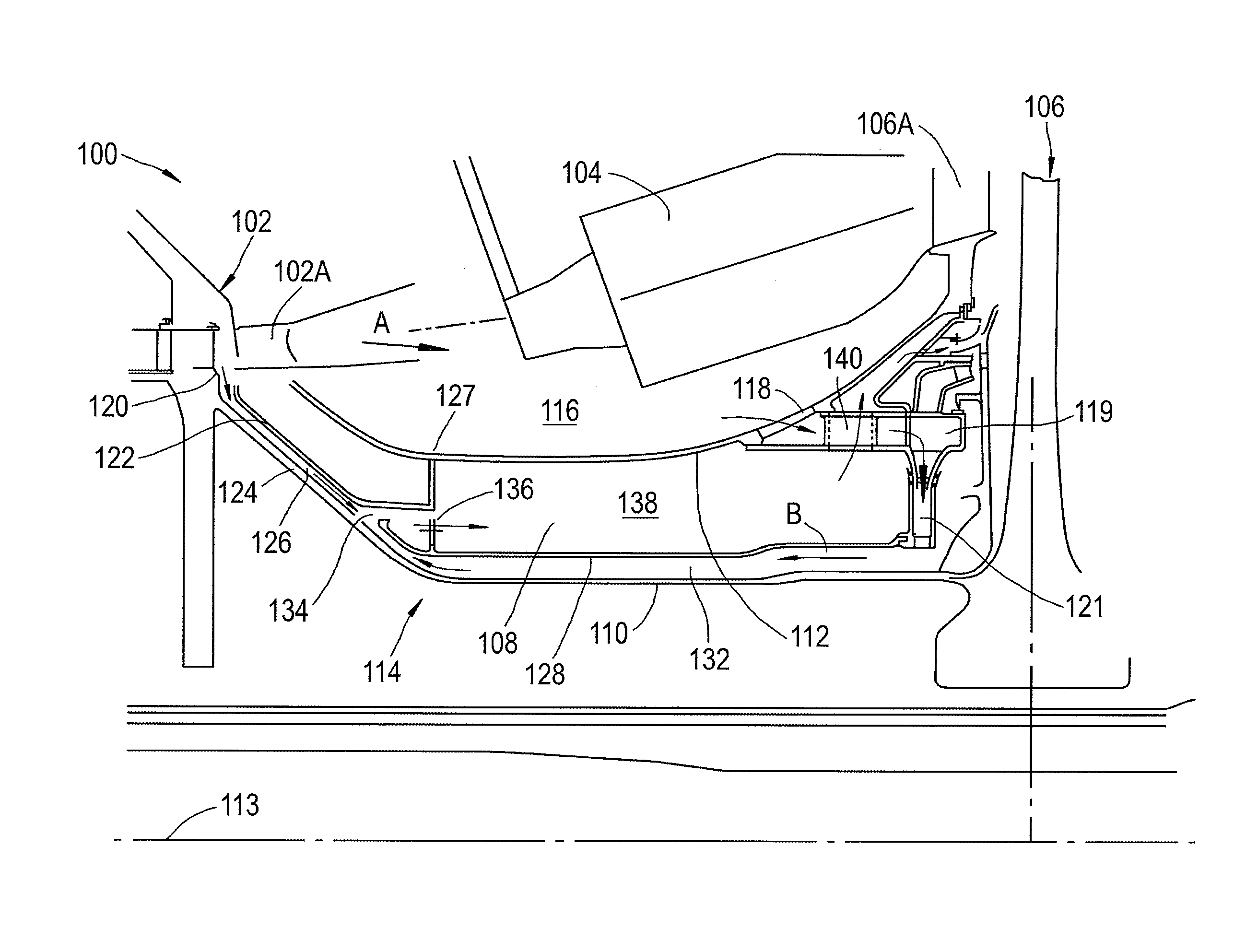

Multi-lumen vascular catheter and method for manufacturing the same

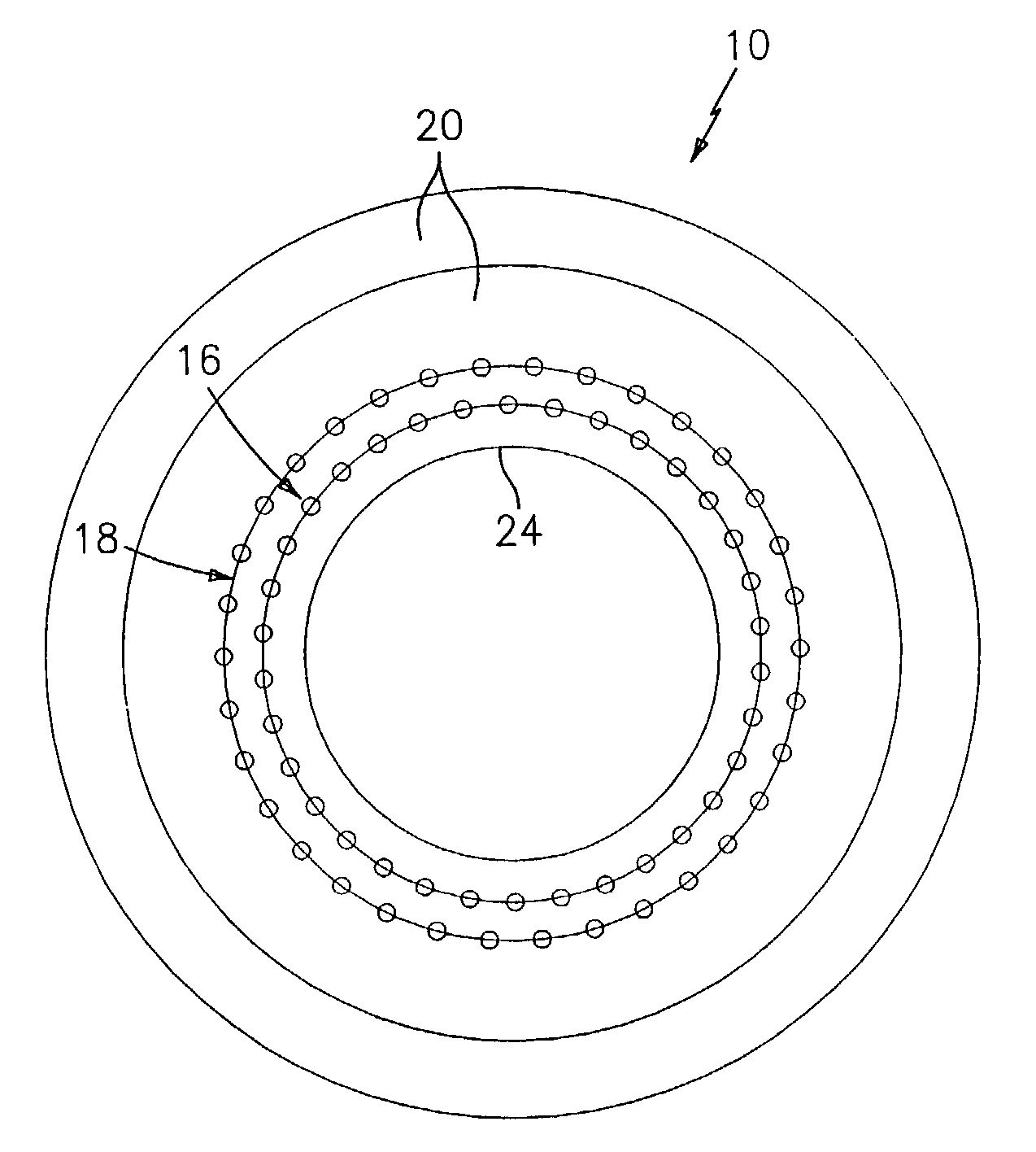

ActiveUS20050288623A1Avoid recyclingMinimize adhesionMulti-lumen catheterMedical syringesVeinVenous blood

A multilumen vascular catheter (1) for treatment of patients by insertion of the vascular catheter in a venous blood vessel (14) by means of a guide-wire (28), the vascular catheter having a proximal connection point (10), a distal end-portion (12) which is terminated within a guide-wire opening (26), and a flexible catheter tube (16) arranged between the proximal connection portion (10) and the distal end-portion (12). The catheter tube (16) has a first lumen (18) for extraction of fluid such as untreated blood from the vessel (1) and a second lumen (20) for introducing fluid such as treated blood to the blood vessel (14). One or more suction openings (22) communicate with the first lumen (18) and are located upstream of one or more outlet openings (24), which in turn communicate with the second lumen (20), the suction openings (22) and the outlet openings (24) being located at the distal end-portion (12). The distal end-portion (12) is permanently bulbous and has a first, widening section (A) starting from the catheter tube (16) with a gradually increasing external cross-section in the direction toward the guide-wire opening (26). The first section (A) transits downstream via a shoulder (30) with a maximum external diameter into a second, narrowing section (B) having a gradually decreasing external cross-section in the direction toward the guide-wire opening (26). One or more of the suction openings (22) are located in the first, widening section (A) of the distal end-portion (12) while one or more of the outlet openings (24) are located in the second, narrowing section (B).

Owner:NORDIC MED COM

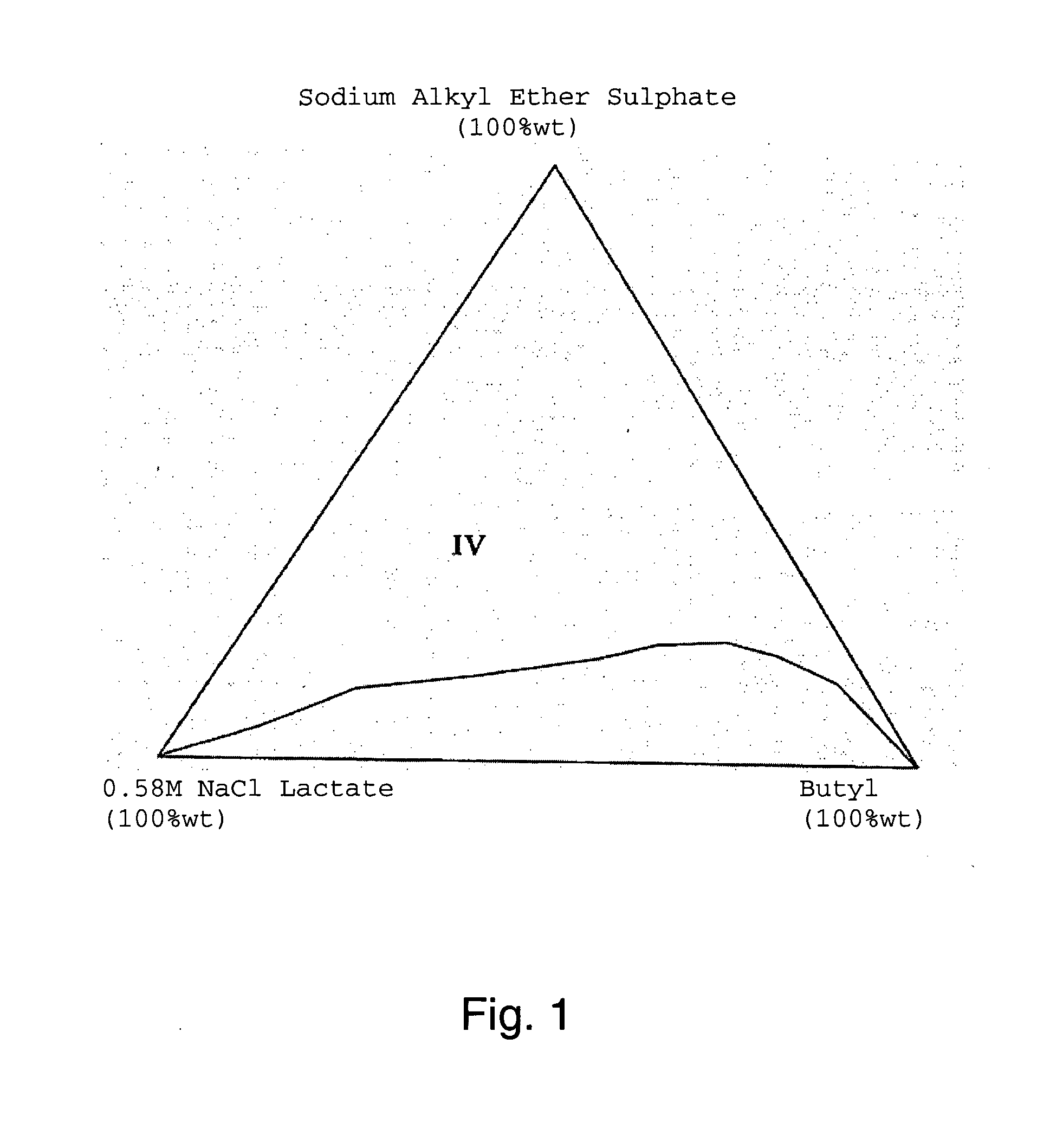

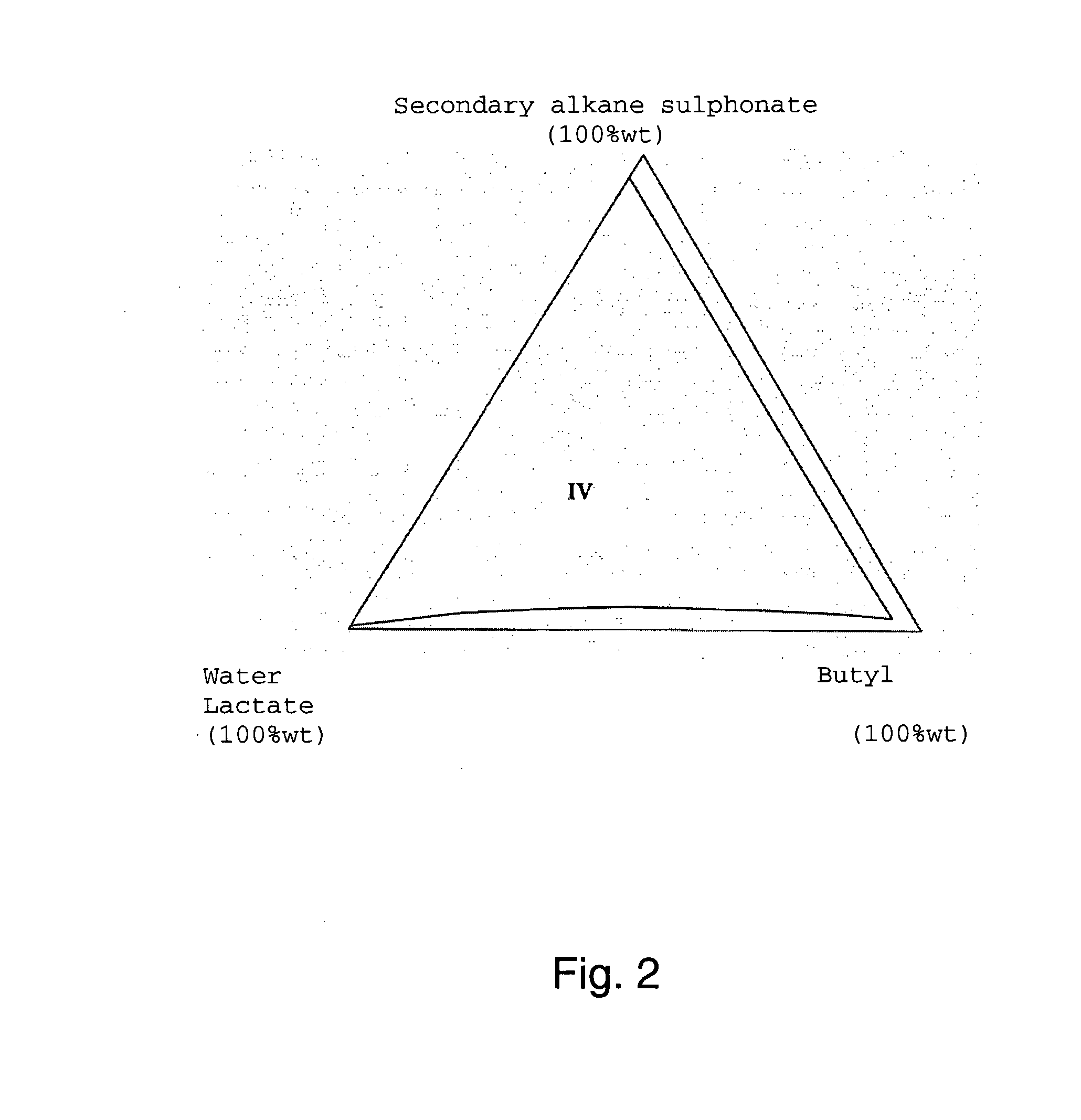

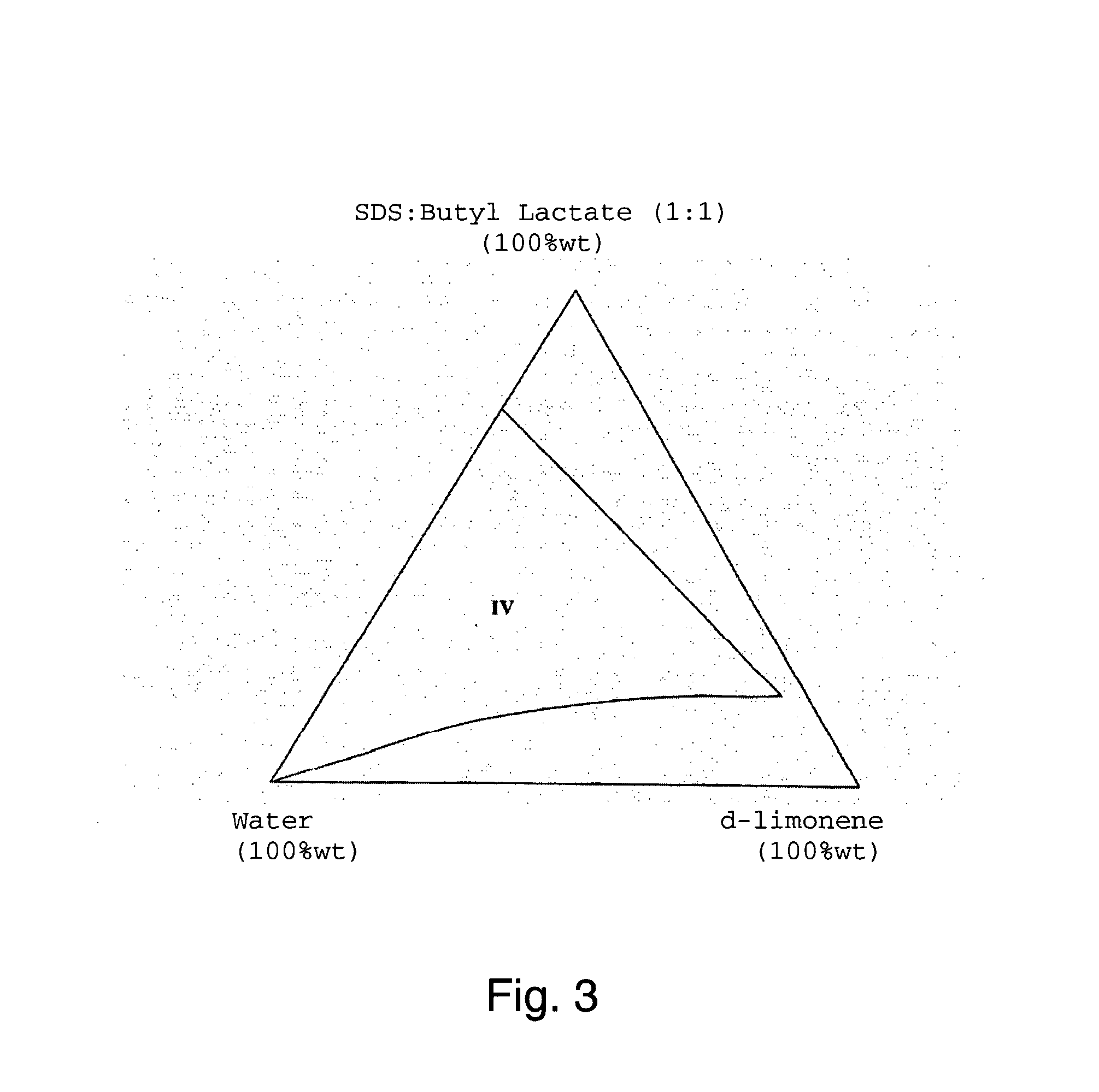

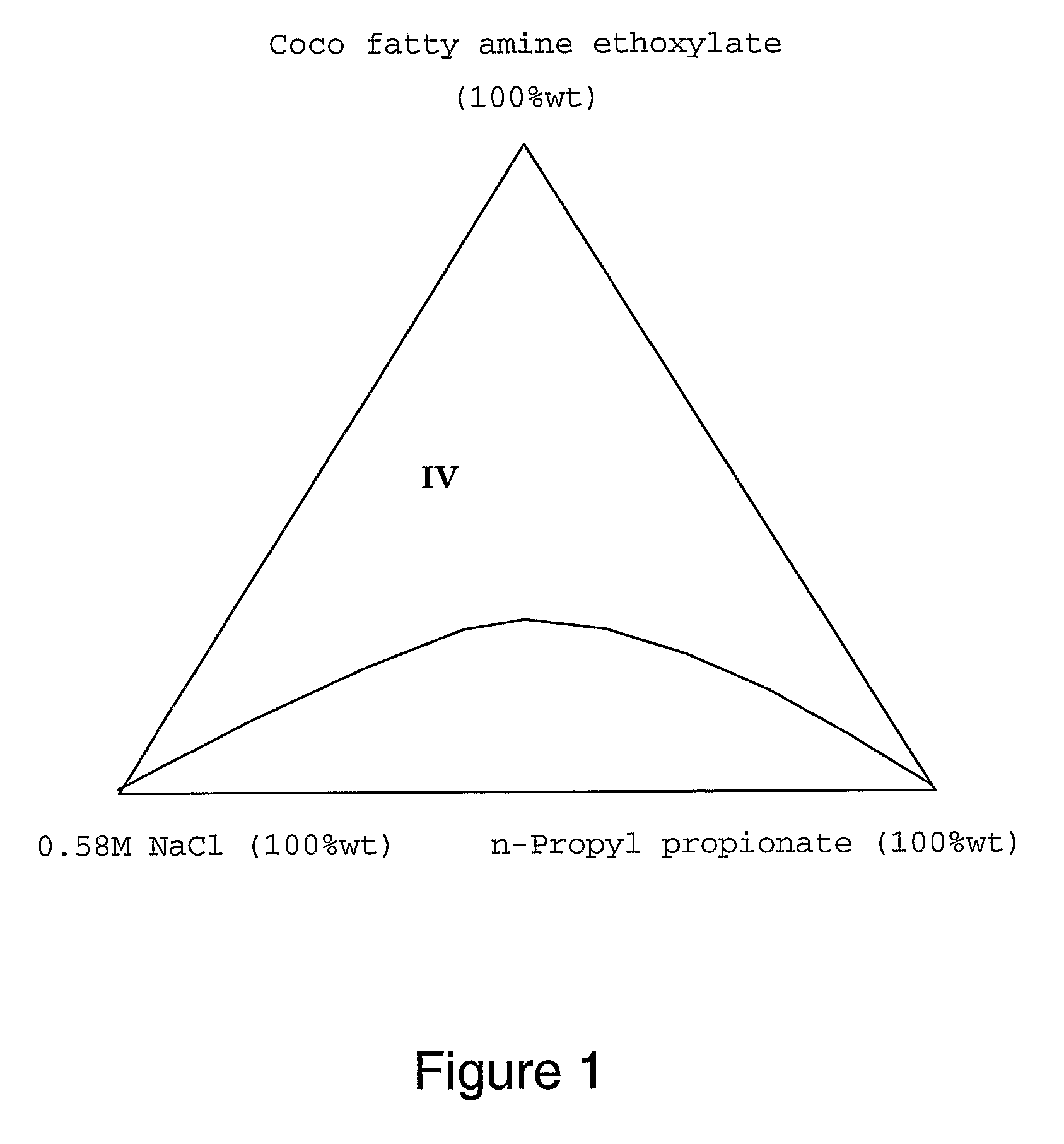

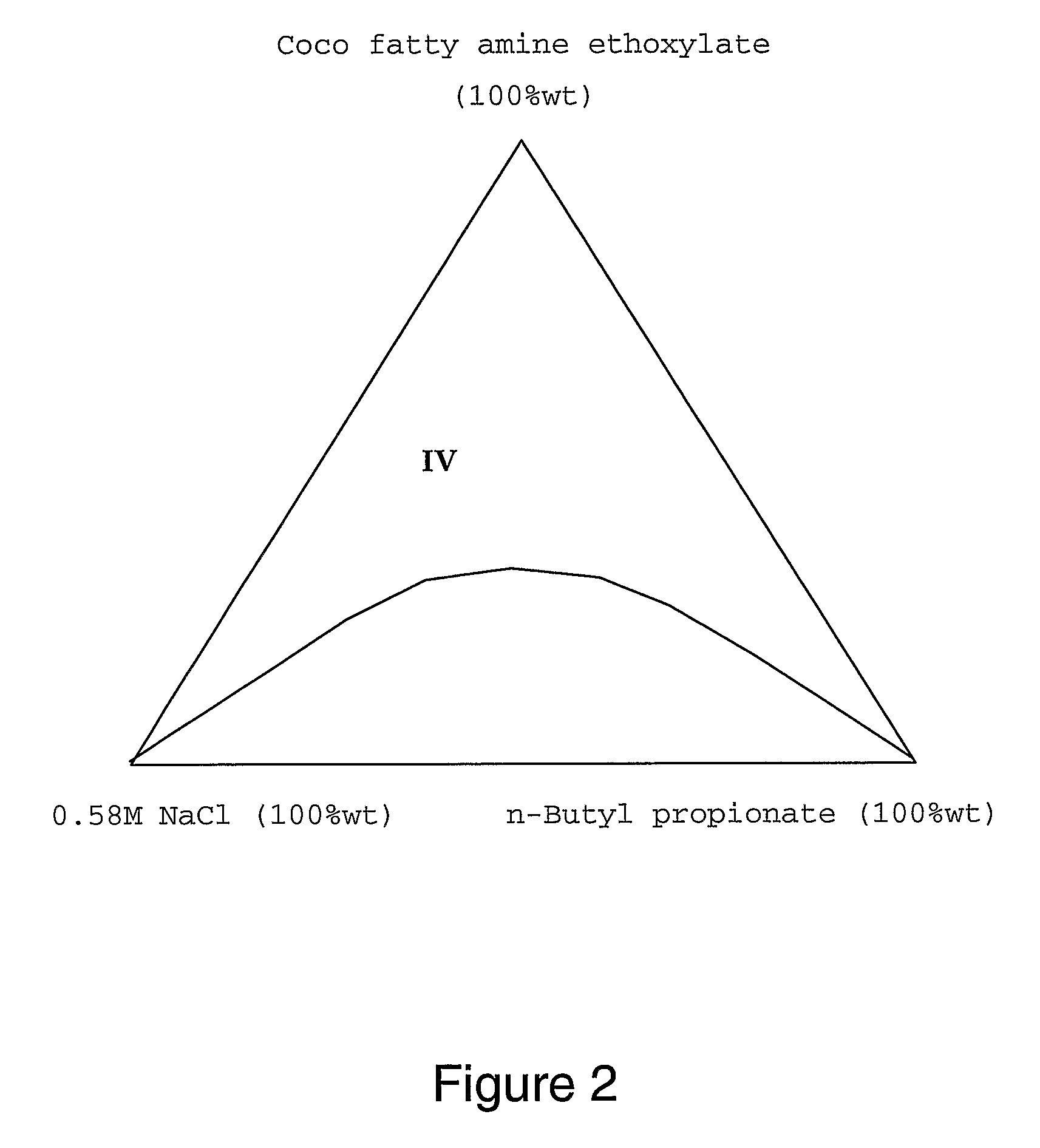

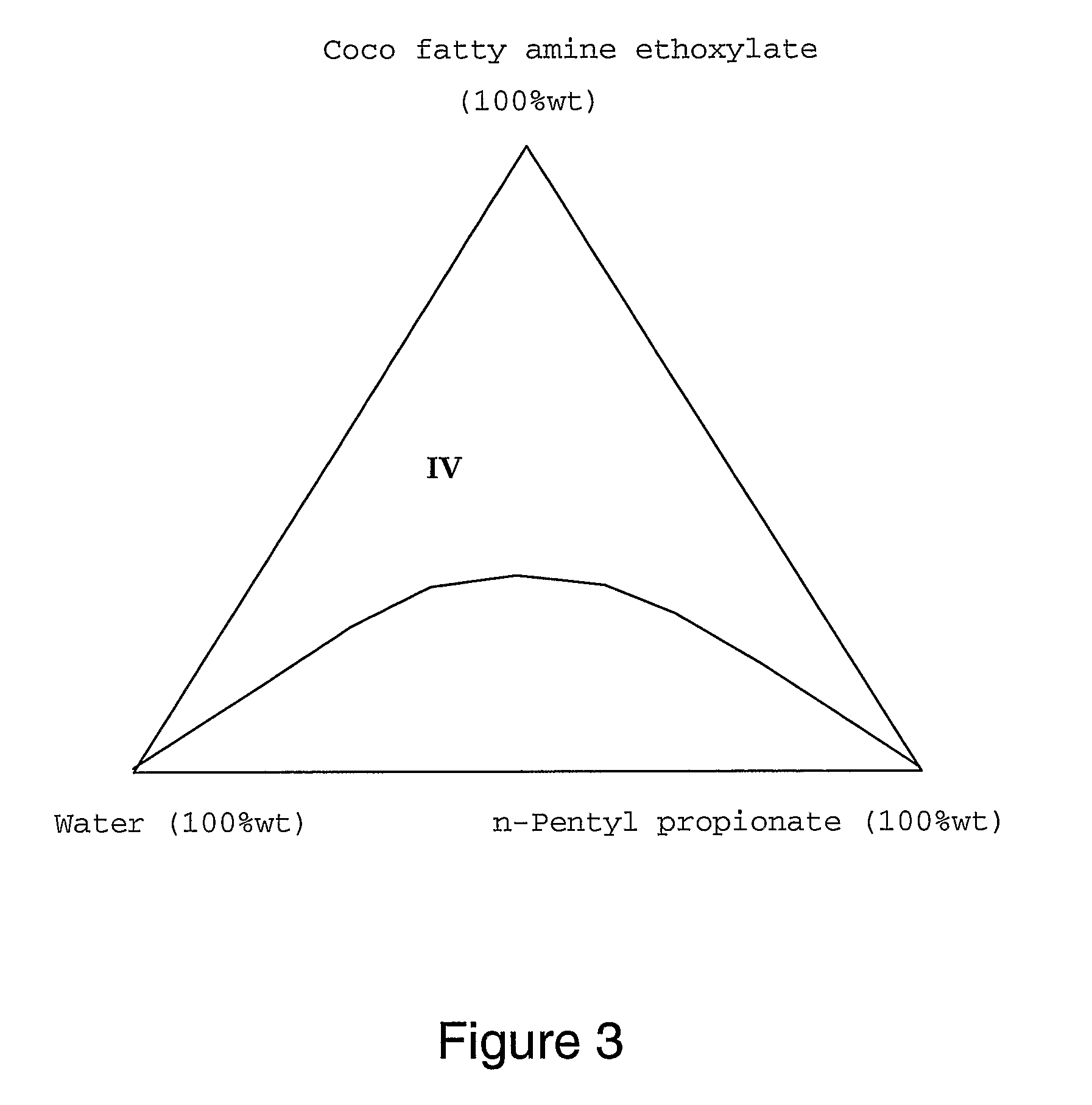

Surfactant System Method

InactiveUS20070295368A1Improve cleaning efficiencyAvoid damageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSurface cleaning

The invention relates to the formulation and application of water based predominantly pH neutral microemulsions and microemulsion forming surfactant systems essentially comprising a surfactant or surfactant˜end, lactates)—esters) of lactic acid—and water / brine and optionally solvent. Uniquely the formulations are acid and caustic free and also do not make use of alcohol, glycol and glycol ether components in the systems as co surfactant, co-solvent or mutual solvent. In particular the invention relates to the methods and the application of this microemulsion technology for use in industrial hard surface cleaning applications especially the inks and printing industries and the oil and gas industry. In addition the formulations can be used in the production of microemulsion based drilling muds (which may or may not be Oil Based Muds—OBMs) and they may be used to enhance the drill cuttings slurrification processes for re-injection purposes or for facilitated cuttings transport.

Owner:SURFACTANT TECH +1

Microemulsion cleaning composition

ActiveUS7902123B2Minimized volumeLow costInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPropionateMicroemulsion

A cleaning composition including which comprises a surfactant and a propionate as co-surfactant and / or co-solvent. The composition can be used, for example, to clean drilling mud containing oils.

Owner:SAS ENVIRONMENTAL SERVICES LTD

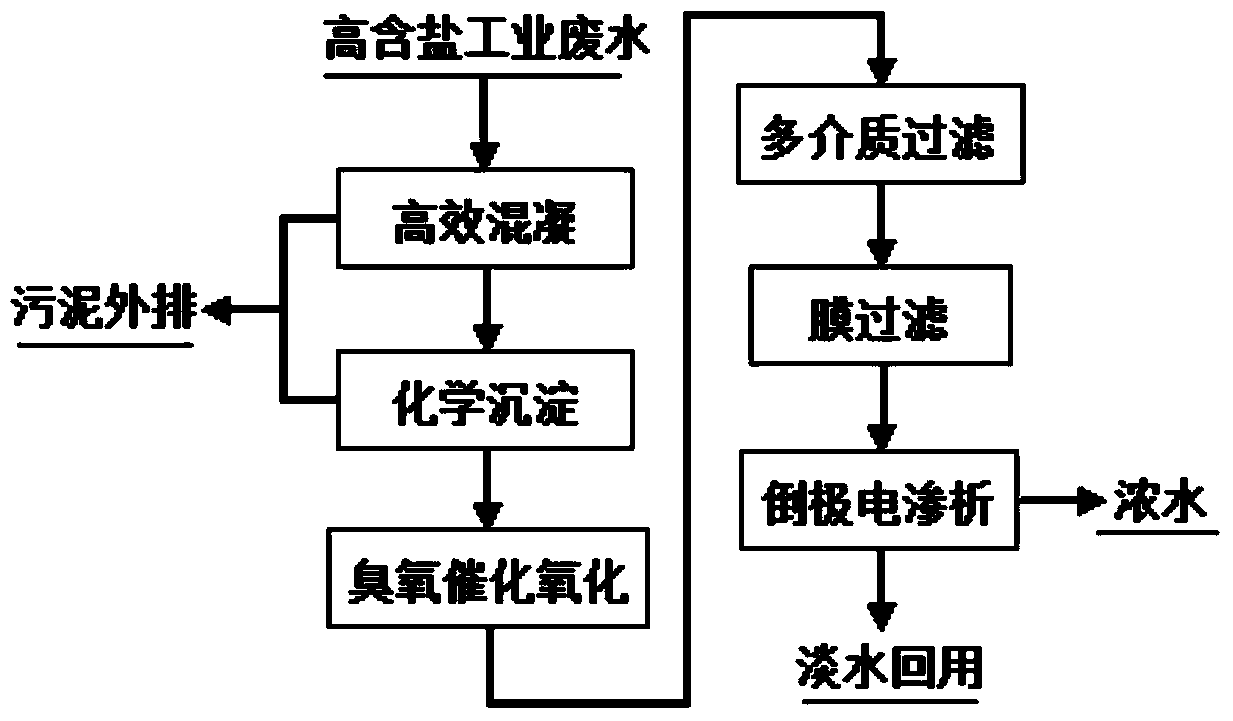

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

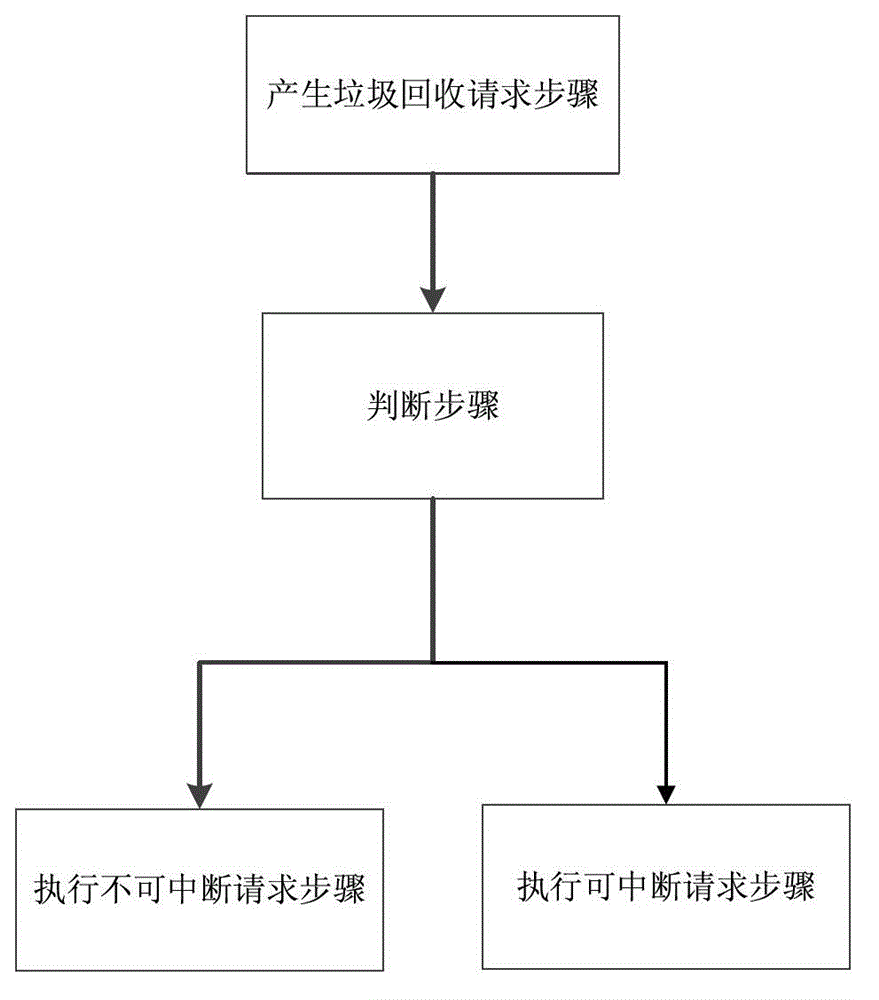

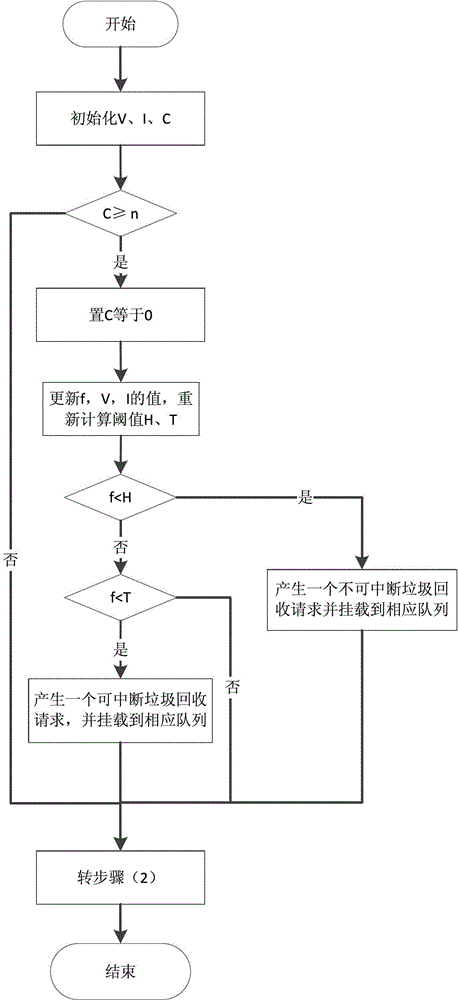

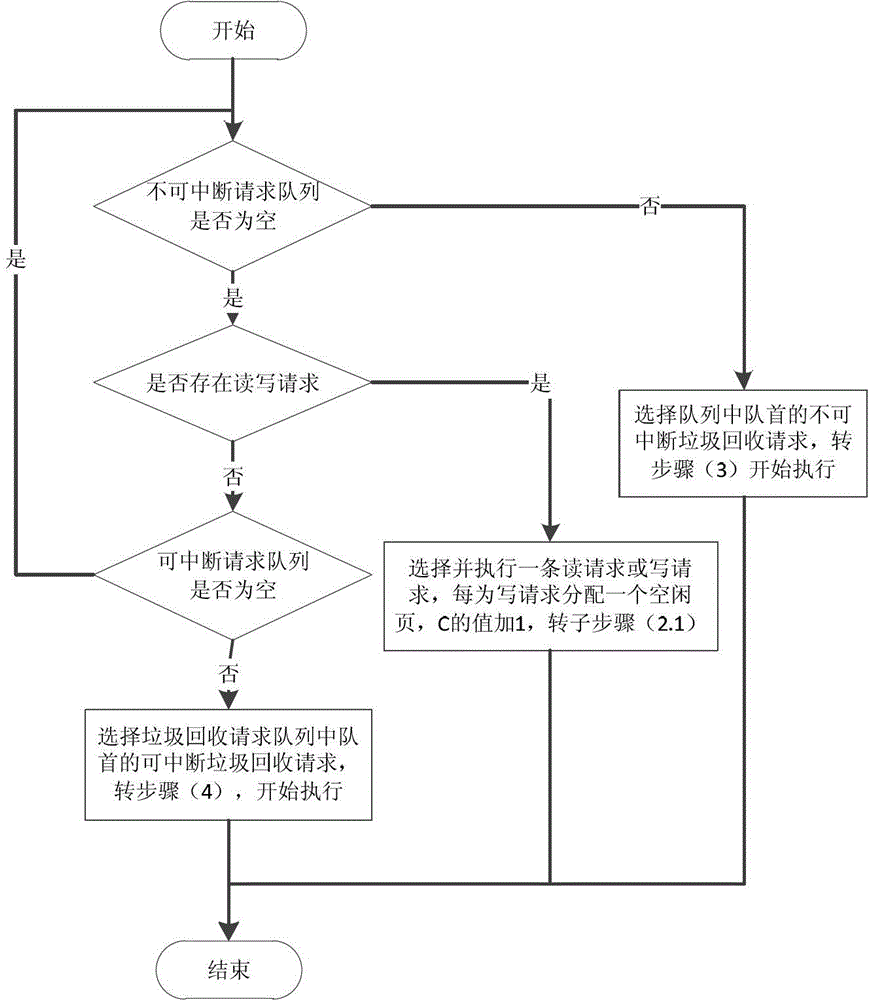

Garbage recovery method for solid-state storage device and system for garbage recovery method

ActiveCN103336744AAvoid recyclingAvoid concentrated outbreaksMemory adressing/allocation/relocationSolid-state storageProcess engineering

The invention relates to a garbage recovery method for a solid-state storage device and a system for the garbage recovery method and belongs to the field of solid-state storage. The garbage recovery method is applicable to the solid-state storage device based on flash memory and is used for solving the problem that the existing garbage recovery method cannot effectively utilize the system idle time to carry out garbage recycling or the garbage recycling consumes a longer time and the reading and writing response delay of a system is increased. The method provided by the invention comprises the steps of generating garbage recovery requests, judging, executing uninterruptible requests and executing interruptible requests. The system provided by the invention comprises corresponding modules. According to the method and the system, the garbage recovery requests are divided into interruptible garbage recovery requests and uninterruptible garbage recovery requests, an interruptible garbage recovery step and an uninterruptible garbage recovery step are respectively called through dynamically adjusting a garbage recovery trigger threshold, the garbage recovery is carried out by making full use of the idle time of the solid-state storage device, and meanwhile, unnecessary garbage recovery is avoided; and the reading / writing performance loss caused by the garbage recovery is reduced effectively under the condition that garbage recovery efficiency is not affected.

Owner:HUAZHONG UNIV OF SCI & TECH

Water polymer integument and method for preparing integument controlled-release fertilizer thereof

InactiveCN101182269AImprove water resistanceImprove targetingFertiliser formsFertilizer mixturesWater basedChemical industry

The invention discloses a water-based polymer coated film and a preparation method of a film-coated controlled release fertilizer thereof, which belongs to the agricultural controlled release fertilizer preparation technical field and relates to using a novel water-emulsion type polymer. The polymer film-coated controlled release fertilizer is coating a layer of novel degradable latex polymer film layer on the surface of granular fertilizer. The granular fertilizer with the diameter of 2 to 5mm is packed inside a film coating device of a rotating drum or a fluidized bed, and the granular fertilizer flows inside the film coating device to be heated to 80 DEG C to 100 DEG C. Organic matter is sprayed on the surface of the granular fertilizer, then complex polymer latex is sprayed on the facial surface of the organic matter film layer of the granular fertilizer to be dried continuously, the water of the film layer is removed by complete drying, and the polymer latex film-coated controlled release fertilizer is obtained. The invention conquers the problem that organic solvent leaks to cause the environmental pollution during the process of the production and avoids the problems of solvent recycling; the manufacturing process is easy for realizing the large scale chemical industry production; the investment cost is low; the production cost is reduced greatly.

Owner:吉林省沃野生态环境治理有限公司

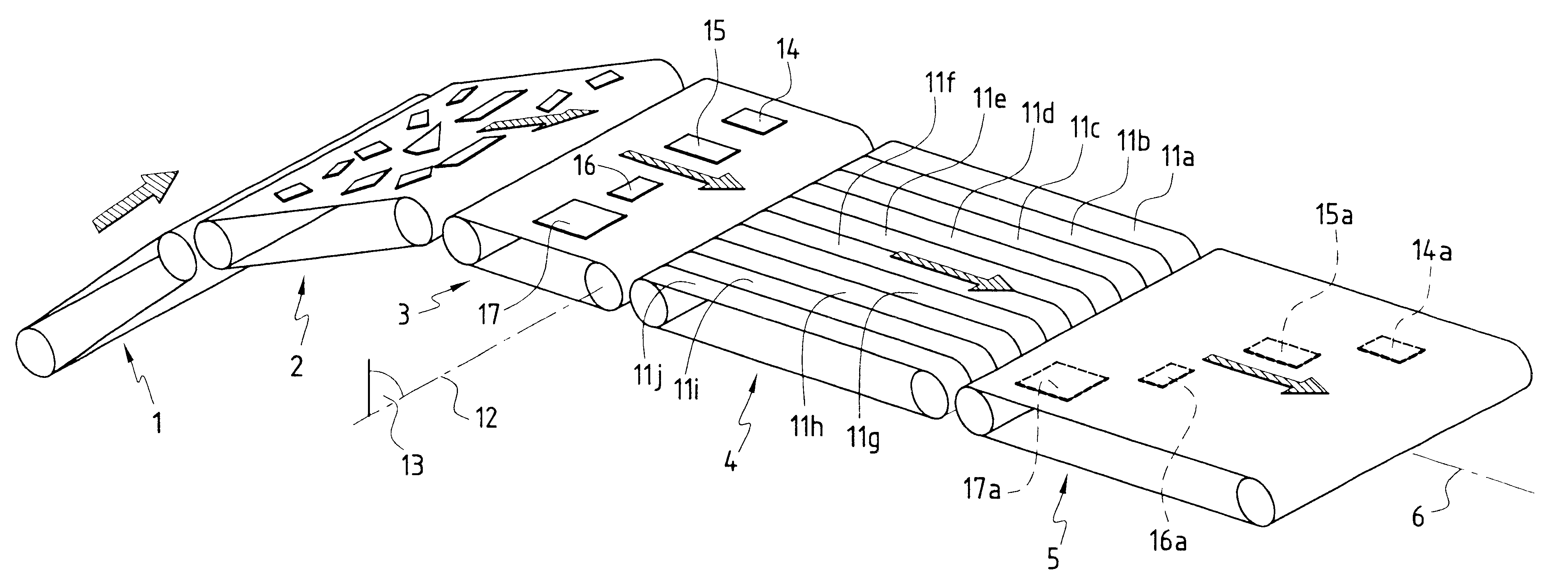

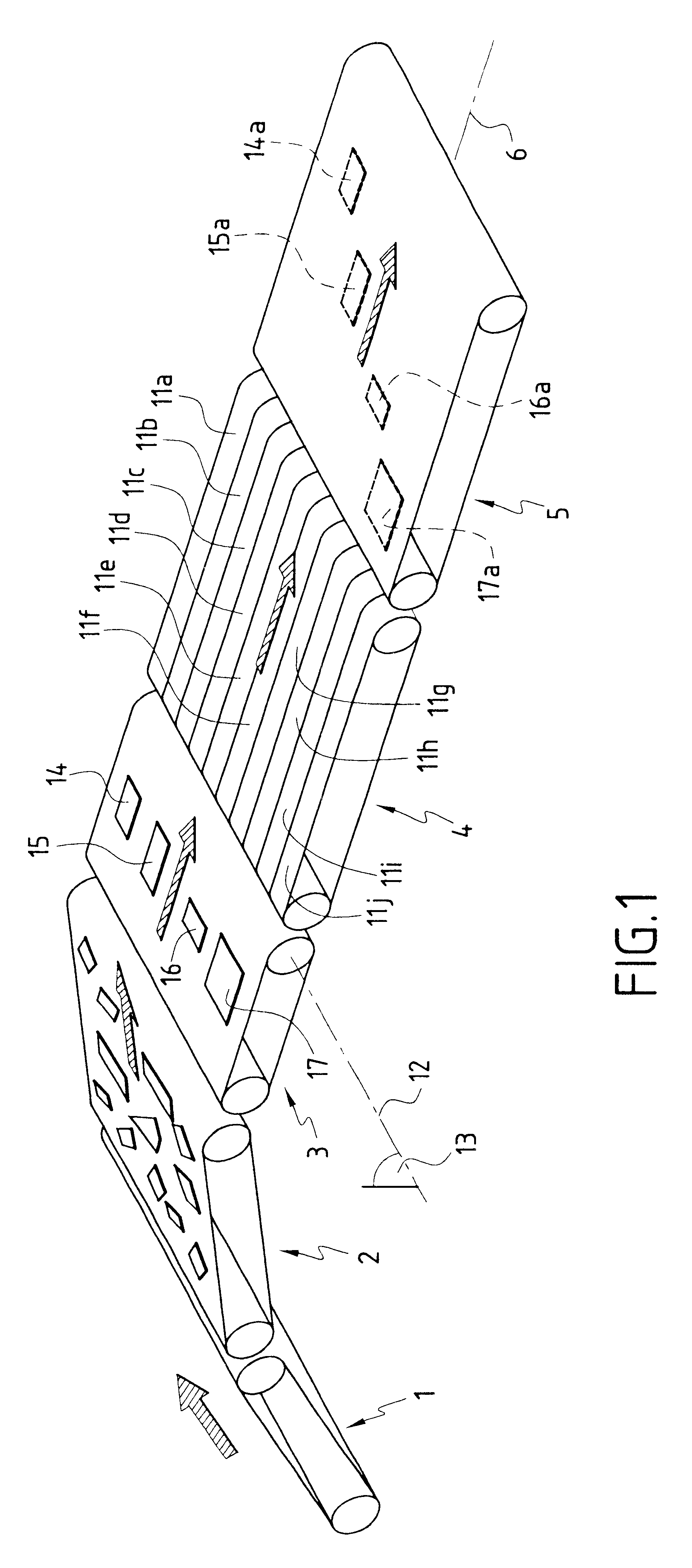

Method and apparatus for putting articles into a queue

InactiveUS6464065B2Avoid recyclingEasy transferControl devices for conveyorsStorage devicesProcess engineeringIndustrial engineering

Owner:CYBERNETIX

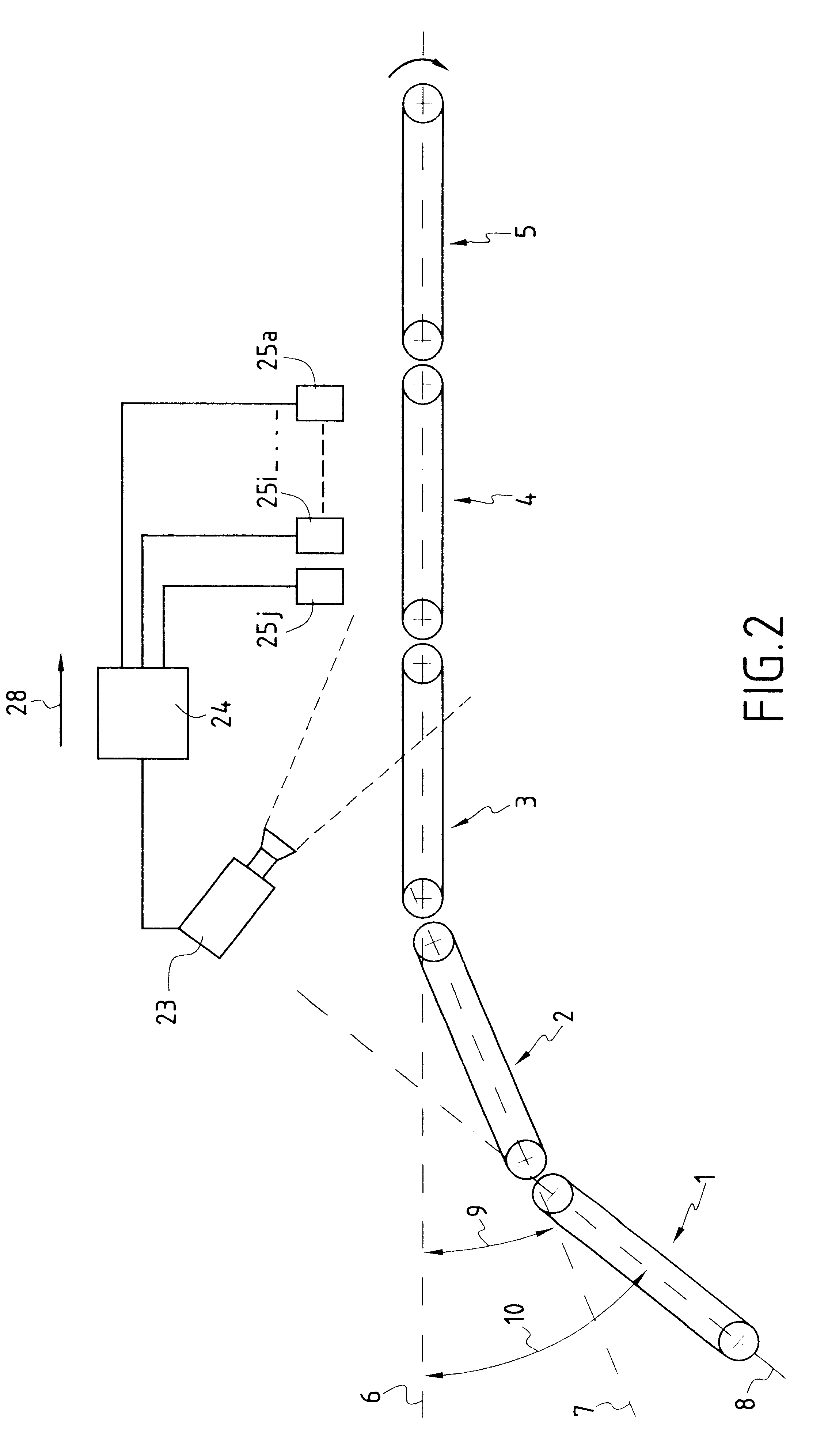

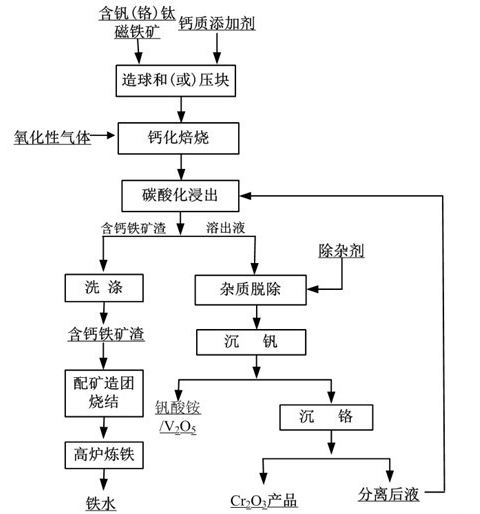

Method for recovering vanadium in vanadium-titanium magnetite ore

ActiveCN102703688ARealize comprehensive utilizationAvoid recyclingProcess efficiency improvementAdhesiveMagnetite

The invention discloses a method for recovering vanadium in vanadium-titanium magnetite ore. The method comprises the process steps of: (1) mixing, pelletizing or briquetting, vanadium-titanium magnetite ore, a calcium additive and an adhesive, drying and oxidizing roasting to obtain roasting clinker; (2) performing carbonation leaching on the roasting clinker by utilizing leaching solution containing CO3<2->, and performing solid-liquid separation to obtain calcium-contained iron ore slag and chrome-vanadium-contained dissolving solution; and (3) adding a reagent with NH4+ into the dissolving solution for ammonia settlement, so as to obtain ammonia vanadate, or adding acid liquor into the dissolving solution, and directly acidifying to obtain V2O5. By adopting calcified roasting-carbonation leaching, the vanadium in the vanadium-titanium magnetite ore is recovered, obtained sintered pellets containing the calcium-contained iron ore slag can be directly applied to blast furnace smelting; and therefore, the problem of recovering the vanadium in the vanadium-titanium magnetite ore is effectively solved, and subsequent blast furnace smelting is not influenced. After the vanadium is recovered by using the method, chromium can be recovered from obtained crystallizing mother solution; and therefore, the vanadium-titanium magnetite ore is effectively and comprehensively utilized.

Owner:HEBEI IRON AND STEEL

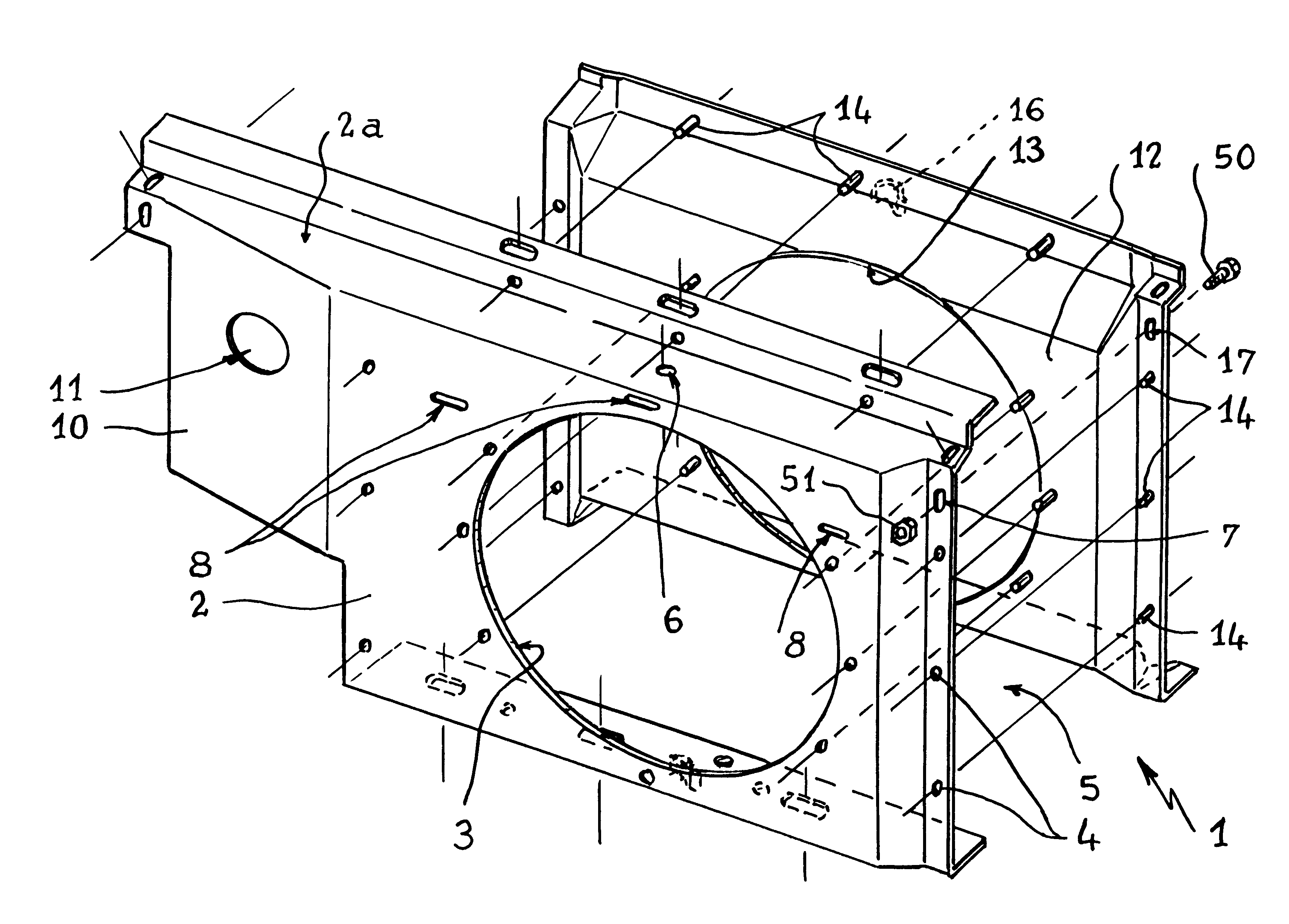

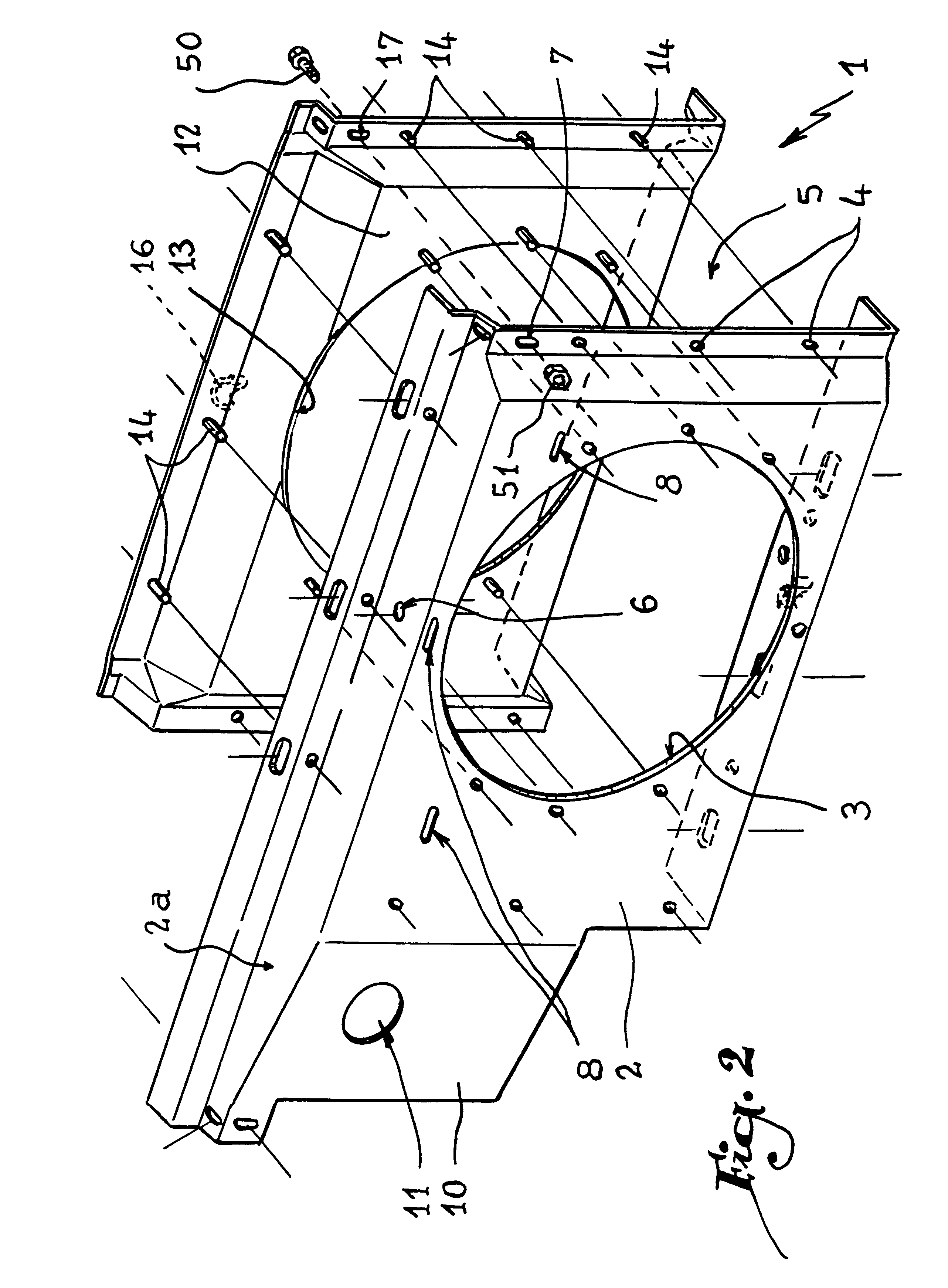

Front panel bodywork element for an automobile including a reinforcing element

InactiveUS6186583B1Conducive to cost controlImprove assembly rigidityVehicle seatsSuperstructure subunitsMobile vehicleEngineering

A composite front panel bodywork element for an automotive vehicle which includes a stamped metal reinforcement defining a cavity in which is seated a portion of a plastic support structure for mounting functional elements associated with the vehicle thereto. The plastic support structure is mounted relative to the metallic reinforcement so as to define open channels therebetween.

Owner:INOPLAST

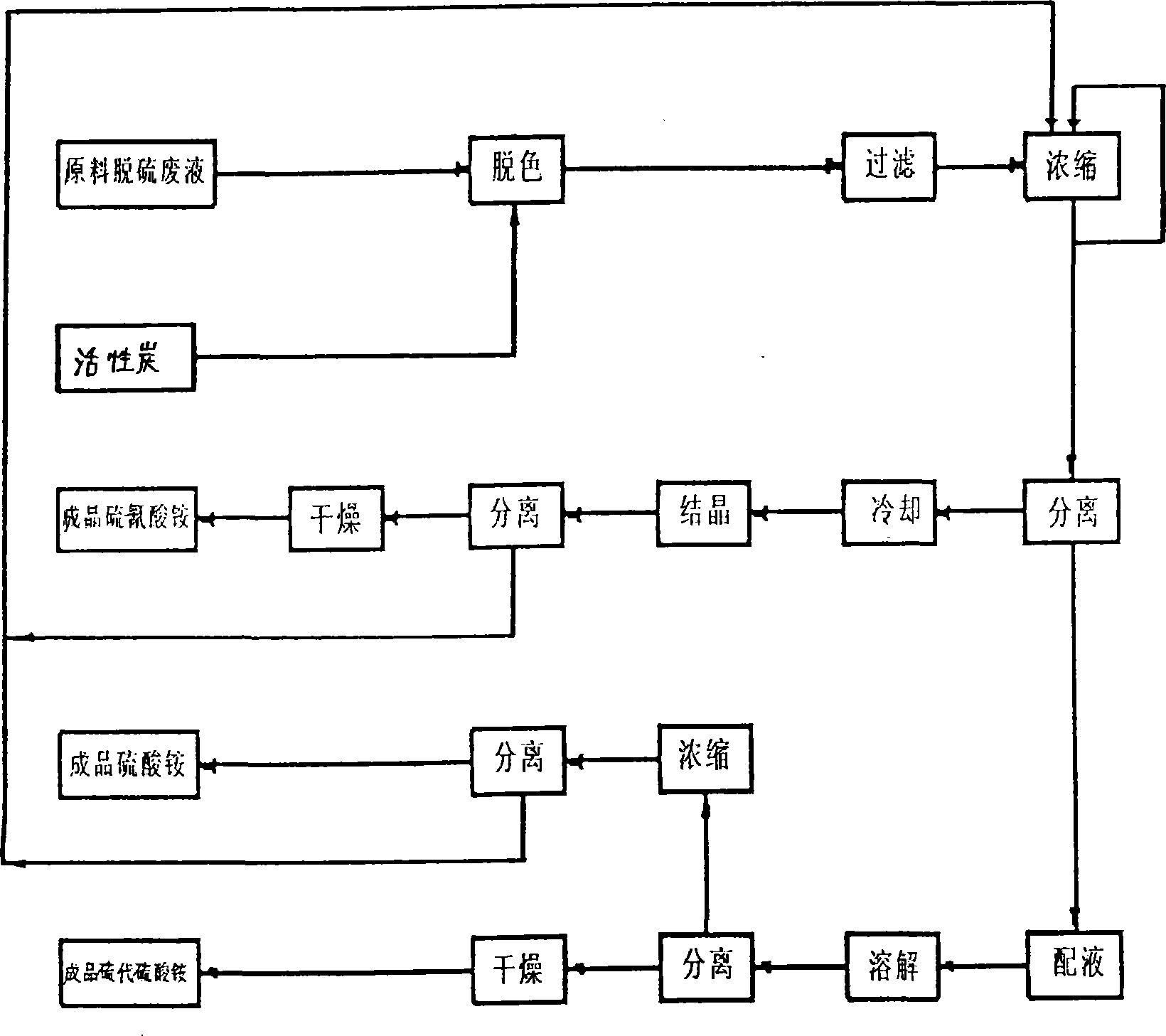

Production technique for reclaiming ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

InactiveCN101125644ASimple processStable operationHydrogenThiosulfates/dithionites/polythionitesPre treatmentChemistry

The invention discloses a production technology for recovering ammonium thiosulfate and ammonium thiocyanate from the desulfuration waste liquid, whose technological steps are: pretreating the waste liquid containing sulfur, concentrating the waste liquid containing sulfur, crystallizing and separating, and purifying the ammonium thiosulfate. The invention has simple technology and stable operation, which performs machining and processing to the waste liquid containing sulfur in the producing process of HPF desulfuration in a plant, thus, the extracted ammonium thiosulfate and ammonium thiocyanate have good quality and yield, thereby effectively solving the recovering process of the waste water containing sulfur in the producing process of HPF desulfuration. The invention not only reduces the waste water exhausting and environmental pollution, but also recovers the chemical industrial material at the same time, increasing the economic benefits of the enterprises.

Owner:SHANGHAI ZEYIN ENG DESIGN

Duct system for high power adapter cards

ActiveUS7843685B2Avoid recyclingDigital data processing detailsFurniture partsExpansion cardComputer module

A method and apparatus for substantially preventing recirculation of heated air from an exhaust outlet of an expansion card to an air inlet of the expansion card, wherein the air inlet and exhaust outlet are both on the same end of the chassis. The apparatus comprises a chassis with a chassis fan, a motherboard within the chassis having an expansion card connector, and an expansion card in communication with the expansion card connector and secured to the front end of the chassis. The expansion card also includes a card fan configured to move cooling air through the air inlet to the exhaust outlet. An air duct redirects the hot air from the exhaust outlet to prevent recirculation into the expansion card and causes the heated air to exit through the chassis fan. The air duct may include a longitudinal segment through a computer module and a lateral segment selectively securable over the exhaust outlet.

Owner:LENOVO GLOBAL TECH INT LTD

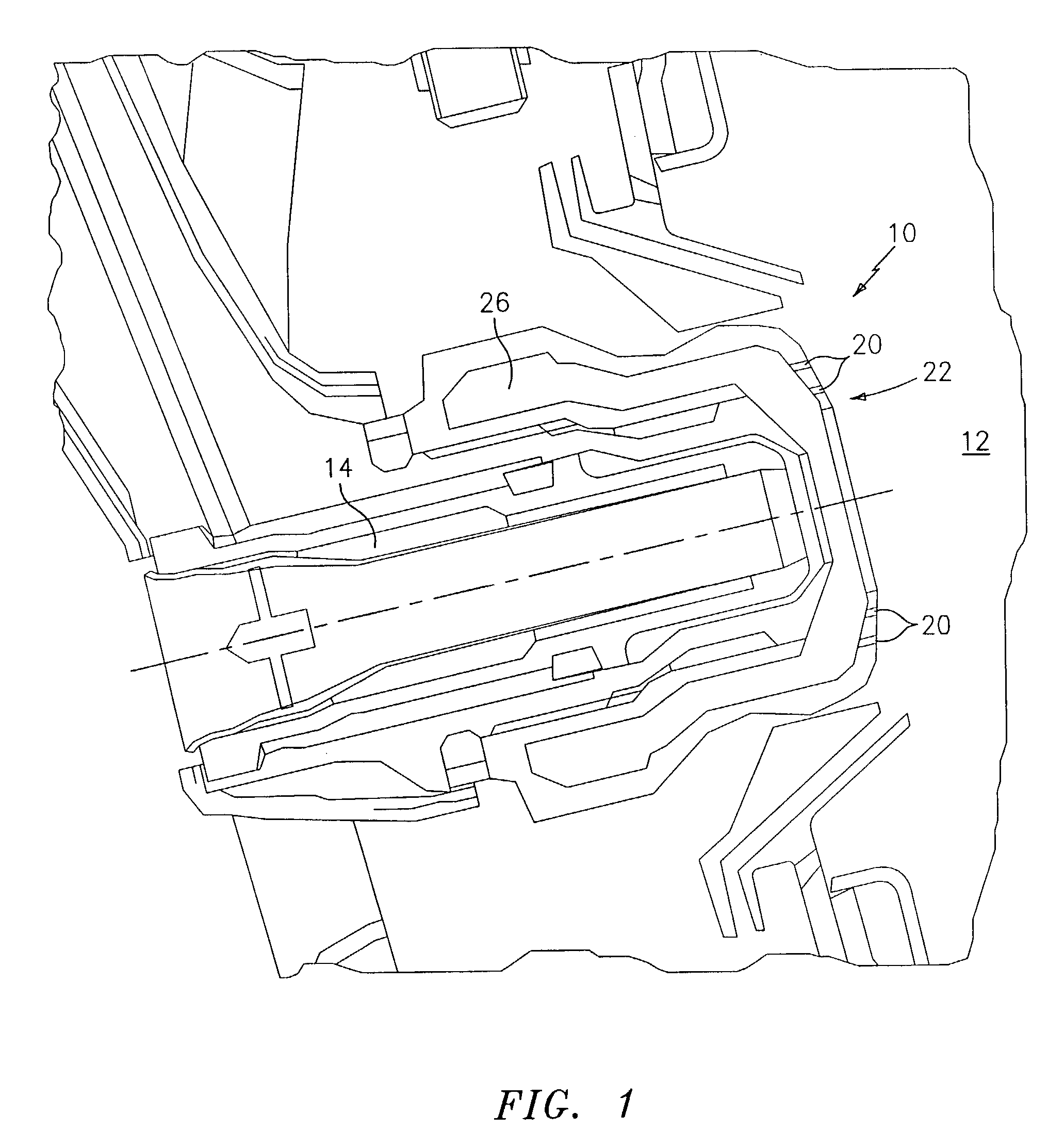

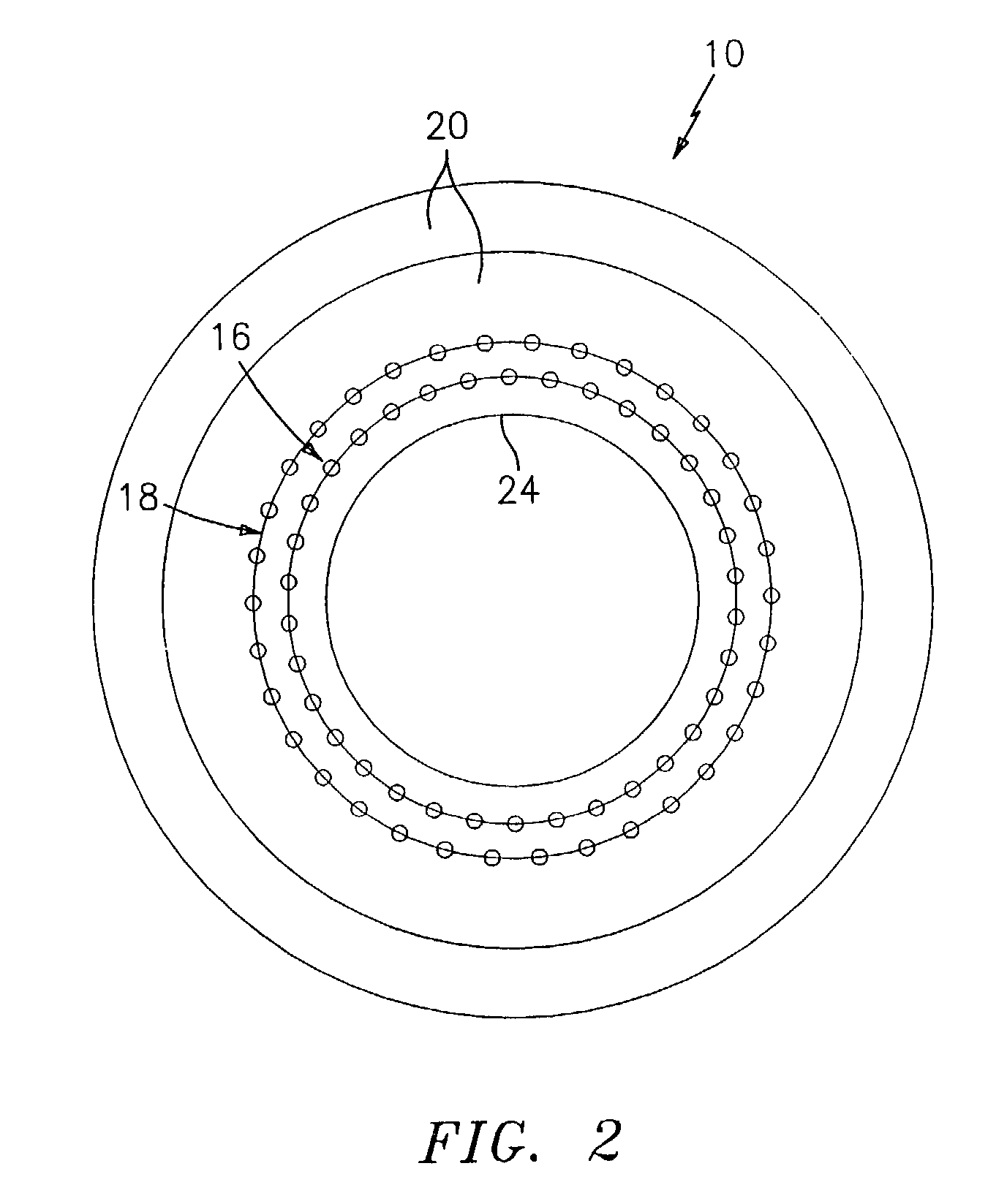

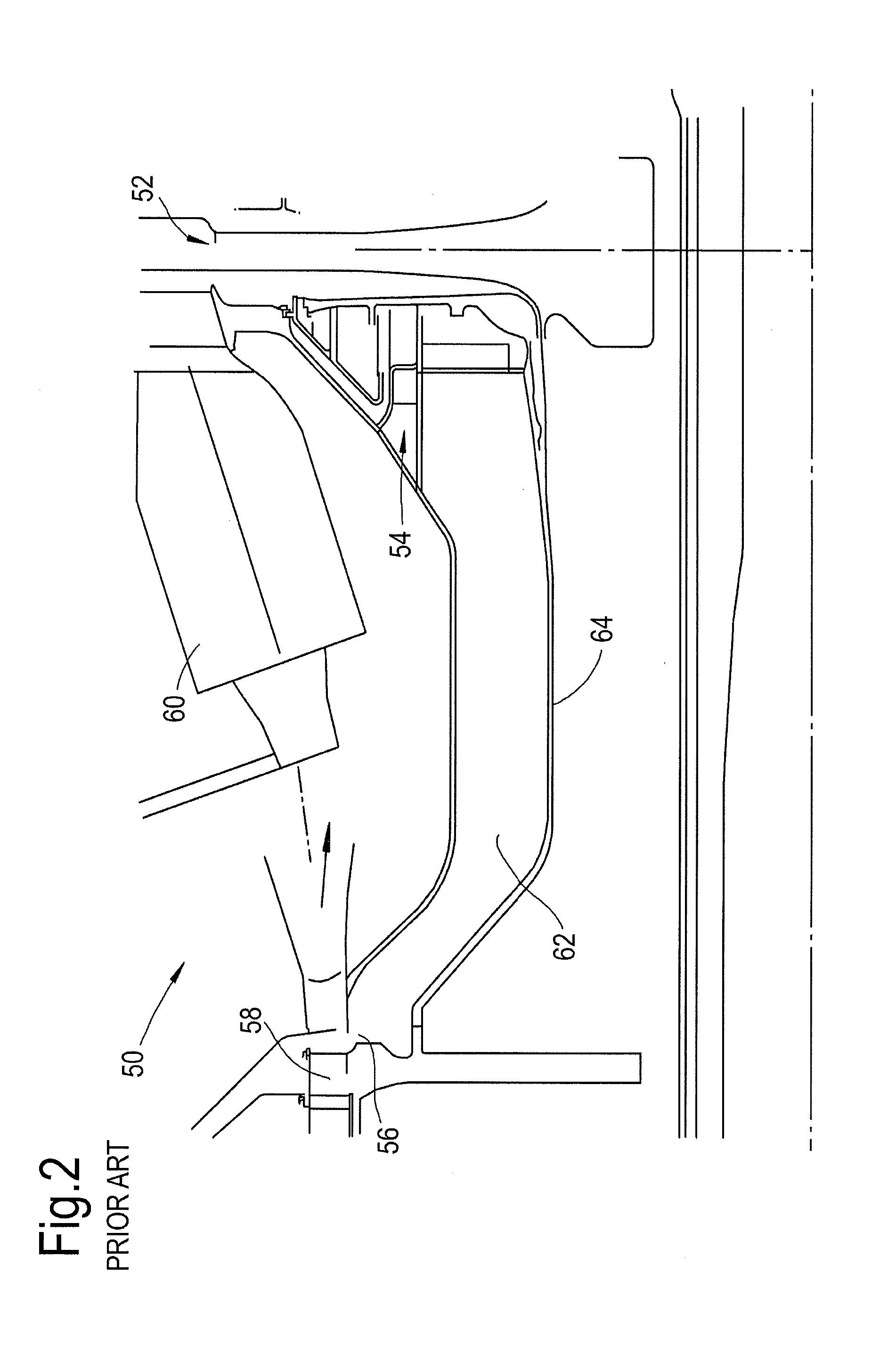

Fuel nozzle design

InactiveUS7007864B2Prolong lifeAvoid recyclingContinuous combustion chamberSpray nozzlesCombustion chamberGas turbines

The present invention relates to a fuel nozzle for use in an engine such as a gas turbine engine. The fuel nozzle includes a fuel injector for injecting fuel into a combustion chamber of the engine and a plurality of rows of holes surrounding the fuel injector for eliminating recirculation of hot gas products onto a face of the fuel nozzle. The holes eject air primarily in an axial direction.

Owner:UNITED TECH CORP

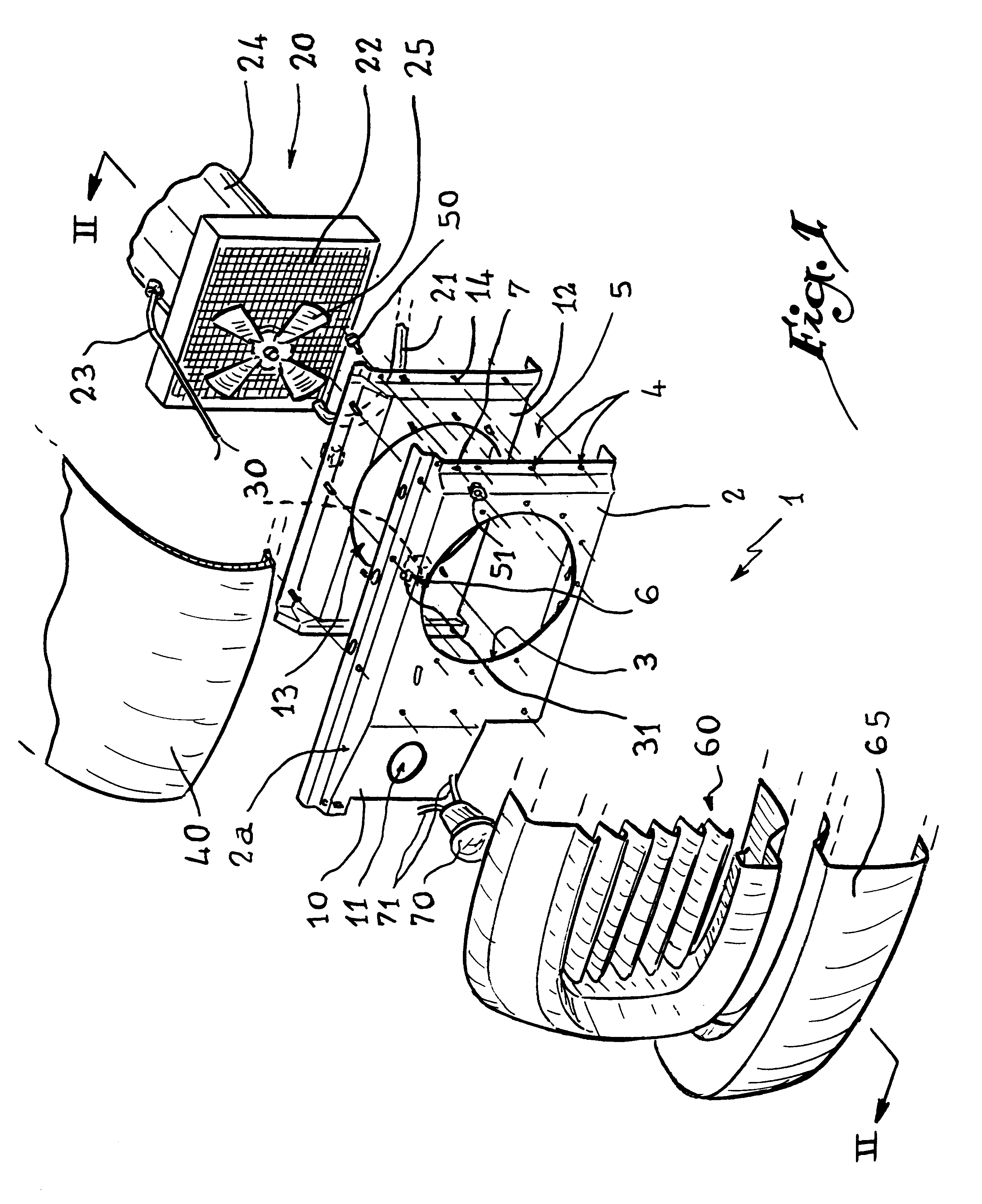

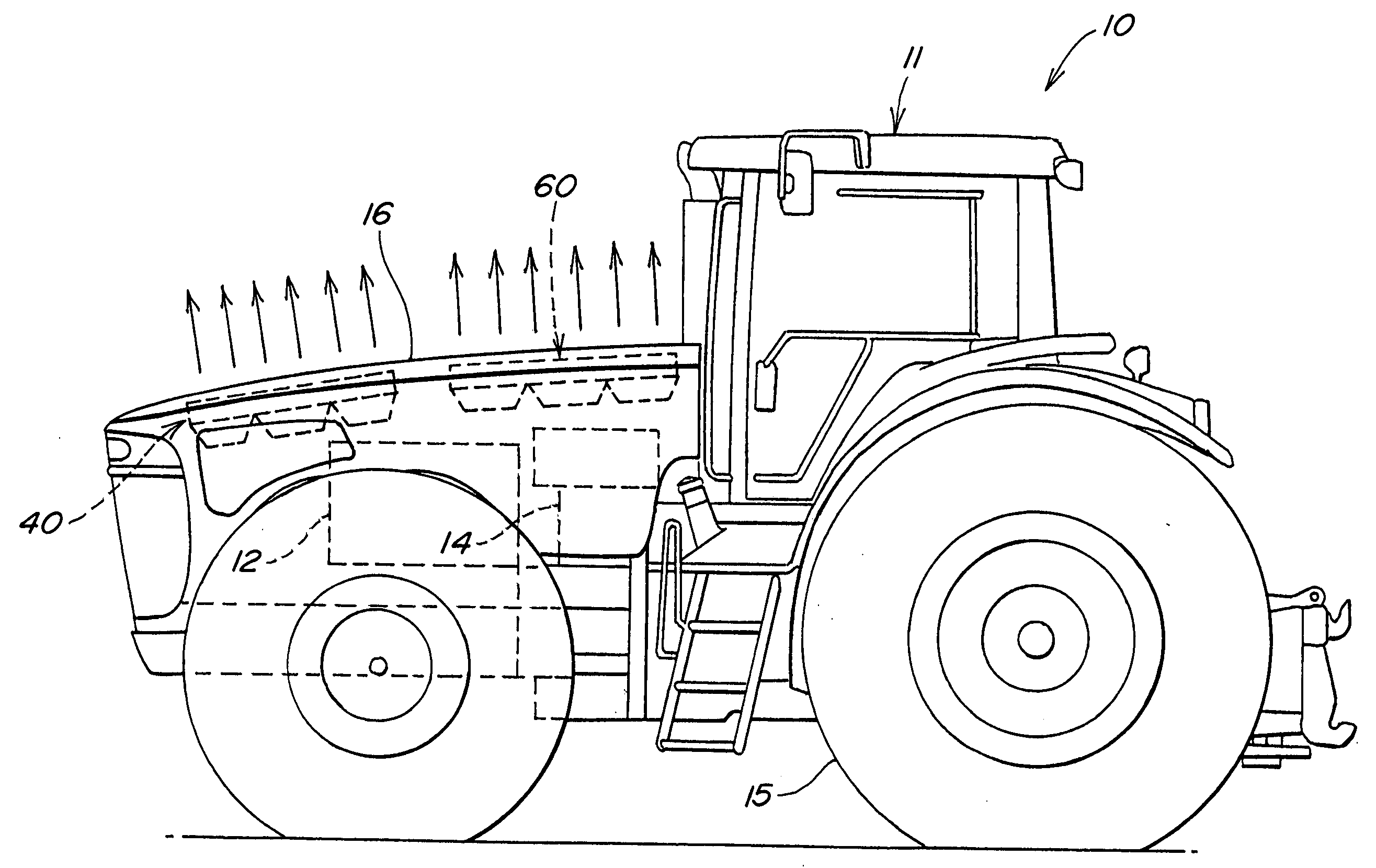

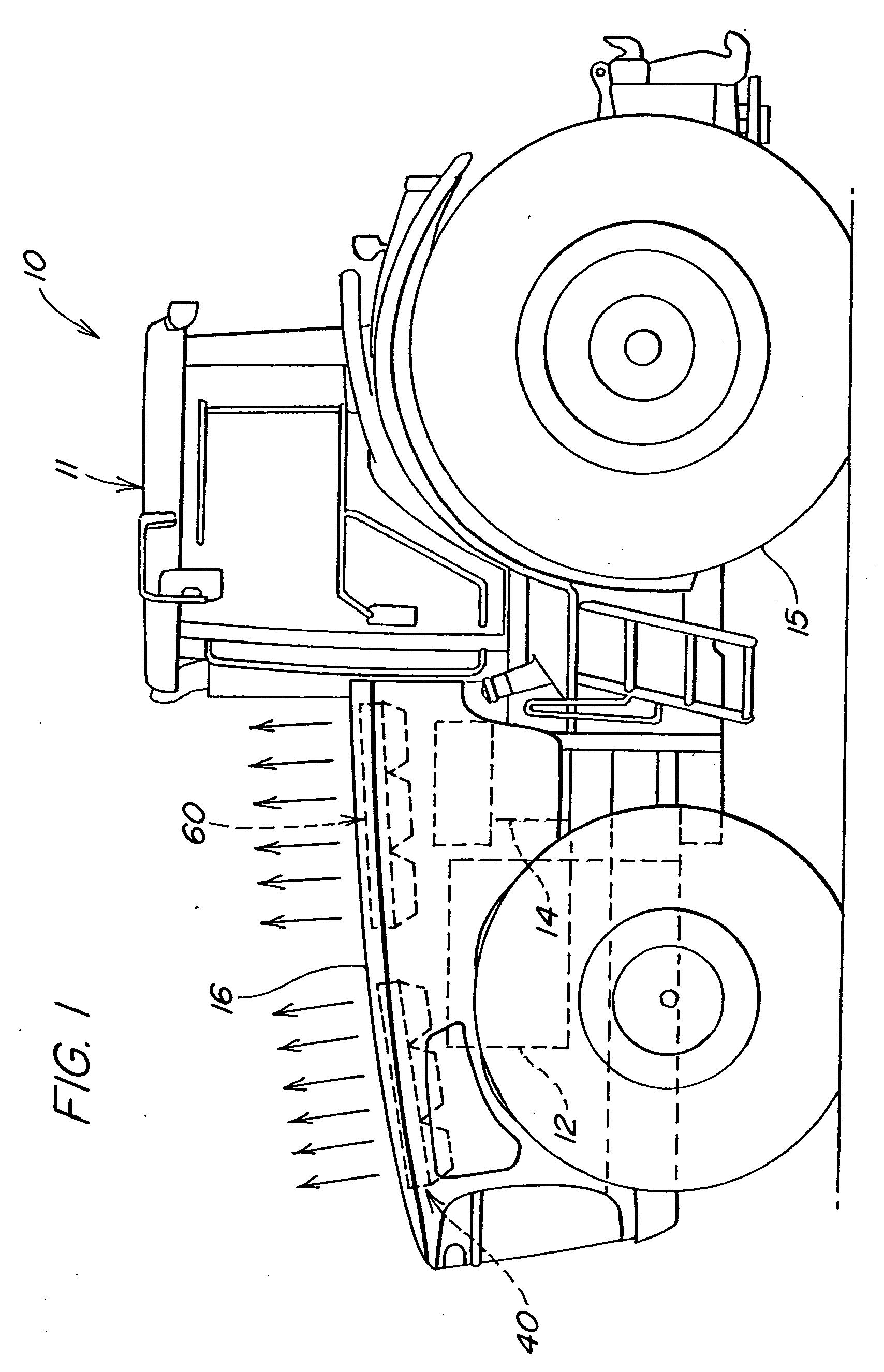

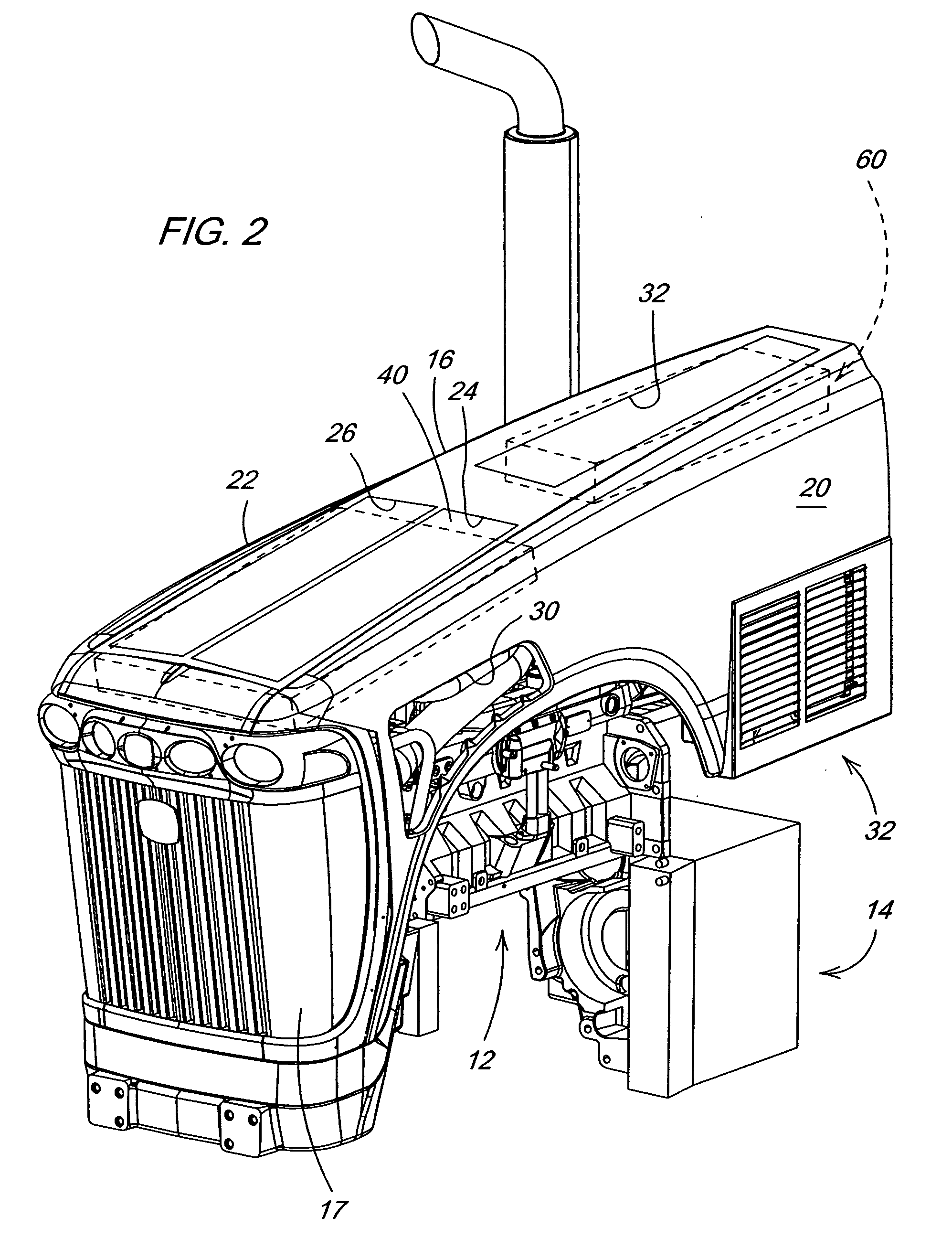

Vertical airflow engine cooling system

A cooling system is provided for a non-rail off-road vehicle, such as an agricultural tractor having an engine with a horizontally oriented rotation axis and a hood covering the engine. The cooling system includes an engine cooling radiator positioned above the engine and between the engine and the hood and a fan unit with electric motor-driven fans blowing air upwardly through the radiator. The fan unit is positioned above the engine and between the engine and the radiator. An engine charge air cooler is also positioned above the engine and between the engine and the hood, and a charge air cooler fan unit has electric motor-driven fans which blow air upwardly through the cooler. The hood has openings in its upper surface through which passes air blown by the radiator fan unit and the charge air cooler fan unit. This cooling system blows heated cooling air vertically upwardly, thus preventing the heated cooling air from being drawn back into the intakes of the cooling system and preventing heated air from being blown onto the exterior of the tractor cab.

Owner:DEERE & CO

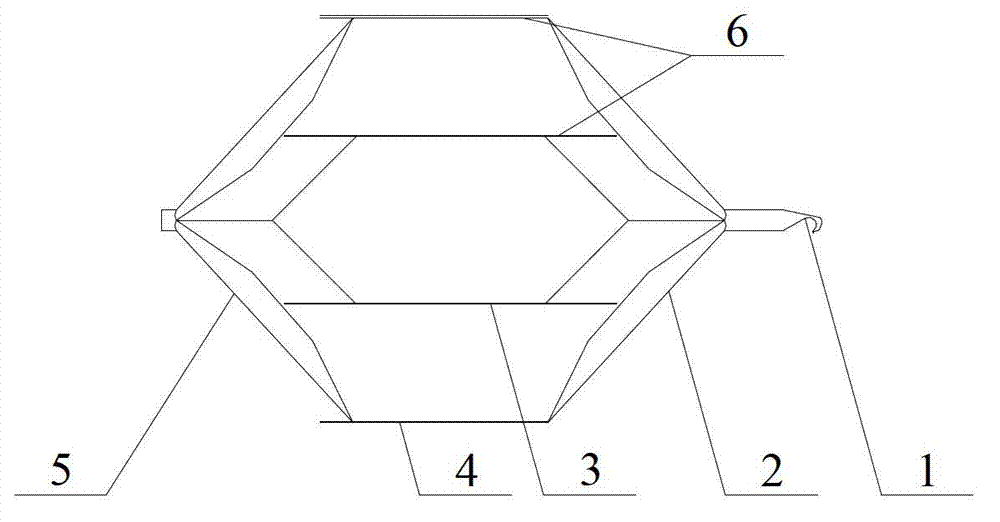

Vena cava filter coated with macromolecular coating and preparation method for macromolecular coating

InactiveCN103027763ASlow endothelializationSlow down the process of endothelializationCoatingsBlood vessel filtersSurface layerAlloy

The invention provides a vena cava filter coated with a macromolecular coating and a preparation method for the macromolecular coating. A recycling part, a pre-filtering part, a supporting part, an anti-shifting part and a filtering capturing part are all formed by cutting a same memory alloy material through laser; the filtering capturing part is characterized in that six V-shaped rods stretch out from a closed annular structure in a parallel form, the structure is equally divided by the V-shaped rods and is rotated, and a branch end is connected with a supporting part, so that a conical netted structure is formed; and the surface layers of the recycling part, the pre-filtering part, the supporting part, the anti-shifting part and the filtering capturing part are all coated with the macromolecular coatings. A metal filter provided by the invention adopts the unique hexahedral column structural design, so that the metal filter has excellent adherence property and is easier to recycle; the endothelialization process after the filter is planted into a vena cava vessel is effectively slowed down and the internal planting time of the filter is prolonged by the macromolecular coating; and the difficulty in recycling the filter is relieved and the harm to the vena cava of a patient caused by a recycling stage is reduced.

Owner:BEIJING TAIJIE WEIYE TECH

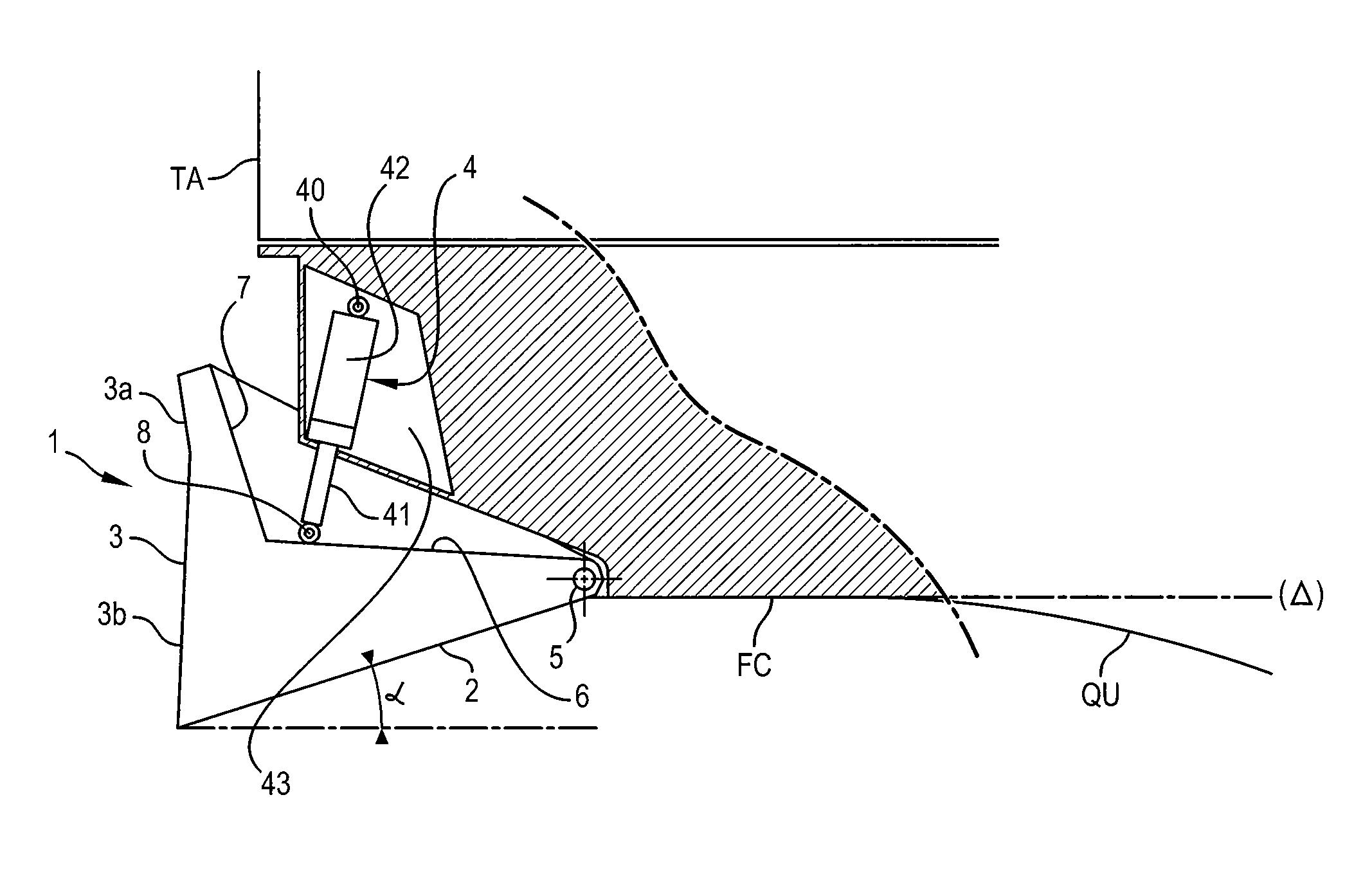

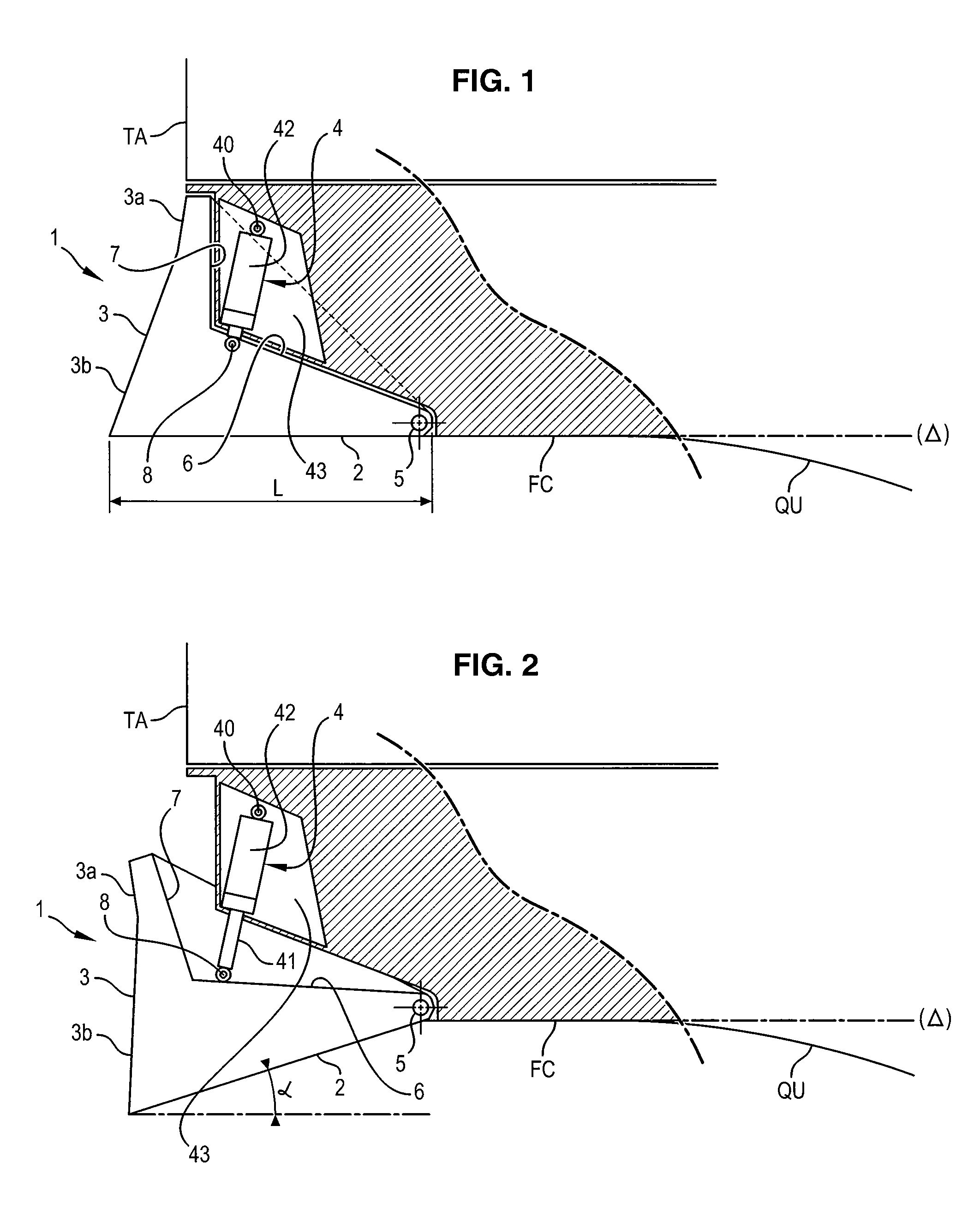

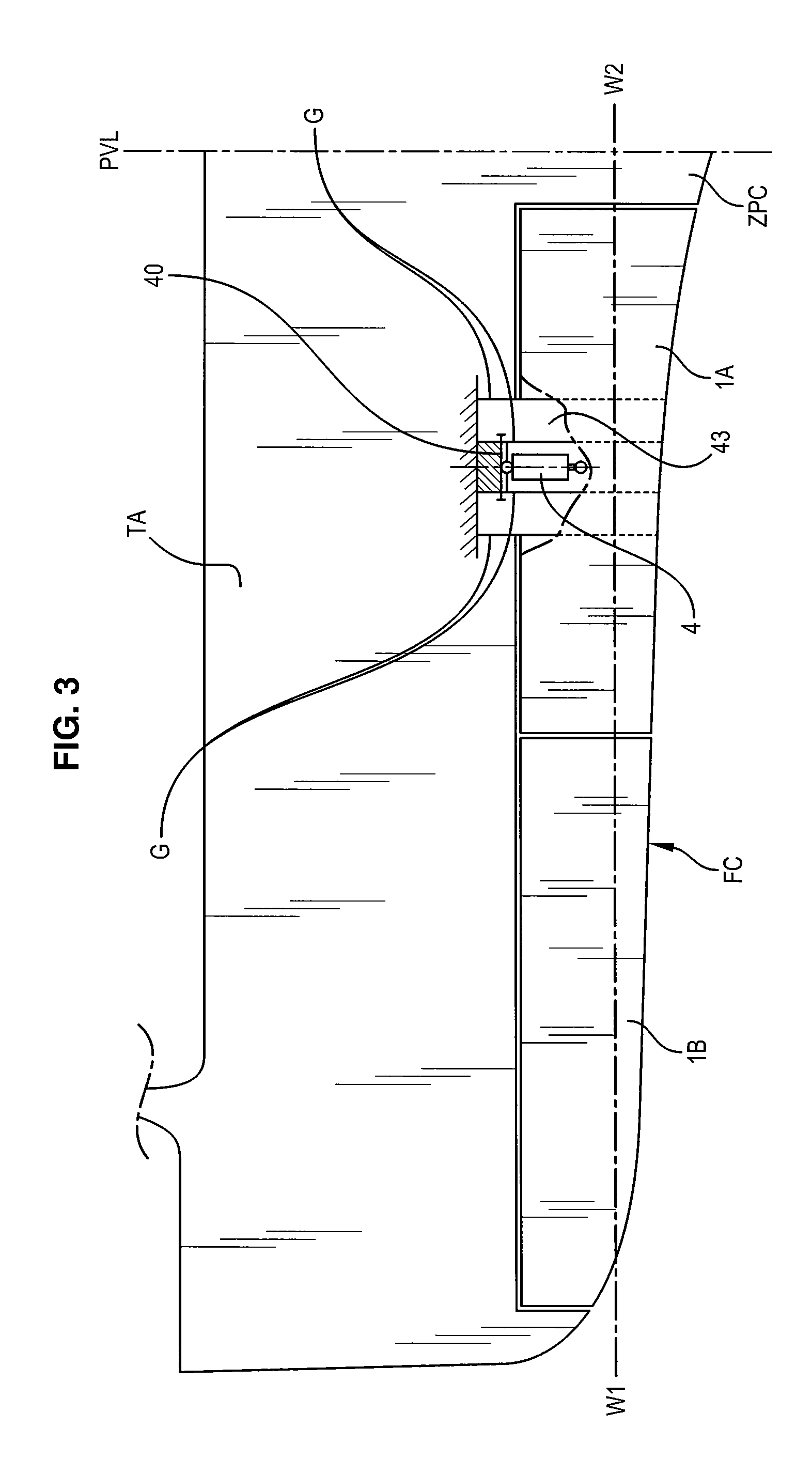

Ship with stern equipped with a device for deflecting a flow of water

ActiveUS8096255B2Increase tonnageSmall sizeVessel stability improvementMovement controllersWater flowStern

The device comprises a plurality of deflector members (1) having a submerged lower face (2), called first face, generally fitting into the extension of the hull bottom (FC) of the ship, toward the rear thereof, while forming an angle (α) in relation to a general plane (Δ) tangent to this bottom (FC), characterized by the fact that these deflector members (1) are articulated to the hull and are juxtaposed side by side, over all, or practically all, the width of the stern, control means (4) making it possible to cause it to pivot in one direction or the other in order to vary said angle (α), these means being housed in part in a protective case.

Owner:STX FRANCE CRUISE

Duct System For High Power Adapter Cards

ActiveUS20090262497A1Avoid recyclingDigital data processing detailsFurniture partsExpansion cardComputer module

Method and apparatus for substantially preventing recirculation of heated air from an exhaust outlet of an expansion card to an air inlet of the expansion card, wherein the air inlet and exhaust outlet are both on the same end of the chassis. The apparatus comprises a chassis with a chassis fan, a motherboard within the chassis having an expansion card connector, and an expansion card in communication with the expansion card connector and secured to the front end of the chassis. The expansion card also includes a card fan configured to move cooling air through the air inlet to the exhaust outlet. An air duct redirects the hot air from the exhaust outlet to prevent recirculation into the expansion card and causes the heated air to exit through the chassis fan. The air duct may include a longitudinal segment through a computer module and a lateral segment selectively securable over the exhaust outlet.

Owner:LENOVO GLOBAL TECH INT LTD

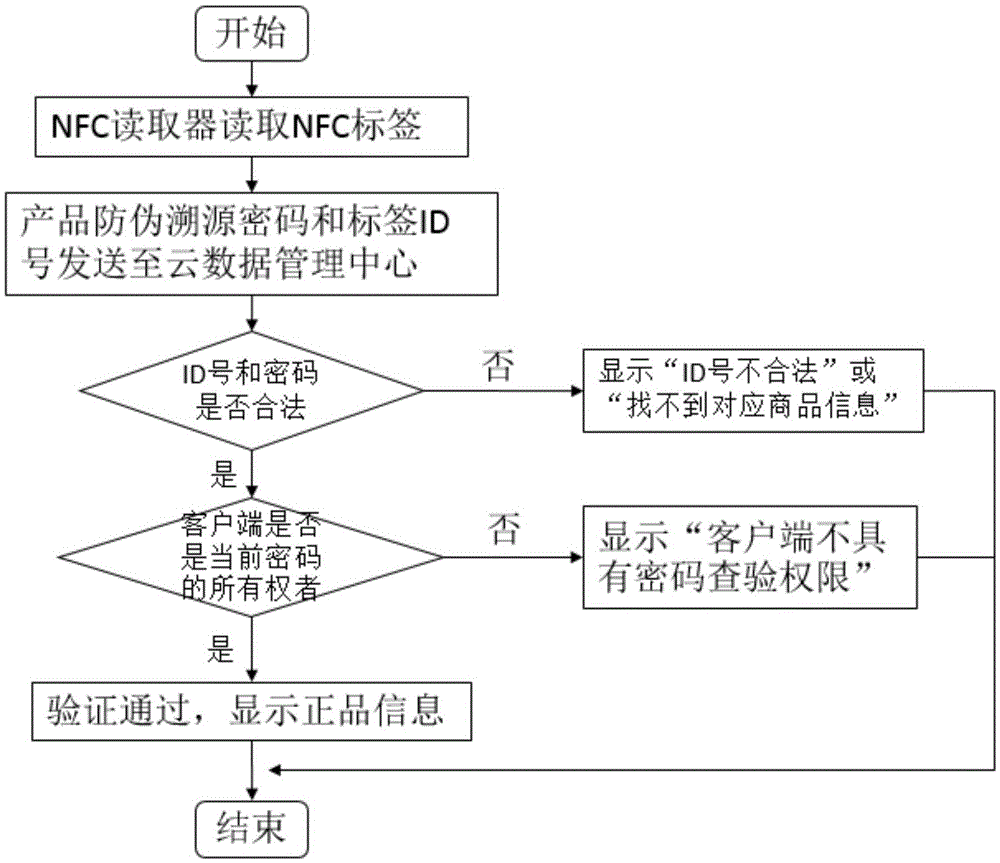

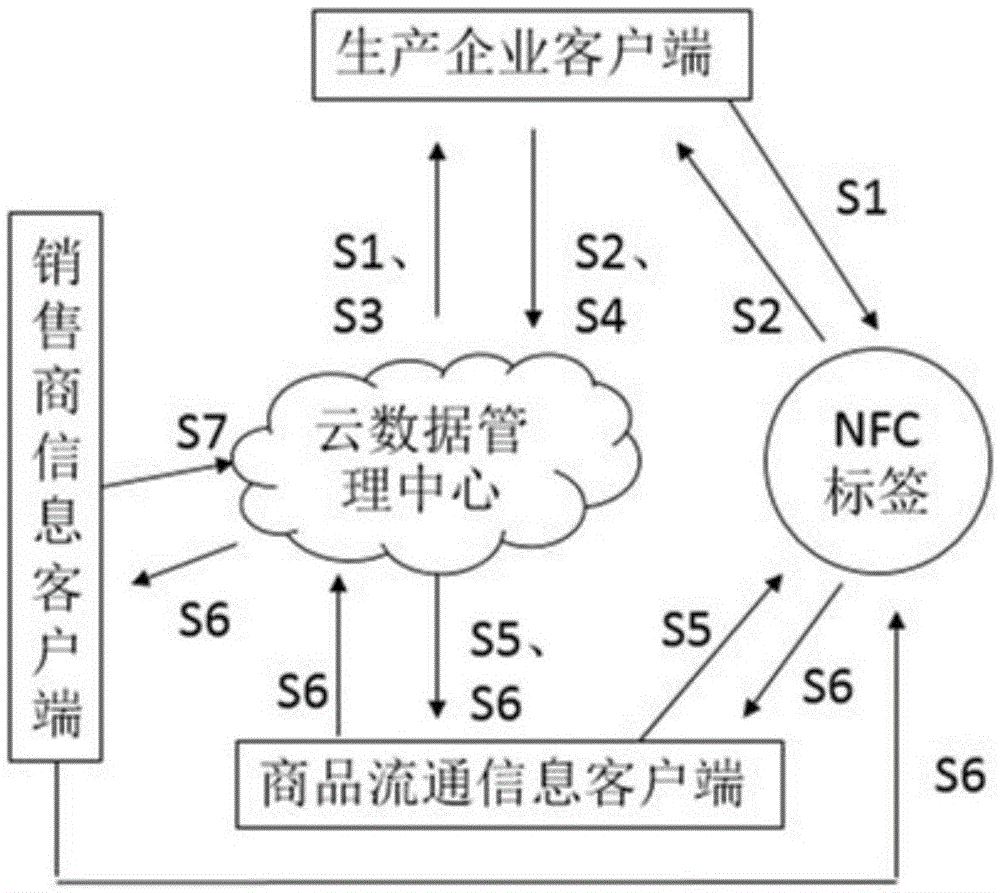

NFC product anti-counterfeiting traceability system and anti-counterfeiting traceability method thereof

InactiveCN105654316ASuppression of cross-sellingAvoid enteringCommerceCloud data managementLogistics management

The invention discloses an NFC product anti-counterfeiting traceability system and an anti-counterfeiting traceability method thereof. The system is characterized by comprising a commodity information cloud data management center and an NFC communication module. The NFC communication module comprises an NFC tag and NFC tag readers. The NFC tag readers are composed of a production enterprise information provision client reader, a commodity circulation information client reader, a retailer information client reader and a consumer client reader. The NFC tag and the NFC tag readers are in communication connection. According to the technical scheme of the NFC product anti-counterfeiting traceability system and the anti-counterfeiting traceability method thereof, the problem that the traditional anti-counterfeiting method easily causes the occurrence of pirates, tedious recycle, cumbersome inquiry and high anti-counterfeiting cost can be solved. Meanwhile, the system can be used for monitoring the steps of commodity production, storage, logistics and the like. Meanwhile, the commodities fleeing phenomenon can be inhibited, and the source of counterfeit and shoddy commodities can be traced.

Owner:HOHAI UNIV

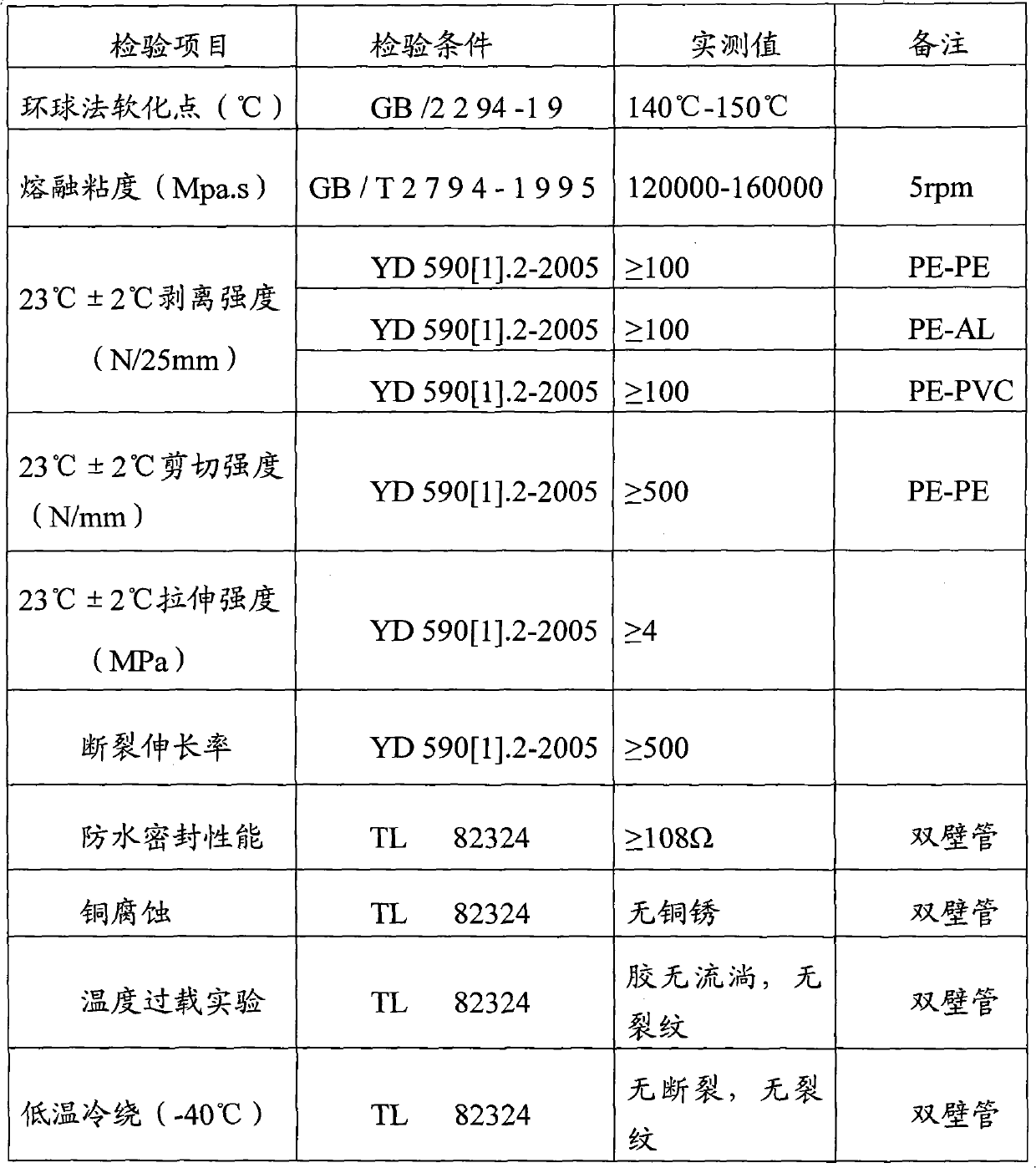

High temperature resistant hot melt adhesive and processing process thereof

The invention provides a formula of a high temperature resistant hot melt adhesive and a processing process of the hot melt adhesive. The formula comprises the following components: polyamide, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, a tackifier, an antioxidant and a modifier. The high temperature resistant hot melt adhesive is high in bonding strength, resistant to high temperature, excellent in insulating and sealing performance, resistant to a low temperature, environment-friendly, non-toxic, simple in production process and good in repeatability.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

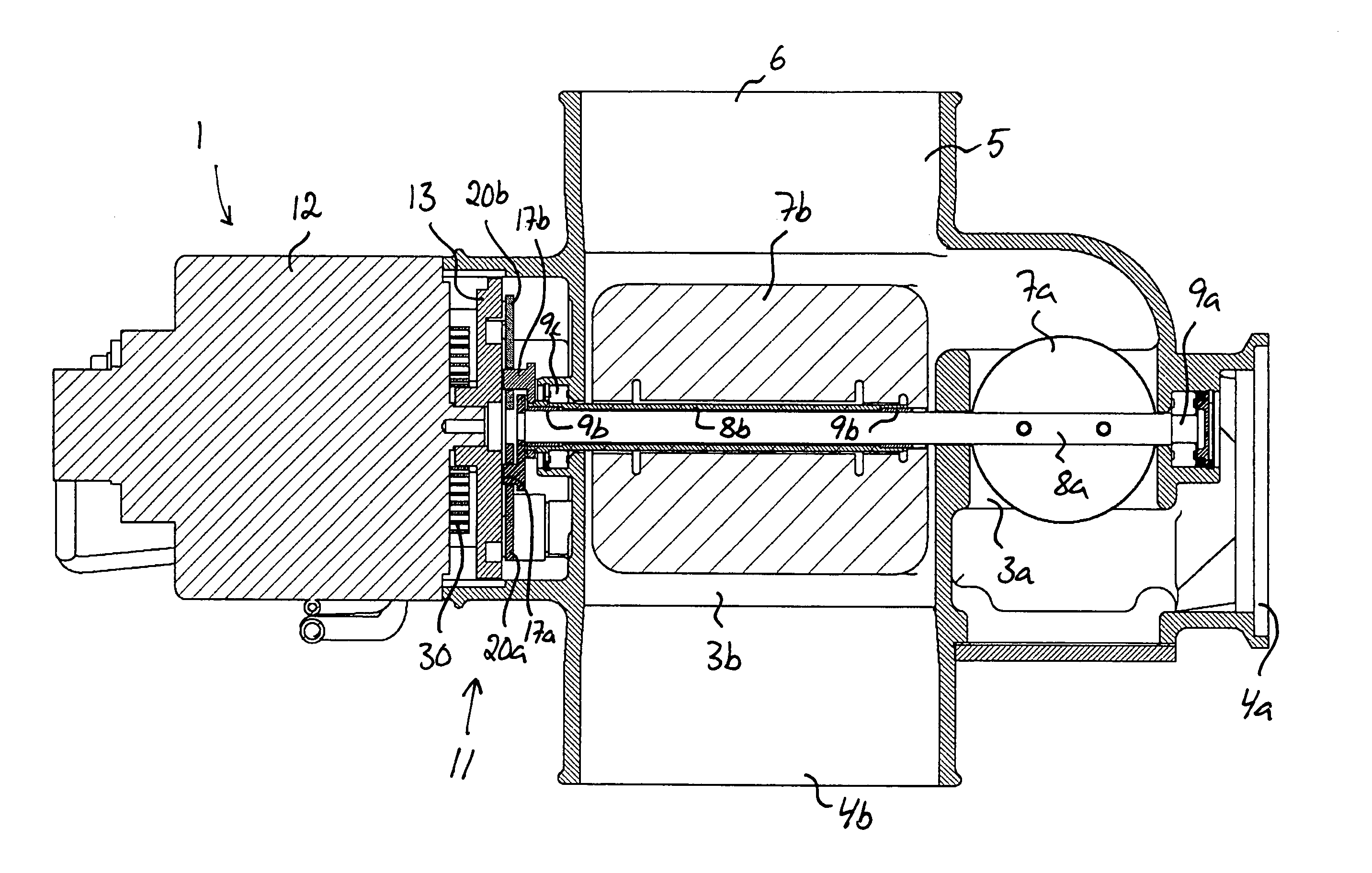

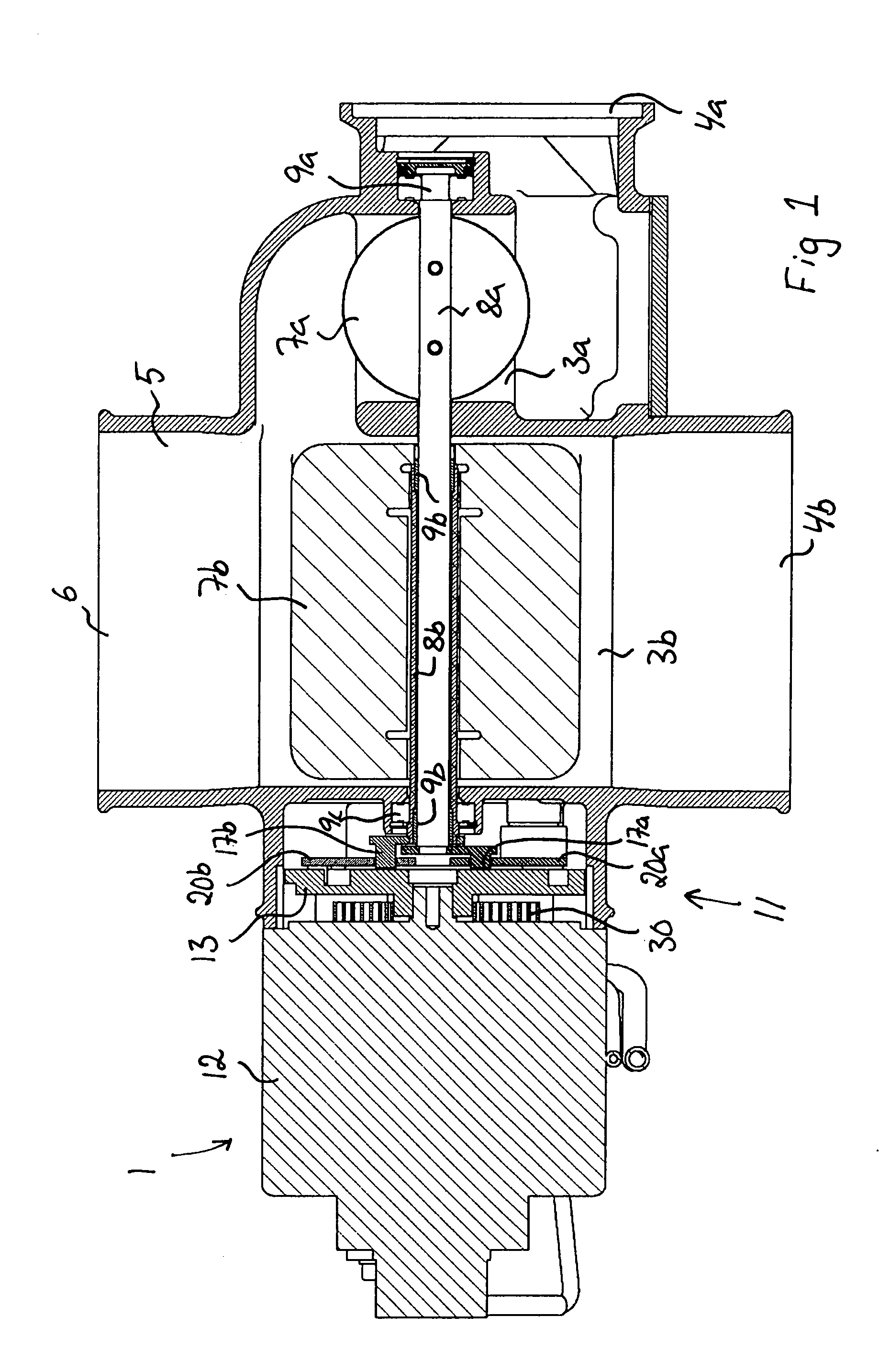

Valve device

InactiveUS7267139B2Avoid recyclingInternal combustion piston enginesEngine operationsControl theoryMotion transfer

The invention relates to a valve device comprising a valve housing (2) with a first and a second flow channel (3a, 3b), and a first and second damper shaft (8a, 8b), which are rotatable relative to the valve housing (2). A first damper (7a) is arranged in the first flow channel (3a) fixed to the first damper shaft (8a) and a second damper (7b) is arranged in the second flow channel (3b) fixed to the second damper shaft (8b). A rotatable regulating member (13) is arranged to control the rotational position of the damper shafts (8a, 8b) via two motion transfer members (20a, 20b), the respective motion transfer member (20a, 20b) being in engagement with a guiding (21) of the regulating member (13) so that the rotational position of the motion transfer member and thereby the rotational position of the associated damper shaft (8a, 8b) is controlled by the rotational position of the regulating member via this guiding (21).

Owner:STT EMTEC AB

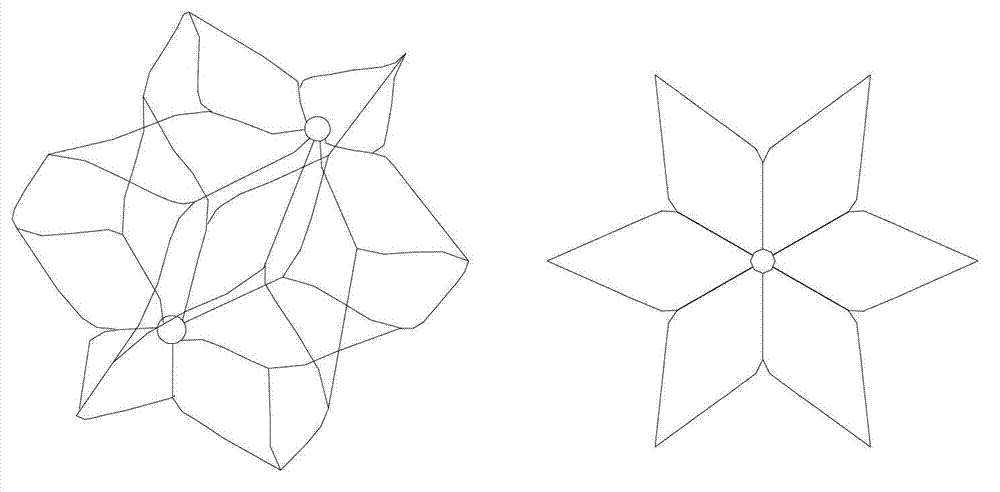

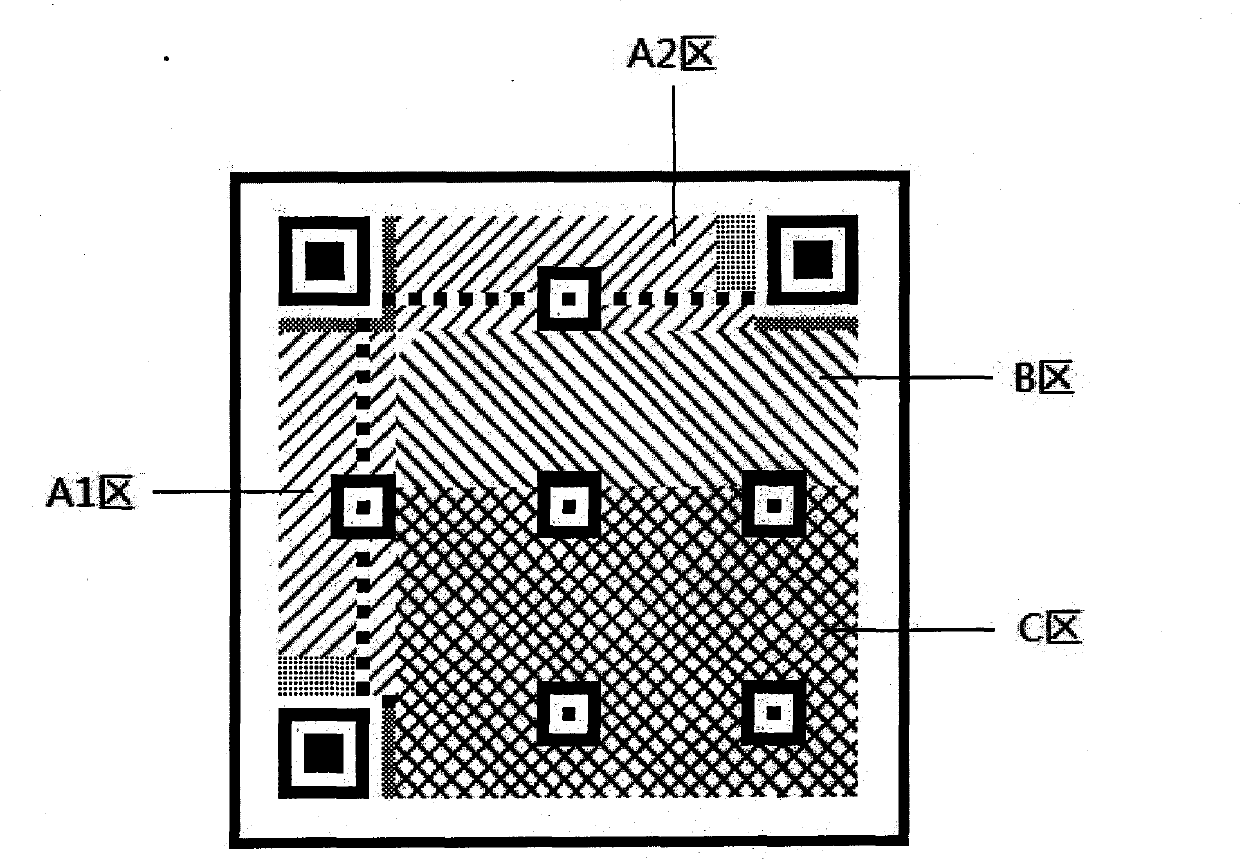

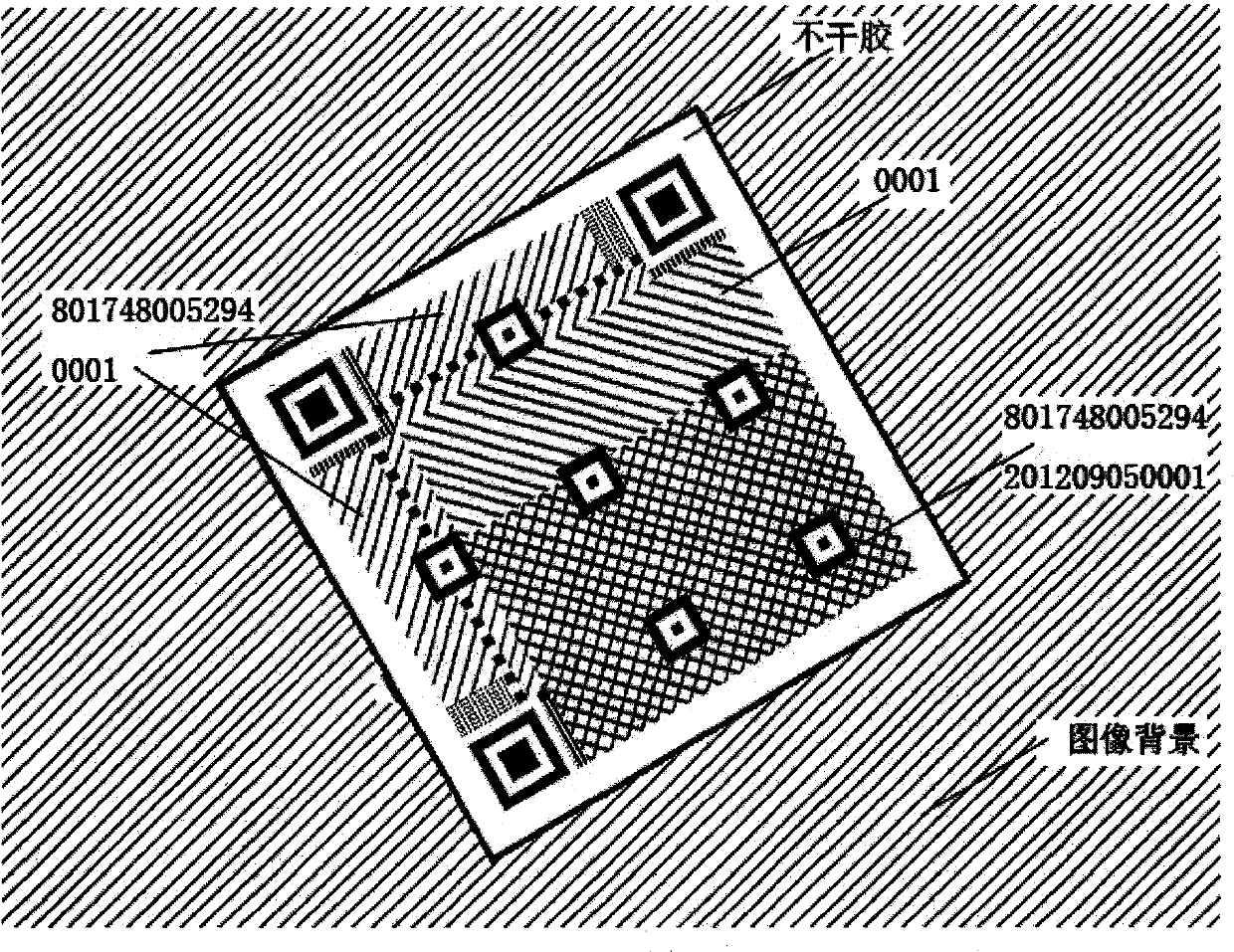

CCQR (Colorful Coded Quick Response) anti-counterfeiting mark

InactiveCN103310252AAvoid recyclingImprove bindingStampsRecord carriers used with machinesGraphicsThe Internet

The invention relates to a product anti-counterfeiting mark, in particular to a CCQR (Colorful Coded Quick Response) anti-counterfeiting mark, which is a novel graphic-symbol automatic recognizing, reading and processing quick-response code based on a computer image processing technique, a combined encoding principle and the like. The code has dual functions of pre-purchase anti-counterfeiting and post-purchase verification, which comprises two separate color anti-counterfeiting areas, a black-white tracing area and a secret code check area to be covered with printed silver. Each color anti-counterfeiting area comprises anti-counterfeiting information. The black-white tracing area comprises unique code information which is generated for each product; and the secret code check area can enable a consumer to scratch off the printed silver which covers the area after the product is purchased, so as to re-verify the truth and the falseness through scanning by using relevant technological mobile phone recognizing and reading software. The CCQR anti-counterfeiting mark has the beneficial effects that the anti-counterfeiting recognizing method can be easily mastered by consumers through mobile phones or special instruments because the quick response characteristic of QR codes are combined; and the consumers can scan the code through the mobile phones or the special instruments (for use of professionals) and the internet is automatically connected through the software to compare the anti-counterfeiting information in a database to know the truth and the falseness.

Owner:CHENGDU THE FAKE PROD DISAPPERANCE TECH

Axial flow machine cooling system

ActiveUS20150047359A1Reduce heat loadIncrease tangential speedEngine fuctionsTurbine/propulsion engine coolingCombustorTurbine

This invention concerns a system for cooling components in a gas turbine engine, the gas turbine engine including a compressor for driving a primary gas flow to a combustor and a turbine arranged to be driven by combustion gases from the combustor, wherein the system includes: an annular cooling flow passage arranged for fluid communication between the compressor and the turbine, the flow passage having a first inlet arranged to receive gas from the primary gas flow downstream of compressor, and a second inlet located upstream of the first inlet, wherein the annular cooling flow passage has at least one internal wall for guiding airflow from the first inlet towards the airflow from the second inlet, the airflow from the first and second inlets coalesce within the annular flow passage prior to passing along the passage in a direction from the compressor to the turbine.

Owner:ROLLS ROYCE PLC

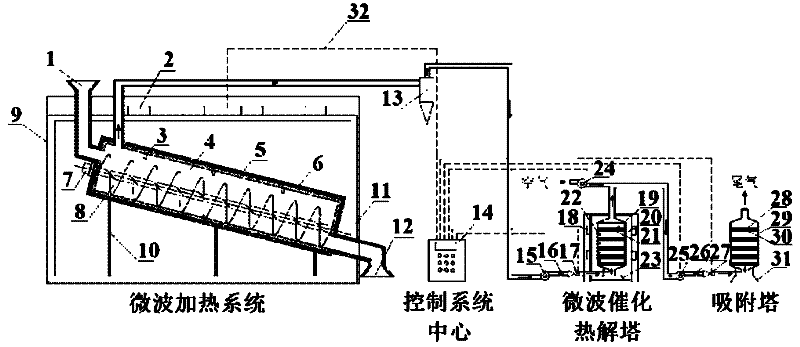

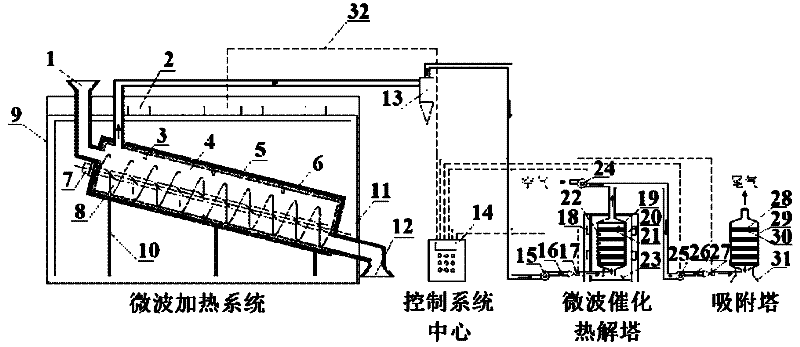

Microwave repair equipment for organic contaminated soil

ActiveCN102380507AMeet the requirement of heating up to 500°CMeet the requirements of heating up to 500°CDispersed particle separationContaminated soil reclamationCatalytic pyrolysisInsulation layer

The invention discloses microwave repair equipment for organic contaminated soil. The equipment comprises a charging and discharging system, a microwave heating system, a deduster, a tail gas treating system and a control system center, wherein, the charging and discharging system is arranged in the microwave heating system, and the microwave heating system, the deduster and the tail gas treatingsystem are connected sequentially. The microwave heating system comprises a first microwave generator and a cylindrical oven body, the inner layer of the cylindrical oven body is a silicon carbide layer, and the external layer of the cylindrical oven body is an alumina silicate heat-insulation layer; the tail gas treating system comprises a microwave catalytic pyrolysis tower and an adsorption tower, the microwave catalytic pyrolysis tower comprises a cylindrical alumina silicate insulation shell, multilayer silicon carbide porous filter boards and a catalyst, the multilayer silicon carbide porous filter boards are vertically inserted in the cylindrical alumina silicate insulation shell at equal distance, and the catalyst is arranged on the silicon carbide porous filter boards. The microwave repair equipment provided in the invention has the advantages of strong capability in treating organic contaminated soil, thorough treatment of tail gas, no secondary pollution, high efficiency, energy conservation and easy operation and control.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of synergetic extraction of coal bed gas of tool post type mined area and lower coal bed

ActiveCN106089290AAvoid recyclingAvoid collapse accidentsFluid removalDrainageEnvironmental engineeringCoal

The invention discloses a method of synergetic extraction of coal bed gas of a tool post type mined area and a lower coal bed. The method comprises the steps that firstly, a mine is surveyed; after the floor failure depth is determined, a horizontal well is constructed; the coal bed gas of the mined area is extracted; when the extraction amount of the coal bed gas during unit time is decreased to 20-40% of Q1, the extraction pressure is decreased circularly so that coal bed gas extraction can be continued; when the extraction amount is decreased to 10-18% of Q1, supercritical CO2 is injected for displacement; when the extraction mount is decreased below 20% of Q1 again, oriented fracturing is conducted, a vertical discharge well is arranged on the other side of the horizontal well, and discharging equipment is arranged for conducting coal bed gas extraction; and when the extraction amount of the coal bed gas is decreased below 20% of Q2, the supercritical CO2 is used for displacement again, and extraction is stopped till the extraction amount is decreased to 10% of Q2. By the adoption of the method, coal bed gas resources close to a thin coal seam is extracted along with the coal bed gas in the tool post type mined area, and recovery of gas resources in abandoned still coal seams is achieved.

Owner:TAIYUAN UNIV OF TECH

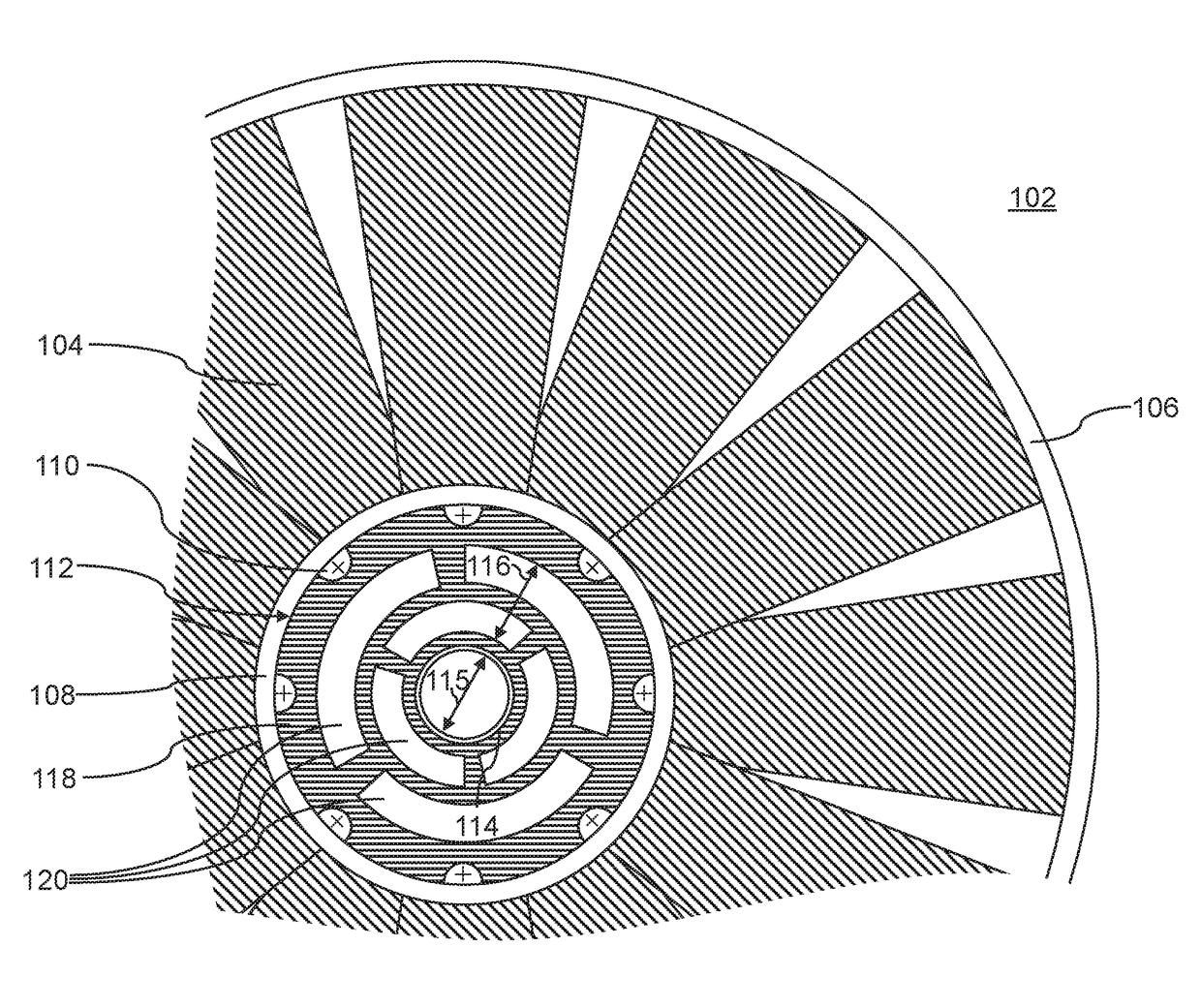

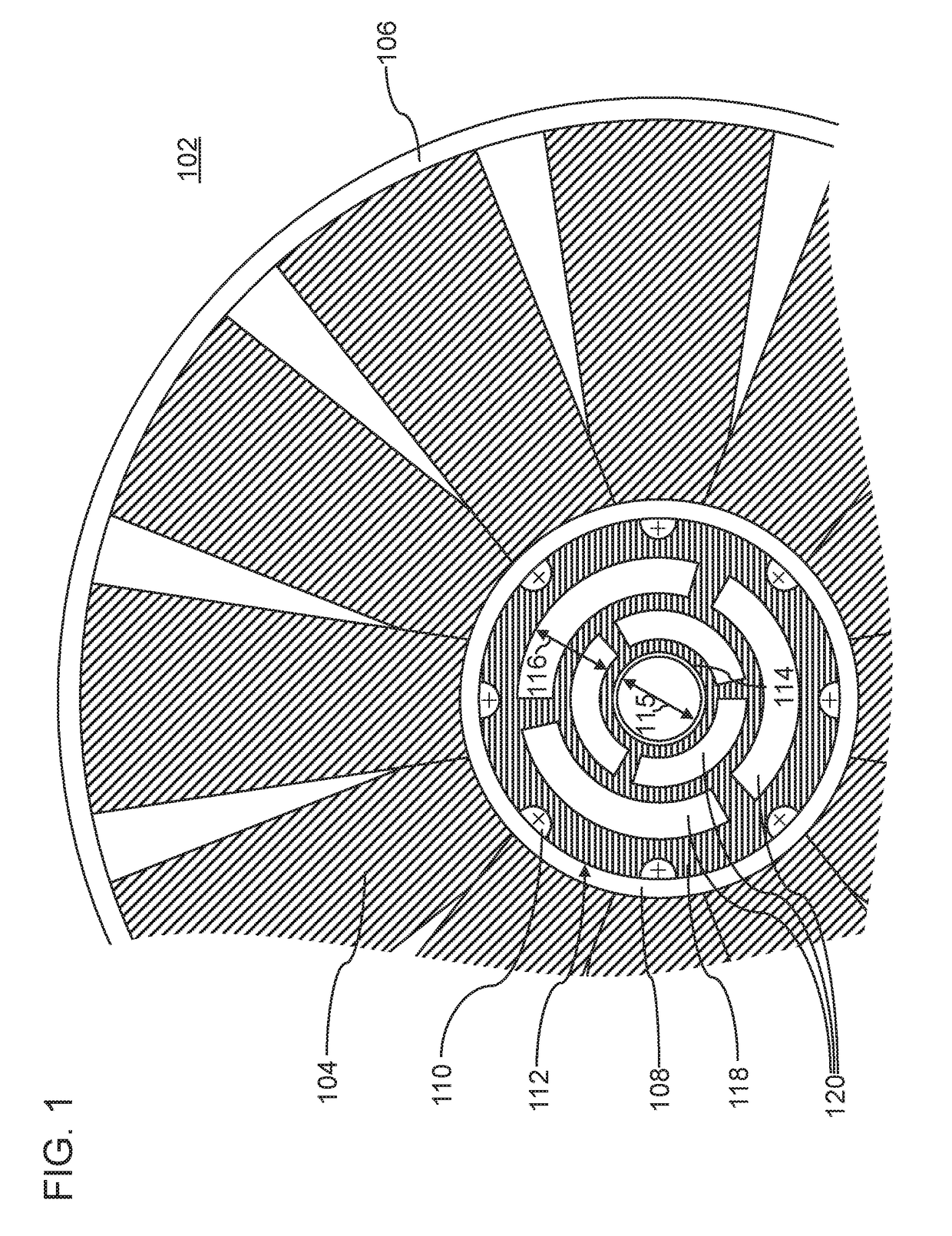

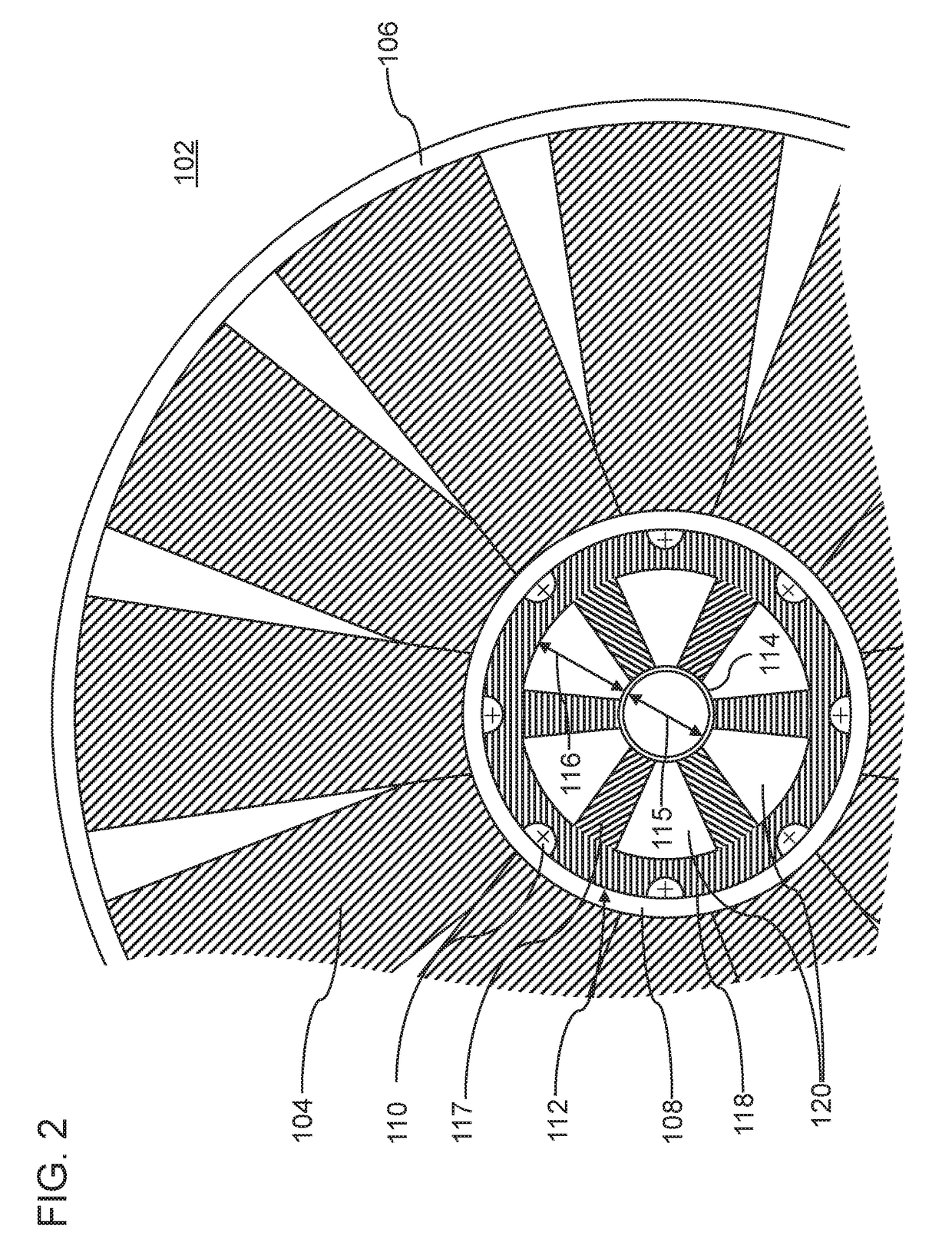

Axial fan wheel

ActiveUS20180112675A1Prevent air recirculationReduce power consumptionAir-treating devicesPump componentsImpellerDrive shaft

An axial fan wheel, in particular for the radiator of a motor vehicle engine, is described. The axial fan wheel includes a crown ring having a multiplicity of rotor blades, a hub having an inner ring which is connected or connectable to a drive shaft, and having, for the purpose of torque transmission, connection surfaces along an outer periphery of the hub which are connected to the inner ring and to the crown ring. The hub has through-passages between the inner ring and the outer periphery. At least one element, arranged rotationally fixedly on the axial fan wheel inside the crown ring, is designed to maintain a pressure difference in the axial direction when the axial fan wheel rotates.

Owner:MAN TRUCK & BUS AG

Sludge curing material for comprehensively utilizing phosphorous gypsum

The invention discloses a sludge curing material for comprehensively utilizing phosphorous gypsum. The sludge curing material consists of the following materials in percentage by weight: 20%-60% of phosphorous gypsum, 5%-25% of coal ashes, 10%-30% of mineral powder, 8%-25% of limestone and 0.2%-3% of an activator. According to the sludge curing material, the waste phosphorous gypsum is used as the main material and supplemented with industrial waste such as the mineral powder, the coal ashes as well as limestone or cheap materials, thereby realizing recycling the industrial waste, and lowering environmental pollution; meanwhile, sludge curing production cost is lowered, quality of a sludge curing product is improved, engineering construction application such as road foundation and foundation filler is realized, needs of aggregate for building are lowered, and therefore, construction material cost and transportation cost are lowered.

Owner:JIANGSU NATURE WAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com