Anti-wearing method for circulating fluidized bed boiler furnace

A technology of circulating fluidized bed and boiler furnace, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in melting state, etc., can solve the problems of circulating fluidized bed boiler furnace water wall wear and other problems, and achieve simple design and no Cost requirements, good anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

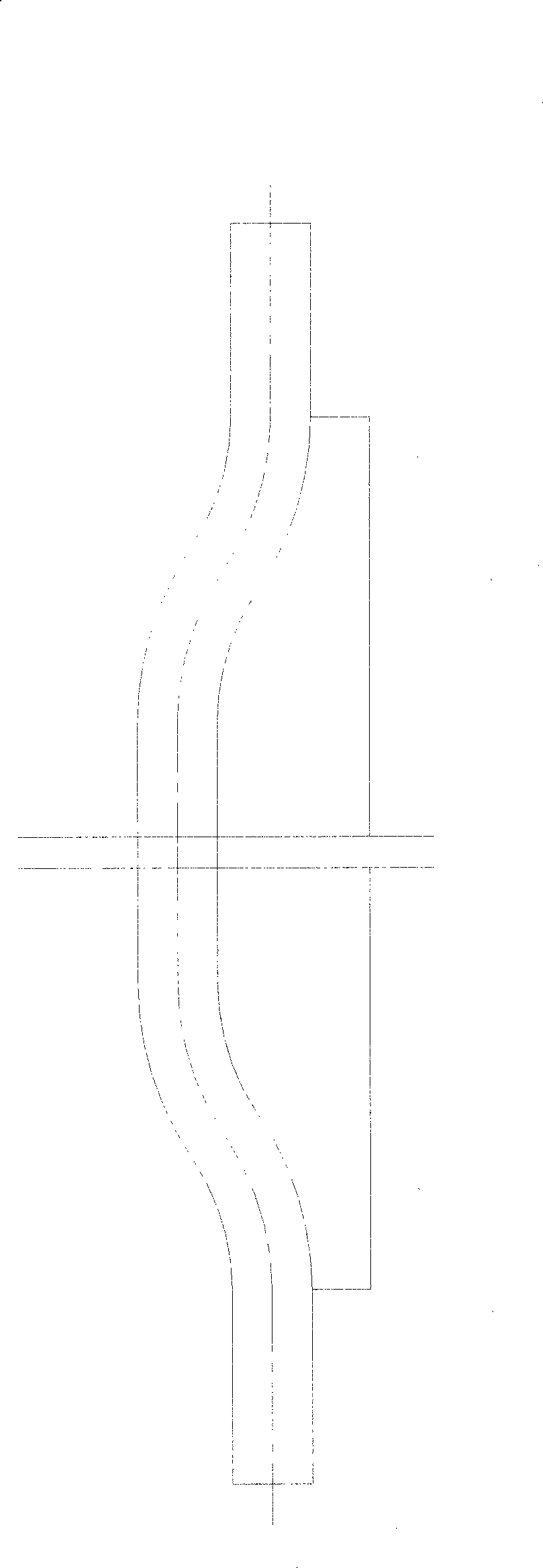

[0010] Embodiment of the present invention: in the design of the water wall of the circulating fluidized bed boiler, a large number of measuring points originally designed at the smooth tube screen of the furnace water wall of the circulating fluidized bed boiler are moved to the similar anti-abrasive material, so that the light The tubes are connected, so that the tube screen step protrusion at the wall passing through the furnace water wall of the circulating fluidized bed boiler is canceled, and its structure is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com