Multi-effect flash evaporation system for utilizing condensed water waste heat in air-heating coil group

An air heating and condensing water technology, applied in lighting and heating equipment, fixed tubular conduit components, heat exchange equipment, etc., can solve the problems of steam waste, increase of steam trap back pressure, and decrease of steam trap displacement, etc. The effect of low evaporation rate, high flash steam temperature, and low flash volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

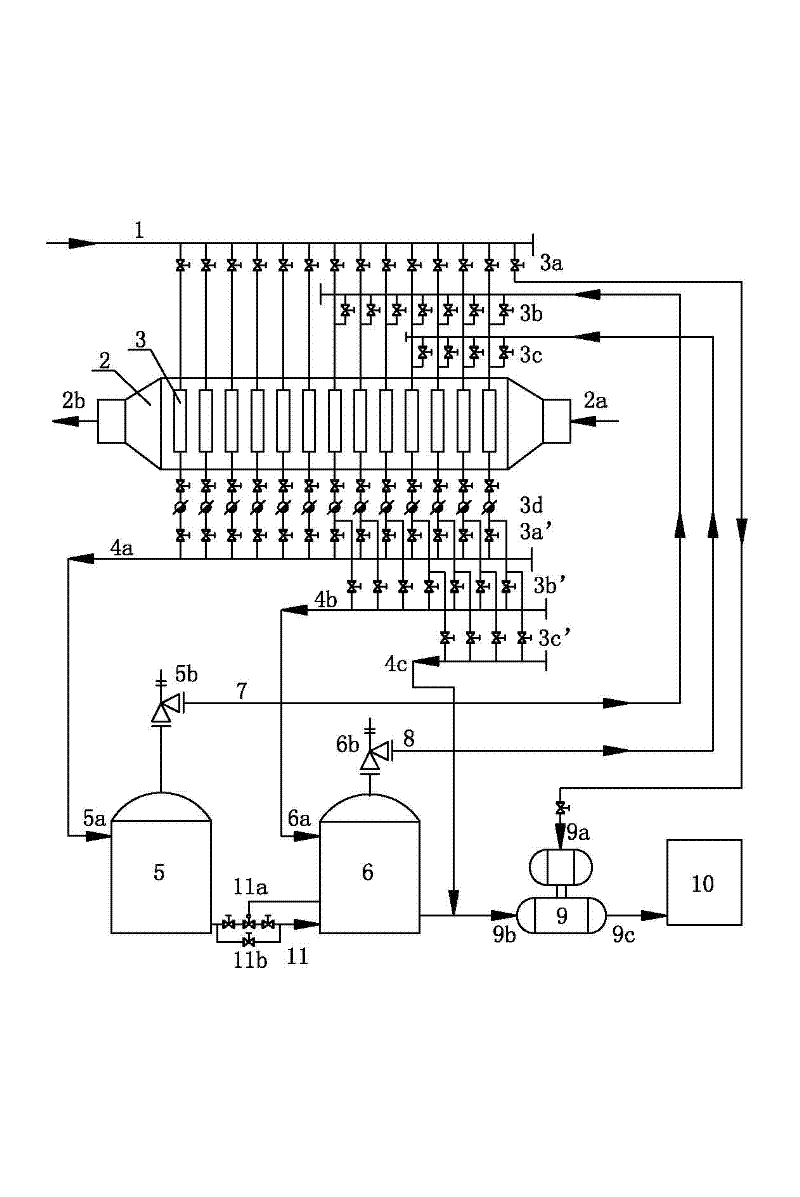

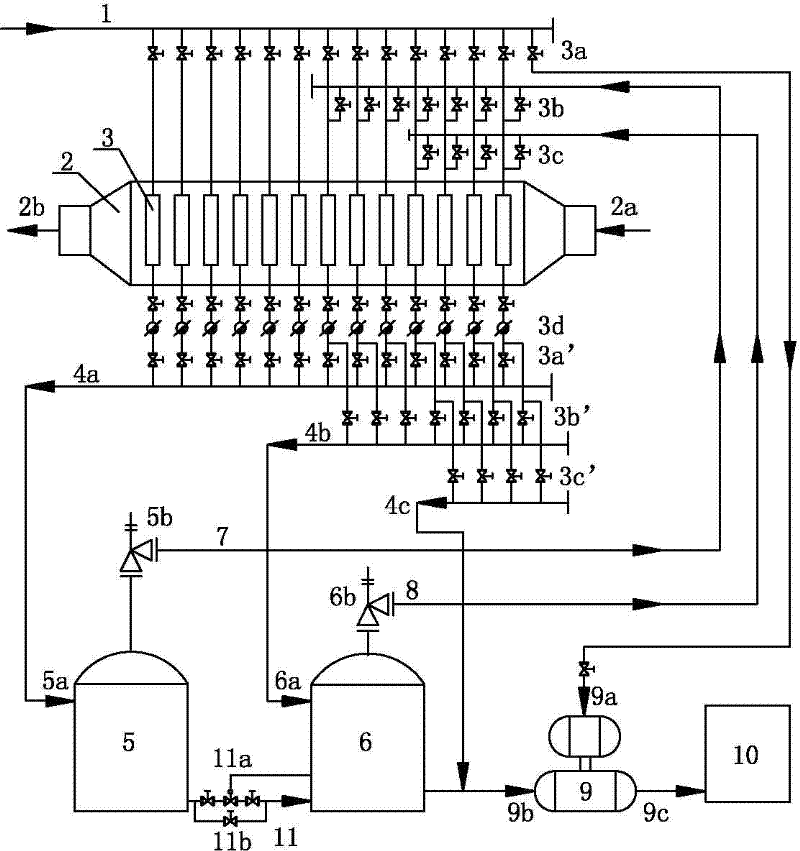

[0014] figure 1 Taking the two-effect flash utilization system as an example, the two-effect flash utilization system includes main steam pipe 1, air heating coil group 2, first-stage flash tank 5, second-stage flash tank 6 and condensate pump; air heating The coil group 2 includes a casing, one end of the casing is provided with a cold air inlet 2a, and the other end is provided with a hot air outlet 2b, and the casing is sequentially provided with an inlet coil heat exchanger and a middle coil heat exchanger along the air flow direction. The inlet of each coil heat exchanger 3 is connected to the main steam pipe 1 through the main steam valve 3a, and the outlet of each coil heat exchanger 3 is respectively connected to the condensate water cut-off before the steam trap. Valve, steam trap 3d, main steam condensate stop valve 3a'.

[0015] The outlets of each main steam condensate shut-off valve 3a' are respectively connected to the main steam condensate pipe 4a, and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com