Patents

Literature

45results about How to "Increase tonnage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of enhancing fine particle dewatering

InactiveUS6855260B1Increase tonnageGood removal effectWaste water treatment from quariesDrying solid materials with heatFine particulateSlurry

A new method of improving the process of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic with its water contact angle considerably below 90°. A low hydrophile-lipophile balance (HLB) number surfactant is then added to the slurry, so that the surfactant molecules adsorb on the moderately hydrophobic surface primarily by hydrophobic attraction and, thereby, increase its contact angle close to or above 90°. By virtue of the greatly enhanced hydrophobicity, the water molecules adhering to the surface are destabilized and removed more readily by a mechanical dewatering process. Any nonionic surfactant with its HLB number below about 15 may be used for the hydrophobicity enhancement. The surfactants may be used in conjunction with appropriate solvents such as light hydrocarbon oils and short-chain alcohols. The moisture reduction can be further improved by using appropriate electrolytes in conjunction with the low HLB surfactants, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and by using combinations thereof.

Owner:YOON ROE HOAN

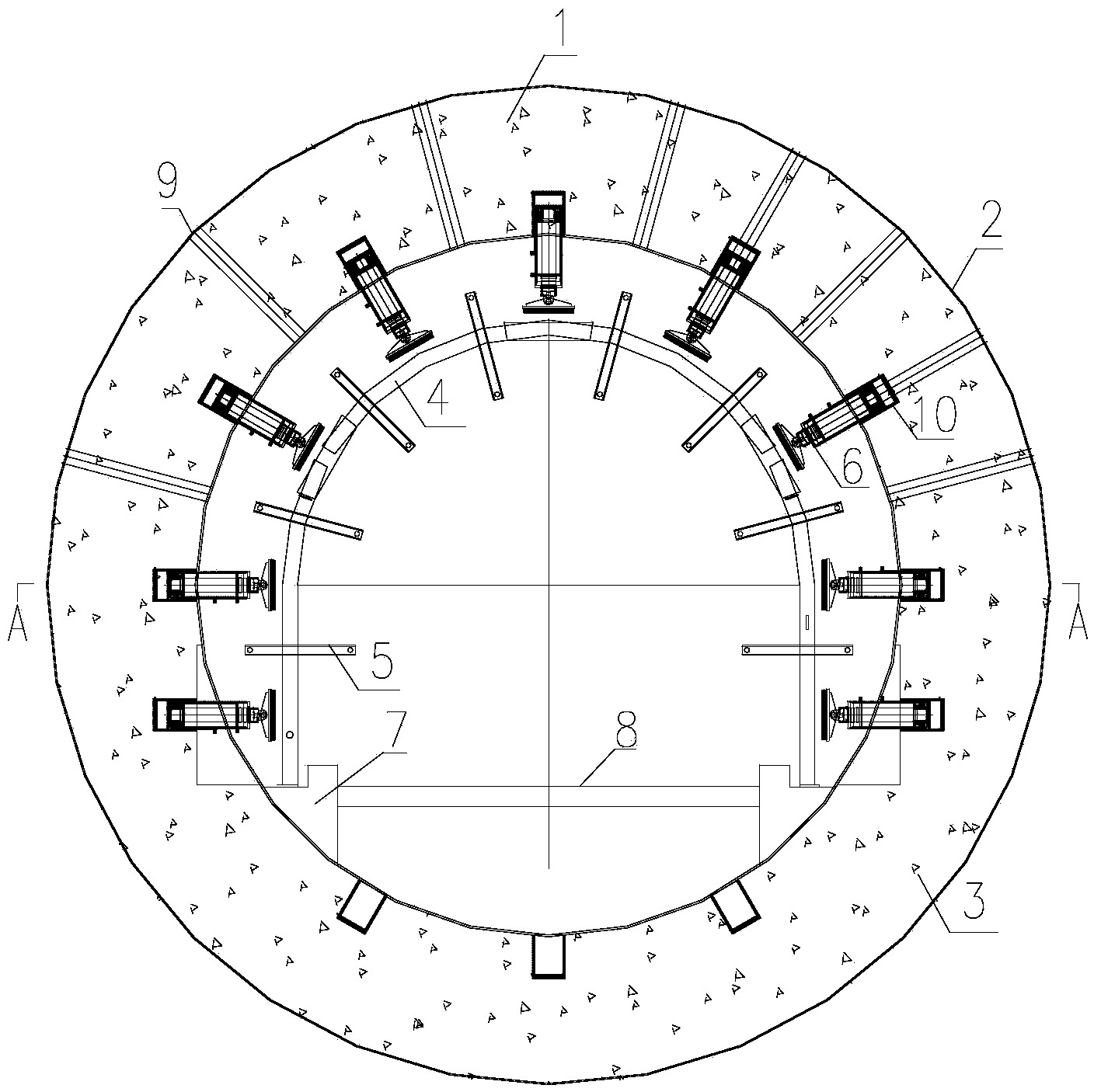

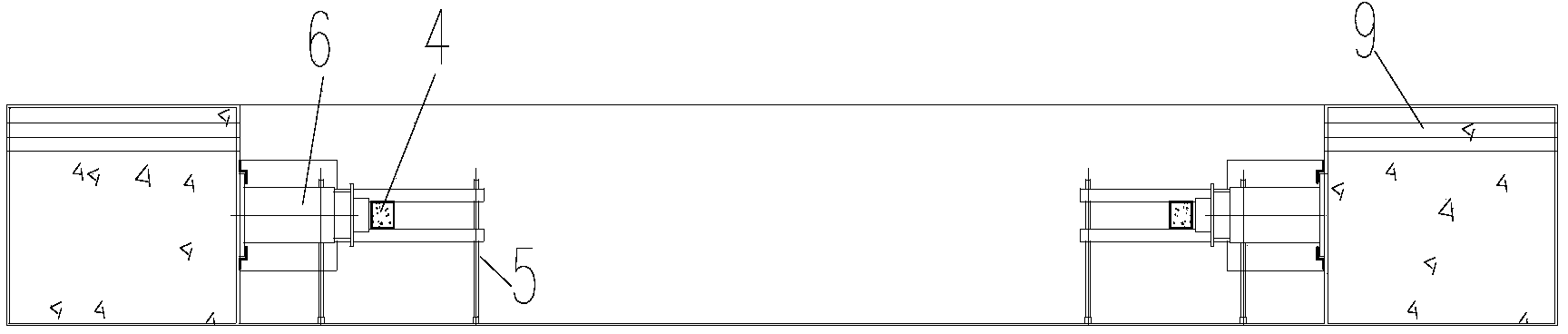

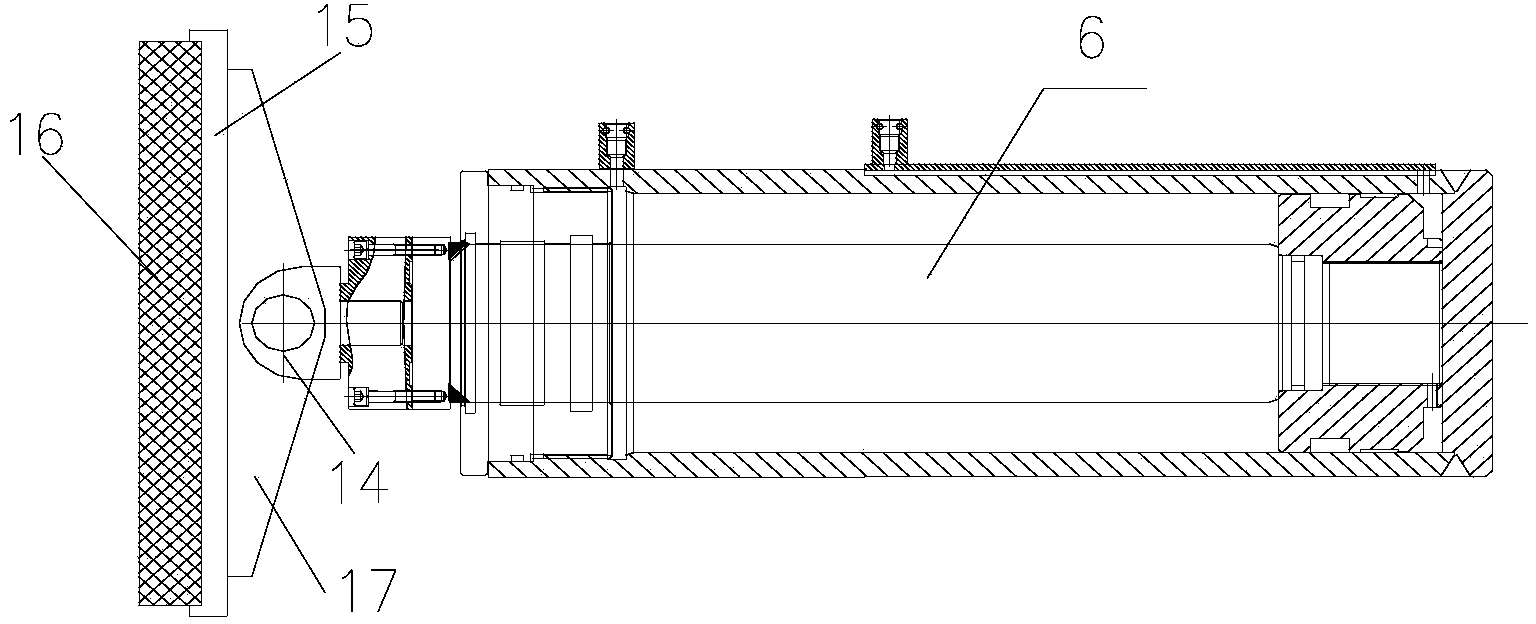

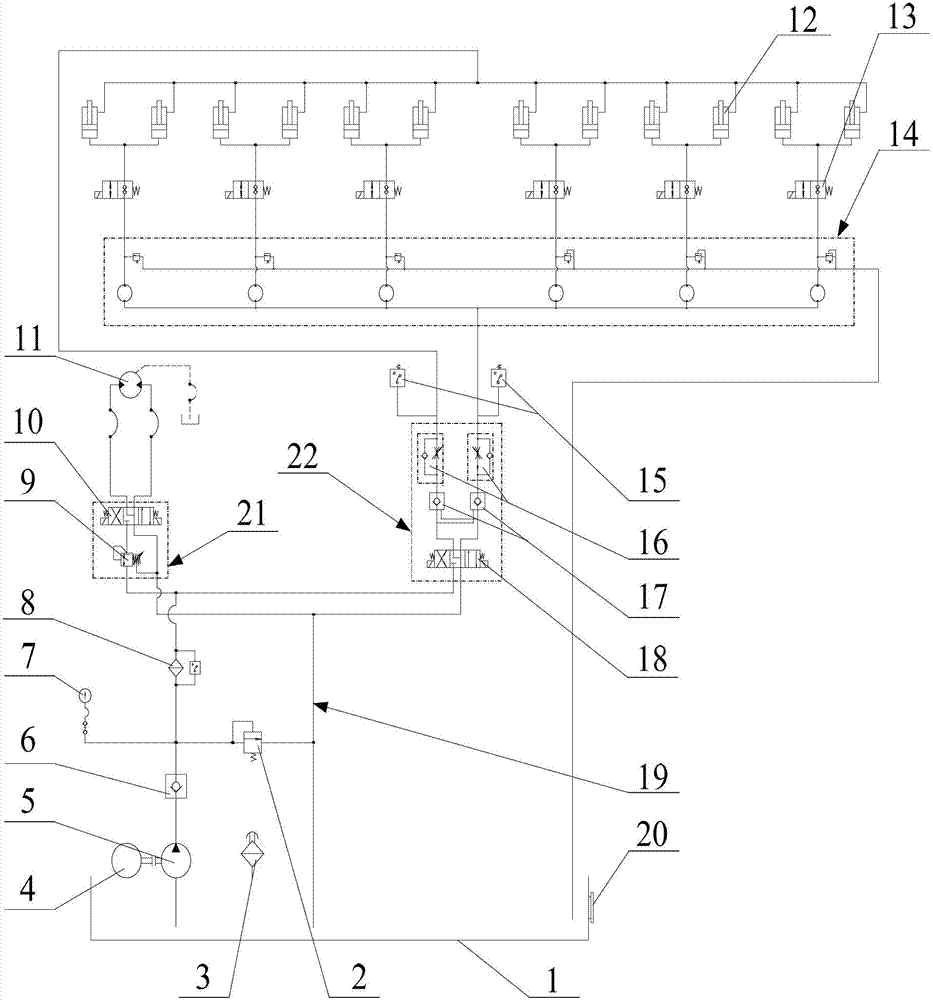

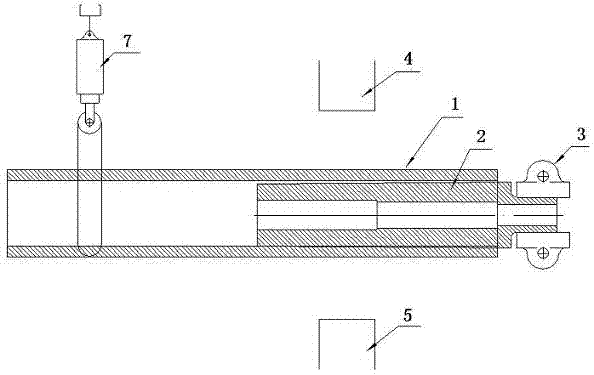

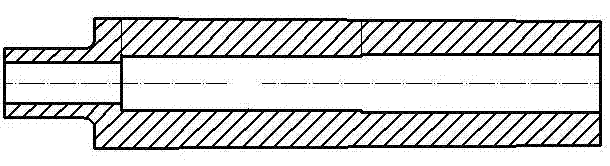

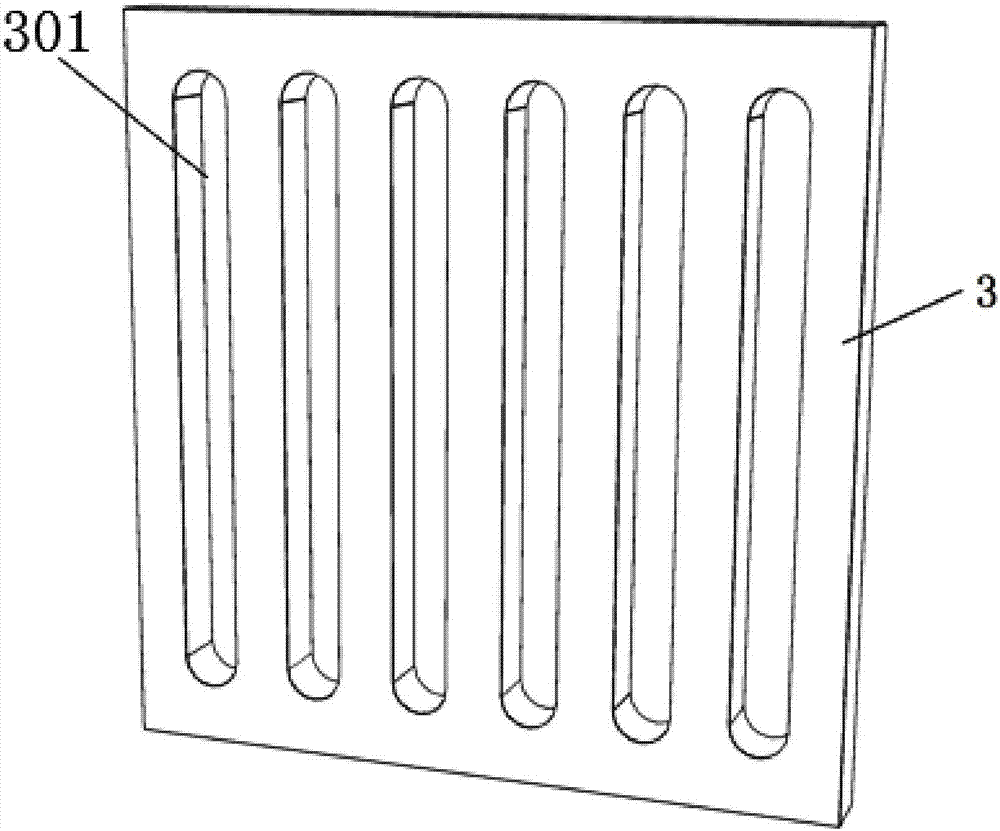

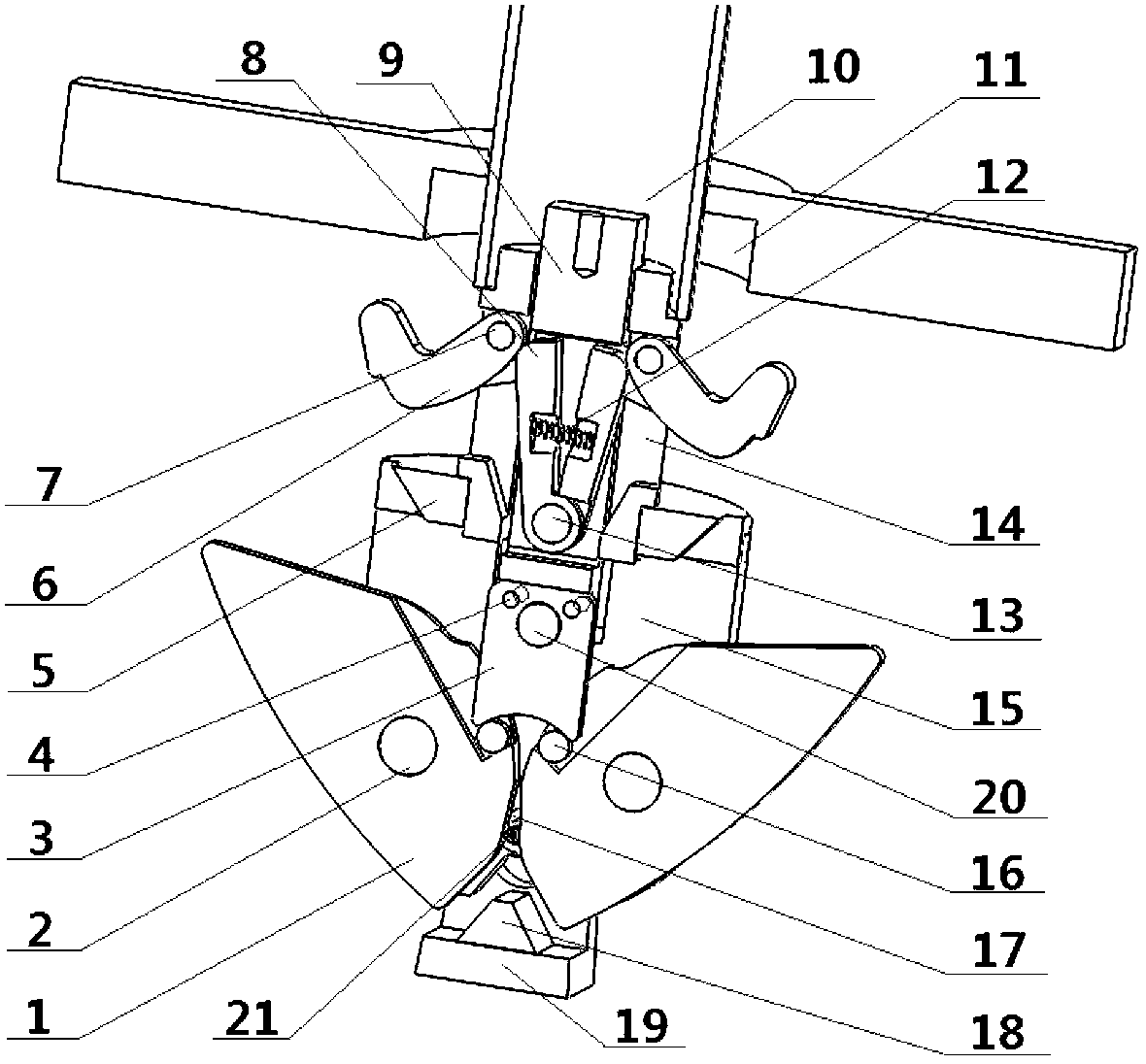

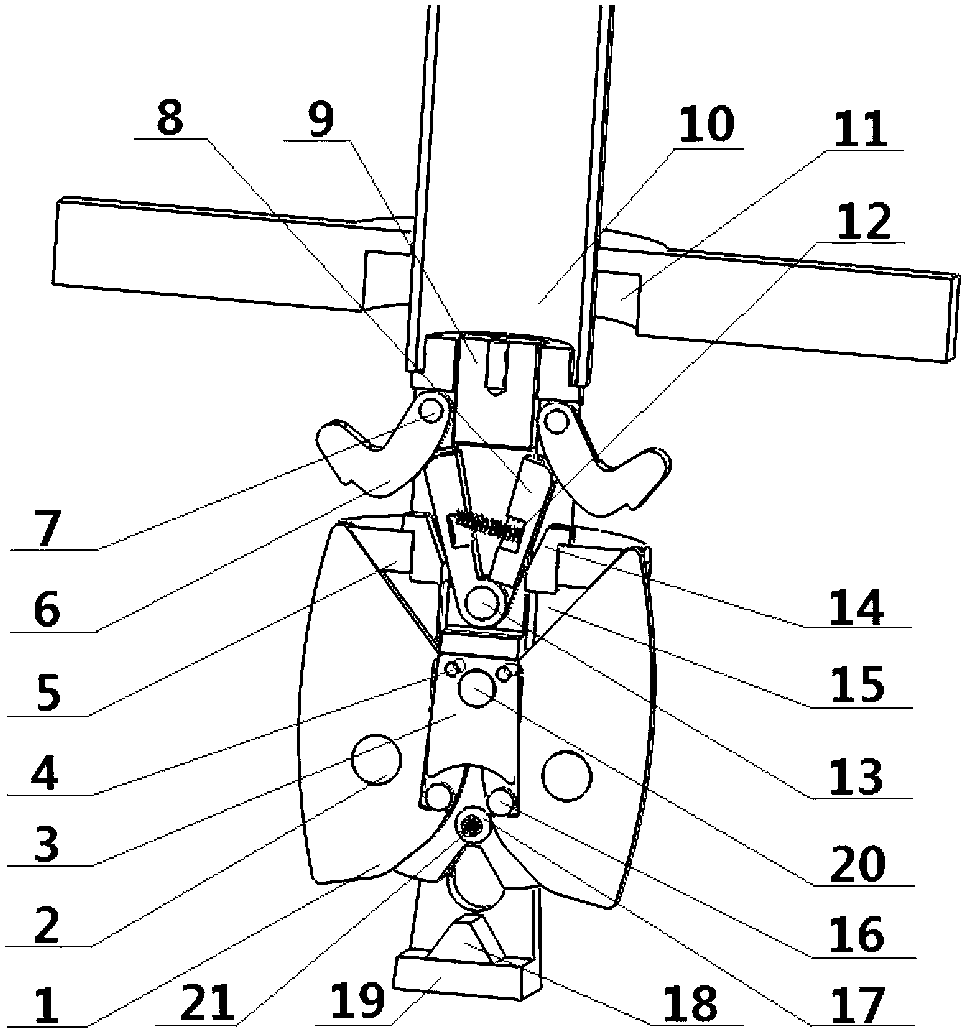

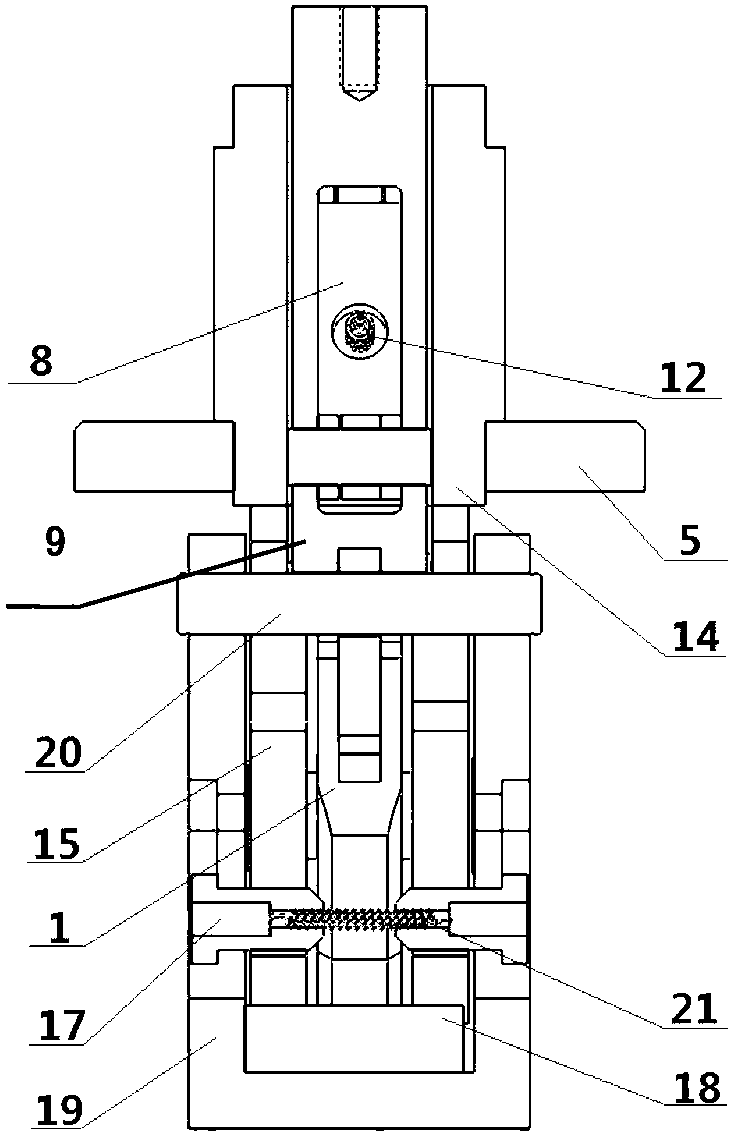

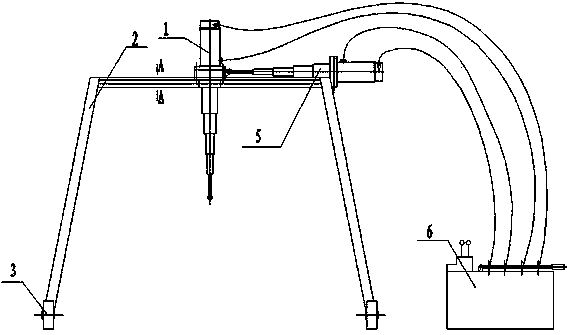

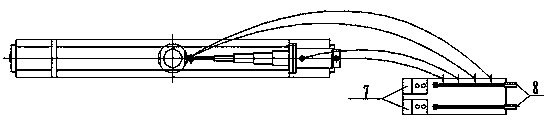

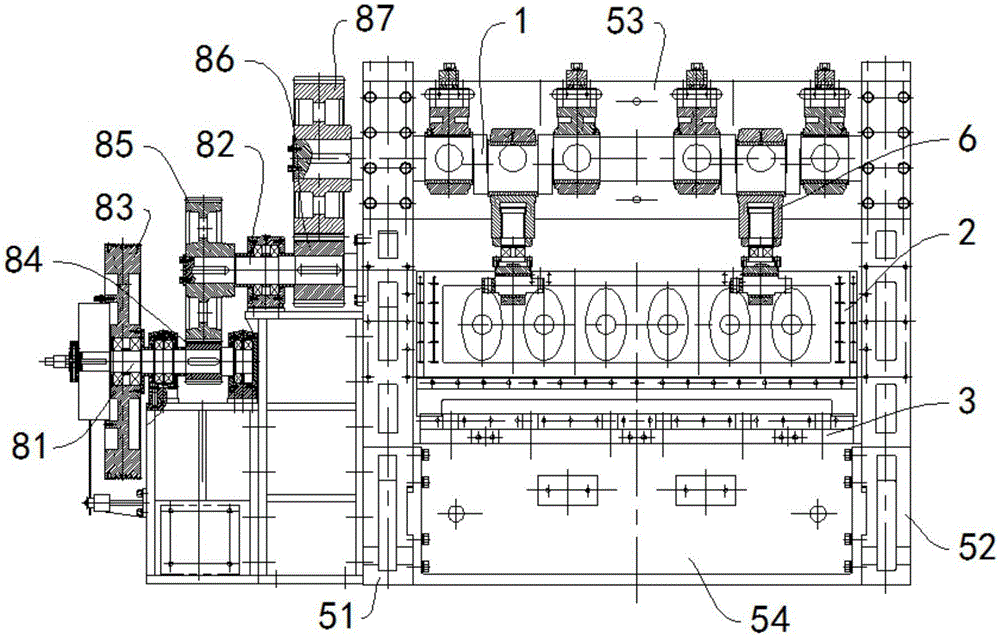

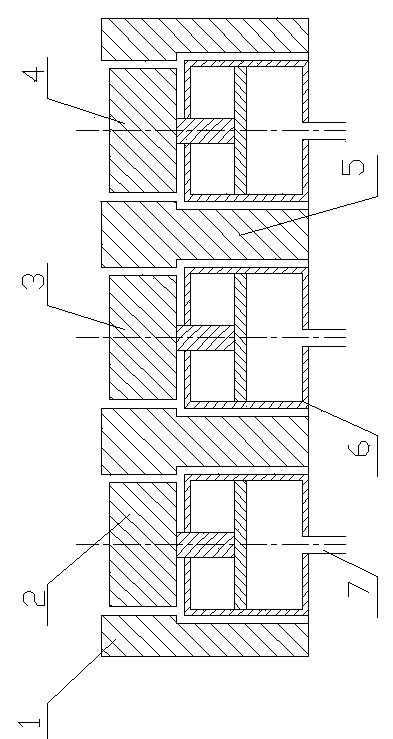

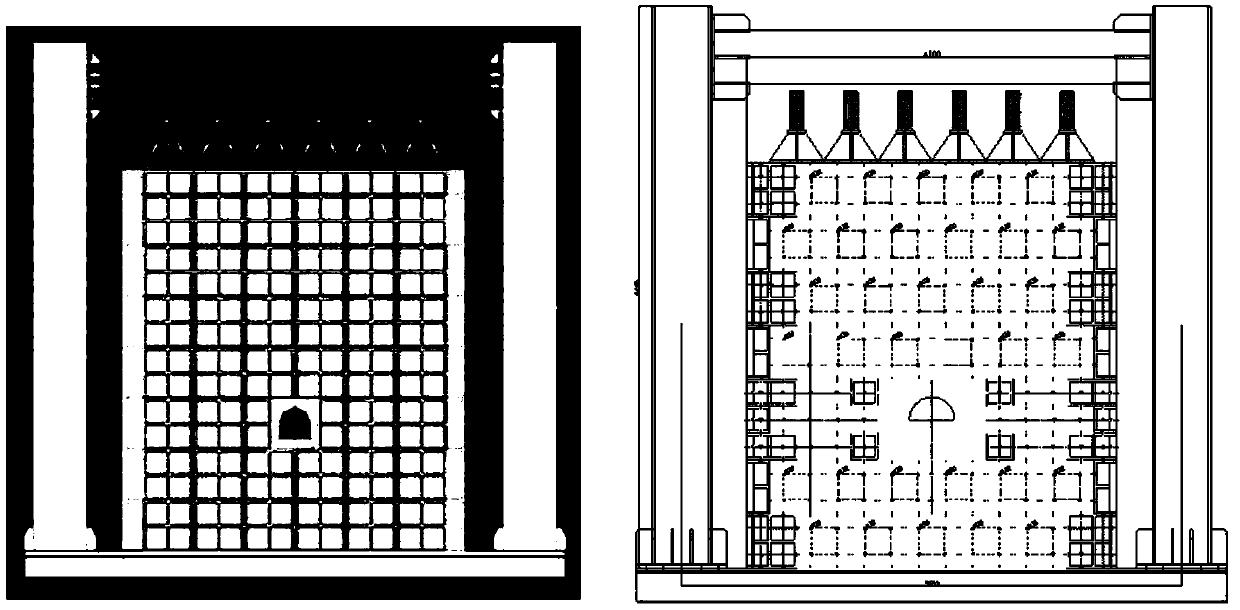

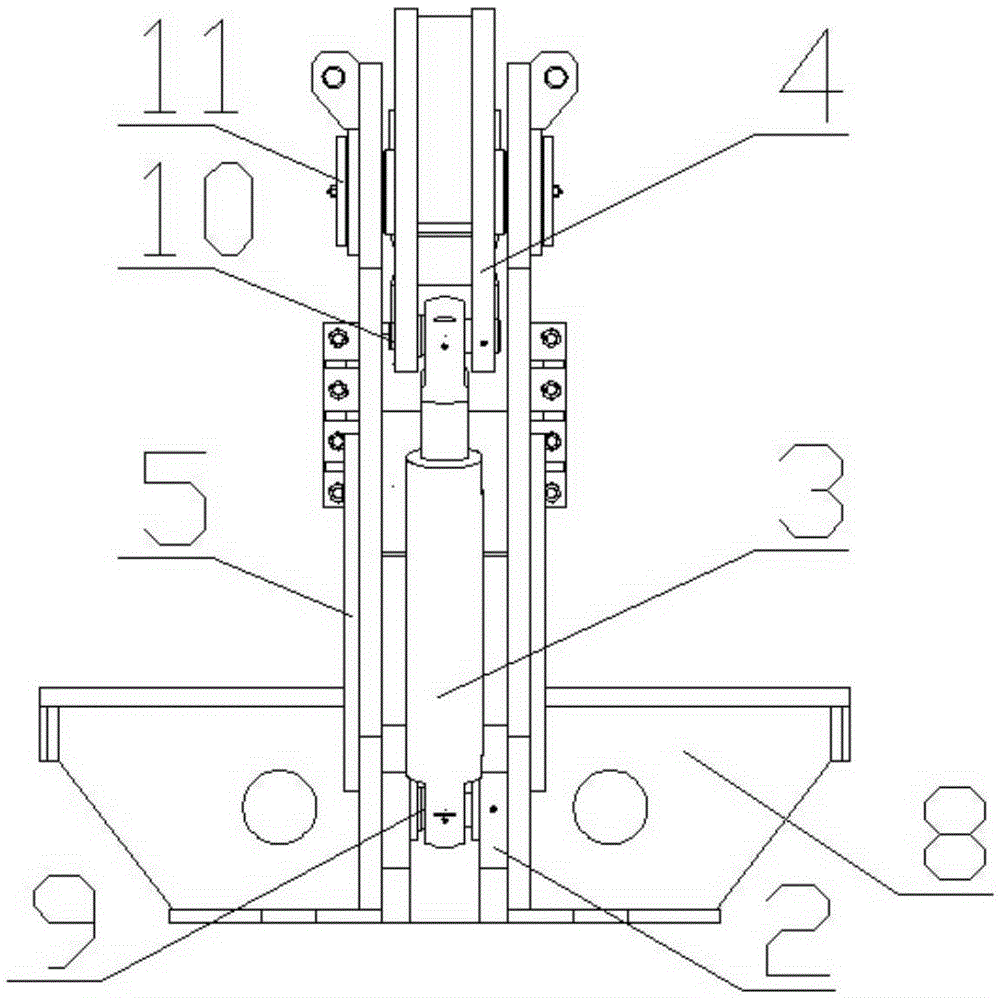

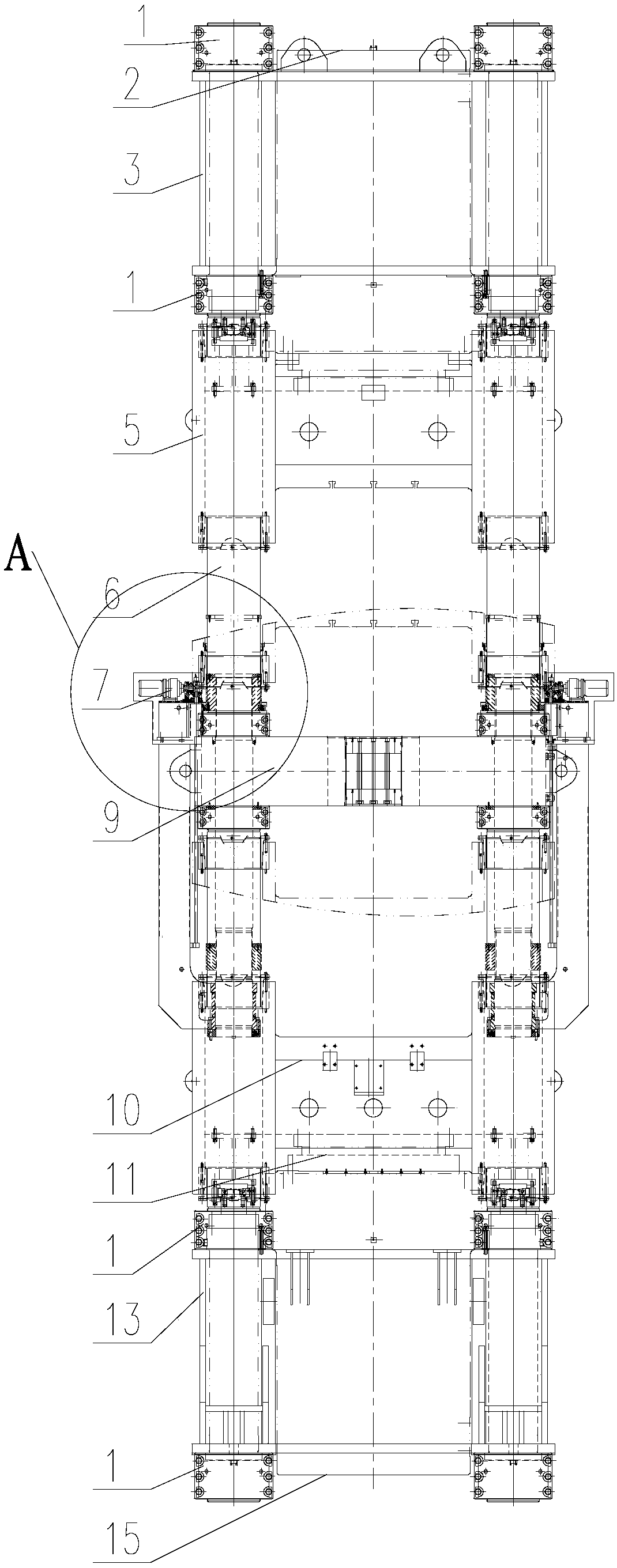

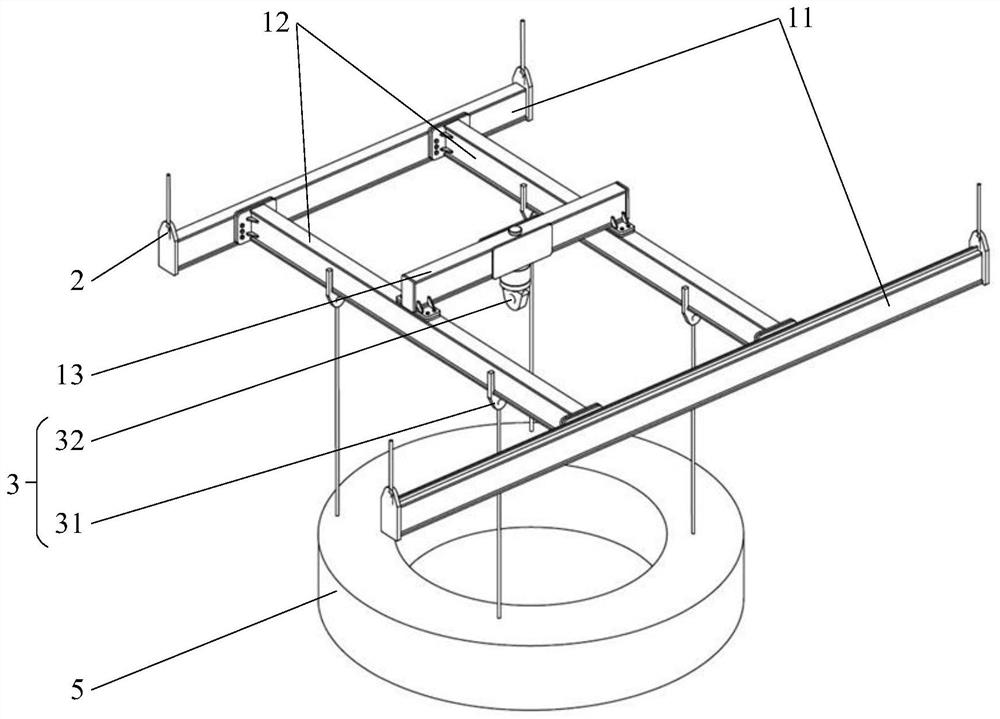

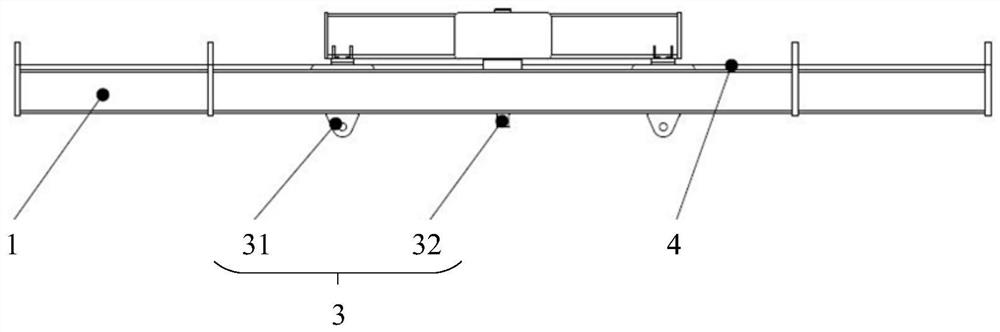

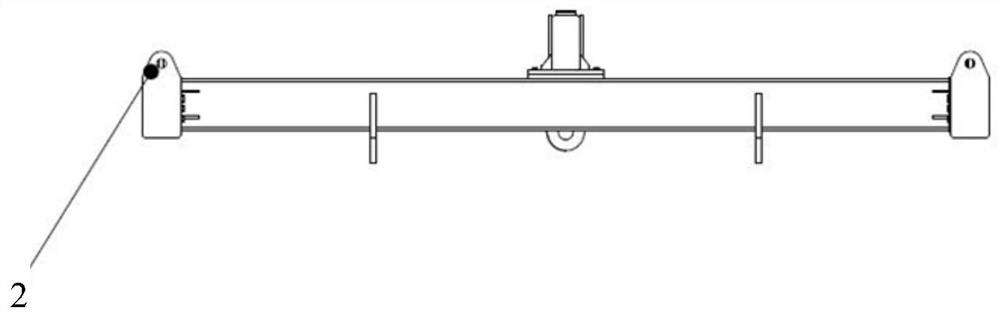

Large mechanical test system for combined adjustable constraint concrete arch frame

ActiveCN103883333AEfficient detection of acoustic emission response behaviorRealize mechanical testUnderground chambersTunnel liningForce structureHydraulic cylinder

The invention relates to a large mechanical test system for a combined adjustable constraint concrete arch frame. The system comprises a monitoring system, a hollow cylindrical counter force structure, a hydraulic loading device and an auxiliary loading device, wherein the monitoring system is used for monitoring and collecting arch frame parameters and data. The inner cylindrical surface of the counter force structure is provided with multiple oil cylinder positioning holes, the hydraulic loading device is disposed in the oil cylinder positioning holes, the hydraulic loading device comprises a hydraulic oil cylinder arranged in the oil cylinder positioning holes, a force transmission dispersion device connected with the hydraulic oil cylinder and a control system, and the hydraulic oil cylinder achieves loading through contact of the force transmission dispersion device and an arch frame to be tested. By means of the system, a 1:1 mechanical test can be carried out on the constraint concrete arch frame and other conventional arch frames, and tests of arch frames of different sizes and shapes can be achieved.

Owner:SHANDONG UNIV +1

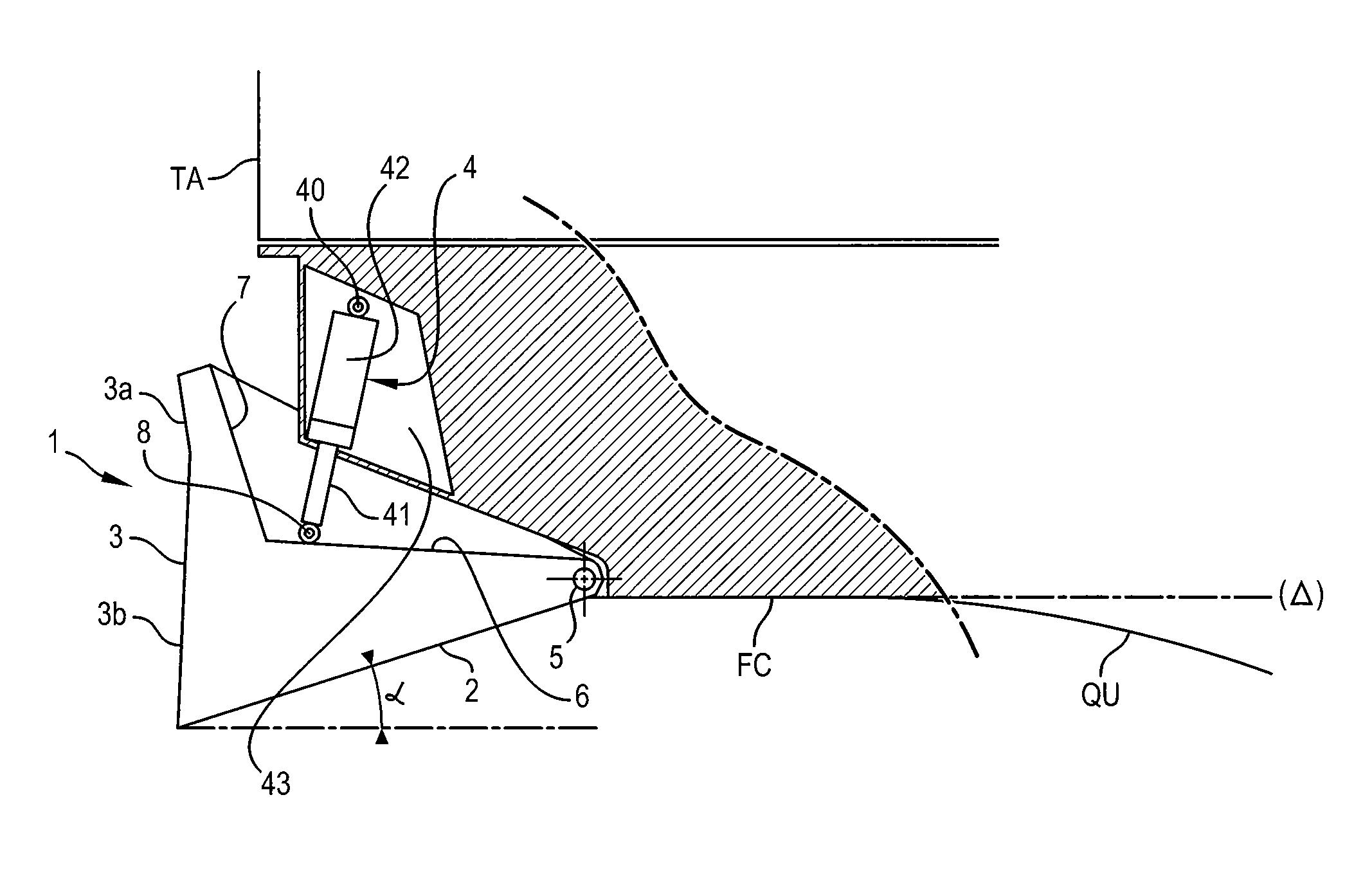

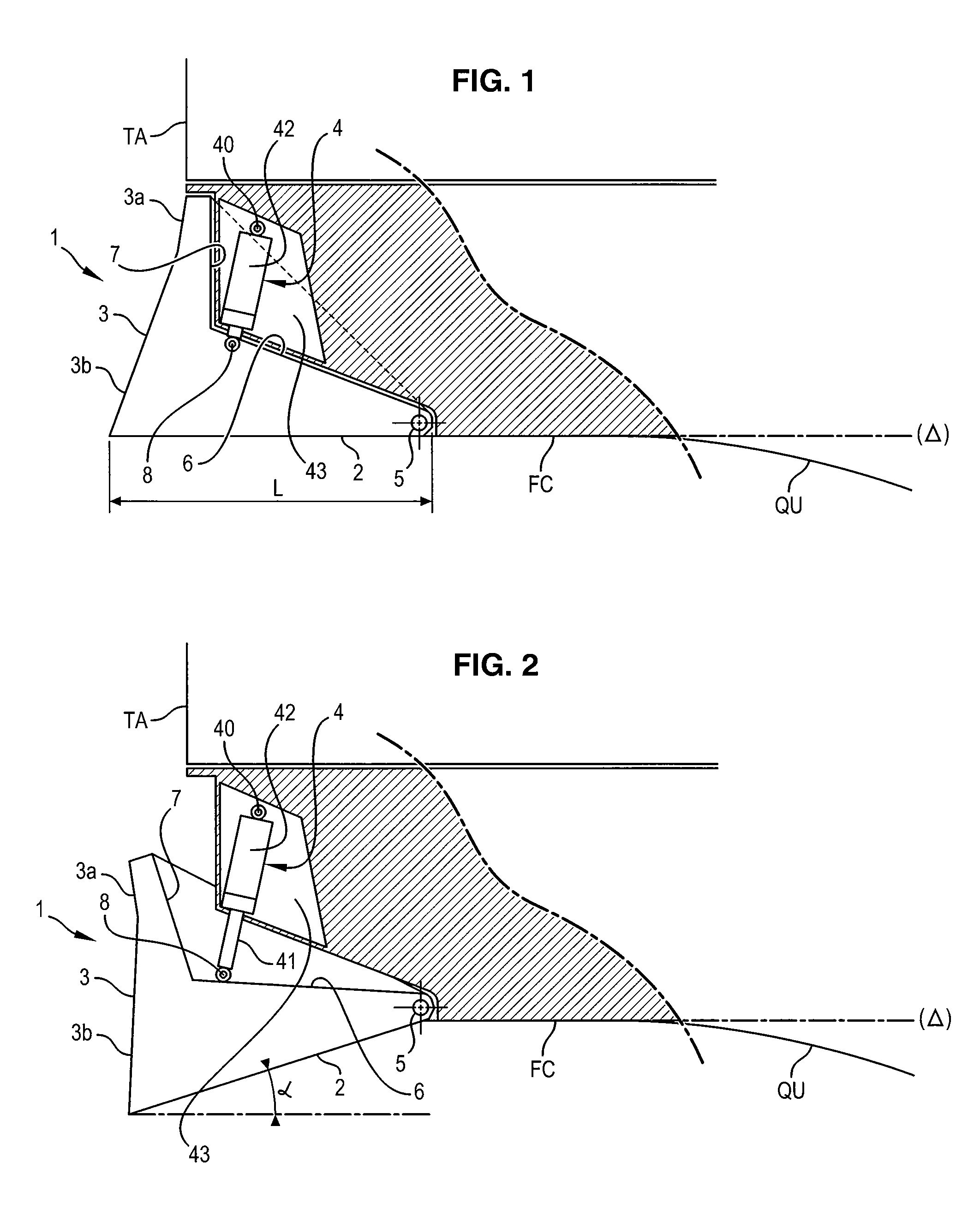

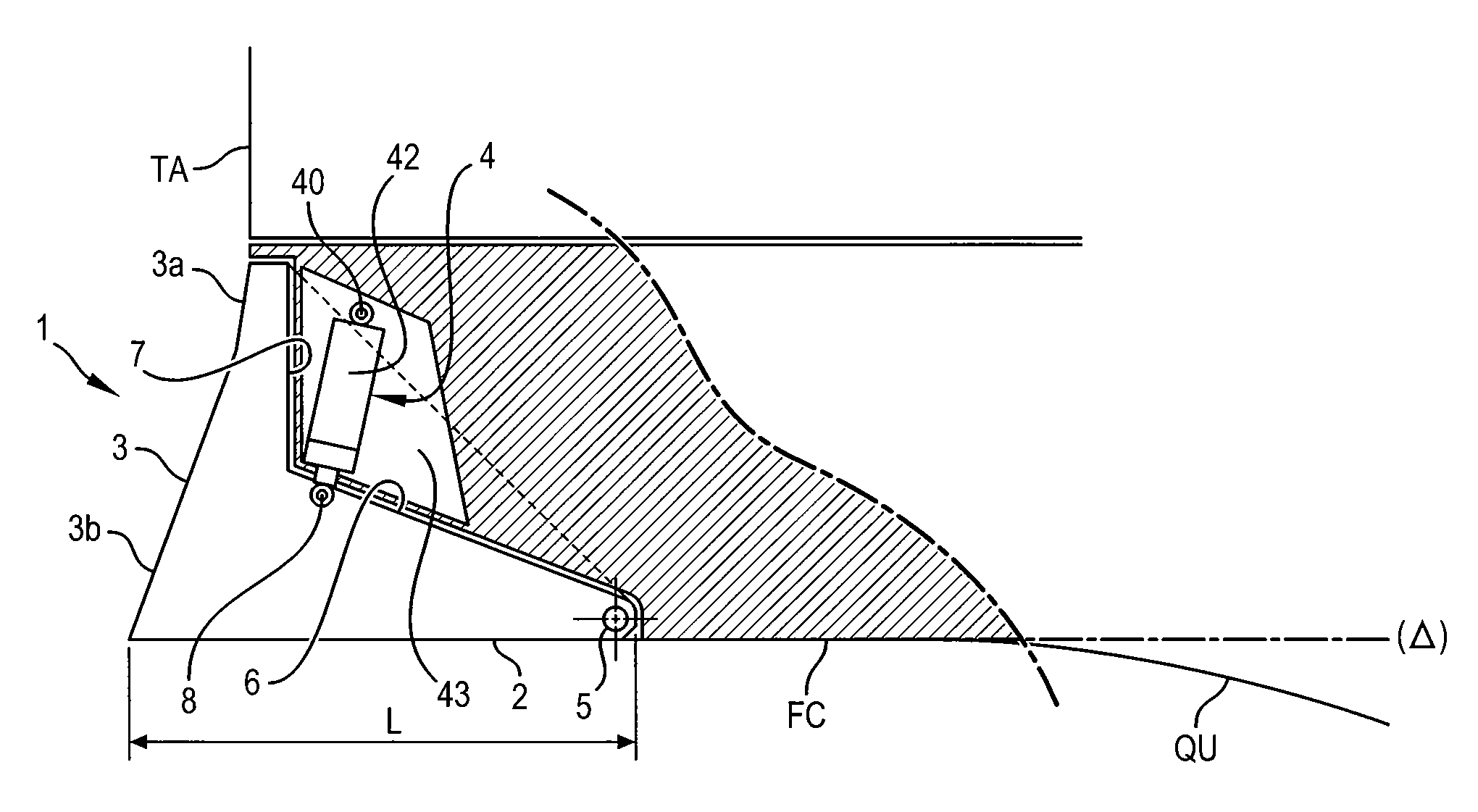

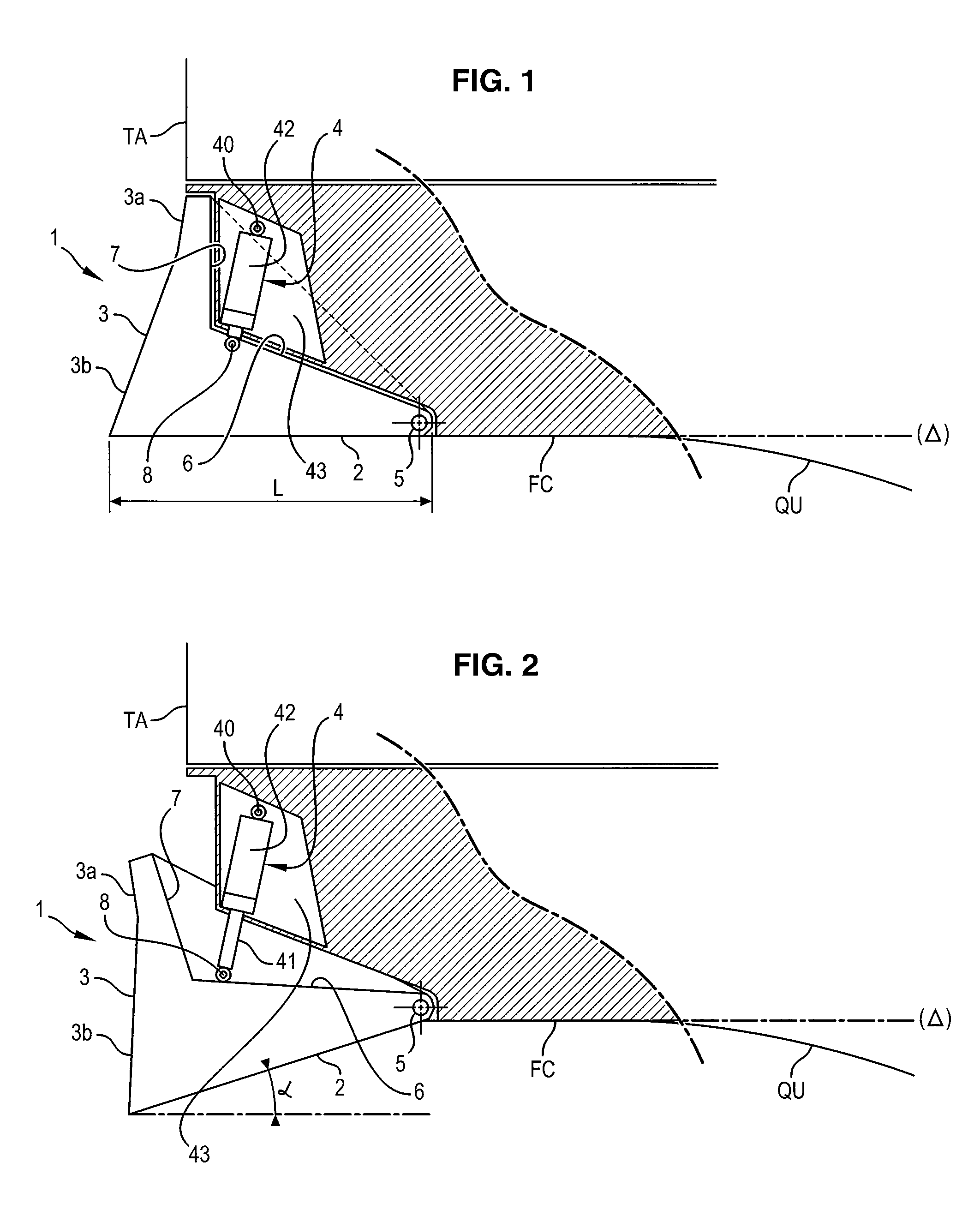

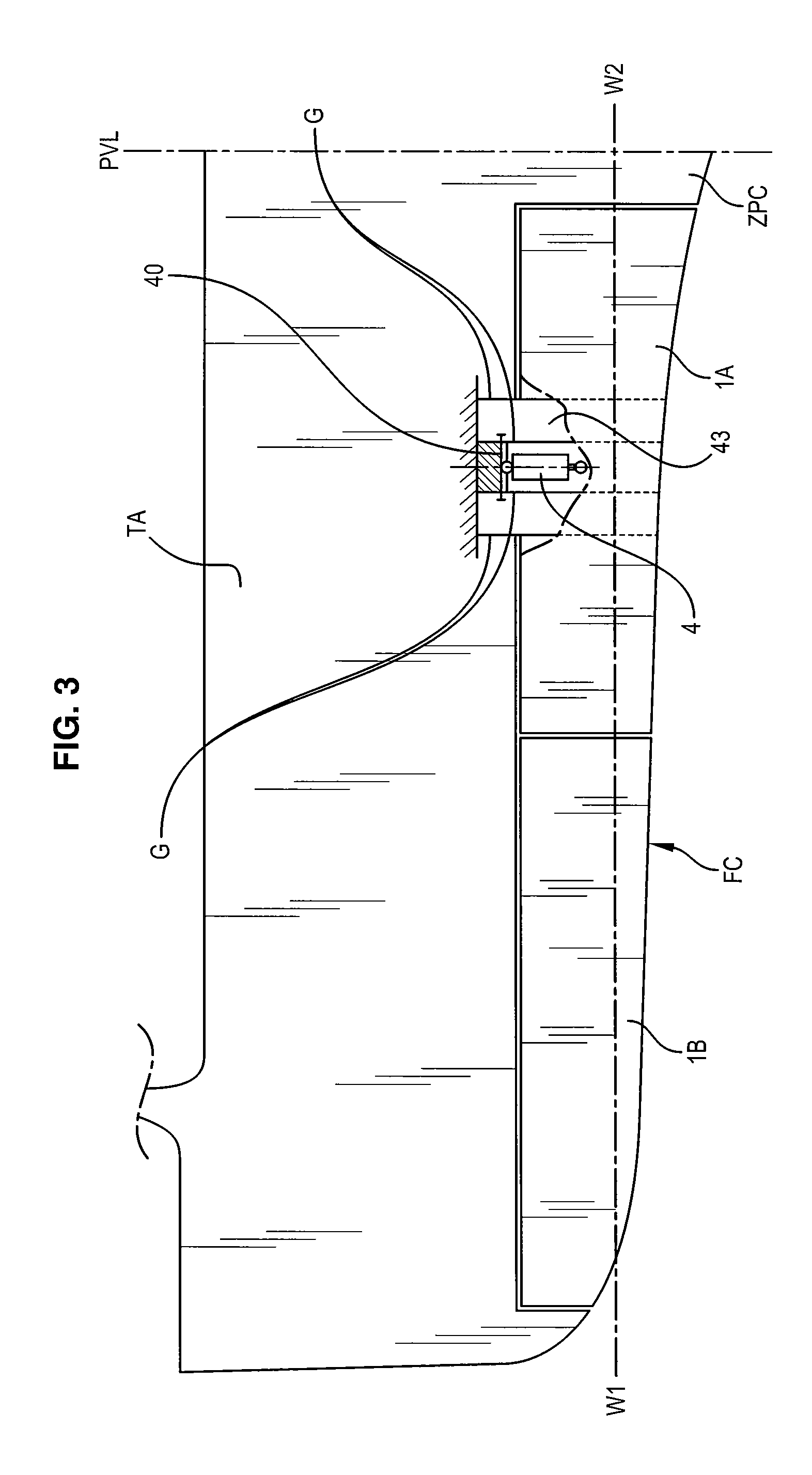

Ship with stern equipped with a device for deflecting a flow of water

ActiveUS8096255B2Increase tonnageSmall sizeVessel stability improvementMovement controllersWater flowStern

The device comprises a plurality of deflector members (1) having a submerged lower face (2), called first face, generally fitting into the extension of the hull bottom (FC) of the ship, toward the rear thereof, while forming an angle (α) in relation to a general plane (Δ) tangent to this bottom (FC), characterized by the fact that these deflector members (1) are articulated to the hull and are juxtaposed side by side, over all, or practically all, the width of the stern, control means (4) making it possible to cause it to pivot in one direction or the other in order to vary said angle (α), these means being housed in part in a protective case.

Owner:STX FRANCE CRUISE

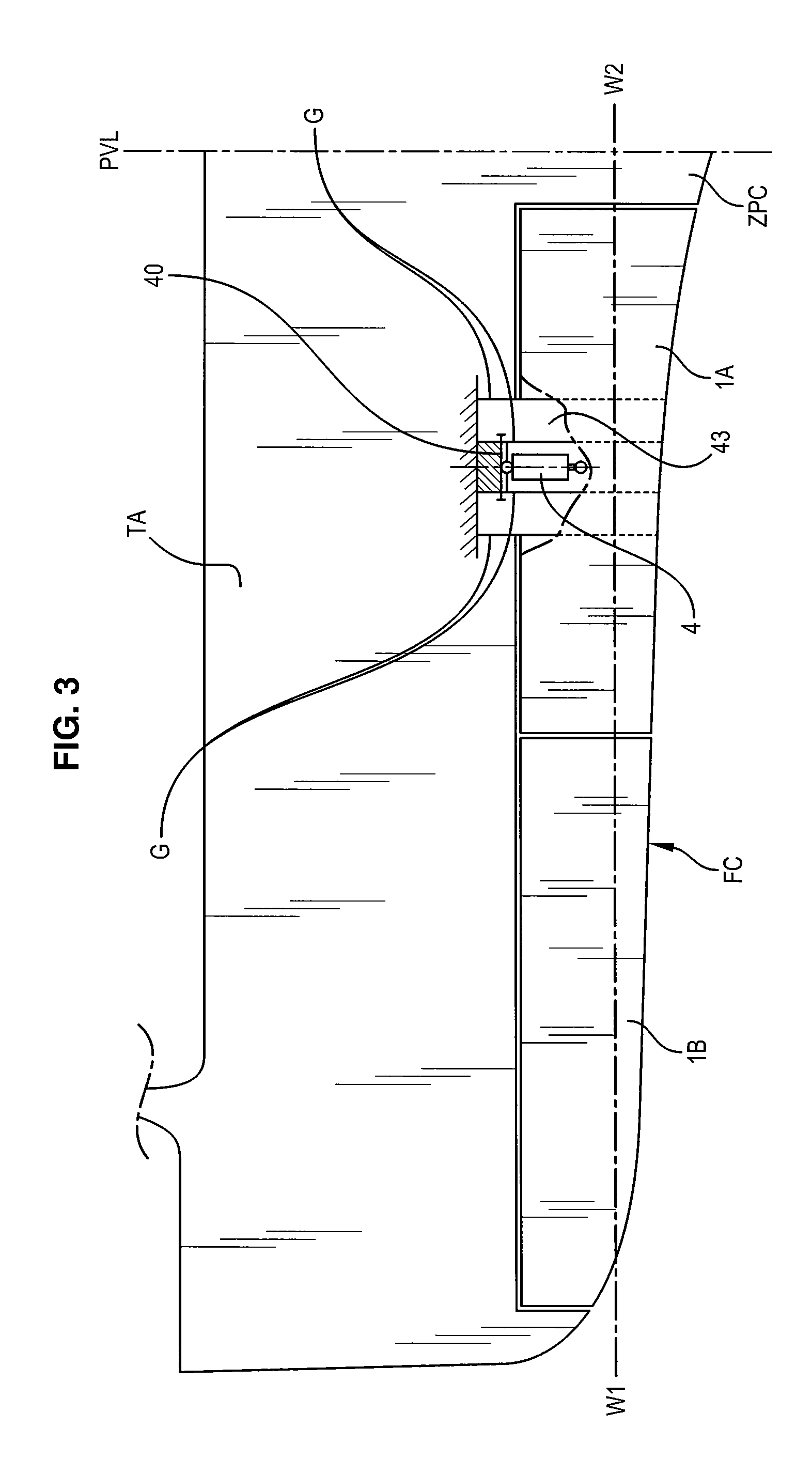

Hydraulic control system for forklift, and forklift

ActiveCN102900715AIncrease tonnageGuaranteed uptimeServomotor componentsServomotorsControl systemFuel tank

The invention provides a hydraulic control system for a forklift. The hydraulic control system comprises an oil tank, a pumping component, a first control branch for controlling and driving the forklift to move forward or backward and a second control branch for controlling and driving the forklift to ascend or descend, wherein the pumping component pressurizes hydraulic oil in the oil tank and conveys the pressurized hydraulic oil to the first control branch and the second control branch; and return oil in the first control branch and the second control branch is conveyed to the oil tank through a return oil pipeline. The invention also provides the forklift. By the technical scheme, the lifting tonnage of the forklift is increased; the forklift stably runs, wide-range stepless speed change is easily realized, and power loss during speed change is reduced simultaneously; by a hydraulic drive mode, the weight of the forklift is greatly reduced, and the service lives of elements are prolonged due to a self-lubricating function of the oil; and besides, the environment is slightly polluted, and the forklift is low in noise.

Owner:BEIJING SUPER HYDRAULIC

Methods of enhancing fine particle dewatering

InactiveUS20050139551A1Increase tonnageGood removal effectWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningFine particulateSlurry

A new method of improving the process of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic with its water contact angle considerably below 90°. A low hydrophile-lipophile balance (HLB) number surfactant is then added to the slurry, so that the surfactant molecules adsorb on the moderately hydrophobic surface primarily by hydrophobic attraction and, thereby, increase its contact angle close to or above 90°. By virtue of the greatly enhanced hydrophobicity, the water molecules adhering to the surface are destabilized and removed more readily by a mechanical dewatering process. Any nonionic surfactant with its HLB number below about 15 may be used for the hydrophobicity enhancement. The surfactants may be used in conjunction with appropriate solvents such as light hydrocarbon oils and short-chain alcohols. The moisture reduction can be further improved by using appropriate electrolytes in conjunction with the low HLB surfactants, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and by using combinations thereof.

Owner:YOON ROE HOAN

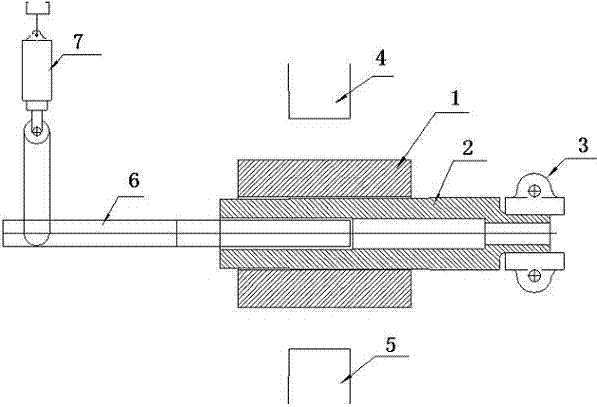

Method for forging super-long hollow part from short core rod through free forging press

ActiveCN102357625ASolve the clamping torque problemIncrease tonnageMetal-working apparatusPunchingTempering

The invention belongs to the technical field of forging and in particular relates to a method for forging a super-long hollow part through an oil pressing and forging machine. The method comprises the steps of heating a steel ingot, cutting and blanking through an oil press, upsetting, punching, chambering, drawing a core shaft, forging to form a finished product, annealing, roughly processing, tempering and finely processing to form the finished product. On the premise of not increasing equipment, the clamping moment problem of a free forging oil press and an operation machine can be solved by using a specific tooling and a unique forging method. According to the method disclosed by the invention, the tonnage for the free forging press to forge the steel ingot can be greatly increased; by using the method, a pipe casting die blank beyond the clamping moment of the free forging press can be successively forged; furthermore, the free forging operation machine cannot operate in overloading the forging process; and the forging capability of the equipment is greatly increased.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Process for the production of seamless tubes

InactiveUS6089066ASimple systemAddress rising pricesMetal rolling stand detailsMetal rolling arrangementsBiomedical engineering

Owner:MANNESMANN AG

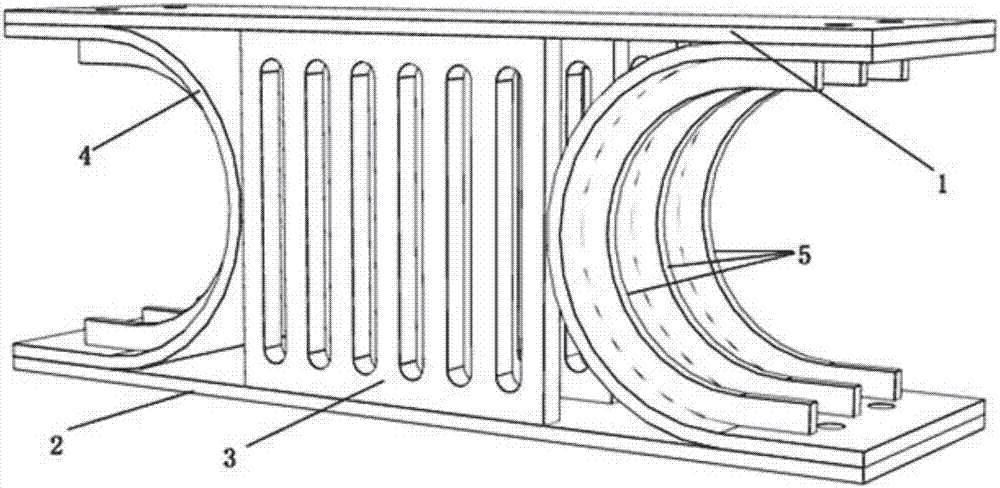

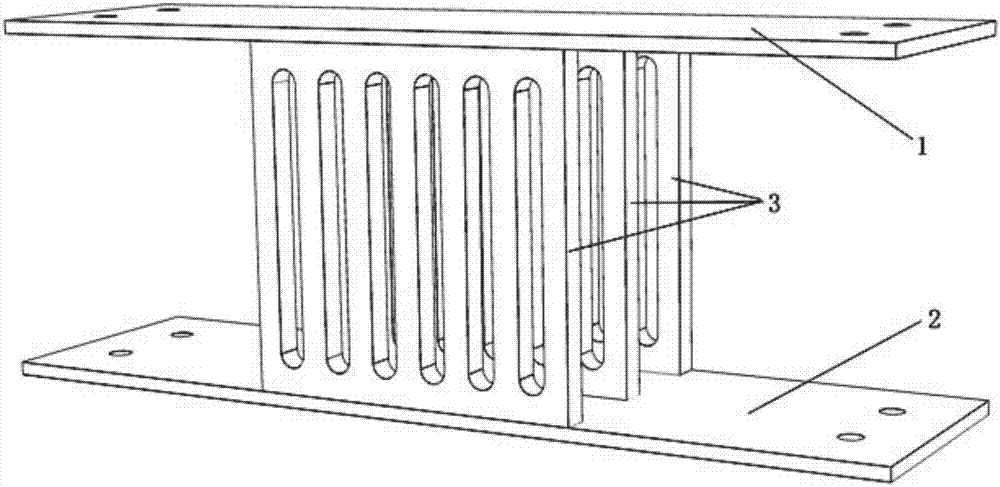

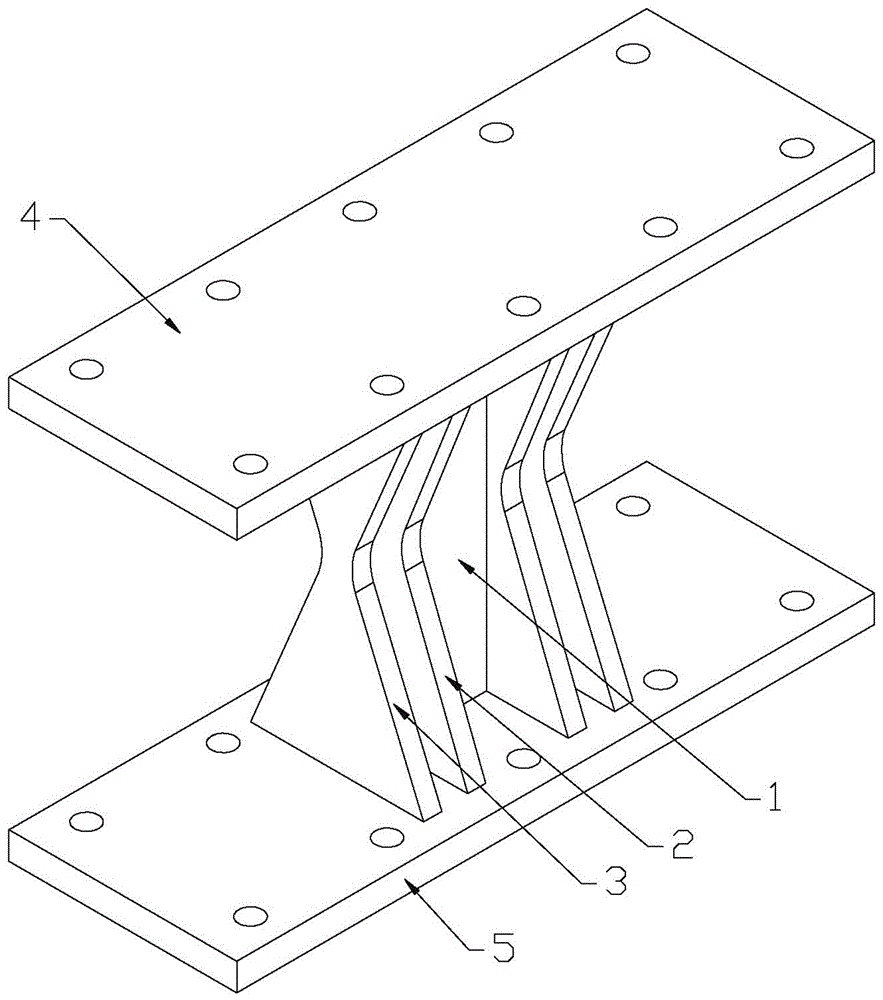

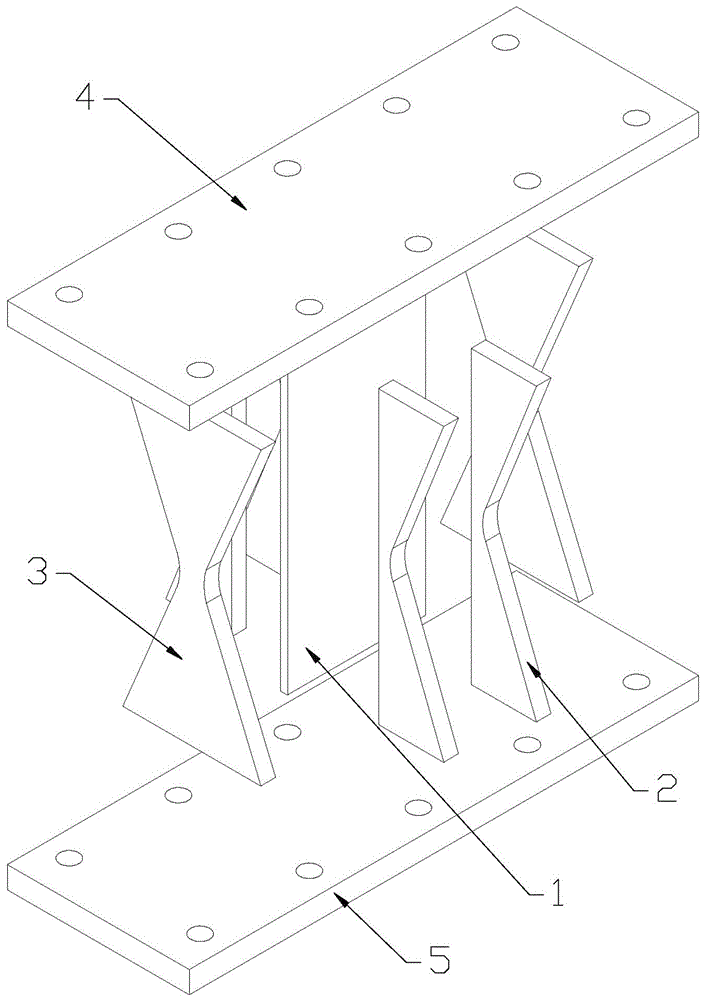

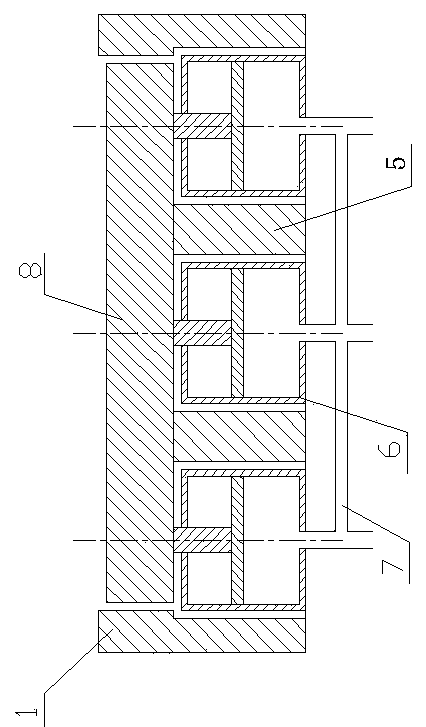

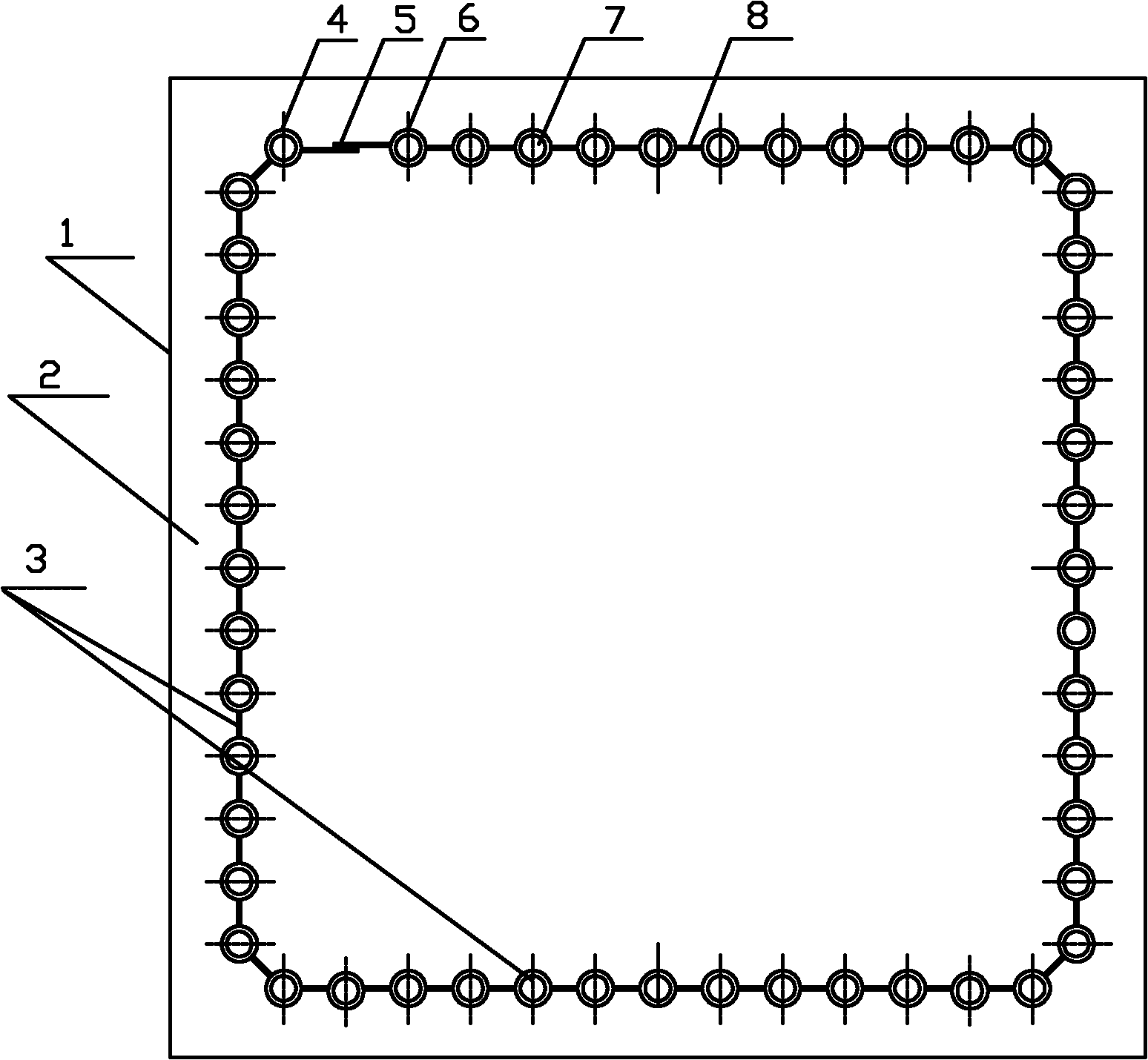

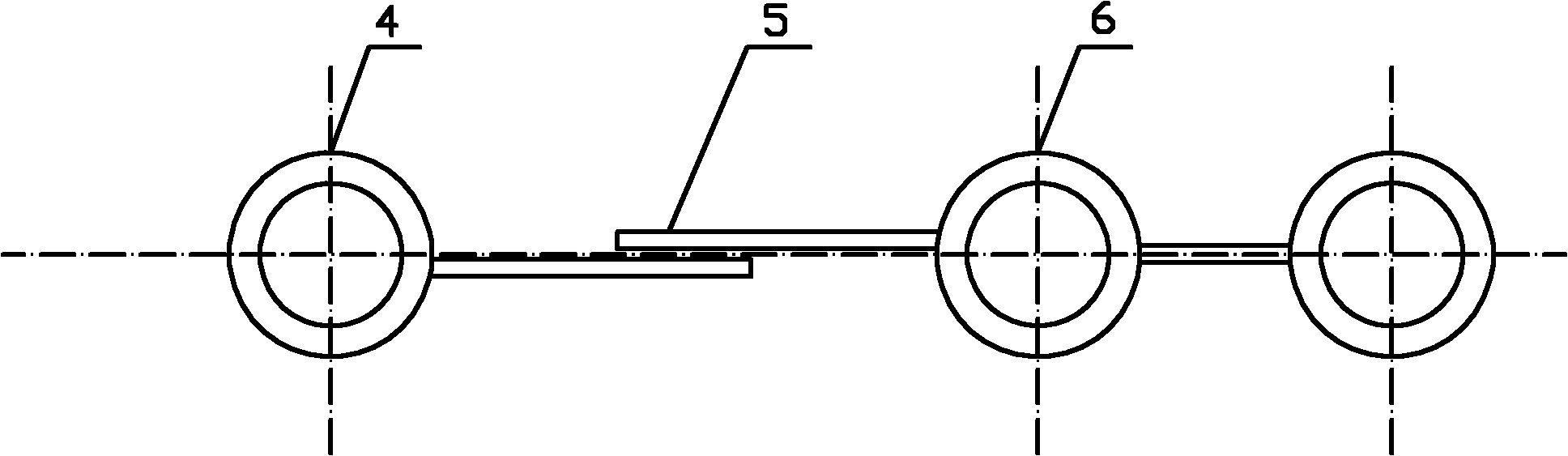

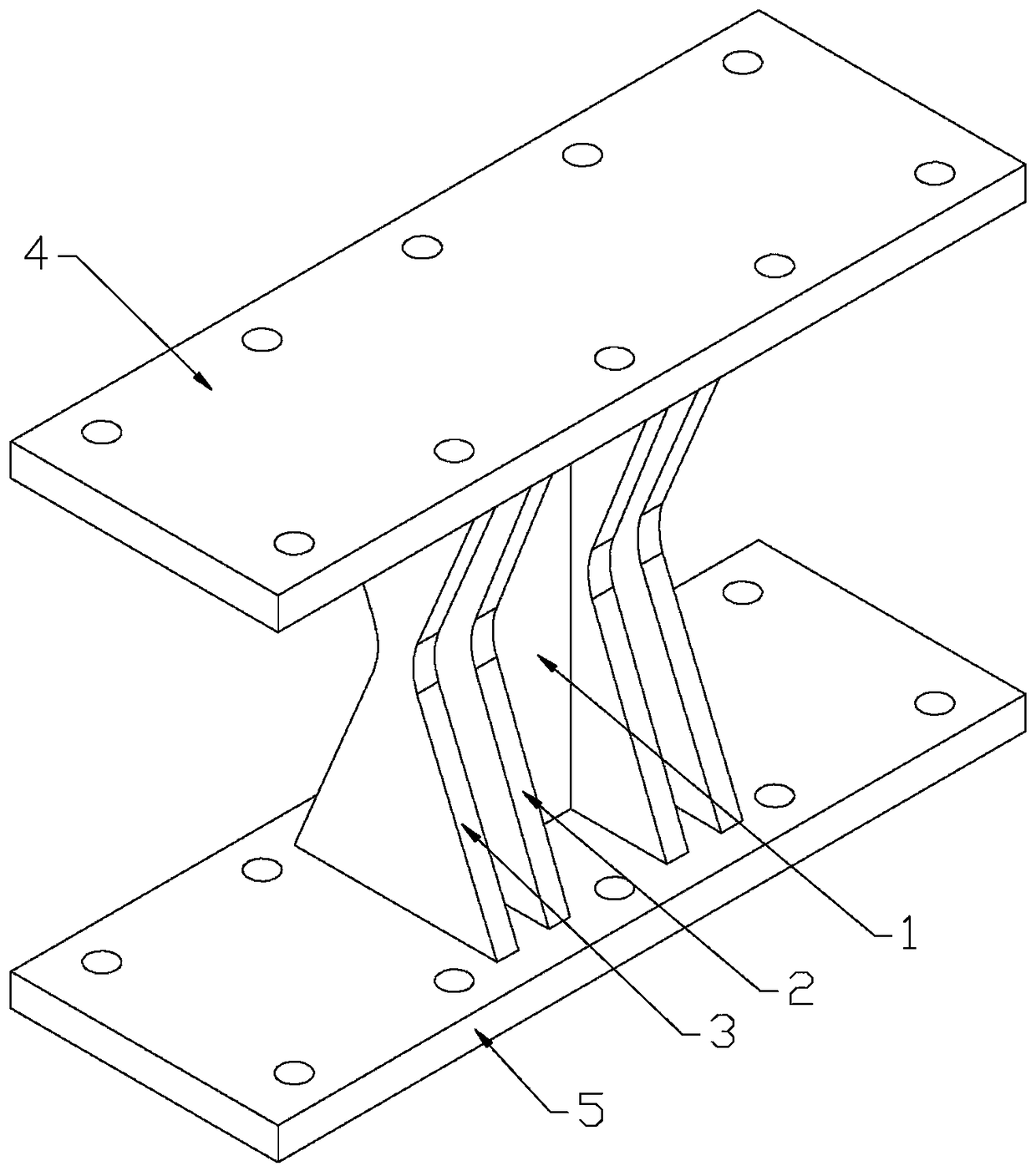

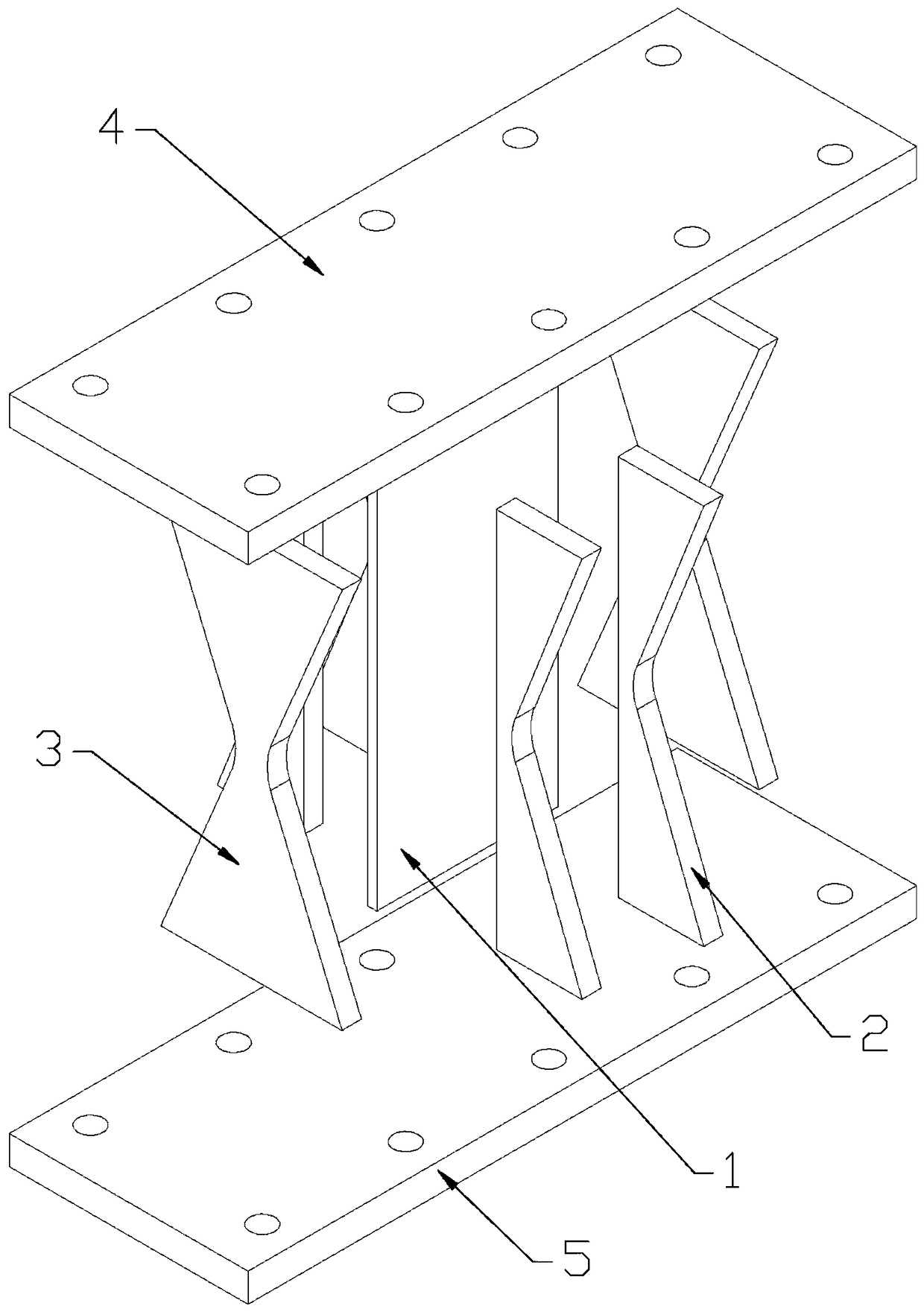

Staged energy-consuming metal damper

PendingCN107419815ASame sizeIncrease tonnageProtective buildings/sheltersShock proofingEconomic benefitsArchitectural engineering

The invention discloses a staged energy-consuming metal damper. The staged energy-consuming metal damper comprises a first connecting plate and a second connecting plate which are arranged in parallel and opposite to each other, wherein at least one first energy-consuming straight steel plate and two second energy-consuming bent steel plates are further arranged between the first connecting plate and the second connecting plate, and the upper end and the lower end of the first energy-consuming straight steel plate are connected with the first connecting plate and the second connecting plate separately and vertically; the two second energy-consuming bent steel plates are symmetrically arranged at the left and right sides of the first energy-consuming straight steel plate in the length direction of the first energy-consuming straight steel plate, and the curved mouth of each second energy-consuming bent steel plate backs on to the first energy-consuming straight steel plate; the upper end and the lower end of each second energy-consuming bent steel plate are connected with the first connecting plate and the second connecting plate separately. According to the staged energy-consuming metal damper, a mode of combination of the shearing energy-consuming straight plate and the shearing U-shaped energy-consuming plate is adopted to form the staged yielding metal damper, and the staged energy-consuming metal damper has good staged yielding capability under small-scale and large-scale vibration; moreover, the staged energy-consuming metal damper has the advantages of being simple in structure, low in cost, convenient for part repairing and replacing and good in economic benefit.

Owner:SHANGHAI INST OF TECH

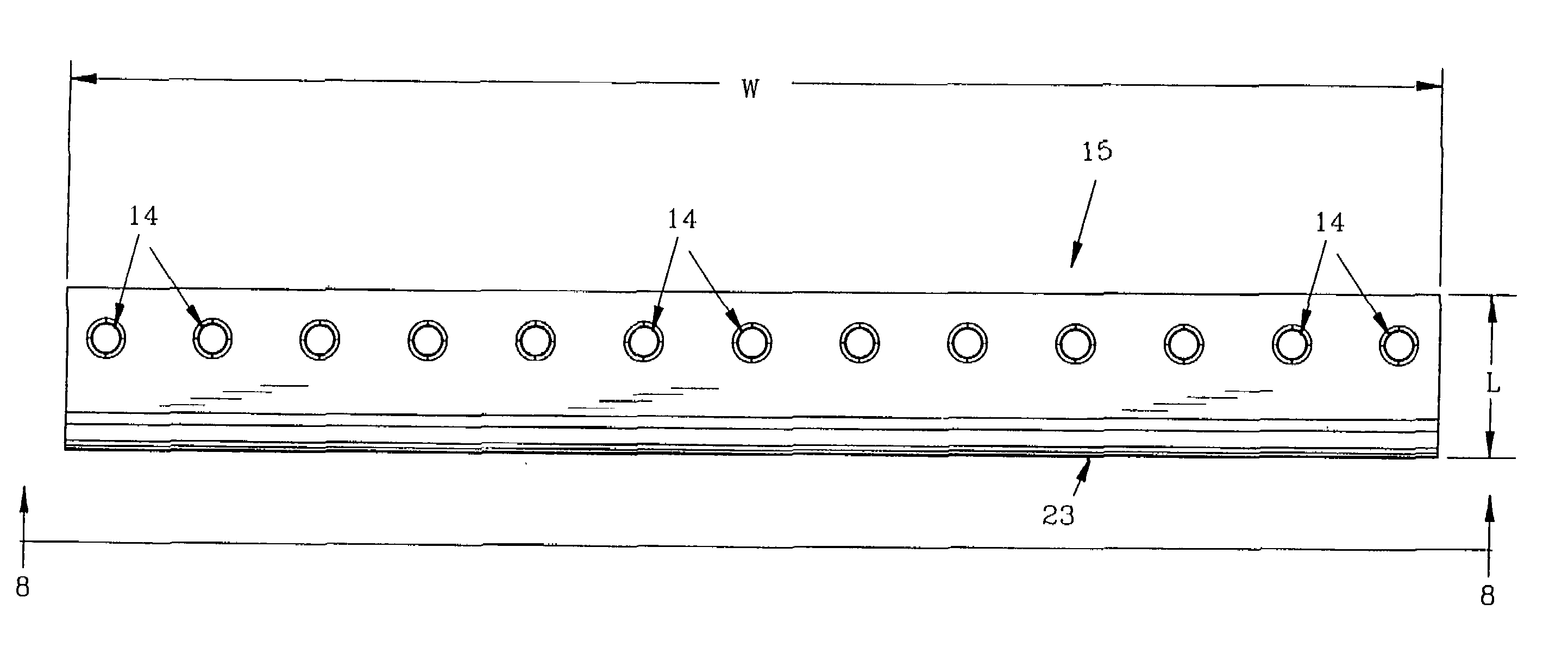

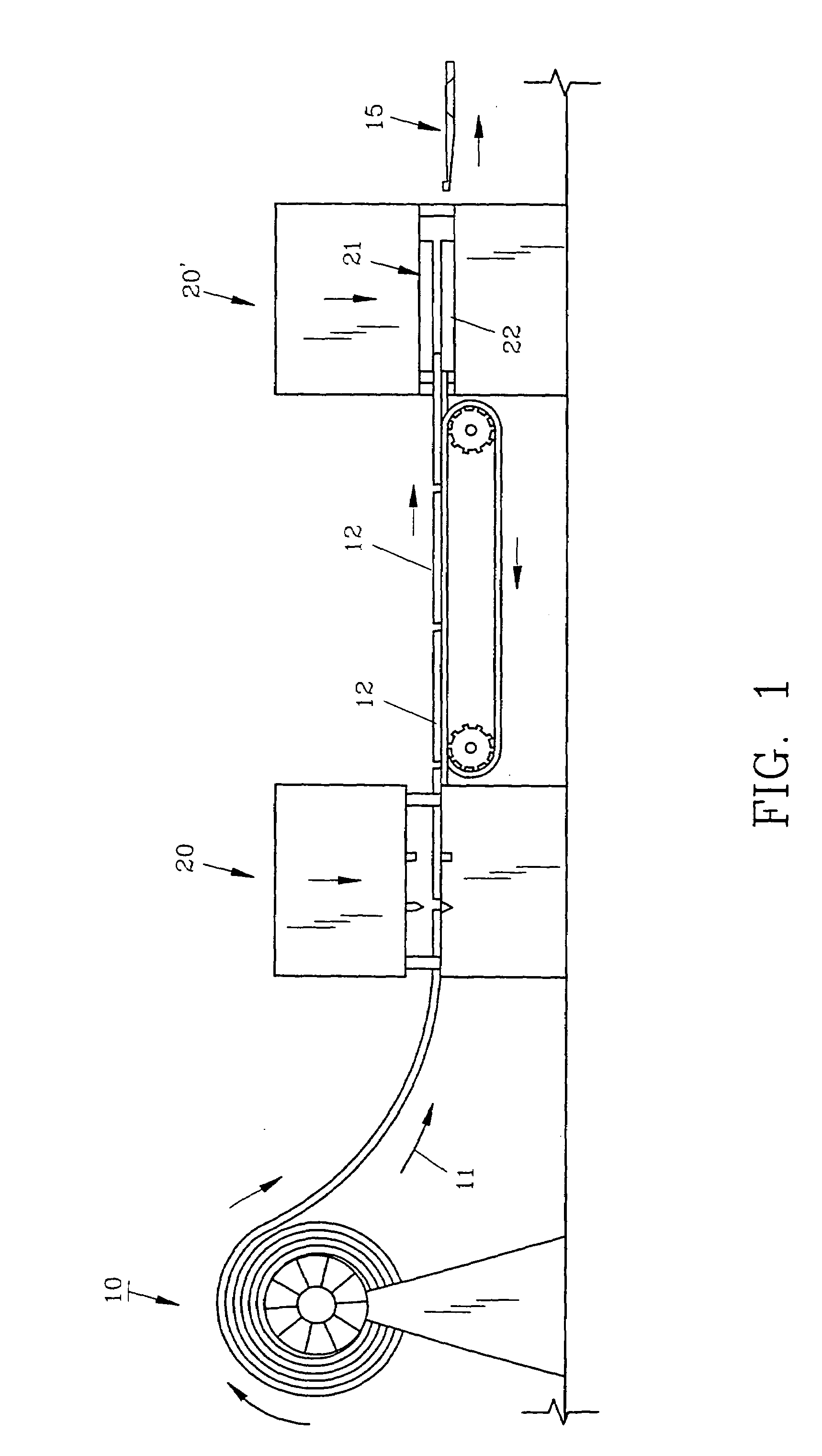

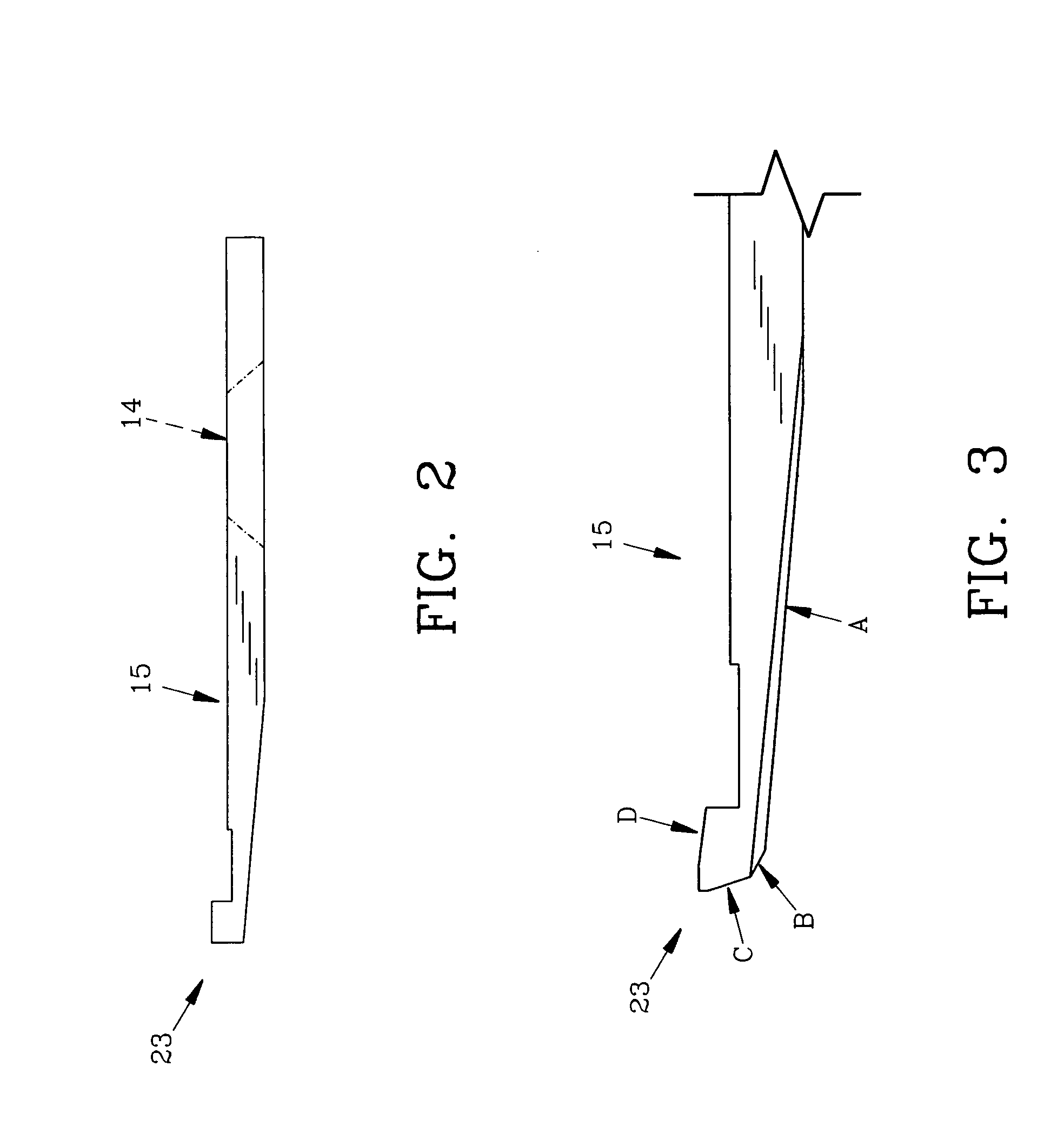

Mower bed blade method

InactiveUS6978532B1Reduce grindingIncrease tonnageMetal-working feeding devicesCutting toolsEngineeringKnife blades

A method of forming a durable mower bed blade is provided in which the grain of the metal is perpendicular to the longitudinal axis of the blade. The blade is formed in part by coining the blade on a hydraulic press which strengthens the cutting edge and other areas to prevent chipping and cracking. Additional steps in the process include shearing the blade to a proper width, heat treating and grinding the edge of the blade to sharpen it.

Owner:JRM

Mixed Feedstocks Processing Using an Ionic Liquid

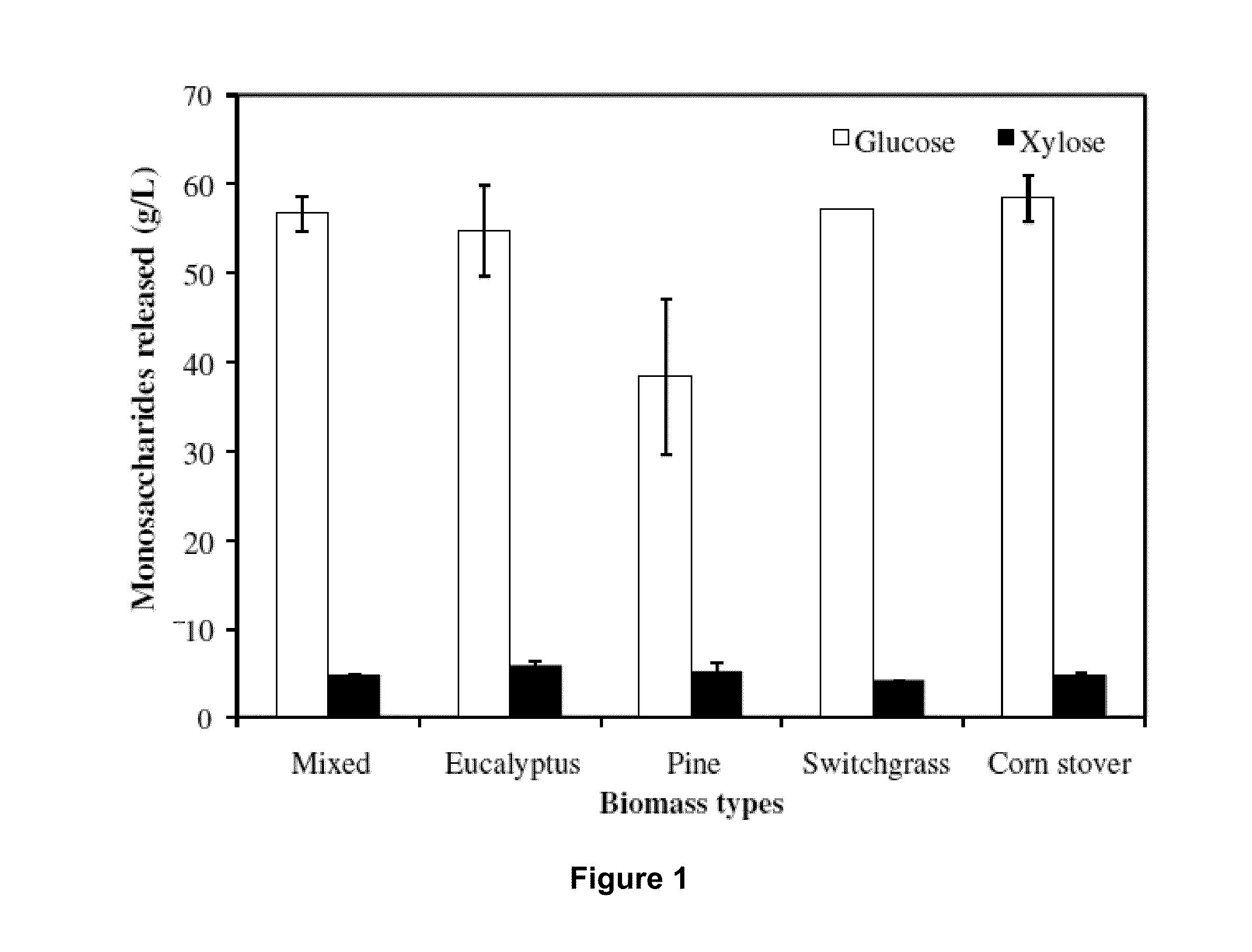

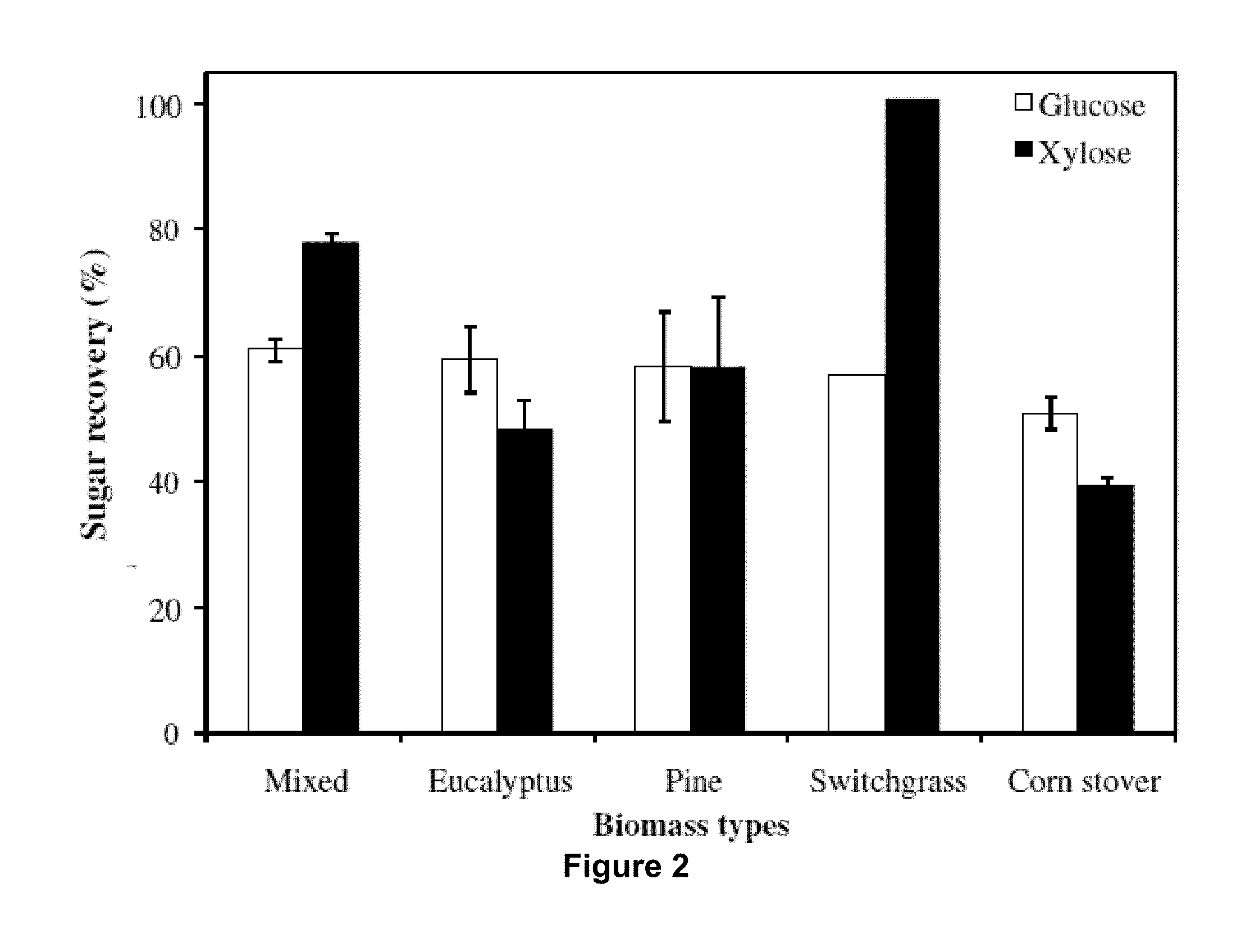

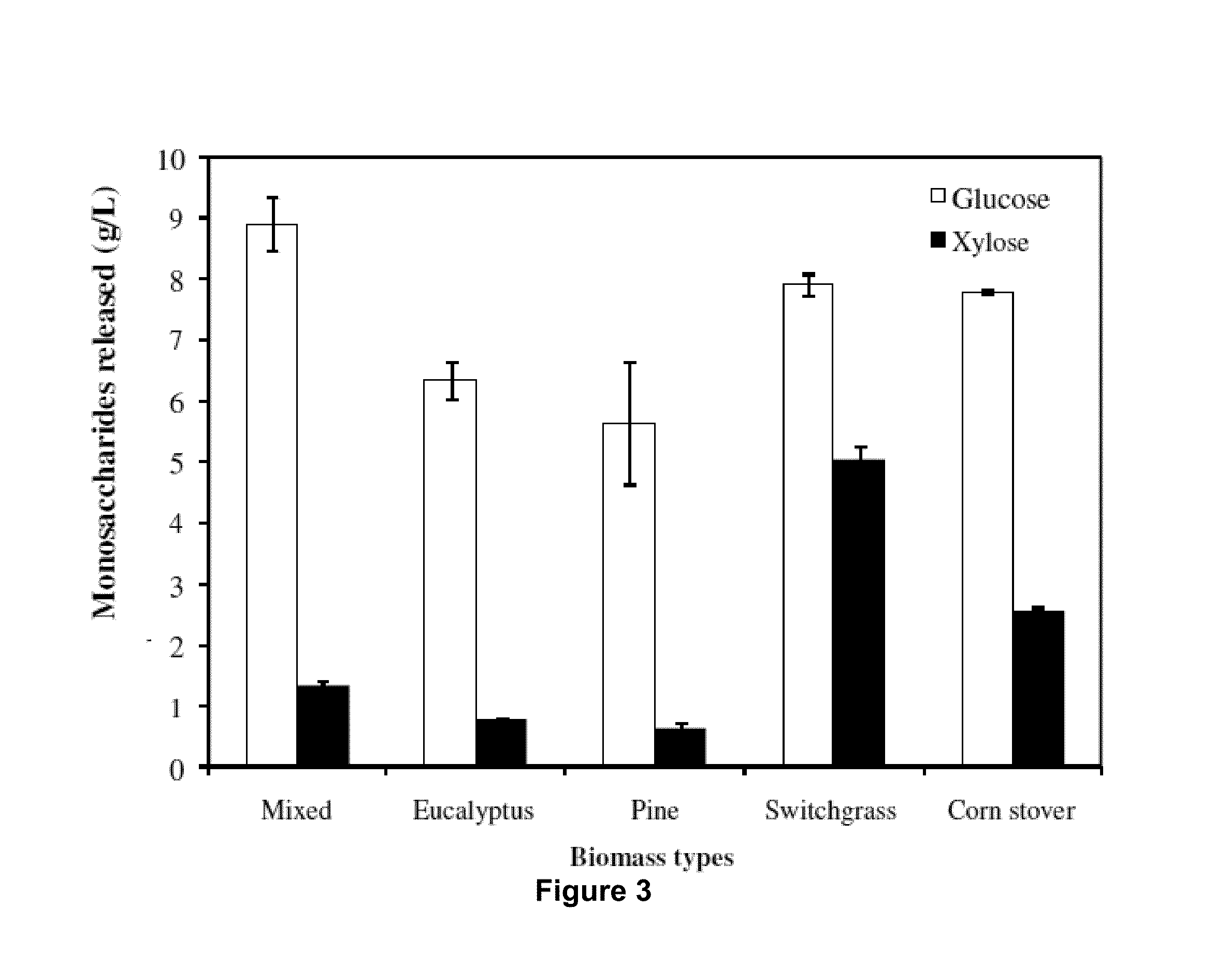

InactiveUS20130183739A1Increase tonnageIncrease energy densityOther chemical processesXylose productionIonic liquidInorganic chemistry

The present invention provides for a composition comprising two or more feedstocks and an ionic liquid (IL). The present invention also provides for a method for treating feedstocks, comprising providing a composition of the present invention comprising two or more feedstocks and an ionic liquid (IL).

Owner:SANDIA +1

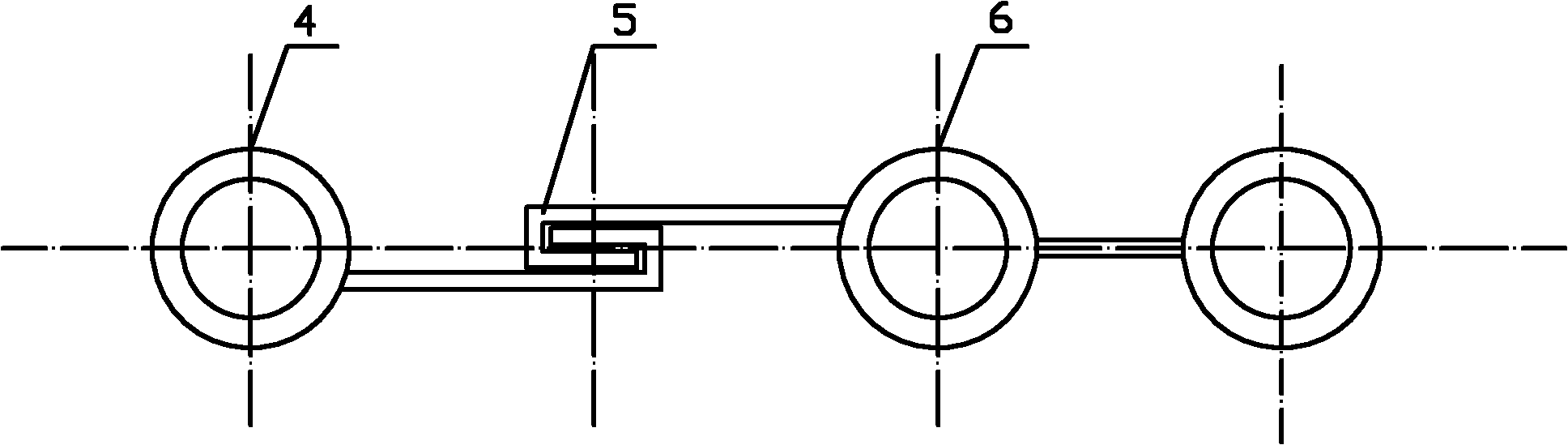

Symmetric lifting rod for lifting and carrying tires

Owner:SHANGHAI JIAO TONG UNIV

Ship with stern equipped with a device for deflecting a flow of water

ActiveUS20100000462A1Increase tonnageSmall sizeVessel stability improvementMovement controllersWater flowStern

The device comprises a plurality of deflector members (1) having a submerged lower face (2), called first face, generally fitting into the extension of the hull bottom (FC) of the ship, toward the rear thereof, while forming an angle (α) in relation to a general plane (Δ) tangent to this bottom (FC), characterized by the fact that these deflector members (1) are articulated to the hull and are juxtaposed side by side, over all, or practically all, the width of the stern, control means (4) making it possible to cause it to pivot in one direction or the other in order to vary said angle (α), these means being housed in part in a protective case.

Owner:STX FRANCE CRUISE

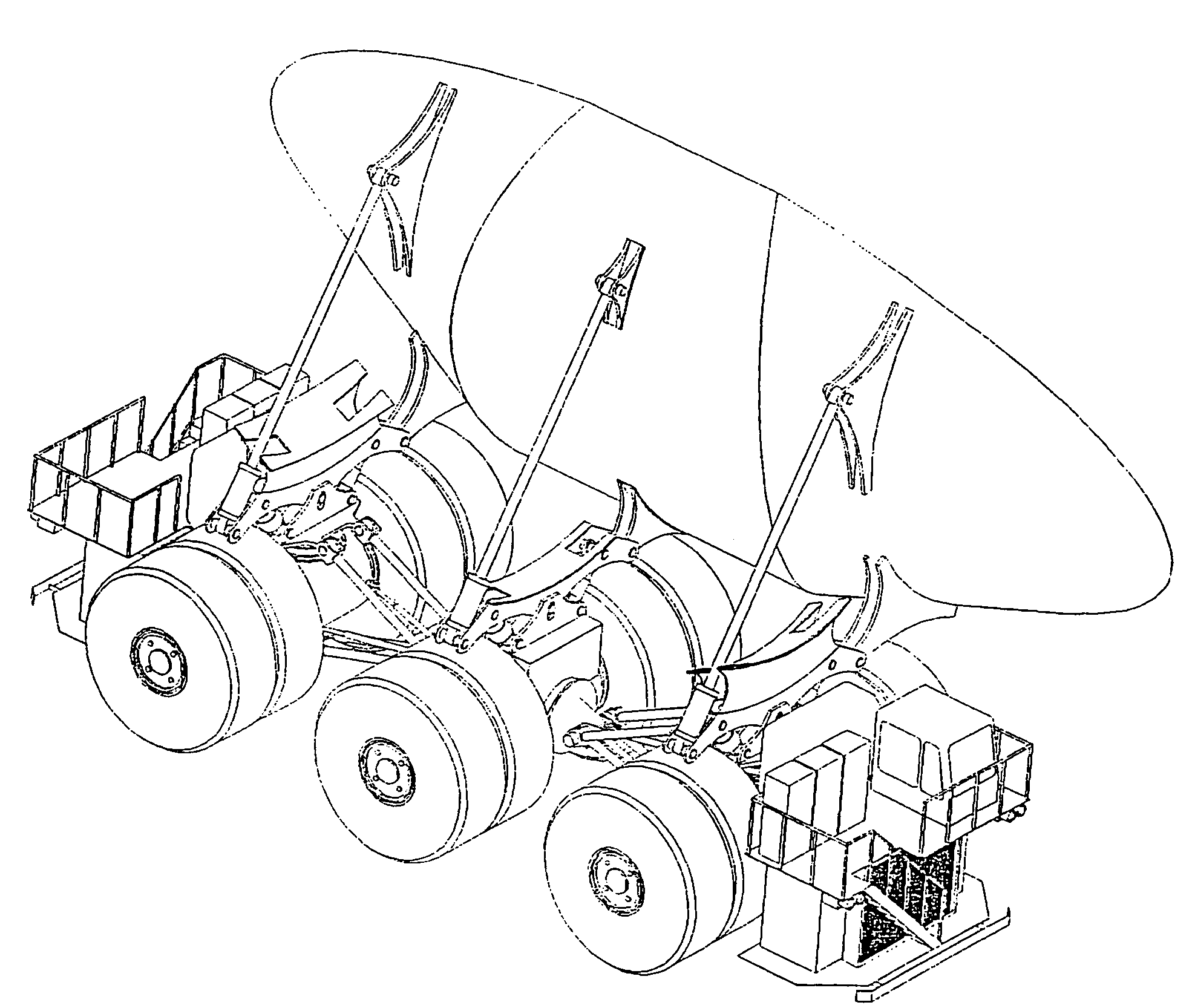

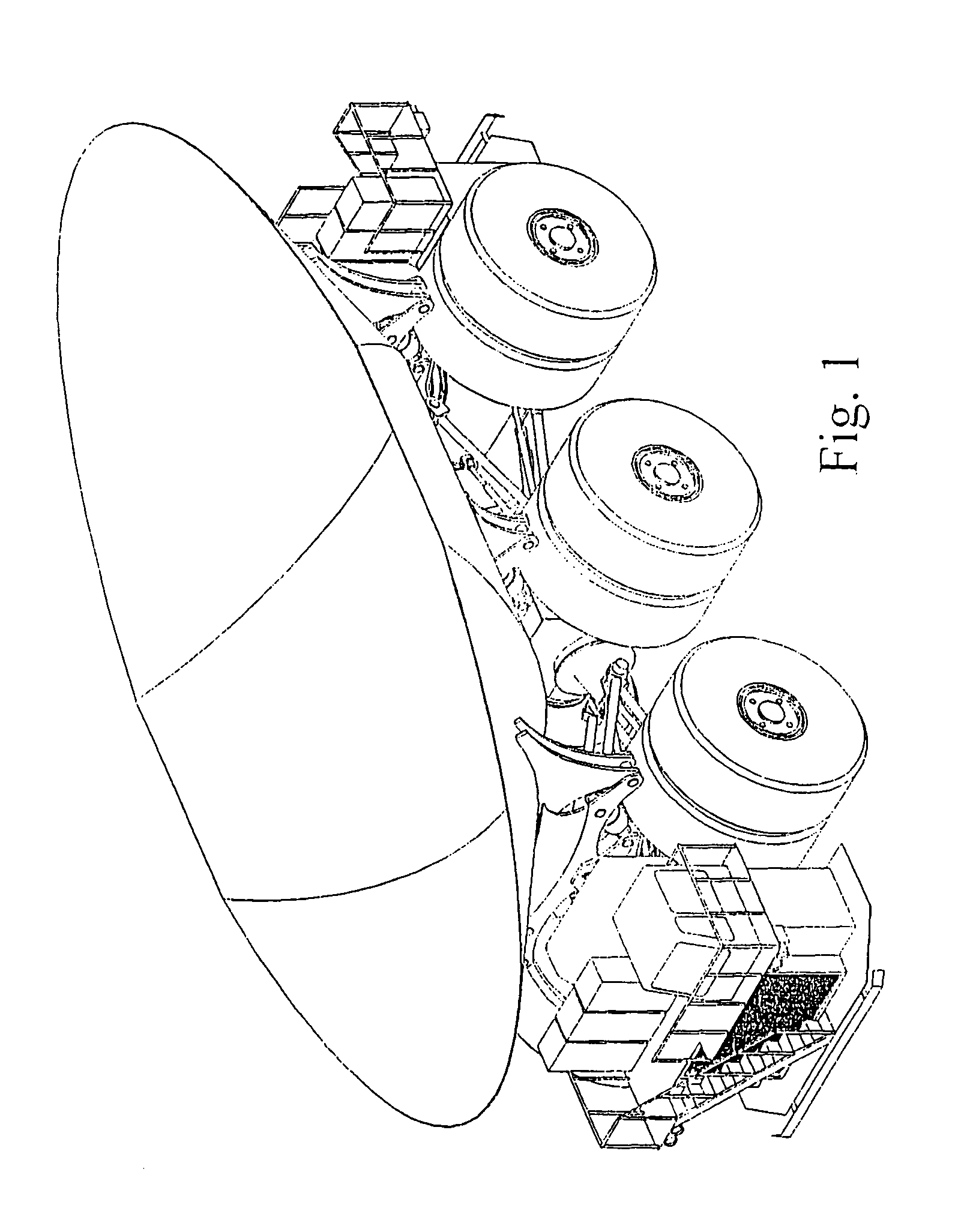

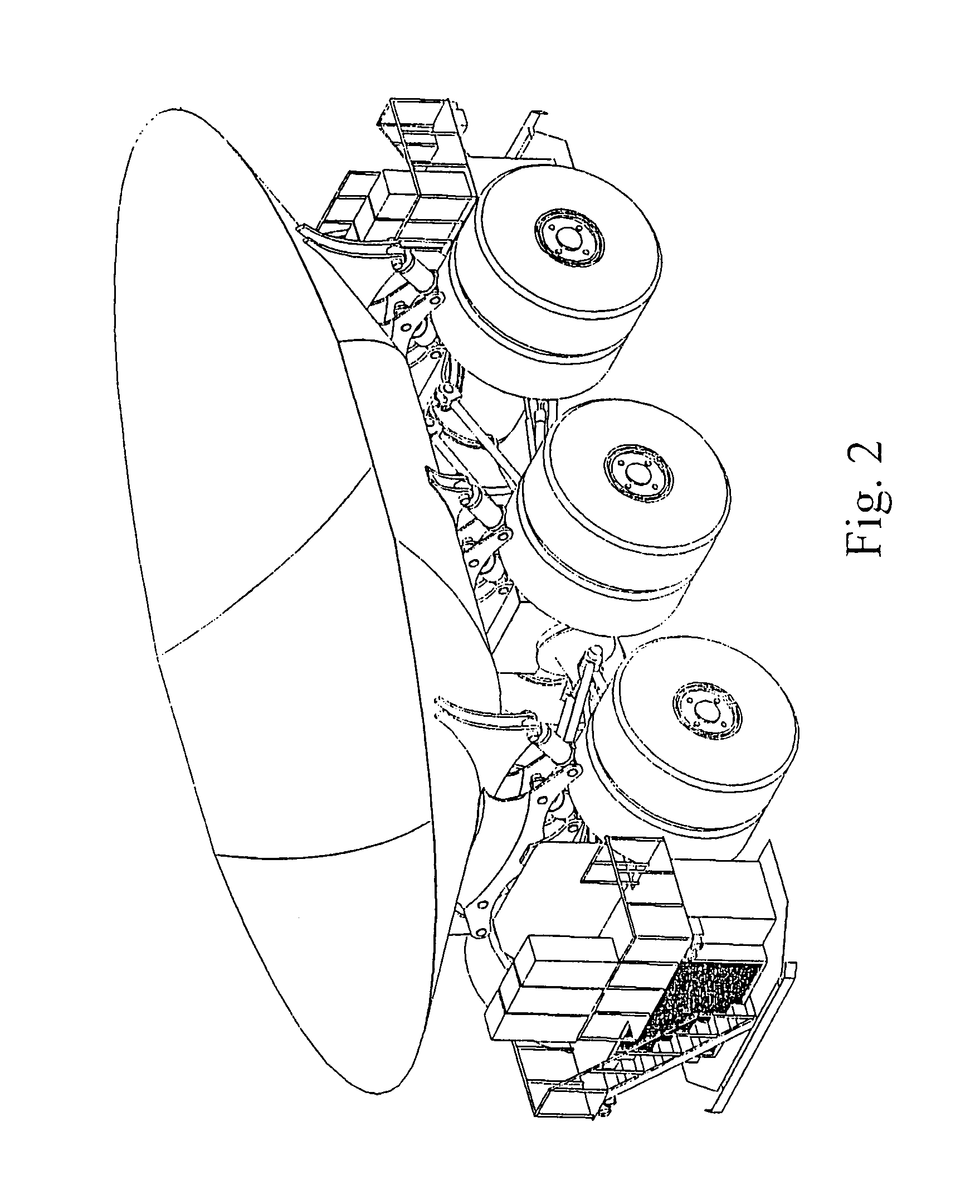

High tonnage ultra light mining truck with a greater load efficiency for off-road applications that comprises a lightweight power and traction system, a steering system and a lateral suspension and tipping system for the lightweight curved dump

InactiveUS7267409B2Improve efficiencyIncrease tonnageSteering linkagesRigid suspensionsState of artTraction system

The present invention refers to a high tonnage ultra light mining truck with a greater load efficiency for off-road applications that, in addition to the body, comprises a lightweight curved dump body and a knuckle joined lightweight power and traction system, a steering system, and a lateral suspension and tipping system for the lightweight curved dump body. The truck of the present invention has a payload capacity up to three times greater than that of similar trucks of the prior art.

Owner:DIESEL MACHINERY INT CORP

Composite ceramic roller for hot rolling

InactiveCN1338342AImprove thermal cracking resistanceImprove wear resistanceRollsOther manufacturing equipments/toolsVacuum pressureHigh density

A composite ceramic roller for hot rolling is made up of tungsten carbide, Co, Cr, Ni and zirconium oxide through proportioning, mixing, loading in mould, cold pressing, pre-sintering, vacuum pressure sintering and machining. It has high bending strength up to 2200-2500 Mpa, high hardness up to 75-85 HRA and high density up to 10-14 g / sq.cm. Its productivity is increased by 400 tons of single pass.

Owner:邢台市特种合金轧辊厂

Combined and phased yield metal damper

ActiveCN106193752ASame sizeIncrease tonnageProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention discloses a combined and phased yield metal damper. The damper comprises an upper connecting plate (4) and a lower connecting plate (5). A first energy consumption steel board (1), second energy consumption steel boards (2), and third energy consumption steel boards (3) are fixedly arranged between the upper connecting plate (4) and the lower connecting plate (5). The first energy consumption steel board (1) is vertically arranged between the upper connecting plate (4) and the lower connecting plate (5) in order to bear the energy consumption effect under small vibration. The third energy consumption steel boards (3) are arranged on two sides of the first energy consumption steel board (1) and used for constraining the first energy consumption steel board (1) and supporting the effect of energy consumption at large vibration. The side wall of the first energy consumption steel board (1) between the two third energy consumption steel boards (3) is provided with the second energy consumption steel boards (2), as reinforcing ribs of the first energy consumption steel board (1), and used for supporting energy vibration at large vibration. The metal damper has good phased yield capacities at small and great vibration and capable of effectively improving tonnage of the damper and is conveniently constructed.

Owner:NANJING UNIV OF TECH

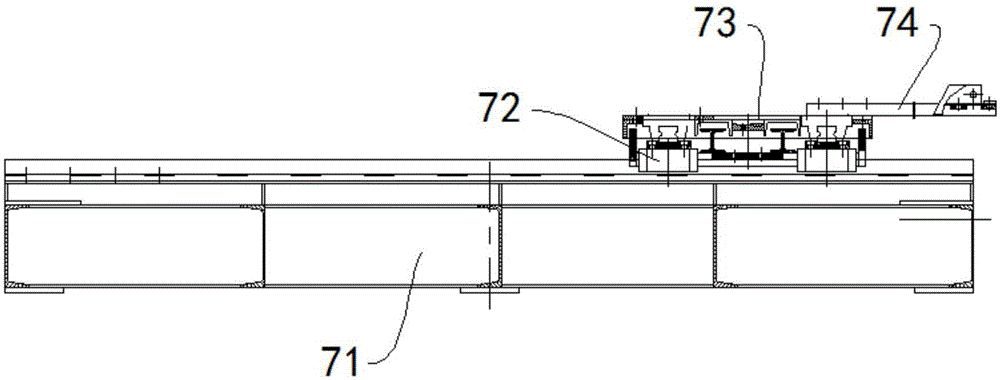

Hydraulic lifting travelling crane

The invention discloses a hydraulic lifting travelling crane. The hydraulic lifting travelling crane comprises a lifting cylinder and a travelling device, wherein the travelling device comprises a travelling crane frame and travelling wheels, the travelling crane frame is provided with a slide groove, the lifting cylinder is provided with an installation flange which is clamped in the slide groove and can move along the length direction of the slide groove, a horizontal cylinder is arranged at one side of the travelling device, the piston rod of the horizontal cylinder is hinged with the lifting cylinder, the horizontal cylinder and the lifting cylinder are connected with a manual reversing hydraulic system through pipelines, and when the manual reversing hydraulic system works, the lifting cylinder acts, the piston rod of the lifting cylinder stretches and withdraws so as to lift up or lay down heavy objects; the horizontal cylinder acts, the piston rod of the horizontal cylinder stretches and withdraws so as to push or pull the lifting cylinder, so that the lifting cylinder slides in the slide groove through the installation flange so as to horizontally reciprocate on the travelling crane frame. The lifting travelling crane can effectively prevent generation of electric spark, and is widely used in a coal mine, a gasoline station, a gas station and the like where combustible gas exists.

Owner:焦作市华科液压机械制造有限公司

Manufacturing technology of spiral cone gear

InactiveCN105983847AIncrease profitImprove mechanical propertiesPortable liftingGearing elementsPunchingManufacturing technology

The invention relates to a manufacturing technology of a spiral cone gear. The manufacturing technology comprises following steps of discharging, hot forging, flashing cutting, continuous skin punching, annealing, shot blasting treatment, phosphating and saponification, cold forging, cuttings machining and heat treatment. Compared with traditional machining, the manufacturing technology improves the material utilization rate and greatly reduces the production cost. According to the spiral cone gear subject to extrusion forming, the mechanical property is improved. According to the manufacturing technology, hot forging and cold forging are successively carried out, and the defect existing only through hot forging machining or cold forging machining is overcome.

Owner:CHANGZHOU FEITIAN GEAR

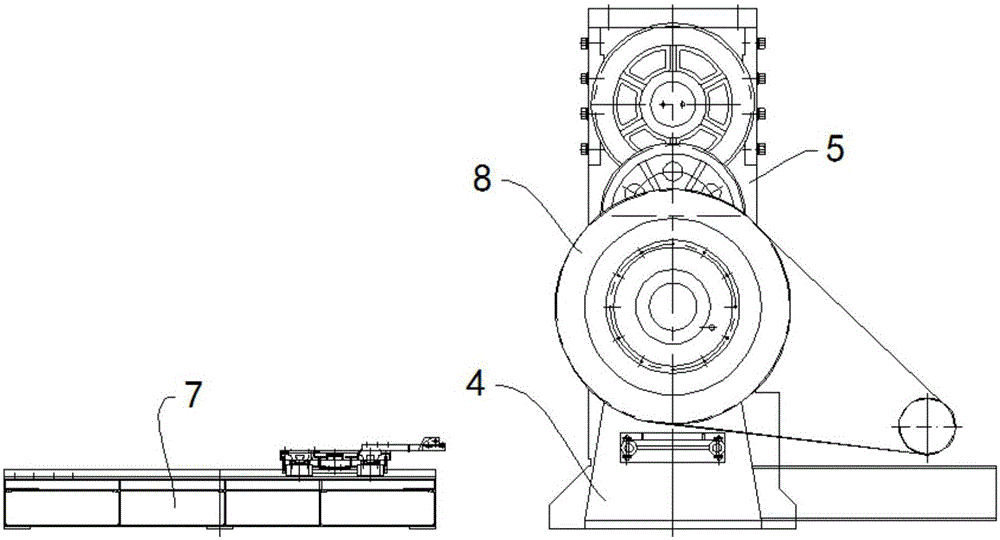

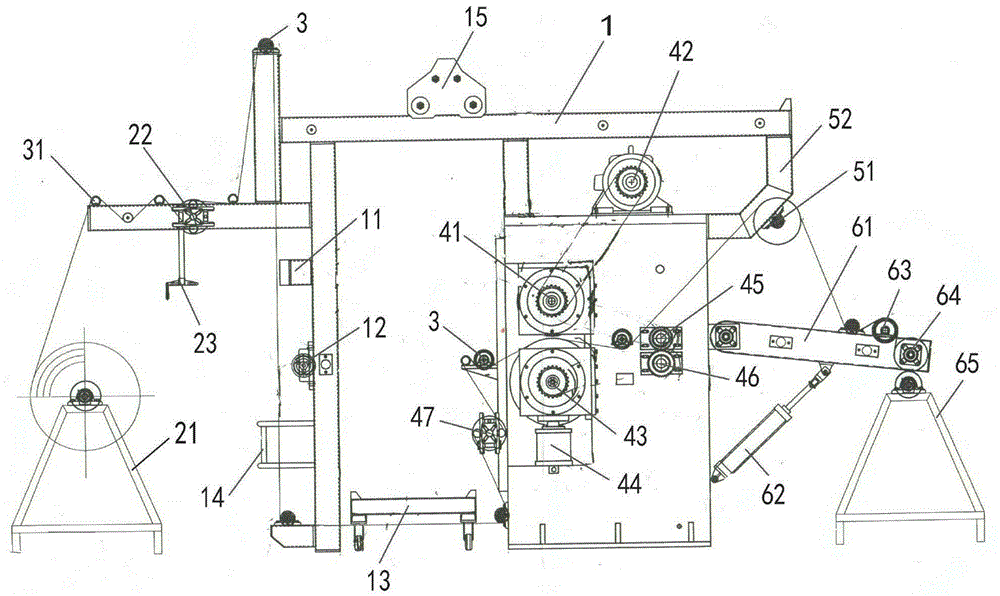

Mesh machine with feed table

The invention relates to a mesh machine with a feed table. The mesh machine comprises a driving device, a transmission device, a crankshaft, an upper tool holder, a lower tool holder, a side base, a frame and at least two link mechanisms, wherein the side base is arranged on one side of the frame; the frame comprises a left upright post, a right upright post, an upper beam and a lower beam; the upper beam is arranged at the upper parts of the left upright post and the right upright post; the lower beam is arranged at the lower parts of the left upright post and the right upright post; the driving device and the transmission device are arranged on the side base; the crankshaft is arranged below the upper beam; the driving device is in transmission connection with the crankshaft through the transmission device; the lower tool holder is arranged above the lower beam; the upper tool holder is arranged between the lower tool holder and the crankshaft, and is connected with the crankshaft through the link mechanisms; the mesh machine further comprises the feed table used for feeding a material to the mesh machine. The mesh machine has the advantages that the feed table moves in two directions, while the main body of the mesh machine only moves up and down, so that the tonnage of the whole structure can be improved, and steel mesh boards requiring larger shearing force can be machined conveniently.

Owner:安陆市华誉金属网机制造有限公司

Air cushion single ejector cap of press machine

InactiveCN104174750AGuaranteed full tonnage tensile pad pressureIncrease tonnageControl switchAir cushion

The invention discloses an air cushion single ejector cap of a press machine, and relates to the field of machinery, in particular to the field of technical transformation of accessories of the press machine. The air cushion single ejector cap comprises a stretching cushion base, wherein the stretching cushion base is internally and vertically provided with at least two air cylinders, each air cylinder is respectively connected with an air inlet pipeline, baffle plates are respectively arranged between every two adjacent air cylinders, a telescopic end of each air cylinder is connected with the same stretching cushion integrated ejector cap, each baffle plate is respectively arranged under the stretching cushion integrated ejector cap, the air inlet pipelines of the air cylinders are connected in parallel, and the synchronous work of the air cylinders can be realized by using one control switch. By using the air cushion single ejector cap disclosed by the invention, a single ejector cap stretching cushion function can be realized by a multi-ejector cap press machine, the situation of supplying total tonnage pressure on a stretching cushion can be ensured during the production of the press machine, and the stretching cushion tonnage needed by the forming of a small die is effectively increased.

Owner:YIZHENG SHENWEI STAMPING

Horizontal boiler radiation segment structure

InactiveCN101893230AImprove sealingReduce heat lossBoiler water tubesFluid removalEngineeringFree edge

The invention relates to the field of boiler design and manufacturing and discloses a horizontal boiler radiation segment structure which is applicable to oil field steam injection boilers. The horizontal boiler radiation segment structure comprises an outer protective layer, wherein a member wall with a square section is arranged in the outer protective layer and comprises a plurality of boiler tubes connected in a coiled way and a closing plate connected between the boiler tubes. The horizontal boiler radiation segment structure is characterized in that: the closing plate between an outlet boiler tube and an inlet boiler tube of the boiler tubes comprises two connection plates with free edges and fixed edges; and the fixed edges of the two connection plates are connected with the outlet boiler tube and the inlet boiler tube, while the free edges are interlaced mutually.

Owner:XI AN JIAOTONG UNIV +1

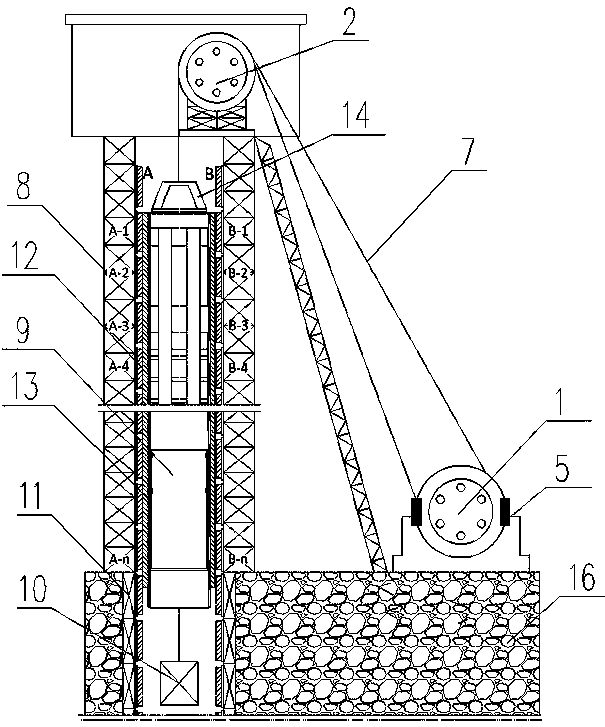

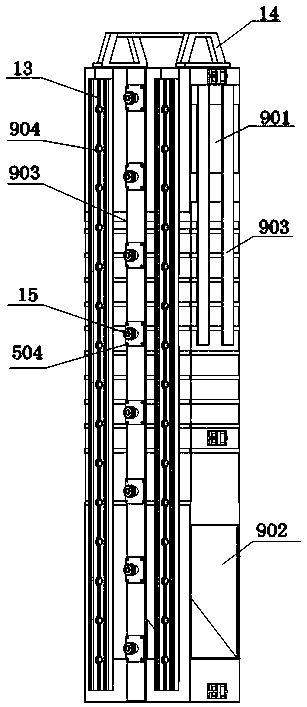

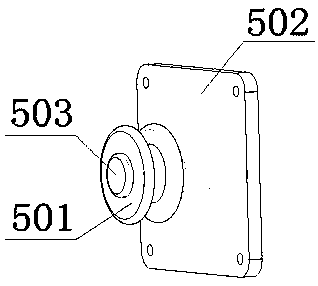

Vertical linear motor assisted driving type super-deep well extra-large-tonnage skip hoisting system

PendingCN110921471AReduce workloadIncrease lifting tonnage and lifting distanceElevatorsMine liftsVertical motionWire rope

The invention discloses a vertical linear motor assisted driving type super-deep well extra-large-tonnage skip hoisting system. The vertical linear motor assisted driving type super-deep well extra-large-tonnage skip hoisting system comprises a steel wire rope hoisting system, a linear motor assisted hoisting system and a control system. On the basis of an original steel wire rope hoisting system,an original cage guide structure is eliminated, an embedded linear guide rail is used for replacing a cage guide for functioning, a vertical moving type linear motor is mounted on a tower, a truss inthe well wall and a skip, and electromagnetic driving force generated through up-down linear movement of the linear motor is used for assisting in transporting of minerals; and an additionally-mounted linear motor assisted driving system works in cooperation with the steel wire rope hoisting system, so that on the premise of ensuring the structural strength of the hoisting system, the hoisting tonnage and the hoisting depth of the hoisting system are increased, and then the hoisting system meets the requirement of hoisting of the super-deep well extra-large-tonnage skip.

Owner:CHINA UNIV OF MINING & TECH

Calender

The invention discloses a calender. The calender comprises a frame, a cloth feeding device, a cloth guide roller, a cloth pressing device, a cooling device and a cloth discharge device are arranged on the frame, the cloth pressing device comprises a mirror heating roller, a cloth pressing end motor for driving the mirror heating roller to self-rotate around the mirror heating roller axis, a hydraulic homogenization roller and a cloth pressing end hydraulic cylinder for driving the hydraulic homogenization roller to lift or drop, the hydraulic homogenization roller is located above the mirror heating roller, the cloth pressing device also comprises a transmission mechanism, the transmission mechanism comprises a first gear link-connected to the mirror heating roller and a second gear in a link transmission relationship with the hydraulic homogenization roller, the first gear is engaged with the second gear, a metal detecting instrument and a rectification machine are arranged between the cloth feeding device and the cloth pressing device, and the cooling device is arranged between the cloth pressing device and the cloth discharge device. A cloth is fed by the cloth feeding device, goes through the cloth guide roller, enters into the hydraulic homogenization roller and the mirror heating roller of the cloth pressing device, is subjected to heating calendaring, then is cooled by the cooling device, then is fed into the cloth discharge device and is discharged.

Owner:WUJIANG HAI WEI MECHANICAL RUBBER PROD CO LTD

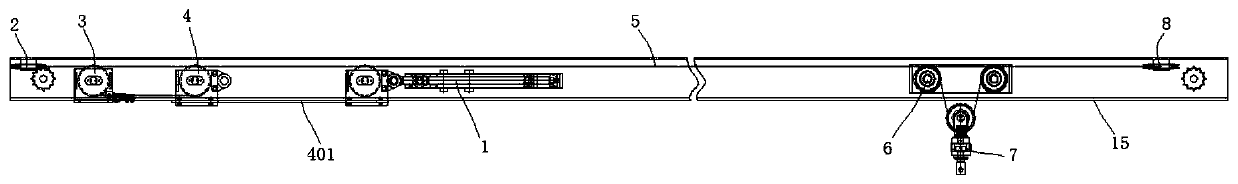

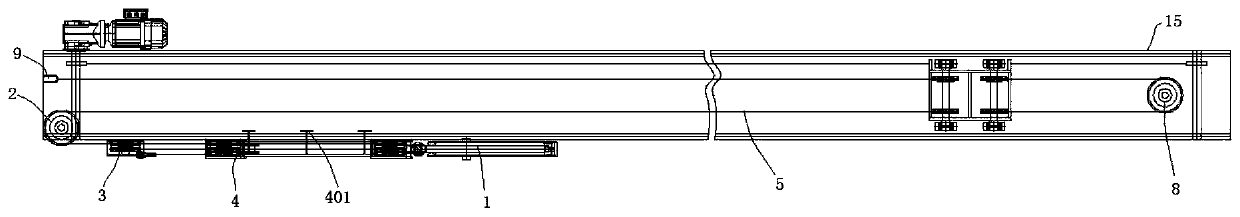

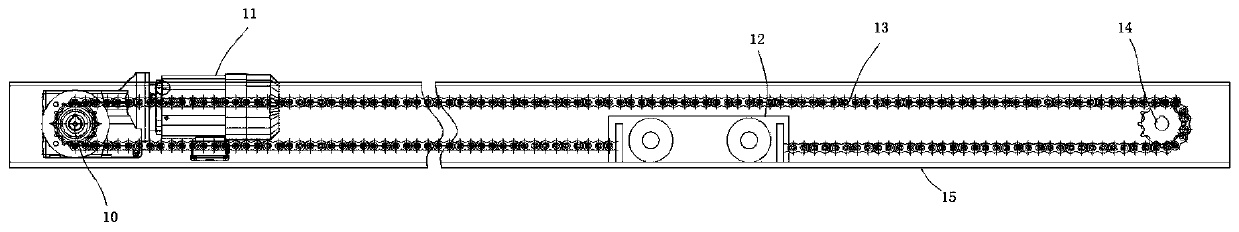

Integrated box type track beam closed chain-driven steel wire rope single beam crane

PendingCN110723645AMeet the lifting requirementsSave lifting headroom sizeUnderground chambersTunnel liningSteering wheelMarine engineering

The invention discloses an integrated box type track beam closed chain-driven steel wire rope single beam crane, and relates to the technical field of cranes. According to the crane, a lifting mechanism comprises a hydraulic oil cylinder, a horizontal steering wheel, a fixed pulley group, a movable pulley group, a lifting pulley, a lifting sling, a tail end balance wheel and a fixed end; and an operating mechanism comprises a driving chain wheel, an operating driver, an operating trolley and a driven chain wheel, a track beam is of a plate splicing type semi-closed box type structure, and a trolley track and a chain track are arranged in the inner space of the track beam. According to the integrated box type track beam closed chain-driven steel wire rope single beam crane, the lifting mechanism is arranged inside the integrated box type track beam, so that the lifting clearance size is effectively saved; all the moving parts are located in a hollow cavity inside the integrated box typetrack beam, so that the influence of mud water brought by the external construction environment is effectively isolated, and the service life is prolonged; the equipment load capacity optional rangeis large, so that the lifting and conveying requirements of prefabricated segments with larger weight are met; and a control loop is simple, the electrical principle is simple, and the maintenance iseasy.

Owner:苏州必艾姆起重设备有限公司

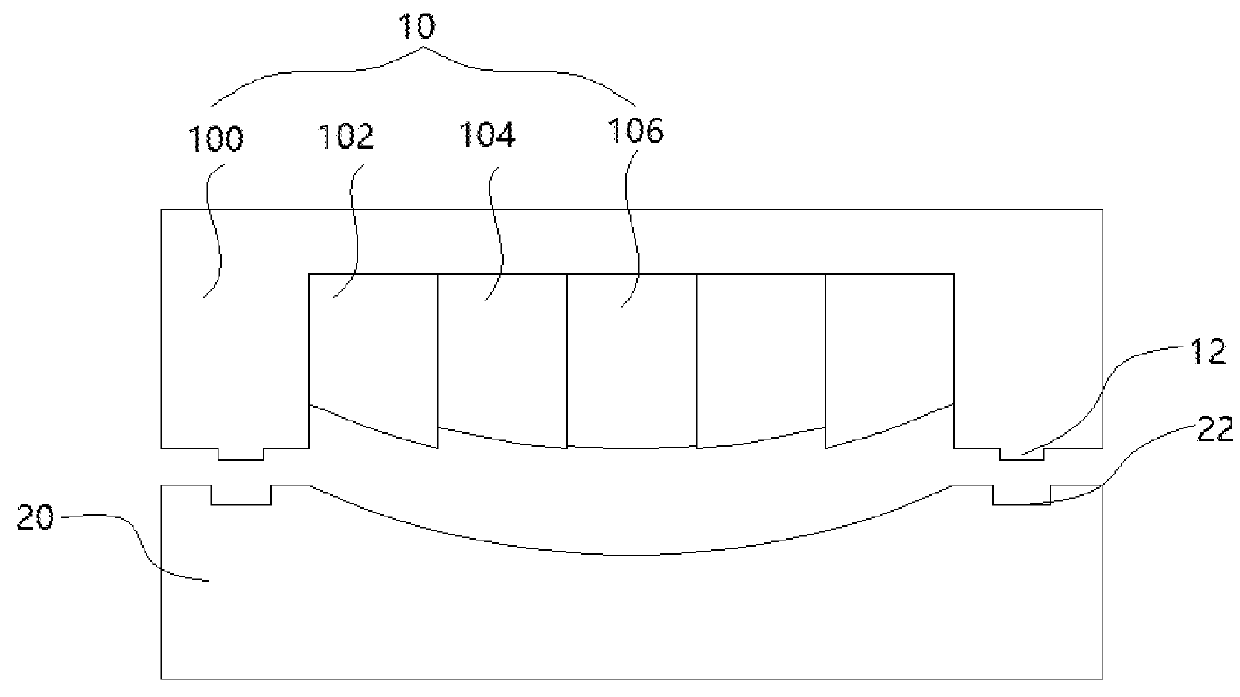

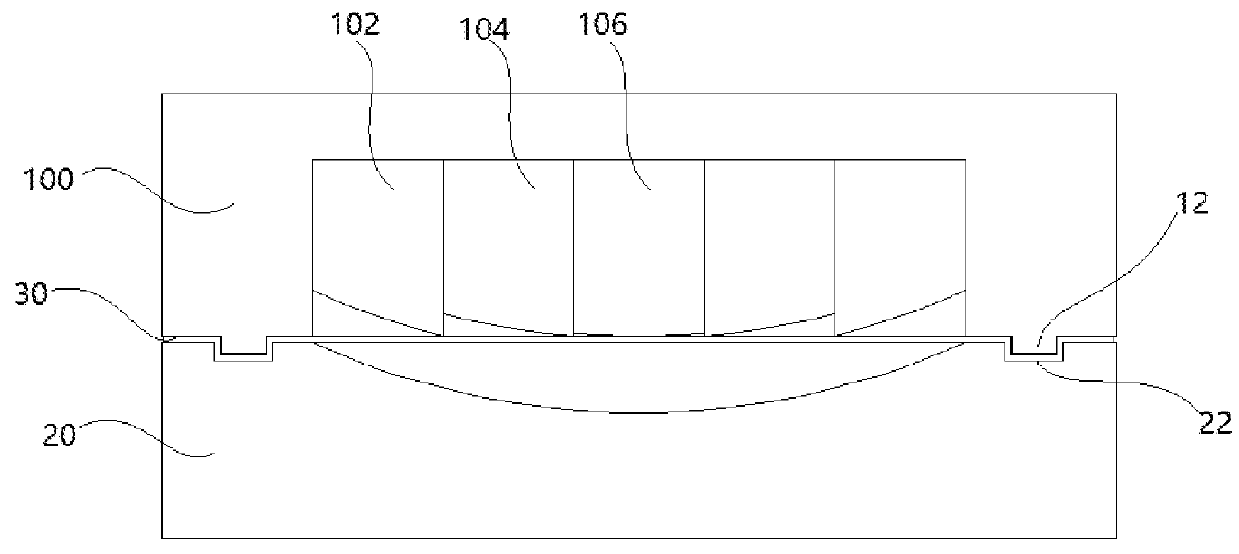

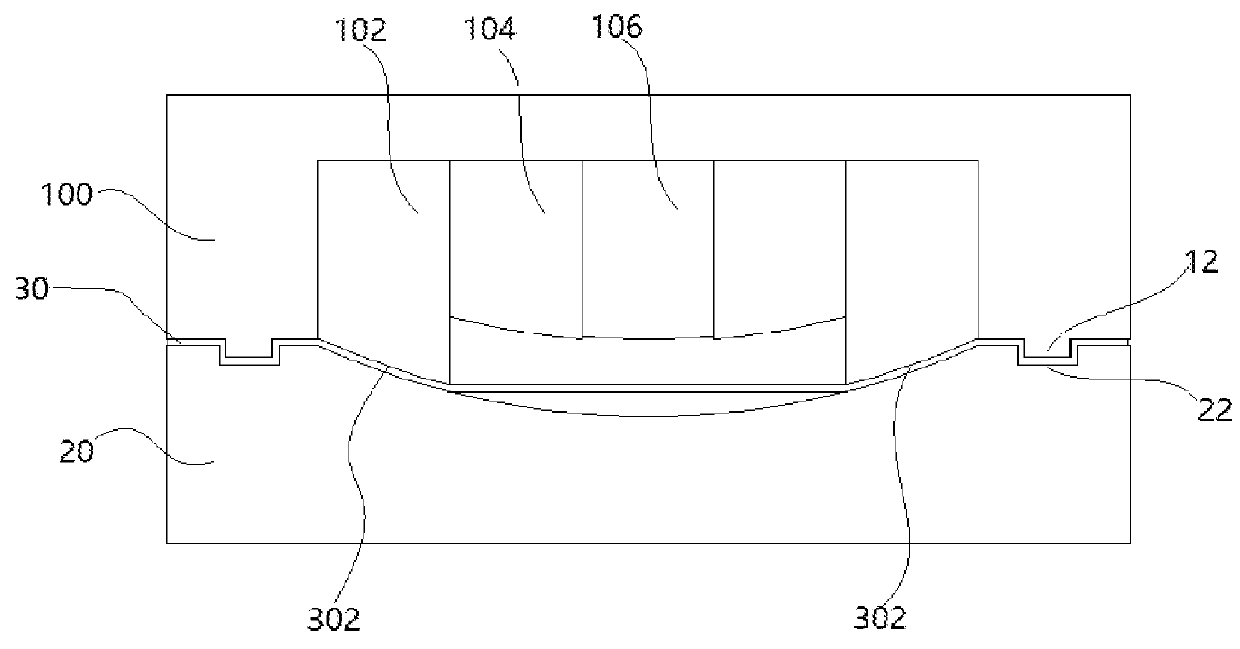

Backplate molding devices and methods for curved displays

InactiveUS20180093313A1Reduce demandSpeed up the flowShaping toolsDomestic articlesPunchingDisplay device

A backplate molding device includes a top mold and a down mode. The top mold includes a plurality of punching heads having curved operation surfaces and a pressure plate. The punching heads are arranged in multi-sections and the pressure plate is arranged at a lateral side of the punching heads in the multi-section. An operation surface of the down mold is a curved surface engageable with the operation surfaces of the punching heads in the multi-section, and edges of the down mold cooperatively engages with the pressure plate to fix backplate materials. A punching process is applied toward the backplate material by bonding the operation surface of the punching heads with the operation surface of the down mold in sequence to plastically deform the backplate materials. The present disclosure also relates to a backplate molding method.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

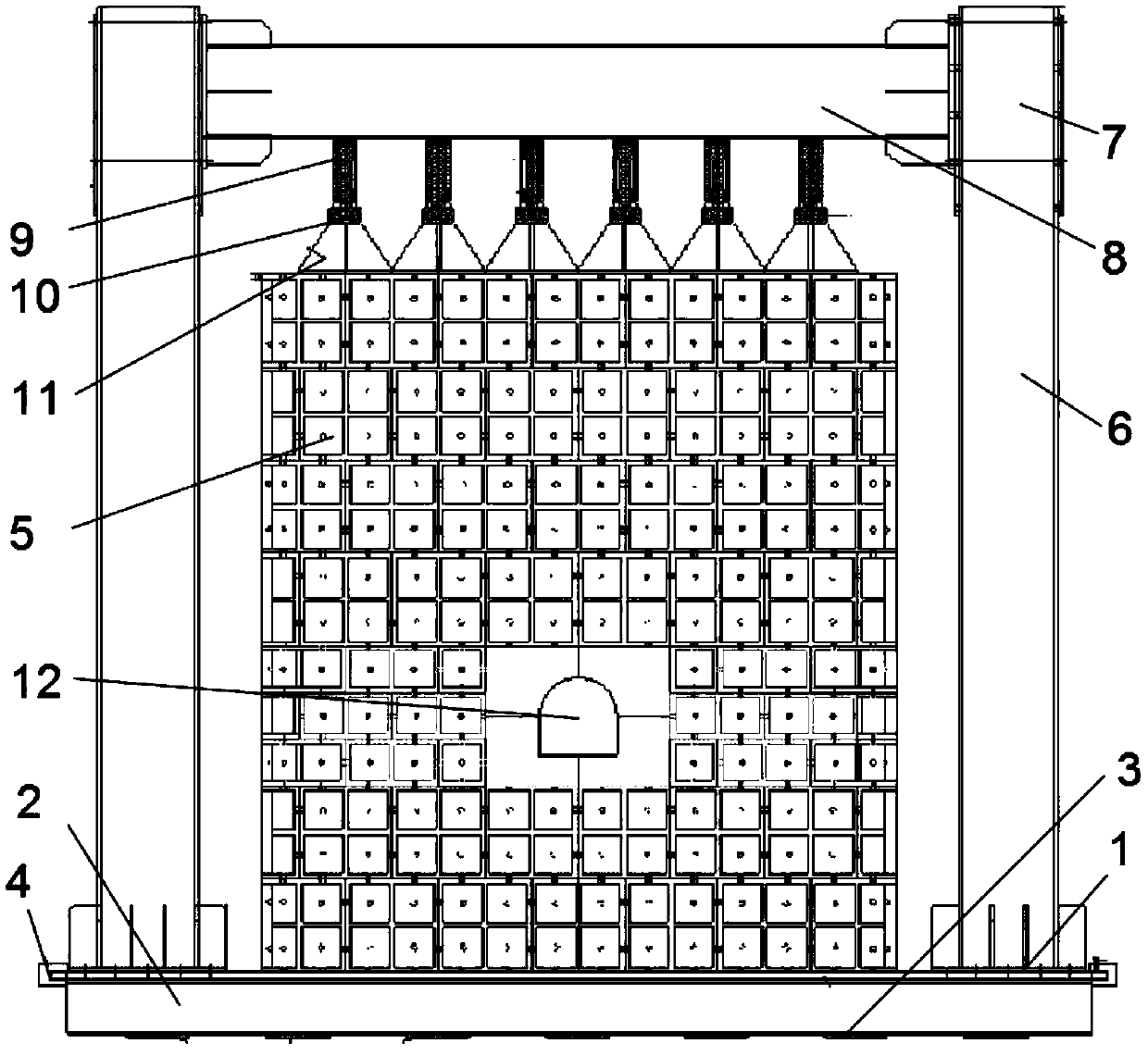

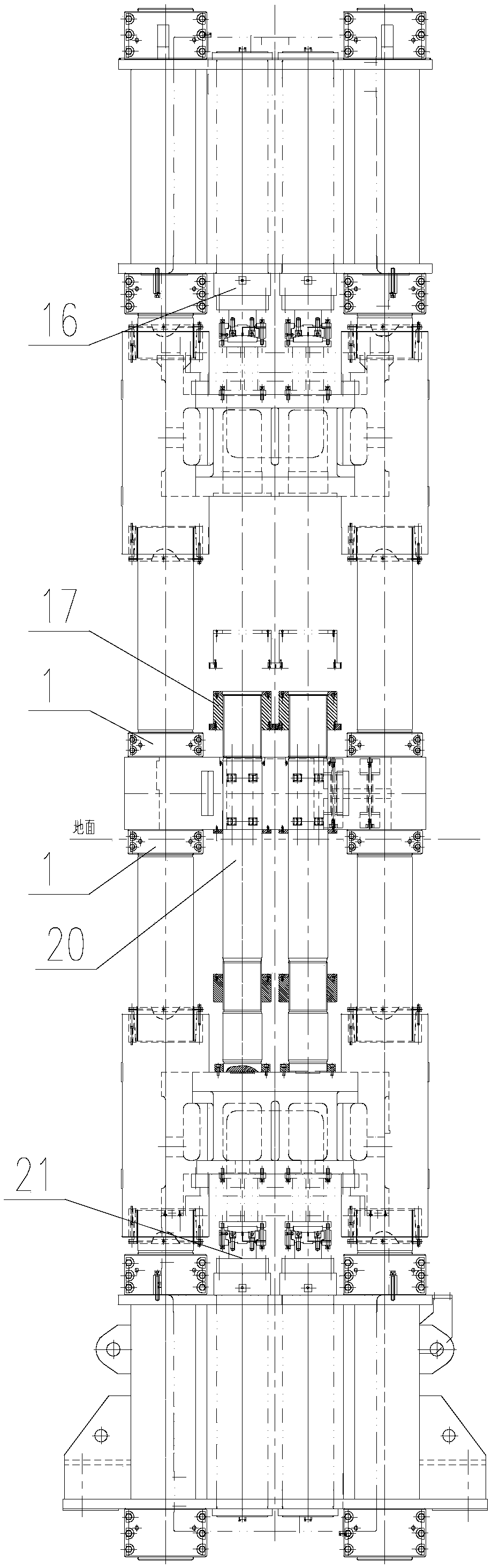

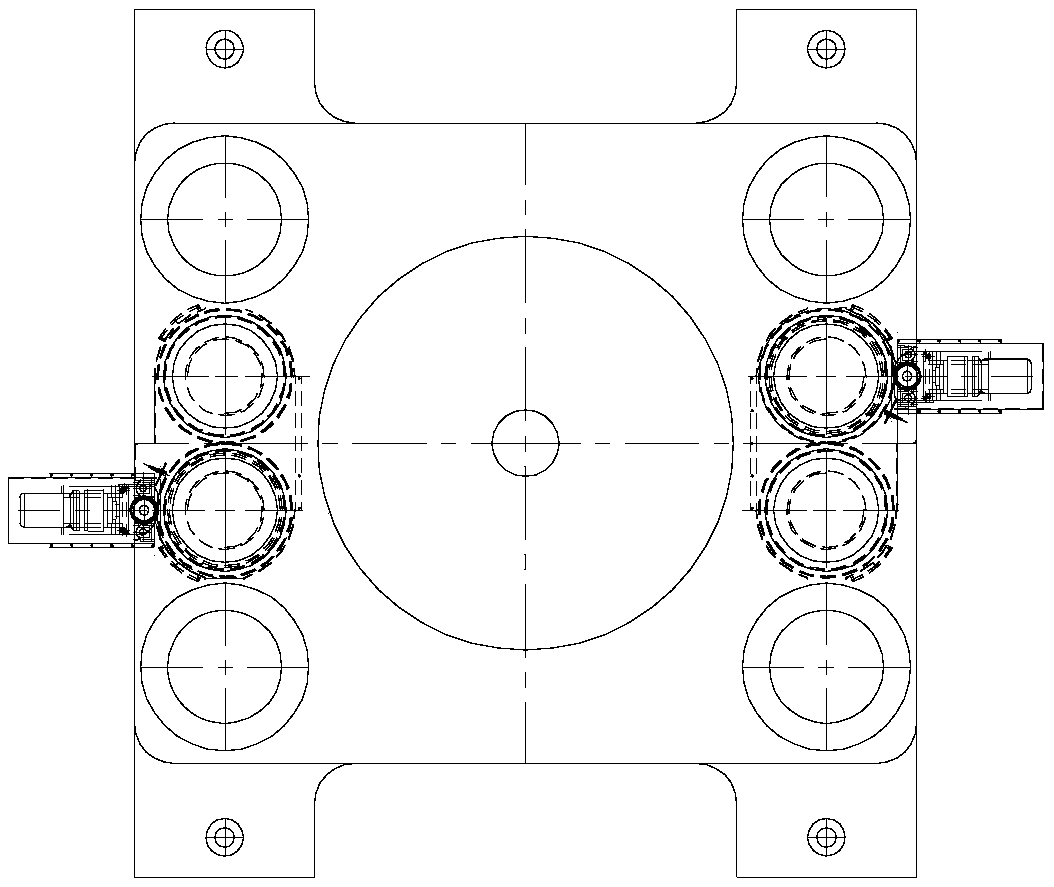

Advanced geomechanical model test system

PendingCN110987630AImprove reinforcementHigh strengthMaterial strength using tensile/compressive forcesEarth material testingModel testRock bolt

The invention discloses an advanced geomechanical model test system. The system comprises a model test bench device system, a hydraulic loading system and a strain displacement test system. The modeltest bench device system comprises a bottom plate. A plurality of bottom plate cross beams are evenly arranged at the bottom of the bottom plate, a plurality of bottom plate cross beam connecting plates are evenly arranged at the bottoms of the bottom plate cross beams, bottom plate clamping plates are arranged on the side wall of the bottom plate, four stand columns are evenly arranged at the positions, close to the four corners, of the top of the bottom plate, and cross beam stand column connecting plates are fixedly connected to the tops of the stand columns. According to the invention, thestability simulation of the excavation process of underground geotechnical engineering such as tunnels (pits), underground engineering caverns and the like can be effectively completed, the anchor rod (cable) support can be simulated, the stress and displacement in the tunnel surrounding rock can be analyzed, the tunnel surrounding rock fracture can be studied, and the reinforcement measures canbe optimized.

Owner:63653 FORCES PLA

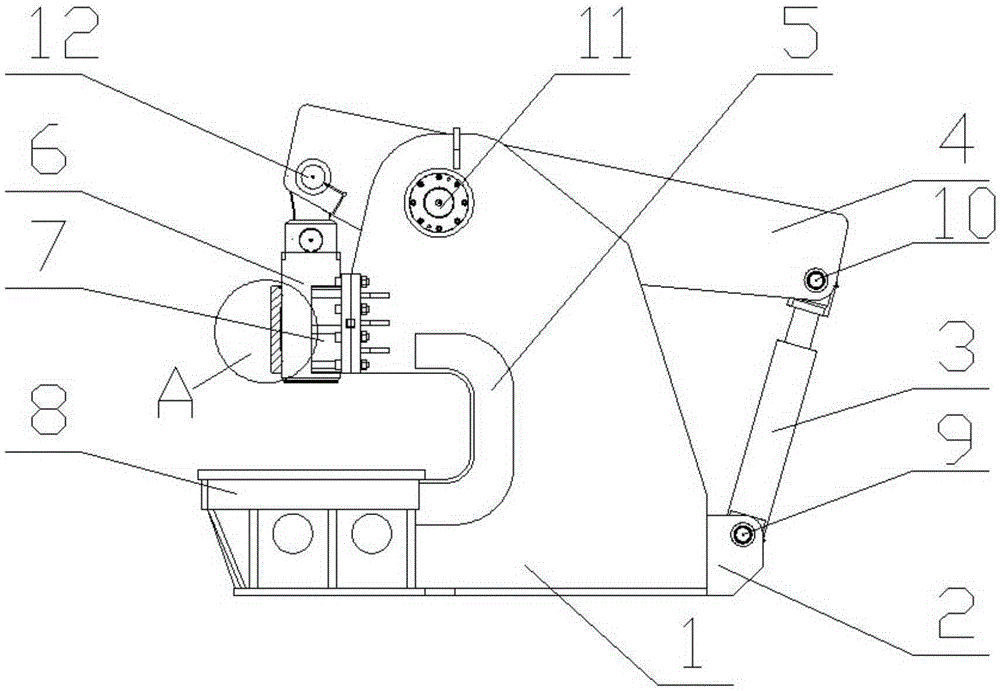

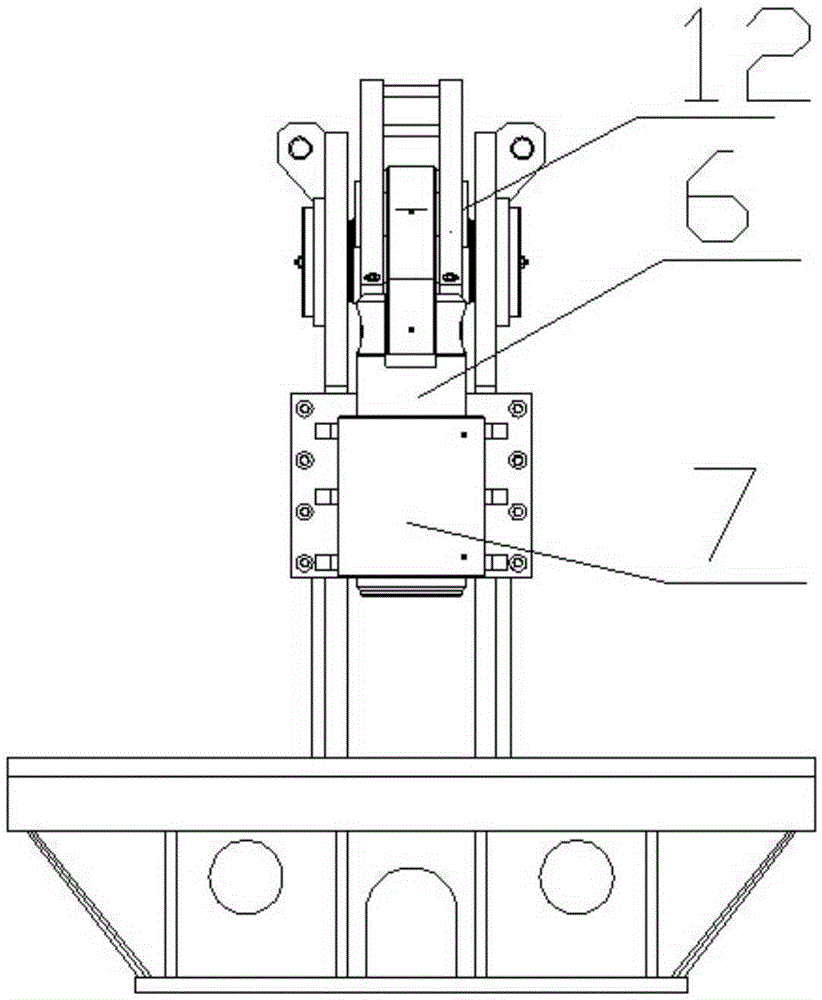

Hydraulic machine and application method thereof

The invention discloses a hydraulic machine and an application method thereof, belongs to the field of pressing machines, and aims to solve the problem of the pressure of a conventional hydraulic machine cannot be further improved due to the limit of oil cylinder volume. The hydraulic machine comprises a machine body, an oil cylinder, a sliding block and a worktable; the worktable is arranged on the lower side of the 'C'-shaped opening direction of the machine body; the hydraulic machine further comprises a beam arm and a guiding slideway; the beam arm is arranged at the top of the machine body; a second pin shaft hole and a fourth pin shaft hole are respectively formed in the two ends of the beam arm; an oil cylinder seat is arranged on the lower side at the opposite end of the 'C'-shaped opening direction of the machine body; one end of the oil cylinder is connected onto the oil cylinder seat through a first pin shaft, and the other end of the oil cylinder is connected onto the second pin shaft hole through a second pin shaft; one end of the sliding block is connected onto the fourth pin shaft hole through a fourth pin shaft, and the other end of the sliding block penetrates through the guiding slideway and faces and is perpendicular to the worktable. The bottleneck that the tonnage of the conventional hydraulic machine is limited by the oil cylinder volume is broken through, the pressure of the hydraulic machine is further increased, meanwhile, the production cost is not increased, the use is relatively flexible, and the production efficiency is improved.

Owner:安徽省华夏机床制造有限公司

Five-beam four-column type explosive pressing hydraulic machine

The invention discloses a five-beam four-column type explosive pressing hydraulic machine comprising stand columns, upper cross beams, lower cross beams, upper sliding blocks, lower sliding blocks, amiddle fixing beam, an upper main oil cylinder, a lower main oil cylinder, upper side oil cylinders and lower side oil cylinders. A cylinder block of the upper main oil cylinder and cylinder blocks ofthe upper side oil cylinders are fixed to the upper cross beams. A plunger rod of the upper main oil cylinder and plunger rods of the upper side oil cylinders are fixed to the upper sliding blocks. Cylinder blocks of the lower main oil cylinder and the lower side oil cylinders are fixed to the lower cross beams. A plunger rod of the lower main oil cylinder and plunger rods of the lower side oil cylinders are fixed to the lower sliding blocks. The lower sliding blocks are provided with locating columns. The locating columns penetrate through the middle fixing beam. Through the arrangement of the upper main oil cylinder, the lower main oil cylinder, the upper side oil cylinders and the lower side oil cylinders, the tonnage of the five-beam four-column type explosive pressing hydraulic machine can be improved, and the development demand of the military industry is met.

Owner:HEFEI METALFORMING MACHINE TOOL

A Combined Staged Yield Metal Damper

ActiveCN106193752BSame sizeIncrease tonnageProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention discloses a combined and phased yield metal damper. The damper comprises an upper connecting plate (4) and a lower connecting plate (5). A first energy consumption steel board (1), second energy consumption steel boards (2), and third energy consumption steel boards (3) are fixedly arranged between the upper connecting plate (4) and the lower connecting plate (5). The first energy consumption steel board (1) is vertically arranged between the upper connecting plate (4) and the lower connecting plate (5) in order to bear the energy consumption effect under small vibration. The third energy consumption steel boards (3) are arranged on two sides of the first energy consumption steel board (1) and used for constraining the first energy consumption steel board (1) and supporting the effect of energy consumption at large vibration. The side wall of the first energy consumption steel board (1) between the two third energy consumption steel boards (3) is provided with the second energy consumption steel boards (2), as reinforcing ribs of the first energy consumption steel board (1), and used for supporting energy vibration at large vibration. The metal damper has good phased yield capacities at small and great vibration and capable of effectively improving tonnage of the damper and is conveniently constructed.

Owner:NANJING TECH UNIV

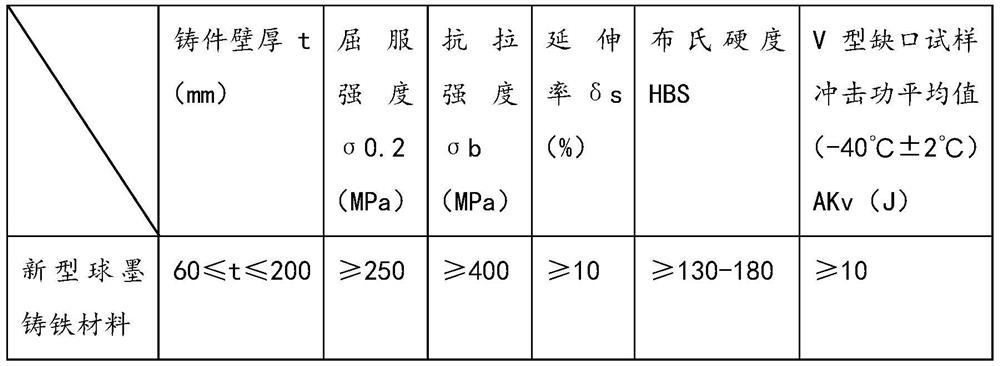

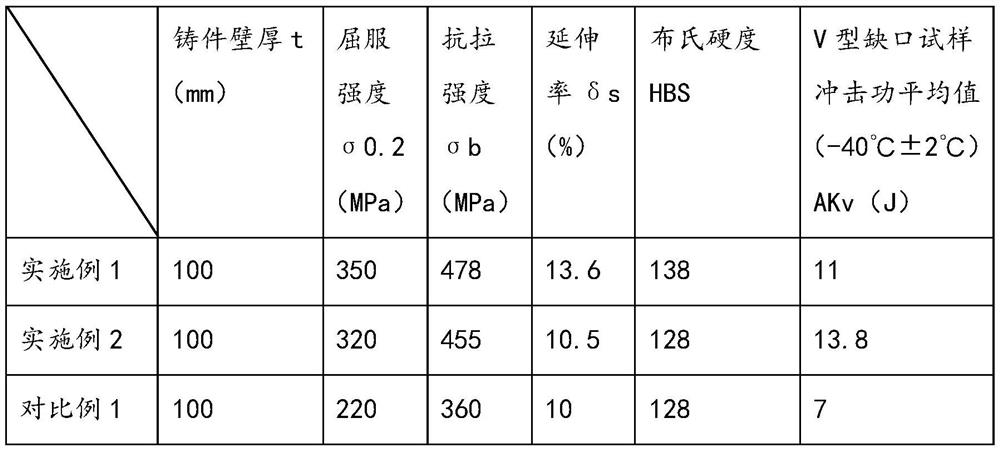

Nodular cast iron material for draught fan and preparation method and application of nodular cast iron for draught fan

InactiveCN112359269AHigh strengthImprove toughnessMachines/enginesEngine componentsManganeseDuctile iron

The invention discloses a nodular cast iron material for a draught fan and a preparation method and application of the nodular cast iron material for the draught fan, and belongs to the field of windturbines. The nodular cast iron material for the draught fan comprises, by mass, 3.5-3.9 % of carbon, less than or equal to 0.2 % of manganese, less than or equal to 2.3 % of silicon, less than or equal to 0.003 % of phosphorus, less than or equal to 0.025 % of sulfur, less than or equal to 1.7 % of nickel, less than or equal to 0.005 % of antimony, less than or equal to 0.05 % of magnesium residues, less than or equal to 0.03 % of RE residues and the balance iron and impurities generated in the preparation process. Compared with the prior art, by means of the obtained nodular cast iron, the proportion content of each component is precise, and therefore each performance of the QT400-18AL nodular cast iron in an ultralow-temperature environment can be improved. The nodular cast iron is optimized QT400-18AL nodular cast iron, and by changing the percentage content of the nodular cast iron composition, the applicability of the material is enhanced, and the nodular cast iron material stillmaintains the excellent characteristics of high strength and high toughness of the nodular cast iron in a large-section, high-tonnage and ultralow-temperature (-40 DEG C) environment.

Owner:GUODIAN UNITED POWER TECH

Hoisting device and hoisting method

PendingCN113071984AIncrease tonnageImprove securityLoad-engaging elementsControl engineeringStructural engineering

The invention discloses a hoisting device and a hoisting method. The hoisting device comprises a body, a first hoisting lug group and a second hoisting lug group, and the first hoisting lug group is arranged on the upper end surface of the body and is used for being matched with hoisting hooks of more than two bridge cranes on a hoisting station; and the second hoisting lug group is arranged on the lower end face of the body and used for being matched with a hoisting point of a to-be-hoisted part so that the to-be-hoisted part can be vertically hoisted. The hoisting device can enable more than two bridge cranes to participate in hoisting at the same time, so that the hoisting tonnage of the cranes is increased; and in addition, the function of transferring the bridge cranes and the to-be-hoisted part is achieved, the hoisting hooks with the fixed positions of the bridge cranes is converted into a hoisting point matched with the to-be-hoisted part, the problem that the lifting point position of the to-be-hoisted part cannot meet the hoisting standard of two or more cranes is solved, under the limited hoisting condition on a hoisting station, the reliable and safe hoisting operation on large parts is completed, the application range of the bridge cranes in a construction site or a factory is enlarged, and the hoisting time is saved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com