Centrifugal gas-liquid separator

A gas-liquid separator, centrifugal technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of power consumption, instability, need for driving devices, etc., to improve safety and reliability, Good separation effect, saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

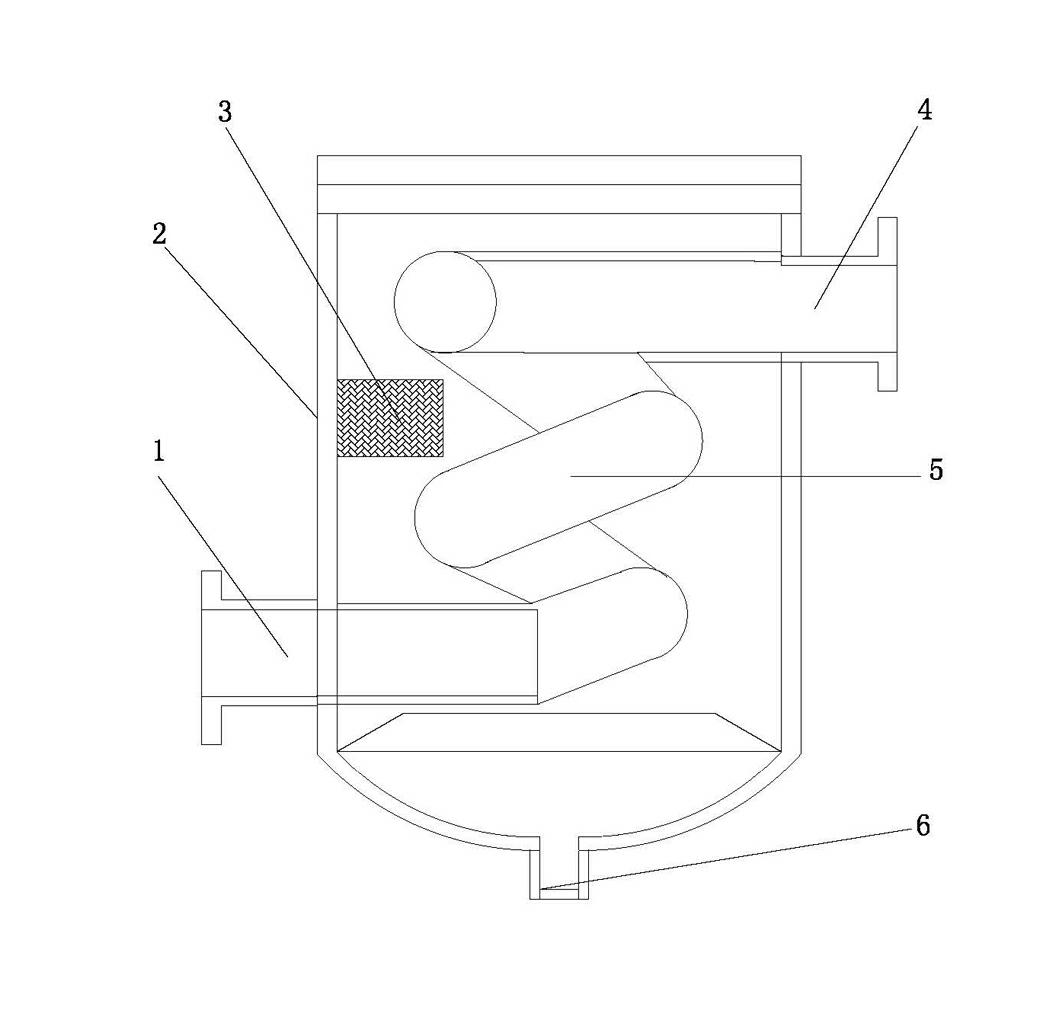

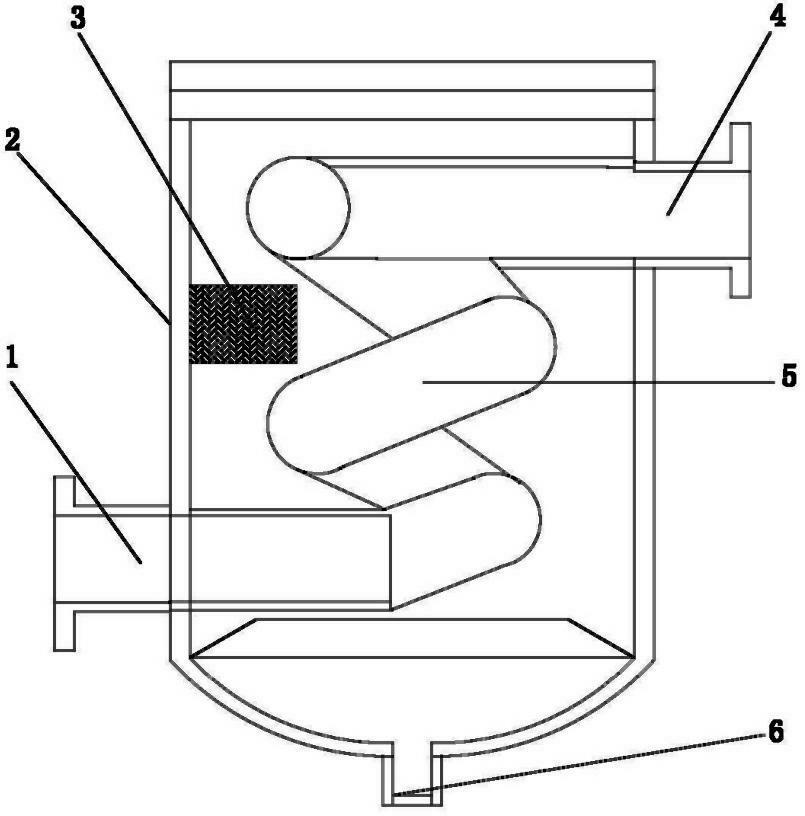

[0012] as attached figure 1 As shown, the present invention discloses a centrifugal gas-liquid separator mainly used in conjunction with an air compressor. The centrifugal gas-liquid separator comprises a tank body 2, the bottom of the tank body 2 is provided with an air inlet pipe 1, the upper part of the tank body 2 is provided with an air outlet pipe 4, and the bottom of the tank body 2 is provided with a drain valve 6, and the inside of the tank body 2 is provided with Spiral pipe 5, one end of the spiral pipe 5 communicates with the air inlet pipe 1, and the other end communicates with the outlet pipe 4, the pipe wall of the spiral pipe 5 is provided with vent holes, the tank body 2 is filled with silk screen 3, and the spiral pipe 5 is in the tank. The body 2 is in a spiral state. The space b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com