Patents

Literature

656 results about "Steam trap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. Most steam traps are nothing more than automatic valves. They open, close or modulate automatically.

Steam trap monitoring

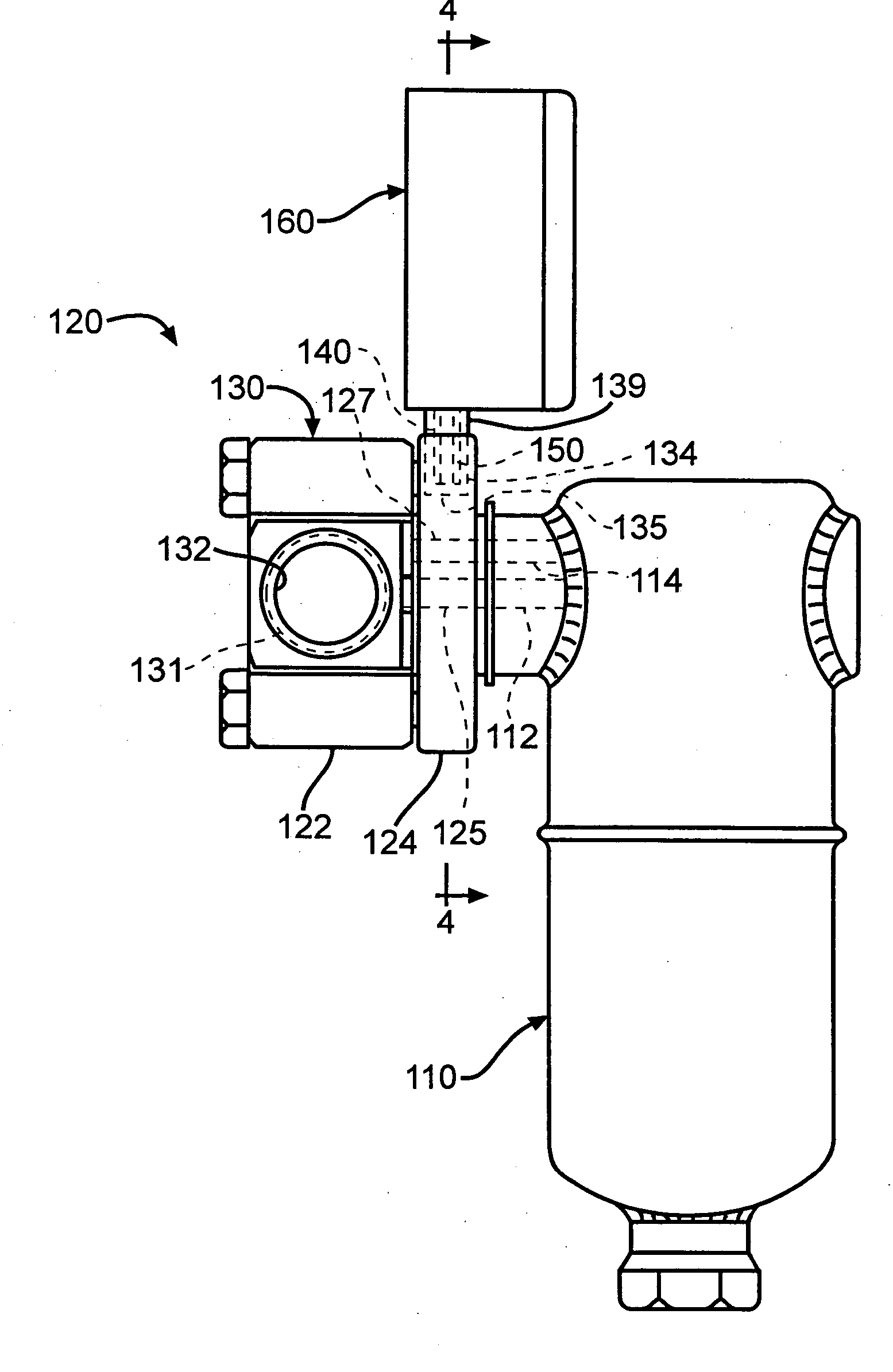

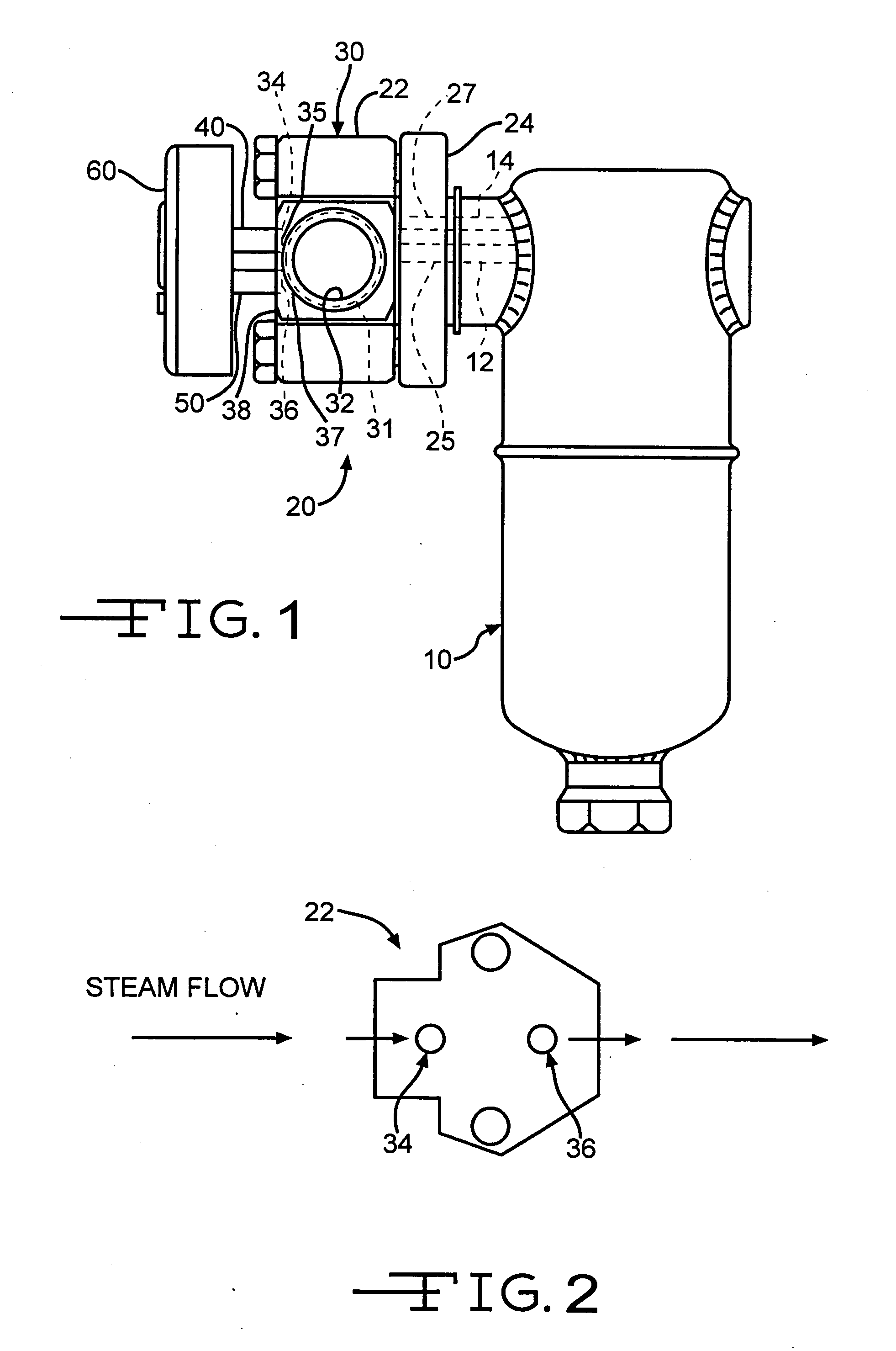

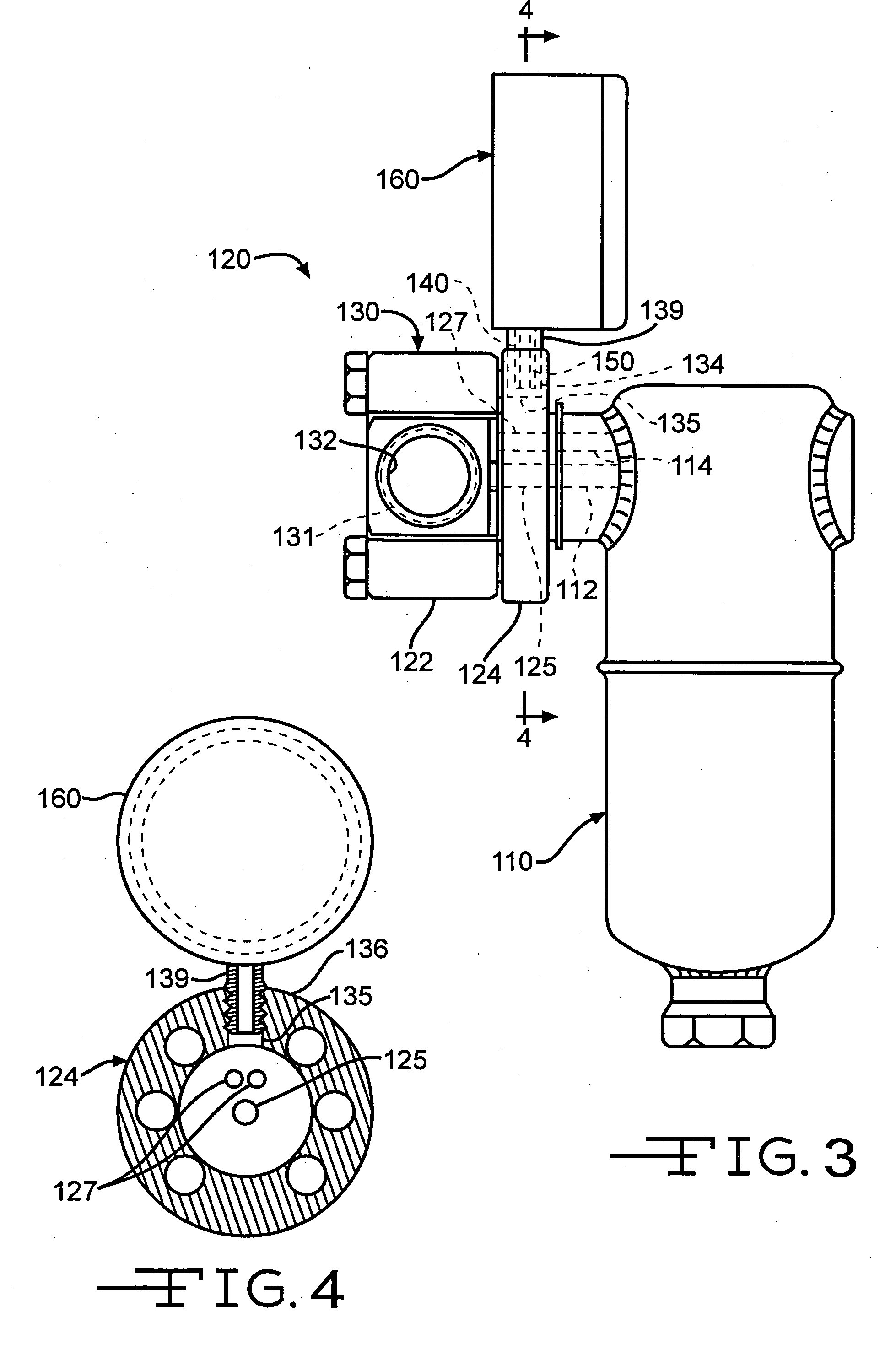

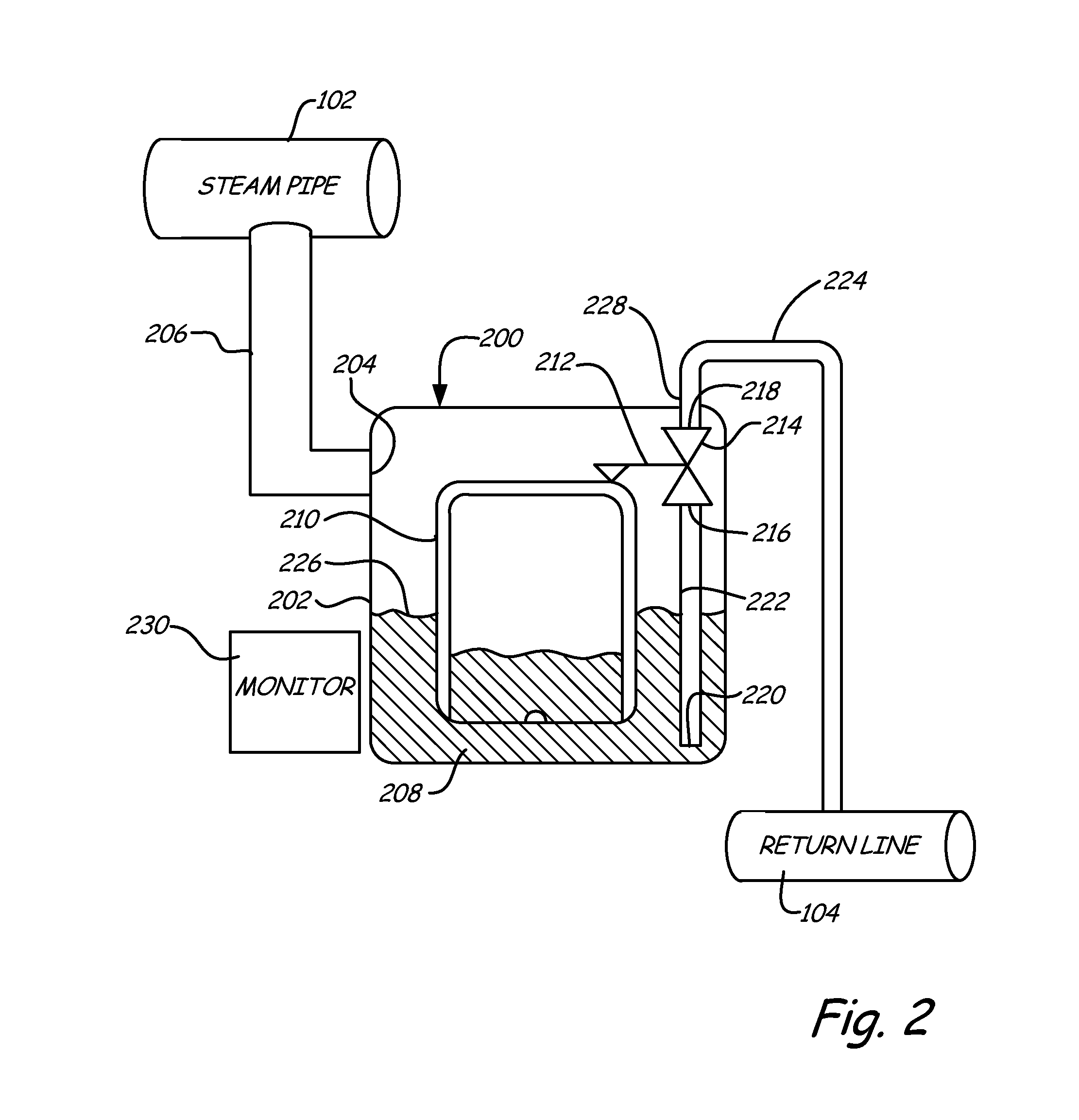

ActiveUS20060118648A1Temperature control without auxillary powerFlow propertiesEngineeringSteam trap

Owner:ARMSTRONG INT INC

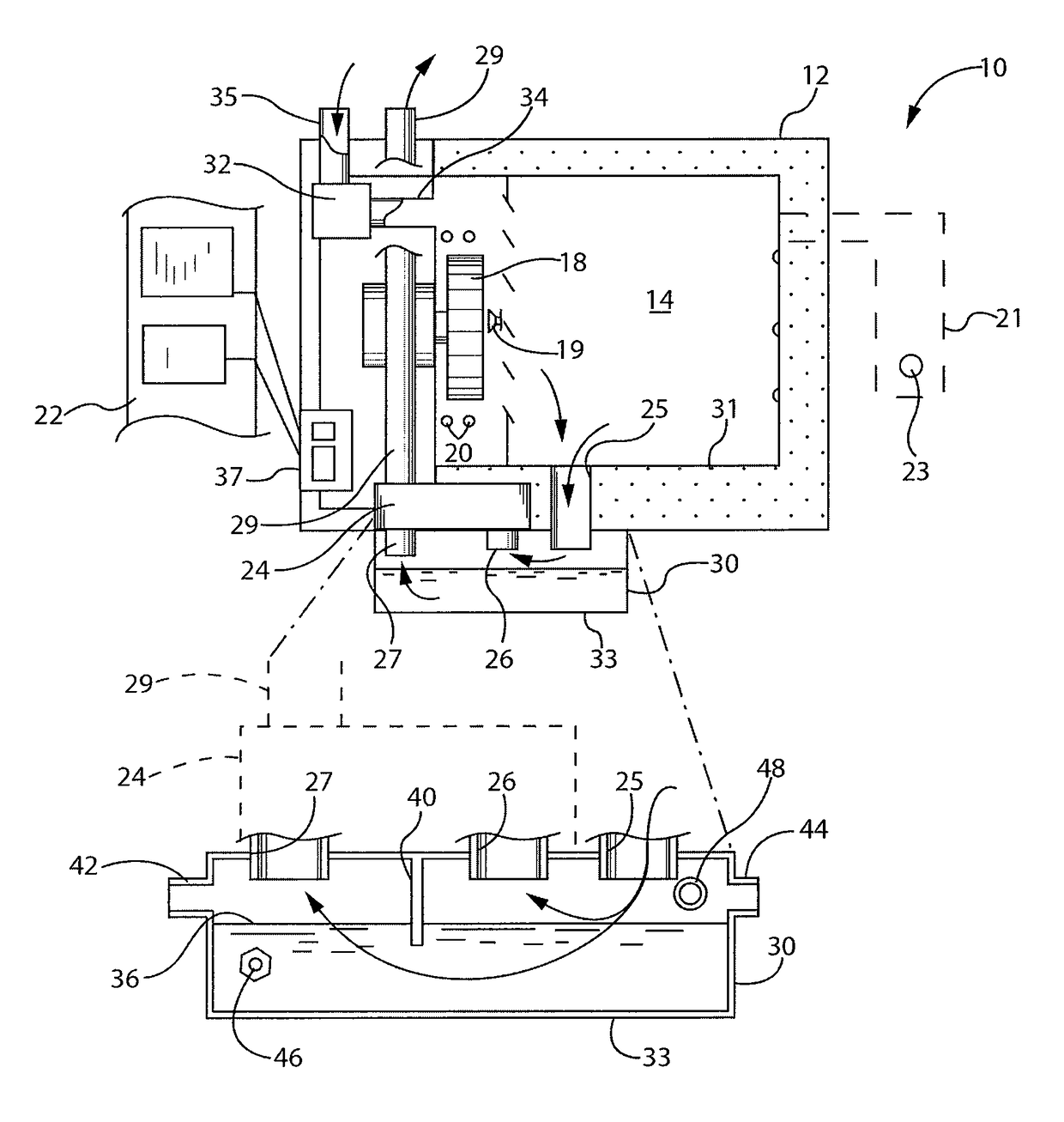

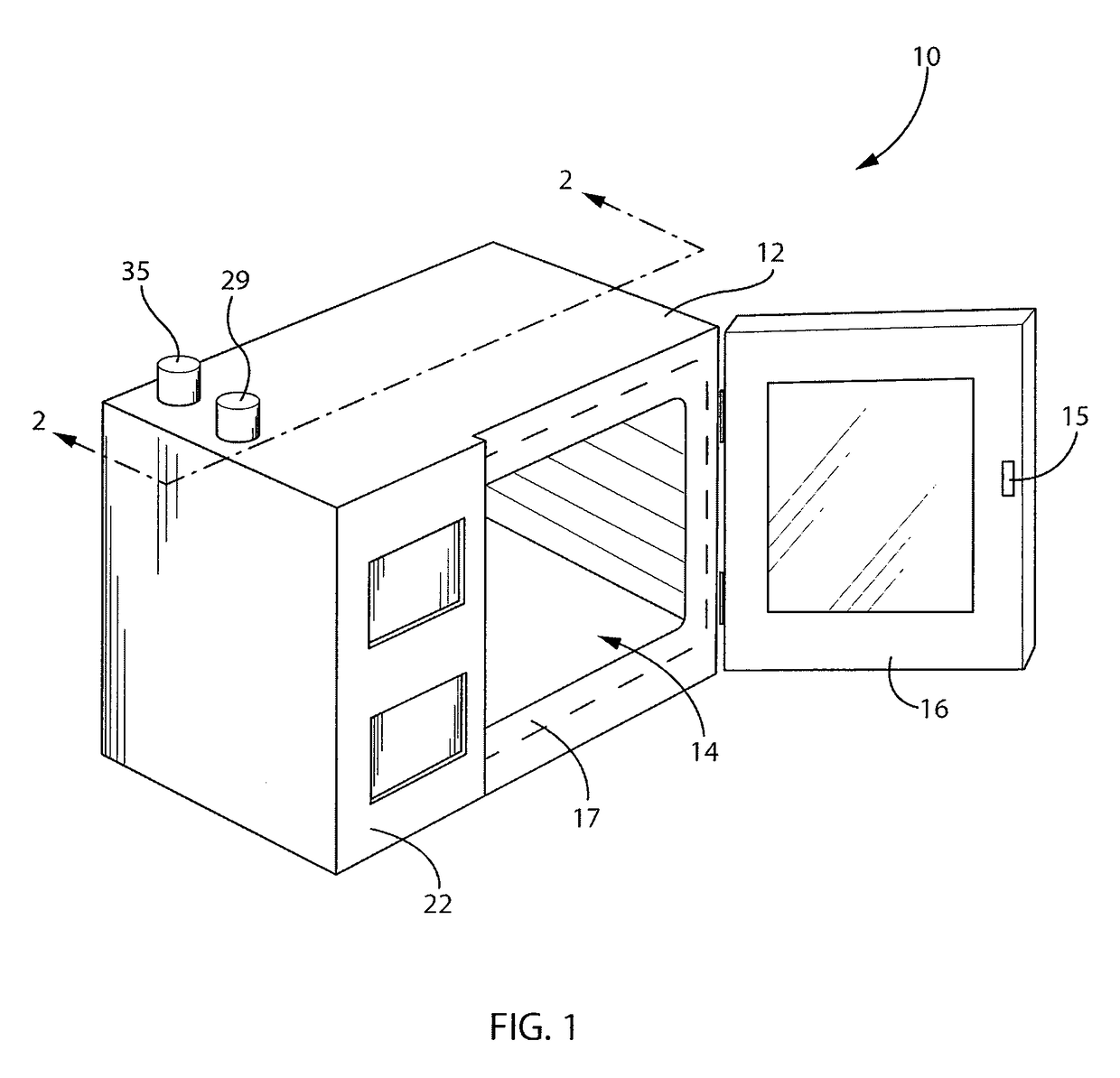

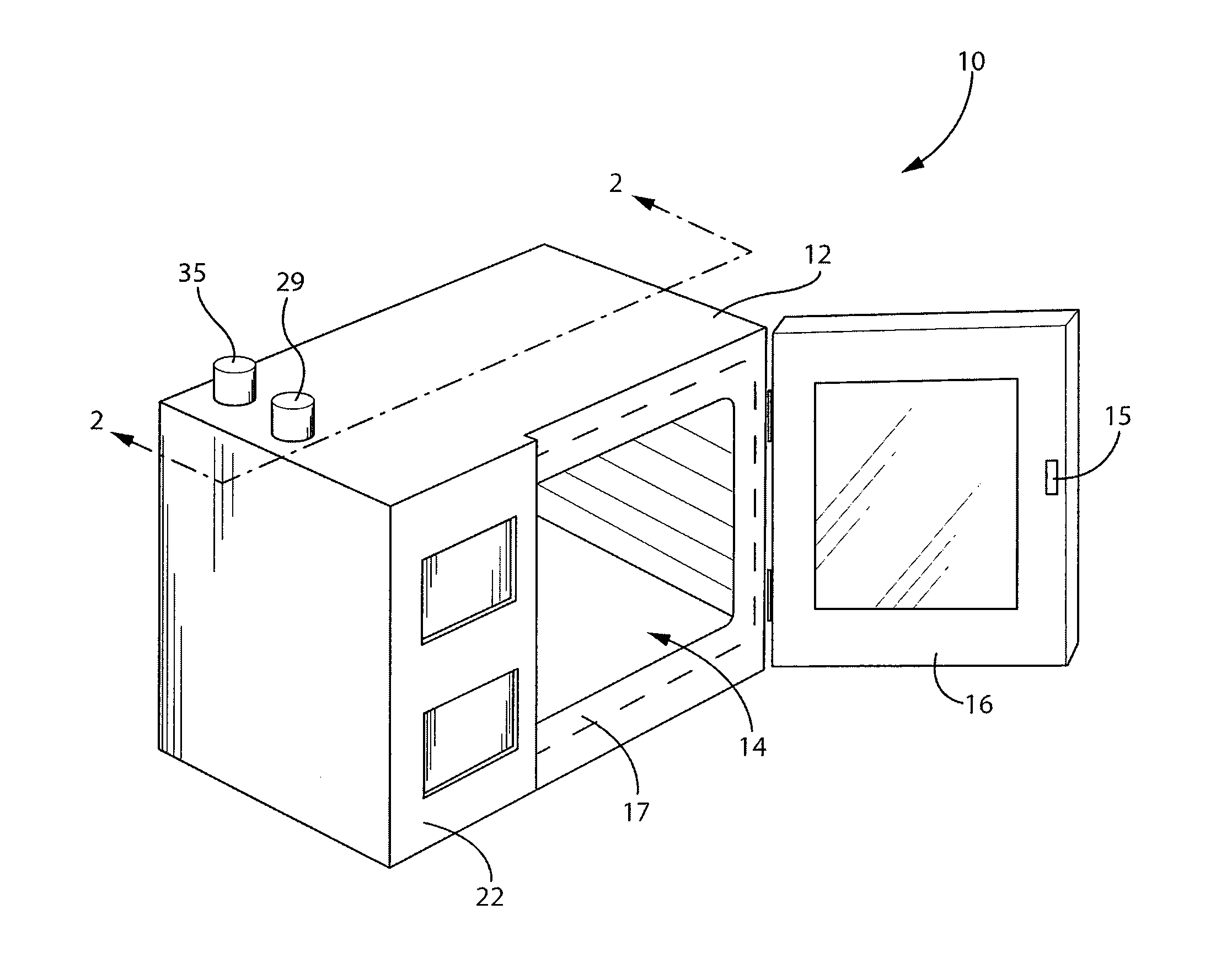

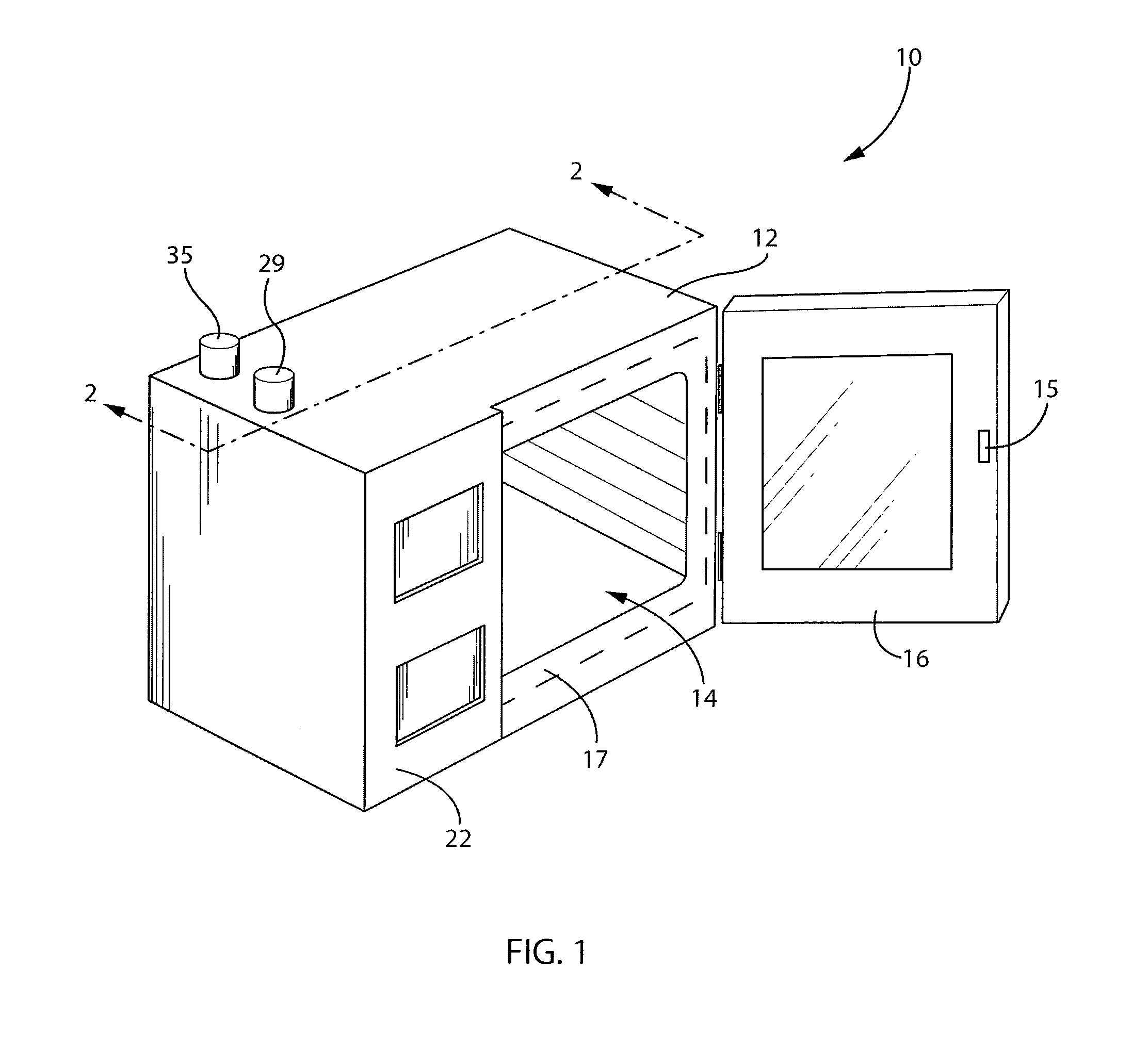

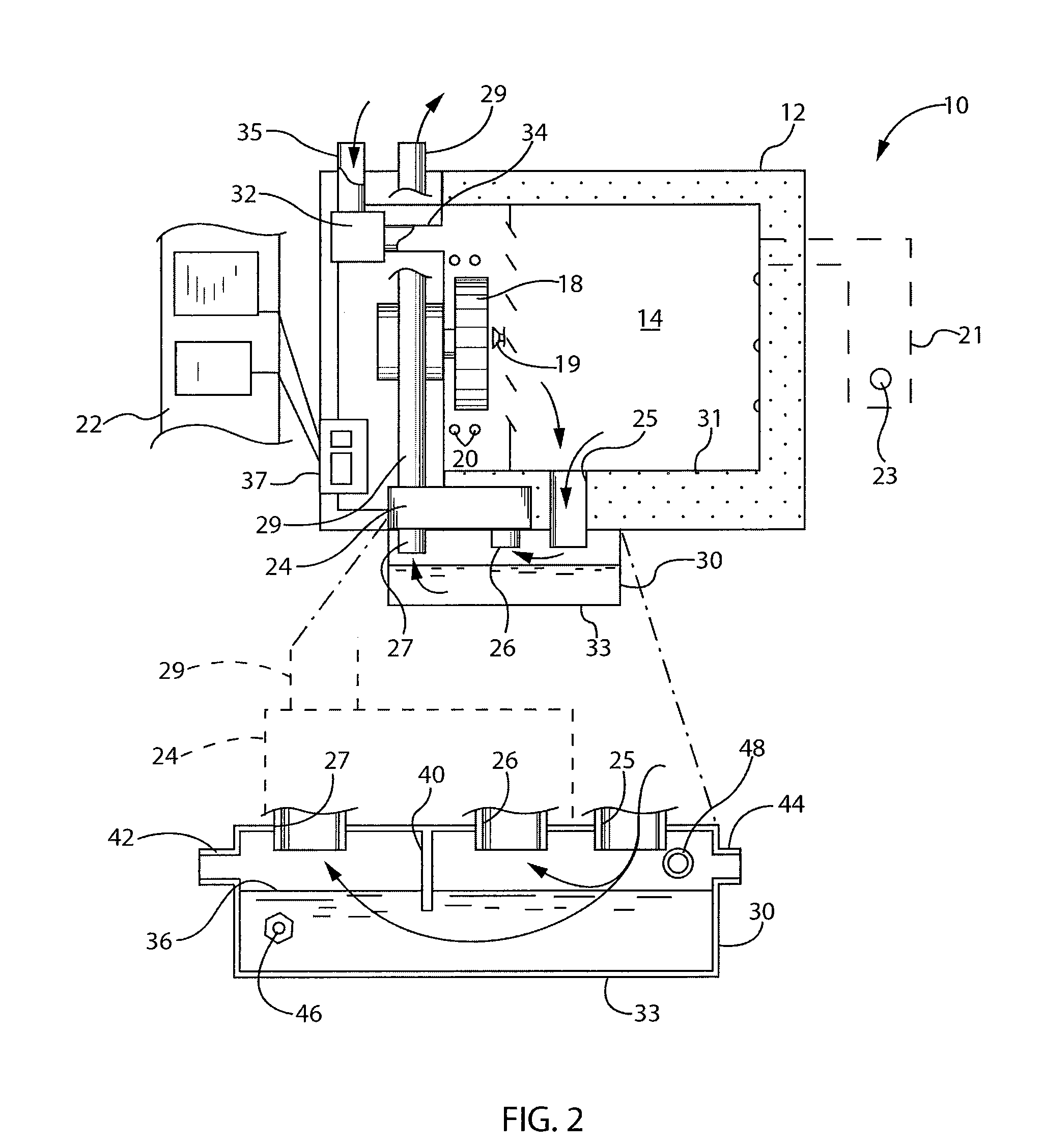

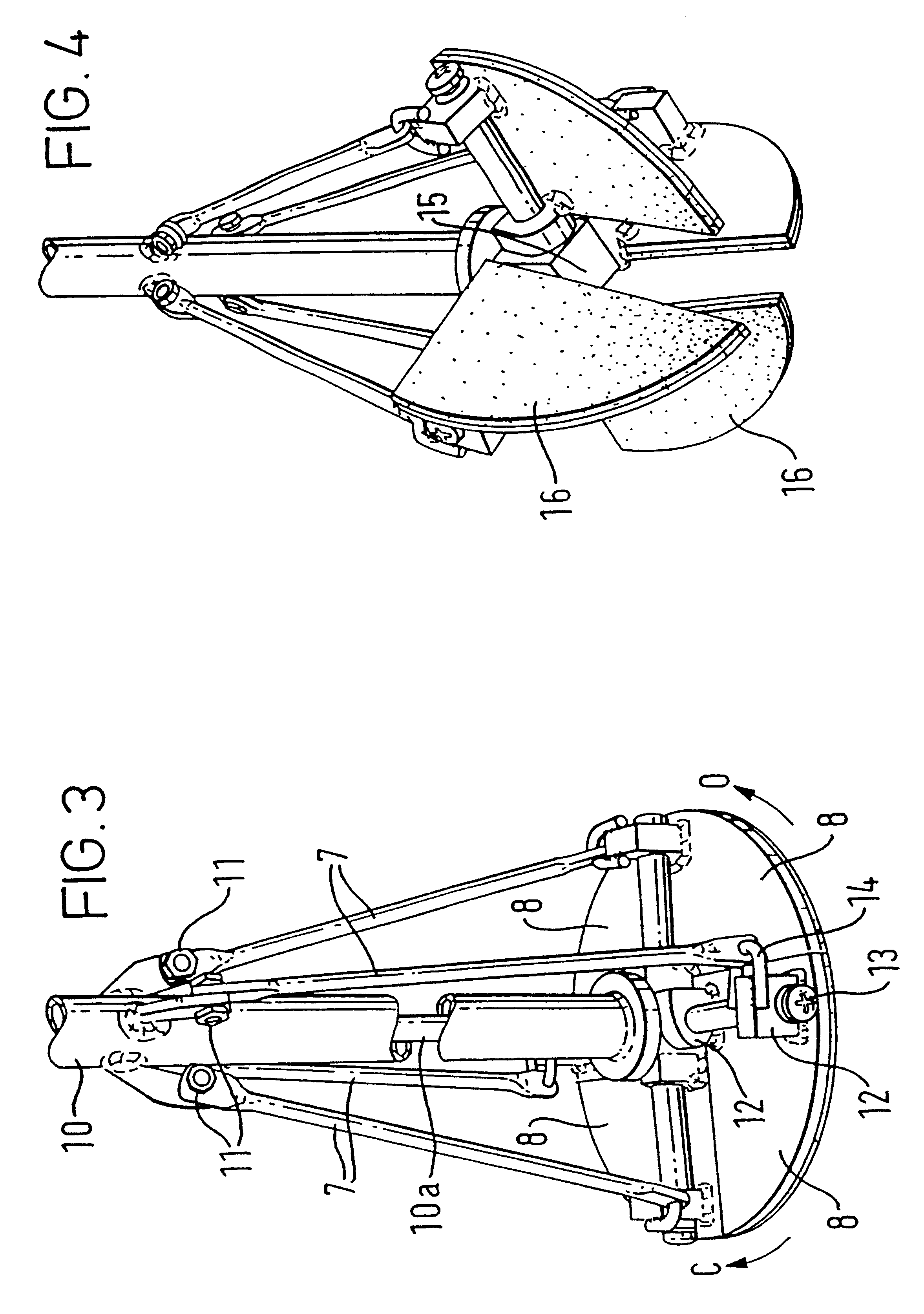

Oven with automatic open/closed system mode control

ActiveUS10119708B2Reduce the possibilityDomestic stoves or rangesLighting and heating apparatusHigh humidityUser input

A commercial oven, such as a combination oven providing steam and convection heating, may provide for motorized dampers allowing the oven to move automatically between a closed-state high humidity operating mode and an open-state low humidity operating mode according to user input reflecting a desired cooking process. The dampers operate with a conventional steam trap and may provide integrated bypass valves preventing over or under pressure of the cooking volume.

Owner:ALTO SHAAM

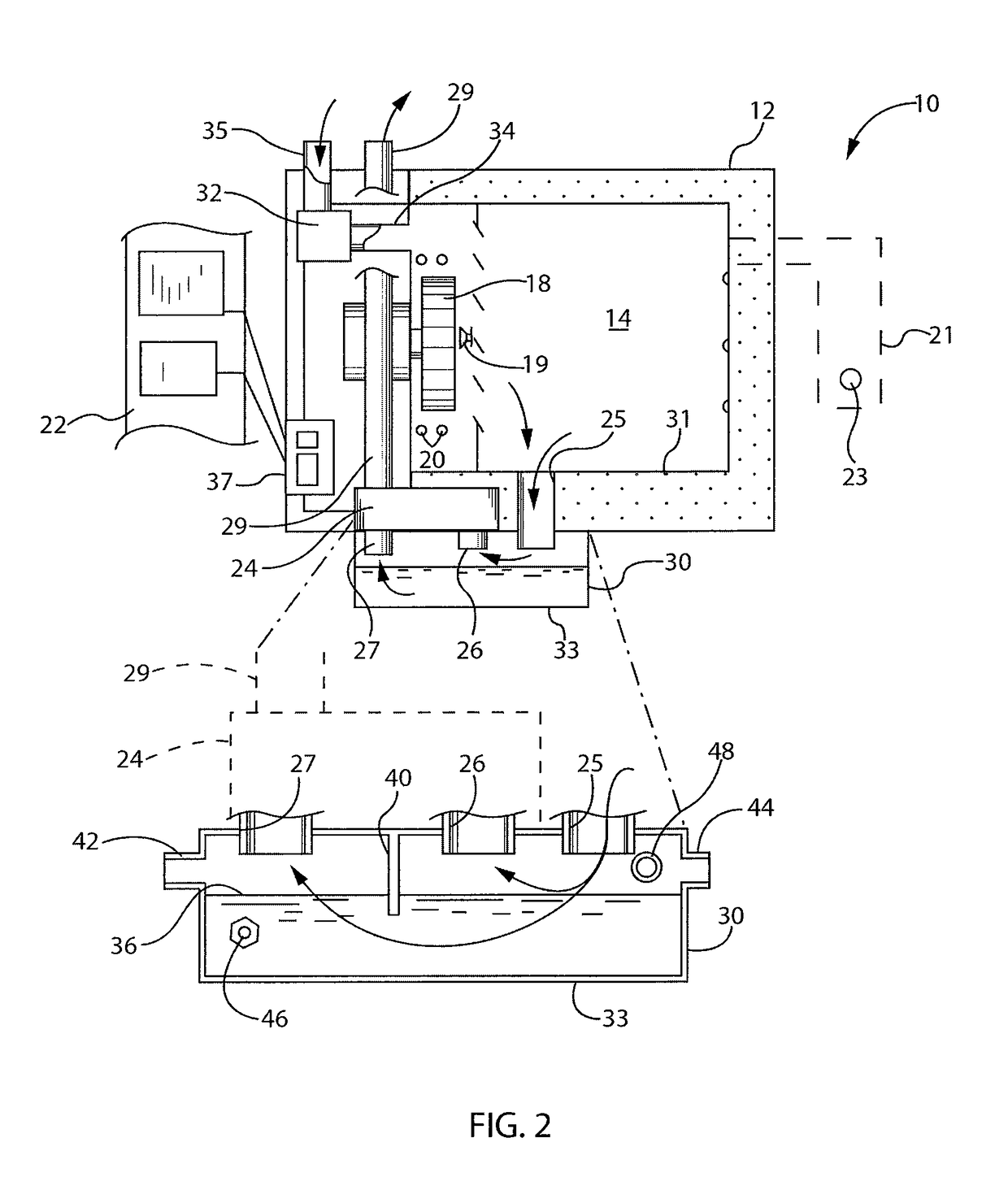

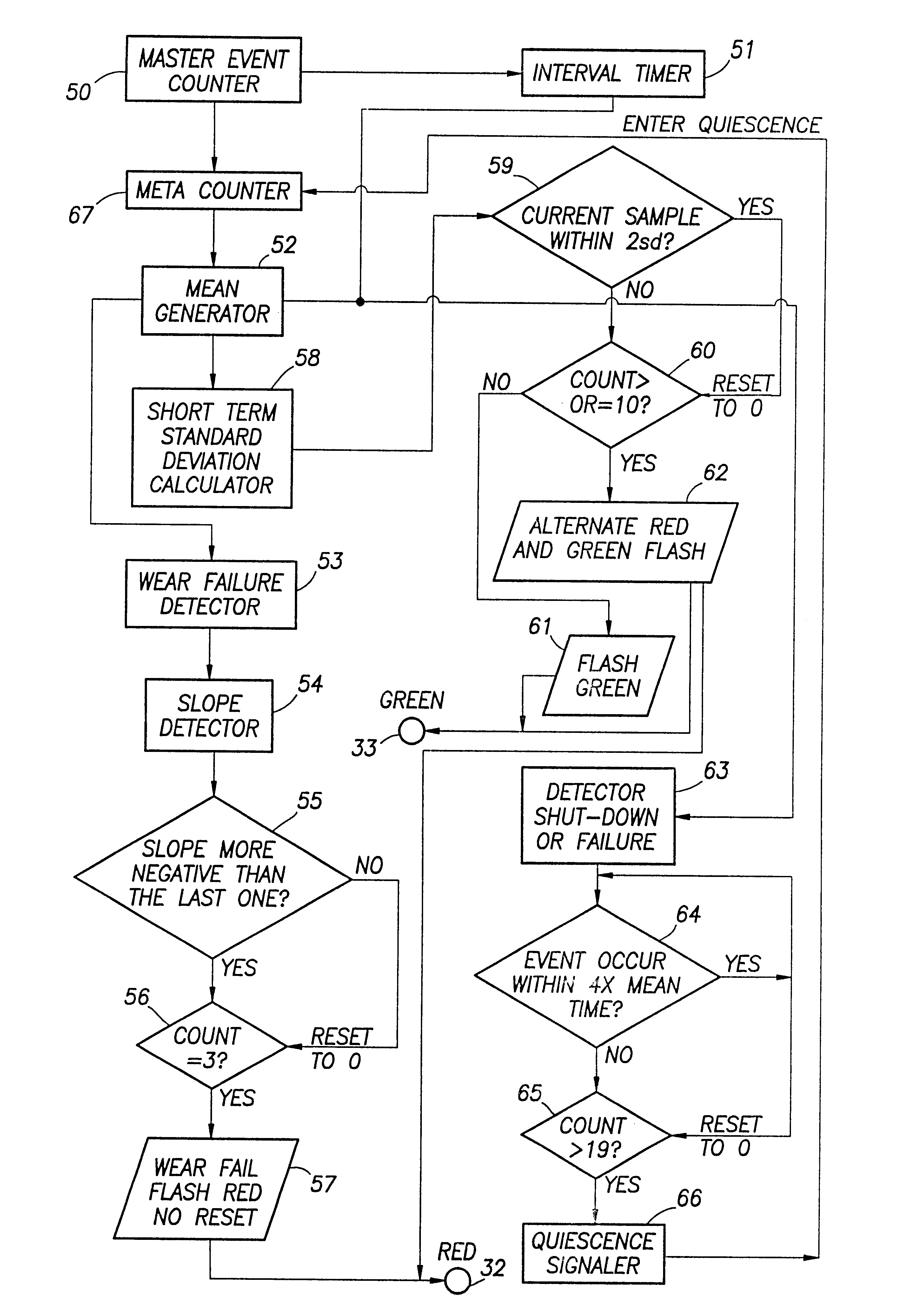

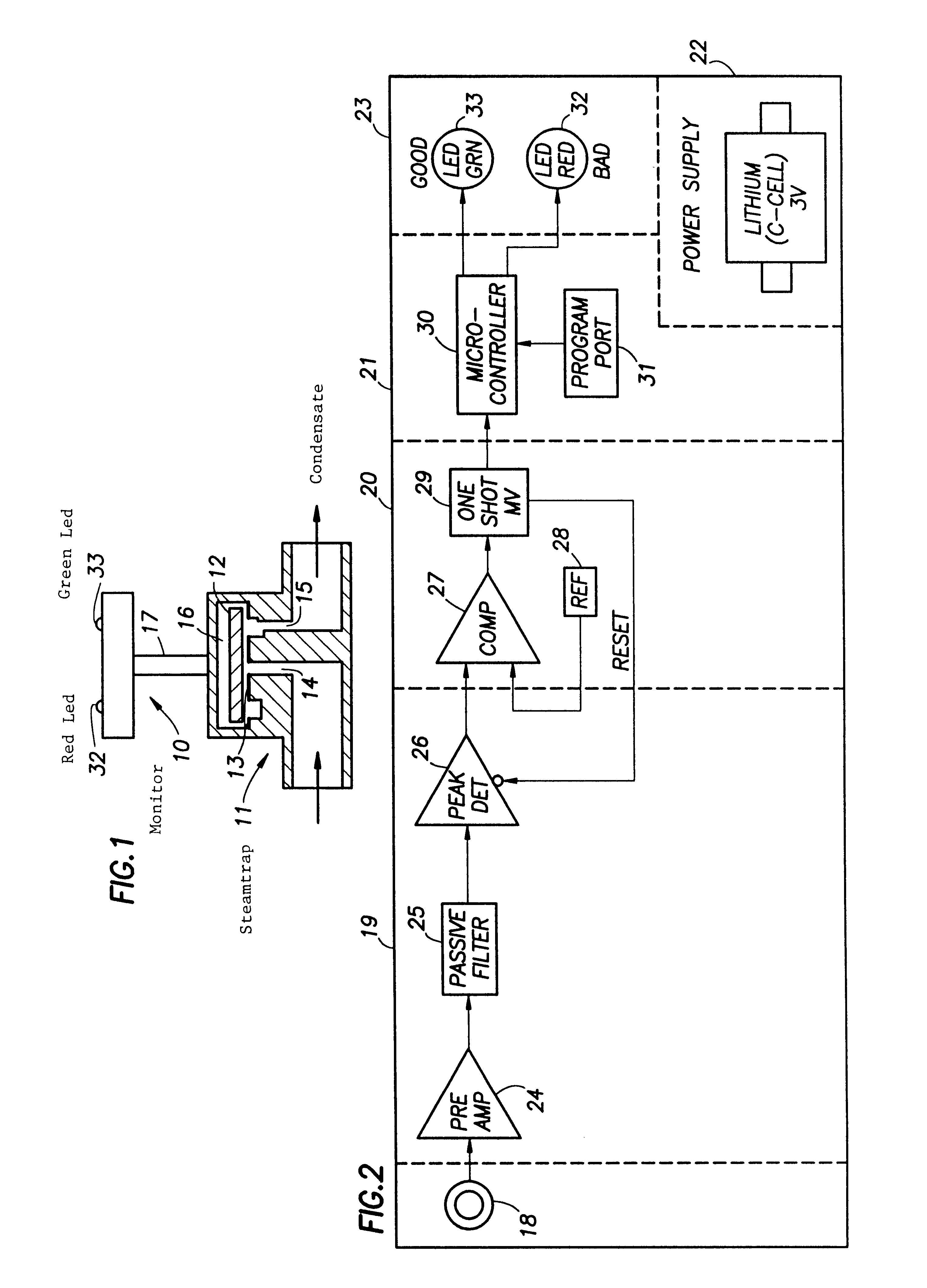

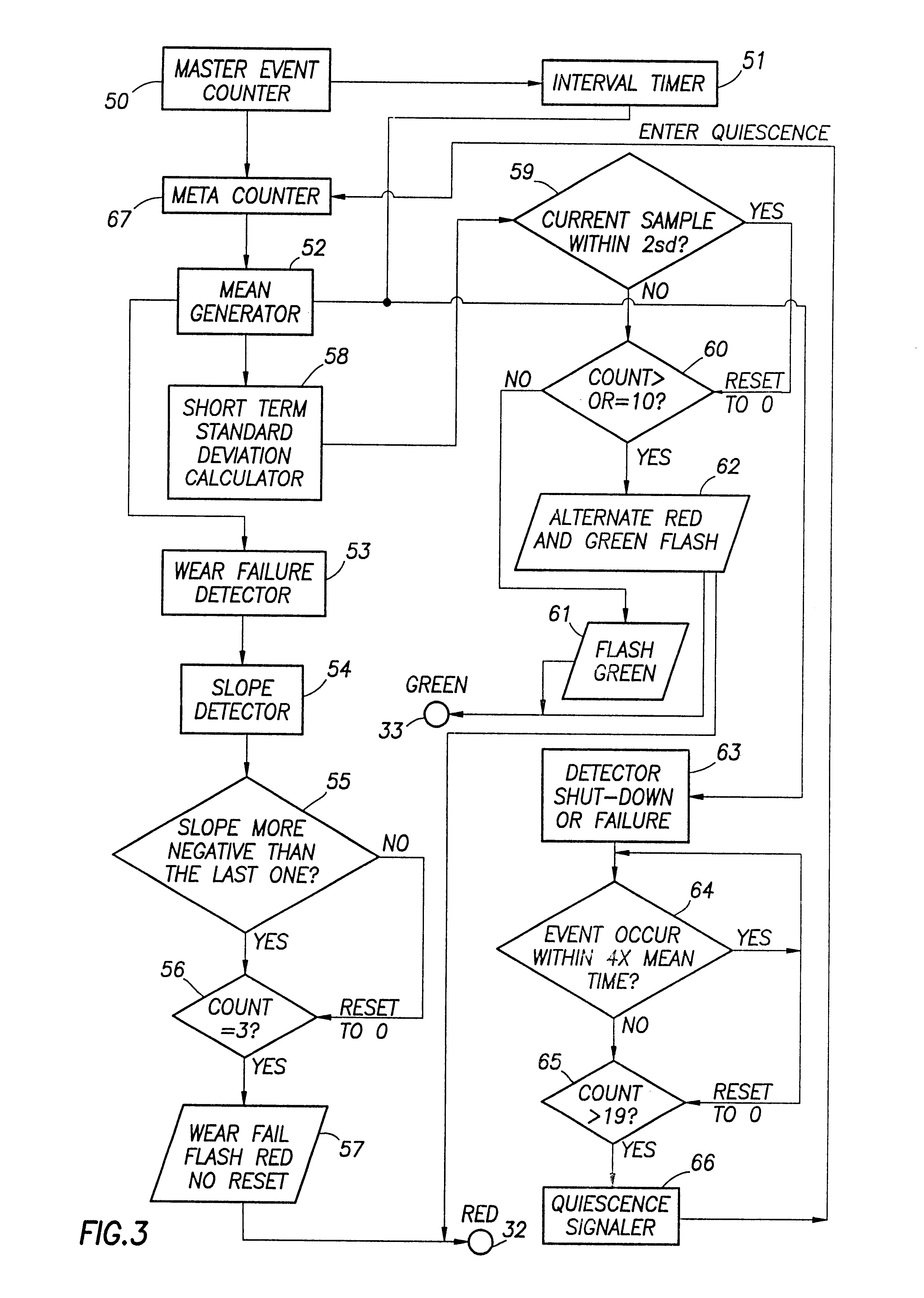

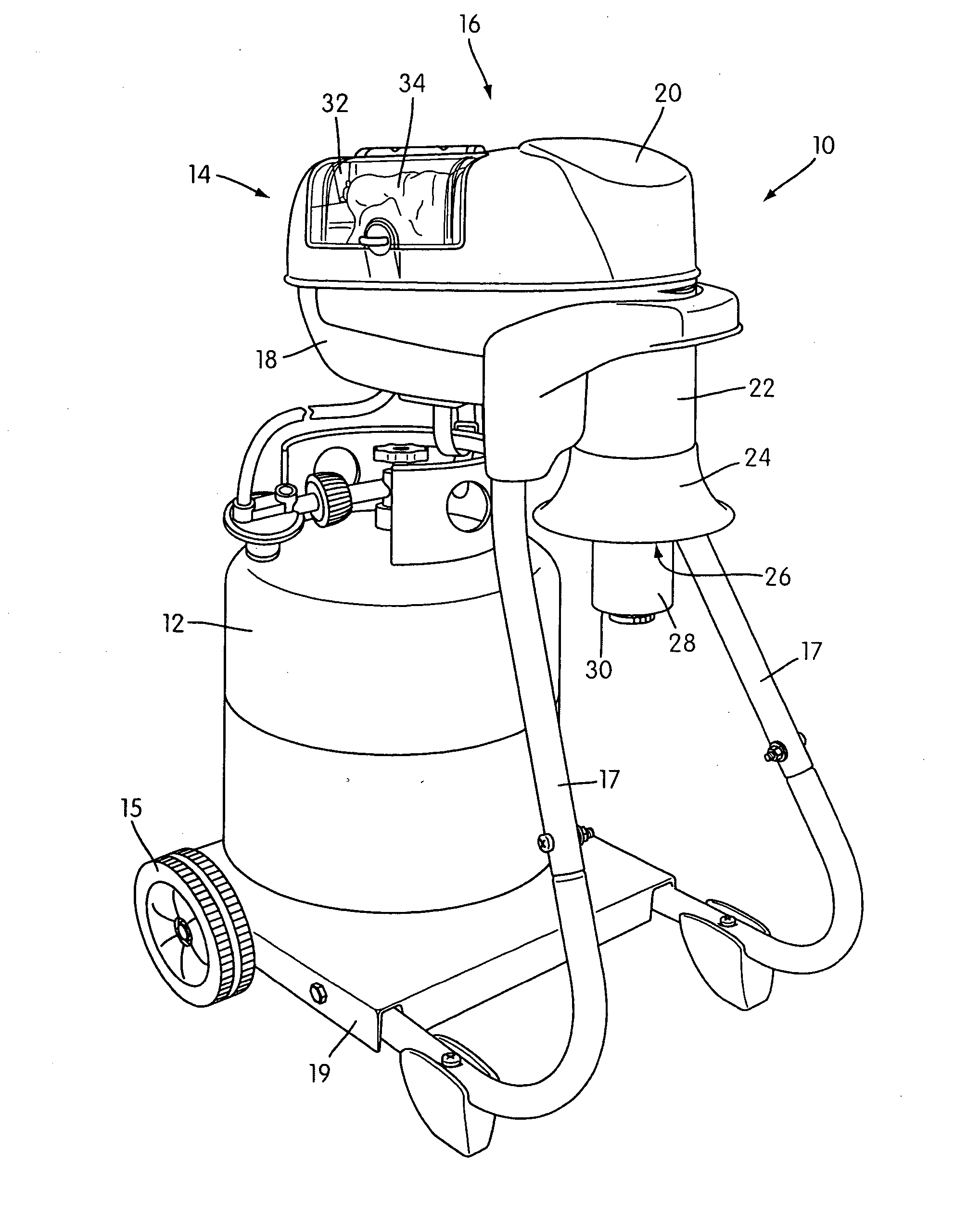

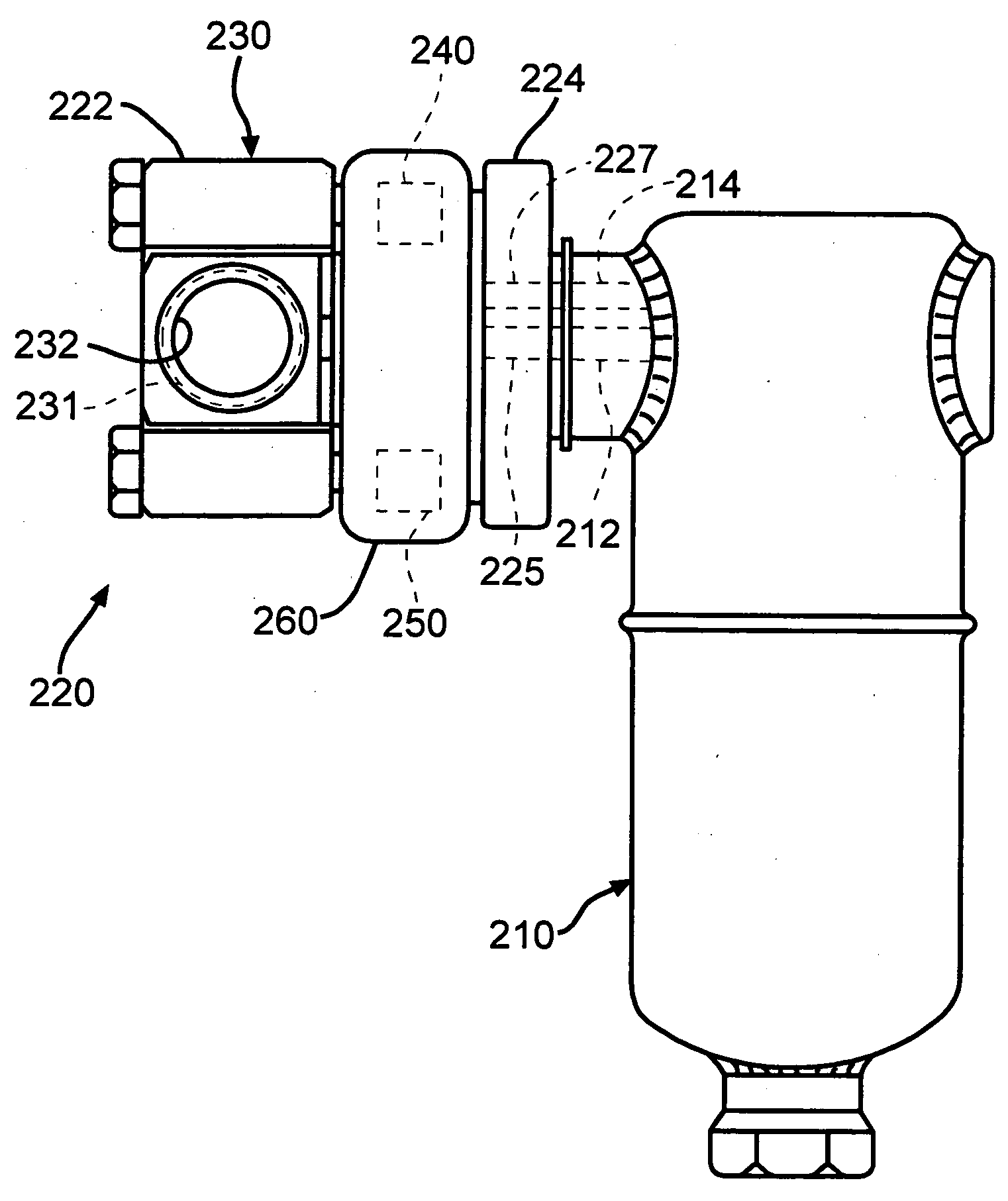

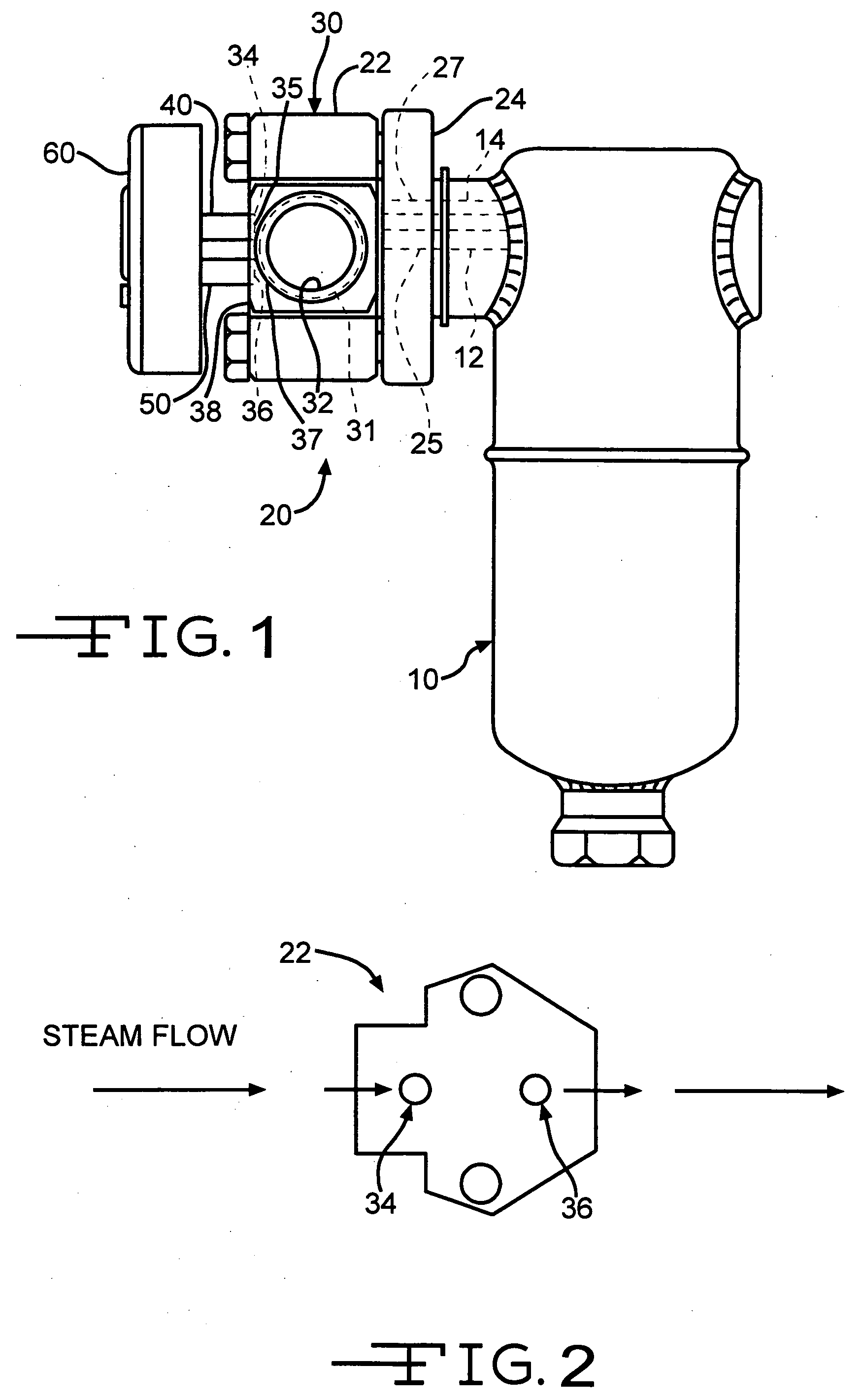

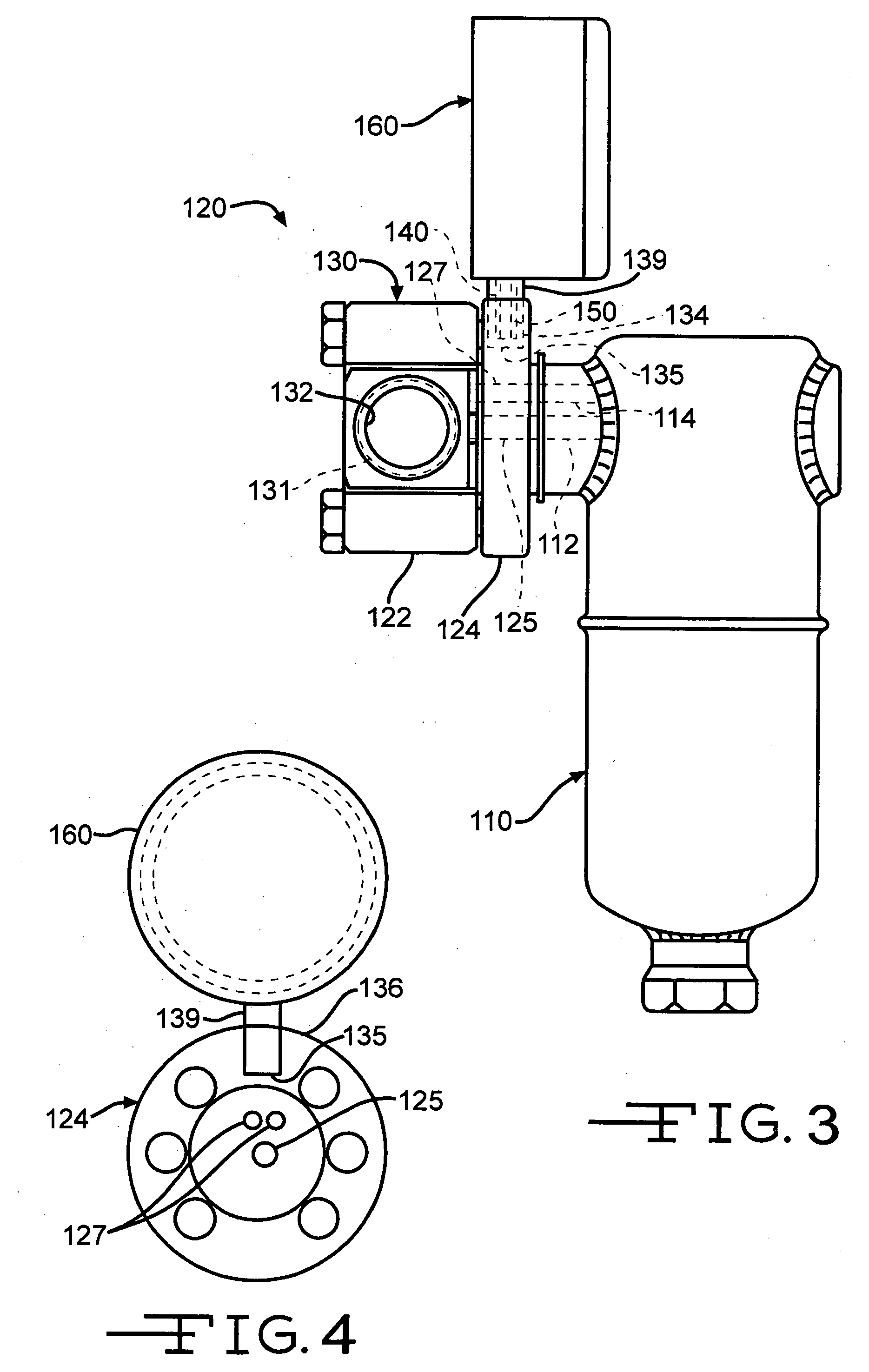

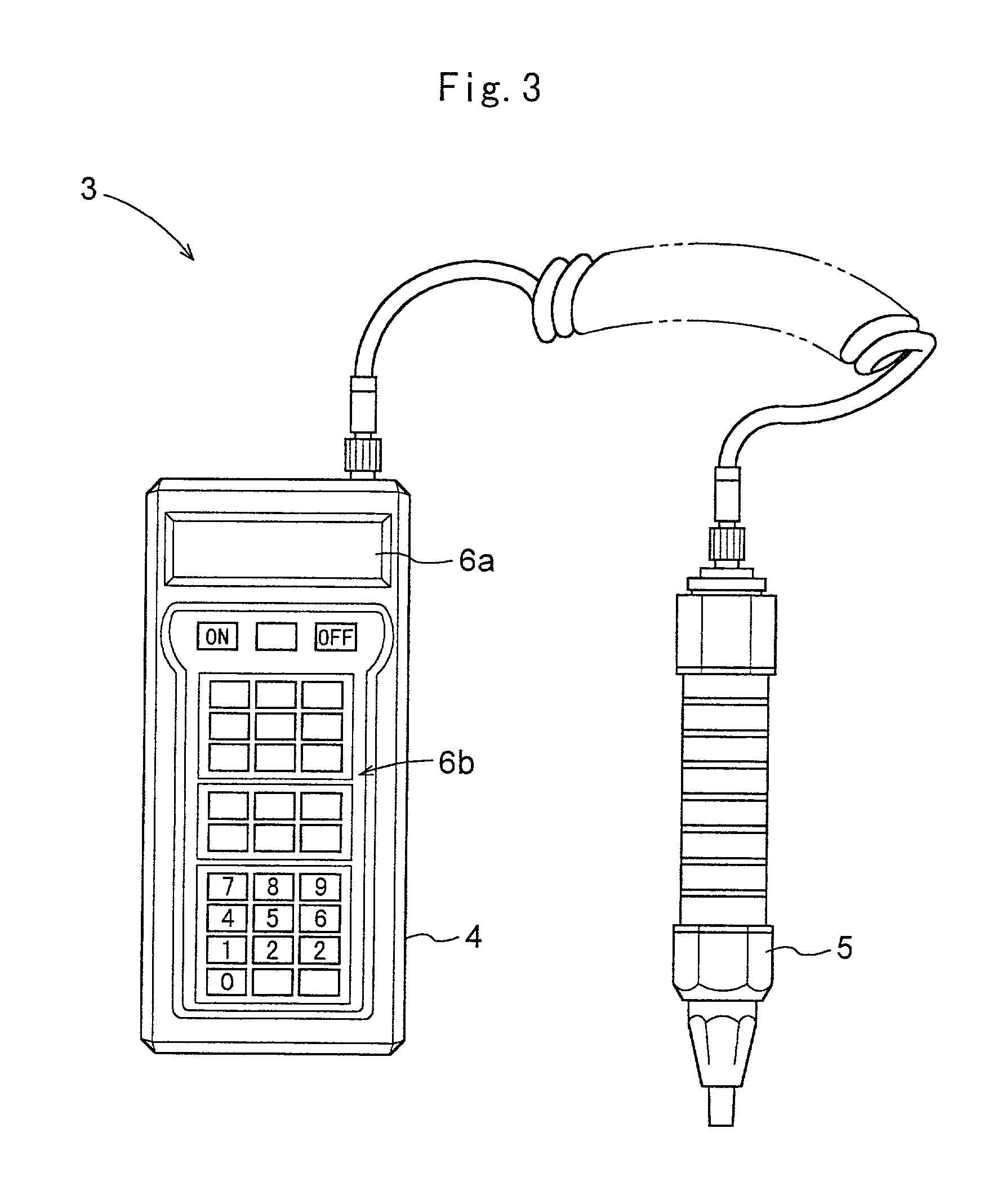

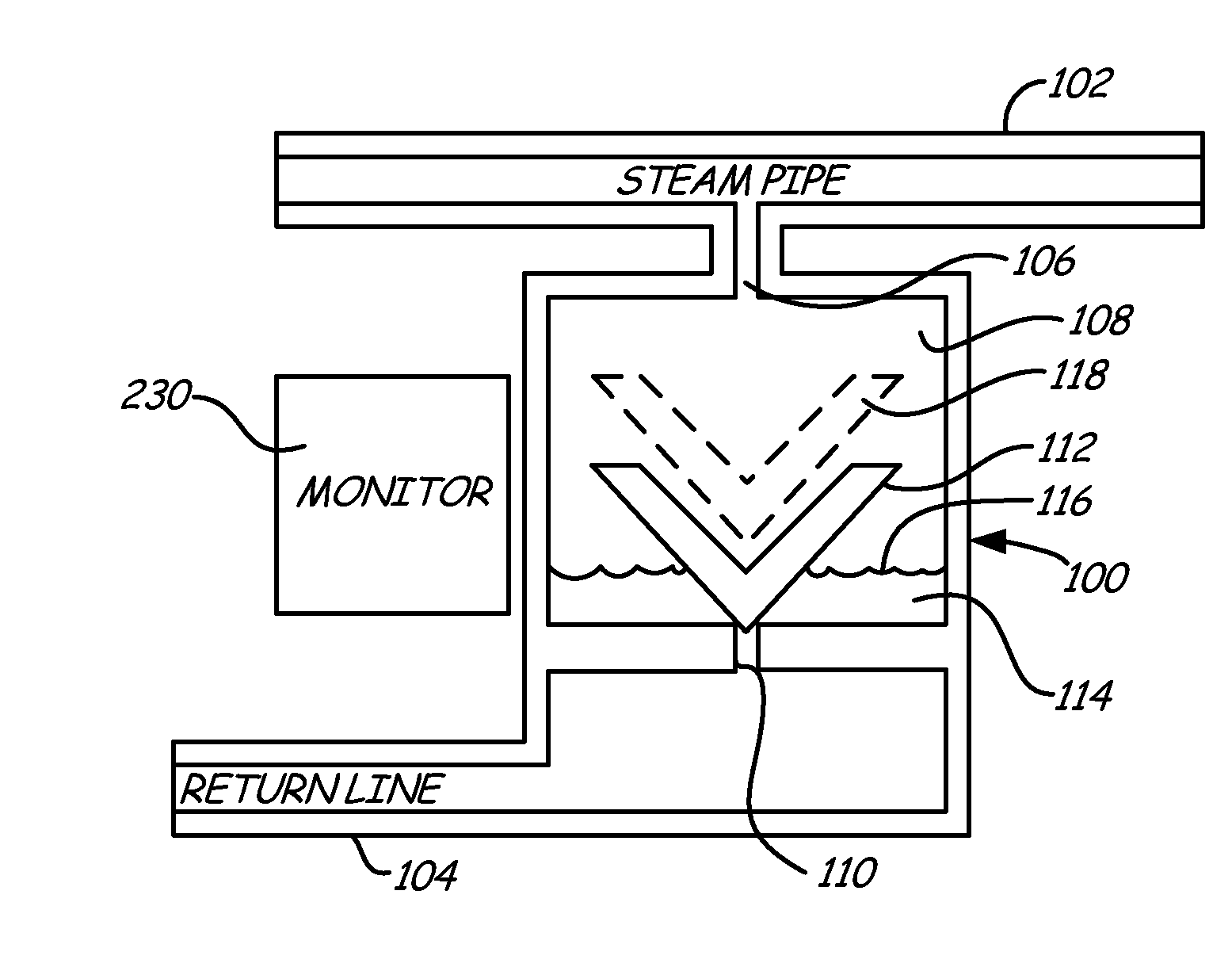

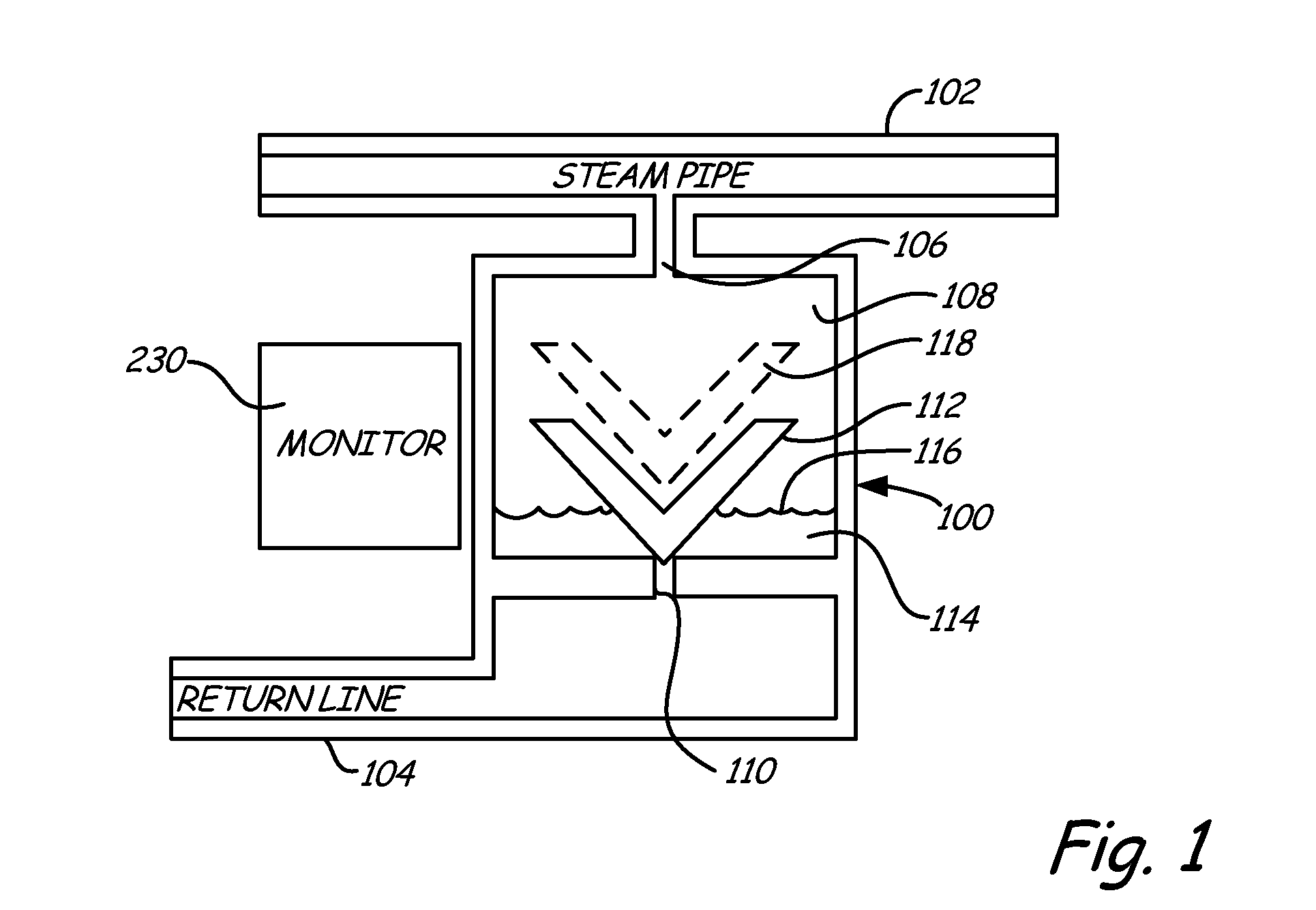

Self-contained steam trap monitor

InactiveUS6571180B1Easy to moveProlong lifeDetection of fluid at leakage pointMachine part testingBaseline dataData set

A self-contained system to continuously monitor a mechanism used to process, control or regulate fluid flow or pressure and provide a continuing indication of the status or condition of the monitored mechanism. A specific form of the invention employs a low frequency sonic-to-electrical transducer that monitors opening and closing of a disk-type steam trap. The detected sonic signal is processed and sent to a microprocessor that is programmed to develop a time-based, baseline data set representative of normal operation of the steam trap in the environment in which it operates. The baseline data set is compared with the data from on-line operations of the steam trap. As the environment and the steam trap operation change during normal on-line operations, the baseline data set is updated to change with the changing environment and the changing steam trap operation.

Owner:TYCO VALVES & CONTROL INC

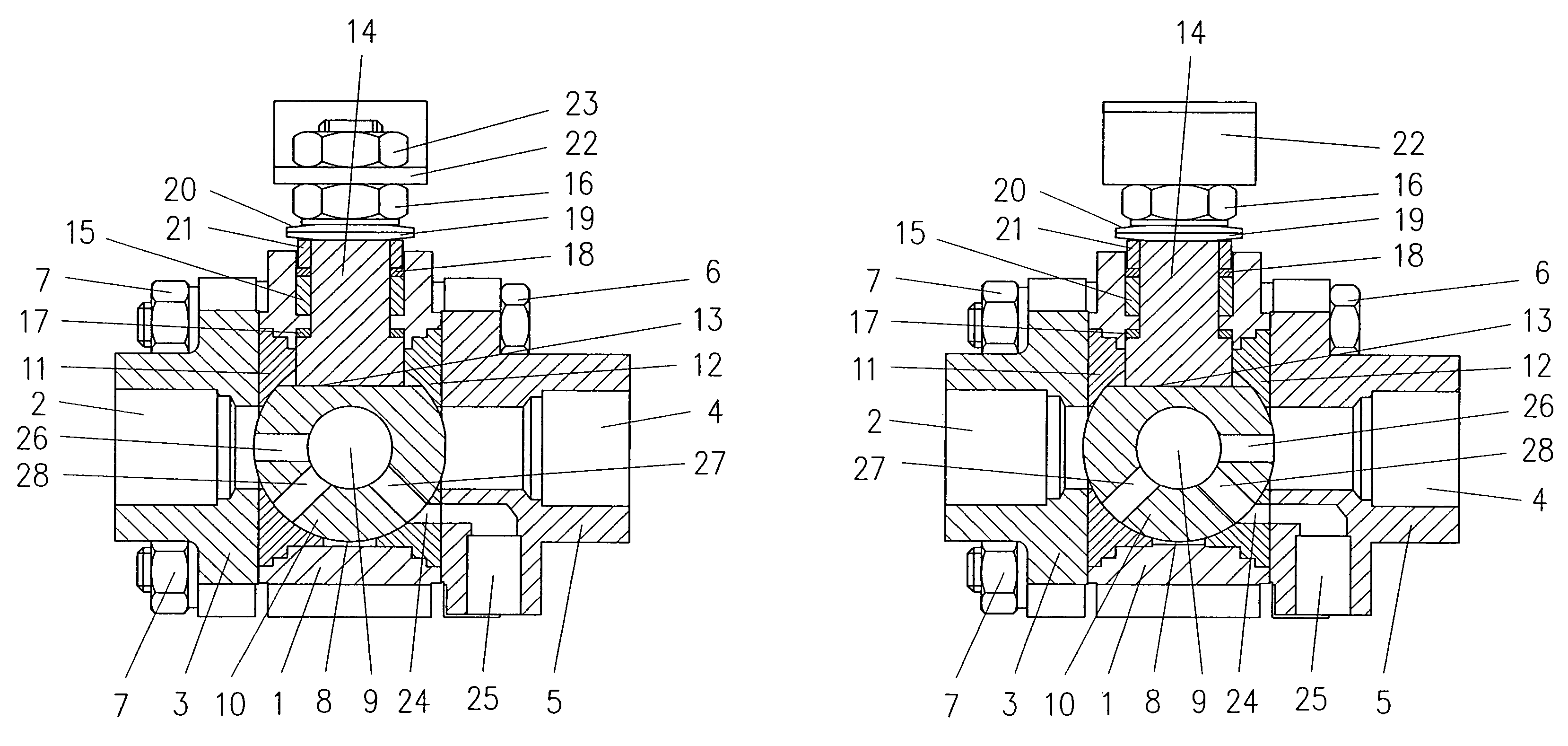

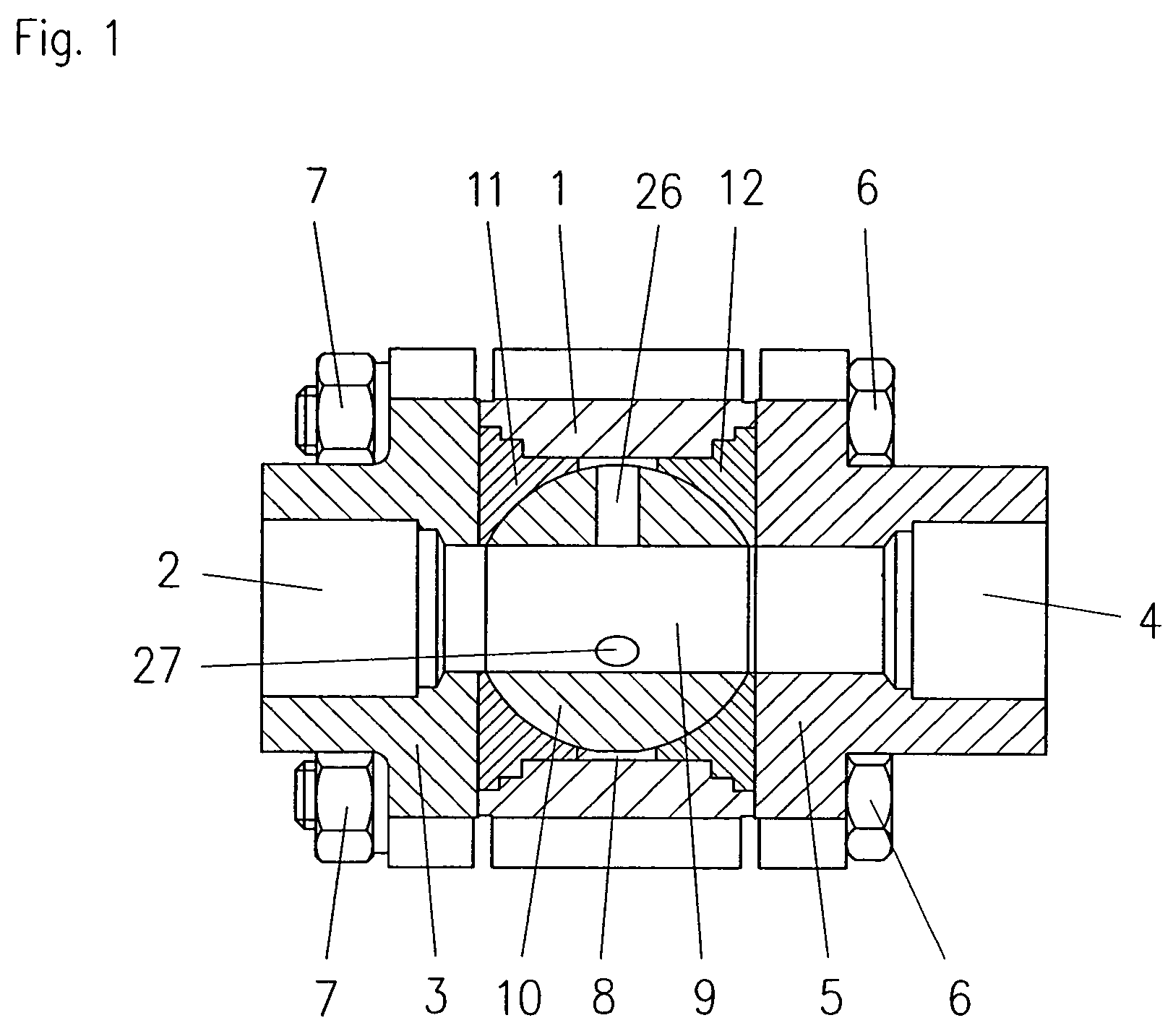

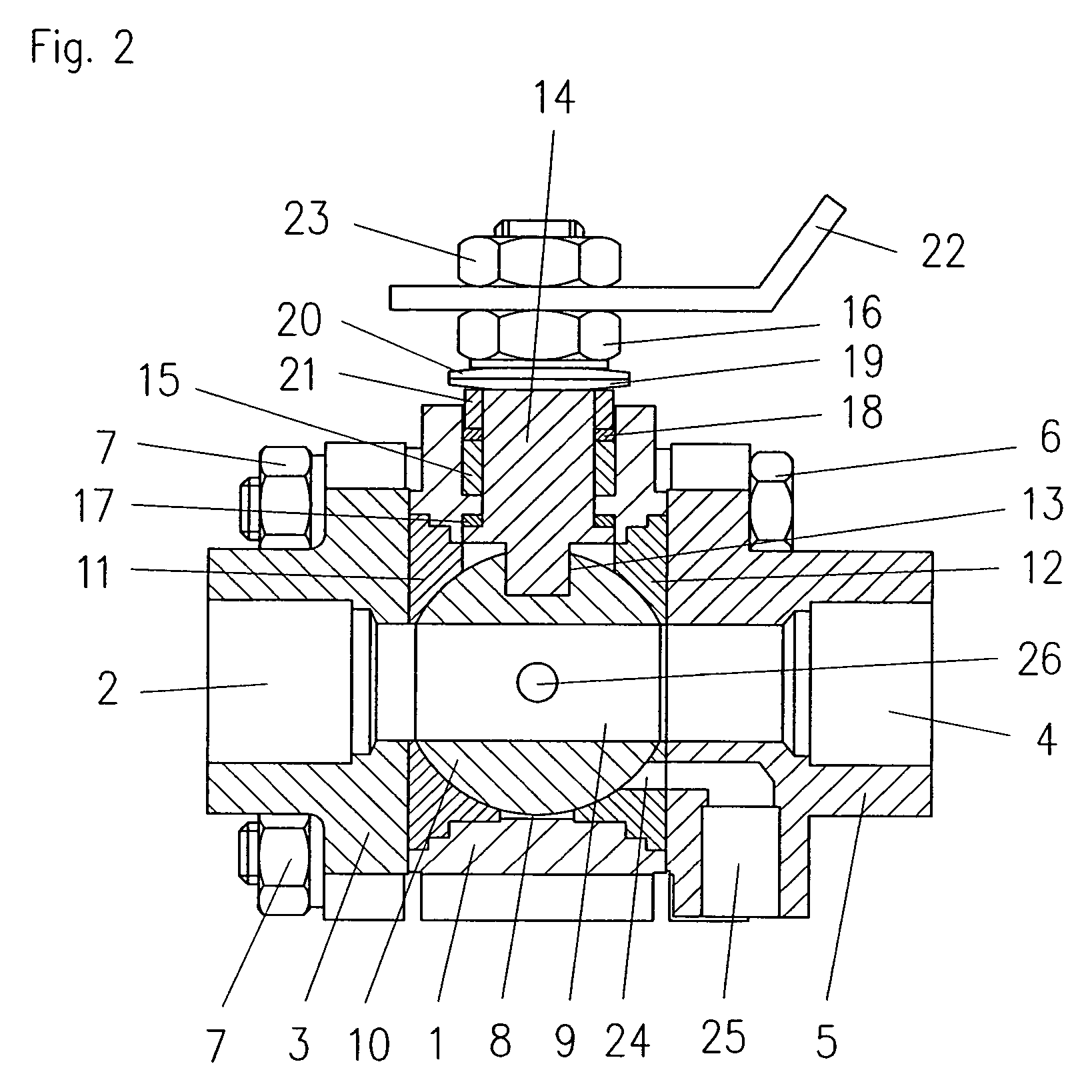

Ball valve

The present invention is a ball valve which may be attached to a fluid pipe for connection / disconnection between an entrance and an exit. More particularly, the present invention is a ball valve having a discharge orifice communicating with ambient air in addition to the entrance and the exit for connection / disconnection between the entrance and the discharge orifice and / or between the exit and the discharge orifice. The ball valve of the present invention may be attached to piping systems such as, for example, the secondary side of a steam trap, which blocks steam but automatically discharges condensed water, and is used for checking a discharging state of the primary side steam trap and / or releasing remaining pressure on the secondary side.

Owner:TLV CO LTD

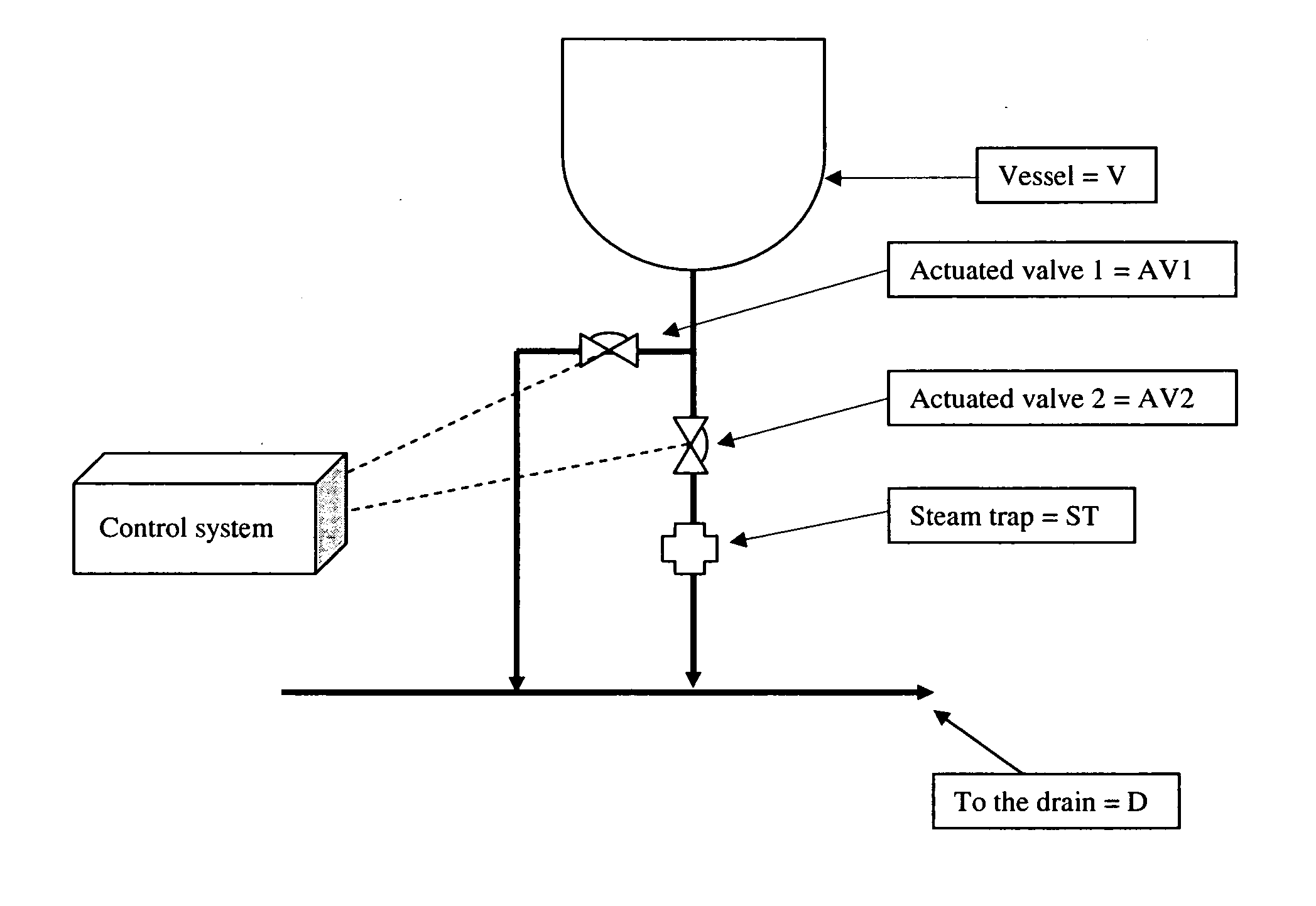

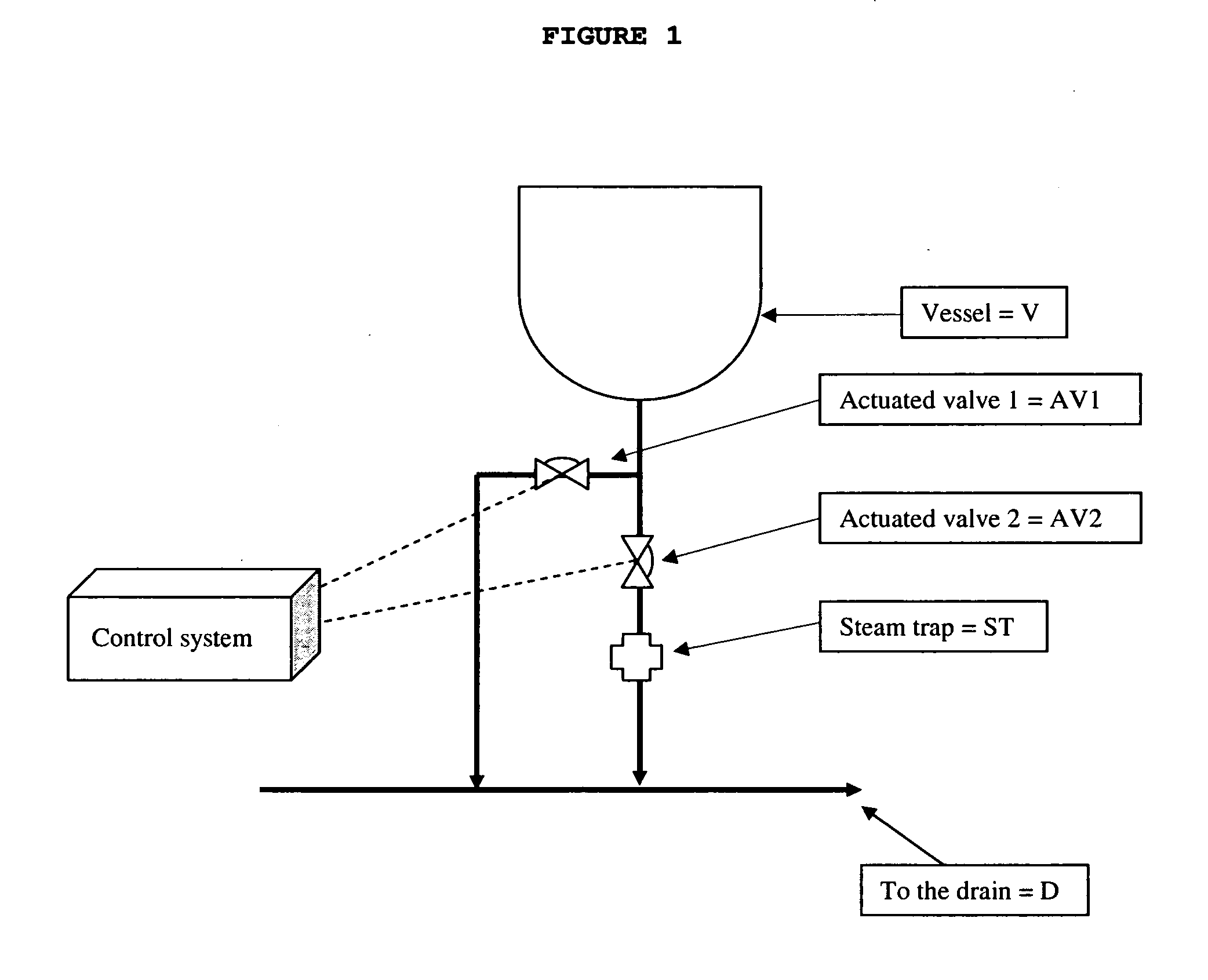

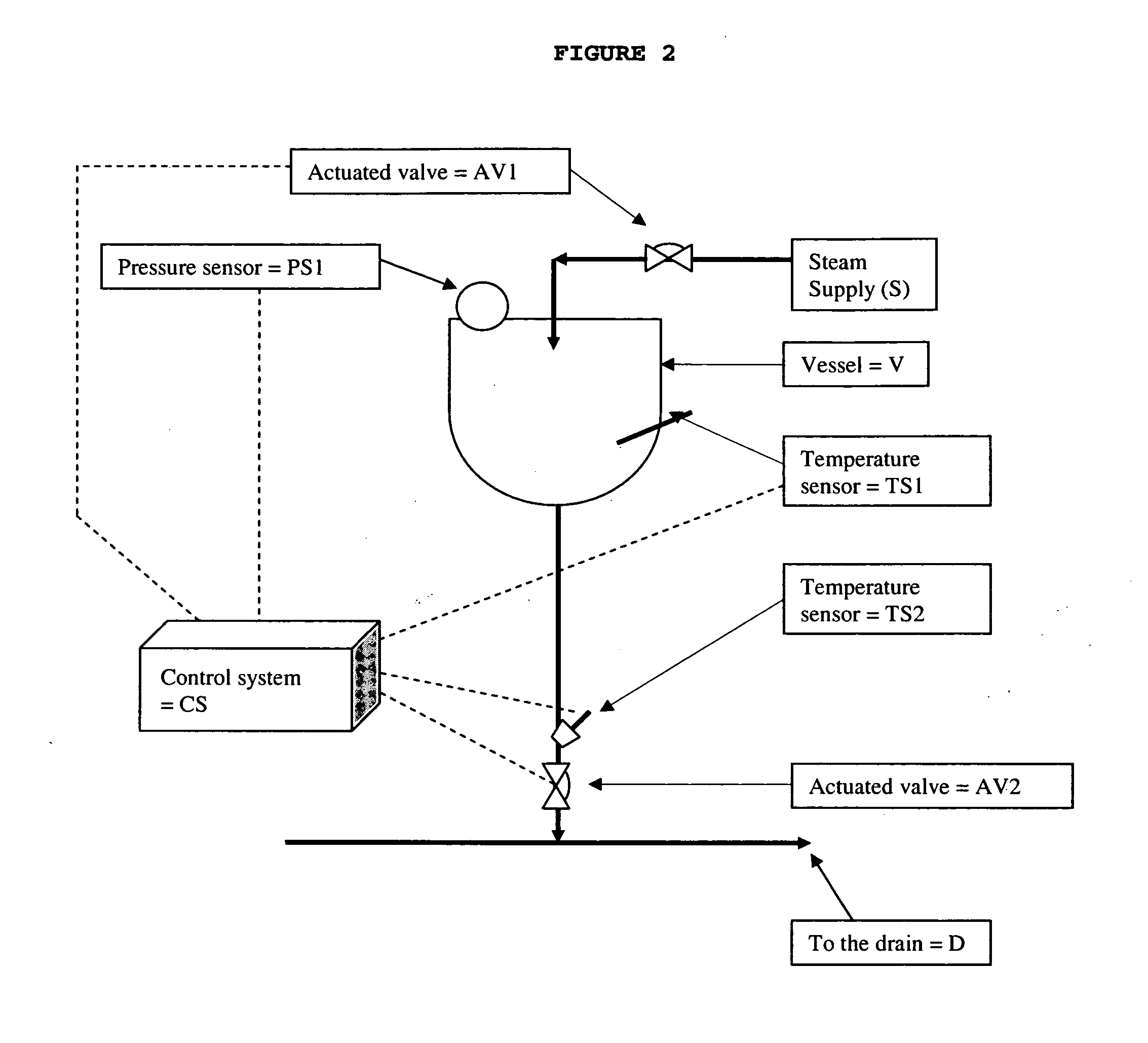

Programmable steam trap apparatus

An apparatus and a method for removing condensate and unwanted gas from vapor / liquid systems while preventing steam loss are provided. The steam trap apparatus replaces the automatic valve type steam trap with an efficient, controllable, and programmable steam trap. In addition, the improved steam trap apparatus allows for real-time data collection during sterilization and other operations.

Owner:TEVA PHARMA IND LTD

Trap with flush valve

The present application discloses a flying insect trapping device configured to be used with a fuel supply containing combustible fuel. One aspect of the invention provides a fuel regulator for controlling fuel flow in intermittent pulses and another aspect provides a valve for enabling flushing of the combustion device.

Owner:WOODSTREAM CORP +1

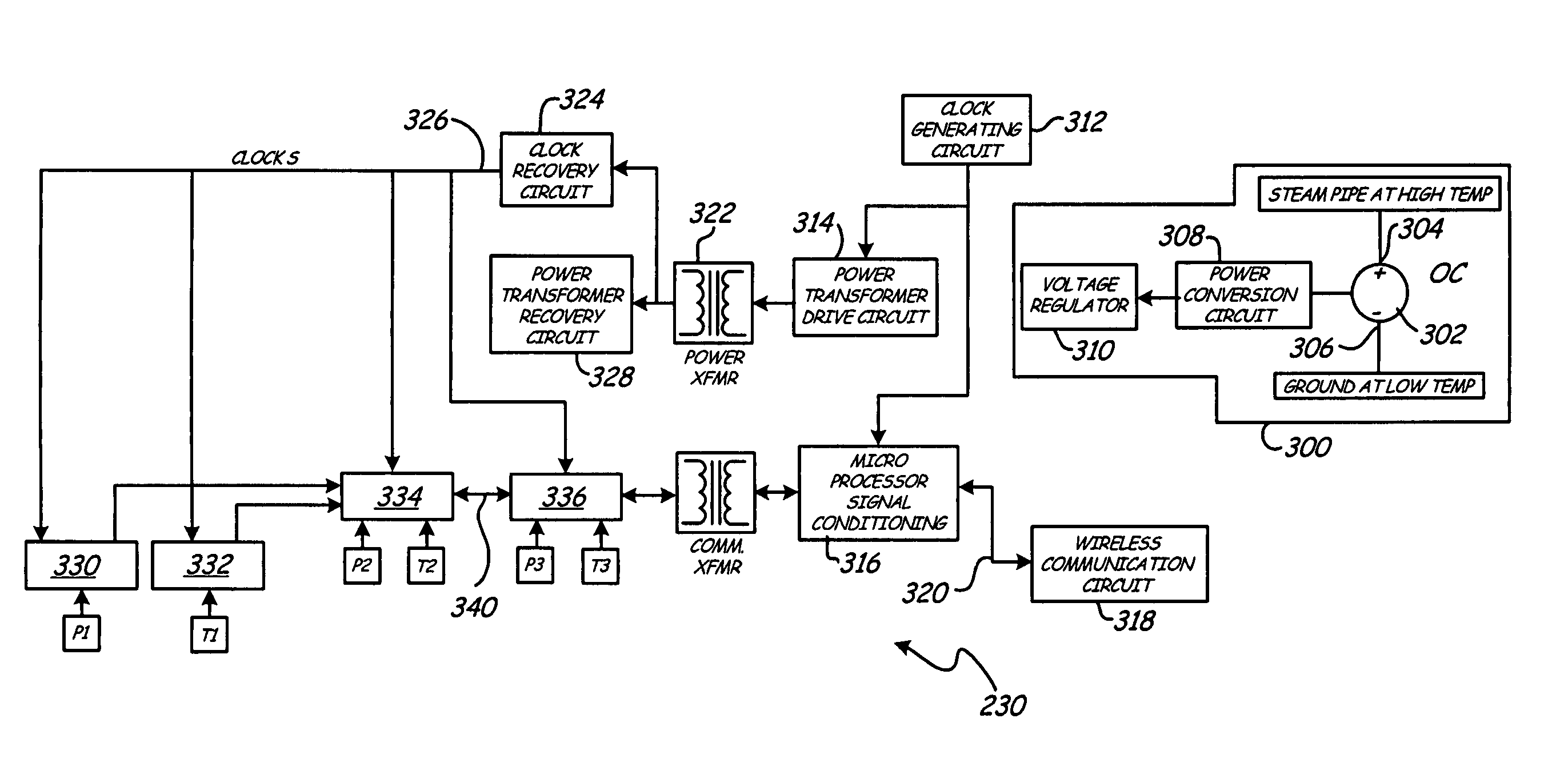

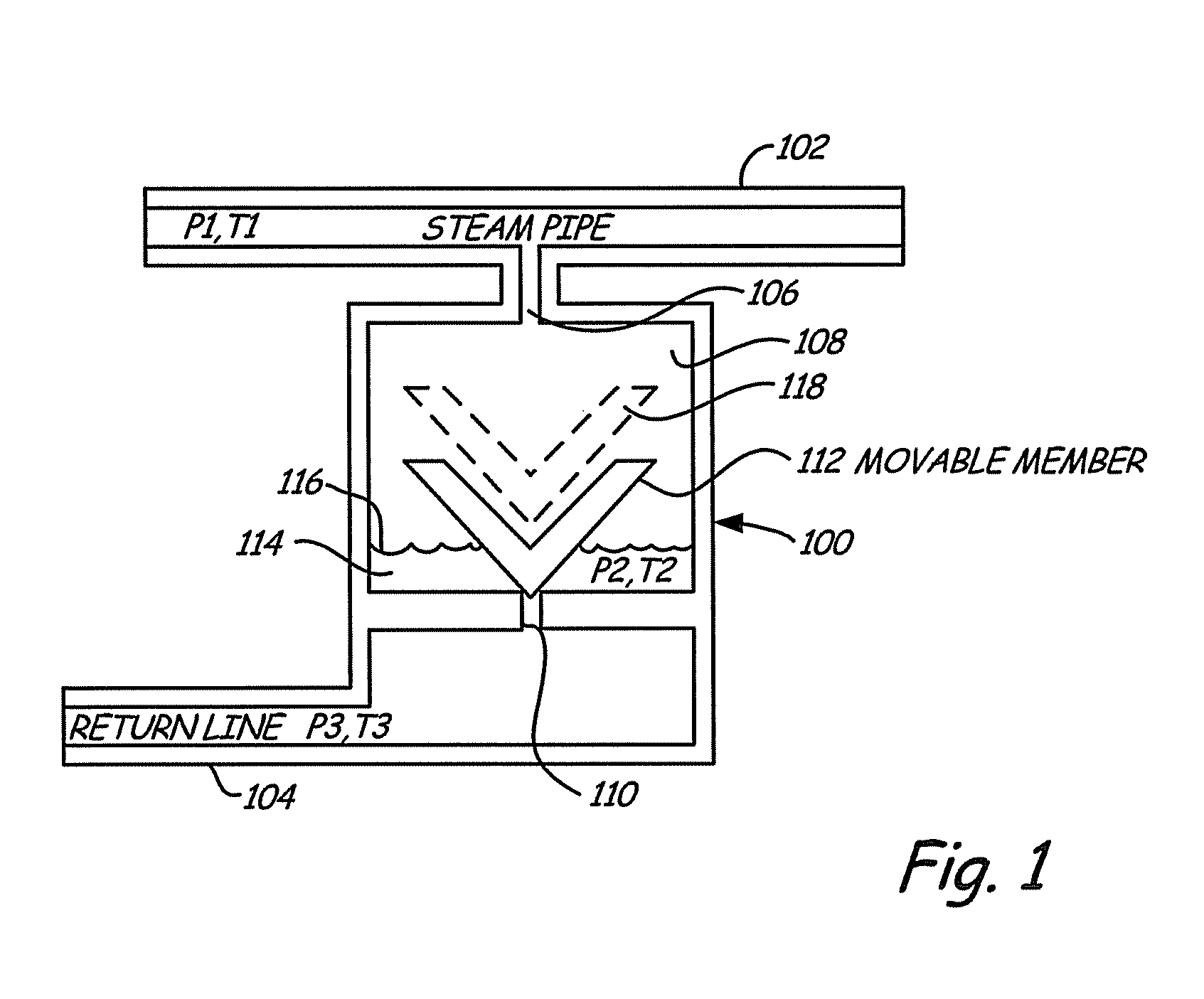

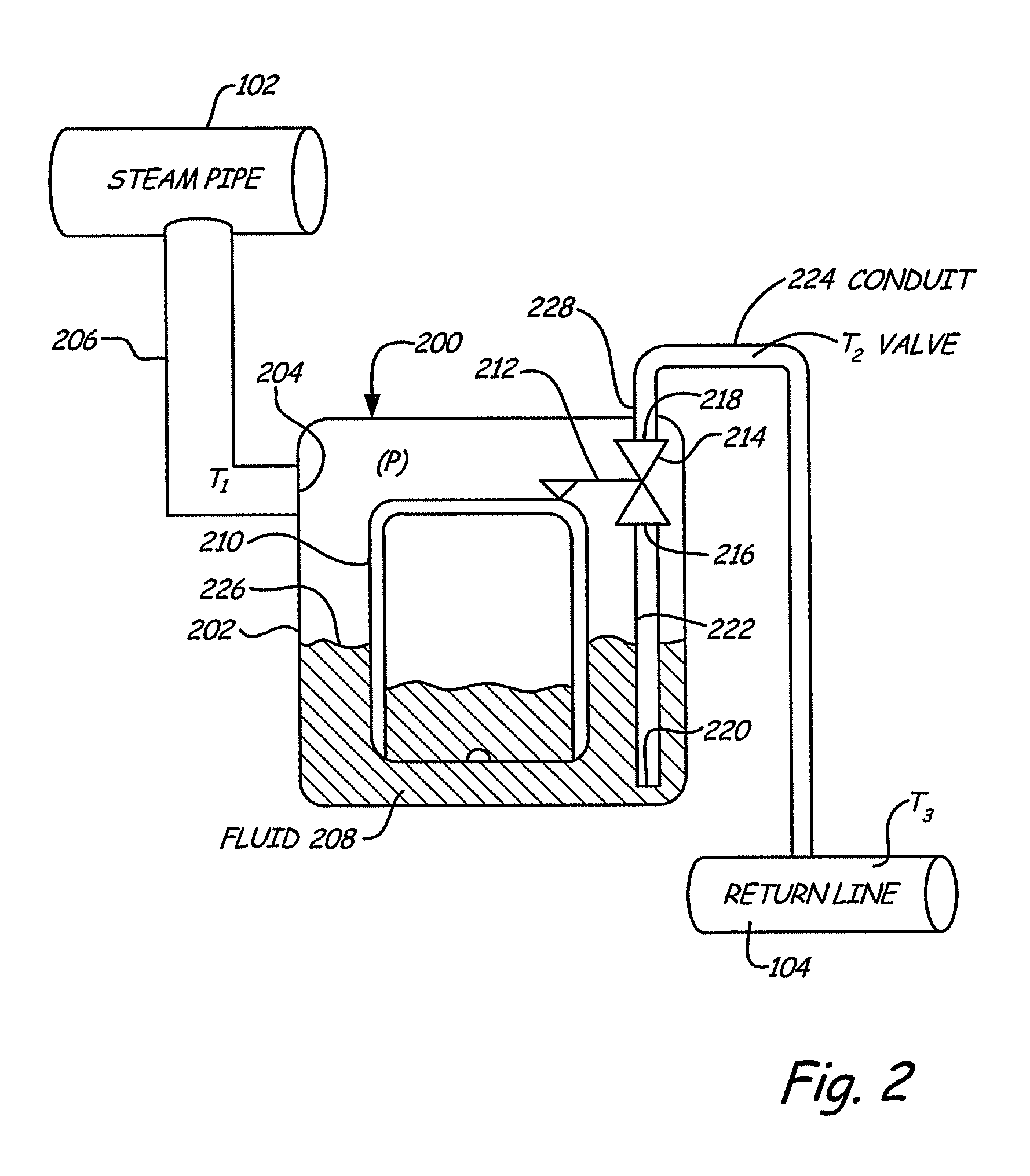

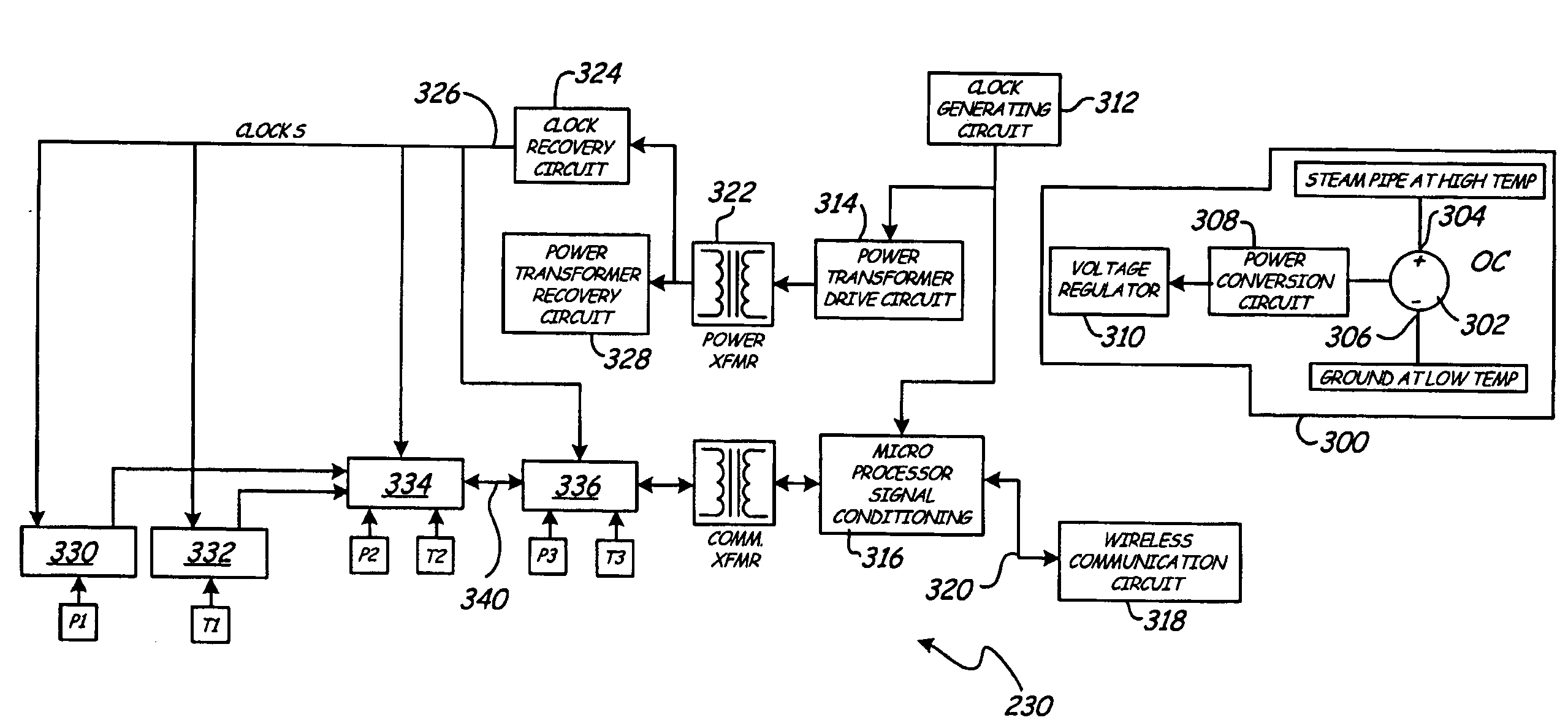

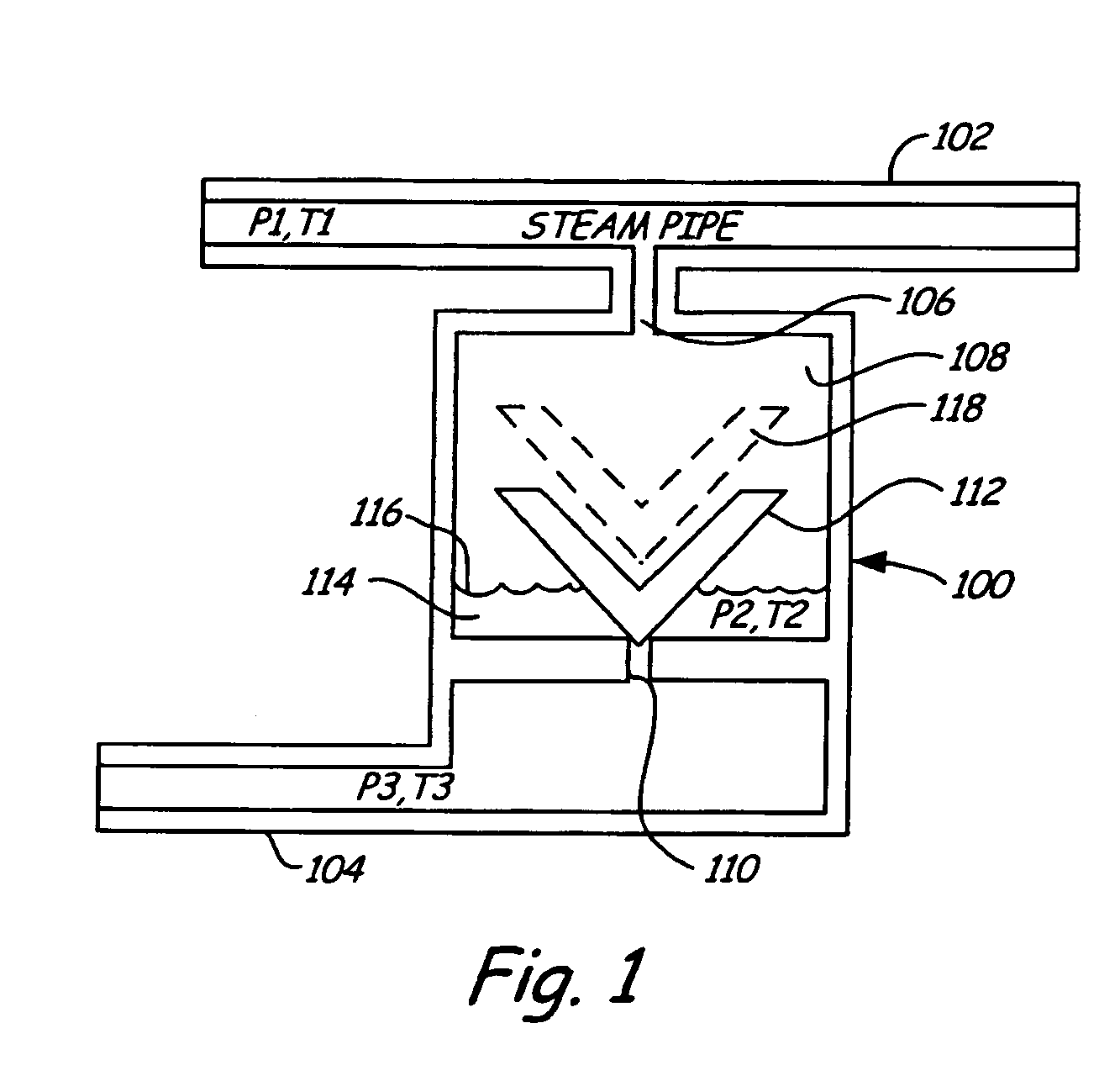

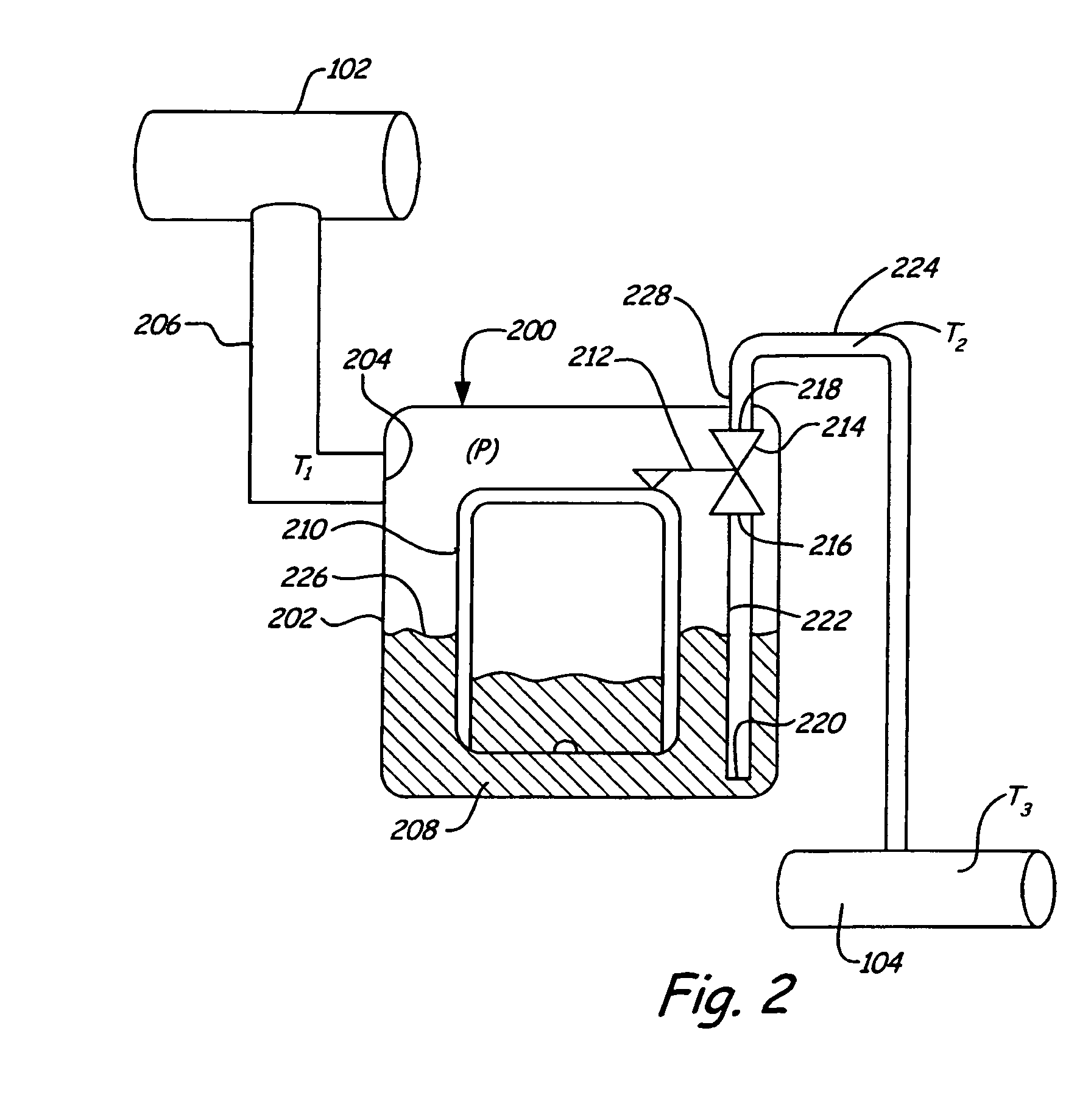

Remote monitor for steam traps

ActiveUS20060118647A1Temperature control without auxillary powerFlow propertiesEngineeringSteam trap

An apparatus and method for monitoring the status of at least one steam trap includes at least one monitor including at least one sensor for sensing at least one process condition of the steam trap; at least one means for calculating an average of the at least one monitored process condition; and, at least one transmitter for transmitting at least one signal responsive to the averaged monitored process condition.

Owner:ARMSTRONG INT INC

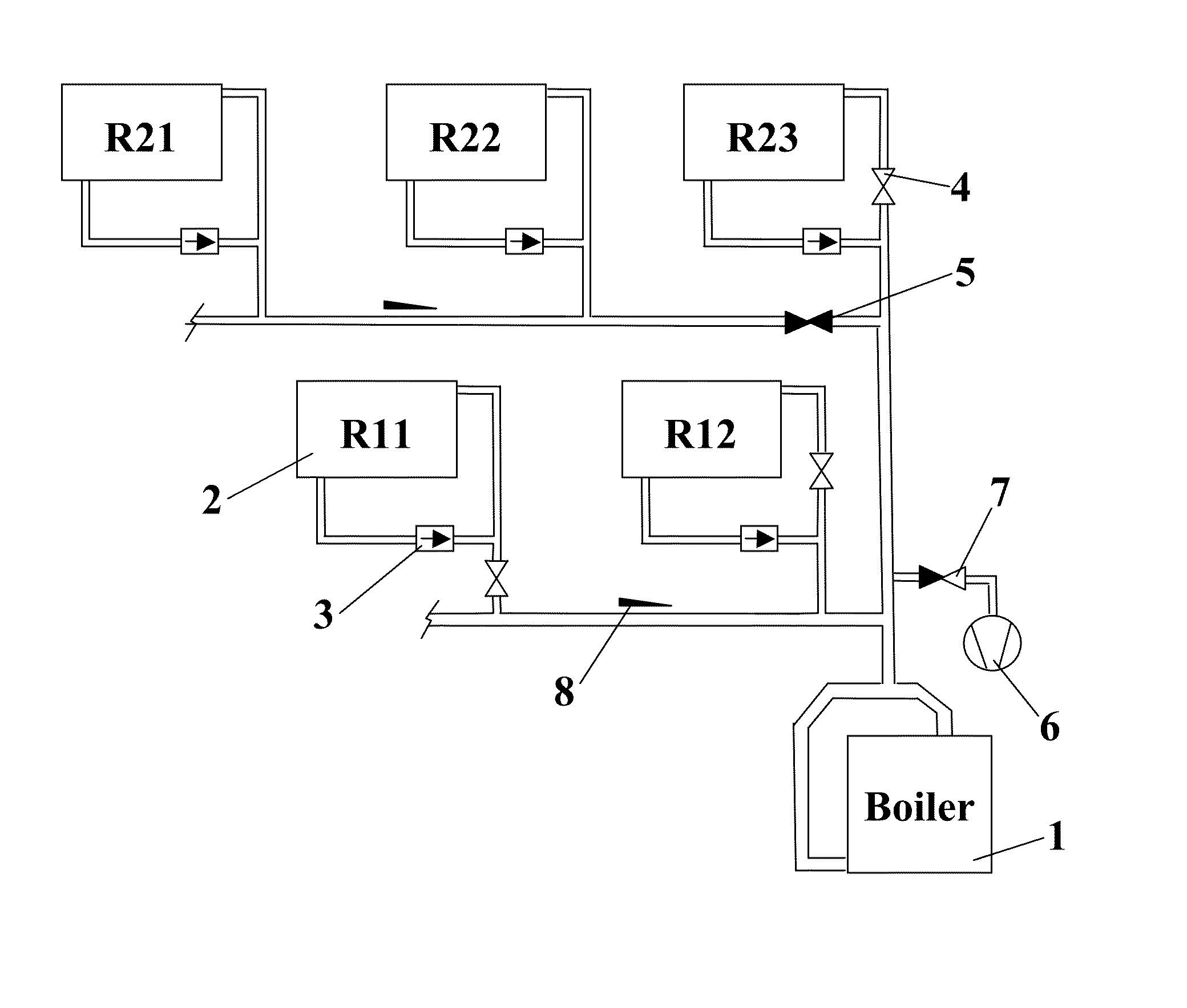

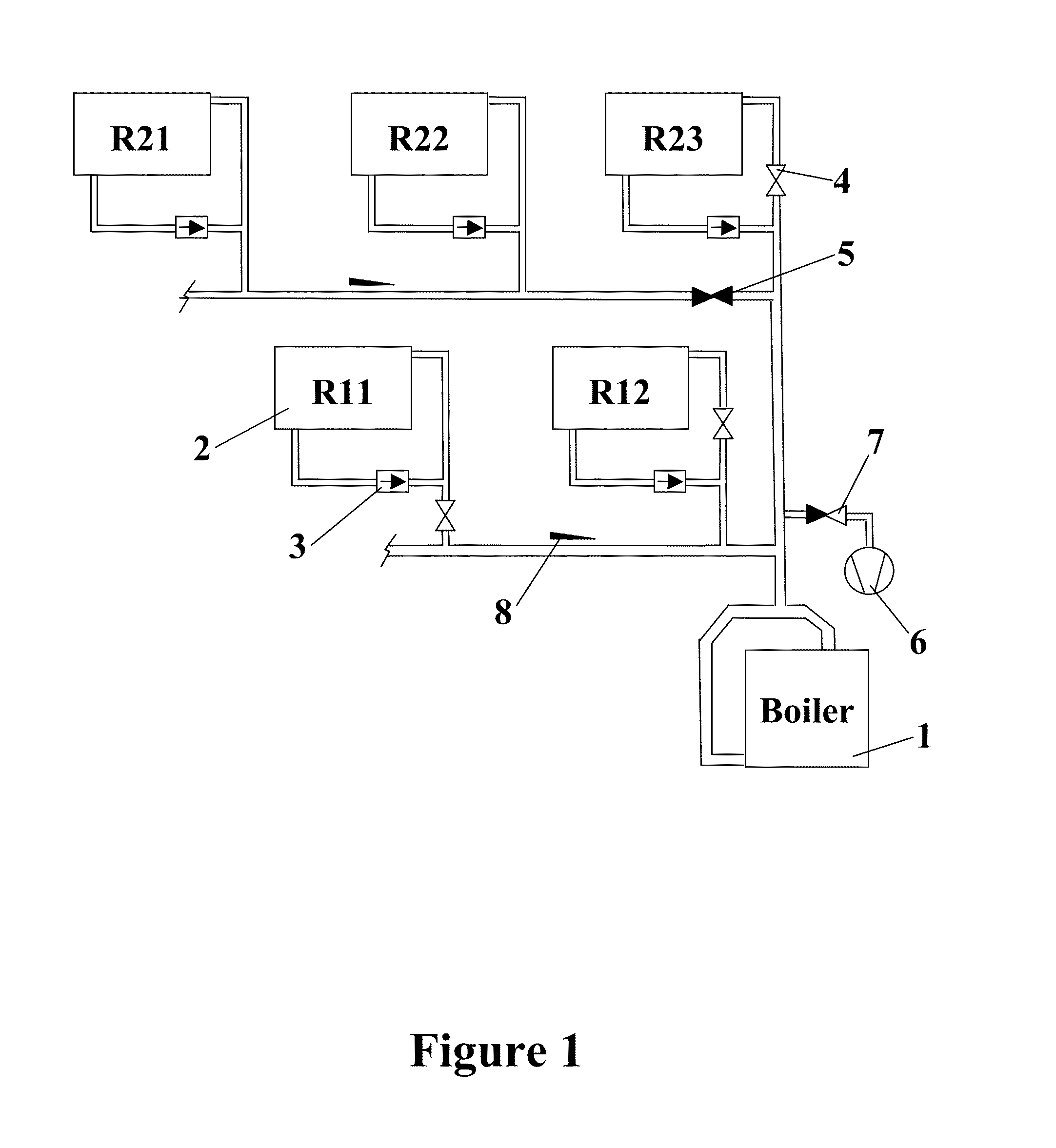

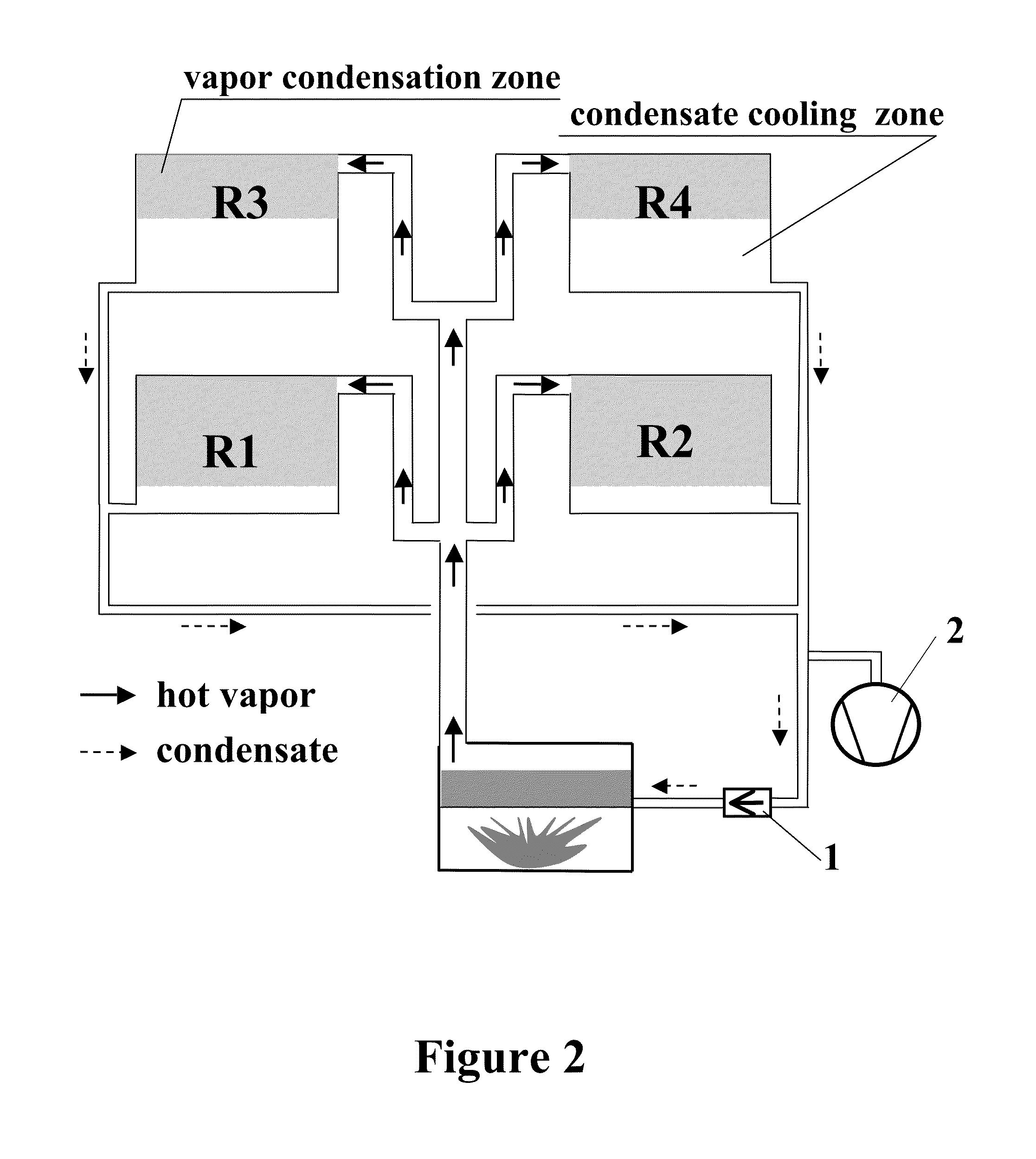

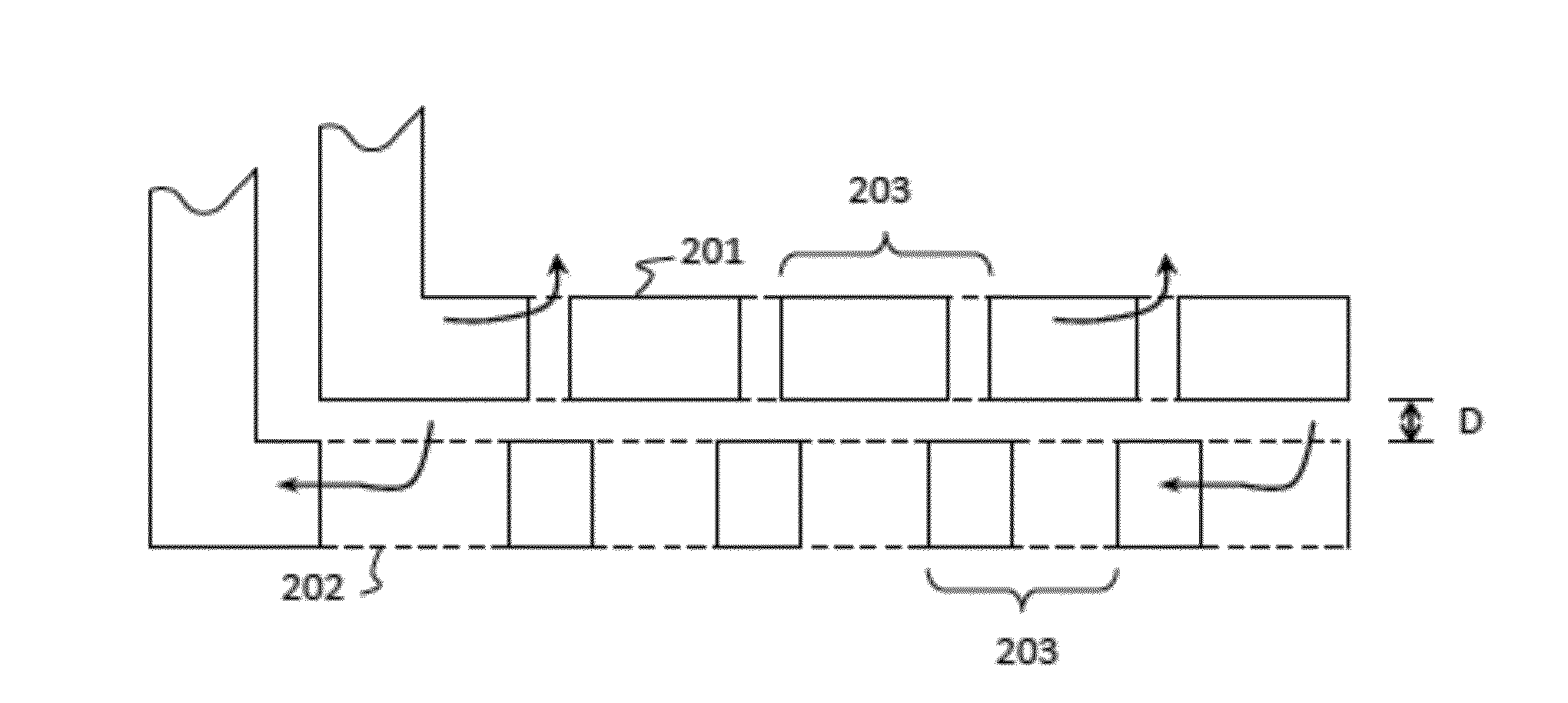

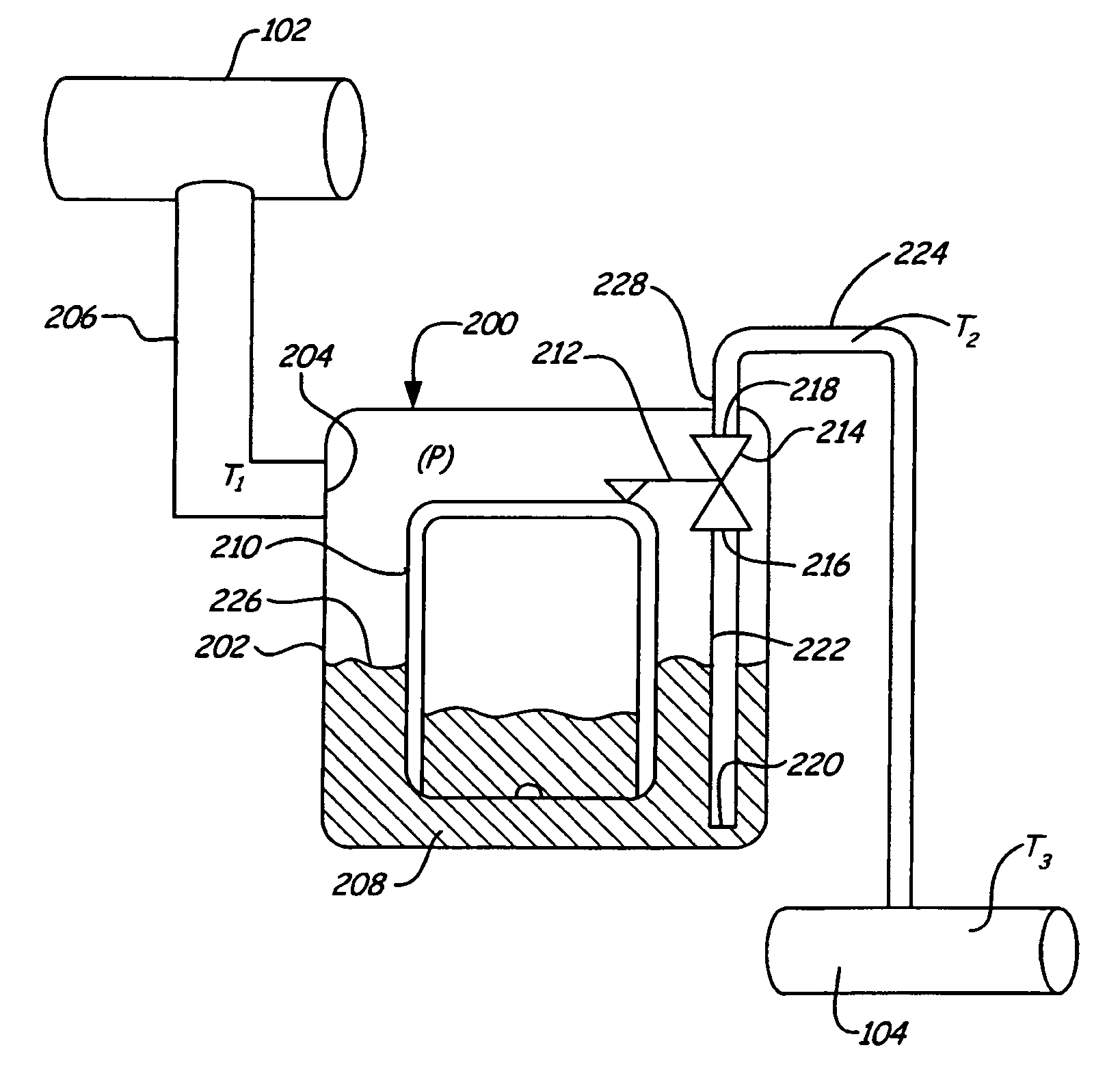

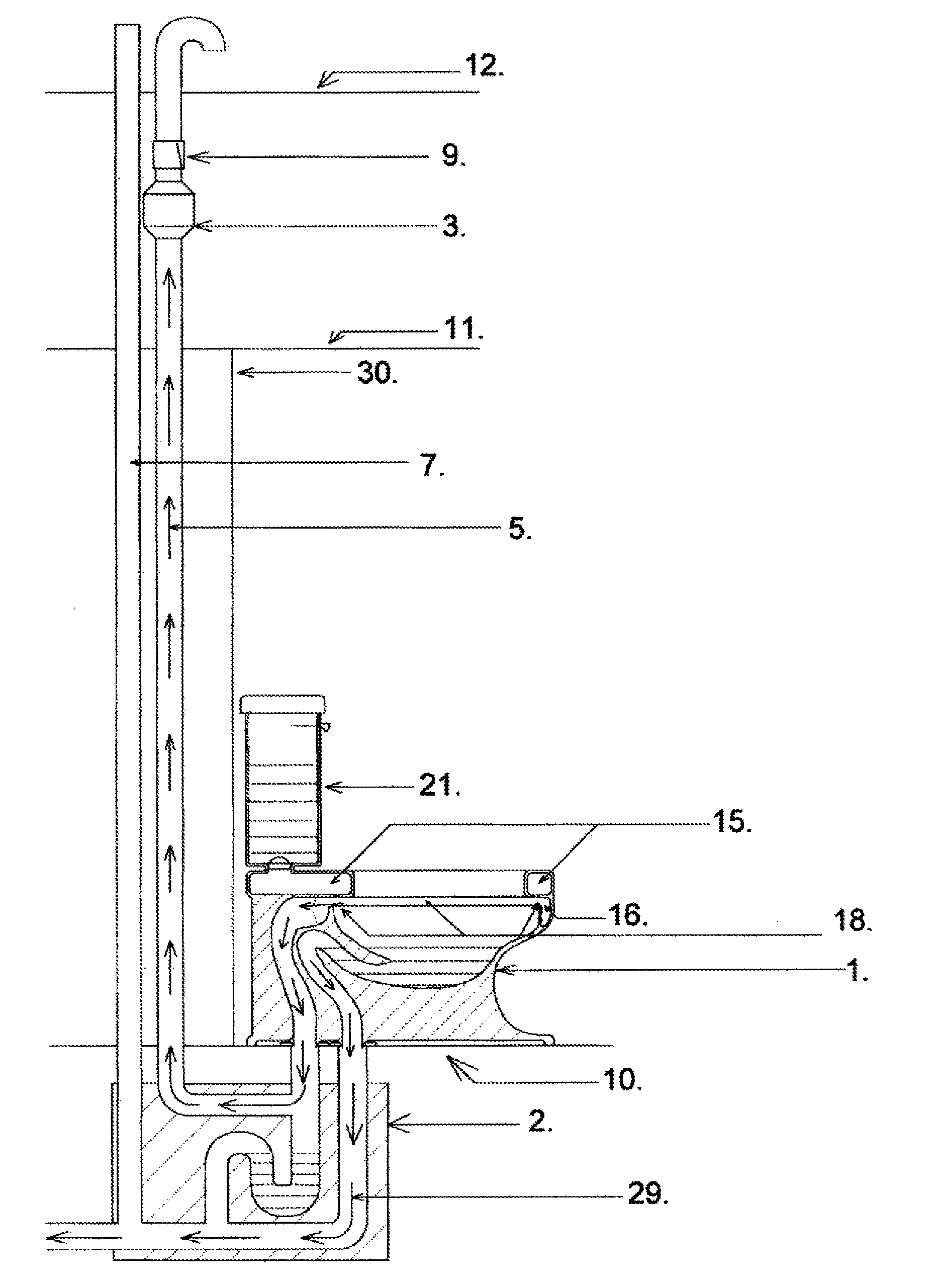

Vapor vacuum heating systems and integration with condensing vacuum boilers

ActiveUS20140034743A1Prevent backflowCentral heating componentsSteam useProcess engineeringSteam trap

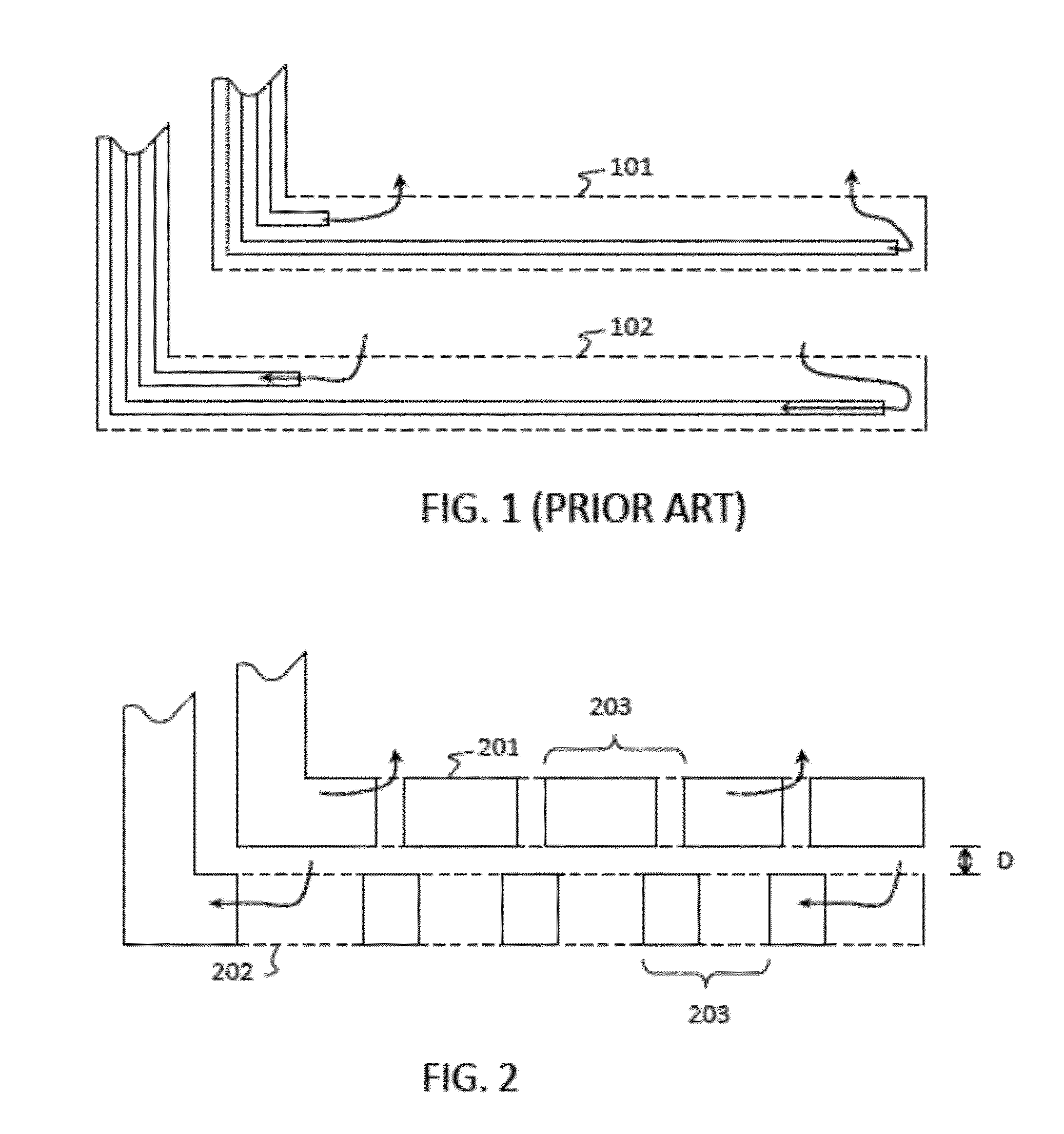

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, first presented is a novel system and method for a vapor vacuum system having low temperature condensate return which can operate without steam traps in both single-pipe and dual-pipe configurations. Secondly is disclosed systems and methods for integrating the disclosed vapor vacuum system with a condensing boiler. Thirdly is presented several systems and method of operating radiators having low temperature condensate return with the disclosed vapor vacuum system. Finally is presented condensing vacuum boiler designs that can be utilized with the disclosed vapor vacuum system. Also presented are embodiments having naturally-induced vacuum and utilizing district heat as well as combined heat and power. All innovations presented herein make vapor vacuum steam more efficient and economical for industrial, commercial, and home applications.

Owner:ZHADANOVSKY IGOR

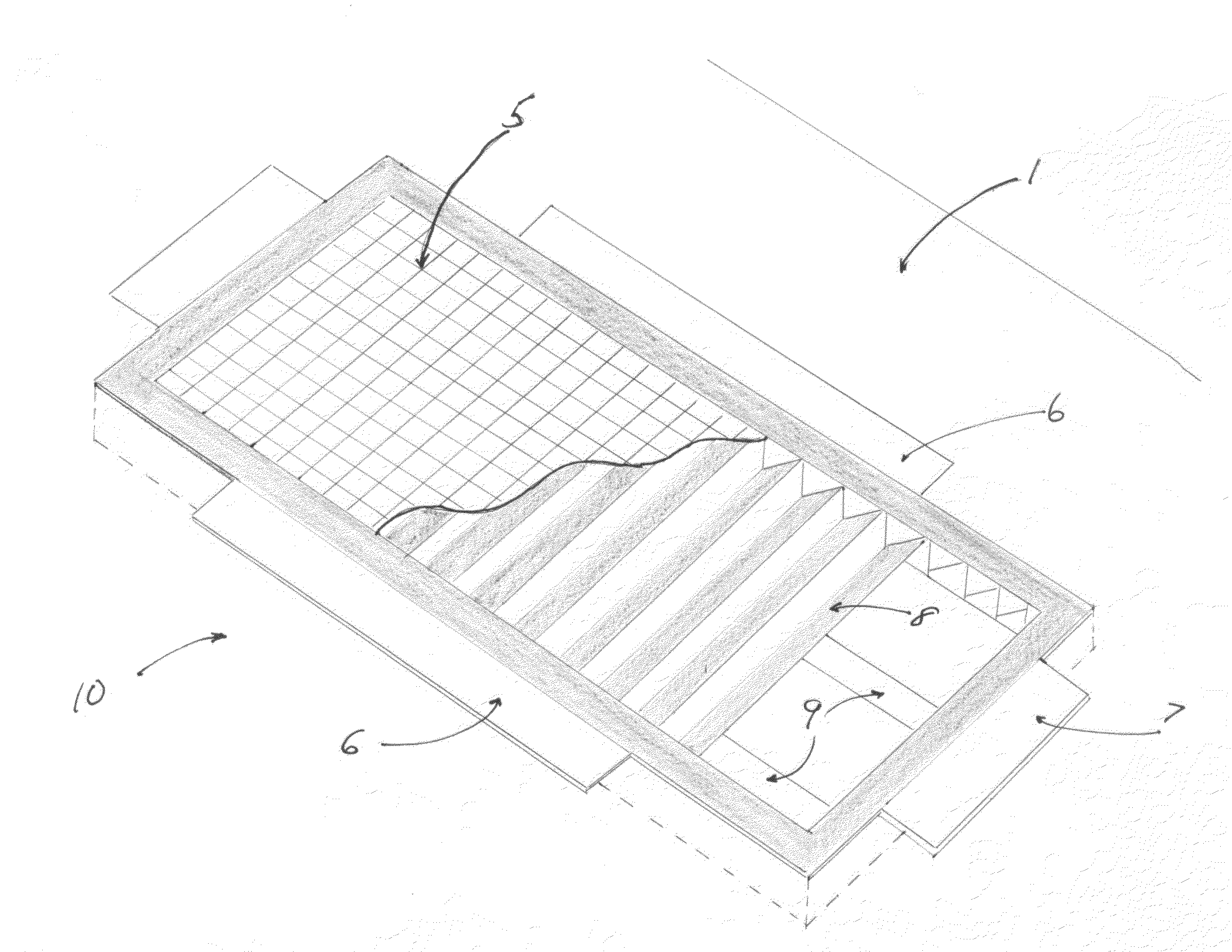

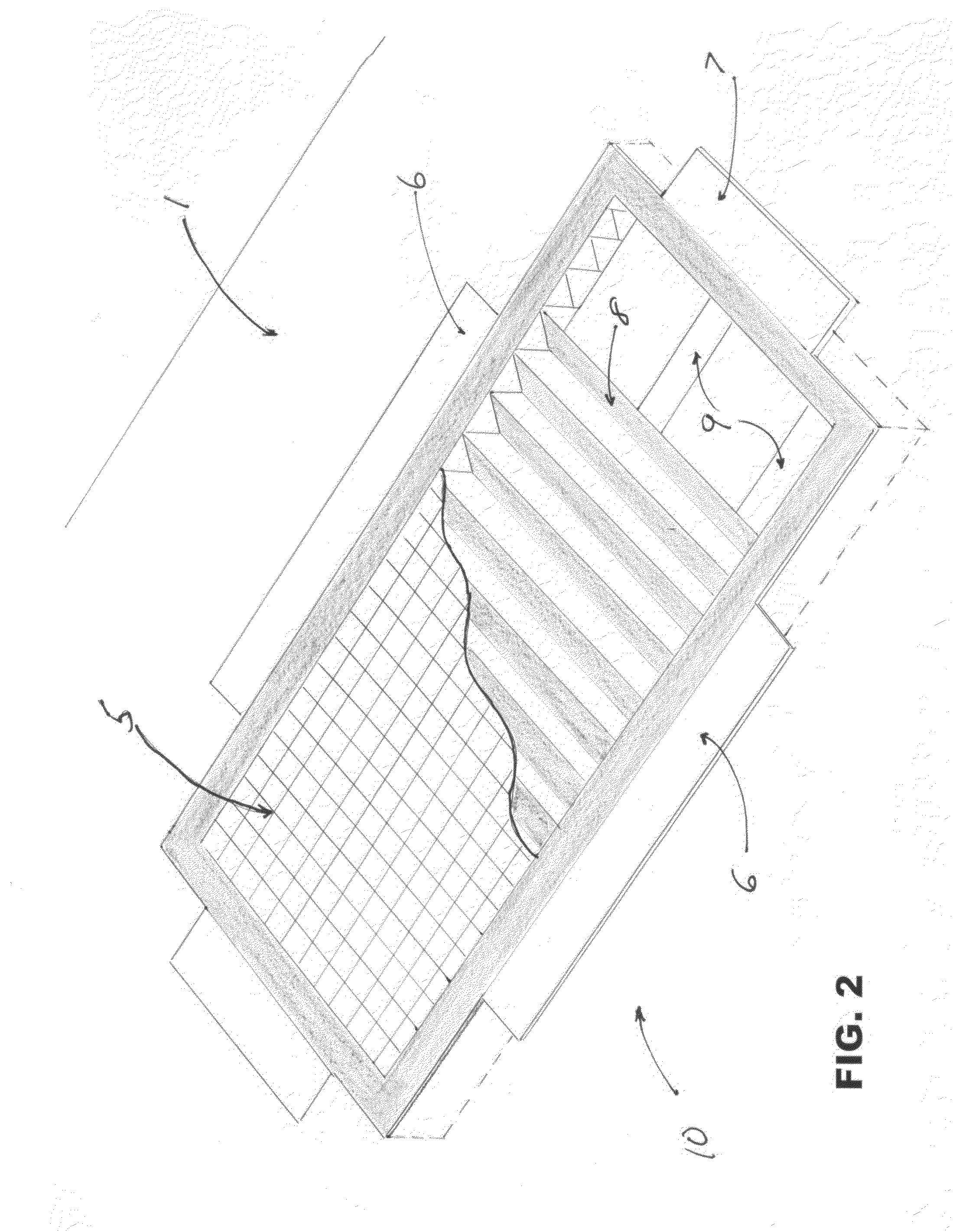

Debris trap and filter cover for vent opening

InactiveUS20080160903A1Easy to installImprove efficiencyDucting arrangementsLighting and heating apparatusAir filterSteam trap

A temporary debris trap and air filter which may be installed on floor vent openings in the early stages of home or commercial construction. After the floors are cut open for vent openings, the trap and filter is laid over the opening and easily affixed by adhesive strips on the flanges. The screen on top prevents construction debris from entering the duct boots and duct system and the filter below prevents dust and fine particles from entering the system while simultaneously allowing the free flow of cooled or heated air to enter the room area. The air will not be obstructed so the building and construction materials can be acclimatized during the construction period, the HVAC system can be tested and adjusted for proper air balance and the construction workers can breath filtered and conditioned air.

Owner:FONTANA RICHARD G

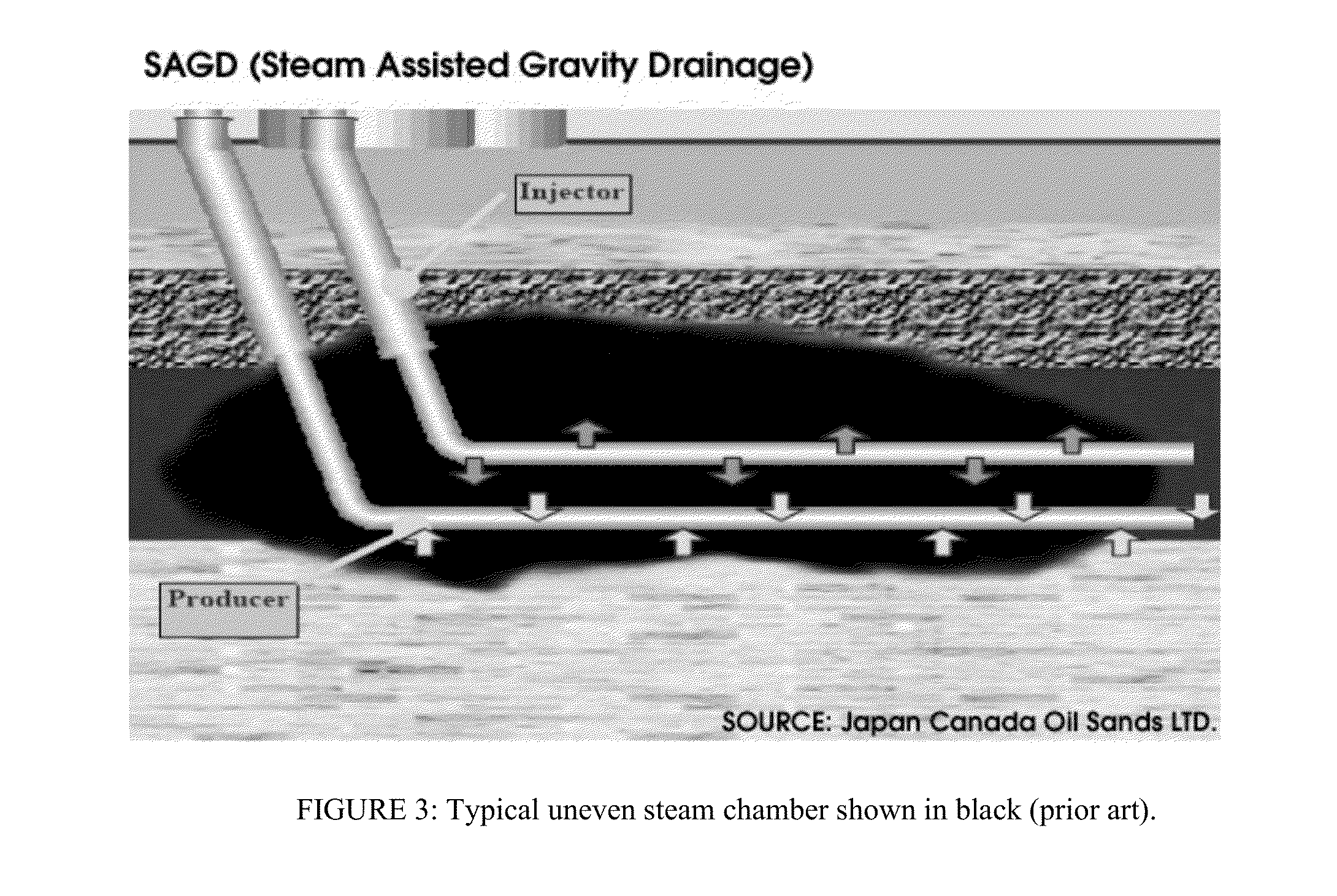

Sagd steam trap control

ActiveUS20130213652A1Reduce startup timeLow costFluid removalDrinking water installationStart up timeEngineering

This present disclosure describes methods and systems related to SAGD injection and / or production wells that utilize flow distribution control devices. Additionally, methods and systems using limited vertical spacing separating the wells are described. These methods and systems improve steam assisted gravity drainage (SAGD) oil production, reduce SAGD start-up time and costs, and improve overall SAGD performance.

Owner:CONOCOPHILLIPS CANADA RESOURCES +2

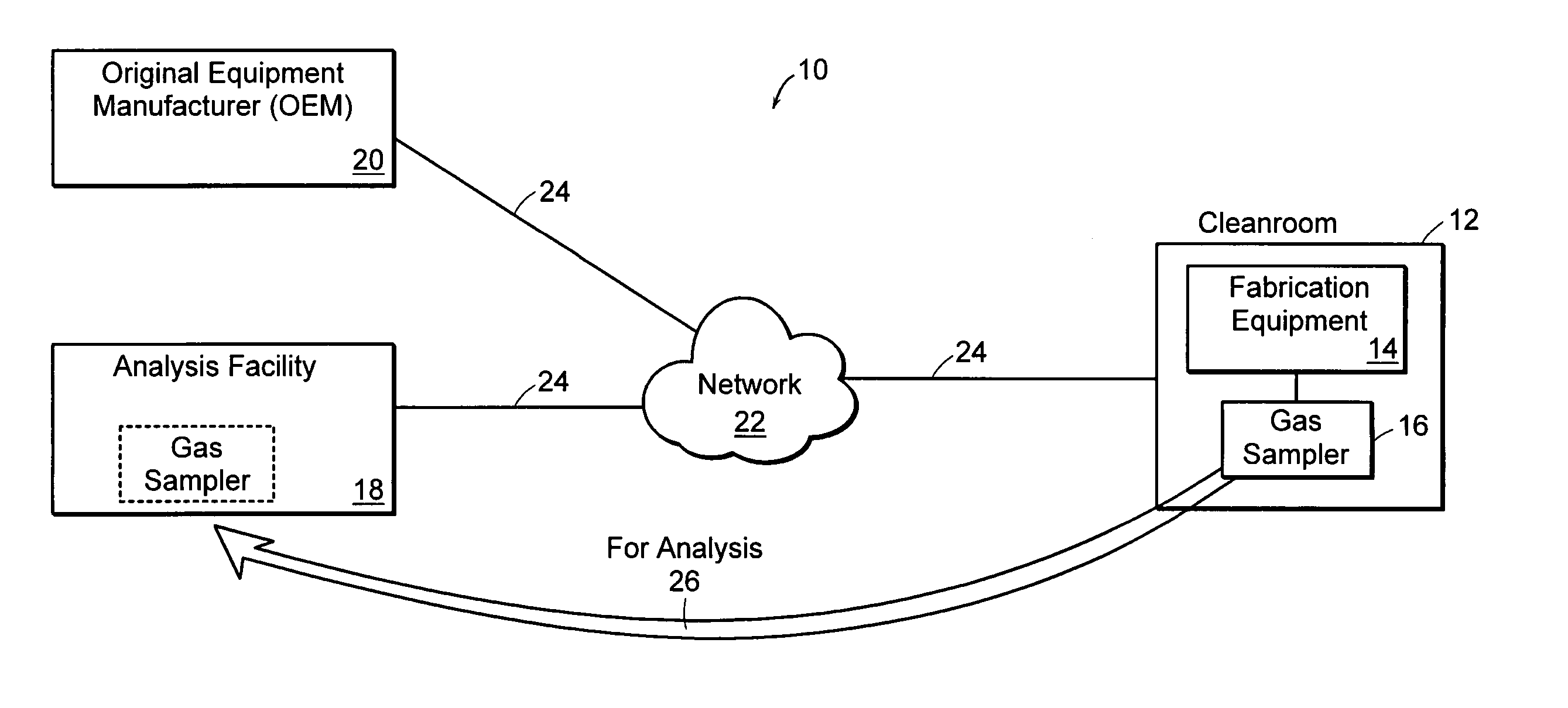

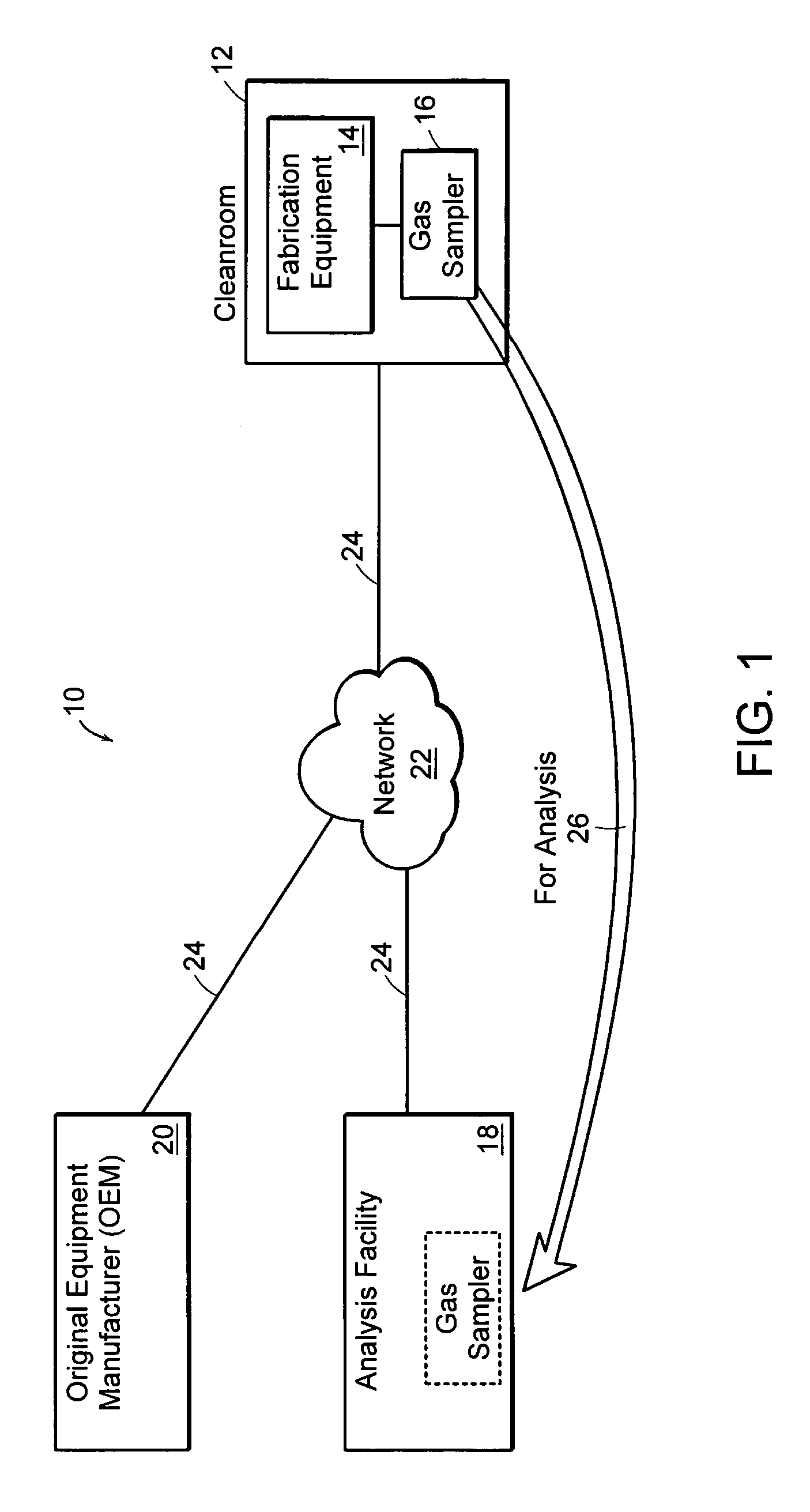

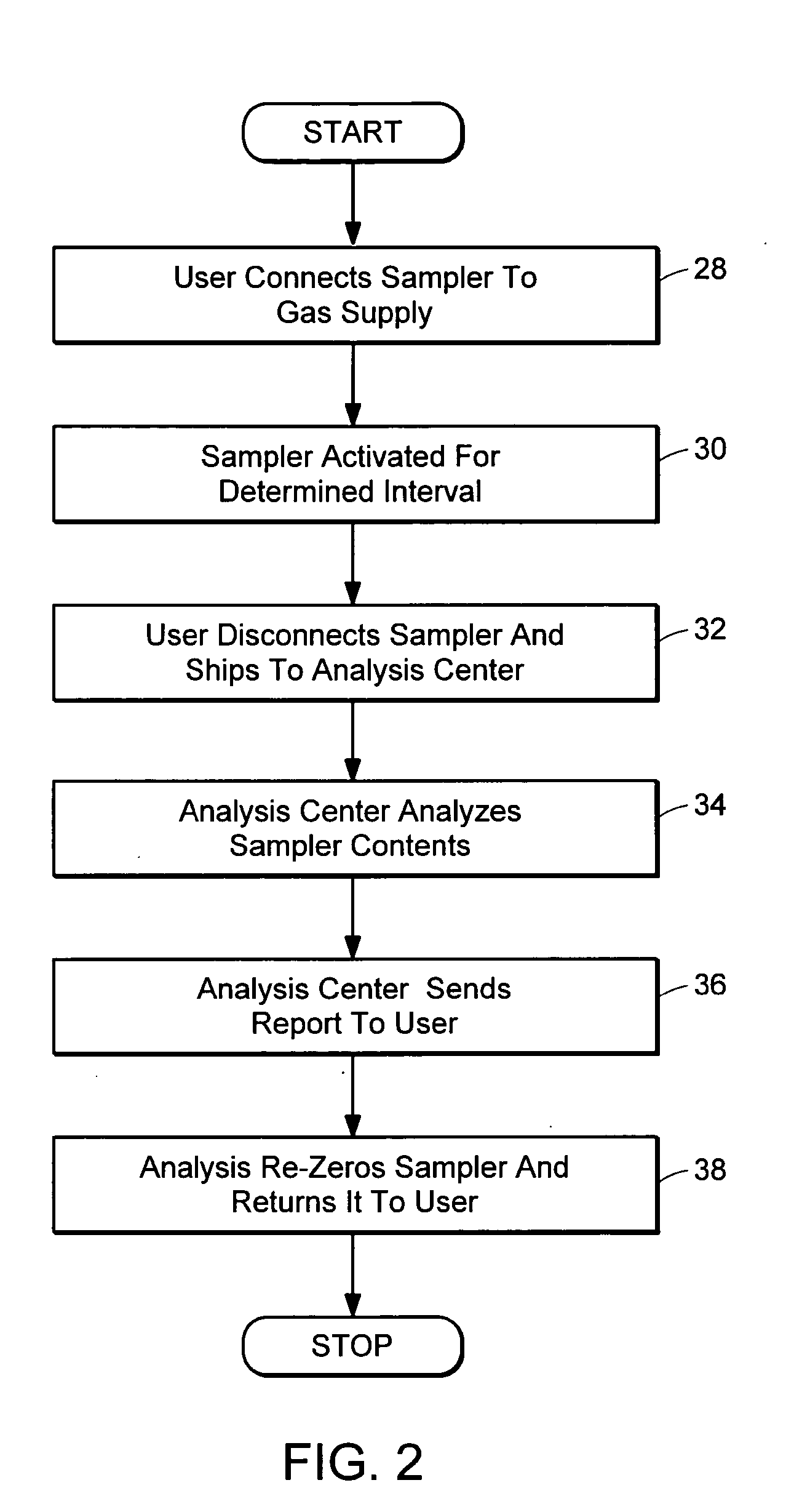

Systems and methods for detecting contaminants

InactiveUS20050120775A1Improve capture efficiencySemi-permeable membranesMembranesTenaxMulti pollutant

The present invention relates to a system and method for sampling a gas flow to measure one or more contaminants within a semiconductor processing tool. The system includes a portable unit containing one or more dry traps, Tenax traps and, if desired, wet impingers. The unit is coupled to a gas flow in a clean room and the dry traps. Tenax traps and wet impingers measure contaminants contained in the gas supply for a determined sampling interval. When the sampling interval is done, the unit is sent to an analysis facility for processing.

Owner:ENTEGRIS INC

Oven with Automatic Open/Closed System Mode Control

ActiveUS20140311360A1Reduce the possibilityAir-treating devicesDomestic stoves or rangesHigh humidityMode control

A commercial oven, such as a combination oven providing steam and convection heating, may provide for motorized dampers allowing the oven to move automatically between a closed-state high humidity operating mode and an open-state low humidity operating mode according to user input reflecting a desired cooking process. The dampers operate with a conventional steam trap and may provide integrated bypass valves preventing over or under pressure of the cooking volume.

Owner:ALTO SHAAM

Apparatus for removing dissolved and suspended contaminants from waste water

ActiveUS7686961B1Obstruct passageStop the flowWater cleaningFatty/oily/floating substances removal devicesWaste streamWastewater

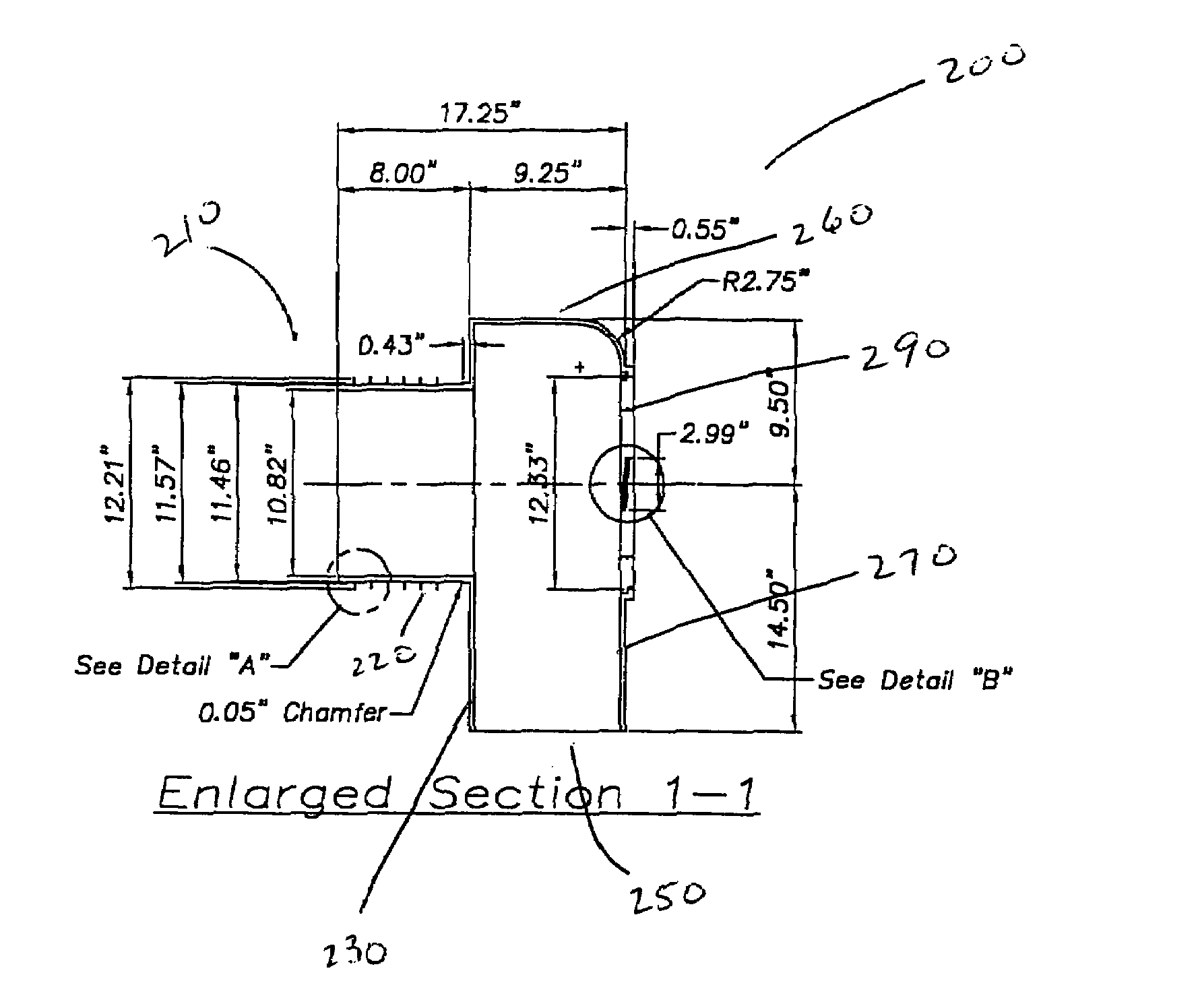

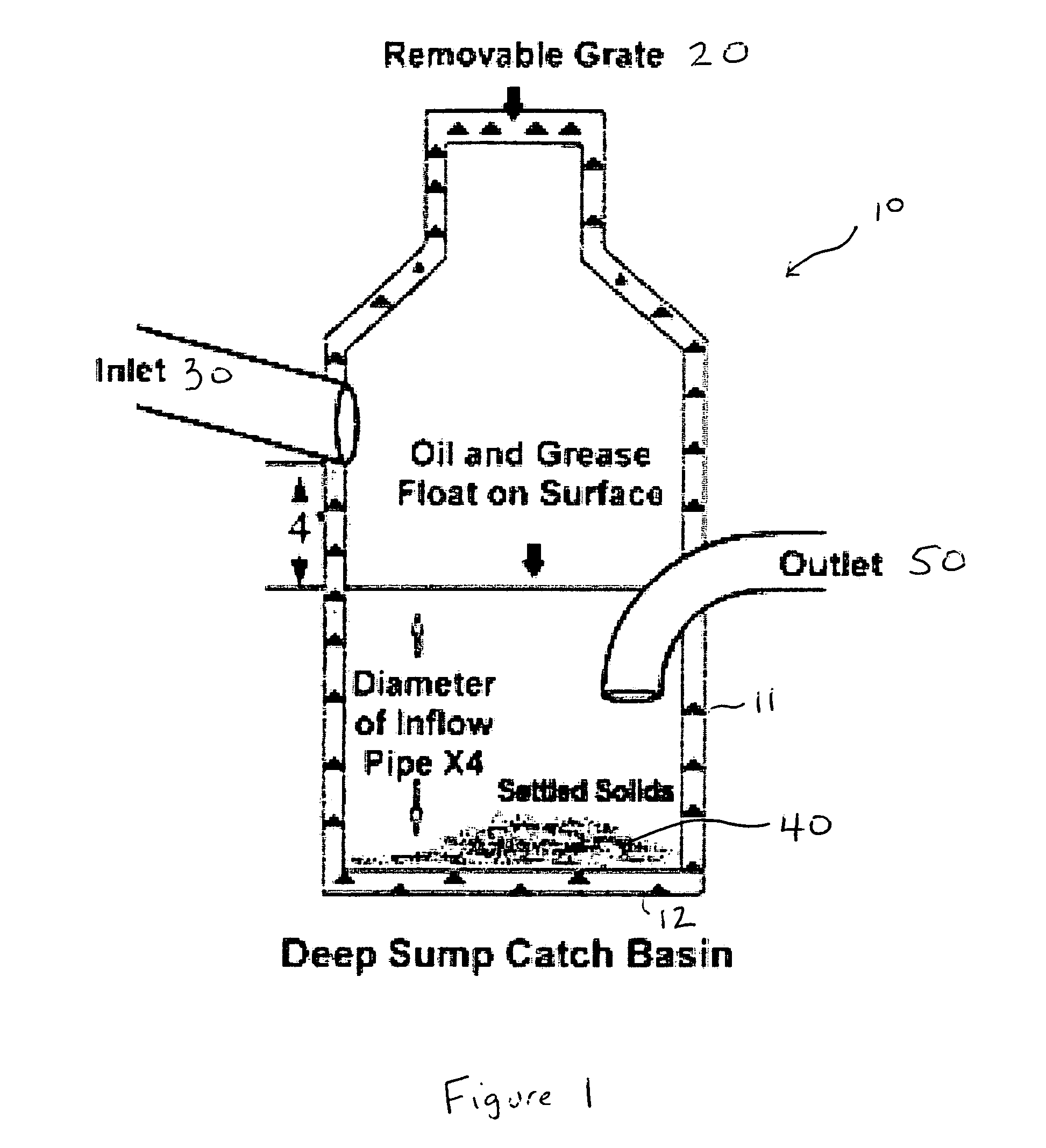

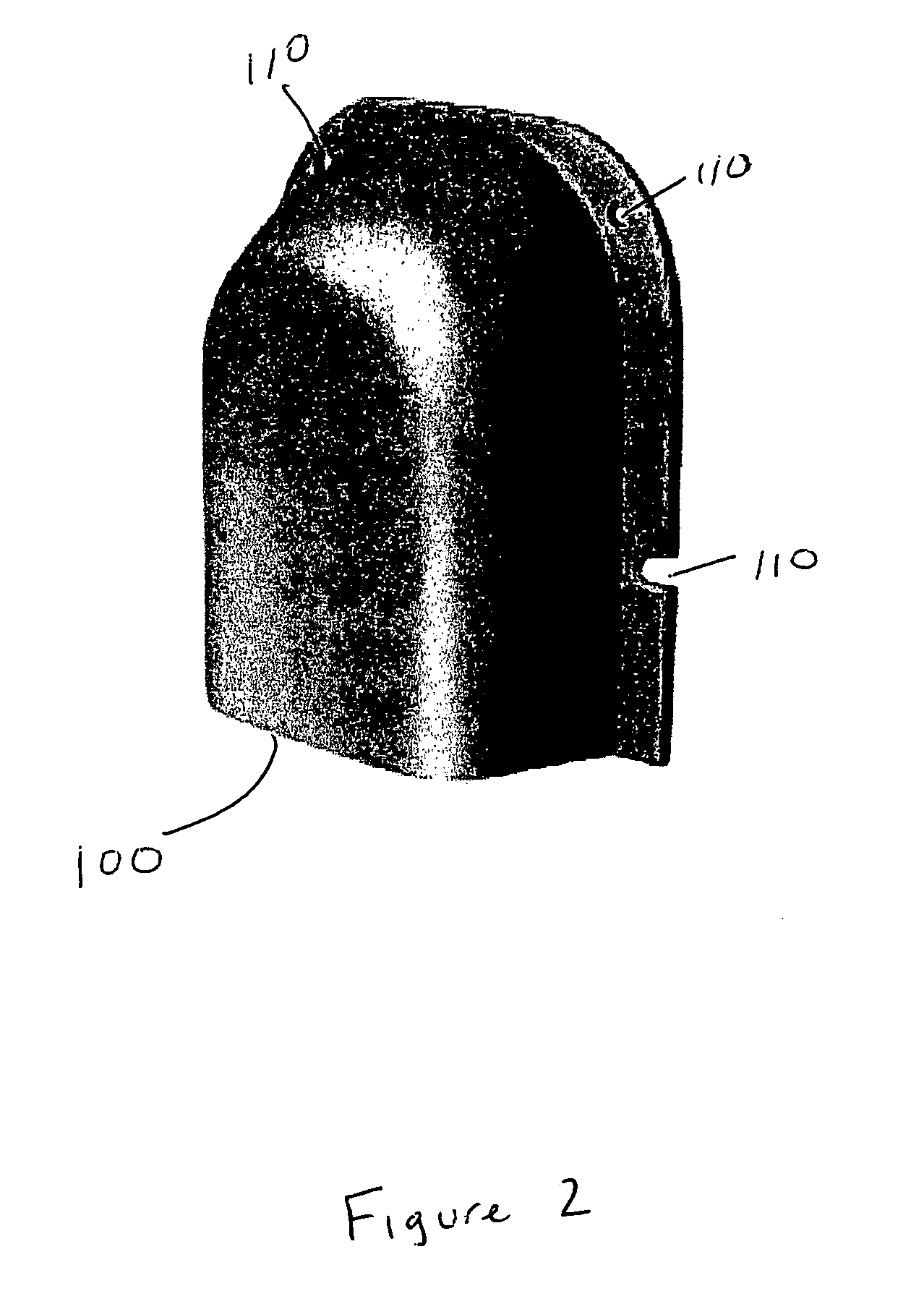

The present invention provides a method and apparatus for the treatment of waste water, particularly for the treatment and / or reduction of floating pollutants in storm water waste streams. The apparatus of the invention achieves a high containment level of floating pollutants compared to conventional oil / gas traps available for catch basin use. In a preferred embodiment, the device of the invention is a catch basin trap that arrests the flow of pollutants, particularly floating pollutants. The trap is designed and installed in such a manner that a sealed system is created, ensuring that all fluid flow (e.g., storm water discharge) must pass through the trap and cannot bypass the trap due to unreliable trap attachment mechanisms or unsealed joints. Containment of floating pollutants is achieved.

Owner:GLYNNE MICHAEL J

Steam trap monitoring

Electronic steam trap monitoring is disclosed. An electronic steam trap monitor is operably coupled to an outlet of a steam trap and is configured to measure at least one process variable of fluid (liquid or gas) flowing through the trap, when the trap is known to be working normally. The steam trap monitor stores the process variable information obtained during the known operating condition for later comparison. The steam trap monitor obtains a later process variable measurement and compares it to the stored measurement to selectively generate a leakage indication. The steam trap monitor preferably uses a local power source and communicates wirelessly.

Owner:ROSEMOUNT INC

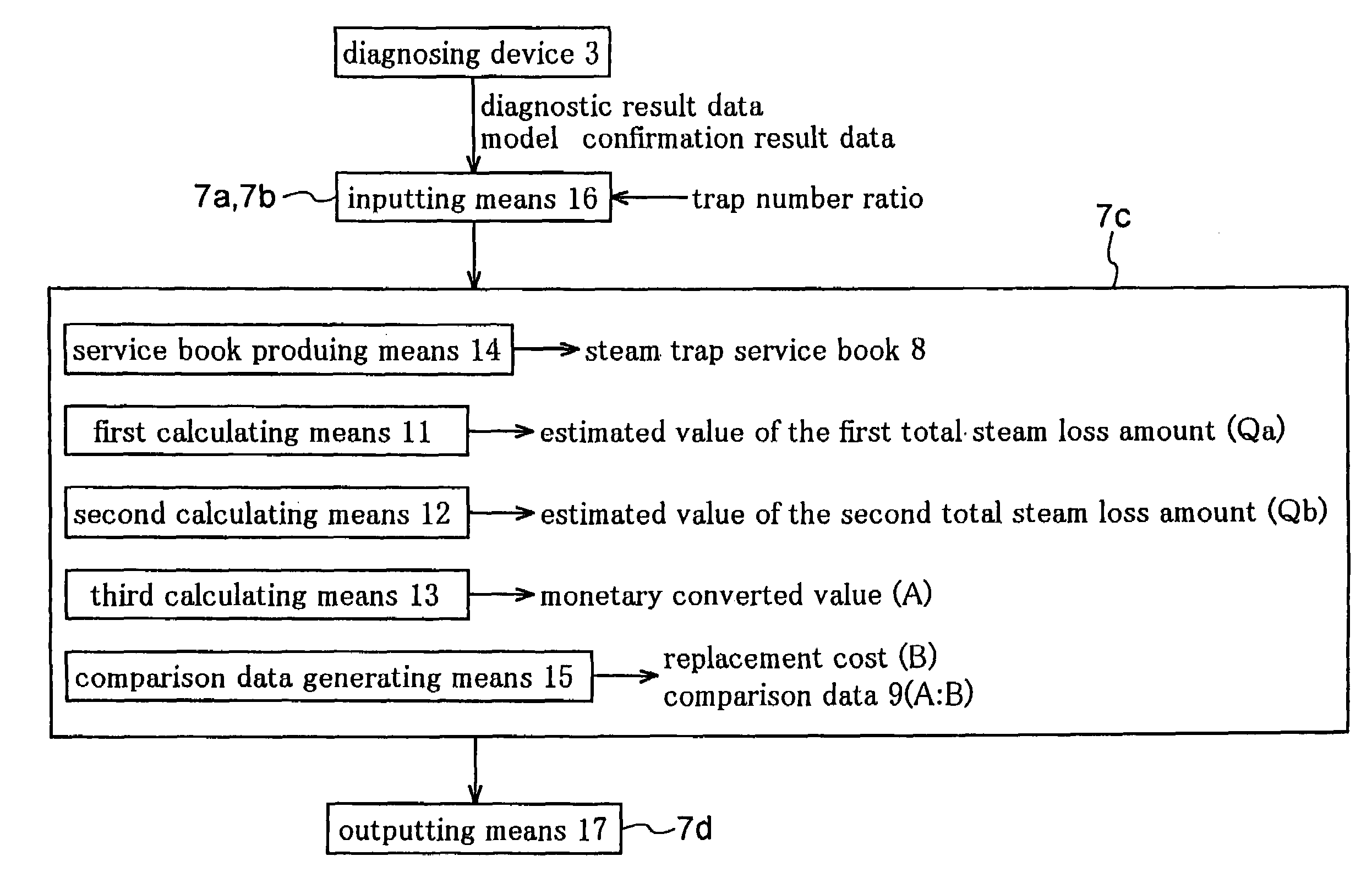

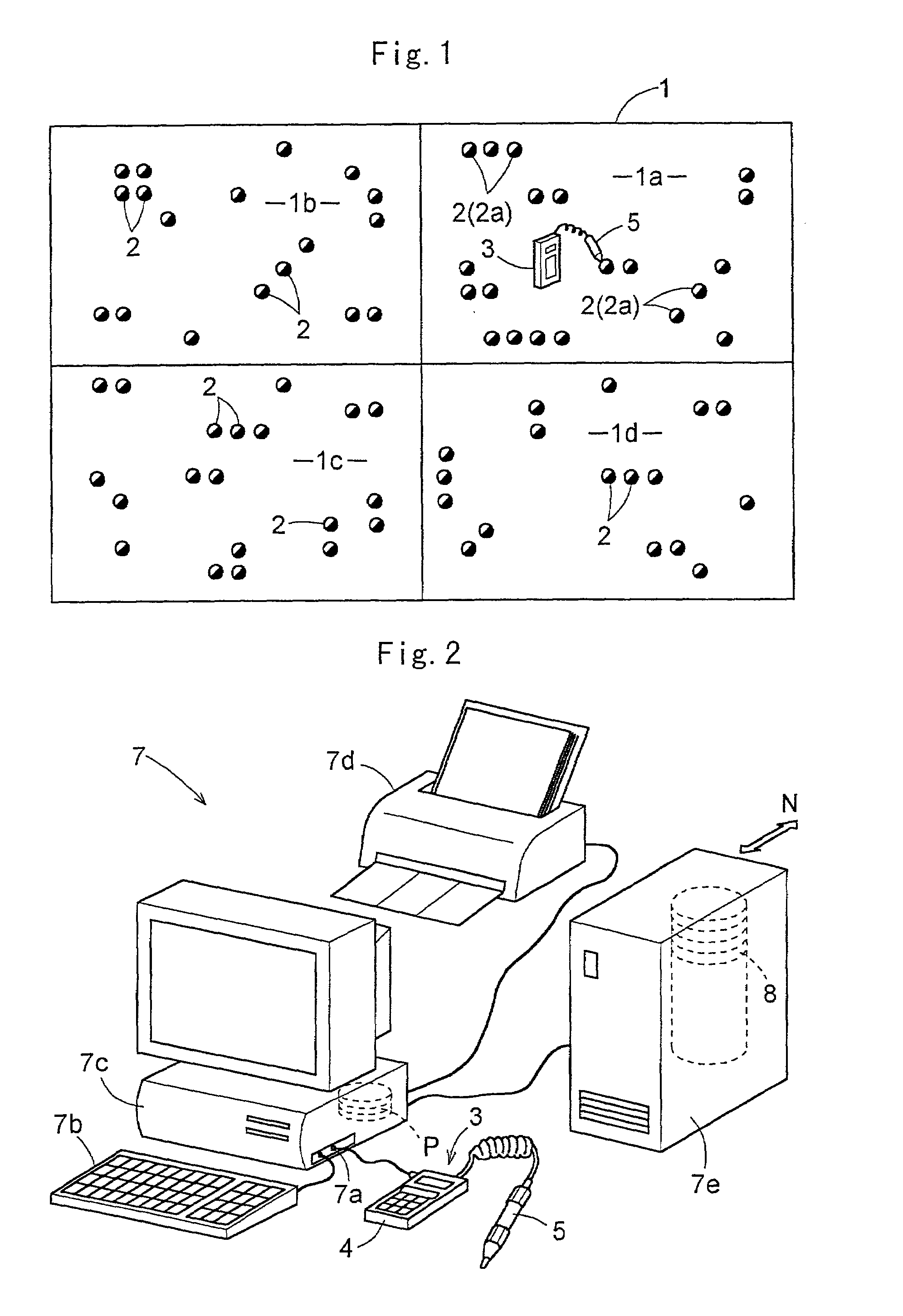

Method of supporting sales and maintenance of steam traps and aggregating system for use in the method

ActiveUS7130804B2Easy to implementEasy to operateRegistering/indicating machine productionNuclear monitoringSteam trapEngineering

Disclosed is a system for supporting sales and maintenance activities of steam traps by a seller of the traps to a customer. The system utilizes an aggregating system which effects a step of inputting stored diagnostic result data and model confirmation result data from a diagnostic device which has diagnosed a working condition of each of a plurality of existing steam traps installed in a customer's plant. Based on the diagnostic result data, a first total steam loss amount due to malfunction of steam traps is calculated, the first total steam loss amount comprising aggregation of steam leak amounts of all the existing steam traps. Based on the model confirmation result data, a second total steam loss amount is calculated, which comprises aggregation of differences between inherent steam leak amounts of the existing steam traps under their normal working conditions and inherent steam leak amounts of recommended steam traps under their normal working conditions. A monetary conversion value of an integrated value of a sum of the first total steam loss amount and the second total steam loss amount integrated for a predetermined period is calculated. Comparison data is generated allowing comparison between the monetary converted value and a replacement cost required for lump-sum replacement of all the existing steam traps by the recommended steam traps. The comparison data is outputted for presentation to the customer in sales and / or maintenance activities of the recommended steam traps.

Owner:TLV CO LTD

Steam trap monitoring

Owner:ROSEMOUNT INC

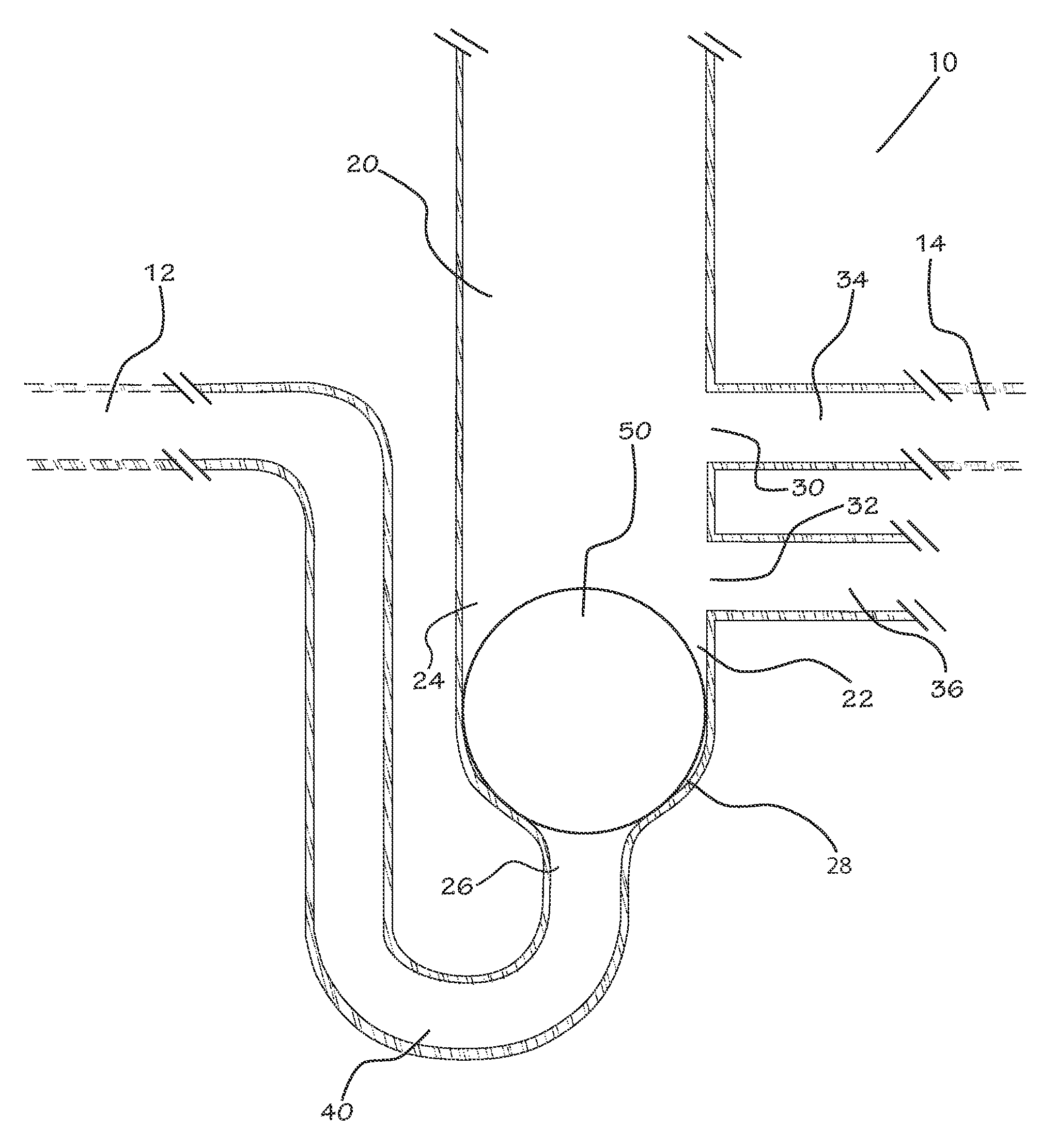

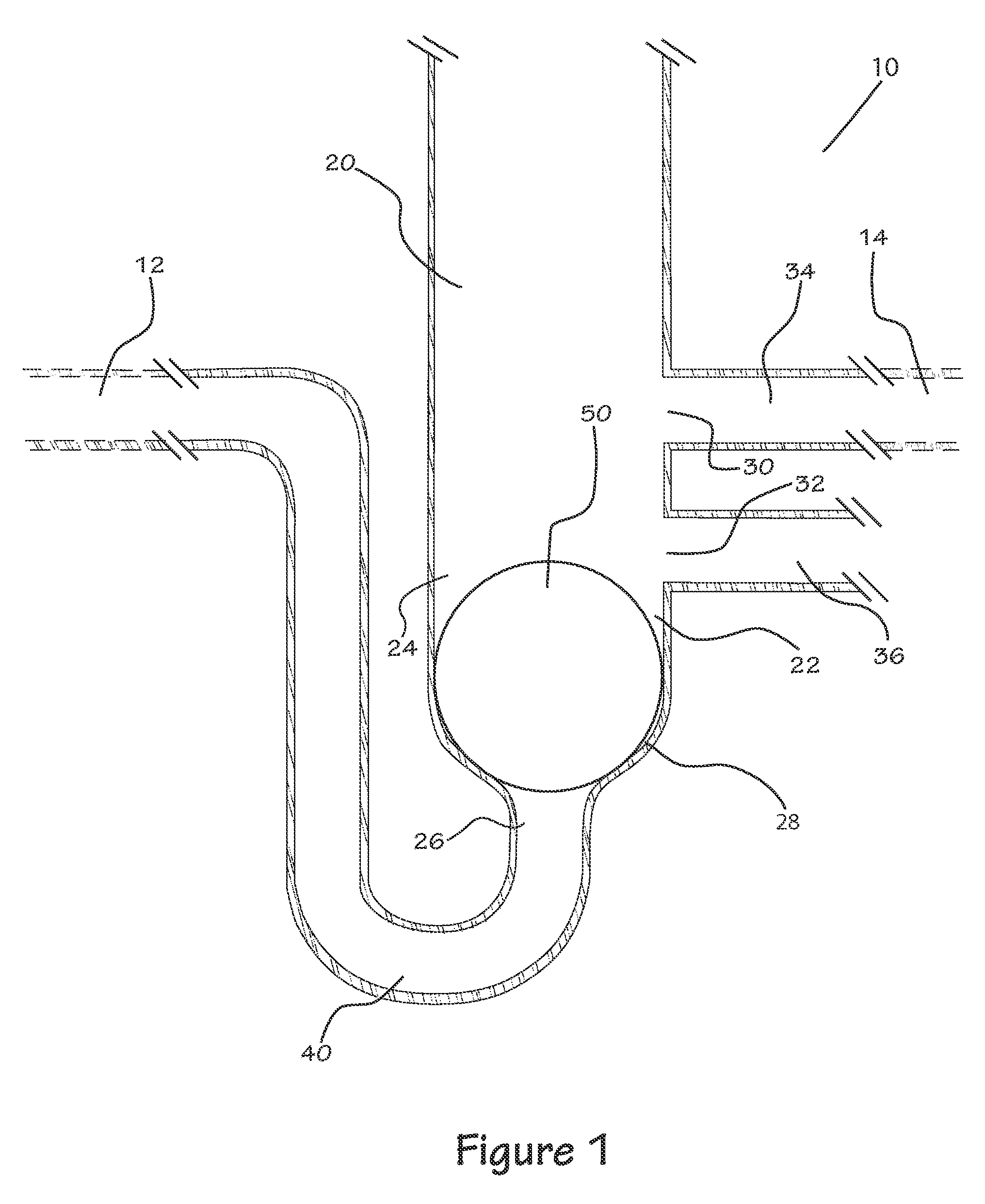

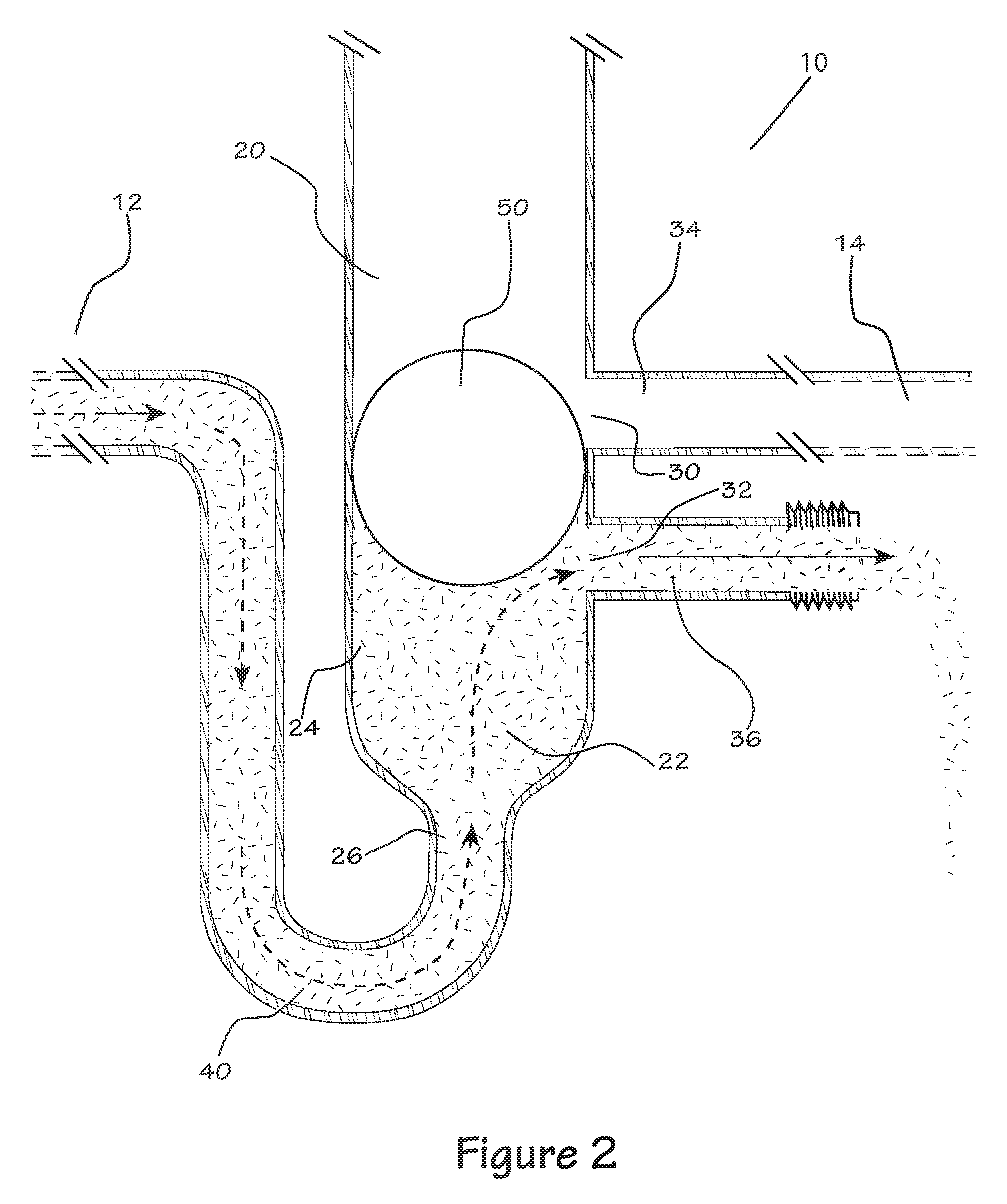

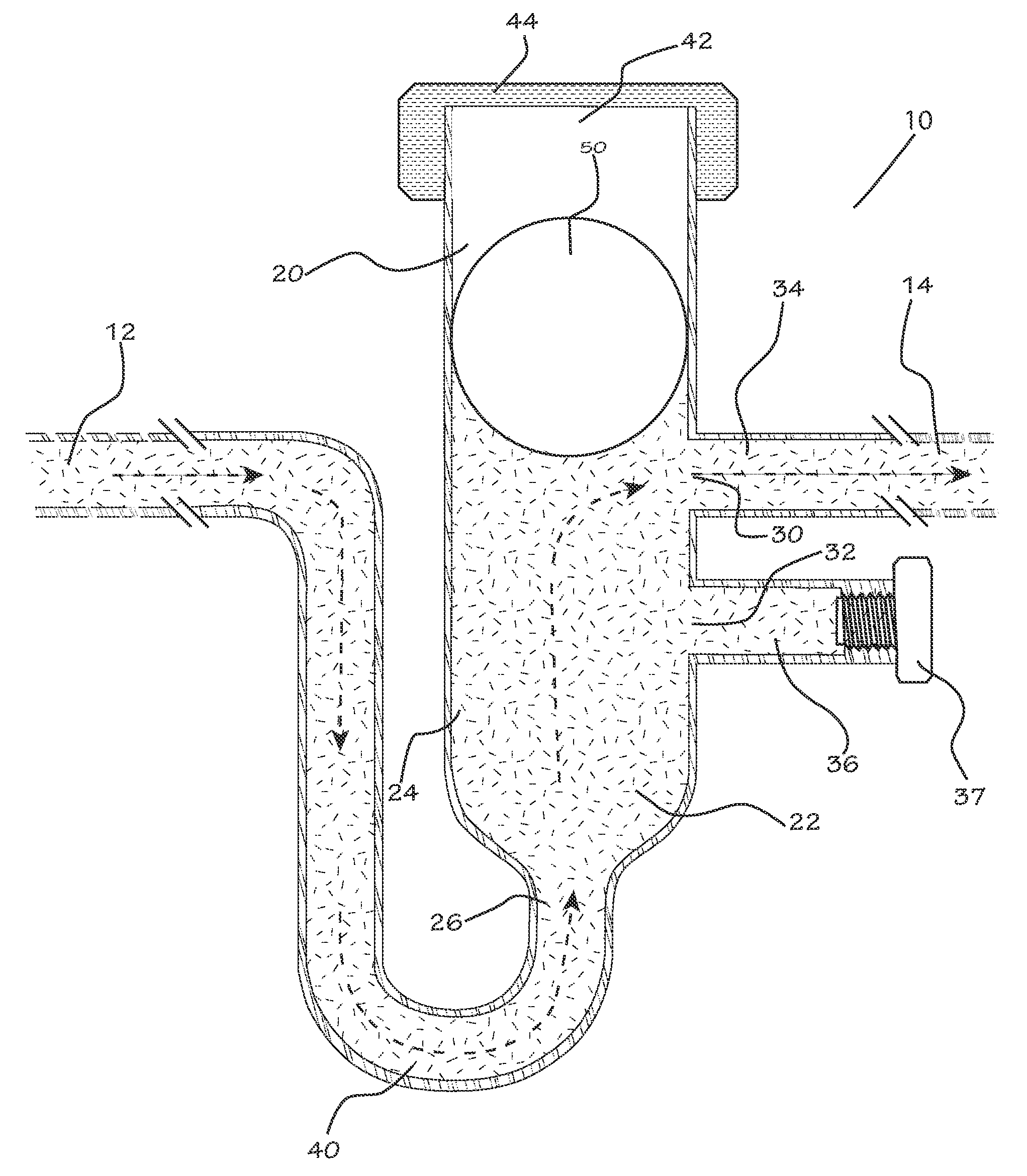

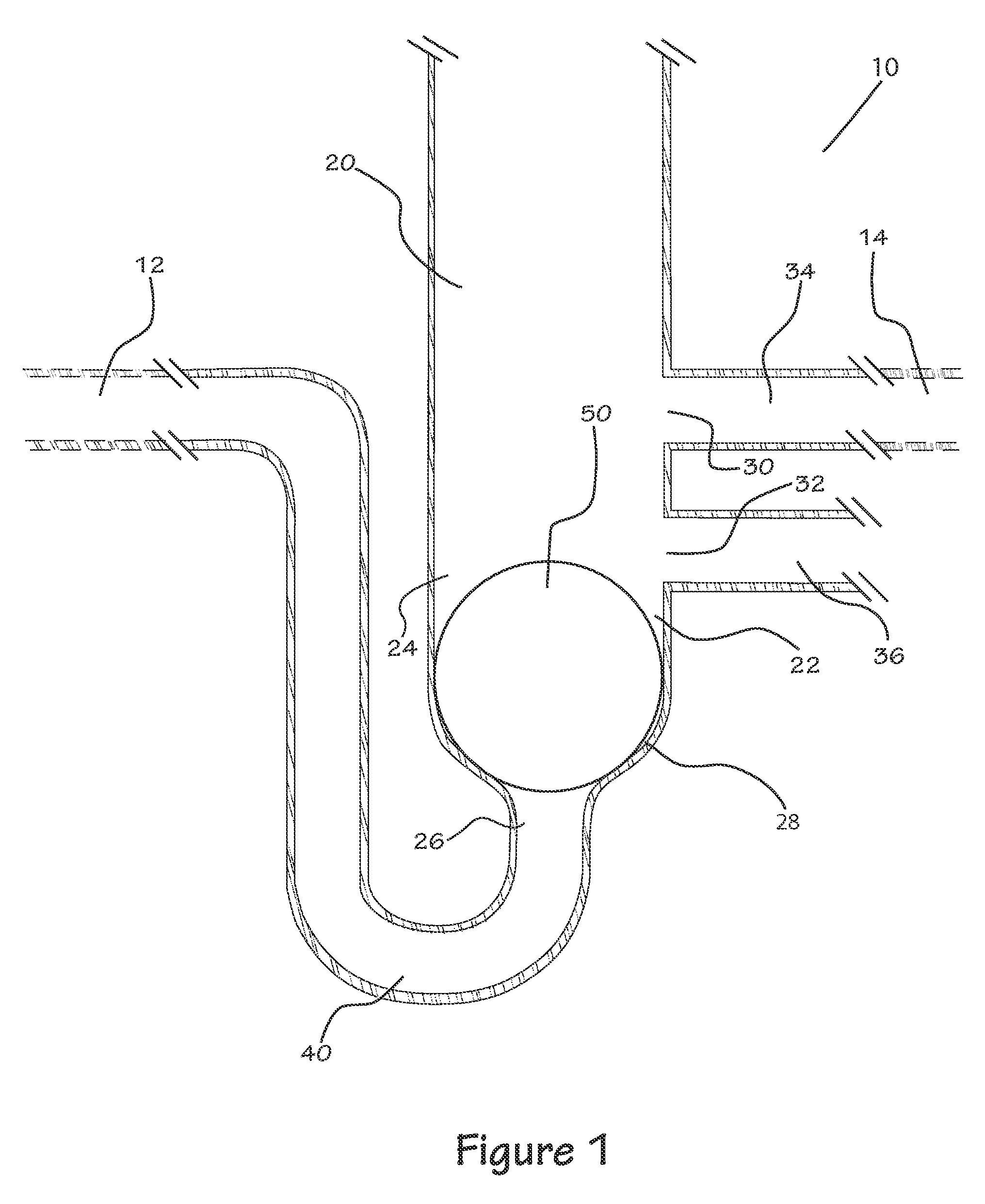

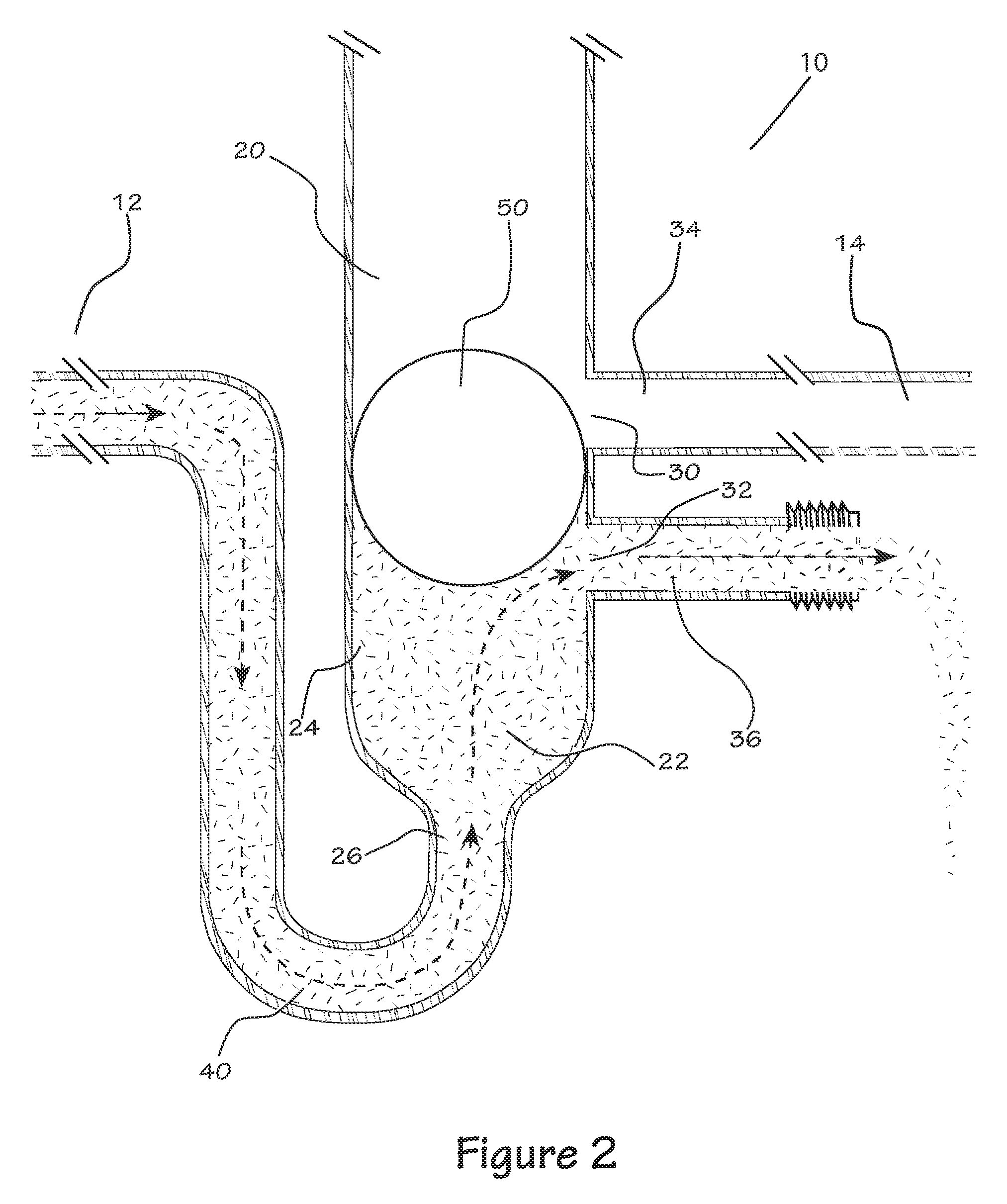

Conduit trap and condensation recovery device

The present invention provides a conduit trap, which can also operate as condensation recovery device when installed in a refrigeration system drainage line. The conduit trap is generally a hollow body defining a fluid path that includes an upper conduit 20, having a waste outlet 30 and optionally a condensation collection outlet 32. A lower conduit 22 extends downwardly from the upper conduit and has a narrowing that creates an inner sealing region for receiving a sealing means, such as float 50. Condensation can be directed from the refrigeration system through the conduit trap for recovery or for disposal without exposing the refrigeration drainage line and occupied space in which the refrigeration unit is located to sewer gasses even in dry weather when a gravity based, fluid-filled trap would fail.

Owner:ZATARAIN JESUS M

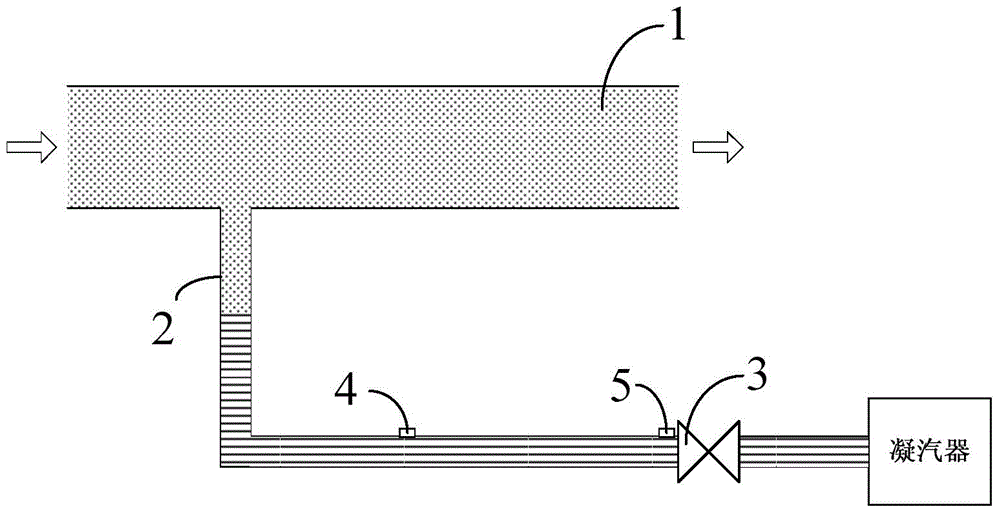

Online leak detection device for steam trap of steaming-water pipeline of thermal power plant

InactiveCN103016948AAccurate judgmentEasy to install and maintainSteam trapsPower stationEngineering

The invention relates to an online leak detection device for a steam trap of a steaming-water pipeline of a thermal power plant. The online leak detection device is composed of digital temperature sensors, a digital temperature signal collector, a 485 communication cable, an optical modem, an optical cable and a data processing computer, wherein the digital temperature sensors adopt DS18B20, and a plurality of digital temperature sensors arranged in the circumferential direction of the outer side of the downstream drain water pipeline of the same steam trap share one digital temperature signal collector; the digital temperature signal collector adopts a microprocessor ARM7, and collected signals are transmitted to the data processing computer through a data communication line to be processed; and according to the data of the downstream wall surface temperature of the steam trap and the rate of change of the data, a principle of fuzzy pattern recognition is adopted to carry out fuzzy recognition on the leakage level of the steam trap. The online leak detection device has the advantages of simple system and convenience for installation and maintenance, can monitor on line in real time, and accurately judges the leakage of the steam trap in time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

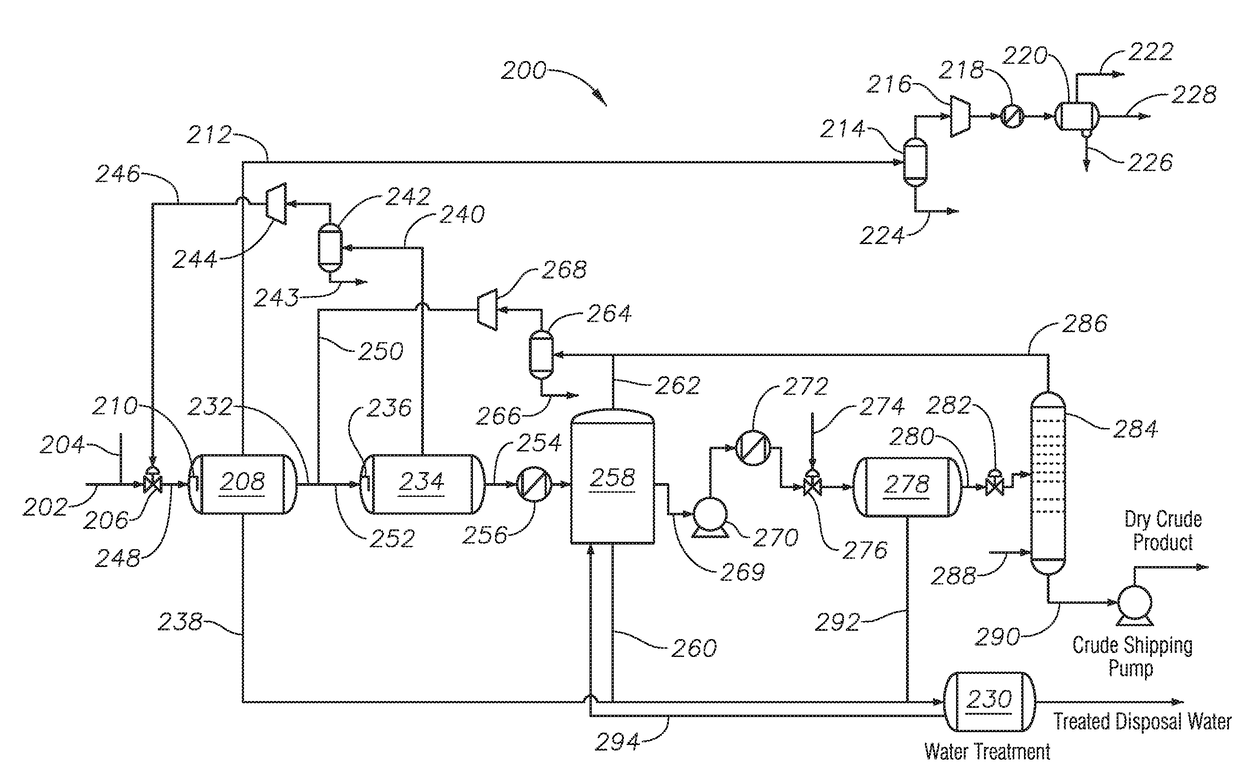

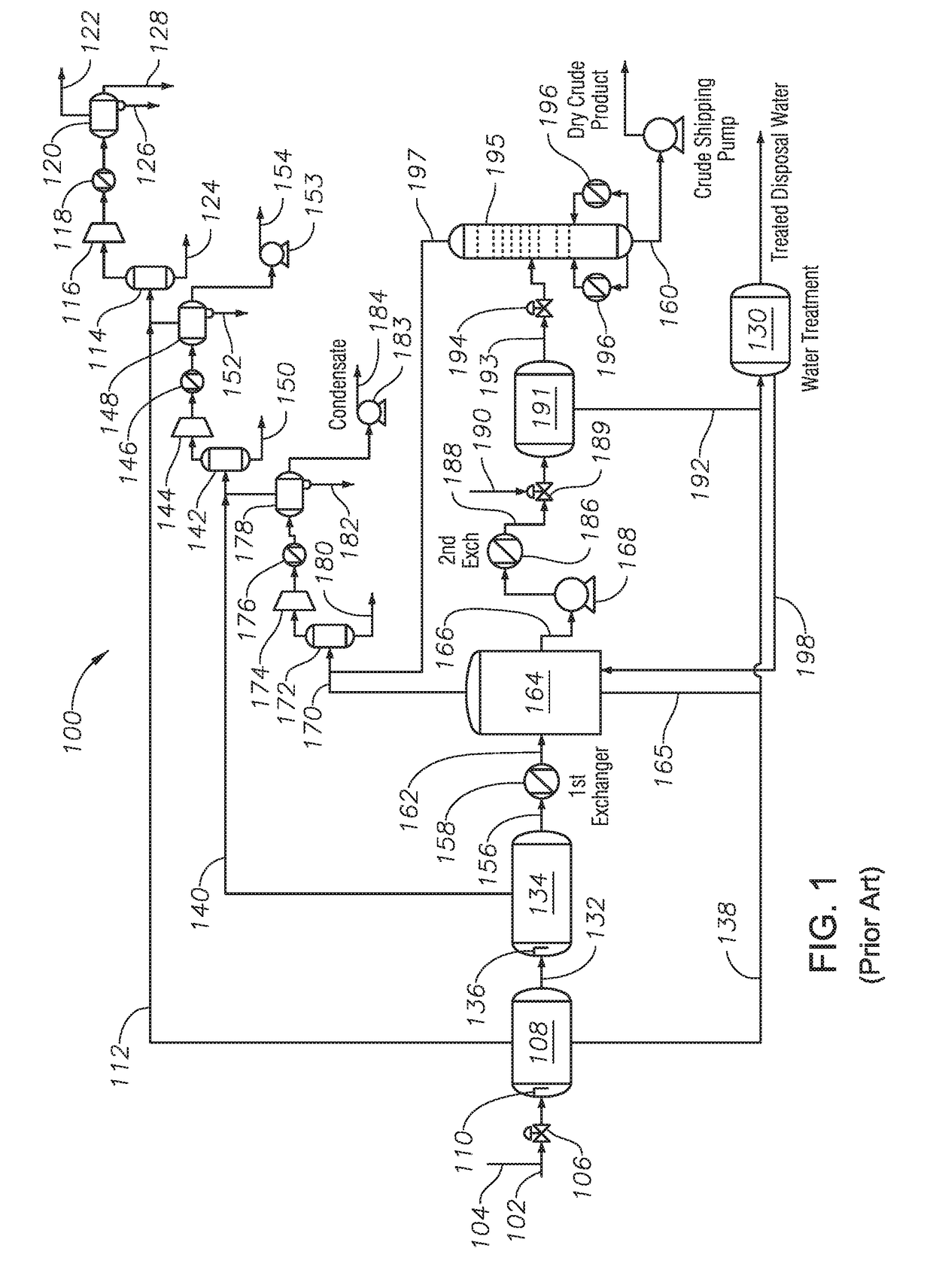

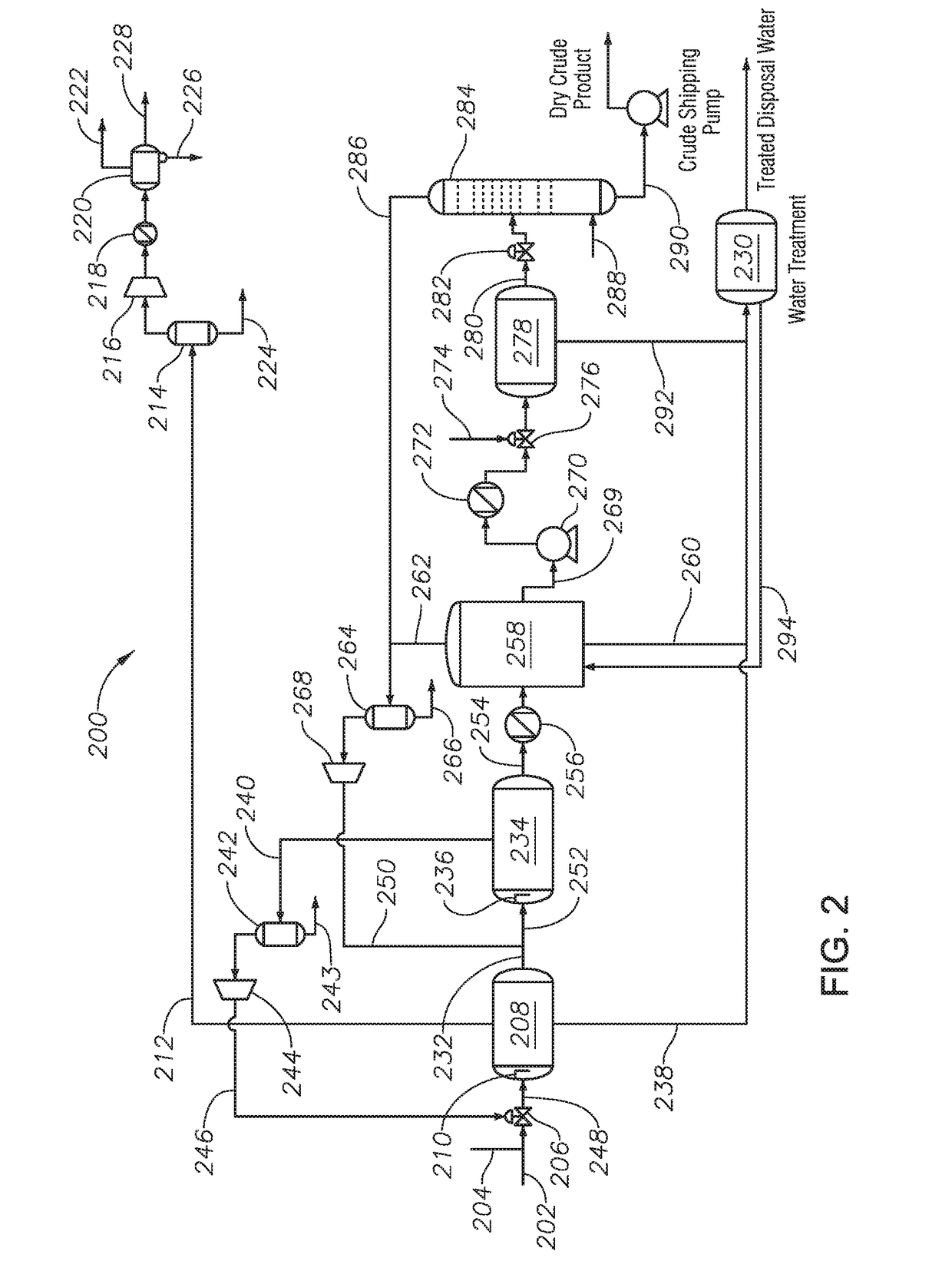

Integrated Gas Oil Separation Plant for Crude Oil and Natural Gas Processing

ActiveUS20180066194A1Low costReduce expenditureDewatering/demulsification with electric/magnetic meansLiquid hydrocarbon mixture recoveryNatural-gas processingOil separation

Systems and methods of integrated gas oil separation are disclosed. Systems include a high pressure production trap (HPPT), a low pressure production trap (LPPT), a low pressure degassing tank (LPDT), a first knockout drum (KOD) fluidly coupled to the LPDT and operable to accept an atmospheric pressure off-gas from the LPDT, an atmospheric pressure compressor fluidly coupled to the first KOD and operable to compress the atmospheric pressure off-gas to introduce the atmospheric pressure off-gas from the LPDT into the LPPT inlet feed stream, a second KOD fluidly coupled to the LPPT and operable to accept a low pressure off-gas from the LPPT, and a low pressure compressor fluidly coupled to the second KOD and operable to compress the low pressure off-gas to introduce the low pressure off-gas from the LPPT into the crude oil inlet feed stream.

Owner:SAUDI ARABIAN OIL CO

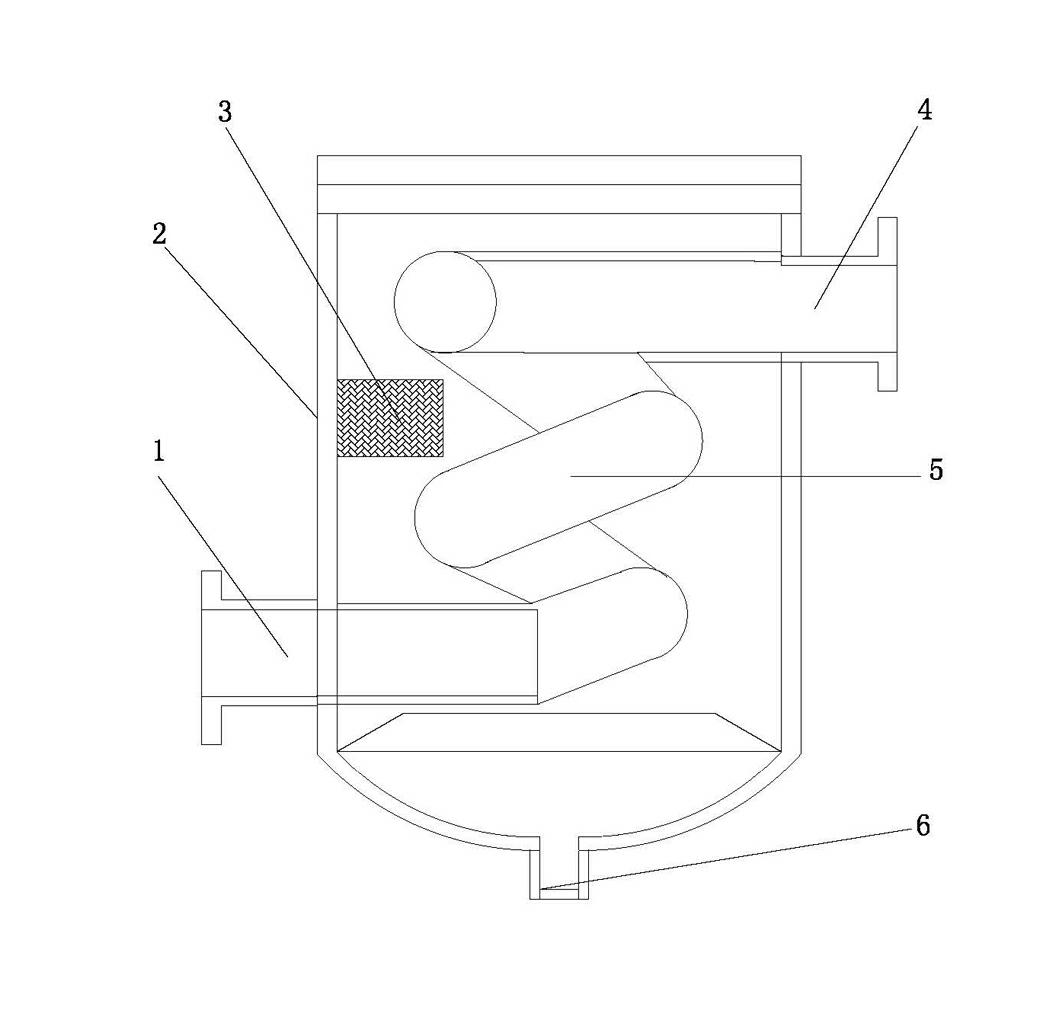

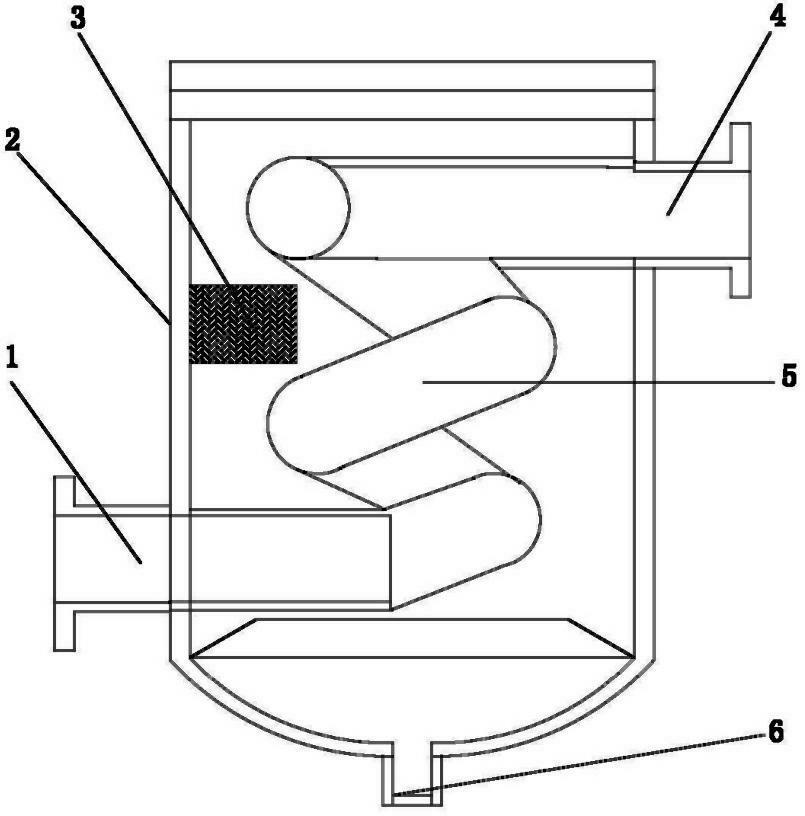

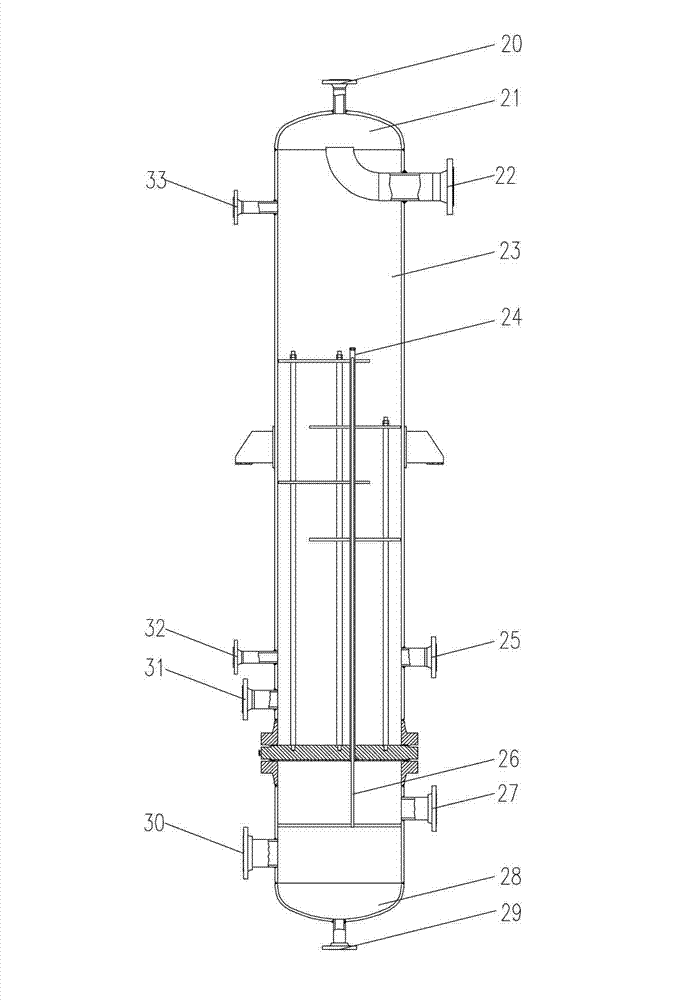

Centrifugal gas-liquid separator

InactiveCN102671469AEasy to separateImprove securityDispersed particle separationVapor–liquid separatorMaterial consumption

The invention discloses a centrifugal gas-liquid separator which comprises a tank, a gas inlet pipe is arranged on the lower portion of the tank, a gas outlet pipe is arranged on the upper portion of the tank, a drain valve is arranged at the bottom of the tank, a spiral pipe is arranged in the tank, one end of the spiral pipe is communicated with the gas inlet pipe, the other end of the spiral pipe is connected with the gas outlet pipe, vent holes are arranged on the pipe wall of the spiral pipe, and a stainless steel screen is filled in the tank. When the centrifugal gas-liquid separator is used with an air compressor, effect of separating liquid-gas mixture is good, material consumption is avoided, electric energy and manual control are unused, convenience and quickness are achieved, and working is stable and reliable.

Owner:GUANGDONG HIWAVE TECH

Conduit trap and condensation recovery device

The present invention provides a conduit trap, which can also operate as condensation recovery device when installed in a refrigeration system drainage line. The conduit trap is generally a hollow body defining a fluid path that includes an upper conduit 20, having a waste outlet 30 and optionally a condensation collection outlet 32. A lower conduit 22 extends downwardly from the upper conduit and has a narrowing that creates an inner sealing region for receiving a sealing means, such as float 50. Condensation can be directed from the refrigeration system through the conduit trap for recovery or for disposal without exposing the refrigeration drainage line and occupied space in which the refrigeration unit is located to sewer gasses even in dry weather when a gravity based, fluid-filled trap would fail.

Owner:ZATARAIN JESUS M

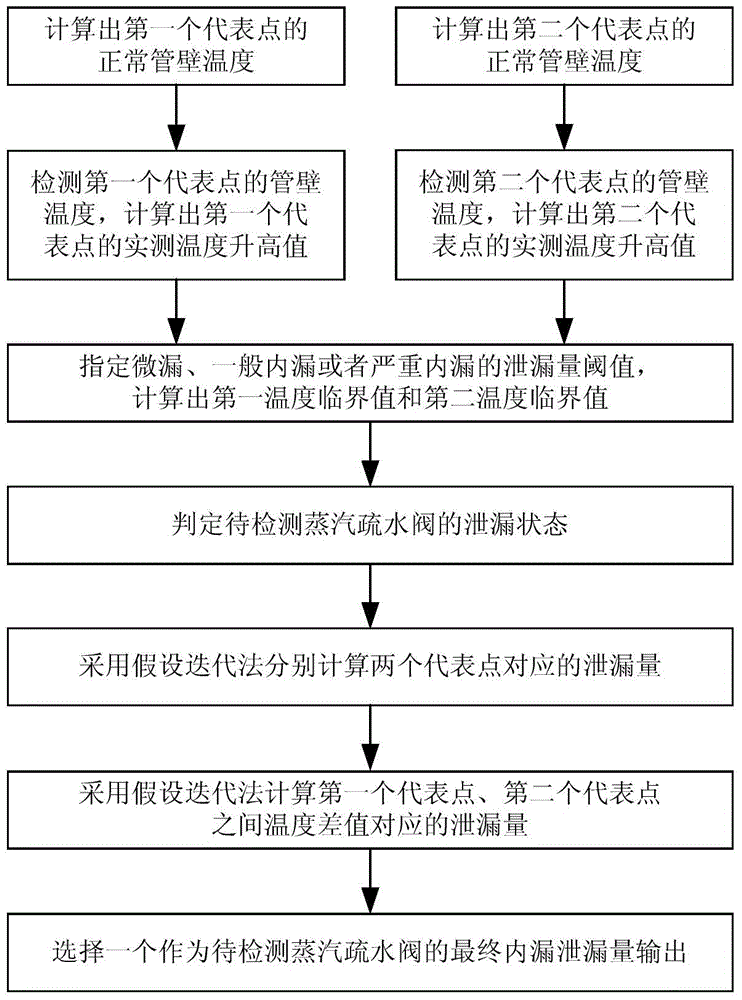

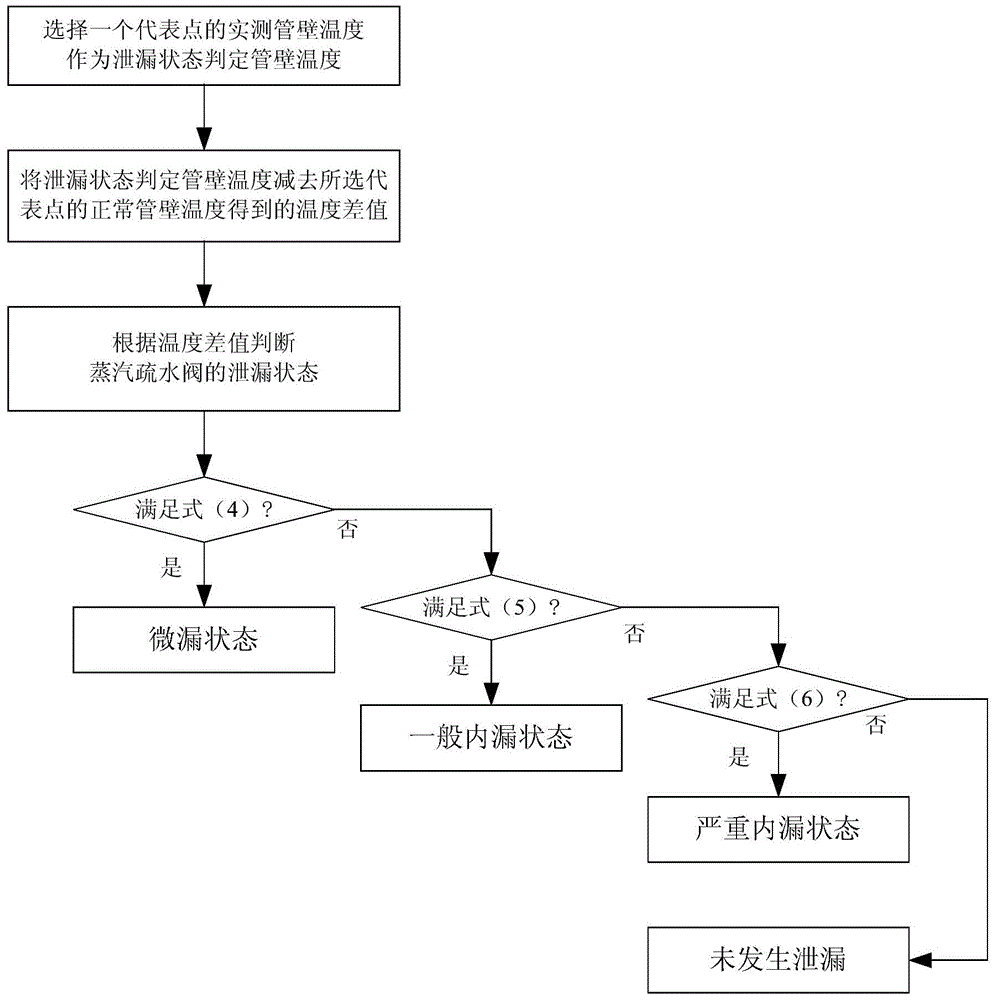

Method for detecting inner leakage of steam hydrophobic valve based on valve front pipe wall temperature detection

ActiveCN103557992AReflect the leakAvoid planned downtimeFluid-tightness measurementTemperature differenceEngineering

The invention discloses a method for detecting inner leakage of a steam hydrophobic valve based on valve front pipe wall temperature detection. The method includes the following steps that a first representative point and a second representative point are selected at the positions where the front end specified distance and the interval specified distance of the steam hydrophobic valve are detected respectively, modeling is conducted on the theoretical pipe wall temperature of the first representative point and the theoretical pipe wall temperature of the second representative point through a statistical regression model, pipe wall temperatures corresponding to the representative points are actually measured, then, according to a hypothesis iterative algorithm, the leakage rate corresponding to the first representative point, the leakage rate corresponding to the second representative point and the leakage rate corresponding to the temperature difference of the two representative points are acquired, and one of the three leakage rates acquired by calculation is selected as the final leakage rate of inner leakage of the steam hydrophobic valve to be detected and then output. Qualitative and quantitative detection or online monitoring of inner leakage of the valve can be achieved, and the method has the advantages of being high in inner leakage detection accuracy and detection speed and wide in application range.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

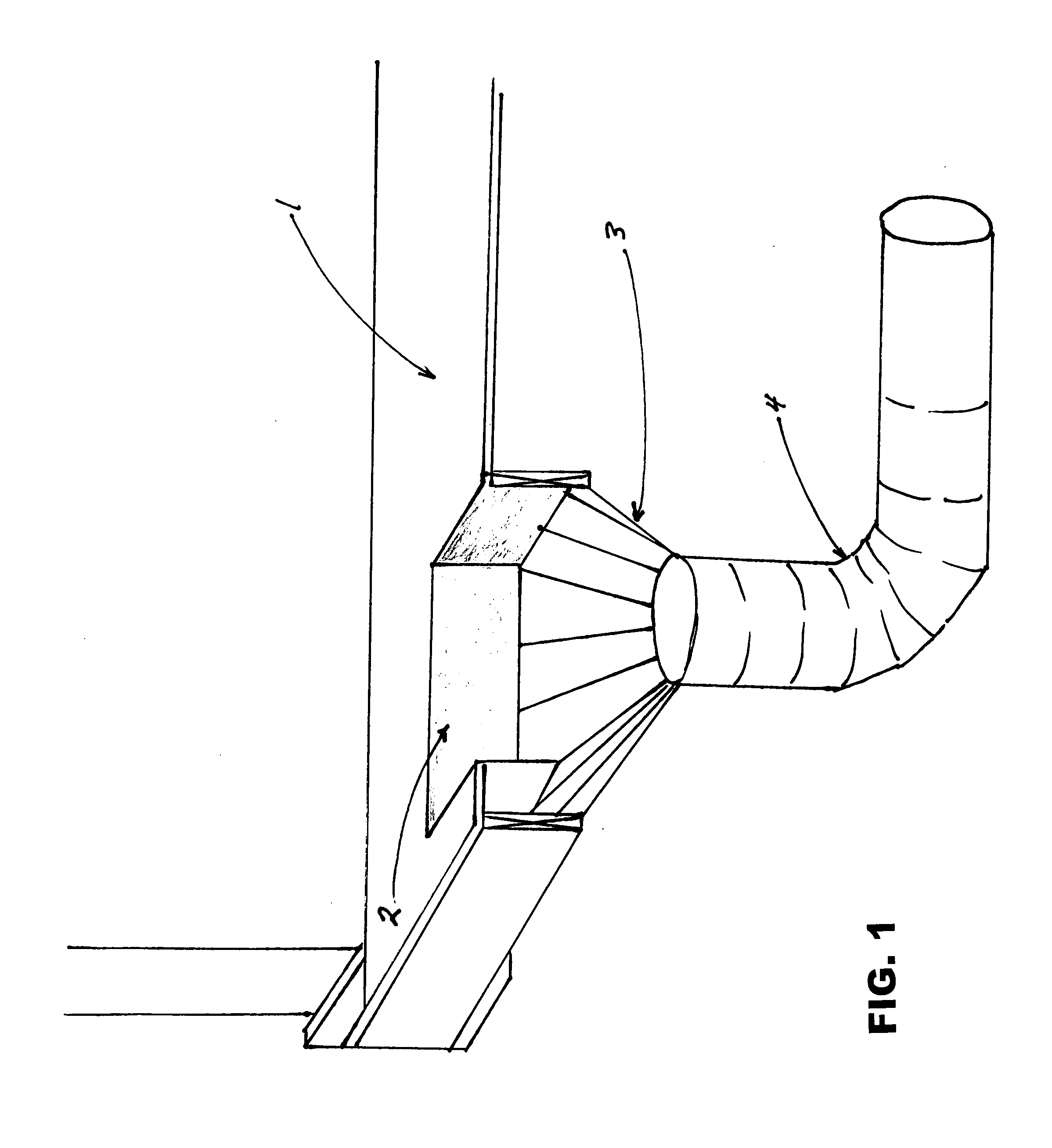

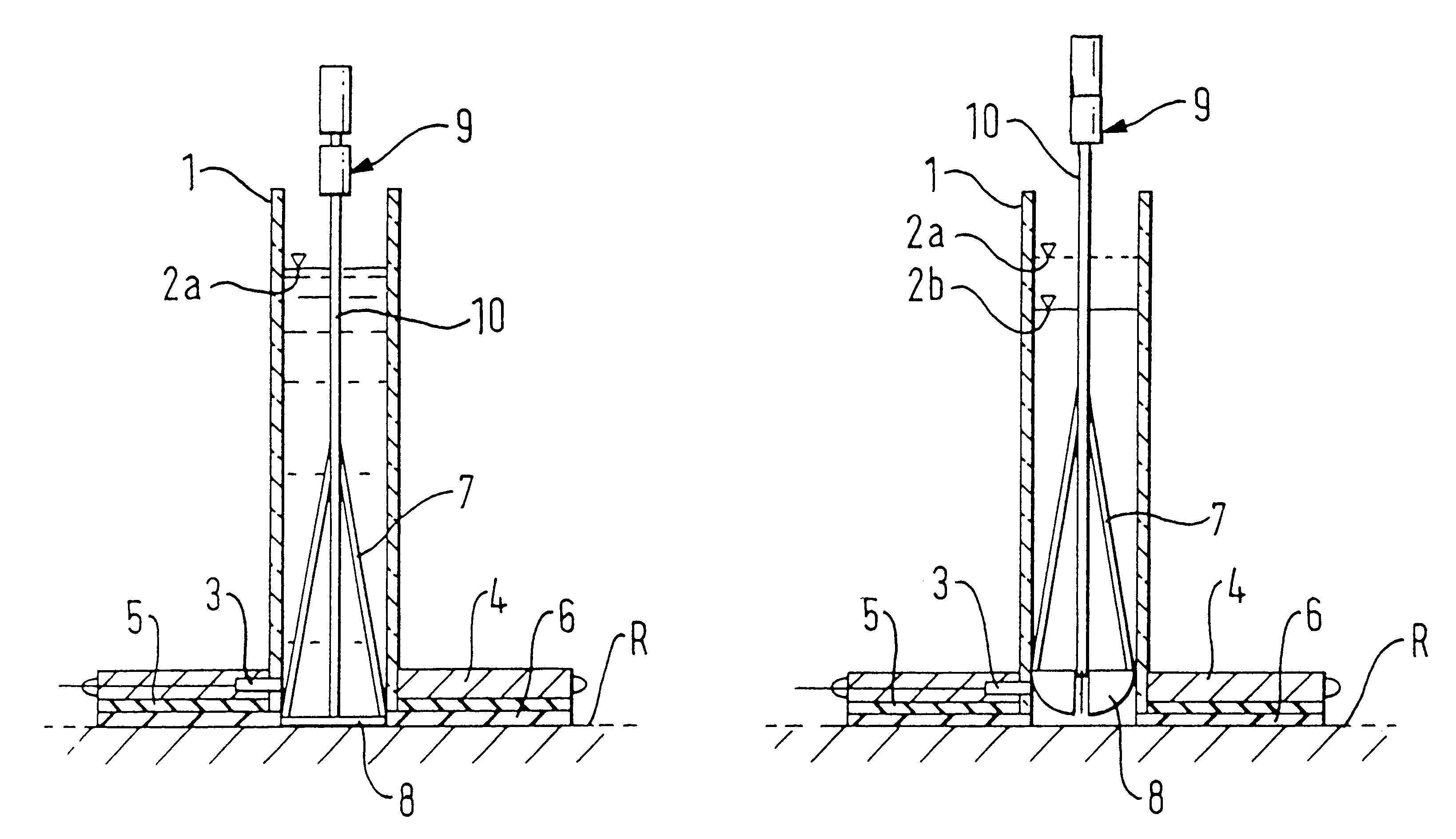

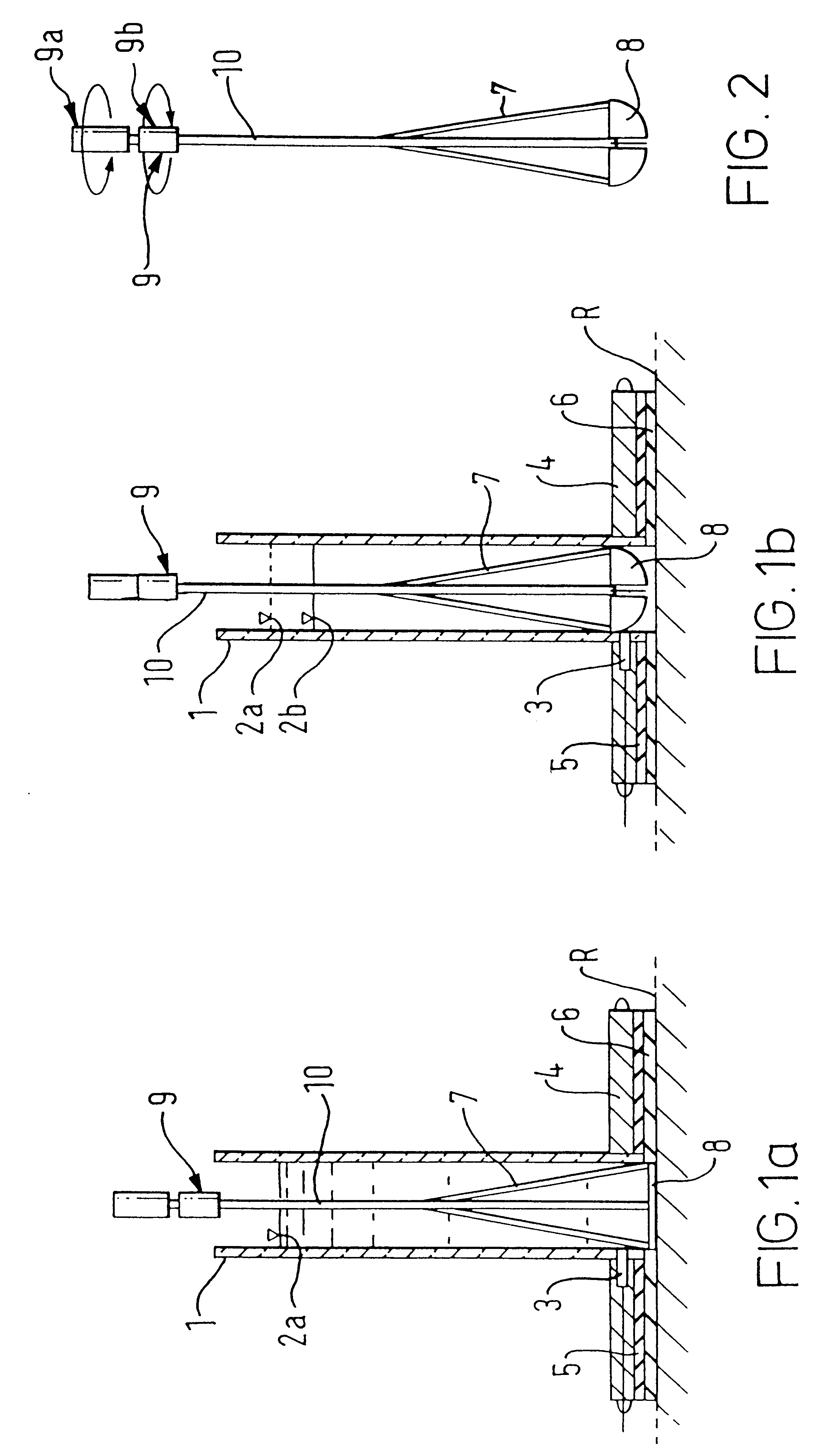

Drainage testing of porous asphalt road mixes

InactiveUS6367310B1Accurate measurementSimple and inexpensiveMaterial testing goodsPermeability/surface area analysisConversion factorTransducer

A field permeameter for performing a falling head permeability test on porous road surfaces with three-dimensional flow through the road surface or test slab comprises a clear plastic cylinder (1), and a rubber lined base flange (5, 6) to seal the test cylinder against the road surface during operation. A trap or valve assembly (7, 8, 9) in the closed position permitting the setting up of the falling head test at any desired initial head water level in the test cylinder. The activation of the test being initiated by the sudden release of the trap (8) which causes the water retained in the cylinder to flow through the test road section. The falling head of water through the road being measured by a submersible pressure transducer (3) at the base of the cylinder. From the falling head data, and the conversion factors for converting three-dimensional to one-dimensional flow property, the permeability (k) and the flow exponent (m) of the porous road specimen can be determined.

Owner:NAT UNIV OF SINGAPORE

Steam trap monitoring

Electronic steam trap monitoring is disclosed. An electronic steam trap monitor is operably coupled to an outlet of a steam trap and is configured to measure at least one process variable of fluid (liquid or gas) flowing through the trap, when the trap is known to be working normally. The steam trap monitor stores the process variable information obtained during the known operating condition for later comparison. The steam trap monitor obtains a later process variable measurement and compares it to the stored measurement to selectively generate a leakage indication. The steam trap monitor preferably uses a local power source and communicates wirelessly.

Owner:ROSEMOUNT INC

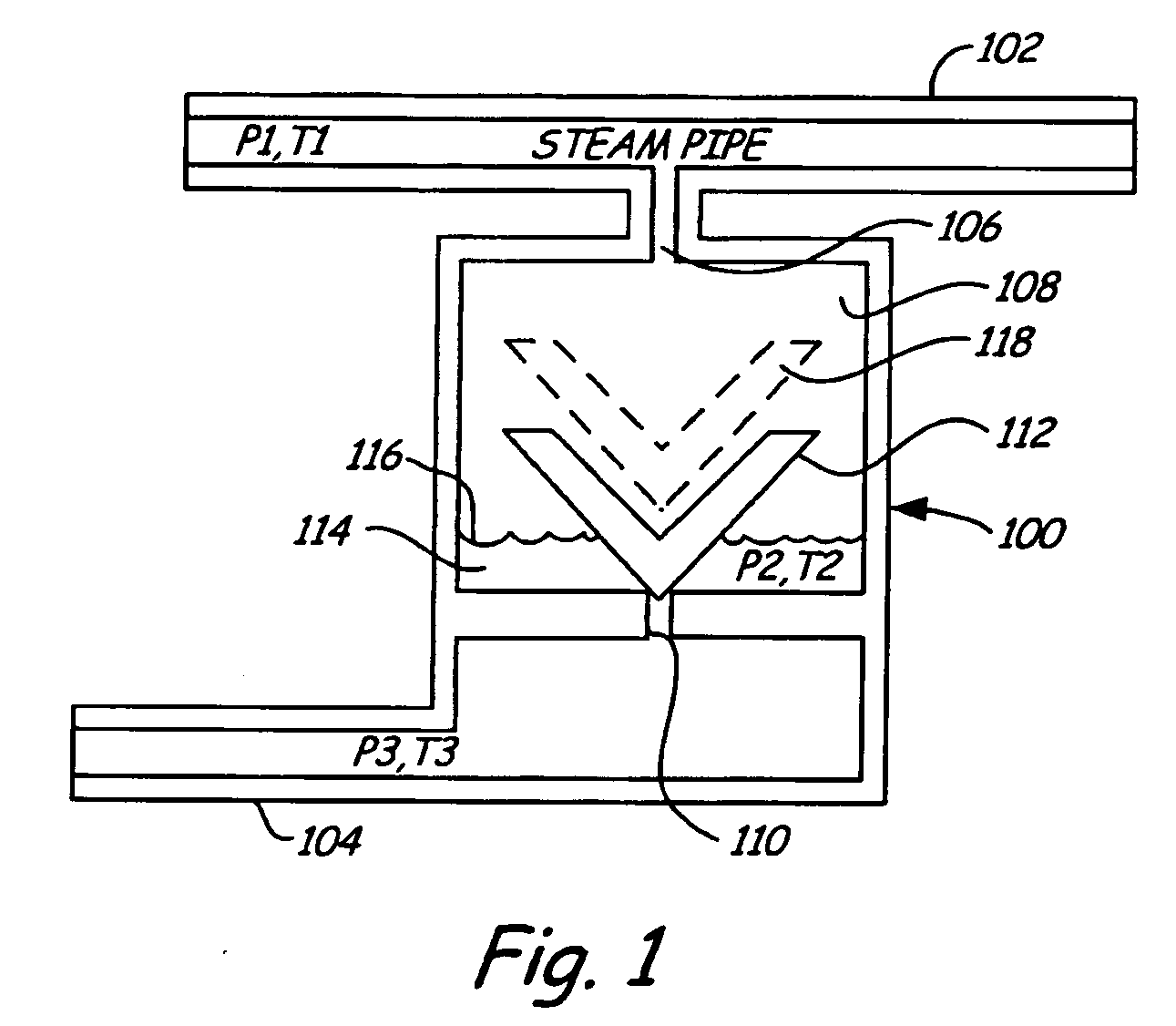

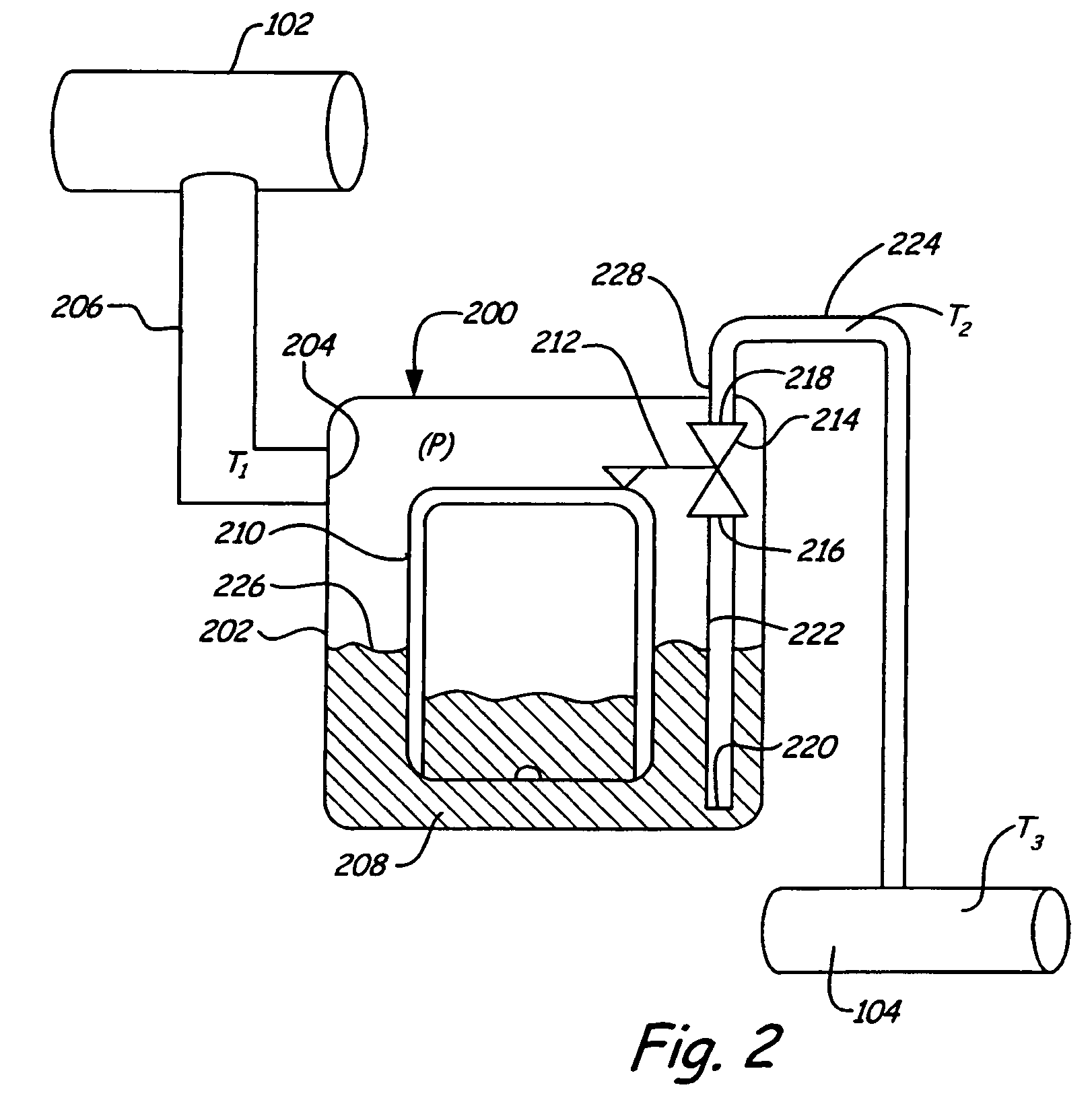

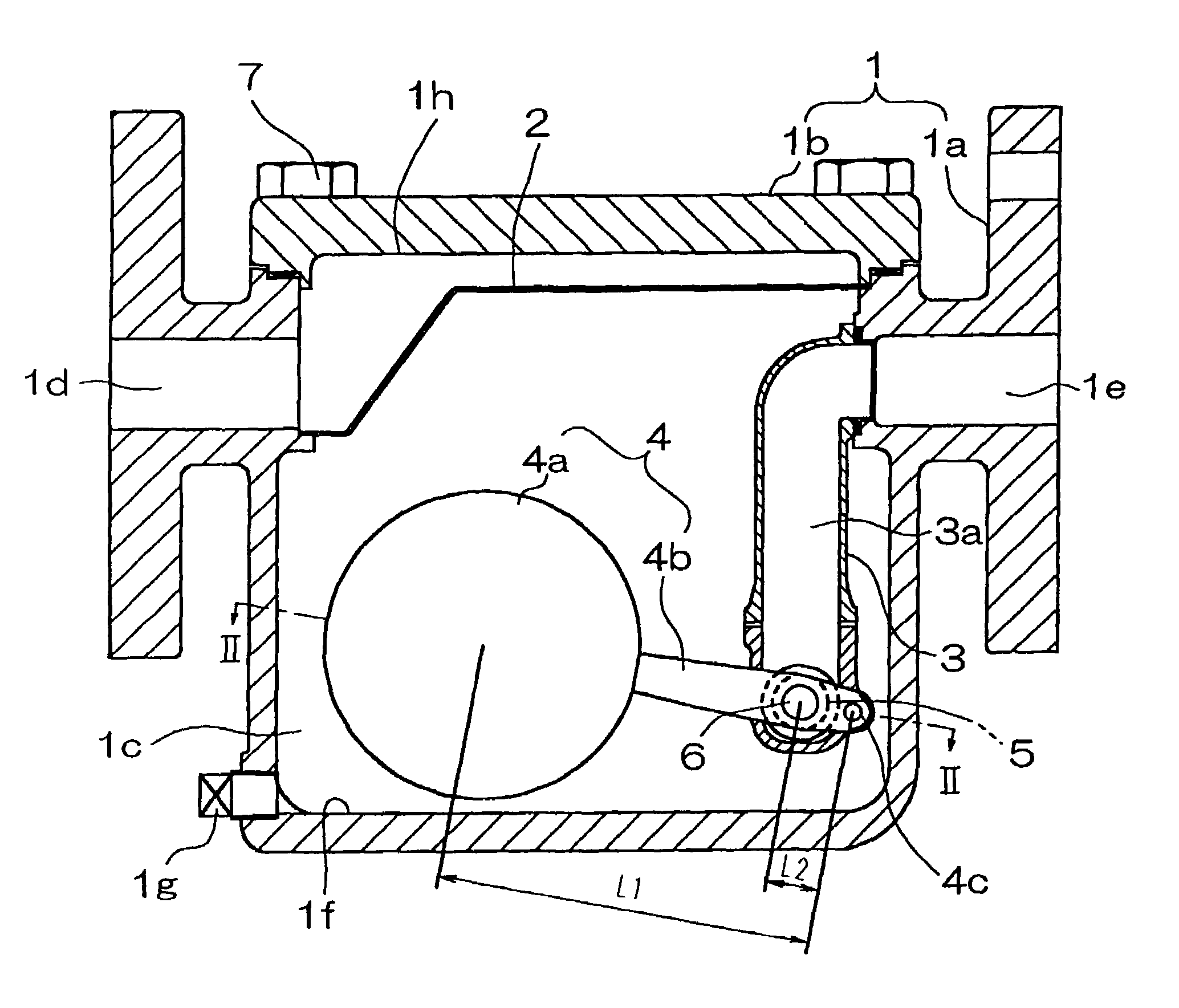

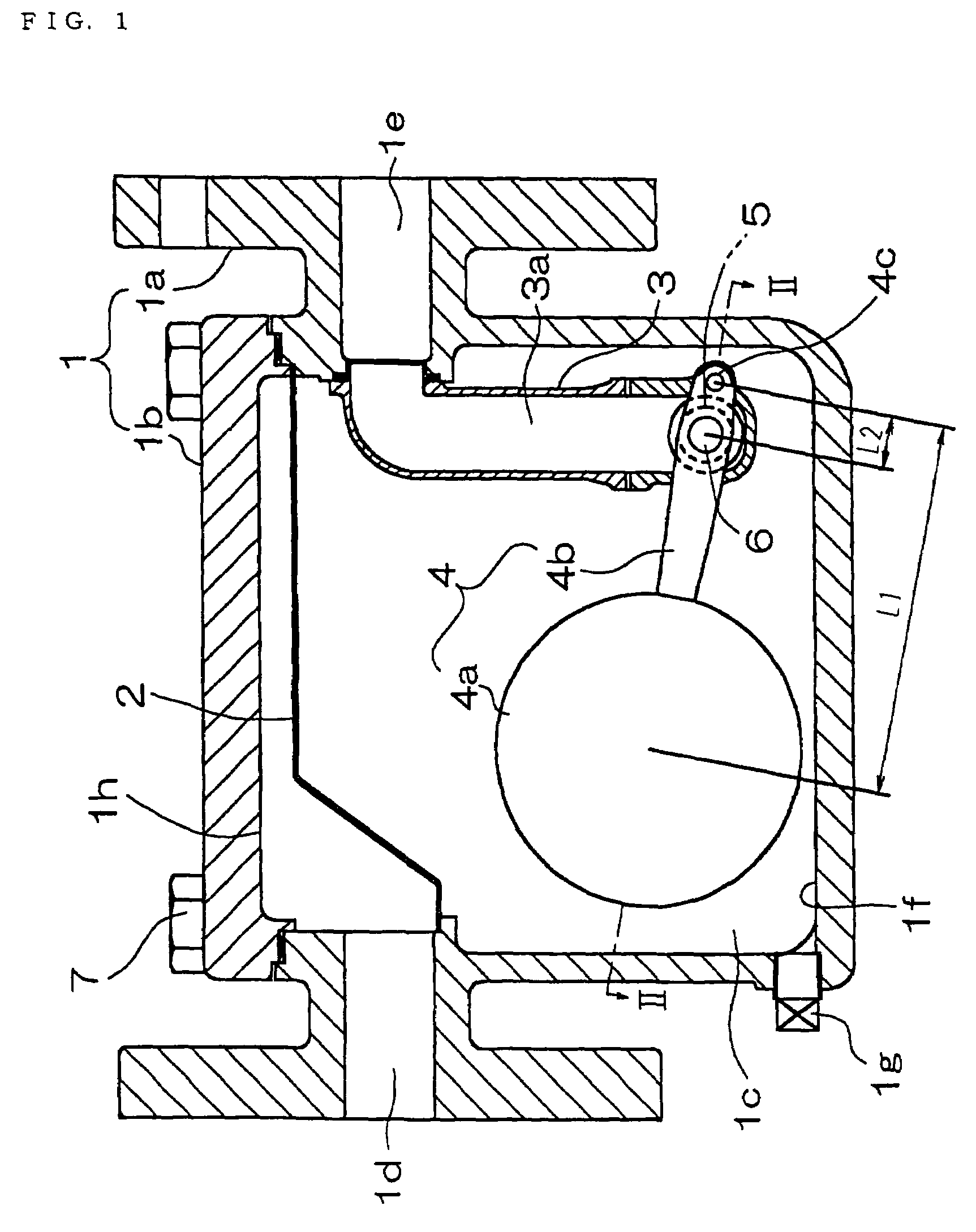

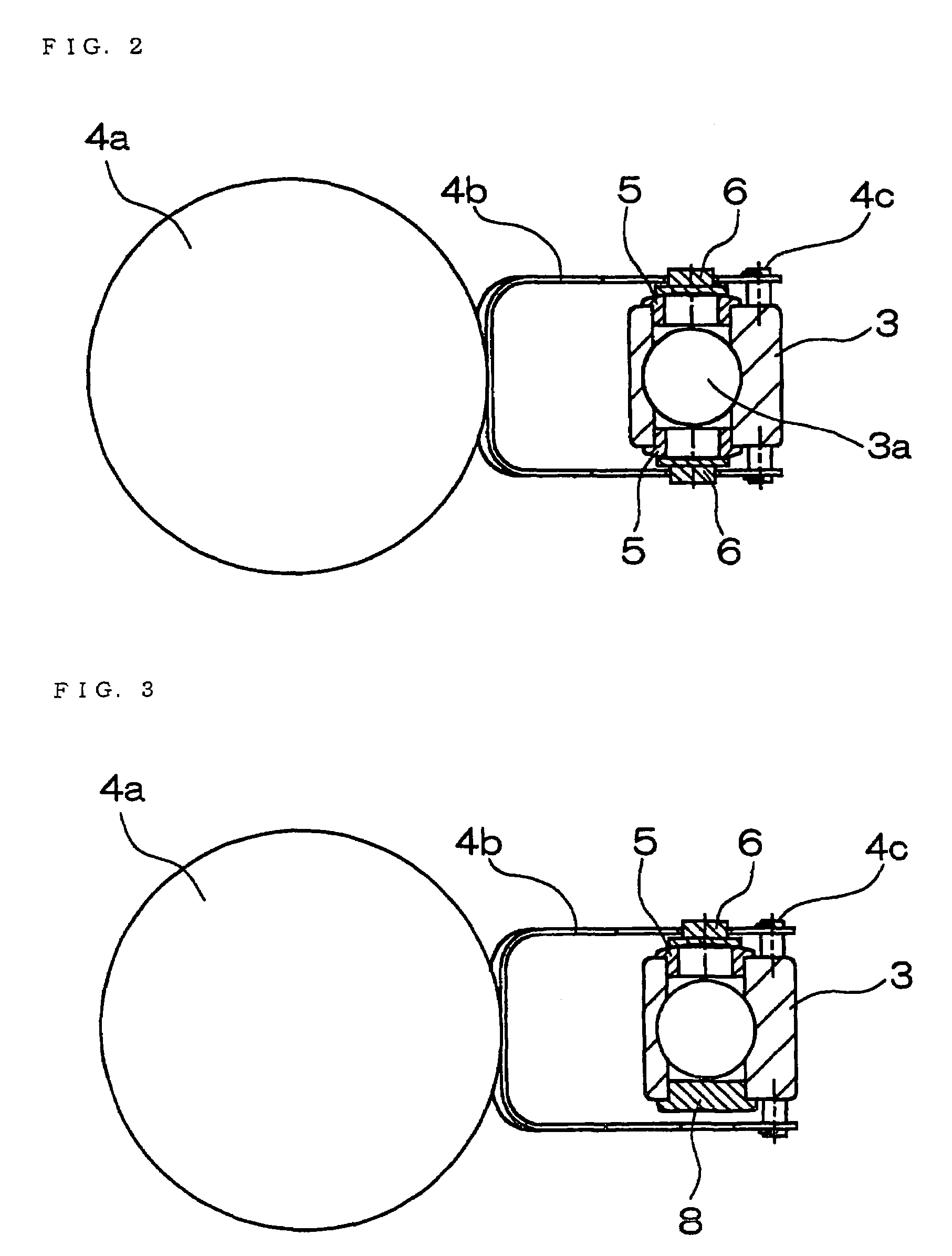

Float type steam trap

InactiveUS7096880B2Improve valve closing performanceReduce device sizeOperating means/releasing devices for valvesSteam trapsSteam trapValve seat

There is provided a float type steam trap having a casing having a float chamber formed with an inflow port and an outflow port. A holder has a flow path communicating with the outflow port. A valve seat on the holder communicates with the outflow port. A float has a float body and a lever with a valve element. One end of the lever is fixed to the float body, and the other end is supported by the holder. The valve element slides with the up-and-down movement of the float body to open and close the valve seat 5.

Owner:MOTOYAMASEISAKUSHO

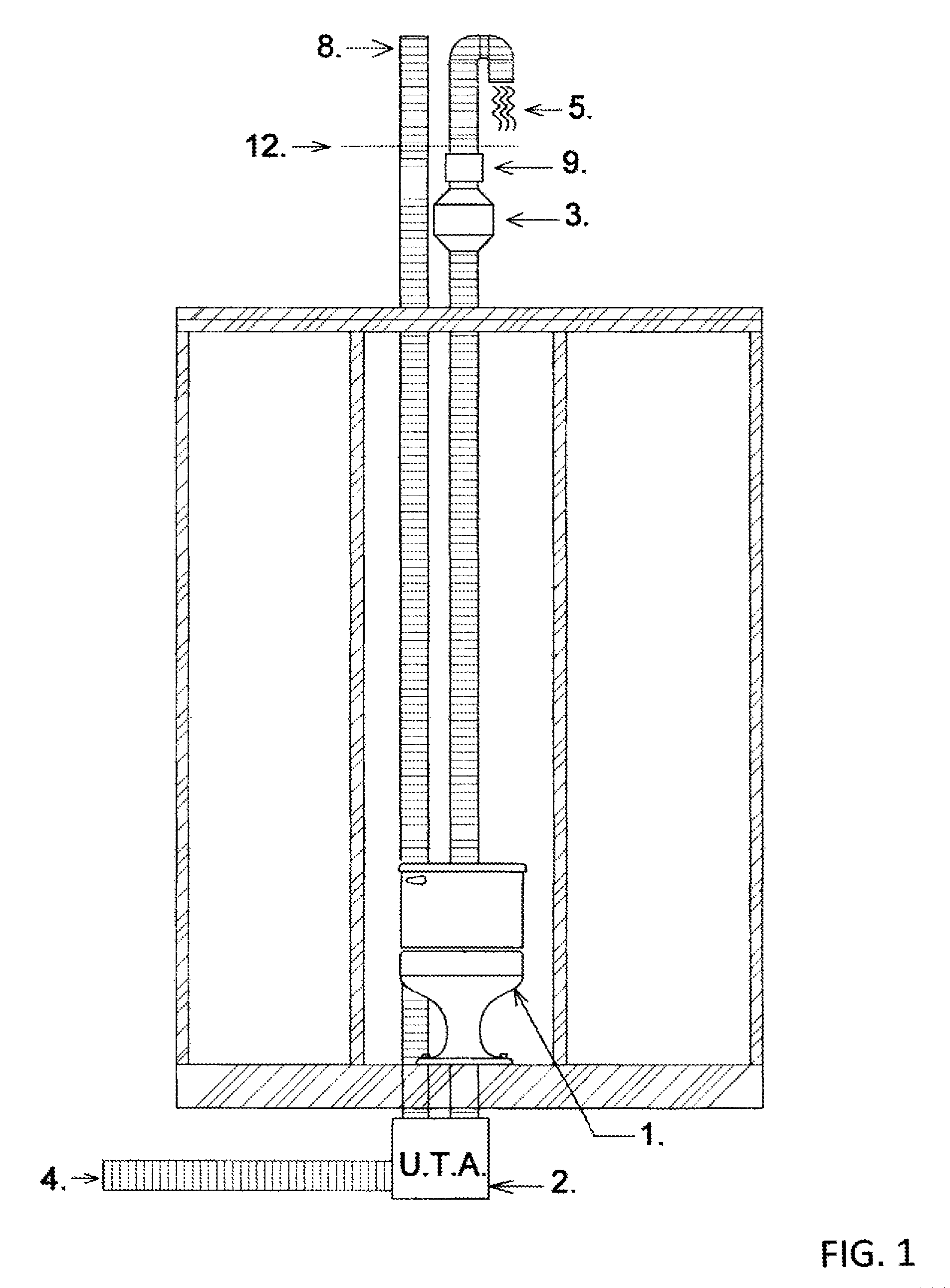

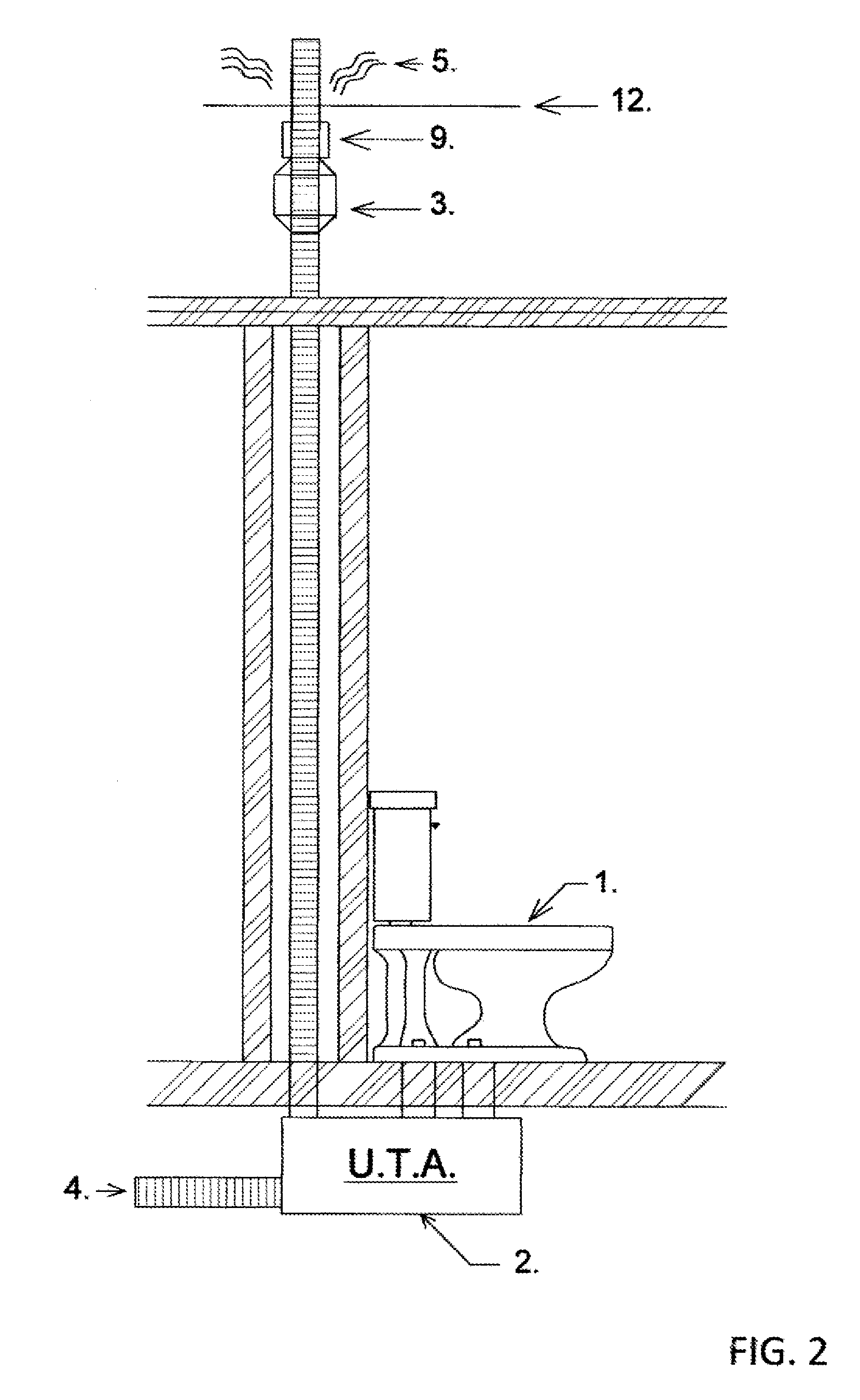

Odorless and overflow-less toilet system

The technology described herein provides an odorless and overflow-less toilet system. The technology provides for the removal of odor at its source and aids in overflow protection. The technology provides a toilet system having a second chamber running in fluid communication with a first chamber and a second exit port to allow for the continuation of the second chamber flow to a trap assembly. The trap assembly is configured to separate exhaust odors and overflows. The trap assembly prevents sewage gasses from escaping back through the toilet. The trap assembly allows overflows to be routed back to a sewage out line. The trap assembly provides for the flow of odors from the toilet with an inline exhaust fan. The inline exhaust fan pulls odors from the toilet through the second chamber and exit port of the toilet through the trap assembly and then through the inline exhaust fan to exit.

Owner:PICKLE RONALD FERRELL

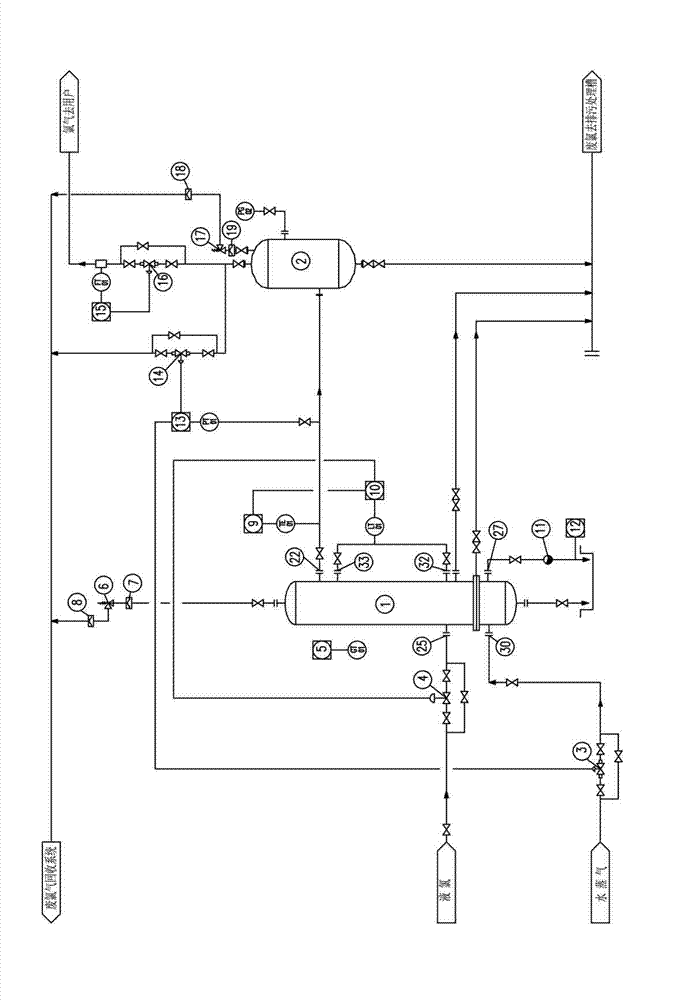

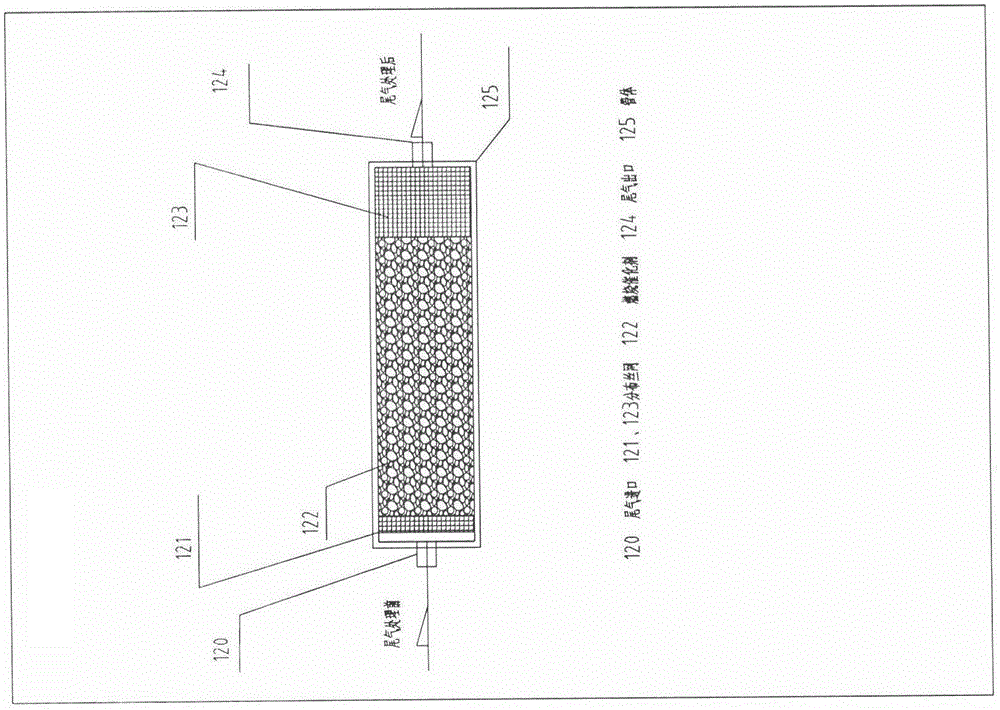

Liquid chlorine gasifying system

ActiveCN102767692AIncrease productivityReduce heat transfer areaContainer filling methodsPressure vesselsBuffer tankHeat transfer efficiency

The invention relates to a liquid chlorine gasifying system. The technical scheme is as follows: the liquid chlorine gasifying system is formed by a liquid chlorine gasifying part, a water steam heating part and a chlorine gas buffering part; the liquid chlorine gasifying part is characterized in that a liquid chlorine inlet of a gasifying device is connected with a liquid level adjusting valve; a pipeline between a chlorine gas outlet and a buffering tank is provided with a temperature measuring meter and a pressure measuring meter; the temperature measuring meter and the pressure measuring meter are connected in series, and a liquid level measuring meter is connected with a liquid level meter opening and the liquid level adjusting valve respectively; and a chlorine gas leakage detection alarming instrument is arranged outside the gasifying device. The water steam heating part is characterized in that a water steam inlet is connected with a pressure adjusting valve, and a condensed water outlet is sequentially connected with a condensed water steam trap and an acidic degree analyzer; and the pressure adjusting valve is connected with the pressure measuring meter. The chlorine gas buffering part is characterized in that a flow adjusting valve and a flow meter are sequentially arranged on a chlorine gas outlet pipeline of the buffering tank; a leaking valve is arranged on a pipeline between the buffering tank and the flow adjusting valve; and the leaking valve is connected with the pressure measuring meter. The liquid chlorine gasifying system has the advantages of stability in production and operation, safety and reliability, high gasification efficiency and heat transferring efficiency, and low energy consumption.

Owner:沈阳东方钛业股份有限公司

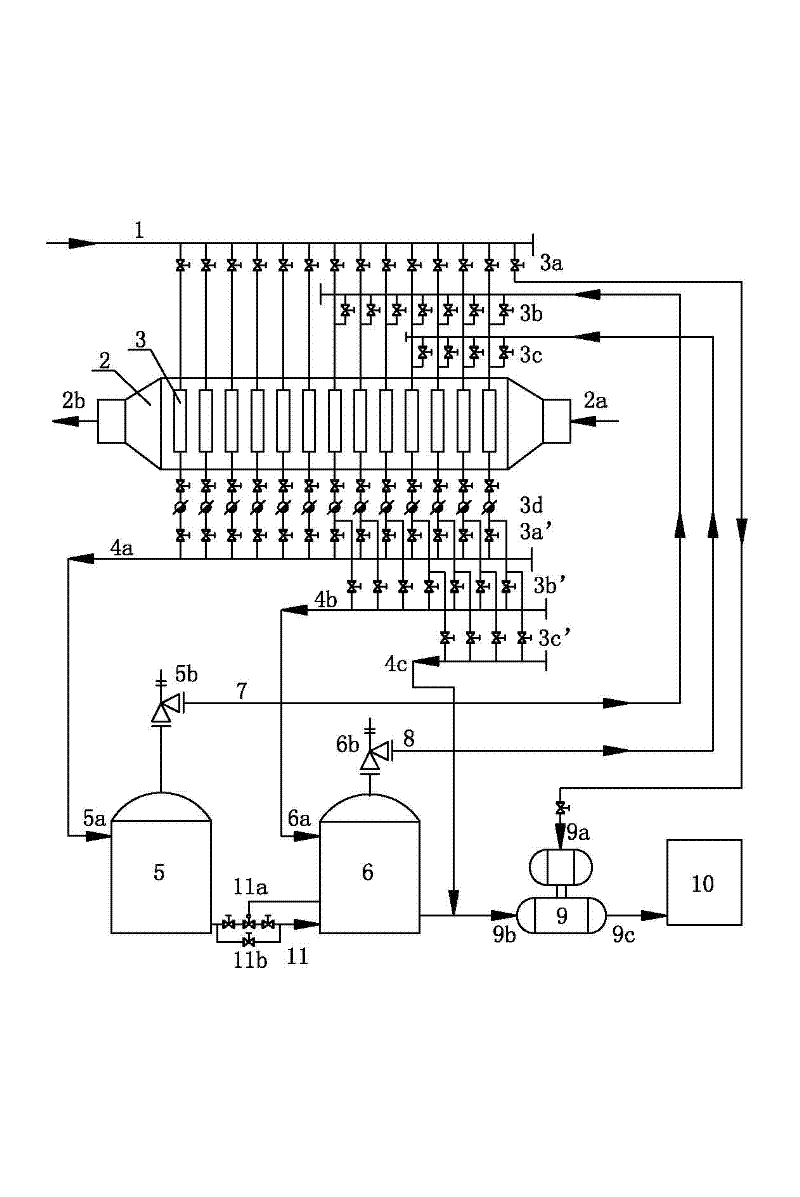

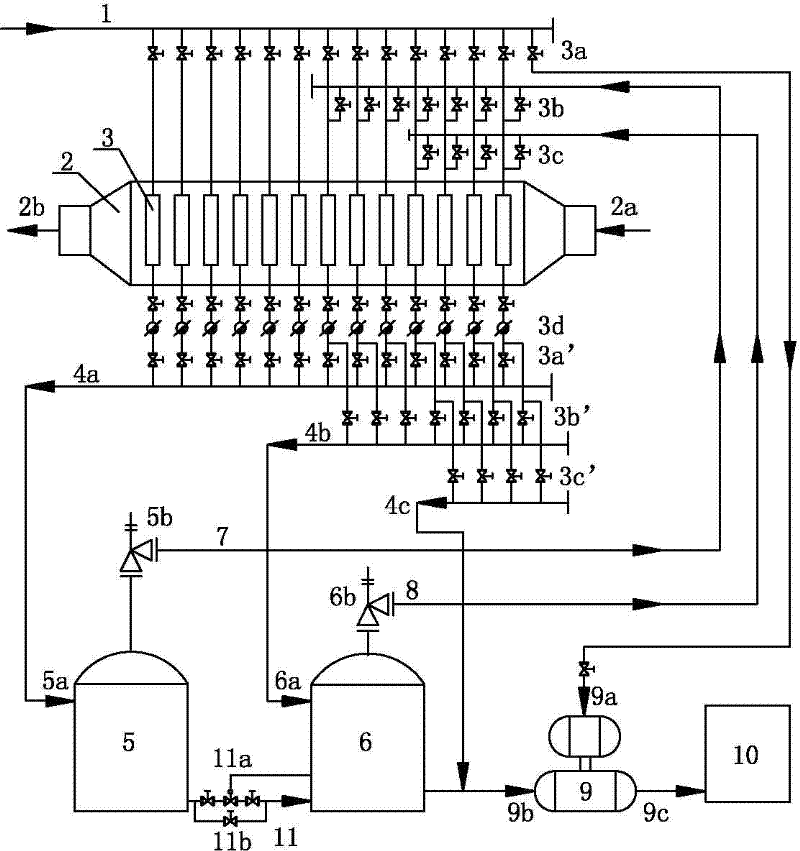

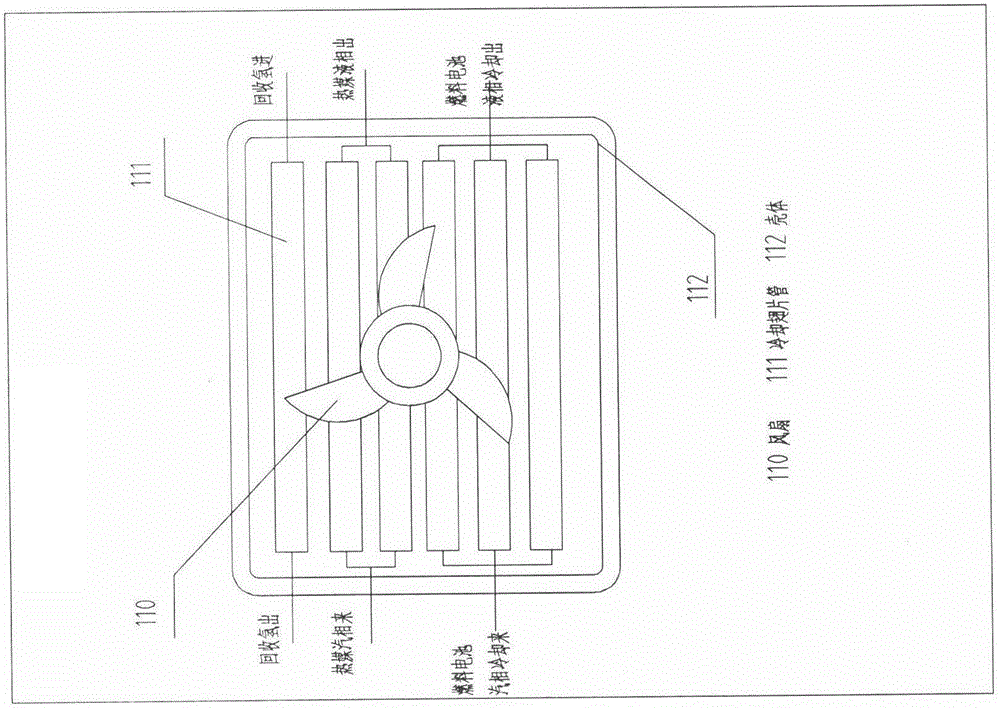

Multi-effect flash evaporation system for utilizing condensed water waste heat in air-heating coil group

ActiveCN102410755AGuaranteed to eat dryLow flash rateStationary tubular conduit assembliesHeat exchange apparatusSteam pressureEngineering

The invention relates to a multi-effect flash evaporation system for utilizing condensed water waste heat in an air-heating coil group. A plurality of groups of coil heat exchangers capable of making steam pressure be increased gradually in sequence along an air flowing direction are arranged in the air-heating coil group, and a drain valve is arranged at an outlet of each coil heat exchanger; the coil heat exchanger close to a hot air outlet is connected with a main steam pipe through a main steam valve, condensed water is introduced to a first-stage flash-evaporation tank for flash evaporation and the steam obtained after the flash evaporation is introduced into the coil heat exchanger with the steam pressure inferior to main steam pressure by one stage for heat emission, the condensed water is introduced into a second-stage flash-evaporation tank for flash evaporation and the steam obtained after the flash evaporation is introduced into the coil heat exchanger with the steam pressure inferior to the main steam pressure by two stages for heat emission, the condensed water is introduced into a third-stage flash-evaporation tank for flash evaporation, and so on; and the final-stage flash-evaporation steam is introduced into the coil heat exchanger close to a cold air inlet, the discharged condensed water is introduced into a condensed water pump, and an outlet of the condensedwater pump is connected into a condensed water recovering system. The multi-effect flash evaporation system disclosed by the invention can be used for not only guaranteeing the temperature of hot airto reach a process requirement, but also increasing the utilization efficiency of the steam and reducing the energy consumption of a unit product.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

Steam trap monitor with diagnostics

A steam trap monitor includes a process variable sensor configured to sense a process variable related to operation of a steam trap. A memory contains information related to a baseline parameter of the process variable. Diagnostic circuitry calculates a current parameter of the process variable sensed by the process variable sensor and compares the current parameter of the process variable with the baseline parameter. Based on the comparison, the diagnostic circuitry responsively provides a diagnostic output based upon the comparison. The baseline and current parameter are based on a time period during which the steam trap is open or closed.

Owner:ROSEMOUNT INC

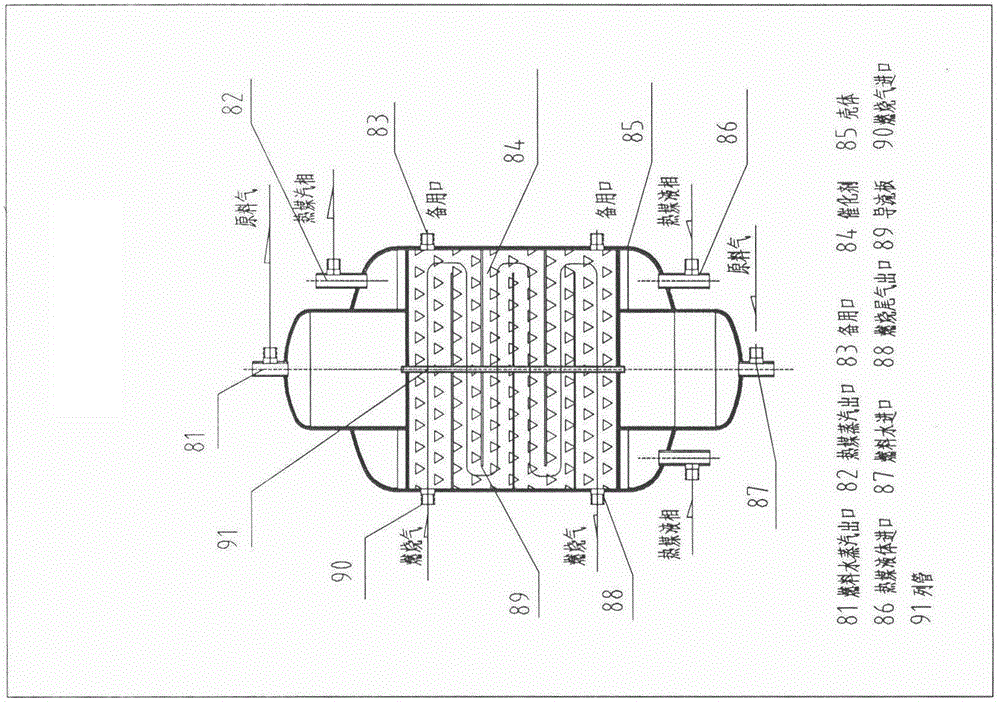

Distributed non-combustion type constant-temperature pressurized power generation system

InactiveCN105895936ASmall fluctuations in heat recoveryExtend your lifeFuel cell auxillariesFuel cell detailsCarbon monoxideVapor–liquid separator

The invention provides a distributed non-combustion type constant-temperature pressurized power generation system. The system comprises a water tank (1), a fuel storage tank (2), a fuel water proportioning pump (3), a mixer A (4), a fuel atomizer (5), a second heat exchanger (26), a first heat exchanger (25), dehydration tanks (27, 28 and 12), a carbon monoxide removal reactor (11), a catalytic combustion reactor (6), a fuel water reforming reactor (29), a composite air-cooling heat sink (22), a hydrogen-air pressure balancer (14), a fuel cell cooling liquid tank (13), a compressed air heat exchanger (23), a fuel cell cooling circulation pump (15), a recycled hydrogen compressor (21), a hydrogen-rich storage tank (19), a hydrogen recycle membrane separator (17), a hydrogen fuel cell pack (16), an exhaust purifier (7), an expansion compressor (9), a control valve (18), a (normal-pressure fuel water) vapor-liquid separator (20), a mixer B (8), a mixer C (10), a mixer D (24), a steam trap (30), a system controller (31), a one-way valve (41) and valves (42-54). By applying an energy state theory, a vapor-liquid two-phase coexistence constant-temperature condensation or evaporation principle and phase-change heat-transfer highest efficiency principle, hydrogen production by reforming and constant-temperature control on a hydrogen fuel battery are achieved.

Owner:YANGZHOU SANYE NEW ENERGY SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com