Control method of combustion system of circulating fluidized bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied to fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problem of limiting the variable load rate of CFB units, not considering the impact, and not being able to provide timely adjustments To achieve the effect of quickly and accurately following load changes, ensuring performance robustness, and ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

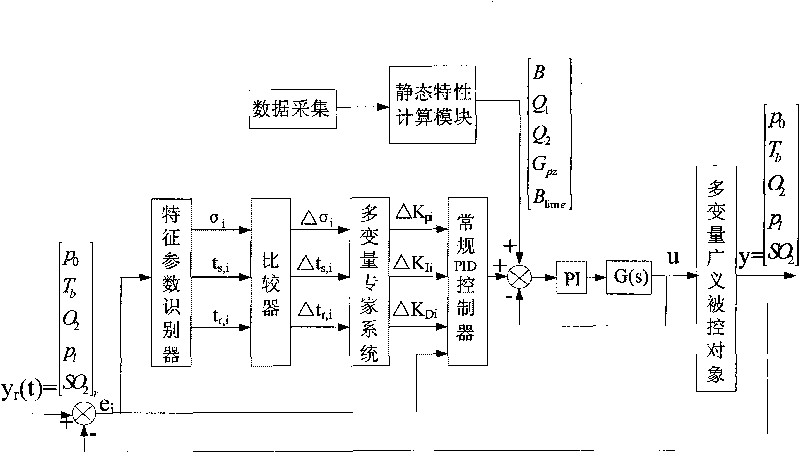

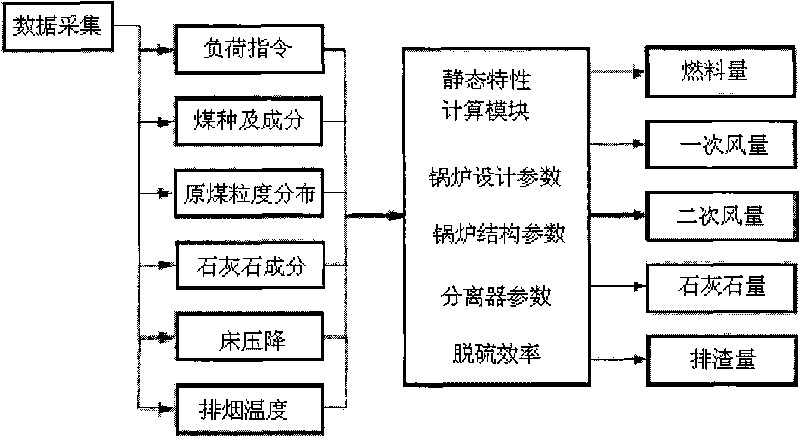

[0021] Such as figure 1 and 2A control method for a circulating fluidized bed boiler combustion system includes an online calculation module for boiler static characteristics and a multivariable expert intelligent self-tuning PID control system. The specific method of the control is as follows:

[0022] First, set up the online calculation module of the static characteristics of the circulating fluidized bed boiler, calculate the coal feed volume, limestone volume, and slag discharge volume that can ensure the optimal combustion of the CFB boiler under different loads, and optimize the primary air volume and secondary air volume required for the optimal ratio. Air volume; apply them as load feed-forward signals to the main steam pressure control loop, limestone volume adjustment loop, bed pressure drop control loop, bed temperature control loop and oxygen volume control loop;

[0023] Secondly, expert intelligent self-tuning PID controllers are used for each control loop to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com