Patents

Literature

92 results about "Boiler design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler design is the process of designing boilers used for various purposes. The main function of a boiler is to heat water to generate steam. Steam produced in a boiler can be used for a variety of purposes including space heating, sterilisation, drying, humidification and power generation. The temperature or condition of steam required for these applications is different, so boiler designs vary accordingly.

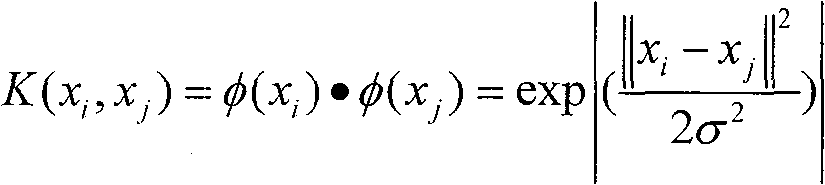

Boiler combustion optimizing method

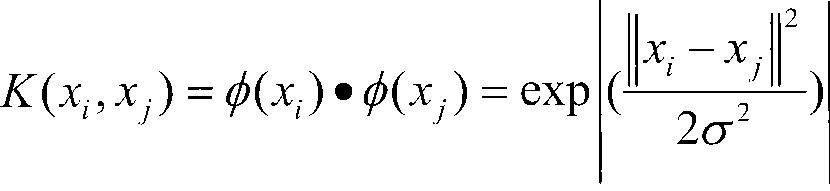

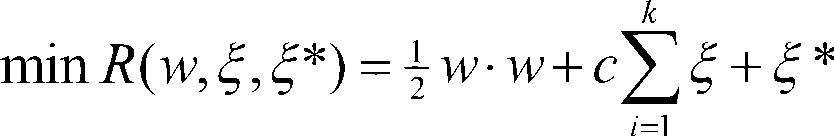

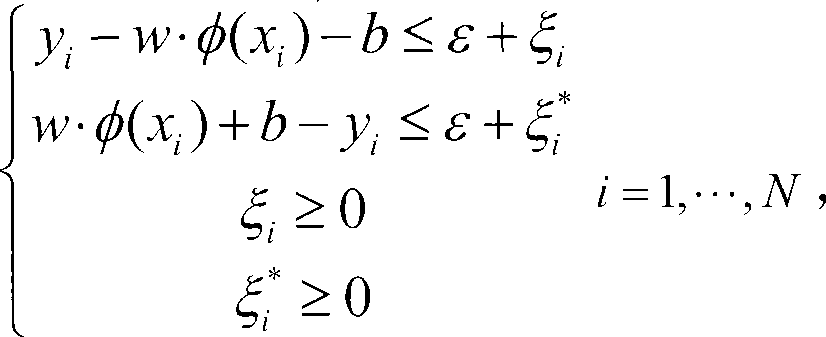

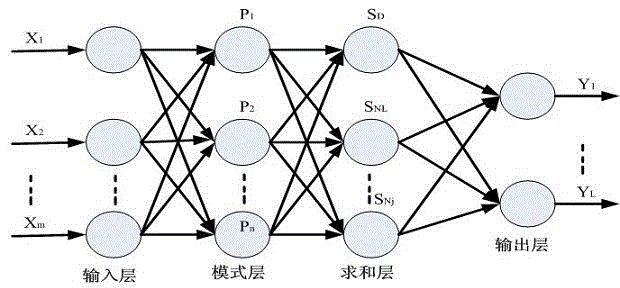

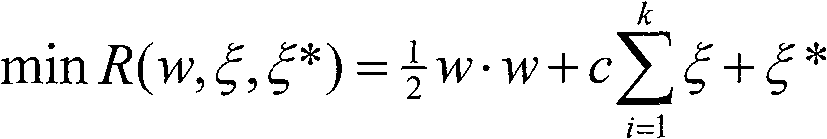

InactiveCN101498457AAvoid negative effectsImprove predictive performanceAdaptive controlProgramme total factory controlSupport vector machineRadial basis function neural

The invention relates to a method for optimizing combustion of a boiler. The combustion optimization of the prior boiler mainly depends on debugging stuffs to do experiments, thereby taking time and labor and obtaining limited parameter combinations. The method includes the following steps: collecting working parameters of the boiler and corresponding indexes characterizing the combustion characters of the boiler and building a real-time database; adopting an integrated modeling method supporting a vector machine to carry out modeling under the condition that the real work load is 60 percent smaller than the design load of the boiler and adopting a radial basis function neural network integrated modeling method to carry out modeling under the condition that the real work load is60 percent larger than or equal to the design load of the boiler to build boiler combustion models with different indexes; and utilizing the particle swarm optimization algorithm and combining with the built models to optimize the combustion parameter setting of the boiler according to different combustion indexes or index combinations of the boiler. The invention improves the predictive ability of the integral model, greatly improves the predictive ability of the models, and carries out one-line optimization and off-line optimization.

Owner:HANGZHOU DIANZI UNIV

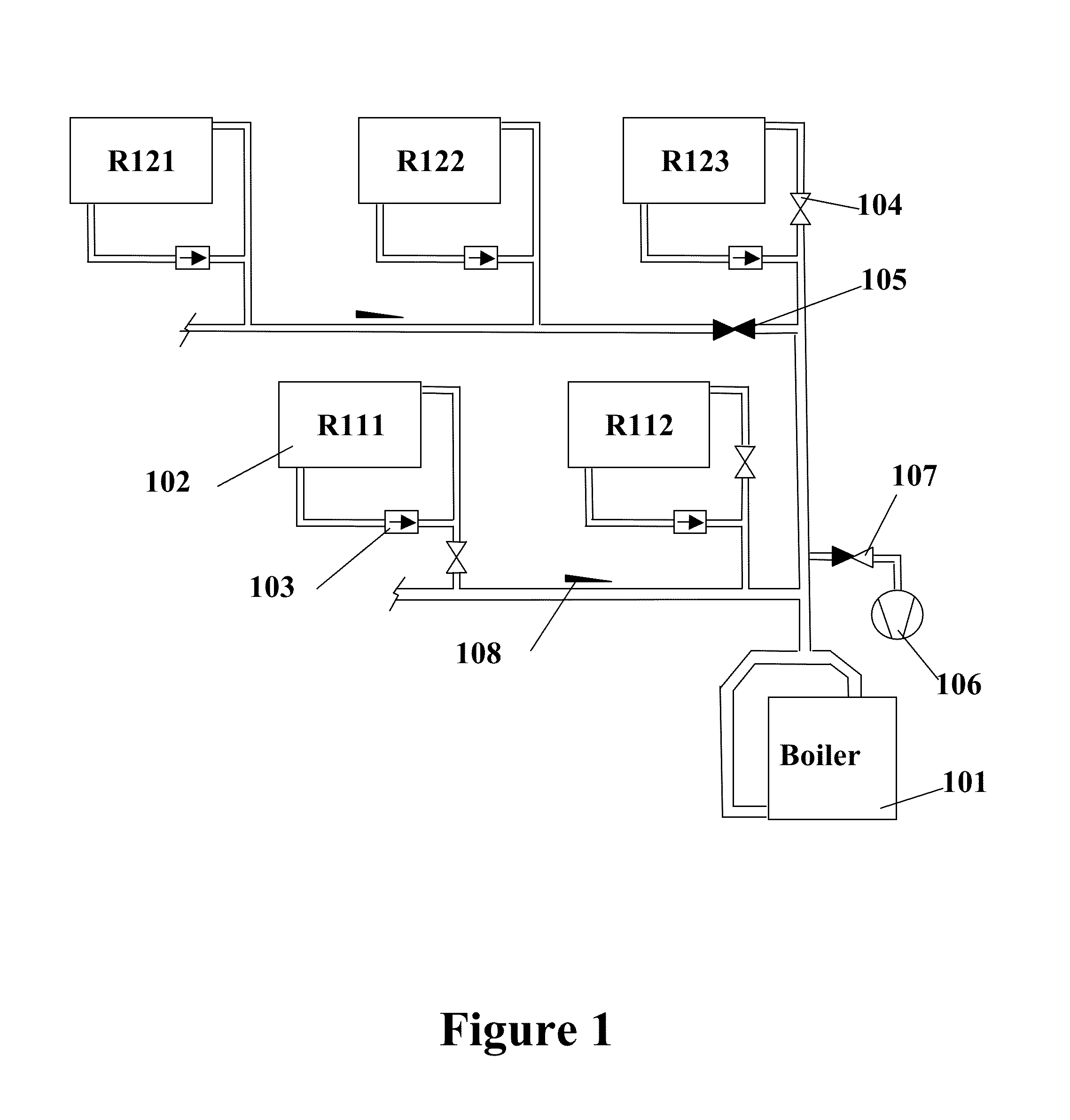

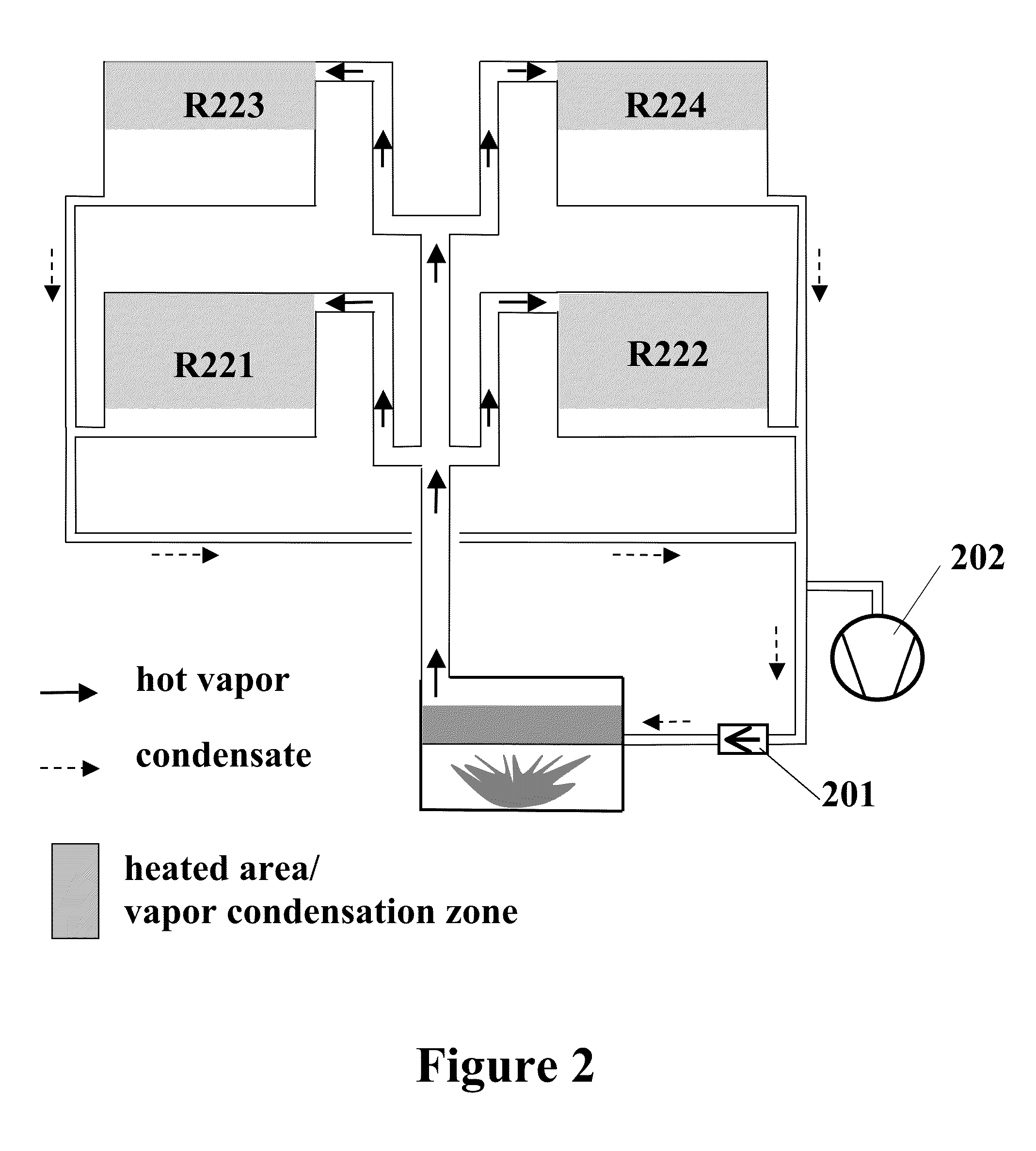

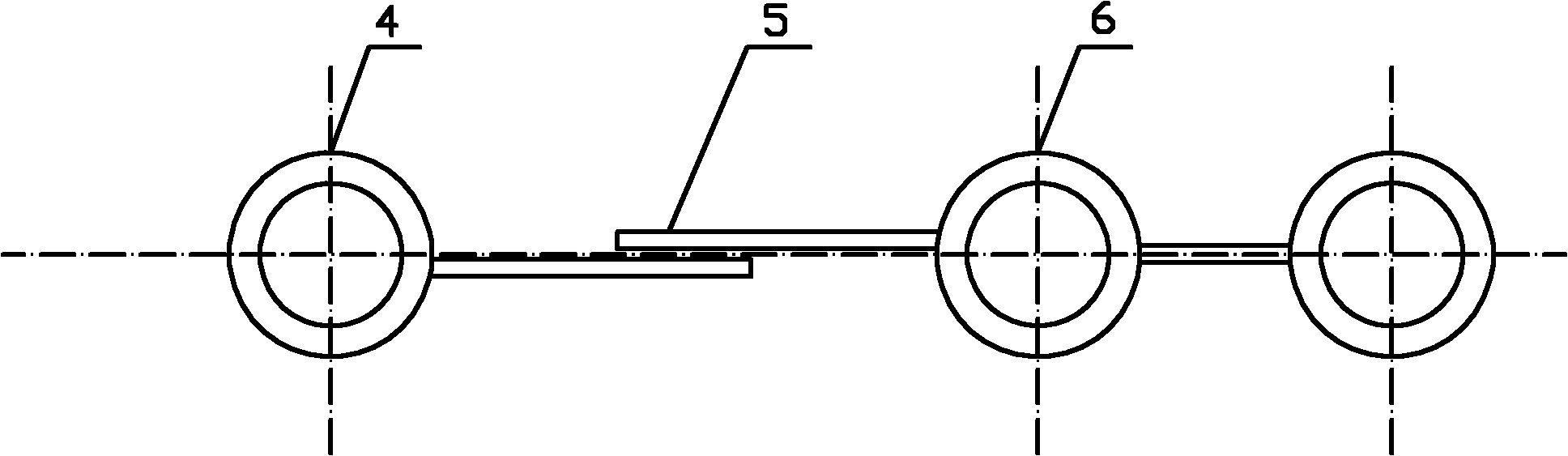

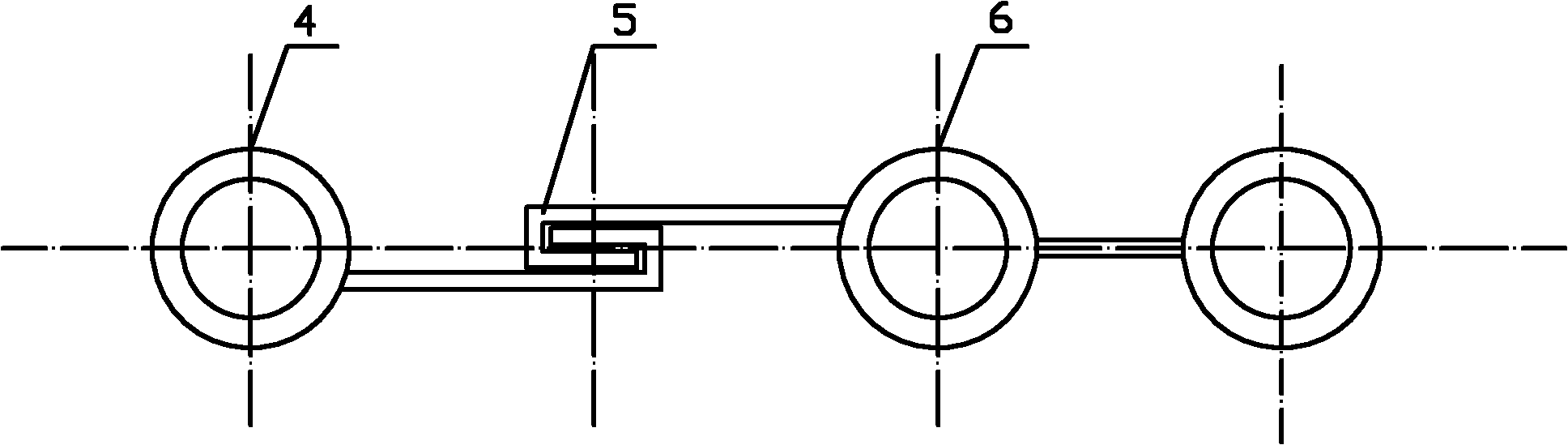

Vapor vacuum heating systems and integration with condensing vacuum boilers

ActiveUS20140034743A1Prevent backflowCentral heating componentsSteam useProcess engineeringSteam trap

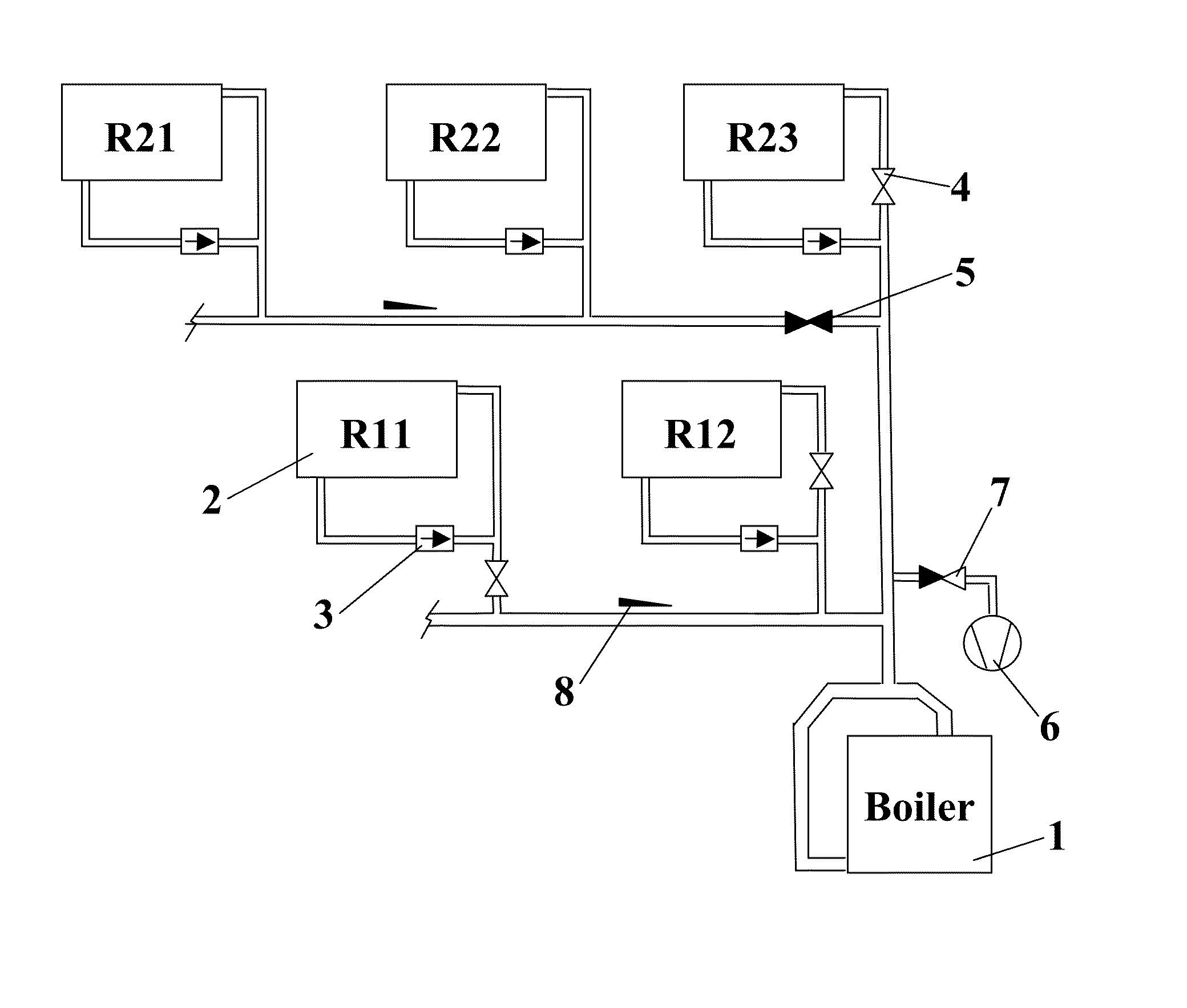

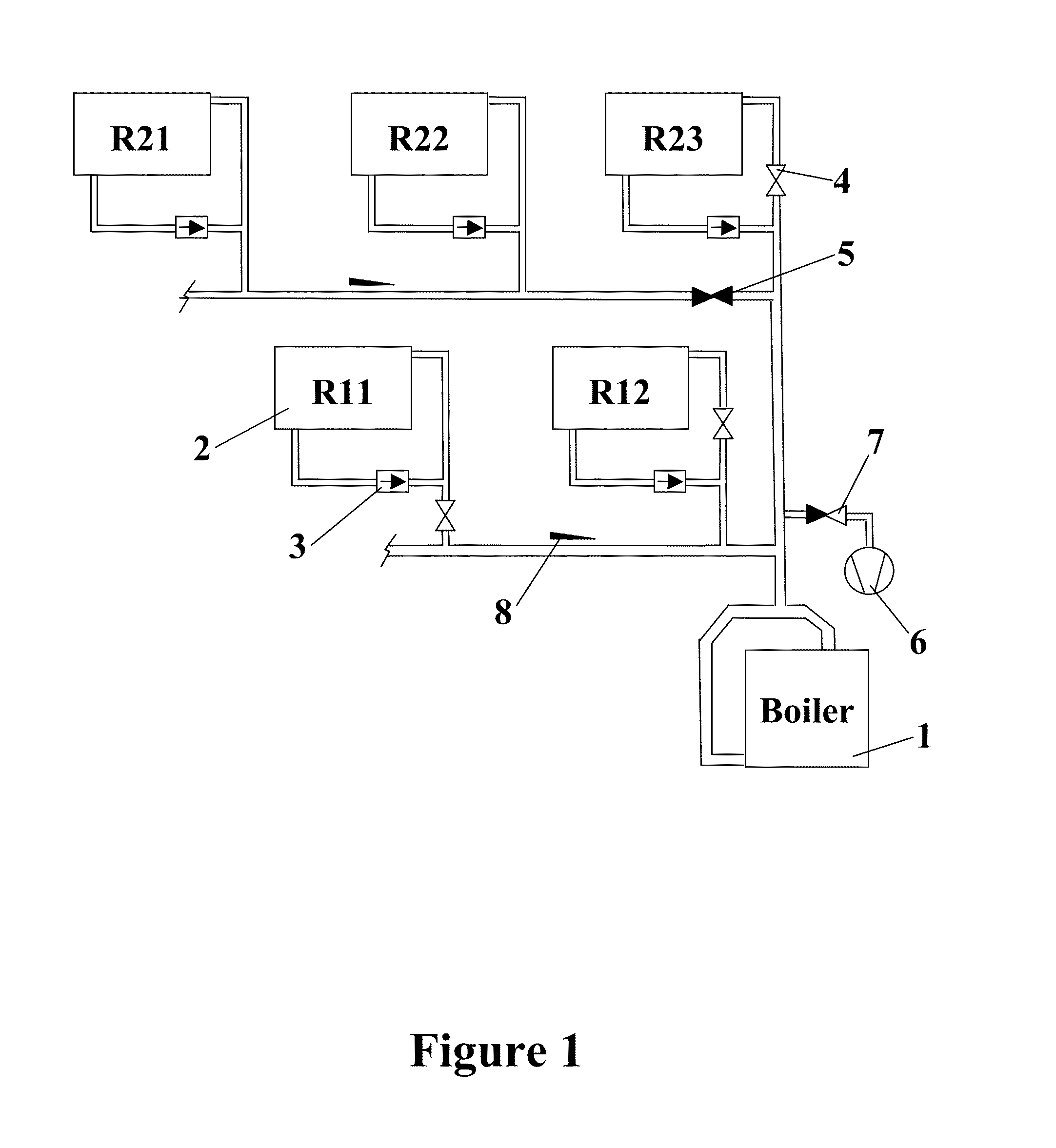

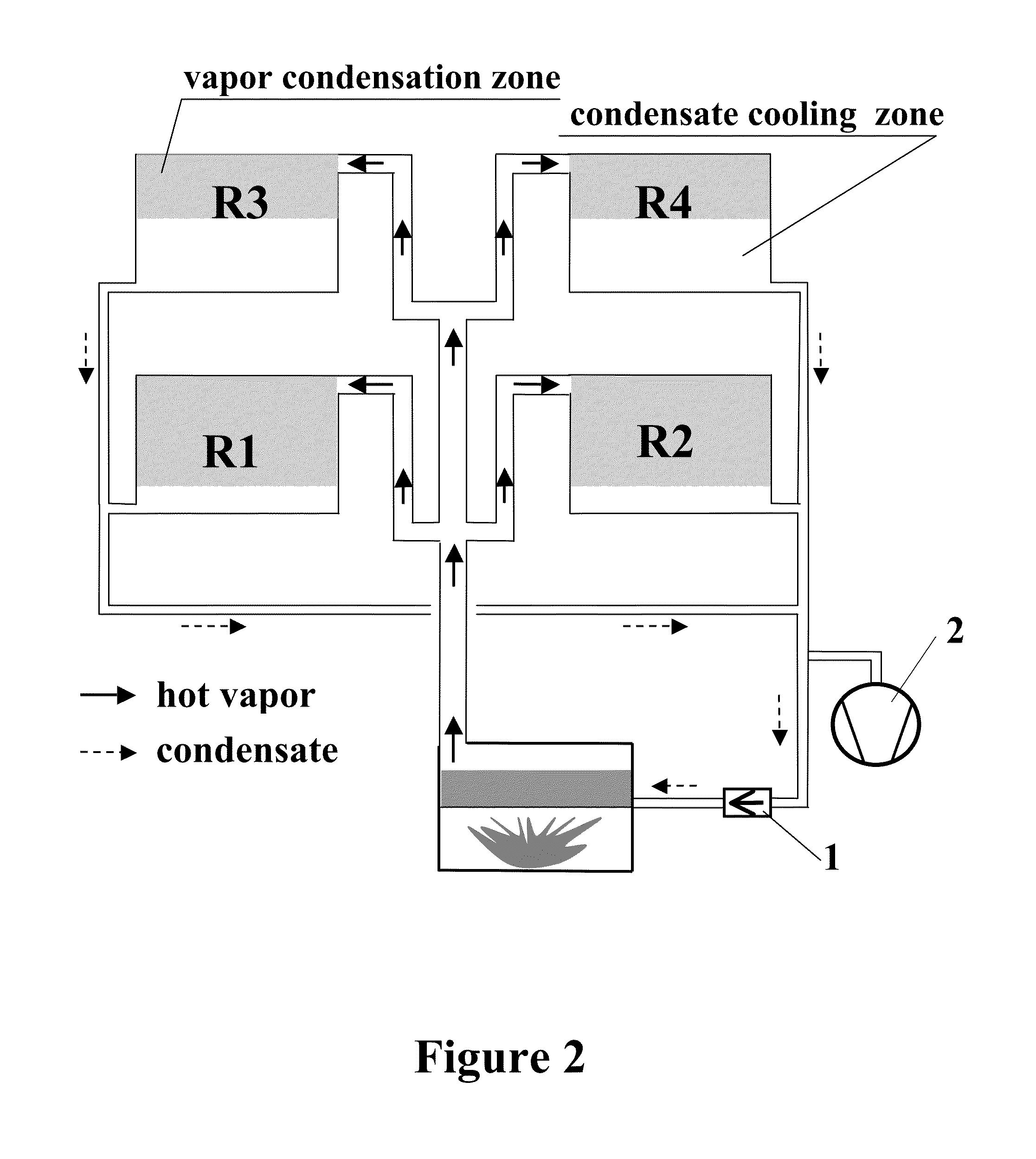

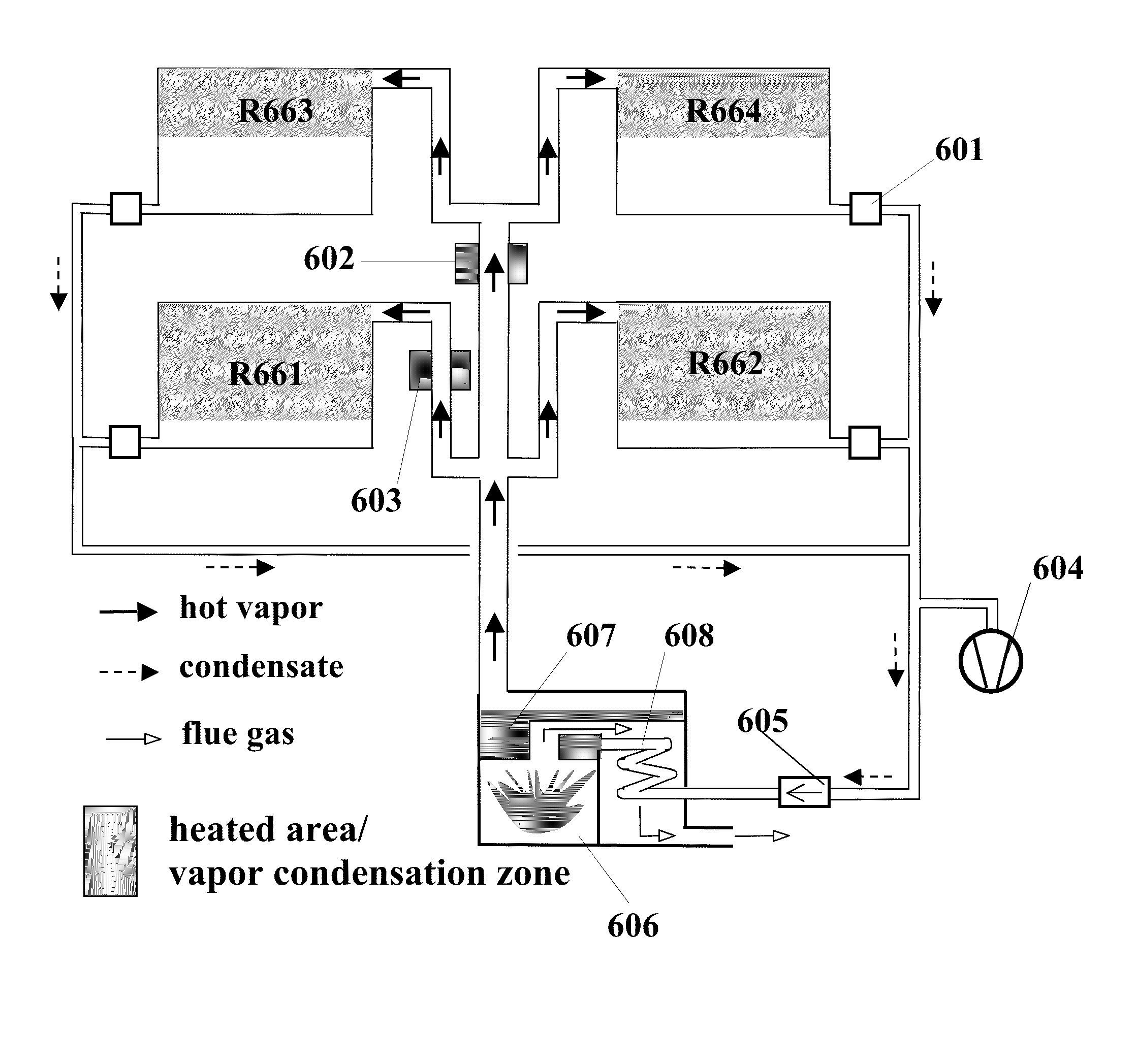

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, first presented is a novel system and method for a vapor vacuum system having low temperature condensate return which can operate without steam traps in both single-pipe and dual-pipe configurations. Secondly is disclosed systems and methods for integrating the disclosed vapor vacuum system with a condensing boiler. Thirdly is presented several systems and method of operating radiators having low temperature condensate return with the disclosed vapor vacuum system. Finally is presented condensing vacuum boiler designs that can be utilized with the disclosed vapor vacuum system. Also presented are embodiments having naturally-induced vacuum and utilizing district heat as well as combined heat and power. All innovations presented herein make vapor vacuum steam more efficient and economical for industrial, commercial, and home applications.

Owner:ZHADANOVSKY IGOR

Method for acquiring coal parameter of thermal power generating unit boiler cost minimum mixed coal

InactiveCN104156781AGuaranteed reasonablenessGuaranteed economyForecastingMathematical modelProcess engineering

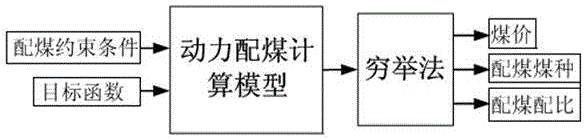

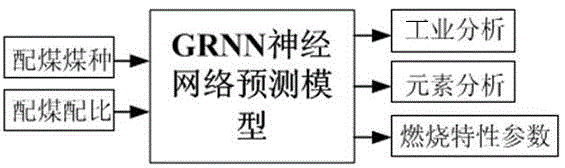

The invention discloses a method for acquiring a coal parameter of thermal power generating unit boiler cost minimum mixed coal. The method adopts the objective functions that high-grade coal composition is minimum, poor coal composition is maximum and raw coal unit cost is minimum to establish a dynamic coal composition mathematical model, and predicts the model according to a general regression neural network, so that the acquired coal quality parameter value of the mixed coal is more reasonable, and rationality and economy of boiler operation are ensured. The method comprises the following steps: adopting the objective functions that high-grade coal composition is minimum, poor coal composition is maximum and raw coal unit cost is minimum, adopting the constraint conditions of single coal database, boiler design coal quality and historical coal data, establishing the dynamic coal composition mathematical model, and adopting the general regression neural network technology to establish coal quality characteristic prediction model for the mixed coal. The method is suitable for acquiring the coal parameter of thermal power generating unit boiler cost minimum mixed coal.

Owner:STATE GRID CORP OF CHINA +1

Device and method for boiler superheat temperature control

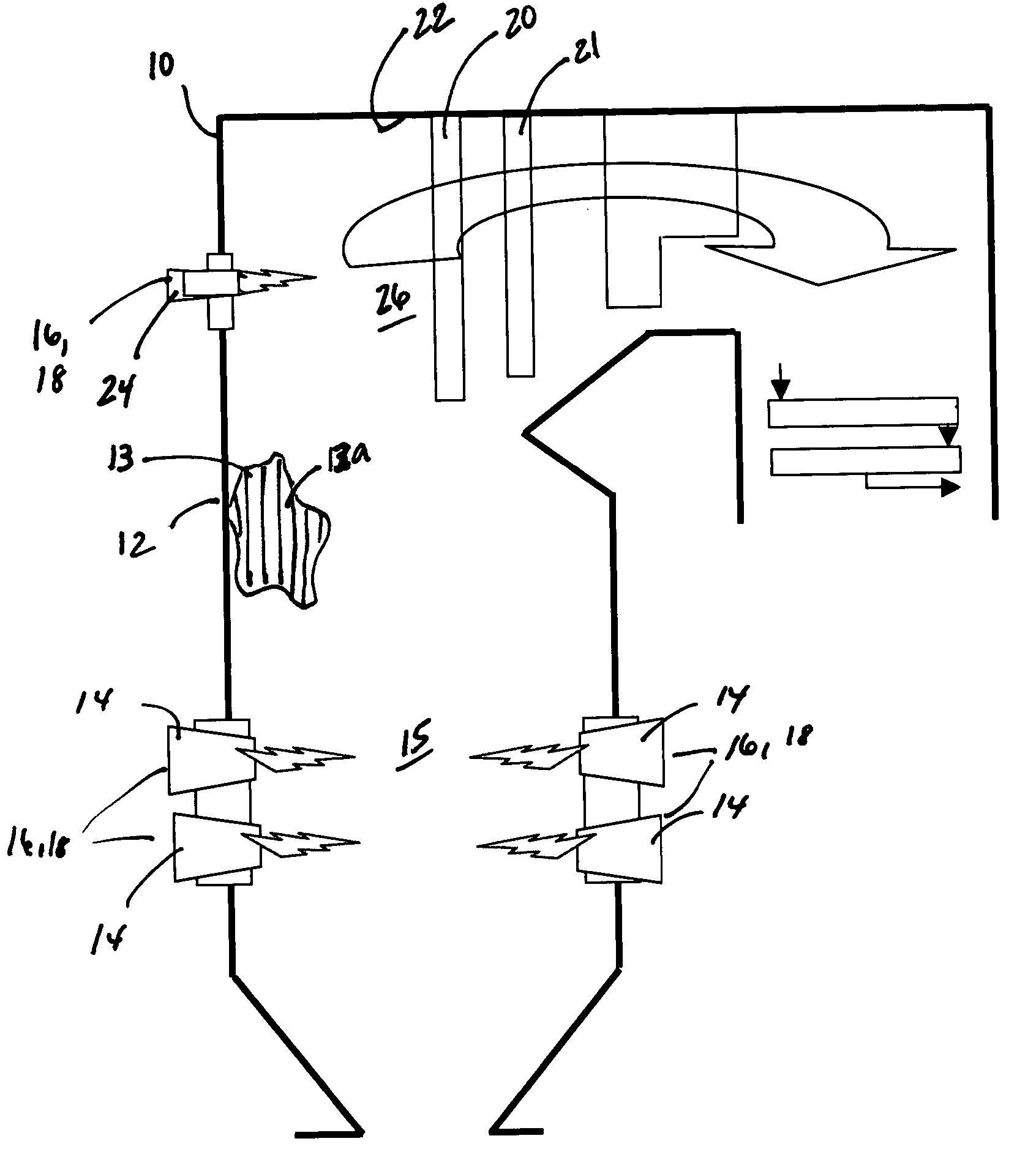

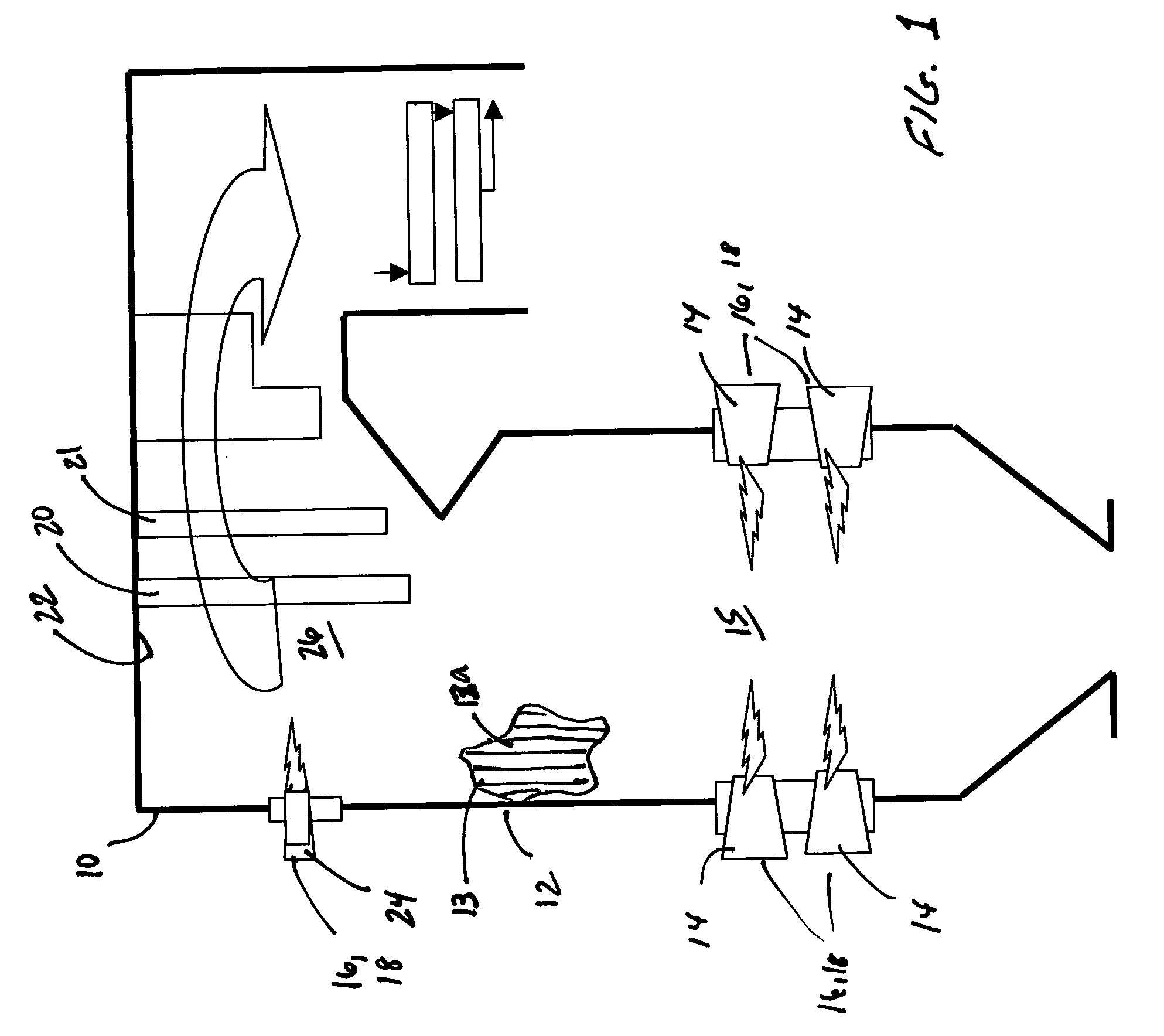

InactiveUS20050072379A1Increase temperatureQuality improvementBoiler water tubesWater-tube boilersTemperature controlCombustor

A boiler designed or retrofitted to produce less greenhouse gasses by using a substantially pure oxygen atmosphere in which to burn fuel. The boiler having a primary burner and water tubes is provided. The boiler further comprises at least one secondary burner located as needed in a zone above the primary burner area and below the boiler steam outlet. The secondary burner providing heat or energy to increase the temperature and quality of the steam. The secondary burner providing the heat or energy lost through the diminished flow rate of exhaust gases through the boiler as a result of the use of oxygen rather than pressurized air.

Owner:JUPITER OXYGEN CORP

Vapor vacuum heating systems and integration with condensing vacuum boilers

ActiveUS8702013B2Prevent backflowHeat recovery systemsCentral heating componentsCogenerationProcess engineering

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, first presented is a novel system and method for a vapor vacuum system having low temperature condensate return which can operate without steam traps in both single-pipe and dual-pipe configurations. Secondly is disclosed systems and methods for integrating the disclosed vapor vacuum system with a condensing boiler. Thirdly is presented several systems and method of operating radiators having low temperature condensate return with the disclosed vapor vacuum system. Finally is presented condensing vacuum boiler designs that can be utilized with the disclosed vapor vacuum system. Also presented are embodiments having naturally-induced vacuum and utilizing district heat as well as combined heat and power. All innovations presented herein make vapor vacuum steam more efficient and economical for industrial, commercial, and home applications.

Owner:ZHADANOVSKY IGOR

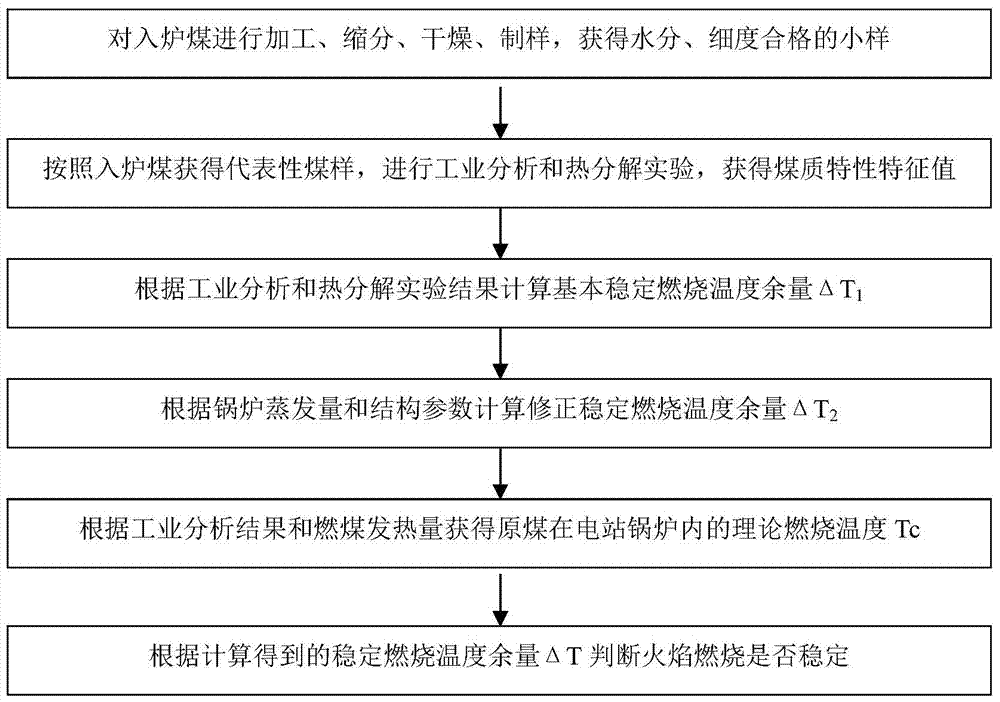

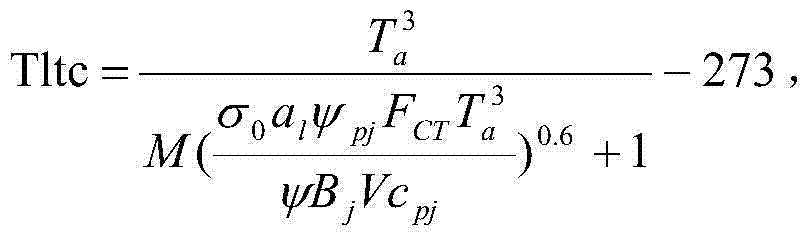

Combustion stability determining method based on thermal decomposition

ActiveCN104850755AAchieving full load forecastingAvoid hysteresisSpecial data processing applicationsHysteresisThermal decomposition method

The invention relates to a combustion stability determining method based on thermal decomposition. The pulverized coal combustion stability determination condition is acquired by the raw coal thermal decomposition method, the boiler design parameters are combined additionally, and the combustion stability of one power plant boiler is predicted previously. Compared with the prior art, the method has the advantages that the target of preventing and intervening power plant boiler blended combustion previously is achieved, the hysteresis and randomness caused by real-time monitoring are avoided, the full-load prediction of pulverized coal combustion stability can be implemented, and the applicability of combustion stability determination is improved.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

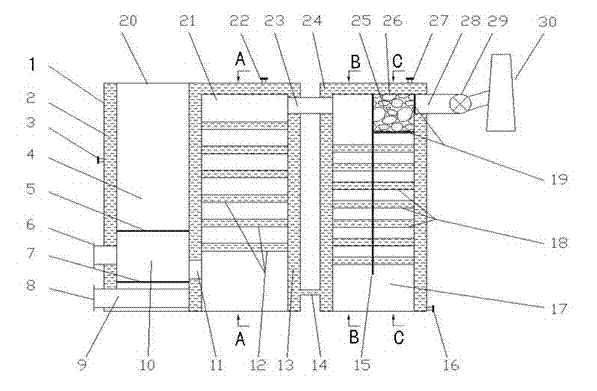

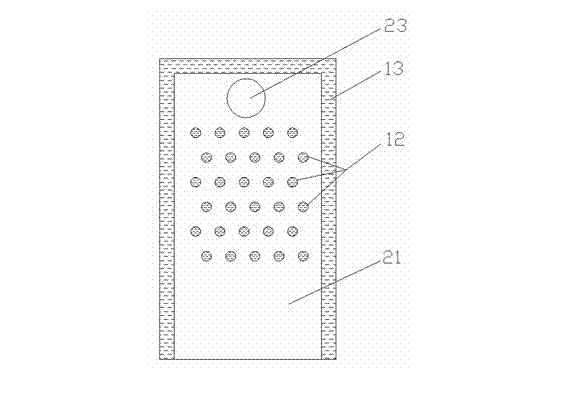

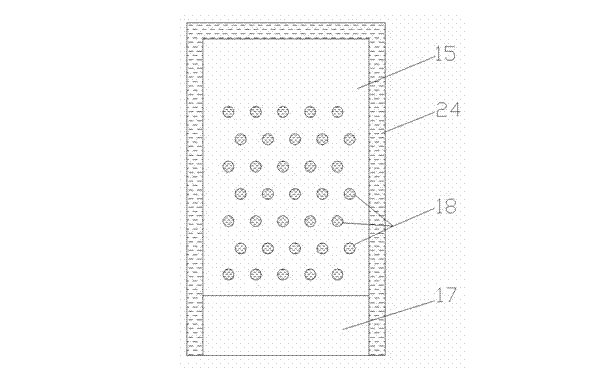

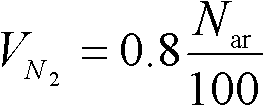

Novel biomass anti-burning type water heating boiler

The invention discloses a novel biomass anti-burning type water heating boiler. The novel biomass anti-burning type water heating boiler comprises a boiler body (1), wherein a boiler water interlayer (2) is arranged in the inner cavity of the boiler body (1); and the boiler water interlayer (2) is divided into an upper furnace cavity (4) and a lower furnace cavity (10) by using an upper fire grate (5). The novel biomass anti-burning type water heating boiler is characterized in that: a discharge flue (11) is formed in the side wall of the lower furnace cavity (10) and is communicated with the inner cavity of a boiling water tank (21); the inner cavity of the boiling water tank (21) is connected with the inner cavity, serving as a flue, of a hot water tank (17) through a communicating pipeline (14) and a boiling water tank discharge flue (23); and an exhaust port (28) formed at the upper end of the hot water tank (17) is connected to a chimney (30) through a pipeline and a draught fan (29). The novel biomass anti-burning type water heating boiler has the advantages of full combustion, high heating efficiency, energy conservation and environment friendliness. The boiler is designed to be an upper feeding mode, an air inlet and a material inlet are combined integrally, automatic feeding is realized under the action of the gravity of fuel and the draught fan, and manpower is saved. A flue gas purifier is arranged at the exhaust port of the boiler, so that tar and ash in flue gas can be removed effectively; therefore, the pollutant discharge is far below national standards.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH +1

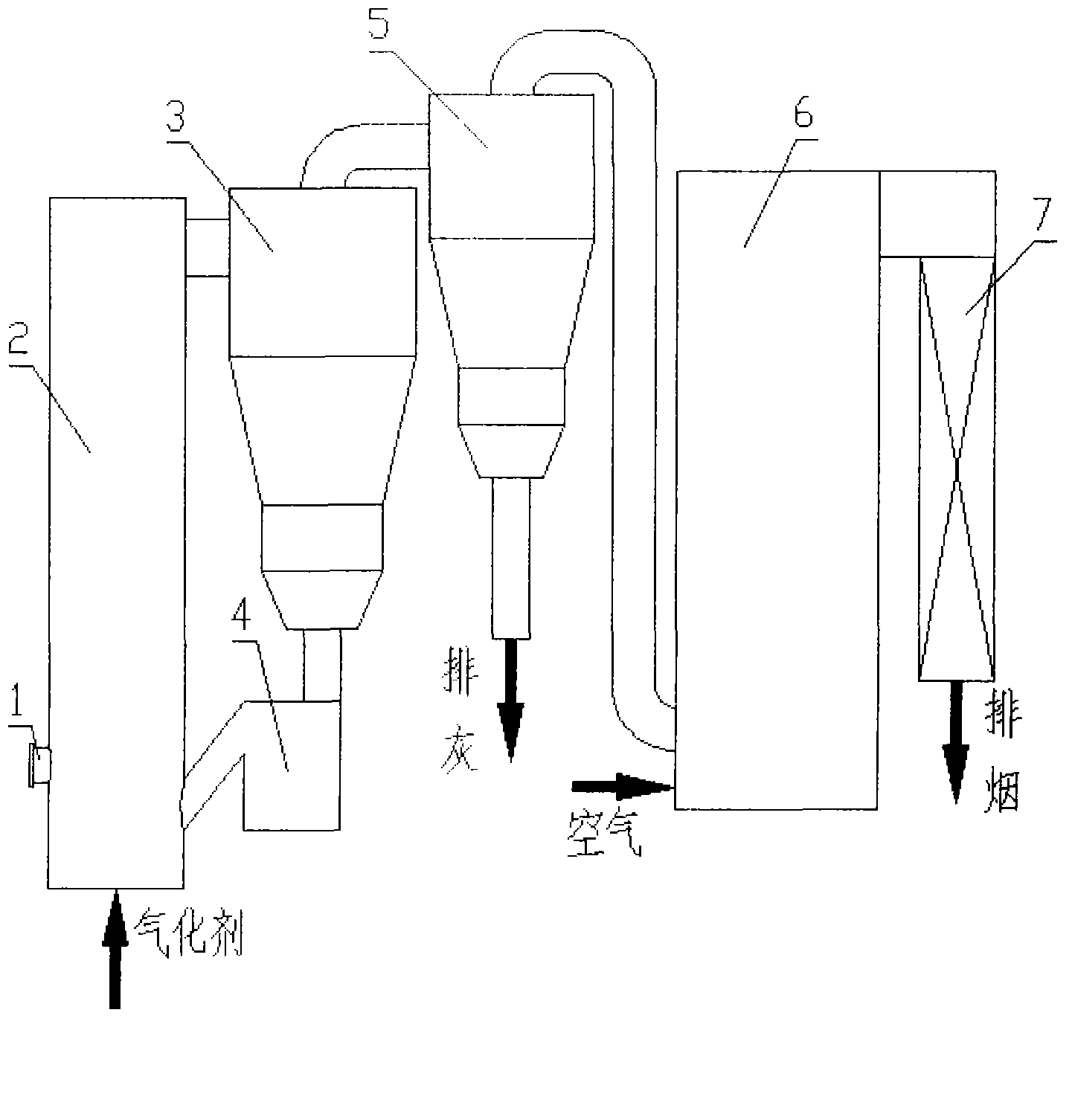

Biomass gasifying burning boiler

The invention discloses a biomass gasifying burning boiler. The working process of the biomass gasifying burning boiler comprises a biomass gasifying stage and a fuel gas burning stage; at the gasifying stage, pyrolysis and gasification of biomass are realized by adopting a circular fluidized bed gasifying process, incompletely-reacted carbon residues are separated from generated fuel gas through a cyclone separator, and the carbon residue return to the gasifying furnace through a return feeder for gasifying once again; and at the burning stage, the separated fuel gas is dedusted through a cyclone deduster, is fed into a hearth, and is mixed with the air for burning to provide a heat source for a heated surface. According to the biomass gasifying burning boiler designed by adopting the process structure, a biomass gasifying process and the burning process of the fuel gas are separated, and fuel gas entering the hearth is high-quality fuel gas with low dust content, so that the technical problems of low burning temperature, incomplete burning, corrosion of alkali metals, dust accumulation on heated area and the like existing in the conventional biomass boiler are solved.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

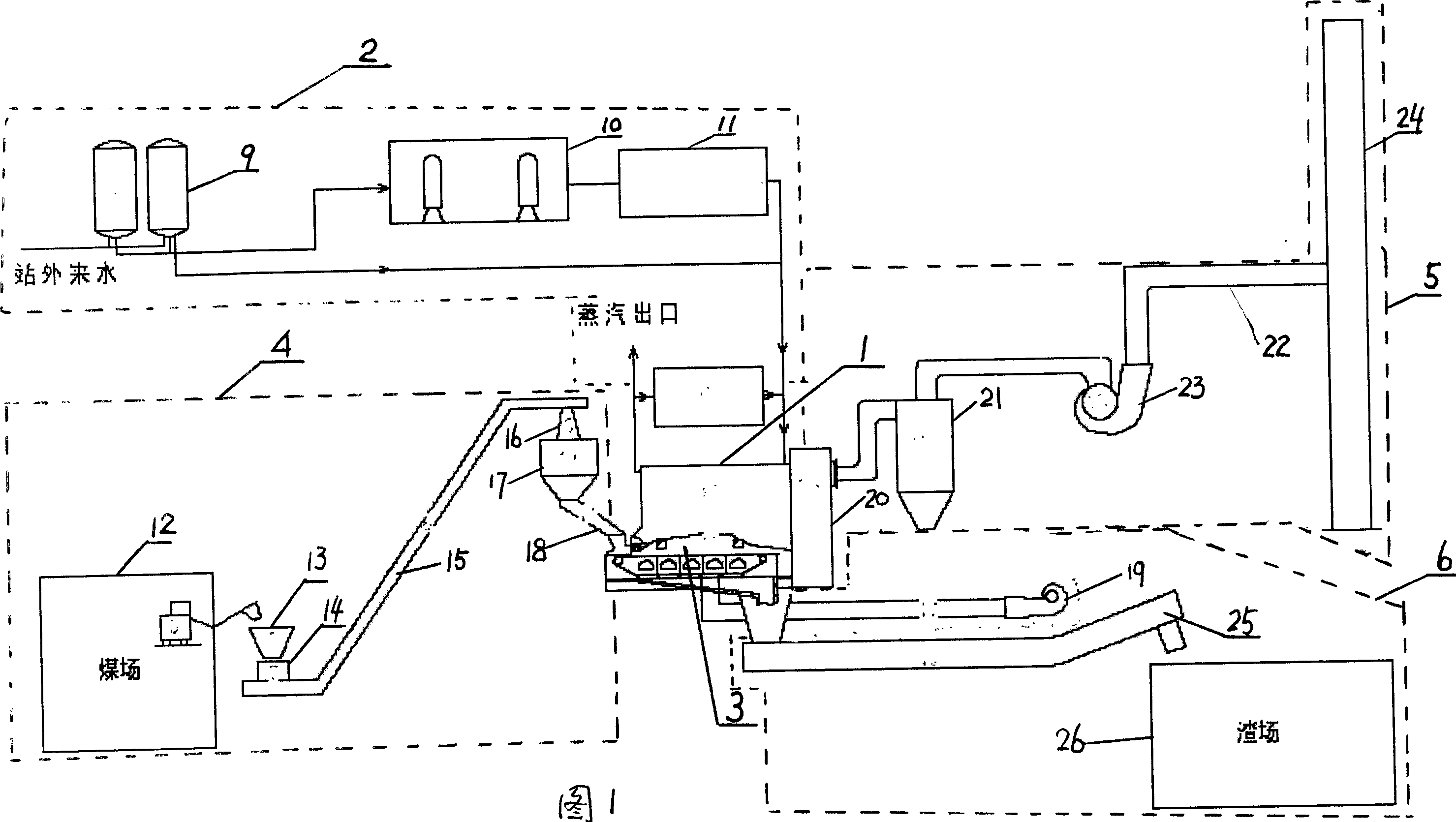

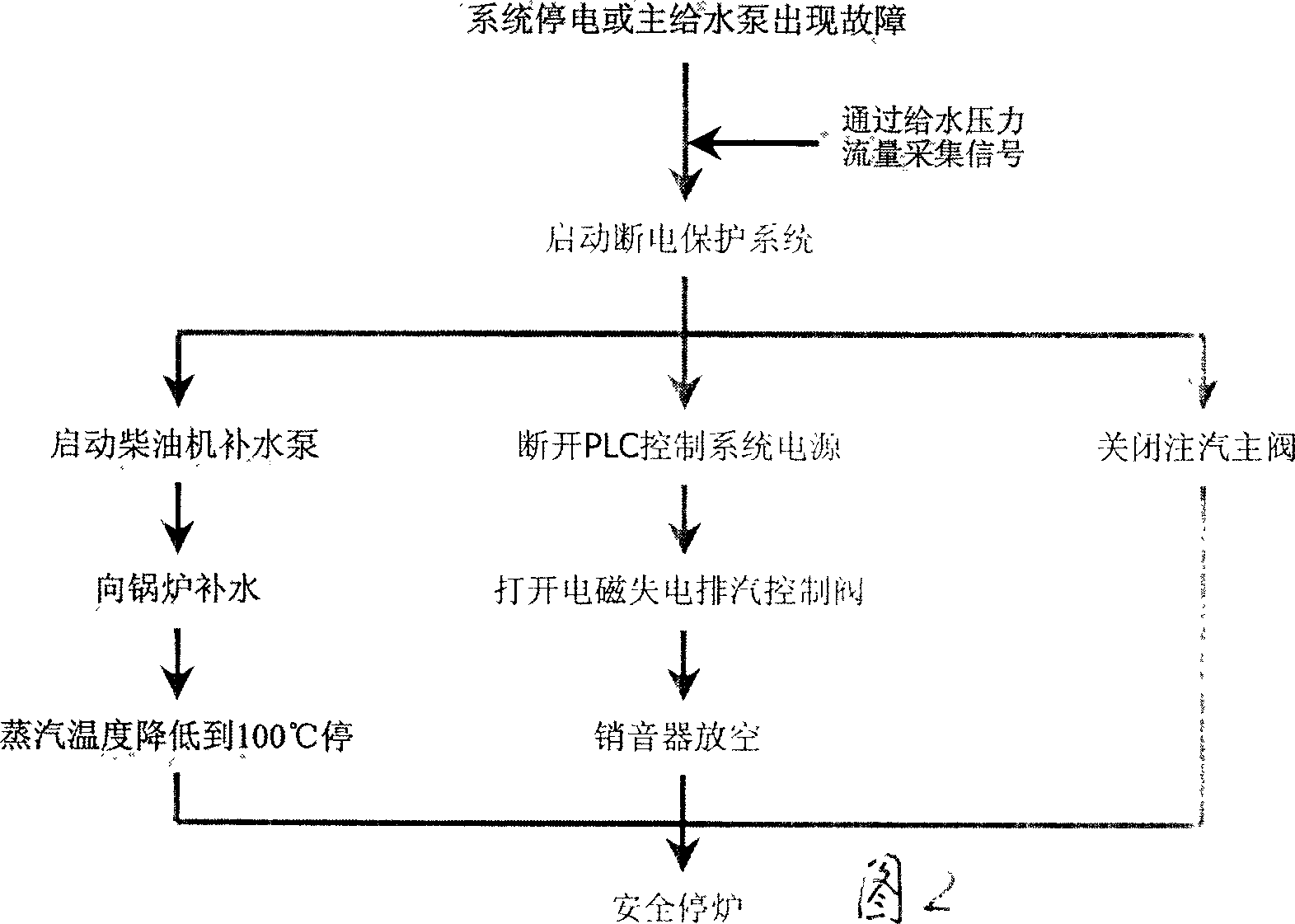

Thick oil exploiting coal firiag steam boiler

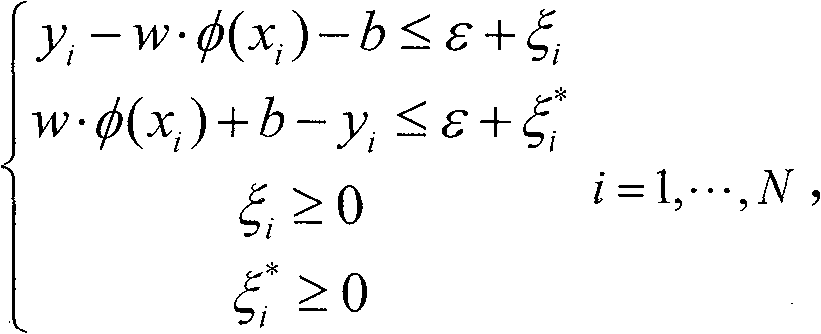

InactiveCN1888528AReduce mining costsAlleviate shortagesDrum steam boilersFluid removalCombustion chamberWind system

A thickened oil recovery coal-fired steam injection boiler mainly consists of a boiler body, a water-steam system, a fuel system, a combustion system, a smoke wind system, an ash system, a control system and a power-off protection system. The hydraulic supply line and the steam pipeline of the water-steam system are separately connected with the water inlet and the steam outlet of the boiler body. The fuel system is used for feeding the coal into the combustion system via a layer coal feeder. The combustion system feeds the coal fed by the fuel system into upper, middle and lower decks grates in the coal particles, and then burns in the high and low temp. combustion chambers in the hearth. The ash and the smoke wind system are in communication with the slagging mouth and the flue of the boiler hearth separately. The control and the power-off protection systems are connected with the boiler body.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Boiler combustion optimizing method

InactiveCN101498457BAvoid negative effectsImprove predictive performanceAdaptive controlProgramme total factory controlSupport vector machineRadial basis function neural

The invention relates to a method for optimizing combustion of a boiler. The combustion optimization of the prior boiler mainly depends on debugging stuffs to do experiments, thereby taking time and labor and obtaining limited parameter combinations. The method includes the following steps: collecting working parameters of the boiler and corresponding indexes characterizing the combustion characters of the boiler and building a real-time database; adopting an integrated modeling method supporting a vector machine to carry out modeling under the condition that the real work load is 60 percent smaller than the design load of the boiler and adopting a radial basis function neural network integrated modeling method to carry out modeling under the condition that the real work load is60 percentlarger than or equal to the design load of the boiler to build boiler combustion models with different indexes; and utilizing the particle swarm optimization algorithm and combining with the built models to optimize the combustion parameter setting of the boiler according to different combustion indexes or index combinations of the boiler. The invention improves the predictive ability of the integral model, greatly improves the predictive ability of the models, and carries out one-line optimization and off-line optimization.

Owner:HANGZHOU DIANZI UNIV

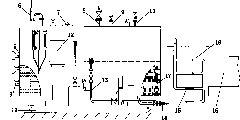

High-power pulse combustion steam boiler with multi-combustor parallel heating

The invention discloses a high-power pulse combustion steam boiler with multi-combustor parallel heating, belonging to the technical field of advanced energy sources. In the invention, the heat is supplied for the steam boiler by adopting a linkage mode of a plurality of groups of pulse combustors, that is to say, the plurality of pulse combustors are soaked in a boiler shell in parallel; safety ignition and control of the parallel pulse combustors are set by an electric control system program, therefore, independent ignition-flameout protection-restarting of each pulse combustor in the plurality of parallel pulse combustors can be realized, and the safe and automatic control function can be achieved; and a pipe network is added as a waste heat recovery device in a decoupling chamber so as to fully utilize the heat and improve the heat efficiency of the steam boiler. The high-power pulse combustion steam boiler realizes the high-power steam boiler design on the premise of ensuring the stable operation of the pulse combustors; the automatic control program of safety ignition-flameout protection-starting of the combustor groups ensures the ignition safety and reliability of the pulse combustors; and the waste heat recovery device ensures that the flue gas temperature is reduced to 180 DEG C and the heat loss is reduced.

Owner:CHINA AGRI UNIV

Coal-fired power station boiler reheater working medium flow online correction method

InactiveCN109141541AAchieve correctionAccurate online real-time monitoringVolume/mass flow measurementVolume variation compensation/correction apparatusEnergy balancingMeasurement point

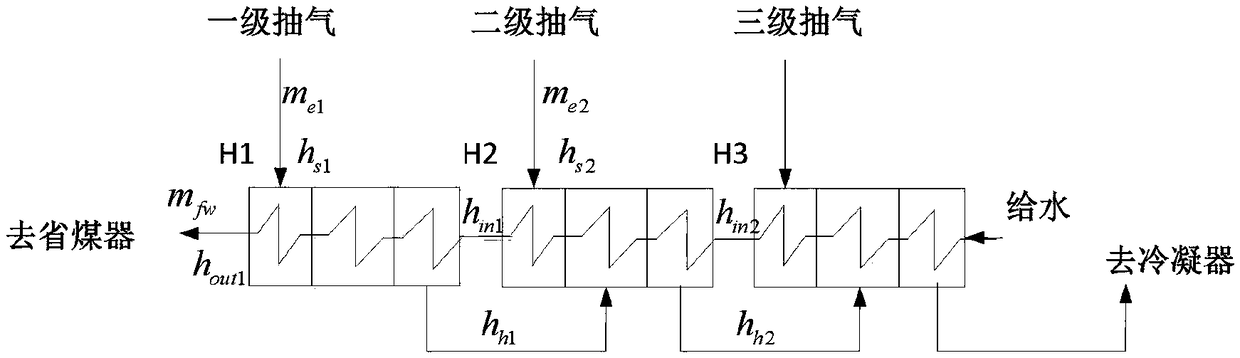

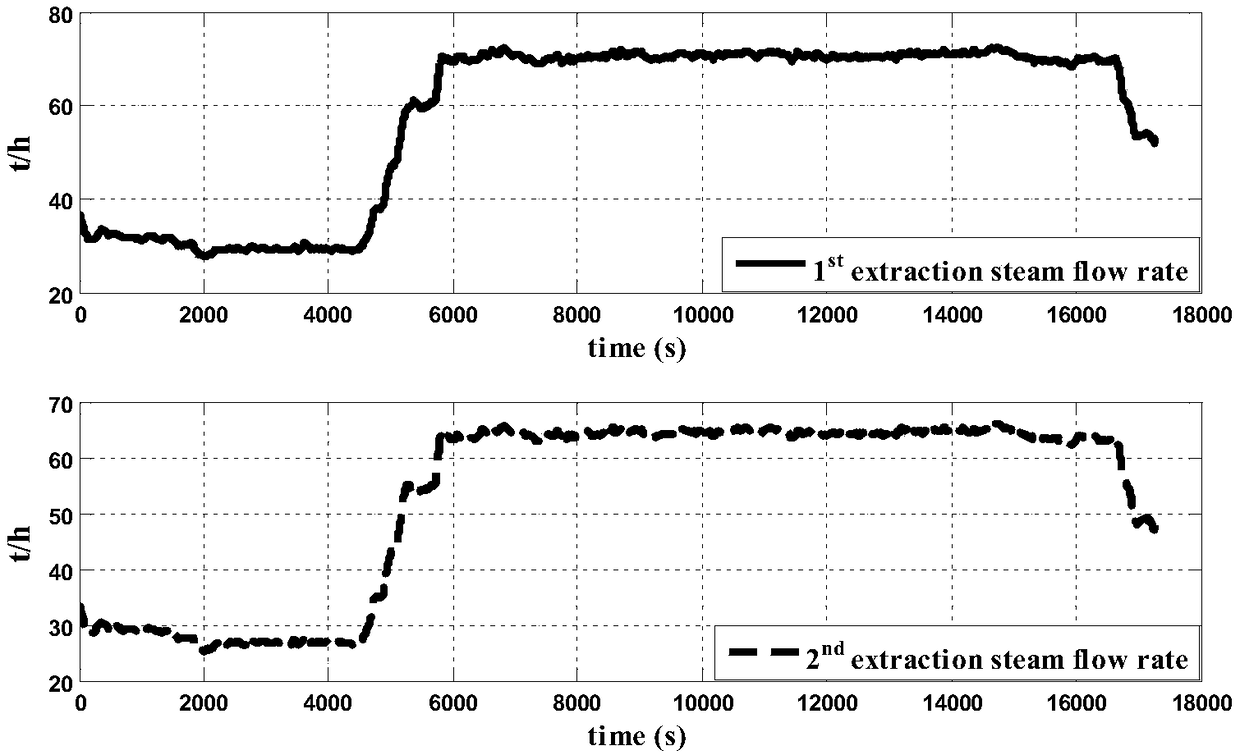

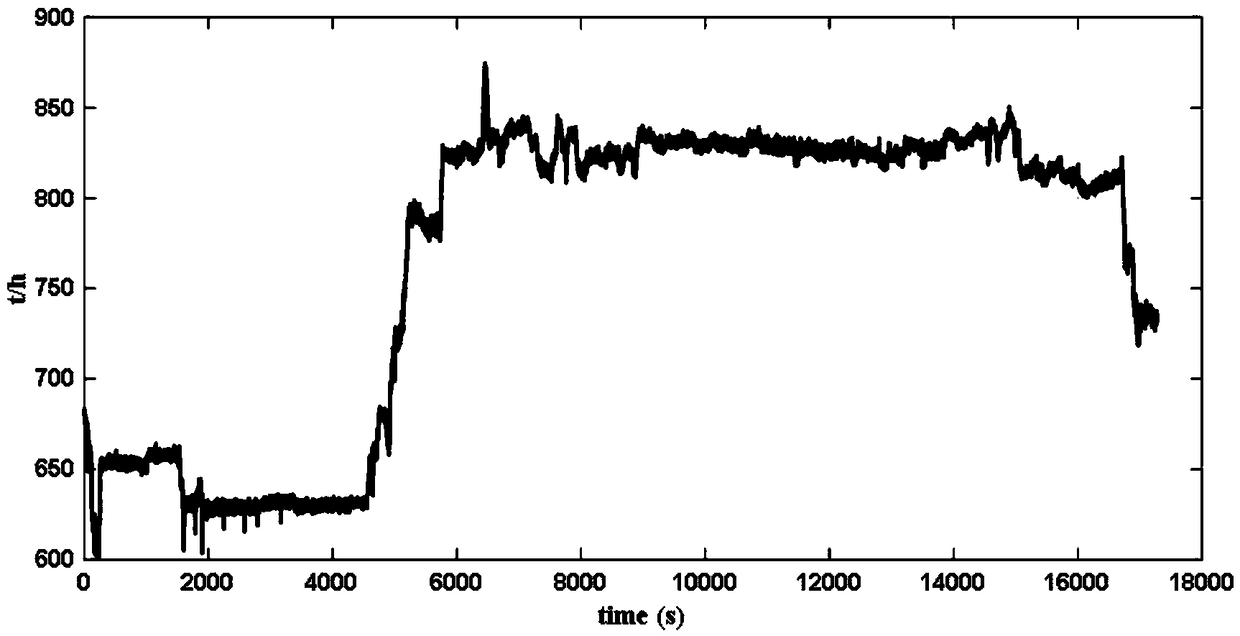

The invention discloses a coal-fired power station boiler reheater working medium flow online correction method. The method comprises the following steps: acquiring related boiler running data in realtime from an engineer station in a boiler distributed control system (DCS) after selecting fixed sampling time; establishing a working medium physical property parameter library for online computation of water and vapor enthalpy values; setting a design parameter of a boiler related superheater system according to boiler design drawing; performing dead pixel processing and data smoothing processing on the collected running parameter of the boiler; establishing a boiler reheating system working medium mass and energy balancing equation based on mass and energy balancing; modifying an energy balancing equation in the step 4 according to heat storage change of a working medium and a metal heat-absorbing surface under the temperature pressure change; obtaining temperature, pressure and flow at each measurement point of the reheater system from the measurement point, and obtaining the temperature, pressure and flow related data of the working medium; simultaneously acquiring exhaust volumes of the primary exhaust and the secondary exhaust by combining the corrected mass and energy balancing equation; and finally obtaining the corrected reheater working medium flow.

Owner:ZHONGBEI UNIV

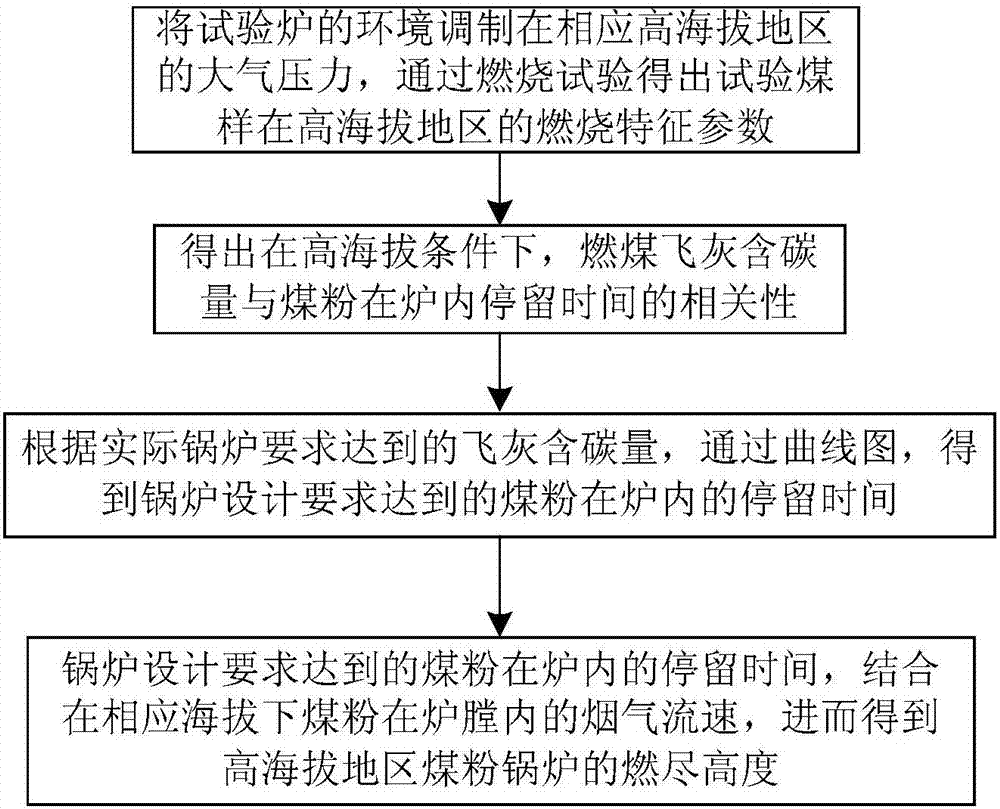

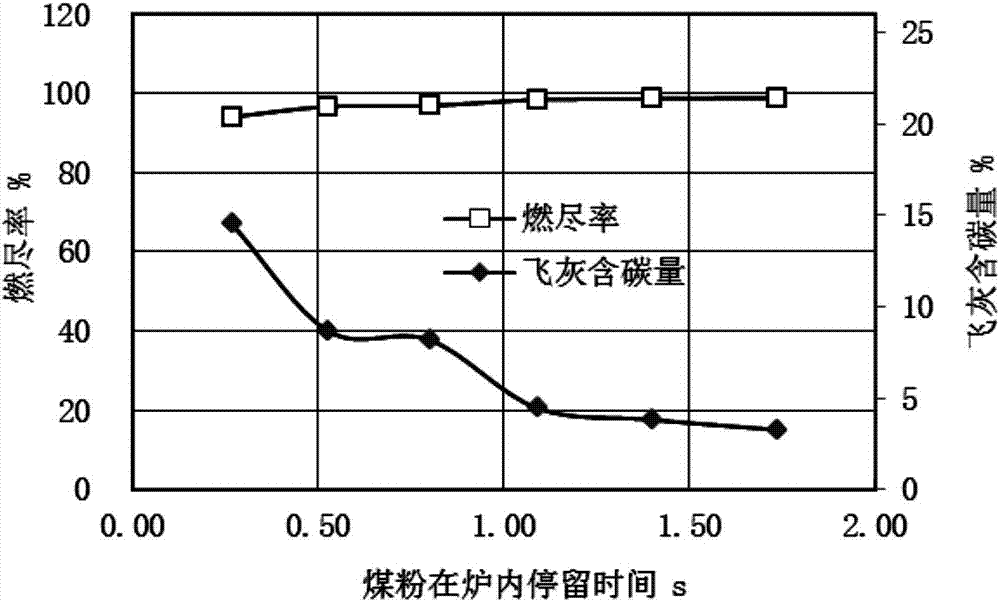

Method for determining burnout height of combustion chamber of pulverized coal boiler

The invention provides a method for determining the burnout height of a combustion chamber of a pulverized coal boiler. The method comprises the steps as follows: Step 1: a high-altitude environment is simulated, and combustion characteristic parameters of fire coal in the high-altitude state are acquired through a combustion test of the fire coal on a test bed; Step 2: according to the characteristic parameters, the correlation between the carbon content of coal-fired fly ash of the fire coal and the dwell time of pulverized coal of the fire coal in the boiler is obtained; Step 3: according to the correlation between the carbon content of the fly ash and the dwell time of the pulverized coal in the boiler, the dwell time value, corresponding to the limit value, required to be reached during actual boiler design, of the carbon content of the fly ash, of the pulverized coal in the boiler is obtained, and the burnout height of the combustion chamber is obtained in combination with the flue gas velocity of the pulverized coal in the combustion chamber. With the method for determining the burnout height, the boiler design in a high-altitude area has more scientific bases, the problems of high carbon content of the fly ash and low boiler combustion efficiency due to insufficient burnout time which is possibly caused by the fact that the burnout height of a boiler in the high-altitude area is determined as per the empirical formula only are solved, and the boiler design risk is effectively reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +3

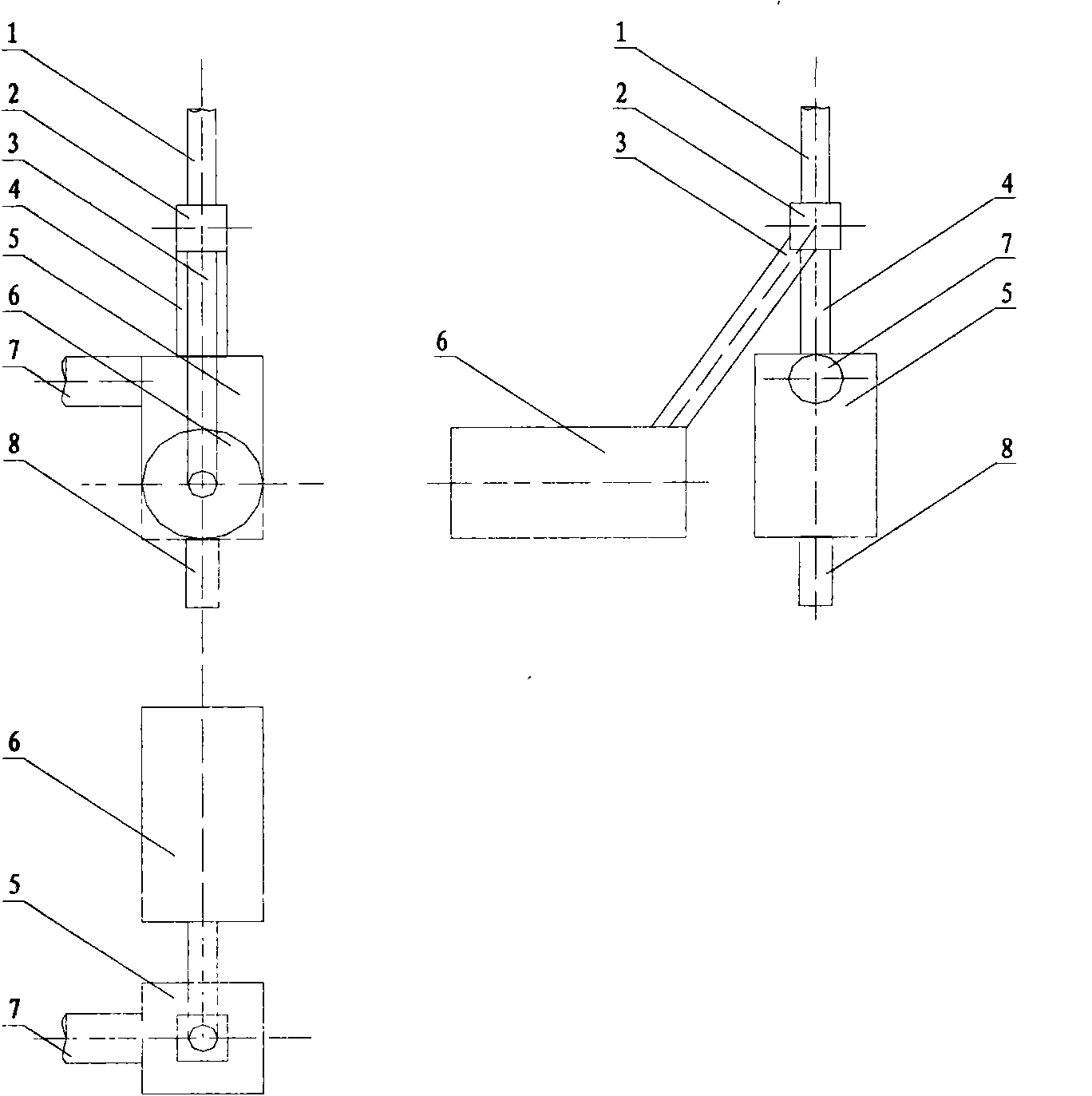

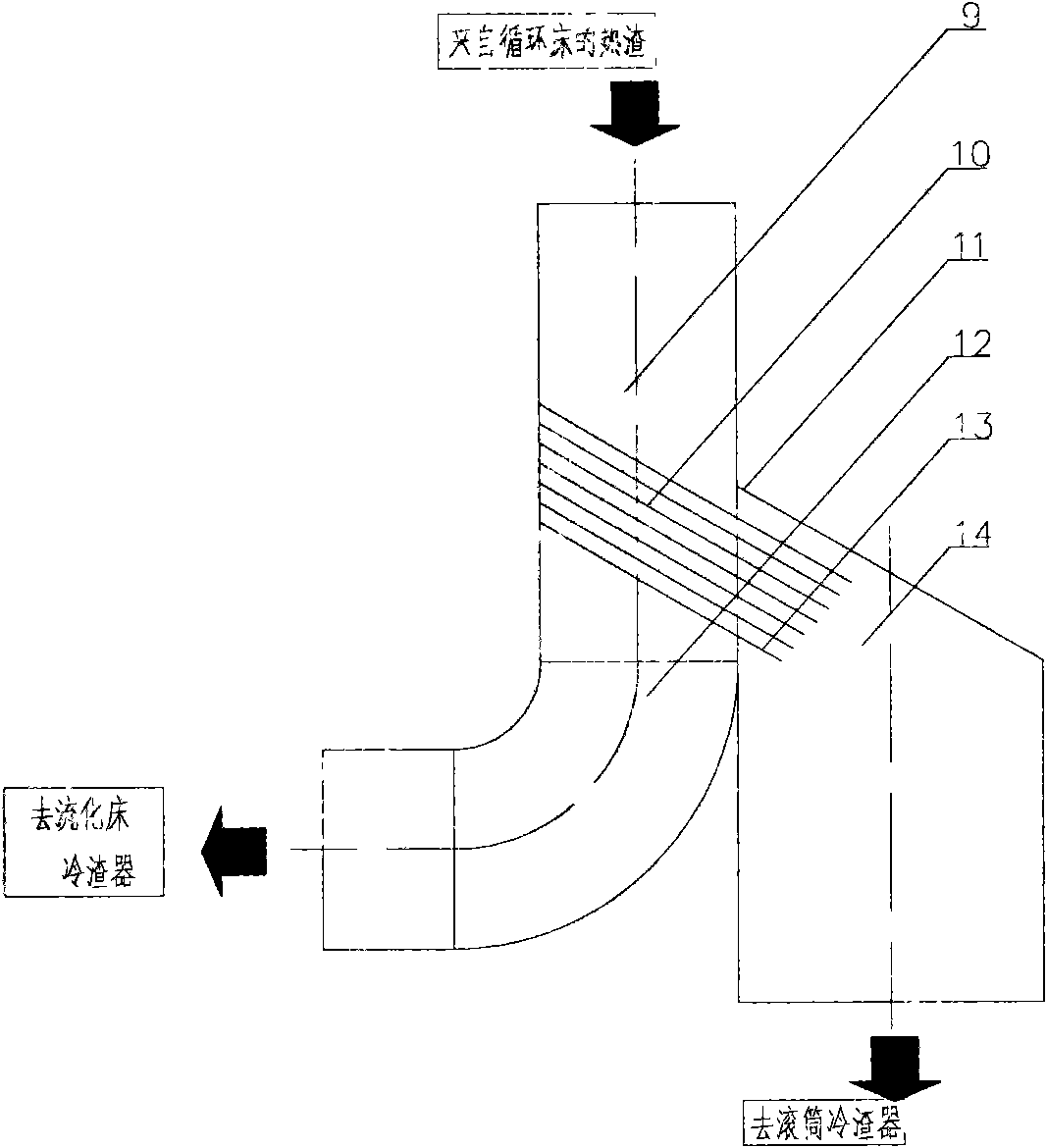

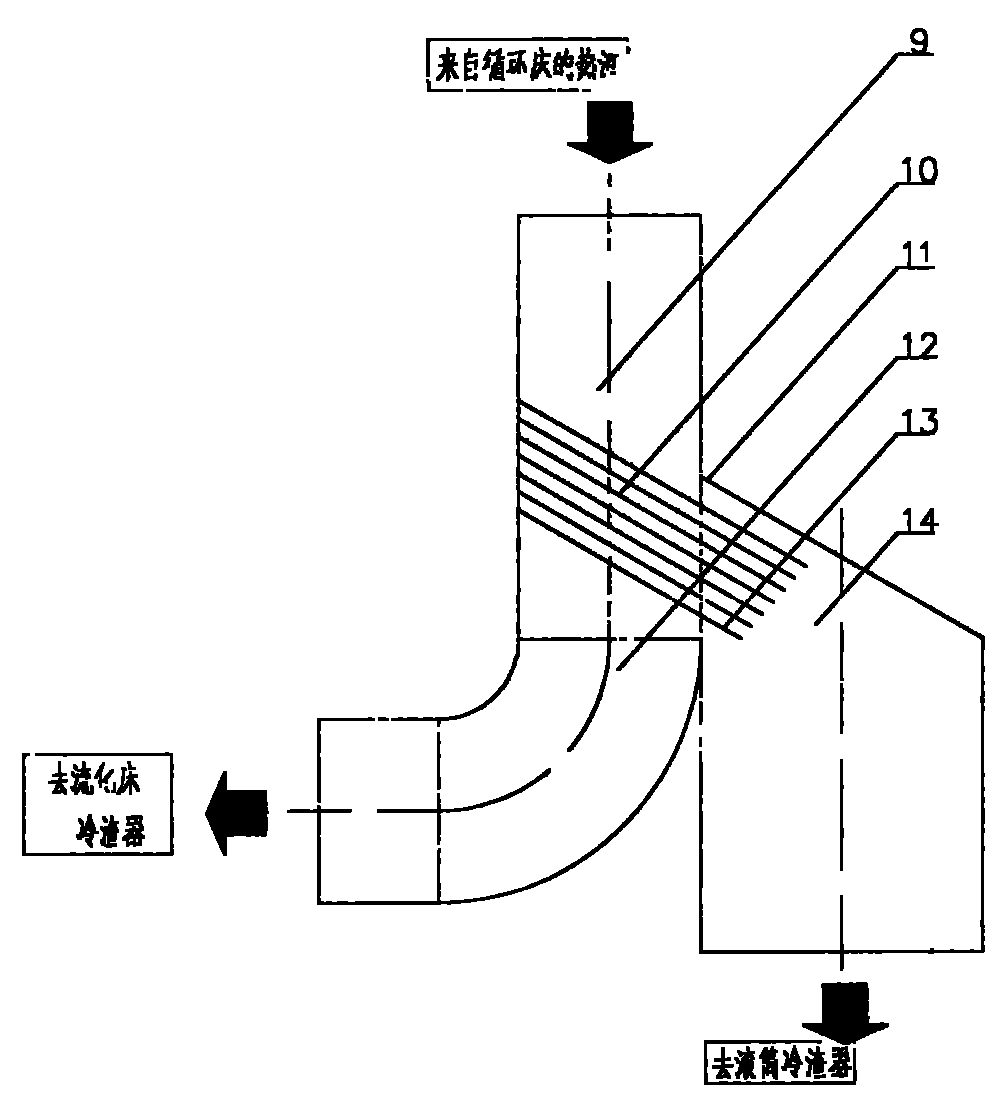

Ash-slag cooling and sorting device and circulating fluidized bed boiler using same

InactiveCN101900344AStrong ability to cool slagImprove adaptabilitySievingFluidized bed combustionSlagFluidized bed

The invention provides a device for cooling high-temperature ash and slag of a circulating fluidized bed boiler, and belongs to the high-temperature ash and slag cooling field of the circulating fluidized bed boiler. The device consists of a hot ash sorting mechanism, a roller slag cooler and a fluidized bed heat exchanger. The hot ash from a slag discharge pipe of the circulating fluidized bed boiler is divided into large granules and small granules through the hot ash sorting mechanism, wherein the large granules enter the roller slag cooler through an inlet pipe of the roller slag cooler; and the small granules enter the fluidized bed heat exchanger through an inlet pipe of the fluidized bed heat exchanger to discharge heat and then are returned to a hearth of the circulating fluidized bed boiler along with fluidized air through an outlet pipe. The device has the advantage of fully exerting the technical advantages of an air-water combined cooling fluidized bed slag cooler and the roller slag cooler by high-temperature separation of the hot ash. Through the technical route that the hot ash is cooled according to the sizes respectively, the fine ash is returned to the hearth through the fluidized bed slag cooler and the crude slag is cooled for other use, the dust pollution of the roller slag cooler is effectively restricted. The graded cooling of the granules can effectively reduce the volume of the slag cooler, and is convenient for boiler design and boiler operation.

Owner:刘柏谦 +1

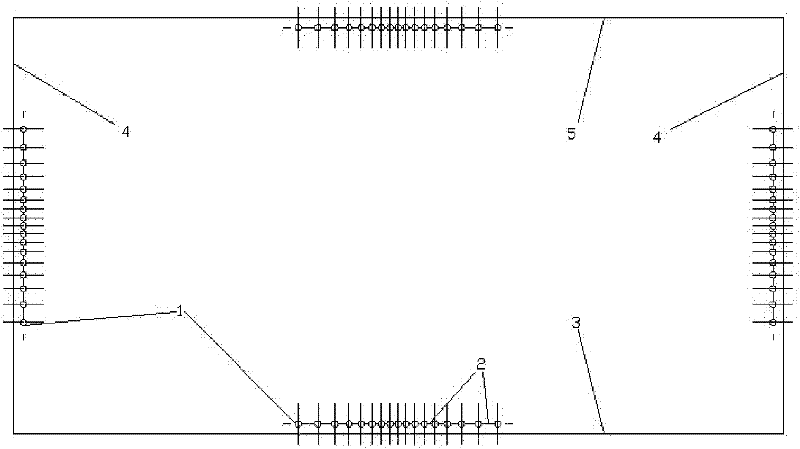

Low-mass flow rate perpendicular water cooled wall arrangement method

ActiveCN102444886AReduce the risk of pipe burstsReduce friction pressureBoiler water tubesSupercritical steam generatorHeat flow

A low-mass flow rate perpendicular water cooled wall arrangement method belongs to the technical field of boiler design. Water cooled wall ascending tubes are arranged in an unequal interval mode, the distance between the ascending tubes of both-side areas in a furnace-cavity low heat-flow density range is large, the distance between the ascending tubes of the middle area in a furnace-cavity highheat-flow density range is small, and the distance between every two tubes is inversely proportional to heat-flow distribution. Meanwhile, by the adoption of low-mass flow rate, self resistance of the water cooled wall ascending tubes is reduced. By adopting the low-mass flow rate water cooled wall ascending tubes in the unequal interval mode to arrange furnace-cavity heating surfaces, temperature deviation and flow deviation of water cooled wall outlet working media are improved, complexity level of the existing supercritical boiler water cooled wall arrangement mode is greatly decreased, self resistance of the water cooled wall is reduced, overhaul and maintenance is led to be convenient, and simultaneously water power safety can be ensured.

Owner:TSINGHUA UNIV

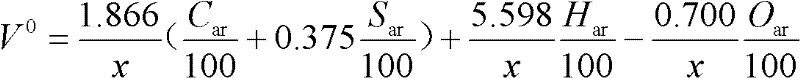

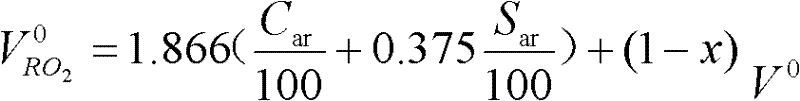

Method for calculating fuel combustion and heat balance in O2/CO2 atmosphere

The invention discloses a method for calculating fuel combustion and heat balance in O2 / CO2 atmosphere. The method comprises the following steps of: (1) calculating fuel combustion; and (2) calculating the heat balance of a boiler. Related parameters and correlations in the traditional thermodynamic calculation method are changed, combustion calculation, flue gas characteristic calculation and flue gas enthalpy calculation in fuel combustion calculation are mainly researched, and heat balance calculation is also performed, so that a calculation formula is suitable for an O2 / CO2 combustion mode under different oxygen concentrations. The solving result of the method can be used as the reference of researching the O2 / CO2 combustion process in detail and designing the boiler by a combustion technology.

Owner:SOUTH CHINA UNIV OF TECH

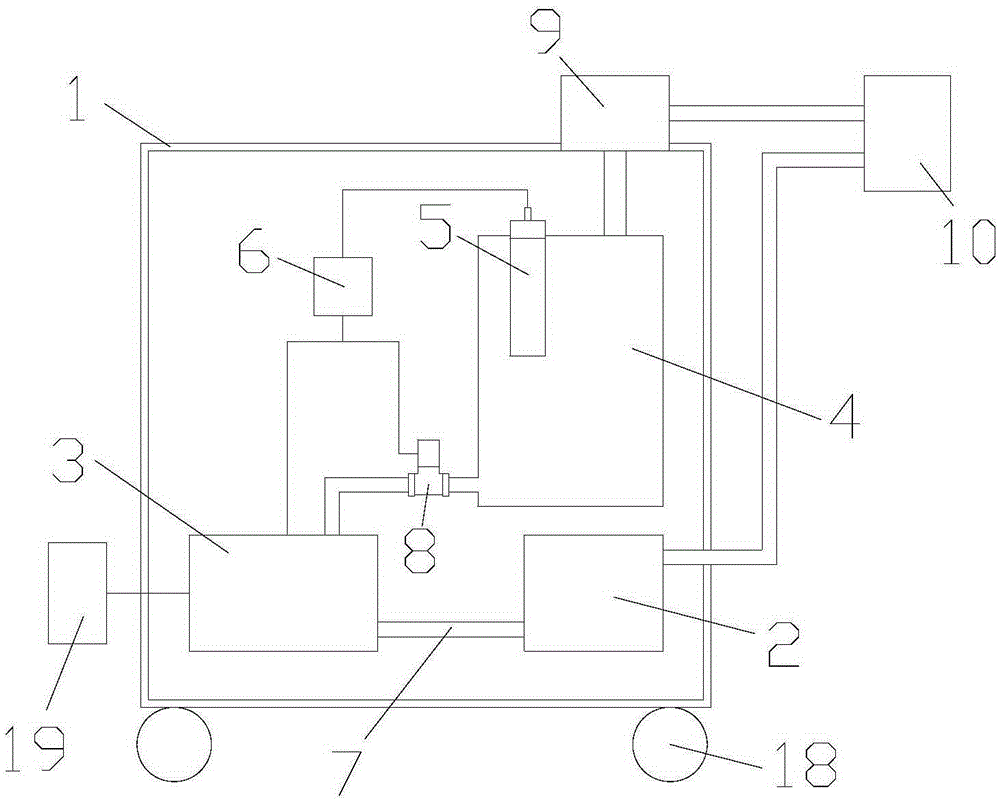

Vertical full-automatic steam boiler

InactiveCN105351909ASimple designRealize fully automatic functionEnergy industrySteam generation plantsAutomatic controlReed relay

The invention discloses a vertical full-automatic steam boiler. The vertical full-automatic steam boiler comprises a shell. A water storage tank and a steam generator are arranged in the shell and are connected through a water pipe. A booster pump and an electromagnetic valve are arranged on the water pipe. A barrel is arranged on the steam generator. A hollow guiding pipe is arranged in the barrel and is provided with a water shortage level dry reed relay, a lower water level dry reed relay and an upper water level dry reed relay from bottom to top. A floating ball is arranged on the hollow guiding pipe. The vertical full-automatic steam boiler is simple in design and capable of automatically controlling water inflow and achieving environmental protection and energy conservation.

Owner:嘉善宝丰合同能源管理有限公司

Method for preventing slagging based on design angle of boiler

PendingCN111594828ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The invention relates to a method for preventing slagging based on the design angle of a boiler. The method comprises the steps: selecting hearth thermal parameters which can reduce the temperature level of a burner area, make the heat load in the boiler uniform and ensure that pulverized coal has sufficient residence time in the upper part of a hearth to burn out, adopting a square large cut-angle hearth or a large cut-angle hearth that tends to a square, selecting an appropriate burner type and a nozzle arrangement type, reducing the imaginary tangent circle diameter of a burner, the thermalpower of a single primary air nozzle of the burner and the ratio of primary to secondary air momentum, having a good aerodynamic working condition in the boiler, and preventing the air flow with powder from leaning against a wall. The method improves the safety and reliability of boiler operation.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

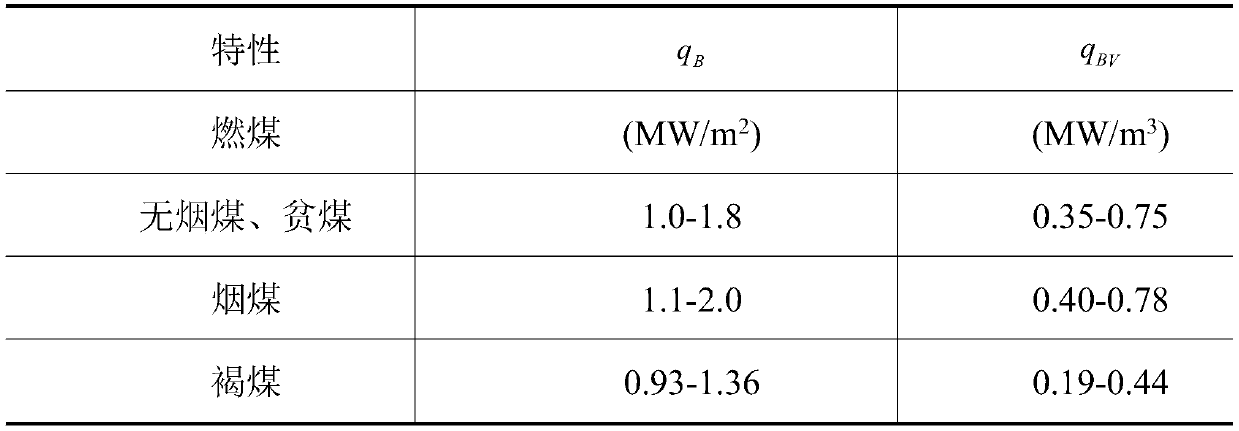

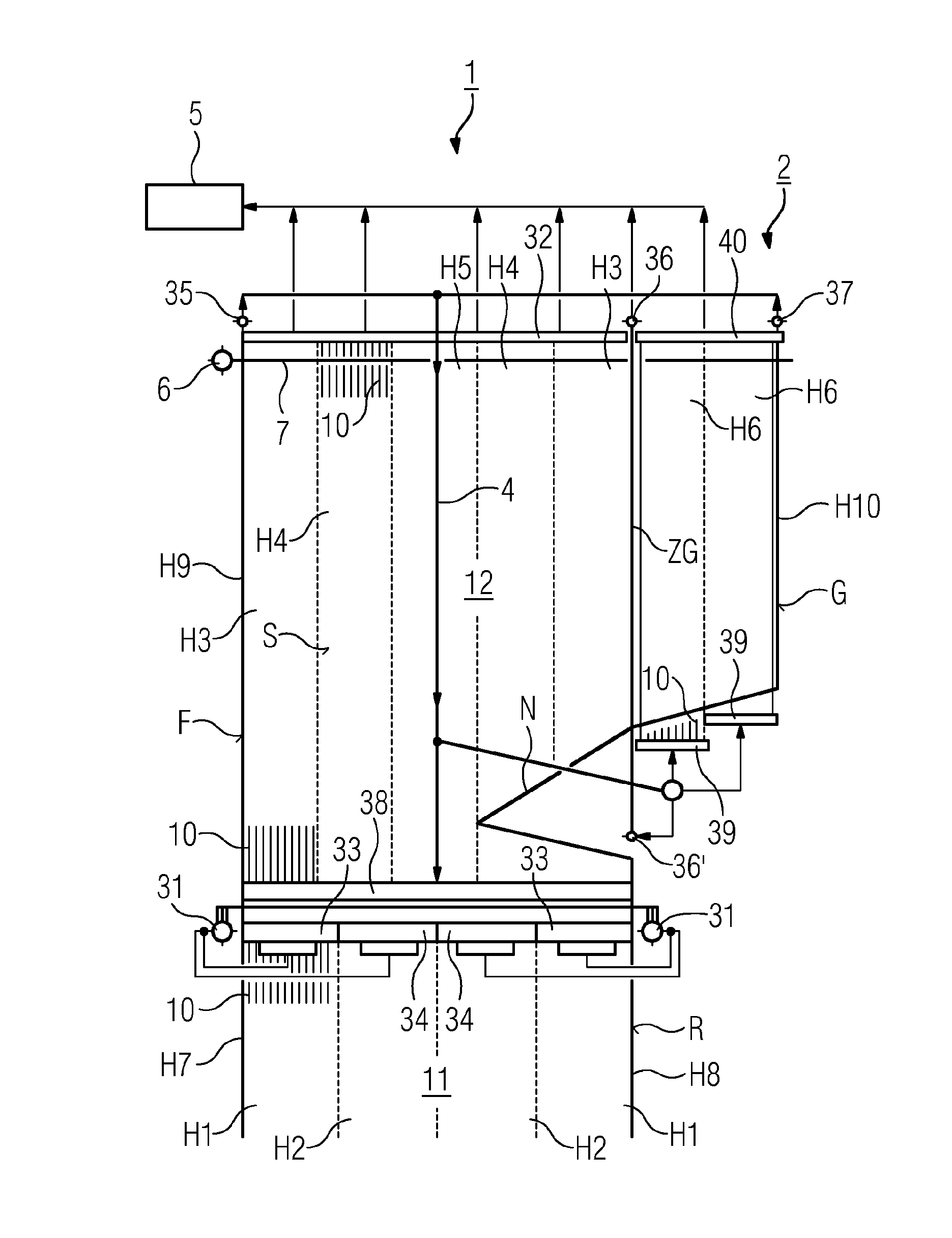

Continuous flow steam generator with a two-pass boiler design

ActiveUS20160178188A1Quality improvementHigh trafficWater circulationBoiler water tubesCombustion chamberFlue gas

A continuous flow steam generator includes a combustion chamber, having substantially rectangular cross-section and a lower and upper combustion chamber region, and has a horizontal gas pass connected downstream of the combustion chamber on the flue-gas side. Gas-tight and gas-permeable peripheral walls of the generator are completely or partly made of steam generator pipes welded together and through which a flow medium can flow, and collectors are arranged and connected to the steam generator pipes such that groups of steam generator pipes connected in parallel form heating surface segments of the peripheral walls. First passage collectors are arranged and connected such that the flow medium from first heating surface segments of two parallel first peripheral walls of the lower combustion chamber region are mixed with the fluid medium from second heating surface segments of second peripheral walls, standing perpendicular to the first peripheral walls, of the upper combustion chamber region.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

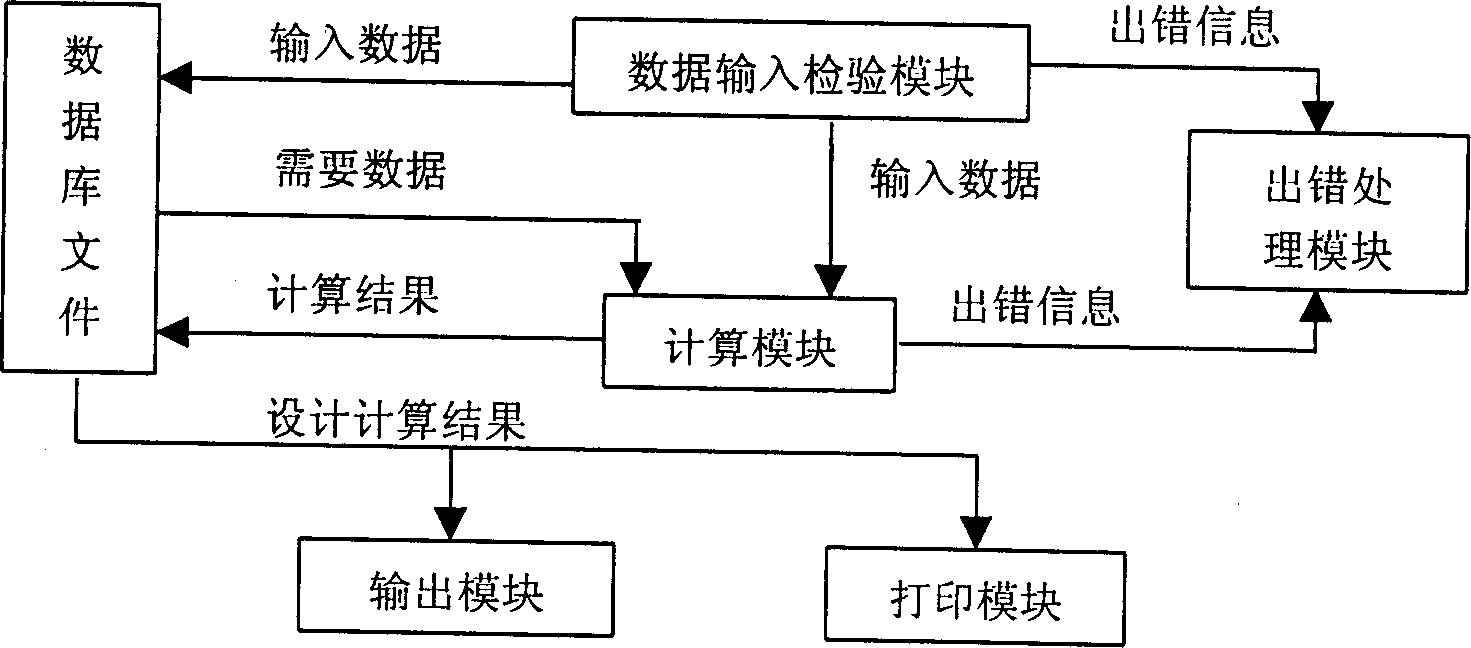

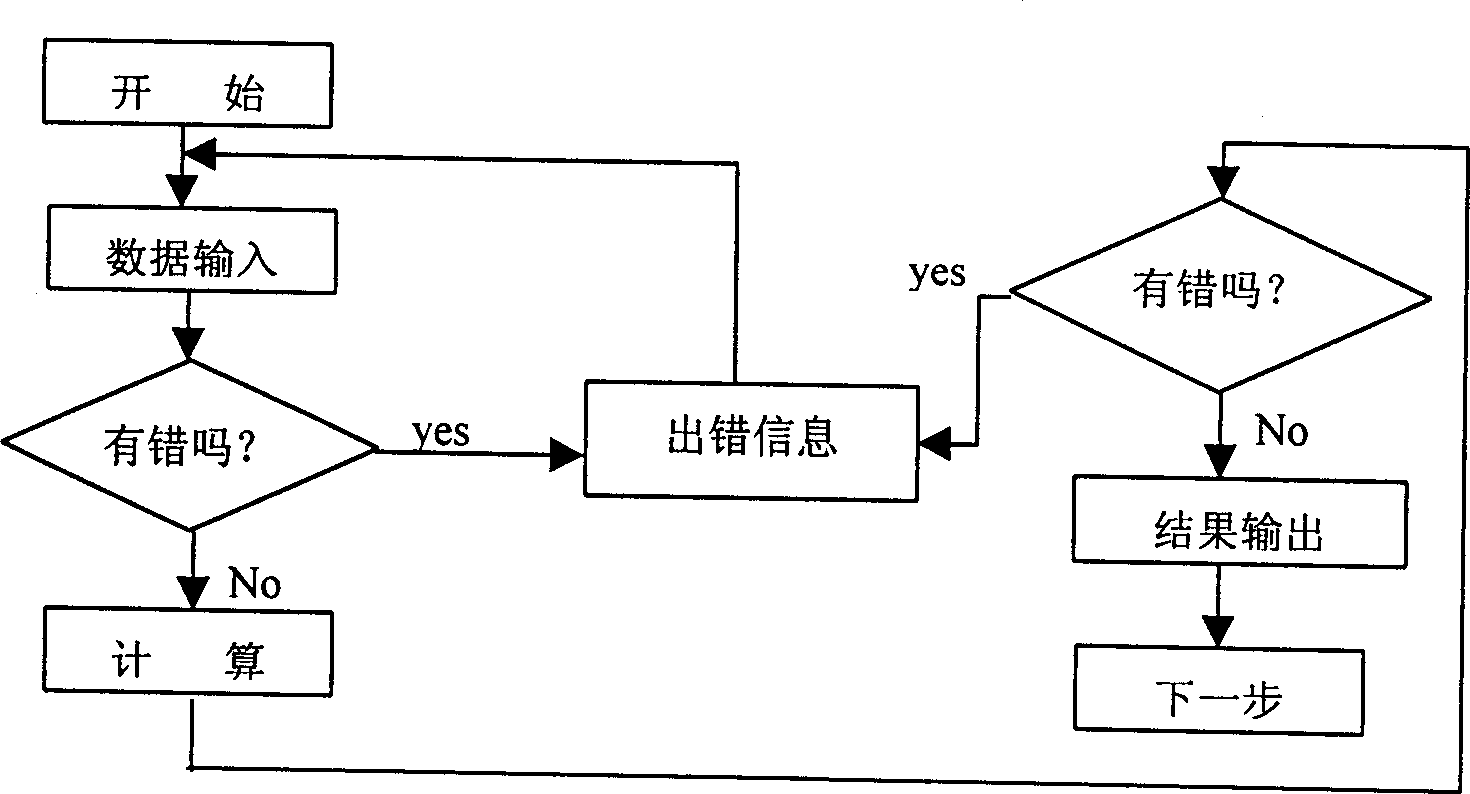

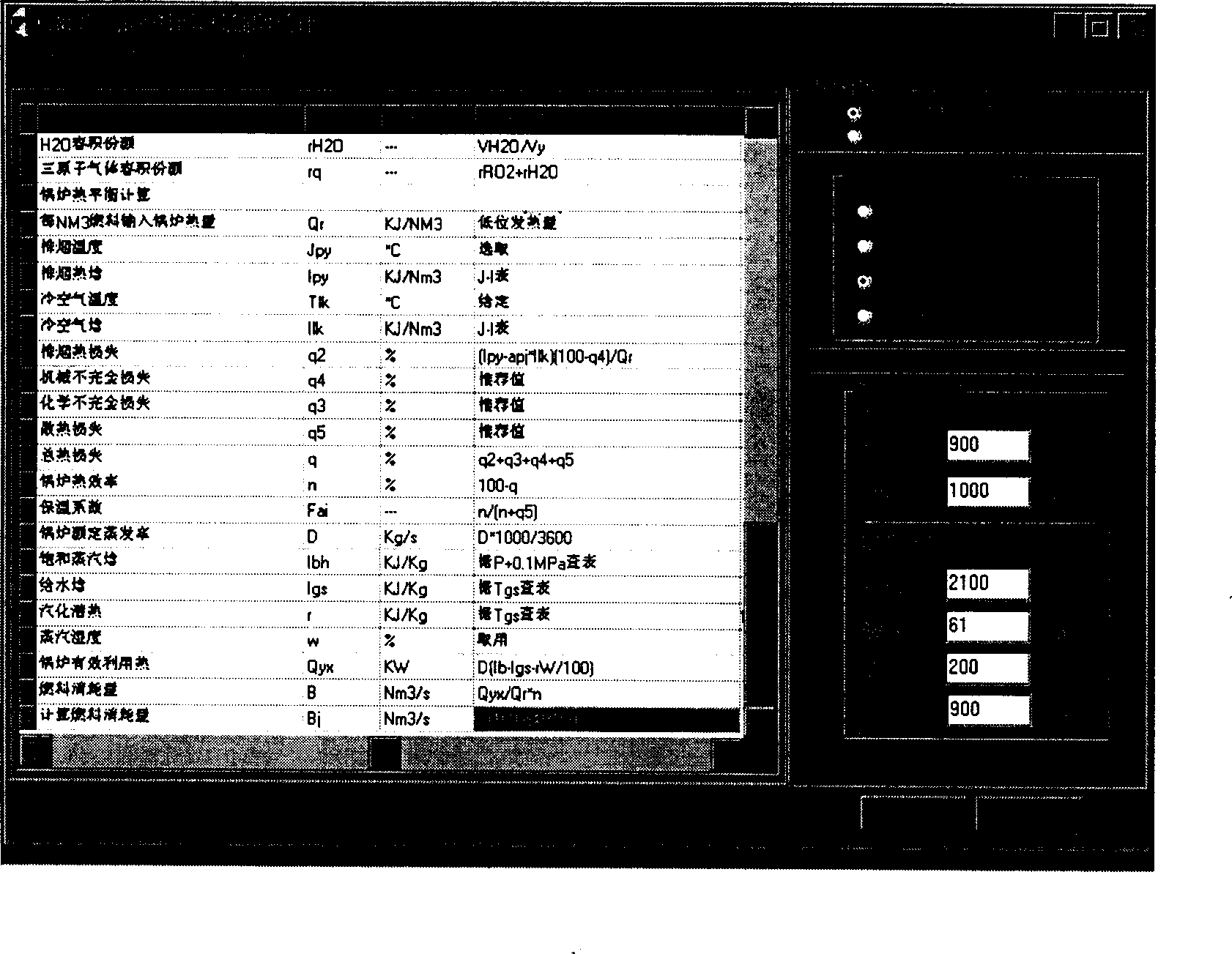

CAD software for horizontal internal combustion boil using oil or gas as fuel

InactiveCN1381804ASimple interfaceEasy to storeSpecial data processing applicationsEngineeringUltimate tensile strength

A CAD software for horizontal internal combustion type boiler using oil or gas as fuel is composed of modules for heat calculation, calculating the resistance of smoke and wind, calculating the strength of stressed part, and automatically drawing the views of different parts with corresponding strectural dimensions by a printer or plotter, or displaying them by a display screen so as to liberate the designer from the busy calcualtion and drawing.

Owner:XI AN JIAOTONG UNIV

Equipressure air feeding device of large industrial chain grate boiler

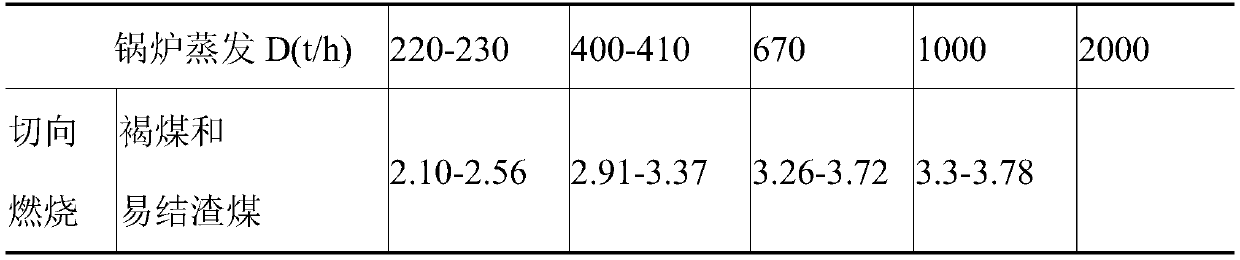

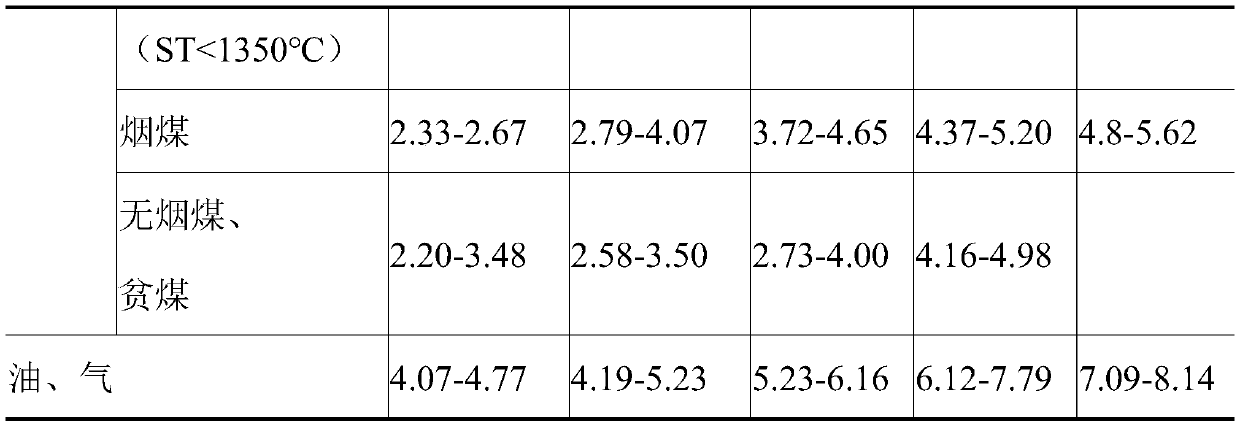

InactiveCN101464003AAchieve ideal combustion conditionsAir/fuel supply for combustionAir volumeMathematical model

The invention relates to an equipressure air supply device for a large industrial chain grate boiler. By adopting aerodynamic principles and the design principle of fire coal chain grate boiler and facing new projects arising from upsizing and ultra-large type development of future 230MW-630MW industrial chain grate boiler, the invention aims at establishing new combination of content knowledge, a brand-new mathematical model concept so as to put into use a new equipressure air supply device on the industrial chain grate boiler featuring upsizing and ultra-large type development so as to satisfy the on-line control of equipressure air supply of transverse and longitudinal burning of the upsizing or ultra-large type industrial chain grate boiler, and the on-line random variation regulation and control of combustion conditions and combustion air amount under the centralized control of the chain grate boiler, namely, an equipressure air supply way to control dynamic pressure and maintain balance of static pressure on the precondition of unchanged set air quantity and wind pressure on the condition of adapting to quite unstable operating conditions of the upsizing or ultra-large type industrial chain grate boiler. The equipressure air supply way is an important link in realizing high working efficiency and energy saving of upsizing or ultra-large type chain grate boiler and ideal combustion conditions of the boiler. The invention relates to an equipressure air supply way employing devices such as two symmetrical variable cross section equipressure ducts, a lateral grouping uniform cross section air outlet and an equipressure wind chamber.

Owner:王聪会 +1

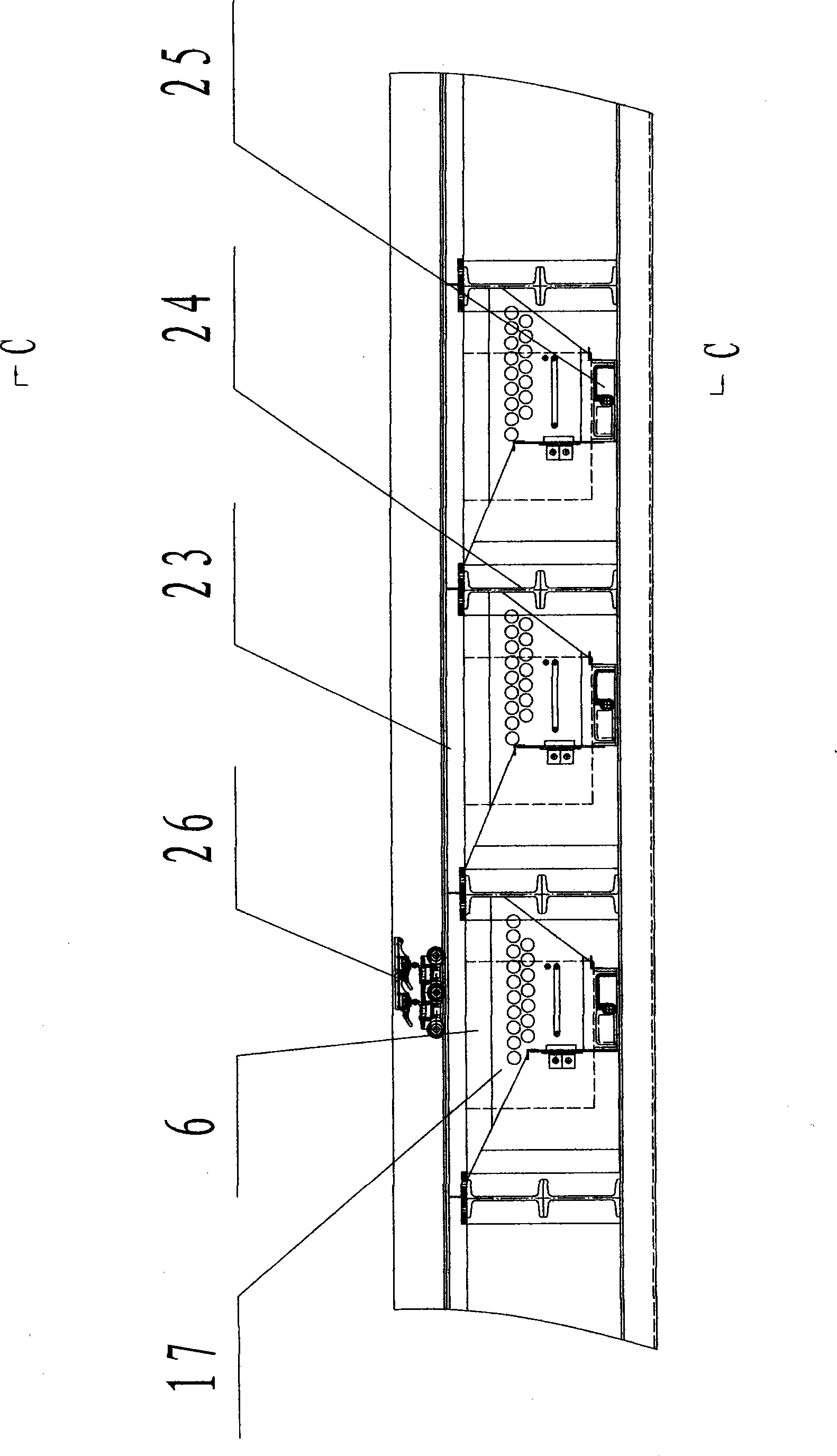

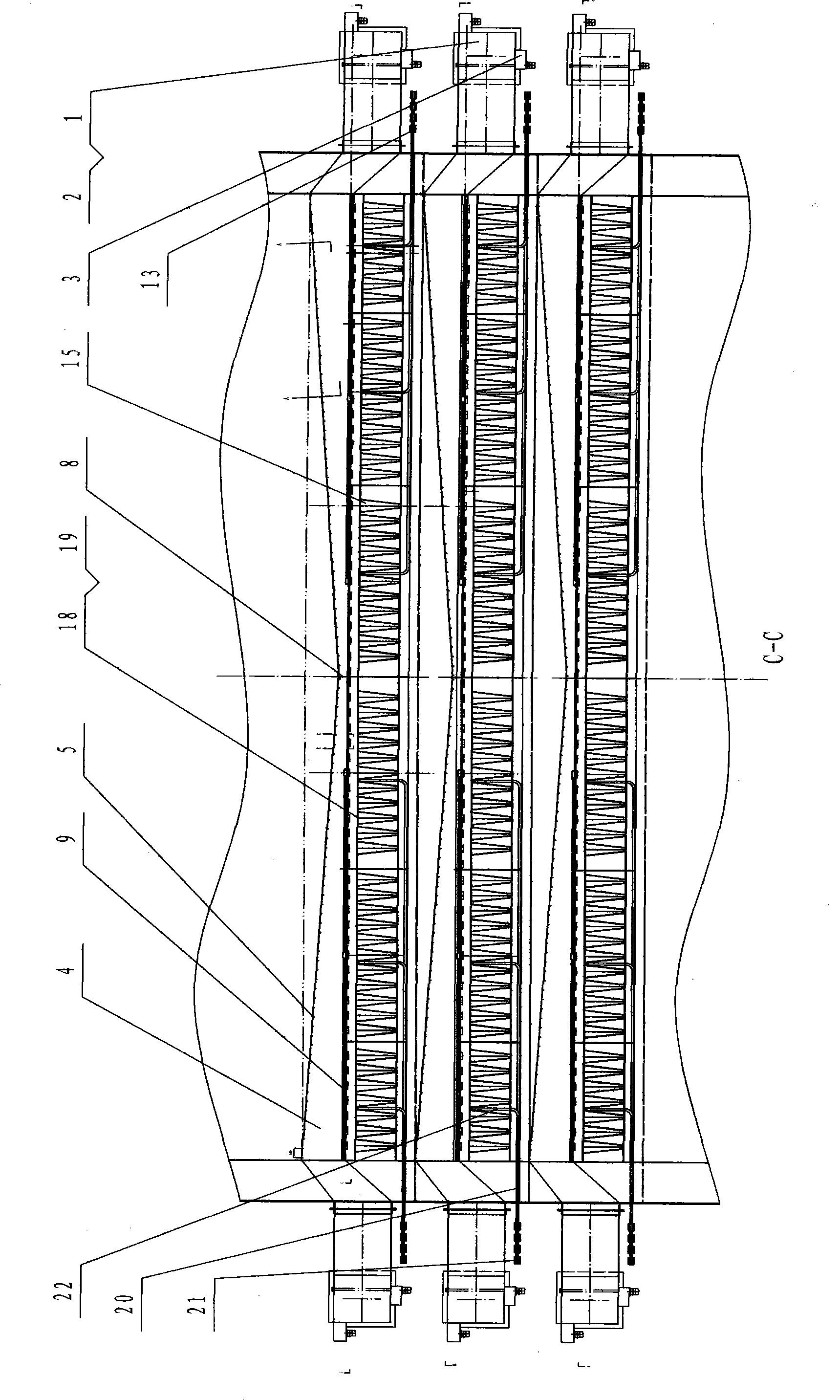

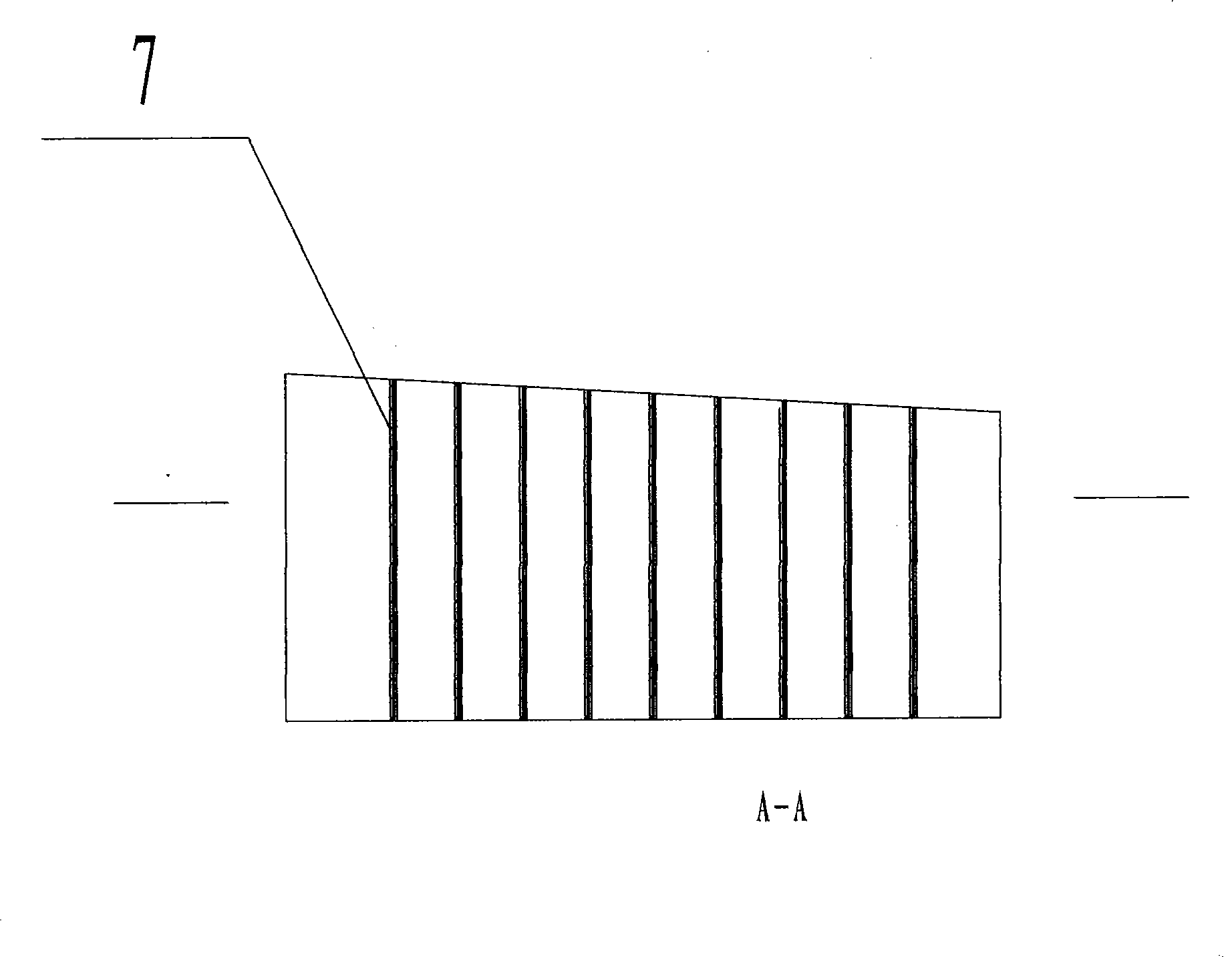

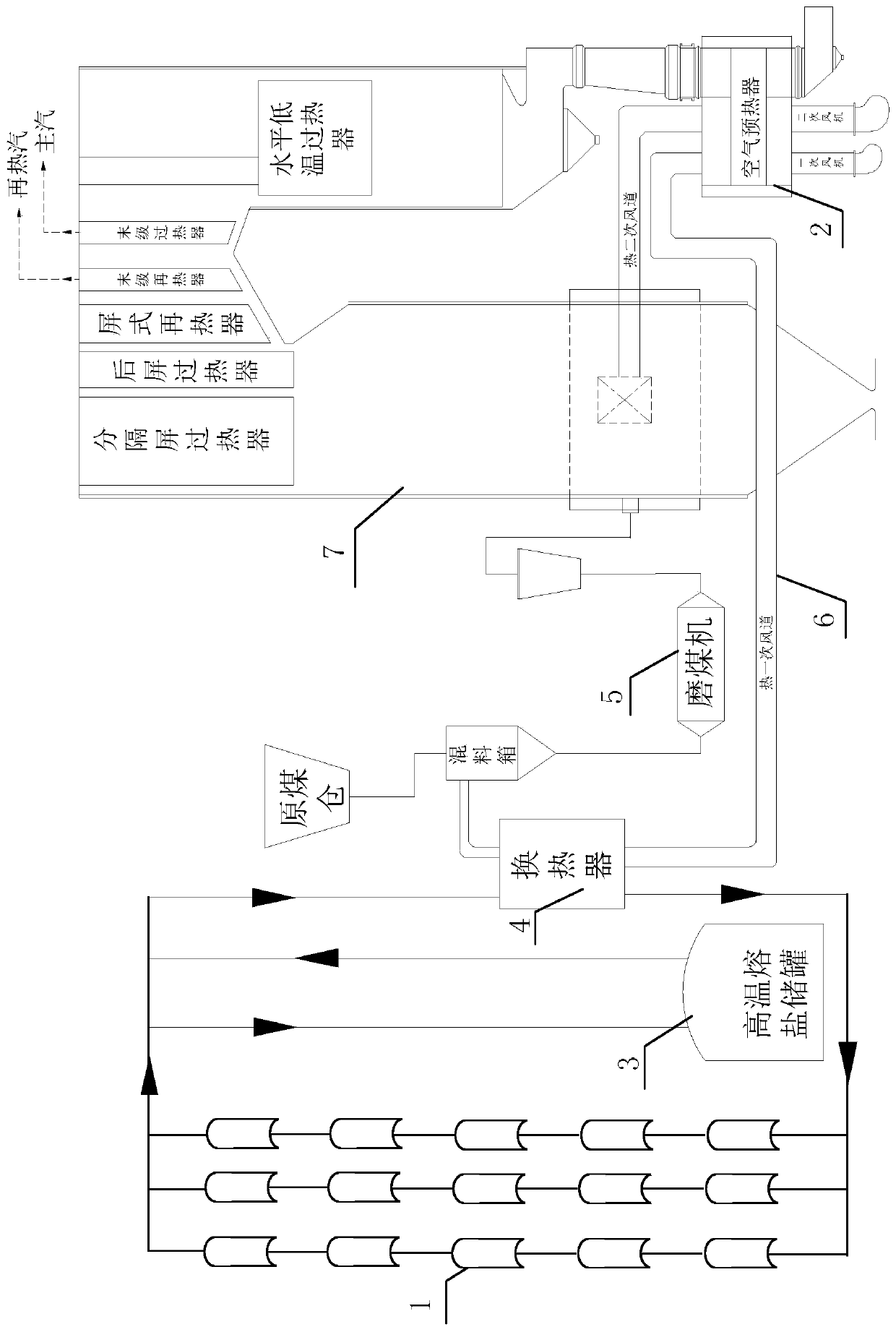

System for heating hot primary air of coal-fired boiler by groove type solar heat-conducting oil heat-collecting working medium

InactiveCN110332718AKeep drySolve the problem of insufficient drying outputSolar heating energySolar heat storageNew energyHeat conducting

The invention provides a system for heating hot primary air of a coal-fired boiler by a groove type solar heat-conducting oil heat-collecting working medium and relates to the technical field of new energy utilization. The invention aims to solve the problem that the temperature of the hot primary air of the boiler cannot meet the requirement caused by the fact that the drying output of a coal mill is insufficient when the water content of a coal type for combustion of a power plant is high. A renewable solar resource is coupled with the coal-fired boiler to form a high-energy-level utilizingsystem of solar energy. Heat of solar energy resources is collected into heat-conducting oil by a solar heat collector, the obtained high-temperature heat-conducting oil exchanges heat to the hot primary air of a boiler preheater outlet through a heat exchanger, the hot primary air is heated, the temperature of the hot primary air reaches to a boiler design value and the hot primary air serving asa drying agent of a pulverizing system enters the coal mill, so that the drying capability of the pulverizing system is improved, combustion air distribution reaches to an ideal effect, the boiler can operate at full load, and the problems of high-water-content coal for combustion and insufficient drying output of the coal mill can be solved completely.

Owner:HARBIN BOILER

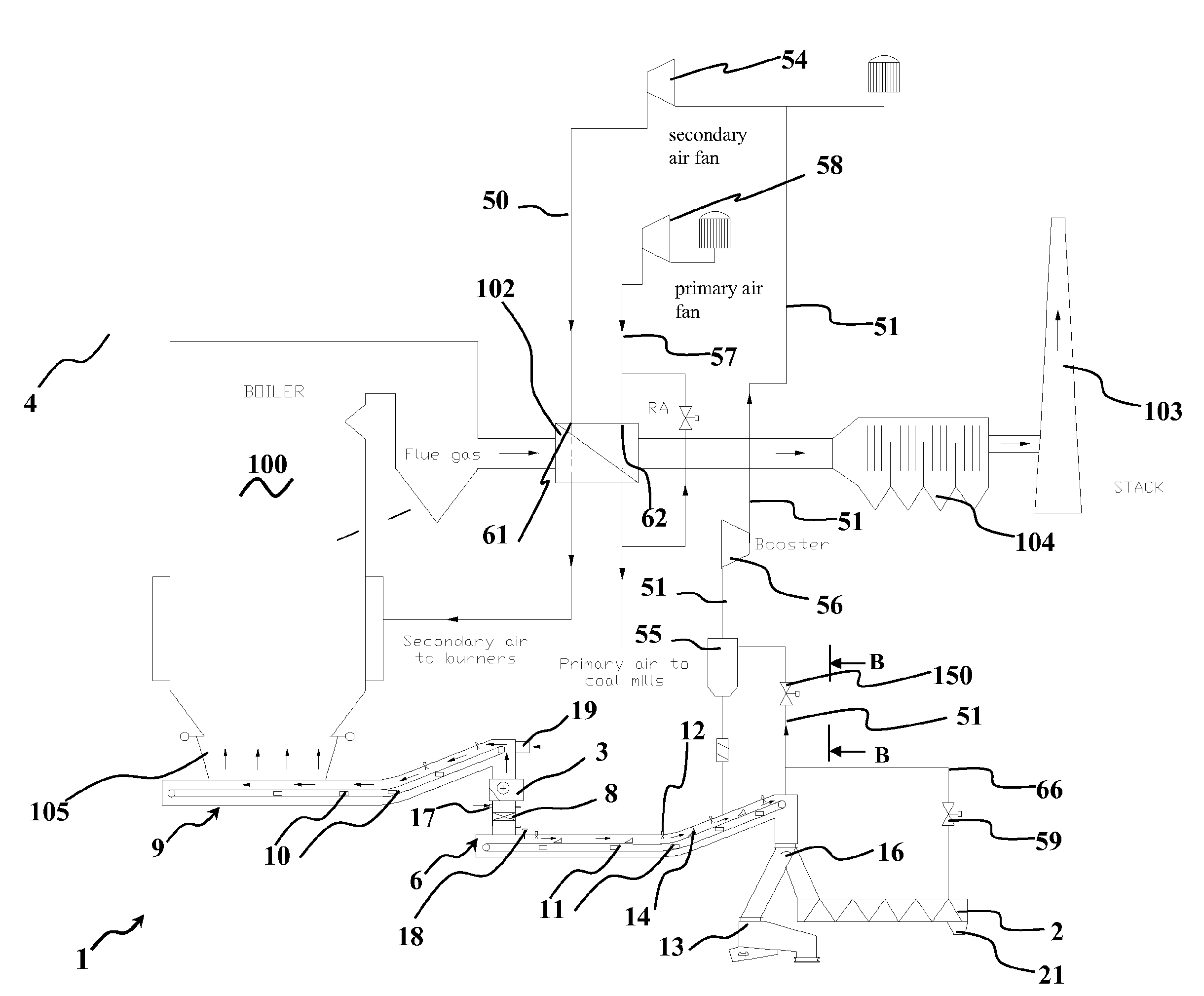

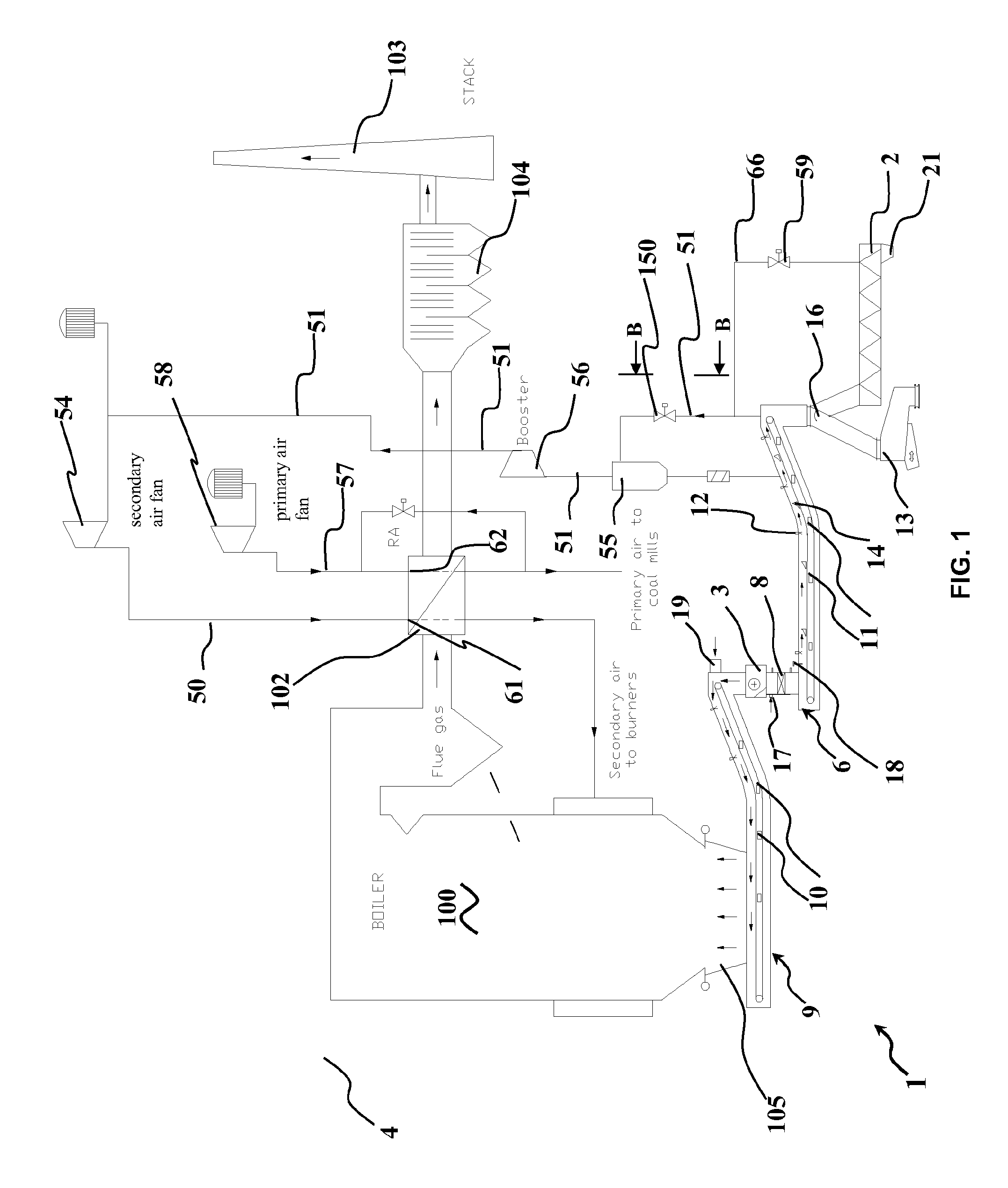

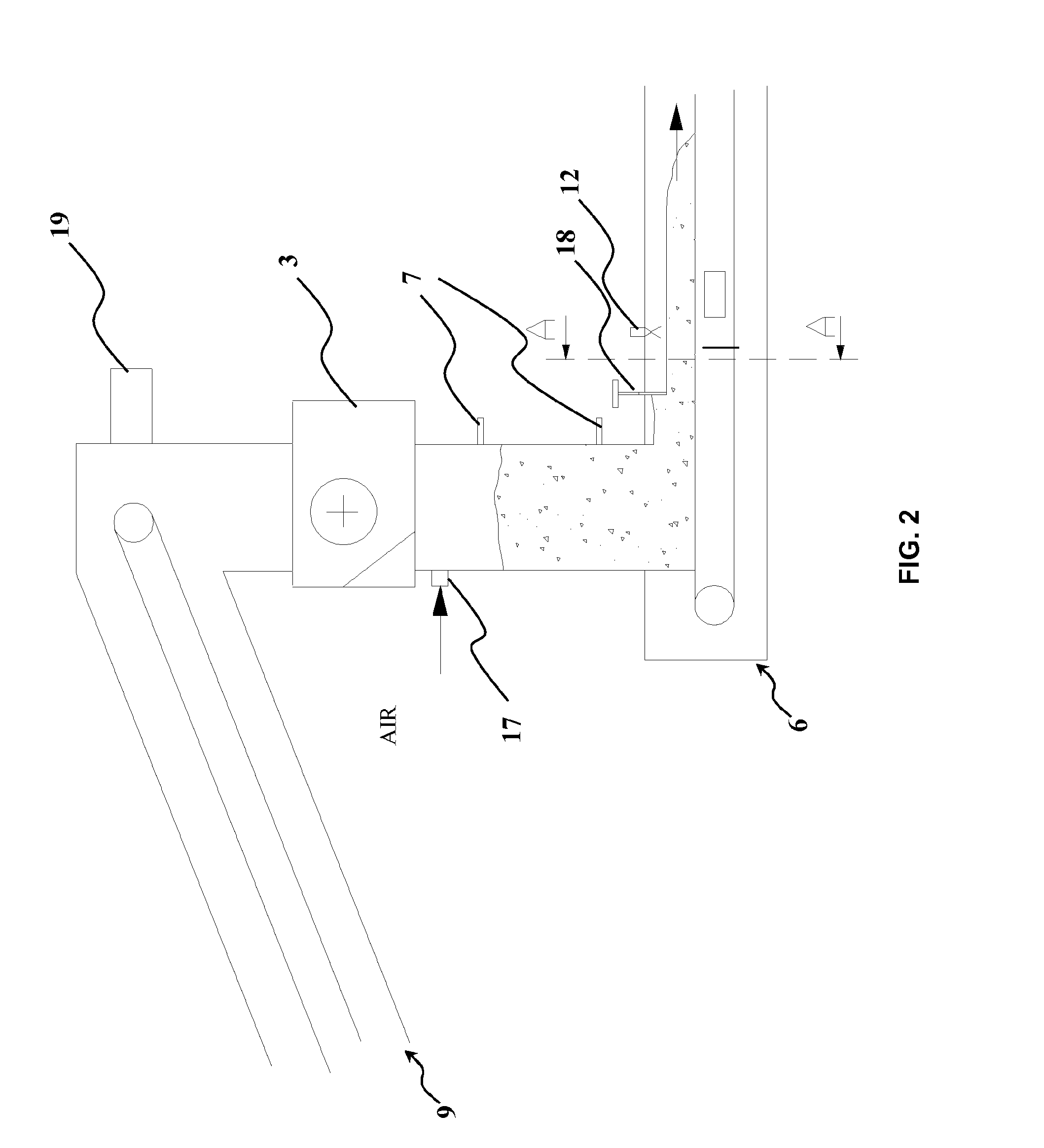

Extracting and cooling system for large flows of heavy ashes with efficiency increase

InactiveUS20110297061A1Maximize recoverySolid removalCombustible gas productionSolid fuelEngineering

The present invention relates to a system for extracting and recovering energy for large for large flows of heavy ashes produced by solid fuel boilers, able to decrease the final temperature of the extracted ash without increasing the air flow entering the boiler flue, usually fixed by the boiler designers at a value around 1.5% of the total combustion air. When the air flow needed to the cooling exceeds the maximum quantity allowable in the boiler, the system allows the air and the possible vapour to be sent to the air inletting duct entering the air / fume exchanger on the air side, thanks to a separation of the cooling environments made by the ash itself. The separation of the environments of the cooling system is handled automatically based upon a temperature signal of the ash to the discharge from the system. If the cooling air is not sufficient to cool down the ash, the cooling efficiency can be increased by the addition of nebulised water.

Owner:MAGALDI IND SRL

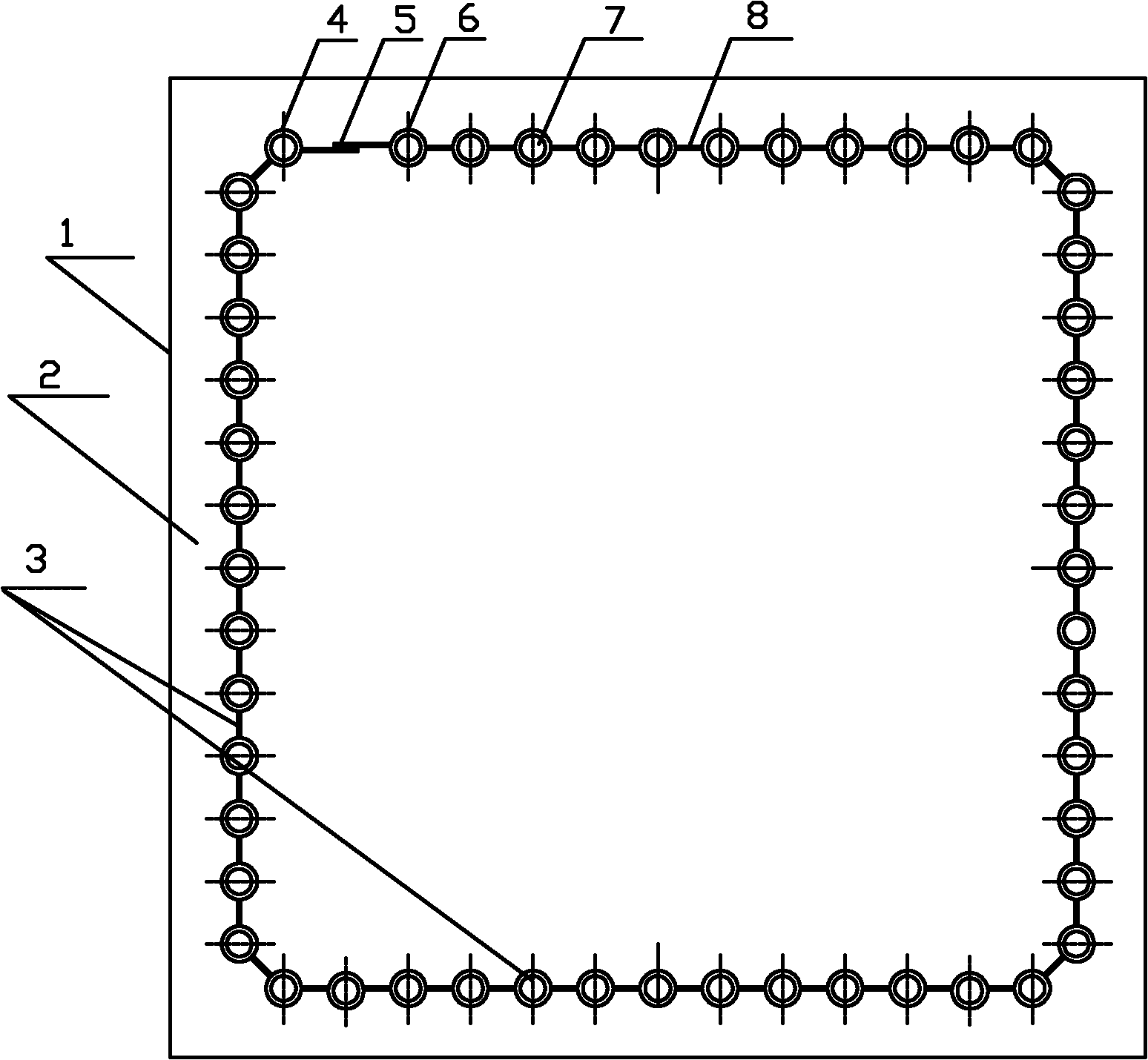

Horizontal boiler radiation segment structure

InactiveCN101893230AImprove sealingReduce heat lossBoiler water tubesFluid removalEngineeringFree edge

The invention relates to the field of boiler design and manufacturing and discloses a horizontal boiler radiation segment structure which is applicable to oil field steam injection boilers. The horizontal boiler radiation segment structure comprises an outer protective layer, wherein a member wall with a square section is arranged in the outer protective layer and comprises a plurality of boiler tubes connected in a coiled way and a closing plate connected between the boiler tubes. The horizontal boiler radiation segment structure is characterized in that: the closing plate between an outlet boiler tube and an inlet boiler tube of the boiler tubes comprises two connection plates with free edges and fixed edges; and the fixed edges of the two connection plates are connected with the outlet boiler tube and the inlet boiler tube, while the free edges are interlaced mutually.

Owner:XI AN JIAOTONG UNIV +1

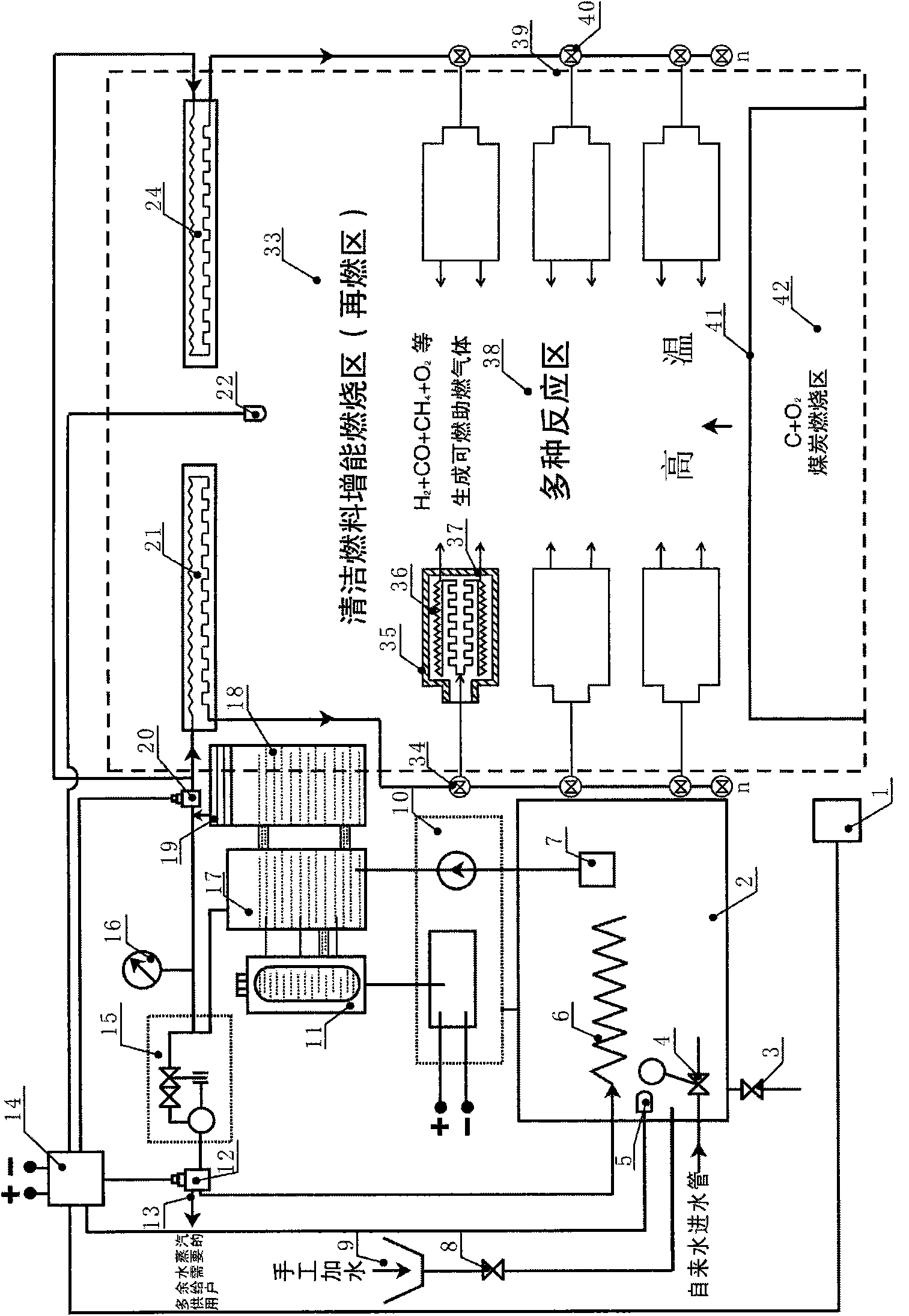

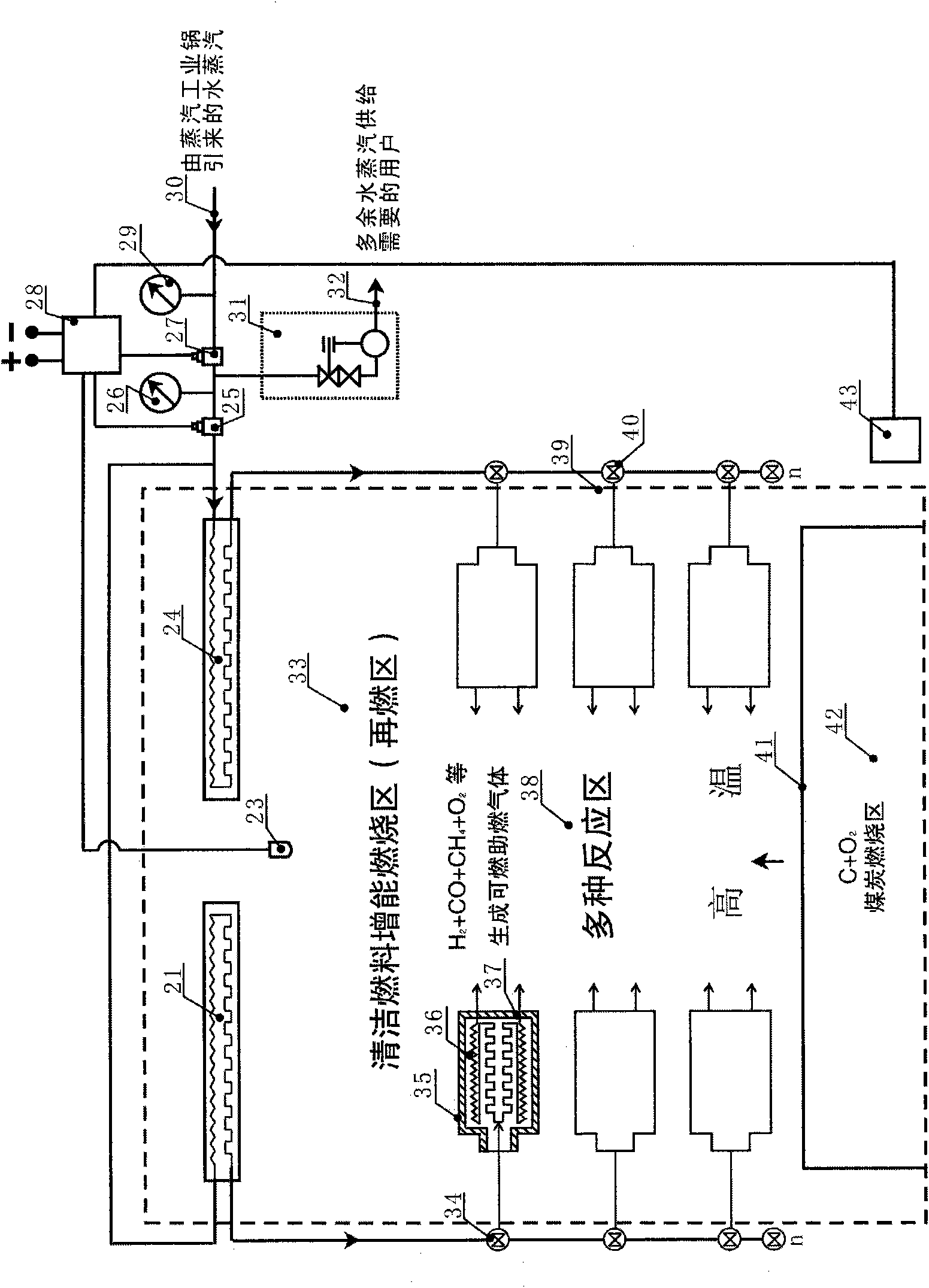

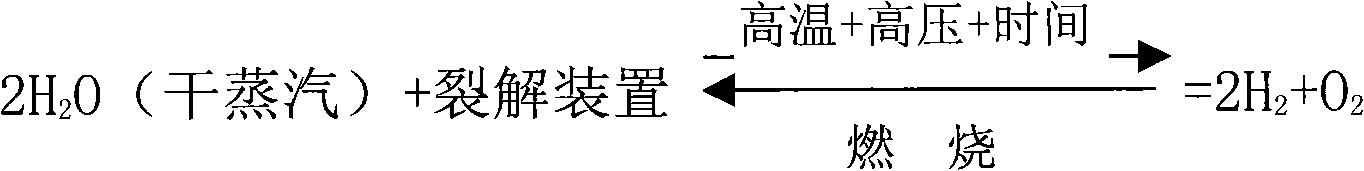

Gas reburning energy-increasing environment-friendly boiler

InactiveCN101922791AIncrease profitReduce pollutionHydrogen productionWater heatersCombustion chamberWater vapor

The invention relates to an energy-increasing environment-friendly boiler which performs cracking reaction on most dry water steam into combustible and combustion-supporting gas through high temperature generated by fire coal combustion by using dry steam of water, also decomposes the other small part uncracked dry water steam into combustible and combustion-supporting gas through a plurality of reactions in a high-temperature region. The combustible and combustion-supporting gas can be reburned in a combustion chamber so as to improve the thermal power. The boiler has two types of: 1, a gas reburning energizy-increasing hot-water boiler; and 2, a gas reburning energy-increasing steam industrial boiler. The two boilers have substantially same design principles that: the gas reburning energy-increasing hot-water boiler consists of a part which producing combustible and combustion-supporting gas part by using the dry water and a fuel combustion gas reburning energy-increasing part; and the gas reburning energizing steam industrial boiler also consists of a part which producing combustible and combustion-supporting gas part by using water vapor generated from the boiler and the fuel combustion gas reburning energy-increasing part. Due to the preparation of dry steam by using water vapor and increasing energy, the energy-increasing environment-friendly boiler has the advantages of greatly improving the energy utilization rate, saving the fire coal and reducing the environmental pollution.

Owner:李根钧

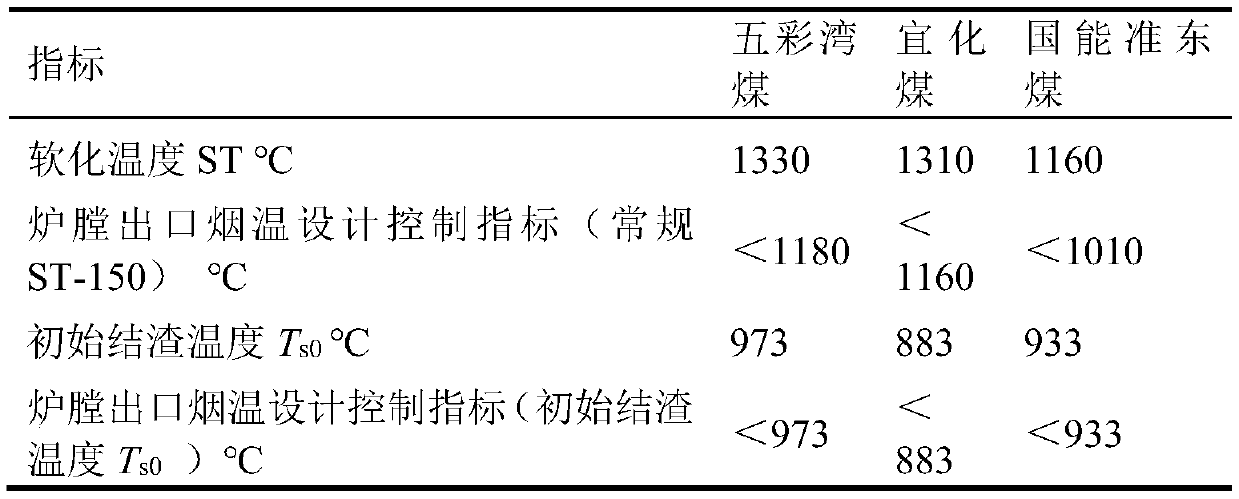

Design control method of boiler furnace outlet gas temperature

The invention discloses a design control method of a boiler furnace outlet gas temperature. The design control method comprises the following steps: 1, testing the ash fusion property DT and ST of a coal sample according to the national standard GB / T219-2008, and testing the ash compositions Na2O, K2O, CaO and Fe2O3 of the coal sample according to the national standard GB / T1574-2007; 2, calculating the initial slagging temperature Ts0, wherein Ts0=3.57(18-Ki) +1025, the potassium, sodium, calcium and iron index Ki=(K2O+Na2O)2+0.048(Fe2O3+CaO), and each molecular formula represents the coal ashcomposition weight of the compound represented by the above measured molecular formula; and 3, enabling the boiler furnace outlet gas temperature FEGT to meet the following condition: (a), FEGT is less than Ts0; (b), FEGT is less than DT-100; and (c), FEGT is less than ST-150. With adoption of the design control method, the design control index with higher precision and suitable for the boiler furnace outlet gas temperature is obtained according to the conventional available coal quality data to provide technical base for design and operation of a power station boiler.

Owner:XIAN THERMAL POWER RES INST CO LTD

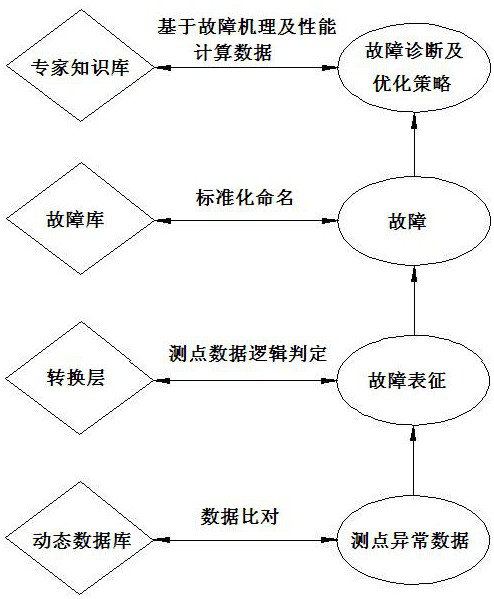

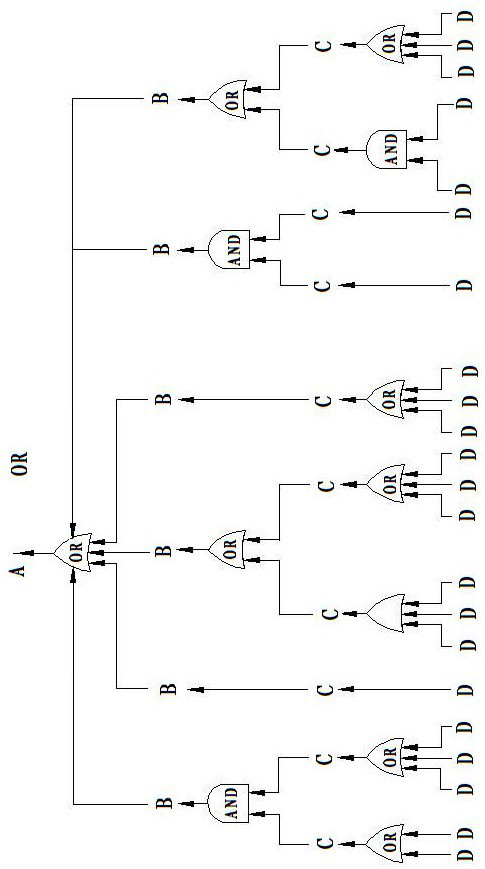

Boiler abnormal working condition diagnosis and operation optimization method based on fault tree

PendingCN111612181AGuaranteed uptimeSolve the disadvantages of low efficiencyForecastingResourcesBoiler designIndustrial engineering

The invention discloses a boiler abnormal working condition diagnosis and operation optimization method based on a fault tree. At present, boiler operation, maintenance and fault processing take measures depending on personal experience, judgment and operation optimization methods for abnormal working conditions have large differences, improper operation can cause shutdown of a boiler, and damageis caused to boiler equipment. The method comprises the following steps: 1, carding expert knowledge, establishing an expert knowledge base, and constructing a top-layer decision mechanism of a faulttree; 2, building a fault library covering all abnormal working conditions of all types of boilers, and building a middle transition layer of a fault tree; 3, constructing a boiler performance dynamicdatabase by using boiler design data and operation data, comparing the boiler performance dynamic database with boiler actual operation data, and establishing a fault tree base layer; and 4, establishing an intermediate conversion layer unit, connecting the boiler measuring point abnormal data with the boiler abnormal working condition, and correspondingly connecting the fault tree with the boiler database. The method is used for boiler abnormal working condition diagnosis and operation optimization based on the fault tree.

Owner:HARBIN BOILER

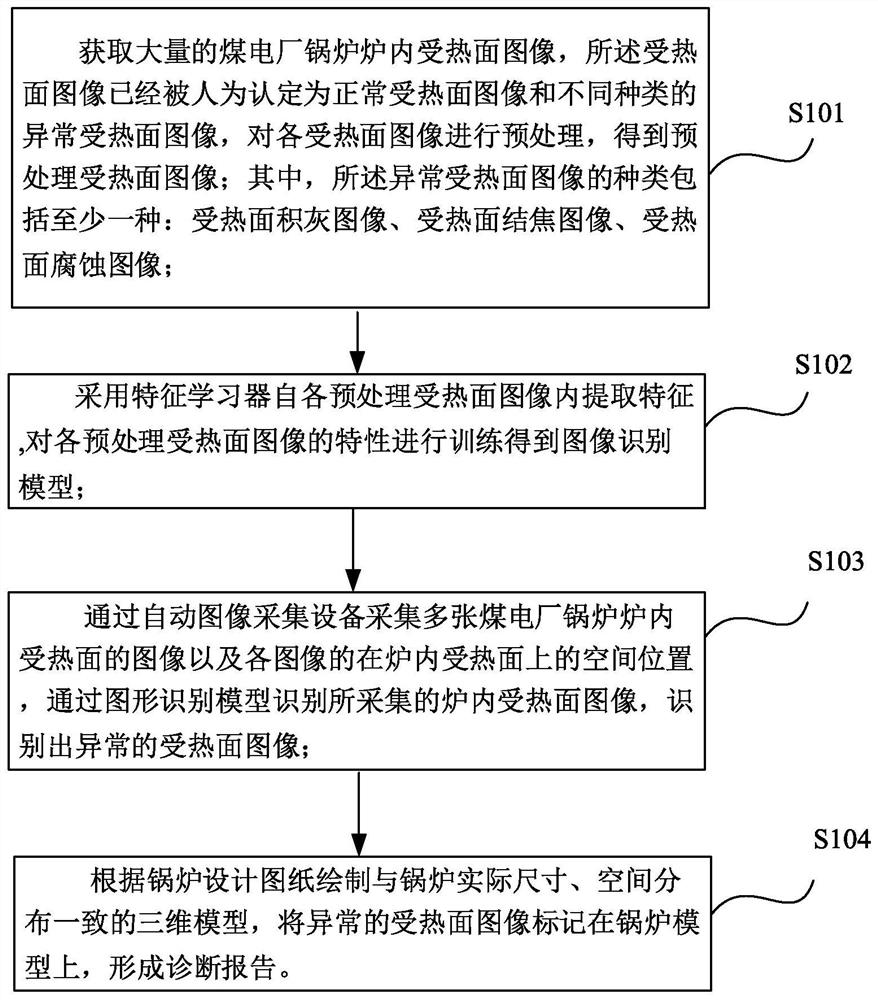

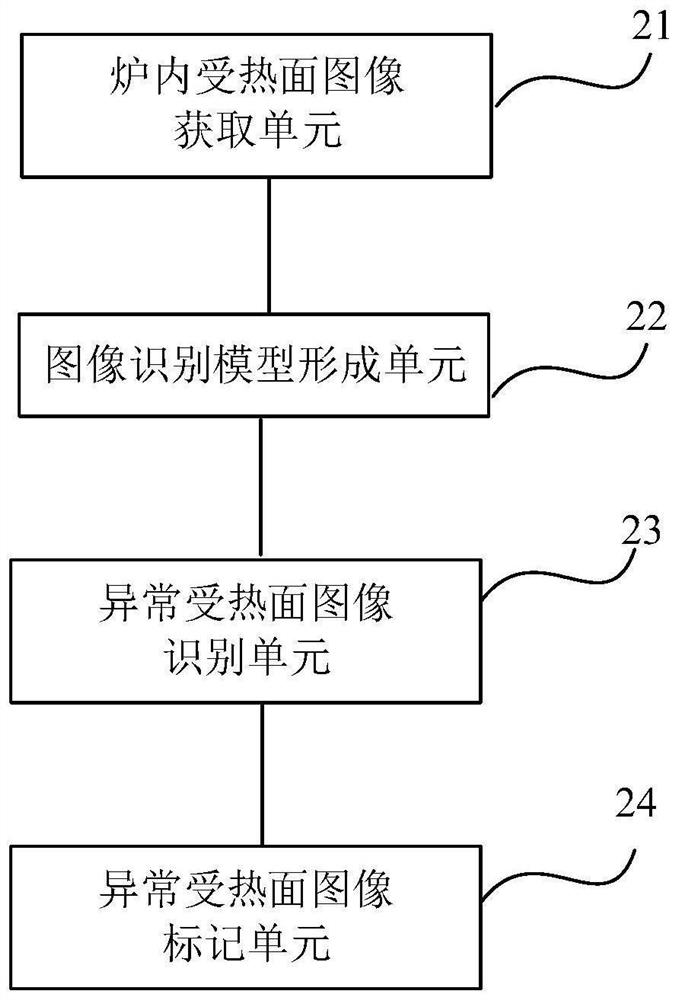

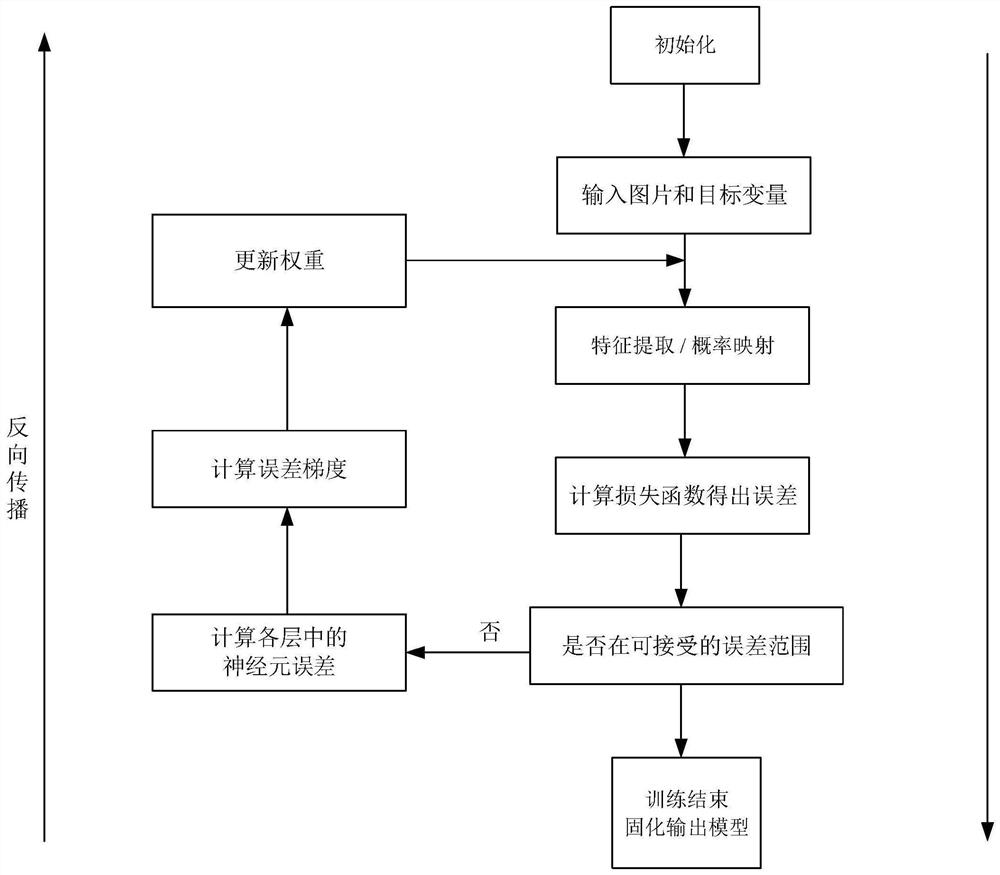

Boiler heating surface abnormal image identification and marking method and system

PendingCN112884036AReduce human inputData processing applicationsCharacter and pattern recognitionRadiologyImage pair

The embodiment of the invention provides a boiler heating surface abnormal image identification and marking method and system, and the method comprises the steps: obtaining a large number of in-boiler heating surface images which are artificially identified as normal heating surface images and different types of abnormal heating surface images, and carrying out the preprocessing of each heating surface image, and obtaining preprocessed heating surface images; extracting features from each preprocessed heating surface image by using a feature learner, and training the features of each preprocessed heating surface image to obtain an image identification model; identifying the collected heating surface image in the furnace through the image identification model, and identifying an abnormal heating surface image; and drawing a three-dimensional model consistent with the actual size and spatial distribution of the boiler according to a boiler design drawing, and marking the abnormal heating surface image on the boiler model to form a diagnosis report. Whether the heating surface in a boiler is abnormal or not is identified through the image identification model, the abnormal heating surface image is marked on the boiler model and sent to maintenance workers, and manpower input is reduced.

Owner:北京京能能源技术研究有限责任公司 +1

Anti-wearing method for circulating fluidized bed boiler furnace

ActiveCN101392906ASimple designNo fee requiredFluidized bed combustionApparatus for fluidised bed combustionBoiler furnaceObservation point

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

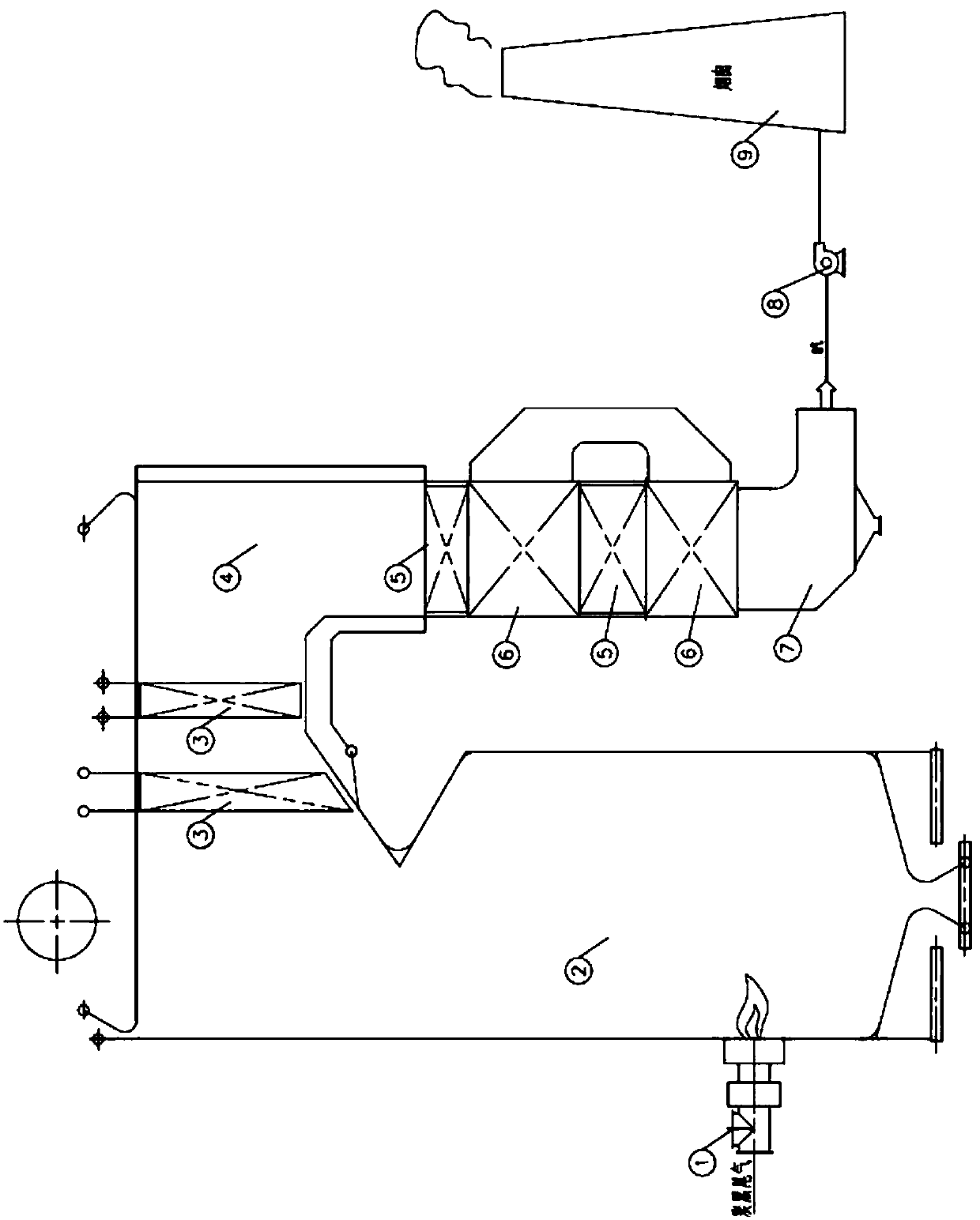

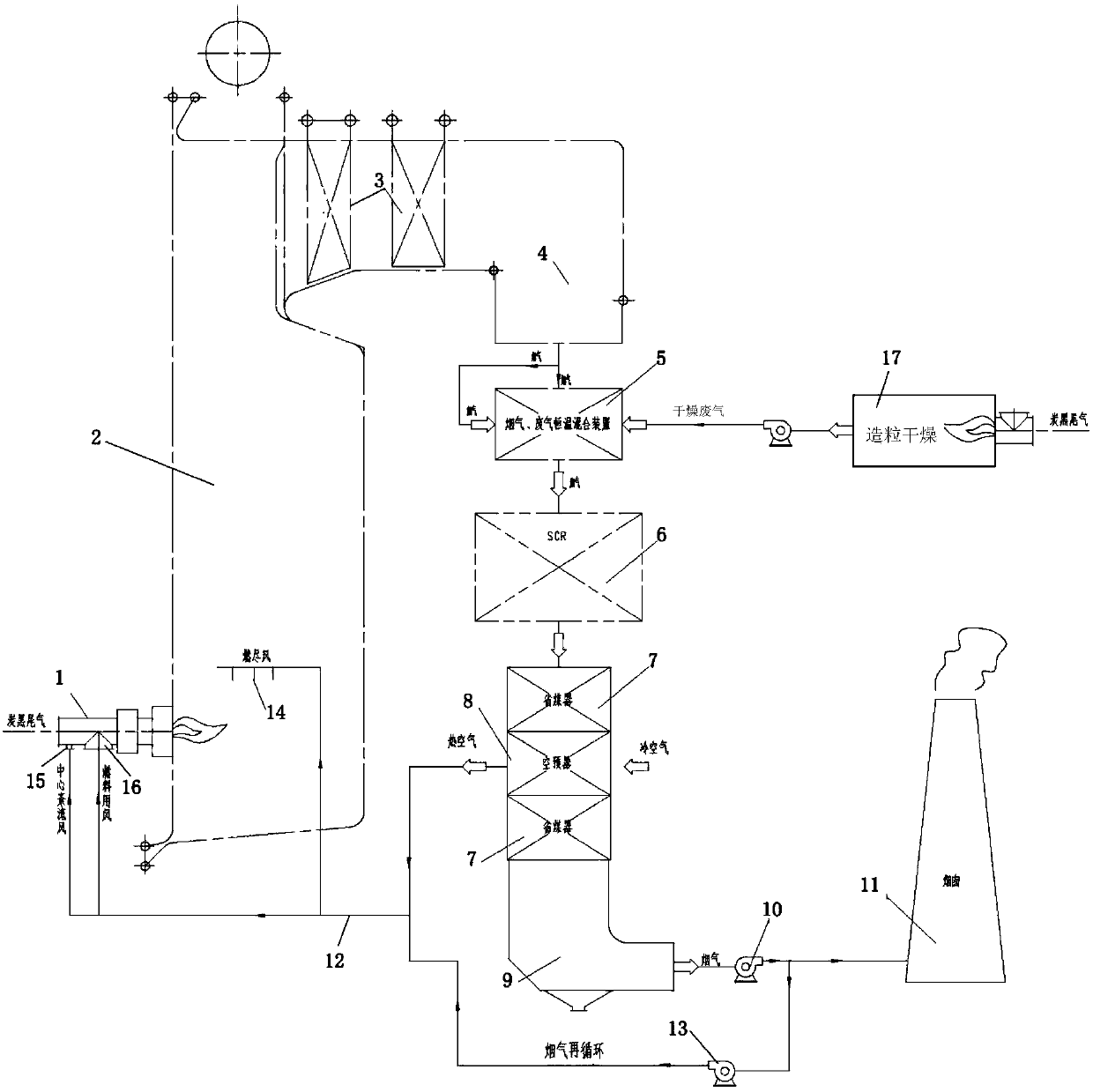

Carbon black tail gas incineration boiler with carbon black dry waste gas treatment function

PendingCN107860011AReasonable designLow investment costEmission preventionIndirect carbon-dioxide mitigationExhaust fumesExhaust gas emissions

The invention discloses a carbon black tail gas incineration boiler with a carbon black dry waste gas treatment function. The carbon black tail gas incineration boiler comprises a carbon black tail gas incineration boiler body and a smoke exhaust pipeline and further comprises a dry waste gas branch way and a smoke and waste gas constant-temperature mixing device. One inlet of the smoke and wastegas constant-temperature mixing device is connected with a smoke outlet of the carbon black tail gas incineration boiler body through a pipeline, and the other inlet of the smoke and waste gas constant-temperature mixing device is connected with a waste gas outlet of the dry waste gas branch way. An outlet of the smoke and waste gas constant-temperature mixing device is connected with an inlet ofthe smoke exhaust pipeline. The carbon black tail gas incineration boiler with the carbon black dry waste gas treatment function is reasonable in design, low in investment and running cost and capableof comprehensively reducing the carbon black production waste gas exhaust environment protection pressure and greatly promoting synchronous development of the treatment technology and the energy-saving and emission-reducing technology of carbon black waste gas.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com