Patents

Literature

365 results about "Fluidized bed combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels. In its most basic form, fuel particles are suspended in a hot, bubbling fluidity bed of ash and other particulate materials (sand, limestone etc.) through which jets of air are blown to provide the oxygen required for combustion or gasification. The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC plants are capable of burning a variety of low-grade solid fuels, including most types of coal and woody biomass, at high efficiency and without the necessity for expensive fuel preparation (e.g., pulverising). In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace, so may offer significant advantages over the latter in terms of cost and flexibility.

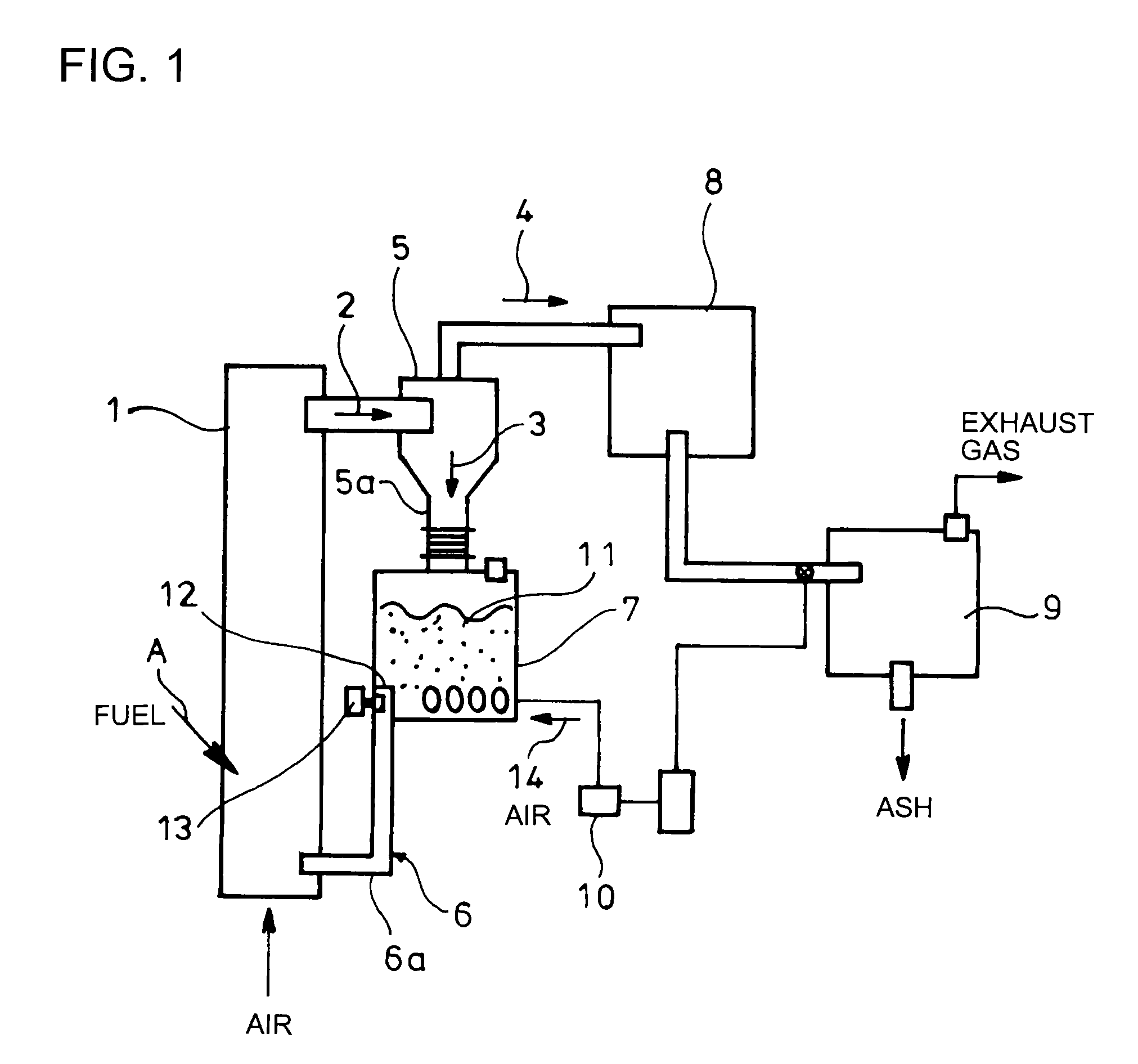

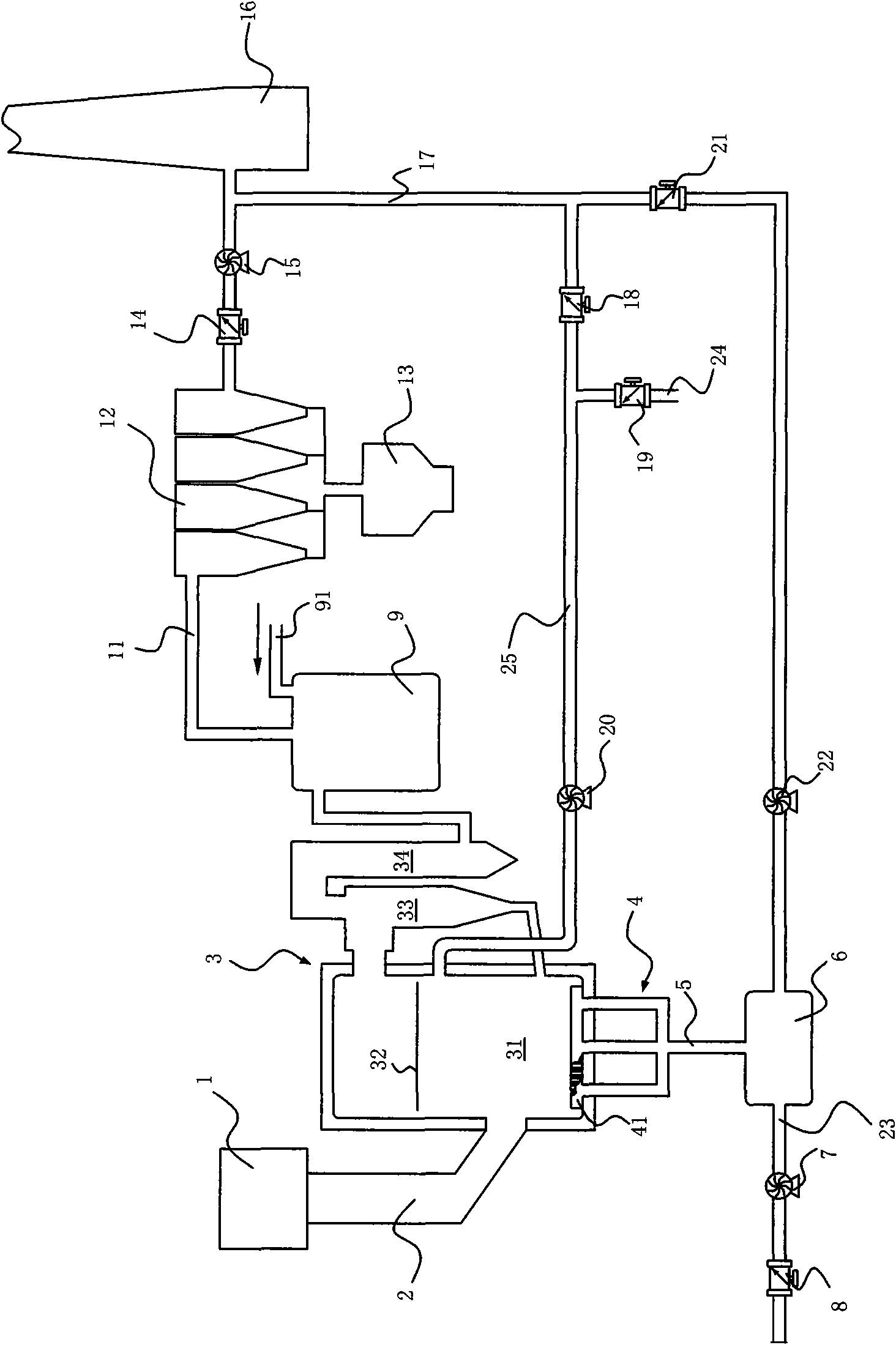

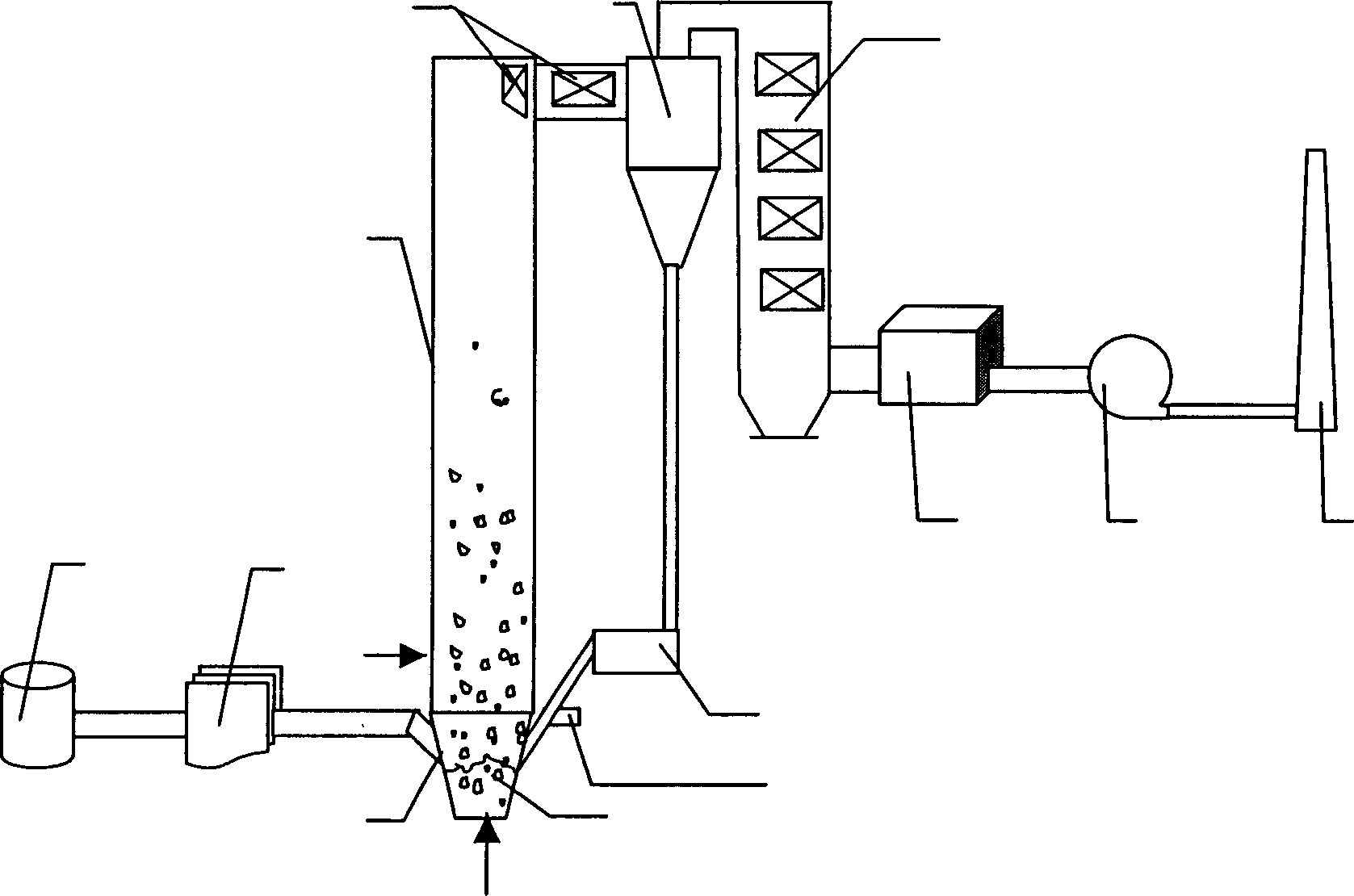

Method and device for pyrolyzing and gasifying organic substances or substance mixtures

InactiveUS7214252B1Small particle sizeAllow useFluidized bed combustionSolid waste disposalReaction zoneAmount of substance

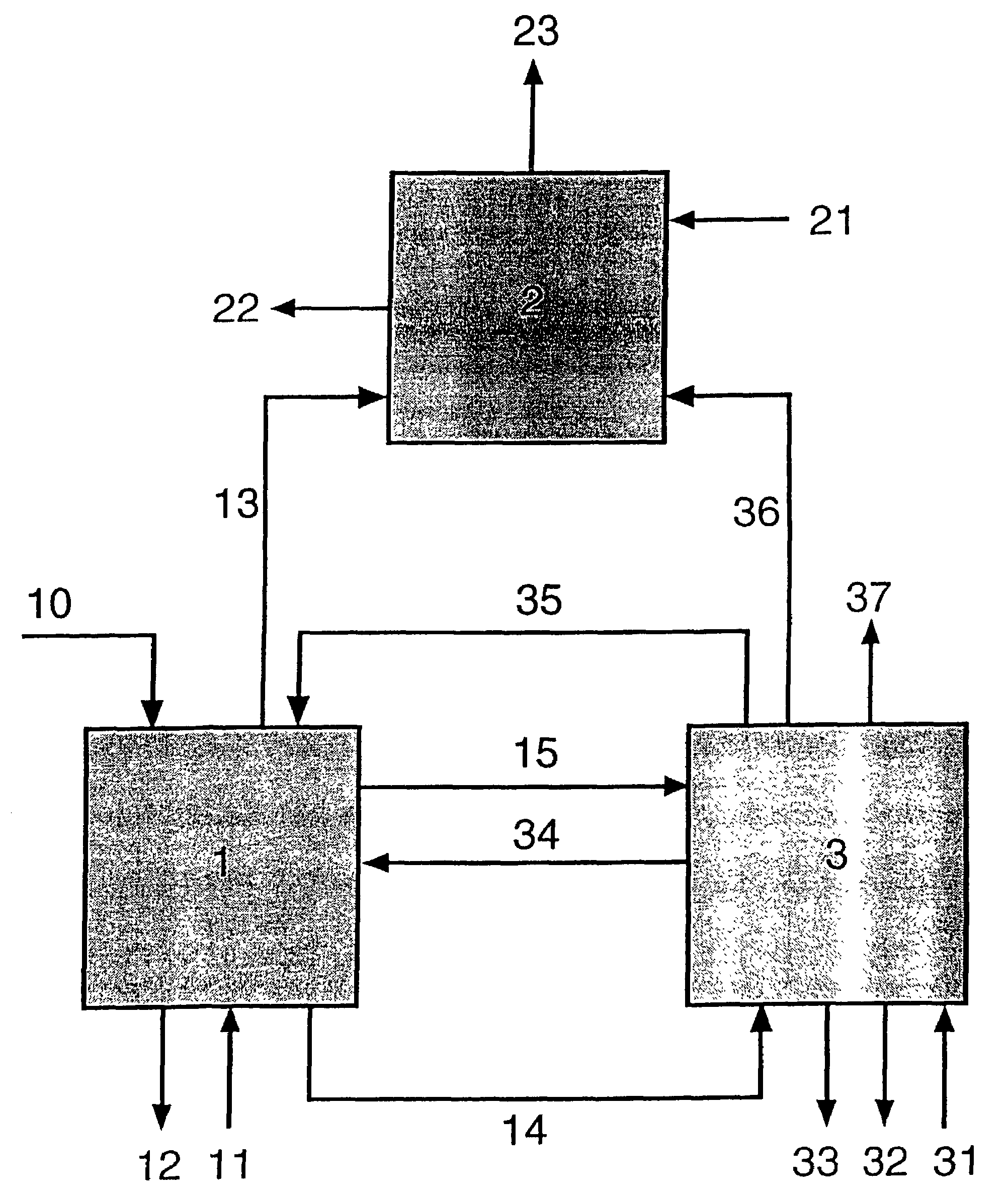

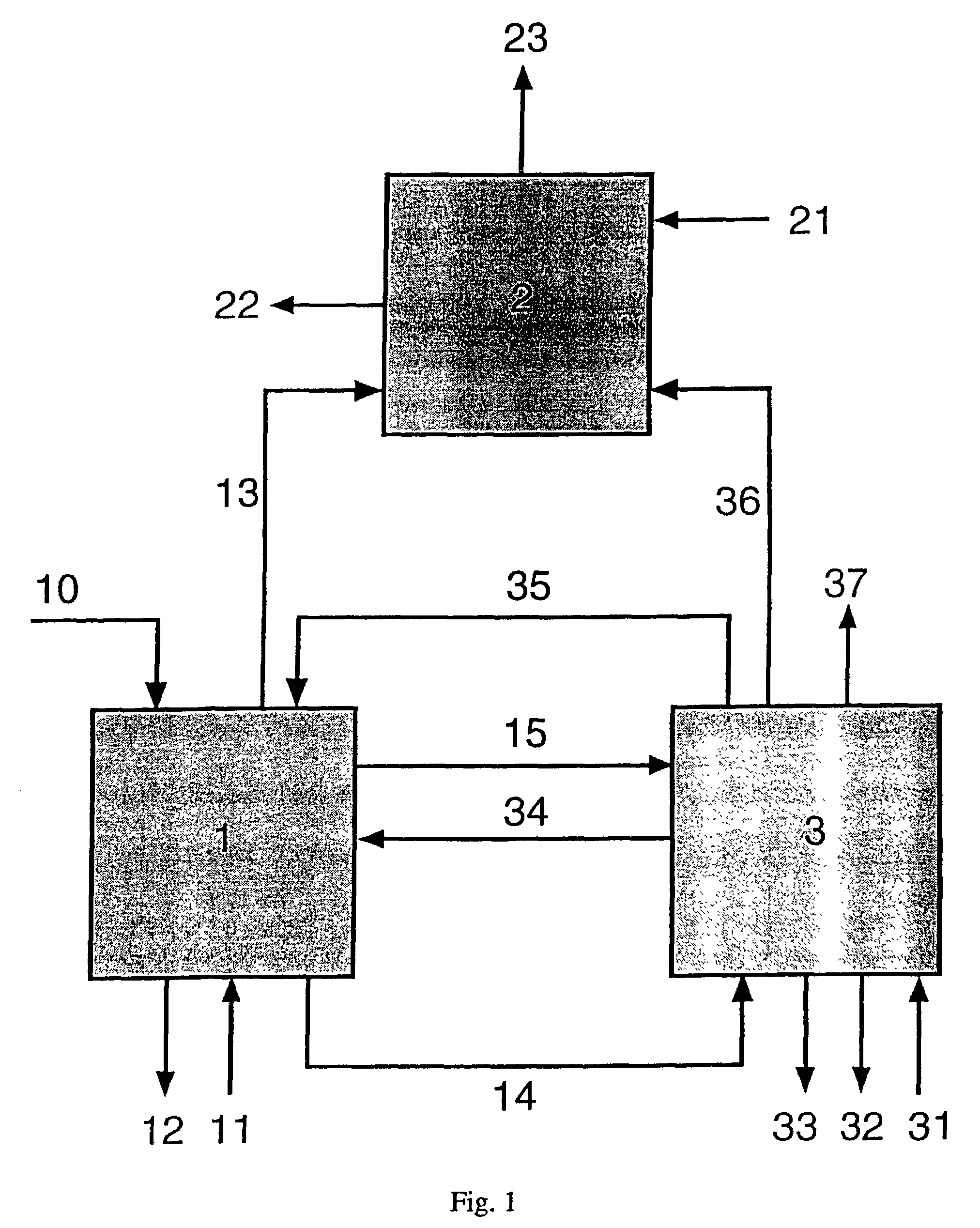

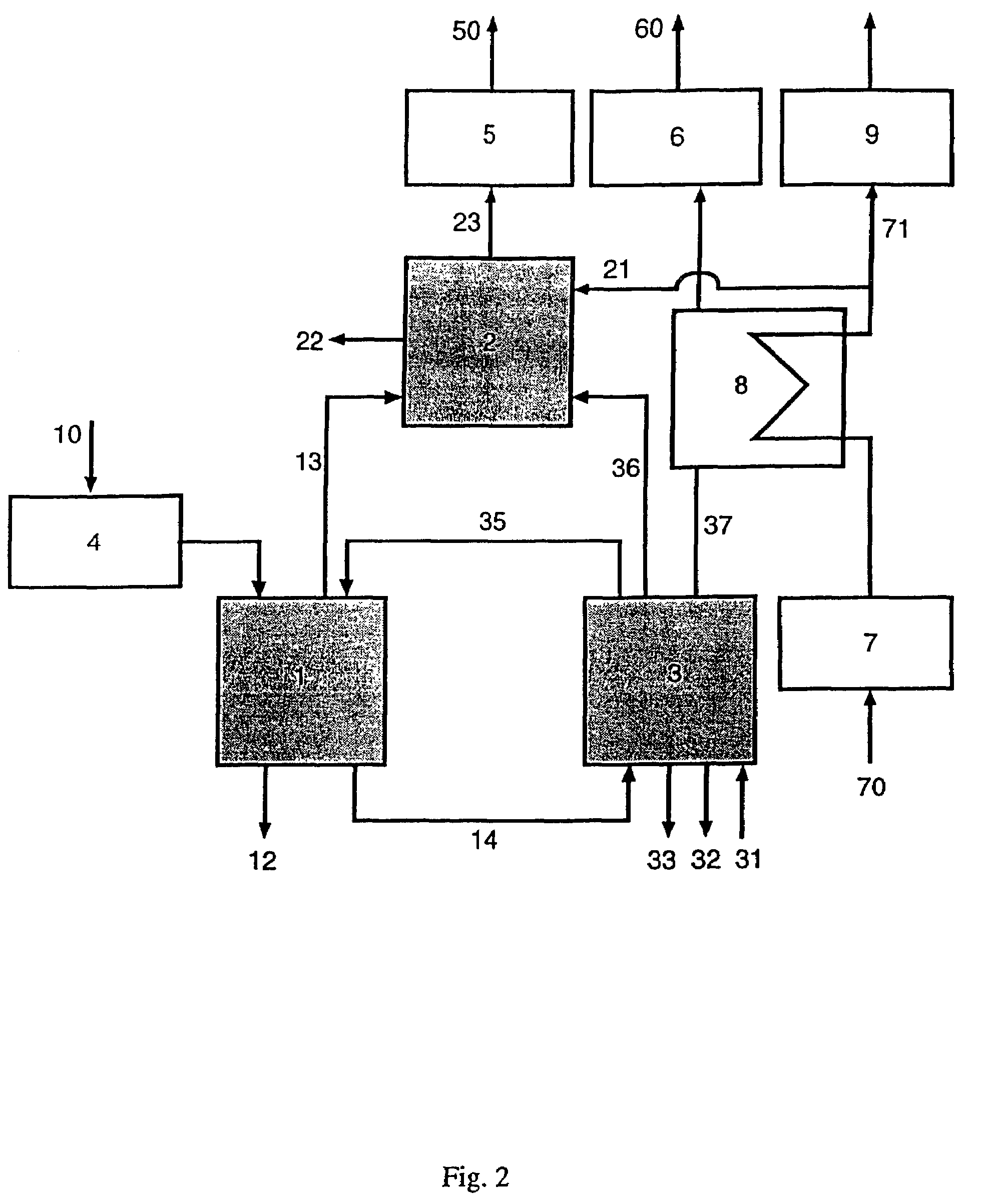

An apparatus for pyrolysis and gasification of organic substances and mixtures thereof is provided with a pyrolysis reactor (1), a fluidized-bed firing (3) for pyrolysis residue, a reaction zone (2) for the pyrolysis gases (13) and circulating fluidized-bed material (35). The pyrolysis reactor (1) has a sluice for introducing application material (10) thereinto. An inlet for the fluidized-bed material (35) is disposed next to the combustion fluidized bed (3). Transport apparatus (14) for mixture of solid pyrolysis residue and circulating fluidized bed material (35) is disposed at or near a bottom of the fluidized bed (3) and lower end of the pyrolysis reactor (1). An overflow is situated at or near the top of the fluidized bed (3) while a heat transfer member is positioned within the reaction zone (2).

Owner:HERHOF UMWELTTECHN

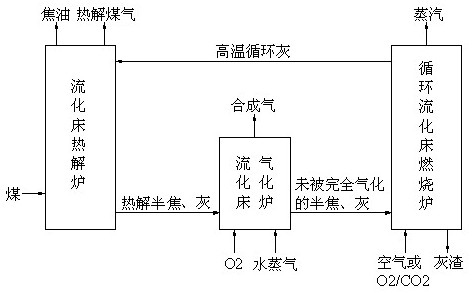

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

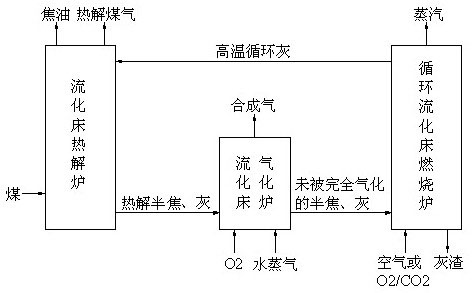

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

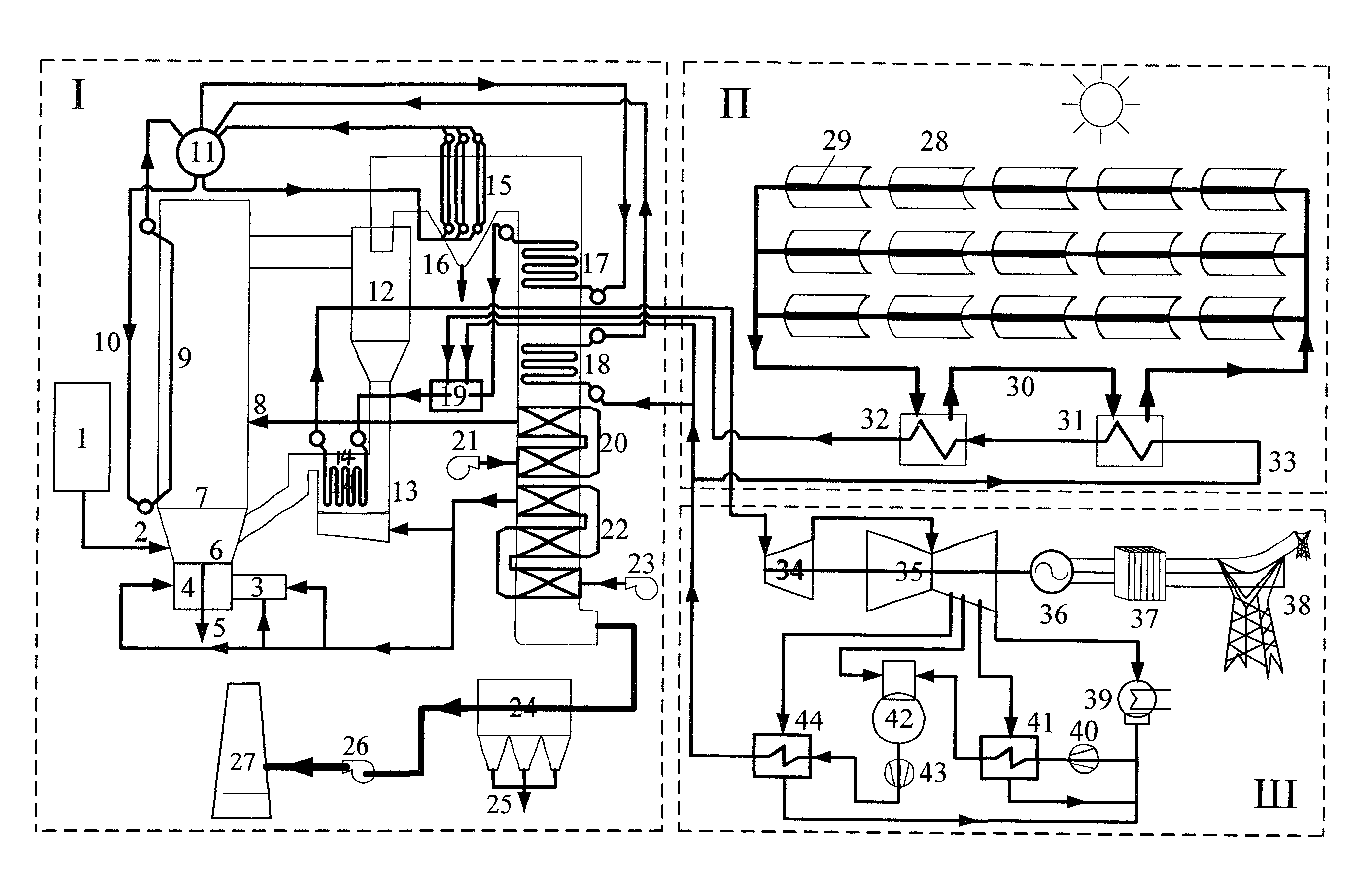

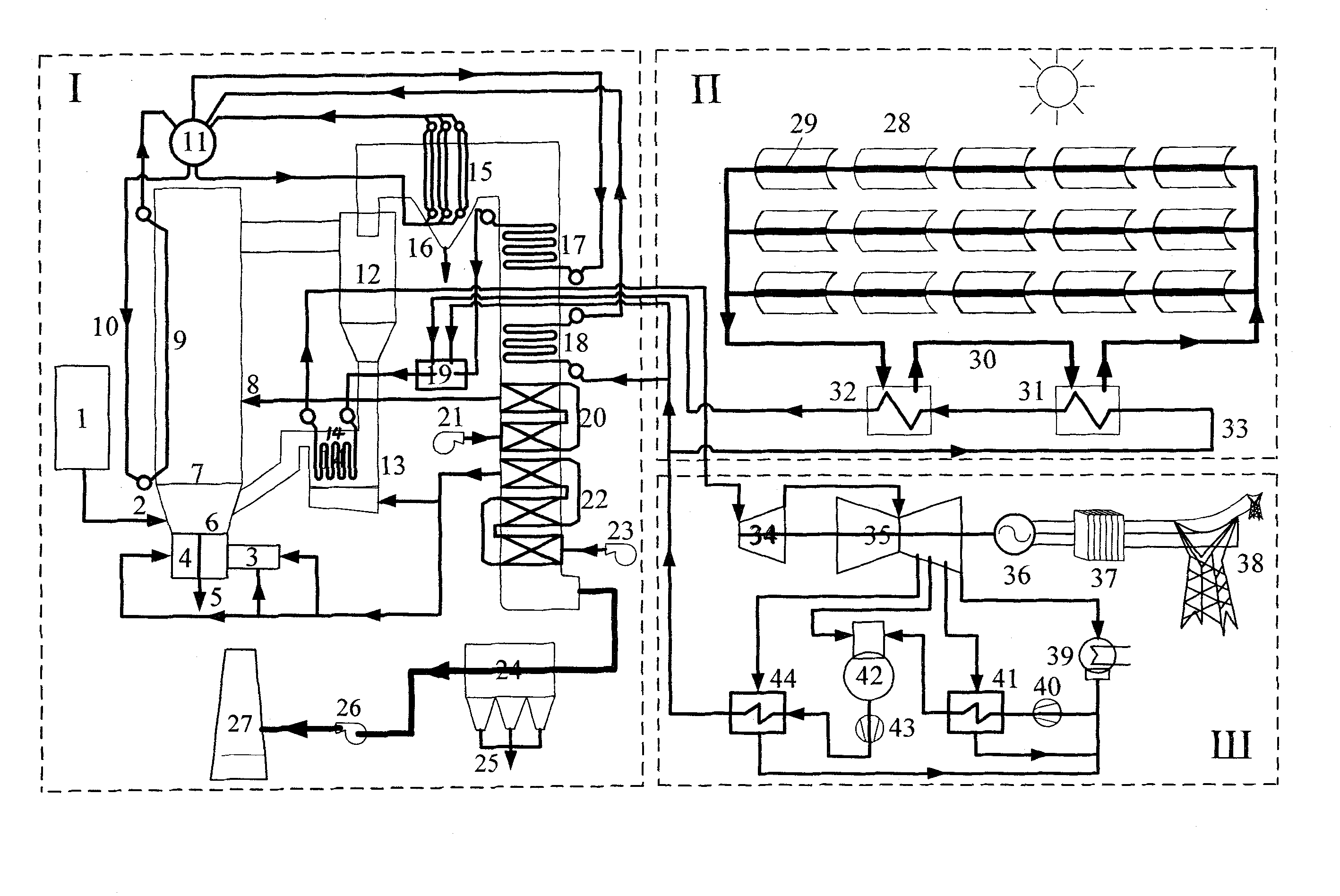

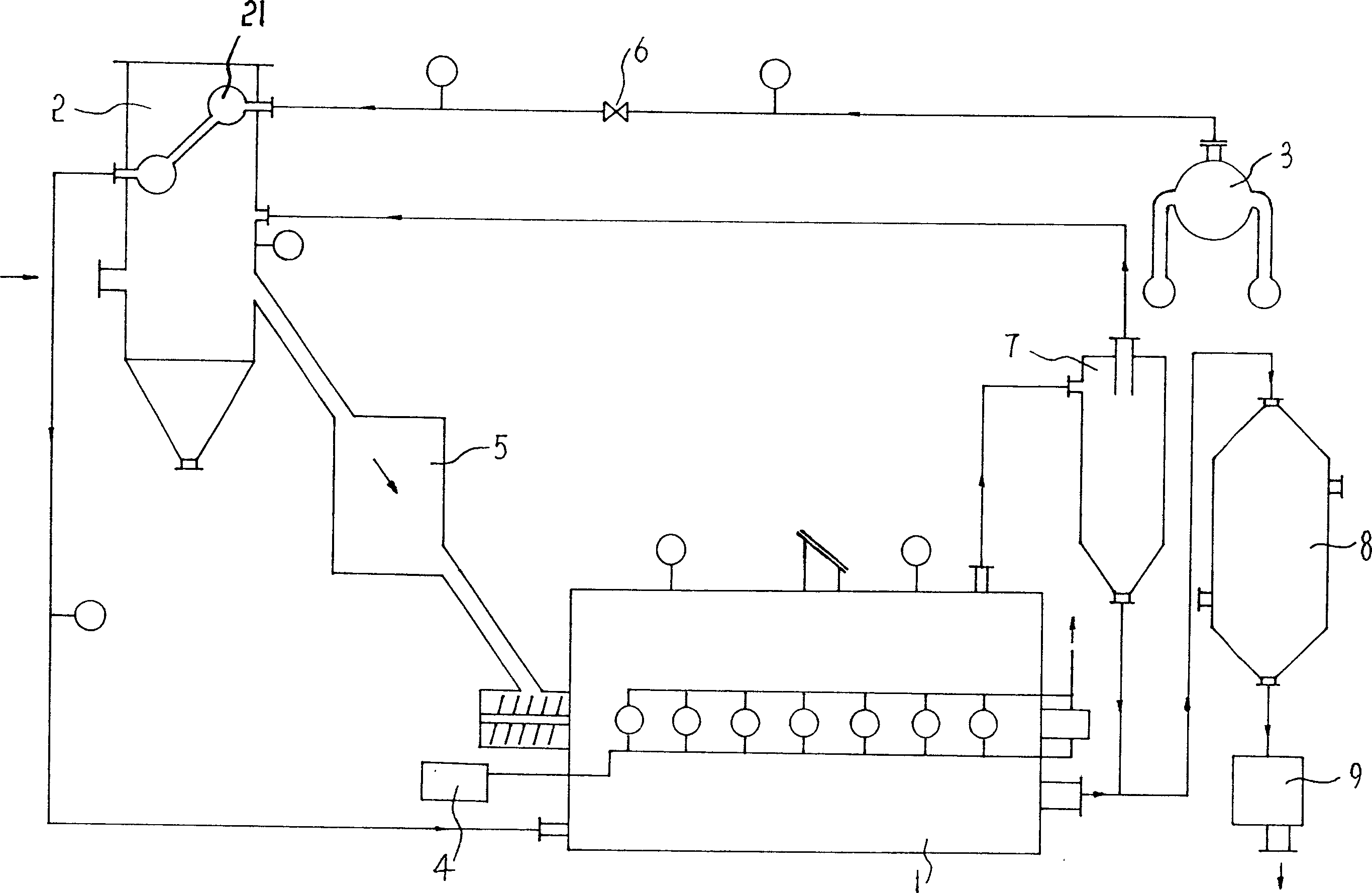

Solar energy and biomass energy integrated complementary combined thermal power generating system

ActiveCN101787906ARealize rationalityRealize comprehensive utilizationSteam generation heating methodsFrom solar energyEngineeringSystem stability

The invention discloses a solar energy and biomass energy integrated complementary combined thermal power generating system, which comprises a biomass circulating fluidized bed combustion boiler system, a solar heat absorption conversion system and a team turbine power generating system, wherein under the condition of the sun radiation, the biomass circulating fluidized bed combustion boiler system and the solar heat absorption conversion system are combined with the steam turbine power generating system to run, so the solar energy radiation heat is converted to the heat energy to be used for heating water, and finally the steam is heated to be the middle-temperature middle-pressure or the high-temperature high-pressure steam so as to drive the steam turbine unit to generate power; and under the condition that no sun radiation exists or the solar heat absorption conversion system has malfunction and is required to be examined, the solar heat absorption conversion system is disconnected, but the biomass circulating fluidized combustion boiler system and the steam turbine power generating system are still maintained to run normally. The solar heat utilization system is reasonably integrated into the biomass power generating system; and moreover, the combined power generating system has the advantages of low investment cost, high power generation efficiency, good system stability and the like.

Owner:SOUTHEAST UNIV

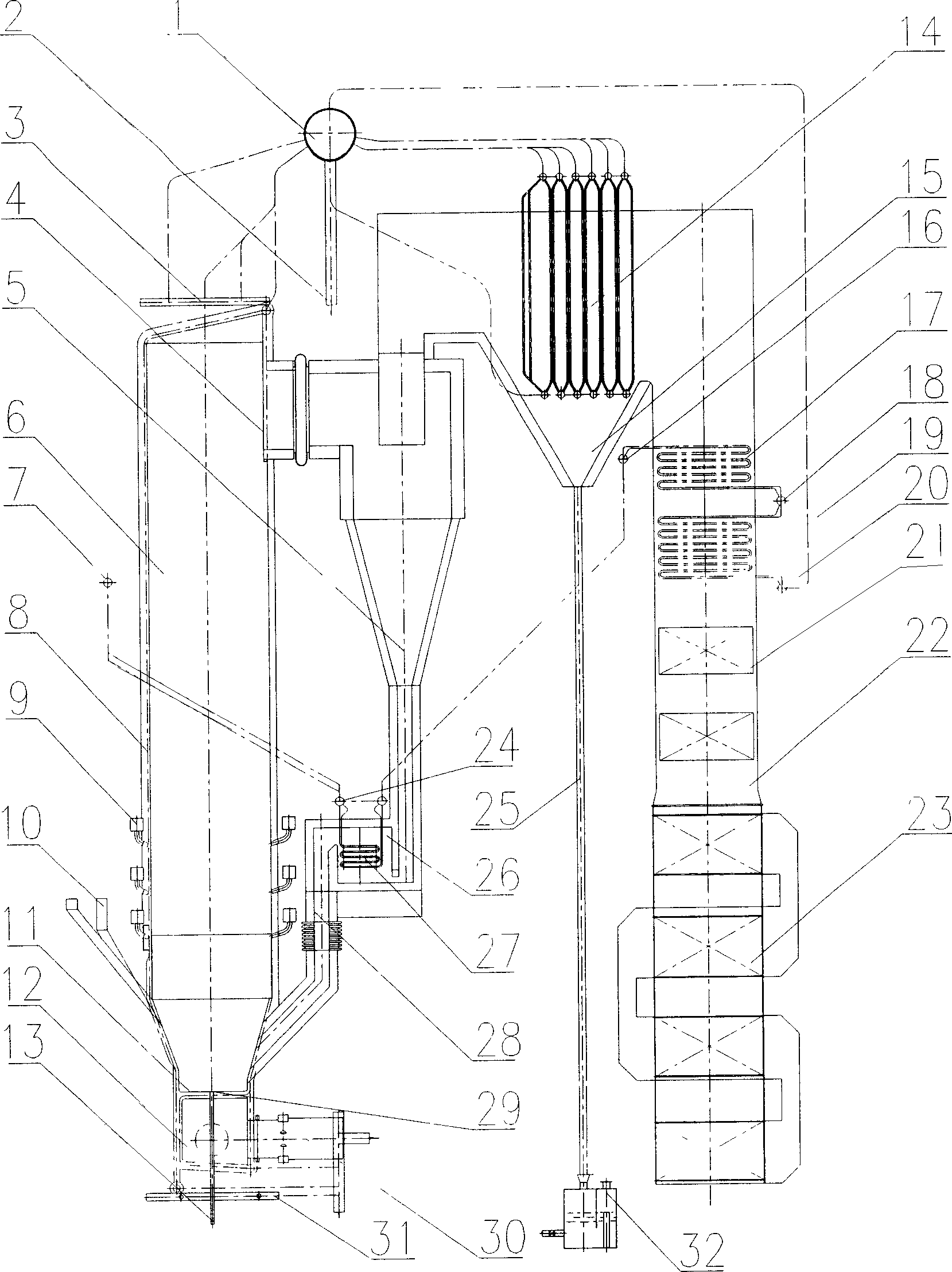

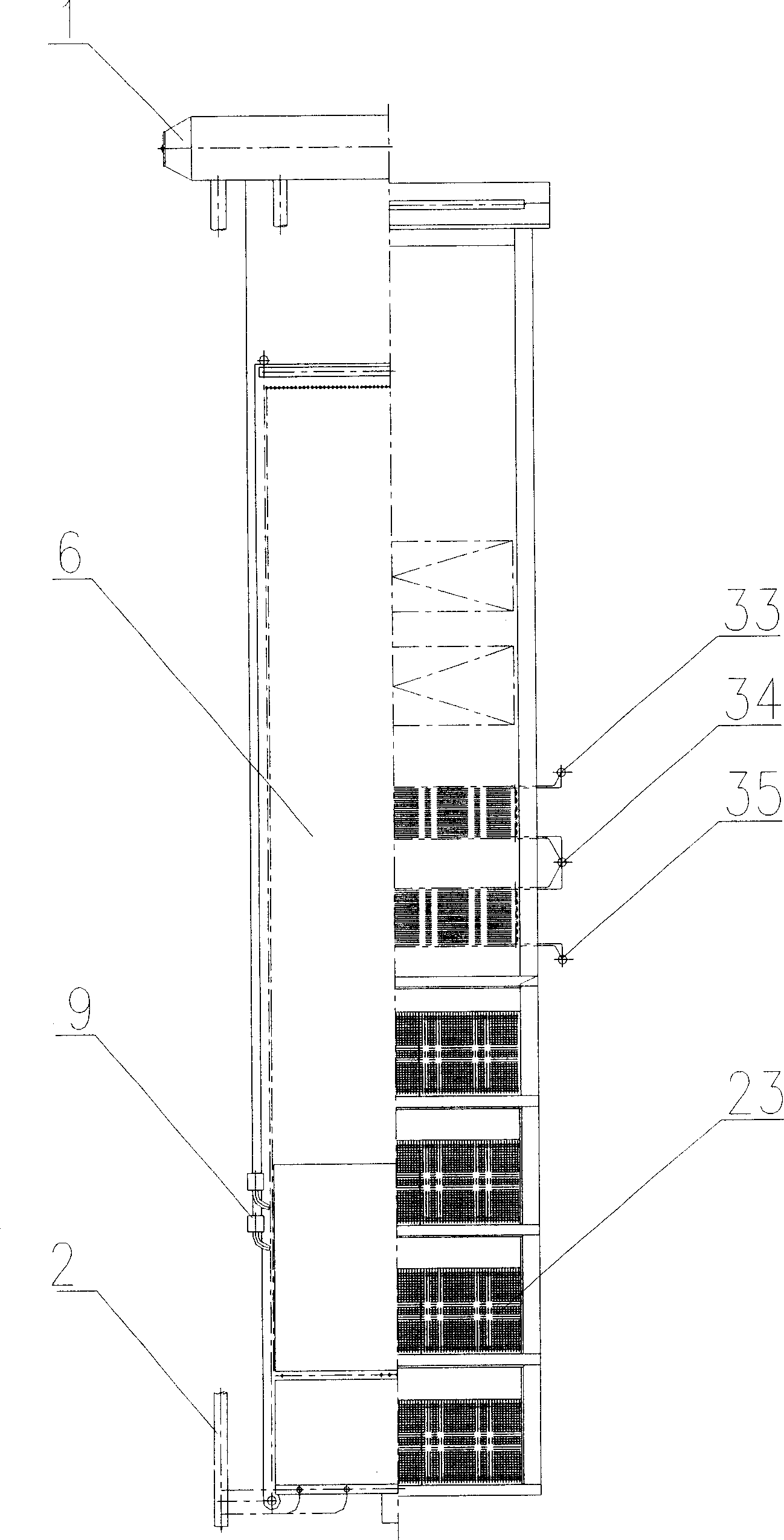

Straw circulation fluidized-bed combustion boiler

InactiveCN1912461AGood load regulation performanceAvoid corrosionFluidized bed combustionCombined combustion mitigationAir preheaterCombustion chamber

A recirculation fluidized bed combustion boiler of straw is prepared as setting material feed mouth and residue extraction mouth on firepot, setting cooling device being connected to ignition combustion chamber and refeeder with secondary wind opening at bottom of firepot, using water cooling wall with top and bottom collection boxes as side wall of firepot, connecting outlet of firepot to separation device being connected to refeeder and two stages of thermo reduction devices separately, connecting one stage of thermo reduction device to a overheat unit with economizer and preheater as well as setting steam pocket and water supply pipe at top of firepot.

Owner:SHANDONG GUODIAN TECH CONSULTING +1

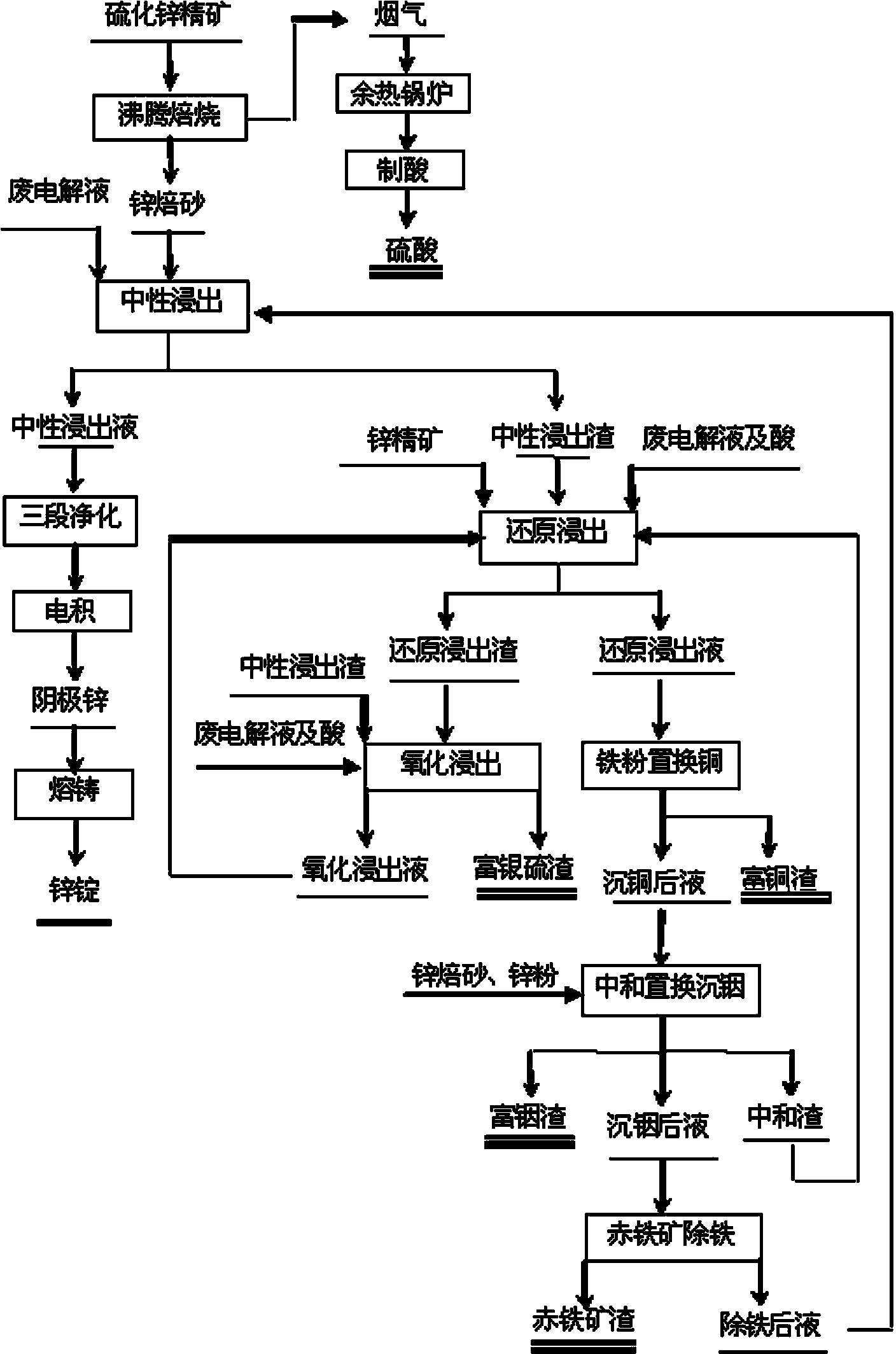

Method for individually processing high-iron zinc sulfide concentrate

ActiveCN103409622AThe process is highly targetedHigh enrichment ratioProcess efficiency improvementIndiumHydrometallurgy

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for individually processing high-iron zinc sulfide concentrate. The method comprises a step of subjecting the high-iron zinc sulfide concentrate to calcination in a fluidized bed combustion boiler to obtain zinc calcine; a step of subjecting the zinc calcine to neutral leaching to produce neutral leaching solution and neutral leaching residue; a step of, after the neutral leaching residue and the high-iron zinc sulfide concentrate are mixed, successively performing reduction leaching and oxidation leaching, and circulating oxidation leaching solution to the reduction leaching to produce reduction leaching solution and silver-rich sulfur residue; a step of replacing the reduction leaching solution by using iron powder to precipitate copper and to produce copper-rich slag and solution after copper precipitation; a step of subjecting the solution after copper precipitation to pre-neutralization by using the zinc calcine, and then replacing by using zinc powder to precipitate indium and to produce indium-rich slag and solution after indium precipitation; and a step of bubbling oxygen into the solution after indium precipitation, heating and removing iron to obtain iron removal solution and hematite slag. The hematite slag can be utilized as a raw material for ironmaking. The method has strong pertinence, short technological process and high metal recovery yield, and the method is clean, efficient, energy-saving and environmental friendly. Separation and comprehensive utilization of zinc, indium, copper and iron are achieved.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

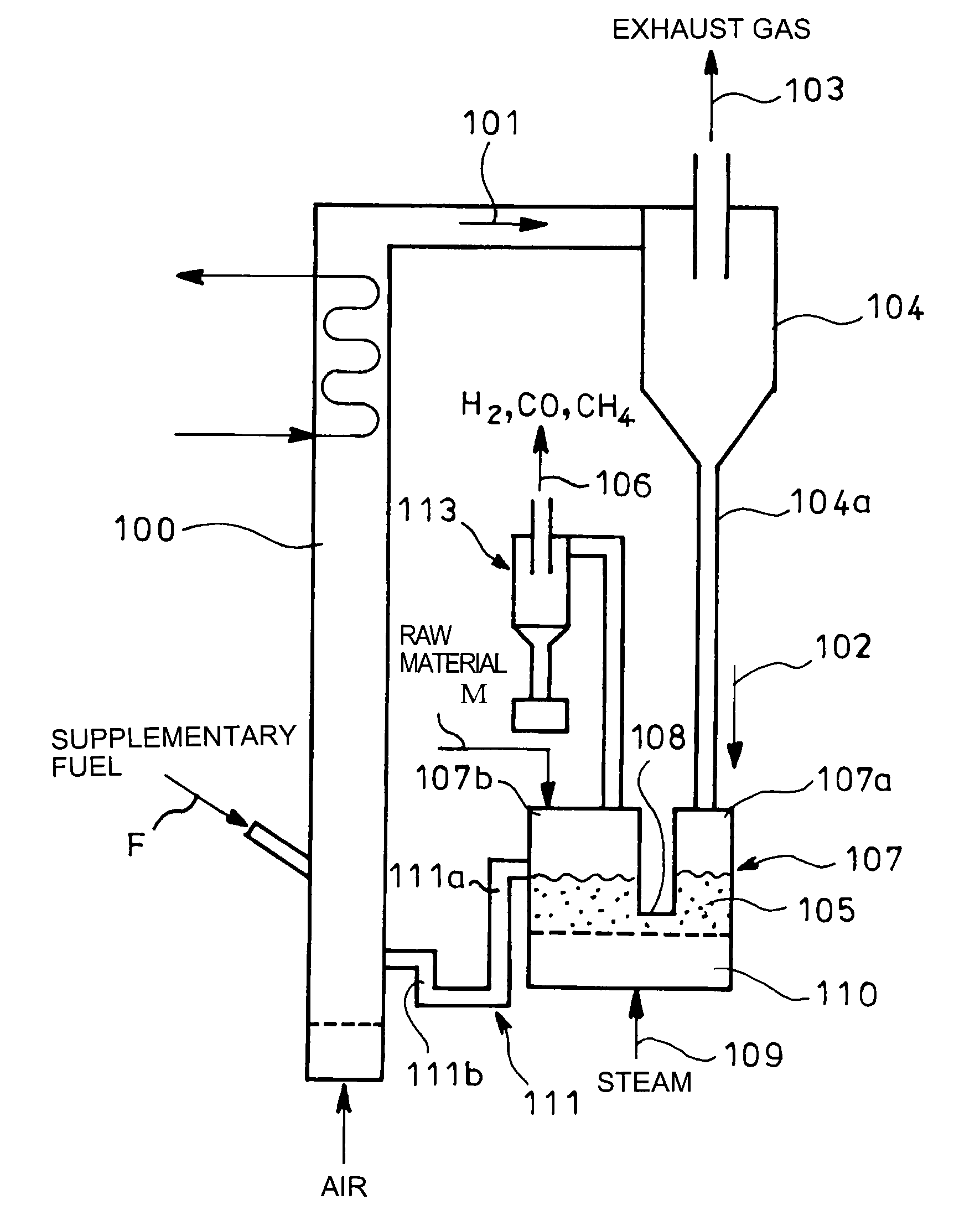

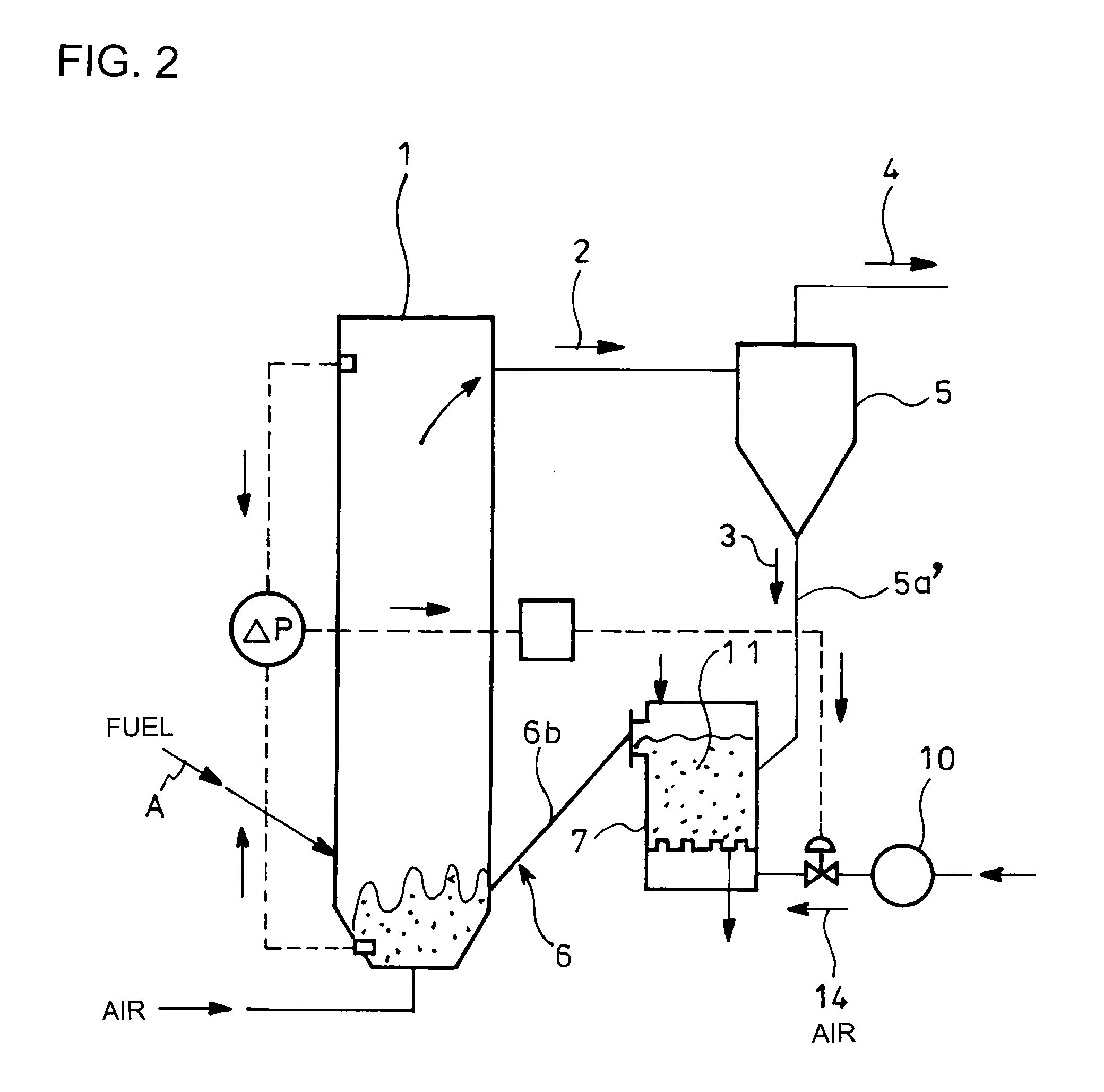

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS20100024297A1Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

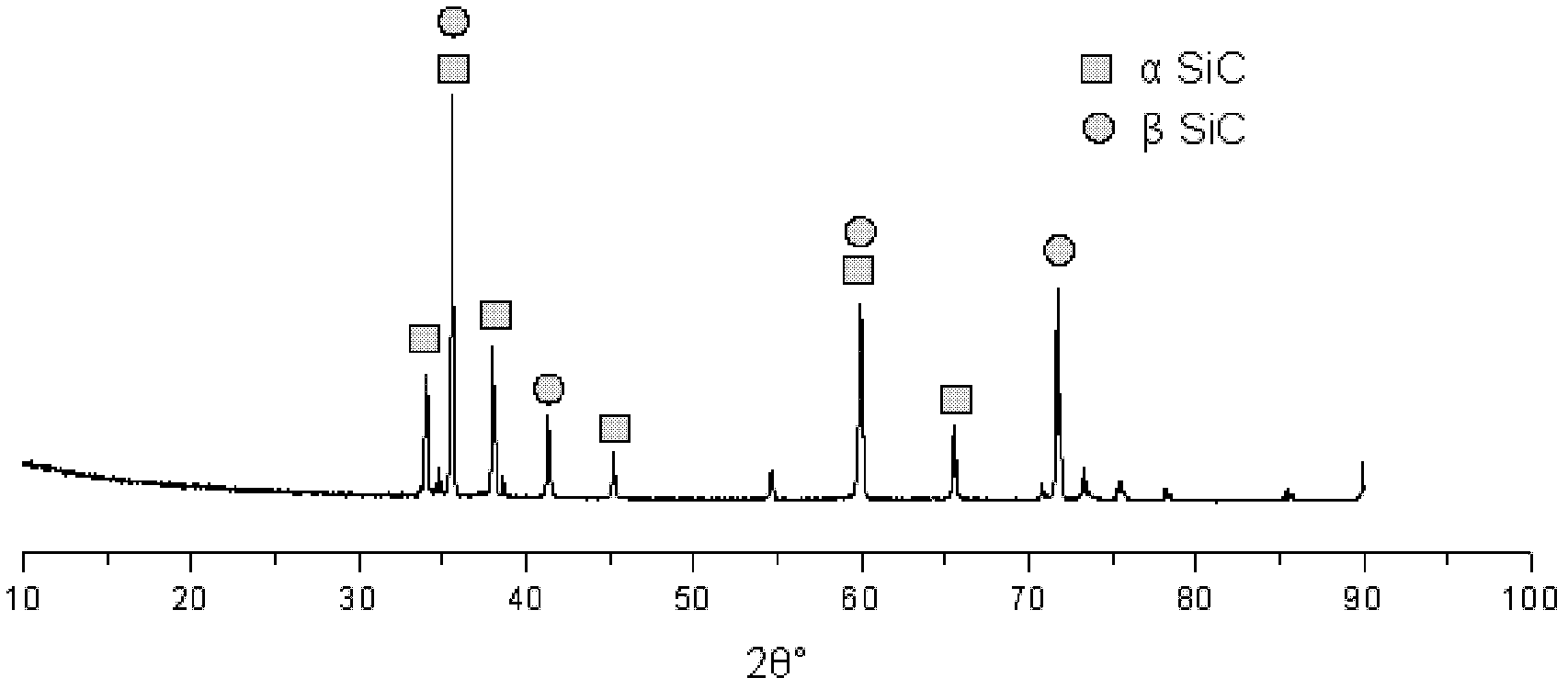

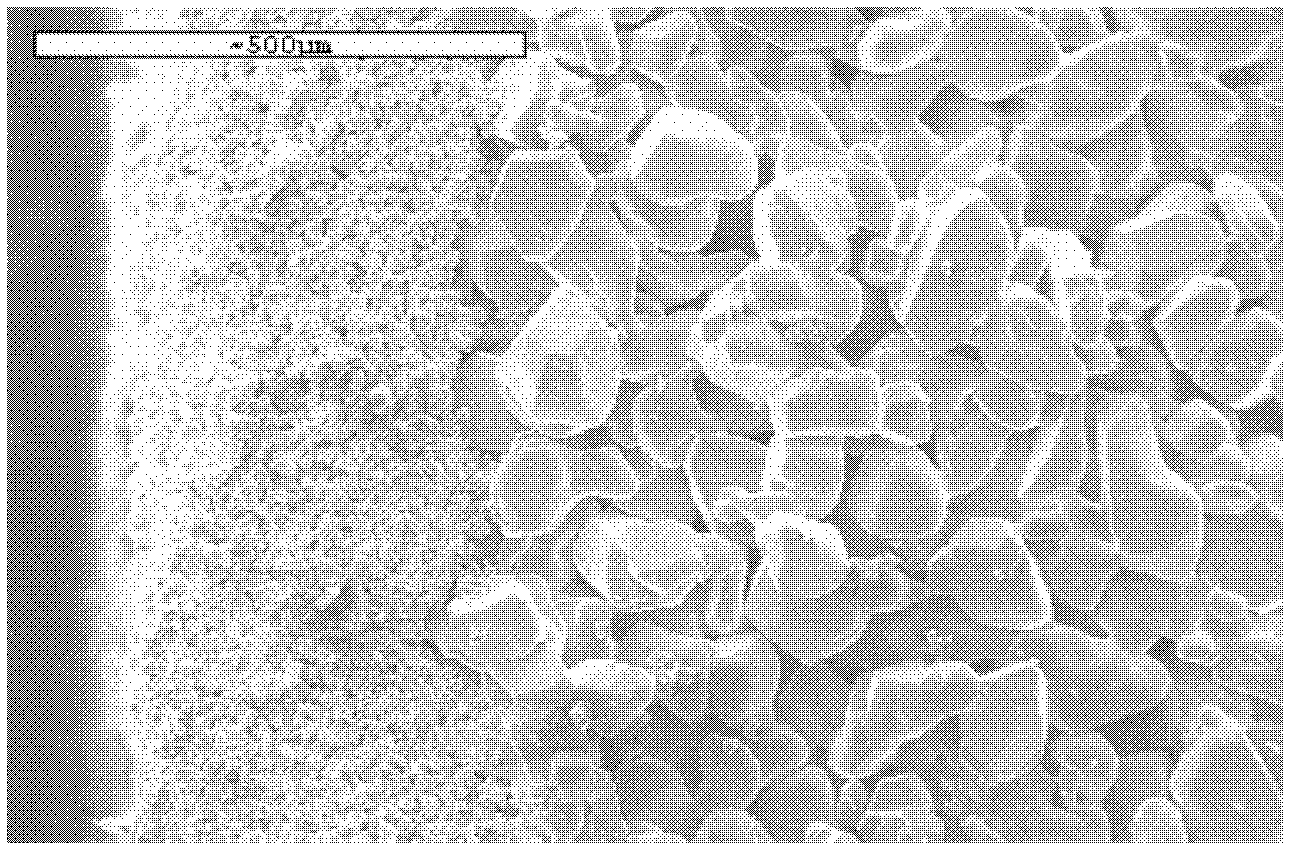

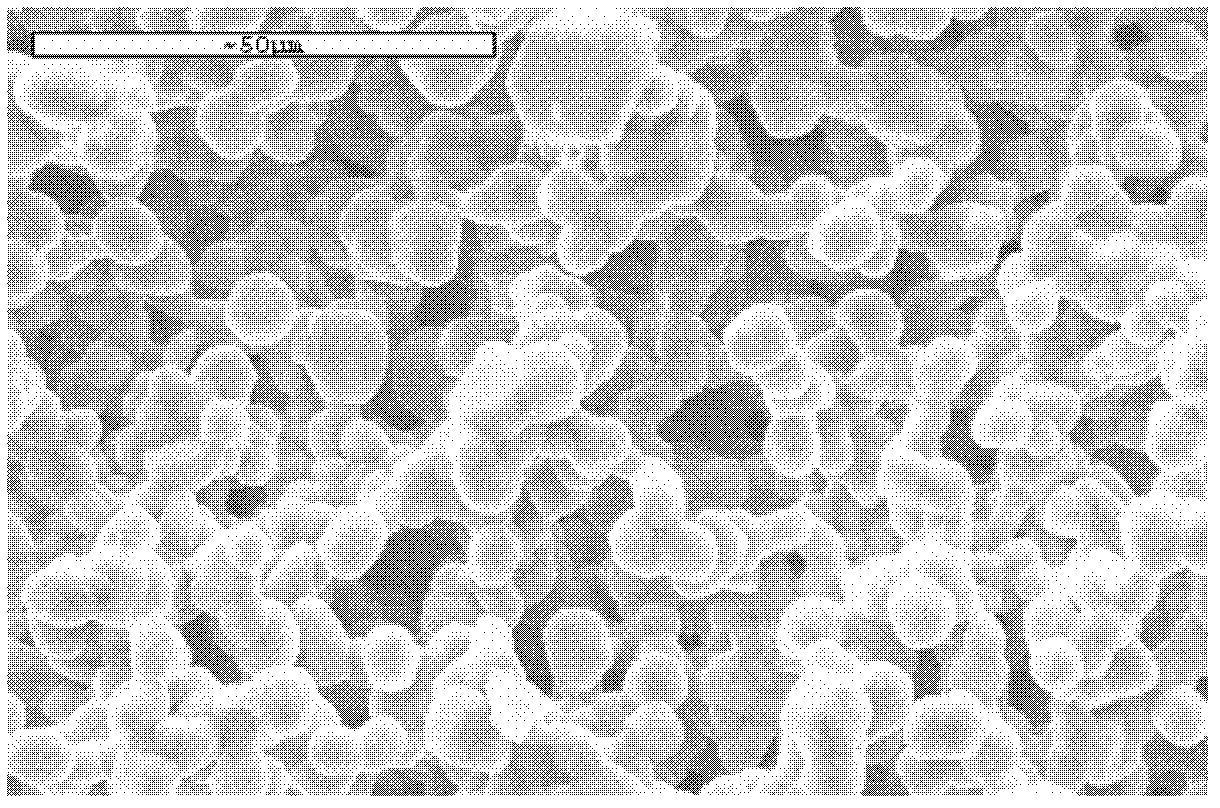

Pure silicon carbide filtering membrane and preparation method thereof

ActiveCN102659447AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

The invention belongs to the technical field of porous ceramic materials and their preparation and especially discloses a pure silicon carbide filtering membrane and a preparation method thereof. The pure silicon carbide filtering membrane has a high porosity, a low pressure drop, high strength, good thermal shock resistance and a high use temperature. The preparation method can be realized easily and can guarantee product performances. The pure silicon carbide filtering membrane comprises pure SiC, is a surface membrane layer obtained by pile-up and binding of fine SiC particles and has aperture sizes of 0.1 to 20 microns and membrane porosity of 25 to 50%. Fine SiC particles, silicon powder, a pore-forming additive and one or more organic resins as raw materials are prepared into a surface membrane layer by spraying or dipping and the surface membrane layer is dried and sintered to form the pure silicon carbide filtering membrane. The pure silicon carbide filtering membrane can be used in an oxidation atmosphere and in a reducing atmosphere, has strong acid corrosion and alkaline corrosion resistance, and can be used for various high / low temperature fluid filtering purification fields such as coal gasification chemical engineering, integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) coal gasification power generation, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

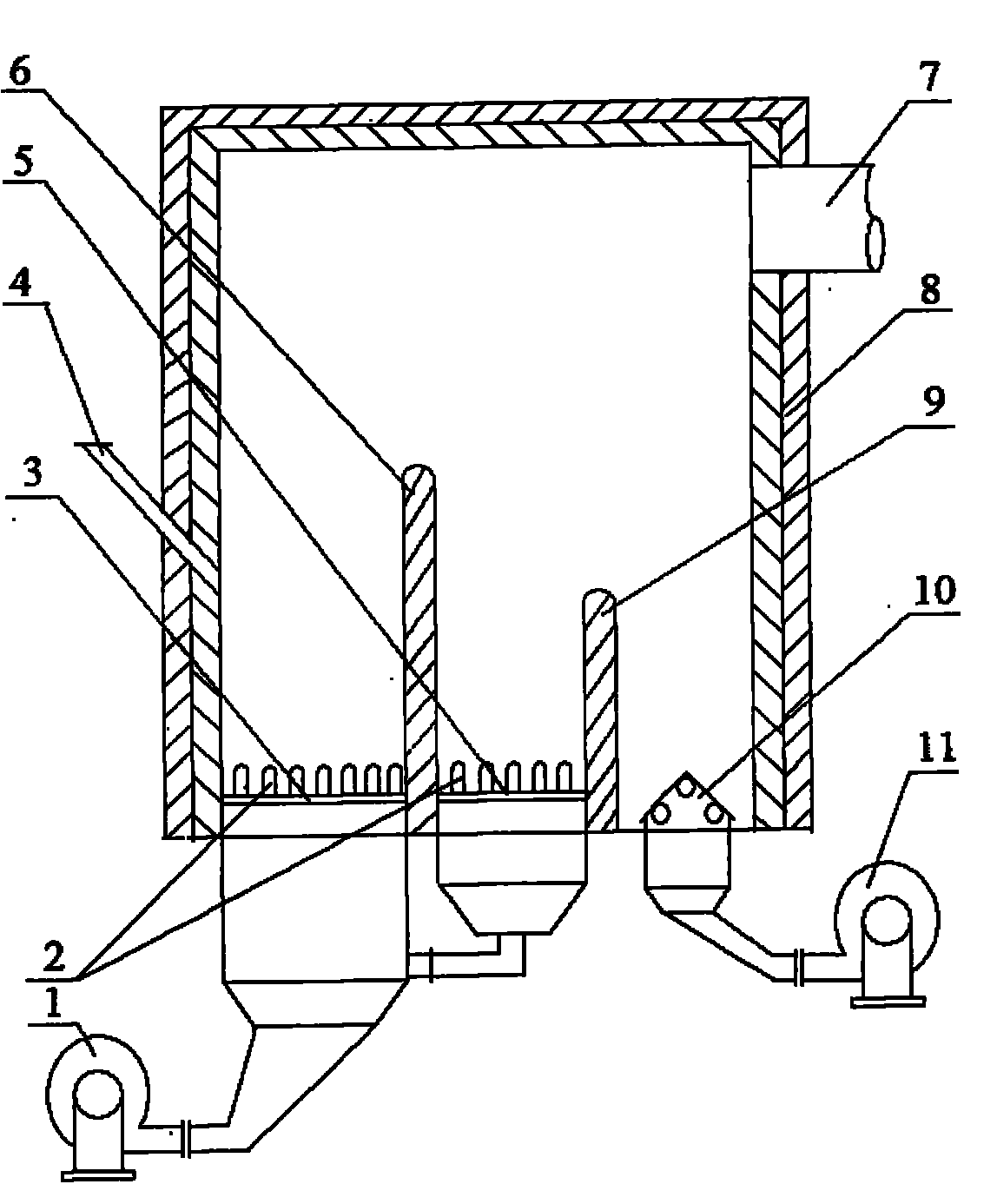

Fluidized-bed boiler

InactiveCN101592336AIncrease profitEmission reductionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberFlue gas

The invention provides a fluidized-bed boiler, which comprises a fluidized-bed combustion chamber. The bottom of the fluidized-bed combustion chamber is provided with a wind chamber of a wind distributor, and the fluidized-bed combustion chamber is communicated with a blower; combusted flue gas of the combustion chamber is exhausted from a chimney through an induced draught fan; the outlet of the induced draught fan is connected with a flue gas recirculation tube which is respectively communicated with the fluidized-bed combustion chamber and the wind chamber; an upper layer wind adjusting valve is arranged between the flue gas recirculation tube and the fluidized-bed combustion chamber; an upper layer fan is arranged between the upper layer wind adjusting valve and the combustion chamber; an air draft pipe with an air regulating valve is arranged between the upper layer fan and the upper layer wind adjusting valve; upper layer wind is formed by the air and flue gas; the blower is connected with an air-flue gas mixing chamber; the other end of the mixing chamber is communicated with the flue gas recirculation pipe through a flue gas secondary fan and a flue gas secondary regulating valve; and the upper part of the mixing chamber is communicated with the air chamber to form one-time wind. The fluidized-bed boiler has the advantages of improving the utilization rate of fuel, reducing the emission of pollutants, and having higher desulphurization efficiency and wide application of coal fuel.

Owner:NINGBO YINUO ENERGY TECH

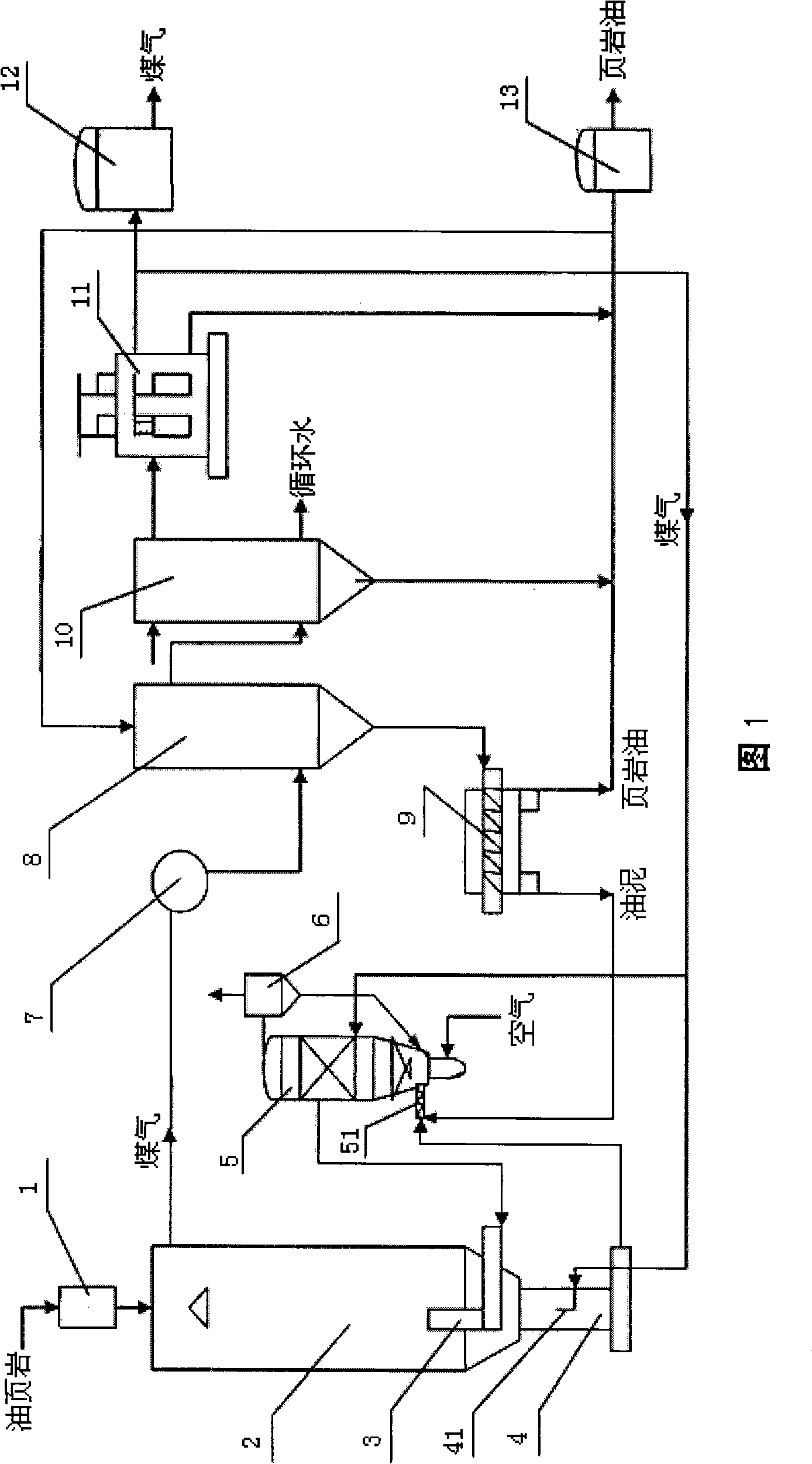

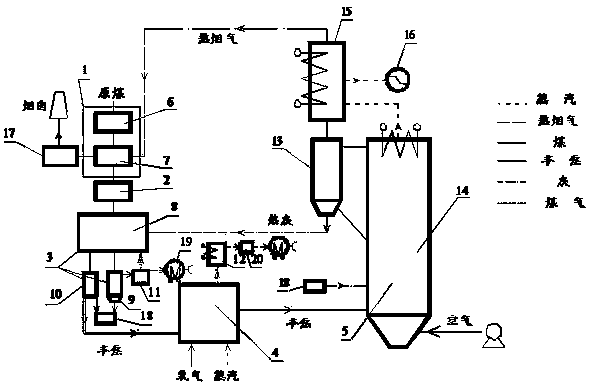

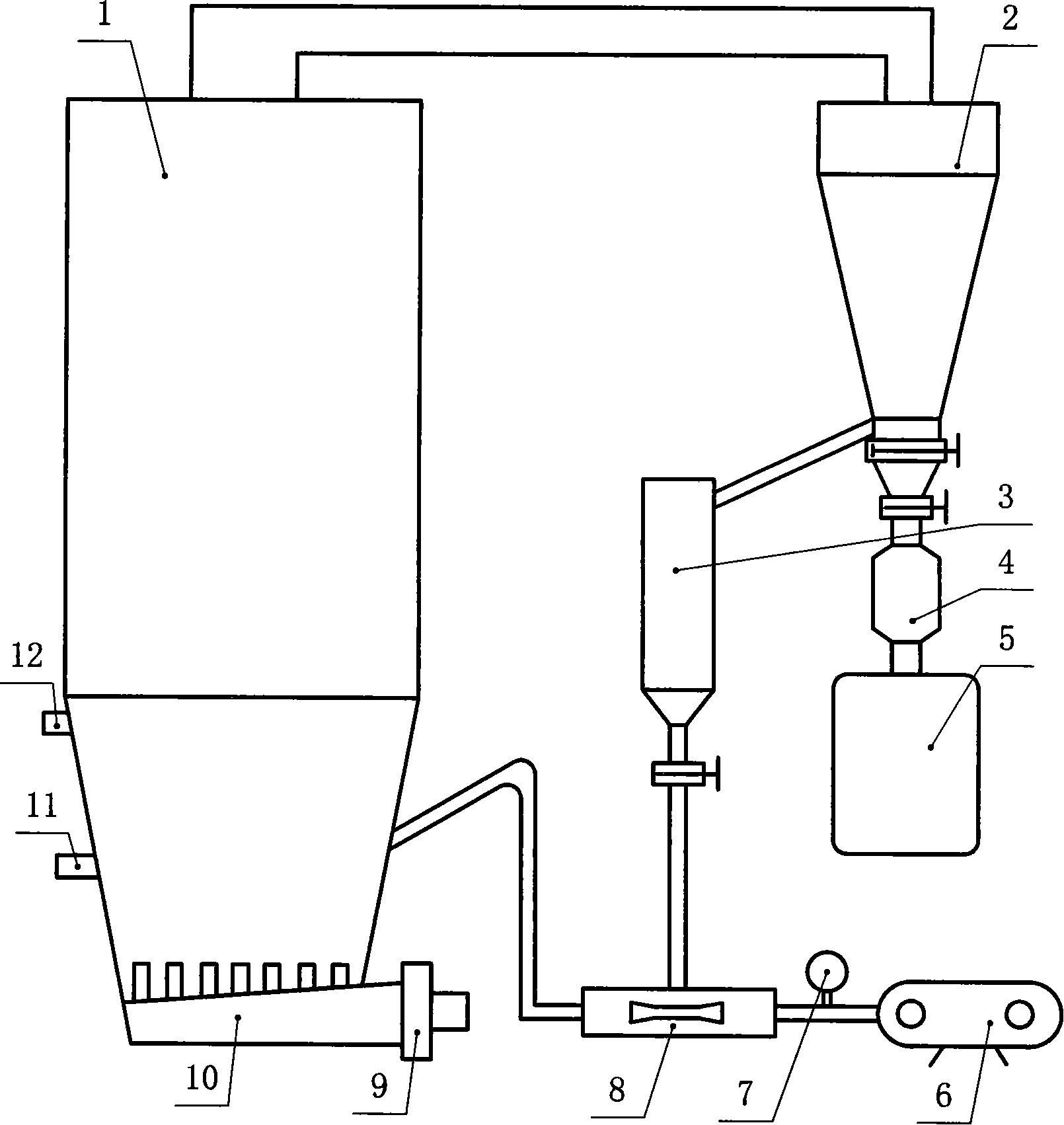

Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

InactiveCN101280201AHigh calorific valueAchieve separationSpecial form destructive distillationDistillationOil sludge

The invention provides a full cycle dry distillation process and a system which use oil shale (coal) to produce shale oil; the technological process includes that the distillation of the oil shale is processed in an oil shale distillation system which is composed of an oil shale input storage tank, a non-oxygen coal-gas heating retort and a semi-coke discharge device to generate pyrogenous coal gas and the semi-coke; the pyrogenous coal gas is separated and purified by a pyrogenous coal gas multi-stage purifying system composed of a coal gas collecting pipe, an oil-washing tower, an intercooling tower and an electrical oil trap; the obtained coal gas is preheated by a coal gas preheating system composed of a fluidized bed combustion furnace, a spiral feeder and a duster collector and then is fed into the non-oxygen coal-gas heating retort for the dry distillation of the oil shale; the oil product separated from the oil-washing tower, the intercooling tower and the electrical oil trap is purified and collected through an oil product purifying and collecting system so that the shale oil product is obtained; the semi-coke and the sludge generated during the dry distillation and purification process are used as the materials for the preheating of the coal gas. The dry distillation process in the invention can effectively realize the functions of dry distillation, dust separation and combusting the semi-coke and sludge generated during the process of dry distillation for the preheating of the coal gas; thereby, the sources is utilized sufficiently and the environmental protection requirement is fulfilled.

Owner:ZHUHAI TOP ENERGY TECH

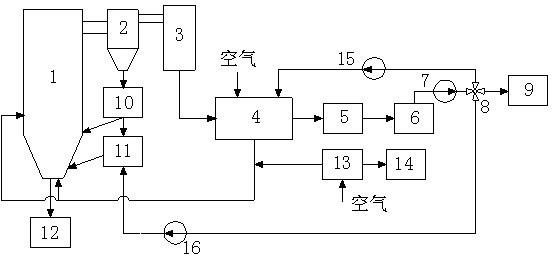

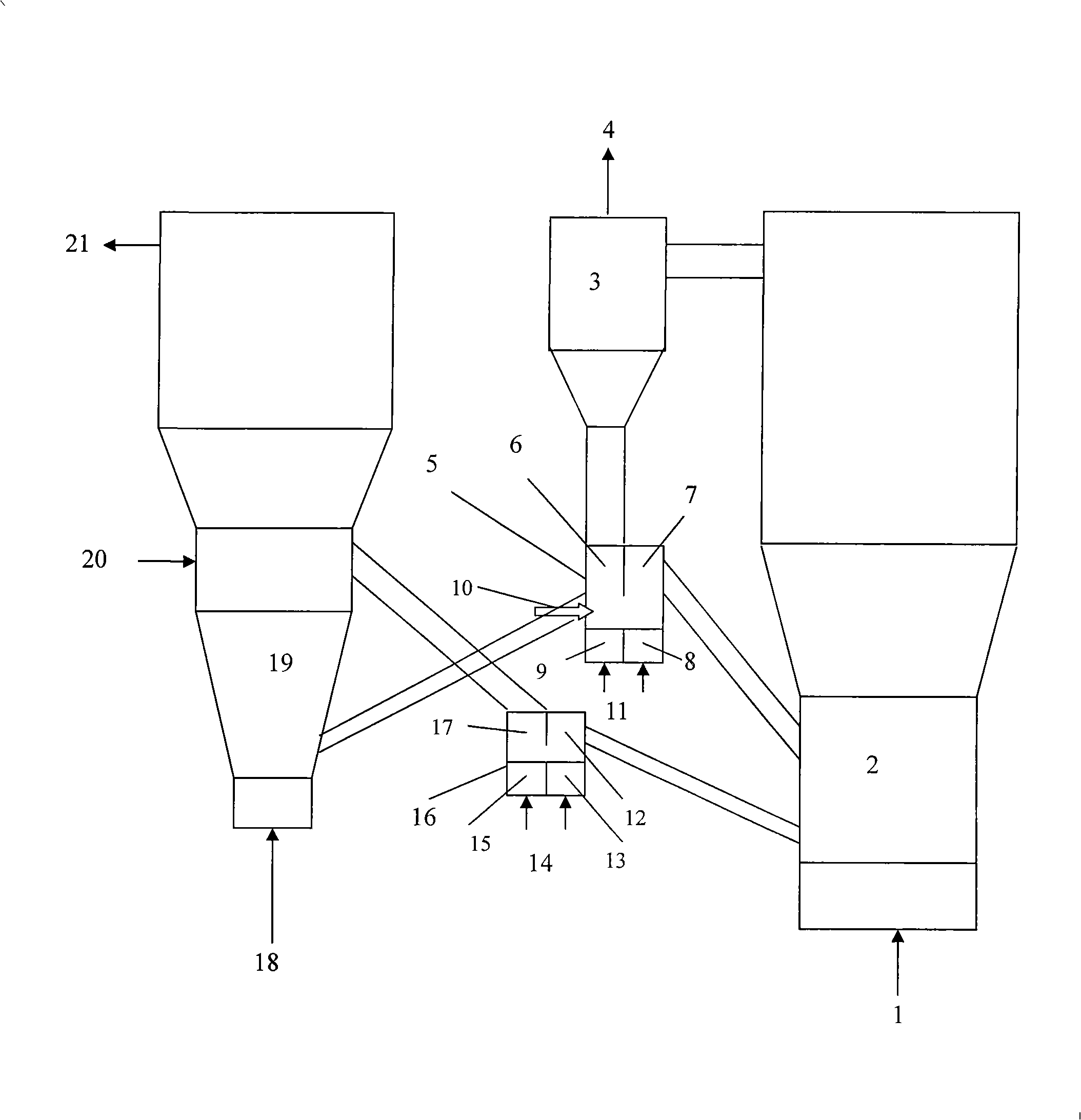

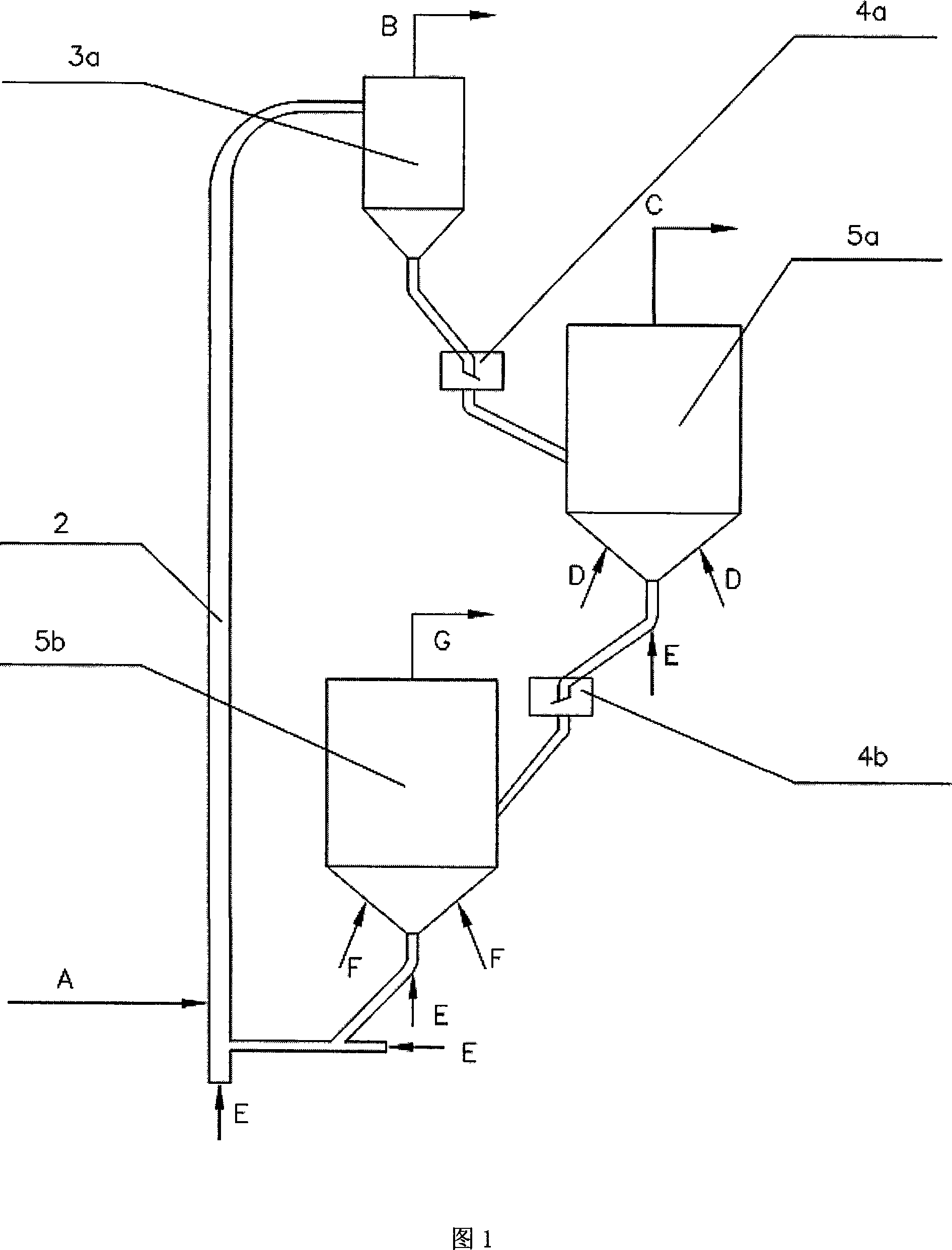

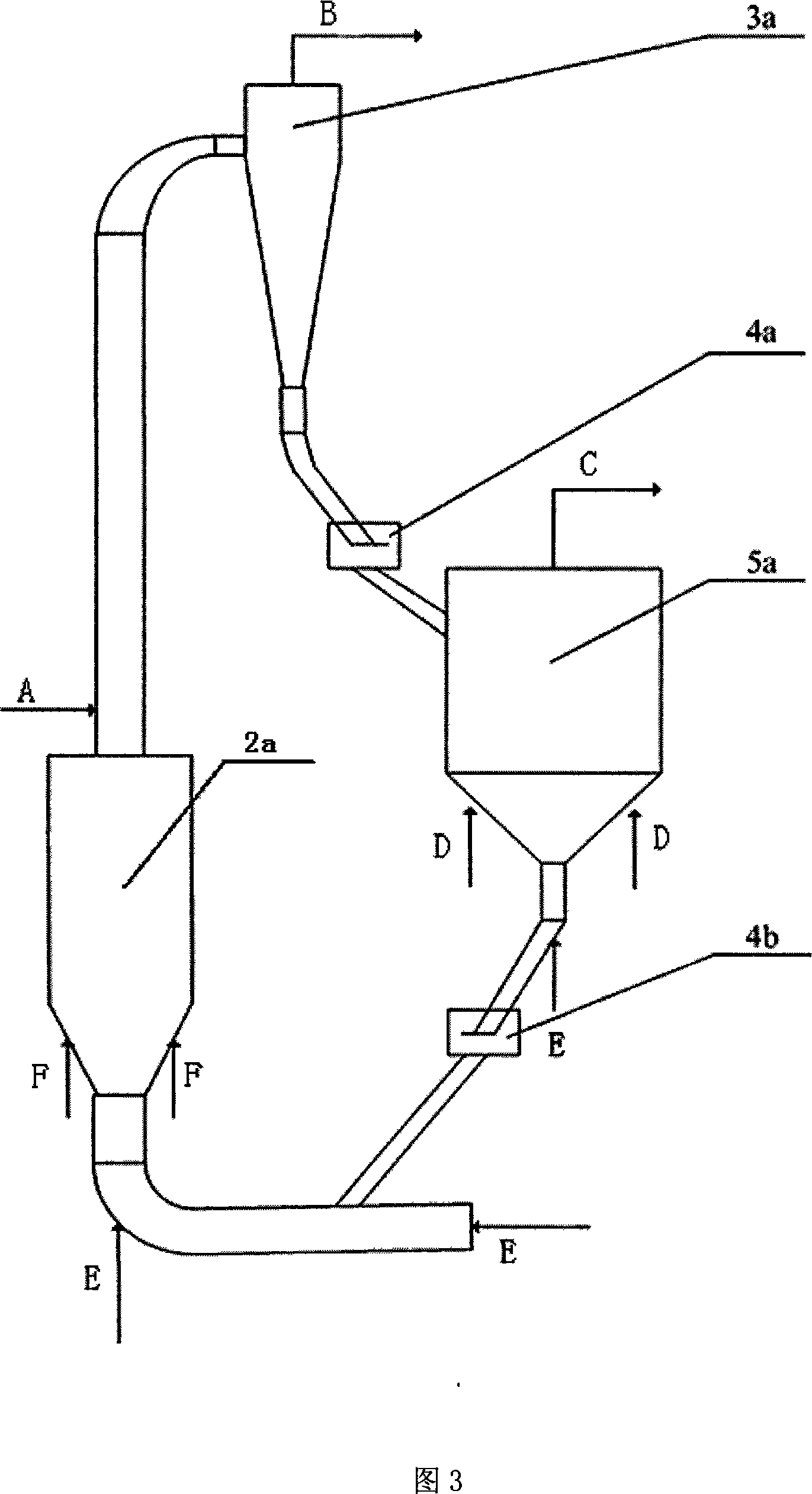

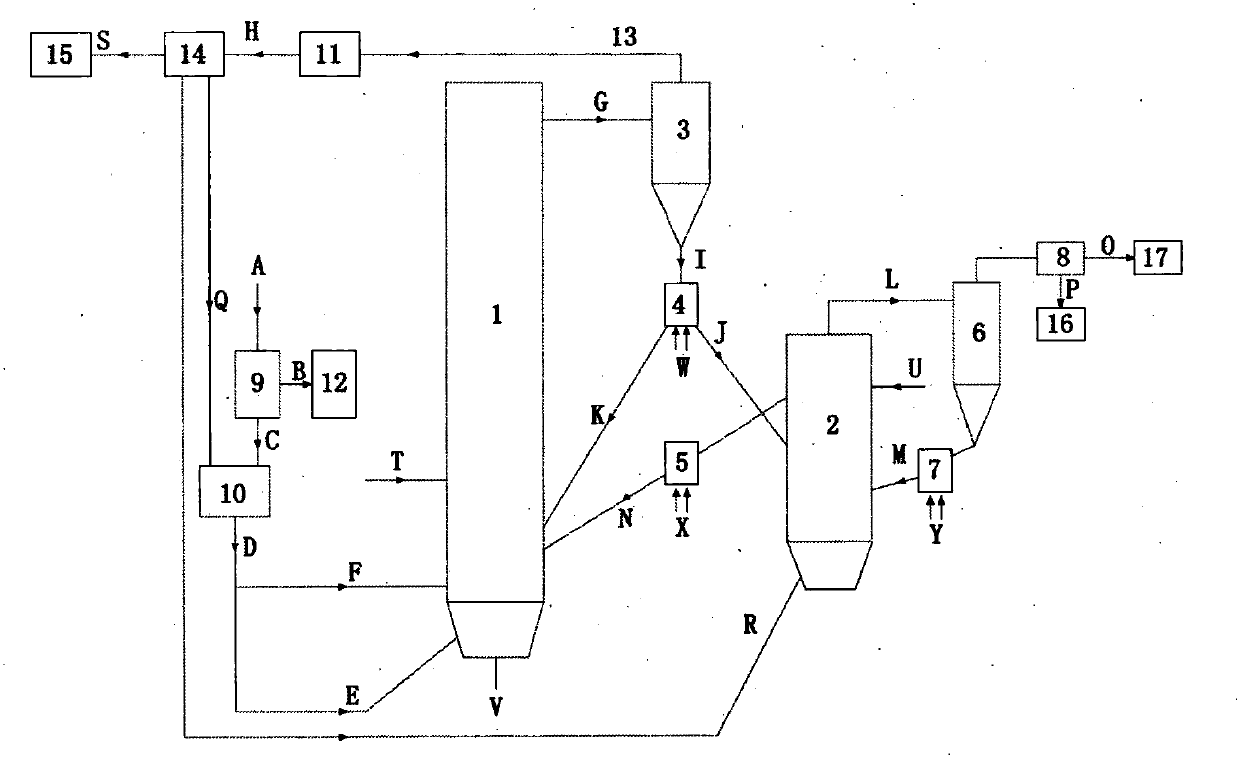

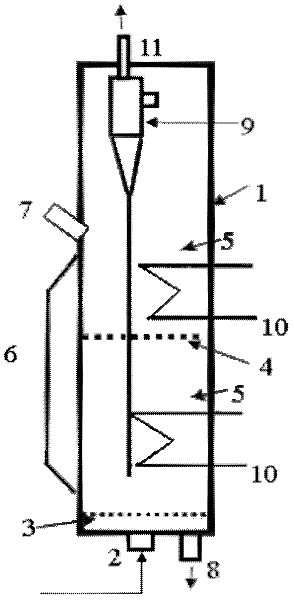

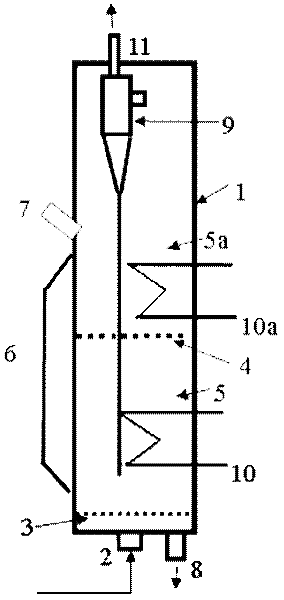

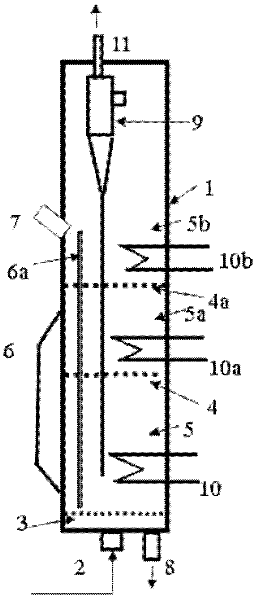

Circulating system for double fluidized bed combustion gasification materiel

ActiveCN101255987AReasonable useControl operating temperatureFluidized bed combustionApparatus for fluidised bed combustionFluidized bed gasifierEngineering

The invention discloses a double fluidized beds combustion-gasification material circulating system comprising a fluidized bed gasification furnace and a circulating fluidized bed combustion furnace; the middle portion of the fluidized bed gasification furnace is connected with a material charging chamber of a material returning chamber, and then is connected with the lower portion of the circulating fluidized bed combustion furnace through a material discharging chamber of the material returning device; the upper portion of the circulating fluidized bed is connected to a material charging chamber of a bi-directional material control device through a hyperthermia separator, then is divided into two paths, one path is connected with the lower portion of the fluidized bed gasification furnace through a hyperthermia conical valve on the side surface of the material charging chamber of the bi-directional material control chamber, and the other path is connected with the lower portion of the circulating fluidized bed combustion furnace through the material returning chamber of the bi-directional material control chamber. The circulating fluidized bed combustion furnace and the fluidized bed gasification furnace are combined tightly to implement gasification, combustion, classification and conversion of coal in one set of system, which leads to highly efficiency conversion of coal; the inventive system is also can be used broadly in combustion, gasification, catalysis and regeneration processes.

Owner:ZHEJIANG UNIV +1

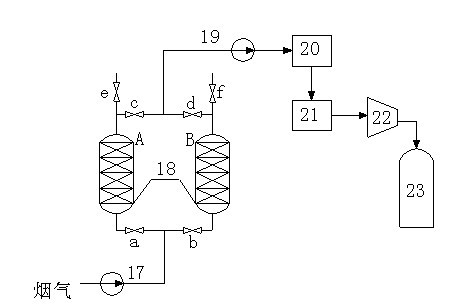

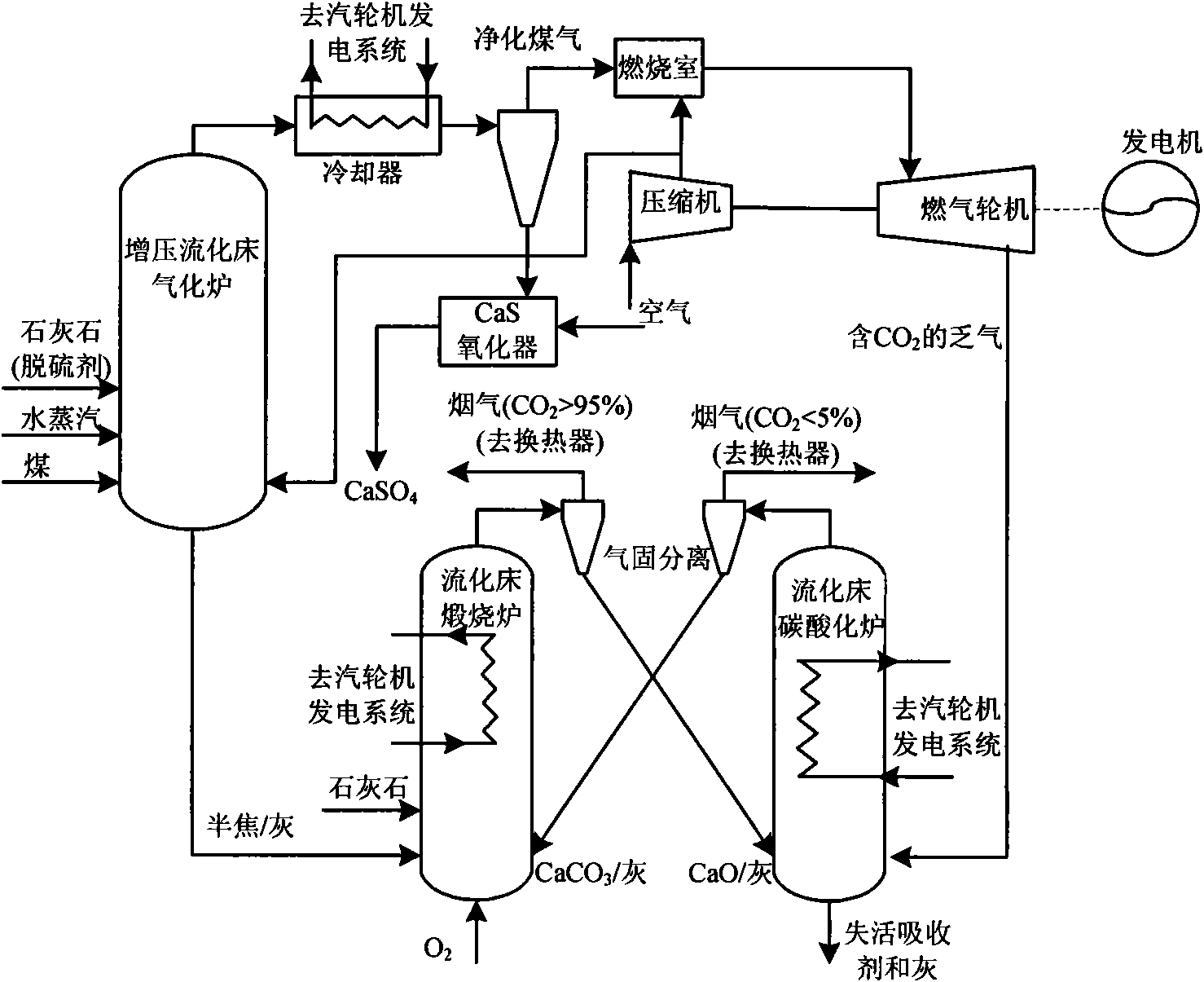

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycle generating system

InactiveCN101539037AReasonable realization of graded conversionRaise the inlet temperatureGas turbine plantsSteam engine plantsEngineeringCarbonatation

The invention relates to a method for catching carbon dioxide by a pressurized fluidized bed combustion combined recycle generating system, which is a method for catching the carbon dioxide by using CaO generated by calcining limestone or dolomite aiming at a gasification / semi-coking pressurized fluidized combustion combined recycle generating system of a coal pressurized part, coal enters into a pressurized fluidized bed gasification furnace using air as gasifying agent so as to be gasified to generate coal gas and semicoke, the coal gas is combusted after being purified to produce high-temperature fuel to enter a combustion turbine for applying work and generating electricity. Exhaust gas containing CO2 enters into a carbonatation furnace and a calciner double fluidized system, CO2 in the exhaust gas is catched by using circulation carbonatation / calcining reaction of CaO. Steam produced by a coal gas cooler and the double fluidized bed system enters into the turbine system for applying work and generating electricity, therefore, a fuel gas / steam combined recycle generating system catching CO2 is formed. The system has high generating efficiency and low energy consumption, and can realize near-zero exhaust of a plurality of pollutants of SO2, CO2 and the like.

Owner:SOUTHEAST UNIV

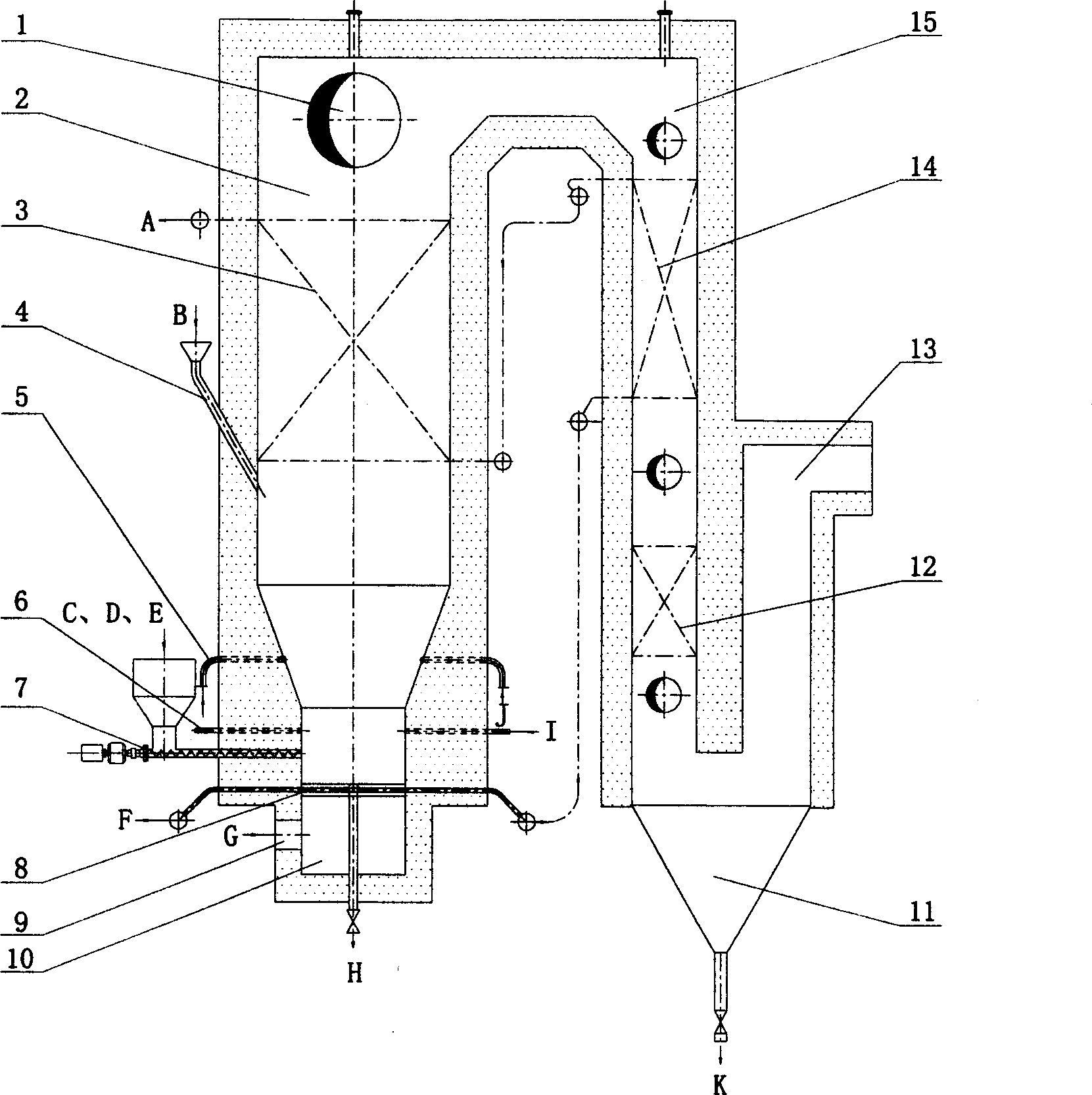

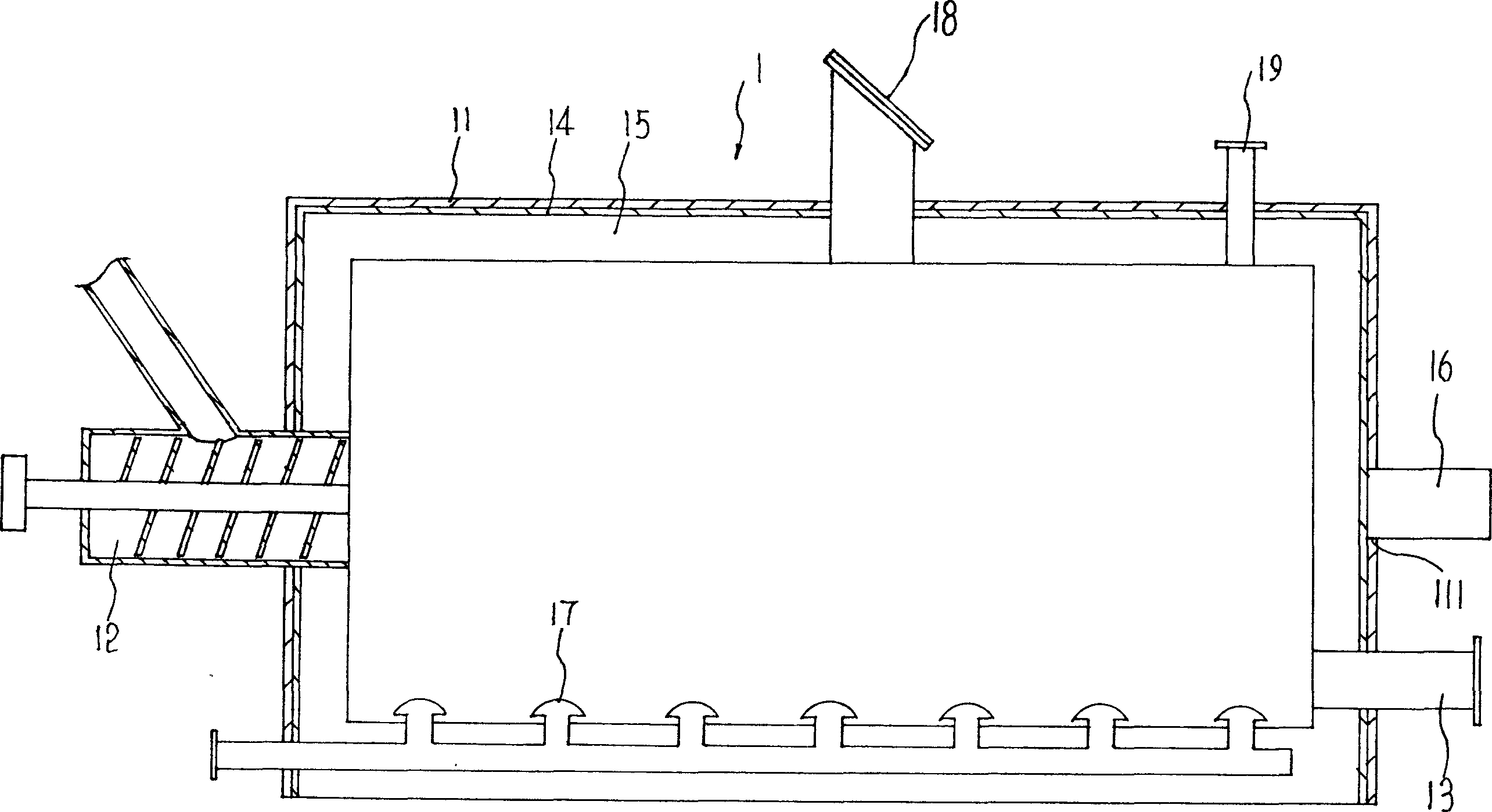

City sludge fluidized bed combustion device and method

InactiveCN1800063AEnhancing large-scale perturbationsEasy to fluidizeSludge treatment by oxidationByproduct vaporizationAir preheaterHeat carrier

Urban sludge fluid bed burning devices and its method relates to urban sludge burning disposal and excess heat-recovering method, belonging to volume reduction, innocence, and resources handling field. Said burning equipment is made up of incinerator body (2), wind-distributing plate (8), wind room (10) and tail end chimney flue (15), the top of incinerator body (2) and tail-end chimney flue (15) are connected together; wind-distributing plate (8) whose under-part is wind room (10) is fixed at the bottom of incinerator body (2) with mass-flow burning area at its bottom and dilute phase area on its top; dry sludge after drying is added to incinerator through worm distributor by grading air supply technique; cooling medium of wind-distributing plate adopts organic heat carrier. Smoke gas flows across tail-end convection heating surface and air heater after entering tail-end chimney flue from dilute phase, being introduced to tail gas handling system after cooling to below 200 Deg C to remove dust, wash, and released to air through exhauster and chimney finally.

Owner:SOUTHEAST UNIV

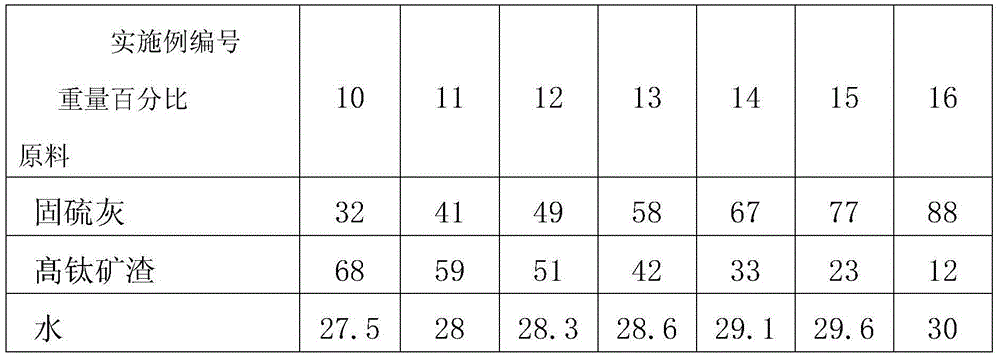

Fluidized bed combustion ash and high titanium slag compounded stable pavement base material

ActiveCN104003638AElicit activityHigh strengthSolid waste managementNatural resourceRoad engineering

The invention discloses a fluidized bed combustion ash and high titanium slag compounded stable pavement base material. The fluidized bed combustion ash and high titanium slag compounded stable pavement base material is formed by mixing 30-90wt% of fluidized bed combustion ash with 10-70wt% of high titanium slag. The fluidized bed combustion ash, the high titanium slag and water are stirred and mixed, and the obtained mixture is molded and maintained to make a fluidized bed combustion ash and high titanium slag compounded stable pavement base. The compounded stable pavement base material completely utilizes difficult-treatment and high-discharge-amount industrial wastes comprising the fluidized bed combustion ash and the high titanium slag, contains no lime or fly ash, and has better performances than traditional lime-fly ash stable pavement base material; and the compounded stable pavement base material has the advantages of low cost, no consumption of natural resources, simple and easy preparation method, suitableness for being used in areas short of traditional road engineering materials, substantial economic benefit, wide market prospect and strong practicality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Circulation fluid bed hydrogen preparation reaction technology and reaction device by reforming methane and water steam

InactiveCN101054161ACause inactivationLow costHydrogen separationChemical recyclingSteam reformingWater vapor

A reaction technics of producing hydrogen from methane reforming with steam on circulating fluidized bed and reaction apparatus thereof, belongs to petrochemical industry technique field. The technics comprises three main steps of reforming methane with steam, oxidating catalyst for removing carbon deposit and reducing and regenerating catalyst, the whole process combines selfrecharging of reaction heat with catalyst regeneration to reduce energy consumption and increase productivity of hydrogen; the invention utilizes combination of endothermic and exothermic and reaction combination of reduction of metal oxide and metal oxidizing reaction, uses catalyst solid particles as carrier of heat and oxygen to realize binary cycle of heat and oxygen; main reaction apparatus of the technics comprises: a riser reactor for reforming methane with steam, a fluidized bed combustion reactor for removing catalyst oxidation and carbon deposit, and a catalyst regeneration device; whole apparatus of the invention have simple and compact structure.

Owner:TSINGHUA UNIV

Polygeneration technology for gradient utilization of low-rank coal

InactiveCN103740389AIncrease added valueEmission reductionDirect heating destructive distillationSpecial form destructive distillationWaxBrown coal

The invention discloses a polygeneration technology for gradient utilization of low-rank coal. According to the polygeneration technology, a circulating fluidized bed combustion boiler, a circulating fluidized bed dry distillation reactor and a circulating fluidized bed gasification reactor are taken as cores; series power generation equipment achieves gradient cyclic utilization of low metamorphic coals; the low-rank coal is firstly subjected to lignite wax extraction after crushing and drying, and then enters a brown coal pyrolysis reactor; a raw gas of the gasification reactor is adopted as a fluidizing agent; tar and the raw gas are obtained after dry distillation; semicoke enters the gasification reactor to carry out partial gasification; a part of coal gas is generated as a fluidizing agent of a dry distillation reactor; incompletely gasified semicoke enters the combustion boiler as a fuel; heat and steam generated by combustion are applied to power generation; a by-product low-pressure steam can be used as a raw material of the gasification reactor; the high-temperature semi-coke and hot ashes obtained by combustion enter the dry distillation reactor and the gasification reactor as heat carriers, so as to finish a cycle. By adopting the polygeneration technology, the economic value of the low-rank coal can be obviously improved, emission of pollutants can be significantly reduced by gradient cyclic utilization, and the technology is safe and reliable.

Owner:BEIJING TIANSU SUNLIGHT LOW CARBON TECH

Method and device for manufacturing reduced iron using microwave fluid bed

InactiveCN1733943AGood for balance controlReduce consumptionFluidised-bed furnacesWater vaporReaction temperature

The invention discloses a method to prepare reduced iron with microwave fluid bed. Wherein, mixing smashed iron ore and coal with proper proportion, preheating to reaction temperature on first fluid bed to convey into second microwave fluid bed; using water vapor to drive material as fluidized state; iron reacts with vapor to generate water-gas to reduce ferric oxide; cooling, magnetic separating, and obtaining the product; the feeding mechanism pipes of two beds connect with each other; arranging microwave tube with independent air cooling mechanism on out shell of the bed and windshield connected to steam boiler pipe on bottom of microwave fluid bed. This invention distributes technological in reason, and needs low cost.

Owner:孔凡逸 +1

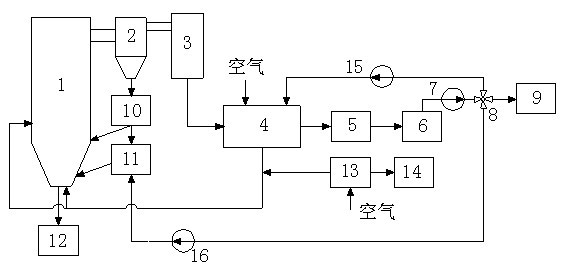

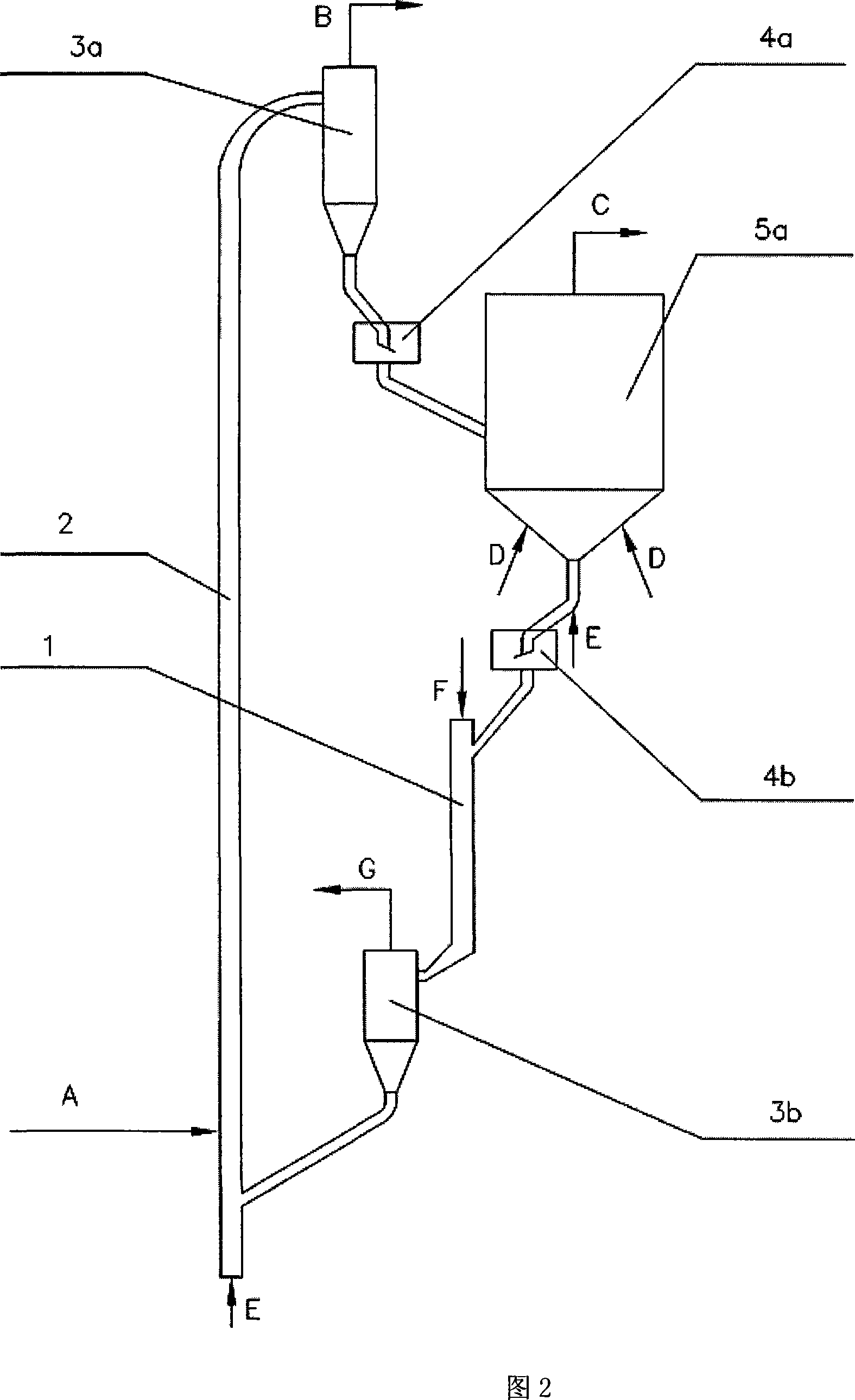

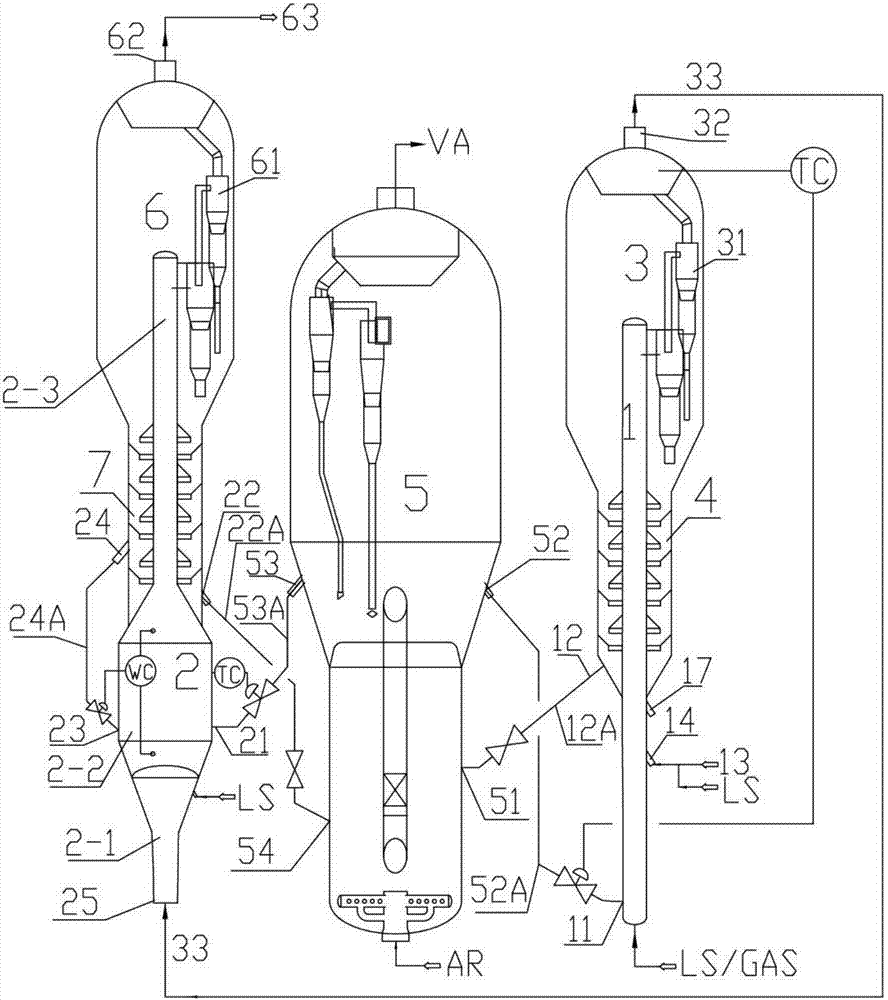

Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

ActiveCN103742899AImprove utilization efficiencyIncrease operating temperatureNitrogen purification/separationFluidized bed combustionGeneration processFlue gas

The invention provides an oxygen-enriched combustion circulating fluidized bed poly-generation system. The oxygen-enriched combustion circulating fluidized bed poly-generation system comprises a circulating fluidized bed combustion furnace and a circulating fluidized bed gasification furnace, wherein the circulating fluidized bed combustion furnace is connected with a separator I, the separator I is connected with a flue at the tail and a two-way material control device, the two-way material control device is connected with the circulating fluidized bed combustion furnace and the circulating fluidized bed gasification furnace respectively, the circulating fluidized bed gasification furnace is connected with the circulating fluidized bed combustion furnace by a return feeder I, the circulating fluidized bed gasification furnace is connected with a ceramic dust collector and a coal gas purification system by a separator II, the flue at the tail is connected with a flue gas distribution valve by a glue gas dust-removal, desulfurization and denitration device, and an outlet of the flue gas distribution valve is divided into three paths. The invention also provides an oxygen-enriched combustion circulating fluidized bed poly-generation process. The oxygen-enriched combustion circulating fluidized bed poly-generation system has high fuel utilization rate, high coal gas yield, good tar quality, small pollutant discharge and low recycling cost, and fuel and flue gas at the tail can be utilized to the maximum extent.

Owner:SHANGHAI BOILER WORKS

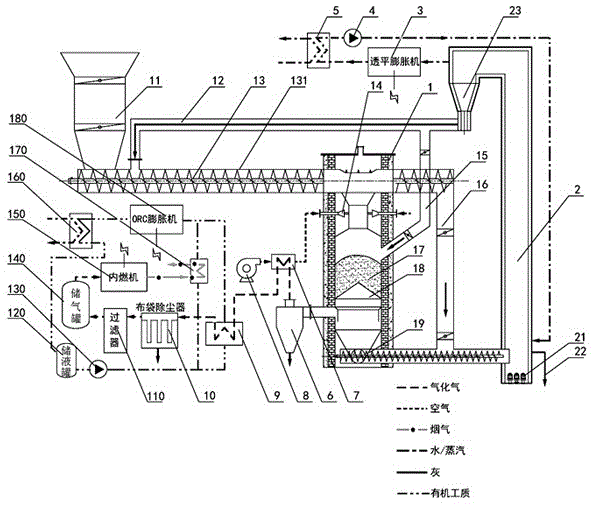

Low tar biomass gasification power generation system

InactiveCN105542858AReduce consumptionAchieve transformation and recyclingInternal combustion piston enginesEnergy inputOrganic Rankine cycleExternal combustion engine

The present invention relates to a low tar biomass gasification power generation system, the system is additionally provided with a combustion section, and brings greater convenience to a gasification system furnace-starting process, a furnace of the gasification system is warmed directly by combustion heat of a small size fluidized bed system, the fuel oil consumption of the furnace-starting can be greatly saved, heat produced by fluidized bed combustion can be recovered by a steam water system, a small steam turbine is sued for power generation to achieve the conversion recovery of chemical energy in carbon residue, high-temperature gasification gas discharged out of the gasification furnace and high-temperature exhaust gas after power generation of an internal combustion engine both can be recovered by a heat exchanger, an organic Rankine cycle system is used for realization of recovery of flue gas and process waste heat, and the energy conversion efficiency of the gasification system is significantly improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

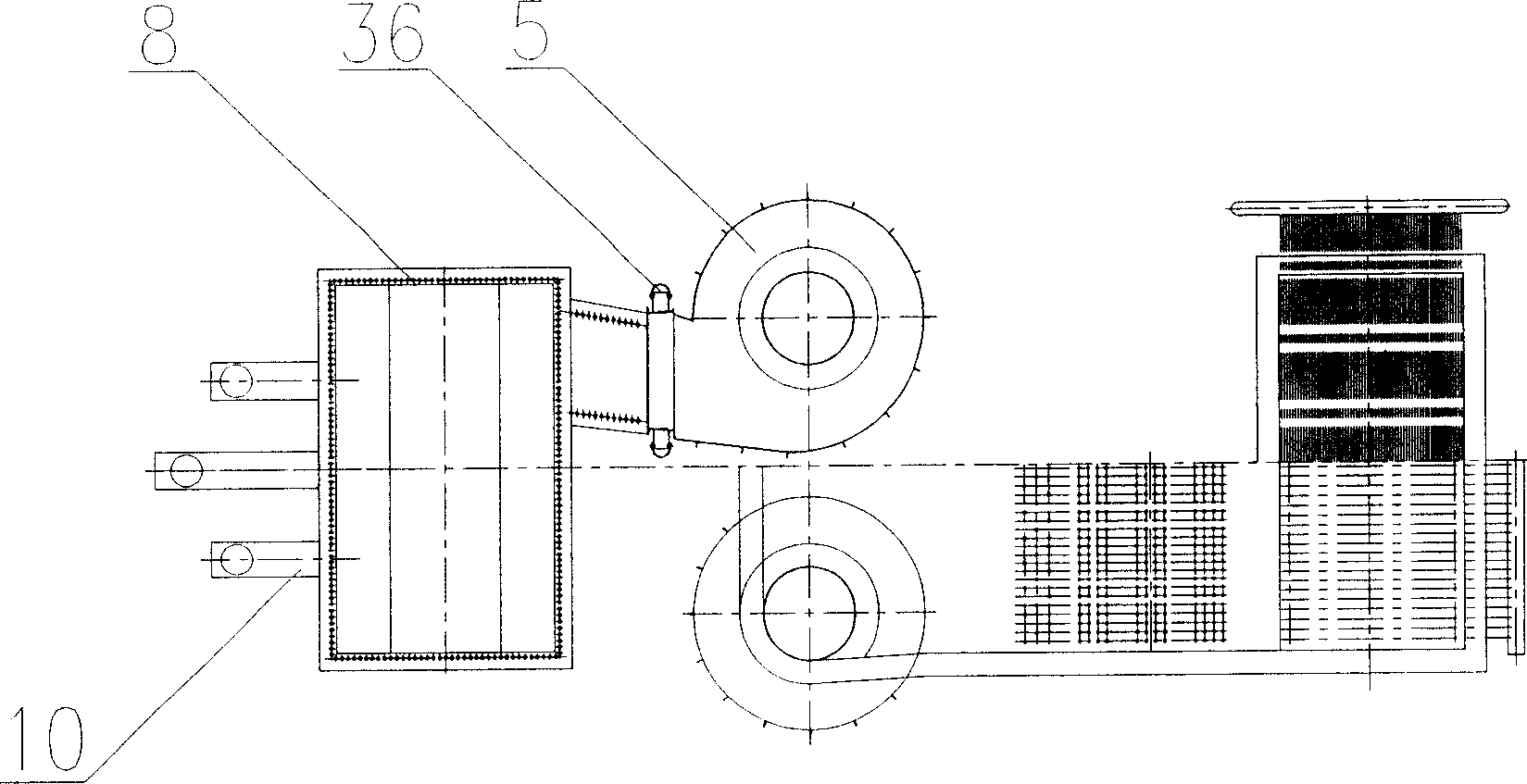

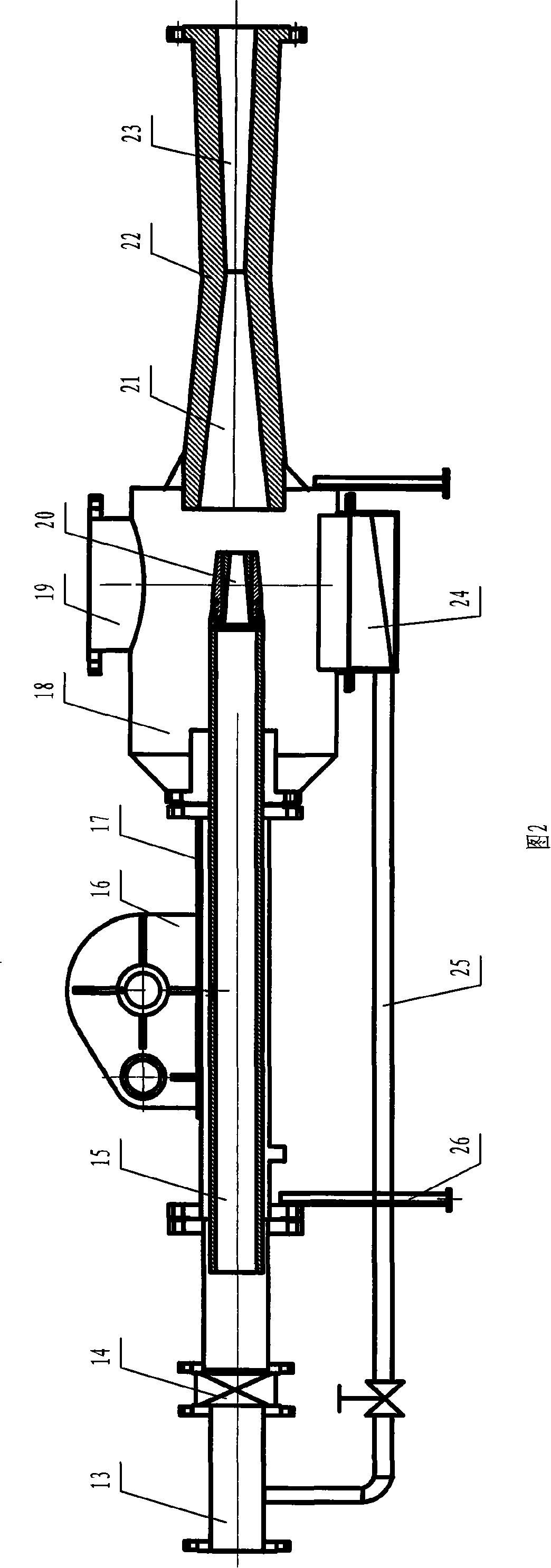

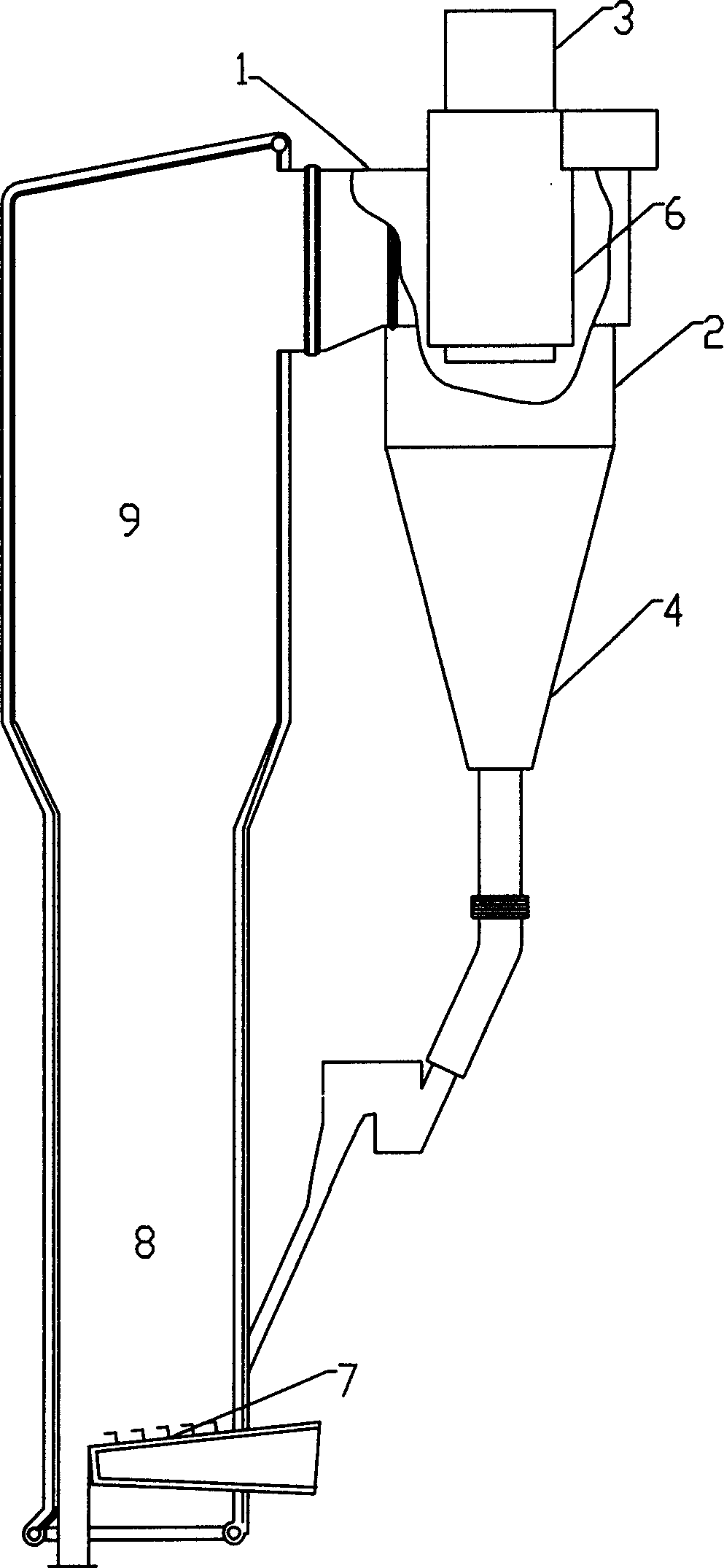

Taper tube and ash returning pump and ash recombustion type circulated fluid bed combustion equipment

The invention discloses a reducing and increasing pipe and an ash returning pump and a fly ash re-burning circulating fluidized bed combustion apparatus. The pipe is constituted by a reducing pipe section and an increasing pipe section, the small end diameters of two frusto-conical inner surfaces are same and are axially butt-jointed, and the bore cone angle of the reducing pipe section is larger than the cone angle of the increasing pipe. The ash returning pump comprises the reducing and increasing pipe, a mixture chamber, a holdfast, a movable injection pipe, a fixed cavity, and a vent pipe, and the fly ash re-burning circulating fluidized bed combustion apparatus comprises the ash return pump, a burner, a dust cleaner, and a fan, wherein the upper end of the dust cleaner is communicated with the vent pipe of the ash return pump, the lower end is communicated with an ash inlet which is arranged on the upper end of the mixture chamber, the fan is communicated with the vent pipe of the ash return pump, and the reducing pipe section on the discharge end of the reducing and increasing pipe is communicated with the dense phase region of the burner through a fly ash pipe. The invention has the advantages of simple structure, excellent spraying effect, and favorable economic and social benefits, which can guarantee the continuous, even and stable fly ash transfer.

Owner:巩义市泰华机械厂

Circulating fluidized bed combustion device with biomass fuel and combustion method thereof

ActiveCN1804460AGuaranteed combustion spaceReduced risk of increased incomplete combustion lossesFluidized bed combustionIncinerator apparatusBiological materialsBiomass burning

The invention relates to a cycle fluid bed burning device and relative method which uses biological material as fuel. Said device comprises a furnace, a furnace outlet and a horizontal gas flue. Wherein, the horizontal gas flue has a heated surface, a cyclone separator with middle temperature connected with its back; the upper end of cyclone separator is connected to the tail gas flue, the dust cleaner, the wind guide device, and the chimney; the lower end of cyclone separator is connected to the cycle circuit and the furnace dense-phase area; the circle circuit is connected with bed material and additive feeding inlet to apply the additive which can solve the problem of alkali metal; the biological fuel via the parallel feeding inlets at the front of furnace, the breaking pretreatment is blown by the wind into the section-variable dense-phase area of furnace; and the straw should be first broken into 10cm. The invention has wider raw material and high burning efficiency while it can solve the problem of alkali metal.

Owner:ZHEJIANG UNIV +1

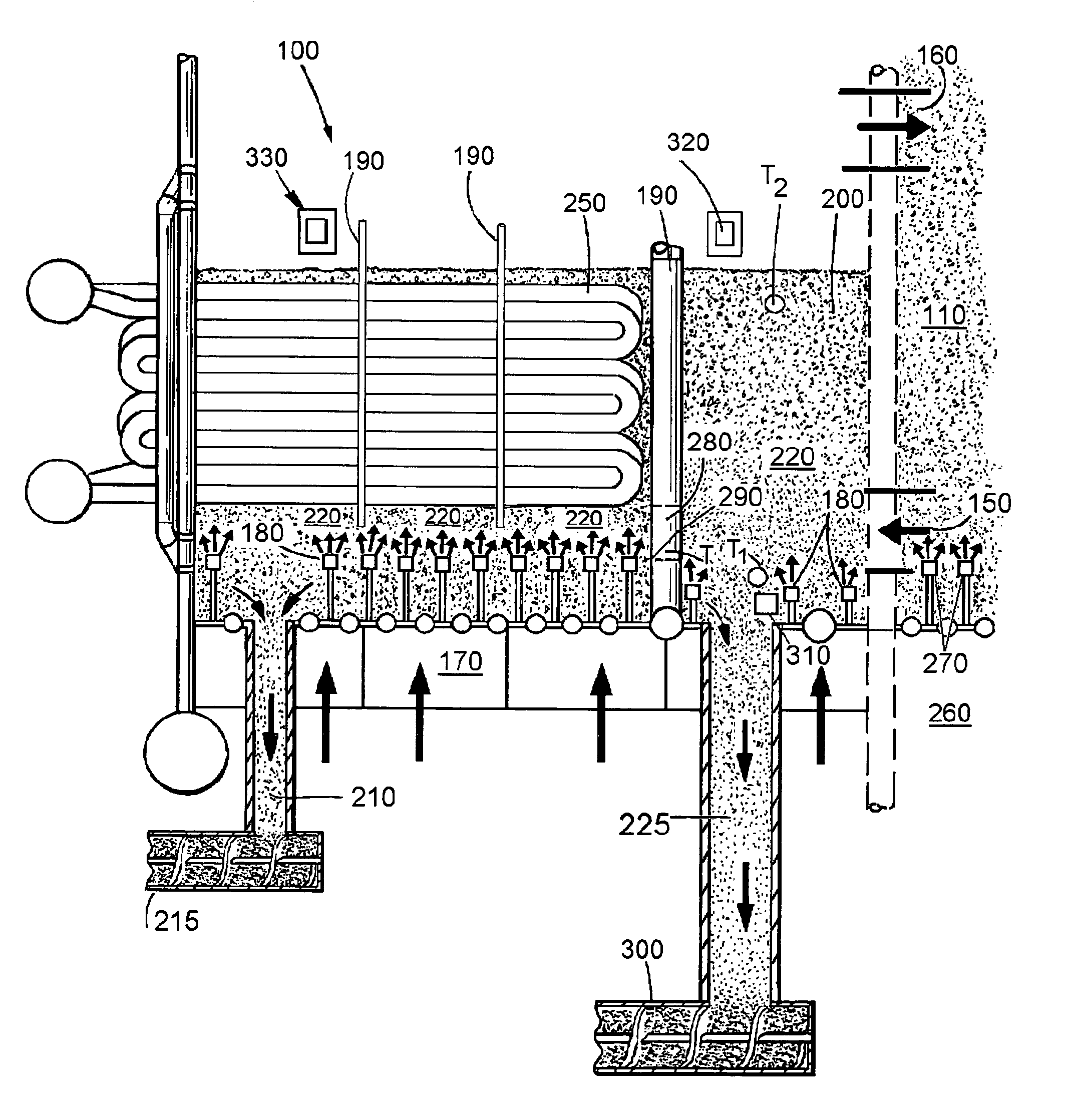

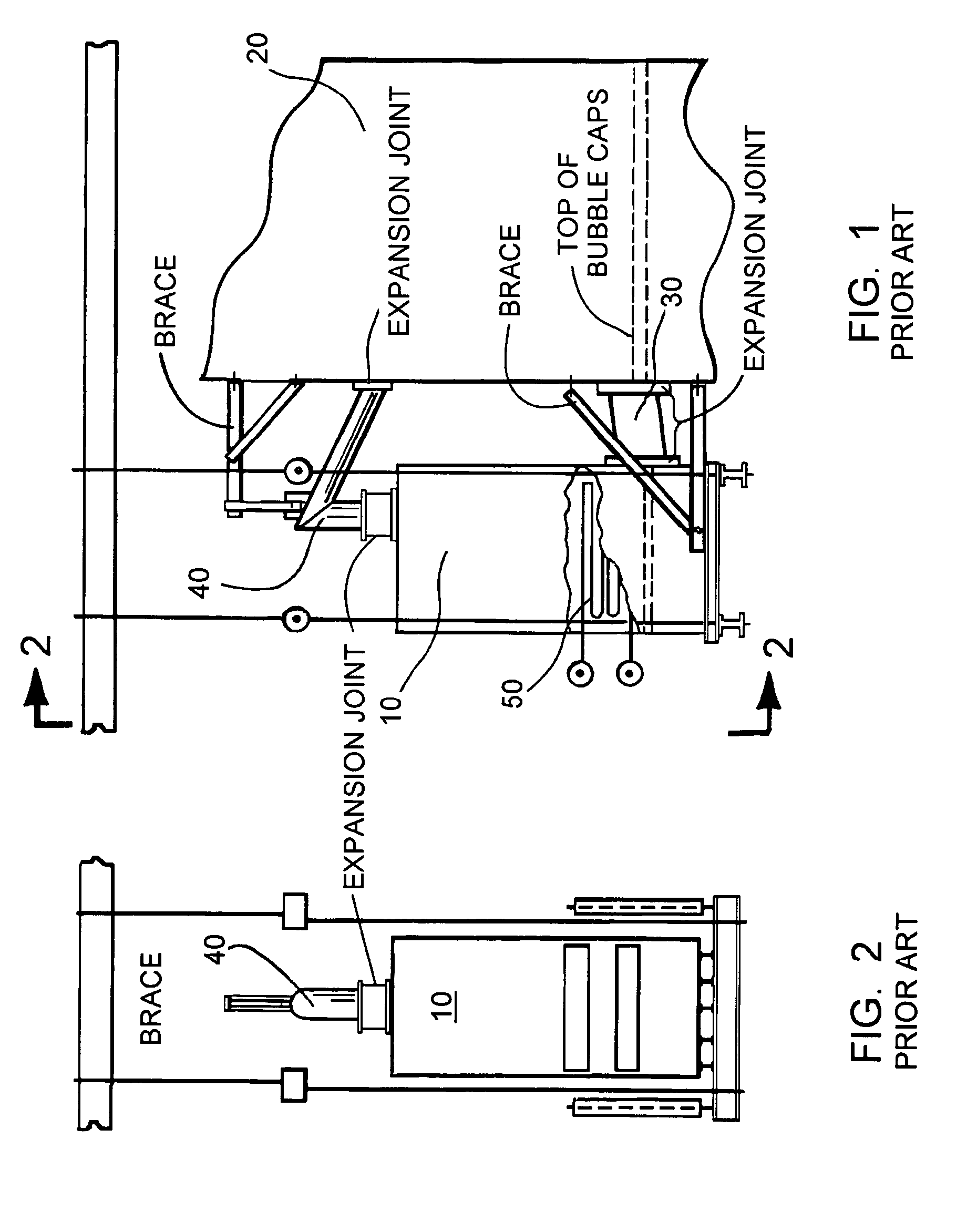

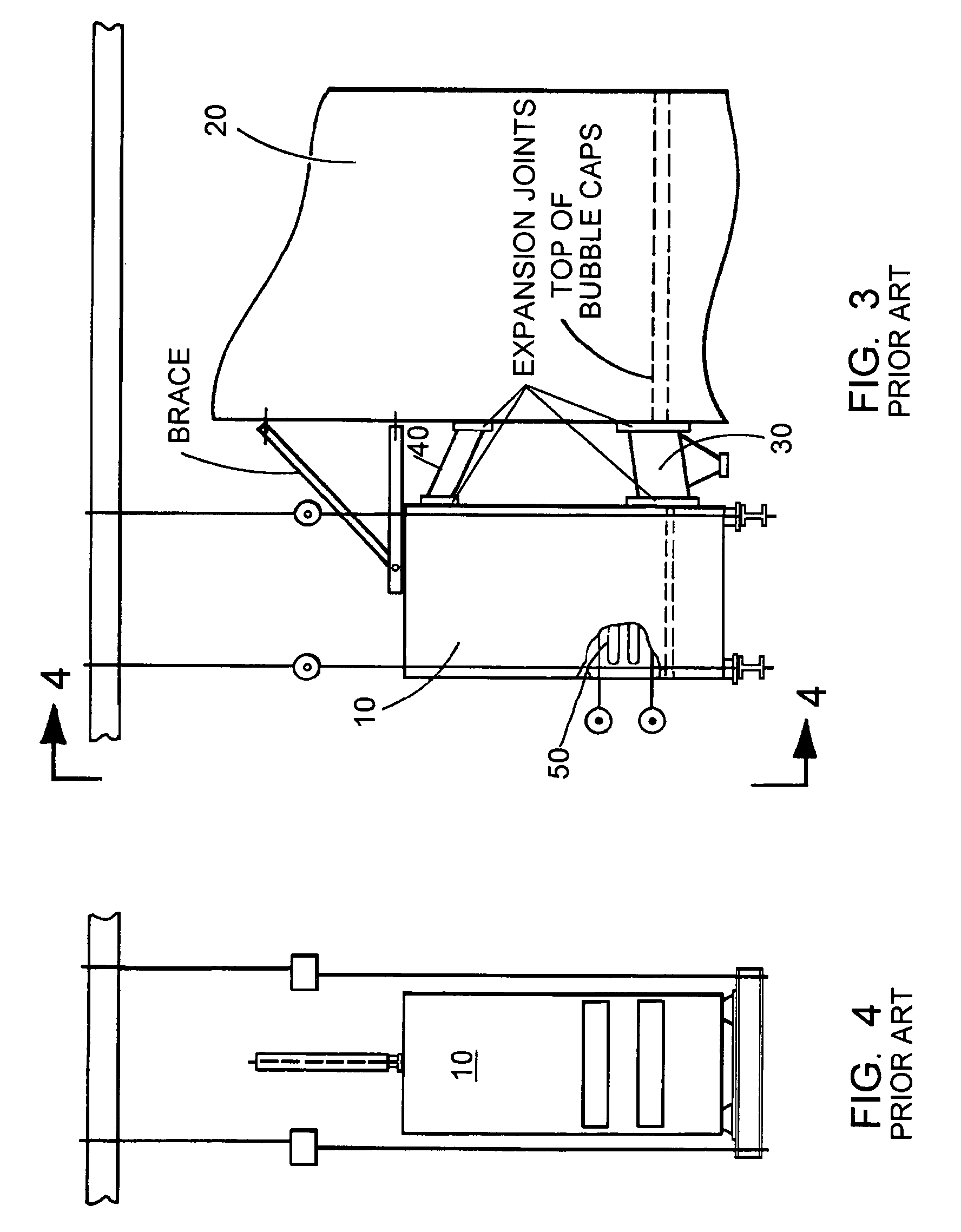

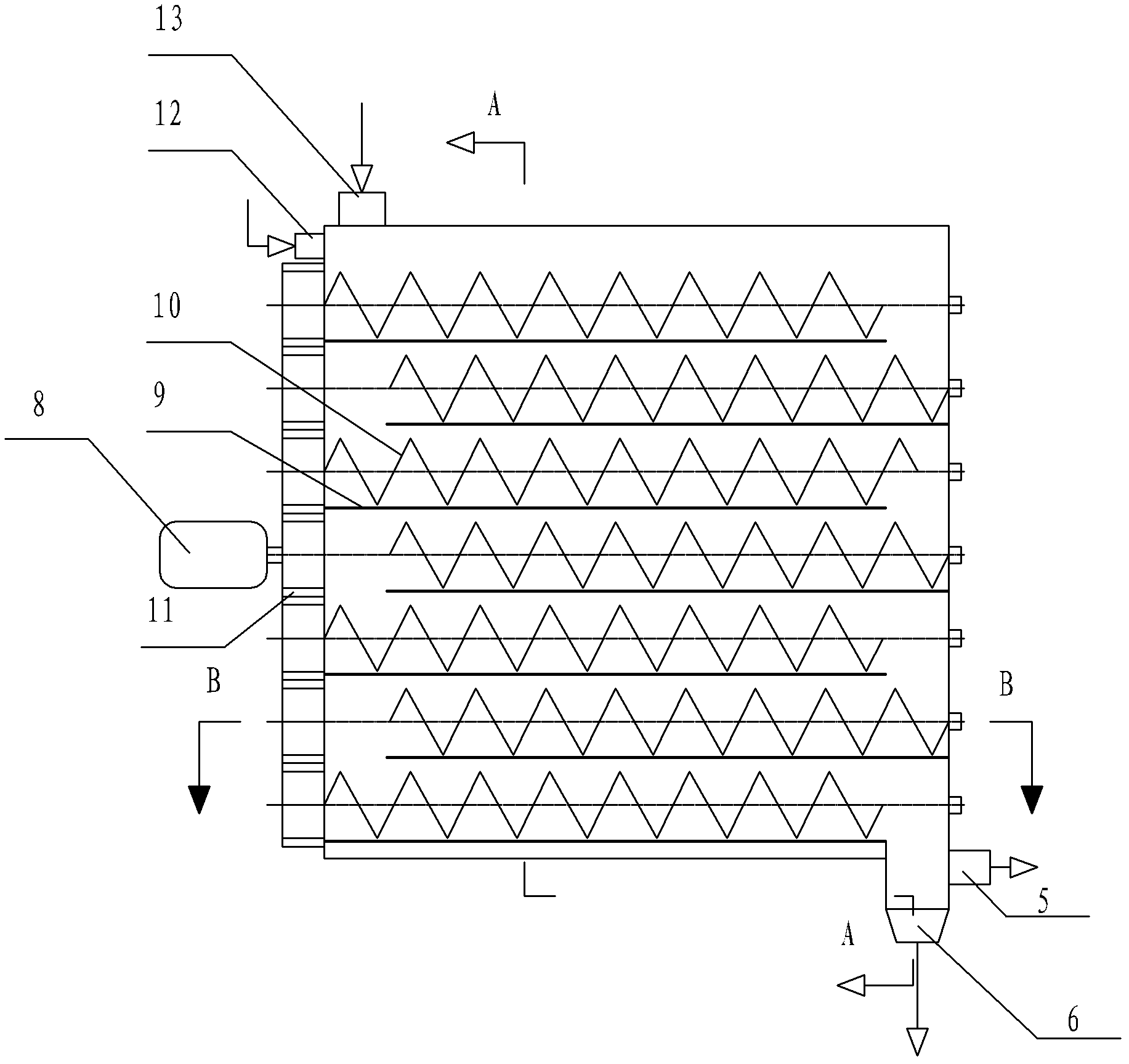

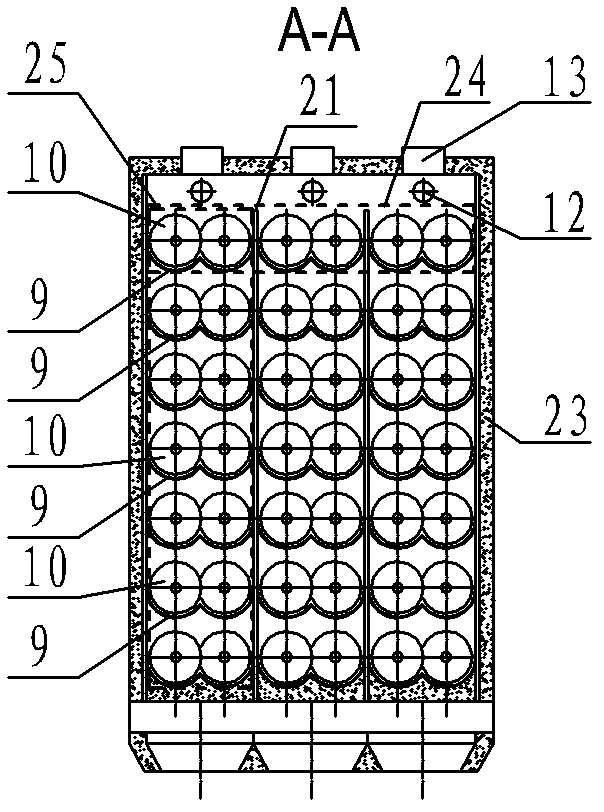

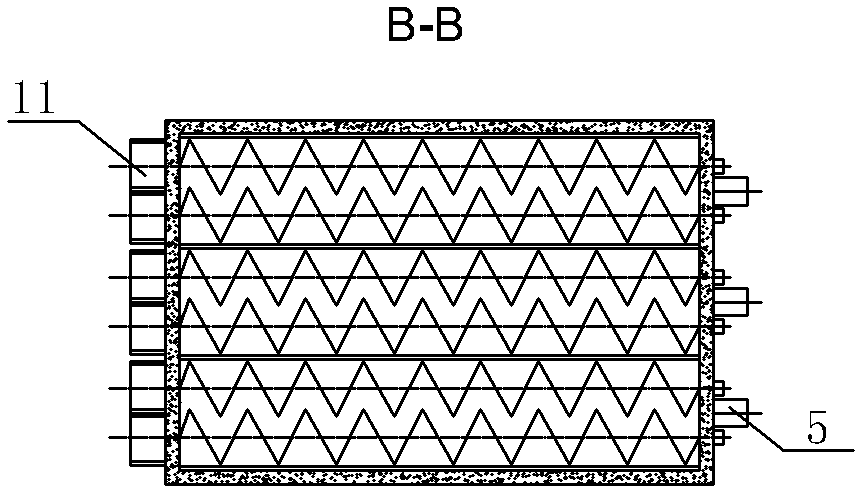

Integrated fluidized bed ash cooler

ActiveUS7464669B2Reduction in size and weight and costSimple designFluidized bed combustionFluidised-bed furnacesHigh elevationEngineering

An integrated fluidized bed ash cooler for a fluidized bed boiler, particularly a circulating fluidized bed (CFB) boiler, employs at least two fluidized bed sections positioned in series along a solids flow path. Each section contains fluidizing means, the first section along the solids path being separated from a following section with a threshold. The first section contains means for measuring a bed temperature in the vicinity of the fluidizing means and at a higher elevation within the fluidized bed. Means are provided for removing oversized bed material from the first section to facilitate the removal of ash while minimizing the possibility of ash plugging during operation.

Owner:THE BABCOCK & WILCOX CO

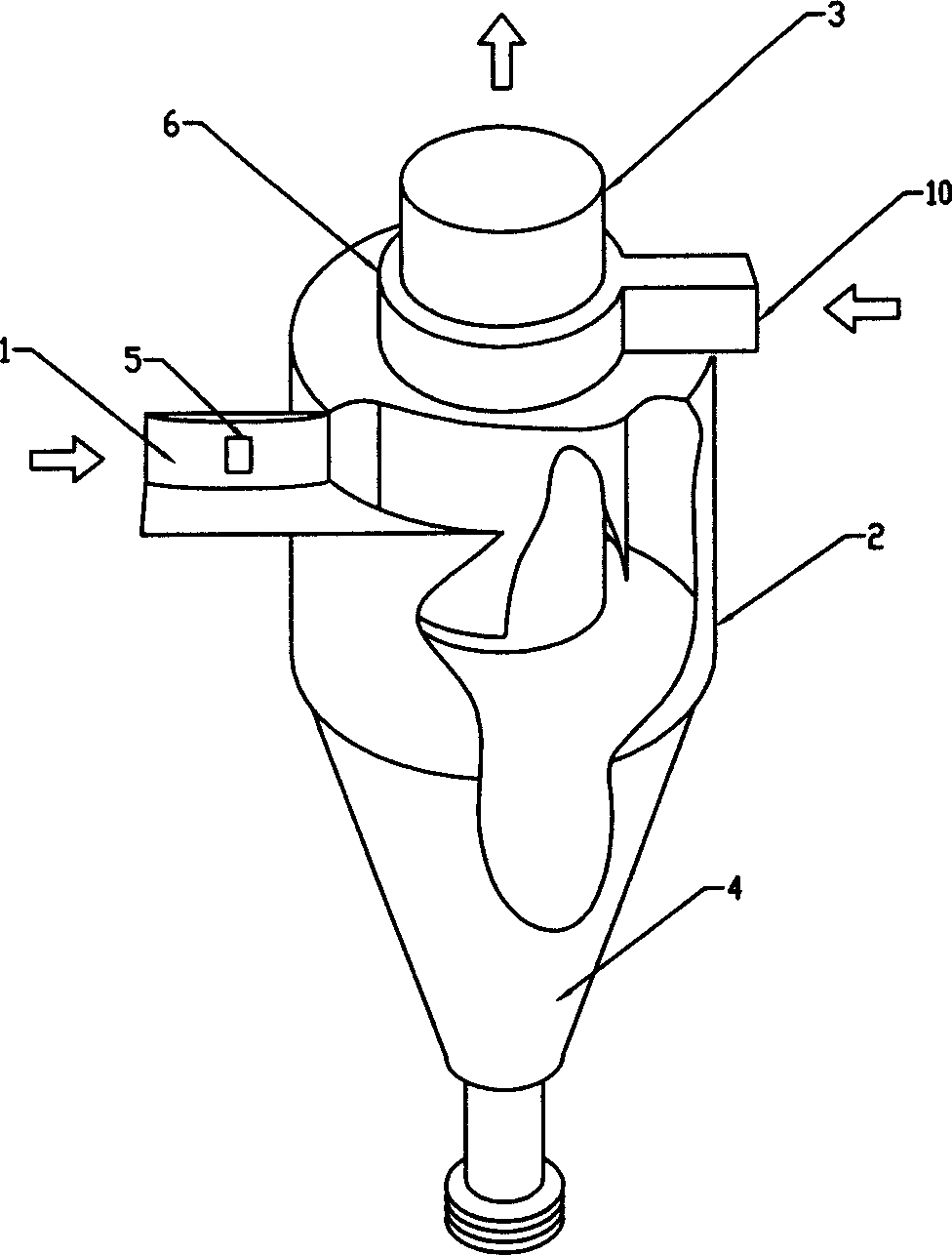

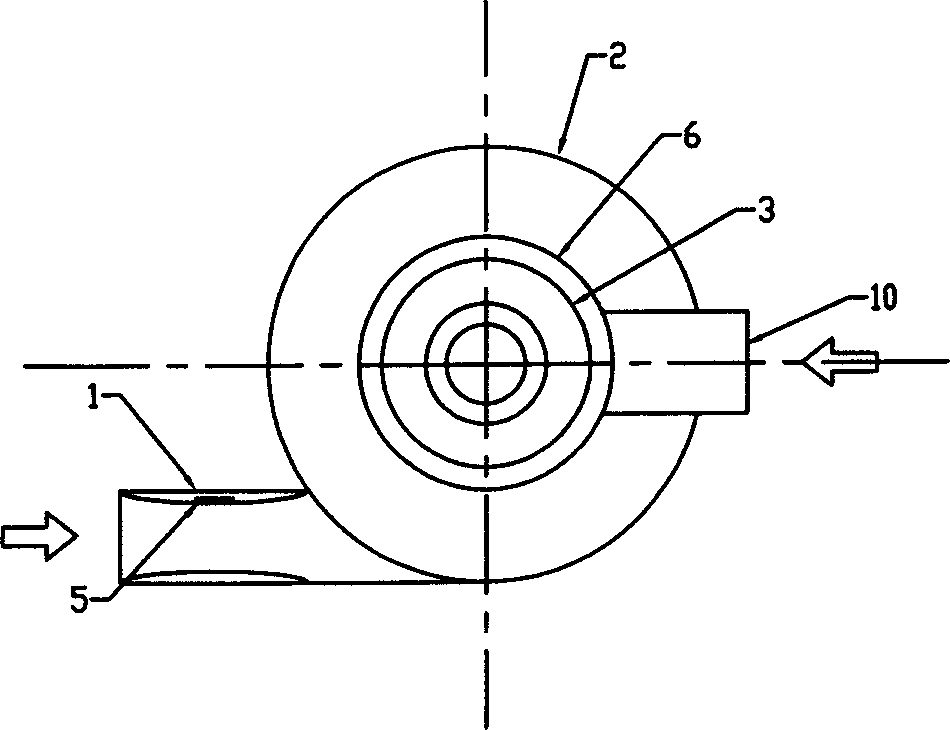

Fluidized bed boiler with multifunctional cyclone separator

InactiveCN1477329AExtended high temperature oxygen enrichment processFully meet the combustion requirementsFluidized bed combustionApparatus for fluidised bed combustionCycloneCombustion chamber

The present invention relates to a fluidized-bed boiler with cyclone separator having double functions of separating and burning volatile component. Said separator includes an inlet section whose internal wall form is Venturi throat, external cyclone cylinder, exhaust cylinder and gas-burning air sleeve barrel mounted between external cyclone cylinder and exhaust cylinder, on the inlet section a gas-burning air hole is set, and the top of the gas-burning air sleeve barrel is equipped with hot air inlet. It can make the combustion space of fluidized-bed space be extended into the separator.

Owner:清华紫光环保有限公司 +1

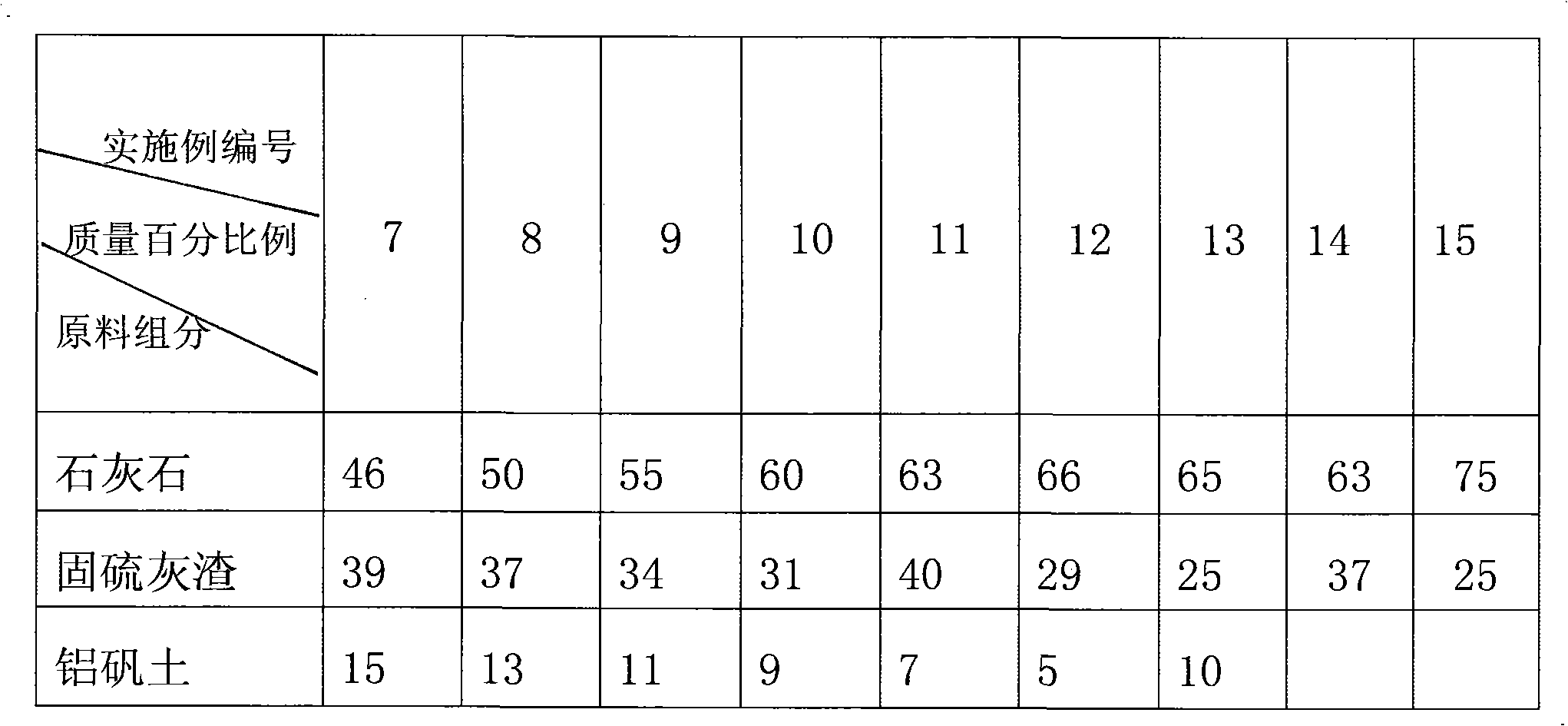

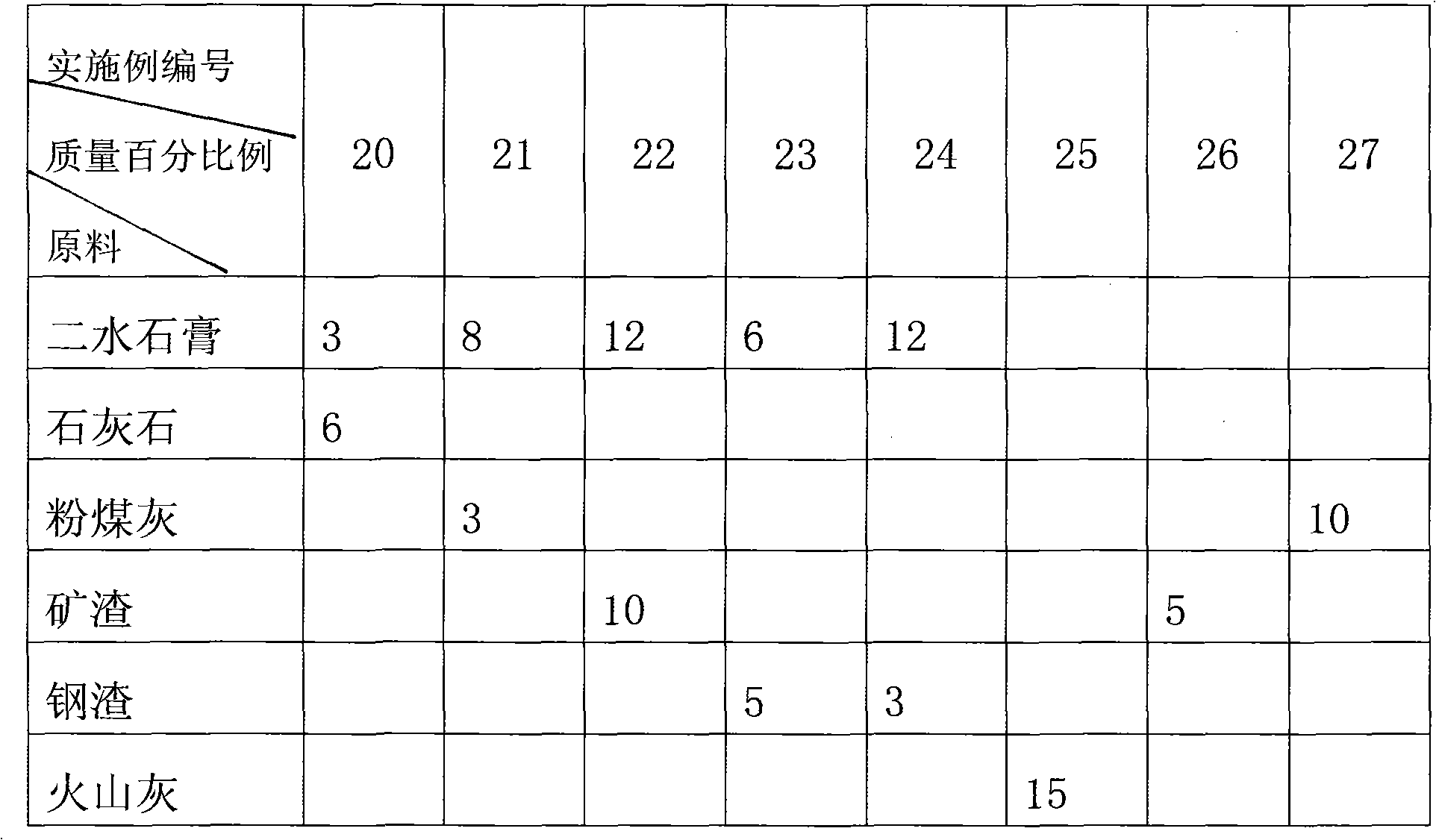

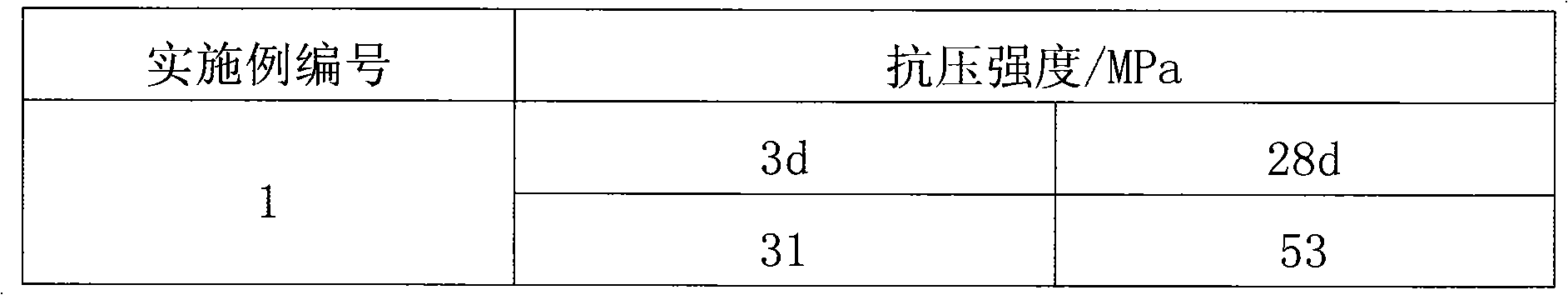

Method for preparing special cement by circulating fluidized bed combustion ash

ActiveCN101913786AReduce manufacturing costSolve resource problemsCement productionMixed materialsToxic industrial waste

The invention discloses a method for preparing special cement by circulating fluidized bed combustion ashes, comprising the following steps: raw materials are taken out, which comprise the following components in percentage by weight: 45-75 wt% of limestone, 25-40 wt% of fluidized bed combustion ash and 0-15 wt% of bauxite; the raw materials are broken and levigated to be evenly mixed to prepare a mixed material; the mixed material is calcined at the temperature of 1100-1450 DEG C for 10-90 min, cooled and prepared into clinker; dihydrate gypsum which accounts for 0-15 wt% of cement is added into the clinker; and all the materials are mixed and levigated to prepare the special cement. The invention takes industrial waste residue-fluidized bed combustion ash as the raw material to prepare the special cement which takes Belite, calcium sulphoaluminate and iron phase as main minerals. The invention utilizes a great quantity of waste, lowers cement production cost, improves environment protection benefit, has low calcining heat and lowers energy consumption, and the prepared cement has favorable construction workability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

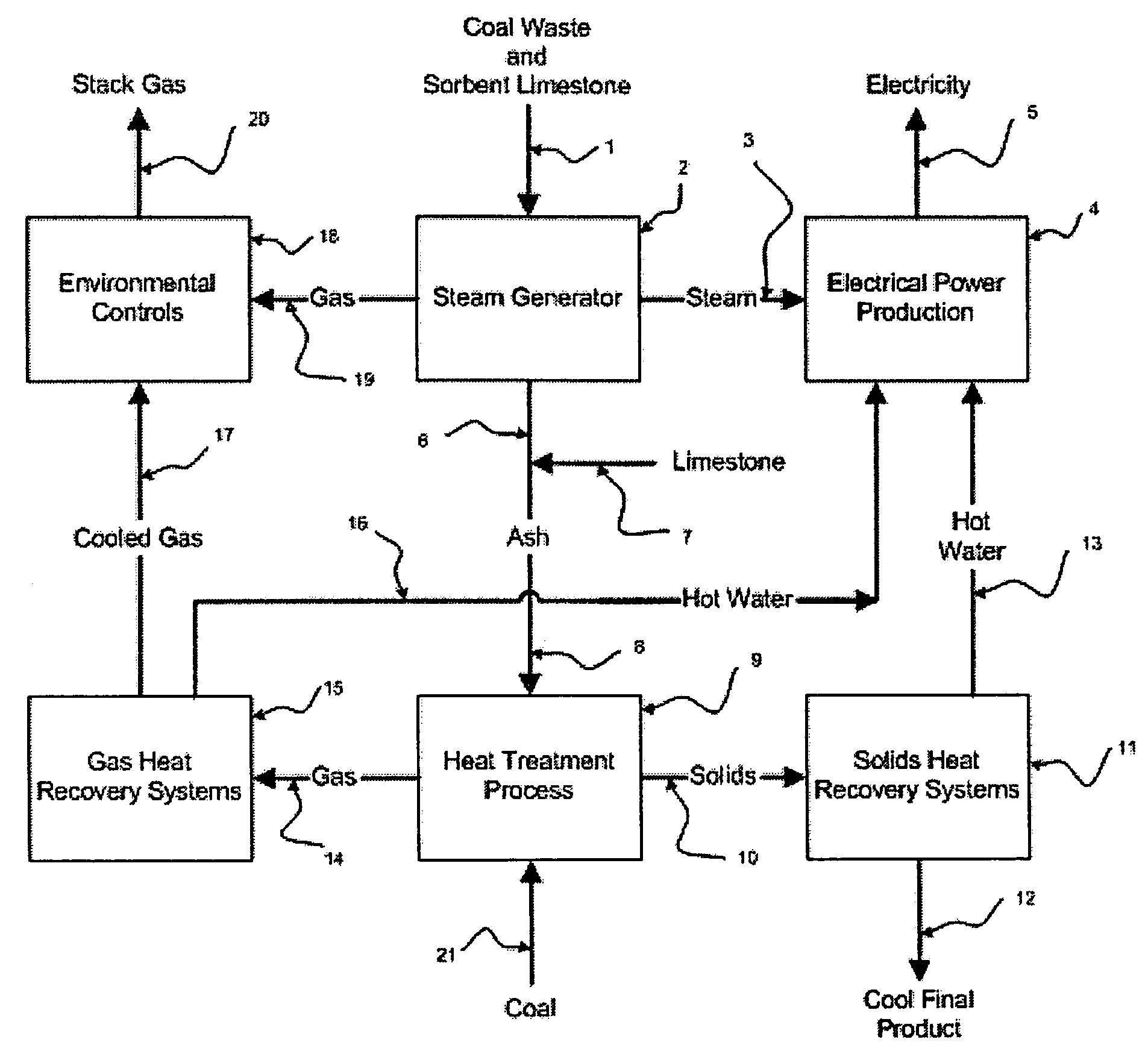

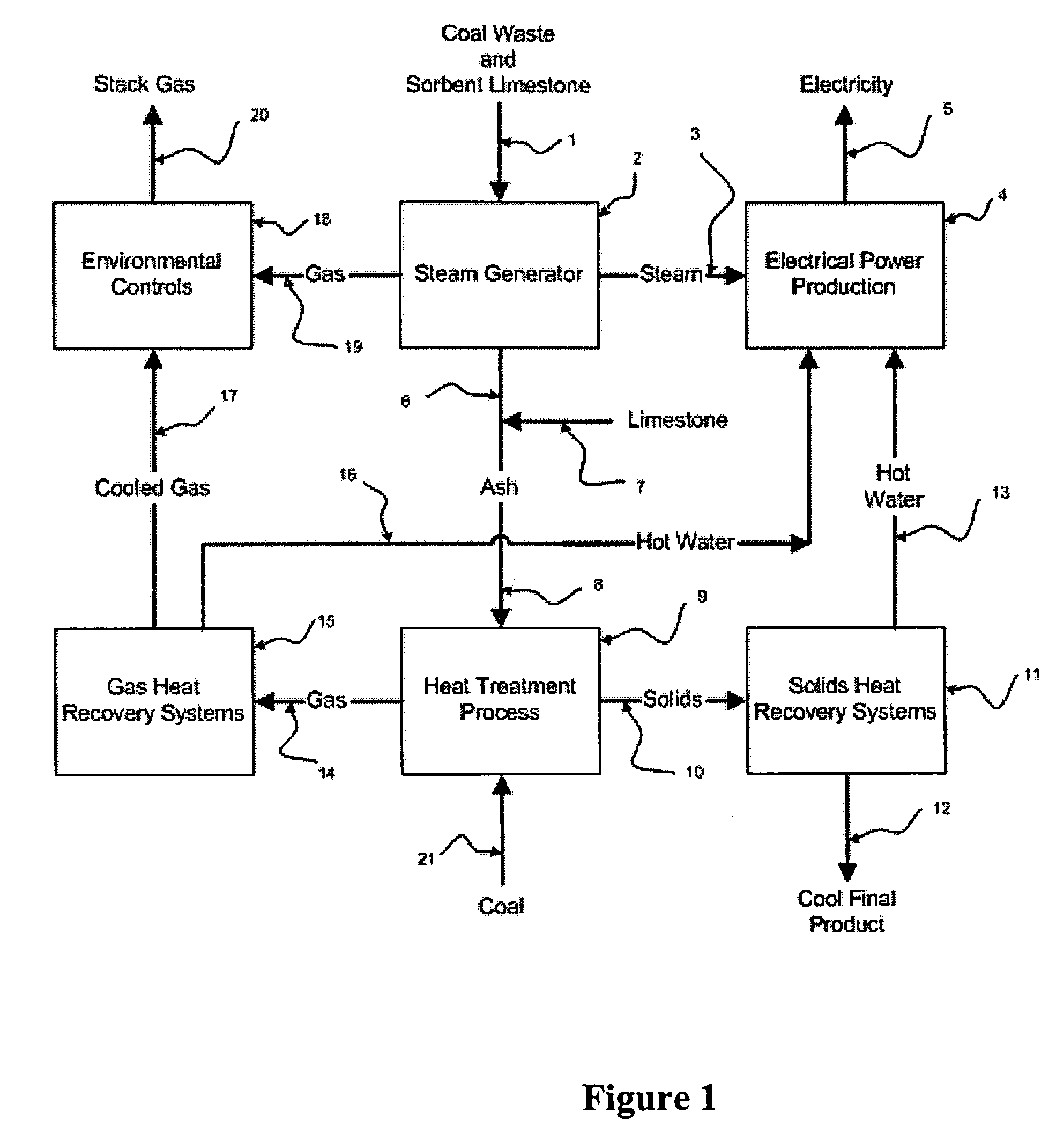

Method of making pozzolands and cementitious materials from coal combustion by-products

InactiveUS20060032408A1Permanently eliminating damageSpace is requiredSolid waste managementMaterials sciencePozzolan

Ash produced by many coal-fired utilities has little or no commercial value as a cement additive or as a component in building materials because of its chemical or mineralogical composition. This condition is especially common with ash materials produced by Fluidized Bed Combustion boilers (FBC) or Circulating Fluidized Bed Combustion boilers (CFBC) fired with bituminous coal or waste coals (gob) reclaimed from inactive coal mine sites. The present invention describes a novel process that converts otherwise low-value materials such as bottom and fly ashes produced by a FBC or CFBC boilers, for example, into materials that have desirable physical, chemical and mineralogical compositions that can be used as a valuable cement additive or component in building materials. The novel process closely integrates the boiler (steam generator) that produces the ash with a new high-temperature process, such as a kiln. The ash is mixed with limestone or other bulk materials to provide a feed for the kiln of the desired chemical composition. The mixture is treated at elevated temperatures in the kiln to produce a product, that in combination with further processing, exhibits desirable pozzolanic properties. Integrating boiler and kiln operations provides economic and environmental benefits. Waste heat produced by the kiln that would otherwise be released into the atmosphere is made available to the steam or turbine cycle, thus improving the overall boiler heat rate. Effluents and gases produced by the kiln may be efficiently treated by the boiler environmental control systems or independent environmental control systems. Novel production methods and feed materials will be claimed.

Owner:STRABALA WILLIAM M

Fluidized bed reactor for preparing methanol by synthesis gas and method

ActiveCN102513037AExtend your lifeCompression costs lessOrganic compound preparationHydroxy compound preparationHydrogenHigh carbon

The invention discloses a fluidized bed reactor for preparing methanol by synthesis gas and a method, belonging to the technical field of methanol preparation. One or a plurality of transverse band-hole gas distribution plates are arranged on the fluidized bed at different axial heights; the fluidized bed is divided into two or more catalyst dense-phase accumulation areas at the axial heights, meanwhile independent heat exchangers are arranged in different catalyst dense-phase areas for temperature change. The fluidized bed reaction disclosed by the invention has the advantages of permitting low hydrogen 2 / carbon monoxide (H2 / CO) rate operation, remarkably improving the methanol outlet concentration of the reactor and remarkably reducing cyclic hydrogen quantity, along with high heat exchange performance, low power consumption, high reactor section production flux, high operation operational flexibility, high carbon monoxide (CO) conversion rate, low methanol production cost and the like.

Owner:TSINGHUA UNIV

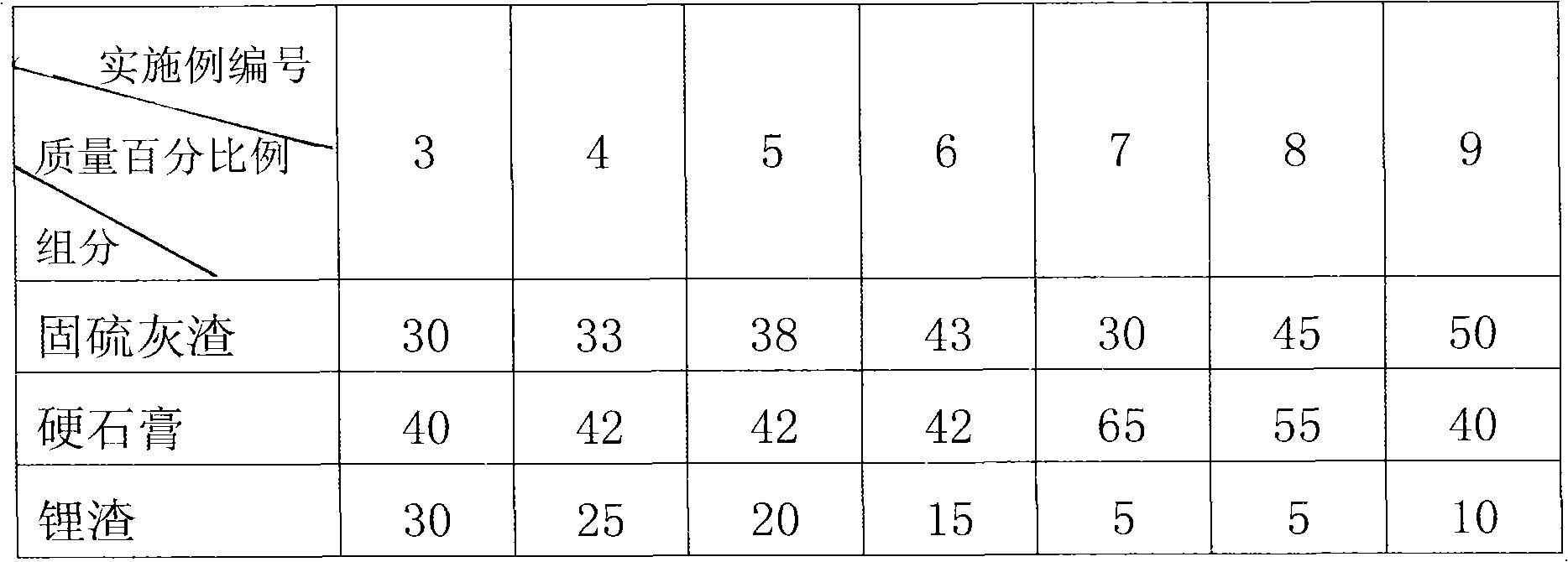

Concrete expansion agent containing circulating fluidized bed combustion coal solid sulfur clinker

The invention discloses a concrete expansion agent containing circulating fluidized bed combustion coal solid sulfur clinker. The concrete expansion agent is characterized by comprising the following components in percentage by mass: 30 to 50 percent of solid sulfur clinker, 40 to 65 percent of anhydrite and 5 to 30 percent of lithium slag. During preparation, after the components are crushed and ground, the components are taken according to the proportion and mixed uniformly to obtain a product without calcining. Because industrial wastes such as the solid sulfur clinker, the lithium slag and the like are used as main raw materials, the concrete expansion agent changes the wastes into valuable, has low cost, reduces environmental pollution, has simple production process, low energy consumption and good performance, and has market competitiveness and strong practicability compared with like products.

Owner:SOUTHWEAT UNIV OF SCI & TECH

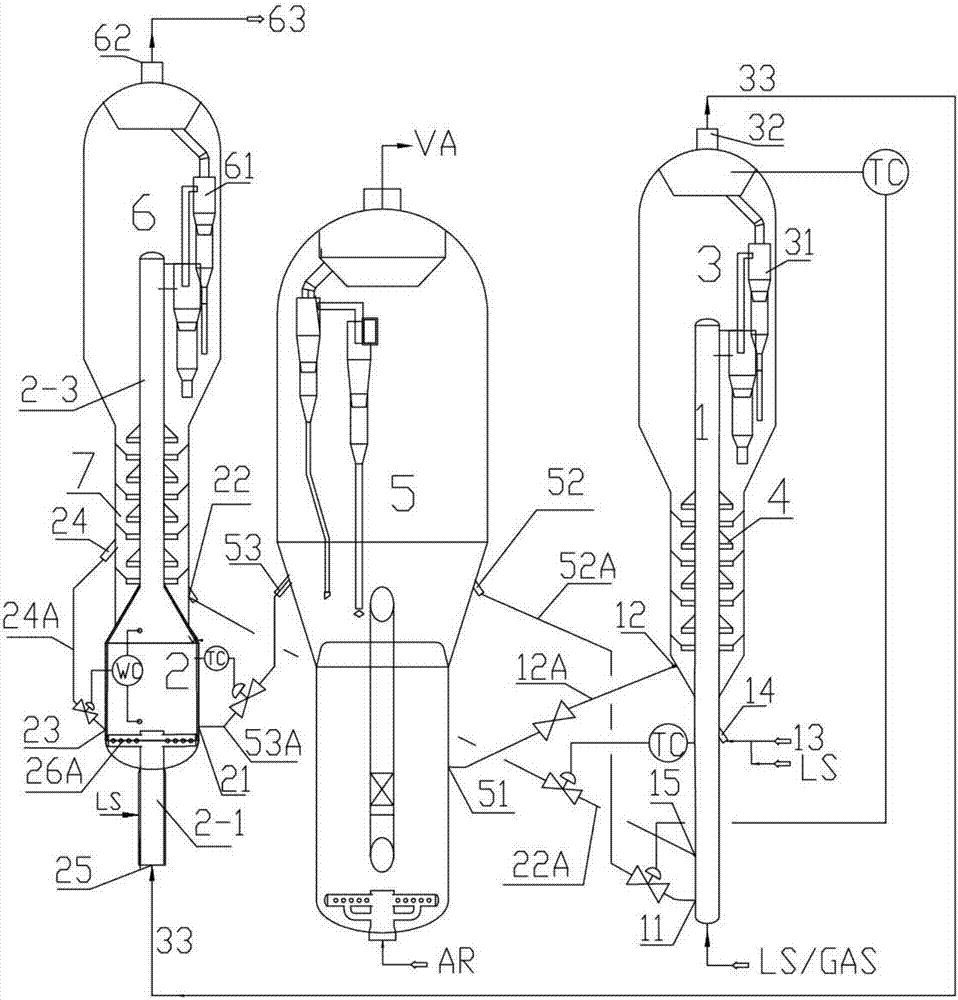

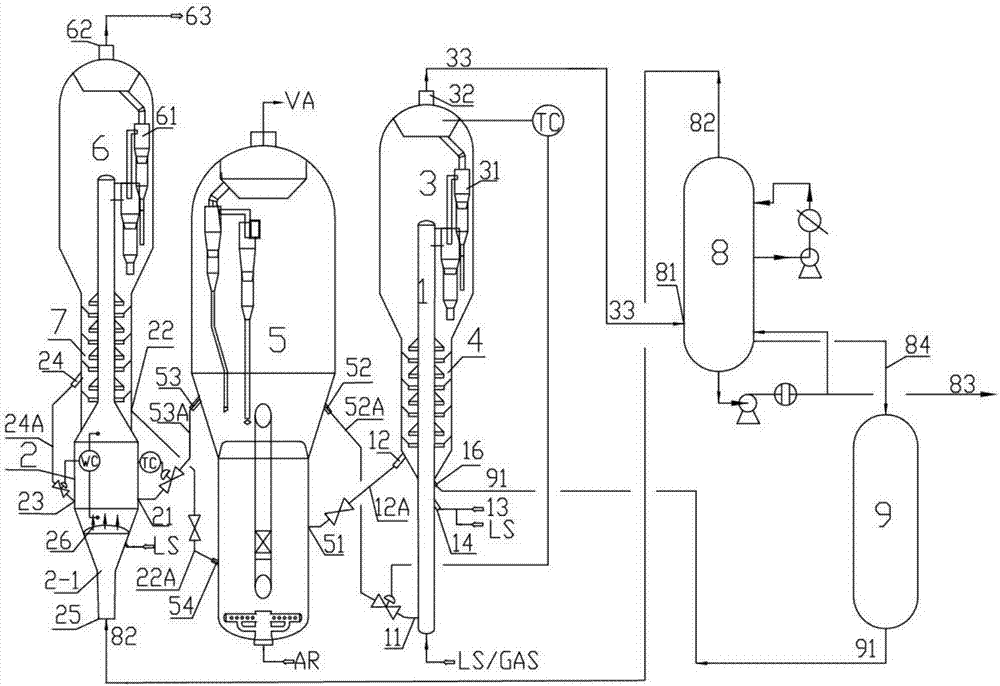

High propylene yield catalytic conversion method

ActiveCN107286972AReduce energy consumptionIndependent high temperature cracking reactionCatalytic crackingChemical/physical processesReactive systemCracking reaction

The invention belongs to the technical field of petroleum hydrocarbon catalytic conversion, and especially relates to a high propylene yield catalytic conversion method. According to the method, a catalyst regenerator and two reaction systems are arranged, raw oil (13) carries out catalytic reactions in the first reaction system, all reaction products (or part of the reaction products) enter the second reaction system in a gas form and carry out catalytic reactions; a second reactor catalyst (22A) to be regenerated and a catalyst from the catalyst regenerator enter the second reactor (2); the fluidized catalytic cracking reaction of first reactive oil gas (33) is realized again, two reaction systems use a same catalyst, and the reaction products are separated in individual precipitators to realize gas-solid separation and then discharged from the precipitators. The energy consumption is reduced, individual high temperature cracking reaction is realized, fluidized bed reaction is stopped rapidly, the contradiction between propylene increasing and dry gas reducing is solved, the propylene yield is increased, and at the same time, the yield of dry gas and coke is prominently reduced.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

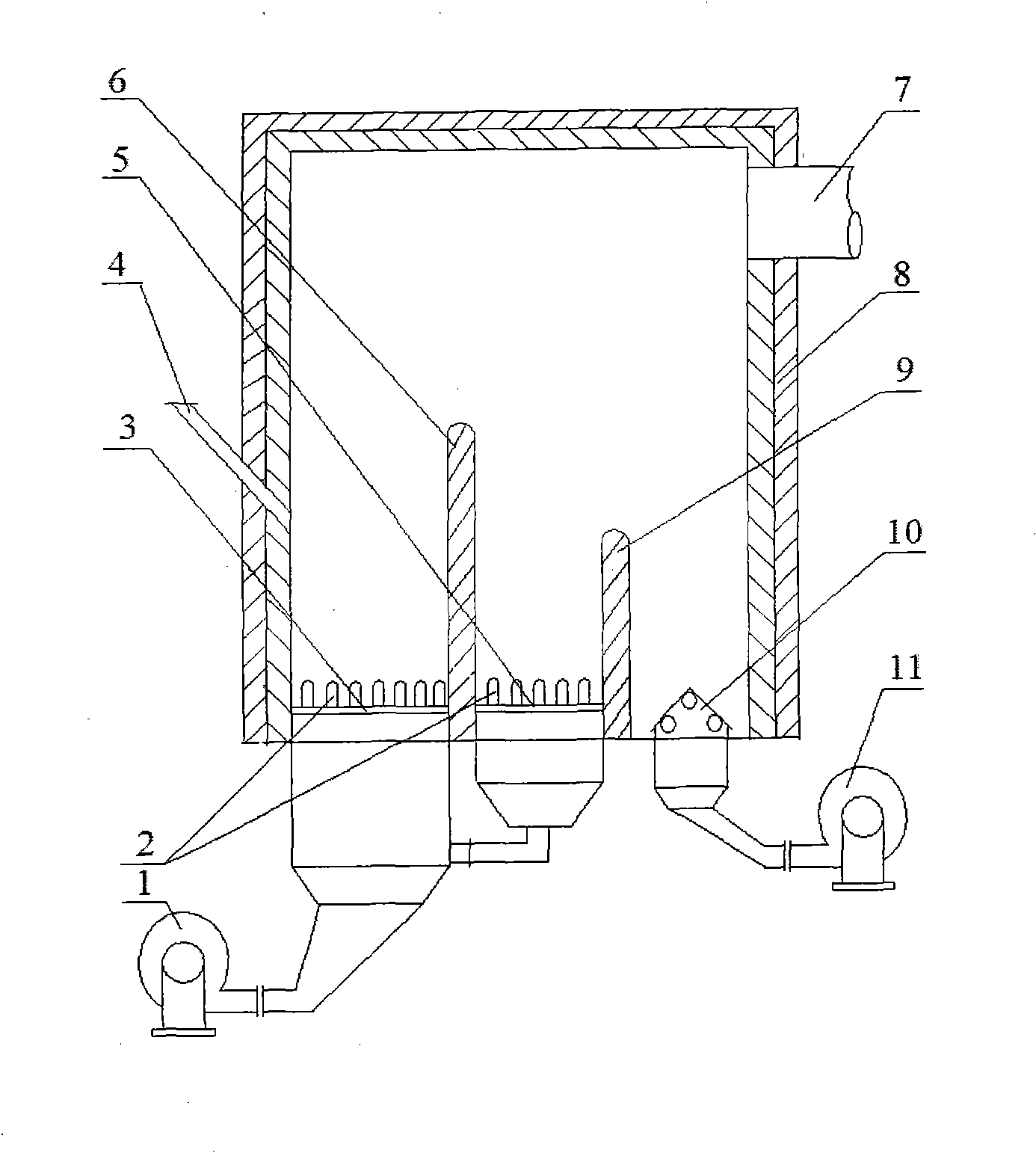

Fluidized bed furnace used for vanadium extraction and decarbonization of stone coal

The invention particularly relates to a fluidized bed furnace used for the vanadium extraction and the decarbonization of stone coal. The invention has the following technical scheme that: a main bed (3), an auxiliary bed (5) and a cold bed (10) which are positioned at the bottom of a furnace body (8) are sequentially isolated from left to right respectively by a first fire bulkhead (6) and a second fire bulkhead (9), and gas burners (2) are evenly arranged on both the main bed (3) and the auxiliary bed (5) and externally connected with a gas source by a gas pipeline; the lower faces of the main bed (3) and the auxiliary bed (5) are respectively communicated with a first blower (1) by pipelines; the lower face of the cold bed (10) is communicated with a second blower (11) by a pipeline; and the upper part of the right side of the furnace body (8) is provided with a flue (7), and the middle part of the left side of the furnace body (8) is provided with a feed pipe (4). The invention has the following advantages of simple structure, high decarbonization speed and high stability; the invention can realize the fluidized-bed combustion of vanadium-containing stone coal with low heating value; and under the condition of deslagging in a large slag quantity, the invention realizes that the deslagging temperature is smaller than 150 DEG C.

Owner:WUHAN UNIV OF SCI & TECH

Sludge multi-stage drying device, fluidized bed combustion treatment device and fluidized bed combustion treatment method

ActiveCN102583945AIncrease specific volumeImprove heat transfer efficiencySludge treatment by de-watering/drying/thickeningIncinerator apparatusAir preheaterAir blower

A fluidized bed combustion treatment device and method with a sludge multi-stage drying device belongs to the field of sludge treatment and aims at solving the problem that heat cannot be self-balanced and operation cost is high in the sludge combustion technology. The drying device is characterized in that at least three stages of packing augers are installed in a drying chamber, and a motor is installed on the drying chamber and builds a transmission relationship with the various stages of packing augers through gears. The treatment device and the treatment method are characterized in that a dry sludge storing cabin is arranged under a dry sludge outlet of the drying device, a steam outlet is connected with a cyclone separator, a large amount of steam is heated through a heat exchanger and then returns back to the drying device to continuous drying wet sludge, asmall amount of steam generates sewage after spraying dehydration through a spraying tower, the generated sewage is sent into a sewage treatment plant for treatment, non-condensable gas is burnt out after being sent into a fluidized bed combustion furnace, the air required in sludge combustion passes through the heat exchanger under effect of an air blower, then passes through an air preheater and is sent into the fluidized bed combustion furnace for combustion. The sludge multi-stage drying device, the fluidized bed combustion treatment device and the fluidized bed combustion treatment method are used in sludge treatment.

Owner:HARBIN HUAWEI HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com